Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

312results about How to "Solve the hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green bioactive organic fertilizer

InactiveCN101786931APrevent compactionAvoid pollutionBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention relates to a green bioactive organic fertilizer, which effectively solves the problems of soil hardening, environmental pollution, and harm from residual chemical substances of grains, vegetables and fruits to human bodies. The solved technical scheme is that the green bioactive organic fertilizer is prepared by taking sludge, waste powder, poultry and animal feces, straw powder, residues, feather powder, amino acid original powder, phosphoesterases complex, a first group of complex bacteria, and a second group of complex bacteria as raw materials; uniformly mixing the sludge, the waste powder, the poultry and animal feces, the straw powder, the phosphoesterases complex and the first group of complex bacteria; stacking and covering the mixture with a sack for performing a biogenic reaction, and keeping a reaction product at the temperature of 50 to 55 DEG C for 2 days; adding the residues, the feather powder, the amino acid original powder into the reaction product, uniformly mixing the mixture for performing a secondary reaction, and keeping a reaction product at the temperature of 50 to 55 DEG C for 7 to 10 days; and adding the second complex bacteria into the latest reaction product, uniformly mixing, palletizing, checking and packaging the mixture. The green bioactive organic fertilizer has the advantages of scientific formulation, simple preparation method, good effect, no pollution and no harm to human bodies.

Owner:徐贵阁

Rubber sealed and shock-reducing sound-absorbent material coated on metal sheet and method for preparing same

InactiveCN1721484AImprove high temperature resistanceGood resistance to various mediaOther chemical processesUnspecified rubber coatingsLiquid mediumMetallic materials

The present invention is sealing, damping and silencing material comprising metal sheet and coating. The coating consists of rubber, stuffing and compound ingredient. The compound ingredient includes sulfur, zinc oxide, stabilizer, etc.; the rubber is one or two selected from fluororubber, NBR, SBR, etc.; and the stuffing may be graphite, carbon black, kaolin, etc. The sealing, damping and silencing material may be machined into sealing washer in required shape, can resist the corrosion of various gas and liquid medium, operate in the temperature up to 400 deg.c and pressure up to 120 kg / sq cm, and possesses reliable sealing.

Owner:舟山海山机械密封材料股份有限公司

Non-methanal environment-friendly type plant protein modified adhesion agent

InactiveCN101319131AMeet emission testing standardsSolve the hazardProtein adhesivesGlue/gelatin preparationFiberRapeseed

The invention relates to a formaldehyde-free environment-friendly vegetable protein modified adhesive, which aims to solve the problem that the prior urea-formaldehyde adhesive, phenolic aldehyde adhesive and melamine aldehyde adhesive release formaldehyde and cause environmental hazard and pollution, etc. The compositions in portion by weight of the modified adhesive are: 30 to 50 portions of natural plant dregs, 5 to 12 portions of basic material, 5 to 10 portions of calcium hydroxide emulsion, 6 to 15 portions of urea, 4 to 10 portions of alkyl sodium sulfate, 2 to 5 portions of 10 to 20 percent of inorganic acid and 90 to 120 portions of deionized water. The invention takes macromolecular proteins in natural plant soybean dregs, peanut dregs, rapeseed dregs, cottonseed dregs, linseed dregs and sunflower seed dregs as raw materials so as to synthesize a new-generation formaldehyde-free environment-friendly vegetable protein modified adhesive through chemical modification. The formaldehyde-free environment-friendly vegetable protein modified adhesive has the characteristics of uniform and stable product, high adhesion strength, hydrolysis resistance and nontoxicity, etc.; moreover, the performance and the price of the modified adhesive are suitable for wood adhesion and for making artificial fiber boards such as plywood, shaving board and fiber board.

Owner:上海世鹏聚氨酯科技发展有限公司

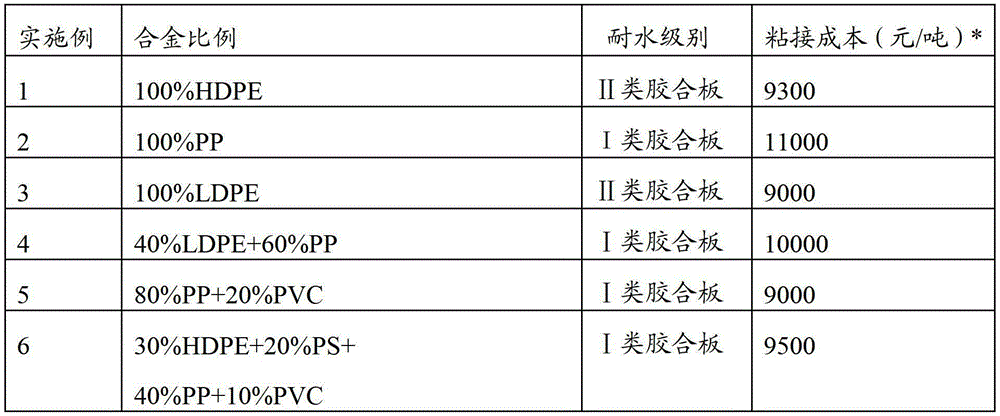

Formaldehyde-free plywood and fabrication method thereof

ActiveCN103144152ASolve the hazardImprove physical and mechanical propertiesLayered product treatmentPlastic recyclingEnvironmental resistanceWood veneer

A method for fabricating a formaldehyde-free plywood with waste plastic alloy is used for fabricating the novel plywood without free formaldehyde being released by fabricating a plastic alloy film with different waste plastics and taking the plastic alloy film as a bonding material. The method comprises the steps of smashing and cleaning the different waste plastics, allowing the waste plastics to be independent or mixing the waste plastics to a scale, adding relevant packing and assistant, conducting film blowing and calendering to prepare the plastic alloy adhesive film in certain breadth and thickness, conducting crossed assembly with a wood veneer, conducting hot pressing and cold pressing, and obtaining the formaldehyde-free plywood. The fabrication method for the nontoxic and environment-friendly formaldehyde-free plywood with the waste plastics solves the problem that the free formaldehyde released by the ordinary plywood has a toxic action on an environment and a human body, and a recycling approach for the waste plastics is provided.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Processing method for fumigating eel

InactiveCN101496615ASolve the excessive residue of benzopyreneSolve the problem of poor product flavorMeat/fish preservationFood preparationNational standardCooling down

The invention discloses a bloating processing method for eel. The method is characterized in that: the method comprises the following steps: (1) seasoning and preservation: preparing a salt preserving liquid through edible salt and water, and placing the eel into the salt preserving liquid for seasoning and preservation after cleaning the eel raw material; (2) impregnation smoking: immersing the eel in a smoking liquid for smoking after cleaning the obtained eel through the step (1); (3) drying: drying the obtained eel through the step (2) in the air; (4) spray smoking: carrying out the spray smoking on the obtained eel through the step (3); and (5) cooling: cooling down the eel undergoing the spray smoking. The bloated eel has a good taste and a lower residual quantity of benzopyrene. In addition, the residual quantity of benzopyrene in the smoked eel is lower than 5mu g / k1g , which is lower than the allowable limit of benzopyrene in the smoked eel regulated by Chinese national standard GB7104-94 the Sanitary Standard for the Limited Quantity of Benzopyrene in Food. Therefore, the edibility safety of the smoked eel product is guaranteed.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

