Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1725 results about "Itaconic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Itaconic acid, or methylidenesuccinic acid, is an organic compound. This dicarboxylic acid is a white solid that is soluble in water, ethanol, and acetone. Historically, itaconic acid was obtained by the distillation of citric acid, but currently it is produced by fermentation. The name itaconic acid was devised as an anagram of aconitic acid, another derivative of citric acid.

Prepn of polyacrylonitrile-base high-performance raw carbon fiber

InactiveCN1417393AReduce gel particlesHigh strengthFibre chemical featuresMethyl methacrylateItaconic acid

The present invention relates to the preparation of high-performance polyacrylonitrile-based carbon fiber. Acrylonitrile, itaconic acid and methyl methacrylate in a certain weight proportion are reacted to obtain spinning dope, and the spinning dope is made into greign fiber of high-performance carbon fiber through filtering, solidification, water washing, drafting in hot water, oiling, drying and densifying, re-oiling, drying and densifying for the second time, steam drafting and drying setting. The present invention has the advantages of high drafting rate, homogeneous fibre structure, and small mechanical performance variation coefficient.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

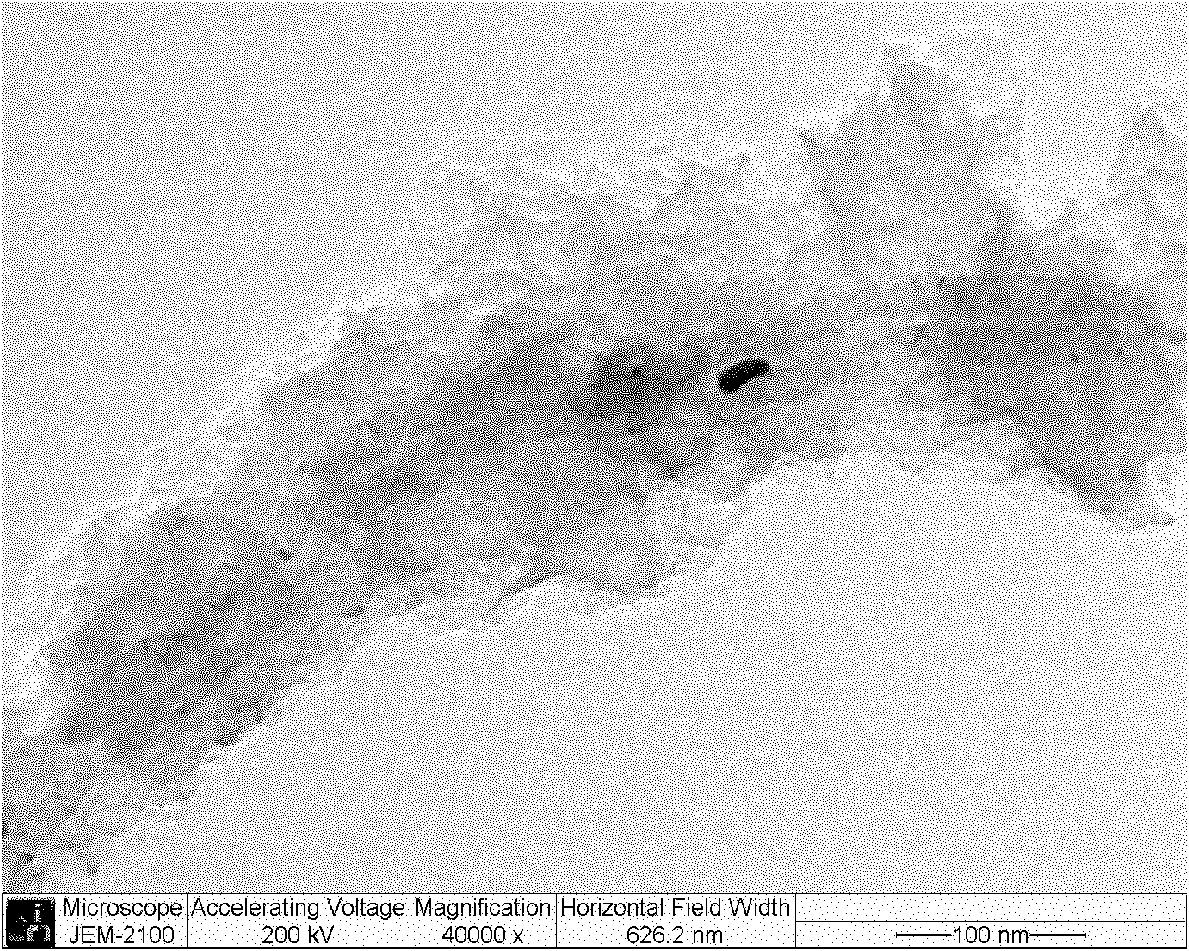

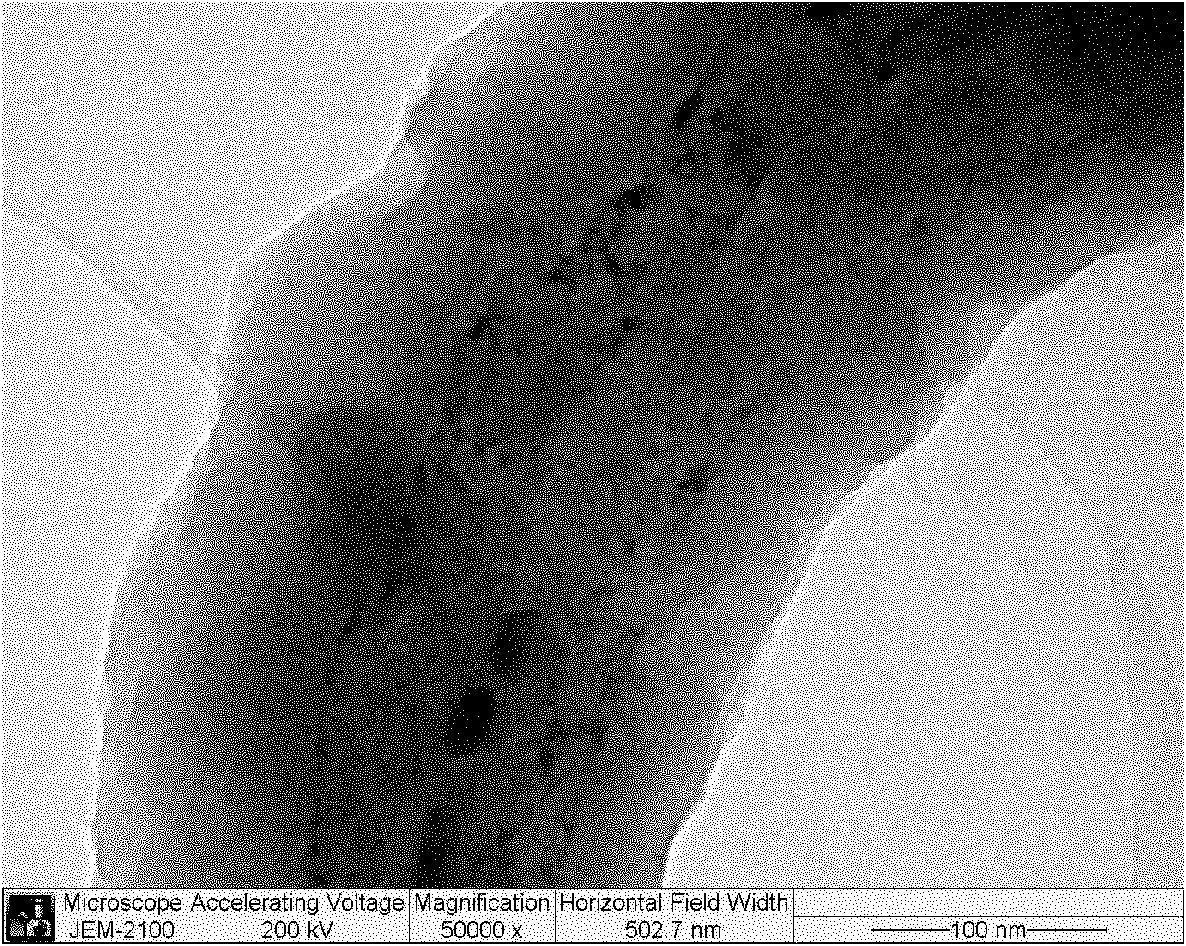

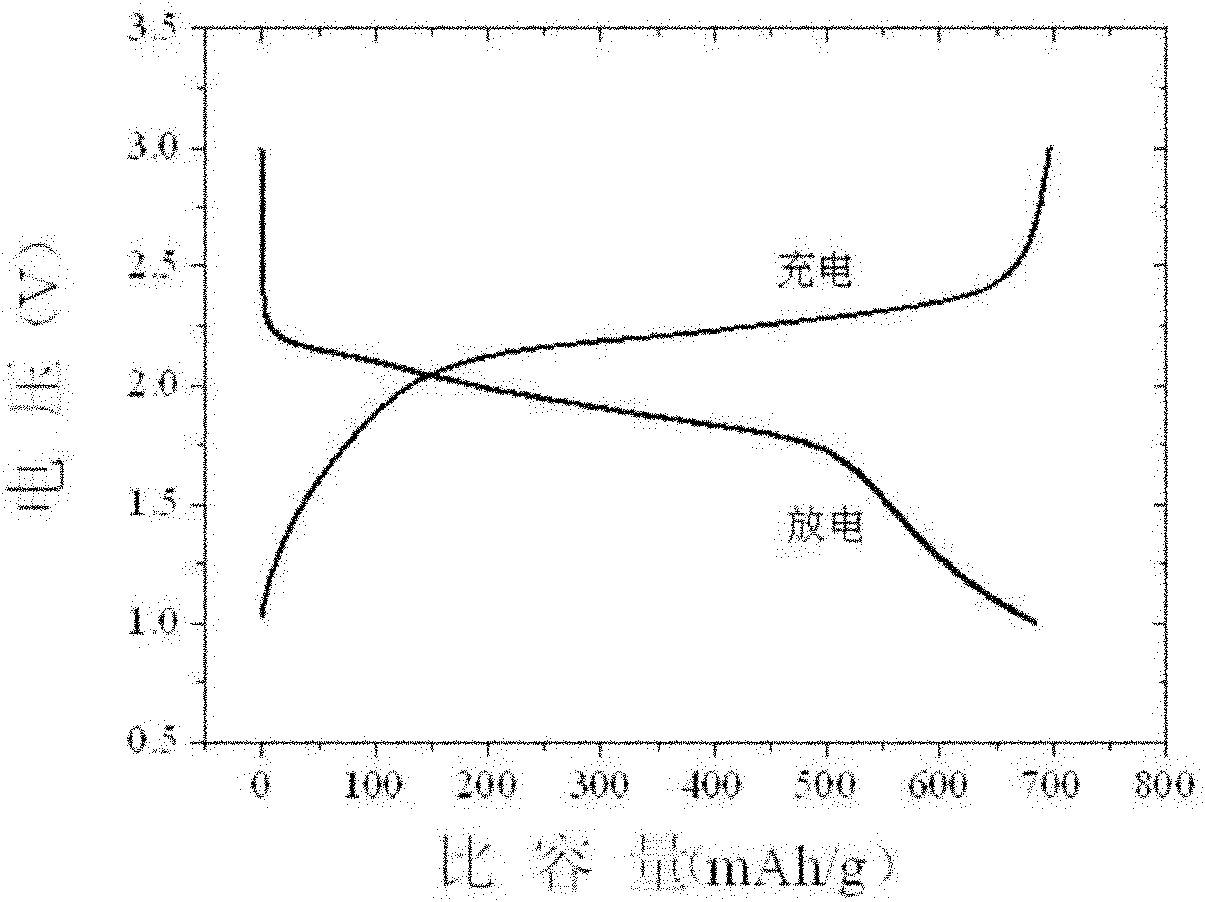

Carbon nano tube-containing sulfur-based composite cathode material and preparation method thereof

ActiveCN101891930AIncrease contentImprove power characteristicsNon-aqueous electrolyte accumulator electrodesIn situ polymerizationAcrylonitrile

The invention discloses a carbon nano tube-containing sulfur-based composite cathode material and a preparation method thereof. The sulfur-based composite cathode material is a ternary composite material AxByCz, wherein A is a dehydrocyclization product of an acrylonitrile-itaconic acid copolymer; B is elemental sulfur; C is a carbon nano tube; x is more than or equal to 30 weight percent and less than or equal to 60 weight percent; y is more than or equal to 30 weight percent and less than or equal to 60 weight percent; and z is more than or equal to 1 weight percent and less than or equal to 20 weight percent. The preparation method comprises the following steps of: in-situ polymerizing an acrylonitrile-itaconic acid monomer on the surface of the multi-wall carbon nano tube, and performing thermal treatment on both of the acrylonitrile-itaconic acid copolymer and the elemental sulfur, so that the sulfur is uniformly dispersed in a substrate formed by the dehydrocyclization of the acrylonitrile-itaconic acid copolymer. The carbon nano tube-containing sulfur-based composite cathode material and a lithium cathode form a secondary lithium-sulfur battery which is charged and discharged at the room temperature. The carbon nano tube-containing sulfur-based composite cathode material has the reversible specific capacity of 697 mAh / g and high cyclical stability.

Owner:SHANGHAI JIAO TONG UNIV

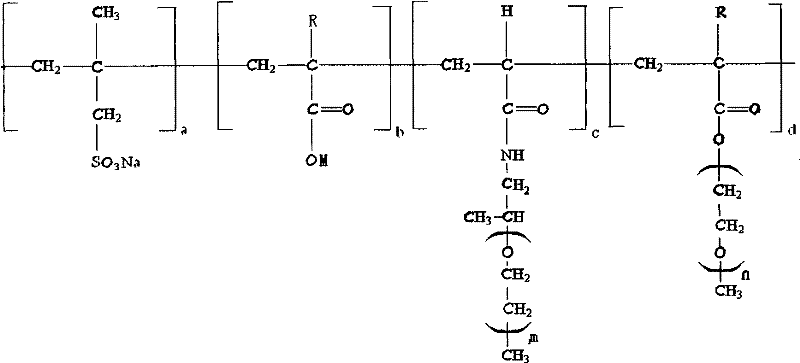

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

Treatment of recreational water

An oxidizing agent comprising a pre-measured amount of stabilized potassium hydrogen peroxymonosulfate and a buffer in a sealed water-soluble pouch, said pouch comprising a hydrolyzed copolymer of vinyl acetate and at least one of acrylic acid, methacrylic acid, maleic acid, itaconic acid, and esters thereof is disclosed.

Owner:LENKSESS CORP

Methyl acrylate pressure-sensitive adhesive for LCD polarizer and preparation method thereof

InactiveCN101693820AStrong initial adhesionHigh peel strengthFilm/foil adhesivesEster polymer adhesivesFunctional monomerCross linker

The invention relates to a methyl acrylate pressure-sensitive adhesive for an LCD polarizer and a preparation method thereof, which belong to the technical field of tackiness agent. The pressure-sensitive adhesive comprises the following three materials with the quality shares: a. weight average molecular weight Mw is 100000-2000000, dispersion degree Mw / Mn is 4-20 acrylate copolymer 100 shares, b. coupling agent, c. cross linker 0-15 shares, the comonomer of prepared acrylate copolymer comprises two parts: 1. (methyl) acrylate monomer : 90%-99.5%, 2. functional monomer: 0.5%-10%, wherein the functional monomer is one or several of (methyl) acroleic acid and (methyl) acroleic acid hydroxy ethyl, (methyl) acroleic acid hydroxypropyl acrylate, itaconic acid, acrylamide, N-hydroxymethyl acrylamide and maleic anhydride. The methyl acrylate pressure-sensitive adhesive does not contain elasticizer or low-molecular-weight acrylate copolymer and the like, can reach the use requirement without cross linker under the condition that the requirement to sticking property is low, and the glue layer has better stress relaxation property, and pressure-sensitive adhesive initial adhesion and stripping strength are both extremely ideal.

