Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7231 results about "Large particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid Diffusion of Large Polymeric Nanoparticles in the Mammalian Brain

ActiveUS20130183244A1Reduce deliveryHigher drug payloadPowder deliveryNervous disorderGene deliveryHydrophilic coating

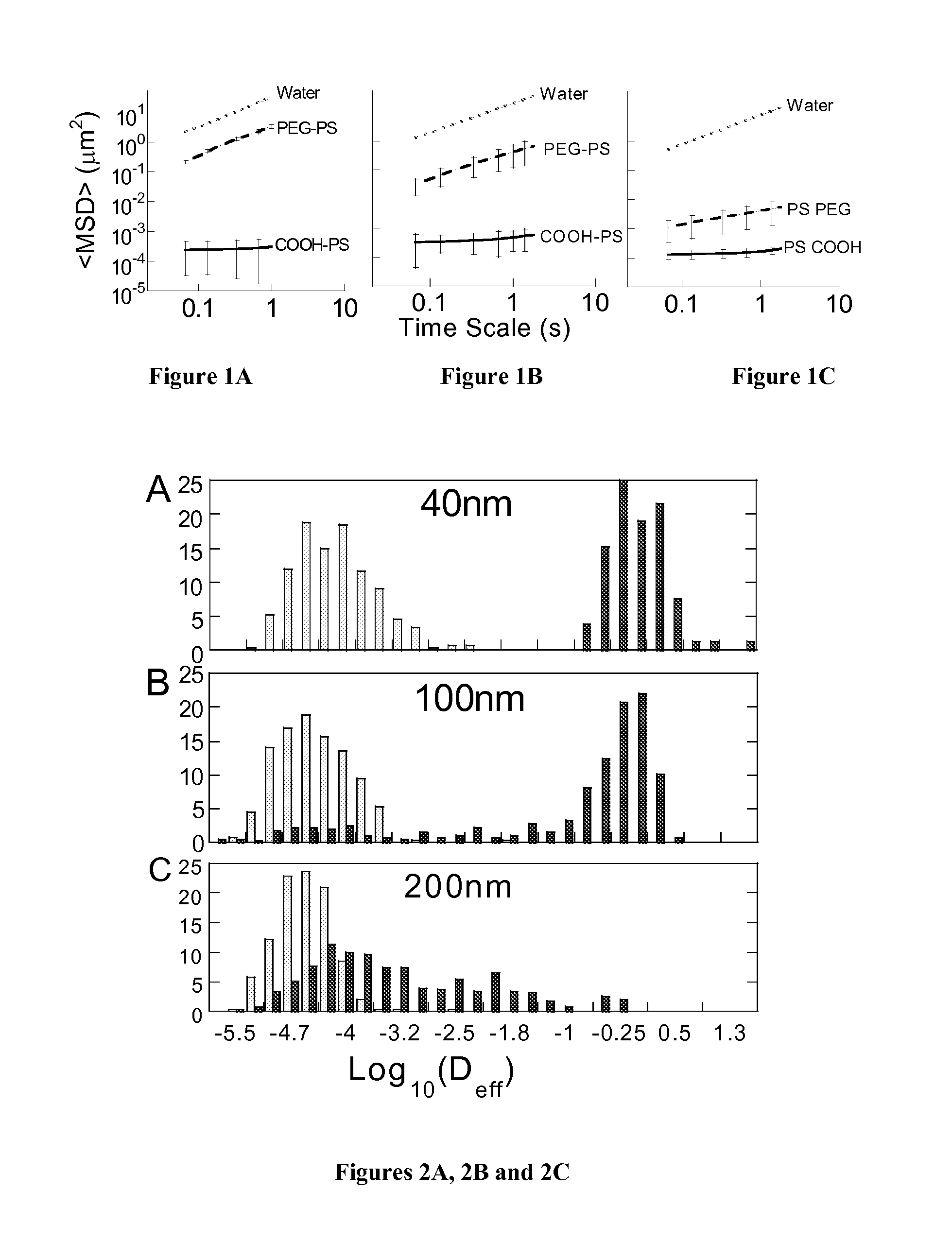

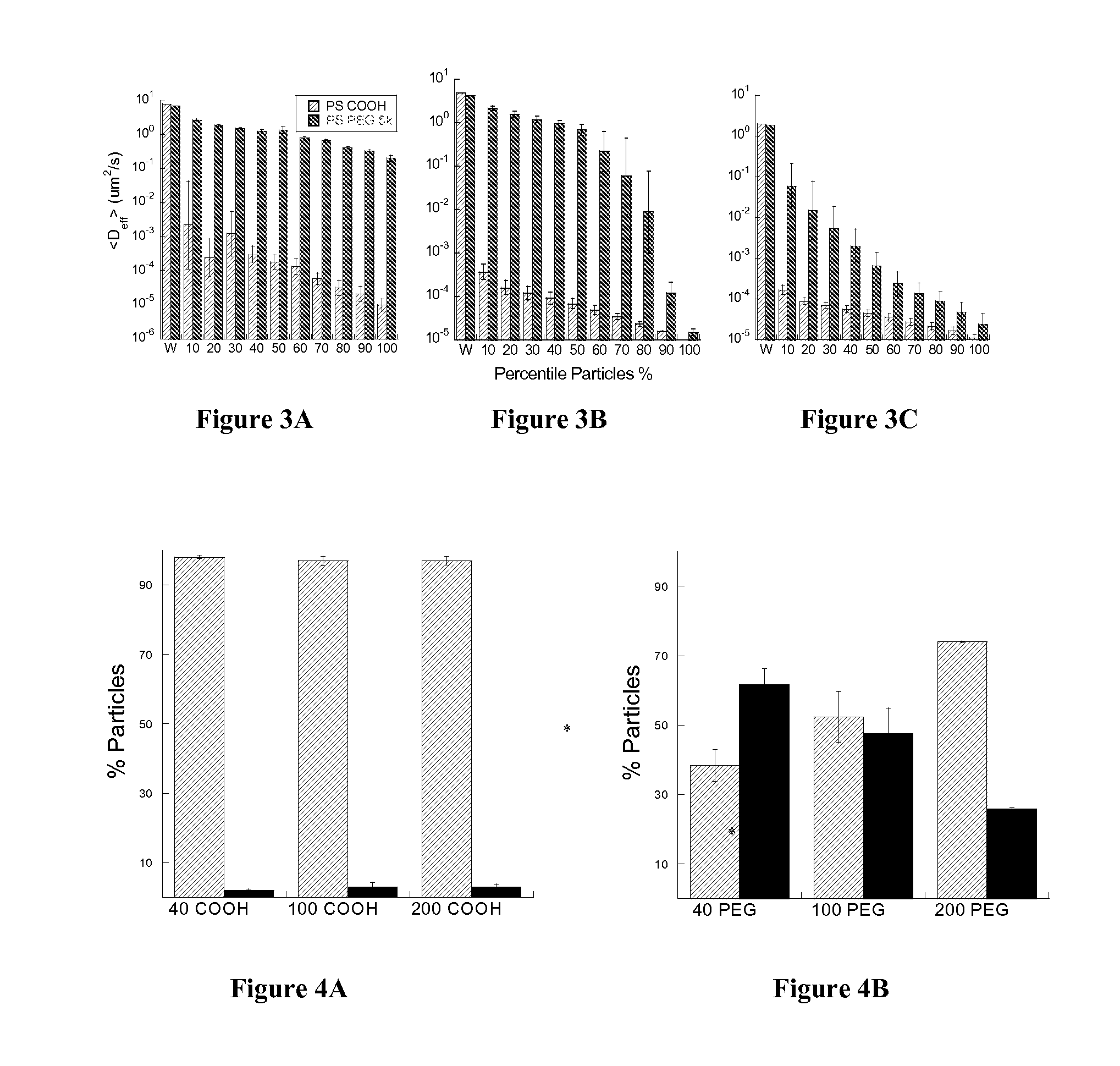

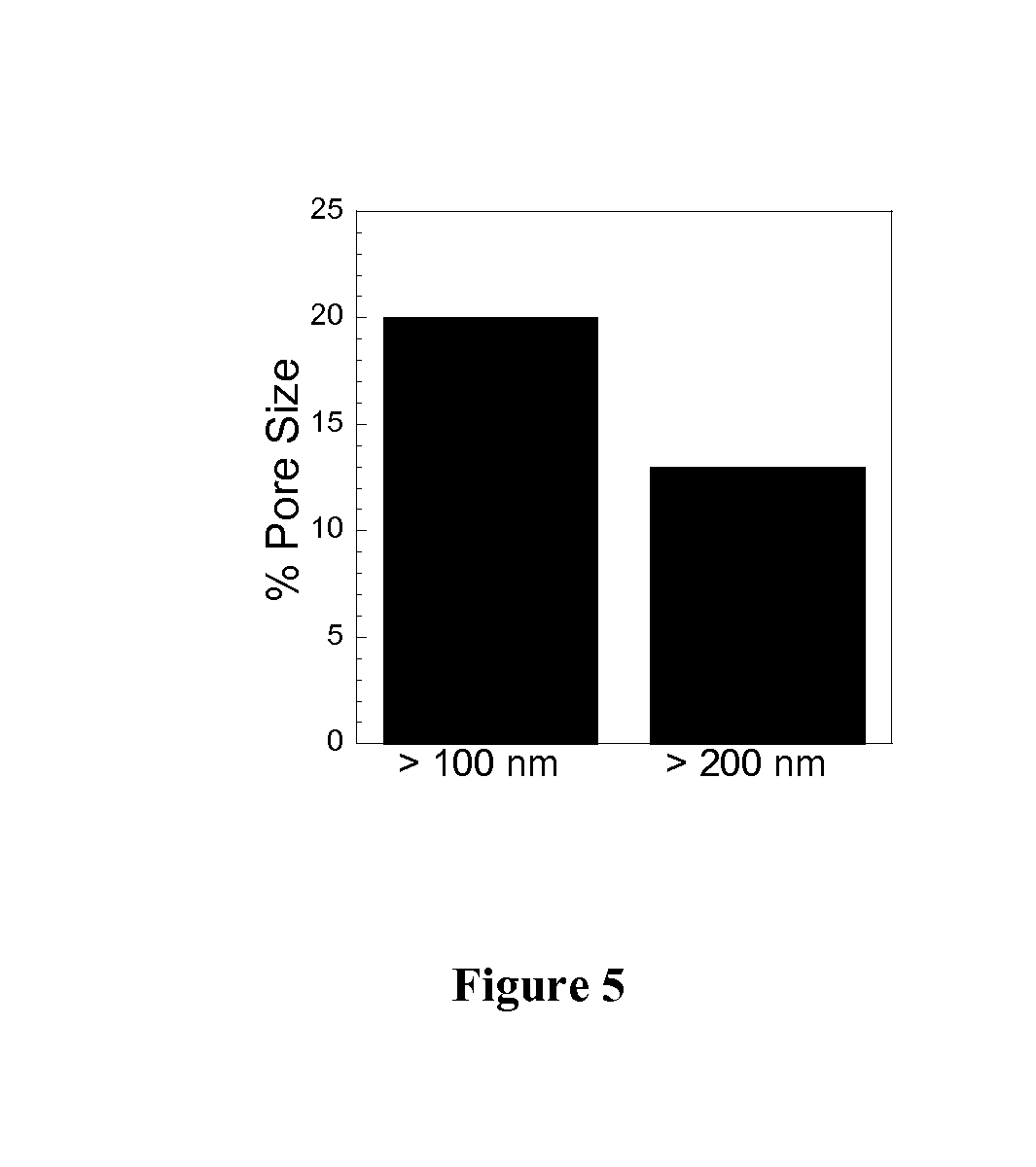

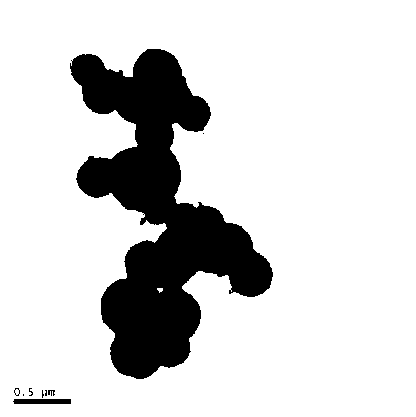

Non-adhesive particles as large as 110 nm can diffuse rapidly in the brain ECS, if coated with hydrophilic coatings such as PEG coatings and preferably having neutral surface charge. The ability to achieve brain penetration with larger particles will significantly improve drug and gene delivery within the CNS since larger particles offer higher drug payload, improved drug loading efficiency, and significantly longer drug release durations.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Honeycomb structure

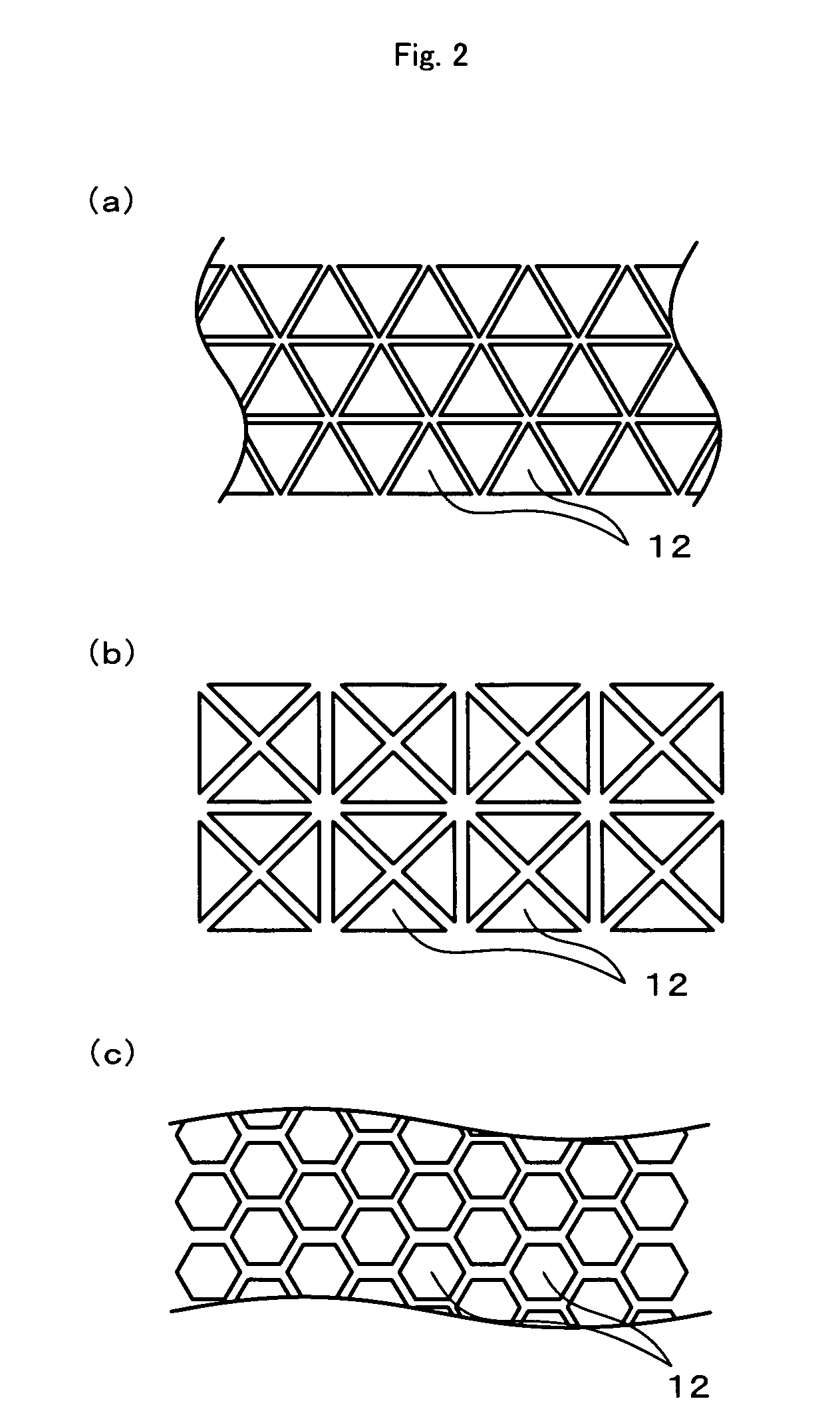

InactiveUS20050266992A1High strengthGood dispersionDispersed particle filtrationExhaust apparatusFiberHoneycomb structure

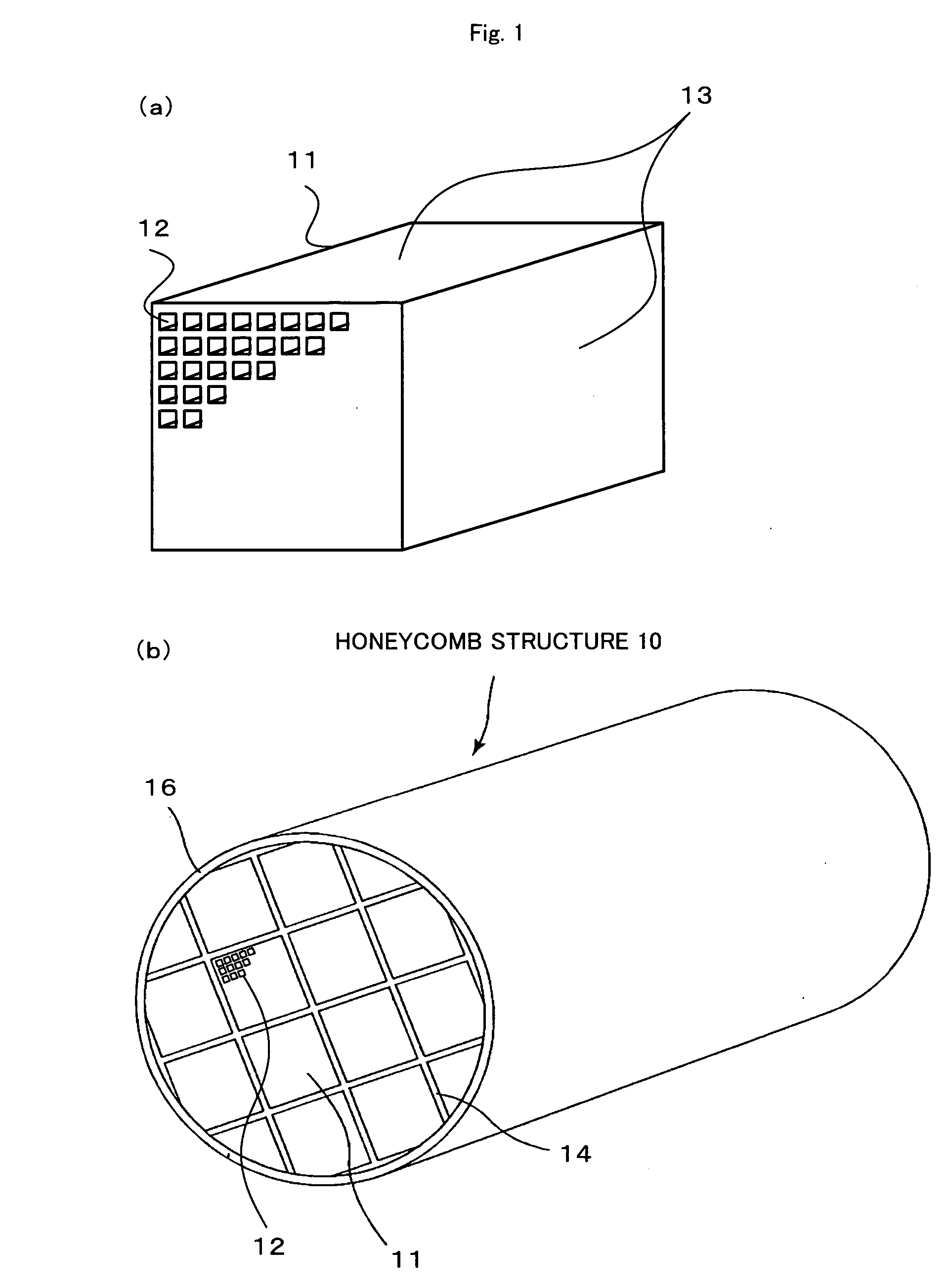

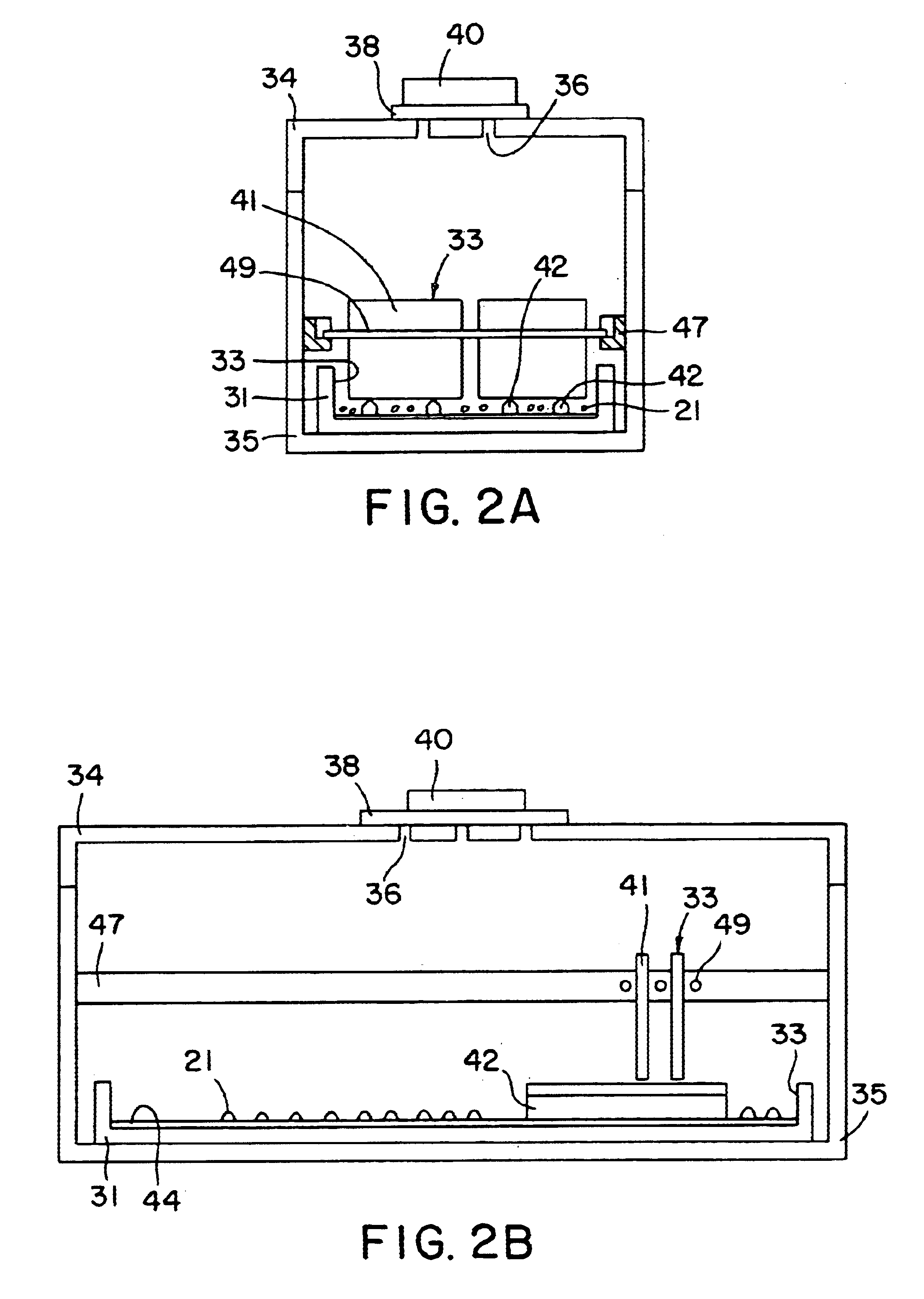

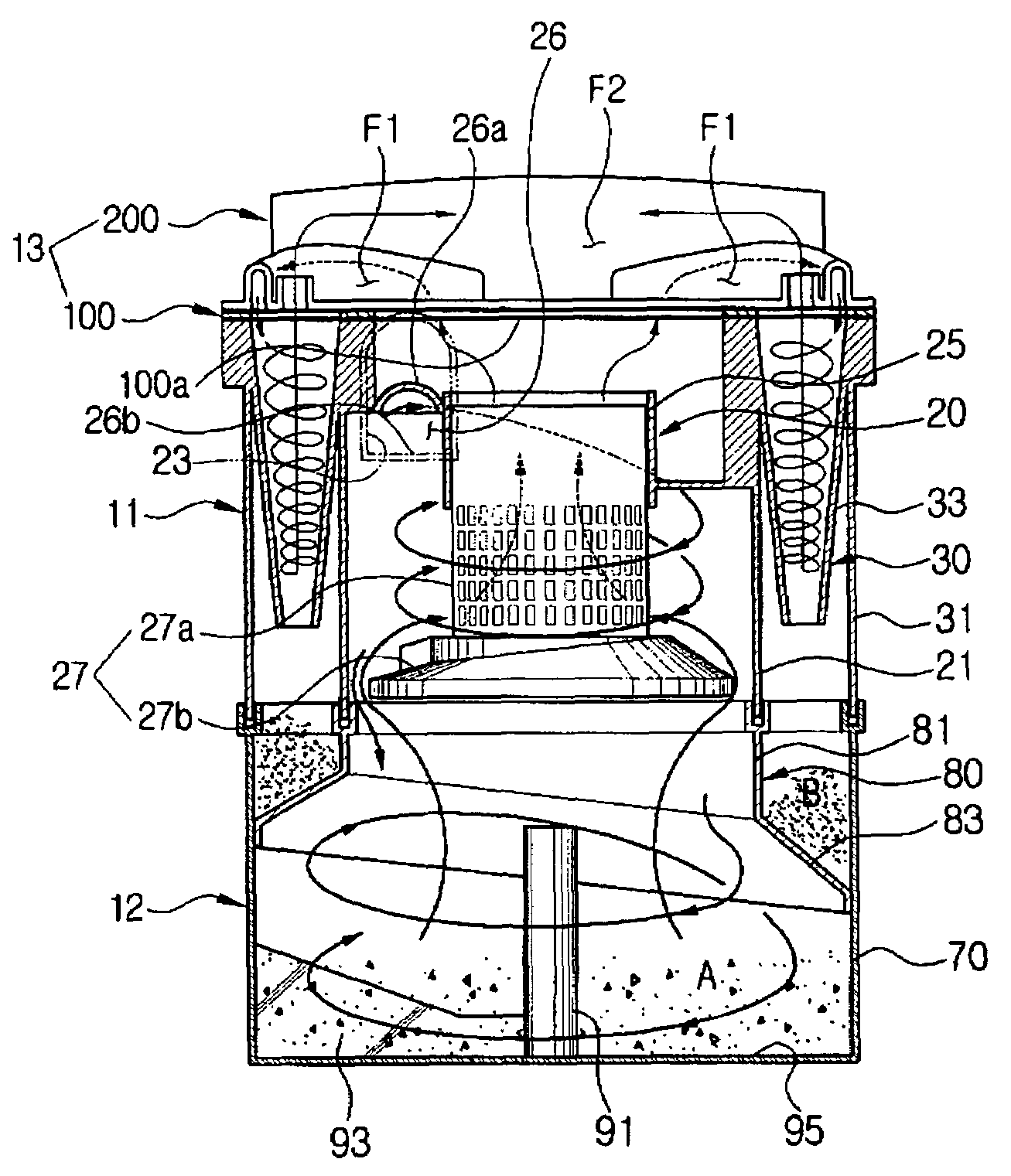

A honeycomb structure 10 of the present invention comprises: porous honeycomb units 11 having multiple through-holes, including the first form of an inorganic material (for example, ceramic particles), the second form of an inorganic material (for example, inorganic fibers or ceramic particles having large particle sizes), and an inorganic binder; and sealing material layers 14 jointing the porous honeycomb units 11 at outer surfaces 13 where the through-holes are not open. The cross-sectional area perpendicular to the through-holes is about 5 to about 50 cm2. The ratio of the total cross-sectional area of the porous honeycomb units 11 to the cross-sectional area of the honeycomb structure 10 is not less than about 85%. The honeycomb structure 10 reduces thermal stress or vibration applied to each porous honeycomb unit 11, by the sealing material layers 14, and allows for amore effective use of surface on which catalyst components are dispersed.

