Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1785 results about "Silicone tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

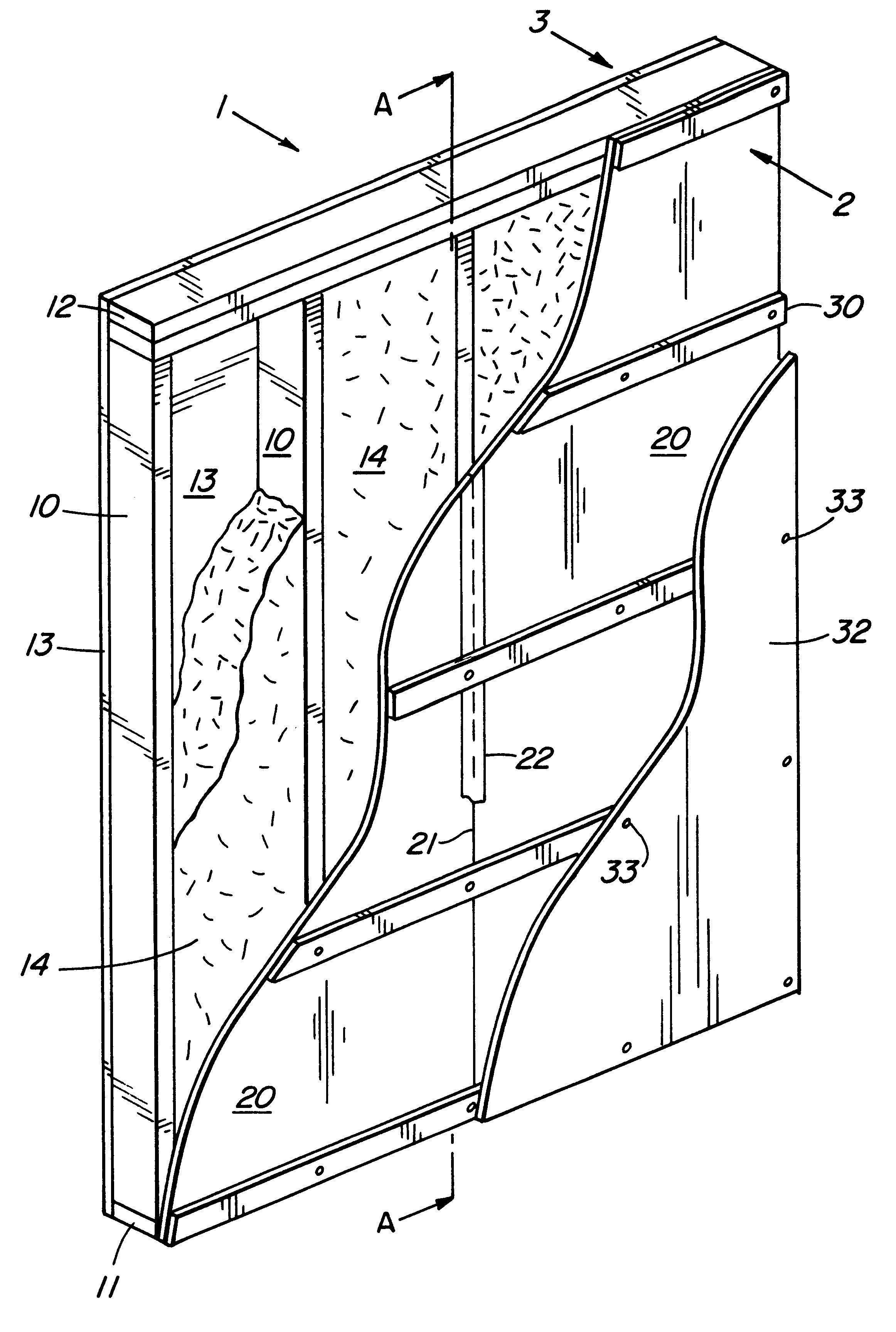

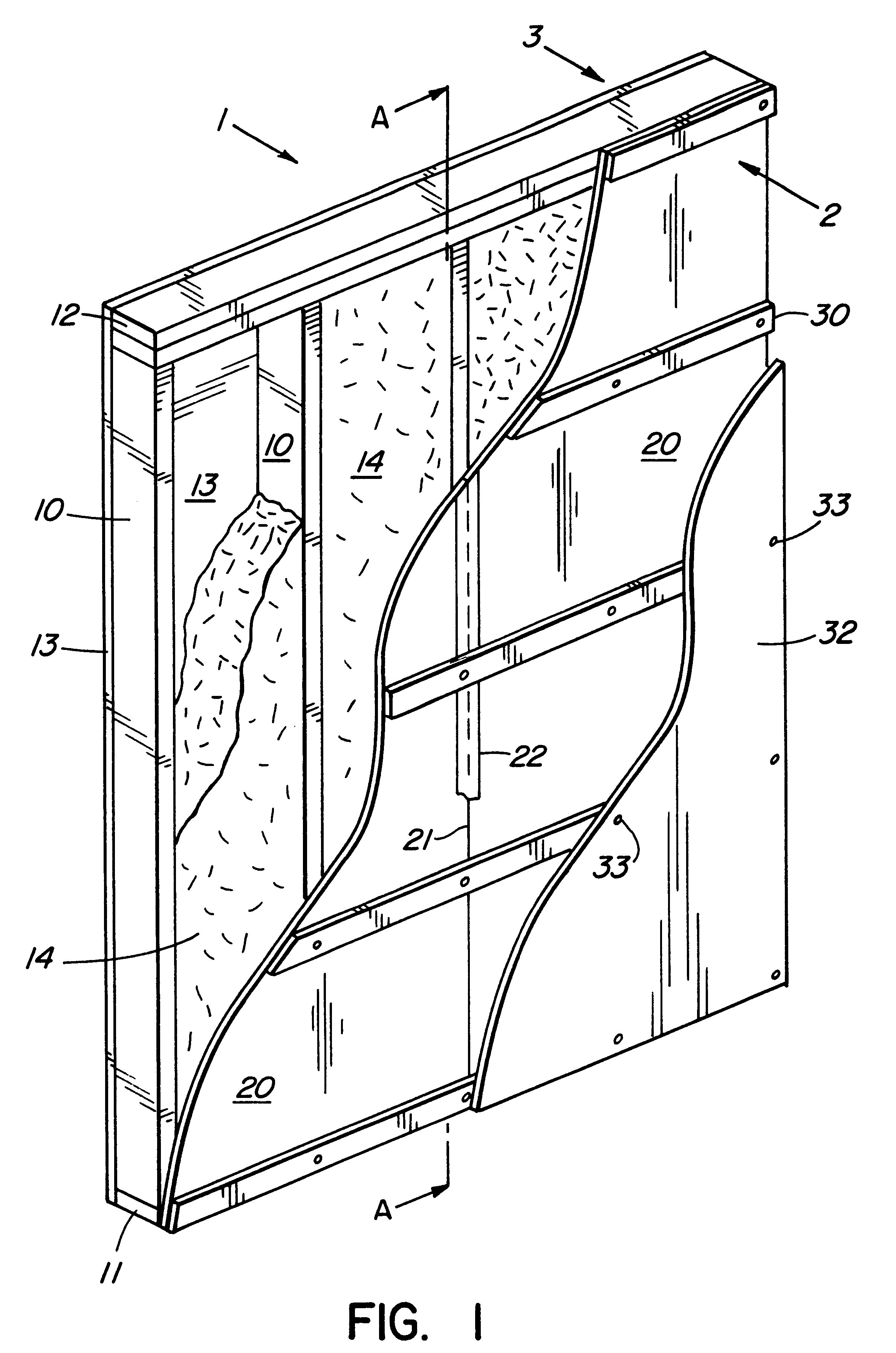

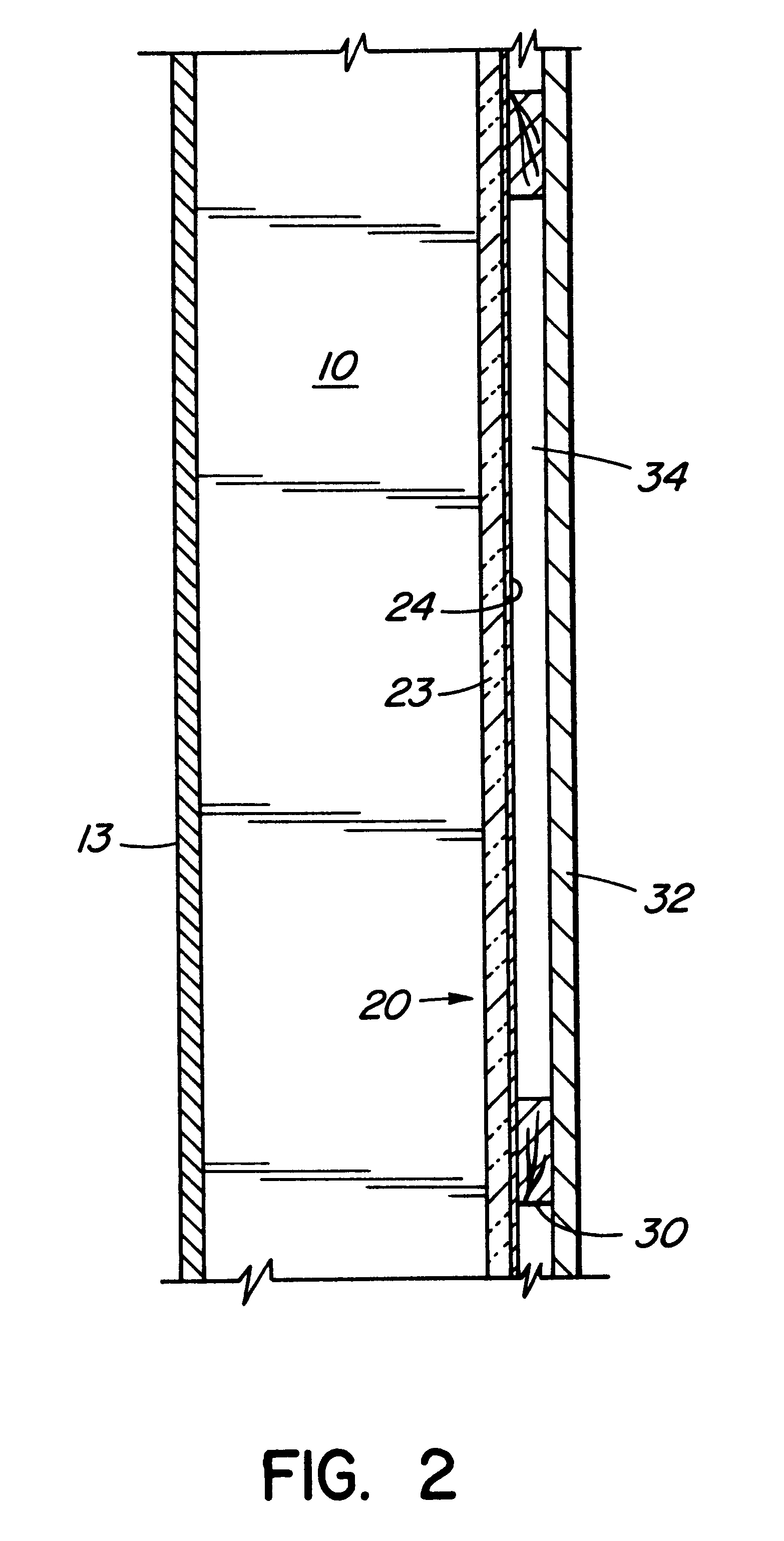

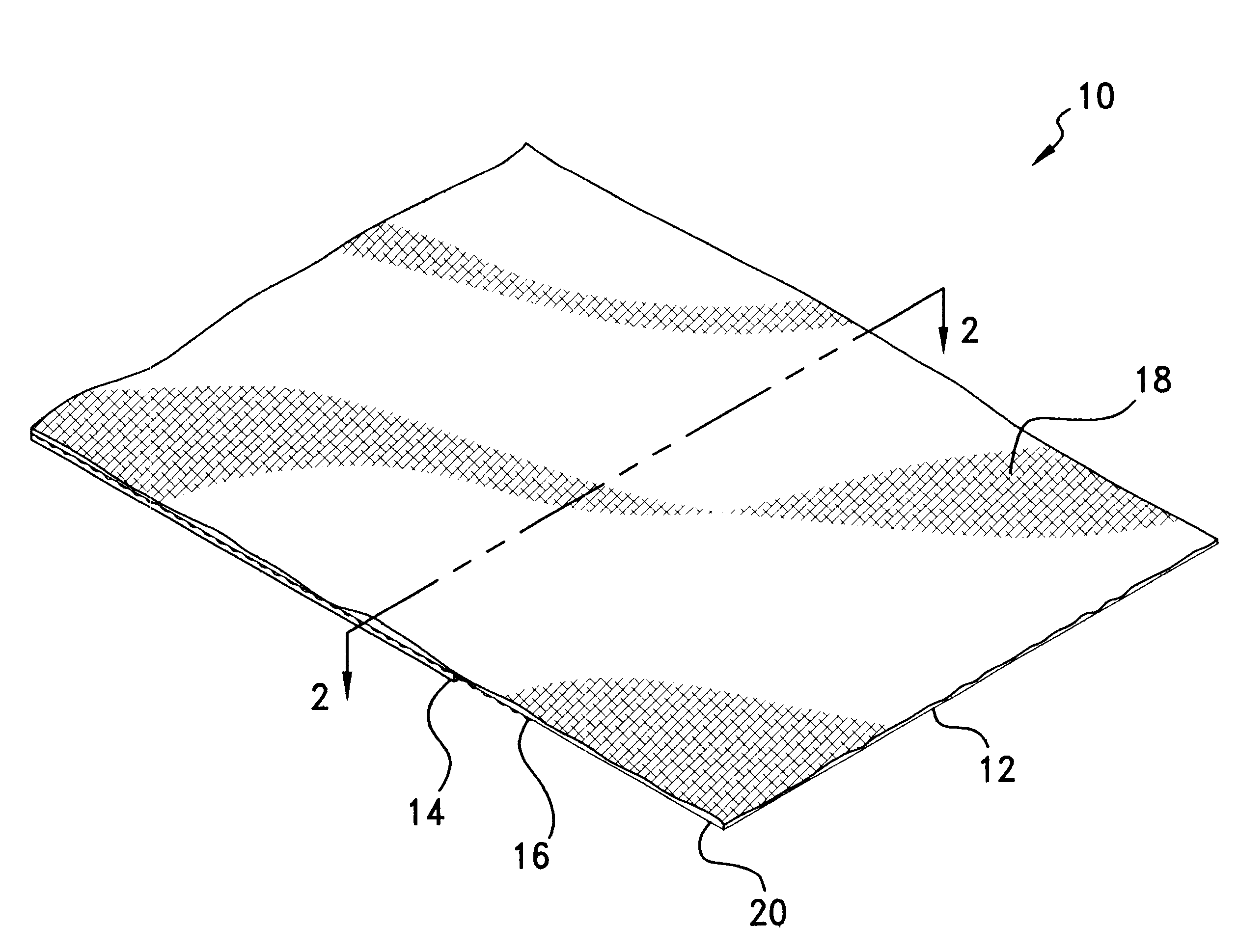

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

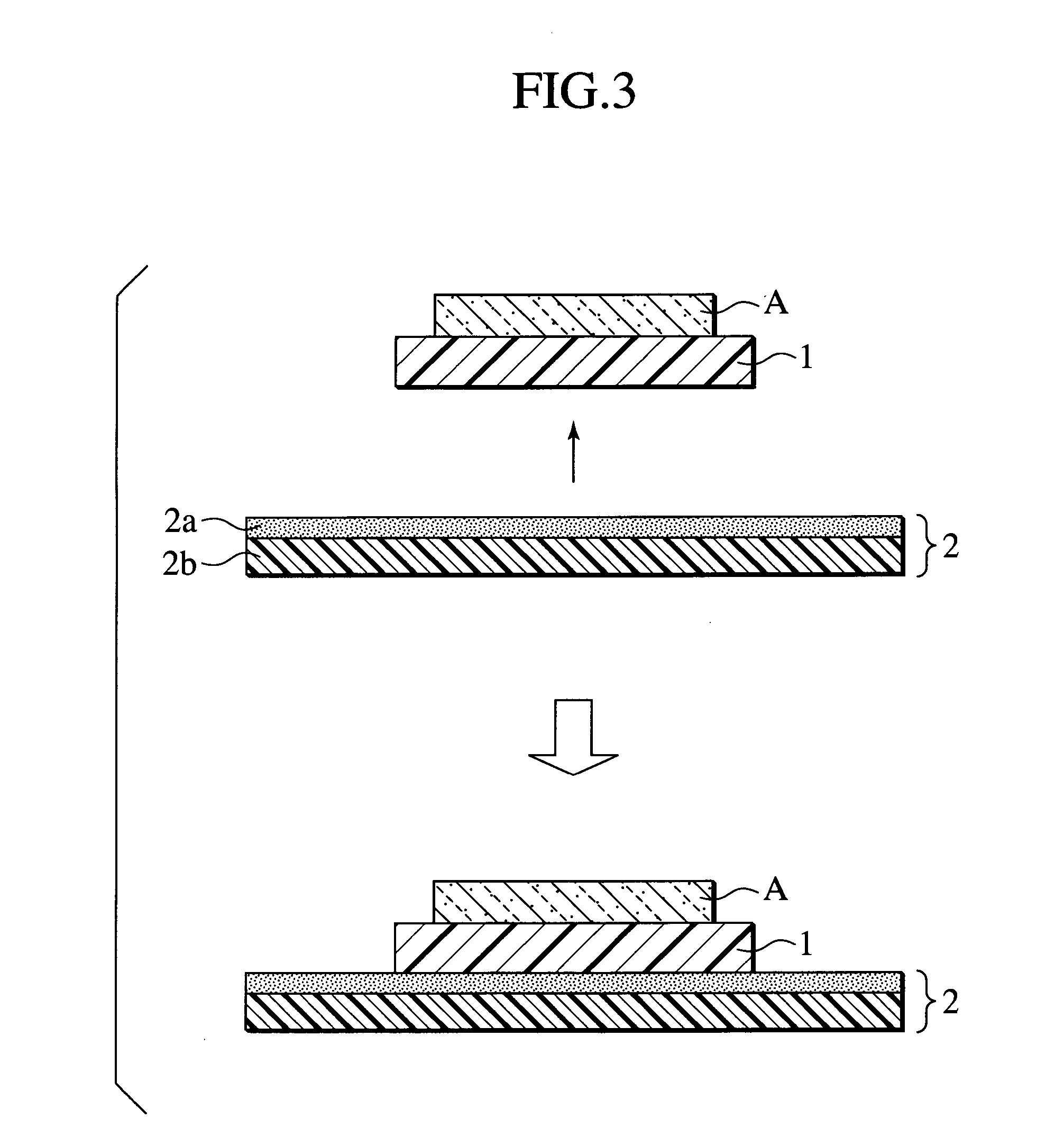

Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

InactiveUS20060128065A1Efficient cuttingImprove bond reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeDevice material

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:HITACHI CHEM CO LTD

Polywoven pinch bottom open mouth bag

A pinch bottom open mouth bulk material bag fabricated from polywoven material has closures at one or both ends that are non-sewn and which comprise a strip of tape running in the cross-bag direction. The tape is folded over the respective bag end, which may be modified, and is glued in place to close the end. The closure has no holes or other openings through which contaminants may enter the bag interior.

Owner:STANDARD MULTIWALL BAG MFG

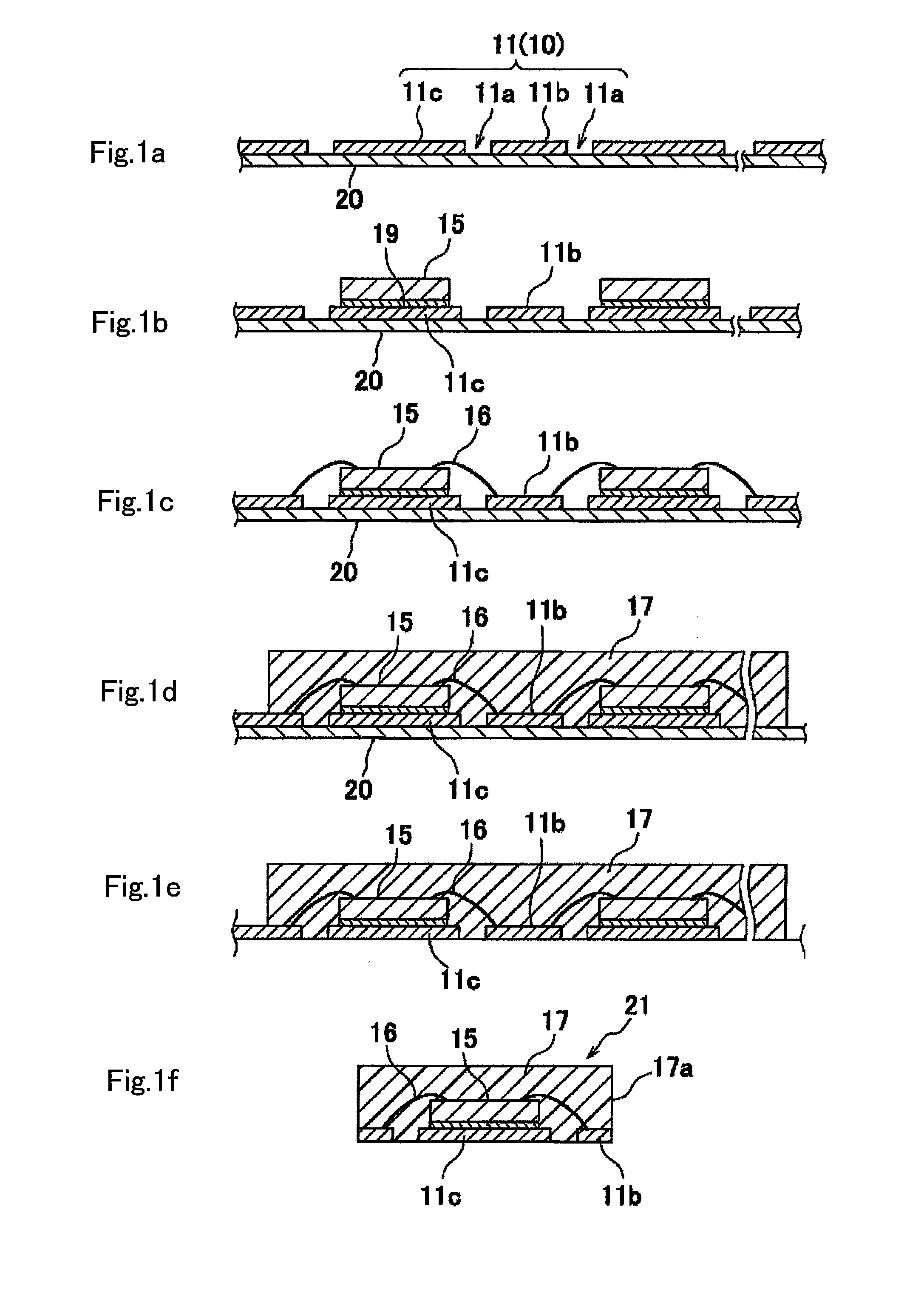

Adhesive tape for resin-encapsulating and method of manufacture of resin-encapsulated semiconductor device

InactiveUS20110111563A1Prevent resin leakageEffective preventionFilm/foil adhesivesSemiconductor/solid-state device detailsEngineeringSemiconductor

An adhesive tape for resin-encapsulating used in a method of manufacture of a resin-encapsulated semiconductor device has a base material layer and an adhesive agent layer laminated on the base material layer, a total film thickness of the base material layer and the adhesive agent layer of 25 to 40 μm. According to the adhesive tape for resin encapsulating of the present invention, resin leakage can be efficiently prevented during the resin encapsulating operation.

