Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1219 results about "Azobisisobutyronitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Azobisisobutyronitrile (abbreviated AIBN) is an organic compound with the formula [(CH₃)₂C(CN)]₂N₂. This white powder is soluble in alcohols and common organic solvents but is insoluble in water. It is often used as a foamer in plastics and rubber and as a radical initiator.

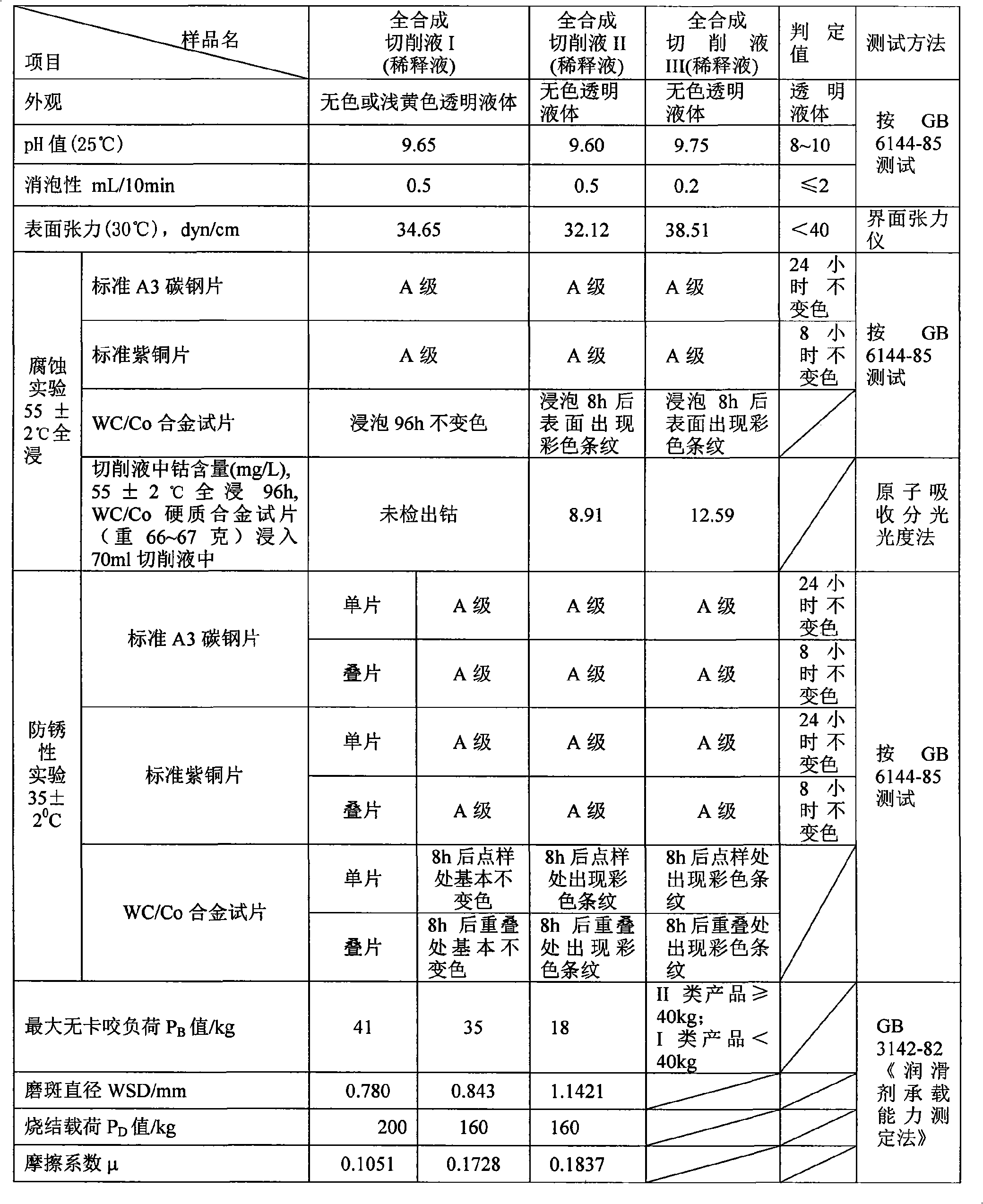

Fully synthetic cutting fluid

InactiveCN101560430ASolve the problem of protocobaltAvoid leachingLubricant compositionActive agentPolyethylene glycol

The invention discloses a fully synthetic cutting fluid which comprises anion active agent, non-ionic surface active agent, polyethylene glycol, borax, bactericide, foam suppressor, pH regulator, water and additive; wherein, the additive is prepared by the following method: the surface active agents are dissolved by acetone, the mixed solution is added with toluene and heated up to 50-60 DEG C, and the reaction system is dripped with acrylate monomer as well as azodiisobutyronitrile (AIBN) or ammonium persulfate (APS) evocating agent; after that, the temperature is preserved for 3-5h, the reaction stops, and organic solvent is removed, so that the additive is obtained. Compared with the existing fully synthetic cutting fluid, the fully synthetic cutting fluid of the invention can completely inhibit leaching of cobalt element in hard alloy containing cobalt when metal is processed, well solves the problem of separating the cobalt in the existing fully synthetic cutting fluid, and is environment-friendly and efficient.

