Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

779 results about "Carbon alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

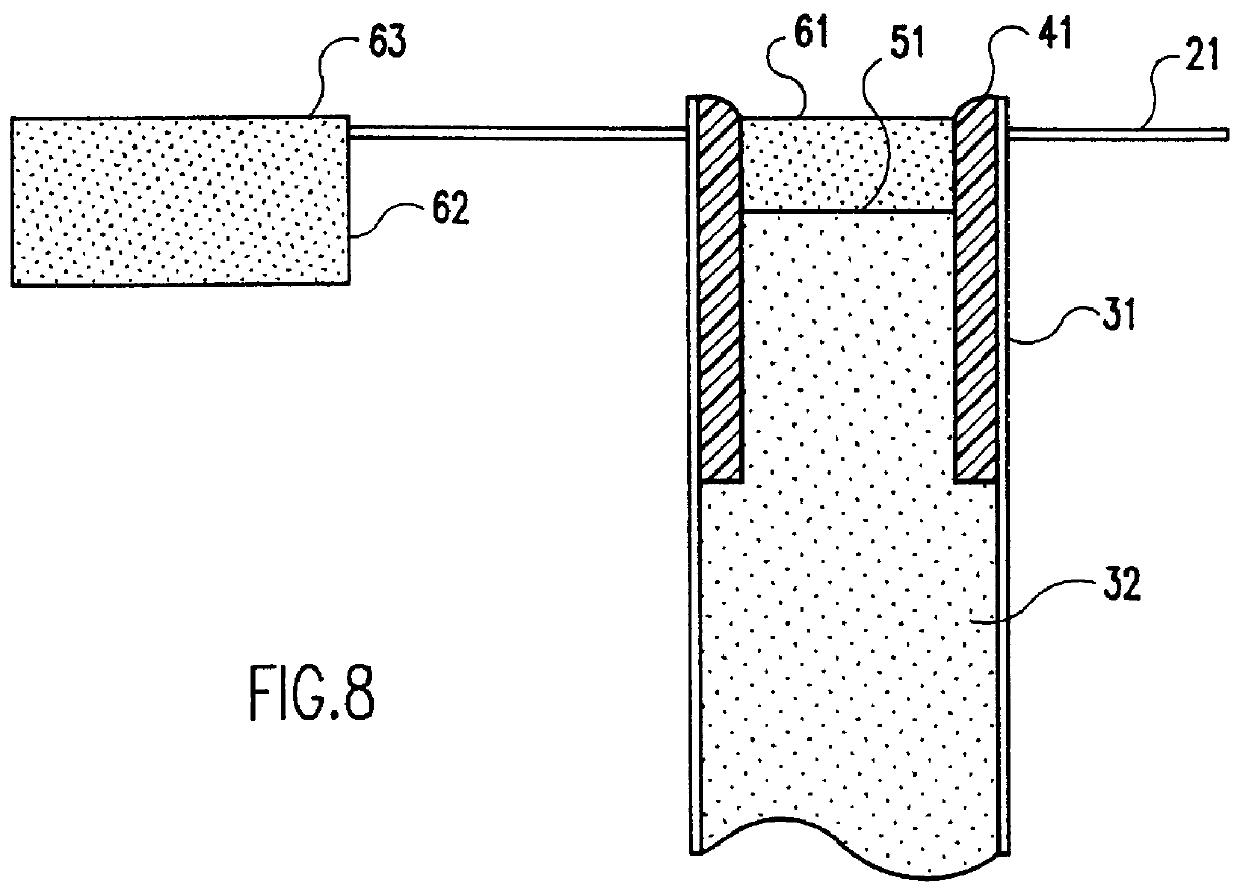

Method of depositing silicon on carbon materials and forming an anode for use in lithium ion batteries

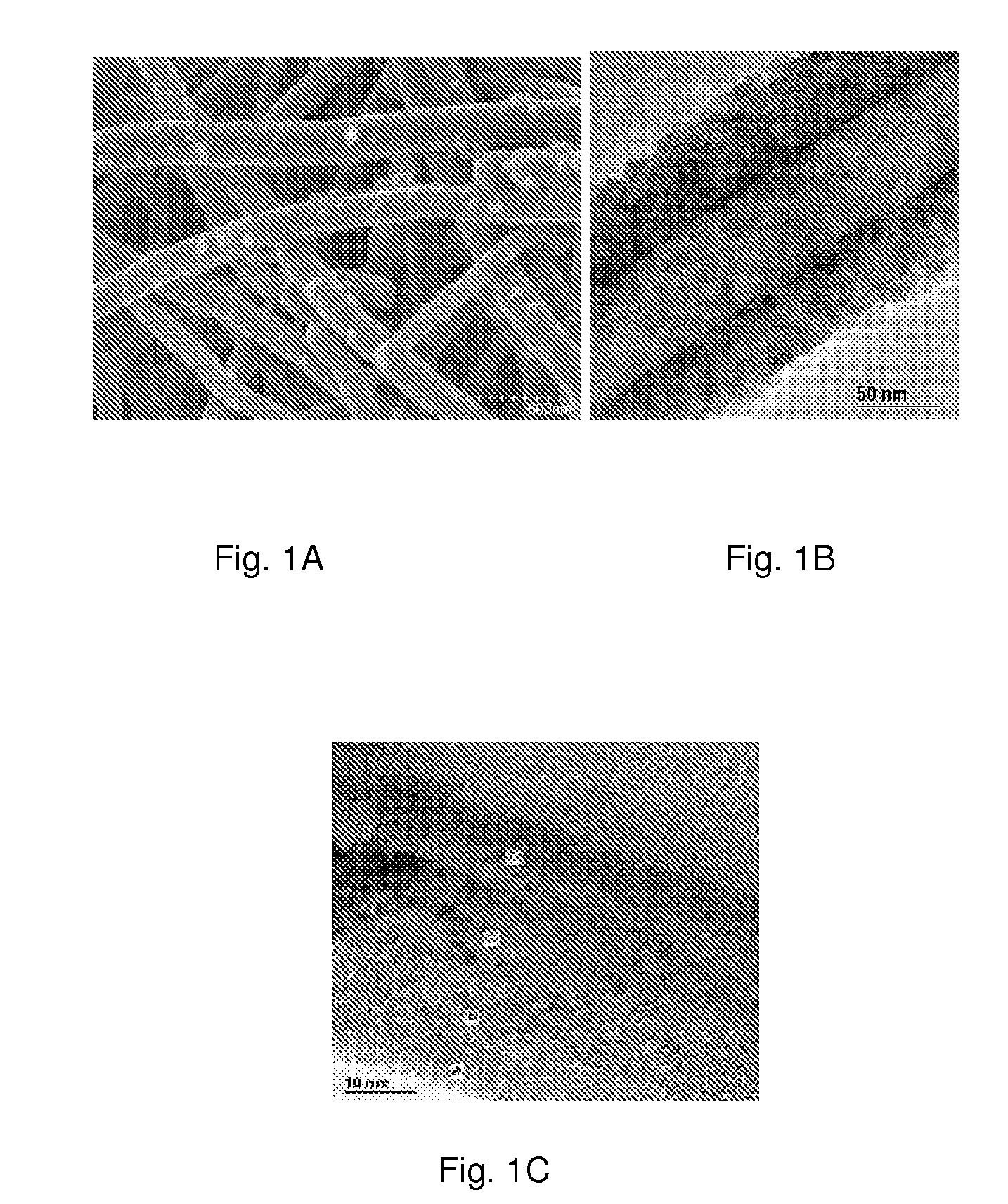

ActiveUS20080261116A1Increase rangeMaterial nanotechnologyNanoinformaticsPhysical chemistryCarbon nanofiber

A method of modifying the surface of carbon materials such as vapor grown carbon nanofibers is provided in which silicon is deposited on vapor grown carbon nanofibers using a chemical vapor deposition process. The resulting silicon-carbon alloy may be used as an anode in a rechargeable lithium ion battery.