Owner:IBIDEN CO LTD

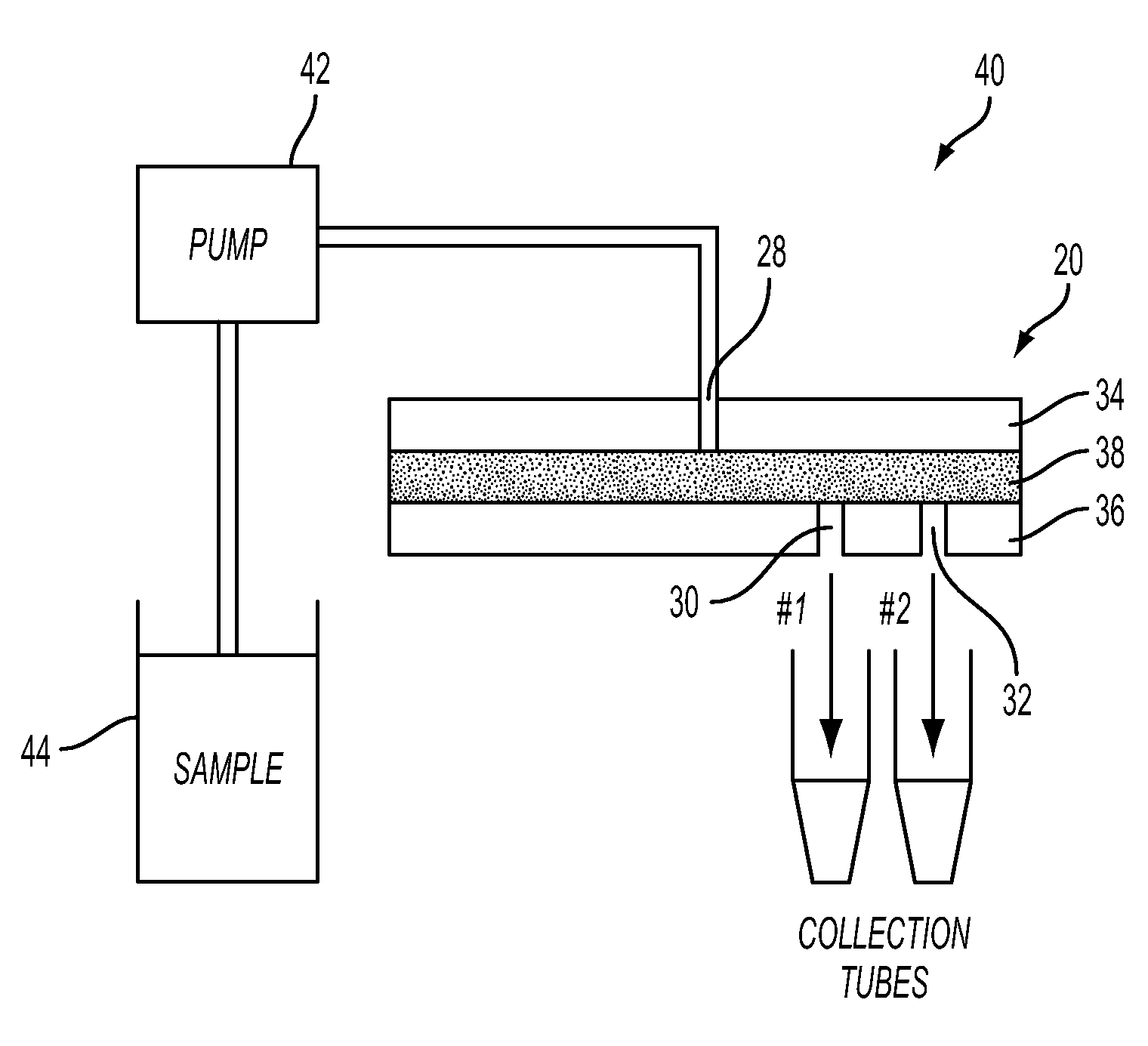

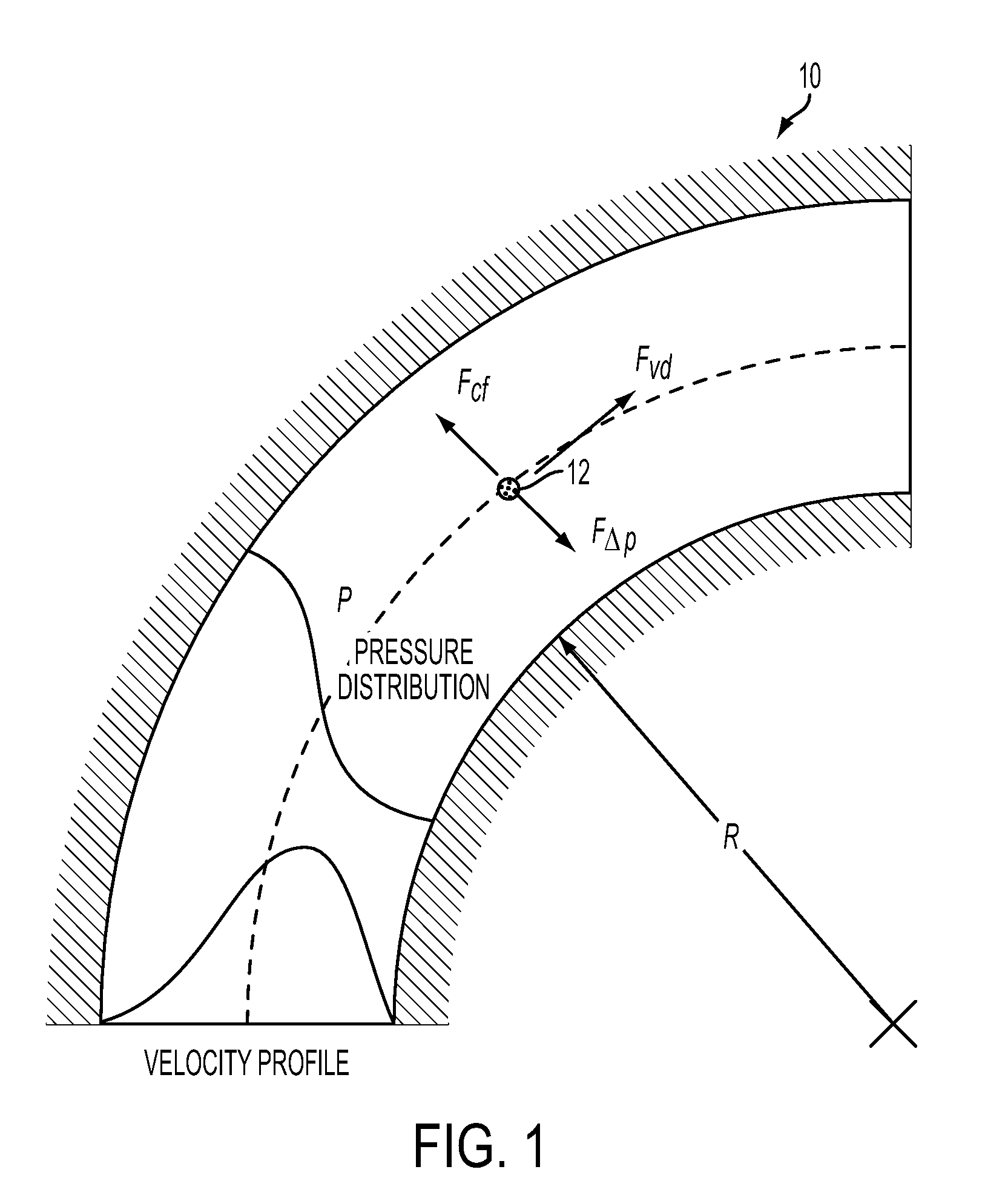

Particle separation and concentration system

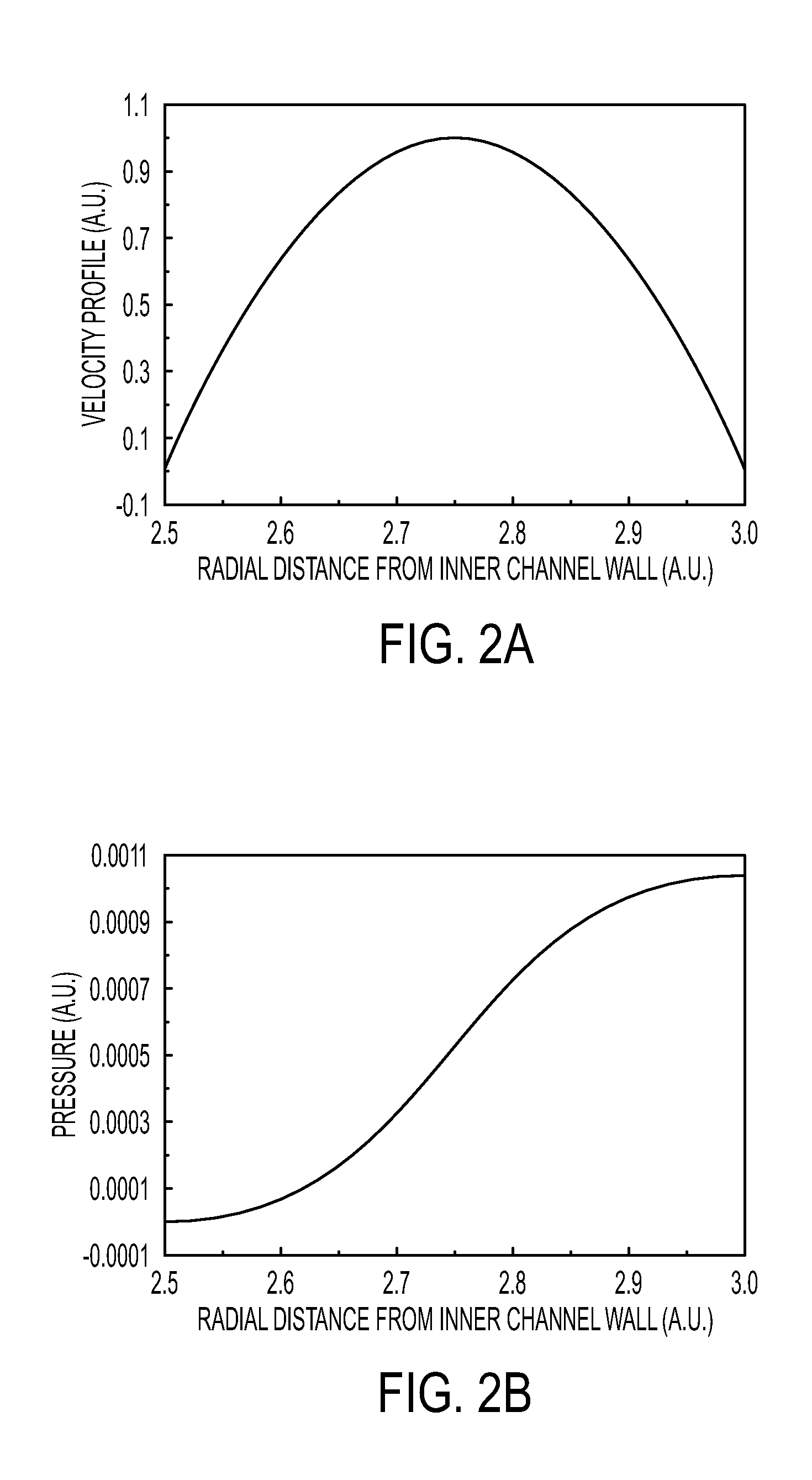

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

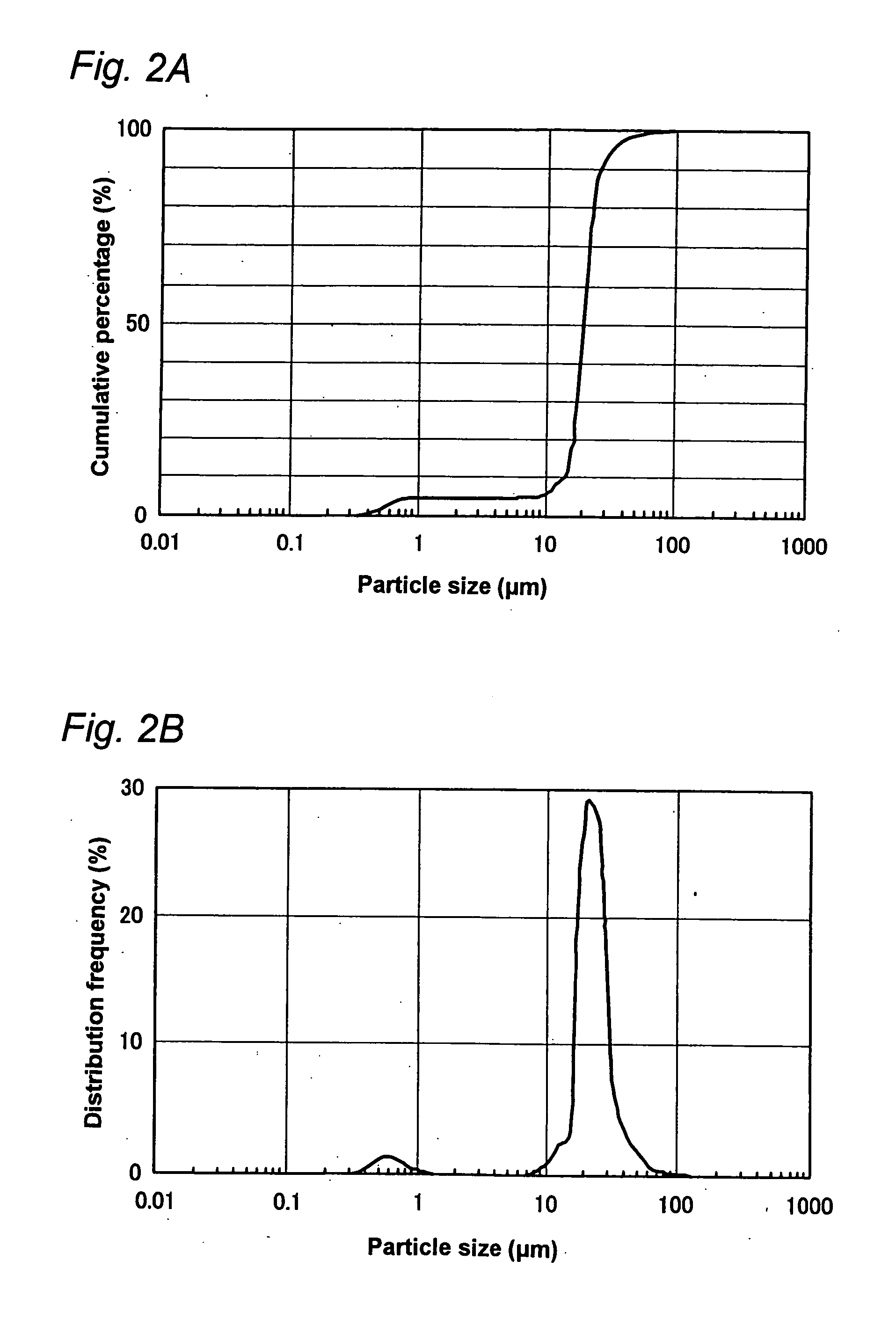

Light emitting diode, optical semiconductor device, epoxy resin composition suited for optical semiconductor device, and method for manufacturing the same

InactiveUS20050224821A1Light emission characteristicSuppress the variation in the chromaticity of the light emittedDischarge tube luminescnet screensLamp detailsEpoxyLength wave

A light emitting diode comprising an LED chip having a light emitting layer made of a nitride compound semiconductor and a light transmitting resin that includes a fluorescent material which absorbs at least a part of light emitted by the LED chip and emits light of a different wavelength, wherein the fluorescent material includes a fluorescent particles of small particle size and a fluorescent particles of large particle size, the fluorescent particles of large particle size being distributed in the vicinity of the LED chip in the light transmitting resin to form a wavelength converting layer, the fluorescent particles of small particle size being distributed on the outside of the wavelength converting layer in the light transmitting resin.

Owner:NICHIA CORP

Rupturing controlled release device having a preformed passageway

ActiveUS20050008702A1Increase release rateLarge particle sizePill deliveryCapsule deliveryControlled releaseMedicine

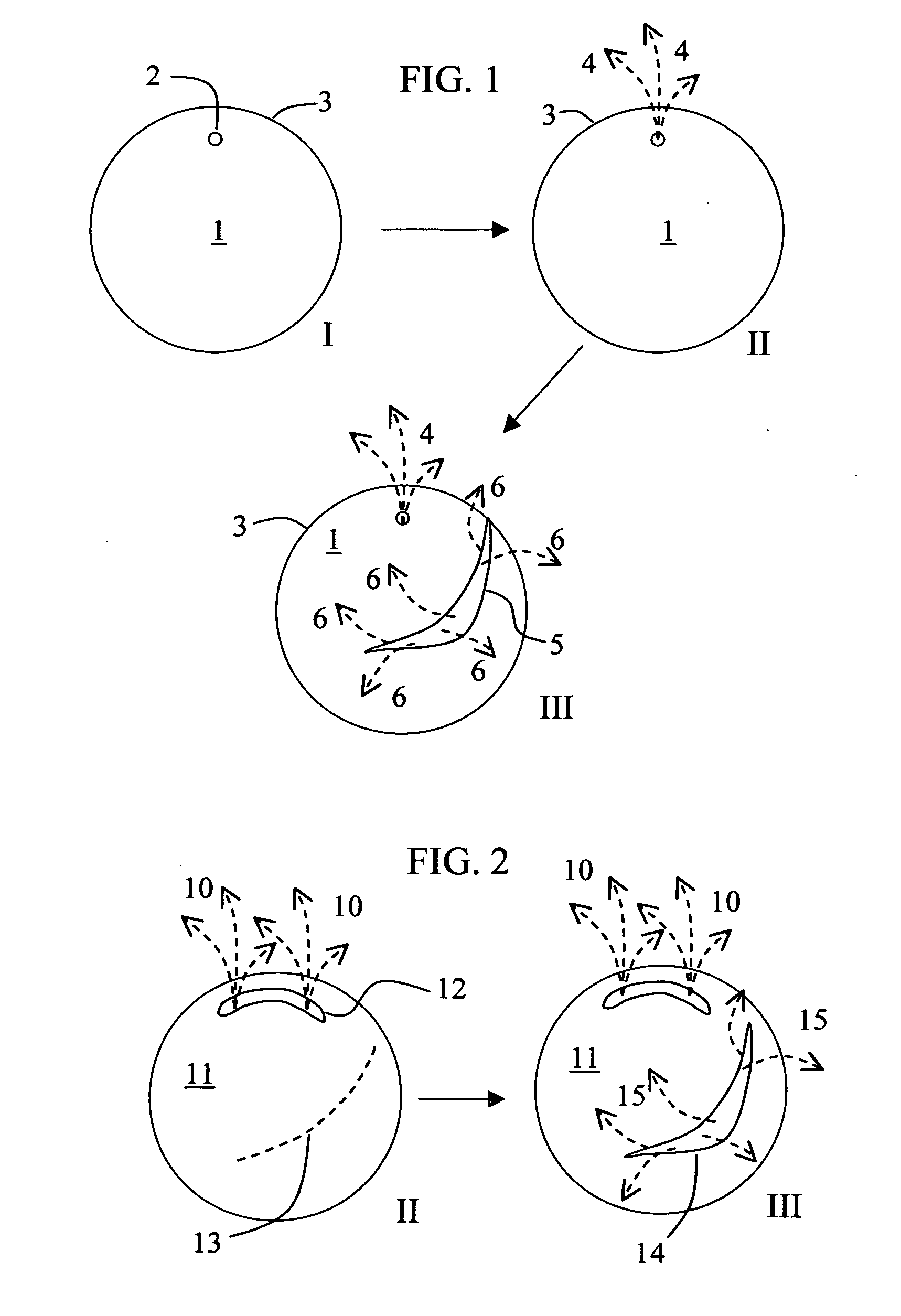

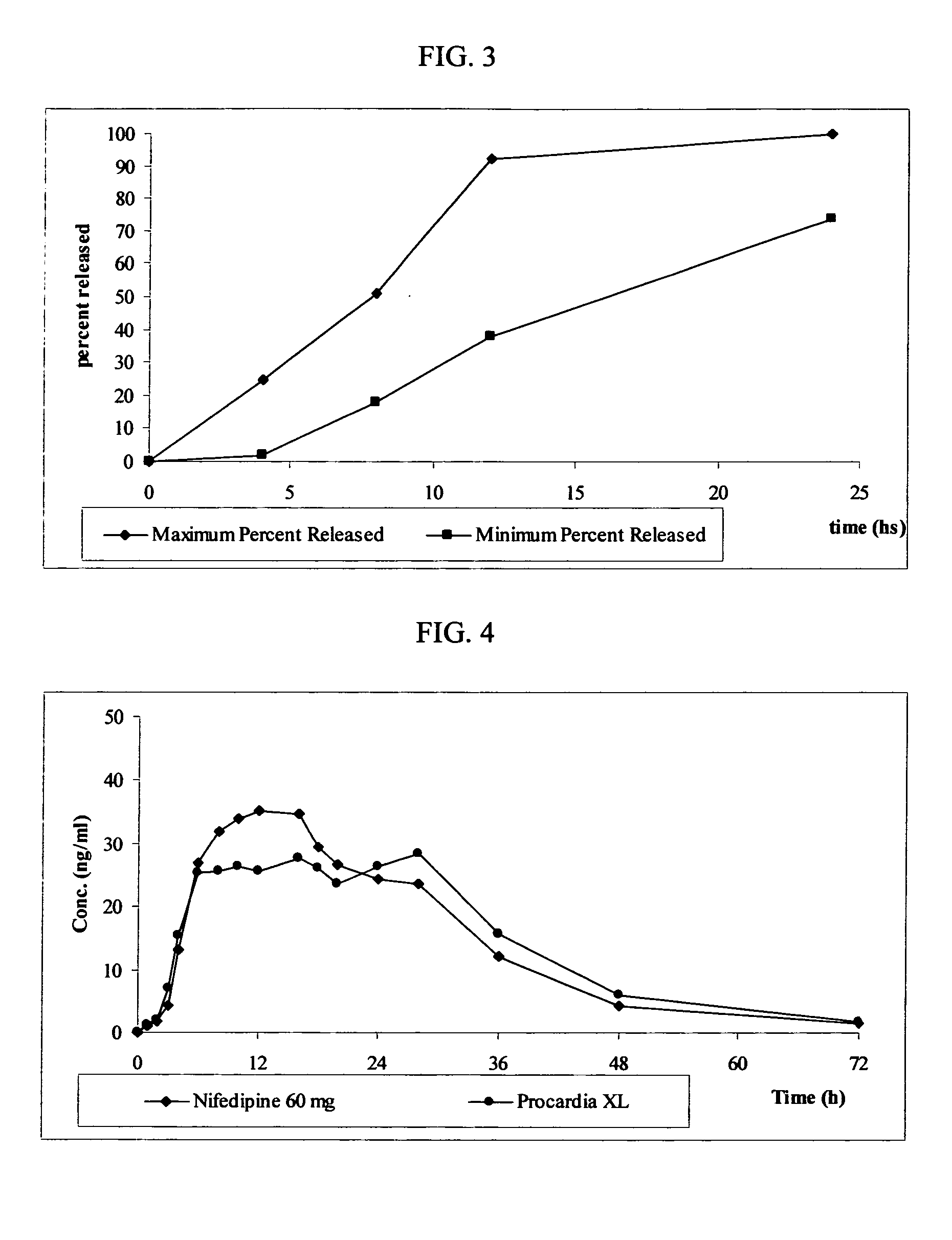

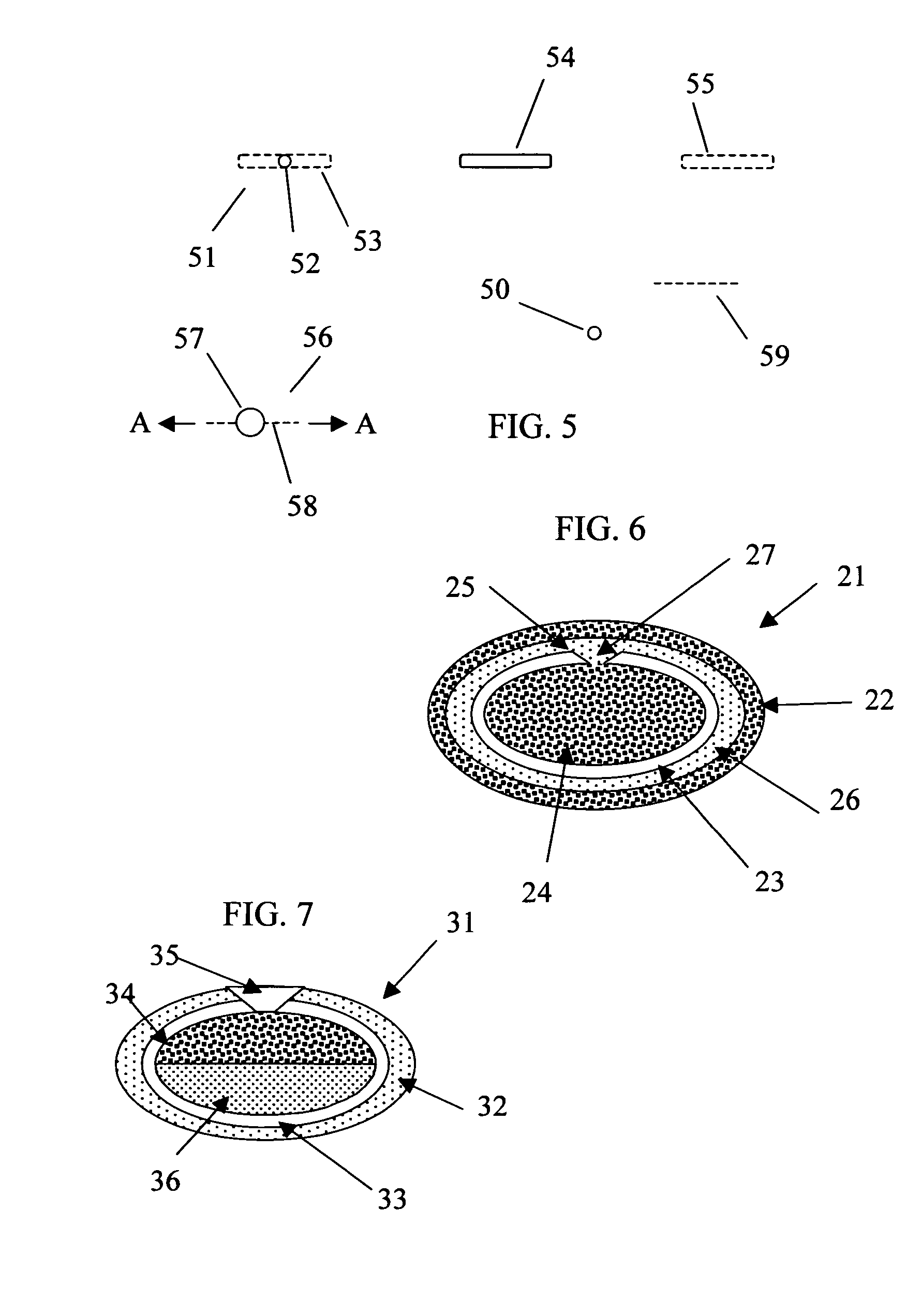

The present invention provides a simple and improved osmotic device that is capable of providing a controlled release of active agent contained in the core first through a preformed passageway and then through an in situ formed second passageway into an environment of use. One or both of the passageways optionally increases in size during use of the osmotic device. The preformed passageway and / or the second passageway increase the release rate of the active agent, enable the release of large particles containing active agent, and / or enable the release of active agents that are substantially insoluble in the environment of use. By virtue of the in situ formation of the second aperture, the device is able to release a greater overall percentage of active agent than it would release in absence of the second aperture.