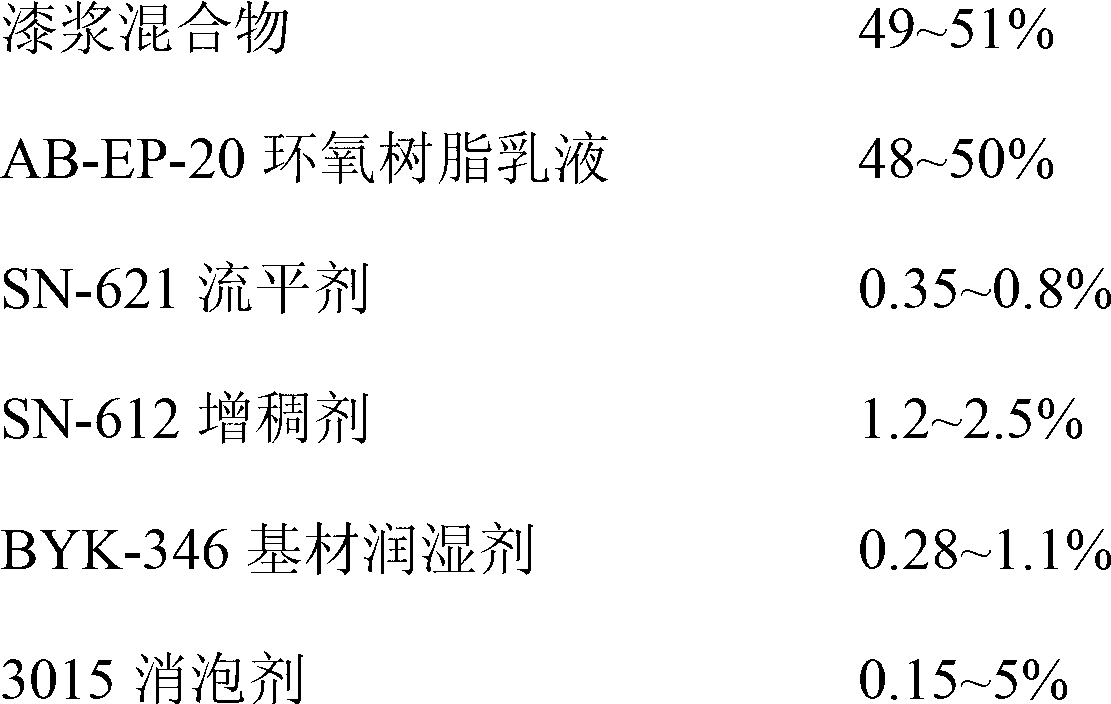

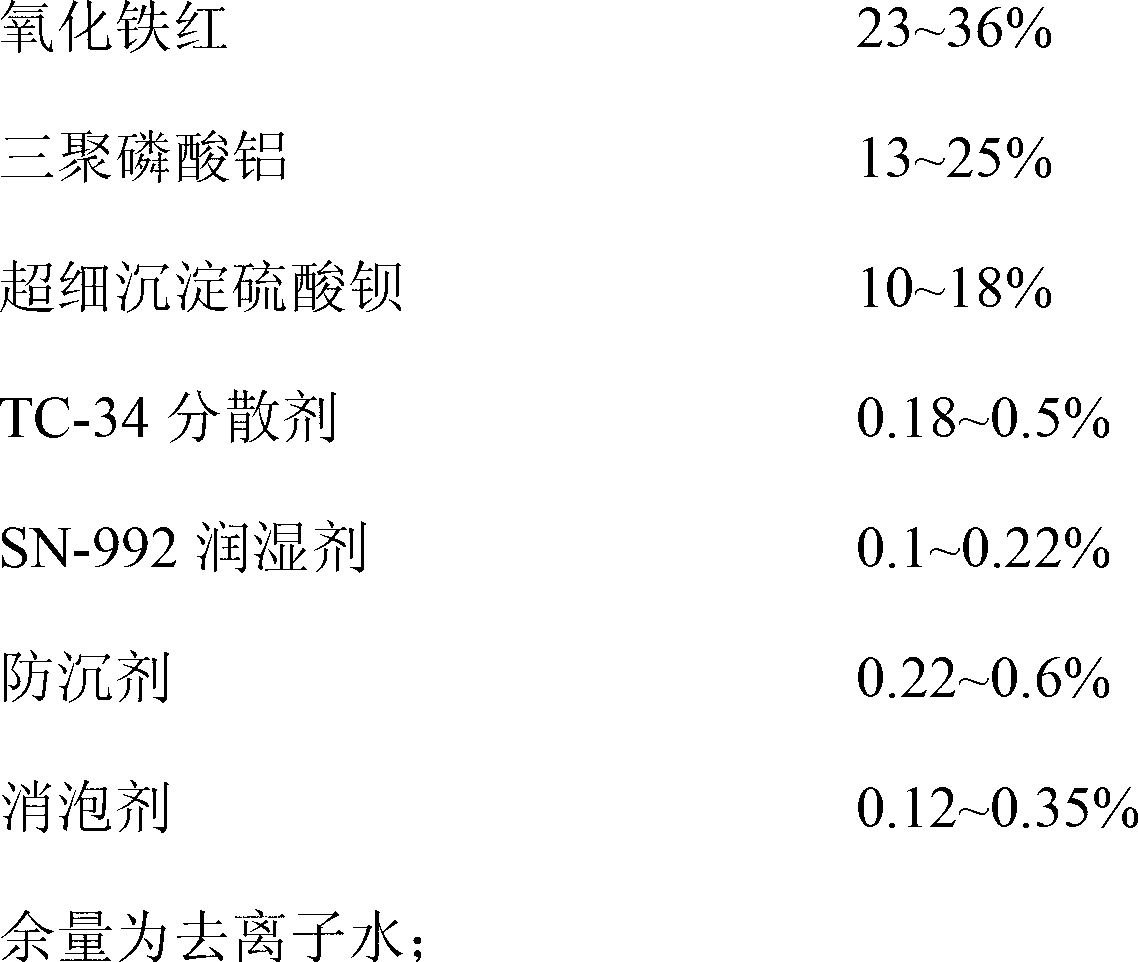

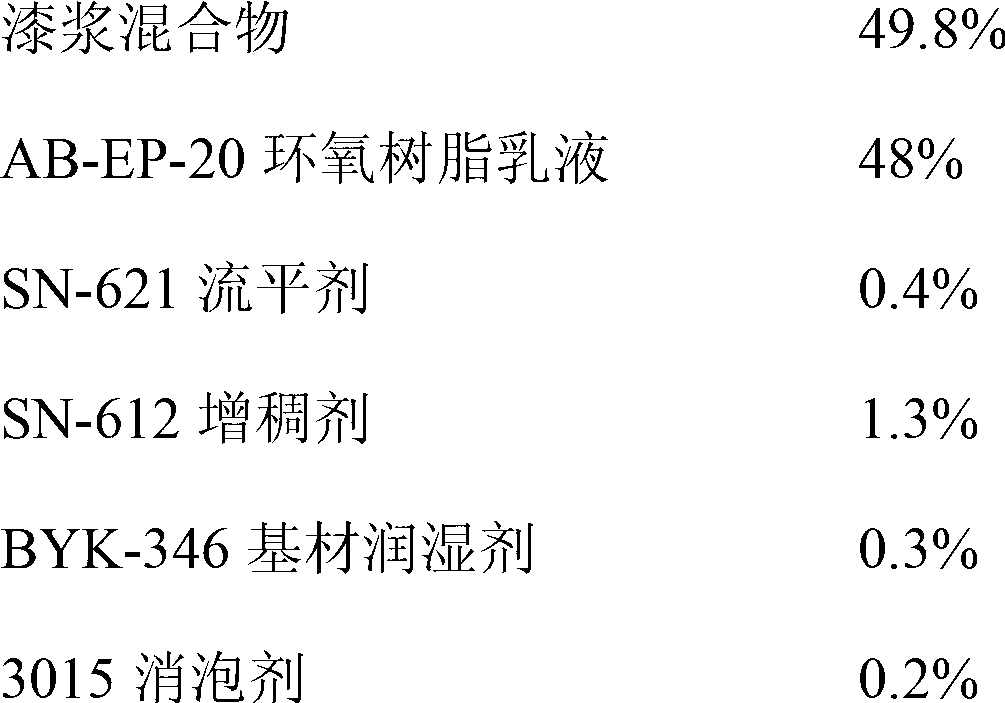

Waterborne epoxy antirust paint and preparation method

ActiveCN102993906AImprove performanceSolve the hazardAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEmulsion

The invention relates to a waterborne epoxy antirust paint and a preparation method. The antirust paint mainly comprises a component A and a component B; the component A comprises the following constituents in percentage by mass: 40-55% of paint paste mixture, 43-58% of epoxy resin emulsion and 1.2-8% of auxiliary II, wherein the total of the constituents aforementioned is 100% by weight; the paint paste mixture comprises the following constituents in percentage by mass: 40-85% of pigments and fillers, 0.3-6% of auxiliary I and the balance of water; and the component B is a curing agent. The preparation method comprises the following steps of: preparing the paint paste mixture according to prescription amounts, and mixing and stirring the paint paste mixture, the epoxy resin emulsion and the auxiliary II according to prescription amounts to obtain the component A; and packaging the component A and the component in a ratio by mass. The waterborne epoxy antirust paint obtained by the prescription disclosed by the invention is excellent in water-resistant, oil-resistant, acid-base-resistant, salt-mist-resistant performances and the like, excellent in anti-rust and anti-corrosion performances, and good in mechanical performances of adhesion force, flexibility, impact resistance and the like.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

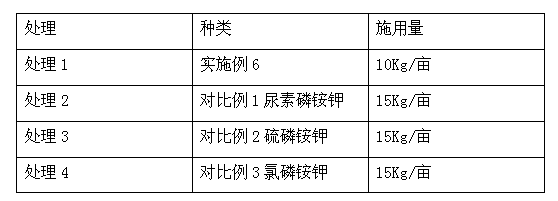

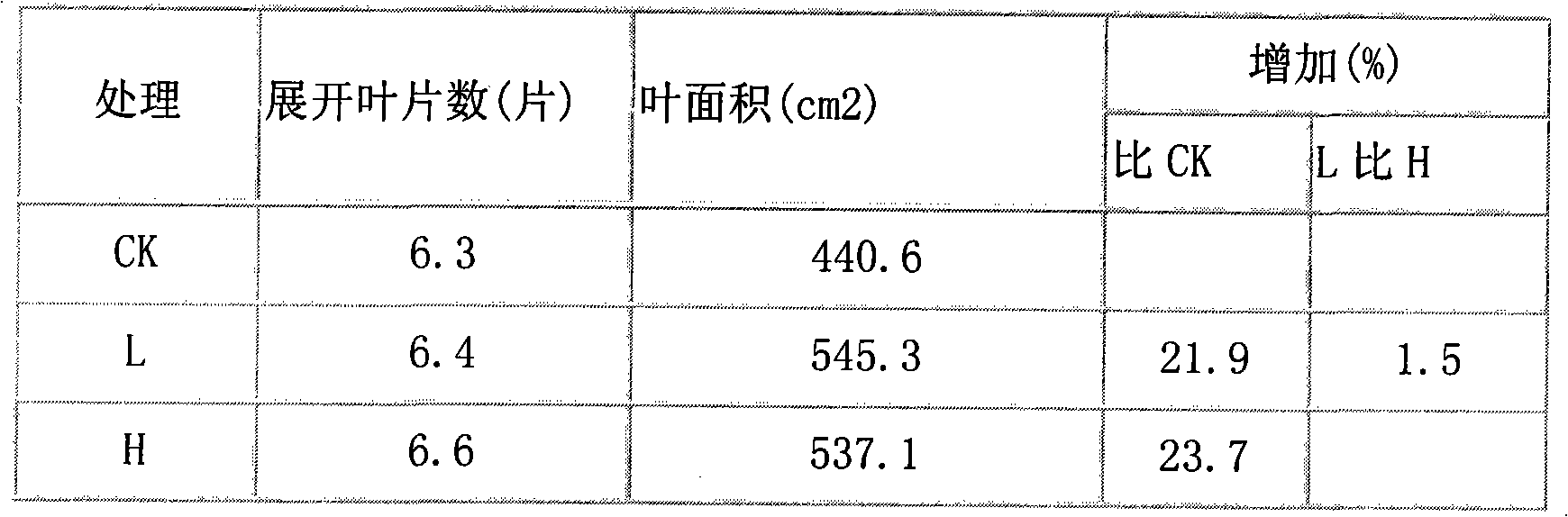

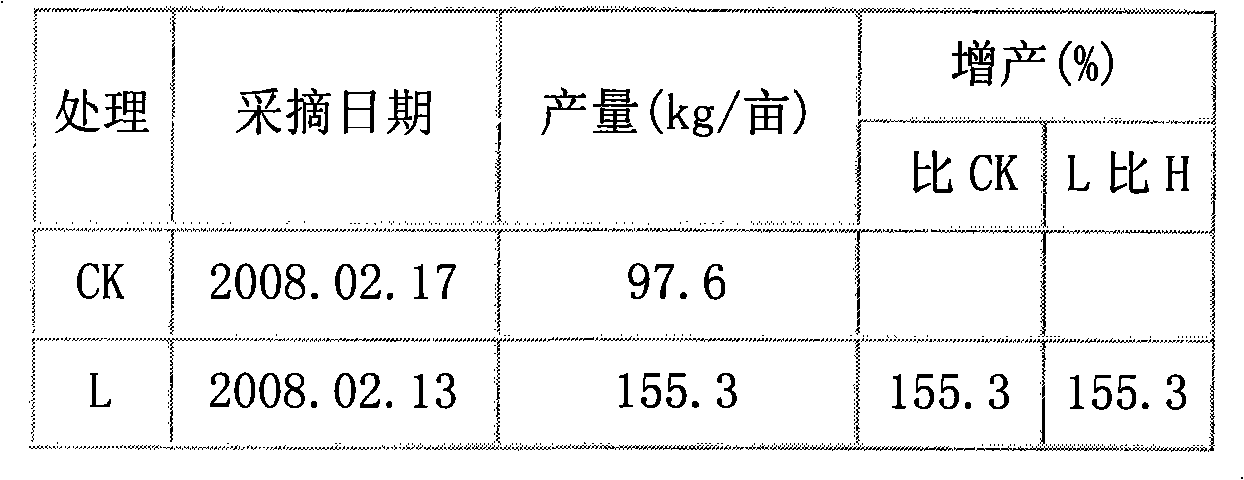

Vermicompost organic compound fertilizer capable of being used for ryegrass, and preparation method thereof

