Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

653 results about "Capacity loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

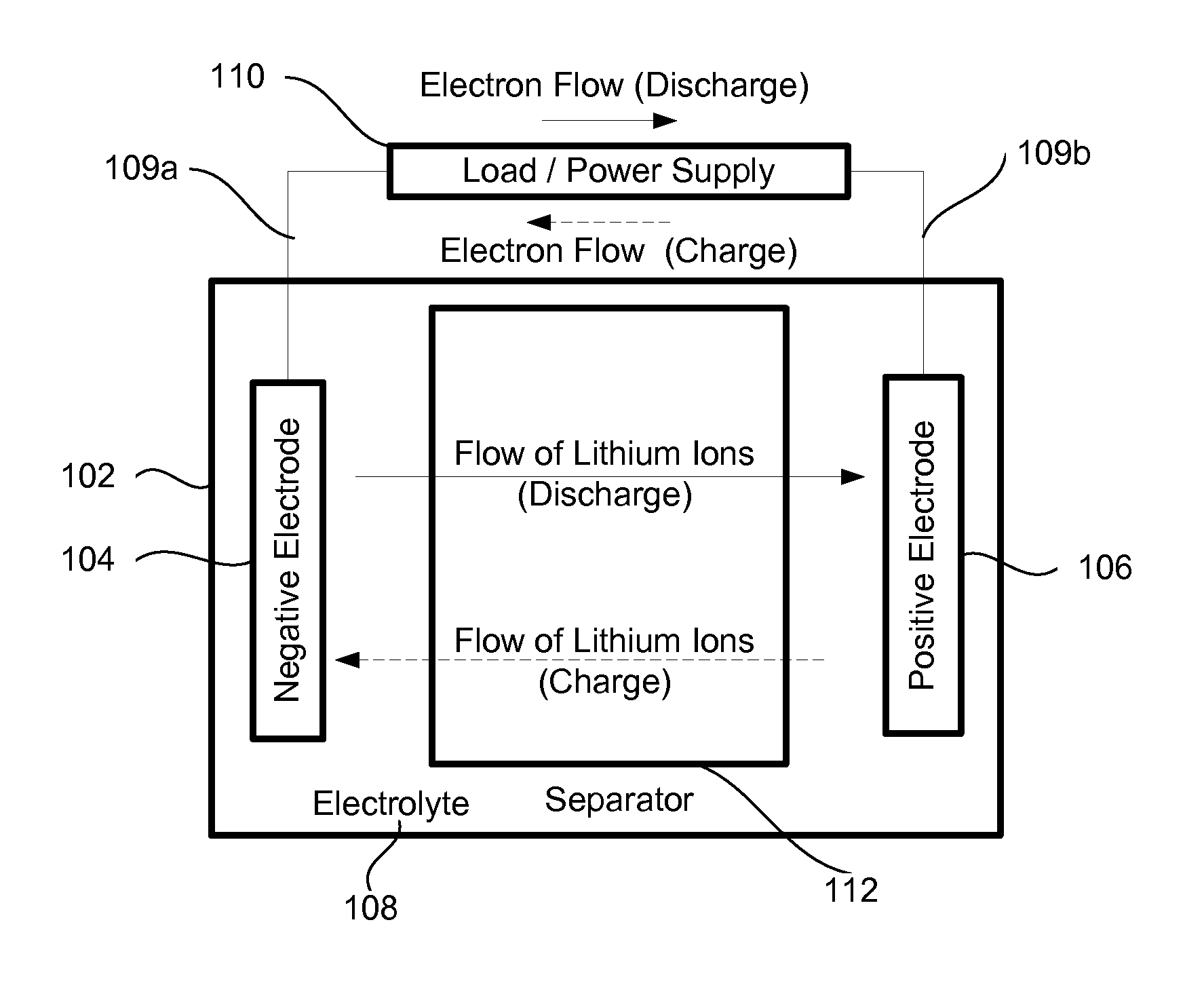

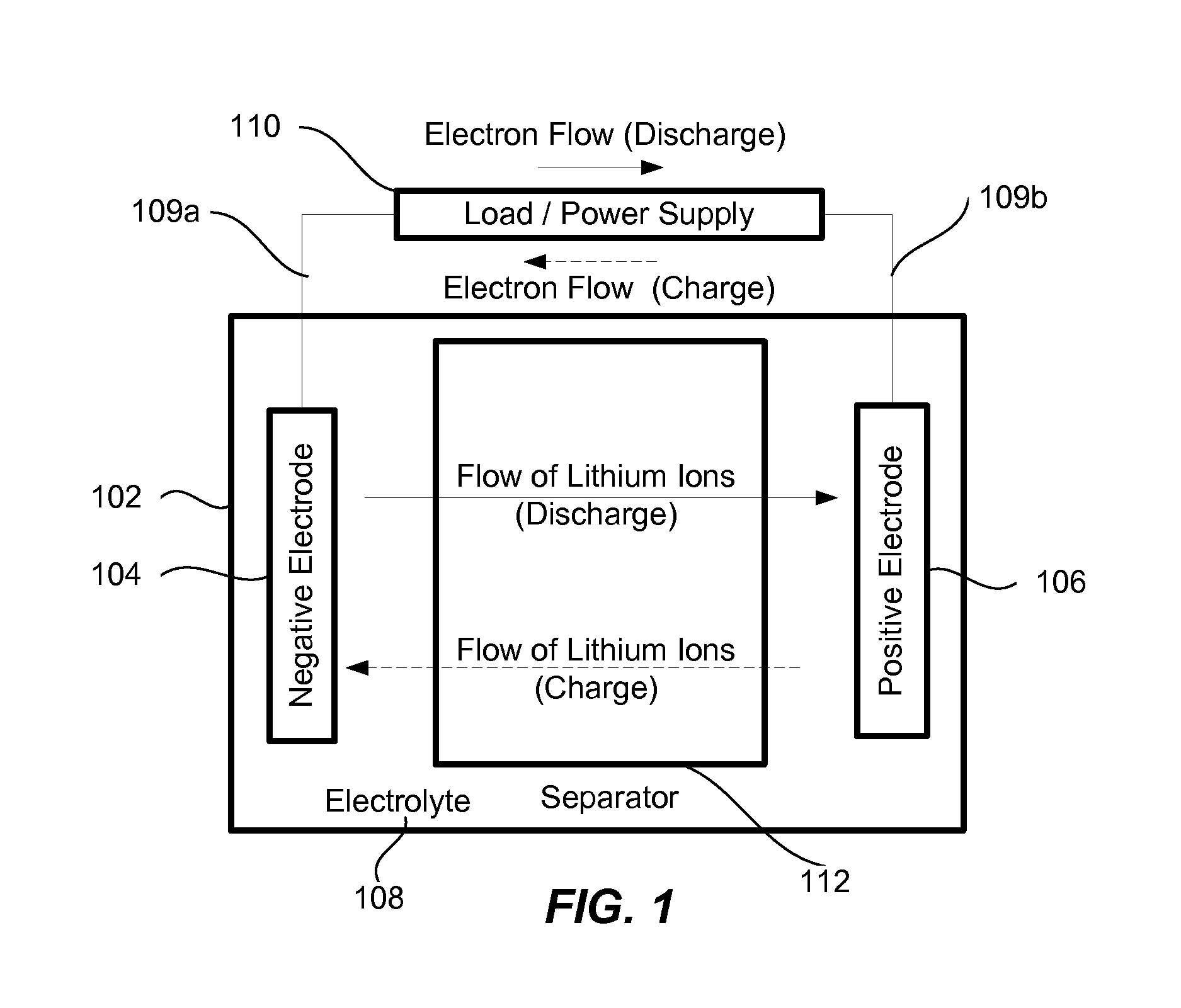

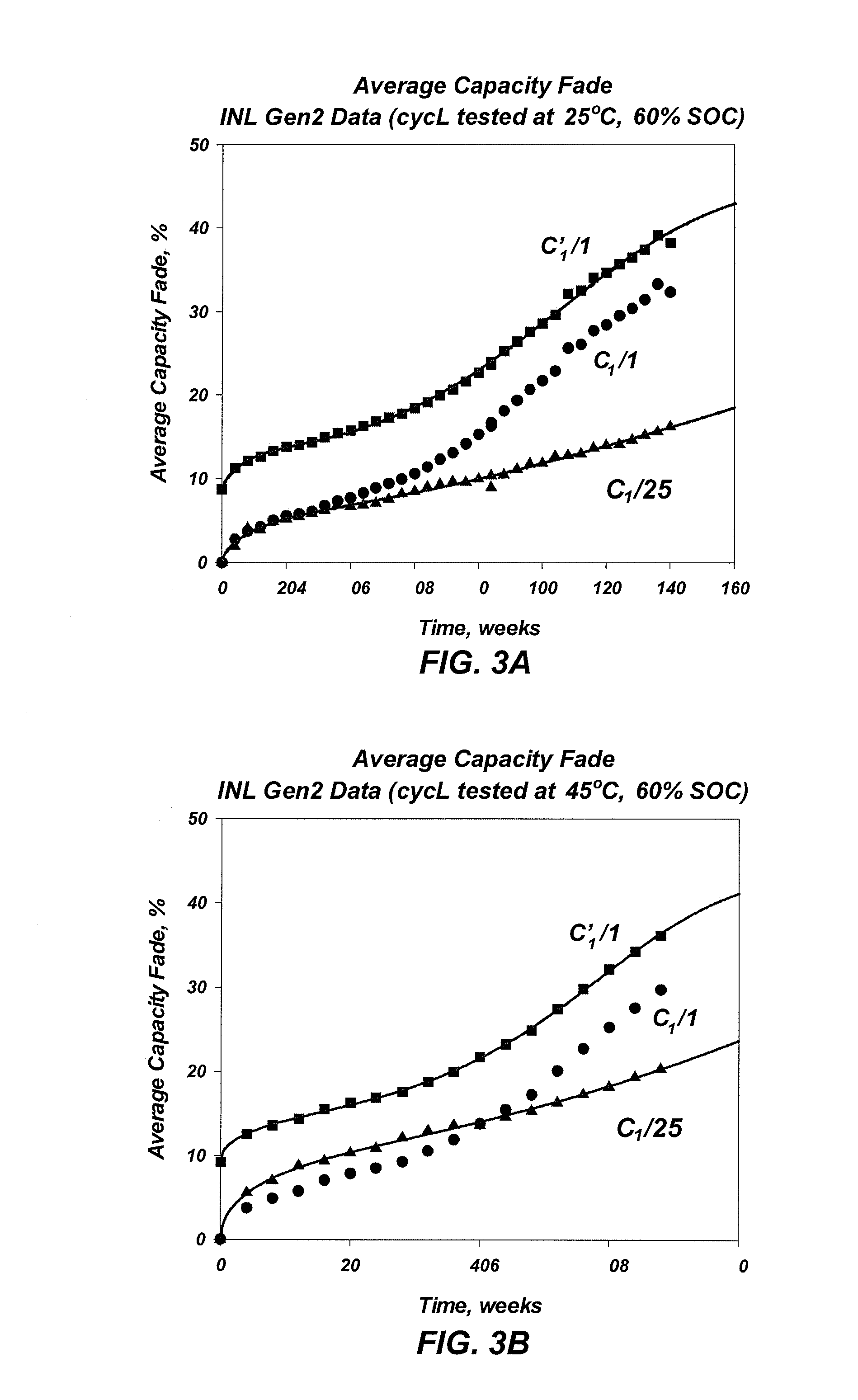

Capacity loss or capacity fading is a phenomenon observed in rechargeable battery usage where the amount of charge a battery can deliver at the rated voltage decreases with use. In 2003 it was reported the typical range of capacity loss in lithium-ion batteries after 500 charging and discharging cycles varied from 12.4% to 24.1%, giving an average capacity loss per cycle range of 0.025–0.048% per cycle.

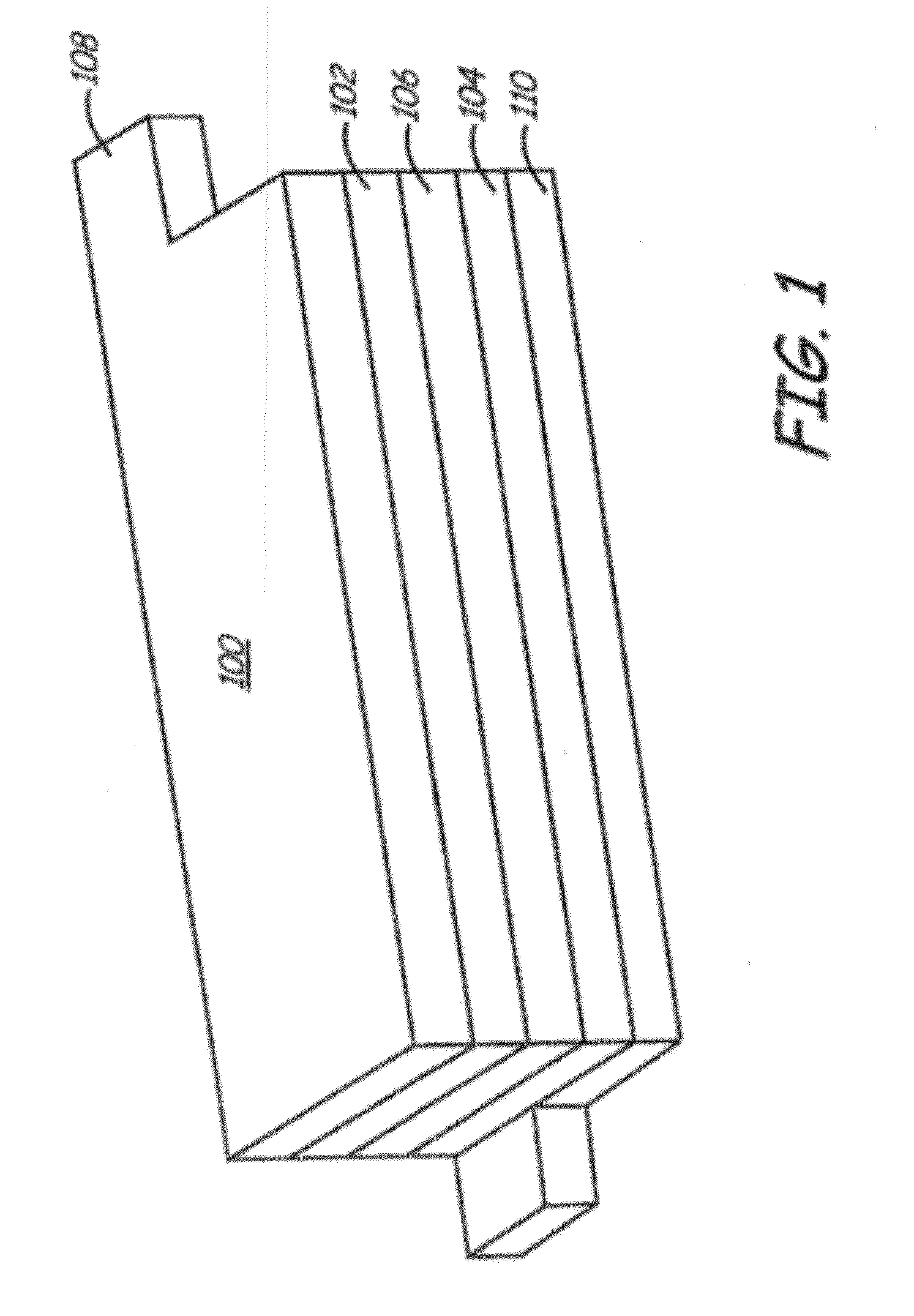

High Capacity Anode Materials for Lithium Ion Batteries

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

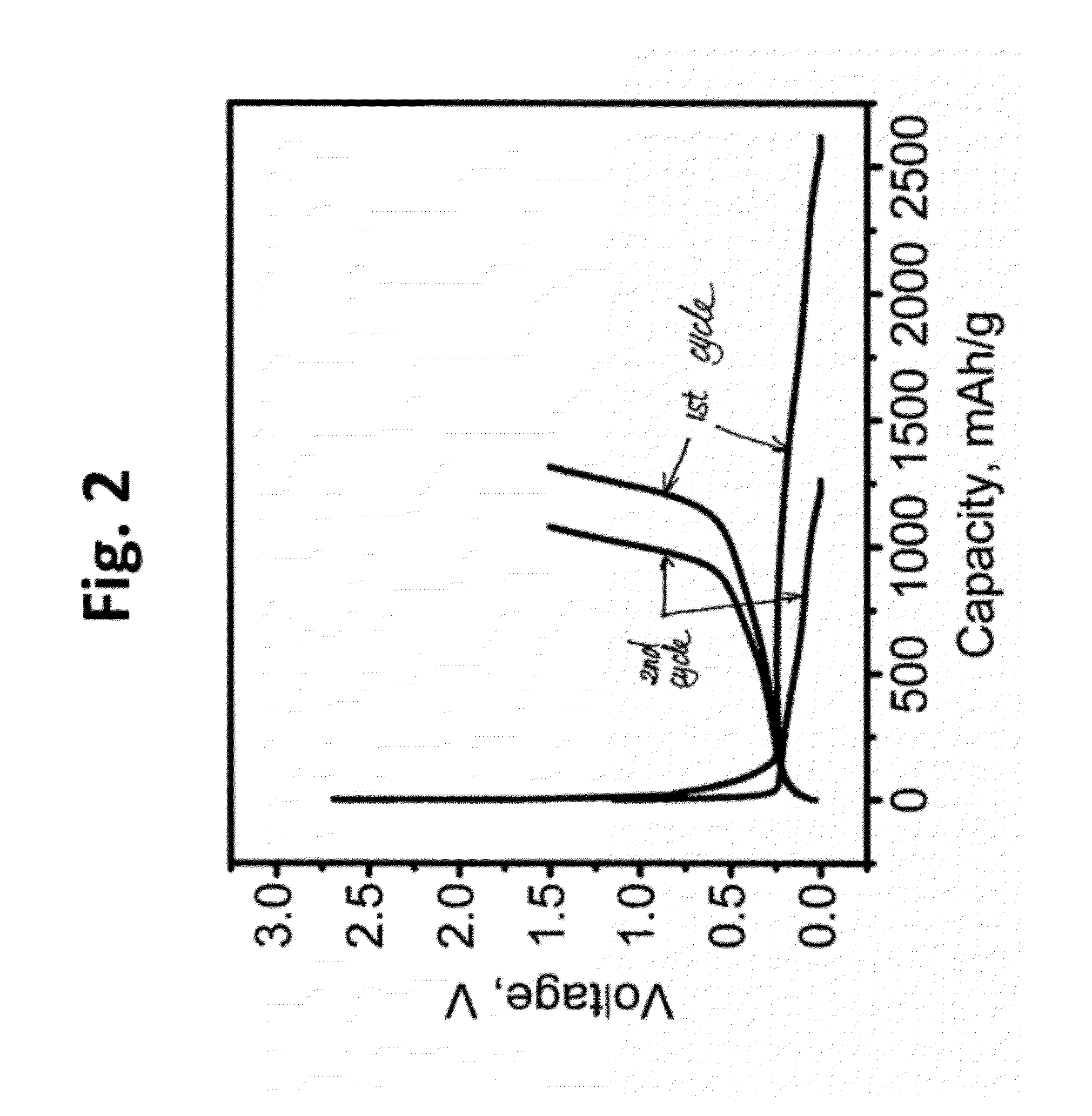

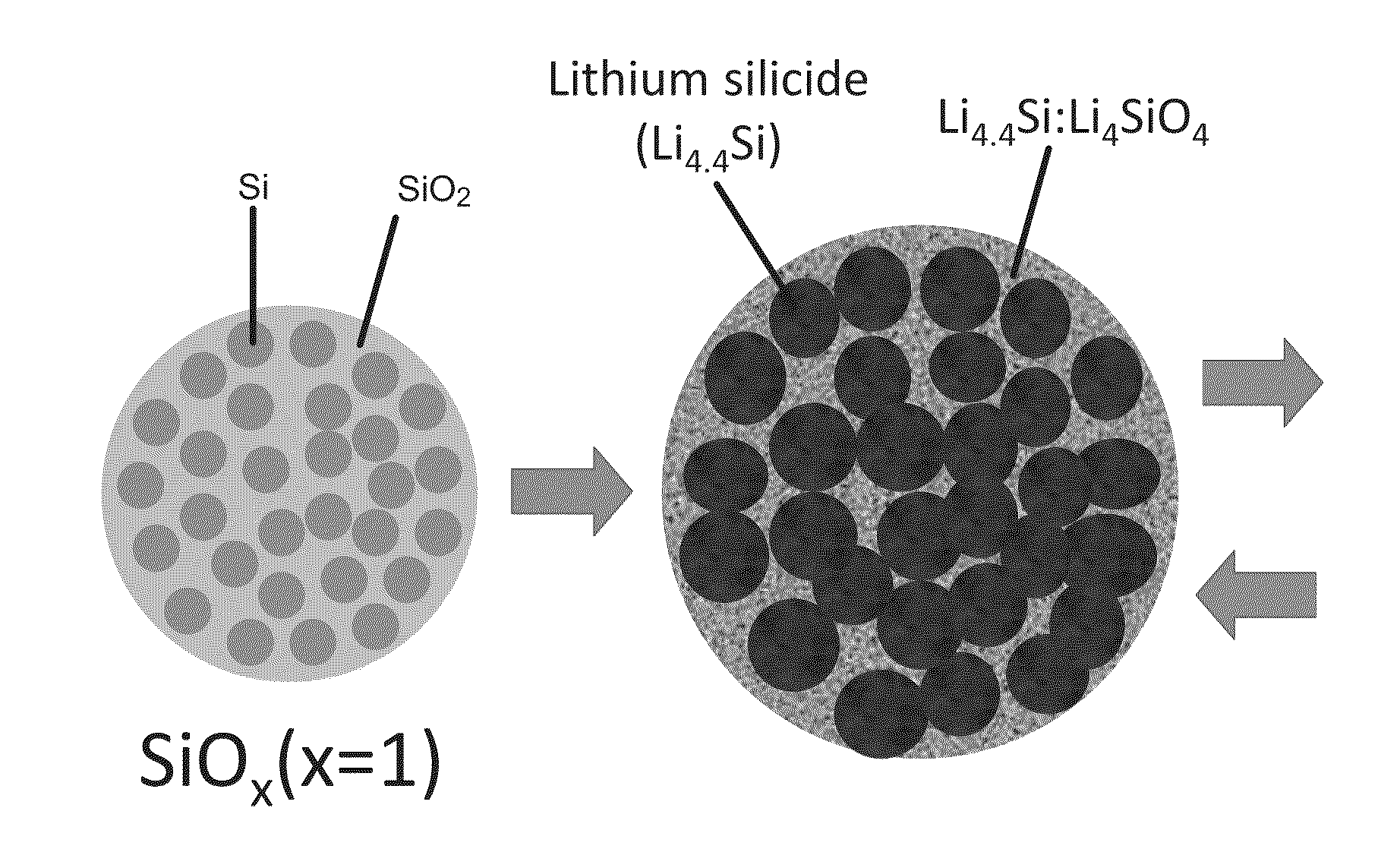

Silicon oxide based high capacity anode materials for lithium ion batteries

Silicon oxide based materials, including composites with various electrical conductive compositions, are formulated into desirable anodes. The anodes can be effectively combined into lithium ion batteries with high capacity cathode materials. In some formulations, supplemental lithium can be used to stabilize cycling as well as to reduce effects of first cycle irreversible capacity loss. Batteries are described with surprisingly good cycling properties with good specific capacities with respect to both cathode active weights and anode active weights.

Owner:IONBLOX INC

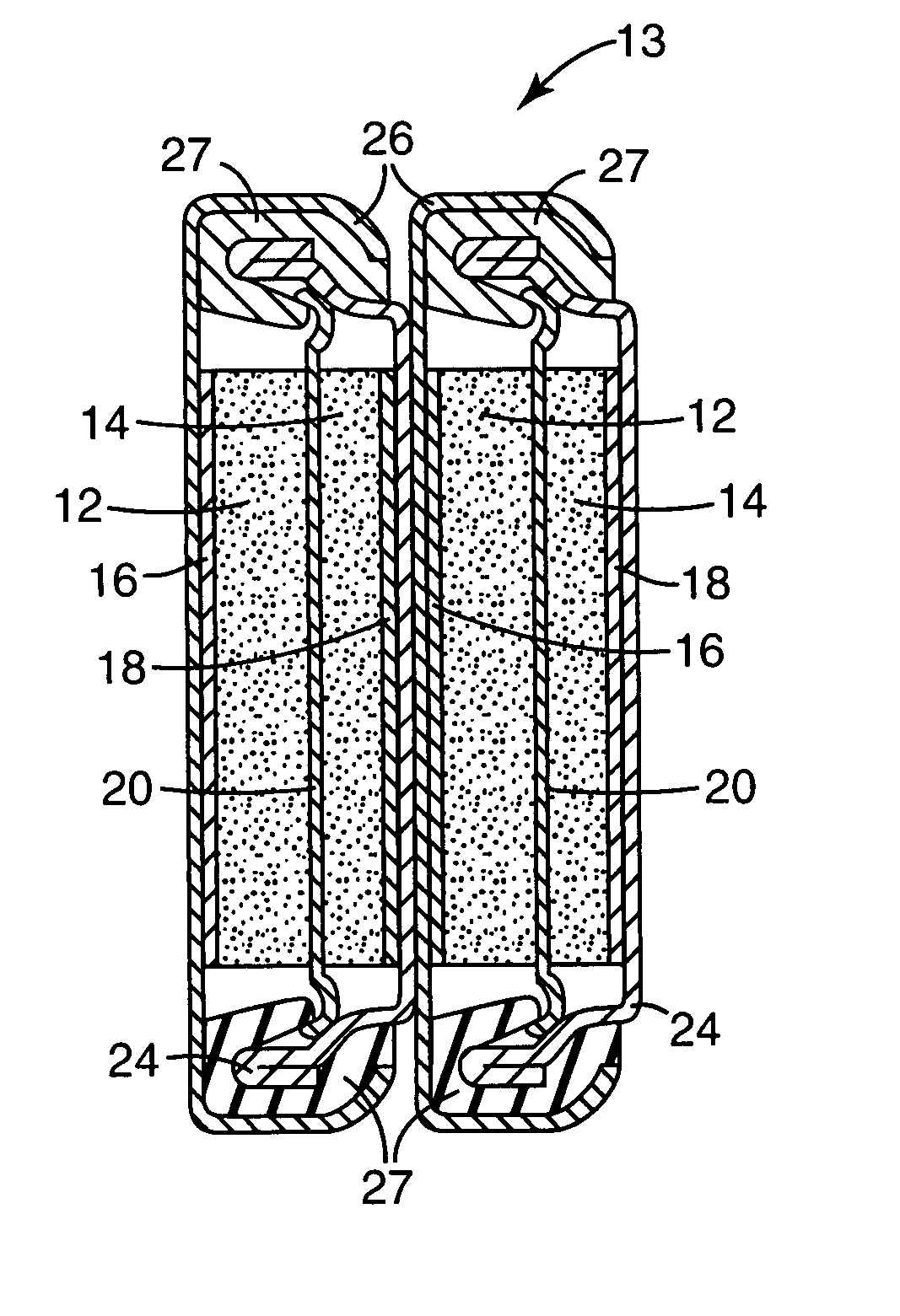

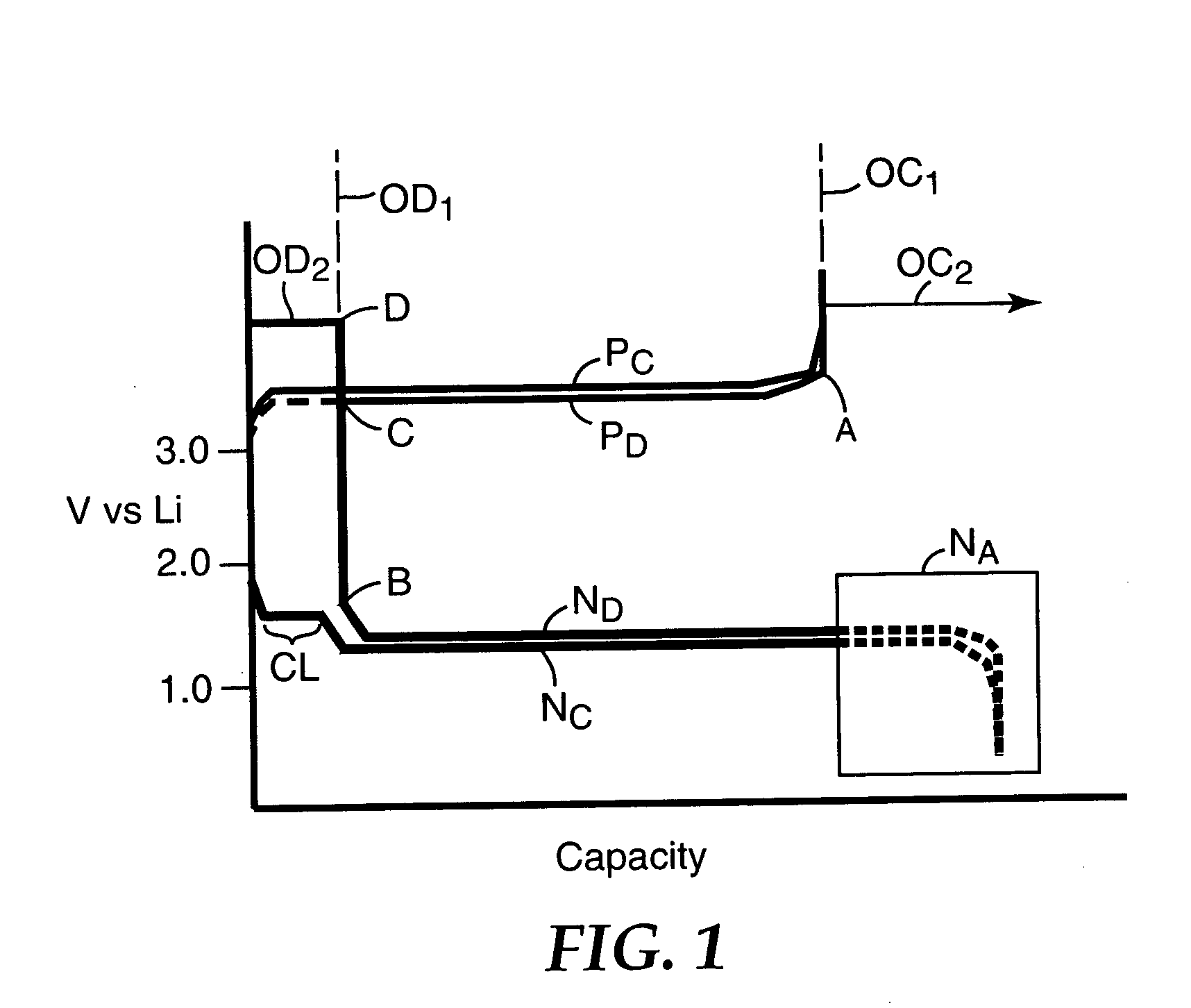

Redox shuttle for overdischarge protection in rechargeable lithium-ion batteries

InactiveUS20050221168A1Wide windowLarge capacityNon-aqueous electrolyte accumulatorsElectrolytic capacitorsElectrode potentialCapacity loss