Owner:APPLIED SCI

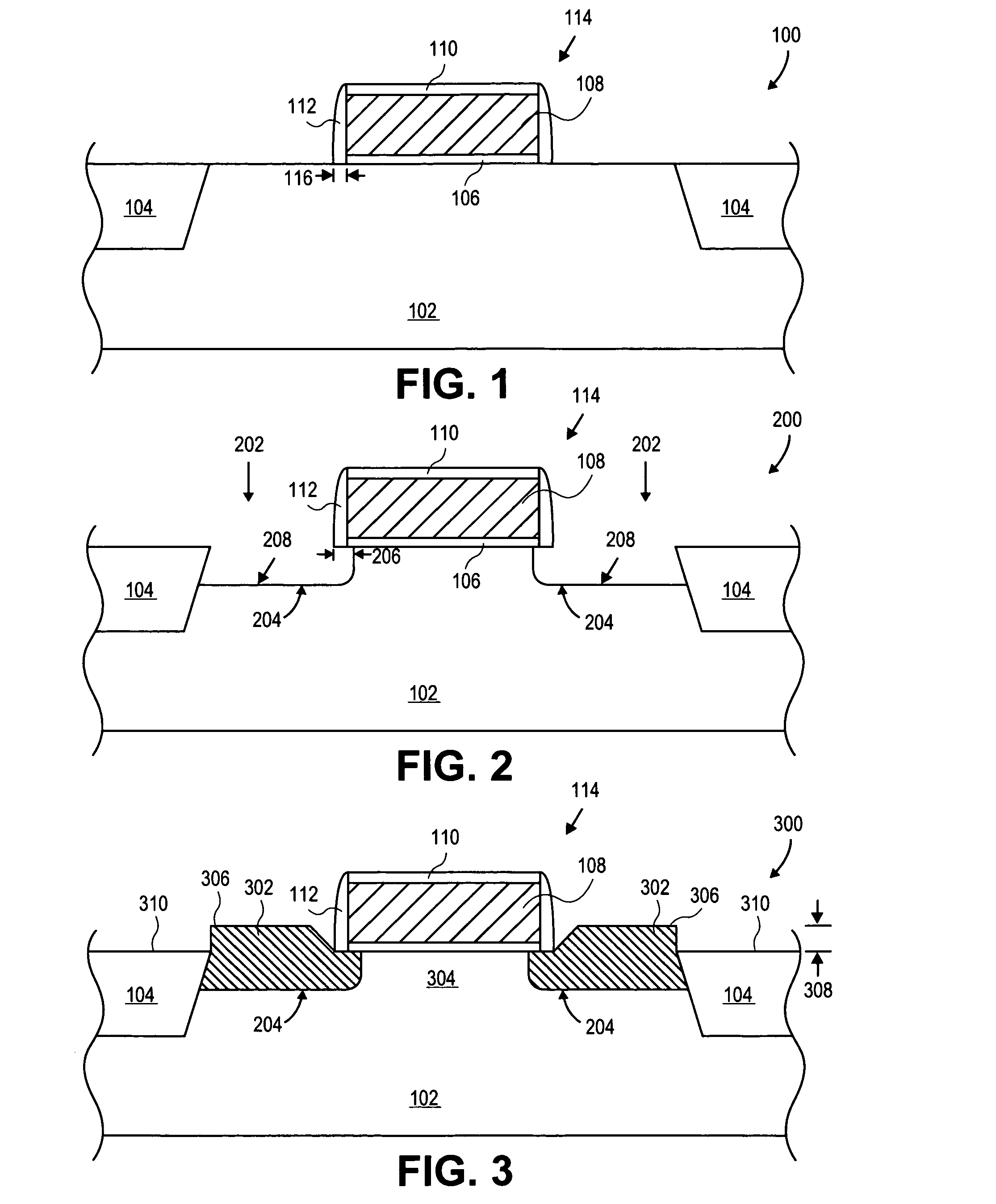

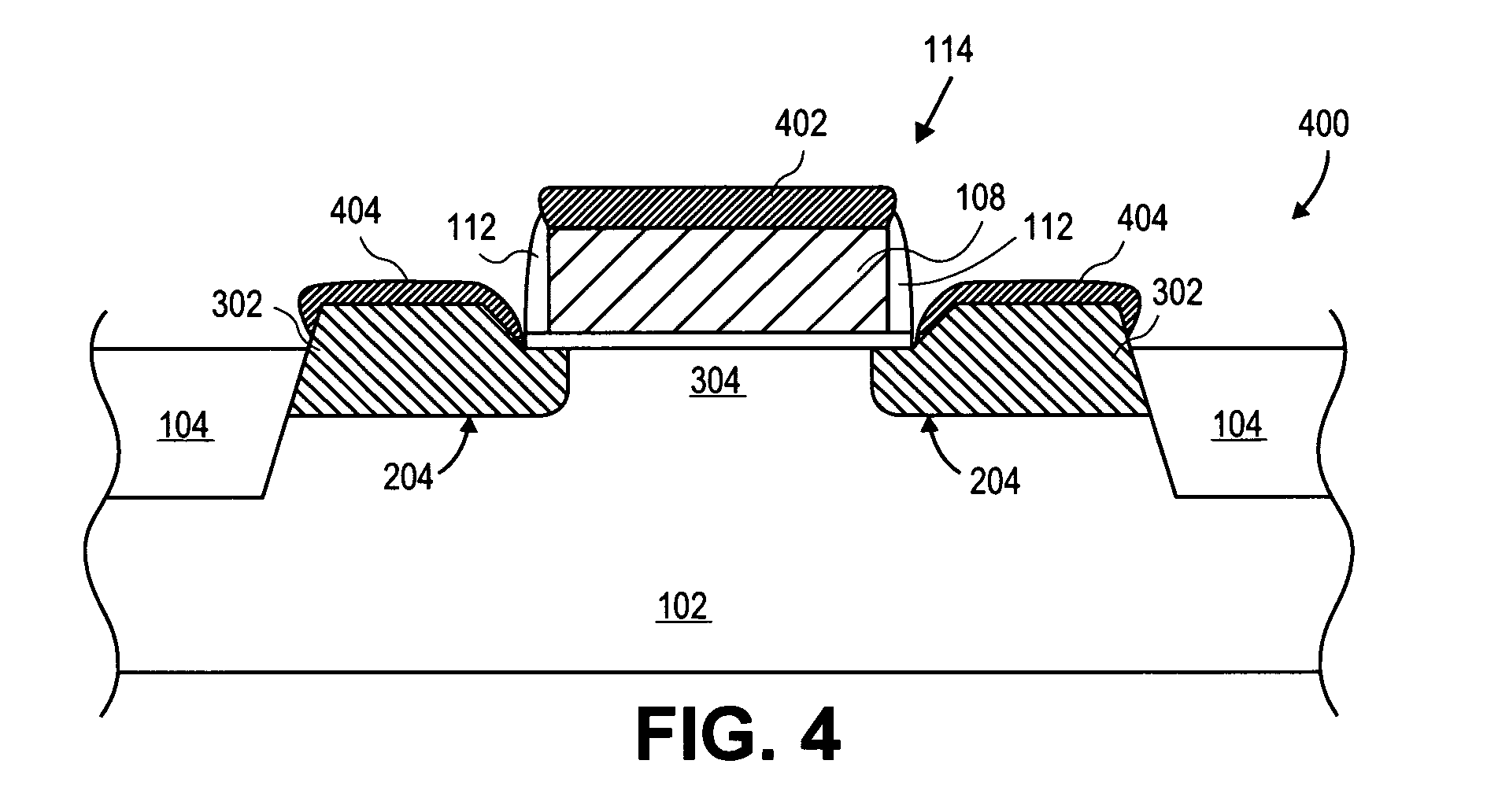

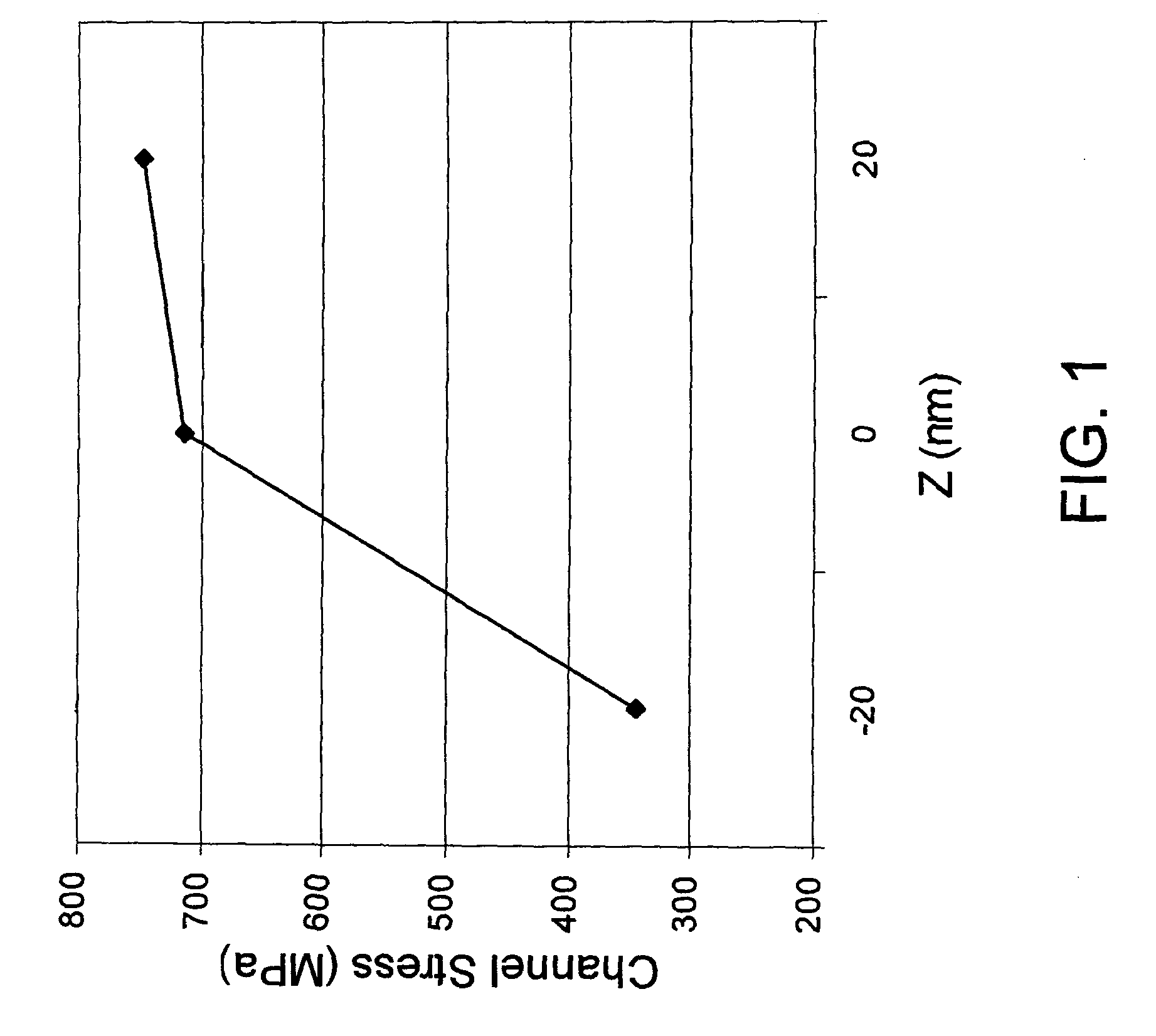

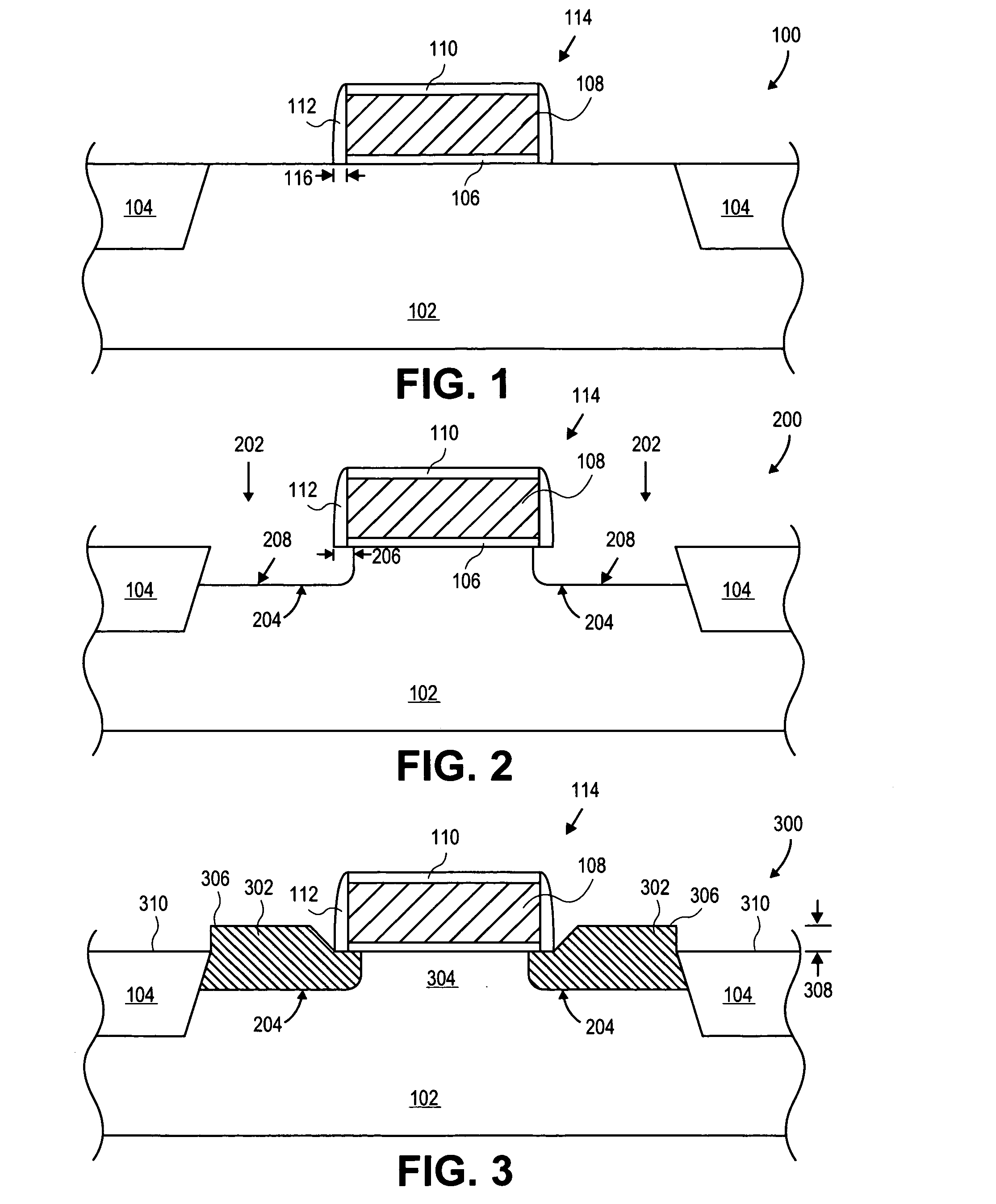

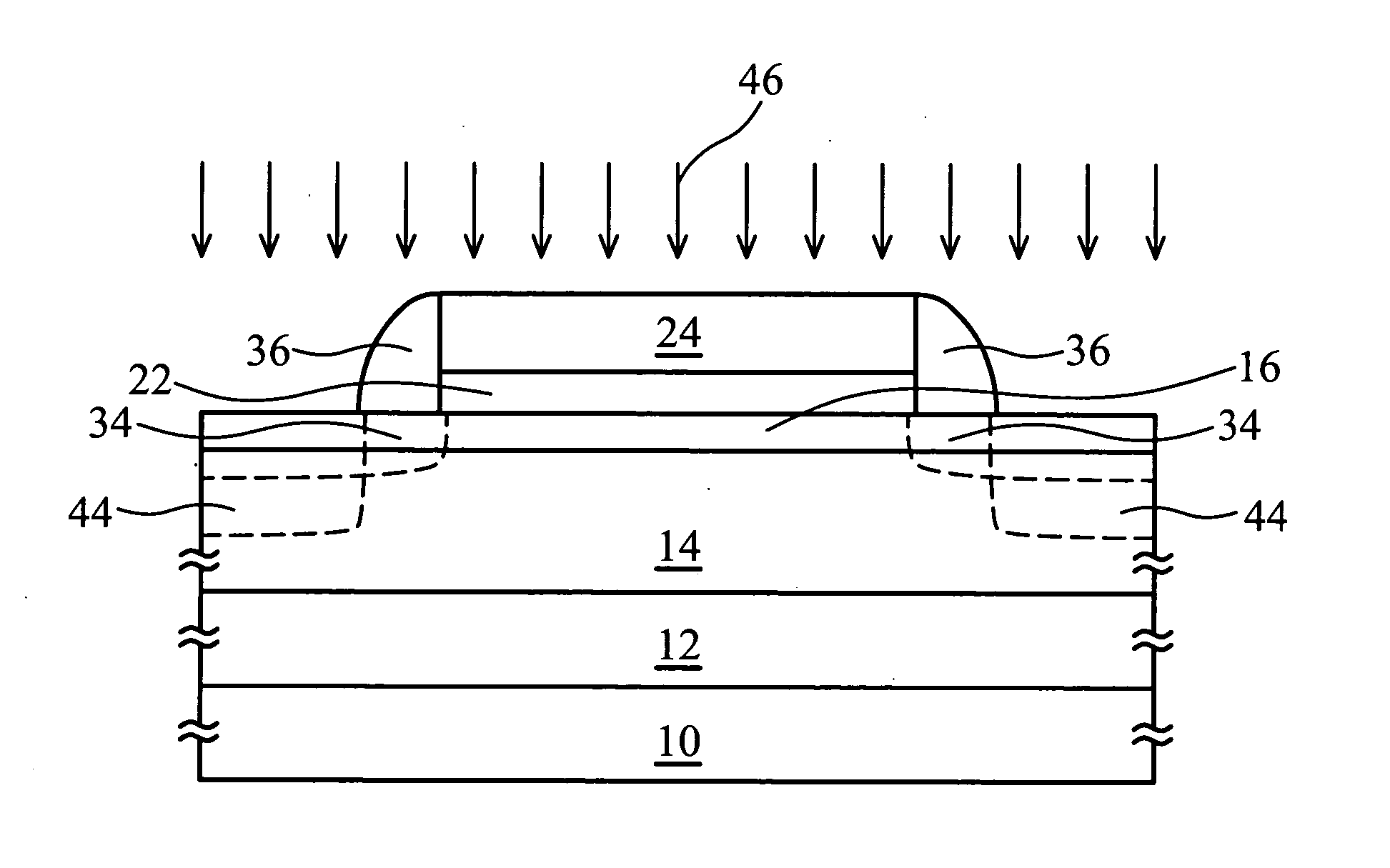

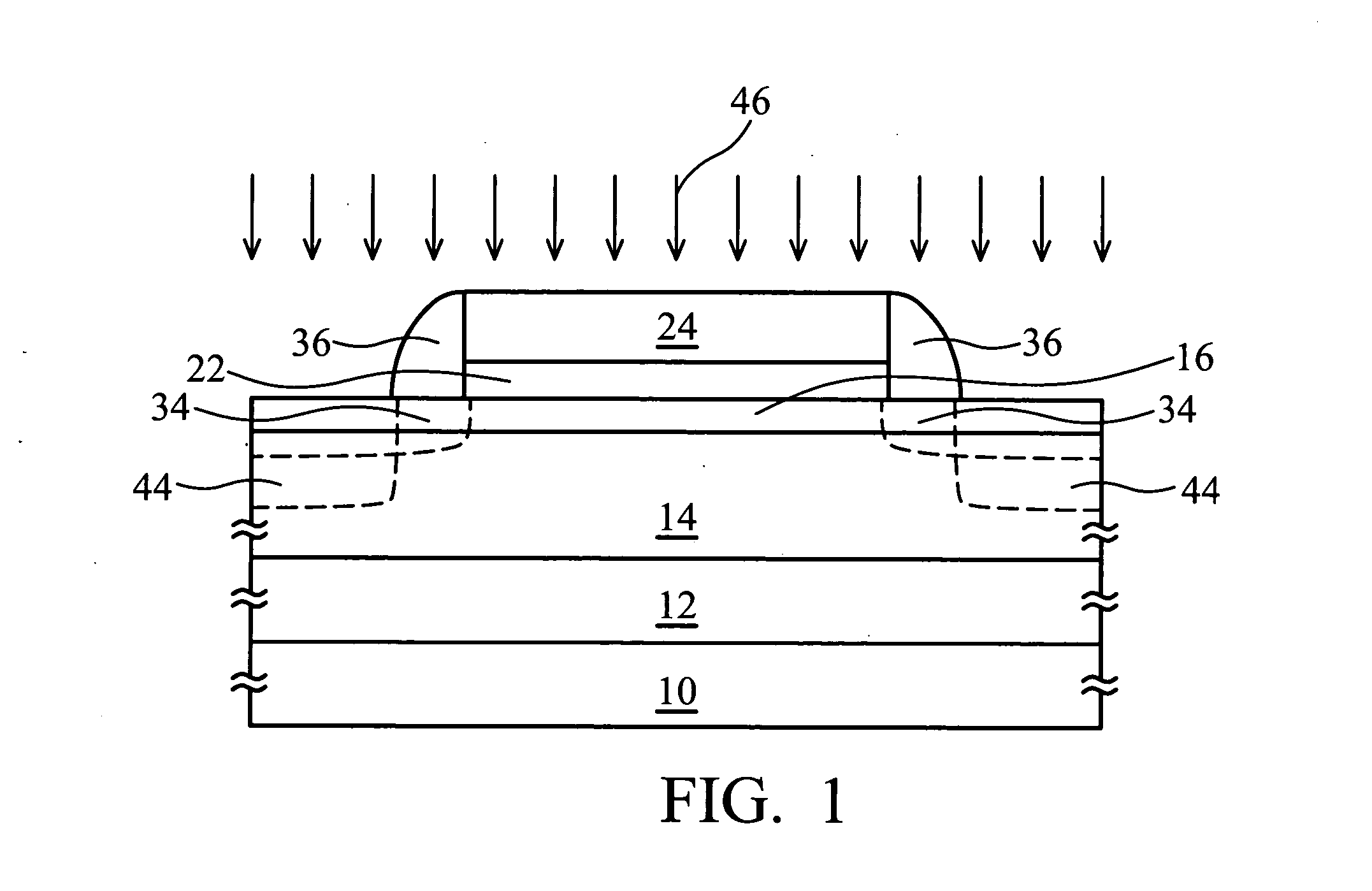

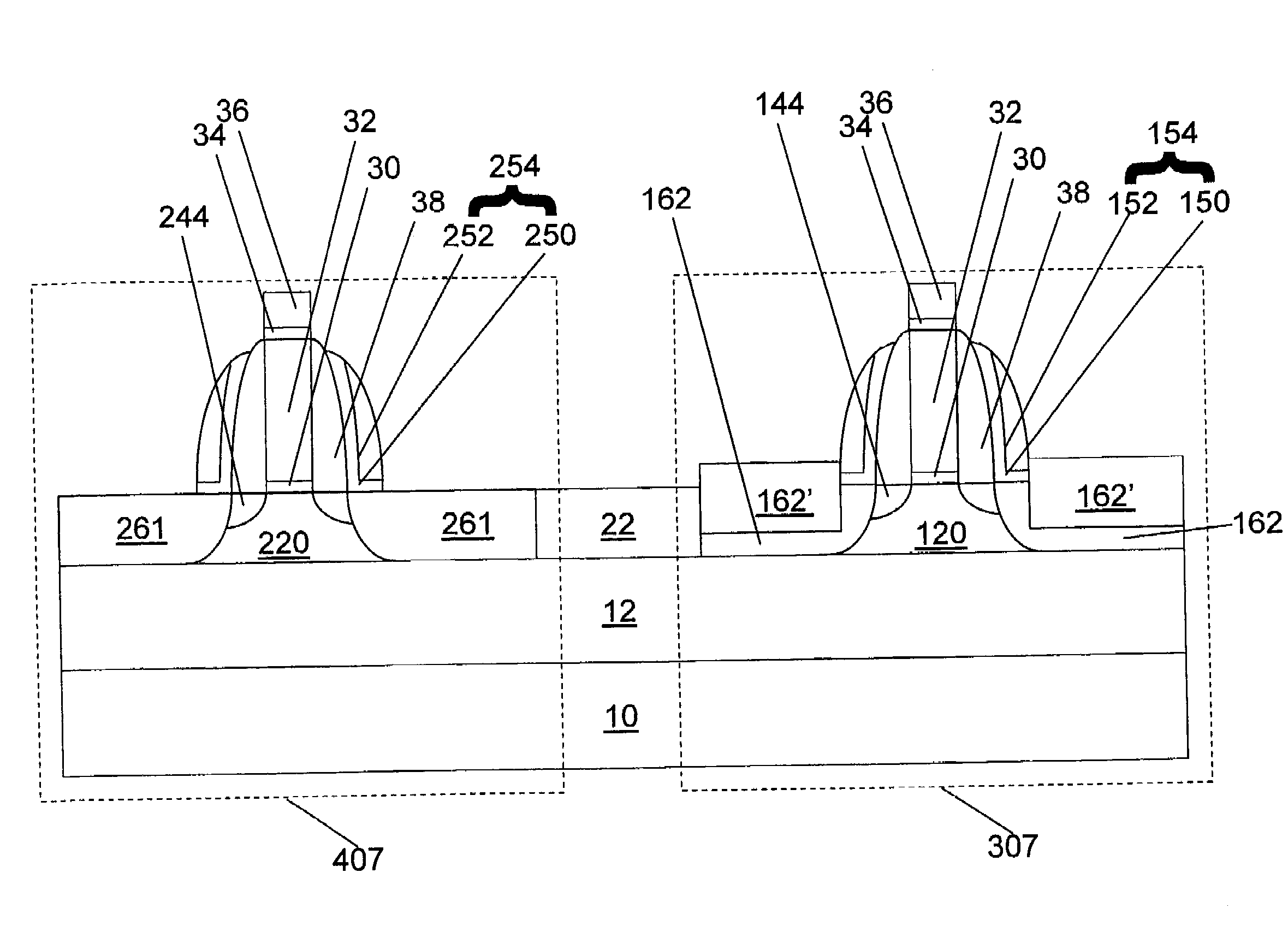

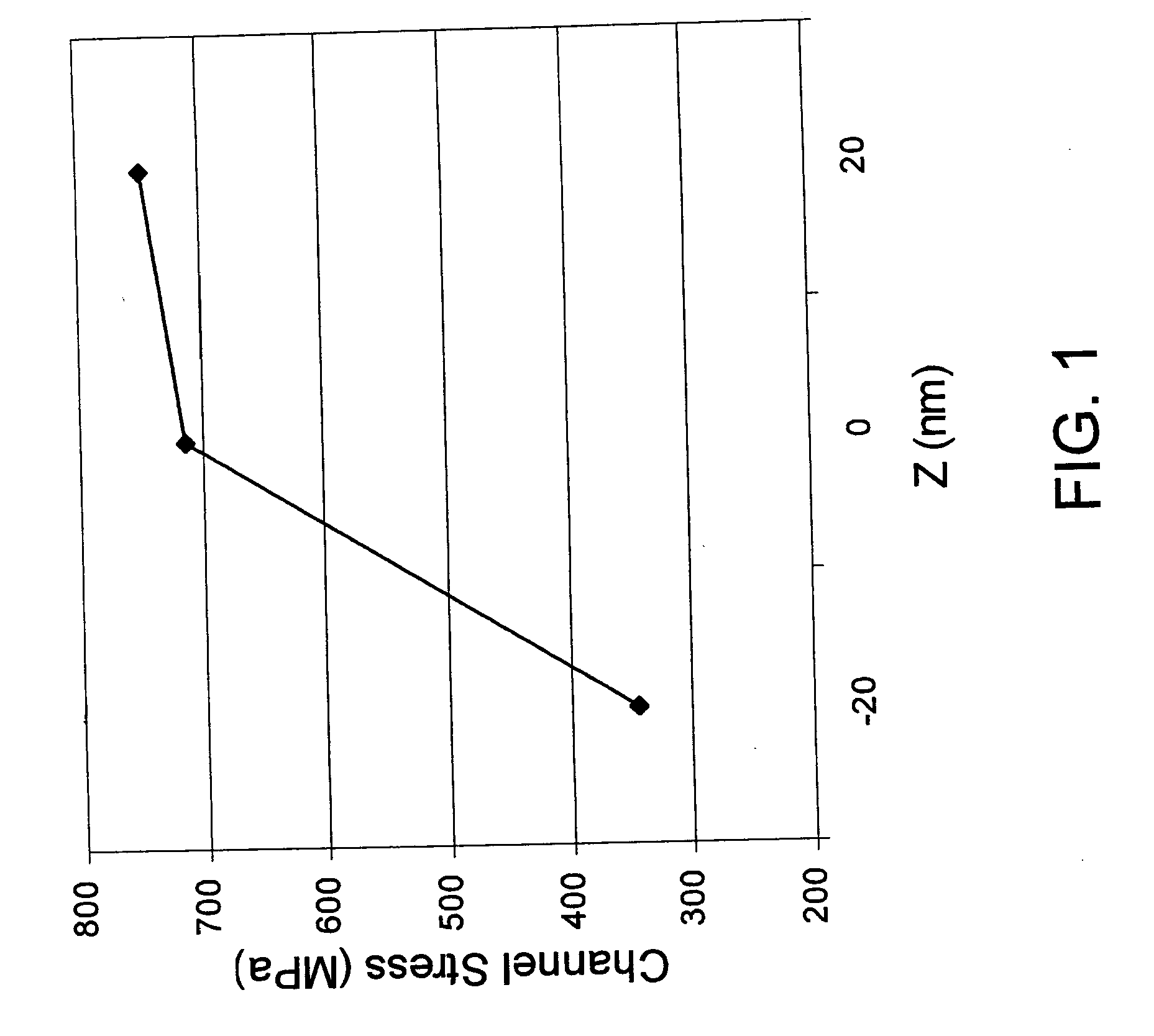

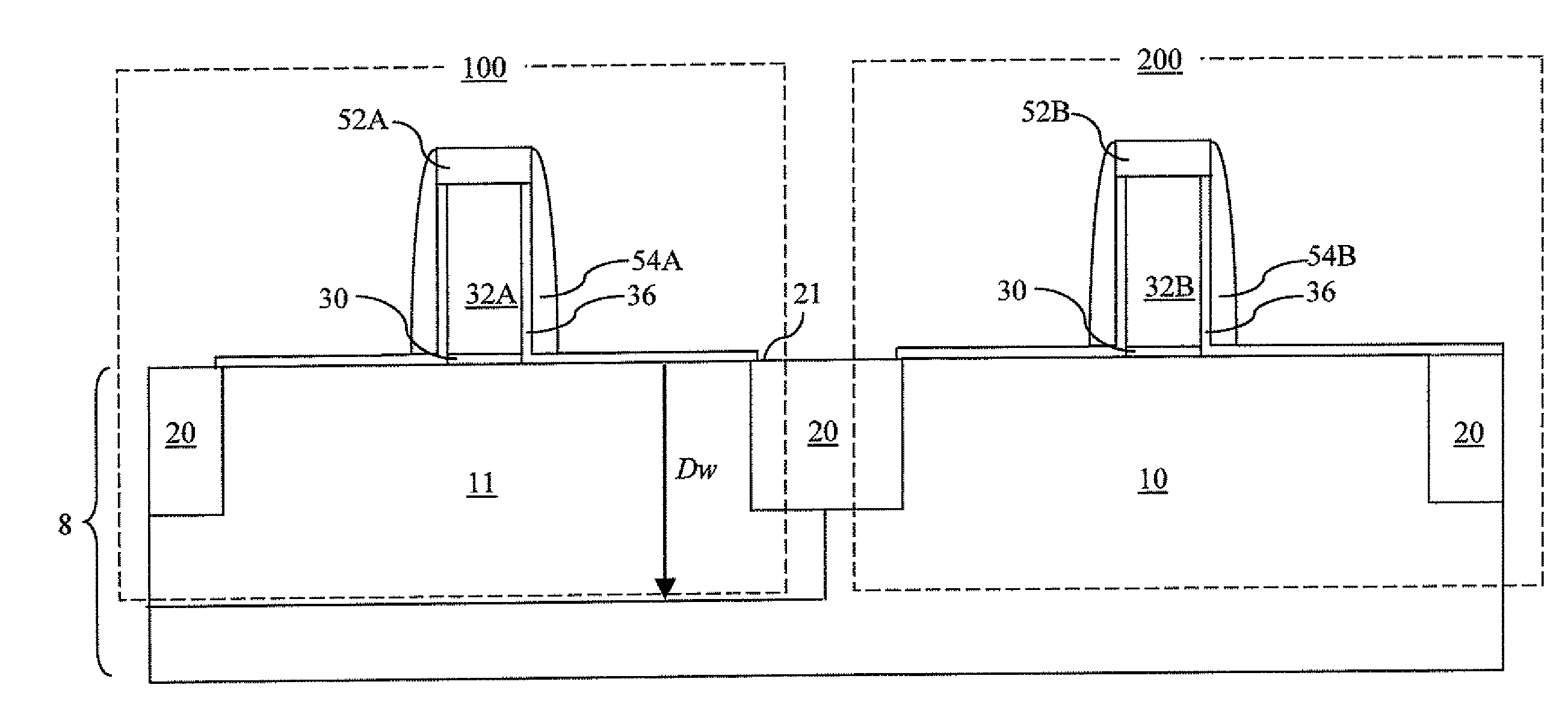

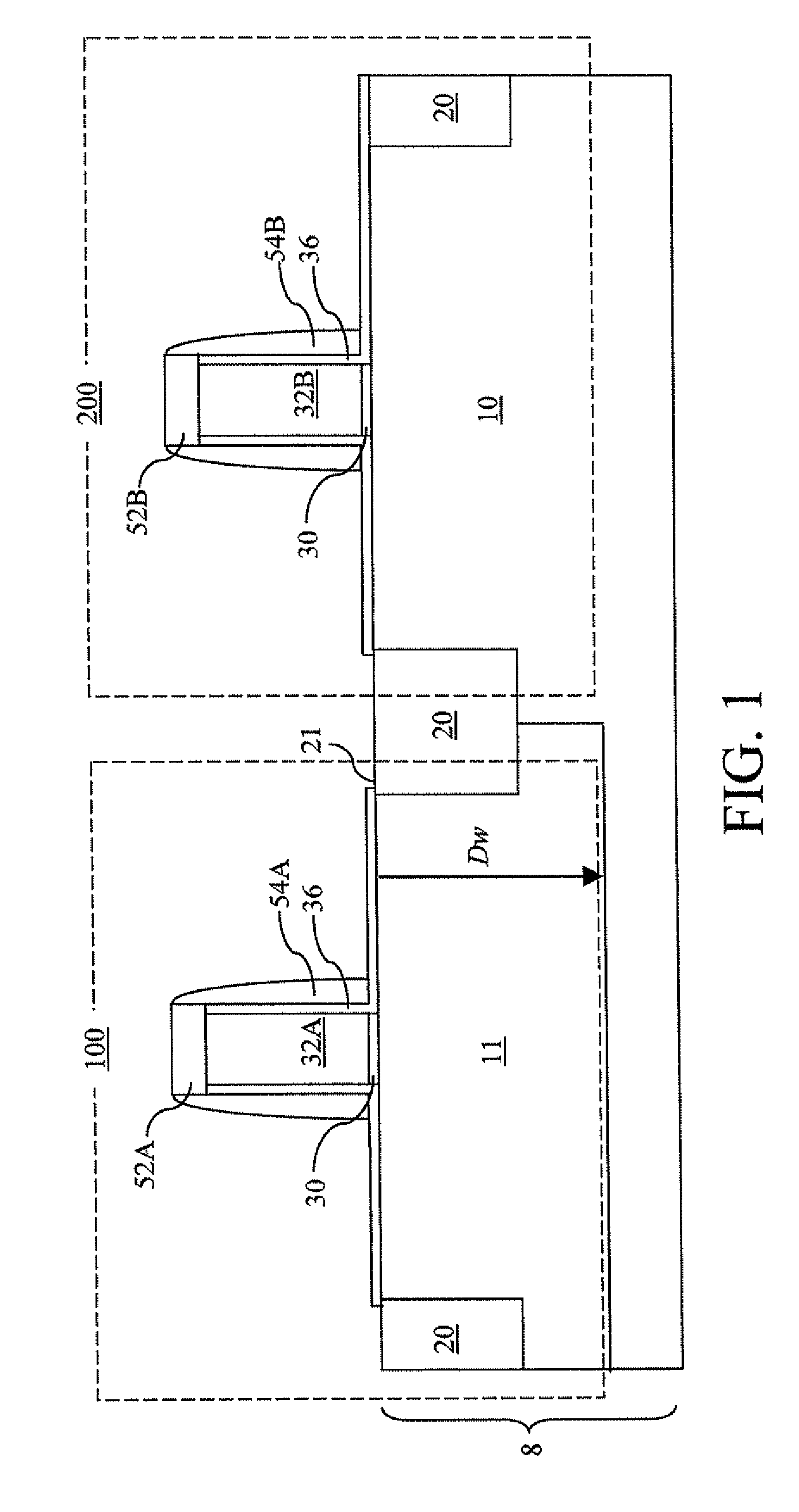

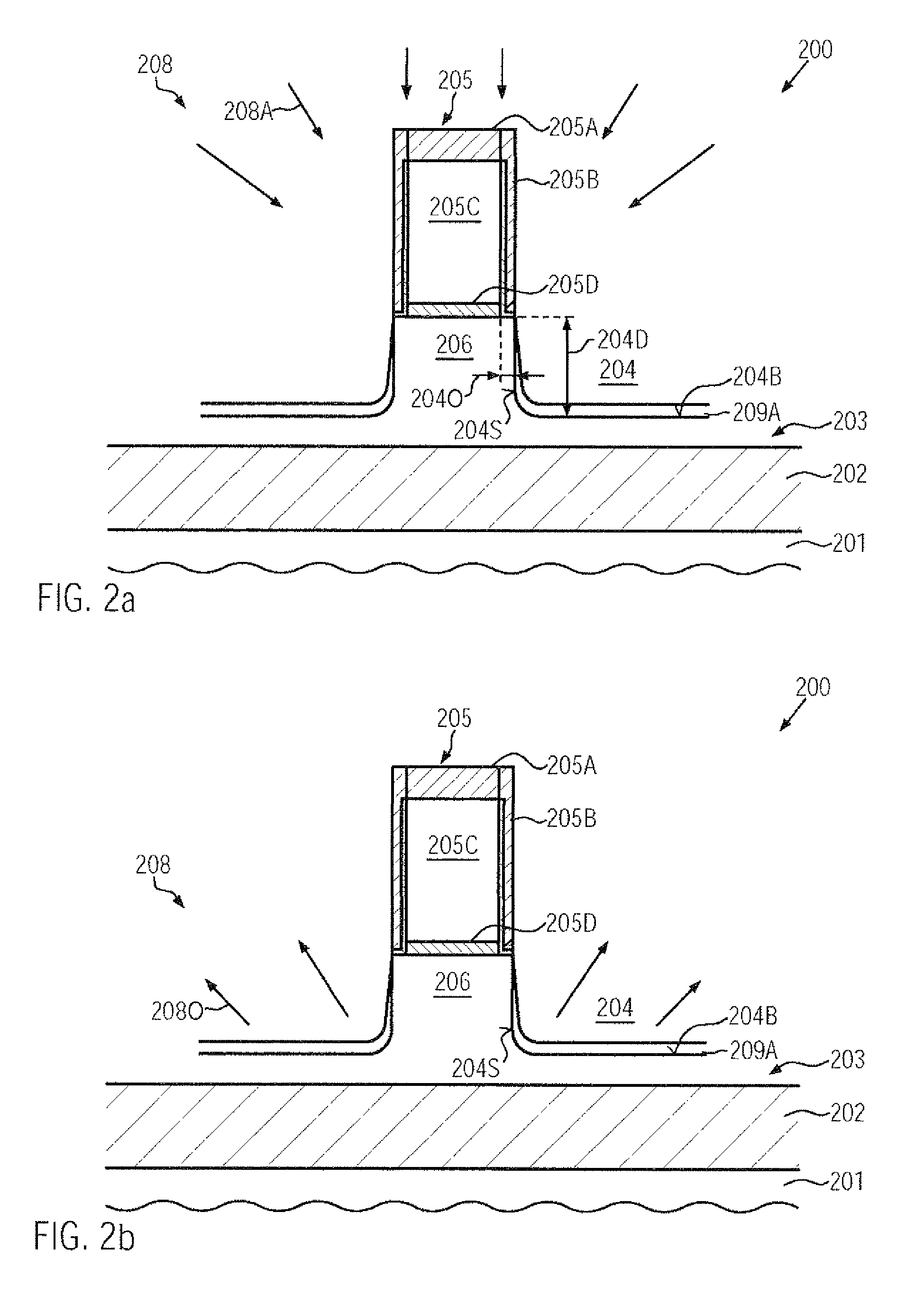

Method for forming an integrated circuit

ActiveUS7402872B2Semiconductor/solid-state device manufacturingSemiconductor devicesContact resistanceEpitaxial silicon

A method is described for manufacturing an n-MOS semiconductor transistor. Recesses are formed in a semiconductor substrate adjacent a gate electrode structure. Silicon is embedded in the recesses via a selective epitaxial growth process. The epitaxial silicon is in-situ alloyed with substitutional carbon and in-situ doped with phosphorus. The silicon-carbon alloy generates a uniaxial tensile strain in the channel region between the source and drain, thereby increasing electron channel mobility and the transistor's drive current. The silicon-carbon alloy decreases external resistances by reducing contact resistance between source / drain and silicide regions and by reducing phosphorous diffusivity, thereby permitting closer placement of the transistor's source / drain and channel regions.