InactiveCN103708878ASolve the hazardLong-lasting fertilizerFertilizer mixturesPhosphoric acidPotassium

The invention discloses vermicompost organic compound fertilizer capable of being used for ryegrass, and a preparation method thereof, and belongs to a manner of cycle use of agricultural wastes. The organic compound fertilizer comprises, by weight, 6-9 parts of the vermicompost and 1-2 parts of inorganic fertilizer, wherein the inorganic fertilizer comprises, by weight, 3.5-7 parts of urea, 4.5-9 parts of phosphorus superphosphate and 2-4 parts of potassium chloride. The vermicompost organic compound fertilizer directly provides a reasonable use path of the vermicompost organic compound fertilizer, and indirectly solves the harmful problems of livestock and poultry breeding organic wastes such as pig manure and goat manure to the environment. The compound fertilizer is reasonable in organic and inorganic proportions, has long-term fertilizer capacity of organic fertilizer and short-term fertilizer capacity of inorganic fertilizer at the same time. By applying enough base fertilizer once during a planting process of the ryegrass and applying the compound fertilizer once in a harvest middle stage, nutritional requirements of the ryegrass during the whole production period can be met. Fertilizer cost is reduced; a topdressing stage during the planting process of the ryegrass is omitted, so that production and management cost for the ryegrass can be saved.

Owner:四川正东农牧集团有限责任公司

Method for preparing ternary complex antiager and emulsion and application thereof in neoprene

InactiveCN101665585AImprove thermal stabilityImprove antioxidant efficiencyTernary complexPolymer science

The invention provides a method for preparing ternary complex antiager and an emulsion and an application thereof in neoprene. The ternary complex antiager is prepared by formulation and mixing of a bisphenol mono-acrylate antiager, a hindered phenolic antiager and a sulfoether antiager according to specified proportioning. The preparation method comprises the following steps: dissolving the ternary complex antiager prepared by the above method with an organic solvent at room temperature; adding an emulsifying agent prepared by the mixture of disproportionated rosin acid soap water solution and sulfoacid anionicsurfactant water solution for fully mixing; and obtaining the ternary complex antiager emulsion after dispersing. In the process of synthesizing the neoprene rubber latex, the ratioof the dry glue of the neoprene in terms of the added ternary complex antiager emulsion is 1:0.03-0.07. The research of an aging test shows that the neoprene product prepared by adding the ternary complex antiager emulsion of the invention is superior to the neoprene product prepared by using the antiager BHT in the aspects of appearance color, Mooney viscosity, Mooney scorch time and mechanicalintensity property indexes.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Comprehensive recycling method for high-arsenic soot

The invention discloses a comprehensive recycling method for high-arsenic soot. The method specifically comprises the following steps that two-stage leaching is conducted on the high-arsenic soot; two-stage leaching liquid enters a cyclone electrolytic system for extracting copper, and a copper product is obtained through two-stage deep decoppering; then arsenic removal is conducted, and copper-arsenic slag and a zinc sulfate solution are obtained; the copper-arsenic slag is subjected to alkaline leaching, oxidization-crystallization, prereduction and the cyclone electrolytic technology, and simple substance arsenic is produced; lead and silver in high-pressure leaching residuals are subjected to lead conversion through ammonium bicarbonate and ammonium hydroxide, the lead is made to enter feed liquid, and a lead-containing solution is obtained after solid-liquid separation to recycle the lead; and the leaching residuals are leached through thiourea, a silver-containing solution is obtained, and silver powder is obtained through replacement. According to the comprehensive recycling method, various valuable metals in the high-arsenic soot are recycled through different techniques; and meanwhile, the techniques are combined organically, basically no waste slag or waste water or waste gas or other matter is generated from the whole system, the recycling degree is high, the techniques are advanced, the recycling rate is high, the recycling cost is low, and the comprehensive recycling method has quite remarkable environment protection significance.

Owner:浙江科菲科技股份有限公司

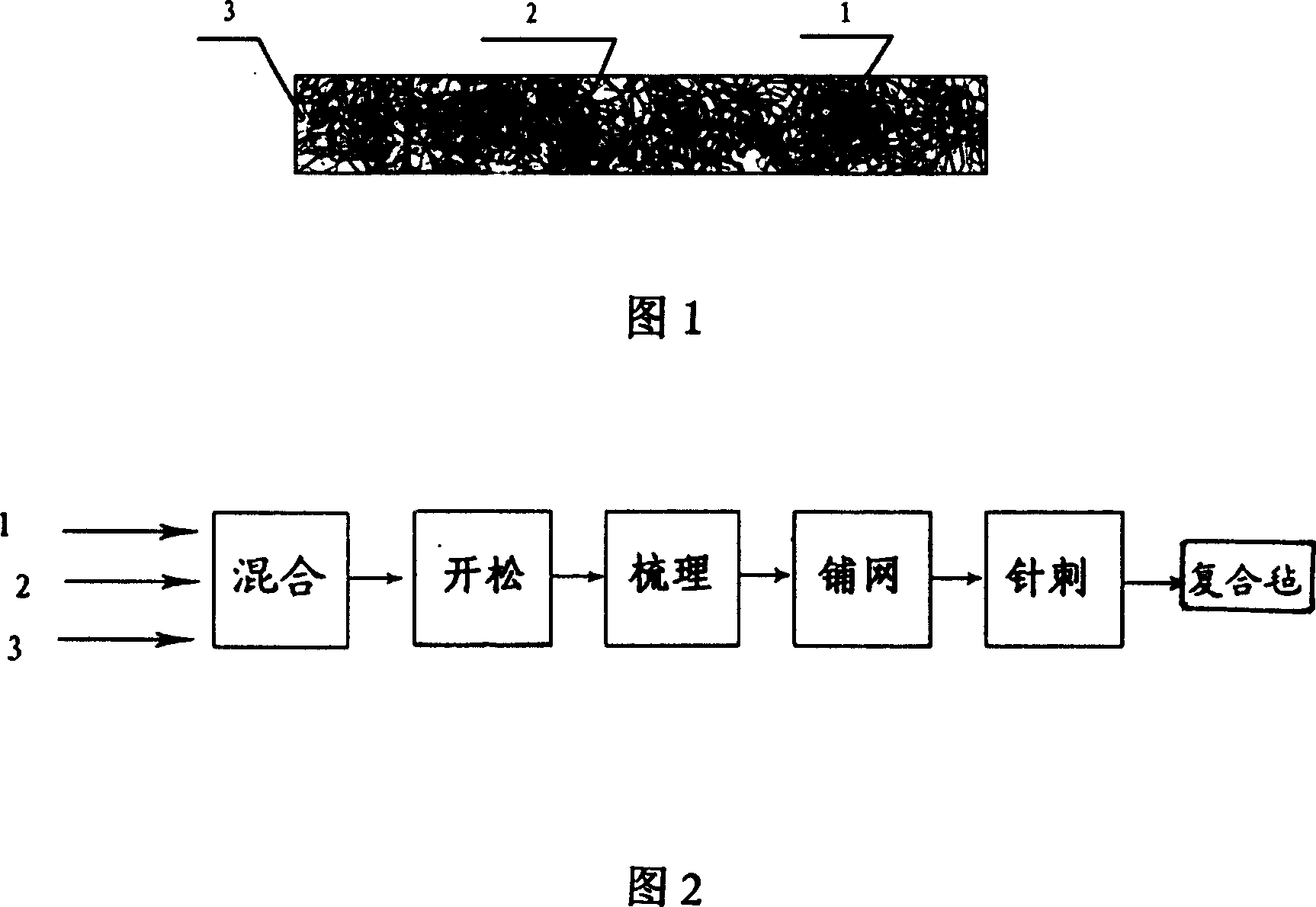

Composite felt made of waste wool, waste terylene, and composite fiber

InactiveCN1952240ASolve the hazardSolve environmental problemsNon-woven fabricsFiberMature technology

The invention relates to a compound felt produced by waste hair, waste nylon and compound fiber, characterized in that it is needled by waste hair, waste nylon and compound fiber. The method is that 10%-80% waste hair by wt, 10%-50% waste nylon by wt and 10%-40% compound fiber by wt are mixed; compound felt with the density of 50g / m 2-500g / m2 is produced by the non-woven technology with loosening, combing, meshing, needling and winding. The invention can take place of sound insulation, heat insulation, anti shock material compounded by waste hair and phenol resin in automobile. The felt compounded by waste hair, waste nylon and compound fiber by mature technology in the invention does not contain formol and odor and can recycle so that the pollution problem to drivers in automobile is solved.

Owner:刘畅

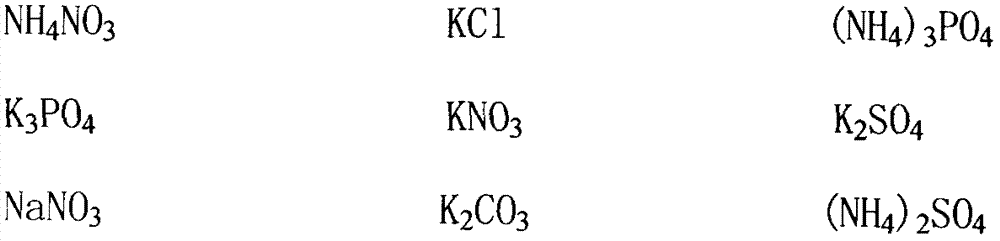

Fertilizer prepared by hydrolysis of bulk propellant powder and/or explosives and preparation method thereof

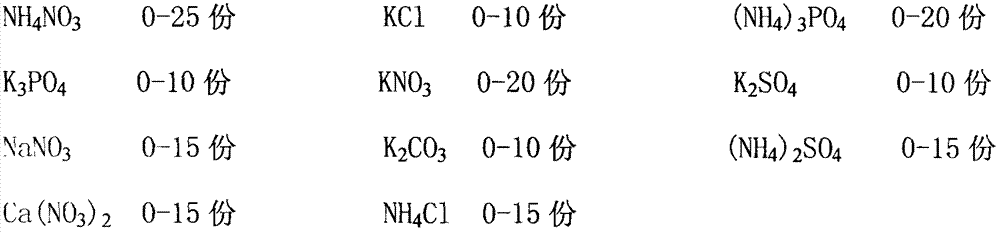

The invention belongs to the field of processing methods of energy-containing materials, in particular to a fertilizer prepared by hydrolysis of bulk propellant powder and / or explosives and a preparation method of the fertilizer. The method disclosed by the invention comprises the following specific steps of: crushing the propellant powder and / or the explosives, then adding an alkaline solution and sodium / potassium humate, reacting in a reaction kettle, and supplementing P2O5, H3PO4, HCl, HNO3 or of K2SO4, Na2SO4, KNO3, (NH4)3PO4 or selenium salt according to the content of each element in the solution after the end of the reaction to get the fertilizer. The method disclosed by the invention has the beneficial effects that, by adopting the method, the propellant powder and / or the explosives can be processed for hydrolysis and then further manufactured into the fertilizer which can be utilized by humankind, so that the problem that the propellant powder and / or the explosives can cause harm to the humankind and a survival environment of the humankind can be solved, and the wastes can be turned into useful things and further become the fertilizer with economic value.