Owner:CENT SOUTH UNIV

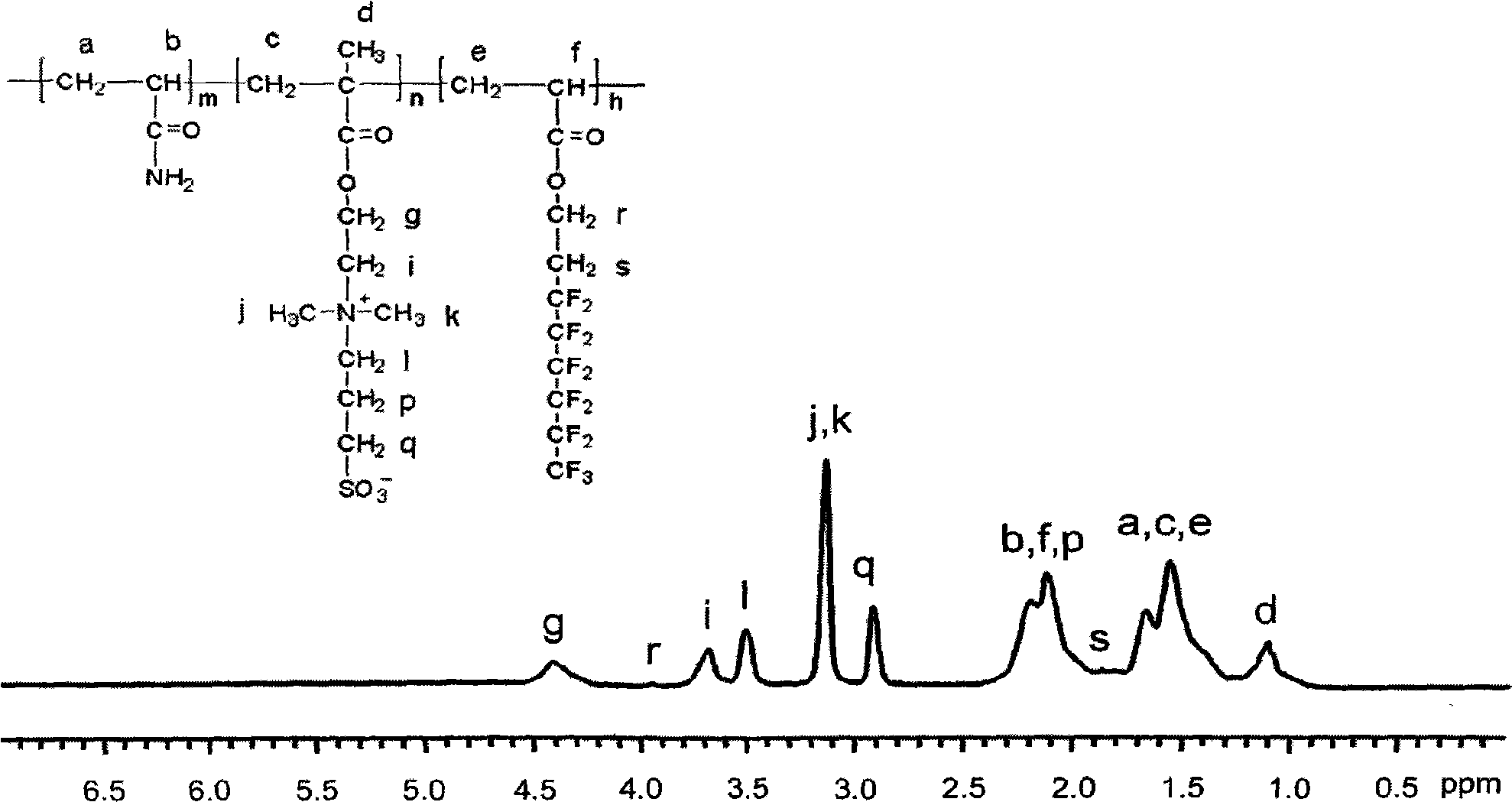

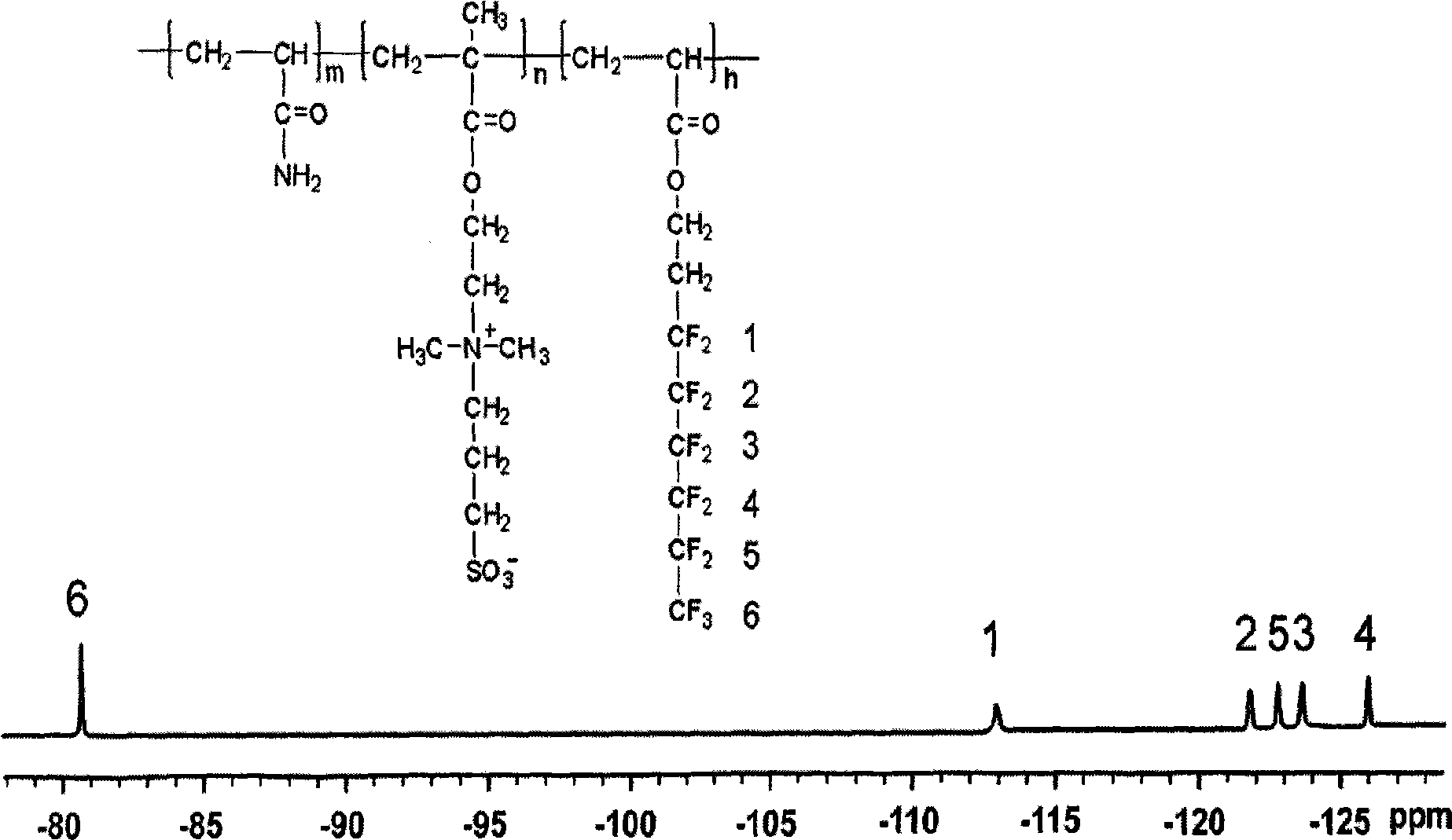

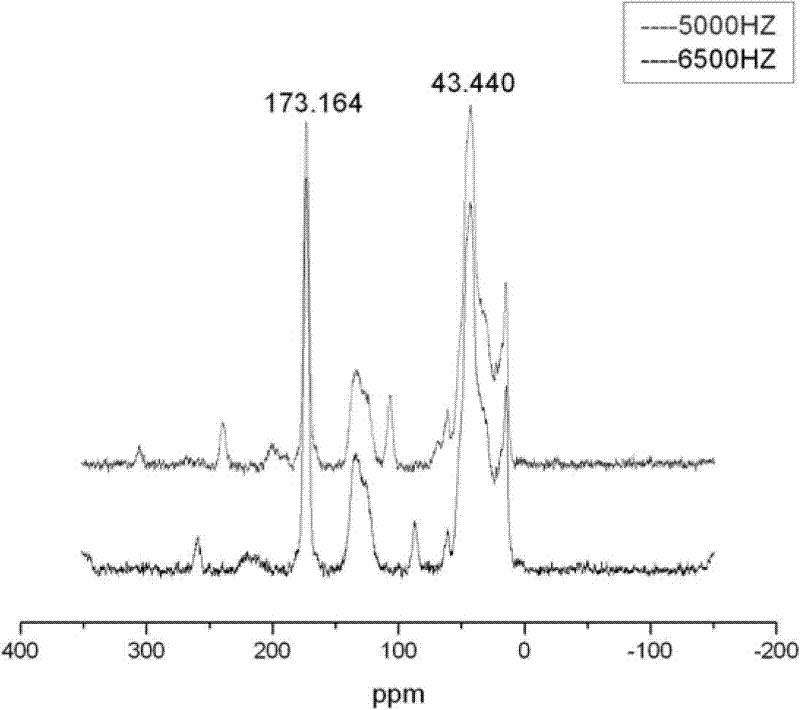

Method for preparing fluorine-containing modified amphoteric water-soluble polymer

The invention relates to a method for preparing a fluorine-containing modified amphoteric water-soluble polymer, in particular to a method for preparing the fluorine-containing modified amphoteric water-soluble polymer by a cosolvent method and belongs to the technical field of water-soluble macromolecular synthesis. Methacryloyl ethyl-N and N-dimethyl propanesulfonic acid (DMAPS) as amphoteric monomers and perfluoro hexyl ethyl acrylate (PFHEA) and acrylamide (AM) as hydrophobic monomers are copolymerized in a single solvent; azobisisobutyronitrile (AIBN) is used as a catalyst; and the fluorine-containing modified amphoteric water-soluble polymer is obtained. The polymer has good water solubility and remarkable interface activity, thickening, shearing resistance, temperature resistance and salt resistance. Through a mixed solution of anhydrous acetone and anhydrous ether, the polymer is precipitated, dried and pulverized to obtain a powdery product; and the powdery product has wide application prospect in the development of an oil field, dope, printing, household chemical, medicament and other fields.

Owner:SHANDONG UNIV

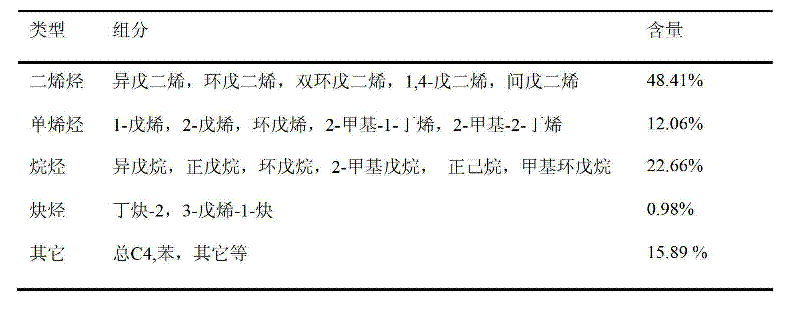

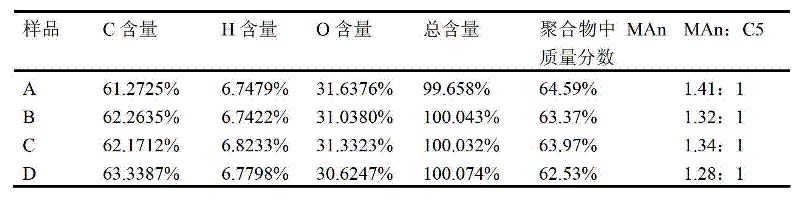

Copolymer containing functional group and prepared by C5 mixture and maleic anhydride, and preparation of copolymer

The invention provides a copolymer containing a functional group and prepared by a C5 mixture and maleic anhydride and a preparation of the copolymer, belonging to the field of applications of C5 resource. The preparation method comprises the following steps of: adding monomer maleic anhydride and initiator azobisisobutyronitrile (AIBN) into ester medium under the protection of nitrogen, dissolving completely, adding C5 mixture into the system, and dissolving, wherein the mol ratio of the maleic anhydride and the C5 is 1:1, reacting for 0.05-7 hours at 50-90 DEG C so as to obtain a milky and stable solid-liquid disperse system of the copolymer of C5 and maleic anhydride, centrifugally separating and drying at vacuum condition so as to obtain the white solid powder of copolymer of C5 and maleic anhydride. According to the invention, the C5 mixture is directly used as the raw material to prepare the highly crosslinked copolymer containing the functional group in one-step reaction, in this way, the C5 resource is used reasonably and effectively.