Owner:NITTO DENKO CORP

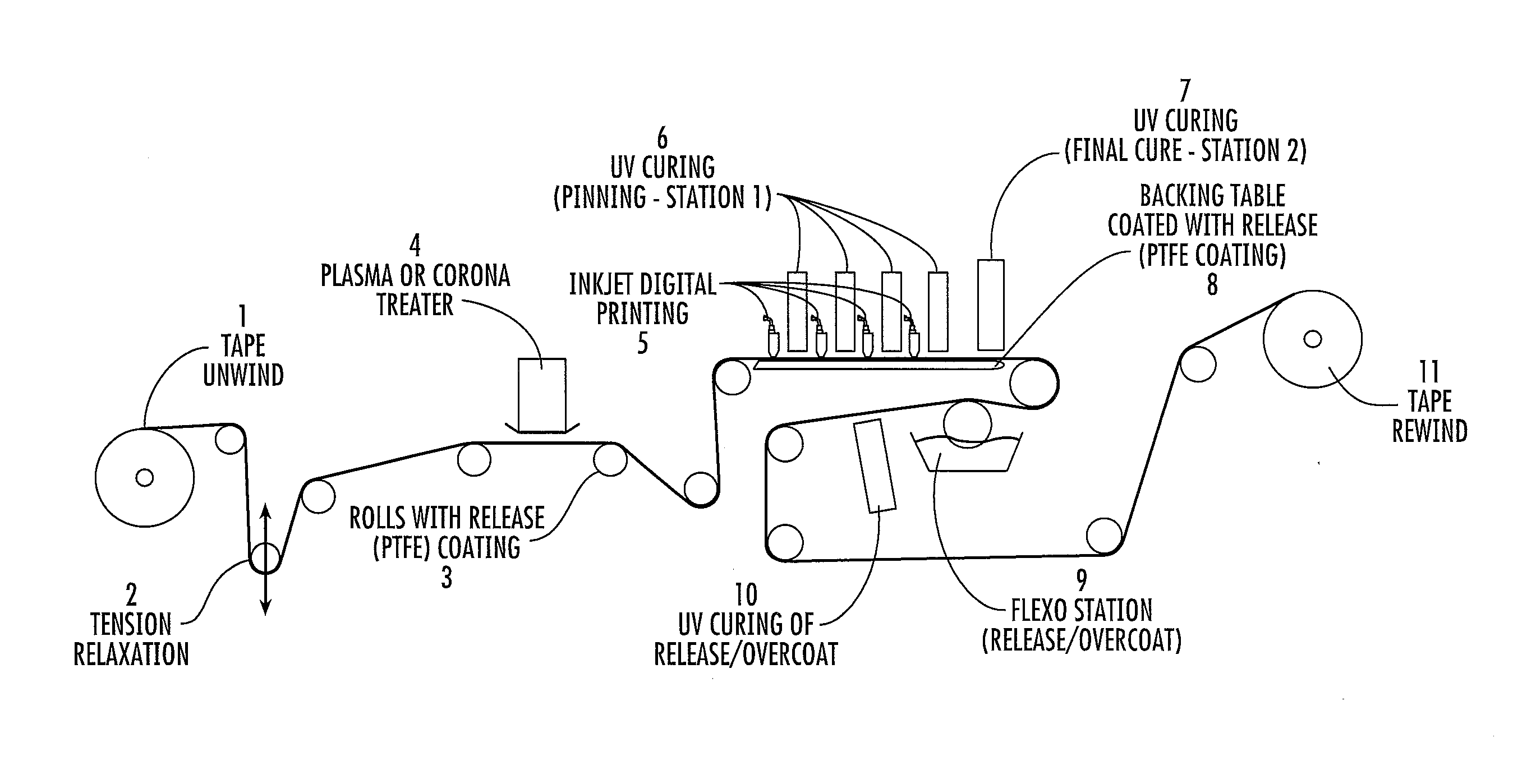

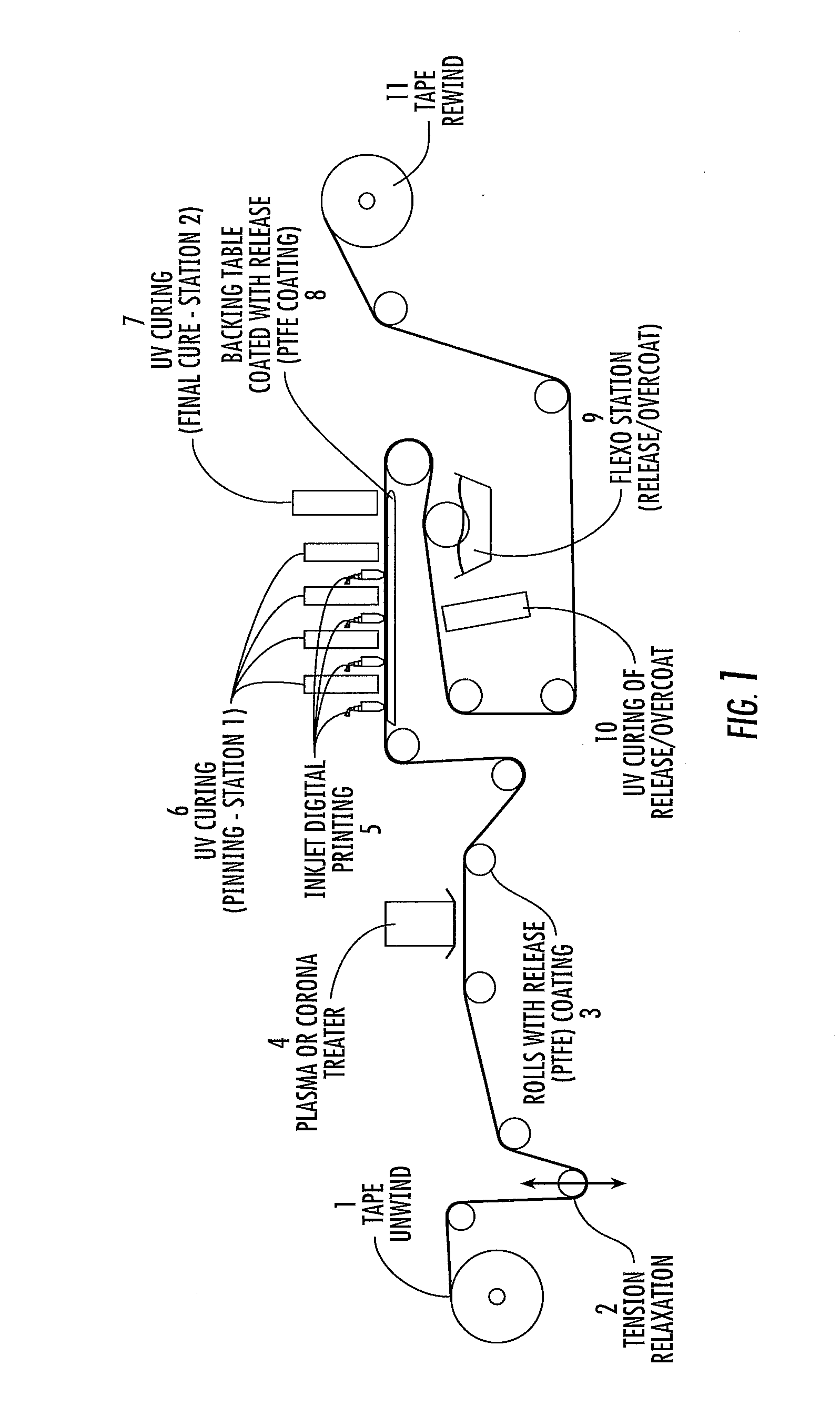

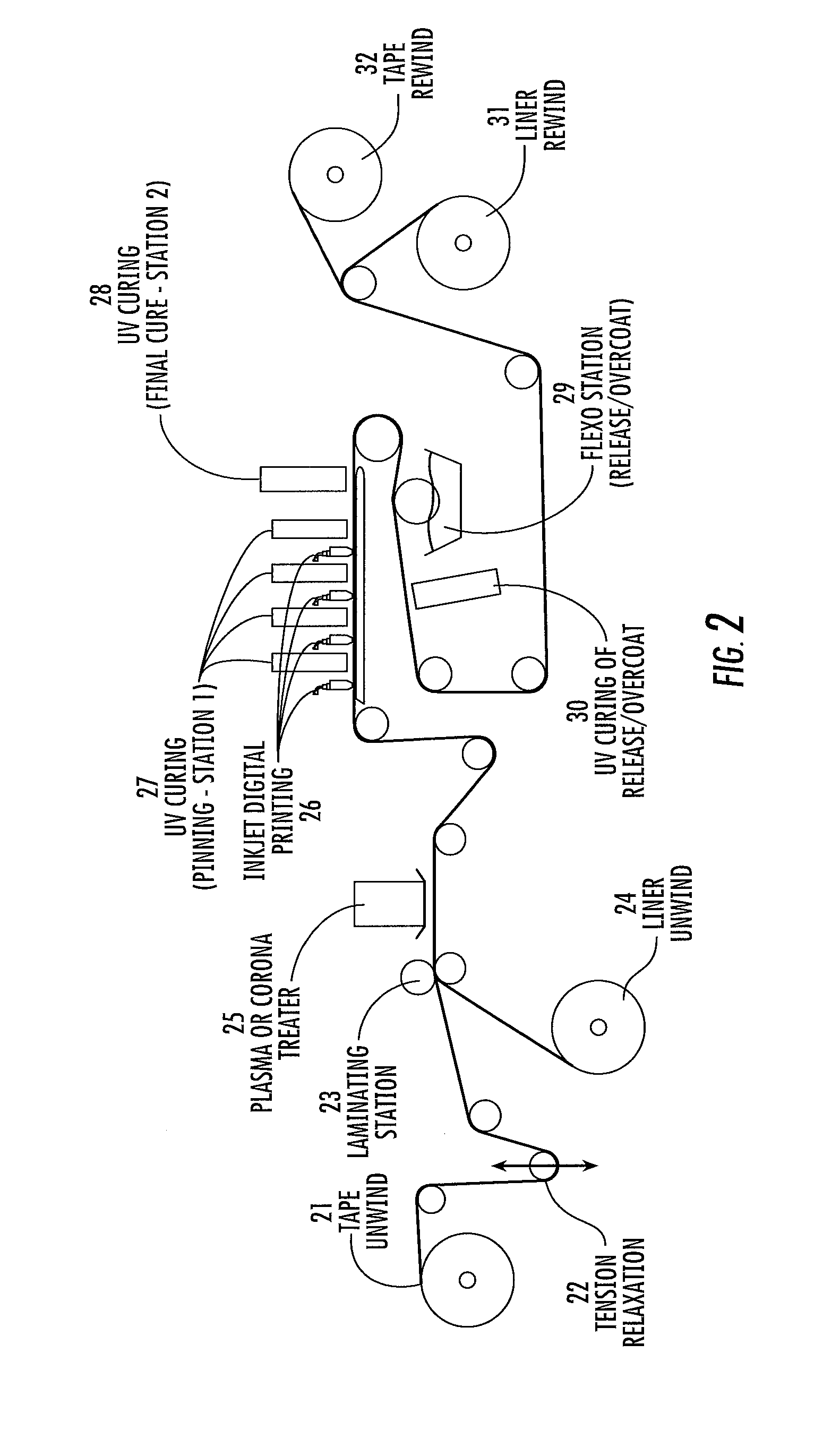

Digital printed duct tape

ActiveUS20150030823A1Fast and inexpensiveLayered productsFilm/foil adhesivesDual stageUltraviolet lights

A duct tape and a method of making a duct tape having a customized, printed design on a surface of the duct tape. The method comprises providing a design for printing on the duct tape, digitally printing the design on the surface of the duct tape, and curing the ink printed on the duct tape with ultraviolet light in dual stages. The method further comprises applying on the digitally printed duct tape a material or composition having overcoat properties, release properties, or a combination thereof.

Owner:SHURTAPE TECH LLC

Double-side thermally conductive adhesive tape for plastic-packaged electronic components

InactiveUS20020012762A1Easy `` peel and stick '' installationPrecise thermal and adhesive propertiesInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringElectronic component

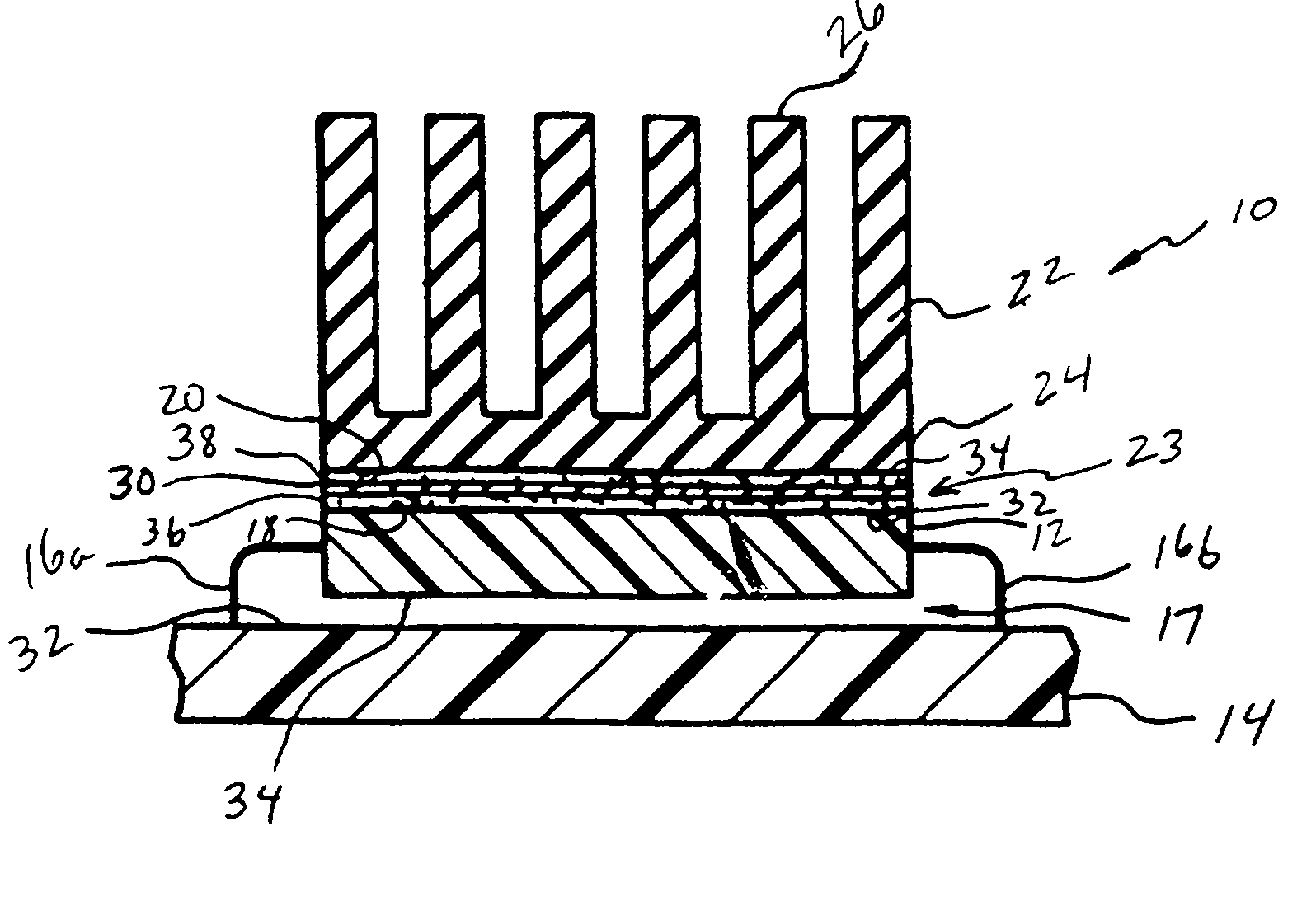

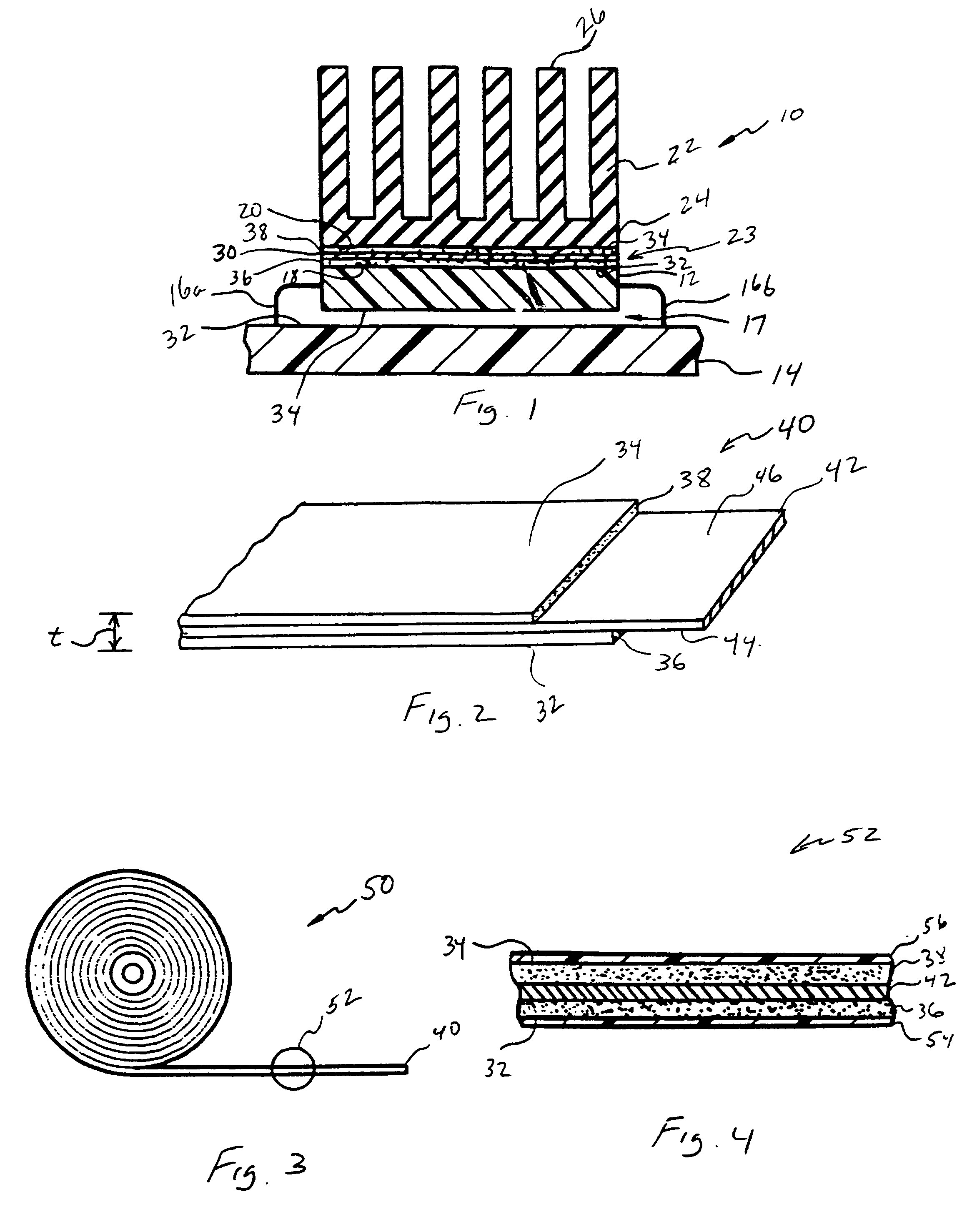

A thermally conductive interface, which may be in the form of a double-sided, pressure sensitive adhesive tape, disposable intermediate a heat-generating source having a first heat transfer surface formed of a first material having a low surface energy, and a thermal dissipation member having a second heat transfer surface which is formed of a second material having a surface energy substantially higher than the surface energy of the first material, and which is disposable opposite the first heat transfer surface of the heat-generating source in a spaced-apart, heat transfer adjacency therewith. The interface includes a first pressure sensitive adhesive (PSA) surface which is bondable under pressure to at least a portion of the first heat transfer surface of the heat-generating source, and an opposing second pressure sensitive adhesive (PSA) surface bondable under pressure to at least a portion of the second heat transfer surface of the heat-generating source. The first PSA surface is presented from a layer of a thermally-conductive, first pressure sensitive adhesive composition, preferably silicone-based, having an affinity to the first heat transfer surface of the heat generating source. In turn, the second PSA surface is presented from a layer of a second pressure sensitive adhesive composition, preferably acrylic-based, different from the first composition and having an affinity to the second heat transfer surface of the thermal dissipation member. The interface is particularly adapted for bonding a plastic packaged electronic component to a metal heat sink.

