Positive electrode material and preparation method and application thereof

A technology of positive electrode material and average particle size, applied in the field of positive electrode material and its preparation, can solve problems such as poor voltage resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

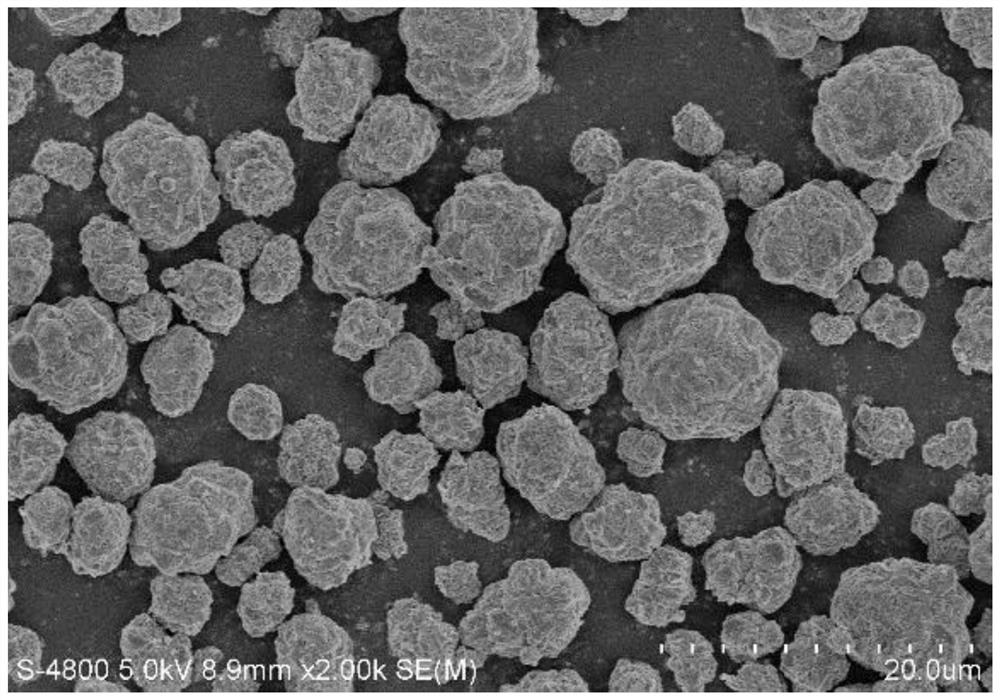

Embodiment 1

[0098] S1: Dissolve nickel sulfate, cobalt sulfate and manganese sulfate in water according to the molar ratio of nickel, cobalt and manganese elements of 60:20:20 to obtain a mixed salt solution with a concentration of 2 mol / L; dissolving sodium hydroxide in water Dissolve to obtain a precipitant solution with a concentration of 8 mol / L; dissolve ammonia water in water to obtain a complexing agent solution I with a concentration of 5.2 mol / L and a complexing agent solution II with a concentration of 10.3 mol / L.

[0099] S2: According to the molar ratio of the mixed salt (based on the total molar amount of metal elements), the precipitating agent, the first complexing agent and the second complexing agent of 1:4:2.6:5.15, mix 100L of mixed salt solution The precipitating agent solution and the complexing agent solution I are passed into the reaction kettle in a co-current manner, and the first mixing is carried out for 18h under the conditions that the pH is 12.2, the temperatu...

