Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "High cycle capacity retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

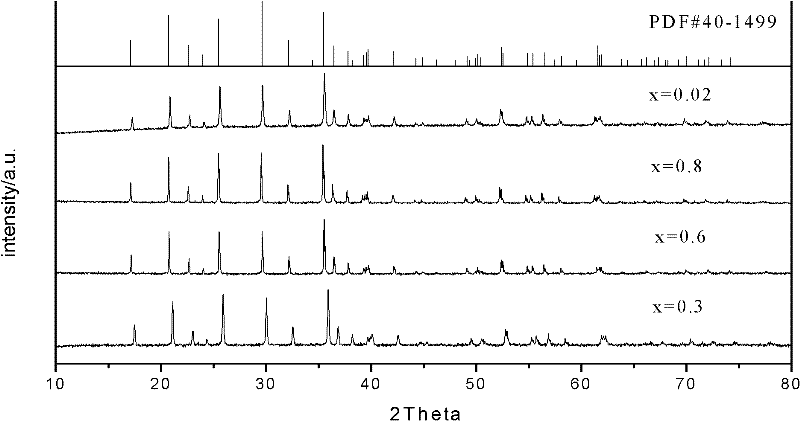

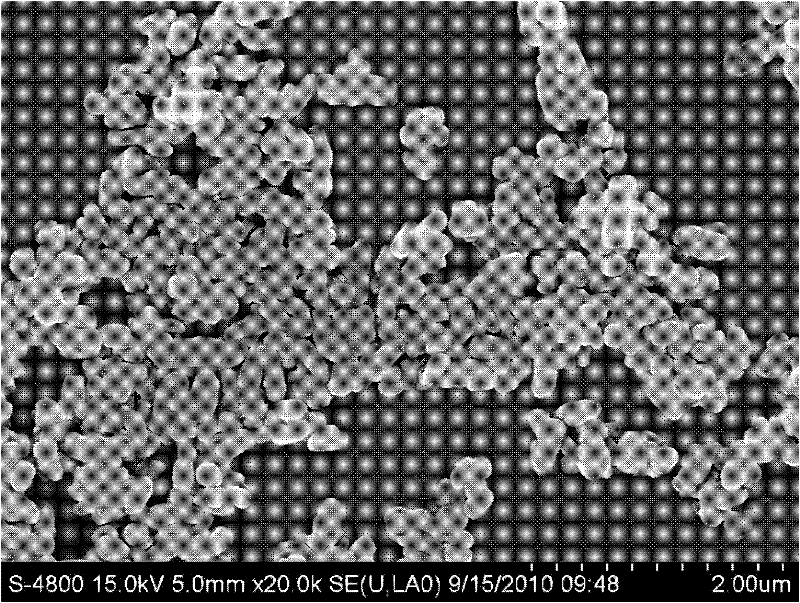

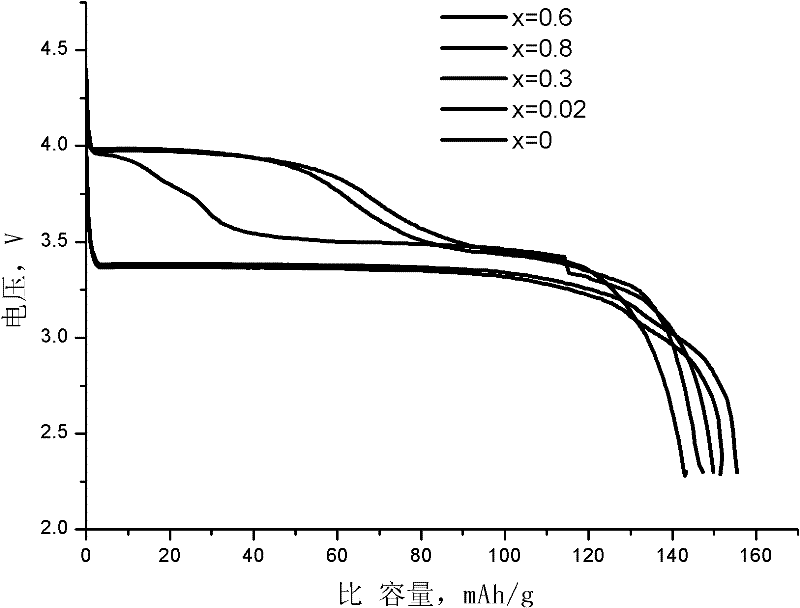

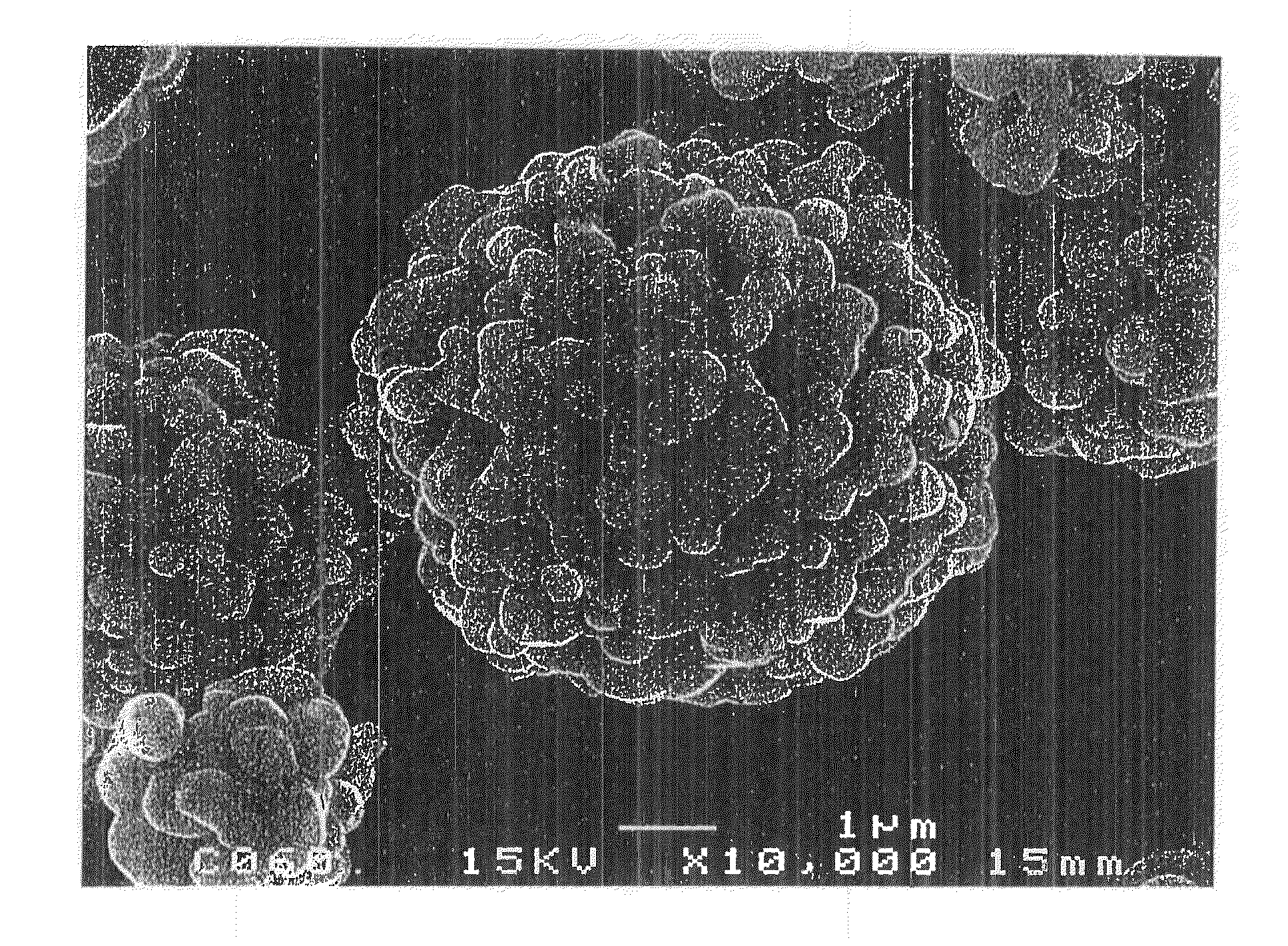

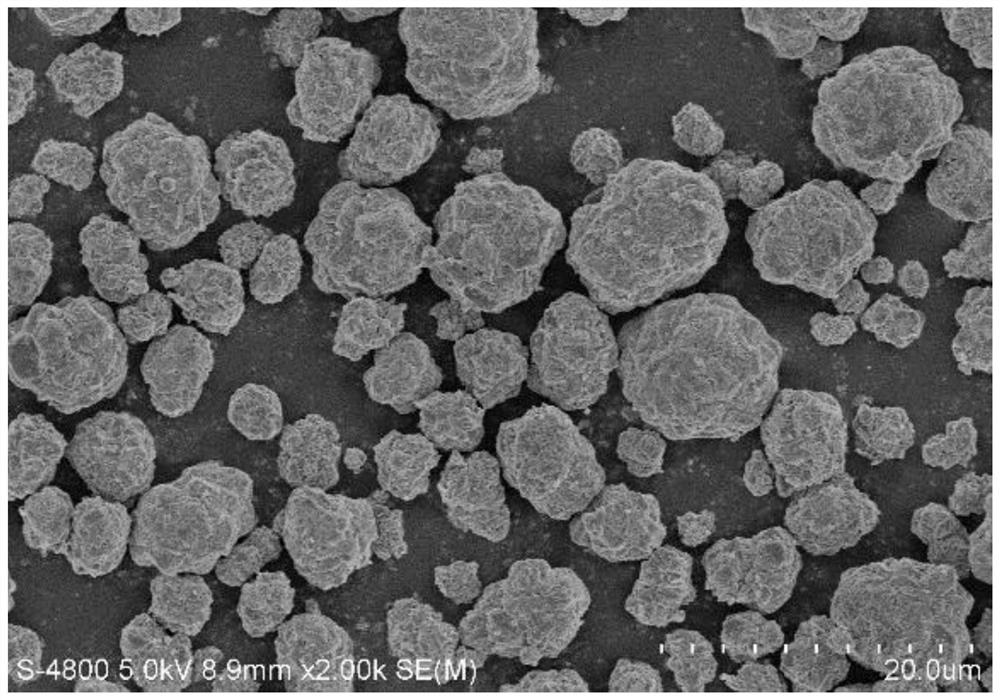

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

Powders for positive-electrode material for lithium secondary battery, process for producing the same, positive electrode for lithium secondary battery employing the same, and lithium secondary battery

InactiveUS20130011726A1High bulk densityCost reductionElectrode carriers/collectorsActive material electrodesPore distributionLithium