Owner:OSMOTICA KERESKEDELMI & SZOLGALTATO

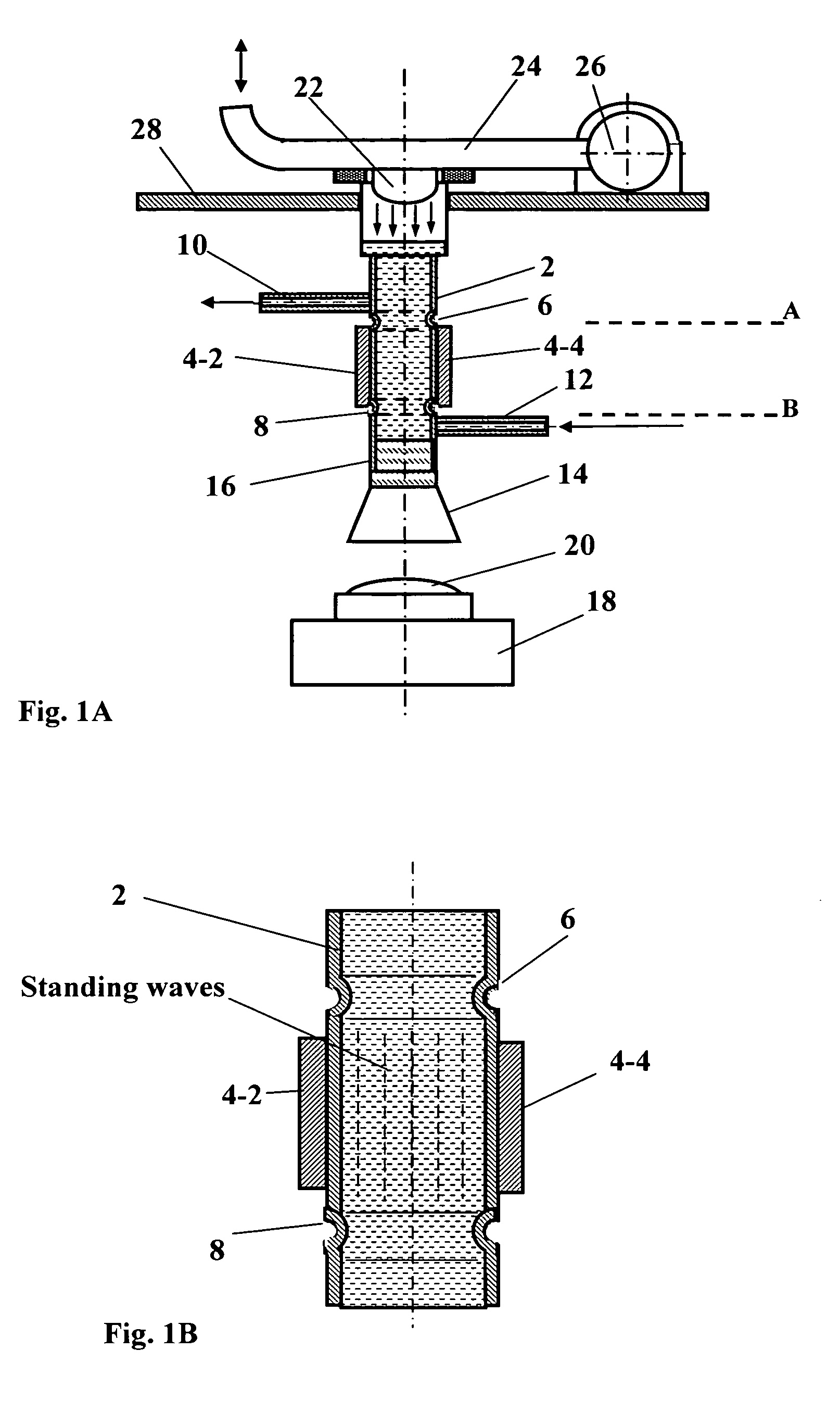

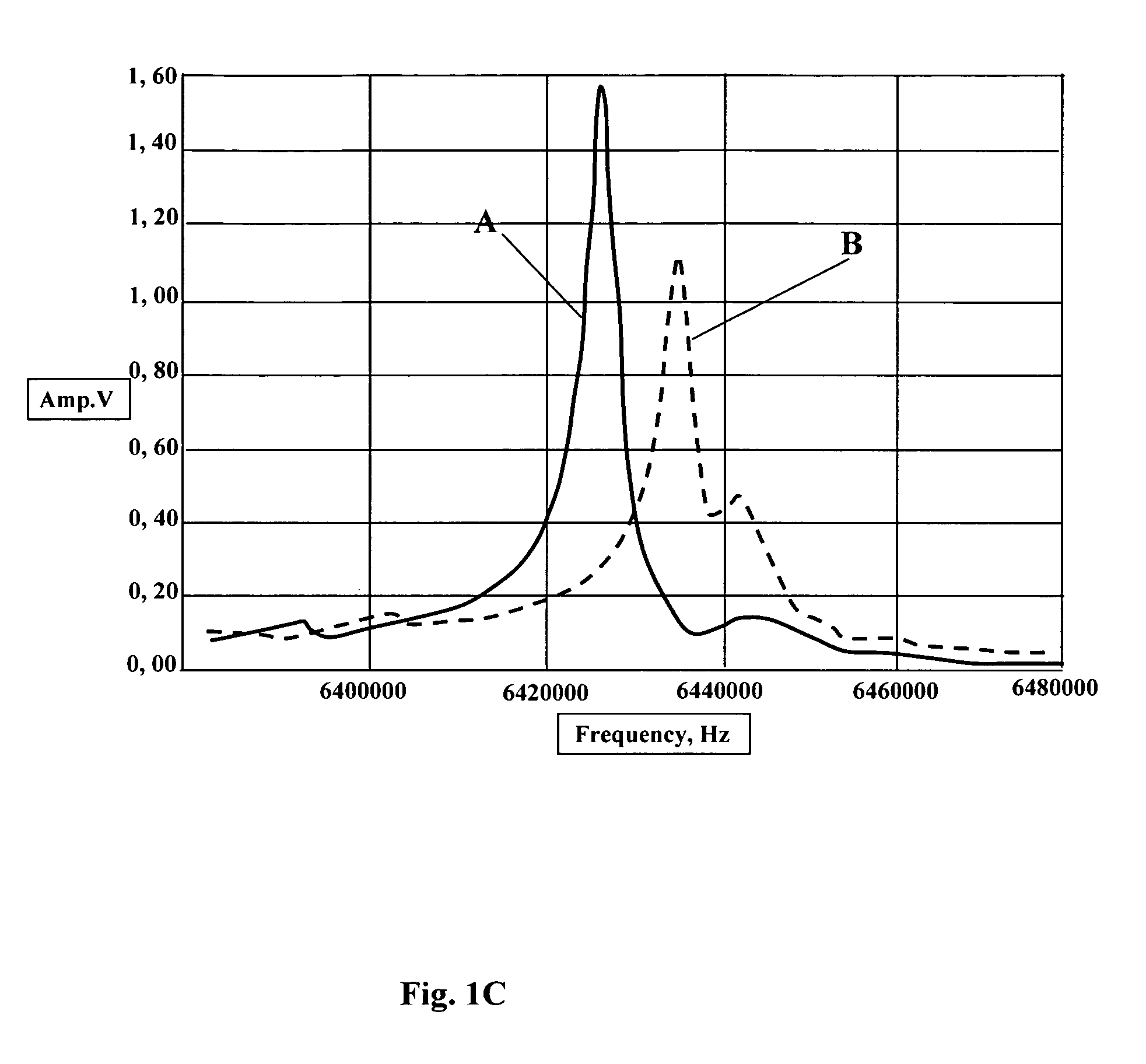

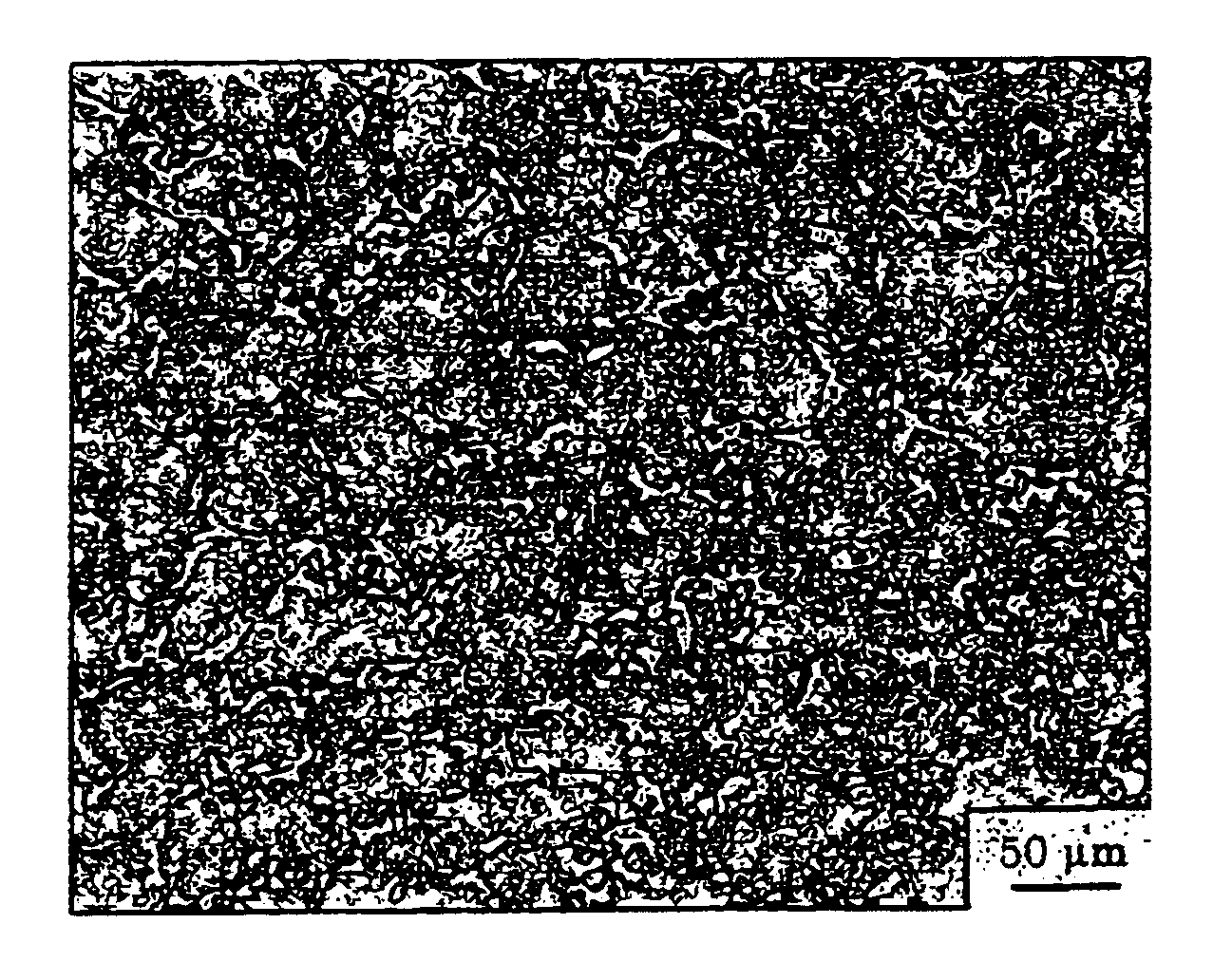

Ultrasonic filtration for cmp slurry

InactiveUS20100206818A1Water/sewage treatment with mechanical oscillationsSedimentation separationFiltrationSlurry

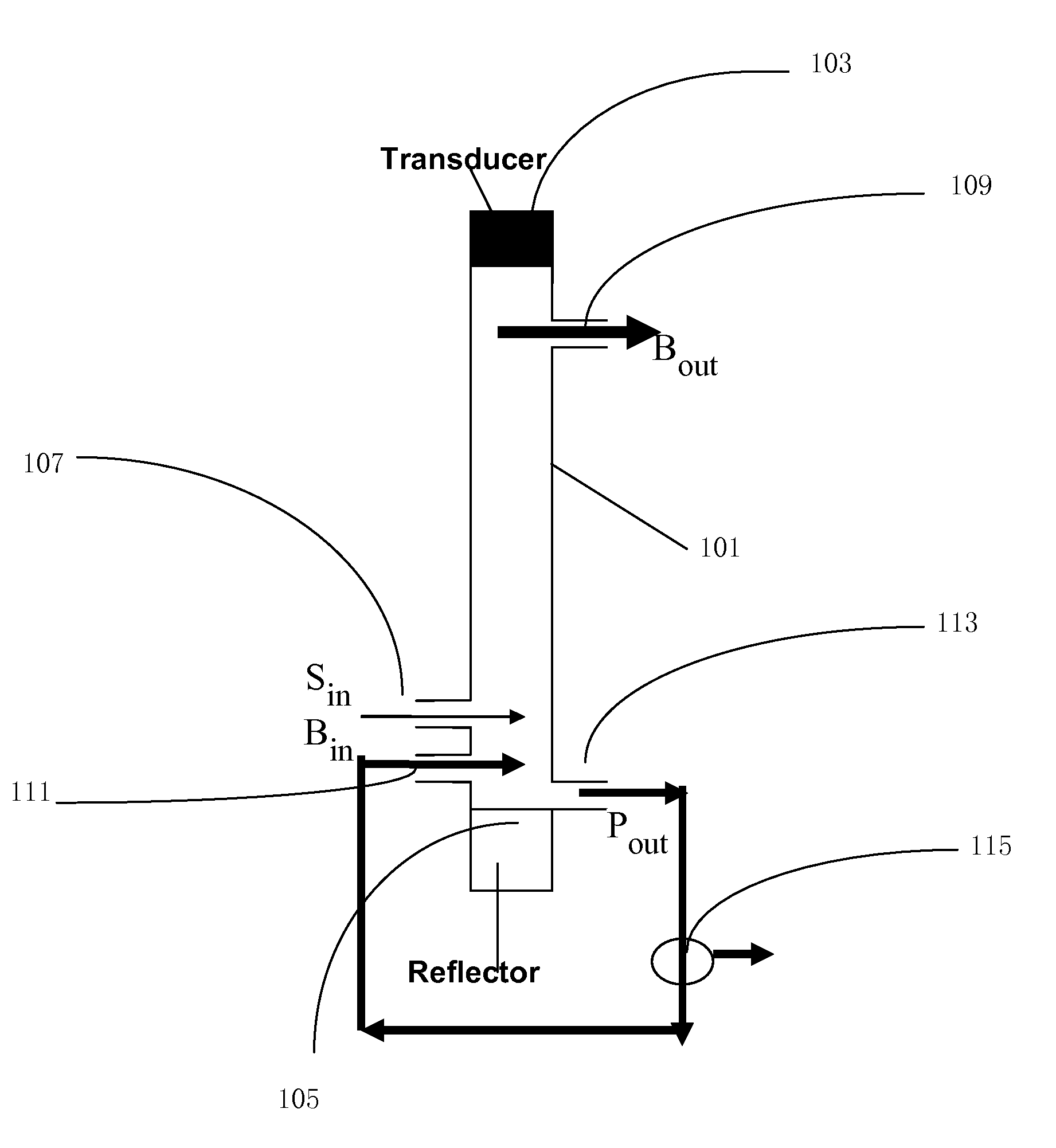

The present invention relates to semiconductor processing. In particular, it relates to a tunable ultrasonic filter and a method of using the same for more effective separation of large particles from slurry. In one embodiment a standing wave is produced in the filter and large particles are accumulated at the nodes of the standing waves while the slurry is flowed out of the filter.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Powder comprising silica-coated zinc oxide, organic polymer composition containing the powder and shaped article thereof

InactiveUS20060167138A1Help shapeSufficient UV shielding abilityPigmenting treatmentMaterial nanotechnologyMicroparticleSilicon dioxide

A powder comprising silica-coated zinc oxide fine particles in which the surface of each particle is coated with silica, wherein large particles of 5 μm or more account for 0.1 mass % or less. A powder comprising surface-hydrophobicized silica-coated zinc oxide fine particles in which the silica-coated zinc oxide fine particles whose surfaces have been coated with silica are further treated with a hydrophobicity-imparting agent, wherein large particles of 5 μm or more account for 0.1 mass % or less.

Owner:SHOWA DENKO KK

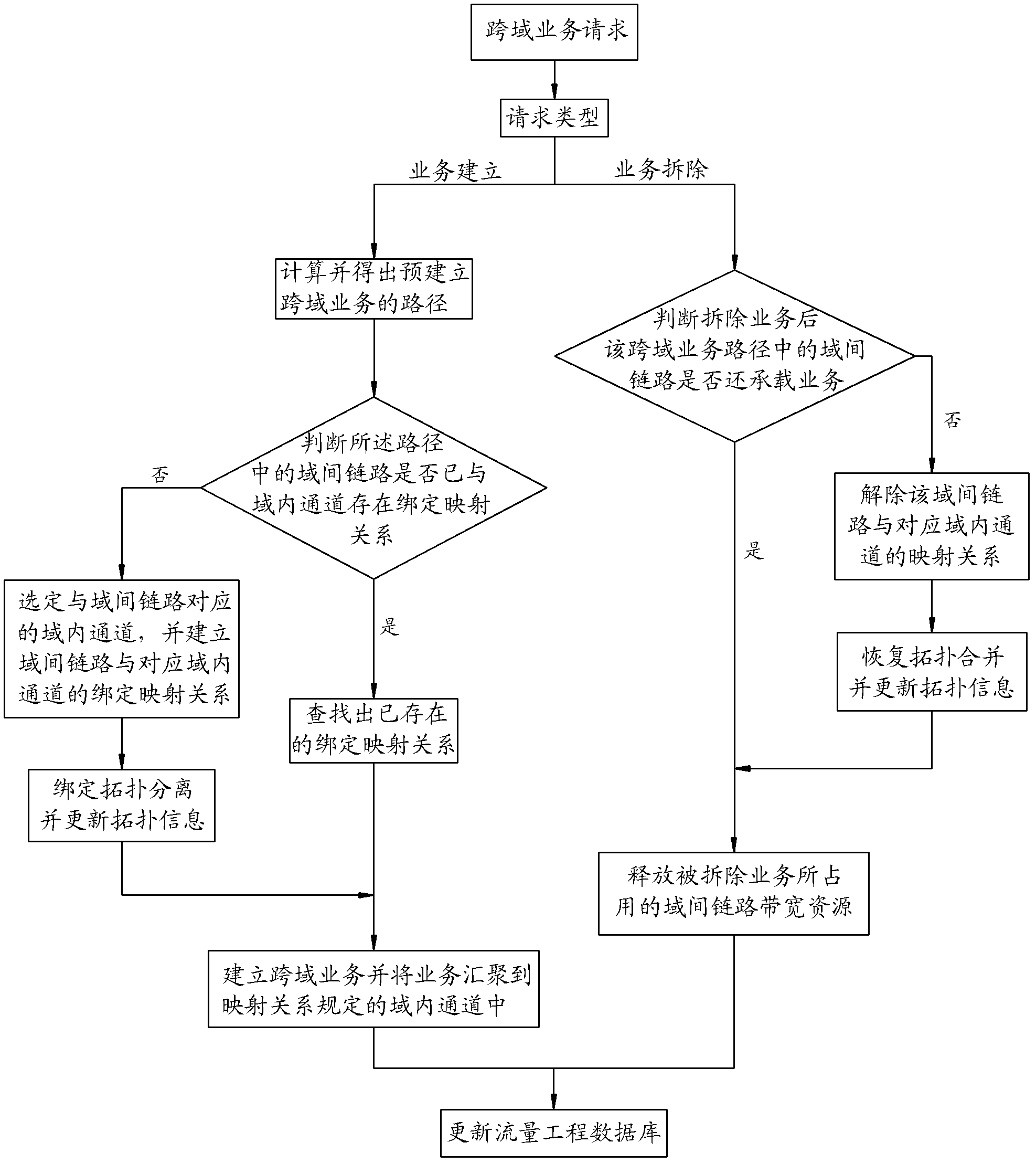

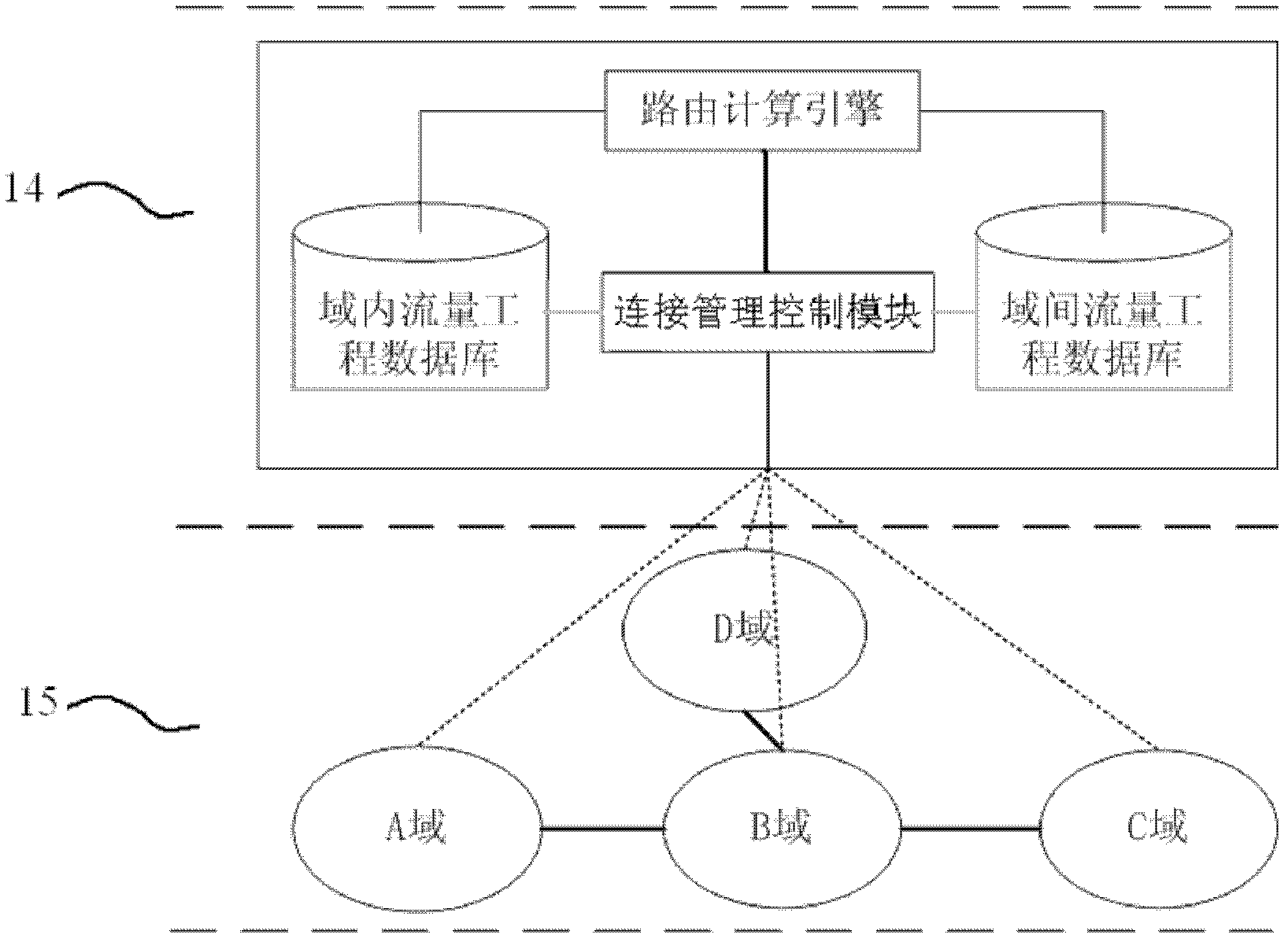

Method and device for binding and mapping control of inter-domain links and intra-domain channels for cross-domain services

InactiveCN102299852ARealize dynamic controlAvoid routing failureData switching networksComputer scienceInter-domain

Owner:TSINGHUA UNIV

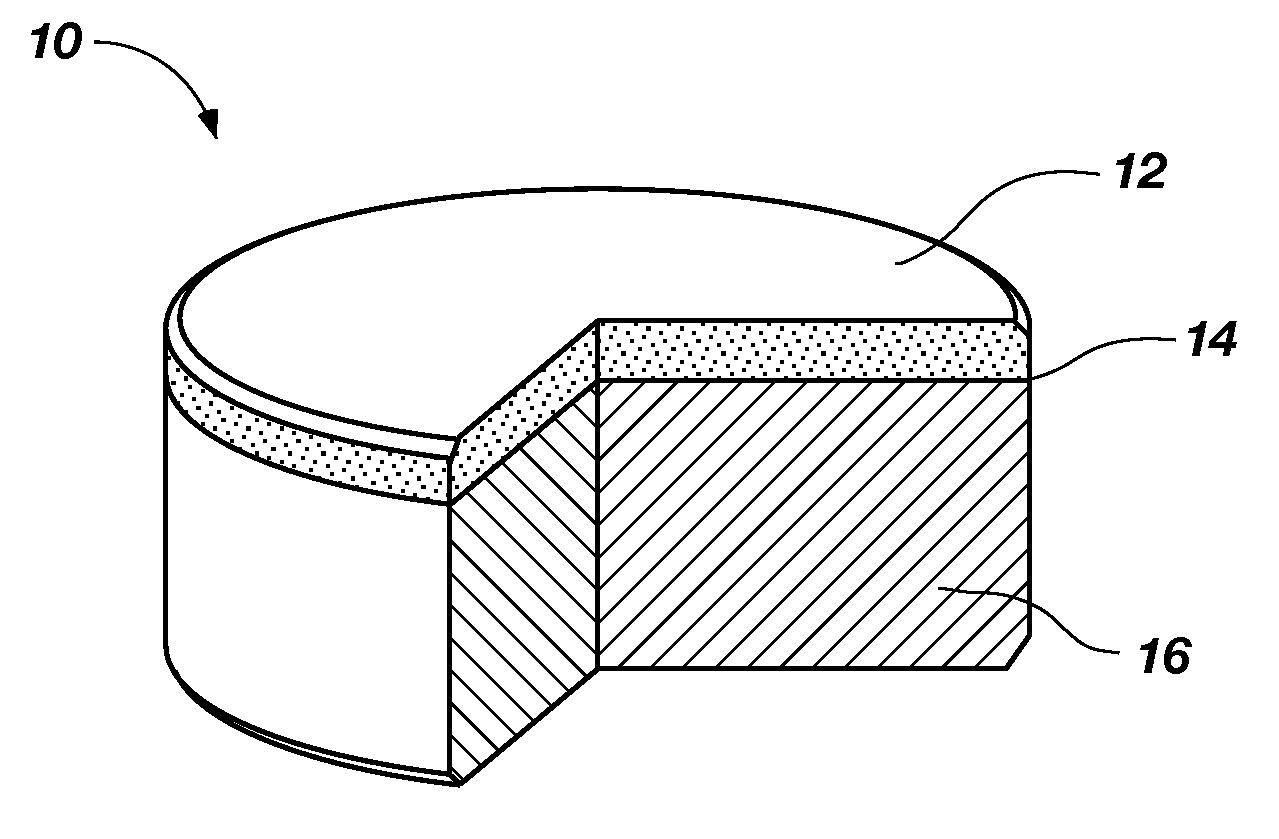

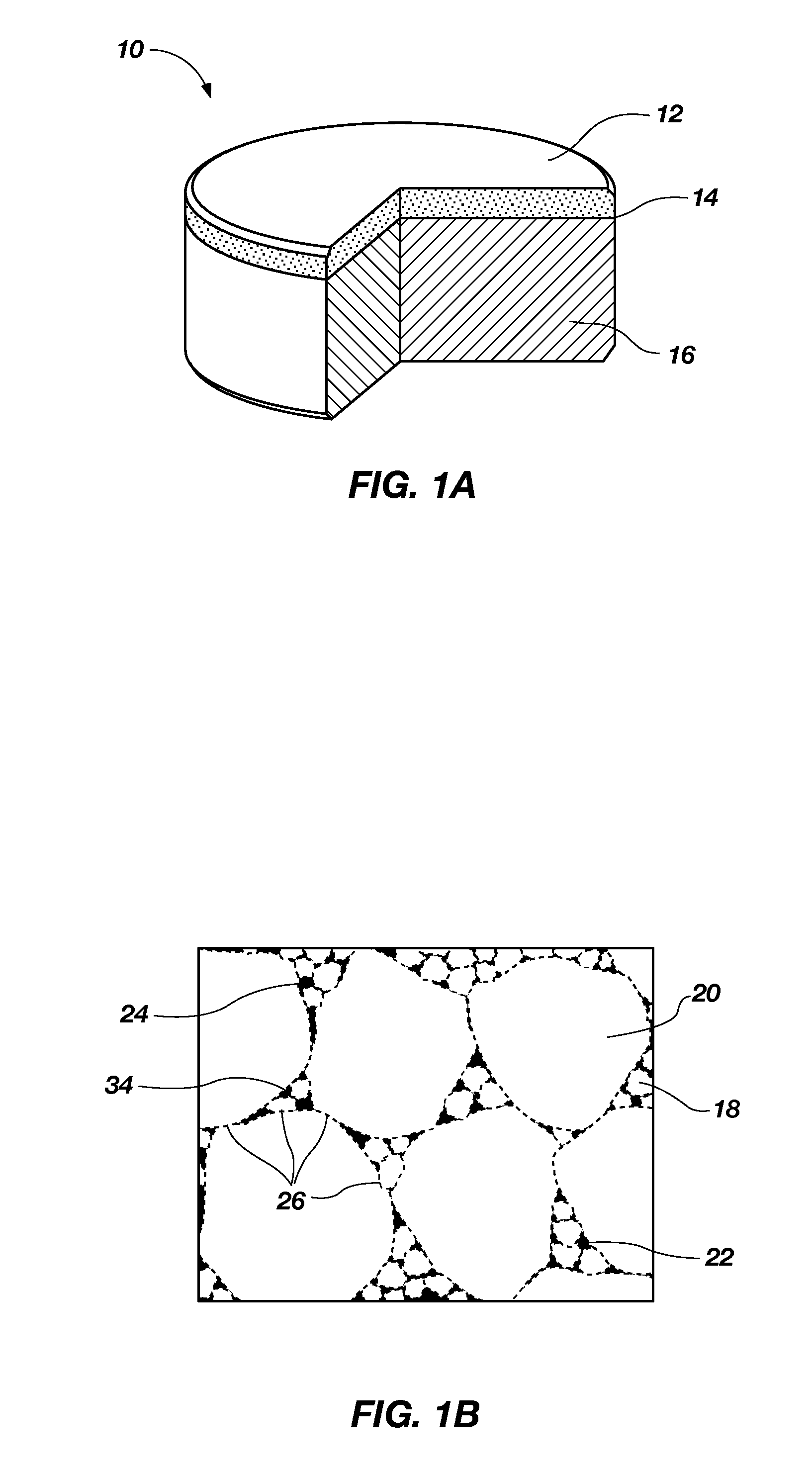

Polycrystalline compacts having material disposed in interstitial spaces therein, cutting elements and earth-boring tools including such compacts, and methods of forming such compacts