Owner:BEIJING UNIV OF CHEM TECH

Pesticide compositions including polymeric adjuvants

Pesticidal compositions of improved effectiveness are provided, including a pesticide (e.g., an insecticide or herbicide) together with a copolymer adjuvant or additive selected from the group consisting of acid or salt copolymers containing individual quantities of maleic and itaconic moieties. The compositions of the invention provide multiple-fold increases in effectiveness, as compared with an equal amount of the pesticide in the absence of the copolymer.

Owner:VERDESIAN LIFE SCI

Method for synthesizing carboxyl butadiene-styrene latex used for cement group water-proofing material

ActiveCN101139413AAvoid pollutionReduce energy consumptionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEthylenediamine

This invention relates to a synthesis method for carboxylated styrene-butadiene latex used in the cement-based waterproof coating. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 30 to 55 shares of styrene, 0.1 to 5 shares of methyl acrylate , 1 to 5 shares of itaconic acid, 1 to 8 shares of n-butyl acrylate butyl acrylate, 1.2 to 2.8 hares of emulsifier, 0.3 to 1.2 hares of initiator potassium supersulphate, 0.2 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer sodium bicarbonate, 0.01 to 5 shares of electrolyte, 0.01 or 5 shares of chelating agent ethylenediamine tetraacetic acid or endrate disodium and 100 to 150 shares of soft water for polymerization. The electrolyte is the combination of potassium phosphate and disodium hydrogen phosphate, with the ratio of 3 to 2: 1; in the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The latex produced by the present invention is of good compatibility with the additives as the paint during the paint preparation. The prepared paint is of excellent fluidity, water retention and machinery stability under the high-cut condition. The improved mortar has the advantages of good permeability, high bond strength and so on.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

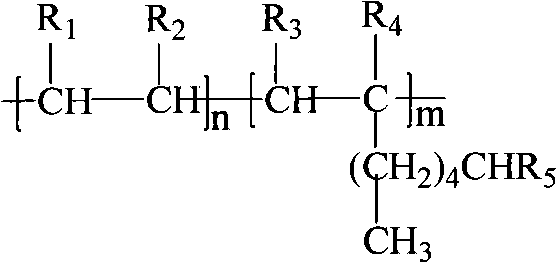

Cation acrylamide copolymer water-in-water emulsion and its preparation method

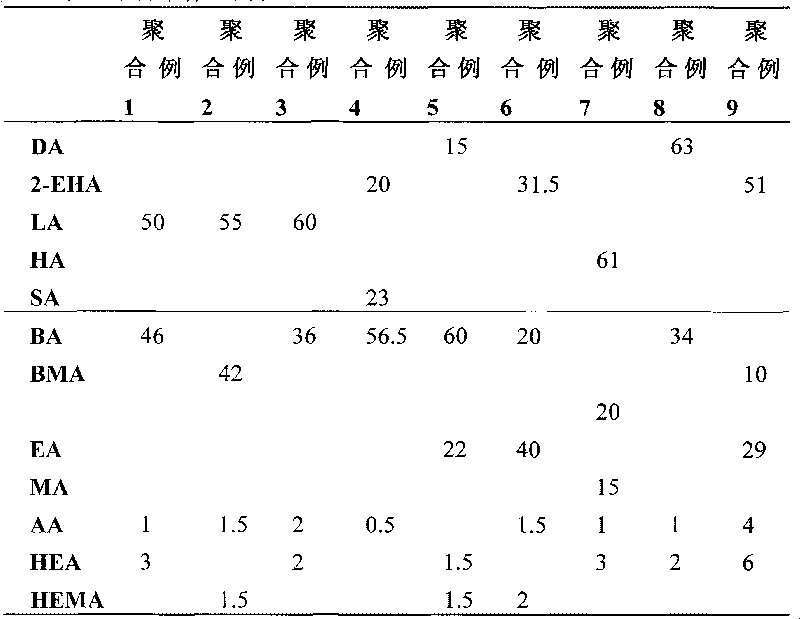

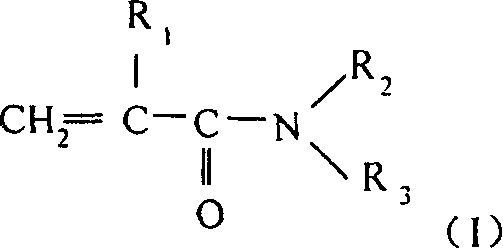

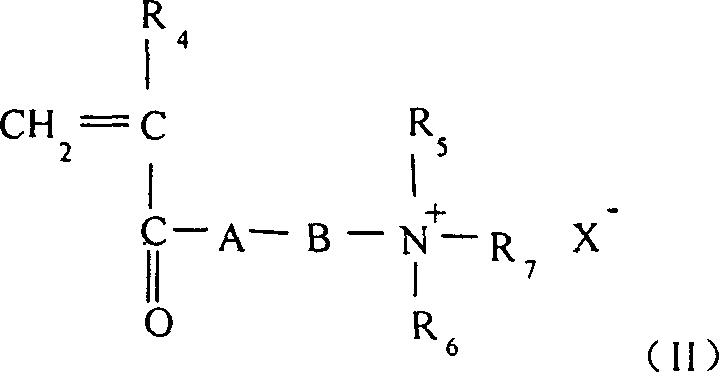

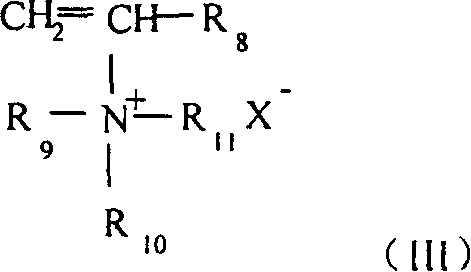

The invention relates to a cationic acrylamide copolymer aqueous emulsion-water and the method for preparing the same. The compound comprises 5-25 wt% of cationic polymer, 1.0-15 wt% of polymer stabilizer and 15-32 wt% inorganic salt. Said active cationic polymer comprises 72.8-90 mol% of at least one water-soluble monomer (A), 10-26 mol% of at least one cationic monomer (B), and 0.2-1.0 mol% of at least one hydrophobic monomer (C), and said polymer is prepared through free radical polymerization with pH being 3-8. The monomer (A) (B) possesses general formula respectively, monomer (c) is C1-C8 dialkyl ester of itaconic acid or C1-C32 alkyl ester of acroleic acid or C1-C32 alkyl ester or diene monomer of methacrylic acid. The method is multi-stage, and it can reduce polymerization system viscosity, increase active material content and stability of aqueous emulsion-in-water, which is characterized by high concentration, low cost, good fluidity and easiness for treatment.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

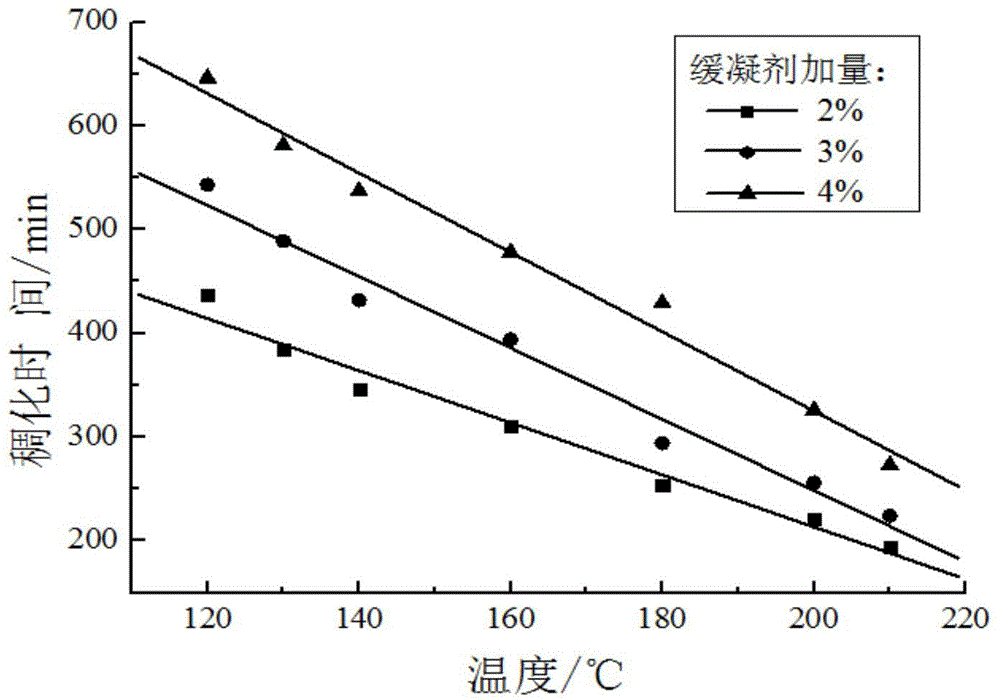

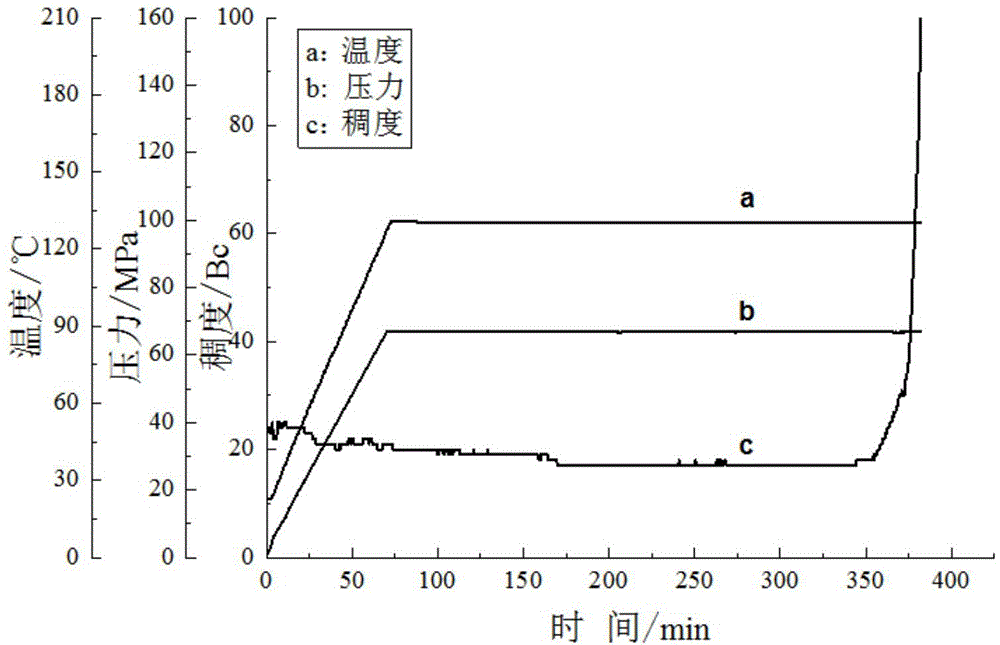

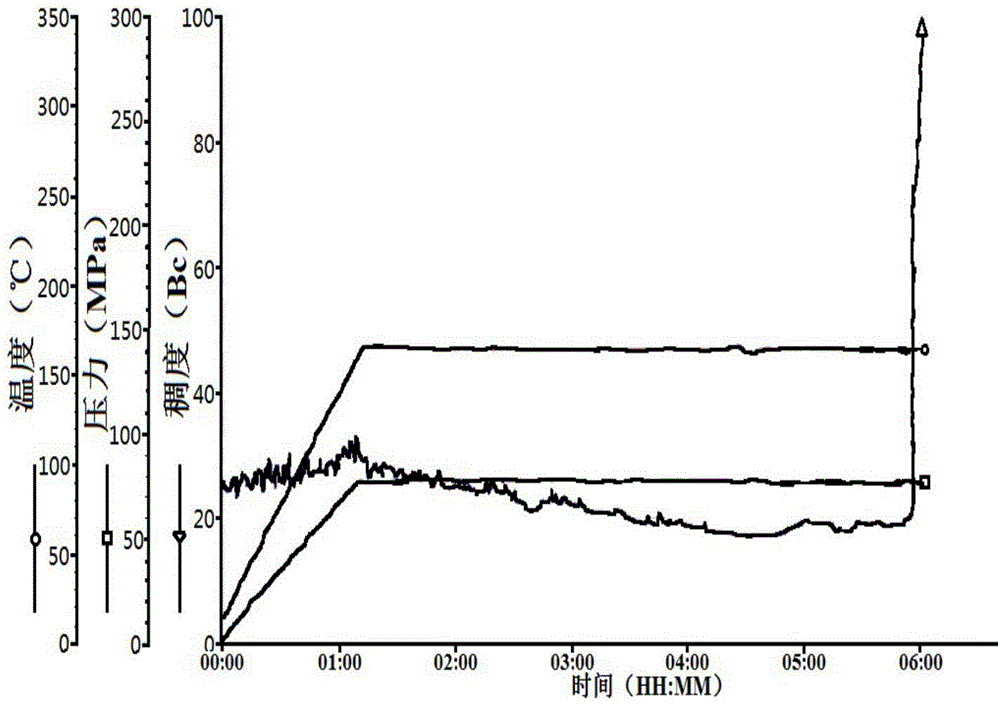

High-temperature-resistant copolymer oil well cement retarder and preparation method thereof

ActiveCN104403056AImprove performanceSolve the problem of severe subsidence at high temperatureDrilling compositionPolymer scienceFumaric acid

The invention relates to a high-temperature-resistant copolymer oil well cement retarder and a preparation method thereof. The preparation method comprises: respectively weighing four polymerization monomers such as 2-acrylamide-2-methylpropanesulfonic acid, diallyldimethylammonium chloride, maleic anhydride or itaconic acid or fumaric acid, and acrylic acid or methacrylic acid according to the mass ratio of 45-80:5-17:7-18:8-20, dissolving the first three monomers in water, then adding sodium polyphosphate and diphenylcarbazide, then successively adding a chain transfer reagent and an initiator, and finally dropwise adding the forth monomer, performing heating reaction and adjusting the pH value, so as to obtain the copolymer retarder. The invention also provides the high-temperature-resistant copolymer oil well cement retarder prepared by the above preparation method. The retarder is resistant to a high temperature up to 230 DEG C and is weak in dispersibility at a high temperature, the cement paste strength develops fast at a low temperature, the addition amount of the retarder has good linear relation with the cement paste hardening time, and the cement paste comprehensive performance is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

