Double-side thermally conductive adhesive tape for plastic-packaged electronic components

a technology of thermally conductive adhesive and electronic components, which is applied in the direction of transportation and packaging, laminating printed circuit boards, and improving the adhesion of metals to insulating substrates, etc., can solve the problems of increasing the complexity of circuit designs of modem electronic devices such as televisions, radios, and communications equipment, and the size of devices has continued to shrink and increase the complexity of designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

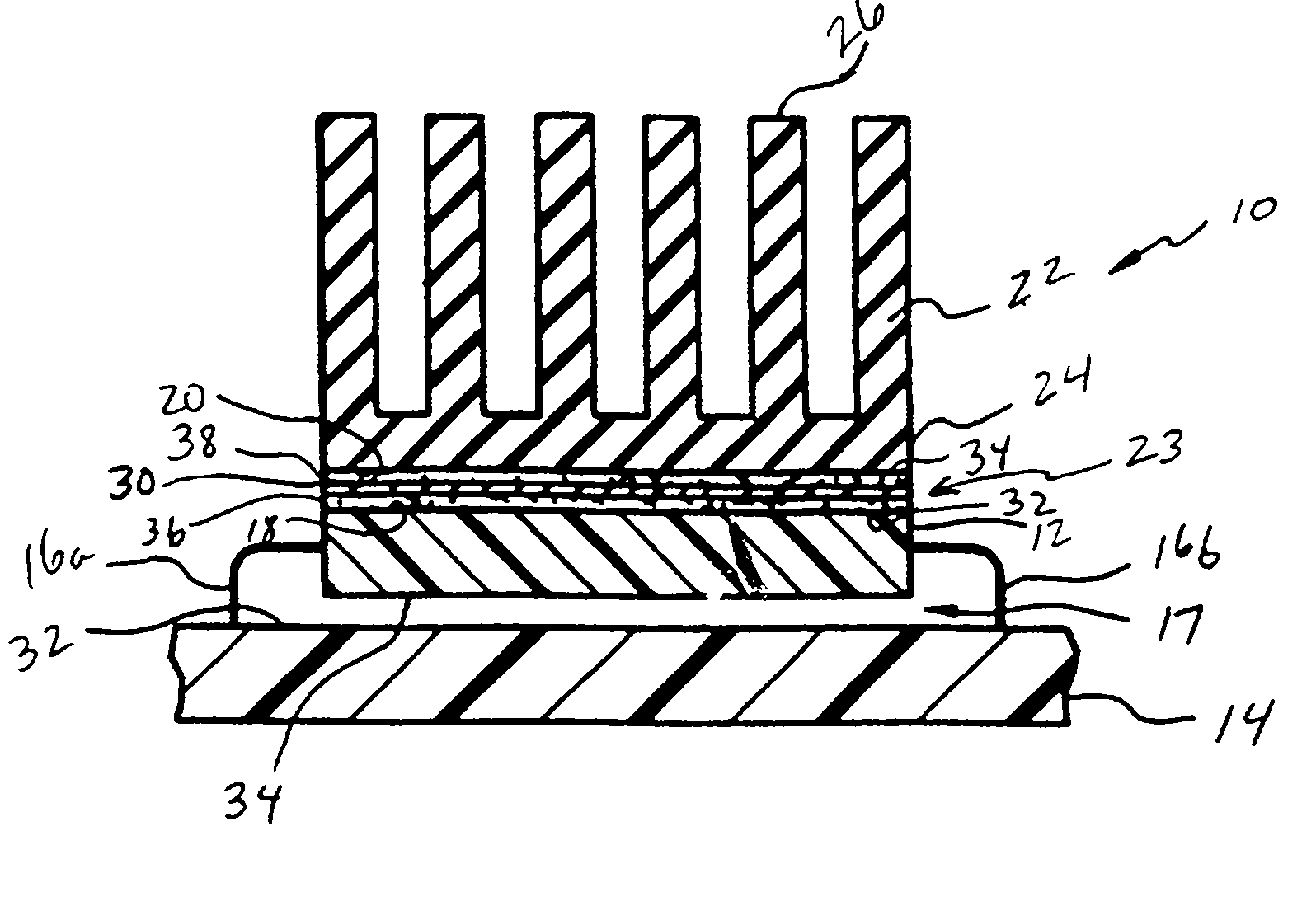

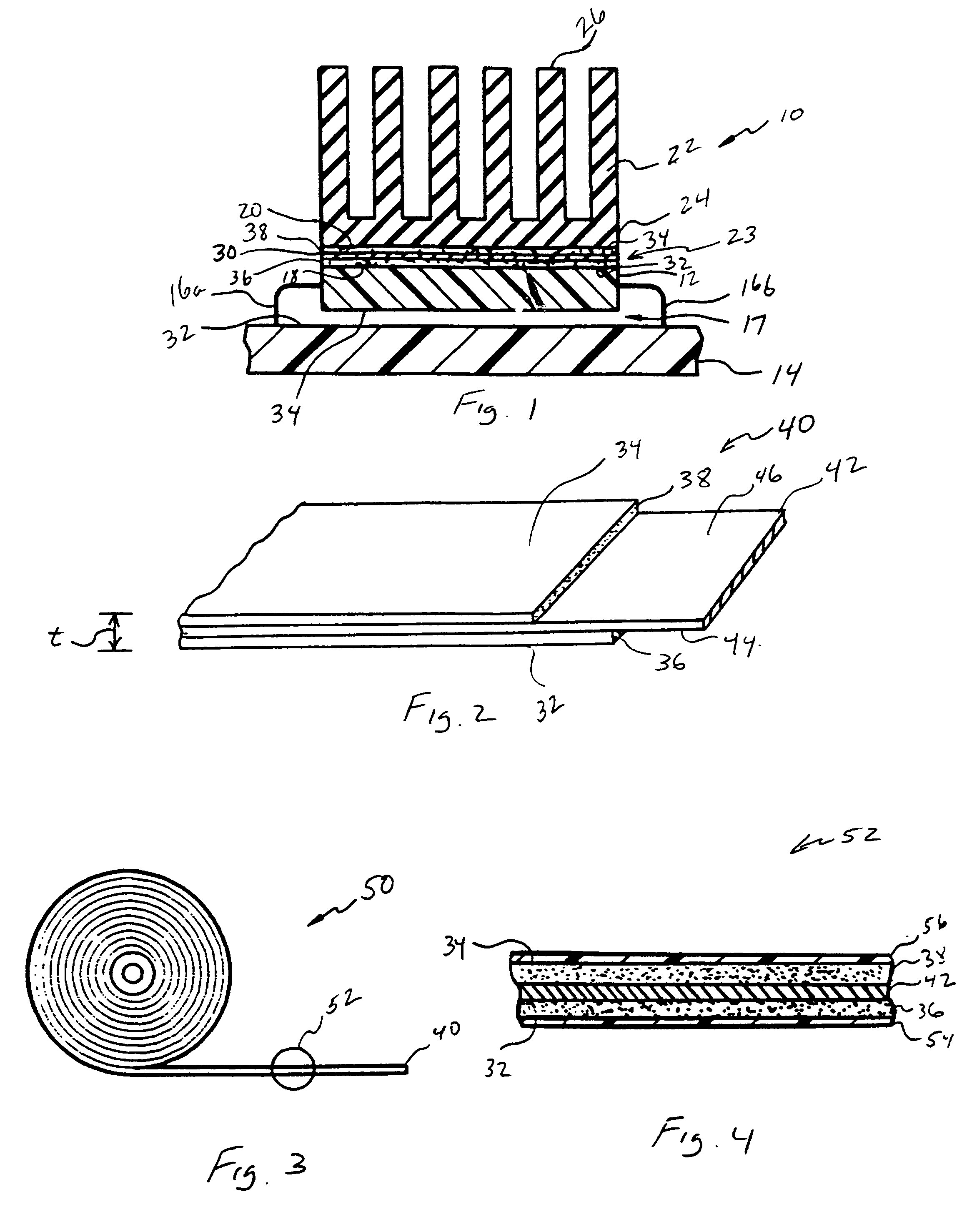

[0064] A thermally-conductive interface laminate was prepared according to the presented invention for characterization by cold nipping a 2-3 mil (0.05-0.075 mm) layer of an acrylic PSA component (H&N Chemicals Polytack.TM. 100 LV) blended with about 50% by weight of tabular aluminum oxide (Alcoa, Pittsburgh, Pa.) onto a first side of a 0.002 in (0.050 mm) thick aluminum foil carrier. Onto the second side of the carrier was cold nipped a 2-3 mil (0.05-0.075 mm) layer of a silicone PSA component (Adhesives Research 8026) to form a double-sided PSA tape. Such tape was observed to exhibit the following physical properties:

