Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2907 results about "Vacuum distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum distillation is a method of distillation performed under reduced pressure, which lowers the boiling point of most liquids. As with distillation, this technique separates compounds based on differences in boiling points. This technique is used when the boiling point of the desired compound is difficult to achieve, will cause the compound to decompose or simply to save energy in heating. A reduced pressure decreases the boiling point of compounds. The reduction in boiling point can be calculated using a temperature-pressure nomograph using the Clausius–Clapeyron relation.

Catalyst for hydrorefining and/or hydroconversion and its use in hydrotreatment processes for batches containing hydrocarbons

This invention relates to a catalyst for hydrorefining and / or hydroconversion of hydrocarbon-containing feedstocks that contain compounds whose boiling point is higher than 520° C. and that contain sulfur and possibly metals, as well as its use in hydrorefining and / or hydroconversion processes of heavy feedstocks. A petroleum residue of atmospheric distillation (RA) or of vacuum distillation (RSV) or a deasphalted oil (DAO) are representative feedstocks of the feedstocks treated within the scope of this invention.

Owner:INST FR DU PETROLE

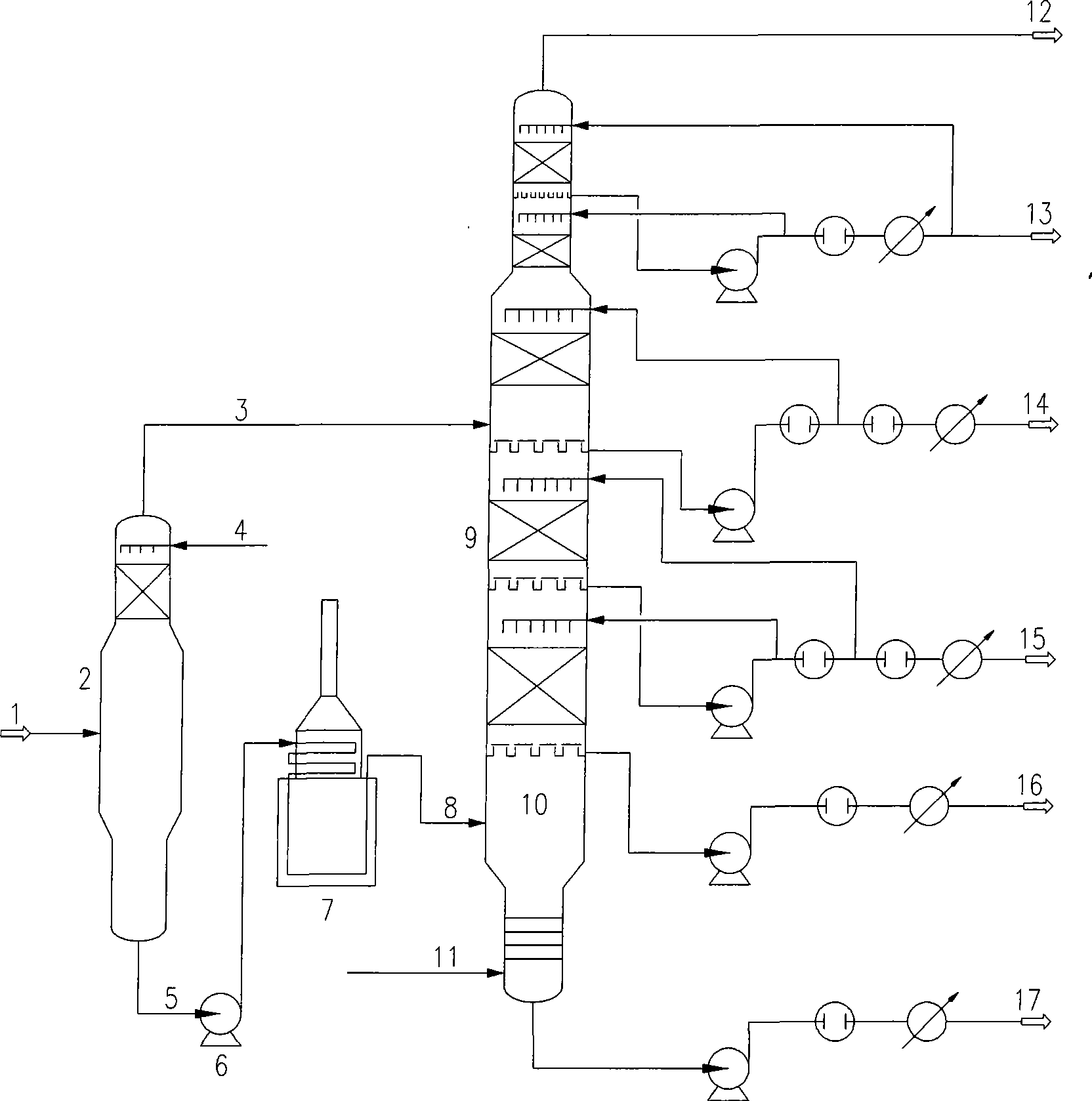

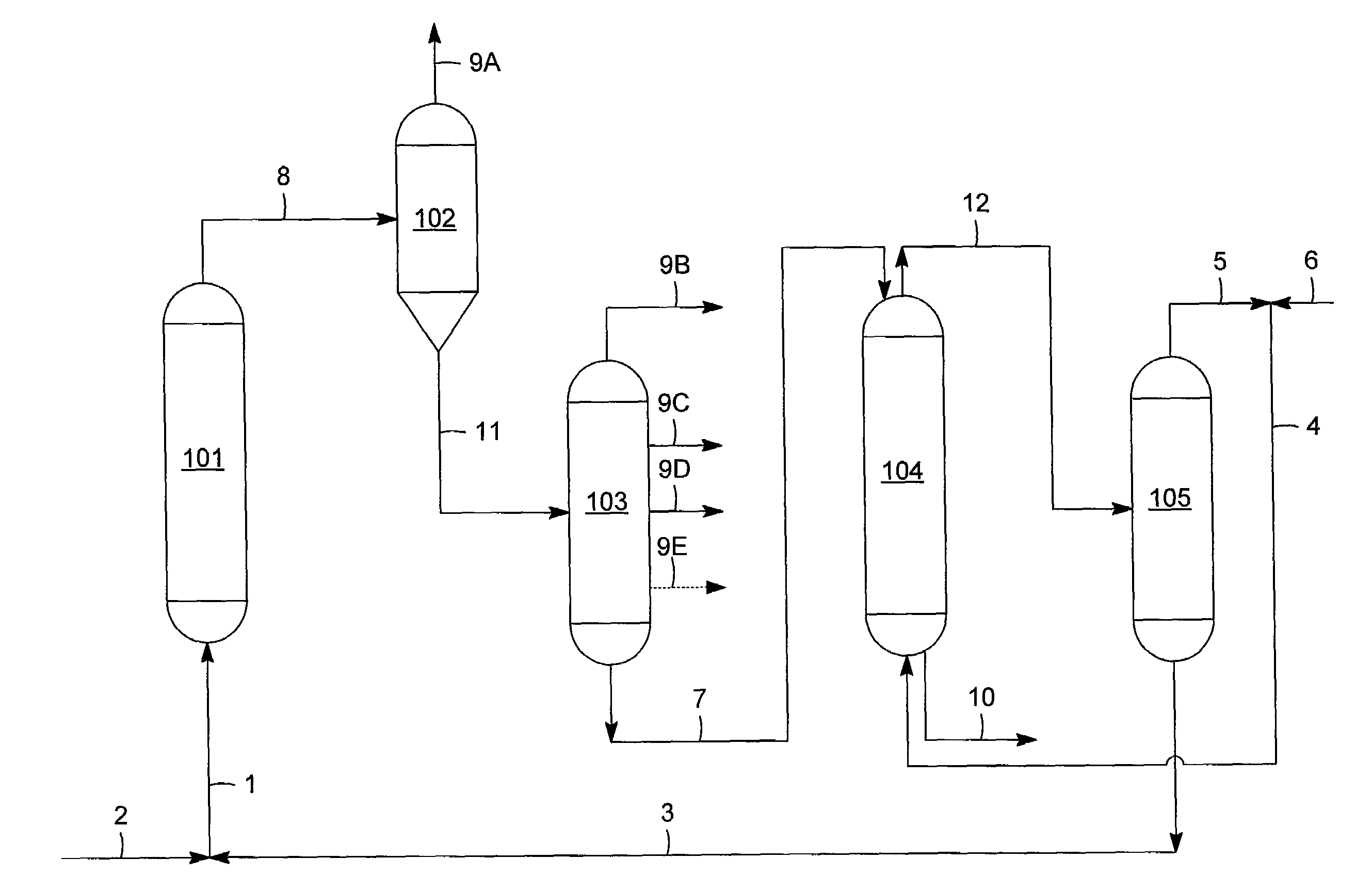

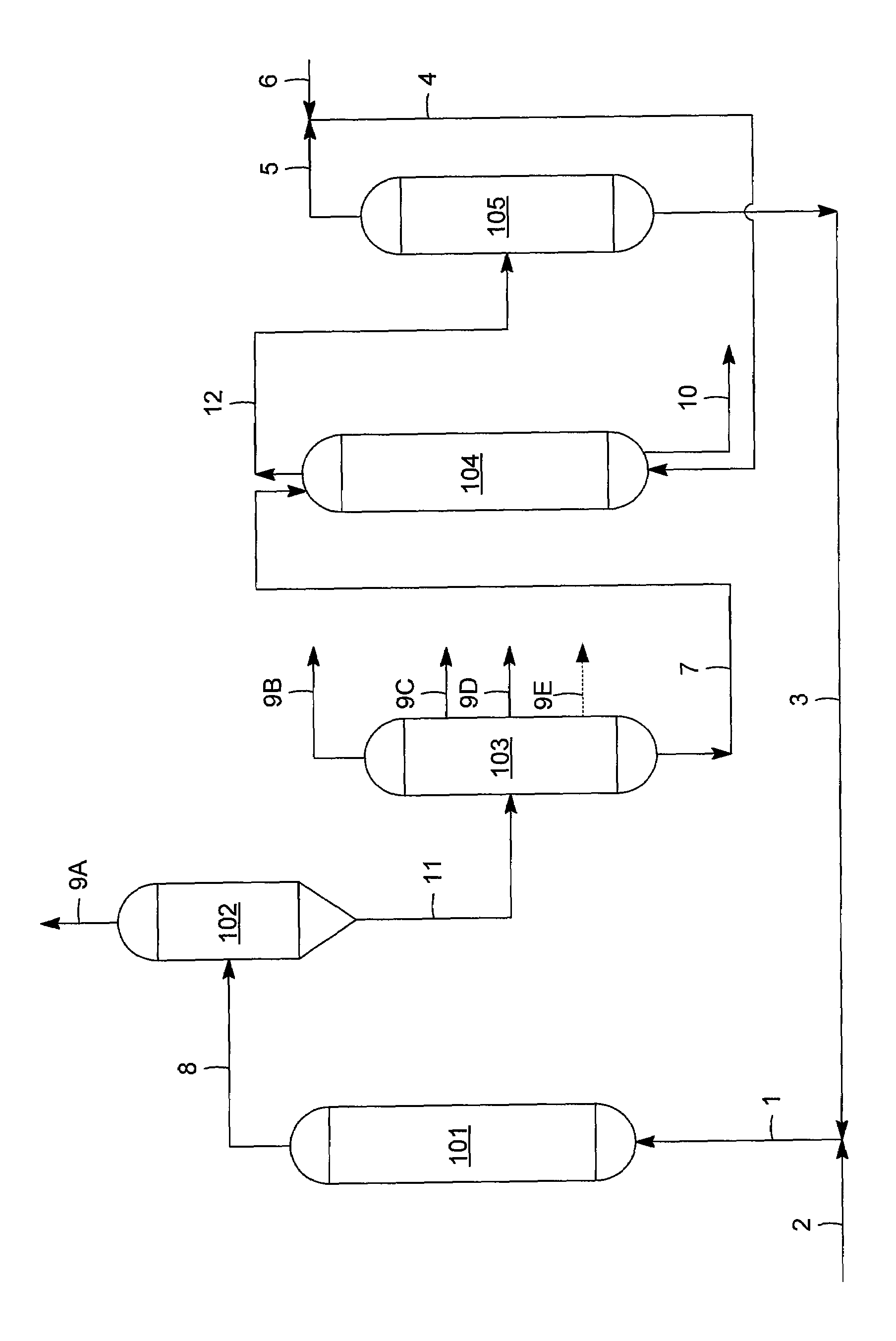

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

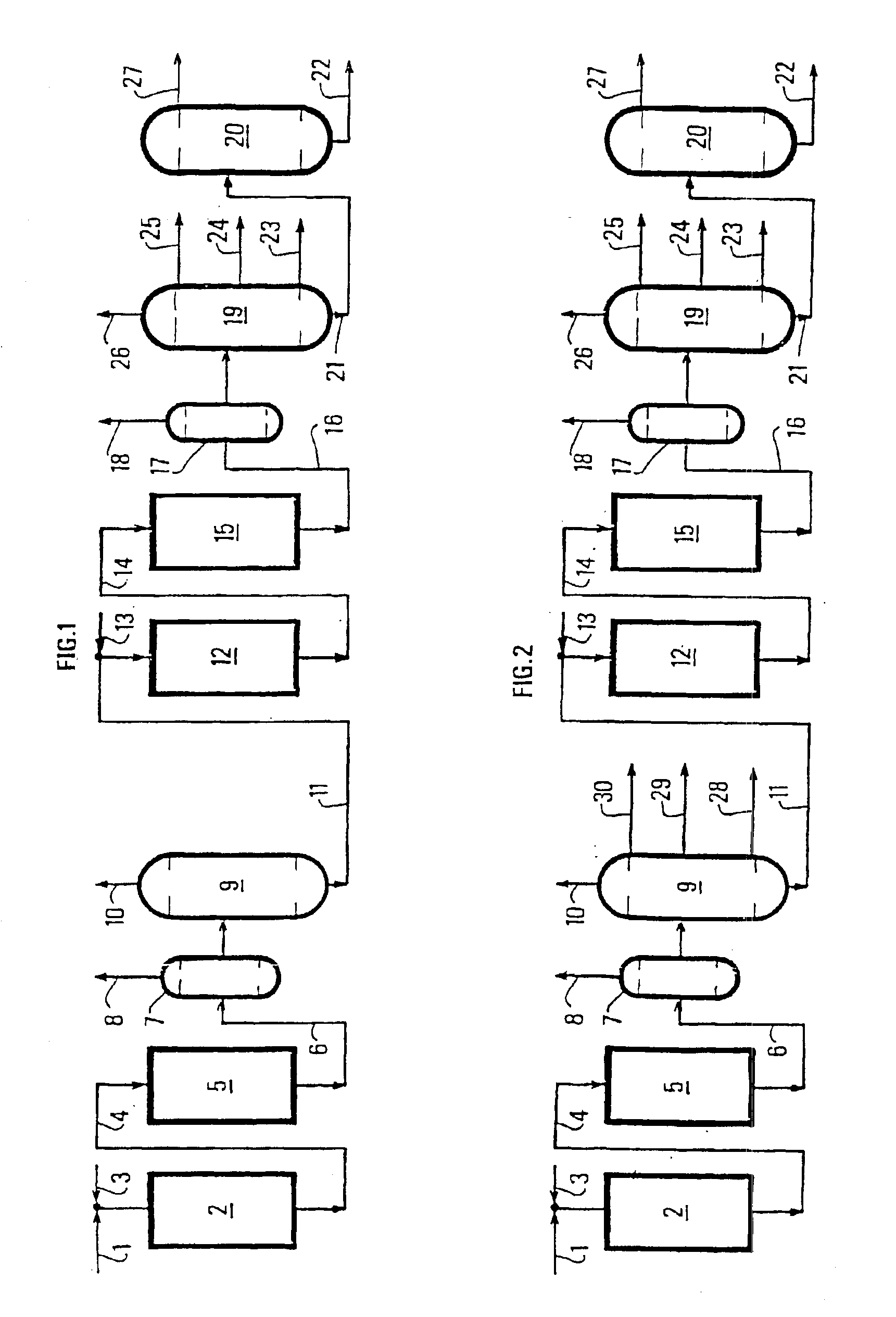

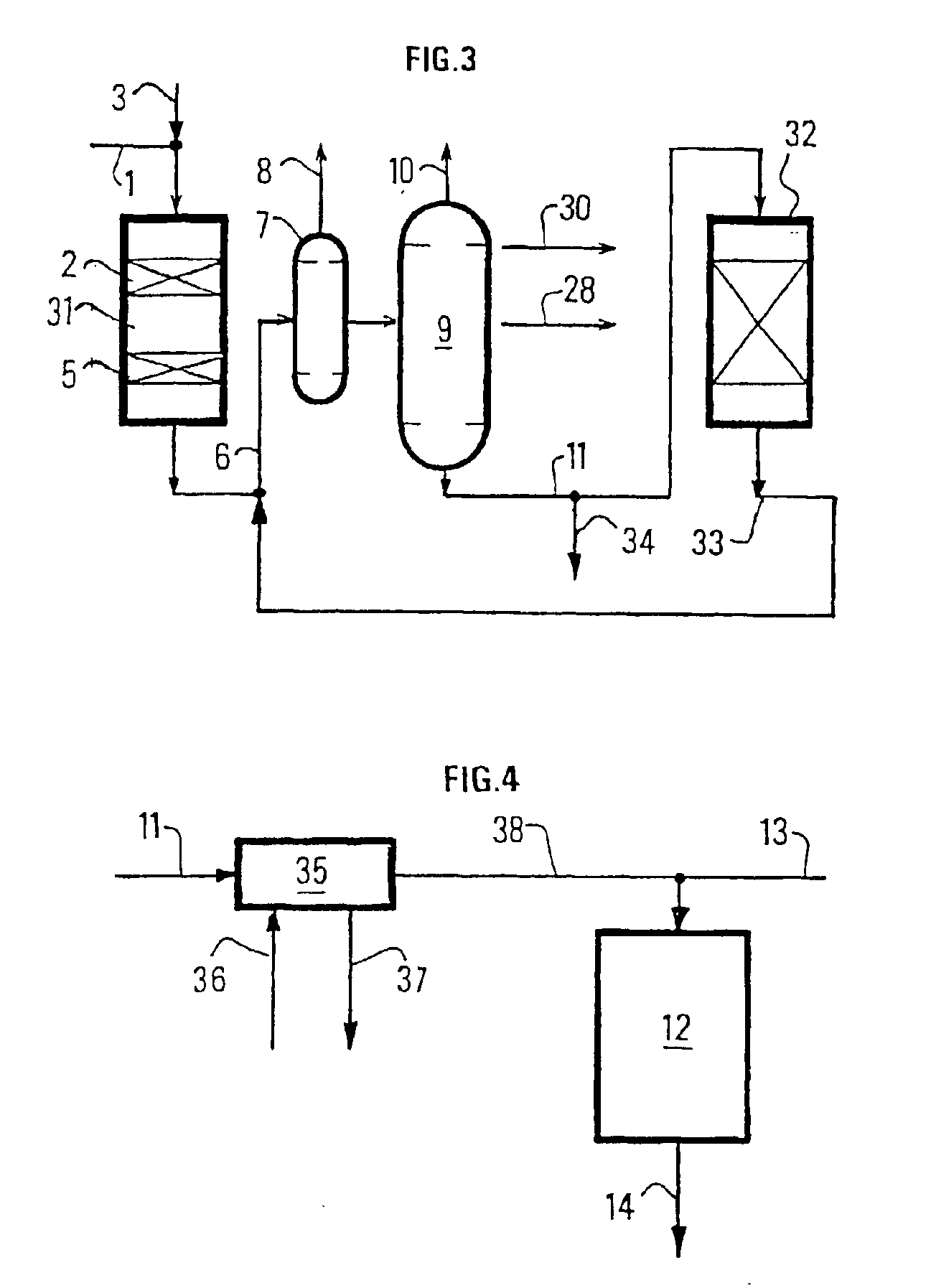

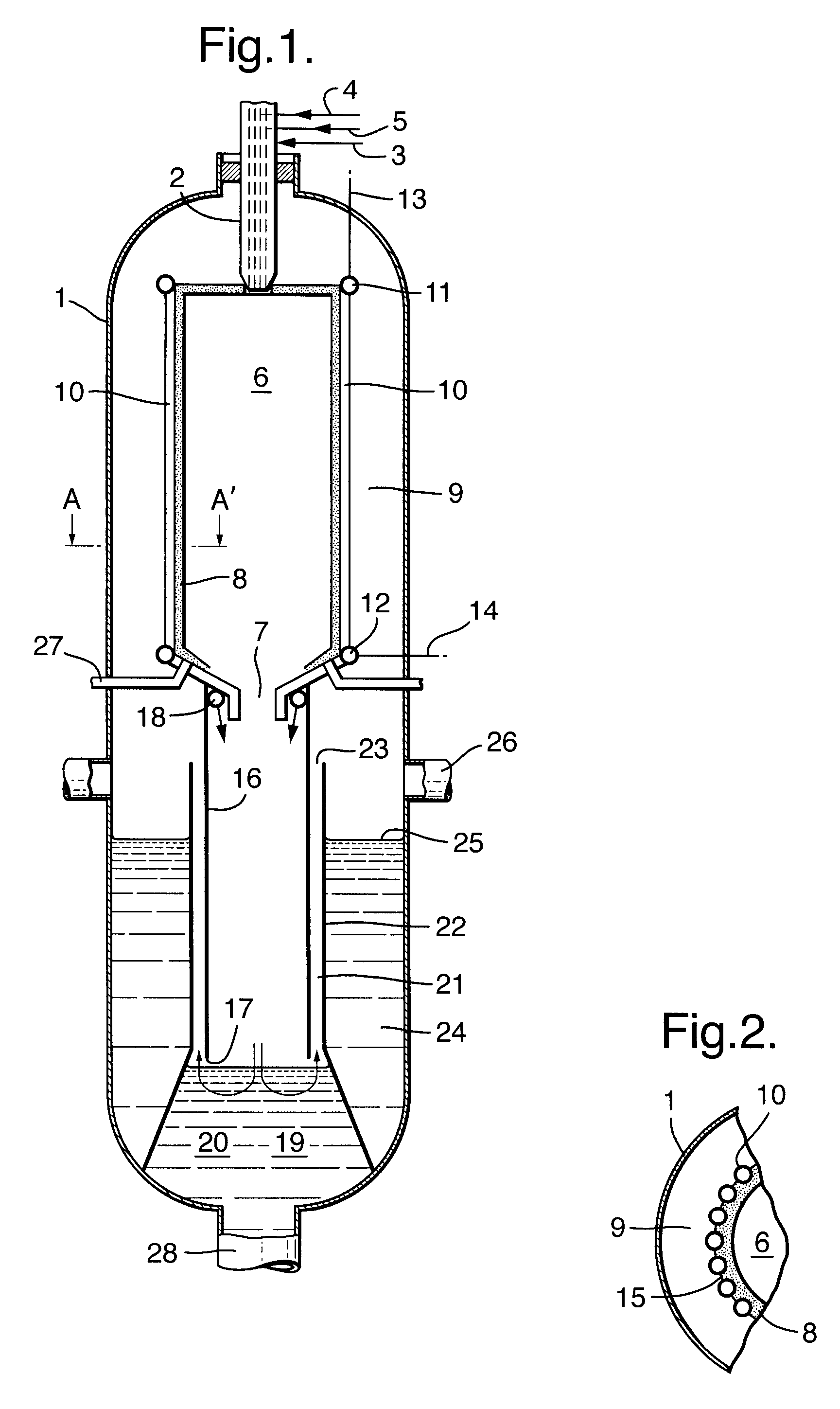

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

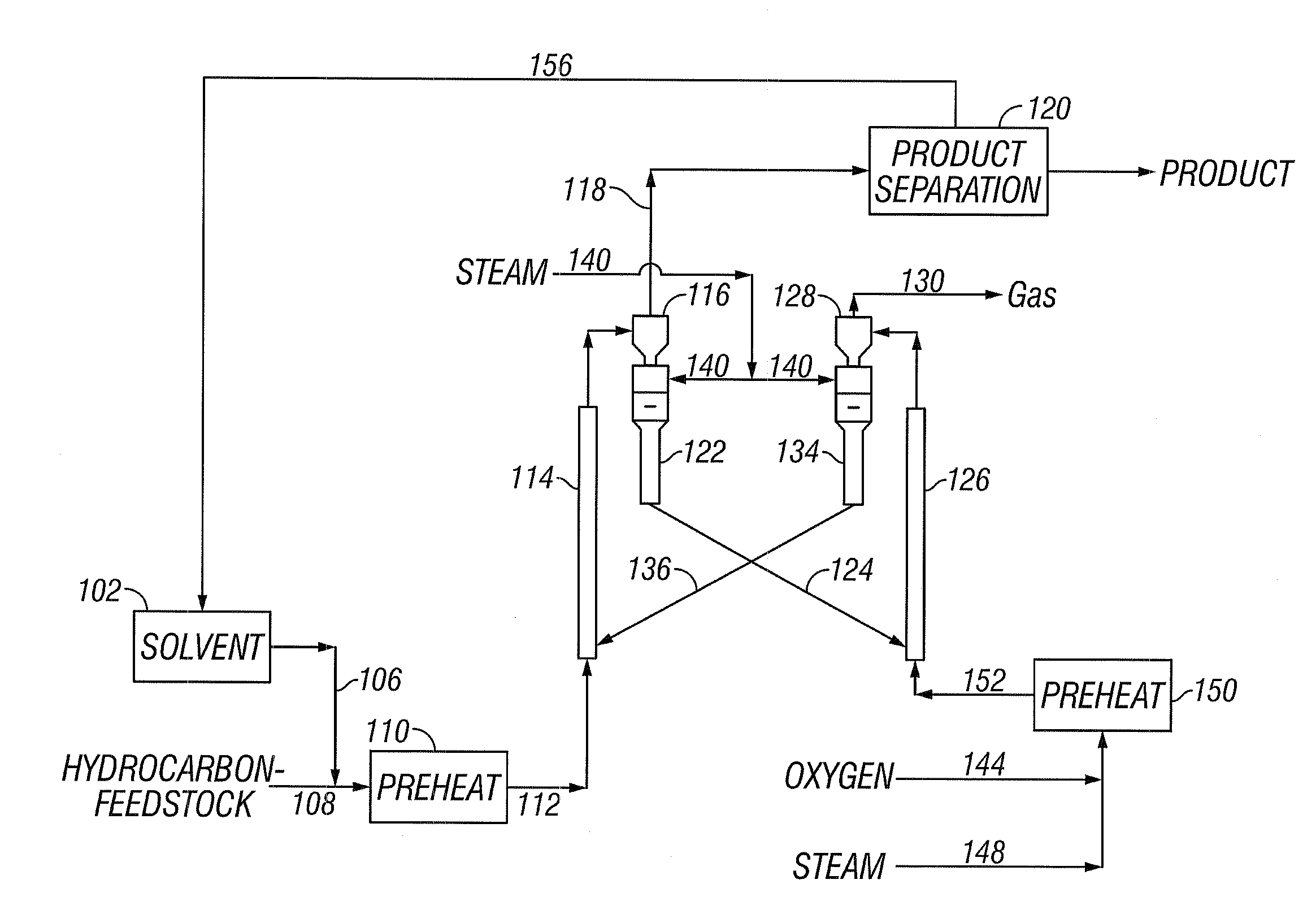