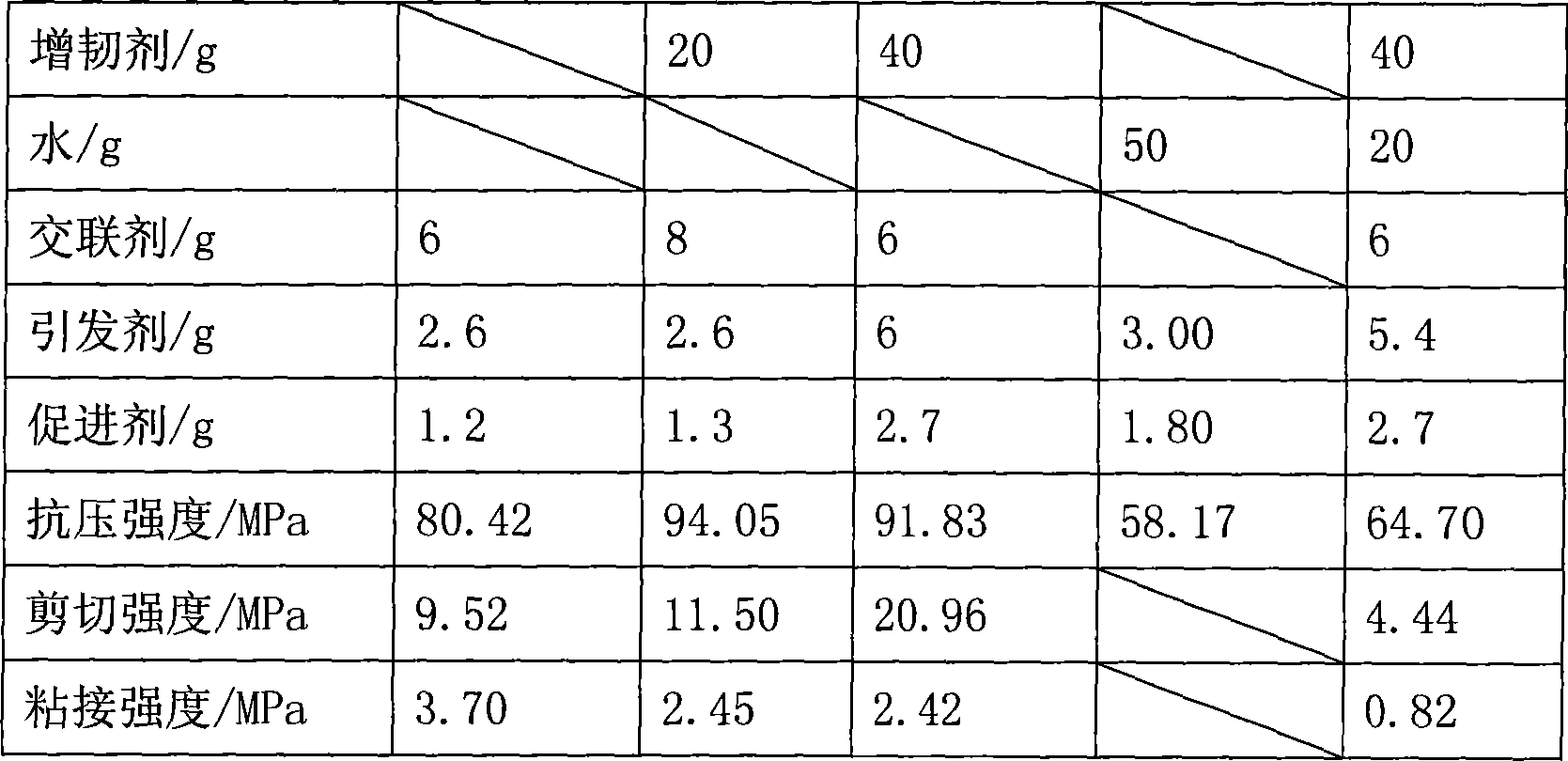

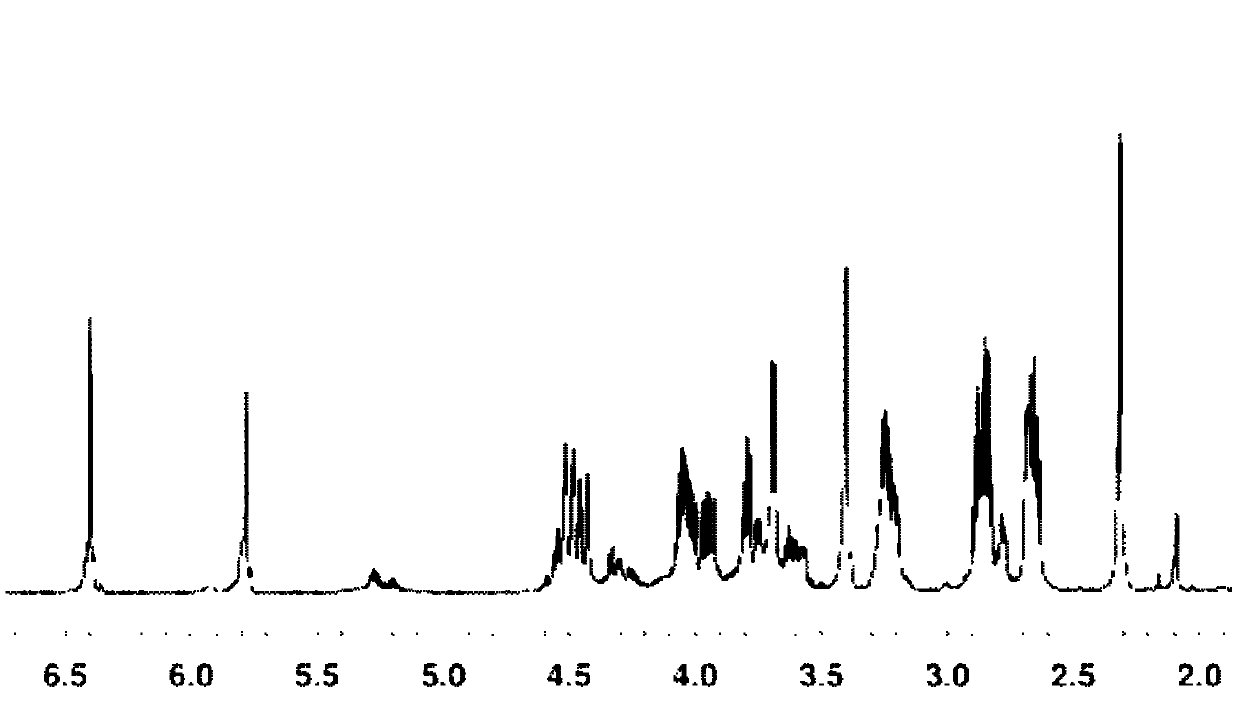

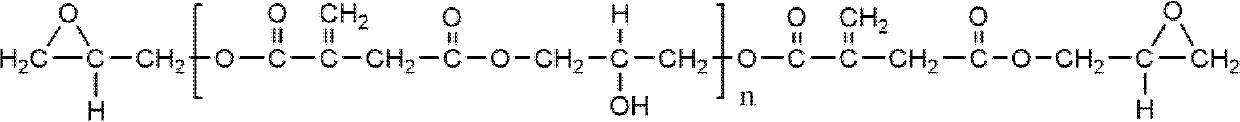

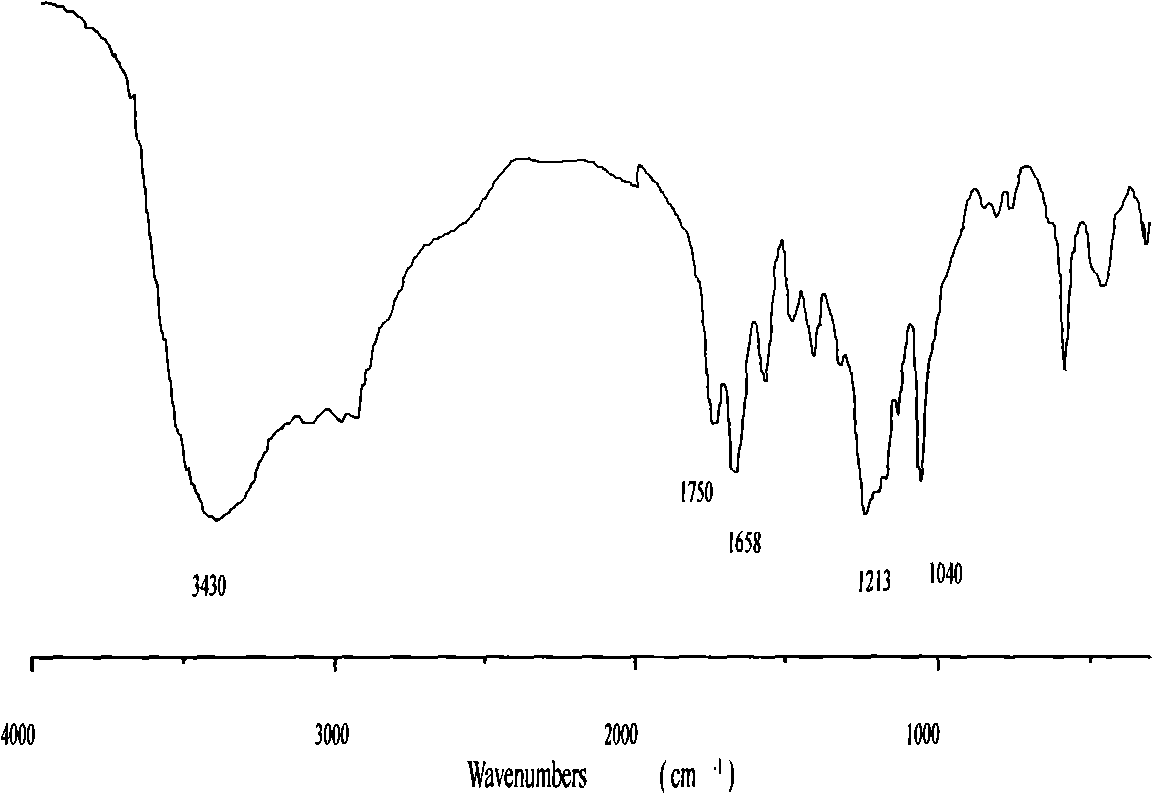

High-strength water-based itaconic acid epoxide resin grouting material and preparation method thereof

The invention discloses a high-strength grouting material of aqueous itaconic acid epoxy ester resin and making method, which comprises the following parts: 30-80% neutralized aqueous itaconic acid epoxy ester resin, 10-70% diluent, 0-100% water, 1-10% crosslinking agent, 0-0.1% storing stabilizer, 0-0.5% deoxidizer, 1-4% initiator, 0.5-4% accelerant and 0-2% boosting accelerant. The invention reduces the water content of grouting material to add the content of polymerisable component and increase the mechanic strength of the material, which is fit for kinds of engineering reinforcing and water shutoff course to make high-strength aqueous epoxy cement slurry through blending with cement slurry.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

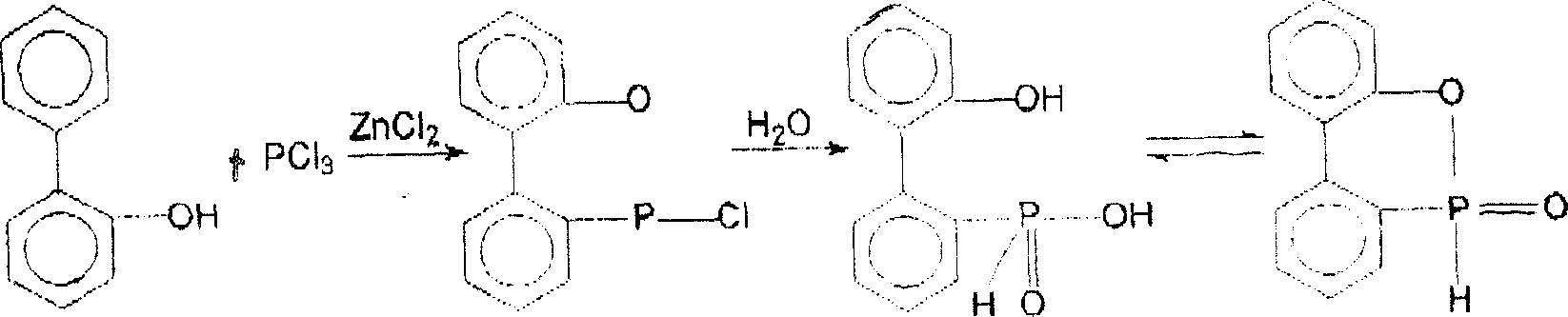

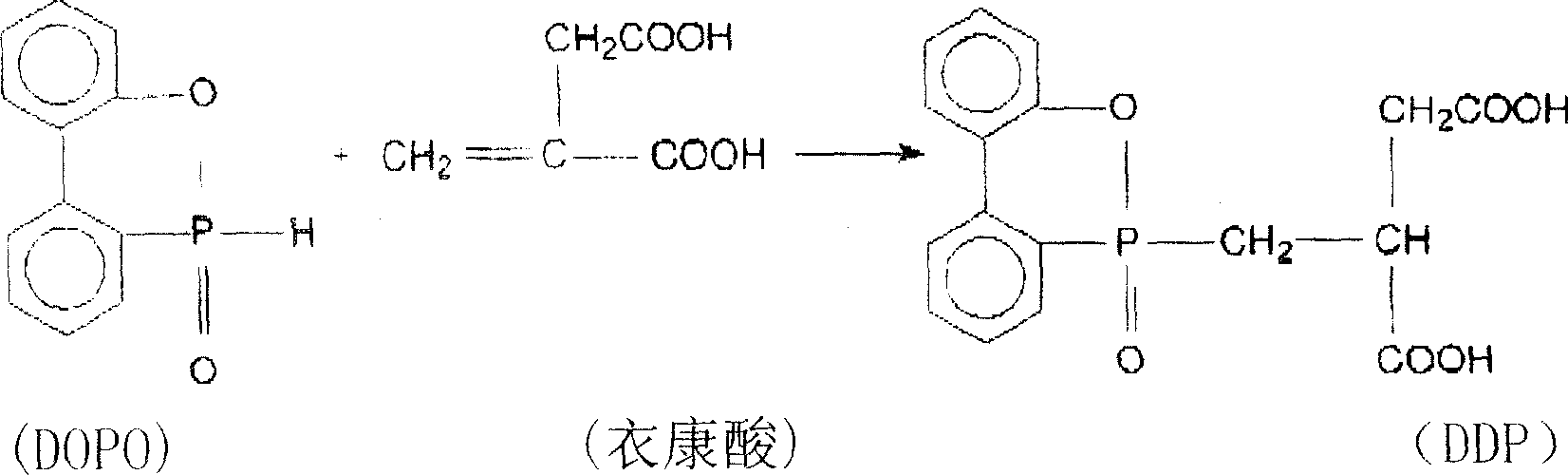

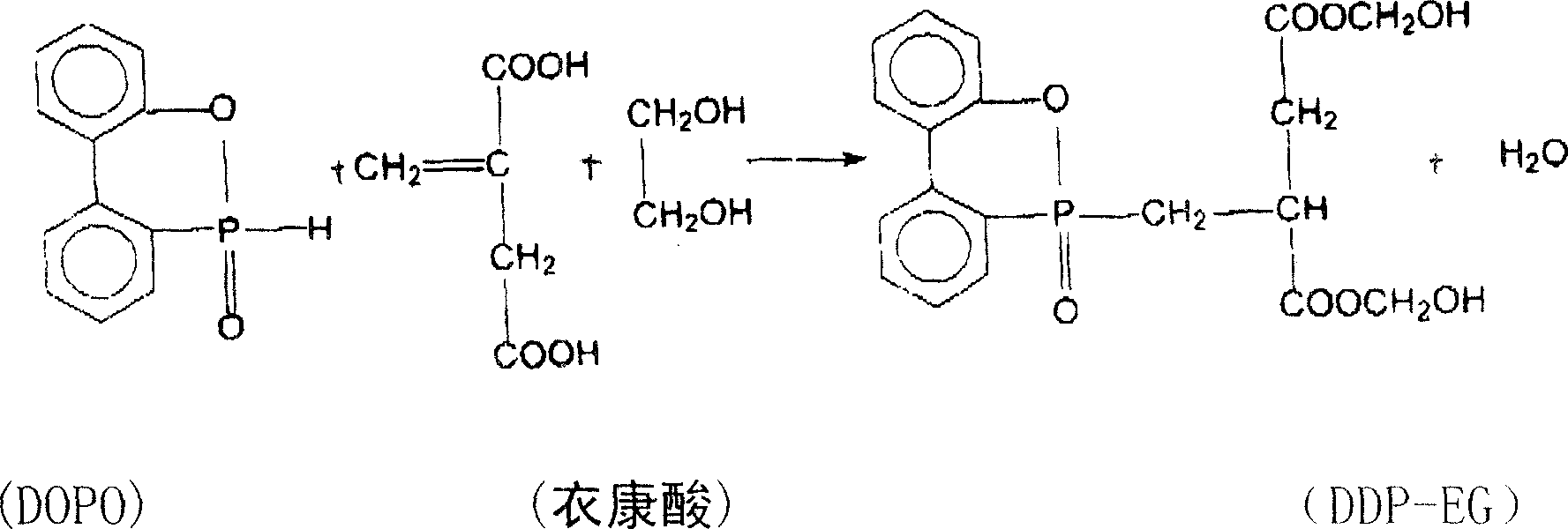

9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

InactiveCN101108864ALight colorHigh yieldGroup 5/15 element organic compoundsGlycol synthesisPhosphorus trichloride

The invention discloses a preparation method of the 9, 10-dihydro-9-oxa-10-phosphahenanthrene-10-oxide and the derivatives DDP, DDP-EG and DOPO-BQ. The invention has three steps to synthesize the DOPO: (1) preparation of CDOP, the O-phenylphenol (OPP) reacts with the Phosphorus trichloride (PCl3) with ZnCl2 as the catalyst. (2) purification of CDOP, vacuum distillation is carried out. (3) DOPO with high purity and yield is gained through the hydrolysis and crystallization. The preparation materials comprises the O-phenylphenol, the Phosphorus trichloride, the toluene, the alcohol, the deionized water, the itaconic acid, the ethylene glycol, the p-benzoquinone and the acetone. The invention simplifies the process conditions, improves the product purity with good production stability and repeatability. The purity of the product reaches over 99.0 per cent, the content of the chloride is below 50ppm, the OPP is about 0.01 per cent, the color is about 10 (10 per cent solution of acetone), the zinc-ion is less than 10ppm. The preparation method of the derivatives DDP, DDP-EG, DOPO-BQ is simple, good in stability and high in yield.

