Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Excellent tensile elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

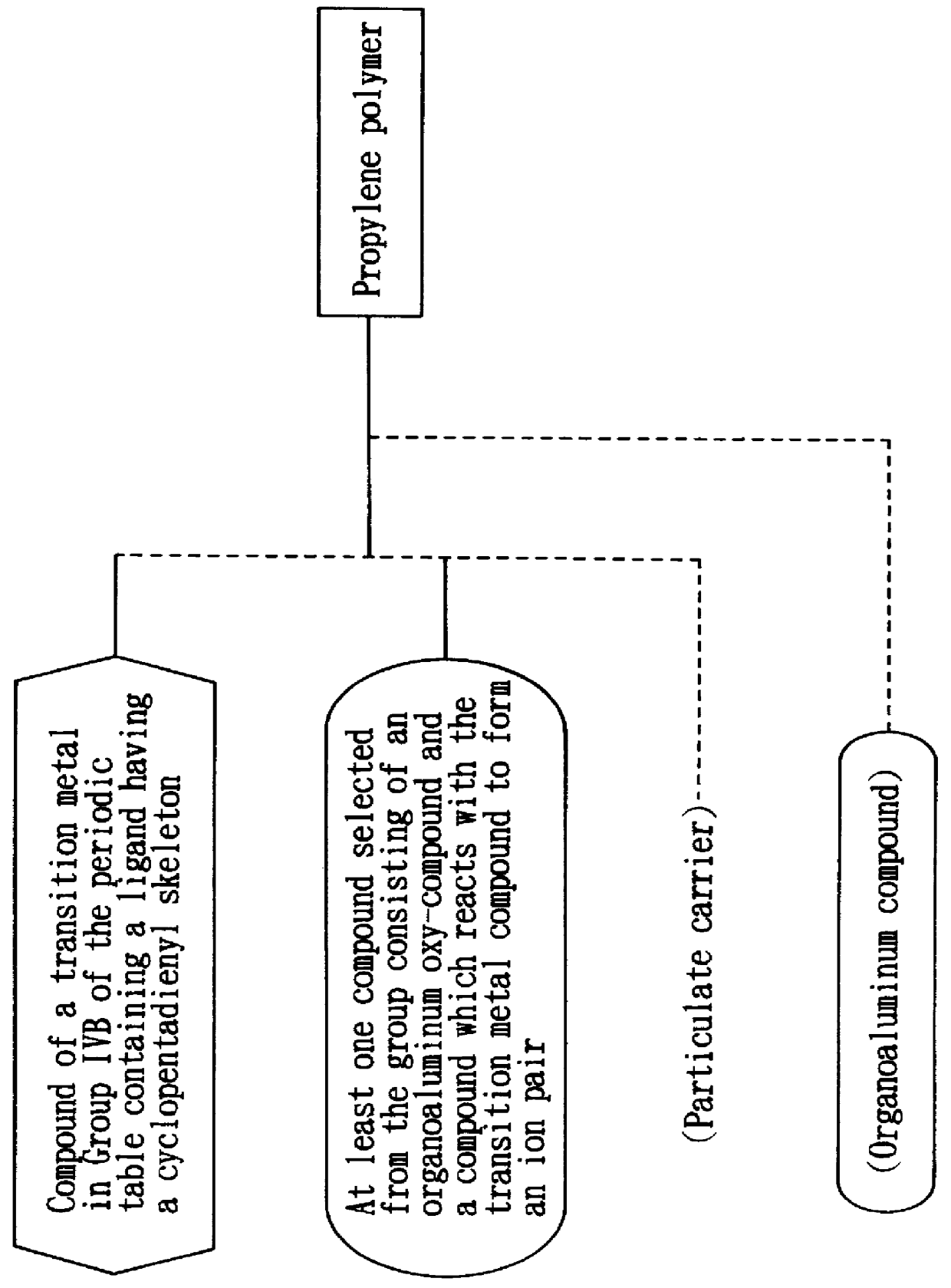

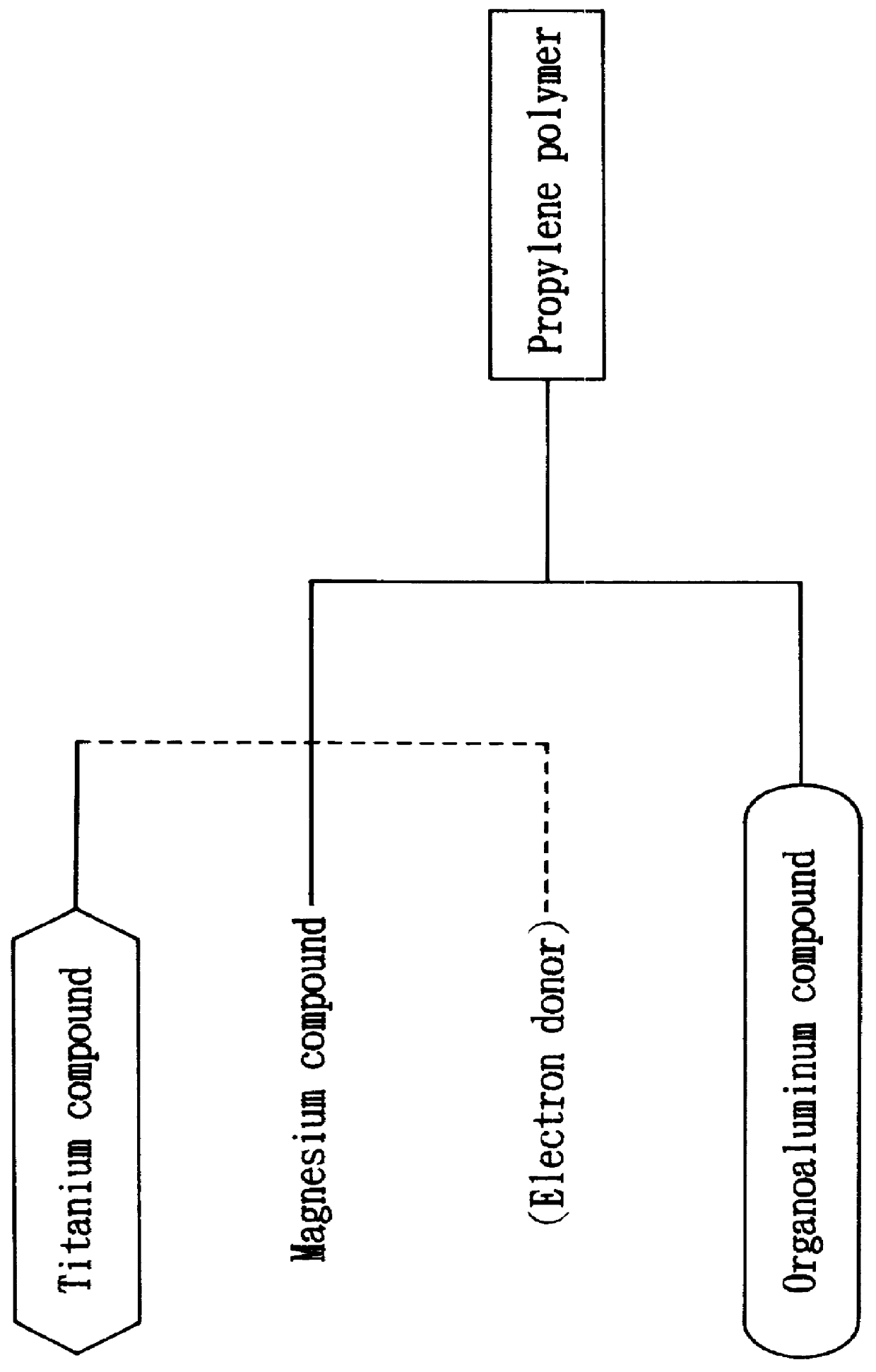

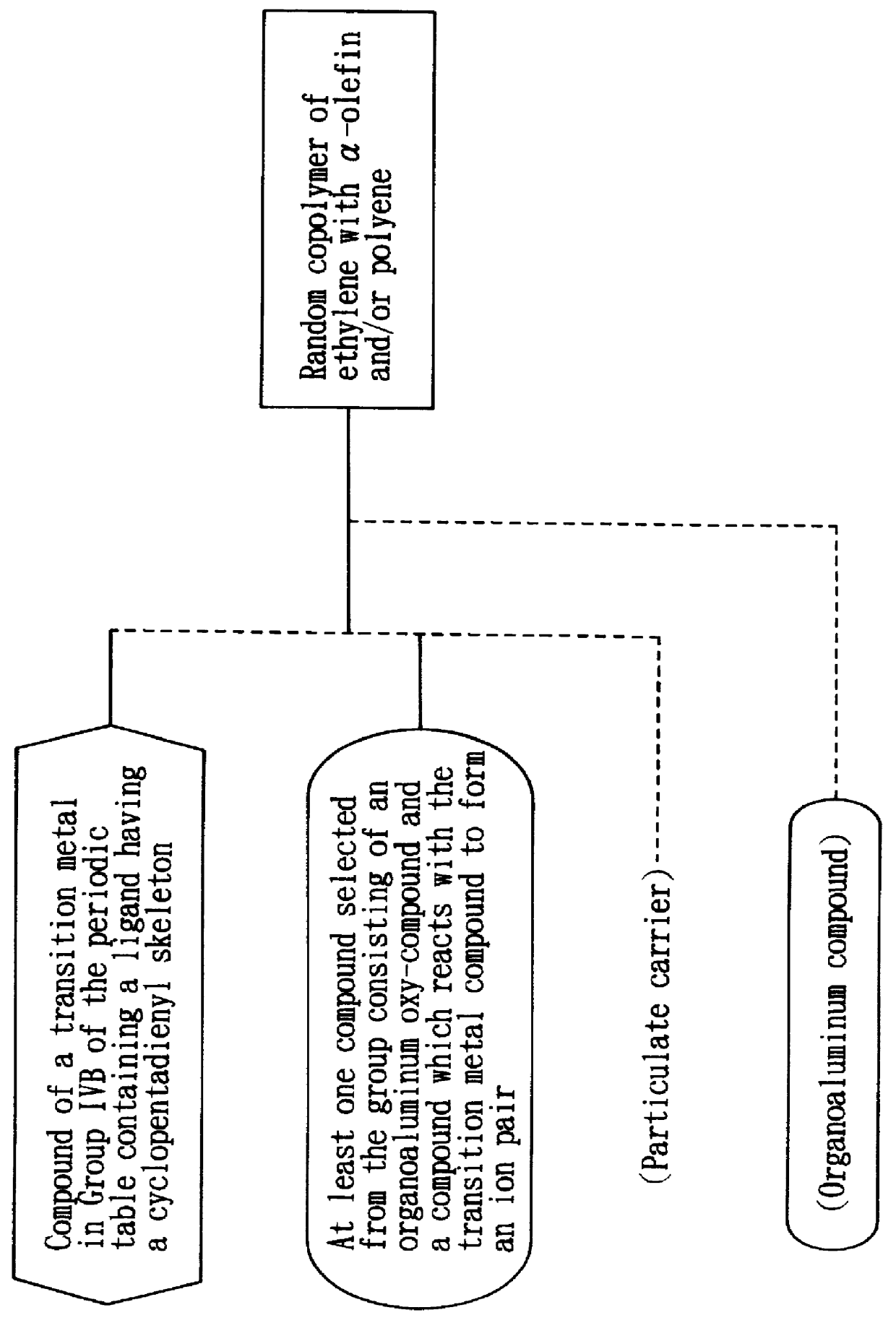

Propylene polymer compositions containing a propylene homo- or co-polymer obtained using a bridged metallocene catalyst and another propylene homo- or co-polymer

InactiveUS6156844AImprove heat resistanceExcellent in mechanical strength elongationPolymer scienceHeat resistance

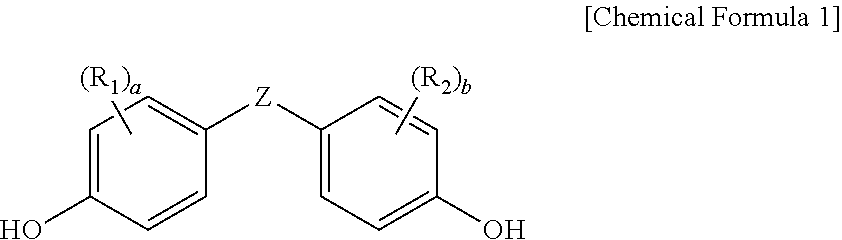

PCT No. PCT / JP94 / 00024 Sec. 371 Date Sep. 8, 1994 Sec. 102(e) Date Sep. 8, 1994 PCT Filed Jan. 11, 1994 PCT Pub. No. WO94 / 16009 PCT Pub. Date Jul. 21, 1994A propylene polymer composition is prepared by mixing a first propylene polymer prepared using an olefin polymerization catalyst containing a specific metallocene catalyst component of formula (I), e.g., rac-dimethylsilylene-bis{1-(2-ethyl-4-phenylindenyl)} zirconium dichloride, and an organoaluminum-oxy cocatalyst, with a second propylene polymer component. The compositions are excellent in heat resistance, mechanical strength, tensile elongation at break, and other properties and can be used to produce various structural materials, sheets and films.

