Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2696 results about "Silicon alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon alloys are metallic or semiconductor alloys with silicon as a significant element. Silicon is an important alloying addition in metallurgy, particularly for a range of aluminium-silicon alloys, even though it only forms a minor proportion of the alloy.

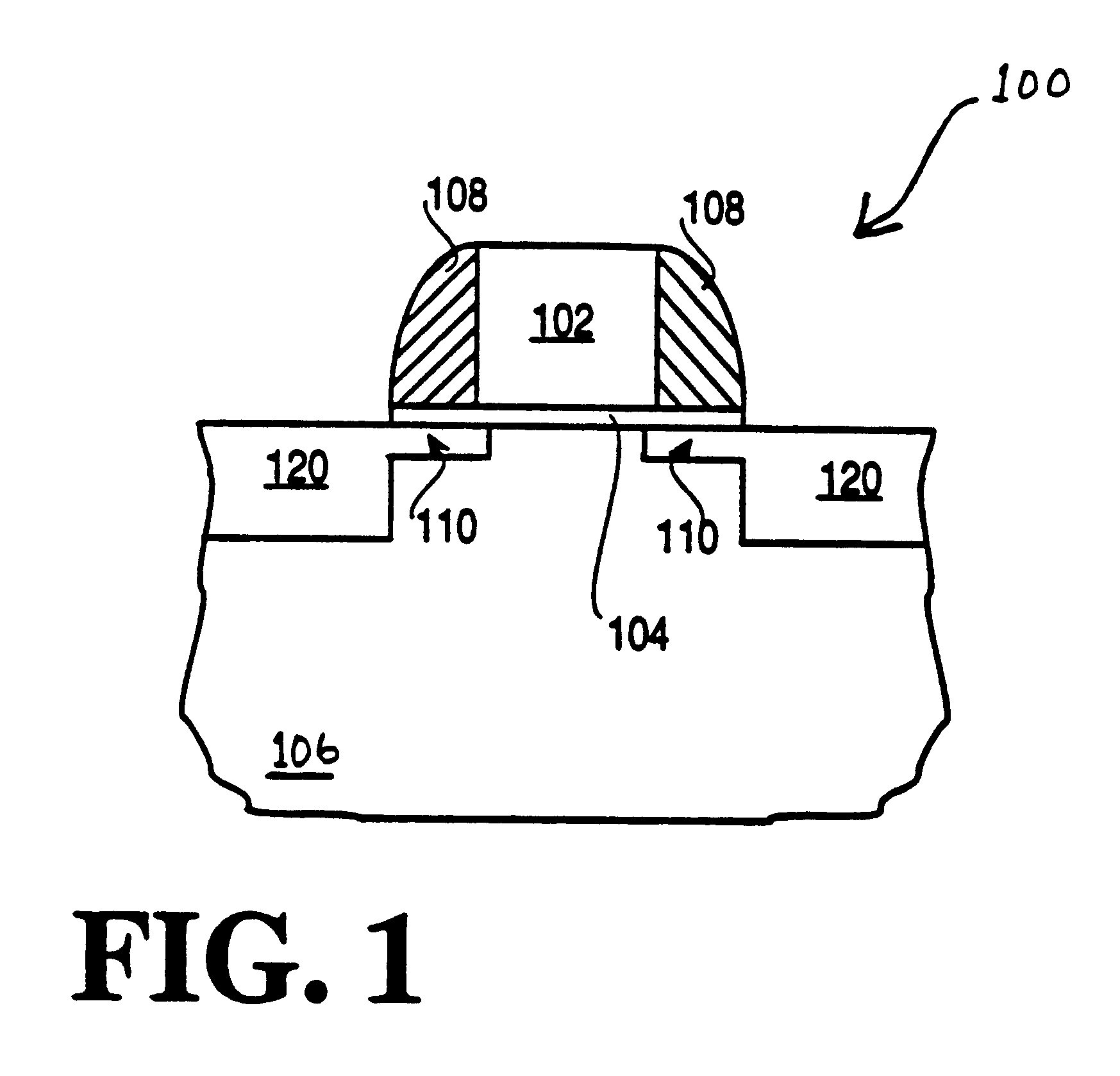

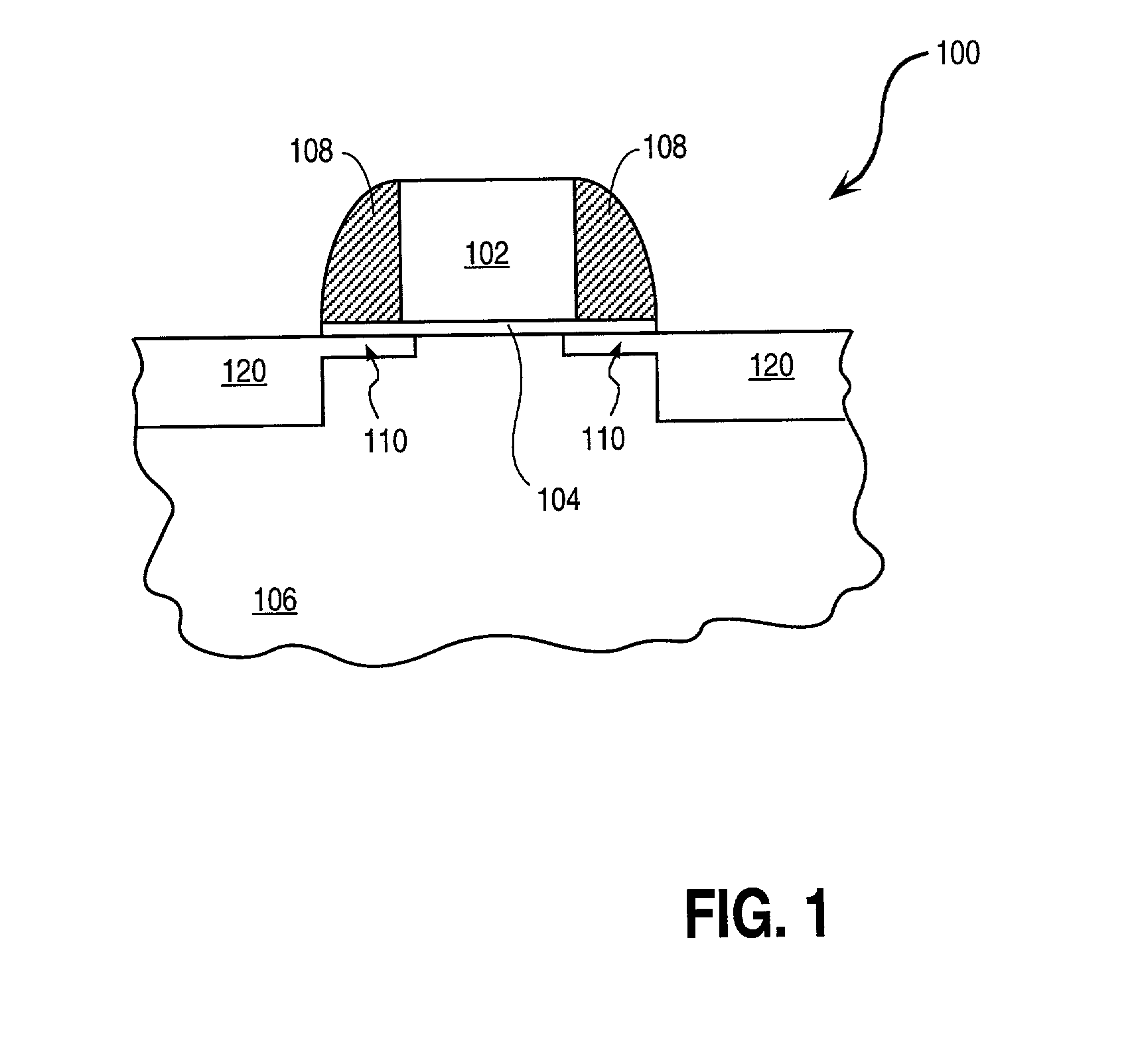

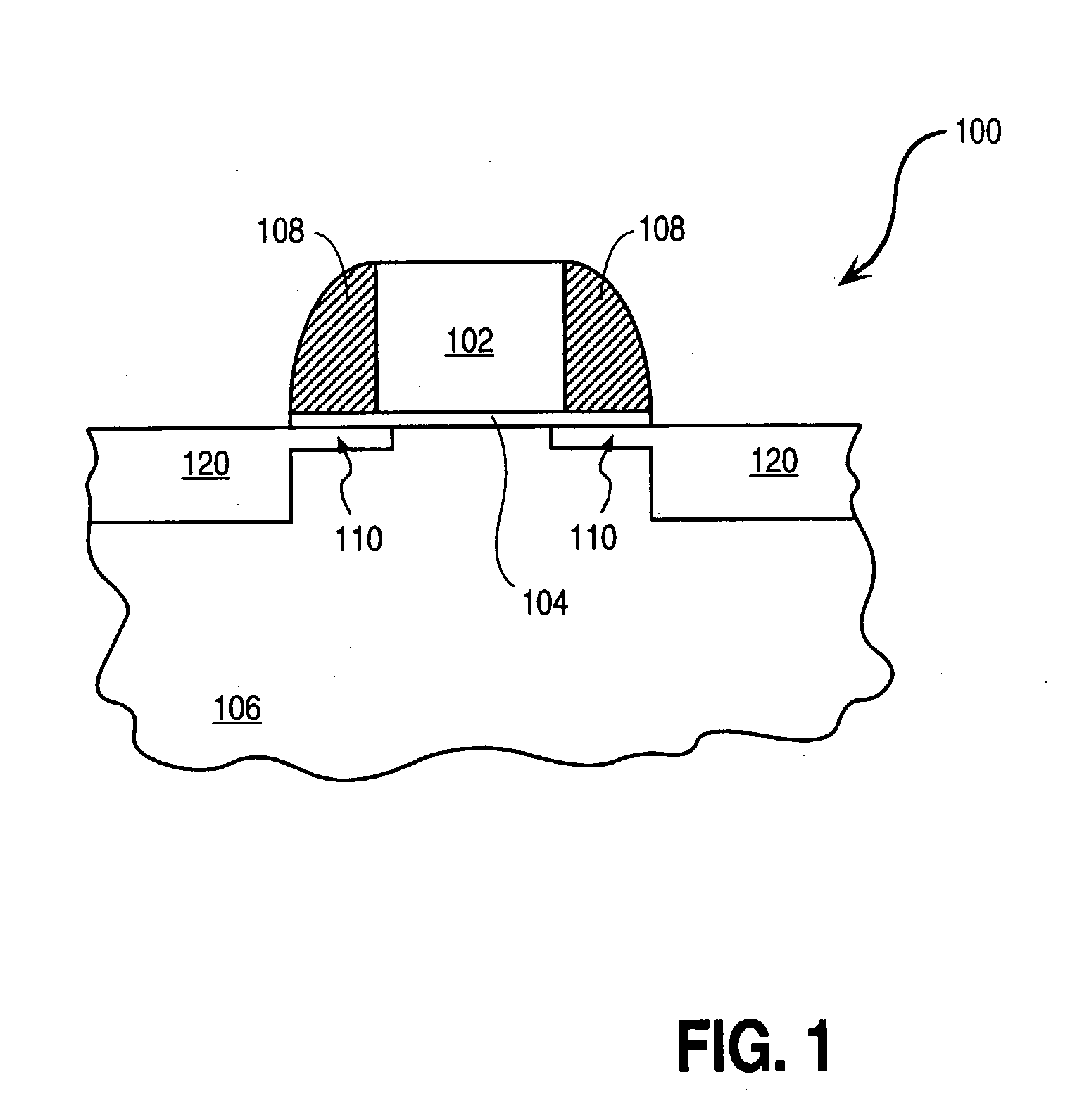

Semiconductor device having deposited silicon regions and a method of fabrication

InactiveUS6235568B1Semiconductor/solid-state device manufacturingSemiconductor devicesThin oxideSilicon alloy

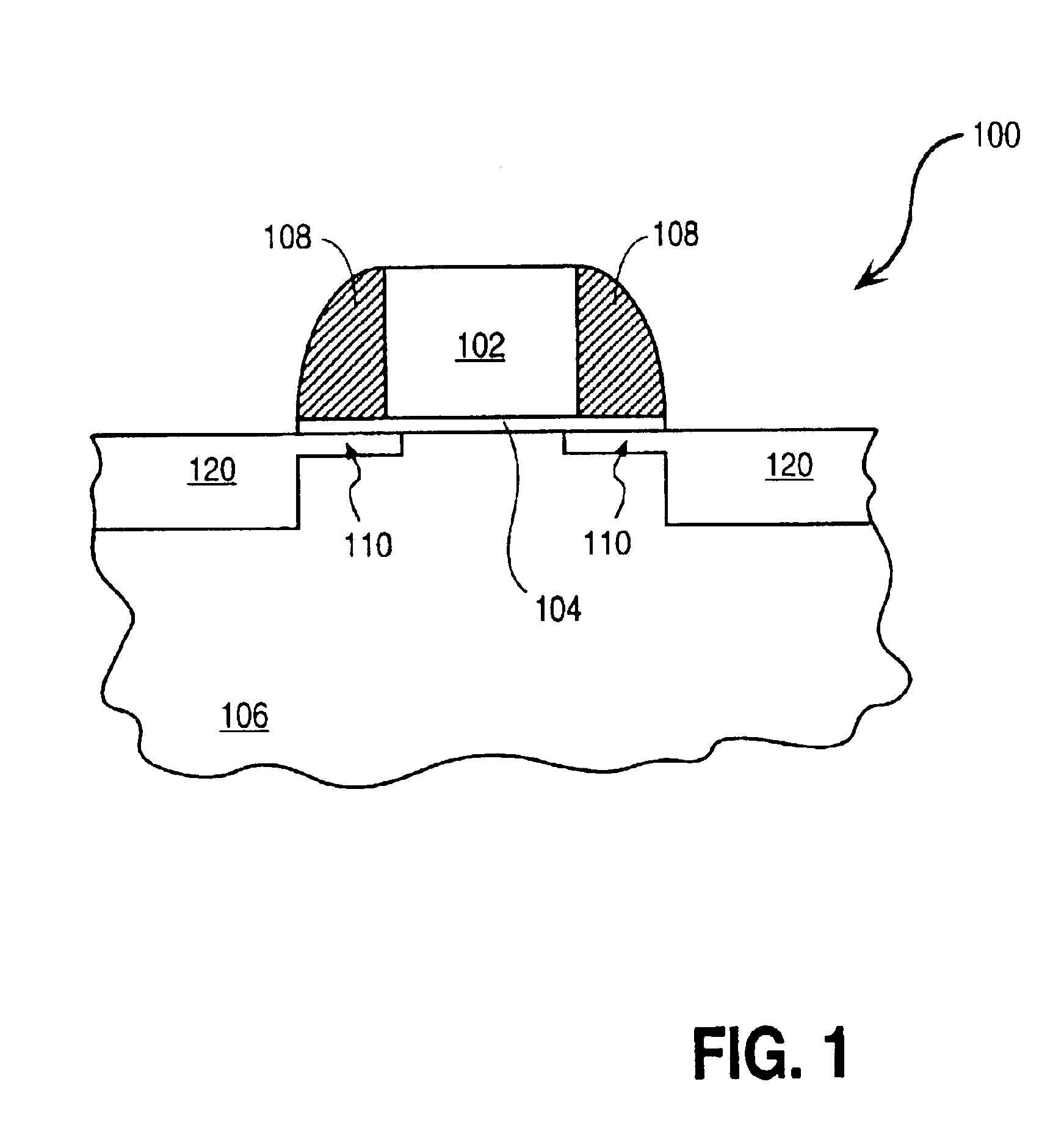

The present invention describes an MOS device having deposited silicon regions and its a method of fabrication. In one embodiment of the present invention a substrate having a thin oxide layer formed on a silicon surface is heated and exposed to an ambient comprising germane (GeH4) to remove the thin oxide from the silicon surface. A silicon or silicon alloy film can then be deposited onto the silicon surface of the substrate.