Owner:PARKER INTANGIBLES LLC

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

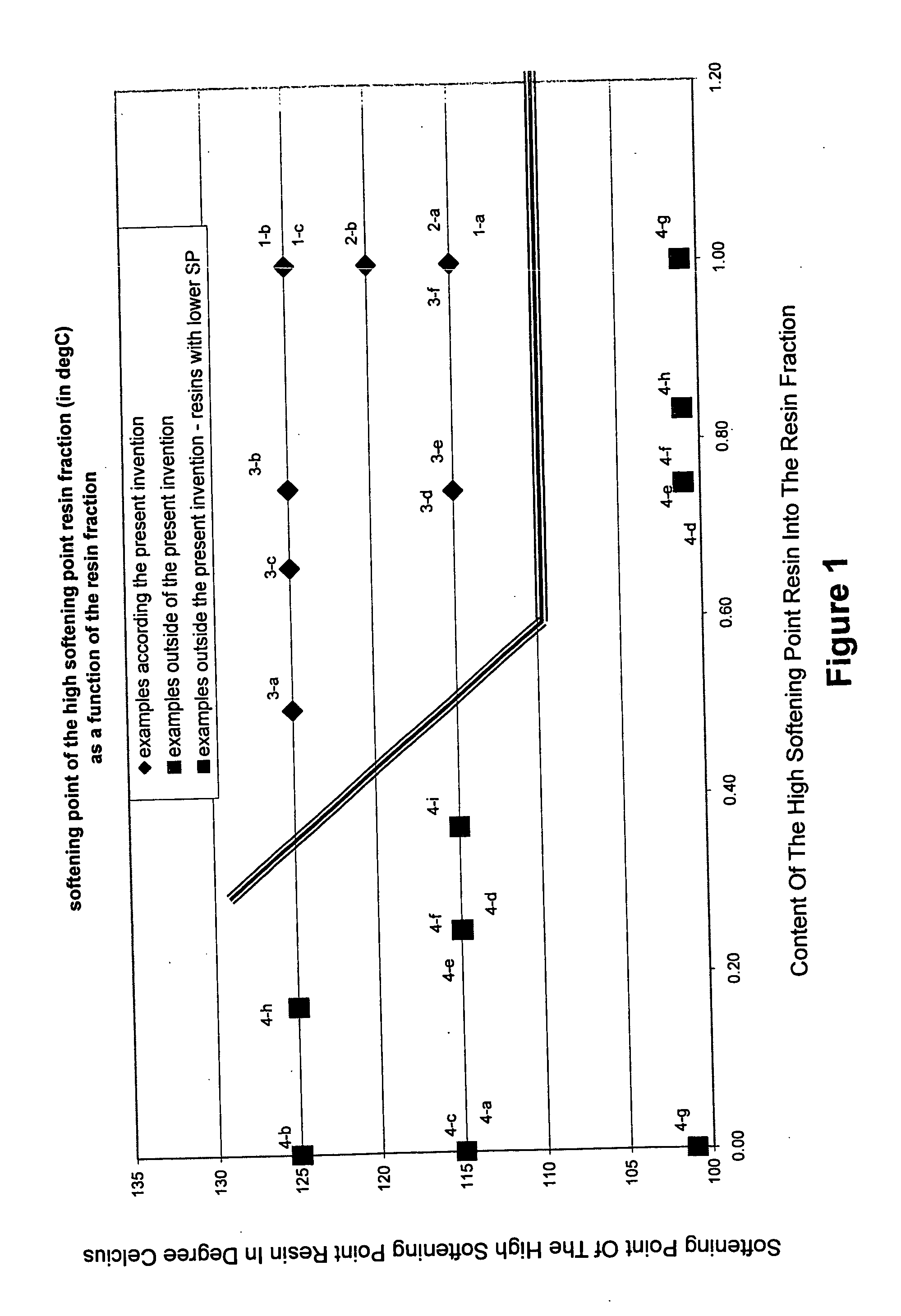

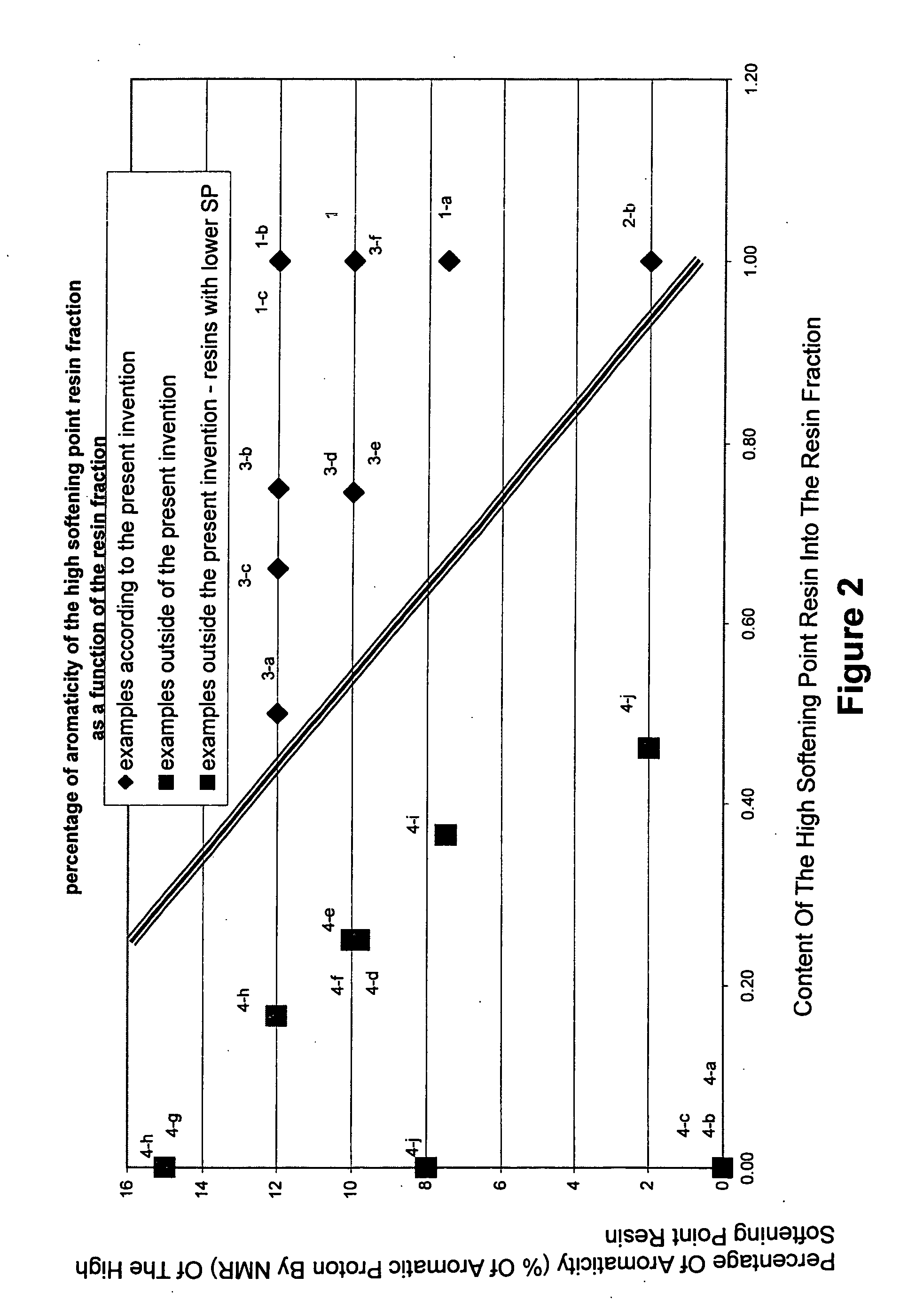

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

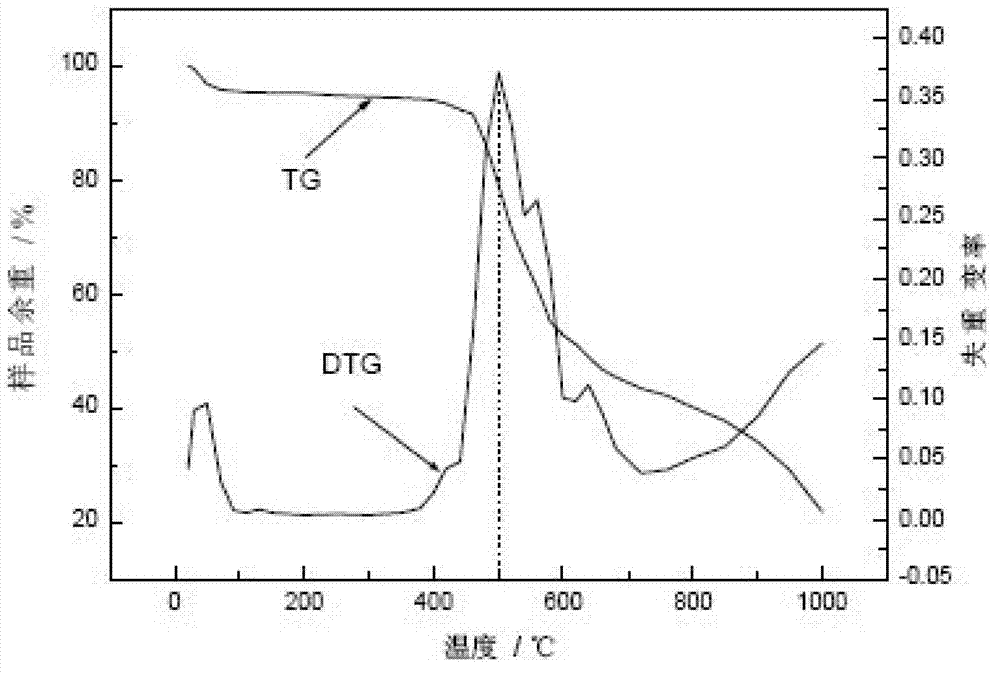

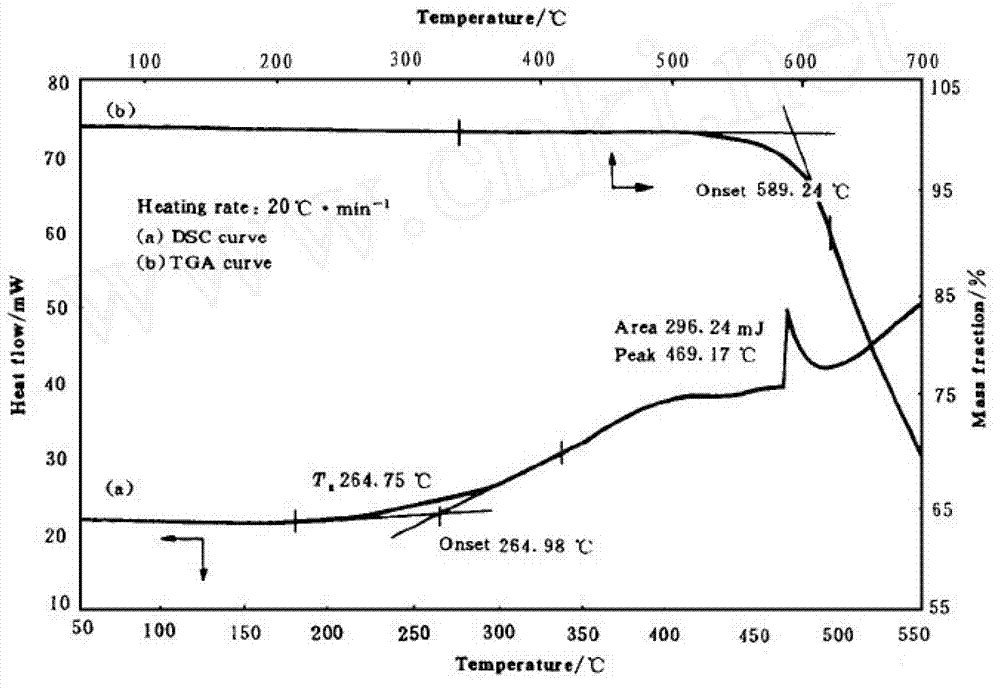

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

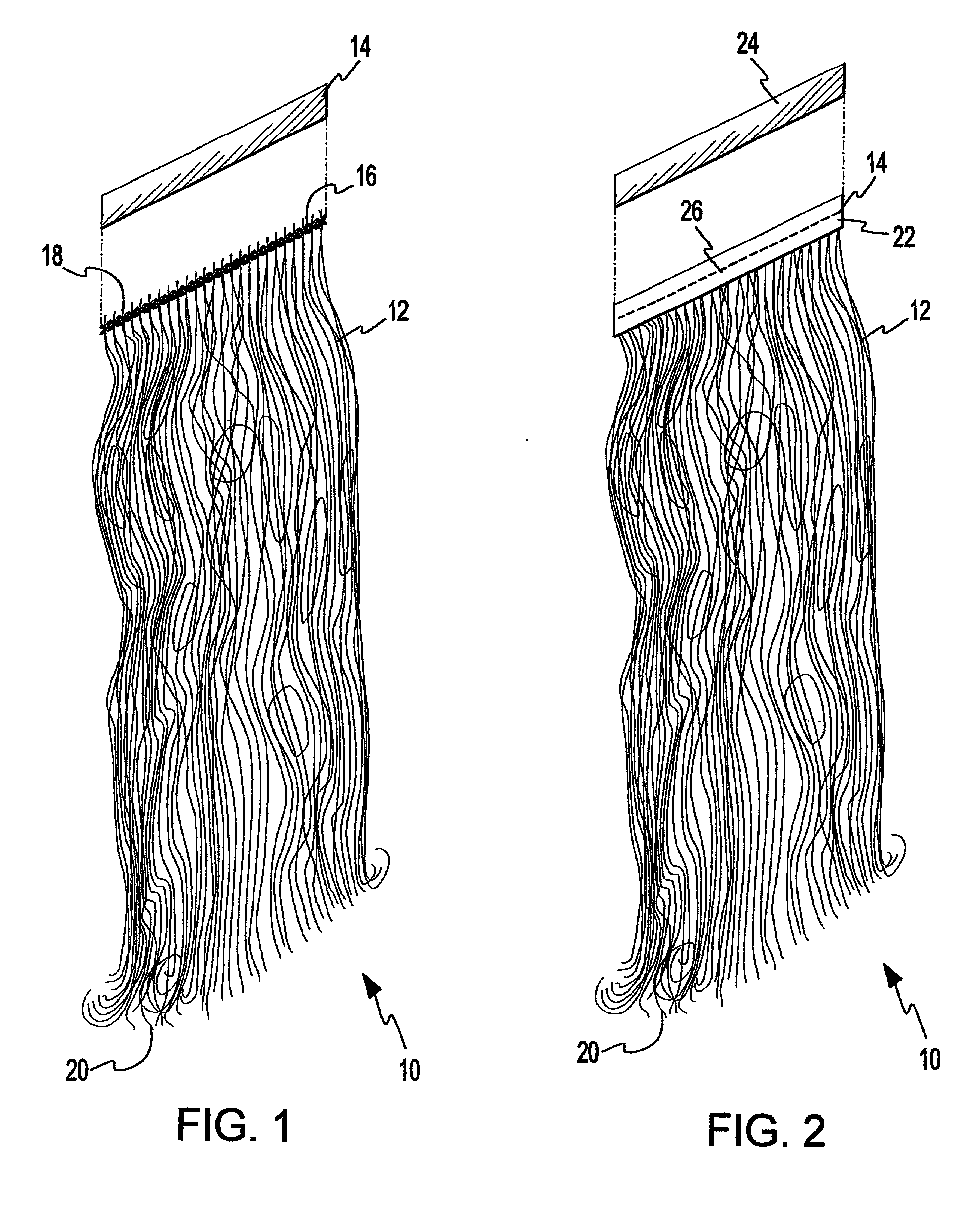

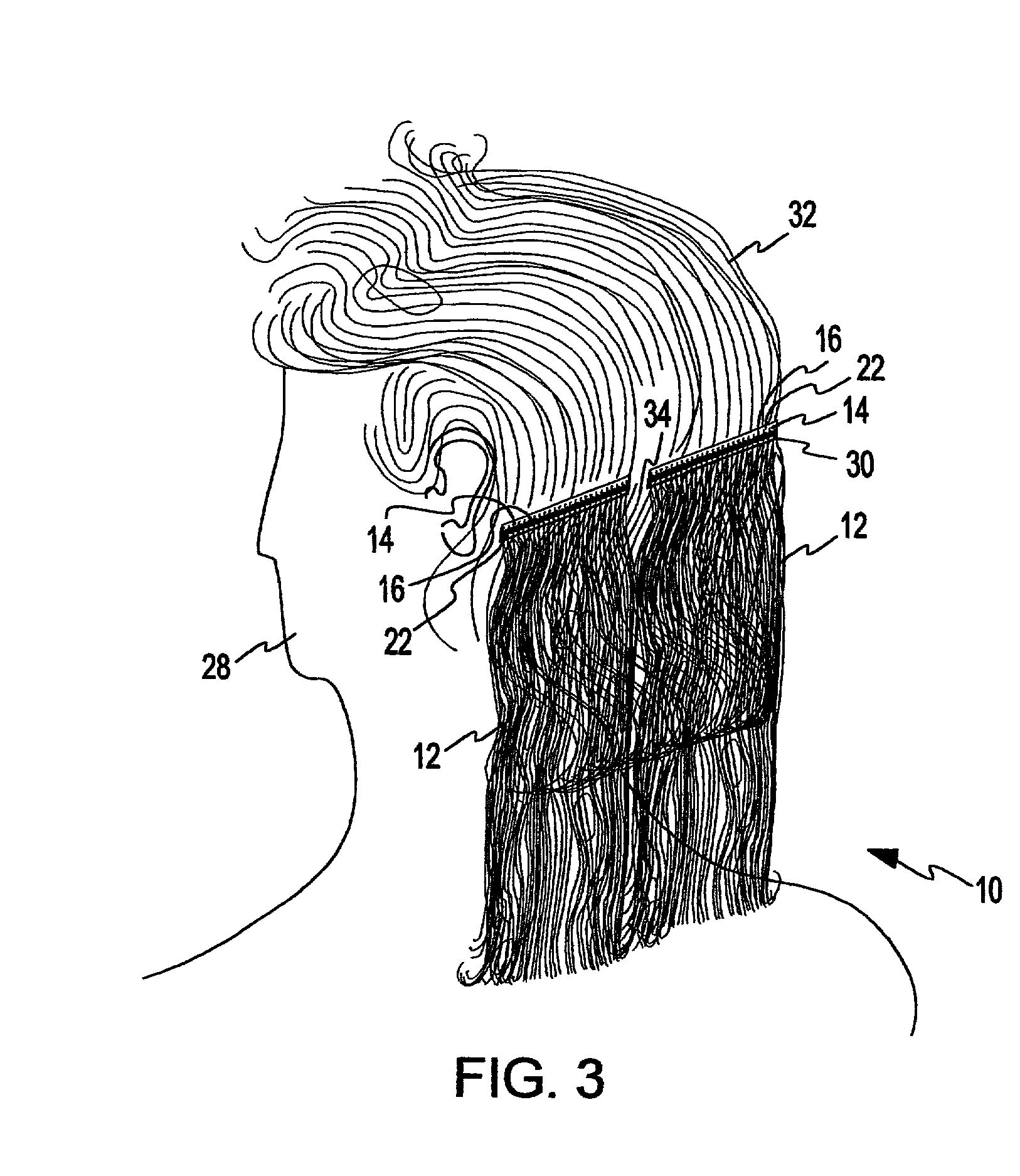

Self adhesive hair extension

The present invention resides in self adhesive hair extensions and a method of attaching then to the head of a wearer. The self adhesive hair extensions comprise a plurality of either natural or synthetic hair strands attached to a base support unit comprising a strip of woven material or hair attachment weave or welt at one end. A fastener comprising a self adhesive tape portion and removable backing is sewn or otherwise secured by stitching it to the hair extensions in order to prevent the adhesive tape from being separated or repositioned during use. The method of use comprises separating a user's hair along a part line into an upper portion and a lower portion wherein the upper portion is temporarily swept up and away from the part line. The backing is removed from the adhesive hair fastener exposing the removable self adhesive tape, said self adhesive tape is applied to the scalp or back of the head of user.

Owner:TOWNSEND VALERIE

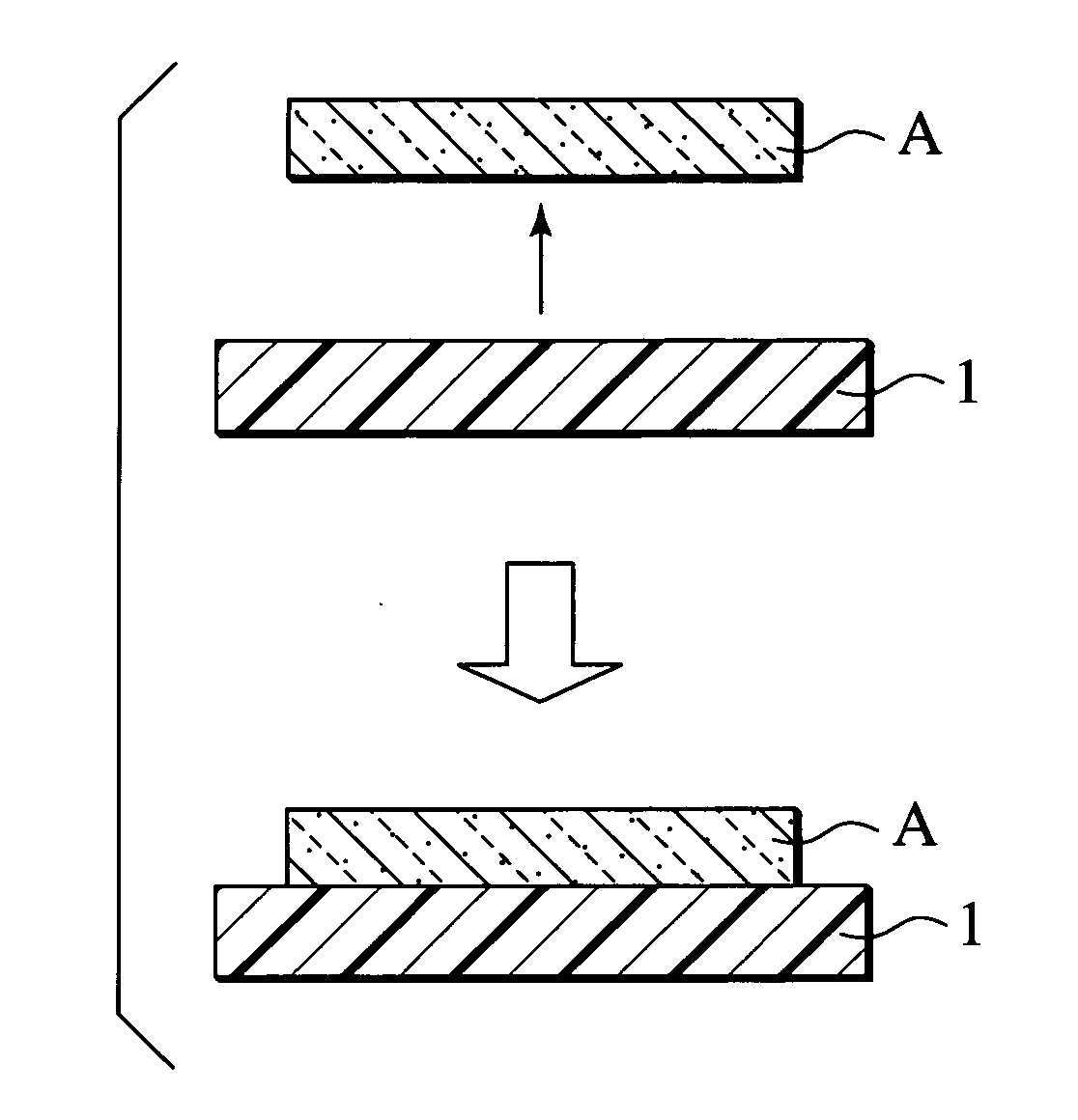

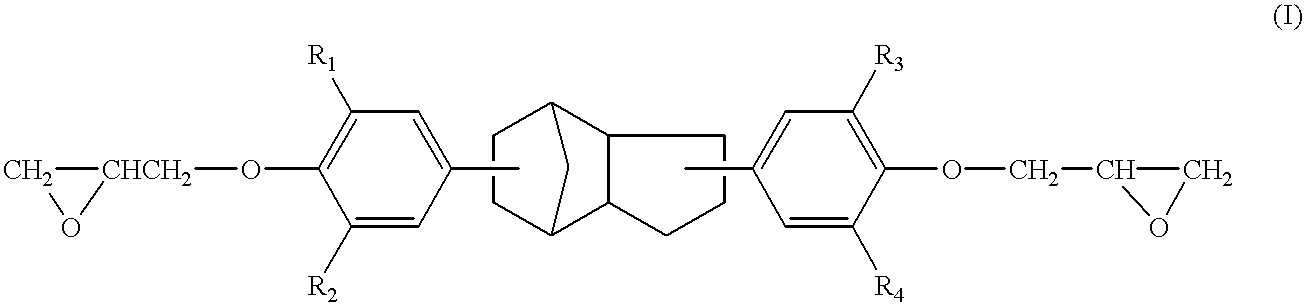

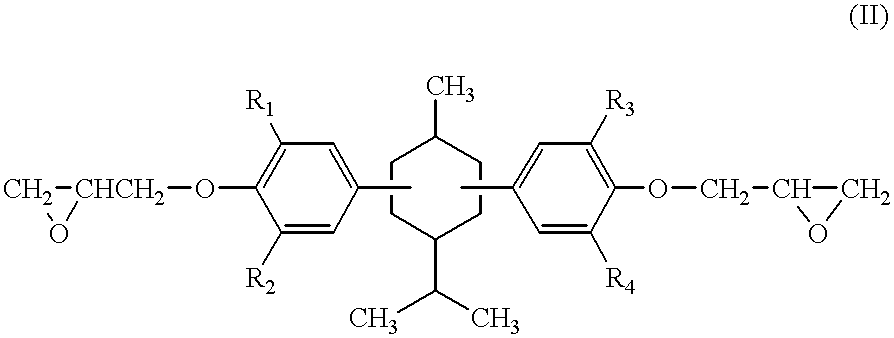

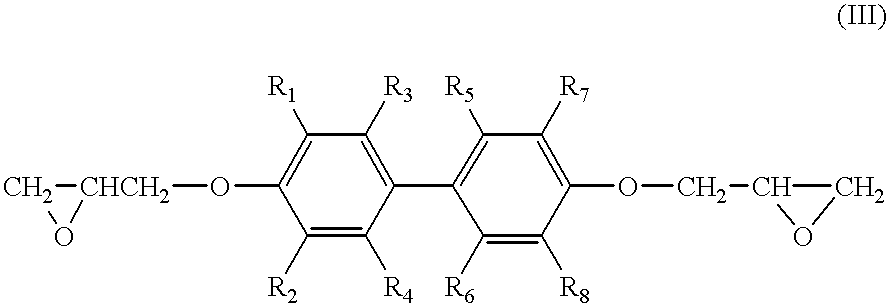

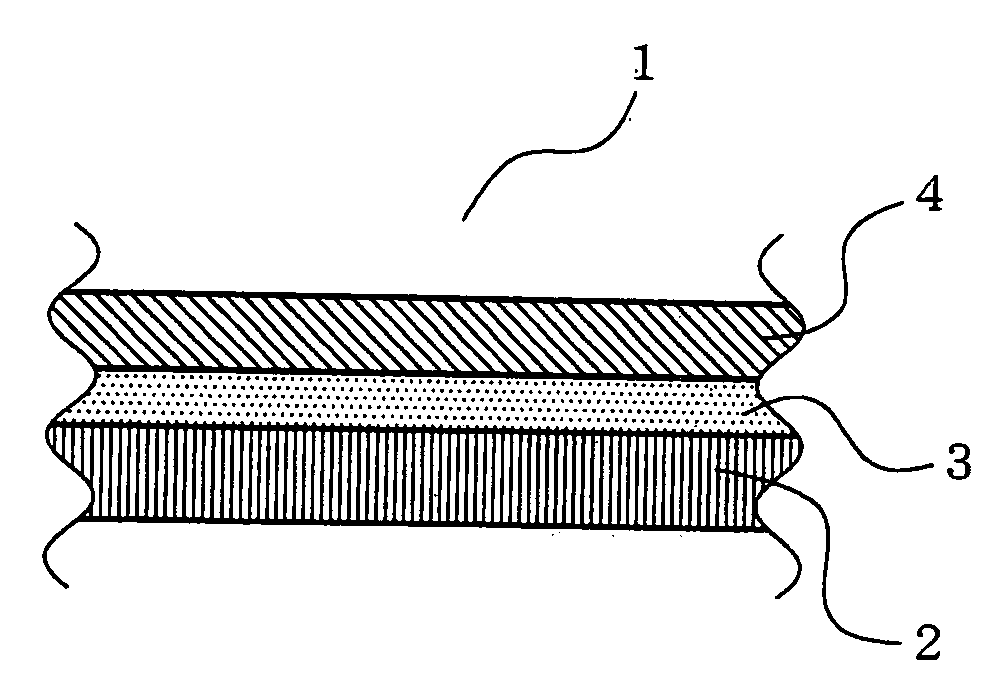

Adhesive sheet for semiconductor connecting substrate, adhesive-backed tape for tab, adhesive-backed tape for wire-bonding connection, semiconductor connecting substrate, and semiconductor device

InactiveUS6303219B1Semiconductor/solid-state device detailsSolid-state devicesInsulation resistanceChemistry

An adhesive sheet for a semiconductor connecting substrate consisting of a laminate having an adhesive layer on a substrate, wherein said adhesive layer contains a thermoplastic resin (A) and an epoxy resin (B) and said epoxy resin (B) contains at least one epoxy resin (B) selected from (I) dicyclopentadiene skeleton-containing epoxy resins, (II) terpene skeleton-containing epoxy resins, (III) biphenyl skeleton-containing epoxy resins and (IV) naphthalene skeleton-containing epoxy resins as an essential component; an adhesive-backed tape for TAB consisting of a laminate having an adhesive layer and a protective film layer on a flexible organic insulating film, wherein said adhesive layer has a softening temperature of 60 to 110° C. after having been cured and 50 hours or more in the insulation resistance dropping time after having been allowed to stand in an environment of 130° C. and 85% RH with DC 100 V applied; and a tape with adhesive for wire bonding connection consisting of a laminate having an adhesive layer and a protective film layer on a flexible organic insulating film, wherein said adhesive layer has a softening temperature of 120 to 170° C. after having been cured, a storage elastic modulus E' of 20 to 100 MPa at 150° C. and an insulation resistance dropping time of 50 hours or more after having been allowed to stand in an environment of 130° C. and 85% RH with DC 100 V applied. The adhesive sheet for a semiconductor connecting substrate, the adhesive-backed tape for TAB and the adhesive-backed tape for wire bonding connection of the present invention are excellent in adhesive strength, insulatability, dimensional accuracy, etc., and can improve the reliability of a semiconductor integrated circuit connecting substrate and a semiconductor device respectively for high density packaging.

