Preparation method for benzoxazine intermediate and synthetic resin of intermediate

A technology of benzoxazine and synthetic resin, which is applied in the field of thermosetting resin and its preparation, can solve the problem of no combination of benzoxazine and raw lacquer, and achieve the elimination of human toxicity, enhanced heat resistance and system stability , High heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

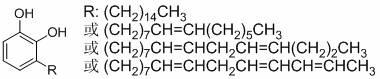

Embodiment 1

[0067] Add 1.5g paraformaldehyde and 2.3g aniline to 20mL dioxane, control the reaction temperature not to exceed 30°C, and adjust the pH value to 8 with triethylamine to generate N-dimethylol compound and keep the temperature constant for 30min , then add a mixed solution of 9.0g urushiol and 10mL dioxane, heat up to 90°C to reflux, keep the mixed solution reacting at this reflux temperature for 6h, and generate a benzoxazine intermediate solution. After the reaction, the obtained solution was distilled off under reduced pressure to remove dioxane, and 100 mL of dichloromethane was used to dissolve the product, washed 3 times with water, and anhydrous MgSO 4 After drying, dichloromethane was distilled off under reduced pressure, and the red viscous liquid was obtained by vacuum drying, which was a novel benzoxazine intermediate containing urushiol-like structure.

[0068] Pour the above-mentioned benzoxazine intermediate into a mold, and cure in sections in an electric thermo...

Embodiment 2

[0070] Add 3.0 g of paraformaldehyde and 5.0 g of 4,4'-diaminodiphenylmethane into 20 mL of dioxane, control the reaction temperature not to exceed 30 ° C, and adjust the pH value to 8 with triethylamine to generate N-dimethylol compound and keep it for 30min, then add a mixed solution of 17.9g urushiol and 20mL dioxane, heat up to reflux at 90°C, keep the mixed solution reacting at this reflux temperature for 6h, and generate benzoxazine intermediate solution. After the reaction, the obtained solution was distilled under reduced pressure to remove dioxane, and 100 mL of dichloromethane was used to dissolve the product, washed with water for 3 times, and anhydrous MgSO 4 After drying, dichloromethane was distilled off under reduced pressure, and the red viscous liquid was obtained by vacuum drying, which was a novel benzoxazine intermediate containing urushiol-like structure.

[0071] Pour the above-mentioned benzoxazine intermediate into a mold, and cure in sections in an el...

Embodiment 3

[0073] Add 1.5g of paraformaldehyde, 2.3g of aniline, and 9.0g of urushiol into the reaction flask, mix well with mechanical stirring at low temperature (0-10°C), heat to 90°C for 1.5h, and keep stirring vigorously during this period . After the reaction, the volatile small molecules were distilled off under reduced pressure, cooled at room temperature, added a fat-soluble solvent to dissolve the product, filtered and washed 5 times with water, using anhydrous MgSO 4 After drying, the solvent is distilled off under reduced pressure, and vacuum-dried to obtain a novel benzoxazine intermediate containing an urushiol-like structure.

[0074] Pour the above-mentioned benzoxazine intermediate into a mold, and cure in sections in an electric thermostat to obtain a thermosetting benzoxazine resin material containing an urushiol-like structure. The curing temperature rise process is 100°C / 1h, 140°C / 1h, 180°C / 1h, 220°C / 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com