Owner:MITSUI CHEM INC

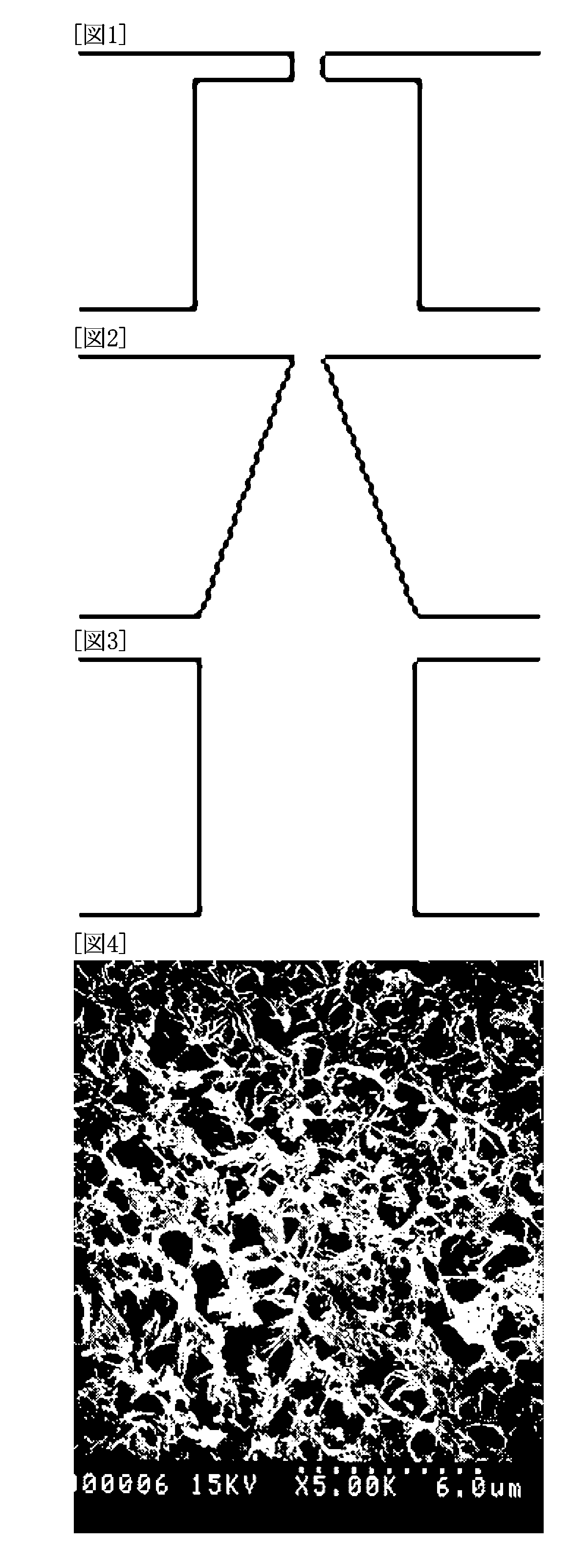

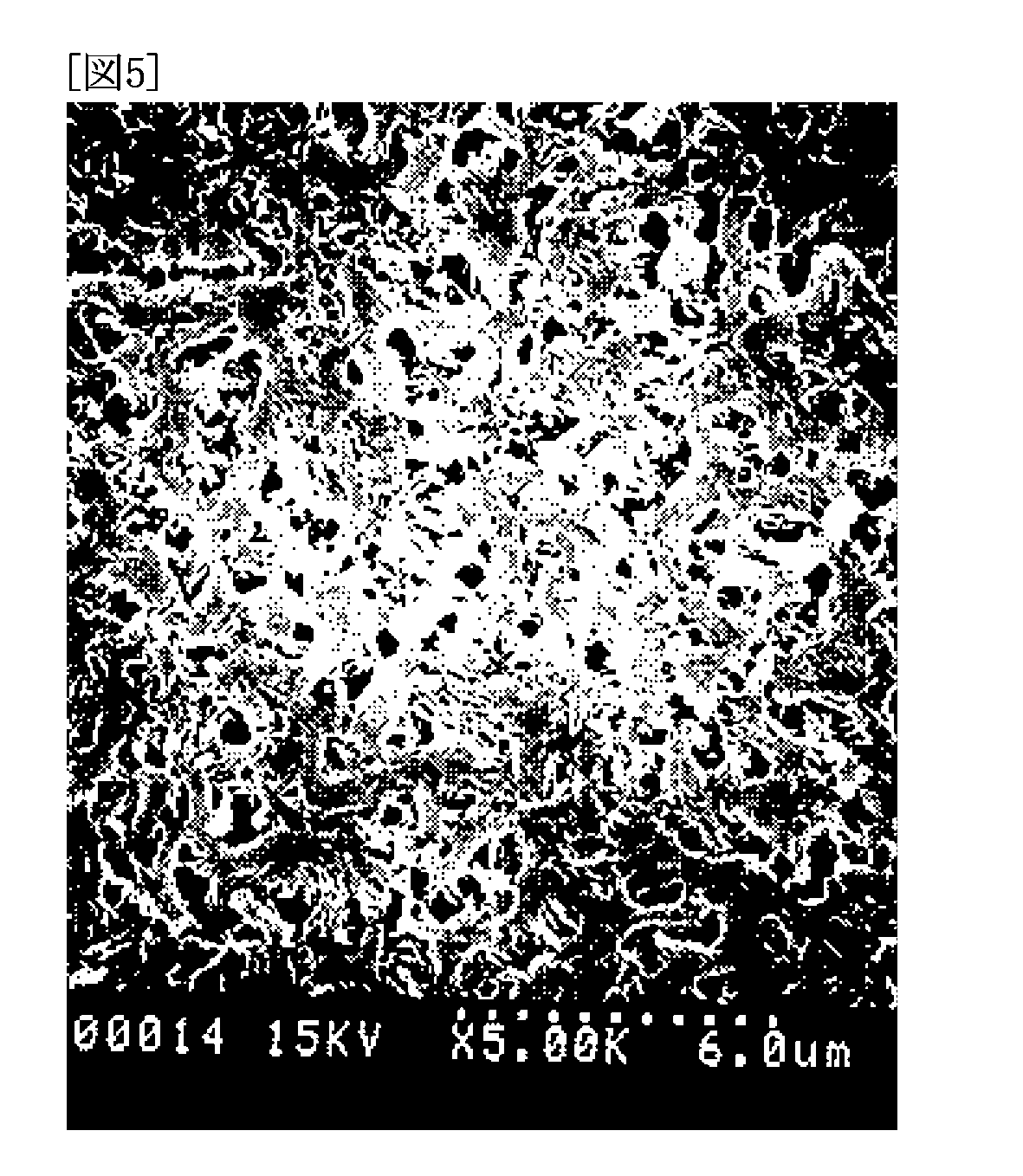

Polyvinylidene fluoride hollow yarn type microporous film and process for production of the same

InactiveUS20090283469A1Easy to separateImprove permeabilitySemi-permeable membranesMembranesYarnFiber

Problems: To provide a polyvinylidene fluoride microporous membrane which has high water permeability and separation performance and is excellent in mechanical and chemical strength; and a process for producing the film.Means for Solving Problems: An anisotropic polyvinylidene fluoride hollow fiber microporous membrane characterized in that the porosity of the cross-sectional bulk layer is higher than the membrane surface porosity of the outer layer and that in the cross section of the membrane, the dense microstructure of the outer surface changes substantially discontinuously into the coarse structure of the bulk layer. The microporous membrane can be produced by introducing by a dry-wet method a dope prepared by dissolving a polyvinylidene fluoride resin together with a water-soluble latent solvent at high temperature into a cooling bath consisting of water or a mixture thereof with a water-soluble latent solvent and subjecting the dope to membrane formation wherein the cross-sectional bulk layer is formed mainly by thermally-induced phase separation and the outer layer is formed mainly by nonsolvent-induced phase separation.

Owner:TOYO TOYOBO CO LTD

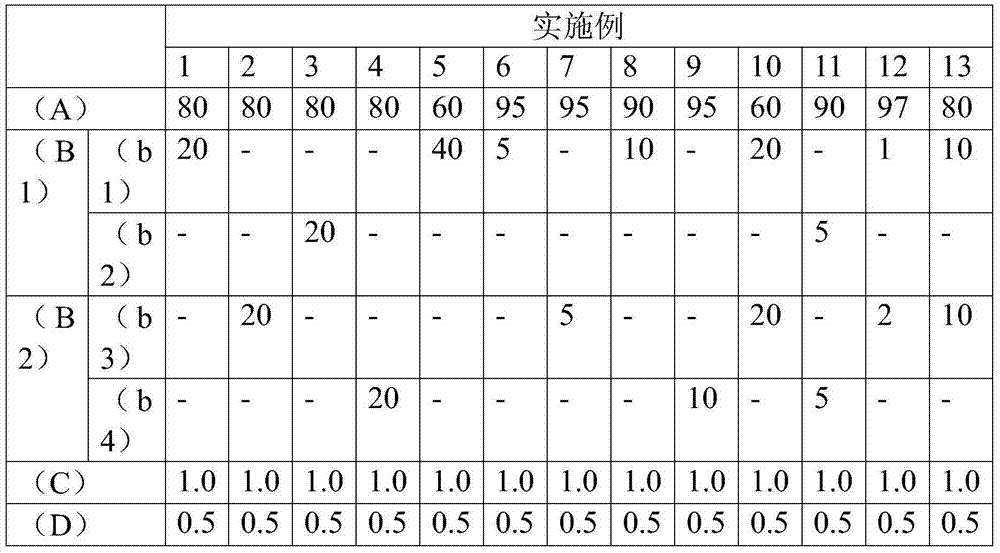

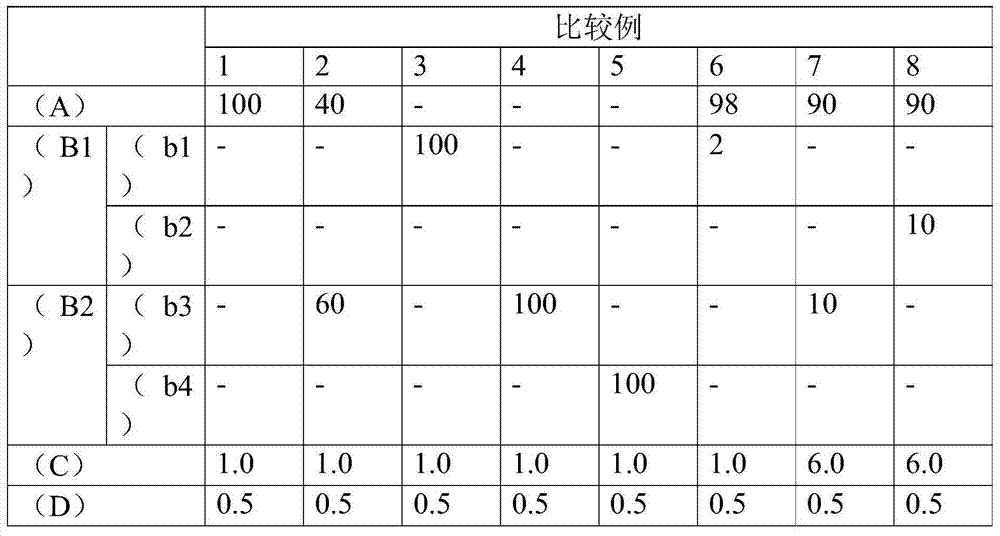

Polycarbonate-Based Resin Composition for Carrier Tape Having Excellent Electric Conductivity

InactiveCN104212143AImprove conductivityImprove productivityNon-conductive material with dispersed conductive materialPackagingProduction ratePolymer resin

An electric conductive resin composition comprises about 0.5 to about 5 parts by weight of (C) carbon nanotubes, based on about 100 parts by weight of a base resin comprising about 50 to about 97% by weight of (A) a polycarbonate resin and about 3 to about 50% by weight of (B) a rubber-modified aromatic vinyl resin (B1), a semi-crystalline polymer resin (B2), or a mixture thereof. The electric conductive resin composition has a surface resistance of about 105Ω / □ or less and can have excellent conductivity. Further, the composition can have excellent productivity, tensile strength and / or tensile elongation, and / or generates little dust.

Owner:CHEIL IND INC

Light-weight heat-conducting organosilicon pouring sealant base sizing material as well as composition and preparation methods thereof

ActiveCN106701012AImprove thermal conductivityReduce product densityNon-macromolecular adhesive additivesSizingOrganosilicon

The invention discloses a light-weight heat-conducting organosilicon pouring sealant base sizing material which comprises unsaturated hydrocarbon terminated polydiorgnosiloxane and light-weight heat-conducting filler with density of 0.1-2.0g / cm<3>. The invention aims at providing a light-weight heat-conducting organosilicon pouring sealant base sizing material and also provides a preparation method of the base sizing material, as well as a composition prepared by using the base sizing material and a preparation method thereof. A pouring sealant prepared by the base sizing material has the advantages of light weight, and good heat-conducting property.

Owner:GUANGZHOU TINCI MATERIALS TECH

High strength heat resistant modified polyurethane composite material

InactiveCN105778472AImproved heat and weather resistanceImproved flame retardancy and media resistanceStearic acidOxide

The invention discloses a high strength heat resistant modified polyurethane composite material. The material comprises the following raw materials in parts by weight: 100 parts of polyurethane, 25 to 40 parts of chloroprene rubber, 15 to 30 parts of methyl vinyl silicone rubber, 3 to 5 parts of stearic acid, 0.5 to 2 parts of zinc oxide, 0.5 to 1.5 parts of sulfur, 2 to 3 parts of MgO, 10 to 18 parts of fume colloidal silica, 5 to 15 parts of attapulgite, 3 to 15 parts of hollow glass micro-beads, 10 to 20 parts of polyurethane modified filler, 2 to 5 parts of diphenyl silanediol, 2 to 3.5 parts of hexamethyl disilazane, 0.5 to 2 parts of an accelerant and 1 to 2 parts of an antiager. The high strength heat resistant modified polyurethane composite material is high in strength, excellent in heat resistance and long in service life.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

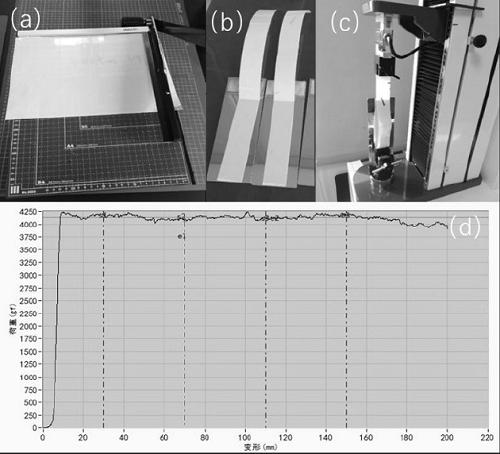

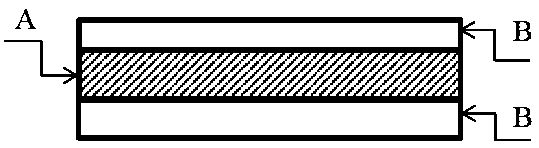

Easy-to-pull removable double-sided adhesive tape of TPU base material

ActiveCN109575826AHigh tensile strengthHigh tensile elongationNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceSilicone tape

The invention discloses an easy-to-pull removable double-sided adhesive tape of a TPU base material. The adhesive tape comprises the following components in parts by mass: 80-150 parts of rubber raw materials, 75-130 parts of tackifying resins, 100-350 parts of toluene, 0.1-5 parts of adhesion promoters and 5-15 parts of color paste. The adhesive tape of the TPU base material is a double-sided fixing adhesive tape with higher adhesive strength, can be used after stripping release paper or laminating release films when in use, can be removed only by stretching the adhesive tape when needed, andcan bring great convenience to workers in the maintenance of electronic components.

Owner:苏州世诺新材料科技有限公司

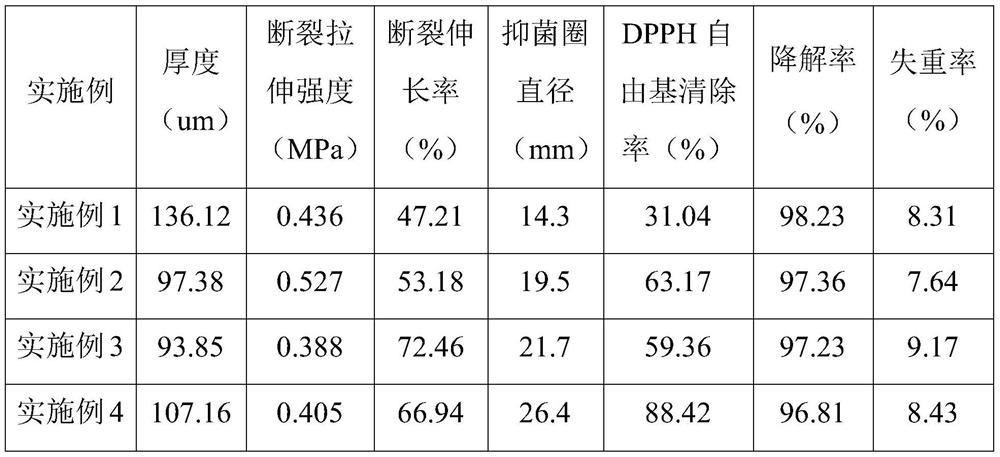

Preservative film containing peanut coat procyanidine inclusion compound and preparation method thereof

InactiveCN112409615AWide variety of sourcesLow priceFlexible coversWrappersPolymer scienceProanthocyanidin

The invention discloses a preparation method of a preservative film containing peanut coat procyanidine clathrate compound, which comprises the following steps: based on 100 parts by mass, adding 4-6parts of the peanut coat procyanidine clathrate compound, 0.6-0.8 part of corn starch, 1.2-1.6 parts of gelatin, 0.4-0.8 part of chitosan, 1.6-2 parts of glycerol and the balance of deionized water into a magnetic stirrer, stirring the components for a period of time, adding glycerol, and continuously stirring and degassing the components; pouring the mixture into film forming vessel, and drying and cooling the mixture to obtain preservative film containing peanut coat procyanidine inclusion compound. The preparation method of the peanut coat procyanidine clathrate compound comprises the following steps: adding 1 part of peanut coat procyanidine and 4 parts of hydroxypropyl-beta-cyclodextrin into 200 parts of deionized water, clathrating the mixture on a magnetic stirrer, and freezing anddrying the mixture to obtain the peanut coat procyanidine clathrate compound. The preservative film containing the peanut coat procyanidine inclusion compound has good antioxidant and bacteriostatic effects and a good preservation effect, and can be quickly degraded under natural conditions.