Owner:BEIJING UNIV OF CHEM TECH

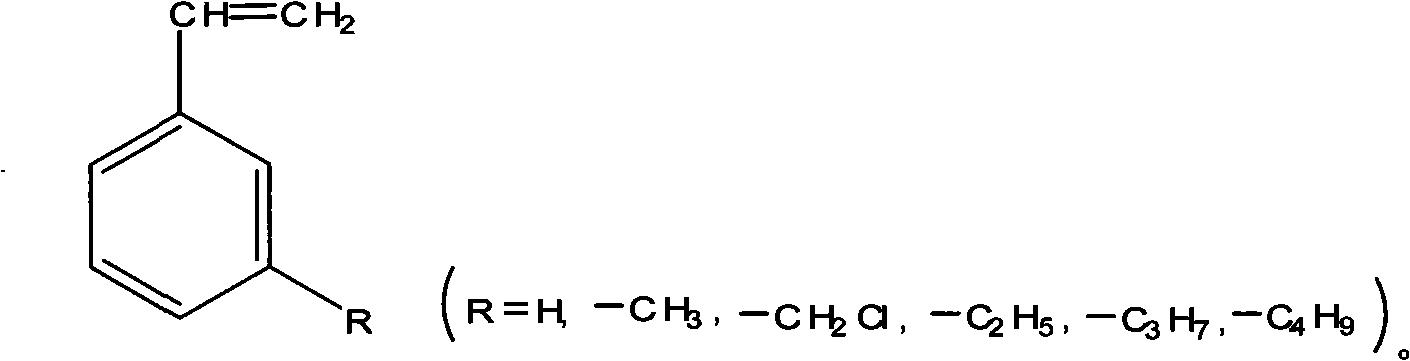

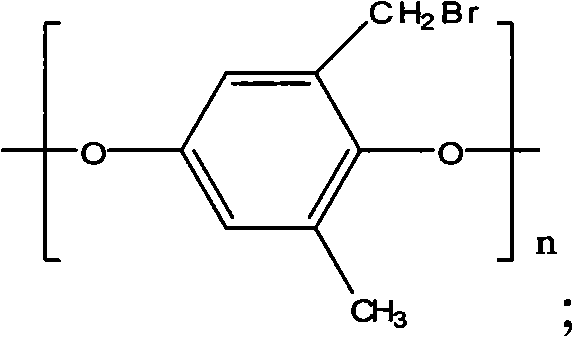

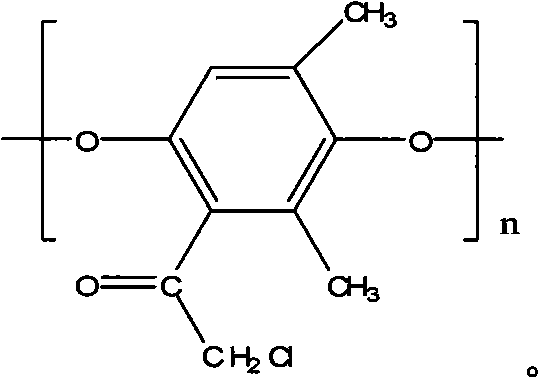

Homogeneous phase anion-exchange membrane and preparation method thereof

ActiveCN101306331AHigh strengthHas a cross-linked structureSemi-permeable membranesAnion exchangersCross-linkBenzoyl peroxide

The invention discloses a homogeneous anion exchange membrane as well as the preparation method thereof. The invention is characterized in that the homogeneous anion exchange membrane takes chloromethylated styrene, styrene or / and alkyl styrene as monomers, takes divinyl benzene as a cross-linking agent, takes benzoyl peroxide or azobisisobutyronitrile as an initiator, and takes bromomethylation poly (1,4- dimethyl2, 6- phenylene oxide) or chloroacetylized poly (1,4-dimethyl2, 6-phenylene oxide) as a polymer reinforcing agent, so as to prepare a uniform solution which is used for pasting a membrane on reinforced fabrics, and the homogeneous anion exchange membrane can be obtained by pretreating a basal membrane obtained by polymerization and then carrying out quaternary ammoniation. The invention obtains a functional group through adopting aromatic polymer, thereby the obtained anion exchange membrane has high exchange capacity, good electrochemical properties, uniform structure and good heat resistance; the slurry is homogeneous, thereby being easy for pasting; the monomers serving as the solvent can be polymerized, thereby being a green and solvent free process; the polymer content and the cross-linking degree can be adjusted, and the types of the sustainer can be changed, thereby obtaining products with different structural morphologies and functions.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

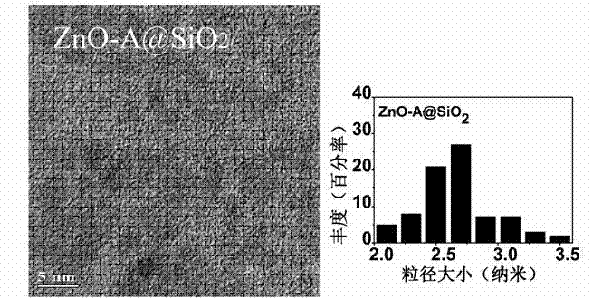

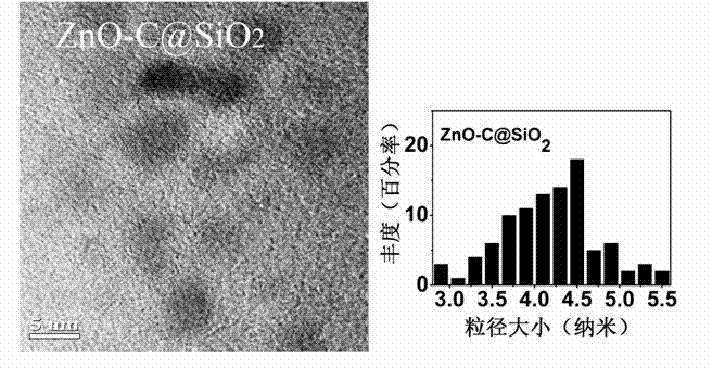

Core-shell zinc oxide-silica nanoparticle, and preparation method and application thereof

InactiveCN102732248ALuminous stabilityBright colorMicrobiological testing/measurementFluorescence/phosphorescenceMethacrylateLithium oxide

The invention specifically relates to a core-shell zinc oxide-silica nanoparticle, and a preparation method and application thereof, belonging to the technical field of nano-materials. The method comprises the following steps: subjecting lithium hydroxide and zinc methacrylate to hydrolysis at room temperature to produce luminous ZnO nanoparticles, adding siloxane monomers containing double bonds and azodiisobutyronitrile, carrying out heating to initiate polymerization so as to form a single organosilicon layer on the surface of the ZnO nanoparticles, then adding other siloxane and ammonia water, and carrying out hydrolysis at room temperature to form a silicon dioxide layer so as to prepare the core-shell zinc oxide-silica nanoparticles. The core of a core-shell zinc oxide-silica nanoparticle is a single zinc oxide luminous quantum dot and has a diameter of 2.7 to 4.6 nm; the shell of the nanoparticle is a thin silica layer; and the core-shell zinc oxide-silica nanoparticle is safe and nontoxic, has high quantum efficiency, stably emits light under continuous UV excitation in cells, can be used for preparing fluorescent labels for biological cells and is especially applicable to preparation of fluorescent labels for cervical carcinoma cells.

Owner:FUDAN UNIV

Production of cationic microsphere with crosslinked swelling function

InactiveCN101029109AEasy speed controlControllable swelling ratioDrilling compositionCross-linkPersulfate

Production of cationic micro-sphere with cross-linking swelling function is carried out by taking persulfate and sulfite or persulfate and azo-diisobutyl nitrile binary composite or persulfate, sulfite and 2,2'-azo-(2-(2-imidazoline-2-radical)propane)dihydrochloride(VA-044)ternary composite as initiating agent, adding into dispersant and cross-linking agent, initiating DMC monomer and AM monomer in mixed medium of cyclohexane-water or industrial white oil-water or 120#solvent oil-water and reverse suspension polymerizing to obtain the final product. The grain size is 1-50 mu m, it has controllable swelling speed ratio and can be used for third oil-extraction plugging materials.