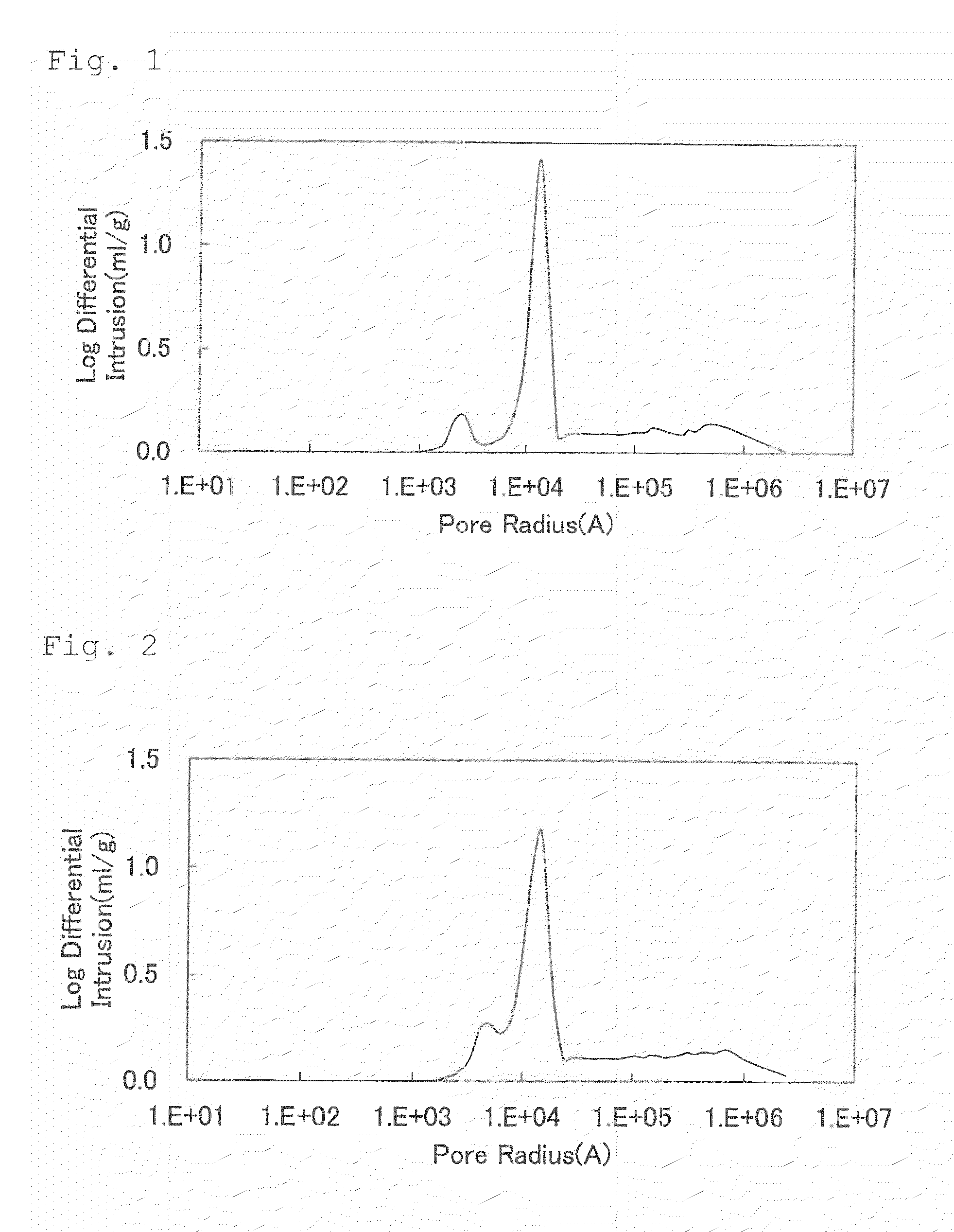

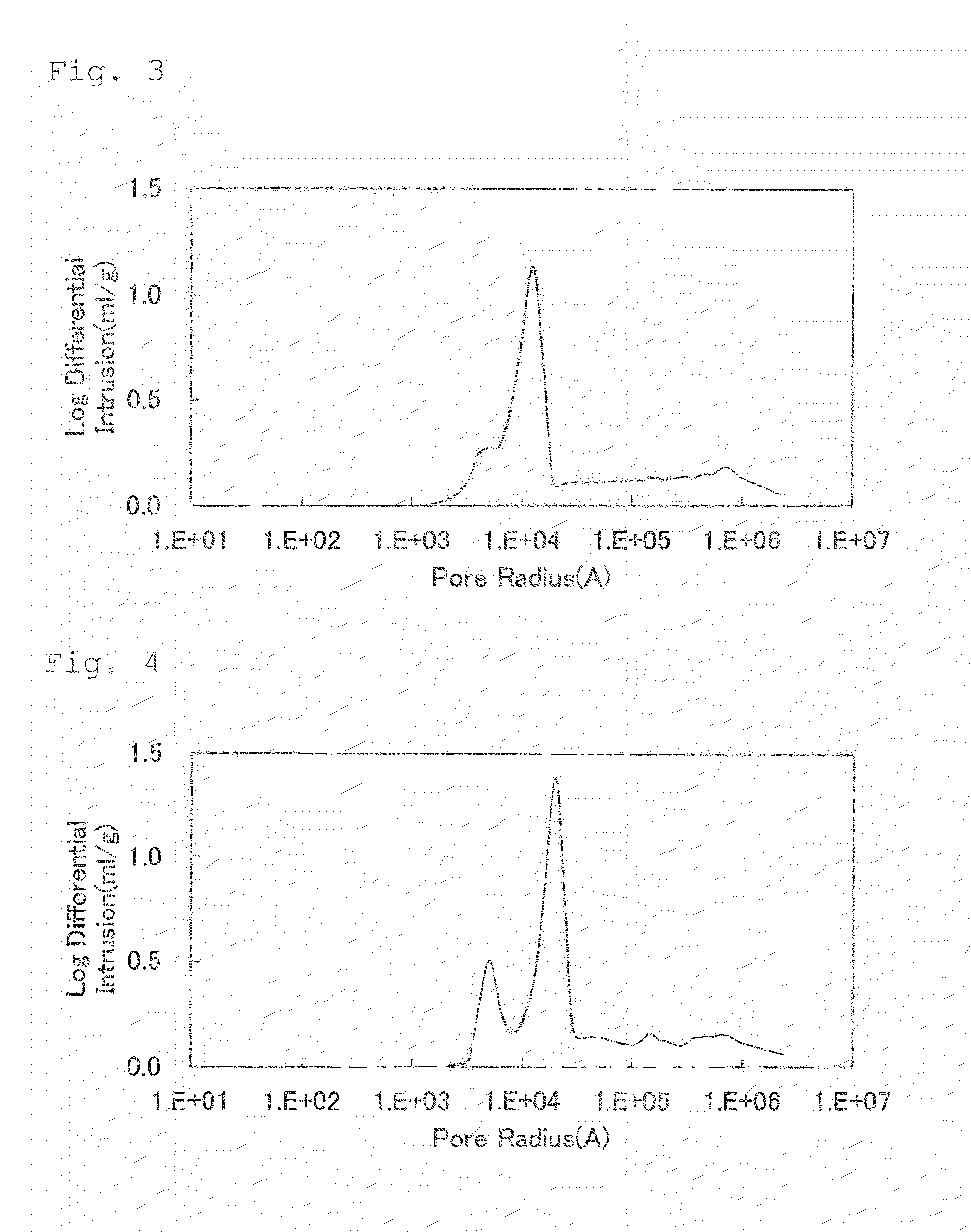

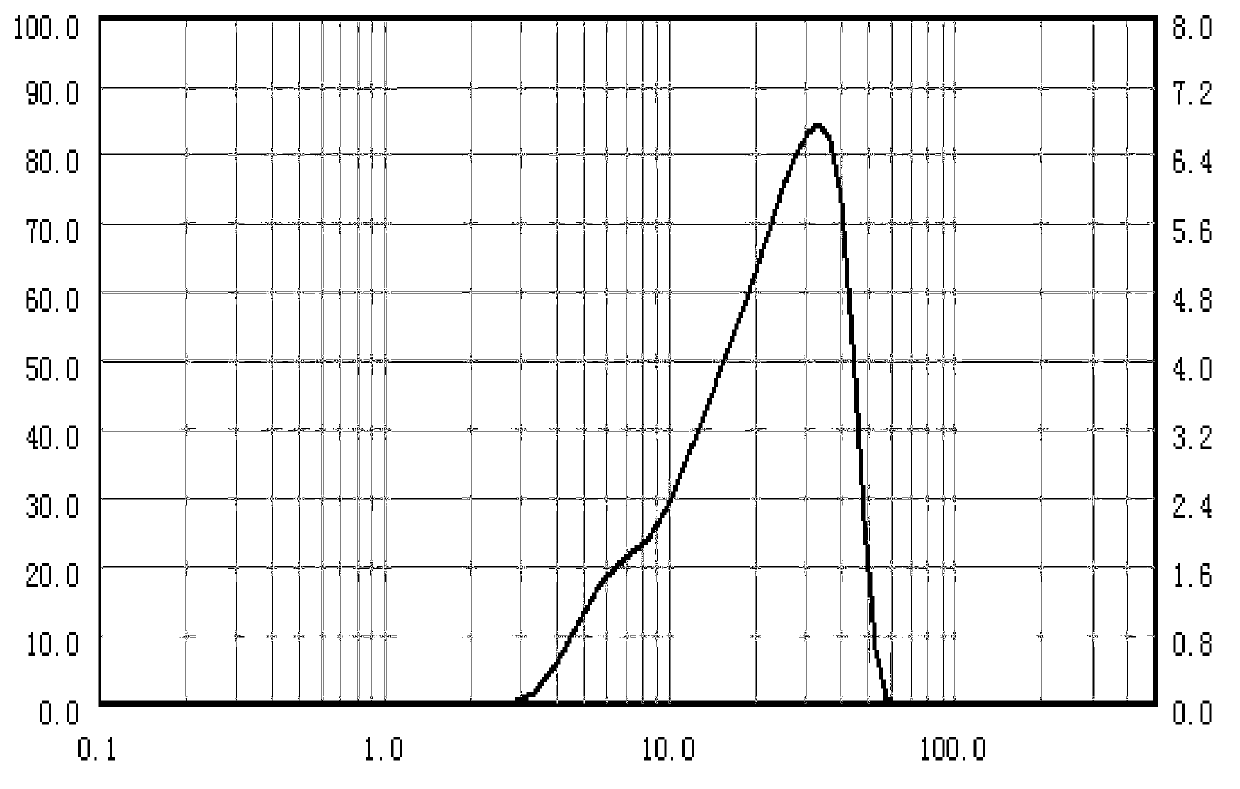

The invention relates to a lithium-transition metal compound powder for a positive-electrode material for lithium secondary battery which comprises secondary particles configured of primary particles having two or more compositions and a lithium-transition metal compound having a function of being capable of insertion and release of lithium ions, wherein the powder gives a pore distribution curve having a peak at a pore radium 80 nm or greater but less than 800 nm, and the secondary particles include primary particles of a compound represented by a structural formula including at least one element selected from As, Ge, P, Pb, Sb, Si and Sn, wherein the primary particles of the compound are present at least in an inner part of the secondary particles.

Owner:MITSUBISHI CHEM CORP

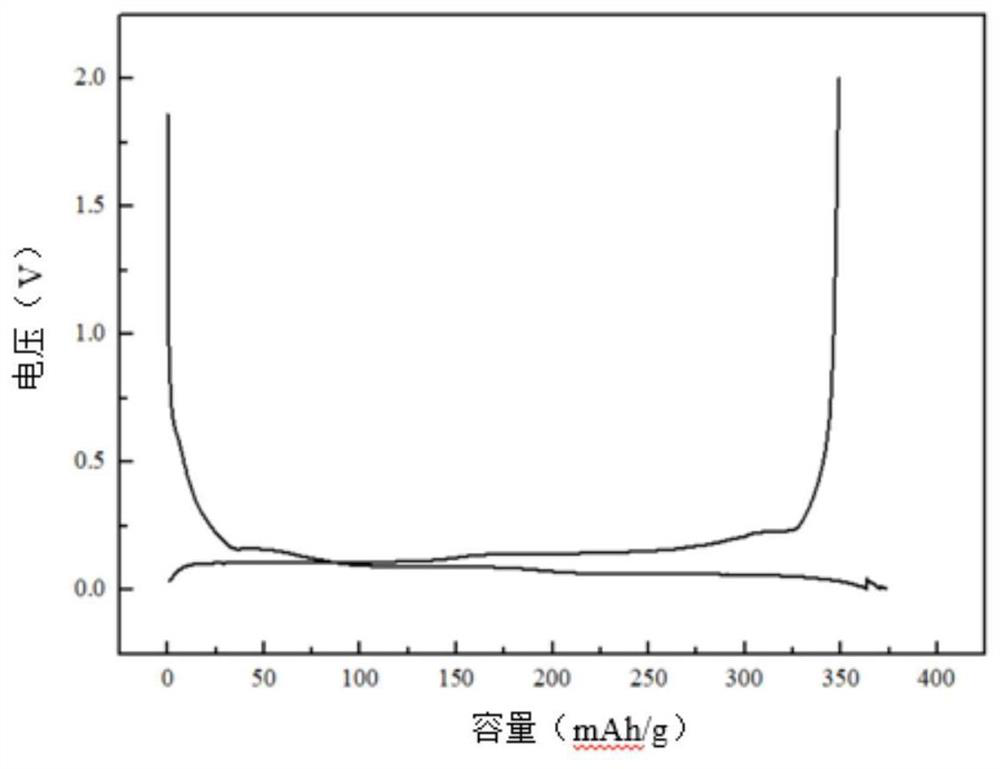

Lithium ion battery carbon microsphere negative electrode material and preparation method thereof

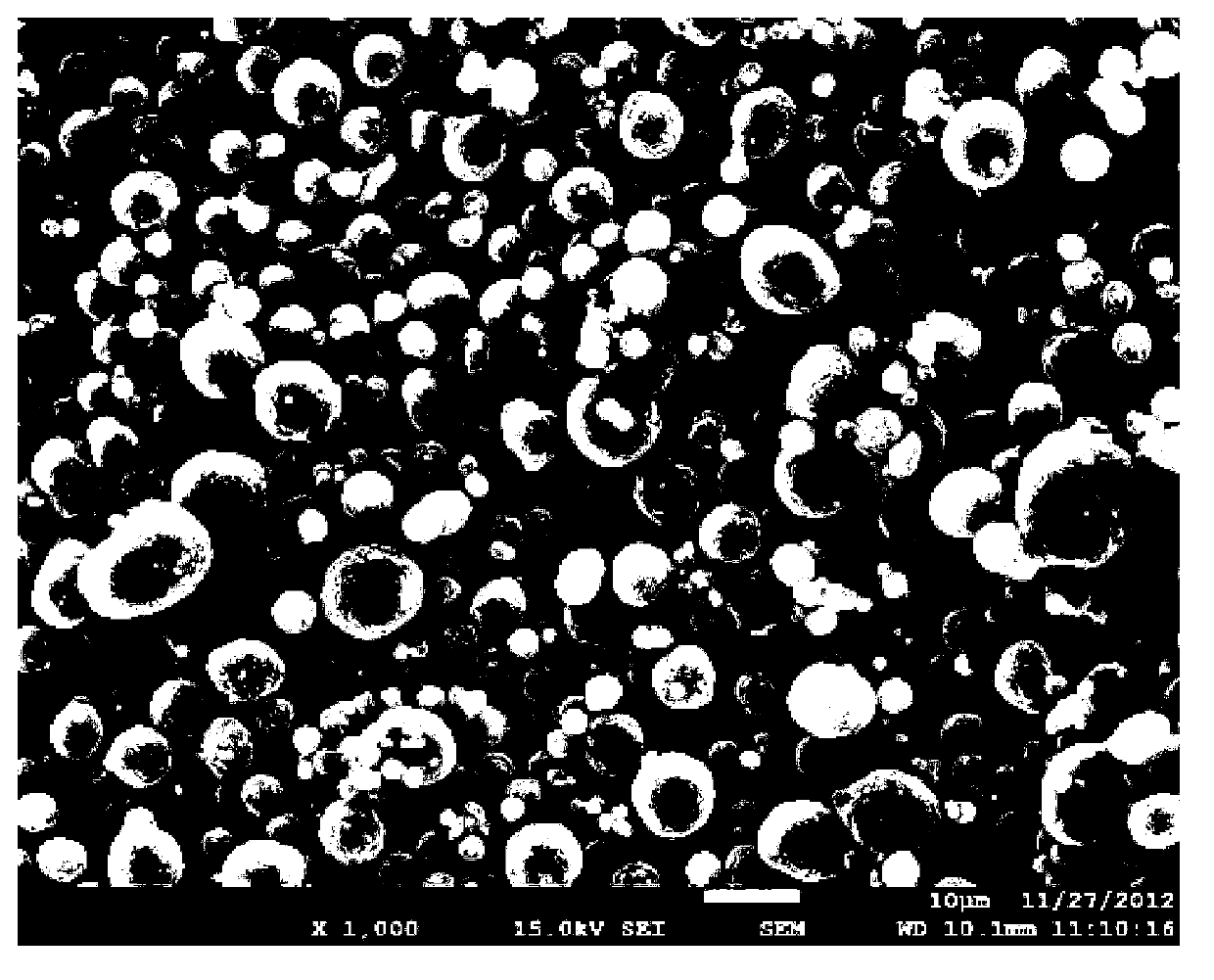

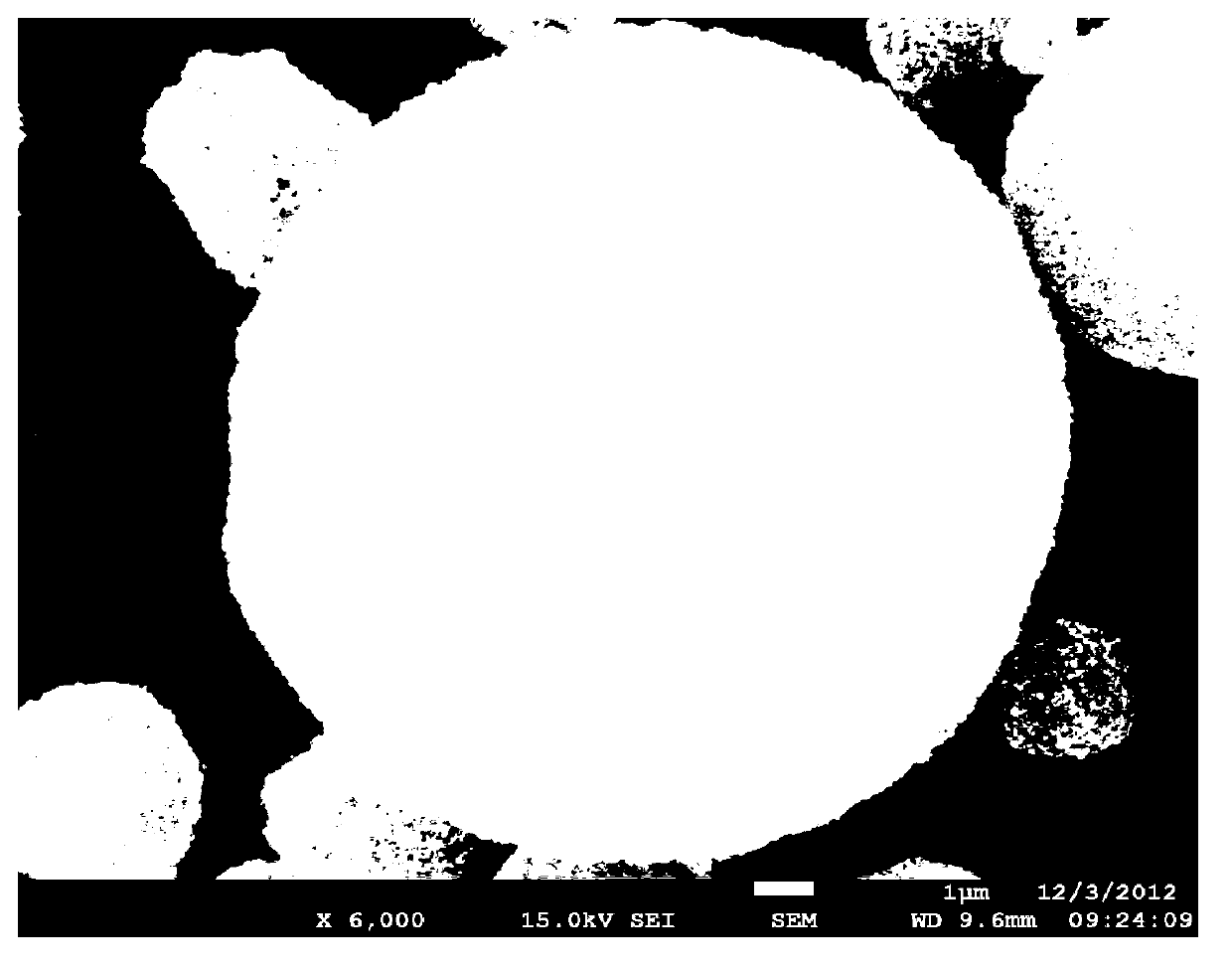

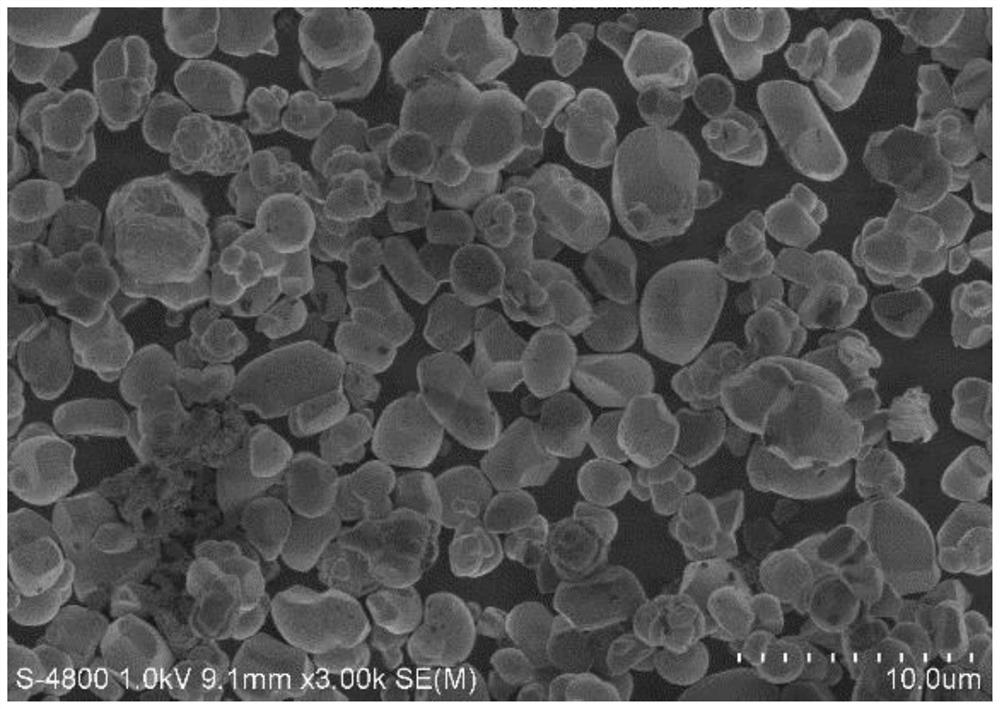

ActiveCN103107319AHigh rate characteristicsLow costCell electrodesSecondary cellsSolventCarbon black

The invention relates to a preparation method of a lithium ion battery carbon microsphere negative electrode material. The method comprises: mixing carbon black, a binder and a solvent to prepare a slurry, conducting spray drying for molding, and then carrying out a high temperature treatment so as to obtain the lithium ion battery carbon microsphere negative electrode material. The lithium ion battery carbon microsphere negative electrode material provided in the invention has a high degree of sphericity and a controllable particle size, so that close packing of the negative electrode material is realized, the volume energy density of electrodes is enhanced. Meanwhile, lithium ions can be embedded from all directions, and the structural stability, the rate capability and the first coulombic efficiency of the material are improved. The carbon microspheres internally have size-controllable gaps, which make up a plurality of ion transport channels, thus being conducive to improving the charge-discharge capacity and cyclic capacity retention rate of the material. Also, the main preparation raw material is carbon black, which has wide sources, no need for breaking, and a low price. And the preparation method has the advantages of simple process, environmental friendliness, low energy consumption and cost, and is easy for large scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