Owner:ANYANG INST OF TECH

Non-substrate easy-to-pull removable adhesive tape as well as preparation and use method thereof

ActiveCN108570293AConvenient after-sales maintenanceConvenience for other needsMacromolecular adhesive additivesFilm/foil adhesives without carriersTolueneElectronic component

The invention discloses a non-substrate easy-to-pull removable adhesive tape. The adhesive tape has a thickness of 20 to 300 mu m, is prepared from the following components in parts by mass: 80 to 150parts of thermoplastic rubber, 60 to 150 parts of tackifying resin, 100 to 330 parts of toluene, 1 to 30 parts of softener, 1 to 10 parts of color paste, and 0.1 to 1 part of leveling agent. The non-substrate adhesive tape is a double-sided fixing tape with high bonding strength, can be used without pretreatment, and can be used after just peeling off the release paper or the release film. When the adhesive tape needs to be removed, the adhesive tape is only stretched to remove. The adhesive tape can bring great convenience to the staff during the maintenance of the electronic components.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

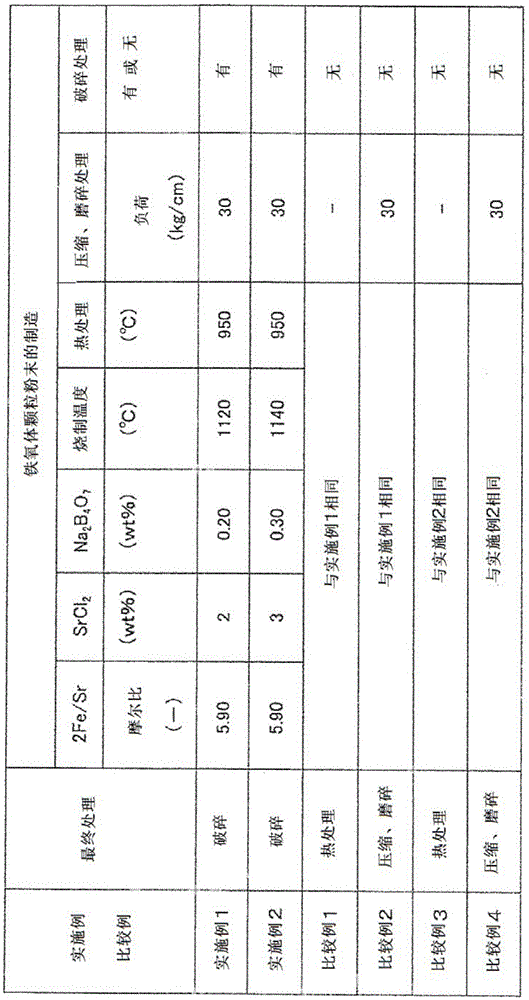

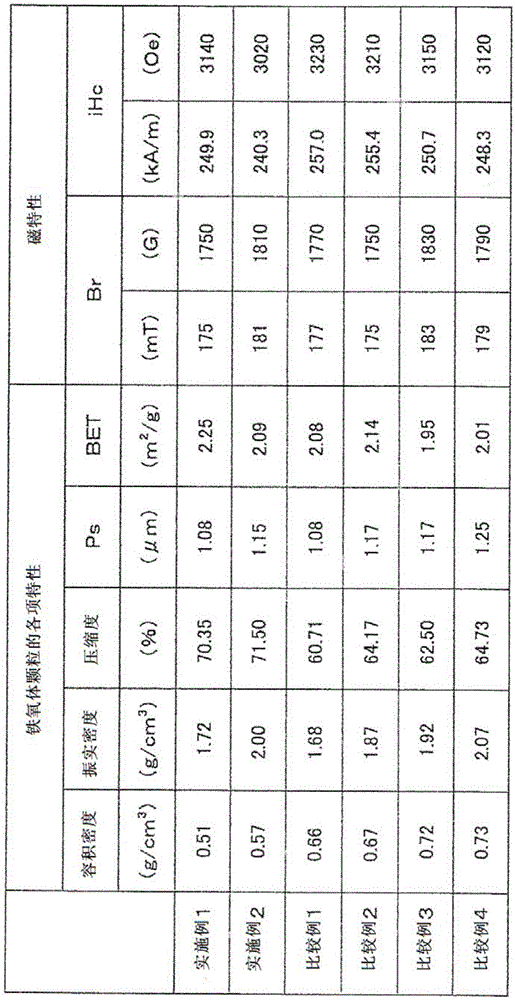

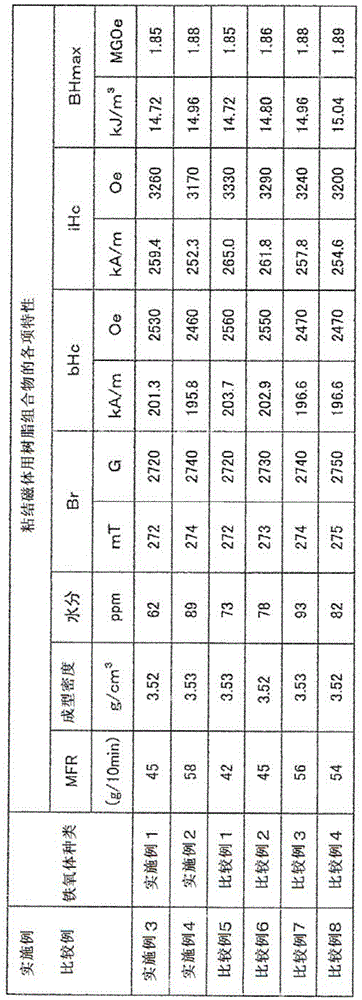

Ferrite particle powder for bonded magnet, resin composition for bonded magnet, and molded article using ferrite particle powder and resin composition

ActiveCN105637601AGood dispersionHigh strengthInorganic material magnetismIron compoundsMagnetic characteristicMaterials science

The present invention provides: a ferrite particle powder for a bonded magnet and a resin composition for a bonded magnet which make it possible to obtain a bonded magnet molded article having good tensile elongation and excellent magnetic characteristics; and a bonded magnet molded article, such as a rotor, using the composition. The present invention pertains to: a ferrite particle powder for a bonded magnet, said ferrite particle powder having a bulk density of at least 0.5g / cm3 but less than 0.6g / cm3, and a degree of compression of at least 65%; a resin composition for a bonded magnet, said resin composition using the ferrite particle powder for a bonded magnet; and a molded article.