Owner:中国人民解放军济南军区72465部队

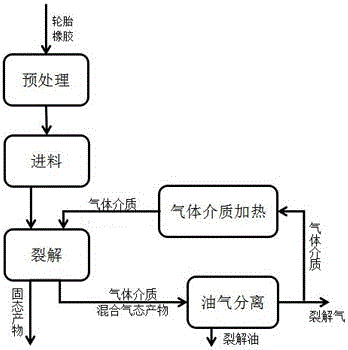

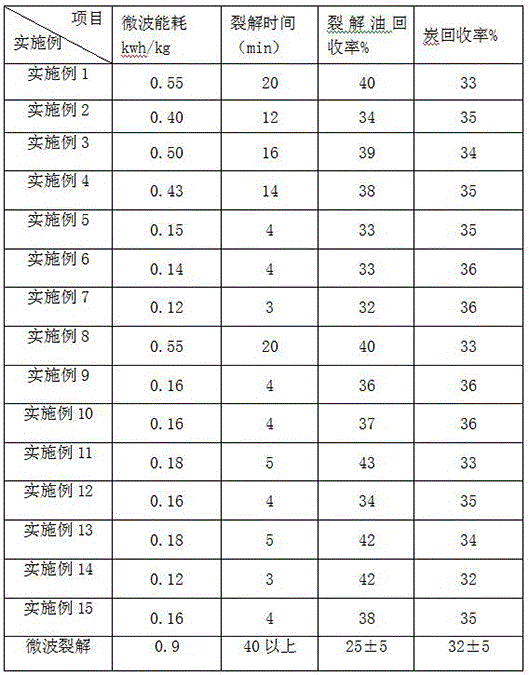

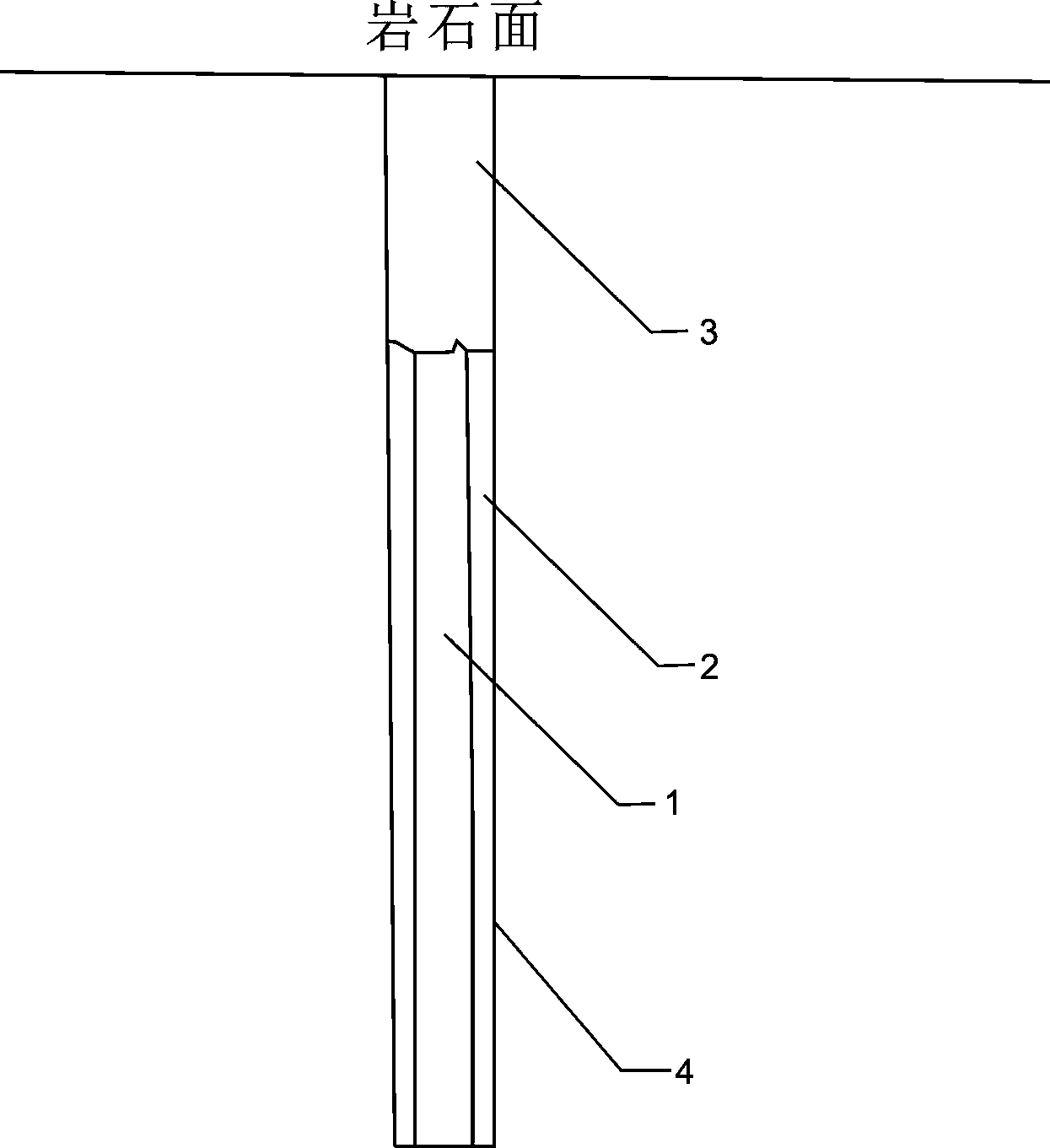

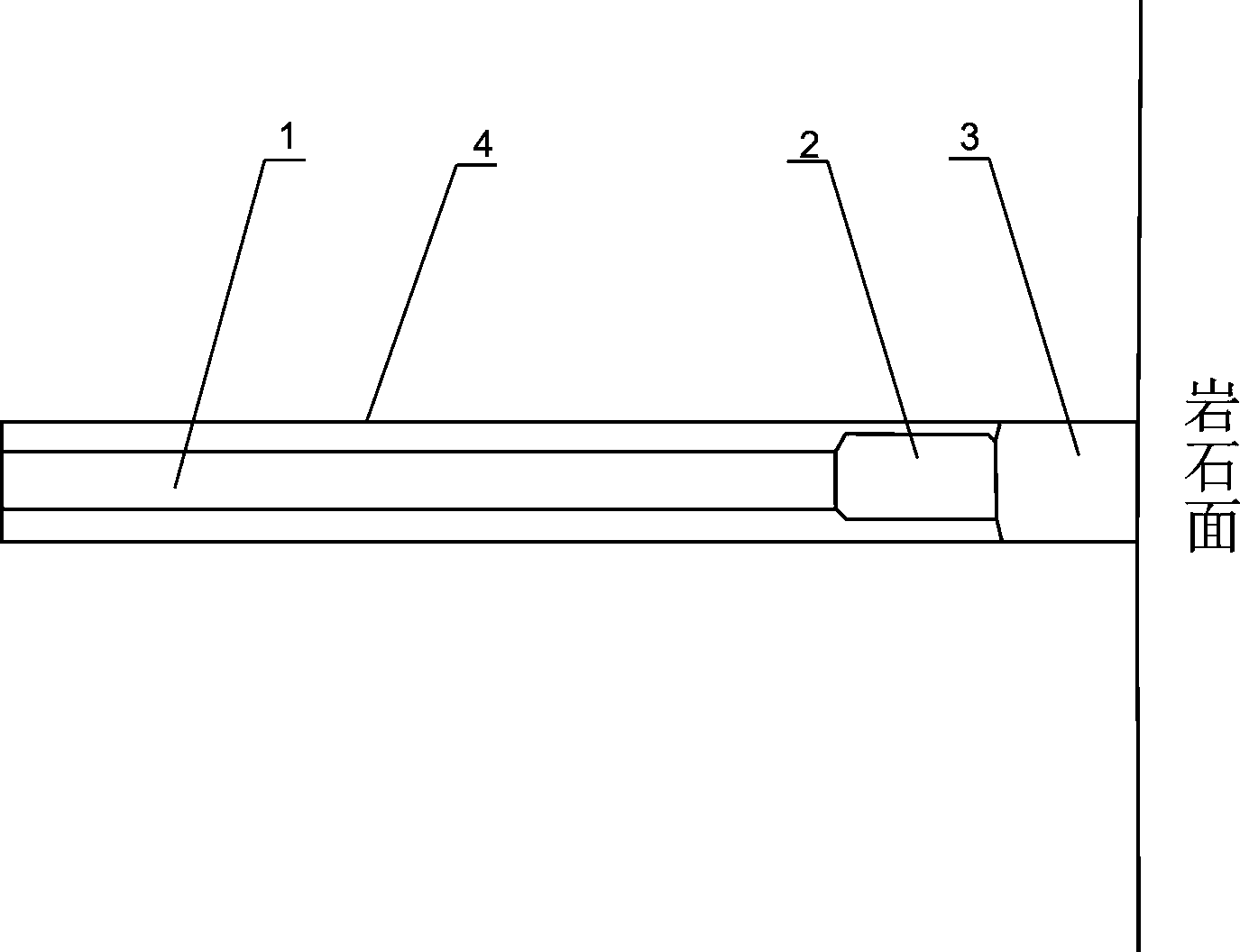

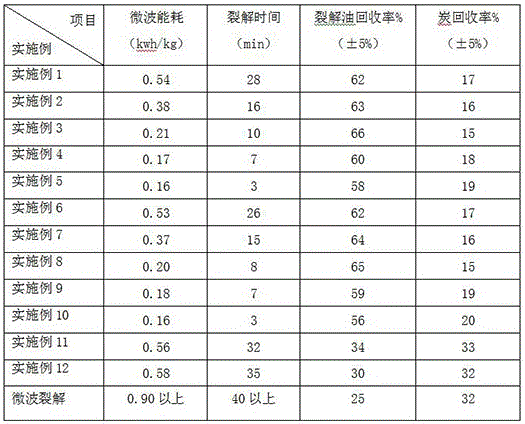

Tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves

ActiveCN105733644AStrong process controllabilityImproved microwave absorption propertiesProductsReagentsMicrowaveProduct gas

