Foamed aluminium and aluminum alloy tackifying foaming preparation method

A technology of aluminum alloy and aluminum foam, which is applied in the field of foaming aluminum foam and aluminum alloy to increase viscosity and foaming, can solve the problem of difficult control of pore structure uniformity and consistency, high cost of tackifier and foaming agent, and difficulty in process parameters. To master other problems, to achieve the effect of simple and effective treatment method, not easy to be distorted, and prolong the stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

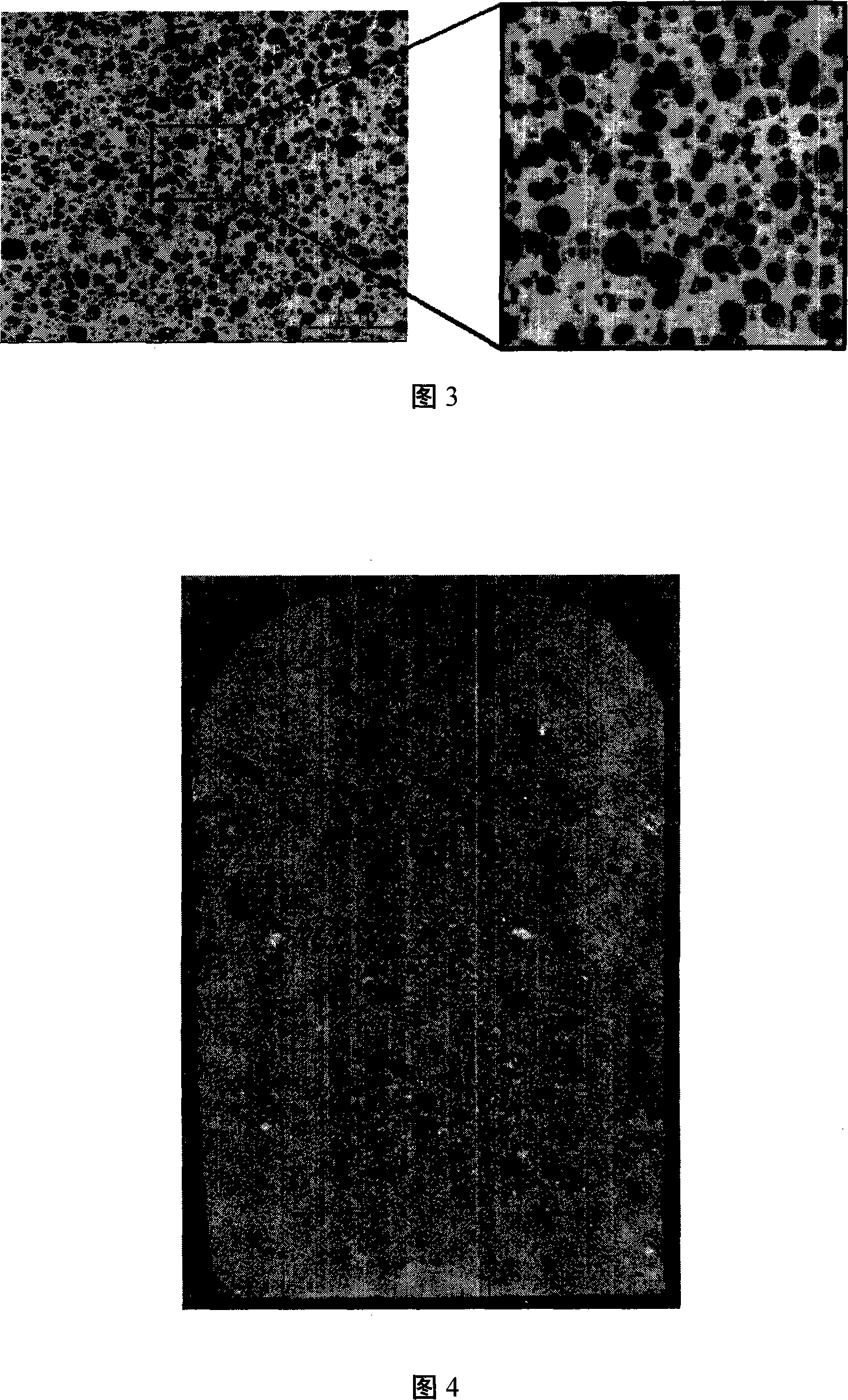

Embodiment 1

[0018] Heat the aluminum ingot to 670° C., keep it warm until the aluminum ingot is completely melted, add a calcium carbonate thickener with a mass percentage of 1.5%, and stir at a speed of 400 r / min to increase the viscosity to a preset viscosity. In order to make the tackifier fully mixed, determine the stirring time according to the reading of the torque meter, generally 5-10min, and then add calcium carbonate foaming agent powder treated with sodium sulfate, (add 10g sodium sulfate to 100mL water to make an aqueous solution, and then Add 50g of light calcium carbonate powder and stir well, bake it in an oven at 50℃ until fully dry, take it out and crush it, and pass through a 200-mesh sieve) The mass fraction is 1.5%, high-speed stirring is carried out, the speed is controlled at 800~1100r / min, and the stirring is 1.5~ After 3.5 minutes, raise the stirring paddle and keep the temperature in the furnace for 15-90s. In order to prevent the pore structure from collapsing, when ...

Embodiment 2

[0020] The aluminum ingot is heated to 665-700°C, kept until the aluminum ingot is completely melted, and 1.0%-2.0% by mass of calcium carbonate thickener is added, and stirred at a speed of 400r / min to increase the viscosity to a preset viscosity. In order to mix the tackifier thoroughly, determine the stirring time according to the reading of the torque meter, usually 5-10 minutes, and then add calcium carbonate foaming agent powder mixed with a small amount of titanium hydride (100g calcium carbonate powder mixed with 15g titanium hydride powder and stir well Mixing) The mass fraction is 1.0%~2.5%, high-speed stirring, the speed is controlled at 800~1100r / min, the stirring paddle is raised after 1.5~3.5min, the furnace is kept for 15~90s, in order to prevent the pore structure from collapsing and growing When it is close to the target size, it should be quickly taken out of the oven and cooled and solidified using a water cooling system.

Embodiment 3

[0022] The first step: add sodium sulfate or sodium fluoride and other sulfate and fluoride water-soluble salt solutions, which account for 5-15% of the water mass fraction, into a certain volume of water, and stir to fully dissolve;

[0023] The second step: add calcium carbonate powder, which accounts for 30-80% of the mass fraction of the aqueous solution, to the above-mentioned salt solution, stir it thoroughly and put it in an oven for drying, and crush it through a sieve to form a powder for use;

[0024] The third step: Take a certain amount of calcium carbonate powder, add 2-55% of the calcium carbonate mass fraction of titanium hydride powder to it, mix well, and set aside;

[0025] Step 4: Put the pure aluminum or aluminum alloy aluminum ingot into a heat-resistant crucible and heat it to 665-700°C, keep it warm until the aluminum ingot is completely melted, and the temperature of the aluminum liquid is uniform and stable;

[0026] Step 5: Lower the electric stirring pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com