Owner:JIANGNAN UNIV

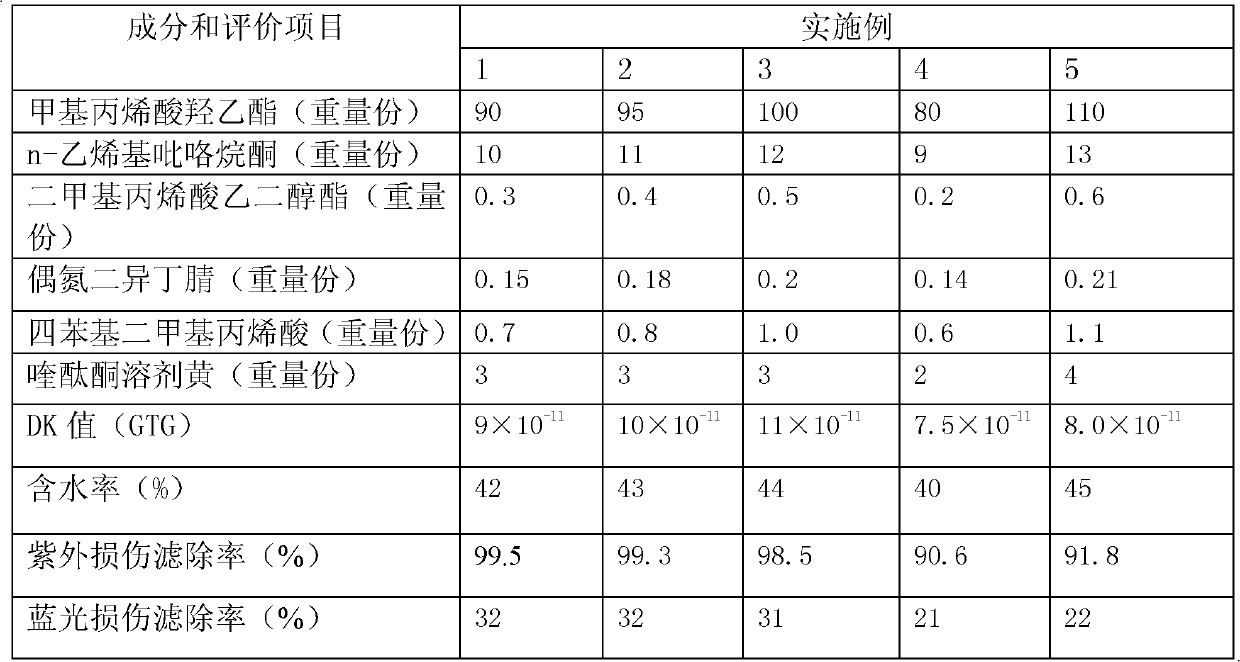

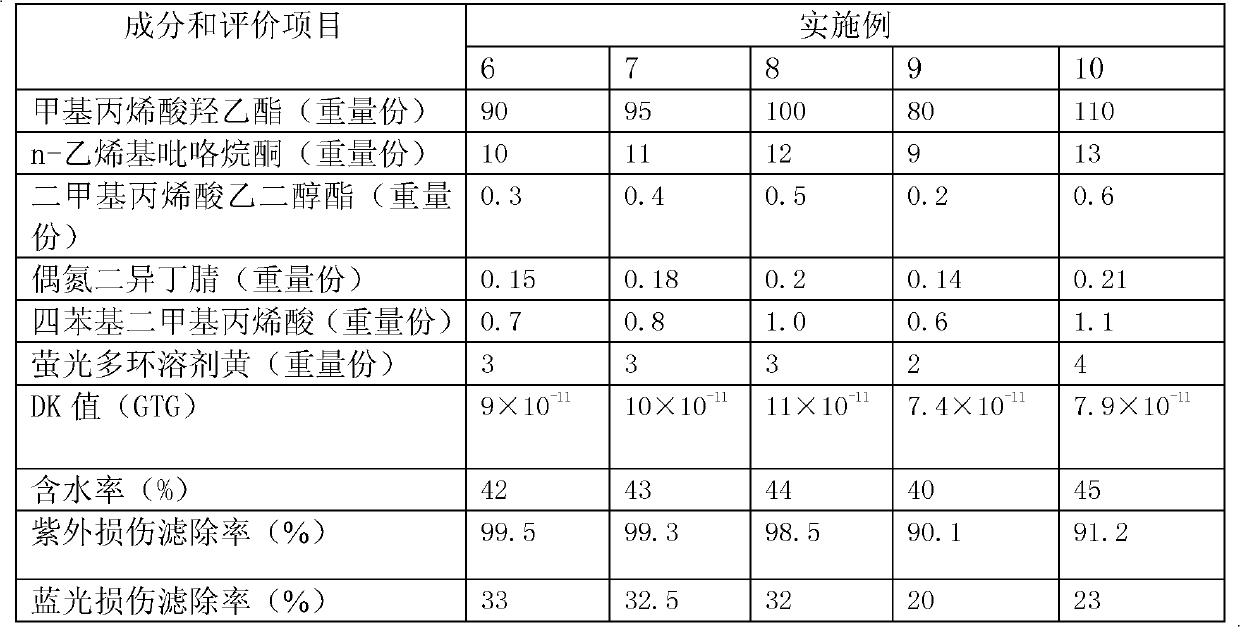

Radiation-proof light-filtering contact lens and production method thereof

ActiveCN102382237AGood oxygen transmission coefficientIncrease moisture contentOptical articlesOptical parts(Hydroxyethyl)methacrylateUltraviolet

A radiation-proof light-filtering contact lens is characterized in that the weight ratio of each component of liquid material is as follows: 90 to 100 parts of hydroxyethyl methacrylate; 10 to 12 parts of ethenyl pyrrolidinone; 0.3 to 0.5 part of 2-propenoic acid, oxybis(2,1-ethanediyloxy-2,1-ethanediyl)ester; acrylic acid, diester with tetraethylene glycol; 0.15 to 0.2 part of 2,2'-dicyano-2,2'-azopropane azobisisbutyronitrile; 0.7 to 1 part of 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate; and 3 parts of yellow pigment and dye for contact lenses. The contact lens has a good oxygen permeation coefficient, high moisture content, moderate hardness and fewer residues, and also has a good ultraviolet radiation protection effect and a good filtering effect on purple light and blue light.

Owner:北京自然美光学有限公司

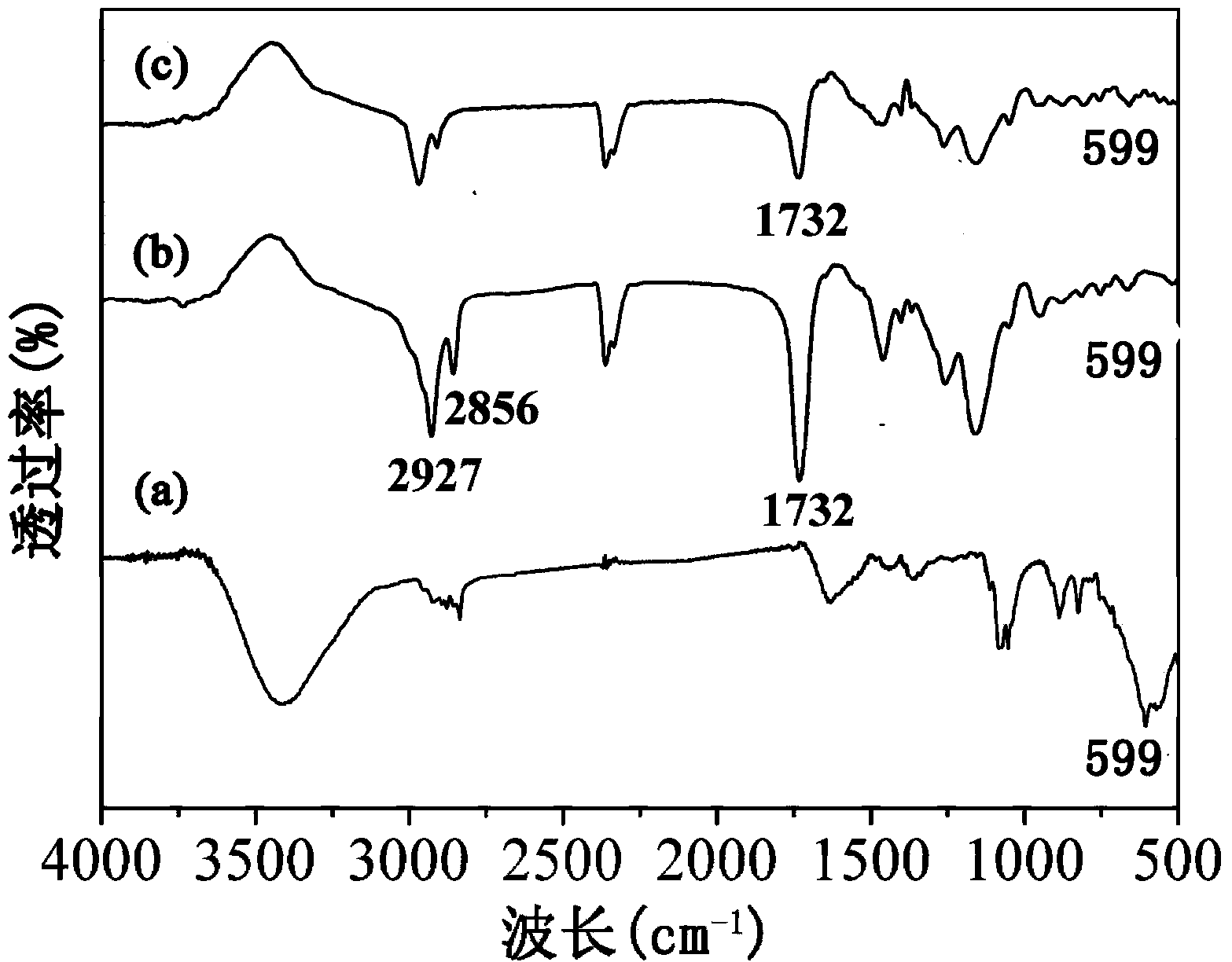

Temperature-sensitive magnetic sulfadimidine molecular imprinted adsorbent as well as preparation method and application thereof