Owner:TODA IND

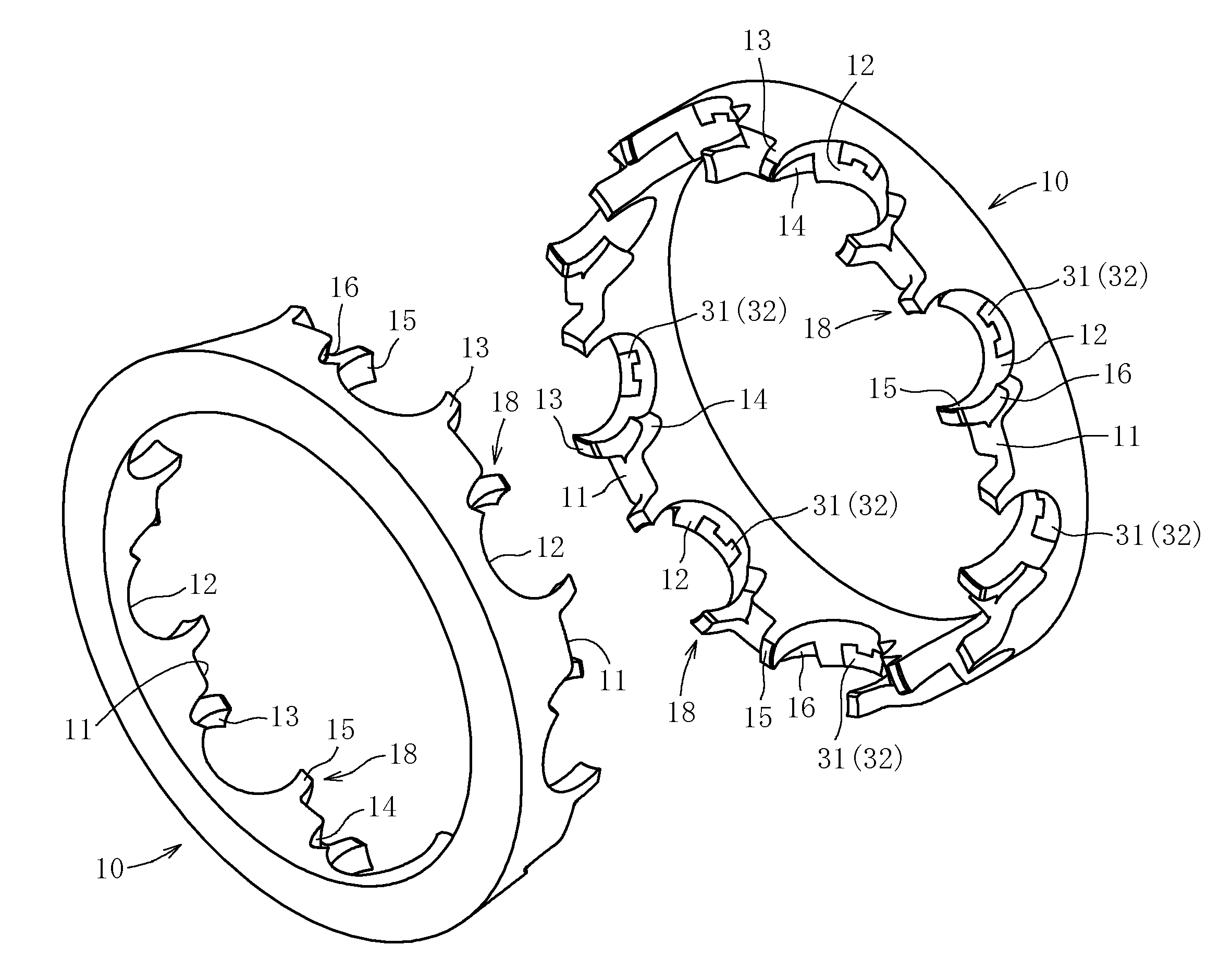

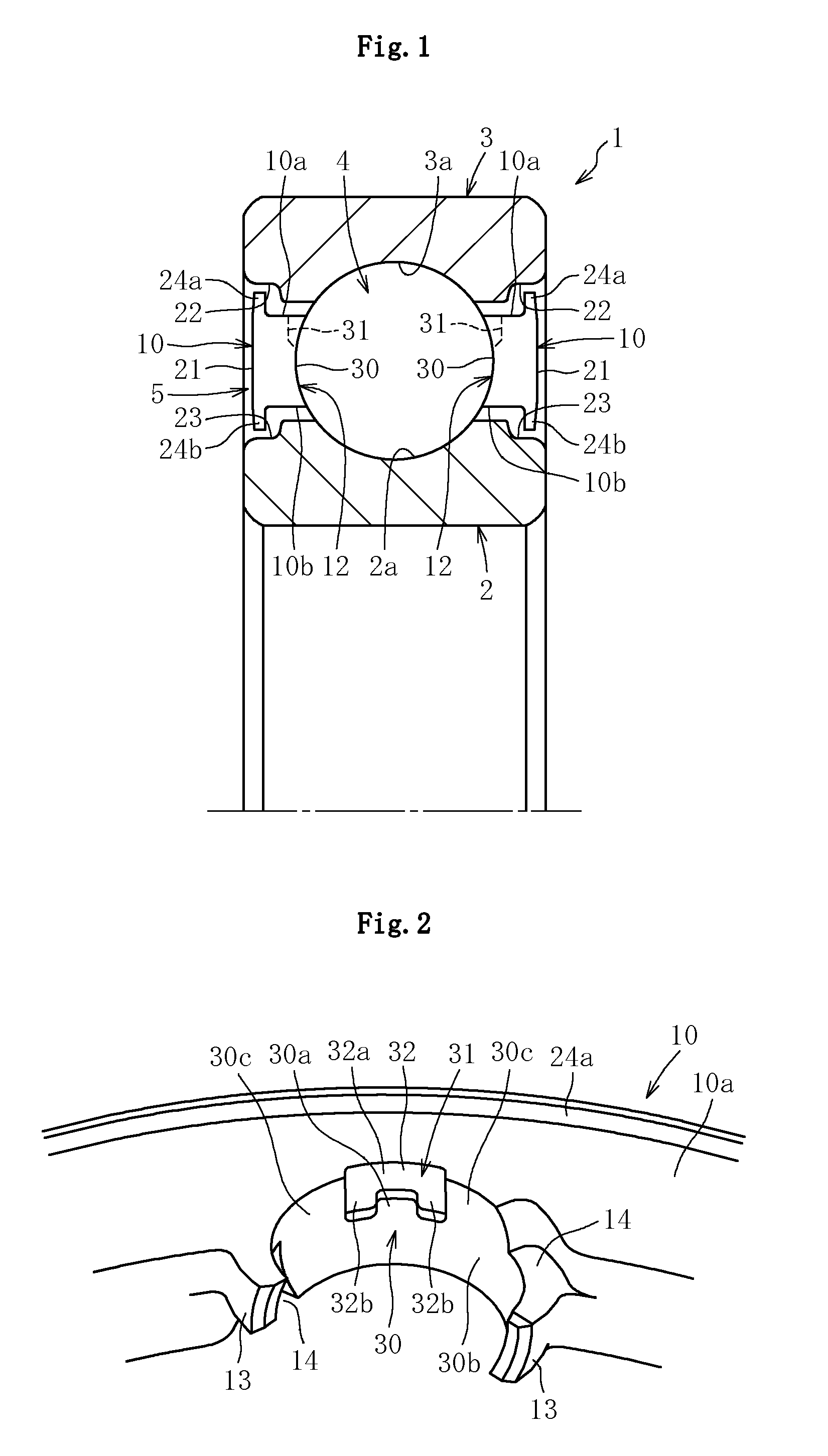

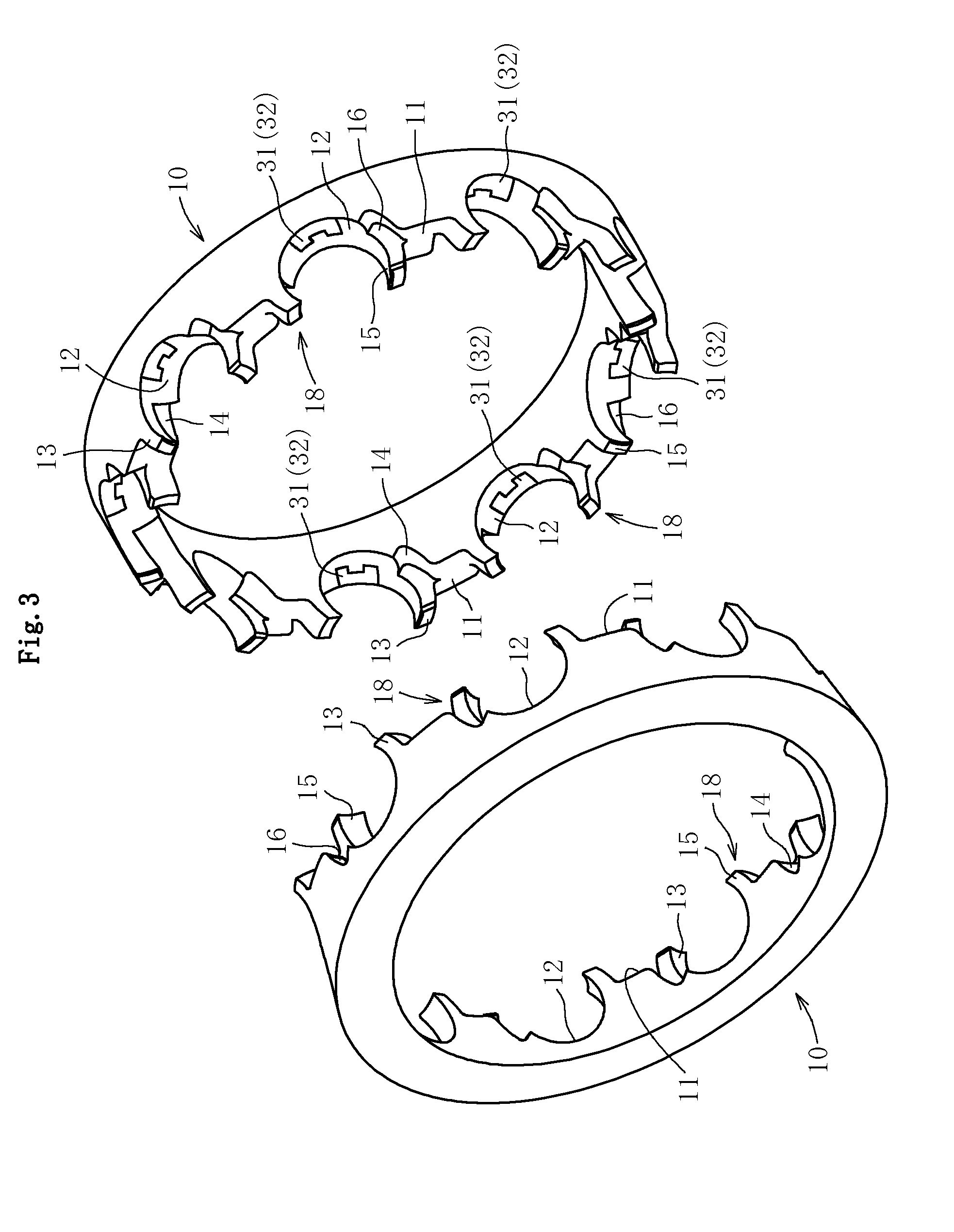

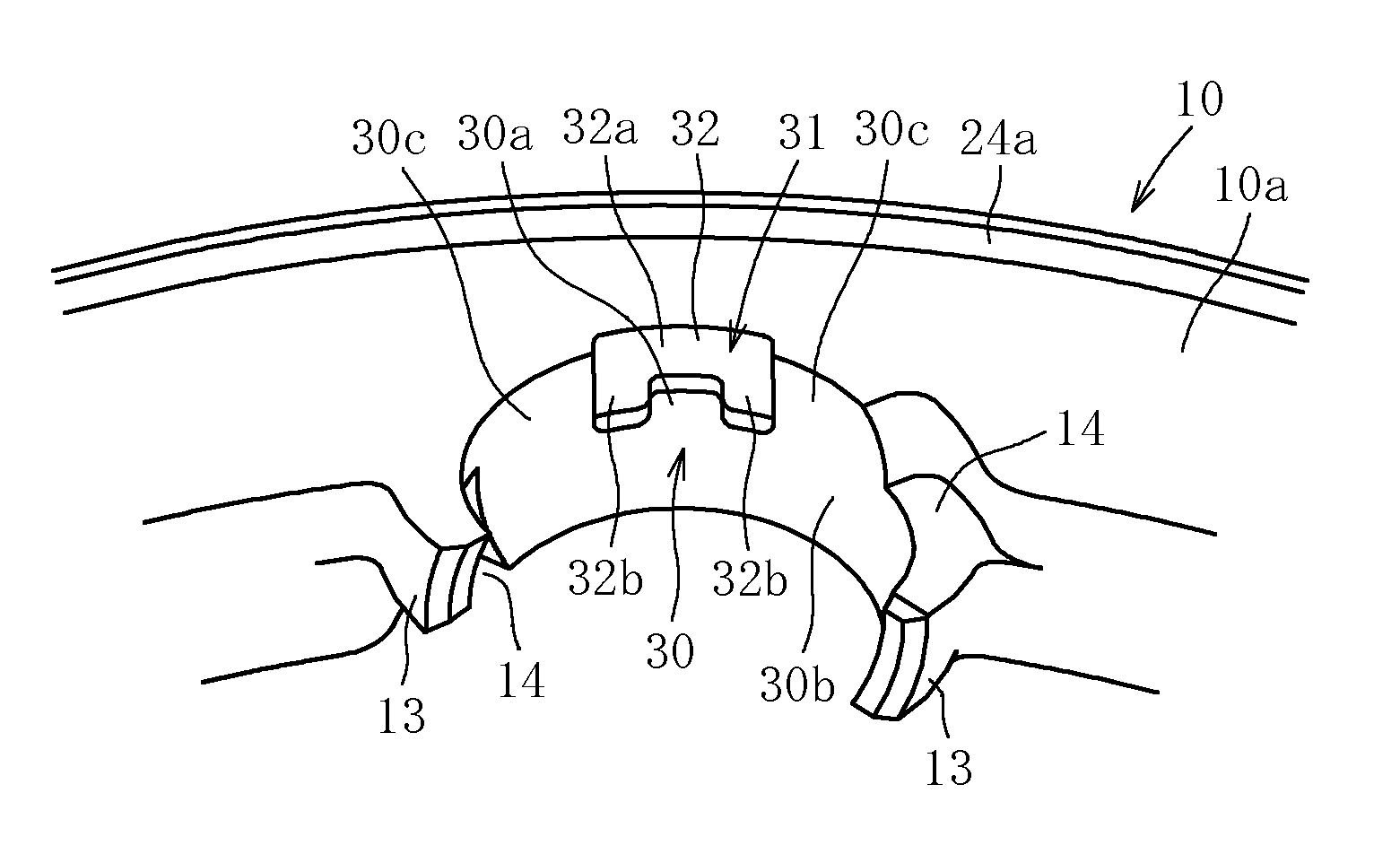

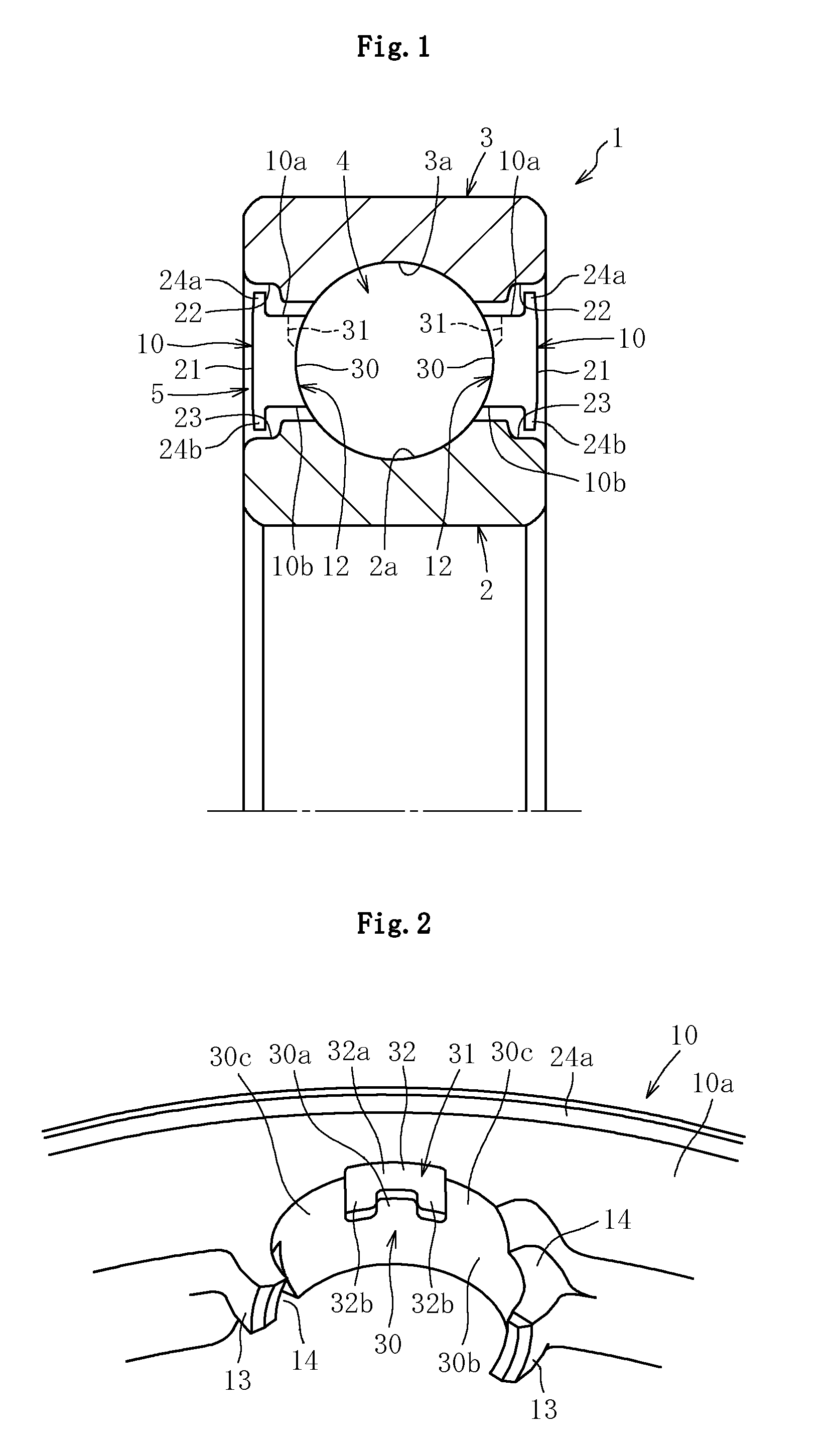

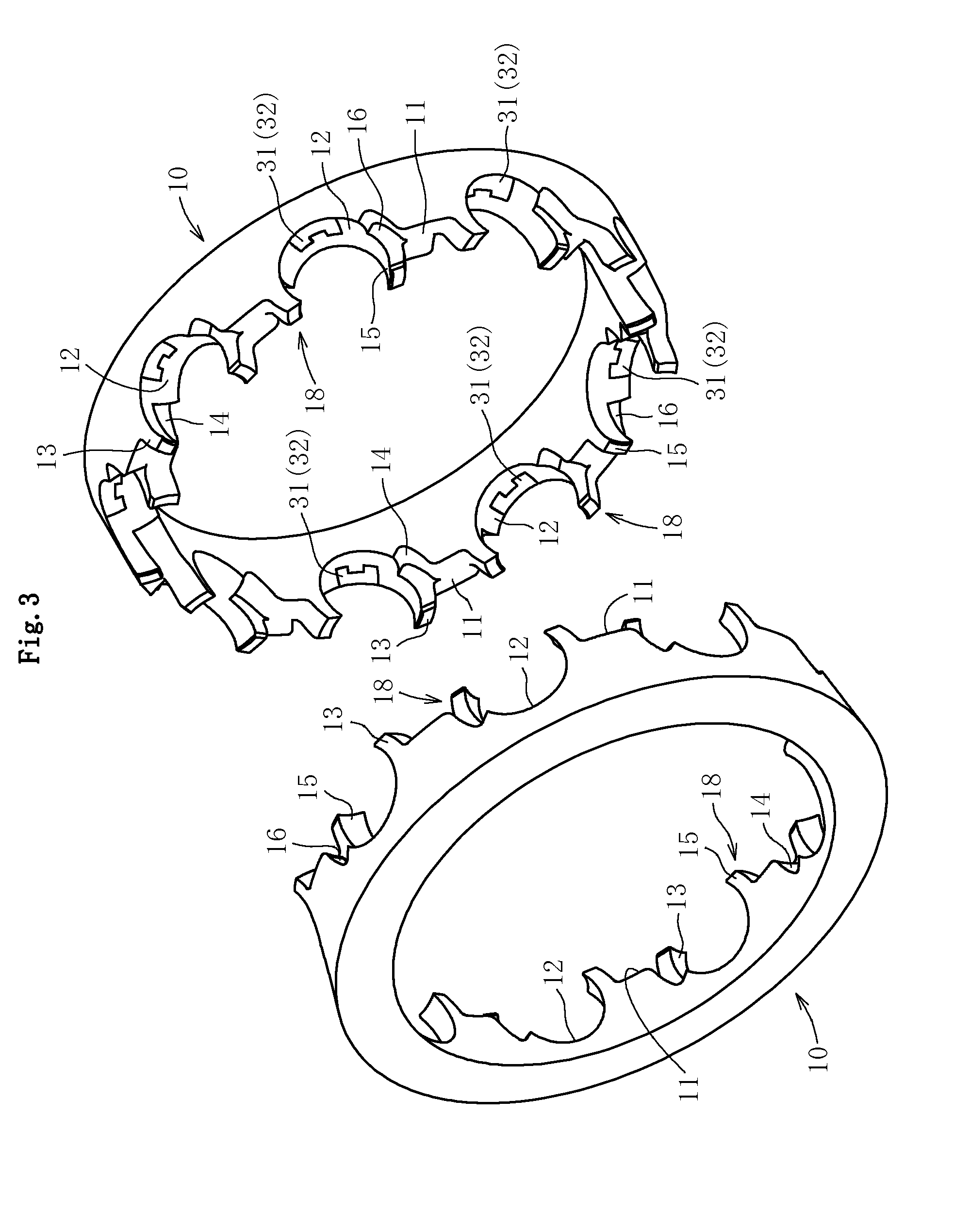

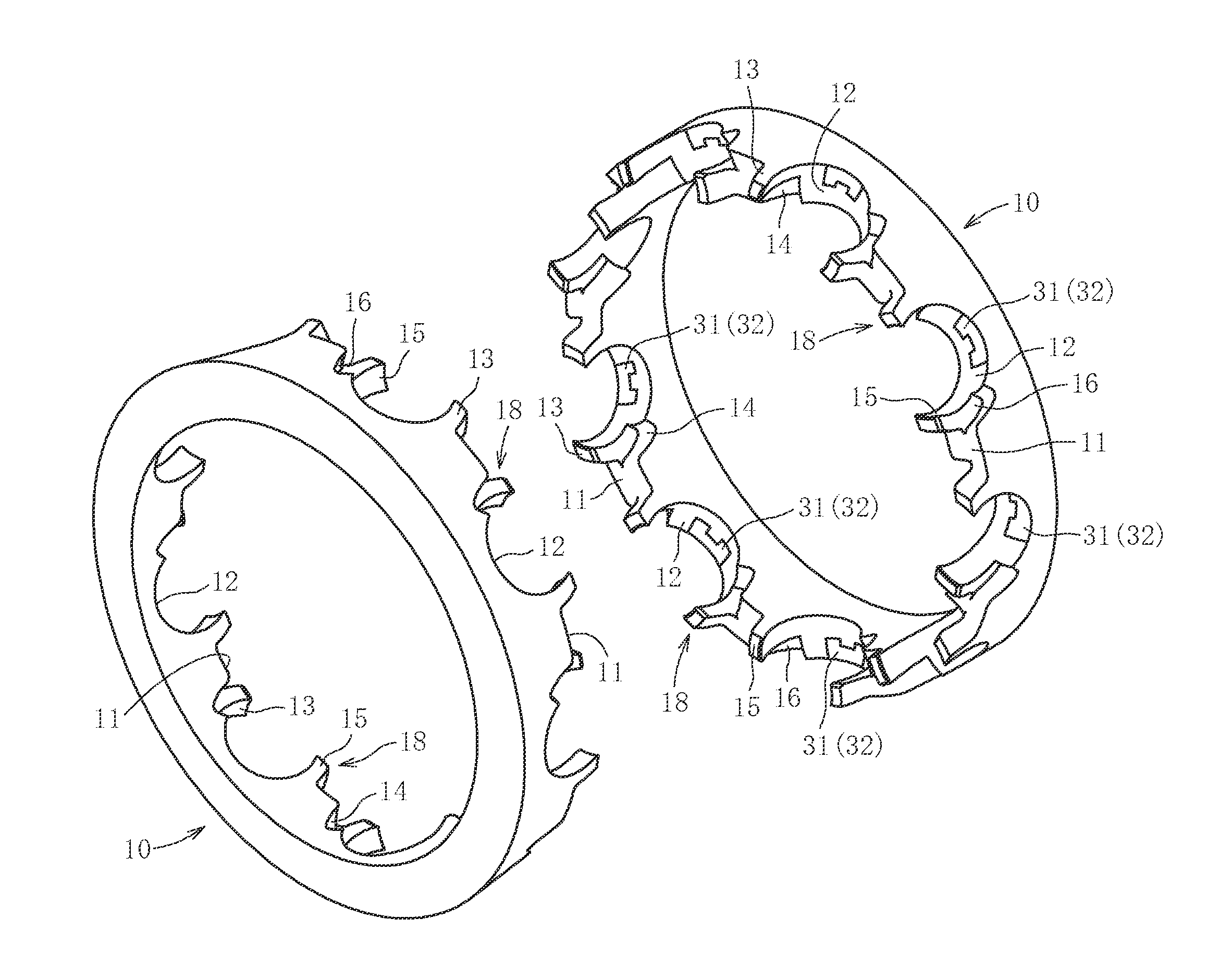

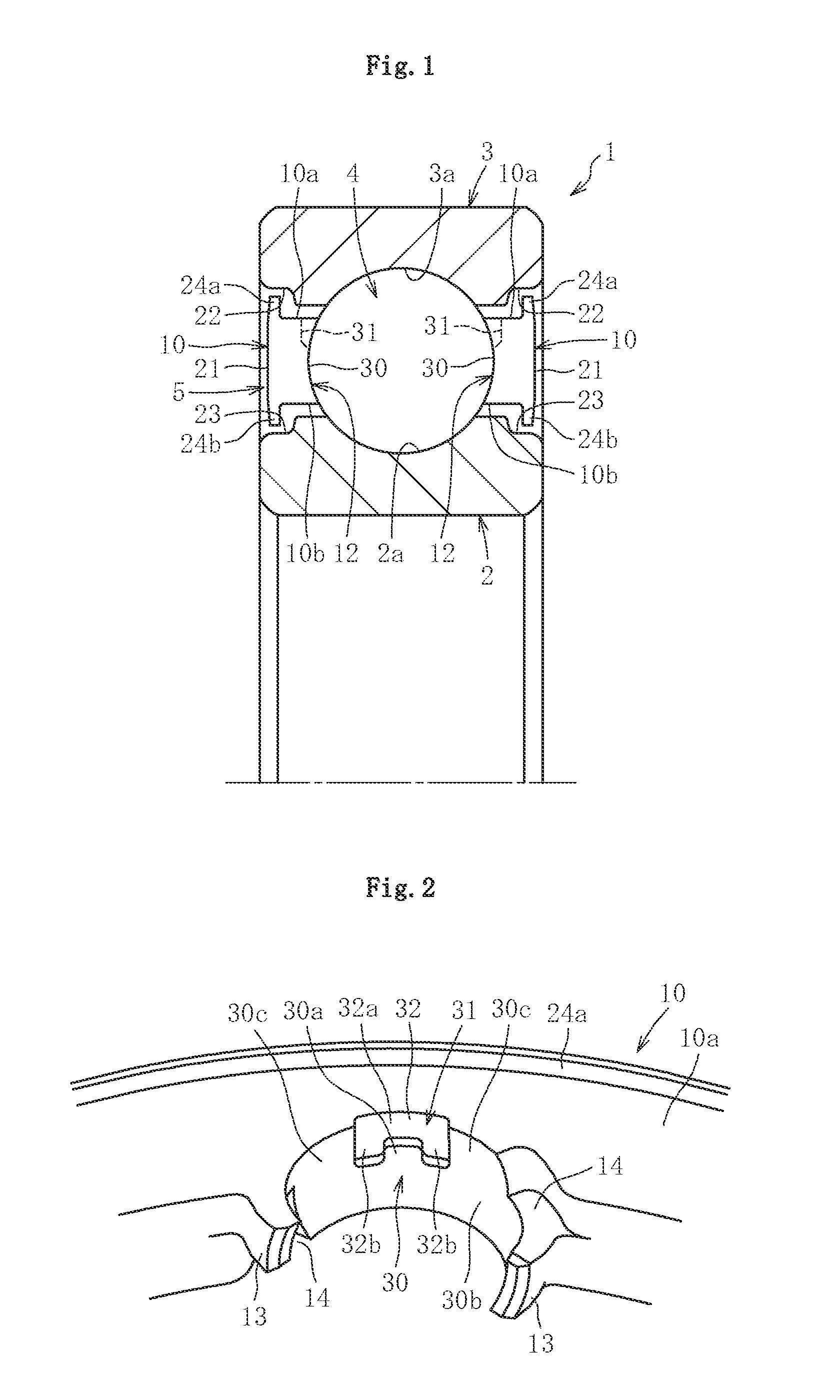

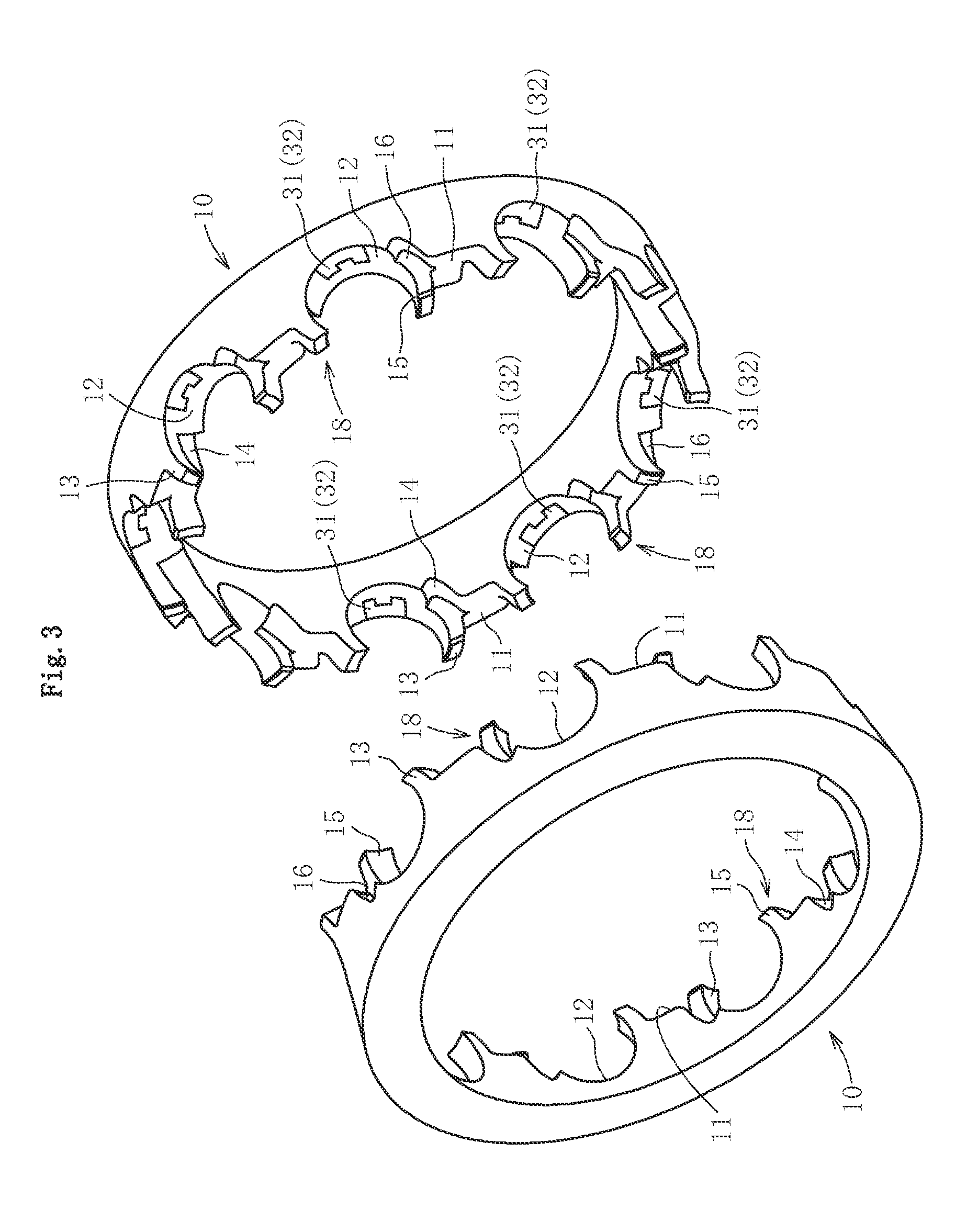

Retainer for ball bearing, and ball bearing

InactiveUS20140064649A1Reduce resistanceReduce torqueBearing assemblyBall bearingsBall bearingEngineering

A retainer for a ball bearing includes two annular members that face each other in an axial direction thereof. The two annular members include opposed surfaces each having hemispherical pockets that are formed at positions in a circumferential direction of each of the two annular members and configured to receive balls. The opposed surfaces are snap-fitted to each other to couple together the two annular members. The hemispherical pockets each have an inner peripheral surface provided with ball contact and ball non-contact surfaces. The ball contact surface is formed at a central portion in a pocket circumferential direction and at least at a central portion in a pocket axial direction of the inner peripheral surface. The ball non-contact surface includes a recess recessed to an opposite side to a corresponding ball across the ball contact surface and is opened in at least one of pocket axial ends.

Owner:NTN CORP

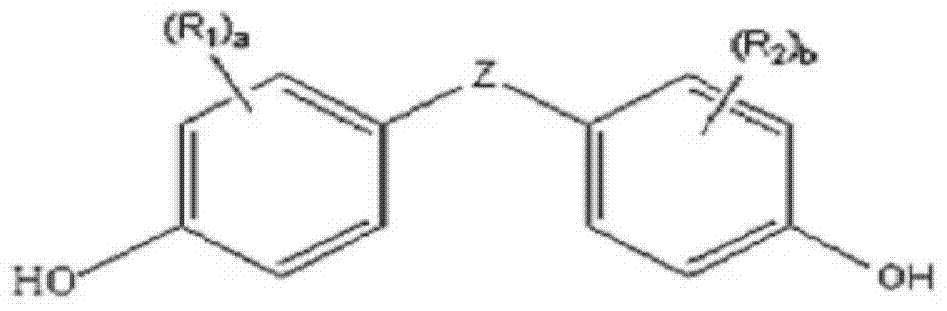

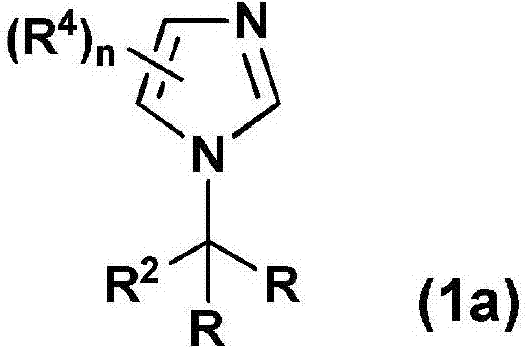

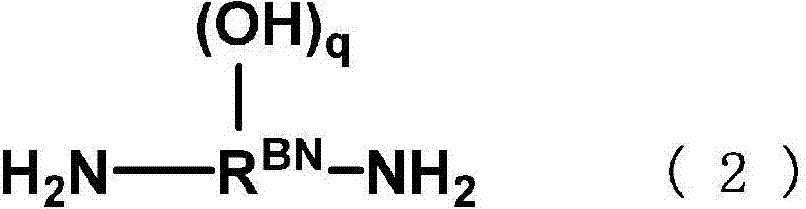

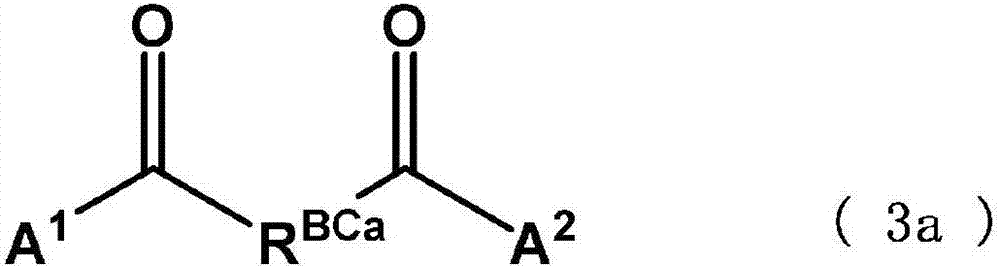

Energy-sensitive resin composition

ActiveCN107429059ALow dielectric constantImprove heat resistancePhotomechanical apparatusImidePolymer science

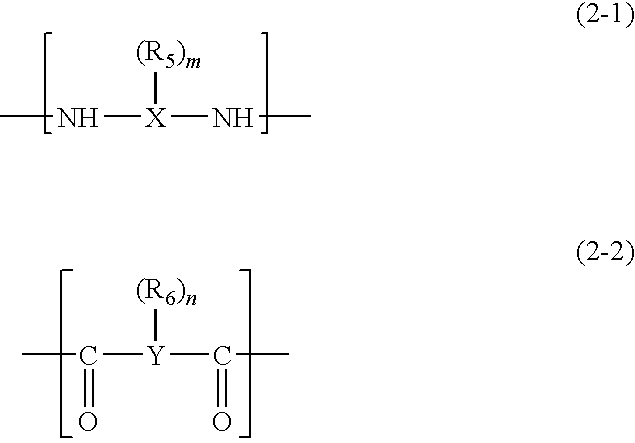