Owner:INTEL CORP

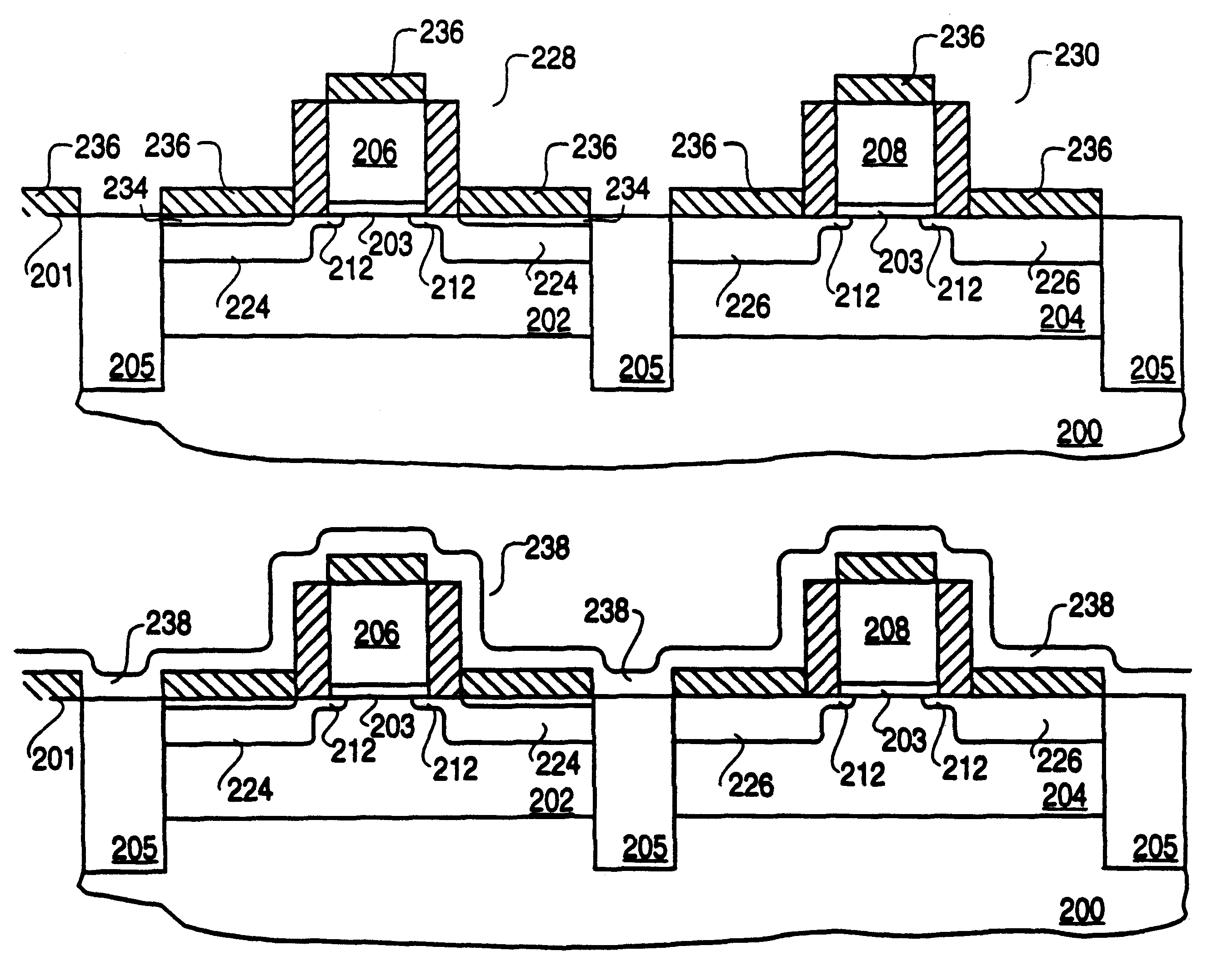

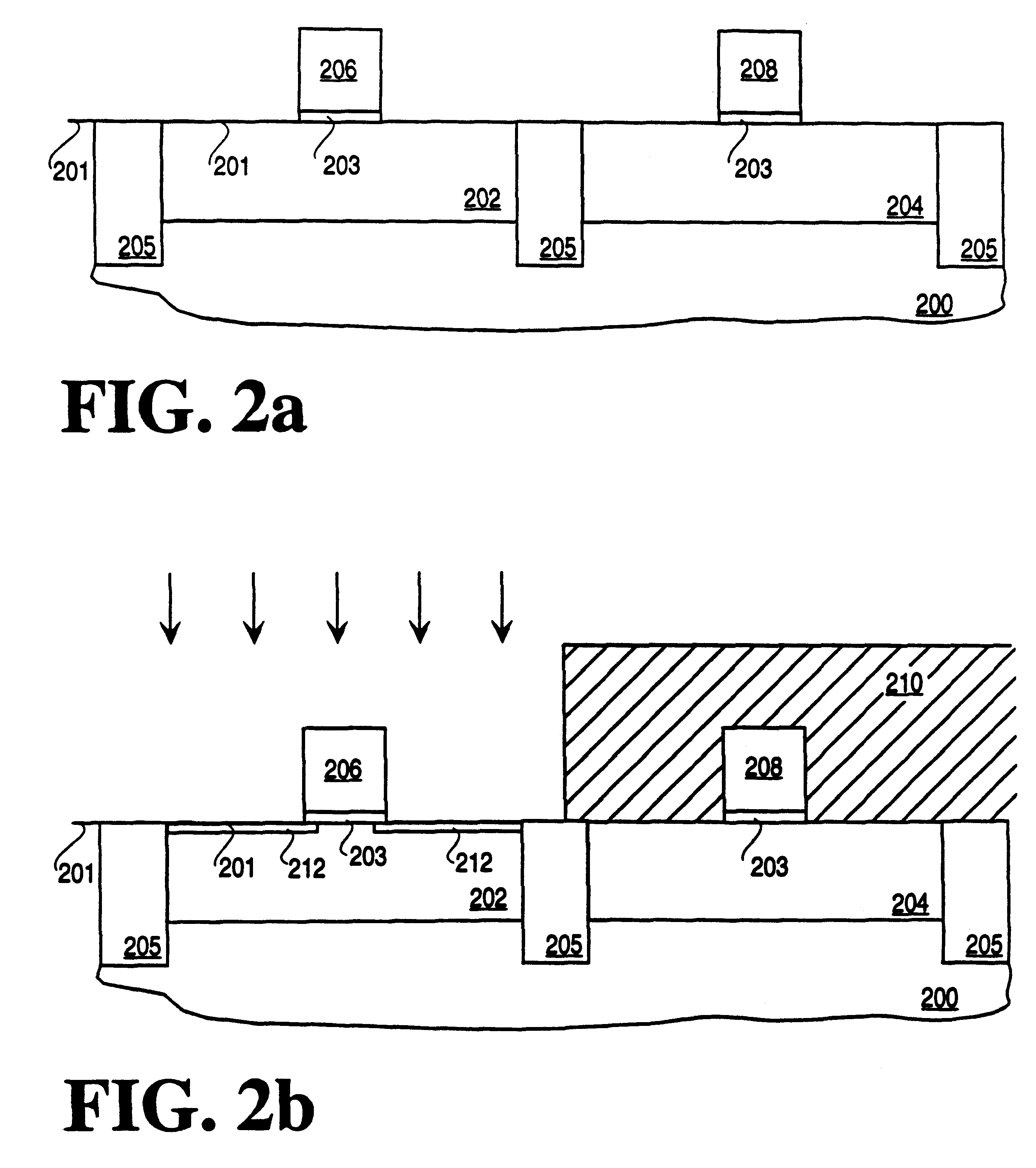

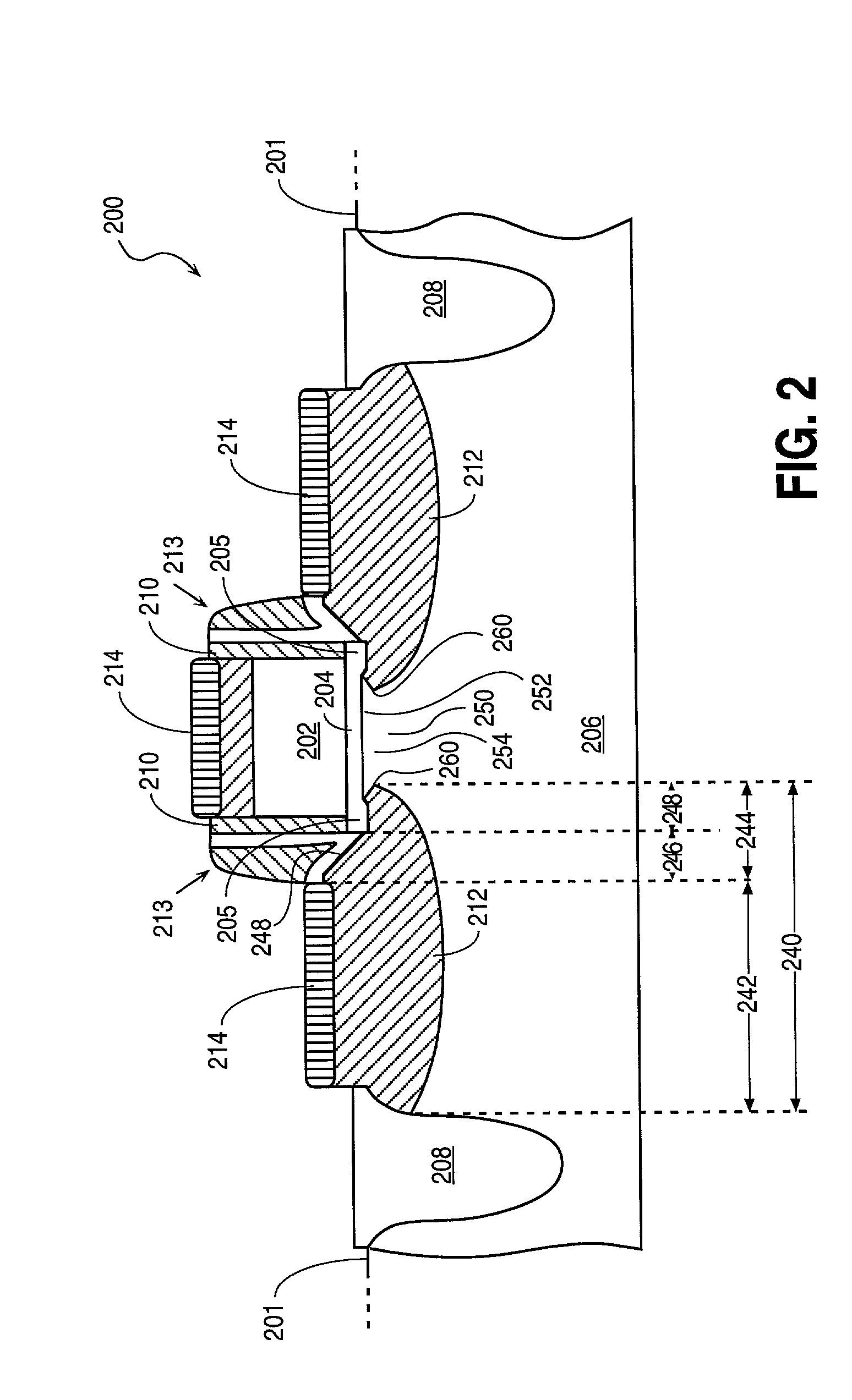

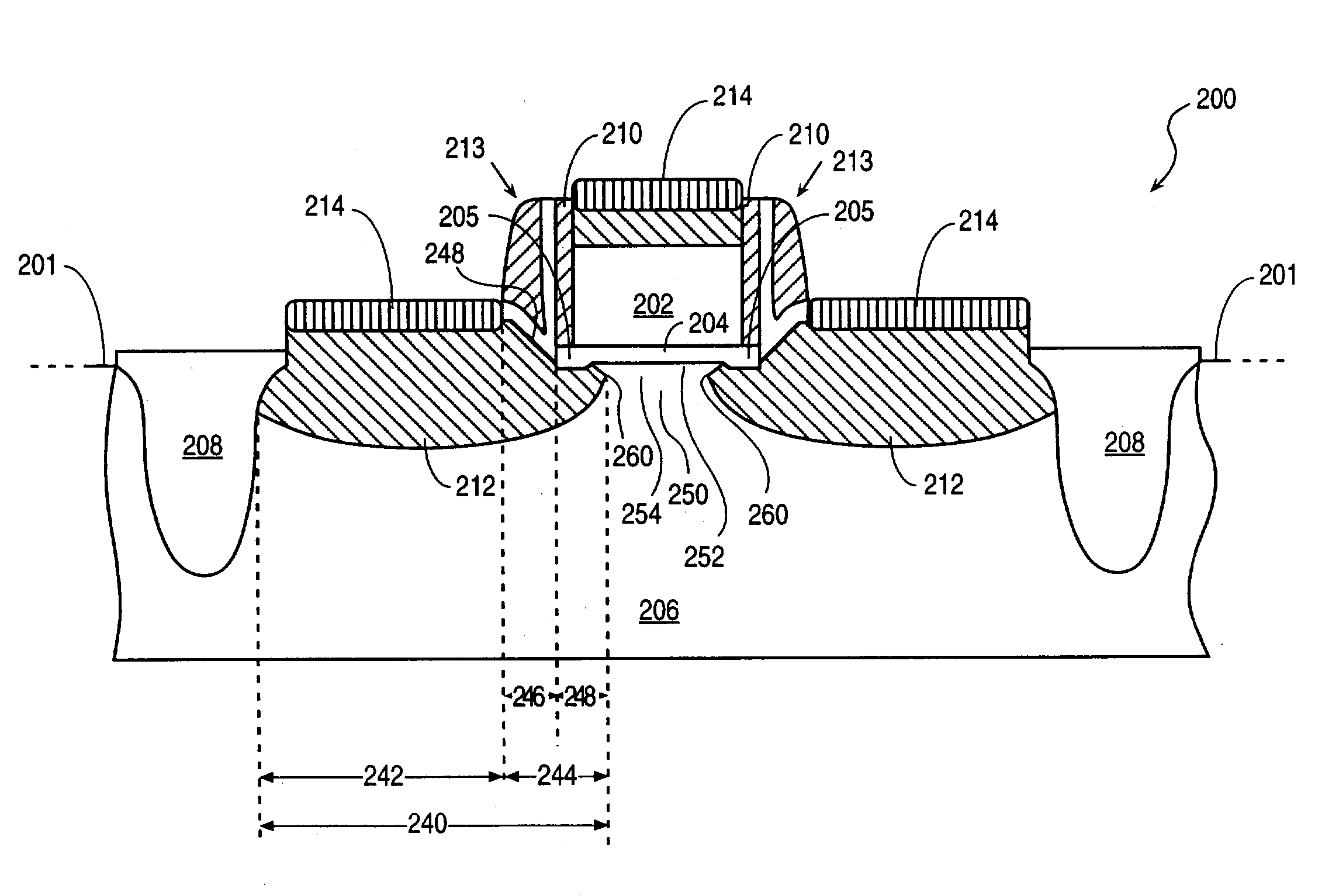

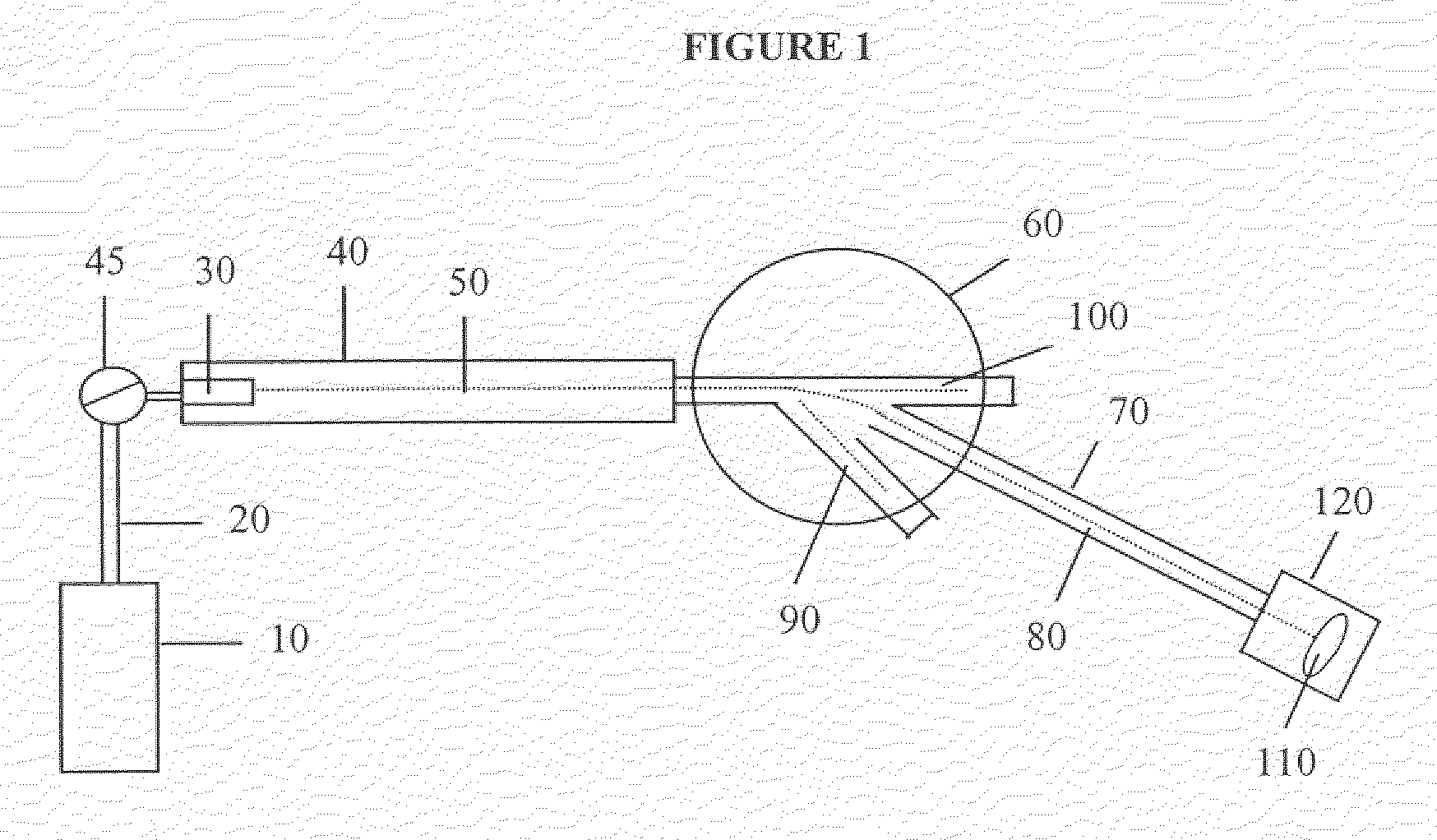

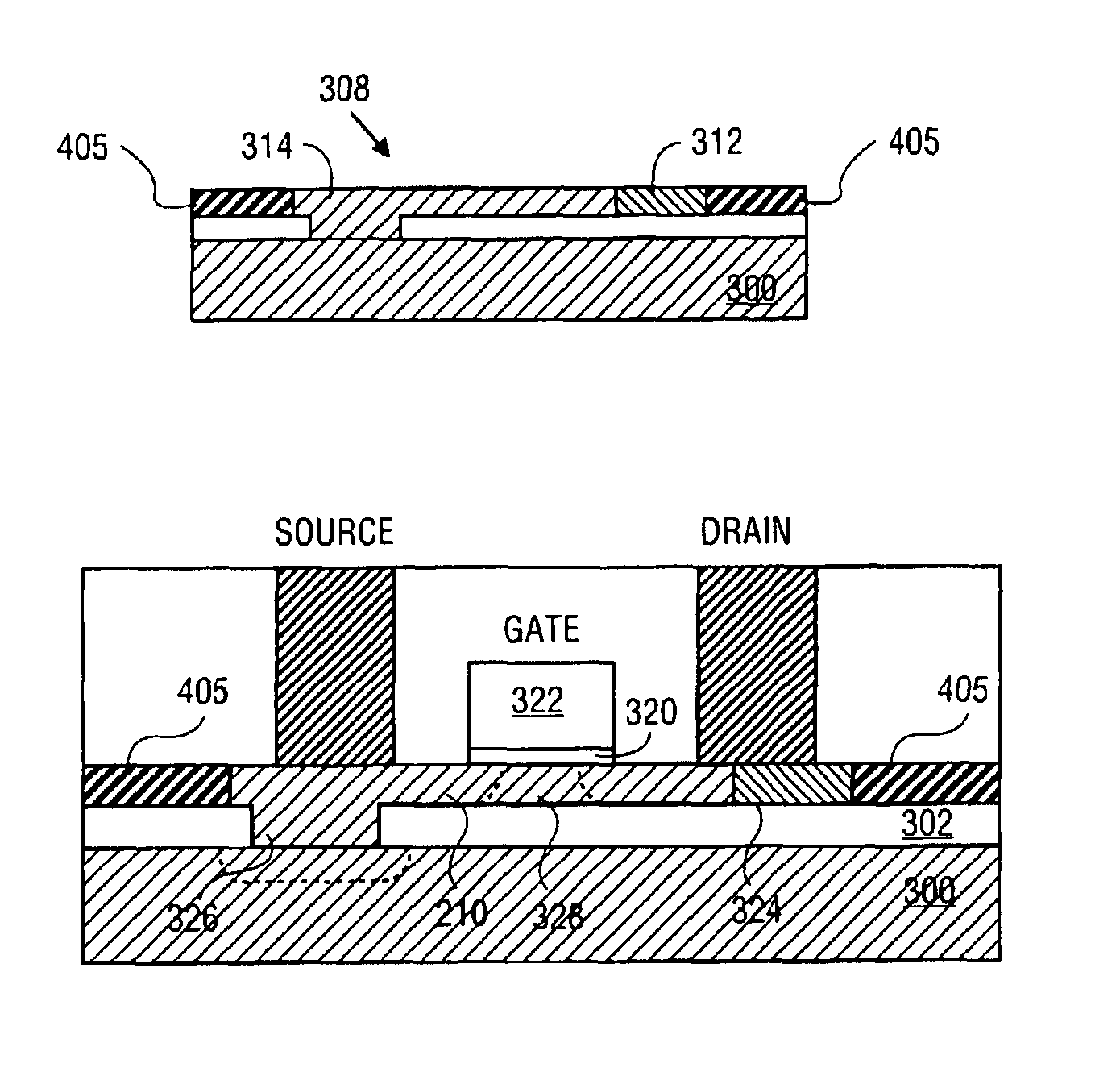

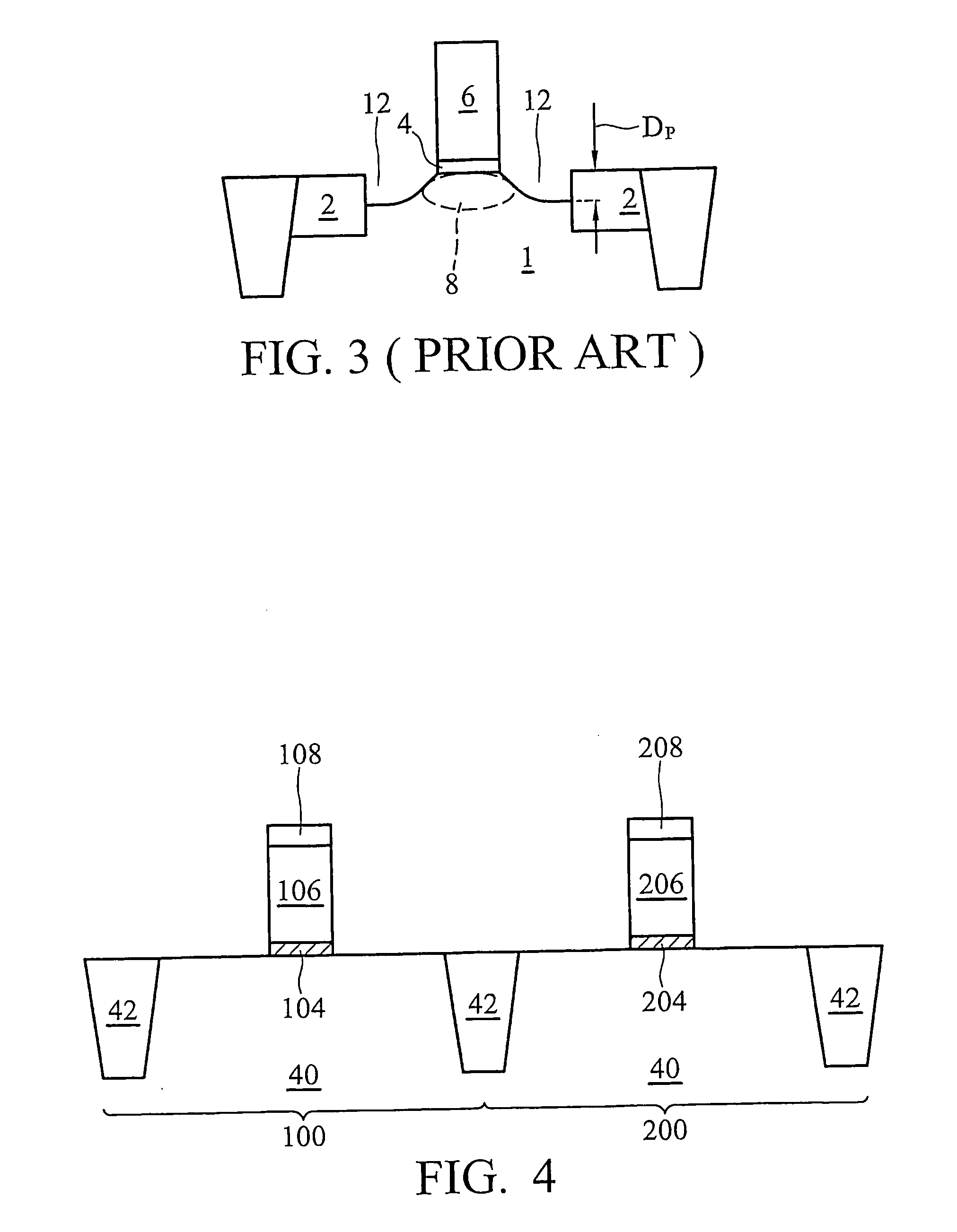

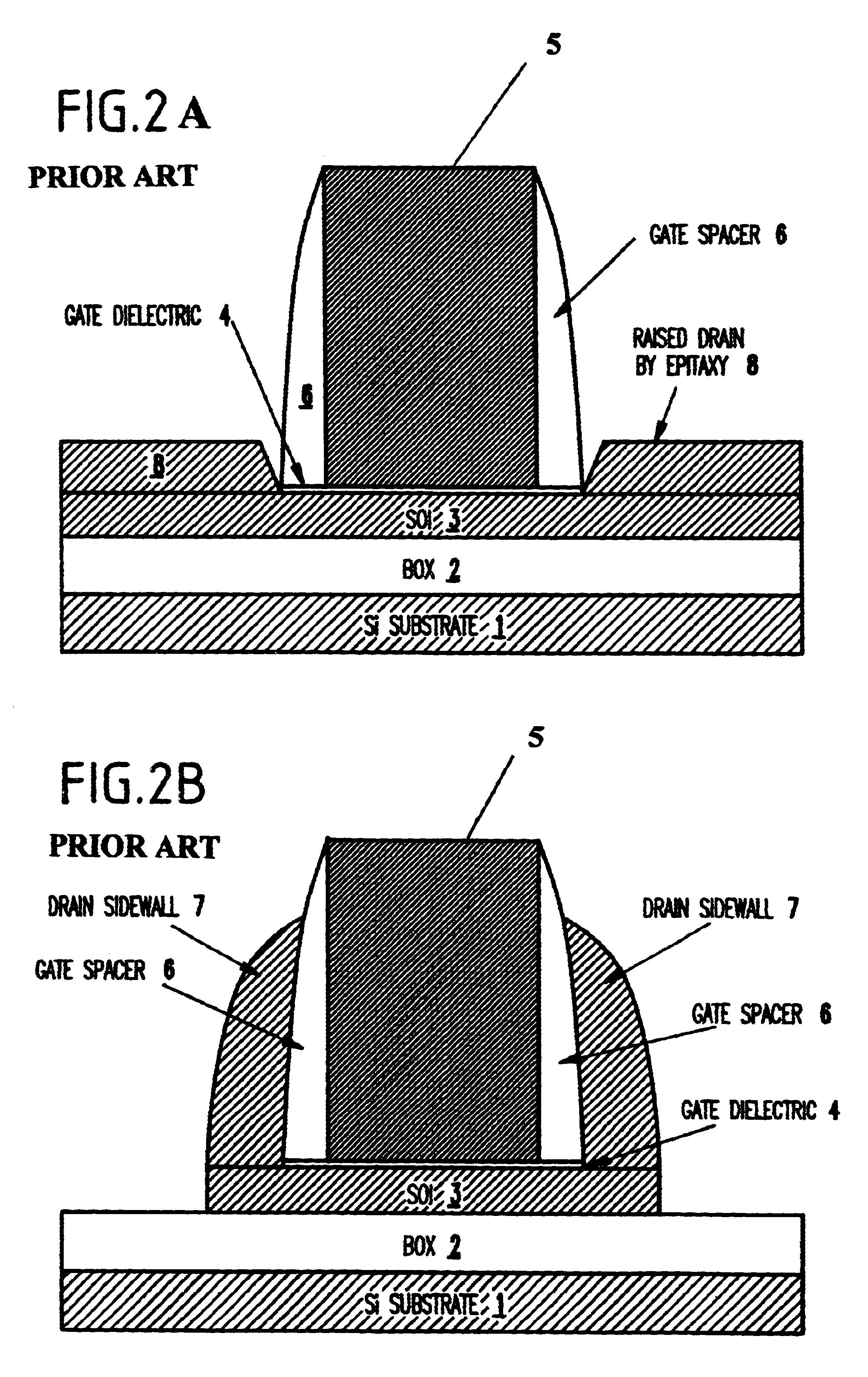

Novel mos transistor structure and method of fabrication

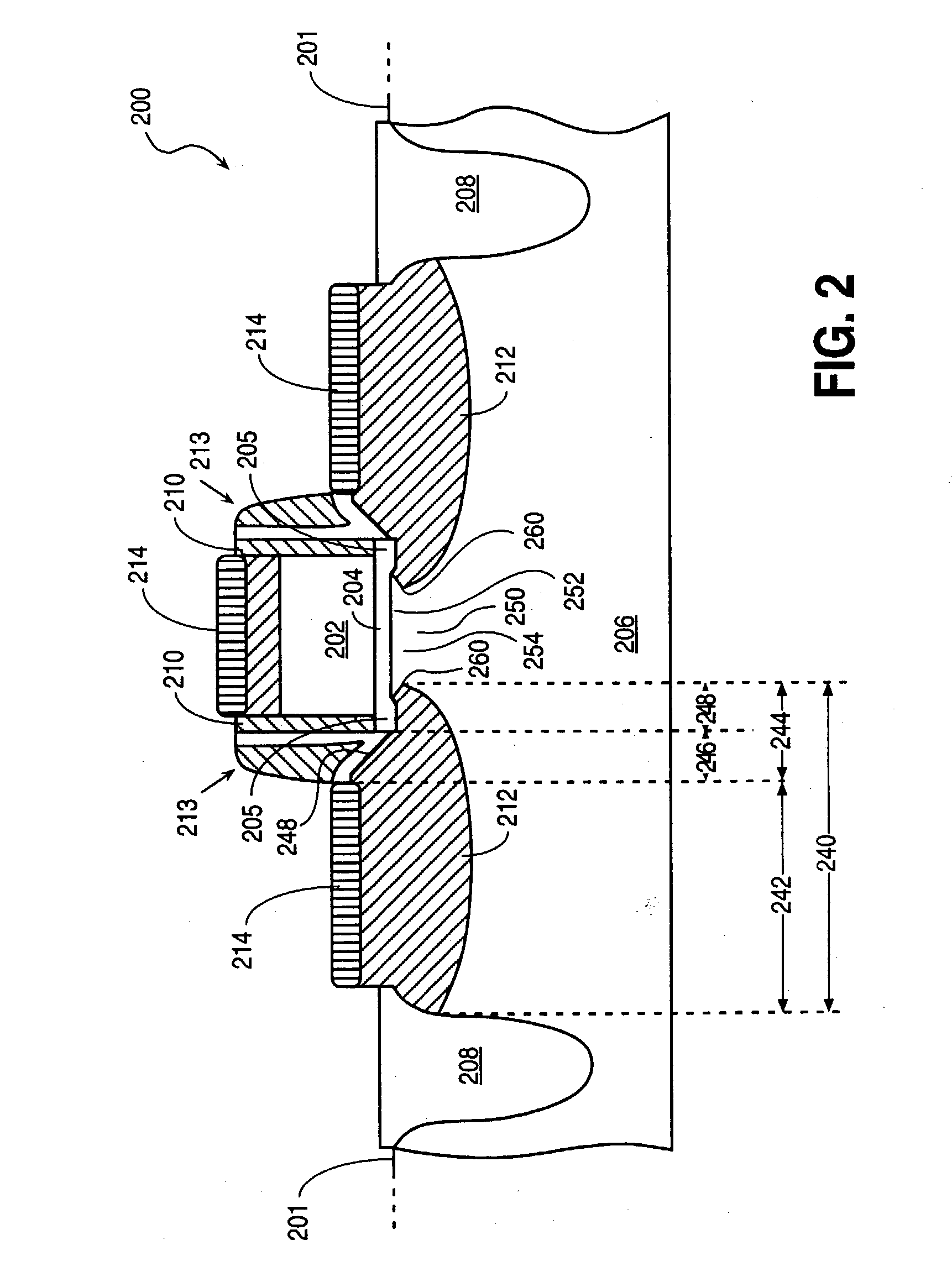

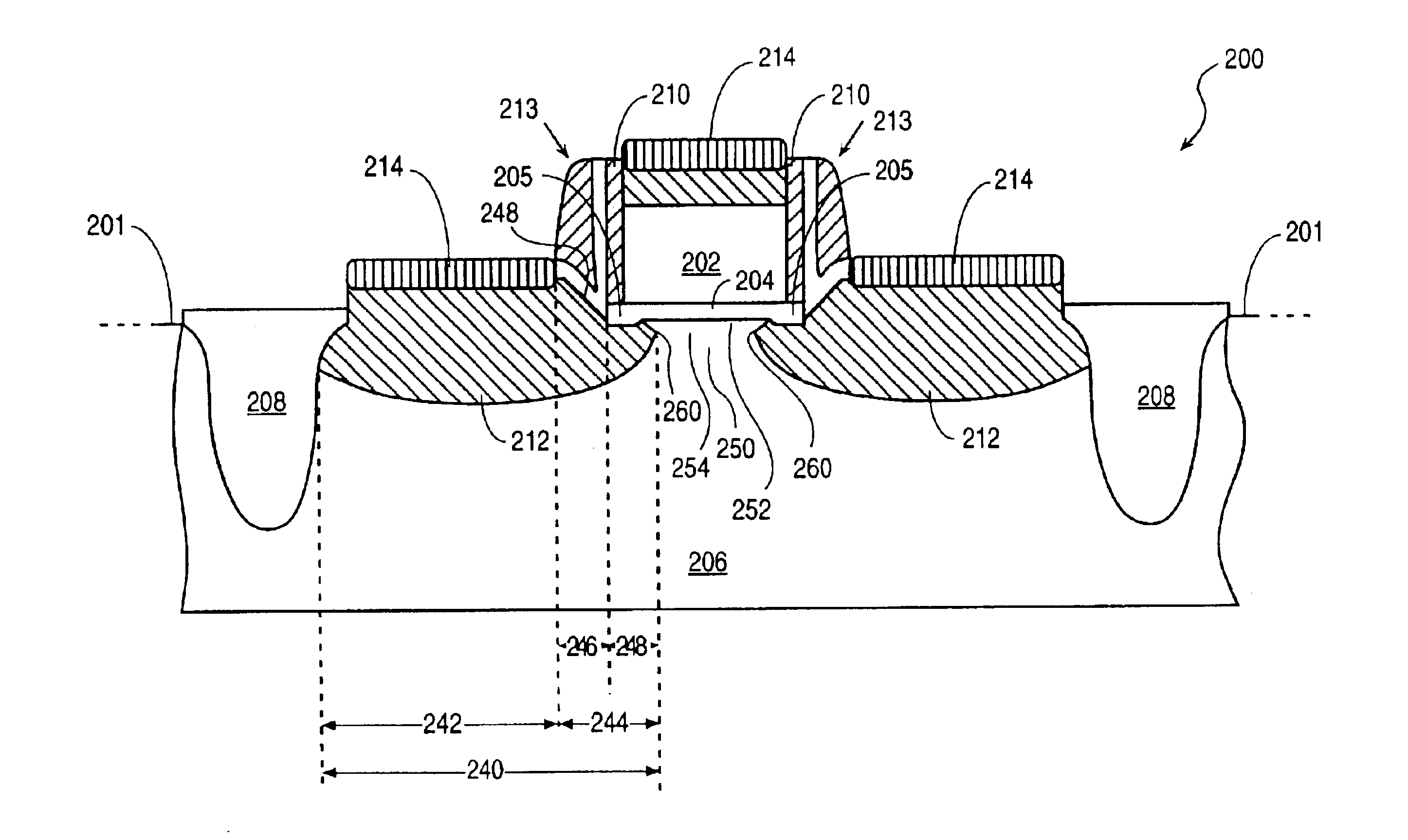

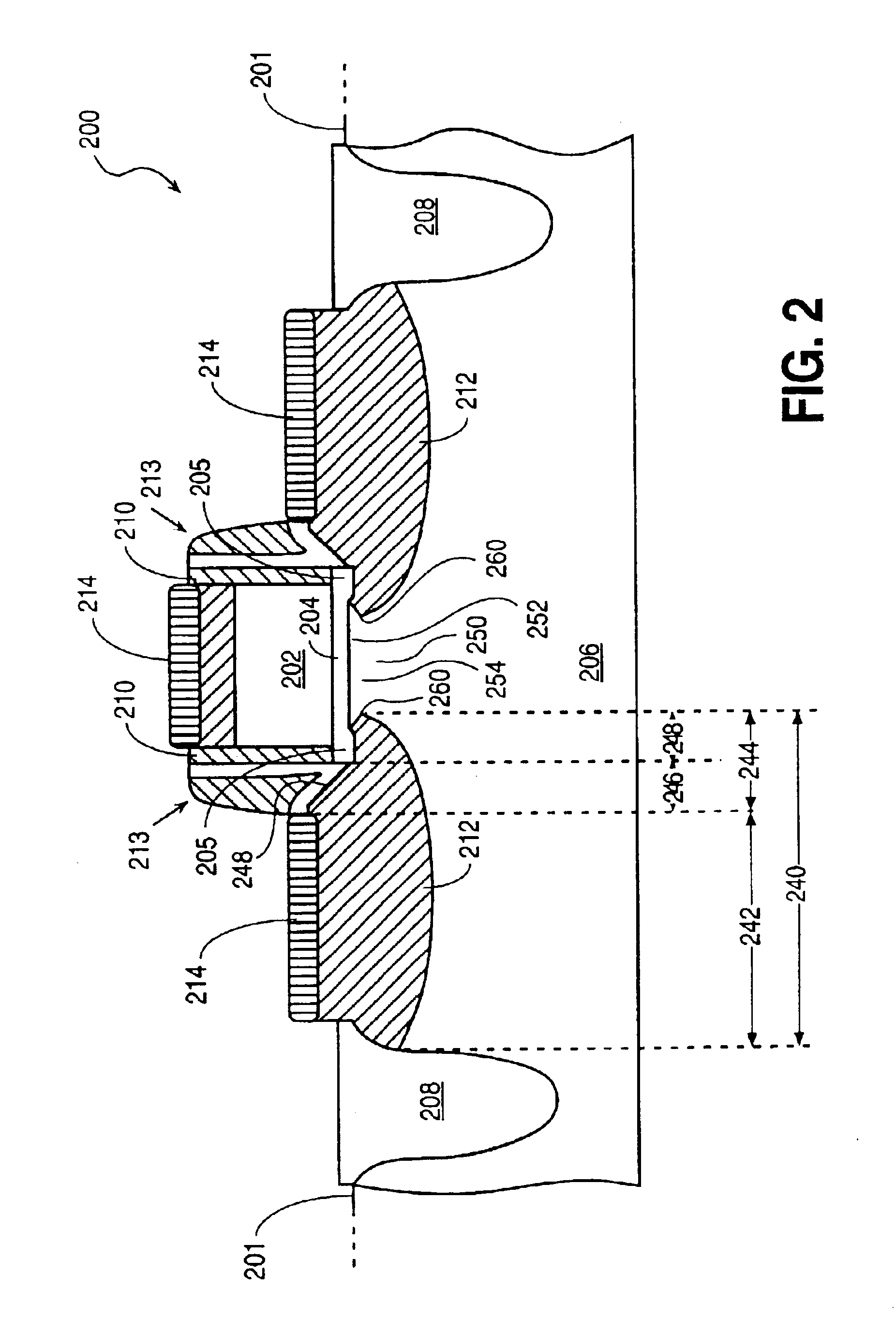

An MOS device comprising a gate dielectric formed on a first conductivity type region. A gate electrode formed on the gate dielectric. A pair of sidewall spacers are formed along laterally opposite sidewalls of the gate electrode. A pair of deposited silicon or silicon alloy source / drain regions are formed in the first conductivity region and on opposite sides of a gate electrode wherein the silicon or silicon alloy source / drain regions extend beneath the gate electrode and to define a channel region beneath the gate electrode in the first conductivity type region wherein the channel region directly beneath the gate electrode is larger than the channel region deeper into said first conductivity type region.

Owner:INTEL CORP

Novel MOS transistor structure and method of fabrication

InactiveUS20030098479A1TransistorSemiconductor/solid-state device manufacturingGate dielectricSilicon alloy

An MOS device comprising a gate dielectric formed on a first conductivity type region. A gate electrode formed on the gate dielectric. A pair of sidewall spacers are formed along laterally opposite sidewalls of the gate electrode. A pair of deposited silicon or silicon alloy source / drain regions are formed in the first conductivity region and on opposite sides of a gate electrode wherein the silicon or silicon alloy source / drain regions extend beneath the gate electrode and to define a channel region beneath the gate electrode in the first conductivity type region wherein the channel region directly beneath the gate electrode is larger than the channel region deeper into said first conductivity type region.

Owner:INTEL CORP

MOS transistor structure and method of fabrication

InactiveUS6797556B2TransistorSemiconductor/solid-state device manufacturingGate dielectricSilicon alloy

An MOS device comprising a gate dielectric formed on a first conductivity type region. A gate electrode formed on the gate dielectric. A pair of sidewall spacers are formed along laterally opposite sidewalls of the gate electrode. A pair of deposited silicon or silicon alloy source / drain regions are formed in the first conductivity region and on opposite sides of a gate electrode wherein the silicon or silicon alloy source / drain regions extend beneath the gate electrode and to define a channel region beneath the gate electrode in the first conductivity type region wherein the channel region directly beneath the gate electrode is larger than the channel region deeper into said first conductivity type region.

Owner:INTEL CORP

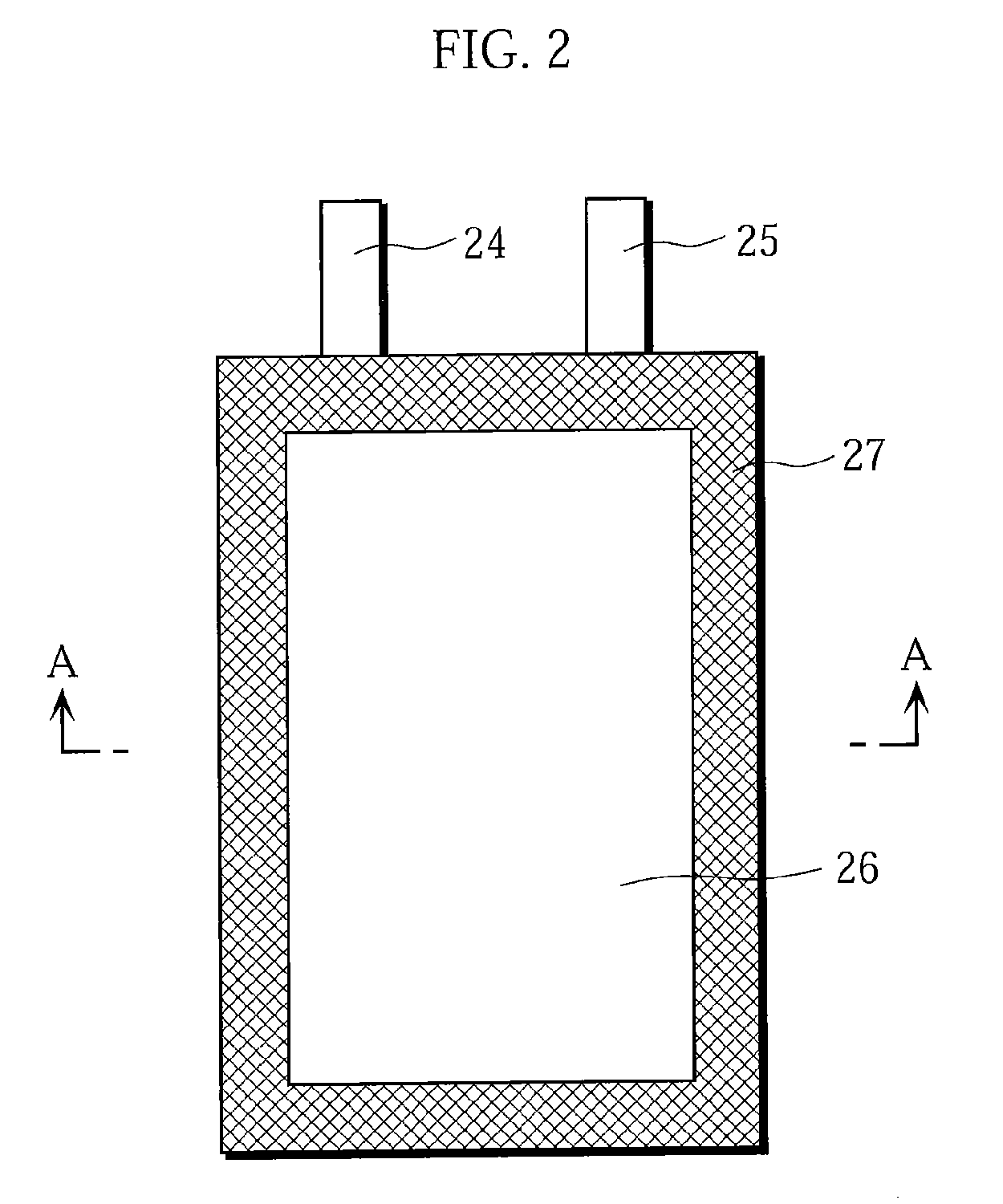

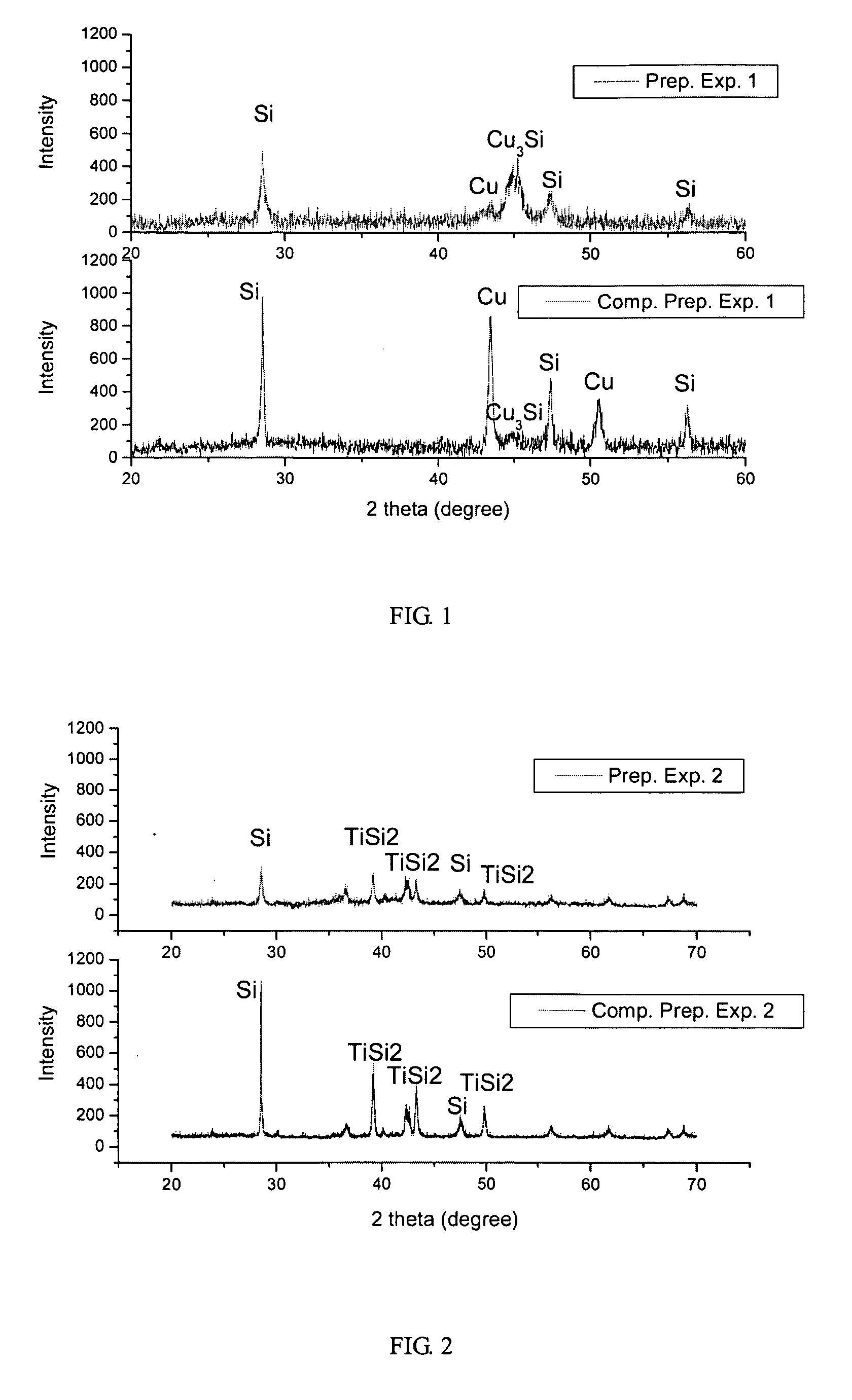

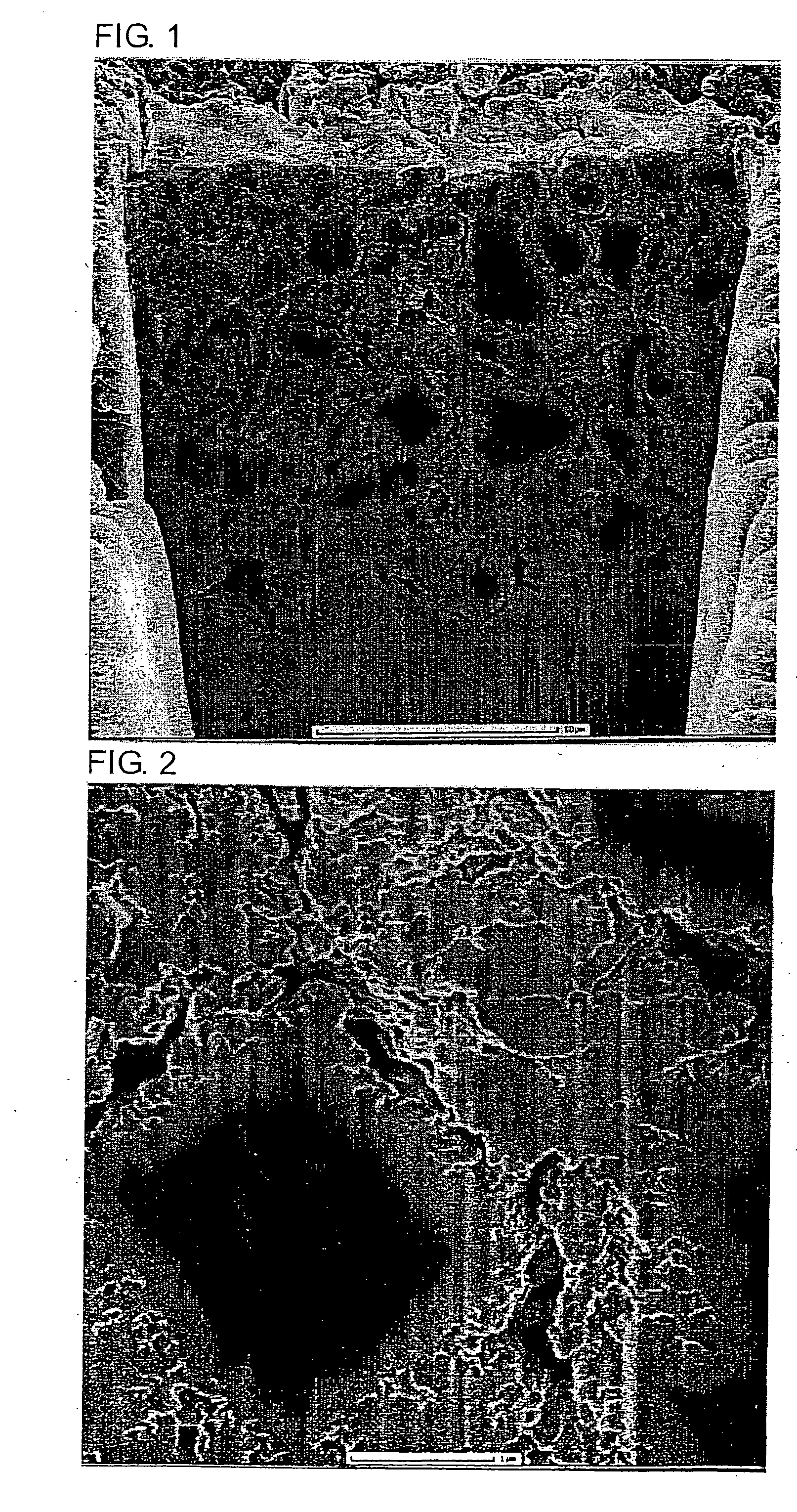

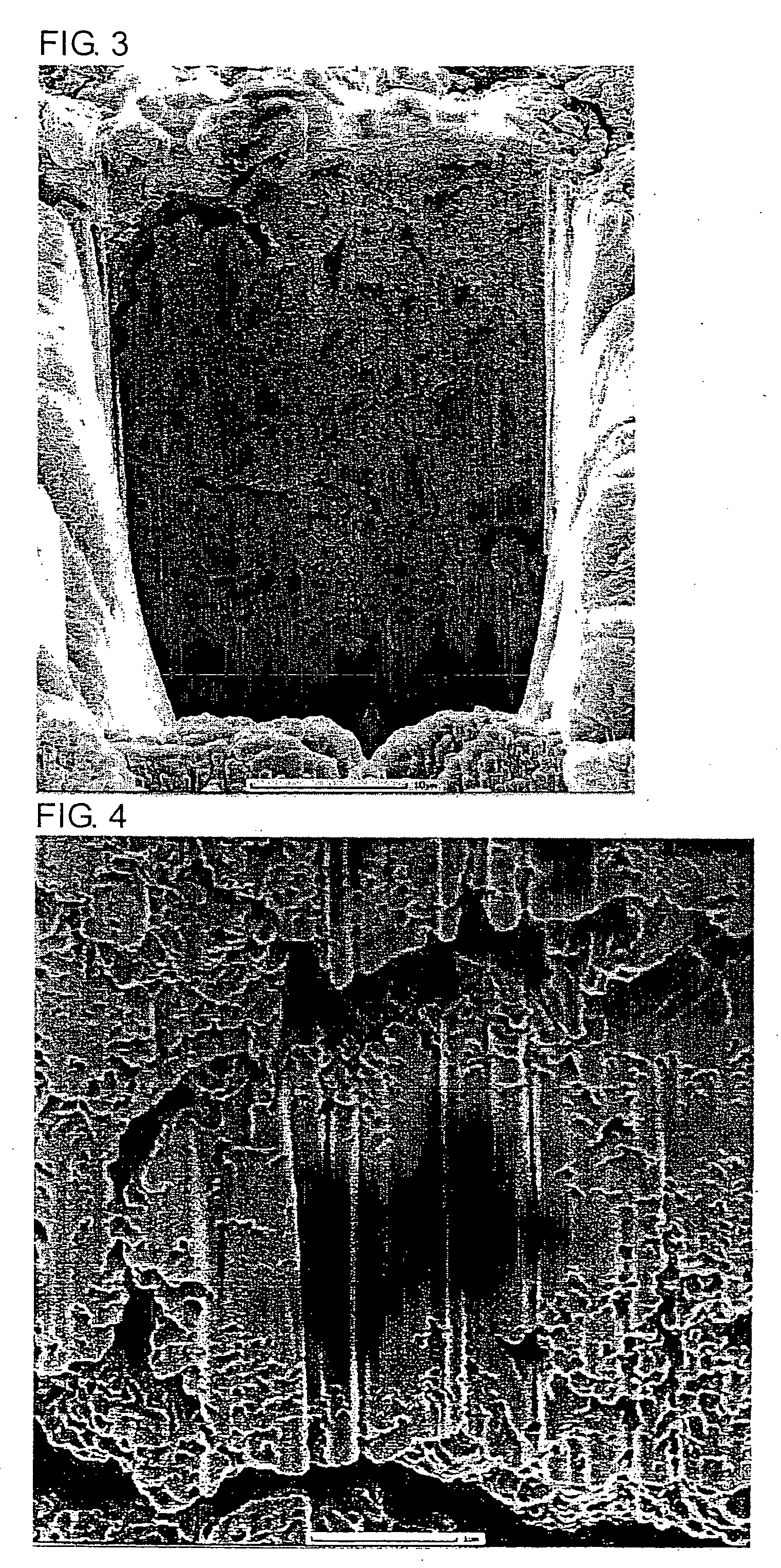

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

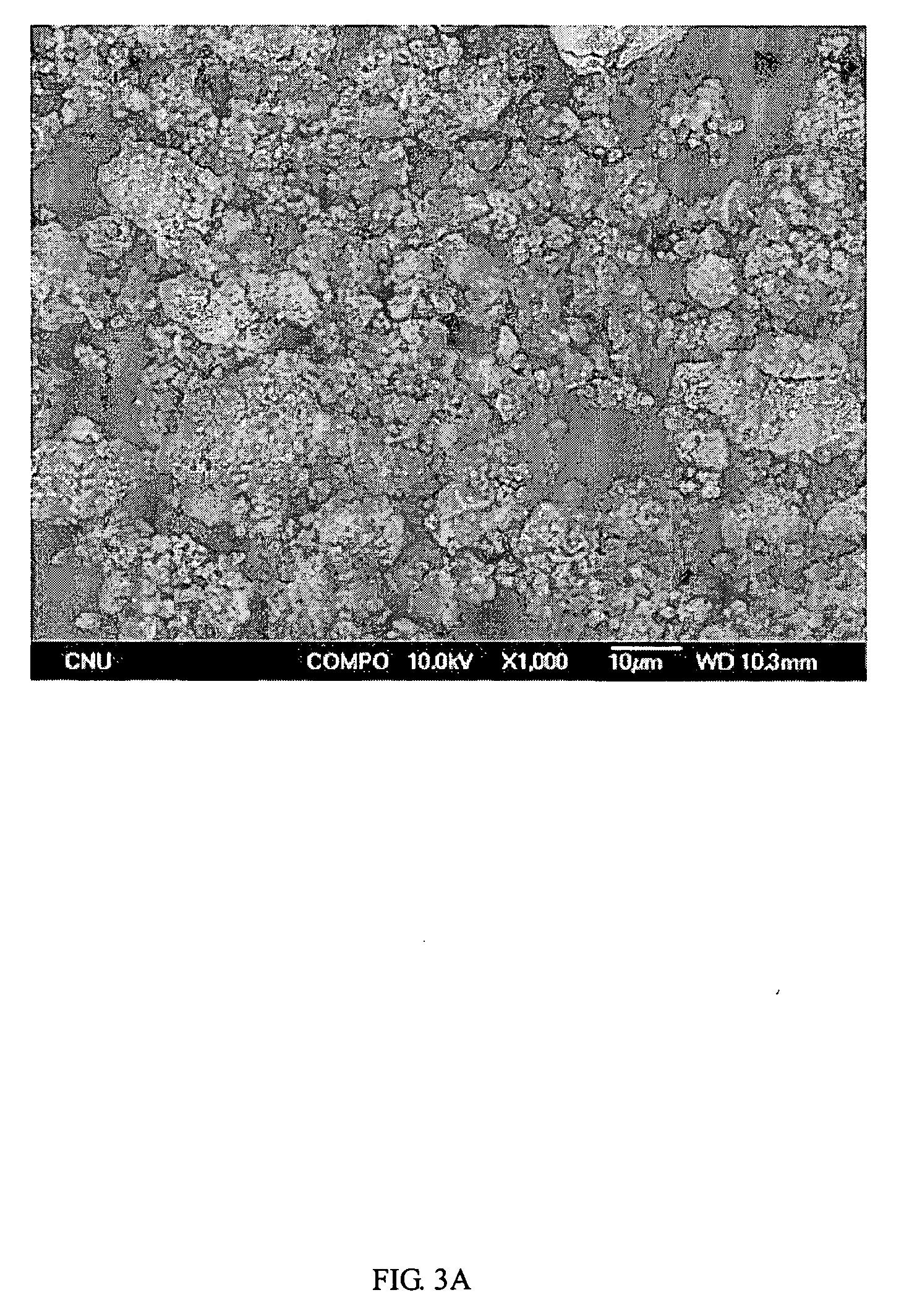

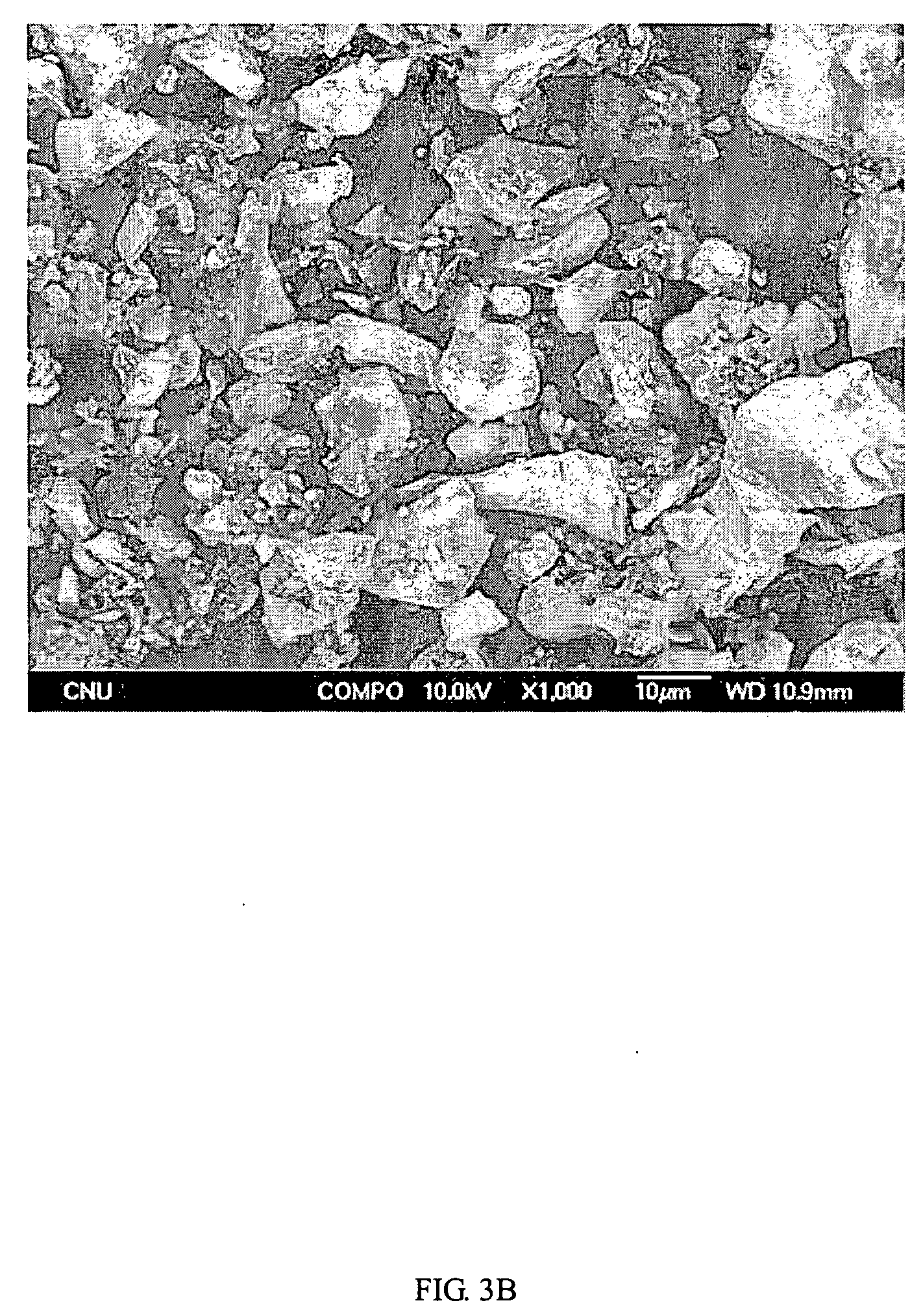

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

Lithium secondary battery

InactiveUS20090087731A1Improve charge-discharge cycle performanceCell electrodesSecondary cellsSilicon alloyComposite oxide

