Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

895results about "Lithium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

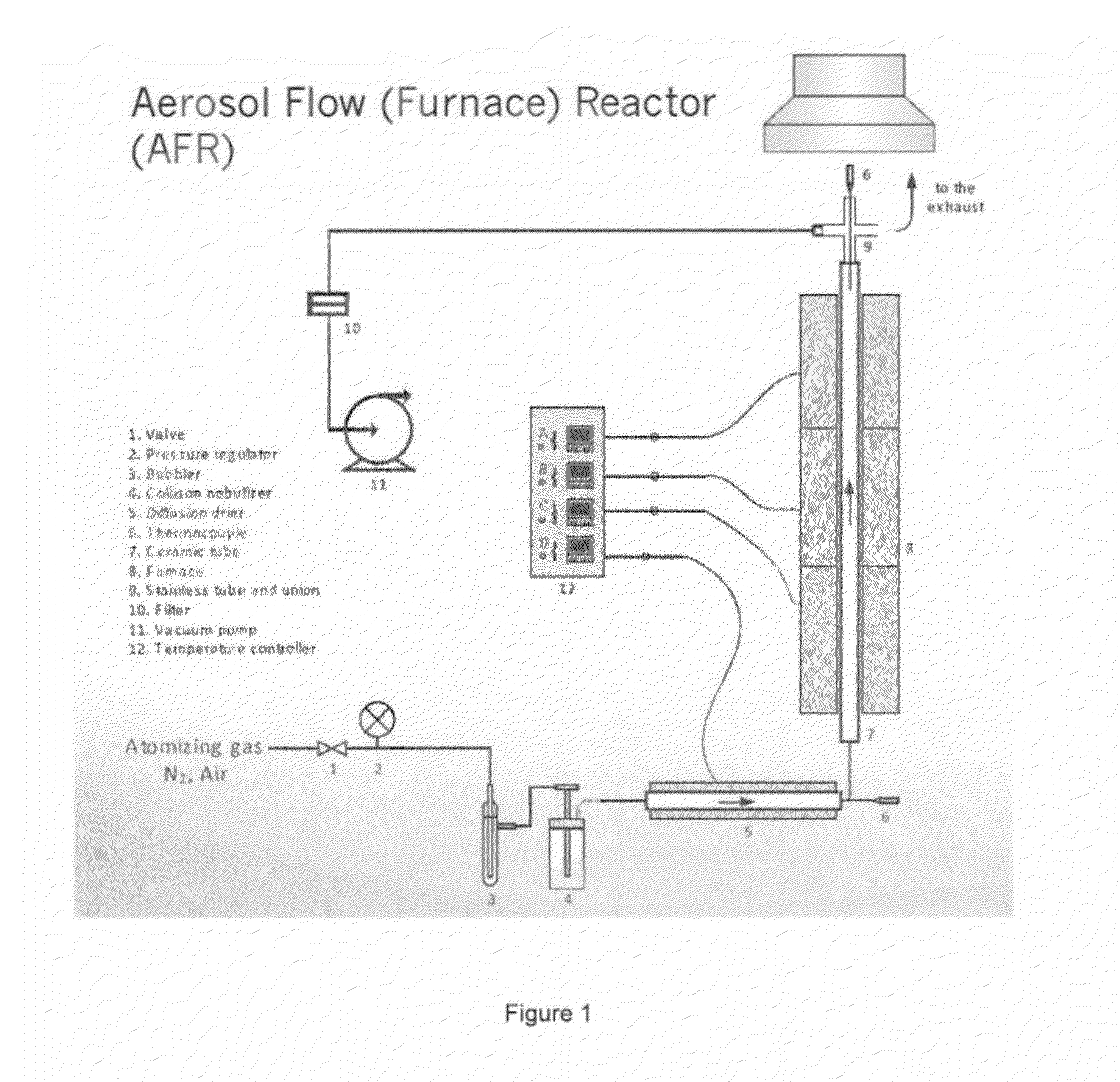

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

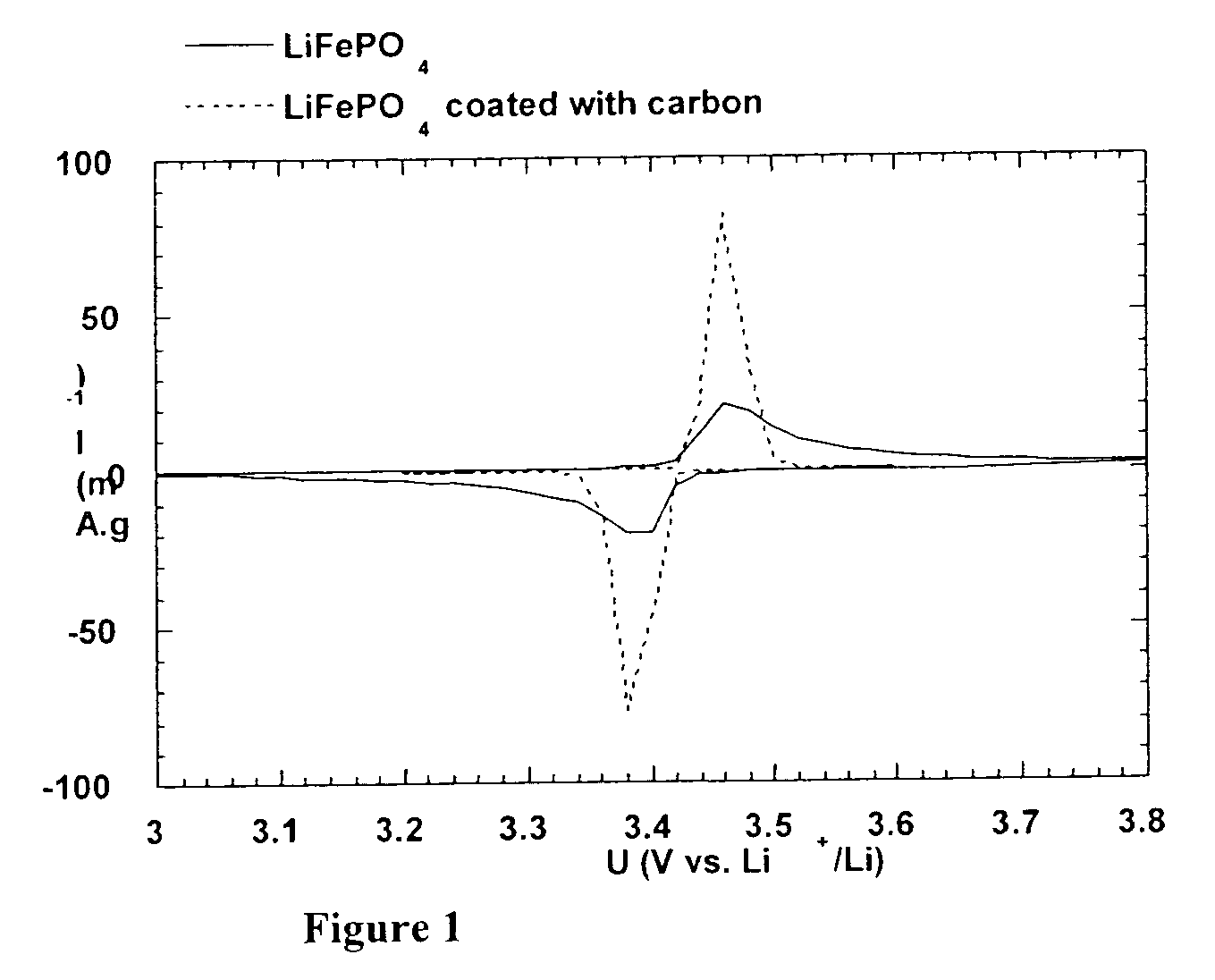

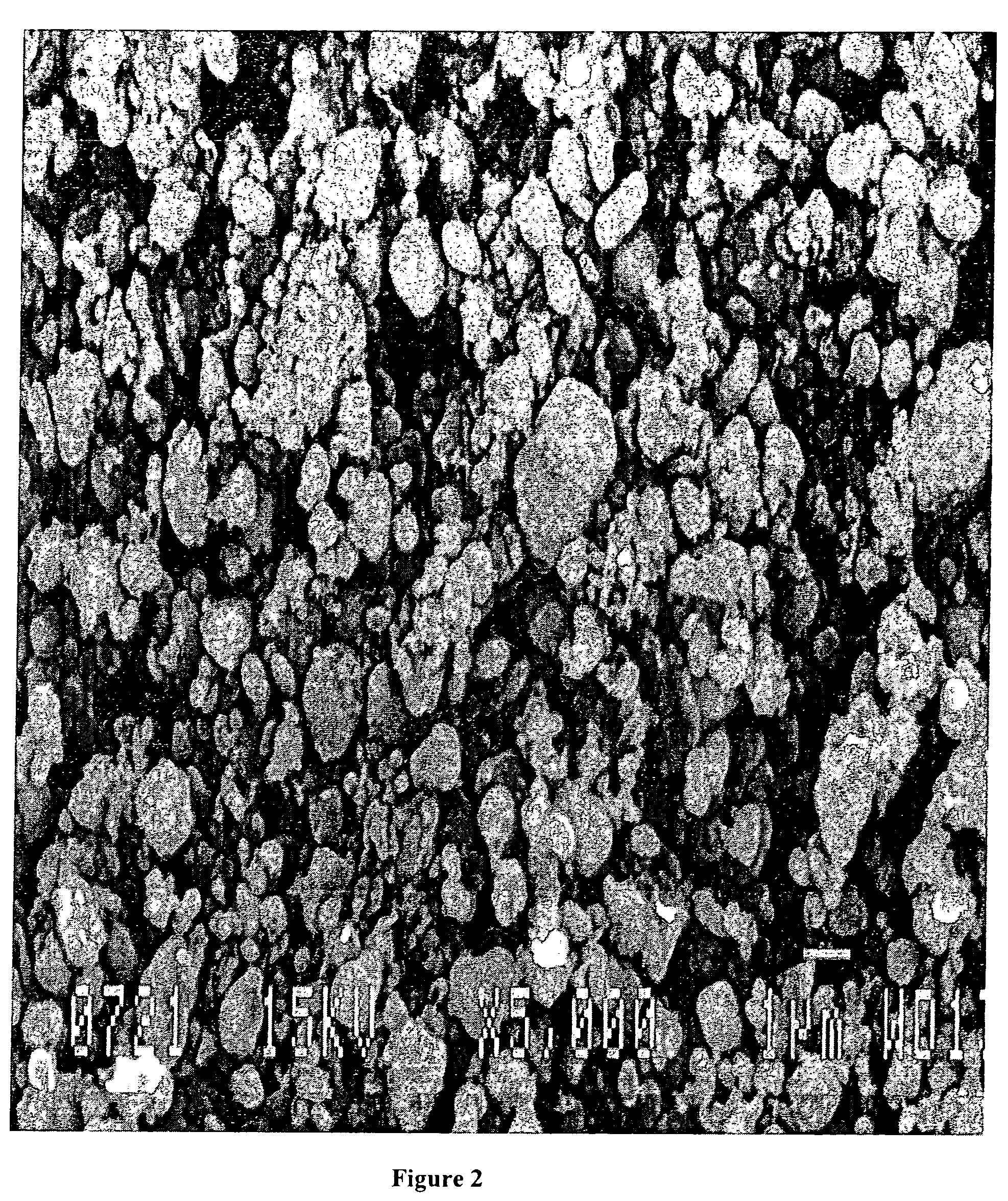

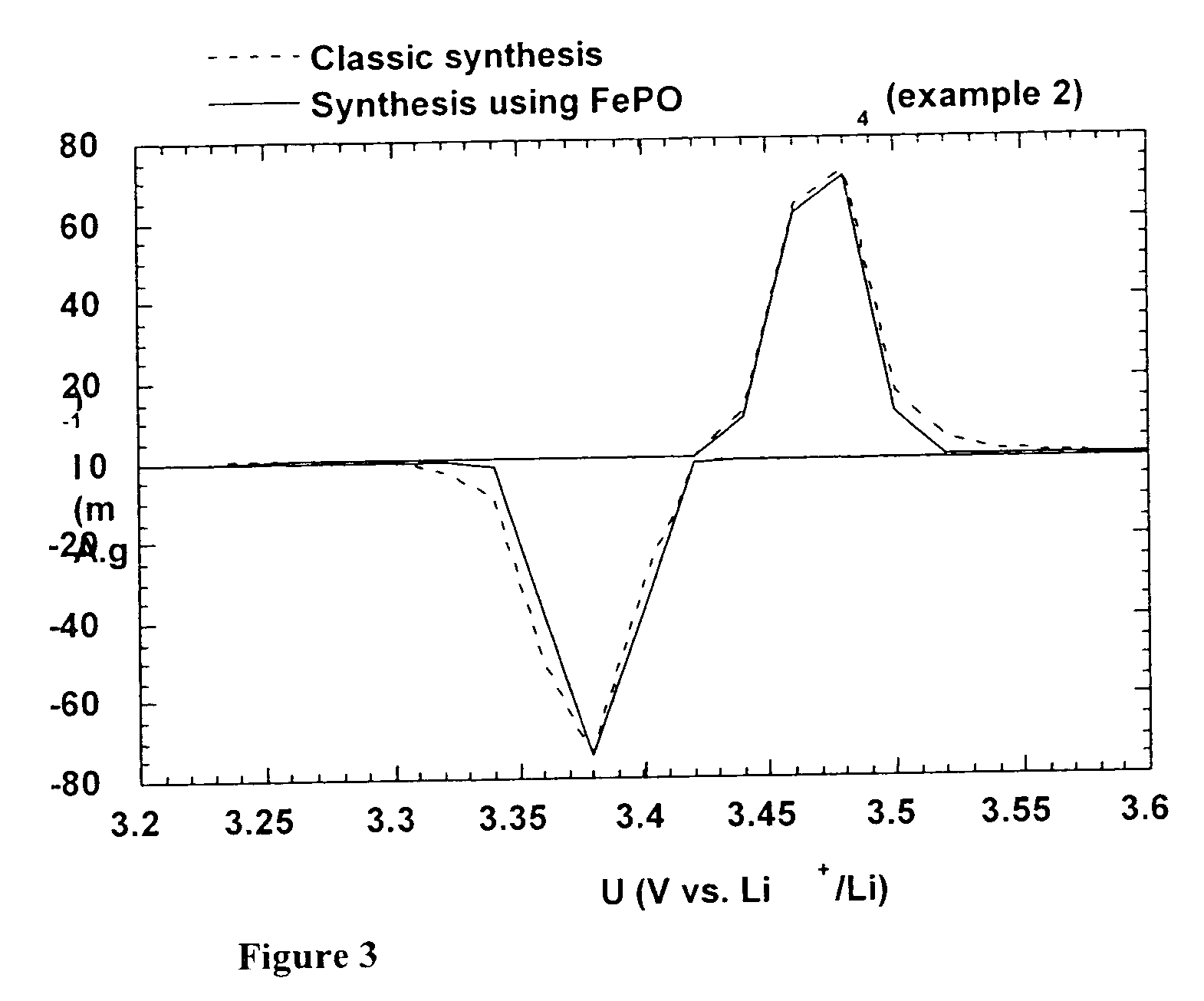

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Cathode Active Material Coated With Fluorine Compound for Lithium Secondary Batteries and Method for Preparing the Same

InactiveUS20090087362A1Inhibition of performance deteriorationHigh voltageElectrode manufacturing processesLithium compoundsLithiumHigh rate

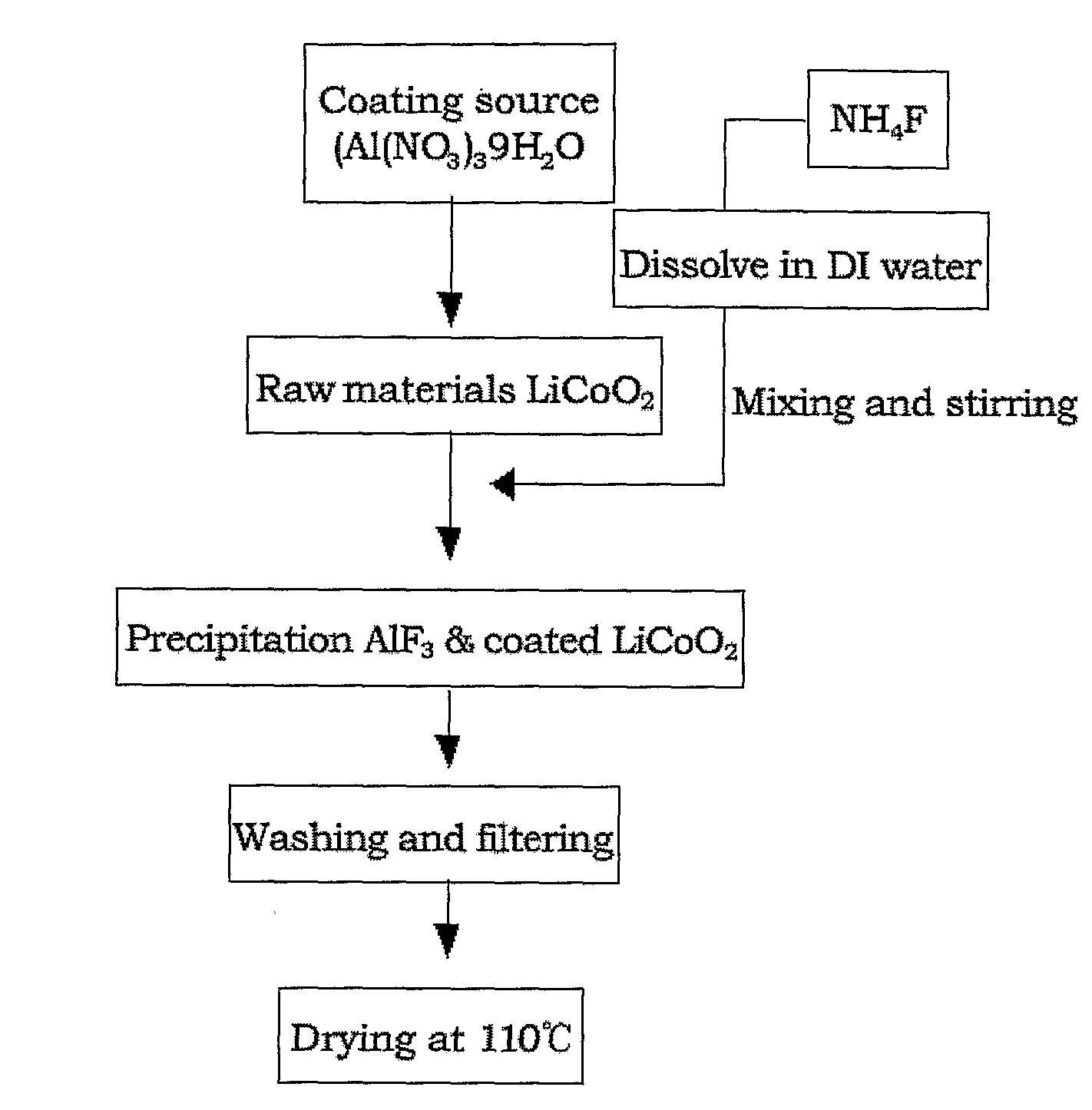

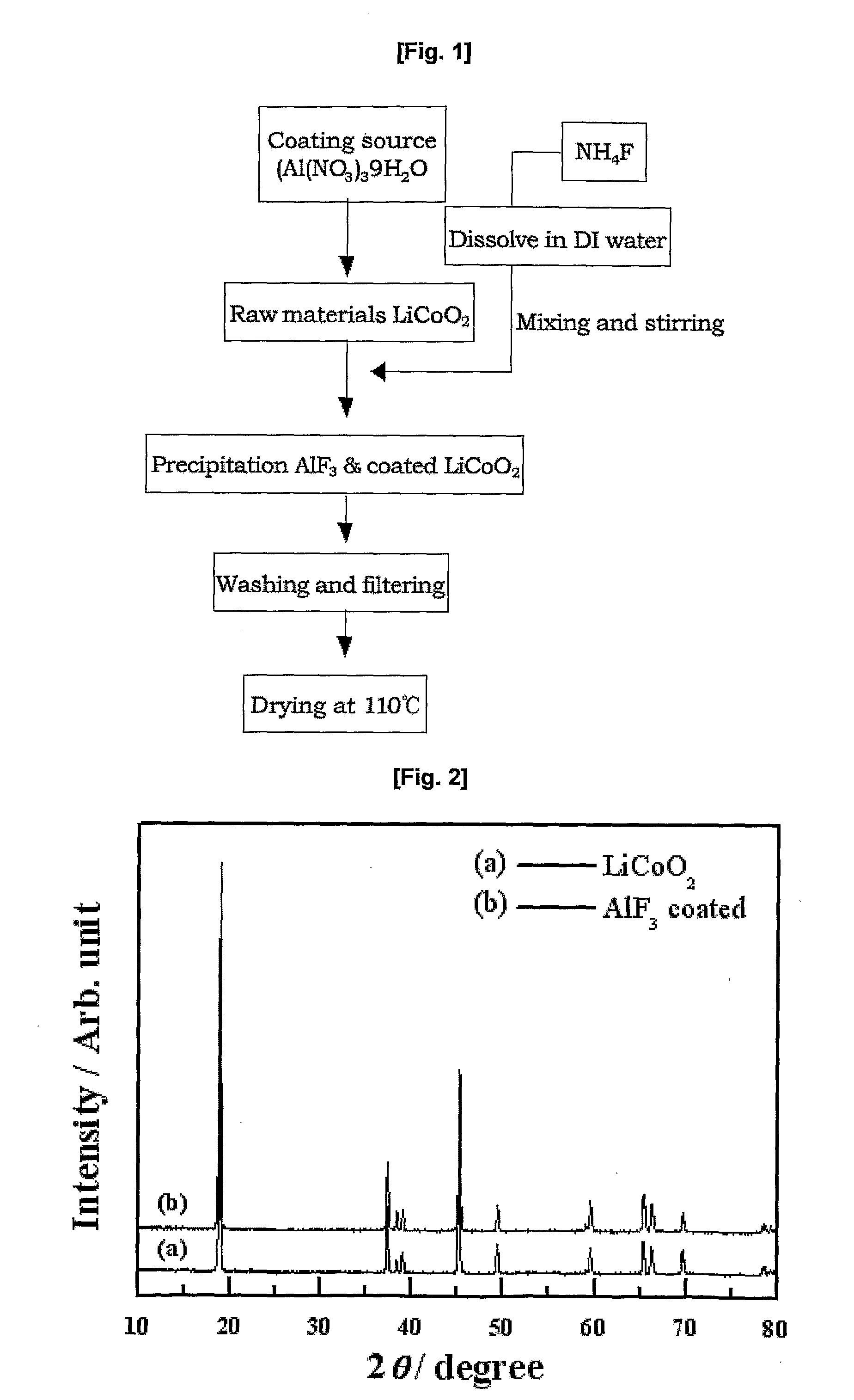

Disclosed herein is a cathode active material coated with a fluorine compound for lithium secondary batteries. The cathode active material is structurally stable, and improves the charge-discharge characteristics, cycle characteristics, high-voltage characteristics, high-rate characteristics and thermal stability of batteries.

