Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Difficult to prepare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

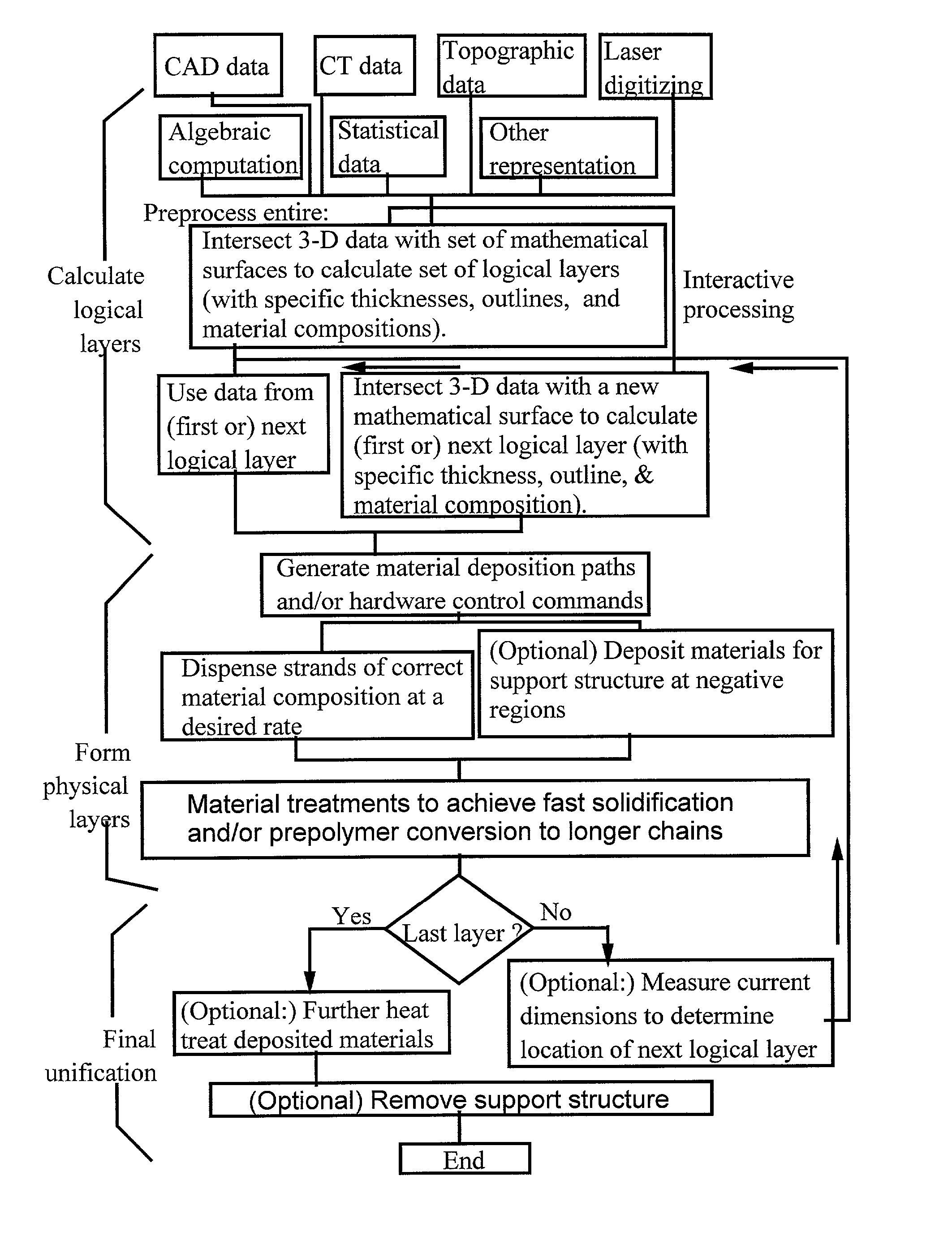

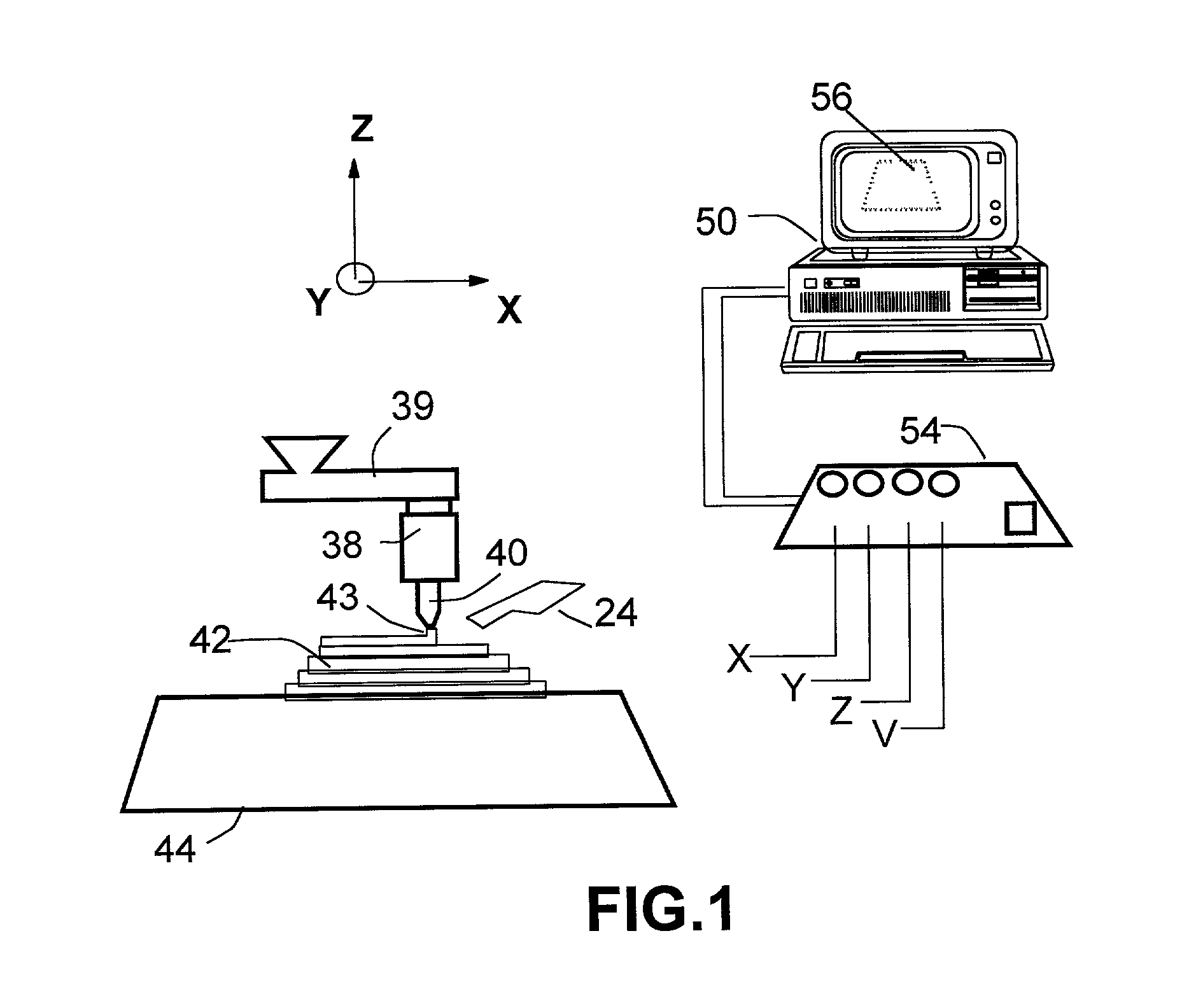

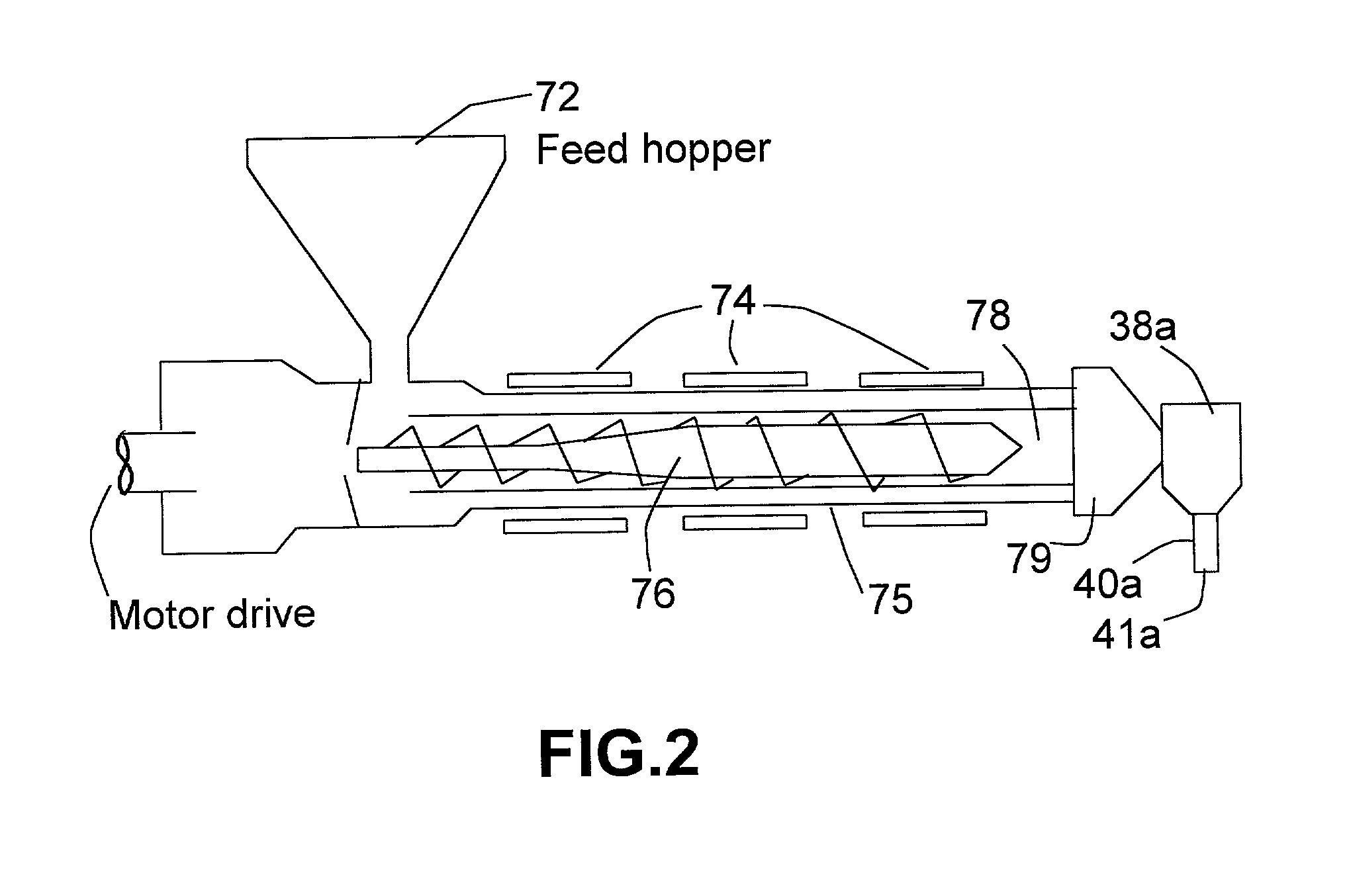

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

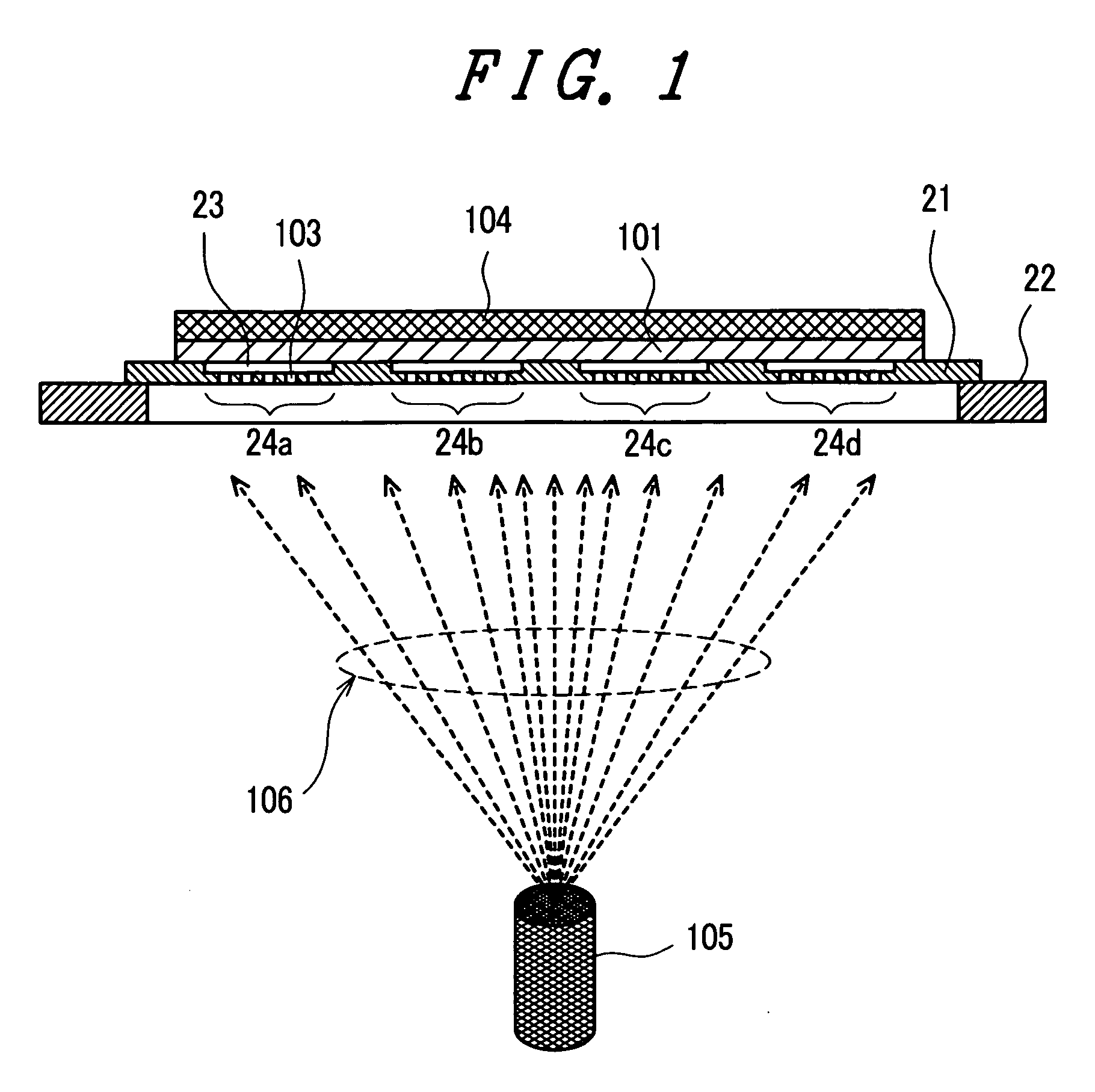

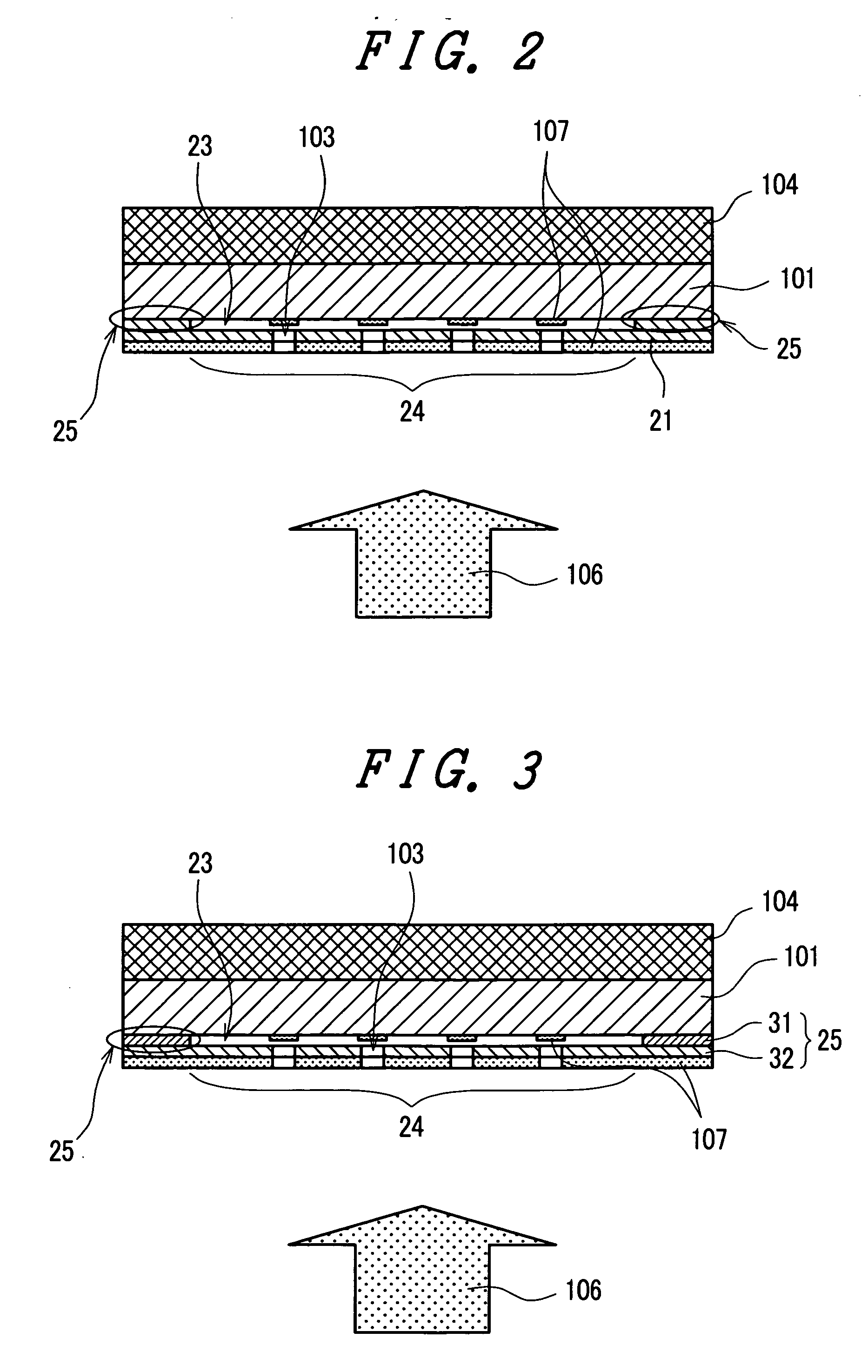

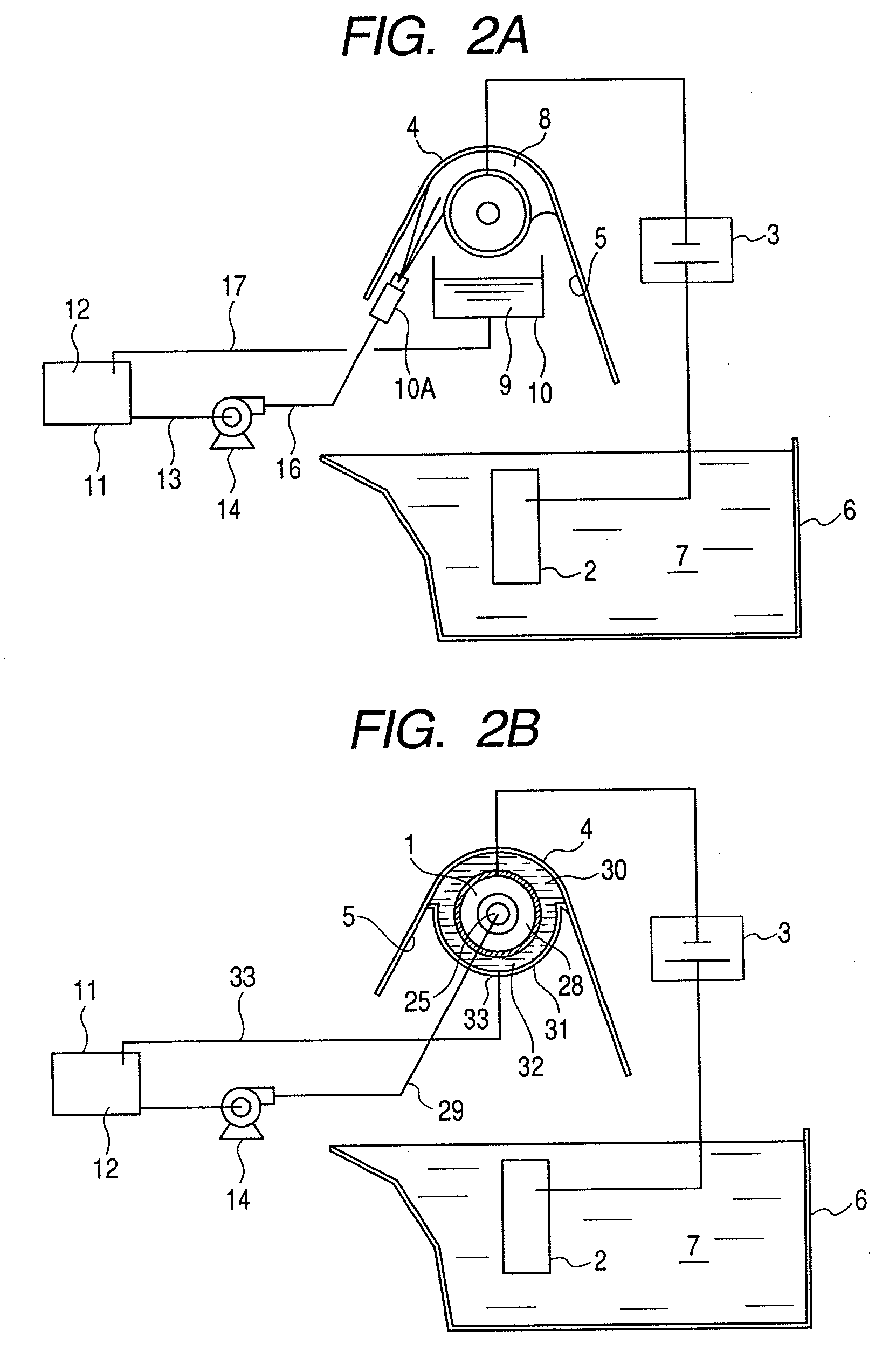

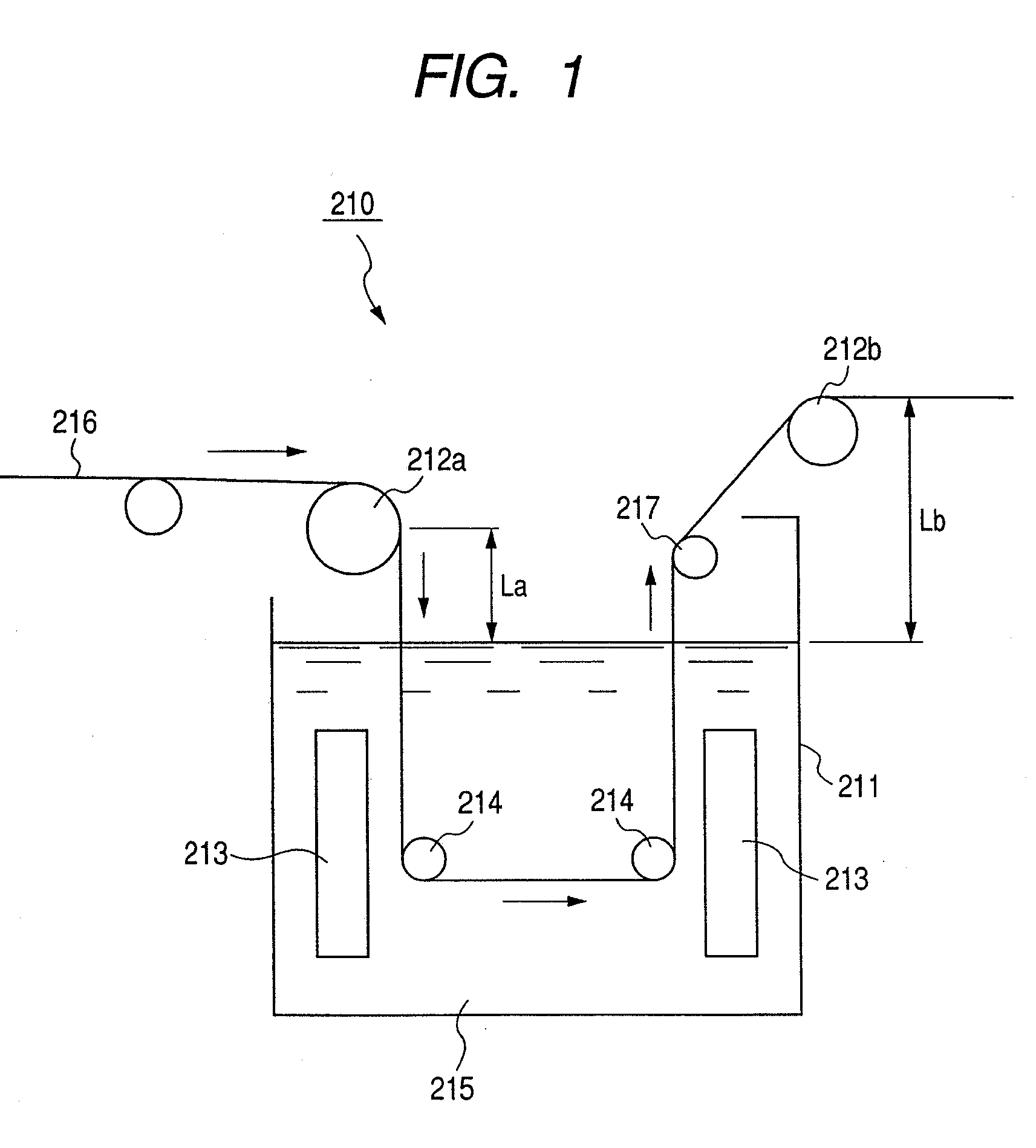

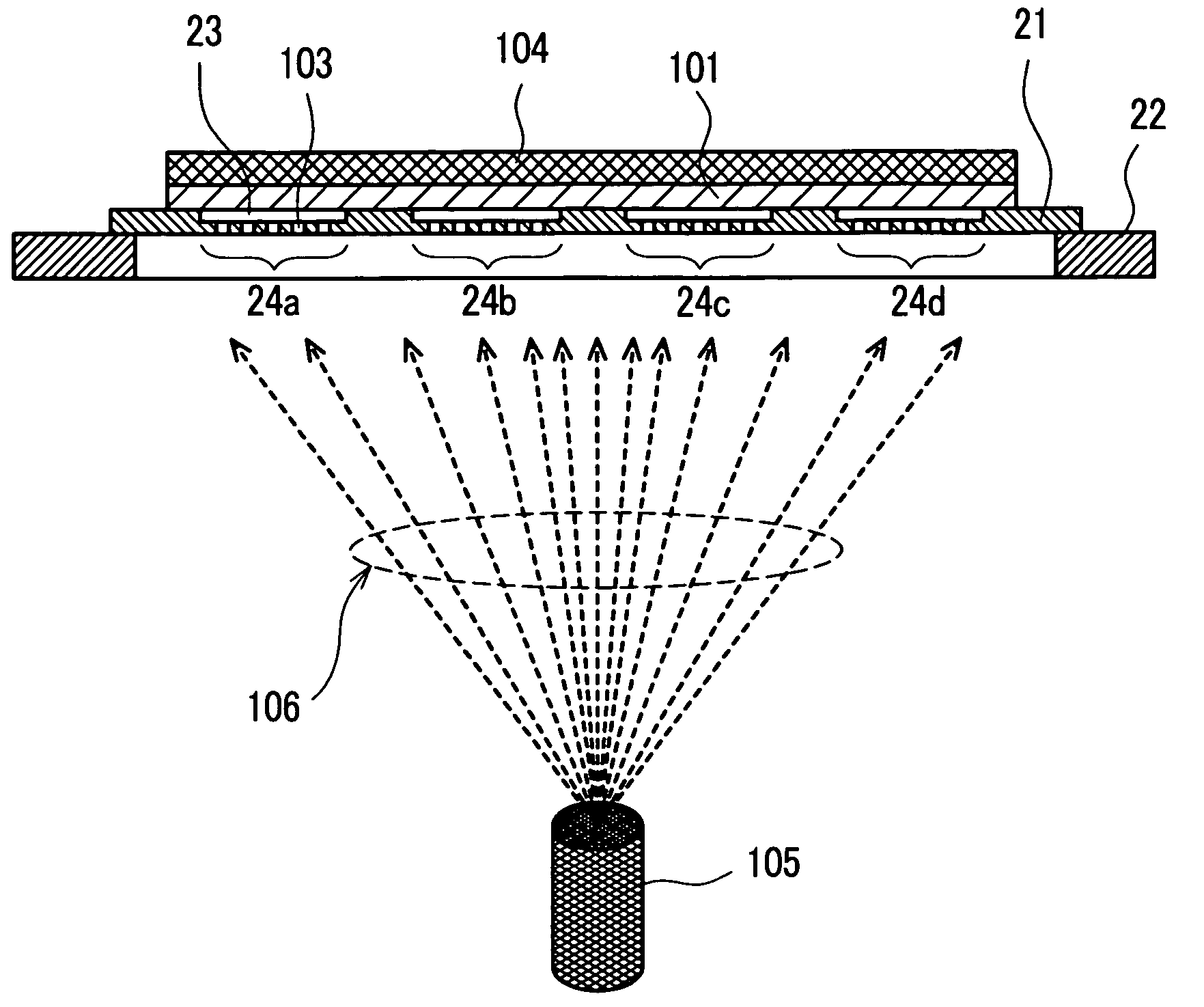

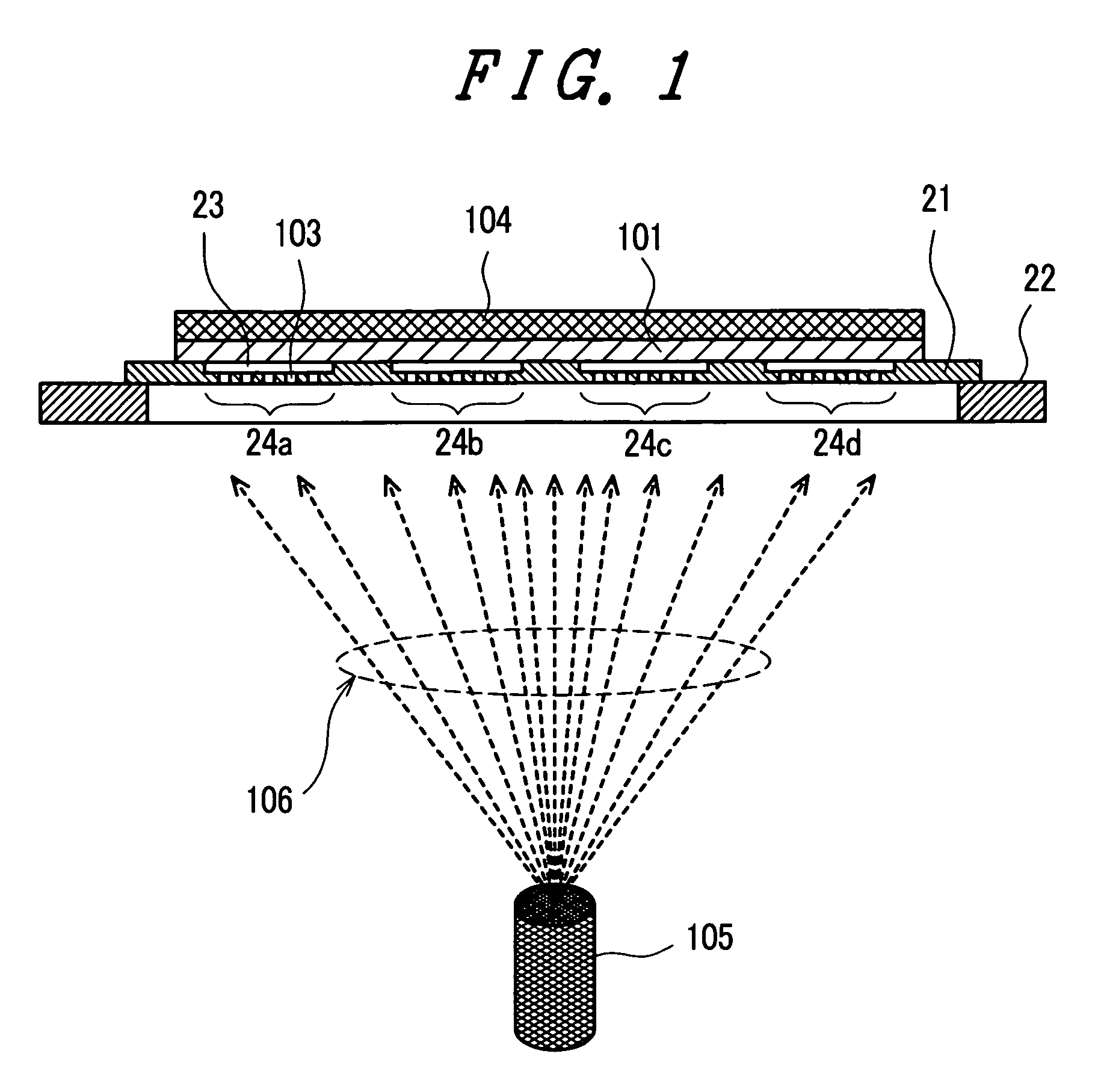

Method of manufacturing the organic electroluminescent display and organic electroluminescent display manufactured by the method

ActiveUS20070072337A1Suppress deterioration of propertyNot to damageSolid-state devicesVacuum evaporation coatingOrganic filmEngineering

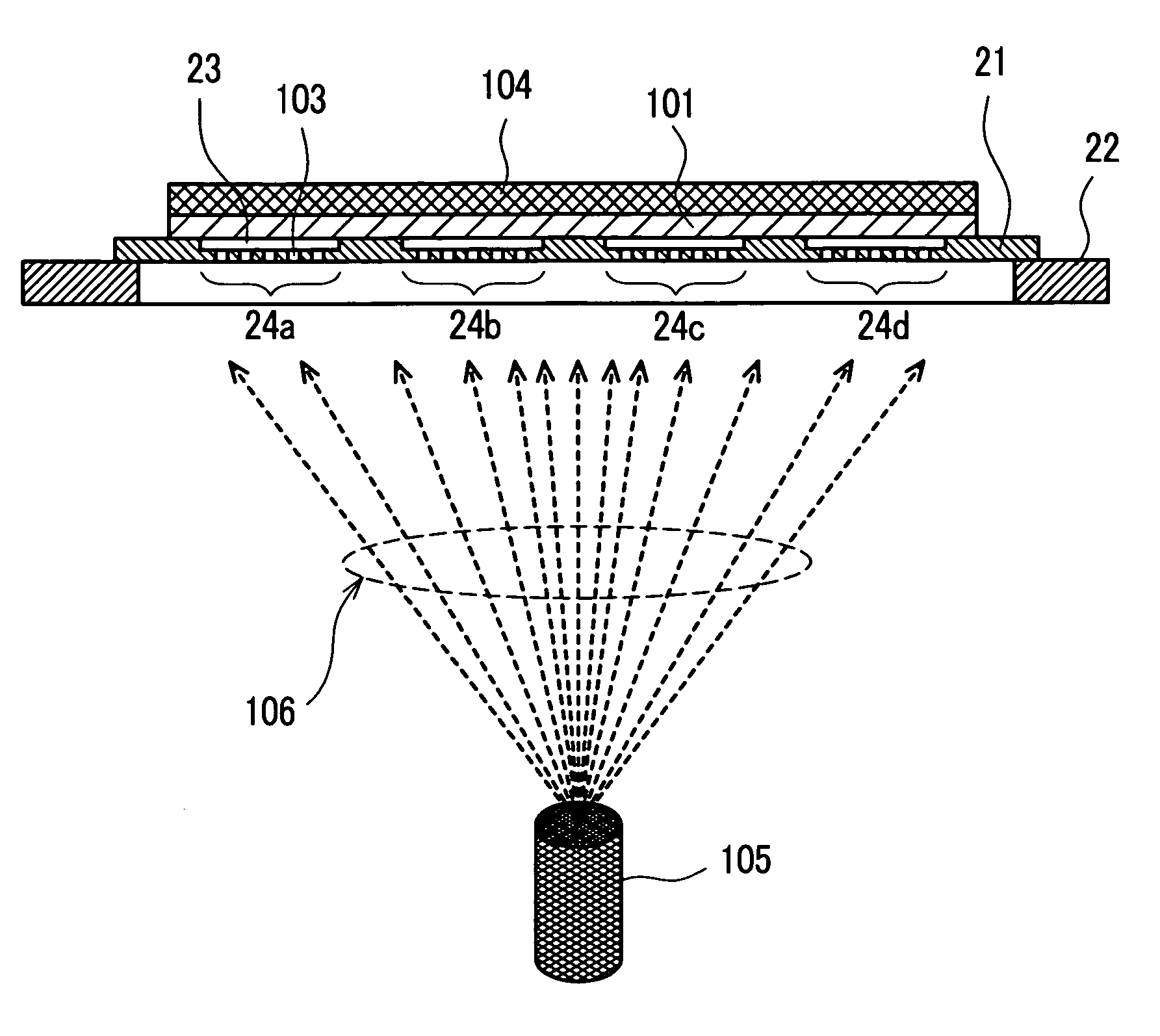

The present invention provides an organic EL display panel manufacturing method which is capable of forming a desired organic film or the like with high accuracy without imparting damages to a substrate and an organic film and an organic EL display panel which is manufactured by the method. An opening portion which corresponds to a panel pattern region of a display panel is formed in a vapor deposition mask. The opening portion has a bottom surface in the inside of a recessed surface which is retracted from a surface on which the vapor deposition mask is brought into contact with the substrate. The opening portion of the vapor deposition mask is spaced apart from the substrate with a predetermined gap space and evaporated particles from an evaporating source are vapor-deposited to the substrate through the opening portion.

