Anode active material, preparation method therefor, and lithium secondary battery comprising same

A technology of negative electrode active material and carbon material, applied in the direction of lithium battery, active material electrode, negative electrode, etc., can solve the problems of volume expansion and capacity reduction of lithium secondary battery, so as to enhance mechanical properties, compensate for irreversible capacity loss, suppress The effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] According to another aspect of the present invention, there is provided a method for preparing a negative electrode active material, comprising: preparing a mixed powder by mixing carbon materials and silicon particles; and mechanically over-mixing the mixed powder.

[0065] According to an embodiment of the present invention, the mixed powder preparation step may prepare a mixed powder by mixing carbon materials and silicon particles.

[0066] According to an embodiment of the present invention, the overmixing step may mechanically overmix the mixed powder.

[0067] According to an embodiment of the present invention, the overmixing may be performed by a milling process. The milling process may include milling from a bead mill, a high energy ball mill, a planetary mill, a stirred ball mill, a vibration mill, SPEX At least any one selected from the group consisting of SPEX mill, Planetary mill, Attrition mill, Magneto-ball mill and vibration mill kind. The bead and b...

Embodiment 1

[0111] Graphite (Tokai carbon, BTR, etc.) is mechanically ground and mixed with silicon nanoparticles at a ratio of 7:3. Use Hosokawa Mikron (NOB, Mechano Fusion) mixer to mix at a speed of 2000rpm to 6000rpm for 30 minutes to 480 minutes, thereby preparing a negative electrode active material of about 10 μm based on D50, and using soft carbon (Soft carbon) to form the outer coating.

Embodiment 2

[0113] In Example 1, a negative electrode active material was prepared in the same manner as in Example 1 except that the particle size was 20 μm.

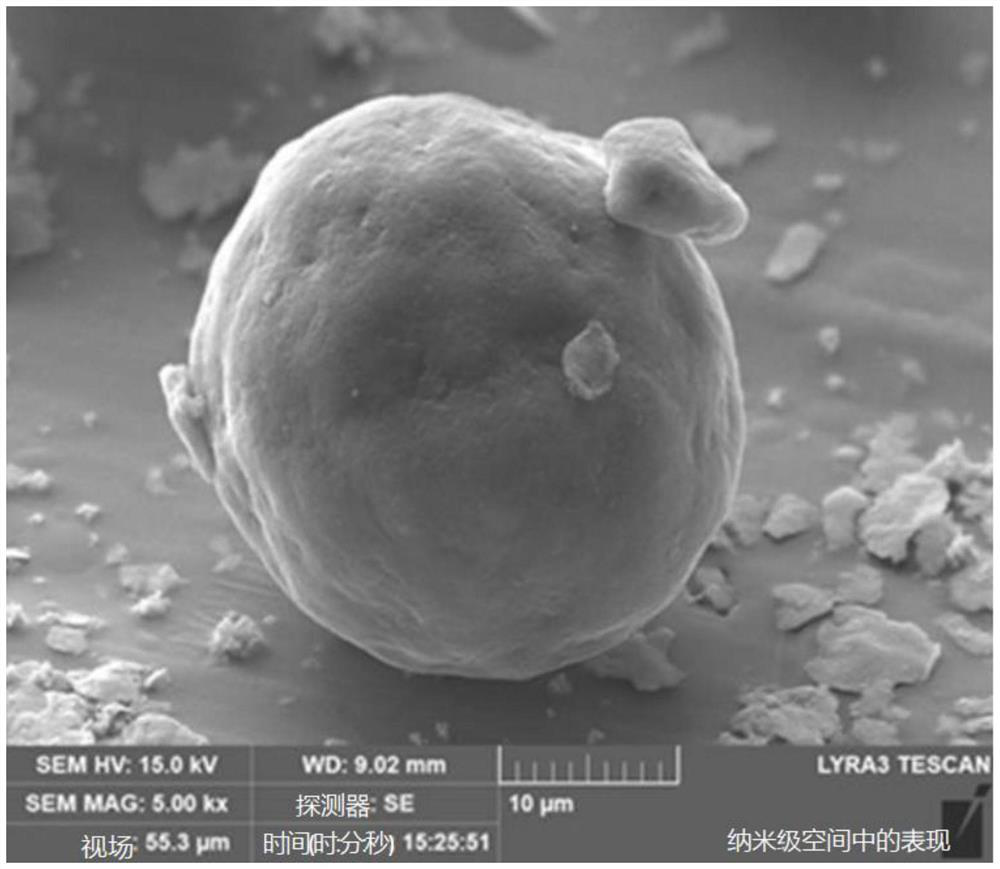

[0114] Scanning Electron Microscopy (SEM) Analysis - Particle Shape of Electrode Active Material

[0115] A scanning electron microscope (SEM) analysis was performed on the negative electrode active materials according to Examples 1 and 2. For scanning electron microscope (SEM) analysis, JSM-7600F of JEOL was used. The particle shape of the negative electrode active material and its cross section were analyzed.

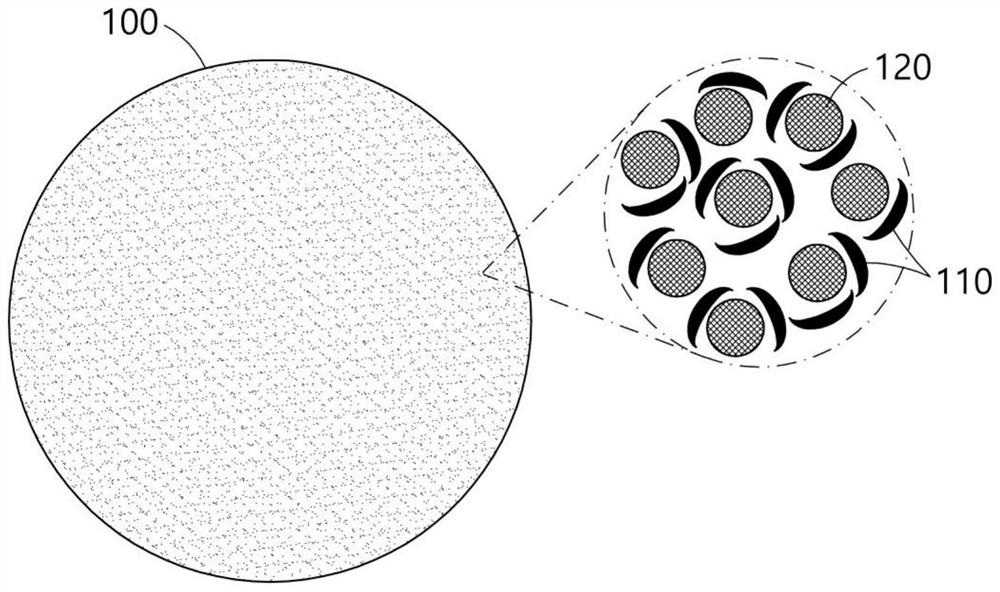

[0116] image 3 To show a scanning electron microscope (SEM) image of the particle shape of the negative electrode active material according to Example 1 of the present invention, Figure 4 It is an enlarged view showing a particle cross-section of the cathode active material according to Example 1 of the present invention. refer to image 3 and Figure 4 , it can be seen that graphite and silicon particles are unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com