Owner:ENERCERAMIC

Method for preparing lithiumion cell positive material Iron-lithium phosphate

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

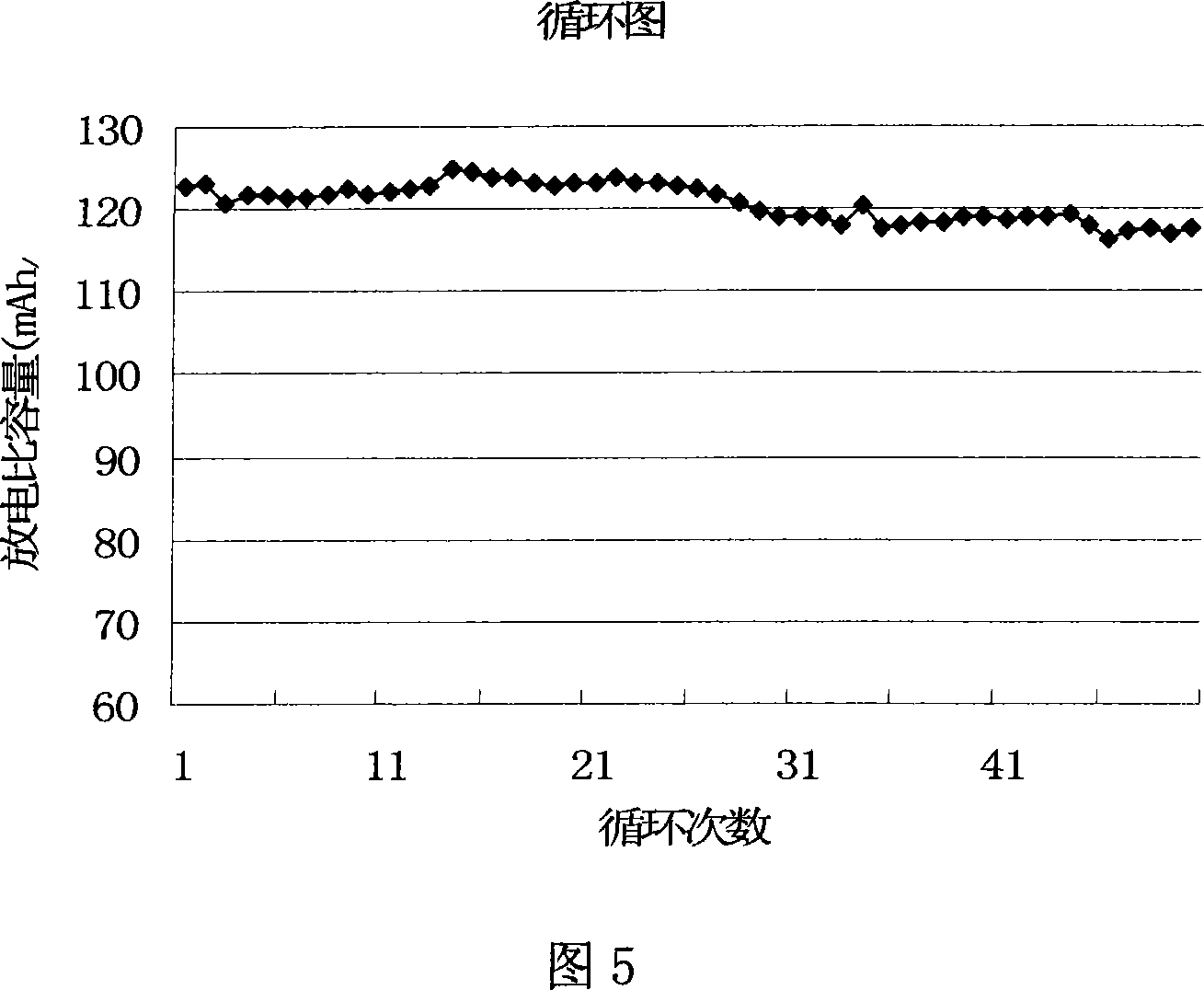

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

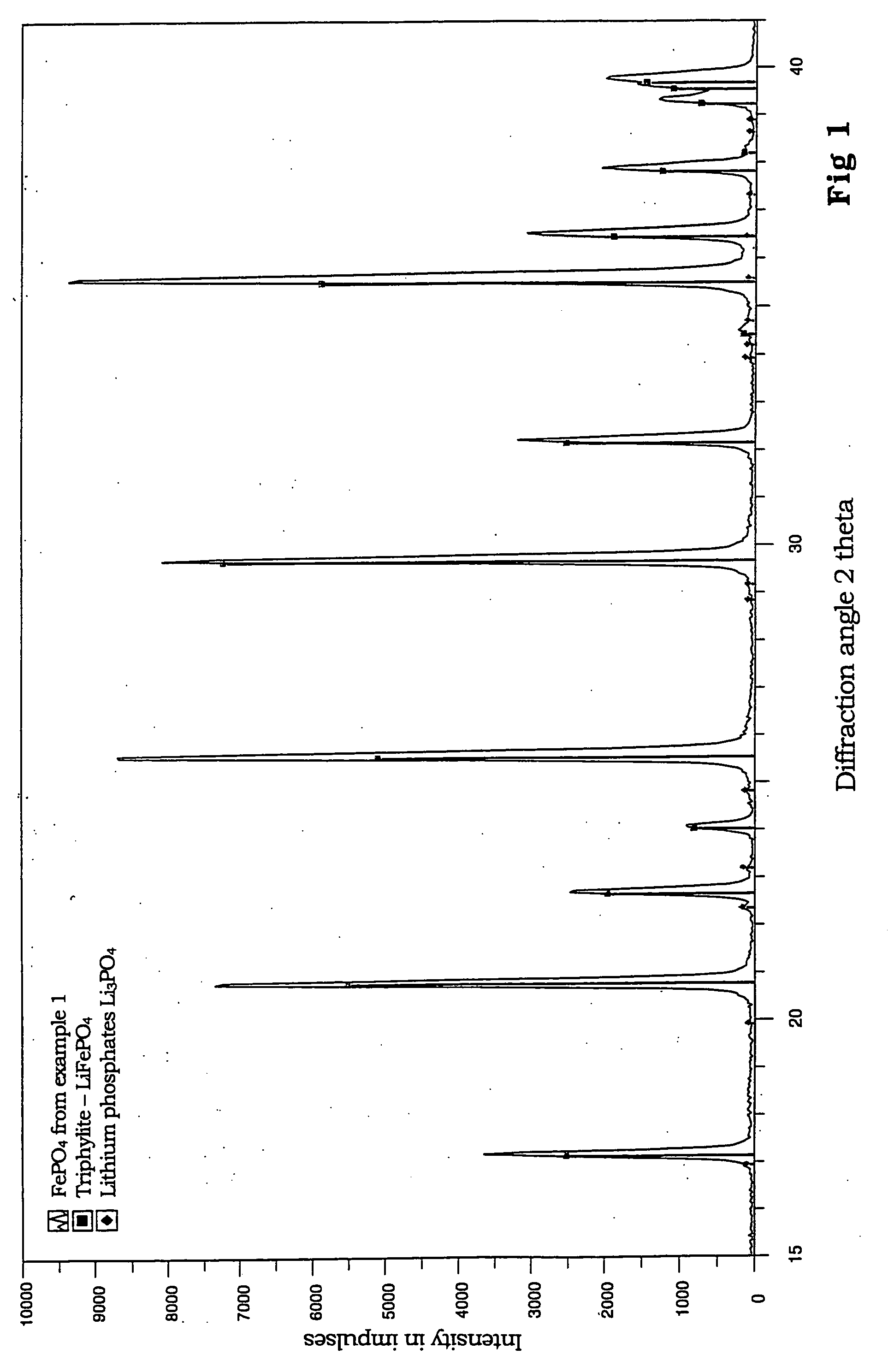

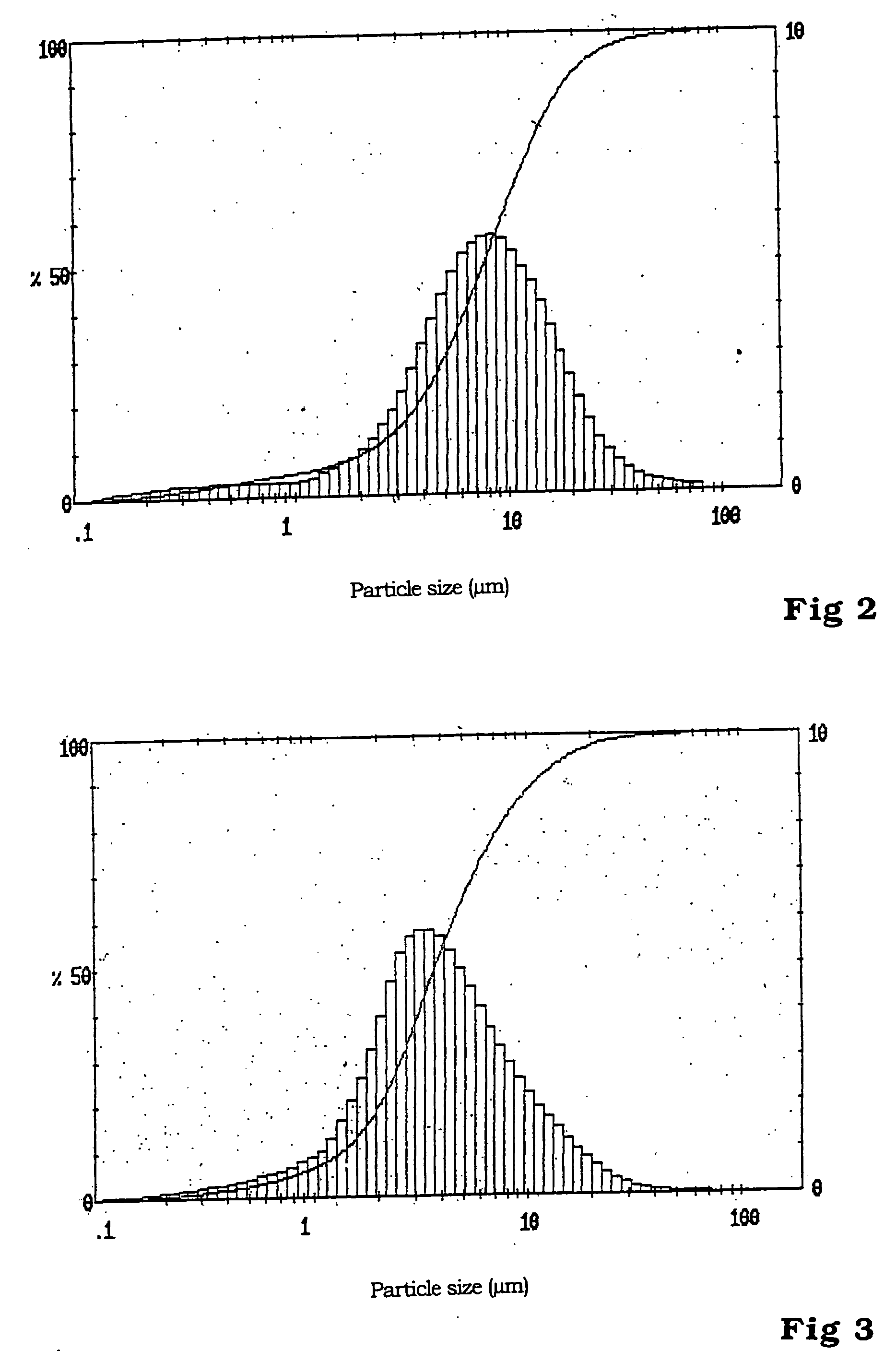

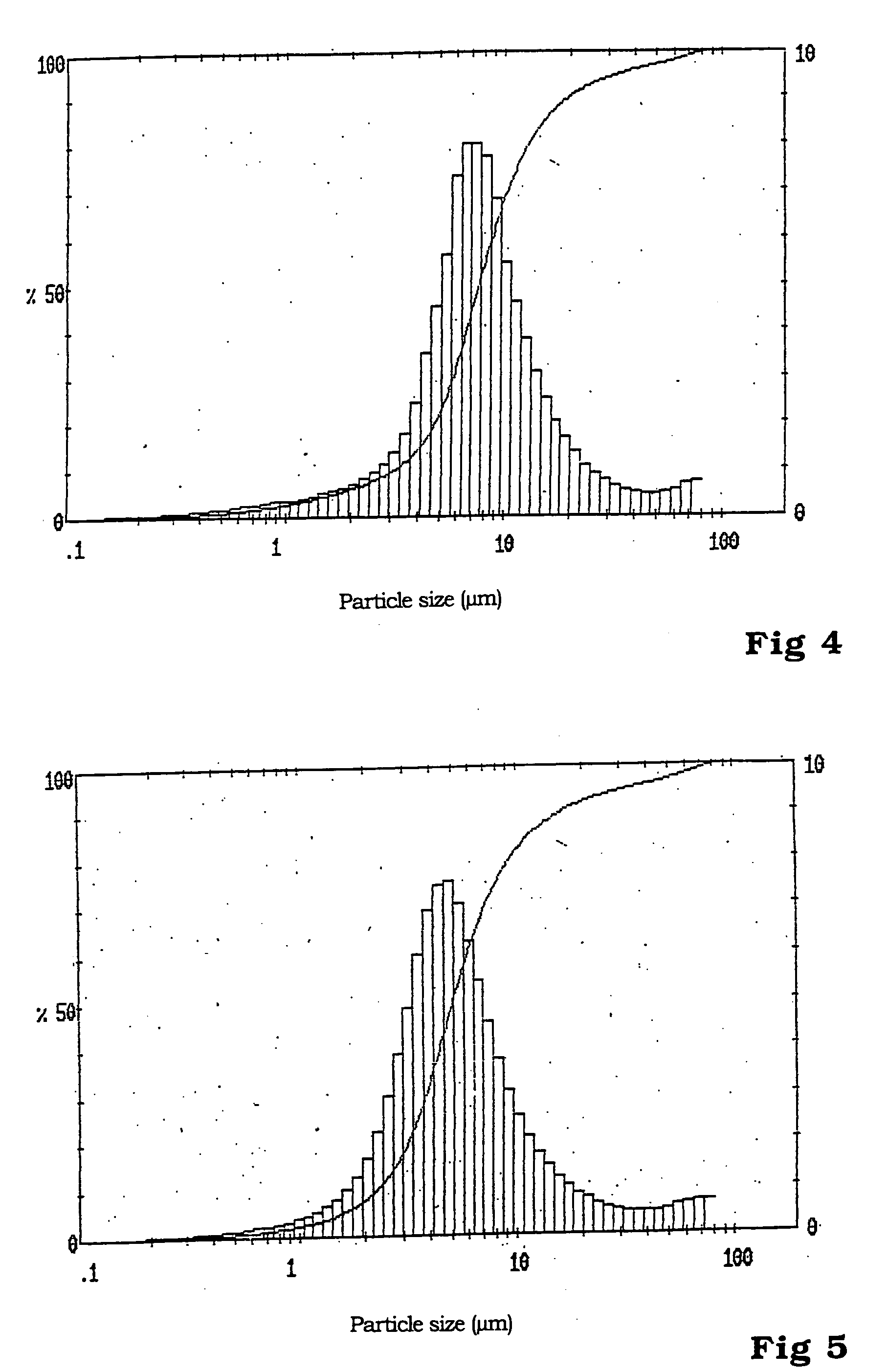

Binary, ternary and quaternary lithium phosphates, method for the production thereof and use of the same

ActiveUS20040151649A1High specific capacitySimple and inexpensivePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRoom temperatureReducing atmosphere

The invention relates to binary, ternary and quaternary lithium phosphates of general formula Li(FexM<1>yM<2>z)PO4 wherein M<1 >represents at least one element of the group comprising Sc, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Be, Mg, Ca, Sr, Ba, Al, Zr, and La; M<2 >represents at least one element of the group comprising Sc, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Be, Mg, Ca, Sr, Ba, Al, Zr, and La; x=between 0.5 and 1, y=between 0 and 0.5, z=between 0 and 0.5, provided that x+y+z=1, or x=0, y =1 and z=0. The said lithium phosphates can be obtained according to a method whereby precursor compounds of elements Li, Fe, M<1 >and / or M<2 >are precipitated from aqueous solutions and the precipitation product is dried in an inert gas atmosphere or a reducing atmosphere at a temperature which is between room temperature and approximately 200° C. and tempered at a temperature of between 300° C. and 1000° C. The inventive lithium phosphates have a very high capacity when used as cathode material in lithium accumulators.