Owner:TAHOE RES LTD

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

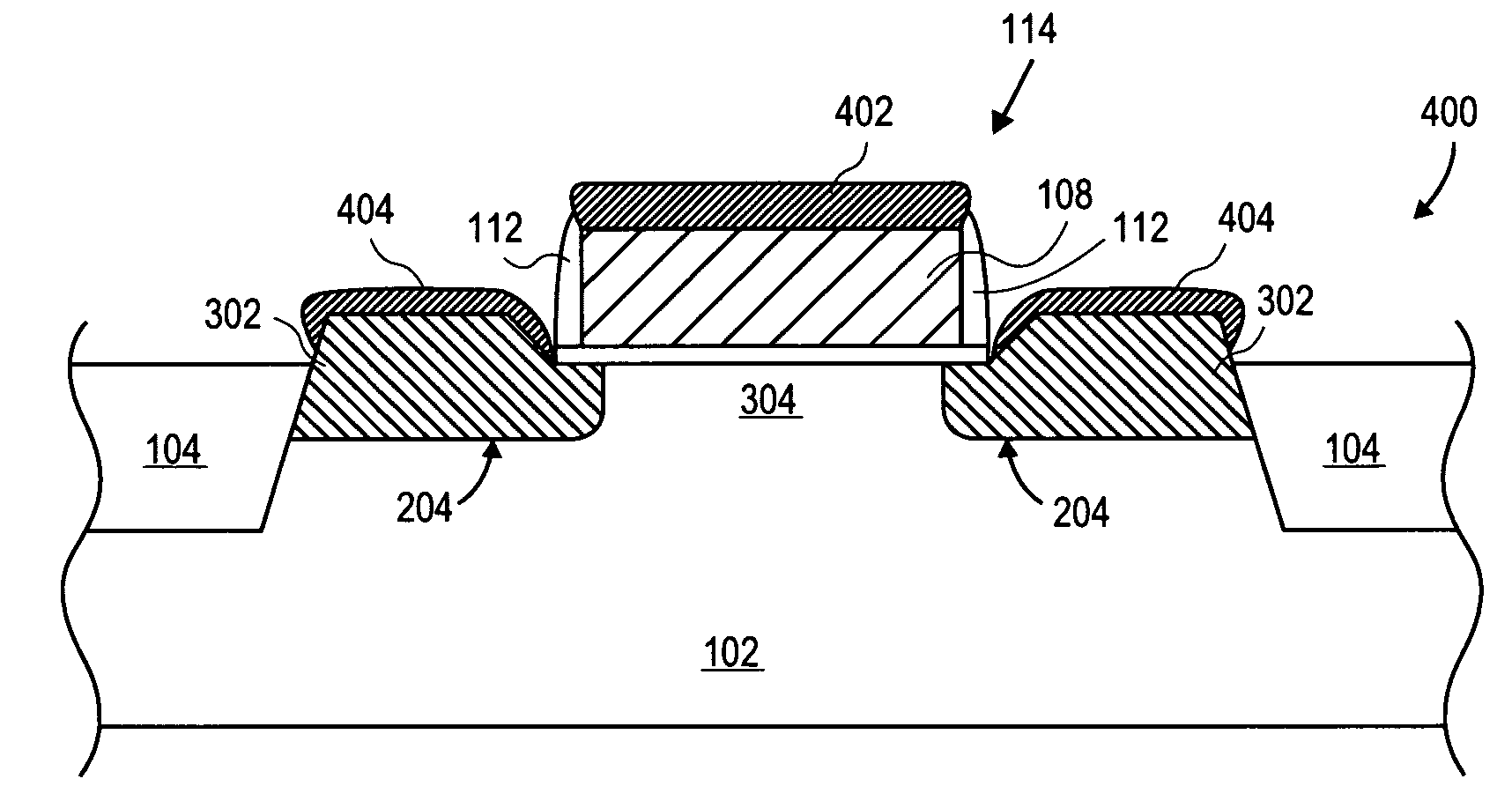

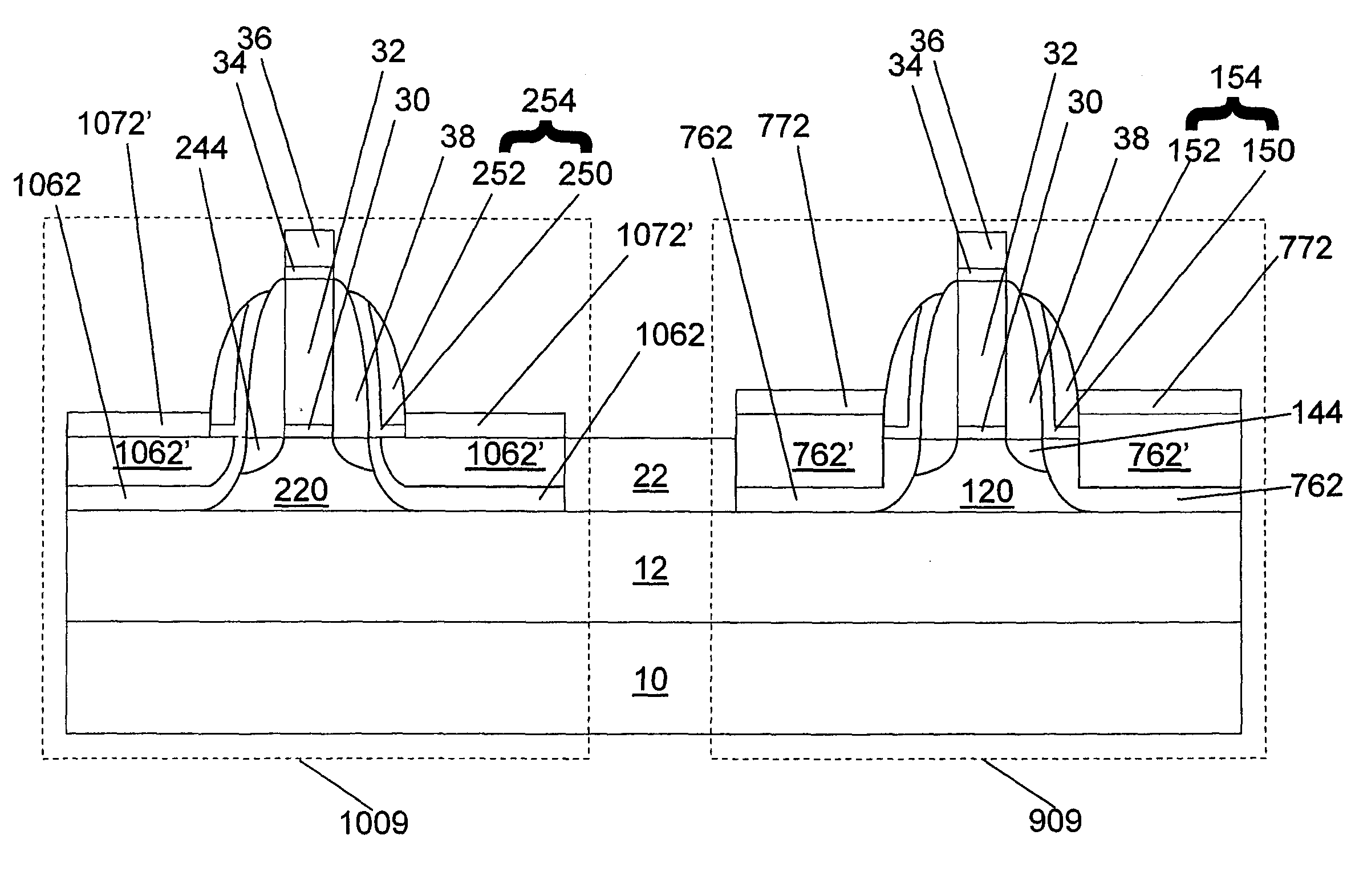

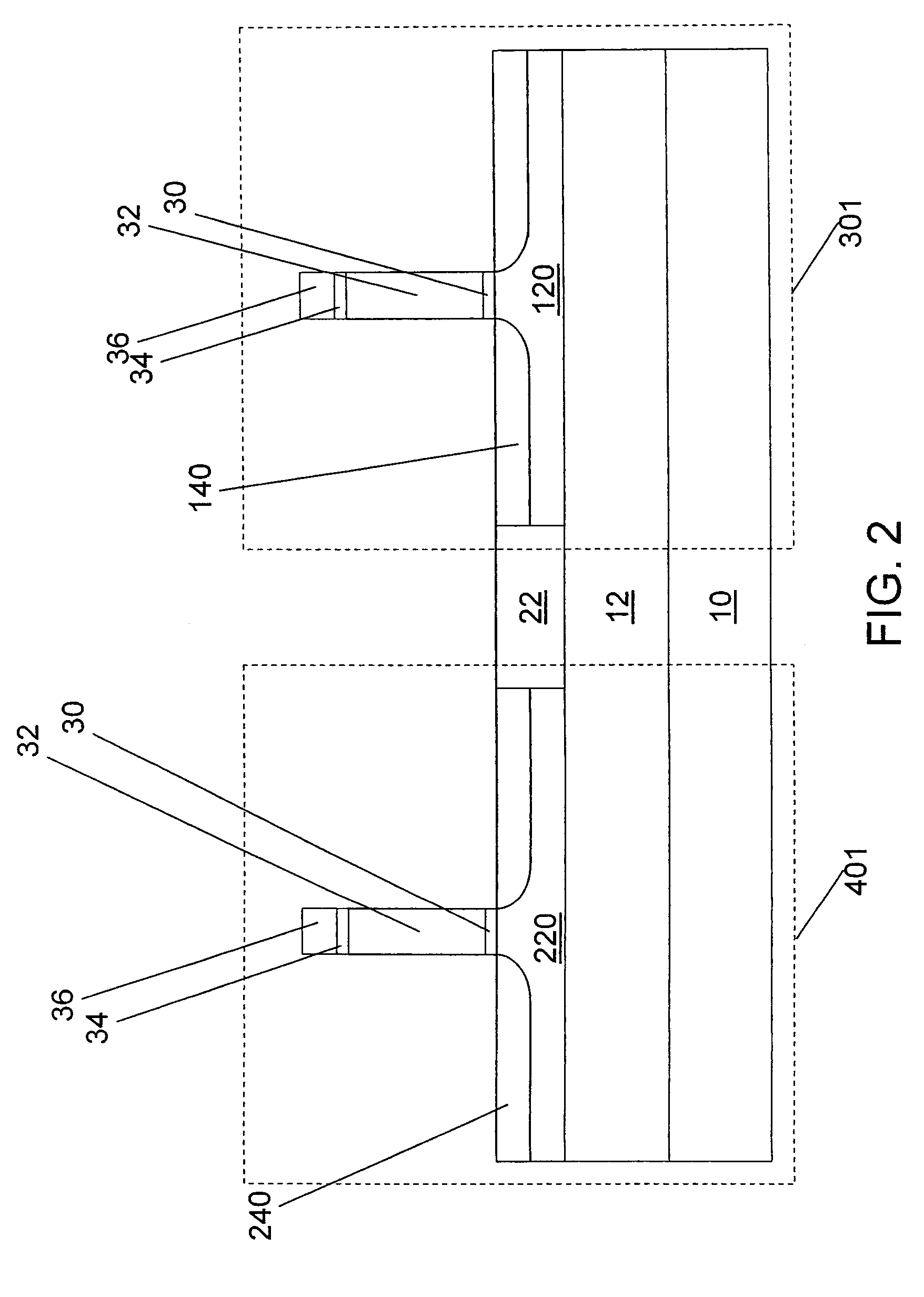

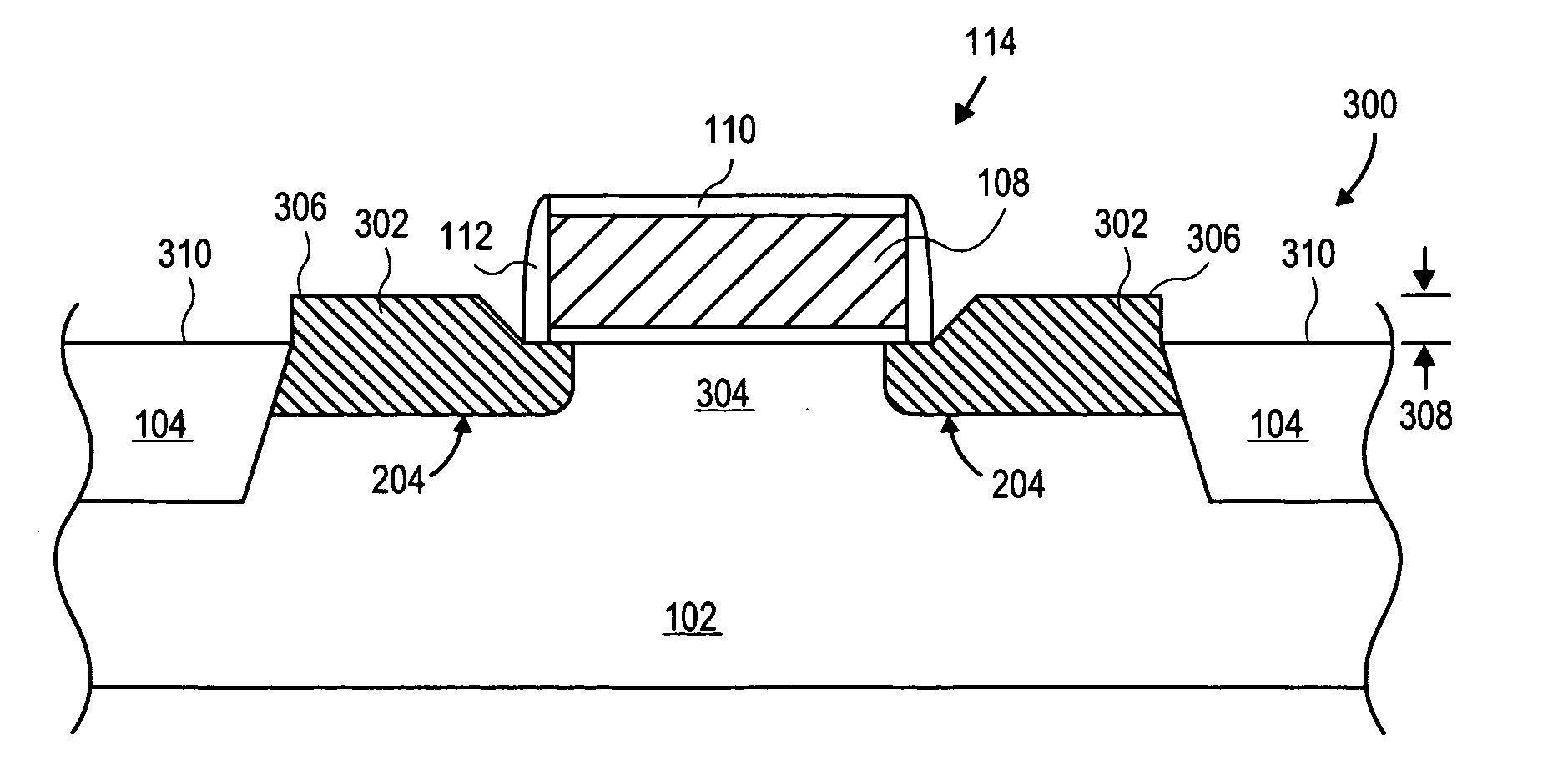

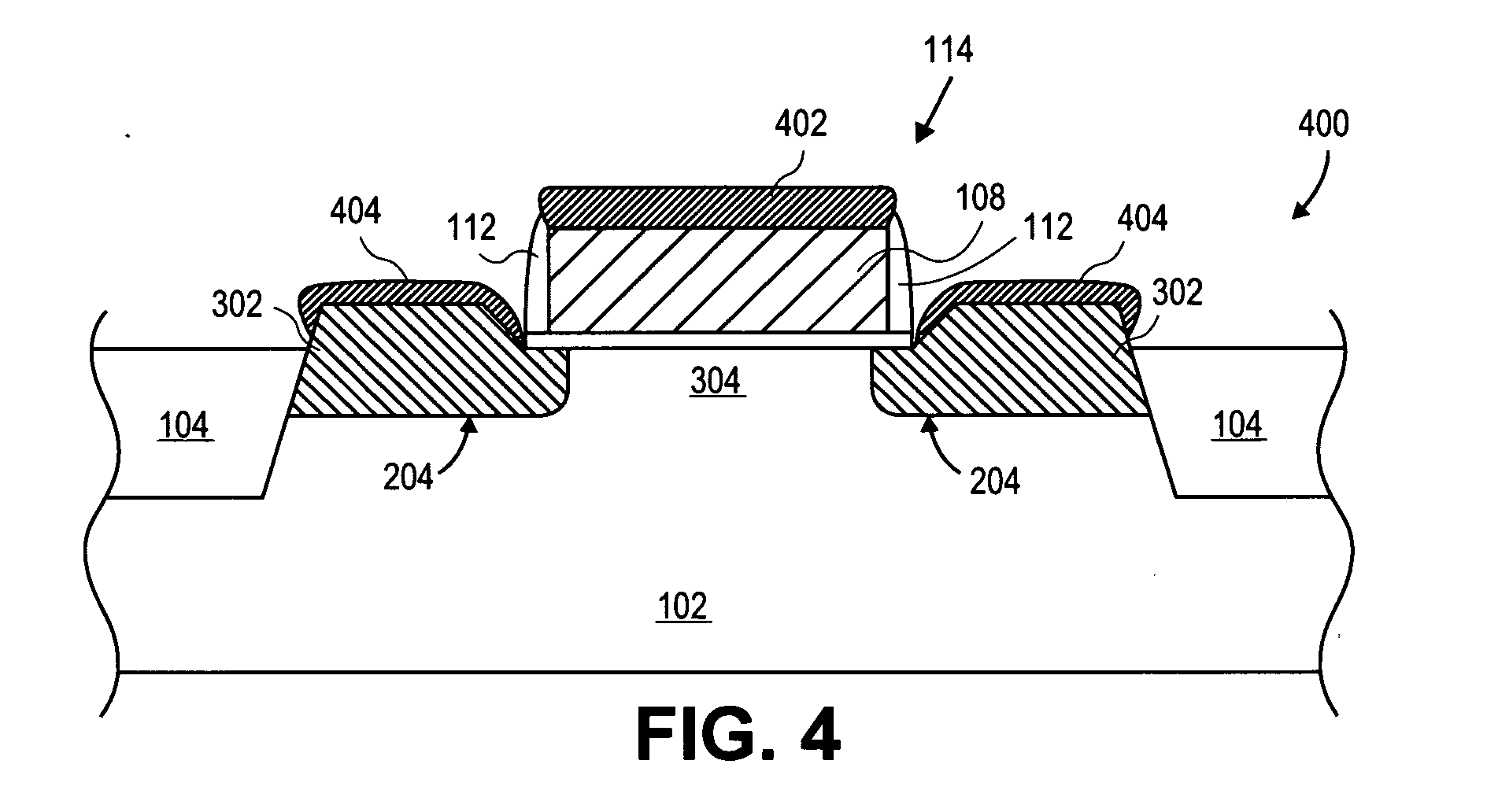

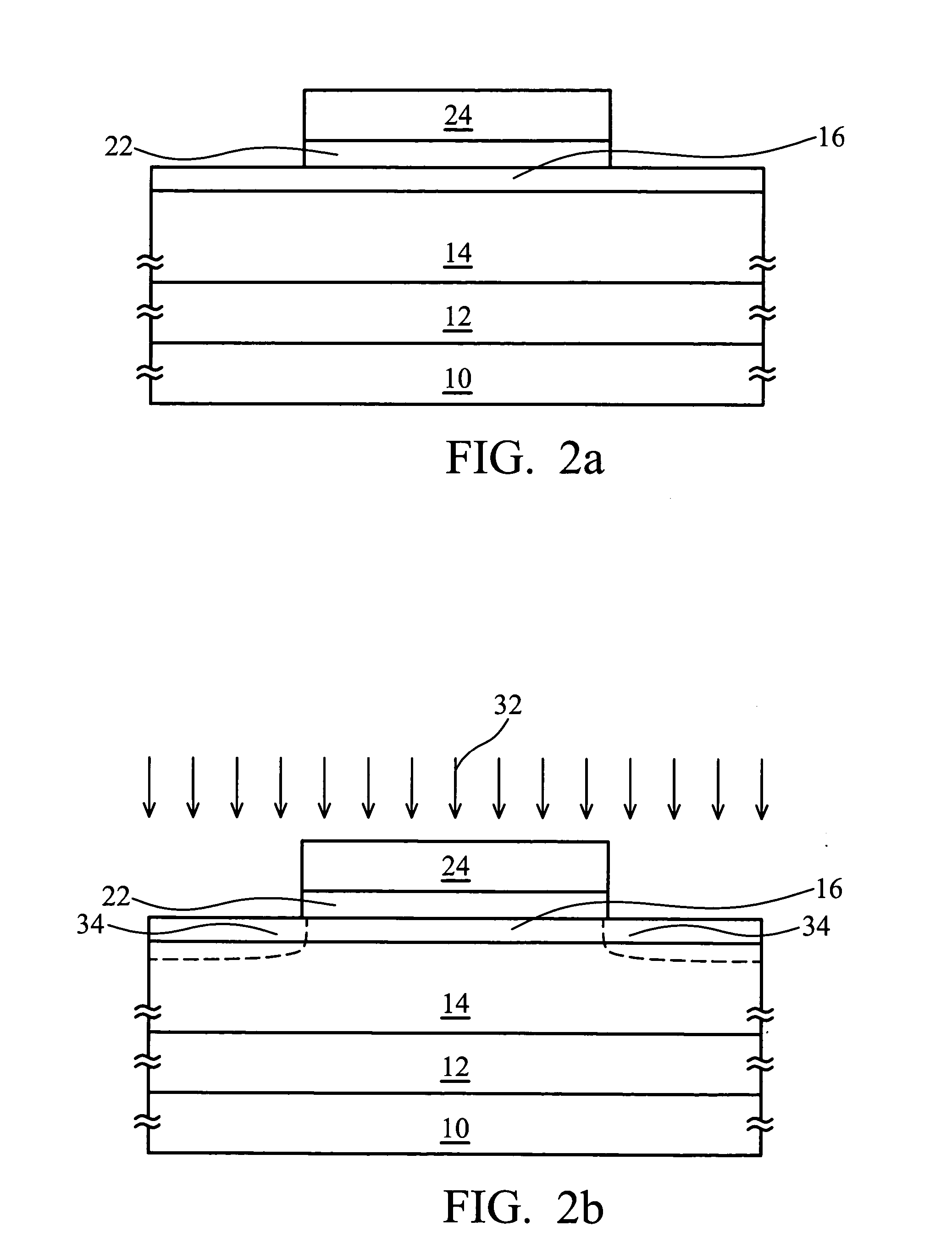

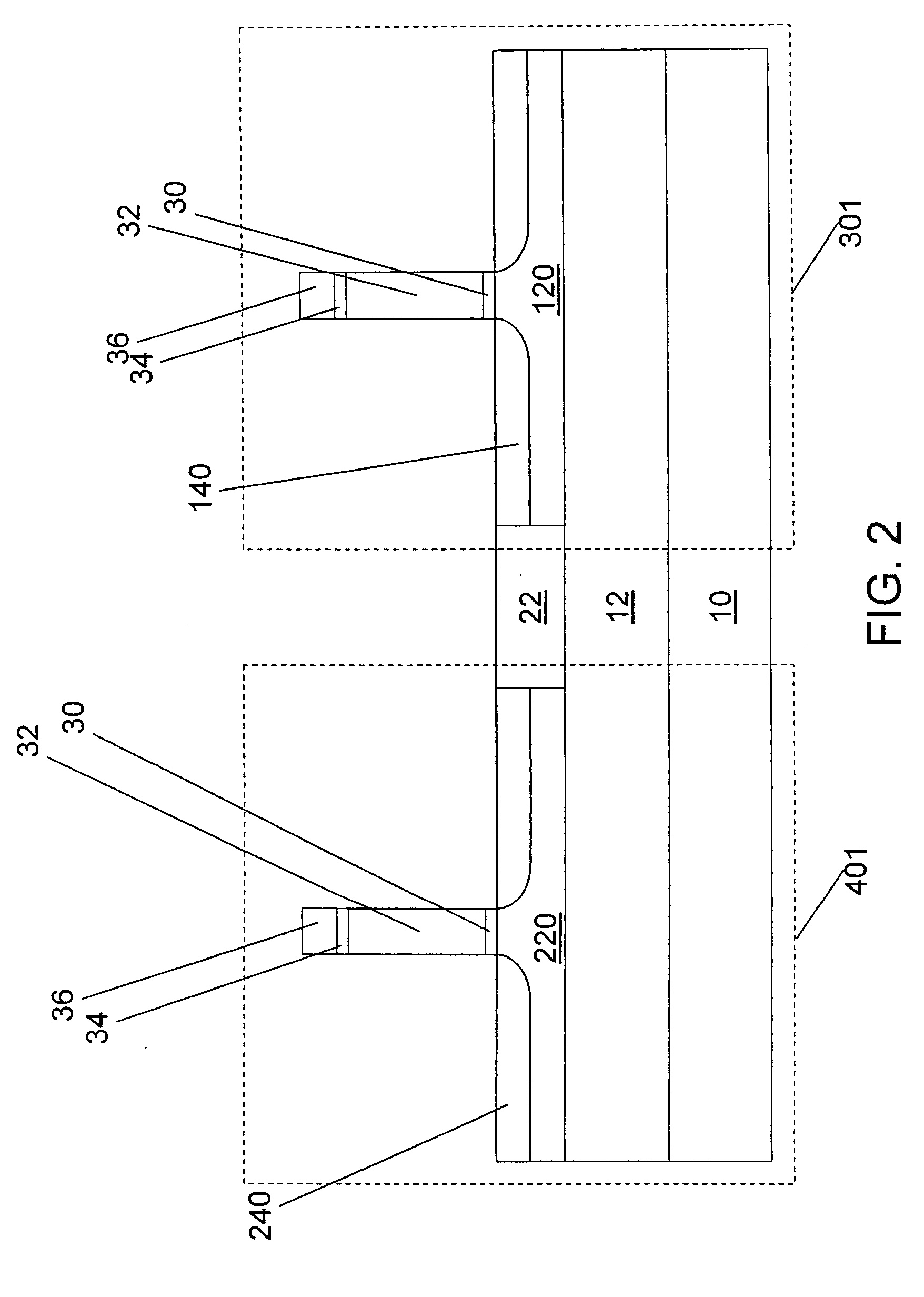

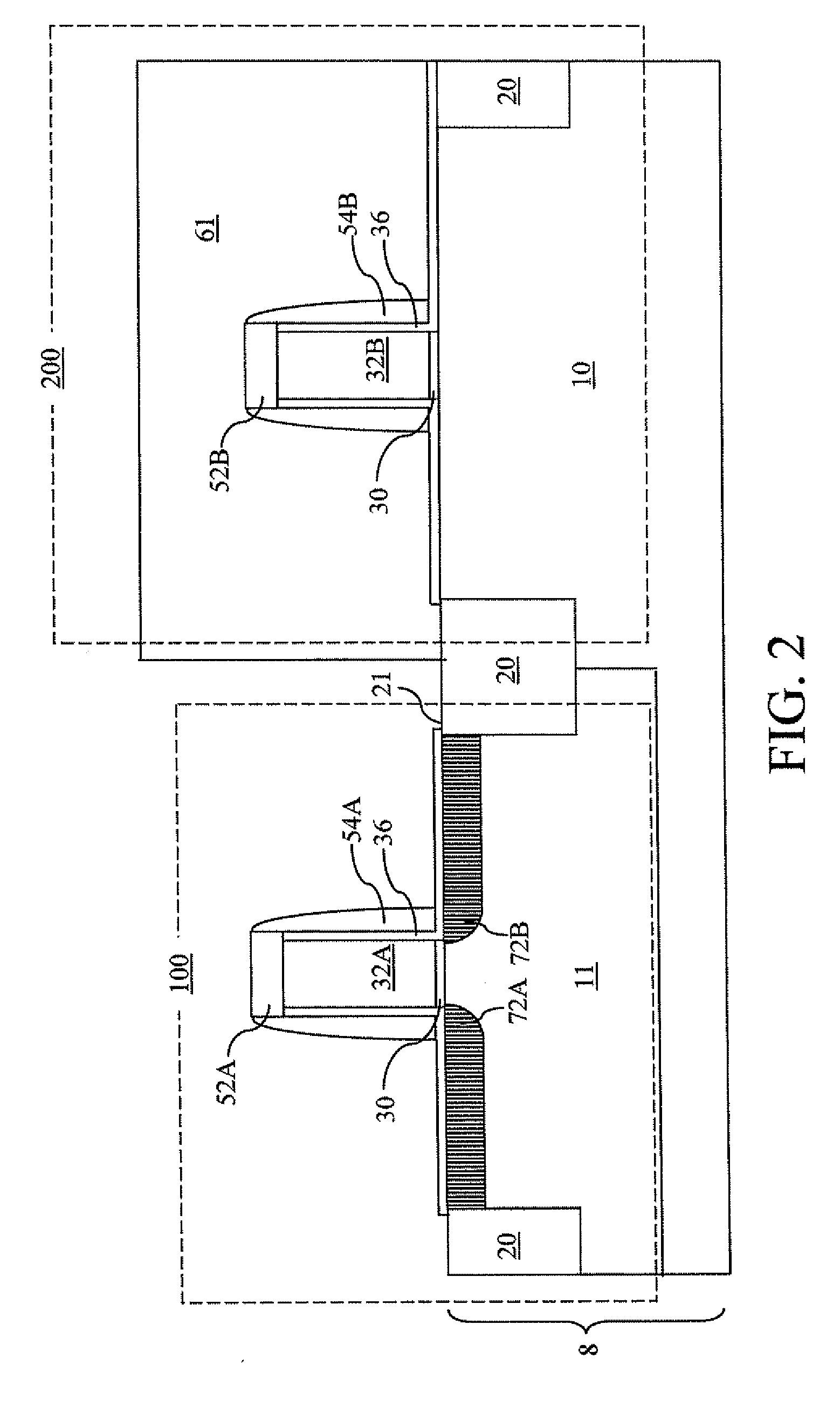

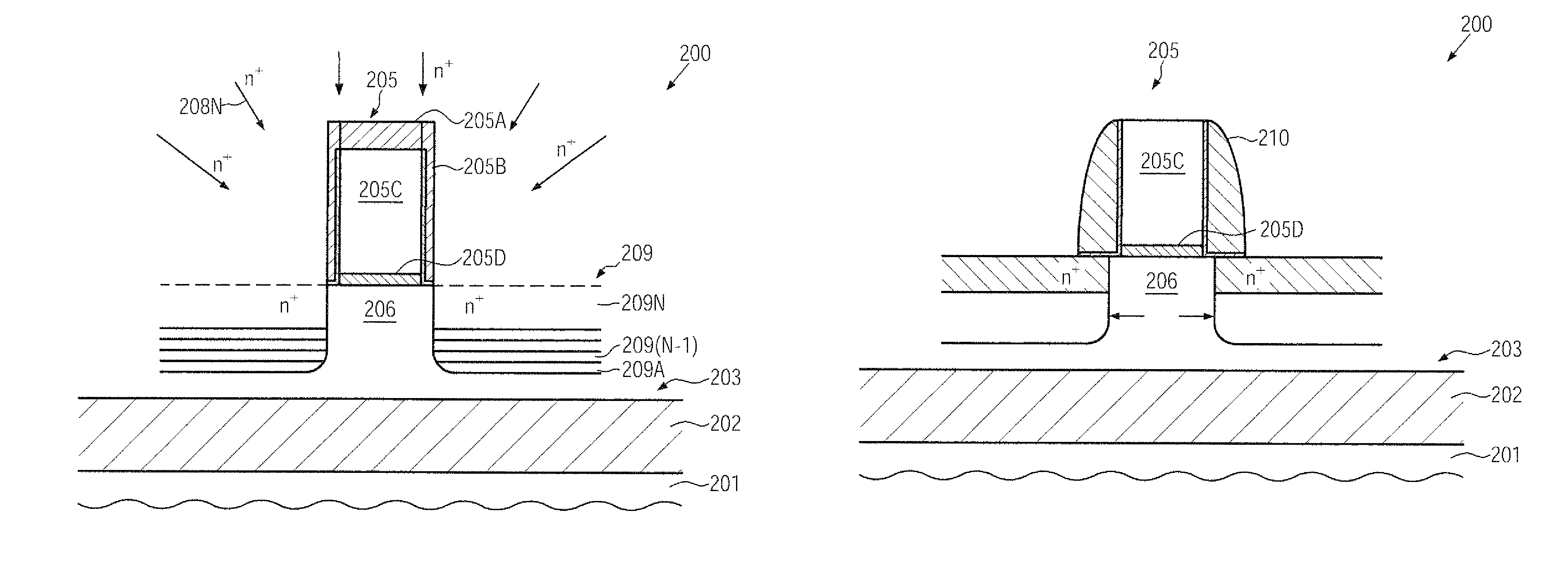

Structure and method for mobility enhanced MOSFETs with unalloyed silicide

ActiveUS8217423B2Stable and low contact resistanceReduce contact resistanceTransistorSolid-state devicesMOSFETSalicide

While embedded silicon germanium alloy and silicon carbon alloy provide many useful applications, especially for enhancing the mobility of MOSFETs through stress engineering, formation of alloyed silicide on these surfaces degrades device performance. The present invention provides structures and methods for providing unalloyed silicide on such silicon alloy surfaces placed on semiconductor substrates. This enables the formation of low resistance contacts for both mobility enhanced PFETs with embedded SiGe and mobility enhanced NFETs with embedded Si:C on the same semiconductor substrate. Furthermore, this invention provides methods for thick epitaxial silicon alloy, especially thick epitaxial Si:C alloy, above the level of the gate dielectric to increase the stress on the channel on the transistor devices.

Owner:AURIGA INNOVATIONS INC

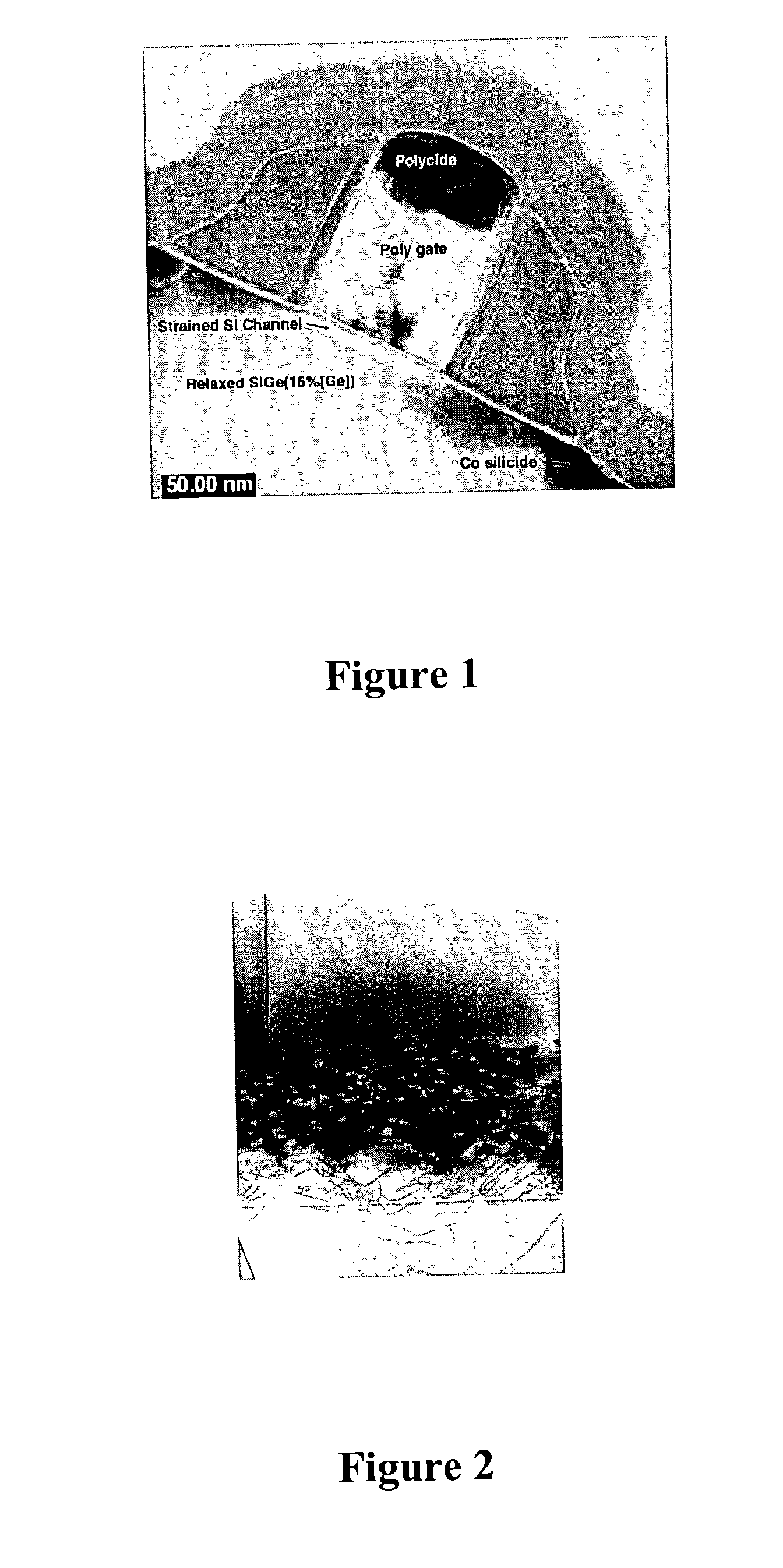

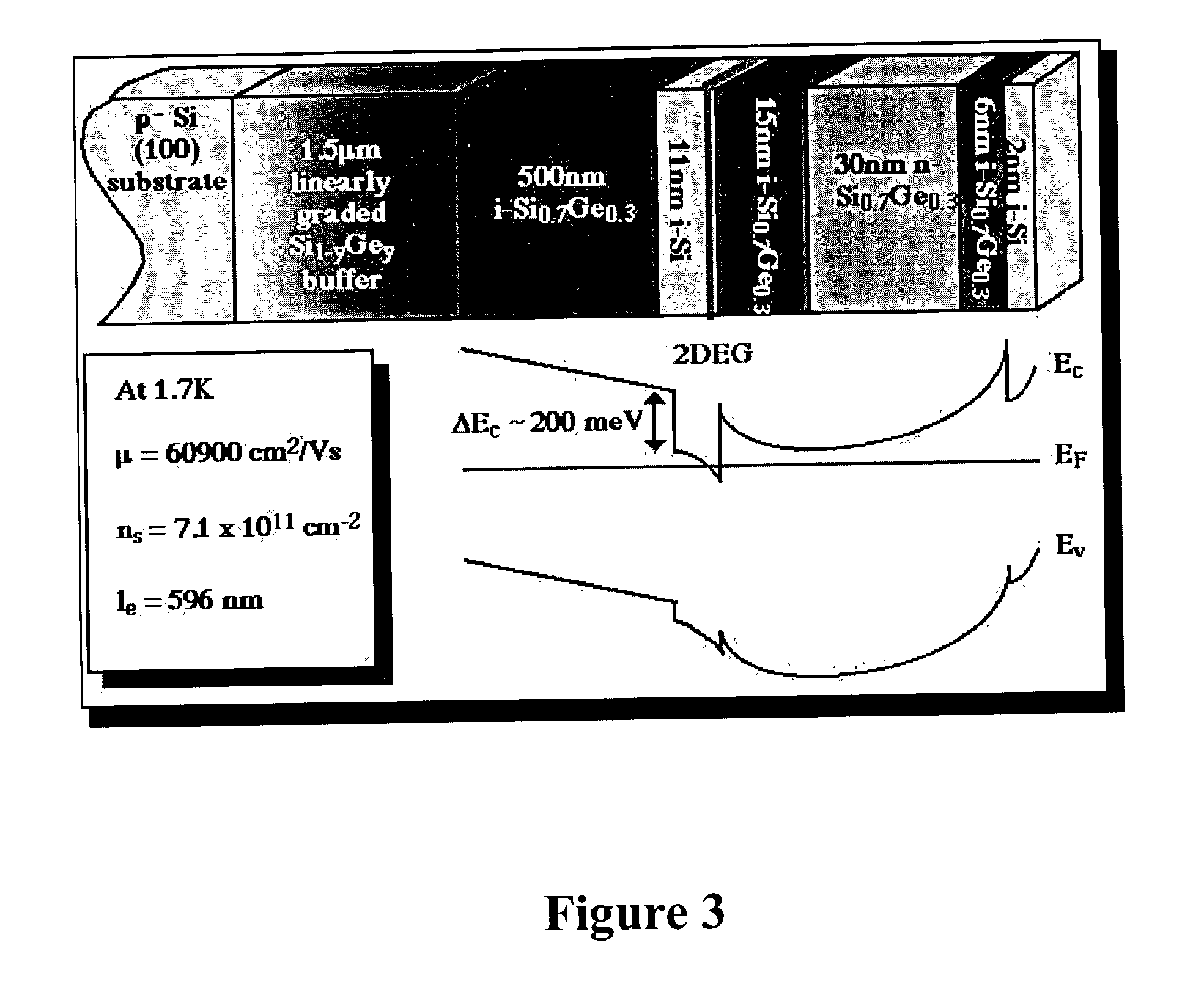

Heterojunction field effect transistors using silicon-germanium and silicon-carbon alloys