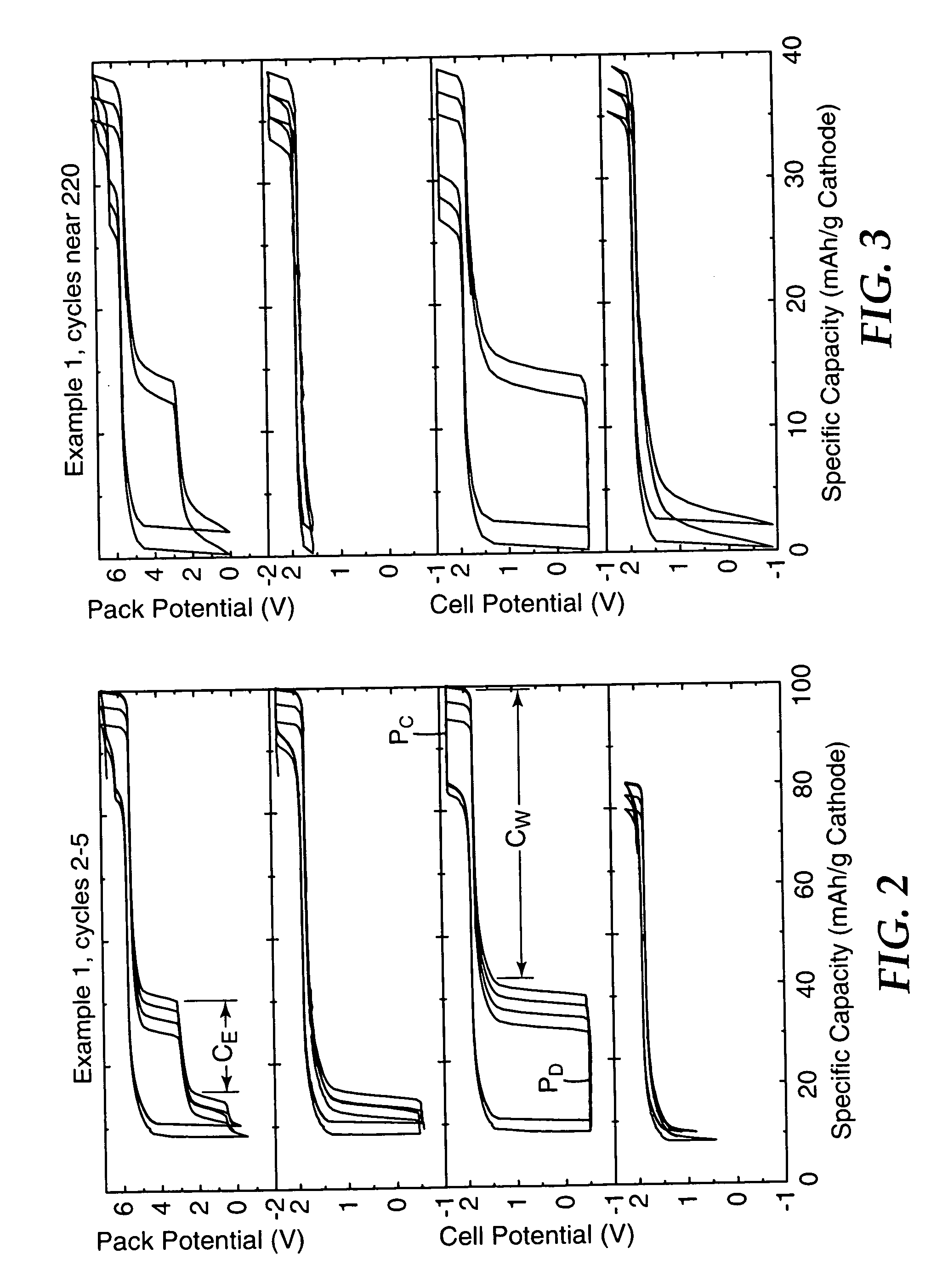

A battery of series-connected rechargeable lithium ion cells each of which contains a negative electrode; a negative electrode current collector; a positive electrode; a positive electrode current collector; and an electrolyte comprising charge carrying medium, lithium salt and cyclable redox chemical shuttle. The negative electrode has a larger irreversible first cycle capacity loss than that of the positive electrode, and is driven to a potential above that of the positive electrode if the cell is discharged to a state of cell reversal. The shuttle has an electrochemical potential above the positive electrode maximum normal operating potential, and prevents the negative electrode potential from reaching even higher and more destructive positive values during overdischarge. The current collector has a lithium alloying potential below the negative electrode minimum normal operating potential. The battery chemically limits or eliminates cell damage due to repeated overdischarge, and may operate without electronic overdischarge protection circuitry.

Owner:3M INNOVATIVE PROPERTIES CO

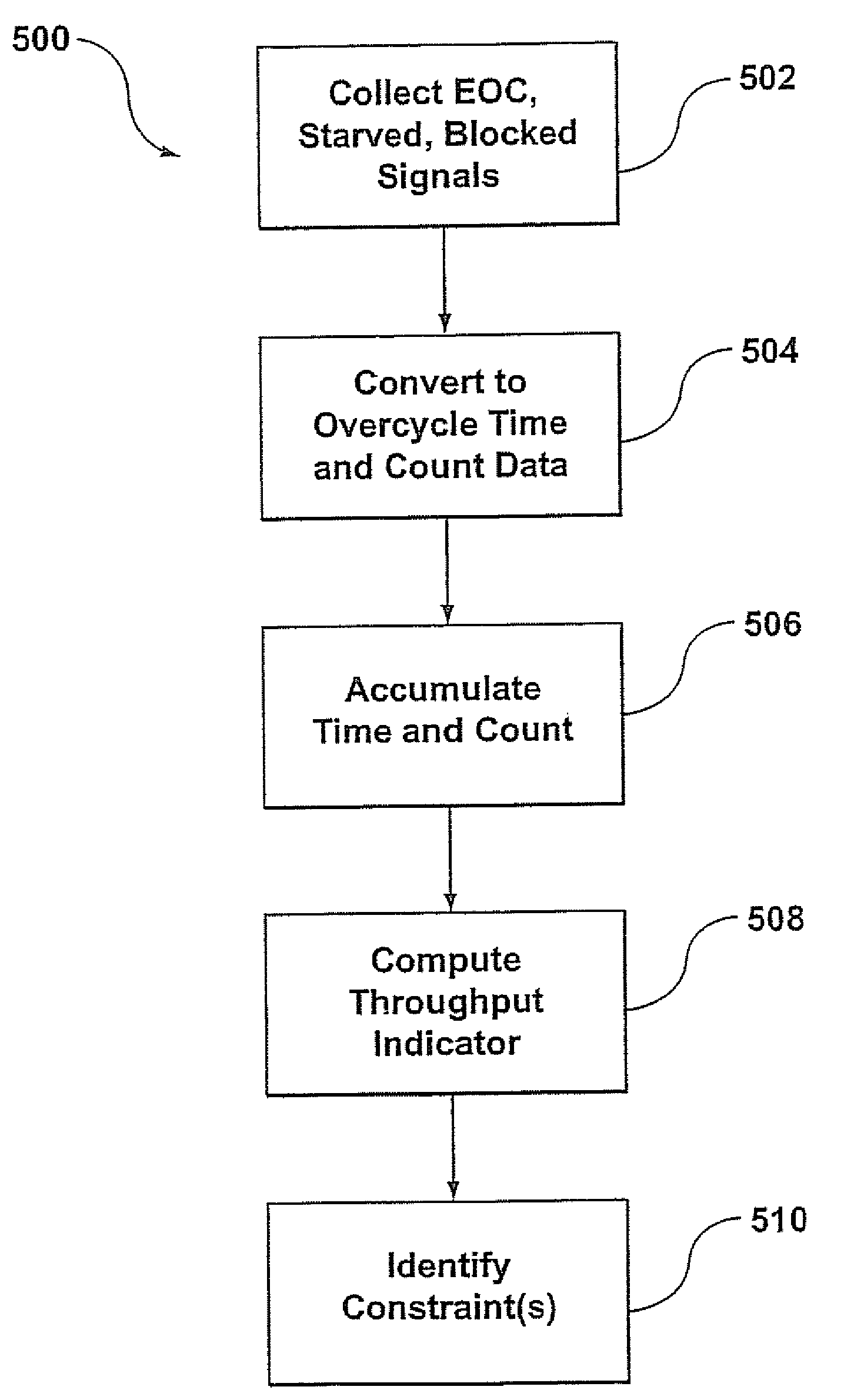

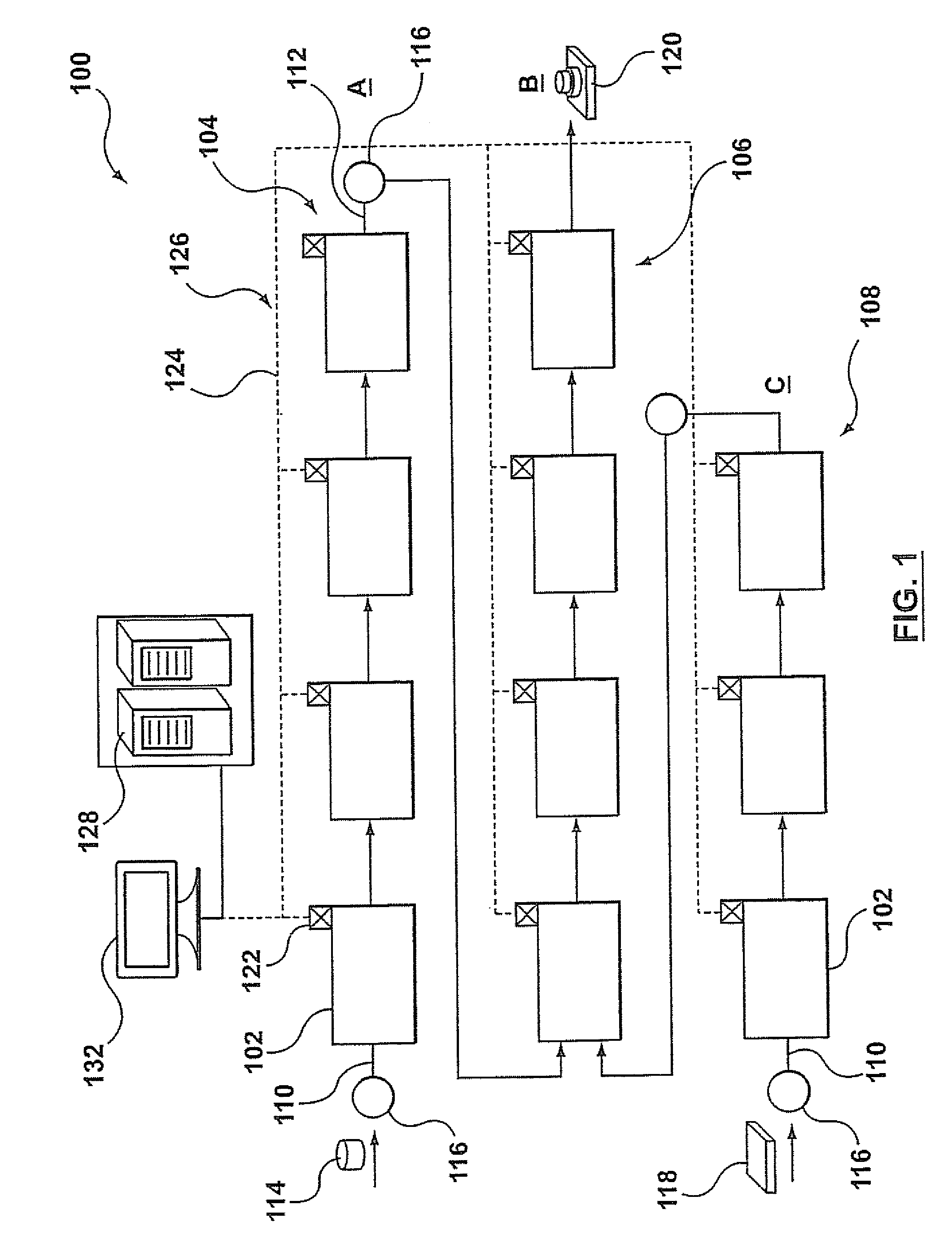

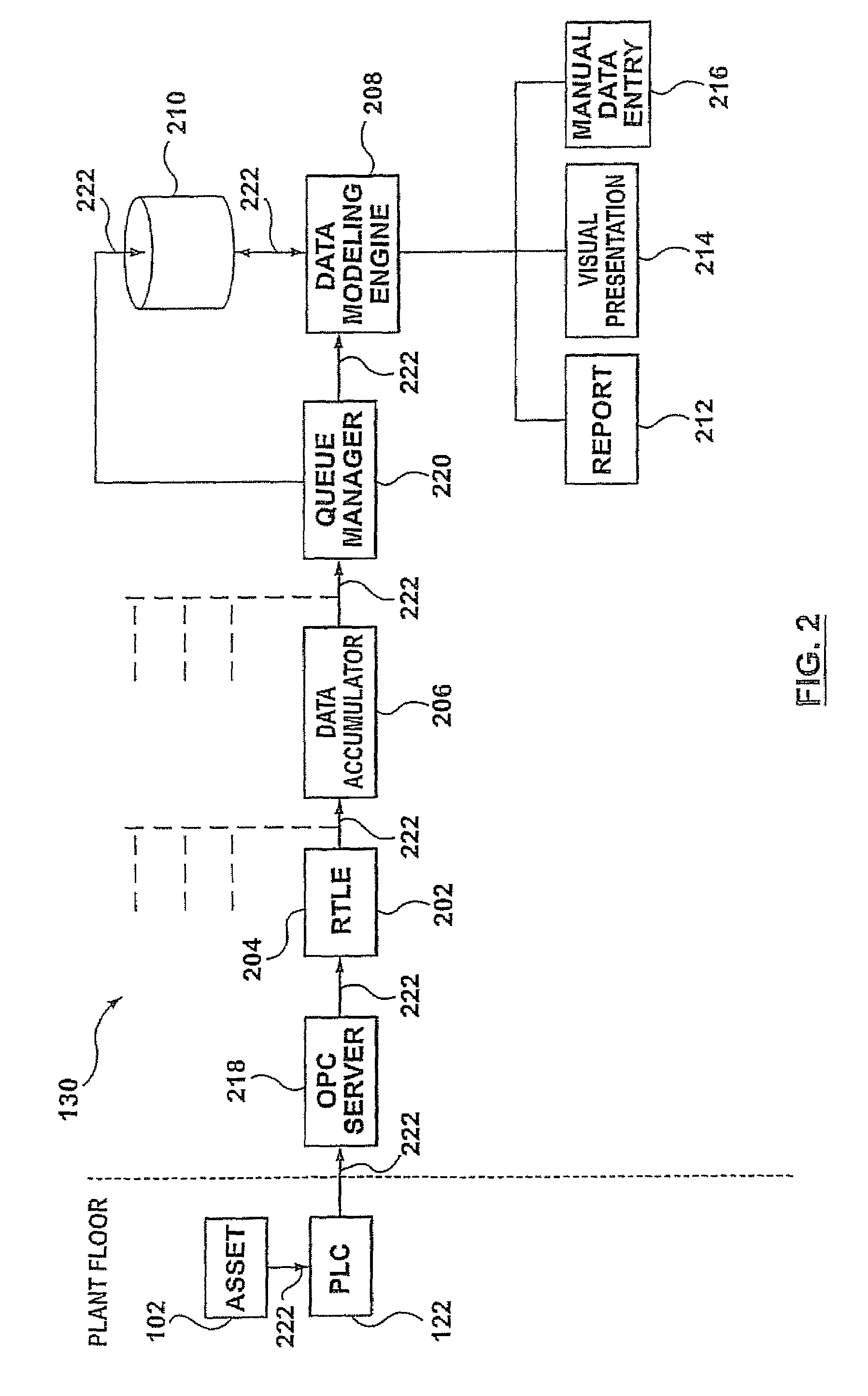

System and method of monitoring and quantifying performance of an automated manufacturing facility

ActiveUS7379782B1Programme controlComputation using non-denominational number representationProduction lineGraphics

The present invention is directed to a method and system for identifying, quantifying and presenting to a user constraints in an automated manufacturing or processing facility. A data processing system continuously receives basic status signals and state signals from automation equipment in the facility and evaluates and processes these signals to derive a throughput capability measure (a measure of constraint) of each given manufacturing workstation in the process. The throughput capability measure is expressed as a ratio of an ideal cycle time to an accumulated overcycled time. The accumulated overcycled time includes only delays and excludes any speed-up of a workstation. A constraint is identified as the workstation that has the lowest throughput capability measure as compared with all other workstations in a production line. Preferably, throughput capability measures for all workstations are presented to users graphically. Further drill-down can be provided for obtaining more detailed information about the constraint and capacity loss as well as entering information relevant to the constraint, such as a stoppage or slow-down.

Owner:APTEAN INC

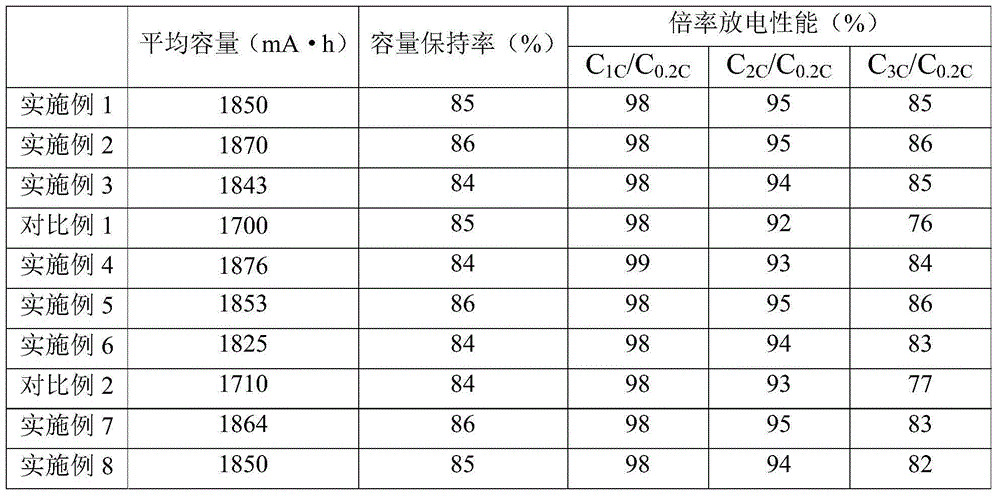

Positive electrode and preparation method therefor, and lithium secondary battery

InactiveCN105702913ACompensation for irreversible capacity lossIncrease energy densityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesCapacity lossHigh rate

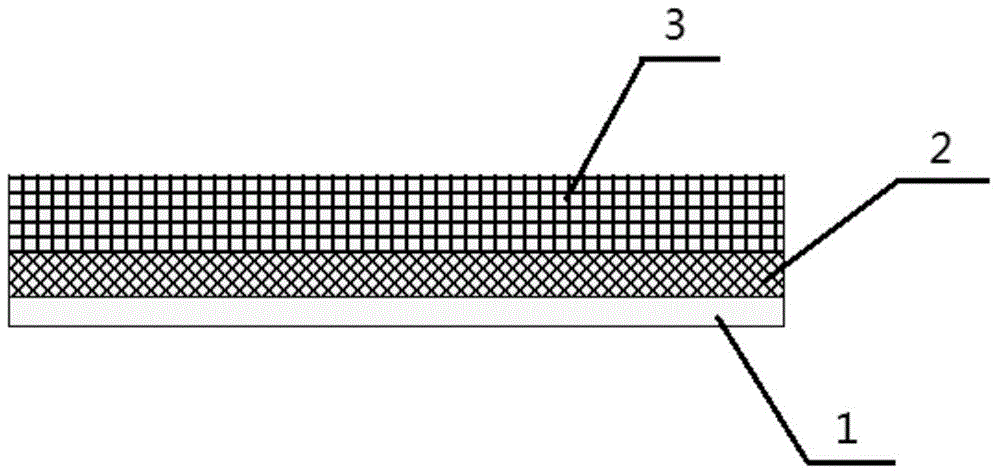

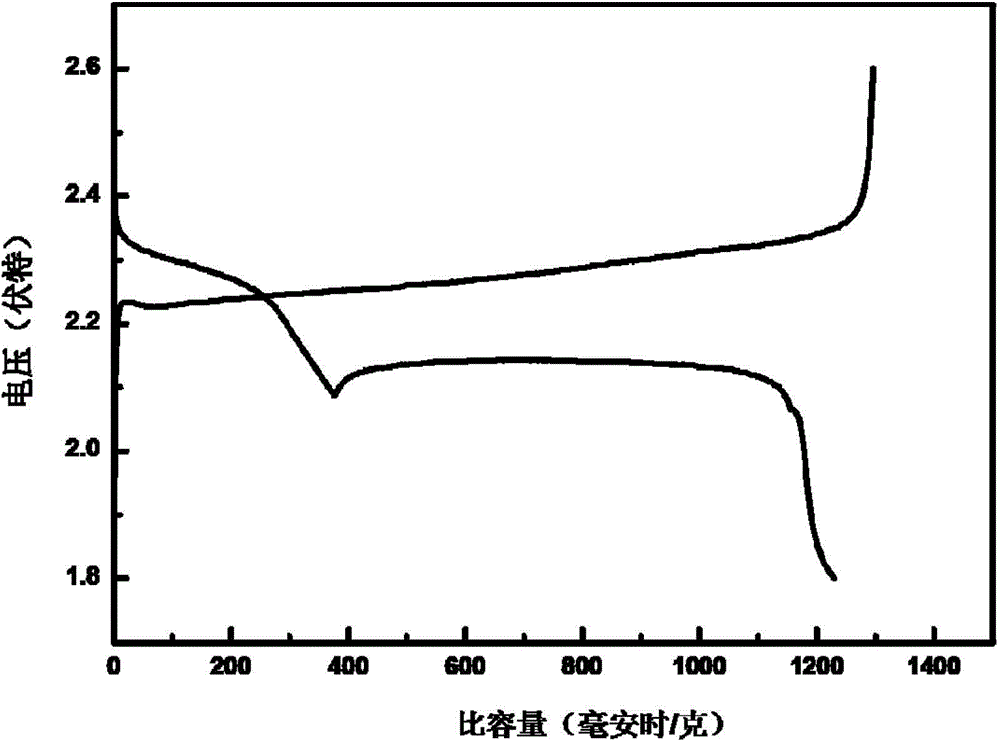

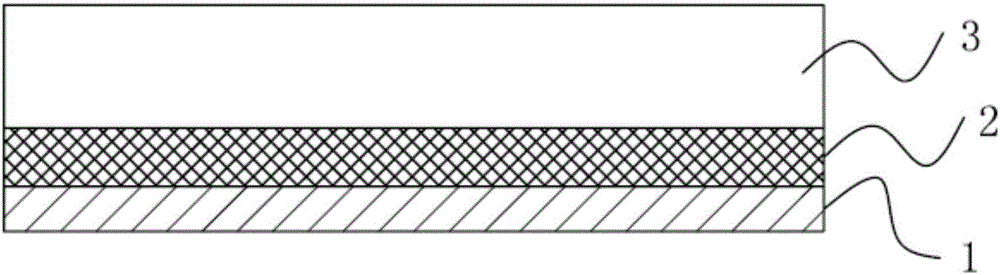

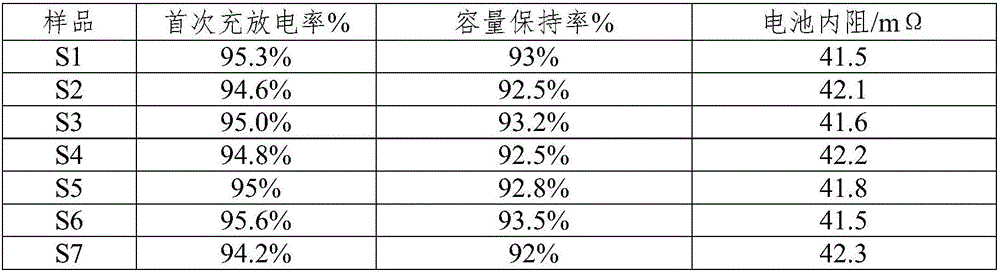

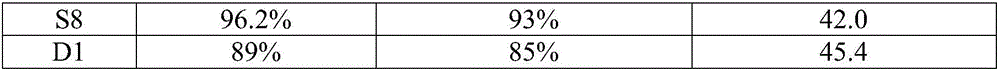

The invention discloses a positive electrode and a preparation method therefor, and a lithium secondary battery employing the positive electrode. The positive electrode comprises a conductive substrate, a positive electrode active material layer and a lithium-compensating layer which is arranged between the conductive substrate and the positive electrode active material layer; the lithium-compensating layer comprises at least a kind of lithium-containing compound, at least a kind of conductive agent and at least a kind of binder; the lithium-containing compound is chosen from the group formed by the compound as shown in the formula Li<x>A, wherein A is O, P, S or N; and x is greater than 0 and less than or equal to 3. The positive electrode provided by the invention has the lithium-compensating function, and is capable of effectively compensating the irreversible capacity loss of the lithium secondary ion in the charging-discharging process and improving the energy density of the battery; the lithium secondary ion has excellent cycling performance and high-rate discharging performance; the positive electrode provided by the invention does not require metal lithium; compared with the battery adopting metal lithium, the severity on the operating environment and operation process is lowered; and therefore, the positive electrode provided by the invention can be prepared by a conventional process under conventional conditions.