Owner:魏铭杉

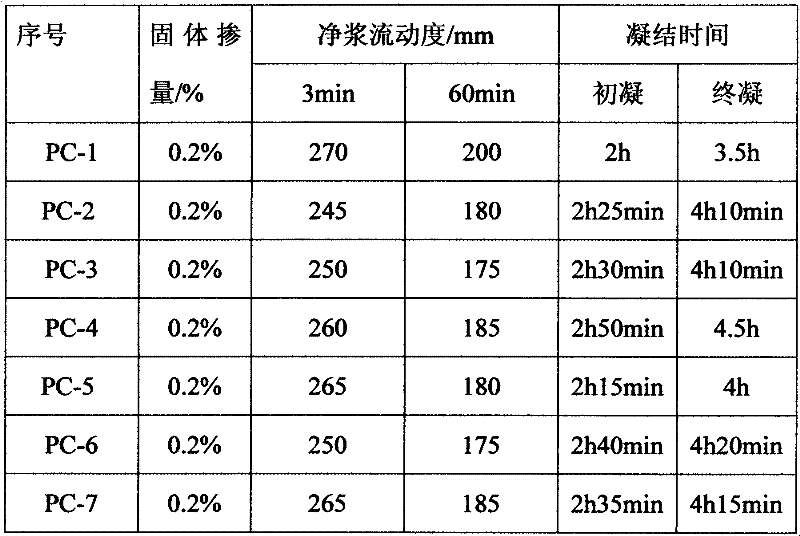

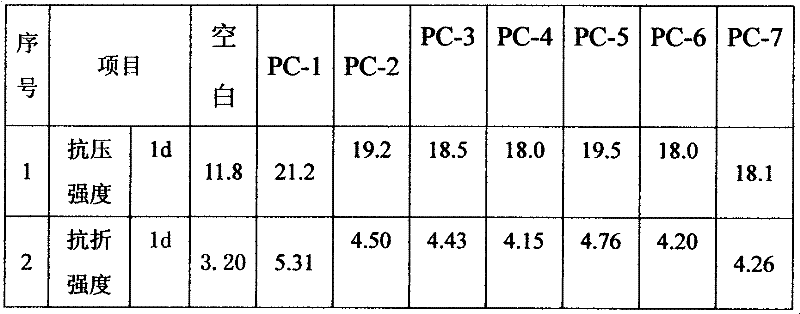

Early-strength polycarboxylic acid water reducing agent

The invention relates to an early-strength polycarboxylic acid water reducing agent and a preparation method thereof. The early-strength polycarboxylic acid water reducing agent is in a liquid state, and the solid content is 40%. The preparation method comprises the following steps: polymerizing modified polyoxyethylene ether or polyoxypropylene ether, (methyl)acrylic acid or itaconic acid, acrylamide, sodium methyl propenyl sulfonate and other monomers under the actions of a molecular weight chain initiator and a chain transfer agent; and neutralizing to obtain the water reducing agent containing carboxy, amino, sulfonic and polyethenoxy side chains. The early-strength polycarboxylic acid water reducing agent provided by the invention has the advantages of low alkali content and high water reducing rate; and when the early-strength polycarboxylic acid water reducing agent, which accounts for 0.6-1.4 wt of the cementing material, is added to the cementing material, the concrete is labor-saving for operation, and the cement mixture has high flowability and good workability. The early-strength polycarboxylic acid water reducing agent can effectively shorten the setting time and enhance the early strength. The invention has the advantages of simple production technique, easily controlled reaction conditions and no environmental pollution.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Super-tough nylon alloy and preparation method thereof

The invention discloses a super-tough nylon alloy, which is characterized by comprising raw material by weight percent: 65-90% of nylon, 10-35% of itaconic acid grafting ethylene-alpha-octylene copolymer (POE-g-ITA), 0.1-1% of antioxygen, 0.2-1% of lubricating agent, TAF. A method for preparing the super-tough nylon alloy is characterized by comprising the following steps: placing all raw material into a high mixer and mixing the raw materials for 5-10min; then placing the mixed raw materials into a double screw extrusion machine for extrusion and pelleting; carrying out traction, cooling and grain-sized dicing, finally drying the grain material; wherein main engine speed is 200-400r / min, temperature is 250-280 DEG C. The invention aims to prepare a novel super-tough nylon material which can be widely applied to the fields such as automobiles, electric products, office appliances and constructional engineering.

Owner:BEIJING UNIV OF CHEM TECH

Article comprising ionomer and polyamide

InactiveUS20090298372A1Synthetic resin layered productsCellulosic plastic layered productsPolyamideCarboxylic acid

A multilayer structure comprises a surface layer, a substrate, and optionally additional layers wherein the surface layer comprises or is produced from a blend comprising an ionomer and a polyamide; the ionomer is or must be derived from at least three repeat units derived from ethylene, an α,β-unsaturated C3-C8 carboxylic acid, and a dicarboxylic acid or its derivative; and the dicarboxylic acid or its derivative is maleic acid, fumaric acid, itaconic acid, maleic anhydride, fumaric anhydride, itaconic anhydride, maleic acid monoester, fumaric acid monoester, itaconic acid monoester, or combinations of two or more thereof.