InactiveUS20040007715A1Without of performanceWithout strainTransistorSolid-state devicesHeterojunctionSemiconductor

Semiconductor devices, e.g., heterojunction field effect transistors, fabricated with silicon-germnanium buffer layer and silicon-carbon channel layer structures. The invention provides a method of reducing threading defect density via reducing germanium content in a SiGe relaxed buffer layer on which a strained silicon channel layer is formed, by forming the strained silicon channel layer of a silicon-carbon alloy, e.g., containing less than about 1.5 atomic % C substitutionally incorporated in the Si lattice of the alloy.

Owner:INTERNATIONAL RECTIFIER COEP

Method for forming an integrated circuit

ActiveUS20060131665A1Semiconductor/solid-state device manufacturingSemiconductor devicesContact resistanceEpitaxial silicon

A method is described for manufacturing an n-MOS semiconductor transistor. Recesses are formed in a semiconductor substrate adjacent a gate electrode structure. Silicon is embedded in the recesses via a selective epitaxial growth process. The epitaxial silicon is in-situ alloyed with substitutional carbon and in-situ doped with phosphorus. The silicon-carbon alloy generates a uniaxial tensile strain in the channel region between the source and drain, thereby increasing electron channel mobility and the transistor's drive current. The silicon-carbon alloy decreases external resistances by reducing contact resistance between source / drain and silicide regions and by reducing phosphorous diffusivity, thereby permitting closer placement of the transistor's source / drain and channel regions.