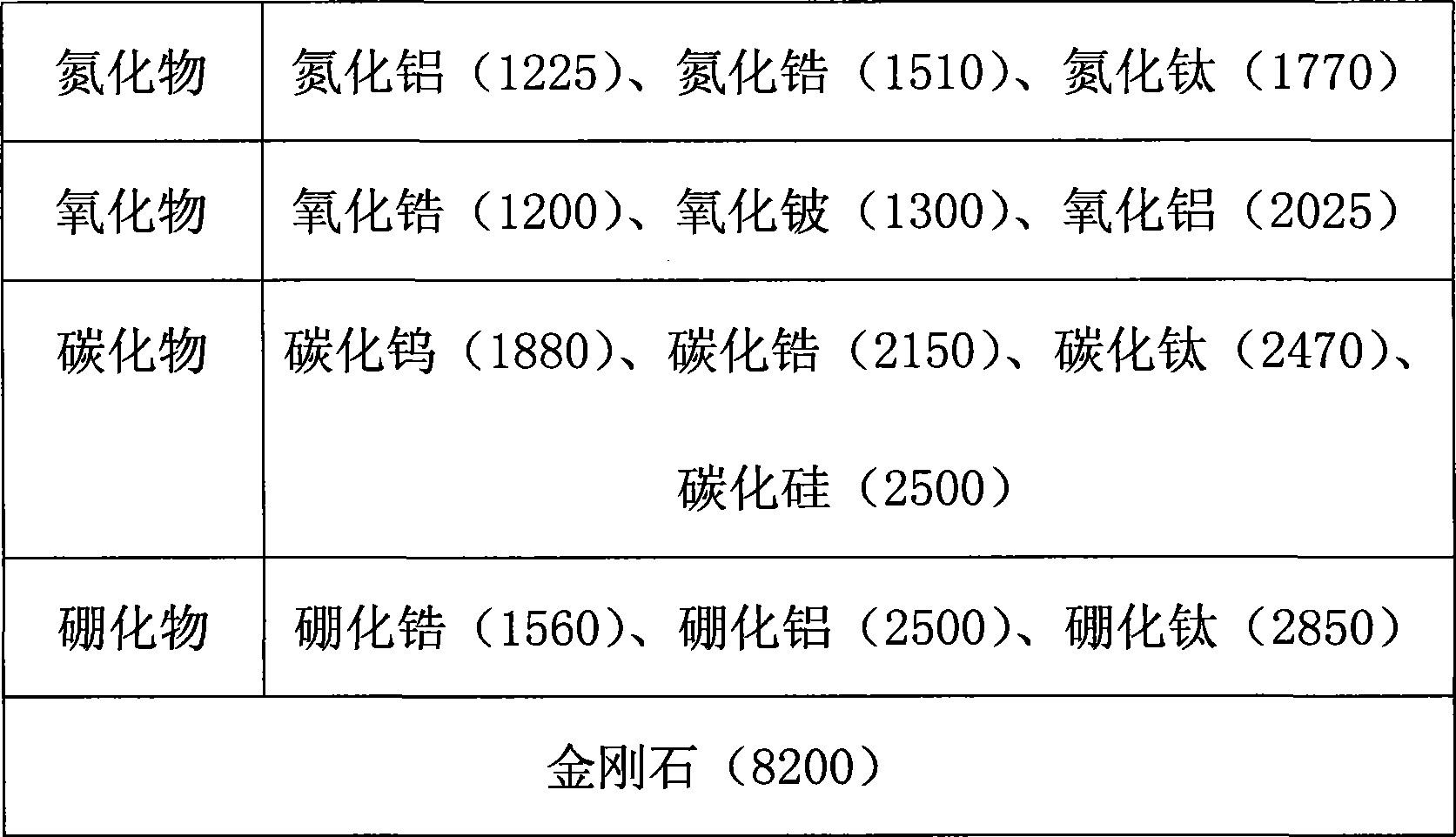

Polycrystalline compacts include smaller and larger hard grains that are interbonded to form a polycrystalline hard material. The larger grains may be at least about 150 times larger than the smaller grains. An interstitial material comprising one or more of a boride, a carbide, a nitride, a metal carbonate, a metal bicarbonate, and a non-catalytic metal may be disposed between the grains. The compacts may be used as cutting elements for earth-boring tools such as drill bits, and may be disposed on a substrate. Methods of making polycrystalline compacts include coating smaller hard particles with a coating material, mixing the smaller particles with larger hard particles, and sintering the mixture to form a polycrystalline hard material including interbonded smaller and larger grains. The sizes of the smaller and larger particles may be selected to cause the larger grains to be at least about 150 times larger than the smaller grains.

Owner:BAKER HUGHES INC

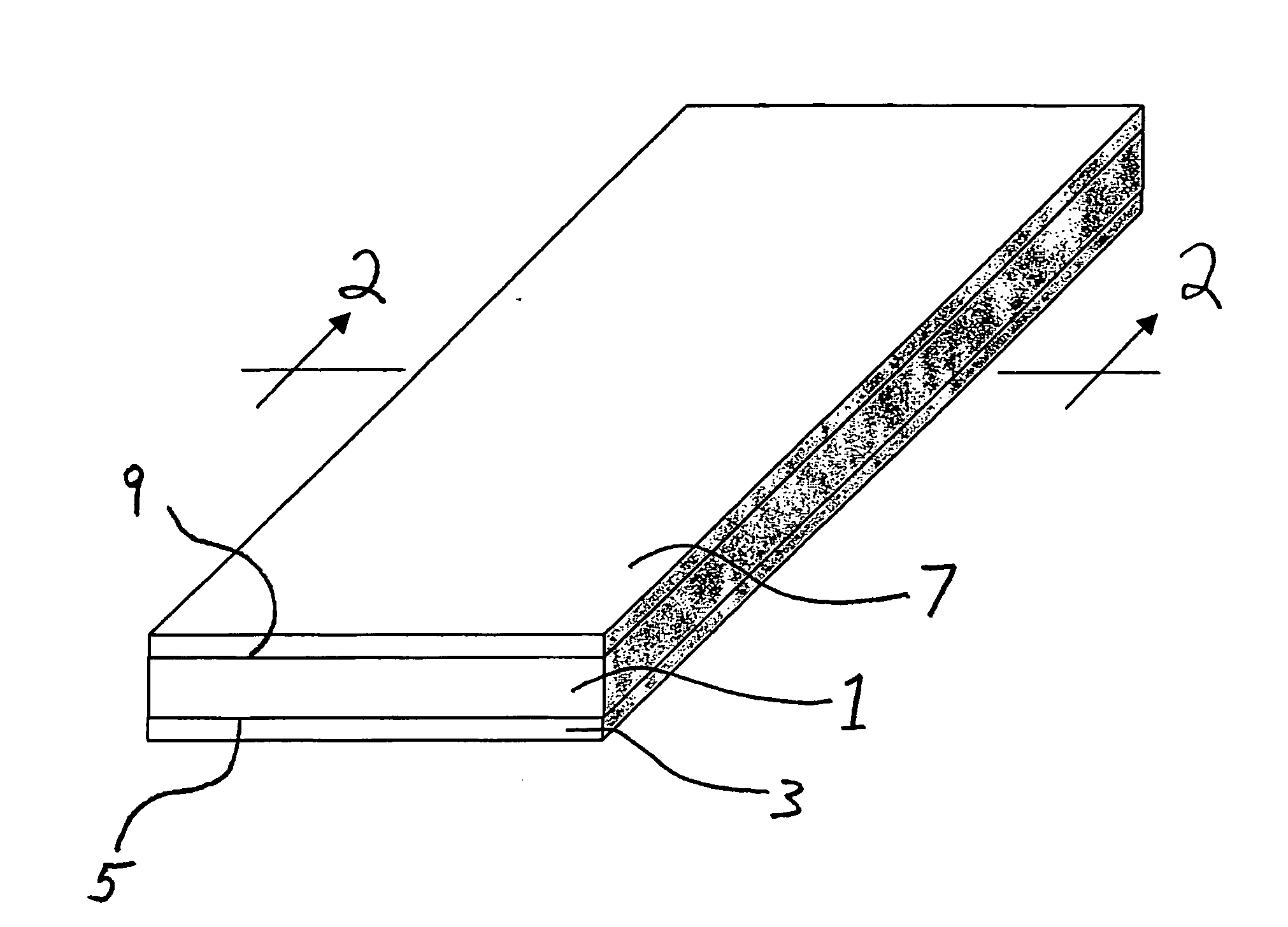

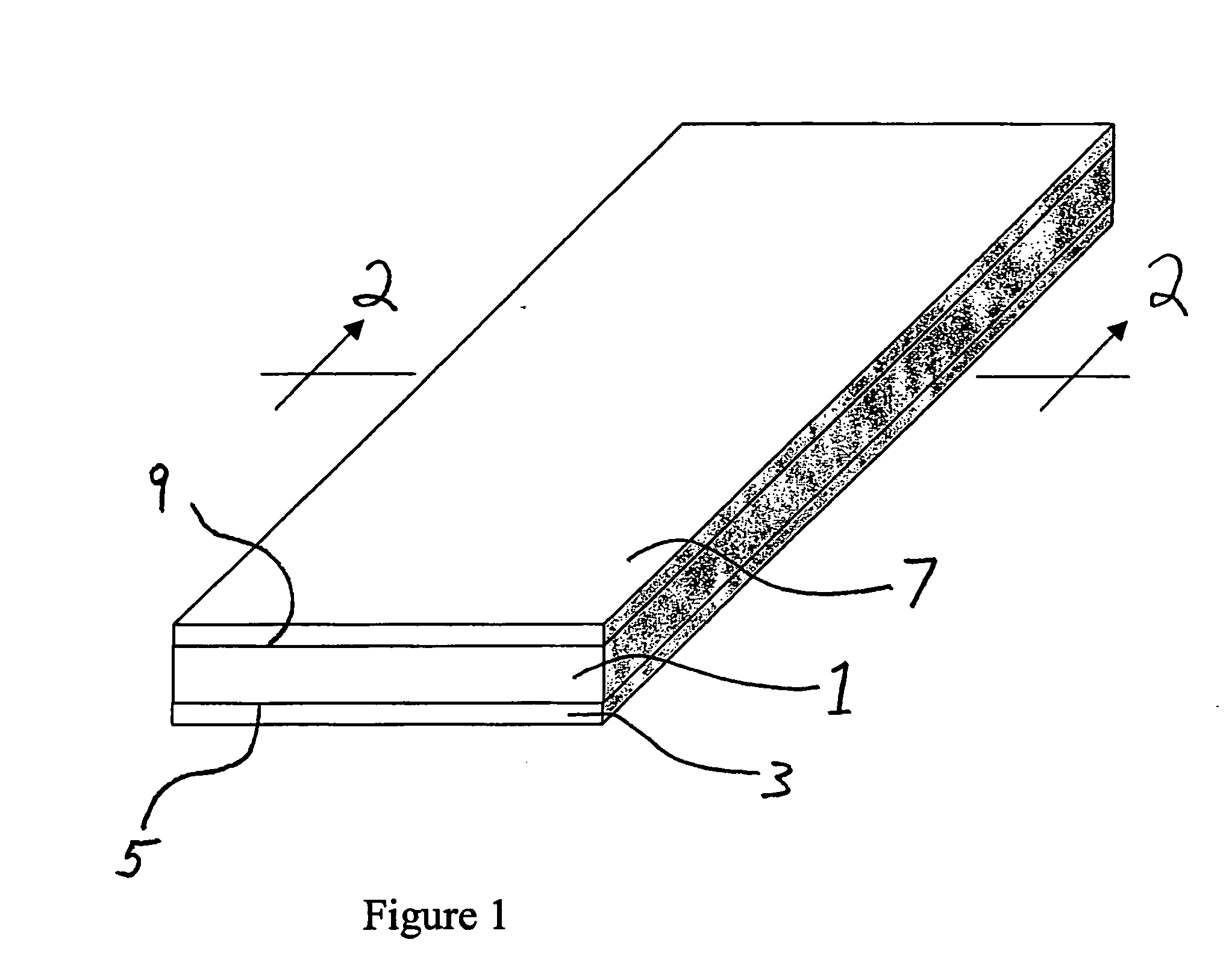

Coating system for sag resistant formaldehyde-free fibrous panels

ActiveUS20070055012A1Low costMaintain resistanceConstruction materialSynthetic resin layered productsFiberHydrophilic coating

A coating system on a fibrous substrate, such as a fibrous ceiling panel, having a first surface and a second surface. A first coating is disposed on the first surface of the substrate and includes a first binder and a first filler material. A second coating may be disposed on the second surface of the substrate. The second coating includes a second binder and a second filler material. The first coating and the second coating expand at different rates in the presence of humidity in order to help prevent sagging of the substrate in presence of humidity. The first coating is preferably a hydrophobic coating having a large particle size, high elastic modulus filler material. The second coating is preferably a hydrophilic coating having a lower concentration of high elastic modulus material and a polymer having a hydrophilic moiety.

Owner:AWI LICENSING

Cosmetic compositions containing nacreous pigments of large sized synthetic mica

InactiveUS20050142084A1High transparencyHigh glossCosmetic preparationsHair cosmeticsCompressibilityLarge particle

Cosmetic compositions containing nacreous pigments of large particle size coated synthetic mica and method for increasing or improving the gloss, glint, brightness, whiteness, transparency and compressibility of cosmetic compositions employing same.

Owner:SUN CHEM CORP

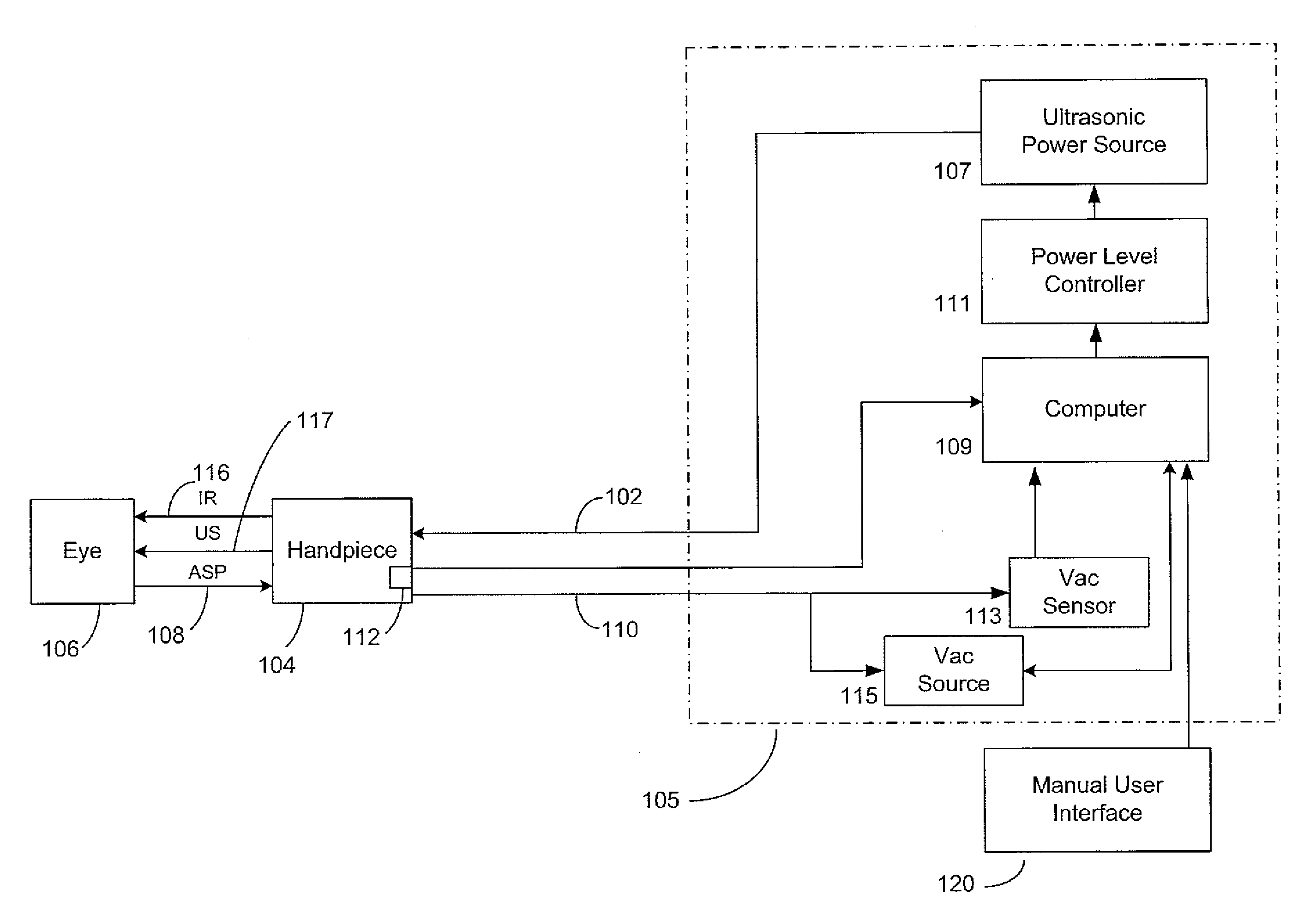

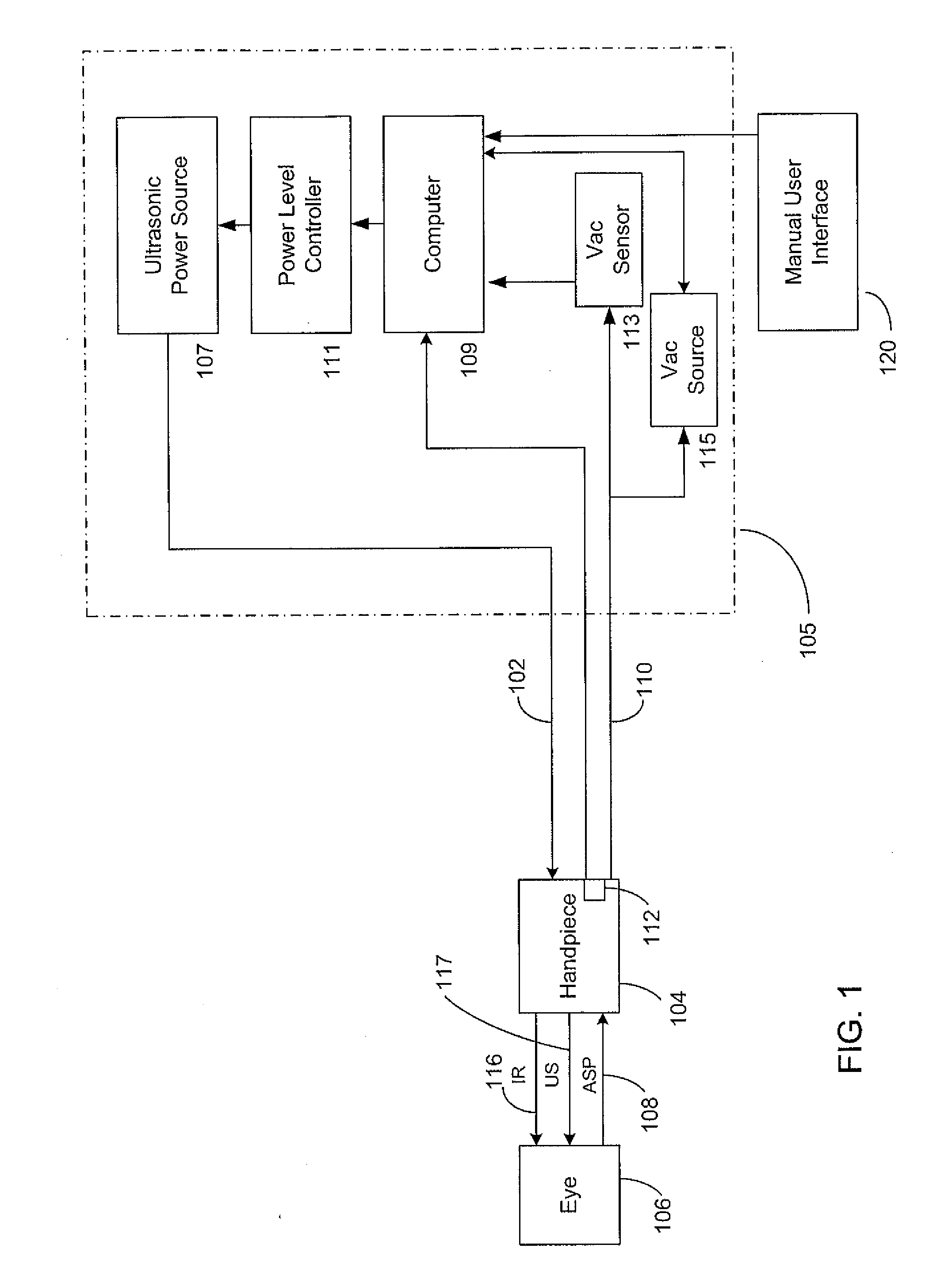

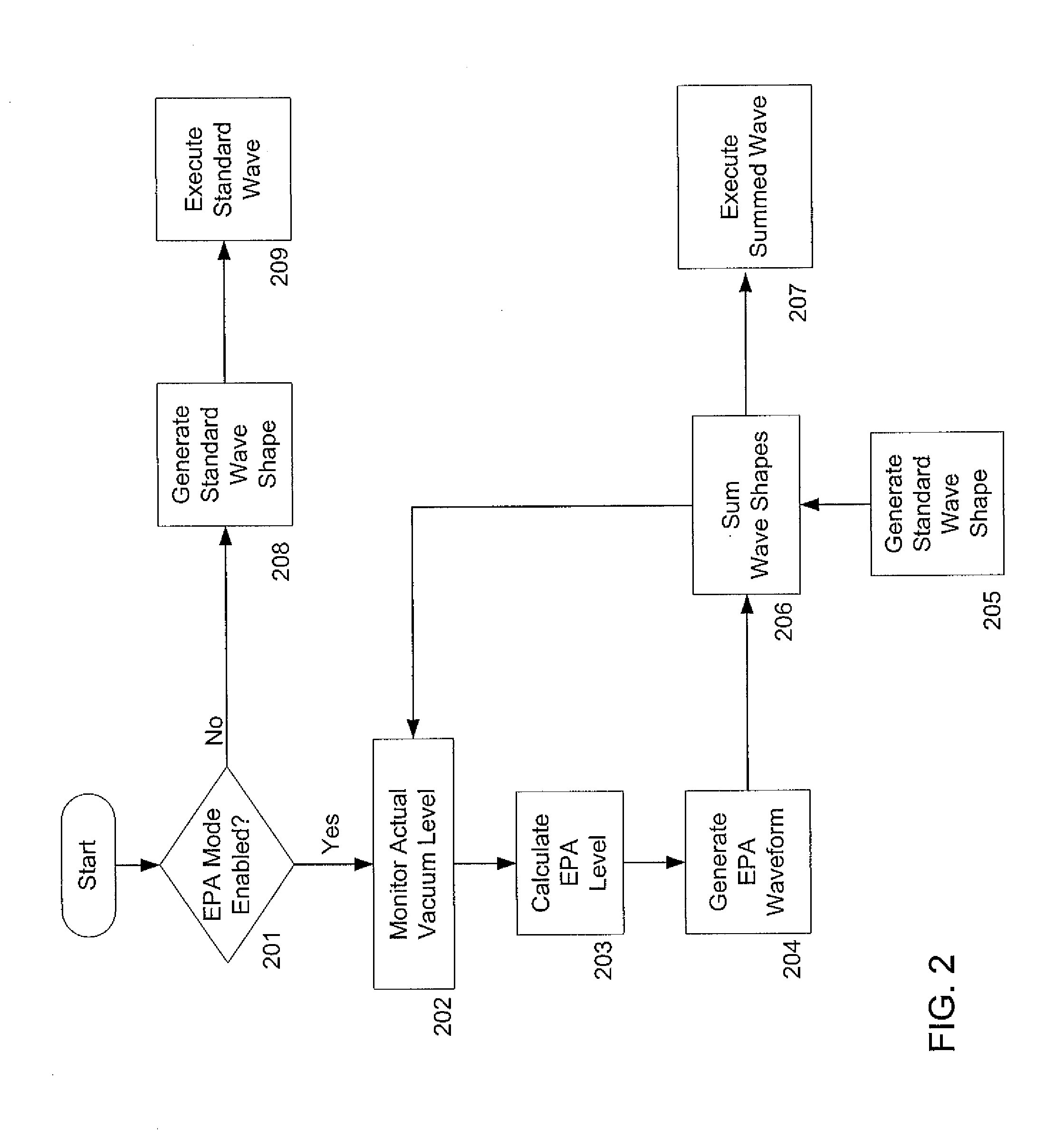

Vacuum sense control for phaco pulse shaping

ActiveUS20080033342A1Mechanical/radiation/invasive therapiesEye surgeryPulse shapingPhacoemulsification

A method and apparatus for precisely controlling particle movement relative to a phacoemulsification needle tip is provided. The design monitors actual vacuum present and calculates a pulse shape amplitude waveform proportional to the amount of measured vacuum. An increase in vacuum indicates that the handpiece / needle is becoming occluded by a large particle. The present design determines whether additional power is required to bump or move a large particle away from the needle tip. The present design may employ a control loop that senses and continuously monitors vacuum. The design may dynamically vary the amount of ultrasonic energy delivered to the surgical area in response to the observed actual vacuum, and can actively vary the amount of power delivered to the surgical area based on the size of the particle and the resultant vacuum realized.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Method of preparing molding compositions with fiber reinforcement and products obtained therefrom

InactiveUS6103779AIncreased shelf stabilityImprove stabilityImpression capsDental splintsAcrylic resinFluid responsiveness

A method of preparing fiber reinforced acrylic thickened compositions which can be molded under low pressures and temperatures to provide thermoset articles, wherein liquid reactive components are slowly absorbed in high molecular weight solid acrylic resin in the form of large particles. The acrylic resin functions as a thickener which delays the viscosity build allowing fiber reinforcement to be incorporated before molding. The molding composition is well suited for use in dentistry and other fields where small amounts or molding composition are used occasionally.

Owner:REINFORCED POLYMER

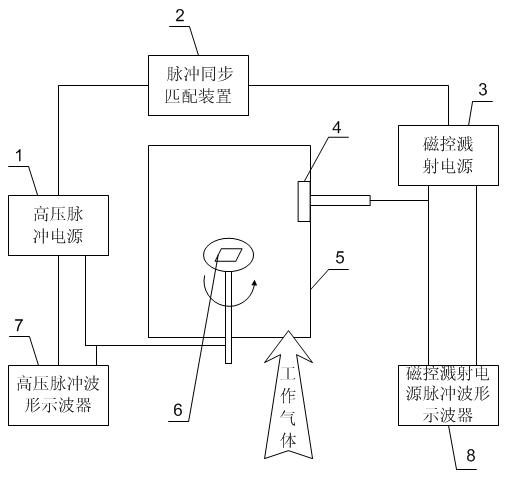

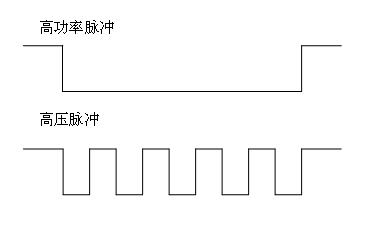

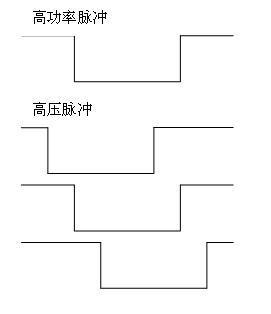

Ion implantation and deposit method of high-power composite pulse by magnetic control sputtering

ActiveCN101838795AIncrease ionization rateHigh bonding strengthVacuum evaporation coatingSputtering coatingPhase differenceHigh pressure

The invention discloses an ion implantation and deposit method of high-power composite pulse by magnetic control sputtering, which belongs to the field of material surface treatment technology and solves the problems of large particles and low film deposit efficiency in an adopted method in which negative high voltage pulse is applied to a workpiece. The method disclosed by the invention comprises the steps of: 1. placing the workpiece on a sample platform in a vacuum chamber, connecting the workpiece with a high-voltage pulse power supply, and connecting a magnetic control sputtering target source with a magnetic control sputtering power supply; and 2. implanting and depositing: when the vacuum degree in the vacuum chamber is lower than 10-2Pa, introducing working gas until the vacuum degree in the vacuum chamber reaching 0.011-10 Pa, starting up the high-voltage pulse power supply, adjusting the voltage value of output pulse of the high-voltage pulse power supply to 0.5-100kV, adjusting the pulse frequency to 0-1000Hz, adjusting the pulse width to 0-500 microseconds, starting up the magnetic control power supply, adjusting required process parameters by direct-current luminance pre-ionization, and controlling the voltage phase difference of the two power supplies to be -1000-1000 microseconds to perform the ion implantation and deposit.