Owner:ZENT FUR SONNENENERGIE & WASSERSTOFF FORSCHUNG BADEN WURTTEMBERG GEMEINNUTZIGE STIFTUNG

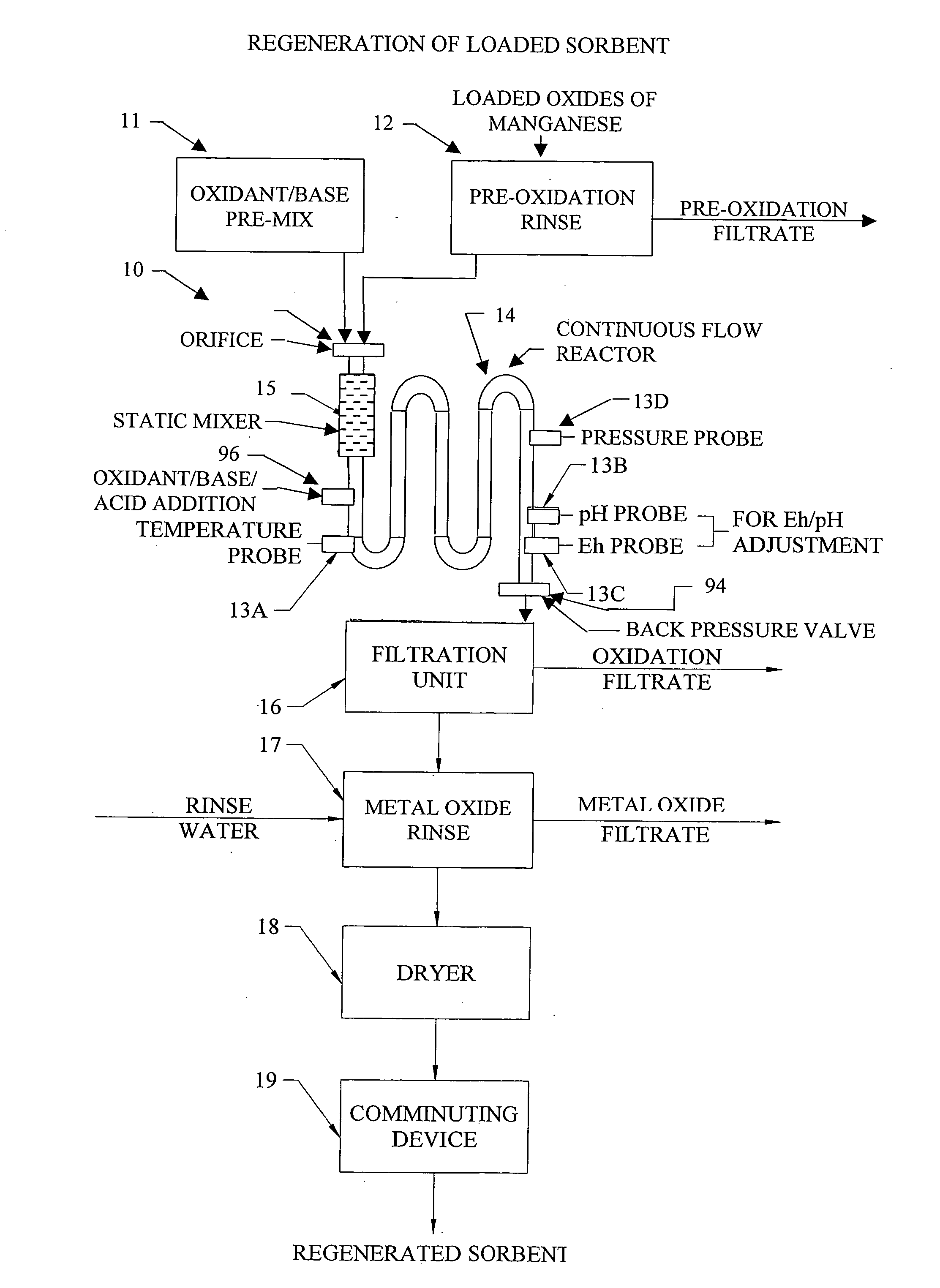

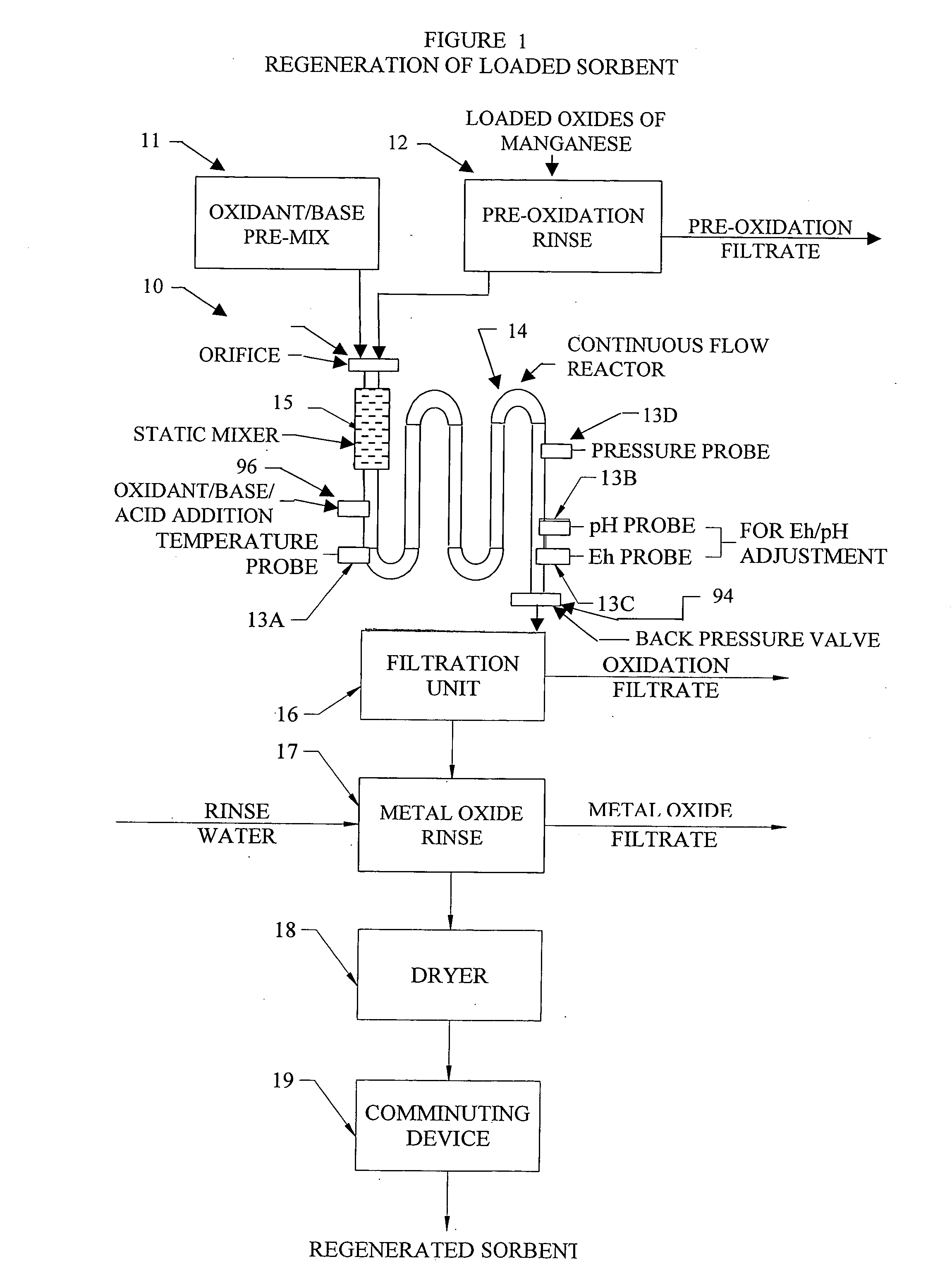

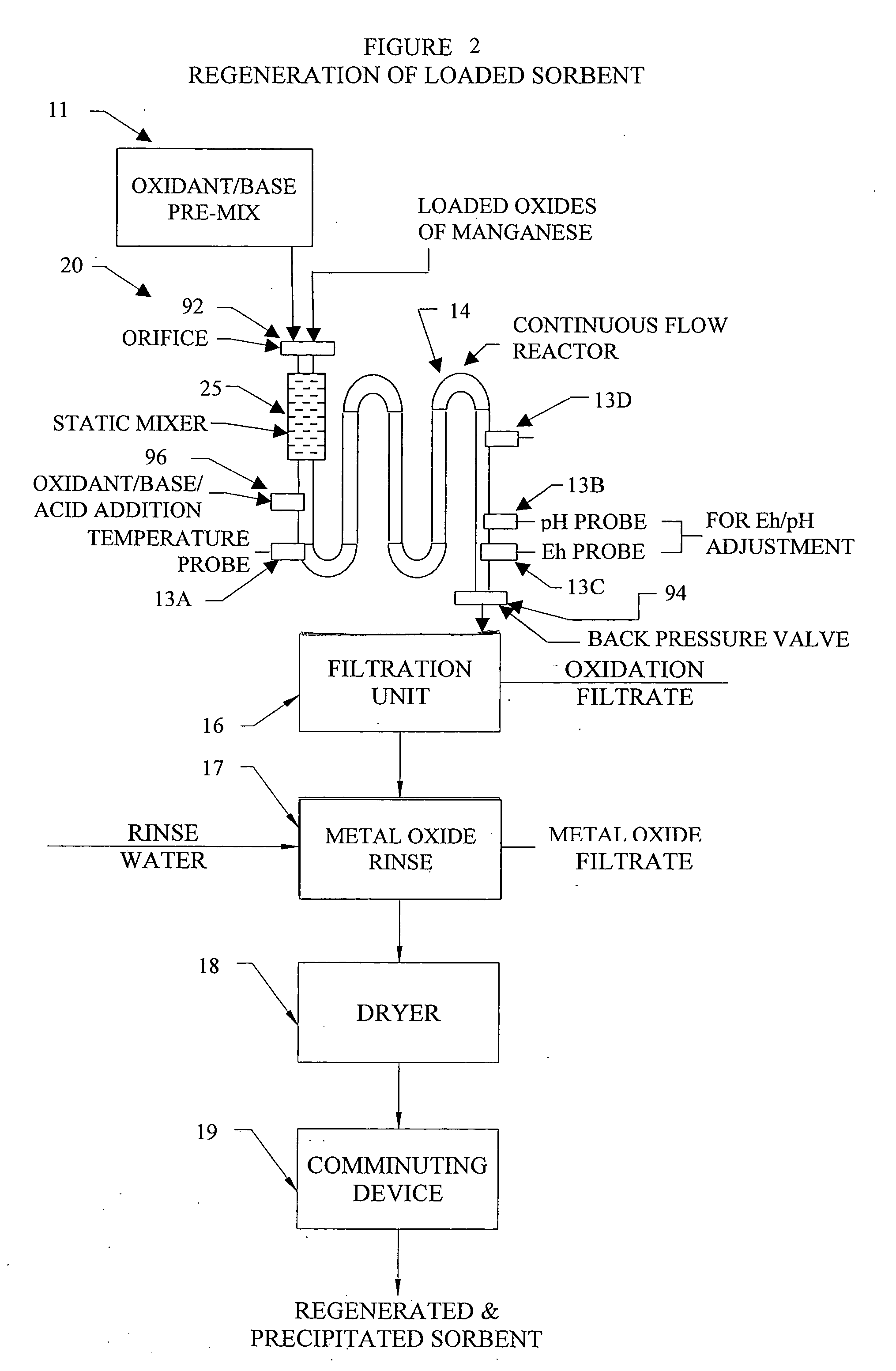

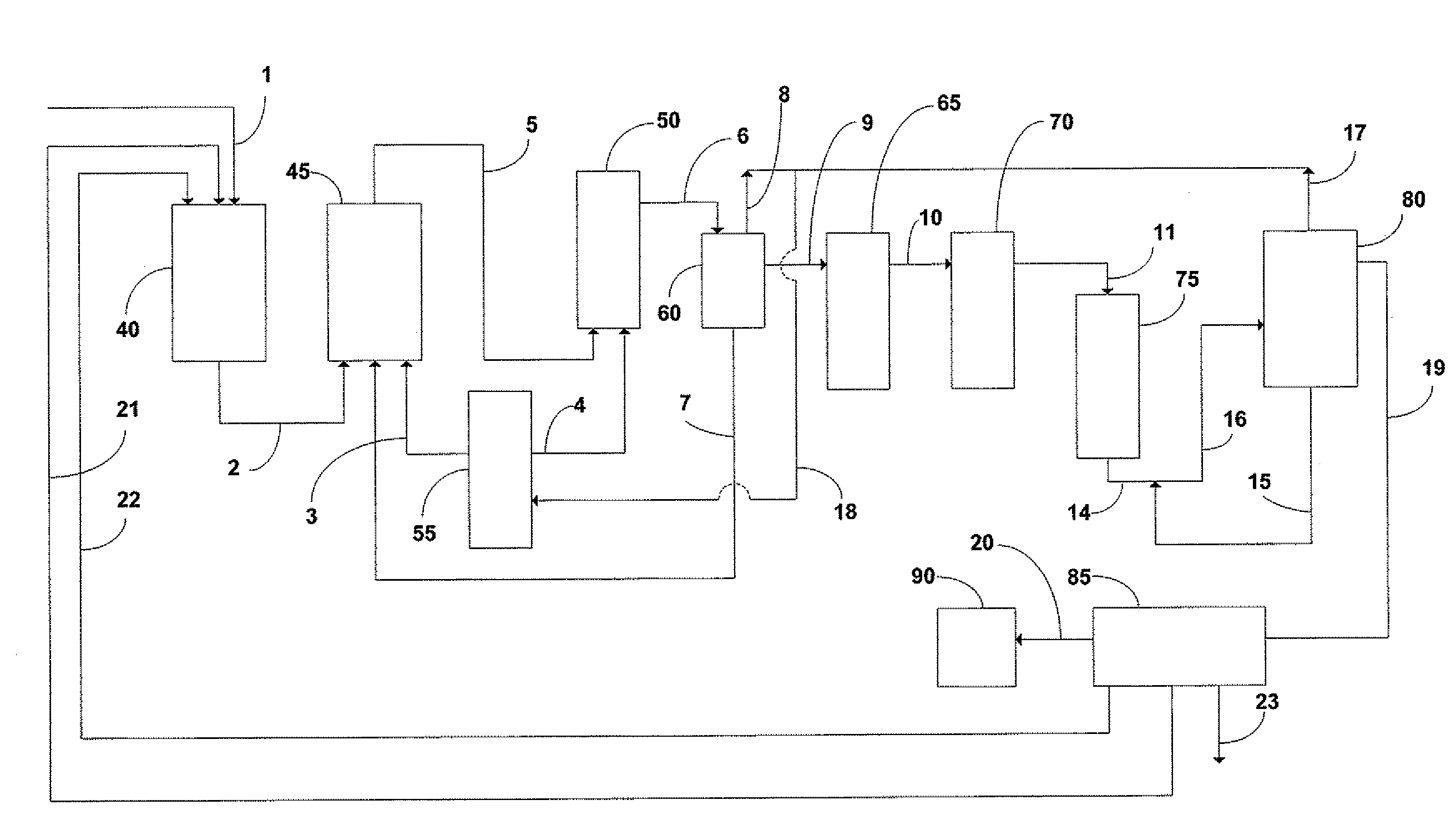

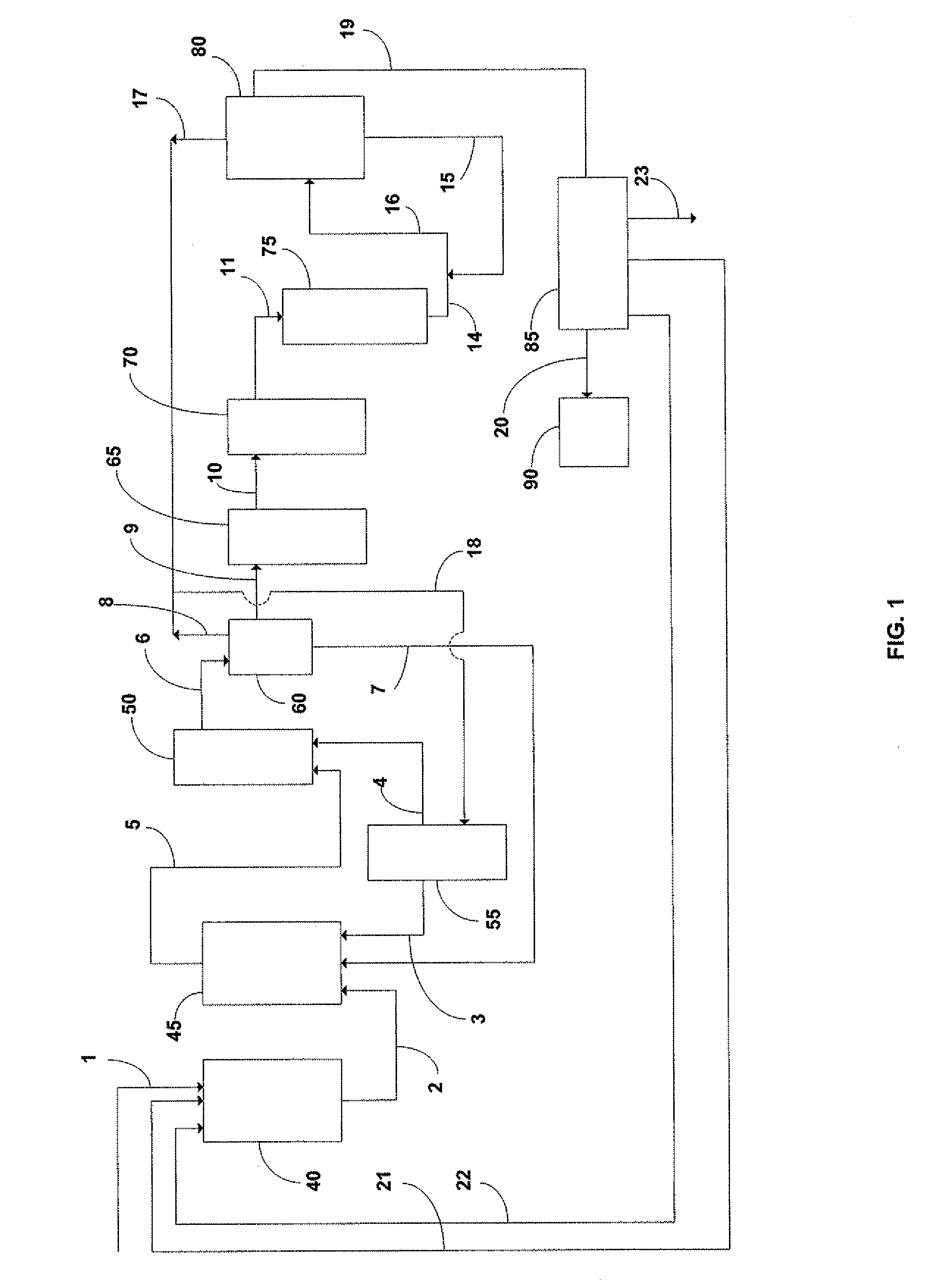

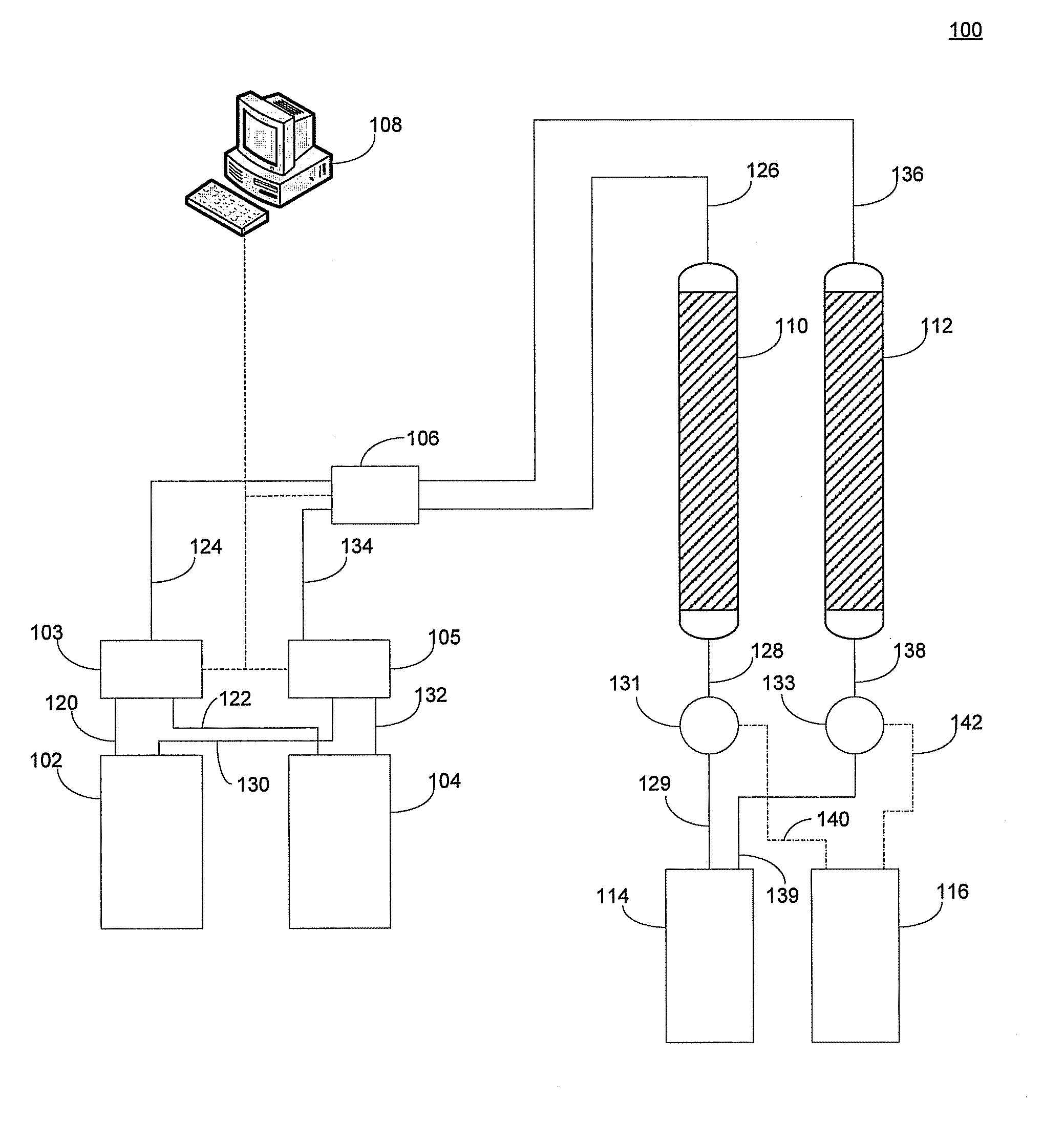

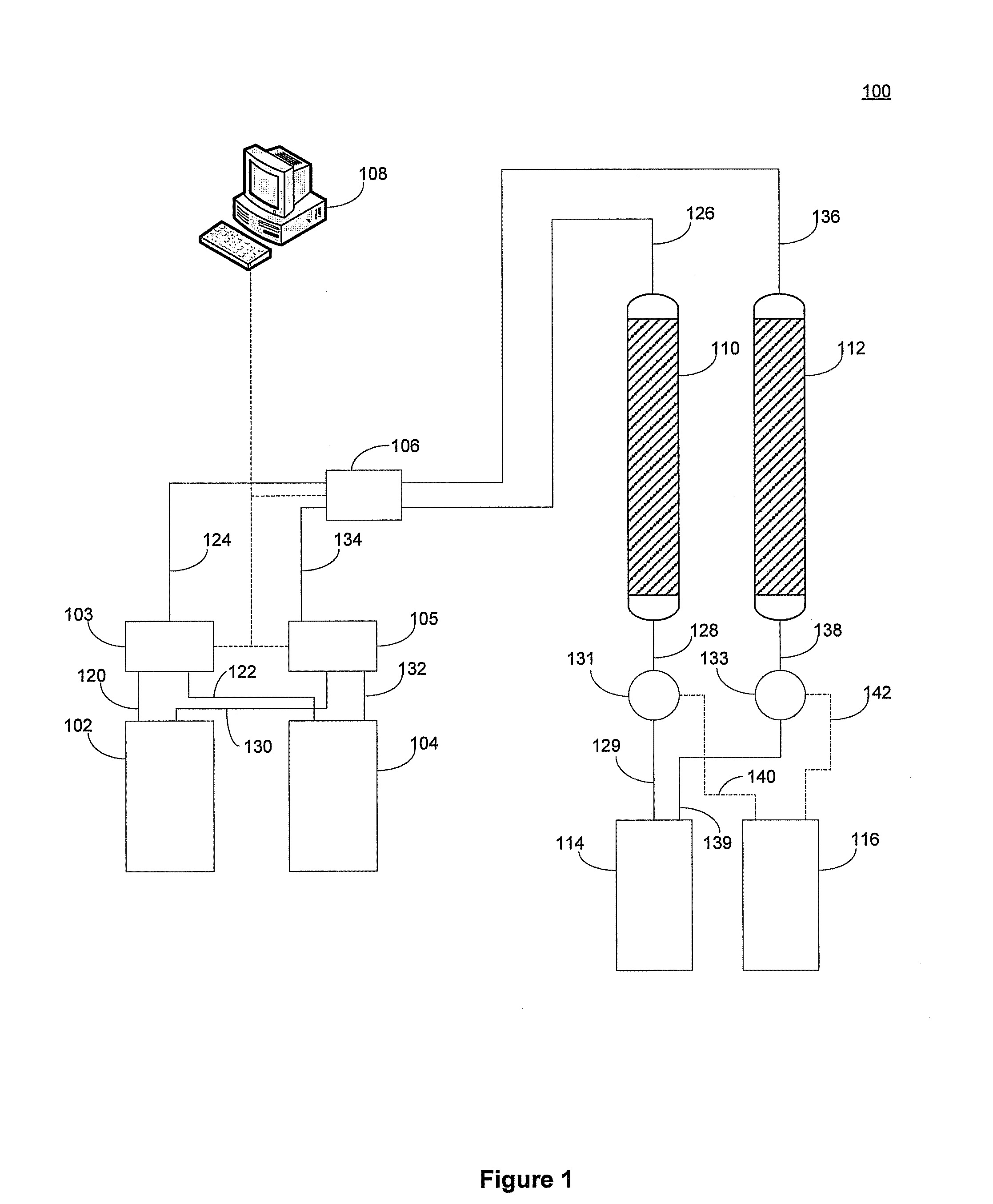

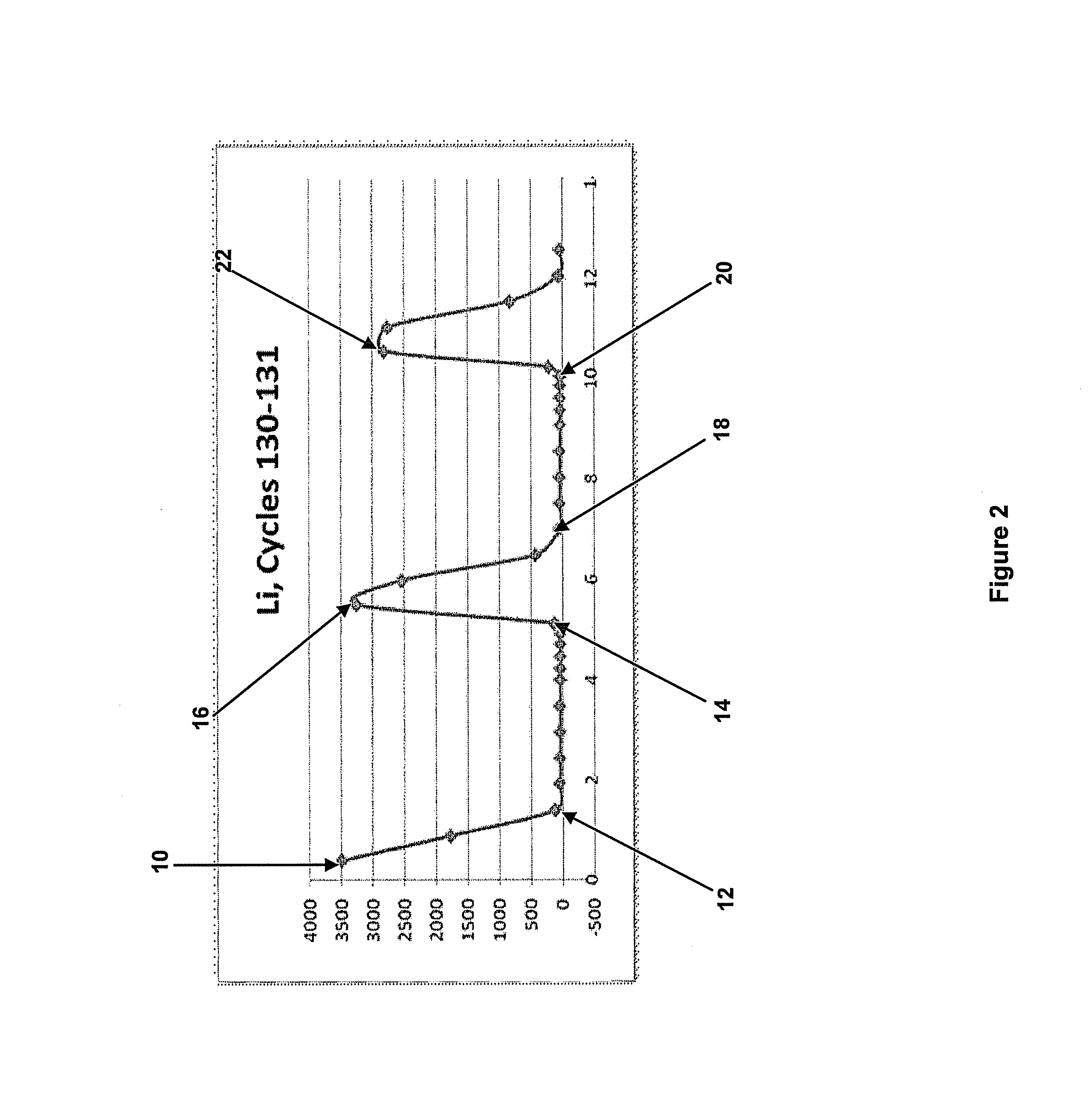

Metal oxide processing methods and systems

InactiveUS20050074380A1Move quicklyIncrease load capacityCombination devicesTemperatue controlIndustrial gasBatch processing

Methods and systems for processing metal oxides from metal containing solutions. Metal containing solutions are mixed with heated aqueous oxidizing solutions and processed in a continuous process reactor or batch processing system. Combinations of temperature, pressure, molarity, Eh value, and pH value of the mixed solution are monitored and adjusted so as to maintain solution conditions within a desired stability area during processing. This results in metal oxides having high or increased pollutant loading capacities and / or oxidation states. These metal oxides may be processed according to the invention to produce co-precipitated oxides of two or more metals, metal oxides incorporating foreign cations, metal oxides precipitated on active and inactive substrates, or combinations of any or all of these forms. Metal oxides thus produced are, amongst other uses; suitable for use as a sorbent for capturing or removing target pollutants from industrial gas streams or drinking water or aqueous streams or for personal protective respirators.