Owner:TORAY IND INC

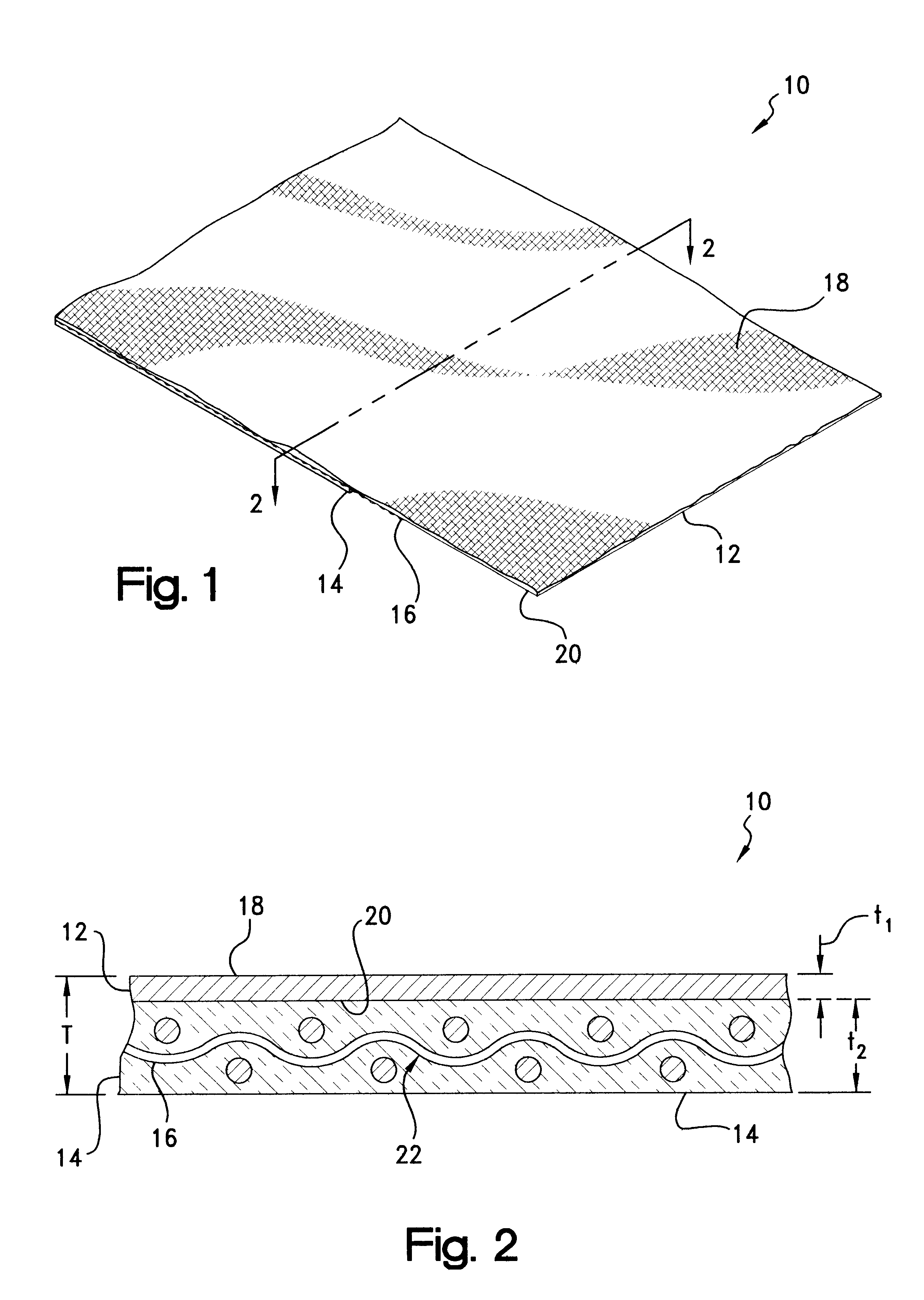

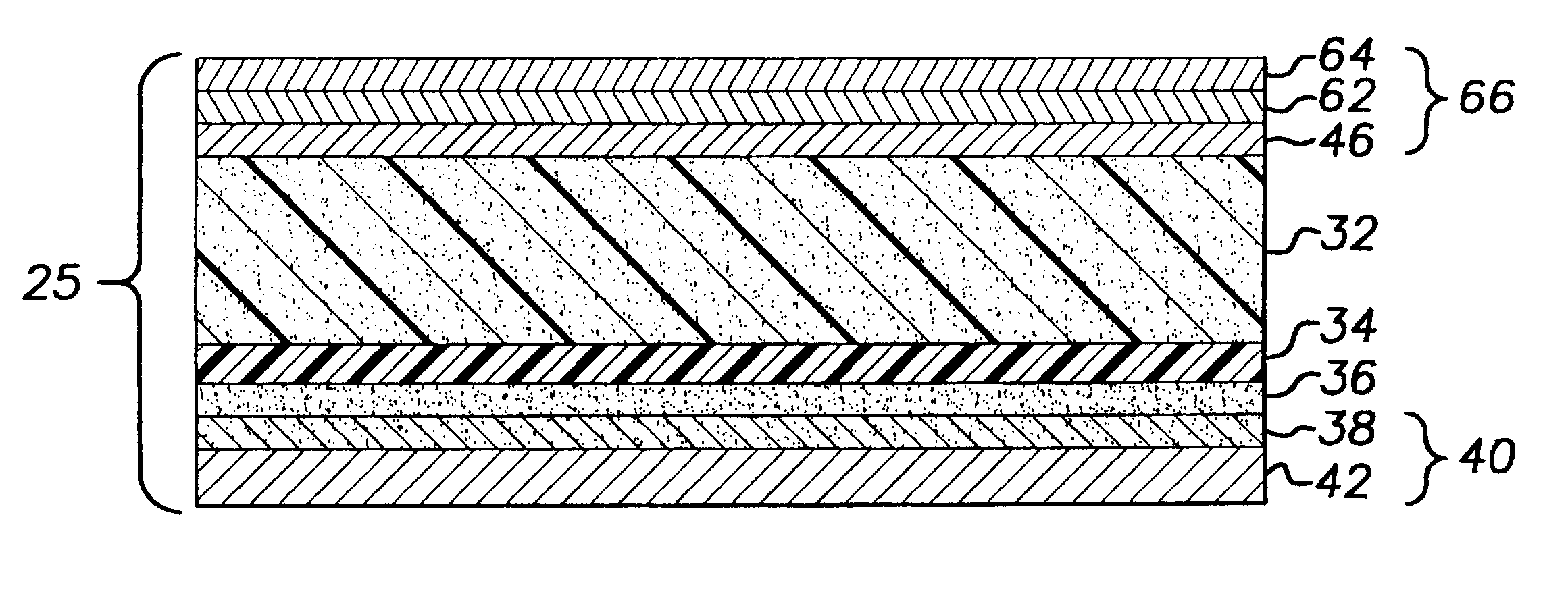

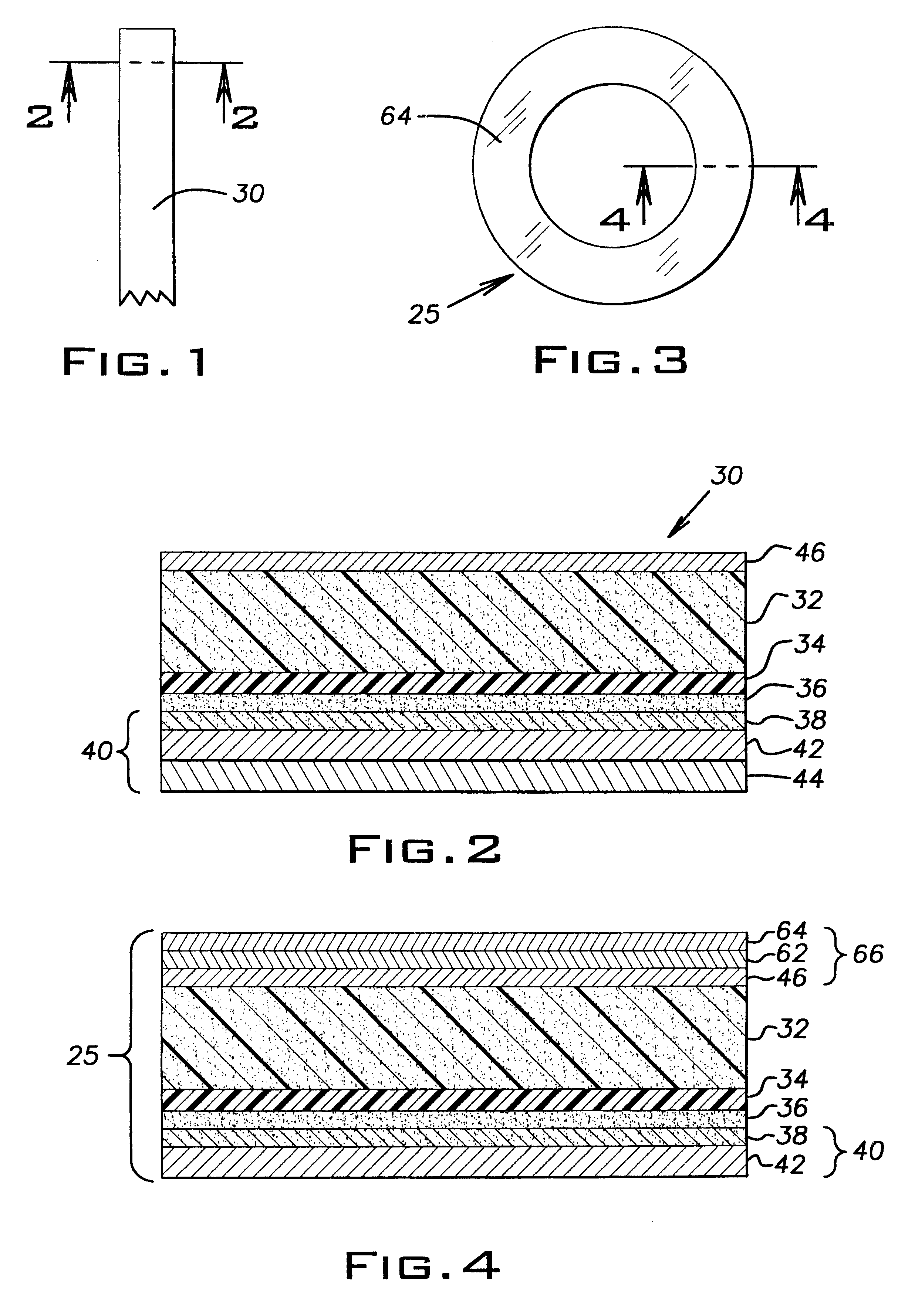

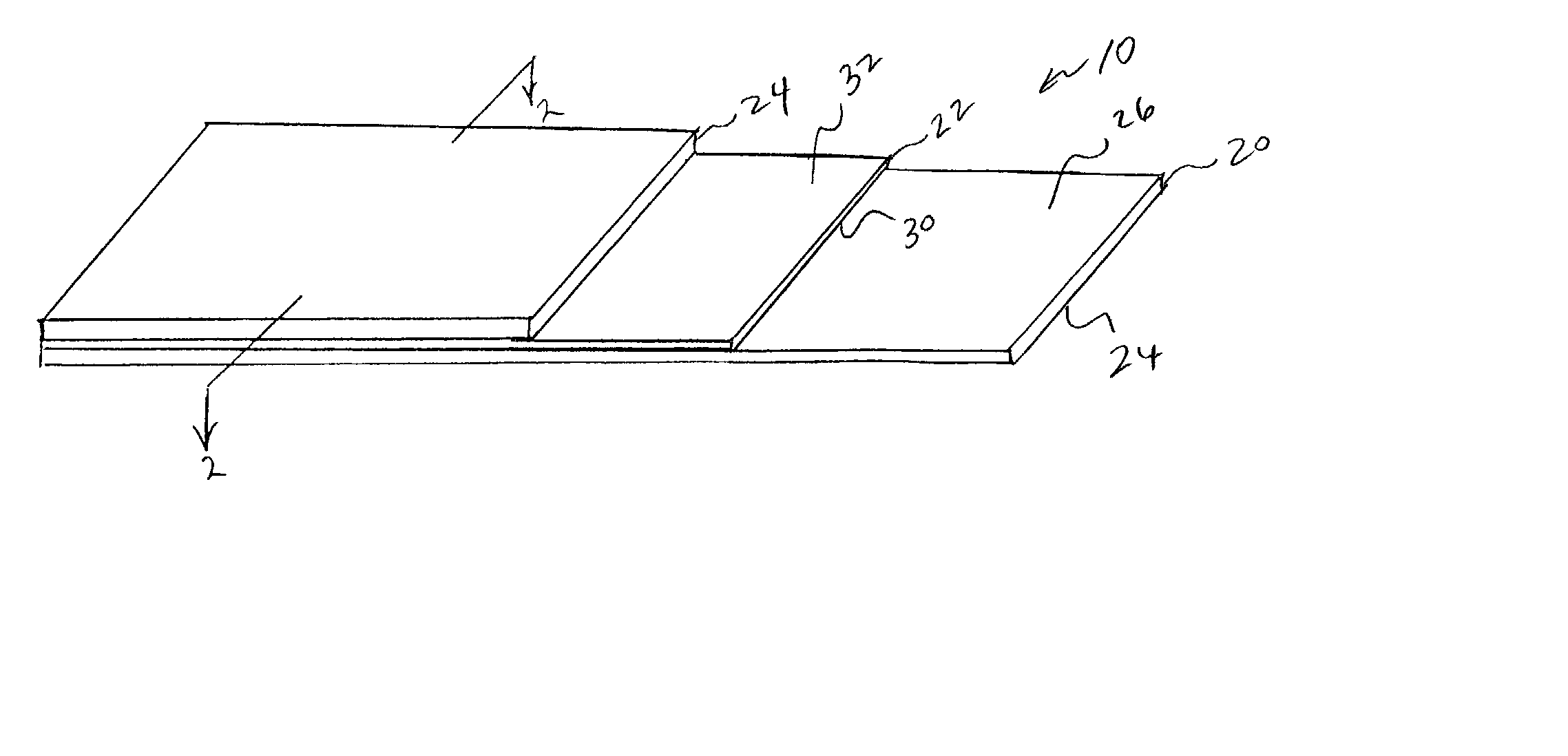

Double-sided self-adhesive reinforced foam tape

A double-sided self-adhesive reinforced foam tape comprising a release liner having upper and lower surfaces which are release surfaces, a first layer of pressure sensitive adhesive applied to the upper release surface, a layer of flexible polymeric film, preferably polyester film, applied to the first pressure sensitive adhesive layer, a layer of flexible foam, preferably closed cell PVC flexible foam, thermally bonded to the flexible polymeric film layer, and a second layer of pressure sensitive adhesive applied to the flexible foam layer. A length of material for use as a double-sided tape is provided, along with a method of making the length of material. An alternative embodiment, suitable for die-cutting, including a second release liner applied to the second pressure sensitive adhesive layer is provided. The tape may be used in automobiles and other applications.

Owner:SYLVESTER MICHAEL S

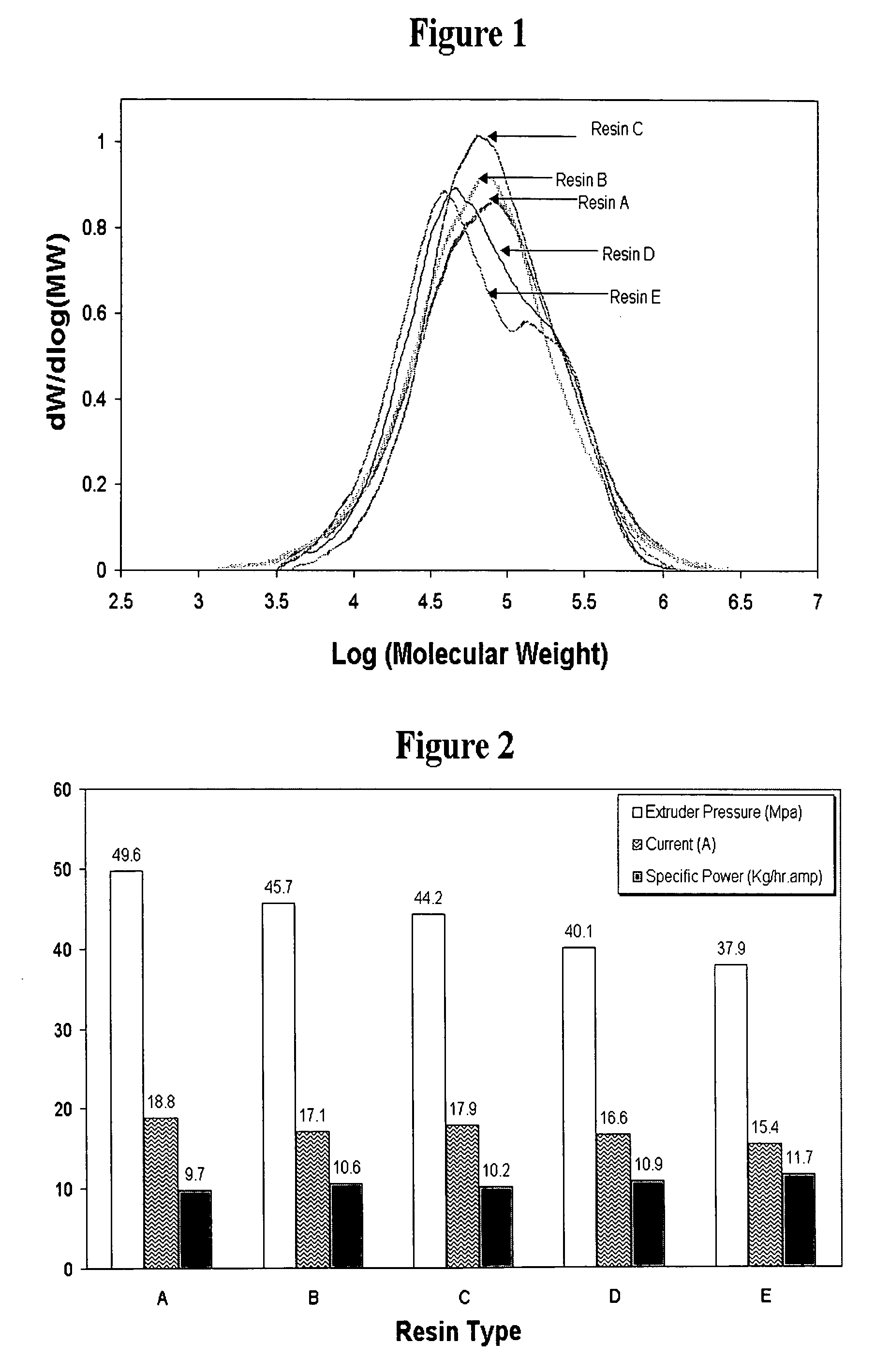

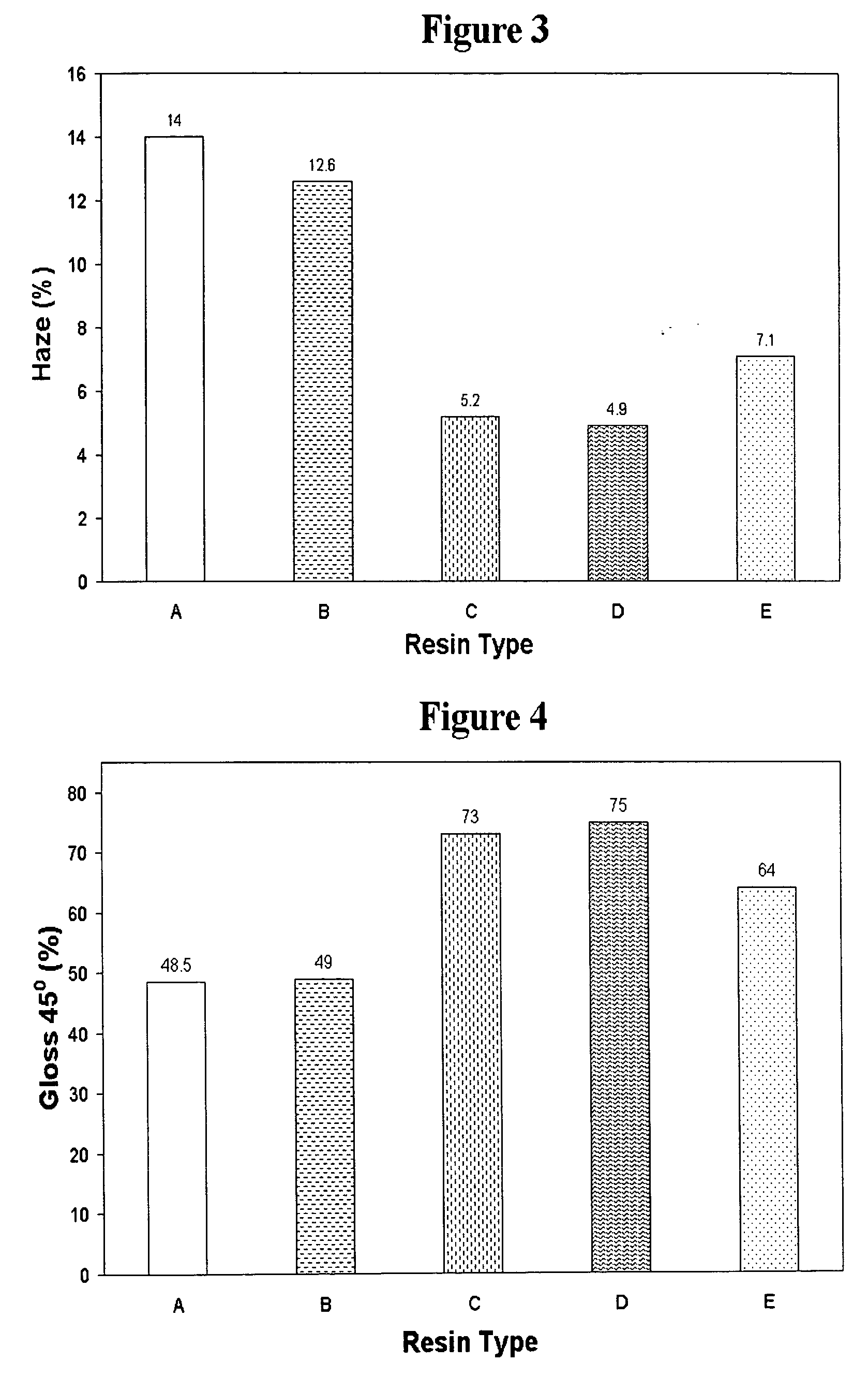

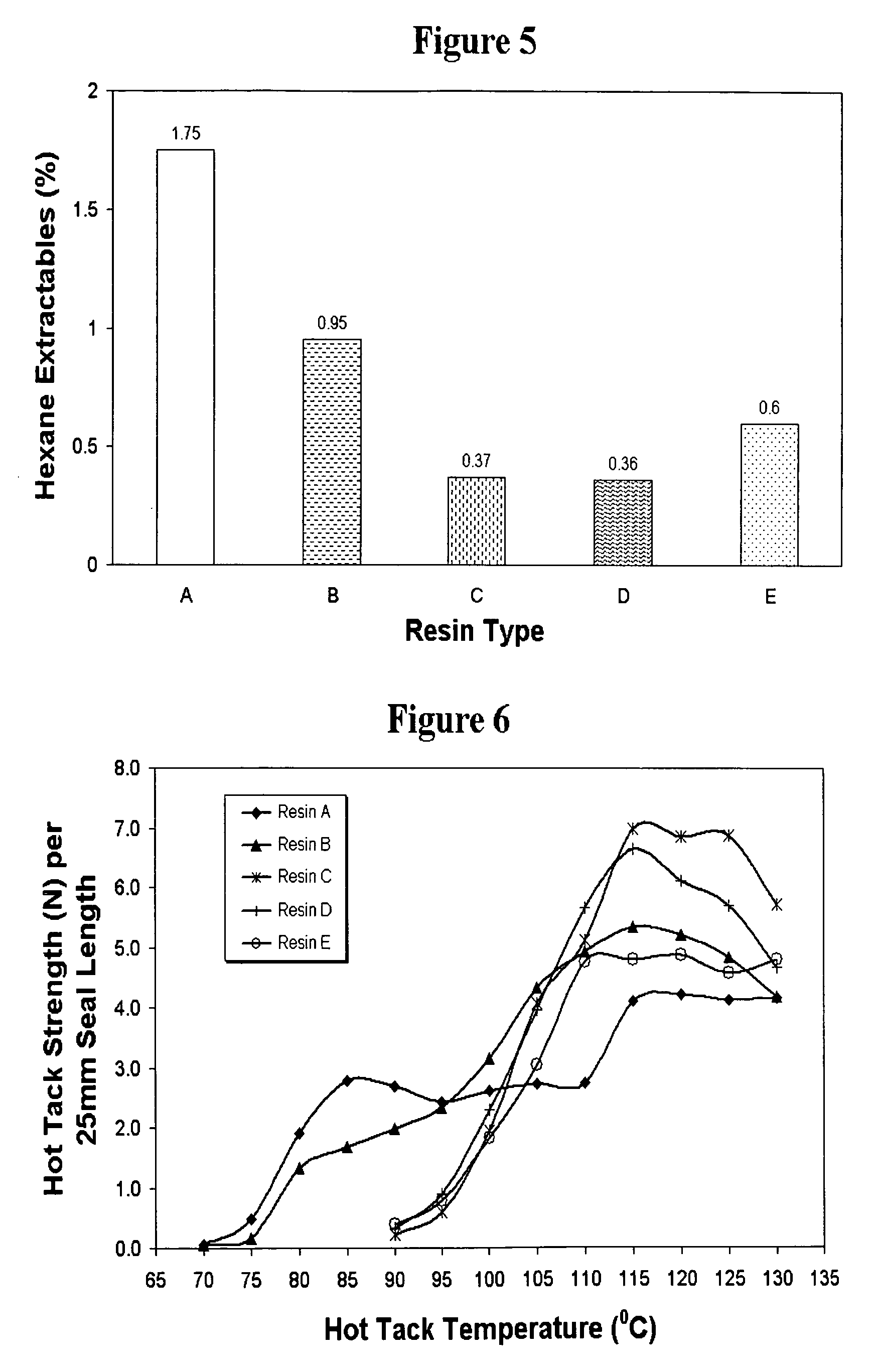

Dual reactor polyethylene resins for electronic packaging-films, tapes, bags and pouches

InactiveUS20060247373A1Good optical performanceHeat sealabilityLinear low-density polyethylenePolymer science