A lithium secondary battery includes: a positive electrode having a positive electrode active material layer disposed on a positive electrode current collector, the positive electrode active material layer containing a positive electrode binder and a positive electrode active material containing a layered lithium-transition metal composite oxide; a negative electrode having a negative electrode current collector and a negative electrode active material layer disposed on the negative electrode current collector, the negative electrode active material layer containing a negative electrode binder and a negative electrode active material containing particles of silicon and / or a silicon alloy; and a non-aqueous electrolyte. Al2O3 particles are firmly adhered to a surface of the lithium-transition metal composite oxide so that a BET specific surface area of the positive electrode active material after the adherence of the Al2O3 particles is from 1.5 times to 8 times greater than that before the adherence of the Al2O3 particles

Owner:SANYO ELECTRIC CO LTD

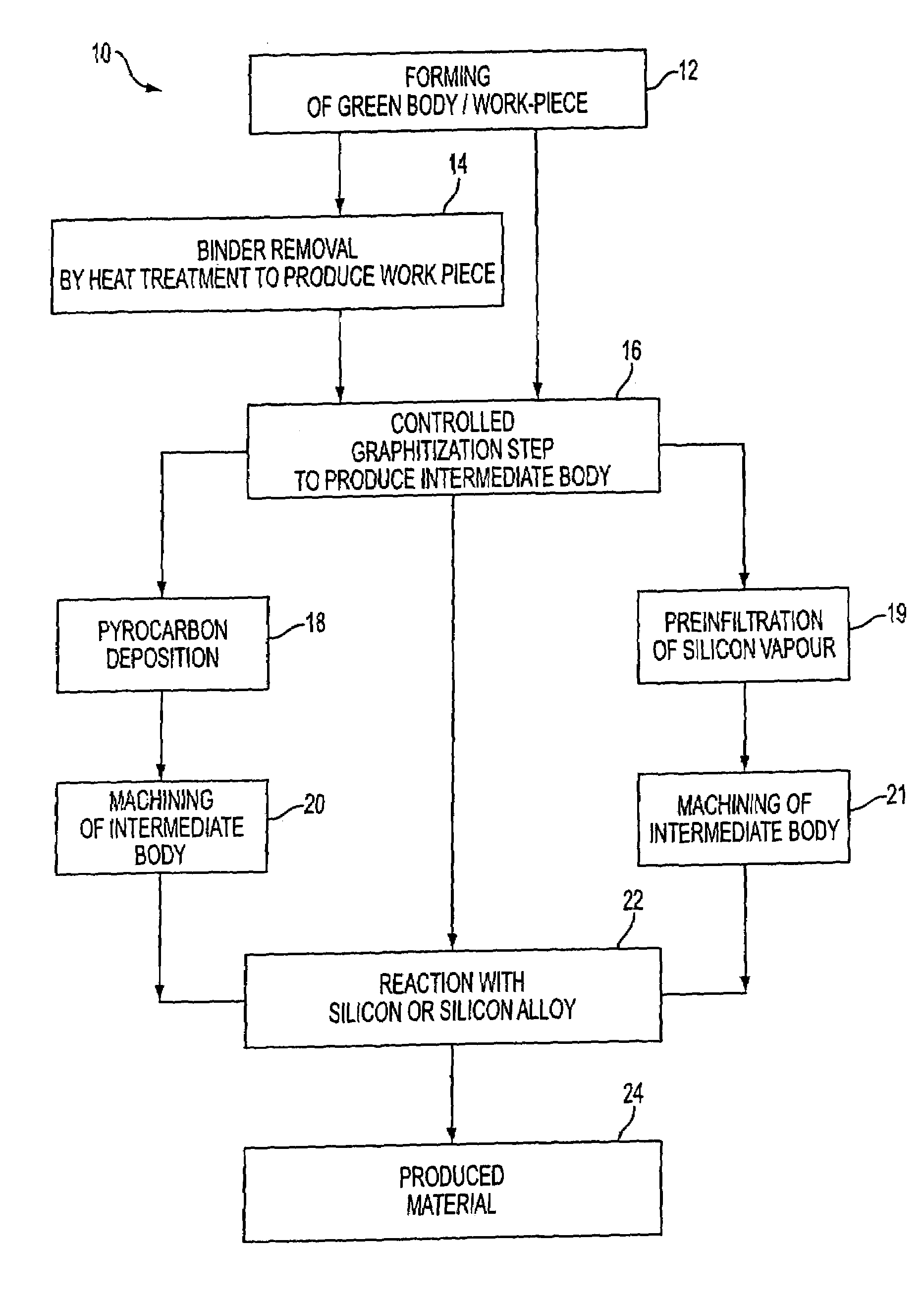

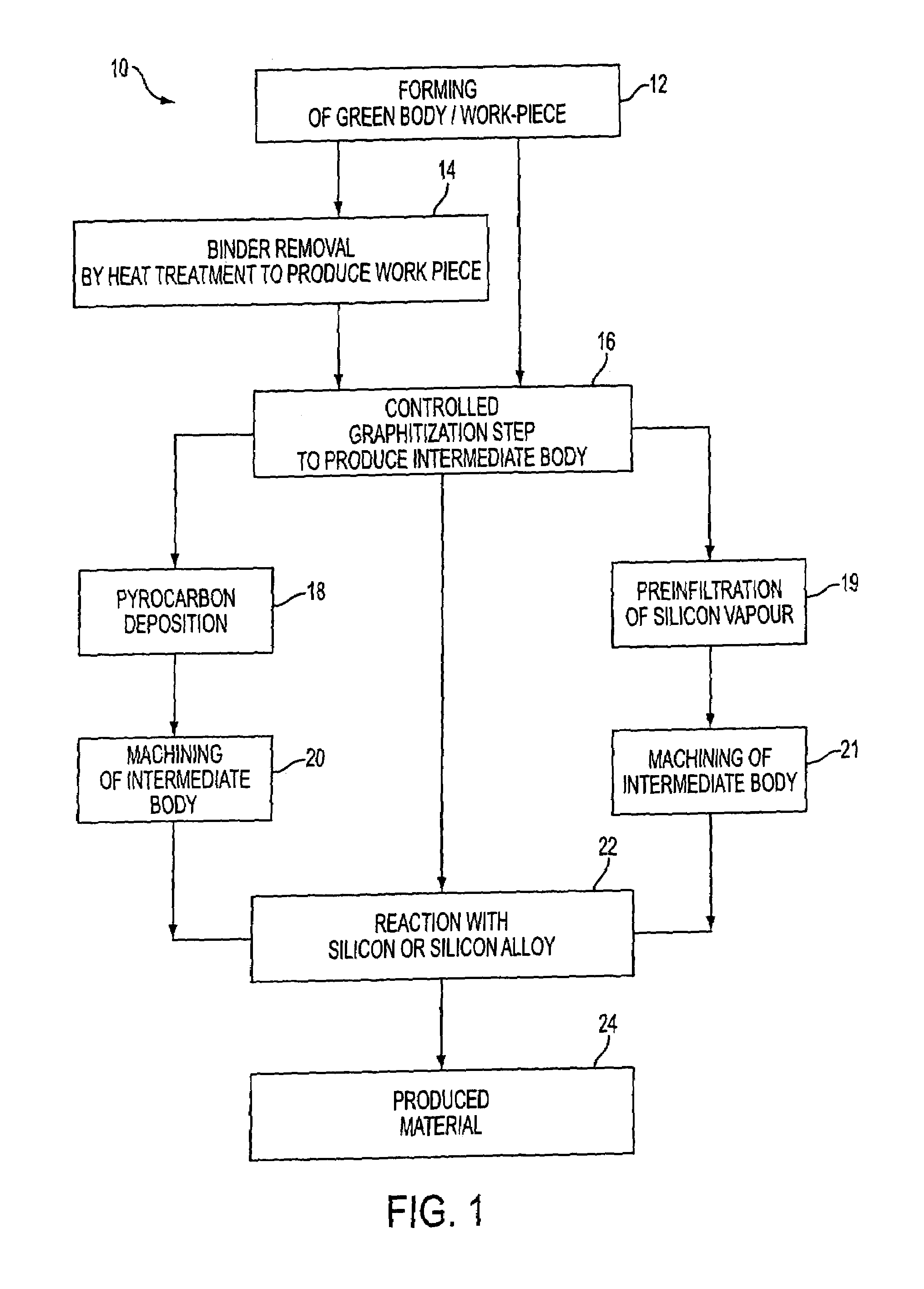

Method of manufacturing a diamond composite and a composite produced by same

InactiveUS7008672B2Simple production equipmentComplex shapeOther chemical processesNatural mineral layered productsHeating timeSilicon alloy