Owner:SAMSUNG DISPLAY CO LTD +1

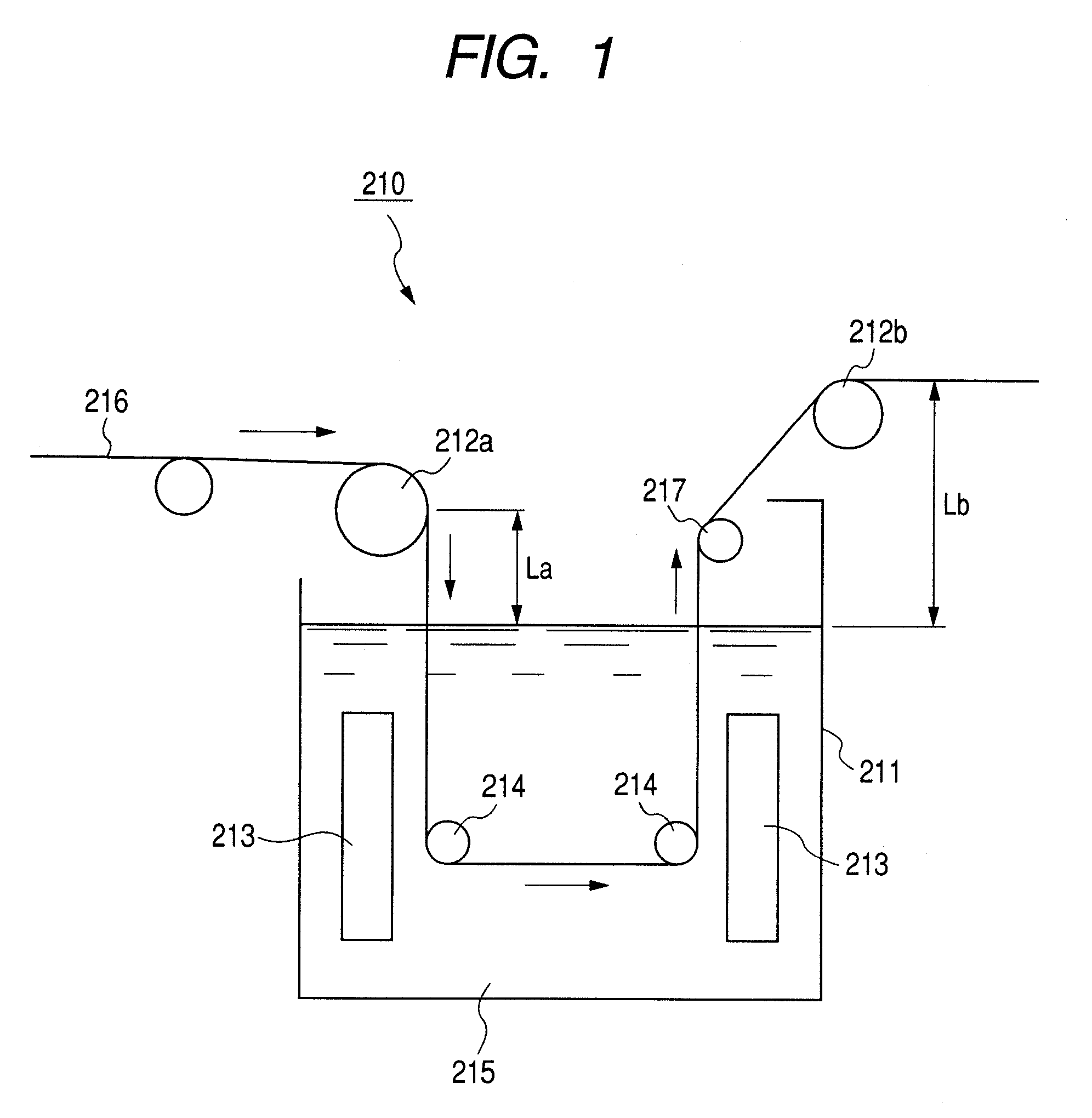

Photosensitive material for forming conductive film, conductive film, light transmitting electromagnetic wave shielding film and method for manufacturing the same

InactiveUS20090029125A1Excellent electromagnetic wave shielding performanceImprove pressure resistanceSemiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialEmulsionAntioxidant

To provide a conductive film forming photosensitive material from which a conductive film having high electromagnetic wave shielding properties and high transparency simultaneously can be manufactured and which is reduced with respect to pressure properties.A conductive film forming photosensitive material including a support having thereon an emulsion layer containing a silver salt emulsion and capable of manufacturing a conductive film by exposing the emulsion layer, performing a development treatment and further performing physical development and / or plating treatment, wherein the emulsion layer is disposed substantially in an uppermost layer; and the emulsion layer contains an antioxidant.

Owner:FUJIFILM CORP

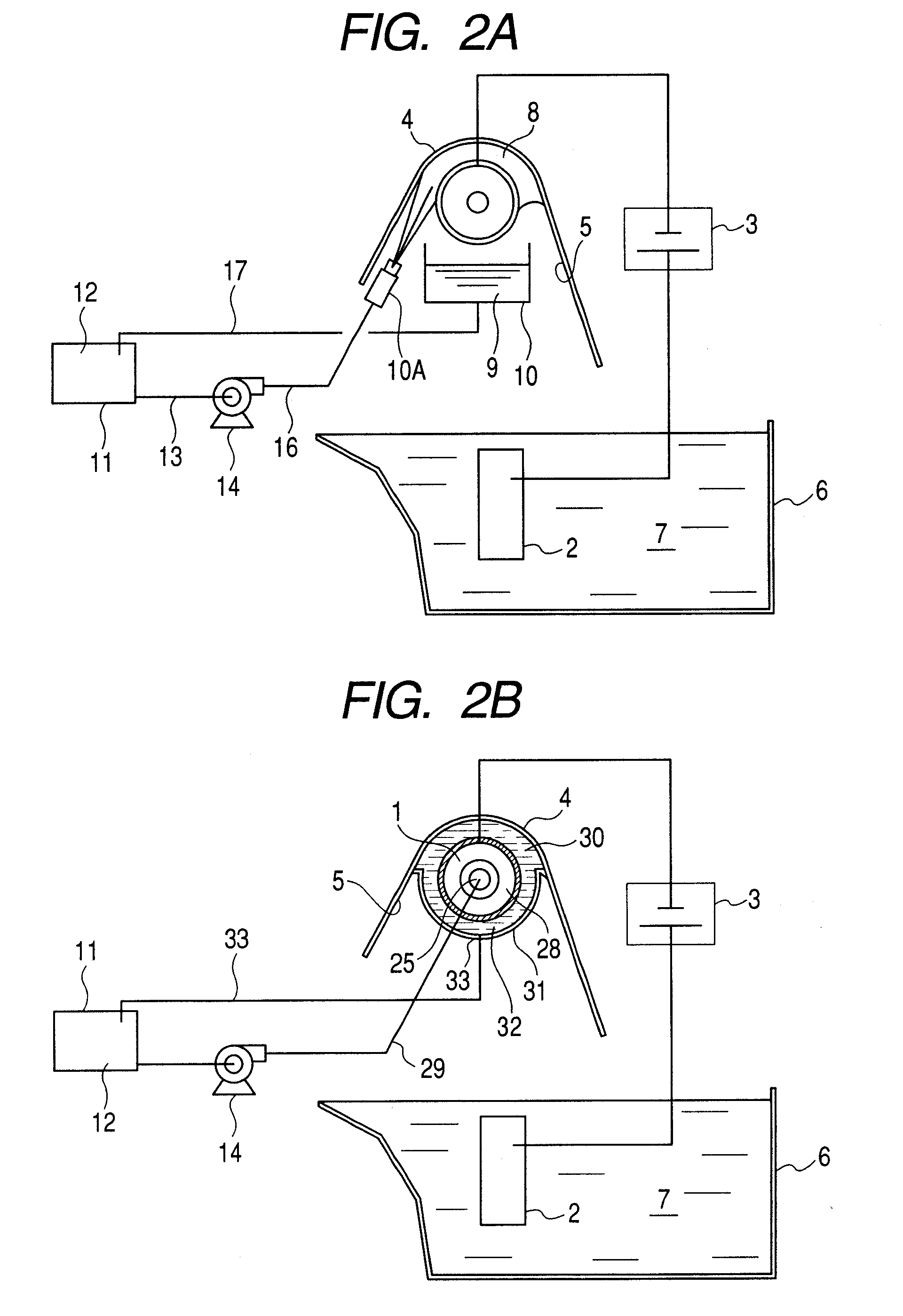

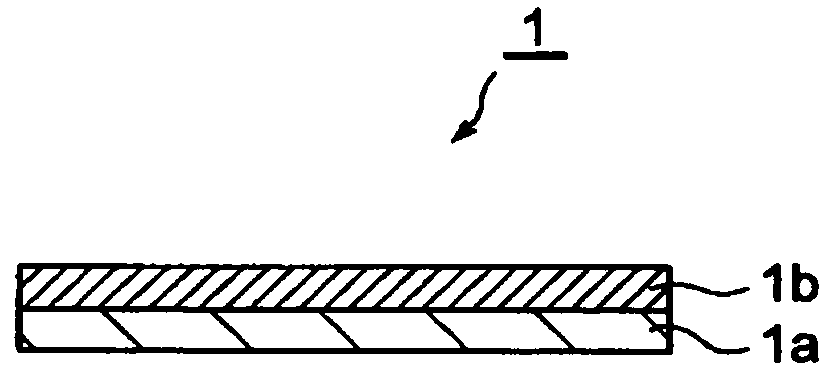

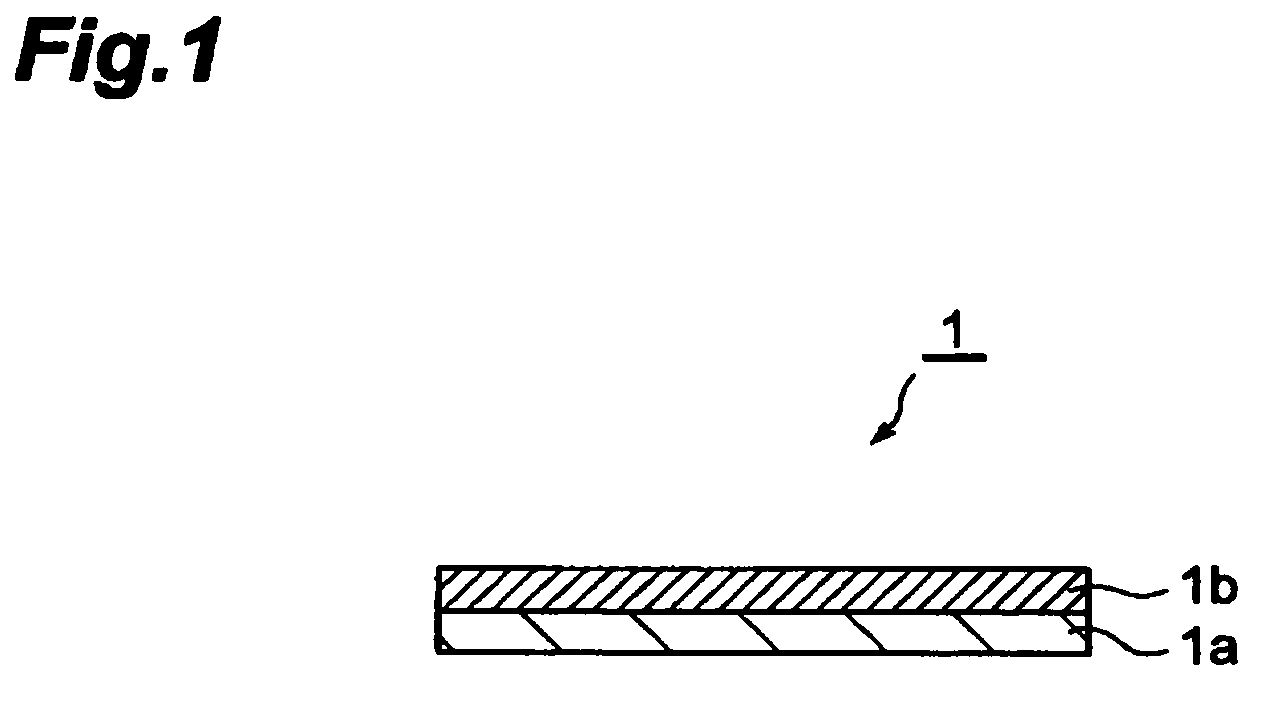

Electrode with conductive polymer-covered carbon nanotubes and electrochemical element employing the same

ActiveUS7691533B2Increase capacityInsufficient improvementMaterial nanotechnologyFinal product manufactureConductive polymerCarbon nanotube

The invention provides an electrode 1 comprising a collector 1a with electron conductivity and an electrode active material-containing layer 1b with electron conductivity formed on the collector 1a, wherein the electrode active material-containing layer 1b includes conductive polymer-covered carbon nanotubes.

Owner:TDK CORPARATION

Foamed aluminium and aluminum alloy tackifying foaming preparation method

The viscosity increasing and foaming process for preparing foamed aluminum or aluminum alloy includes the following steps: compounding water solution of sulfate or fluoride salt; adding carbonate powder via stirring, stoving and powdering the mixture; mixing carbonate powder and titanium hydride powder; heating aluminum or aluminum alloy to melt; adding carbonate powder or compound foaming agent powder via stirring; maintaining in the furnace; and fast water cooling to solidify after growing to reach the required size. The process can form spherical pores in the foamed aluminum or aluminum alloy.