Owner:ENVIROSCRUB TECH CORP

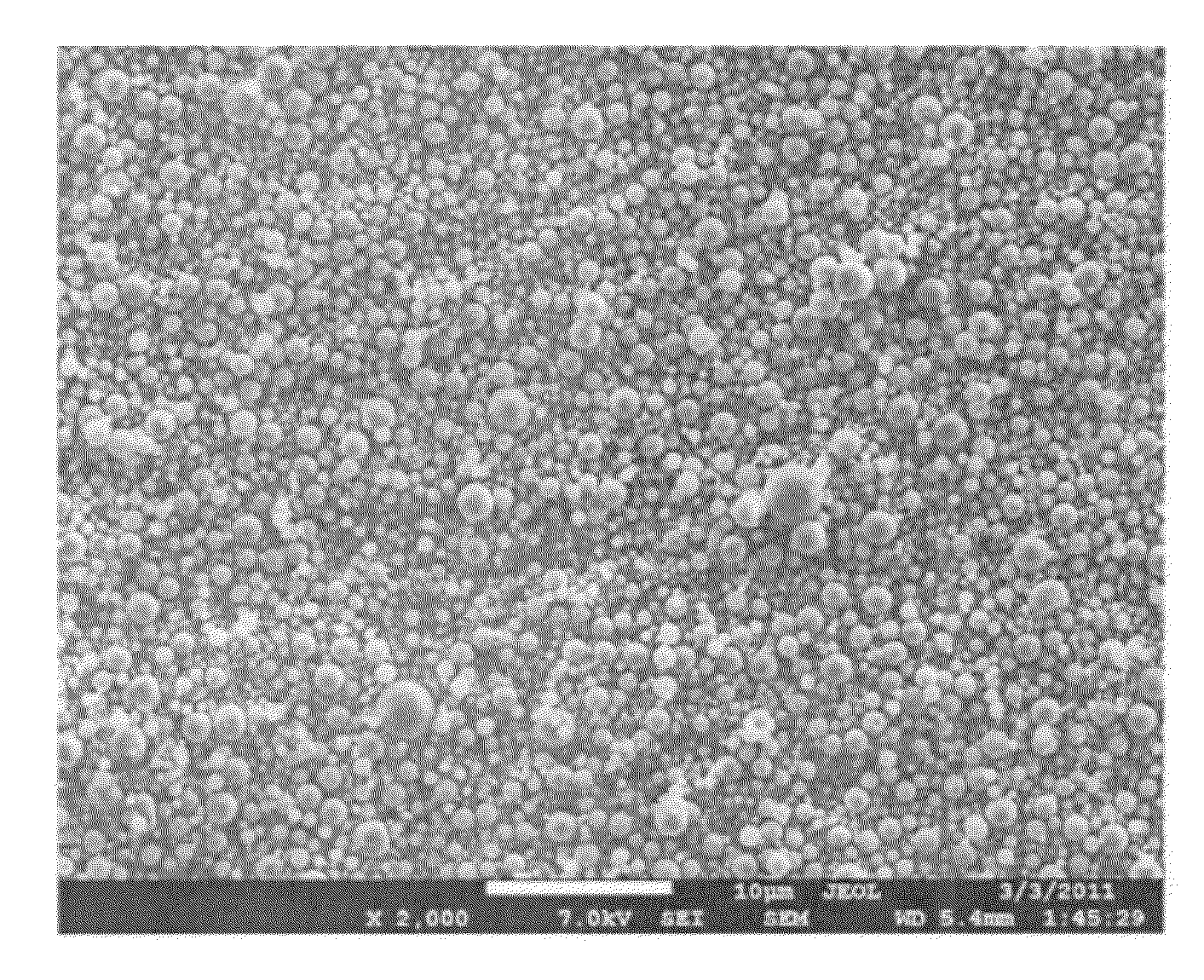

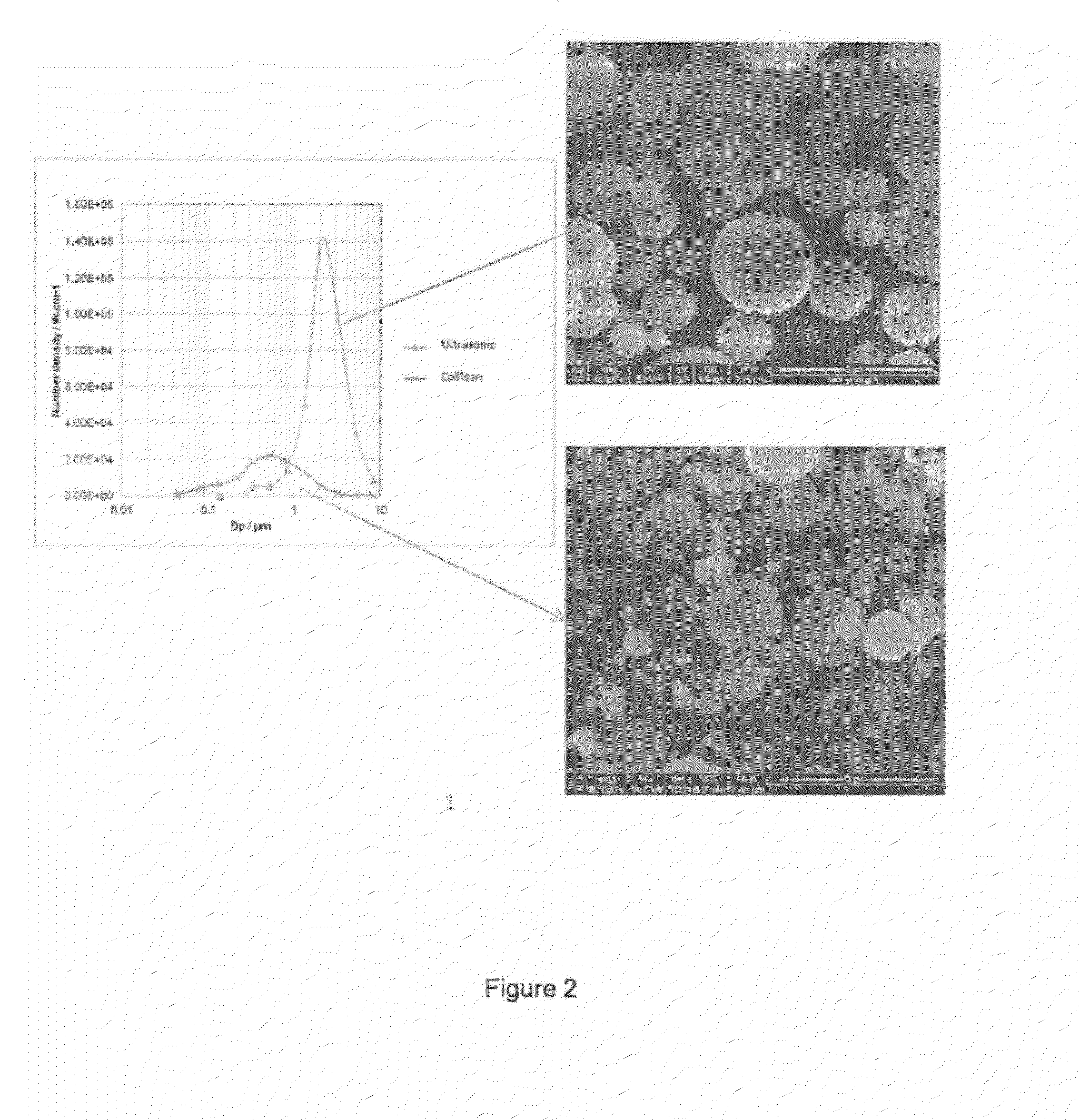

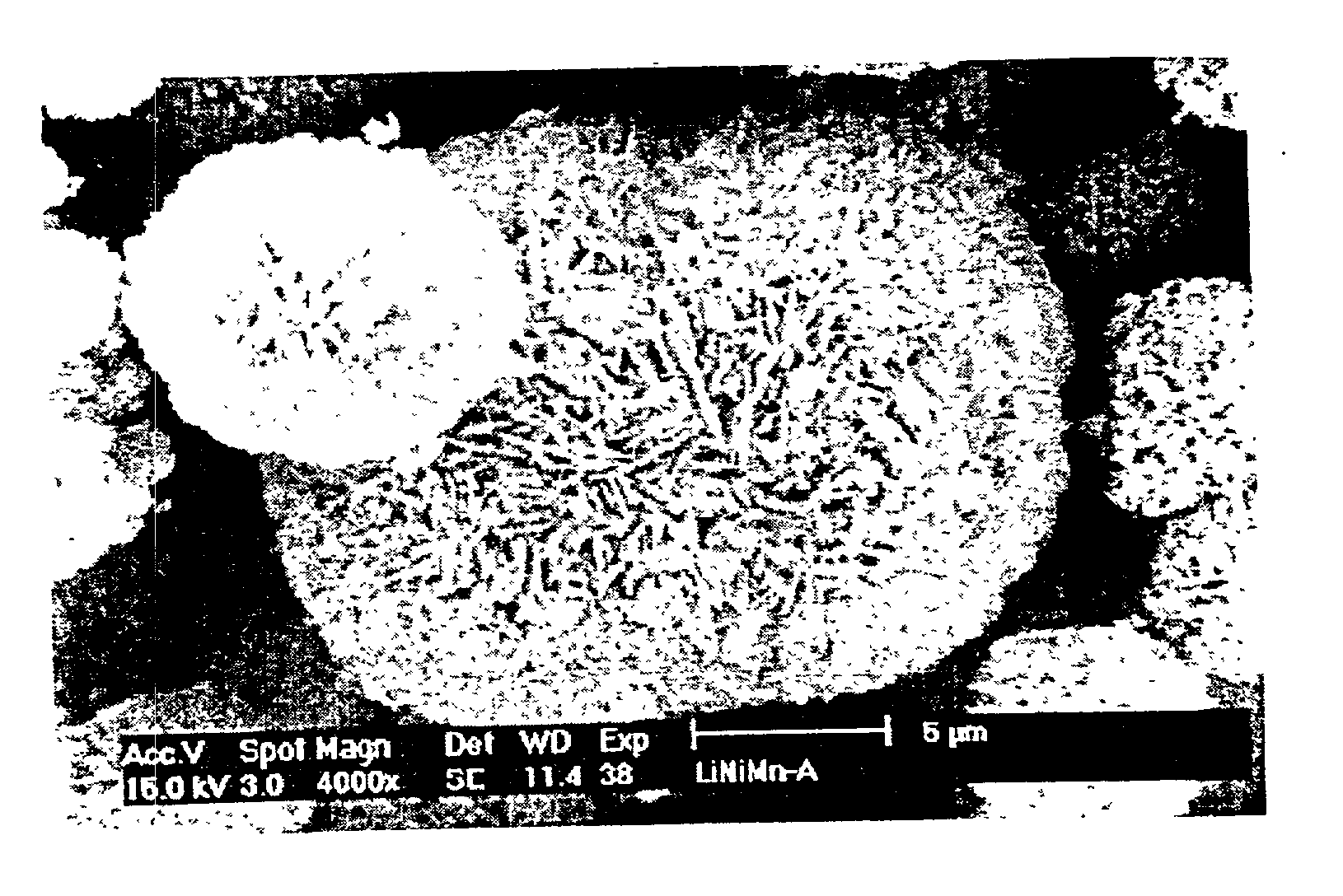

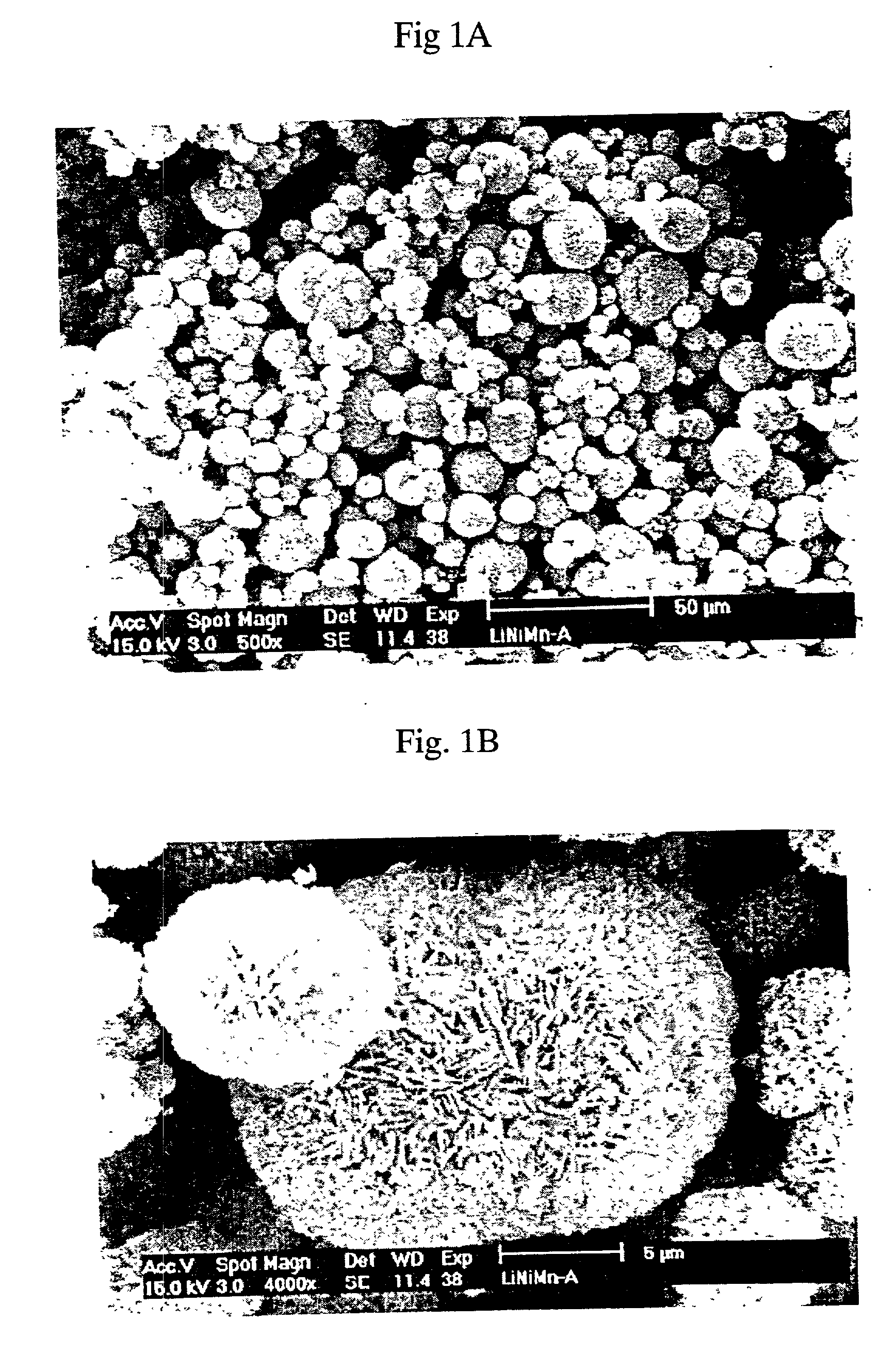

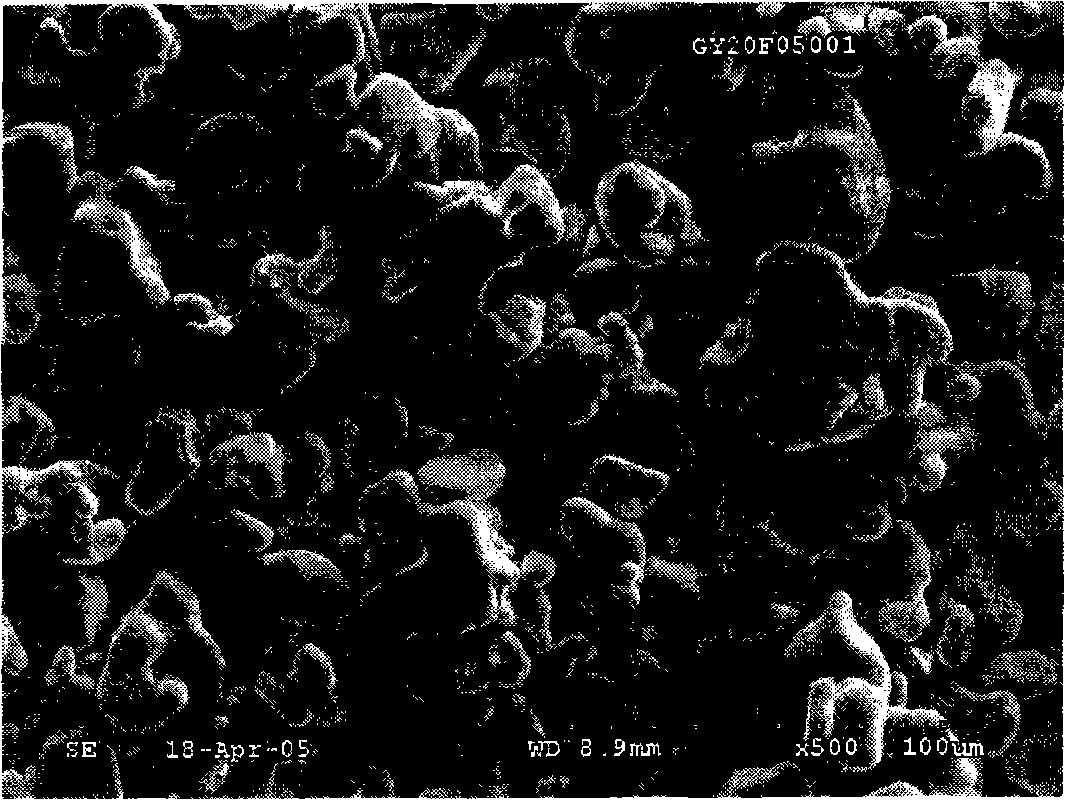

Spray Pyrolysis Synthesis of Mesoporous Positive Electrode Materials for High Energy Lithium-Ion Batteries

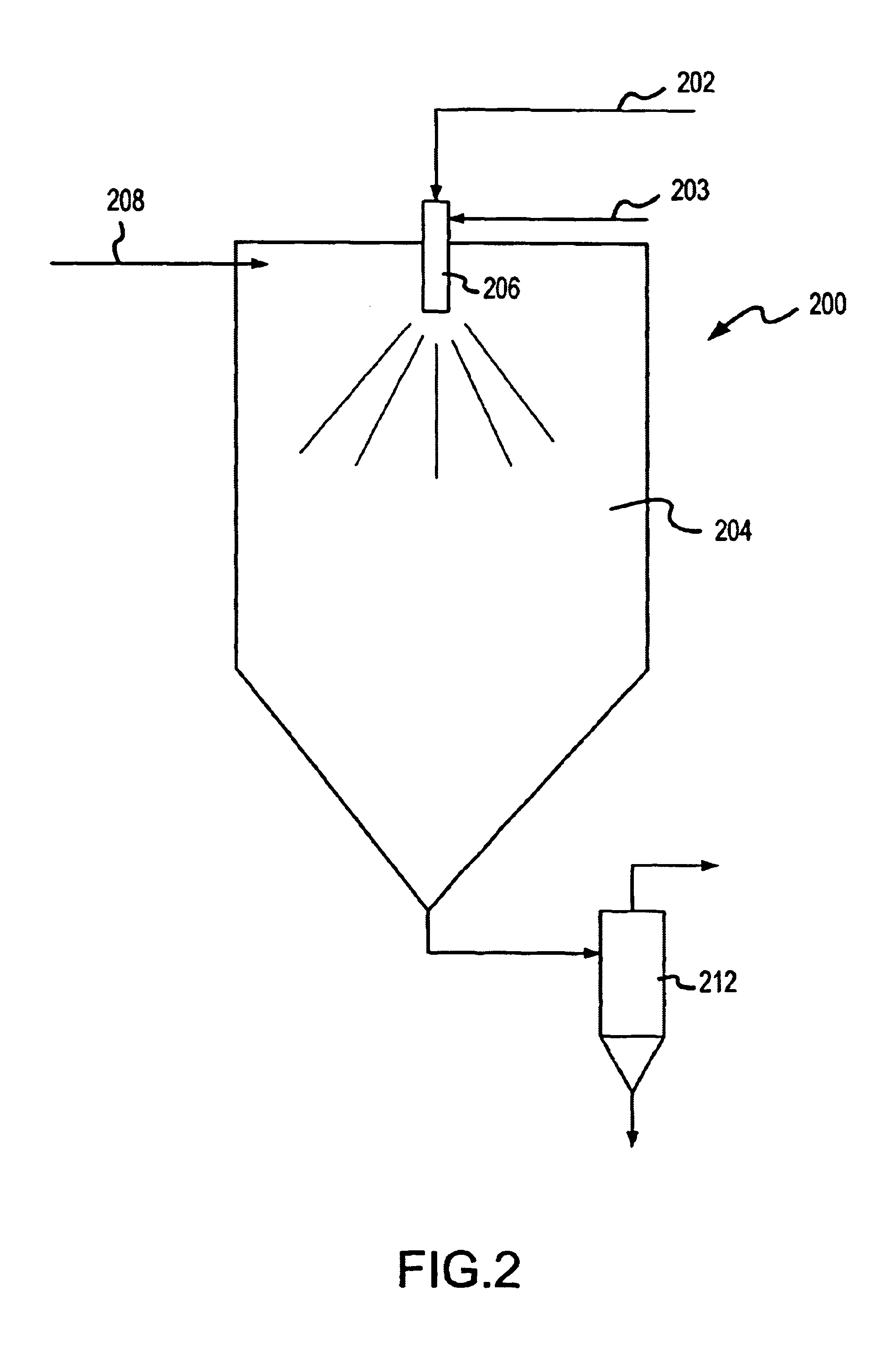

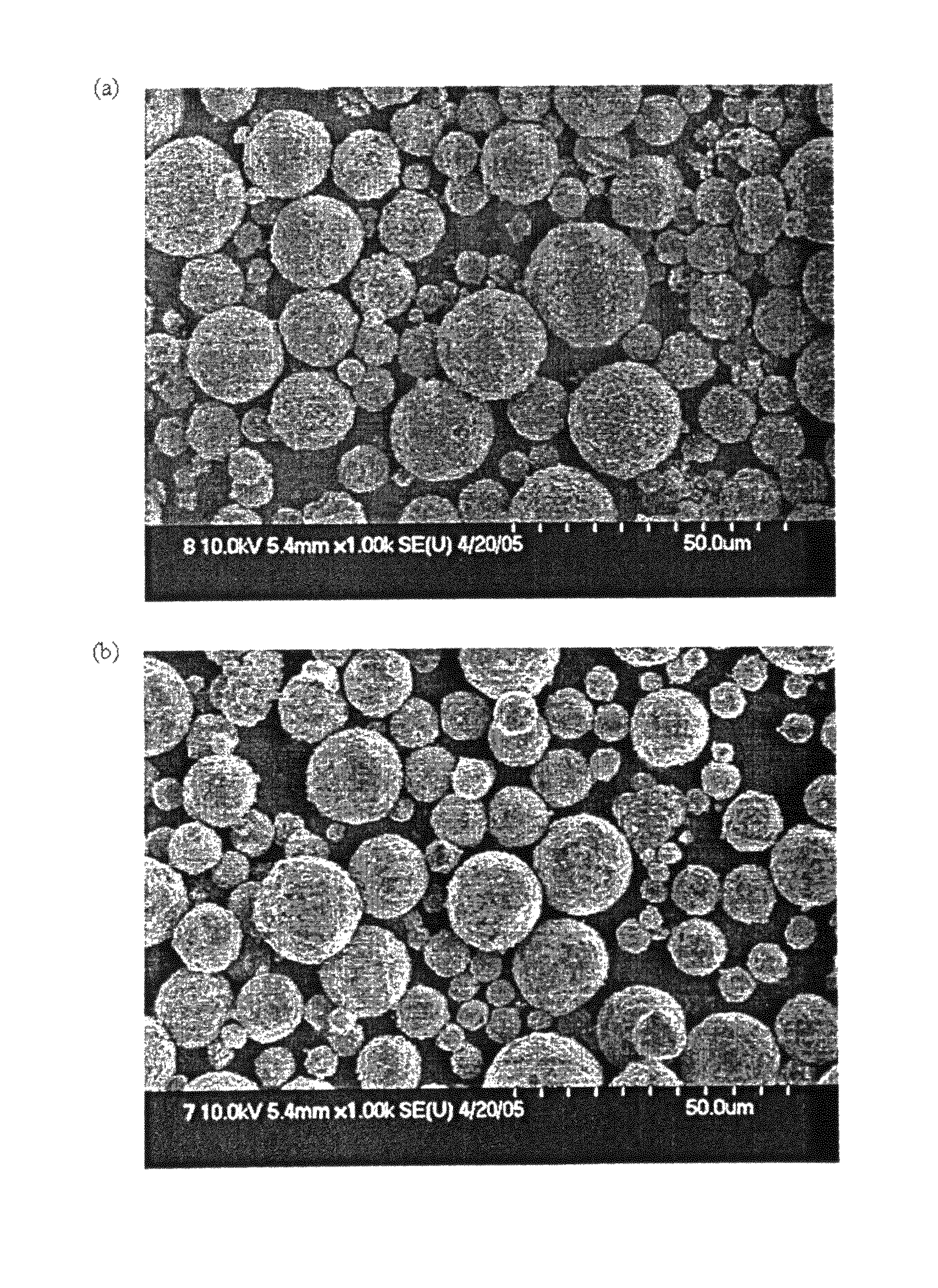

A lithium metal oxide positive electrode material useful in making lithium-ion batteries that is produced using spray pyrolysis. The material comprises a plurality of metal oxide secondary particles that comprise metal oxide primary particles, wherein the primary particles have a size that is in the range of about 1 nm to about 10 μm, and the secondary particles have a size that is in the range of about 10 nm to about 100 μm and are uniformly mesoporous.

Owner:WASHINGTON UNIV IN SAINT LOUIS

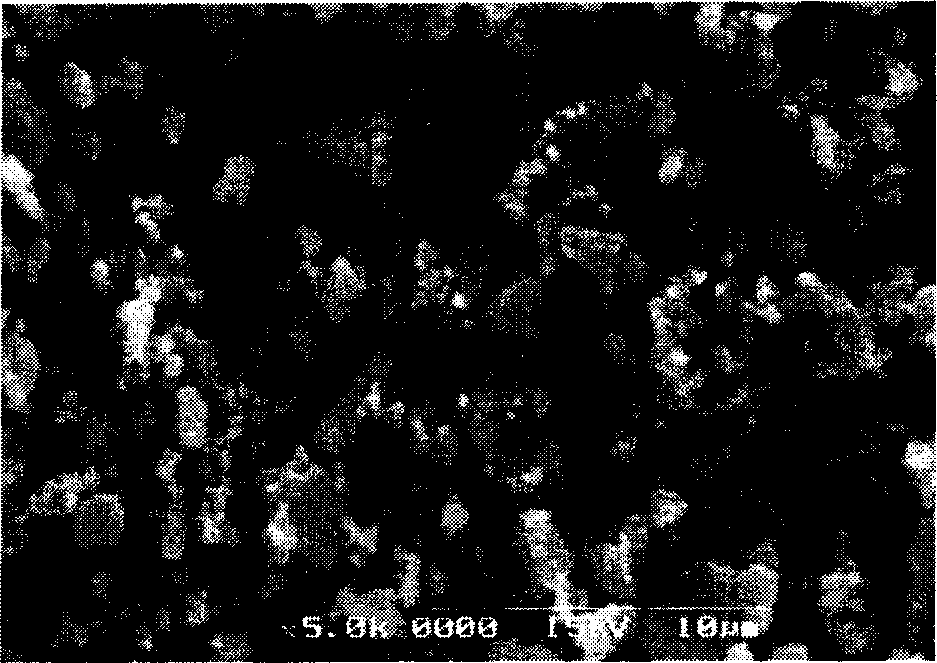

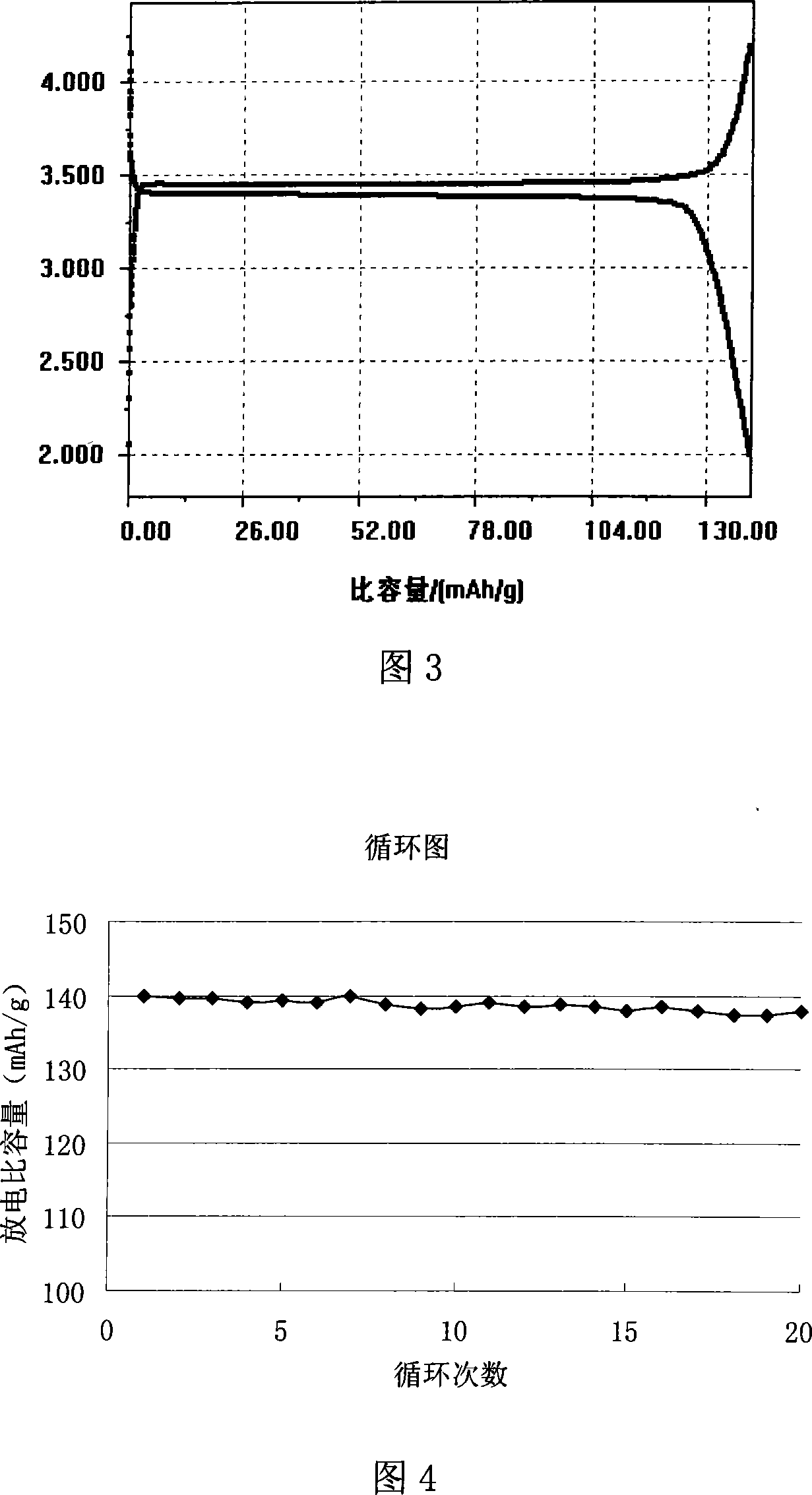

Method for preparing high-density spherical ferric lithium phosphate as anode material of lithium-ion battery

InactiveCN1635648AHigh bulk densityIncrease volume capacityElectrode manufacturing processesLithium compoundsPhosphateLithium-ion battery

This invention discloses the method for preparing high-density spherical lithium ferric phosphate used as the positive material of lithium ion cell, which contains synthesizing the ferric iron salt aqueous solution, phosphorus source aqueous solution and alkali aqueous solution to form spherical or spheroid ferric phosphate precursor, uniformly mixed with lithium source, carbon source and doped metal compound after being washed and dried, high temperature heat treating at 600-900 degree centigrade for 8-48 hr under inertia or reducing atmosphere protection to obtain lithium ferric phosphate with mean grain size of 7-12 micrometer,2.0-2.2g / cm3 of tap density, high buck density of 140-155mAh / g first discharge ratio capacity at normal temperature, and high volume ratio capacity.