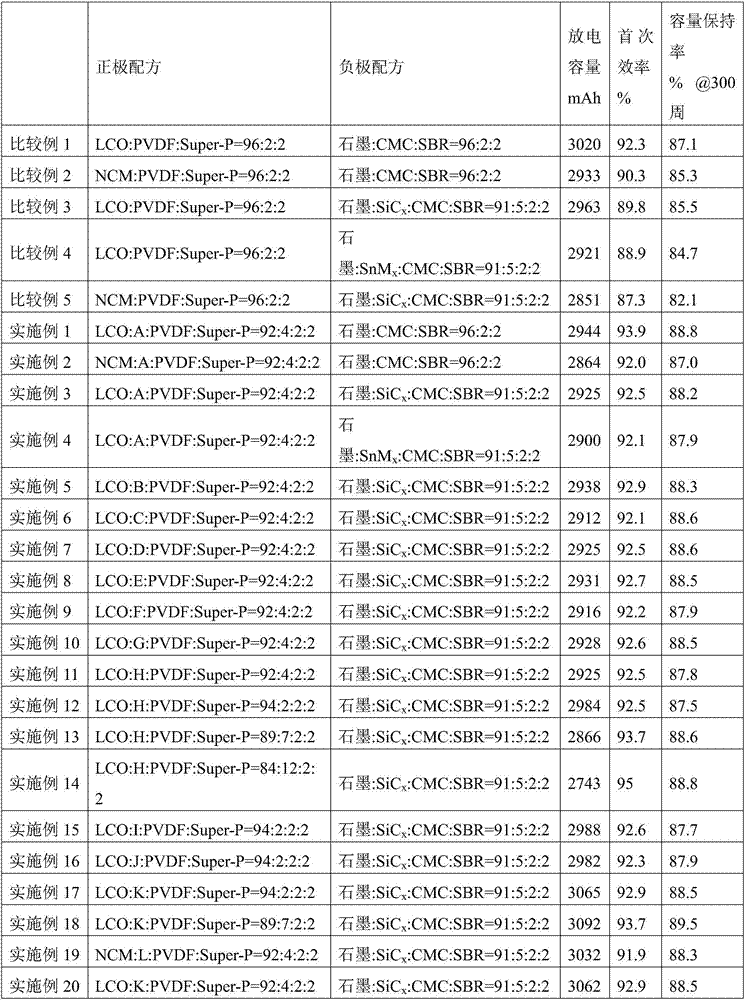

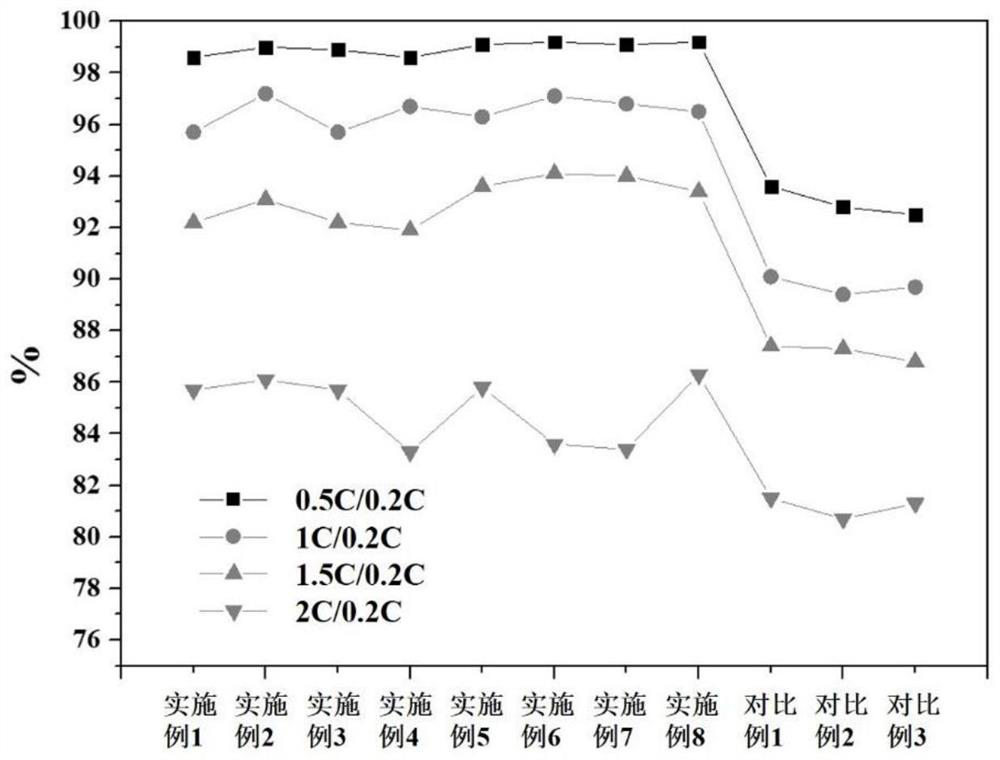

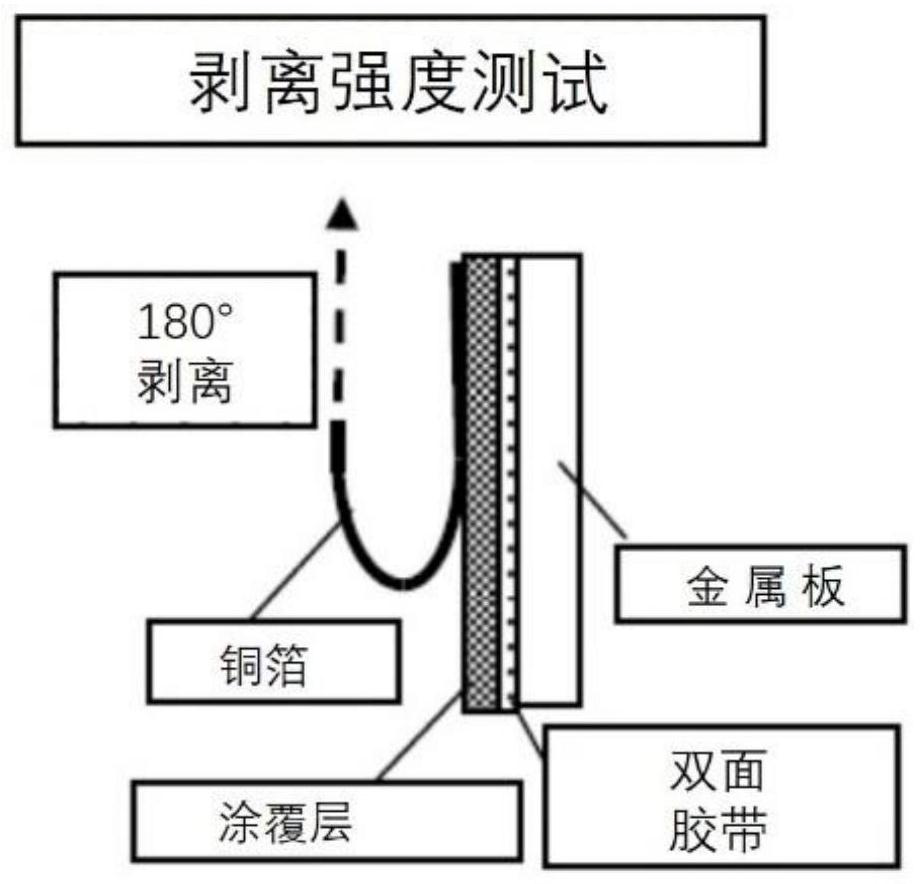

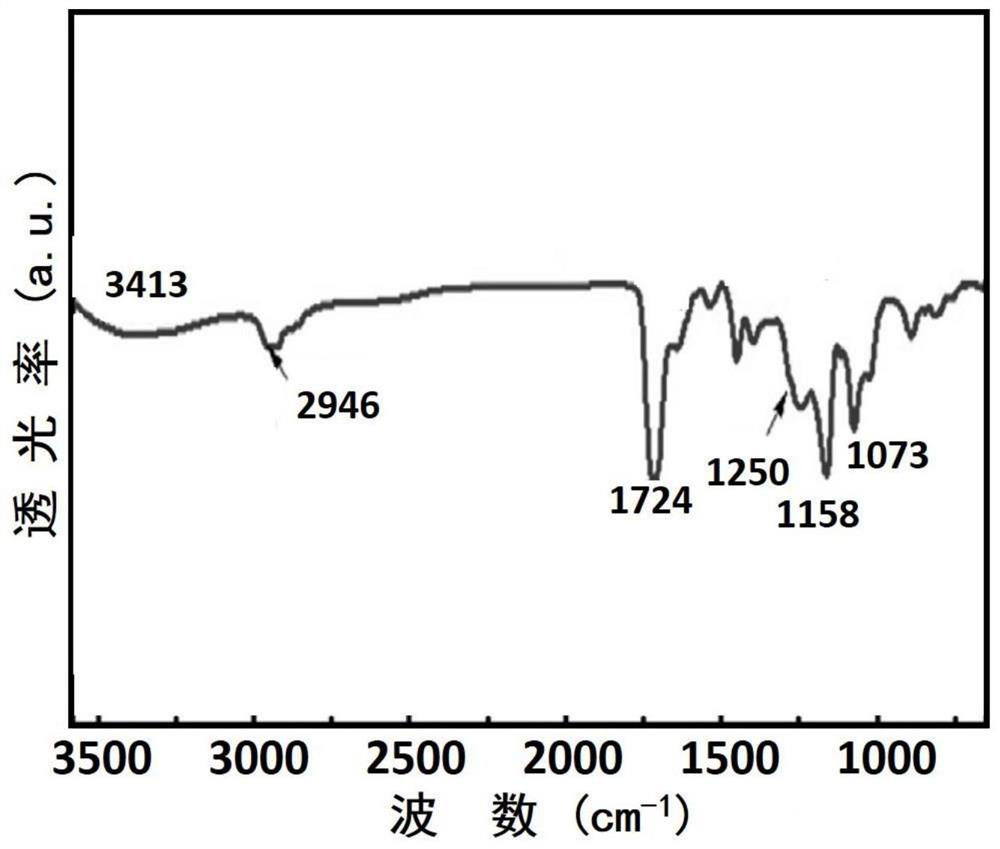

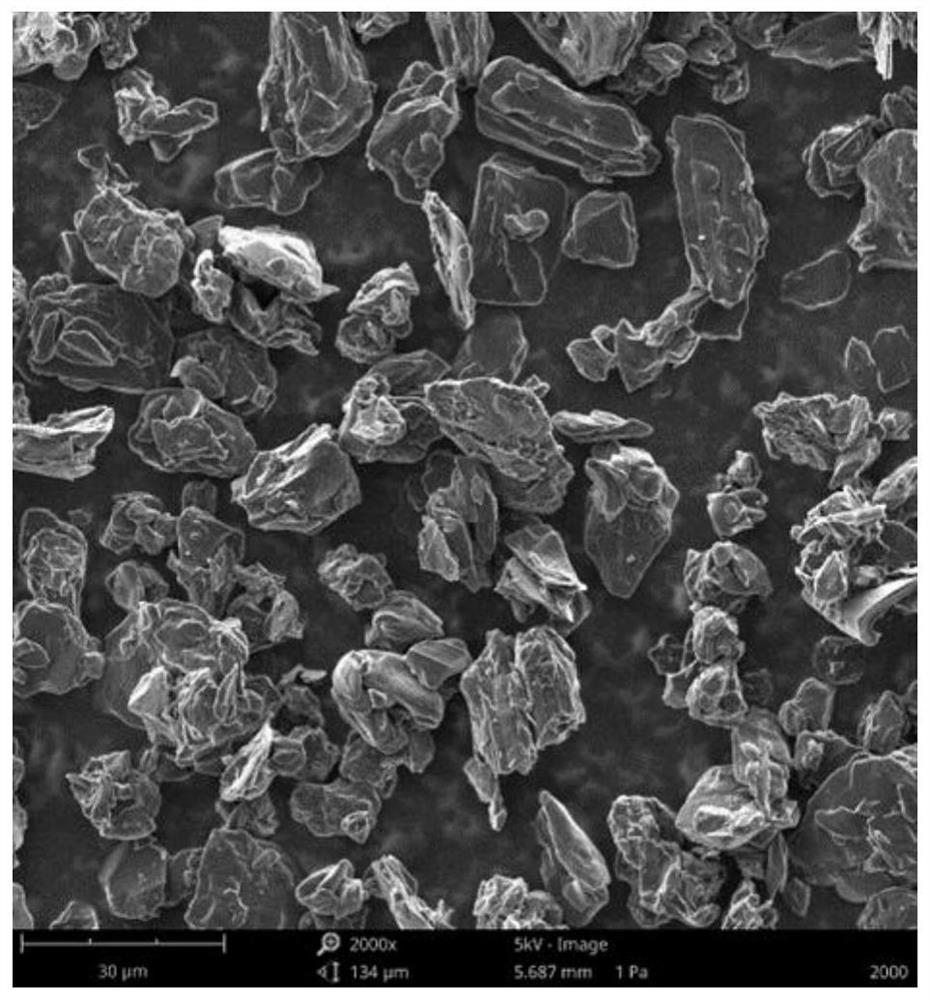

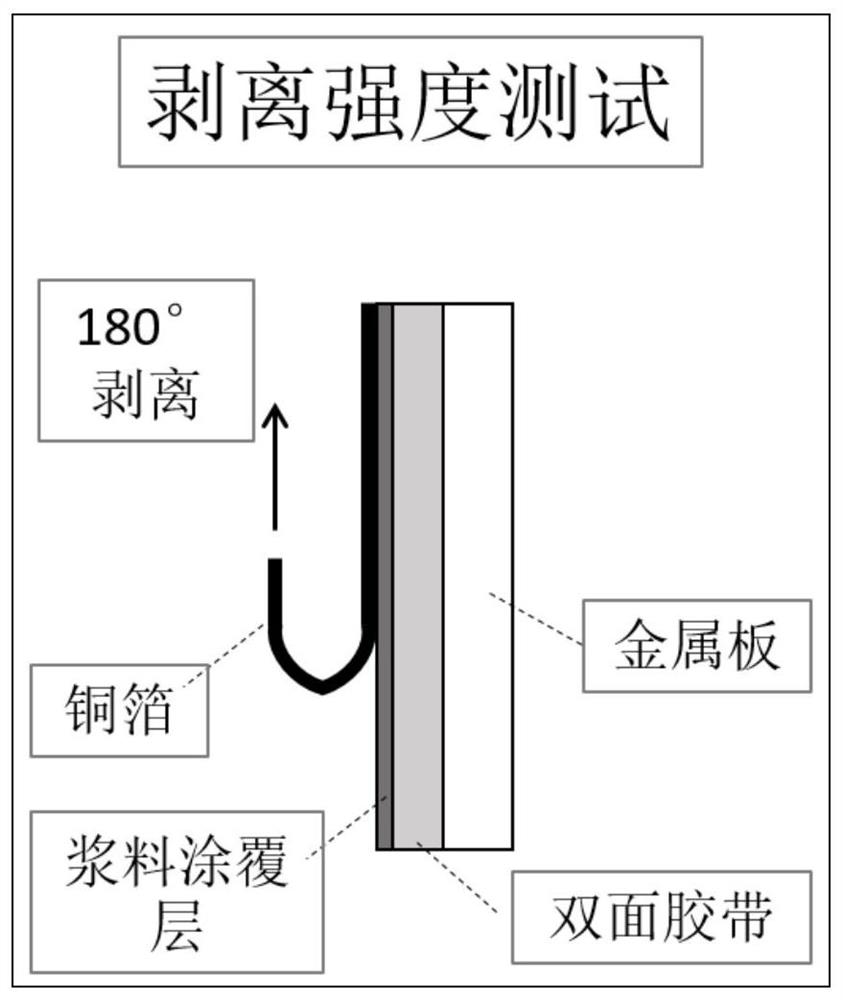

Preparation method of vinylidene fluoride polymer of lithium ion battery electrode material binder

ActiveCN104497190AHigh peel strengthIncrease energy densityCell electrodesChemical industryLithium electrode

The invention discloses a preparation method of vinylidene fluoride polymer of a lithium ion battery electrode material binder, and belongs to the technical field of fluor chemical industry. The preparation method comprises the following steps: 1) adding deionized water, a dispersing agent, a pH modifier, a chain transfer agent, vinylidene fluoride and a second monomer to a polymerization reactor; 2) heating the reactor to 32-52 DEG C, reacting at the reaction pressure of 6.0-9.0MPa and the rotating speed of 800-1600r / min, adding an initiator, and finishing reaction for 4-8 hours, so as to prepare vinylidene fluoride slurry; and 3) degassing, washing and drying the polymer slurry to prepare the product. According to the preparation method of vinylidene fluoride polymer of the lithium ion battery electrode material binder, the vinylidene fluoride polymer with ultra-high molecular weight, small particle size, high purity and high heat-resisting stainability is obtained; and the lithium ion battery prepared by the polymer has the advantages of low binder amount, high peeling strength, high energy density and high circulating capacity retention rate.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

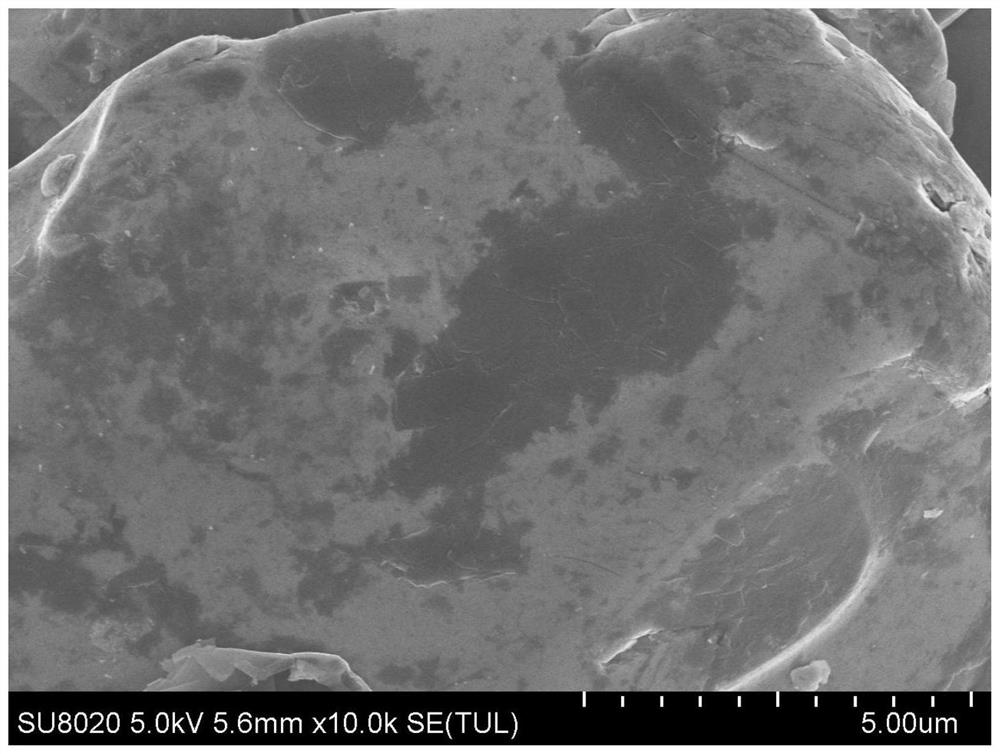

Composite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN111162268AHigh cycle capacity retentionImproved magnification performanceSecondary cellsNegative electrodesLithium-ion batteryBattery cell

The invention provides a composite negative electrode material, a preparation method thereof and a lithium ion battery. The composite negative electrode material comprises an inner core and a coatinglayer coating the inner core, the core is composed of a silicon-containing material, and the coating layer is a carbon material layer. The Raman spectrum of the composite negative electrode material has a peak A between 450 cm <-1 > and 550 cm <-1 >, a peak B between 1300 cm <-1 > and 1400 cm <-1 >, a peak C between 1530 cm <-1 > and 1630 cm <-1 > and a peak D between 2500 cm <-1 >. The preparation method comprises the following steps of introducing a protective atmosphere, introducing a reaction gas, and reacting with the silicon-containing material at a reaction temperature of 700-1450 DEGC to obtain the composite negative electrode material, wherein the reaction gas comprises a carbon-containing gas. The composite negative electrode material has the advantages of high cycle capacity retention ratio, good rate capability, small high-temperature aging loss and the like.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Lithium ion battery positive plate capable of supplementing lithium and lithium ion battery

ActiveCN107248567AHigh cycle capacity retentionEasy to manufactureCell electrodesElectrolyte/reactants regenerationDischarge efficiencySilicon alloy

The invention discloses a lithium ion battery positive plate capable of supplementing lithium and a lithium ion battery containing this positive plate. This positive pate can provide the lithium source at the first charging, thereby placing the effect of compensating the lithium consumption when the positive and the negative form an SEI film, the first charging / discharging efficiency and the cycle performance are promoted, and the charging capacity and the energy density can be promoted, the lithium ion battery positive plate is especially suitable for the negative system with the low first charging / discharging efficiency, such as: the negative system containing silicon, silicon alloy, silicon oxide, or tin, tin alloy, and tin oxide.

