Rubber sealed and shock-reducing sound-absorbent material coated on metal sheet and method for preparing same

A metal sheet, rubber coating technology, applied in chemical instruments and methods, unspecified rubber coatings, coatings, etc., can solve problems such as increased maintenance costs, maintenance or replacement, inability to meet, and achieve good resistance to various media. , Make up for the effect of temperature resistance and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

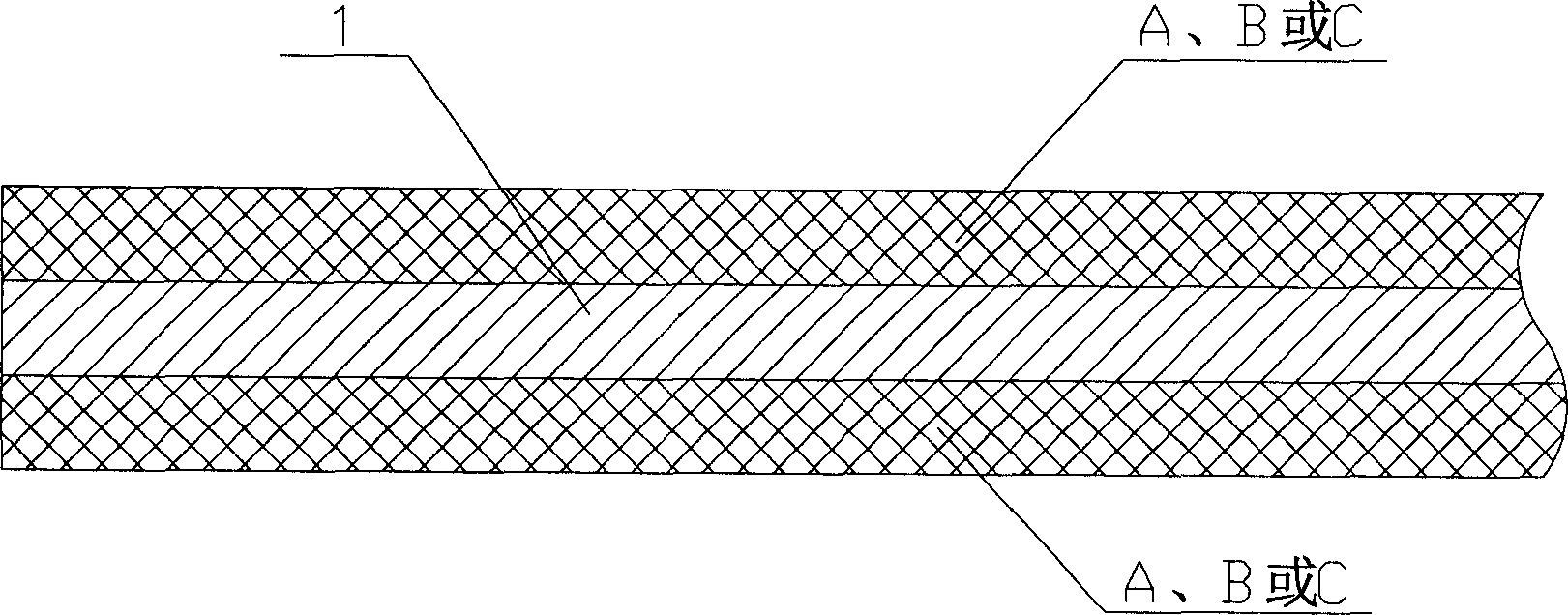

[0027] A method for preparing a rubber-coated sealing and shock-absorbing and sound-absorbing material for a metal sheet 1, wherein the coating layer (A) coated on the metal sheet is composed of rubber, fillers and compounding agents, and the specific composition ratio (weight Percentage) is as follows:

[0028] Rubber 60wt%

[0029] Filler 40wt%

[0030] Addition, compounding agent 2.4wt%

[0031] Among them, the manufacturing process of the coating layer (A) is:

[0032] 1) The rubber is fluorine rubber.

[0033] According to the capacity of the open mill (open rubber mill), the actual composition of each vehicle is calculated according to the above formula ratio. Put a certain weight of fluorine rubber into the open mill for rubber breaking and rolling, and then put in various batches and fillers for mixing in sequence.

[0034] Compounding agents include accelerators, vulcanizing agents, white carbon black, plasticizers, stabilizers, smoothing agents, acid absorbents and the l...

Embodiment 2

[0042] Another method for preparing a rubber-coated sealing and damping and sound-absorbing material for a metal sheet 1, wherein the coating layer (B) coated on the metal sheet is composed of rubber, fillers and compounding agents, and the specific composition ratio ( The weight percentage) is as follows:

[0043] Rubber 70wt%

[0044] Filler 30wt%

[0045] Addition, compounding agent 2.9wt%

[0046] Among them, the manufacturing process of the coating layer (B) is:

[0047] 1) The rubber is selected from styrene-butadiene rubber, or used in combination with natural rubber or butadiene rubber.

[0048] According to the capacity of the open mixer (open rubber mixer), the actual composition of each car is calculated according to the above formula ratio.

[0049] SBR generally does not need to be masticated, but according to the characteristics of this product, a certain degree of mastication can be appropriately carried out to improve the smoothness of the product. Plastic refining...

Embodiment 3

[0058] Another method for preparing a rubber-coated sealing and shock-absorbing and sound-absorbing material for a metal sheet 1, wherein the coating layer (C) coated on the metal sheet is composed of rubber, fillers and compounding agents, and the specific composition ratio ( The weight percentage) is as follows:

[0059] Rubber 50wt%

[0060] Filler 50wt%

[0061] Addition, compounding agent 2.0wt%

[0062] Among them, the manufacturing process of the coating layer (C) is:

[0063] 1) The rubber is nitrile rubber or acrylic rubber.

[0064] According to the capacity of the open mill, the actual component dosage of each car is calculated according to the above formula ratio.

[0065] Put the calculated certain weight of nitrile rubber into the open mill for mastication. Nitrile rubber usually needs to be masticated. Nitrile rubber has high toughness and low plasticizing effect, so a low-roller temperature, small-roller distance, and low-volume plasticizing process is required. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com