Owner:PERFORMANCE MATERIALS NA INC

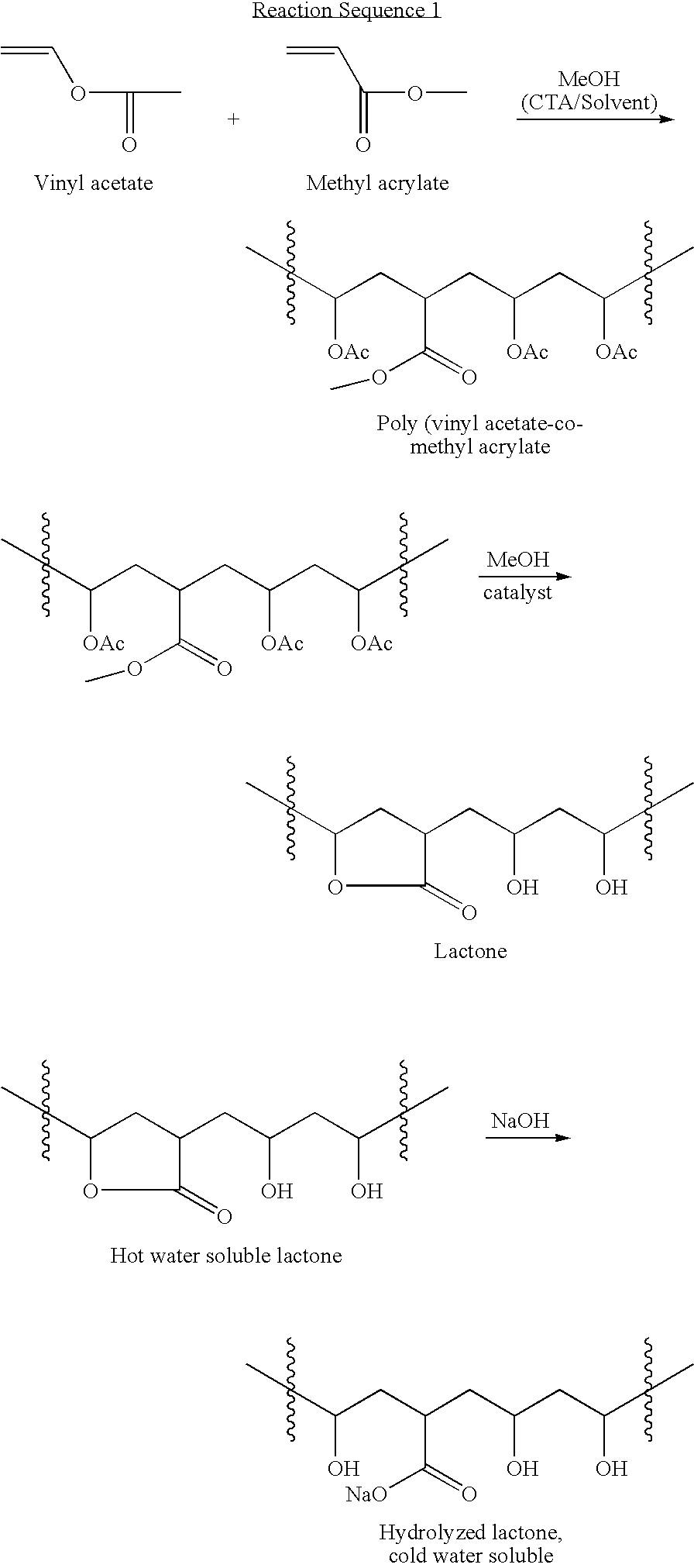

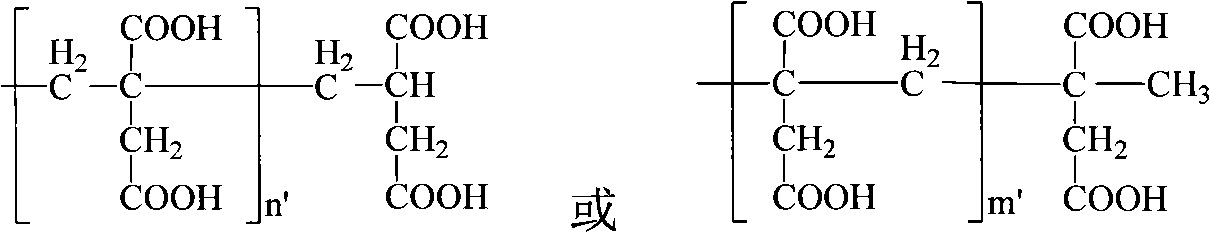

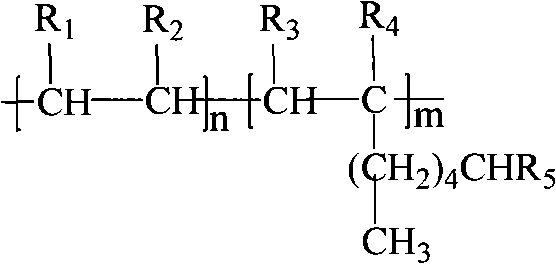

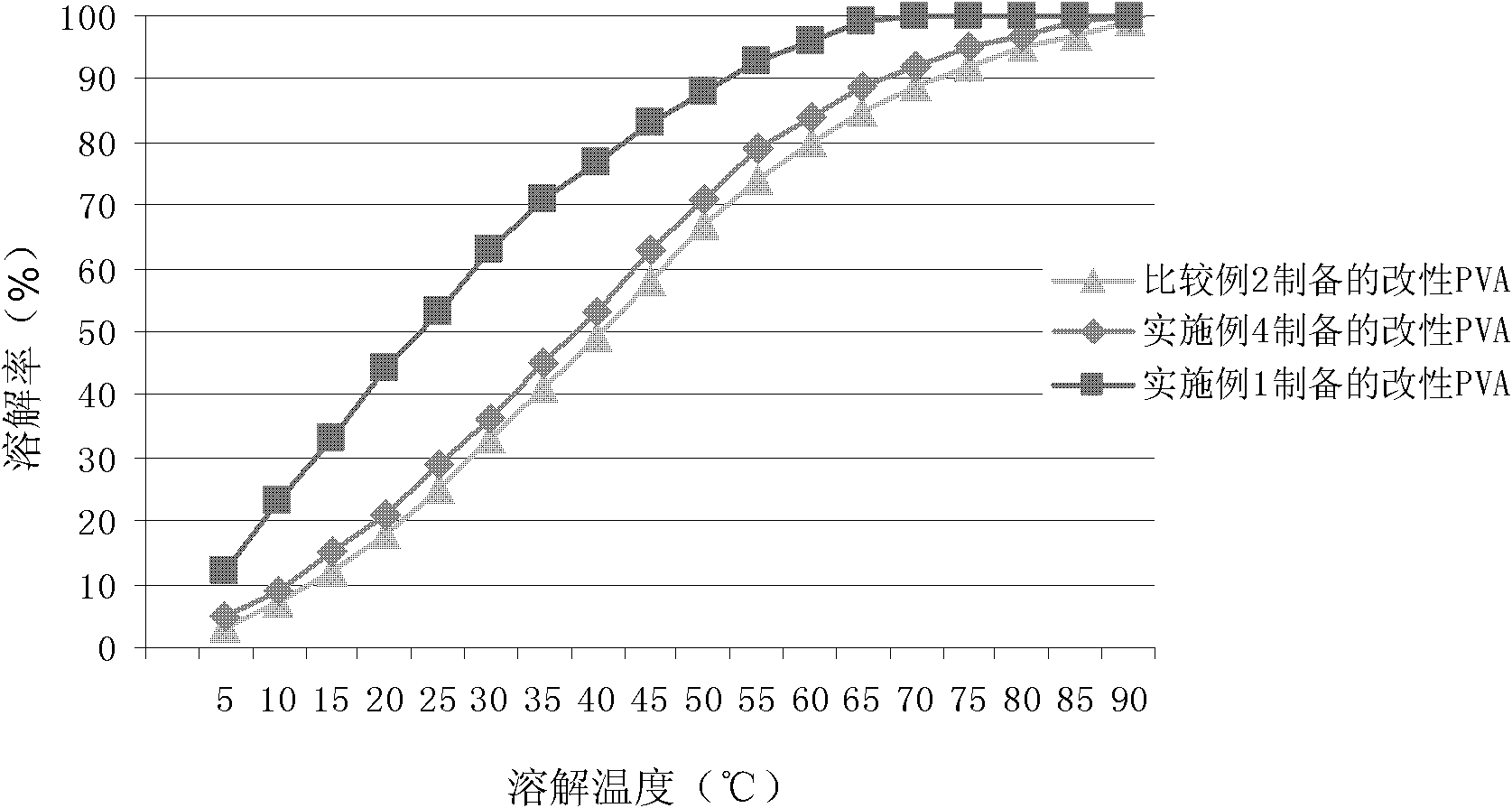

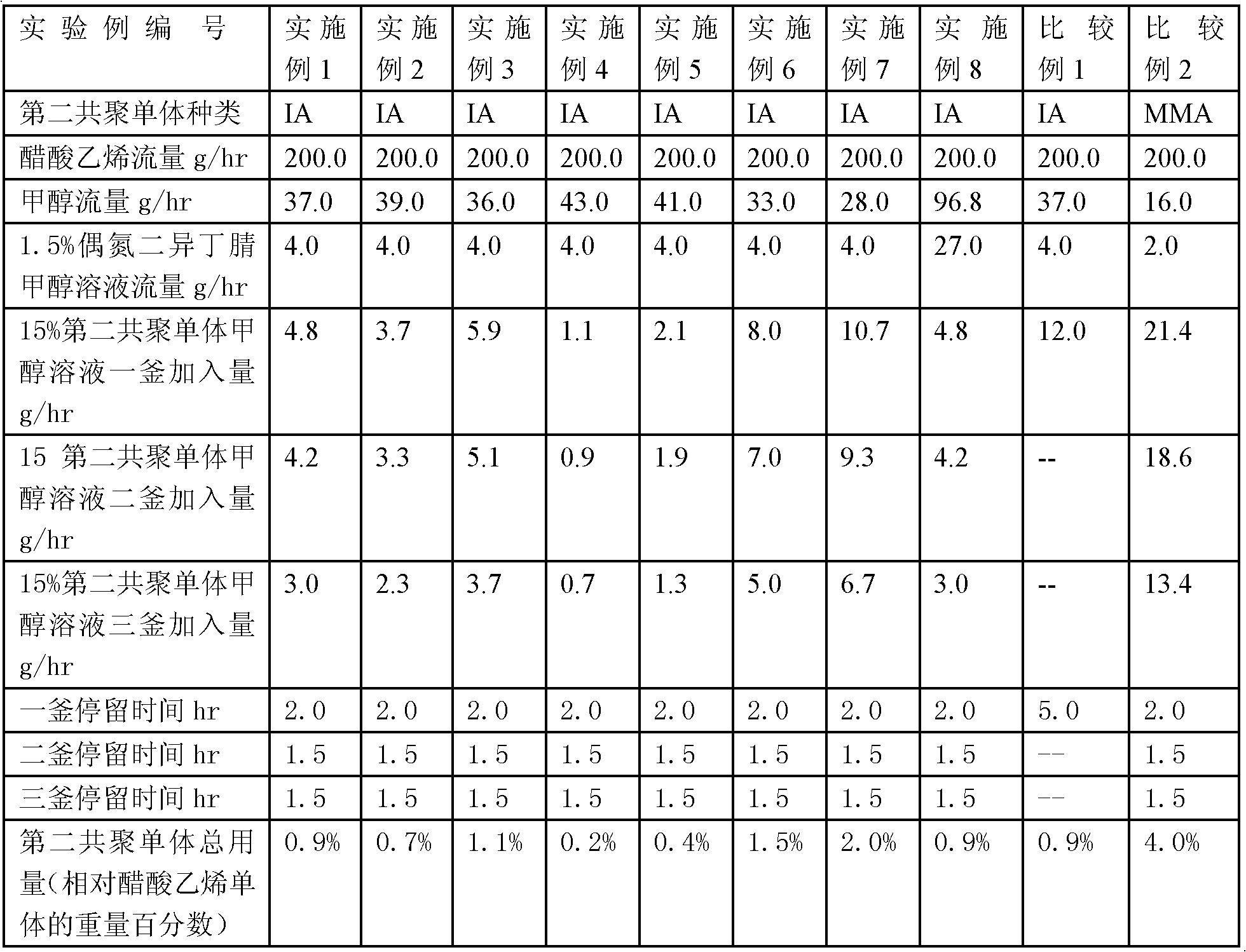

Carboxyl modified polyvinyl alcohol and method for preparing same

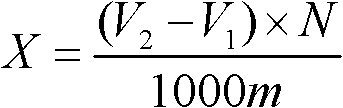

Provided is carboxyl modified polyvinyl alcohol, which is prepared with raw materials of a monomer, an initiator and a solvent. The monomer comprises vinyl acetate and a second comonomer, the second comonomer is one solvent or a combination of any solvents selected from maleic acid, itaconic acid, glutaconic acid and itaconic acid anhydride. The preparation method comprises that the continuous polymerization in three kettles is adopted; the vinyl acetate monomer, the second comonomer prepared with the above solvents and the initiator solution are added into three serial polymerization kettles to react; the residence time of the reaction in each polymerization kettle is 60-180 min; and the carboxyl modified polyvinyl alcohol is then prepared through alcoholysis. The method has advantages of high polymerization efficiency, high production efficiency and simple operation. The carboxyl modified polyvinyl alcohol is characterized by excellent cross linking reaction performance, water solubility performance, dispersing performance, rheological performance, anti-skinning performance and anti-foaming performance.

Owner:CHINA PETROCHEMICAL CORP +1

Polyacrylonitrile-based hollow carbon fiber precursor and preparation method thereof

ActiveCN101768791ASmall outer diameterTightly boundHollow filament manufactureWet spinning methodsCarbon fibersItaconic acid

The invention relates to a polyacrylonitrile-based hollow carbon fiber precursor and a preparation method thereof. The polyacrylonitrile-based hollow carbon fiber precursor of the invention can be used for preparing polyacrylonitrile-based hollow carbon fibers. An acrylonitrile binary copolymerization system containing itaconic acid or an acrylonitrile ternary polymerization system containing itaconic acid and methyl acrylate is adopted for spinning by a wet spinning process matched with a circular arc slit spinneret plate, and multiple filament bundles of the hollow carbon fiber precursor can be obtained, wherein the dimension of the outer diameter and the structure of the precursor meet the requirement of a conventional preoxidation carburizing process for precursor fibers, and the groove structure on the surface of the fiber is favorable for improving the interface performance of composite materials.

Owner:BEIJING UNIV OF CHEM TECH

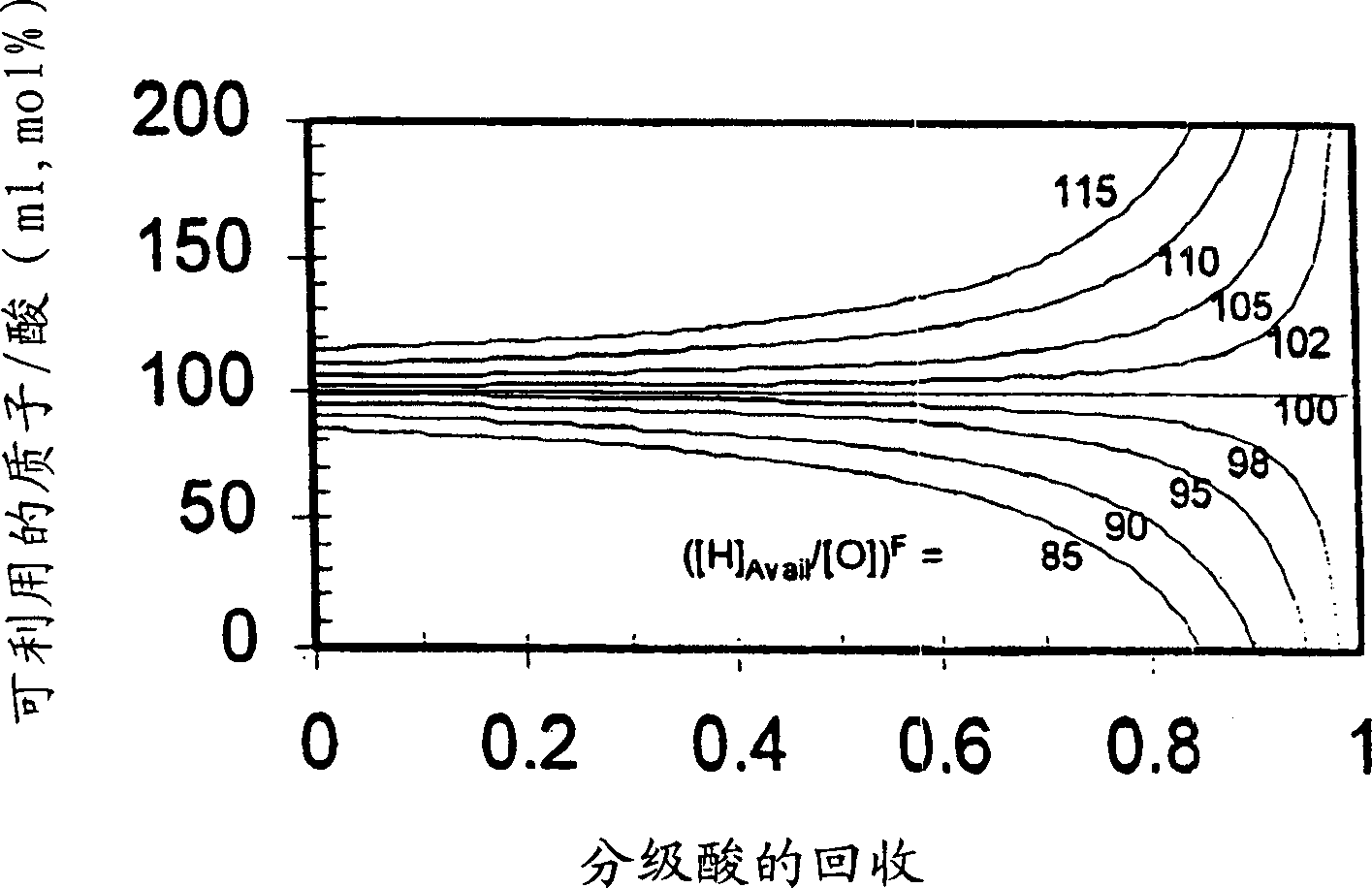

Process for recovery of organic acids from aqueous solutions

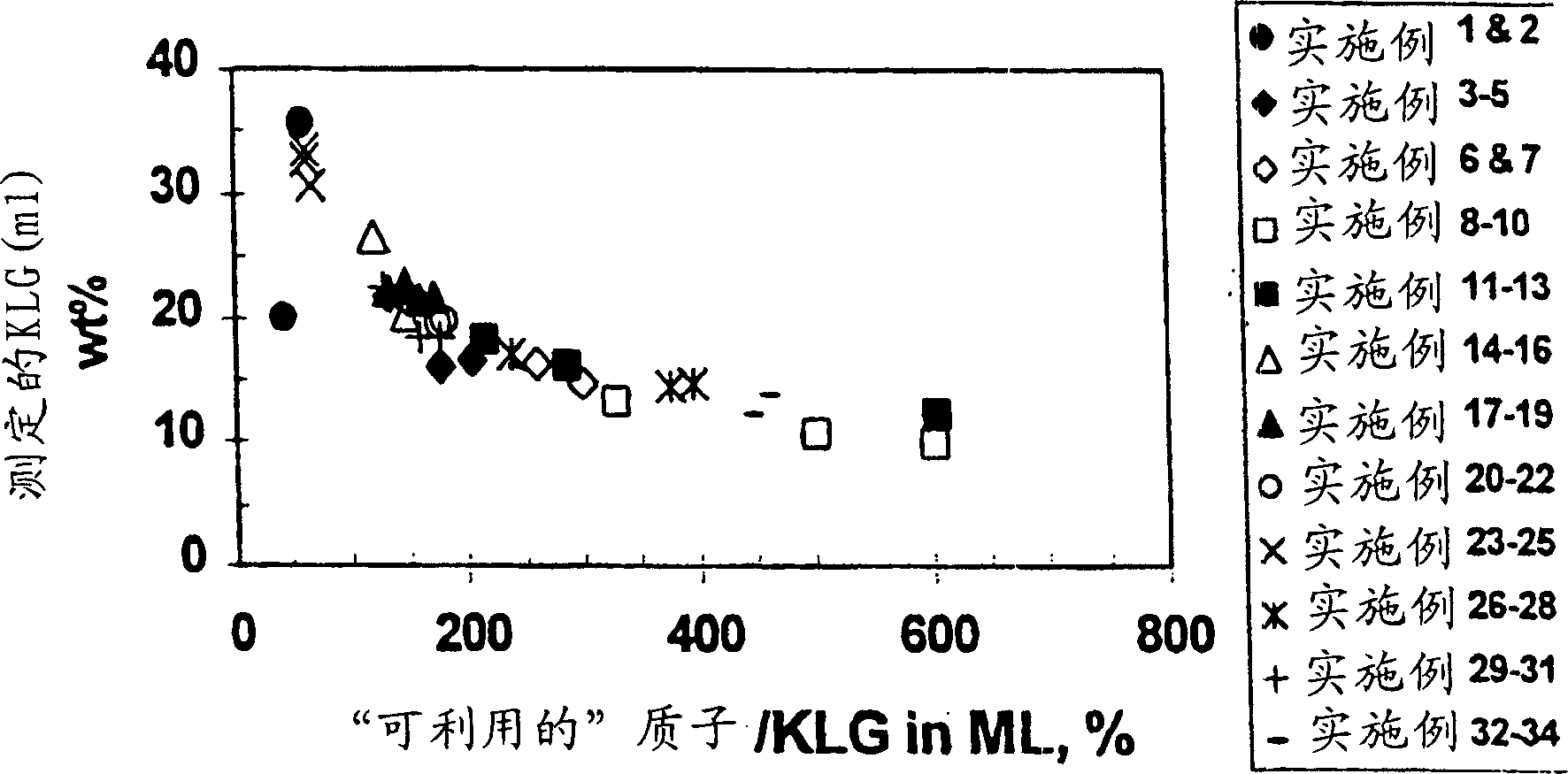

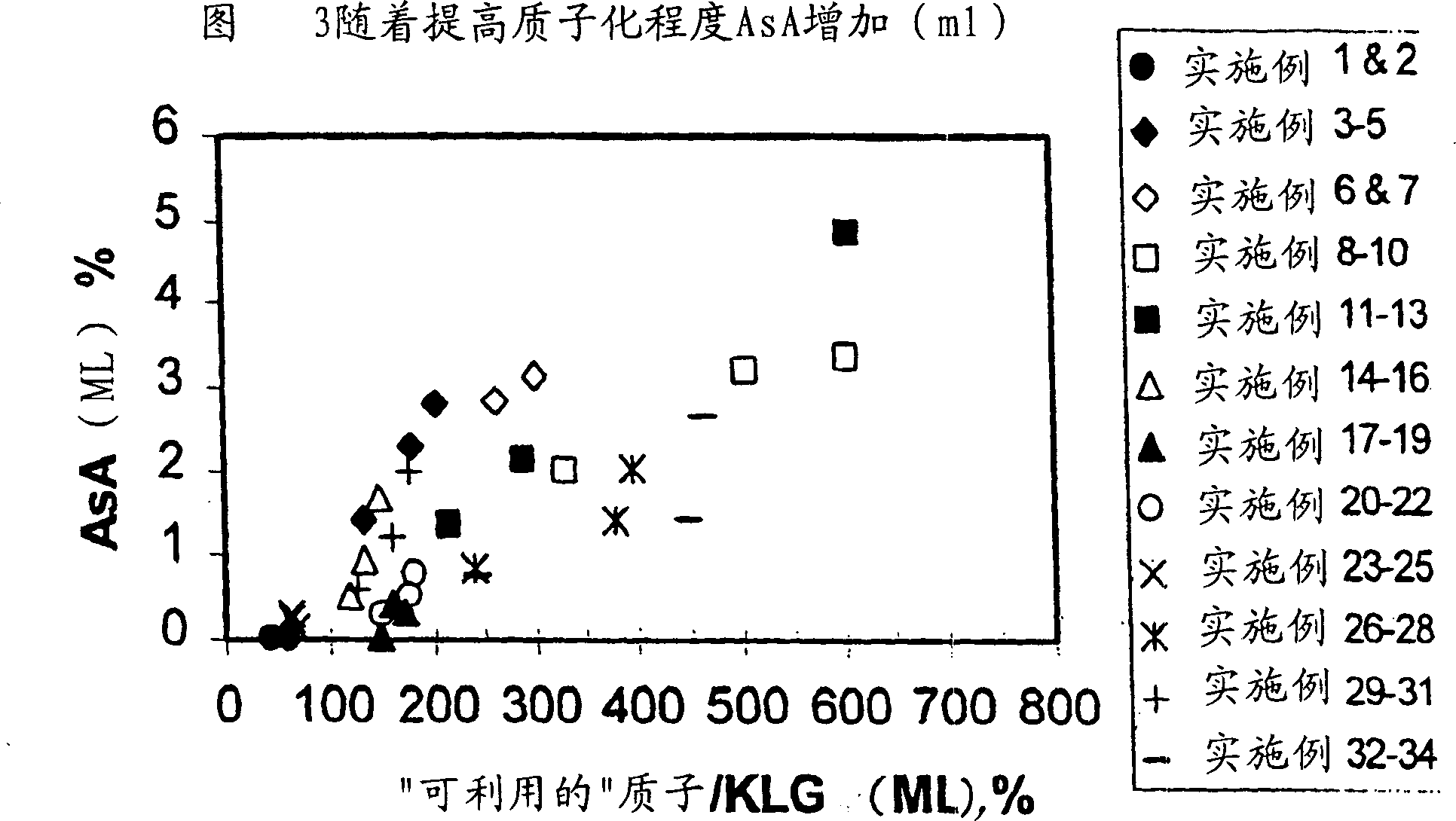

A process for recovering a desired organic acid from a solution includes the steps of: providing an aqueous solution including at least one desired organic acid or its acid anion; adjusting the proton concentration in the aqueous solution to a desired level, with the desired proton concentration being selected, at least in part, by the amount of available protons needed to associate with the acid anions of the desired organic acid(s) to be recovered and / or acid anions that are weaker than the desired organic acids; and recovering at least a portion of the at least one desired organic acid from the aqueous phase. The desired proton concentration can be based on the amount of available protons being greater than, less than or substantially equal, to the amount of protons needed to associate with the anion of the desired organic acid(s) and acid anions that are weaker than the desired organic acid(s).Specific examples of suitable organic acids include, but are not limited to, ascorbic, succinic, tartaric, glyconic, gulonic, citric, lactic, hialic, maleic, acetic, formic, gluconic pyruvic, propionic, butyric, itaconic acids and mixtures thereof. One embodiment of the present invention relates to the recovery of 2-keto-L-gulonic acid (KLG) from aqueous solutions such as fermentation baths.