Owner:SKELETON TECH

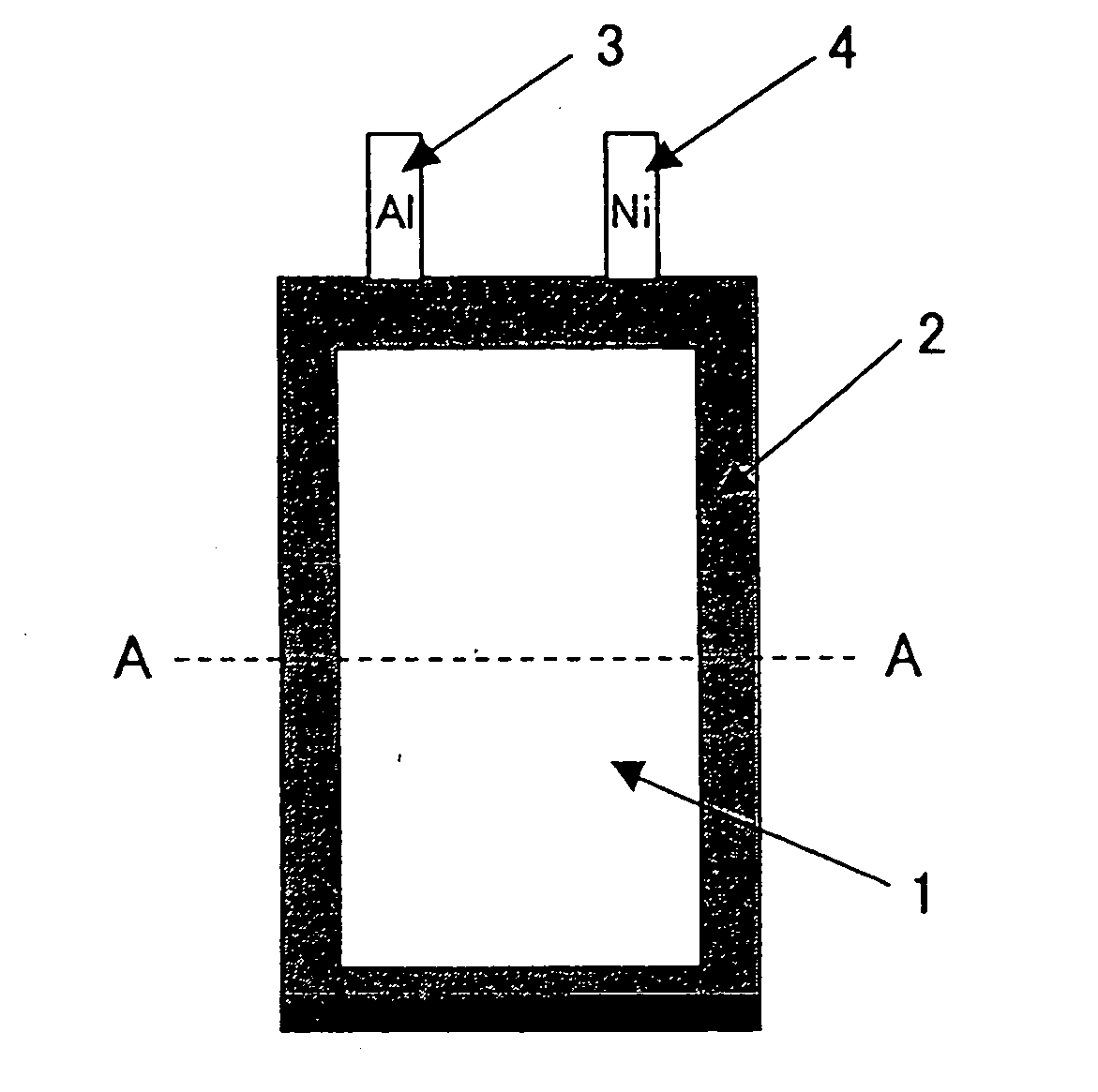

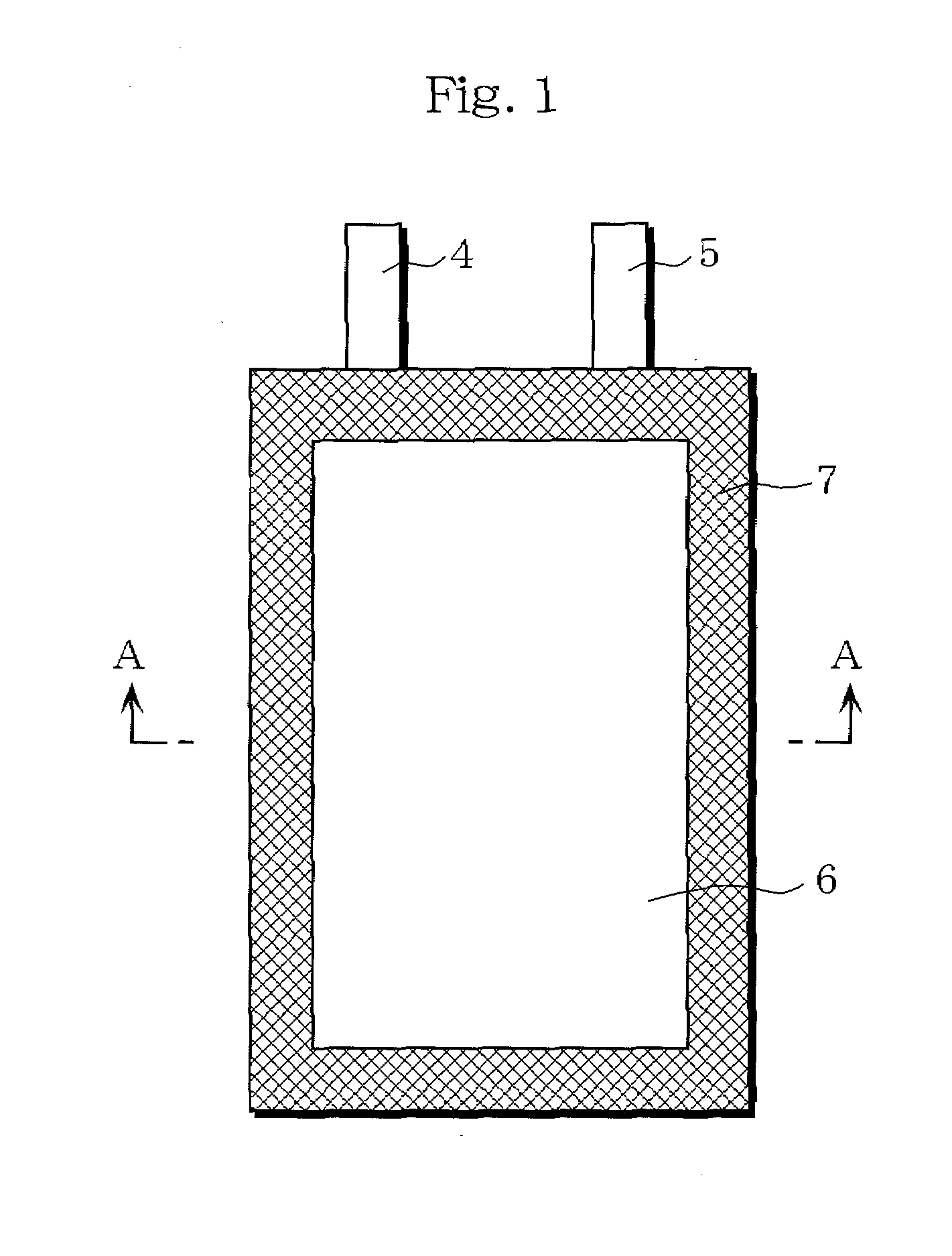

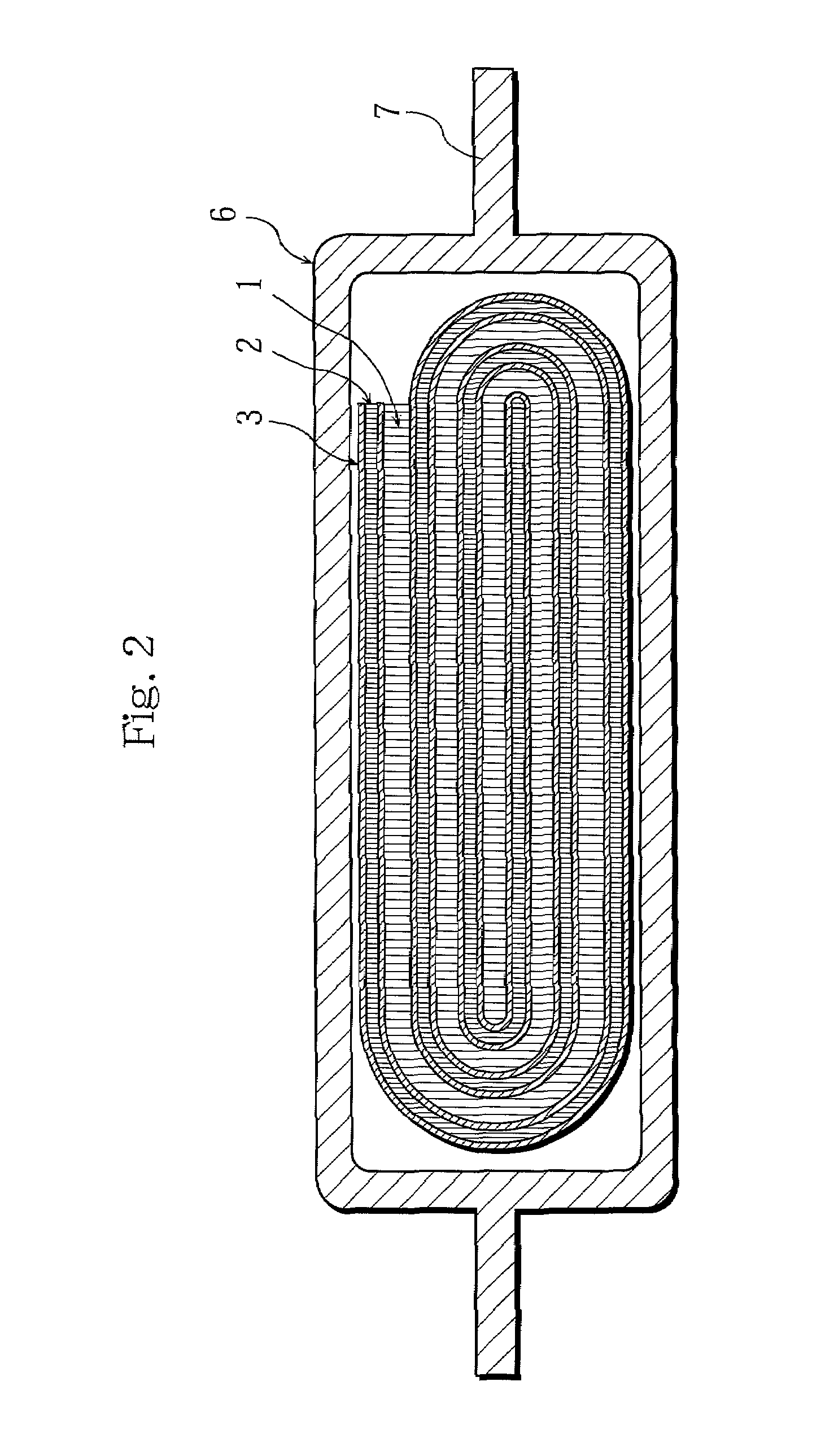

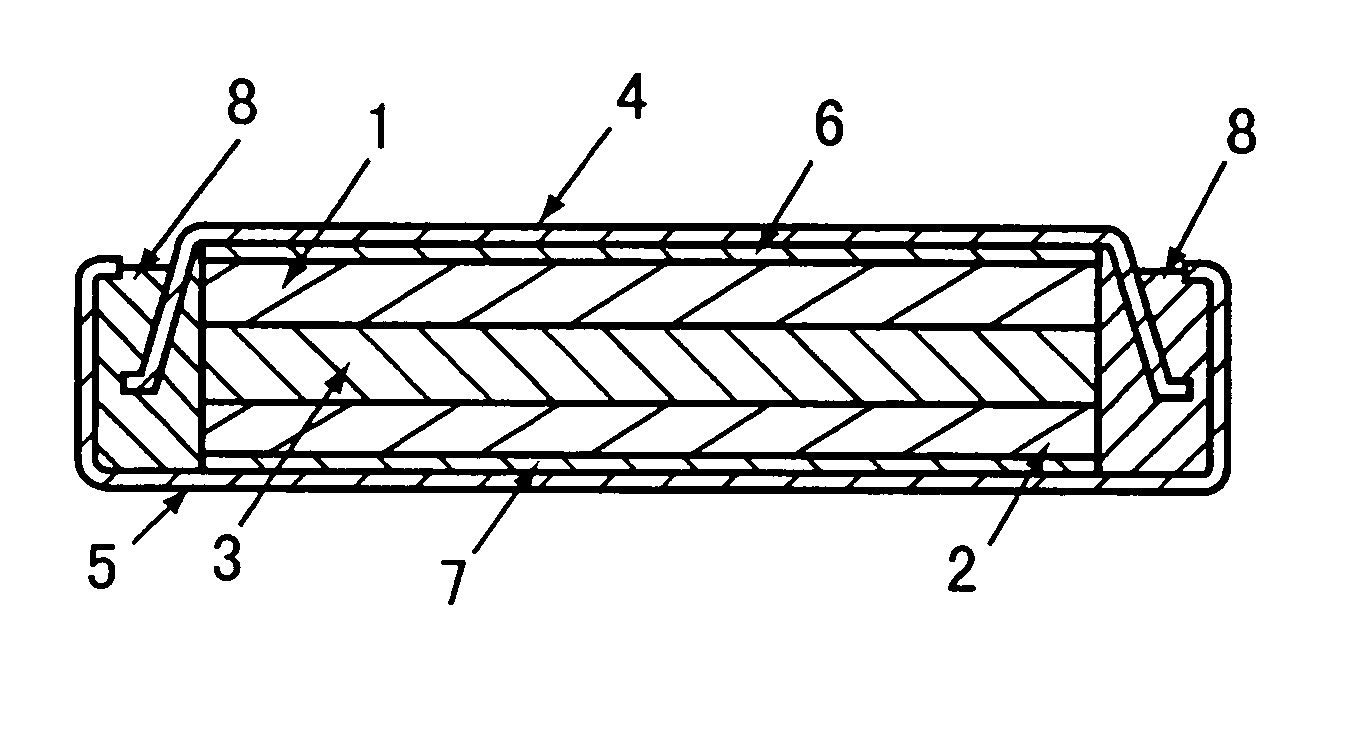

Lithium secondary battery and method of manufacturing the same

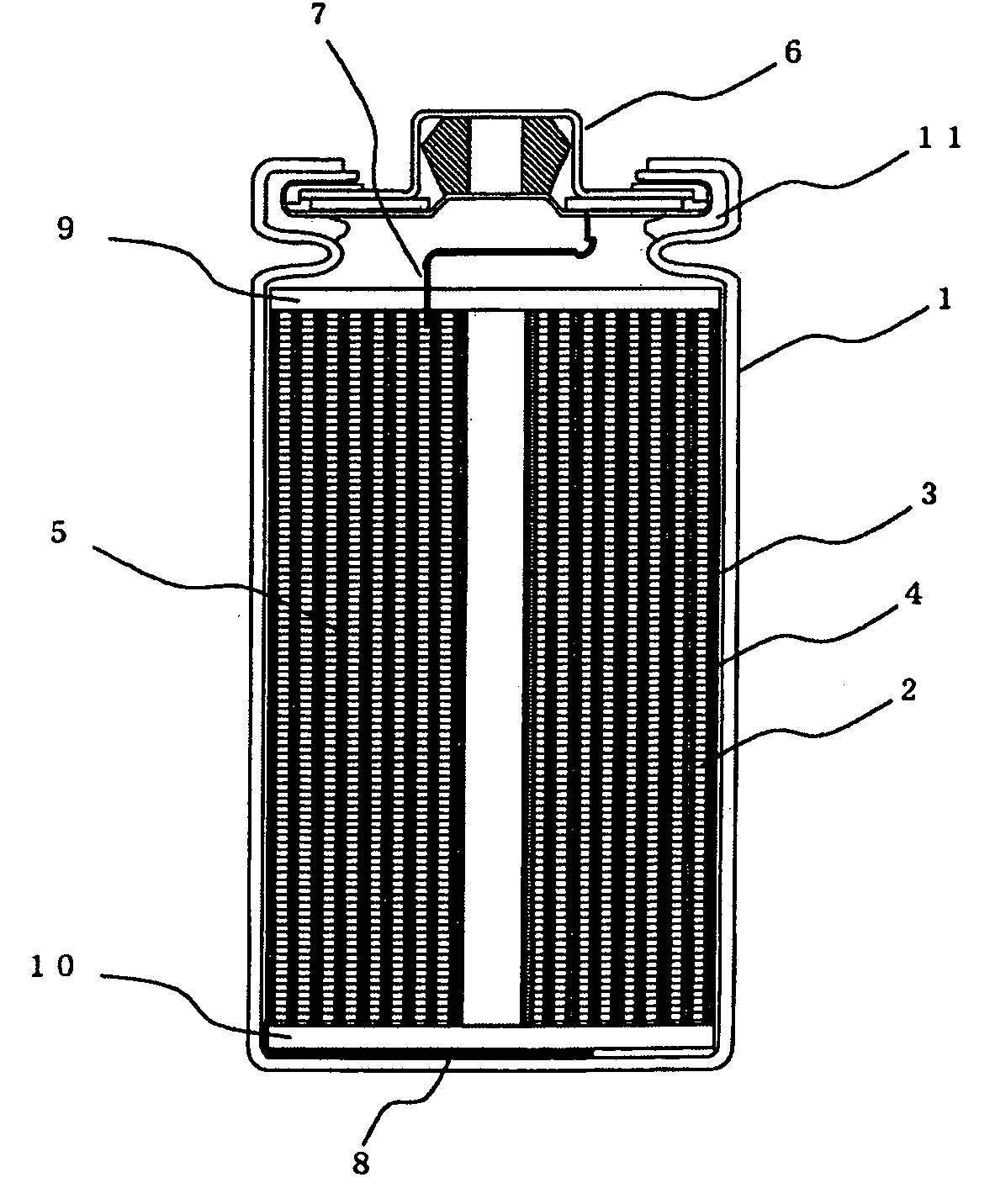

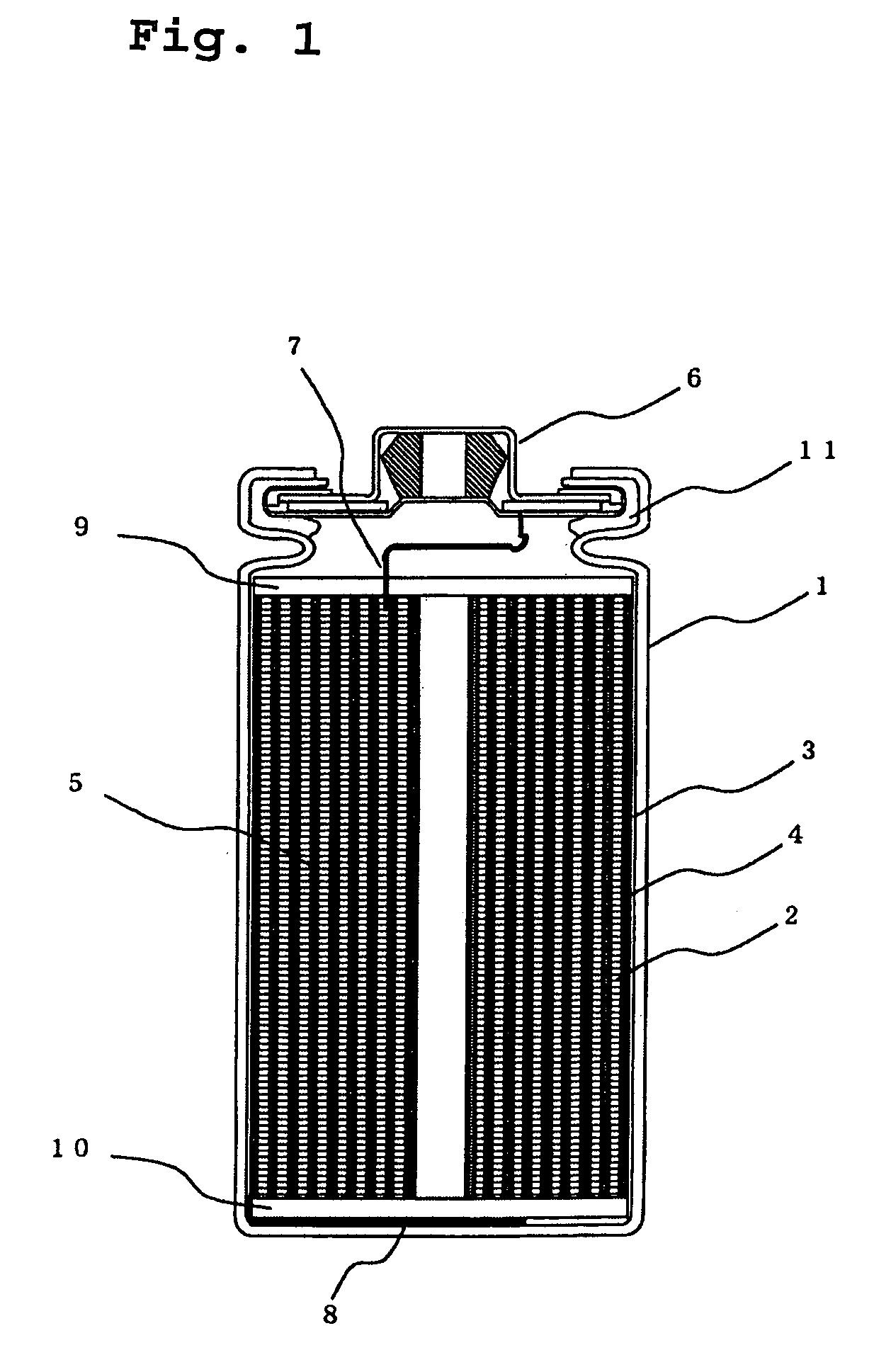

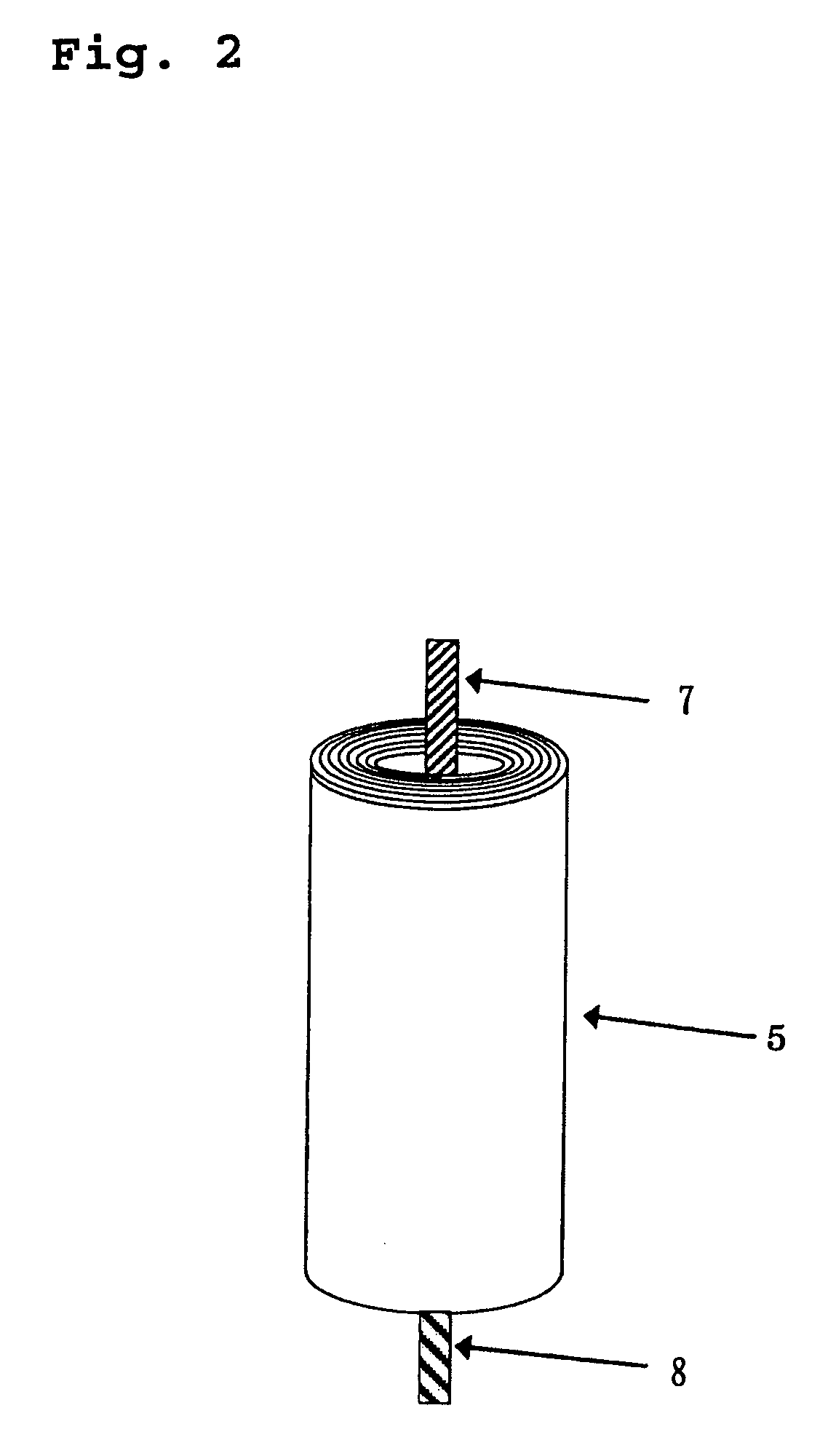

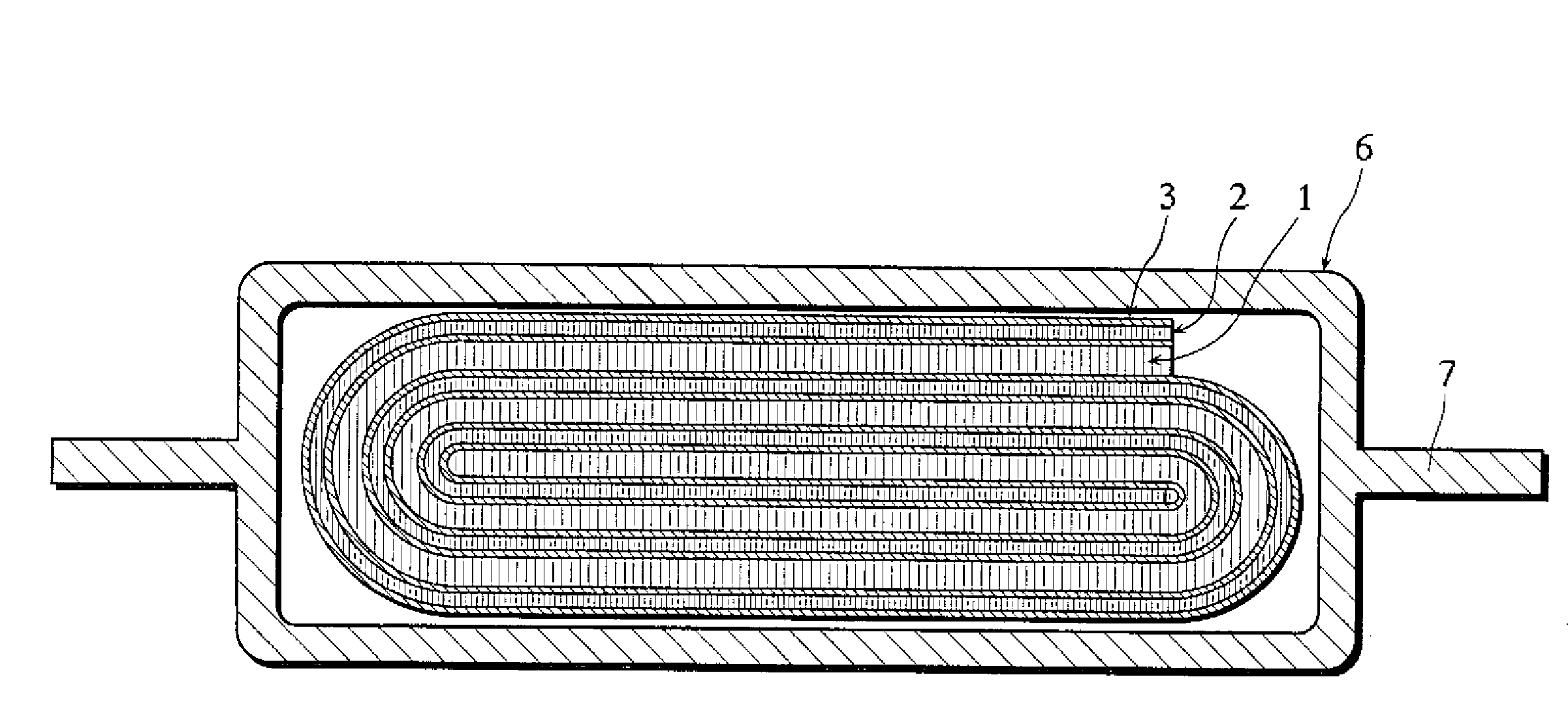

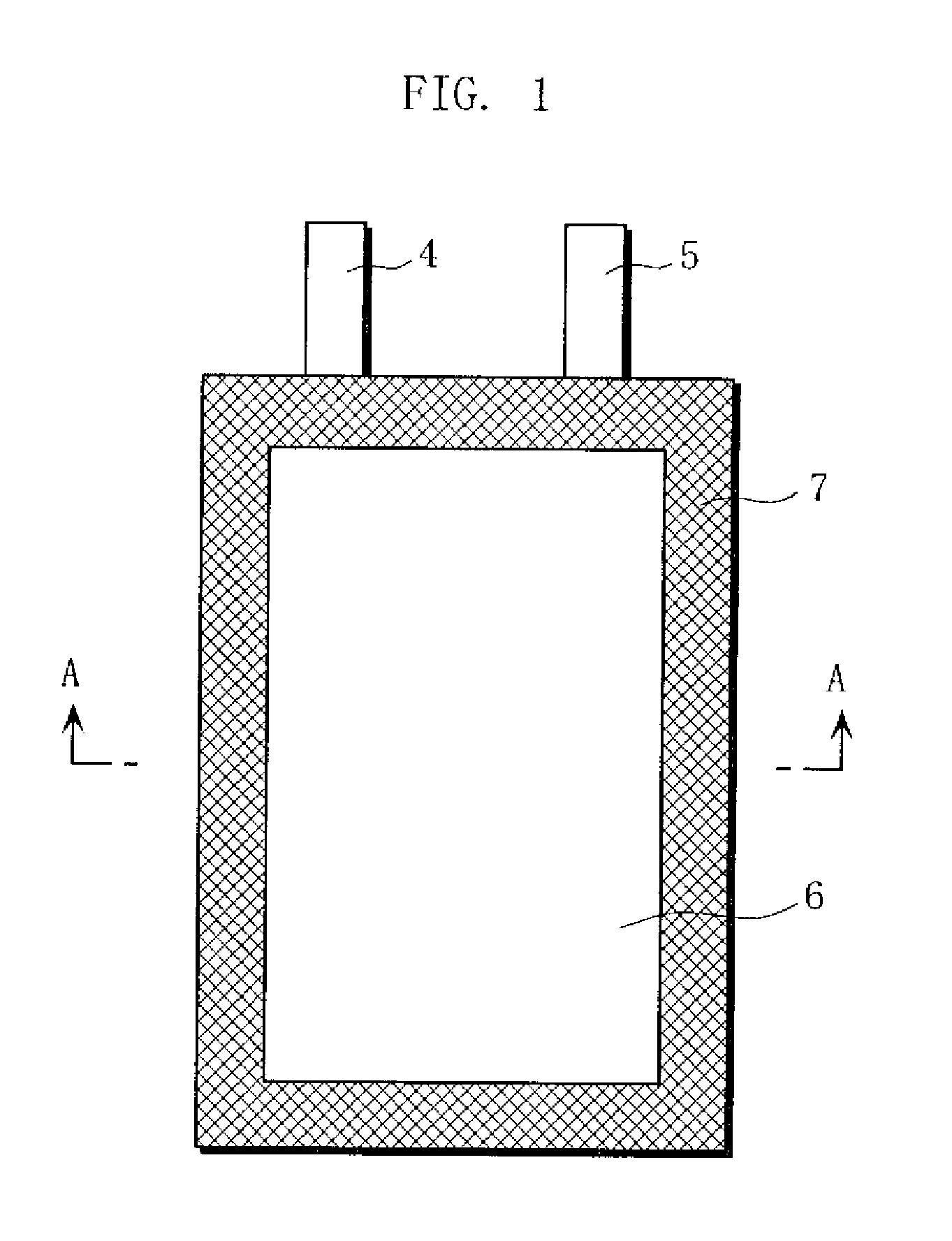

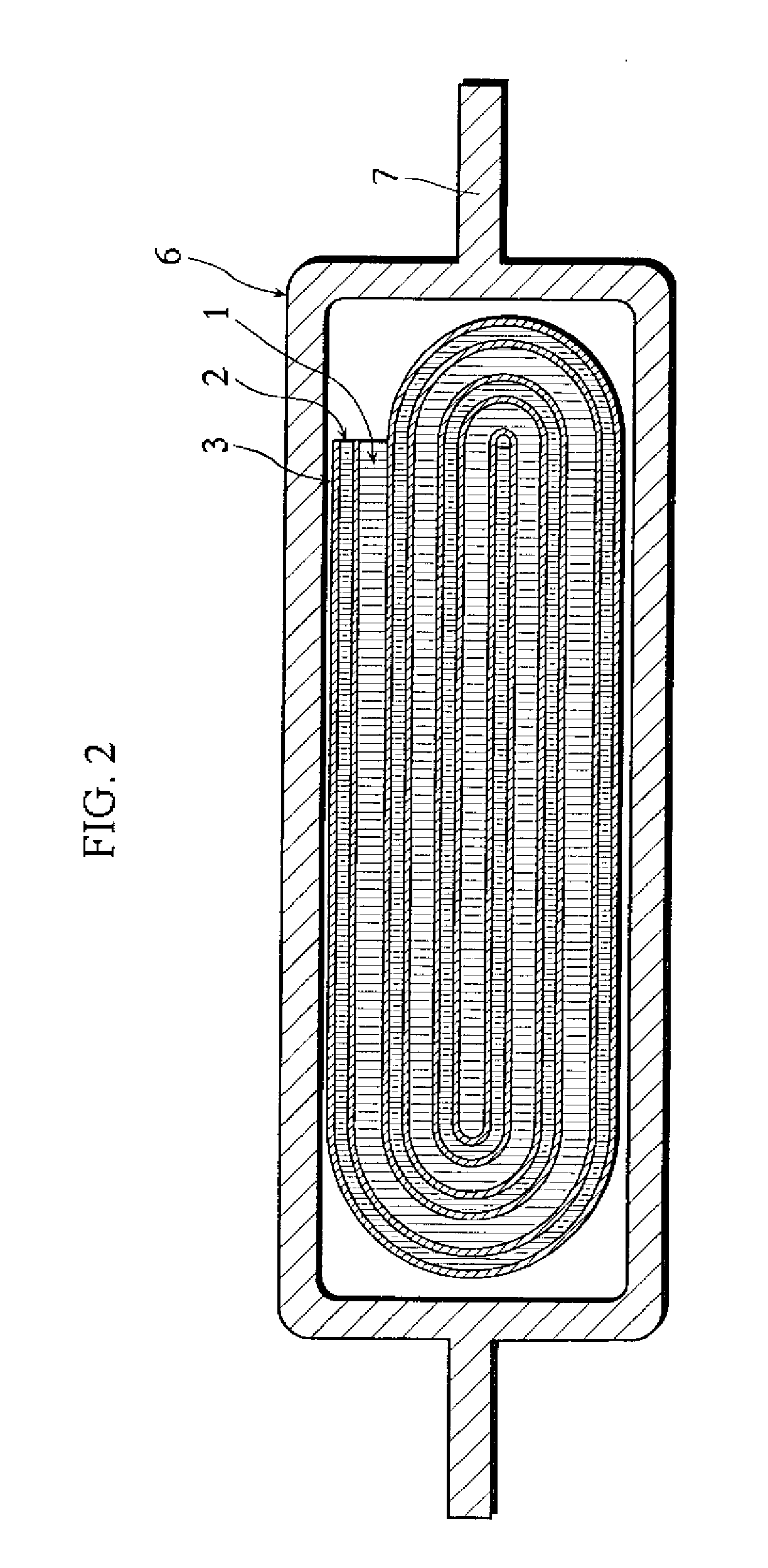

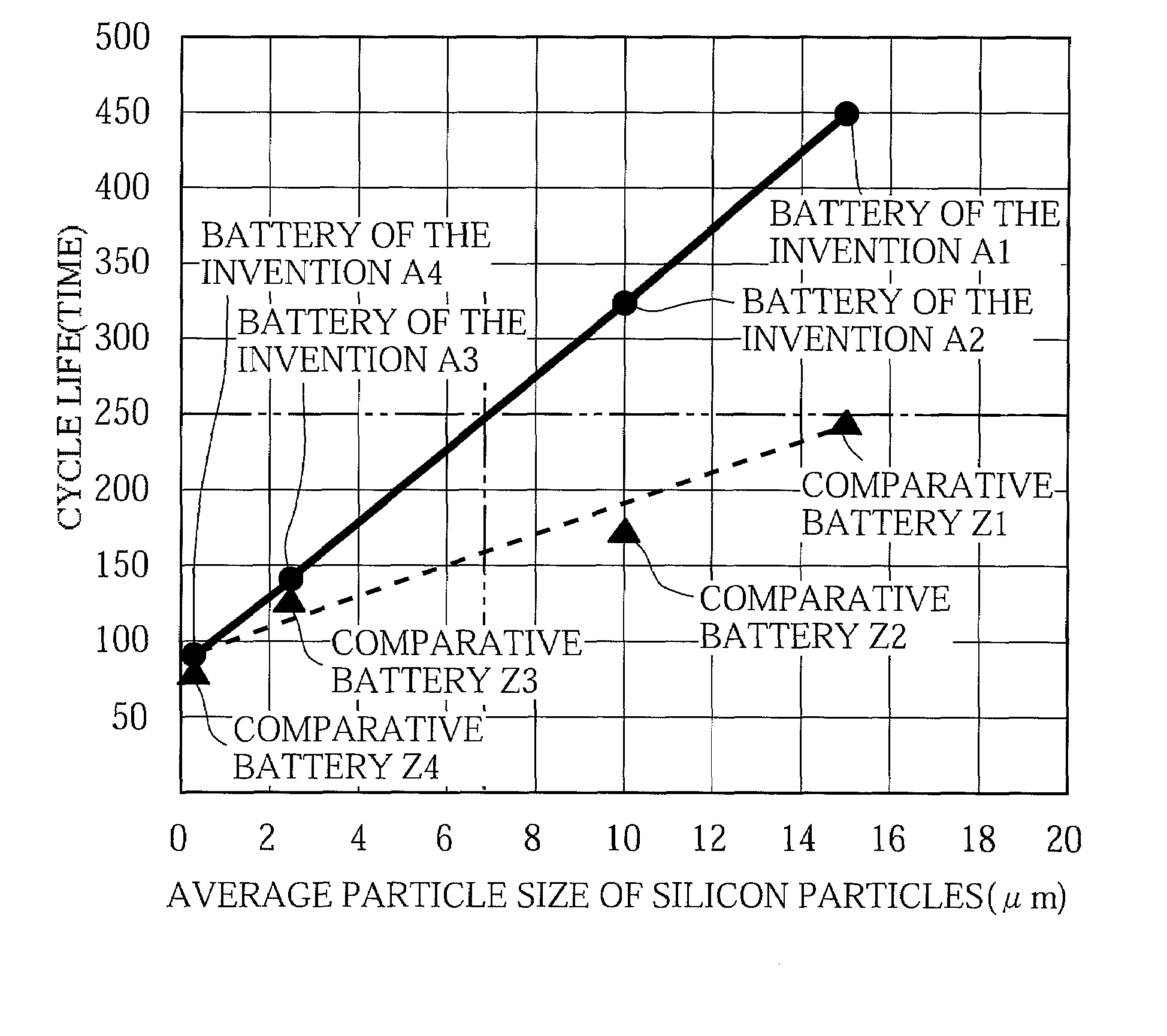

ActiveUS20080124631A1Avoid fracturesImprove cycle performanceElectrode carriers/collectorsNegative electrodesSilicon alloyMaterials science

A lithium secondary battery includes an electrode assembly having a positive electrode (1), a negative electrode (2) having a negative electrode current collector and a negative electrode active material layer formed on a surface of the negative electrode current collector and composed of a binder and negative electrode active material particles containing silicon and / or a silicon alloy, and a separator (3) interposed between the electrodes. The electrode assembly is impregnated with a non-aqueous electrolyte. The binder contains a polyimide resin represented by the following chemical formula (1):where R contains at least a benzene ring, and n is within the range of from 10 to 100,000, and the negative electrode active material particles have an average particle size of 5 μm or greater.

Owner:SANYO ELECTRIC CO LTD

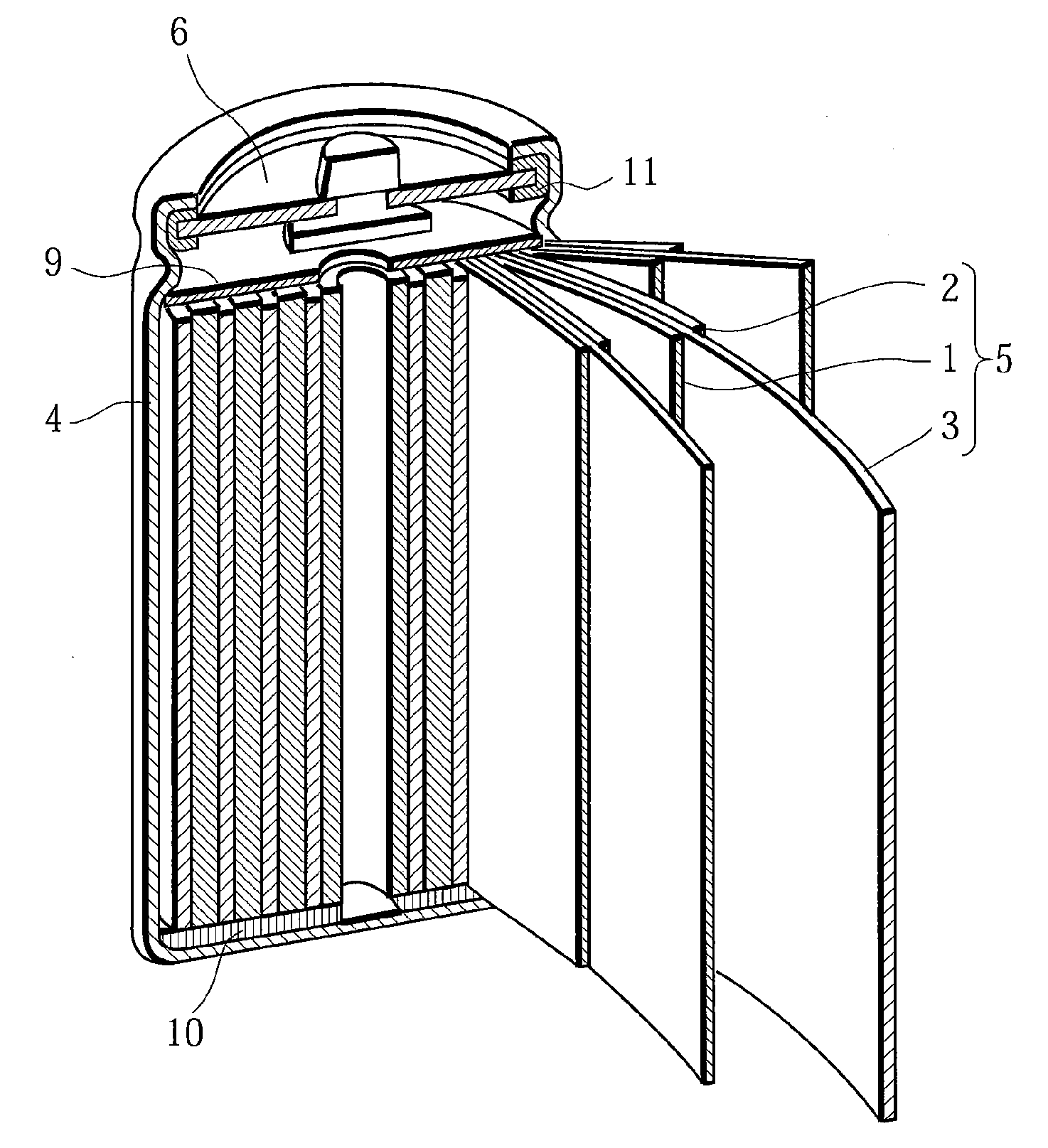

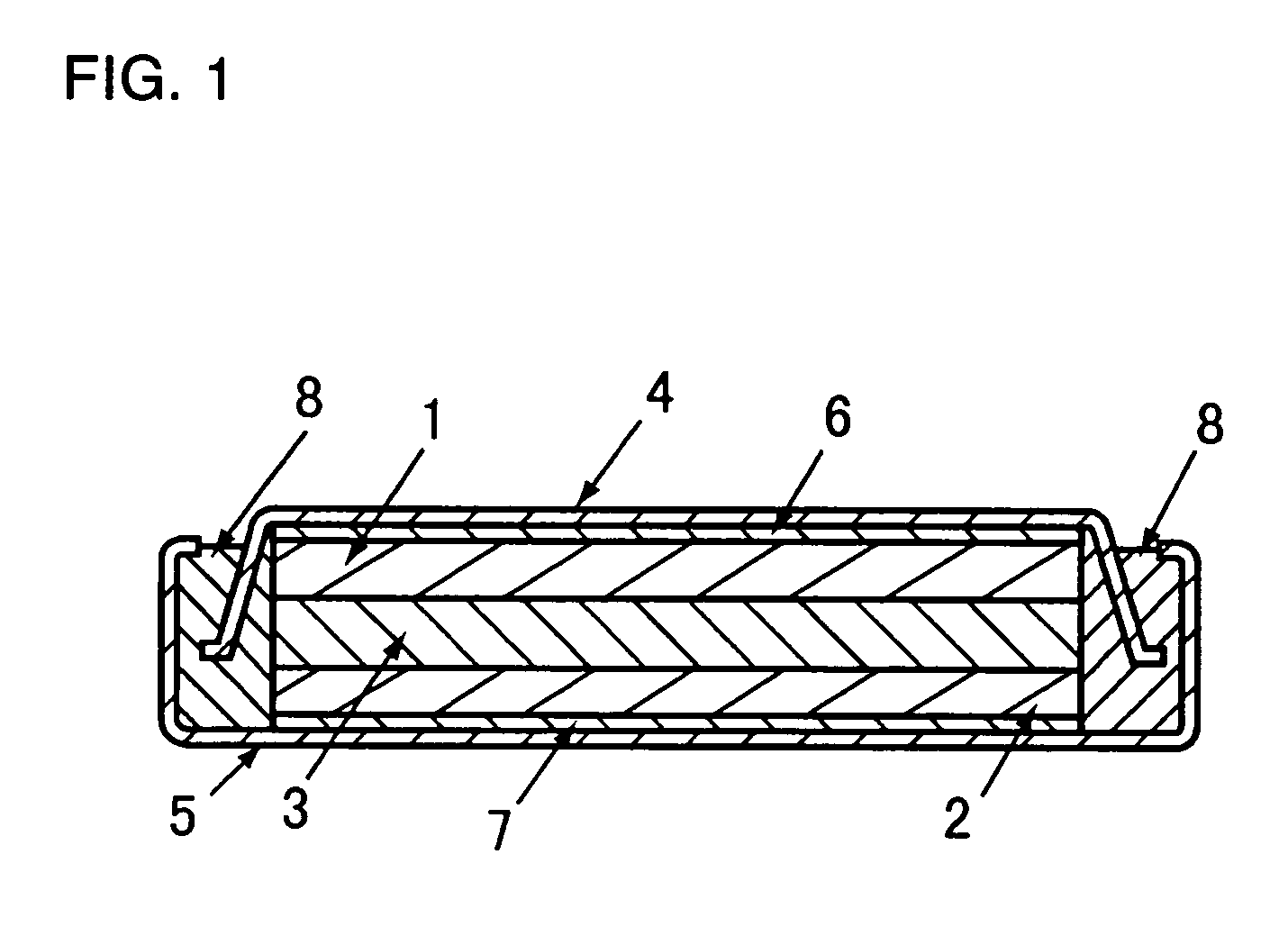

Cylindrical lithium secondary battery

InactiveUS20080241647A1Increase energy densityHigh mechanical strengthFinal product manufactureElectrode carriers/collectorsLithiumMetal foil

A cylindrical lithium secondary battery includes a positive electrode (1) having a positive electrode mixture layer disposed on a surface of a positive electrode current collector made of a conductive metal foil and containing a positive electrode active material, and a negative electrode (2) having a negative electrode mixture layer disposed on a surface of a negative electrode current collector made of a conductive metal foil and having a negative electrode active material containing silicon particles and / or silicon alloy particles. The amount of the positive electrode active material is 50 mg or less per 1 cm2 of the positive electrode, the average particle size of the silicon particles and / or silicon alloy particles is from 5 μm to 15 μm, and the theoretical electrical capacity ratio of the negative electrode to the positive electrode is 1.2 or greater.

Owner:SANYO ELECTRIC CO LTD

Anode active material hybridizing carbon nanofiber for lithium secondary battery

InactiveUS20090053608A1Material nanotechnologyNon-aqueous electrolyte accumulator electrodesFiberCarbon nanofiber

The present invention provides a composite silicon anode material hybridizing carbon nanofiber for lithium secondary battery prepared by the steps comprising: i) preparing a support made by amorphous silicon alloy after processing amorphous silicon and metal; ii) dispersing the catalyst selected from Fe, Co, Ni, Cu, Mg, Mn, Ti, Sn, Si, Zr, Zn, Ge, Pb or In on the surface of said support made by amorphous silicon alloy; and iii) growing the carbon nanofiber using a carbon source selected from carbon monoxide, methane, acetylene or ethylene on said support by a chemical vapor deposition method, wherein the amount of grown carbon nanofiber is 1˜110 wt % of the amount of said support.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

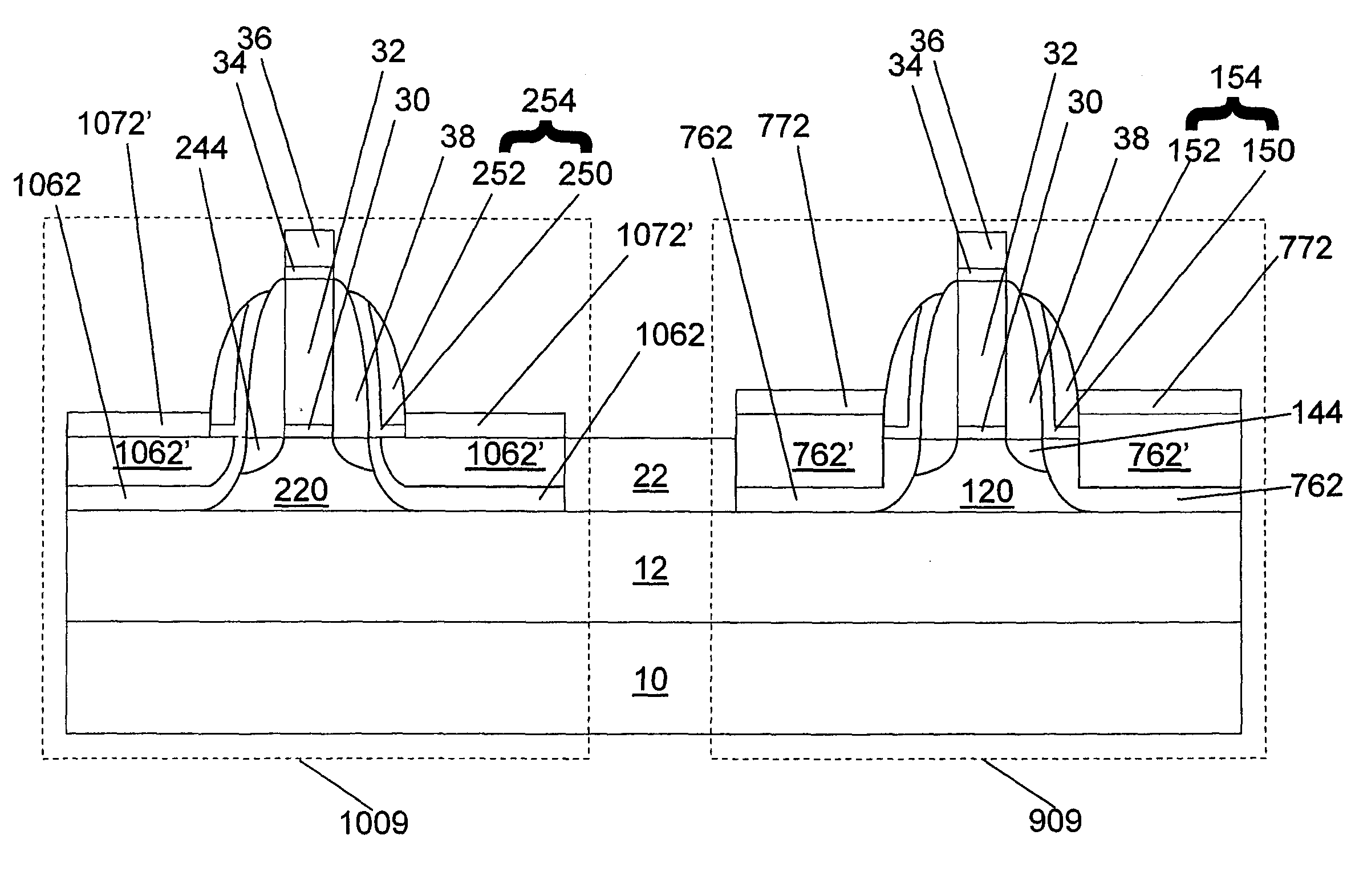

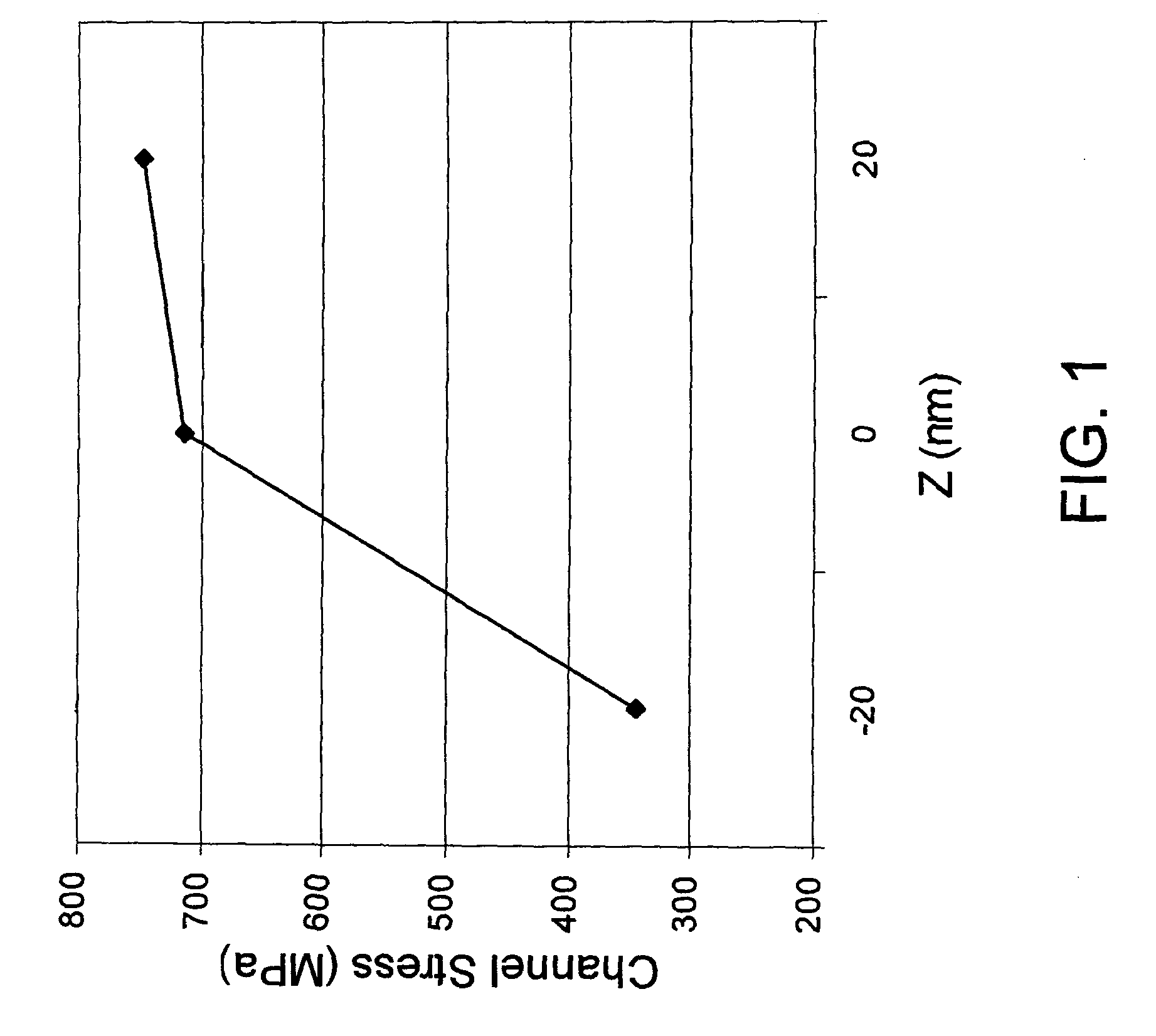

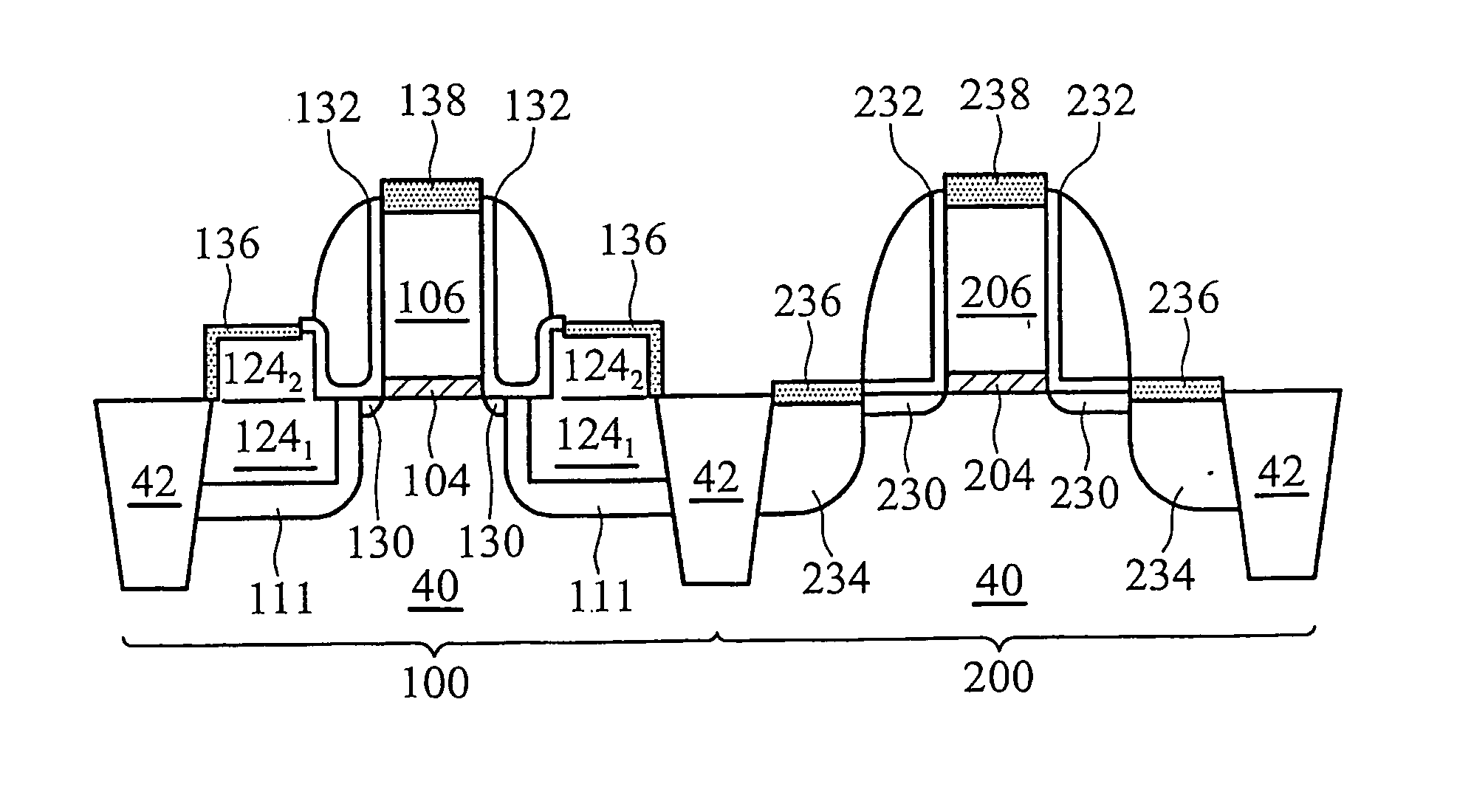

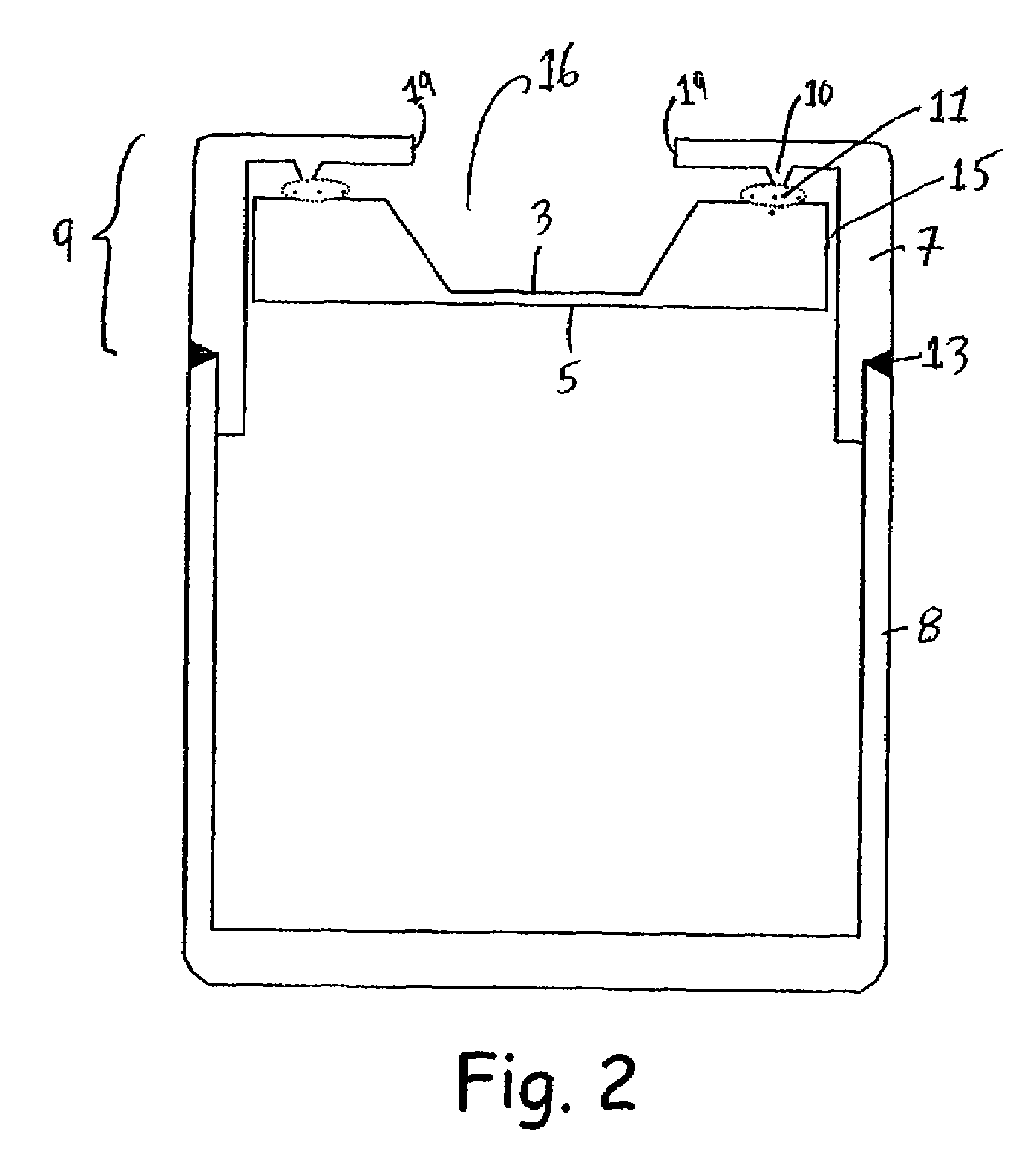

Structure and method for mobility enhanced MOSFETs with unalloyed silicide

ActiveUS8217423B2Stable and low contact resistanceReduce contact resistanceTransistorSolid-state devicesMOSFETSalicide

While embedded silicon germanium alloy and silicon carbon alloy provide many useful applications, especially for enhancing the mobility of MOSFETs through stress engineering, formation of alloyed silicide on these surfaces degrades device performance. The present invention provides structures and methods for providing unalloyed silicide on such silicon alloy surfaces placed on semiconductor substrates. This enables the formation of low resistance contacts for both mobility enhanced PFETs with embedded SiGe and mobility enhanced NFETs with embedded Si:C on the same semiconductor substrate. Furthermore, this invention provides methods for thick epitaxial silicon alloy, especially thick epitaxial Si:C alloy, above the level of the gate dielectric to increase the stress on the channel on the transistor devices.

Owner:AURIGA INNOVATIONS INC

Lithium secondary battery and method for producing same

ActiveUS20060003226A1High charge and discharge capacityExcellent cycle characteristicsElectrode thermal treatmentFinal product manufactureSilicon alloyMetal foil

A rechargeable lithium battery including a negative electrode made by sintering, on a surface of a conductive metal foil as a current collector, a layer of a mixture of active material particles containing silicon and / or a silicon alloy and a binder, a positive electrode and a nonaqueous electrolyte, characterized in that the nonaqueous electrolyte contains carbon dioxide dissolved therein.

Owner:SANYO ELECTRIC CO LTD

Dopant Precursors and Processes

<heading lvl="0">Abstract of Disclosure< / heading> Silicon alloys and doped silicon films are prepared by chemical vapor deposition and ion implantation processes using Si-containing chemical precursors as sources for Group III and Group V atoms. Preferred dopant precursors include (H3Si)3-xMRx, (H3Si)3N, and (H3Si)4N2, wherein R is H or D, x = 0, 1 or 2, and M is selected from the group consisting of B, P, As, and Sb. Preferred deposition methods produce non-hydrogenated silicon alloy and doped Si-containing films, including crystalline films.