Owner:TSINGHUA UNIV

Processes for preparing highly pure lithium carbonate and other highly pure lithium containing compounds

ActiveUS20110200508A1Electrolysis componentsLithium organic compoundsLithium carbonateLithium hydroxide

Owner:TERRALITHIUM LLC

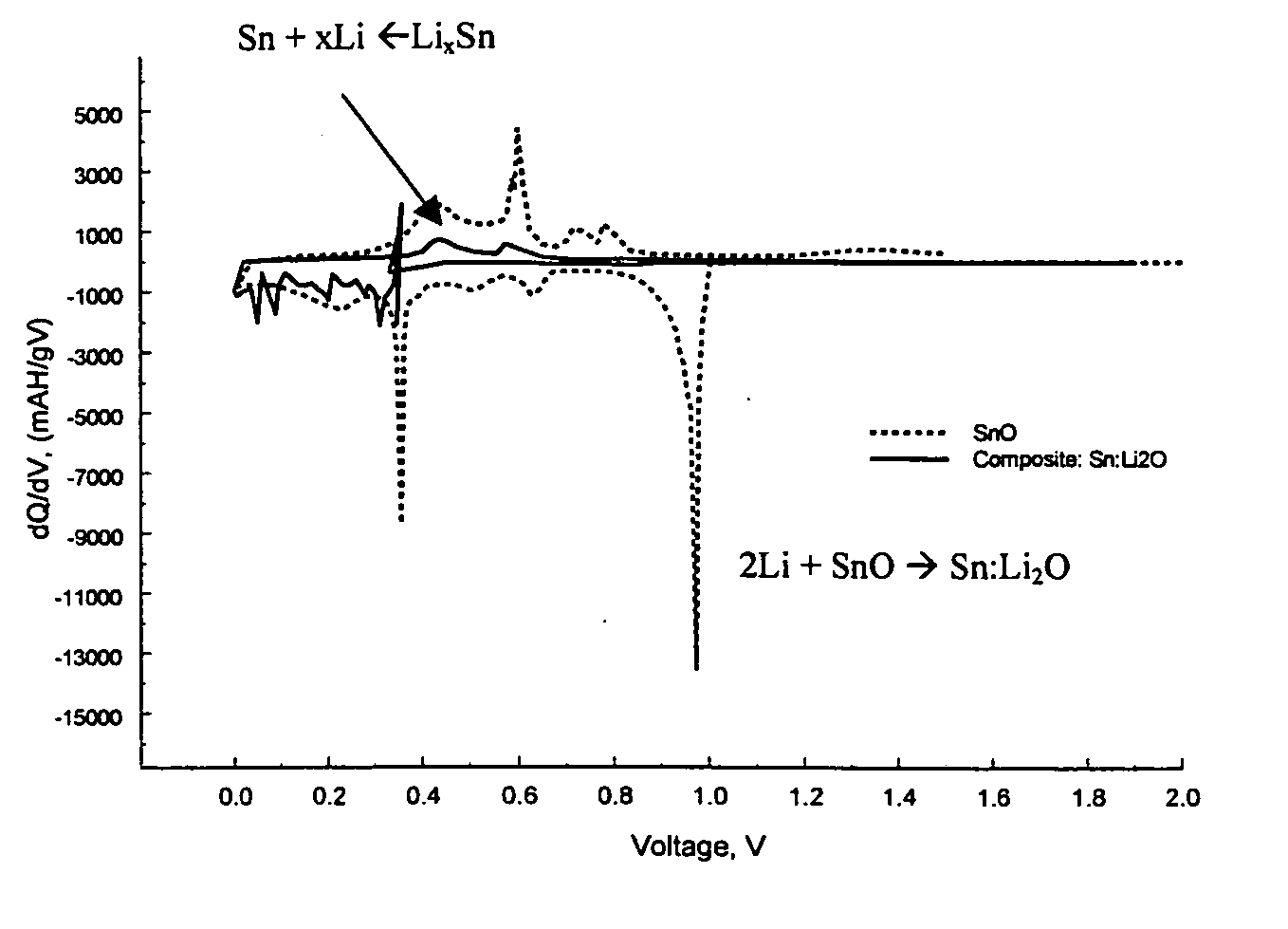

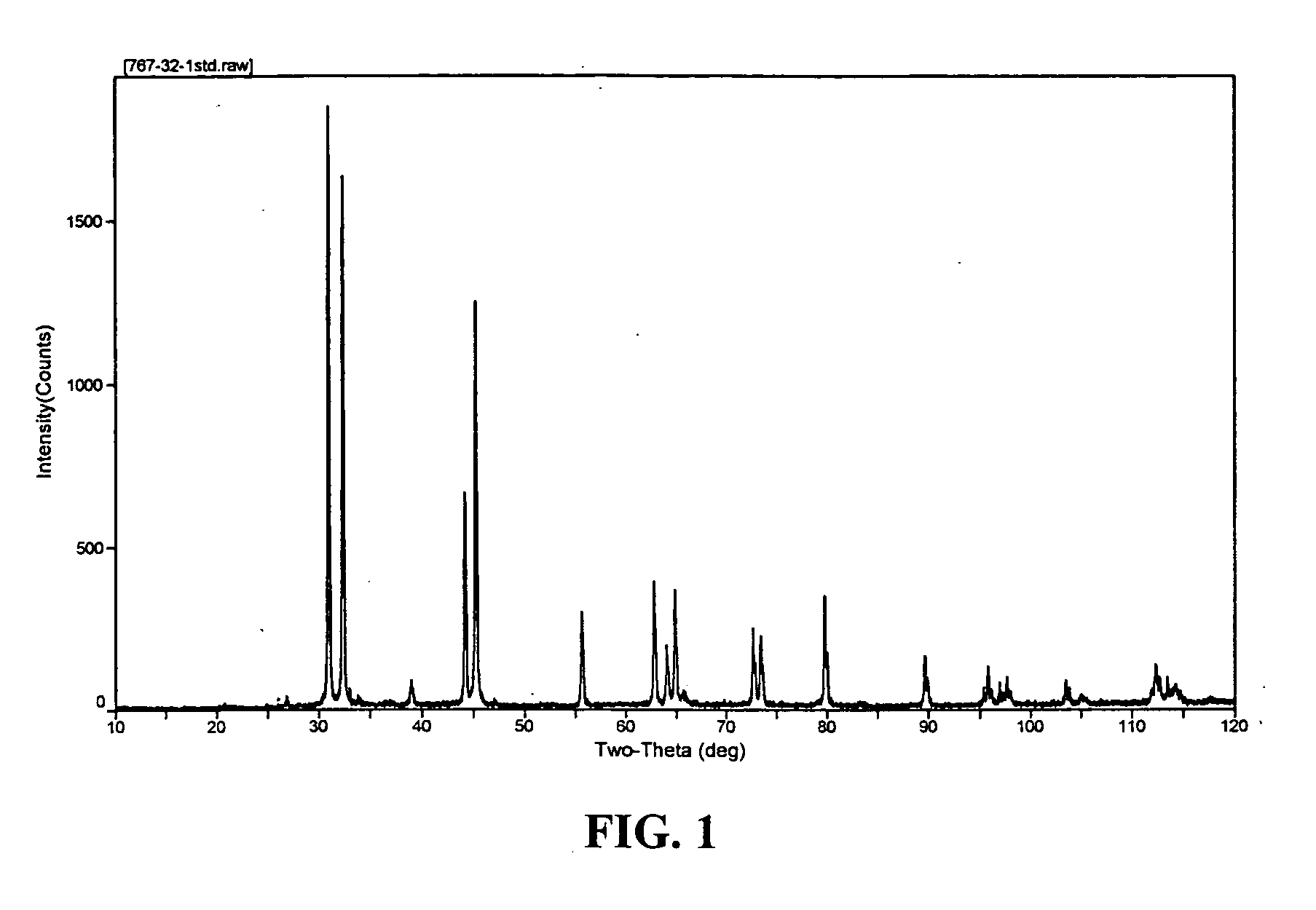

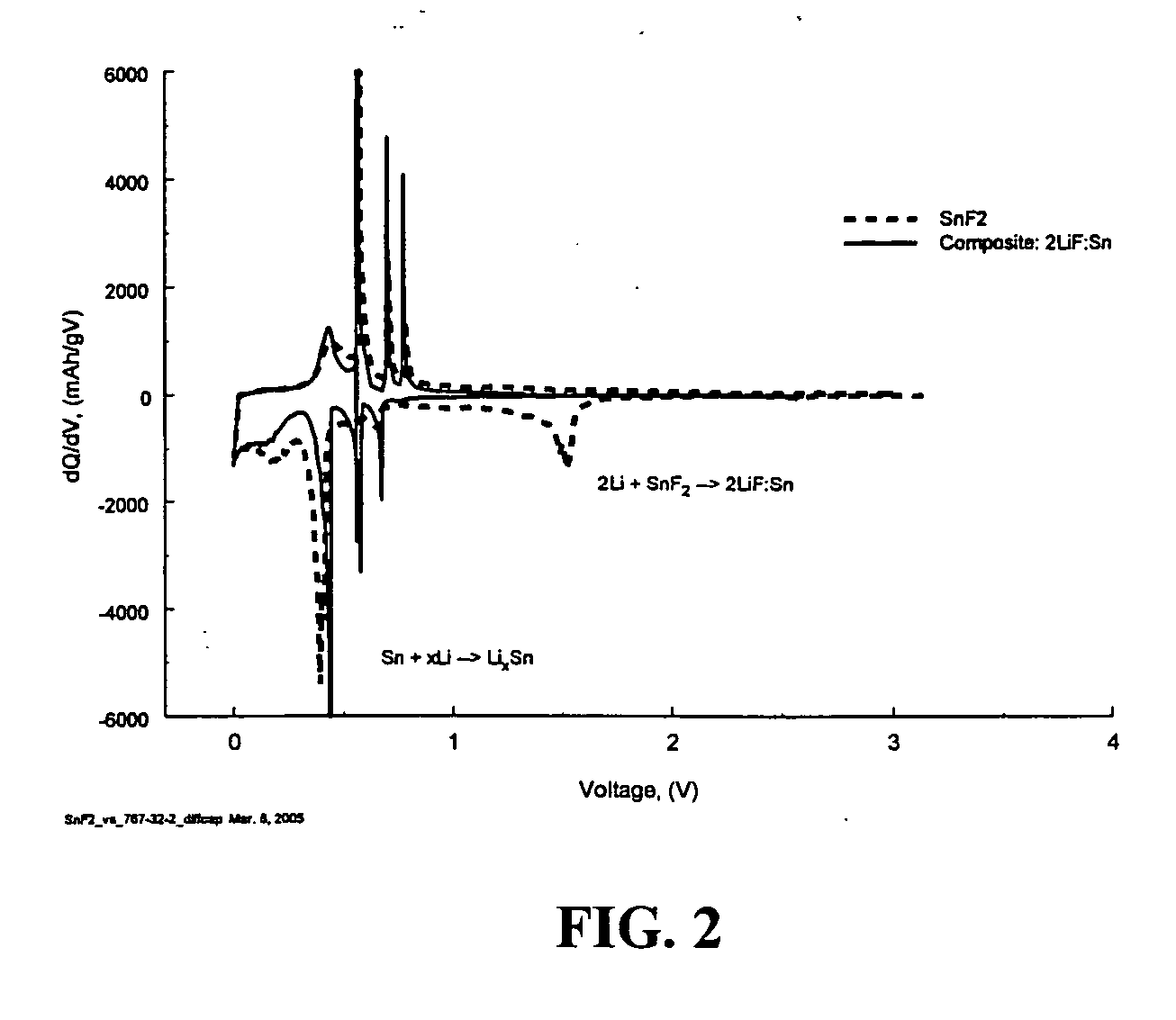

Composite materials of nano-dispersed silicon and tin and methods of making the same

Composite compounds of tin and lithium, silicon and lithium, or tin, silicon, and lithium having tin and silicon nano-dispersed in a lithium-containing matrix may be used as electrode materials and particularly anode materials for use with rechargeable batteries. Methods of making the composite compounds include the oxidation of alloys, the reaction of stabilized lithium metal powder with tin and silicon oxides, and the reaction of inorganic salts of lithium with tin and silicon containing compounds.