Owner:TAHOE RES LTD

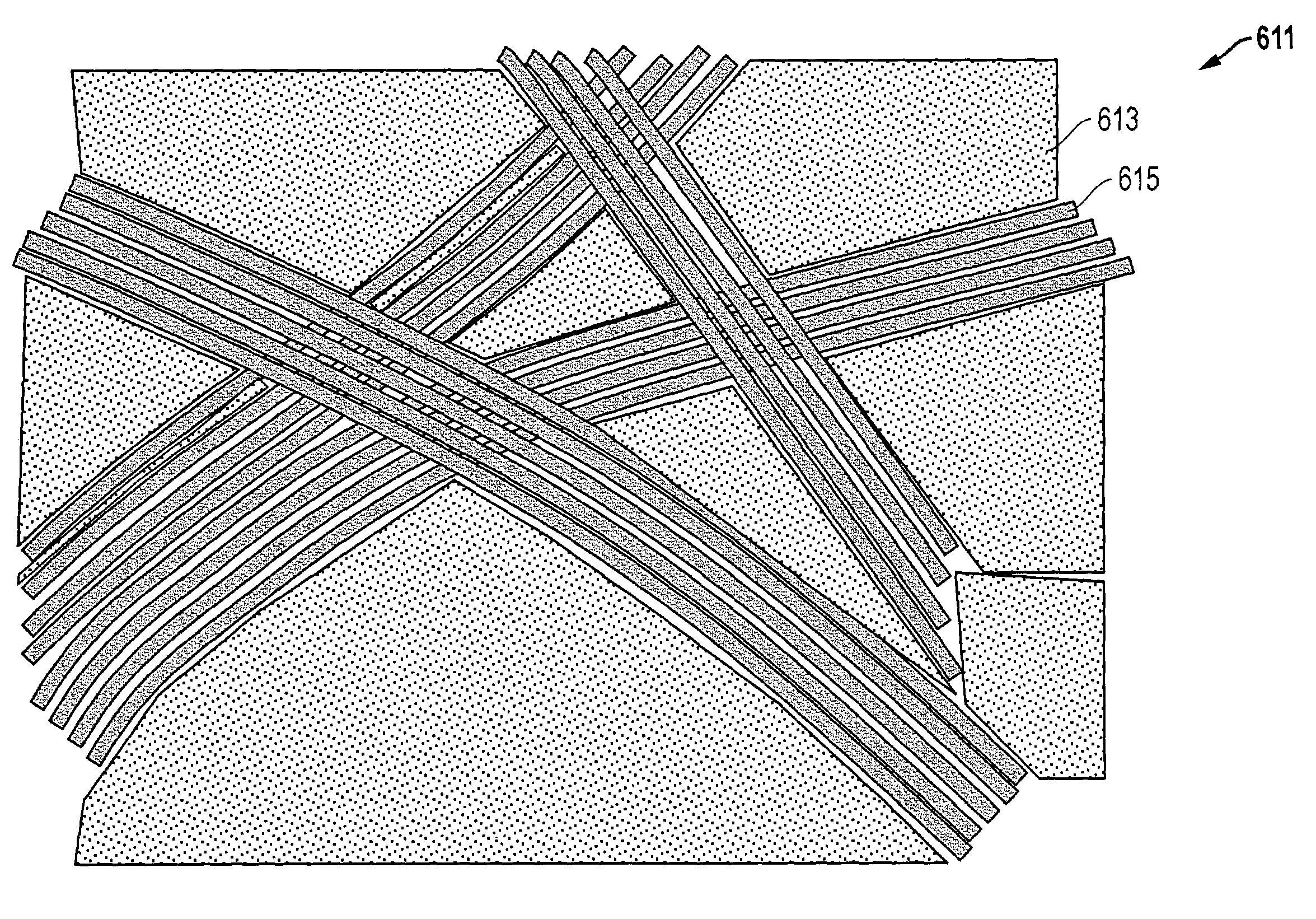

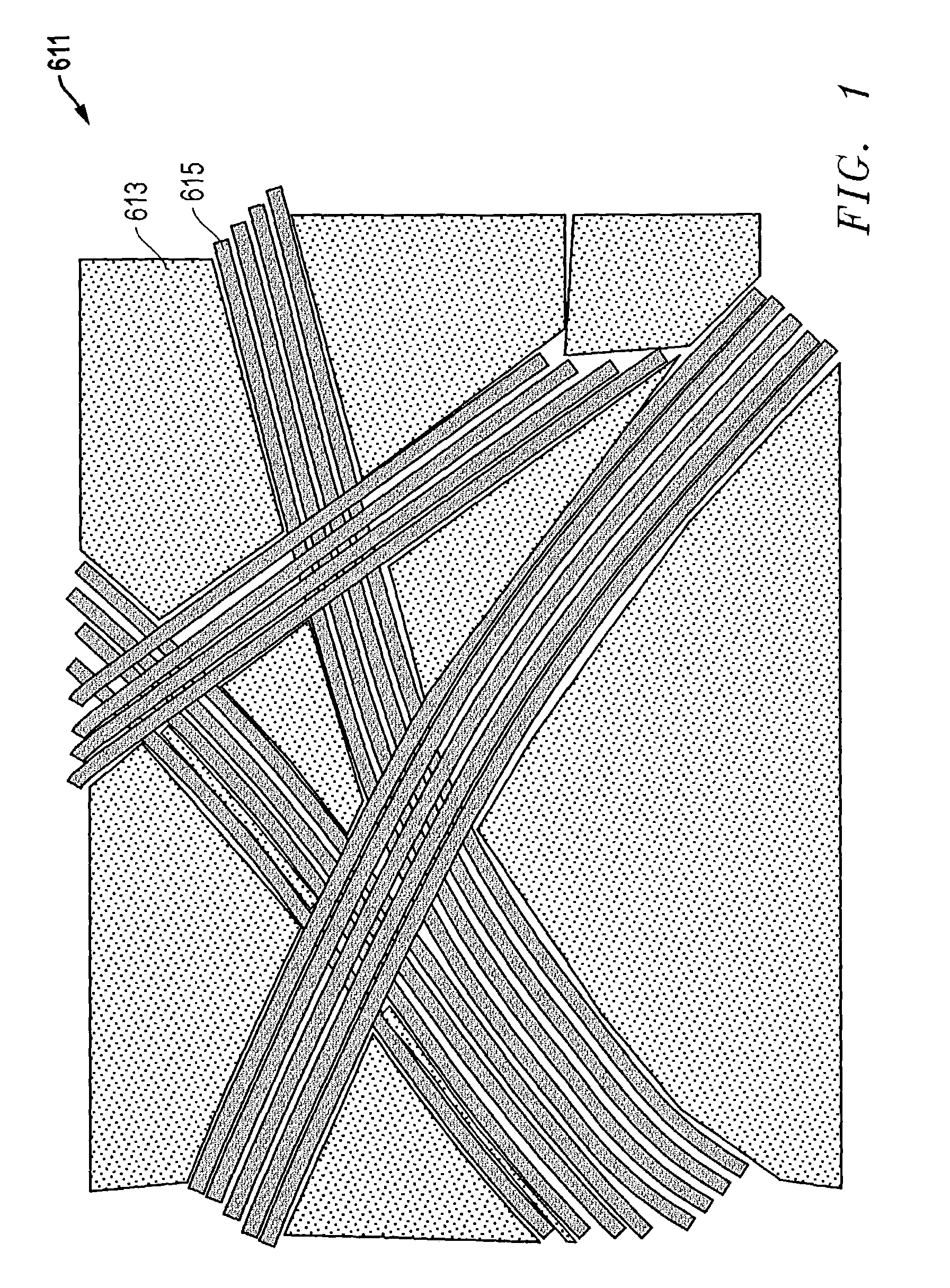

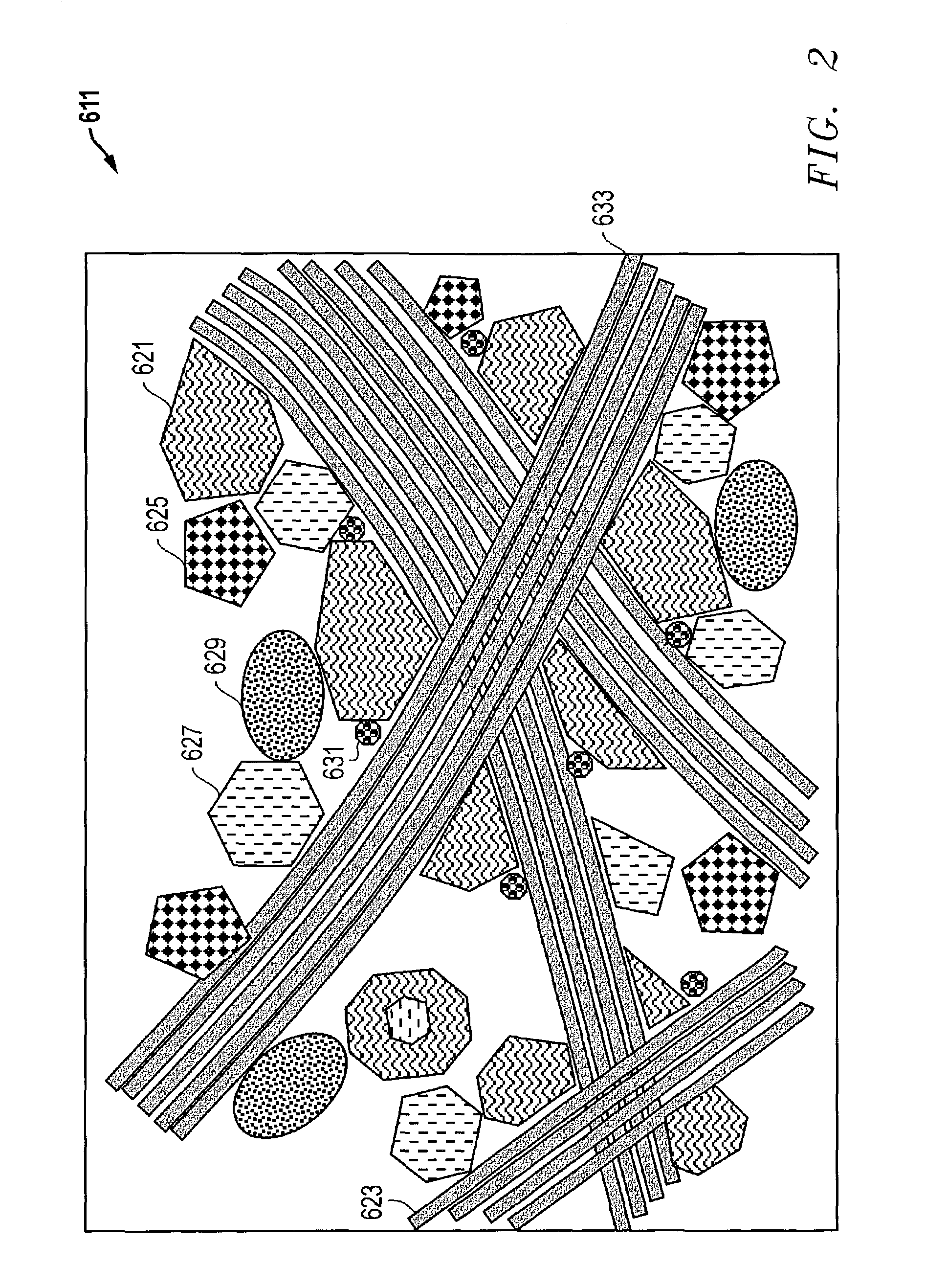

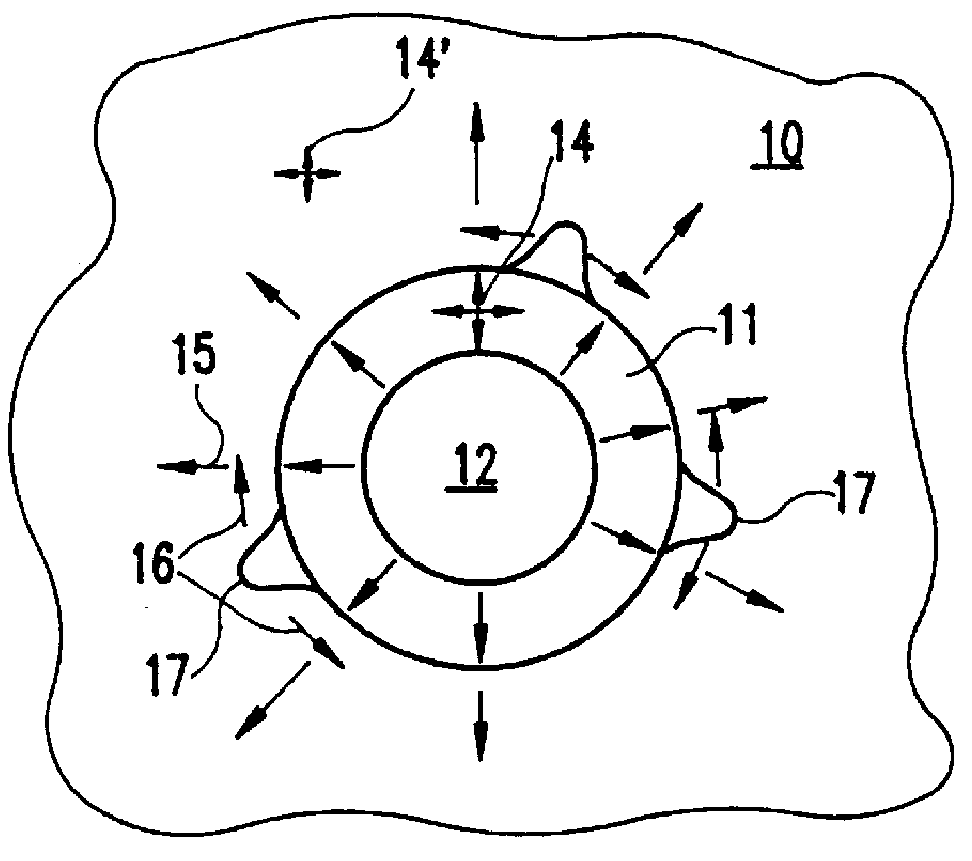

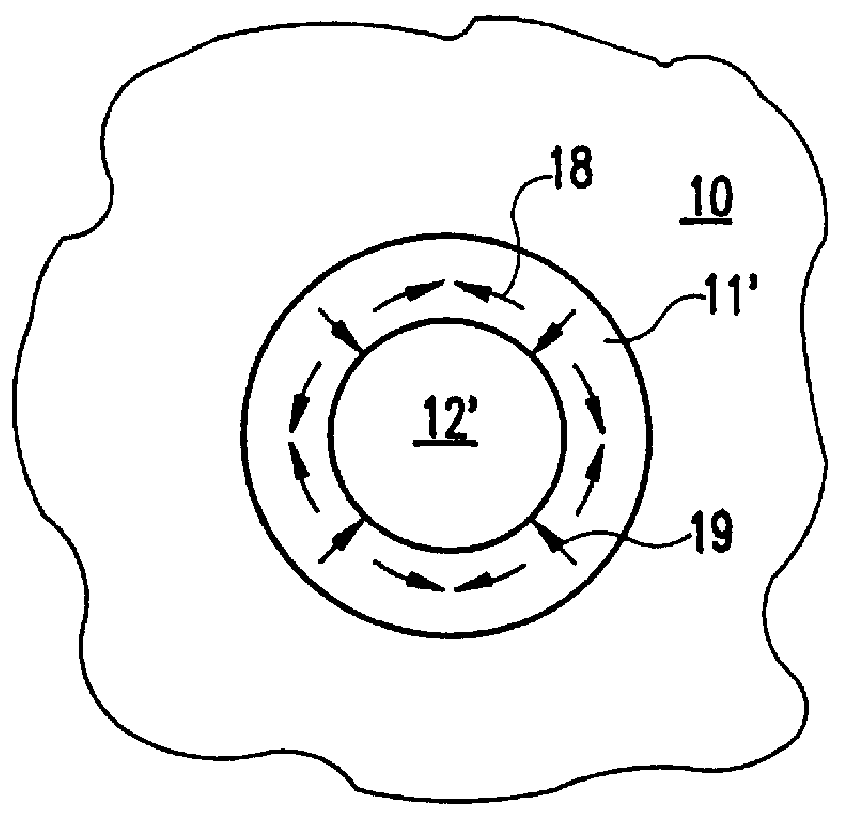

Pure carbon isotropic alloy of allotropic forms of carbon including single-walled carbon nanotubes and diamond-like carbon

InactiveUS7097906B2Enhance particular propertyNot add to structural performanceMaterial nanotechnologyLayered productsCarbon alloyCarbon nanotube

An isotropic carbon alloy is formed from various carbon allotropes such as SWCNT, fullerenes, MWCNT, diamond-like carbon, diamond, nanocrystalline diamond, diamondoids, amorphous carbon, graphitic polyhedral crystals, graphite, graphene, HOPG, and hydrogenated amorphous carbon. The SWCNTs are present in different morphologies such as ropes, bundles, single filaments, tangled webs, etc. The SWCNT have large aspect ratios and weave throughout the alloy. Many morphologies of ICA are possible with a range of properties attainable as a function of the composition of carbon allotropes and post-processing techniques. Post-processing can be done to enhance particular properties of the ICA and may include HIP, furnace heating, ion beam irradiation, electron beam irradiation, laser irradiation, electric resistive heating, inductive heating, IR irradiation, etc. Contaminants may be present in the ICA as a consequence of the process equipment, process feedstock, or catalysts used in the reactors.

Owner:LOCKHEED MARTIN CORP

Strained silicon carbon alloy MOSFET structure and fabrication method thereof

ActiveUS20050023520A1Minimizing device dimensionImproving device current driving forceTransistorSemiconductor/solid-state device manufacturingMOSFETPolysilicon gate

A MOSFET structure utilizing strained silicon carbon alloy and fabrication method thereof. The MOSFET structure includes a substrate, a graded SiGe layer, a relaxed buffer layer, a strained silicon carbon alloy channel layer, a gate dielectric layer, a polysilicon gate electrode (or metal gate electrode) and a source / drain region.

Owner:TRANSPACIFIC IP LTD

Structure and method for mobility enhanced mosfets with unalloyed silicide

ActiveUS20080164491A1Increase heightStable and low contact resistanceTransistorSolid-state devicesMOSFETElectrical resistance and conductance

While embedded silicon germanium alloy and silicon carbon alloy provide many useful applications, especially for enhancing the mobility of MOSFETs through stress engineering, formation of alloyed silicide on these surfaces degrades device performance. The present invention provides structures and methods for providing unalloyed silicide on such silicon alloy surfaces placed on semiconductor substrates. This enables the formation of low resistance contacts for both mobility enhanced PFETs with embedded SiGe and mobility enhanced NFETs with embedded Si:C on the same semiconductor substrate. Furthermore, this invention provides methods for thick epitaxial silicon alloy, especially thick epitaxial Si:C alloy, above the level of the gate dielectric to increase the stress on the channel on the transistor devices.

Owner:AURIGA INNOVATIONS INC

Low-temperature high-strength, high-toughness steel and preparing method therefor

InactiveCN101024870AHigh strengthGuaranteed toughnessHeat treatment process controlLift systemThermal treatment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

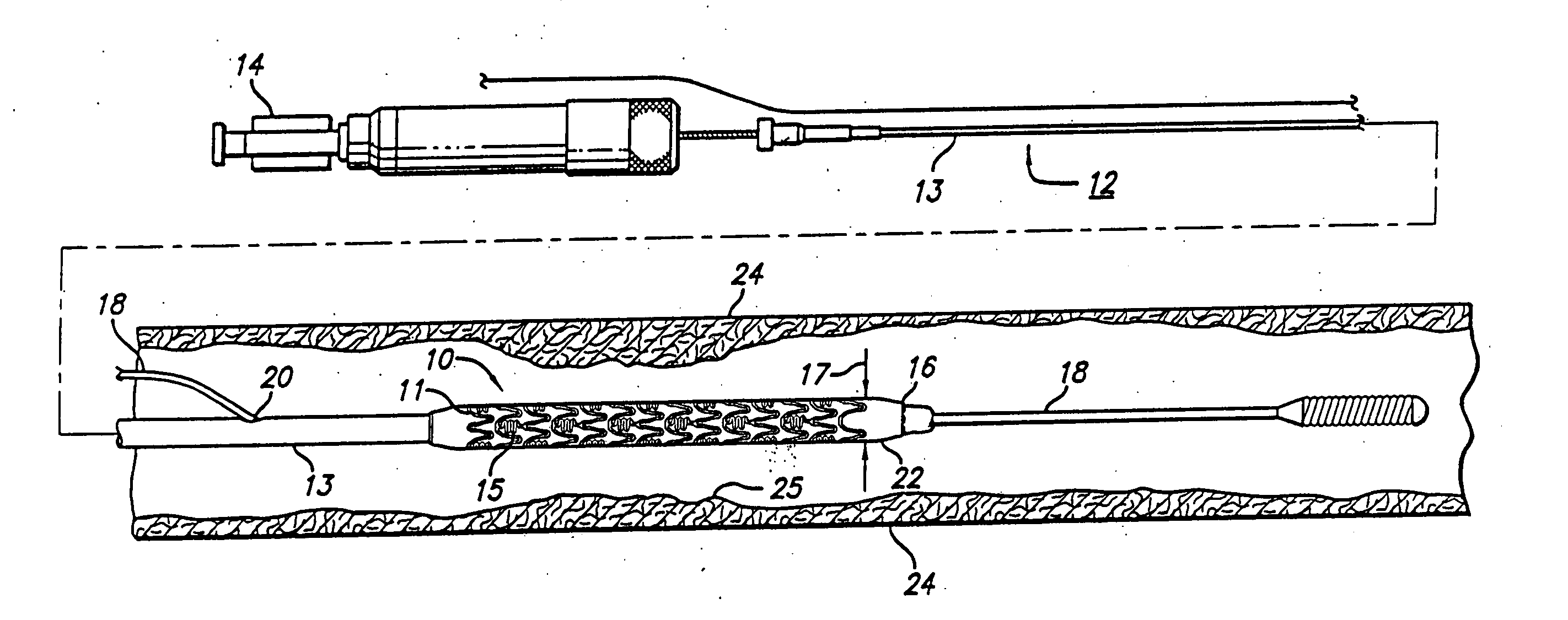

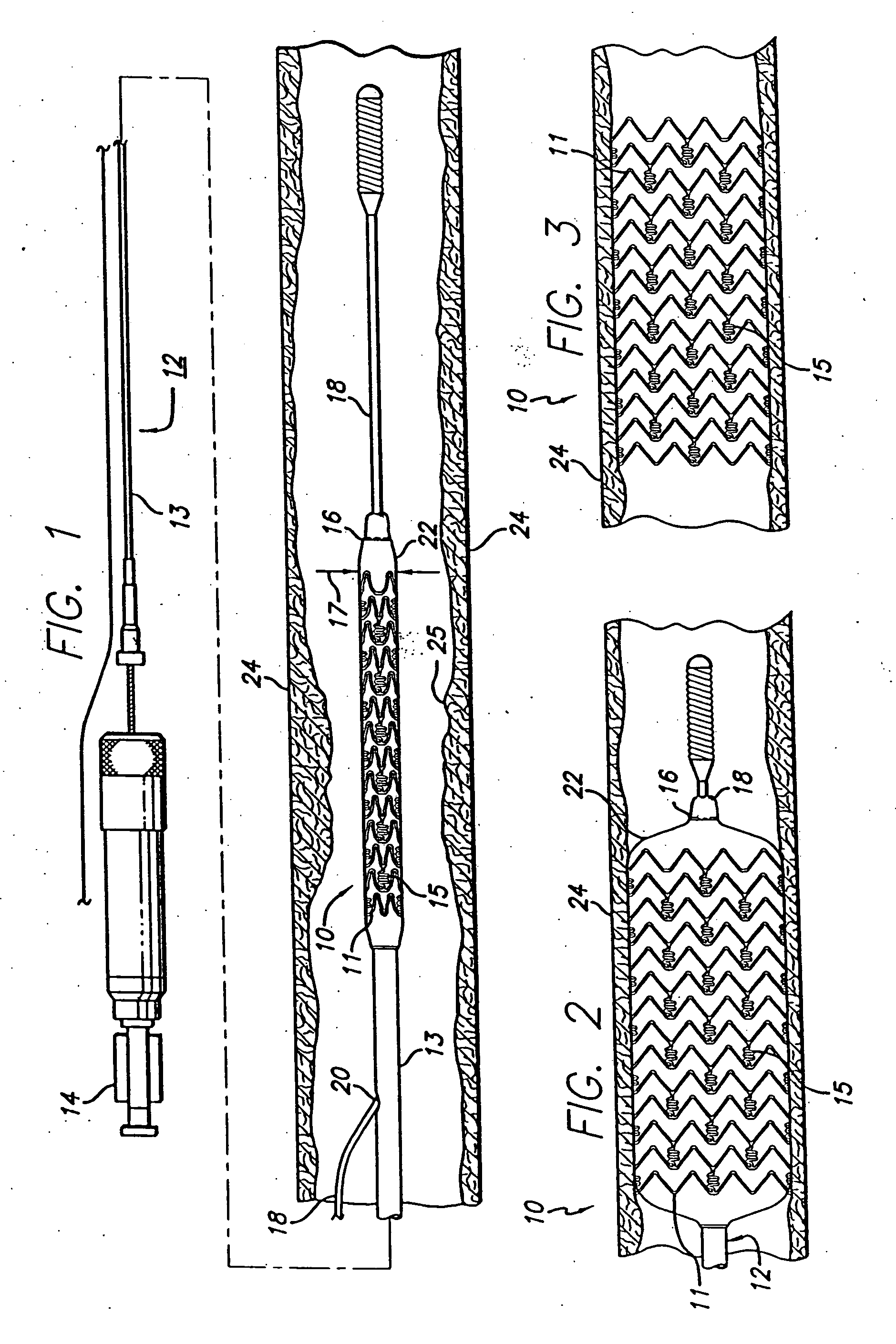

Bioabsorbable medical device

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of an iron carbon alloy that is subjected to DET heat treatment to impart high strength and high ductility in combination with an accelerated corrosion rate.

Owner:ABBOTT CARDIOVASCULAR

Graphene growth on a carbon-containing semiconductor layer

A semiconductor-carbon alloy layer is formed on the surface of a semiconductor substrate, which may be a commercially available semiconductor substrate such as a silicon substrate. The semiconductor-carbon alloy layer is converted into at least one graphene layer during a high temperature anneal, during which the semiconductor material on the surface of the semiconductor-carbon alloy layer is evaporated selective to the carbon atoms. As the semiconductor atoms are selectively removed and the carbon concentration on the surface of the semiconductor-carbon alloy layer increases, the remaining carbon atoms in the top layers of the semiconductor-carbon alloy layer coalesce to form a graphene layer having at least one graphene monolayer. Thus, a graphene layer may be provided on a commercially available semiconductor substrate having a diameter of 200 mm or 300 mm.