Owner:BYD CO LTD

Lithium doped cathode material

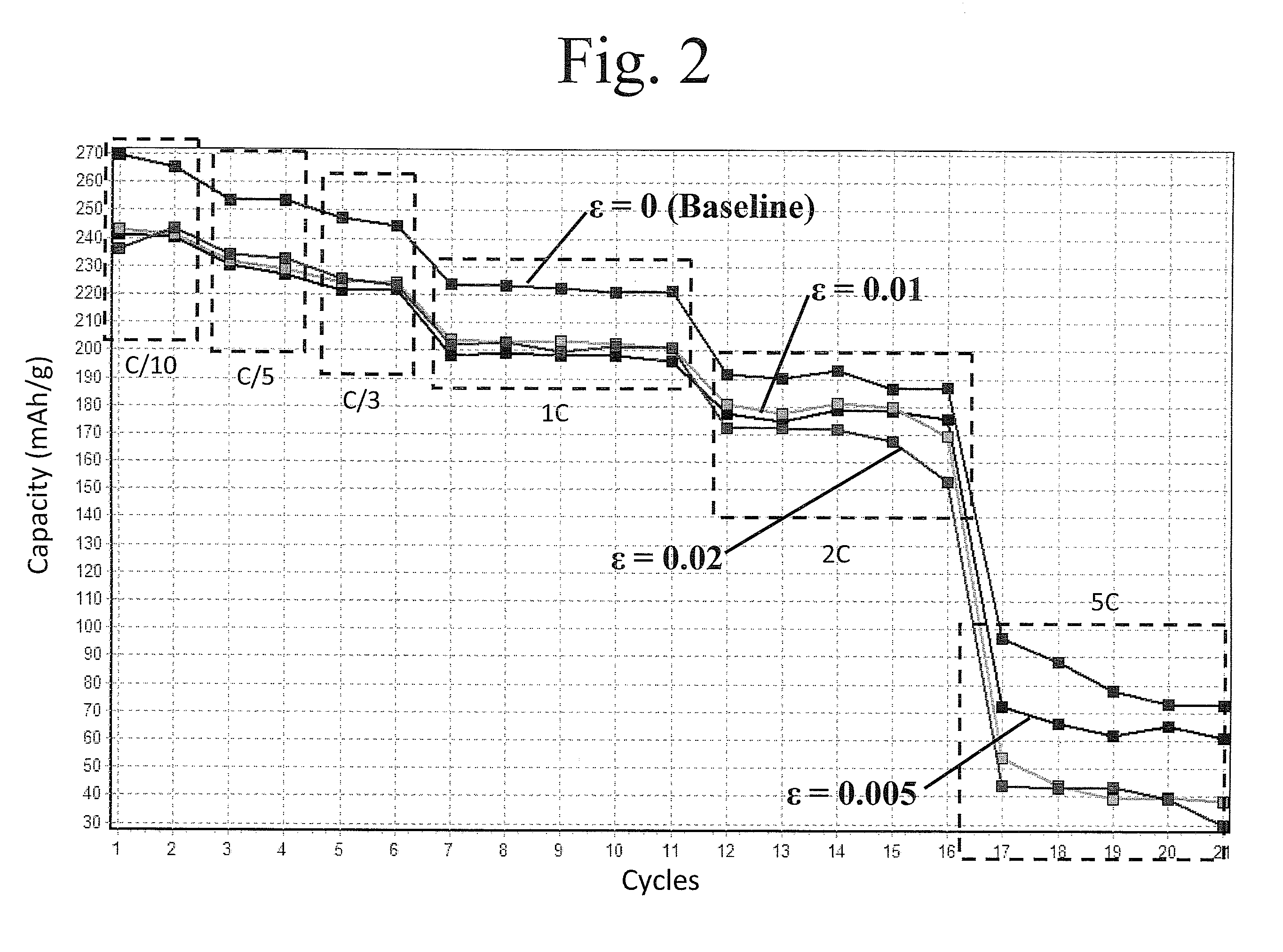

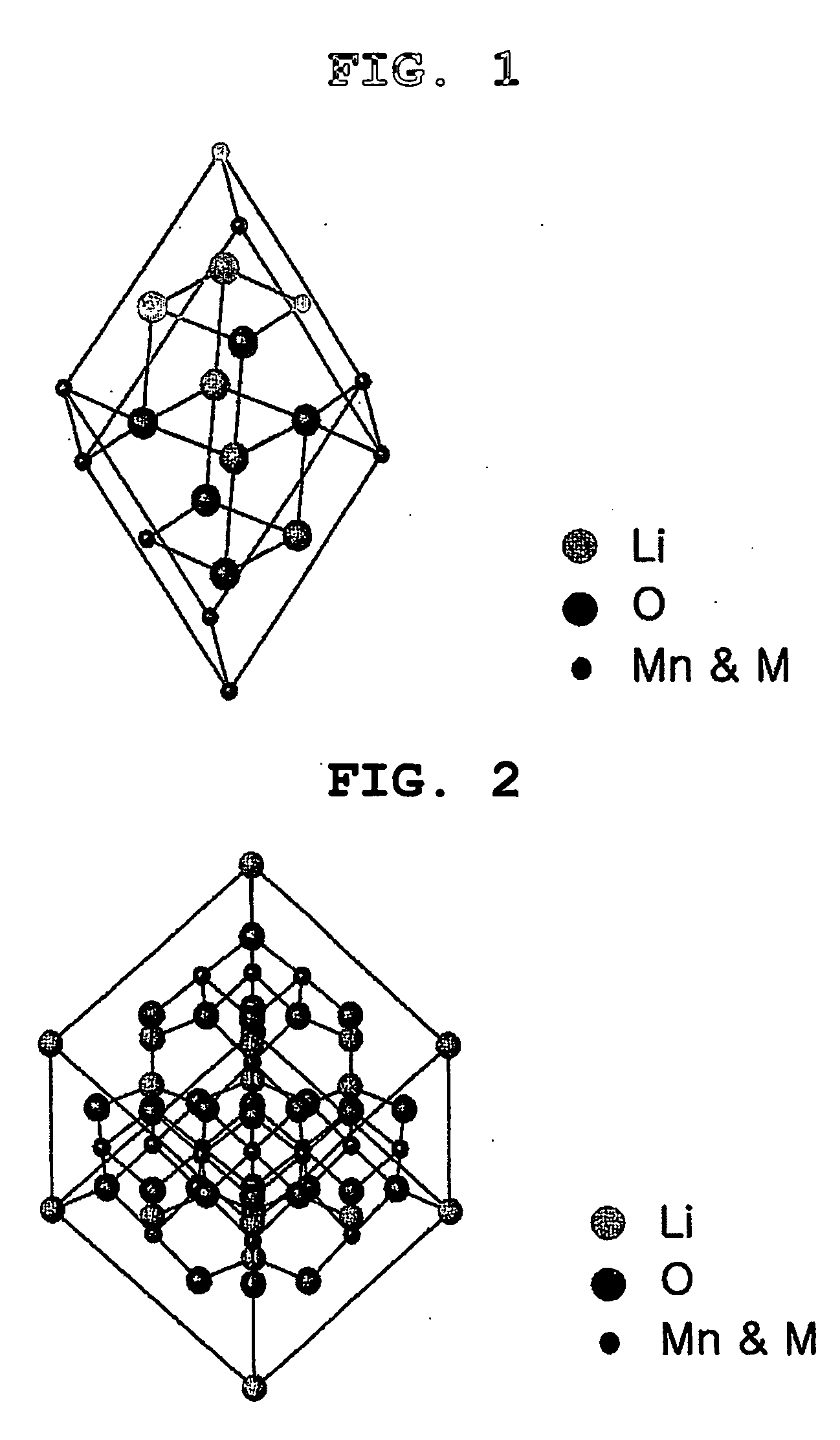

Lithium dopant is introduced into lithium rich high capacity positive electrode active materials as a substitution for manganese within the complex metal oxides. In some embodiments, the lithium doped compositions can be written in a two component notation as x.Li2MnO3.(1−x)LiNiu+ΔMnu−Δ−dLidCowO2, where d ranges from about 0.004 to about 0.25 and 2u+w is approximately equal to 1. The materials are believed to form a layer-layer composite crystal structure that has very good cycling properties at high voltages, although the materials exhibit significant first cycle irreversible capacity loss.

Owner:IONBLOX INC

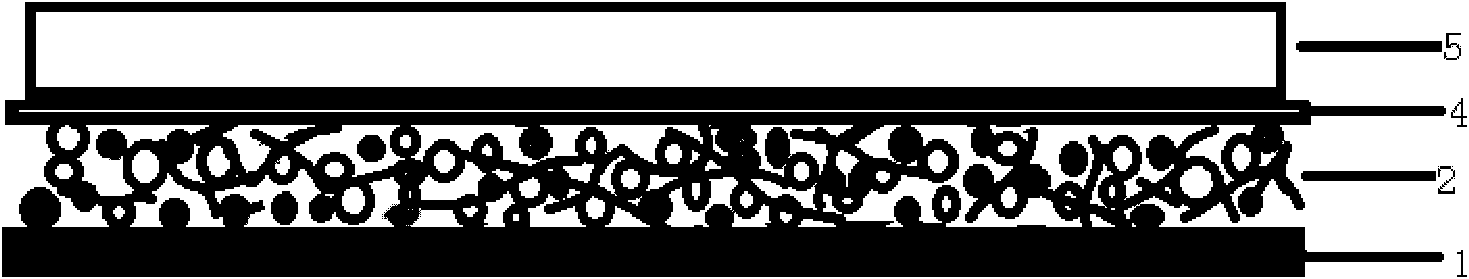

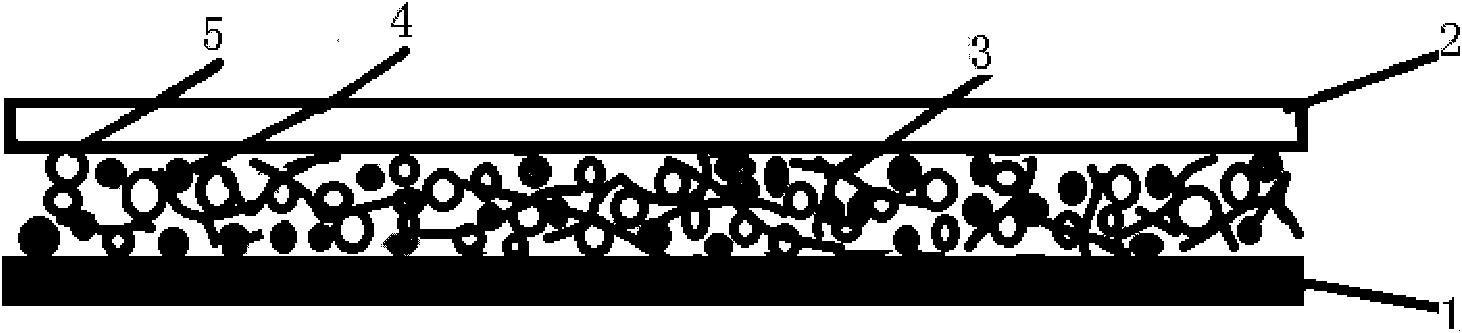

Positive electrode of lithium-sulfur battery with multifunctional elastic protection layer

InactiveCN105322132AThere is no effect on the charging and discharging processImprove stabilityNon-aqueous electrolyte accumulator electrodesCapacity lossLithium–sulfur battery

The invention relates to a positive electrode of a lithium-sulfur battery with a multifunctional elastic protection layer. The positive electrode of the lithium-sulfur battery comprises a positive material layer and the multifunctional elastic protection layer, wherein the multifunctional elastic protection layer is formed on the surface of the positive material layer and comprises a polymer and / or a conductive carbon material; and the thickness of the multifunctional elastic protection layer is 0.1-50 microns. The multifunctional elastic protection layer is introduced to the surface of the positive material layer of the lithium-sulfur battery; the multifunctional elastic protection layer has elasticity and conductivity; and has no influence on charge and discharge processes of the positive electrode of the lithium-sulfur battery; compared with the positive electrode of the lithium-sulfur battery without protection from a multifunctional elastic layer structure, the prepared positive electrode of the lithium-sulfur battery with the protection of the multifunctional elastic layer structure has good stability; a structural damage to the positive electrode caused by the volume effect in a charge-discharge cycle process of the battery can be relieved; and meanwhile, the added multifunctional elastic layer structure can ensure that an active material in the positive electrode is not greatly dissolved into an electrolyte to cause the capacity loss.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Lithium ion secondary battery anode and lithium ion secondary battery including the same

ActiveCN101471435AImprove securityReduce capacityActive material electrodesSecondary cellsCapacity lossAdhesive

The invention provides a positive electrode of a Li-ion secondary battery. The positive electrode comprises a current collector, and a coating layer and a positive electrode material layer on the current collector, wherein the coating layer contains a positive active material, a positive temperature coefficient material and an adhesive. The invention also provides a Li-ion secondary battery including the positive electrode. The positive electrode can improve the battery safety performance and can ensure no capacity loss of the battery.

Owner:BYD CO LTD

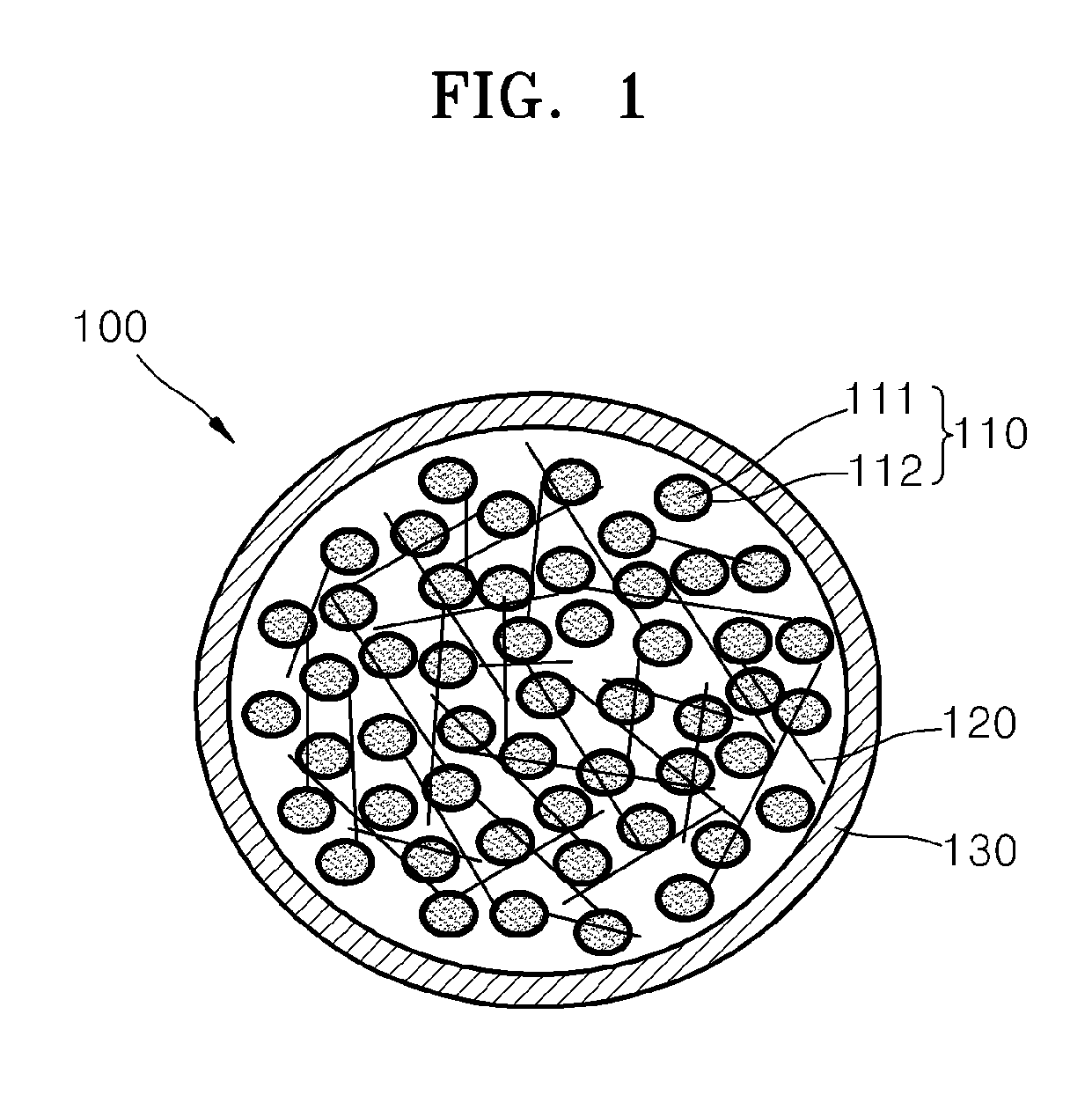

Negative active material, method of preparing the same, and lithum battery including negative active material

ActiveUS20130004846A1Improve cycle lifeMaterial nanotechnologyElectrode manufacturing processesCapacity lossEngineering

A negative active material, a method of preparing the same, and a lithium battery including the negative active material are disclosed. The negative active material includes a silicon-based nanocore and a first amorphous carbonaceous coating layer that is formed of carbonized organic material and that is uniformly and continuously formed on a surface of the silicon-based nanocore, whereby irreversible capacity losses due to volumetric expansion / contraction caused when a lithium battery is charged and discharged are compensated and cycle lifetime characteristics are enhanced.

Owner:SAMSUNG SDI CO LTD

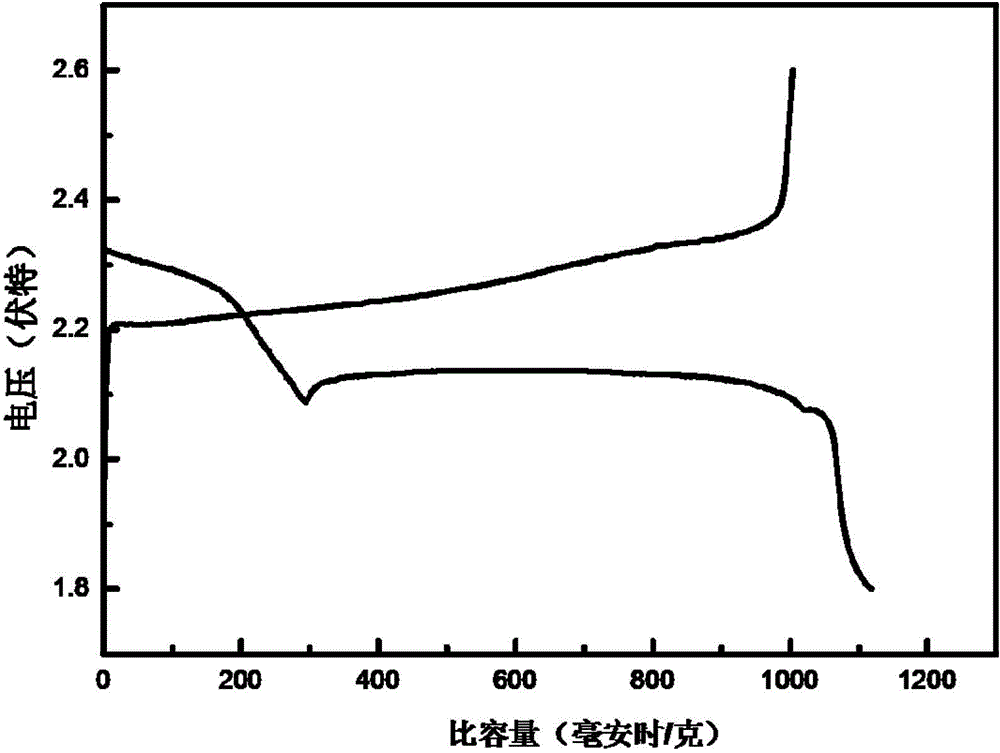

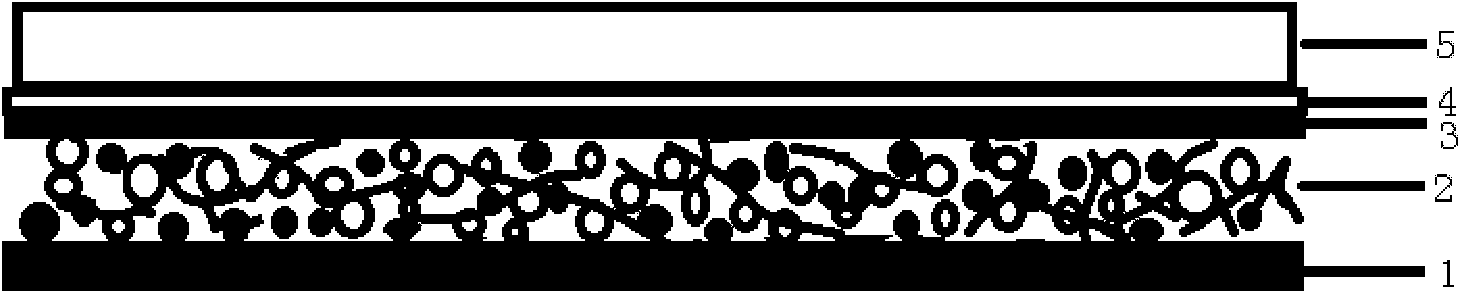

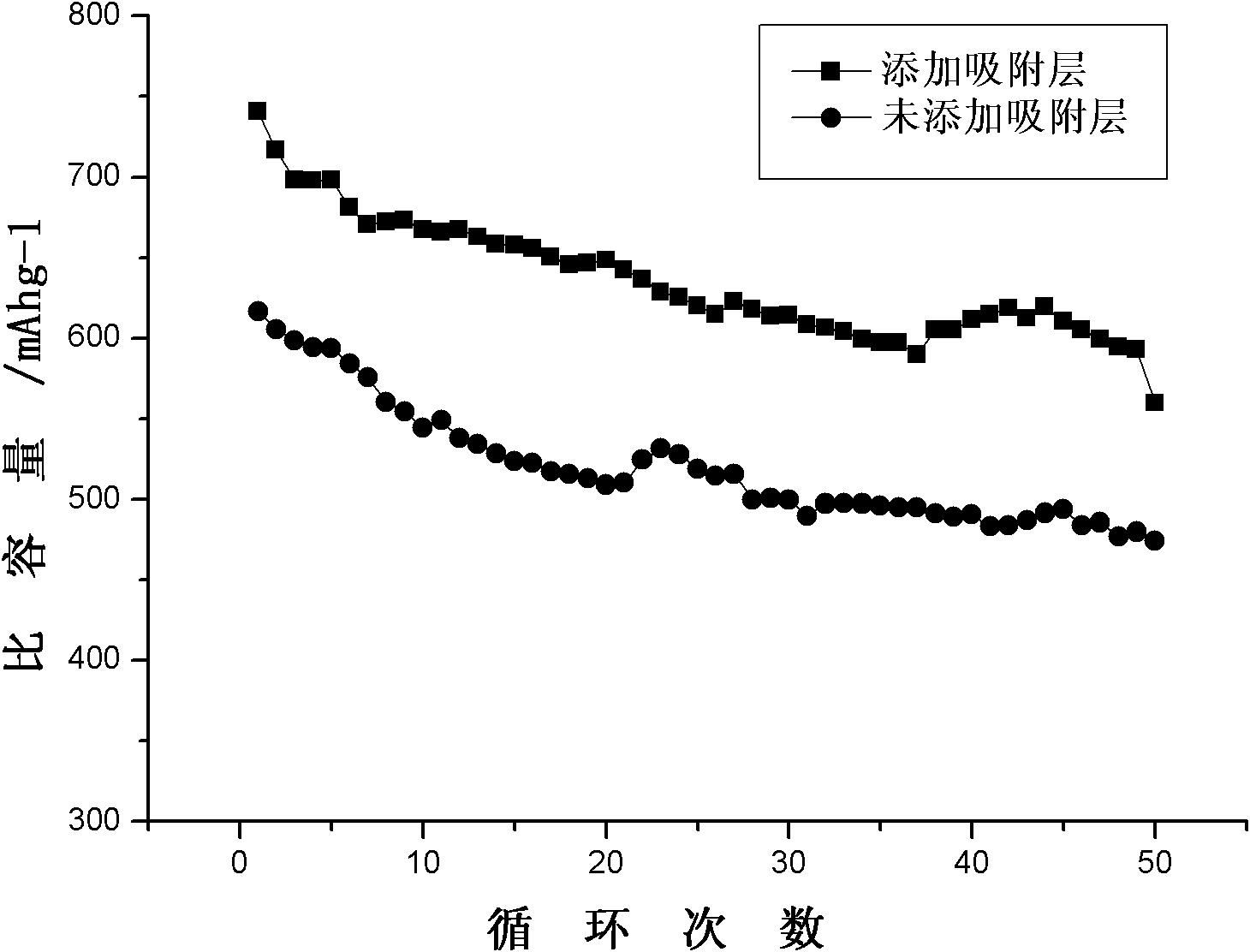

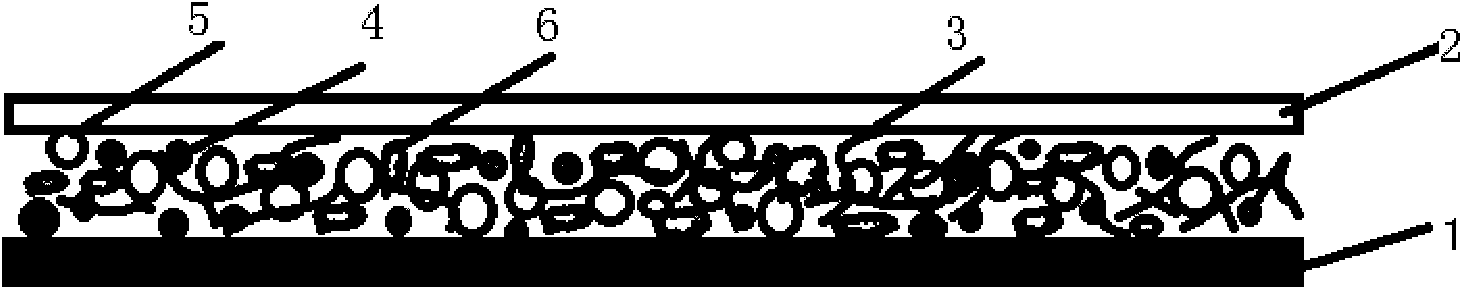

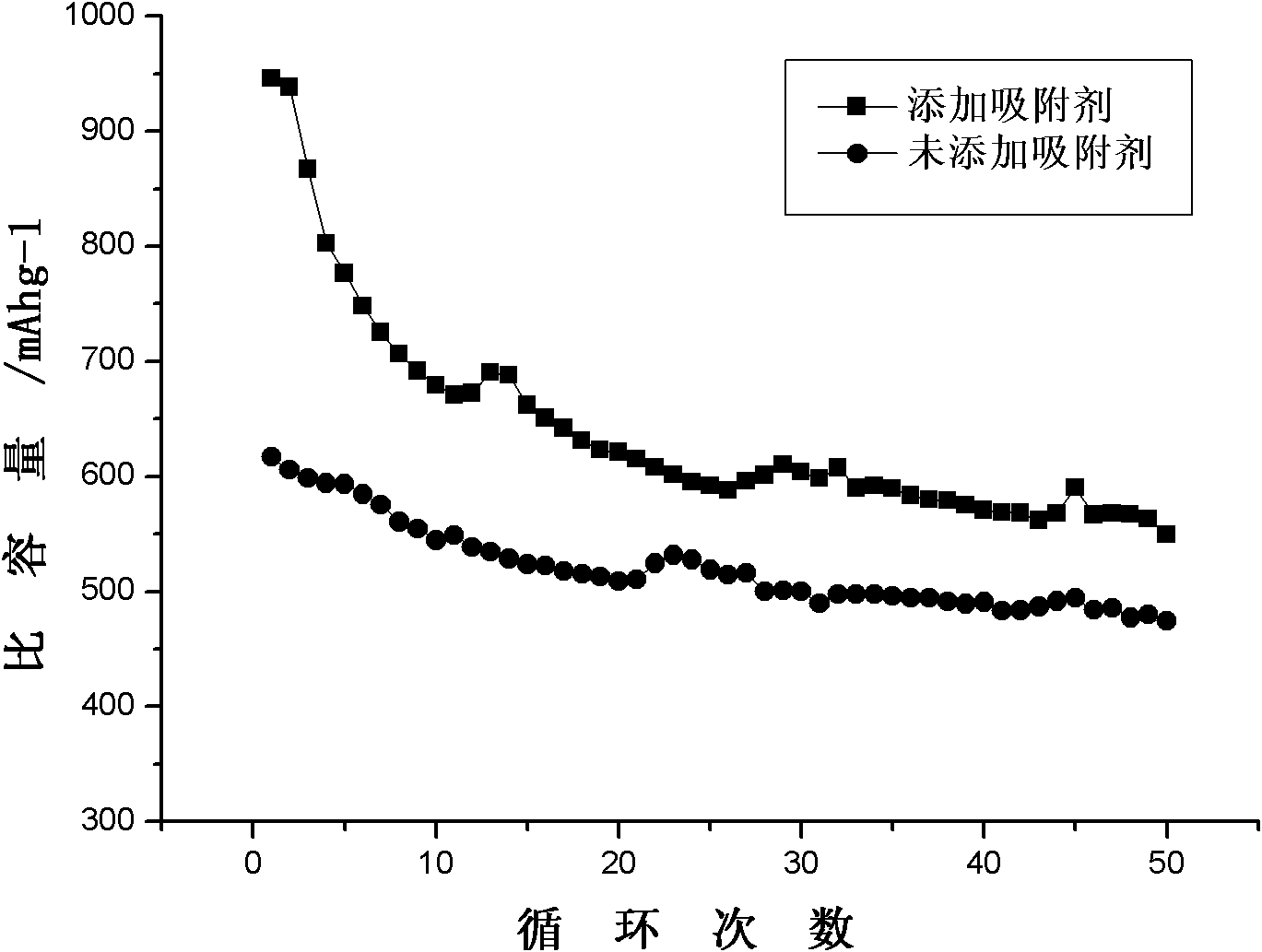

Lithium sulfur battery provided with adsorption layer

The invention relates to a lithium sulfur battery provided with an adsorption layer. The adsorption layer is added in the lithium sulfur battery, is made of a strong-adsorption material with a high specific surface area and a porous structure, and is positioned between an anode pole piece and a porous diaphragm. The adsorption layer can adsorb polysulfide formed in charging and discharging processes of the lithium sulfur battery and prevent the polysulfide dissolved in electrolytic solution from scattering to the surface of a cathode to generate corrosion reaction with lithium and cause irreversible capacity losses of the battery. Therefore, the adsorption layer can improve the performance of the lithium sulfur battery.