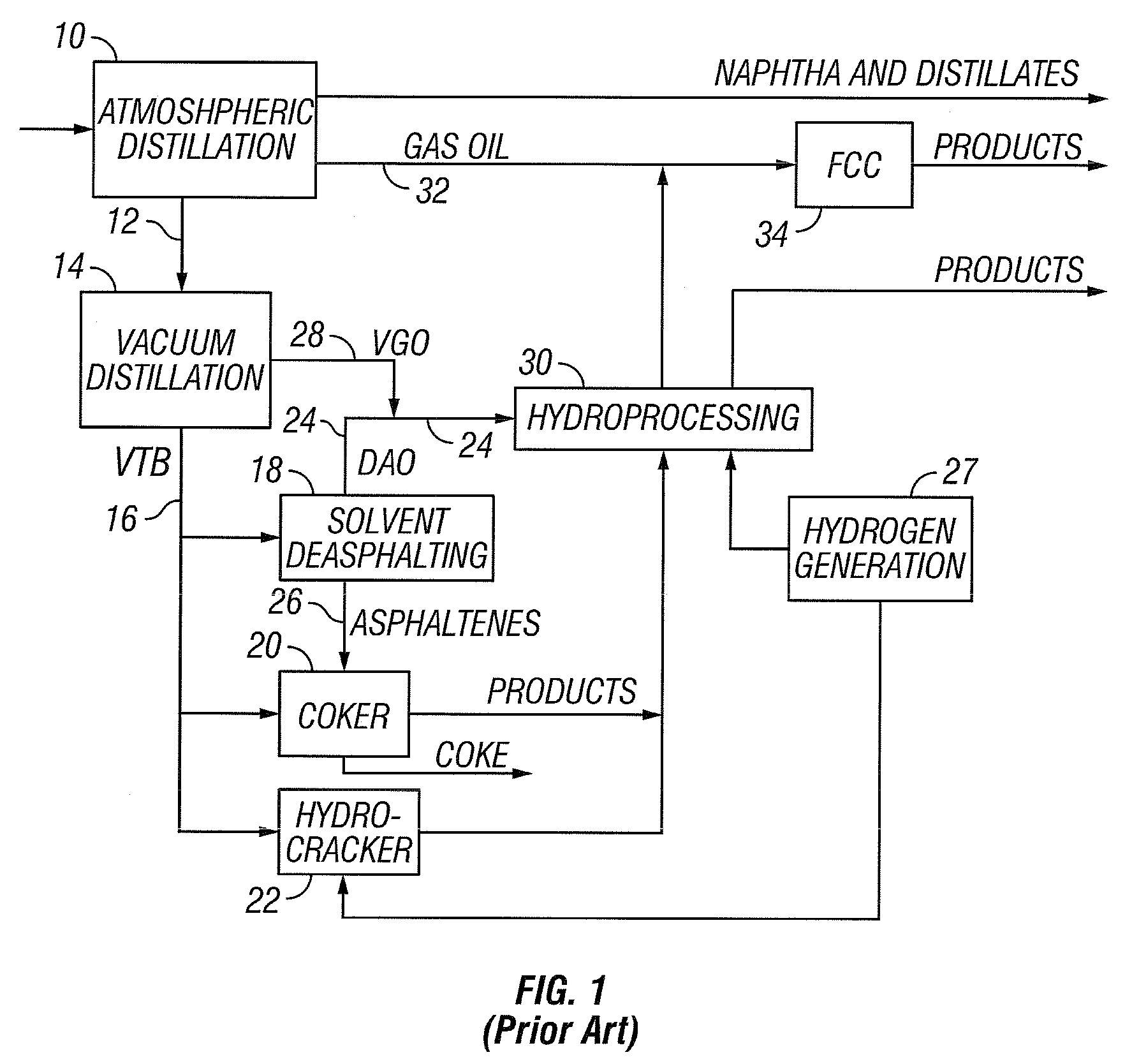

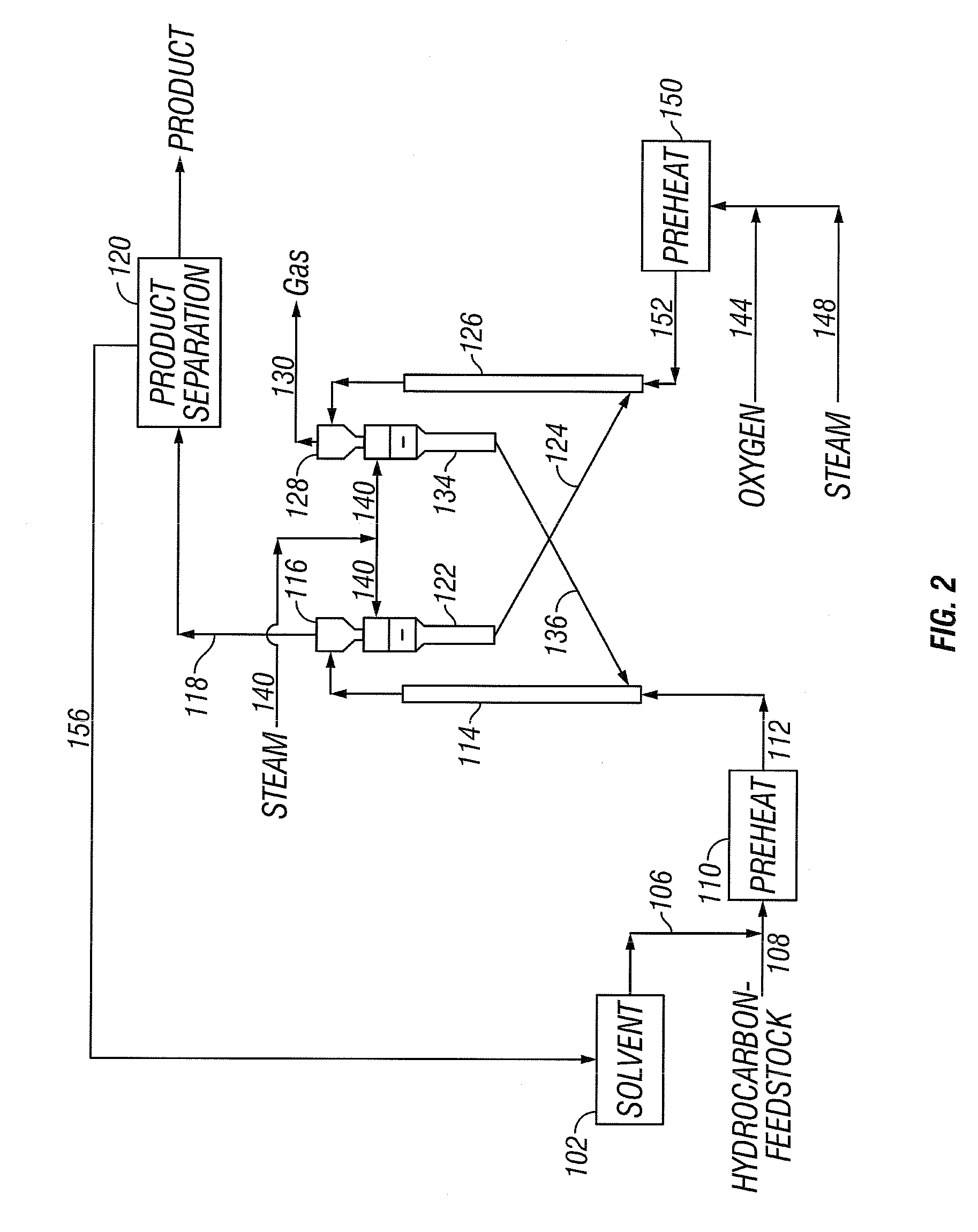

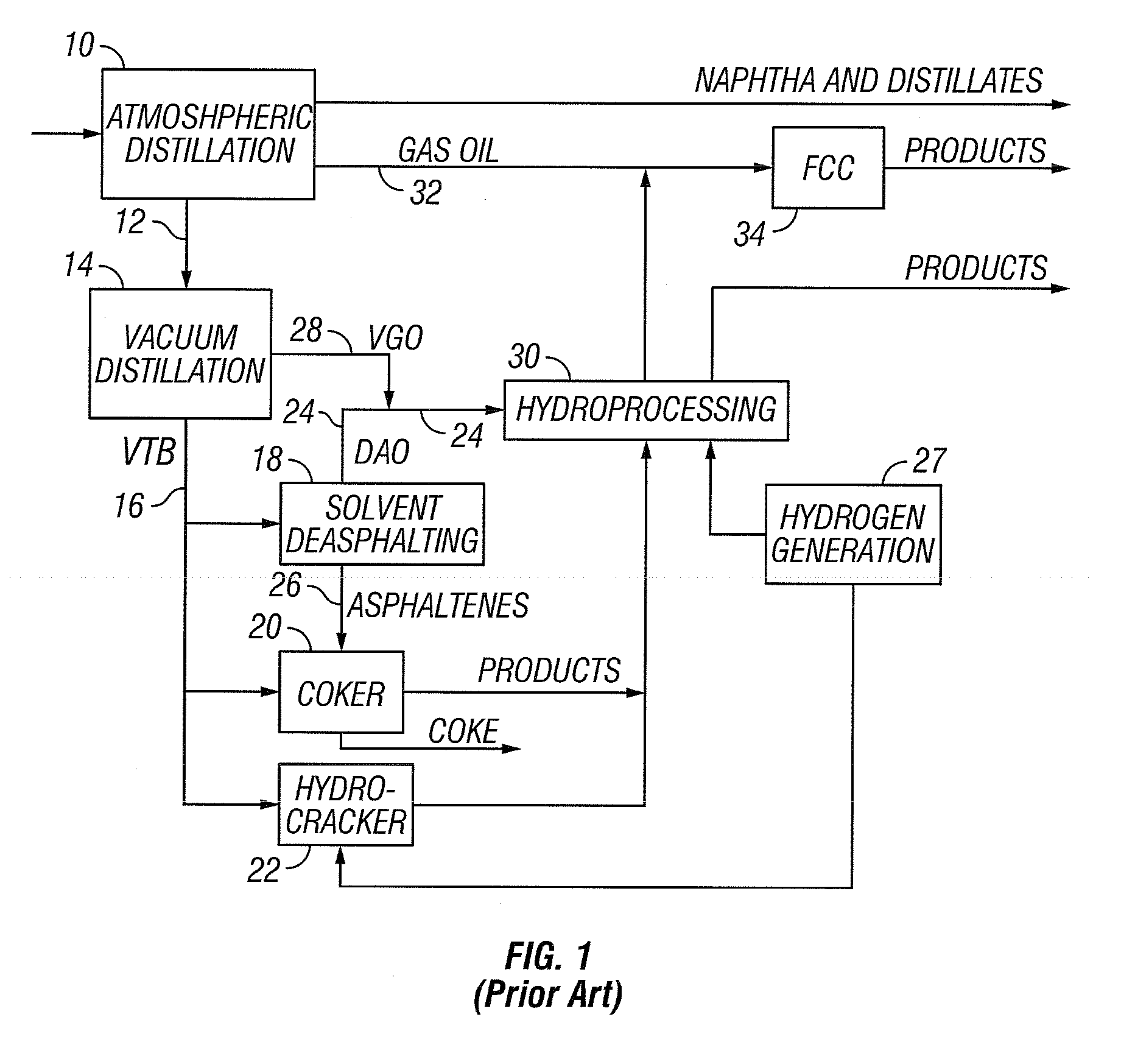

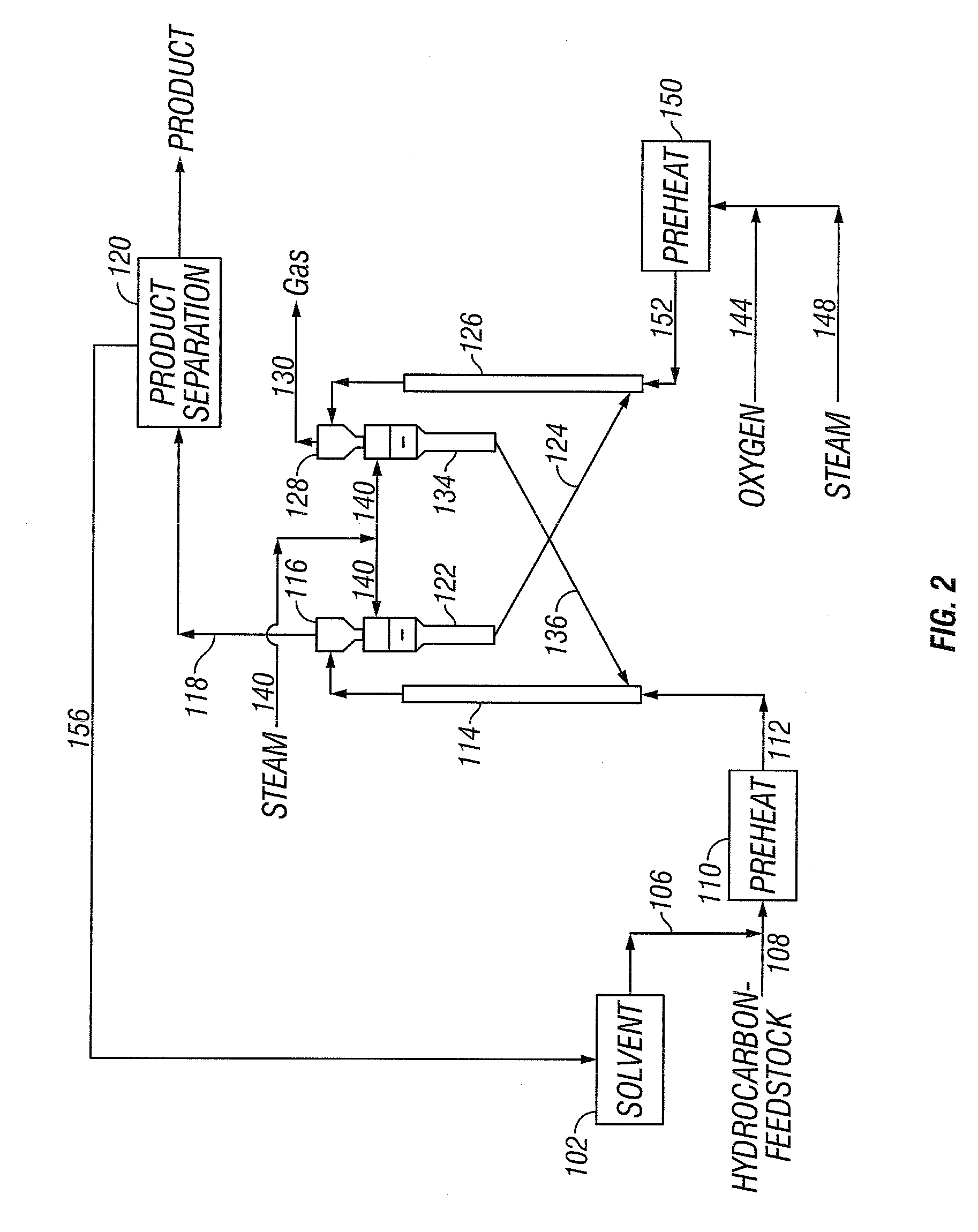

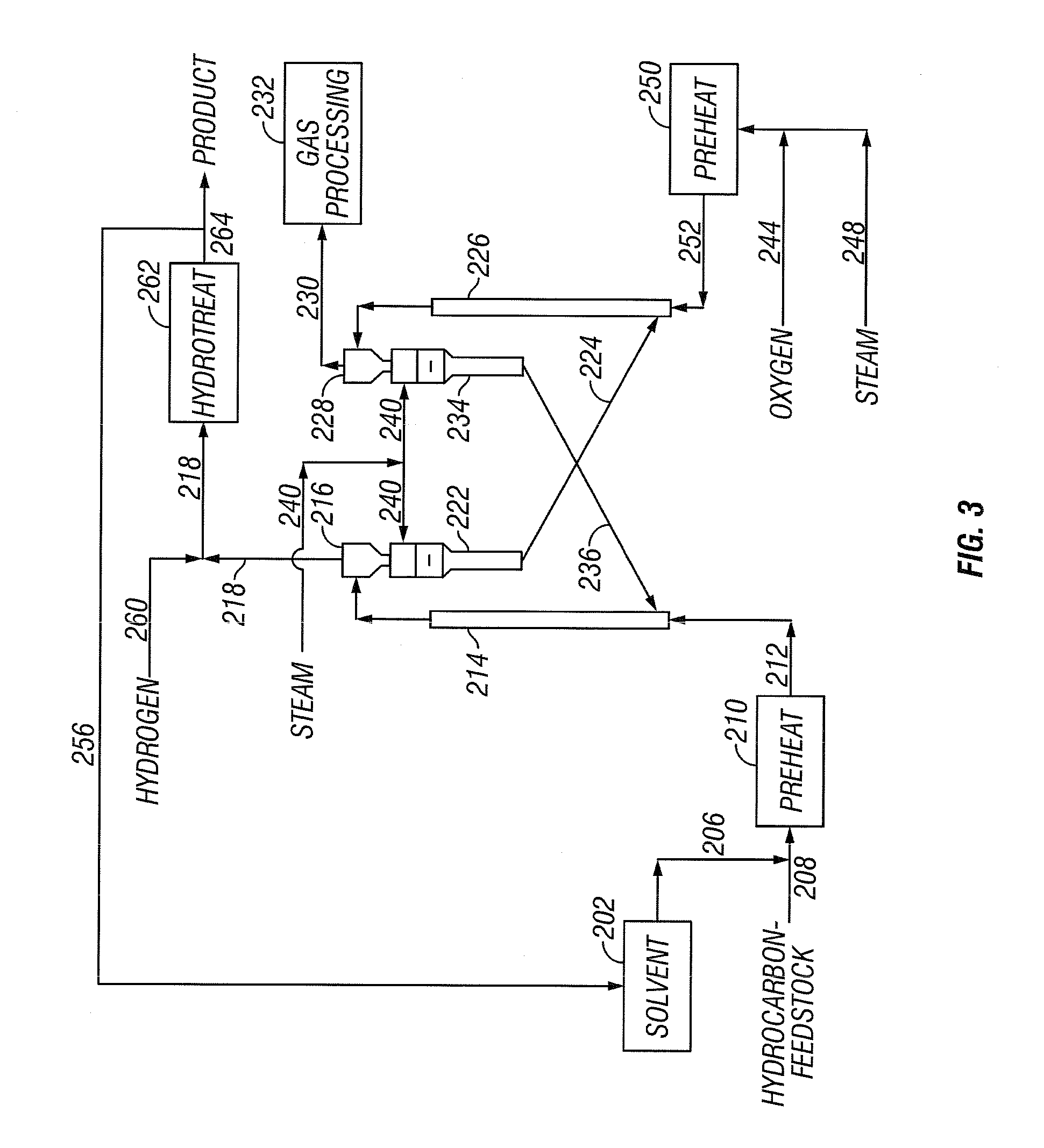

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

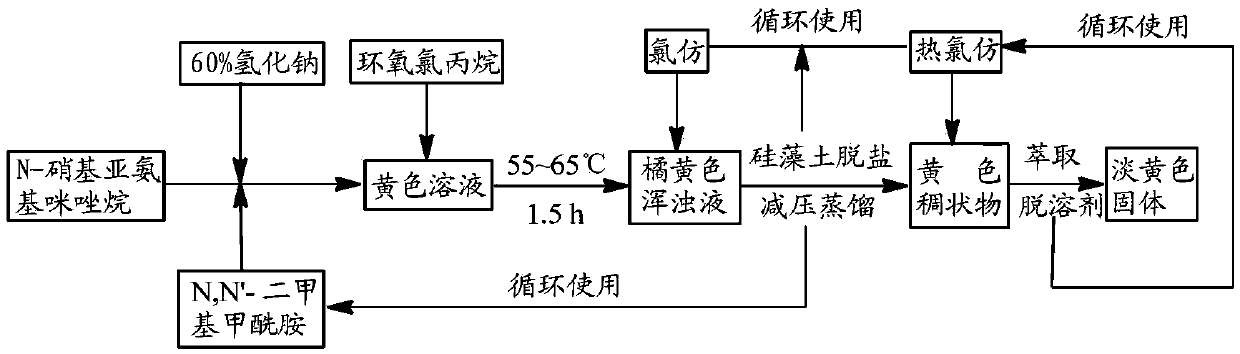

Method for preparing cycloxylidin

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

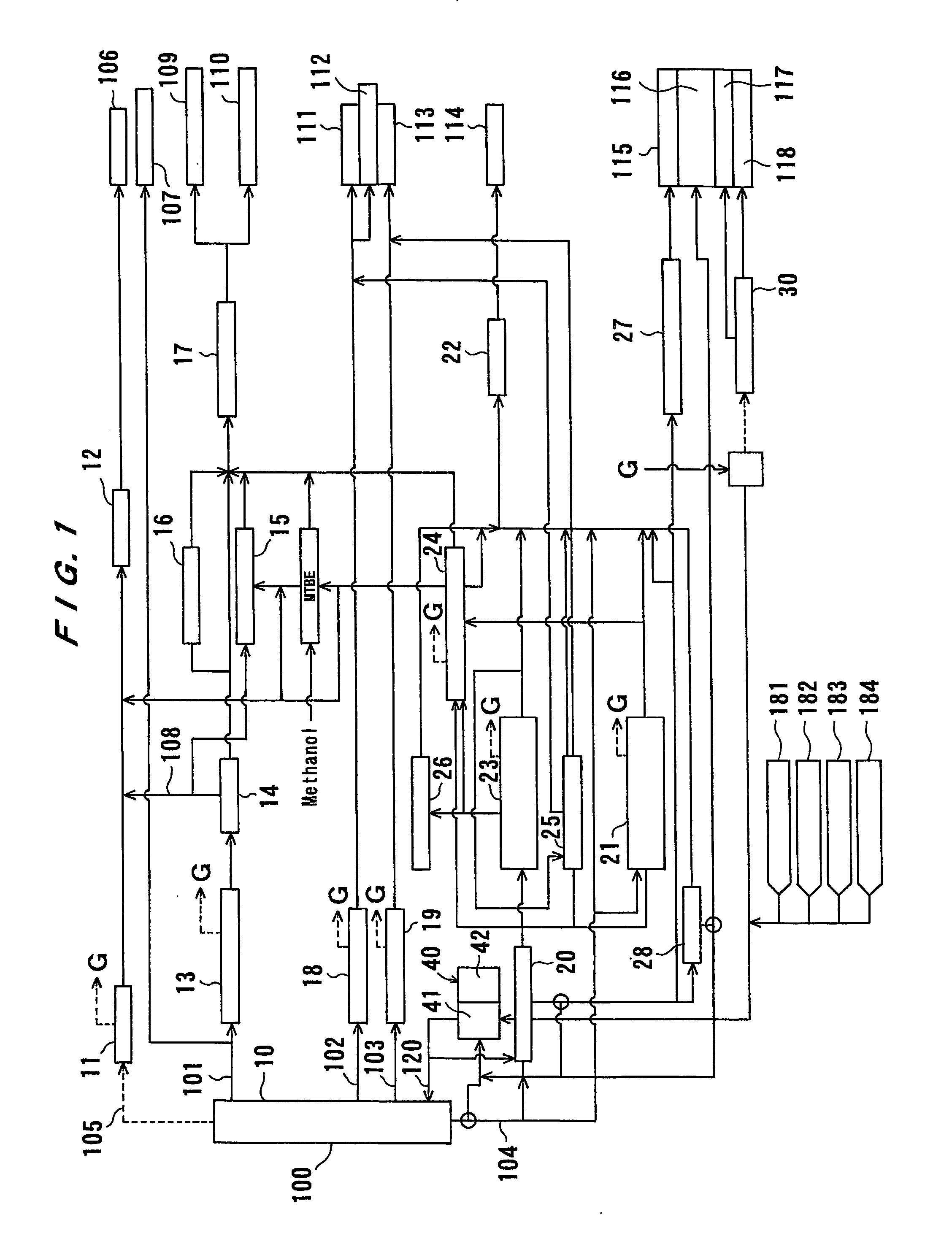

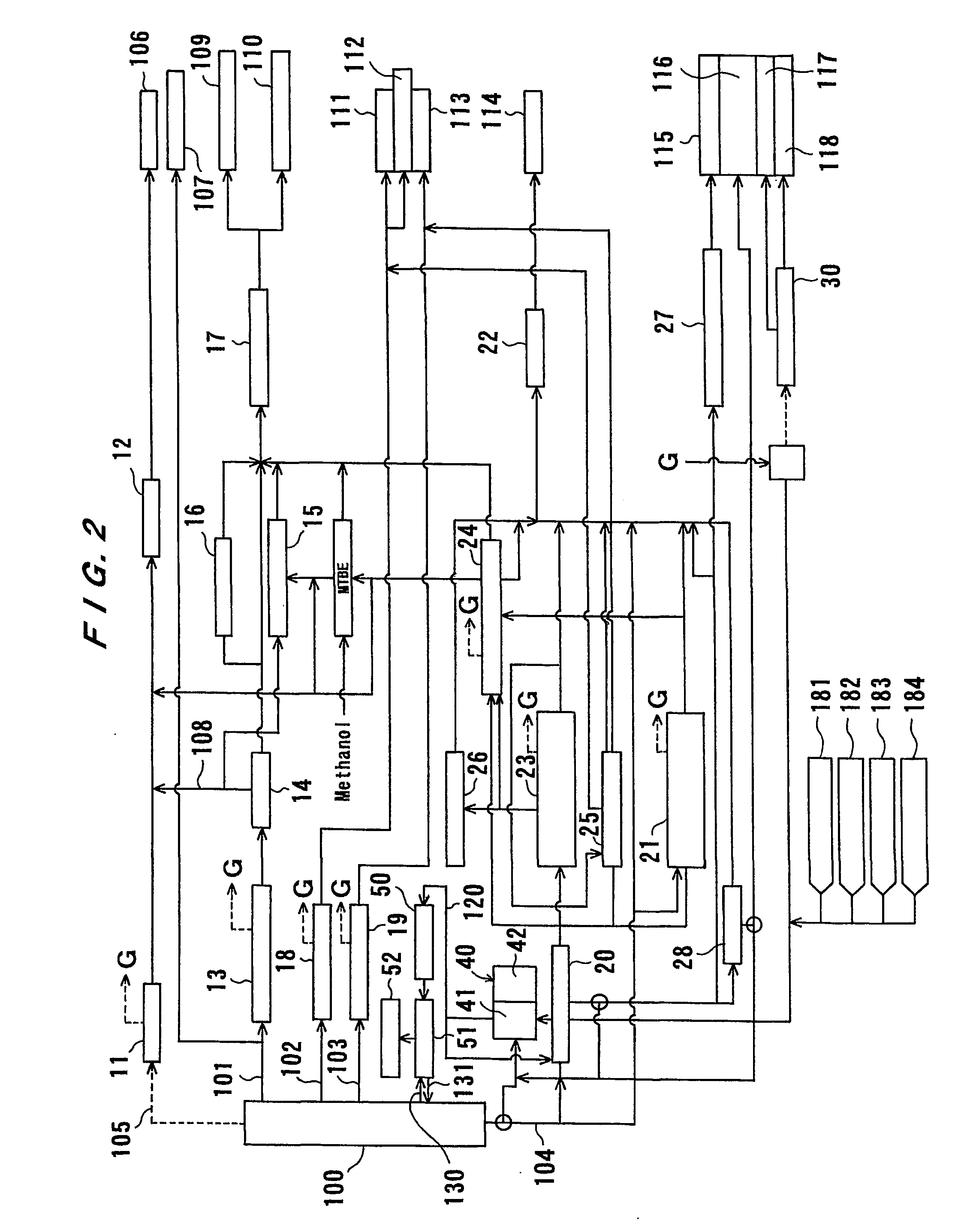

Recycling method and system

InactiveUS20060194990A1Low costThermal non-catalytic crackingTreatment with plural parallel cracking stages onlyDecompositionPetrochemical

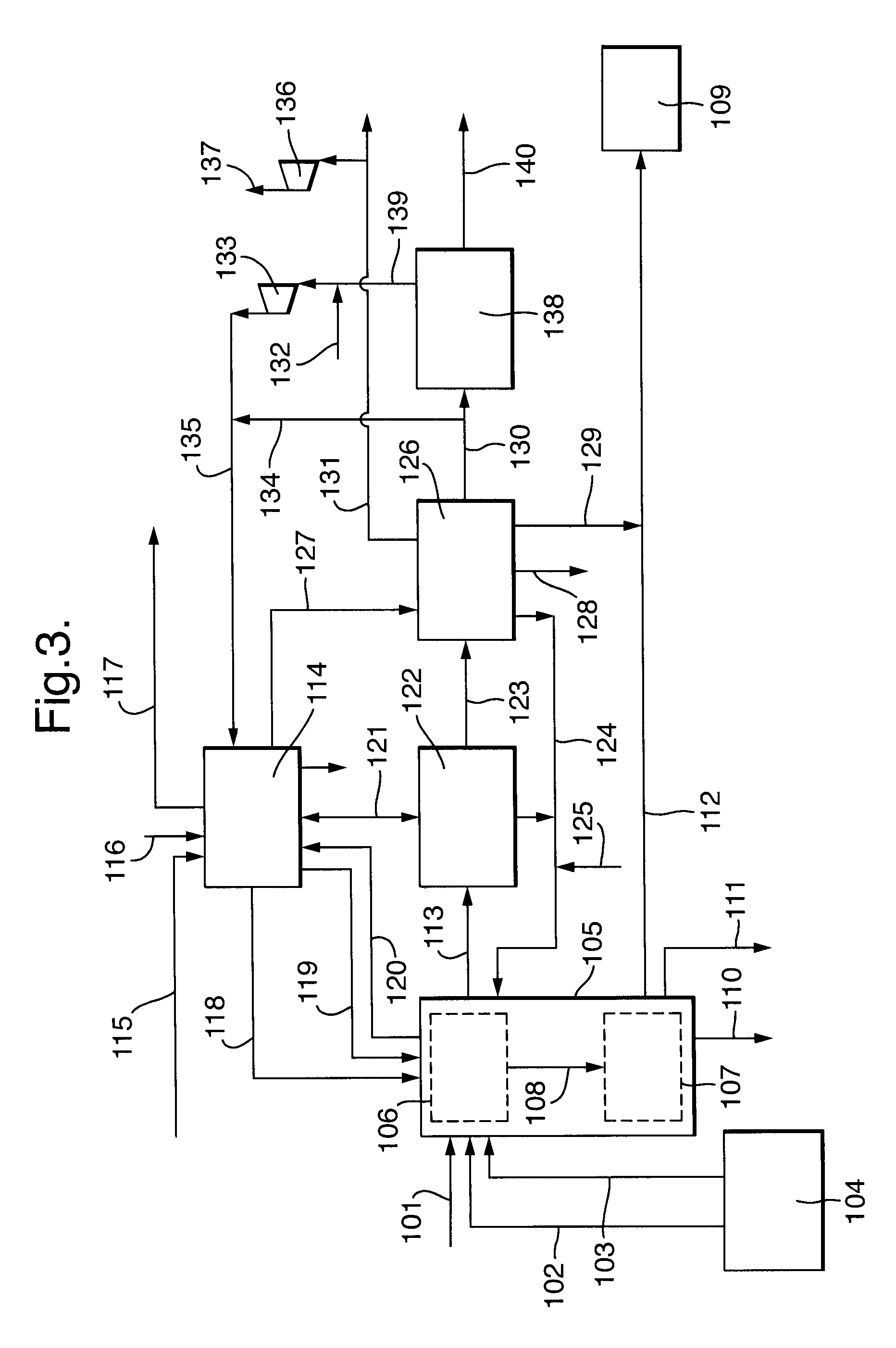

A recycling system has a pyrolysis apparatus (40) having a combustion section (42) for selectively combusting a carbon component in materials, and a gasification section (41) for pyrolyzing and gasifying the materials by using heat of combustion in the combustion section (42). The materials include residual oil from an atmospheric distillation unit (10), a vacuum distillation unit (20), and a decomposition unit (28), various wastes including waste plastics (181), wastes (182), and shredder dust (183), and organic matter such as biomass (184). The recycling system has a passage for supplying pyrolysates (120) produced in the gasification section (41) to an oil refinery system or a petrochemical system.

Owner:EBARA CORP

Flexible method for producing oil bases with a ZSM-48 zeolite

InactiveUS6884339B2Reduce contentImproves UV stabilityTreatment with plural serial cracking stages onlyCoke ovensBase oilAzeotropic distillation