InactiveCN102784626AHigh mechanical strengthImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceFunctional monomer

The invention discloses a temperature-sensitive magnetic sulfadimidine molecular imprinted adsorbent as well as a preparation method and application thereof, belonging to the technical field of preparation of environment functional materials. A gamma-Fe2O3 / SiO2 magnetic composite material is prepared by using a sol-gel method and is subjected to vinyl modification by using 3-(methylacryloyloxy) trimethoxypropylsilane; with a vinyl-modified magnetic composite material (MPS (Modified Polystyrene)-gamma-Fe2O3 / SiO2) as a substrate material, sulfadimidine as a template molecule, acrylamide as a functional monomer, N-isopropylacrylamide as a temperature-sensitive monomer, ethylene glycol-bis(methylacrylic acid) ester as a cross-linking agent and 2,2'-azobisisobutyronitrile as an initiator, a temperature-sensitive magnetic molecular imprinted polymer is prepared by using a free group polymerization process and is applied to selective recognition and separation of the sulfadimidine in an aqueous solution; and the obtained polymer has the advantages of remarkable heat and magnet stability, sensitive magnet and heat inducting effect, higher adsorption capacity, reversible adsorption / release function along with the temperature and remarkable recognition performance of a sulfadimidine molecule.

Owner:JIANGSU UNIV

Binary acrylonitrile copolymer spinning fluid and preparation method thereof

InactiveCN101158060AUniform chain structureImprove spinnabilityMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention relates to binary acrylonitrile copolymer spinning solution and a corresponding production method. The spinning solution comprises main monomer acrylonitrile and dimethyl sulfoxide solution with copolymer of itaconic acid Beta- monoester; the weight of the main monomer accounts for 90% to 99.5% of that of monomer, while the weight of the comonomer accounts for 0.5% to 10% thereof. The monomer is composed of the main monomer and the comonomer and the weight percentage concentration of the monomer is from15% to 25%. The dimethyl sulfoxide solution, the main monomer acrylonitrile, the comonomer, free radical initiator of azobisisobutyronitrile are added to a reactor by proportion and then mixed at room temperature and reacted for six to thirty six hours at a constant temperature of 50 DEG C to 70 DEG C to remove bubble of residual monomer and obtain the solution with protection from nitrogen which has bubbled for twenty minutes. The solution has a uniform chain structure and itaconic acid Beta-monoester contains two functional groups of carboxy and ester, thus being able to improve spinnability of polyacrylonitrile resin as well as regulate an oxidation-carbonization process of carbon fiber precursor. Due to introduction of a bifunctional group of monomer itaconic acid Beta-monoester, the amount of acrylonitrile comonomer is greatly reduced to improve performance of carbon fiber.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

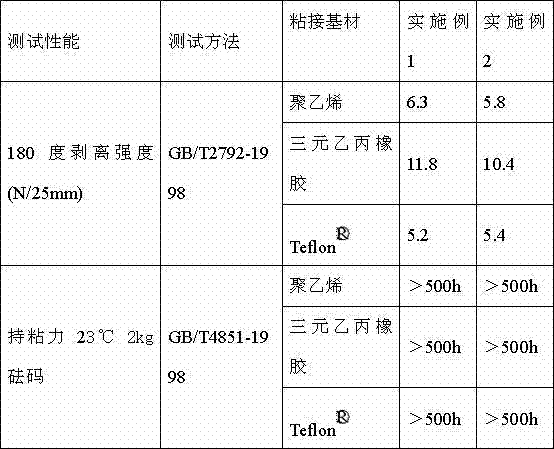

Adhesive tape for bonding low-surface-energy material and preparation method thereof

InactiveCN102504717ASolve the problem of poor aging resistanceLow priceFilm/foil adhesivesEster polymer adhesivesPolymer scienceBenzoyl peroxide

The invention provides an adhesive tape for bonding a low-surface-energy material. The adhesive tape consists of the following components in percentage by mass: (1) 30-50 percent of an acrylic ester monomer, (2) 50-70 percent of ethyl acetate or toluene serving as a solvent, (3) 0.2-1.5 percent of a crosslinking agent and (4) 0.1-0.6 percent of azobisisobutyronitrile or benzoyl peroxide serving as an initiator, wherein the acrylic ester monomer consists of 60-90 percent of soft monomer, 5-35 percent of hard monomer, 1-5 percent of crosslinking monomer and 2-10 percent of fluorine-containing acrylic ester. A preparation method of the adhesive tape comprises the following steps of: preparing an acrylic ester polymer solution, adding the acrylic ester monomer, the solvent and the initiator into a three-neck flask provided with a reflux unit, introducing nitrogen gas, stirring for half an hour, exhausting oxygen, putting into a water bath boiler, and reacting at the temperature of 60-80 DEG C under the protection of nitrogen gas for 6 hours; and coating the adhesive tape: mixing an obtained acrylic ester polymer solution with a crosslinking agent, standing, defoaming, coating onto a releasing film with a bar, drying at the temperature of 110 DEG C for three minutes, compounding with a PET (Polyethylene Terephthalate) film which is 30 mum in thickness and is subjected to corona surface treatment, and standing at the normal temperature for seven days.

Owner:TONSAN ADHESIVES INC

Tsiklomitsin molecular engram polyalcohol and uses of the same

InactiveCN101130580AImprove purification efficiencyHighly selective separation and enrichmentComponent separationFunctional monomerSpatial structure

The invention discloses an abricycline molecule stamp polymer, which is characterized by the following: mixing mold fermentmycin molecule, functional monomer methacrylic acid, cross linker dimethyl acroleic acid glycol ester and trigger azobisisobutyronitrile with mass ratio at 1-5 : 2-10 : 80 : 0. 1-0. 5; polymerizing at original position; possessing 'memory' function for the spatial structure of the abricycline mold molecule; possessing high selective separating enriched property for abricycline and oxytetracycline in residue analysis sample solution; filling the product into small column of polypropene shell; getting abricycline molecule stamp solid phase extraction column.

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

Method for preparing magnetic molecularly imprinted polymer through suspension polymerization

InactiveCN103881023AHigh mechanical strengthImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMethacrylatePolymeric surface

The invention relates to a method for preparing magnetic molecularly imprinted polymers (MIPs) through suspension polymerization, belonging to the technical field of preparation of environmental functional materials. In particular, in the method for preparing the magnetic MIPs through suspension polymerization, Fe3O4 magnetic particles are synthesized through a hydrothermal synthesis method, methacrylic acid is taken as a functional monomer, 2,4,6-trichlorophenol (2,4,6-TCP) is taken as template molecules, azodiisobutyronitrile is taken as an initiator, methylbenzene is taken as a pore-foaming agent, ethylene glycol dimethacrylate is taken as a crosslinking agent, and polyvinyl alcohol is taken as a stabilizing agent. The obtained MIPs are regular spheres, holes of specific shapes and sizes left by a plurality of template molecules are formed in the surfaces of the polymers, and specifically-arranged binding sites are arranged in the holes. By adopting the MIPs, highly-selective adsorption of a target pollutant, namely, 2,4,6-trichlorophenol can be realized.

Owner:JIANGSU UNIV

Multifunctional adsorption particles capable of treating industrial organic wastewater with imbalance of nitrogen and phosphorus and preparation method thereof

InactiveCN103611514AHas the function of slow-release nitrogen and phosphorusSimple preparation processOther chemical processesWater/sewage treatment by sorptionSorbentNitric acid

The invention discloses multifunctional adsorption particles capable of treating industrial organic wastewater with imbalance of nitrogen and phosphorus and a preparation method thereof. The preparation method comprises the steps of preparing a mixed solution F from a NH4HCO3 solution, a Ca(NO3)2 solution, a (NH4)2HPO4 solution, a NaOH solution, a nitric acid solution, a urea water solution and an ethylenediaminetetraacetic acid calcium sodium solution; preparing a mixed solution L from urea and a formaldehyde water solution; preparing a mixed solution M from a styrene chloroform solution, a divinyl benzene chloroform solution and an azobisisobutyronitrile chloroform solution; dropping the mixed solution L into the mixed solution M to obtain a mixed solution N; dropping the mixed solution F into the mixed solution N to obtain a mixed solution O; dropping the mixed solution O into a polyvinyl alcohol solution to obtain a mixed solution P; adding the polyvinyl alcohol solution into the mixed solution P, and performing centrifugal separation to obtain the multifunctional adsorption particles capable of treating the industrial organic wastewater with imbalance of nitrogen and phosphorus. The preparation process disclosed by the invention is simple, and a prepared multifunctional adsorbent has the function of nitrogen and phosphorus sustained release and the function of adsorbing pollutants in industrial organic wastewater.