Owner:EASTMAN CHEM CO

Animal feed and/or water amendments for lowering ammonia concentrations in animal excrement

ActiveUS20140106024A1Reduce gaseous ammonia concentrationGood effectAnimal feeding stuffAccessory food factorsItaconic acidWater soluble

Improved animal feeds and / or waters are provided, which include amendments comprising one or more copolymer salts serving to reduce volatilized ammonia derived from the excrement of animals. The copolymers are preferably water soluble and have substantially equimolar amounts of maleic and itaconic moieties.

Owner:VERDESIAN LIFE SCI

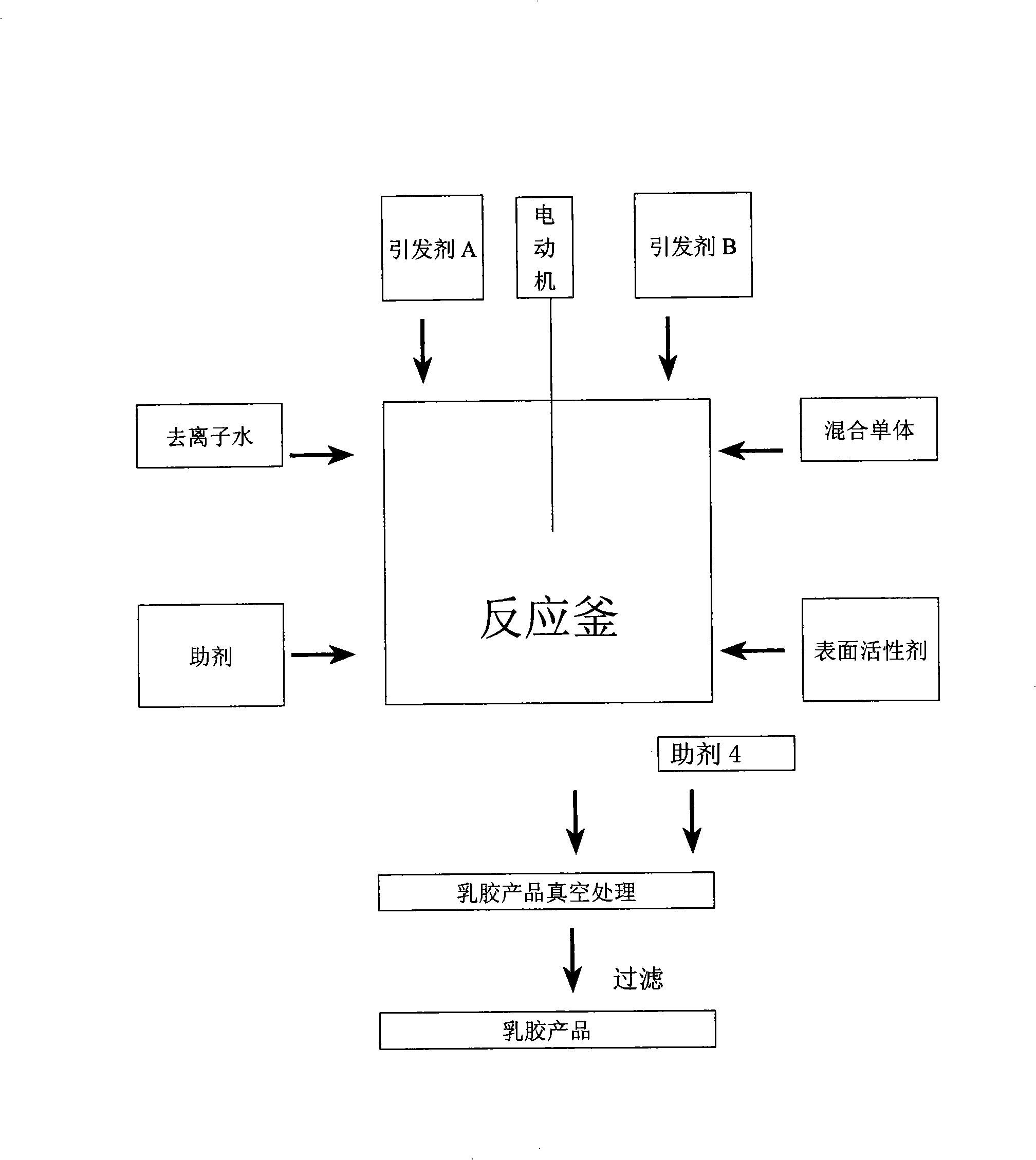

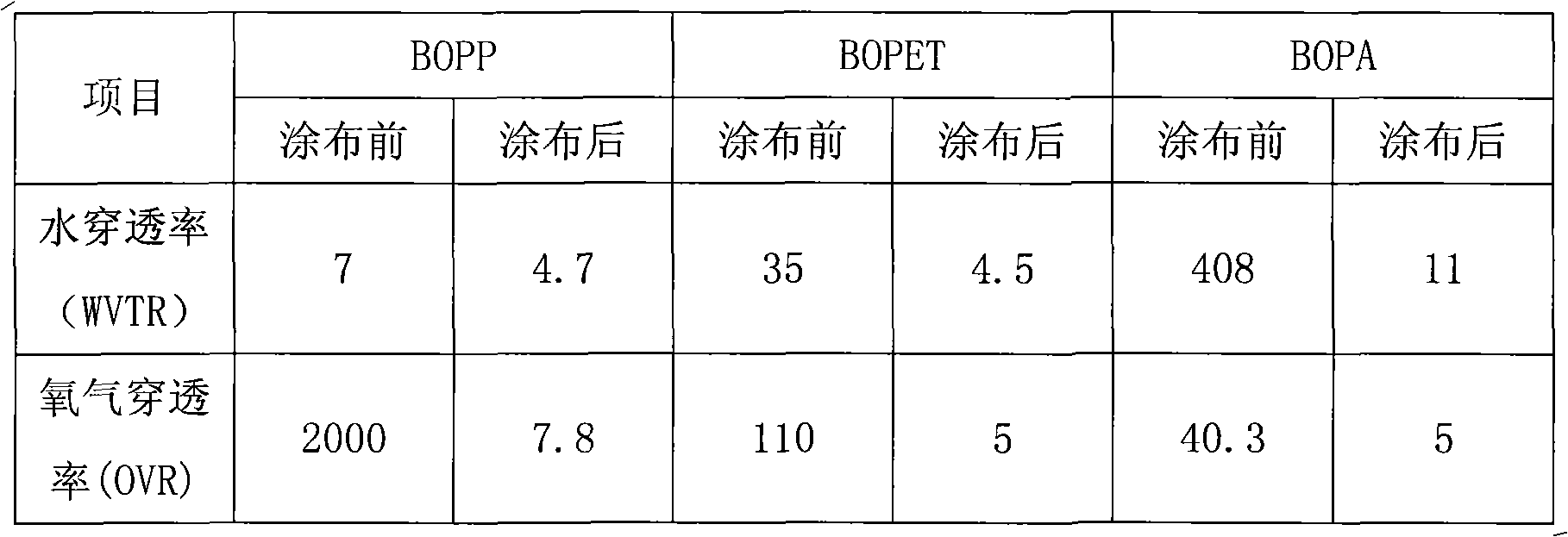

High barrier food package coated membrane latexes by thermal sealing at low temperature and preparation method

InactiveCN101358054AExtended shelf lifeHigh barrierFlexible coversWrappersCoated membraneVinylidine chloride

The invention relates to a low-temperature heat-sealing high-barrier food packaging film coating latex. The composition points of the mixed monomer of the latex is that vinylidene chloride accounts for 80 to 93 percent of the total amount of the mixed monomer; methyl acrylate, methyl ethyl oxalate, methyl methacrylate, butyl ester, acrylonitrile or methacrylonitrile account for 2 to 10 percent of the total amount of the mixed monomer; itaconic acid, acrylic acid, methacrylic acid account for 0.5 to 5 percent of the total amount of the mixed monomer; the surfactants added are 0.7 portion of SAS and 0.3 portion of sodium dodecyl sulfate; the additive 3 is 0.01 portion of metallic salt. The preparation method includes the following steps: deionized water, surfactant and additive are added in a reactor; the reactor is vacuumized and the gas is replaced by nitrogen gas; the mixed monomer is added. The product of the invention has the advantages of low temperature heat sealing and high barrier performance, and the food using the product has longer shelf life.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Itaconic acid glycidyl ester, and preparation method and application thereof

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Well cementing high-temperature inhibiting agent for oil gas well and preparation method

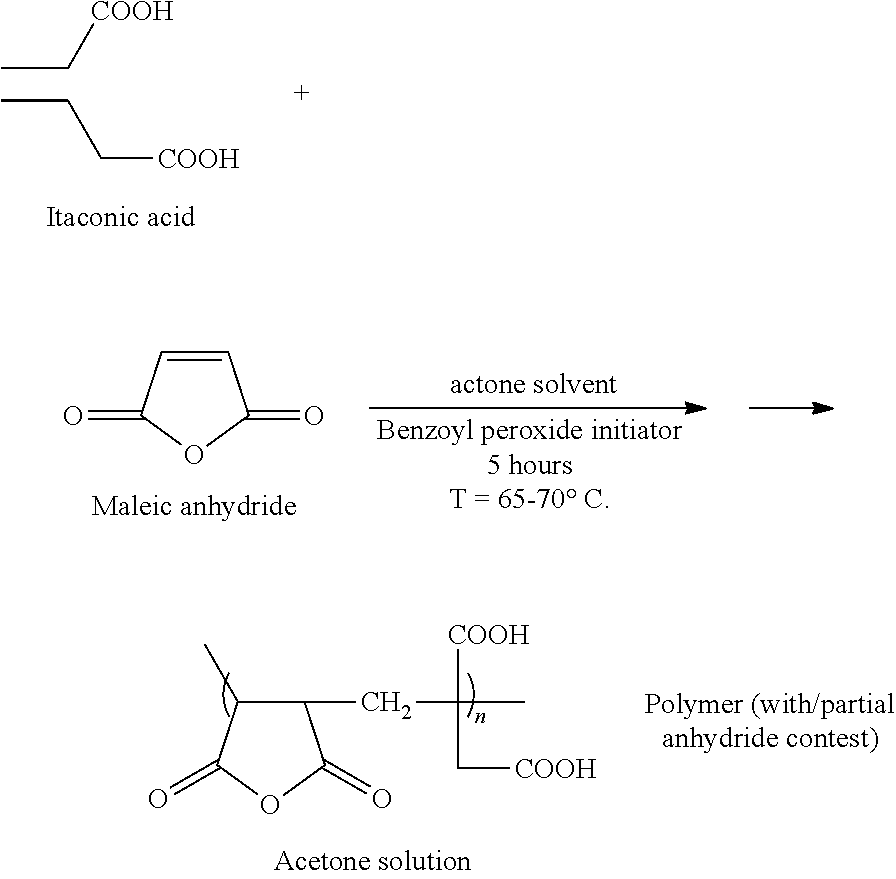

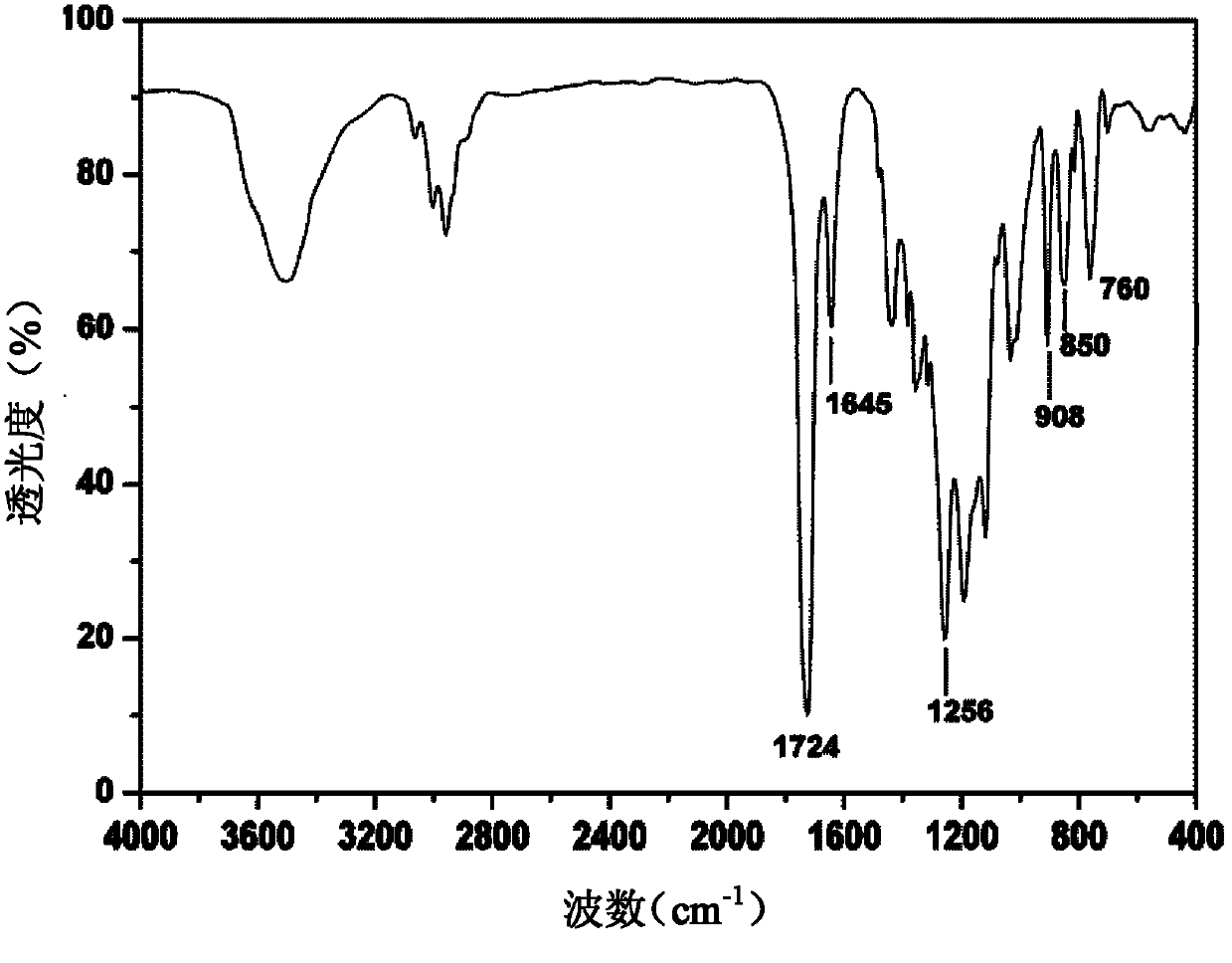

InactiveCN101402849AMeet the needs of safe constructionThickening time adjustableDrilling compositionItaconic acidWell cementing