Owner:GLOBALFOUNDRIES US INC

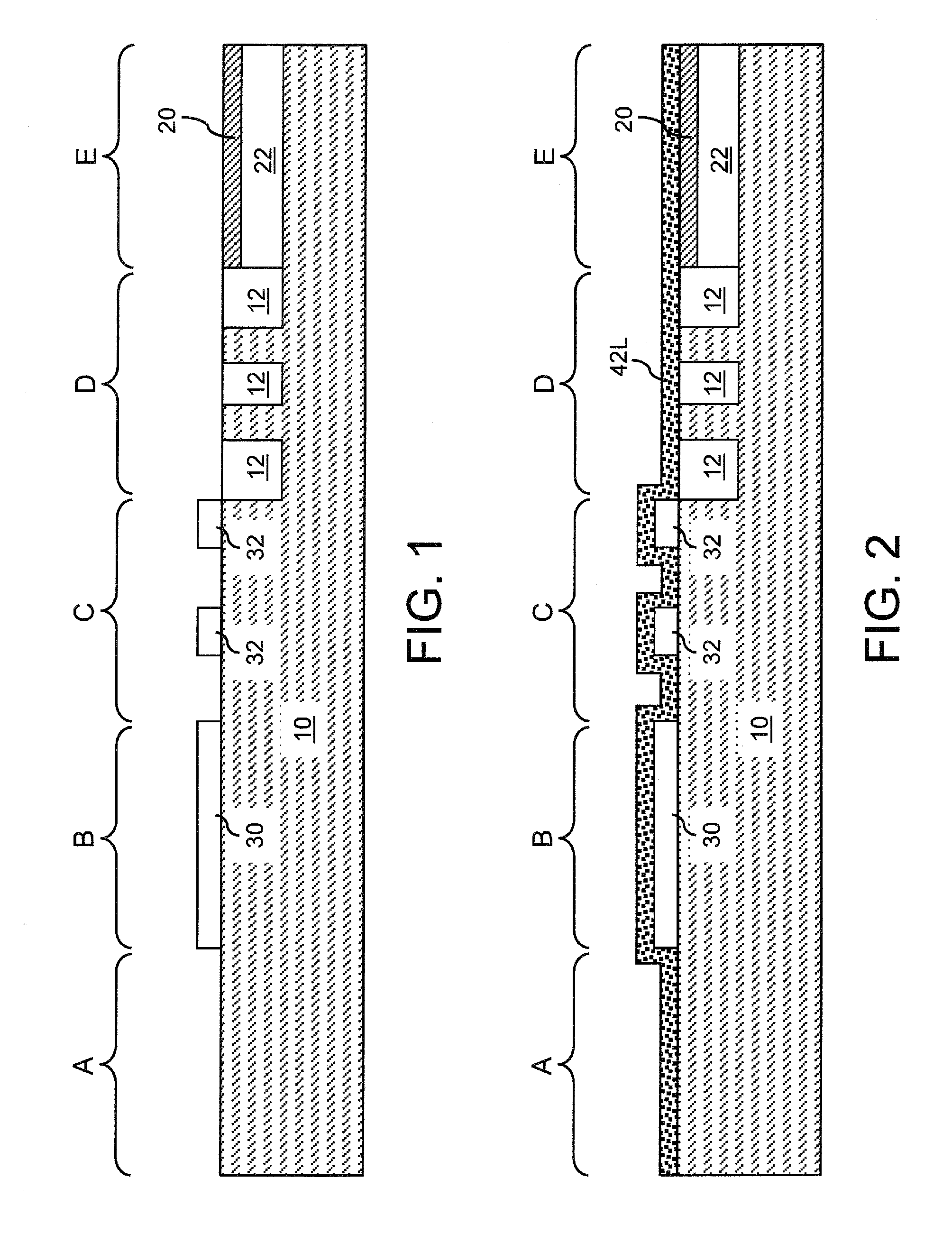

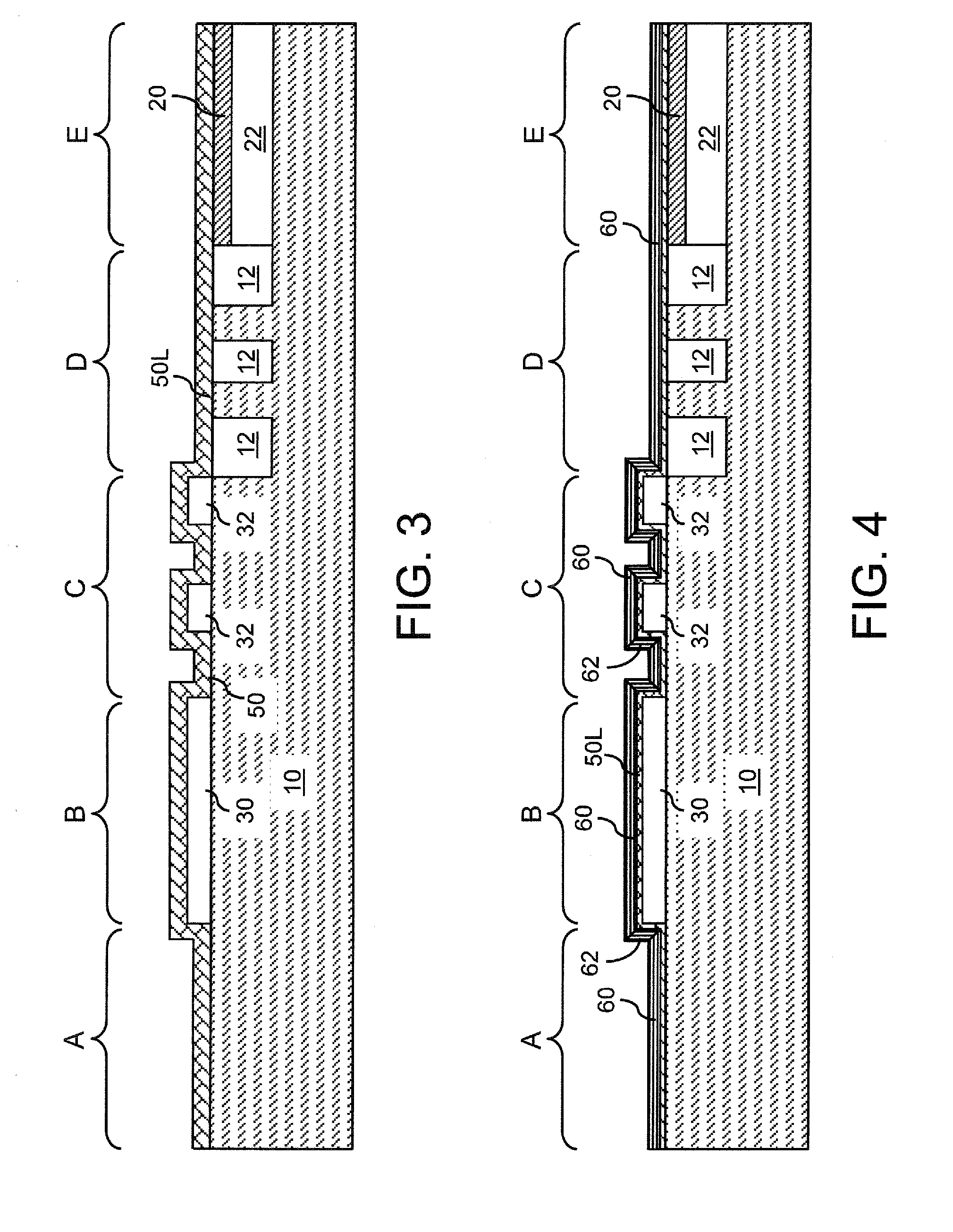

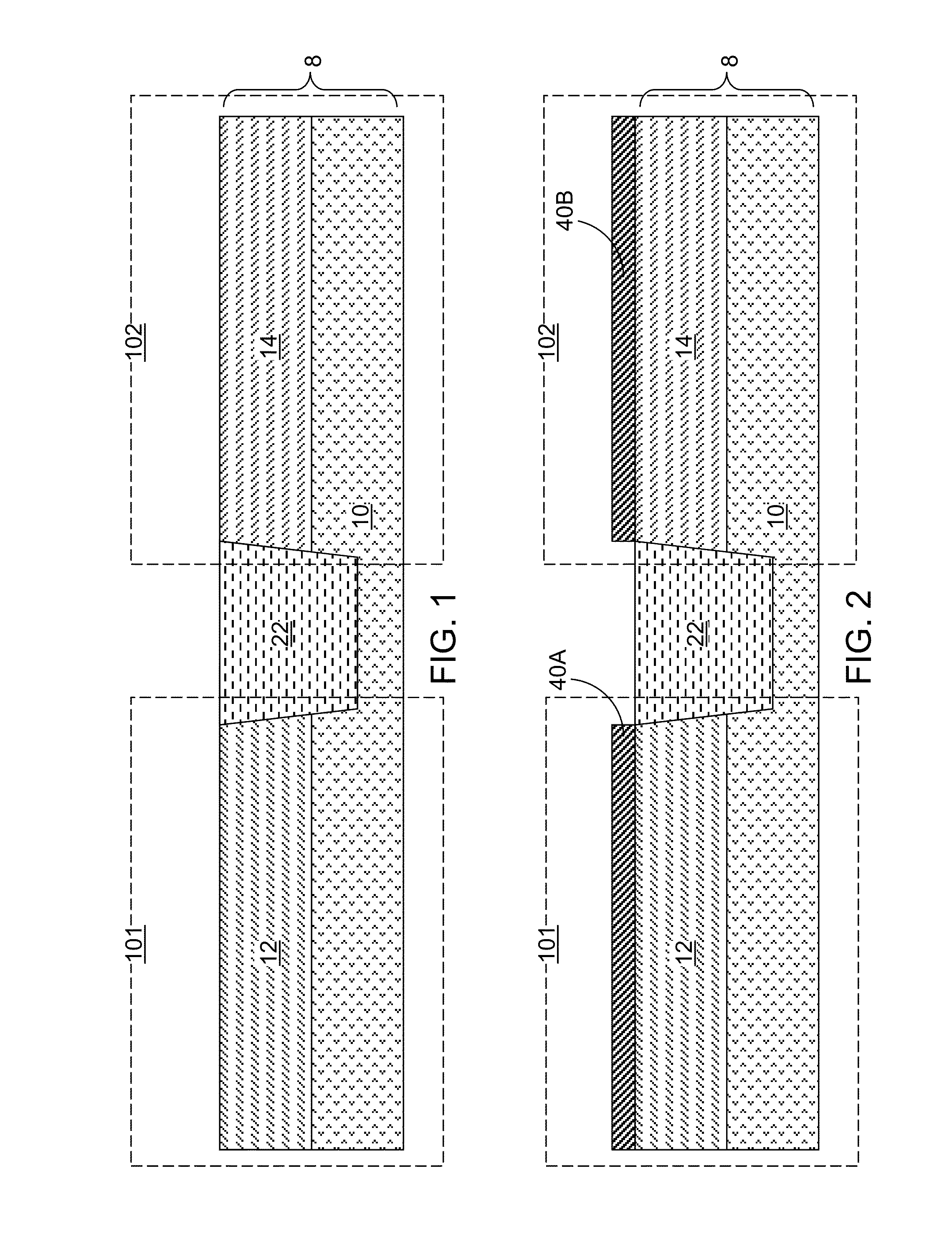

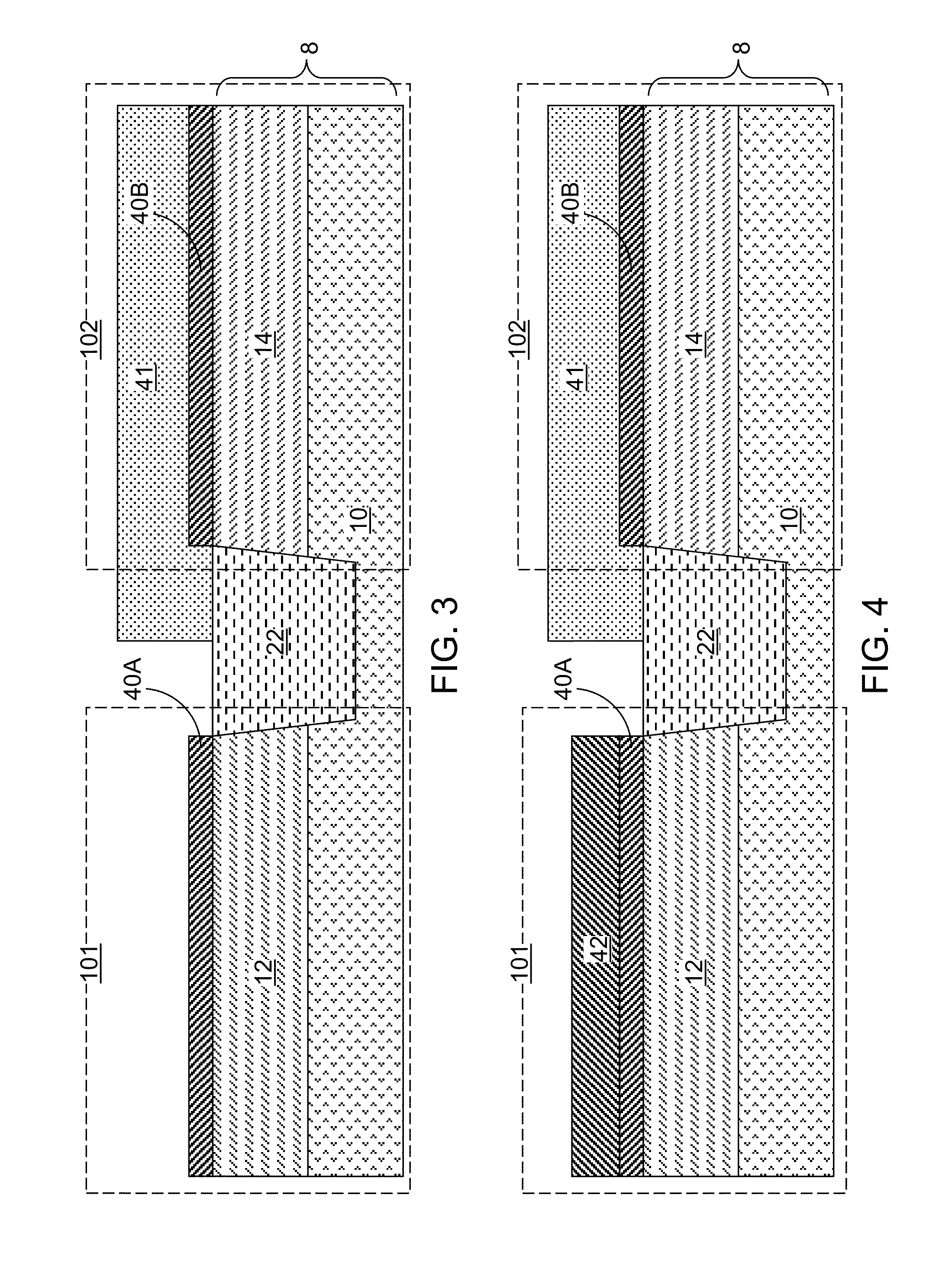

Local stress engineering for CMOS devices

A first dielectric layer is formed over a PFET gate and an NFET gate, and lithographically patterned to expose a PFET area, while covering an NFET area. Exposed PFET active area is etched and refilled with a SiGe alloy, which applies a uniaxial compressive stress to a PFET channel. A second dielectric layer is formed over the PFET gate and the NFET gate, and lithographically patterned to expose the NFET area, while covering the PFET area. Exposed NFET active area is etched and refilled with a silicon-carbon alloy, which applies a uniaxial tensile stress to an NFET channel. Dopants may be introduced into the SiGe and silicon-carbon regions by in-situ doping or by ion implantation.

Owner:GLOBALFOUNDRIES US INC

Method of depositing silicon on carbon materials and forming an anode for use in lithium ion batteries

Owner:APPLIED SCI

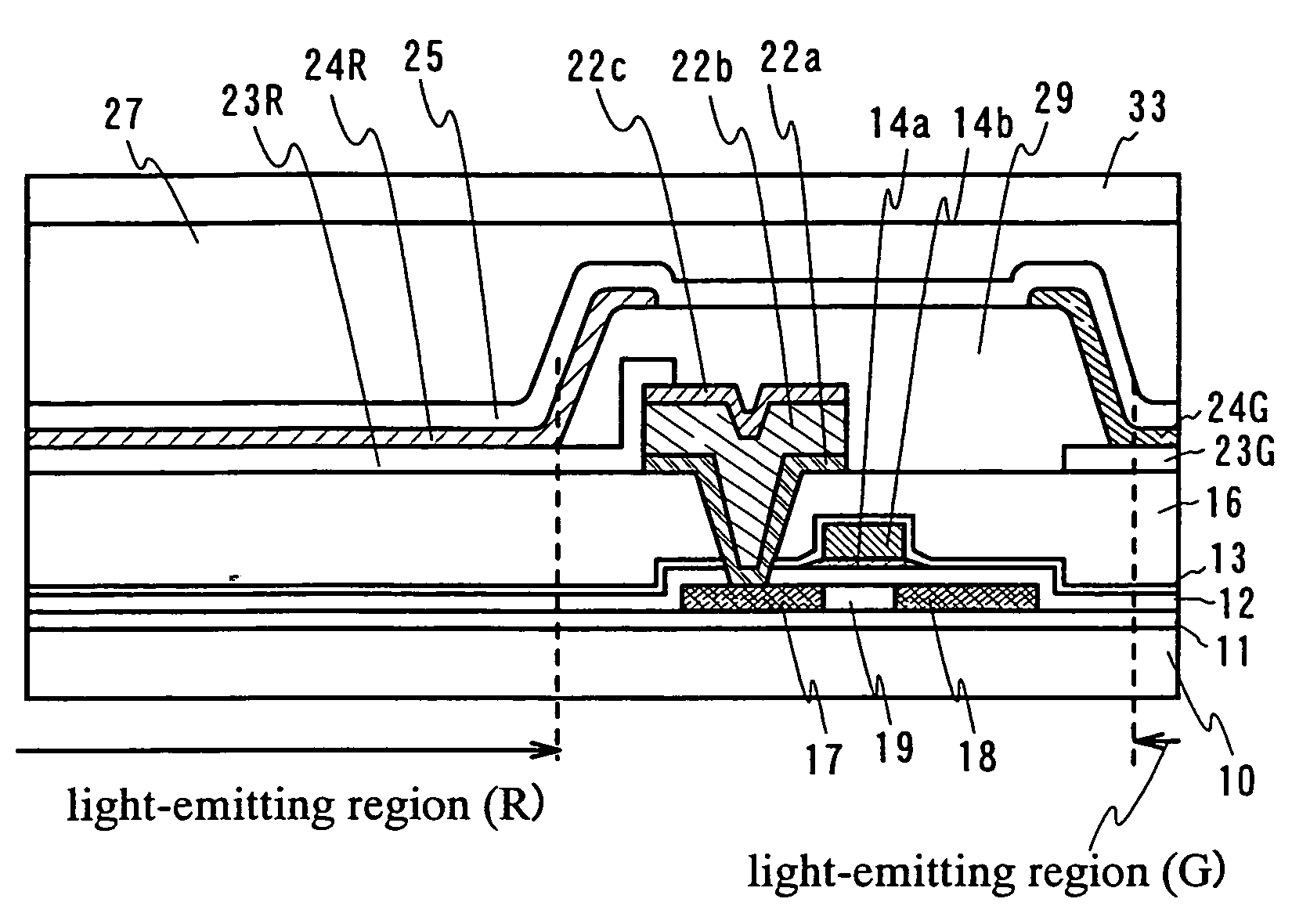

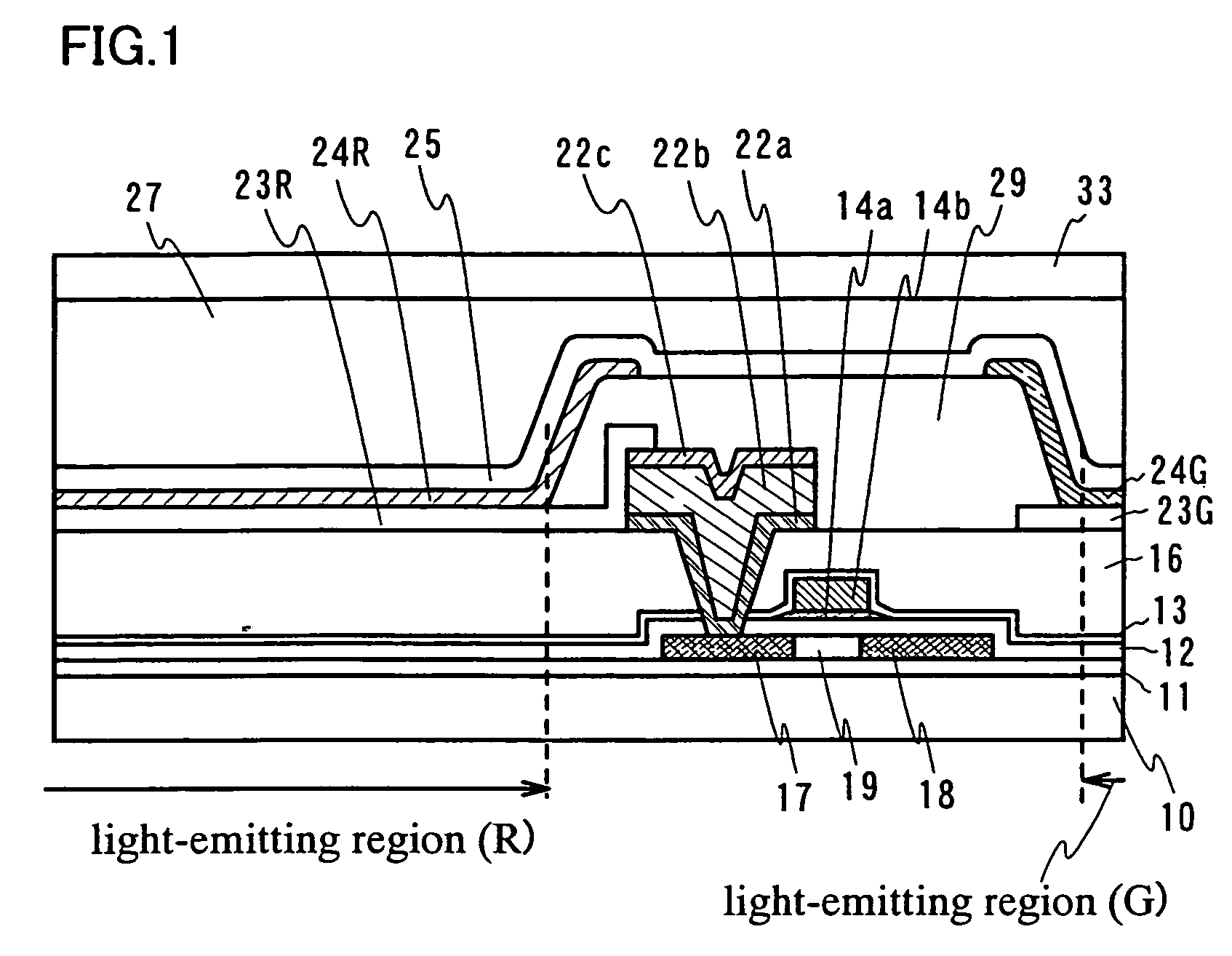

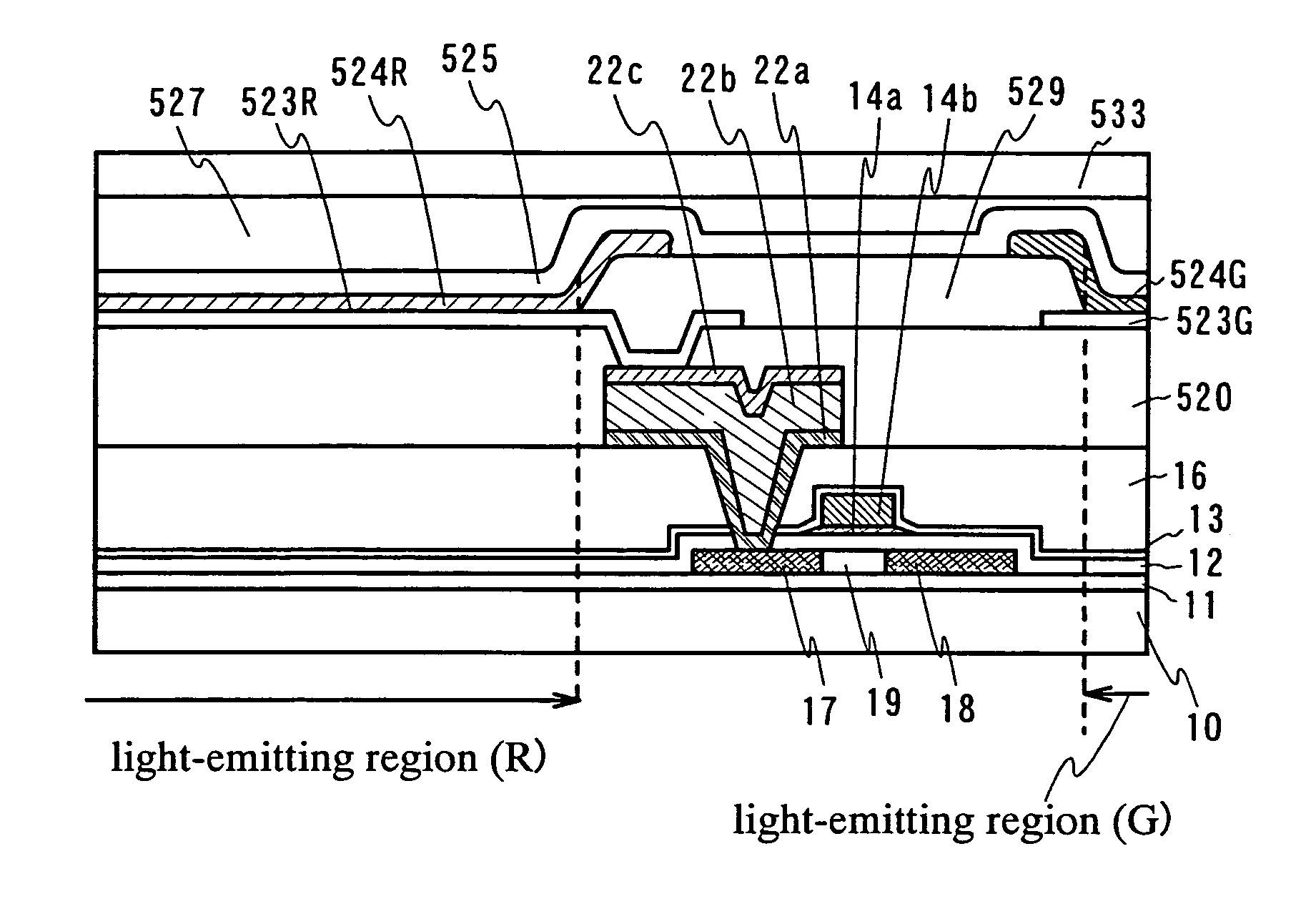

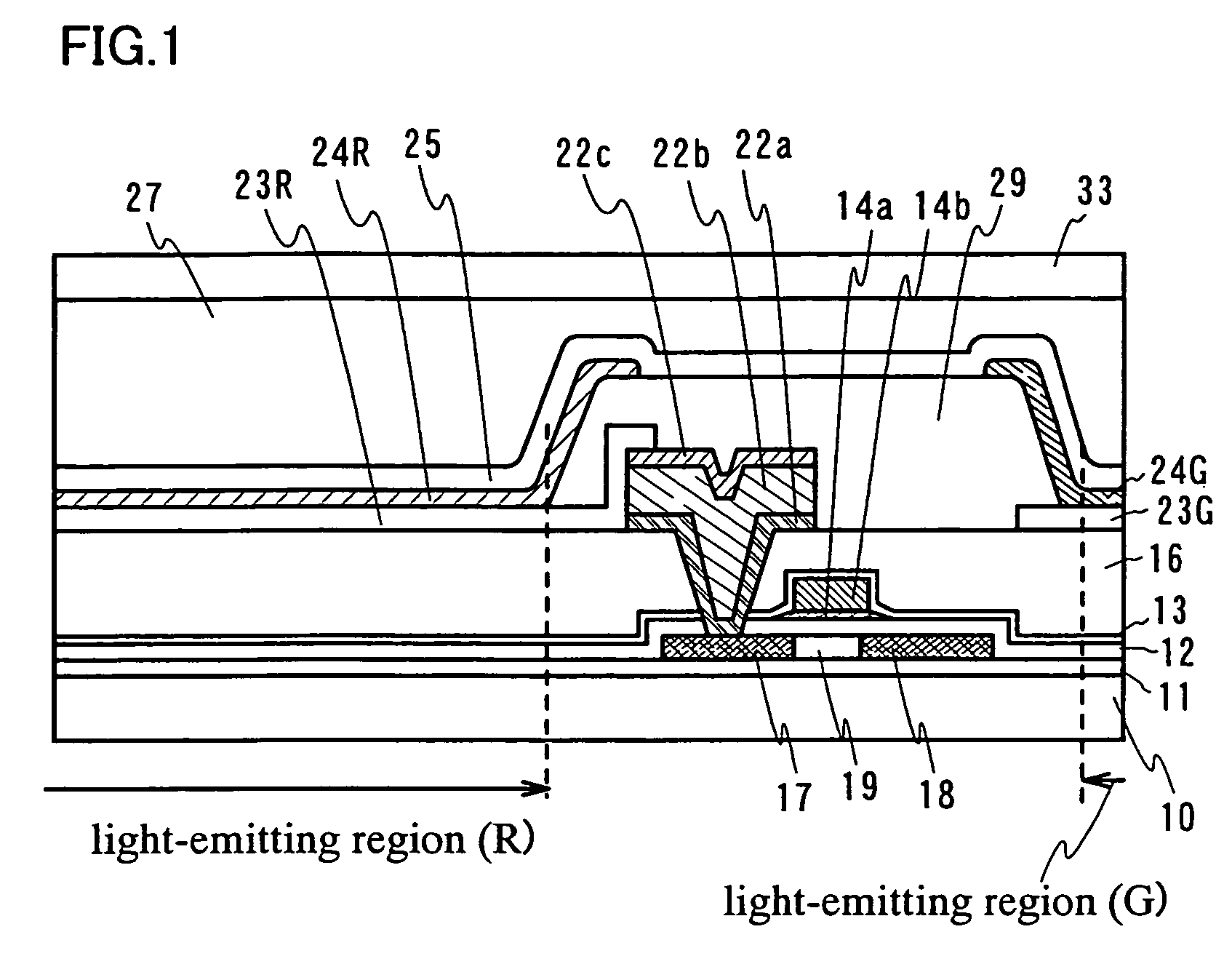

Semiconductor device and manufacturing method thereof

ActiveUS20060038176A1Good ohmic contactSuperior electrodeSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixOhmic contact

According to the present invention, wirings, electrodes or the like formed from two films (an ITO film and an aluminum film) which are incompatible with each other are connected, and low power consumption is realized even if a display screen size is increased in an active matrix display device. A three-layer structure or a two-layer structure is employed to obtain a favorable ohmic contact with ITO. The structure of a wiring or an electrode includes a layer having an aluminum carbon alloy which does not react with ITO. The wiring or an electrode is contacted with ITO.