Owner:安普瑞斯(无锡)有限公司

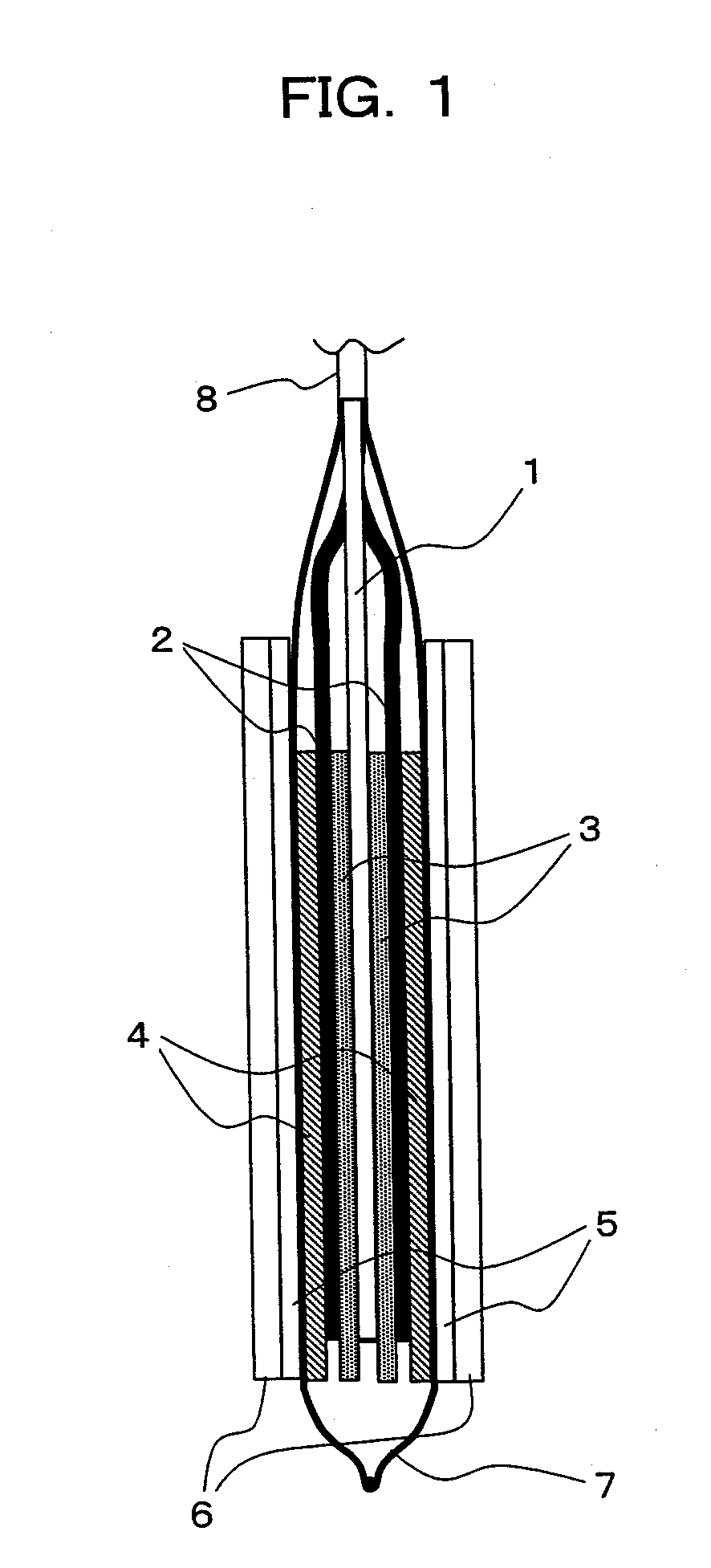

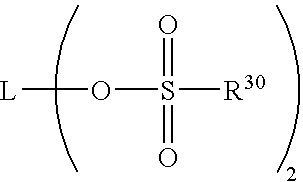

Lithium Secondary Battery

InactiveUS20080311478A1Suppression amountImprove featuresLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentOpen-circuit voltage

In order to provide a lithium secondary battery having high terminal-to-terminal open circuit voltage at the end of charge, suppressed amount of evolved gas on continuous charge, and superior cycle characteristics, the electrolyte solution thereof comprises either both vinylethylene carbonate compound and vinylene carbonate compound, lactone compound having a substituent at its a position in an amount of 0.01 weight % or more and 5 weight % or less, lactones having an unsaturated carbon-carbon bond in an amount of 0.01 weight % or more and 5 weight % or less, or sulfonate compound represented by the formula below.In the formula, L represents a bivalent connecting group consisting of at least one carbon atom and hydrogen atoms, and R30 represents, independently of each other, an unsubstituted or fluorine-substituted aliphatic saturated hydrocarbon group.

Owner:MITSUBISHI CHEM CORP

Gel polymer electrolyte power battery

ActiveCN106654353AImprove protectionImprove gas production performanceSecondary cellsPolymer electrolytesLithium

The invention belongs to the technical field of a power battery, and particularly relates to a gel polymer electrolyte power battery. The gel polymer electrolyte power battery comprises a negative electrode, a positive electrode, a gel polymer electrolyte and a diaphragm, wherein a negative electrode active material layer comprises graphite and a composite material dispersed in gaps of the graphite; a positive electrode active material layer comprises at least one kind of NCA, NCM and a lithium-rich manganese material; the gel polymer electrolyte comprises a liquid electrolyte, a polymer monomer and an initiator; and the polymer monomer is selected from at least one kind of TPGDA and PETEA. Compared with the prior art, the gel polymer electrolyte power battery with high energy density, excellent electrochemical performance and high safety can be obtained through synergistic interaction based on reasonable and creative matching and interaction of the positive electrode material, the negative electrode material and the gel polymer electrolyte; and particularly, the gel polymer electrolyte can well protect the positive electrode material, thereby improving the electrochemical performance and the safety of the battery.

Owner:南通市懋略科技有限公司

Method for lithium supplement of lithium ion battery negative electrode plate, lithium-supplement negative electrode plate and lithium ion battery

InactiveCN109888192AImprove the first Coulombic efficiencyHigh cycle capacity retentionElectrode manufacturing processesSecondary cellsElectrolytic agentElectrical battery

The invention relates to the field of lithium ion batteries, in particular to a method for lithium supplement of a lithium ion battery negative electrode plate, a lithium-supplement negative electrodeplate and a lithium ion battery. The method for the lithium supplement of the lithium ion battery negative electrode plate comprises the step of drying the negative electrode plate and a lithium hydrogencarbonate solution after contact to obtain the lithium-supplement negative electrode plate. The invention also provides the lithium ion battery fabricated by the lithium-supplement negative electrode plate. The lithium ion battery is obtained by assembly and formation of the lithium-supplement negative electrode plate, a positive electrode plate, a separator and an electrolyte. According to the method for lithium supplement of the lithium ion battery negative electrode plate, the employed lithium hydrogencarbonate solution (lithium source) is not toxic, the problem of safety does not exist, the method can be performed without protection of inert gas, and industrial production is facilitated; and moreover, the lithium ion battery provided by the invention employs the negative electrodeplate subjected to lithium supplement (namely, the negative electrode plate comprising lithium carbonate on a surface) and a lithium carbonate-containing electrolyte, the negative electrode plate andthe electrolyte are jointly matched, and the initial coulombic efficiency and the cycle capacity retention rate of the battery are greatly improved.

Owner:沁新集团(天津)新能源技术研究院有限公司

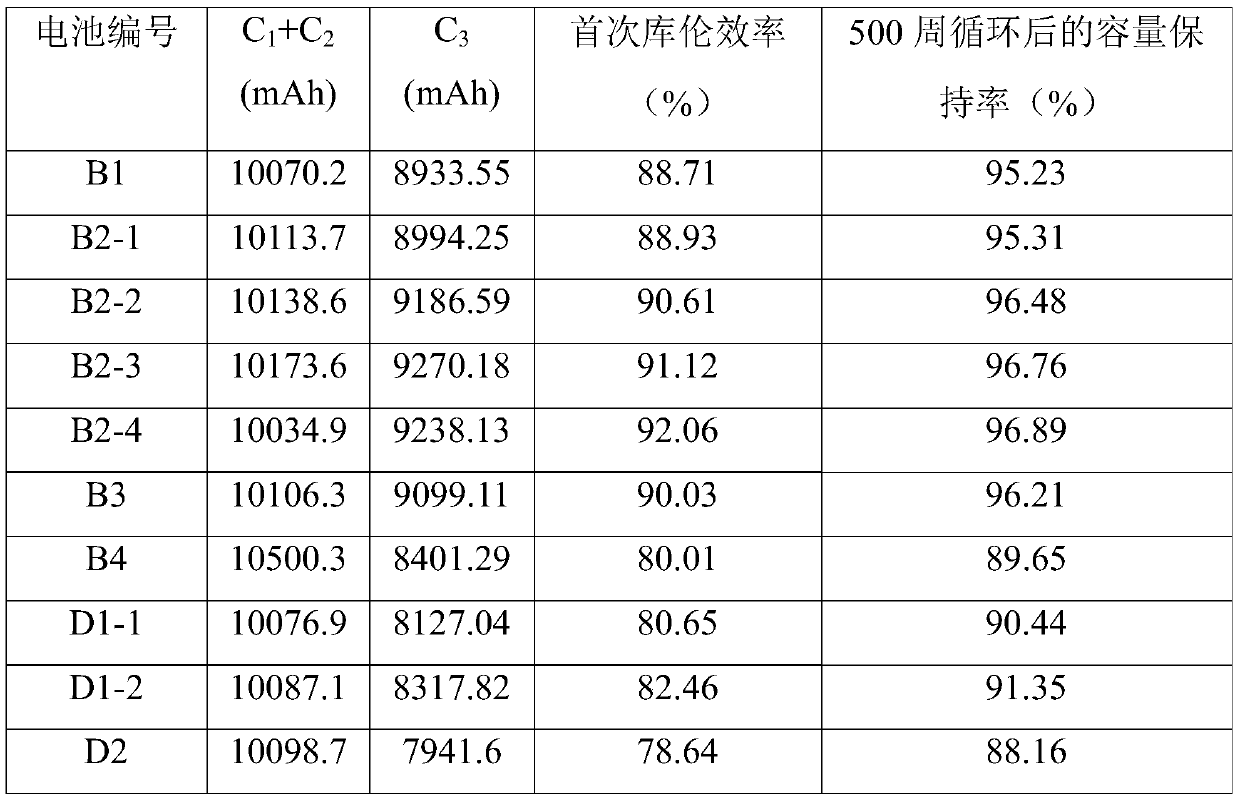

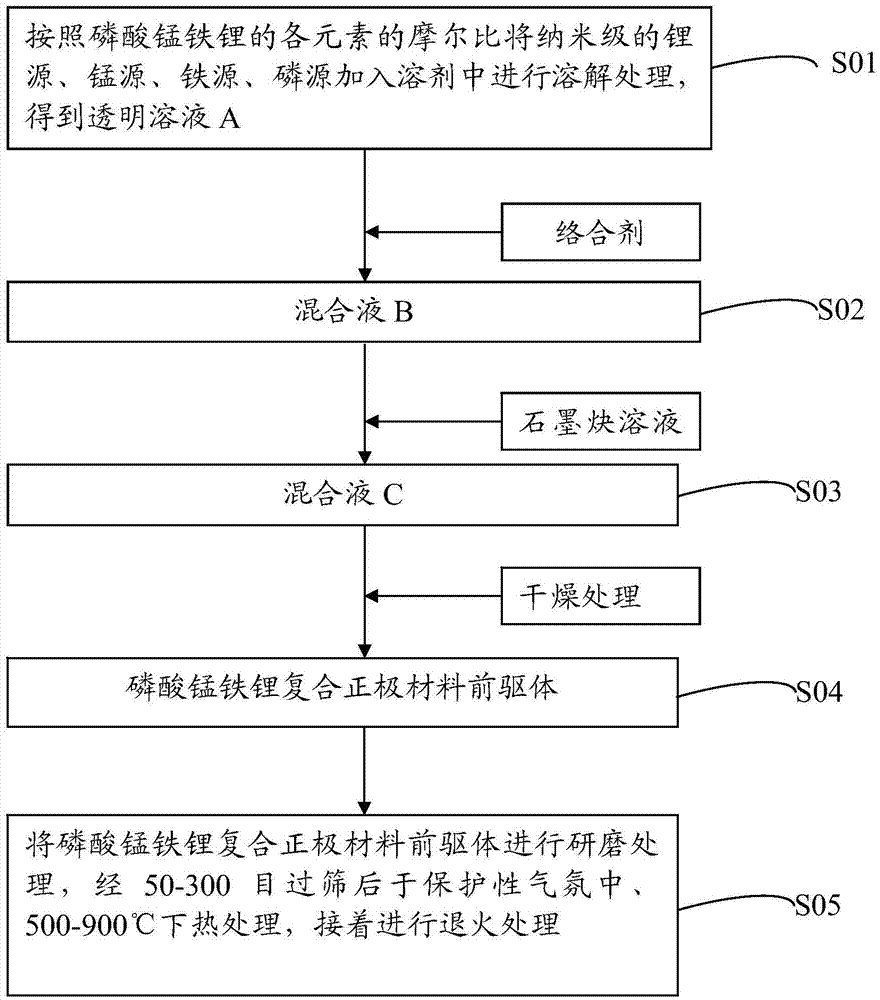

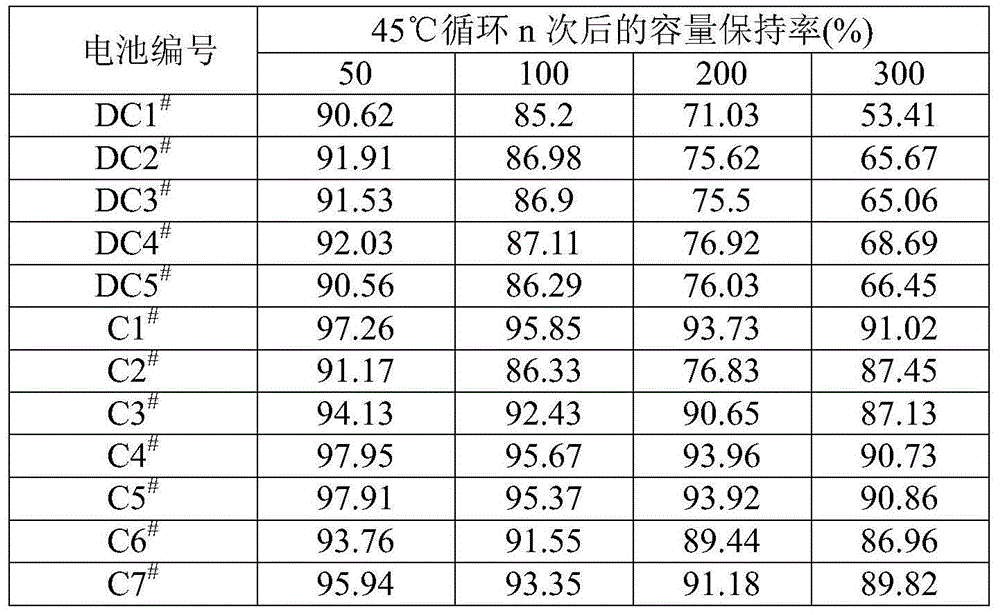

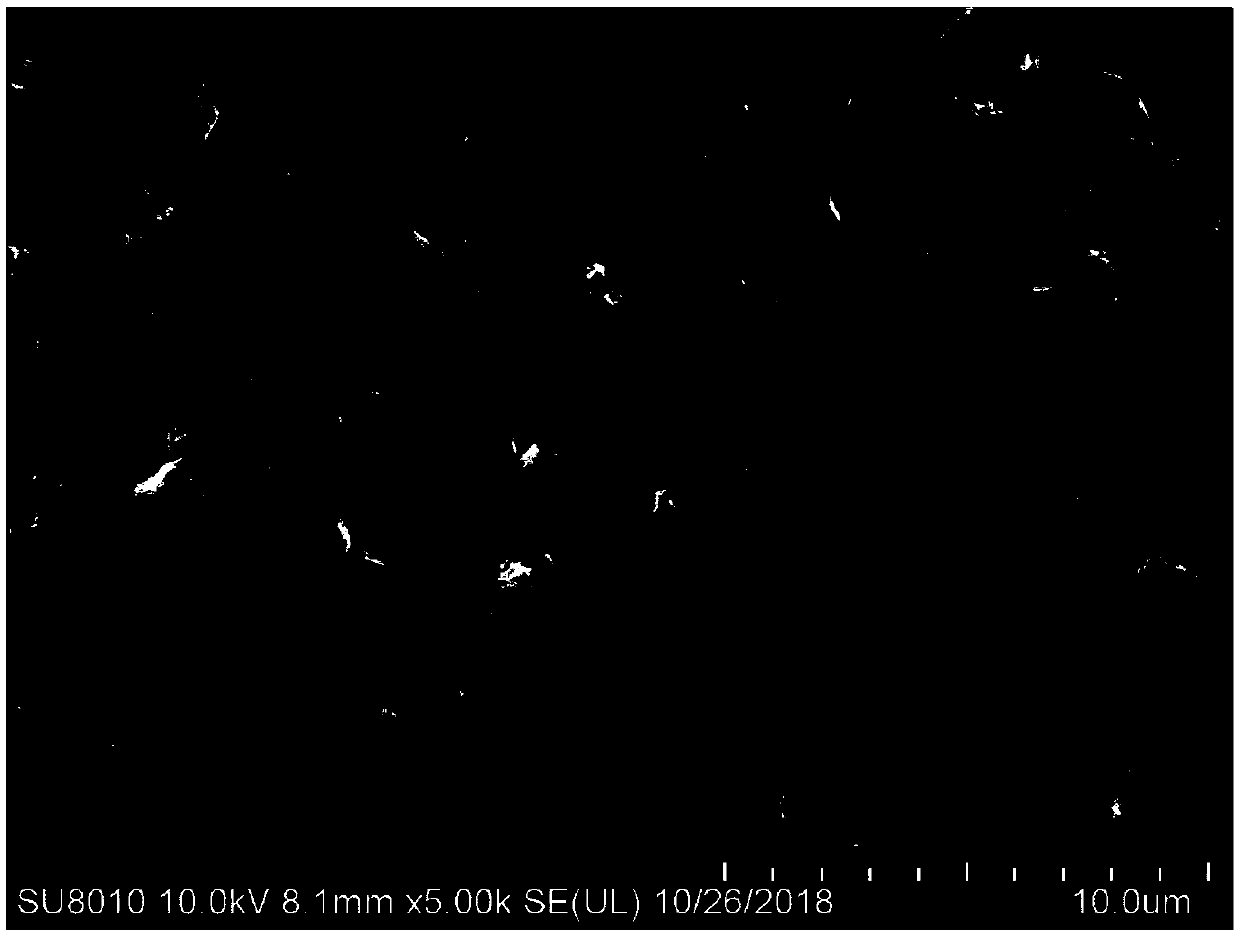

Lithium iron manganese phosphate composite positive electrode material and preparation method, positive electrode and lithium battery

ActiveCN104124453AReduced voltage platformImprove conductivityMaterial nanotechnologyCell electrodesNickel–lithium batteryLithium-ion battery

The invention discloses a lithium iron manganese phosphate composite positive electrode material and a preparation method thereof, a lithium battery positive electrode and a lithium battery. The size of the lithium iron manganese phosphate composite positive electrode material is nano-scale, graphdiyne is compounded in a lithium iron manganese phosphate base material, and the mass of the graphdiyne is 0.1-10% that of the lithium iron manganese phosphate base material. The preparation method comprises the steps of dissolving nano-scale lithium source, manganese source, iron source and phosphorus source in a solvent according to the molar ratio of the elements of lithium iron manganese phosphate to form a solution, sequentially adding a complexing agent and a graphdiyne solution into the solution, then drying, grinding, sintering and annealing. Both the lithium battery positive electrode and the lithium battery contain the lithium iron manganese phosphate composite positive electrode material. According to the lithium iron manganese phosphate composite positive electrode material, the migration paths of Li<+> and electrons are shortened by reducing the primary particle size, so that the electric conductivity of the material is improved. According to the preparation method, the performance stability of the lithium iron manganese phosphate composite positive electrode material can be ensured. The discharge gram volume and circulating volume retention rate of the lithium battery is high.