The invention discloses a novel cement high temperature retarder used for cementing an oil (gas) well as well as a preparing method thereof. The invention relates to a macromolecular polymer which has high temperature resistance and is prepared by using an acetone liquid to deposit and wash an itaconic acid, 2-acrylamide-2-methyl propane sulfonic acid (AMPS), benzoperoxide and the like which are taken as materials. The novel cement high temperature retarder added into a cement pulp has the characteristics of good retardation effect, good fluidity as well as salt and calcium resistance under high temperature and the like. The invention can meet the demands of safe construction on cementing depth wells and ultra-deep wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

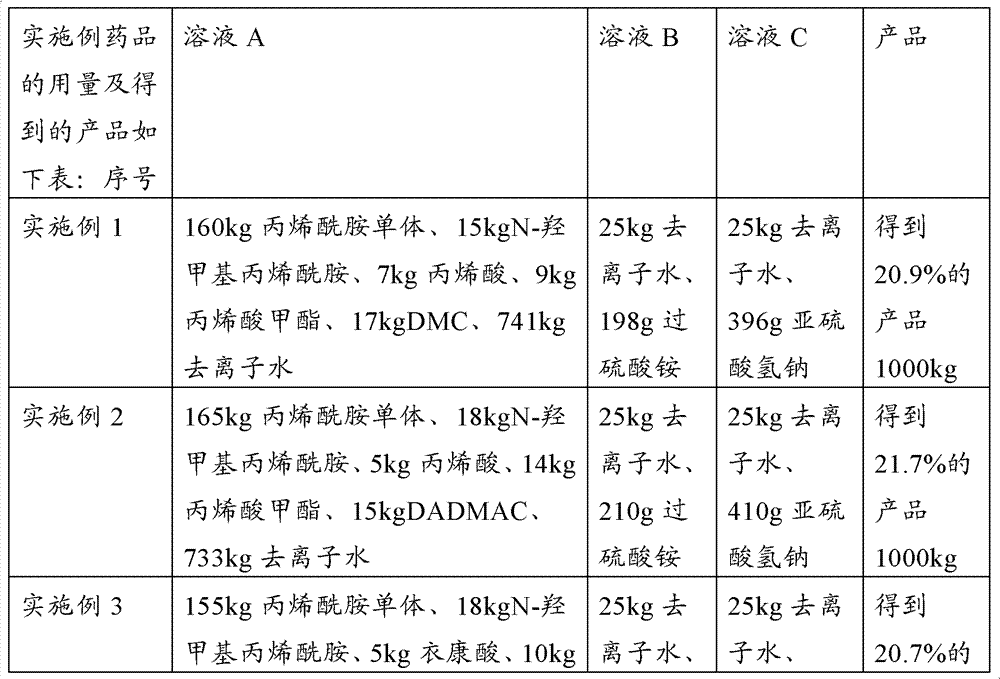

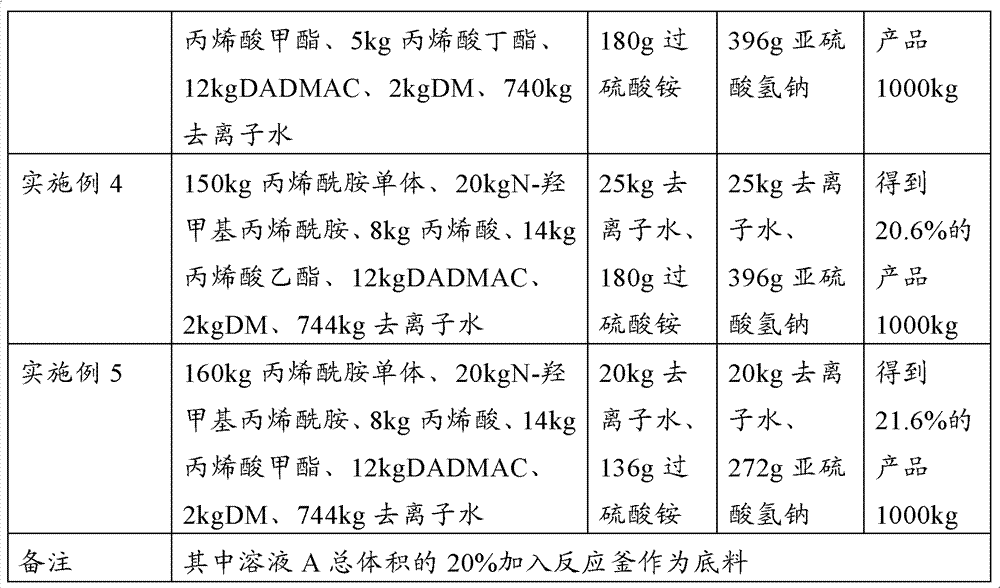

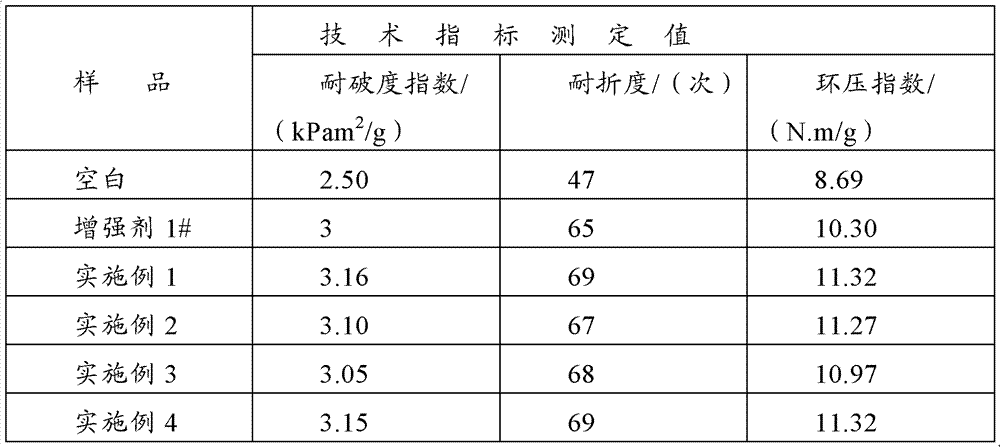

Reinforcing agent for papermaking and preparation method thereof

ActiveCN102776802ASmooth responseSimple processReinforcing agents additionPaper/cardboardCelluloseItaconic acid

The invention relates to a reinforcing agent for papermaking and a preparation method thereof. The reinforcing agent provided by the invention comprises the following raw materials expressed in mass parts: 15 to 16 parts of acrylamide monomers, 1.4 to 2 parts of N-methylolacrylamide, 1.4 to 2.4 parts of acrylic acid, itaconic acid and acrylate monomers, 1.6 to 2.6 parts of cationic monomers, 75 to 80 parts of water and a redox initiation system accounting for 0.1 to 0.5% of the total amount of the monomers. According to the invention, since N-methylolacrylamide, acrylic acid, itaconic acid and the acrylate monomers are added into the reinforcing agent for papermaking, the reinforcing agent is capable of carrying out self-crosslinking to form a net structure, acting forces among the reinforcing agent and between the reinforcing agent and cellulose are improved, and finally, action effects of the reinforcing agent are enhanced; meanwhile, introduction of the cationic monomers into polymer chains enables the reinforcing agent to have good resistance to interference by hetero-ions and improved adaptability.

Owner:湖北广发纸业有限公司

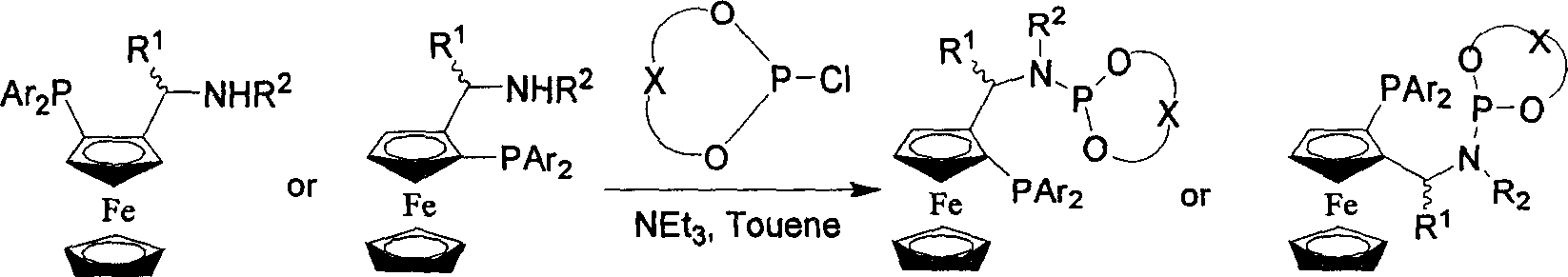

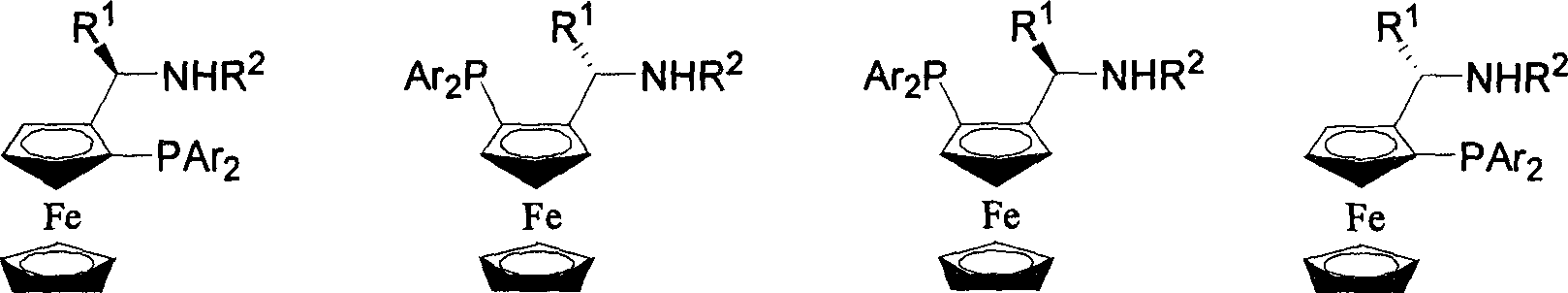

Catalyst using phosphine-phosphoramidite ester as ligand, its preparation method and application

InactiveCN1768944AThe synthetic route is simpleHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPt element

The invention relates to a catalyst which uses the phosphor-phosphamide as ligand, which is the phosphor-phosphamide ligand metallic complex of chiral ferrocenyl bone, wherein, the metal is rhodium, ruthenium, iridium, platinum or palladium; and the mol rate between the ligand and the metal precursor is 1.1:1-2.2:1. The ligand is compounded from chiral ferrocenyl to intermediate compound via several reaction steps, to be processed condensation with phosphite ester chloridate to attain the phosphor-phosphamide ligand with different chiral centers. Said ligand has new structure, stable property, simple compounding method, and wider application to the catalyst, which has higher catalysis activity (TON reaches 10000) and higher spatial selectivity (ee reaches more than 99%) in catalyzing asymmetry hydrogenization of itaconic acid, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