Owner:BEIJING NORMAL UNIVERSITY

Multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

ActiveCN102733011AImprove mechanical propertiesCollusion is strongFibre chemical featuresCarbon fibersAcrylonitrile

The invention discloses a multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and a preparation method of the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution. The preparation method comprises the steps of combining acrylonitrile, methyl acrylate, 2-acrylamide-2-methylpro panesulfonic acid and itaconic acid to be a polymer monomer, respectively and sufficiently dissolving the weighed solid monomer (itaconic acid) and an initiator (azodiisobutyronitrile) into a dimethyl sulfoxide solution; conducting ammoniation on the dimethyl sulfoxide solution of the itaconic acid by ammonia water; and sequentially adding all the materials into a polymerizing pot, adding the initiator (azodiisobutyronitrile) to conduct batch polymerization reaction, gathering, defoaming and filtering to obtain the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution. According to the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and the preparation method, the comonomer structure of a multiple-copolymerization system is changed by the ammonia water, and dimethyl sulfoxide is taken as a solvent for homogeneous solution polymerization to prepare the polyacrylonitrile-based carbon fiber spinning solution, so that the hydrophily of the spinning solution is improved, and further, the high-performance fiber with high structure compacting degree, good mechanical property and high bonding strength is obtained.

Owner:XIAN KANGBEN MATERIAL

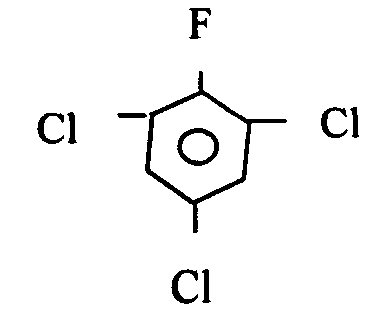

Method for preparing 2,4,6-trichloro-fluorobenzene

InactiveCN101177379ALow costLower requirementOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationState of artSocial benefits

The invention relates to a preparation method for the two, four, six-three-chlorine fluorobenzene, belonging to fluorin chemical engineering technical field. The invention is characterized in that three and five-two chlorine and four fluorin are used as the materials, which are catalyzed and chlorinated with the chlorine under the action of a catalyst in order to make the two, four and six-three-chlorine fluorobenzene; the reaction temperature ranges from one hundred and fifty and two hundred and fifty DEG C; the catalyst is chosen from oxidation benzoyl, azobisisobutyronitrile, and crown ether; the dosage accounts for zero point zero three percent to one percent of the three and five-two-chlorine-four-nitrobenzene. The invention has the advantages that the defects of the preparation method in the prior art such as low yield, high reaction temperature and the rigorous equipment condition are overcome; the preparation method enables the reaction to be completed below two hundred and twenty DEG C; the reaction equipment and the corresponding matched auxiliary equipment has low cost; the material transformation rate and the yield are increased; the purity of the products can reach ninety-nine point eight percent; the materials of the invention can be chosen from the leftovers which can be seen commonly in chemical enterprises and the rectifying remaining, which can save the prior resources with good economic benefit, environmental benefits and social benefits.

Owner:ZHEJIANG FUSHENG HLDG GROUP

Preparation method of dispersing nano molybdenum disulfide in lubricating oil system

The invention discloses a preparation method of dispersing nano molybdenum disulfide in a lubricating oil system. Nano molybdenum disulfide, styrene, deionized water and anhydrous alcohol are used as main raw materials, azoisobutyronitrile (AIBN) is used as an initiating agent, and polyvinylpyrrolidone (PVP) is used as a dispersing agent to modify a nano molybdenum disulfide powder body; the modified nano molybdenum disulfide is easily and stably dispersed in an anhydrous alcohol solution; and an anhydrous alcohol solution system containing the modified nano molybdenum disulfide is dispersed in an oil solvent by using an additive to form stable oily liquid of which the appearance is between blue gray and dark gray. The method of the invention has the advantages of simplicity, low cost, small raw material toxicity and short synthetic time and has high application value and commercial prospect.

Owner:HEFEI UNIV OF TECH

Method for preparing magnetic porous polystyrene microspheres on basis of suspension polymerization

InactiveCN103627022AIncrease productionHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesMagnetic stabilityPolymer science

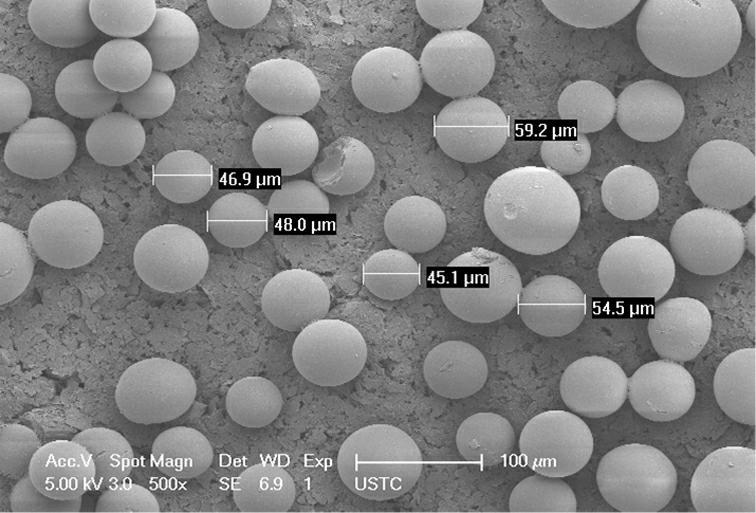

The invention relates to a method for preparing magnetic porous polystyrene microspheres on the basis of suspension polymerization, belonging to the technical field of preparation of environmental functional materials. The method comprises the following steps: synthesizing Fe3O4 magnetic particles by a solvothermal process; and preparing magnetic porous polystyrene microspheres by suspension polymerization by using styrene and divinylbenzene as functional monomers, azodiisobutyronitrile as an initiator and toluene and cyclohexanol as pore-forming agents. The obtained microspheres have abundant pores on the surface, thereby being beneficial to enhancing adsorbability; and the Fe3O4 magnetic particles inside the microspheres have magnetic stability, and can be quickly separated under the action of an external magnetic field. The adsorbent is used in a water environment for selectively adsorbing 2,4-dichlorophenol and 2,6-dichlorophenol. The static adsorption experiment result indicates that the magnetic porous microspheres prepared by the method have the advantages of favorable adsorption capacity, quick adsorption kinetic property and favorable regenerability.

Owner:JIANGSU UNIV

High-oil-absorption resin and preparation method thereof

InactiveCN105254818ASolve the problem that the adsorption capacity is still not large enoughImprove adsorption capacityOther chemical processesPolymer sciencePolyvinyl alcohol

The invention relates to high-oil-adsorption resin and a preparation method thereof, and belongs to the technical field of oil-adsorption resin. The high-oil-adsorption resin comprises an oil phase and a water phase, wherein the oil phase is prepared from, by weight, 4-8 parts of divinyl benzene, 20-30 parts of styrene, 20-30 parts of n-lauryl acrylate, 20-30 parts of butyl acrylate, 20-30 parts of butadiene rubber, 3-9 parts of azodiisobutyronitrile and 40-50 parts of methylbenzene, and the water phase is prepared from, by weight, 5-9 parts of polyvinyl alcohol, 10-20 parts of gelatin, 5-8 parts of NaCl, 5-10 parts of CaCO3 and 500-600 parts of deionized water. According to the high-oil-adsorption resin and the preparation method thereof, the high-oil-adsorption resin is prepared by taking adopting a suspension polymerization technology, taking the styrene, the n-lauryl acrylate, the butyl acrylate and the butadiene rubber as the raw materials, taking the azodiisobutyronitrile as an initiator and taking the divinyl benzene as a cross-linking agent, and the adsorption quantity of the oil-adsorption resin is greatly increased.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Water-soluble crylic acid resin and preparation method thereof

The invention discloses a waterborne acrylic resin and the preparation method, which aims to provide a waterborne acrylic resin and the preparation method which can not only keep the performance of organic solvent type acrylic resins, but also have friendly environmental protection property. The invention comprises the following matters of mass portion: 1 to 2 of acrylic, 15 to 29 of methyl methacrylate, 18 to 22 of butyl acrylate, 3 to 7 of styrene, 3 to 7 of 2-hydroxyethyl methacrylate, 0.25 to 0.65 of mercaptoethanol, 0.3 to 0.7 of azobisisobutyronitrile, 3 to 5 of isopropanol, 15 to 20 of ethanol, 2.5 to 8.75 of monoethanolamine and 25 to 31.5 of water.