Owner:SEMICON ENERGY LAB CO LTD

Lithium ion battery electrolyte and high-energy-density lithium ion battery using same

InactiveCN109659614AImproved High Temperature StoragePromote circulationSecondary cells servicing/maintenanceOrganic electrolytesHigh energyElectrical impedance

The invention provides a lithium ion battery electrolyte and a high-energy-density lithium ion battery using the same. The lithium ion battery electrolyte comprises a non-aqueous organic solvent, a lithium salt and additives. The additives comprise a negative electrode film-forming additive, a nitrile or ether nitrile compound, an acid anhydride compound and a lithium salt type additive. Accordingto the lithium ion battery electrolyte, 0.3-20wt% of the negative electrode film-forming additive such as vinylene carbonate and / or fluorocarbonate can form an excellent SEI film on a carbon-containing negative electrode, a silicon-containing negative electrode or a silicon carbon alloy negative electrode and the like, thereby stabilizing the negative electrode and ensuring excellent battery performance; 0.2-6.5wt% of the nitrile or ether nitrile compound, the acid anhydride compound and a combination of them can complex metal ions of a positive electrode or form a protective film on the surface of the positive electrode, thereby stabilizing the positive electrode and improving battery performance; and the 0.5-3 wt% of the lithium salt type additive in the lithium ion battery electrolytecan lower the impedance of the battery so as to improve the low temperature performance of the battery or improve the high temperature performance of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20090101242A1Improve toughnessHigh tensile strengthFurnace typesHeat treatment furnacesWater basedNiobium

Owner:TENARIS CONNECTIONS

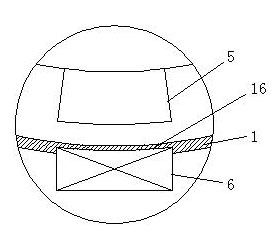

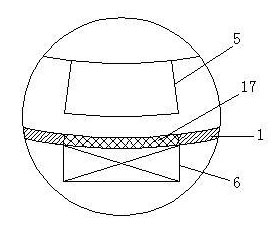

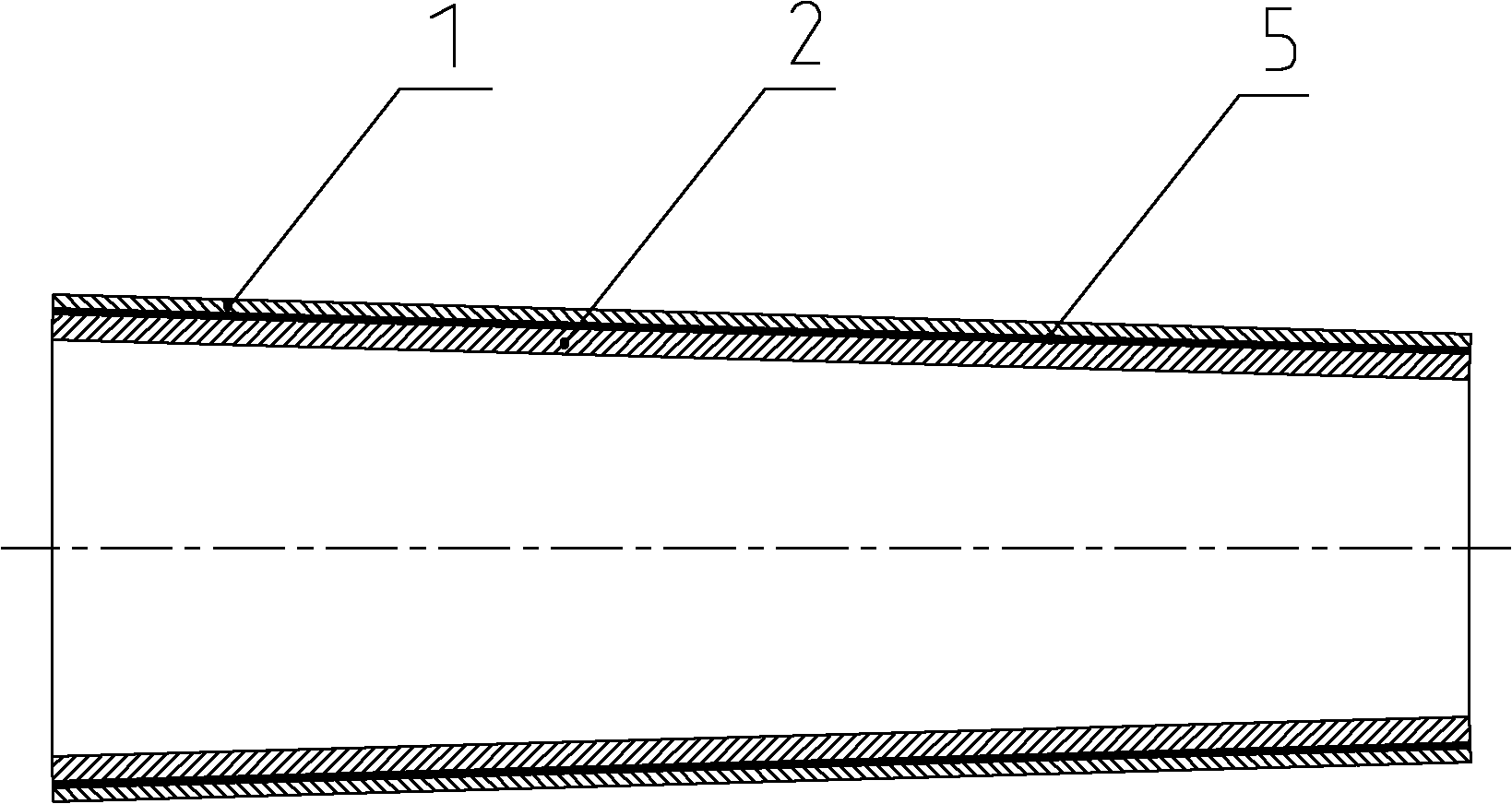

External thin-wall vacuum duct maglev traffic system of power system

The invention provides an external thin-wall vacuum duct maglev traffic system of a power system. A vacuum duct with small wall thickness is adopted, a linear motor coil, a track levitation mechanism and other communication, detecting and control devices are arranged outside the duct and provide power, levitation force and control to vehicles in the duct in the state that one thin duct wall is used for separation. The material of the duct wall is required to have no effect on the electromagnetic field of a linear motor and the levitation magnetic field of a levitation device, for example, non-magnetized stainless steel, carbon alloy, glass fiber reinforced plastics or high-strength organic materials are adopted, or the duct is made of a composite material. The arrangement has the advantages that the installation construction of a linear motor stator and the levitation mechanism can be conveniently performed outside the duct; routine maintenance and repair during operation can also be performed outside the duct; mechatronic systems can be well cooled, and heat aggregation in the vacuum duct is avoided; and the space in the duct is not occupied; and the construction, maintenance and system operation costs of the vacuum duct high-speed maglev traffic system can be lowered.

Owner:张耀平

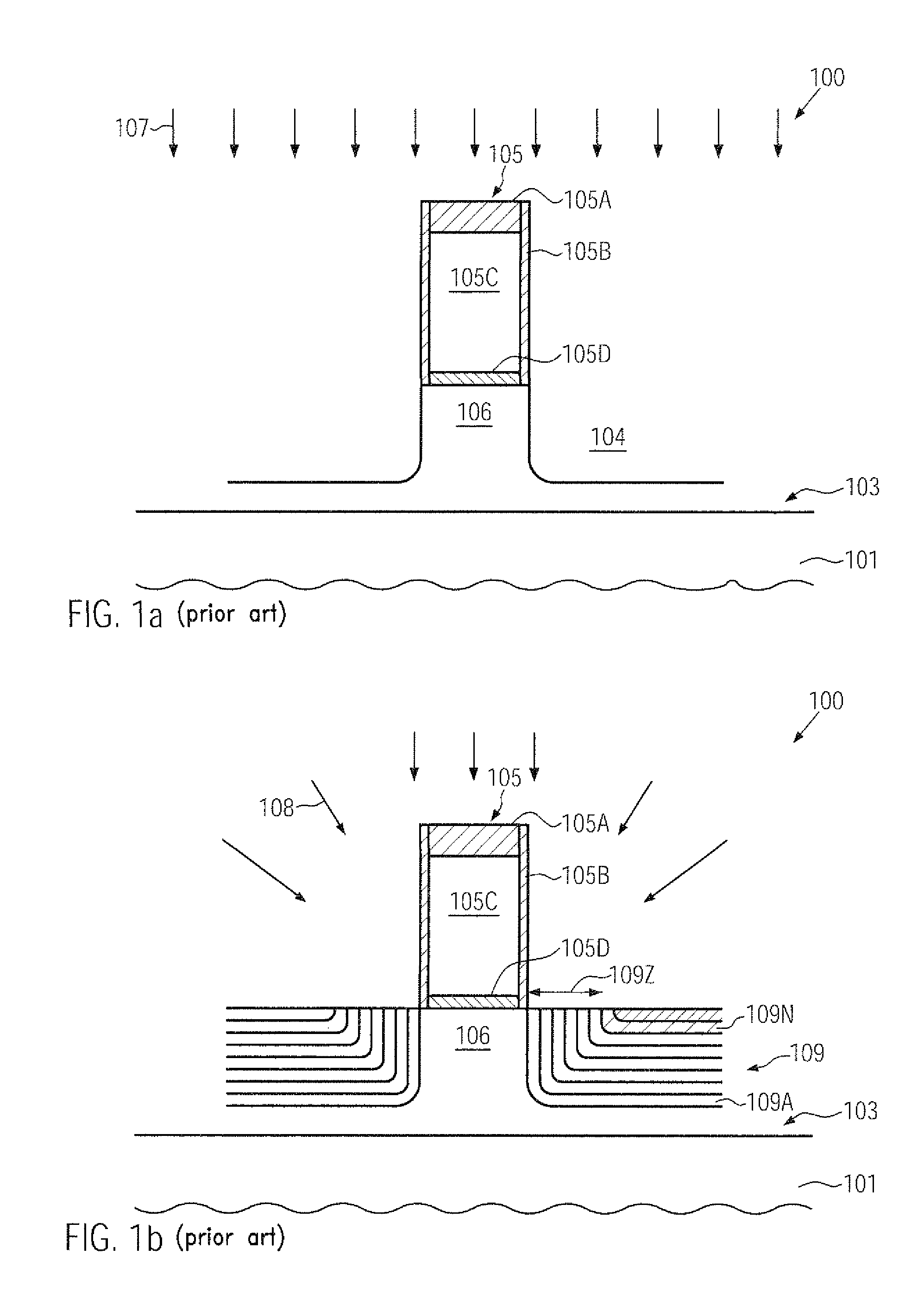

Shallow pn junction formed by in situ doping during selective growth of an embedded semiconductor alloy by a cyclic growth/etch deposition process

ActiveUS20100025779A1Increase strainImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingIn situ dopingUltra-high vacuum

A silicon / carbon alloy may be formed in drain and source regions, wherein another portion may be provided as an in situ doped material with a reduced offset with respect to the gate electrode material. For this purpose, in one illustrative embodiment, a cyclic epitaxial growth process including a plurality of growth / etch cycles may be used at low temperatures in an ultra-high vacuum ambient, thereby obtaining a substantially bottom to top fill behavior.

Owner:ADVANCED MICRO DEVICES INC

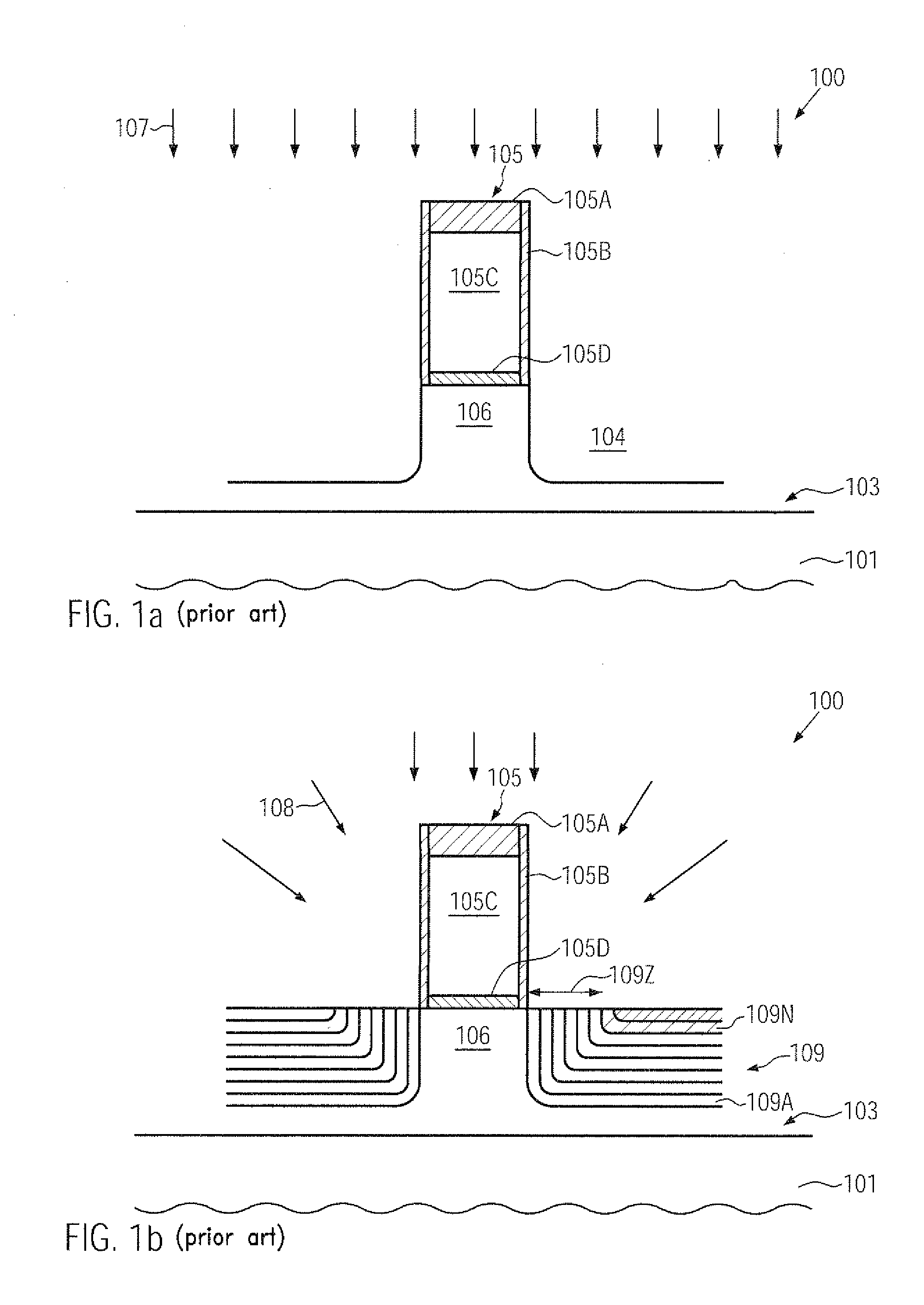

Shrink-wrap collar from DRAM deep trenches

InactiveUS6069049AReliable formingImprove integration densitySolid-state devicesSemiconductor/solid-state device manufacturingShrink wrapDislocation

Crystal lattice dislocations in material surrounding trench capacitors and other trench structures are avoided by alteration of stresses such as decreasing compressive stresses and / or development of persistent tensile forces within material deposited in the trench and thus at the material interface formed by the trench. Such alteration of stresses is achieved by volume reduction of a film deposited in the trench. The material is preferably a hydrogenated nitride of silicon, boron or silicon-carbon alloy which may be reduced in volume by partial or substantially complete dehydrogenation during subsequent heat treatment at temperatures where the film will exhibit substantial creep resistance. The amount of volume reduction can be closely controlled by control of concentration of hydrogen or other gas or volatile material in the film. Further fine adjustment of stresses can be achieved in combination with this mechanism by volume reduction of other materials which may be used, in part, to confine the film through other mechanisms such as annealing.

Owner:SIEMENS MOBILITY INC

Semiconductor device having a wiring including an aluminum carbon alloy and titanium or molybdenum

ActiveUS7417249B2Without increasing the cross sectional area of the wiringsReduce power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixOhmic contact

According to the present invention, wirings, electrodes or the like formed from two films (an ITO film and an aluminum film) which are incompatible with each other are connected, and low power consumption is realized even if a display screen size is increased in an active matrix display device. A three-layer structure or a two-layer structure is employed to obtain a favorable ohmic contact with ITO. The structure of a wiring or an electrode includes a layer having an aluminum carbon alloy which does not react with ITO. The wiring or an electrode is contacted with ITO.

Owner:SEMICON ENERGY LAB CO LTD

Online softening rolling method for medium carbon alloy cold forging steel

InactiveCN101045238AAvoid surface decarburizationReduce intensityWork treatment devicesRoll mill control devicesHardnessEnergy conservation

An in-line softening and rolling technology for the cold-foraged medium-carbon alloy steel features use of high-speed wire rolling mill and includes such steps as heating billet to 950-1180 deg.C, primary, medium and pre-fine rollings, cooling to 700-820 deg.C by water tank, fine rolling, water cooling to 680-780 deg.C, discharging wire, cooling at the cooling speed of 0.01-0.5 deg.C / S for 600-2400 S, and natural cooling. Its advantages are high speed and product quality and saving energy.