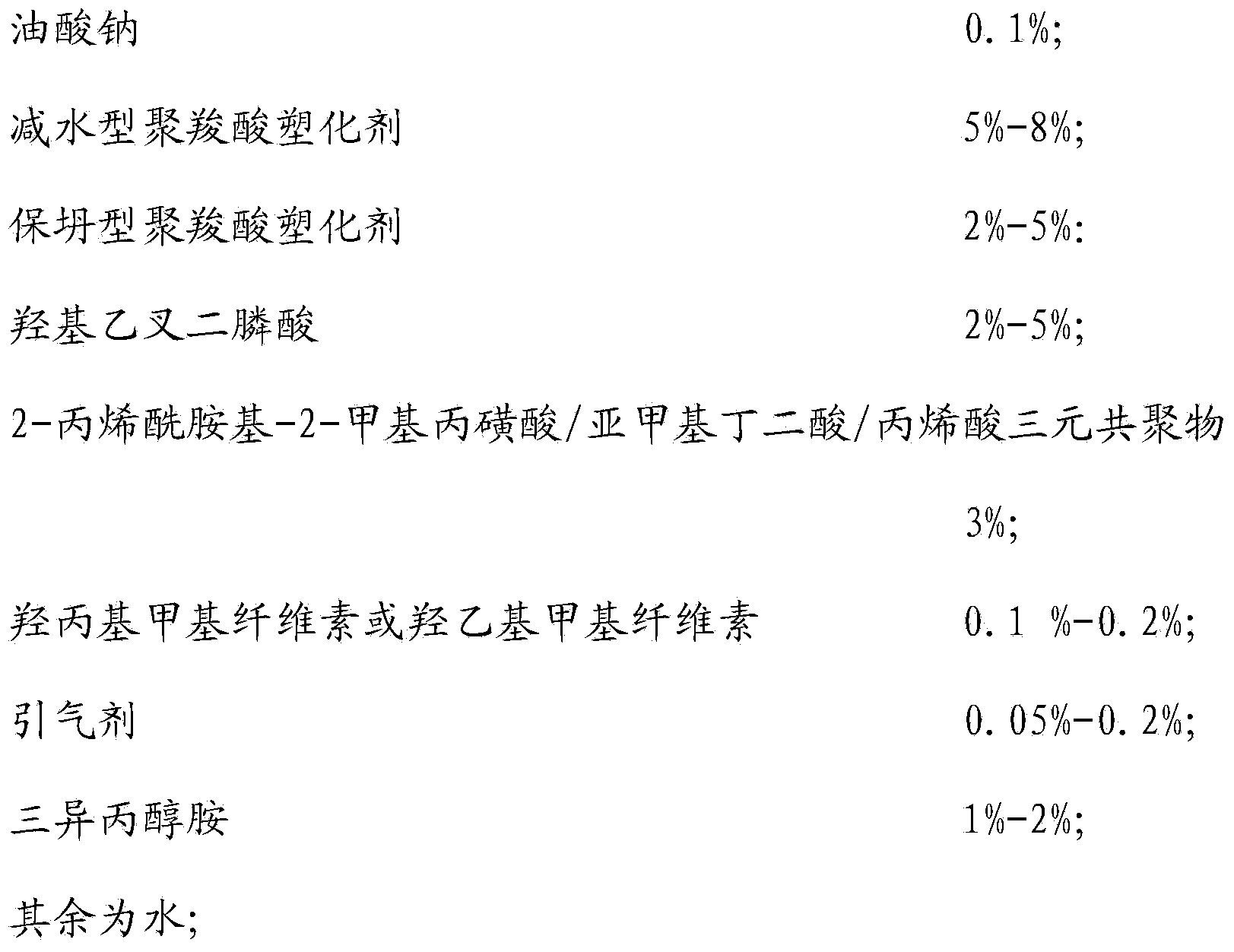

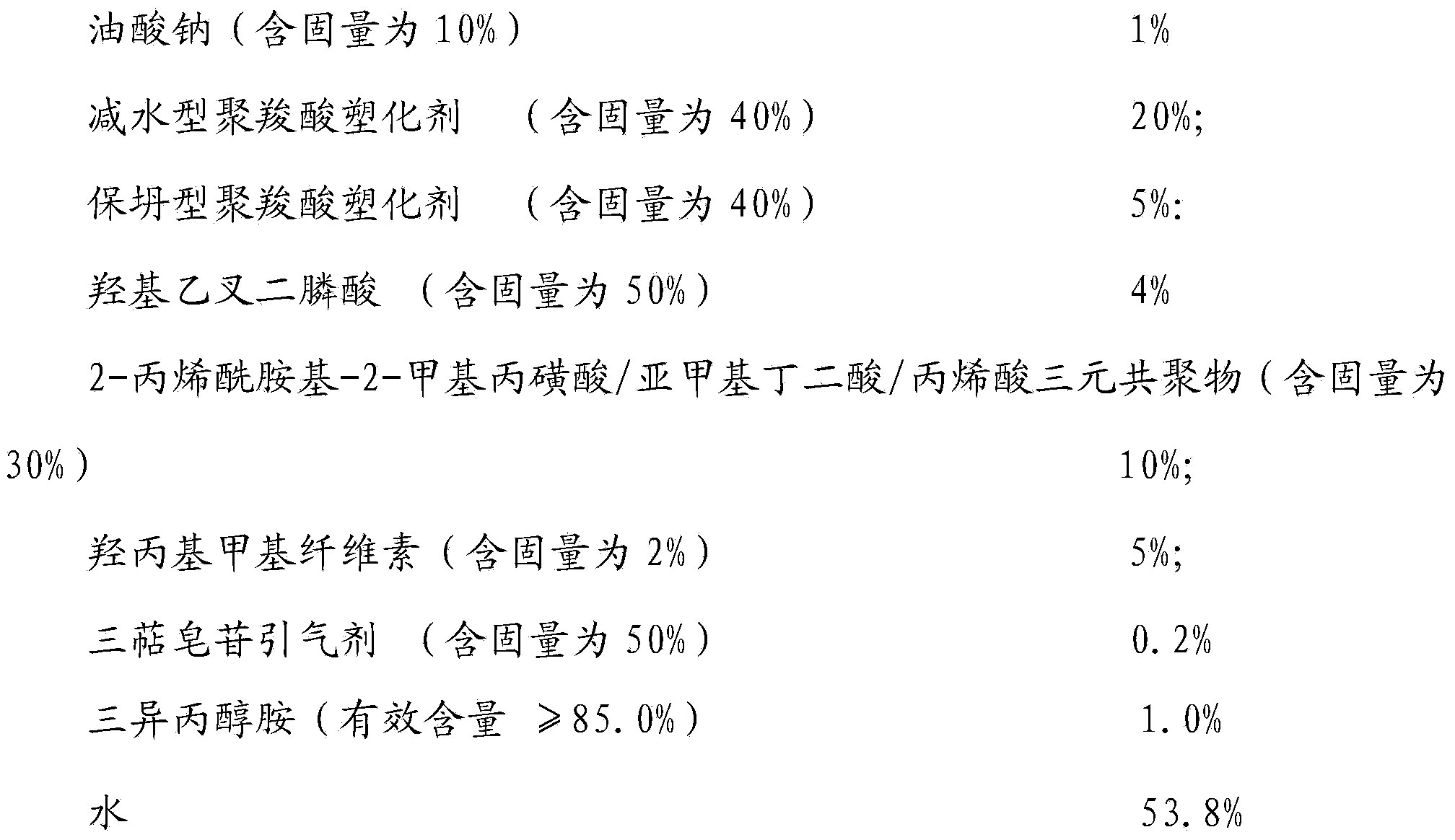

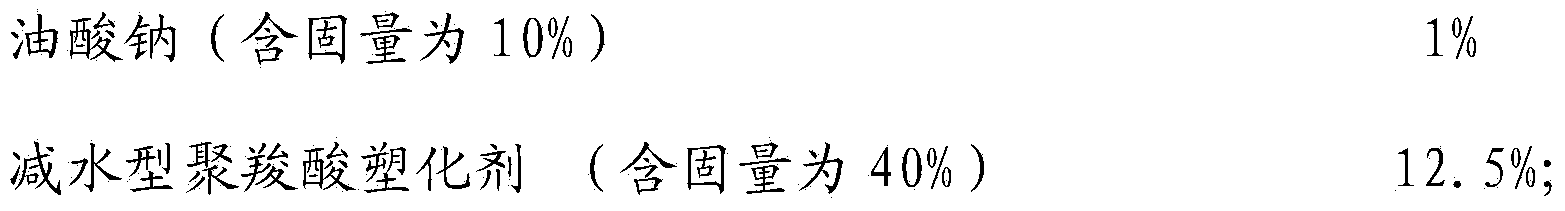

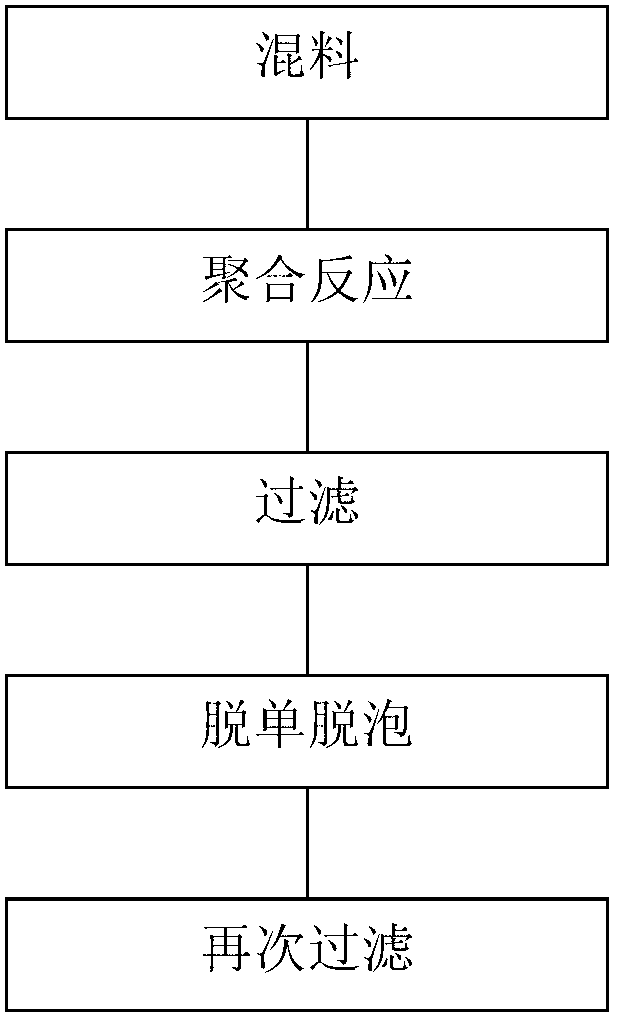

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

Binary acrylonitrile copolymer spinning fluid and preparation method thereof

InactiveCN101158060AUniform chain structureImprove spinnabilityMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention relates to binary acrylonitrile copolymer spinning solution and a corresponding production method. The spinning solution comprises main monomer acrylonitrile and dimethyl sulfoxide solution with copolymer of itaconic acid Beta- monoester; the weight of the main monomer accounts for 90% to 99.5% of that of monomer, while the weight of the comonomer accounts for 0.5% to 10% thereof. The monomer is composed of the main monomer and the comonomer and the weight percentage concentration of the monomer is from15% to 25%. The dimethyl sulfoxide solution, the main monomer acrylonitrile, the comonomer, free radical initiator of azobisisobutyronitrile are added to a reactor by proportion and then mixed at room temperature and reacted for six to thirty six hours at a constant temperature of 50 DEG C to 70 DEG C to remove bubble of residual monomer and obtain the solution with protection from nitrogen which has bubbled for twenty minutes. The solution has a uniform chain structure and itaconic acid Beta-monoester contains two functional groups of carboxy and ester, thus being able to improve spinnability of polyacrylonitrile resin as well as regulate an oxidation-carbonization process of carbon fiber precursor. Due to introduction of a bifunctional group of monomer itaconic acid Beta-monoester, the amount of acrylonitrile comonomer is greatly reduced to improve performance of carbon fiber.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

The invention relates to a binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and a preparation method thereof. The spinning solution is prepared by taking dimethyl sulfoxide as a solvent, azodiisobutyronitrile as an initiator and acrylonitrile and itaconic acid as polymer monomers. The spinning solution is subjected to wet spinning, coagulating and molding, coagulation bath drafting, water washing, hot water dragging, oil coating, drying and compacting, saturated pressurized steam drafting, steam shaping and after-treatment, thereby obtaining a polyacrylonitrile protofilament. According to the testing, the monofilament tensile strength of the polyacrylonitrile protofilament is from 6.0 to 6.7 CN / dtex; the tensile modulus is from 100 to 110 N / dtex; the elongation at break is from 13.5 to 14.6%; the boiling water shrinkage is from 6.0 to 6.5%; the oil content rate is from 0.6 to 1.0%; and the fineness is 1.152 to 1.176 dtex. Under the observation of a microphotograph, the protofilament is round and bright in cross section and free of generating pores and holes. Based on the testing of preoxidation and carbonization, the strength of carbon fibers is from 3.8 to 4.2 GPa.

Owner:XIAN KANGBEN MATERIAL

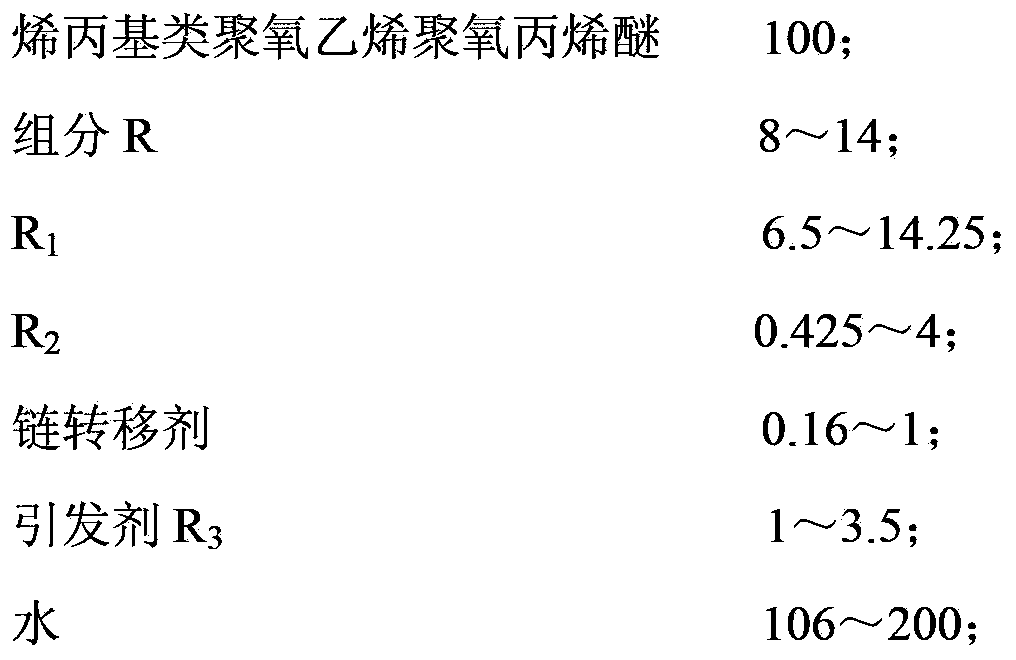

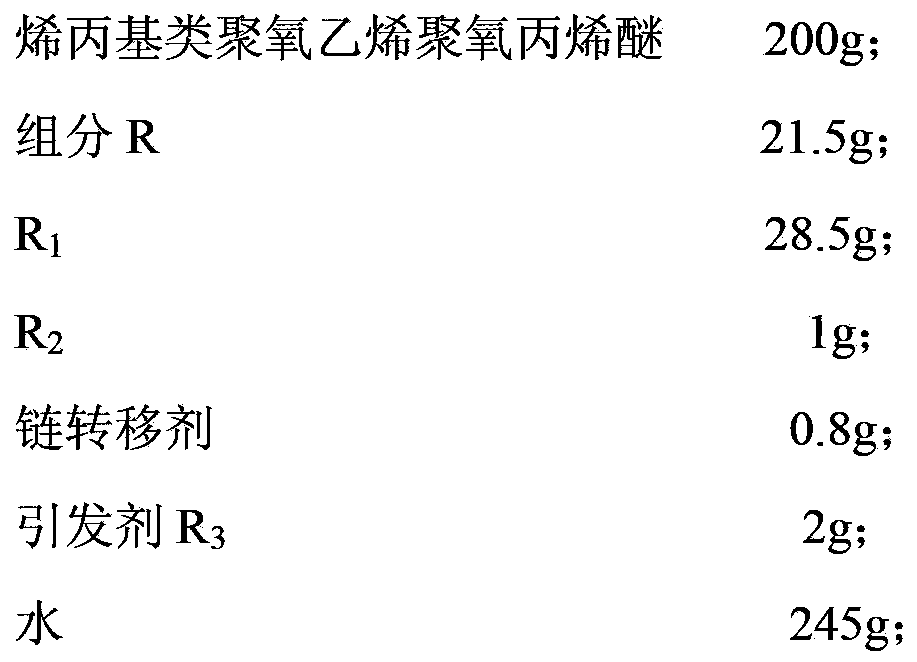

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer which is prepared from the following components: allyl polyoxyethylene polyoxypropylene ether, components R, R1 and R2, a chain transfer agent, an initiating agent R3 and water, wherein the component R is one or more of maleic anhydride, sodium methallyl sulfonate, vinyl acetate, itaconic acid, itaconic anhydride and fumaric acid; R1 is one or a mixture of two of acrylic acid and methylacrylic acid; R2 is one or more of ascorbic acid, sodium formaldehyde sulfoxylate, ferrous sulfate, tin sulfate, sodium hypophosphite, sodium hydrogen sulfite and oxalic acid. The invention further discloses a preparation method for the mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer has the following benefits: the water solubility and the steric hindrance of polycarboxylic acid are effectively kept; a large amount of non-hydrophilic structures on branch chains can be used for effectively preventing soil interlayer adsorption, so that the adsorption speed and effect are greatly reduced and the mud-resistant purpose is achieved.

Owner:SICHUAN TONGZHOU CHEM TECH

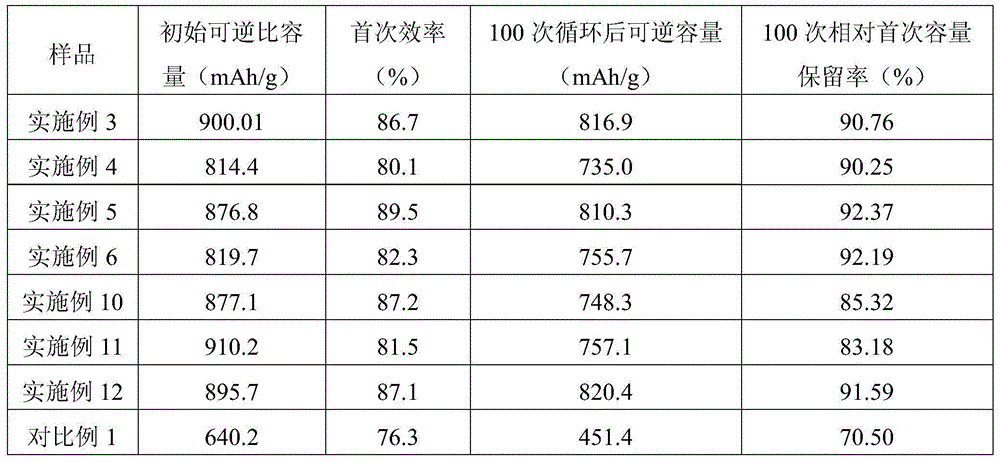

High-performance binder for silicon materials for lithium ion batteries and preparation method thereof

ActiveCN104538635AImprove conductivityImprove microscopic compositionCell electrodesCyclic processAcrylonitrile

The invention provides a high-performance binder for silicon materials for lithium ion batteries, which is a polyacrylonitrile copolymer, a polymeric monomer of the copolymer comprises acrylonitrile, also comprises a second monomer and / or a third monomer; and the second monomer is a monobutyl itaconate monomer, and the third monomer is selected from a mixture of one or more of an itaconic acid, sodium allylsulfonate, acrylamide, amino, a pyridyl or acylamino monomer, n-butyl acrylate or methyl acrylate. The invention also provides a preparation method of the binder. Compared with existing binders, the binder disclosed by the invention has better binding power, can effectively improve the expansion of silicon materials in the processes of charging and discharging, and can improve the performance of a silicon electrode in the process of cycling. Meanwhile, the binder is simple in preparation method, low in cost and good in repeatability, and can achieve the practical need of mass production.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com