Silicon-carbon alloy cathode material used in lithium ion battery, and preparation method thereof

A lithium-ion battery, alloy anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of pole piece powdering, industrialization obstacles of silicon anode materials, falling off, etc., and achieves simple preparation process, good cycle performance, Low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

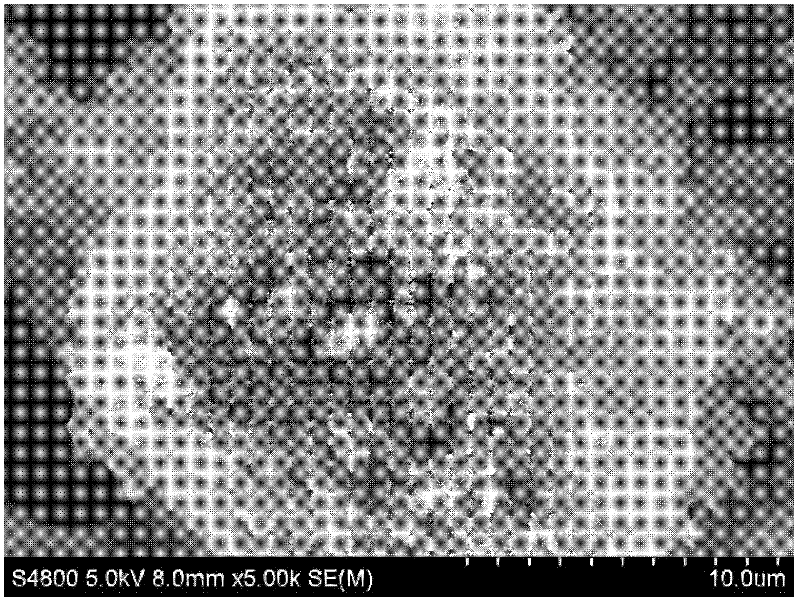

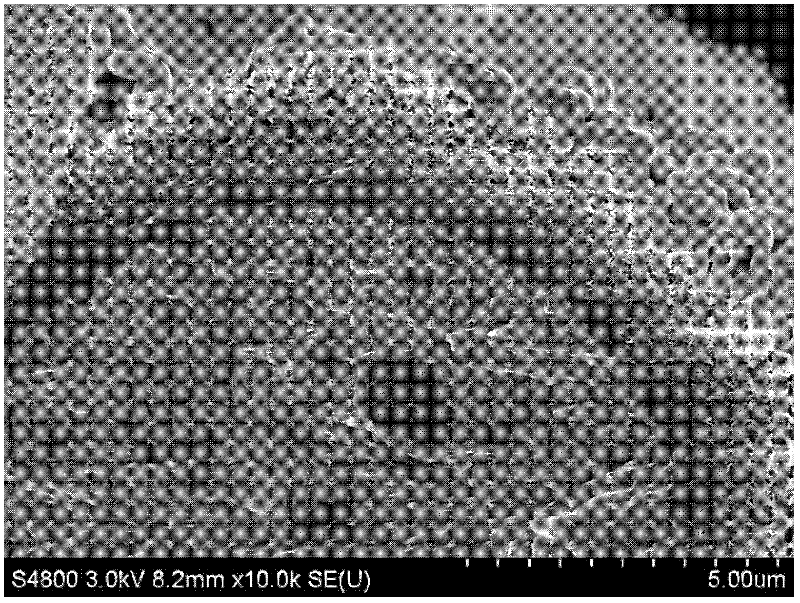

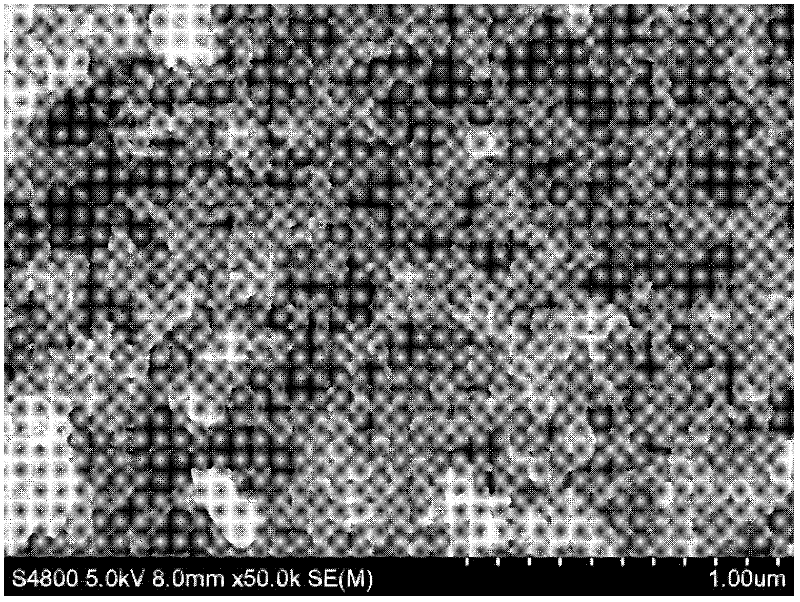

[0025] The preparation method of the lithium-ion battery silicon-carbon alloy negative electrode material of the present invention comprises the following steps of obtaining the silicon-carbon alloy negative electrode material for lithium-ion batteries by coating amorphous carbon-coated silicon powder precursor particles by chemical vapor deposition:

[0026] 1. According to the mass ratio, weigh 1 to 9% of the CVD catalyst precursor, 1 to 5% of the additive and 86 to 98% of the 20 to 250nm silicon powder, put them into the ultrasonic pool, press the catalyst precursor, the additive and the silicon powder The ratio of the sum of the powder mass to the mass g of the organic solvent to the volume L is 100:0.5~1, the catalyst precursor, additives and silicon powder are mixed in the organic solvent, and the ultrasonic power is 1600W / m 2 , and shaken for 1-20 hours to obtain a slurry.

[0027] The CVD catalyst precursor is more than one of iron salt, nickel salt and copper salt iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com