Owner:MAANSHAN IRON & STEEL CO LTD

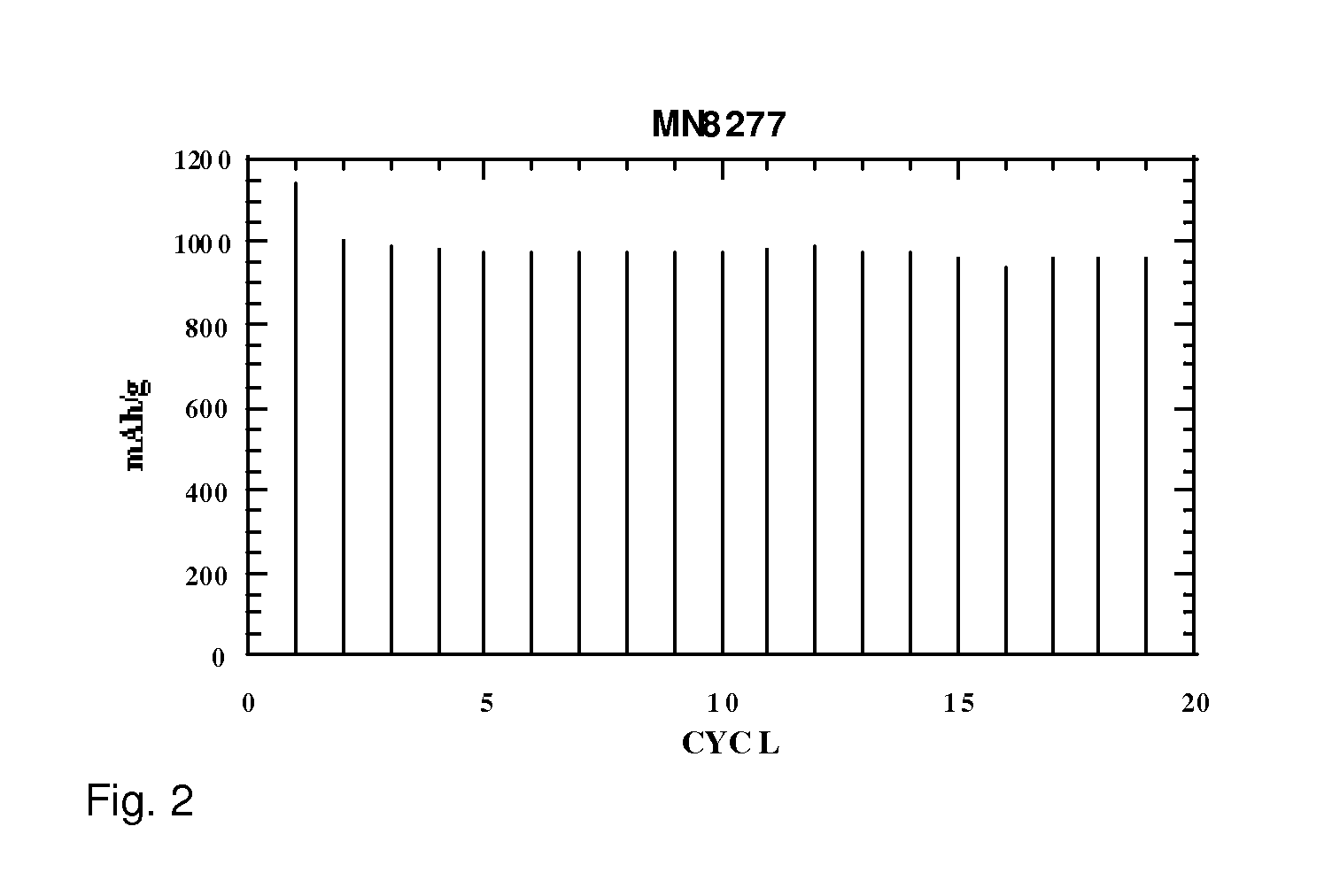

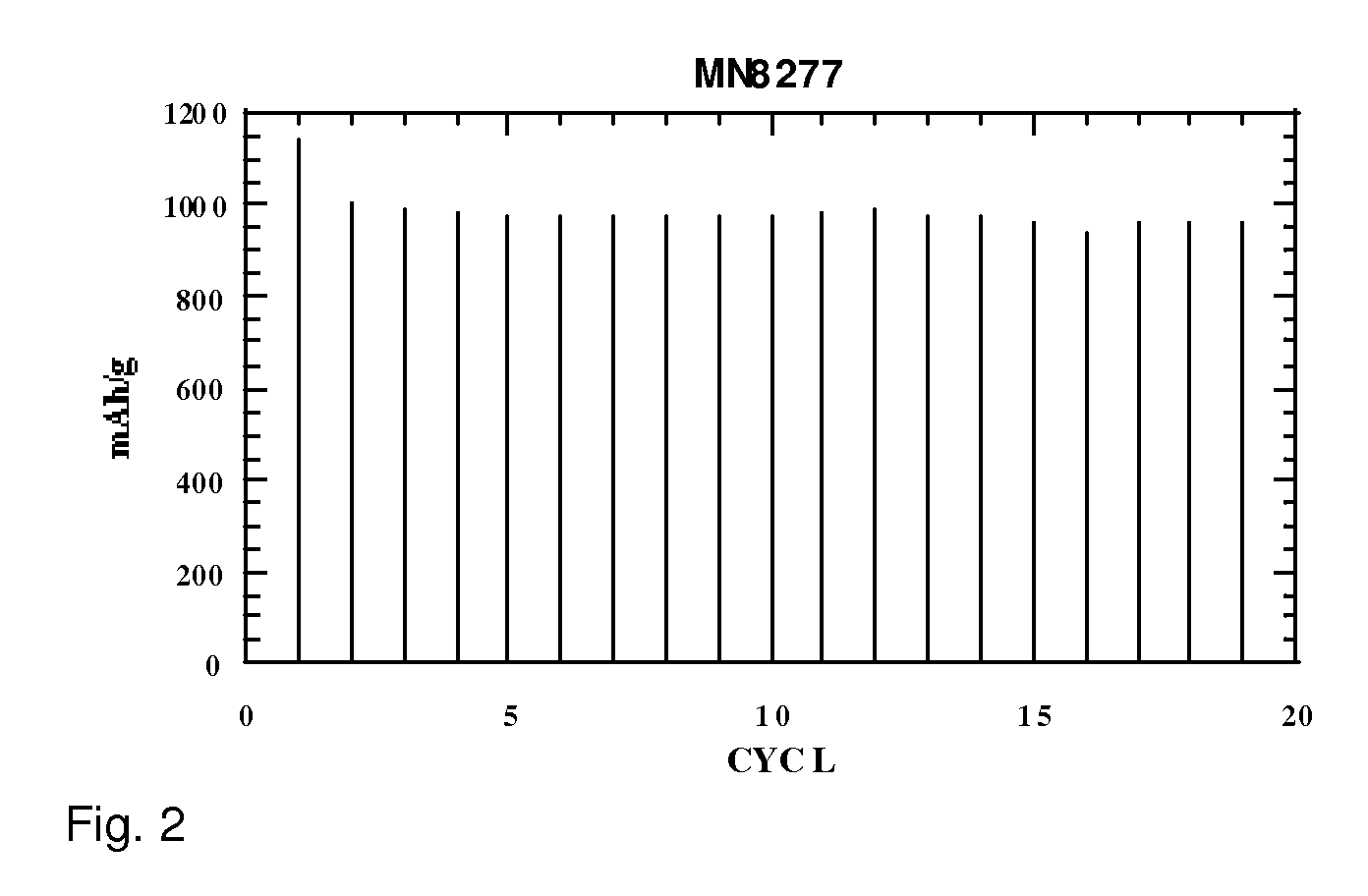

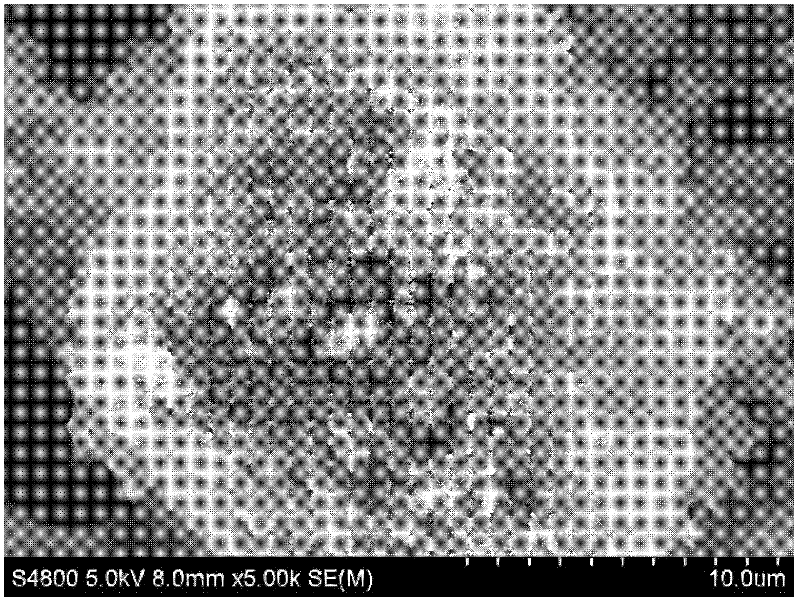

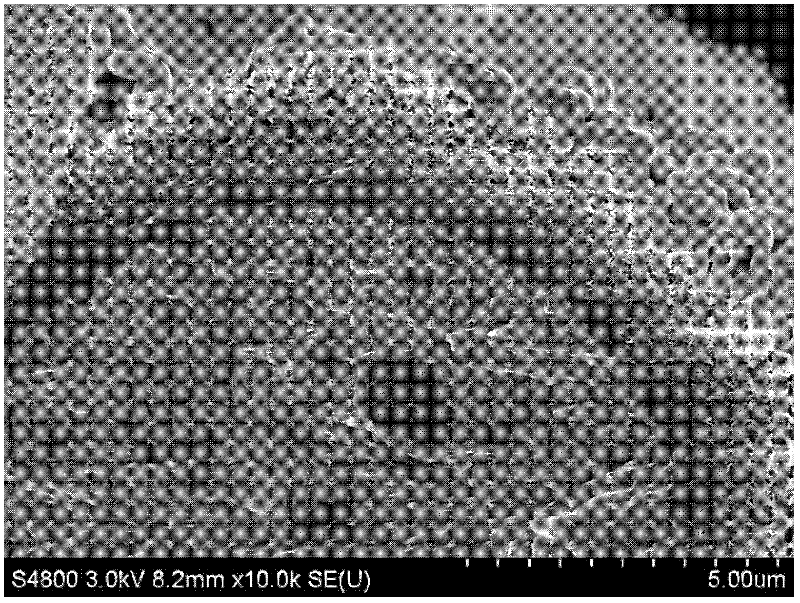

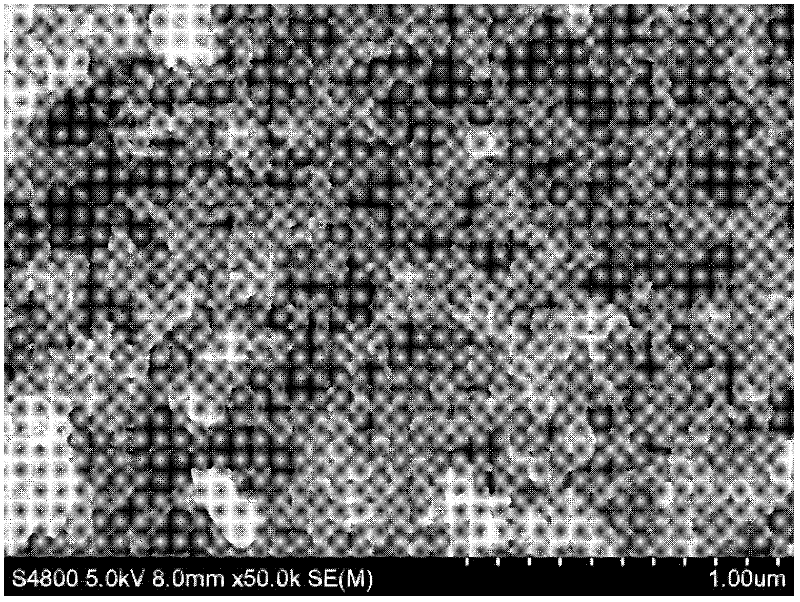

Silicon-carbon alloy cathode material used in lithium ion battery, and preparation method thereof

The invention discloses a silicon-carbon alloy cathode material used in a lithium ion battery, and a preparation method thereof. The invention aims at improving the cycling performance of the silicon-carbon alloy cathode material. According to the silicon-carbon alloy cathode material, silicon powder particles with particle sizes of 20-250nm are adopted as substrates; carbon nano-tubes and amorphous carbon are coated on the surfaces of the substrates; the thicknesses of the carbon nano-tubes and amorphous carbon are 100-300nm; the carbon nano-tubes and amorphous carbon are short-strip-shaped, block-shaped, or layered hollow-structured cracked carbon. The preparation method provided by the invention comprises steps of: slurry preparing, drying and powder preparing, calcining, and chemical vapor depositing. Compared to prior arts, the silicon-carbon alloy cathode material is advantaged in high specific capacity, good cycling performance, a capacity greater than 1000mAh / g, and a capacity maintenance rate above 90% with 20 times of circulation. The preparation method provided by the invention is advantaged in simple technology and low raw material cost. The material and the method provided by the invention are suitable for various high-capacity lithium ion battery cathode materials.

Owner:BTR NEW MATERIAL GRP CO LTD

Shallow PN junction formed by in situ doping during selective growth of an embedded semiconductor alloy by a cyclic growth/etch deposition process

ActiveUS8053273B2Increase strainImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingIn situ dopingUltra-high vacuum

A silicon / carbon alloy may be formed in drain and source regions, wherein another portion may be provided as an in situ doped material with a reduced offset with respect to the gate electrode material. For this purpose, in one illustrative embodiment, a cyclic epitaxial growth process including a plurality of growth / etch cycles may be used at low temperatures in an ultra-high vacuum ambient, thereby obtaining a substantially bottom to top fill behavior.

Owner:ADVANCED MICRO DEVICES INC

Nickel-base high-temperature alloy GH4720Li smelting technique

The invention discloses a nickel-base high-temperature alloy GH4720Li smelting technique. The technique comprises the following step: carrying out smelting by a triple (VIM+VAR+VAR) smelting technique according to the composition requirements for the GH4720Li alloy (No.1 or No.2 Ni, vacuum-degassed Cr, sponge Ti, Al beans, metal Co, NiW alloy, NiMo alloy, carbon, NiMg alloy, NiB alloy and zirconium sponge), thereby obtaining the GH4720Li high-temperature alloy cast ingot. The novel triple smelting technique enhances the metallurgical quality of the GH4720Li alloy; especially the gamma' phase forming elements Al and Ti for performing the main reinforcement function in the GH4720Li alloy have high composition control precision and favorable uniformity; and the other alloy elements have the advantages of less segregation and high composition control precision. The obtained alloy has impurity element content, and the properties have long-term stability at 650-750 DEG C.

Owner:西部超导材料科技股份有限公司

Taper pipe for concrete pumping device and manufacturing method thereof

InactiveCN102128312AImprove hardenabilityHigh hardnessBulk conveyorsRigid pipesMetallic materialsShock resistance

The invention relates to a taper pipe for a concrete pumping device. The taper pipe comprises an inner pipe and an outer pipe which are made from different metal materials, the rigidity of the inner pipe is higher than that of the outer pipe; and the toughness of the outer pipe is higher than that of the inner pipe; materials can be used for the inner pipe comprise medium and high carbon low-alloy steel, wear-resisting cast steel, wear-resisting cast iron and tool steel; and the materials of the outer pipe can be common carbon steel and low-carbon alloy steel. The invention also relates to a method for manufacturing the taper pipe. A double-layer composite taper pipe provided by the invention has the advantages that the wall thickness design of a thin large end and a thick small end conrresponds with the design principle of equal service life; the raw materials are saved; the inner pipe has high through quenching capability, smooth surface, and high rigidity and good wear resistance; the outer pipe has low rigidity, good toughness and high capability of shock resistance, and can protect the inner pipe well; and simultaneously the comprehensive requirement on the abrasion resistance and toughness of the taper pipe for the pumping device is satisfied.

Owner:SANY HEAVY IND CO LTD (CN)

Method for clearly displaying low carbon low alloy steel austenite crystal

InactiveCN101349621AGuaranteed product performancePreparing sample for investigationAustenite grainDistilled water

The invention relates to a method for clearly displaying lower carbon and low alloy steel austenite crystal, which belongs to the technical field of physical detection. The method is used to solve the problem that lower carbon and low alloy steel can not clearly display the austenite crystal thereof. The method comprises a quenching process and a corrosion process, which is characterized in that the proportion of corrosive agent in the process of corroding is that CrO3 8g-10g, NaOH 40g-50g, picric acid 1.6g-2g, epoxyethane 2ml-4ml and distilled water 80ml-100ml. The method adopts specific corrosive agent and is matched with a correct corrosion method, which can clearly display austenite grain boundary. The method fills a gap of low carbon alloy steel austenite grain boundary display technology, which provides an important theoretical basis for a manufacturing enterprise to research the influence of technological parameters to microstructure evolution when the steel is deforming, and plays an important function for producing low carbon alloy steel, reasonably controlling technological parameters and guaranteeing the property of products.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

CMOS having a SiC/SiGe alloy stack

A delta doping of silicon by carbon is provided on silicon surfaces by depositing a silicon carbon alloy layer on silicon surfaces, which can be horizontal surfaces of a bulk silicon substrate, horizontal surfaces of a top silicon layer of a semiconductor-on-insulator substrate, or vertical surfaces of silicon fins. A p-type field effect transistor (PFET) region and an n-type field effect transistor (NFET) region can be differentiated by selectively depositing a silicon germanium alloy layer in the PFET region, and not in the NFET region. The silicon germanium alloy layer in the PFET region can overlie or underlie a silicon carbon alloy layer. A common material stack can be employed for gate dielectrics and gate electrodes for a PFET and an NFET. Each channel of the PFET and the NFET includes a silicon carbon alloy layer, and is differentiated by the presence or absence of a silicon germanium layer.

Owner:GLOBALFOUNDRIES US INC

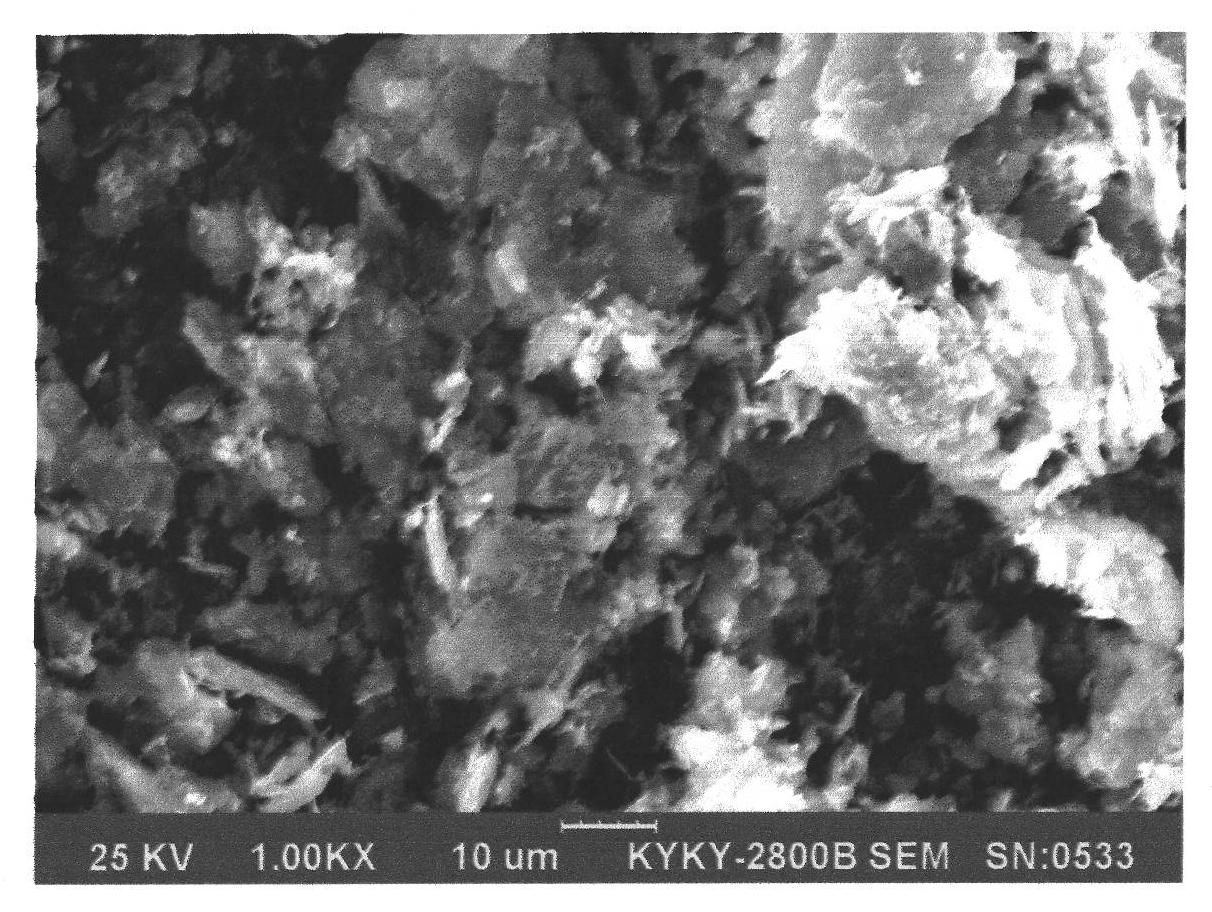

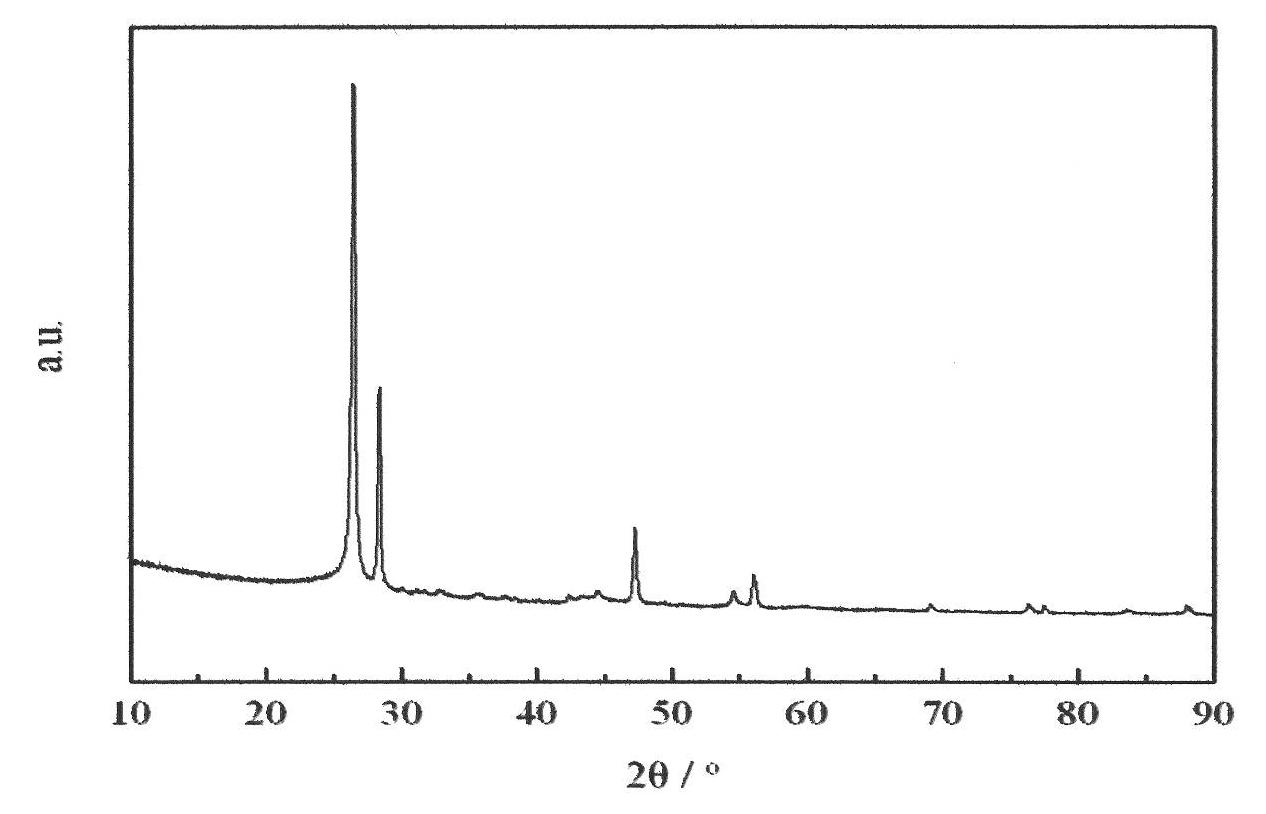

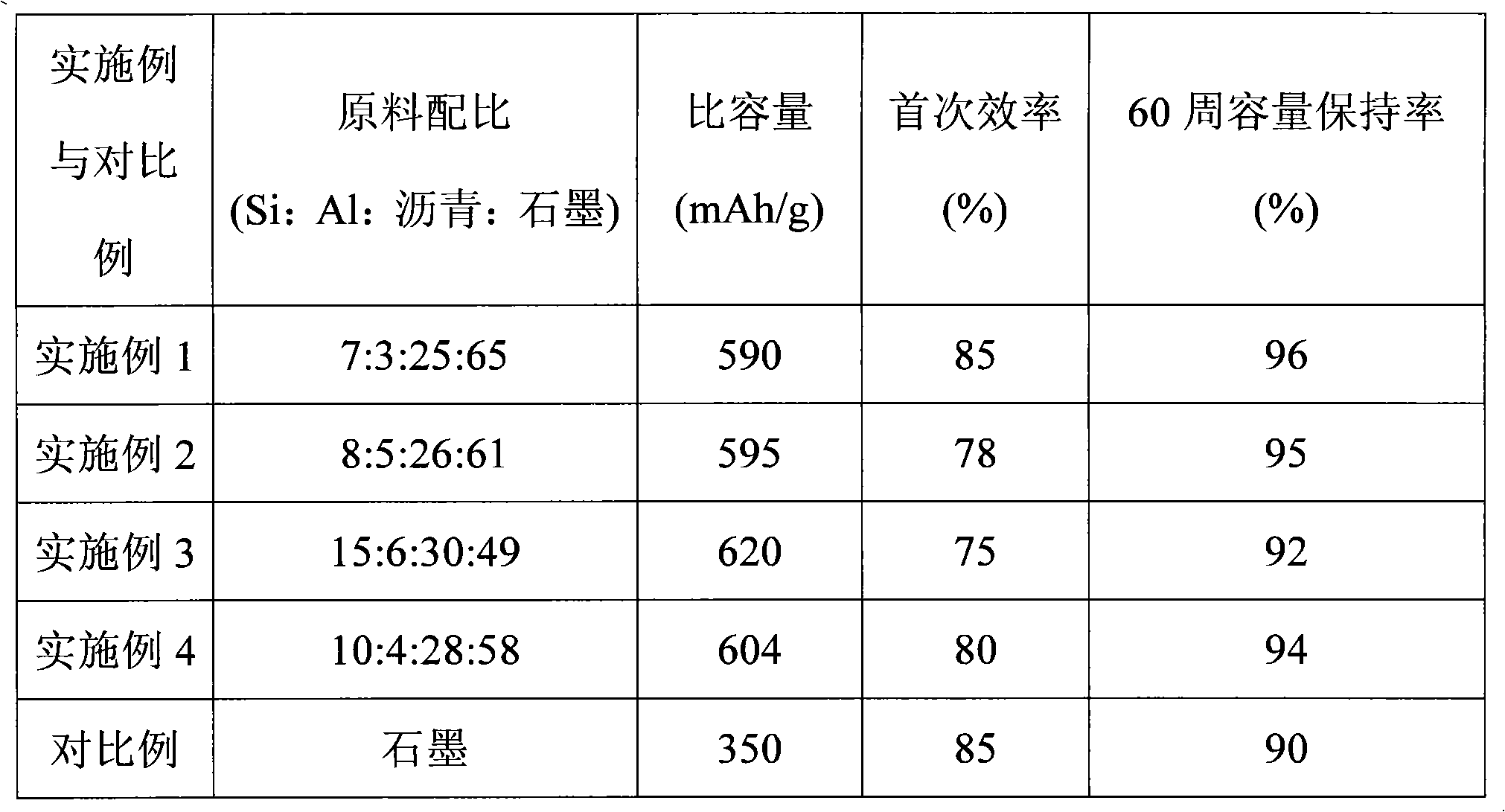

Silicon-carbon alloy cathode material for lithium ion batteries and preparation method thereof

ActiveCN101969111AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesSilicon alloyAlloy composite

The invention discloses a silicon-carbon alloy cathode material for lithium ion batteries and a preparation method thereof. The invention aims to enhance the specific capacity of the lithium ion battery and have excellent cycle performance. The cathode material comprises the matrix which is physically compounded from a silicon alloy and graphite powder, and the surface of the cathode material is coated with a carbon material. The preparation method comprises the following steps: mixing aluminium powder, asphalt and simple substance silicon powder, adding graphite, mixing, drying and roasting to obtain the silicon-carbon alloy composite material. Compared with the prior art, the reversible specific capacity of the silicon-carbon alloy cathode material is higher than 590 mAh / g, the first cycle coulombic efficiency is higher than 75%, and the capacity conservation rate after 60 cycles is higher than 92%; the silicon-carbon alloy cathode material has excellent lithium embedding and removing capacity, and high cycle stability; and the preparation technique has the advantages of simple operation and low cost, and is suitable for high-capacity lithium ion battery cathode materials for various portable devices.

Owner:GUANGDONG DONGDAO NEW ENERGY

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

A low carbon alloy steel tube and a method of manufacturing the same, in which the steel tube consists essentially of, by weight: about 0.06% to about 0.18% carbon; about 0.5% to about 1.5% manganese; about 0.1% to about 0.5% silicon; up to about 0.015% sulfur; up to about 0.025% phosphorous; up to about 0.50% nickel; about 0.1% to about 1.0% chromium; about 0.1% to about 1.0% molybdenum; about 0.01% to about 0.10% vanadium; about 0.01% to about 0.10% titanium; about 0.05% to about 0.35% copper; about 0.010% to about 0.050% aluminum; up to about 0.05% niobium; up to about 0.15% residual elements; and the balance iron and incidental impurities. The steel has a tensile strength of at least about 145 ksi and exhibits ductile behavior at temperatures as low as -60 DEG C.

Owner:TENARIS CONNECTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com