Owner:WUHAN UNIV OF TECH

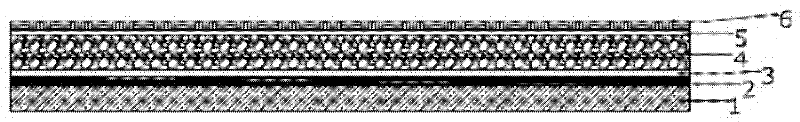

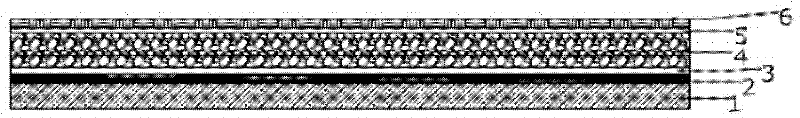

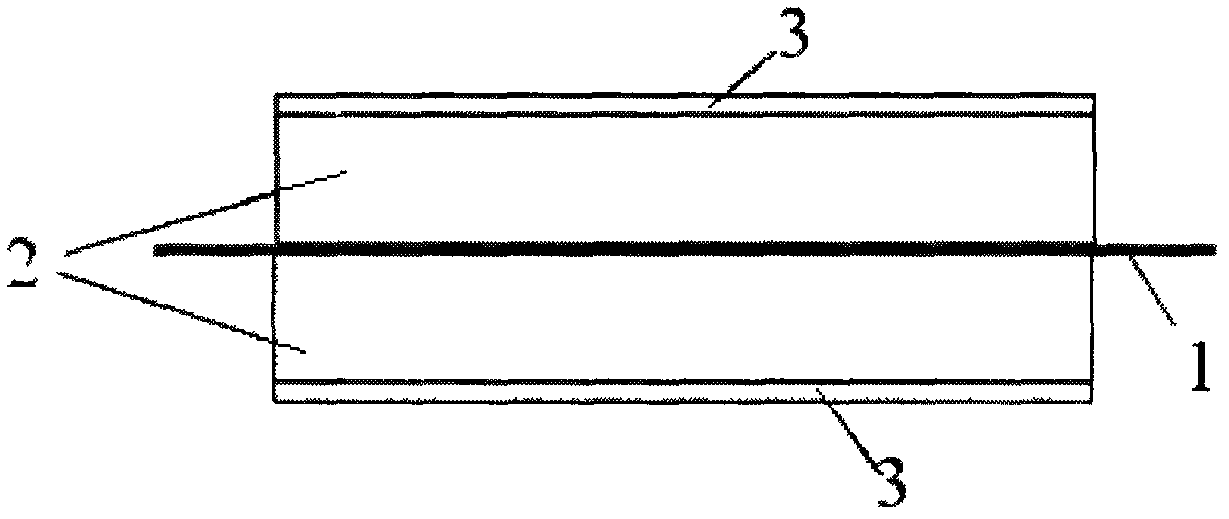

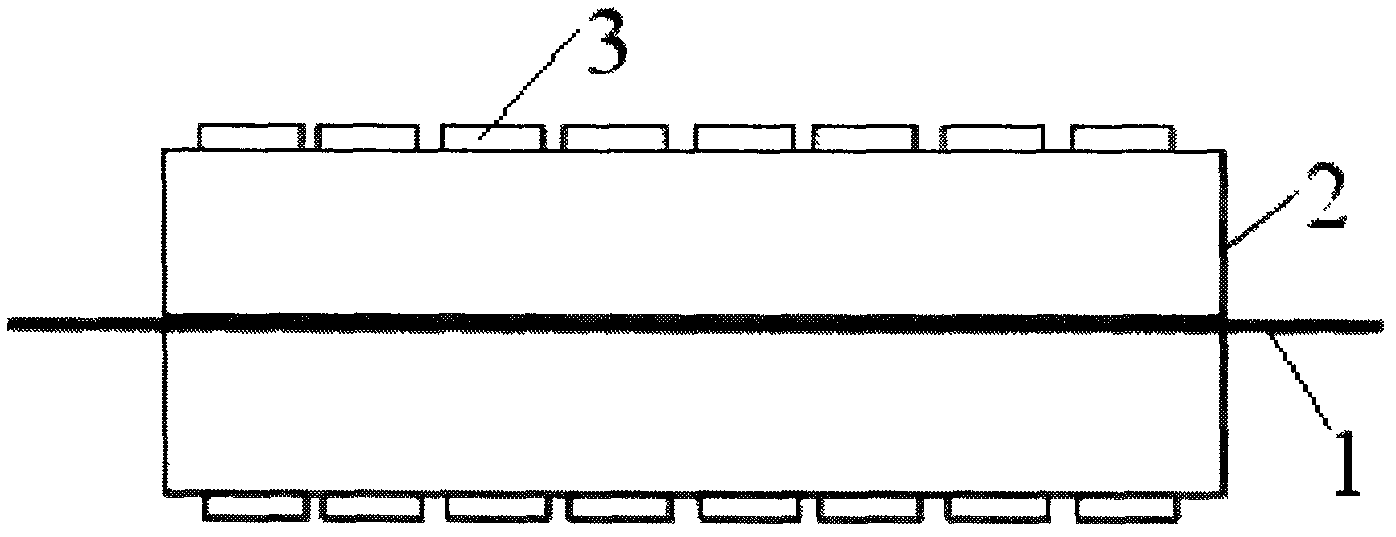

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

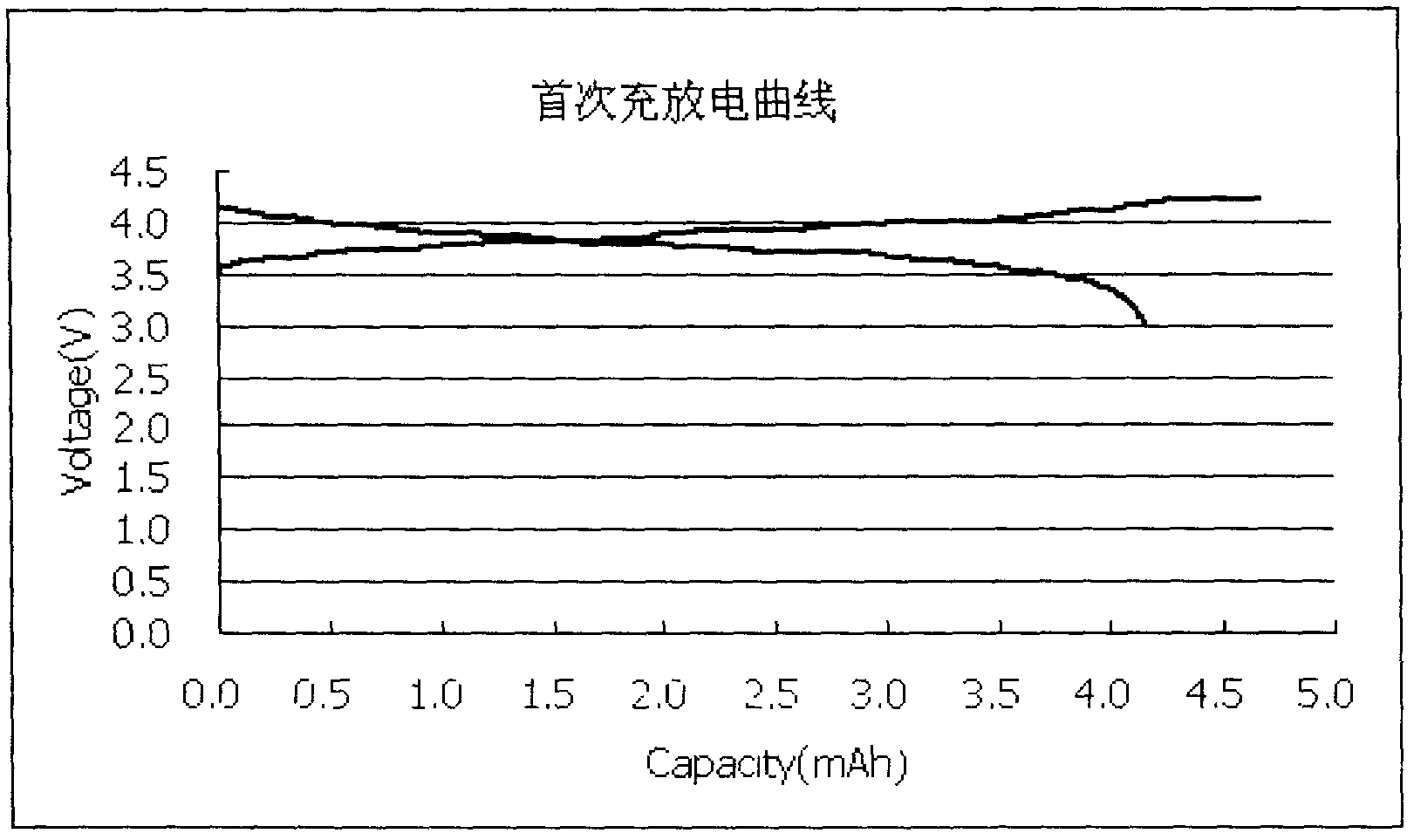

Method for preparing lithium ion battery

InactiveCN102610861AIncrease energy densityDoes not affect activityFinal product manufactureElectrolyte accumulators manufactureCapacity lossEngineering

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a method for preparing a lithium ion battery. The method includes steps: firstly, pressing metal lithium sheets on at least one surface of a cathode sheet and forming a processed cathode sheet; secondly, assembling an anode sheet, a diaphragm and the processed cathode sheet into a cell, packing the cell into a package bag, filling liquid into the package bag, and allowing the packaging bag to stand still so that a solid electrolyte [SEI (solid electrolyte inter-phase)] film is formed on the surface of the cathode sheet; and thirdly, carrying out formation capacity operation and obtaining the lithium ion battery. Compared with the prior art, the method has the advantages that the cathode sheet and the metal lithium sheets are pressed together when the battery is assembled, the SEI film is formed on the surface of an anode material by means of standing and storing before formation of the integral battery while activity of a cathode material and activity of electrolyte are unaffected, the SEI film is formed in advance, irreversible capacity loss of initial charge is effectively reduced, and energy density of the battery is increased.

Owner:NINGDE AMPEREX TECH +1

Cathode compositions and method for lithium-ion cell construction having a lithum compound additive, eliminating irreversible capacity loss

InactiveUS20060121352A1Reduce irreversible capacity lossReduce capacitySecondary cellsPositive electrodesCapacity lossChemical composition

Owner:LITHDYNE

Variable capacity cell assembly

InactiveUS20110171502A1Increase electrode capacityLarge capacityBatteries circuit arrangementsAlkaline accumulatorsCapacity lossActive component

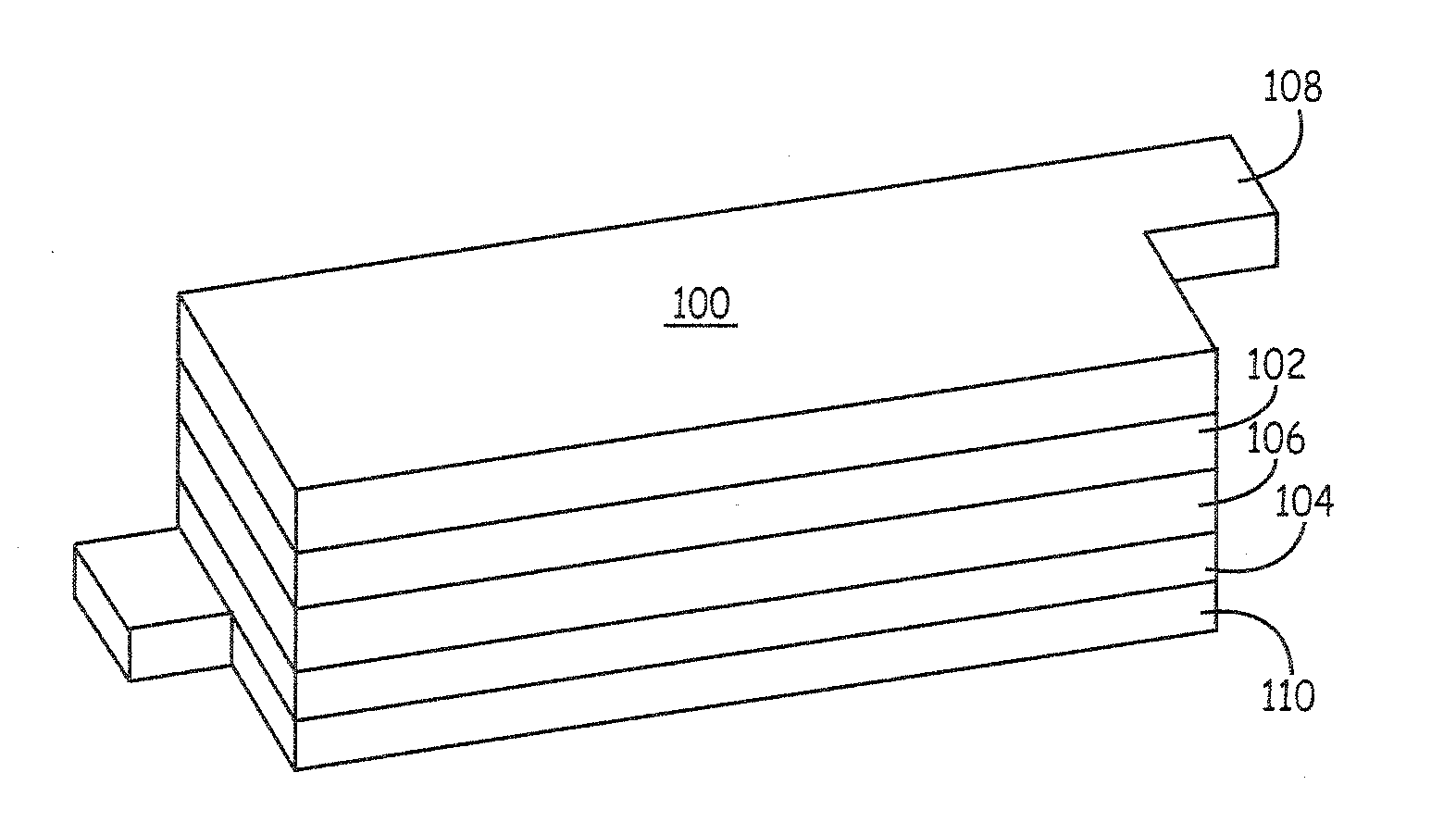

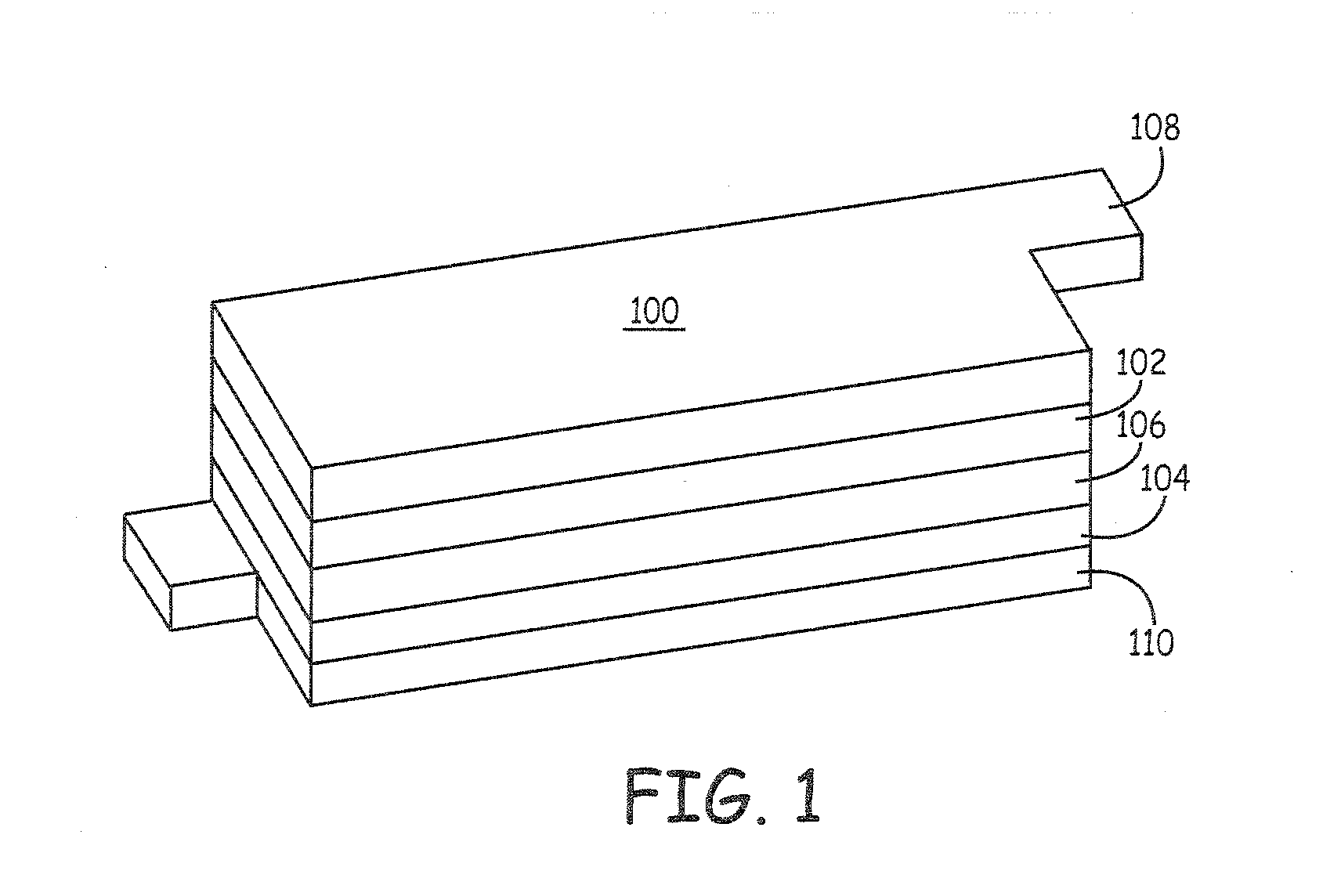

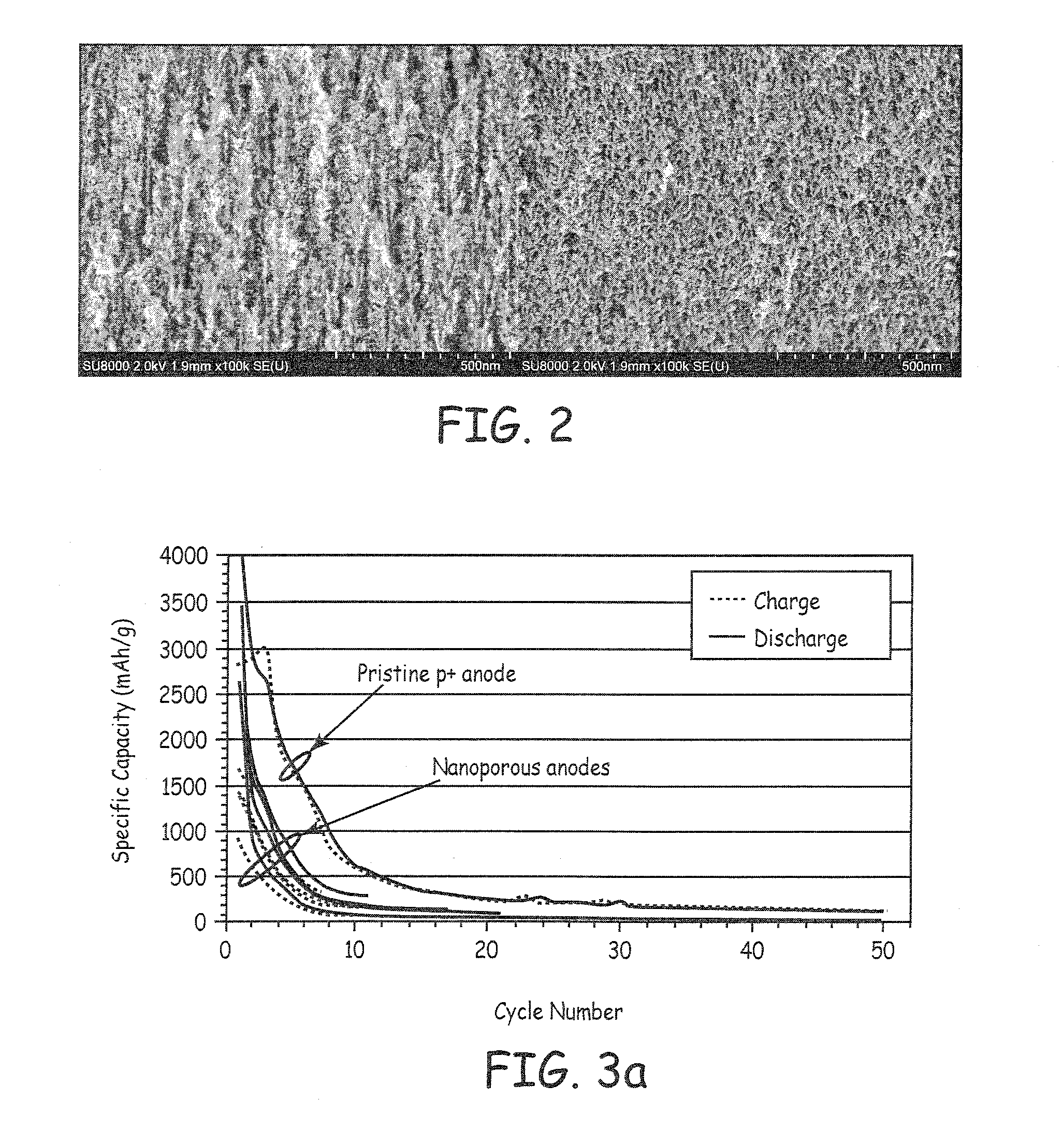

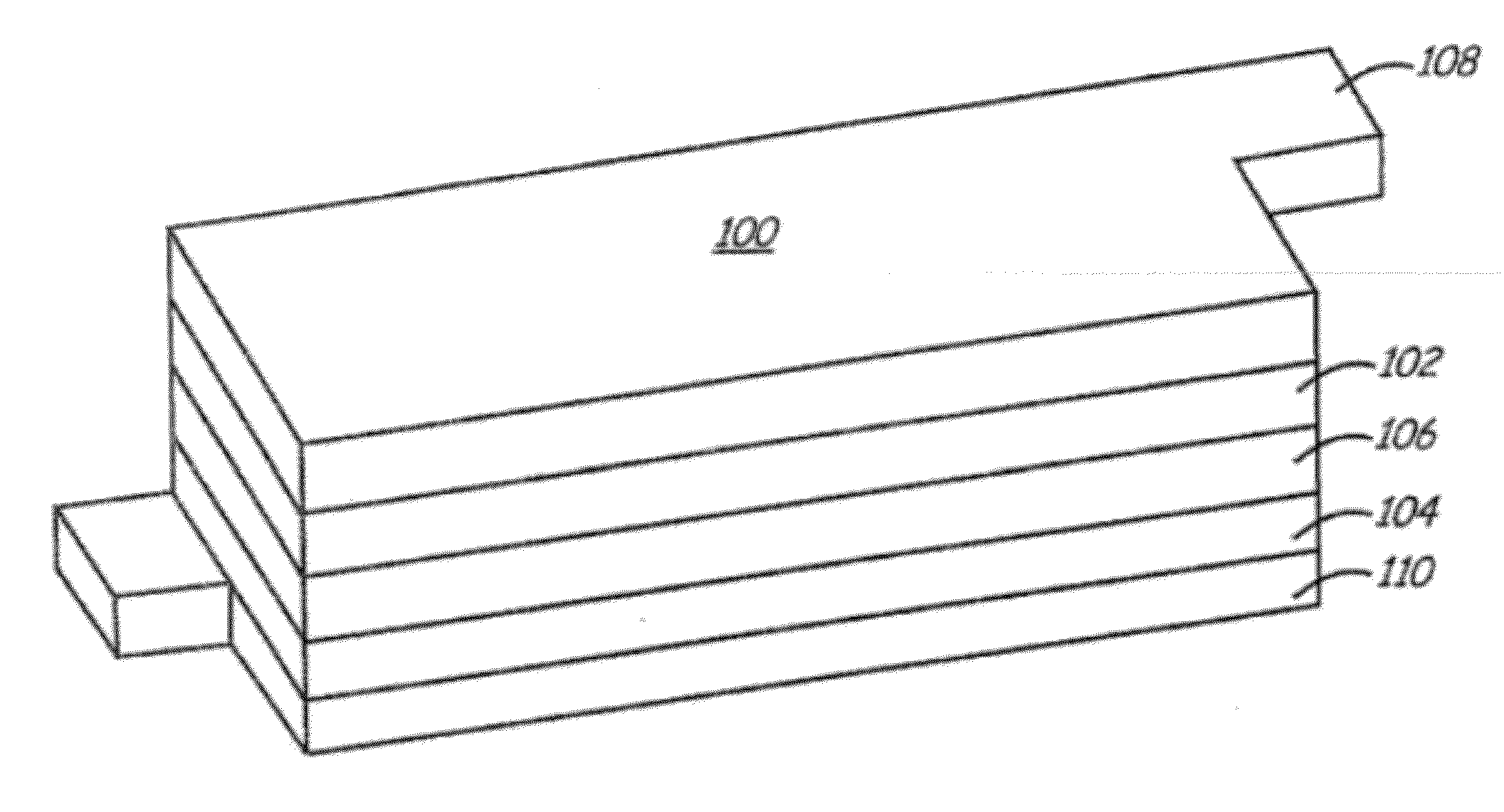

Electrochemical cells containing nanostructured negative active materials and composite positive active materials and methods of fabricating such electrochemical cells are provided. Positive active materials may have inactive components and active components. Inactive components may be activated and release additional lithium ions, which may offset some irreversible capacity losses in the electrochemical cells. In certain embodiments, the activation releases lithium ion having a columbic content of at least about 400 mAh / g based on the weight of the activated material.