Owner:HARBIN INST OF TECH

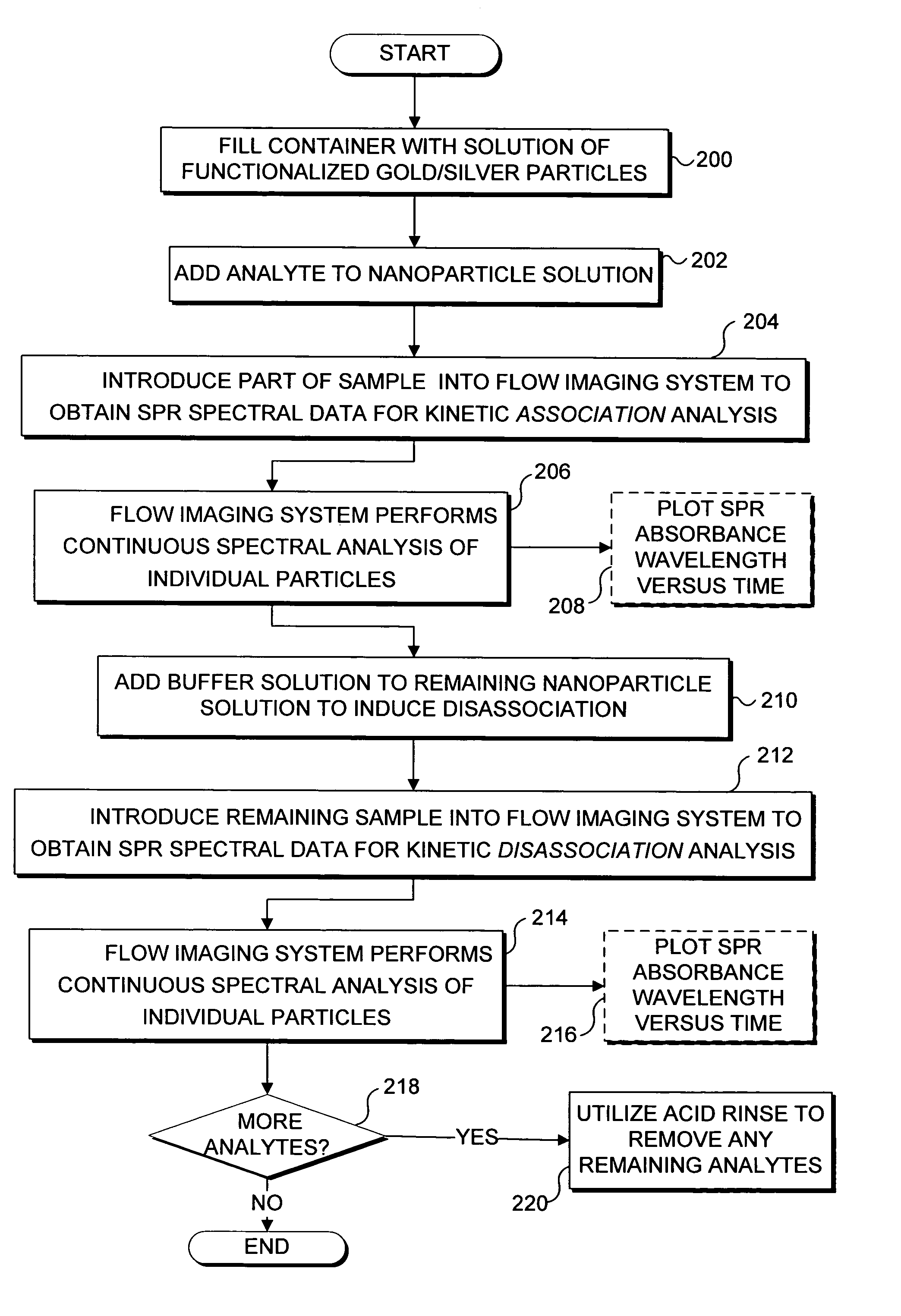

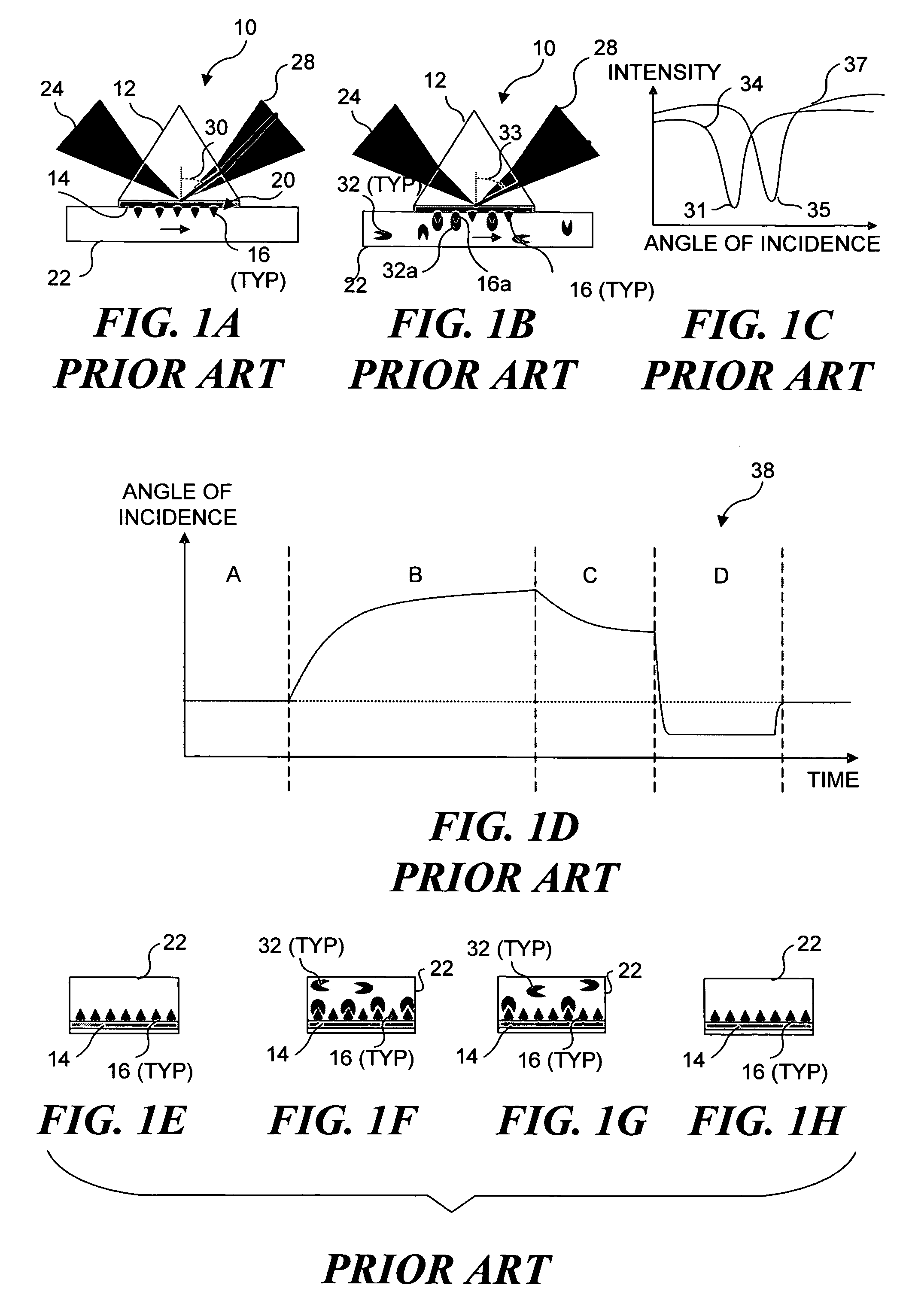

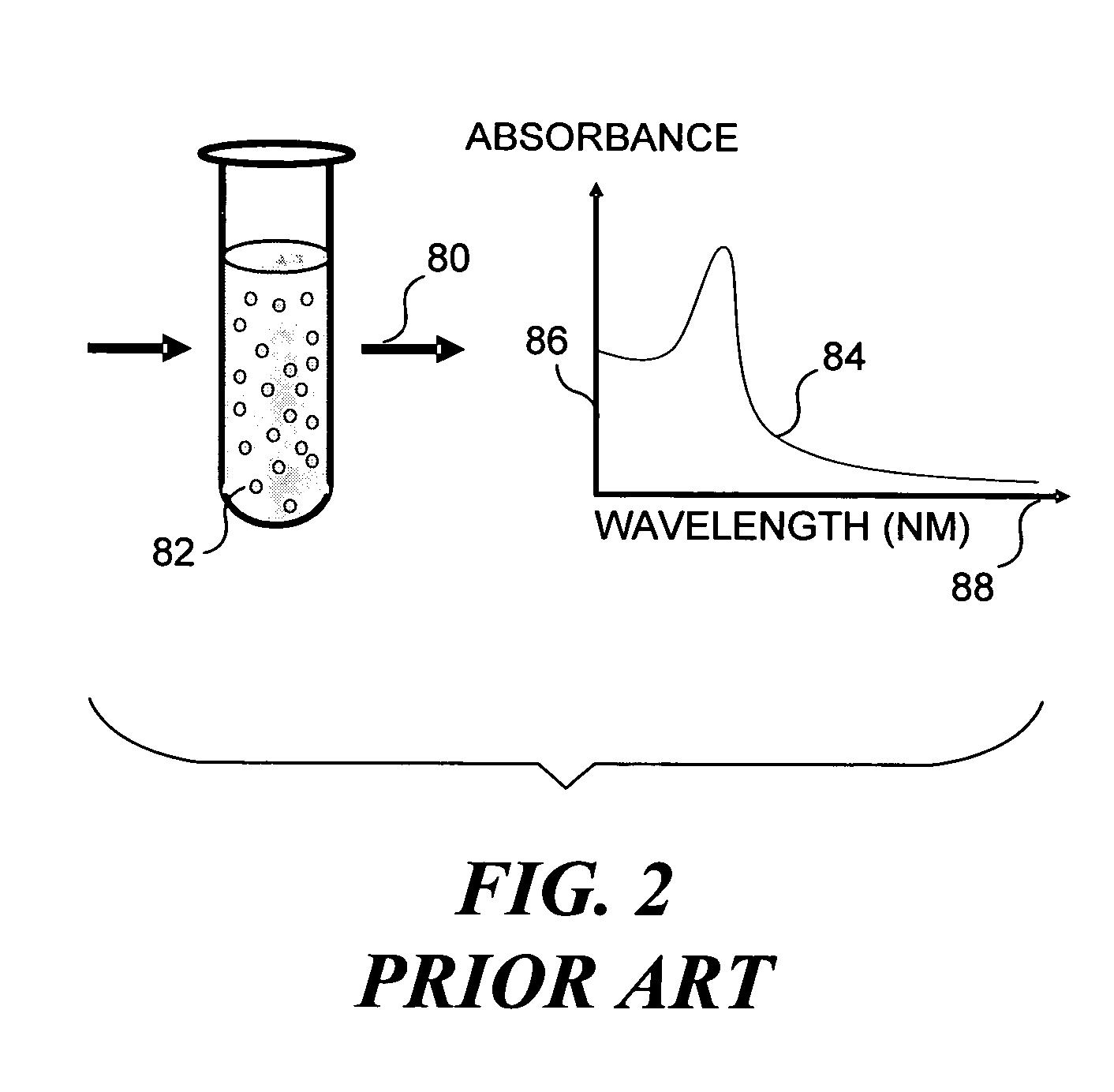

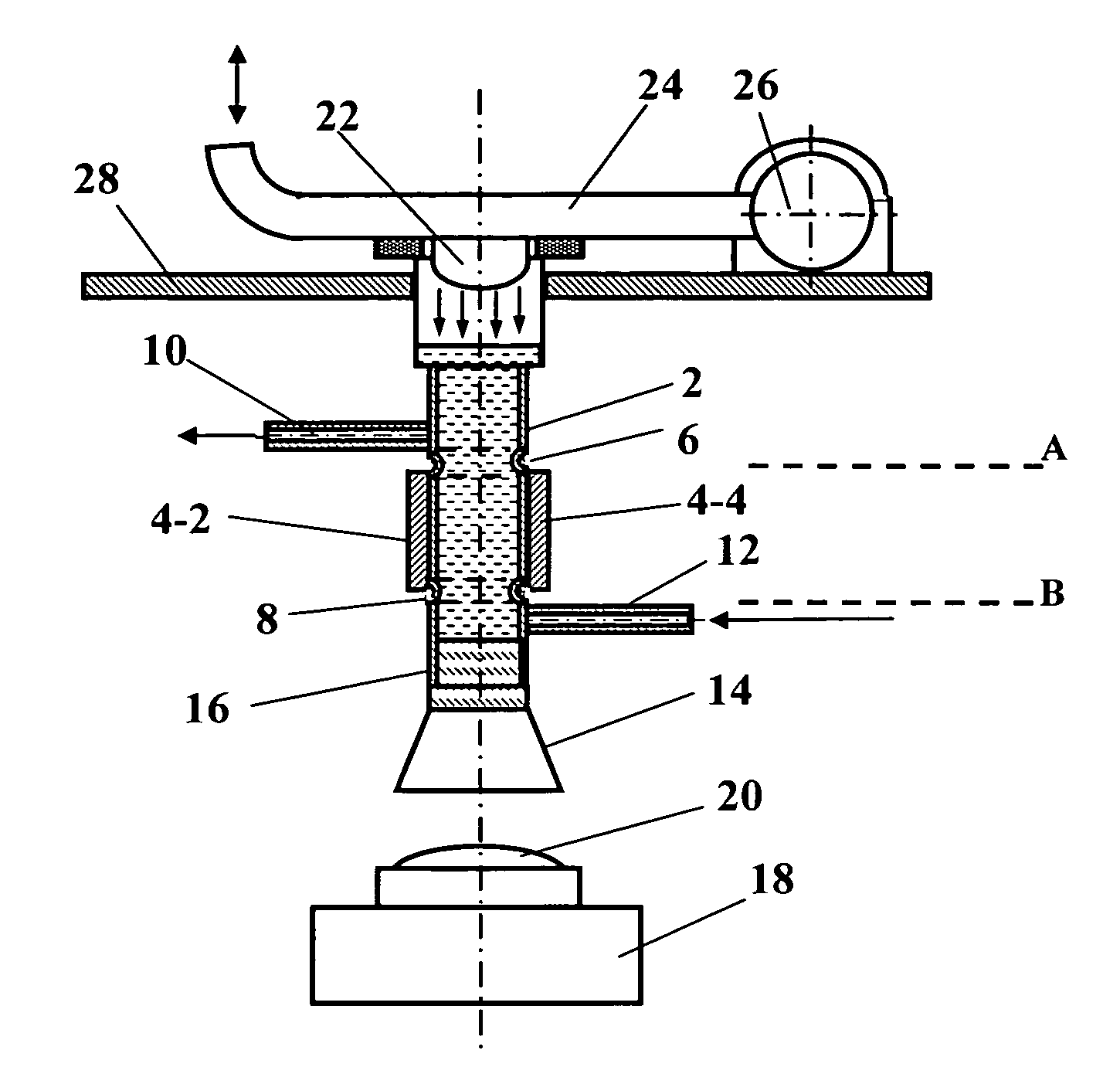

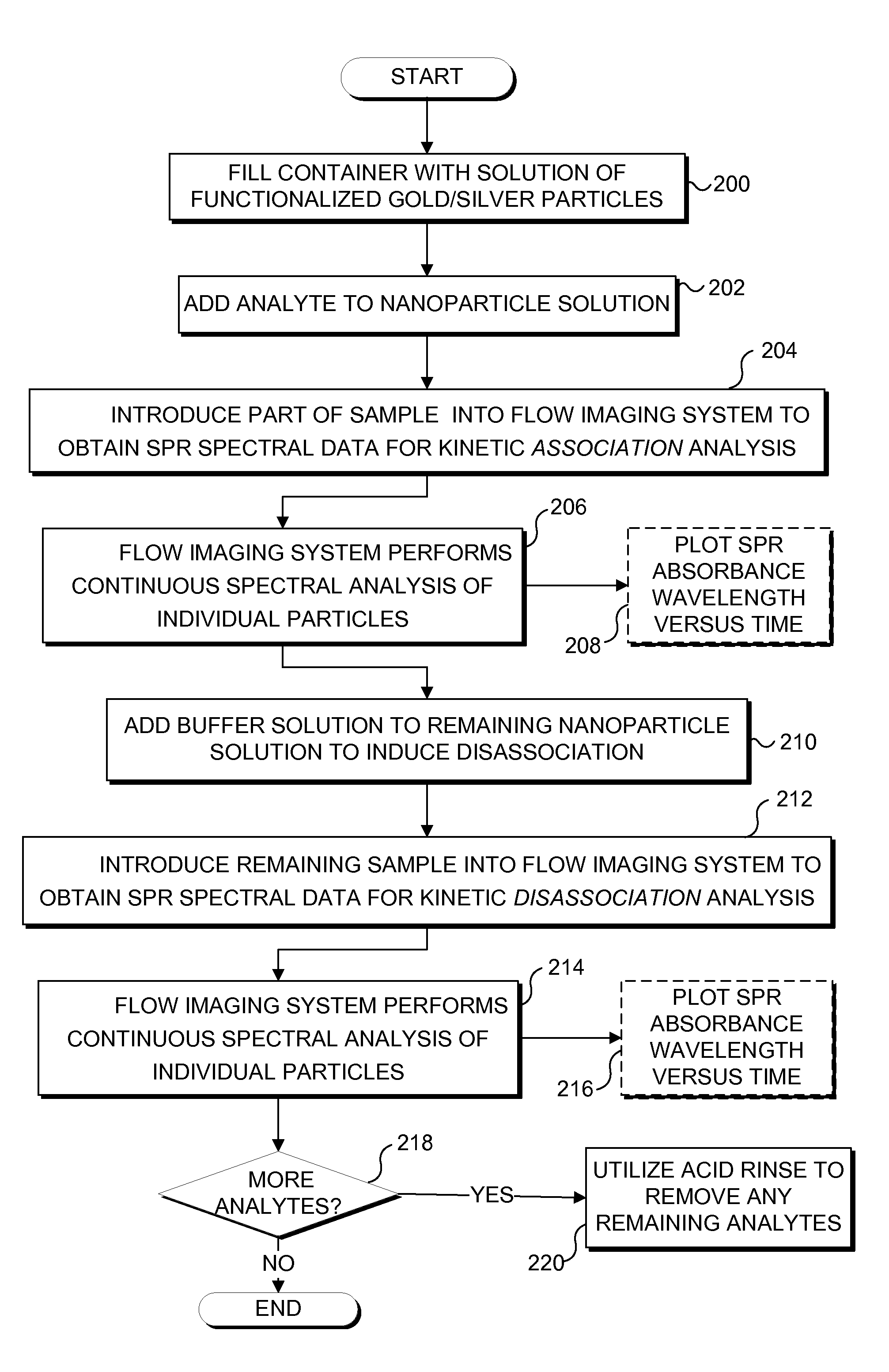

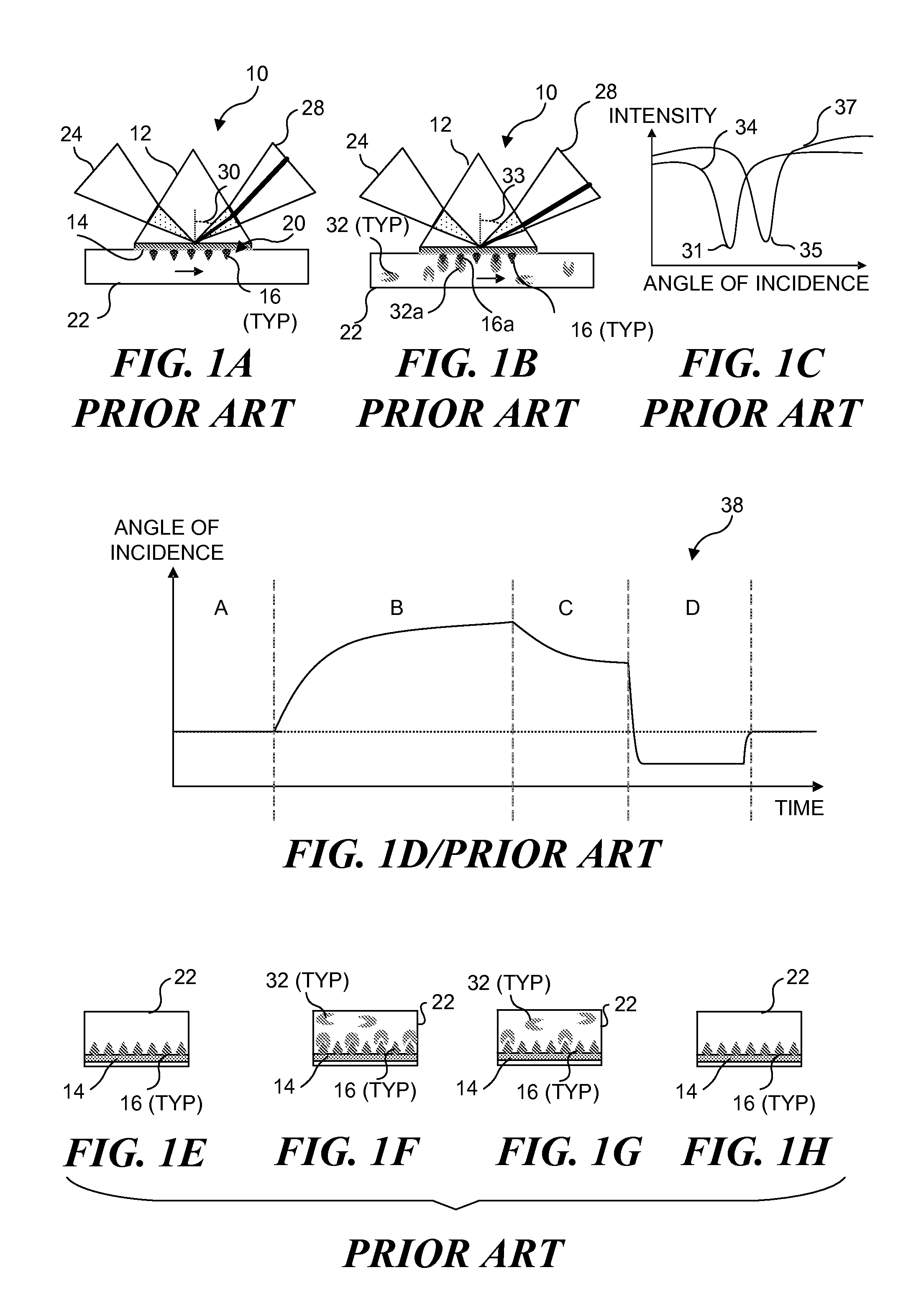

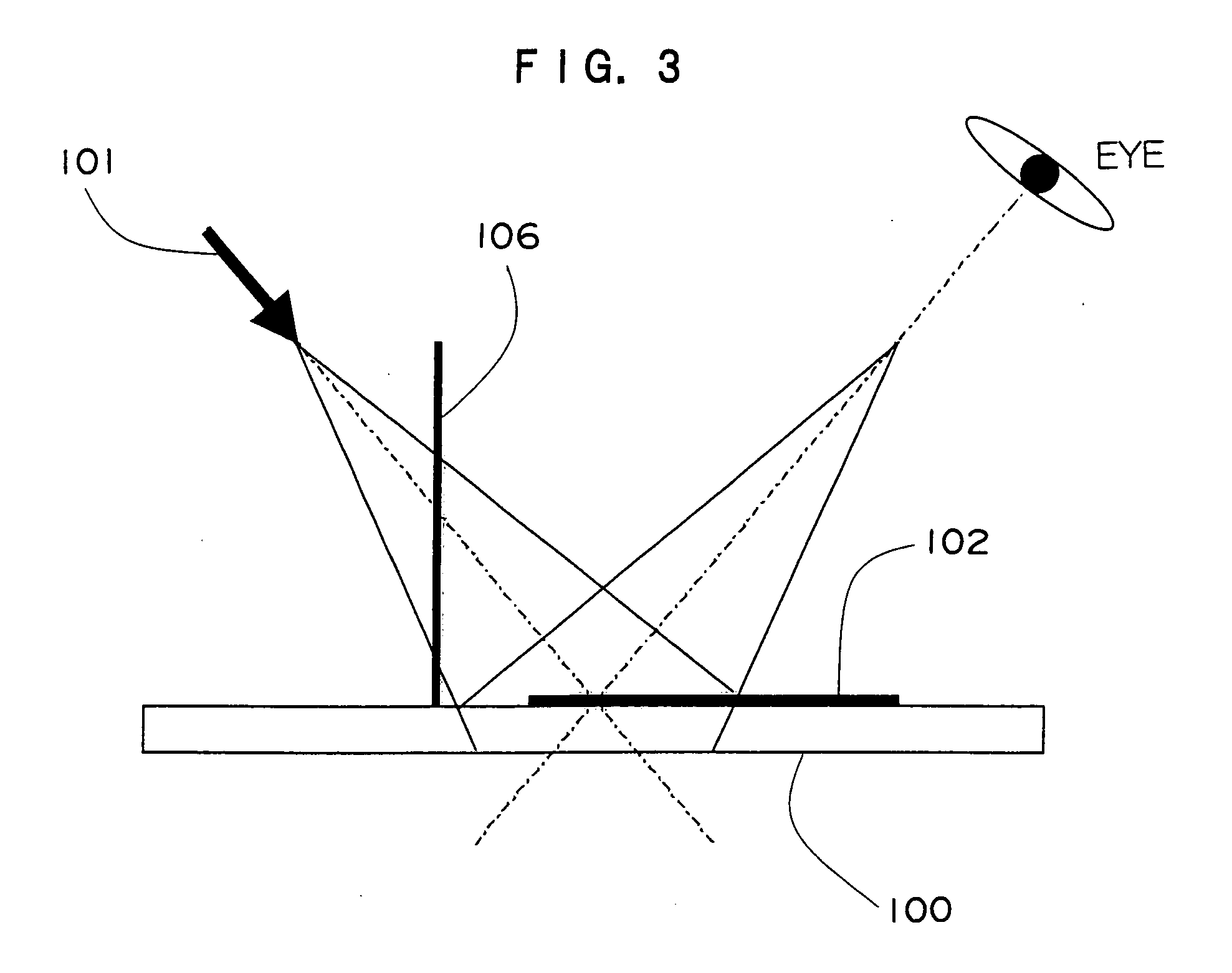

Imaging platform for nanoparticle detection applied to SPR biomolecular interaction analysis

InactiveUS7057732B2Increase curve 's linearityAccurate CalibrationSpectrum investigationInvestigating moving fluids/granular solidsSurface plasmonic resonanceAnalyte molecule

A flow imaging system is used to implement surface plasmon resonance (SPR) detection to study bio-molecular interactions. The flow imaging system is used to capture SPR absorption spectra of large numbers of objects, where each object includes both a metal film capable of exhibiting SPR, and detecting molecules. Analyte molecules are added to a solution of such objects, and the result is introduced into the flow imaging system which collects full SPR spectral data from individual objects. The objects can be nanoparticles or larger particles that support metal island films. The SPR spectral data can be used to determine specificity, kinetics, affinity, and concentration with respect to the interactions between the detecting molecules and the analyte molecules.