The present invention provides an energy-sensitive resin composition with which it is possible, even if the precursor polymer is heat-treated at low temperatures, to produce a film or molded article comprising an imide ring-containing polymer having excellent heat resistance, tensile elongation and chemical resistance with a low dielectric constant, or a film or molded article comprising an oxazole ring-containing polymer having excellent heat resistance, tensile elongation and chemical resistance. Also provided are a method of manufacturing the film or molded article; a method of forming a pattern using the energy-sensitive resin composition; and a permanent film having excellent heat resistance, tensile elongation and chemical resistance. The energy-sensitive resin composition comprises an imidazole compound (A) represented by formula (1a), a resin precursor component (B), and a solvent (S), wherein the resin precursor component (B) is at least one resin precursor component selected from the group consisting of: a monomer component comprising a diamine compound represented by formula (2), a dicarbonyl compound represented by formula (3a) and / or a tetracarboxylic acid dianhydride represented by formula (3b); and a precursor polymer having a repeating unit represented by formula (4).

Owner:TOKYO OHKA KOGYO CO LTD

Resin composition

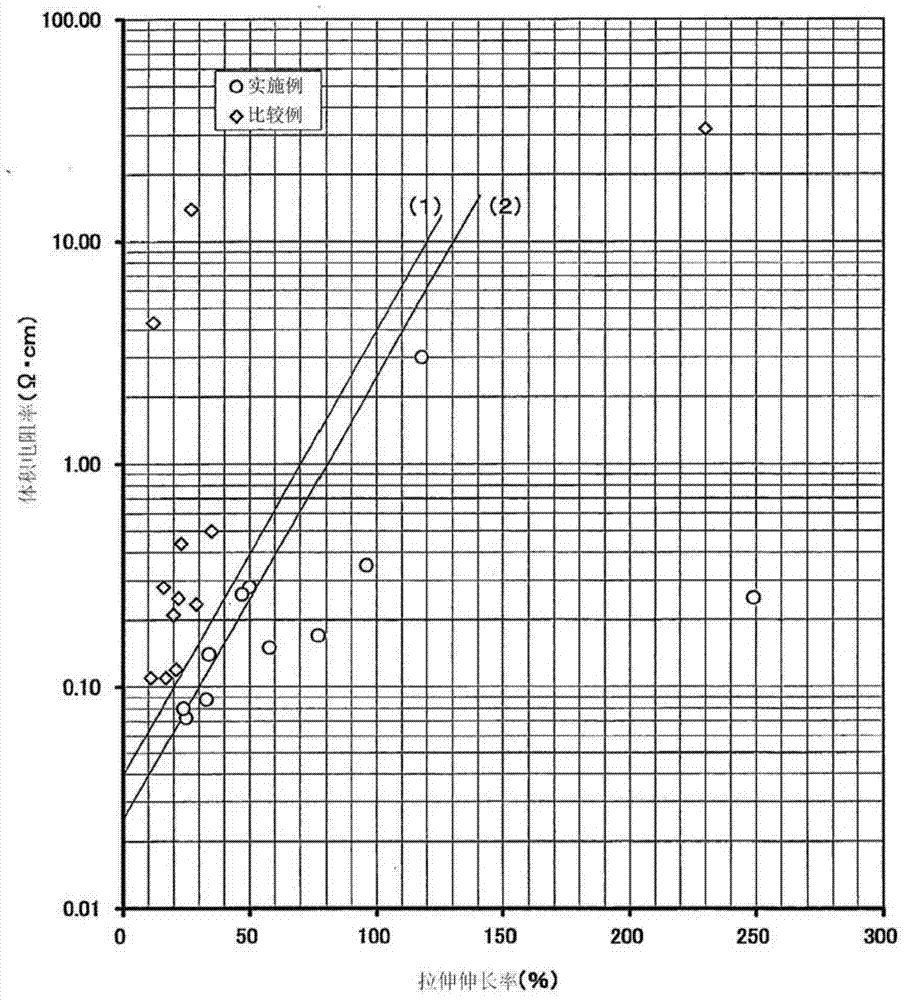

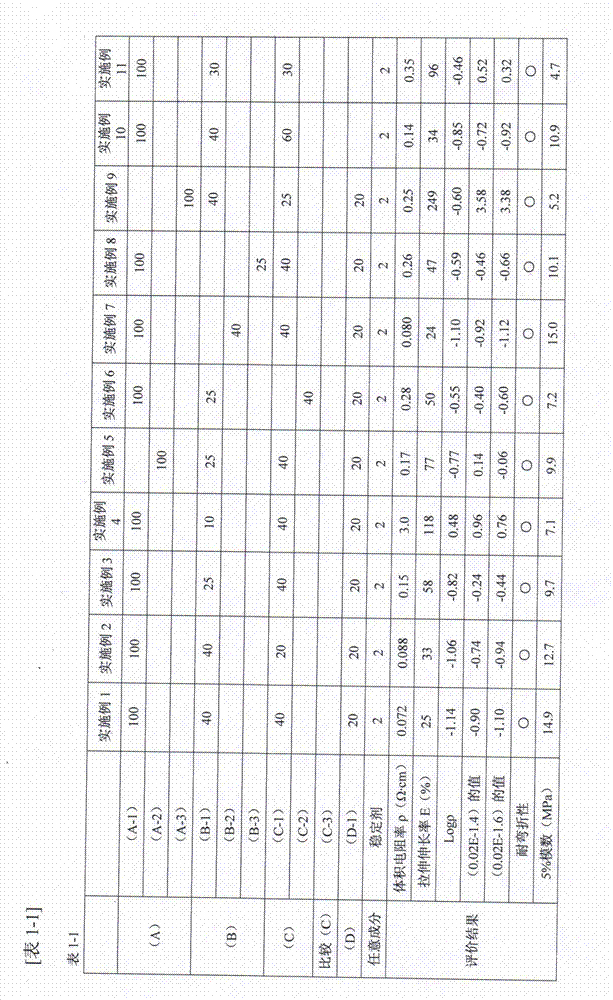

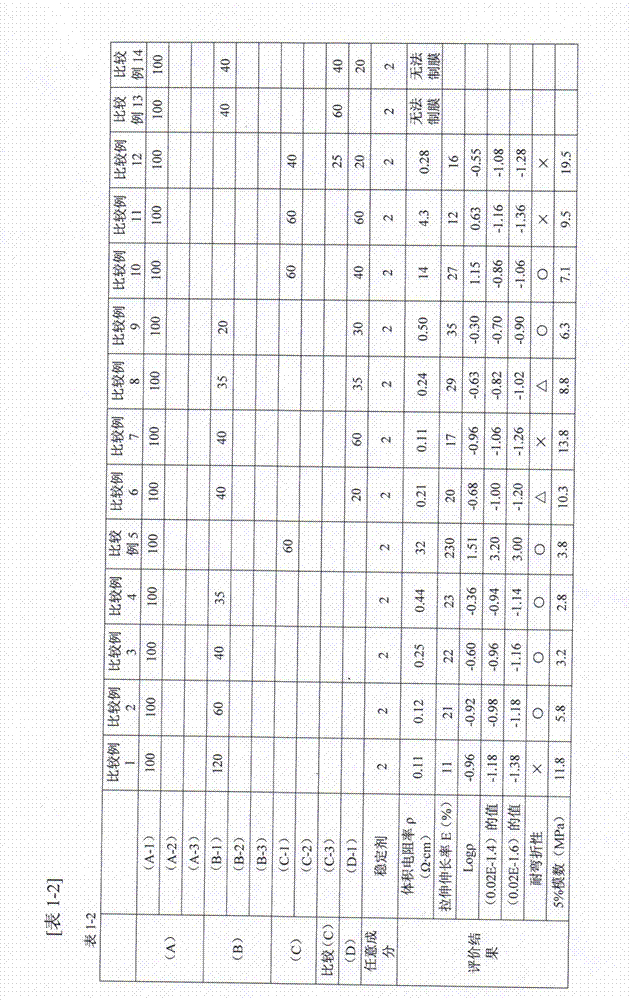

ActiveCN104245852AImprove conductivityExcellent bending resistance and flexibilityCell electrodesRegenerative fuel cellsChemistryCarbon nanotube

Provided is a resin composition for an electroconductive resin film offering excellent electroconductivity, tensile elongation, bending resistance, and flexibility, and suitable for an electrode in a redox flow cell or the like or for covering and protecting the same. A resin composition comprising (A) 100 parts by mass of a thermoplastic resin, (B) 1-60 parts by mass of carbon nanotubes, and (C) 1-100 parts by mass of at least one type selected from the group consisting of acetylene black and graphite.