Owner:AMPRIUS INC

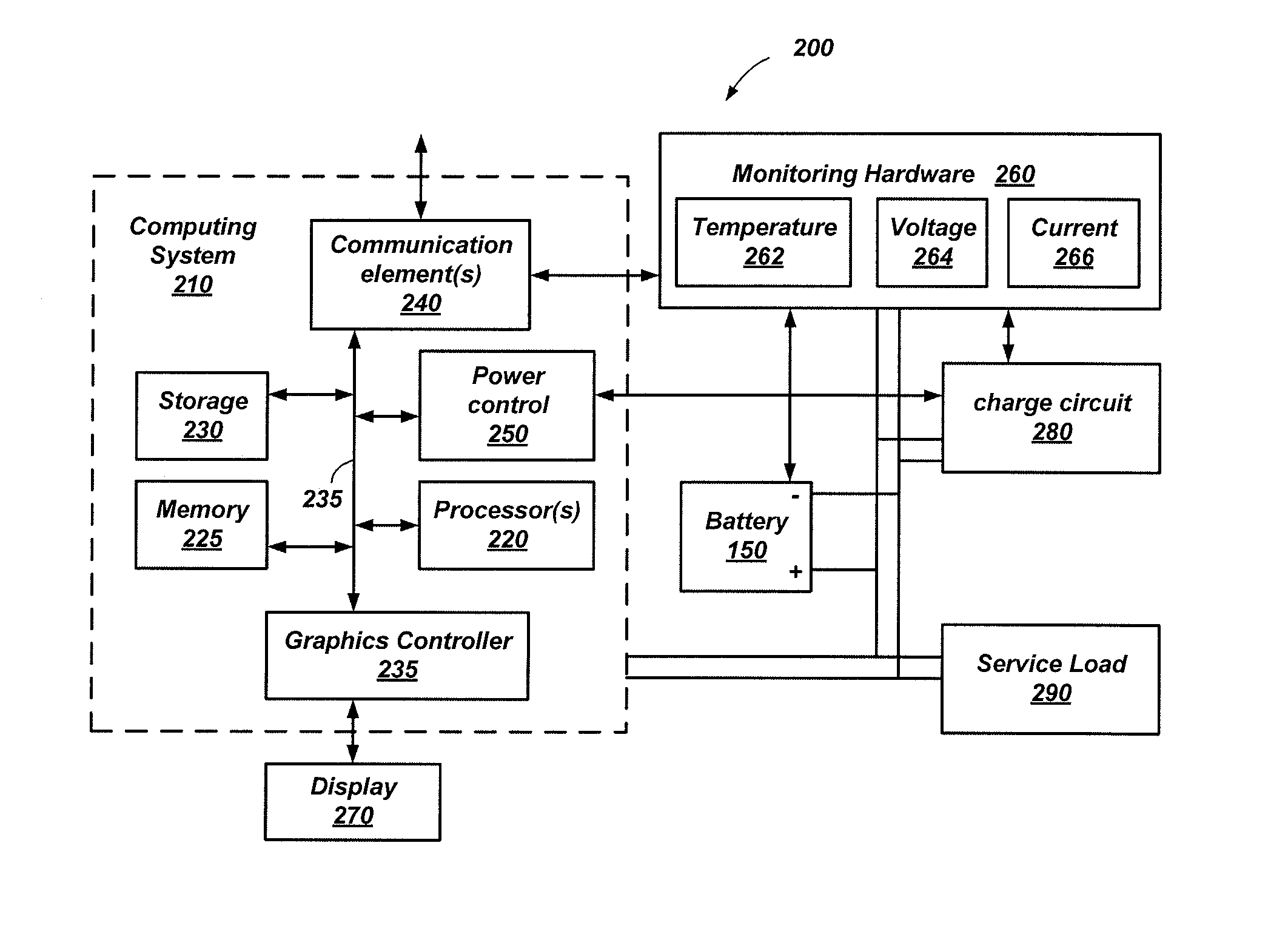

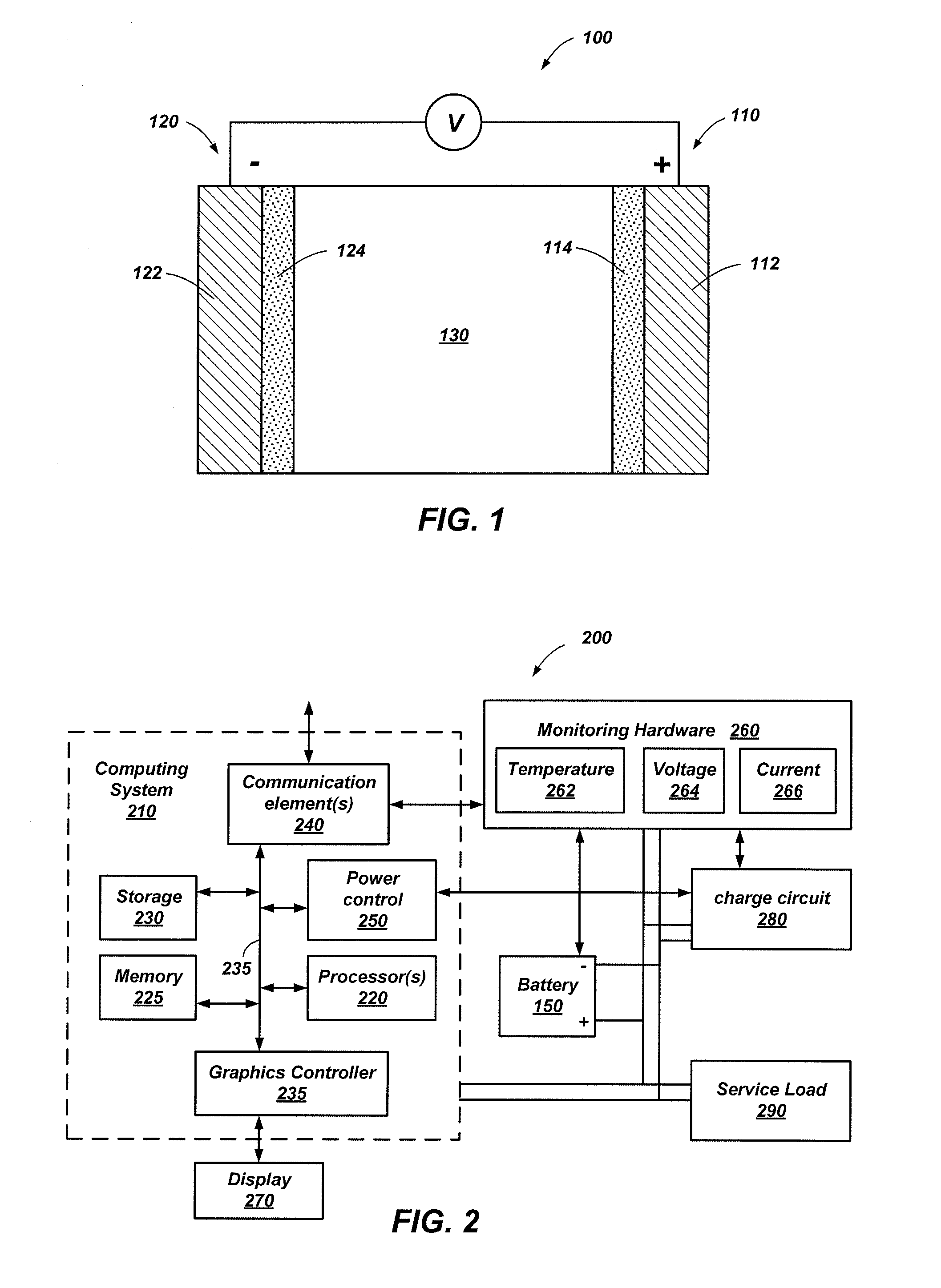

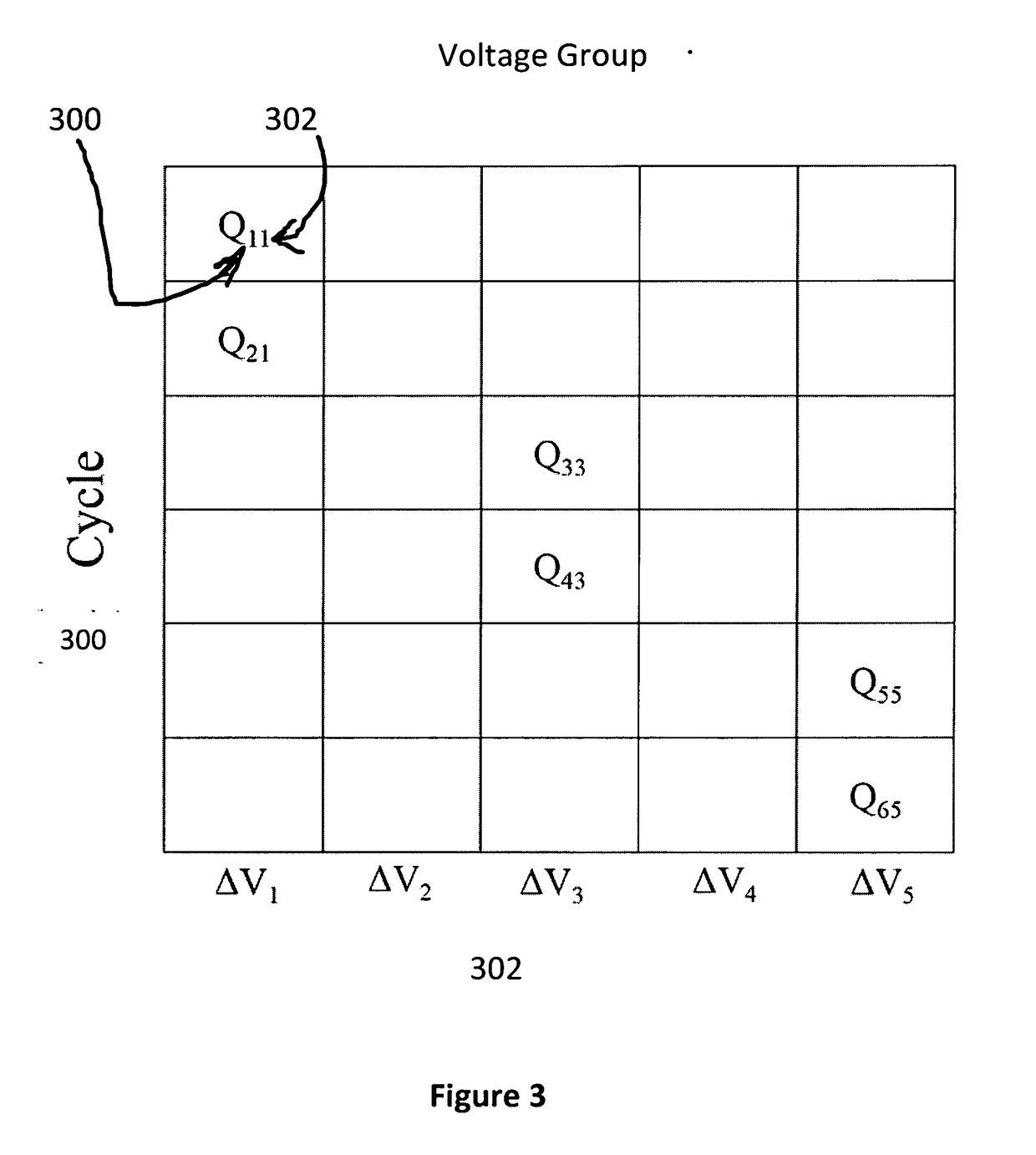

Systems, methods and computer readable media for estimating capacity loss in rechargeable electrochemical cell

ActiveUS20110077880A1Analogue computers for electric apparatusElectrical testingCapacity lossComputer science

A system includes an electrochemical cell, monitoring hardware, and a computing system. The monitoring hardware periodically samples charge characteristics of the electrochemical cell. The computing system periodically determines cell information from the charge characteristics of the electrochemical cell. The computing system also periodically adds a first degradation characteristic from the cell information to a first sigmoid expression, periodically adds a second degradation characteristic from the cell information to a second sigmoid expression and combines the first sigmoid expression and the second sigmoid expression to develop or augment a multiple sigmoid model (MSM) of the electrochemical cell. The MSM may be used to estimate a capacity loss of the electrochemical cell at a desired point in time and analyze other characteristics of the electrochemical cell. The first and second degradation characteristics may be loss of active host sites and loss of free lithium for Li-ion cells.

Owner:BATTELLE ENERGY ALLIANCE LLC

Lithium ion battery positive electrode sheet, preparation method of lithium ion battery positive electrode sheet, and lithium ion battery

ActiveCN106384808ACompensation for irreversible capacity lossIncrease energy densitySecondary cellsNon-aqueous electrolyte accumulator electrodesCapacity lossLithium compound

In order to solve the problems of capacity loss of the existing lithium ion secondary battery in the SEI film forming process and harsh operation requirements and poor lithium supplementing effect of the existing lithium supplementing mode, the invention provides a lithium ion battery positive electrode sheet, which comprises a first current collector, a lithium supplementing layer and a positive electrode active layer, wherein the lithium supplementing layer is positioned between the positive electrode active layer and the first current collector; the lithium supplementing layer also comprises reducing lithium compounds; the reducing lithium compounds comprise one or more of L-lithium ascorbate, D-lithium erythorbate, lithium pyrosulfite, lithium sulfite and lithium phytate. Meanwhile, the invention also discloses a preparation method of the positive electrode sheet and a lithium ion battery using the positive electrode sheet. By using the technical scheme, the lithium loss of the positive electrode active layer in the first charging and discharging process can be reduced; the energy density of the battery is increased.

Owner:湖南三迅新能源科技有限公司 +1

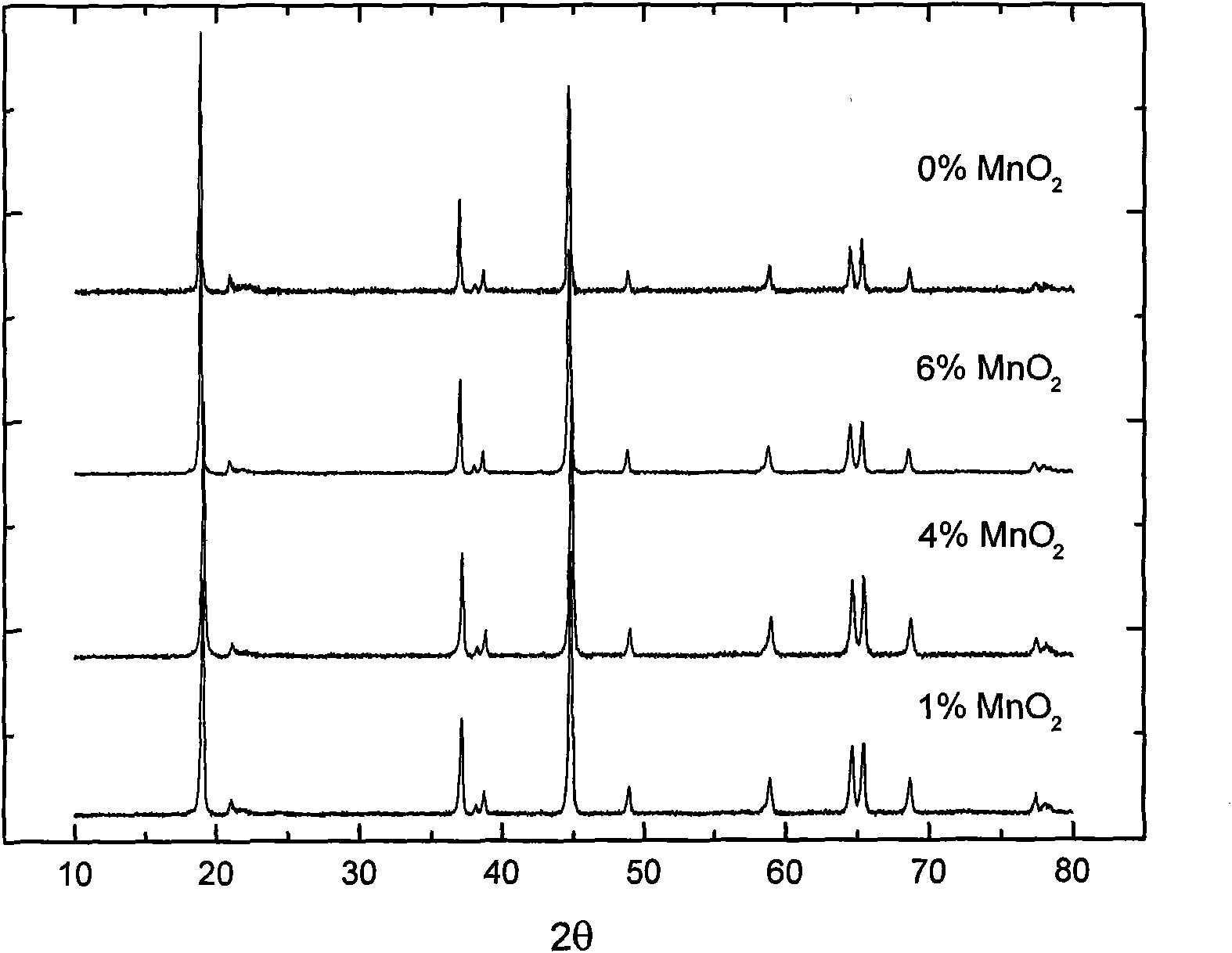

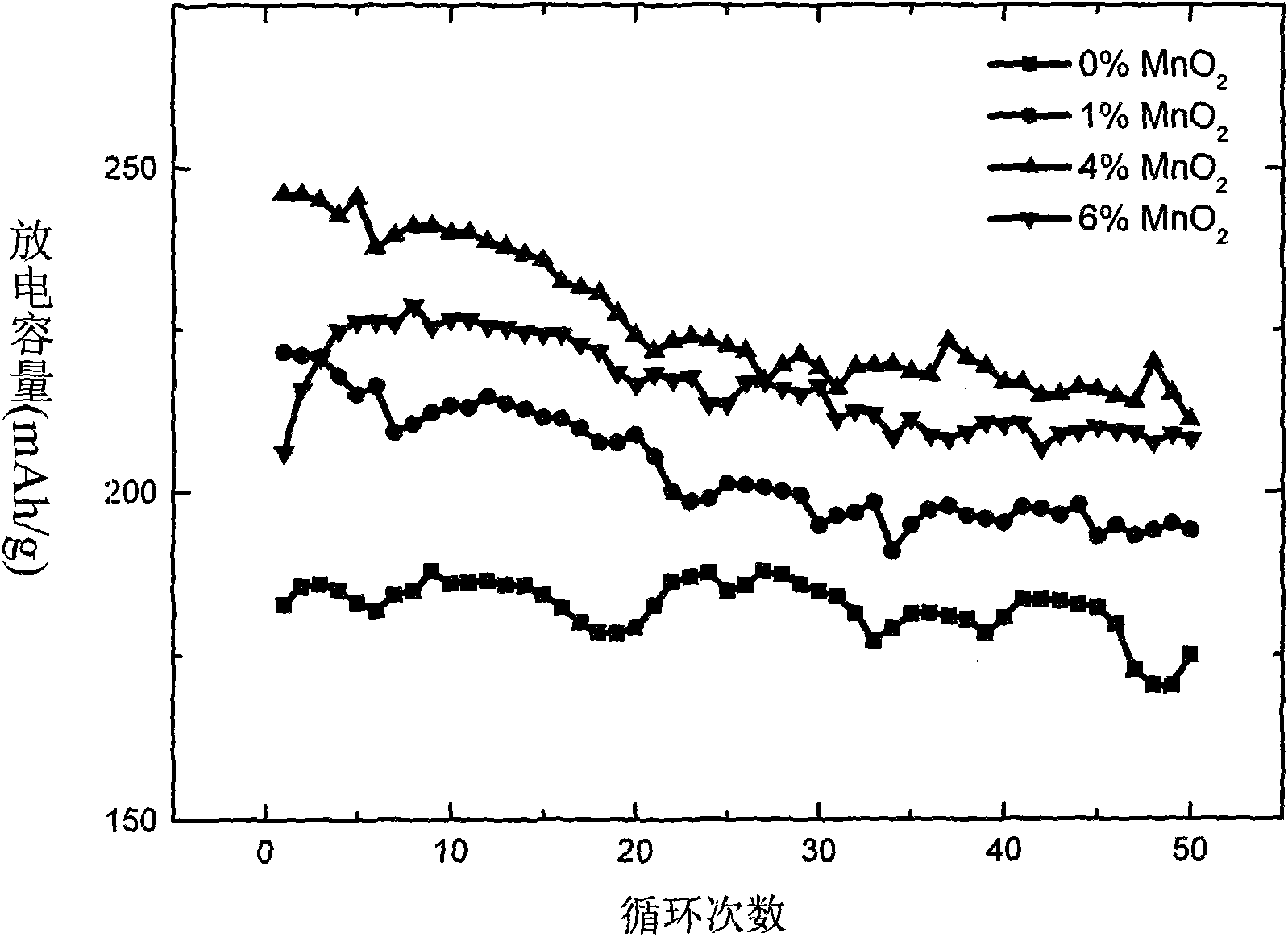

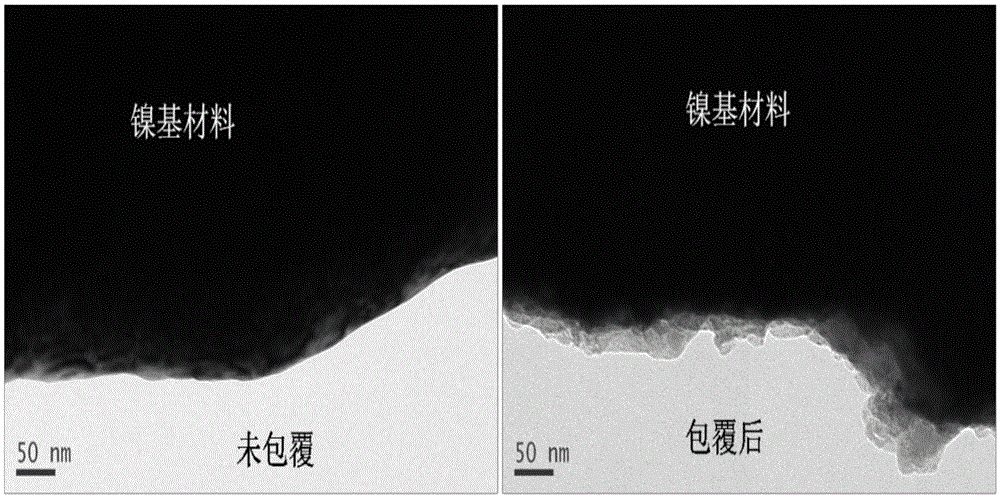

Method for modifying high-rate lithium-rich anode material

InactiveCN101562245AImproved magnification performanceSimple processElectrode manufacturing processesPeristaltic pumpCapacity loss

The invention belongs to the fields of lithium ion battery anode materials and electrochemistry. A lithium-rich material with high capacity and stable cycle performance cannot meet the requirement of quick charge and discharge of a high-power lithium ion battery. A surface modified lithium-rich material comprises a coating layer MnO2 and a main phase Li[NixLi1 / 3-2x / 3Mn2 / 3-x / 3]O2(x is more than or equal to 1 / 5 and less than or equal to 1 / 3), and the mass ratio of the coating layer and the main phase is 0 to 6 percent. A preparation method comprises that: the obtained lithium-rich anode material Li[Ni0.2Li0.2Mn0.6]O2 is dispersed in 0.194-1.17 g / L MnSO4 solution, subjected to ultrasound for 1 hour, and violently stirred for 2 hours; and 0.122-0.731 g / L Na2CO3 solution is added into the violently stirred MnSO4 solution dropwise by a peristaltic pump, and the mixed solution is filtered after the dropwise addition, dried at 120 DEG C and sintered at a temperature of between 300 and 500 DEG C for 4 to 8 hours to obtain the surface modified Li[NixLi1 / 3-2x / 3Mn2 / 3-x / 3]O2(x is more than or equal to 1 / 5 and less than or equal to 1 / 3). The preparation method reduces initial irreversible capacity loss of the lithium-rich material, greatly improves the cycle performance under high rate, and can meet the requirement of the high-power lithium ion battery.

Owner:BEIJING UNIV OF TECH

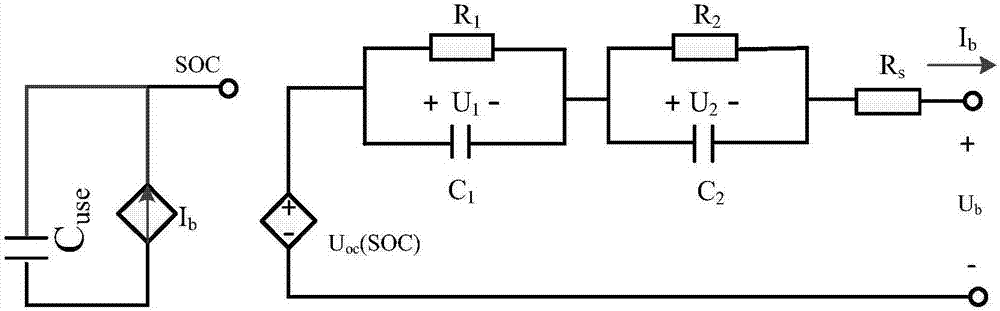

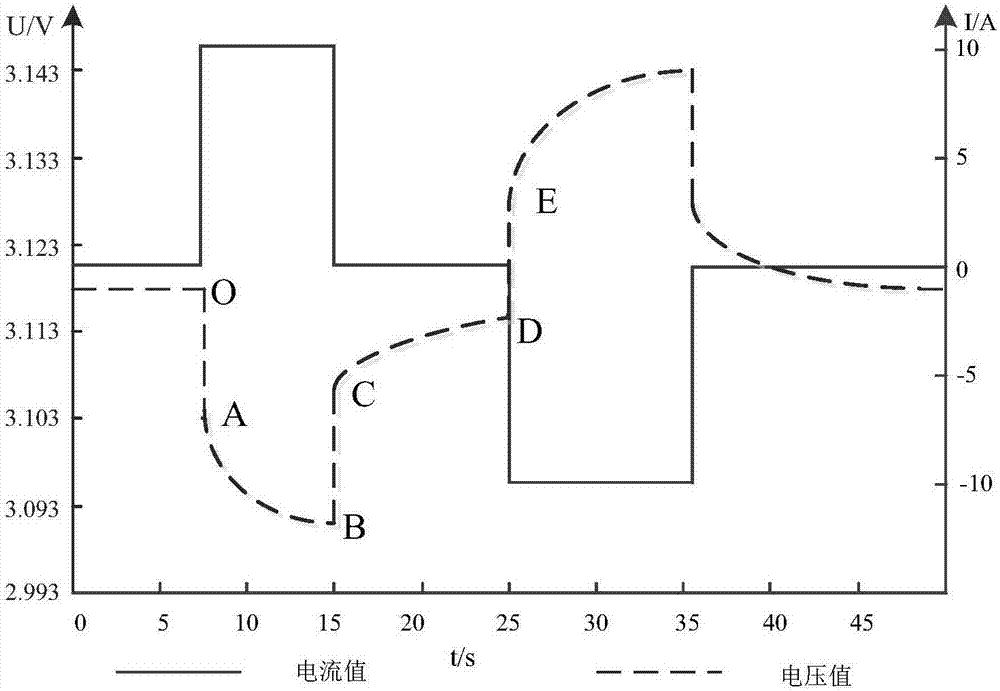

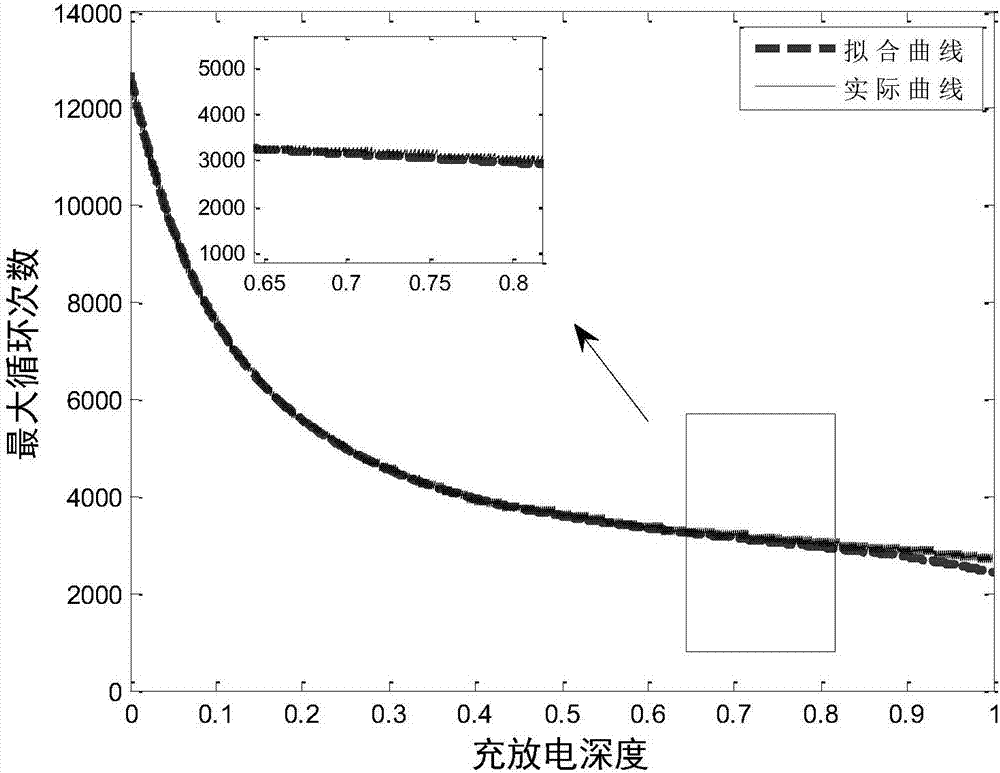

Lithium iron phosphate battery modeling and SOC estimating method in account of capacity loss

ActiveCN106909716AImprove output accuracyHigh applicable valueElectrical testingDesign optimisation/simulationCapacitanceMathematical model

The invention provides a lithium iron phosphate battery modeling and SOC estimating method in account of capacity loss. The method is provided based on the facts that the working state of the existing lithium iron phosphate battery is influenced by many factors of temperature, current, cycle times, depth of discharge and the like, and thus the modeling process is very complicated. According to the method, based on the Thevenin equivalent circuit, the modeling work is conducted on the lithium iron phosphate battery; the model open-circuit voltage, resistance and capacitance value identification method are given; and the capacity loss of the lithium iron phosphate battery in the life cycle is taken into account; a capacity estimation mathematical model is established; the output precision of a lithium iron phosphate battery model is improved; and the lithium iron phosphate battery SOC estimating problem brought by uncertainty noise is solved with extended Kalman filtering (EKF) algorithm. The method has the advantages of being simple, scientific and reasonable, high in application value, good in effect and the like.

