Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6057 results about "Triethylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethylamine is the chemical compound with the formula N(CH₂CH₃)₃, commonly abbreviated Et₃N. It is also abbreviated TEA, yet this abbreviation must be used carefully to avoid confusion with triethanolamine or tetraethylammonium, for which TEA is also a common abbreviation. It is a colourless volatile liquid with a strong fishy odor reminiscent of ammonia and is also the smell of the hawthorn plant. Like diisopropylethylamine (Hünig’s base), triethylamine is commonly employed in organic synthesis.

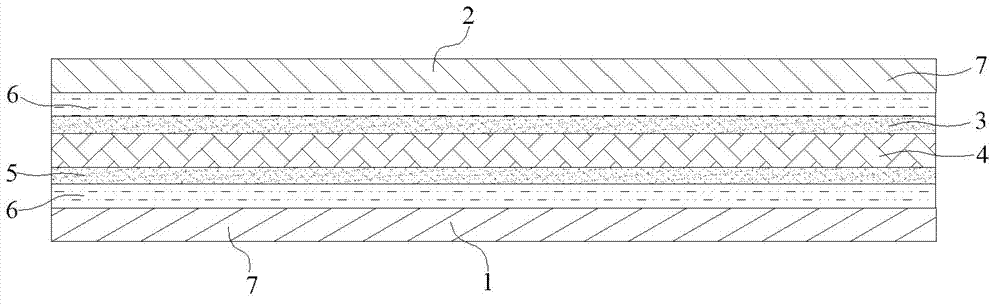

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

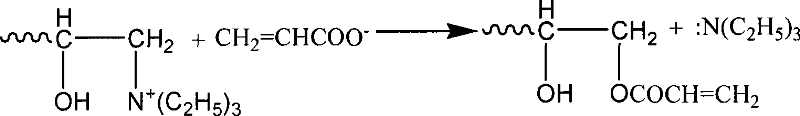

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

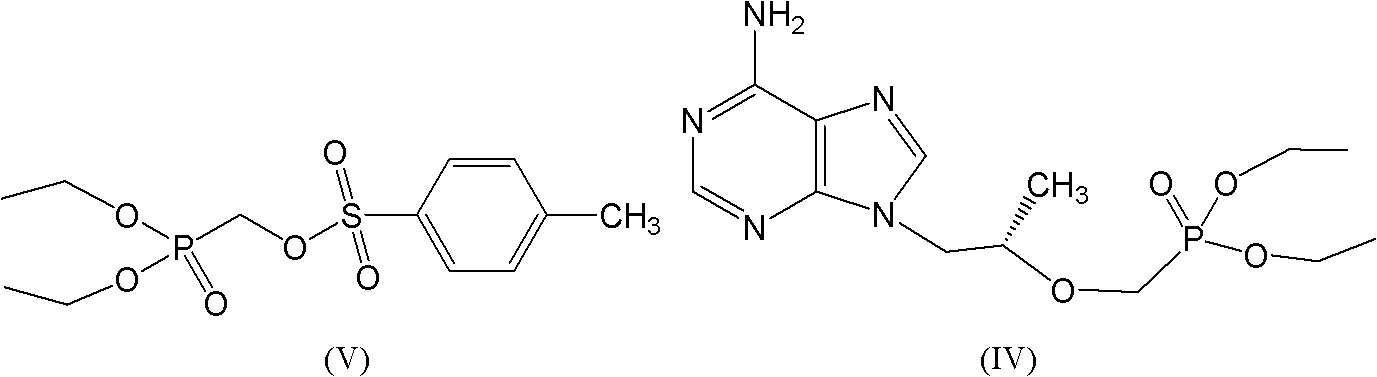

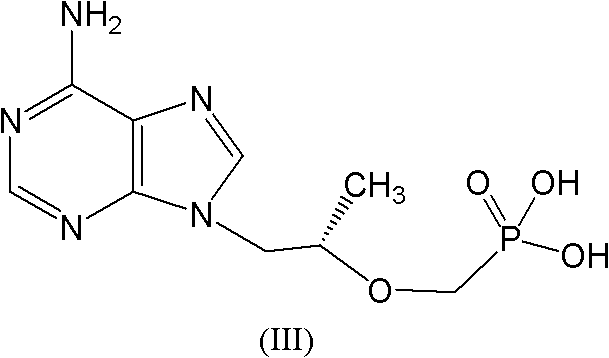

Industrial production process for tenofovir disoproxil fumarate

InactiveCN101870713AImprove securitySolve the problem of excessive contentGroup 5/15 element organic compoundsAlcoholPropylene carbonate

The invention discloses an industrial production process for tenofovir disoproxil fumarate represented by a structural formula (II). The production process comprises the following steps of: (1) preparing R-9-(2-hydroxypropyl)adenine by taking adenine and R-propylene carbonate as initial raw materials; (2) performing a condensation reaction on the obtained R-9-(2-hydroxypropyl)adenine and diethyl(tosyloxy)methylphosphonate under the catalytic action of magnesium alkoxide to prepare R-9[2-(diethyl-phosphonic acid methoxy)propyl]adenine; (3) hydrolyzing R-9[2-(diethyl-phosphonic acid methoxy)propyl]adenine to obtain tenofovir; and (4) performing condensation on the tenofovir and the chloromethyl isopropyl carbonate under the catalytic action of triethylamine to prepare the tenofovir disoproxil fumarate. The process of the invention has the characteristics of low cost, safe process, high product quality and suitability for industrial production.

Owner:杭州和素企业管理有限公司

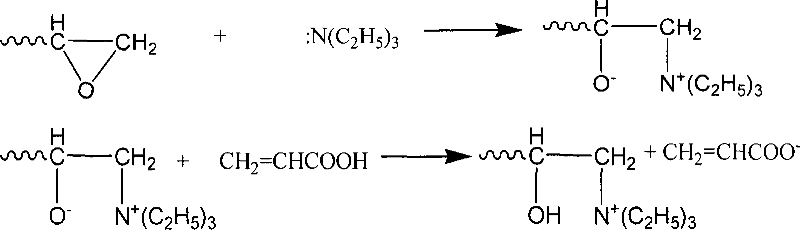

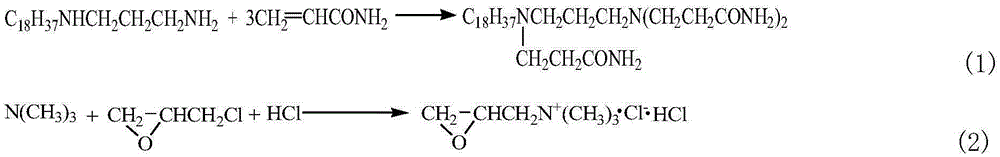

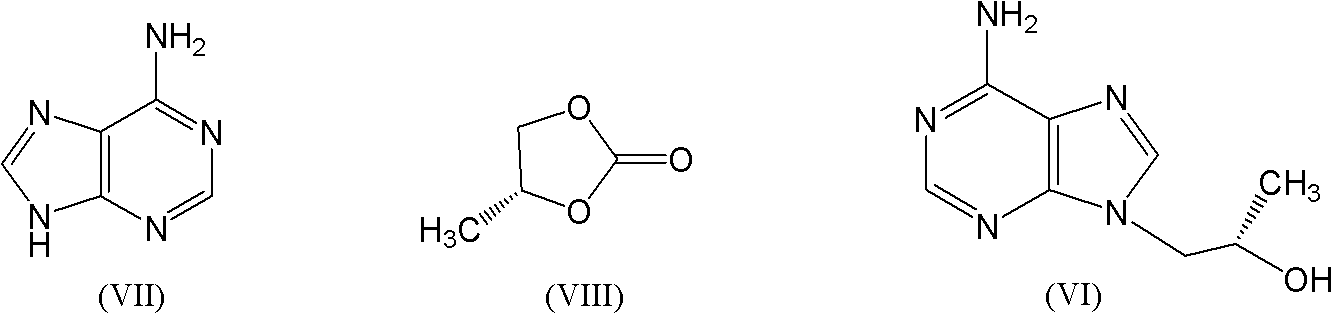

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

Preparation method of phosphite ester

ActiveCN101684130AEasy to removeReduce Chloride ContentGroup 5/15 element organic compoundsPhosphite esterPhenol

The invention discloses a preparation method of phosphite ester. The method comprises the following steps: dissolving chlorinated phosphite ester in dichloromethane, dissolving phenol in triethylamine or a mixed solution of triethylamine and dichloromethane, mixing the solutions to react and obtain raw product, and purifying the raw product through post-treatment to obtain the desired product. The preparation method of phosphite ester of the invention uses dichloromethane as reaction solvent to synthesize phosphite ester; the preparation process does not have any link with high viscosity material, the product is easy to clean and filtrate, the chlorine ions in the product can be removed conveniently and effectively and the quality of the product can be increased.

Owner:SHANGHAI HUAYI ENERGY CHEM

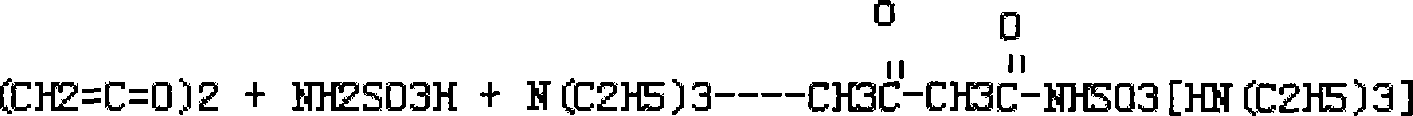

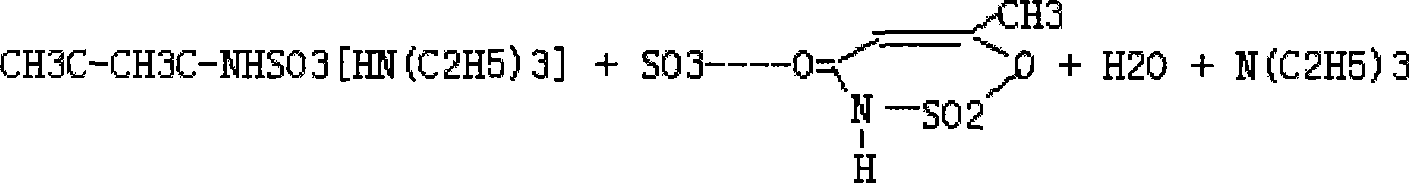

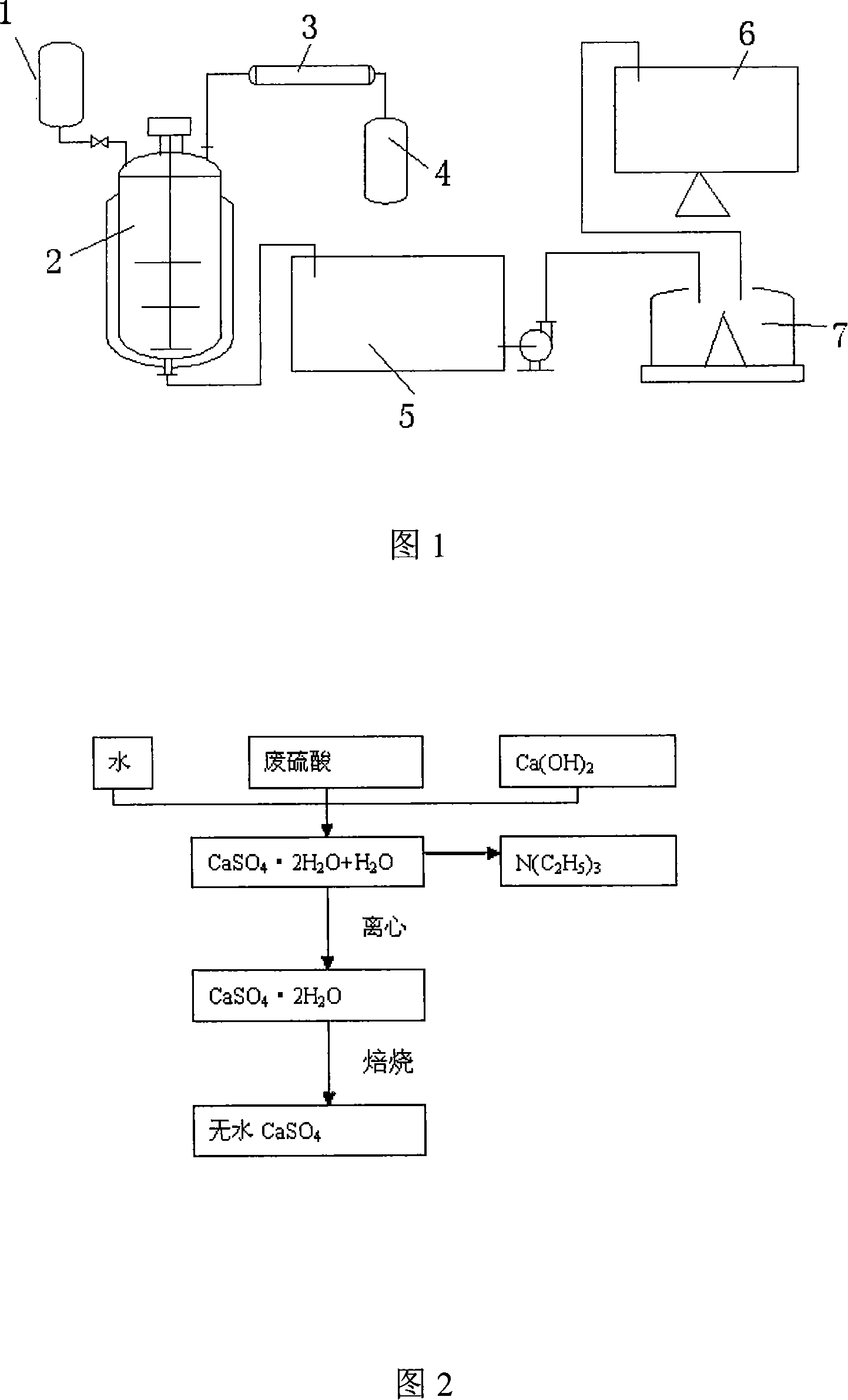

Process for reclaiming catalyst for use in synthesis of acesulfame potassium

InactiveCN1883790ANo pollutionHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsSulphate IonPotassium