Owner:LIVENT USA CORP

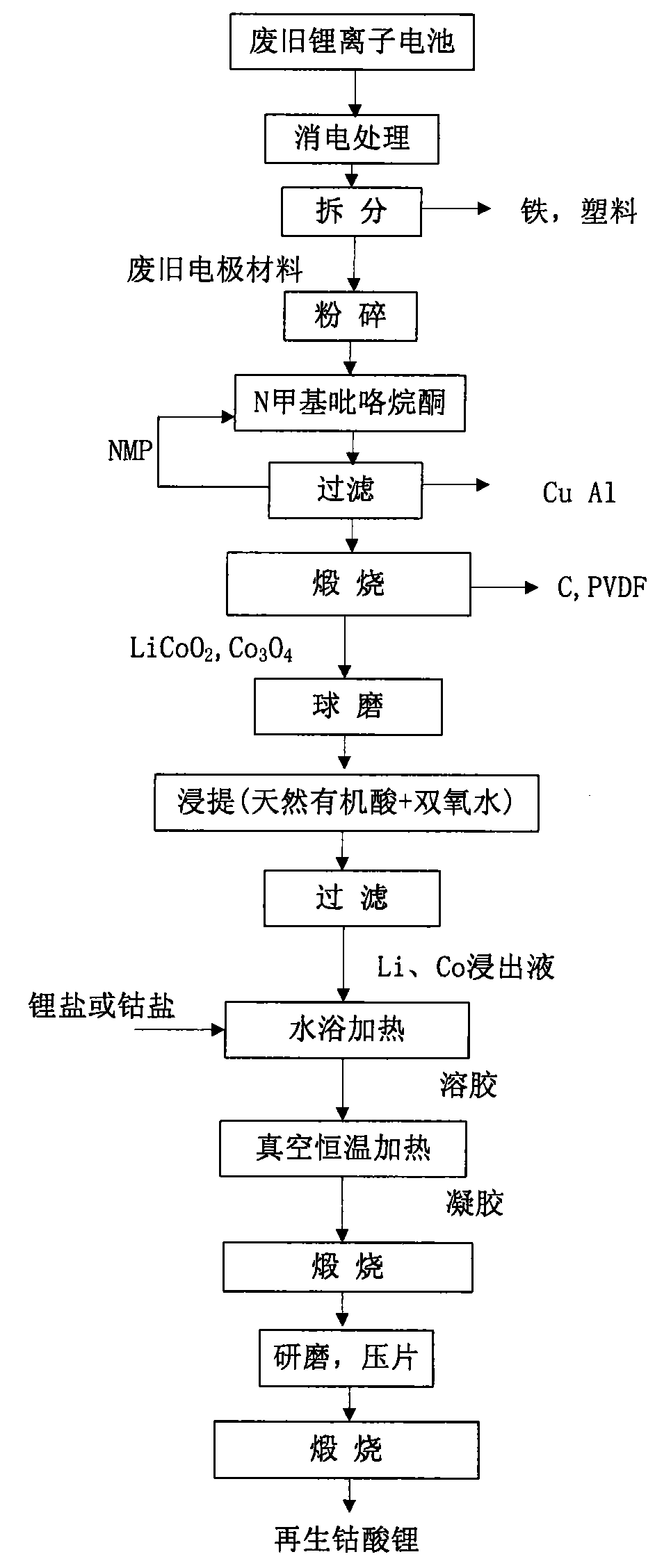

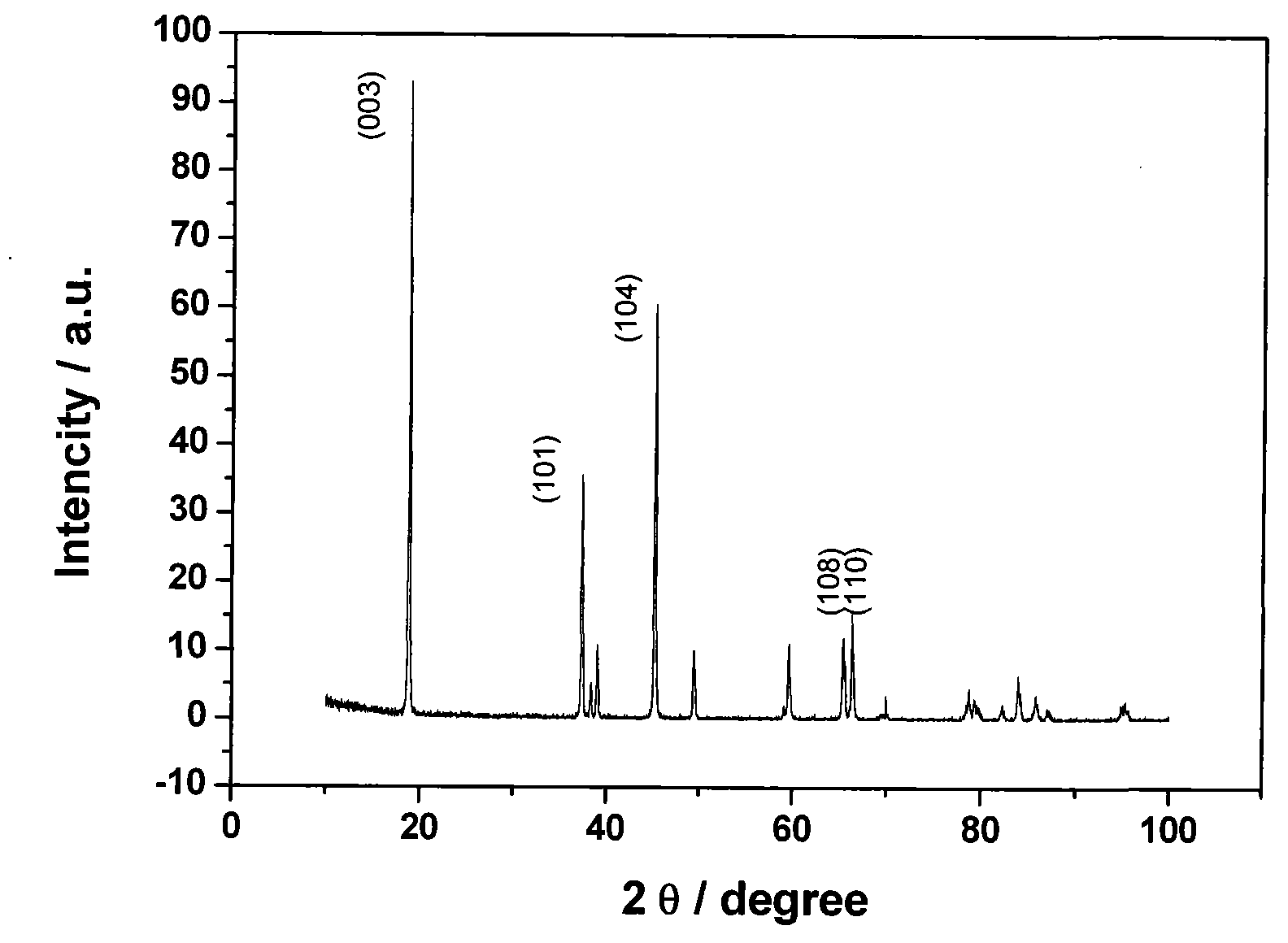

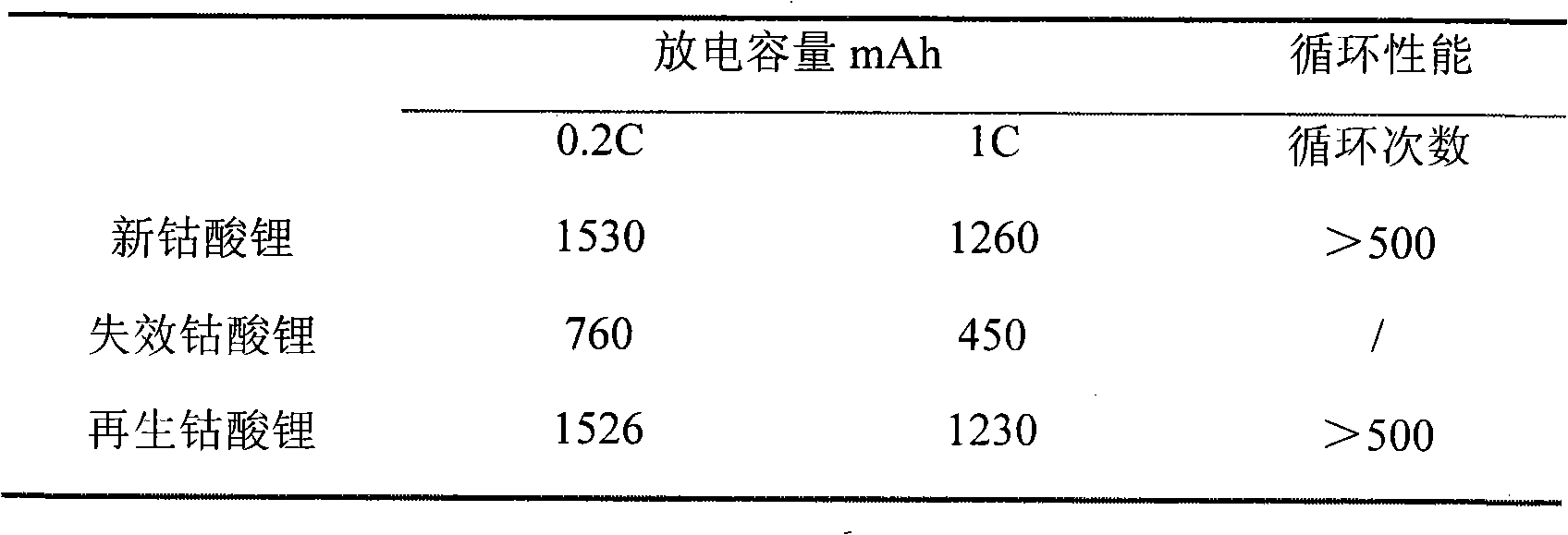

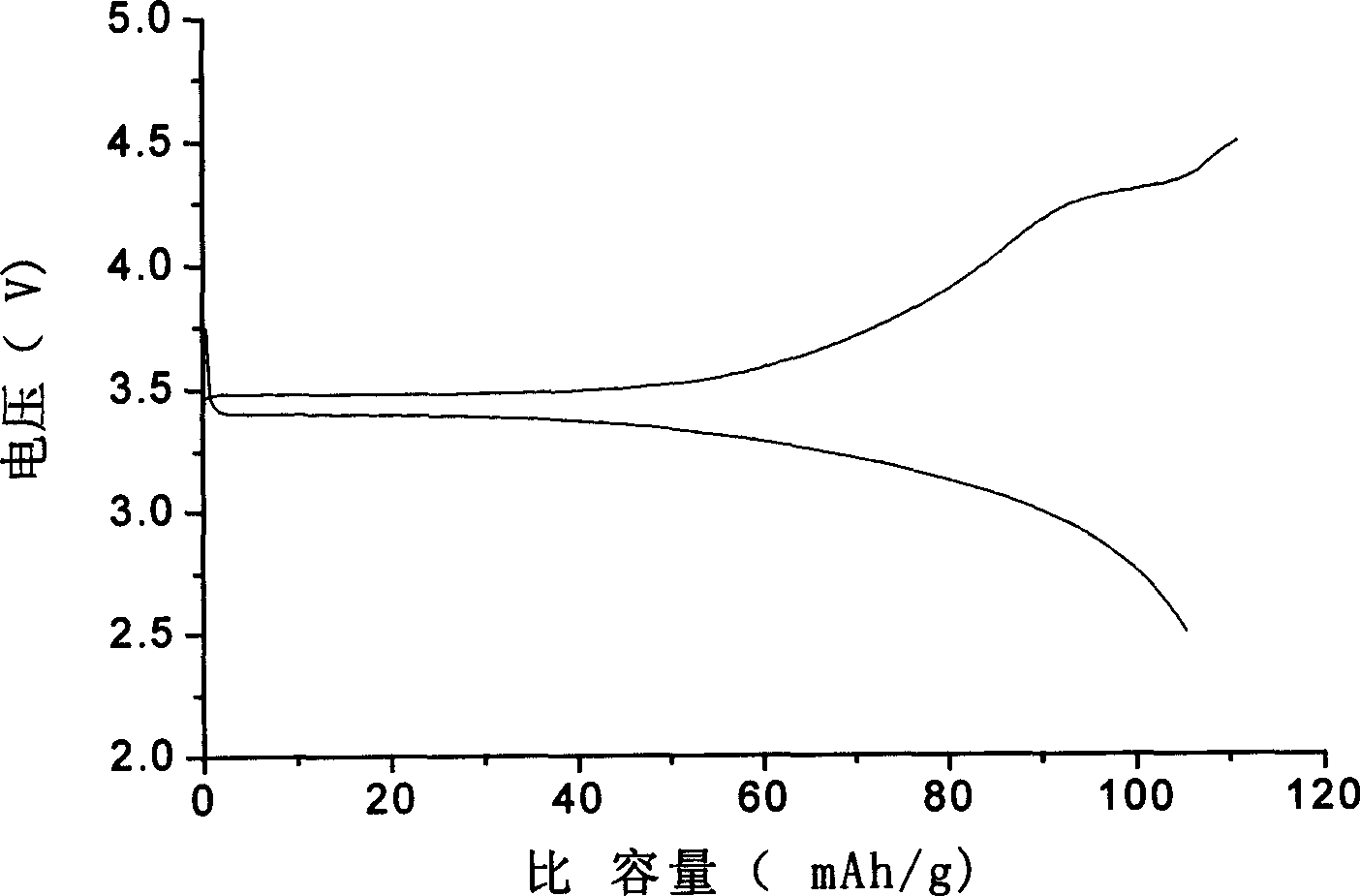

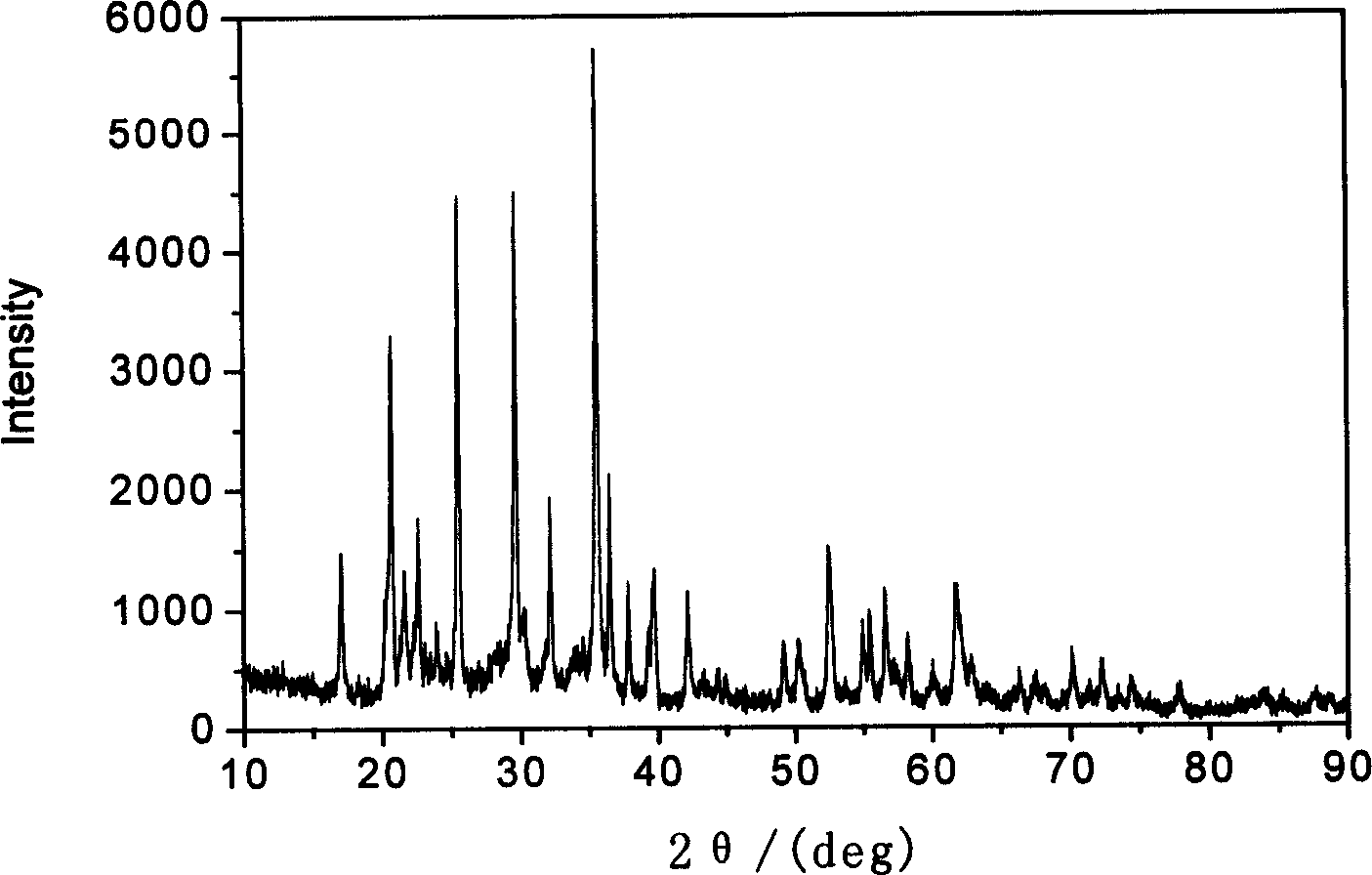

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

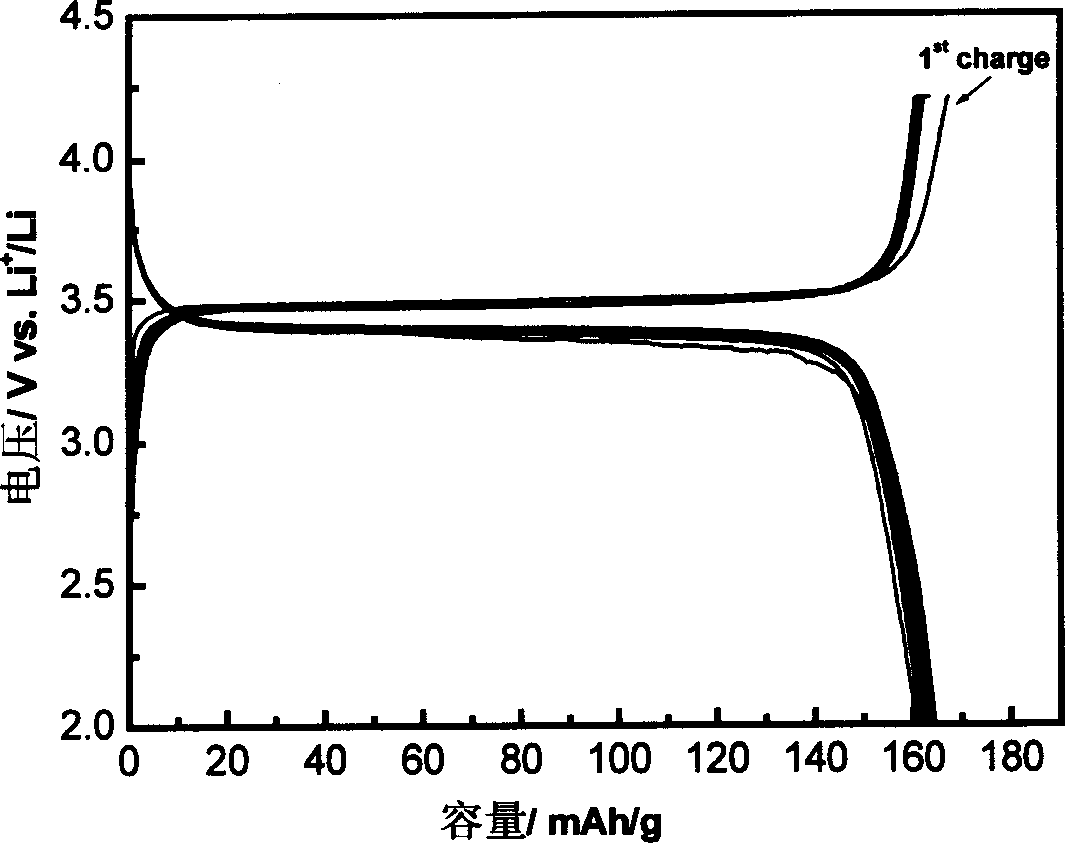

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

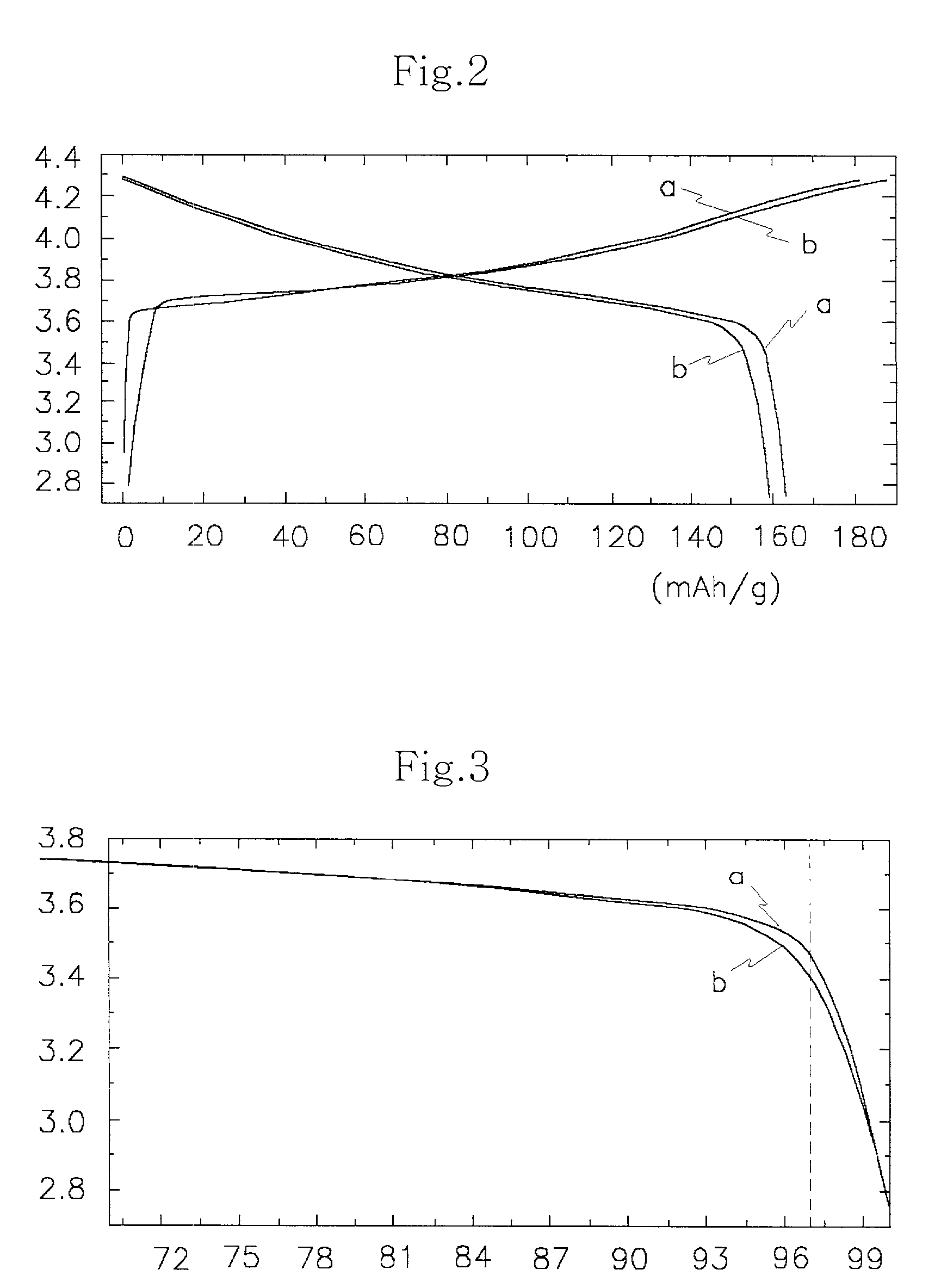

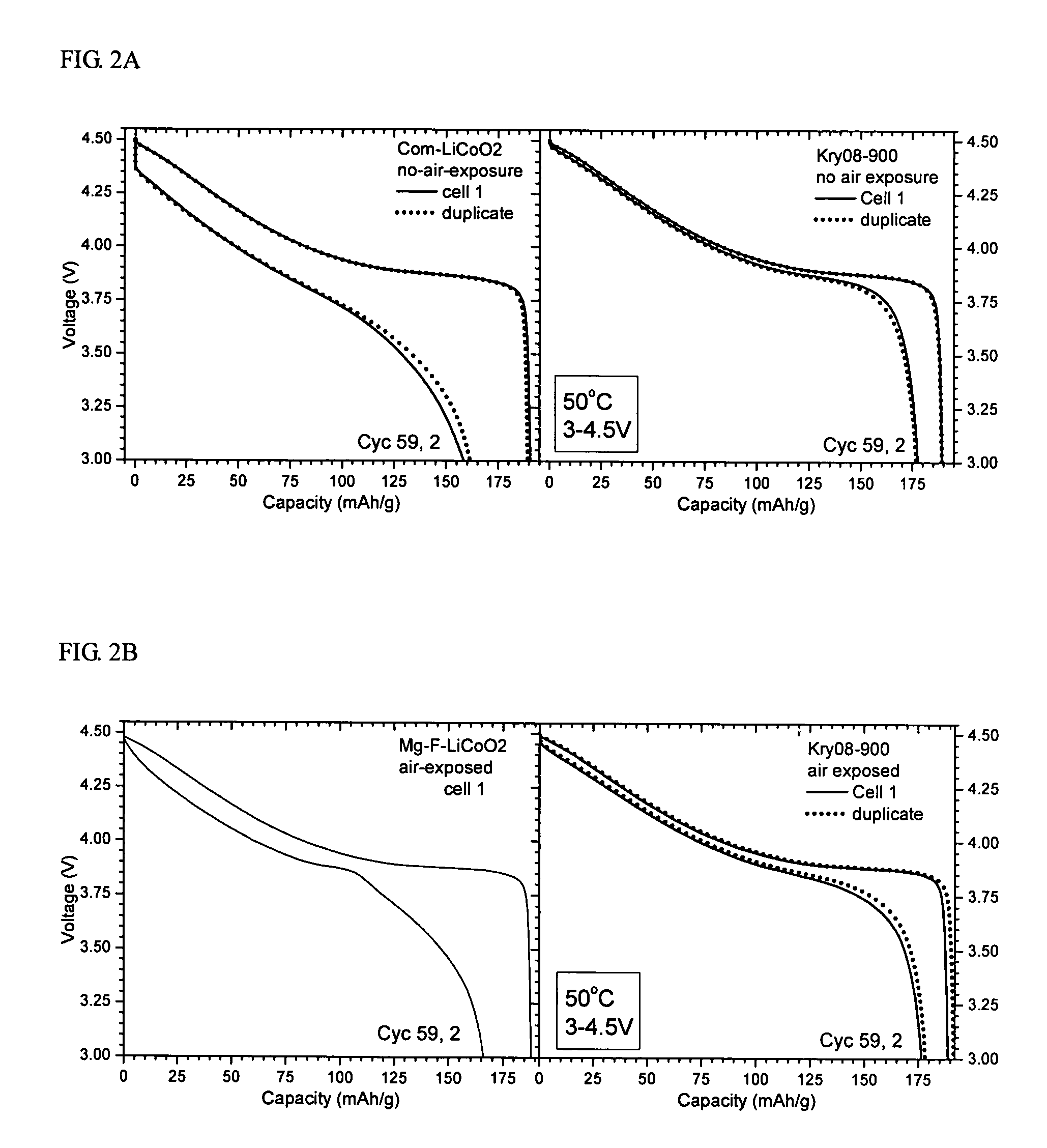

Method for preparing positive active material for rechargeable lithium battery and positive active material prepared by same

ActiveUS7326498B2Inhibiting high-temperature swellingElectrode manufacturing processesNon-aqueous electrolyte accumulatorsRare-earth elementAlkaline earth metal

Disclosed is a method of preparing a positive active material for a rechargeable lithium battery including adding first and second compounds to a solvent to prepare an acidic solution with a pH from 0.01 to 3, the first compound including an element that is capable of forming a double bond with an oxygen of a lithium metal oxide, and the second compound including at least one element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals and rare-earth elements; adding a lithium-containing compound to the acidic coating solution to coat the lithium-containing compound; and heat-treating the coated lithium-containing compound to form a surface-treatment layer comprising a compound represented by the formula MXOk where M is an element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals, rare-earth elements and combinations thereof; X is an element that is capable of forming a double bond with oxygen; and k is an integer from 2 to 4.

Owner:SAMSUNG SDI CO LTD

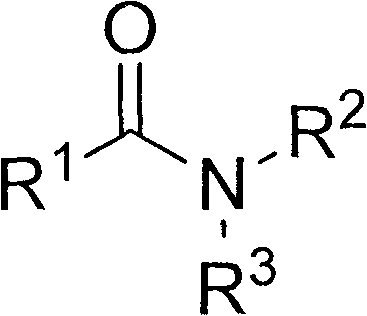

Method for extracting lithium salts in lithium-containing brine

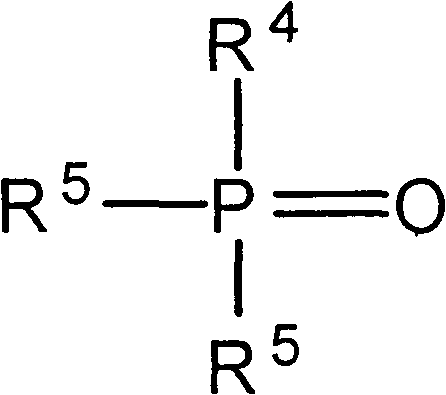

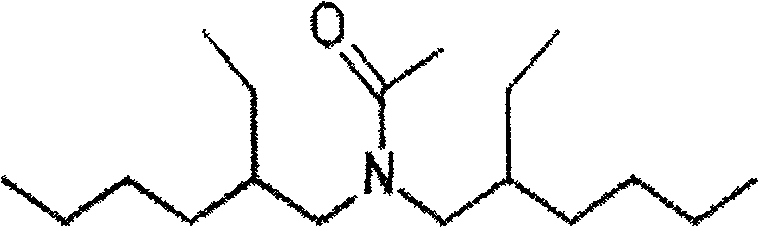

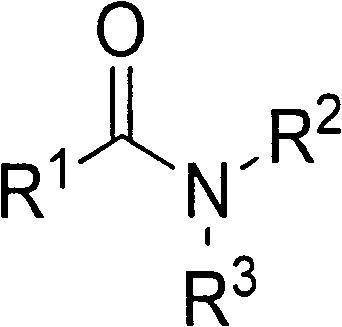

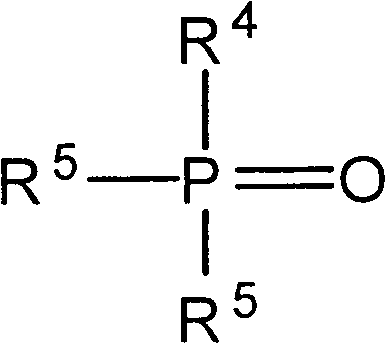

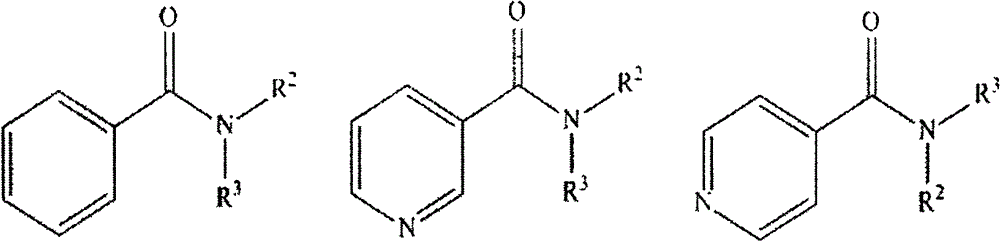

ActiveCN103055539AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumStructural formula

The invention provides a method for extracting lithium salts in lithium-containing brine. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to the industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

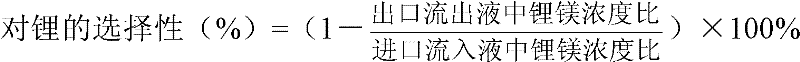

Nano-filtration method for separating magnesium and enriching lithium from salt lake brine

InactiveCN1542147AEfficient recyclingSimple processSemi-permeable membranesLithium compoundsIon contentLithium chloride

The nanofiltration process is suitable for Mg-Li separation and Li enriching of Li containing bittern or Li containing solution from salt lake to prepare lithium carbonate or lithium chloride with the Li enriching bittern. Nanofiltration membrane is used in separating and enriching lithium from lithium containing bittern, which contains Mg, Ca and other cations and sulfate radical and other anions and has Li ion concentration of 0.1-11.5 g / L and Mg / Li ion weight ratio 1-200, to obtain lithium enriched bittern suitable for preparing lithium carbonate or lithium chloride. The said process is effective, and can obtain lithium enriched bittern with Mg / Li ion weight ratio 0.6-5 and Li ion content of 0.6-20 g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS20020055042A1Improve thermal stabilityElectrode manufacturing processesZirconium compoundsPhysical chemistryLithium battery

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 andl a metal oxide or composite metal oxide layer formed on the compound. <table-cwu id="TABLE-US-00001"> <number>1< / number> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="OFFSET" colwidth="42PT" align="left" / > <colspec colname="1" colwidth="77PT" align="left" / > <colspec colname="2" colwidth="98PT" align="center" / > <row> <entry>< / entry> <entry>< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyF2< / entry> <entry>(1)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyS2< / entry> <entry>(2)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aFa< / entry> <entry>(3)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aSa< / entry> <entry>(4)< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> < / tgroup> < / table-cwu> (where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, IPu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<=y<=0.99, 0<=,z<=0.5, and 0<=a<=0.5)