Owner:CYTEK BIOSCI

Composite particles and method for production thereof and use thereof

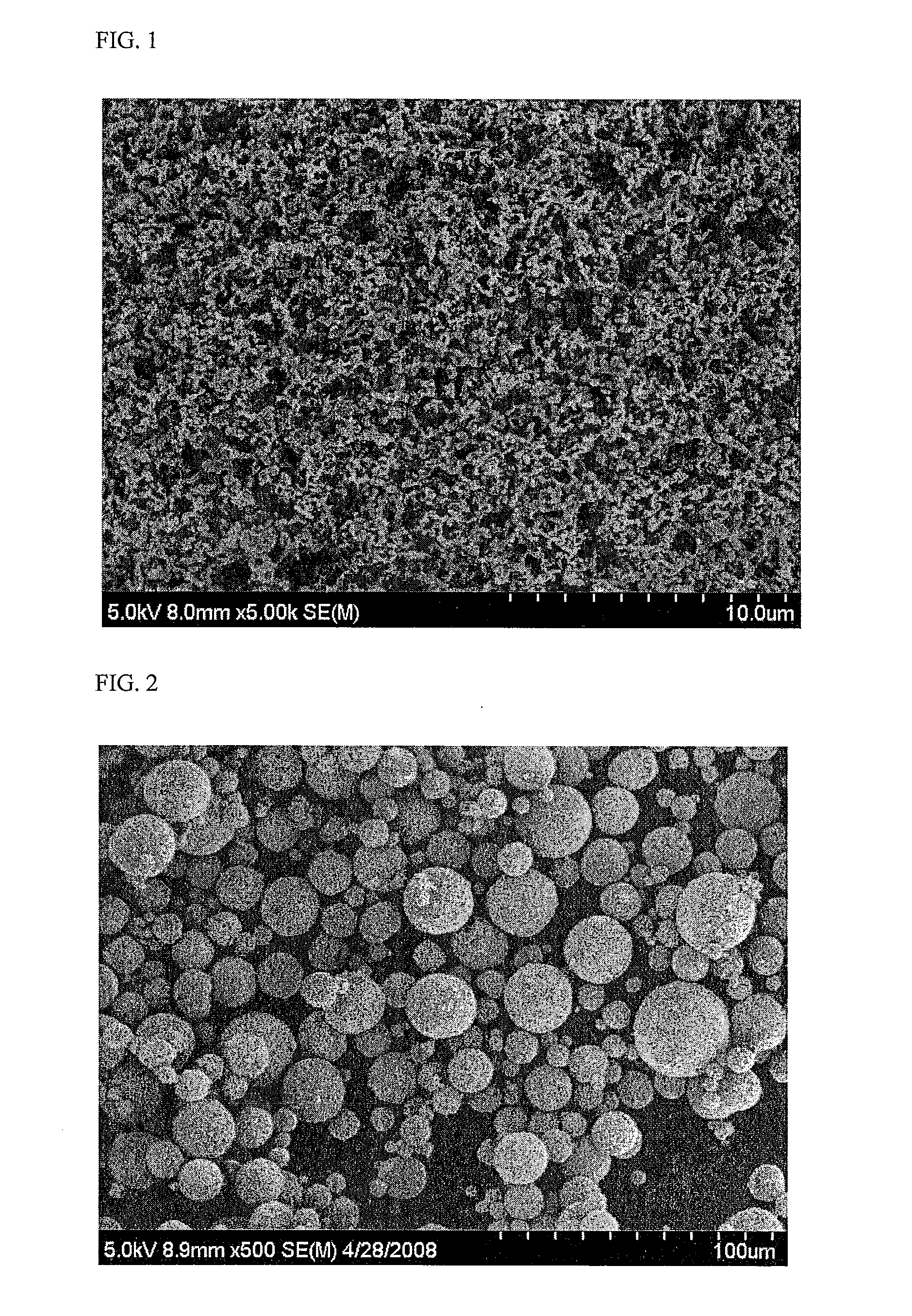

InactiveUS20060116279A1Improve photocatalytic activityImprove efficiencyPigmenting treatmentMaterial nanotechnologyFiberUltraviolet

A composite particle comprised of a larger particle and, supported thereon, smaller particles wherein the smaller particles are photocatalyst-containing fine particles with an average particle diameter of 0.005-0.5 μm as calculated from a BET specific surface area, and the larger particle has an average particle diameter of 2-200 μm as measured by the laser diffraction-scattering particle size measuring method. The smaller particle is preferably a composite particle of titanium dioxide with an inorganic compound exhibiting no catalytic activity, such as silica, or a particle containing a Brφonsted acid salt, especially on the surface thereof; and an advantageous method for producing the above composite particles wherein the above larger particles and smaller particles are dry mixed by a ball-mill or mixed by rotation of blades or by shaking, with an energy constant controlled within a specific range. A composition comprising an organic polymer and the above composite particles can give a shaped article, such as fiber, film or a molding, exhibiting ultraviolet ray-screening function.

Owner:SHOWA DENKO KK

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS20070119239A1Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

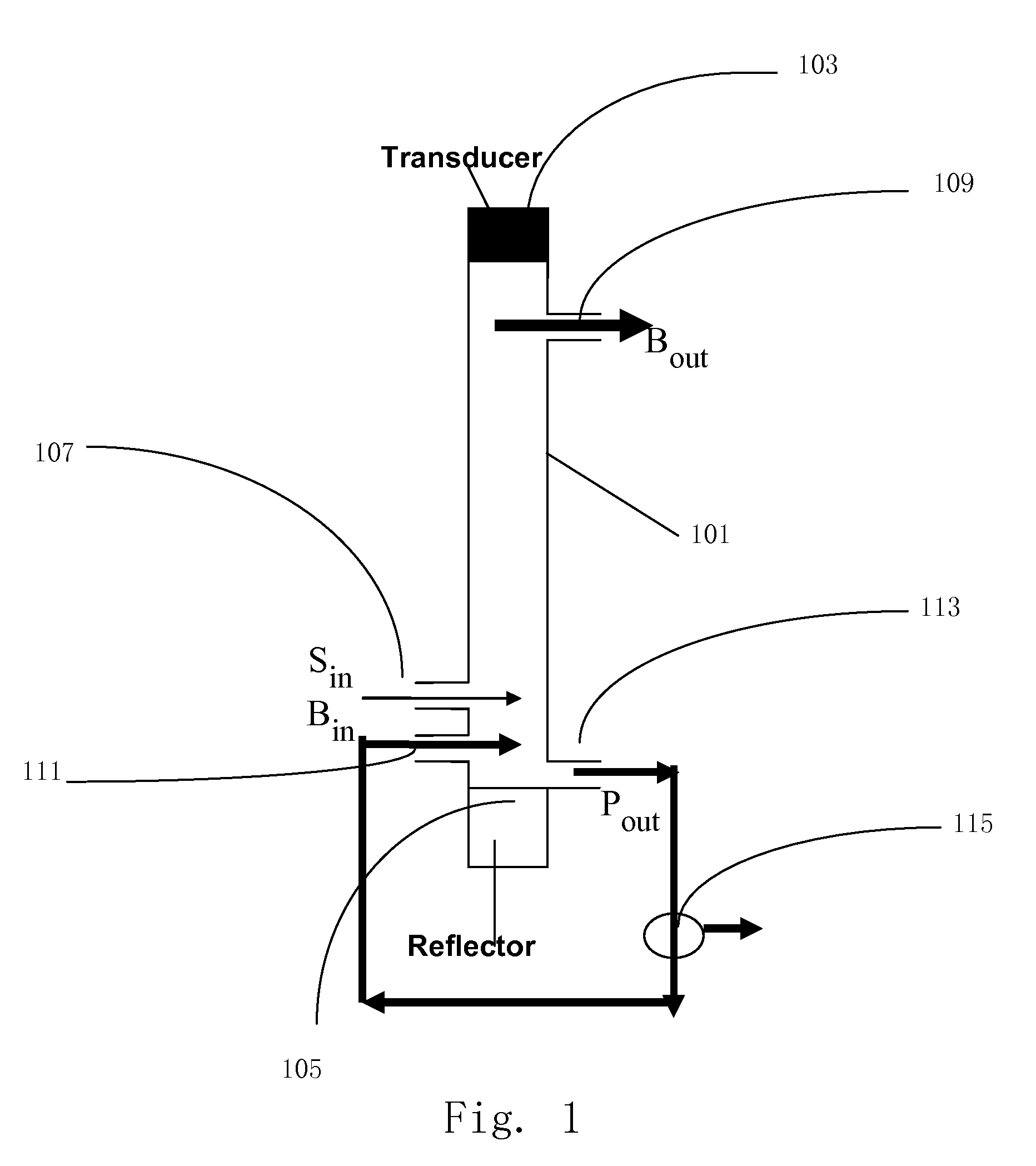

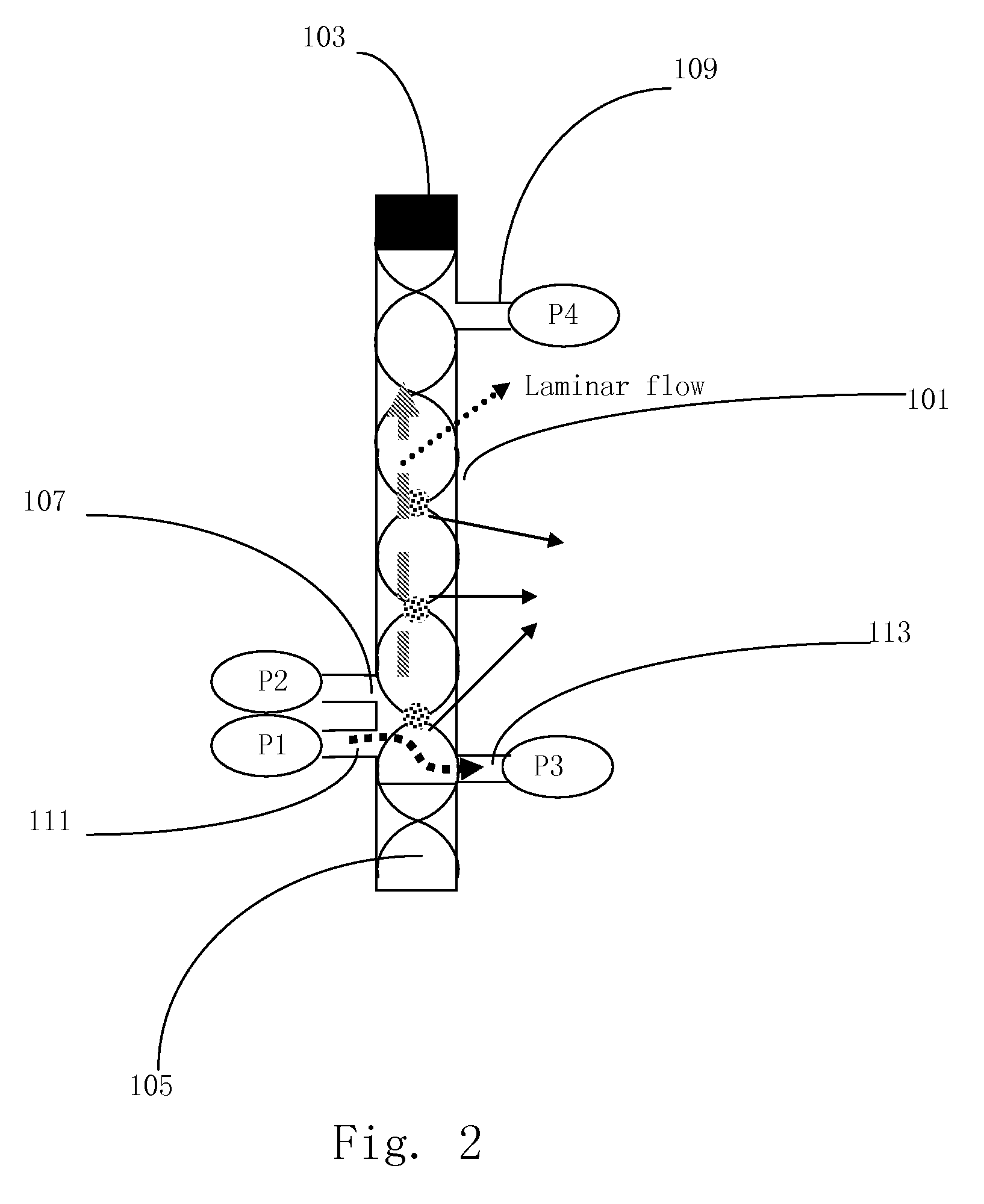

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

Boron carbide composite bodies, and methods for making same

InactiveUS6862970B2Less expensivelyLow production costDoor/window protective devicesLayered productsReaction bonded silicon carbideHigh stiffness

A composite body produced by a reactive infiltration process that possesses high mechanical strength, high hardness and high stiffness has applications in such diverse industries as precision equipment and ballistic armor. Specifically, the composite material features a boron carbide filler or reinforcement phase, and a silicon carbide matrix produced by the reactive infiltration of an infiltrant having a silicon component with a porous mass having a carbonaceous component. Potential deleterious reaction of the boron carbide with silicon during infiltration is suppressed by alloying or dissolving boron into the silicon prior to contact of the silicon infiltrant with the boron carbide. In a preferred embodiment of the invention related specifically to armor, good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers such as boron carbide, and by limiting the size of the largest particles making up the mass. The instant reaction-bonded silicon carbide (RBSC) composite bodies surpass previous RBSC's as armor materials, and in this capacity approach the ballistic performance of current carbide armor ceramics but with potentially lower cost manufacturing methods, e.g., infiltration techniques.

Owner:II VI DELAWARE INC +1

Fluorosilicone material for super-hydrophobic coating and its preparation method and use method

InactiveCN103224719ALower surface energyReduce usageCoatingsSpecial surfacesSilicon oxideSilicon dioxide

The invention relates to a fluorosilicone material for a super-hydrophobic coating and its preparation method and use method. The fluorosilicone material is prepared from fluorinated nano-silica and / or nano-titanium dioxide sol having two particle sizes. The fluorinated nano-silica or nano-titanium dioxide sol having the small particle size has the average particle size of 10 to 150nm. The fluorinated nano-silica or nano-titanium dioxide sol having the large particle size has the average particle size of 200 to 500nm. Through utilization of fluorine-containing siloxane in silica and / or titanium dioxide preparation, surface energy of the fluorosilicone material as a coating is effectively reduced. Through utilization of non-fluorinated dichlorodialkylsilane, coating surface hydrophily is partly reduced and a fluorine-containing silane use amount and a cost are reduced.

Owner:HUBEI UNIV

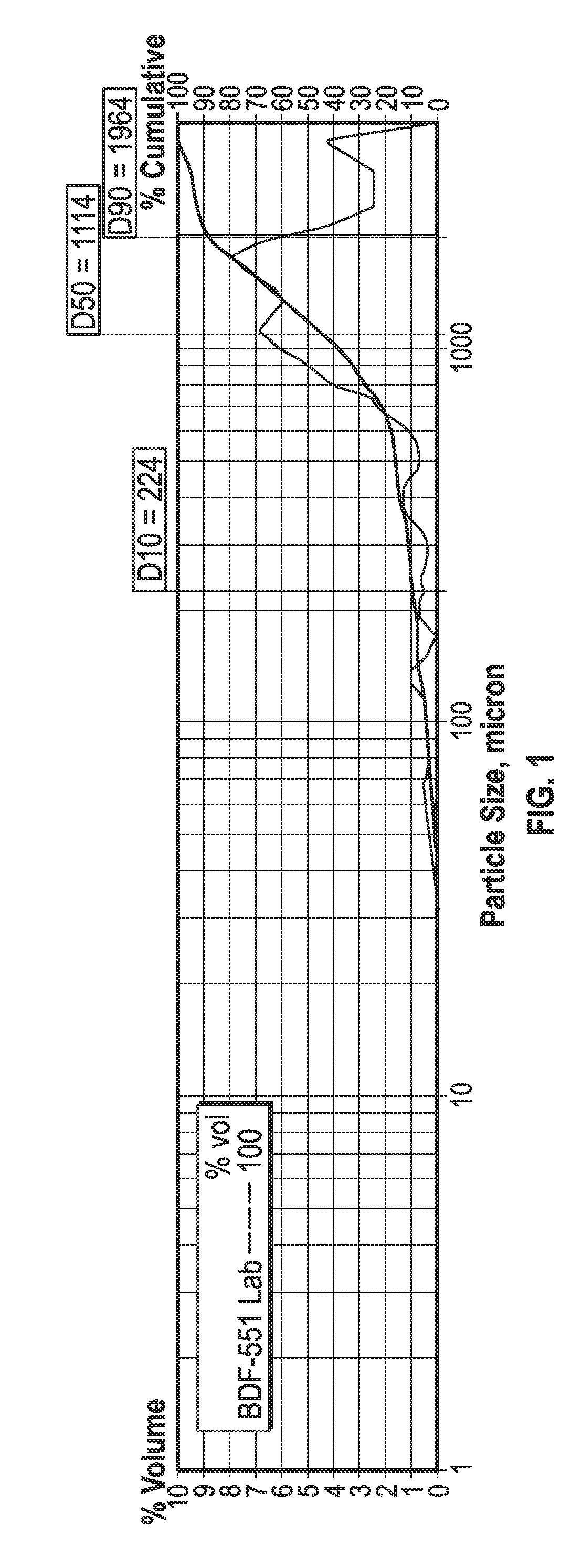

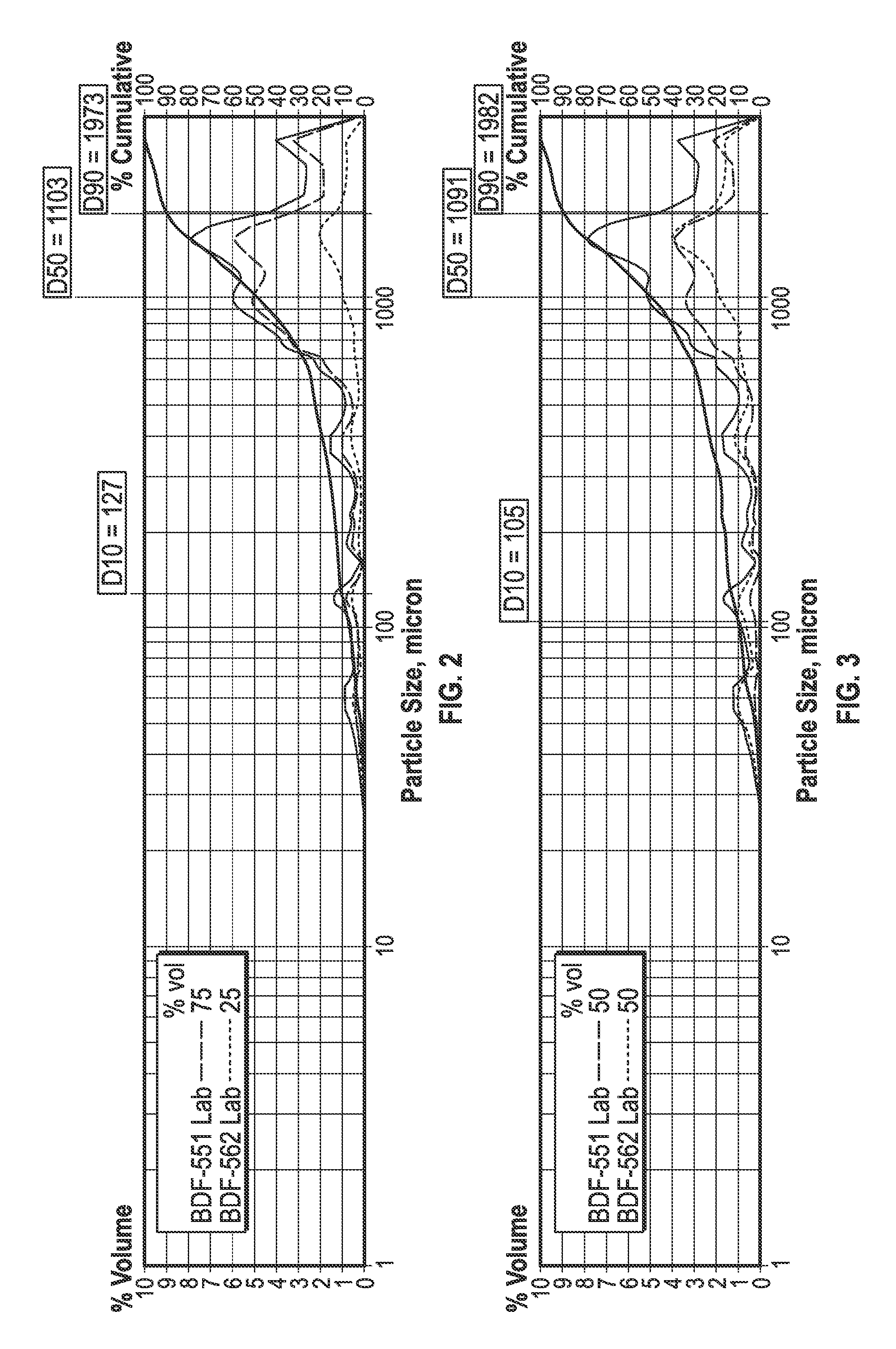

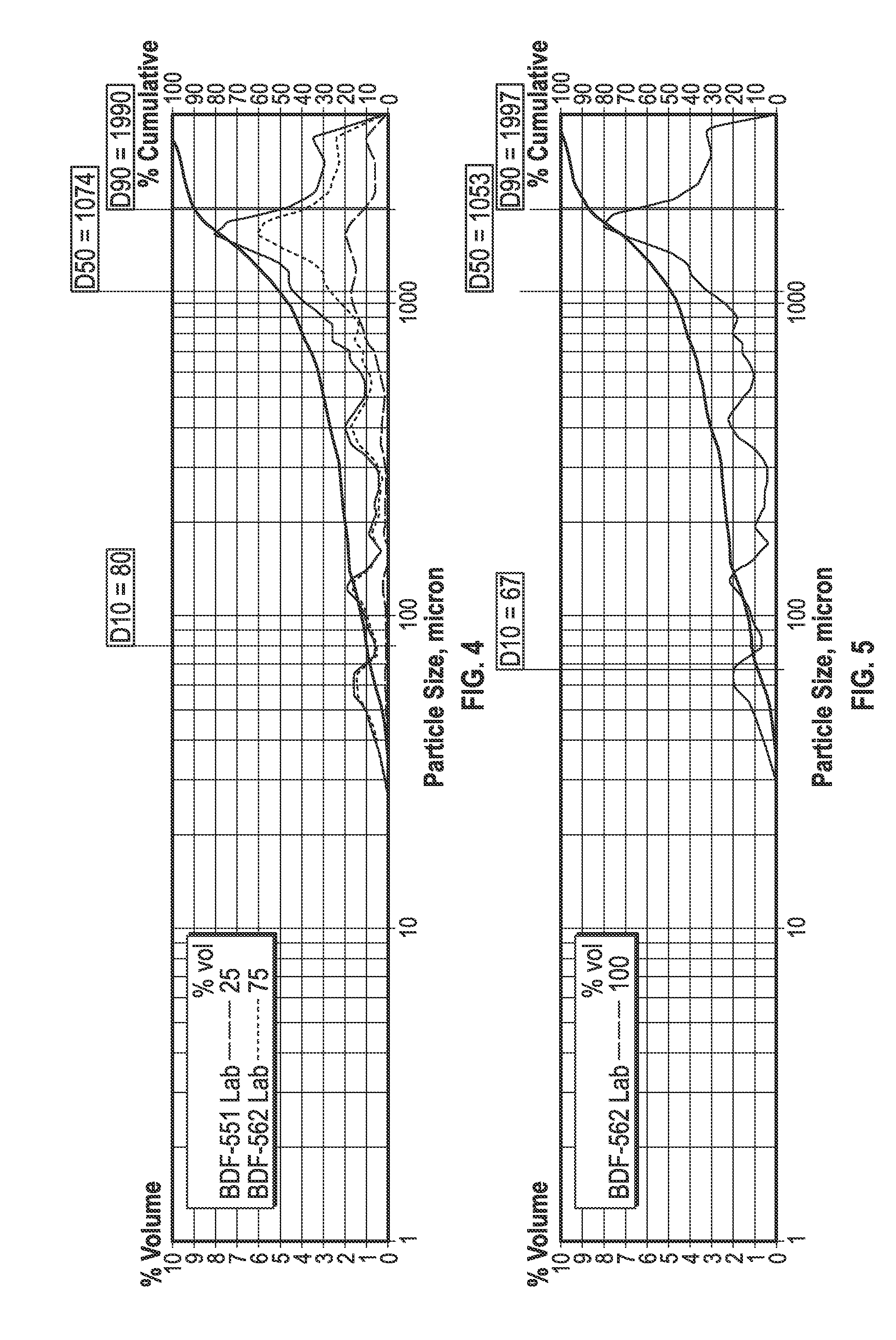

Lost Circulation Material With A Multi-Modal Large Particle Size Distribution

InactiveUS20140038857A1Increase concentrationWide rangeFlushingDrilling compositionHigh concentrationModal particle

Compositions for lost circulation materials (LCM) and methods for using same in drilling and / or completing wellbores that help solve lost circulation problems in a wide range of fracture sizes, thereby advantageously eliminating the need for a variety of products for lost circulation in a field at any one time. An unexpected synergy and improved reduction in lost circulation is obtained. The invention provides specific LCM components in specific ratios that are analogs to lost circulation fractures and that yield superior performance in preventing or alleviating lost circulation in drilling and cementing boreholes. The invention compositions have a multi-modal particle size distribution (PSD) which provides a higher concentration of component materials in the same range of two or more fracture widths, thus allowing plugging to occur over a wider range than a single mode or narrow PSD.

Owner:HALLIBURTON ENERGY SERVICES INC

Lithium iron phosphate having olivine structure and method for preparing the same

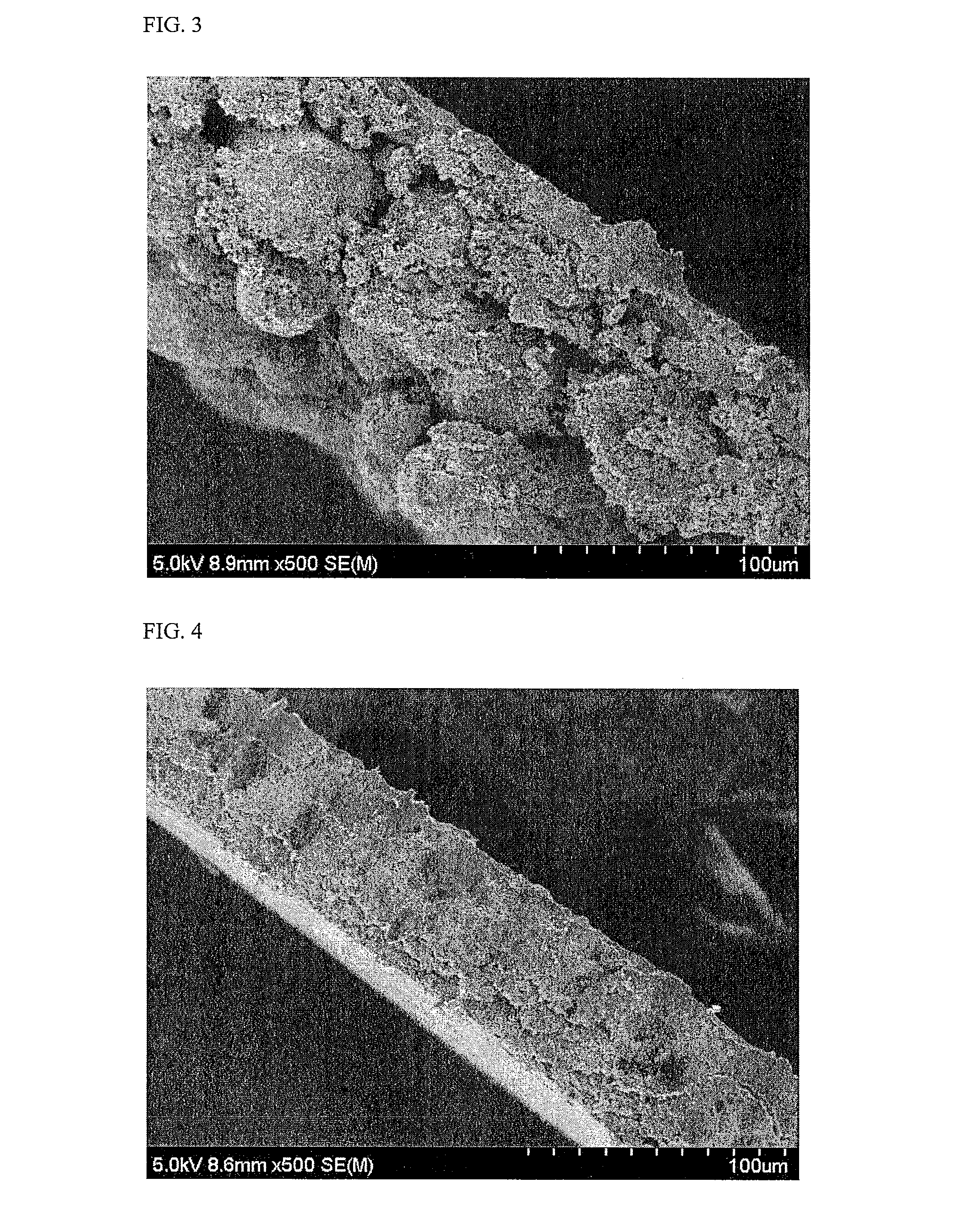

ActiveUS20100233540A1Improve conductivityStable crystal structureNon-aqueous electrolyte accumulator electrodesPhosphorus compoundsPorosityLithium iron phosphate

Provided is an olivine-type lithium iron phosphate composed of secondary particles having a mean particle diameter (D50) of 5 to 100 μm, formed by aggregation of primary particles having a mean particle diameter (D50) of 50 to 550 nm, wherein the primary and secondary particles have a composition represented by Formula I below and the secondary particles have a porosity of 15 to 40%: Li1+aFe1-xMx(PO4-b)Xb (I) wherein M, X, a, x and b are as defined above.The olivine-type lithium iron phosphate is in the form of secondary particles, thus imparting a high bulk density to lithium secondary batteries and exhibiting superior process efficiency due to shortened mixing time, when used to fabricate the lithium secondary batteries. Furthermore, the olivine-type lithium iron phosphate has the high porosity, thus allowing at least a portion of the secondary particles to be deformed and converted into primary particles in the process of pressing to fabricate electrodes and preventing deterioration in ionic conductivity due to the large particle diameter.