The invention discloses a process for recovering catalyst in synthesizing potassium acetylsulfanilate, which includes steps of: (1) neutralizing mixture containing triethylamine sulphate with base or basic salt, rising the temperature to 70-120 DEG C for distilling triethylamine. (2) removing water of triethylamine received in step (1) to obtain high purity triethylamine. In addition, acid could be added to the mixture of removing triethylamine in step (1) to neutralizing excess base, and gypsum is obtained by filtrating reactive liquid. The excellence of this method is that the process is simple, processing time is short, damage to the device is slight, having no contamination to environment, the retrieving triethylamine have high purity and can be used for synthesizing potassium acetylsulfanilate after removing water, and the byproduct such as gypsum also has some economic benefit

Owner:SUZHOU HOPE TECH

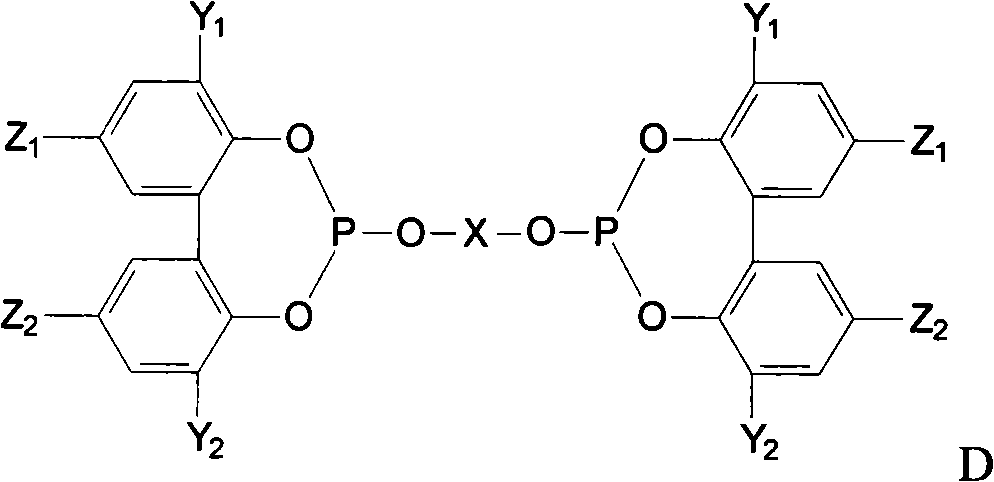

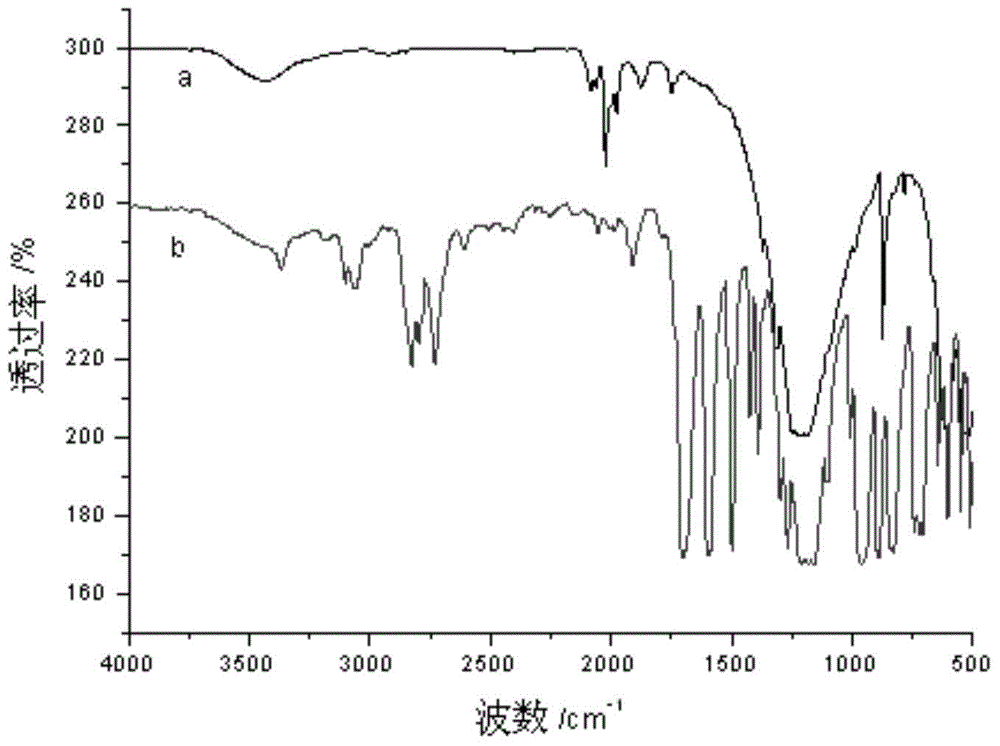

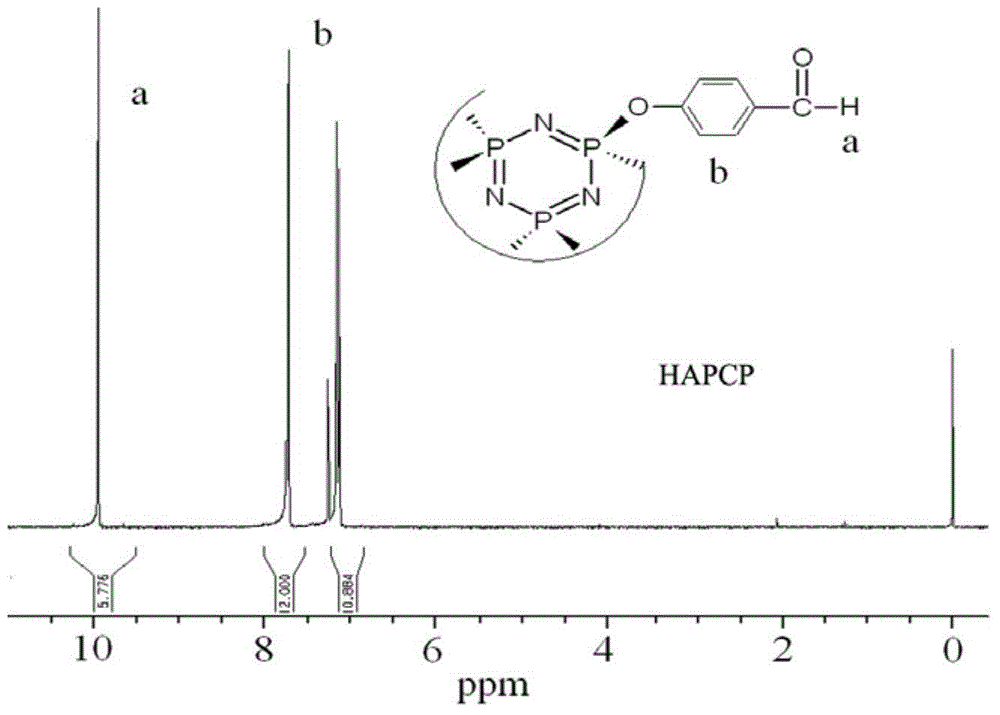

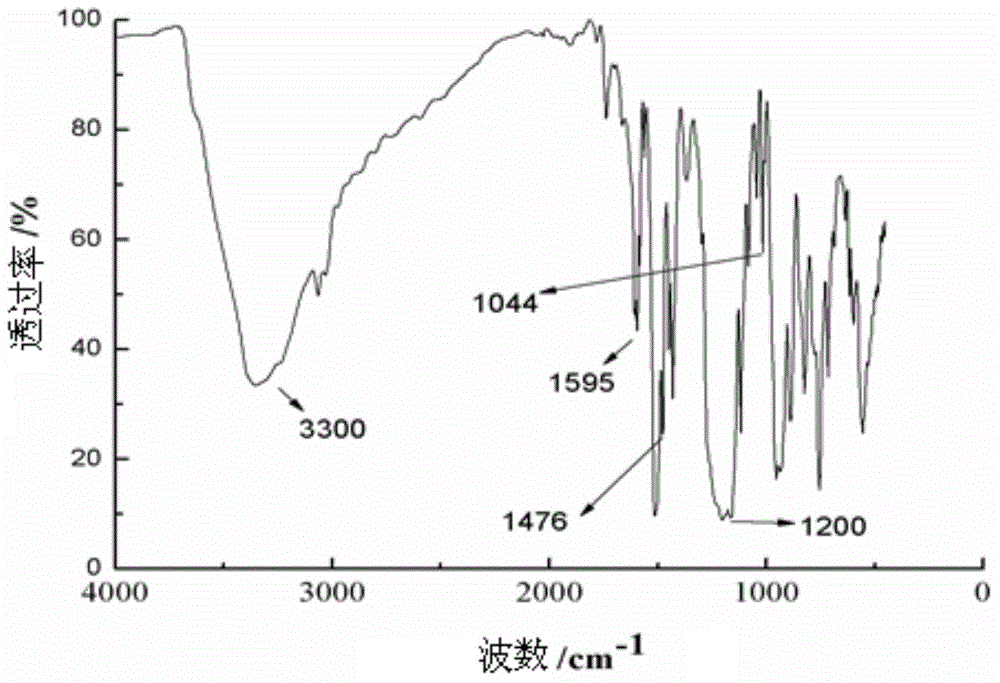

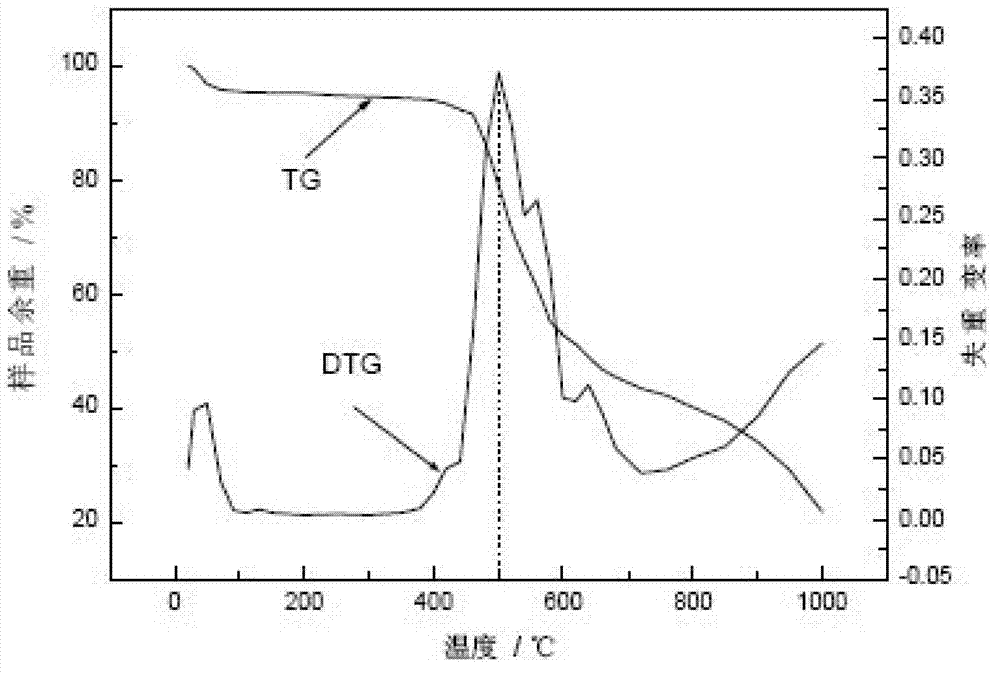

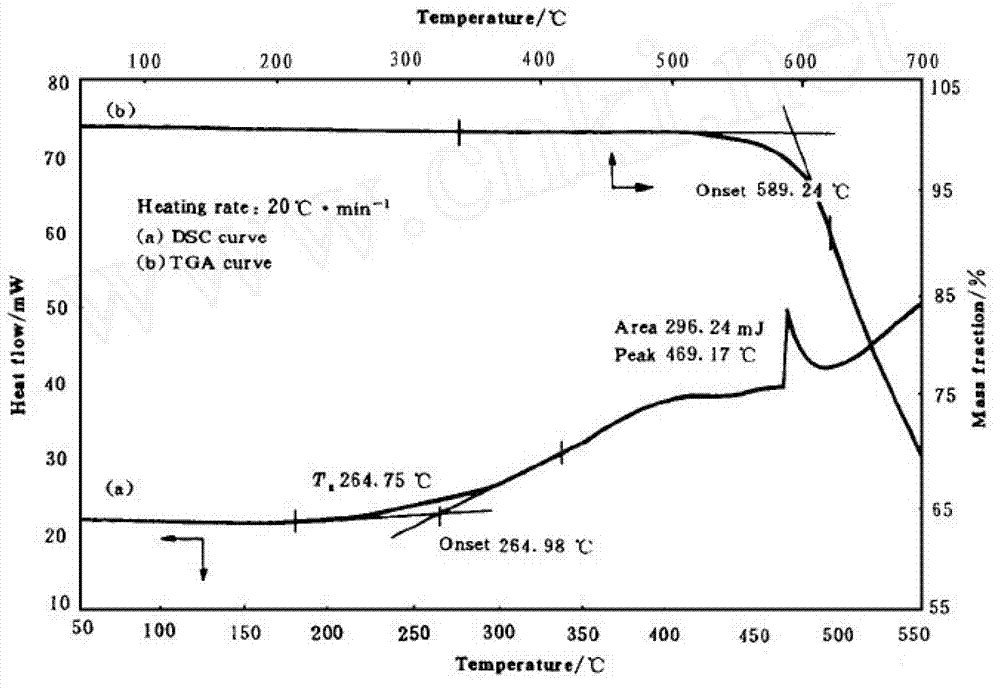

Phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant, preparation method of phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant, and flame-retardant epoxy resin prepared from phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant

InactiveCN104403128AEfficient flame retardant effectImprove thermal stabilityGroup 5/15 element organic compoundsEpoxyFiltration

The invention relates to a phosphorus-containing fire retardant, a preparation method of the phosphorus-containing fire retardant and a flame-retardant epoxy resin prepared from the phosphorus-containing fire retardant, and especially relates to a phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant, a preparation method of the phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant, and flame-retardant epoxy resin prepared from the phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant. The flame-retardant epoxy resin solves the problem that the existing epoxy resin has low flame retardation efficiency and poor compatibility between a polymer matrix and a fire retardant. The preparation method comprises the following steps of 1, dissolving p-hydroxybenzaldehyde and tetrahydrofuran, adding triethylamine into the solution and carrying out stirring, 2, dissolving phosphonitrilic chloride trimer in tetrahydrofuran, dropwisely adding the solution into the reaction system, and carrying out heating and stirring, 3, cooling the reaction system, concentrating the filtrate, pouring the filtrate into water for precipitate separation, carrying out pumping filtration, carrying out recrystallization on the precipitates and carrying out drying to obtain intermediates, and 4, dissolving the intermediates by a solvent, adding p-aminophenol into the solution, carrying out heating reflux, adding DOPO into the reflux product, carrying out condensation, pouring the concentrate into cold ethanol for solid precipitation, and washing and drying the solids to obtain the phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant. The flame-retardant epoxy resin comprises epoxy resin, a curing agent and the phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant. The preparation method is used for preparing the phosphorus-containing nitrile / DOPO double-base structure phosphorus-containing fire retardant.