Owner:NORTHEAST DIANLI UNIVERSITY +1

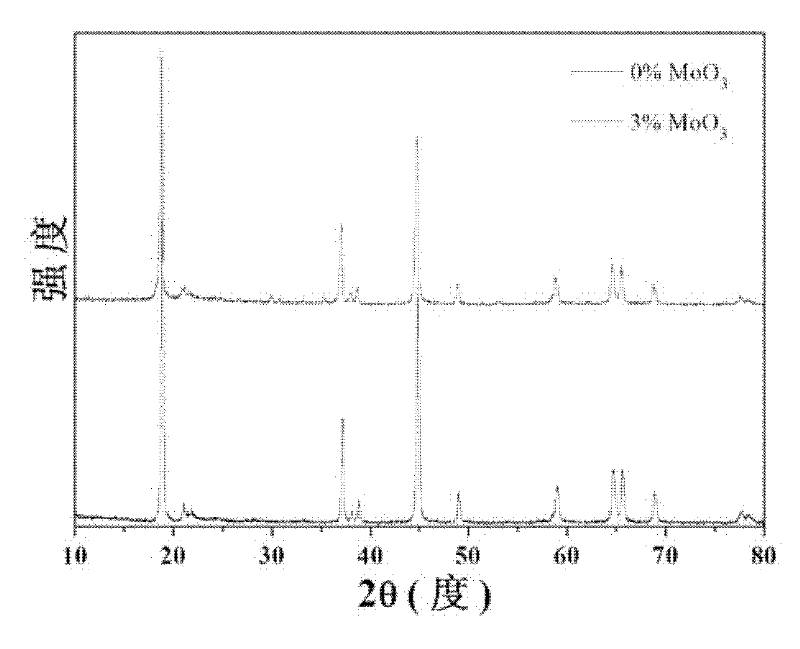

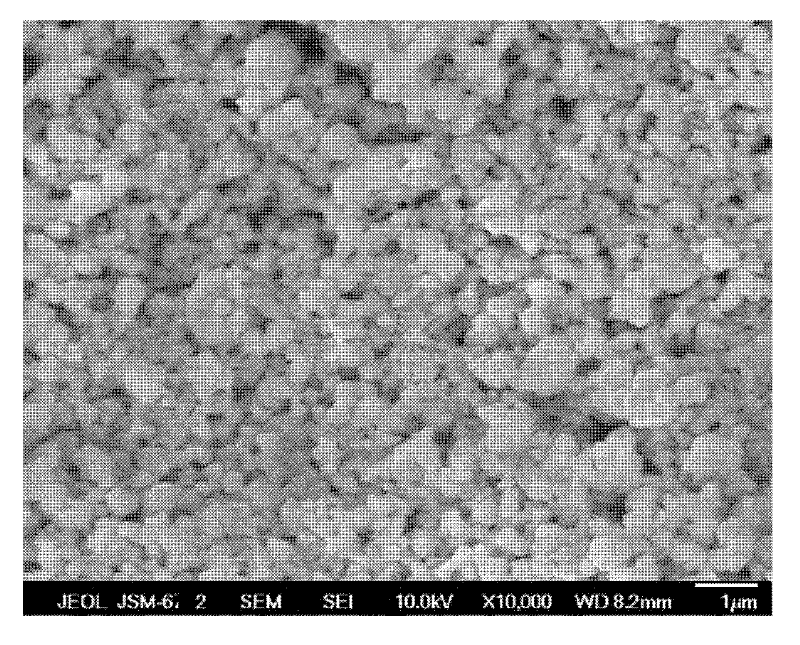

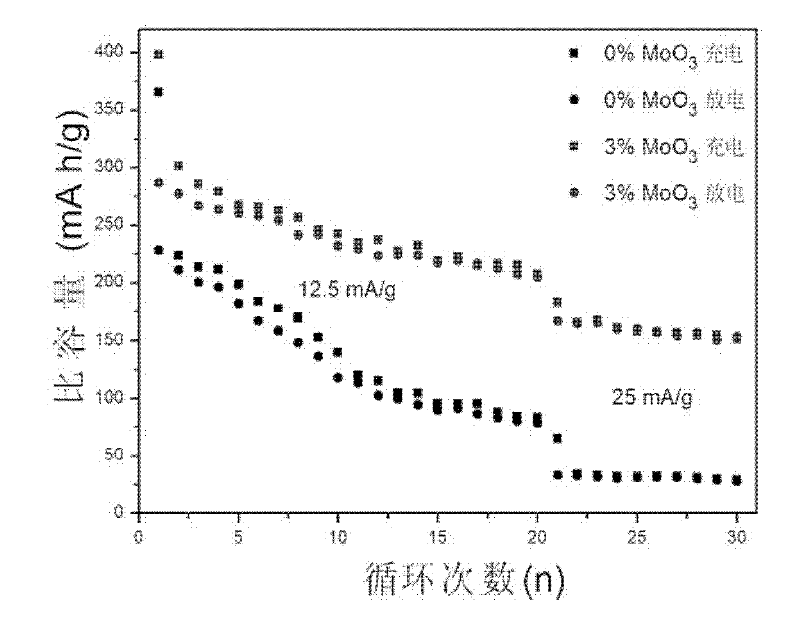

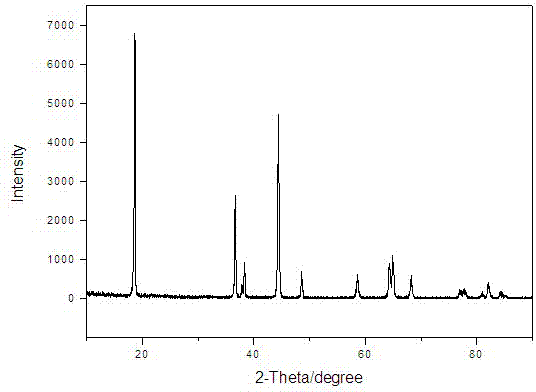

Composite lithium-rich anode material, its preparation method and its application

InactiveCN102244259AReduce the first irreversible capacity lossImproved magnification performanceCell electrodesCapacity lossPower performance

The invention discloses a composite lithium-rich anode material of a lithium battery, its preparation method and its application. According to the invention, the surface modified lithium-rich material comprises a metal salt of a coating layer (M' denotes Mo, Zn, Ti, V, W) and a main phase Li[Li1-x-y-zMnxCoyNiz] O2 (0.1<=y=z<x<=2 / 3), wherein the mass ratio of the two is 0-50%. The preparation method comprises the following steps: dissolving the obtained Li [Li1-x-y-zMnxCoyNiz]O2 (0.1<=y=z<x<=2 / 3) lithium-rich material in a transition metal salt solution of 0.02-10g / L, well mixing and drying the solution under the temperature of 50 - 150 DEG C, and then calcining under the temperature of 200 DEG C - 800 DEG C for 2 - 12 hours to obtain the surface modified Li [Li1-x-y-zMnxCoyNiz]O2 (0.1<=y=z<x<=2 / 3) lithium ion battery anode materials. The present invention reduces initial irreversible capacity loss of the lithium-rich material, and is capable of greatly improving the multiplying power performance and the cycle performance, as well as meeting the requirement of the high-power lithium ion battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Lithium sulphur battery anode piece added with absorbent and lithium sulphur battery

InactiveCN102185127ALi-accumulatorsNon-aqueous electrolyte accumulator electrodesCapacity lossCorrosion reaction

The invention relates to a lithium sulphur battery anode piece added with an absorbent and a lithium sulphur battery. In the invention, a material which has the characteristics of high specific surface area and strong absorption performance is used as the absorbent; the absorbent is added into the anode piece of the lithium sulphur battery; and the addition amount of the absorbent is more than 5% of the mass of the anode piece. The added absorbent can absorb the polysulfide of the lithium sulphur battery in the charge and discharge courses, thereby avoiding the polysulfide from being absorbed on the surface of a sulfhydryl composite material to reduce the electrical conductivity, and can simultaneously prevent the polysulfide from being scattered on the surface of the cathode and generating a corrosion reaction with lithium to further cause the irreversible capacity loss of the battery. Thus, the added absorbent can be used for improving the performance of the lithium sulphur battery provided by the invention.

Owner:WUHAN UNIV OF TECH

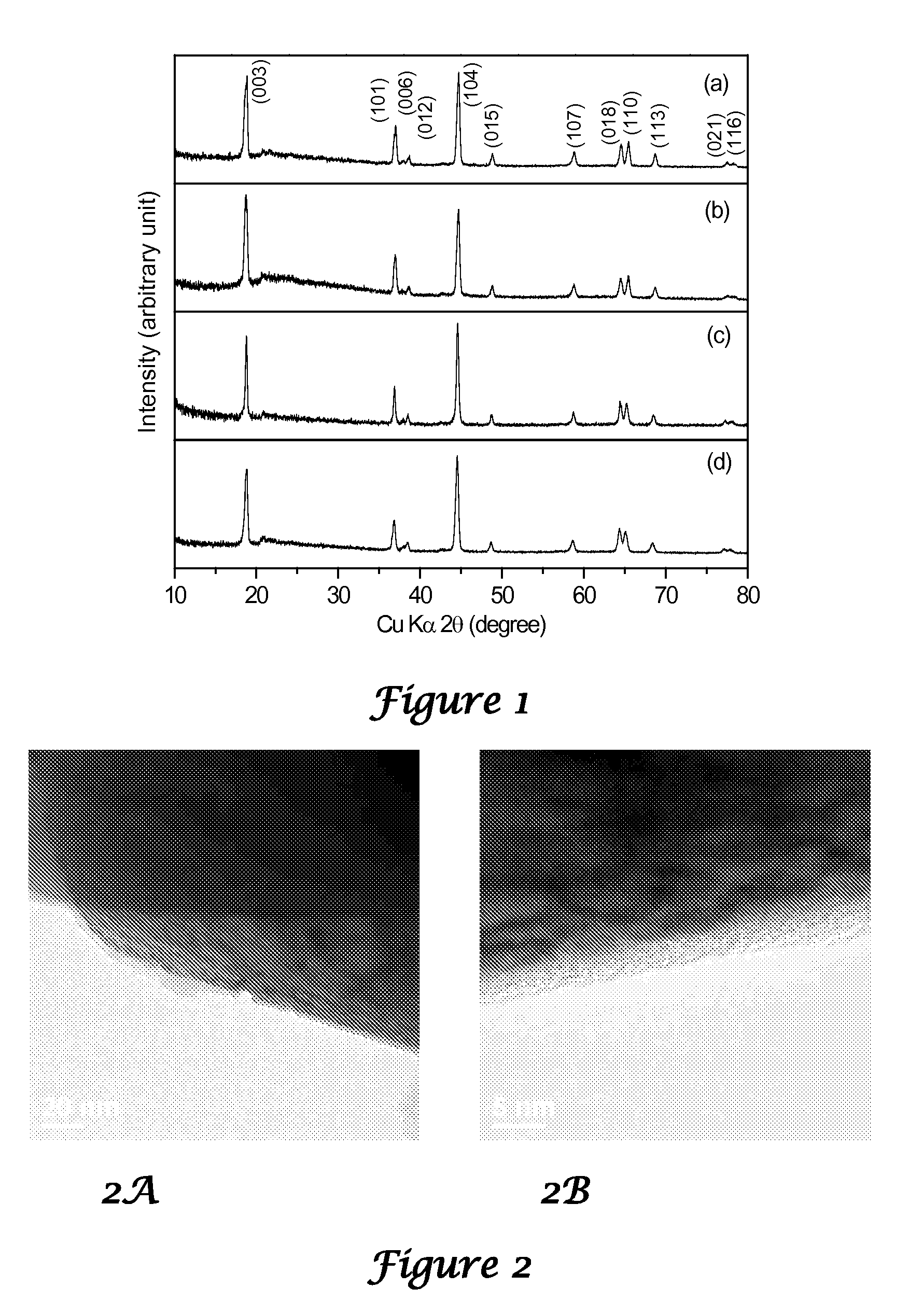

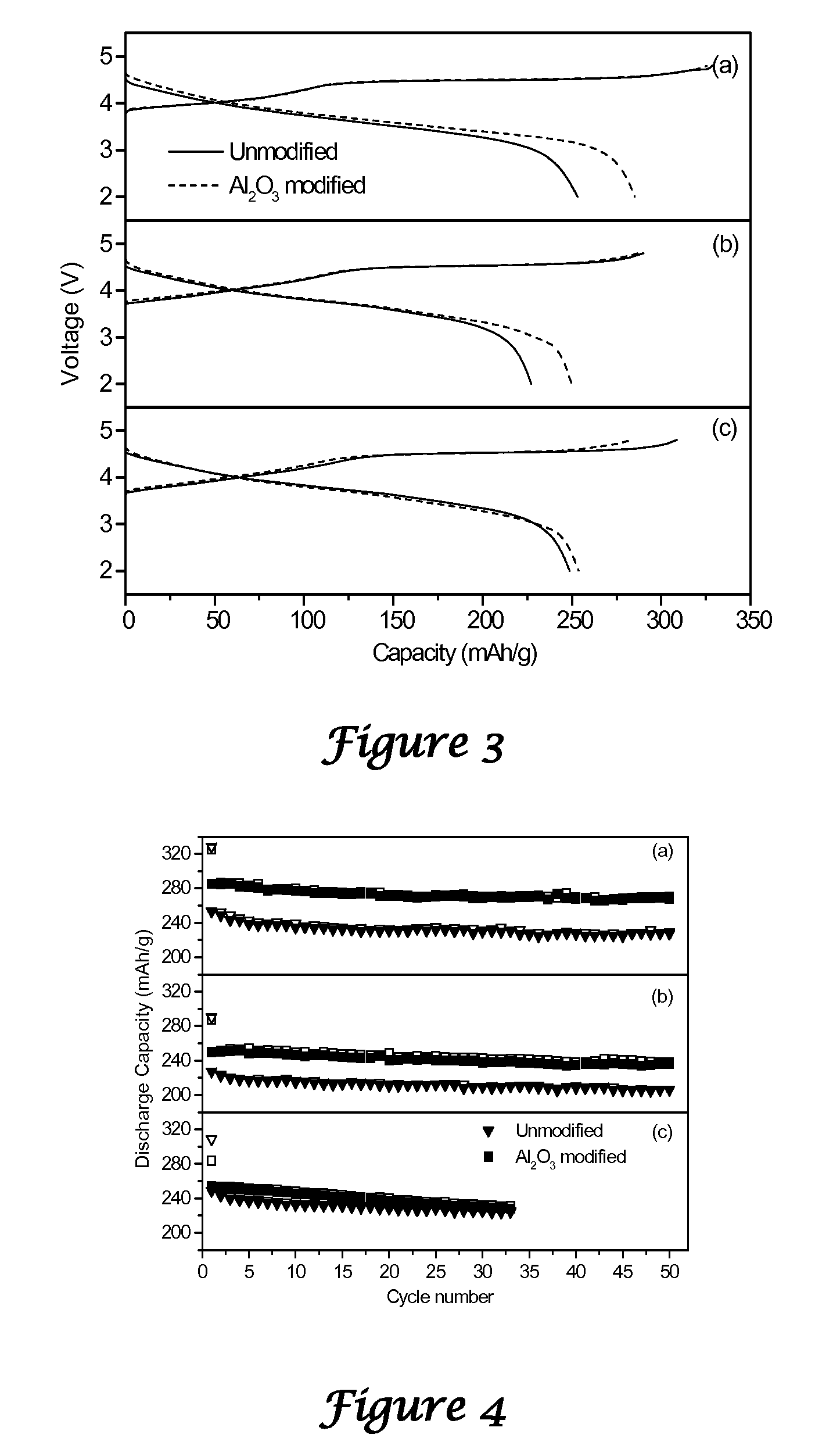

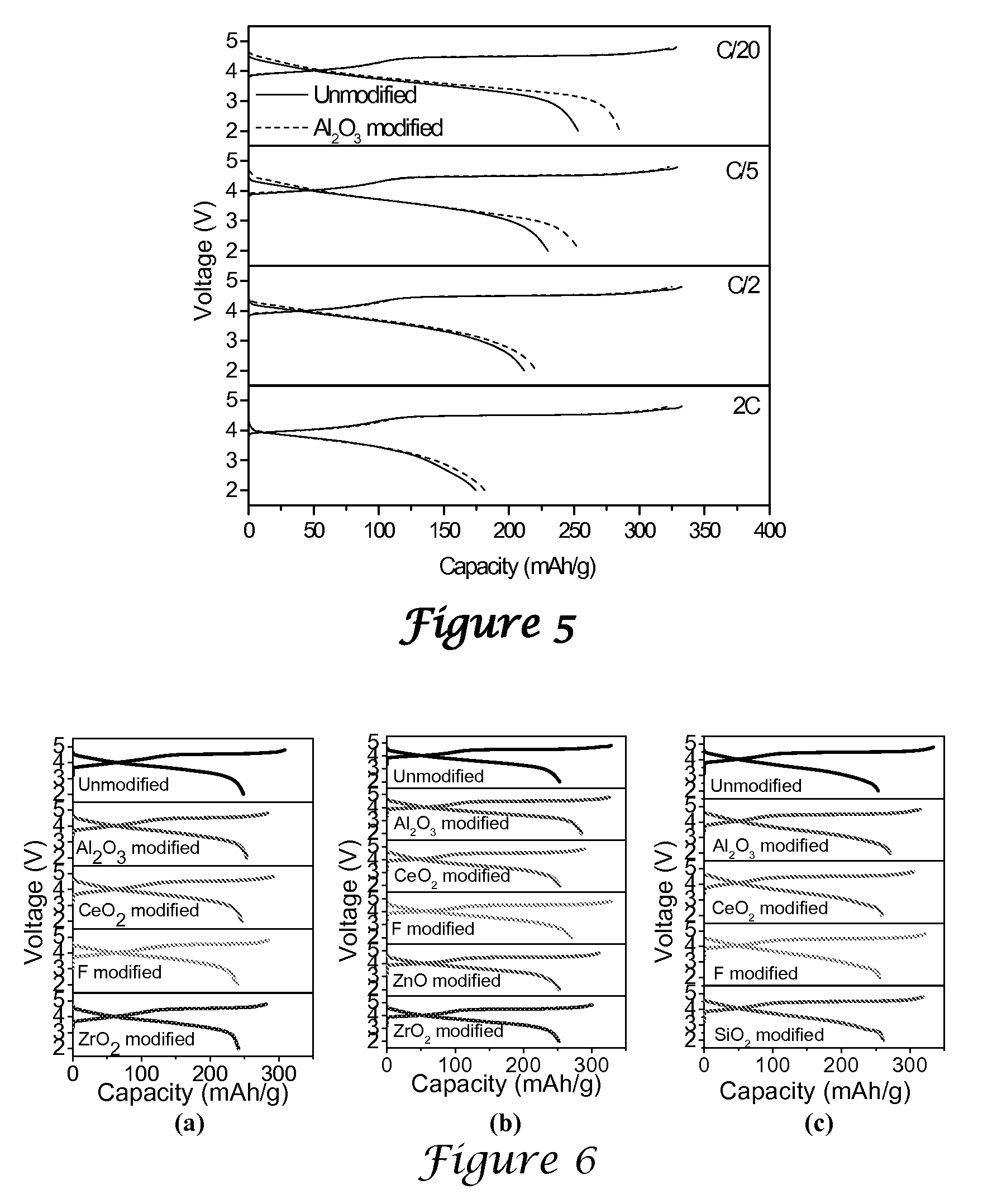

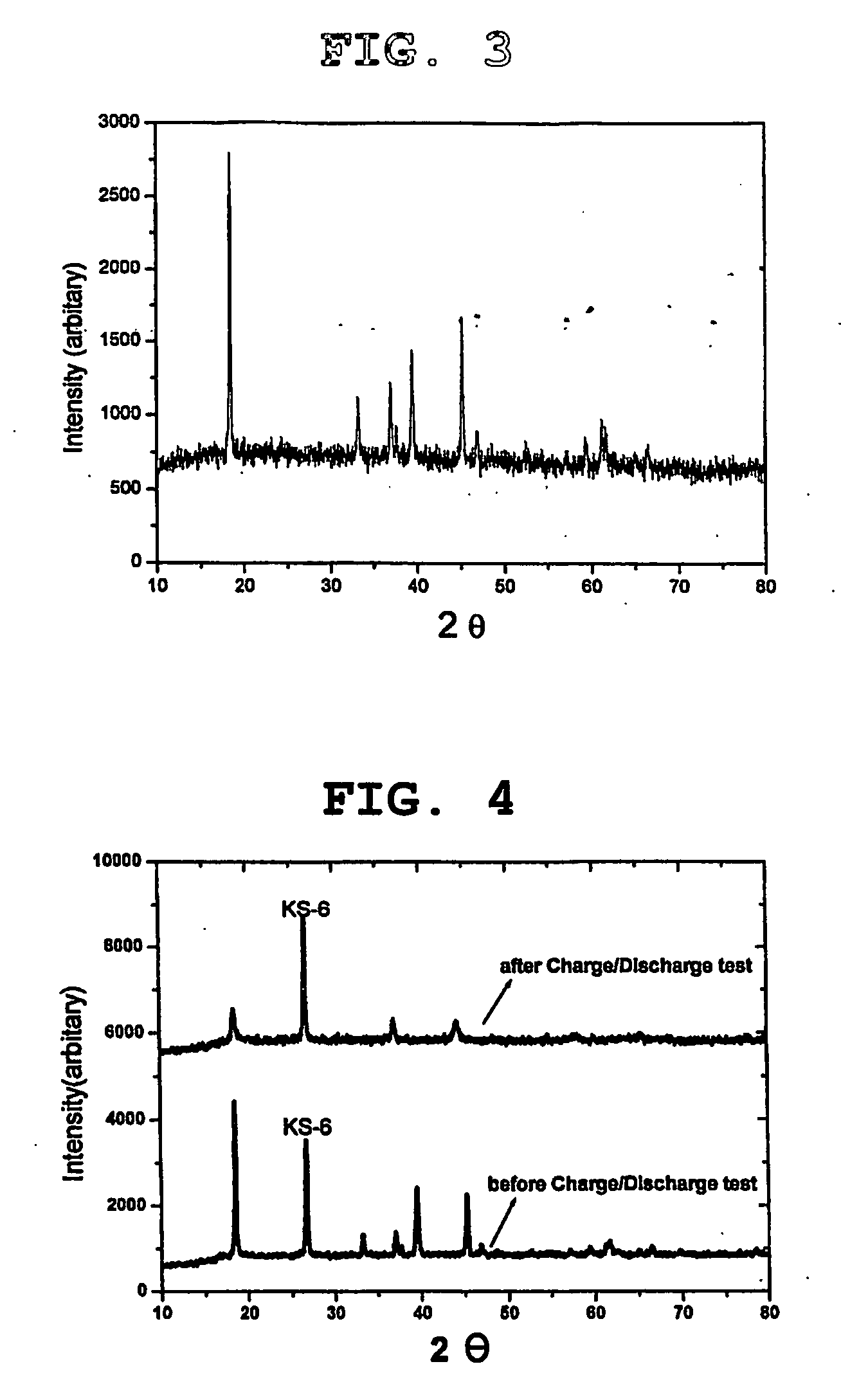

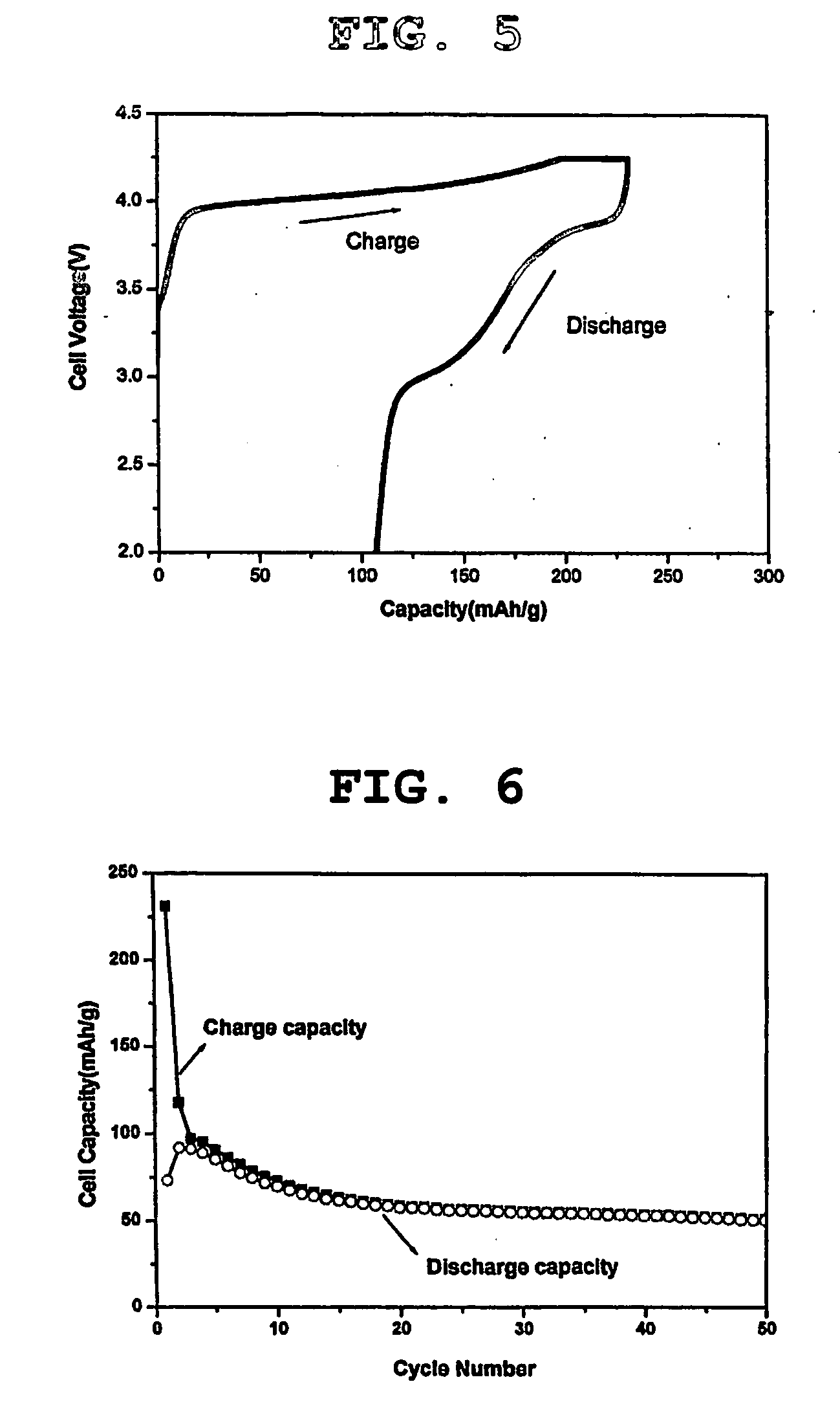

Surface and Bulk Modified High Capacity Layered Oxide Cathodes with Low Irreversible Capacity Loss

InactiveUS20090224212A1Large capacityLow costNon-metal conductorsConductive materialCapacity lossCrystal structure

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

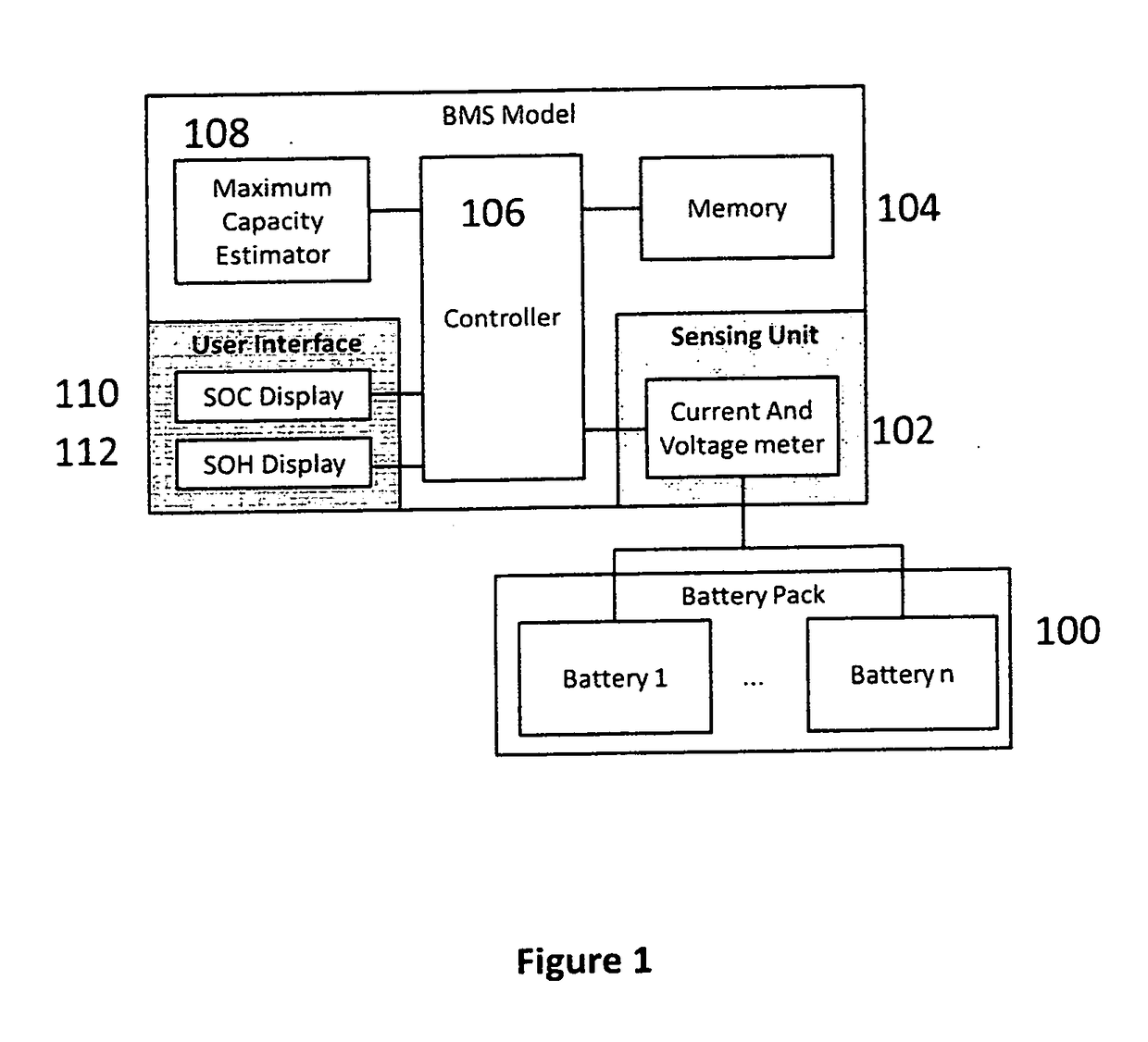

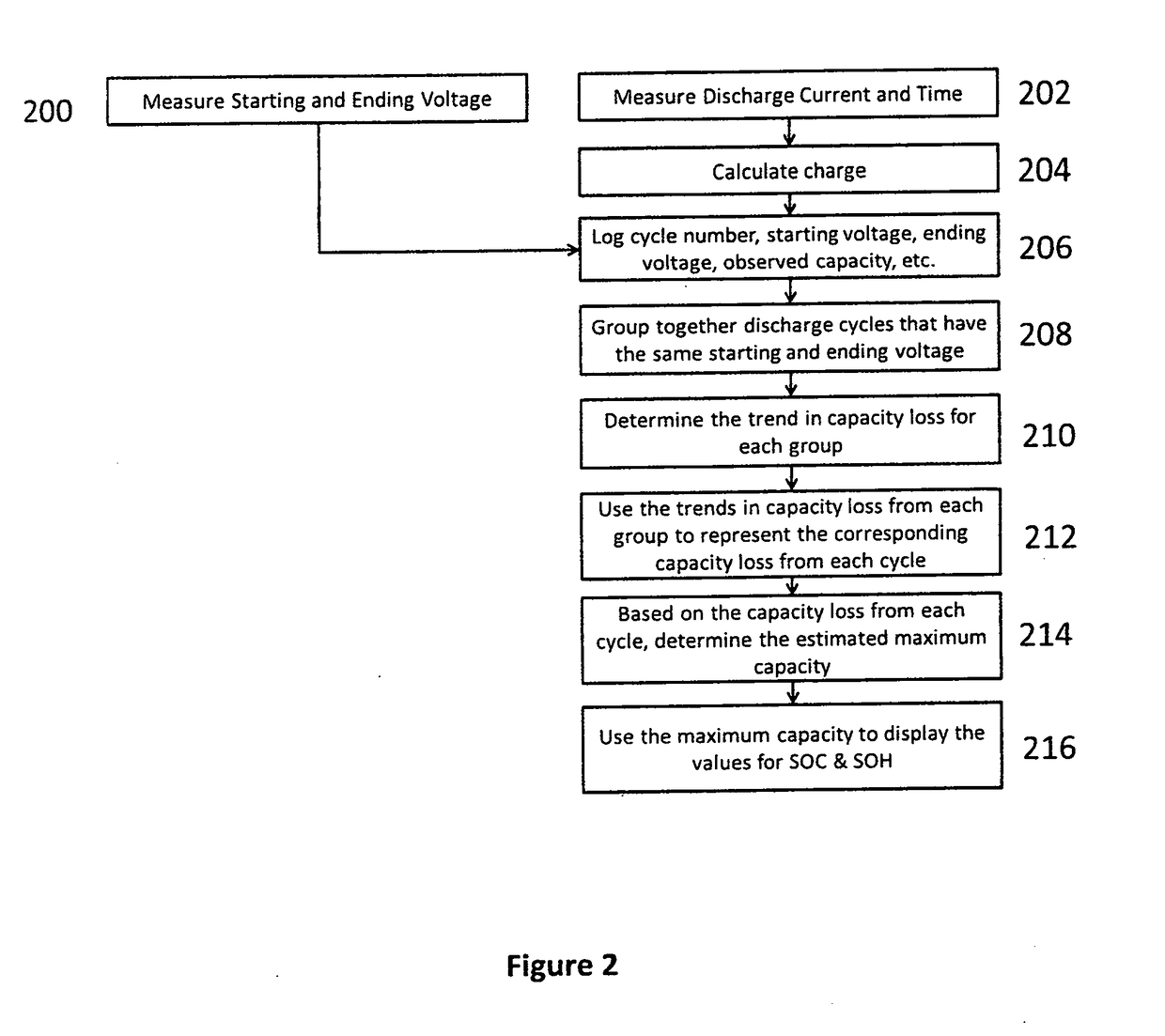

Maximum capacity estimator for battery state of health and state of charge determinations

InactiveUS20170115355A1Large capacityEliminate the effects ofElectrical testingElectrical resistance and conductanceCapacity loss

A method for determining the maximum capacity a battery to store charge for the benefit of state of charge and state of health determinations, otherwise known as the maximum capacity estimator, is described. In an embodiment, a memory storage unit is used to collect input data from a battery or battery pack over the life cycle of the battery. As the battery operates, discharge cycles are analyzed to determine the similarity between different cycles throughout the operational phase. The maximum capacity at a given time for storing charge is then determined by comparing the trend of capacity loss in similar cycles and then applying that trend to the reduction of the maximum capacity of the battery. This method allows state of health and state of charge measurements to be made and updated with respect to battery degradation without the need for scheduled maintenance checks-ups such as mandatory discharge cycles or impedance / resistance measurements.