Owner:FOSHAN DYNANONIC +1

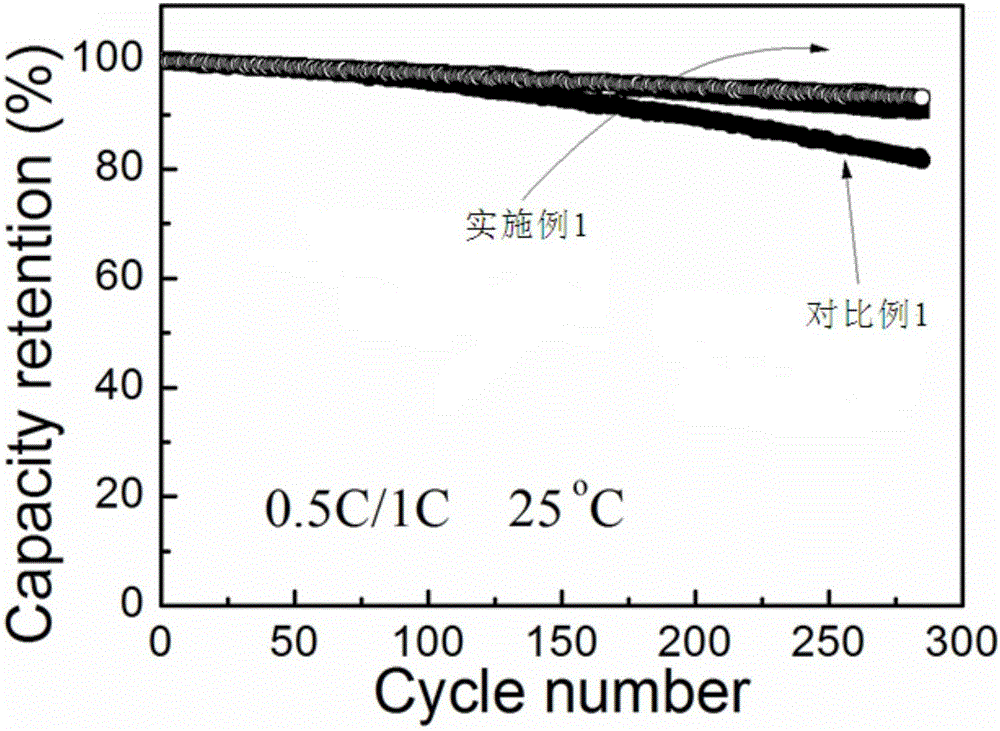

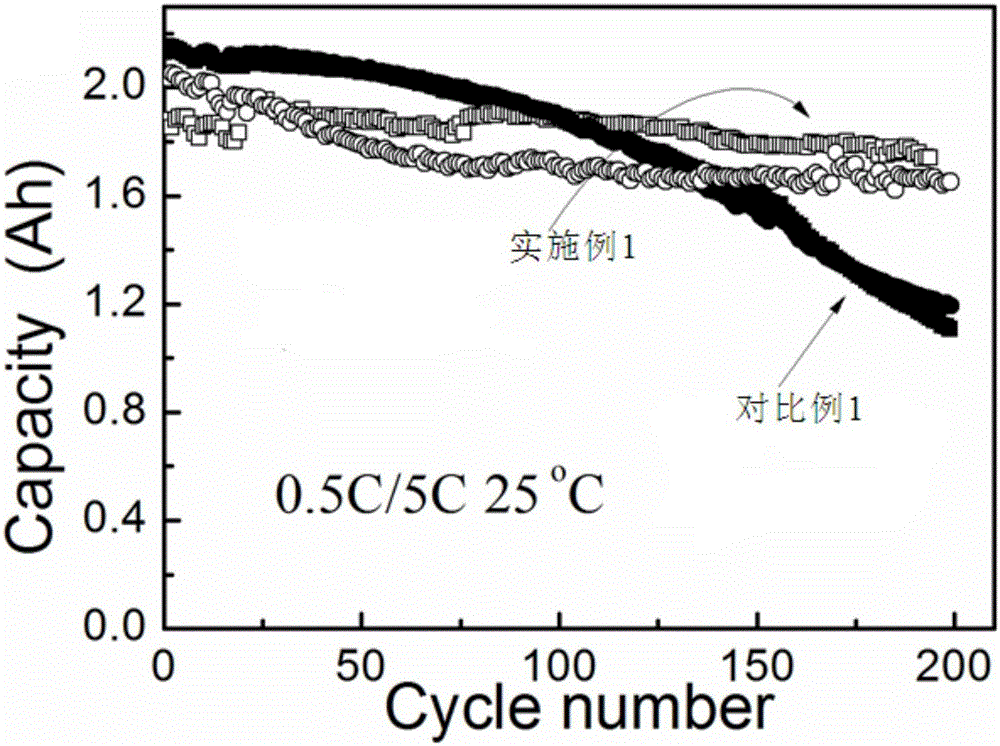

Electrolyte of lithium ion battery and lithium ion battery utilizing same

ActiveCN104466248AReduce oxidationIncrease loopSecondary cellsOrganic electrolytesOrganic solventInternal resistance

The invention discloses electrolyte of a lithium ion battery. The electrolyte comprises an organic solvent, electrolyte lithium salt and additives, wherein the additives include butanedinitrile, fluorobenzene and lithium tetrafluoroborate; the mass percentage of the fluorobenzene in the electrolyte is 0.1 to 15 percent; the mass percentage of the butanedinitrile in the electrolyte is 0.1 to 10 percent; the mass percentage of the lithium tetrafluoroborate in the electrolyte is 0.01 to 1 percent. By adopting the electrolyte, while the charging upper limit voltage and high temperature intermittent cycling performance of the lithium ion battery are improved, simultaneously the expansion rate of the battery is reduced, the internal resistance is reduced, and the stability and the safety of the lithium ion battery can be improved.

Owner:DONGGUAN AMPEREX TECH +1

Carbon-coated silicon nanosheet, silicon-based composite and preparation methods of carbon-coated silicon nanosheet and silicon-based composite

InactiveCN109686960AReduce bloatInhibit swellingMaterial nanotechnologySecondary cellsCarbon layerDouble coating

The invention discloses a preparation method of a carbon-coated silicon nanosheet, and the carbon-coated silicon nanosheet. The preparation method of the carbon-coated silicon nanosheet comprises thesteps: 0.1-1 g of a carbon source is added into 5-20 mL of water to be stirred and ultrasonically dispersed for 10-30 min; 0.1-1 g of silicon powder with the D50 particle size being 10-500 nm is addedto be ultrasonically dispersed for 10-30 min; and a hydrothermal reaction is conducted at 100-200 DEG C for 10-24 h, then centrifuging and vacuum drying are carried out, and the carbon-coated siliconnanosheet is obtained. The carbon-coated silicon nanosheet is prepared from a silicon nanosheet and a carbon layer, wherein the periphery of the silicon nanosheet is coated with the carbon layer. Theinvention discloses a silicon-based composite prepared from the carbon-coated silicon nanosheet, and a preparation method of the silicon-based composite. The preparation method of the silicon-based composite comprises the steps: in percentage by mass, 5-12% of the carbon-coated silicon nanosheet, 78-85% of a carbon material and 10% of a carbon source are mixed and ball-milled, the temperature isincreased to be 500-1000 DEG C at 3-10 DEG C / min to carry out calcining for 5-12 h, and the silicon-based composite is obtained. The silicon-based composite is prepared from the carbon-coated siliconnanosheet, the carbon material and a coating carbon layer. The carbon coating layers of the carbon-coated silicon nanosheet and the silicon-based composite buffer volume expansion of silicon, electrical conductivity is enhanced, the double-coating carbon layer of the silicon-based composite further inhibit expansion of the silicon, the first-time charge and discharge efficiency is improved, and the cycle capacity retention ratio is increased.