Owner:SOUTHEAST UNIV

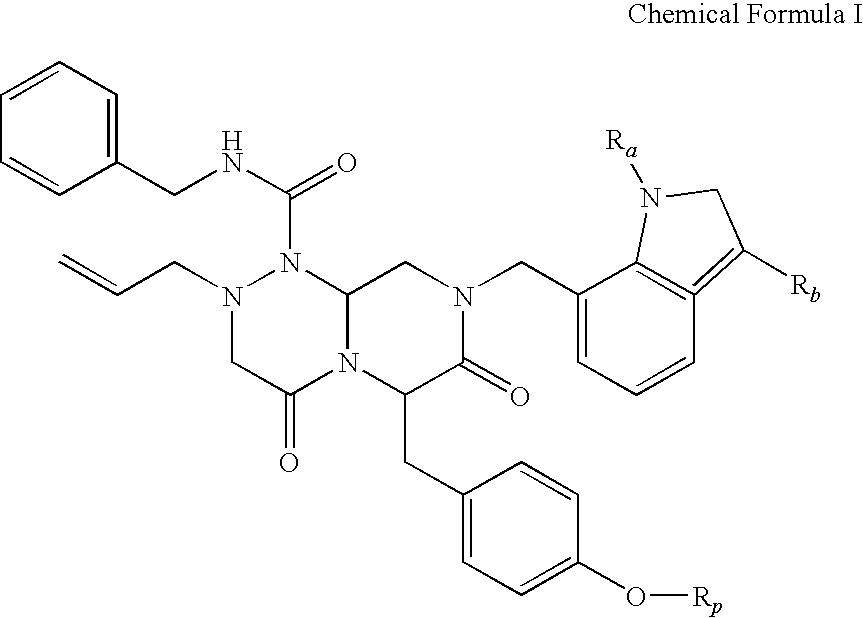

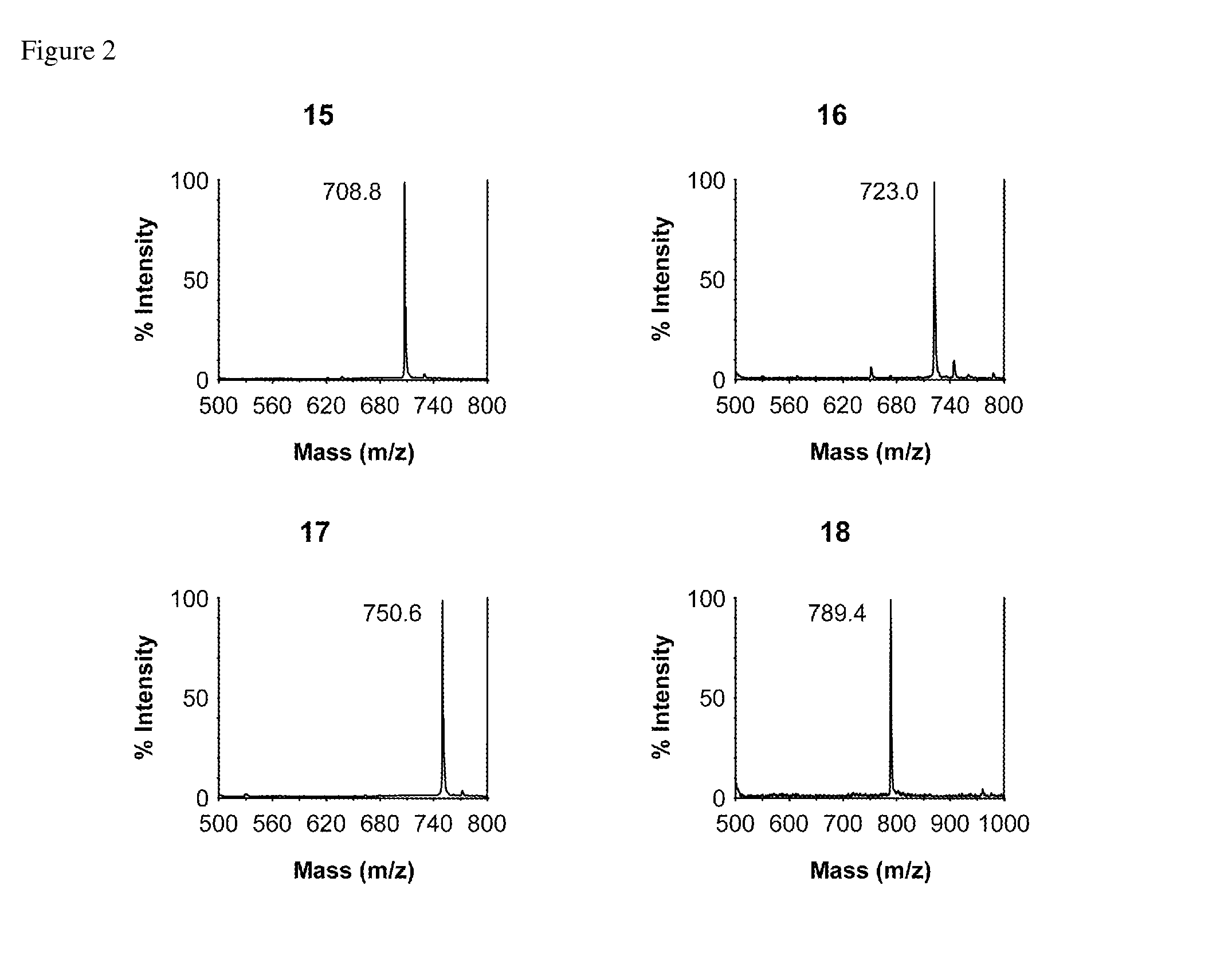

Novel compounds of reverse-turn mimetics, method for manufacturing the same and use thereof

InactiveUS20100267672A1Growth inhibitionInhibit tumor growthBiocideGroup 5/15 element organic compoundsMedicineAML - Acute myeloid leukaemia

Disclosed are novel reverse turn mimetics based on the framework of pyrazino-triazinone, and the use thereof in the treatment of cancers, particularly, acute myeloid leukemia. A method is also provided for manufacturing the reverse turn mimetics on a mass scale.

Owner:JW PHARMA CORP

Photosensitive material for forming conductive film, conductive film, light transmitting electromagnetic wave shielding film and method for manufacturing the same

InactiveUS20090098481A1Promote generationLow costPhotosensitive materialsNon-conductive material with dispersed conductive materialEmulsionAntioxidant

To provide a conductive film forming photosensitive material from which a conductive film having high electromagnetic wave shielding properties and high transparency simultaneously can be manufactured and which is reduced with respect to pressure properties.A conductive film forming photosensitive material including a support having thereon an emulsion layer containing a silver salt emulsion and capable of manufacturing a conductive film by exposing the emulsion layer, performing a development treatment and further performing physical development and / or plating treatment, wherein the emulsion layer is disposed substantially in an uppermost layer; and the emulsion layer contains an antioxidant.

Owner:FUJIFILM CORP

Photosensitive material for forming conductive film, conductive film, light transmitting electromagnetic wave shielding film and method for manufacturing the same

InactiveUS20090117346A1Promote generationLow costPhotosensitive materialsDecorative surface effectsEmulsionPolymer chemistry

To provide a conductive film forming photosensitive material from which a conductive film having high electromagnetic wave shielding properties and high transparency simultaneously can be manufactured and which is reduced with respect to pressure properties.A conductive film forming photosensitive material including a support having thereon an emulsion layer containing a silver salt emulsion and capable of manufacturing a conductive film by exposing the emulsion layer, performing a development treatment and further performing physical development and / or plating treatment, wherein the emulsion layer is disposed substantially in an uppermost layer; and the emulsion layer contains an antioxidant.

Owner:FUJIFILM CORP

Photosensitive material for forming conductive film, conductive film, light transmitting electromagnetic wave shielding film and method for manufacturing the same

InactiveUS20090098480A1Promote generationLow costPhotosensitive materialsDecorative surface effectsEmulsionAntioxidant

To provide a conductive film forming photosensitive material from which a conductive film having high electromagnetic wave shielding properties and high transparency simultaneously can be manufactured and which is reduced with respect to pressure properties.A conductive film forming photosensitive material including a support having thereon an emulsion layer containing a silver salt emulsion and capable of manufacturing a conductive film by exposing the emulsion layer, performing a development treatment and further performing physical development and / or plating treatment, wherein the emulsion layer is disposed substantially in an uppermost layer; and the emulsion layer contains an antioxidant.

Owner:FUJIFILM CORP

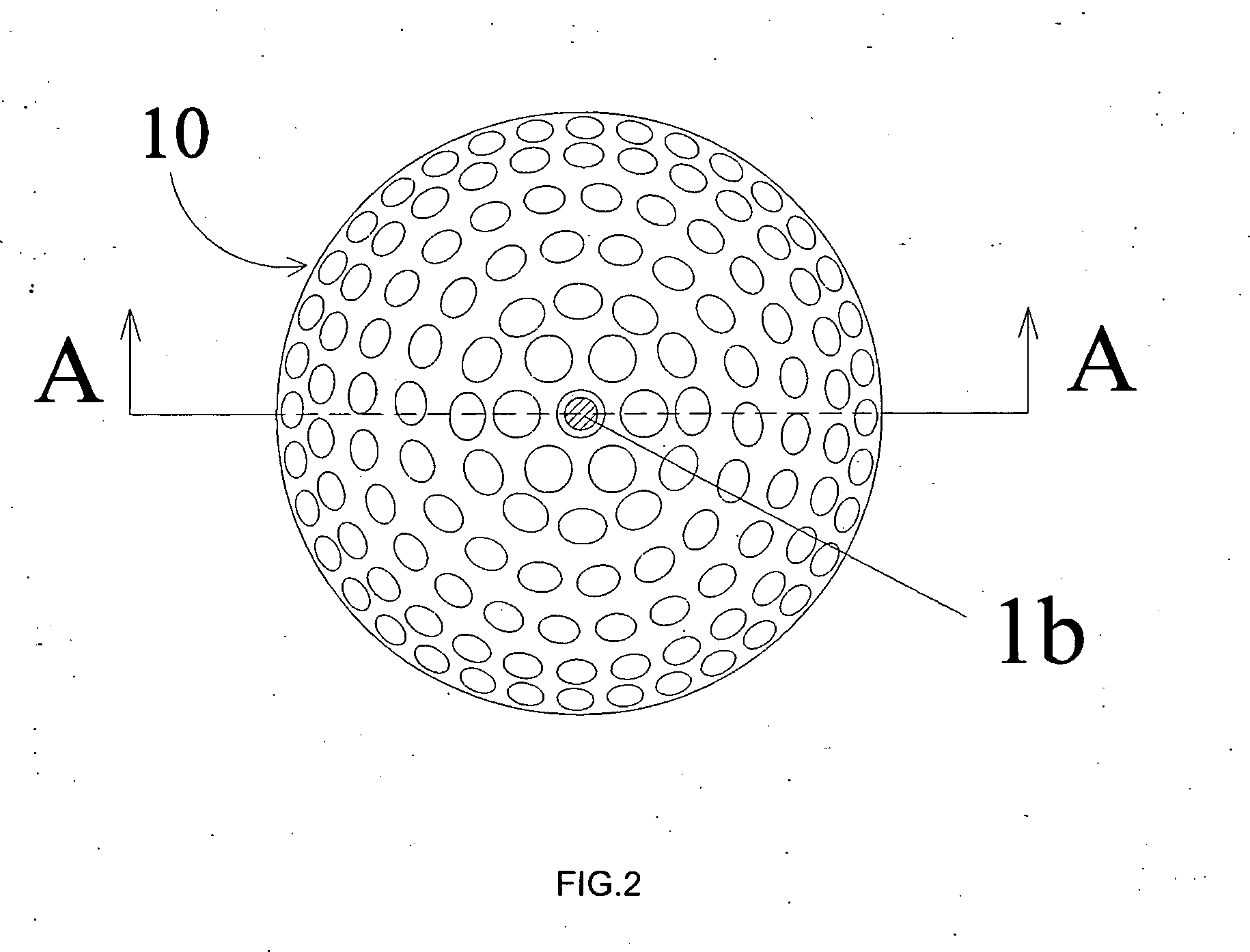

Golf ball-forming composition, golf balls prepared from the composition and the process for preparing thereof

InactiveUS20100248861A1Good water solubilityReduces ball speedHollow non-inflatable ballsHollow wall articlesCelluloseSubstance use

A golf ball-forming composition, golf balls prepared from the composition and the process for preparing thereof. The golf ball-forming composition is composed of the following: polyvinyl alcohol resin 5-80 wt %; filler 0-90 wt %, natural high polymer material 0-60 wt %, and plasticizer 5-50 wt %. The filler is the common filler known by the skilled person in the art; the natural high polymer material is celluloses or amyloses; the plasticizer is the common substances used by the skilled person in the art. The golf ball-forming composition is water soluble and biodegradable. The water soluble and biodegradable golf ball has a hollow inside, and has a surface which is disposed with at least one through hole communicated with the hollow. When the golf ball is hit into water, water will enter the hollow via the through hole, thereby increases the contact area between water and the ball and accelerates the dissolution of the ball, so that the ball may eventually completely biodegraded in the environment.

Owner:PROUDLY ECO FRIENDLY PRODS

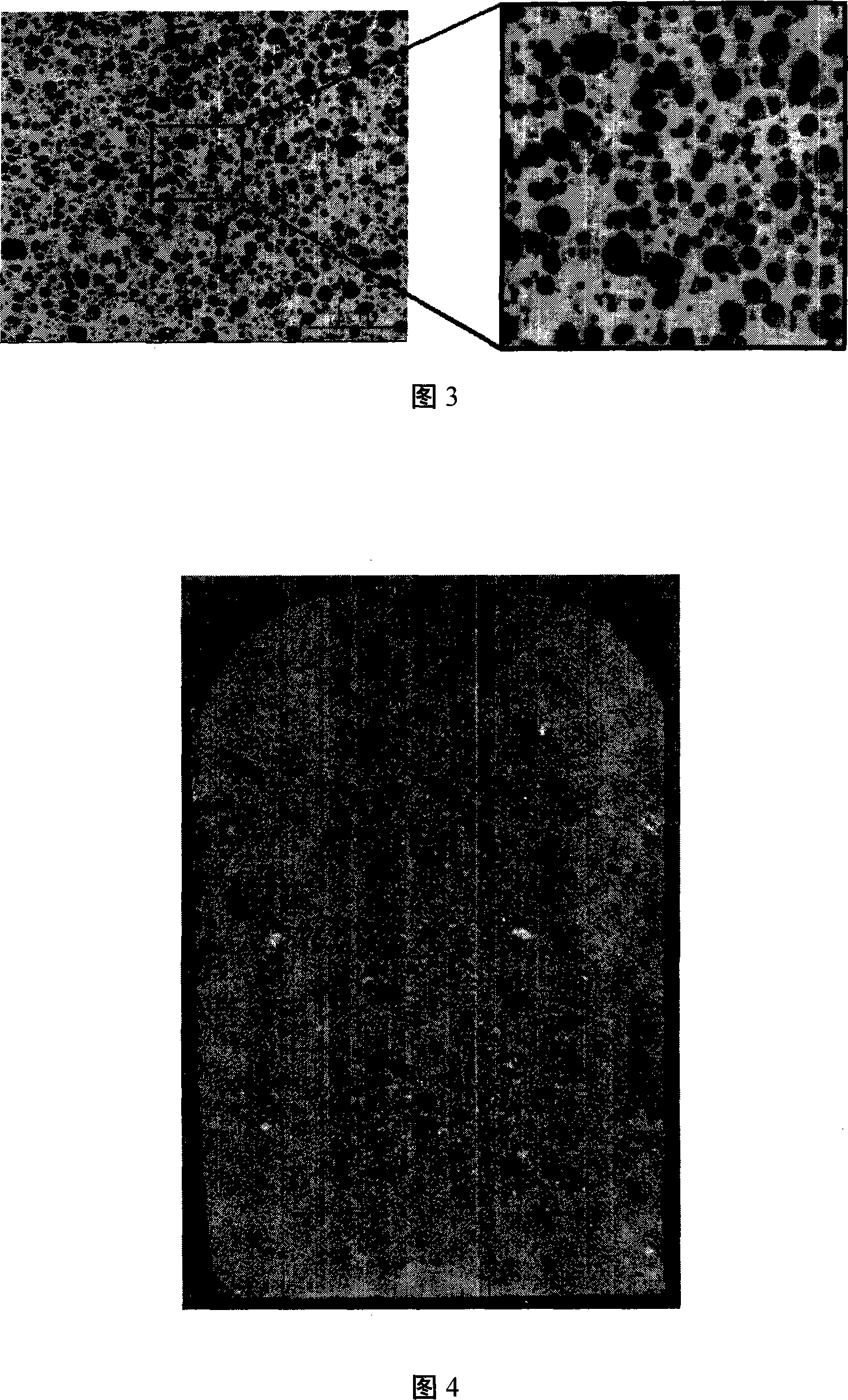

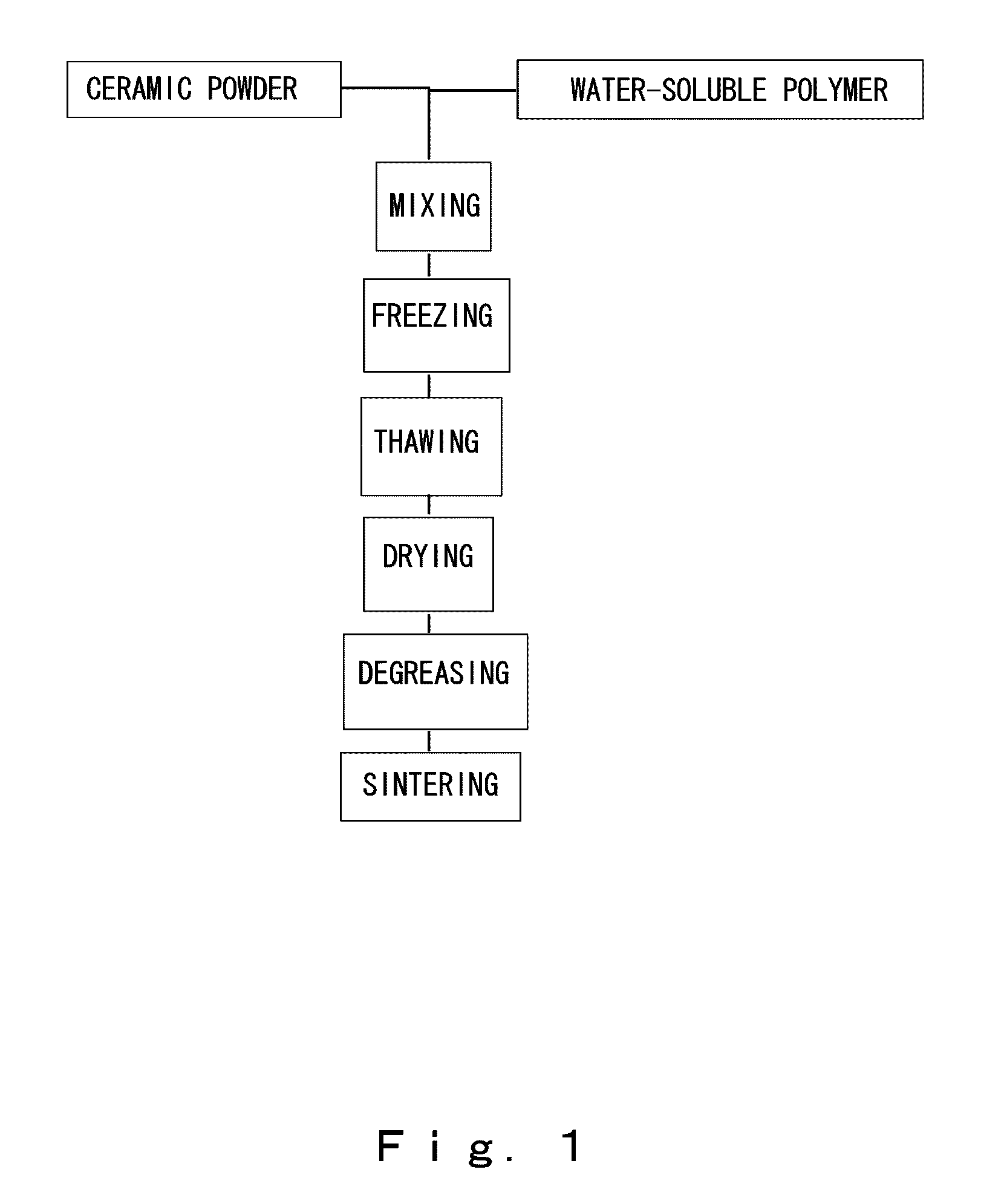

Ceramic porous body with communication macropores and process for producing the ceramic porous body

ActiveUS8262957B2Avoid crackingDifficult to maintainCeramic shaping apparatusCeramicwarePore diameterWater soluble

The present invention is a method for producing a ceramic porous body with high porosity and continuous macropores, which comprises mixing a ceramic powder with an aqueous solution of a gelable water-soluble polymer to form a slurry, gelling for a while to fix the tissue structure, freezing it to produce ice crystals in the gel tissue and creating structures that become continuous pores, thawing the ice by controlled atmospheric substitution-type drying method with the resulting water being replaced without damaging the gel, and then sintering it to produce a ceramic porous body having various porosities, pore diameters and pore shapes, while conventionally cracks and contraction were likely to occur during drying when the solids concentration of the slurry is less than 20 vol %, with the method of the present invention it is possible to control these problems even at a solids concentration of 10 vol % or less, manufacture and provide a ceramic porous body with a porosity of 72% to 99% and a compression strength of 0.4 MPa or more.