Owner:NORTHEAST FORESTRY UNIVERSITY

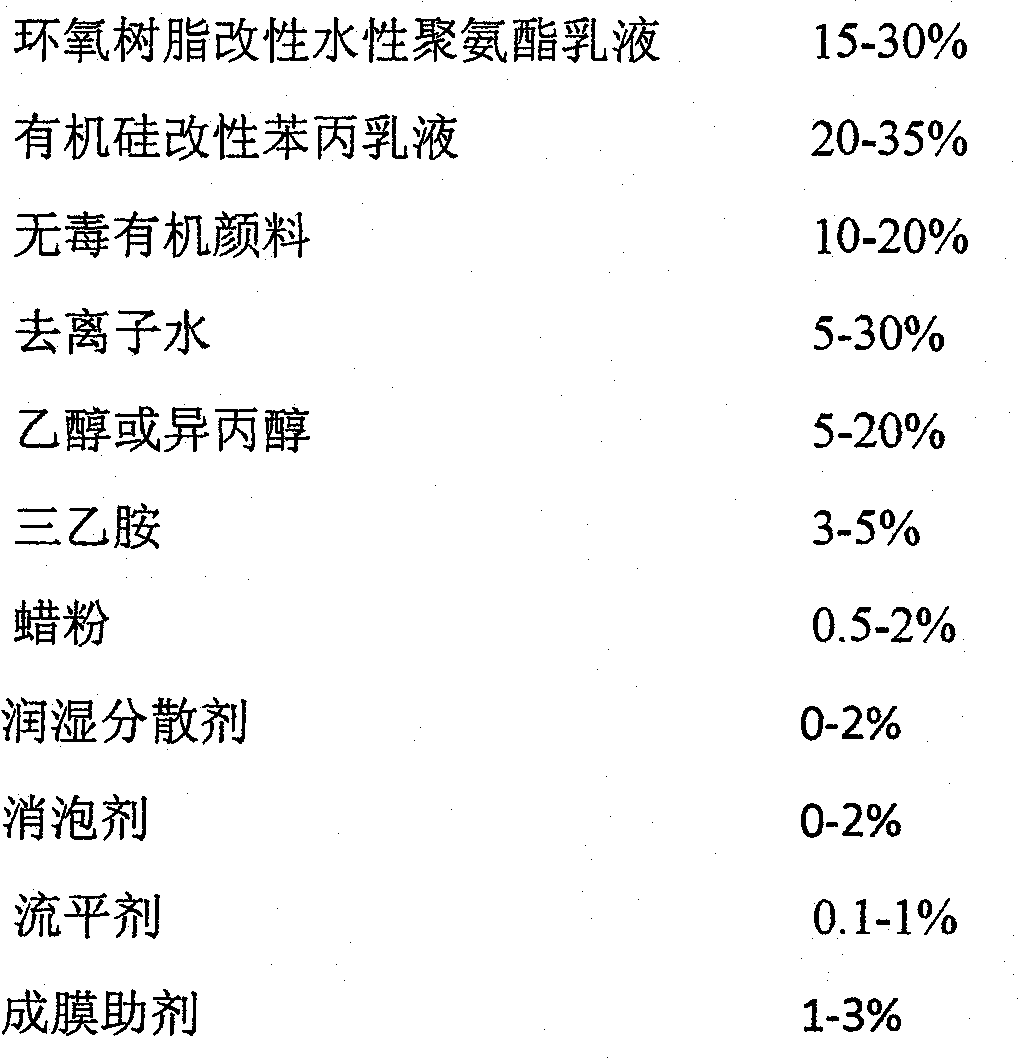

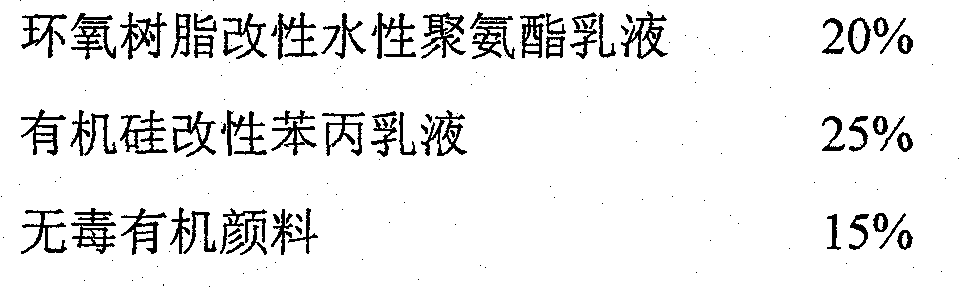

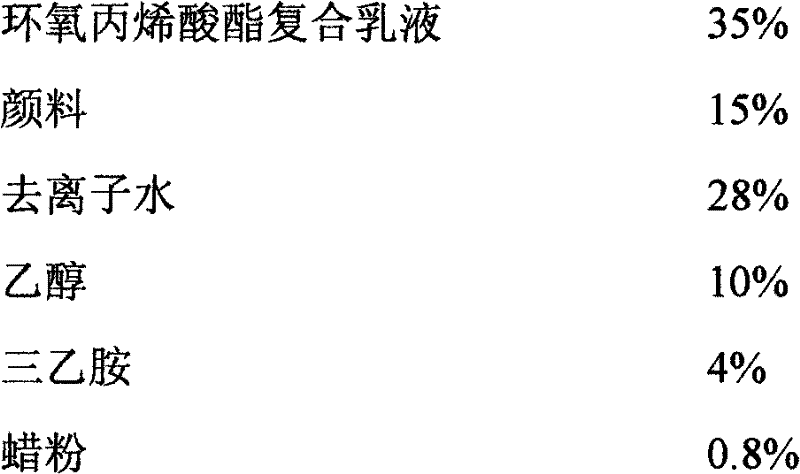

Water-based ink for plastic printing and preparation method thereof

The invention discloses a water-based ink for plastic printing and a preparation method thereof. The water-based ink is prepared by using epoxy resin modified water-based polyurethane emulsion and organic silicon modified styrene-acrylic emulsion as base materials and using deionized water and alcohol as solvents. The water-based ink comprises the following components by weight percent: 15-30% of epoxy resin modified water-based polyurethane emulsion, 20-35% of organic silicon modified styrene-acrylic emulsion, 10-20% of non-toxic organic pigment, 5-30% of deionized water, 5-20% of ethanol or isopropanol, 3-5% of triethylamine and 1.6-10% of additive. The water-based ink does not contain the volatile organic solvent, is incombustible, nonexplosible and non-toxic and has high attachment fastness on the plastic film and good printing effect; the ink has high chemical resistance, acid resistance and alkali resistance; and the ink has good water resistance, heat resistance, freezing resistance and oil resistance. The ink can be widely used in the packaging and printing of the industries such as grain, vegetables, alcohol and tobacco, and food; and the safety and non-toxicity of the ink can be ensured, and the ink is a green and environmentally-friendly product and has considerable market potential.

Owner:哈尔滨绿科科技有限公司

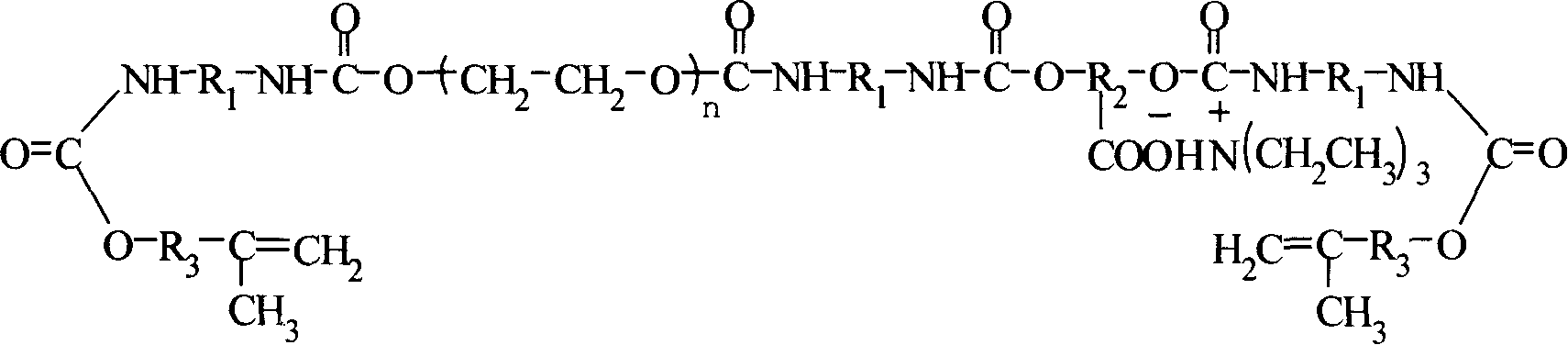

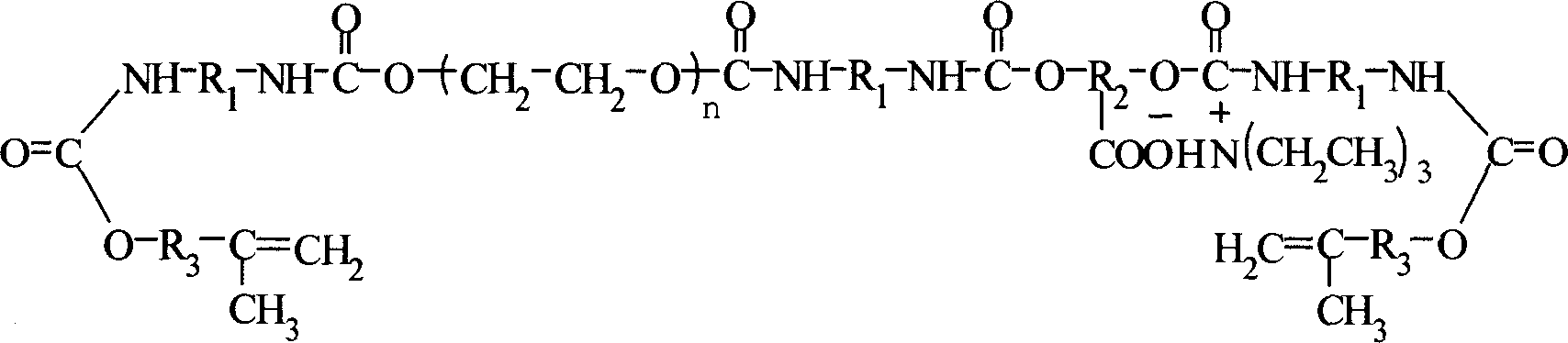

Ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and preparation method thereof

InactiveCN101735599AGood mechanical propertiesImprove water resistanceInksPolyurea/polyurethane coatingsPolyesterPropanoic acid

The invention discloses ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and a preparation method thereof. The method comprises the following steps: firstly, dripping polyester or polyether diol, end hydroxyalkyl silicon oil, trimethylolpropane and the like into aromatic or aliphatic diisocyanate, and reacting the mixture to obtain organic silicon modified polyurethane prepolymer; then, adding polyhydromethyl propionic acid into the organic silicon modified polyurethane prepolymer, and reacting the mixture to obtain chain-extended organic silicon modified polyurethane prepolymer; and performing end capping reaction on the chain-extended organic silicon modified polyurethane prepolymer by using hydroxyethyl methacrylate or hydroxy-propyl acrylate to obtain organic silicon modified polyurethane acrylate oligomer, finally adding a neutralizer such as triethylamine and the like into the oligomer to perform neutralization reaction on the system, adding water into the mixture for diluting, and stirring and emulsifying the mixture to obtain the ultraviolet curing organic silicon modified polyurethane aqueous dispersoid. The ultraviolet cured coating film has better water tolerance and adhesive force, and can be widely applied in the fields of environmental protection, building, household appliances, ink, coating and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