Owner:LG ENERGY SOLUTION LTD

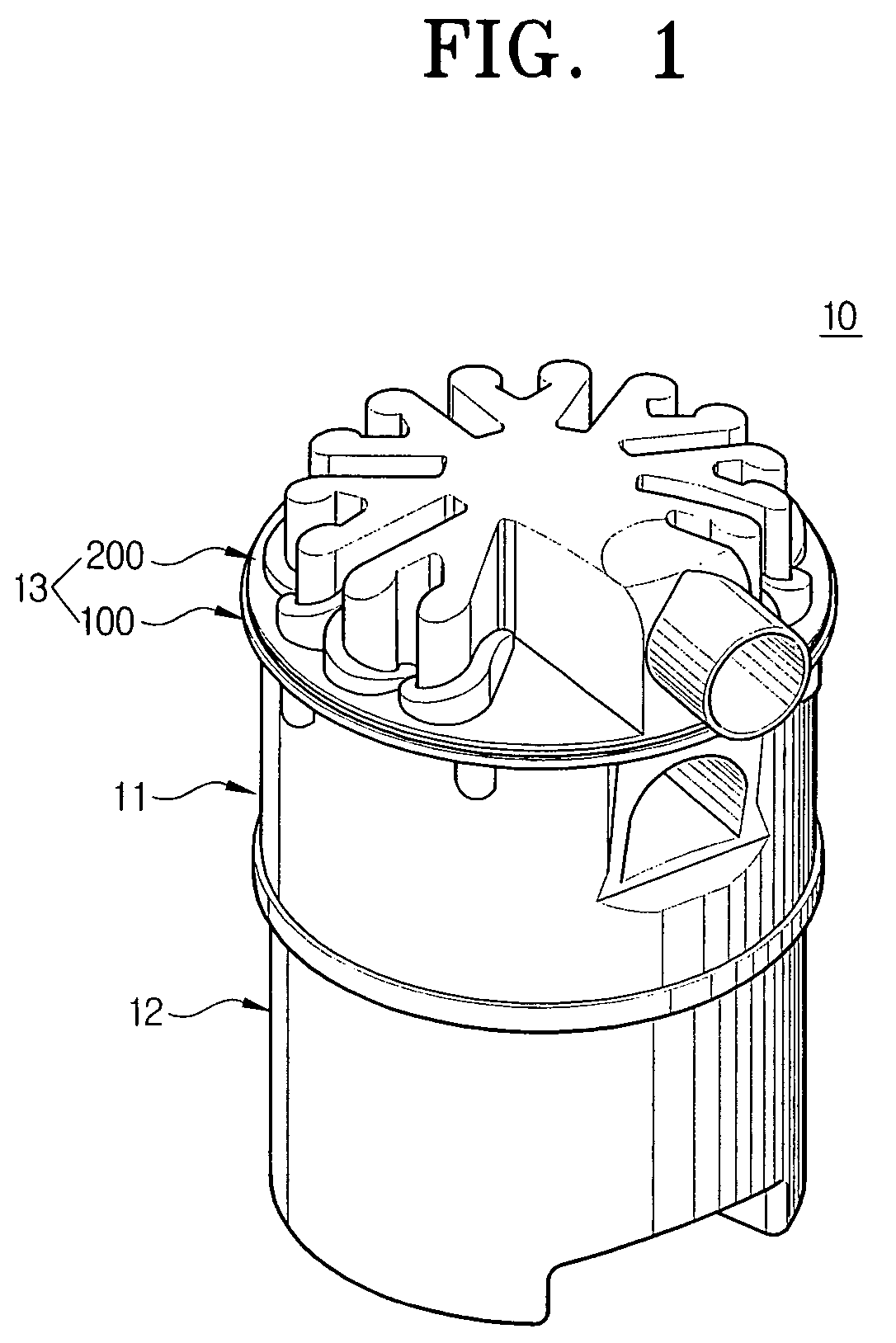

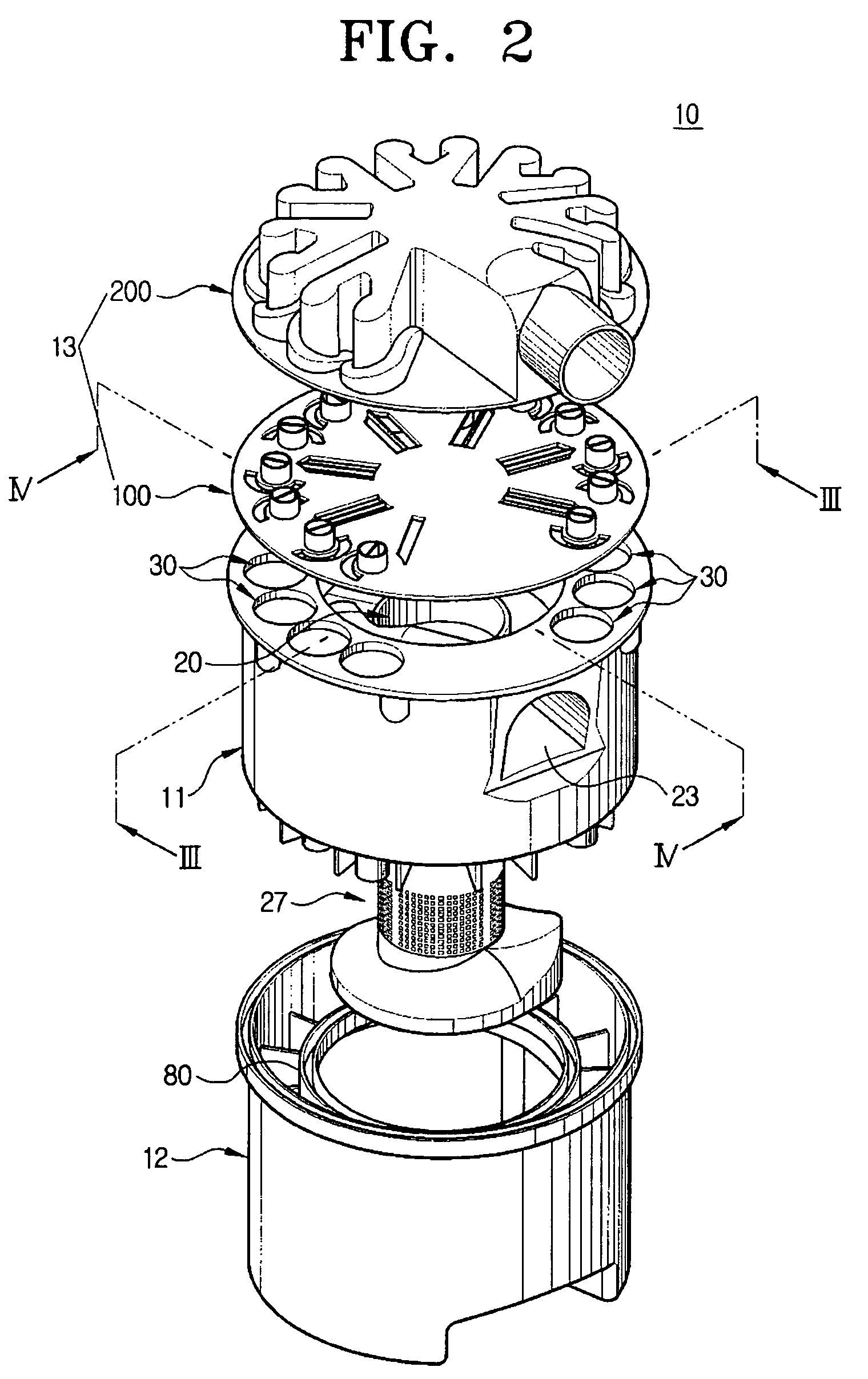

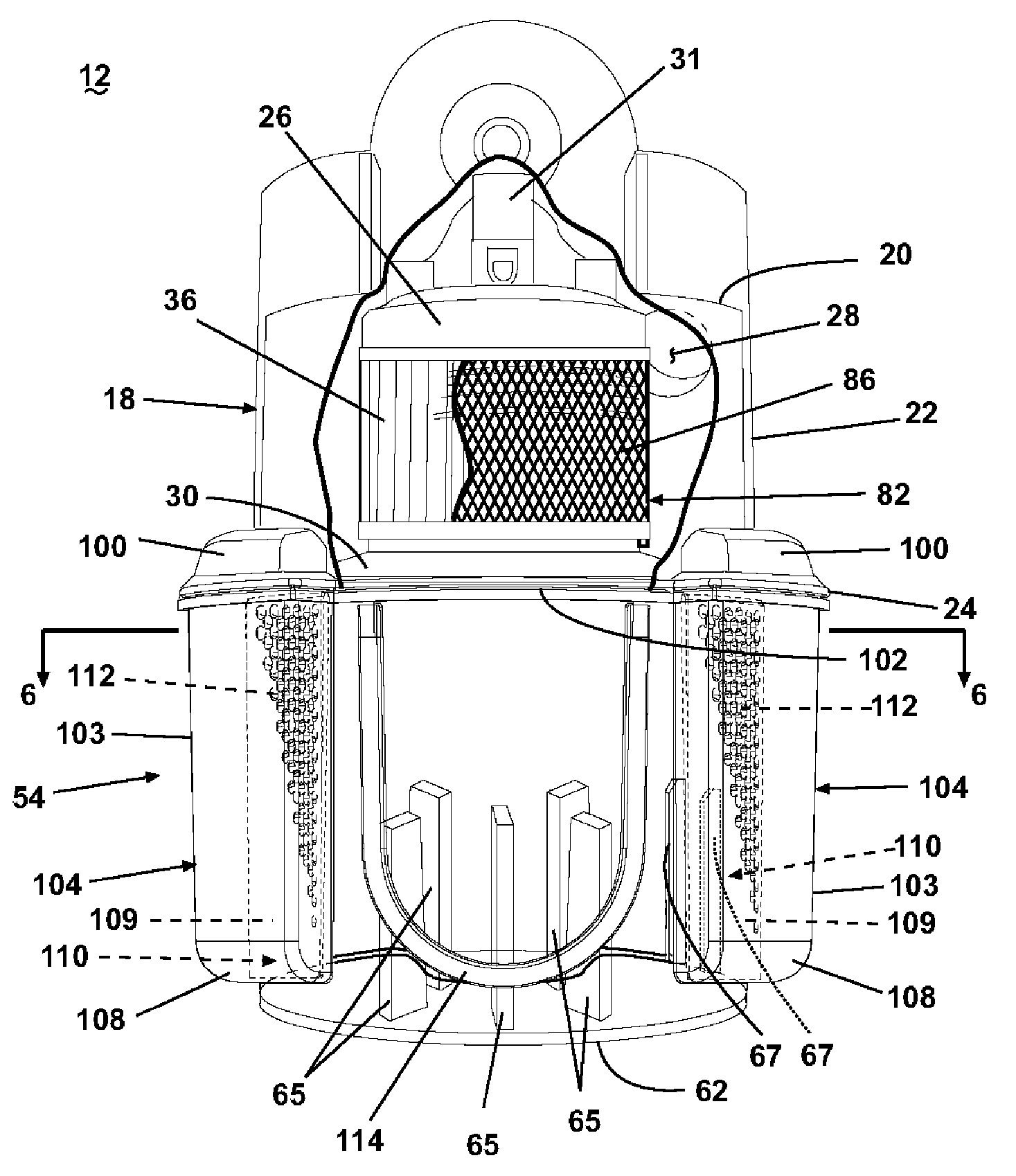

Multi cyclone dust-collecting apparatus

InactiveUS7335242B2Reduce in quantityImprove manufacturabilitySuction filtersReversed direction vortexCycloneEngineering

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

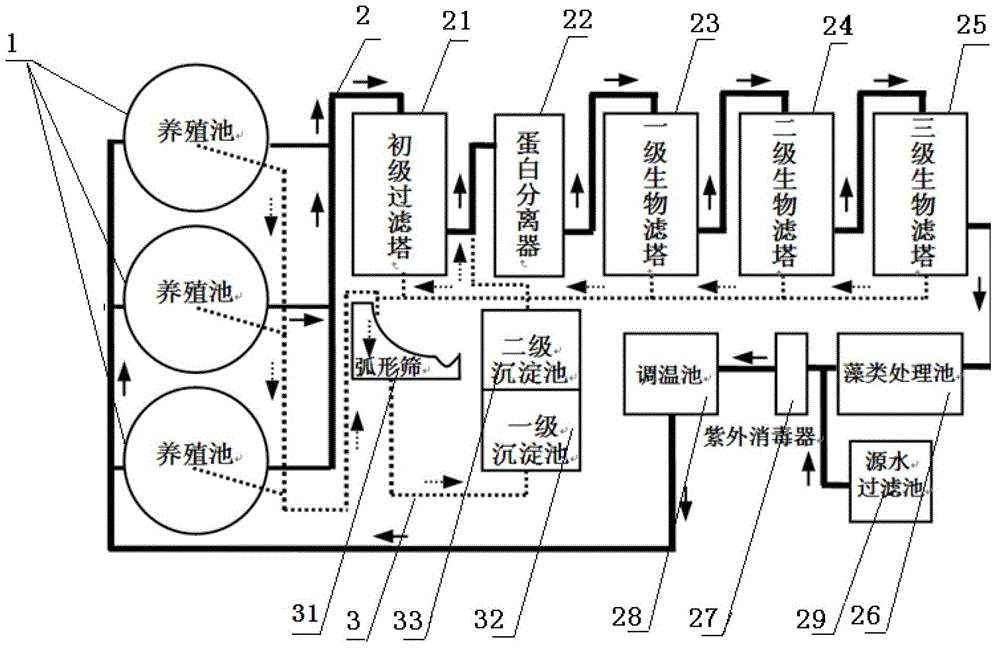

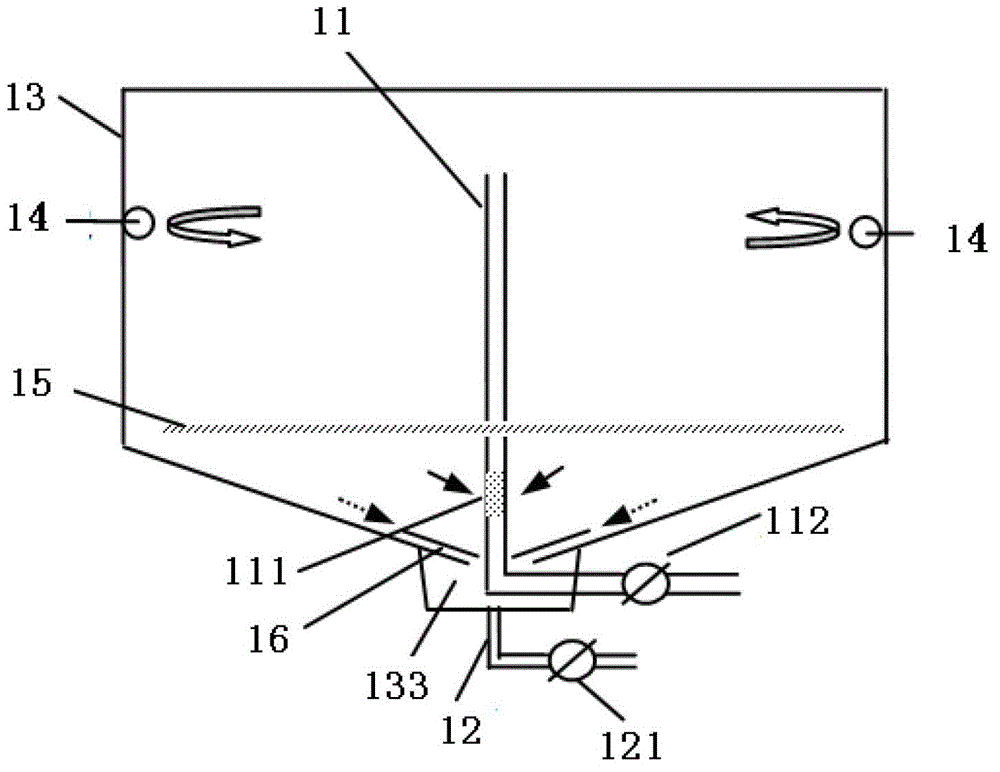

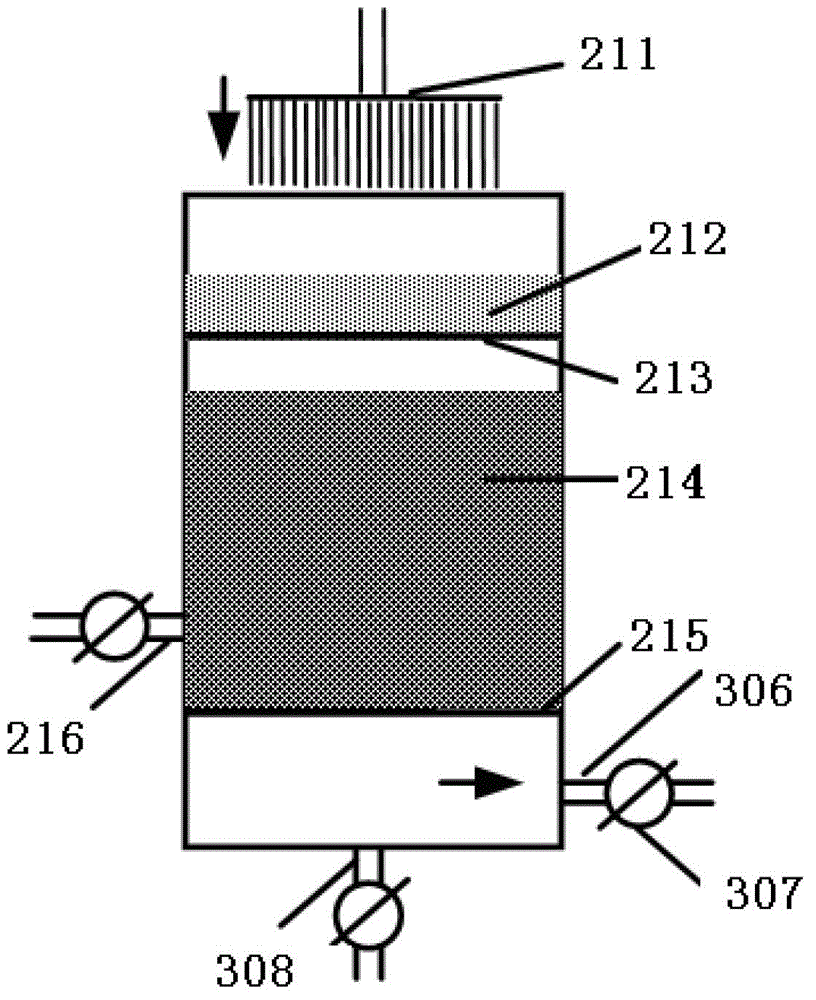

Ecological seawater rare fish factorization circulating water aquaculture system

InactiveCN102742536AReduce flow rateEfficient retentionPisciculture and aquariaResource utilizationBiological filter

The invention discloses an ecological seawater rare fish factorization circulating water aquaculture system which comprises an aquaculture pond, a primary filter tower, an albumen segregator, a primary biological filter tower, a secondary biological filter tower, a tertiary biological filter tower, an algae treating pond, a source water filter pond, a UV (Ultraviolet) sterilizer, a temperature adjusting pond, an arc-shaped sieve, a primary sedimentation pond and a secondary sedimentation pond. A bidirectional drainage system is adopted by the aquaculture pond, the water containing less smaller particles at the lower part of the pond and the water containing more larger particles at the bottom of the pond are respectively drained and then input into different processing units for recycle. Molluscs, sea cucumbers and algae are drawn into aquaculture waste, wastewater disposal and resource utilization by the circulating water aquaculture system, so that the circulating water aquaculture system has an obvious ecological characteristic. The ecological seawater rare fish factorization circulating water aquaculture system has the advantages of high treatment efficiency of aquaculture wastewater and rubbish, simpler equipment, low energy consumption, high backwash efficiency, resource utilization of aquaculture wastewater and rubbish, less circulation supplement water, high treatment efficiency of inorganic nutrient salt in the water and high economic additional value.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Non-sticking lining with wearing resistance and anti-corrosive property and coating method thereof

The invention discloses a non-stick coating with wear resistance and corrosion resistance and a coating method thereof. The coating comprises an anti-corrosive bottom layer, a wear-resistant intermediate layer and a non-stick finish coat, wherein the bottom layer contains a fluoropolymer, 1 to 15 weight percent of at least one heat-resistant polymer adhesive, and 1 to 15 weight percent of pigment and filler; the intermediate layer is coated on the bottom layer, and contains the fluoropolymer and inorganic filler particles; and the finish coat is coated on the intermediate layer and contains the fluoropolymer with non-stick effect. A priming coat has good anti-corrosion performance due to small content and small fineness of the pigment and the filler, an intermediate coating has good wear-resistant property due to the fact that partial large particles in an organic filler are embedded into the bottom layer and are convex into the finish coat, and the finish coat has good non-stick performance.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

Lithium-containing composite oxide and its production method

ActiveUS20090148772A1Large volume capacity densityImprove securityCell electrodesLithium compoundsAlkaline earth metalDischarge rate

The present invention provides a lithium-containing composite oxide for a positive electrode for a lithium secondary battery, which has a large volume capacity density and high safety, and excellent durability for charge and discharge cycles and charge and discharge rate property, and its production method.The lithium-containing composite oxide is represented by the general formula LipNxMyOzFa (where N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, Sn, alkaline earth metal elements and transition metal elements other than Co, Mn and Ni, 0.9≦p≦1.2, 0.965≦x<2.00, 0<y≦0.035, 1.9≦z≦4.2, and 0≦a≦0.05), wherein when a powder of the lithium-containing composite oxide is classified into small particles with an average particle size of 2 μm≦Ds50≦8 μm and large particles with an average particle size of 10 μm≦Dl50≦25 μm, a content of the small particles is from 15 to 40% by weight and a content of the large particles is from 60 to 85% by weight, and 0.01≦ys≦0.06, 0≦yl≦0.02 and 0≦yl / ys<1, where (ys) is a ratio of the M element in the above general formula in the small particles and (yl) is a ratio of the M element in the general formula in the Large particles.

Owner:SUMITOMO CHEM CO LTD

Imaging platform for nanoparticle detection applied to SPR biomolecular interaction analysis

InactiveUS7221457B2Spectrum investigationScattering properties measurementsAnalyte moleculeLarge particle

Owner:CYTEK BIOSCI

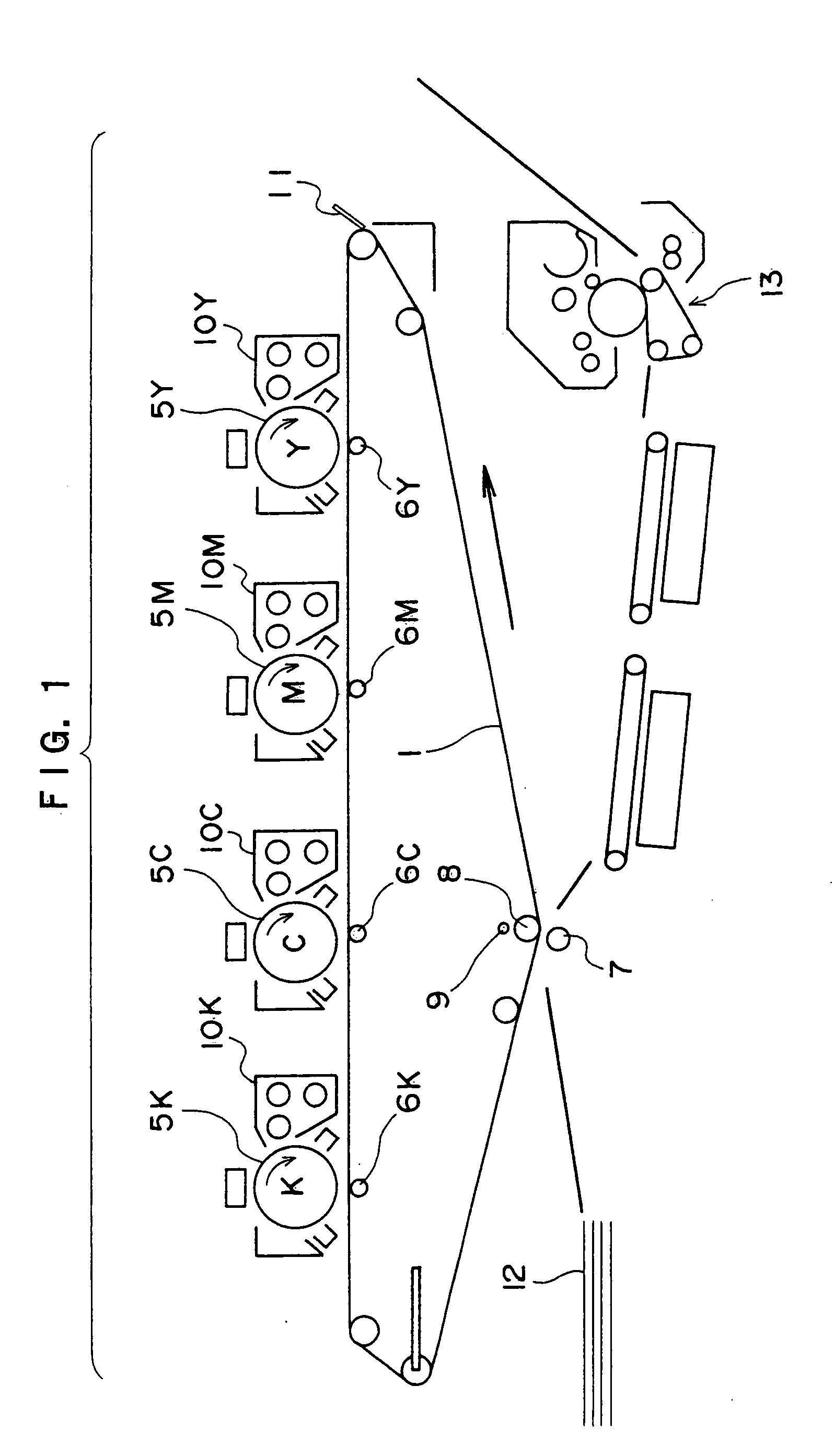

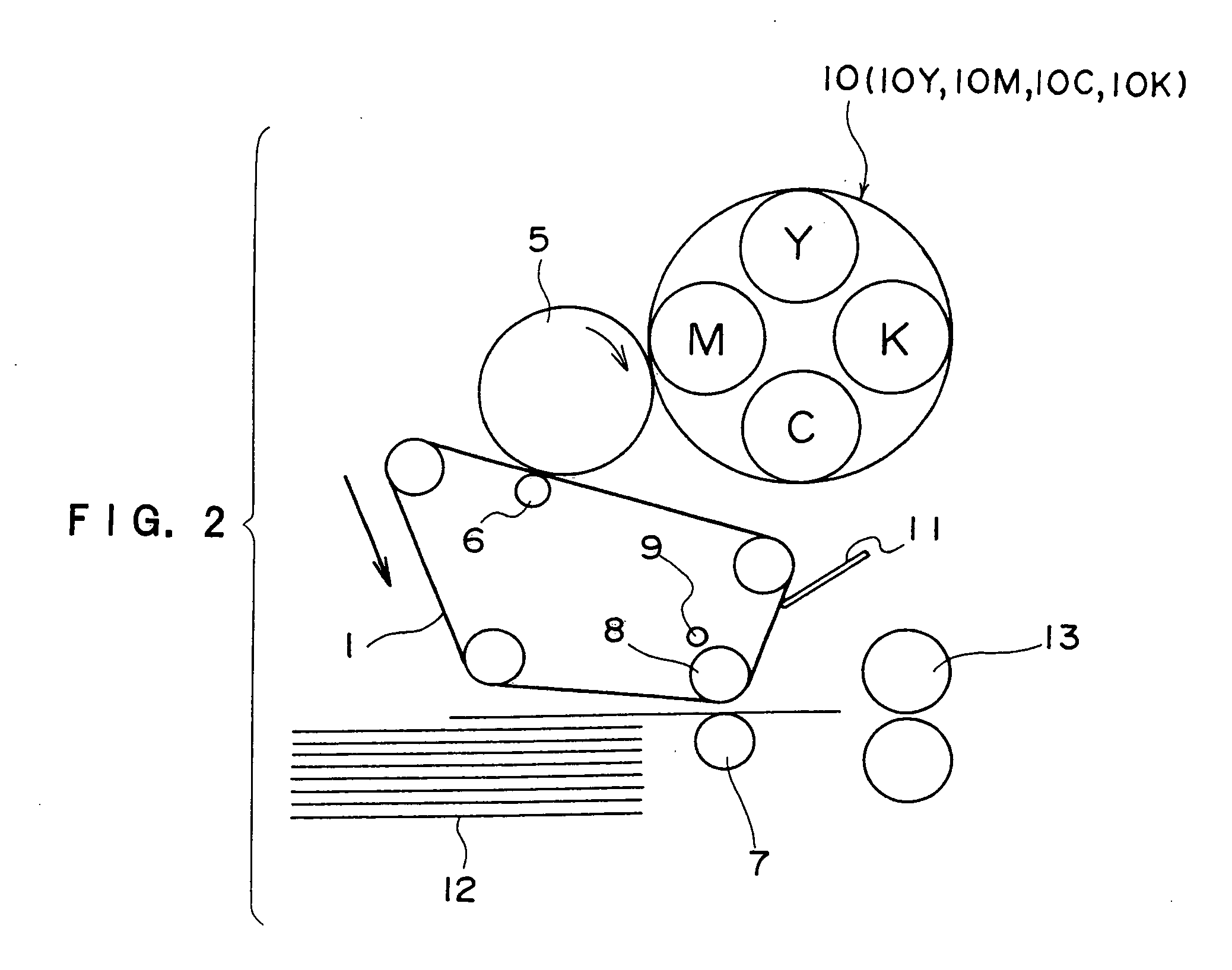

Intermediate transfer belt, production method thereof, and image-forming device using the intermediate transfer belt

InactiveUS20070025740A1Reducing number of raised spot and irregularityHigh definitionElectrographic process apparatusImage formationPolyaniline

The present invention provides an intermediate transfer belt comprising a polyimide resin comprising polyaniline, wherein the absolute maximum length of the largest particle of the polyaniline is approximately 10.0 μm or less, a preparation thereof, and an image-forming device comprising the intermediate transfer belt.