Owner:APPLIED MATERIALS INC

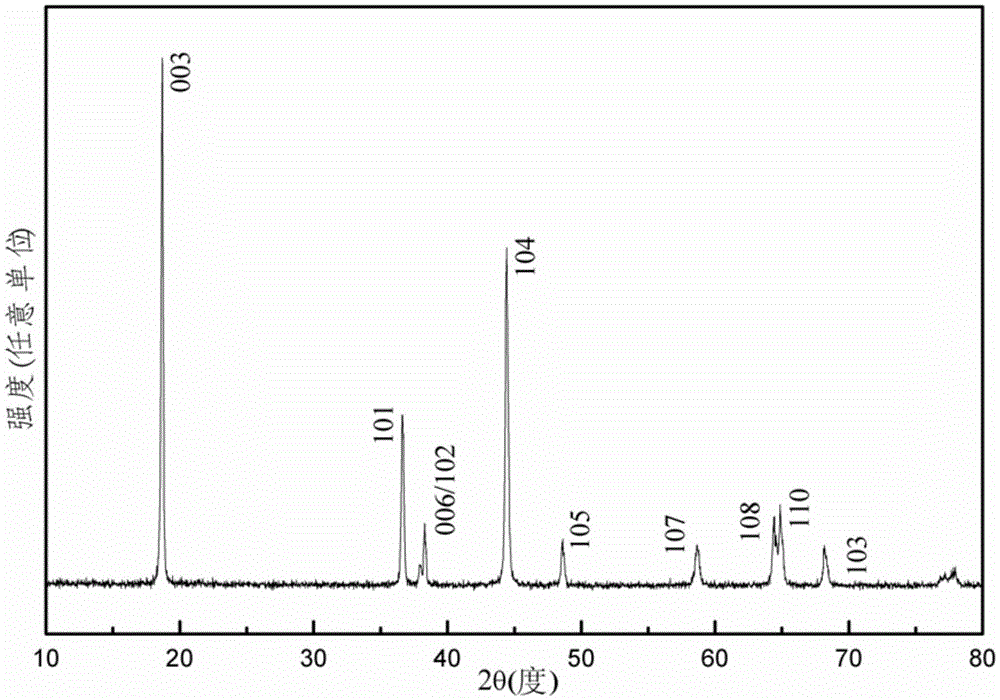

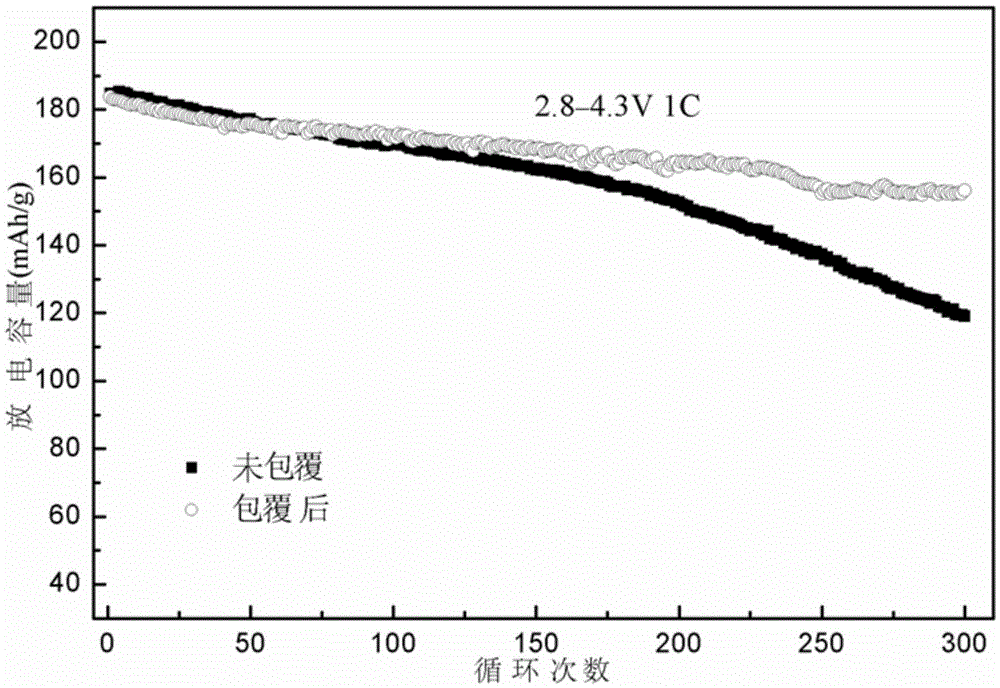

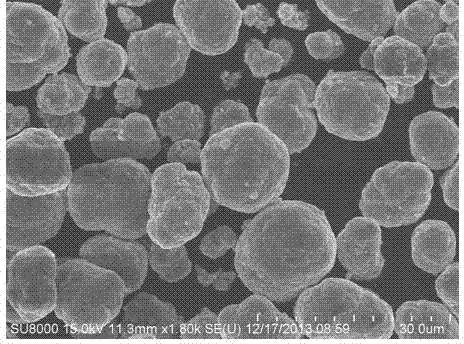

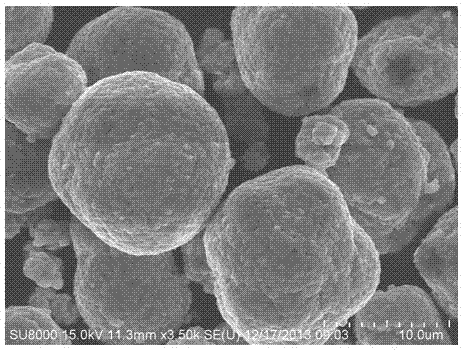

Nickel base trinary positive electrode material and preparation method thereof

ActiveCN105576233AImprove hydrophilic surface propertiesImprove electrochemical performanceCell electrodesSecondary cellsCapacity lossDissolution

The invention provides a nickel base trinary positive electrode material, which is obtained through compounding coupling agents onto the surface of nickel base materials and then performing heat treatment. The hydrophilic surface property of the nickel base trinary positive electrode material is improved by a compound modification method; the problem that the nickel base trinary positive electrode material is sensitive to the moisture in the environment is effectively solved; the residue lithium content on the surface of the particles is reduced; in addition, the discharging specific capacity loss of the nickel base trinary positive electrode material cannot be caused; the dissolution of transition metal ions on the surfaces of the particles in the long-time circulation process can be inhibited; the corrosion of HF generated in the charging and discharging process on the surface of the materials can be reduced; the electrochemical performance of the materials is improved.

Owner:四川浩普瑞新能源材料股份有限公司

Cathode active material comprising additive for improving overdischarge-performance and lithium secondary battery using the same

InactiveUS20070015055A1Increase cell capacityAvoid dischargeElectrode manufacturing processesOrganic electrolyte cellsCapacity lossManganese

Disclosed is a cathode active material providing a cell performance that is not adversely affected by overdischarge, and a lithium secondary cell using the same. More particularly, the cathode active material for a lithium secondary cell comprises a lithium-transition metal oxide capable of lithium ion intercalation / deintercalation, wherein the cathode active material further comprises a lithium manganese oxide having a layered structure represented by the following formula 1 as an additive:[formula 1] LiMxMn1-x02 wherein, x is a number satisfying 0.05 x<0.5, and M is at least one metal selected from the group consisting of Cr, Al, Ni, Mn and Co. The lithium manganese oxide of formula 1 used as an additive for a cathode active material of a lithium secondary cell provides lithium ions in such an amount as to compensate for an irreversible lithium ion-consuming reaction at an anode, or more, thereby providing a lithium secondary cell which is low in capacity loss by over-discharge.

Owner:LG CHEM LTD

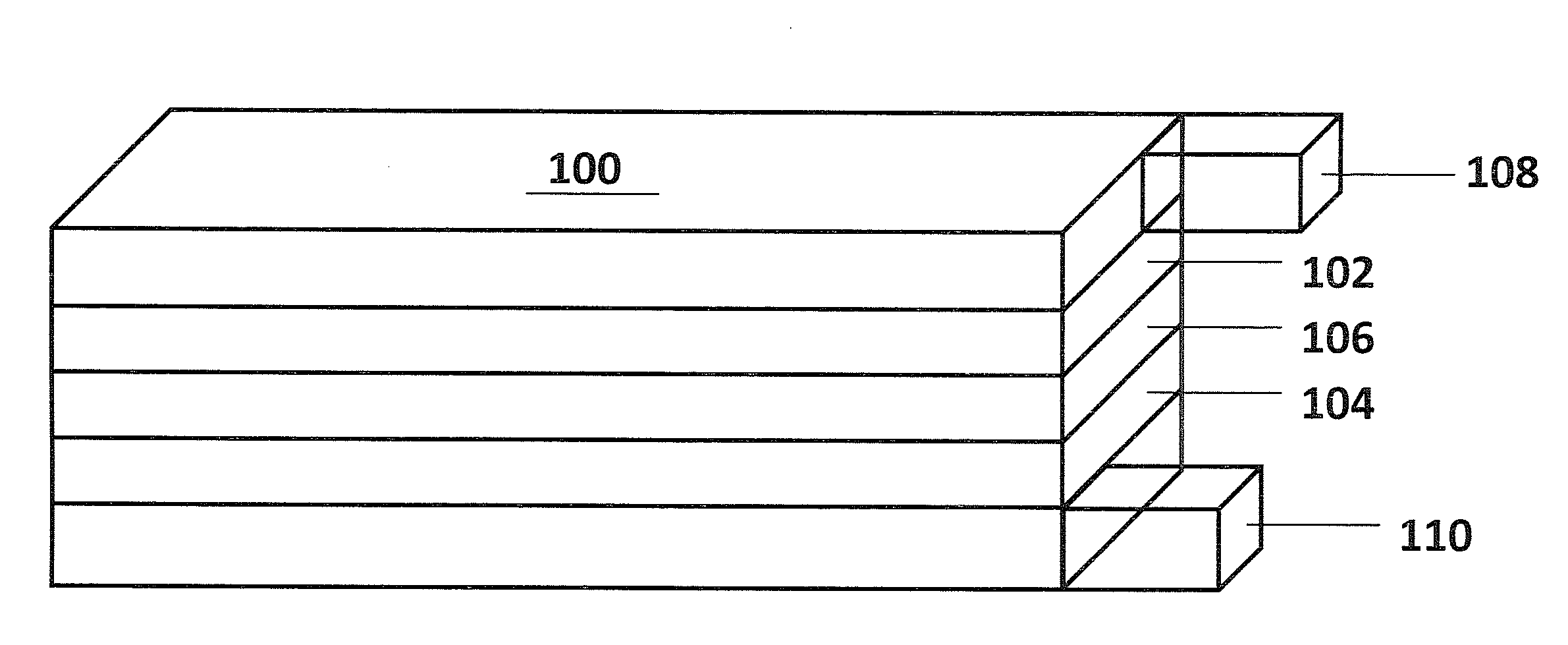

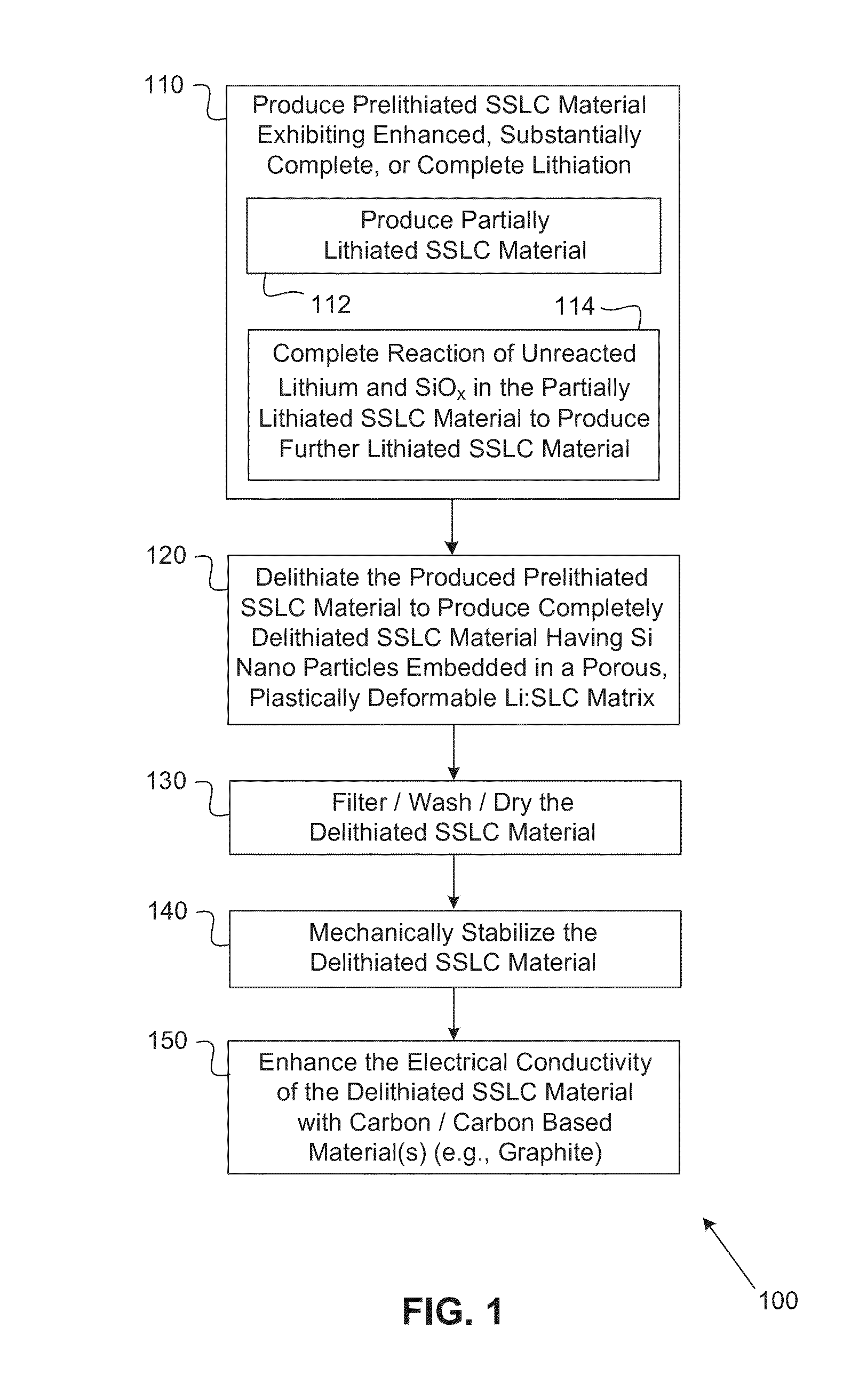

Silicon-silicon oxide-lithium composite material having NANO silicon particles embedded in a silicon:silicon lithium silicate composite matrix, and a process for manufacture thereof

ActiveUS20160260967A1Easy to useGood laminated electrode structureElectrode manufacturing processesSecondary cellsCapacity lossNano silicon

A process for producing a silicon:silicon oxide: lithium composite (SSLC) material useful as a negative electrode active material for non-aqueous battery cells includes: producing a partially lithiated SSLC material by way of mechanical mixing; subsequently producing a further prelithiated SSLC material by way of spontaneous lithiation procedure; and subsequently producing a delithiated SSLC material by way of reacting lithium silicide within the dispersed prelithiated SSLC material with organic solvent(s) to extract lithium from the prelithiated SSLC material, until reactivity of lithium silicide within the prelithiated SSLC material with the organic solvent(s) ceases. The delithiated SSLC material is a porous plastically deformable matrix having nano silicon embedded therein. The delithiated SSLC material can have a lithium silicide content of less than 0.5% by weight. A battery cell having as its negative electrode active material an SSLC material as set forth herein can exhibit an irreversible capacity loss of less than 10%.

Owner:EOCELL LTD

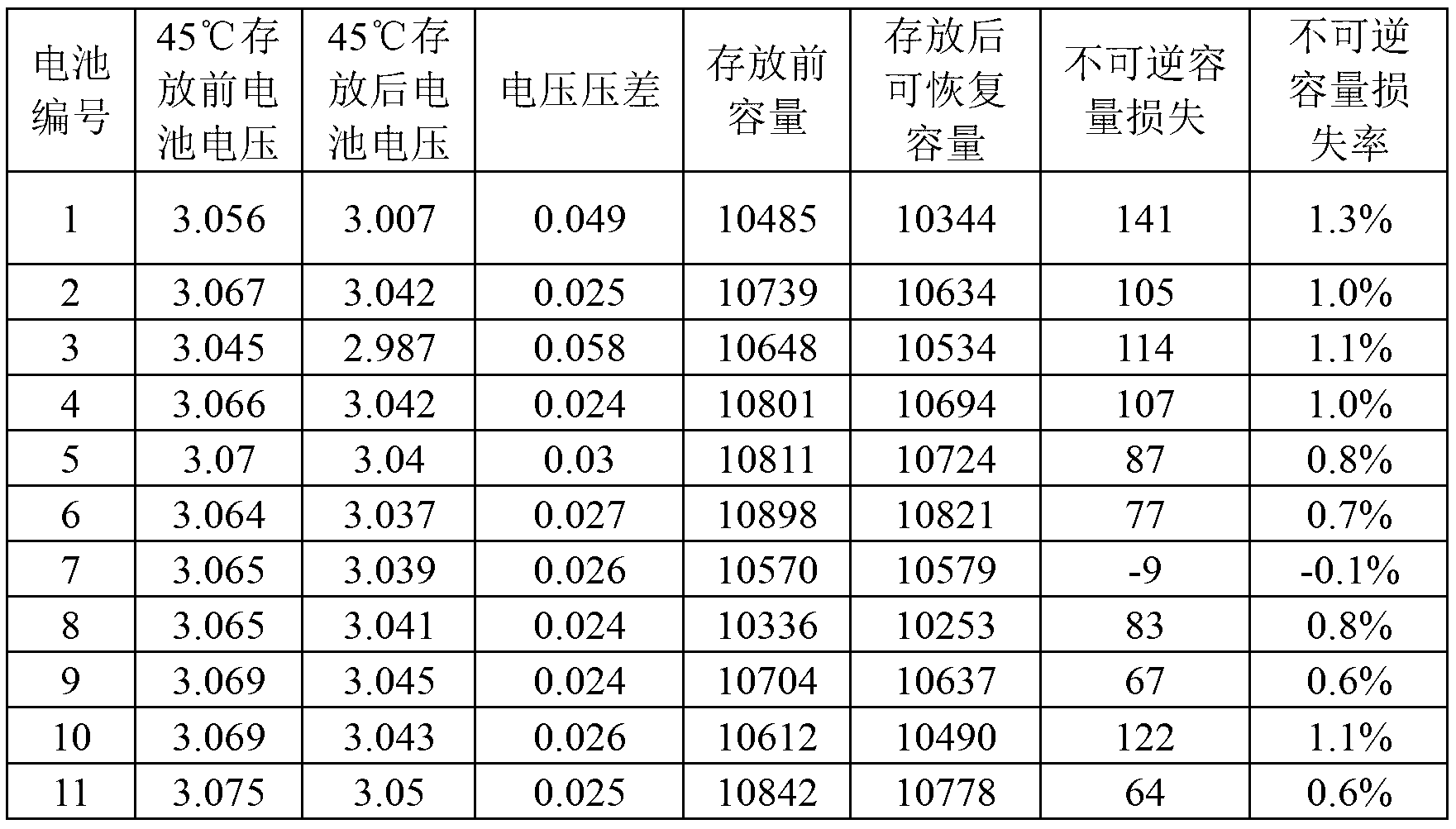

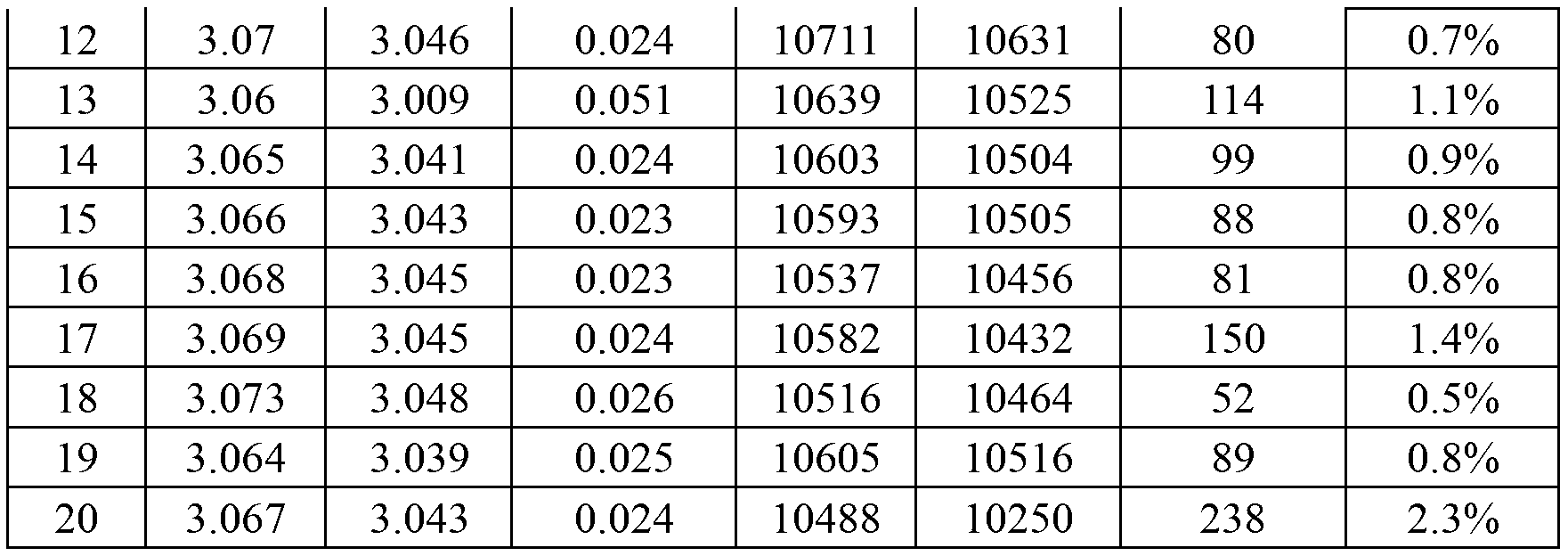

Lithium ion battery self-discharging quick detecting method

InactiveCN103293481AReduce lossesShort self-discharge detection periodElectrical testingCapacity lossPower flow

The invention discloses a lithium ion battery self-discharging quick detecting method. The method includes the steps that under the environment of 20-35 DEG C, a current, with multiplying power being 0.1-0.5, of the battery is discharged in a constant current mode, and voltage is cut off to 2.0-2.5 V; a current with the multiplying power being 0.1-0.5 is charged in a constant current mode, and charging capacity is 5% of rated capacity; after the battery is placed for 12-24 hours, the voltage of the battery is detected; the battery is placed under the environment of 45 DEG C for 3-5 days, and then the voltage of the battery is detected; voltage difference of the battery before being stored and the battery after being stored is compared. The detecting method only takes 3-5 days to detect the lithium ion battery with large self-discharging power, and therefore capacity loss generated during the storage process of the lithium ion battery is low.