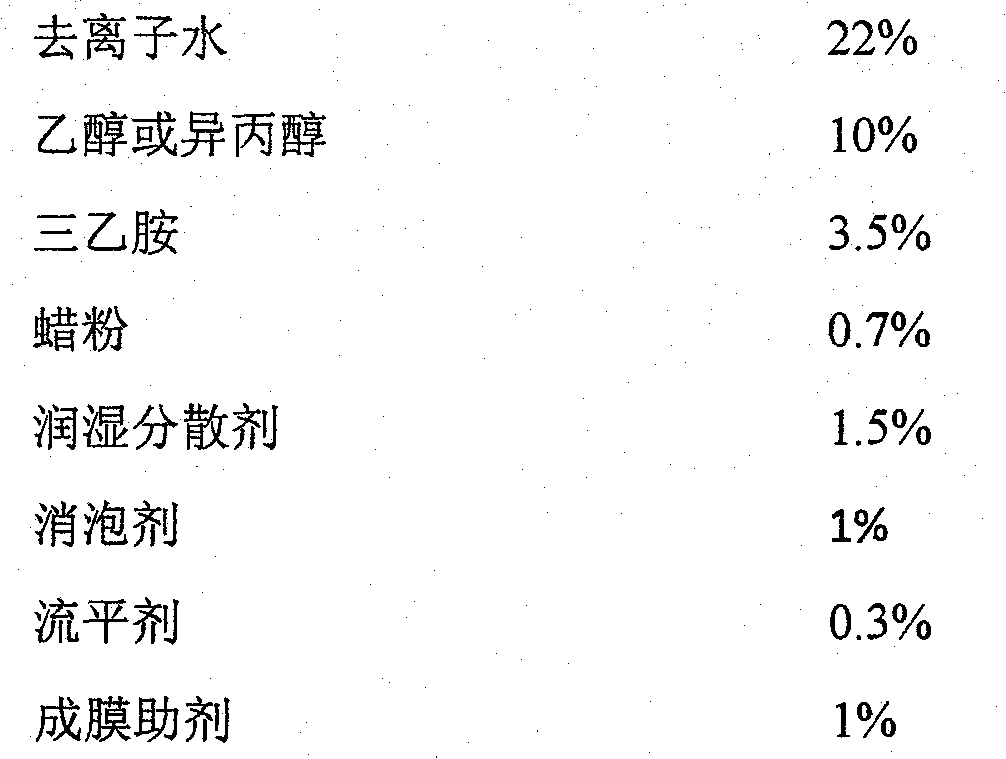

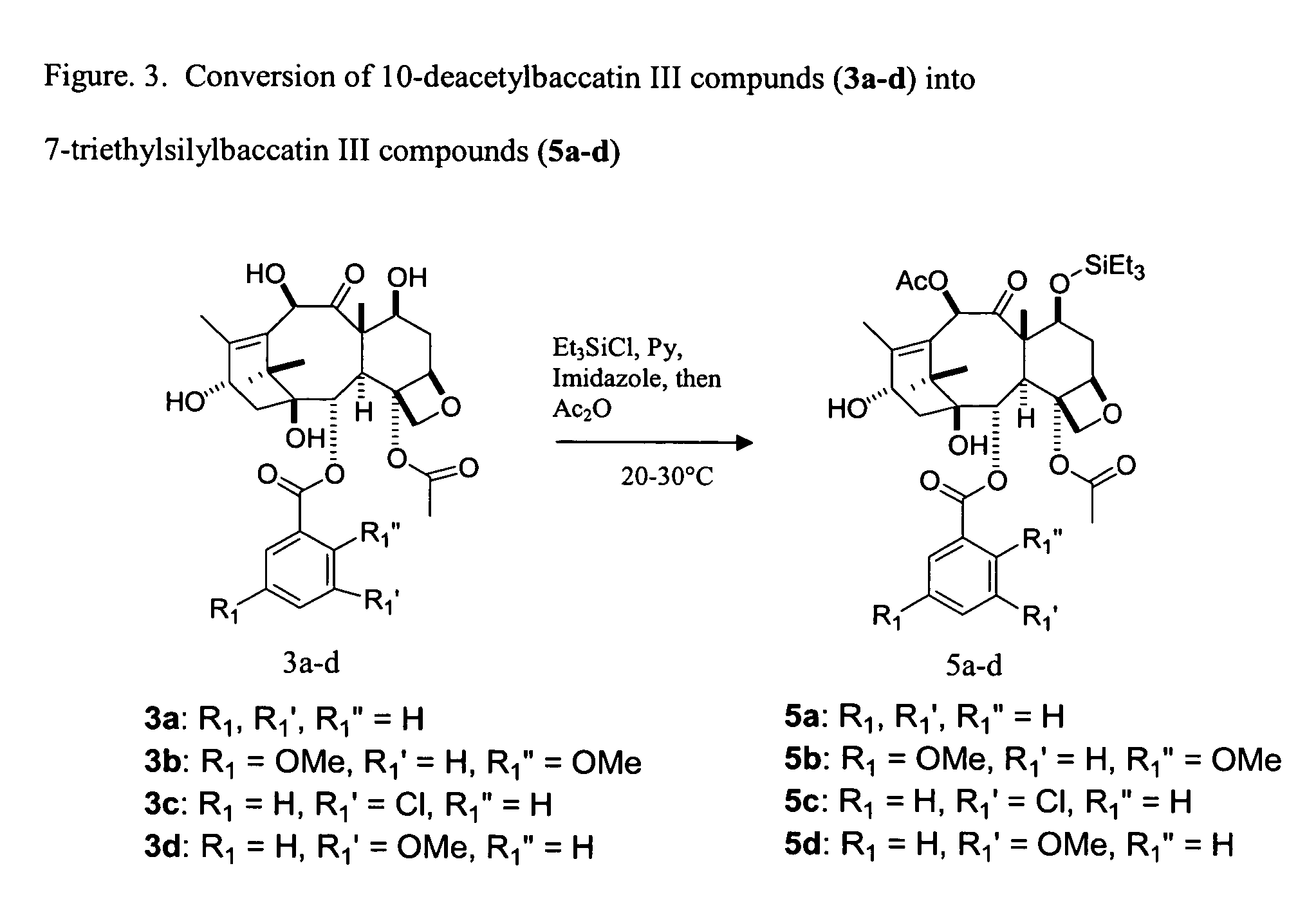

Facile method for synthesizing baccatin III compounds

A process for synthesizing a C-7 protected baccatin III compound represented by formula (A), which comprises reacting a 10-deacetylbaccatin III compound represented by formula (B) with a protecting agent and an acylating agent in the presence of a secondary amine and a nitrogen-containing compound. Also, a process for synthesizing a C-7 protected 10-deacetylbaccatin III compound represented by formula (C), which comprises reacting a 10-deacetylbaccatin III compound represented by formula (B) with a protecting agent in the presence of a secondary amine and a nitrogen-containing compound. In both processes the nitrogen-containing compound is selected from a nitrogen-containing heterocycle or a trialkylamine. When the nitrogen-containing heterocycle is selected, it may be an unsubstituted or a substituted pyridine or an unsubstituted or a substituted pyrazine. When a trialkylamine is selected, it may be, for example, triethylamine or diisopropylethylamine.wherein PG1 represents the organic residue of the protecting agent, PG2 represents the organic residue of the acylating agent, and R represents a simple or substituted aryl group or a heterocyclic group.

Owner:IMMUNOGEN INC

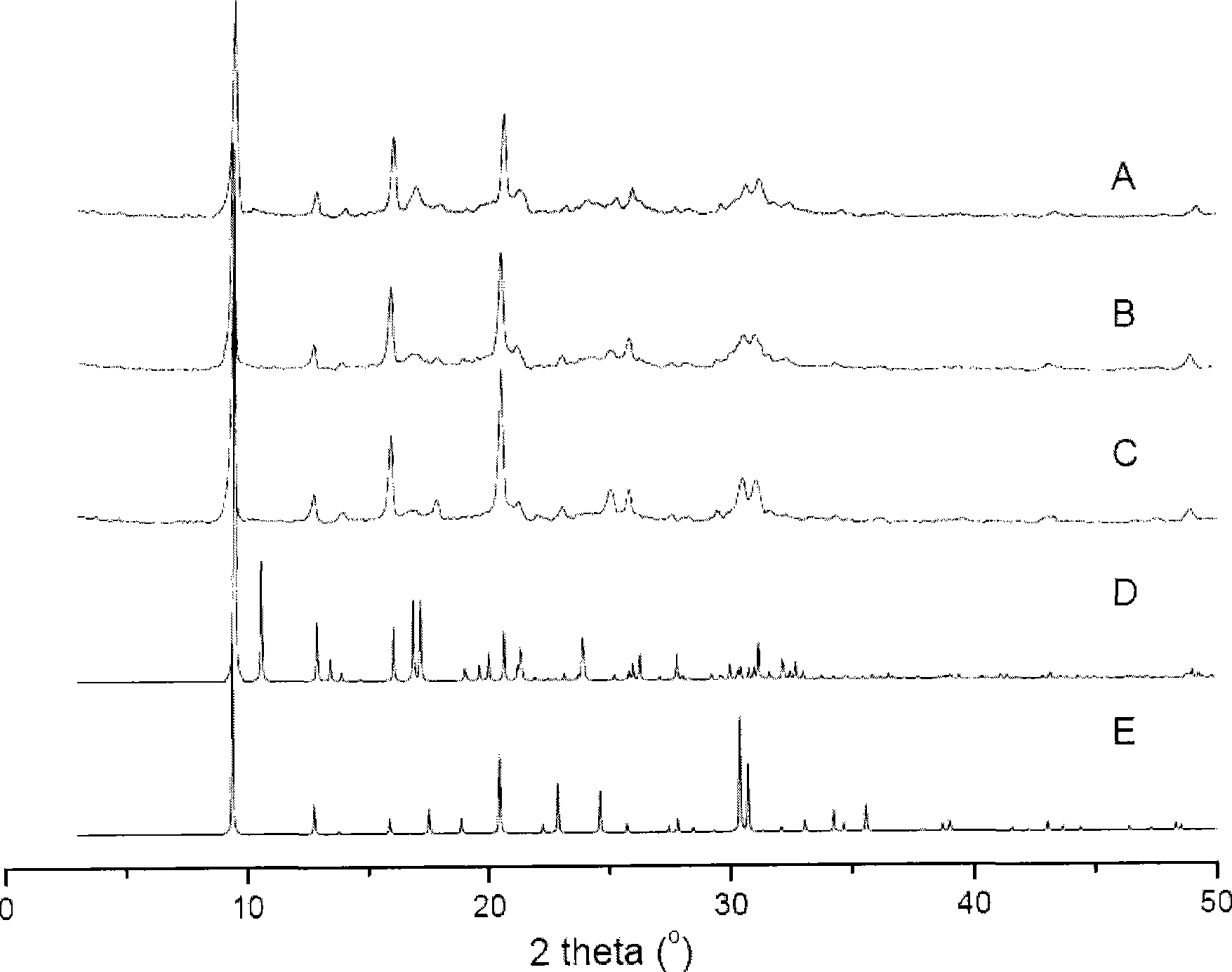

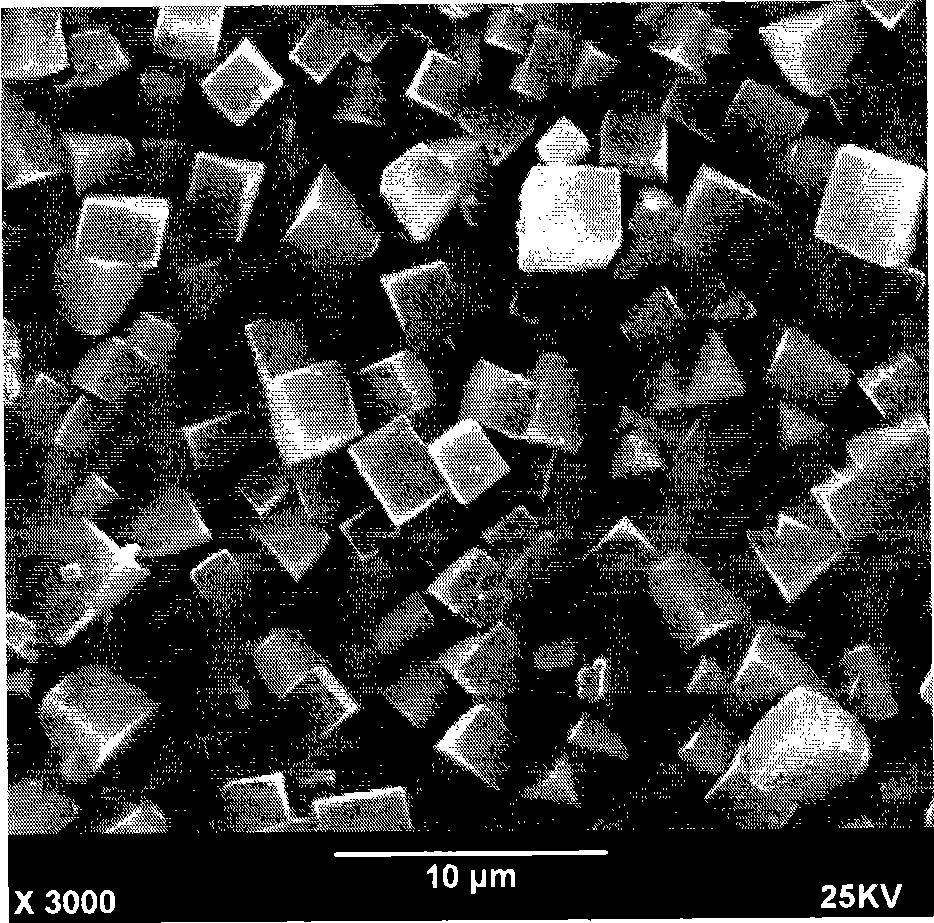

AEI/CHA eutectic molecular sieve containing triethylamine and synthetic method thereof

InactiveCN101450806AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveChemical composition

The invention discloses an AEI / CHA eutectic molecule sieve containing triethylamine. An anhydrous chemical composition of the AEI / CHA eutectic molecule sieve is expressed as mR.(Six.Aly.Pz)O2, wherein x, y and z are molar fractions of Si, Al and P respectively; the x is between 0.001 and 0.98; the y is between 0.01 and 0.6; the z is between 0.01 and 0.6, x+y+z is equal to 1; the R is a template agent, and the m is a mole number of the R; and the value of the m is between 0.02 and 0.6. A preparation method for the AEI / CHA eutectic molecule sieve comprises the following steps: a) according to the mol ratio of oxides of various components, stirring and mixing evenly a silicon source, an aluminum resource, a phosphorus source, the template agent, and water are to obtain an initial gel mixture; and b) transferring the initial gel mixture into a stainless steel synthesis kettle to be sealed, then heating the kettle to a crystallization temperature of between 160 and 250 DEG C, and performing crystallization at constant temperature for 1 to 120 hours under the self-generated pressure, and separating a solid product, washing the solid product to be neutral, and drying the solid product to obtain the AEI / CHA eutectic molecule sieve. The molecule sieve can be used as a catalyst for an acid catalytic reaction after the template agent is removed through the baking.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