Owner:FUJIFILM BUSINESS INNOVATION CORP

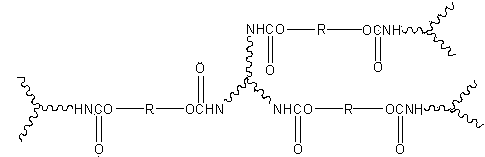

Preparation method of matting leather water-based polyurethane coating agent

ActiveCN103740250AGood light stabilityGood compatibilityFibre treatmentPolyurea/polyurethane coatingsWater basedCross-link

The invention provides a preparation method of a matting leather water-based polyurethane coating agent. According to the preparation method, a polyurethane A component with a cross-linked structure and a large particle size is synthesized, and is mixed with a B component with a small particle size. The A component possesses many molecular branched chains, size of micellar particles is relatively large, and specific gravity of the A component is less than that of the component B; so that the A component will float on film surface, roughness of the film surface is relatively high, delustering effect is achieved, no delustering agent is needed, excellent transparency is obtained after coating, and no influence on leather substances is caused as the delustering effect is achieved.

Owner:SICHUAN DOWELL SCI & TECH INC

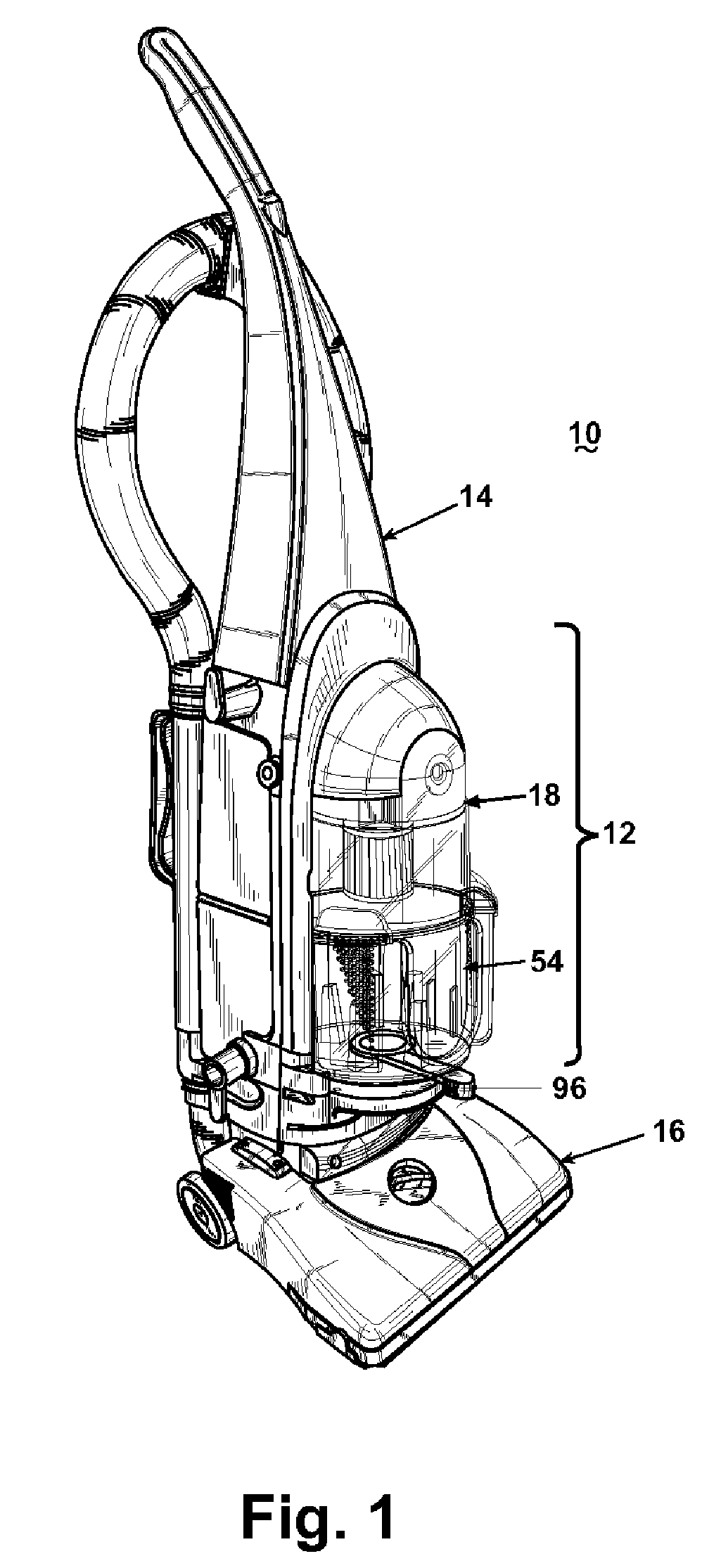

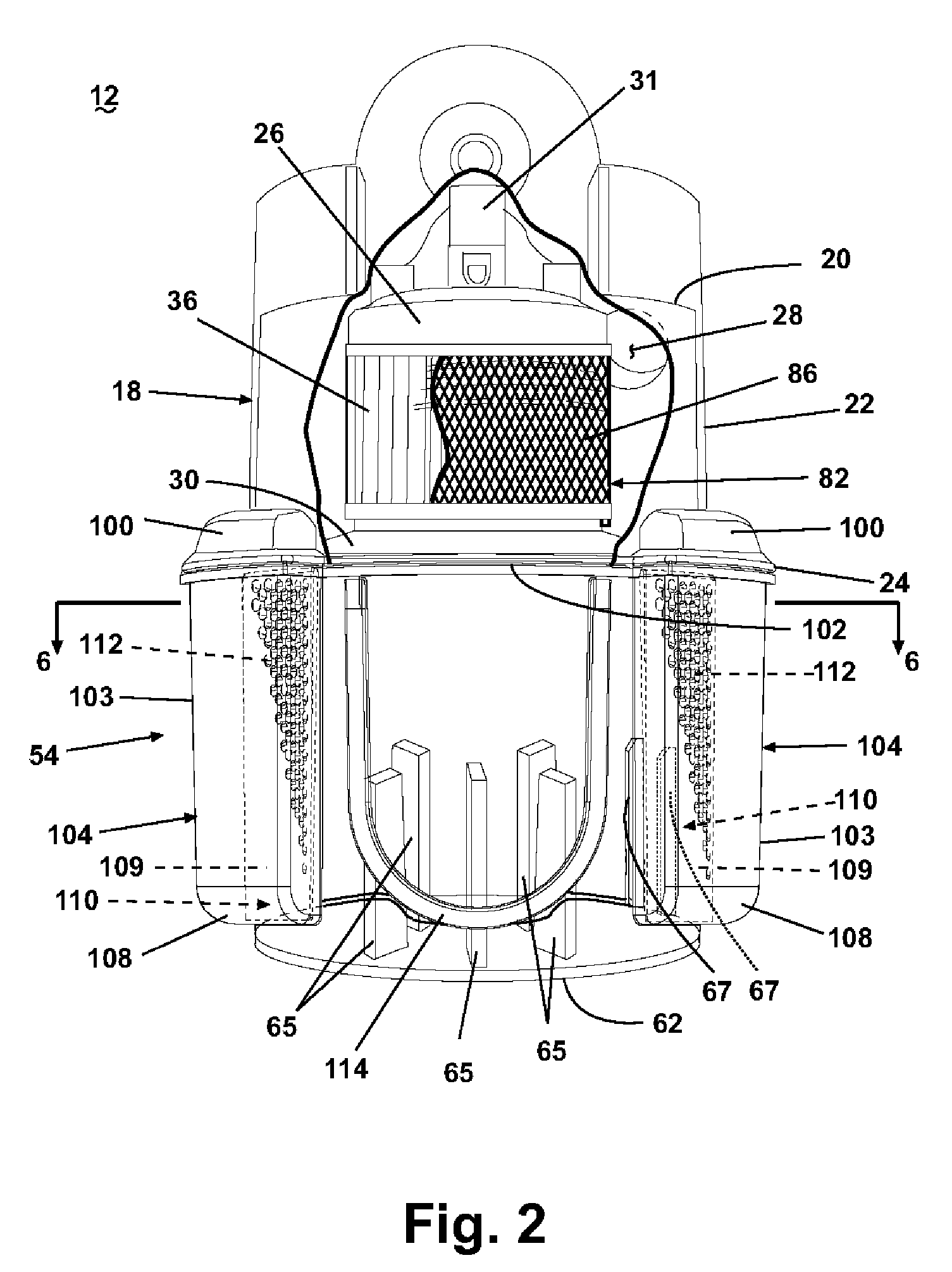

Cyclone separator with fine particle separation member

A cyclone separator assembly comprises a cyclone separator that removes large particles of dirt from a working airstream as it flows through the cyclone separator, and the separated large particles of dirt are deposited into a dirt cup. The cyclone separator assembly further includes a fine particle separation member comprising a plurality of apertures for separating fine particles of dirt from air in the cyclone separator or the dirt cup.

Owner:BISSELL INC

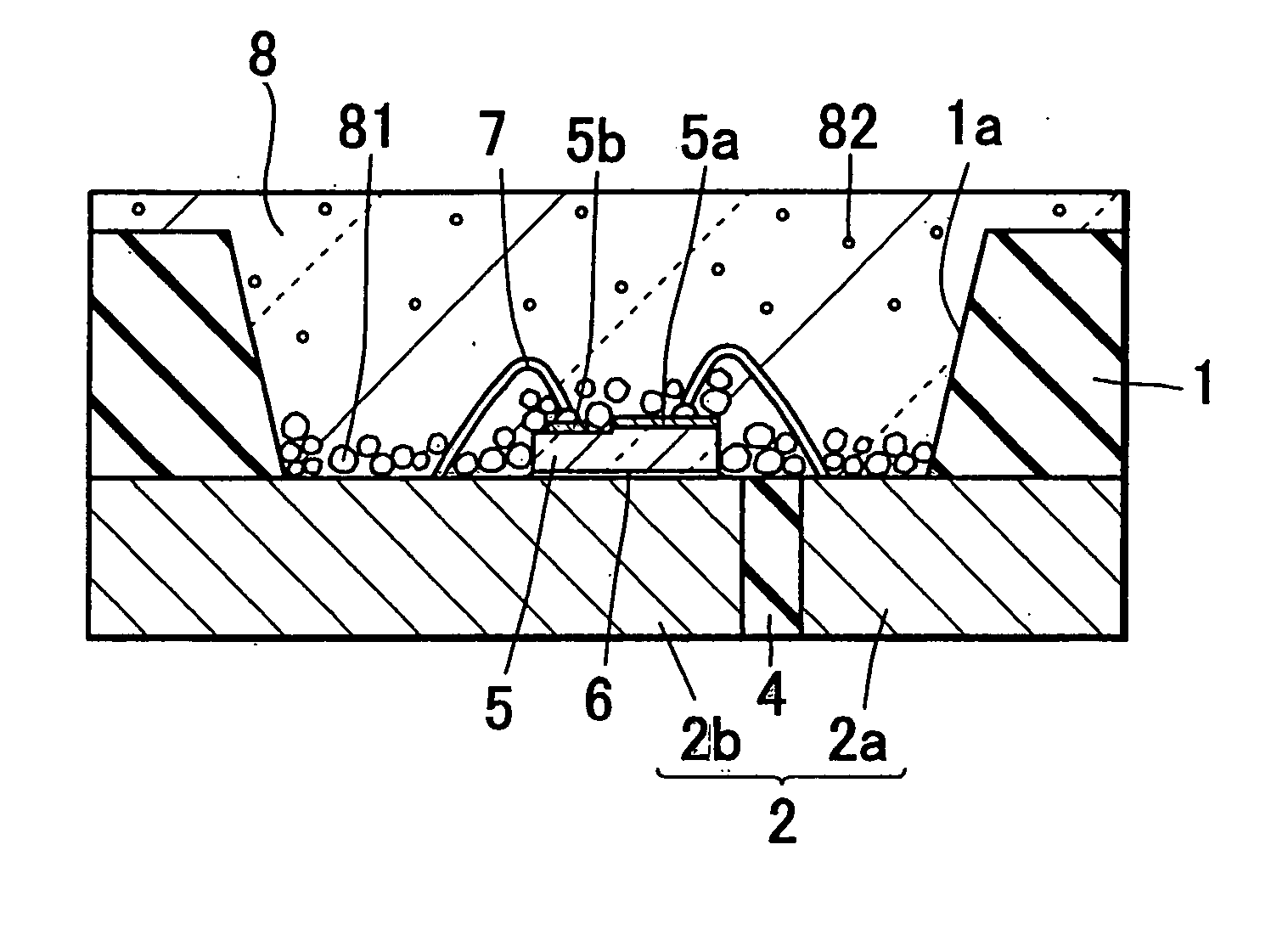

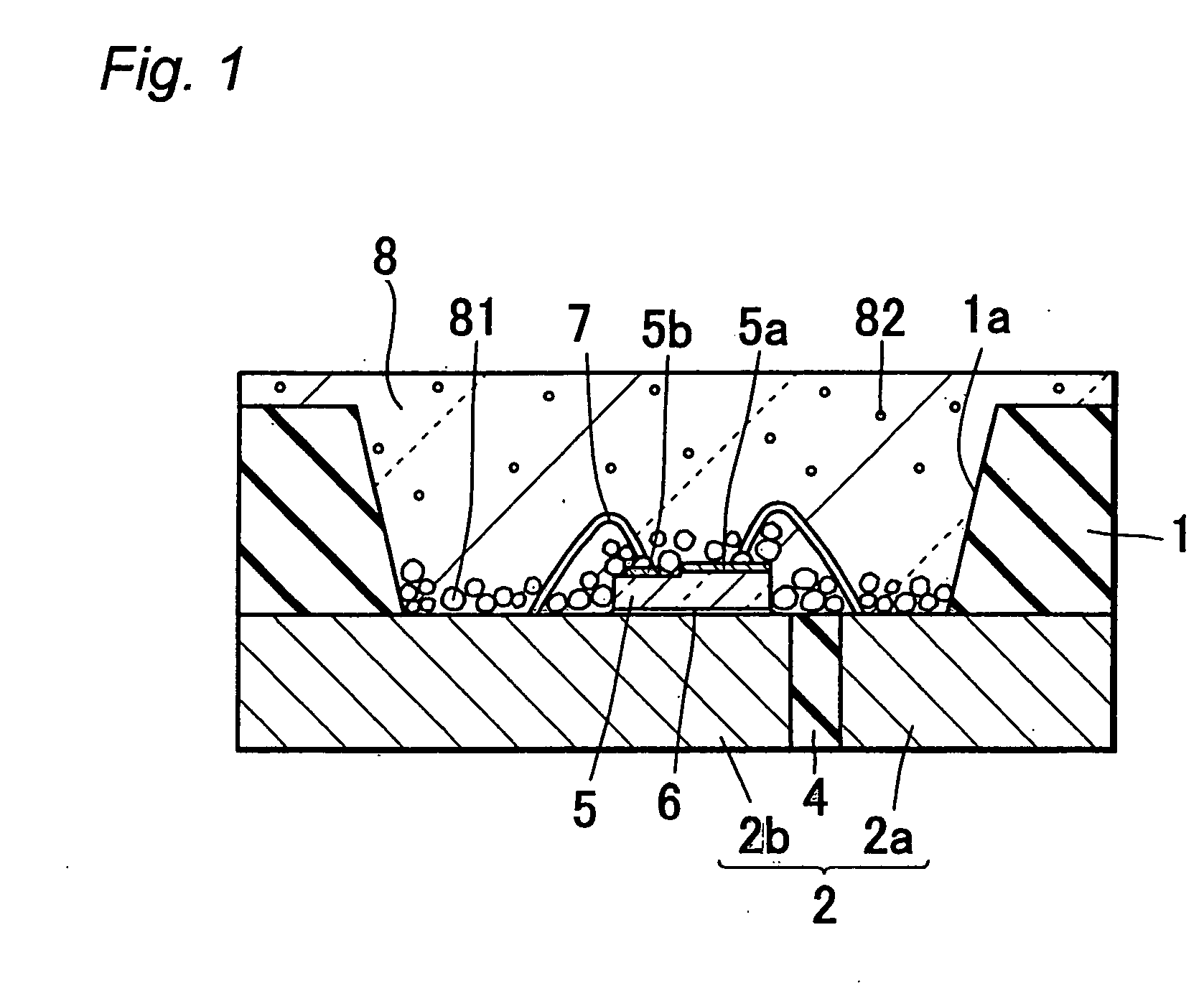

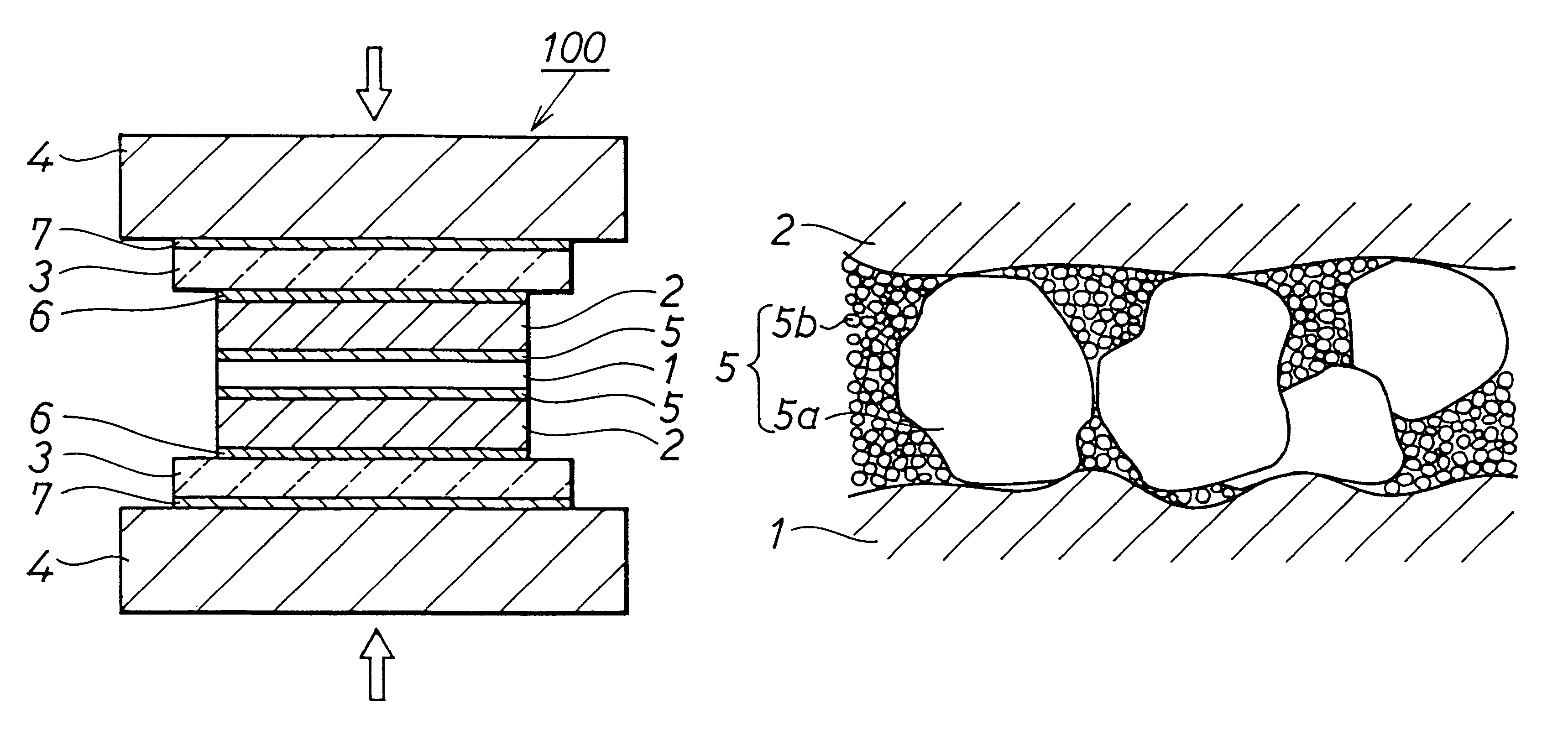

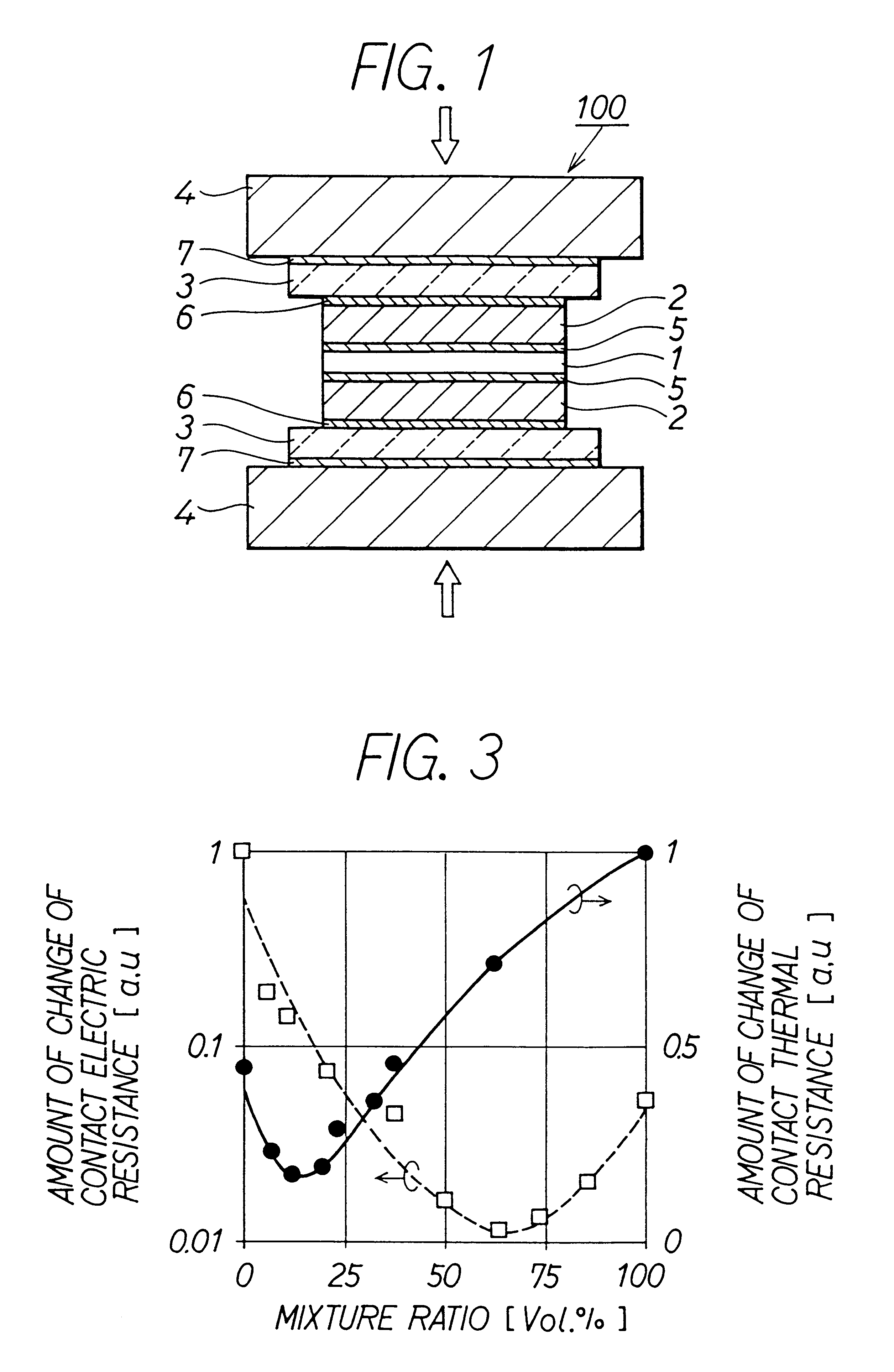

Electric apparatus having a contact intermediary member and method for manufacturing the same

InactiveUS6380622B1Reduce resistanceLower resistanceLayered productsSemiconductor/solid-state device detailsElectrical resistance and conductanceDevice material

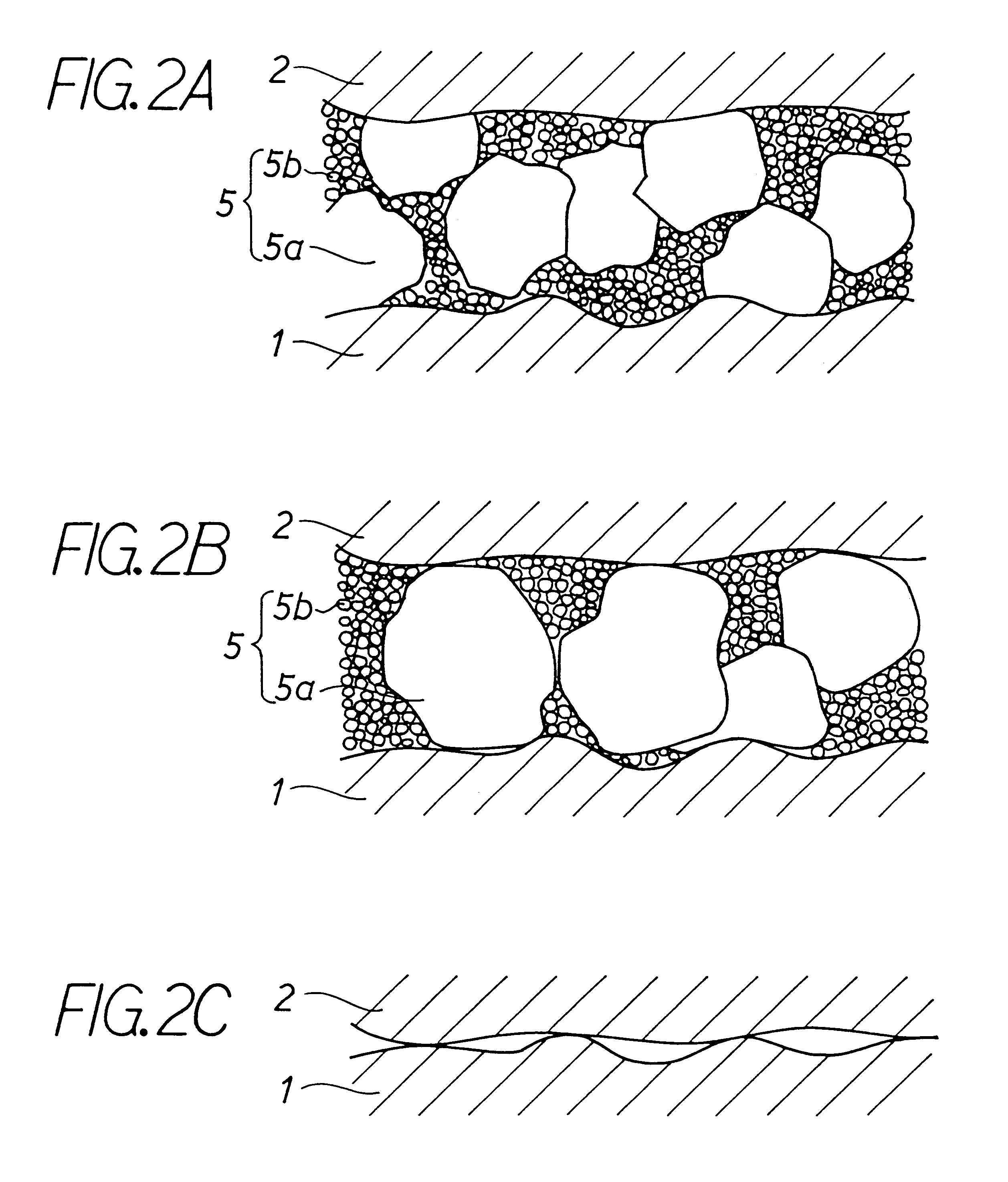

A pressed-contact type semiconductor device in which a main electrode surface of a semiconductor element is contacted with an electrode plate by a pressed-contact, which can reduce both an electric resistance and a thermal resistance between the main electrode surface of the semiconductor element and the electrode plate. The pressed-contact type semiconductor device (100) is provided with a semiconductor element (1) having electrode surfaces, a pair of electrode plates (2) contacted with the electrode surfaces by the pressed-contact, a pair of insulating plates (3) contacted with the outer side of the pair of the electrode plates by the pressed-contact, and a pair of radiating plates (4) contacted with the outer side of the pair of the insulating plates by the pressed-contact. A contact intermediary member (5), which is made up of particle member having at least thermal conductivity and electric conductivity, is intercalated between the semiconductor element and the electrode plate. The particle member of the contact intermediary member includes large particles 5a having an average particle diameter of more than 2 mum, and small particles 5b having an average particle diameter of to or less than 2 mum. Contact intermediary members (6, 7) are intercalated into gaps generated between the electrode plate and the insulating plate, and between the insulating plate and the radiating plate so as to fill up these gaps. The contact intemediary members are made of powder material having at least thermal conductivity.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com