A process for the production of very high quality base oils optionally with simultaneous production of high quality middle distillates comprises the stages for hydrotreatment, preferably hydrocracking, on Y or beta zeolite, and atmospheric distillation. The effluent is subjected to a catalytic dewaxing on the ZSM-48 catalyst. The process then comprises a hydrofinishing stage for hydrogenating the aromatic compounds, preferably on a catalyst that comprises at least one noble metal of group VIII, chlorine and fluorine, and the stages of atmospheric and vacuum distillation. The hydrofinishing stage is conducted at a temperature lower by 20-200° C. than the catalytic dewaxing stage.

Owner:INST FR DU PETROLE

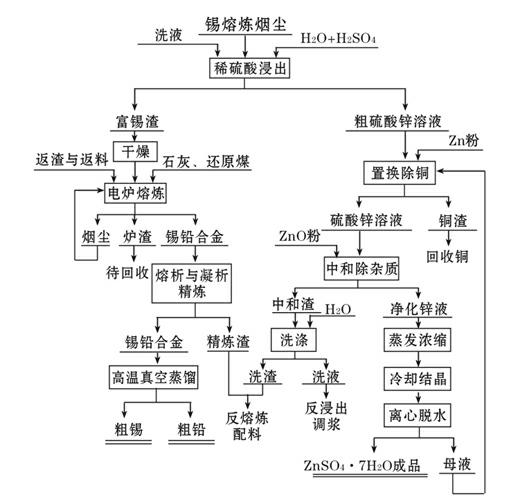

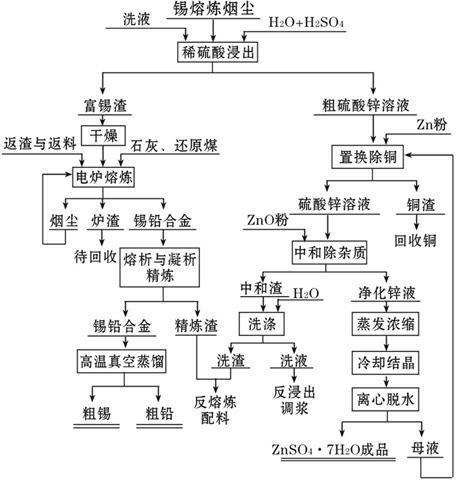

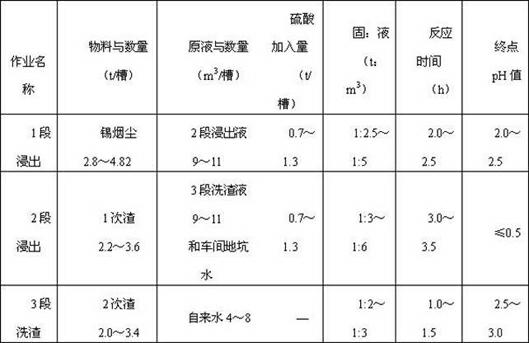

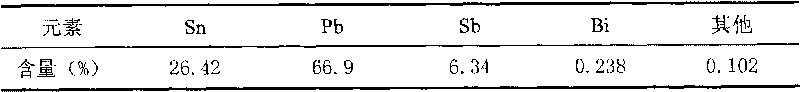

Method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust

InactiveCN102352443AHigh recovery rateReasonable process structureZinc sulatesProcess efficiency improvementSulfateCopper

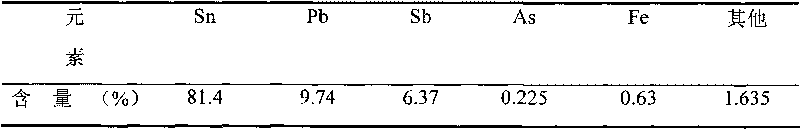

The invention discloses a method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust. The method comprises the following steps of: (1) pretreating the raw material; (2) leaching with a dilute sulphuric acid to separate out zinc; (3) purifying the crude zinc sulfate solution, preparing zinc sulfate heptahydrate; (4) performing electric furnace smelting on the tin-rich residue to prepare a tin-lead alloy; (5) adopting the conventional liquation process (the temperature is 500-600 DEG C) and the agglutination method (the temperature is 230-240 DEG C) to refine the tin-lead alloy and increase the Sn-Pb grade of the alloy to 94%-96%, and sending the refining residue back to the electric furnace to perform smelting and dosing treatment; and (6) performing high temperature vacuum distillation to produce crude tin and crude lead. By adopting the method, the tin smelting dust can be effectively utilized, the resource can be saved and metals such as tin,lead, zinc and copper can be recovered together.