Owner:河南电池研究院有限公司 +1

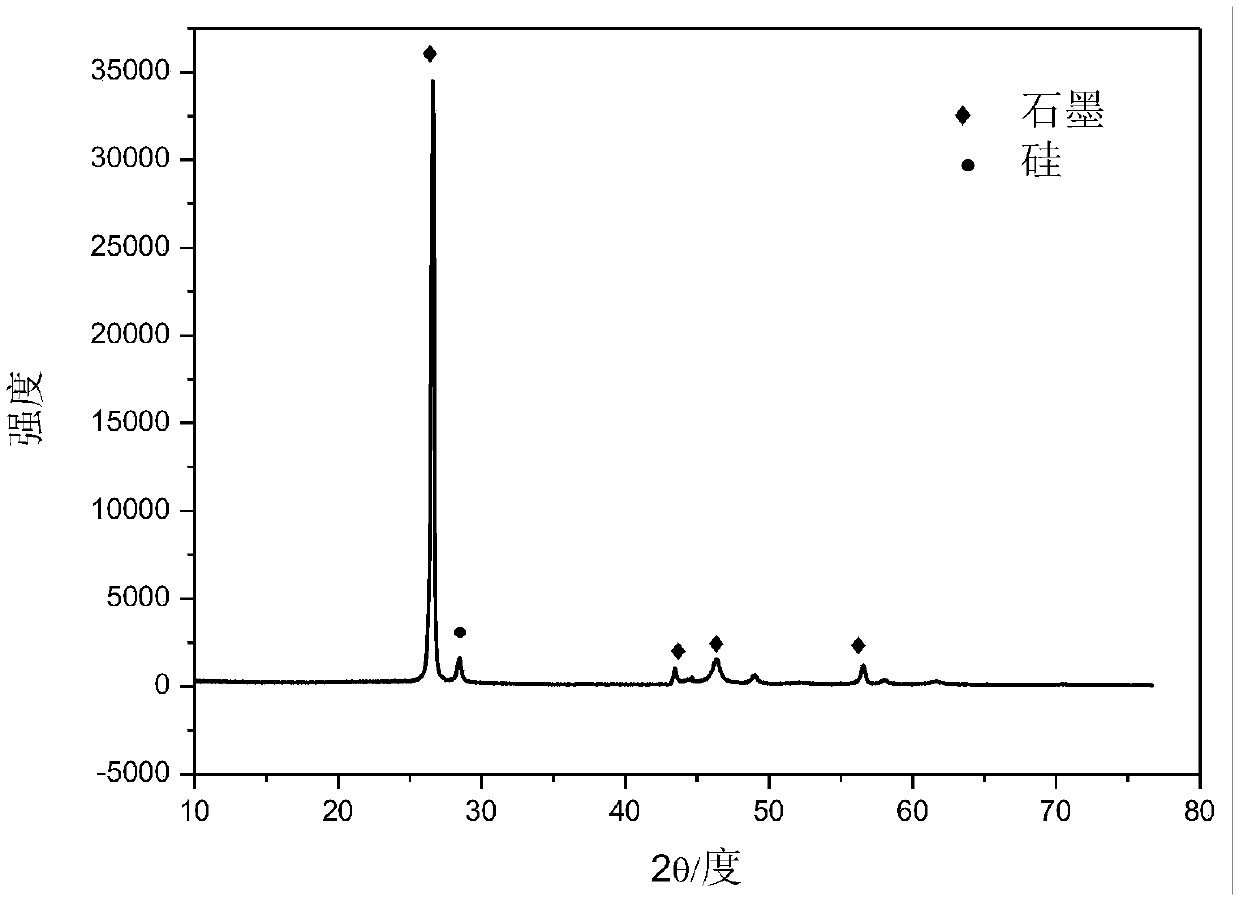

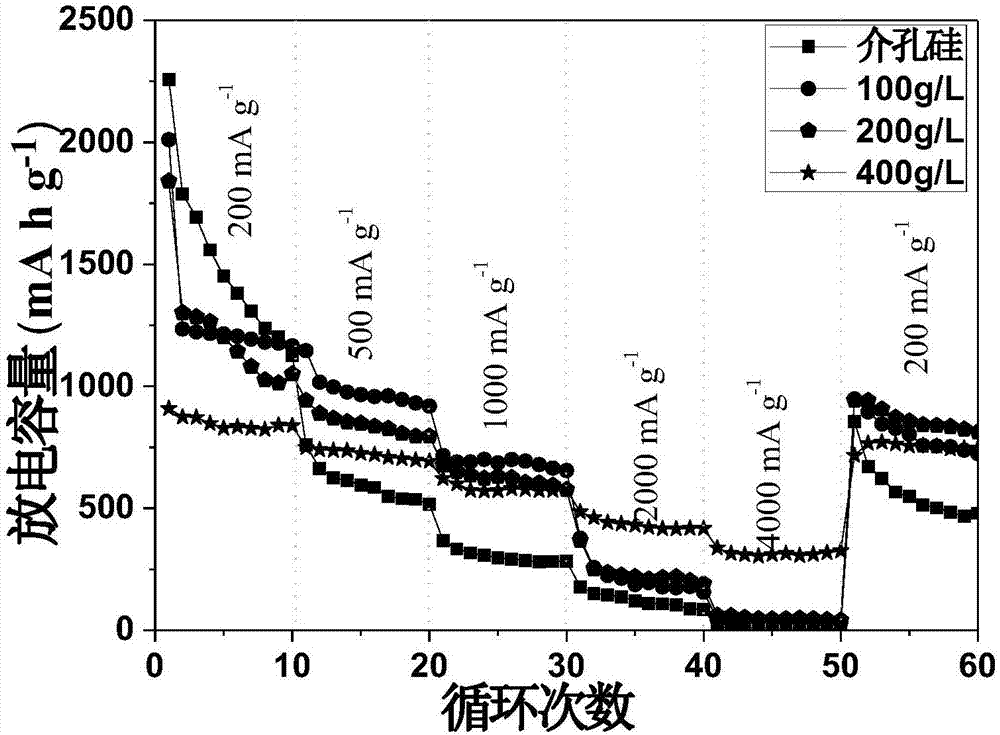

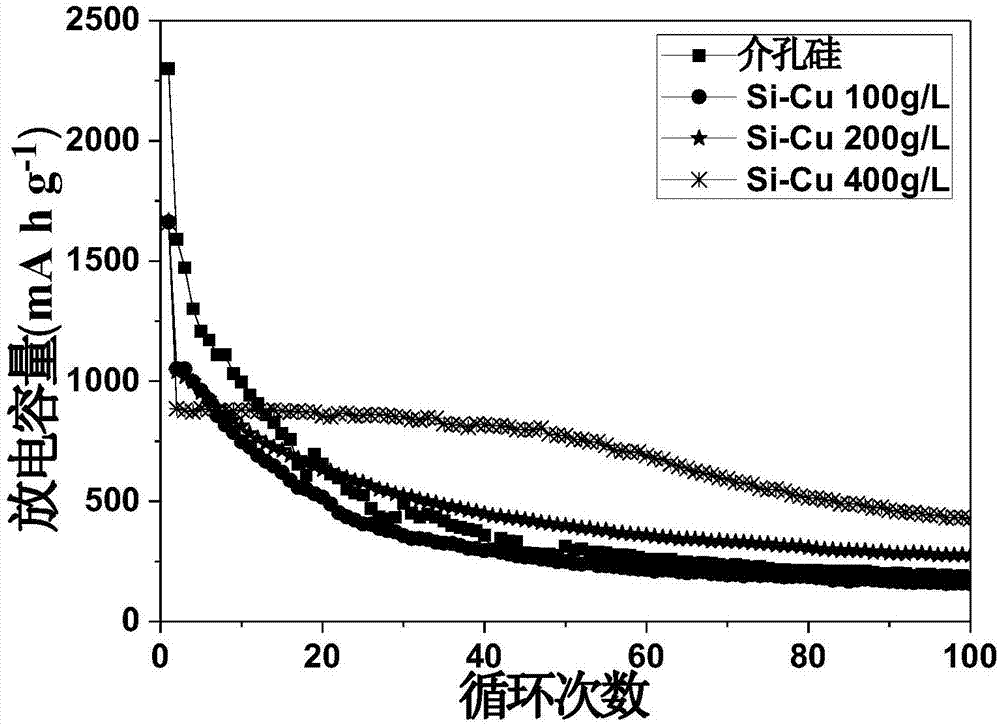

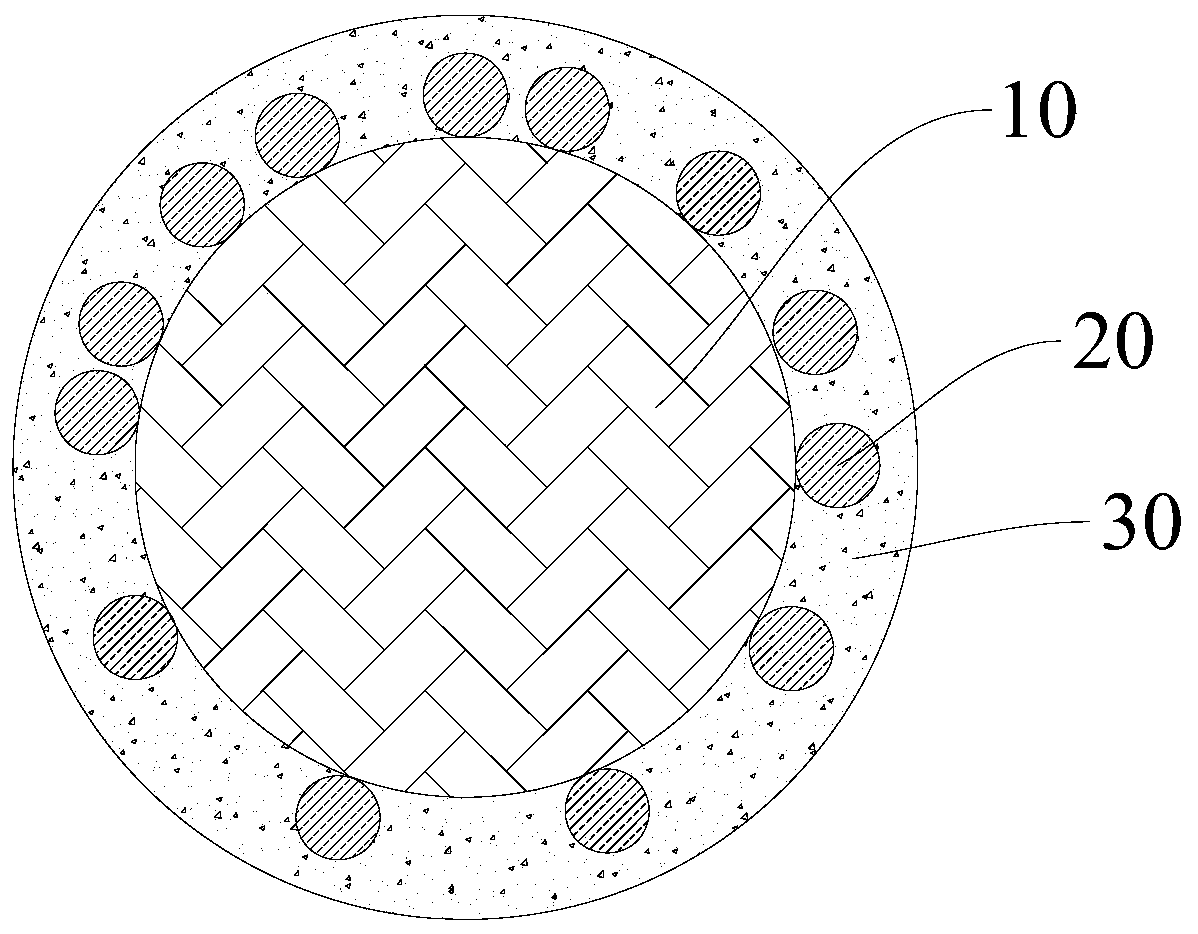

Meso-porous silicon-copper compound electrode material, and preparation method and application thereof

InactiveCN107394150AIncrease energy densityHigh reversible capacityMaterial nanotechnologyCell electrodesMesoporous silicaSilicon dioxide

The invention discloses a meso-porous silicon-copper compound electrode material, and a preparation method and an application thereof. The meso-porous silicon-copper compound electrode material has a 10-100nm porous structure, the specific surface is 60-300m<2> / g and the mass fraction of copper accounts for 15-75%. The preparation method comprises the following steps: performing a magnesium thermal reaction on the mixture of magnesium powder and mesoporous silica to prepare meso-porous silicon; and preparing the meso-porous silicon-copper compound by using a dipping-hydrogen reduction method. The invention further provides an application of the meso-porous silicon-copper compound electrode material in the preparation of lithium ion battery cathodes. The meso-porous silicon-copper compound electrode material provided by the invention has the advantages of high reversible capacity, good circulation stability, high multiplying performance and large scale production, etc.

Owner:SOUTHEAST UNIV

Lithium ion battery cathode material and preparation method thereof and lithium ion battery

PendingCN109698346AReduce residual alkali contentGood rate stabilityCell electrodesSecondary cellsConductive polymerLithium-ion battery

The purpose of the invention is to present a lithium ion battery cathode material and a preparation method thereof and a lithium ion battery. The cathode material includes a cathode active material, lithium phosphate arranged on at least part of the outer surface of the cathode active material, and a coating layer coating the exposed outer surfaces of the cathode active material and the lithium phosphate and including a conductive polymer. Thus, the residual alkali content on the surface of the cathode active material is low, and the rate performance stability and cyclic capacity retention rate of the cathode material can be improved. The lithium phosphate and the conductive polymer enable the cathode material to have ion-electron conductivity (double conduction), and further improve the rate performance stability and cyclic capacity retention rate of the cathode material. The coating layer can reduce or prevent the side reaction between the cathode active material and the electrolyteand improve the service life of the cathode material.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Aluminum-doped small particle spherical tricobalt tetroxide and preparation method thereof

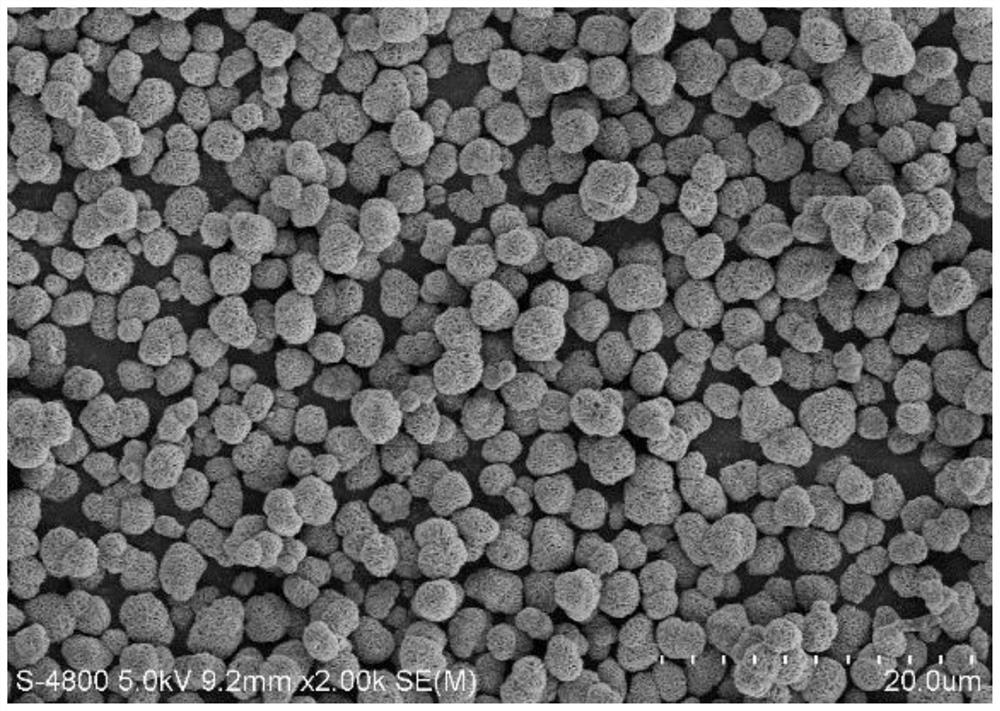

ActiveCN109179516AThe synthesis process is simpleEase of industrial productionCobalt oxides/hydroxidesCobalt(II,III) oxideSpherical shaped

The invention relates to the field of battery materials and particularly relates to aluminum-doped small particle spherical tricobalt tetroxide and a preparation method thereof. The preparation methodcomprises: mixing a metal solution containing aluminum and cobalt and a precipitant solution according to a volume ratio of 1: 0.8 to 1.5, carrying out multiple crystallization reaction processes at30-60 DEG C to obtain crystals with desired sizes, separating a supernatant liquid and final slurry, and sintering the final slurry in stages to obtain aluminum-doped small particle spherical tricobalt tetroxide. The preparation method has the advantages of simple processes, easy control of the reaction, no pollution in the reaction and easy industrial production. The aluminum-doped small particlespherical tricobalt tetroxide has the advantages of uniform distribution of aluminum, regular surface morphology, good sphericity and high tap density.

Owner:CNGR ADVANCED MATERIAL CO LTD +1

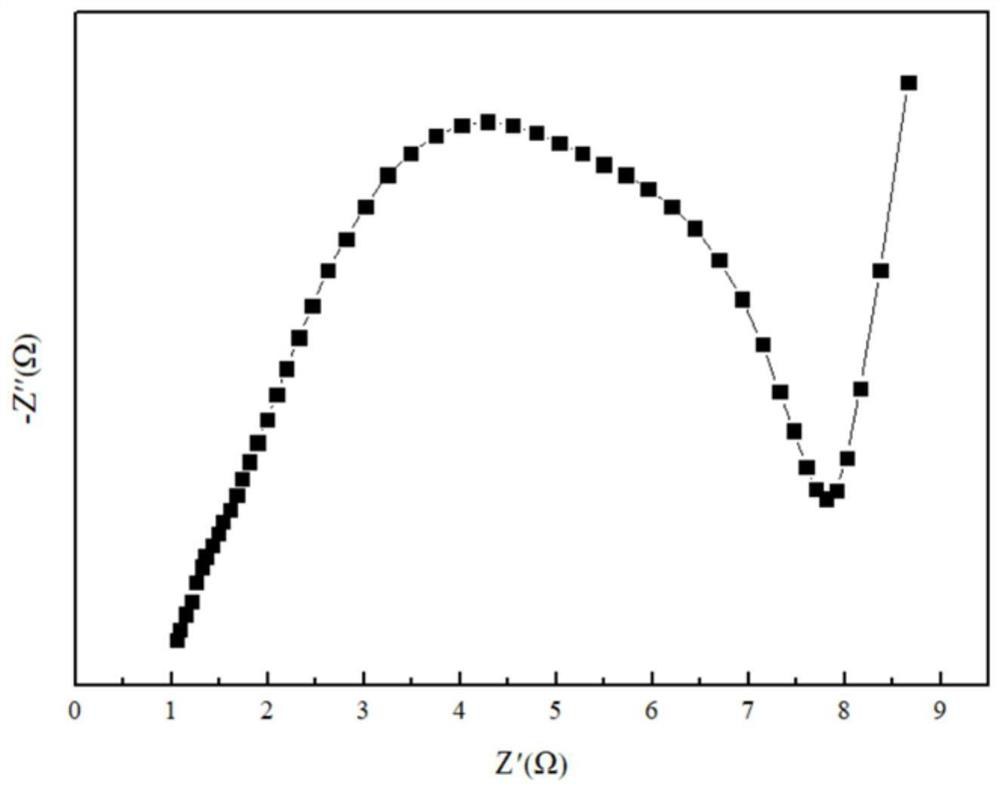

Binder and lithium ion battery containing same

ActiveCN112175134ALower glass transition temperatureReduce expansionCell electrodesSecondary cellsFunctional monomerLithium-ion battery

The invention discloses a binder and a lithium ion battery containing the same. The binder comprises a cross-linked polymer of which the structural formula is -A-B-C, wherein a chain segment A is provided by a monomer A, a chain segment B is provided by a monomer B, and a chain segment C is at least provided by a monomer C; wherein the monomer A is a polymer monomer endowing low glass transition temperature, the monomer B is a hydrophilic functional monomer, and the monomer C is a crosslinking monomer. The polymer has a low glass transition temperature and forms the binder in combination withan SBR emulsion. When the binder is applied to a silicon-based negative electrode, the cycle performance of the lithium ion battery is obviously improved, so that the cycle life of the lithium ion battery is prolonged.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium metal negative electrode protection method for improving lithium utilization efficiency

InactiveCN111799444AHigh cycle capacity retentionReduce generationElectrochemical processing of electrodesSecondary cellsMethacrylateElectrolytic agent

The invention discloses a lithium metal negative electrode protection method for improving lithium utilization efficiency, and relates to the field of lithium batteries. In the lithium battery, lithium metal is deposited on a current collector to serve as a battery negative electrode, and a high-molecular polymer serves as an additive to be added into an ester electrolyte; the high-molecular polymer is prepared by carrying out polymerization reaction on a monomer A which is acrylonitrile or a derivative thereof, a monomer B which is perfluoroalkyl ethyl methacrylate or a derivative thereof anda monomer C which is alkyl alcohol diacrylate or a derivative thereof. The surface of the lithium metal is negatively charged and -CN and-CF3 in the high-molecular polymer are relatively strong electron withdrawing groups, so that the electrolyte additive is promoted to be preferentially adsorbed on the surface of the lithium metal, and contact between other components in the electrolyte and thelithium metal is reduced; and thus continuous side reaction can be avoided, lithium deposition can be finer and more uniform, generation of lithium dendrites is slowed down, and high lithium utilization efficiency of the lithium metal negative electrode is realized.

Owner:XIAMEN UNIV

Negative electrode of solid-state battery and preparation method thereof, and solid-state battery

InactiveCN109698319AEvenly distributedInhibit sheddingElectrode carriers/collectorsNegative electrodesConductive materialsEngineering

The invention provides a negative electrode of a solid-state battery and a preparation method thereof, and a solid-state battery. The negative electrode comprises a conductive material, a bonding layer covering the surface of the conductive material, an active material layer arranged on the surface of the bonding layer, and an electrolyte layer covering the surfaces of the active material layer and the bonding layer. The conductive material provides a fast electron channel for the negative electrode, and the electrolyte layer provides a continuous ion channel for the negative electrode, so asto meet the working requirements of the negative electrode. The active material layer can provide high specific capacity for batteries using the negative electrode. The bonding layer can improve the uniformity of distribution of the active material layer on the surface of the conductive material and avoid serious agglomeration of the negative electrode on the surface of the conductive material. The electrolyte layer is arranged on the surface of the active material layer, which not only can further avoid the falling-off of the active material layer, but also can inhibit the expansion effect ofthe active material in the active material layer to a certain extent. Thus, the thickness or volume of the negative electrode will not be changed in the process of battery charging and discharging.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Negative plate and preparation method thereof as well as lithium ion secondary battery using same

ActiveCN104752684AImprove wettabilityImprove charge and discharge speedNegative electrodesSecondary cellsLithiumPorosity

The invention discloses a negative plate. The negative plate comprises a current collector, a soft charcoal material layer coated on the outer side of the current collector, and an infiltration conductive coating coated on the outer side of the soft charcoal material layer. A contact angle theta between the infiltration conductive coating and a non-aqueous solvent for lithium ion electrolyte is 45-55 degrees; and the porosity of the infiltration conductive coating is 30%-45%. Further, the negative plate also comprises a bonding conductive coating which is positioned between the outer side of the current collector and the soft charcoal material layer. In addition, the invention also discloses a preparation method of the negative plate and a lithium ion secondary battery using the negative plate. The negative plate improves the rate charging and discharging capacity and cycling capacity retention ratio of the lithium ion secondary battery.

Owner:BYD CO LTD

Low-boron-content lithium-boron alloy electrode material for lithium battery and application

ActiveCN111082038AEnhanced electrochemical windowImprove stabilityCell electrodesLi-accumulatorsMetallurgyBattery cell

The invention relates to the field of energy batteries and relates to a low-boron-content lithium-boron alloy electrode material for a lithium battery and application. The electrode material is prepared from the following components in percentage by mass: 85.01 to 95 % of Li; 4.99 to 9.99% of B; and 0.01 to 5% of M, wherein M is selected from at least one of Au, Ag, Si, Al, Zn, C and Mg. When theelectrode material is used as a lithium battery negative electrode material, the specific capacity of the electrode material is 2700-3400 mAh / g. With the low-boron-content lithium-boron alloy electrode material of the invention adopted, the synchronous improvement of high specific capacity and cycle life is realized.

Owner:佛山锂朋新能源有限公司

Artificial graphite negative electrode material, preparation method, application and battery

PendingCN112713264AHigh tap densityImprove efficiencyGraphiteCell electrodesElectrical batteryGraphite

The invention discloses an artificial graphite negative electrode material, a preparation method, application and a battery. The preparation method of the artificial graphite negative electrode material comprises the following steps of (1) carrying out electric demagnetization on graphite fragments with the particle size D50 of 13.5-17.5 microns to obtain a precursor A; (2) the precursor A and a coating agent being modified to obtain a precursor B, and the curing temperature of the coating agent being 80-150 DEG C; and (3) carrying out heat treatment on the precursor B to obtain the artificial graphite negative electrode material. The preparation method of the artificial graphite negative electrode material is simple, short in process time consumption and easy for mass production, the raw materials are common industrial products, and the raw material graphite scraps are low in cost and stable in source; compared with the prior art, the artificial graphite negative electrode material prepared by using the crushed graphite can ensure relatively high tap density, initial efficiency, rate capability and cycle capacity retention ratio, and meets the use requirements of the artificial graphite negative electrode material.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Boric acid derivative modified binder and lithium ion battery containing same

ActiveCN113045702AImprove cycle performanceImprove cycle lifeCell electrodesSecondary cellsCarboxymethyl celluloseFunctional monomer

The invention provides a boric acid derivative modified binder and a lithium ion battery containing the same. The surfaces of emulsion colloidal particles of the binder are provided with abundant boric acid groups (-B(OH)2). When applied to a battery pole piece, the boric acid group and -OH in a dispersant, namely sodium carboxymethyl cellulose or -OH in a functional monomer can undergo a dehydration condensation reaction in the drying process of the pole piece to form a three-dimensional network, so binding power is increased, and the peeling strength of the pole piece is greatly improved. The binder can also obviously improve the cycle performance of the lithium ion battery, so the cycle life of the lithium ion battery is prolonged; compared with a conventional binder, the lithium ion battery using the binder provided by the invention has the advantages that a cycle capacity retention rate is higher, and the expansion rate of the lithium ion battery after circulation is lower, so the expansion rate of the lithium ion battery after long-term use can be remarkably inhibited; and the low-temperature performance of the lithium ion battery using the binder disclosed by the invention is also obviously improved at the same time.

Owner:ZHUHAI COSMX BATTERY CO LTD

Preparation method of lithium manganate battery

InactiveCN111816924ALarge specific surface areaIncrease energy densityFinal product manufactureCell electrodesElectrical batteryMaterials science

The invention provides a preparation method of a lithium manganate battery. A positive electrode active substance of the lithium manganate battery is spinel lithium manganate, and the molecular formula of the spinel lithium manganate is LiMn2-xMxO4, wherein x ranges from 0.01 to 0.1, M is a doped metal element; and a negative electrode active substance of the lithium manganate battery is a carbon-based material. The preparation method comprises the following steps: sieving the spinel lithium manganate material; respectively pulping the active substances under the screen and the active substances on the screen; coating the surface of a current collector with the obtained pulps in sequence; drying to obtain a positive electrode; putting the positive electrode and a counter electrode lithiumsheet into an electrolyte tank; discharging to a first preset voltage; taking out the positive electrode; assembling the positive electrode and a negative electrode clamping diaphragm into a batterycell; putting the battery cell into a shell, and carrying out injection molding to obtain the lithium manganate battery. The battery obtained by the preparation method disclosed by the invention is high in energy density, good in cycle performance and high in capacity retention ratio.