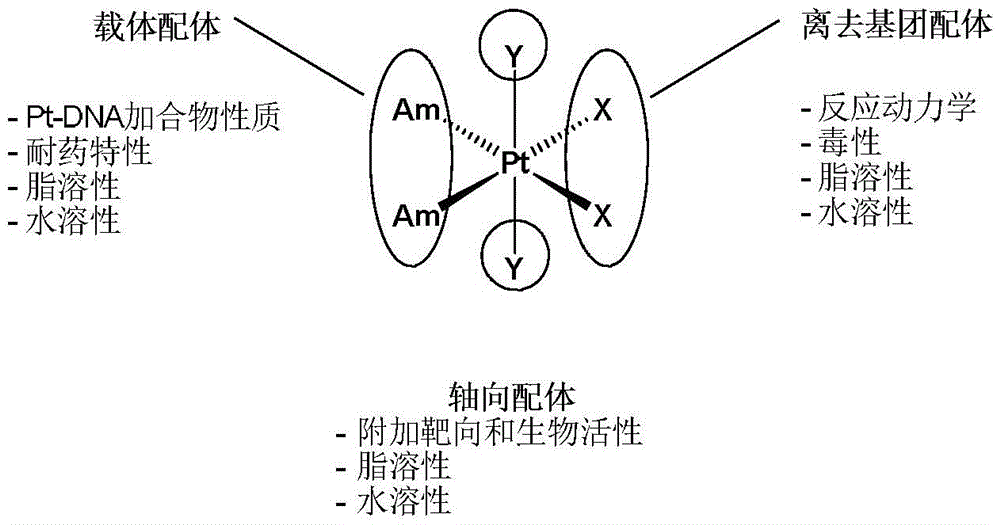

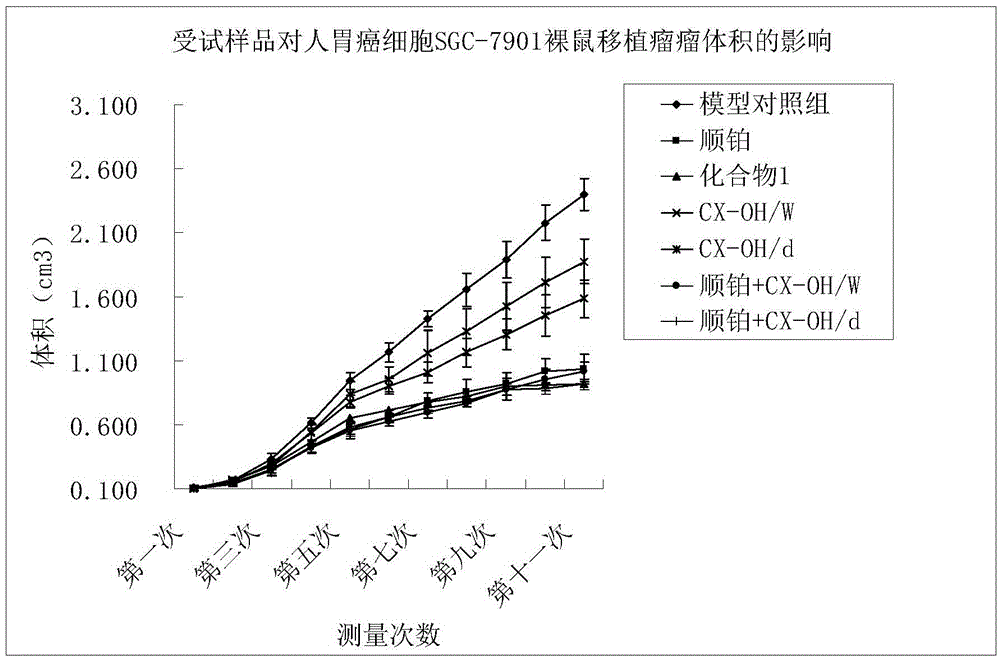

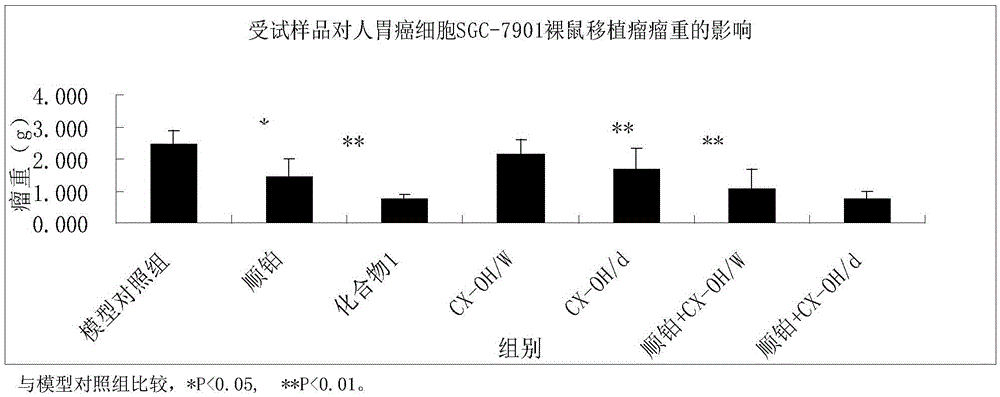

Tetravalent platinum complex with bioactive group and preparation method of tetravalent platinum complex

The invention discloses a tetravalent platinum complex with a bioactive group and a preparation method of the tetravalent platinum complex. The tetravalent platinum complex is a platinum (IV) complex and has the structure shown in the formula II (please see the formula in the description), wherein in the formula II, Y is OH or Cl, and Bio represents the bioactive group. The platinum (IV) complex is prepared according to the equation in the formula III (please see the formula in the description), wherein in the formula III, Y is OH or Cl, Bio-OH represents a compound with bioactivity, TBTU represents a coupling agent O-(benzotriazol-1-yl)-N,N,N',N'-tetramethyluronium tetrafluoroborate, TEA represents a catalyst triethylamine, DMF represents solvent N,N-dimethyl formamide, and DMSO represents solvent dimethylsulfoxide. Cis-platinum is adopted for the bottom face of an octahedron, a small-molecular targeted or medicine active group is introduced to one axial position, a hydroxyl group or helium atom is introduced into another axial position, and the anti-tumor tetravalent platinum complex overcoming cisplatin resistance is provided, so the high-efficiency and low-toxin platinum (IV) complex is obtained.

Owner:SOUTHEAST UNIV

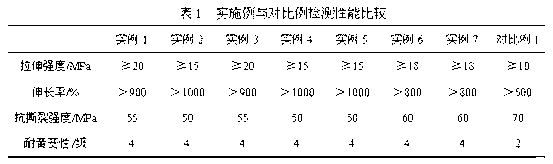

Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

InactiveCN102924683AGood yellowing resistanceEasy to preparePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionPolymer science

The invention discloses an aqueous polyurethane dispersoid for coating yellowing-resistant leather. The aqueous polyurethane dispersoid is prepared through the following steps: performing reaction on polyalcohol, a diisocyanate mixture and a crosslinking agent to generate a prepolymer with -NCO terminal group, wherein the diisocyanate mixture consisting of dicyclohexylmethane diisocyanate and isophorone diisocyanate is taken as a starting material; adding a hydrophilic chain extender into the prepolymer, further reacting and extending the chain by micromolecular dihydric alcohol; and neutralizing by using triethylamine and dispersing into water to obtain the aqueous polyurethane dispersoid. According to the aqueous polyurethane dispersoid prepared by the method, the yellowing-resistant level can reach more than level 4, the tensile strength is more than or equal to 15 MPa, the elongation ratio is more than or equal to 800 percent and the tearing strength is more than or equal to 50 MPa. The coated leather has soft and natural luster and plump and moist handfeel.

Owner:山西省应用化学研究所

Method for measuring alkaloid in tobacco and tobacco product

ActiveCN102004132AQuantitatively accurateGood reproducibilityComponent separationBiotechnologyGas liquid chromatographic

The invention relates to a method for measuring alkaloid in tobacco and tobacco products, which is characterized by dissociating alkaloid from the tobacco and tobacco products by using sodium hydroxide solution, extracting the alkaloid from samples by using triethylamine / trichloromethane solution, and detecting content of five kinds of alkaloid with GC-MS ( Gas Chromatograph-Mass Spectrum) quantitative analysis. Compared with other methods for analyzing the alkaloid, the invention has the advantages that alkaloid is separated from the tobacco by DB-35MS chromatographic columns so as to separate nornicotine and myosmine in the tobacco and accurately quantify target matters; batch sampling is carried out on the separation of nicotinamide and other alkaloid so as to detect the nicotinamide with high content in the tobacco and meet the quantitative analysis of other alkaloid with low content; the standard working curves of standard matters are separately compounded so as to avoid influence on quantization of other alkaloid by alkaloid catabolite existing in the standard samples. The method is simple and convenient and has the advantages of good repeatability, high analyzing and measuring sensitivity, and accurate quantization.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

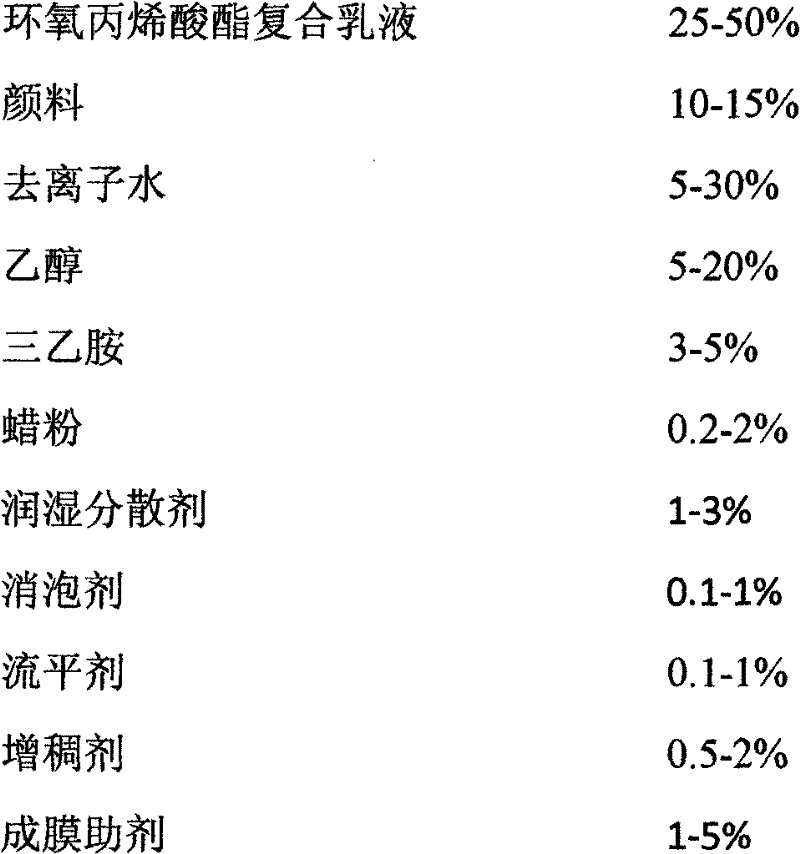

Environment-friendly type water-based intaglio ink used for package printing and preparation method thereof

The invention relates to a water-based ink and a preparation method thereof, especially to an environment-friendly type water-based intaglio ink used for package printing and a preparation method thereof. The ink is prepared by mixing epoxy acrylate composite emulsion, pigments, deionized water, ethanol, triethylamine, wax powder, a wetting dispersant, an anti-foaming agent, a levelling agent, a thickening agent and a film forming auxiliary agent according to a certain mass ratio, wherein, the epoxy acrylate composite emulsion is prepared by modifying acrylate emulsion with an epoxy resin and allowing the epoxy resin and acrylate to organically bind together, has the advantages of good adhesion, thermostability, good chemically-resistant properties and the like and has a certain application value when used as a binder for a water-based ink. The water-based intaglio ink in the invention is applicable to package printing in the field of flexible package which mainly relates to packaging of tobacco, liquor, foodstuffs, beverage, medicines, daily chemical articles and the like; the ink is nontoxic, non-combustible and non-explosible, has no pungent smell, accords with environmental protection requirements, and has a very promising prospect.

Owner:哈尔滨大东方新材料科技股份有限公司

Organic metal framework supported palladium, preparation method and application thereof

InactiveCN101733162AImprove stabilityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryN dimethylformamide

The invention discloses an organic metal framework supported palladium in the technical field of chemical industry, a preparation method and application thereof. The organic metal framework supported palladium is prepared by the method comprising the steps of: dissolving terephthalic acid and zinc nitrate hexahydrate into N, N-dimethylformamide, dripping triethylamine with the stirring, continuing stirring the obtained solution, filtering the obtained solution, and washing a precipitate to obtain a solid, namely MOF-5; and dissolving Na2PdC14 into the N, N-dimethylformamide to obtain solution, adding the MOF-5 into the solution, and then dripping hydrazine hydrate to obtain Pd@MOF-5 through stirring, filtration, washing and vacuum drying. The invention also relates to the method for preparing the organic metal framework supported palladium, application thereof taken as a catalyst in a Sonogashira reaction, and the method for preparing diaryl acetylene. The organic metal framework supported palladium in the invention has good stability, can catalyze the reaction with high selectivity and high efficiency under rather low loading of the catalyst, and can be repeatedly used.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing iodic liquid embolic agent capable of long-time self-developing

ActiveCN101513542AWith long-term developing functionRelieve painSurgeryX-ray constrast preparationsPolyvinyl alcoholBlood vessel

The invention provides a method for preparing an iodic liquid embolic agent capable of long-time self-developing. Water-soluble polyvinyl alcohol (PVA) is added with pyridine to be stirred and evaporated for removing the pyridine. Residual reactant is dehumidified and dissolved in dimethyl sulphoxide (DMSO) organic solvent and then is added with solution of iodic compound and dichloromethane and added with triethylamine; and an obtained iodic product (I-PVA) is poured into a mixture of butyl ether and acetone to be deposited and separated. The iodic product is washed in water, is dried and then is confected into the liquid embolic agent by the dimethyl sulphoxide or N-methyl-ketopyrrolidine organic solvent. The liquid embolic agent prepared by the invention is injectable and can develop under X-ray for a long time. When contacting with blood, the organic solvent diffuses fast for depositing and separating solid to take embolic effect. The embolic agent can be used for embolotherapy of cerebral arteriovenous malformation, tumour and other vascular disease.