Owner:太仓市南仓金属材料有限公司

Supercritical Hydrocarbon Conversion Process

ActiveUS20050167333A1Reduce molecular weightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Recovery processing method of silicon slice cut waste mortar

The invention relates to a recovery processing method of silicon slice cut waste mortar, comprising the following steps: (1) separating solid-liquid components in the silicon slice cut waste mortar; (2) further recovering the remained cutting liquid component in a solid; (3) separating silicon powder and silicon carbide through water flow flotation; (4) recovering the silicon powder; (5) recovering the silicon carbide; (6) coarsely filtering, finely filtering, decoloring, vacuum distilling and dehydrating the recovered cutting liquid, and adding component with corresponding amount for secondary filter. The method can get various recovered products, such as silicon carbide micro powder, cutting liquid and silicon powder, has high recovery rate and recovery profit and can save the cost of the mortar by at least 40 percent; meanwhile, the invention effectively solves the problem of possible secondary pollution caused by single recovery; the cutting function of recovered and treated silicon carbide micro powder is recovered again, thereby changing waste into wealth, realizing the resource reutilization in true sense, and promoting the development of recycling economy; and the method basically realizes the zero emission of waste liquid by reutilizing the treated waste water after combining a sewage treatment process, thereby being beneficial to environment protection.