Owner:陆信甫

Electrolyte and secondary battery

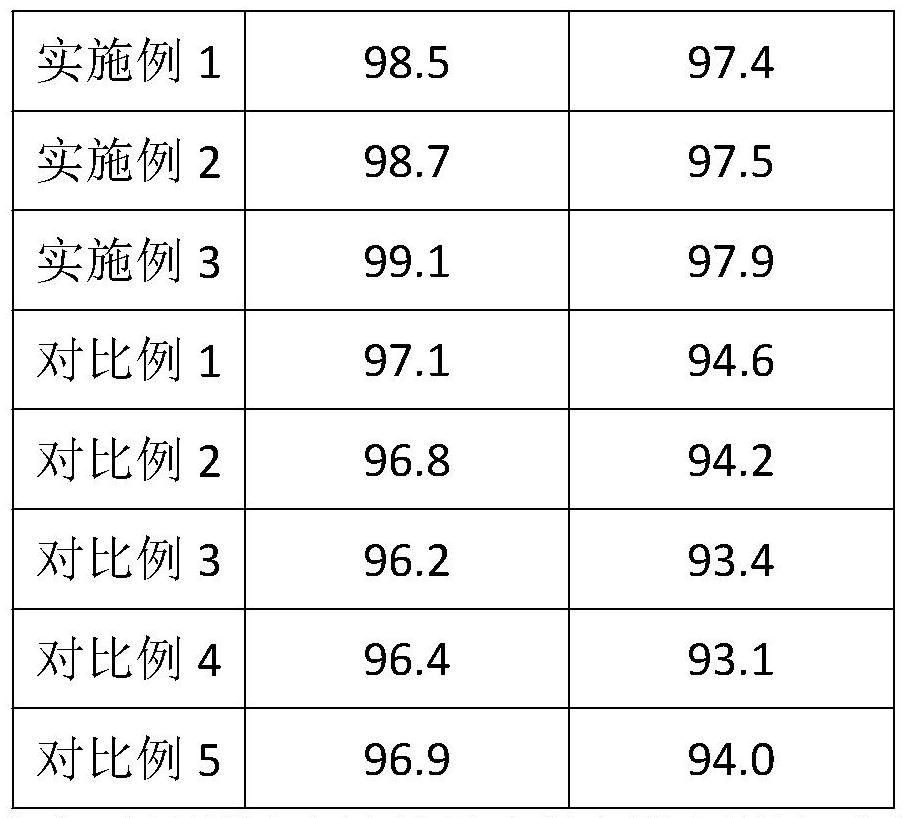

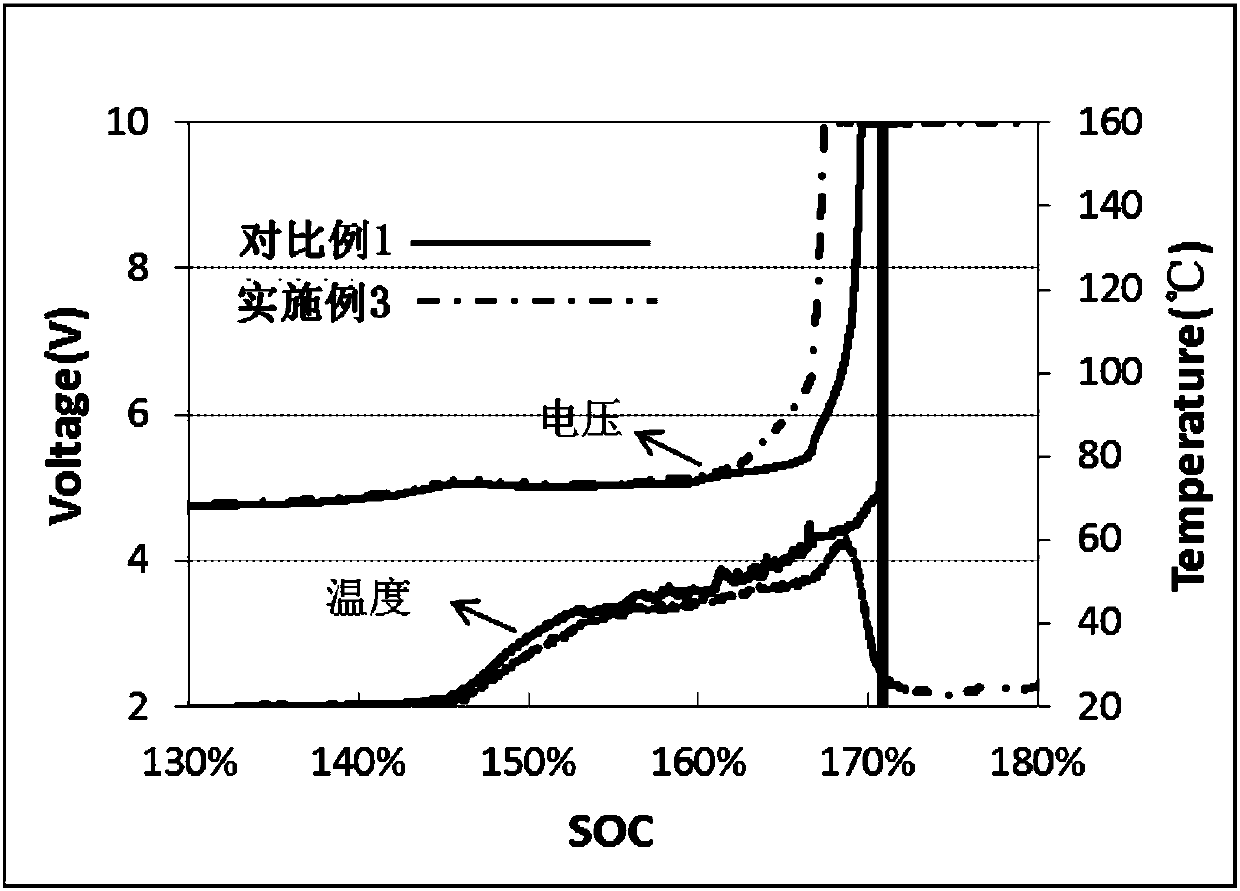

InactiveCN107919497AImproved anti-overcharge performanceImprove anti-overcharge performanceSecondary cells servicing/maintenanceOrganic electrolytesRetention ratioOrganic solvent

The invention provides an electrolyte and a secondary battery. The electrolyte comprises an electrolyte salt, an organic solvent and additives, wherein the additives comprise a benzene single nitrilecompound, cyclic sulfate and fluoroethylene carbonate. When the electrolyte disclosed in the invention is applied to the secondary battery, the anti-overcharging performance of the secondary battery can be obviously improved; and meanwhile, the secondary battery also has relatively low cycle impedance and relatively high cycle capacity retention ratio.

Owner:NINGDE AMPEREX TECH

Positive electrode material and preparation method and application thereof

PendingCN114573043AImprove compactionPower performance impactElectrode manufacturing processesSecondary cellsLithium-ion batteryBattery cell

The invention relates to the field of lithium ion battery positive electrode materials, and discloses a positive electrode material and a preparation method and application thereof. The average particle size d50 and the particle size standard deviation dsigma of primary particles of the positive electrode material meet the following conditions: d50 is less than or equal to 40 microns, dsigma is greater than or equal to 0.25 microns, and 0.7 < = d50 / dsigma < = 120; the chemical formula of the positive electrode material is LiaNibCocMndMeOfJj, in the formula, 0.8 < = a < = 1.2, 0 < b < 1, 0 < c < 0.5, 0 < d < 0.5, 0 < e < 0.4, 1 < = f < 2, 0 < j < = 1, a + b + c + d + e = 2, and f + j = 2; wherein M is selected from at least one element of Ti, Zr, Nb, W, Al, Mg, V, Ca, Sr, Cr, Fe, Ga, In, Mo, Y, Sn, Cu, Ag, Zn, Na and Ba; j is selected from at least one element of S, Si, F and Cl. The positive electrode material provided by the invention is good in compaction performance, and the lithium ion battery prepared from the positive electrode material has relatively high first discharge specific capacity and cycle capacity retention rate.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

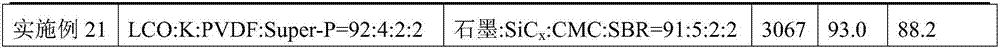

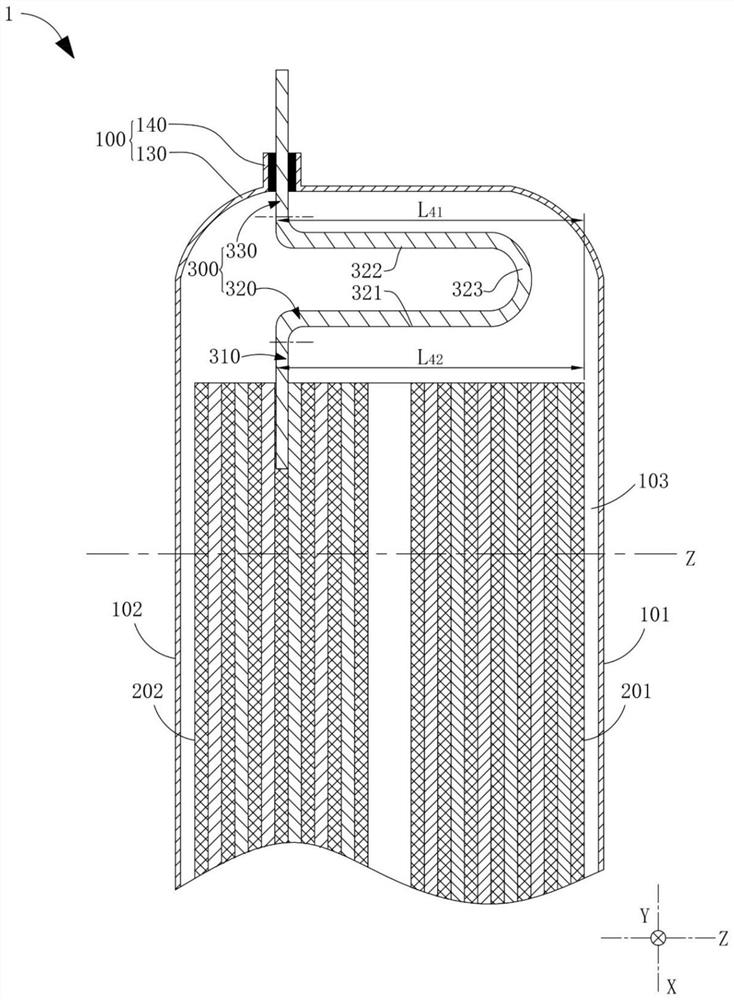

Electrochemical device and electronic device

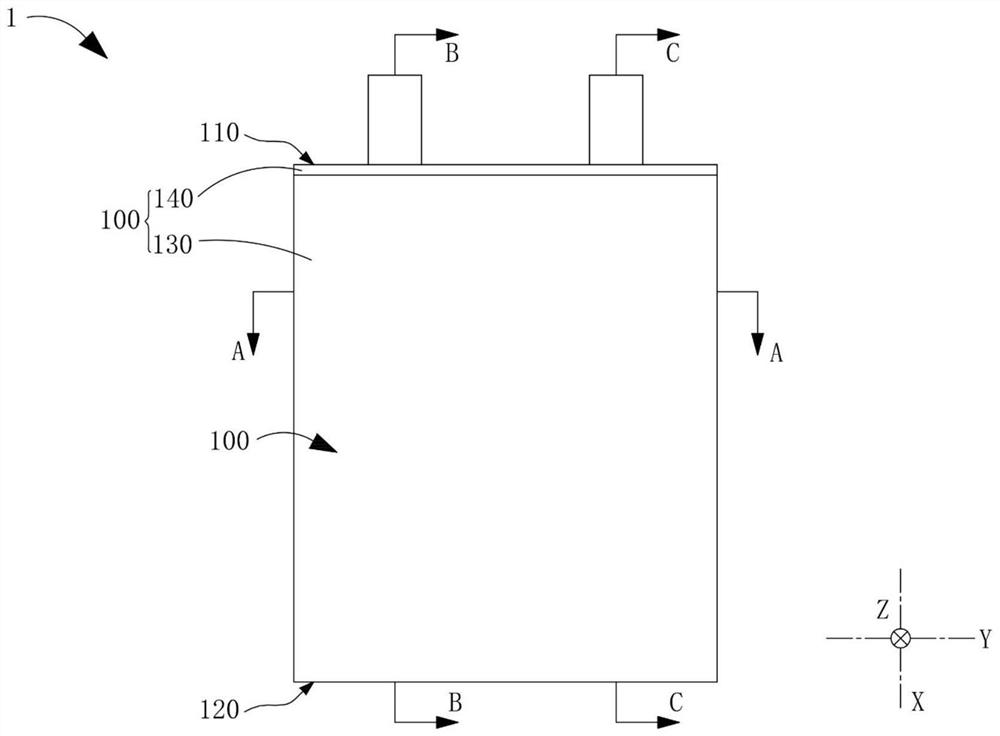

PendingCN114665228ASufficient flow capacityHigh cycle capacity retentionSecondary cellsElectrode collector coatingElectrical batteryEngineering

The invention relates to the technical field of batteries, and discloses an electrochemical device and an electronic device. The electrochemical device comprises a shell, an electrode assembly, a first tab and a second tab, the electrode assembly comprises a first pole piece, a second pole piece and an isolating membrane. The first pole piece comprises a first current collector. The second pole piece comprises a second current collector and a plurality of conducting strips; the plurality of conducting strips protrude from the second current collector along a first direction, the plurality of conducting strips are laminated in the thickness direction of the electrode assembly to form a collection part, and the first direction is perpendicular to the thickness direction. And the first tab is connected with the first current collector. And the second tab is connected with the collection part. The conductivity of the first tab is g1S / mm, the sectional area of the first tab in the direction perpendicular to the extension direction of the first tab is s1mm < 2 >, the conductivity of the plurality of conducting strips is g2S / mm, the sum of the sectional areas of the plurality of conducting strips in the direction perpendicular to the extension direction of the conducting strips is s2mm < 2 >, and (g1 * s1) / (g2 * s2) is larger than or equal to 0.8 and smaller than or equal to 1.2. The electrochemical device can improve the problem of insufficient cycle performance caused by poor consistency of the active material layer of the first pole piece and the active material layer of the second pole piece.

Owner:DONGGUAN POWERAMP TECH LTD

Lithium ion battery electrode containing micro-nano graphene coated single crystal positive electrode material

ActiveCN111969203AImprove performanceLower impedanceMaterial nanotechnologyCell electrodesMicro nanoSingle crystal

The invention relates to the technical field related to lithium ion batteries, and particularly provides a lithium ion battery electrode containing a micro-nano graphene coated single crystal positiveelectrode material. Raw materials comprise the micro-nano graphene coated single crystal positive electrode material, a conductive agent, a binder and a current collector, wherein the preparation rawmaterials of the micro-nano graphene coated single crystal positive electrode material include graphene and a single-crystal positive electrode material, and the single-crystal positive electrode material is a layered single-crystal structure. The invention provides the lithium ion battery electrode containing the micro-nano graphene coated single crystal positive electrode material. Crystal forms and particle size distribution of the single crystal positive electrode material before and after coating are basically consistent, and when the micro-nano graphene coated positive electrode material meeting the conditions is used as the preparation raw material of the battery electrode, comprehensive performance of the battery is favorably optimized.