Owner:NAT INST OF ADVANCED IND SCI & TECH

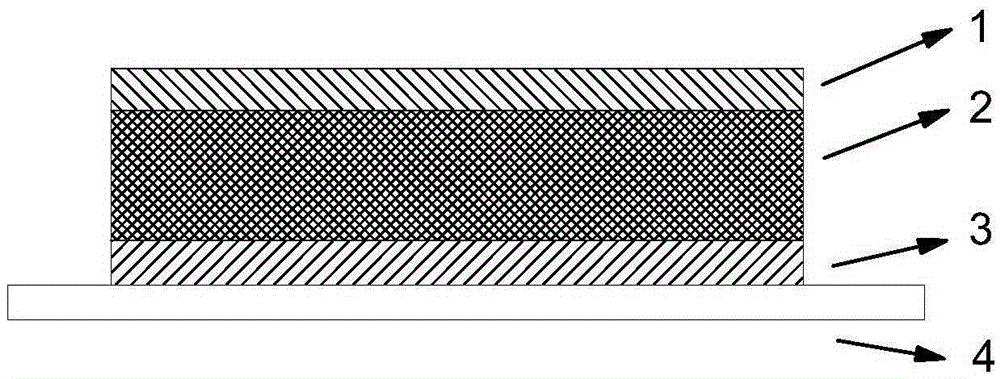

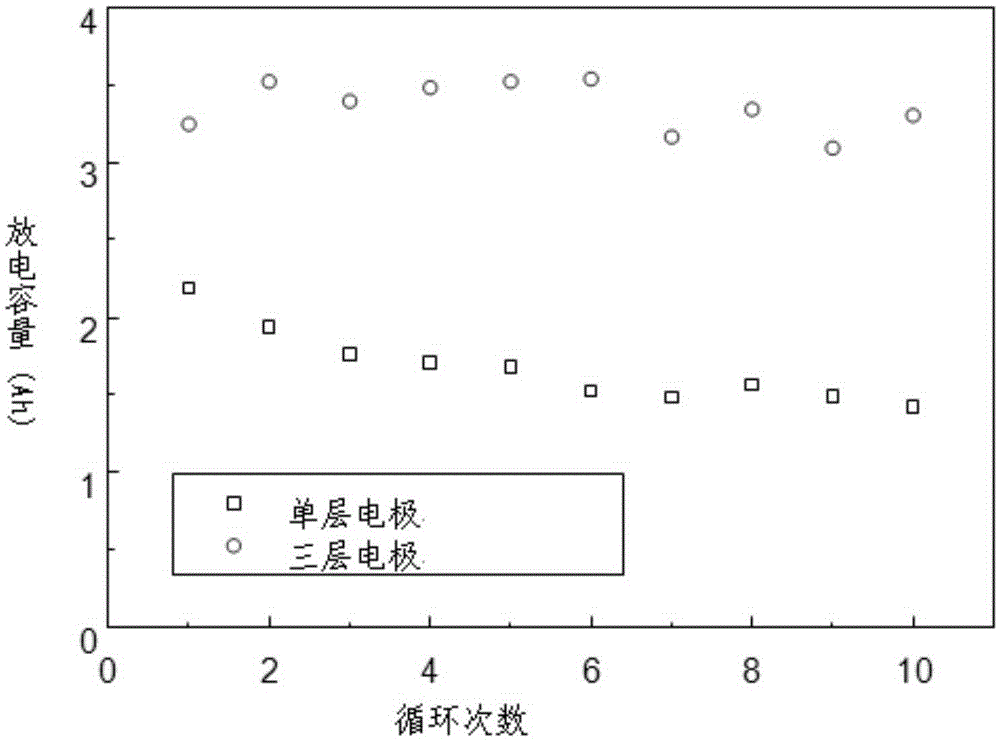

Electrode structure of lithium sulfur battery and processing technology therefor

InactiveCN105374982AImprove solubilityInhibition of the shuttle effectElectrode collector coatingNon-aqueous electrolyte accumulator electrodesCarbon coatingLithium–sulfur battery

The invention discloses an electrode structure of a lithium sulfur battery and a processing technology therefor. The electrode structure comprises a sulfur-containing active substance layer and a current collector; the upper surface of the active substance layer is coated with a first carbon coating layer; the lower surface of the active substance layer is coated with a second carbon coating layer; and the second carbon coating layer is positioned between the active substance layer and the current collector. The electrode structure has the main characteristics that the two sides of the sulfur-containing active substance layer are coated with the carbon coating layers; namely, the surface of the active substance layer, and the space between the active substance layer and the current collector are coated with the carbon coating layers, wherein a carbon material is taken as the main component, and the carbon material with a large specific surface area or low bulk density is preferable; the carbon material with the relatively large specific surface area can absorb polysulfide and restrain a shuttle effect; meanwhile, the carbon material with the low bulk density can form the relatively loosen carbon coating layer so as to store a large amount of electrolyte in the carbon coating layer, and the dissolution of sulfur and the polysulfide is facilitated, a positive electrode reaction is promoted, and the increase of electrolyte viscosity caused by resolution is restrained.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

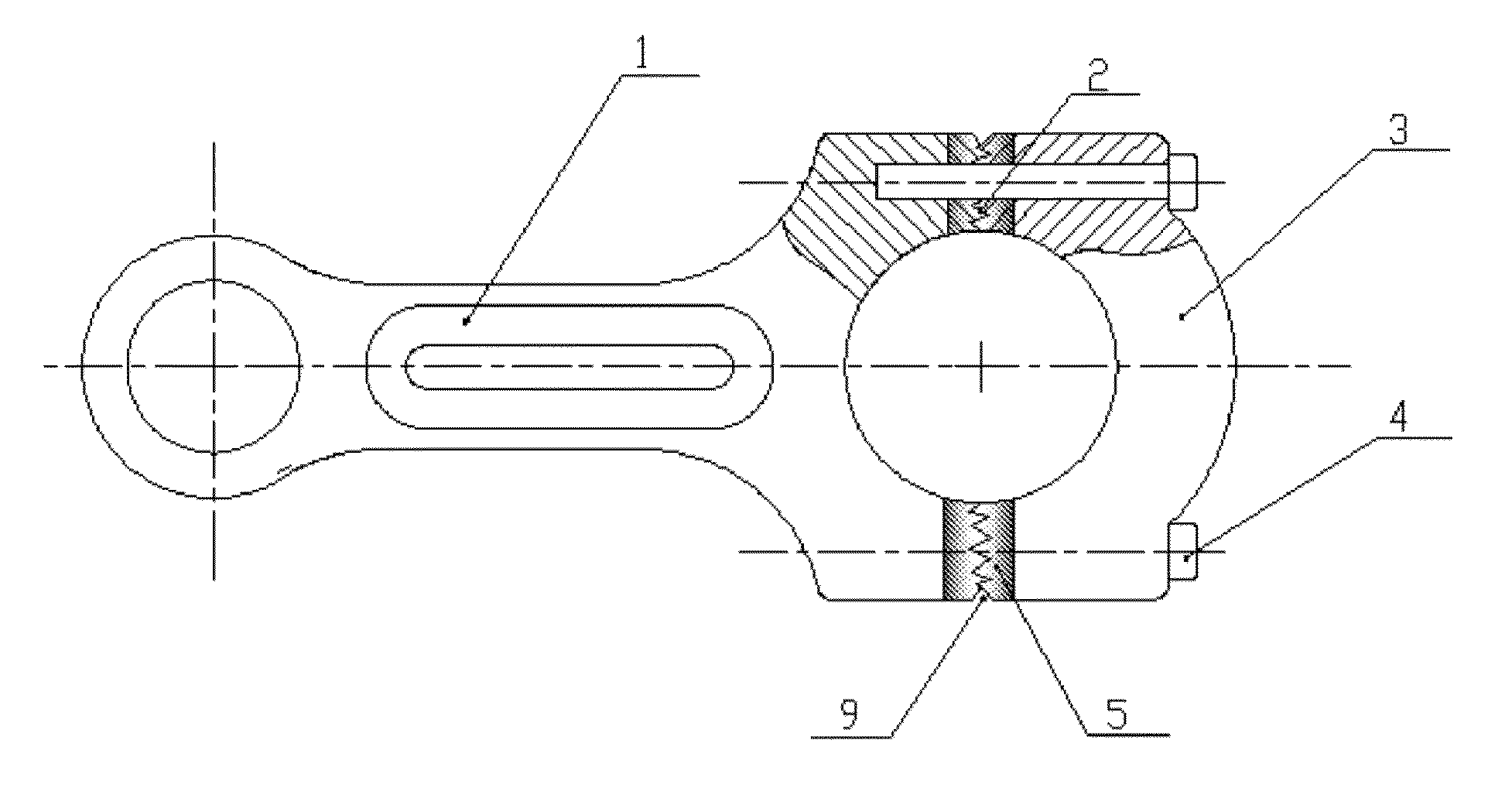

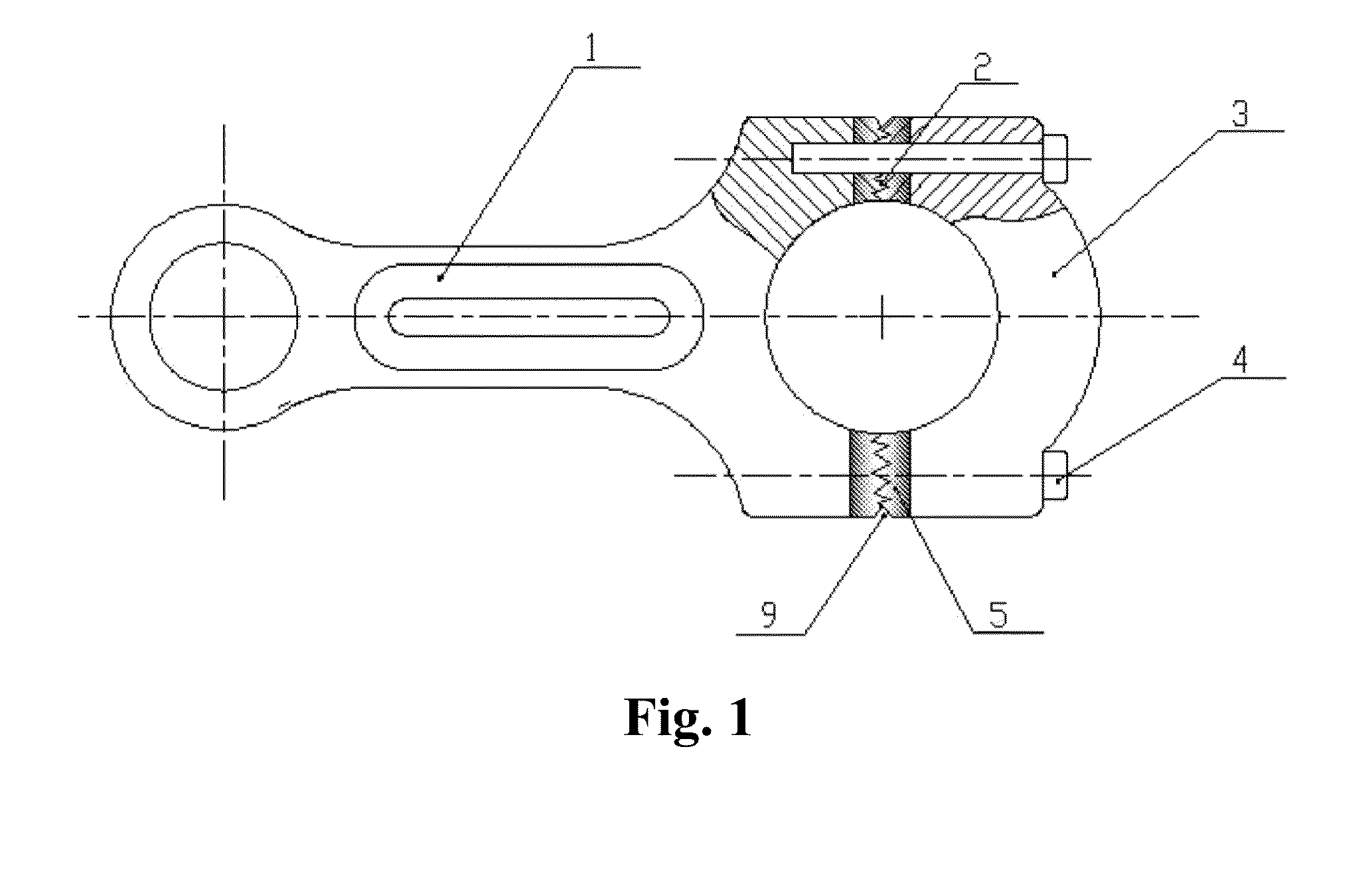

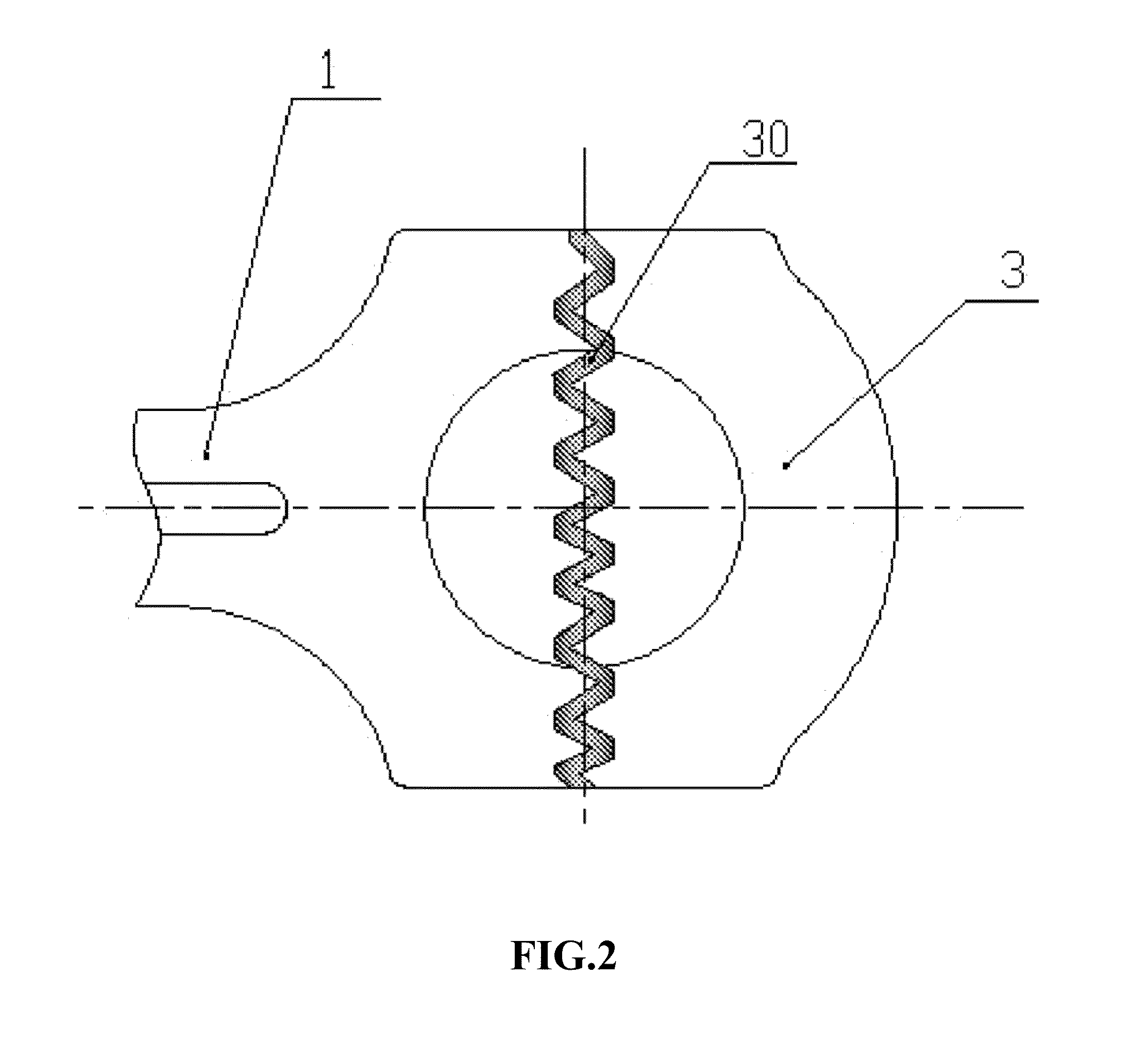

Method for manufacturing composite double-metal fracture splitting connecting rod

InactiveUS20150053363A1Ensures performanceSimplify connection procedureConnecting rodsShaftsMetalMaterials science

The present invention provides a method for manufacturing a composite double-metal fracture splitting connecting rod, comprising the steps of: providing a moveable spacer at a large end of a mold cavity of a connecting rod, to divide the mold cavity into two separate parts; casting a connecting rod body and a connecting rod cap with material for the main body of the connecting rod; removing the spacer from the mold cavity when the majority of the material is solidified, then injecting material for a fracture splitting region into an empty mold cavity obtained after the removal of the spacer, and metallurgically bonding the two types of material to form a composite double-metal casting; then, separating the connecting rod body from the connecting rod cap by a fracture splitting apparatus along preset fracture surfaces; and positioning and accurately assembling through engaged staggered structures on the two fracture surfaces.