Owner:HENAN XINDAXIN SCI & TECH

Conversion of crude tall oil to renewable feedstock for diesel range fuel compositions

ActiveUS20110049012A1Efficient removalEfficient separationFatty oils/acids recovery from wasteFatty acid hydrogenationVolatilesBoiling point

There is disclosed a method for conversion of crude tall oil into high-quality diesel fuels comprising the steps of: (a) removal of non-oil contaminants present in the crude tall oil and recovering valuable organic compounds present in the crude tall oil, thereby forming a refined tall oil stream; (b) removal of the volatile fraction of the refined tall oil stream from step a), thereby forming a volatiles free oil stream comprising organic components with boiling points, at atmospheric pressure, of 170 degrees C. or higher; (c) separation in a vacuum distillation column of the volatiles free oil stream of step b) into two process streams or phases wherein a first process stream or phase is substantially comprising components with boiling points, at atmospheric pressure, in the range of 170-400 degrees C. and a second process stream or phase is substantially comprising components with boiling points, at atmospheric pressure, over 400 degrees C.; (d) lowering the oxygen content in the stream comprised of components with boiling points in the range 200-400 degrees C. from step c) by decarboxylation and / or decarbonylation.

Owner:SUNPINE

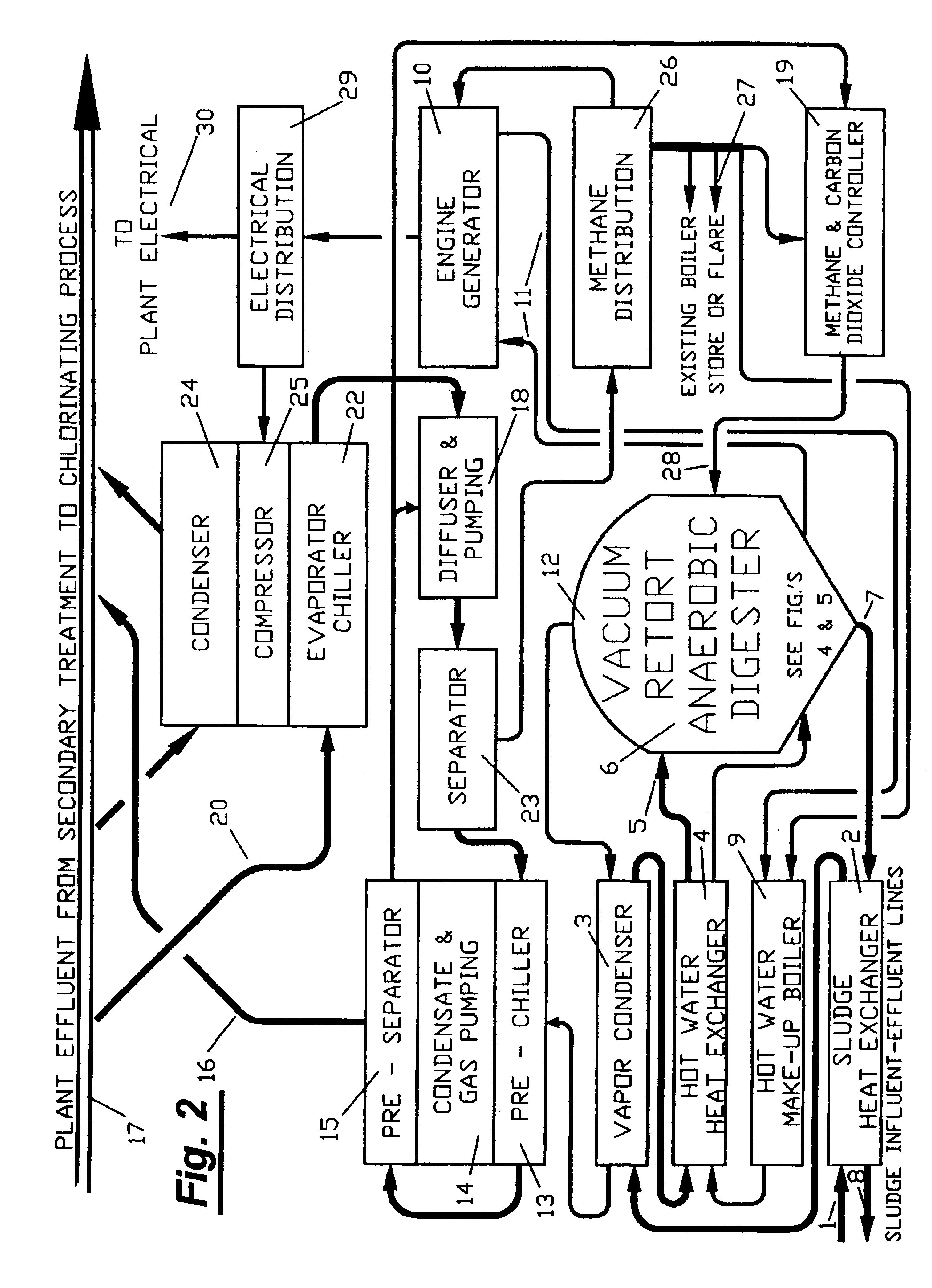

Vacuum retort anaerobic digestion system and process

InactiveUS6942798B2Environmental pollutionWaste based fuelTreatment with anaerobic digestion processesVacuum pressurePulp and paper industry

Anaerobic digestion system and process in which a liquor containing a digestible biomass is processed a retort vessel at a thermophilic temperature and with a vacuum pressure at the surface of the liquor. A pressurized feedstock is introduced into the vessel so that the feedstock impacts upon the surface of the liquor in a manner which serves to break up any scum on the surface and produce a mixing of the liquor.

Owner:MILLER III HERMAN P

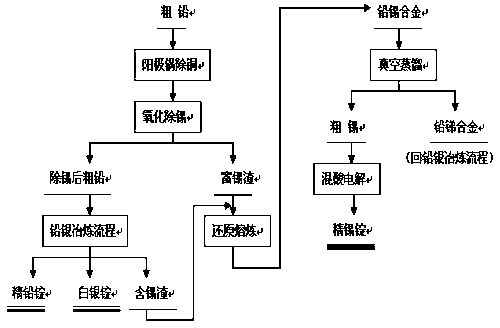

Method for recycling tin from lead bullion

InactiveCN104141152AImprove efficiencyImprove production costsPhotography auxillary processesElectrolysisLead smelting

The invention discloses a method for recycling tin from lead bullion, and belongs to the technical field of pyrogenic process and wet process combined metallurgy. The method comprises the steps that after liguation decoppering processing is carried out on the lead bullion, caustic soda, caustic soda and salt are added into the lead bullion according to the content of the tin in the lead bullion to gather and remove the tin in the lead bullion, and tin-rich slag is obtained; sodium carbonate and reduction coal are added into the tin-rich slag and all tin-containing slag produced by a lead smelting system, and the tin-rich slag and the tin-containing slag generate terne metal through reduction smelting; the terne metal is processed through vacuum distillation to obtain crude tin; highly purified precipitated tin is obtained from the crude tin through electrolytic refining of mixed acid with silicofluoric acid-sulfuric acid as an electrolytic medium, and the precipitated tin is processed through simple smelting to obtain a tin ingot product meeting the national standard. The method sets the precedent for producing tin ingot products through comprehensive utilization of tin resources obtained from lead through smelting, has the advantages of being concise in technology, high in tin product yield, low in processing cost and the like, particularly separates tin alloys through introduction of vacuum distillation, and has the significant advantages in the aspects such as energy conservation and environment protection.

Owner:蒙自矿冶有限责任公司

Method for preparing solar-grade silicon material by melt-salt electrolysis method

InactiveCN101070598AImprove efficiencyReduce energy consumptionPolycrystalline material growthElectrolysis componentsElectrolysisMolten salt

The invention relates to a method for preparing the solar level polysilicon material, and specially relates to the method for using the craft of fusion electrolysis to three fluids fining and then to vacuum distillation to prepare the solar level polysilicon material. The invention first takes SiO2 or others compound of containing silicon as the raw material, and fusion electrolysis technology is adopted to prepare silicon containing alloy Si-M1. Three fluids fusion electrolysis fining technology is adopted to prepare high-purity silicon containing alloy Si-M2 with silicon containing alloy Si-M1 as anode and high-purity metal M2 as cathode. Finally, vacuum distillation technology is adopted to prepare solar level polysilicon material with high-purity silicon containing alloy Si-M2 as material. Compared with traditional Simens craft or improvement Simens craft, the invention has the superiority of high efficiency, low energy consumption, low cost, and low pollution.

Owner:CENT SOUTH UNIV

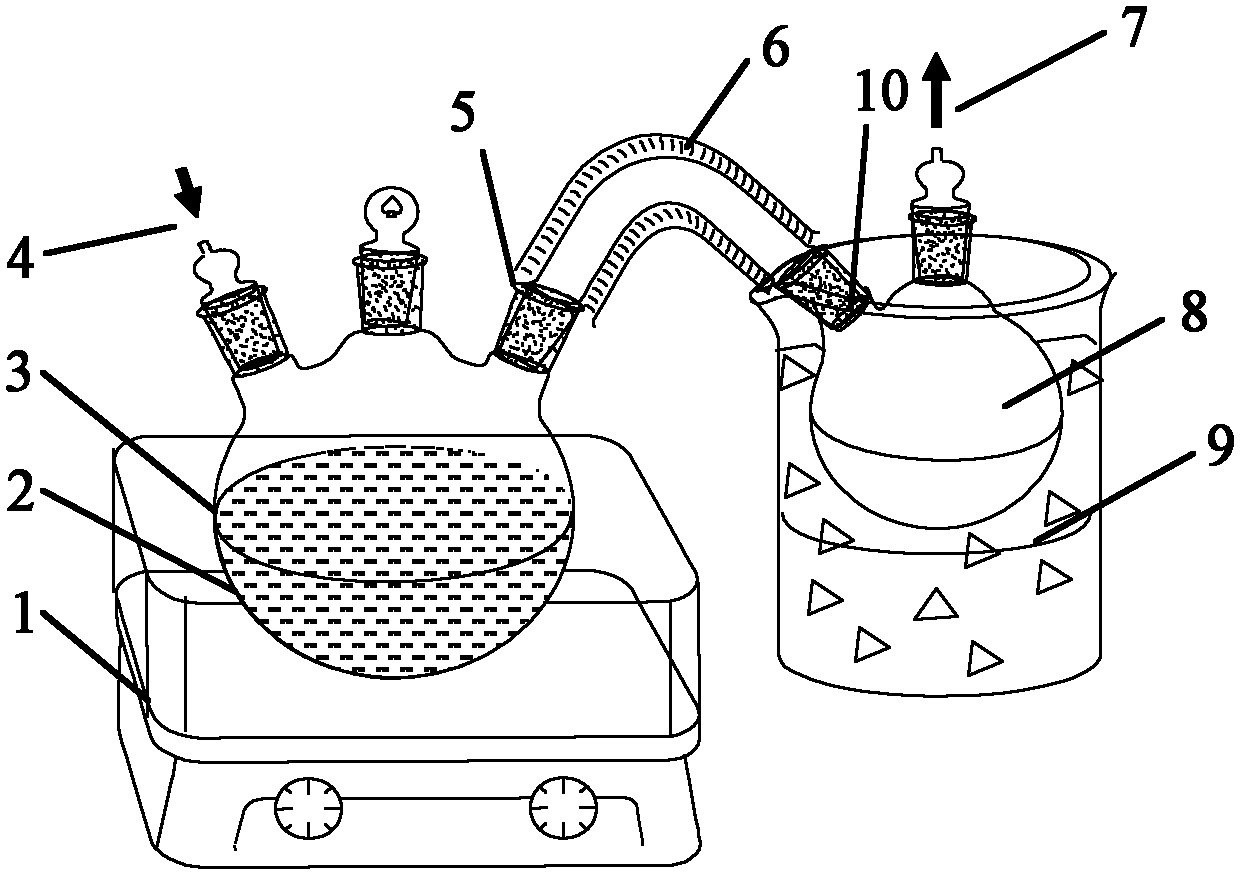

Method for preparing 5-hydroxymethylfurfural by degrading carbonhydrate through ionic liquid

InactiveCN102399203AAvoid separationShort reaction timeOrganic chemistryHydroxymethylfurfuralReaction system

The invention discloses a method for preparing 5-hydroxymethylfurfural (HMF) by degrading carbonhydrate through ionic liquid. The method comprises the following steps of: adding the carbonhydrate, the ionic liquid and a cocatalyst into a reactor, introducing an entrainer, continuously vacuumizing a reaction system to make the vacuum degree kept between 100 and 500Pa, and performing catalysis reaction at the temperature of between 120 and 180DEG C for 10 to 60 minutes; and during reaction, putting a separator connected with a product outlet of the reactor into an ice bath for collecting a product, wherein the separator is communicated with the product outlet of the reactor through a heat insulating connecting tube, and the separator has the same vacuum degree as the reactor. The catalysis reaction and product separation are coupled, and high vacuum distillation is adopted and the entrainer is introduced in the reaction process to make the generated water and 5-HMF leave the reaction system, so that the aim of enhancing the generation of the 5-HMF and the product separation is fulfilled and a problem that the 5-HMF is hard to separate is effectively solved.

Owner:ZHEJIANG UNIV

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN1884441AImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

