Method for preparing metal nano-circular ring

A technology of metal nanoparticles and metal nanoparticles, applied in nanotechnology, electrical components, circuits, etc., can solve the problems of high cost, low production efficiency, and difficult preparation of metal nano rings, and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical scheme and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples, specifically providing the preparation of metal nano-rings composed of a single metal material and metal nano-rings composed of two metals. Two examples of metallic nanocircles.

[0018] Taking the LED structure in the visible light band as an example, metal nano-rings can be grown inside the N-type GaN film, inside the electron blocking layer, inside the P-type GaN film and on the surface of the P-type GaN. The two embodiments of the metal nano-circle manufacturing method given below are both illustrated by growing a metal nano-circle on the surface of P-type GaN as an example.

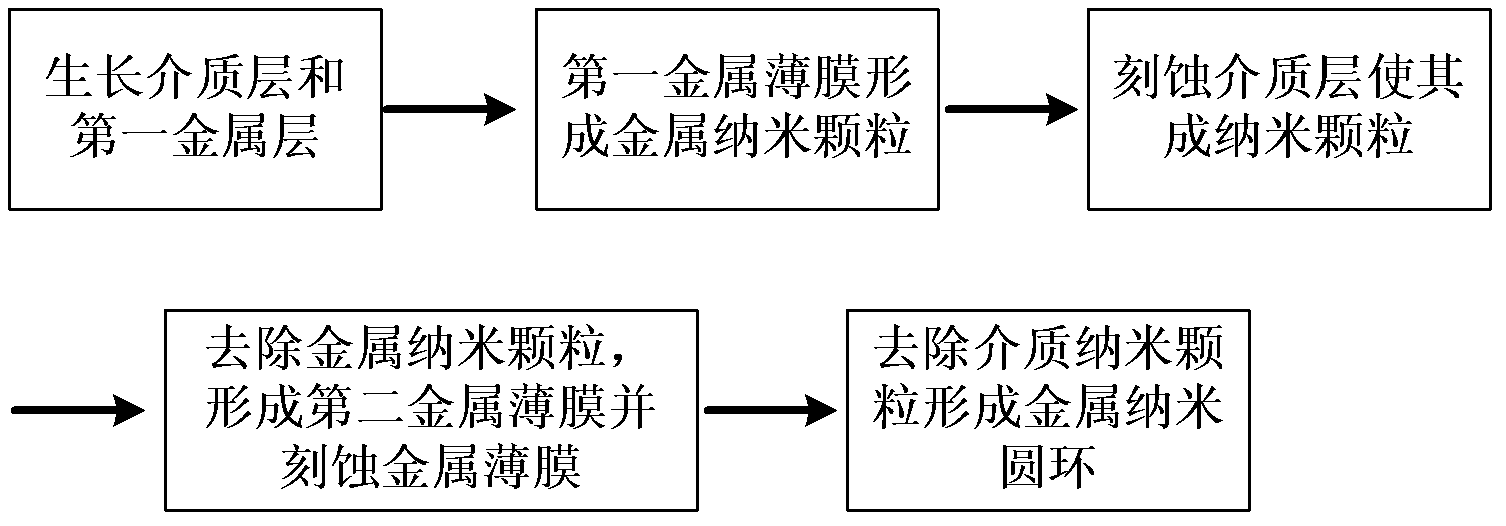

[0019] image 3 A flow chart of the preparation method of the metal nanocircle proposed by the present invention is shown. Such as image 3 As shown, the preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com