Owner:JIANGSU UNIV

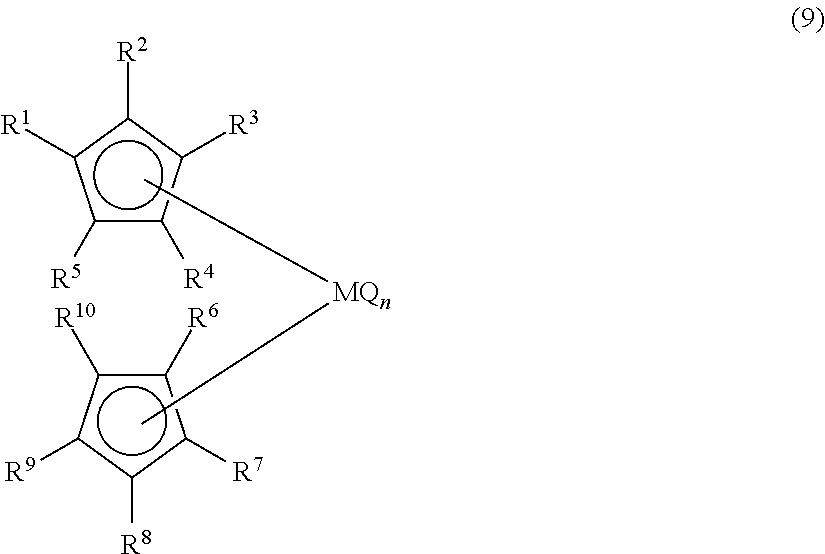

Process for preparing organic alkali metal compound and organic transition metal compound

ActiveUS20120049391A1High yieldSafe preparationLithium organic compoundsMetallocenesOrganic baseAlkali metal

[Problem] To provide a preparation process by which an organic alkali metal compound is obtained in a high yield and a process for preparing an organic transition metal compound using the organic alkali metal compound. [Means to solve the problem] A process for preparing an organic alkali metal compound, which is characterized by adding a compound represented by the following formula (2) in the reaction of an active proton-containing compound represented by the following formula (1) with an alkali metal compound.RHp (1)In the formula (1), R is a hydrocarbon group or an amino group and may contain a halogen atom, a silicon atom, an oxygen atom or a nitrogen atom, H is an active proton, and p is the number of hydrogen atoms abstracted in the reaction with the alkali metal compound.In the formula (2), Ra to Rc are each an atom or a group selected from a hydrogen atom, a hydrocarbon group, a heteroatom-containing group and a silicon-containing group and may be the same as or different from each other, and the neighboring substituents may be bonded to each other to form a ring.

Owner:MITSUI CHEM INC

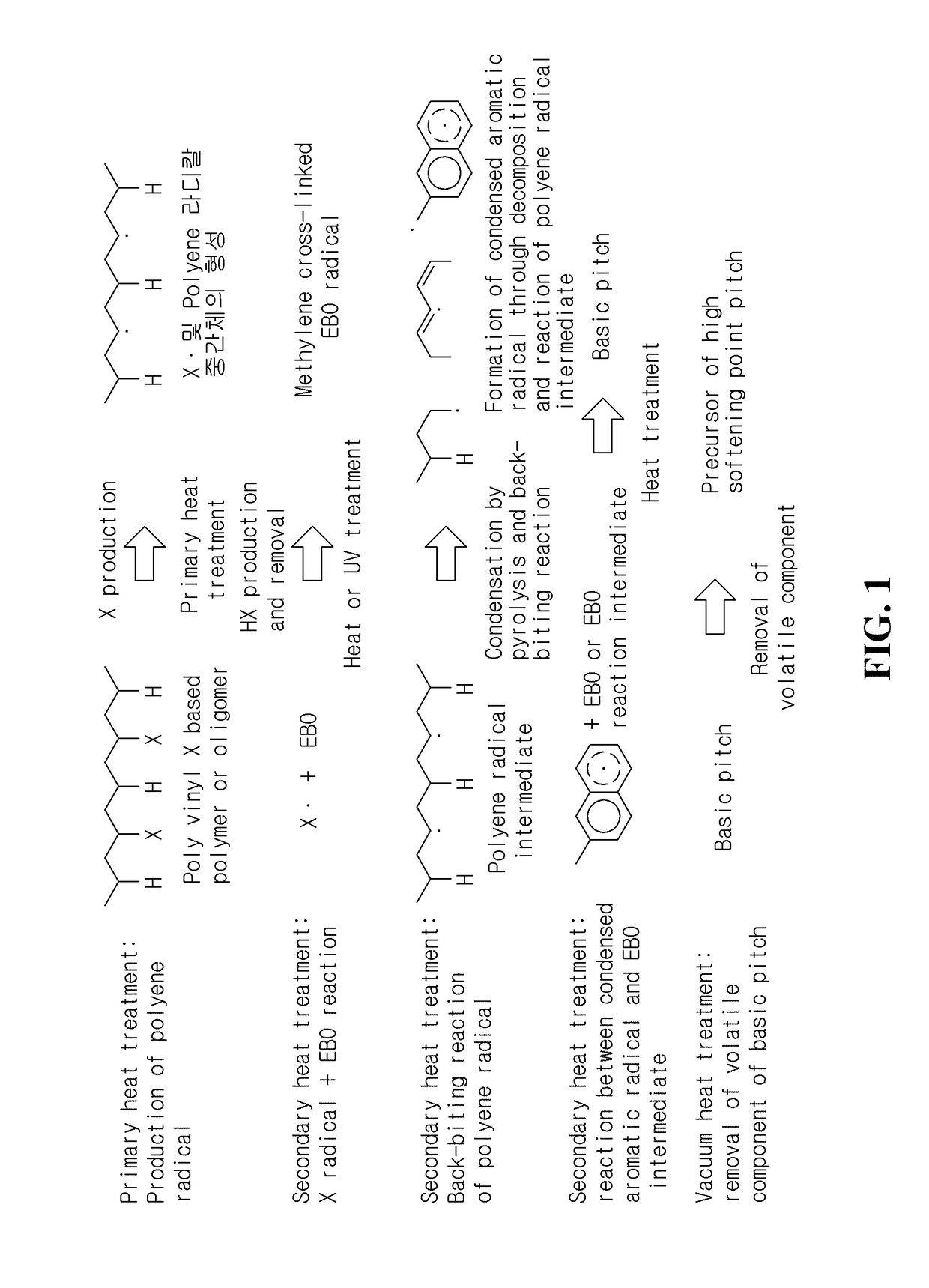

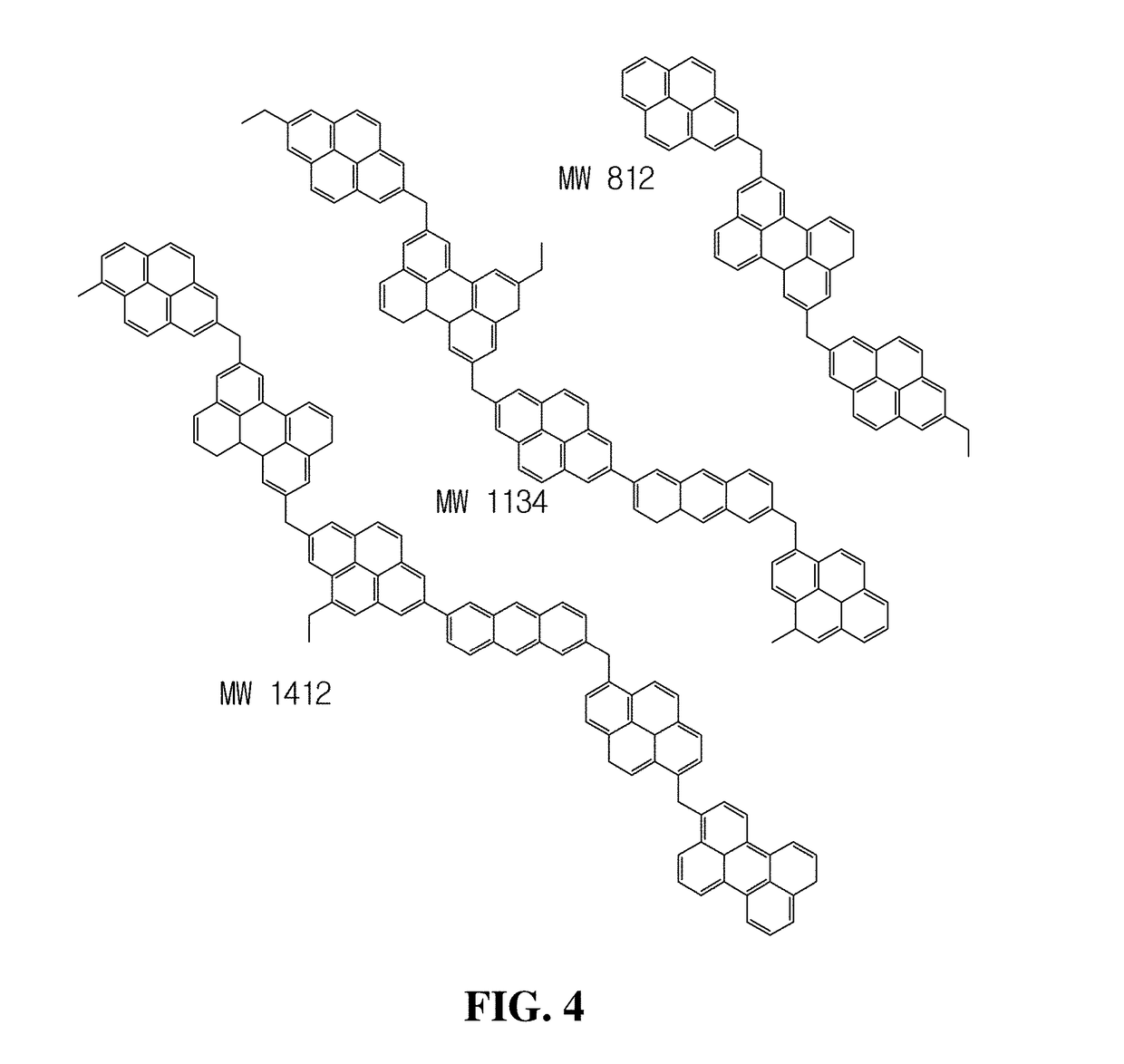

Method of preparing high softening point pitch and high softening point pitch prepared thereby

InactiveUS20170175001A1Improve yieldHigh molecular weightCell electrodesWorking-up pitch/asphalt/bitumen by chemical meansHeat treatedPhotochemistry

Provided are a method of preparing a high softening point pitch and the high softening point pitch prepared thereby, in which a polyene radical intermediate is formed, and an alkylaromatic radial material is linearly linked to the polyene radical intermediate in a benzyl or methylene form to be polymerized. The method includes performing heat treatment by adding a compound, which is able to a polyene radical intermediate, to 1- to 4-ring alkylaromatic condensates to produce a basic pitch, and performing vacuum heat treatment for the basic pitch.

Owner:YUSUNG TELECOM

Near-infrared light emitting microcrystalline glass with embedded Er:YAG microcrystalline phase and preparation method of microcrystalline glass

InactiveCN108439807ARaw material composition is simpleHigh fluorescence efficiencyNear infrared lightX ray irradiation

The invention provides near-infrared light emitting microcrystalline glass with an embedded Er:YAG microcrystalline phase and a preparation method of the microcrystalline glass. A microcrystalline phase substance is YAG, active ions are Er <3+> and uniformly doped into YAG microcrystalline phases, the microcrystalline phases are uniformly distributed in the microcrystalline glass, cationic mole percentage of the near-infrared light emitting microcrystalline glass includes, 13-34.9% of Y<3+>, 65-77% of Al<3+> and 0.1-10% of Er<3+>, and the sum of the mole percentage of the active ions Er<3+> and Y<3+> is 23-35%. Er:YAG microcrystalline separated out from the Er:YAG microcrystalline glass is small and uniform in size, so that the prepared microcrystalline glass has the advantages of high transparency and heat conductivity, resistance to deliquescence and x-ray irradiation, excellent optical performance and the like, and the microcrystalline glass can be applied to the fields of optical amplifiers, lasers and the like.

Owner:WUHAN UNIV OF TECH

Method of manufacturing the organic electroluminescent display and organic electroluminescent display manufactured by the method

ActiveUS7915073B2Solve easy adhesionMechanical damage reduction effect is smallSolid-state devicesVacuum evaporation coatingOrganic filmGas phase

The present invention provides an organic EL display panel manufacturing method which is capable of forming a desired organic film or the like with high accuracy without imparting damages to a substrate and an organic film and an organic EL display panel which is manufactured by the method. An opening portion which corresponds to a panel pattern region of a display panel is formed in a vapor deposition mask. The opening portion has a bottom surface in the inside of a recessed surface which is retracted from a surface on which the vapor deposition mask is brought into contact with the substrate. The opening portion of the vapor deposition mask is spaced apart from the substrate with a predetermined gap space and evaporated particles from an evaporating source are vapor-deposited to the substrate through the opening portion.

Owner:SAMSUNG DISPLAY CO LTD +1

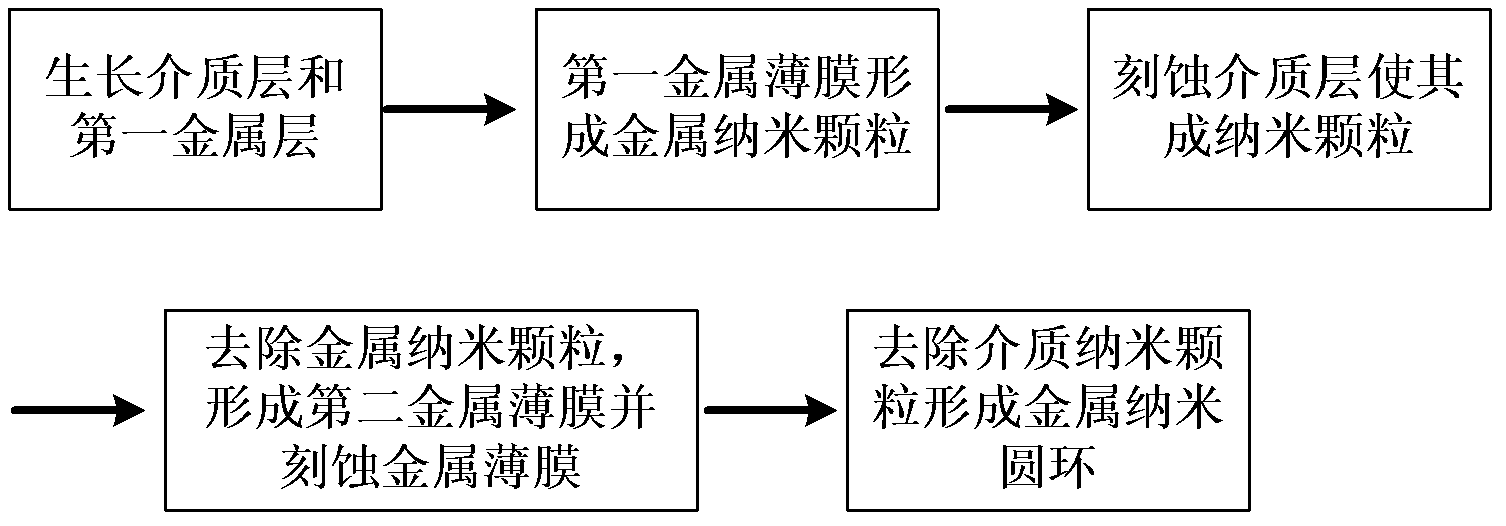

Method for preparing metal nano-circular ring

ActiveCN103268910AEasy to makeDifficult to prepareNanotechnologySemiconductor devicesNanoparticleMetallurgy

The invention discloses a method for preparing a metal nano-circular ring. The method comprises a first step of sequentially planting a medium layer and a first metal layer on the surface of a thin film of a photoelectric device, wherein the metal nano-circular ring needs to be formed on the surface of the thin film, a second step of machining a first metal thin film into metal nano-particles through the annealing process, a third step of etching the medium layer to form medium nano-particles with the metal nano-particles as a reticle mask, a fourth step of removing the metal nano-particles, planting at least one layer of a second metal thin film on the device surface provided with the medium nano-particles and on the tops and the side walls with the medium nano-particles, etching the second metal thin film, and only retaining the second metal thin film on the side walls with the medium nano-particles, and a fifth step of removing the medium nano-particles and finally forming the metal nano-circular ring.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