Owner:SAMSUNG SDI CO LTD

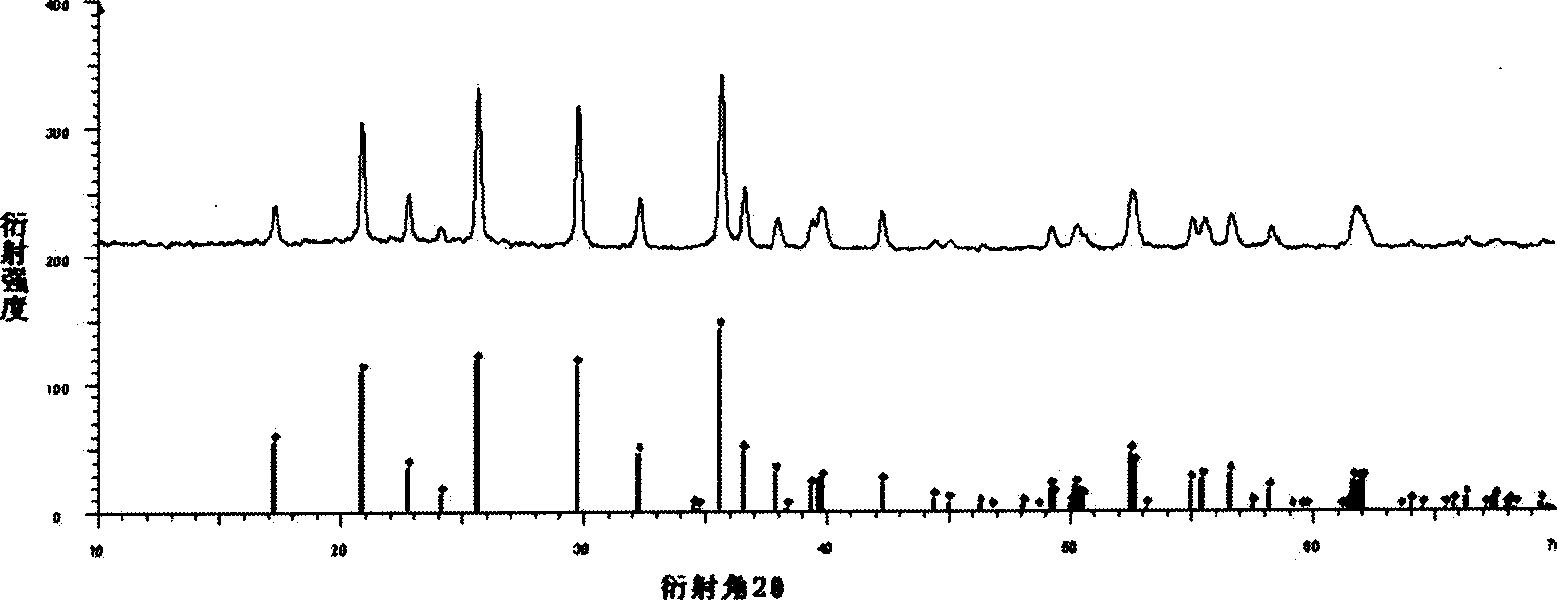

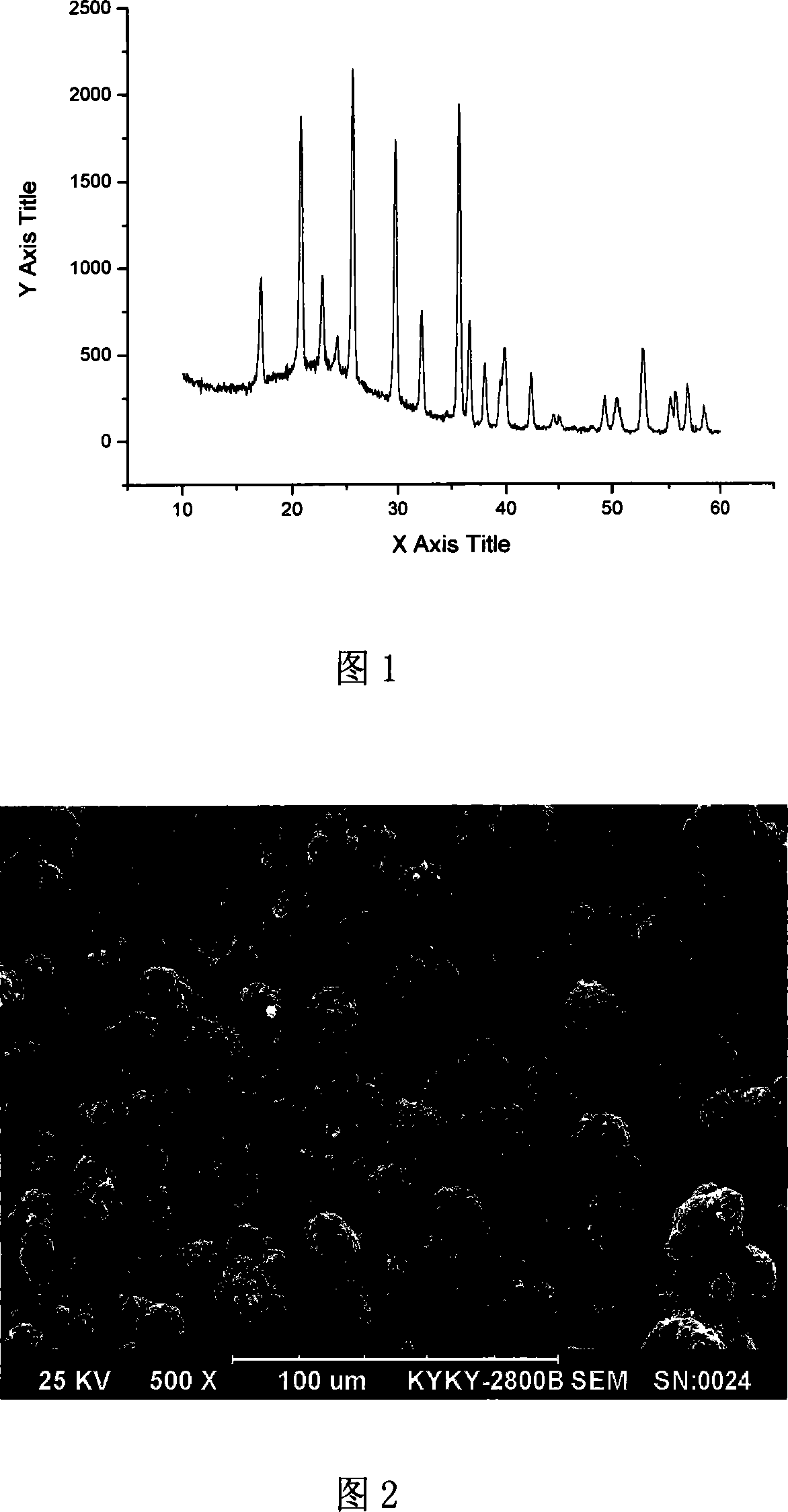

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

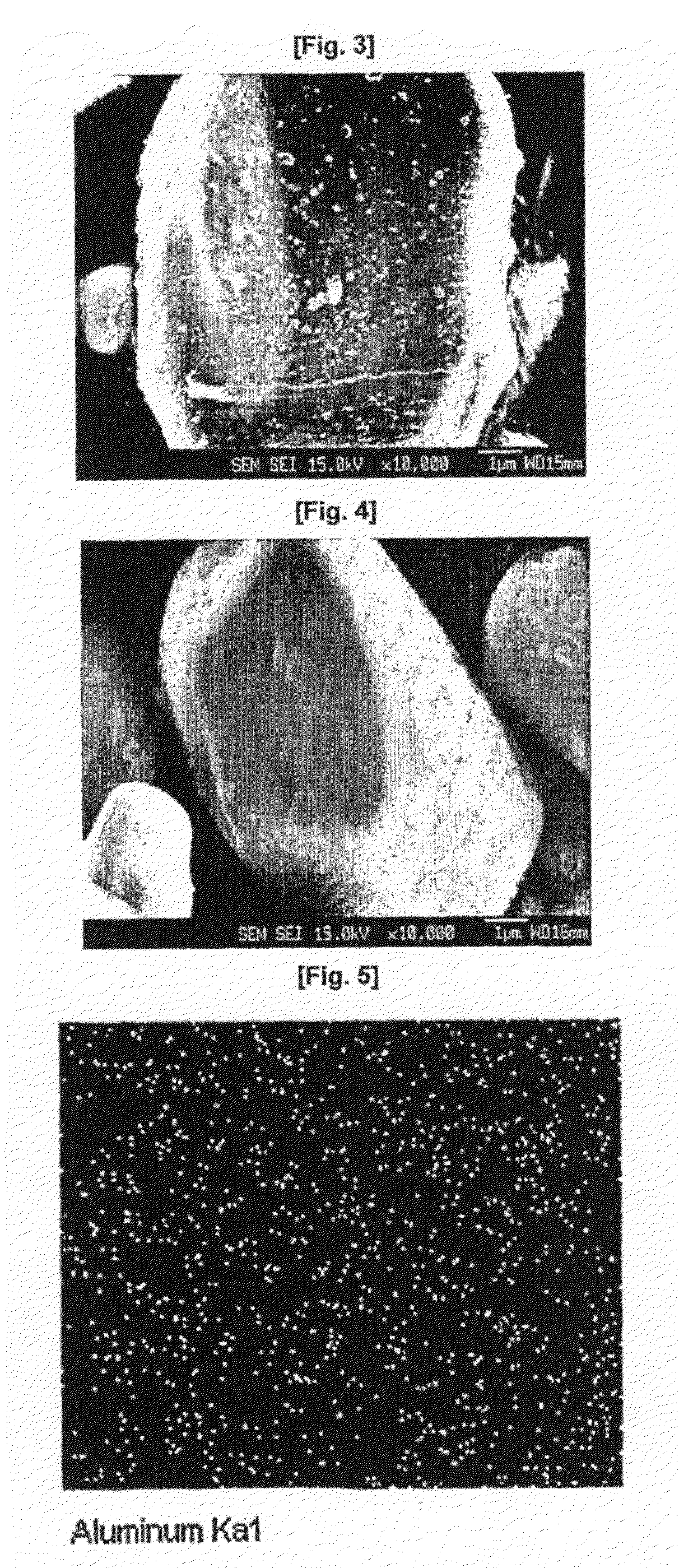

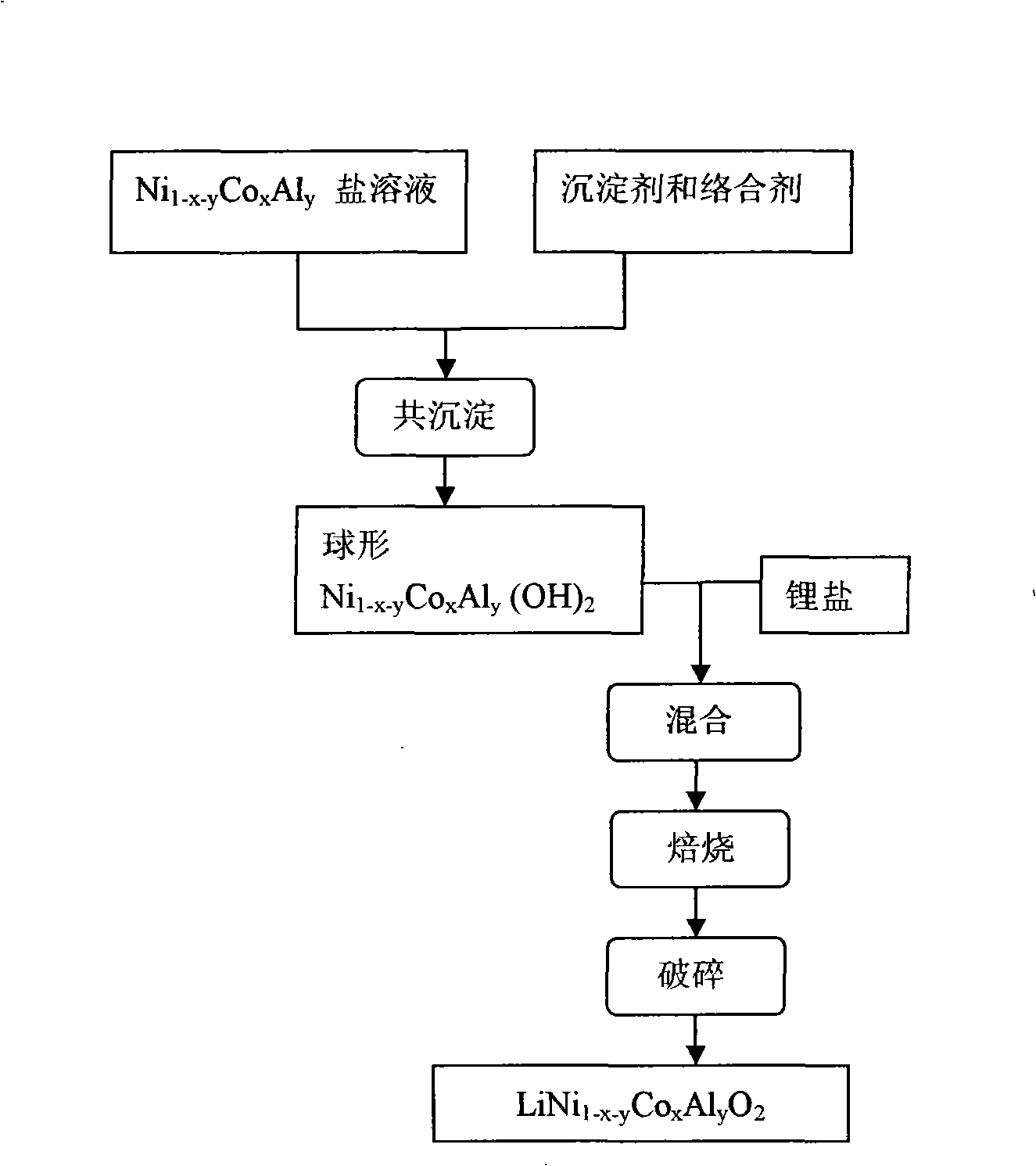

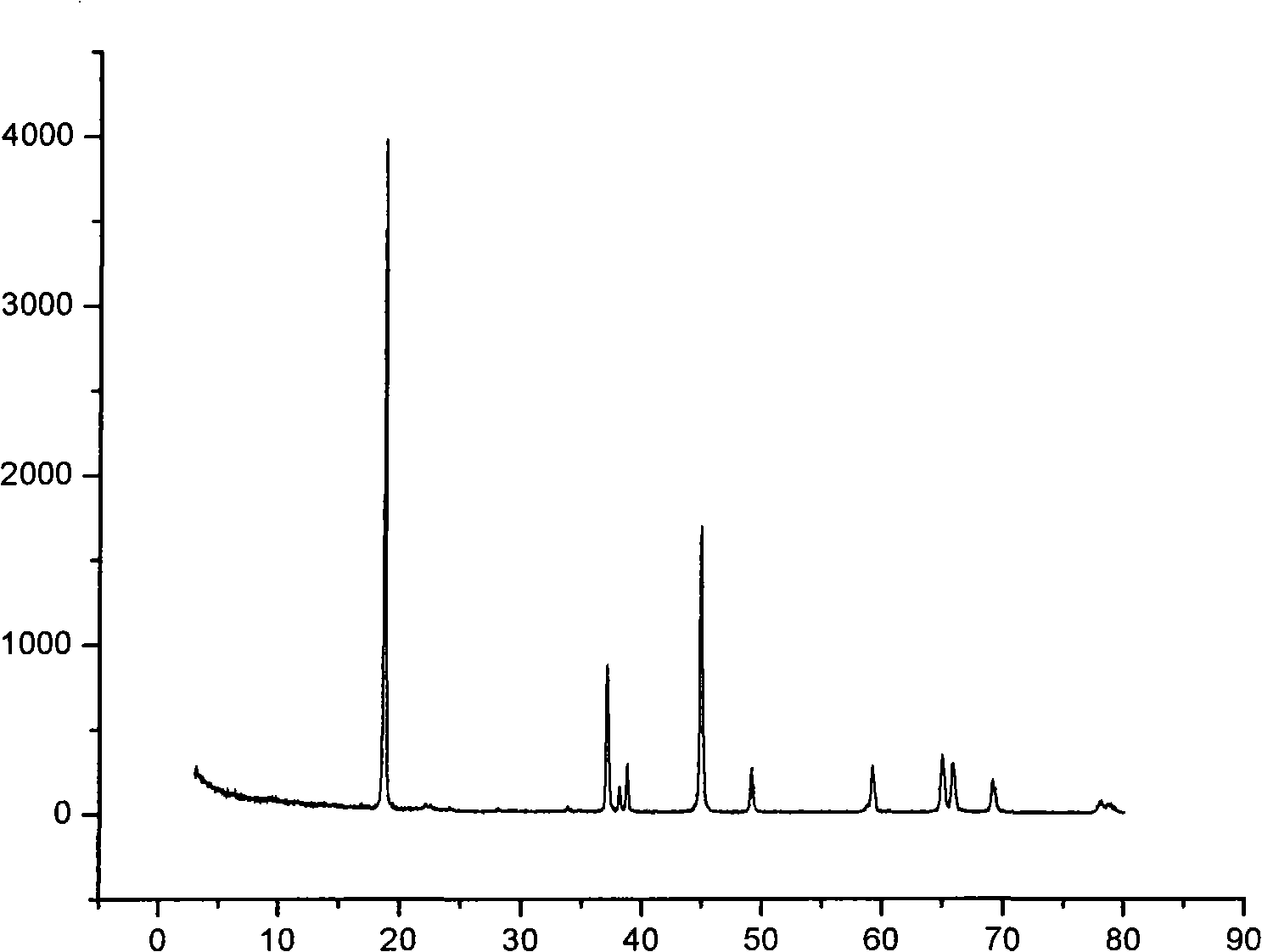

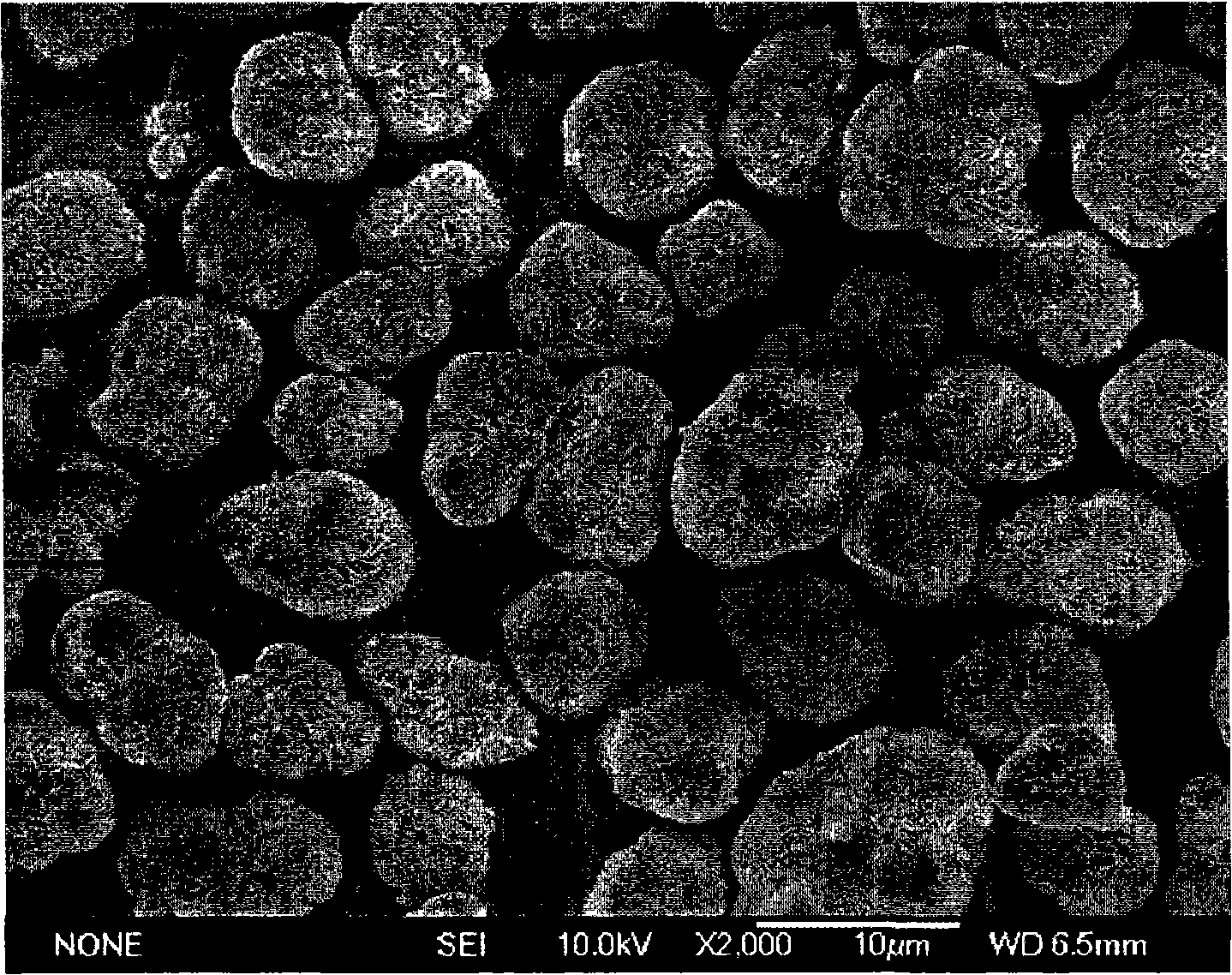

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

Method for preparing lithium adsorbent resin

ActiveCN102631897AGood choiceImprove efficiencyOther chemical processesLithium compoundsLithiumHigh magnesium

The invention discloses a method for preparing lithium adsorbent resin. The method includes steps of 1, preparing a precursor of the lithium adsorbent resin; 2, uniformly mixing the prepared precursor with adhesives and porogen to prepare disperse phase; 3, preparing continuous phase incompatible with the disperse phase; 4, adding the disperse phase into the continuous phase, stirring, leading the disperse phase to be scattered into beads with suitable granularity, and solidifying the beads into spherical particles under certain conditions; and (5) removing substances such as a dispersing agent, the porogen and the like in the spherical particles, and obtaining the lithium adsorbent resin capable of being used for extracting lithium from high-magnesium and low-lithium brine after activating treatment. The preparation method is simple, and the prepared lithium adsorbent resin has the advantages of zero pollution, high efficiency and adsorbent capacity, long service period, recyclability and the like.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

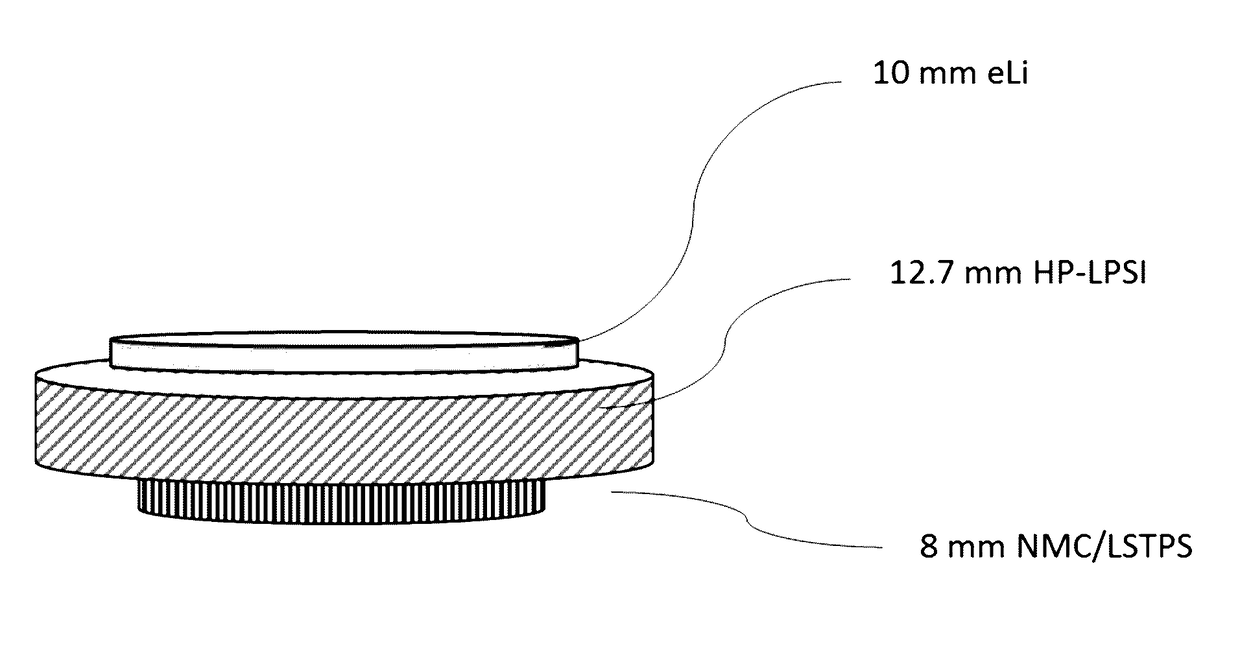

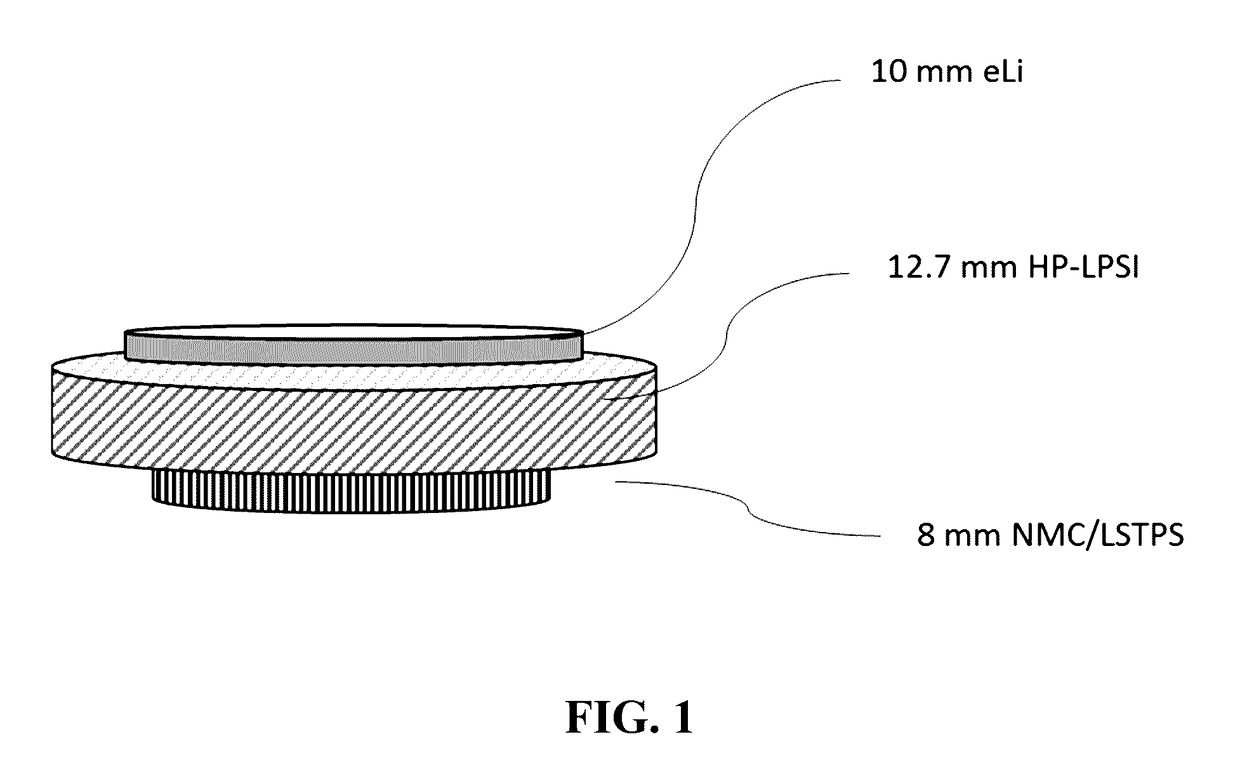

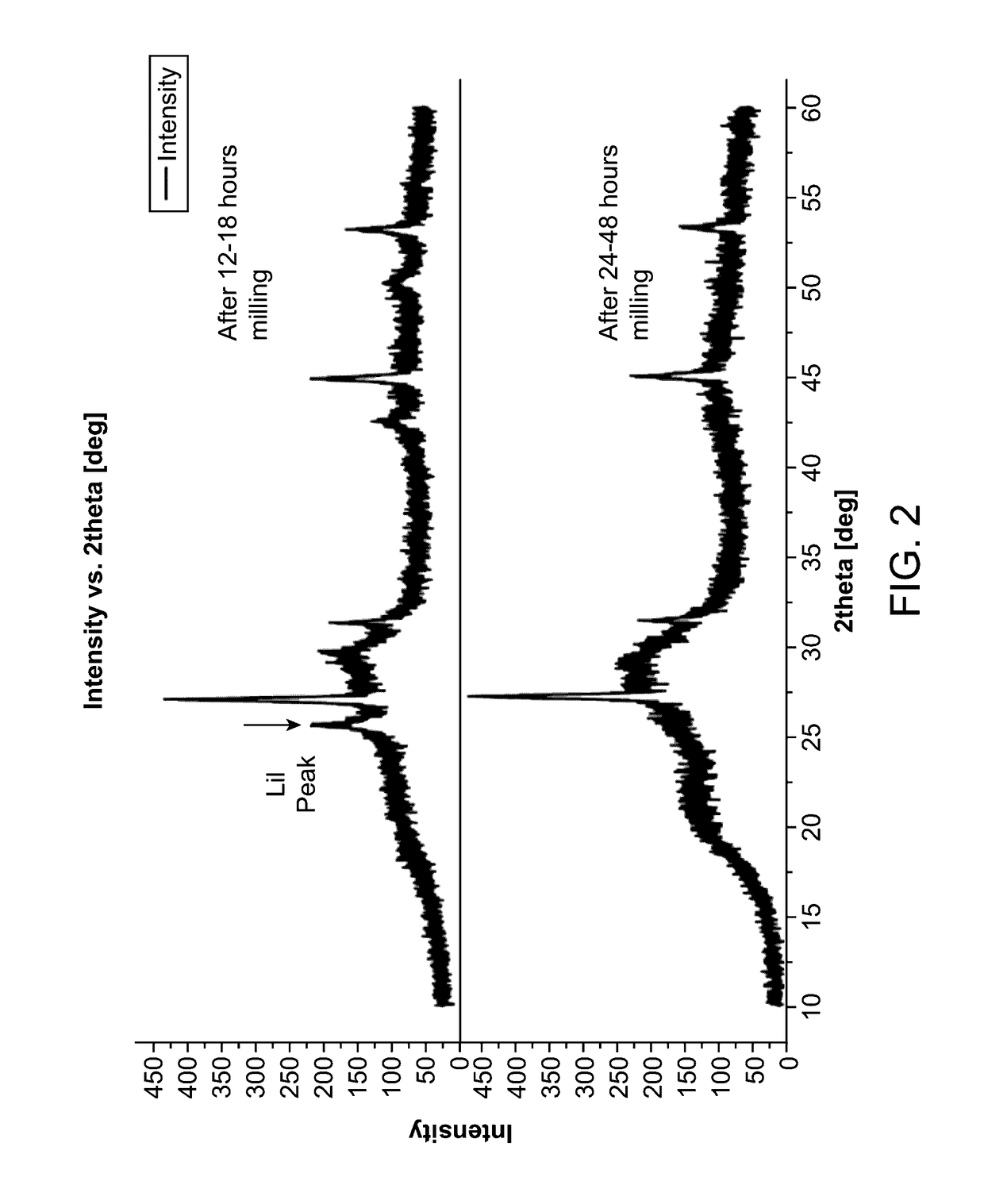

Lithium, phosphorus, sulfur, and iodine including electrolyte and catholyte compositions, electrolyte membranes for electrochemical devices, and annealing methods of making these electrolytes and catholytes

ActiveUS20170162901A1Solid electrolytesPhosphorus sulfur/selenium/tellurium compoundsElectrical conductorElectrochemistry

The present disclosure sets forth battery components for secondary and / or traction batteries. Described herein are new solid-state lithium (Li) conducting electrolytes including monolithic, single layer, and bi-layer solid-state sulfide-based lithium ion (Li+) conducting catholytes or electrolytes. These solid-state ion conductors have particular chemical compositions which are arranged and / or bonded through both crystalline and amorphous bonds. Also provided herein are methods of making these solid-state sulfide-based lithium ion conductors including new annealing methods. These ion conductors are useful, for example, as membrane separators in rechargeable batteries.

Owner:QUANTUMSCAPE BATTERY INC

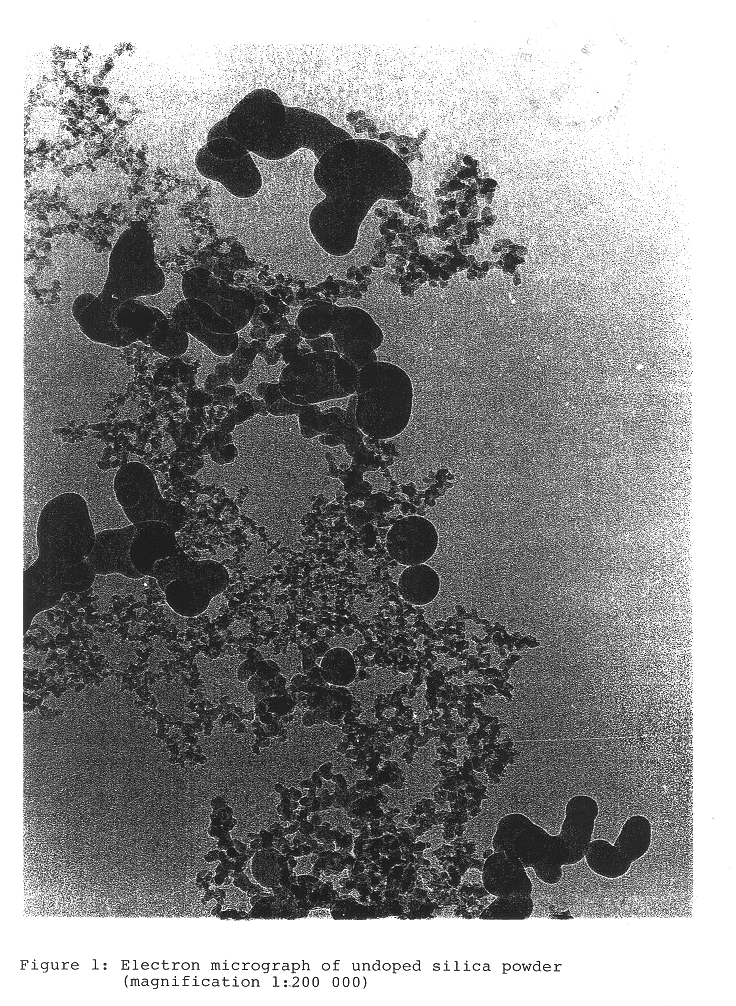

Aqueous dispersion, a process for the preparation and the use thereof

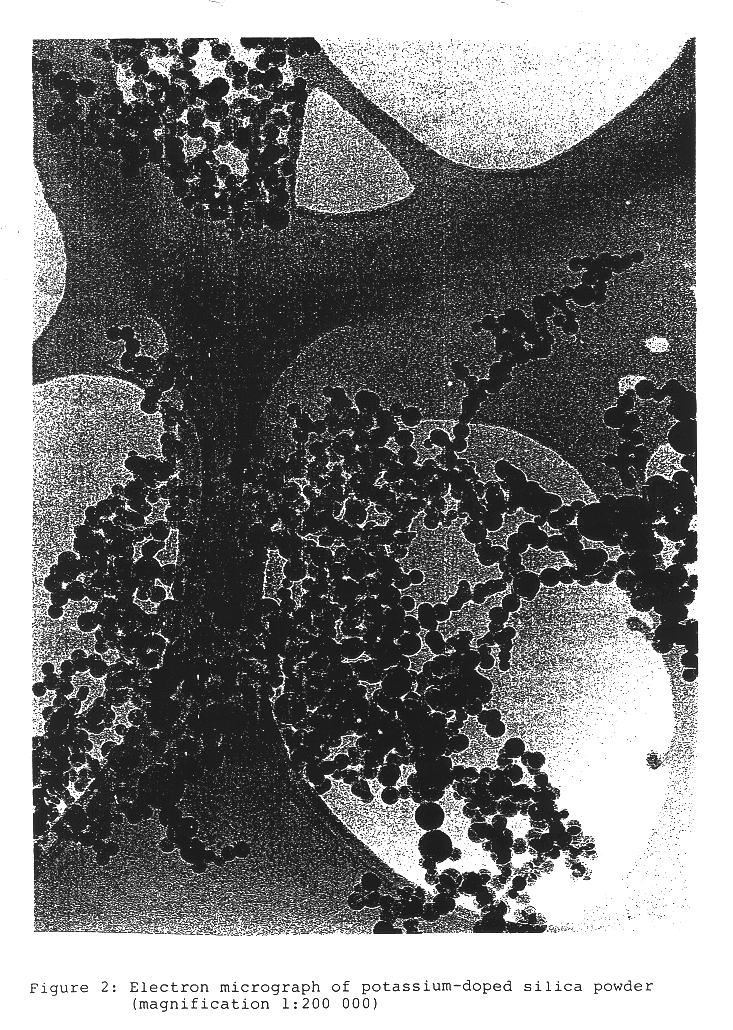

InactiveUS6676719B2Improve stabilityTrend downCosmetic preparationsNon-fibrous pulp additionSilica particleSilicon dioxide

A pyrogenic process is used to prepare alkali-doped silica particles. Particles produced by this process exhibit homogeneous doping, reduced agglomeration, greater stability and higher removal rates. Aqueous dispersions containing alkali-doped pyrogenic silica with average particle size less than 100 nm are used for polishing surfaces (CMP).