Owner:RIKEN TECHNOS CORP

Antibacterial silicone rubber composite

The invention relates to an antibacterial silicone rubber composite. The antibacterial silicone rubber composite provided by the invention includes a silicone rubber matrix and an antibacterial medicament mixed with the silicone rubber matrix. The antibacterial silicone rubber composite provided by the invention maintains good tensile strength, tensile elongation, tear strength and elongation at break of traditional materials; the medicament can slowly release from the composite and achieve effective antibacterial concentration; and the composite has better biocompatibility. The invention provides an optimal process for the preparation of the antibacterial silicone rubber composite.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

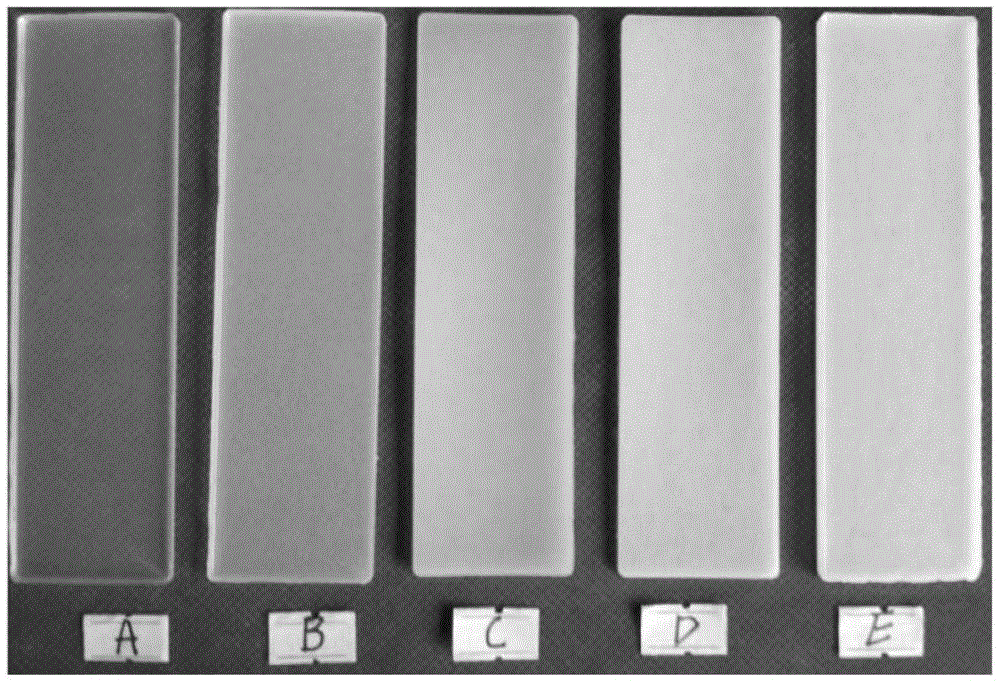

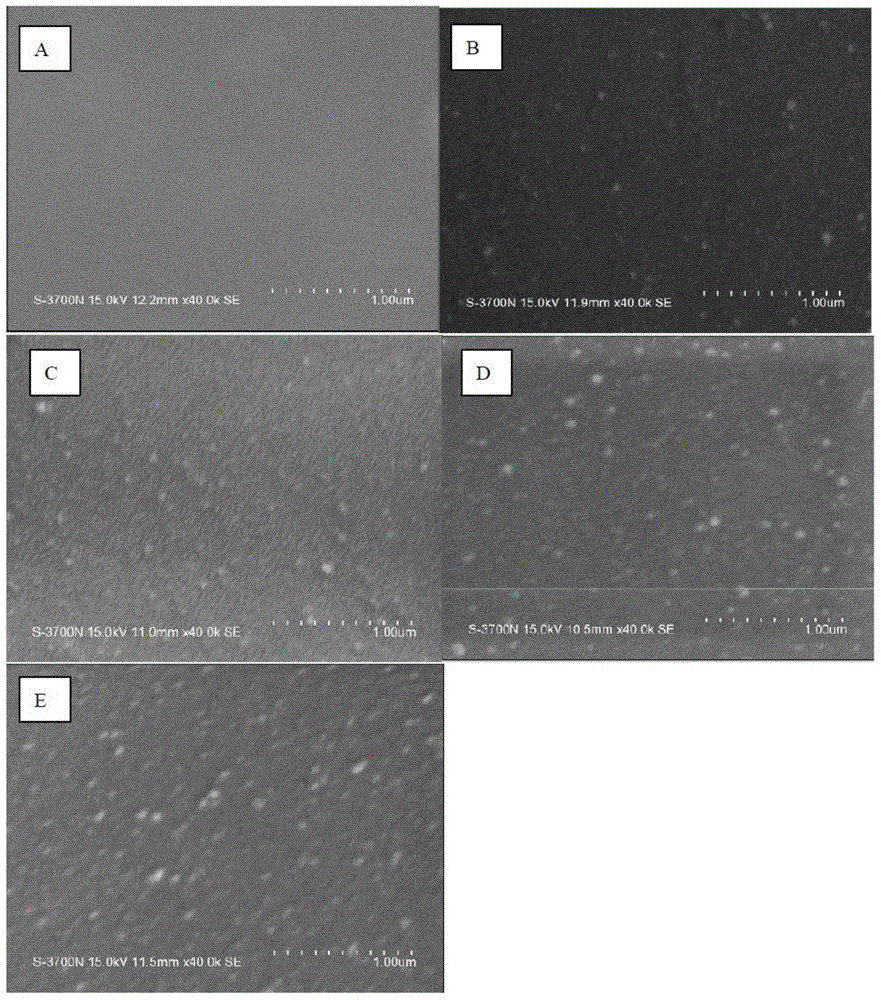

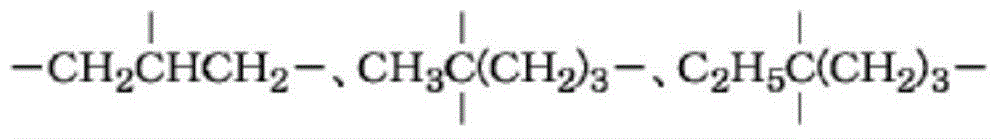

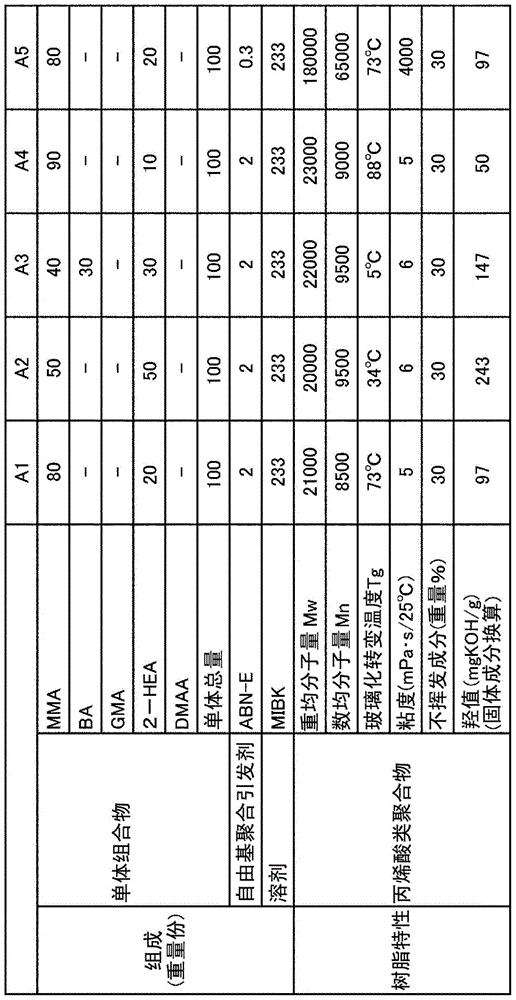

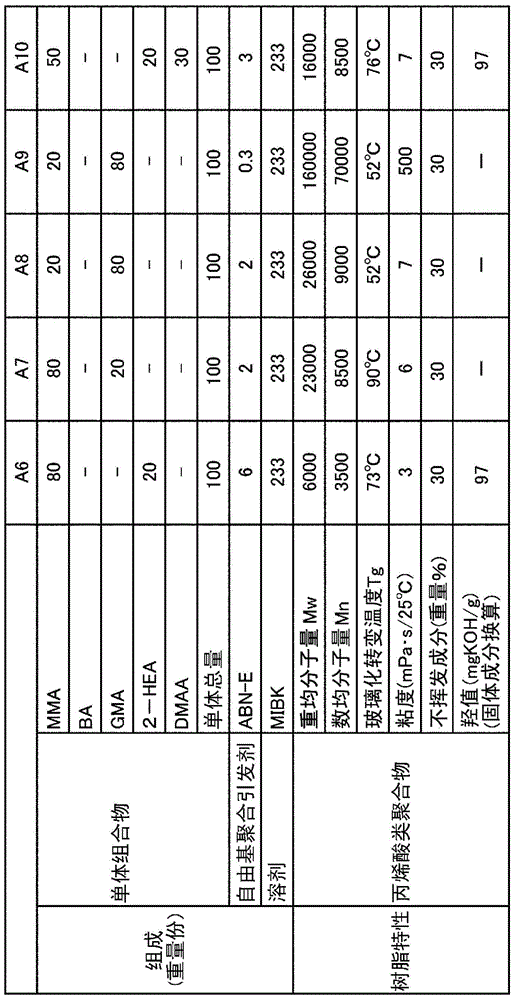

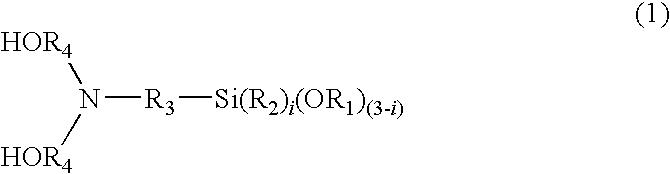

Two-pack type curable coating agent

The present invention provides a two-pack type curable coating agent which is capable of forming a coating layer that has excellent transparency, hardness, scratch resistance, oil wiping-off properties and tensile elongation. A two-pack type curable coating agent of the present invention is characterized by containing: a base material which contains 100 parts by weight of an acrylic polymer that comprises a photopolymerizable group and a hydroxyl group in side chains and has a hydroxyl number of 30-350 mgKOH / g and a weight average molecular weight (Mw) of 5,000-200,000, 0.3-35 parts by weight of a silane coupling agent, 0.3-35 parts by weight of a polyether polyol, 3-70 parts by weight of a polylactone polyol and 6-500 parts by weight of a photopolymerizable polyfunctional compound that comprises two or more photopolymerizable groups in each molecule; and 3-100 parts by weight of a curing agent which contains a polyisocyanate.

Owner:HARIMA CHEM INC

Ferrite particles for bonded magnets, resin composition for bonded magnets, and molded product using the same

ActiveUS9691528B2Good dispersionMaintain good propertiesIron oxides/hydroxidesInorganic material magnetismPolymer chemistryMagnet

The present invention relates to ferrite particles for bonded magnets having a bulk density of not more than 0.75 g / cm3 and a degree of compaction of not less than 65%, a resin composition for bonded magnets using the ferrite particles and the composition, and a rotor. The ferrite particles for bonded magnets and the resin composition for bonded magnets according to the present invention are capable of providing a bonded magnet molded product having a good tensile elongation and an excellent magnetic properties.

Owner:TODA IND

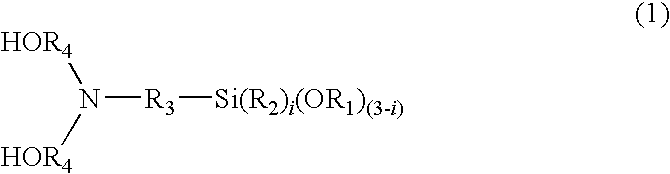

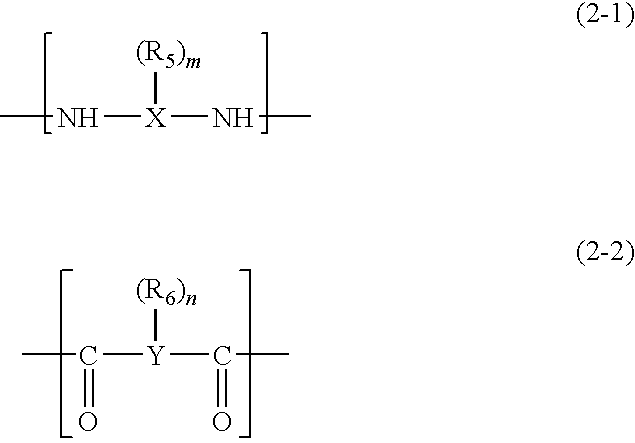

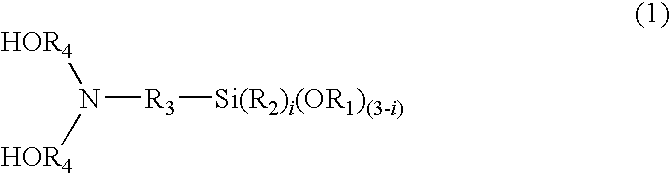

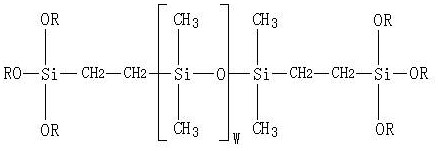

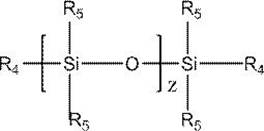

Positive-type photosensitive resin composition, cured film, protecting film, insulating film and semiconductor device and display device using these films

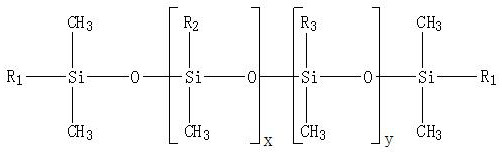

InactiveUS7678514B2Improve adhesionExcellent tensile elongationDiazo compound compositionsPhotosensitive material processingPositive typeDisplay device