Owner:NOVA CHEM (INT) SA

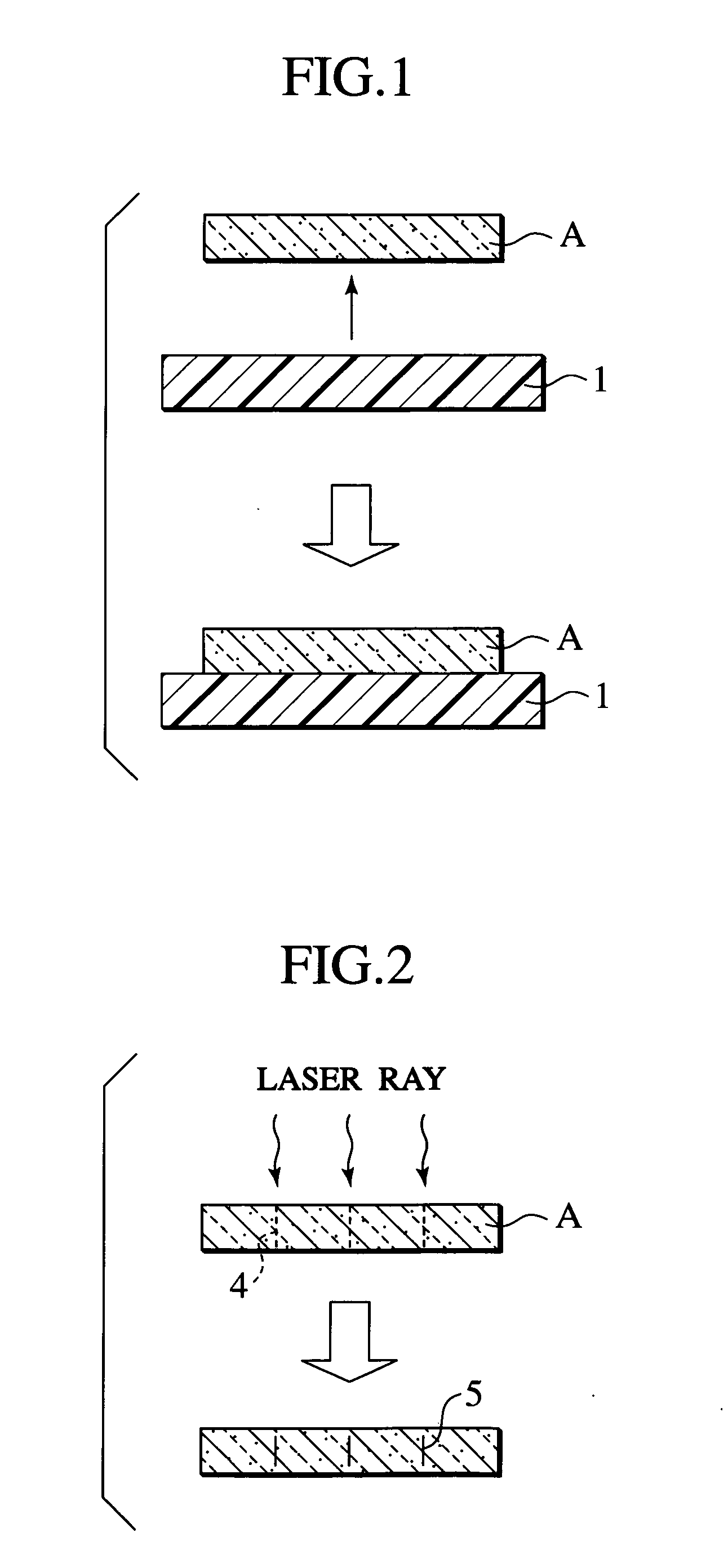

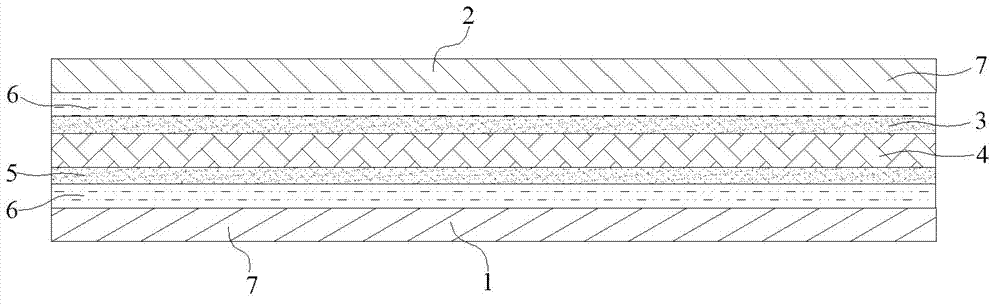

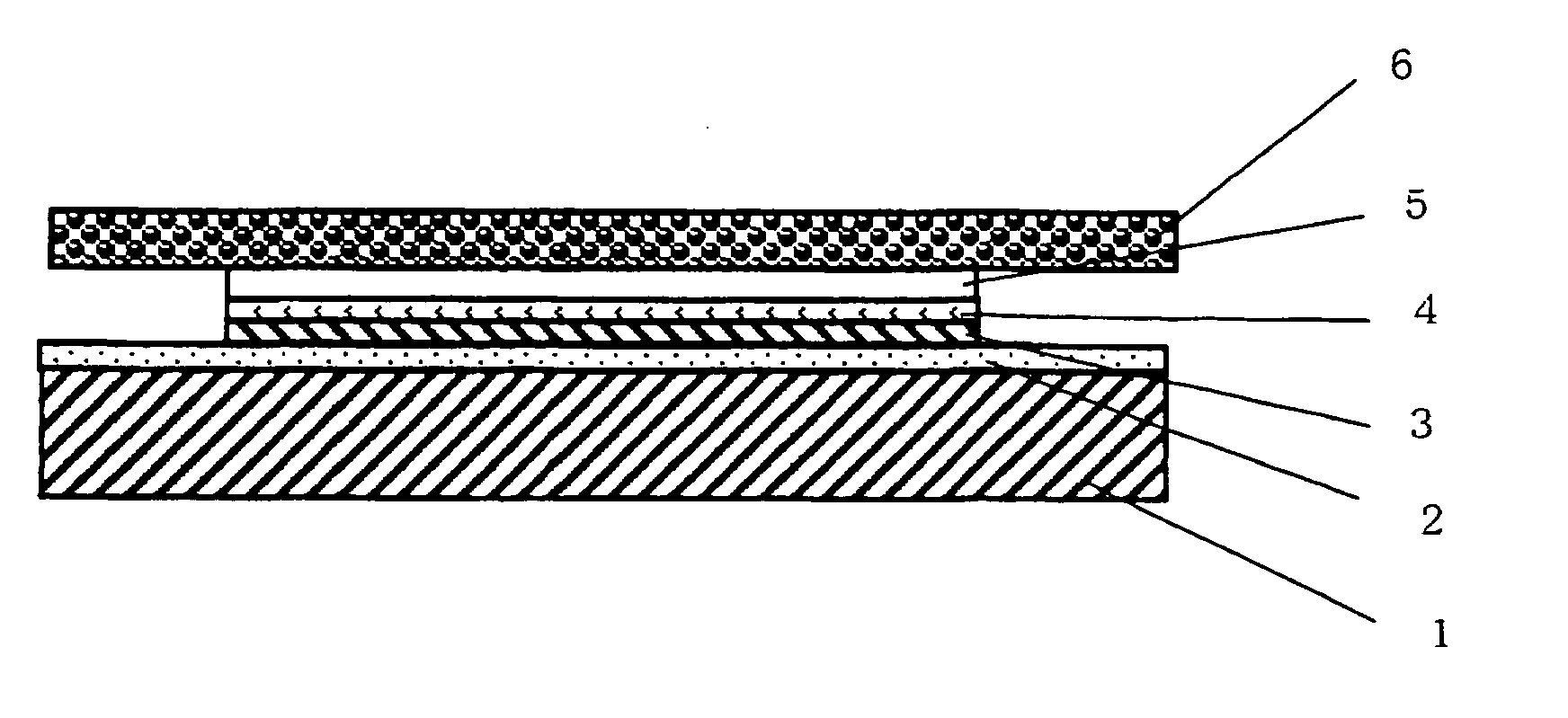

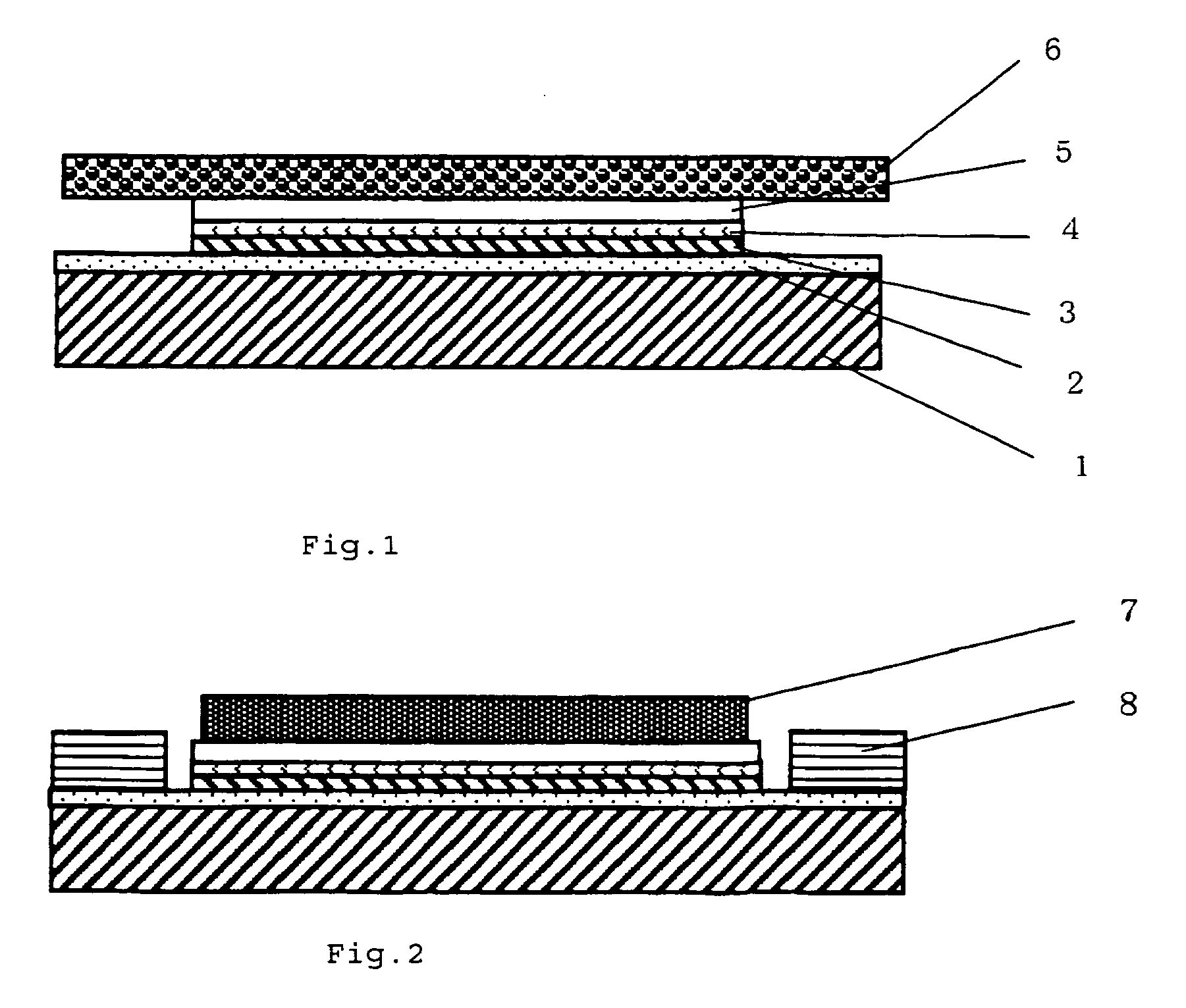

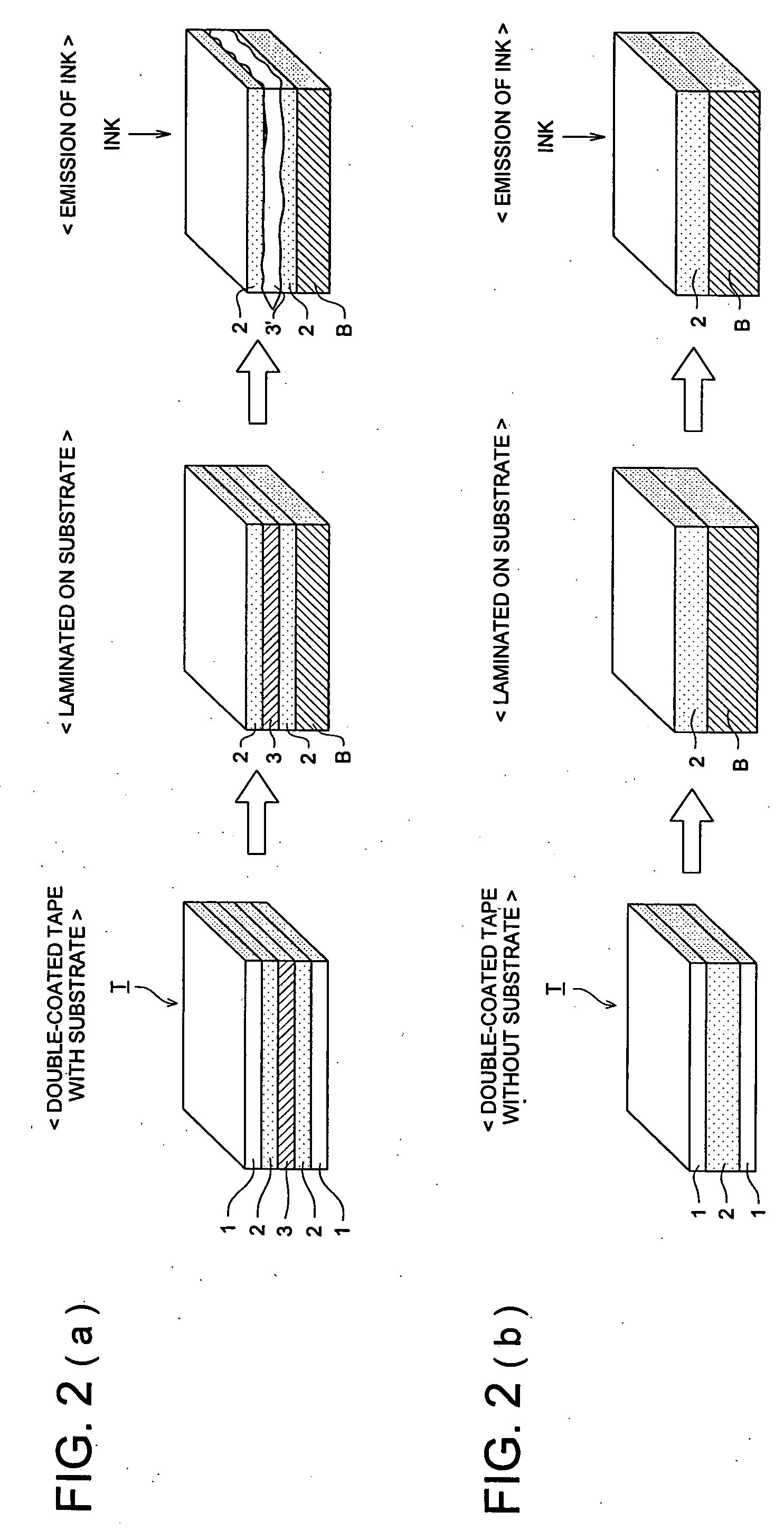

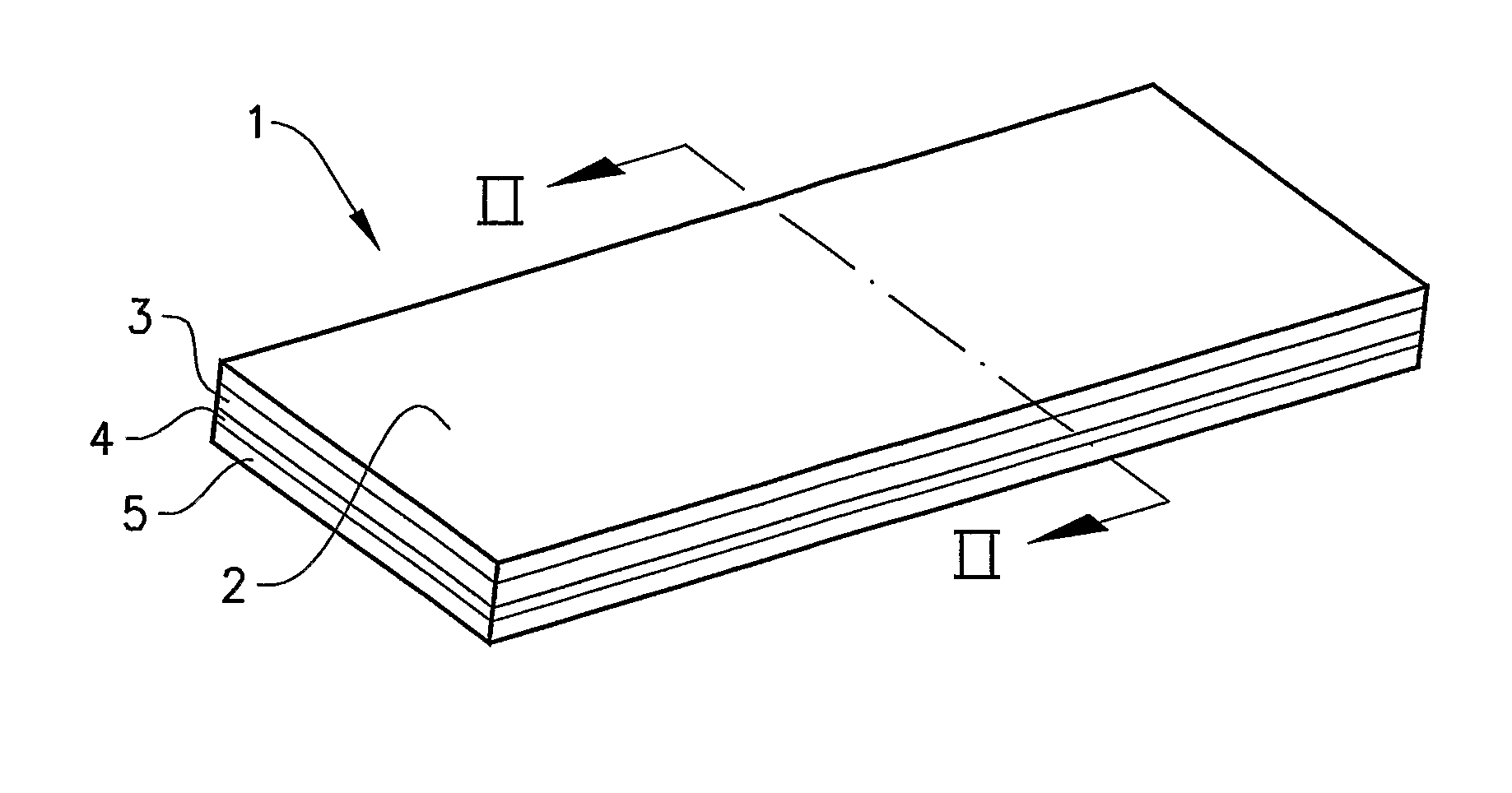

Dicing and die bonding adhesive tape

InactiveUS20070120271A1Prevent crackingAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesPressure sensitiveChemistry

A dicing and die bonding tape, comprising a substrate 1, a pressure sensitive adhesive layer (A) 2 superimposed on the substrate 1, a substrate 3 superimposed on the pressure sensitive adhesive layer (A) 2, a pressure sensitive adhesive layer (B) 4 superimposed on the substrate 3, and an adhesive layer 5 super imposed on the pressure sensitive adhesive layer (B) 4, said dicing and die bonding tape having an adhesion strength between the pressure sensitive adhesive layer (A) 2 and a dicing flame of 0.6 N / 25 mm or larger, and an adhesion strength between the pressure sensitive adhesive layer (B) 4 and the adhesive layer 5 of from 0.05 to 0.5 N / 25 mm.

Owner:SHIN ETSU CHEM CO LTD

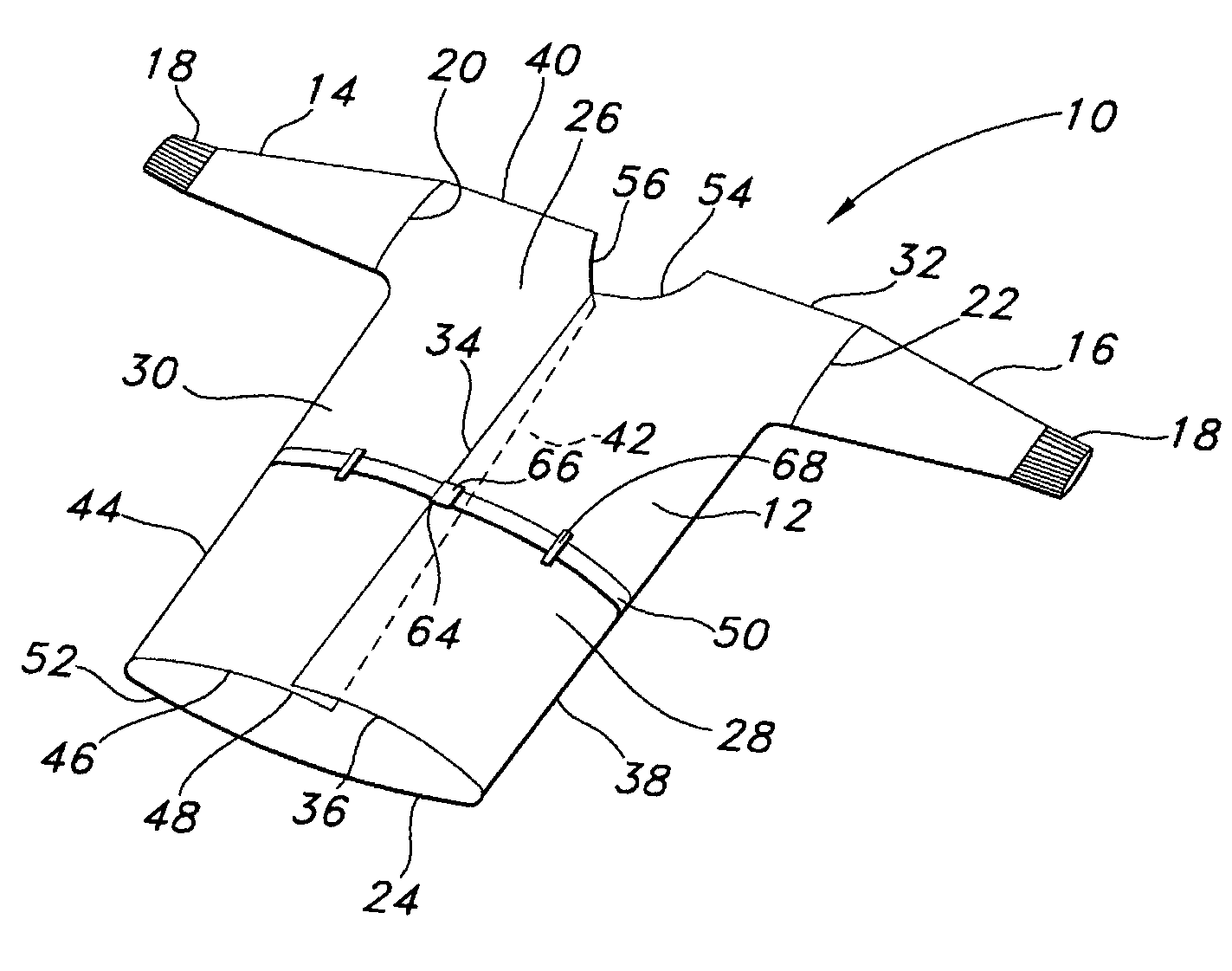

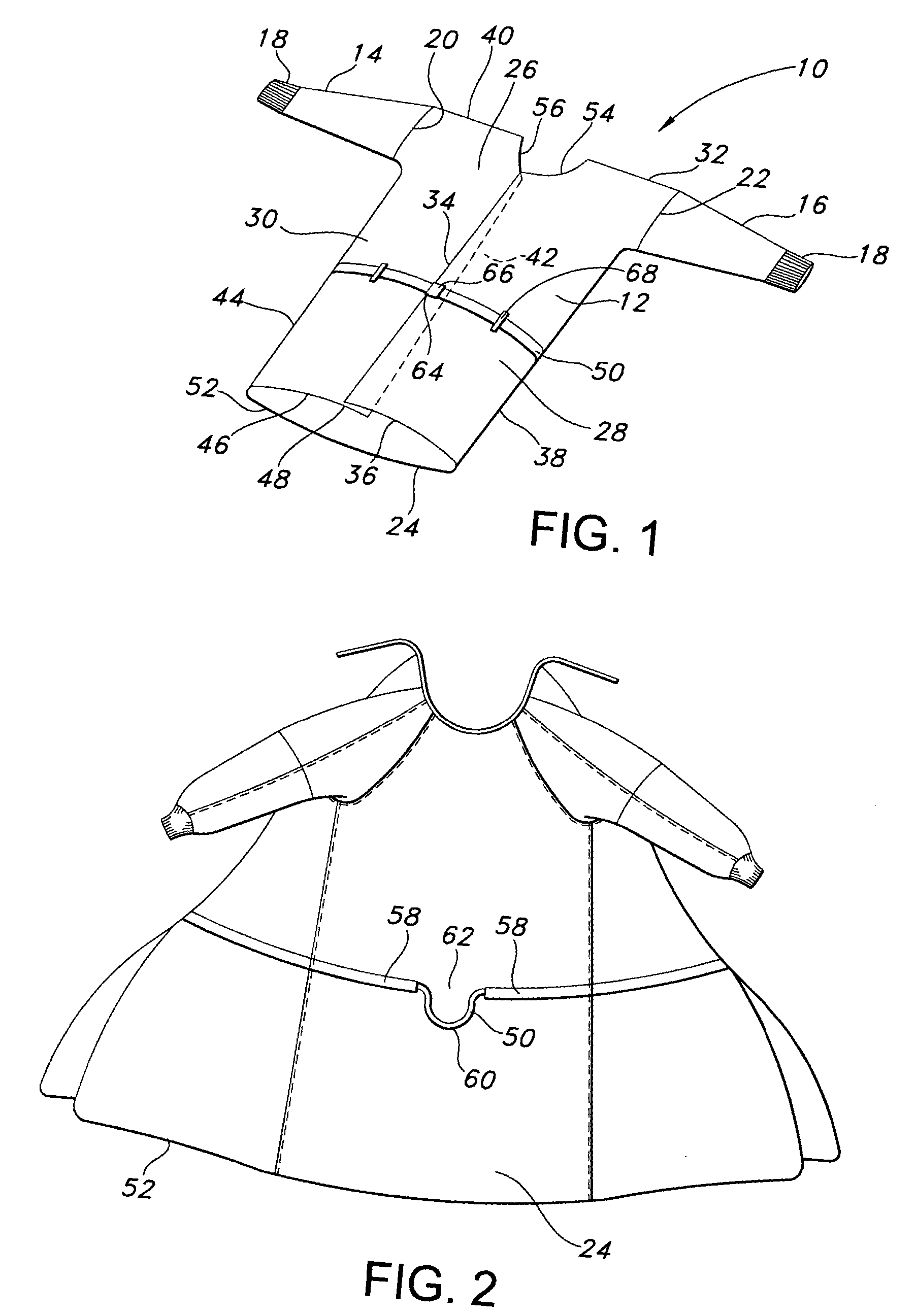

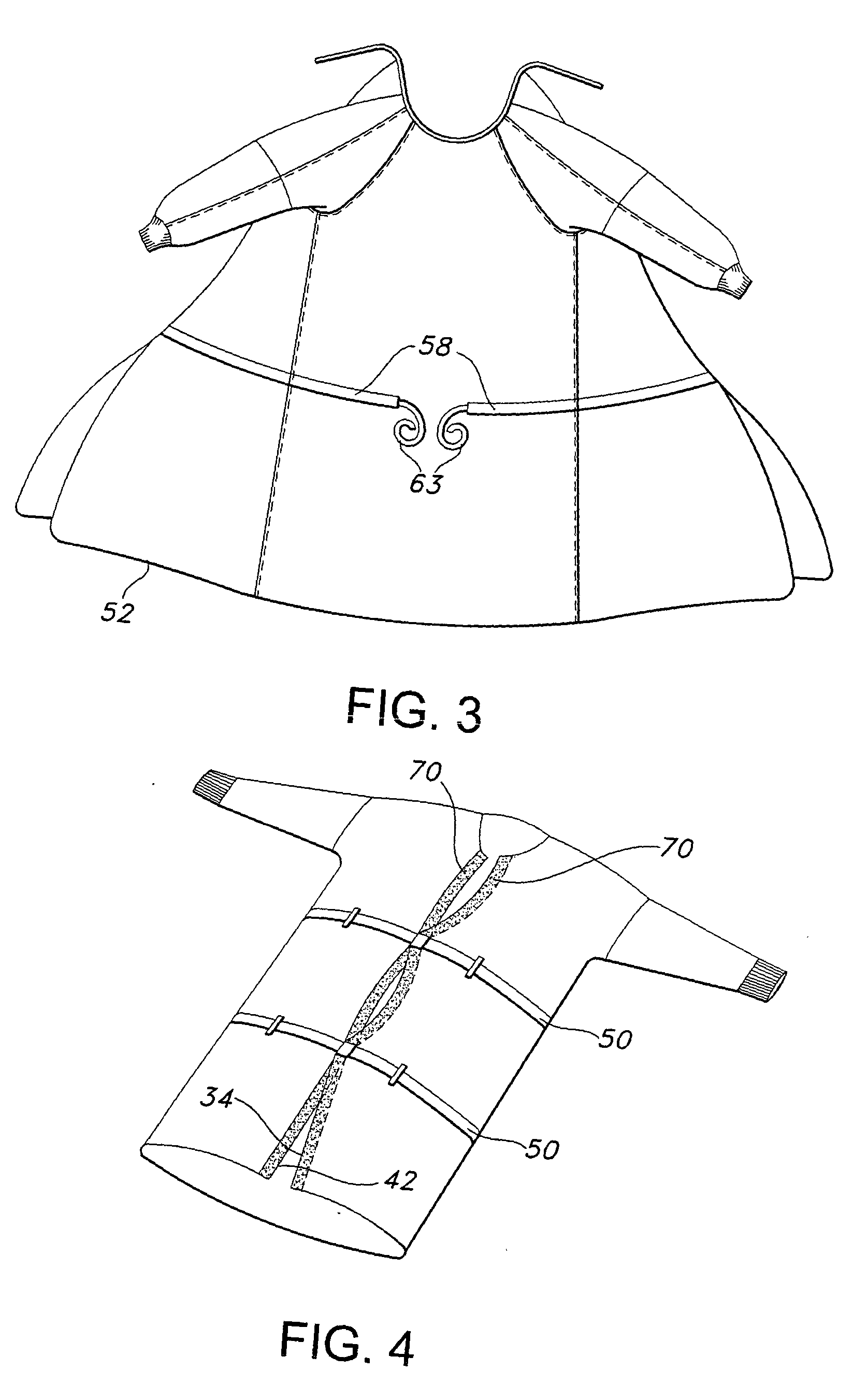

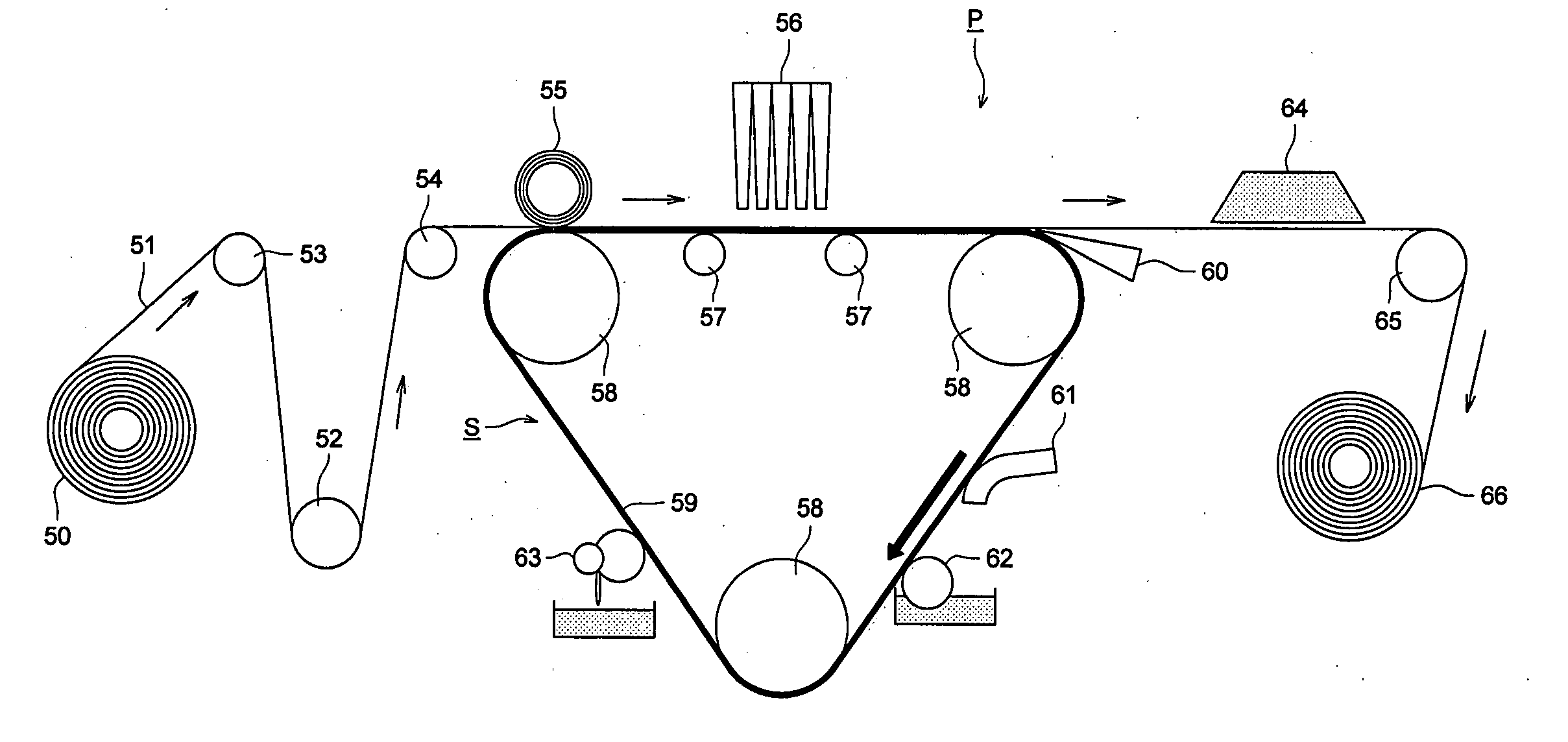

Self-donning surgical gown

The invention relates to a nonwoven gown made of a gown body terminating in two edges at a back of the gown. The gown contains a closure member that extends around the gown body and terminates at each edge. Manipulation of the closure member moves at least one of the edges toward the other thereby closing the back of the gown. A fastener located along at least a portion of at least one of the edges may be provided. Some suitable fasteners include tape, hook and loop type fasteners, and / or snaps. Such a gown enables a wearer to close and secure the gown by himself while keeping his hands sterile.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Compositions and methods for releasing adherent deposits from surfaces and substrates