The invention provides a tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves. The method includes the steps of A, preprocessing tire rubber; B, feeding the preprocessed tire rubber into a composite pyrolysis cavity; C, using a gas heating device to heat gas media to 350-700 DEG C; D, continuously feeding the heated gas into the composite pyrolysis cavity, and allowing the heated gas and the microwaves to jointly act on the tire rubber so as to perform pyrolysis to obtain solid products and mixed gas products; E, performing oil-gas separation on the mixed gas products to remove pyrolysis oil; F, partially feeding the gas obtained after the oil-gas separation in the step E into the gas heating device of the step C, and heating the gas to 350-700 DEG C for the circulation pyrolysis of the step D. By the tire rubber pyrolysis method, pyrolysis energy consumption and pyrolysis time can be reduced and cost is saved.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

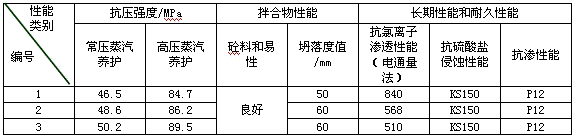

PHC pipe pile concrete and preparation method thereof

The invention relates to PHC pipe pile concrete, characterized by being prepared from the following components: a binding material, a synergist, fine aggregate, coarse aggregate, a water reducer and water, wherein the volume-weight of the concrete is 2400-2600Kg / m<3>, in each cubic meter of concrete, the dosage of the used binding material is 12-22 percent, the dosage of the synergist is 1.0-5 percent, the dosage of the fine aggregate is 22-32 percent, the dosage of the coarse aggregate is 40-52 percent, the mixing amount of the water reducer is 0.2-1.0 percent, and the dosage of the water is 4.0-7.5 percent. By mainly aiming at the defect of the existing PHC pipe pile concrete preparation technology, the invention provides a technology for preparing the concrete by completely replacing natural sand with low-grade machine-made sand, so as to solve the problems that the natural sand resource is scarce, and the low-grade machine-made sand resource is wasted and pollutes the environment.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

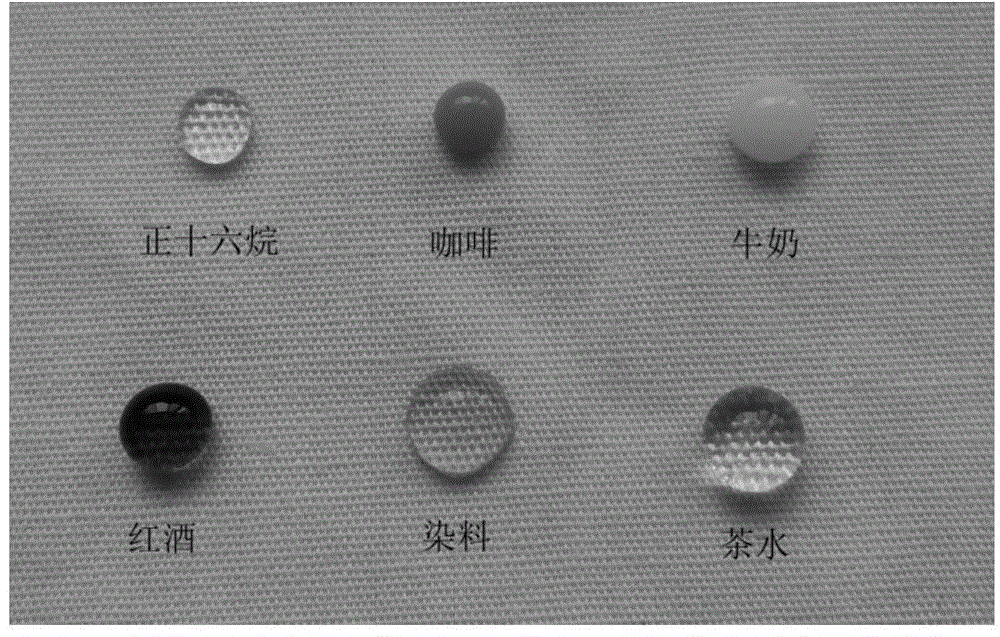

Preparation method of highly hydrophobic edible membrane

ActiveCN104210162ANaturally non-toxic and biocompatibleNon-toxic and biocompatibleFlexible coversWrappersWater activityAcetic acid solution

The invention relates to a preparation method of a highly hydrophobic edible membrane. The method comprises the following steps: adding degreased chitosan into an aqueous acetic acid solution, fully hydrating to obtain an aqueous chitosan acetic acid solution, evenly dispensing the aqueous chitosan acetic acid solution to a glass plate, and drying; preparing an ethanol aqueous solution containing 50%-95% by mass of ethanol, and adding prolamine to obtain a prolamine solution; evenly dispensing the prolamine solution to the treated glass plate, dropwise washing the glass plate with pure water, and drying; preparing an ethanol aqueous solution containing 70%-90% by mass of the ethanol, adding prolamine to obtain a prolamine solution; and evenly dispensing to the treated glass plate, and drying. The edible membrane material can be used for overcoming the defect that the polysaccharide or protein membrane material is poor in waterproof property, and the time of water drops staying on the surface of the membrane during transportation can be shortened, so that the content of water penetrating through a packaging membrane can be reduced, the water activity of food can be guaranteed, and the growth of microorganisms can be inhibited.

Owner:SOUTH CHINA UNIV OF TECH

Na2O-CaO-SiO2 opaque glass and preparation method thereof

The invention discloses Na2O-CaO-SiO2 opaque glass, which consists of the following components in percentage by weight: 59 to 70 percent of SiO2, 6.0 to 10 percent of CaO, 16 to 24 percent of Na2O, 1 to 2 percent of Al2O3, 0.5 to 3 percent of K2O, 1 to 3 percent of MgO, 1.0 to 5.0 percent of P2O and 1.0 to 5.0 percent of ZrO. The invention also discloses a method for preparing the opaque glass, which comprises the following steps of: 1) mixing materials, wherein Na2O is replaced by Na2CO3 with equal molar weight and K2O is replaced by K2CO3 with equal molar weight; 2) heating the mixed materials in a furnace to the temperature of between 1,420 and 1,470 DEG C for melting, and keeping the temperature for 2.8 to 3.2 hours; and 3) pouring molten glass obtained in the step 2) into a mould for forming, and naturally and slowly cooling to room temperature to obtain the milky opaque glass.

Owner:ZHEJIANG UNIV

Lithographic fountain solution composition containing complex surfactants

ActiveCN104309350AFast ink balanceFast balancePrinting pre-treatmentActive agentSurface-active agents

A lithographic fountain solution composition containing complex surfactants is composed of the complex surfactants, buffering electrolytes, water-soluble high-molecular compounds, aqueous germicide and algicide, aqueous antifoaming agents and water. The complex surfactants include two or more nonionic surfactants, anionic surfactants, cationic surfactants or ampholytic surfactants. The lithographic fountain solution composition containing the complex surfactants has the advantages of excellent dynamic ink-water balance performance, low requirements on quality of water for working solution preparation, high adaptability to changes of temperature conditions and the like; using the lithographic fountain solution composition can evidently improve quality of prints, improve printing efficiency and reduce production cost; in addition, the lithographic fountain solution composition contains no poisonous and harmful substances and is high in stability and long in storage time.

Owner:HUNAN NORMAL UNIVERSITY

Granulated paper pad for pets and manufacturing method thereof

The invention provides a granulated paper pad for pets. The granulated paper pad is cylindrical, has the diameter of 3-7mm, the length of 3-20mm, the specific gravity of 320-550g / l and the natural water content being smaller than 7.5% and comprises the main components as follows: at least 70% of paper fiber and 10-20% of talcum powder or light calcium carbonate or kaolin. The manufacturing method of the granulated paper pad for pets comprises the following steps of uniformly crushing, grinding and forming, drying, screening and packing. Though the granulated paper pad for pets and the manufacturing method thereof disclosed by the invention, waste is fully utilized, energy is greatly saved, consumption is largely reduced, no emission and pollution exist in the production process, the liquid absorption amount is maximum compared with pet pads made from any textures, no pollution exists after the granulated paper pad is used, the used granulated paper pad can be directly putted into a sewer for degradation and never blocks the sewer, the opportunity of bacterial reproduction is reduced, the home environment is protected, and the health of persons and pets is strengthened. The granulated paper pad for pets does not have harm to the persons and the pets, is easy to store and is also clean; therefore, the problem that garbage is piled up at home after pads for pets are used, and damage and trouble caused by the persons sprinkling deodorizer for covering the excrement smell of the pets are completely solved.

Owner:青岛正利纸业有限公司

Preparation method of water-blocking oxygen-blocking edible film

ActiveCN104211975AExcellent barrier propertiesExtended shelf lifeFlexible coversWrappersChemistryFilm material

The invention discloses a preparation method of a water-blocking oxygen-blocking edible film. The method comprises the following steps: adding chitosan which accounts for 0.5-2.0% and 0.03-0.06% of the mass of an acetate solution into the acetate solution respectively, sufficiently hydrating the mixtures to obtain a first chitosan acetate solution and a second chitosan acetate solution; adding corn alcohol soluble protein into an ethanol solution to be sufficiently dissolved to obtain a corn alcohol soluble protein ethanol solution; adding the second chitosan acetate solution into the corn alcohol soluble protein ethanol solution, carrying out water-bath rotary evaporation on the obtained material until the mass of the material is 40%-80% of the original mass, centrifuging the solution and taking liquid supernatant; adding corn oil into the liquid supernatant, shearing and homogenizing the mixture to prepare Pickering emulsion; adding the Pickering emulsion into the first chitosan acetate solution, adding glycerol into the solution, ultrasonically treating and the drying the mixture to obtain the water-blocking oxygen-blocking edible film material. According to the invention, in comparison with a chitosan film, the water-blocking oxygen-blocking capacity of the water-blocking oxygen-blocking edible film is greatly improved, and the water vapor blocking cavity of the water-blocking oxygen-blocking edible film is also greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

