Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

A technology of tricobalt tetroxide and large particle size, which is applied in the direction of cobalt oxide/cobalt hydroxide, structural parts, electrical components, etc. It can solve the problem that the uniformity of particle size distribution is not as good as that of cobalt carbonate system, the compound that is easy to separate aluminum, and the uneven incorporation of aluminum etc. to achieve excellent cycle performance, high specific capacity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

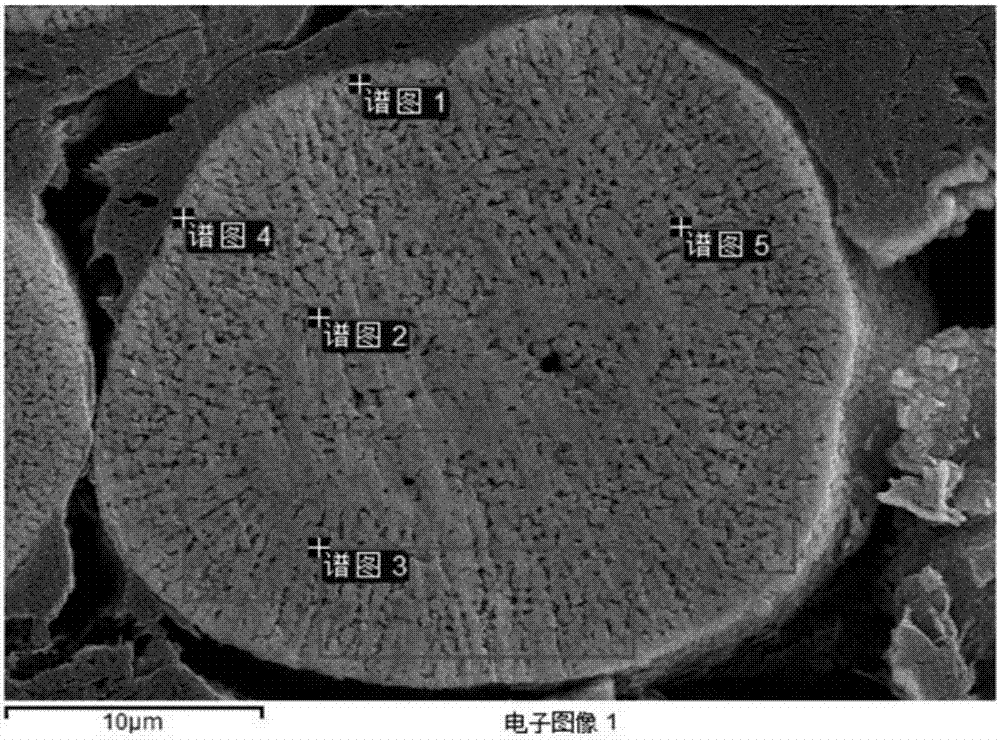

Embodiment 1

[0041] ①Dissolve aluminum sulfate into cobalt sulfate solution, and prepare mixed metal salt solutions with cobalt ion and aluminum ion concentrations of 90g / L and 0.062g / L respectively for use.

[0042] ②Inject a certain amount of pure water into the reaction kettle as the bottom liquid, add ammonium bicarbonate solution to adjust the pH value to 7.5, raise the temperature to 40°C, and mix the cobalt-aluminum mixed salt solution and the carbonic acid concentration of 230g / L at a stirring speed of 140rpm The ammonium hydrogen solution is added into the reaction kettle at the same time to cause precipitation reaction. During the feeding process, the pH value of the reaction solution is controlled at about 7.0 until the material grows to 8 μm. After the feeding is completed, the stirring is stopped. Leave the space to continue feeding, so that the crystals continue to grow;

[0043] ③Reduce the stirring speed to 30rpm, and continue feeding. During the feeding process, control th...