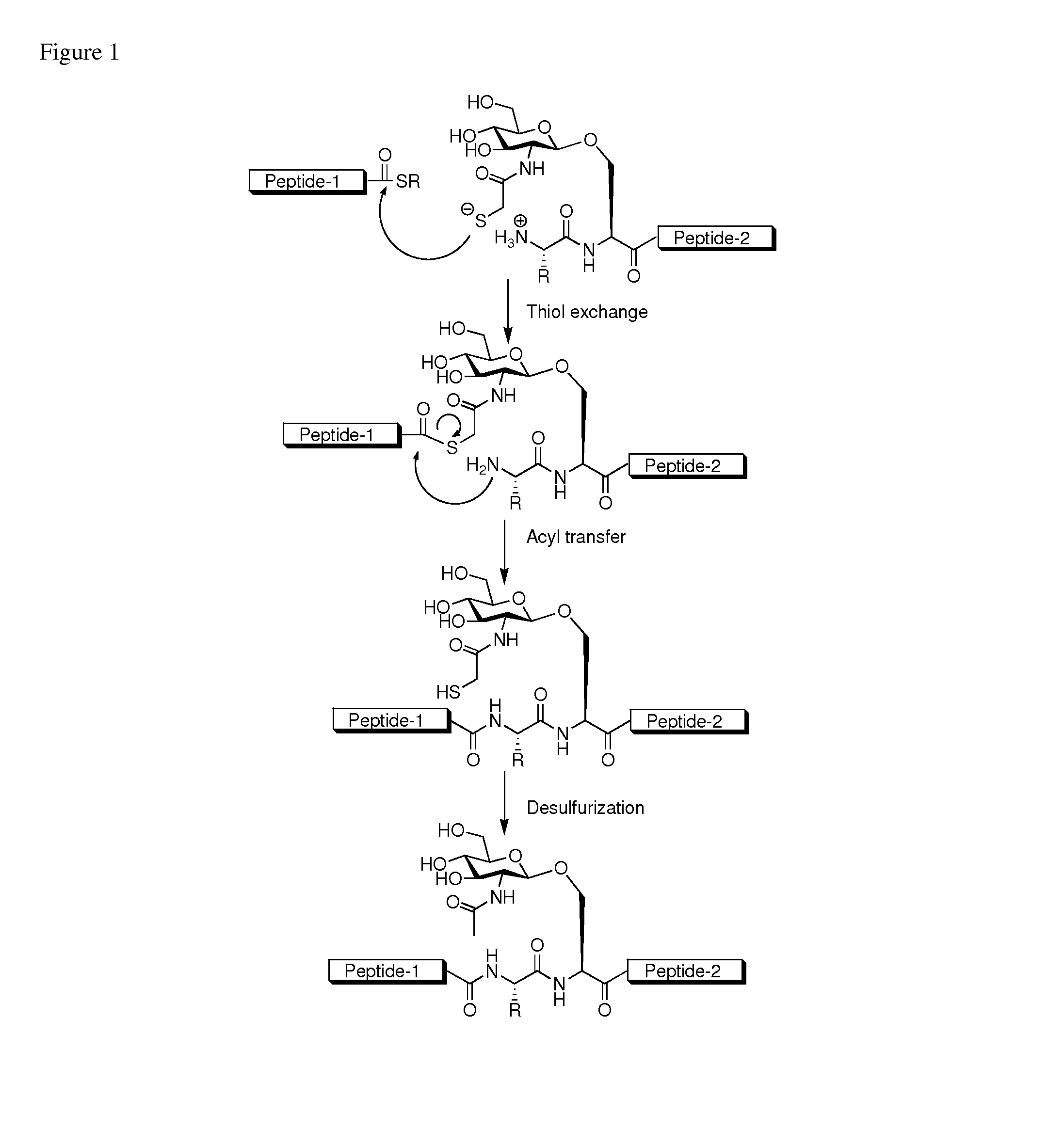

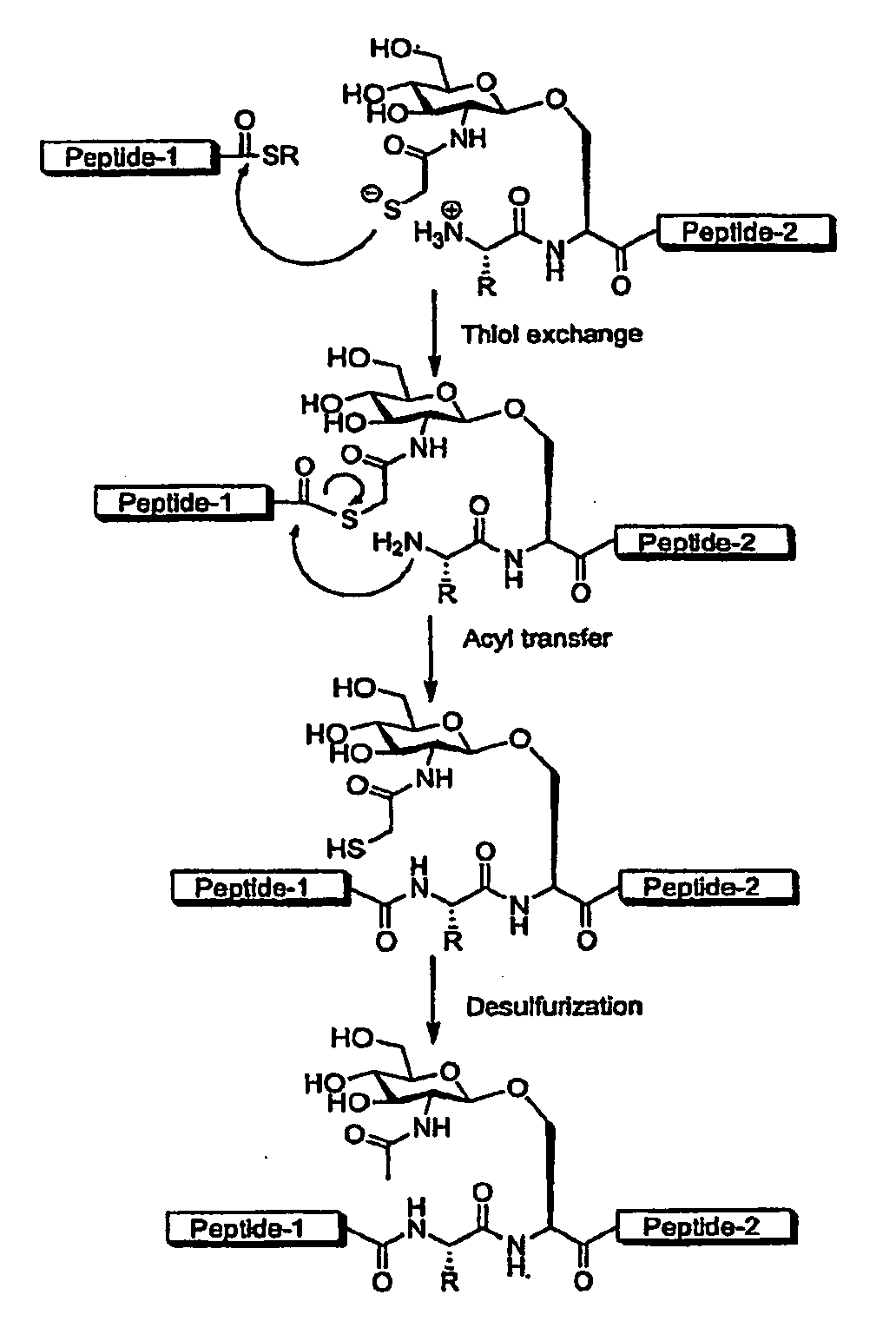

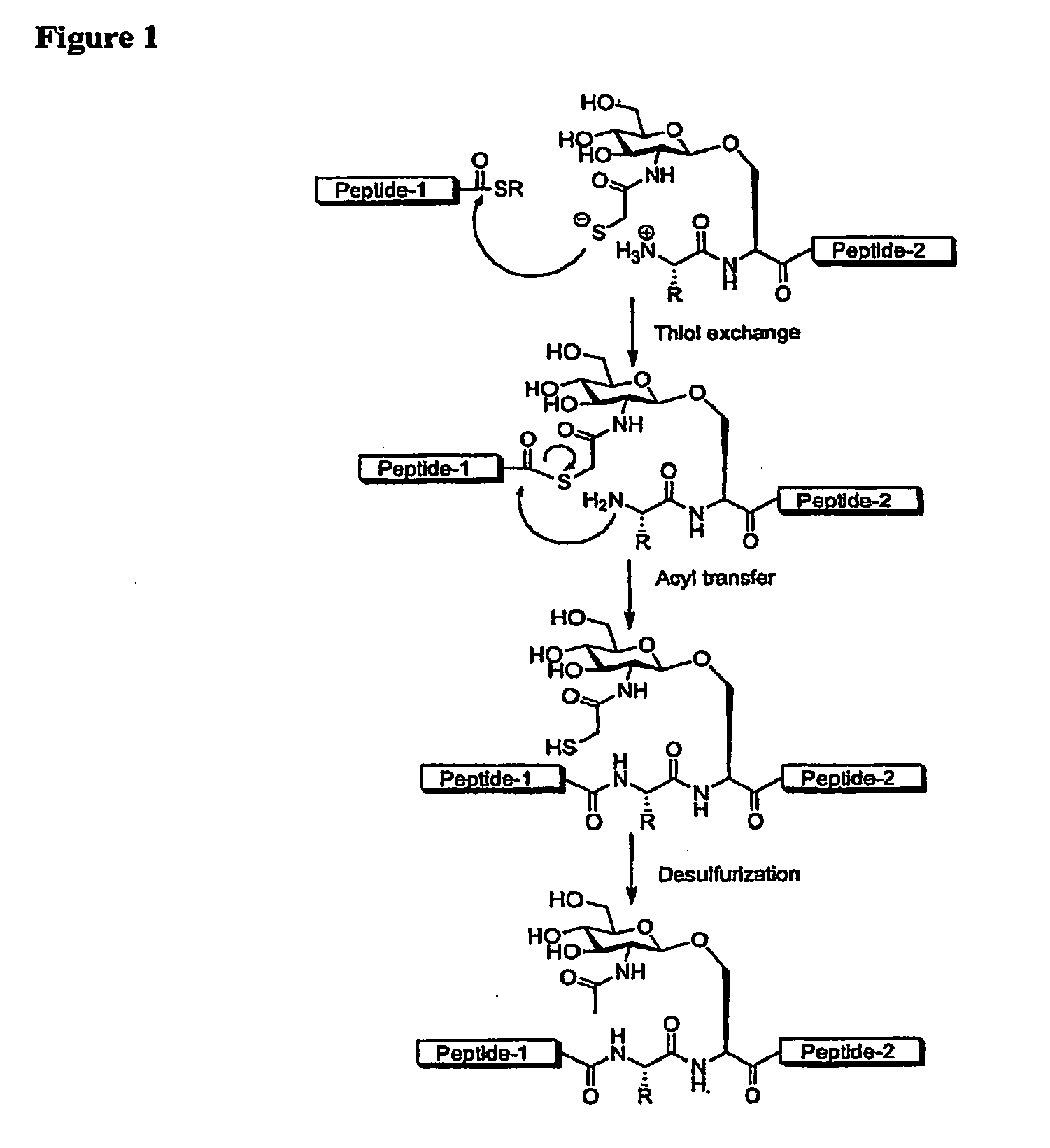

Method of preparing glycopeptides

ActiveUS8816050B2Difficult to prepareHigh yieldSaccharide peptide ingredientsPeptide preparation methodsGlycopeptideCarbohydrate moiety

Owner:THE SCRIPPS RES INST

Release-paper base paper and method for producing same, and release paper

ActiveUS11352751B2Improve sealingImprove curingWater-repelling agents additionPaper/cardboardPolymer sciencePolyvinyl alcohol

Release paper base paper, includes: a substrate; and a coating agent containing a polyvinyl alcohol (A) and a compound (B), the substrate coated with the coating agent, wherein the compound (B) is unsaturated carboxylic acid or a derivative thereof having a pKa of less than 4.00, and 0.1 part by mass or more and 20 parts by mass or less of the compound (B) is contained based on 100 parts by mass of the polyvinyl alcohol (A). The release paper base paper of the present invention is excellent in sealing properties for silicone and waterproofness. The release paper base paper of the present invention is also capable of accelerating curing of silicone in a release layer.

Owner:KURARAY CO LTD

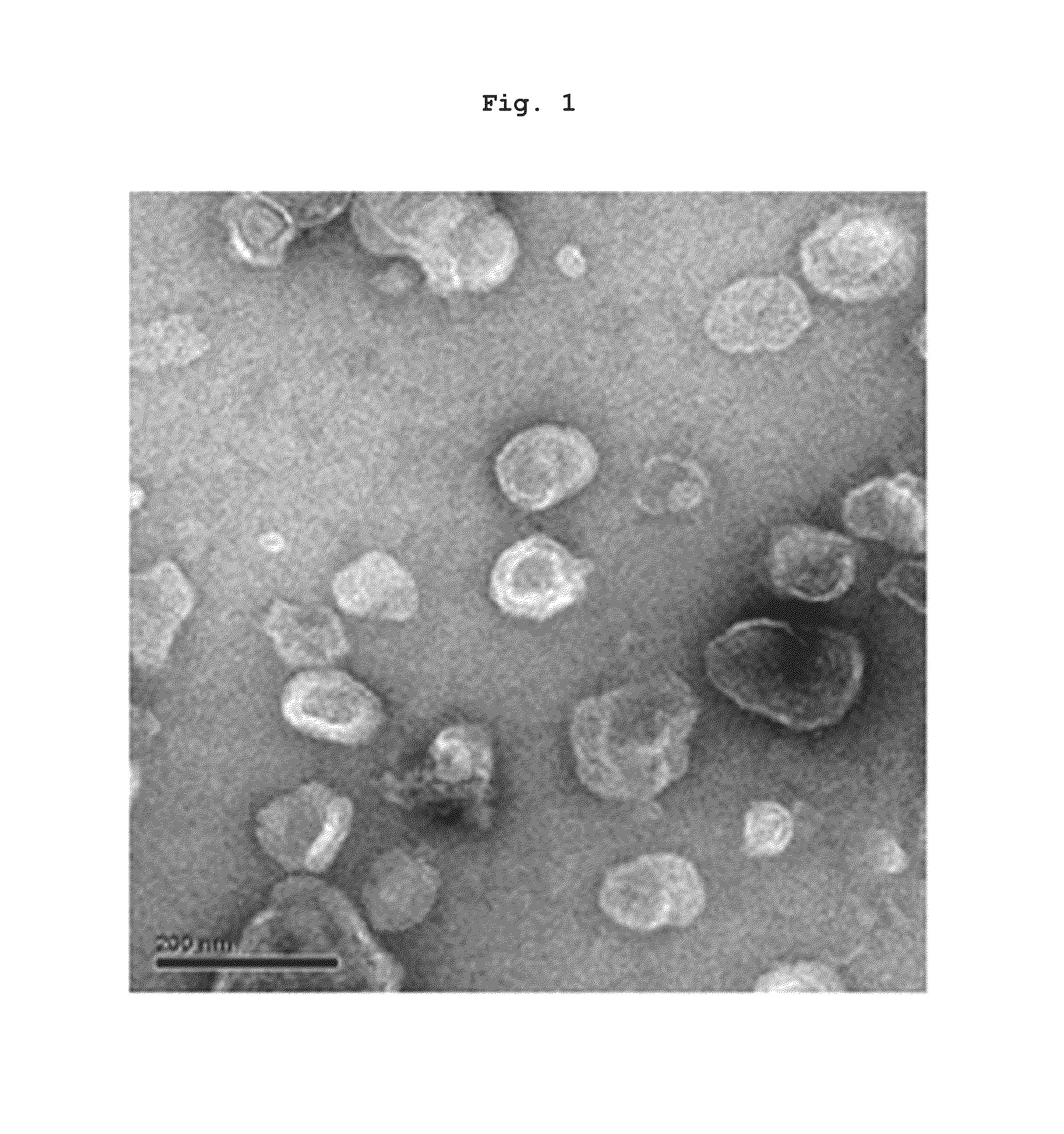

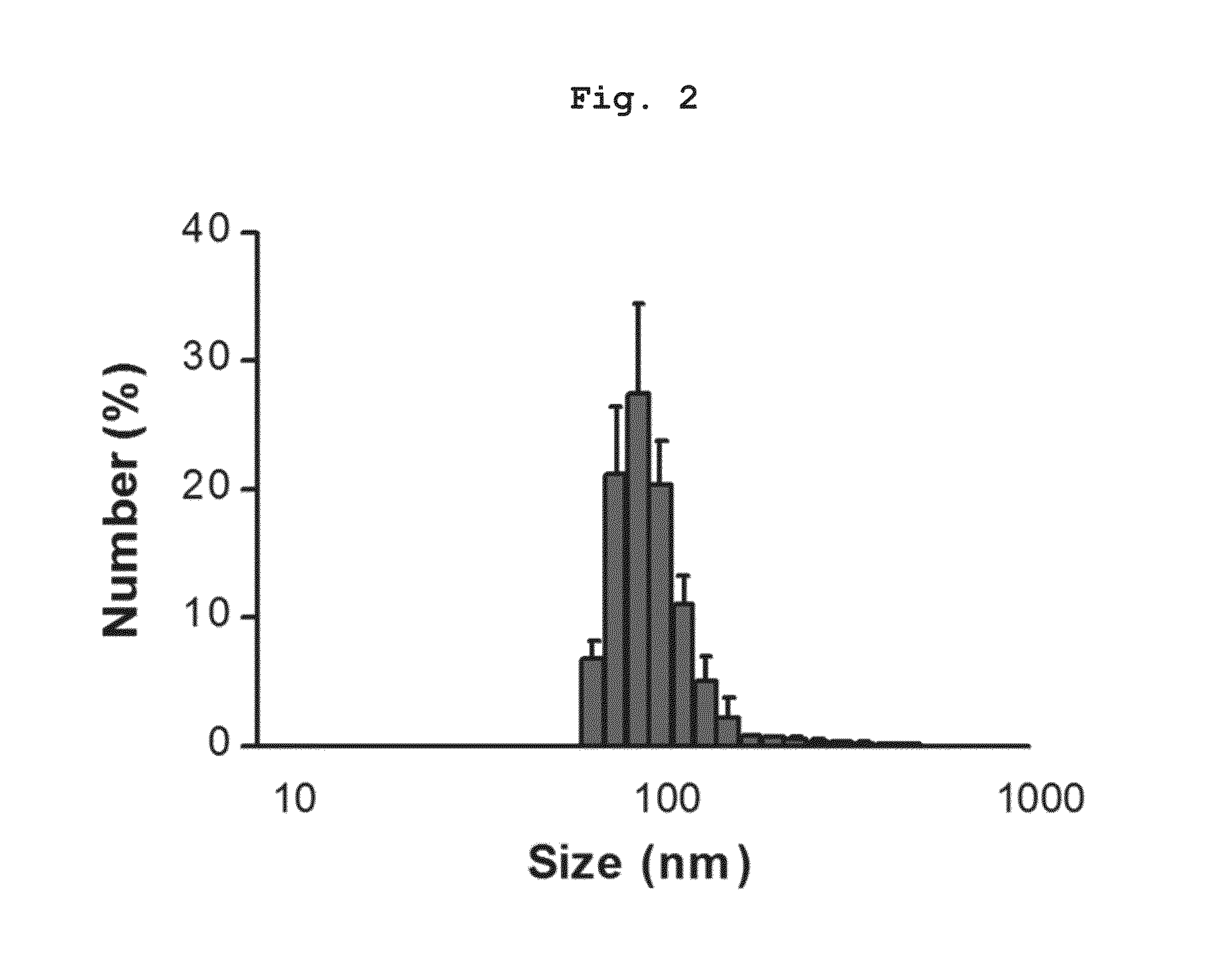

Nano-vehicle derived from tumor tissue, and cancer vaccine using same

ActiveUS9220763B2High yieldEffective activityPeptide/protein ingredientsCancer antigen ingredientsAntigenWilms' tumor

The present invention relates to a cancer vaccine, and specifically, to a pharmaceutical composition for treating cancer containing a nano-vehicle derived from tumor tissue, and a method for treating cancer using the nano-vehicle derived from tumor tissue, and the like. According to the present invention, a nano-vehicle antigen derived from tumor tissue indicates a high yield while having properties similar to those of an exocellular vehicle, and can be variously modified, and is thus expected to be very useful for developing the cancer vaccine.