InactiveUS6929702B1Detergent solventsOrganic non-surface-active detergent compositionsWaxShoe polish

Compositions and methods for release of adherent deposits from surfaces and substrates are provided. The compositions are low volatile organic compound (low VOC) compositions, solutions or mixtures. Adherent deposits removed using the compositions include grease and oil, shoe polish, crayons, candle wax, gum, lipstick, stickers, adhesives, tape and others. The compositions may be used on any surface or substrate including carpet, fabrics, metals, painted surfaces (oil and latex), wallpapers and plastics, without harming the surface or substrate.

Owner:STONER

Inkjet printer and recorded product produced thereby

InactiveUS20060132575A1Possible deformationBlurred imageTypewritersOther printing apparatusPolymer scienceComputer printing

An inkjet printer, comprises a conveying section to holding and conveying a recoding material, and an ink jet print head to jet an ink for the recoding material; wherein the conveyance section has and endless conveying member including an endless base member whose outer peripheral surface is covered with fluororesin and a sticky layer formed by a sticking tape transferred onto the outer peripheral surface of the endless base member, the sticking tape has not a substrate and the sticky layer contains a silicone polymer.

Owner:KONICA MINOLTA INC

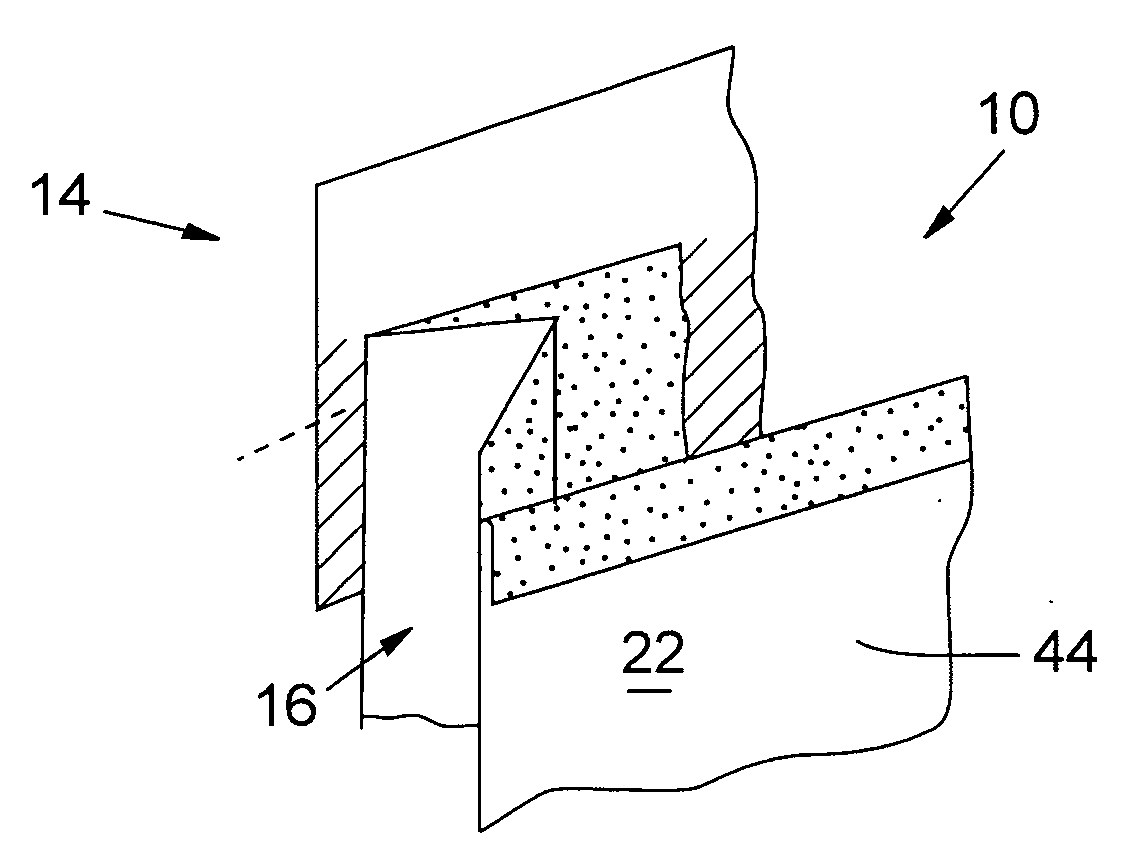

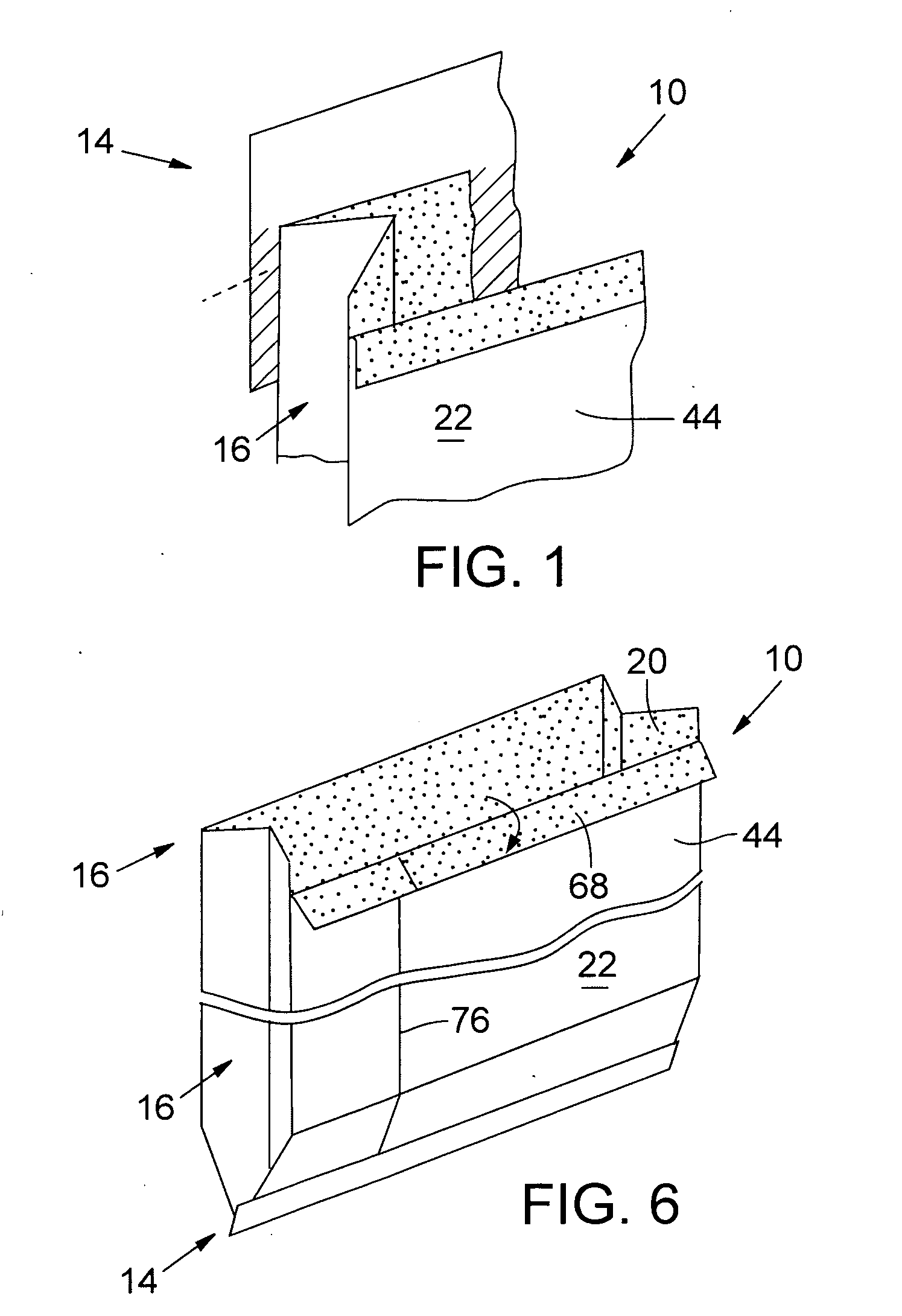

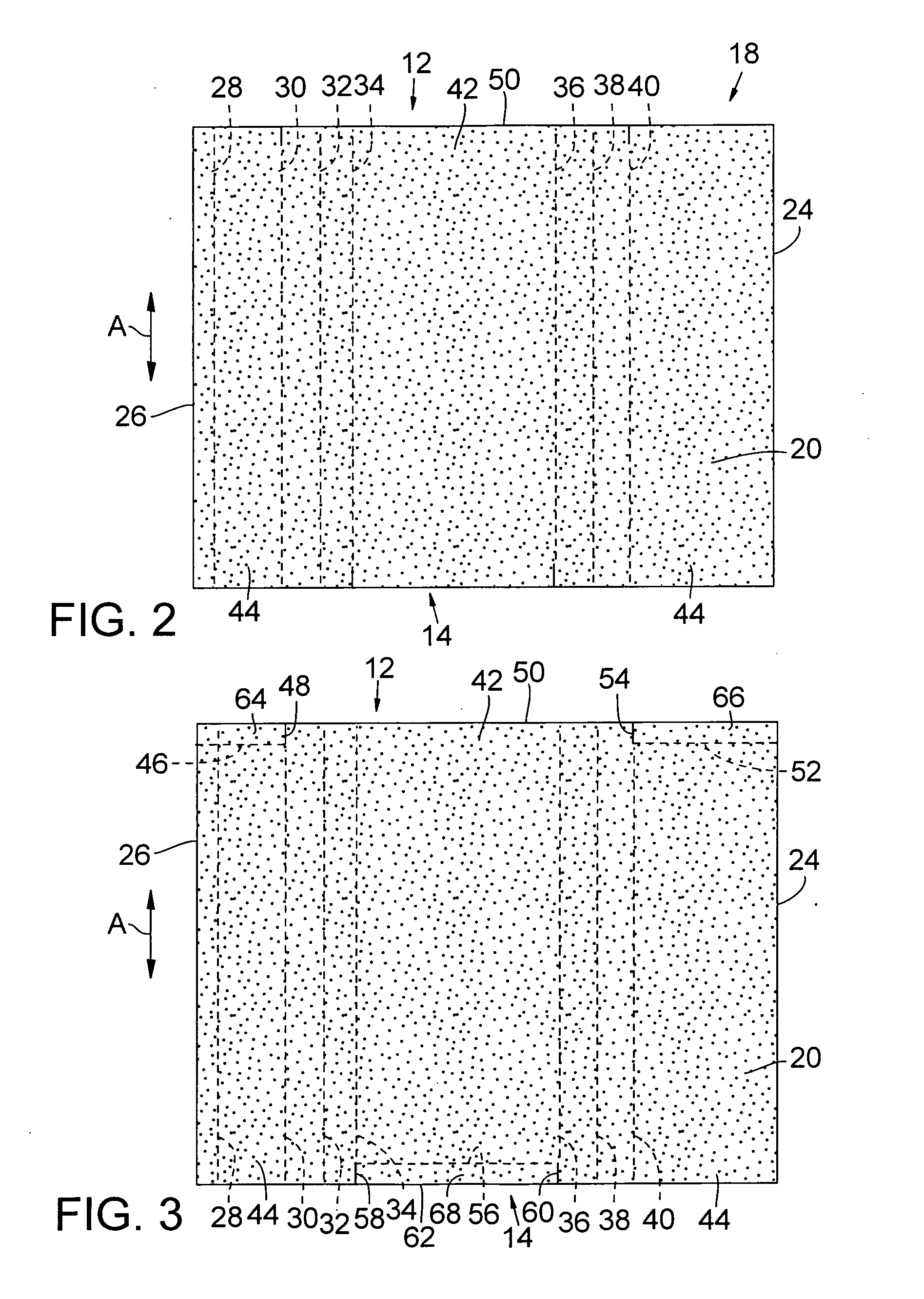

Paper substrates useful in wallboard tape applications

ActiveUS20060191656A1Natural cellulose pulp/paperSpecial paperPulp and paper industryCellulose fiber

This invention relates to paper products and / or substrates suitable for being made and / or converted into wallboard tape; which also may be known as joint tape and / or drywall tape, having a pH of at least 7.0 and containing a plurality of cellulose fibers, a wet strength additive, an alkaline sizing agent, and an anionic promoter, as well as methods of making and using the same.

Owner:INT PAPER CO

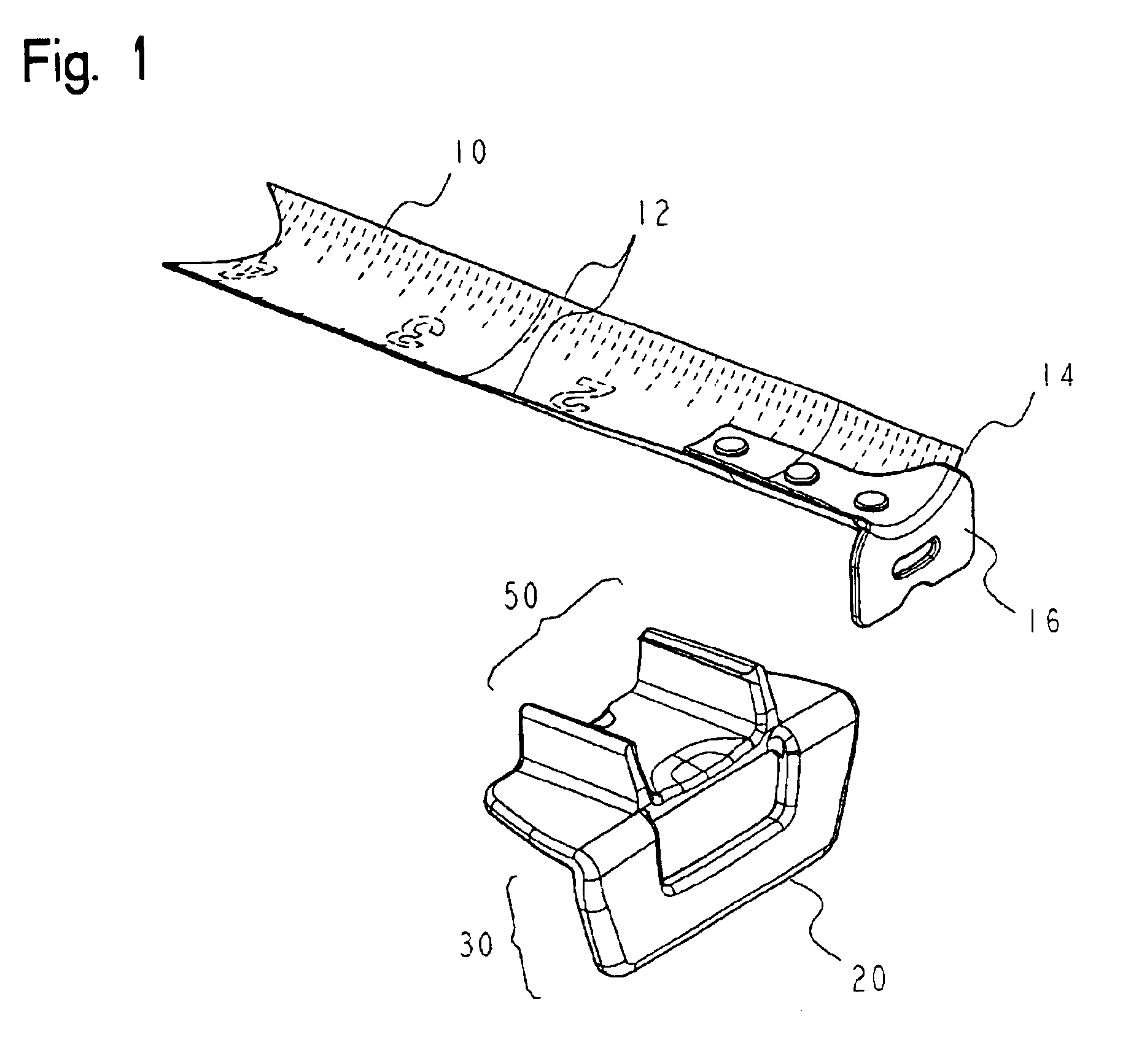

Tape measure attachment

InactiveUS6839981B2Removably attachUseful measurementRulers for direct readingMeasuring tapesTape measureEngineering

An apparatus can be conveniently and temporarily attached to a tape measure to aid in measuring a workpiece. The apparatus has a means of engaging a workpiece at one end of a length to be measured, and has a means of removably attaching to the tape measure. The attachment mechanism consists of a rigid, substantially flat member which is designed to rest under the tape, with two tabs protruding upwards from said rigid member. Each tab has at least one kerf formed in the side of that tab which is adjacent to the tape when the rigid member rests under the tape, so that the curving edges of the tape fit into those kerfs, holding the apparatus in place. In this manner, the apparatus is conveniently attachable to and removable from the tape. Furthermore, while the apparatus is attached to the tape, the apparatus adds stability to the tape, by reinforcing the position of the curving edges of the tape. Also, the apparatus can be conveniently slid along the tape to whatever position is appropriate for engaging a workpiece to be measured. The engagement mechanism of the apparatus consists of a rigid, substantially flat member which is attached to the attachment mechanism at a substantially ninety degree angle, so that the rigid engagement member is substantially perpendicular to the tape. One surface of the engagement member is designed to rest against and engage a workpiece to be measured, in a manner which does not harm or mar the workpiece. The surface engaging the workpiece can be tacky, or can have a protrusion designed to insert into a hollow workpiece, such as a pipe.

Owner:TAPE EASE

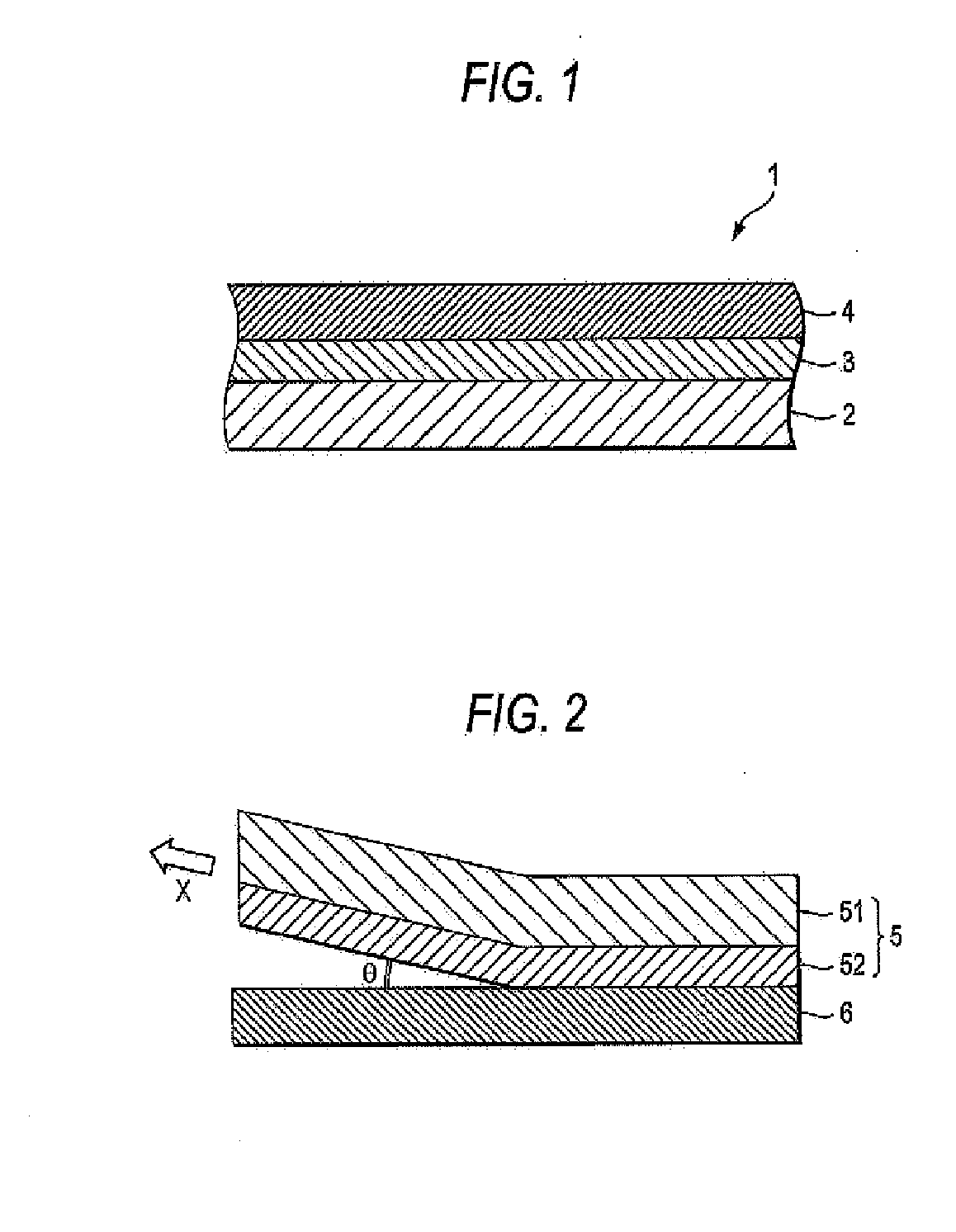

Weatherstrip tape and method for producing the same

InactiveUS7217455B2Reduce stickingReliably used in bondingFilm/foil adhesives without carriersSpecial surfacesMonomerPressure sensitive

The present invention relates to an adhesive tape and to a method for its manufacture, the tape comprising: (A) a heat-activatable adhesive resin layer, wherein the resin is a polymer of one or more monomers selected from the group consisting of olefins, and (B) a pressure-sensitive adhesive layer, comprising an acrylic-type pressure sensitive adhesive, wherein said pressure sensitive adhesive layer is permanently and directly bonded to a first major surface of said heat-activatable adhesive layer. The present invention also relates to an intermediate article comprising the heat-activatable adhesive resin layer (A) releasably bonded to a support layer, to a composite article comprising the adhesive tape and a rubber article bonded to the second major surface of the heat-activatable layer (A), and to a vehicle comprising the composite article.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure-sensitive adhesive tape or sheet for application to active surface in dicing and method of picking up chips of work

InactiveUS20070190318A1Easily pickedFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceDouble bond

The present invention relates to a pressure-sensitive adhesive tape or sheet for dicing which is to be applied to an active surface in the state of being not wholly covered with a native oxide film. The adhesive tape or sheet includes a substrate, and a radiation-curable pressure-sensitive adhesive layer disposed on at least one side of the substrate, in which the pressure-sensitive adhesive layer contains an acrylic polymer (A) having a weight-average molecular weight of 500,000 or higher and at least one radiation-polymerizable compound (B) selected from cyanurate compounds having one or more groups containing a carbon-carbon double bond and isocyanurate compounds having one or more groups containing a carbon-carbon double bond, and the ratio of the radiation-polymerizable compound (B) with respect to 100 parts by weight of the acrylic polymer (A) is 5 to 150 parts by weight.