Owner:山东大正医疗器械股份有限公司

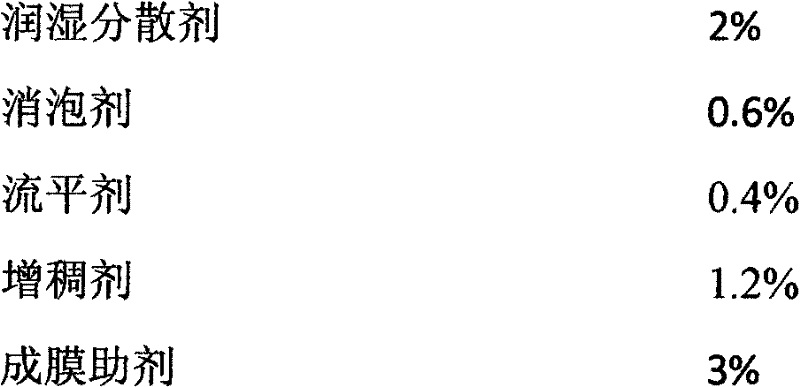

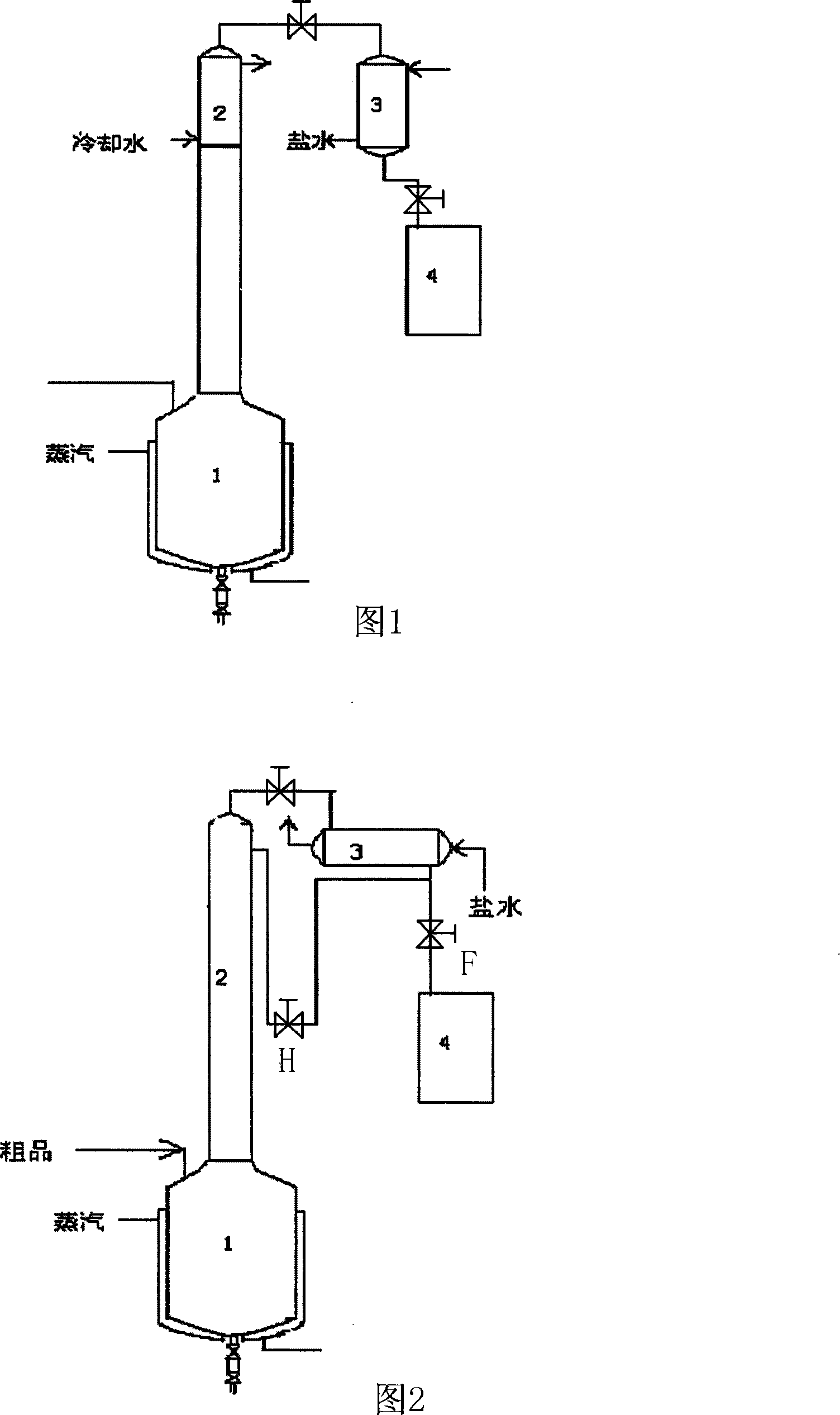

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

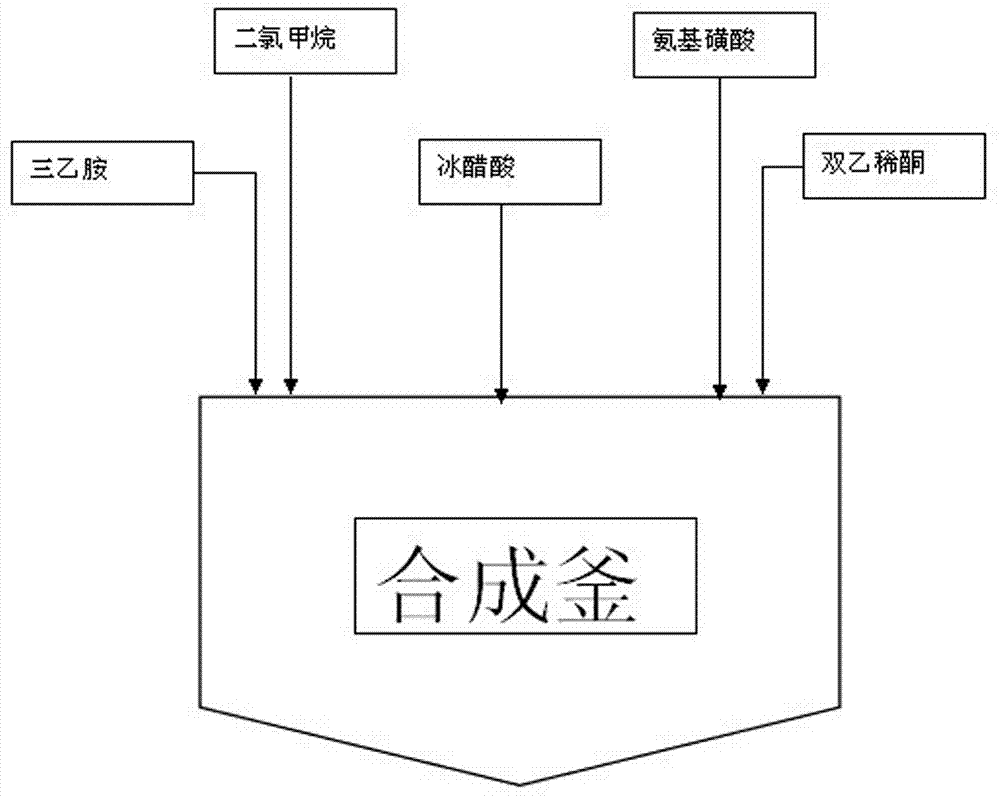

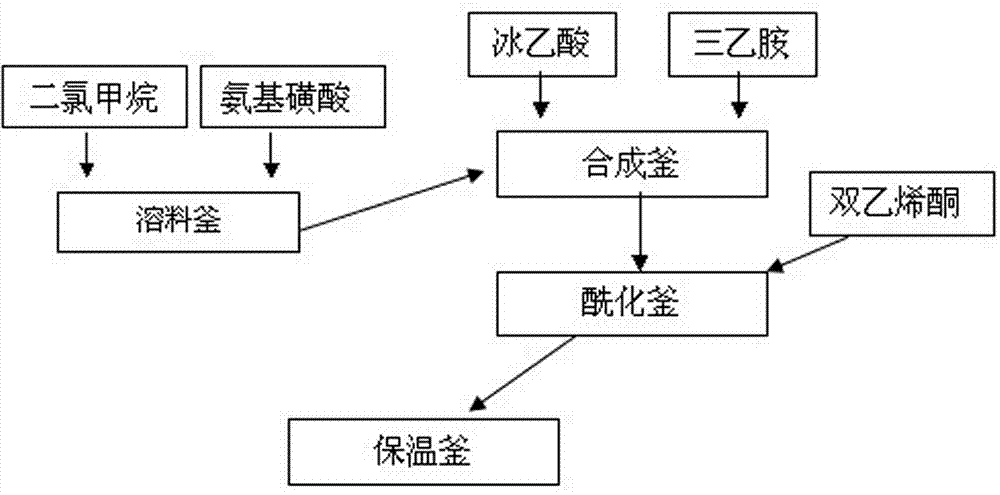

Acesulfame synthesis and acylation production process

InactiveCN103570592AReduce labor intensityImprove continuitySulfuric acid amide preparationAcetic acidEconomic benefits

The invention relates to an acesulfame synthesis and acylation production process, which comprises the following steps of a, putting a sulfamic acid and dichloromethane into a dissolving kettle, and pumping a mixture into a synthesis kettle; b, adding dropwise triethylamine into the synthesis kettle, adding dropwise a glacial acetic acid, and performing natural reaction for 1 hour after the glacial acetic acid is added dropwise; c, placing reactants in the synthesis kettle into an acylation kettle, and adding dropwise diketene for an acylation reaction; and d, after the diketene is added dropwise, circulating a product subjected to the acylation reaction for 1 hour in the acylation kettle, placing into a heat-preservation kettle, performing natural reaction for 1 hour to generate an acetoacetyl-N-sulfonate intermediate, and feeding the acetoacetyl-N-sulfonate intermediate to a sulfonation section for use. The acesulfame synthesis and acylation production process has the advantages that 1, a stepwise reaction mode is adopted, so that compared with a conventional single-kettle production process, the method has the characteristics of production operation continuity and high reaction stability; 2, a multi-kettle stepwise production mode is adopted, so that the production efficiency is greatly improved, the reaction efficiency of the whole production flow is optimized, and the economic benefits of an enterprise are significantly improved.

Owner:ANHUI JINGHE IND

Preparation method of special epoxy resin for aqueous ultraviolet solidifying coating

A method of preparing special epoxy resin for water ultraviolet light curing coating includes steps: a) using bisphenol A type epoxy resin and acrylic acid as raw material, adding catalyst of triethylamine and inhibitor of p-hydroxyanisole, reacting at 70-100 DEG C, after mass concentration of acrylic acid lower than 40-50%, raising temperature to 110-120 DEG C until acid value of the system lower than 5mgKOH / 100g and generating epoxy acrylate; b) mixing the maleic anhydride and the epoxy acrylate according mole ratio of 0.8:1.05-0.8:1.05 and reacting water epoxy acrylate, adding catalyst triethylamine and inhibitor of p-hydroxyanisole under temperature of 60-100 DEG C and reacting for 1-3 h, adding dimethlyethanolamine to neutralizing, adding water and obtaining water epoxy acrylate with certain solid content.

Owner:CHINA PETROCHEMICAL CORP

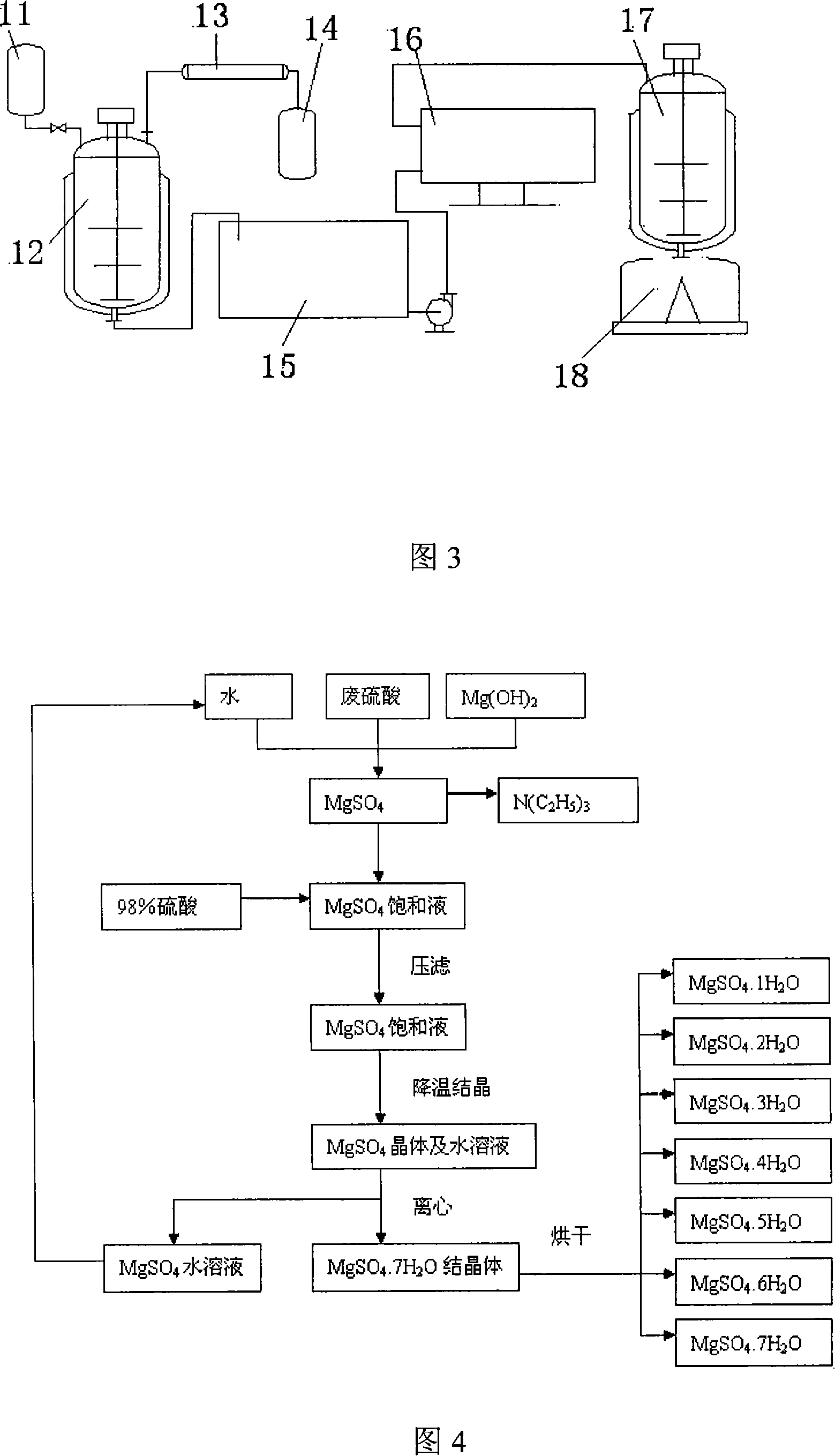

Waste acid treatment method and treatment system for acesulfame preparation technique by sulphuric anhydride cyclization method

ActiveCN101148300ASolve environmental problemsAchieve recyclingMagnesium sulfatesMultistage water/sewage treatmentSewageAcesulfame potassium

The present invention is process of treating waste acid solution from Acesulfame potassium preparing sulfuric anhydride cyclizing process. The process of treating waste acid solution includes the reaction of the waste acid solution and the mixture comprising Mg(OH)2 or MgO and water in a neutralizing reactor to produce triethylamine gas, cooling triethylamine gas in a cooler into triethylamine liquid and collecting in a tank, regulating the pH value of neutralizing reaction resultant in a regulating tank with 98 % concentration sulfuric acid solution into 5-7, filtering, cooling the filtrate in a MgSO4 cooling reactor to separate out MgSO4 hydrate. The present invention has MgSO4 yield up to 95 % and N(C2H5)3 recovering rate up to 95 % and can eliminate environmental pollution caused by Acesulfame potassium production.