Owner:EVONIK DEGUSSA GMBH

Method for extracting lithium salts in lithium-containing brine through extraction method

ActiveCN103055538AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumDiluent

The invention provides a method for extracting lithium salts in lithium-containing brine through an extraction method. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Sorbent for lithium extraction

ActiveUS8753594B1Increase ionic strengthWaste water treatment from quariesAluminium compoundsSorbentLithium aluminate

This invention relates to a method for preparing a lithium aluminate intercalate (LAI) matrix solid and methods for the selective extraction and recovery of lithium from lithium containing solutions, including brines. The method for preparing the LAI matrix solid includes reacting aluminum hydroxide and a lithium salt for form the lithium aluminate intercalate, which can then be mixed with up to about 20% by weight of a polymer to form the LAI matrix.

Owner:TERRALITHIUM LLC

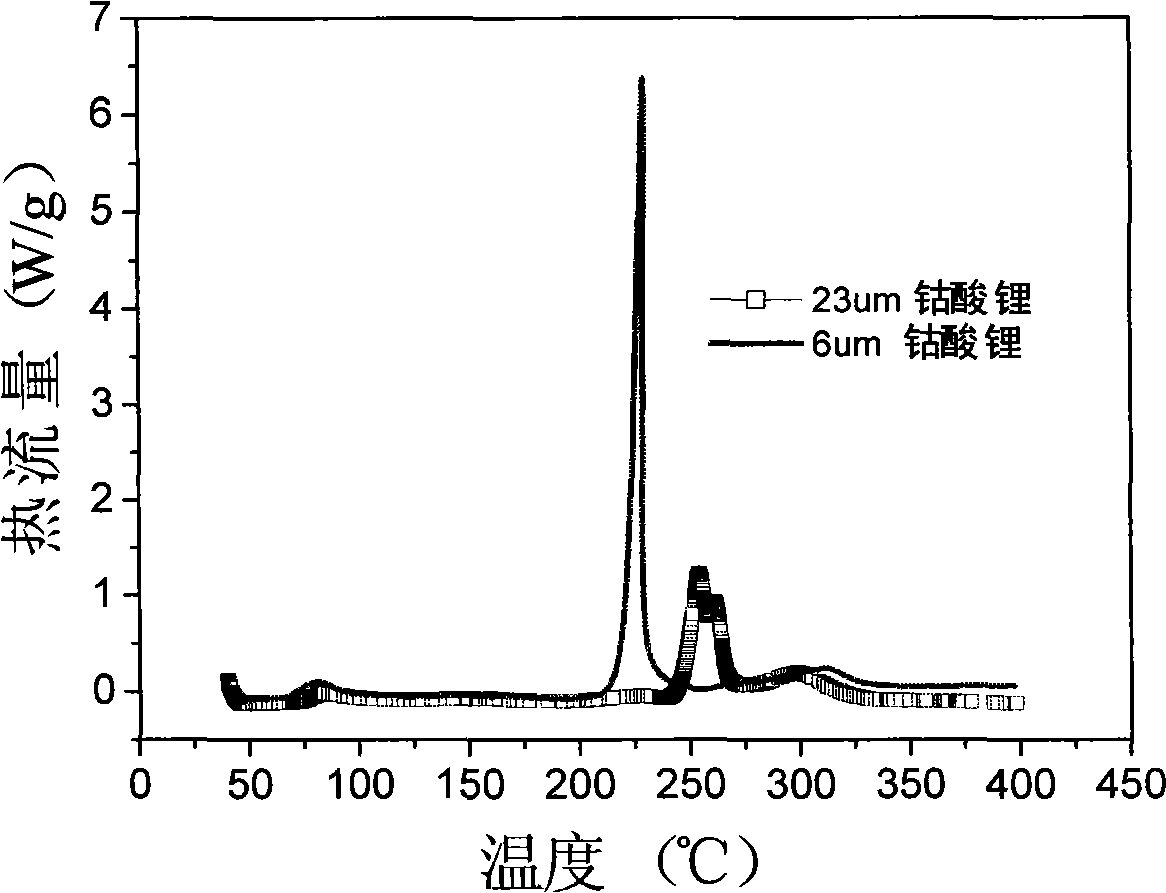

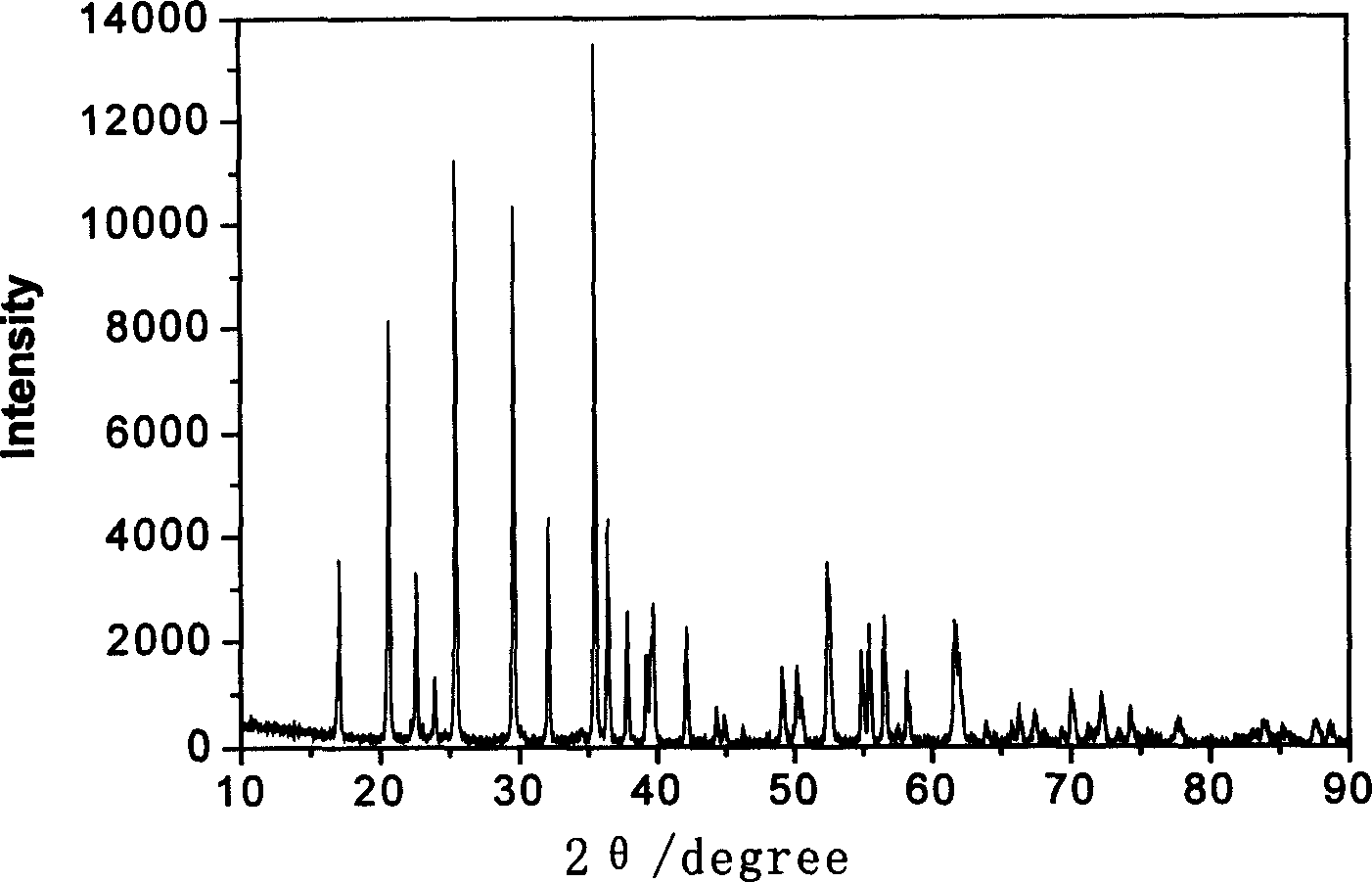

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Method for preparing LiFeP04 material by microwave method

InactiveCN1547273AAvoid growing upPrevent oxidationElectrode manufacturing processesLithium compoundsActivated carbonCrystallite

The invention provides a method for using microwave method to produce LiFePO4 material, the character lies in: it uses microwave synthesis technology, uses the active carbon as the heating material for microwave receptor, thus the LiFePO4 material can be acquired. The process is: the Li2CO3 and FeC2O4íñ2H2O, (NH4) 2HPO4 are confected according to the resultant's proportion, they are put into the agate ball milling pot, uses the acetone as dispersant to ball grind for 4-12 hours, the mixed material are dried and pressed into pieces, and put into the aluminum crucible containing the active carbon and thermal retardation material, then the crucible is put into the household microwave stove, the frequency is 2.45GHz, the power is adjusted to the lower gear-middle gear, the time is 3-30 minutes, the synthesized product can be acquired. The merits of the invention lie in: the heating process is quick, the synthesizing time is short, and it prevents the crystal particle from growing; the energy consumption can be reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing high-density spherical lithium iron phosphate and lithium iron manganese phosphate

InactiveCN1632970AWide variety of sourcesImprove conductivityElectrode manufacturing processesLithium compoundsFerrous ammonium phosphatePersulfate

This invention discloses a high-density ball ferric phosphate lithium and manganous phosphate iron lithium process method used in lithium ion battery positive electrode material in energy material process technique field. The process method comprises the following steps: to use ferric persulfate, phosphor or complex builder or manganese sulfate to process the mixture liquid; to react with the hartshorn solution to generate ball ferrous phosphate ammonium or manganese phosphate ferrous front driver; to mix it with lithium carbonate with mole proportion of one to one after washing and drying; under protection of nitrogen gas and after 600 to 900 degrees for 8 to 48 hours to get the ferric phosphate lithium or manganese phosphate ferrous.

Owner:TSINGHUA UNIV

Lithium-containing composite oxide and its production method

ActiveUS20090148772A1Large volume capacity densityImprove securityCell electrodesLithium compoundsAlkaline earth metalDischarge rate

The present invention provides a lithium-containing composite oxide for a positive electrode for a lithium secondary battery, which has a large volume capacity density and high safety, and excellent durability for charge and discharge cycles and charge and discharge rate property, and its production method.The lithium-containing composite oxide is represented by the general formula LipNxMyOzFa (where N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, Sn, alkaline earth metal elements and transition metal elements other than Co, Mn and Ni, 0.9≦p≦1.2, 0.965≦x<2.00, 0<y≦0.035, 1.9≦z≦4.2, and 0≦a≦0.05), wherein when a powder of the lithium-containing composite oxide is classified into small particles with an average particle size of 2 μm≦Ds50≦8 μm and large particles with an average particle size of 10 μm≦Dl50≦25 μm, a content of the small particles is from 15 to 40% by weight and a content of the large particles is from 60 to 85% by weight, and 0.01≦ys≦0.06, 0≦yl≦0.02 and 0≦yl / ys<1, where (ys) is a ratio of the M element in the above general formula in the small particles and (yl) is a ratio of the M element in the general formula in the Large particles.

Owner:SUMITOMO CHEM CO LTD

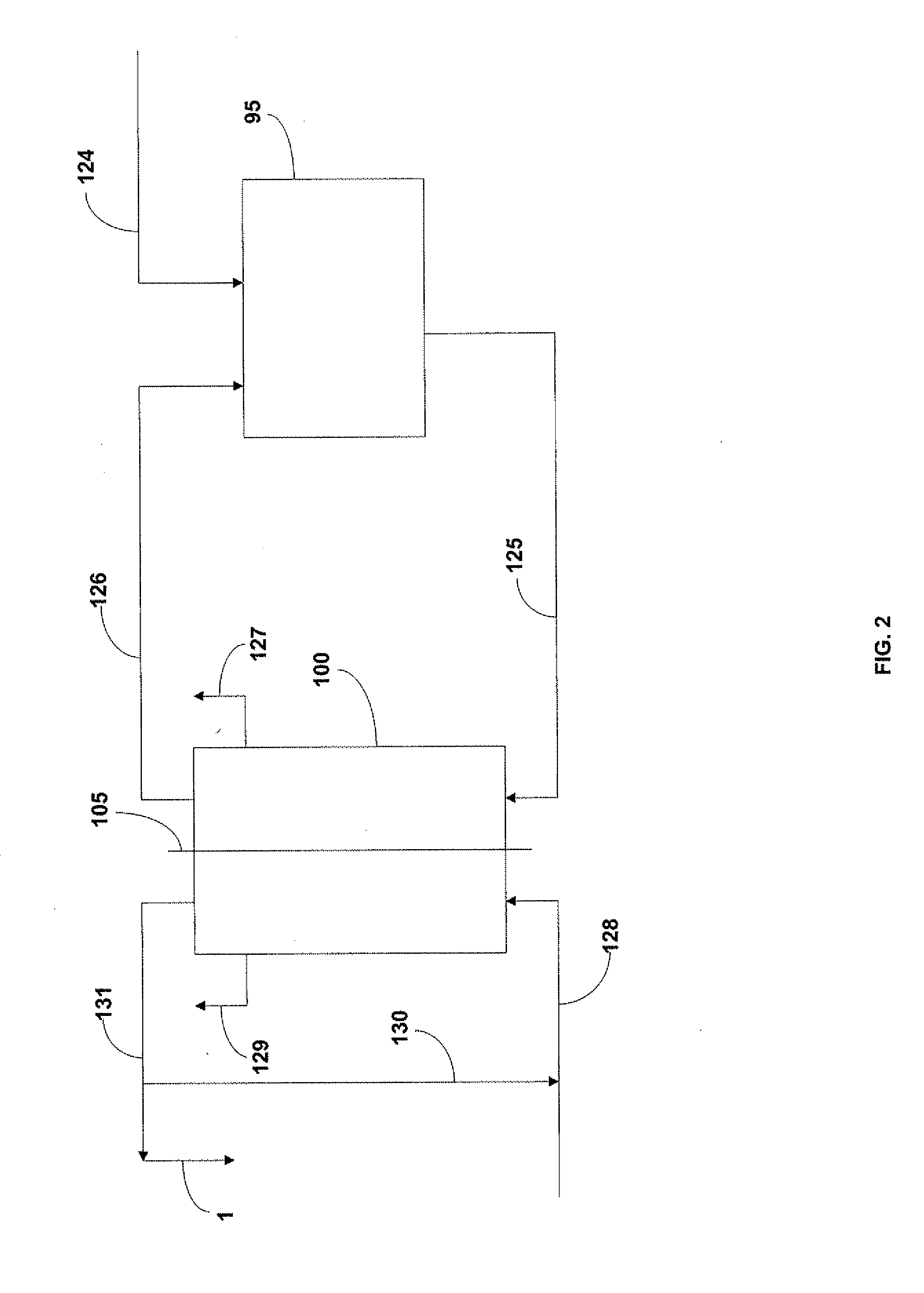

Preparation Method of Lithium-Metal Composite Oxides

ActiveUS20100227221A1High Capacity FeaturesImproved cycle life characteristicsLithium compoundsActive material electrodesLithium metalElectrochemistry

Disclosed is a method for preparing a lithium-metal composite oxide, the method comprising the steps of: (a) mixing an aqueous solution of one or more transition metal-containing precursor compounds with an alkalifying agent and a lithium precursor compound to precipitate hydroxides of the transition metals; (b) mixing the mixture of step (a) with water under supercritical or subcritical conditions to synthesize a lithium-metal composite oxide, and drying the lithium-metal composite oxide; and (c) subjecting the dried lithium-metal composite oxide either to calcination or to granulation and then calcination. Also disclosed are an electrode comprising the lithium-metal composite oxide, and an electrochemical device comprising the electrode. In the disclosed invention, a lithium-metal composite oxide synthesized based on the prior supercritical hydrothermal synthesis method is subjected either to calcination or to granulation and then calcination. Thus, unlike the prior dry calcination method or wet precipitation method, a uniform solid solution can be formed and the ordering of metals in the composite oxide can be improved. Accordingly, the lithium-metal composite oxide can show crystal stability and excellent electrochemical properties.

Owner:HANWHA CHEMICAL CORPORATION +1

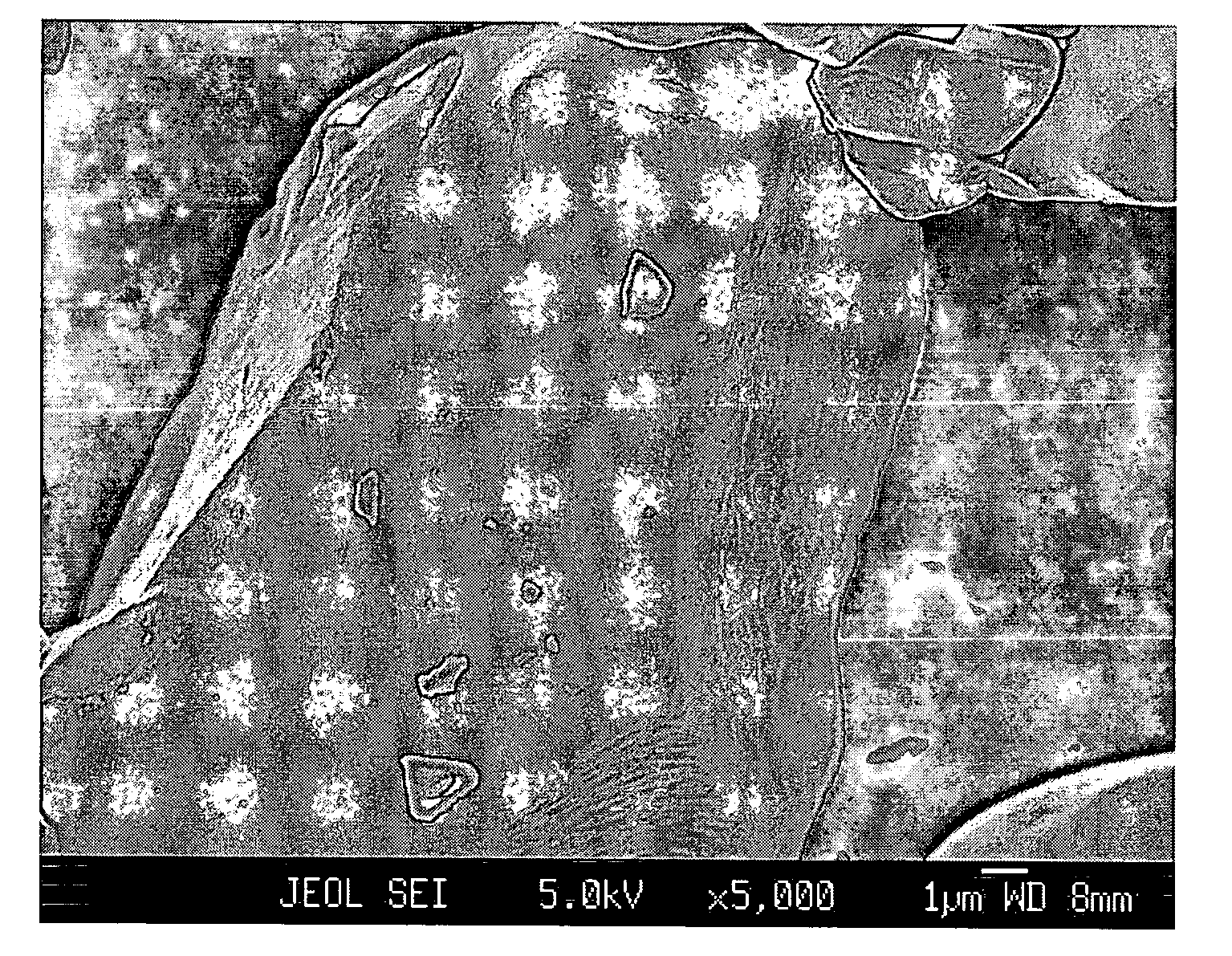

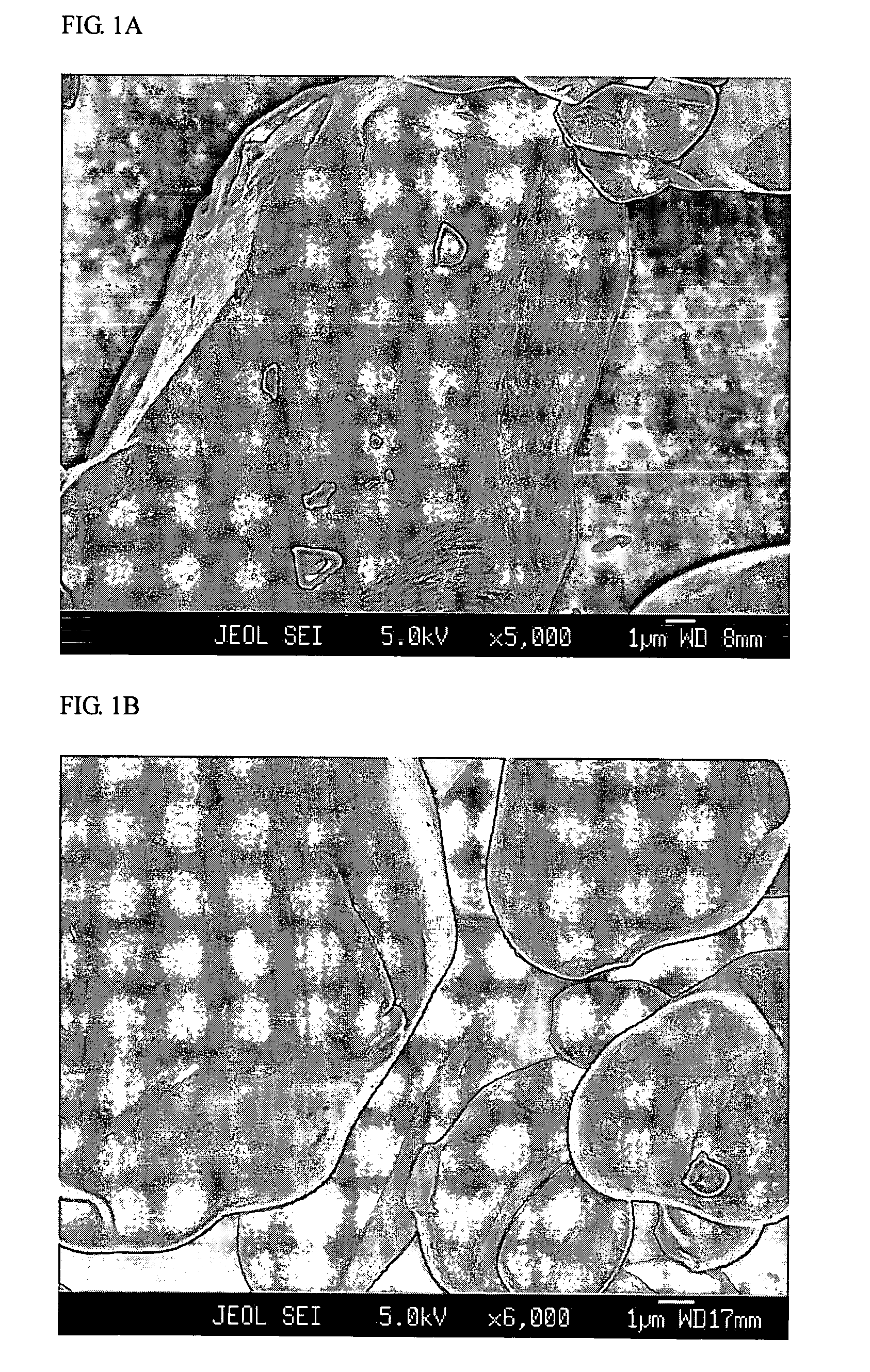

Powdered lithium transition metal oxide having doped interface layer and outer layer and method for preparation of the same

ActiveUS7364793B2Use of materialSimple processLiquid surface applicatorsElectrode thermal treatmentInterface layerMechanical stability

The present invention provides a powdered lithium transition metal oxide useful as a major component for cathode active material of rechargeable lithium batteries, comprising a lithium transition metal oxide particle, a doped interface layer formed near the surface of the particle, and a thermodynamically and mechanically stable outer layer, and a method of preparing the same.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com