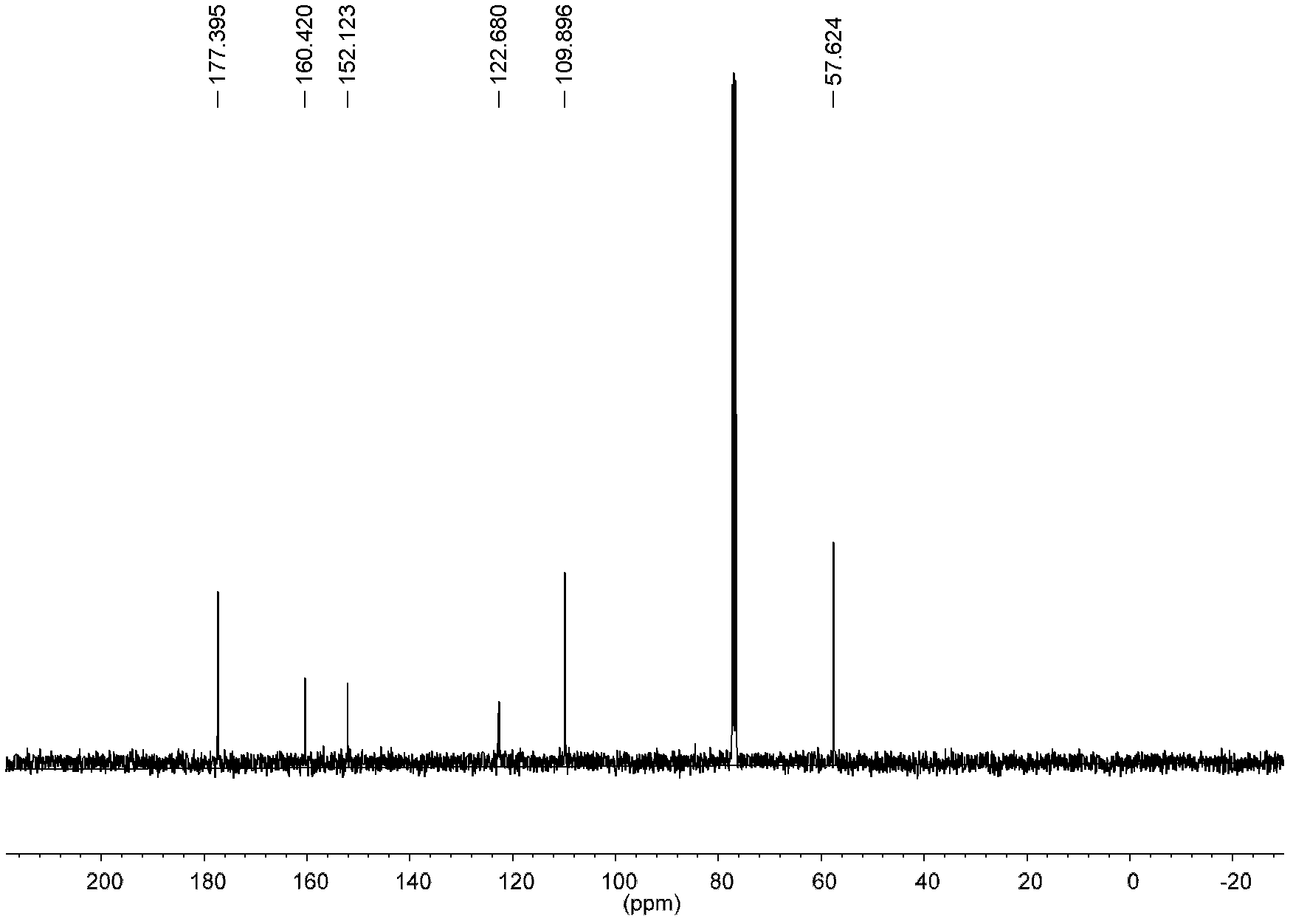

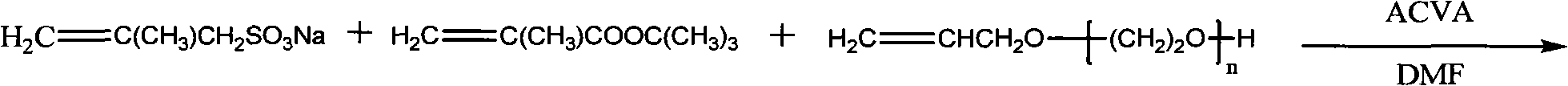

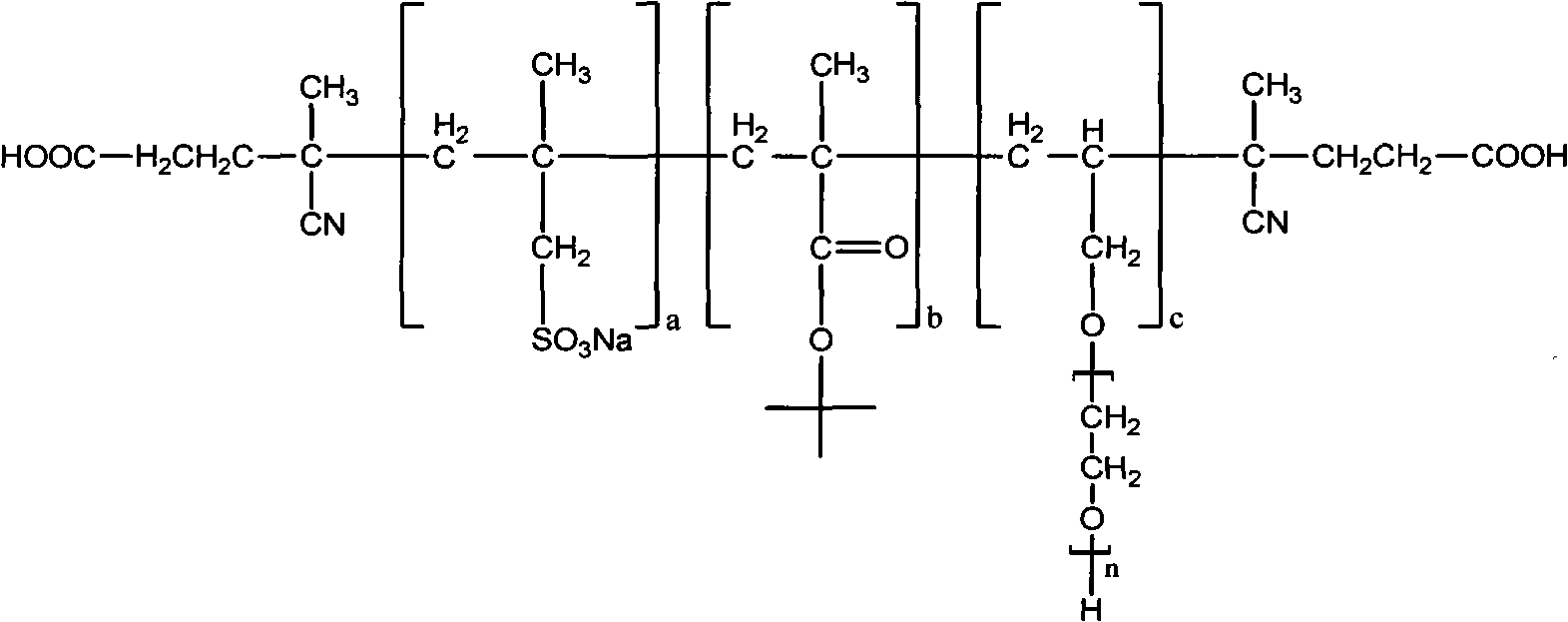

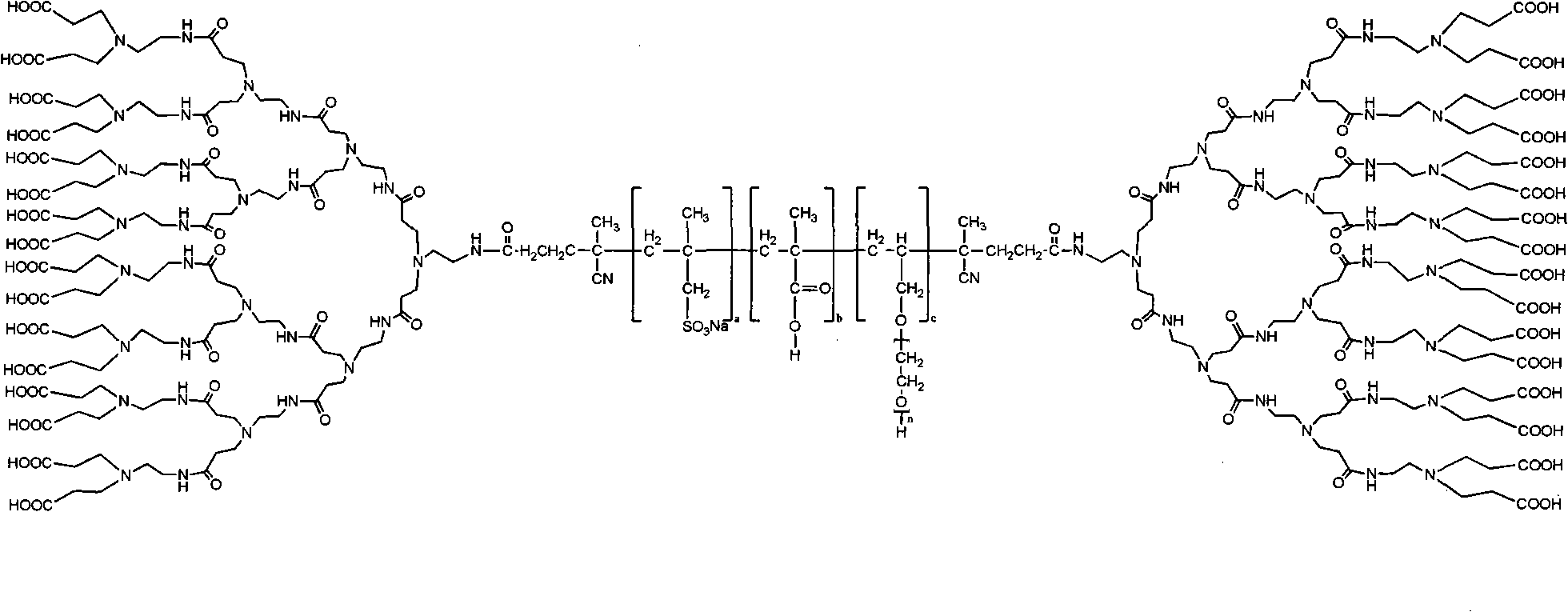

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1) preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by using N-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers and the solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent has the advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

Method for preparing phenolic chemicals through thermo-chemical conversion of industrial lignin

InactiveCN102173980ALow priceObvious cost advantageOrganic compound preparationBulk chemical productionCelluloseBiofuel

The invention provides a method for preparing phenolic chemicals through the thermo-chemical conversion of industrial lignin. The method is as follows: under the common functions of solid acid catalyst and hydrogen supply solvent, industrial lignin performs atmospheric thermo-chemical conversion in high boiling point organic reaction medium to prepare homogeneous low molecular weight organic matter with rich phenolic compounds such as phenol, methoxyphenol, dimethoxyphenol and 2-methoxy-4-methylphenol, and the organic reaction medium is recycled through the technologies such as vacuum distillation. The method has simple process, good stability and low production cost; and the yield of the prepared phenolic compounds is more than 54%. The method plays an important role in the high-valued comprehensive utilization of the renewable resource, namely ndustrial lignin; and the converted phenolic chemicals can be used to synthesize phenolic resin, prepare high efficiency cement water-reducing agent and further separate, purify and prepare bio-chemicals. Particularly, by adopting the method, the lignin in papermaking black liquid and preparation residue of biological fuel ethanol prepared from cellulose can be converted to phenolic chemicals; and the method has wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Solvent recovery method for cellulose fiber preparation with ion liquid as solvent

InactiveCN1804161AImprove protectionGood for healthArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiltration

The invention provides a solvent recovery method in the cellulose fiber preparation process by using ionic liquid as the solvent, which comprises subjecting coagulating bath components to precipitation, filtration, vacuum distillation and normal atmosphere distillation.

Owner:DONGHUA UNIV

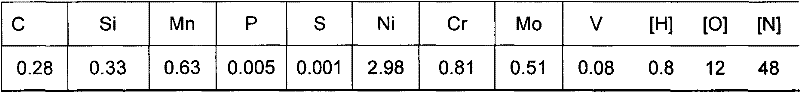

Smelting method of HIC (Hydrogen Induced Crack)/SSCC (Sulfide Stress Corrosion Cracking)-preventing steel

ActiveCN103540833AImprove dynamic conditionsAchieve transformationManufacturing convertersProcess efficiency improvementOxygenStress corrosion cracking

The invention discloses a converter smelting and external refining control method of HIC (Hydrogen Induced Crack) / SSCC (Sulfide Stress Corrosion Cracking)-preventing steel. A smelting process route of converter-CAS (Control Automatic System) station-LF (Low Frequency) refining-VD (Vacuum Distillation) / RH (Relative Humidity) vacuum-calcium treatment-soft blowing-continuous casting is adopted. Low-phosphor requirements of the HIC / SSCC-preventing steel are obtained through controlling the converter smelting process route; and meanwhile, part of deoxidation type inclusions are removed by carrying out strong deoxidation, alloying as well as residue washing in a converter steel-tapping process, and over 60% of sulfur in molten steel is removed by sufficient stirring of the residue washing. In the LF refining process, refining furnace slag which is high in alkalinity, high in Al2O3 and strong in reducibility is obtained by regulating components of the refining furnace slag, and the inclusions are transformed and removed towards a low melting point by virtue of balance of the furnace slag-molten steel-inclusions. Proper vacuum treatment time and vacuum degree are kept at a vacuum treatment furnace so as to remove part of gas and inclusions, excessive calcium line is fed into the molten steel after being broken in air, and then the molten steel is softly blown and stirred for over 20 minutes to obtain the molten steel with ultralow oxygen and ultralow sulfur.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

A kind of separation and recovery method of NMP and catalyst lithium chloride in polyphenylene sulfide production

The invention relates to a separation and recovery method for n-methylpyrrolidone (NMP) and a lithium chloride catalyst during polyphenylene sulfide producing. The method is characterized by: directly carrying out vacuum distillation for a polyphenylene sulfide polycondensation mother liquid until the polyphenylene sulfide polycondensation mother liquid is dried to recover a solvent of the NMP, wherein the NMP can be used in the next recycling production; adding water to the distilled residues, then heating to a temperature of 40 DEG C, carrying out stirring and completely dissolving the distilled residues, carrying out filtering and washing the filter residues, mixing the resulting filtrate and the washing solution, and analyzing lithium content in the mixed solution; adding the mixed solution to a phosphoric acid solution or a sodium aluminate solution, wherein the phosphoric acid solution or the sodium aluminate solution has a lithium reaction equivalent of 105-115%, then completely stirring to enable lithium phosphate or lithium aluminate to be precipitated completely, then carrying out steps of filtering, washing, drying for the lithium phosphate or the lithium aluminate to recover the lithium salt having a purity more than 97%. According to the present invention, the operation of the method is simple; the cost is low; the recovered NMP and the recovered lithium salt havehigh purities.

Owner:NANJING UNIV

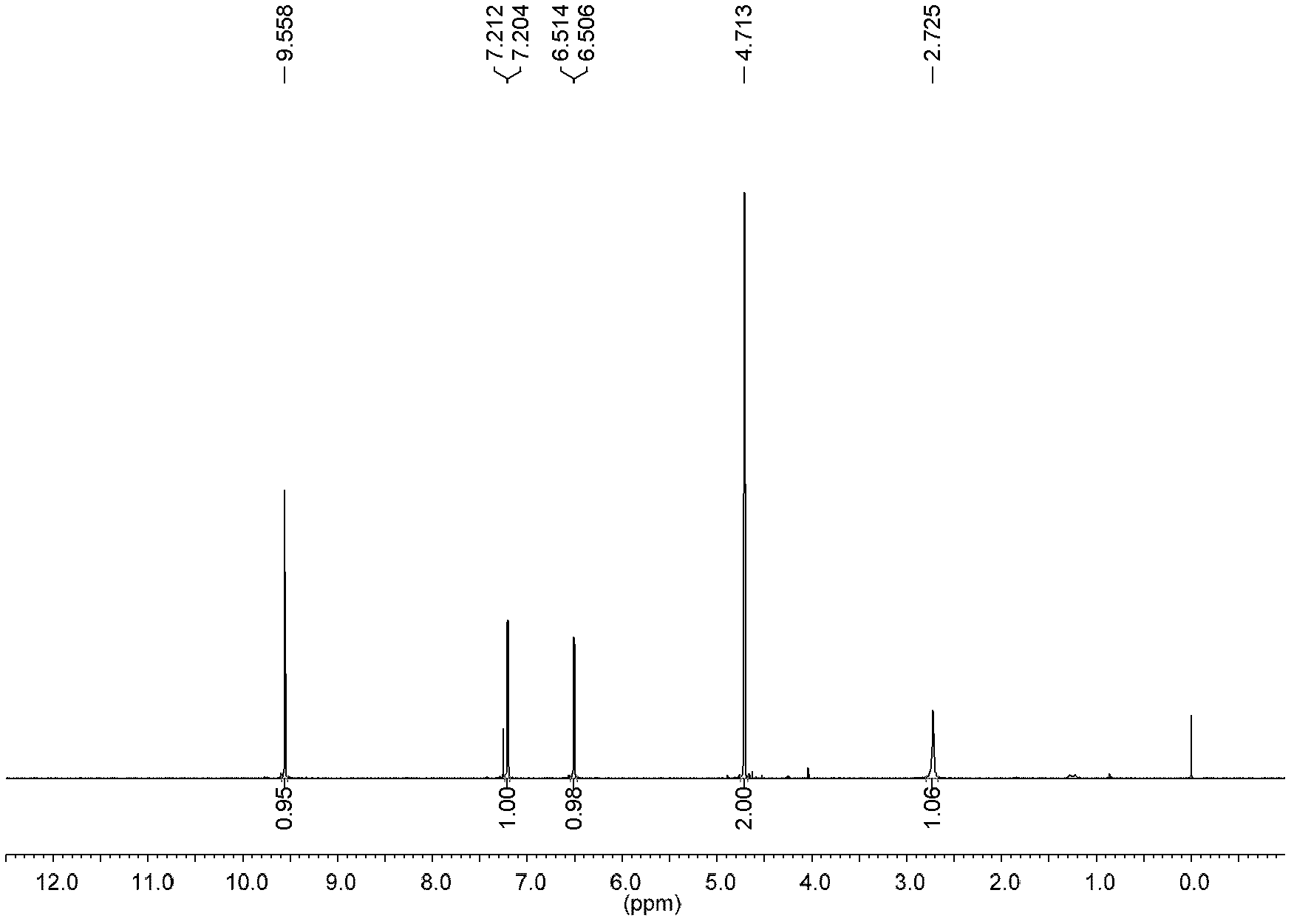

9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

InactiveCN101108864ALight colorHigh yieldGroup 5/15 element organic compoundsGlycol synthesisPhosphorus trichloride