Owner:ASM IP HLDG BV

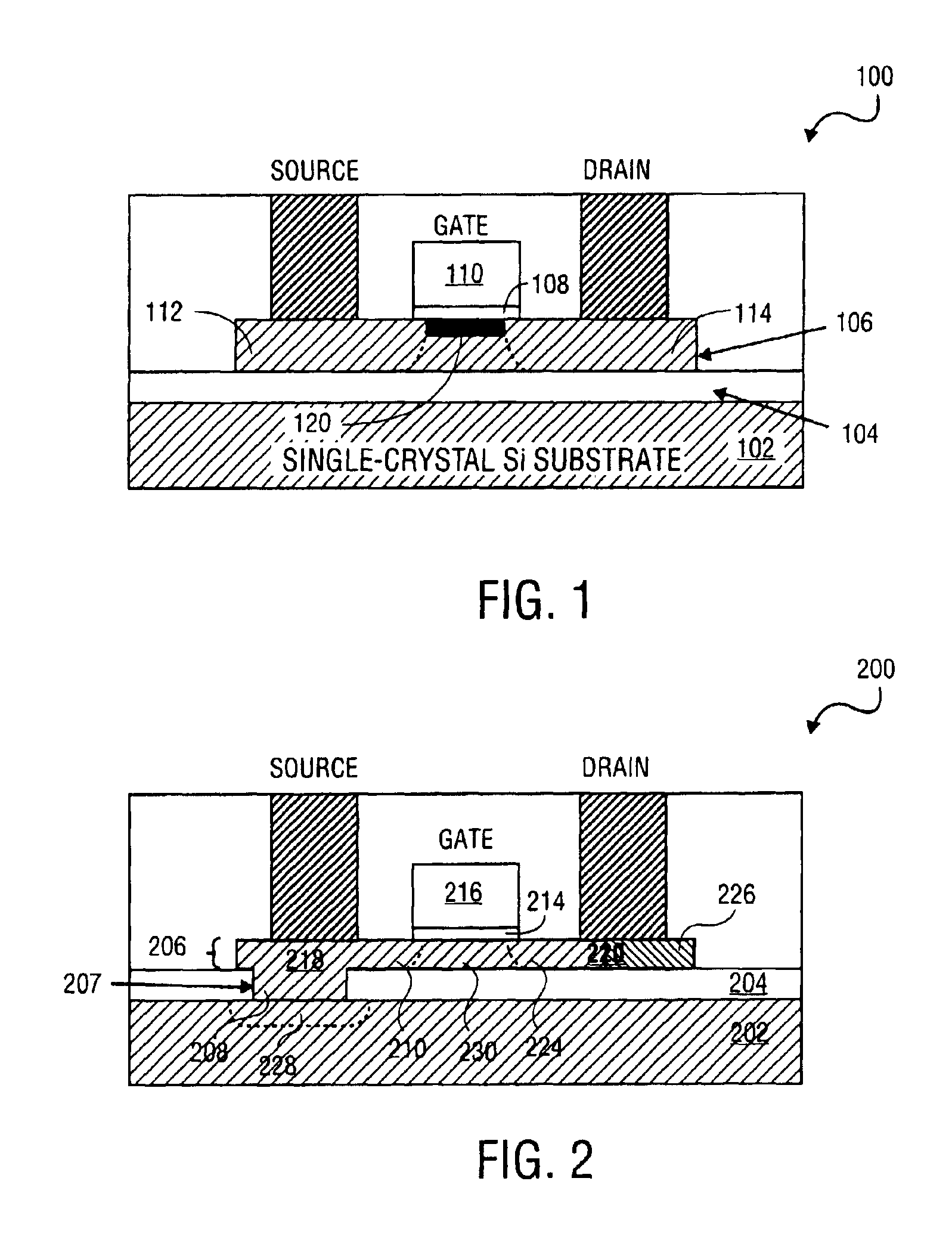

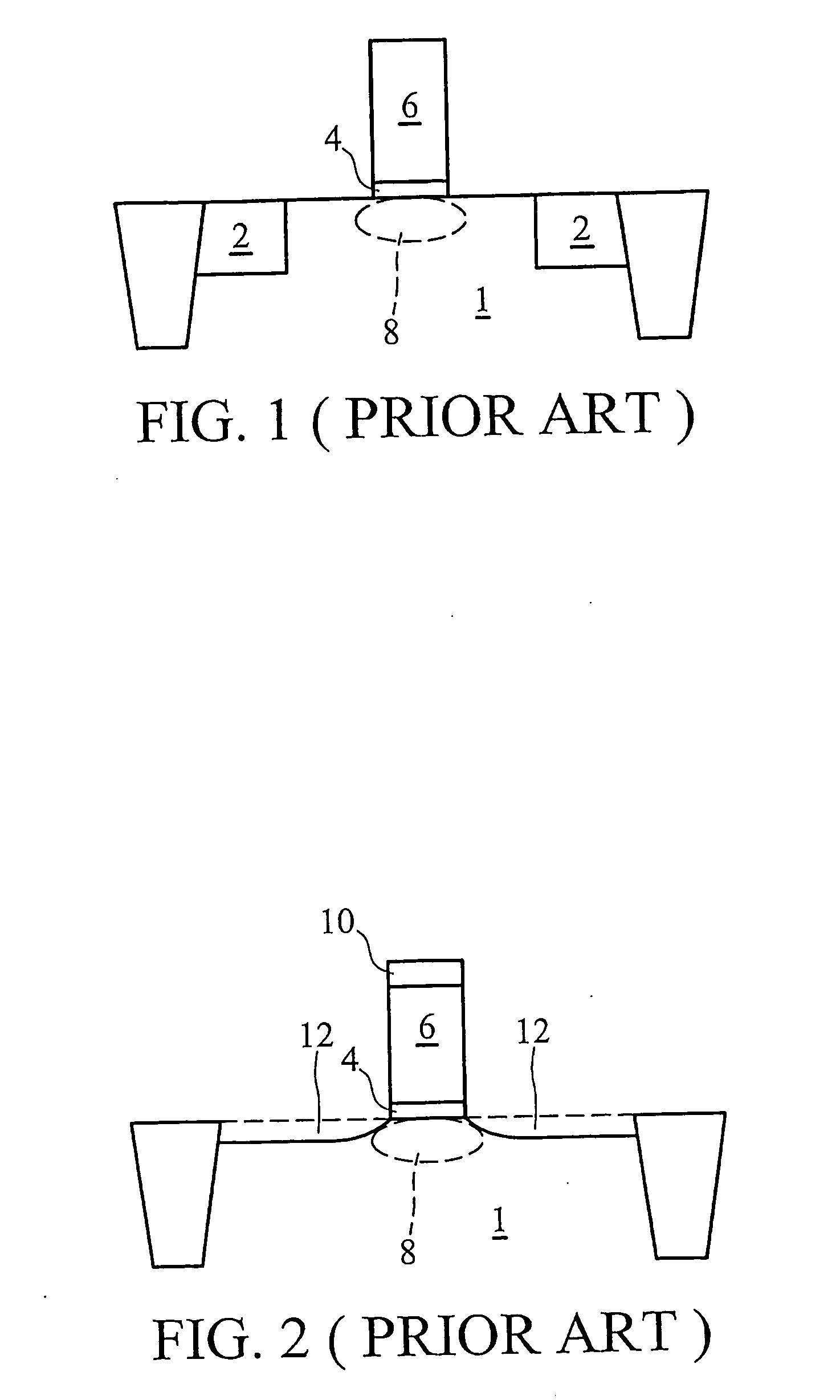

Silicon on insulator (SOI) transistor and methods of fabrication

InactiveUS6919238B2TransistorSemiconductor/solid-state device manufacturingSilicon alloyCrystalline silicon

The present invention is a silicon on insulator (SOI) transistor and its method of fabrication. According to the present invention, an opening is formed in the insulating layer formed on a single crystalline silicon substrate. An amorphous or polycrystalline silicon or silicon alloy is then formed in the opening on the single crystalline silicon substrate and on the insulating layer. The amorphous or polycrystalline silicon or silicon alloy in the opening and at least a portion of the amorphous or polycrystalline silicon or silicon alloy on the insulating layer is crystallized into a single crystalline silicon or silicon alloy film.

Owner:INTEL CORP

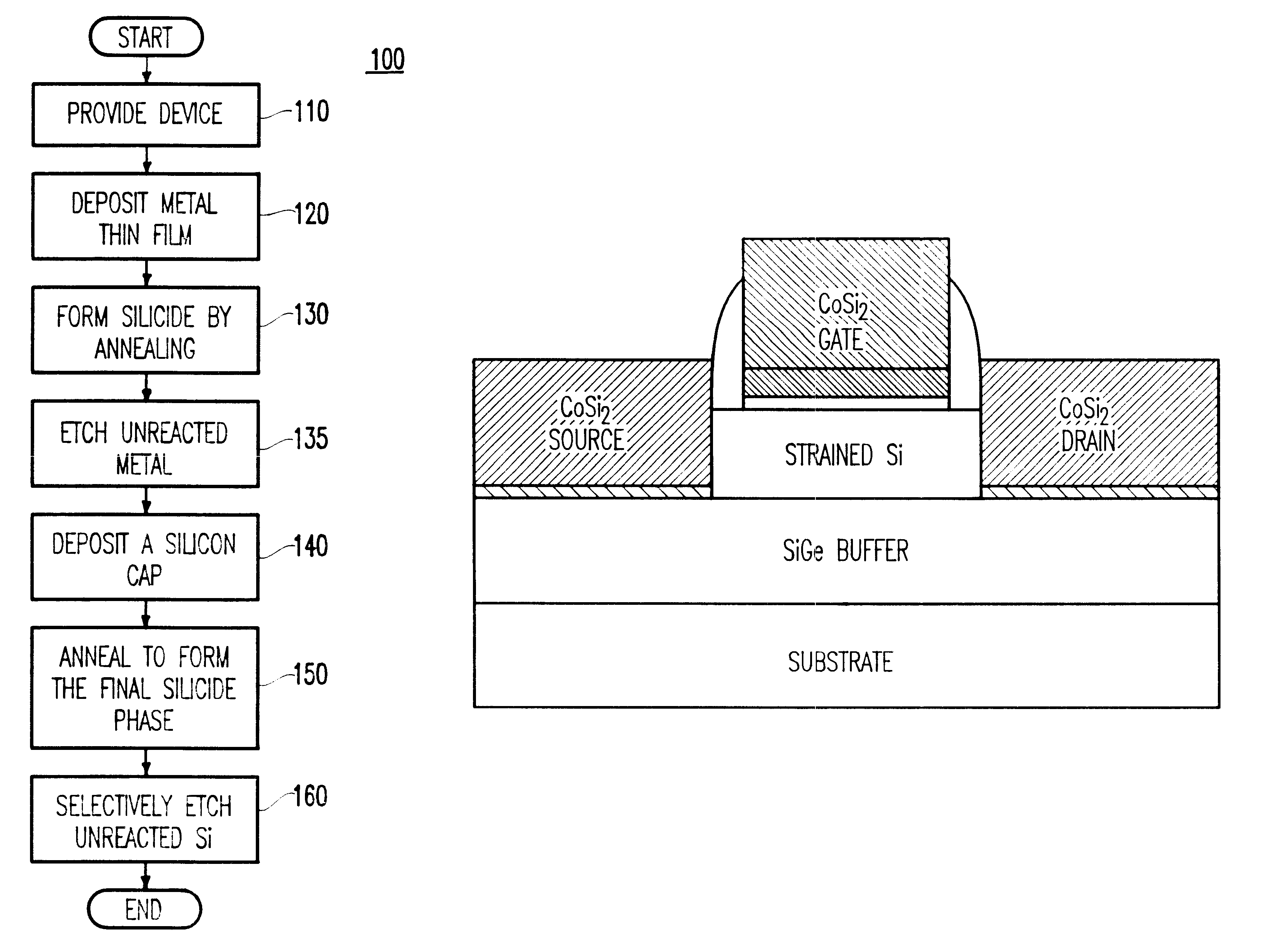

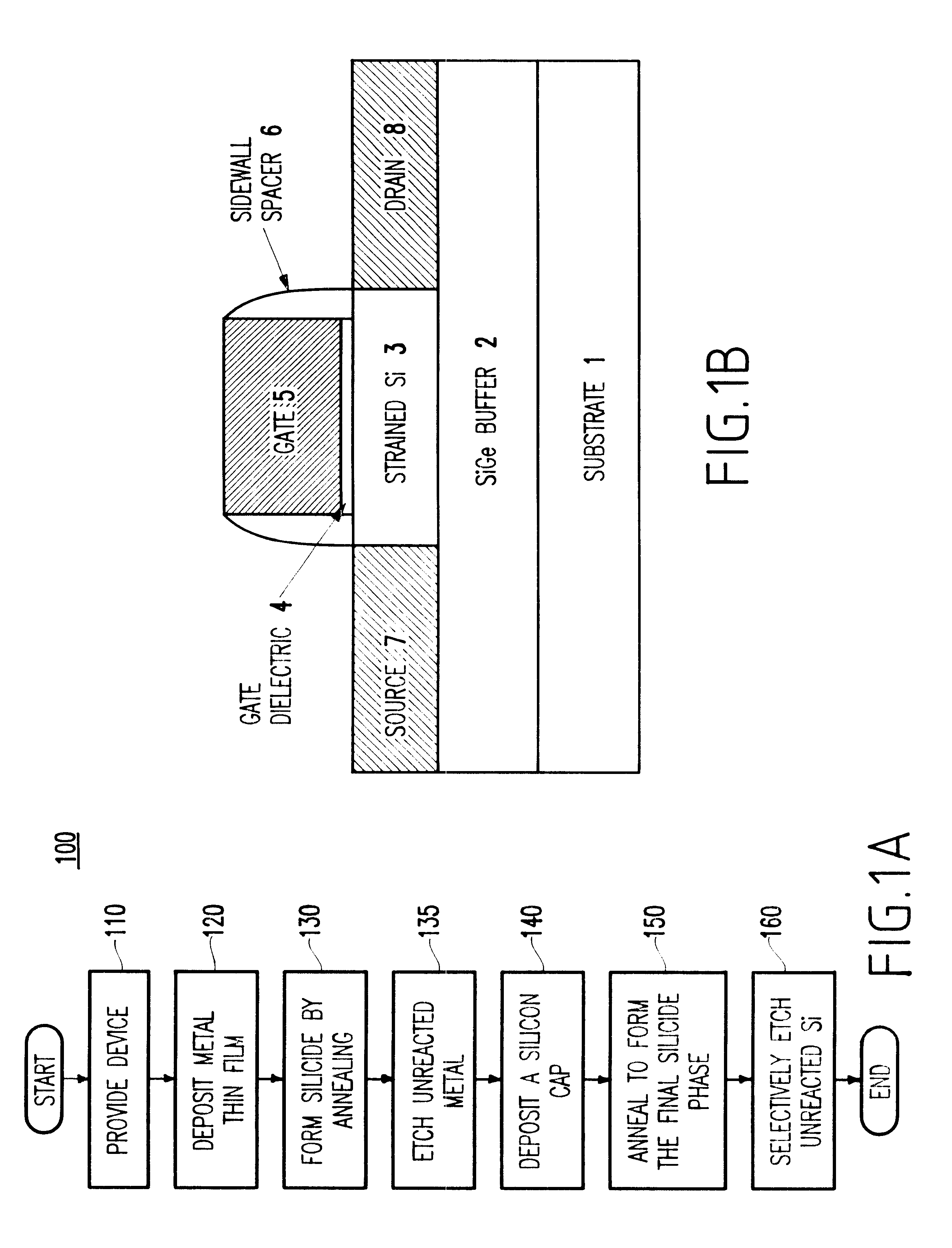

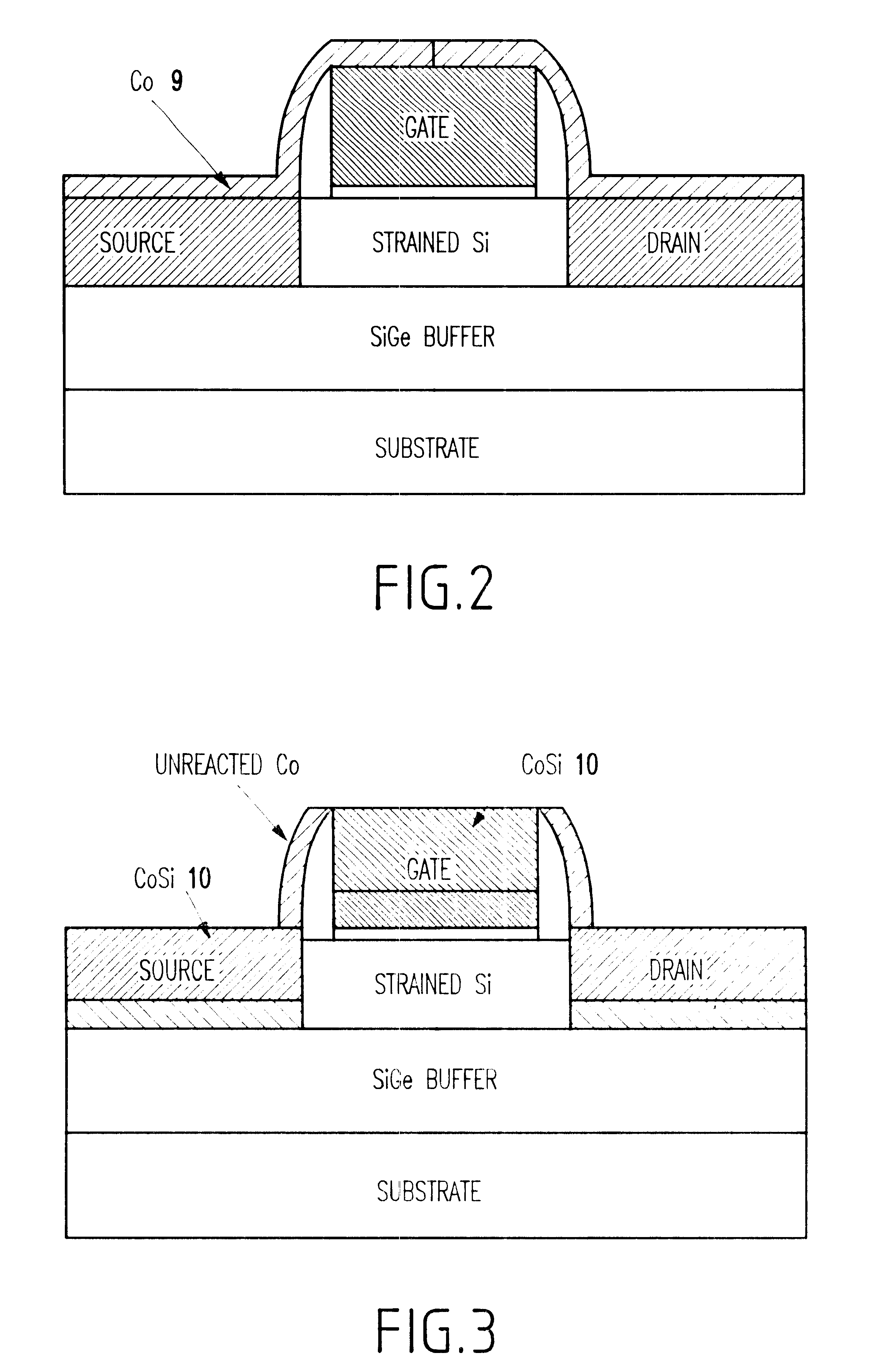

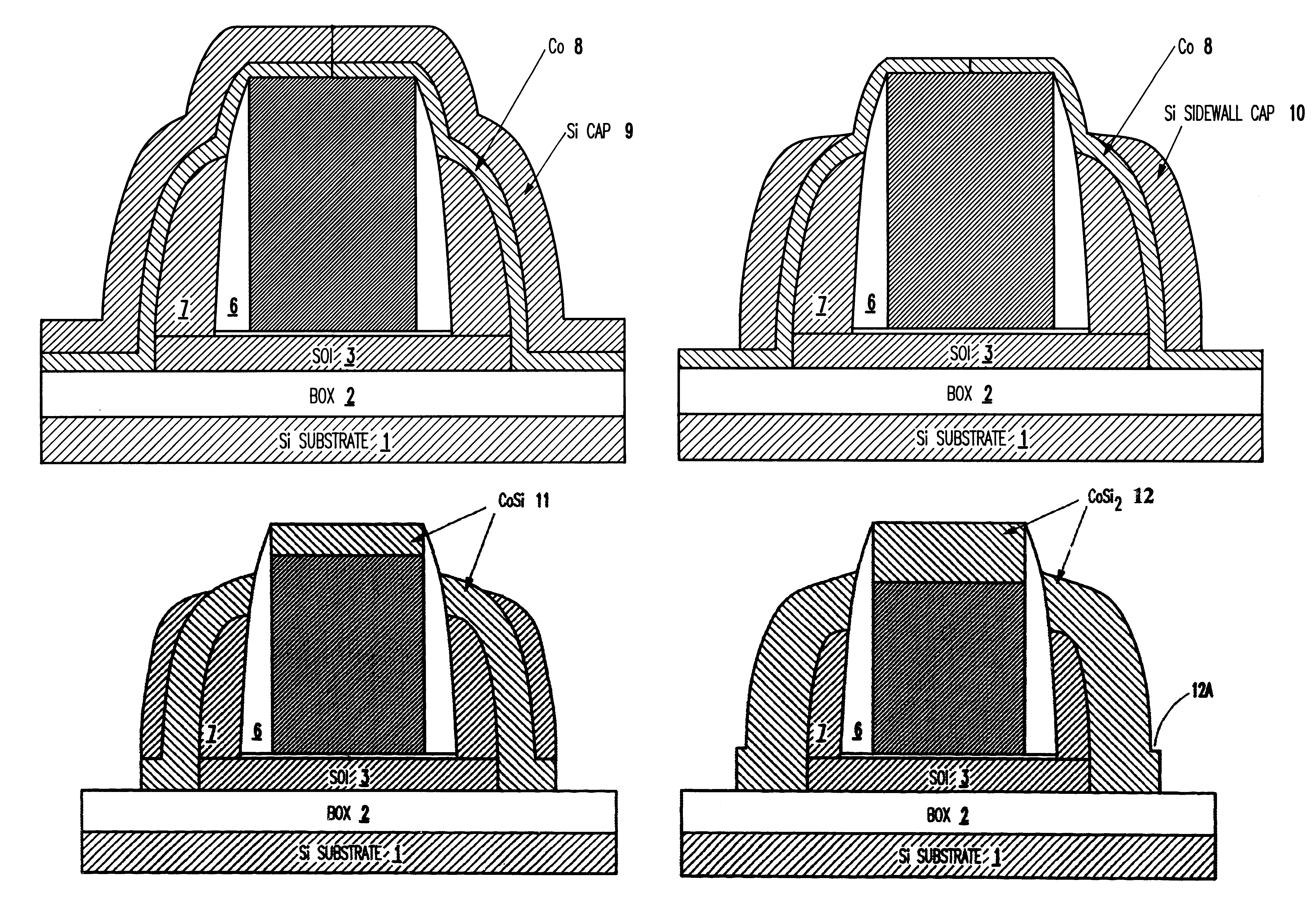

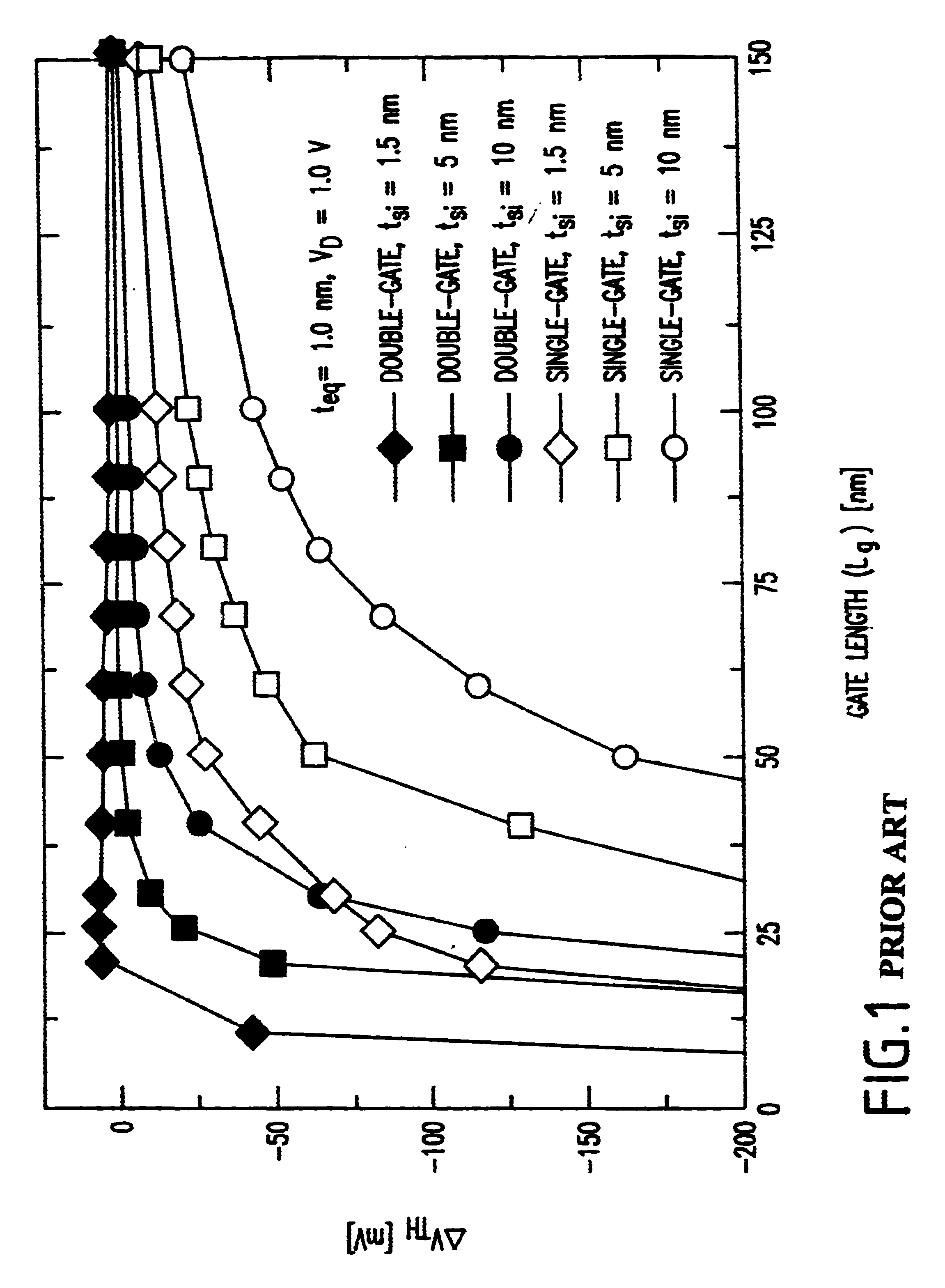

Self-aligned silicide (salicide) process for strained silicon MOSFET ON SiGe and structure formed thereby

InactiveUS6503833B1Semiconductor/solid-state device manufacturingSemiconductor devicesMOSFETSalicide

A method of forming a semiconductor substrate (and resultant structure), includes providing a semiconductor substrate to be silicided including a source and drain formed therein on respective sides of a gate, depositing a metal film over the gate, source and drain regions, reacting the metal film with Si at a first predetermined temperature, to form a metal-silicon alloy, etching the unreacted metal, depositing a silicon film over the source drain and gate regions, annealing the substrate at a second predetermined temperature, to form a metal-Si2 alloy, and selectively etching the unreacted Si.

Owner:IBM CORP

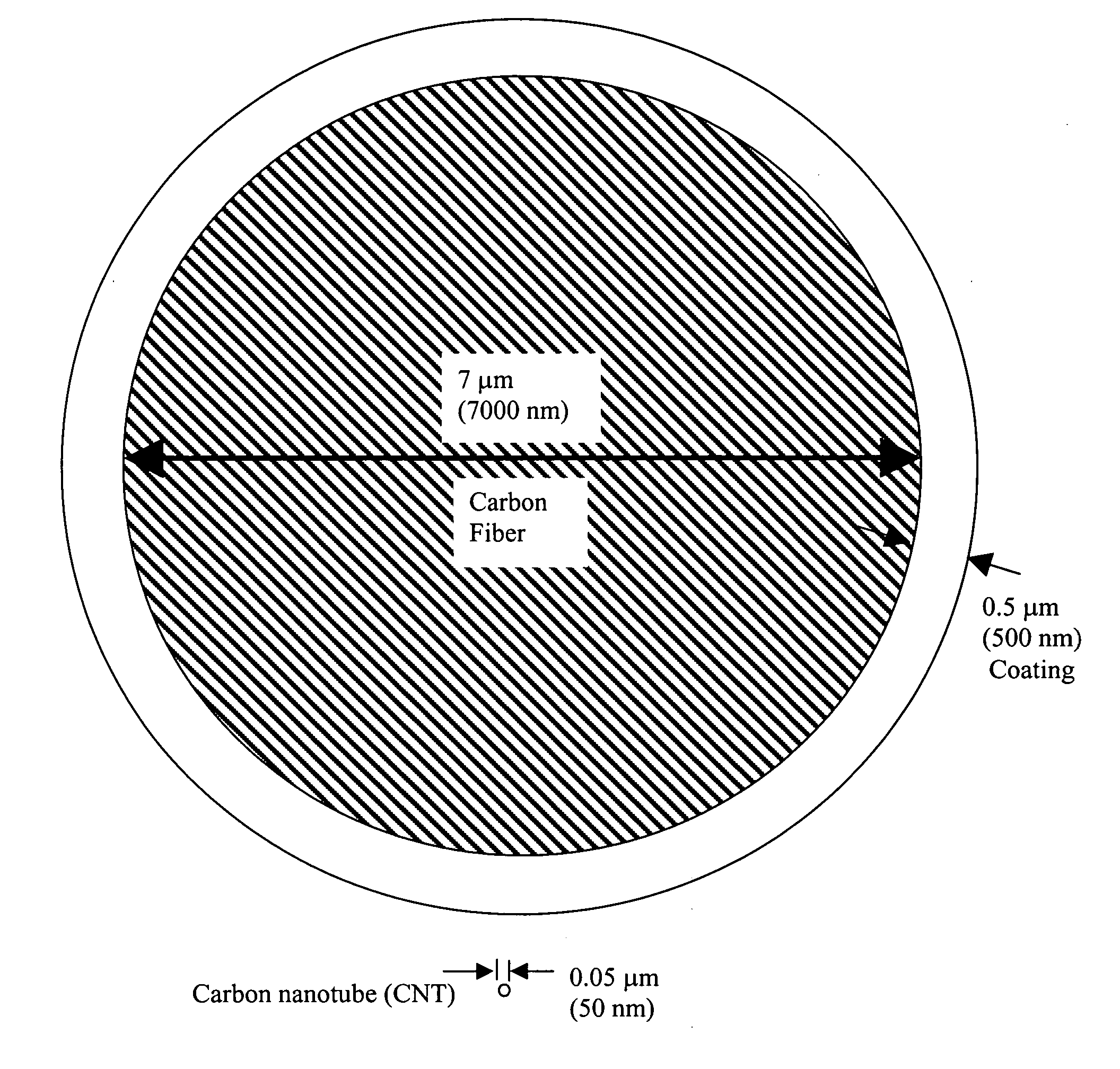

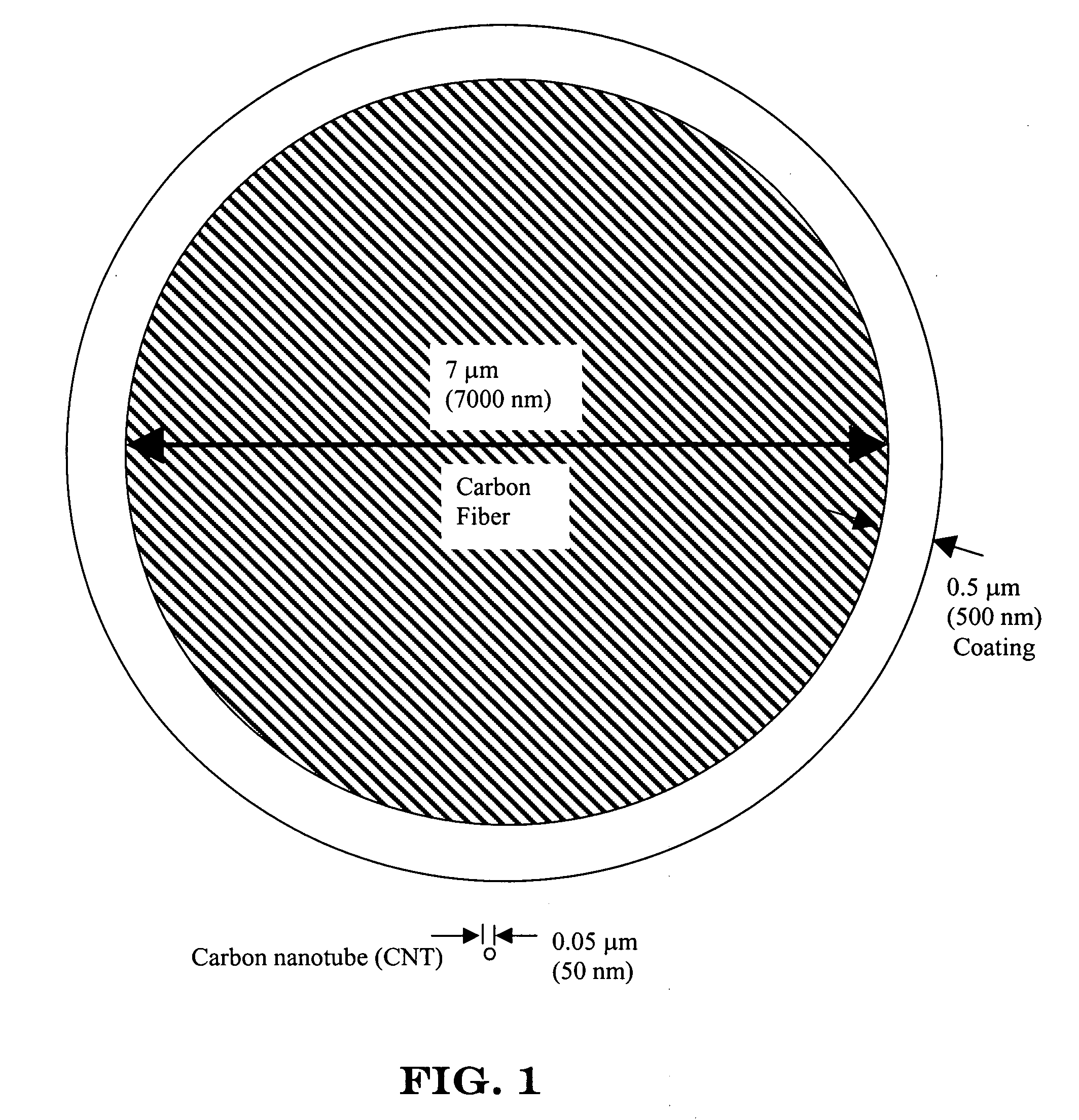

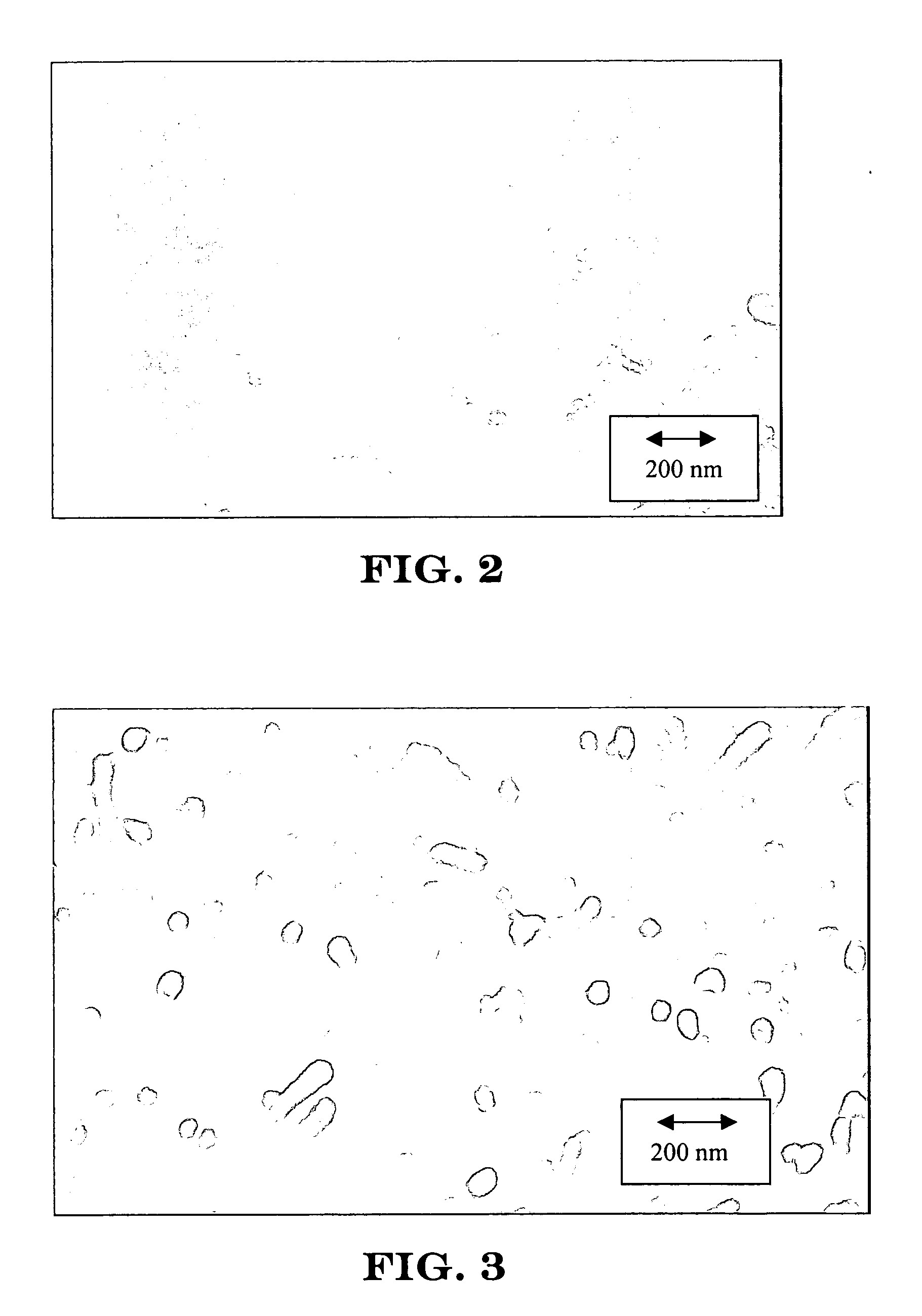

Nanotube-containing composite bodies, and methods for making same

A composite material featuring carbon nanotubes reinforcing a matrix featuring metal or silicon carbide, or both. Such composites can be produced using a molten silicon metal infiltration technique, for example, a siliconizing or a reaction-bonding process. Here, the carbon nanotubes are prevented from chemically reacting with the silicon infiltrant by an interfacial coating disposed between the carbon nanotubes and the infiltrant. Preferably, the coating is free carbon or a carbonaceous precursor material added during preform processing, or after. The reaction-bonding system is designed such that the molten infiltrant of silicon metal or silicon alloy reacts with at least some of the interfacial carbon layer to form in-situ silicon carbide, and that the formed SiC is sufficiently dense that it effectively seals off the underlying carbon nanotube from exposure to additional molten infiltrant. A reaction-bonded composite body containing even a small percentage of carbon nanotubes possessed a significant increase in electrical conductivity as compared to a reaction-bonded composite not containing such nanotubes, reflecting the high electrical conductivity of the nanotubes.