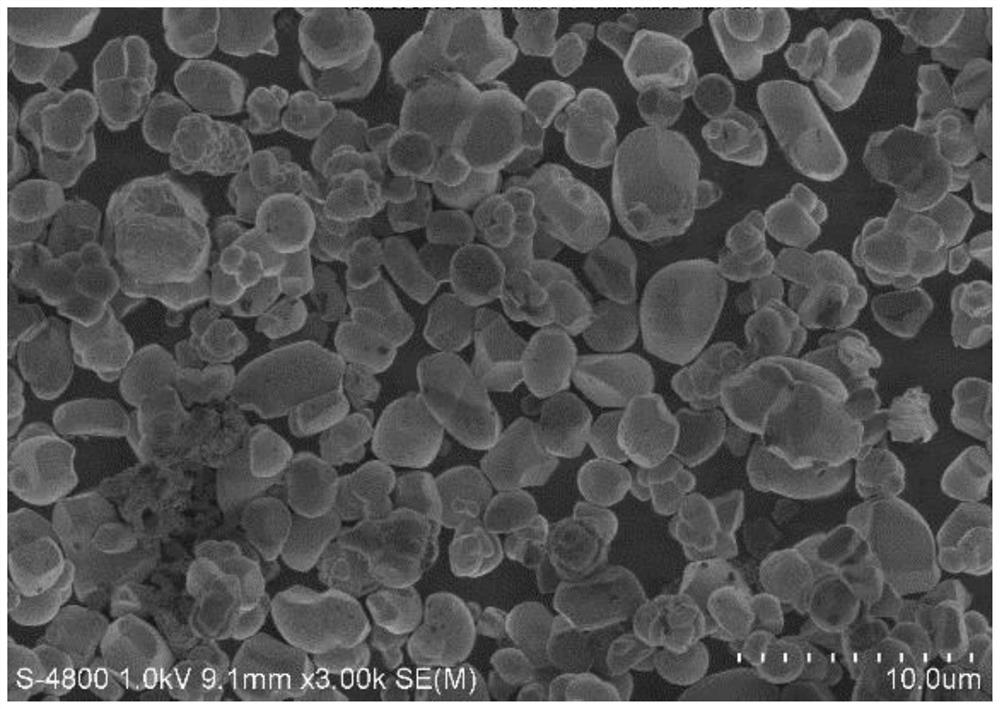

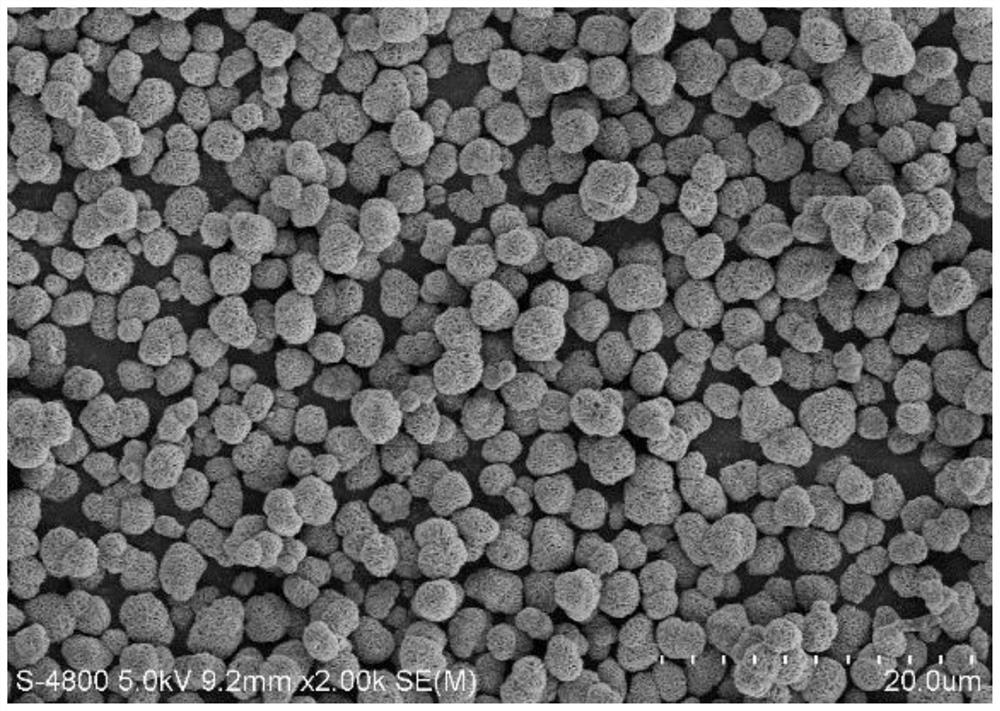

Embodiment 2-9

[0107] The positive electrode material was prepared according to the method of Example 1. The ratio of raw materials and the specific process conditions were shown in Table 1, and the single crystal positive electrode materials Z2-Z9 were obtained, and the corresponding chemical formula was shown in Table 1. Wherein, the calcination products obtained in step S4 of Examples 2-9 all have single crystal structures, and the corresponding chemical formulas are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com