Owner:ANHUI WEIDUO FOOD INGREDIENTS CO LTD

Ultraviolet light solidfication water polyurethane acrylate paint resin and its preparation method

InactiveCN1869139AThe molecular structure is well controlledImprove performancePolyurea/polyurethane coatingsSolubility(Hydroxyethyl)methacrylate

The invention relates to an ultraviolet light solidified water urethane acrylate coating resin. It is mainly made up of aromatic diisocyanate, polyethylene glycol, polyhydroxy-carboxylic acid, dihydric alcohol, hydroxyethyl methacrylate ethyl ester, and tri-ethylamine. It is prepared by adding the above materials orderly. It has the advantages of good water solubility, pliability, and stability.

Owner:SHANTOU UNIV +1

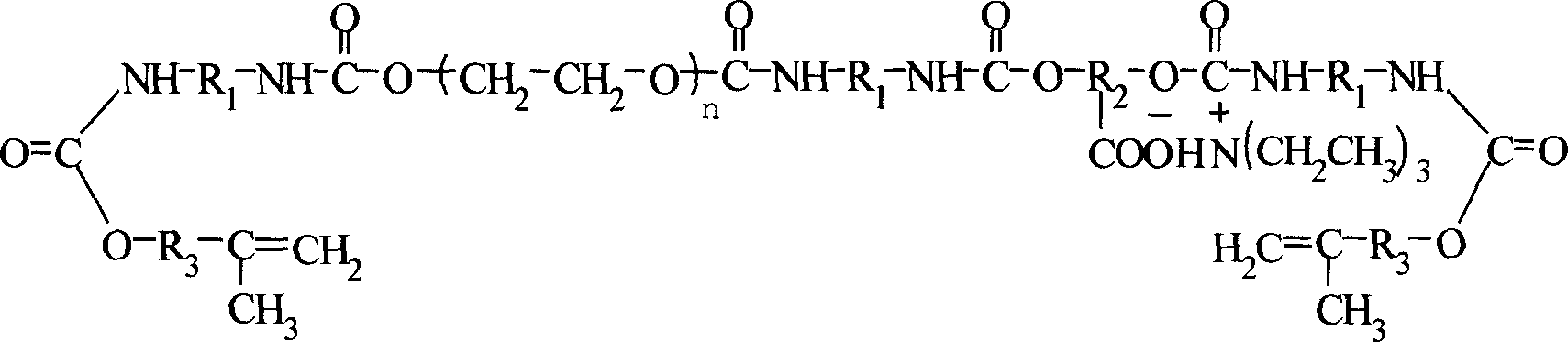

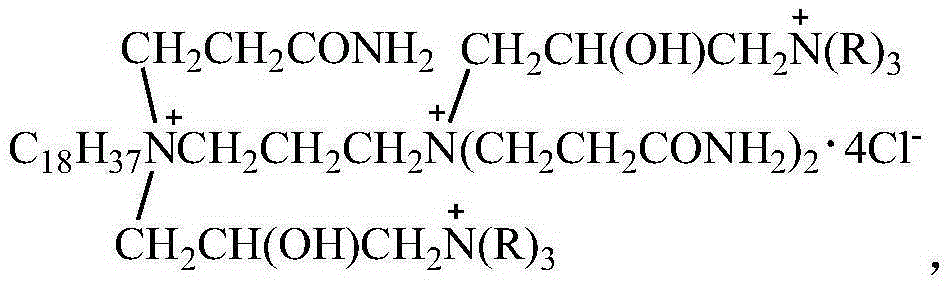

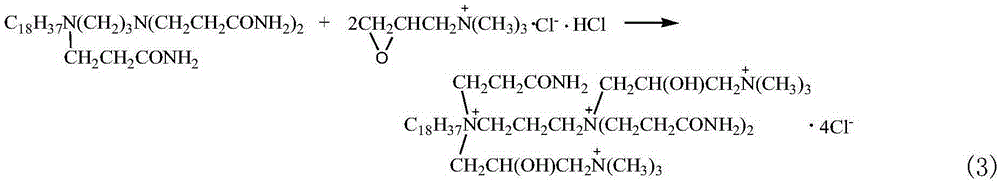

Multi-positive-ion amide-type asphalt emulsifier and preparation method thereof

InactiveCN105399645AGood emulsifying effectImprove hydrophilicityOrganic compound preparationCarboxylic acid amides preparationSolventHigh heat

The present invention discloses a multi-positive-ion amide-type asphalt emulsifier and a preparation method thereof, and the asphalt emulsifier is prepared from raw materials of N-hydrogenated tallow-1,3-propylene diamine, an alcohol solvent, acrylamide, a low-carbon tertiary amine, industrial hydrochloride and epichlorohydrin in the molar ratio of N-hydrogenated tallow-1,3-propylene diamine to alcohol solvent to acrylamide to low-carbon tertiary amine to industrial hydrochloride to epichlorohydrin of 1mol: (5.00-11.00) mol: (3.00-3.10) mol: (2.02-2.10) mol: (2.02-2.10) mol: (2.02-2.08) mol. The alcohol solvent is ethanol, methanol or isopropanol. The low-carbon tertiary amine is a trimethylamine aqueous solution, triethylamine or triethanolamine. The asphalt emulsifier synthetic raw materials are readily available, production cost is low, a process is simple, and a high temperature reaction is not required. The asphalt emulsifier can emulsify a variety of different types of asphalt, the prepared emulsified asphalt is fine, uniform, and good in storage stability, and positive-ion-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

Method for preparing aqueous polyurethane/nano titanium dioxide hybrid material

The invention discloses a method for preparing an aqueous polyurethane / nano titanium dioxide hybrid material and relates to a preparation technology of a modified polyurethane emulsion. The method comprises the following steps of: (1) preparing TBT (Tributyltin) sol; (2) adding polyalcohol and isocyanate which are used as raw material monomers, adding a hydrophilic chain extender, heating up the system to 30-80 DEG C by using N-polyvinyl pyrrolidone as a solvent and then adding a catalyst; (3) after the mixture reacts of 1-6 hours, heating up the system to 60-100 DEG C; continuing to make the mixture react for 1-6 hours, and then cooling to 20-60 DEG C; adding triethylamine used as a salt forming agent, and making the mixture react for 10-60 minutes; dispersing with water by using ethanediamine as a chain extender to obtain an aqueous polyurethane emulsion; maintaining the temperature to 20-50 DEG C, adding a small quantity of gamma-epoxypropyl trimethoxy silane and stirring for 10-90 minutes; adding the TBT sol to the system and dropwise adding a small quantity of hydrochloric acid; and persistently stirring for 12-48 hours to obtain the aqueous polyurethane / nano titanium dioxide hybrid material. The properties such as the weather resistance, the mechanical property, the coating transparency, and the like of the hybrid material are greatly improved.

Owner:JIANGSU UNIV

Method for preparing water polyurethane binder for shoe

InactiveCN101121869AHigh solid contentSimple processSolesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to a method for preparing a water polyurethane adhesive applied to shoes, pertaining to the technical field of polymers. A proper amount of first polyatomic alcohol, second polyatomic alcohol, third polyatomic alcohol and fourth polyatomic alcohol are mixed to achieve polyurethane prepolymers; a proper amount of triethylamine is added for neutralization; the prepared polyurethane prepolymers is dispersed into deionized water and added with surface-active agent to achieve water polyurethane dispersoid; a proper amount of ethylene diamine is added into the water polyurethane dispersoid for chain expanding reaction to achieve water polyurethanes; the acetone is removed by vacuum pressure reduction, and finally mixed with antioxidant, ultraviolet absorbent, leveling agent, antifoaming agent, wetting agent, thickening agent and silane coupling agent to achieve the water polyurethane adhesive. The invention provides a simple process, needs a small dosage of organic solvent, the solid content is above 50 percent, the energy consumption of production is relatively low; besides, the adhesive has excellent bonding strength to various shoe materials such as PVC, polyurethane, leather, SBS, canvas, rubber and so on, and the heat-resistance effect is strong.

Owner:BEIJING CHEM IND RES INST

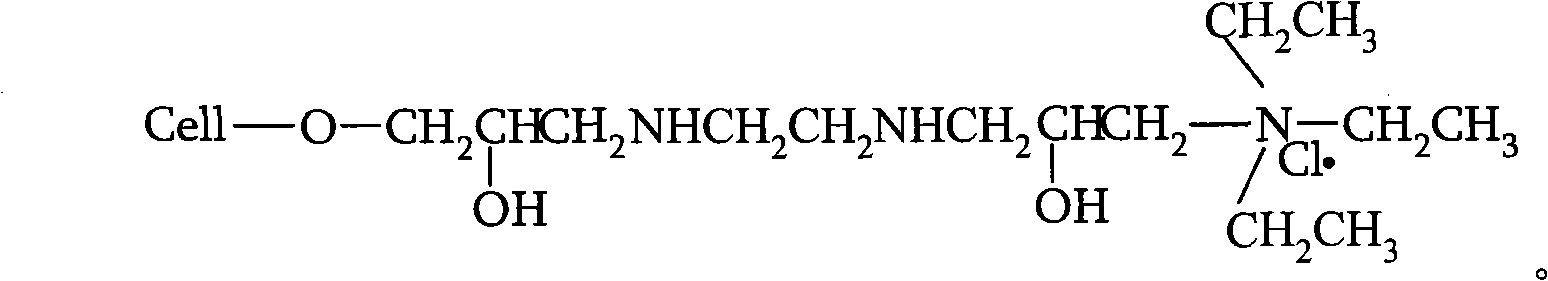

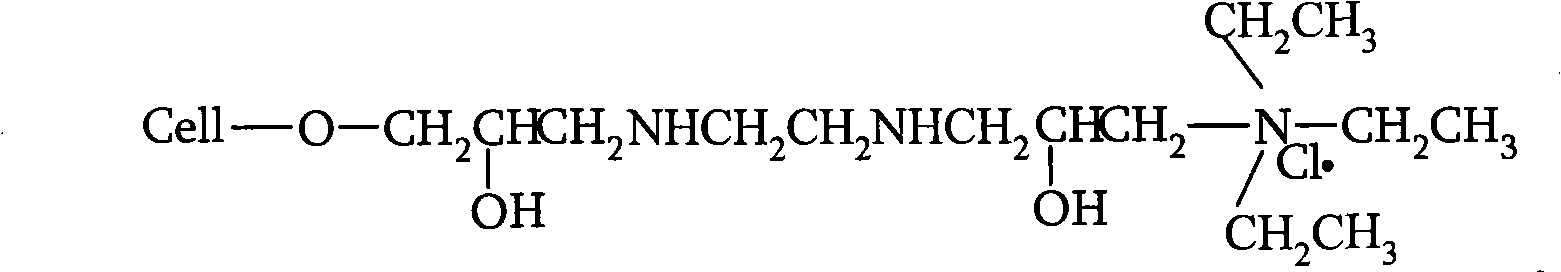

Method for preparing quaternary amines salt cationic adsorption agent with plant of high cellulose content

InactiveCN101342485AGood effectReduce secondary pollutionOther chemical processesWater/sewage treatment by sorptionCelluloseEutrophication

The invention discloses a method for preparing quaternary amine salt ion adsorbent by using a plant with high cellulose content. Straw stalks with high cellulose content, epichlorohydrin and tri-ethylamine are taken as raw materials, ethylene diamine, diethylene triamine pentacetic acid (DTPA) or triethylenetetramine, etc are used as crosslinking agent to prepare the adsorbent under the condition of existence of N, N-dimethyl formamide. The method has the advantages of simple process, low cost, economic and practical, reproducible, etc. The adsorbent prepared by the method has the advantages of high liveweight growth rate, low secondary pollution, high stability, sound adsorption effect, wide application scope, etc; and the adsorbent can be extensively applied to the treatment of eutrophication of waters.

Owner:SHANDONG UNIV

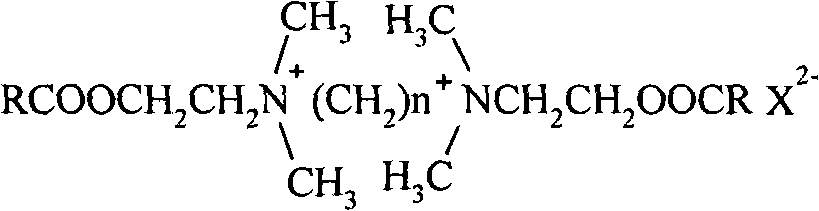

Rosinyl quaternary ammonium salt type gemini surfactant and method for preparing same

InactiveCN101284794AImprove surface activityLow surface tension agent critical micelle concentrationOrganic compound preparationTransportation and packagingFiltrationSolvent

The invention discloses a rosinyl bis-quaternary ammonium surfactant, the general molecular formula of which is as follows. In the formula, R is a rosinyl ricyclic diterpene structure, X is Br or I, and n is larger than or equal to 1 and smaller than or equal to 10. The invention also discloses a method for preparing the compound: firstly, dehydroabietic acid or disproportionated rosin is adopted to prepare rosinyl tertiary amine, and then the rosinyl tertiary amine and saturated dihalide are prepared into the rosinyl bis-quaternary ammonium surfactant through quaternization. The synthesis of the rosinyl tertiary amine comprises the following steps: the dehydroabietic acid or the disproportionated rosin is converted into active acyl chloride intermediate, and then the acyl chloride intermediate and N,N-dimethyl ethanolamine are prepared into the rosinyl tertiary amine in the presence of the triethylamine which is used as the acid-binding agent. The rosinyl tertiary amine and the saturated dihalide are reacted in the solvent isopropyl alcohol, and then vacuum drying is performed after filtration. The prepared surface active agent has good surface activity performance; the raw material is inexpensive and easy to obtain, and can be biodegraded; the synthetic method is assisted with microwave, the reaction time is short, and the product purity is high.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