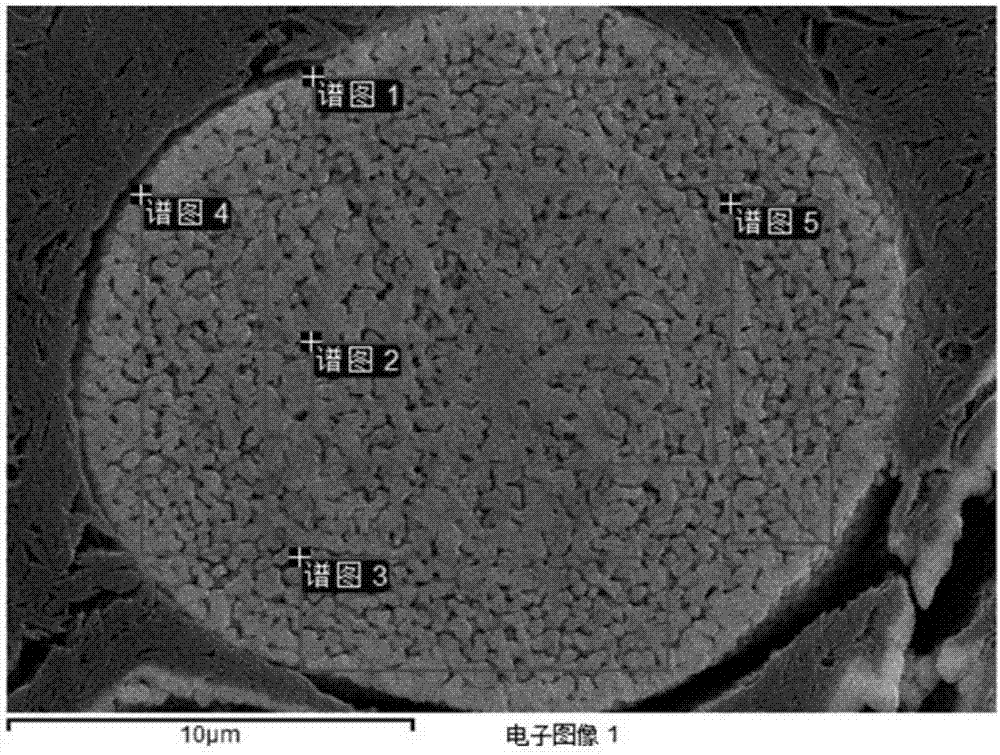

Embodiment 2

[0052] ①Dissolve aluminum chloride into cobalt chloride solution, and prepare mixed metal salt solutions with cobalt ion and aluminum ion concentrations of 120g / L and 0.42g / L respectively for use.

[0053] ②Inject a certain amount of pure water into the reaction kettle as the bottom liquid, add the ammonium carbonate solution to a pH value of 8.0, raise the temperature to 50°C, and add the cobalt-aluminum mixed salt solution and the ammonium carbonate solution with a concentration of 210g / L into the reaction kettle at the same time at 145rpm During the feeding process, the pH value of the reaction solution was controlled at about 7.5 until the material grew to 9 μm. After the feeding was completed, the stirring was stopped. continue to grow;

[0054] ③Reduce the stirring speed to 35rpm, and continue feeding. During the feeding process, control the pH value of the reaction solution within the range of 8.0, and the reaction temperature is 50°C. When the material reaches 85% of t...

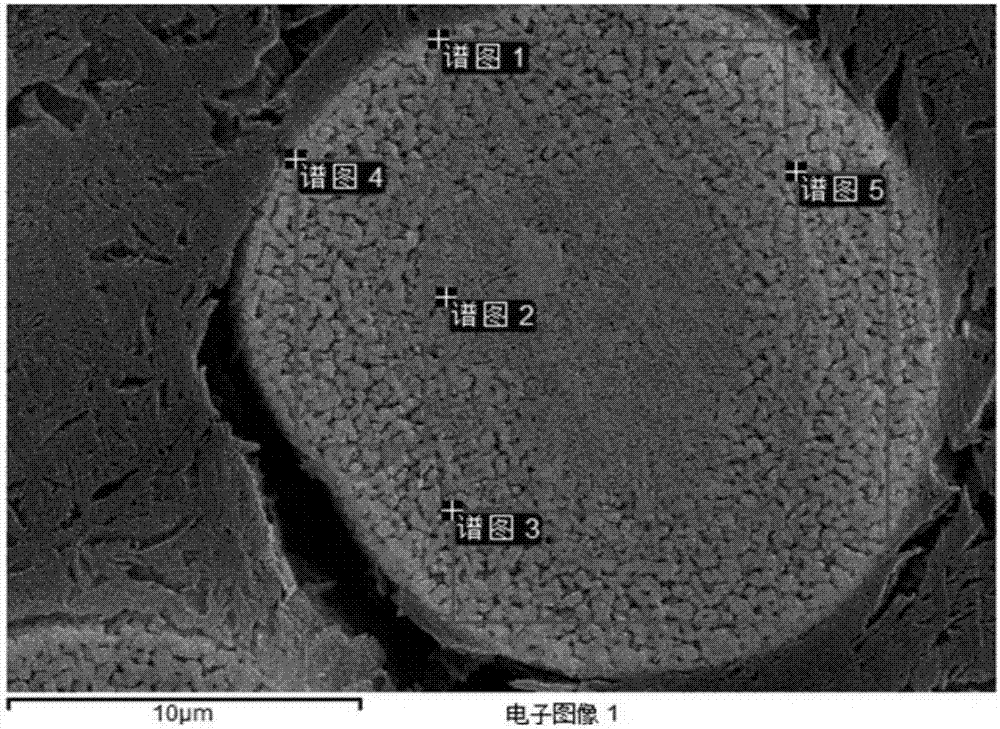

Embodiment 3

[0064] ① Dissolve aluminum nitrate into cobalt nitrate solution, and prepare mixed metal salt solutions with cobalt ion and aluminum ion concentrations of 160g / L and 1.11g / L respectively for use.

[0065] ②Inject a certain amount of pure water into the reaction kettle as the bottom liquid, add ammonium bicarbonate solution to adjust the pH to 7.5, raise the temperature to 60°C, and add a certain concentration of cobalt-aluminum mixed salt solution and ammonium bicarbonate solution into the reaction kettle at the same time at 150rpm Precipitation reaction occurs. During the feeding process, the pH value of the reaction solution is controlled at about 7.3 until the material grows to 10 μm. After the feeding is completed, stop stirring. grow;

[0066] ③Reduce the stirring speed to 40rpm and continue feeding. During the feeding process, control the pH value of the reaction solution within the range of 7.5, and the reaction temperature is 60°C. When the material reaches 85% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com