Owner:KARANDIKAR PRASHANT G

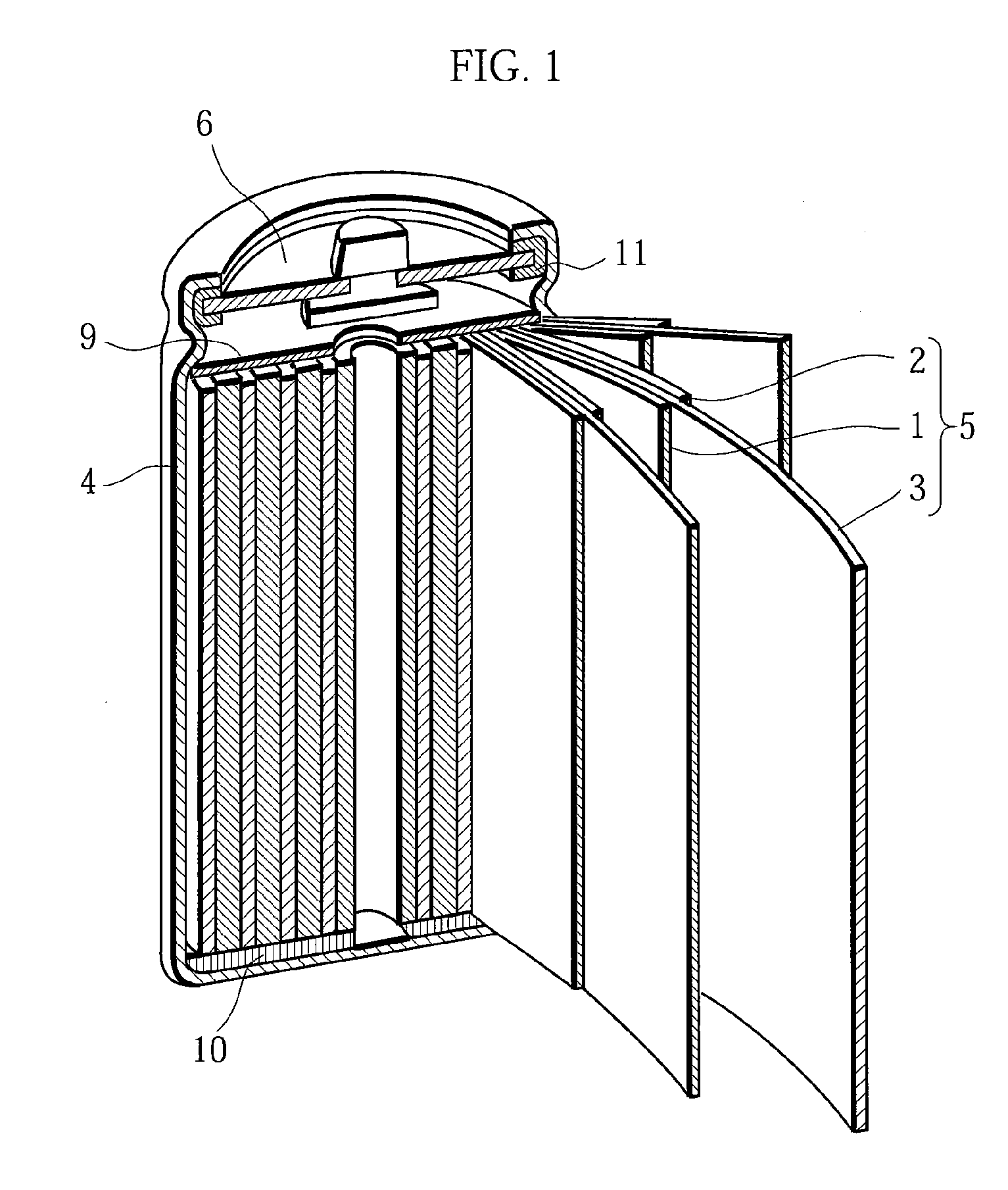

Lithium secondary battery and method of manufacturing the same

ActiveUS20090305129A1Excellent charge and discharge characteristicsImprove responseElectrode manufacturing processesFinal product manufactureSilicon alloyEngineering

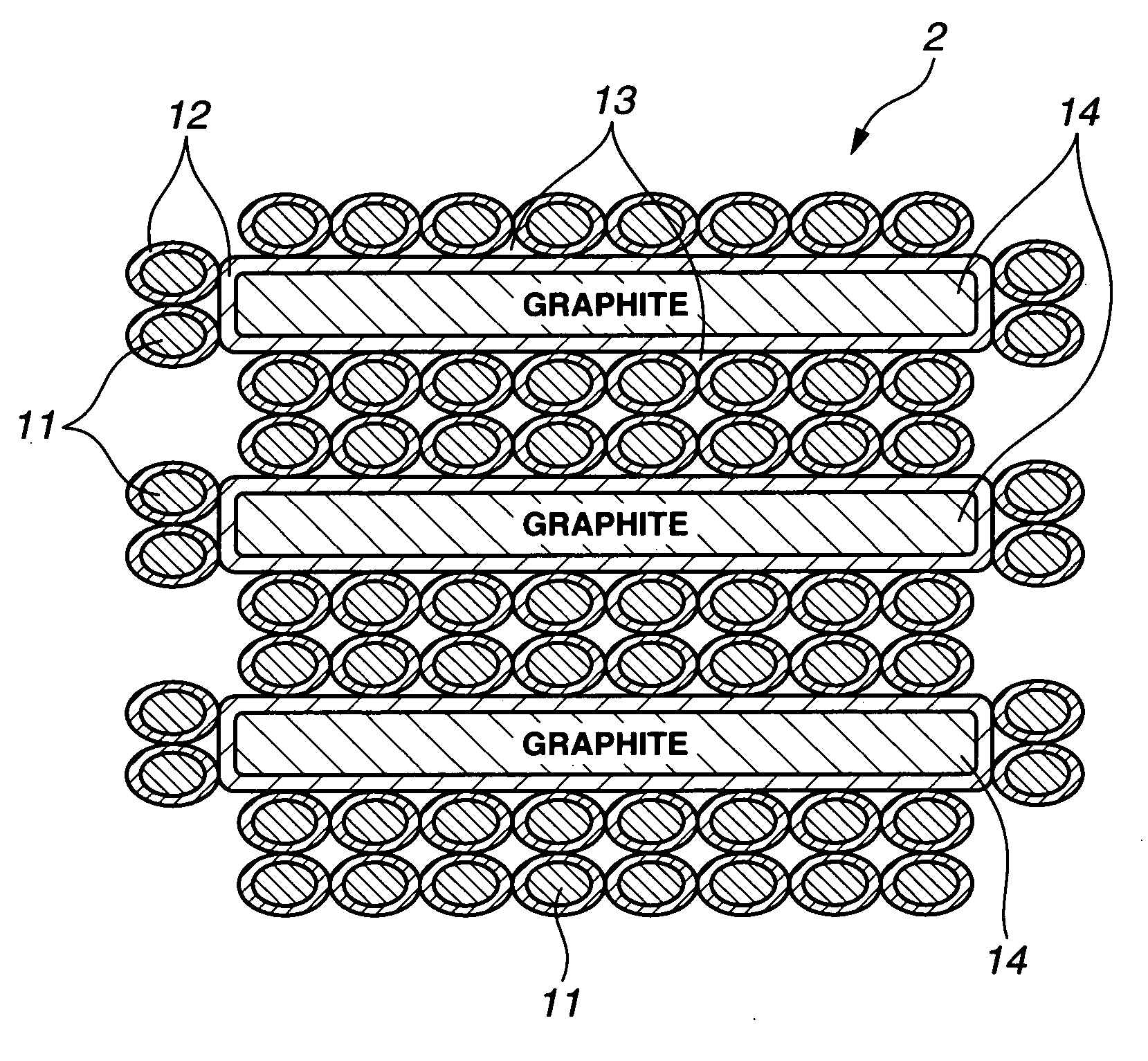

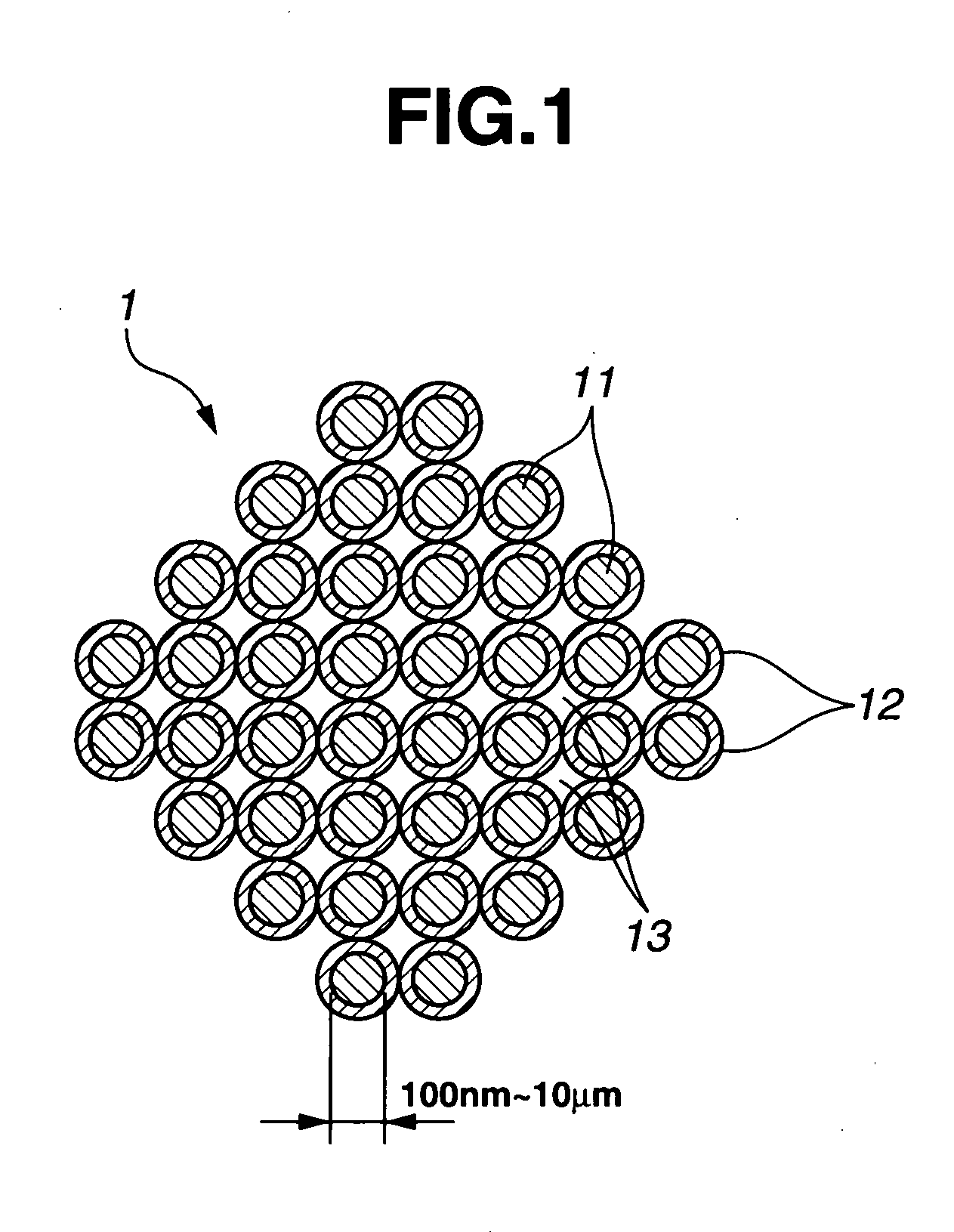

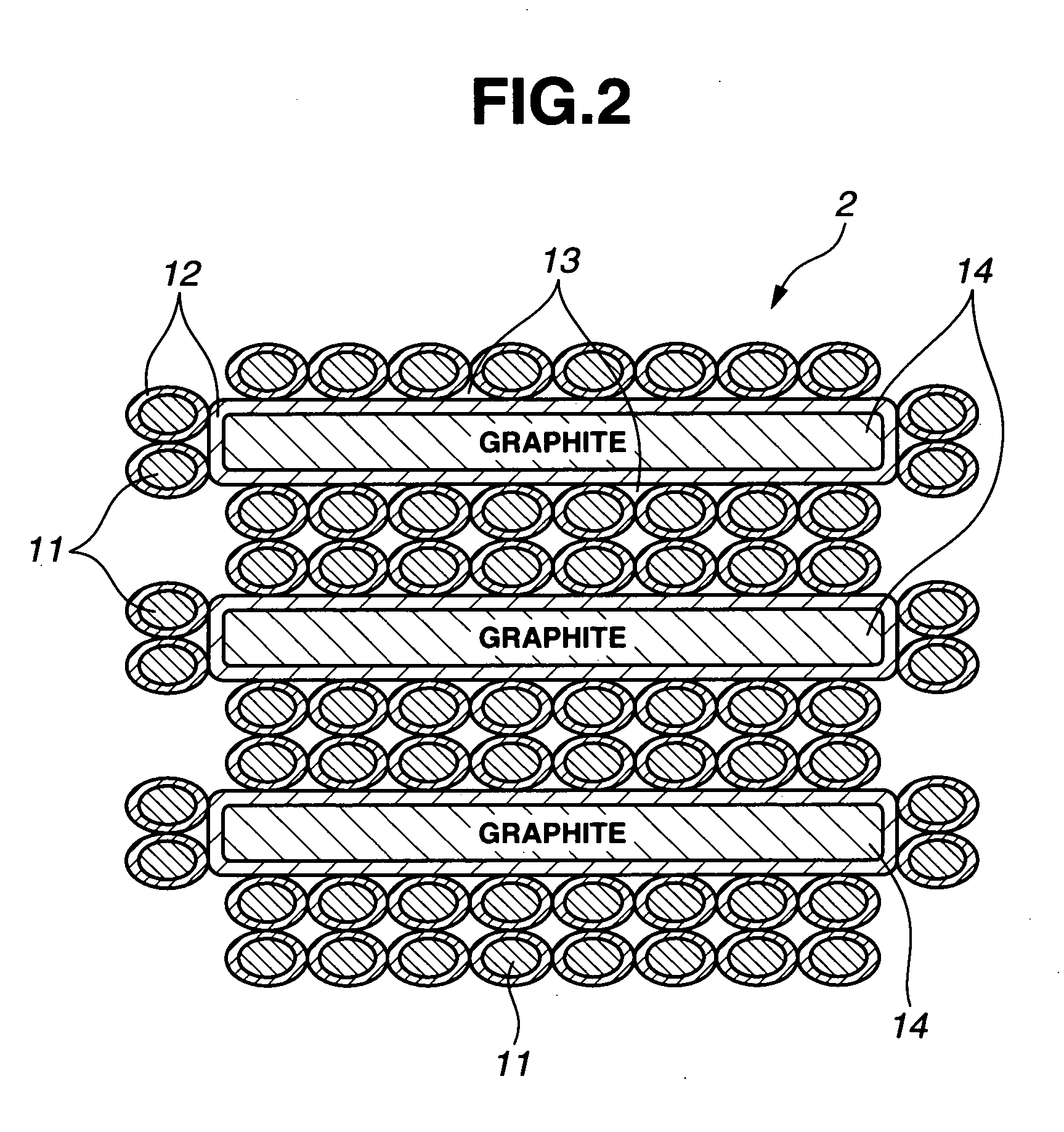

[Problem] An object of the invention is to provide a lithium secondary battery that shows good cycle performance and at the same time prevents a battery thickness increase due to charge-discharge cycles, and a method of manufacturing such a battery.[Means for Solving the Problem] A lithium secondary battery includes a negative electrode (2) having a negative electrode current collector (11) and a negative electrode active material layer (12) disposed on the negative electrode current collector (11), a positive electrode (1) having a positive electrode active material, a separator (3), and a non-aqueous electrolyte. The negative electrode active material layer includes negative electrode active material particles and a negative electrode binder, and the negative electrode active material particles include silicon particles and / or silicon alloy particles. The silicon particles and the silicon alloy particles have a crystallite size of 100 nm or less.

Owner:PANASONIC ENERGY CO LTD

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

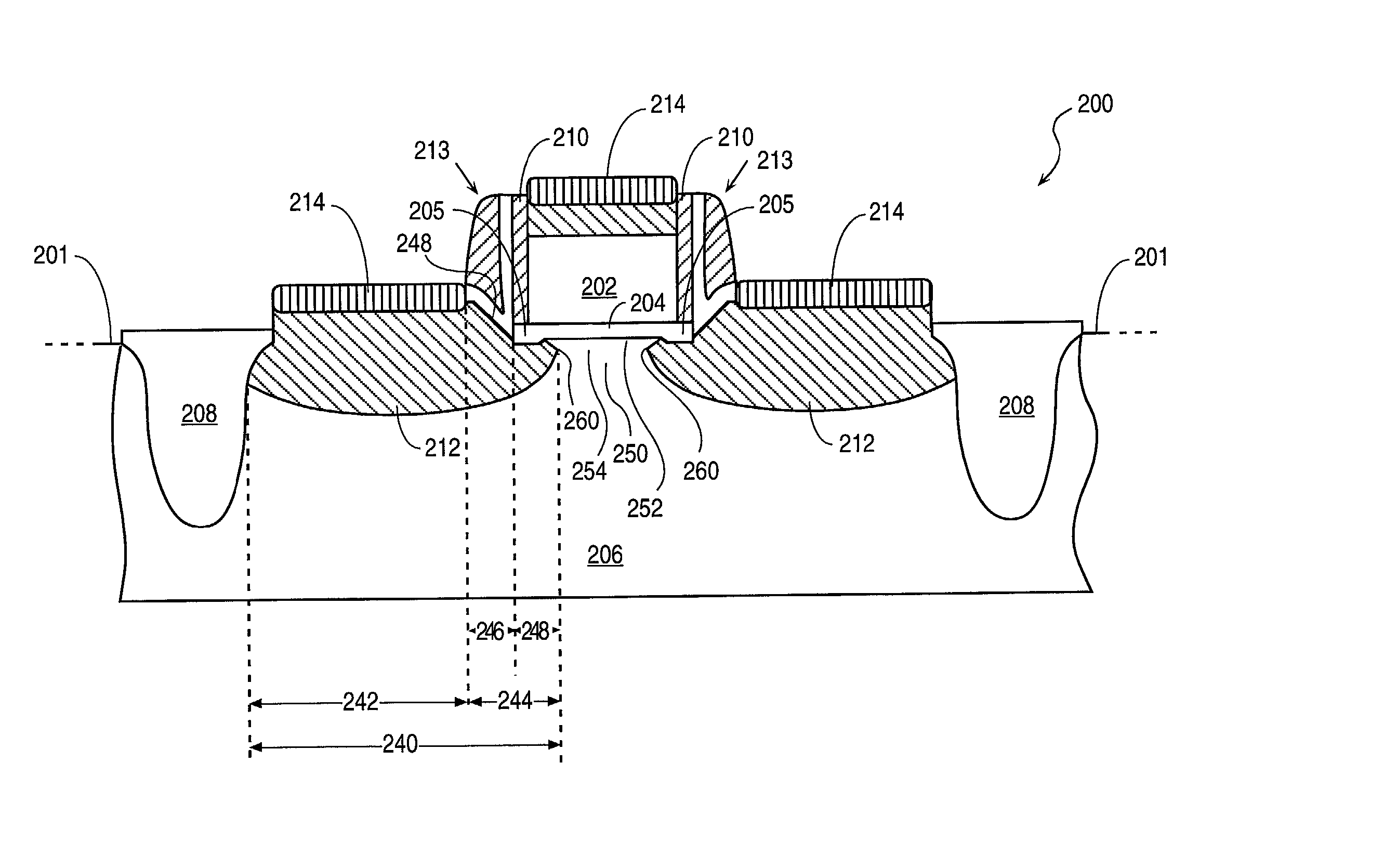

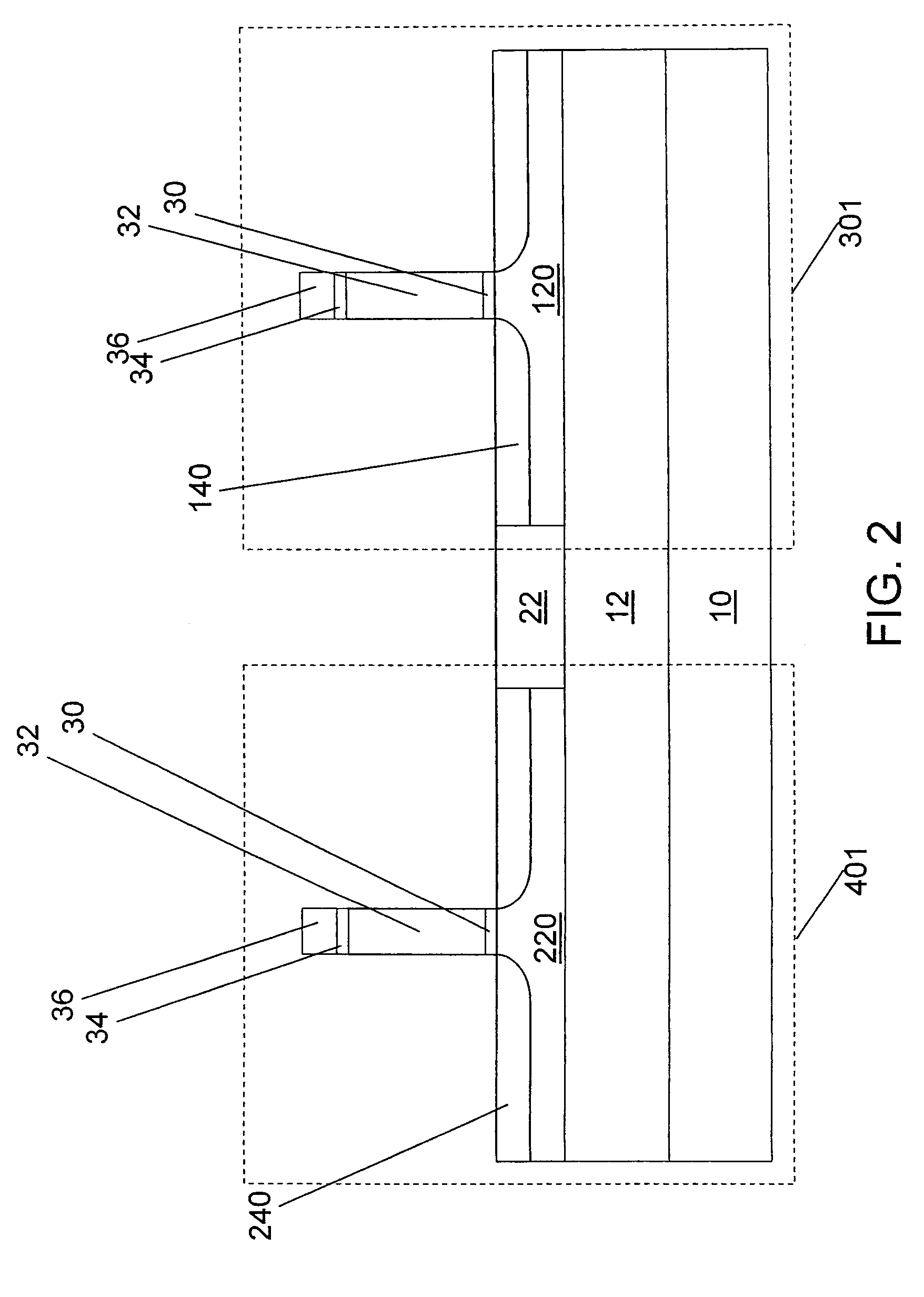

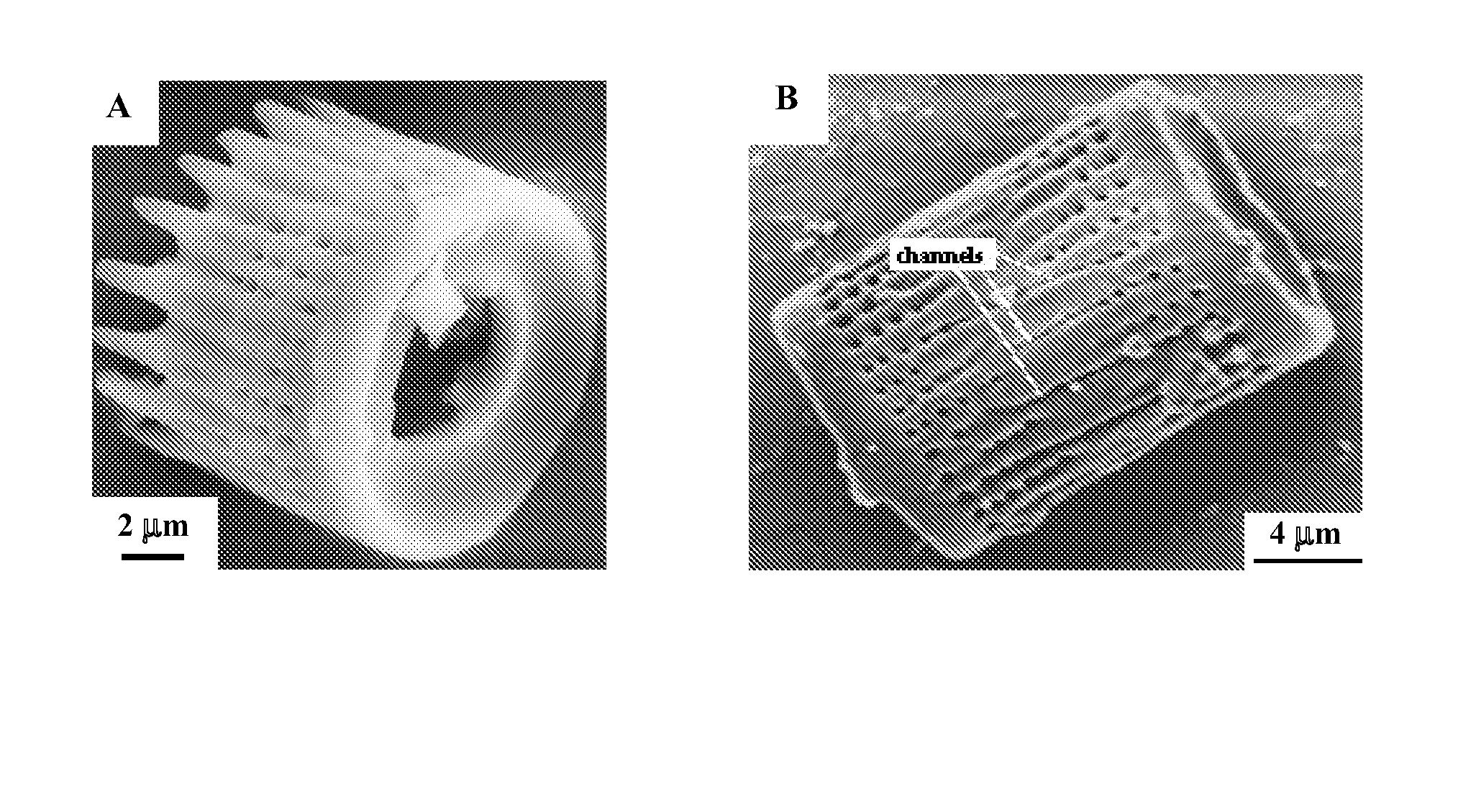

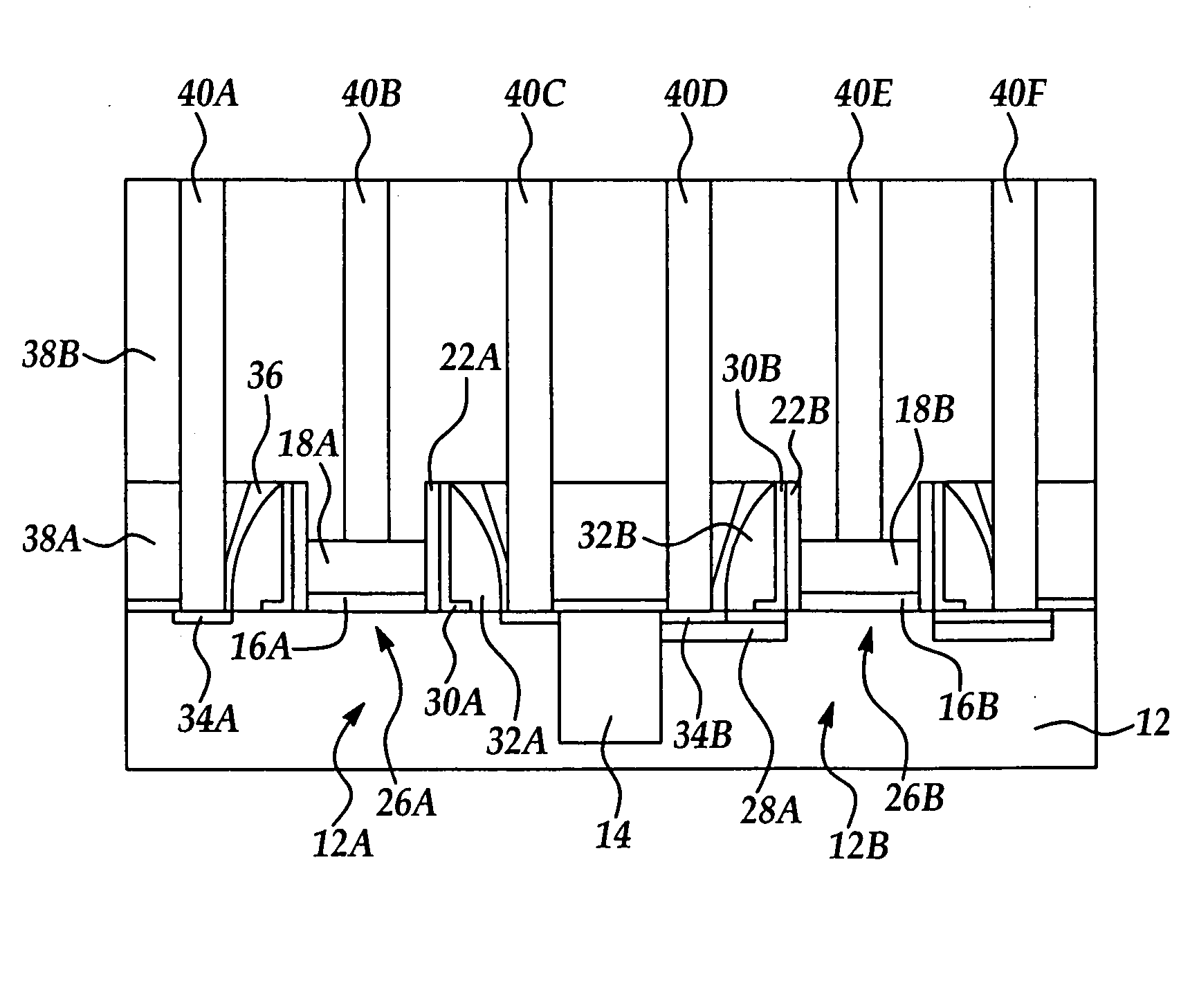

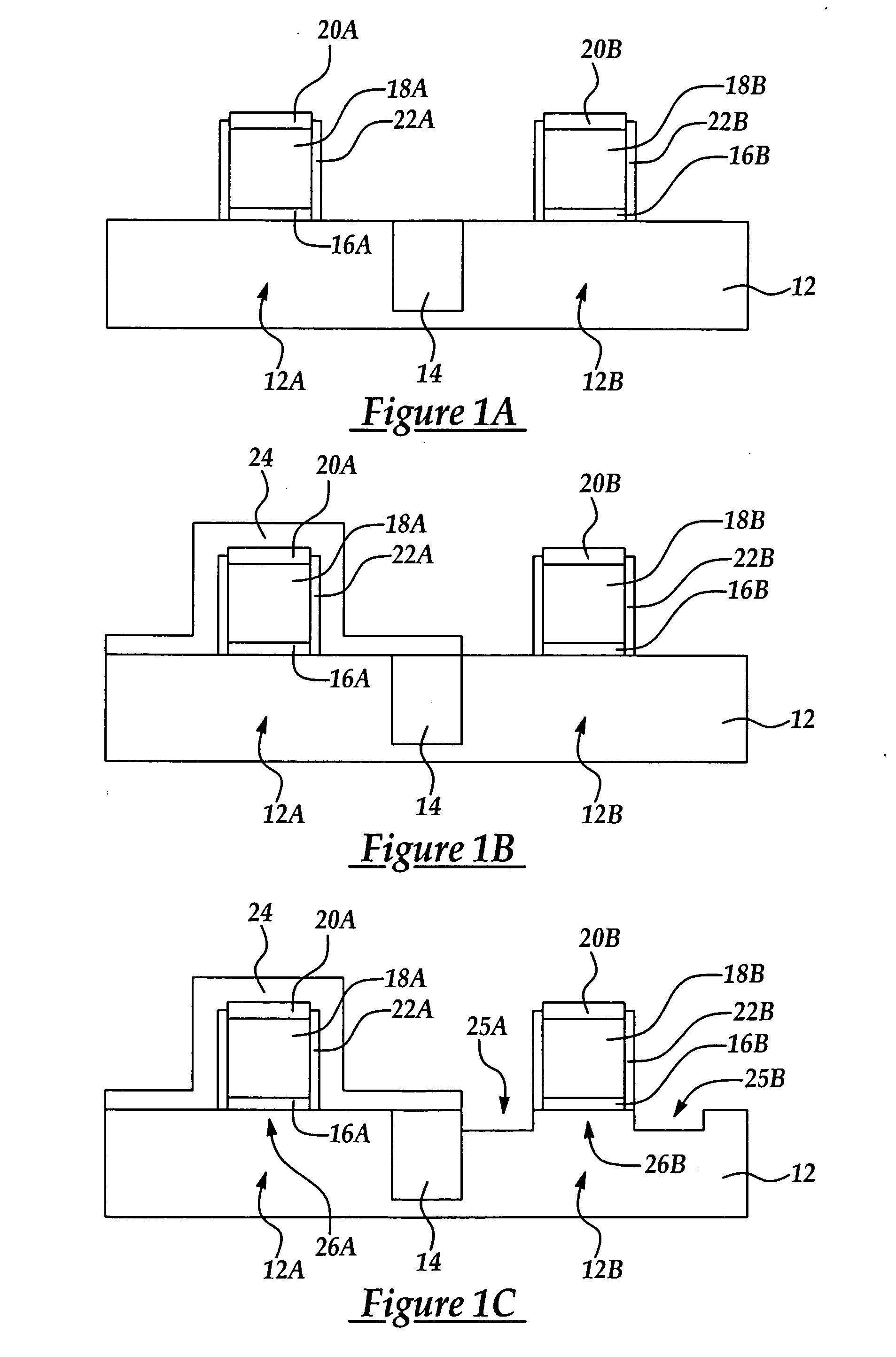

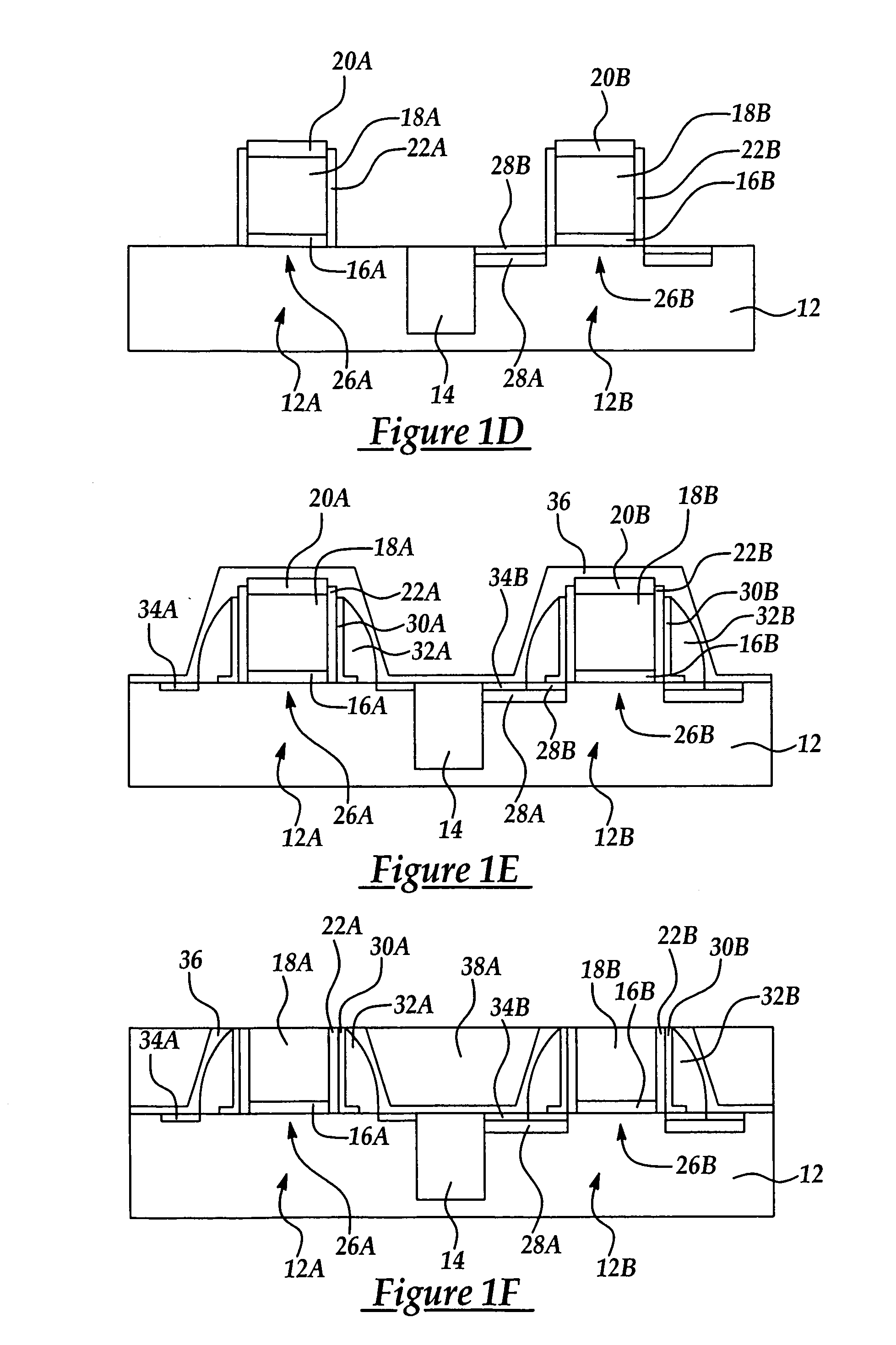

MOS devices with reduced recess on substrate surface

ActiveUS20070034906A1Improve short channel effectHigh device drive currentTransistorSemiconductor/solid-state device manufacturingSilicon alloySubstrate surface

A MOS device having reduced recesses under a gate spacer and a method for forming the same are provided. The MOS device includes a gate structure overlying the substrate, a sidewall spacer on a sidewall of the gate structure, a recessed region having a recess depth of substantially less than about 30 Å underlying the sidewall spacer, and a silicon alloy region having at least a portion in the substrate and adjacent the recessed region. The silicon alloy region has a thickness of substantially greater than about 30 nm. A shallow recess region is achieved by protecting the substrate when a hard mask on the gate structure is removed. The MOS device is preferably a pMOS device.

