Lithium-ion battery positive plate, preparation method thereof, and lithium-ion battery

A lithium-ion battery and cathode sheet technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of capacity loss, harsh operation requirements, and unsatisfactory lithium replenishment effect, and achieves the reduction of harshness, The effect of low decomposition voltage and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

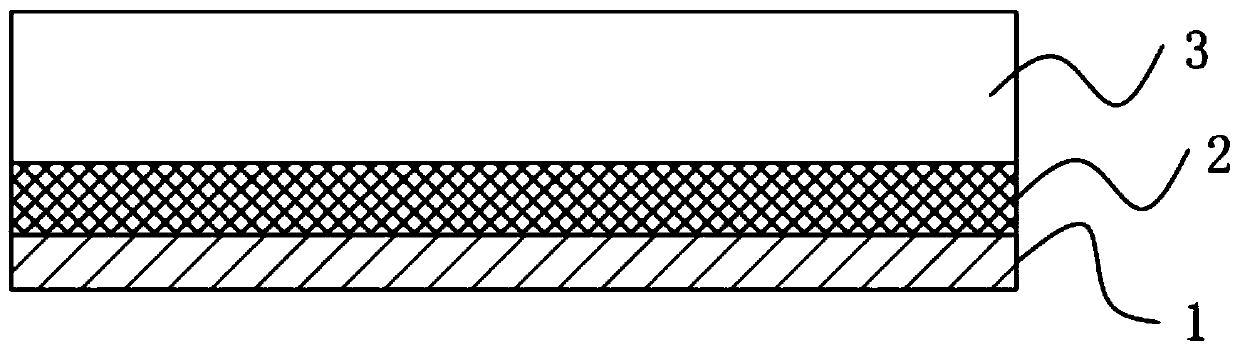

[0075] Another embodiment of the present invention also discloses a method for preparing a positive electrode sheet of a lithium ion battery, comprising the following steps:

[0076] Obtain the lithium supplement slurry; wherein, the lithium supplement slurry includes a reducing lithium compound, and the reducing lithium compound includes L-lithium ascorbate, D-lithium erythorbate, lithium metabisulfite, lithium sulfite and lithium phytate one or more of.

[0077] coating the lithium-replenishing slurry on at least one surface of the first current collector, and drying to form a lithium-replenishing layer;

[0078] Obtain positive electrode active slurry;

[0079] Coating the positive electrode active slurry on the surface of the lithium replenishing layer and drying to form the positive electrode active layer.

[0080] The operation of obtaining the lithium-supplementing slurry includes: dispersing the reducing lithium compound, the second conductive agent and the second bi...

Embodiment 1

[0098] This embodiment is used to illustrate a positive electrode sheet of a lithium-ion battery disclosed in the present invention, a preparation method thereof, and a lithium-ion battery.

[0099] 1. Preparation of lithium supplement layer

[0100] Disperse L-lithium ascorbate (commercially available), conductive carbon black (purchased from Switzerland Temego, the brand is super P) and polyvinylidene fluoride (purchased from Kynar, the brand is HSV900) in N-methylpyrrolidone to form Lithium supplement slurry. Among them, the weight ratio of L-ascorbate lithium: conductive carbon black: polyvinylidene fluoride is 70:20:10, and the solid content is 40%;

[0101] The lithium-supplementing slurry was coated on both sides of an aluminum foil (12 μm in thickness), and then dried at 100° C. for 5 minutes to form a lithium-supplementing layer on both sides of the aluminum foil (the single-layer thickness of the lithium-supplementing layer was 2 μm).

[0102] 2. Preparation of pos...

Embodiment 2

[0111] This embodiment is used to illustrate a positive electrode sheet of a lithium-ion battery disclosed in the present invention, its preparation method, and a lithium-ion battery, including most of the operating steps in Example 1, the difference being:

[0112] In the operation steps of the preparation of the lithium-replenishing layer: D-lithium erythorbate, conductive carbon black (purchased from Swiss Temigo, the brand is super P) and polyvinylidene fluoride (purchased from Kynar, the brand is HSV900) are dispersed In N-methylpyrrolidone, a lithium-supplementing slurry is formed. Among them, the weight ratio of D-lithium erythorbate: conductive carbon black: polyvinylidene fluoride is 70:20:10, and the solid content is 40%;

[0113] The lithium-supplementing slurry was coated on both sides of an aluminum foil (12 μm in thickness), and then dried at 100° C. for 5 minutes to form a lithium-supplementing layer on both sides of the aluminum foil (the single-layer thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com