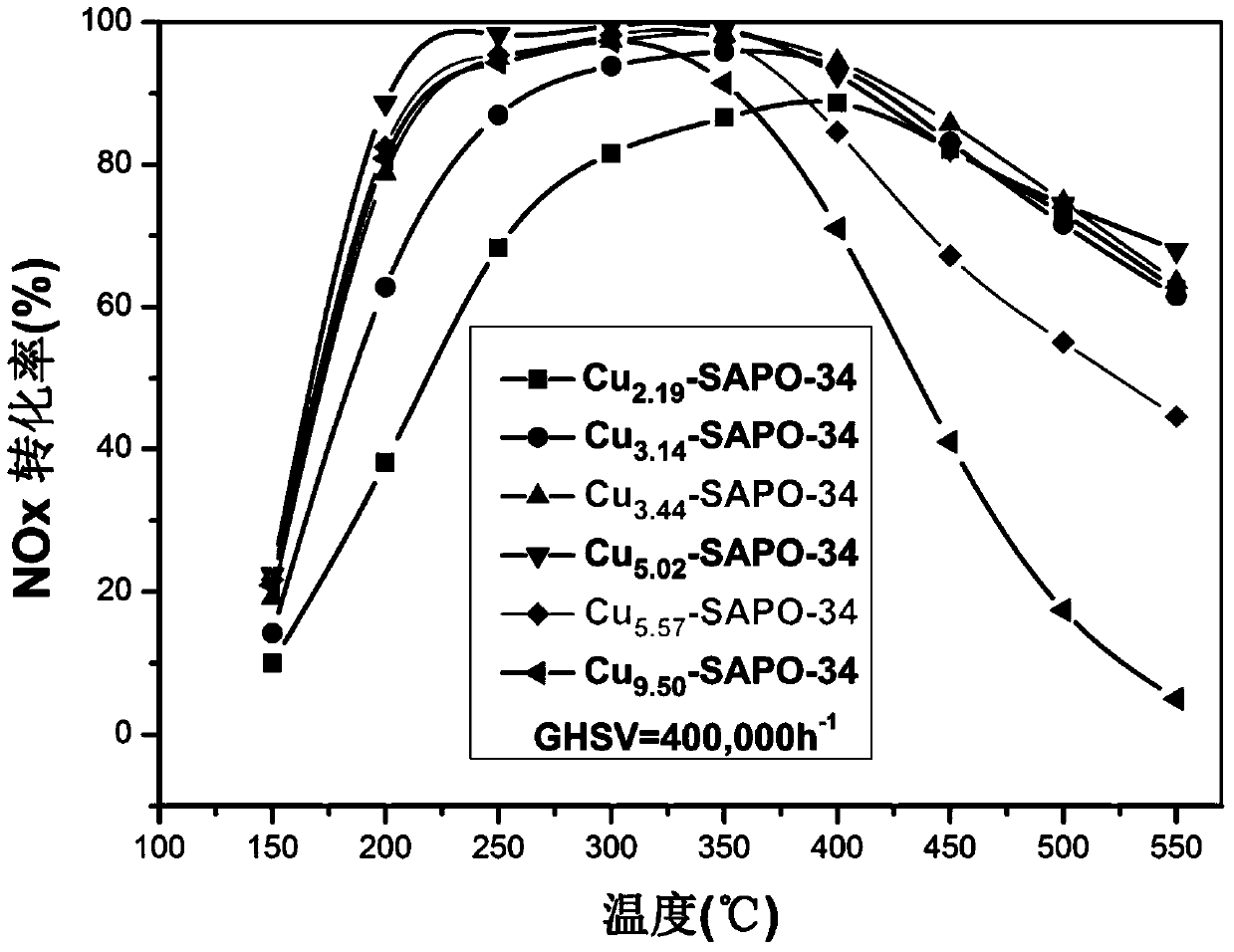

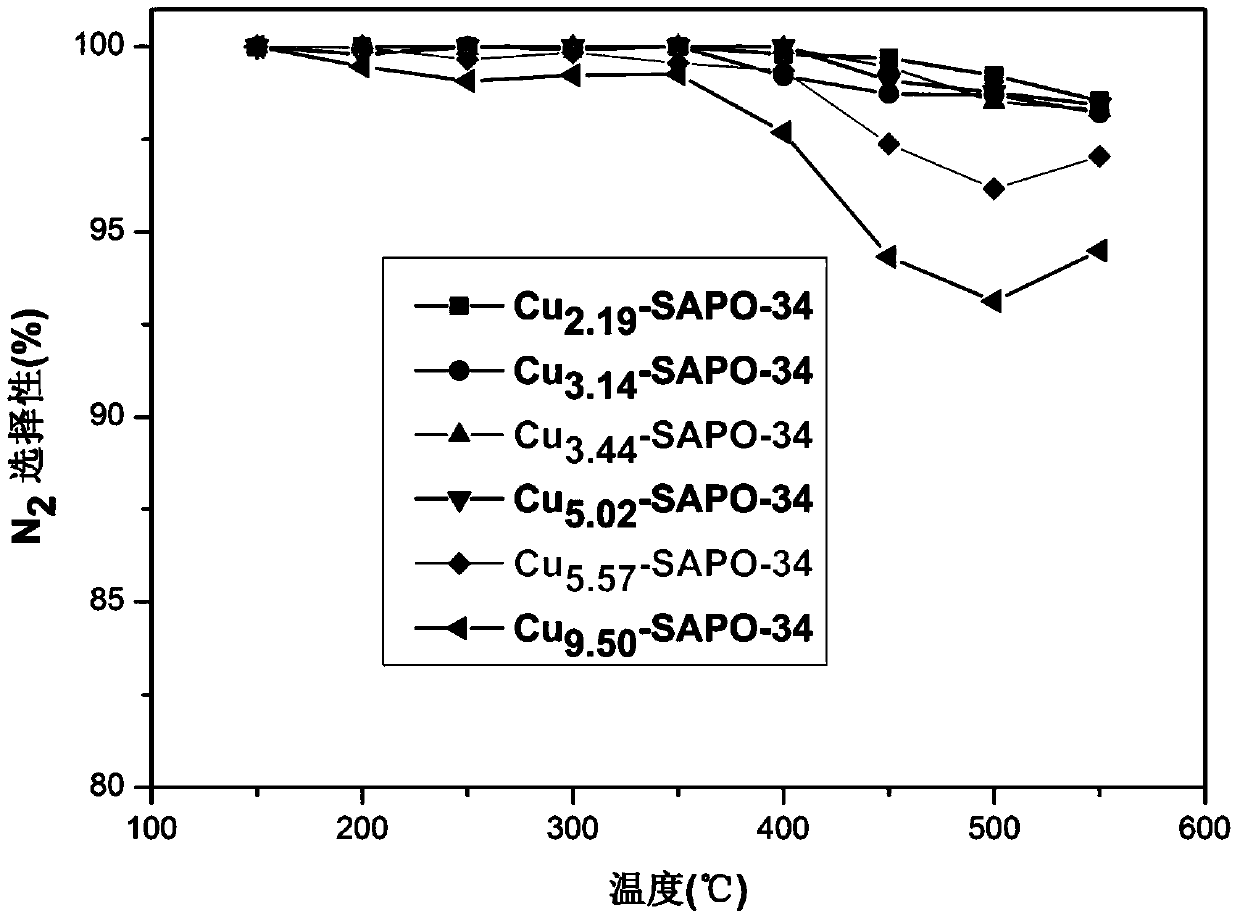

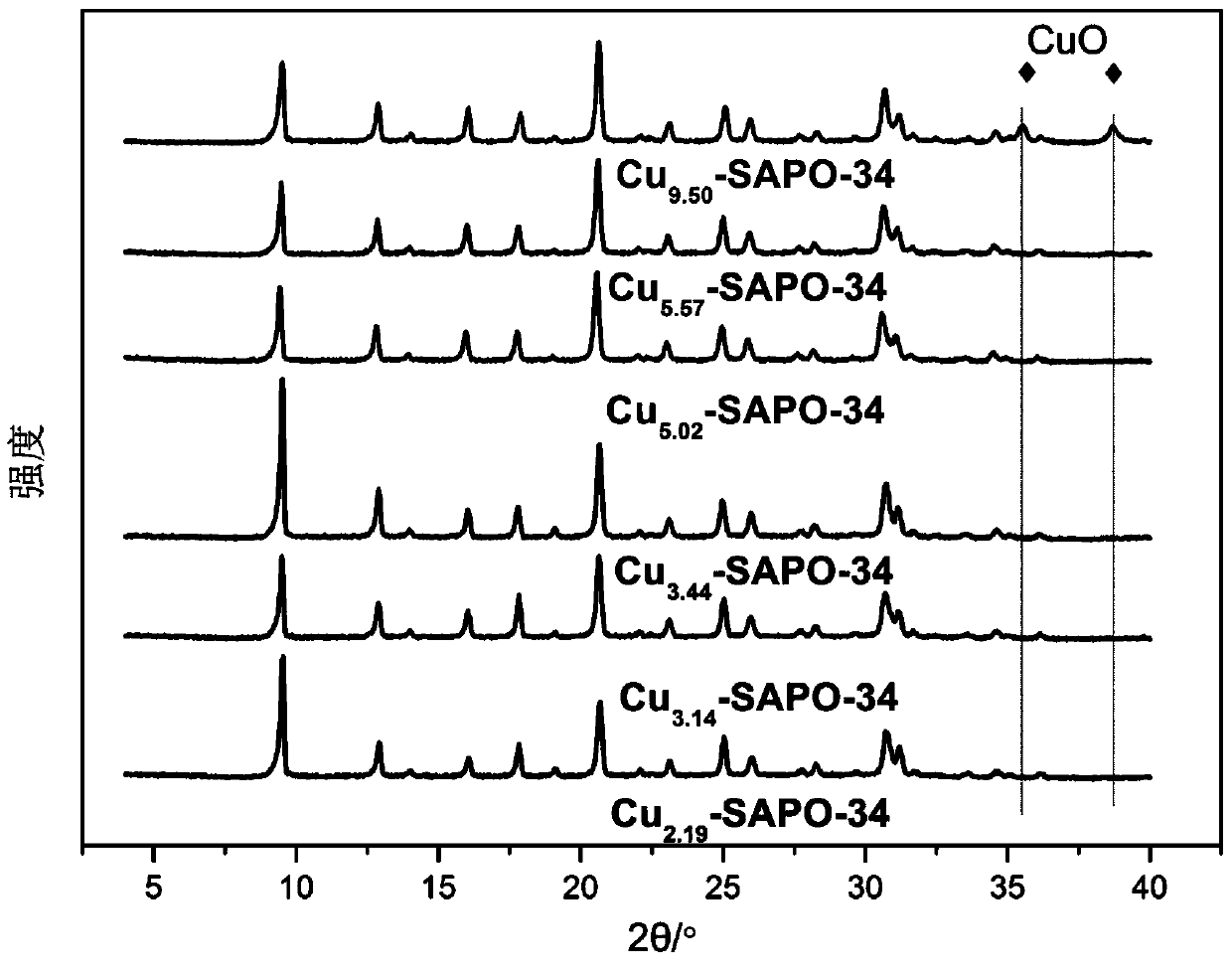

Cu-SAPO-34 molecular sieve catalyst and preparation method and application thereof

ActiveCN104209141ALoad regulationComplete structureMolecular sieve catalystsDispersed particle separationPropylamineFumed silica

The invention provides a Cu-SAPO-34 molecular sieve catalyst and a preparation method and application thereof. The method includes the steps of adding pseudo-boehmite to deionized water, stirring, adding fumed silica or silica sol and orthophosphoric acid, uniformly mixing, adding copper sulfate and tetraethylenepentamine, fully stirring, and adding diethylamine, triethylamine or n-propylamine; placing fully stirred gel in a hydrothermal reaction kettle for crystallization, cooling at room temperature, separating a solid crystalline product from the mother liquor, washing to be in neutral, drying, and calcinating in air at the temperature of 600 DEG C to 850 DEG C to obtain the Cu-SAPO-34 molecular sieve catalyst. The Cu-SAPO-34 molecular sieve catalyst prepared through a one-step hydrothermal synthesis method. And the molecular sieve catalyst of good NH3-SCR catalytic activity and hydrothermal stability is obtained by controlling the using amount of copper sulfate, tetraethylenepentamine and fumed silica or silica sol and the calcination temperature.

Owner:江西中科鸿虔新材料有限公司

Preparing method of polyimide aerogels and hybrid aerogels thereof

InactiveCN106317407ALow dielectric constantReduce dielectric lossMonocomponent synthetic polymer artificial filamentMicrostrip patch antennaFiber

The invention discloses a preparing method of polyimide aerogels and hybrid aerogels thereof, belonging to the field of aerogels. In the preparing of the polyimide precursor, the polyamic acid precipitated fiber having a large specific surface area is dissolved in an aqueous solution of triethylamine, then stirred and dissolved. And the thermal imidization is directly frozen and dried without a long sol-gel process to obtain the polyimide aerogels. At the same time, by introducing the filler with different functional characteristics, the functional diversity of polyimide hybrid aerogels is realized. The prepared hybrid aerogels can be used as flexible conductors, microstrip patch antennas, catalysts, water and oil separation membranes, high performance adsorbent materials, etc., and can be used in the fields of flexible wearable microelectronics, aerospace communications, photocatalysis and oil leakage, etc. The application scope of polyimide materials and aerogels materials is expanded, the value of products is enhanced, the preparing cycle is shortened, and its industrialization process is promoted.

Owner:BEIJING UNIV OF CHEM TECH

Acrylate grafted aqueous polyurethane emulsion and preparation method thereof

ActiveCN102558460AImprove stabilitySmall particle sizeFibre treatmentCoatingsHydrophilic monomerPolymer science

The invention discloses acrylate grafted aqueous polyurethane emulsion and a preparation method thereof. The emulsion is characterized is prepared from polyether polyol, dimethylol propionic acid, isophorone diisocyanate, ethylenediamine, hydroxyethyl acrylate and the like. The preparation method comprises the following steps: carrying out prepolymerization on polyether polyol, dimethylol propionic acid and isophorone diisocyanate so as to introduce a hydrophilic monomer; adding ethylenediamine and hydroxyethyl acrylate to carry out chain extension so as to introduce a functional monomer; adding an acrylate mixed monomer so as to reduce system viscosity; adding triethylamine for neutralization; adding deionized water for emulsification and dispersion under the condition of high-speed shearing to obtain emulsion; then dropwise adding the acrylate mixed monomer and an initiator, raising the temperature and carrying out reaction; and cooling to obtain the PUA (polyurethane-acrylate) emulsion. The emulsion prepared by the method has small grain size and excellent performances such as mechanical performance, is narrowly distributed and can be widely applied to industry fields such as leather finish, coatings, adhesives and fabric coatings.

Owner:顶立新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)