Owner:TAIWAN SEMICON MFG CO LTD

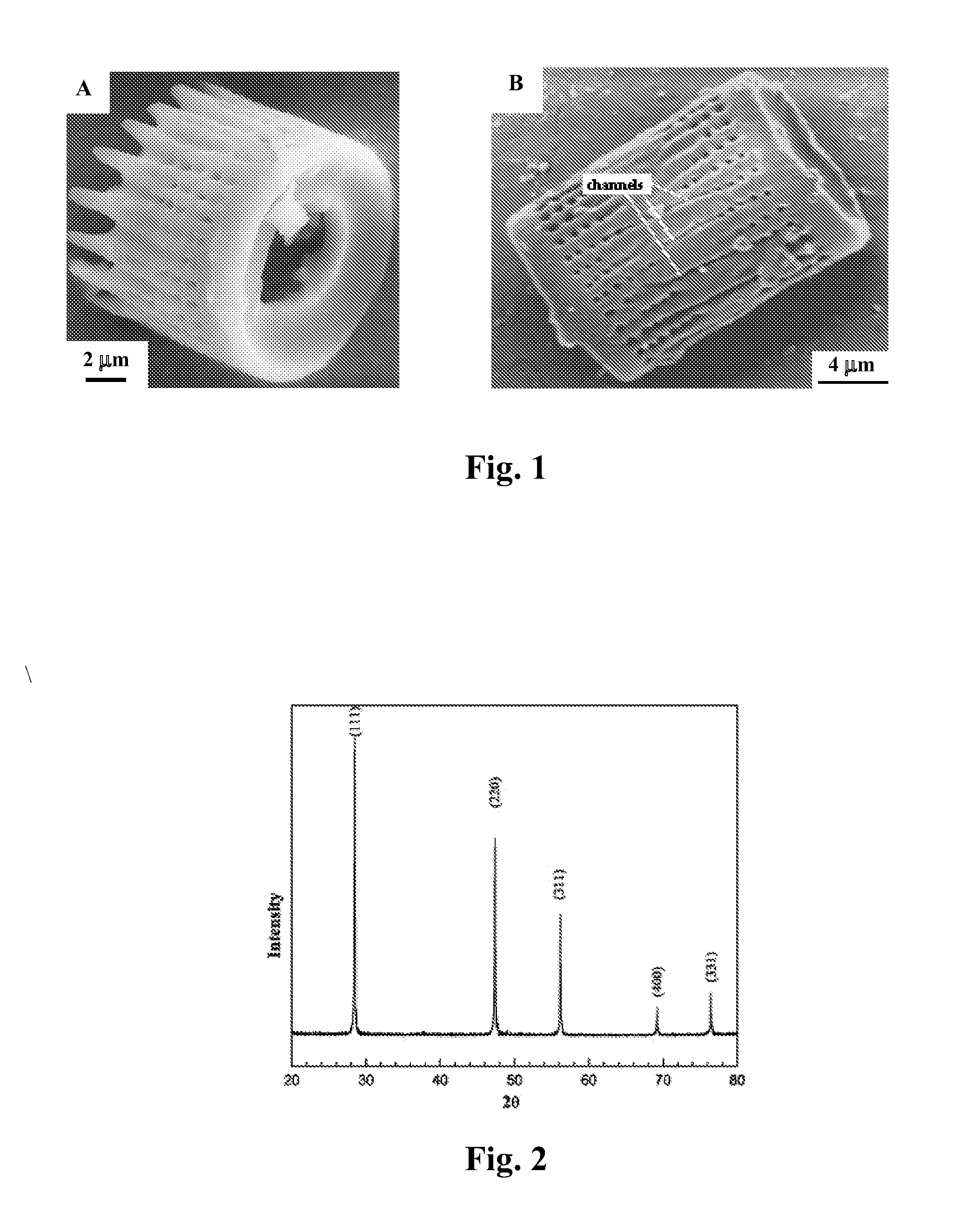

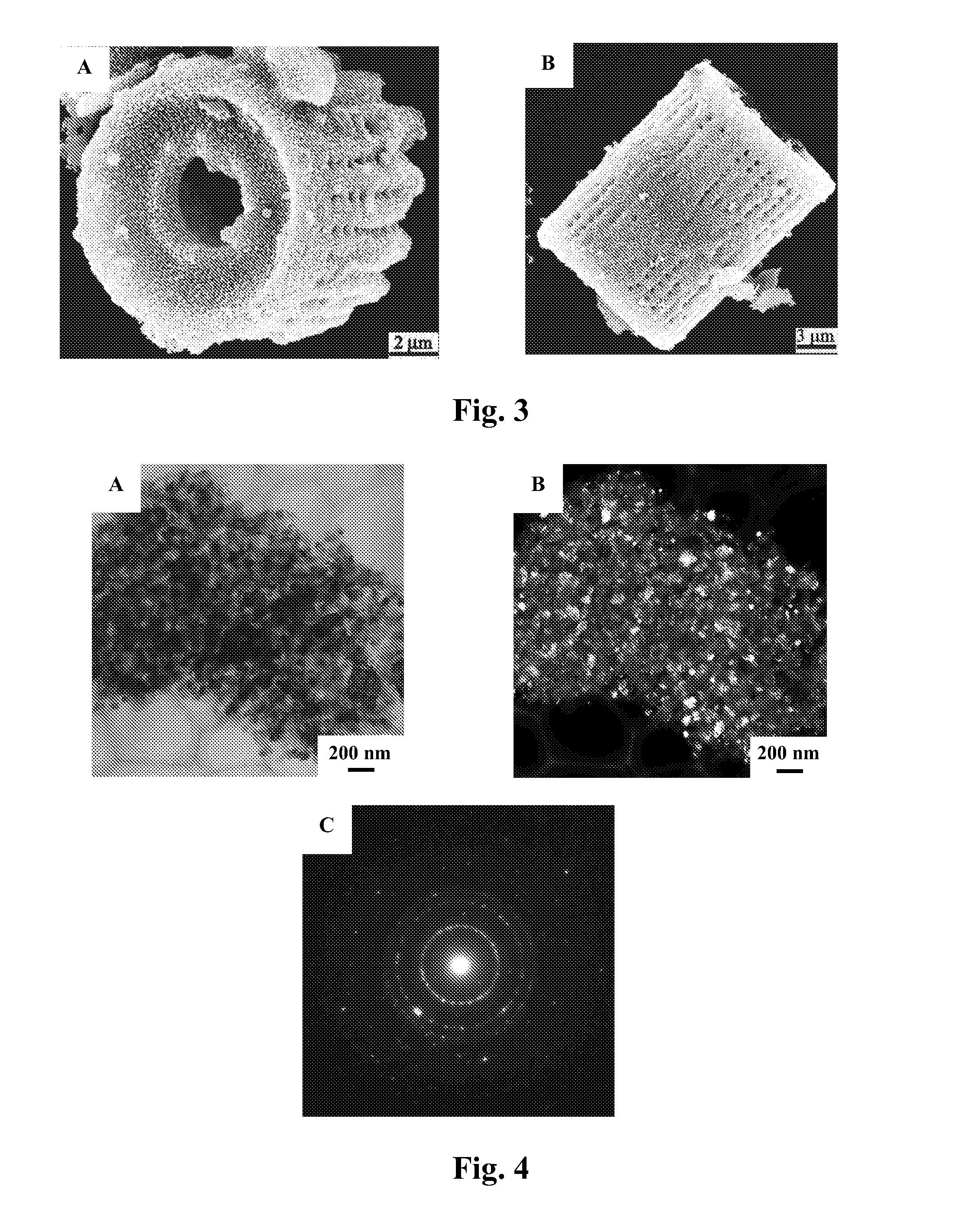

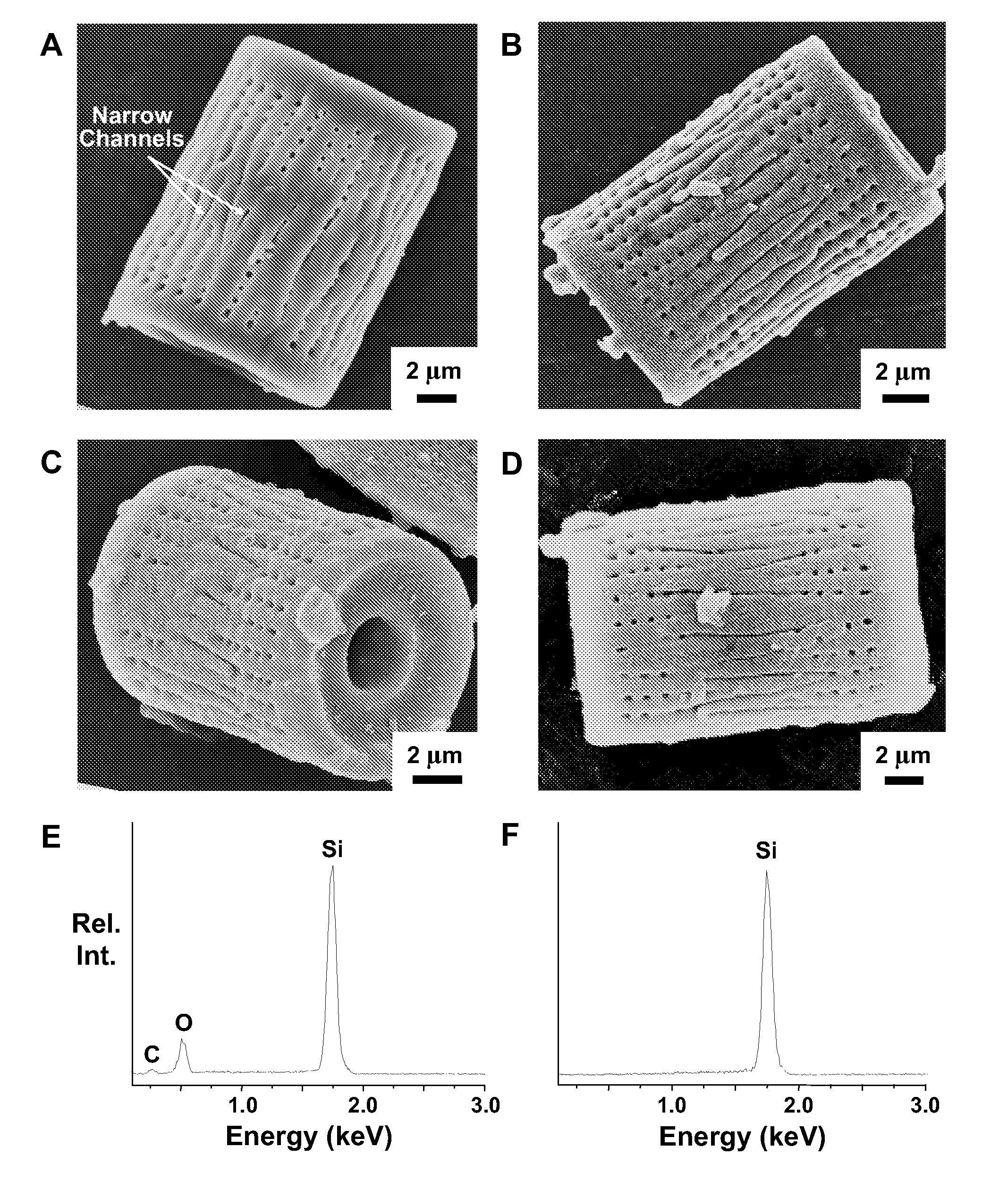

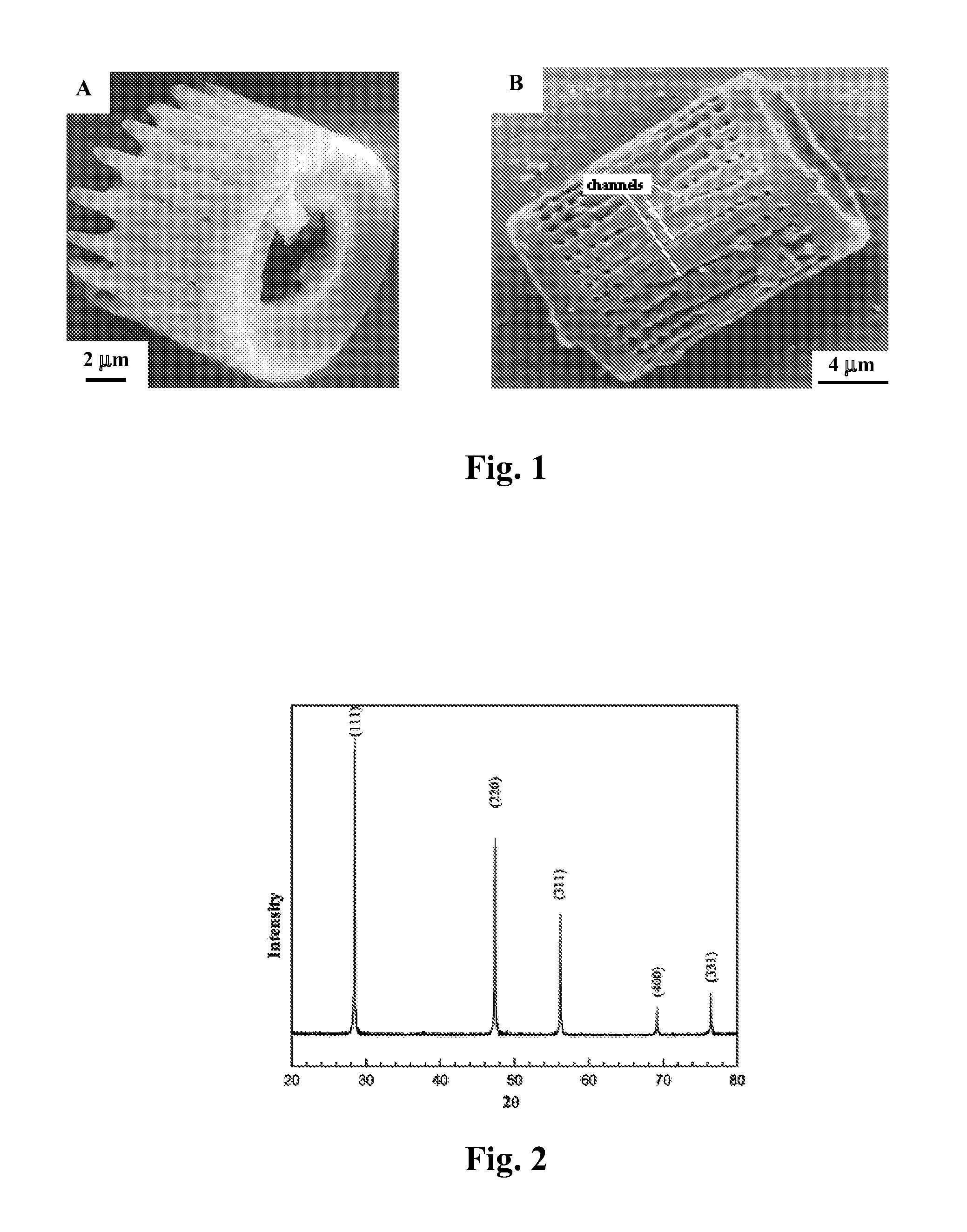

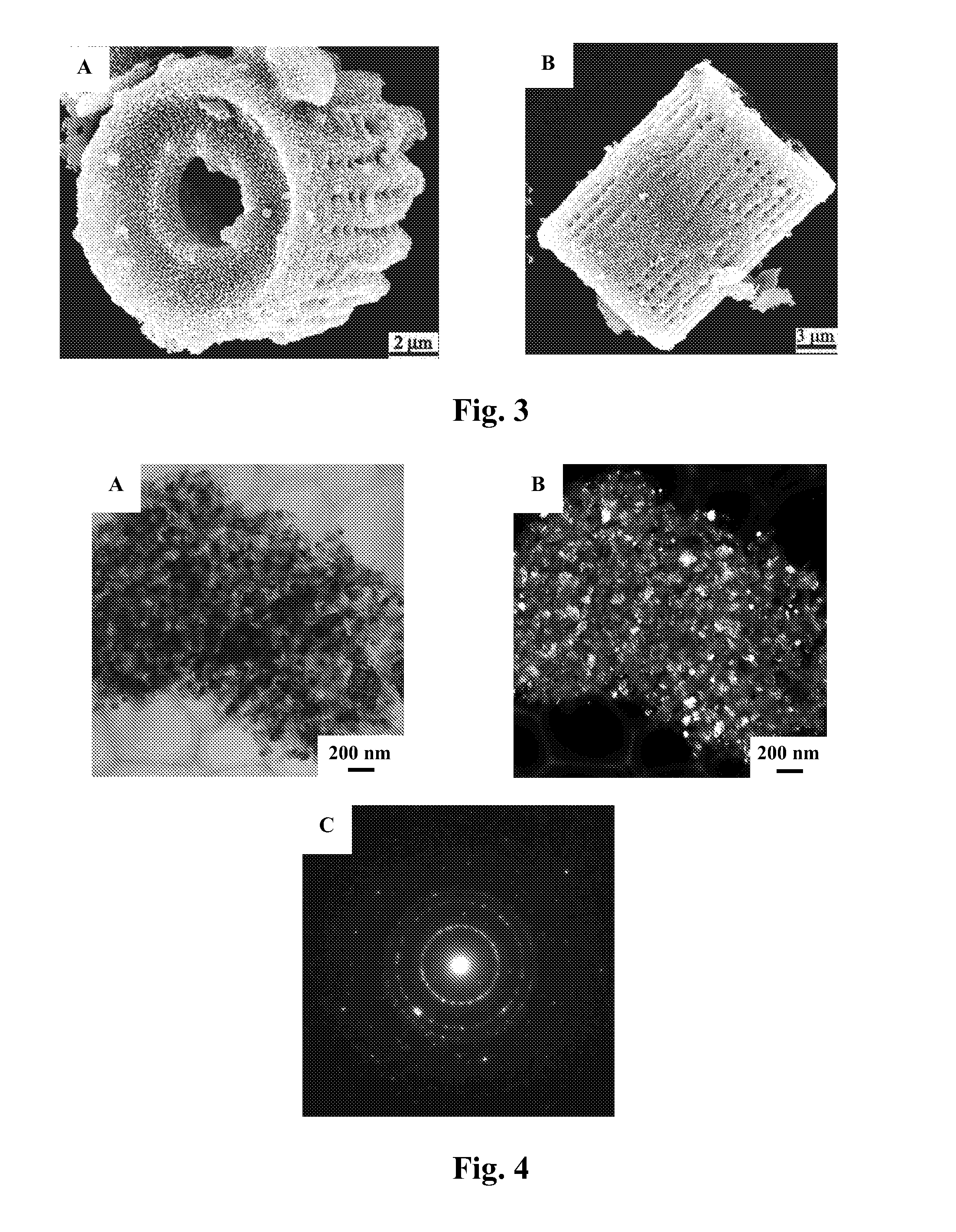

Methods of fabricating nanoscale-to-microscale structures

InactiveUS20080038170A1Attractive and optical propertyAttractive mechanical propertySilicaMixing methodsChemical compositionChemical reaction

Methods for the production of shaped nanoscale-to-microscale structures, wherein a nanoscale-to-microscale template is provided having an original chemical composition and an original shape, and the nanoscale-to-microscale template subjected to a chemical reaction, so as to partially or completely convert the nanoscale-to-microscale template into the shaped nanoscale-to-microscale structure having a chemical composition different than the original chemical composition and having substantially the same shape as the original shape, being a scaled version of the original shape. The shaped nanoscale-to-microscale structure formed comprises an element (such as silicon), a metallic alloy (such as a silicon alloy), or a non-oxide compound (such as silicon carbide or silicon nitride).

Owner:GEORGIA TECH RES CORP

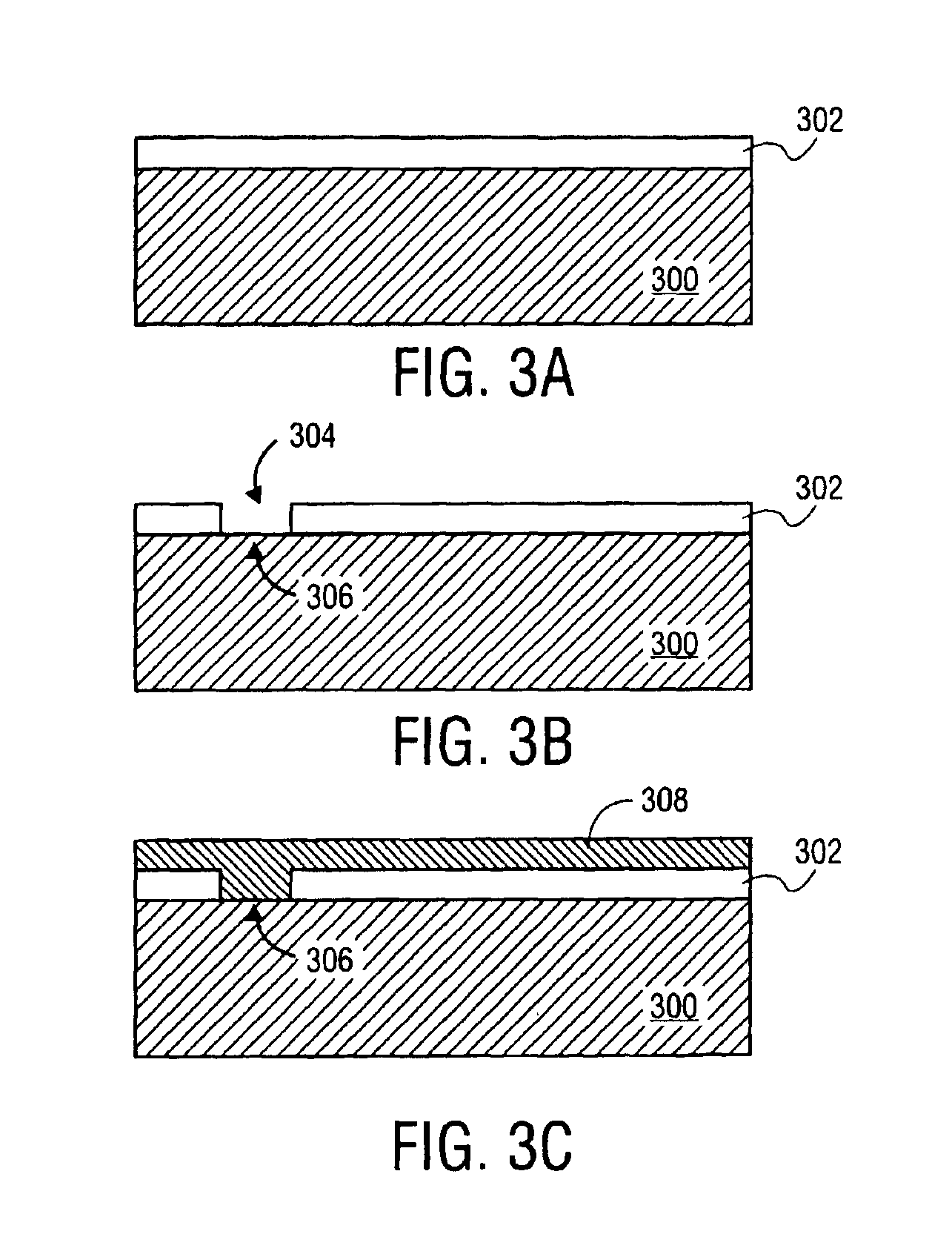

Self-aligned silicide process for silicon sidewall source and drain contacts

A method (and structure formed thereby) of forming a metal silicide contact on a non-planar silicon containing region having controlled consumption of the silicon containing region, includes forming a blanket metal layer over the silicon containing region, forming a silicon layer over the metal layer, etching anisotropically and selectively with respect to the metal the silicon layer, reacting the metal with silicon at a first temperature to form a metal silicon alloy, etching unreacted portions of the metal layer, annealing at a second temperature to form an alloy of metal-Si2, and selectively etching the unreacted silicon layer.

Owner:INT BUSINESS MASCH CORP

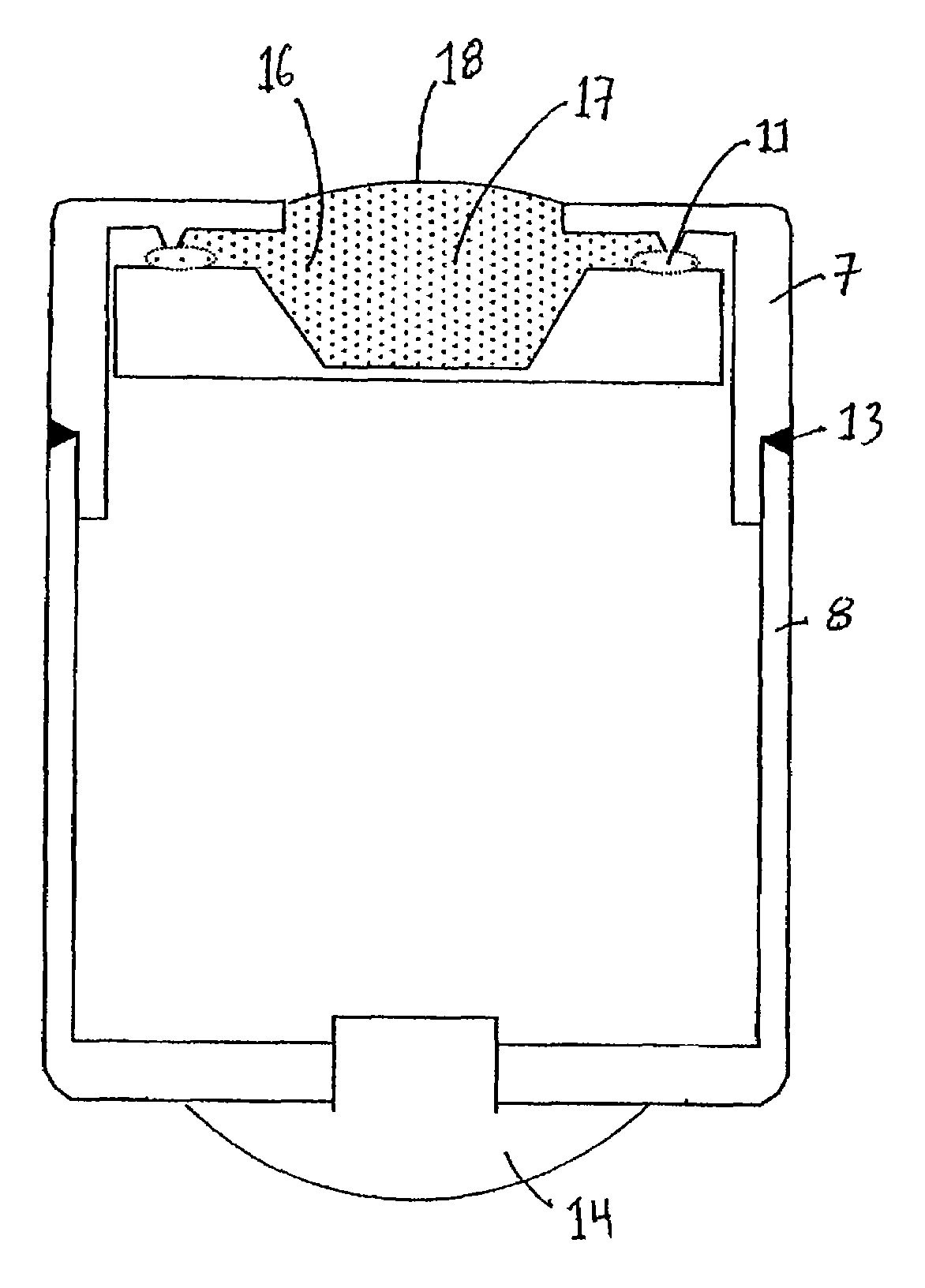

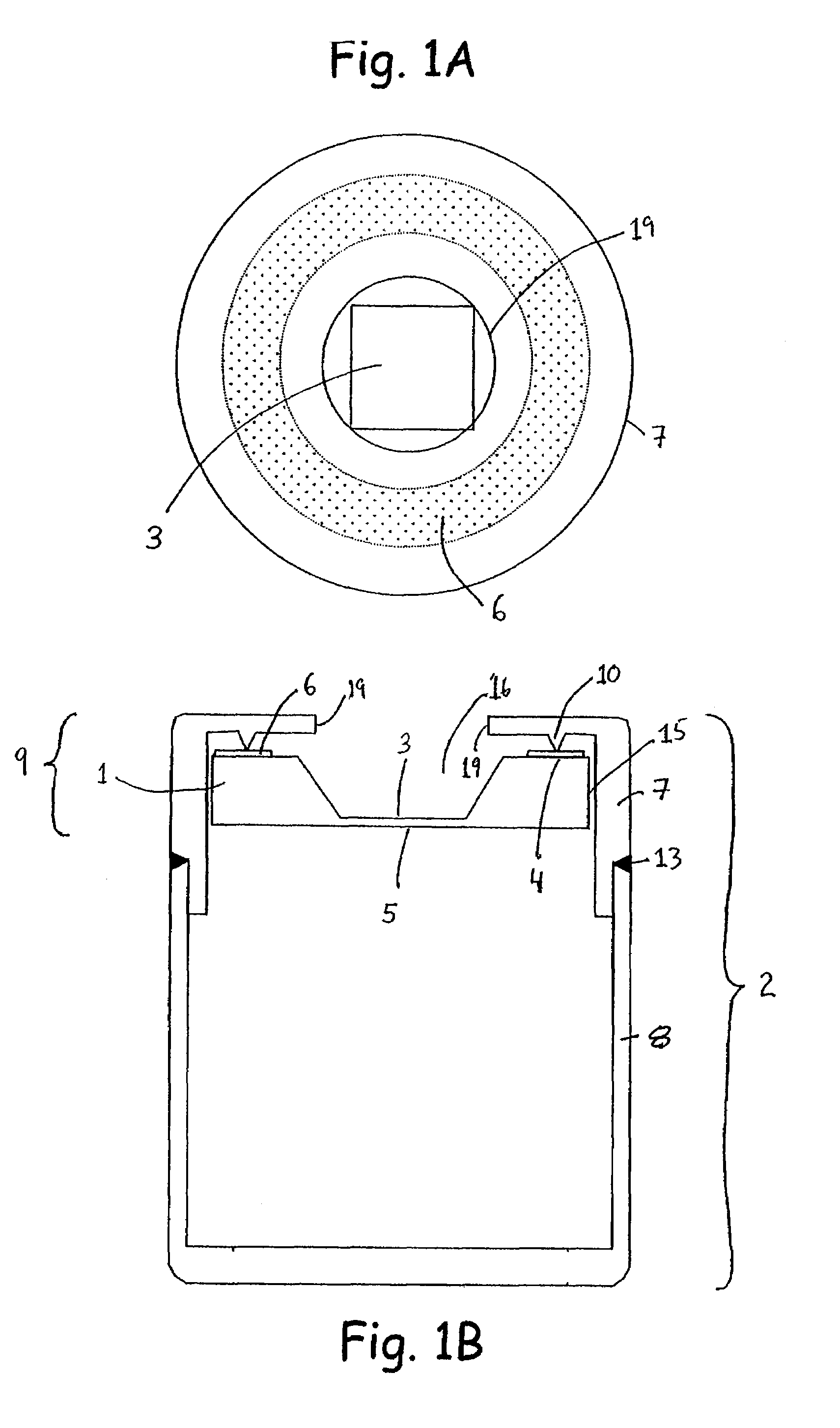

Hermetically sealable silicon system and method of making same

InactiveUS7402899B1Efficient workSemiconductor/solid-state device detailsSolid-state devicesHermetic sealSilicon alloy

A device and method for hermetically sealing a medical device is provided. In one aspect, a silicon device is coupled to a sensor, such as a pressure transducer, which benefits from having direct contact with its environment, which in many cases, is the human body. Thus, a method to hermetically seal the non-sensing portion of a silicon device while allowing the sensing portion (e.g. the pressure transducer) to have direct contact with the body is provided. In one aspect, a silicon chip, a gold preform and a metallic housing are each primed for sealing and are assembled. The assembly is then heated to react the gold preform to the silicon chip and to form a molten gold-silicon alloy in-situ to bind the metallic housing to the non-sensing portion of the silicon chip. In this way, the non-sensing portion of the silicon chip is hermetically sealed and protected from exposure, while still permitting exposure of the sensing portion to the environment.

Owner:PACESETTER INC

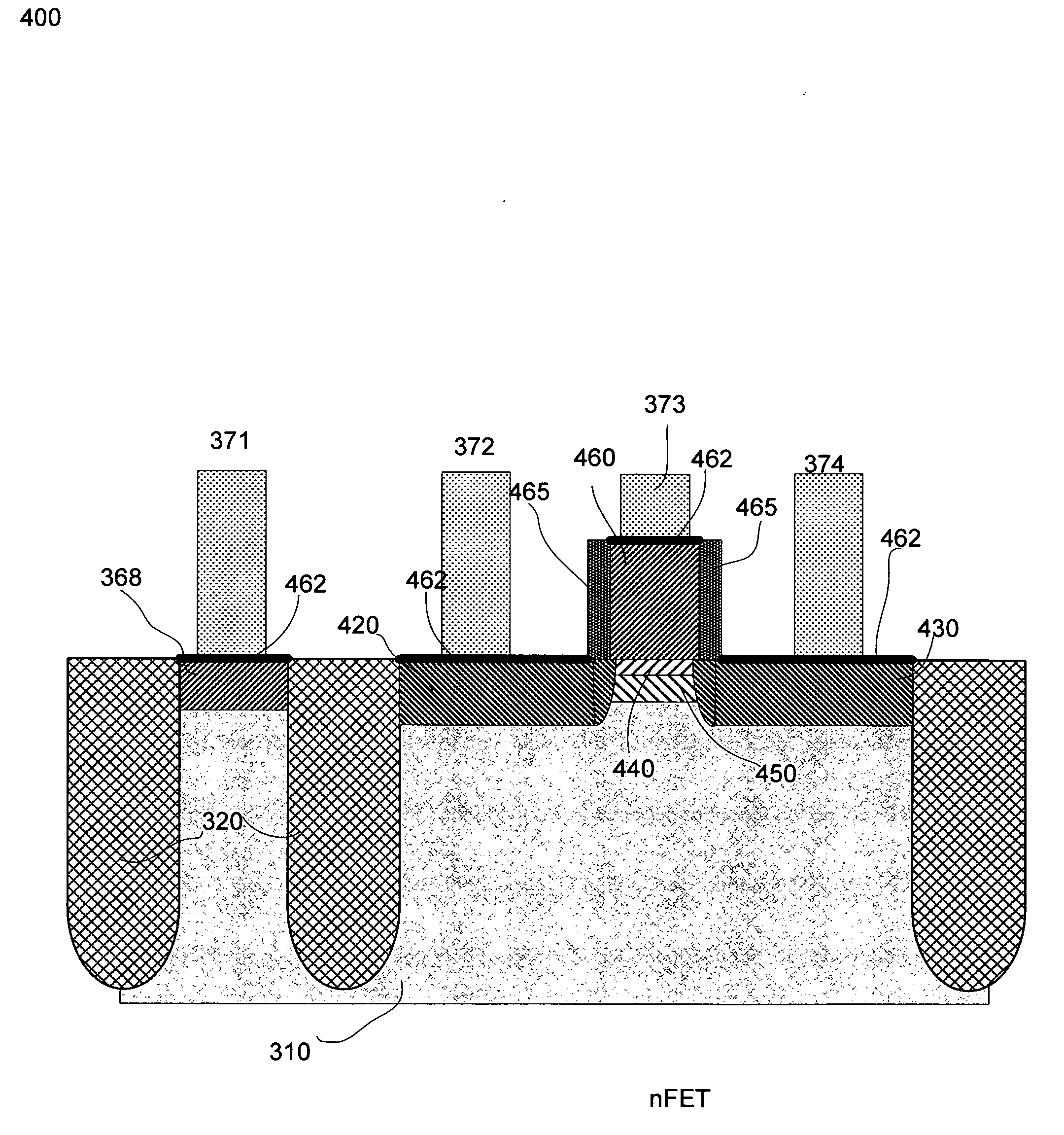

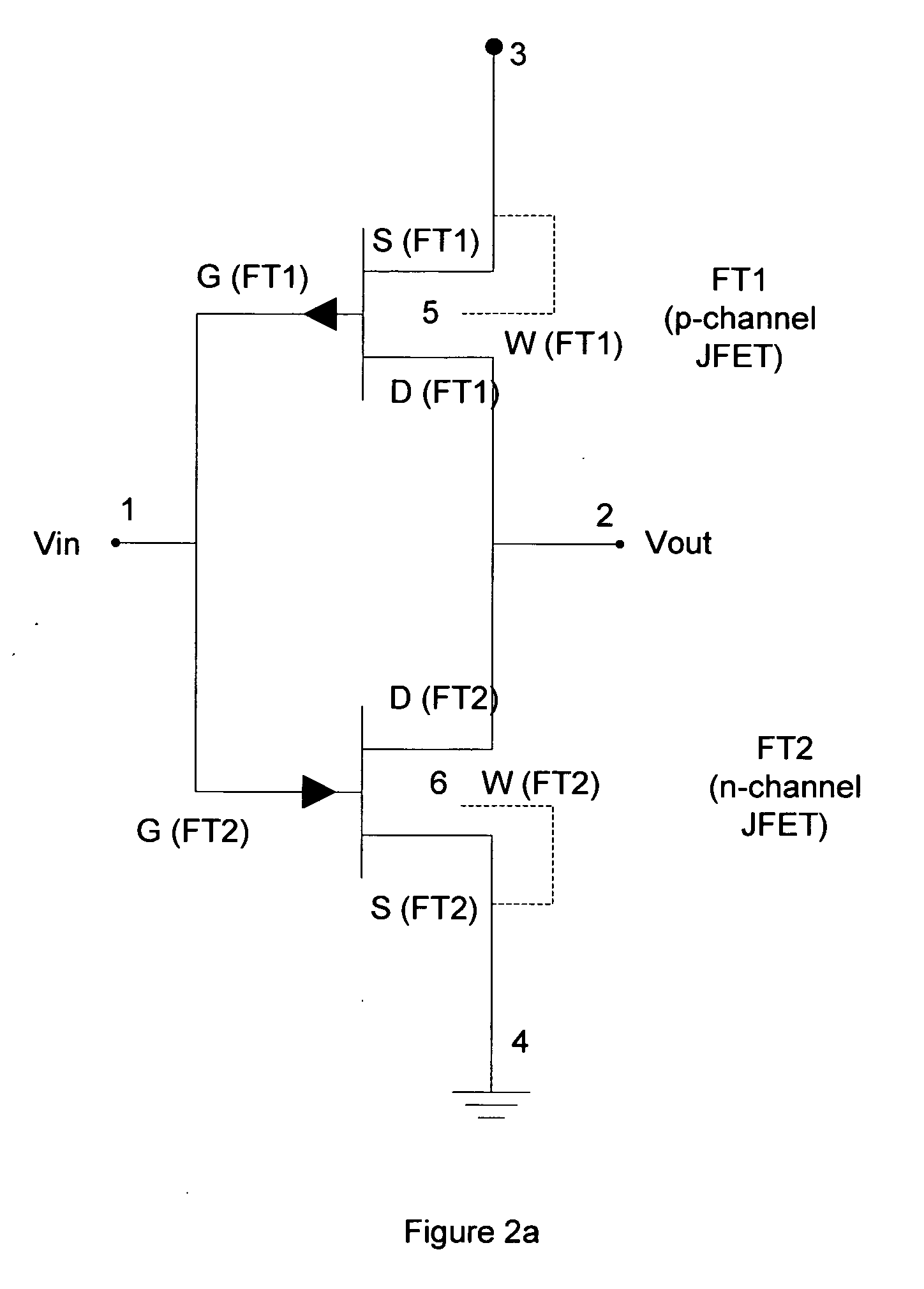

Integrated circuit using complementary junction field effect transistor and MOS transistor in silicon and silicon alloys

InactiveUS20070096144A1Reduce power consumptionReduce gate capacitanceTransistorSolid-state devicesCMOSSilicon alloy

This invention describes a method of building complementary logic circuits using junction field effect transistors in silicon. This invention is ideally suited for deep submicron dimensions, preferably below 65 nm. The basis of this invention is a complementary Junction Field Effect Transistor which is operated in the enhancement mode. The speed-power performance of the JFETs becomes comparable with the CMOS devices at sub-70 nanometer dimensions. However, the maximum power supply voltage for the JFETs is still limited to below the built-in potential (a diode drop). To satisfy certain applications which require interface to an external circuit driven to higher voltage levels, this invention includes the structures and methods to build CMOS devices on the same substrate as the JFET devices.