Owner:NITTO DENKO CORP

Tape pressure roller with patterned surface for tape applicator

InactiveUS20070107828A1Reduce user-applied forceReduce forceCovering/liningsLamination ancillary operationsMechanical engineeringPressure sensitive

Owner:HUBER ENGINEERED WOODS

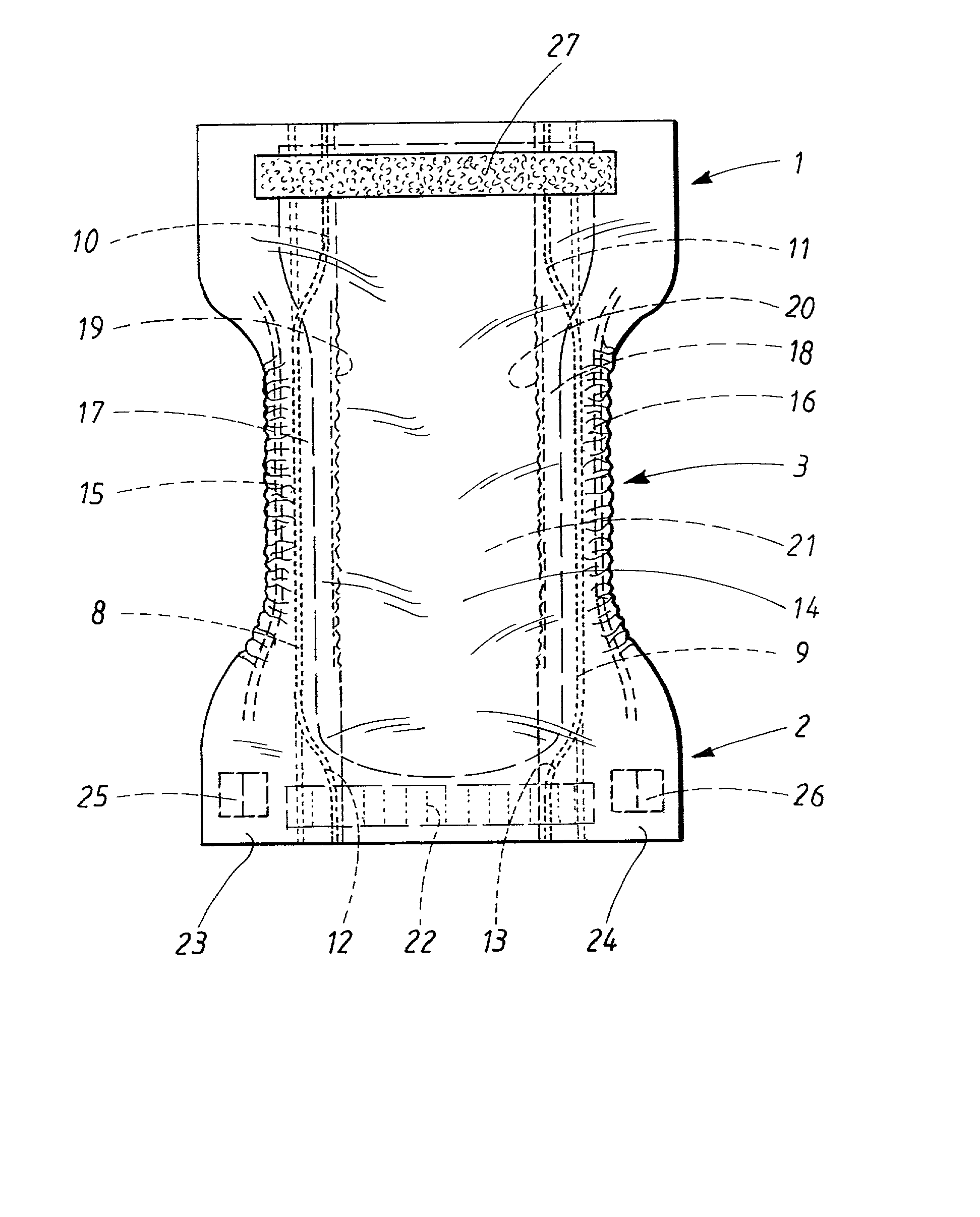

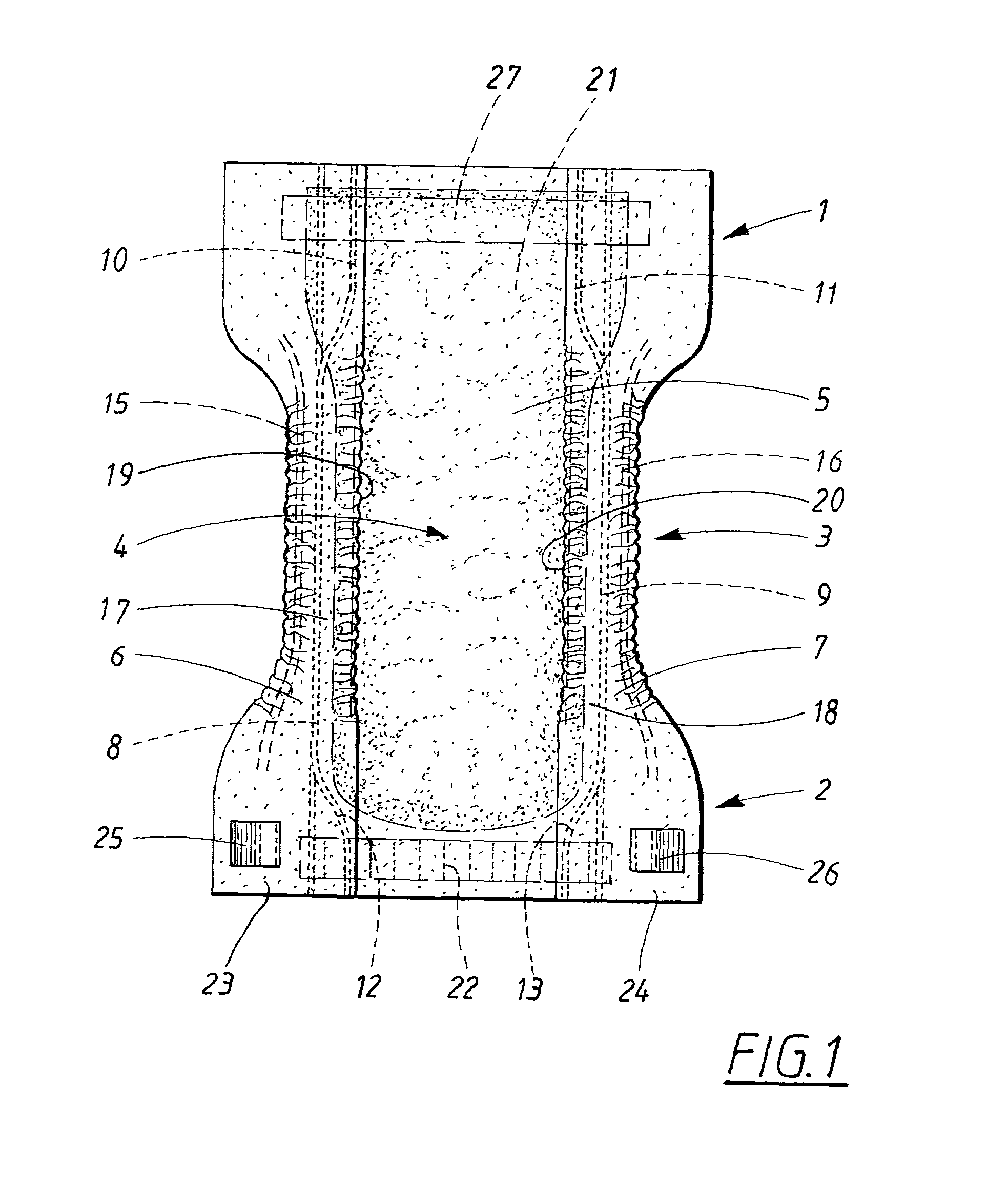

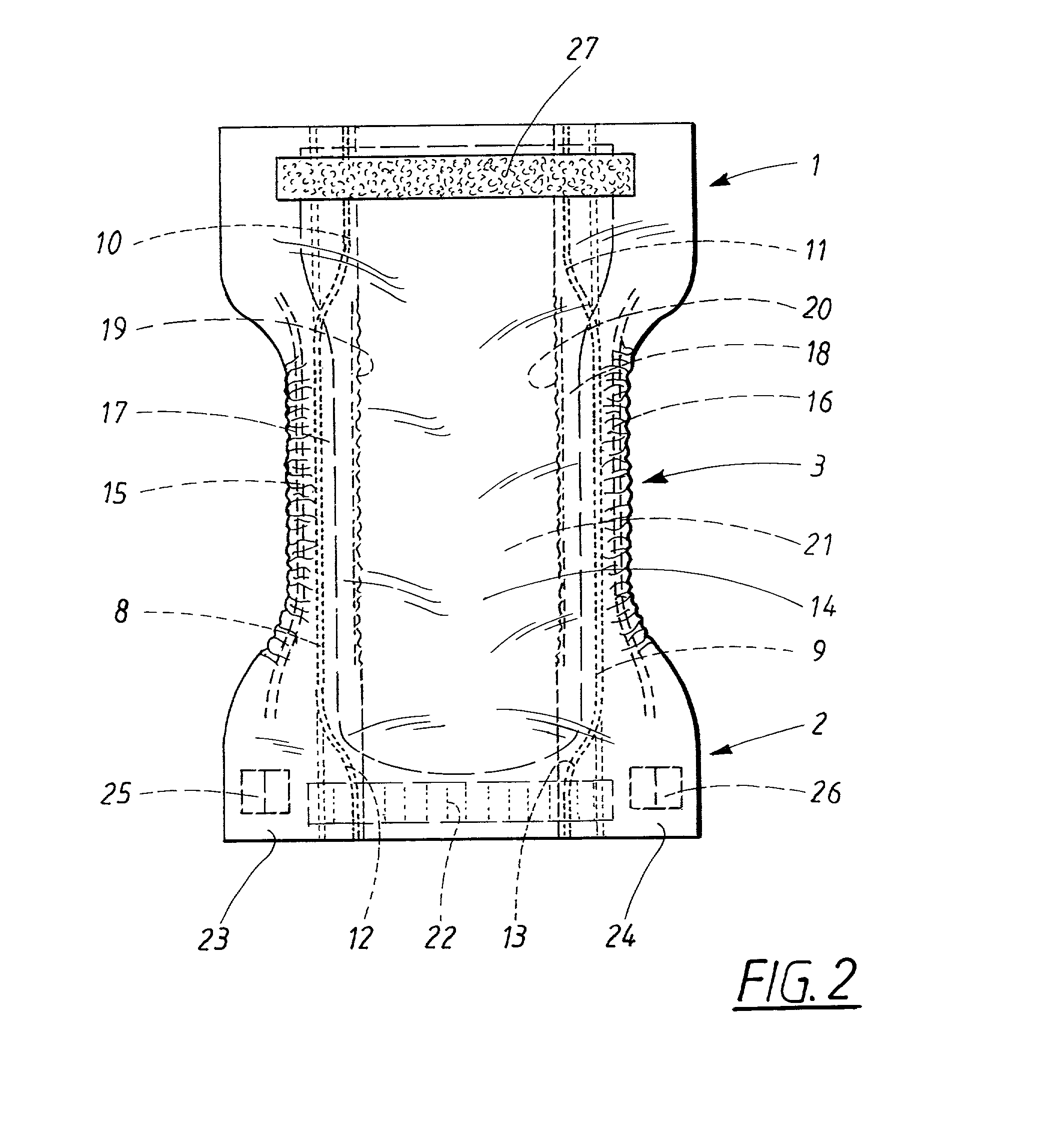

Mechanical tape fastening system for disposable absorbent articles

InactiveUS20020099352A1The method is simple and reliableReduce speedEnemata/irrigatorsBaby linensEngineeringCrotch

A disposable absorbent article, such as an baby diaper, comprising a first end portion (1) and a second end portion (2), and an intermediate crotch portion (3), said portions comprising an inner layer (4), which is turned towards the user during use. The article is formed in the area of the second end portion (2) with mechanical tape fasteners (25, 26) intended, upon application of the article, to be detachably interconnected with one or several fastening parts (27) disposed on the outer layer of the first end portion (1). The article is characterized in that said tape fasteners (25, 26) are arranged on the inner layer (4) of the article and by means of a producer's bonding face (39) they are joined to a first end part (28) of the tape fasteners (25, 26), that a user's bonding face (31) is arranged on the opposite end part (30) of the tape fasteners, the user's end part, that prior to use of the article, the tape fasteners (25, 26) are arranged in a folded storage condition, each one of said tape fasteners being formed with an odd number of folds (38) and the bonding faces of both said producer's bonding face (39) and said user's bonding face (31) being turned towards the inner layer (4) of the article, and that the user's end parts (31) of two opposite tape fasteners (25, 26) face one another in said storage condition and that in the storage condition of said article individual fold parts (28 and 29, respectively) are joined to at least one of the other fold parts (28 and 29, respectively) by means of a bond (32), preferably in the form of thermal or ultrasonic welds, said bond being breakable in order to establish the position of use of said tape fasteners.

Owner:ESSITY HYGIENE & HEALTH AB

Removable hot-melt pressure-sensitive adhesive tape for temporary fixation

InactiveCN102702990AAchieve quantitative coatingImprove affinity and applicabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesSilicone tapePlasticizer

The invention belongs to the field of adhesive tapes and particularly relates to a removable hot-melt pressure-sensitive adhesive tape for temporary fixation. The removable hot-melt pressure-sensitive adhesive tape for the temporary fixation comprises a base material and a hot-melt pressure-sensitive adhesive which is hot-molten and coated on the base material, and is characterized in that the hot-melt pressure-sensitive adhesive consists of the following components in percentage by mass: 40 to 60 percent of thermoplastic rubber, 20 to 40 percent of tackifying resin, 2 to 16 percent of plasticizers and 0.1 to 4 percent of antioxidant and other aids. The tackifying resin is added when the hot-melt pressure-sensitive adhesive tape is prepared, so that the adhesion is improved, and the viscosity of the system is reduced to ensure that the coating is convenient; a plurality of kinds of plasticizers are added, so that soft segment phases (B, I, EB and EP) and a hard segment phase (PS) in elastomer rubber are softened and plasticized, and the affine application property of an adhesive tape product is improved; by using the antioxidant, an adhesive is prevented from pyrolysing and deteriorating in the heating process, so that the adhesion of an adhesive product is stable, the adhesive product can be peeled at high and low rates and can be repeatedly pasted, and the trace of adhesive residue is avoided; and a heating and molten coating process is adopted, so that the release of a volatile organic solvent and the high-temperature energy consumption of an end-of-life process are avoided, and the cost of materials is reduced.