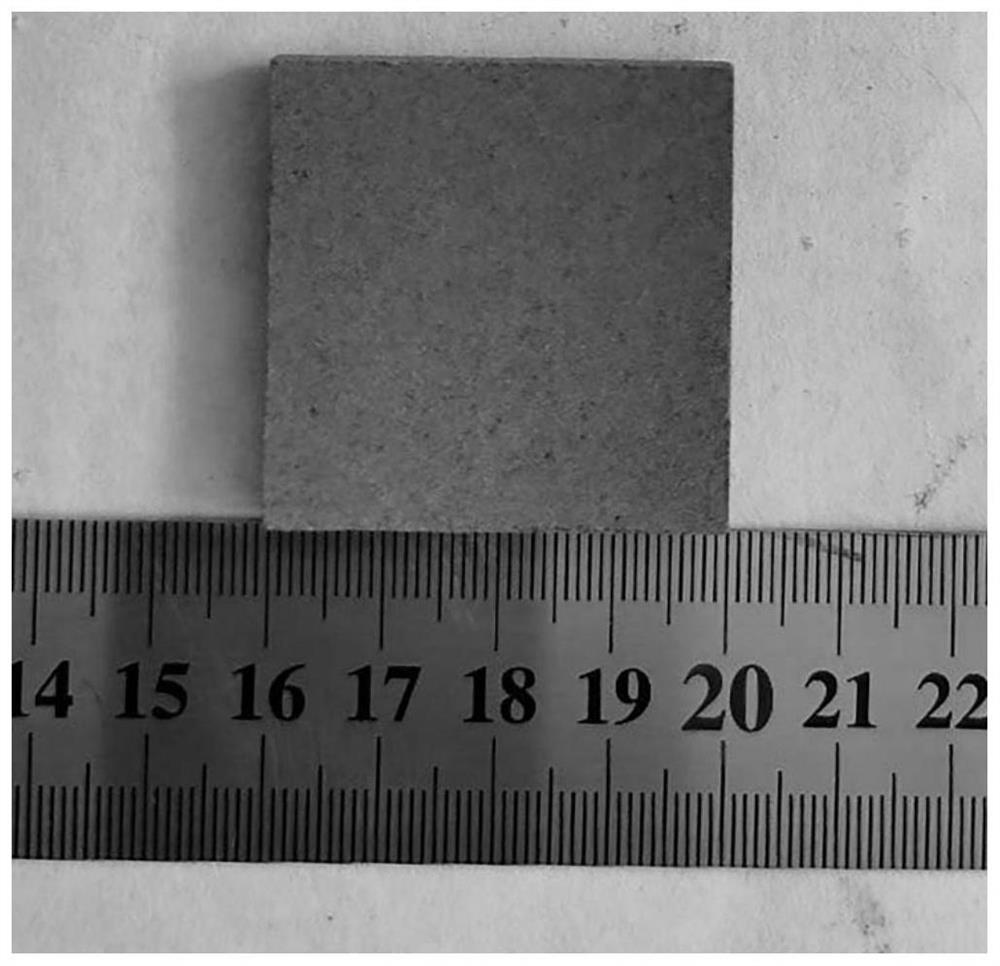

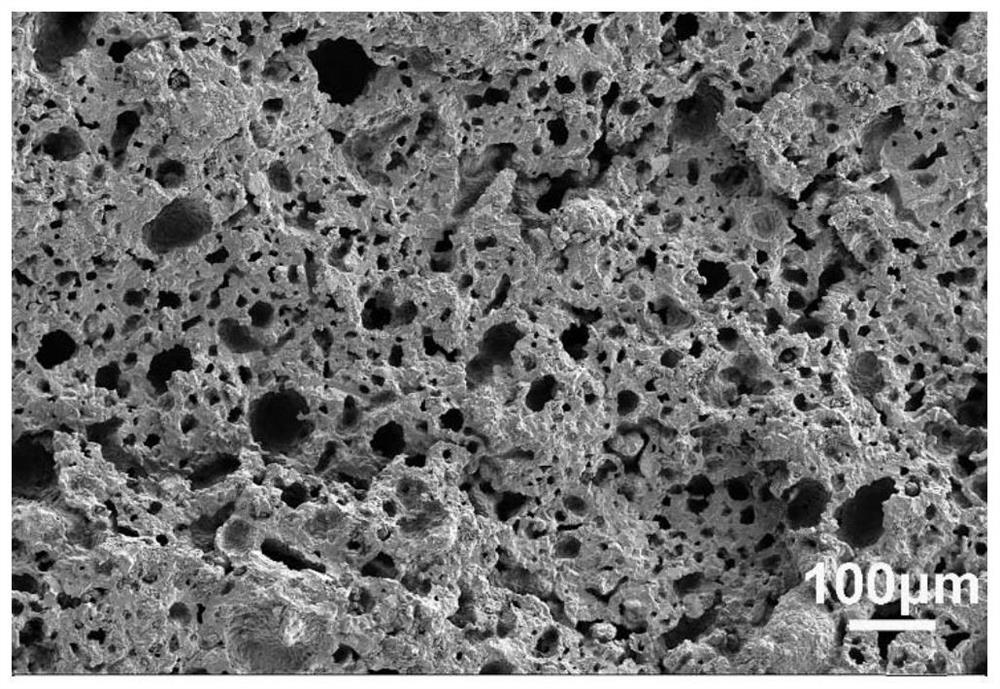

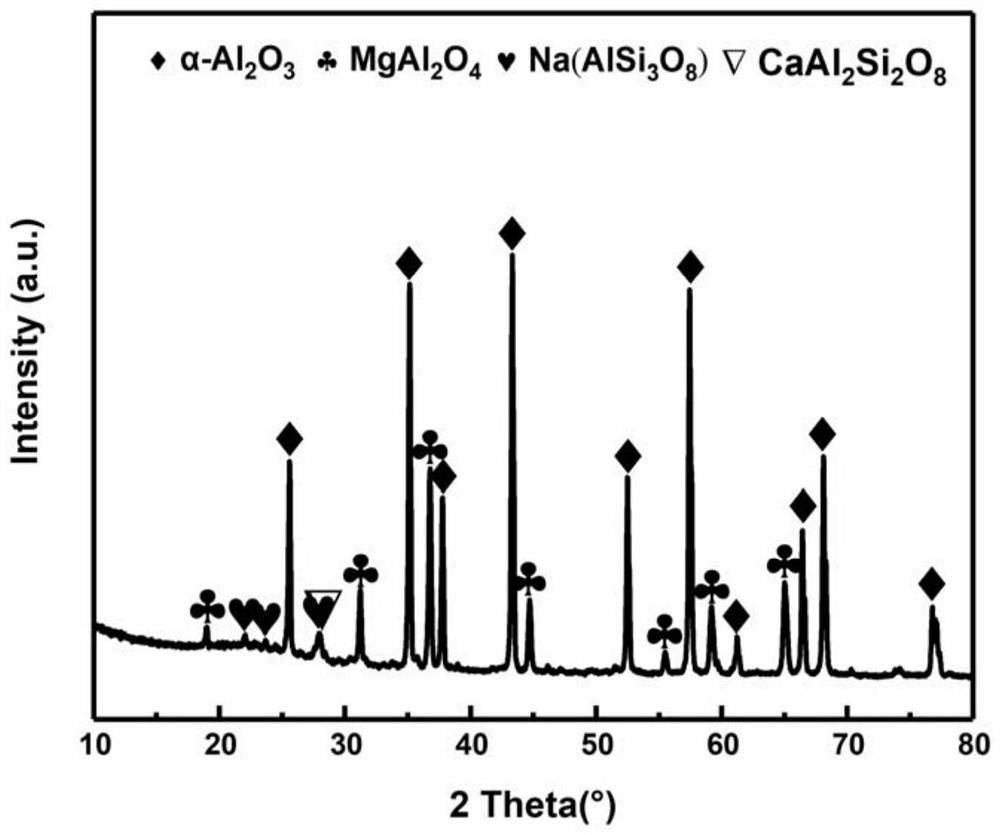

Method for preparing low-shrinkage porous ceramic through high-temperature self-foaming of aluminum ash

ActiveCN113735611ASolve pollutionSolve the hazardCeramic materials productionCeramicwareSpray GranulationThermal insulation

The invention relates to the technical field of comprehensive utilization of solid waste resources, and discloses a method for preparing low-shrinkage porous ceramics through high-temperature self-foaming of aluminum ash residues. Secondary aluminum ash residues obtained after aluminum extraction are used as main raw materials, and the aluminum ash residues do not need to be subjected to desalting and denitrifying treatment; and the secondary aluminum ash is subjected to spray granulation, dry pressing forming and high-temperature sintering, and finally the low-shrinkage porous ceramic material is obtained. According to the method, the technological process is simple and easy to implement, the complex desalting and denitrifying process is omitted, the high-temperature self-foaming process is achieved by fully utilizing the component characteristics of the secondary aluminum ash residues, then a porous structure is obtained, harmless treatment of the secondary aluminum ash residues and resource utilization of solid waste can be achieved, and the prepared porous ceramic material has the characteristics of low shrinkage, high strength, excellent heat insulation performance and the like, and can be applied to the fields of thermal insulation materials and the like.

Owner:UNIV OF SCI & TECH BEIJING

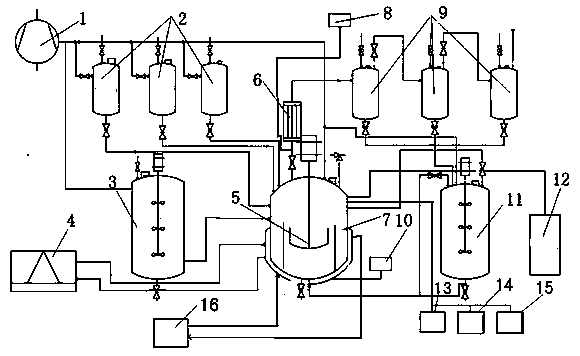

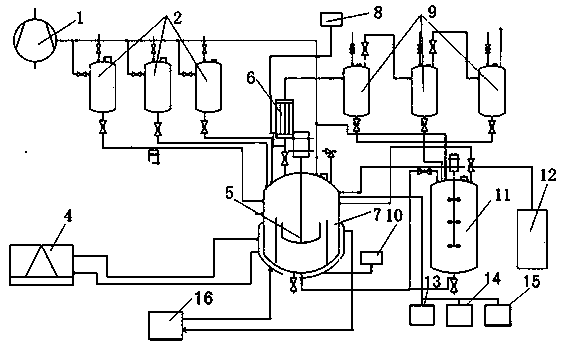

Energy-containing material safe disposal and resource utilization method and system

InactiveCN103408341AReach disposalReach resourcesFertilizer mixturesResource utilizationEconomic benefits

The invention belongs to the technical field of energy-containing material processing, and specifically relates to an energy-containing material safe disposal and resource utilization method, and a special-purposed system for the method. The method comprises the steps that: reaction materials are prepared; feeding is carried out; an energy-removing reaction is carried out; and fertilizer preparation is carried out. Preferably, during the fertilizer preparation process, decomposed microbes are supplemented, such that the capacity for decomposing various elements needed by crops is enhanced, crop absorption and utilization are promoted, and soil fertilizing effect is enhanced. With the method and system, the energy-containing material is processed, such that the problems of environment hazards caused by waste energy-containing material burning and land-filling during a long time are solved. The waste energy-containing materials are centralized and processed, and waste is turned into valuable matters. The waste energy-containing material is concerted into fertilizer, and is used in agricultural production. Therefore, in agricultural production, an environment pollution problem brought by burning and land-filling of the waste energy-containing materials is eliminated, and great economic benefit is brought.

