Positive electrode and preparation method therefor, and lithium secondary battery

A technology of positive electrode and positive electrode active material, which is applied in the direction of lithium battery, battery electrode, non-aqueous electrolyte battery, etc., can solve the problems of increasing the complexity of operation, and achieve the reduction of operating environment and operating process, excellent electrochemical cycle performance, and improvement of The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

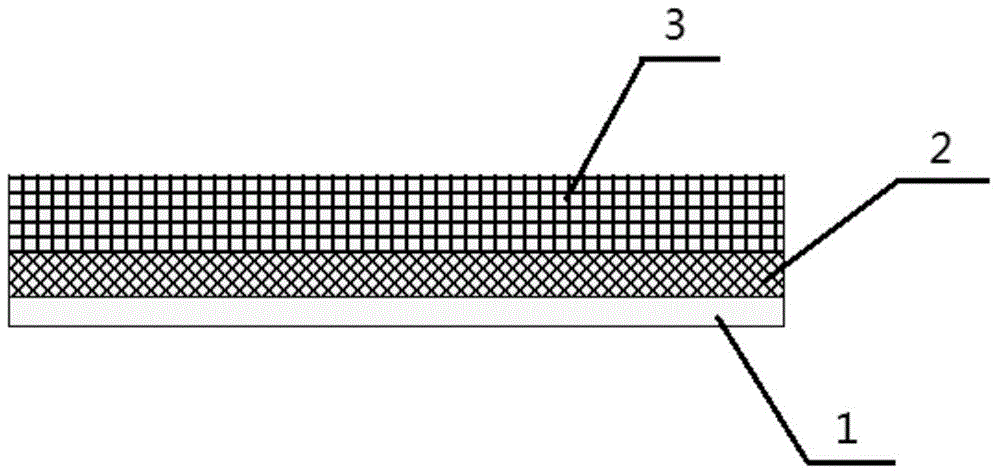

Image

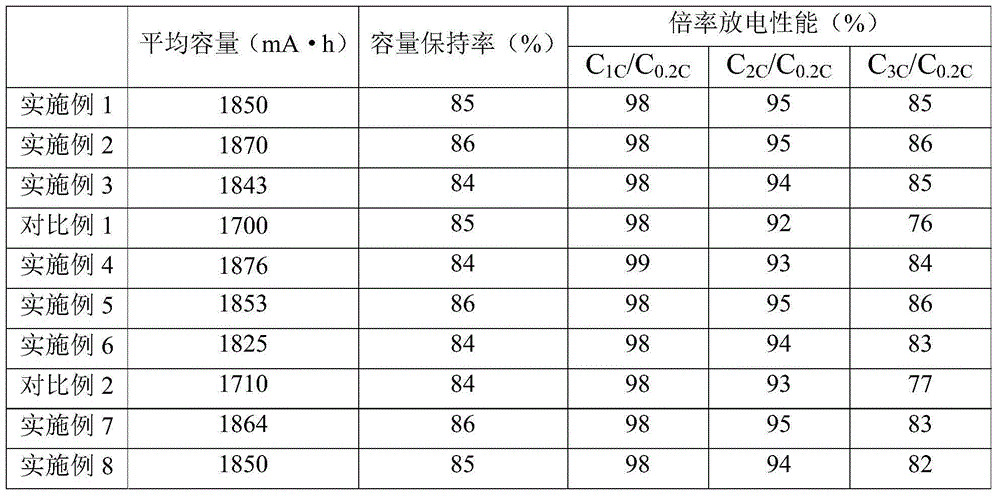

Examples

preparation example Construction

[0080] Step (2) can be carried out under the operating conditions and environment of conventionally prepared positive electrodes of lithium secondary batteries. Generally, step (2) can be carried out in an air atmosphere. In step (2), the drying conditions can be selected conventionally. Specifically, the drying may be performed at a temperature of 60-120°C. The duration of the drying can be selected according to the drying temperature, generally 1-60 minutes, preferably 10-30 minutes.

[0081] Step (3) is used to form a positive electrode active material layer on the surface of the lithium supplement layer. It can be carried out under conventional processes and conditions. Specifically, the positive electrode active material, the second conductive agent, and the second binder can be dispersed in a solvent to form a positive electrode active material slurry, and the positive electrode active material slurry can be coated on the surface of the lithium-replenishing layer. In...

Embodiment 1

[0096] 1. Preparation of positive electrode

[0097] (1-1) Formation of Lithium Supplementary Layer

[0098] Will Li 3 P (purchased from Bailingwei Technology Co., Ltd.), conductive carbon black (purchased from Swiss Temego, the brand is superP) and polyvinylidene fluoride (purchased from Kynar, the brand is HSV900) are dispersed in N-methylpyrrolidone to form a lithium supplement slurry material. Among them, Li 3 P: Conductive carbon black: The weight ratio of polyvinylidene fluoride is 70:15:15, Li 3 The weight ratio of P:N-methylpyrrolidone is 100:40.

[0099] The lithium-replenishing slurry was coated on both sides of an aluminum foil (12 μm in thickness), and then dried at 100° C. for 10 minutes to form a lithium-replenishing layer on both sides of the aluminum foil (the single-layer thickness of the lithium-replenishing layer was 3 μm). Wherein, the total coating amount of the lithium-supplementing slurry is 0.5 g.

[0100] (1-2) Formation of positive electrode act...

Embodiment 2

[0109] Adopt the same method as Example 1 to prepare lithium secondary batteries, the difference is that in step (1-1), polyvinylidene fluoride uses an equivalent amount of polyvinylidene fluoride-hexafluoropropylene (available from Kynar, the trade mark is LBG-1) to prepare a lithium secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com