Owner:浙江英科水墨材料有限公司

Transparent coating capable of absorbing visible light and infrared light, preparing method and use thereof

ActiveCN101033357AReduced full emissivity valueGood infrared transparencyInksRadiation-absorbing paintsNear infrared absorptionNanometre

The invention relates to a kind of absorption transparent coating for visible and infrared light as well as its preparation and application. The coatings is prepared as follow: Firstly, it mixes alpha-methyl acrylate, methyl methacrylate, azobisisobutyronitrile, tributyl phosphate according to the ratio of 1-2:10-12:1-1.5:2-4, then it prepolymerizes them in water to a viscosity of 100 ~ 500cP to achieve the bonding agent of the infrared absorption coating. Secondly, it takes out 40%~60% of the above bonding agent and adds the nano-particles of TiO2, Fe3O4, MnO2, CuO, CdTe, PbS and / or Cr2O3 to achieve an organic near infrared absorber, then it mixes the organic near infrared absorber and the remaining bonding agent to achieve the visible infrared absorption transparent coating.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

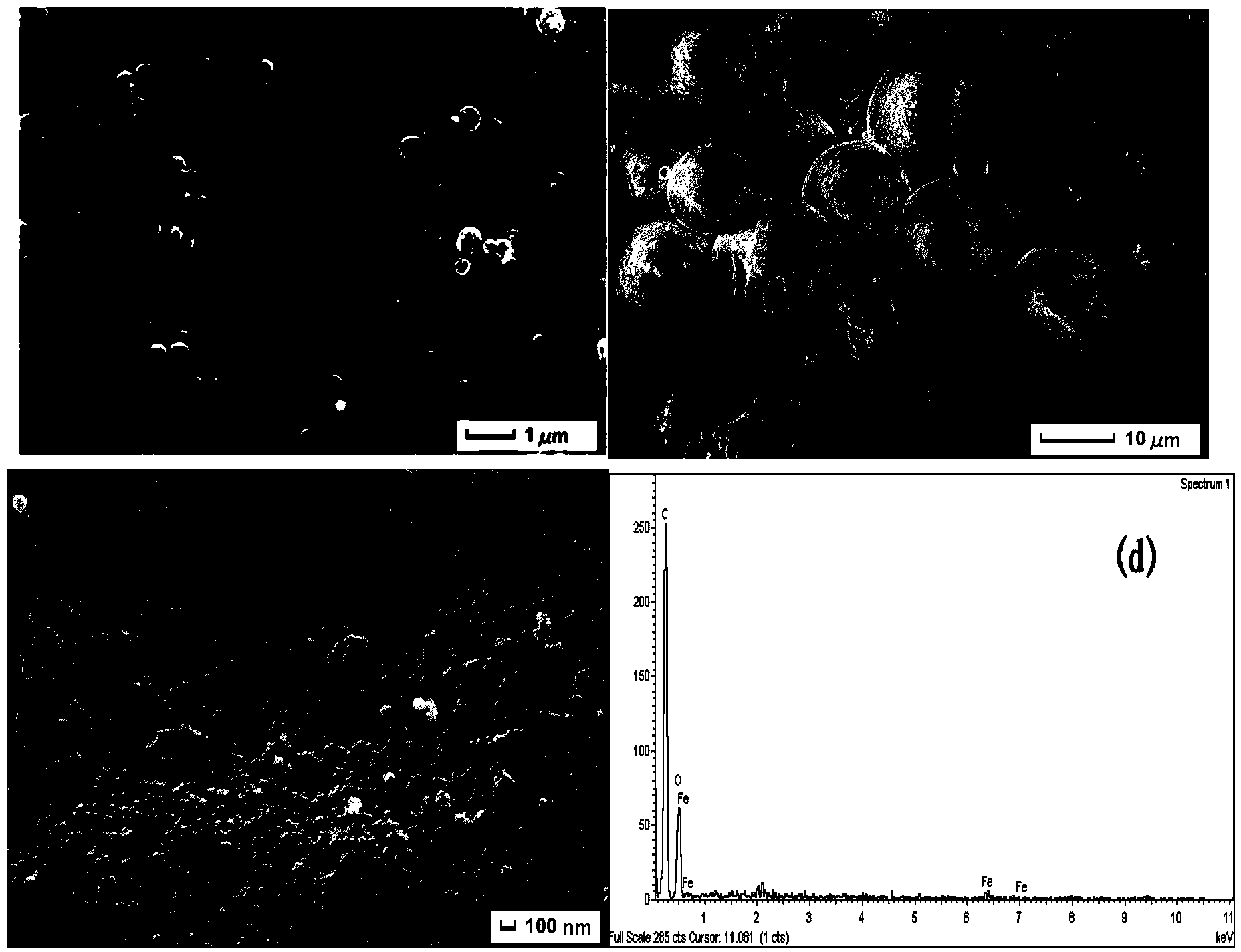

Core-shell type magnetic surface imprinting nanometer composite material preparation method

InactiveCN103601847AEfficient and selective removalEasy to separateOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerMeth-

The present invention relates to a core-shell type magnetic surface imprinting nanometer composite material preparation method, and belongs to the technical field of environmental function material preparation. The preparation method comprises: adopting a solvothermal method to synthesize monodispersed magnetic iron oxide nano-spheres; adopting 3-(methacryloxy)propyl trimethoxyl silane to carry out vinyl functionalization modification on the surface; and adopting acetonitrile as a solvent, adopting tetracycline as template molecule, adopting methacrylic acid as a functional monomer, adopting ethylene glycol dimethacrylate as a cross-linking agent, adopting azobisisobutyronitrile as an initiator monomer, carrying out imprinting polymerization on the surface of the vinyl-modified iron oxide nano-spheres, and carrying out soxhlet extraction of the template molecule to obtain the core-shell type magnetic surface imprinting nanometer composite material. According to the present invention, with multiple characterization methods, morphology, particle size distribution and other parameters of the polymer are revealed; and the material obtained by using the absorption experiment research is adopted to selectively remove tetracycline in the water environment.

Owner:JIANGSU UNIV

Method of preparing vinyl alcohol with low degree of polymerization

The invention relates to a method for producing low polymerization degree polyvinyl alcohol including: mixing the monomer vinyl acetate with solvent carbinol in a mass ratio of 60-80:20, adding ignition primer diisopropyl azodicarboxylate taking 0.1-0.5% of the monomer mass and chain transfer agent 2-mercaptoethanol taking 0.1-0.5% of the monomer mass, producing low polymerization degree polyvinyl acetate by solution polymerization method; dissolving the low polymerization degree polyvinyl acetate in the carbinol to get polyvinyl acetate carbinol solution, adding NaOH carbinol solution, alcoholysis to get low polymerization degree polyvinyl alcohol. The inventive method can produce low polymerization degree polyvinyl alcohol with a low polymerization degree of 50-500.

Owner:ZHONGBEI UNIV

Temperature-sensitive polymer/gold nanoparticle hybrid microspheres and preparation method thereof

InactiveCN102492250AAdjust catalytic performanceHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereNanoparticle

The invention relates to temperature-sensitive polymer / gold nanoparticle hybrid microspheres and a preparation method thereof. The temperature-sensitive polymer / gold nanoparticle hybrid microspheres consist of more than 99.9 weight percent of polymer and less than 0.1 weight percent of gold nanoparticles. The preparation method comprises the following steps of: a) preparing a 2-(methoxycarbonyl)-ethyldithiophenyl ester chain transfer agent; b) synthesizing an N-isopropylacrylamide macromolecular chain transfer agent by using 2-(methoxycarbonyl)-ethyldithiophenyl ester obtained in step a) and azodiisobutyronitrile; c) further polymerizing 4-vinylpyridine by using the macromolecular chain transfer agent obtained in step b) and the azodiisobutyronitrile to obtain a block copolymer; d) preparing polymer microsphere suspension by using the block copolymer obtained in step (c); and e) adding chloroauric acid into the microsphere suspension, and reducing by using excessive sodium borohydride to obtain the temperature-sensitive hybrid polymer microspheres. The temperature-sensitive polymer / gold nanoparticle hybrid microspheres overcome the disadvantages that the gold nanoparticles are not firmly combined and are easy to fall off and the catalytic activity is not adjustable, and can be used for the fields of controllable catalysis and the like.

