Multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

A binary ammoniated polyacrylonitrile-based carbon fiber and spinning solution technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, and can solve the conditions of low-cost, high-efficiency large-scale industrial preparation and polymerization reaction process control that are not applicable Harsh requirements, complex comonomers in the preparation process, etc., to achieve the effect of improving structural compactness, improving hydrophilicity, and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

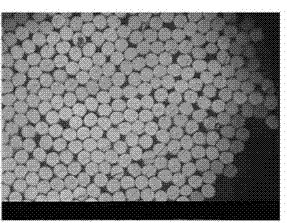

Image

Examples

Embodiment 1

[0028] This embodiment is a binary ammoniated polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0029] In this embodiment, dimethyl sulfoxide is used as a solvent, azobisisobutyronitrile is used as an initiator, acrylonitrile and itaconic acid are used as polymer monomers, and the percentage of the monomers in the total weight of the solution is 20-22%. Acrylonitrile: the weight percent of itaconic acid is 97~98.0:3.0~2.0, and the consumption of azobisisobutyronitrile is 0.75~0.9% by weight of the total amount of monomers. Both the itaconic acid and azobisisobutyronitrile are solid. In this embodiment, the monomer accounts for 20% of the total weight of the solution, the weight percentage of acrylonitrile:itaconic acid is 98.0:2.0, and the amount of azobisisobutyronitrile is 0.75% by weight of the total monomer.

[0030] During preparation, proceed as follows:

[0031] Step 1, weighing materials. The dimethyl sulfoxide solvent accounting f...

Embodiment 2

[0038] This embodiment is a binary ammoniated polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0039] In this example, dimethyl sulfoxide is used as a solvent, azobisisobutyronitrile is used as an initiator, acrylonitrile and itaconic acid are used as polymer monomers, and the weight percentage of the monomers in the total weight of the solution is 20-22%. , acrylonitrile: the weight percent of itaconic acid is 97~98.0:3.0~2.0, and the consumption of azobisisobutyronitrile is 0.75~0.9% by weight of the total amount of monomers. Both the itaconic acid and azobisisobutyronitrile are solid. In the present embodiment, the weight percentage of monomers accounting for the total weight of the solution is 21%, the weight percentage of acrylonitrile:itaconic acid is 97.5:2.5, and the consumption of azobisisobutyronitrile is 0.85% by weight of the total amount of monomers .

[0040] During preparation, proceed as follows:

[0041] Step 1, weighing ...

Embodiment 3

[0048] This embodiment is a ternary ammoniated polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0049] In this embodiment, dimethyl sulfoxide is used as a solvent, azobisisobutyronitrile is used as an initiator, and acrylonitrile, itaconic acid, and 2-acrylamide-2-methylpropanesulfonic acid are used as polymer monomers. The percentage by weight of the monomer accounting for the total weight of the solution is 20-22%, and the percentage by weight of acrylonitrile: itaconic acid: 2-acrylamide-2-methylpropanesulfonic acid is 97.5-98.0:1.5-2.0:0.5, and the polymerized monomer The total amount is 100%, and the amount of azobisisobutyronitrile is 0.75-0.9% by weight of the total amount of monomers. The itaconic acid, azobisisobutyronitrile and 2-acrylamide-2-methylpropanesulfonic acid are all solid. In the present embodiment, the weight percentage of the monomer accounting for the total weight of the solution is 21%, the weight percentage of acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com