Owner:苏州联科纳米净化科技有限公司

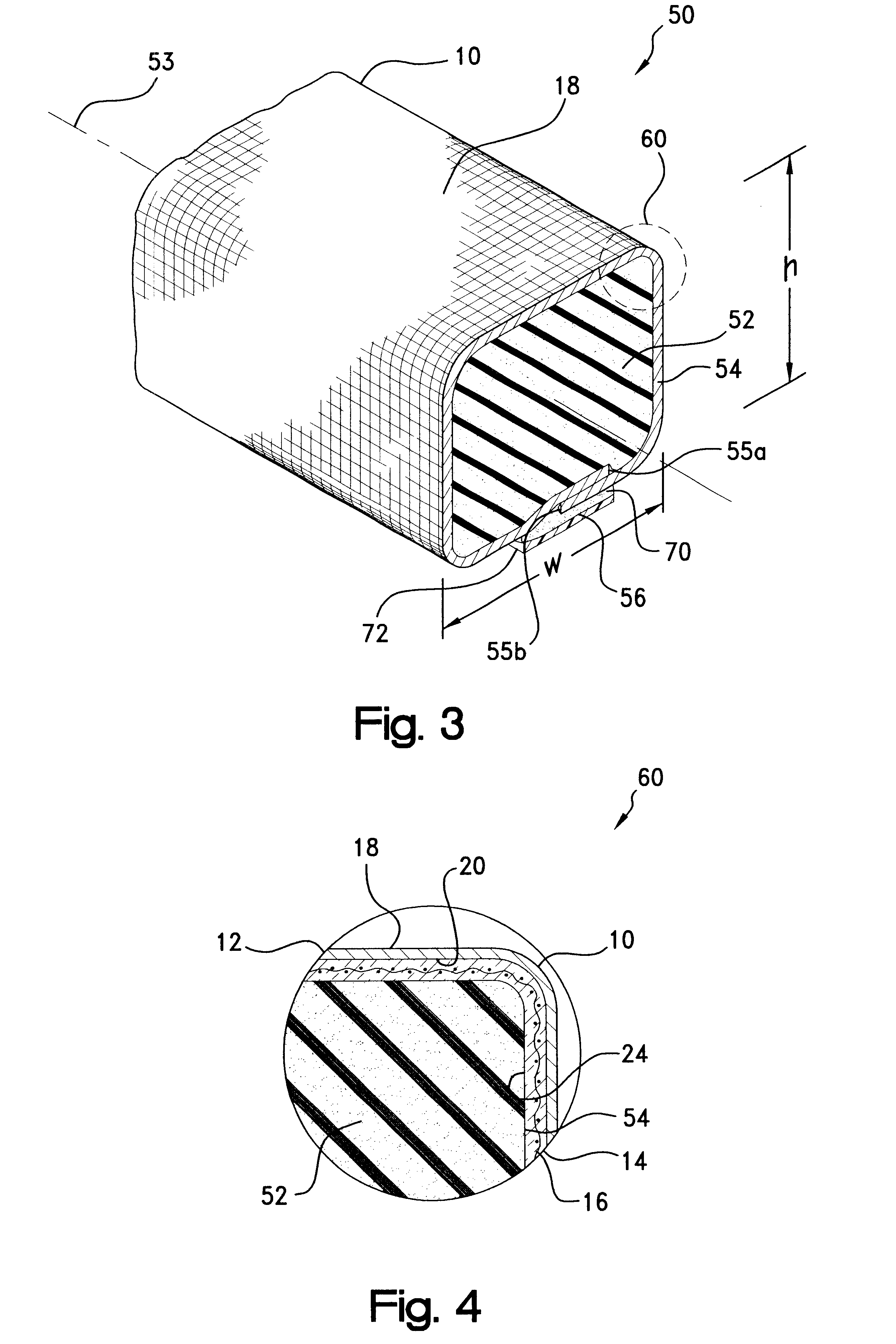

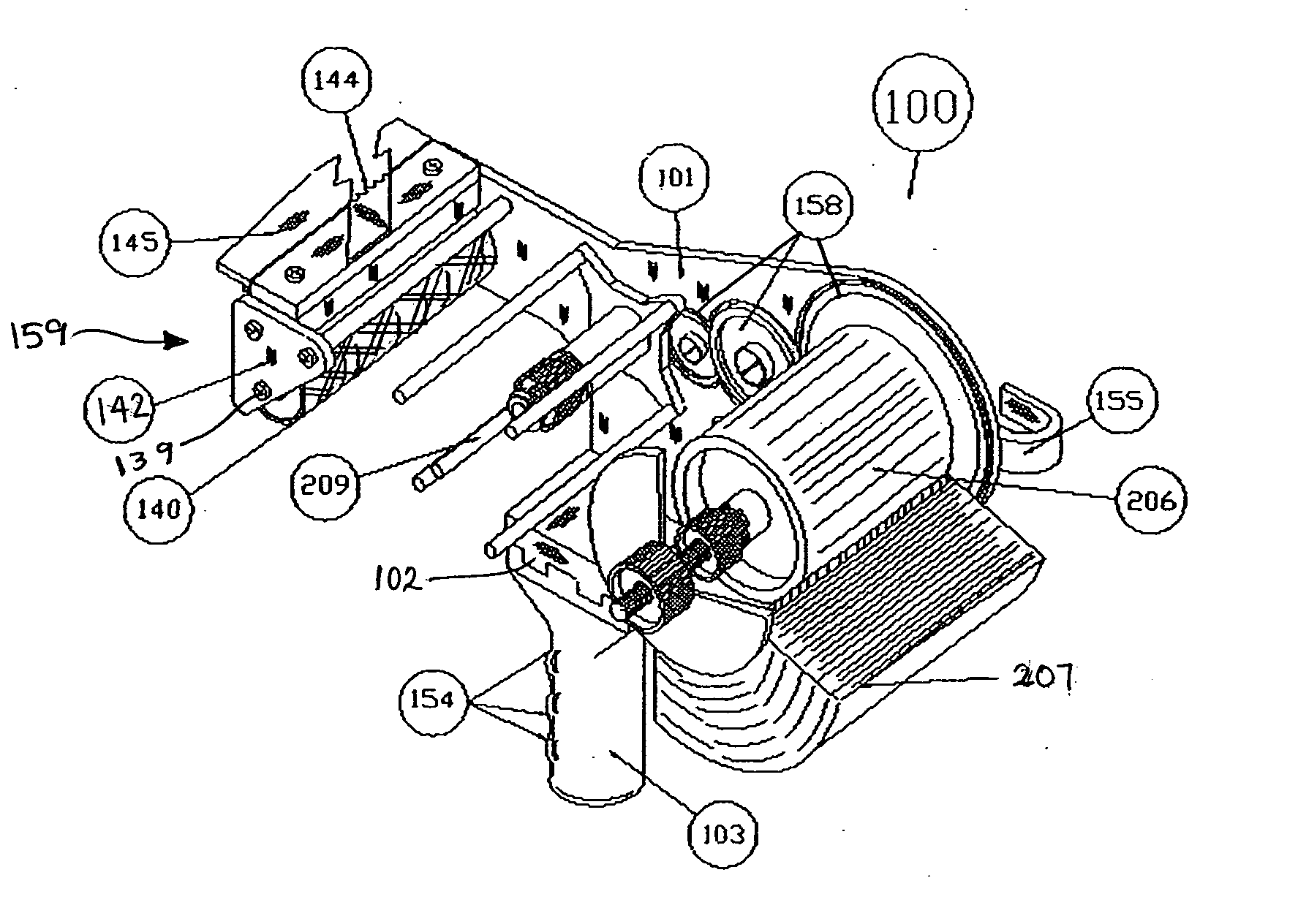

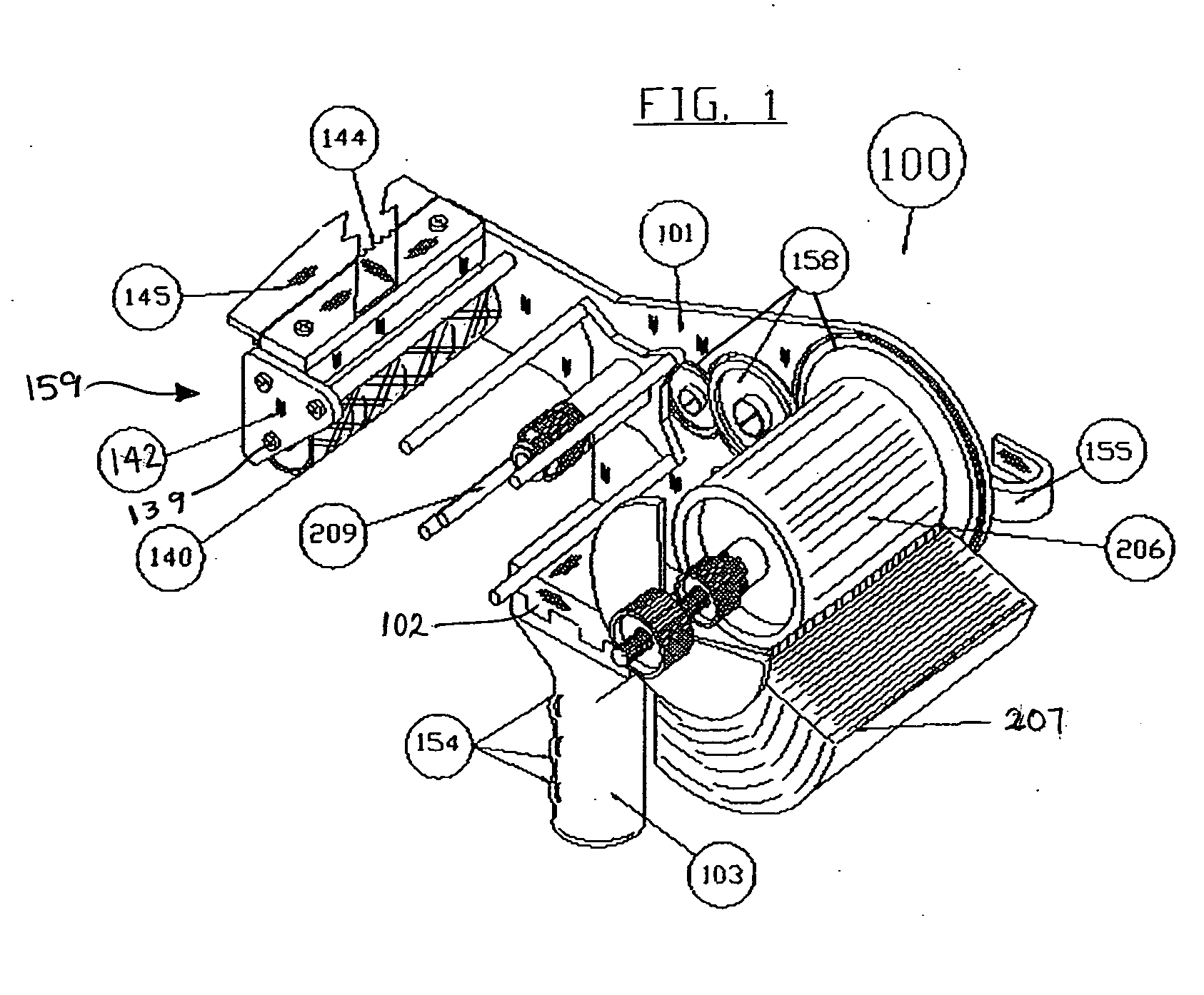

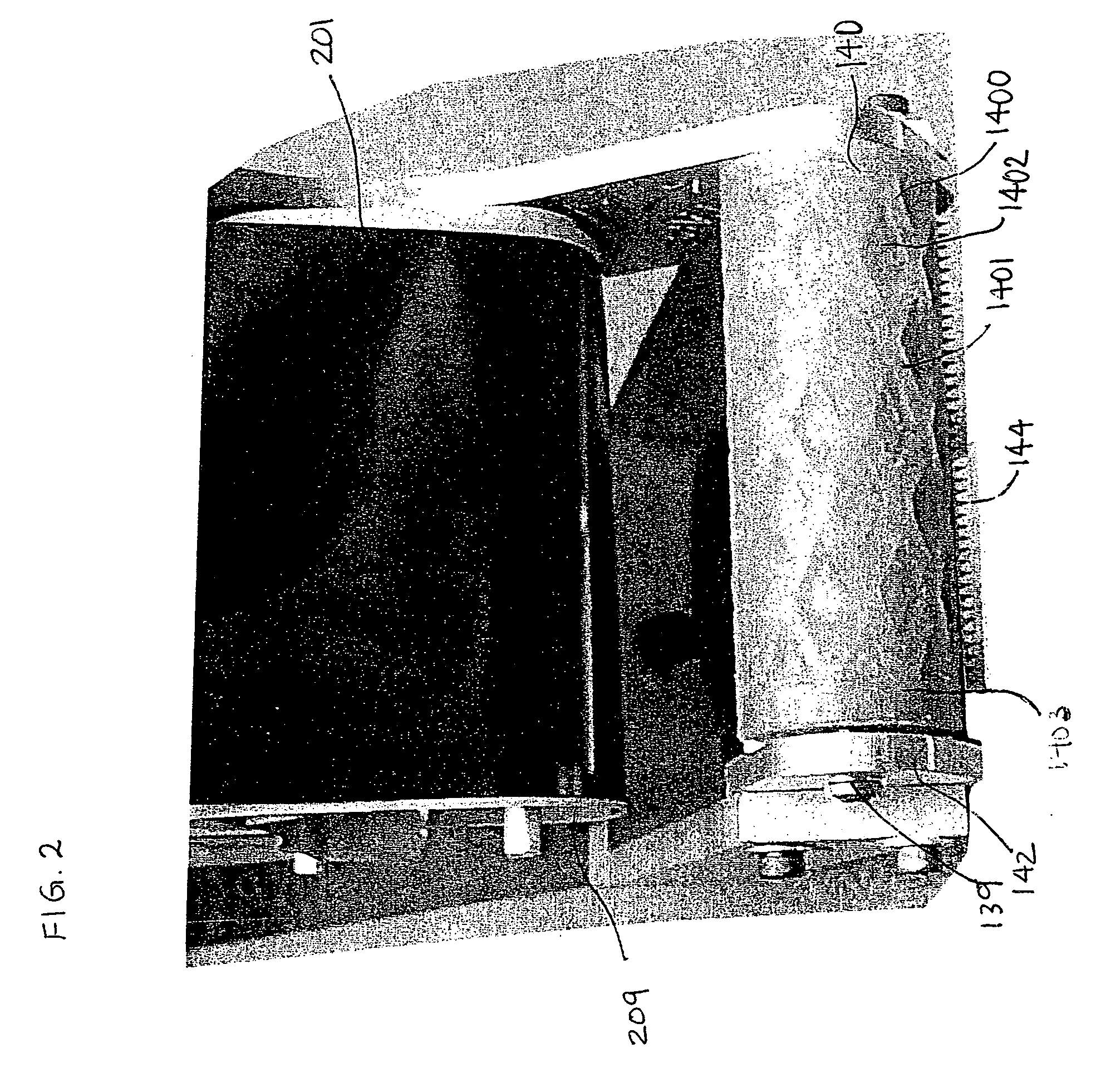

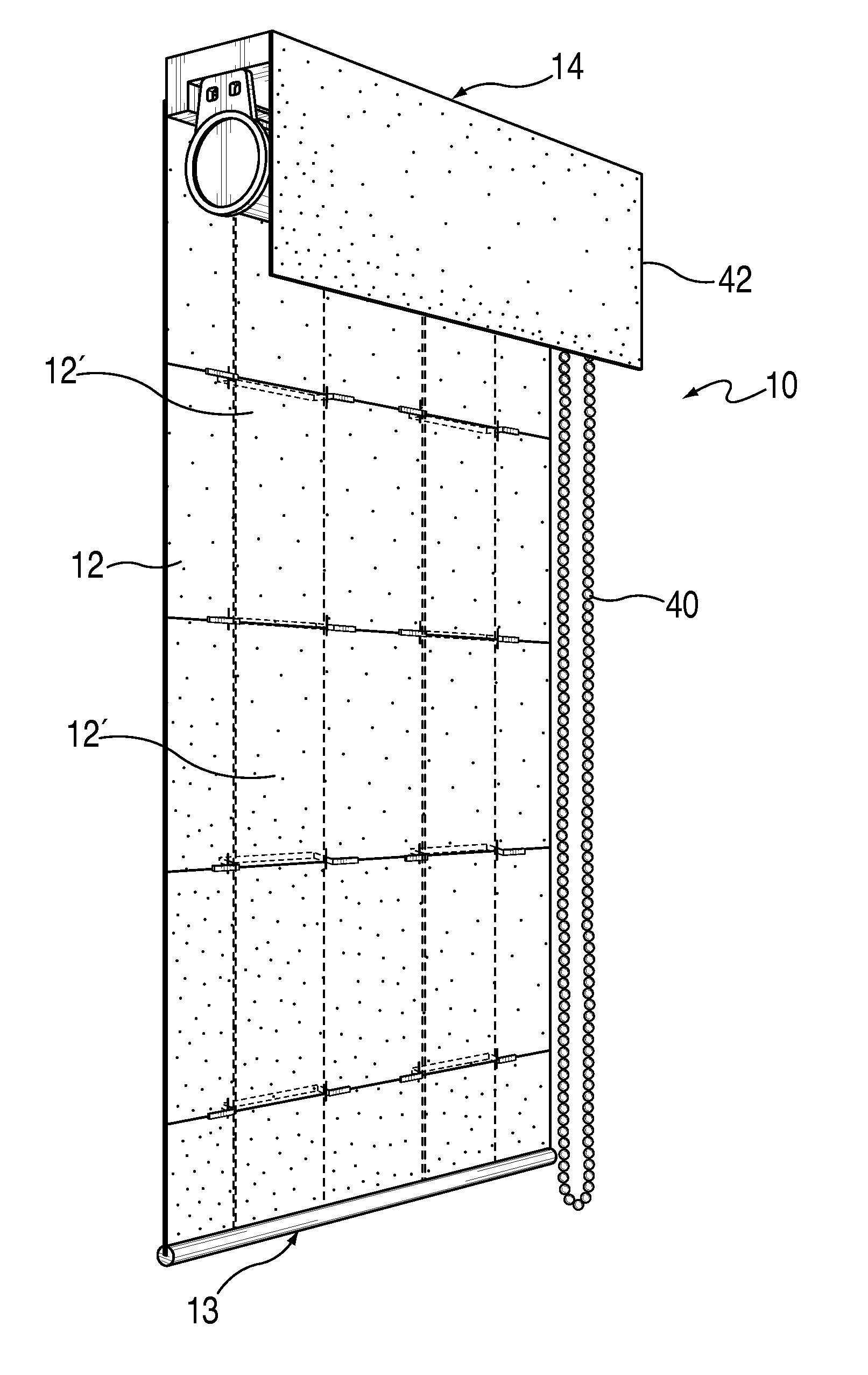

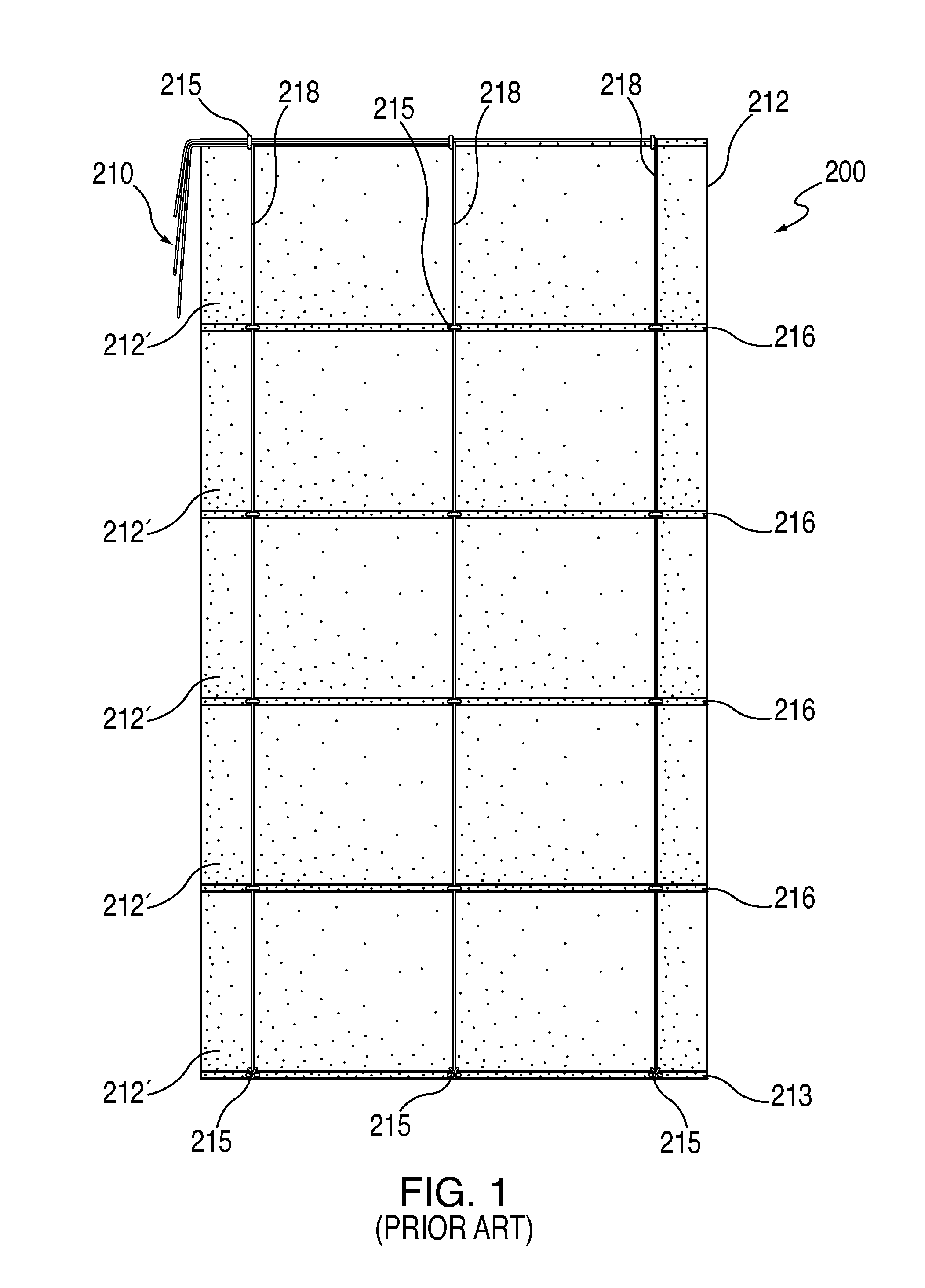

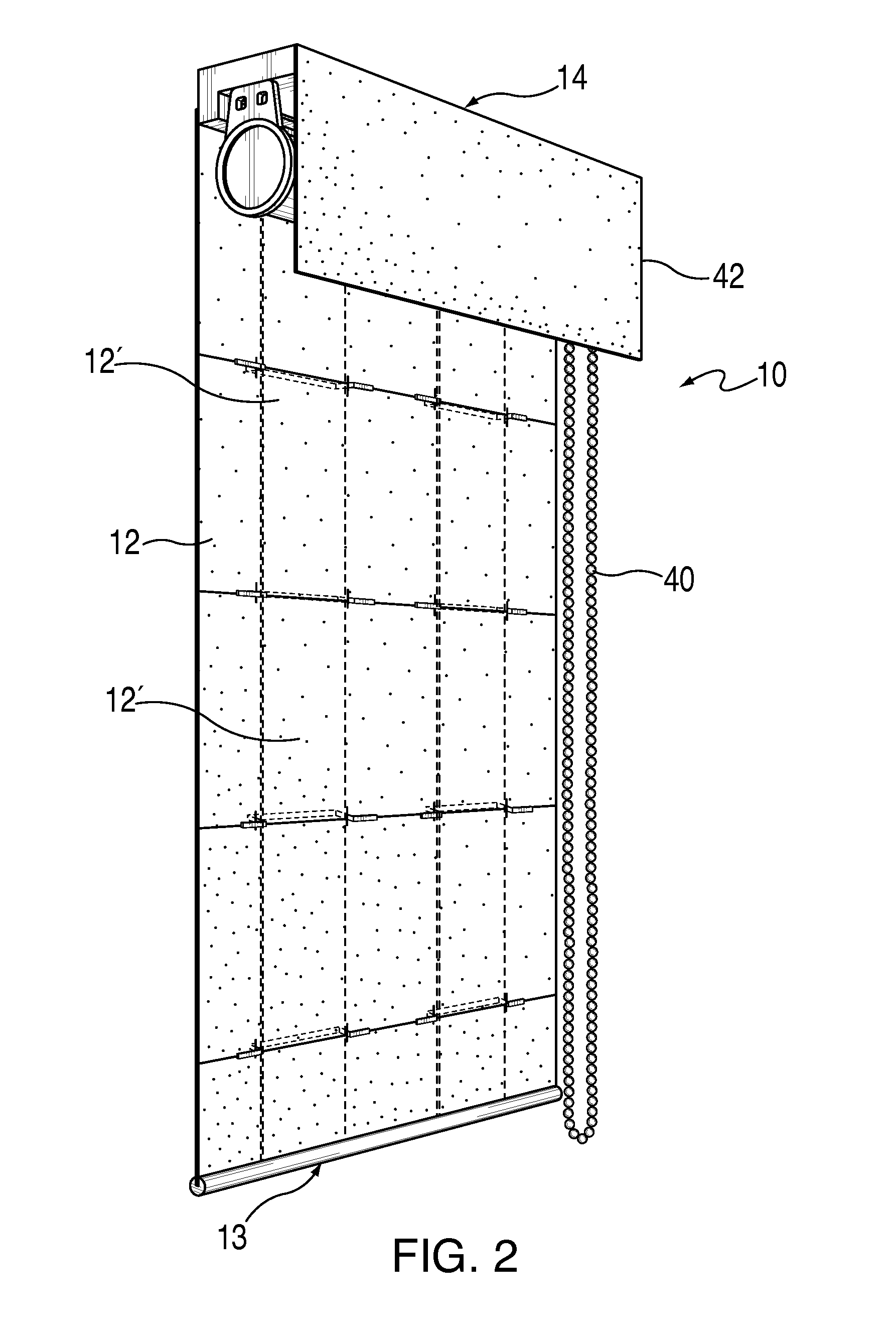

Roman shade lift system

InactiveUS20110192550A1Facilitate rollingFacilitated releaseExtensible doors/windowsShutters/ movable grillesClassical mechanicsStructural engineering

Owner:ROLLERASE INC

Clean release tape for EMI shielding

InactiveUS20030091777A1Adhesive residueScreening gaskets/sealsLayered productsSilicone tapeMechanical engineering

An EMI shielding tape adherable to a surface of a structure. The tape includes a backing layer, and an adhesive layer carried on at least one side of the backing layer. The adhesive layer has an inner face bonded the backing layer, and an opposite outer face which is bondable under pressure to the structure surface to adhere the tape thereto. The adhesive layer is formulated as an admixture of a pressure sensitive adhesive (PSA) composition and one or more electrically-conductive particulate fillers. When adhered to the structure surface, the tape is substantially cleanly releasable therefrom.

Owner:PARKER HANNIFIN CORP

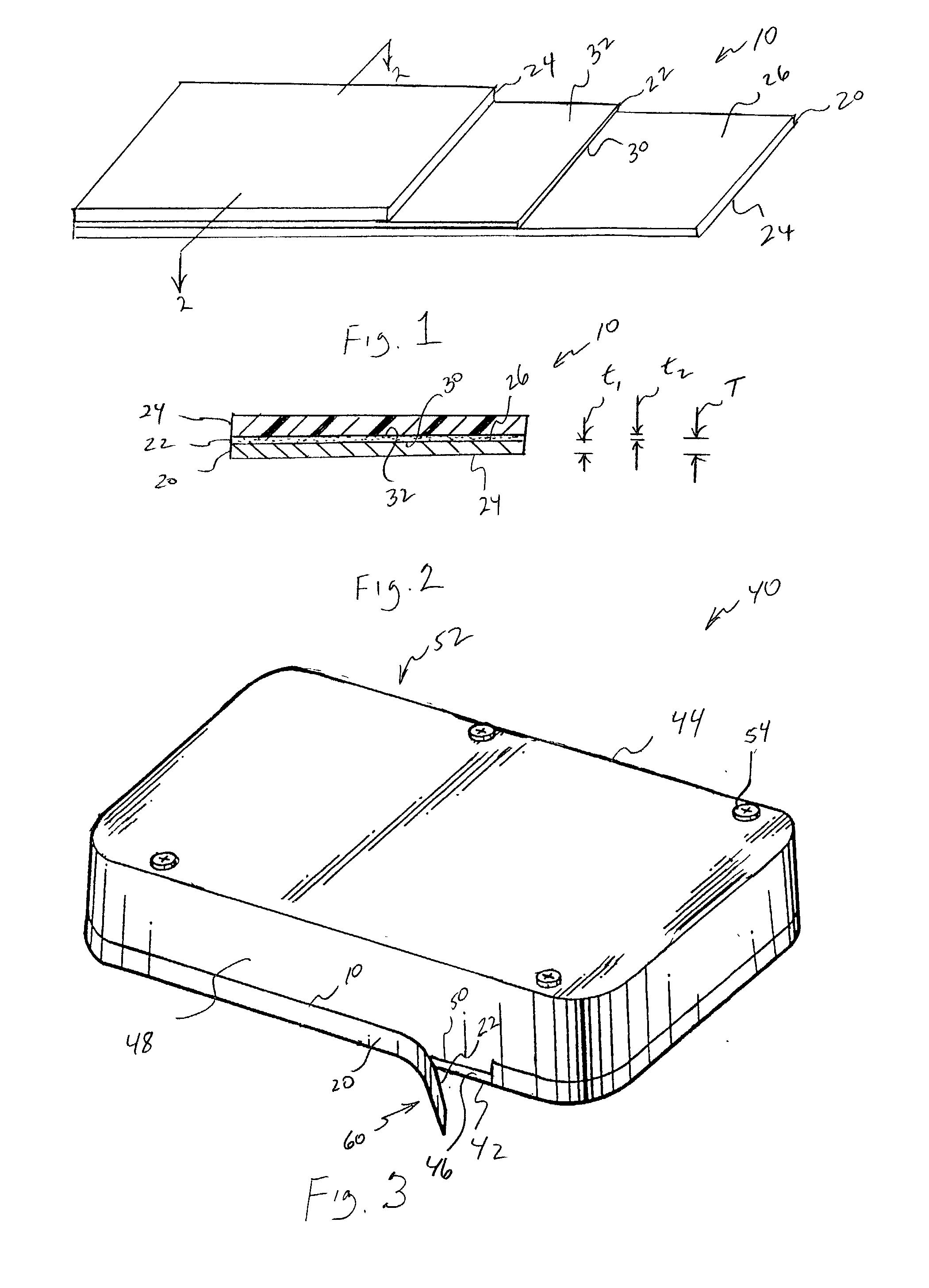

Adhesive tape for bonding low-surface-energy material and preparation method thereof

InactiveCN102504717ASolve the problem of poor aging resistanceLow priceFilm/foil adhesivesEster polymer adhesivesPolymer scienceBenzoyl peroxide

The invention provides an adhesive tape for bonding a low-surface-energy material. The adhesive tape consists of the following components in percentage by mass: (1) 30-50 percent of an acrylic ester monomer, (2) 50-70 percent of ethyl acetate or toluene serving as a solvent, (3) 0.2-1.5 percent of a crosslinking agent and (4) 0.1-0.6 percent of azobisisobutyronitrile or benzoyl peroxide serving as an initiator, wherein the acrylic ester monomer consists of 60-90 percent of soft monomer, 5-35 percent of hard monomer, 1-5 percent of crosslinking monomer and 2-10 percent of fluorine-containing acrylic ester. A preparation method of the adhesive tape comprises the following steps of: preparing an acrylic ester polymer solution, adding the acrylic ester monomer, the solvent and the initiator into a three-neck flask provided with a reflux unit, introducing nitrogen gas, stirring for half an hour, exhausting oxygen, putting into a water bath boiler, and reacting at the temperature of 60-80 DEG C under the protection of nitrogen gas for 6 hours; and coating the adhesive tape: mixing an obtained acrylic ester polymer solution with a crosslinking agent, standing, defoaming, coating onto a releasing film with a bar, drying at the temperature of 110 DEG C for three minutes, compounding with a PET (Polyethylene Terephthalate) film which is 30 mum in thickness and is subjected to corona surface treatment, and standing at the normal temperature for seven days.

Owner:TONSAN ADHESIVES INC

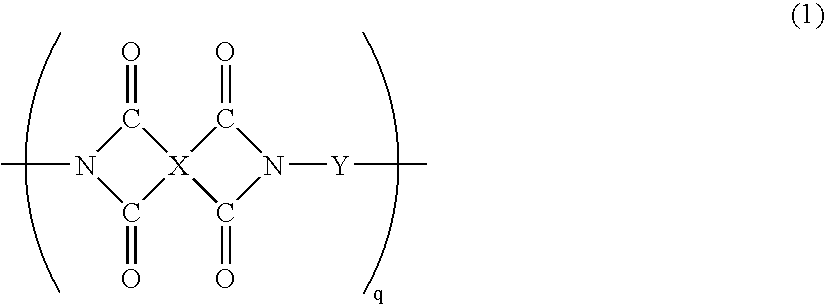

Silicone-Based Pressure-Sensitive Adhesive Composition and Adhesive Tape

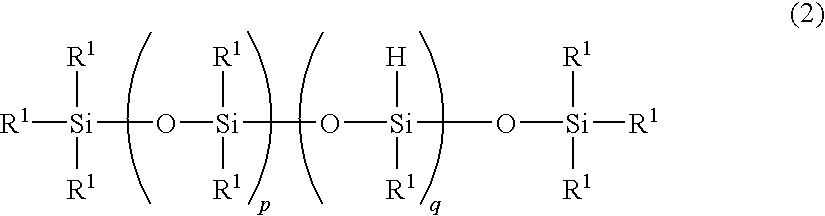

A silicone-based pressure-sensitive adhesive composition comprising (A) a condensation-reaction product obtained by subjecting a diorganopolysiloxane having silanol groups on both molecular terminals and 2 or more silicon-bonded alkenyl groups located in side molecular chains in one molecule (a) and organopolysiloxane resin having one or more hydrolyzable groups in one molecule (b) to a condensation reaction in the presence of catalyst (c), (B) an organohydrogenpolysiloxane, (C) a diorganopolysiloxane having silicon-bonded alkenyl groups on both molecular terminals, (D) an organopolysiloxane resin and (E) a platinum catalyst.

Owner:DOW CORNING TORAY CO LTD

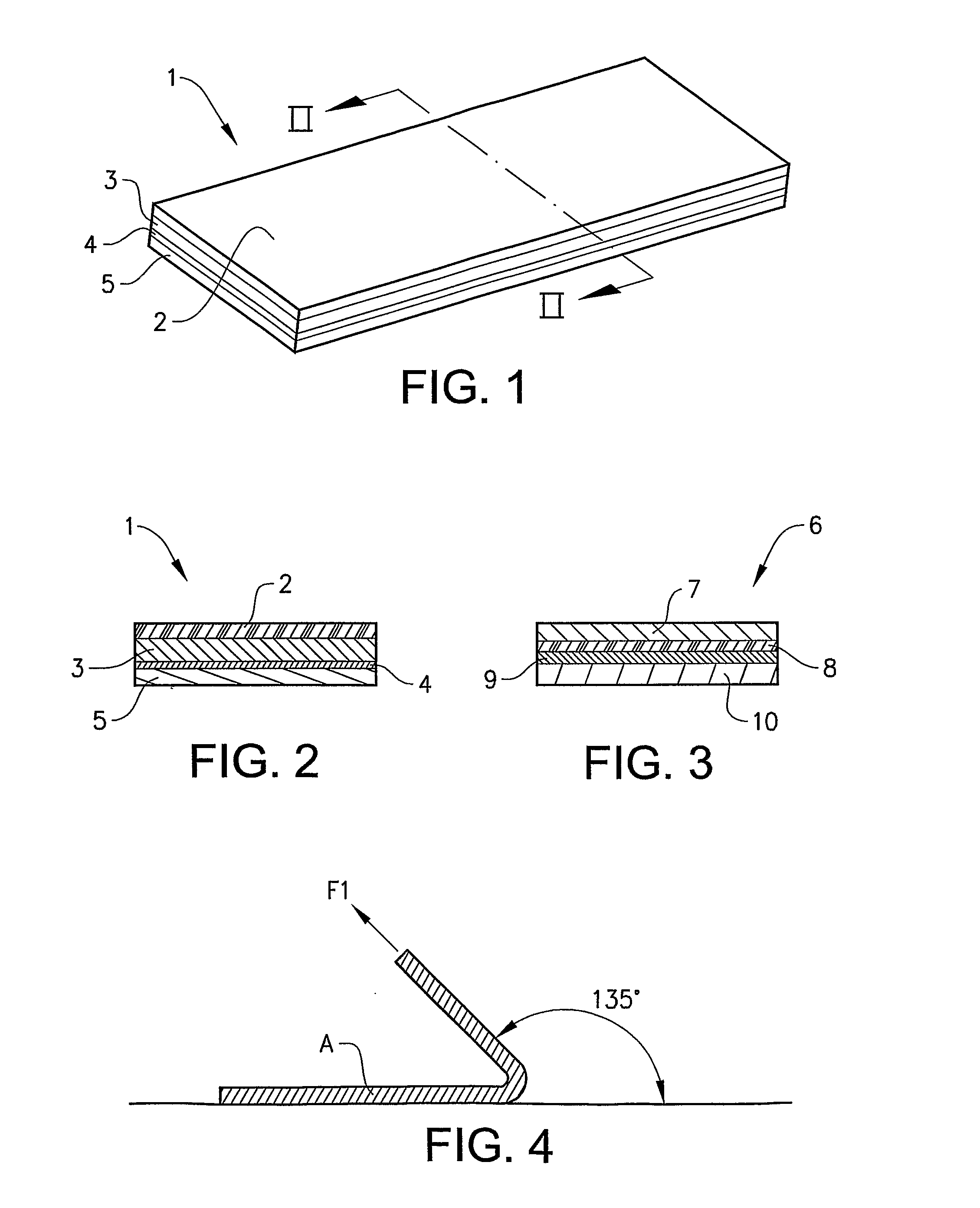

Surgical tape

The present invention relates to a surgical tape (1) including a carrier (2, 3), on one side coated with an adhesive (4) and including a layer of non-woven (3). According to the invention a layer of plastic film (2) is laminated to the layer of nonwoven and the surgical tape (1) is tearable in a cross direction relative its longitudinal direction and liquid impermeable.

Owner:MOLNLYCKE HEALTH CARE AB

Wafer back side coating as dicing tape adhesive

A semiconductor assembly comprises a semiconductor wafer, an adhesive coating disposed on the back side of the wafer, and a bare dicing tape, preferably UV radiation transparent. The assembly is prepared by the method comprising (a) providing a semiconductor wafer, (b) disposing a wafer back side coating on the semiconductor wafer, (c) partially curing the wafer back side coating to the extent that it adheres to the back side of the wafer and remains tacky, and (d) contacting the bare dicing tape to the partially cured and tacky wafer back side coating, optionally with heat and pressure.

Owner:HENKEL IP & HOLDING GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com