Owner:ROSETTA EXOSOME CO LTD

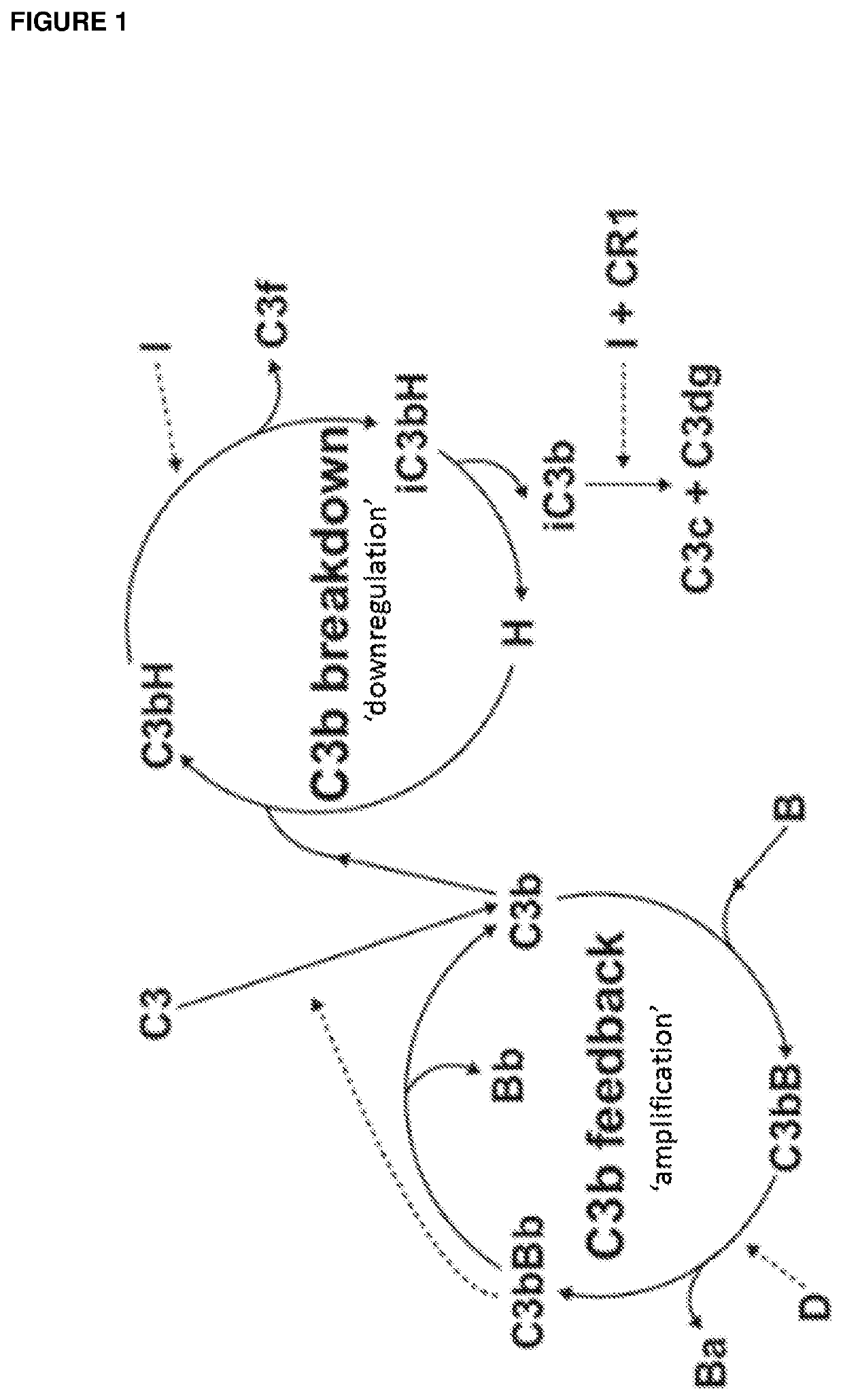

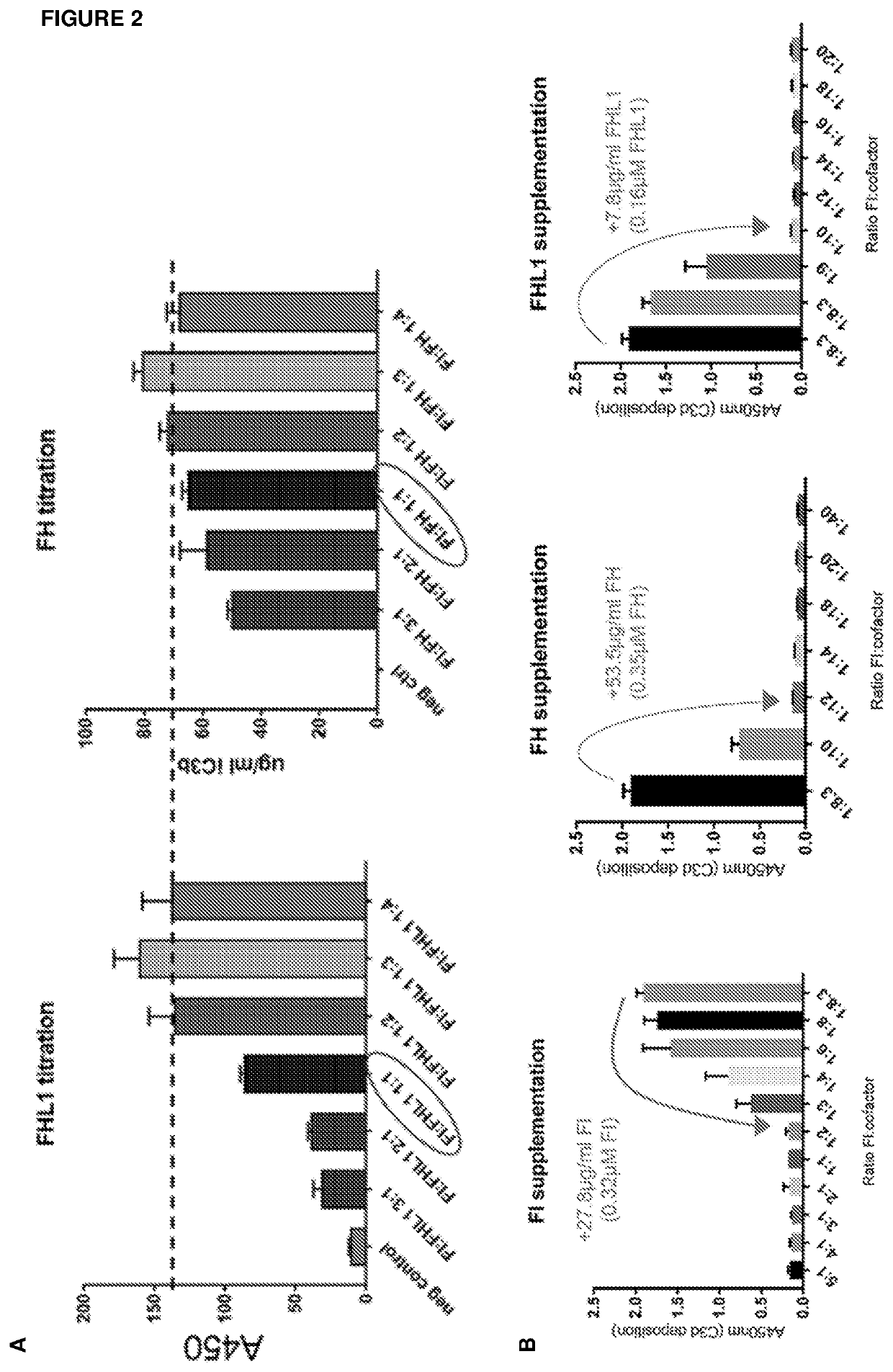

Complement factor i and complement factor i cofactor, vectors encoding therefor and therapeutic use

PendingUS20220072157A1Formation be prevent and reduceReduce the amount requiredSenses disorderPeptide/protein ingredientsNucleotideBiochemistry

Owner:GYROSCOPE THERAPEUTICS LTD

Preparation method of degradable PE film

The invention discloses a preparation method of a degradable PE film, which comprises the following steps: heating gallium to a temperature higher than a melting point to melt, dripping into PE micro powder, continuously stirring, keeping the temperature until the PE micro powder is uniformly mixed with the liquid gallium, then mixing with modified starch, granulating by using an extruder to prepare degradable master batches, and then preparing the degradable master batches into a film by using a blow molding machine. Gallium oxide is used as a photocatalyst to replace silicon dioxide, the silicon dioxide is a light ultraviolet absorbent, and the gallium oxide can be used as a deep ultraviolet absorbent, so that the service life of the degradable plastic under sunlight is prevented from being shortened. When degradation is needed, ultraviolet rays with specific wavelengths are used for digestion, and meanwhile, the ultraviolet rays are mixed with starch degradable substances to generate a synergistic effect.

Owner:NANTONG BAOJIALI NEW MATERIAL CO LTD

Process for preparing organic alkali metal compound and organic transition metal compound

[Problem] To provide a preparation process by which an organic alkali metal compound is obtained in a high yield and a process for preparing an organic transition metal compound using the organic alkali metal compound. [Means to solve the problem] A process for preparing an organic alkali metal compound, which is characterized by adding a compound represented by the following formula (2) in the reaction of an active proton-containing compound represented by the following formula (1) with an alkali metal compound.RHp (1)In the formula (1), R is a hydrocarbon group or an amino group and may contain a halogen atom, a silicon atom, an oxygen atom or a nitrogen atom, H is an active proton, and p is the number of hydrogen atoms abstracted in the reaction with the alkali metal compound.In the formula (2), Ra to Rc are each an atom or a group selected from a hydrogen atom, a hydrocarbon group, a heteroatom-containing group and a silicon-containing group and may be the same as or different from each other, and the neighboring substituents may be bonded to each other to form a ring.

Owner:MITSUI CHEM INC

Composite negative electrode material and preparation method therefor and lithium battery

PendingUS20220320505A1Increase storage capacityHigh cycle capacity retentionSecondary cellsNegative electrodesCarbon coatingGraphite

Provided are a composite negative electrode material, a preparation method therefor and a lithium battery. The composite negative electrode material comprises silicon-containing particles and a carbon coating layer coating at least part of the surface of silicon-containing particles. In Raman spectrum, the composite negative electrode material has a silicon characteristic peak A between 450 cm−1-550 cm−1, a carbon characteristic peak B between 1300 cm−1-1400 cm−1, a carbon characteristic peak C between 1530 cm−1-1630 cm−1, and a graphene structure characteristic peak D between 2500 cm−1-2750 cm−1. The preparation method comprises: in protective atmosphere, introducing reaction gas to react with silicon-containing particles, the reaction temperature being 700° C.-1450° C., and the reaction gas comprising a carbon-containing gas, so that at least part of the surface of silicon-containing particles form a carbon coating layer, so as to obtain the composite negative electrode material.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Foamed aluminium and aluminum alloy tackifying foaming preparation method

Owner:SOUTHEAST UNIV

Zinc oxide sintered body and method for producing same

ActiveUS10717679B2High transparencyGood orientationZinc oxides/hydroxidesConductive materialDopantOxide zinc

There is provided a platy zinc oxide sintered compact containing 0.80 wt % or less at least one first dopant element selected from the group consisting of Al, Ga and In, the balance consisting essentially of ZnO and optionally at least one second dopant element selected from the group consisting of Br, Cl, F, Sn, Y, Pr, Ge, B, Sc, Si, Ti, Zr, Hf, Mn, Ta, W, Cu, Ni, Cr, La, Gd, Bi, Ce, Sr and Ba, the second dopant element being optional component, wherein the (002)-plane orientation in the plate surface is 60% or more. The zinc oxide sintered compact of the present invention has excellent properties such as high orientation in addition to transparency and conductivity.

Owner:NGK INSULATORS LTD

Method of preparing glycopeptides

ActiveUS20110060121A1High yieldHigh puritySaccharide peptide ingredientsPeptide preparation methodsThioester synthesisGlycopeptide

Owner:THE SCRIPPS RES INST

Edible Granules with Varied Flavors and Their Preparation Methods

InactiveUS20210015137A1Difficult to prepareSugar food ingredientsFood ingredient as colourBiotechnologyNatural substance

The present invention discloses edible granules with varied flavors, relating to the technical field of food. The present invention comprises carbohydrates, water, emulsifiers, salt, sweeteners, flavor enhancers, acidity modifiers, food flavors, food colors and antioxidants, wherein the amounts of them are: carbohydrates 70-80%, water 10-20%, emulsifiers 0-10%, salt 0-10%, sweeteners 0-10%, flavor enhancers 0-2%, acidity modifiers 0-2%, food flavors 0.01-1%, food colors 0-0.5% and antioxidants 0.01-0.04%. In the present invention, through different components of carbohydrates, water, emulsifiers, salt, sweeteners, flavor enhancers, acidity modifiers, food flavors, food colors and antioxidants, edible granules with varied flavors may be prepared without adding natural substances in the granules of the present invention, so that the problem that the existing natural seasonings have a single taste and are difficult to prepare is solved.

Owner:PANASIA OLAUGHLIN BIO TECH WUHAN CO LTD

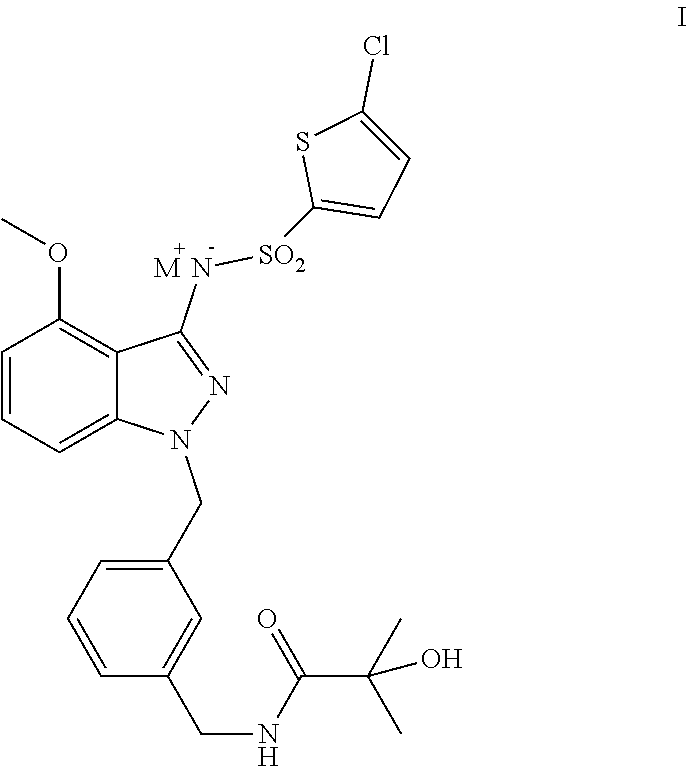

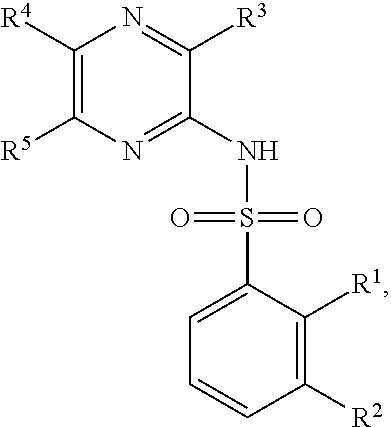

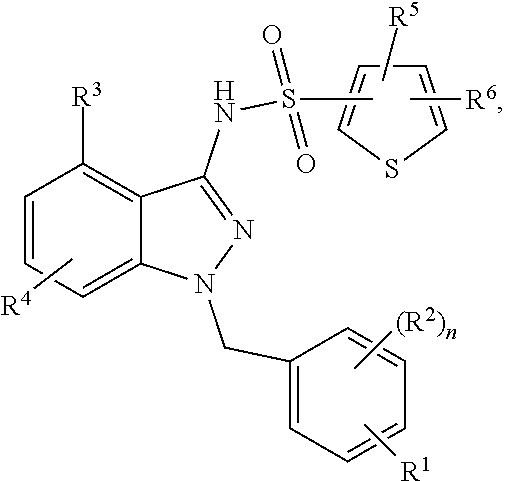

Compound, preparation method therefor, and use thereof

InactiveUS20210078985A1Reduce solubilityDifficult to prepareAntibacterial agentsOrganic active ingredientsDiseasePharmaceutical drug

The present disclosure provides a compound of formula I or a pharmaceutically acceptable salt, a solvate, or a prodrug thereof, wherein M is a monovalent alkali metal. The present disclosure also provides a method for preparing the compound or its pharmaceutically acceptable salt, solvate, or prodrug, and further provides a pharmaceutical composition containing the compound and its use in the preparation of a medicine, which can be used for the treatment of CCR4-mediated diseases.

Owner:MEDSPRING INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com