Owner:宁夏汉尧富锂科技有限责任公司 +1

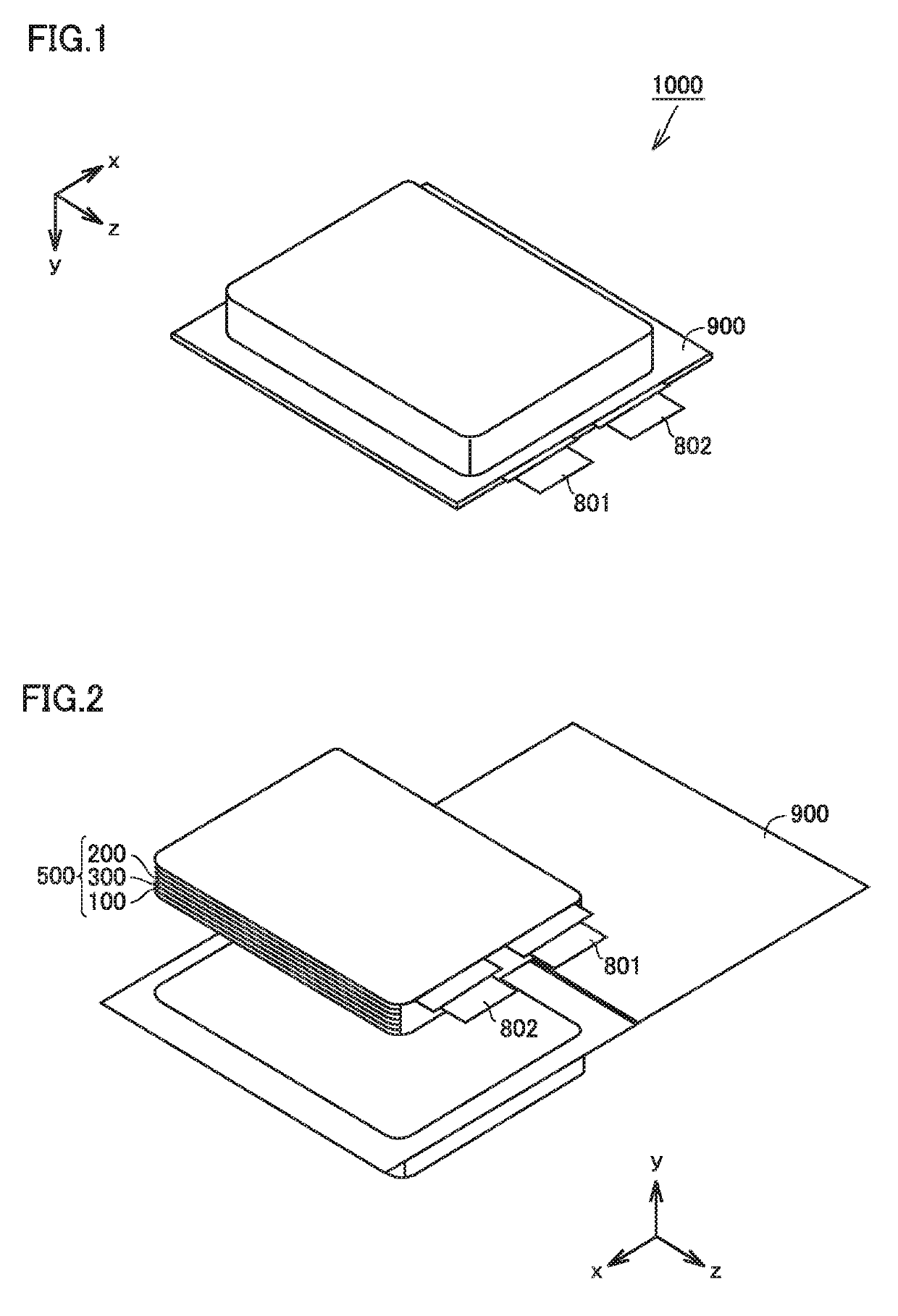

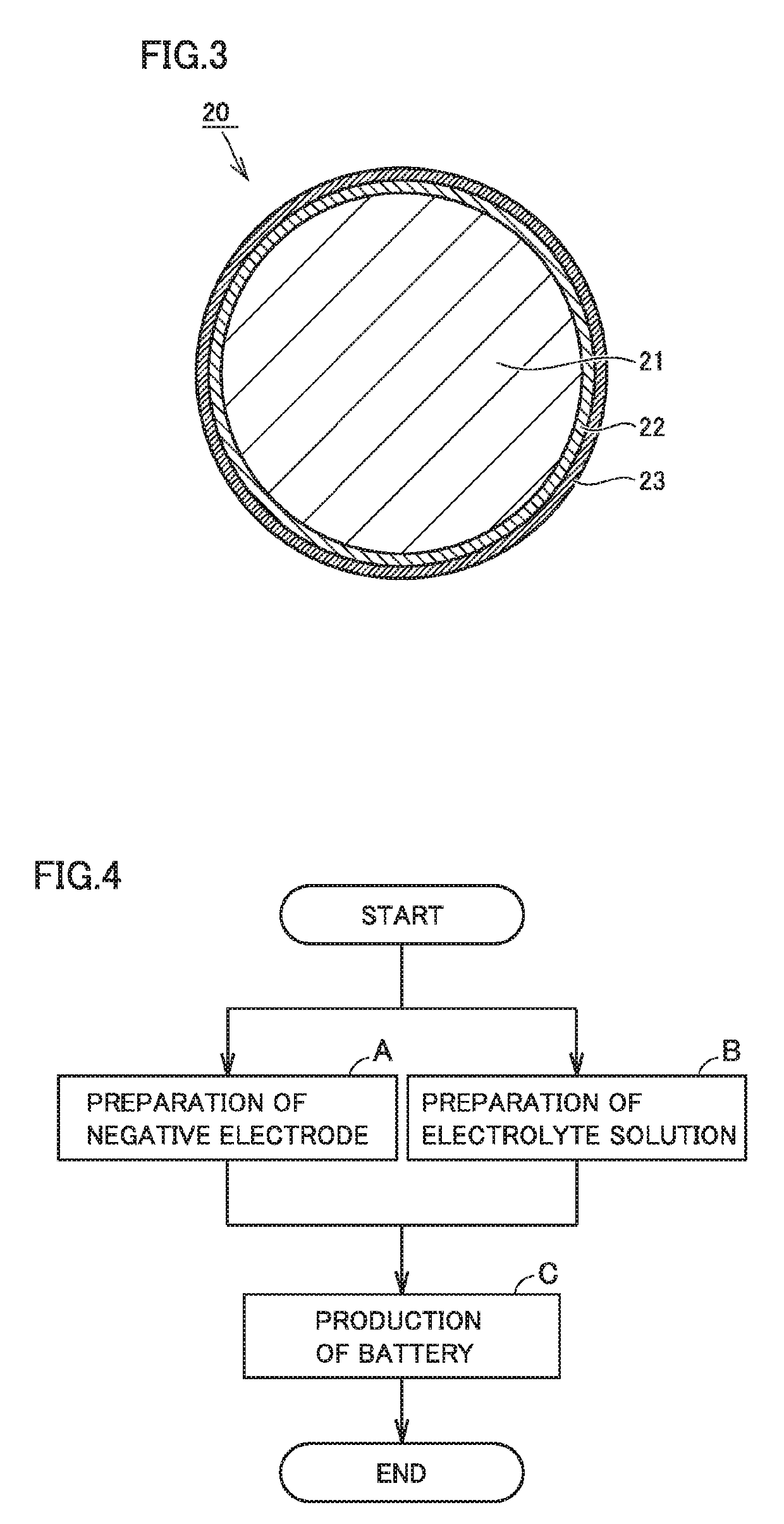

Lithium-ion secondary battery and method of producing the same

ActiveUS20190312302A1Degradation in capacity retentionReduce exposureFinal product manufactureNegative electrodesLithiumElectrolyte

A lithium-ion secondary battery includes at least a negative electrode, a positive electrode, and an electrolyte solution. The negative electrode includes at least negative electrode active material particles. Each of the negative electrode active material particles contains at least a SiOx particle and a Si layer. The Si layer covers a surface of the SiOx particle. The Si layer has a thickness not smaller than 10 nm and not greater than 100 nm. The electrolyte solution contains at least one selected from the group consisting of FEC and VC.

Owner:TOYOTA JIDOSHA KK

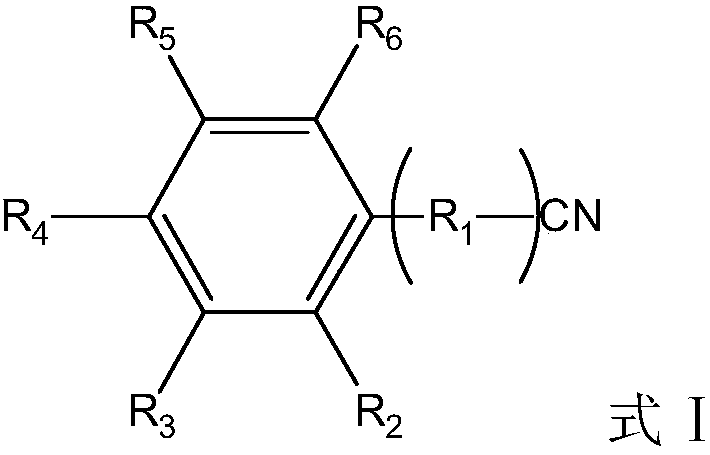

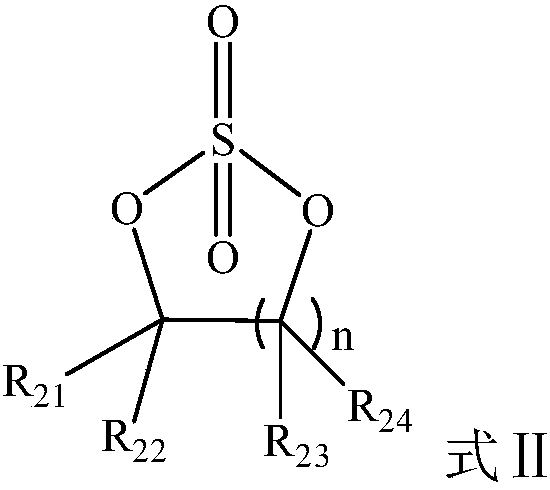

Cyclic phosphamido lithium salt and preparation method thereof, electrolyte additive, electrolyte and battery

PendingCN112952196AImprove stabilityPromote decompositionFinal product manufactureGroup 5/15 element organic compoundsElectrolytic agentAryl

The invention provides a cyclic phosphamido lithium salt, and the structural formula is as shown in formula I in the specification, wherein R1-R8 are independently selected from one of a hydrogen atom, a halogen atom, an alkyl group, a halogenated alkyl group, a substituted or unsubstituted cycloalkyl group, a substituted or unsubstituted aryl group, an electron withdrawing group and a heteroatom-containing heterocyclic group. The invention also provides an electrolyte additive, an electrolyte, a preparation method of the cyclic phosphamido lithium salt and a battery. The cyclic phosphamido lithium salt provided by the invention has relatively high stability when being applied to an electrolyte, and an SEI film formed in a charge-discharge cycle process is more beneficial to the passing of lithium ions, so that the electrical property of a battery can be improved.

Owner:BYD CO LTD

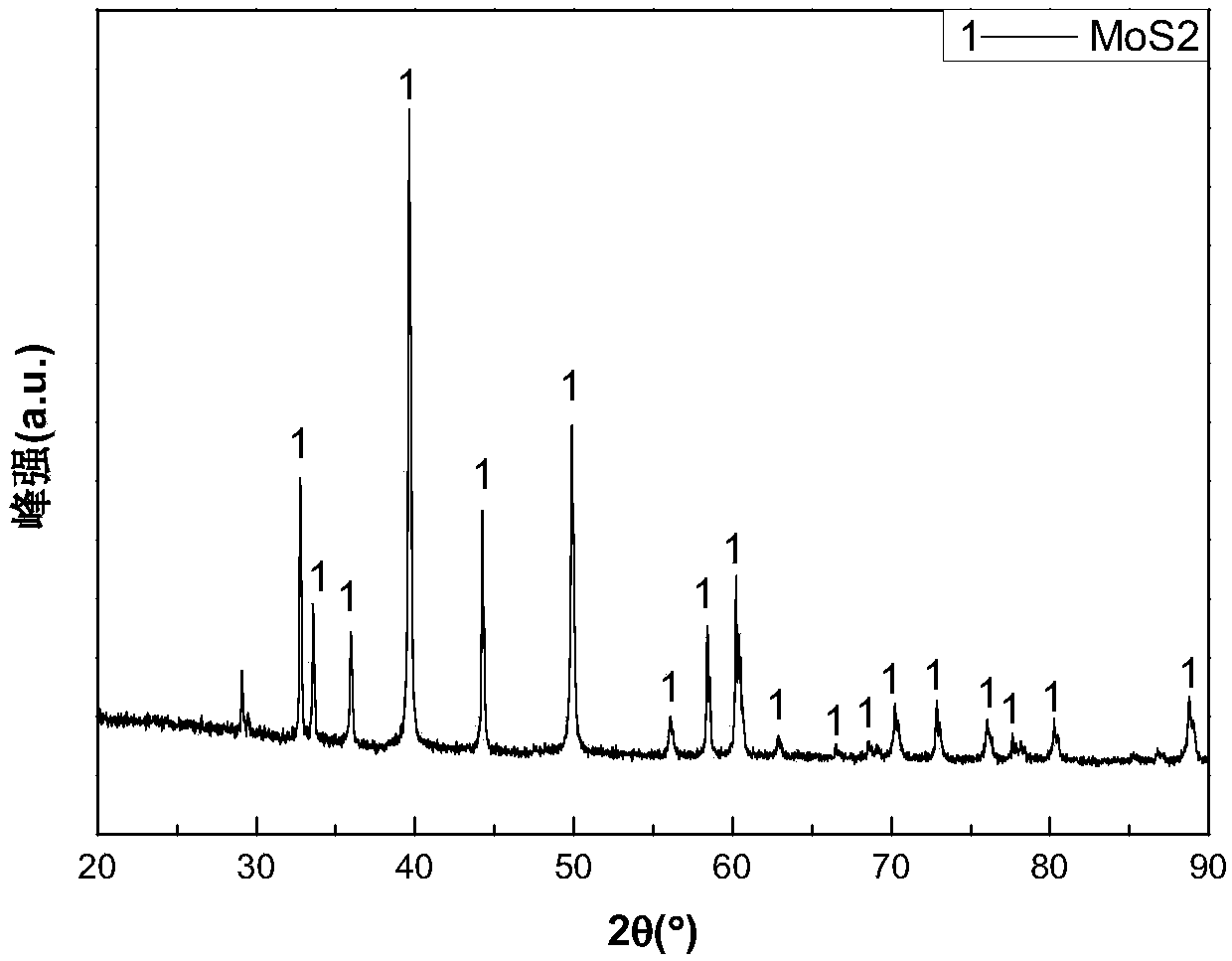

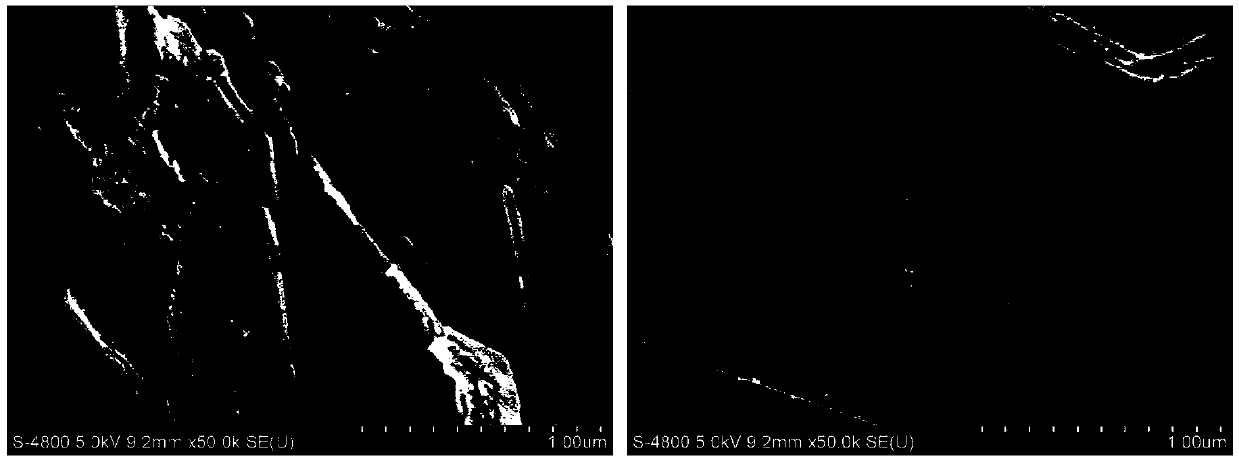

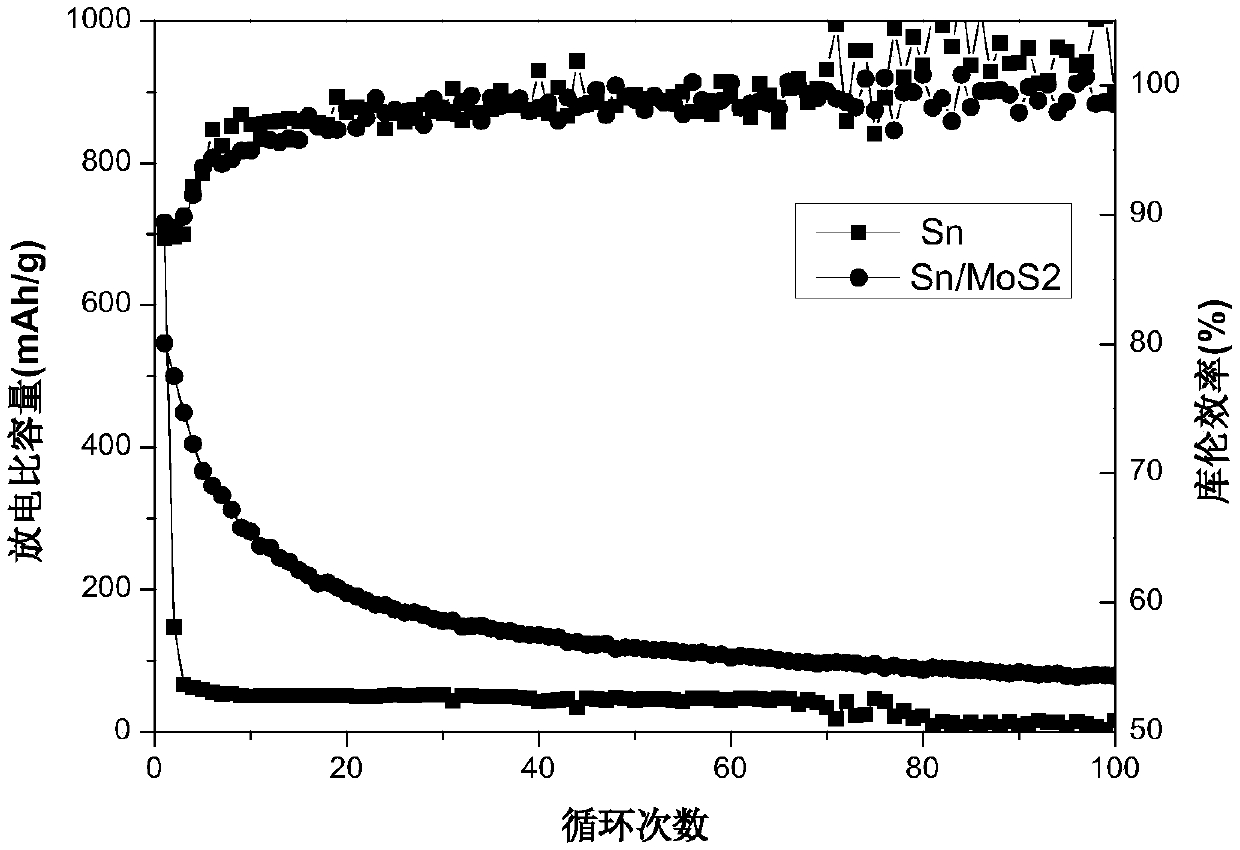

Nanometer tin-molybdenum disulfide compound negative electrode material as well as preparation method and application thereof

ActiveCN109560280AIncrease energy densityHigh reversible capacityNegative electrodesSecondary cellsLithium intercalationMaterials science

The invention discloses a nanometer tin-molybdenum disulfide compound negative electrode material as well as a preparation method and an application thereof. According to the prepared material, molybdenum disulfide is of a laminated structure, and tin is dispersedly distributed on a molybdenum disulfide sheet in a particle form, wherein the particle size of the tin particles is 8 -15 nm. The preparation method comprises the following steps of dipping molybdenum disulfide by using a SnCl4 solution, and preparing and obtaining the tin-molybdenum disulfide compound negative electrode material trough a hydrogenation reduction method. The layered structure of molybdenum disulfide is utilized, so that the volume change of the tin material in the lithium intercalation process is buffered, a partof internal stress is counteracted, and the cycling stability of a tin-based electrode is improved. The cycling capacity retention rate of the prepared tin-molybdenum disulfide compound electrode is obviously improved compared with that of commercial tin powder, the capacity reduction is relatively small when the large-current discharge is carried out, the platform effect is not obvious, and the capacity loss rate after the rate discharge is ended is low.

Owner:包头市石墨烯材料研究院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com