Owner:中国人民解放军济南军区72465部队

Oyster smoking processing method

The invention relates to an oyster smoking processing method, which comprises the following steps: selecting oysters; placing the oysters in a pickling solution for seasoning pickling; then drying the oysters; next, transferring the dried oysters into a smoking solution; carrying out spraying smoking by the smoking solution in a gradient temperature rising mode during smoking, wherein the gradient temperature rising mode adopts the following temperature ranges: 40 to 50 DEG C for 20 to 40 min; 60 to 70 DEG C for 10 to 30 min; and 70 to 80 DEG C for 20 to 40 min; and then, packing the oysters after cooling. The oyster products prepared by the processing method have the advantages of dense smoking flavor, proper texture tenderness and stable quality, good appearance of the oyster products can be ensured, phenomena such as deformation, juice loss and the like caused by nonuniform internal and external heating can not occur, and the added value of oyster processing products is also improved.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Potassium hexatitanate/sodium hexatitanate whisker composite ceramic frication material and preparation method thereof

The invention relates to a composite ceramic fiction material of potassium hexatitanate / sodium hexatitanate whisker belonging to the material technical field, wherein the composite ceramic fiction material comprises 5-20 parts of organic resin, 1-10 parts of rubber powder, 10-40 parts of potassium hexatitanate and sodium hexatitanate whisker, 0-5 parts of aramid fiber, 10-20 parts of graphite and 20-40 parts of filler. The composite ceramic fiction material of the invention doesn't contain asbestos without harming the human body and polluting the environment, which has superiorities in eliminating braking noise and heat degeneracy, improving using life of the product, overcoming adhesive occlusion among friction couples and the like.

Owner:SHANDONG UNIV

Plant acid corrosion organic fertilizer

InactiveCN101323542APrevent compactionSolve the hazardOrganic fertilisersFertilizer mixturesPhosphatePolyamide

The invention relates to a plant acid corrosive organic fertilizer which effectively solves the problems of soil hardening caused by using a plurality chemical fertilizers and harm to people caused by the fertilizers. The technical proposal of the organic fertilizer for solving the problems is that: the organic fertilizer is prepared from materials as follows in proportion by weight: 11 percent to 34 percent of plant acid, 13 percent to 30 percent of compound amino acid, 1 percent to 3 percent of polyamide, 26 percent to 49 percent of plant straws, 3 percent to 15 percent of carbamide, 3 percent to 10 percent of potash feldspar, 3 percent to 13 percent of phosphate ore and 1 percent to 4 percent of propylene oxide, and the total amount is 100 percent. During preparation, the plant acid, the compound amino acid and the plant straws are firstly ground and mixed evenly and the propylene oxide is added into for stirring for reaction for 1.5 hours to 2.5 hours at 18 DEG C to 30 DEG C, when the reaction is carried out completely and gas is given out, the carbamide, the potash feldspar and the phosphate ore are added in turn to stir for reaction for 1.5 hours to 2.5 hours, and finally the polyamide is added into to stir fully for reaction for 1.5 hours to 2.5 hours, and finished products with pH value of 5.5 to 7 are prepared. The organic fertilizer of the invention has simple method, is convenient to use, solves the soil hardening and optimizes the microecological balance in soil, thus being a great creation in the use of agricultural fertilizers.

Owner:李海涛

High-yield planting method for pollution-free tea

InactiveCN105191631AIncrease productionQuality improvementSuperphosphatesExcrement fertilisersDiseasePlant disease

The invention discloses a high-yield planting method for pollution-free tea. The method includes the steps of tea land selection, land preparation, biogas liquid watering and base fertilizer application, tea tree and bead tree interplanting, topdressing, tea garden management, disease and pest prevention and control and leaf fertilizer spraying. The planting method meets the requirements for planting the pollution-free tea in the whole process from tea land selection and construction, fertilizer application management to disease and pest prevention and control. In the planting process, kinds of fertilizer can be used according to nutrition requirements of the tea at different growth stages and are applied reasonably, in this way, nutrition requirements of pekoe tea can be met, the fertilizer loss will not be generated, in the whole process of fertilizer application, with organic fertilizer being the main fertilizer, in combination with a small amount of N, P and K fertilizer, growth of tea trees can be accelerated, and the yield of the tea can be increased. The yield of the tea is increased by about 30%, the tea color and tea taste of the tea are greatly improved, and the tea is popular among consumers in the market.

Owner:GUANGXI BAIRUNYUAN AGRI

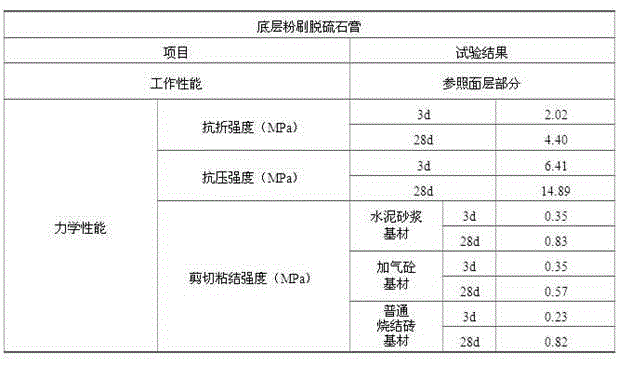

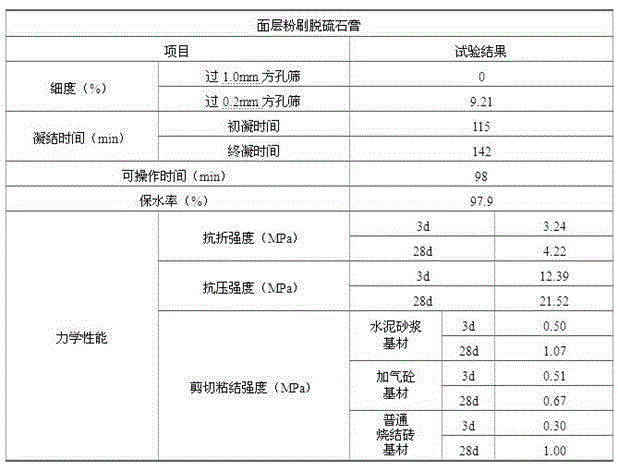

Desulfurization gypsum sand pulp

Desulfurization gypsum sand pulp belongs to construction materials. The desulfurization gypsum sand pulp comprises surface layer painting desulfurization gypsum and bottom layer painting desulfurization gypsum, wherein the surface layer painting desulfurization gypsum comprises 79.6 percent of desulfurization gypsum, 0.35 percent of SC calcium sulphate retarder, 20 percent of coal ash and 0.010 percent of cellulose ether according to weight percentage; the bottom layer painting desulfurization gypsum comprises 79.6 percent of desulfurization gypsum, 0.35 percent of SC calcium sulphate retarder, 20 percent of coal ash, 0.010 percent of cellulose ether and river sand, and the ratio of the mixture of the desulfurization gypsum, the SC calcium sulphate retarder, the coal ash and the cellulose ether to the sand is 1 to 2 according to weight percentage. The desulfurization gypsum sand pulp has the advantages that the desulfurization gypsum sand pulp mainly comprises industrial residue, is suitable for decorative surface plastering to a common clay tile wall, an air-ejecting concrete wall and the like under a dry environment, the desulfurization gypsum sand pulp can be produced in factory, and convenient and fast construction can be achieved. The working performance and the physical and mechanical properties are improved, and radioactivity, hazardous material and corrosion are avoided.