Owner:JIANGSU LITIAN NEW ENERGY TECH

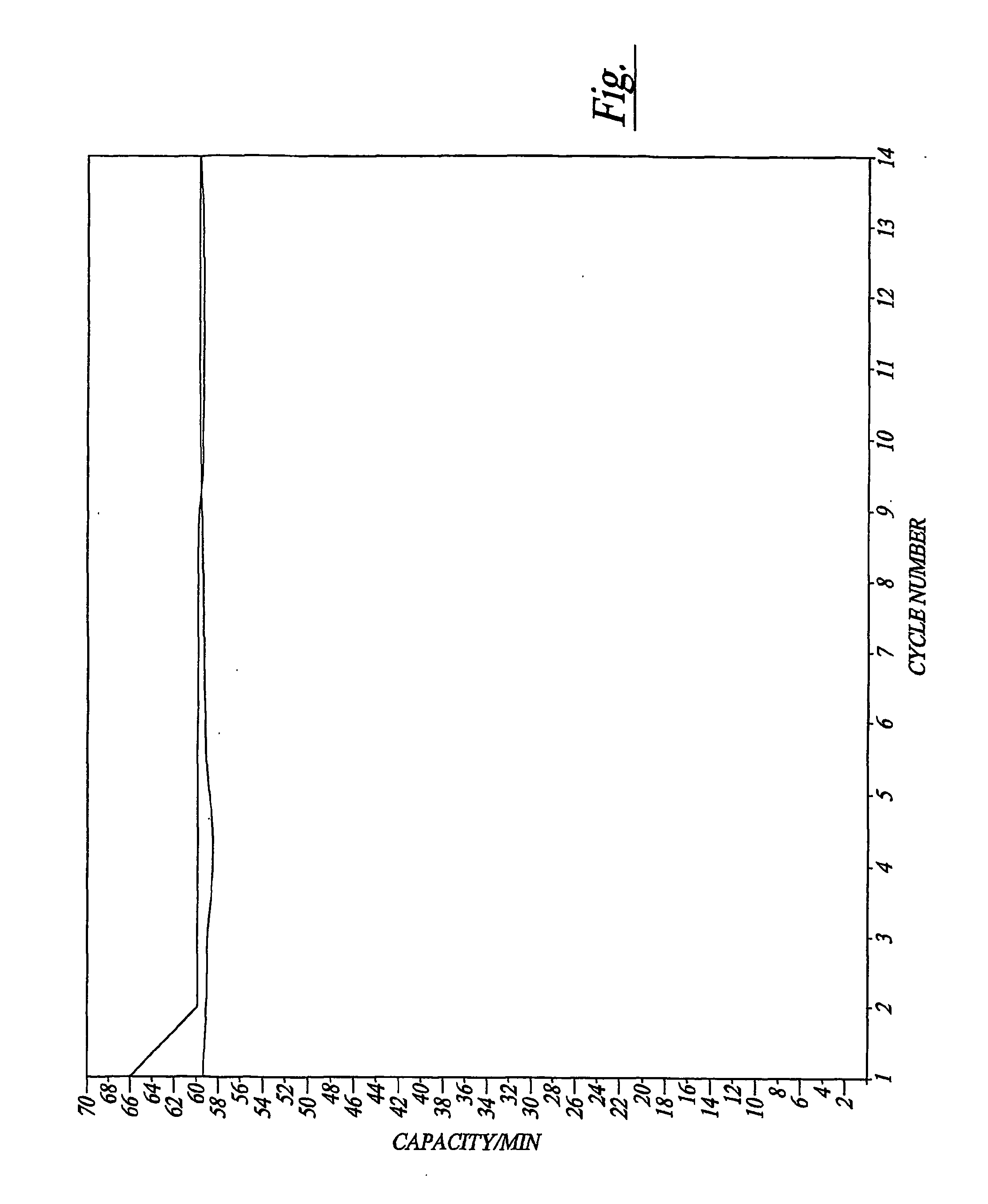

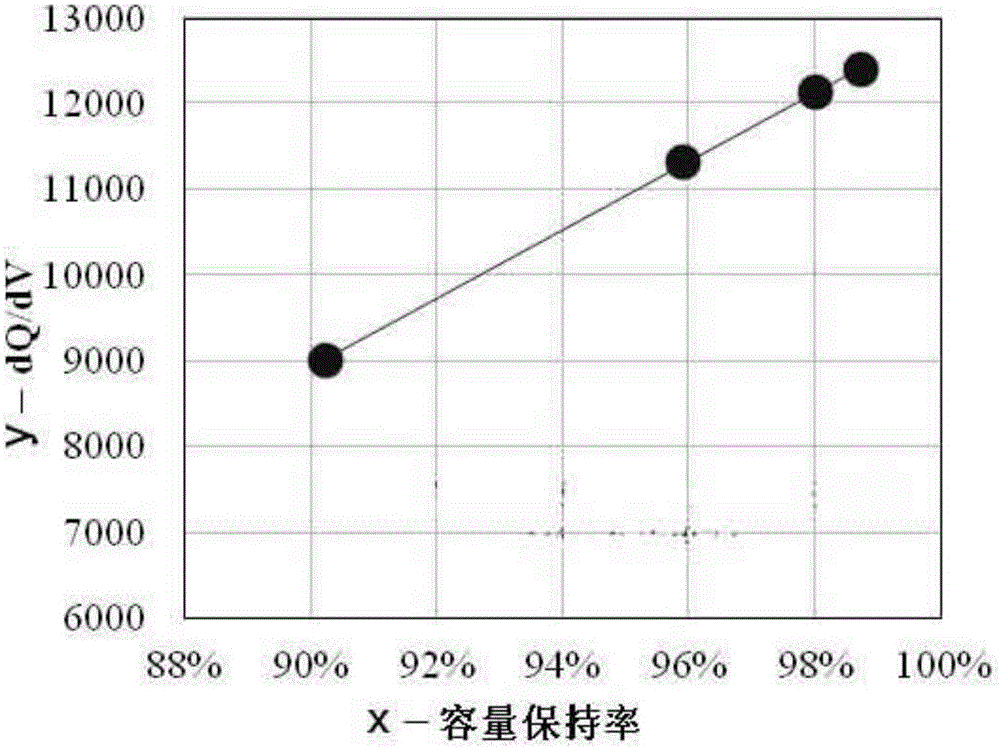

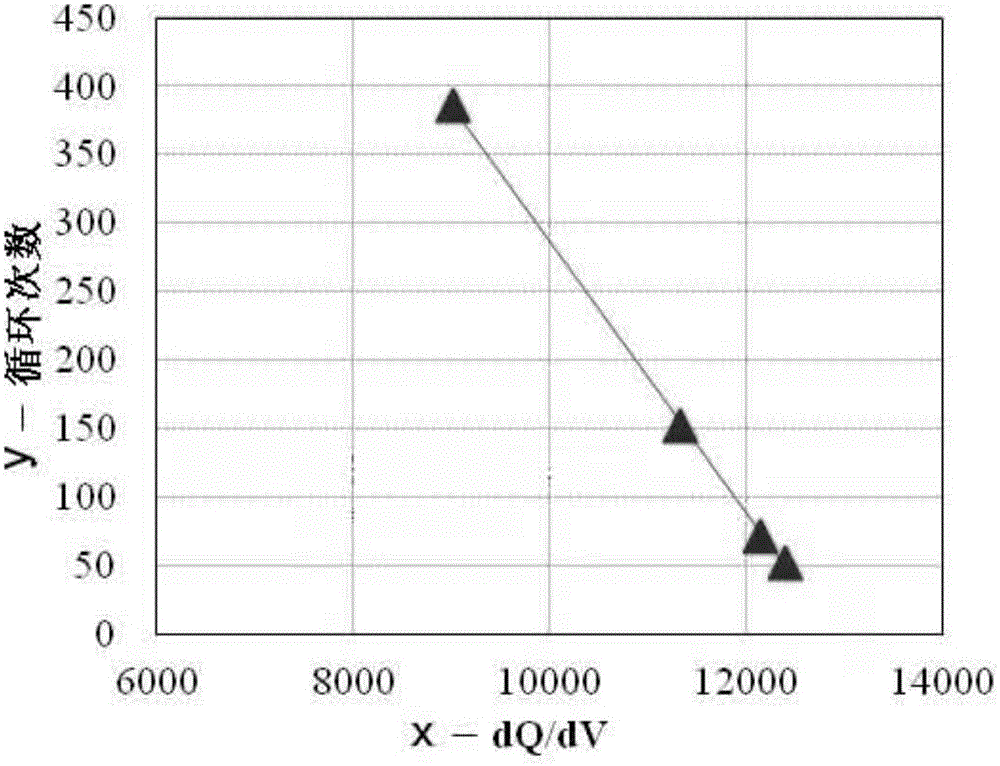

Battery cycle life prediction method

ActiveCN105068009ACycle Life PredictionRapid Evaluation ToolElectrical testingCapacity lossPower flow

The invention discloses a cycle system mode capable of achieving life prediction. The cycle system mode comprises the following steps: placing a to-be-evaluated battery in a cycling condition needing to be evaluated to perform a cycle test, recording an accumulated cycle frequency and the cycle capacity maintenance rate of the battery, performing small-current charging and discharging tests on the battery after each certain cycle frequency or capacity loss rate at the same time, recording voltage and capacity data of the battery in the charging and discharging process, and recording the corresponding cycle frequency and the corresponding capacity maintenance rate; and then performing data fitting and calculation according to the accumulated cycle frequency and the cycle capacity maintenance rate of the battery and differential data of the capacity on voltage, and performing prediction on the battery cycle life. Compared with a conventional cycle test, the cycle system mode greatly shortens the service life evaluation period and prevents energy consumption and resource waste which are generated by a long-term test; and, furthermore, because the data fitting is performed on the basis of short-term actually measured data, the cycle system mode has higher universality and high prediction accuracy compared with a pure theory calculation and experience model.

Owner:深圳一特科技有限公司

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

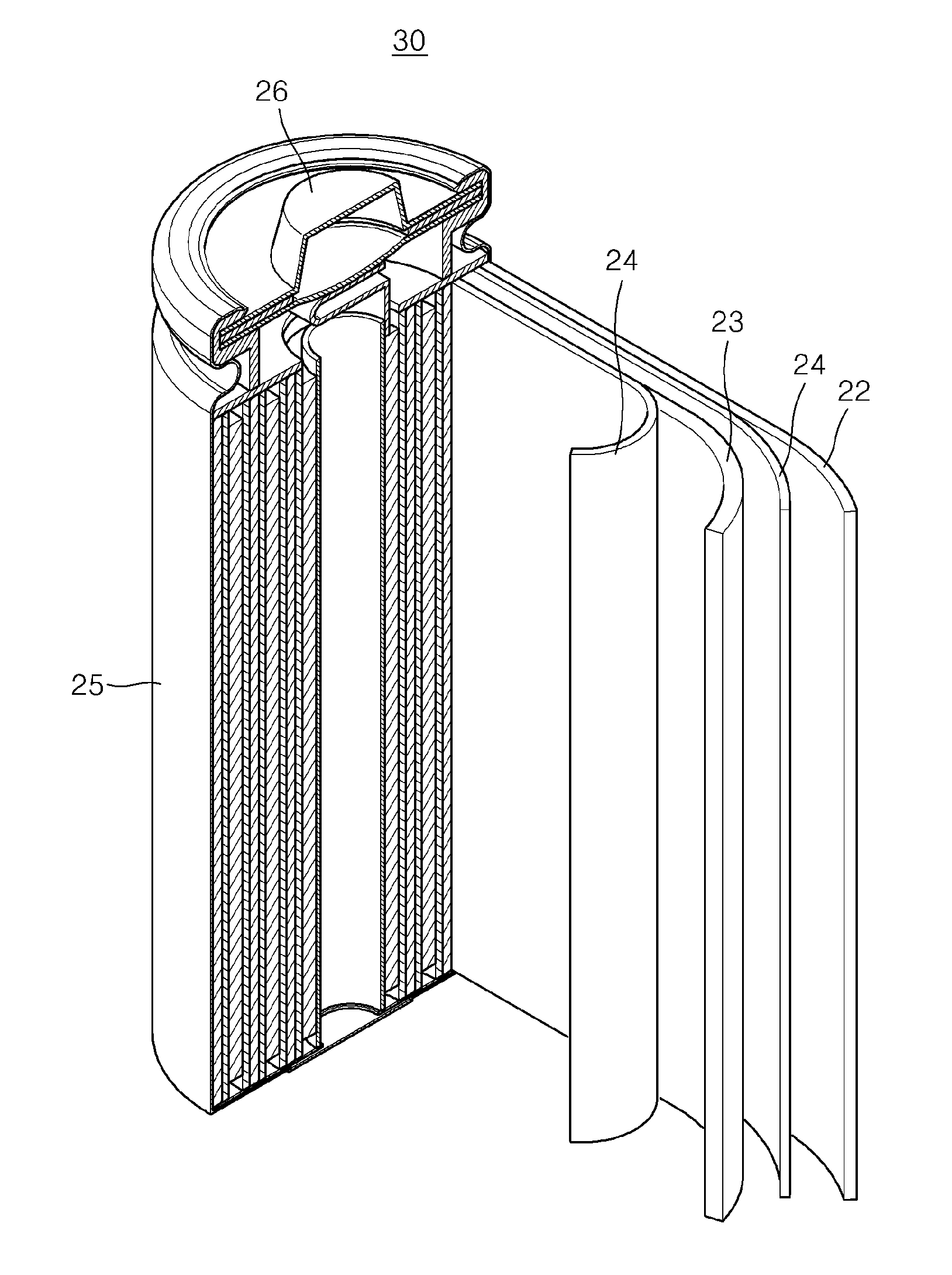

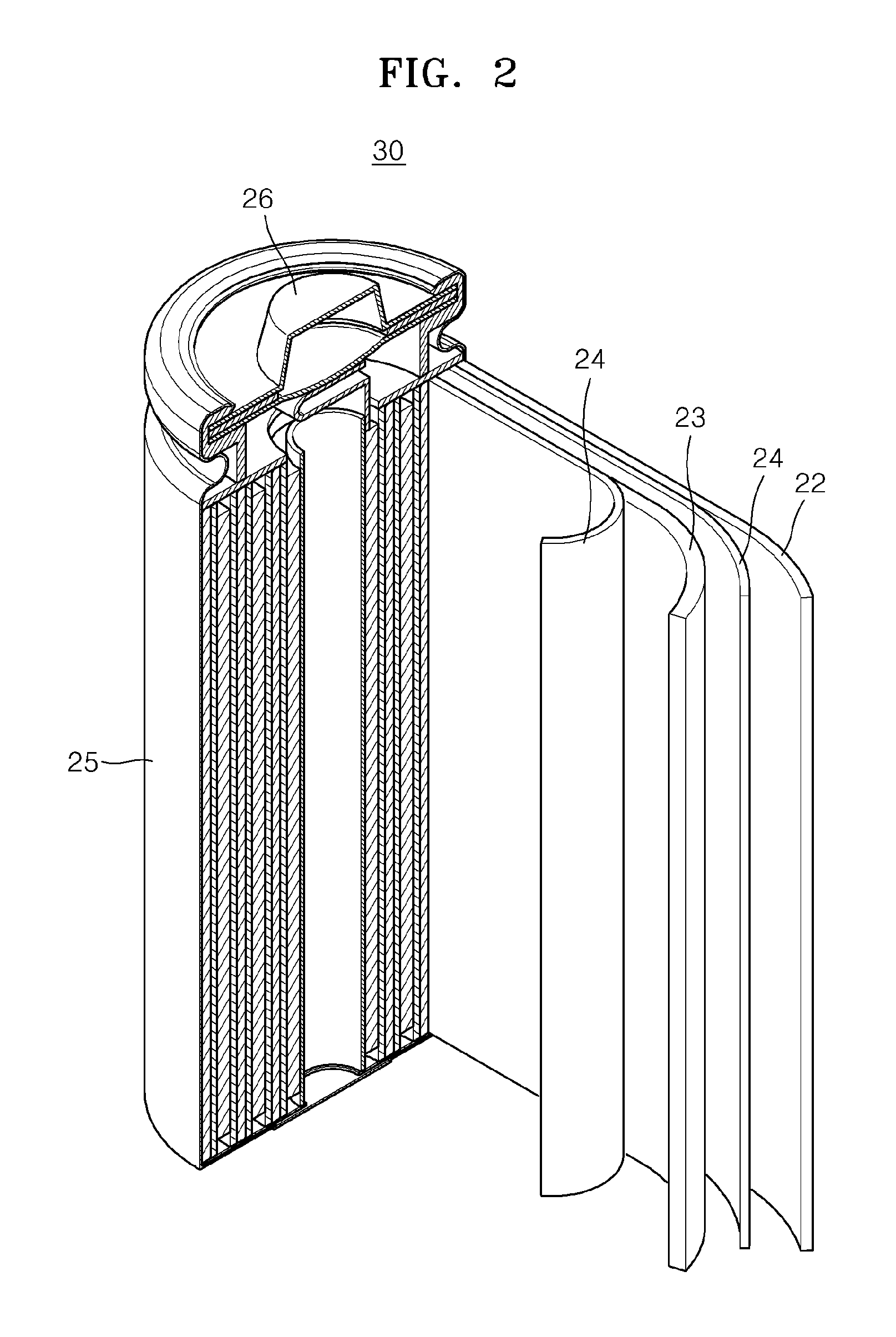

Secondary aluminum battery and preparation method thereof

InactiveCN101764253AReduce manufacturing costSimple processFinal product manufactureCell electrodesElectrolysisSlurry

The invention discloses a secondary aluminum battery and a preparation method thereof. The material of the positive electrode of the battery is organic polysulfide, the material of the negative electrode is aluminum or aluminum alloy, and the electrolyte is halogen aluminic acid ionic liquid; and the organic polysulfide is polysulfide carbine, thereby solving the problems that the elementary active substance is bad in conductivity and the frame is collapsed due to the dissolving of the reducing product. The electrolyte used is non-aqueous ionic liquid so that no oxide film, corrosive product or colloidal secondary product can be produced on the surface of the aluminum negative electrode so as to reduce the capacity loss of the negative electrode; the oxidation reduction reaction of the aluminum electrode in the electrolyte is reversible; and the battery is rechargeable. The preparation method for the secondary aluminum battery comprises the following steps: (1) preparing positive active material paste; (2) coating the positive active material paste on a foam nickel base, baking the paste and rolling the base into a positive plate; (3) rolling the positive plate, glass fiber non-woven membrane and the negative electrode made by taking any one of aluminum powder, aluminum foil and aluminum alloy as the negative active material into a battery core and arranging the battery core in a nickel-plated steel shell; then adding organic electrolyte in the steel shell; and sealing the steel shell to make the AA-type cylindrical secondary aluminum battery. The invention further discloses a preparation method for the positive material polysulfide carbyne of the battery.

Owner:无锡欧力达新能源电力科技有限公司

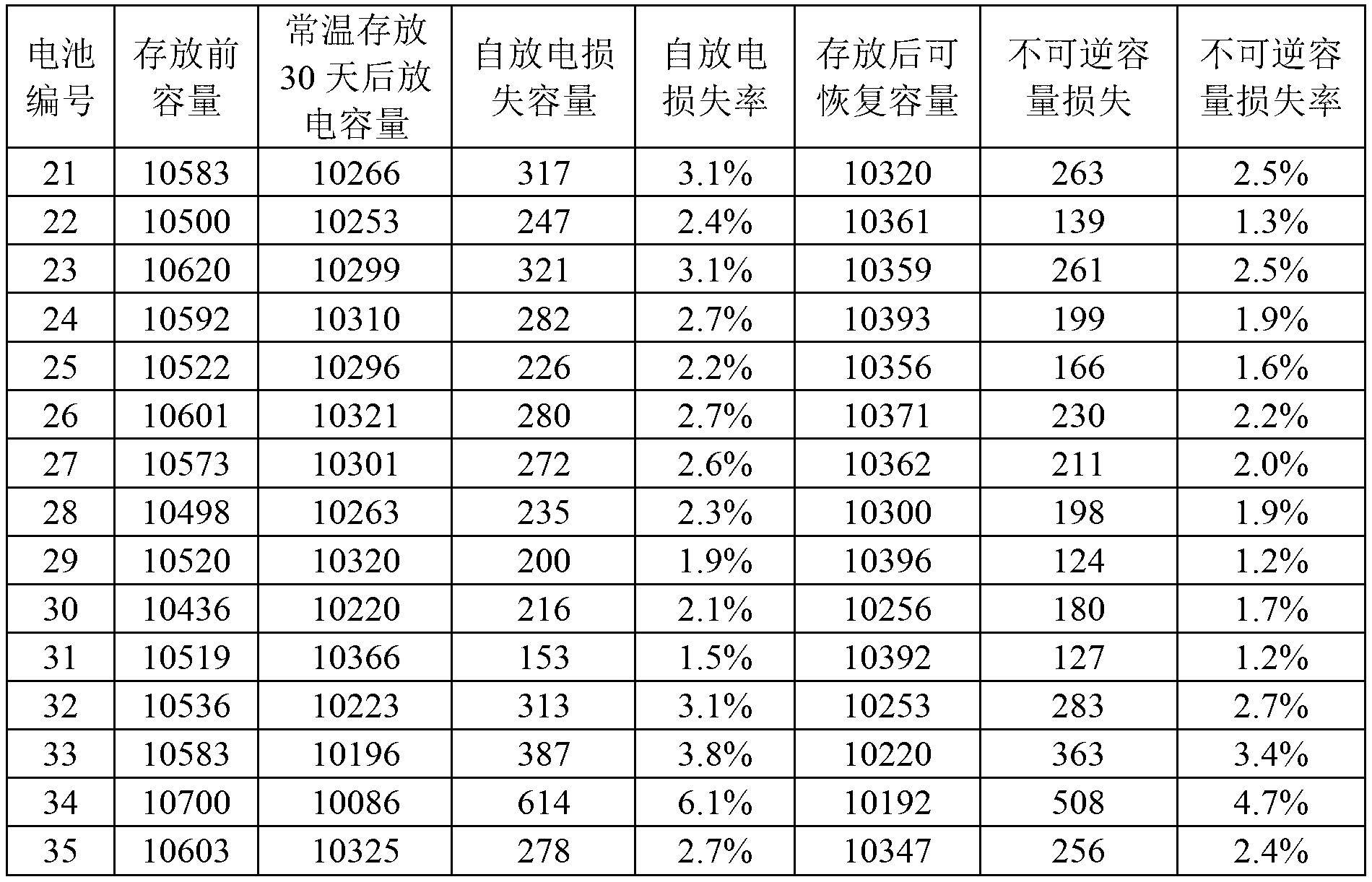

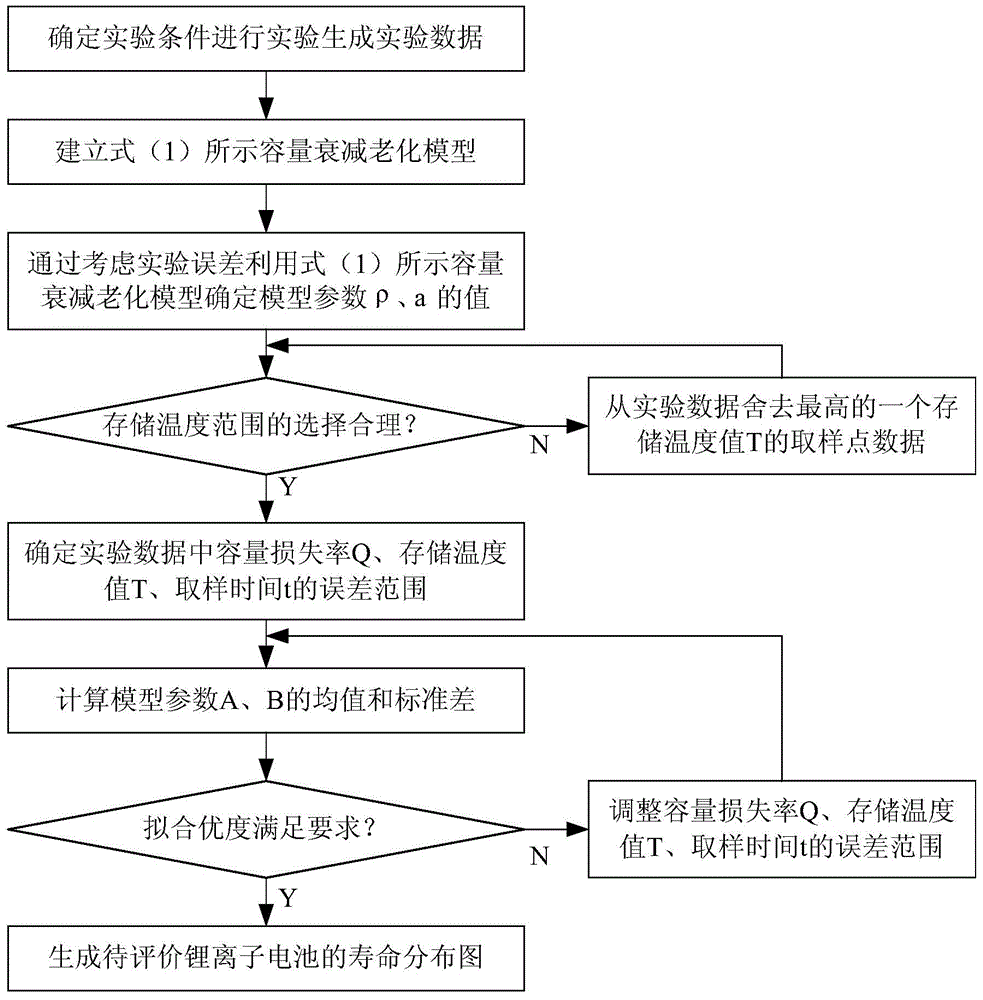

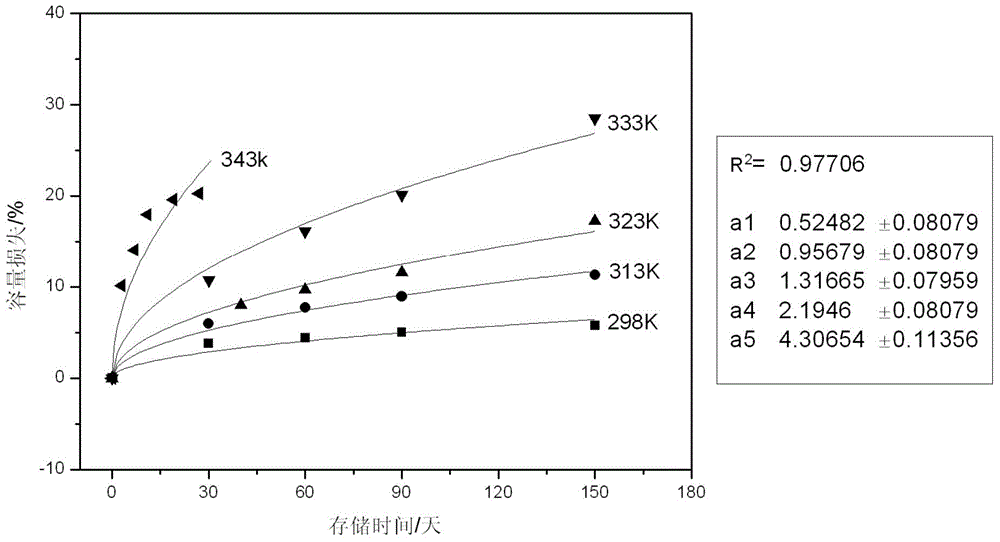

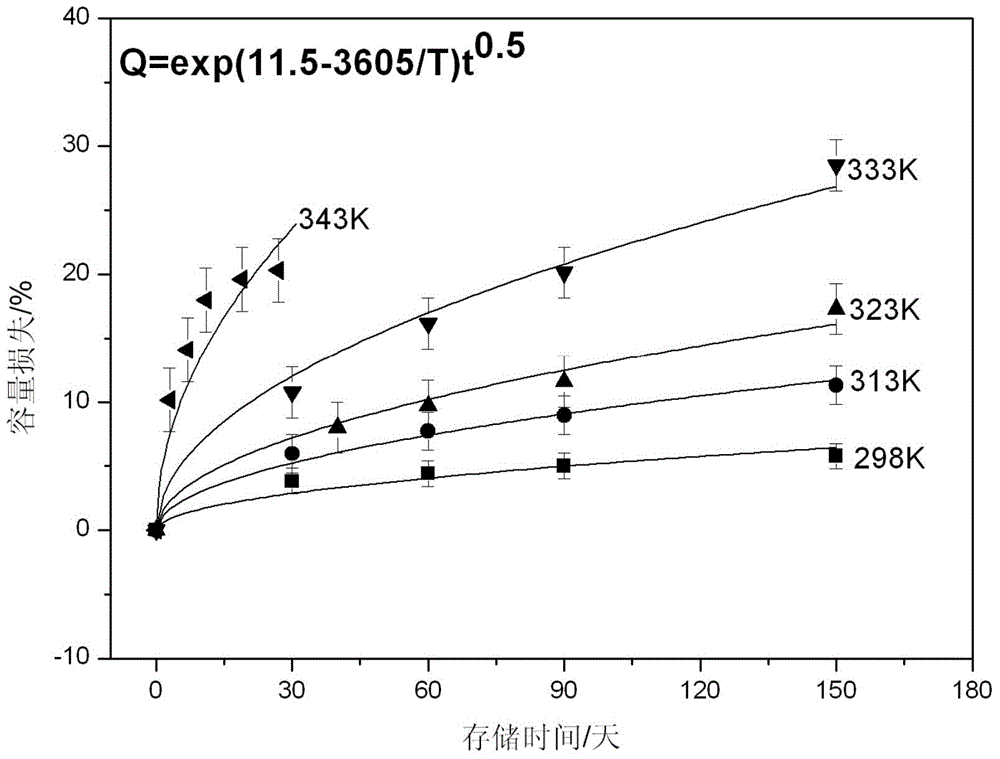

Lithium ion battery full charge storage service life evaluation method

ActiveCN105116337AThe principle of life evaluation is sufficientHigh data reliabilityElectrical testingCapacity lossUltrasound attenuation

The invention discloses a lithium ion battery full charge storage service life evaluation method. The method comprises steps: a battery sample for evaluation of lithium ion battery full charge states is stored at a plurality of storage temperature values T for appointed sampling time t, a capacity loss rate Q is obtained, and experiment data are generated; a capacity attenuation aged model is established, and values of a model parameter rho and a model parameter a are determined; the selection rationality of the storage temperature scope is determined based on the situation whether the model parameter a meets the Arrhenius formula at each storage temperature value T; a mean value and a standard deviation standard deviation of a model A and a model B are obtained through statistics; the value of the model parameter rho and the mean value of the models A and B are substituted into the model and fitting goodness determination is carried out; after fitting goodness is met, the service life of the lithium ion battery to be evaluated is predicted at a normal temperature and a service life distribution diagram is obtained. The evaluation method has advantages of sufficient service life evaluation principle, high data reliability, high precision, short evaluation time, wide application scope, is simple and practicable, and is easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com