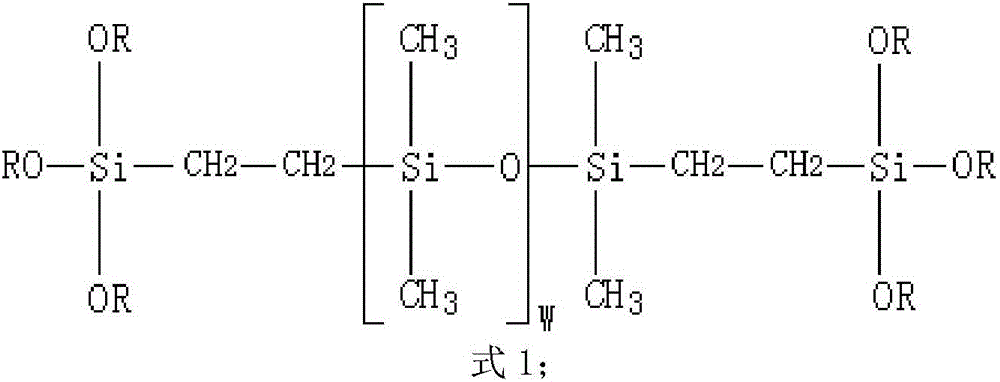

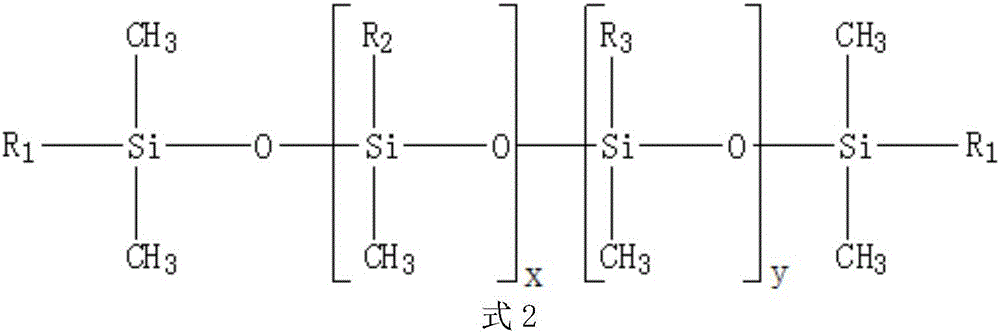

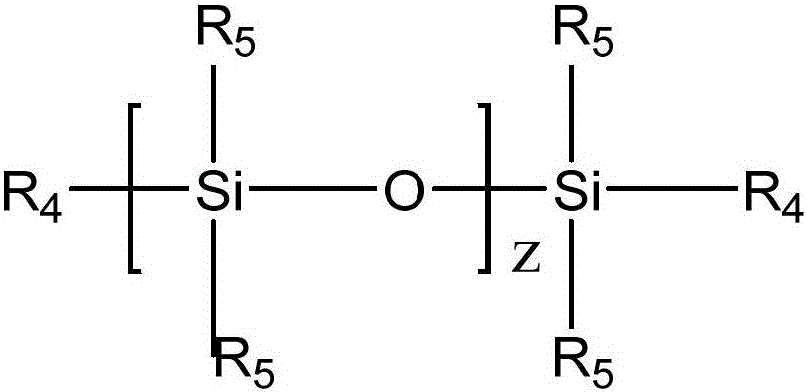

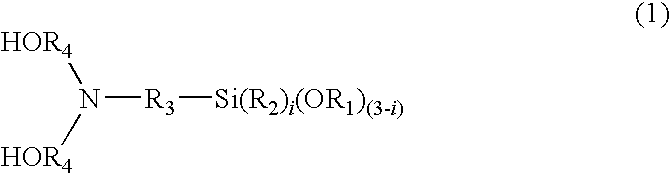

A positive-type photosensitive resin composition that exhibits excellent adhesion to a substrate after a humidification treatment includes (A) an alkali-soluble resin, (B) a photosensitive diazoquinone compound, and (C-1) a silicon compound shown by the following formula (1),wherein R1 and R2 represent alkyl groups having 1 to 10 carbon atoms, R3 represents an organic group, and R4 represents an alkylene group having 1 to 10 carbon atoms, and i represents an integer from 0 to 2.

Owner:SUMITOMO BAKELITE CO LTD

Wire covering material composition, an insulated wire and a wiring harness

InactiveUS7868253B2Wire covering material composition is favorableGuaranteed high growthPlastic/resin/waxes insulatorsInsulated cablesPolytetramethylene terephthalatePhosphoric Acid Esters

A wire covering material composition which is systematically different from a polyolefin resin composition and which possesses favorable flame retardancy, tensile elongation and wear resistance, having 100 parts by weight of a polymer blend containing 40-95 wt % of polybutylene terephthalate, and 1 to 30 parts by weight of a phosphoric ester compound with respect to 100 parts by weight of the polymer blend, wherein 5 to 100 wt % of the total content of the polybutylene terephthalate in the polymer blend is made up of polybutylene terephthalate, whose molecular weight distribution Mw / Mn (where Mw: weight-average molecular weight; Mn: number-average molecular weight) is greater than or equal to 2.5.

Owner:AUTONETWORKS TECH LTD +2

Retainer for ball bearing, and ball bearing

InactiveUS9103374B2Reduce torqueRetention stabilityBearing assemblyBall bearingsBall bearingEngineering

A retainer for a ball bearing includes two annular members that face each other in an axial direction thereof. The two annular members include opposed surfaces each having hemispherical pockets that are formed at positions in a circumferential direction of each of the two annular members and configured to receive balls. The opposed surfaces are snap-fitted to each other to couple together the two annular members. The hemispherical pockets each have an inner peripheral surface provided with ball contact and ball non-contact surfaces. The ball contact surface is formed at a central portion in a pocket circumferential direction and at least at a central portion in a pocket axial direction of the inner peripheral surface. The ball non-contact surface includes a recess recessed to an opposite side to a corresponding ball across the ball contact surface and is opened in at least one of pocket axial ends.

Owner:NTN CORP

Positive photosensitive resin composition, cured layer, protecting layer, insulating layer and semiconductor device and display therewith

InactiveUS20090170026A1Excellent adhesionExcellent tensile elongationDiazo compound compositionsOriginals for photomechanical treatmentCarbon atomOrganic group

A positive-type photosensitive resin composition that exhibits excellent adhesion to a substrate after a humidification treatment includes (A) an alkali-soluble resin, (B) a photosensitive diazoquinone compound, and (C-1) a silicon compound shown by the following formula (1),wherein R1 and R2 represent alkyl groups having 1 to 10 carbon atoms, R3 represents an organic group, and R4 represents an alkylene group having 1 to 10 carbon atoms, and i represents an integer from 0 to 2.

Owner:SUMITOMO BAKELITE CO LTD

Polycarbonate-Based Resin Composition for Carrier Tape Having Excellent Electric Conductivity

InactiveUS20140356579A1Reduce heat resistance requirementsGood dispersionNon-metal conductorsLayered productsProduction ratePolymer resin

An electric conductive resin composition comprises about 0.5 to about 5 parts by weight of (C) carbon nanotubes, based on about 100 parts by weight of a base resin comprising about 50 to about 97% by weight of (A) a polycarbonate resin and about 3 to about 50% by weight of (B) a rubber-modified aromatic vinyl resin (B1), a semi-crystalline polymer resin (B2), or a mixture thereof. The electric conductive resin composition has a surface resistance of about 105Ω / □ or less and can have excellent conductivity. Further, the composition can have excellent productivity, tensile strength and / or tensile elongation, and / or generates little dust.

Owner:CHEIL IND INC

Retainer for ball bearing, and ball bearing

InactiveUS20150233425A1Reduce torqueRetention stabilityBearing assemblyBall bearingsBall bearingEngineering

A retainer for a ball bearing includes two annular members that face each other in an axial direction thereof. The two annular members include opposed surfaces each having hemispherical pockets that are formed at positions in a circumferential direction of each of the two annular members and configured to receive balls. The opposed surfaces are snap-fitted to each other to couple together the two annular members. The hemispherical pockets each have an inner peripheral surface provided with ball contact and ball non-contact surfaces. The ball contact surface is formed at a central portion in a pocket circumferential direction and at least at a central portion in a pocket axial direction of the inner peripheral surface. The ball non-contact surface includes a recess recessed to an opposite side to a corresponding ball across the ball contact surface and is opened in at least one of pocket axial ends.

Owner:NTN CORP

Non-woven fabric for automotive interior skin material and preparation thereof

InactiveCN102159763AReduce high tensile elongationLow modulusFibre treatmentHeating/cooling textile fabricsAlkaline etchingBiomedical engineering

The present invention relates to a non-woven fabric for automotive interior materials and a method for manufacturing the same. Said manufacturing method is characterized by printing a surface or back surface of the non-woven fabric and subsequently alkaline etching the back surface of the non-woven fabric. In addition, said manufacturing method may coat the surface or the back surface of the non-woven fabric before the printing process. Accordingly, the present invention provides a non-woven fabric for interior skin materials for automobiles with various shapes, excellent moldability and sound absorbing properties.

Owner:CARL FREUDENBERG KG

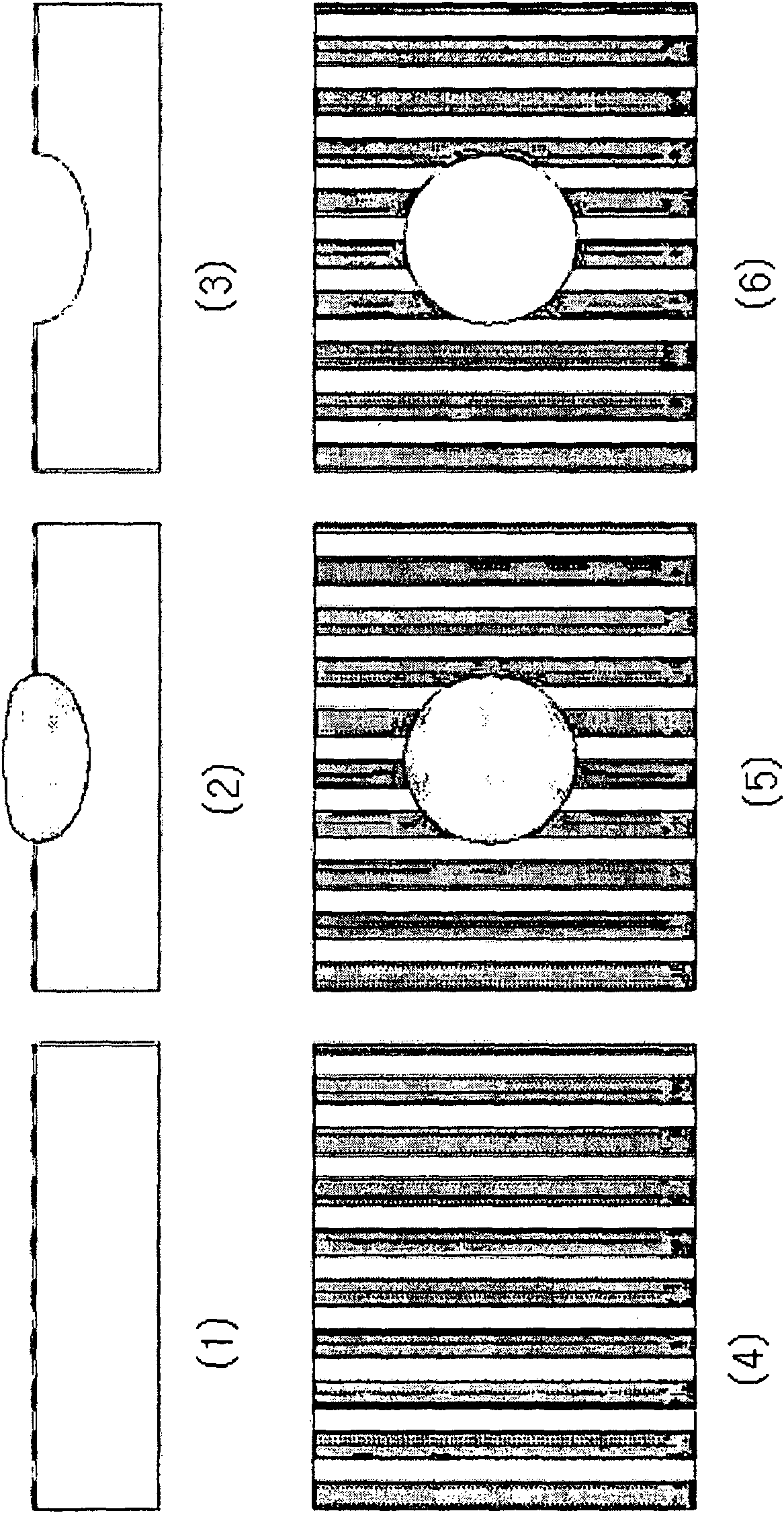

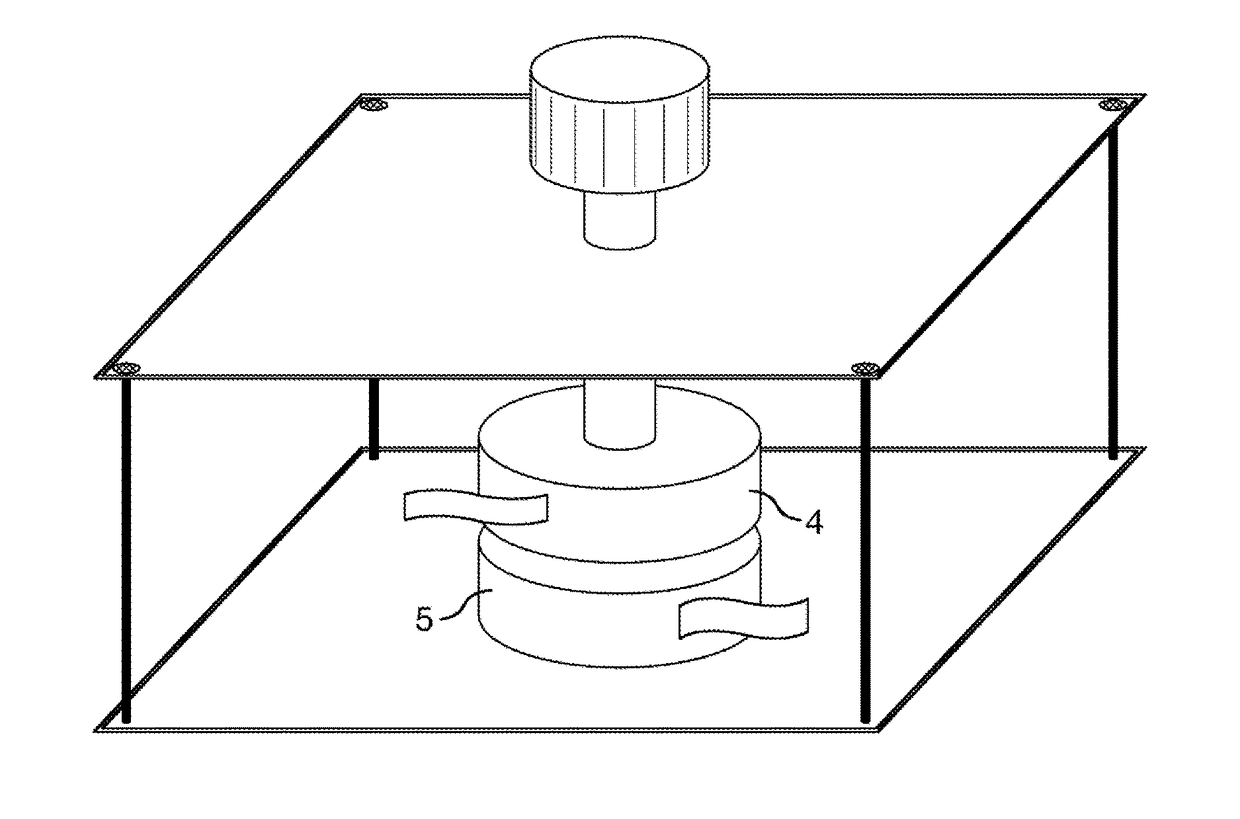

High-strength three-layer co-extrusion durable shed film and preparation method thereof

ActiveCN109130409AHigh strengthImprove coverage efficiencyAgricultural articlesClimate change adaptationBlow moldingPolyvinyl polymer

The invention relates to the field of agricultural she films, in particular to a high-strength three-layer co-extrusion durable shed film and a preparation method thereof. The high-strength shed filmis of a three-layer composite structure made through a co-extrusion blow molding shed film machine set, and comprises an inner layer, a middle layer and an outer layer; the total weight ratio of the inner layer to the middle layer to the outer layer is 1:1:1; preparation raw materials of each layer of the three-layer composite structure include a high-performance polyvinyl polymer.

Owner:YUNNAN QUJING PLASTICS GROUP

Method for producing thermoplastic resin composition film

ActiveUS20170306132A1Improve conductivityIncrease flexibilityLayered productsDomestic articlesCarbon nanotubeGraphite

Embodiments provide a method for producing a film including a thermoplastic resin composition, the method including: (1) a step of subjecting a thermoplastic resin composition to preliminary heating at 100-250° C.; (2) a step of subjecting a first roller and second roller of a calender roll film-forming apparatus to pre-heating; and (3) a step of introducing the thermoplastic resin composition, which has been subjected to preliminary heating in step (1), into the clearance between the first roller and second roller, which have been pre-heated in step (2), and continuously winding a molten film of the thermoplastic resin composition on the first roller. According to at least one embodiment, the rotational speed of the first roller is higher than the rotational speed of the second roller. According to at least one embodiment, the thermoplastic resin composition contains (A) 100 parts by mass of a thermoplastic resin, (B) 1-60 parts by mass of carbon nanotubes and (C) 1-100 parts by mass of at least one type of material selected from the group consisting of acetylene black and graphite.