Owner:CHINA UNIV OF MINING & TECH

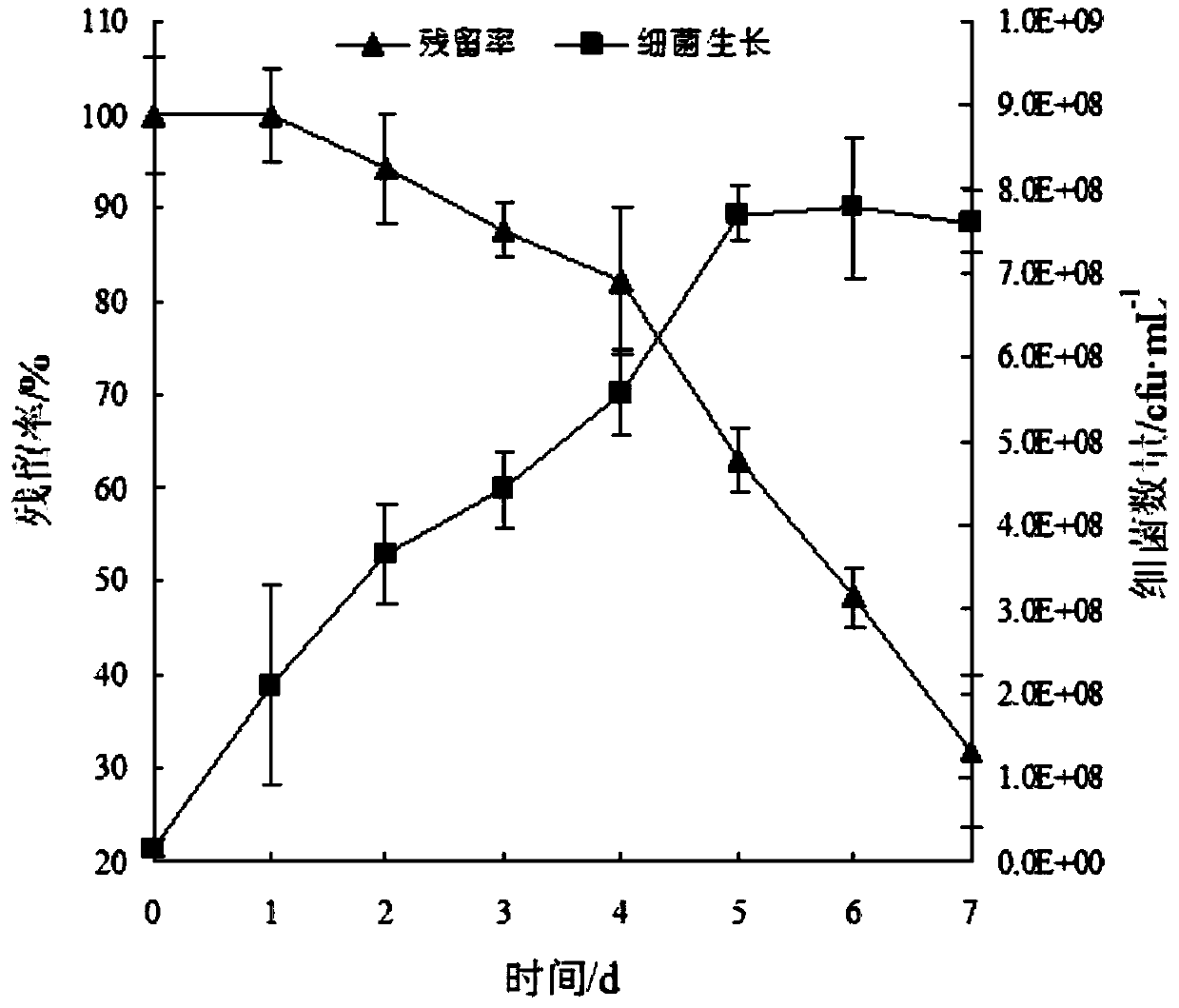

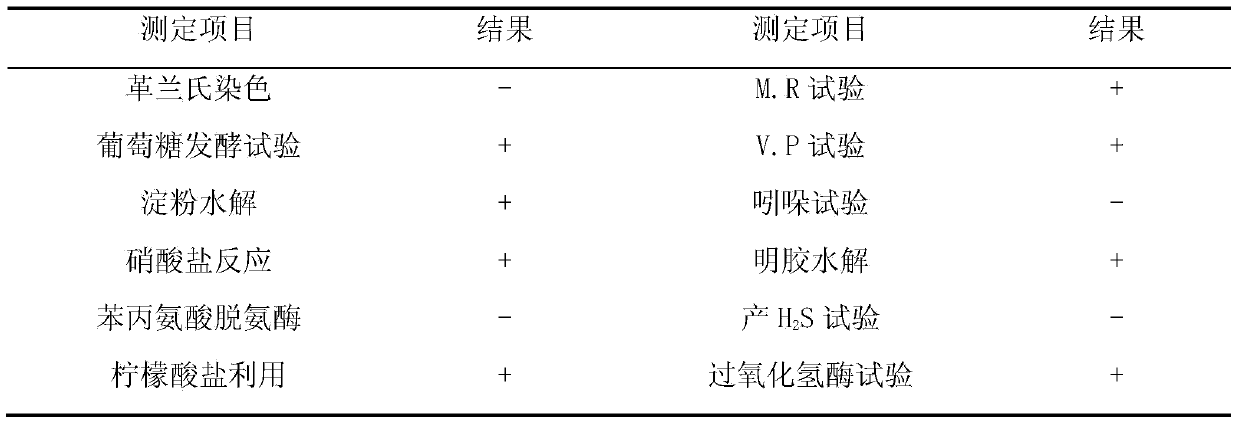

Diethylstilbestrol degradation strain and application thereof in sewage and animal manure treatment

InactiveCN104195084AReduce manufacturing costEasy to useBacteriaWater contaminantsLaboratory cultureFungicide

The invention discloses a diethylstilbestrol degradation strain and an application thereof in sewage and animal manure treatment. Serratieae (Serratia sp.) S is preserved at China General Microbiological Culture Collection Center on August 26, 2014, wherein the strain preservation number is CGMCC 1.12941. The invention also discloses an application of the serratieae S and a fungicide of the serratieae S in degradation of estrogen, especially degradation of diethylstilbestrol. The serratieae S is obtained in a screening manner, the degradation rate on DES (diethylstilbestrol) of which the initial concentration is 50mg L<-1> can reach over 80% after an immobilized bacteria agent which is prepared from the strain is subjected to shake-flask culture in a laboratory for 7d, the immobilized bacteria agent is directly applied to DES-polluted water and animal manure, and the DES residue within a short period of time is reduced by over 90%, so that the problem of hazards of diethylstilbestrol DES to the water environment, animal manure and human health is solved.

Owner:NANJING AGRICULTURAL UNIVERSITY

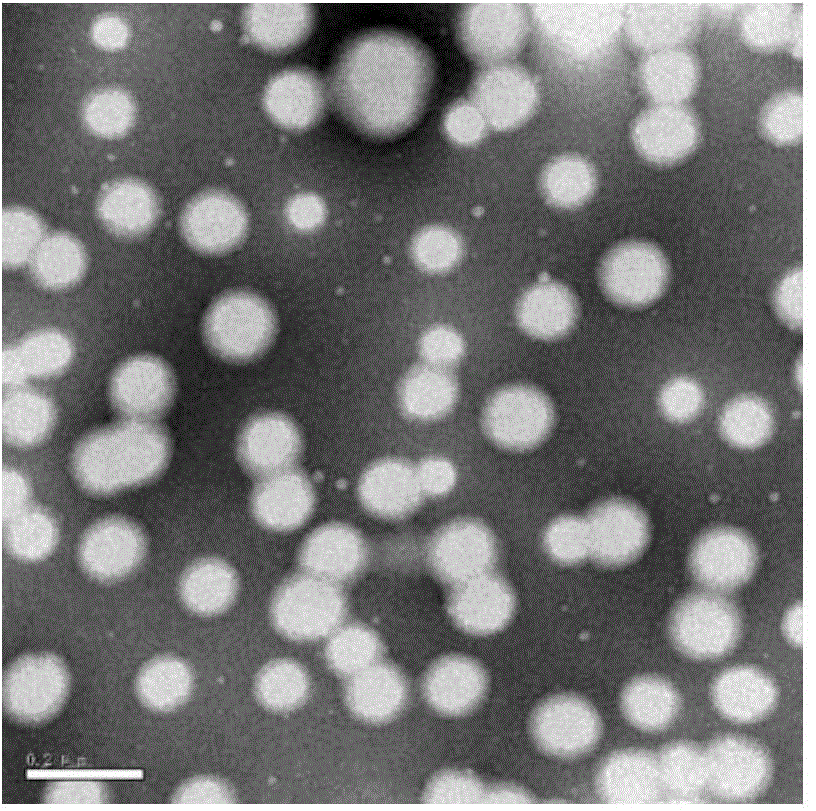

Core-shell type short-chain fluorine-containing acrylate emulsion and preparation method thereof

InactiveCN105440201ASolve the hazardHigh crystallinityCoatingsVegetal fibresFunctional monomerPolymer chemistry

The present invention discloses core-shell short-chain fluorine-containing acrylate emulsion and a preparation method thereof. A series of core-shell short-chain fluorine-containing acrylate emulsion are synthesized from methyl methacrylate (MMA) and butyl acrylate (BA) copolymer as a core and a short fluorocarbon chain 2-(perfluorohexyl) ethyl methacrylate (FMA6) and non-fluoro alkyl methacrylate copolymer as a shell by a multi-step emulsion polymerization method. The core-shell short-chain fluorine-containing acrylate emulsion solves the environmental problem caused by a C8 fluorine-containing monomer as an essential functional monomer used in a main three-control finishing agent, and meanwhile makes up the defect of shortage of product water-repellent and oil-repellent effects when an environmentally friendly C6 fluorine-containing monomer is used as an essential functional monomer. The product has a core-shell structure, the shell layer is rich in a fluorine-containing acrylate component, the amount of the fluorine monomer in the emulsion can be greatly reduced, cost is reduced, water contact angle and oil contact angle of a product latex film are large, and the core-shell short-chain fluorine-containing acrylate emulsion used in textile finishing exhibits excellent water and oil repellency.

Owner:NANJING UNIV OF SCI & TECH

Combined dust settling method for large-area excavation and explosion in water conservancy and hydropower project

ActiveCN104107609ASolve the hazardEasy access to resourcesUsing liquid separation agentToxic gasDetonation

The invention provides a combined dust settling method for large-area excavation and explosion in a water conservancy and hydropower project. The method comprises the following steps: 1) before detonation, injecting water into blastholes; 2) installing a pressurized water pump and a plurality of groups of high pressure spray gun; 3) arranging river-crossing water spraying pipes at the upper stream and lower stream of a riverway located in an explosion area; 4) spraying water to wet the ground of the explosion area before detonation; 5) after detonation, as water injected into the blastholes exerts an inhibitory effect on produced smoke, immediately starting the plurality of groups of high pressure spray gun for water spraying so as to cover rising smoke dust; and 6) opening the river-crossing water spraying pipes at the upper stream and lower stream of the riverway to form a water curtain so as to finish effective dust settling of dust clouds produced during large-area excavation and explosion in the water conservancy and hydropower project. The combined dust settling method for large-area excavation and explosion in the water conservancy and hydropower project can overcome problems of dust, toxic gas and other harm caused by large-area open-air explosion in the water conservancy and hydropower project and is economic, environment-friendly, rapid and effective.

Owner:CHINA THREE GORGES CORPORATION

Centrifugal impeller optimal design method for preventing vibration localization for happening

InactiveCN102374190ASolving Vibration Localization ProblemsAvoid harmPump componentsPumpsImpellerEngineering

The invention relates to a centrifugal impeller optimal design method for preventing vibration localization from happening. The method comprises the following steps of: 1, carrying out static strength verification; 2, drawing a vibration mode graph of a plurality of orders of modals in front of an impeller; 3, analyzing a forbidden band and a passband of the impeller; 4, determining the excitation frequency of an excitation source; 5, judging whether the excitation source drops in the forbidden band or is close to the forbidden band; and 6, optimizing the impeller structure and increasing the isolation margin of the forbidden band of the impeller so as to eliminate influence of detuning. According to the centrifugal impeller optimal design method disclosed by the invention, the vibration localization problem of the impeller in the operation process can be effectively solved, the injuries caused by vibration localization and the failure occurrence rate of the impeller in the operation process are reduced, and a centrifugal impeller unit can be ensured to operate safely and reliably for a long time.

Owner:XI AN JIAOTONG UNIV

Solid organic material cracking method and system

ActiveCN106338066AImproved microwave absorption propertiesStrong process controllabilityProductsReagentsMicrowaveProduct gas

The invention provides a solid organic material cracking method and system. The method comprises the following steps of: A, pre-treating a solid organic material; B, sending the pre-treated solid organic material into a cracking device; C, heating a gas medium to 350-700 DEG C; D, continuously importing the heated gas medium into the cracking device to act on the solid organic material with microwave, so as to carry out cracking to obtain a solid product and a mixed gaseous product; and E, importing a part of the obtained mixed gaseous product into a gas heating device in the step C so as to heat the mixed gaseous product to 350-700 DEG C to be circularly used for the cracking in the step D. The process can effectively decrease the cracking energy consumption and the cracking time, and can save the cost.

Owner:成都德理克新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com