1TABLE 1 Thermal and Mechanical Properties of a Representative Interface Tape Lamination Property Test Method Units Result Thermal Conductivity ASTM D5470 W / m-.degree. K. 0.37 Thermal Impedance ASTM D5470 .degree. C.-in.sup.2 / watt 0.54 90.degree. Peel ASTM D1000 PPI 3.0 Lap Shear Adhesion ASTM D1002 psi (MPa) 170 (1.172) Die Shear Adhesion Chomerics No. 54.sup.1 psi A...

example 2

[0066] Comparative double-sided, thermally-conductive interface tape systems were prepared to confirm the precepts of the present invention. In each of the systems, a 2.5-3 mil (0.056-0.075 mm) thick layer of an acrylic-based PSA component (H&N Chemicals Polytack.TM. 100 LV) blended with about 50% by weight of alumina was nipped onto a first side of a 0.002 in (0.050 mm) thick aluminum foil carrier. In a first system identified as "Sample A" in Table 2 which follows, a 1 mil (0.025 mm) layer of an unfilled, first silicone-based PSA component (Adhesives Research 8026) was nipped onto the second side of one of the carriers. Similarly, in a second system identified as "Sample B" in Table 2, a 1 mil (0.025 mm) layer of an unfilled, second silicone-based PSA component (Flexcon 1078) was nipped onto the second side of the other one of the carriers. The physical properties, namely 90.degree. peel (ASTM D1000), lap shear (ASTM D1002) under different bond pressures, creep adhesion (PSTC #7),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com