Owner:MIE FUJITSU SEMICON

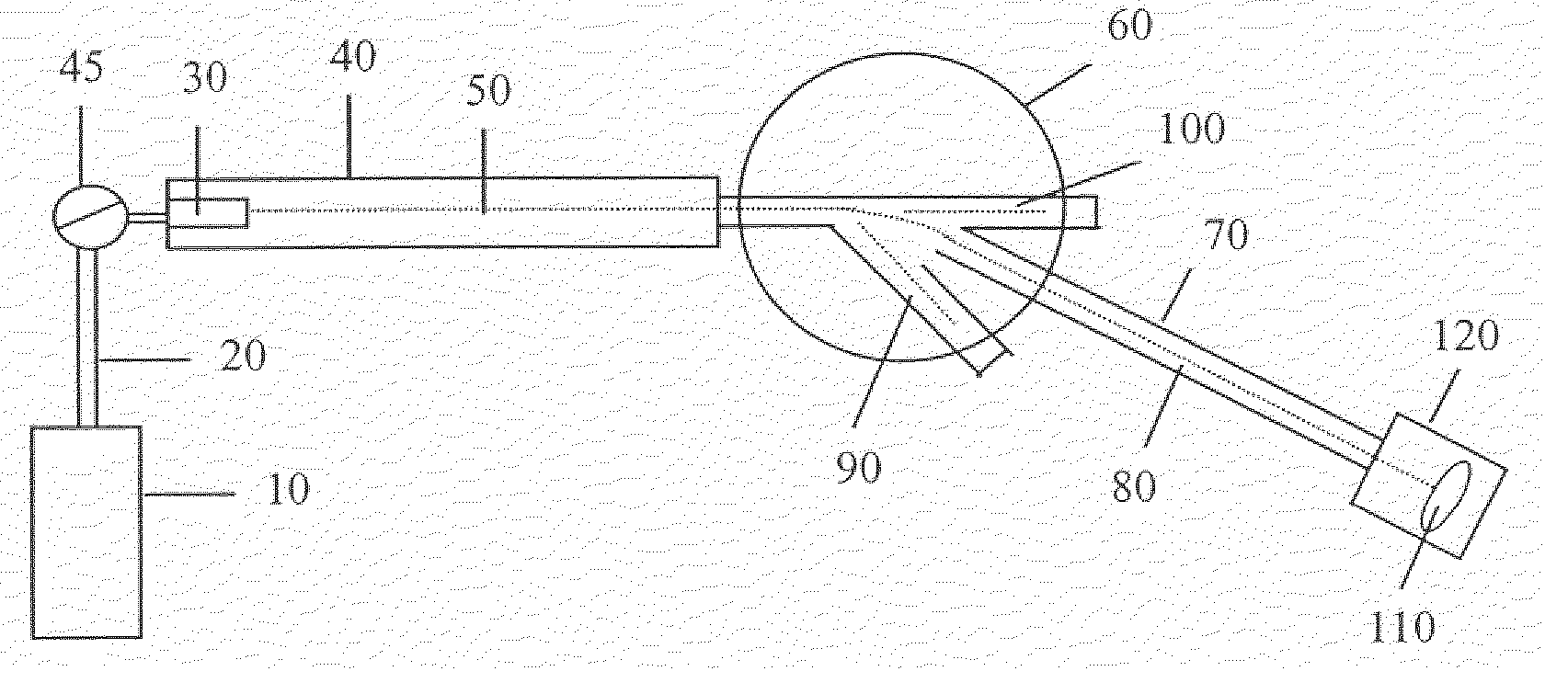

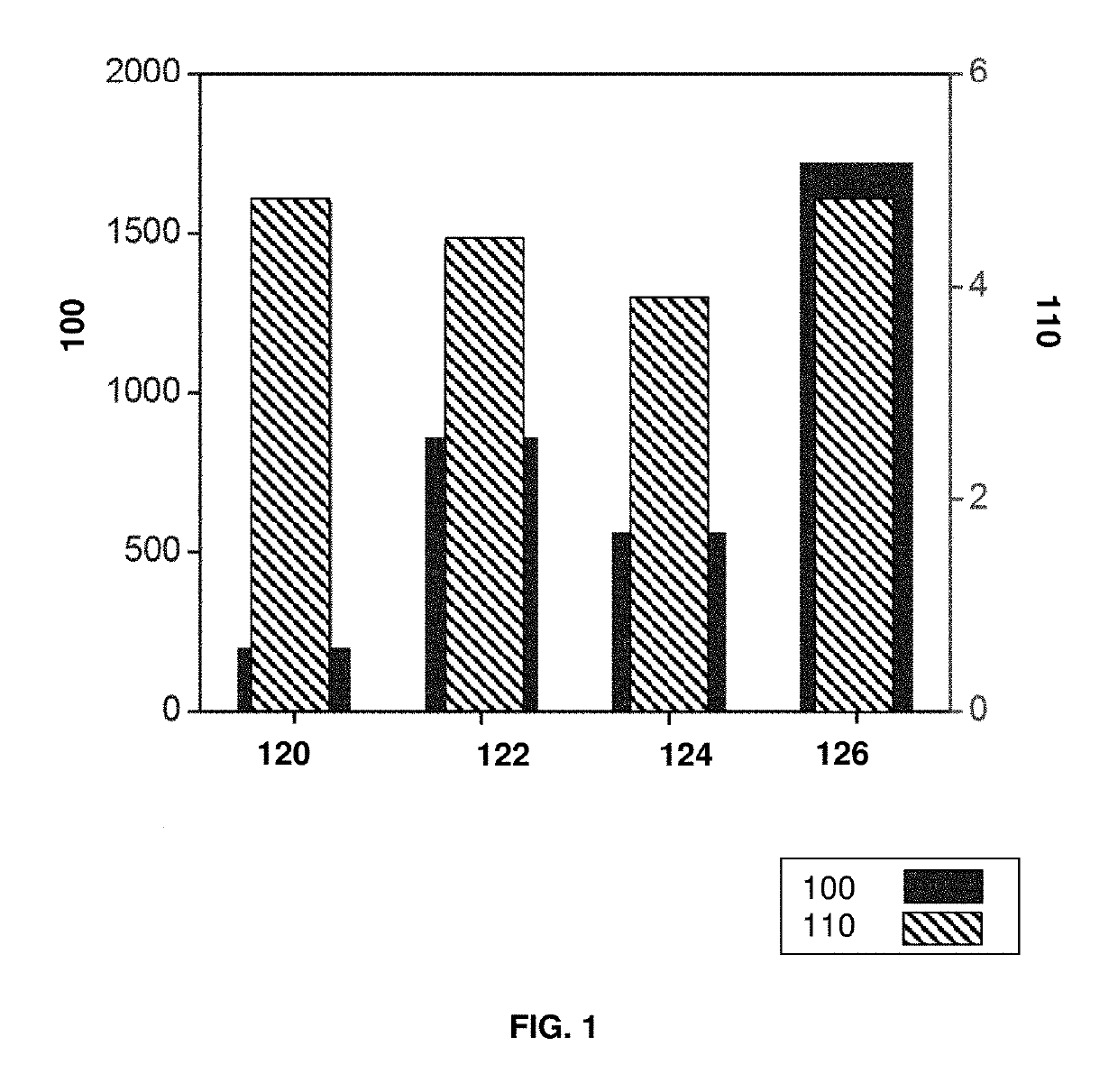

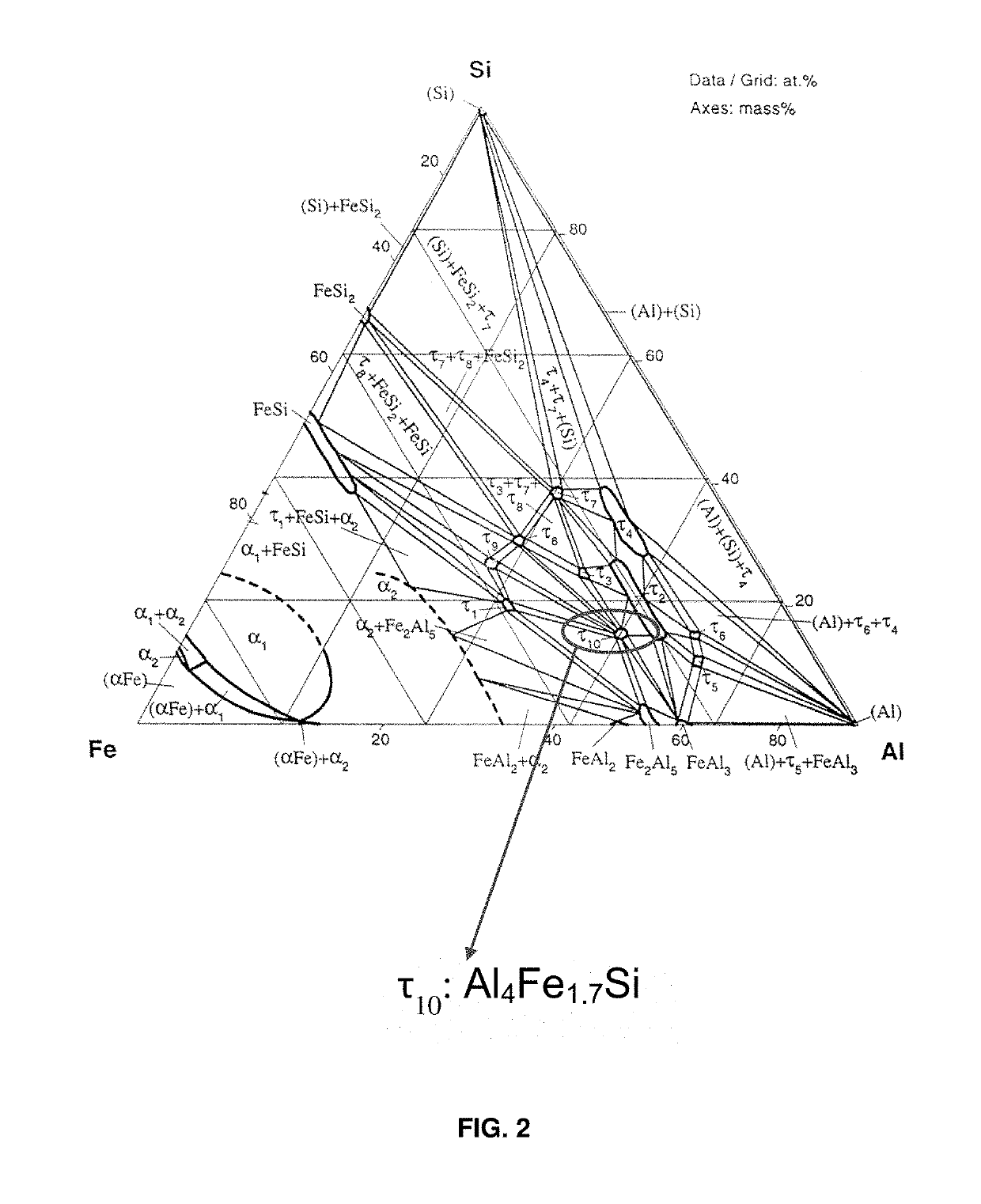

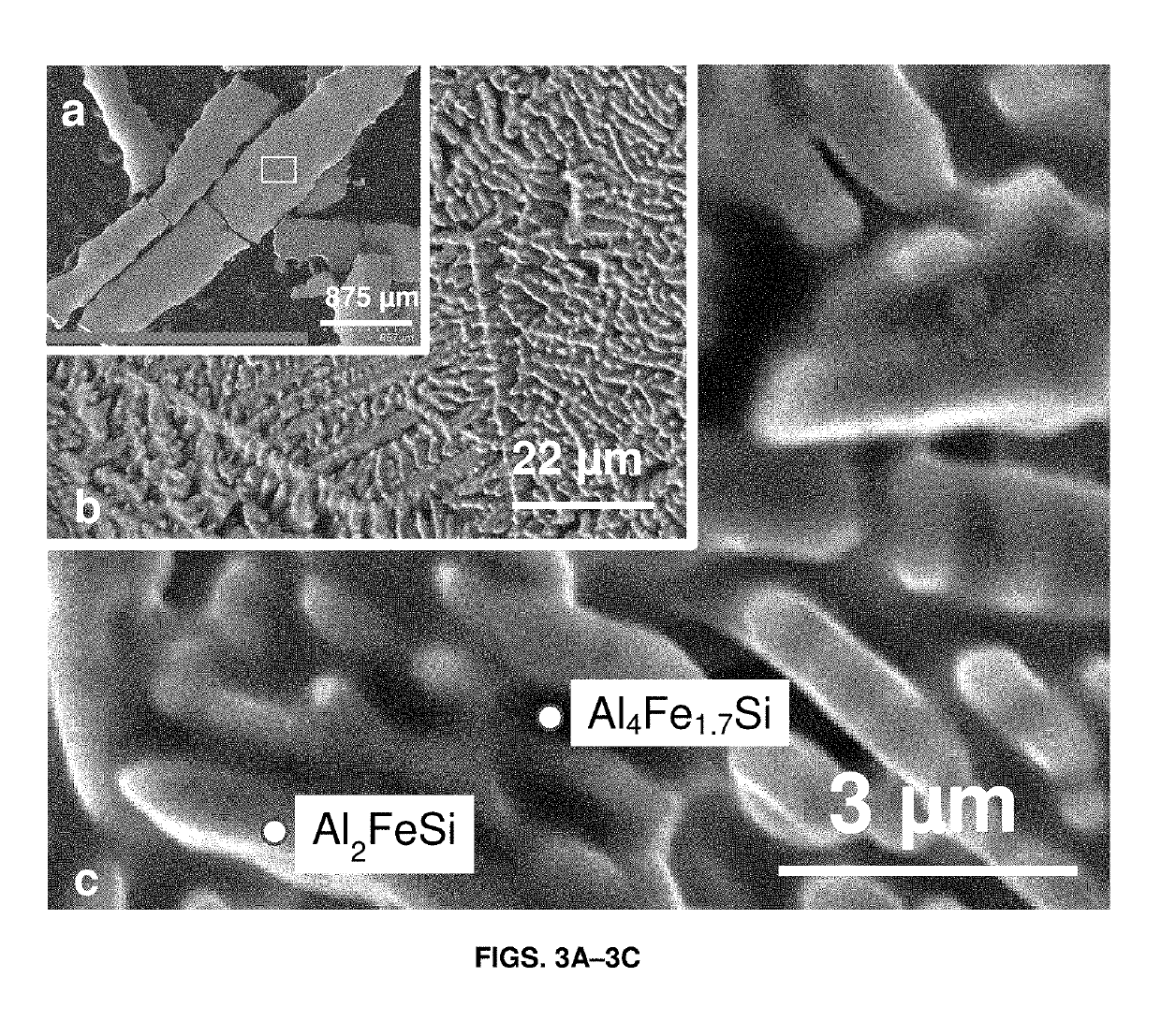

Rapidly solidified high-temperature aluminum iron silicon alloys

InactiveUS10294552B2Large gradientLarge strainAdditive manufacturing apparatusIncreasing energy efficiencySilicon alloyHigh energy

Methods of making high-strength, lightweight alloy components capable of high temperature performance comprising aluminum, silicon, and iron and / or nickel are provided. A high-energy stream, such as a laser or electron beam, may be selectively directed towards a precursor material to melt a portion of the precursor material in a localized region. The molten precursor material is cooled at a rate of greater than or equal to about 1.0×105 K / second to form a solid high-strength, lightweight alloy component comprising a stable ternary cubic phase having high heat resistance and high strength. The stable ternary phase may be AlxFeySiz, where x ranges from about 4 to about 5 or about 7.2 to about 7.6, y is about 1.5 to about 2.2, and z is about 1. The stable ternary phase may also be Al6Ni3Si. Materials and components, such as automotive components, made from such methods are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Strained channel CMOS device with fully silicided gate electrode

InactiveUS20060148181A1Lower electrode resistanceInhibitionSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon alloyMetal silicide

A strained channel NMOS and PMOS device pair including fully silicided gate electrodes and method for forming the same, the method including providing a semiconductor substrate including NMOS and PMOS device regions including respective gate structures including polysilicon gate electrodes; forming recessed regions on either side of a channel region including at least one of the NMOS and PMOS device regions; backfilling portions of the recessed regions with a semiconducting silicon alloy to exert a strain on the channel region; forming offset spacers on either side of the gate structures; thinning the polysilicon gate electrodes to a silicidation thickness to allow full metal silicidation through the silicidation thickness; ion implanting the polysilicon gate electrodes to adjust a work function; and, forming a metal silicide through the silicidation thickness to form metal silicide gate electrodes.

Owner:TAIWAN SEMICON MFG CO LTD

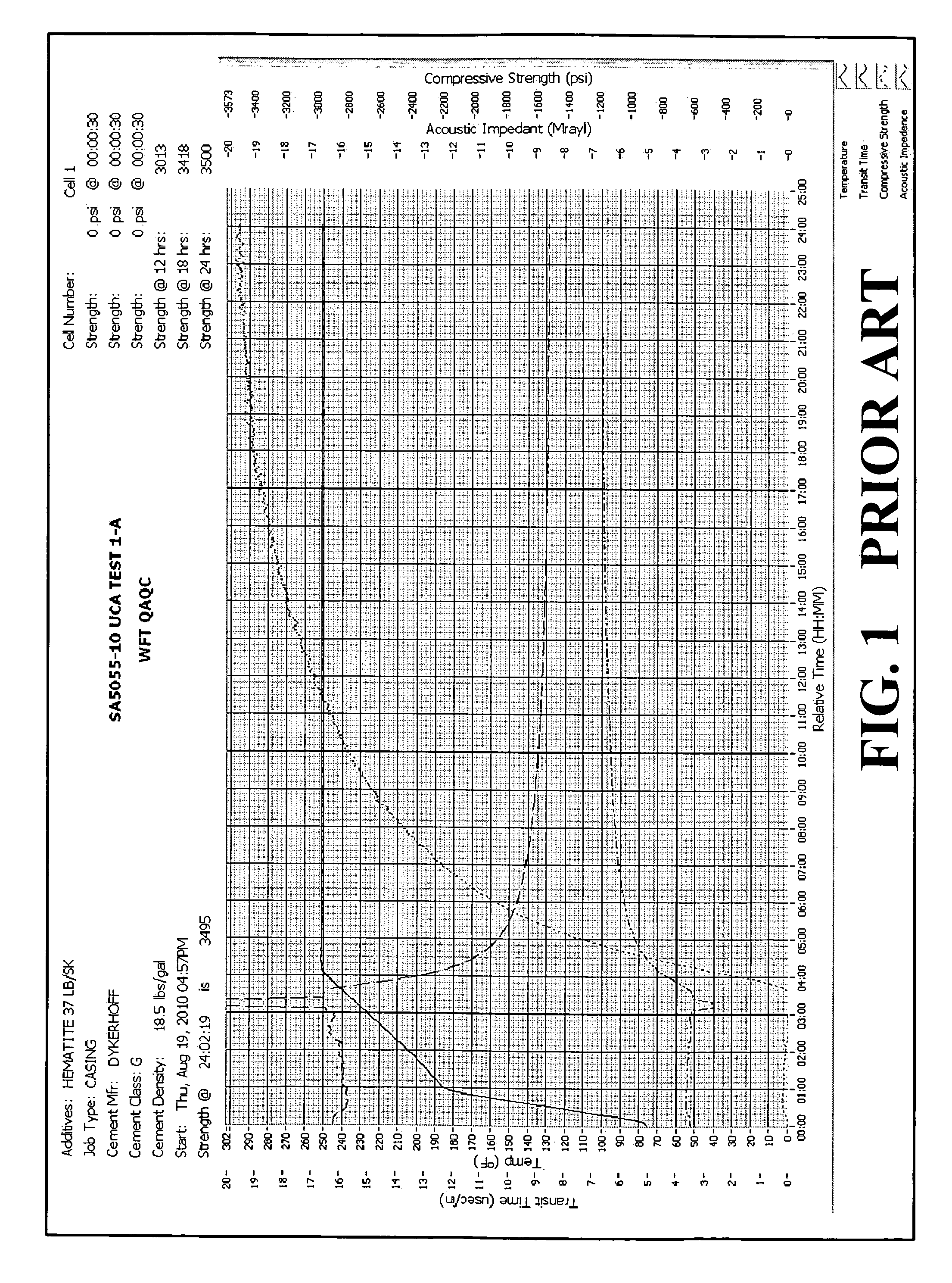

Novel Weight Materials for Use in Cement, Spacer and Drilling Fluids

InactiveUS20120073813A1Improve propertiesEffective amountSolid waste managementFluid removalHigh densitySilicon alloy

A drilling fluid, spacer fluid and cementing compositions for use in subterranean wells are disclosed along with methods for making using same, where the compositions include a weighting system having an effective amount of a metal silicon alloy, mixtures of metal silicon alloys, or mixtures of metal silicon alloys and conventional weighting agents, to produce compositions having a desired high density, while retaining other fluid properties such as pumpability, gas tight sealing, low tendency to segregate, and reduced high temperature cement strength retrogression.

Owner:WEATHERFORD TECH HLDG LLC

Methods of fabricating nanoscale-to-microscale structures

InactiveUS7615206B2Attractive electronic and optical propertyAttractive mechanical propertySilicaMixing methodsChemical reactionChemical composition

Methods for the production of shaped nanoscale-to-microscale structures, wherein a nanoscale-to-microscale template is provided having an original chemical composition and an original shape, and the nanoscale-to-microscale template subjected to a chemical reaction, so as to partially or completely convert the nanoscale-to-microscale template into the shaped nanoscale-to-microscale structure having a chemical composition different than the original chemical composition and having substantially the same shape as the original shape, being a scaled version of the original shape. The shaped nanoscale-to-microscale structure formed comprises an element (such as silicon), a metallic alloy (such as a silicon alloy), or a non-oxide compound (such as silicon carbide or silicon nitride).

Owner:GEORGIA TECH RES CORP

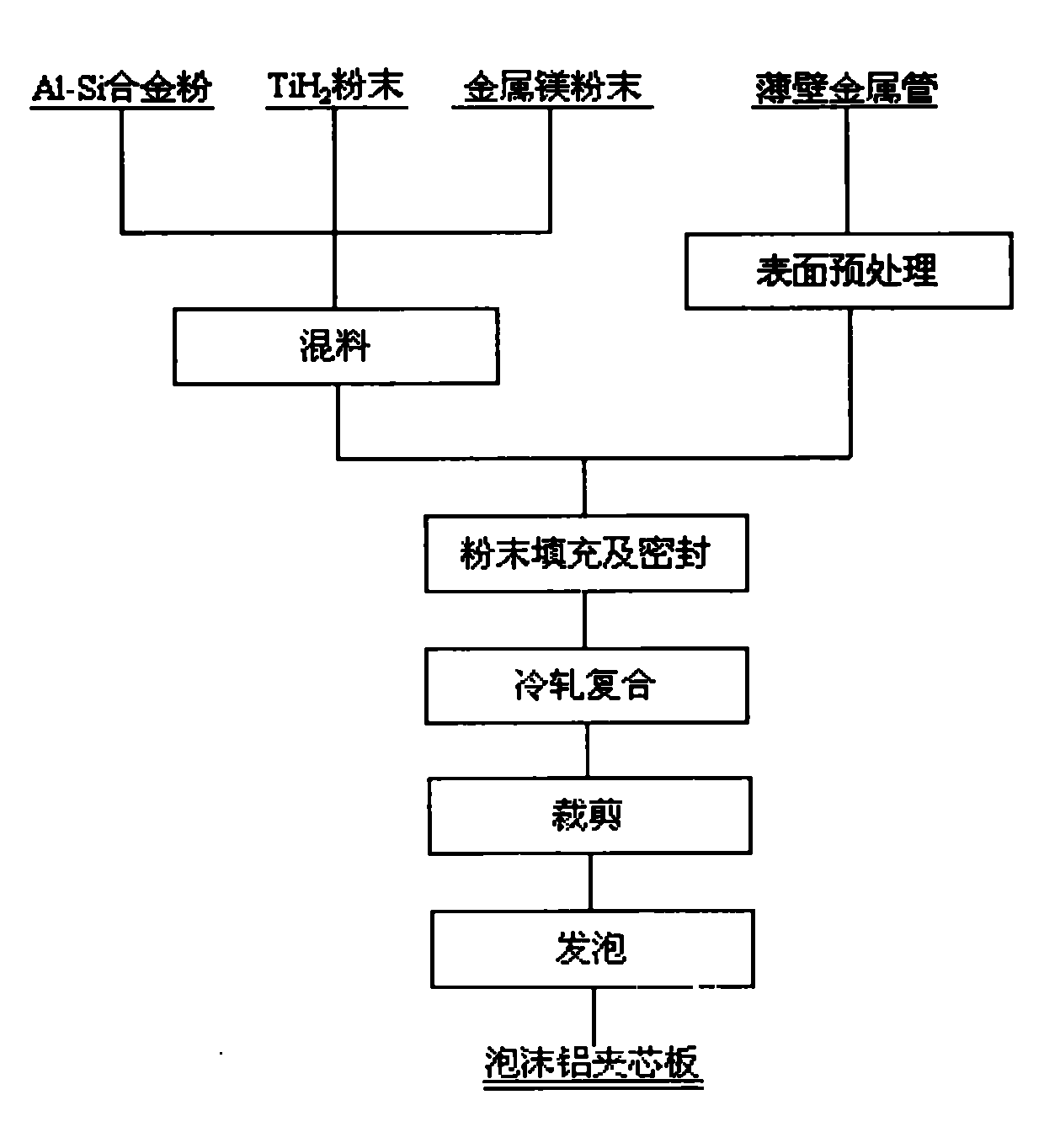

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

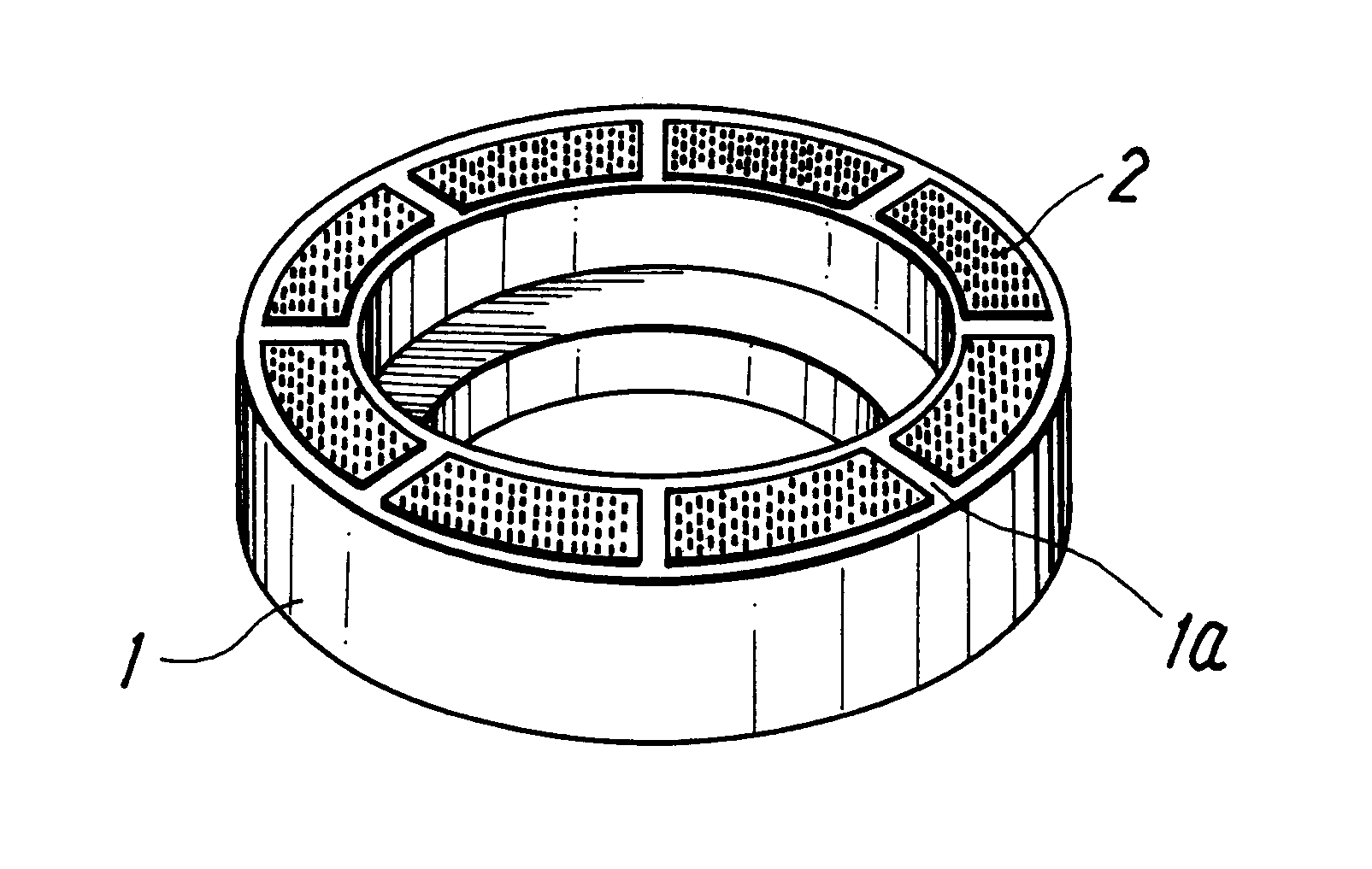

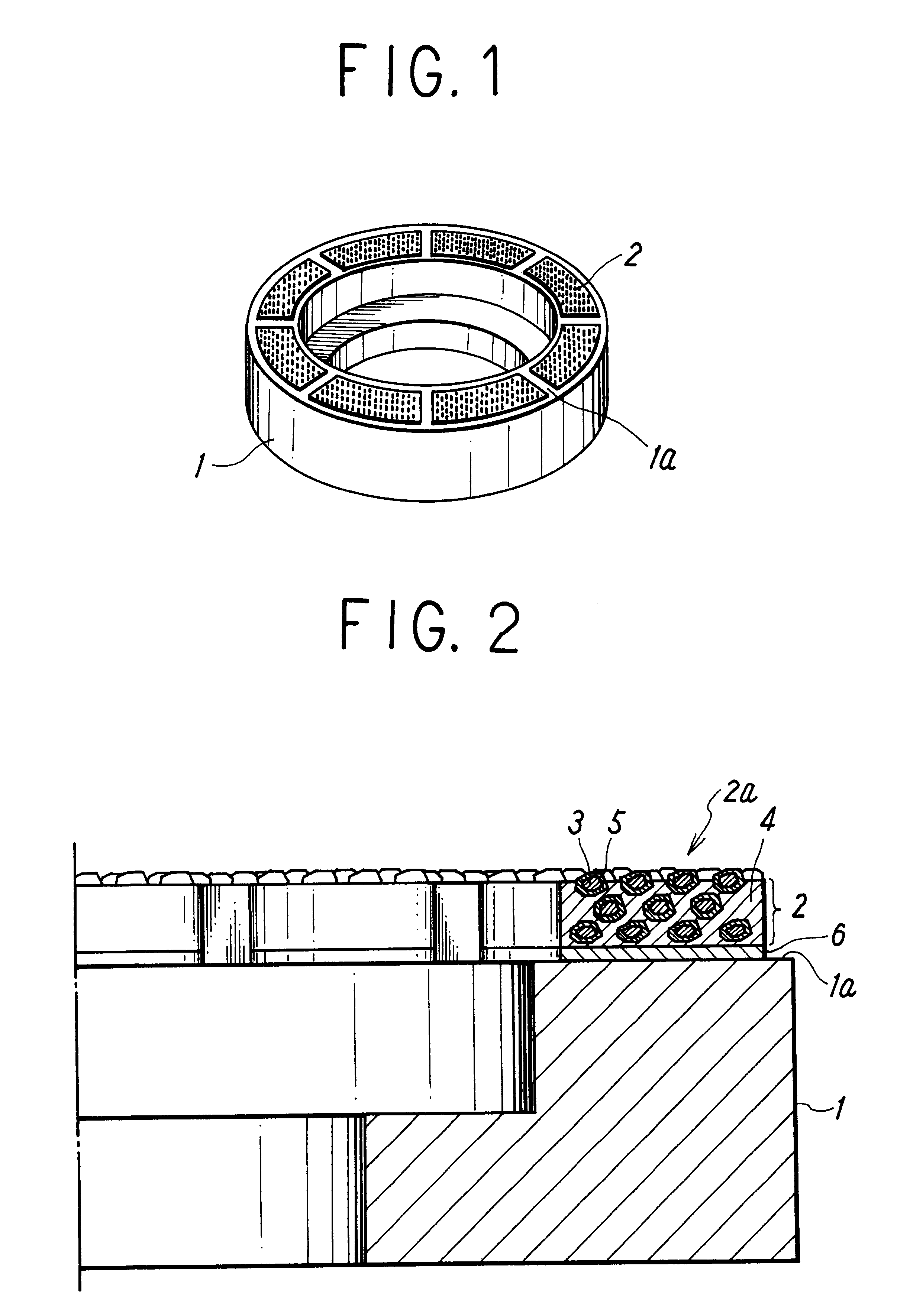

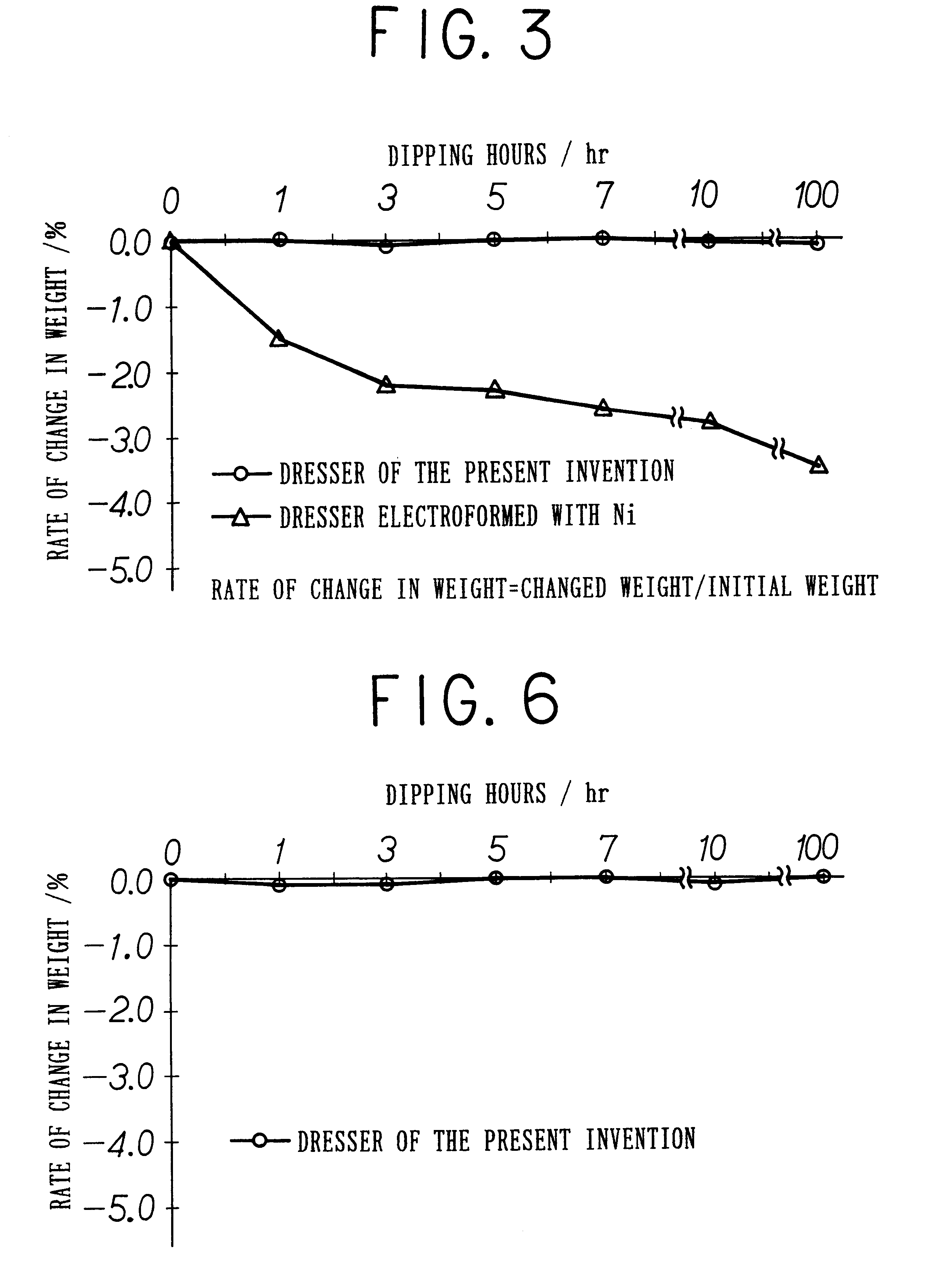

Dresser for polishing cloth and manufacturing method therefor

InactiveUS6293854B1Improve acid resistanceSimplify cleaning stepsGrinding drivesSemiconductor/solid-state device manufacturingSilicon alloyCarbide

The present invention provides a dresser for a chemical and mechanical polishing cloth wherein a bonding material for retaining diamond grit is not dissolved and contamination of chemical slurry caused by dissolving of metal or peeling-off of diamond grit is prevented from occurring. A sintered product constituting the dressing face 2a is obtained by mixing a bonding material 4 consisting of silicon and / or silicon alloy with diamond grit 3, and forming and sintering the mixture. A carbide film 5 generated by sintering silicon in the bonding material into diamond is formed on the surface of the diamond grit 3. Thereby, the diamond grit is firmly bonded with the bonding material, and the bonding material is not dissolved. As a result, the contamination of the chemical slurry or the peeling-off of the diamond grit is prevented.

Owner:RIIDO

Negative electrode for lithium secondary cell and lithium secondary cell

InactiveUS20050244711A1Improve charge and discharge cycle characteristicsImprove featuresElectrode carriers/collectorsActive material electrodesLithiumSilicon alloy

A negative electrode for a lithium secondary cell having a collector composed of an electroconductive metal foil and, provided on the surface thereof, an active material layer containing active material particles containing silicon and / or a silicon alloy and a binder, characterized in that the binder has mechanical characteristics of a tensile strength of 50 N / mm2 or more, an elongation at break of 10% or more, a strain energy density of 2.5×10−3 J / mm3 or more and a coefficient of elasticity of 10000 N / mm2 or less, and preferably characterized in that the collector has mechanical characteristics of a tensile strength of 80 N / mm2 or more, a proportional limit 30 N / mm2 or more, an elongation at break of 1.0% or more and an elastic elongation limit of 0.03% or more.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com