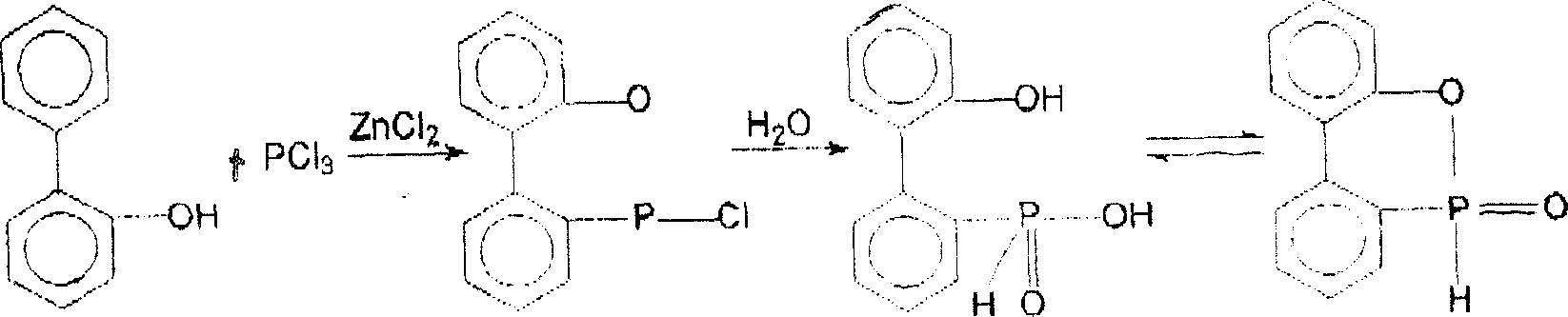

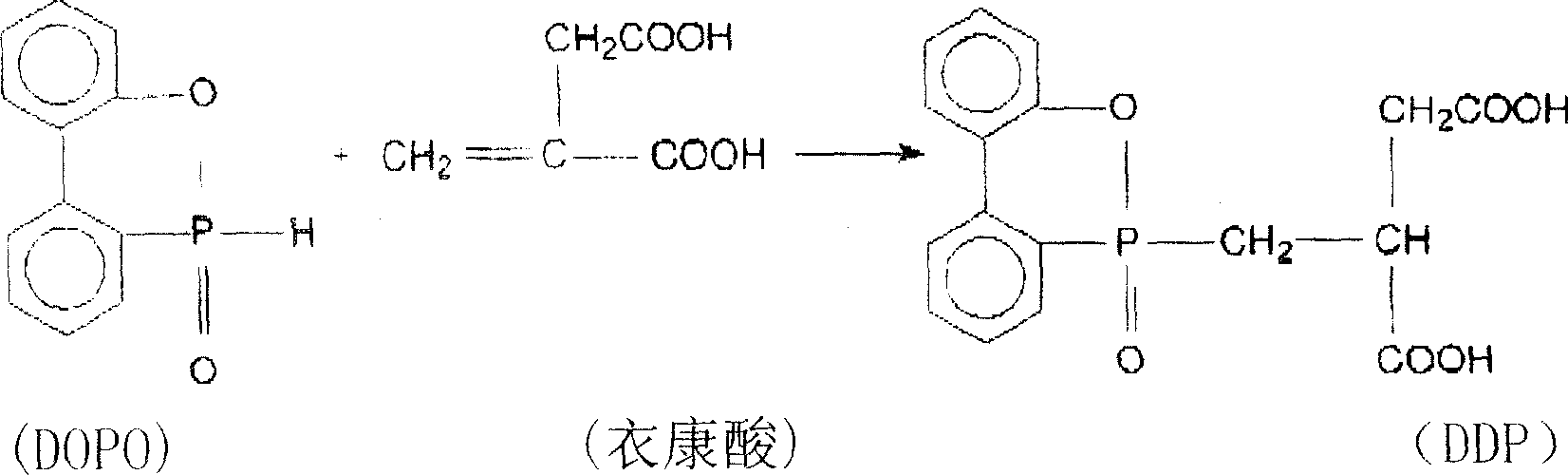

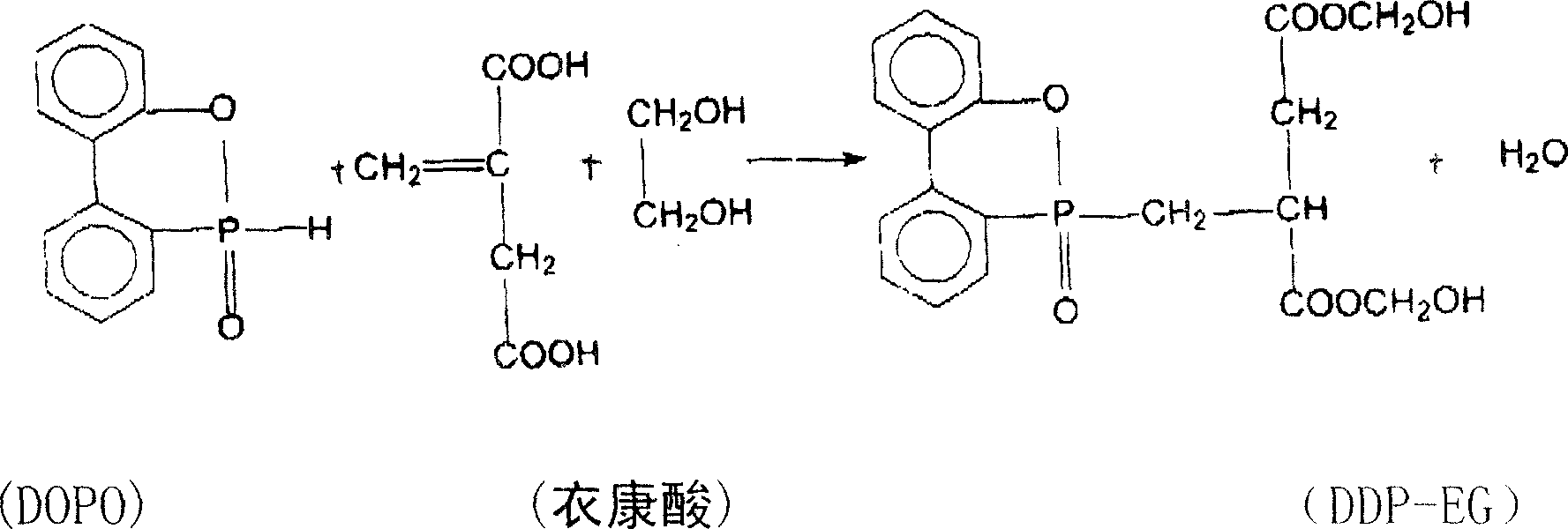

The invention discloses a preparation method of the 9, 10-dihydro-9-oxa-10-phosphahenanthrene-10-oxide and the derivatives DDP, DDP-EG and DOPO-BQ. The invention has three steps to synthesize the DOPO: (1) preparation of CDOP, the O-phenylphenol (OPP) reacts with the Phosphorus trichloride (PCl3) with ZnCl2 as the catalyst. (2) purification of CDOP, vacuum distillation is carried out. (3) DOPO with high purity and yield is gained through the hydrolysis and crystallization. The preparation materials comprises the O-phenylphenol, the Phosphorus trichloride, the toluene, the alcohol, the deionized water, the itaconic acid, the ethylene glycol, the p-benzoquinone and the acetone. The invention simplifies the process conditions, improves the product purity with good production stability and repeatability. The purity of the product reaches over 99.0 per cent, the content of the chloride is below 50ppm, the OPP is about 0.01 per cent, the color is about 10 (10 per cent solution of acetone), the zinc-ion is less than 10ppm. The preparation method of the derivatives DDP, DDP-EG, DOPO-BQ is simple, good in stability and high in yield.

Owner:魏铭杉

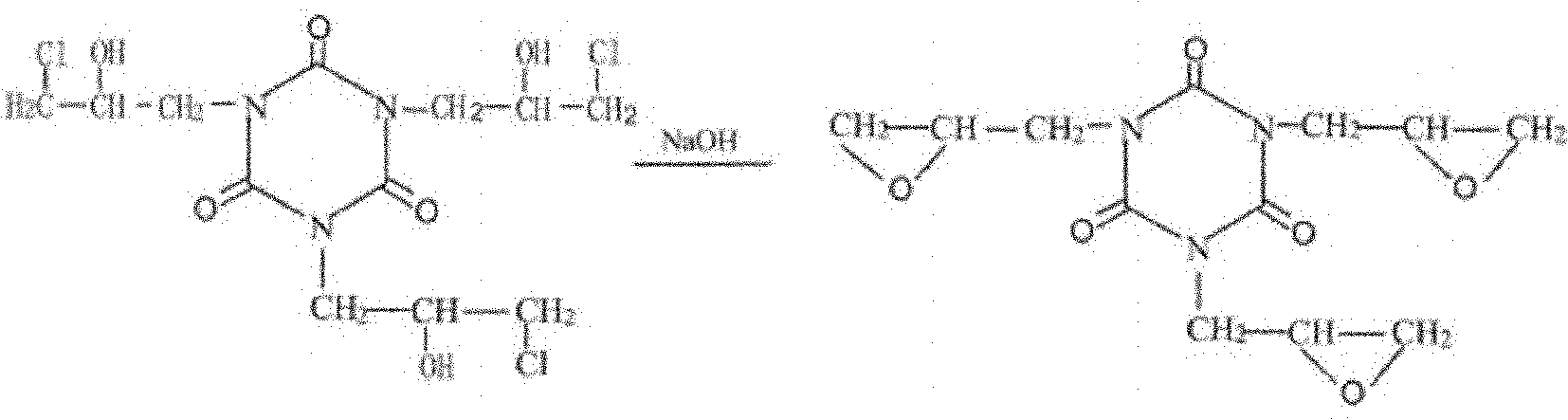

Preparation method of electronic grade triglycidyl isocyanurate

The invention mainly aims to provide a preparation method of electronic grade triglycidyl isocyanurate (TGIC). In order to realize the aim, the technical scheme in the invention is as follows: the preparation method of electronic grade TGIC comprises the following steps: a) adding epichlorohydrin, cyanuric acid, quaternary ammonium salt phase transfer catalyst and water according to a ratio, heating and stirring to react; b) adding flake caustic soda in the reaction system obtained in the step a) to react, then performing pressure filtration to remove solid salt; and c) performing vacuum distillation after the reaction, then using a high vacuum film evaporator to distill and remove epichlorohydrin, crystallizing the coarse product, centrifuging, grinding, and drying to obtain electronic grade TGIC. According to the treatment method provided by the invention, the purity of the TGIC product can be effectively increased, and the purity of TGIC can be increased from 92% to more than 99%, which reaches the electronic grade.

Owner:HUANGSHAN HUAHUI TECH

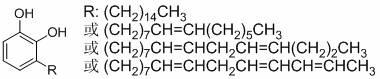

Preparation method for benzoxazine intermediate and synthetic resin of intermediate

InactiveCN102432560AImprove heat resistanceImprove system stabilityOrganic chemistryPolymer scienceOrganic solvent

The invention discloses a preparation method for a benzoxazine intermediate and a synthetic resin of the intermediate. The method comprises the following steps: adding 2 to 2.4 parts by mol of an aldehyde solution with a mass percent of 35 to 40% and 1 part to 1.2 parts by mol of primary amine compounds into 80 to 120 parts by mol of an organic solvent, controlling reaction temperature to be no more than 30 DEG C, adjusting the pH value of an obtained mixture to be 7 to 14, maintaining the mixture at a constant temperature for 30 minutes, adding 1 part by mol of urushiol, heating an obtained mixture to a temperature of 90 DEG C, allowing the mixture to react for 5 to 10 hours, carrying out vacuum distillation on a reaction solution, dissolving a product with a fat-soluble solvent, rinsing the product 3 to 5 times, carrying out drying after removal of the solvents so as to obtain the desired benzoxazine intermediate, and curing the benzoxazine intermediate in an electrothermostat at different stages. According to the invention, the considerable advantages of a simple synthetic method, easily available raw materials, low cost, low viscosity, a liquid state at normal temperature and suitability for industrial production are achieved; polymerized polybenzoxazine has excellent heat resistance and mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

Process for making biodiesel from crude tall oil

InactiveUS20070130820A1Improve overall utilizationIncrease productionBiofuelsLiquid carbonaceous fuelsBiodieselOrganic solvent

A process of making biodiesel from crude tall oil by reacting crude tall oil with a C1-C6 alkanol in the presence of an acid catalyst or by reacting crude tall oil with an acyl halide in the presence of a C1-C6 alkanol. The reaction product of either of these reactions is separated into a suspension liquid by the addition of a polar liquid. The biodiesel product is recovered from the suspension liquid by addition of an organic solvent which produces a polar liquid phase and an organic liquid phase. The biodiesel is recovered from the organic liquid phase by evaporating the organic solvent, which is recovered for use in subsequent separation processes, and vacuum distilling off the product biodiesel from the organic solvent-free organic liquid phase.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