Owner:RIKEN TECHNOS CORP

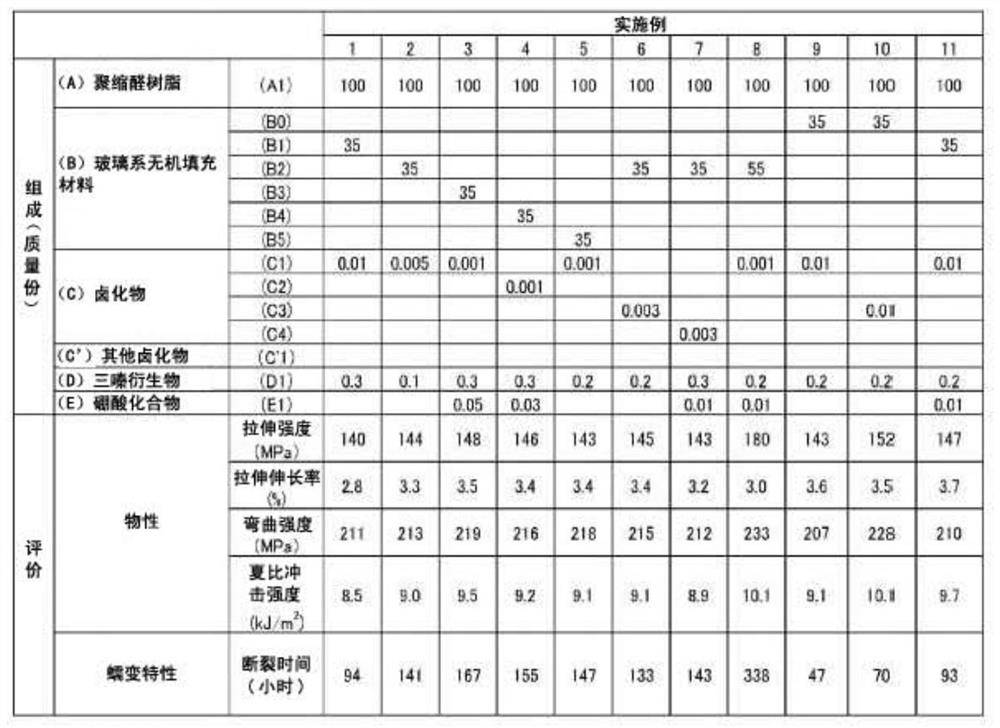

Method for producing polyacetal resin composition

The present invention relates to a method for producing a polyacetal resin composition. [Problem] To provide a method for producing a polyacetal resin composition having excellent mechanical properties such as tensile strength, tensile elongation, flexural strength, and impact resistance, particularly excellent creep properties. [Solution] A method for producing a polyacetal resin composition, wherein (B) a glass-based inorganic filler obtained by surface treatment with a silane coupling agent is added to 100 parts by mass of (A) polyacetal resin 1 mass part to 100 mass parts of the material, (C) 0.0001 mass part to 0.5 mass part of at least one halide selected from magnesium halide and ammonium halide, and (D) a triazine derivative having a nitrogen-containing functional group 0.002 mass parts or more and 10 mass parts or less are melt-kneaded and manufactured.

Owner:POLYPLASTICS CO LTD

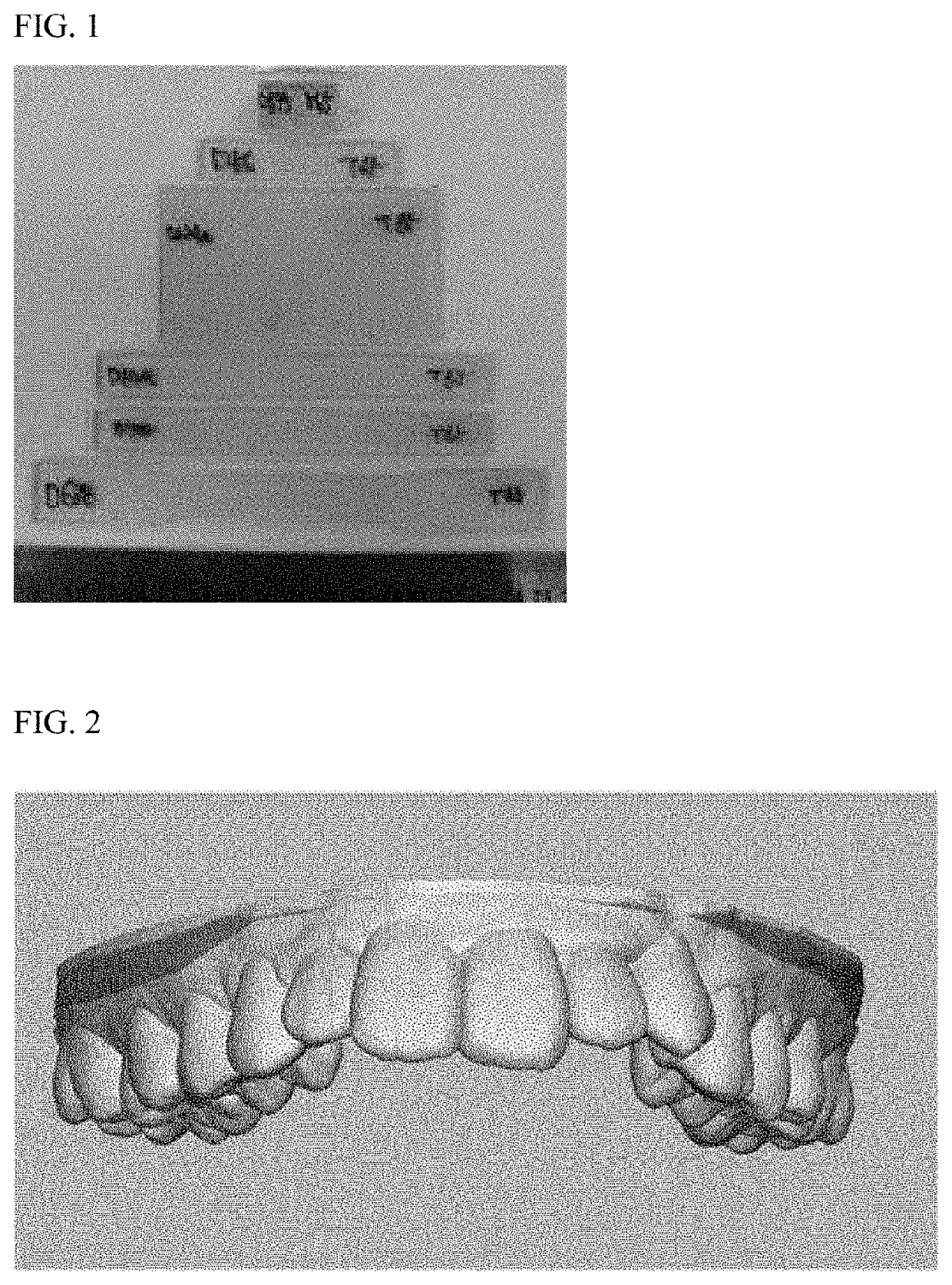

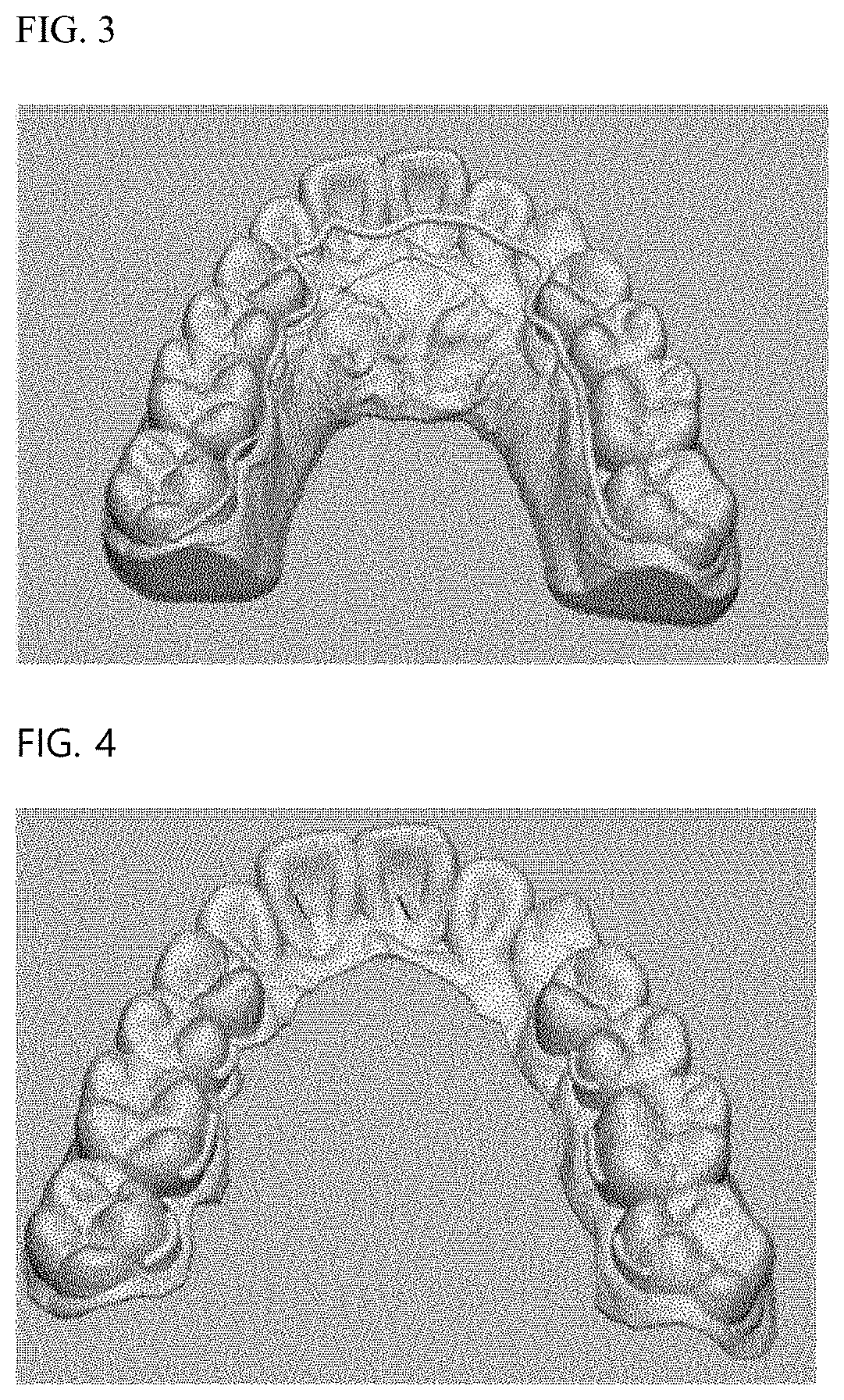

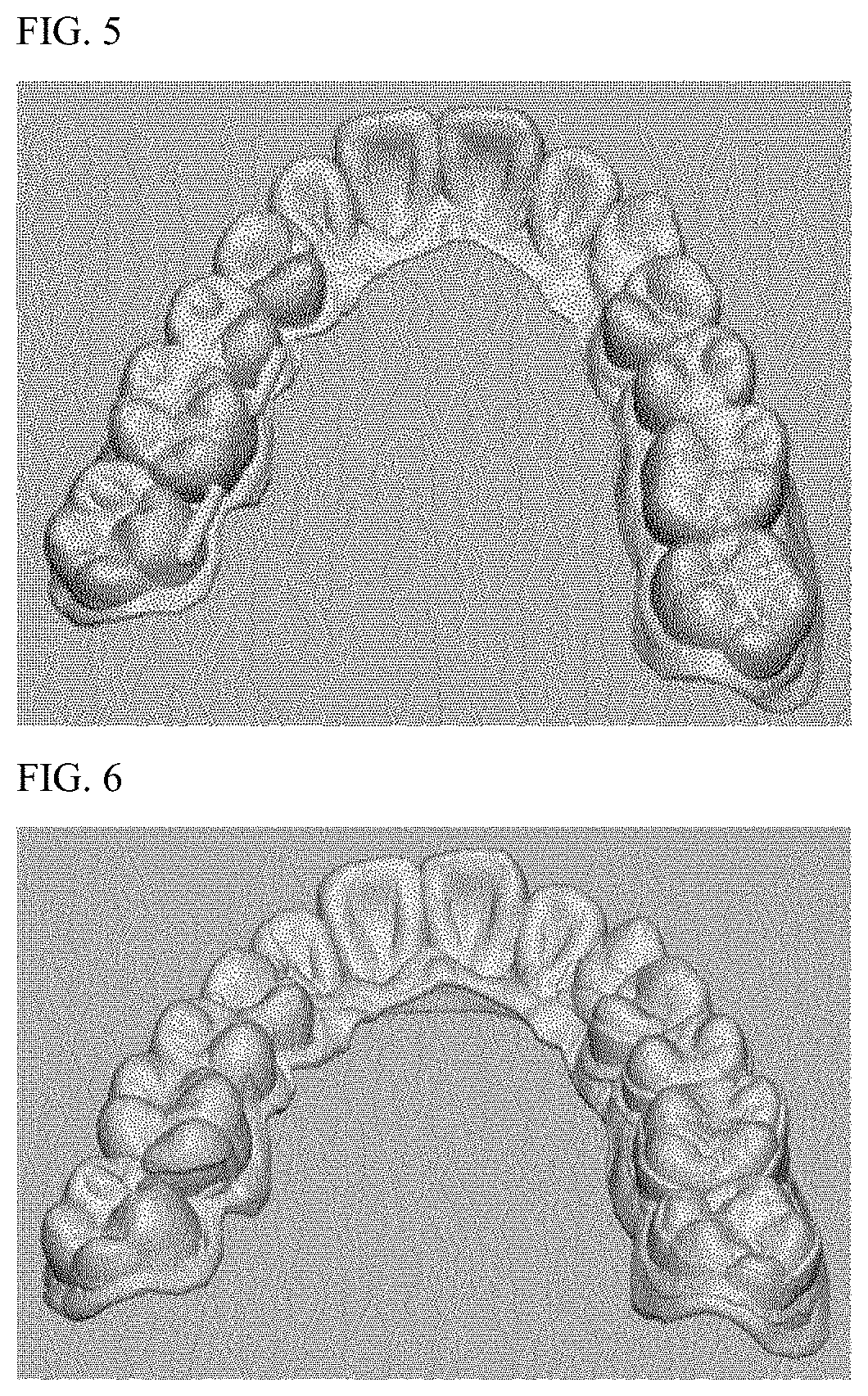

Photocurable composition for 3D printer for producing transparent orthodontic device

ActiveUS20210292580A1Excellent elastic modulusGood physical propertiesArch wiresBracketsMedicineComputer printing

The present invention pertains to a photocurable composition for a 3D printer for producing a transparent orthodontic device. A photocurable composition for a 3D printer can be provided, which has excellent physical properties such as thermal properties, strength, elastic modulus, and tensile elongation, and when used in a patient-customized transparent orthodontic device, the orthodontic device can reduce the pain felt by patients and can enhance orthodontic correction effectiveness due to being closely fitted to the dental structure. Moreover, a 3D-printed transparent orthodontic device can be produced which can be restored to the original shape thereof even when deformed from use.

Owner:GRAPHY

Polypropylene-based resin composition and molded article made thereof

ActiveUS9969869B2Superior in tensile elongation at breakExcellent tensile elongationAlpha-olefinPolypropylene

A polypropylene-based resin composition capable of affording a molded article superior in tensile elongation at break includes a polypropylene resin (A), an ethylene-α-olefin copolymer (B) having a density of 0.865 to 0.890 g / cm3, an ethylene-α-olefin copolymer (C) having a density of 0.855 to 0.859 g / cm3, and an inorganic filler (D), wherein the content of the polypropylene resin (A) is 49 to 76% by weight, the content of the inorganic filler (D) is 9 to 22% by weight, the sum total of the contents of the ethylene-α-olefin copolymer (B) and the ethylene-α-olefin copolymer (C) is 15 to 29% by weight. The sum total of the contents of (A), (B), (C), and (D) is taken as 100% by weight, and the content of the ethylene-α-olefin copolymer (B), x % by weight, and the content of the ethylene-α-olefin copolymer (C), y % by weight, satisfy the formula: 0.07≤x / (x+y)≤0.41.

Owner:SUMITOMO CHEM CO LTD

A lightweight heat-conducting silicone potting compound base compound, composition and preparation method thereof

ActiveCN106701012BImprove thermal conductivityLow densityNon-macromolecular adhesive additivesUnsaturated hydrocarbonOrganosilicon

Owner:GUANGZHOU TINCI MATERIALS TECH

Thermoplastic elastomer composition and formed article

Disclosed is a thermoplastic elastomer composition which is obtained by mixing a rubber (B) in a polyamide polymer (A1) and / or a polyester polymer (A2) in which rubber not less than 30 weight% of gel component is uniformly dispersed, and dynamically crosslinking the rubber therein. The thermoplastic elastomer composition is excellent in heat resistance, oil resistance and mechanical properties, and also excellent in fatigue resistance against bending and a certain tension.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com