Owner:TIANJIN POLYTECHNIC UNIV

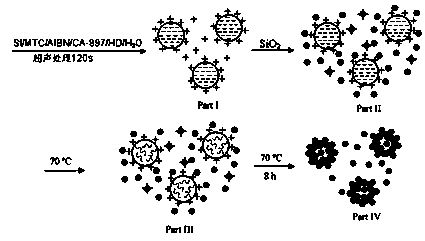

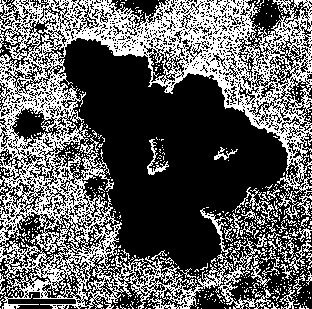

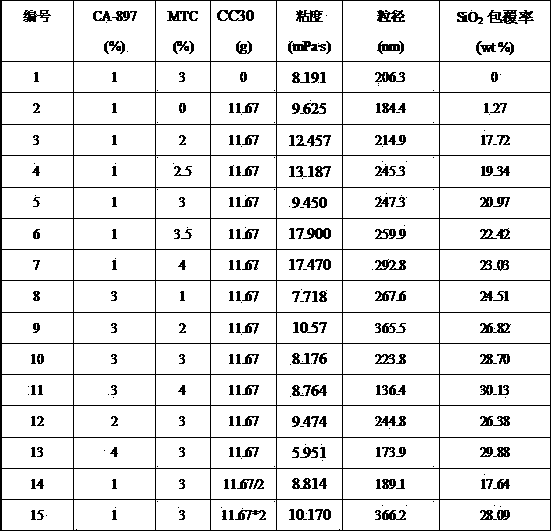

Preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres

The invention relates to a preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres. The preparation method comprises the following steps: in a nitrogen atmosphere, mixing methacryloyloxyethyl trimethyl ammonium chloride, octaphenyl polyoxyethyiene and deionized water to obtain a water-phase mixture; dissolving azodiisobutyronitrile into styrene and n-hexadecane through ultrasonic wave to obtain an oil-phase mixture; dropping the oil-phase mixture into the water-phase mixture by using a constant-pressure dropping funnel to obtain mixed liquid; performing ultrasonic treatment on the mixed liquid under an ice-water mixed bath condition to obtain miniemulsion; dropwise adding silicon dioxide nanosol into the miniemulsion, and heating to obtain milky dispersion liquid; collecting and cooling the dispersion liquid, and centrifugating and dispersing until no free SiO2 particles exist under a transmission electron microscope, so as to obtain the strawberry-type polystyrene-silicon dioxide nanocomposite microspheres finally. The preparation method is simple and relatively low in cost and the SiO2 cladding rate is relatively high.

Owner:HUBEI UNIV

Preparation method and application of thermal-peeling acrylic ester pressure-sensitive adhesive

InactiveCN104371610AWill not cause separationSmall particlesNon-macromolecular adhesive additivesFilm/foil adhesivesMethacrylateIsooctyl acrylate

The invention relates to a thermal-peeling acrylic ester pressure-sensitive adhesive. The thermal-peeling acrylic ester pressure-sensitive adhesive comprises, by weight, 60-140 parts of 2-ethylhexyl acrylate, 60-140 parts of vinyl acetate, 3-10 parts of acrylic acid, 5-15 parts of hydroxyethyl acrylate, 3-10 parts of methyl methacrylate, 0.1-2 parts of N-hydroxymethyl acrylamide, 0.5-2 parts of azodiisobutyronitrile and 200-300 parts of ethyl acetate by polymerization. The polyacrylate pressure-sensitive adhesive is synthesized by (methyl) acrylic monomers through polymerization, and stickiness of an adhesive tape is changed via a temperature variation range. The thermal-peeling acrylic ester pressure-sensitive adhesive has excellent adhesiveness and thermal peeling property, the adhesiveness is larger than 900gf at the temperature lower than 90 DEG C, and the peel strength to a steel plate is smaller than or equal to 1N / m after foaming expansion at the temperature of 130 DEG C. When the pressure-sensitive adhesive tape is sufficiently foamed at the temperature of 130 DEG C, the foaming adhesive layer cannot be separated from a base material. After the pressure-sensitive adhesive tape is sufficiently foamed at 130 DEG C, the foaming agent is small in particles after foaming and the adhesive side is good in flatness.

Owner:新丰杰力电工材料有限公司

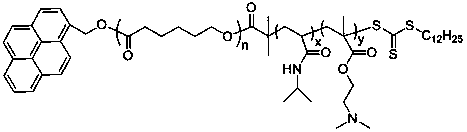

Preparation method of temperature and CO2 double-responsive block copolymer nano micelle

The invention relates to a preparation method of a temperature and CO2 double-responsive block copolymer nano micelle. The preparation method disclosed by the invention comprises the following steps of initiating caprolactone ring-opening polymerization by utilizing pyrene methanol under the protection of inert gas, then, carrying out esterification reaction by utilizing terminal hydroxyl of polycaprolactone and terminal carboxyl of a reversible addition-fragmentation chain transfer polymeric chain transfer agent, thereby obtaining a reversible addition-fragmentation chain transfer polymerized macromolecular chain transfer agent; and carrying out reversible addition-fragmentation chain transfer polymerization of N-isopropylacrylamide and an N,N-dimethylacrylic acid dimethylamino ethyl ester monomer by taking azodiisobutyronitrile as the initiator under the protection of inert gas so as to obtain Py-PCL-b-(NIPAM-coDMAEMA) block copolymer, dissolving the Py-PCL-b-(NIPAM-coDMAEMA) block copolymer in water, thereby obtaining a steady temperature and CO2 responsive nano-micelle. The temperature and CO2 double-responsive block copolymer nano-micelle disclosed by the invention has biodegradability, biocompatibility and bioactivity simultaneously; the steady nano micelle self-assembled in water has temperature and CO2 double-responsive characteristic; the preparation method disclosed by the invention has wide application prospect in the fields, such as drug-controlled release carriers, biological intelligent switches, soft tissue engineering bracket materials and biological sensors; the preparation method disclosed by the invention is simple and practicable and has good popularization and application values; all the raw materials can be industrially produced.

Owner:TONGJI UNIV

Anti-static polyphenylacetylene combination and preparation method and sheet material

ActiveCN101157781ALow humidity sensitivityReduce usageOther chemical processes(Hydroxyethyl)methacrylatePolyethylene glycol

The invention relates to an antistatic plastics sheet, in particular to an antistatic polystyrene combination, a preparation method thereof and the produced sheet prepared by the combination. The antistatic polystyrene combination is made through mixing the components of the following prescription according to weight proportion: 65.0 percent to 85.0 percent of HIPS polystyrene, 8.0 percent to 28.0 percent of methyl-acrylic acid polyethylene glycol single methyl ether ester, 3.14 percent to 6.87 percent of hydroxylethyl methacrylate, 1.72 percent to 3.97 percent of sodium perchlorate, 0.0963 percent to 0.145 percent of azobisisobutyronitrile and 0.92 percent to 2.4 percent of coupling agent. In addition, the invention discloses a sheet that is produced by three layers of materials compounded together, wherein, the materials of the upper layer and the lower layer are the antistatic polystyrene combination gained through mixing the components. The antistatic polystyrene sheet of the invention saves the consumption of the antistatic polystyrene combination, reduces cost, adopts three surface layers combination with the property of no drop-off, is characterized by lasting long effect and low humidity sensitivity and enhances level and advancement of electric products packaging.

Owner:浙江三和塑料有限公司

Strong-polarity macroporous adsorption resin

ActiveCN102974324AIncrease varietyImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionMethacrylatePolymer science

The invention relates to a strong-polarity macroporous adsorption resin belonging to the technical field of high-polymer macroporous adsorption resin. The strong-polarity macroporous adsorption resin comprises the following components by weight parts: 10-30 parts of divinyl benzene taken as an oil phase, 10-20 parts of trimethylolpropane triallyl ester, 10-20 parts of trimethylolpropane trimethylacrylate, 20-40 parts of acrylonitrile, 5-10 parts of methyl acrylate, 5-10 parts of styrene, 50-150 parts of pore-foaming agent, 0.5-1 part of 2, 2-azobisisobutyronitrile (AIBN), and 300-500 parts of distilled water taken as an aqueous phase, 5-15 parts of polyvinyl acetate (PVA) and 20-50 parts of NaCl. The strong-polarity macroporous adsorption resin is synthesized and prepared, and high-water-solubility nitrobenzene, phenol and other organic matters can be effectively adsorbed in the process of treating organic wastewater.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation of triazine phytocide molecular imprinting solid phase extracting material

InactiveCN102174148AEfficient removalEasy to removeIon-exchange process apparatusOther chemical processesPolyvinyl alcoholTriazine

The invention relates to a preparation method of a triazine phytocide molecular imprinting solid phase extracting material. The method comprises the following steps of: 1. dissolving butyltripolycyanamide, alpha-methacrylic acid, glycol di(methacrylic acid)ester and azodiisobutyronitrile into trichloromethane and uniformly mixing to obtain a suspending phase I; 2. dissolving polyvinyl alcohol 1788 into water to obtain a suspending phase II; and 3. stirring and reacting the suspending phase I with the suspending phase II and drying in vacuum to obtain the triazine phytocide molecular imprinting solid phase extracting material. In the invention, by adopting a substituted molecular template, the imprinting effect is ensured and the problem of template seepage is solved; the optimized use condition is more convenient for solid phase extraction and ensures favorable impurity removing function and favorable repeatability; the matrix effect is remarkably weakened; and the triazine phytocide molecular imprinting solid phase extracting material is better than the traditional main stream solid phase extracting product, not only can ensure the detecting accuracy but also can improve the detecting sensitivity and effectively protect a chromatographic column.

Owner:安徽出入境检验检疫局检验检疫技术中心

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com