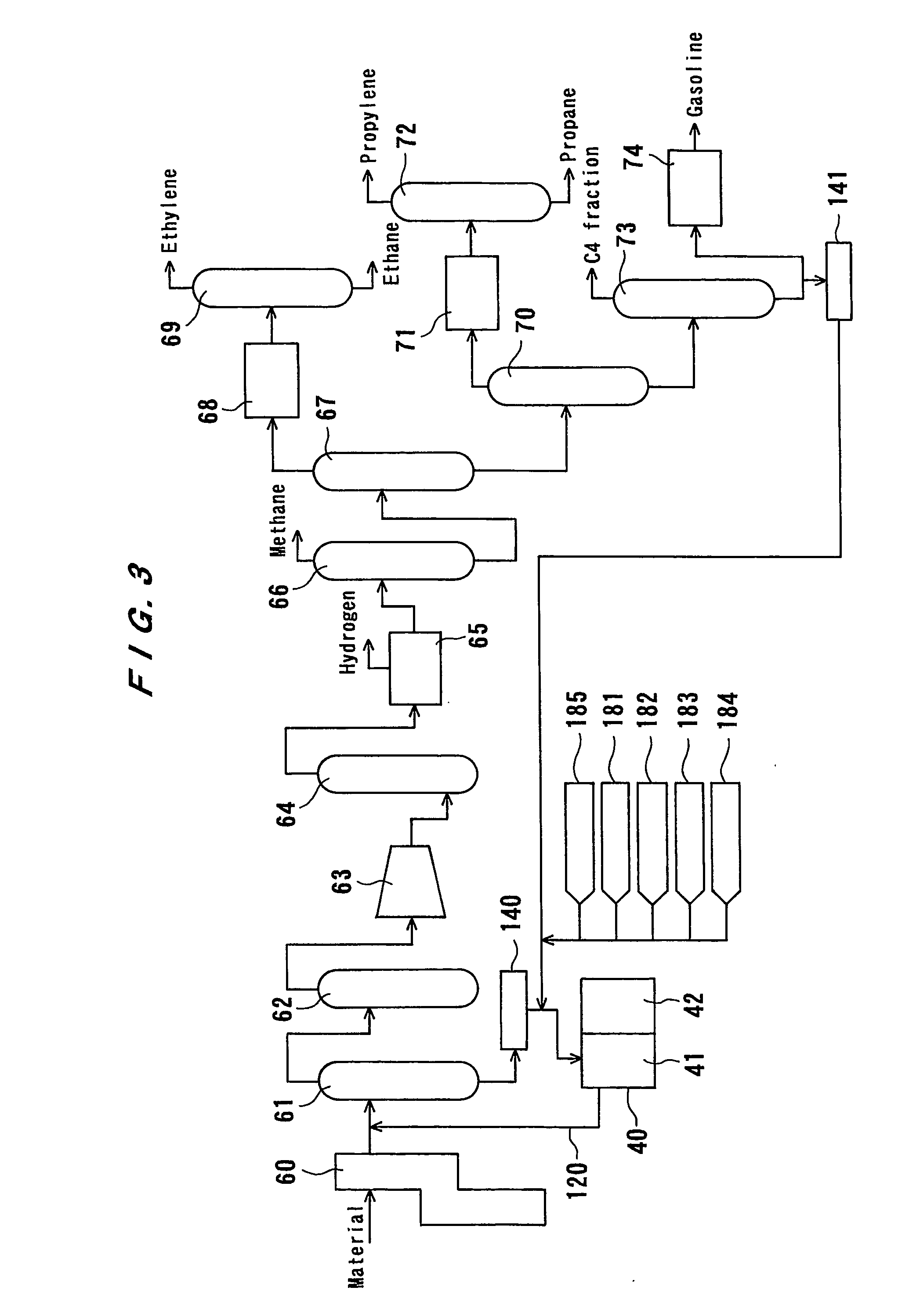

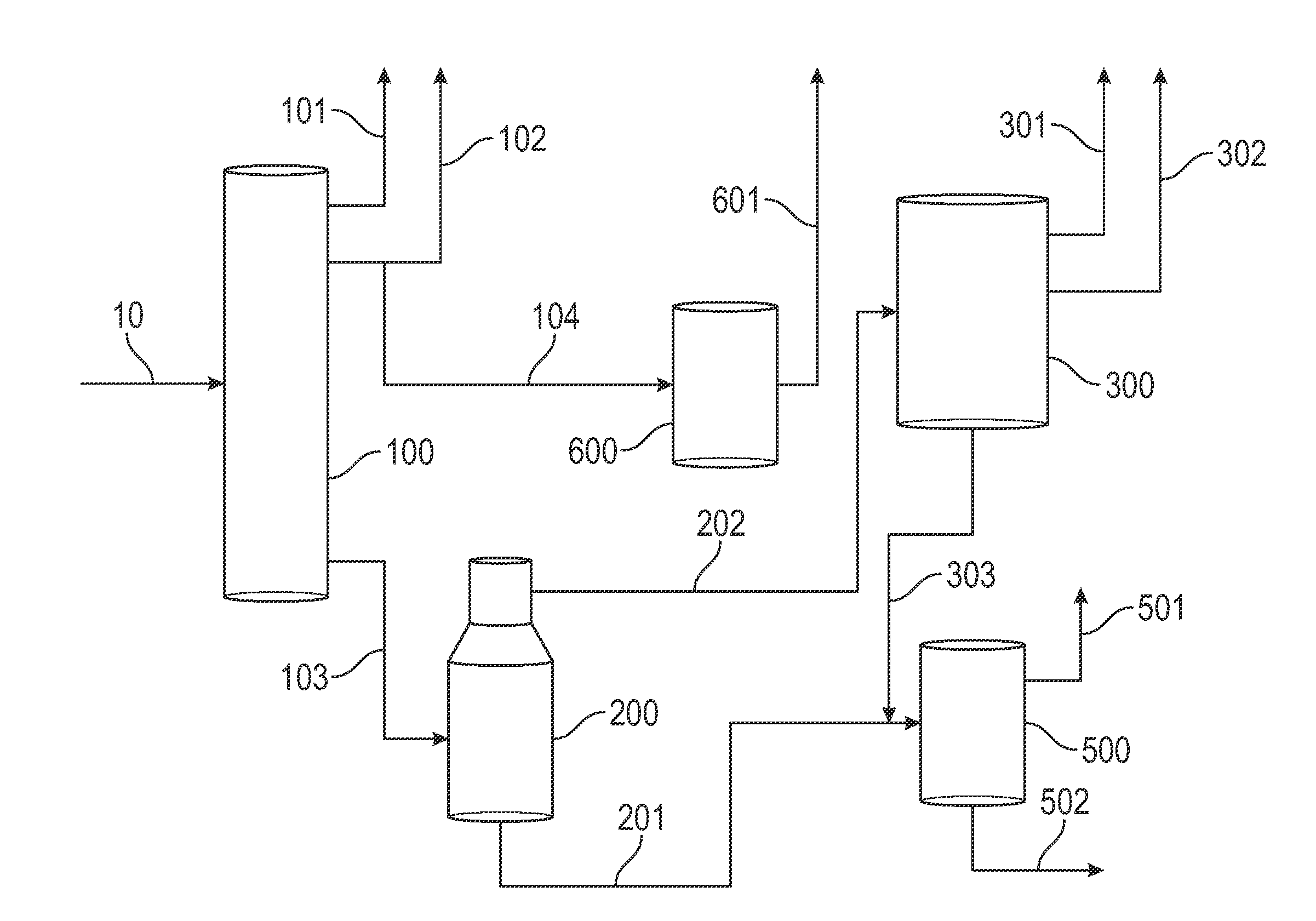

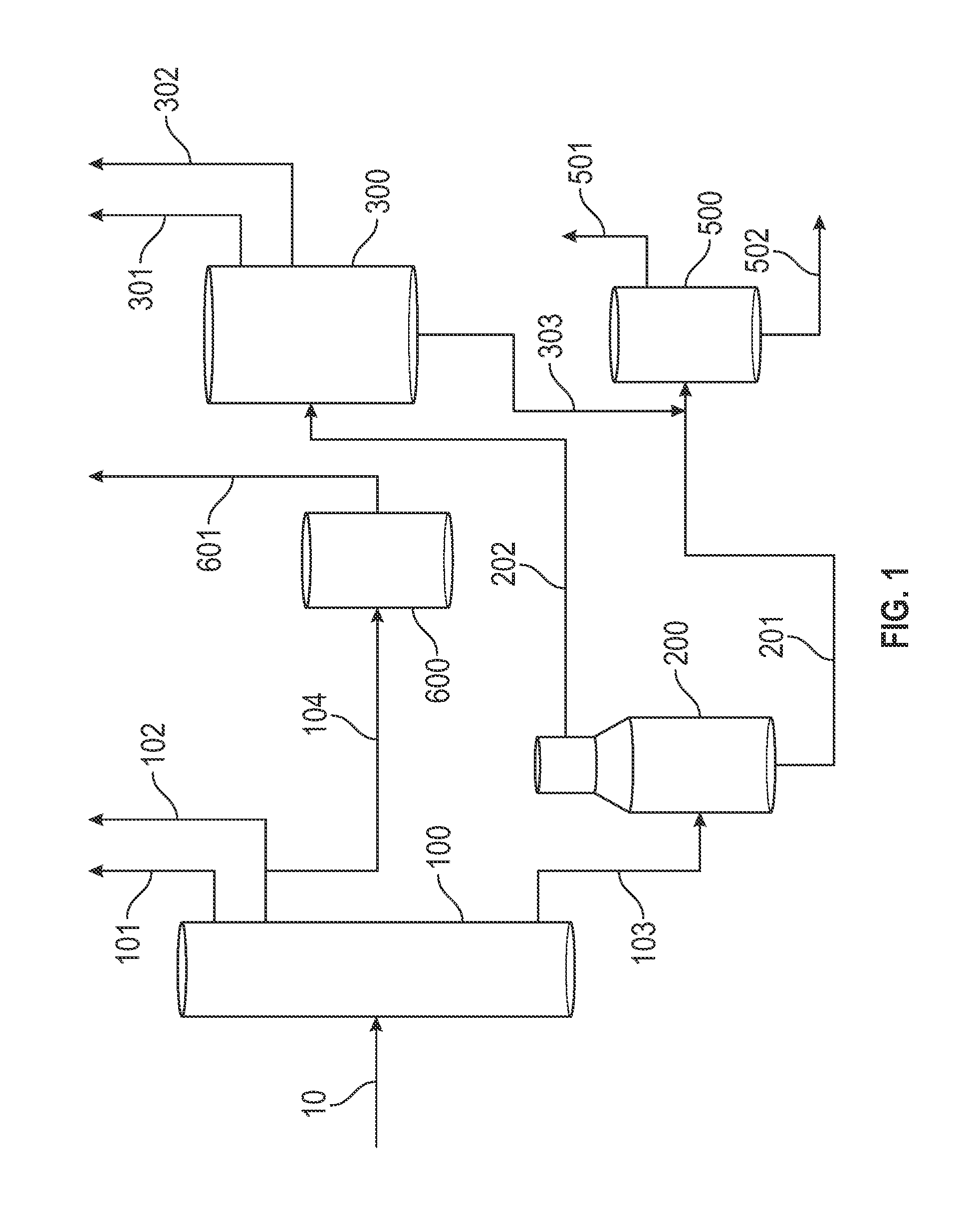

Process for production of hydrocarbon chemicals from crude oil

ActiveUS20130267745A1Efficient processMaximize efficient conversionThermal non-catalytic crackingTreatment with plural parallel cracking stages onlyBoiling pointPhysical chemistry

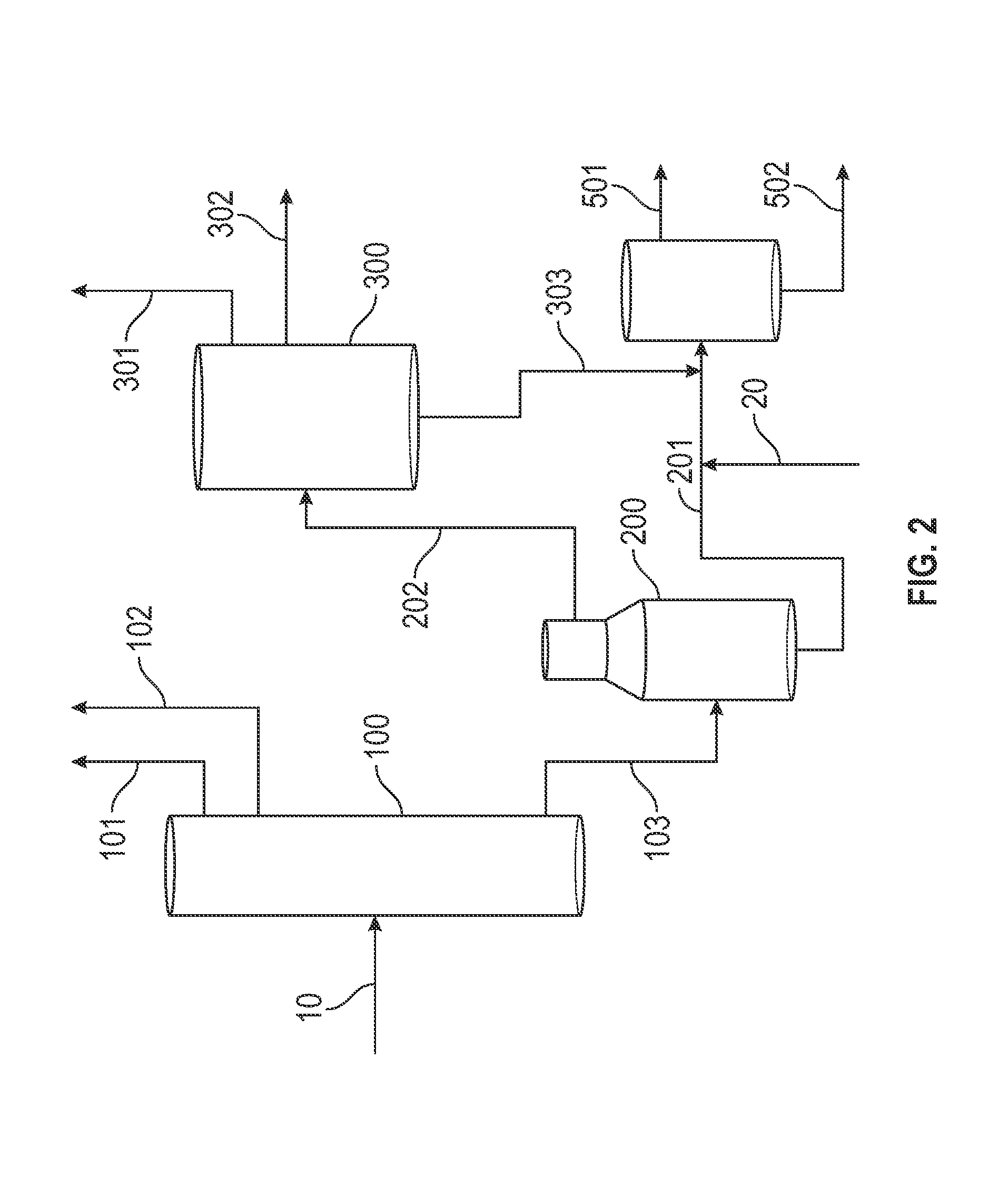

An integrated process comprising to convert crude oil, comprising: converting crude oil (10) in a feed preparation facility (800) by separating the crude oil to a gas fraction (101), liquid fraction (102), and first residuum fraction in an atmospheric distillation unit (100); separating the 1st residuum to a vacuum gas oil fraction (202) and a second residuum (201) in a vacuum distillation unit (200); converting the vacuum gas oil fraction to a CU gas fraction (301,401), a CU liquid fraction (302), and an CU higher boiling fraction (303,402) in a cracking unit (300,400); and processing the second residuum fraction to DCU gas oil / lighter fraction (501) in a coking unit (500); and steam cracking at least one of the gas fraction (101), liquid fraction (102), CU gas fraction (301,401), and DCU gas oil / lighter fraction (501) to the hydrocarbon products (920).

Owner:SAUDI BASIC IND CORP SA

Process to prepare a sweet crude

ActiveUS20080142408A1Hydrocarbon distillationCombustible gas catalytic treatmentOil sandsRemoval Units

A process to prepare a sweet crude from an ash containing and heavy fraction of a tar sand oil by:(a) supplying an atmospheric distillation bottoms of a tar sands originated feed to a vacuum distillation to obtain a vacuum gas oil and a vacuum bottoms,(b) contacting the vacuum gas oil with hydrogen in the presence of a suitable hydrocracking catalyst to obtain a sweet synthetic crude(c) separating the vacuum bottoms obtained in step (a) into an asphalt fraction comprising between 0.1 and 4 wt % ash and a de-asphalted oil,(d) feeding said asphalt fraction to a burner of a gasification reactor where the asphalt fraction is partially oxidized in the presence of an oxidizer gas in a burner to obtain a mixture of hydrogen and carbon monoxide,(e) performing a water gas shift reaction on the mixture of hydrogen and carbon monoxide,(f) separating hydrogen sulphide and carbon dioxide from the shifted gas in an acid removal unit thereby obtaining crude hydrogen,(g) purifying the crude hydrogen to obtain pure hydrogen and(h) using part of the pure hydrogen in step (b), wherein in step (d) the asphalt fraction is provided to the burner in a liquid state and wherein in case separation step (c) fails to provide sufficient feed for step (d), step (d) is performed by feeding the vacuum bottoms of step (a) to the burner in a liquid state.

Owner:AIR PROD & CHEM INC

Method for separating ternary alloy of lead, tin and stibium

InactiveCN101696475AEasy to separateSimplify the refining processProcess efficiency improvementBoiling pointLiquid state

The invention relates to a method for separating a ternary alloy of lead, tin and stibium, which adopts a vacuum distillation method to treat the ternary alloy of lead, tin and stibium, wherein the distillation temperature is controlled at 900 to 1,200 DEG C, the distillation time is 40 to 60min and the vacuum degree is 5 to 15 Pa. The three components in the alloy are distilled in one step, then the tin of a high boiling point is kept in a liquid state, and the lead and the stibium of a low boiling point are volatilized from the alloy in a gas state so as to be separated from the liquid tin. The method can reduce the content of the lead and the stibium in the lead to be less than 1 percent, and the recovery rates of the lead, tin and stibium are over 98 percent.

Owner:KUNMING UNIV OF SCI & TECH +1

Deasphalting of Gas Oil from Slurry Hydrocracking

ActiveUS20100243518A1High value distillateIncrease valueWorking-up pitch/asphalt/bitumen by selective extractionTreatment with hydrotreatment processesSlurryProcess engineering

Integrated slurry hydrocracking (SHC) and solvent deasphalting (SDA) methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a vacuum column resid, a recycled, deasphalted oil obtained from SDA, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Fractionation or distillation in the SHC product recovery section yields a combined SHC gas oil / SHC pitch stream that is sent to SDA. In a representative embodiment, vacuum distillation in the SHC product recovery is avoided, thereby eliminating equipment that is often most susceptible to fouling.

Owner:UOP LLC

Smelting method of axle steel for high-speed motor car

The invention relates to a smelting method of axle steel for a high-speed motor car, which comprises the following steps of: I. smelting in an electric furnace, firstly adding steel scraps into the electric furnace and adding pretreated molten iron, wherein the weight proportion of the pretreated molten iron is 80% to 95%, and in the steel scraps, P is less than or equal to 0.015% and S is less than or equal to 0.010%; blowing oxygen and adding lime, and tapping from the electric furnace after P is less than or equal to 0.008%; adding slagging materials, iron alloys and metals into steel ladles according to the types of steel; II. adopting slag systems with high alkalinity and high Al2O3 content for ladle furnace refining, controlling the alkalinity R of molten slag, wherein R is equal to 4.0 to 6.0; the molten steel comprises following components in percent by weight: 0.26 to 0.31% of C, 0.20 to 0.35% of Si, 0.55 to 0.70% of Mn, less than or equal to 0.005% of S, less than or equal to 0.015% of P, 0.75 to 0.90% of Cr, 2.90 to 3.30% of Ni, 0.45 to 0.55% of Mo and 0.08 to 0.13% of V; and III. feeding Si and Ca into the molten steel and blowing argon from the bottom after carrying out VD (Vacuum Distillation) and the vacuum refining. Inclusions of the steel rolled axle smelted by the smelting method of axle steel for the high-speed motor car meet the using requirements on the high-speed axle.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com