Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

646results about "Magnesium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

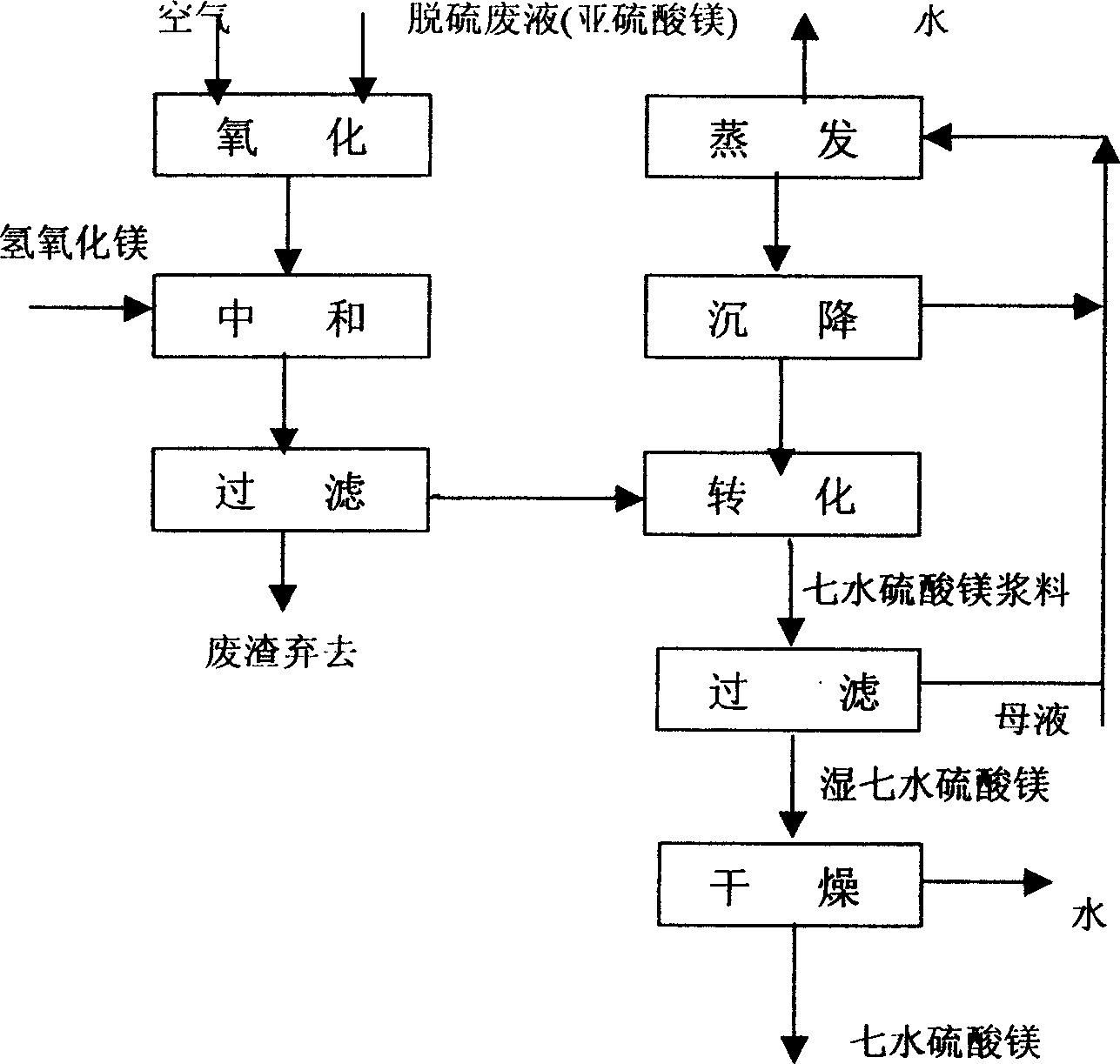

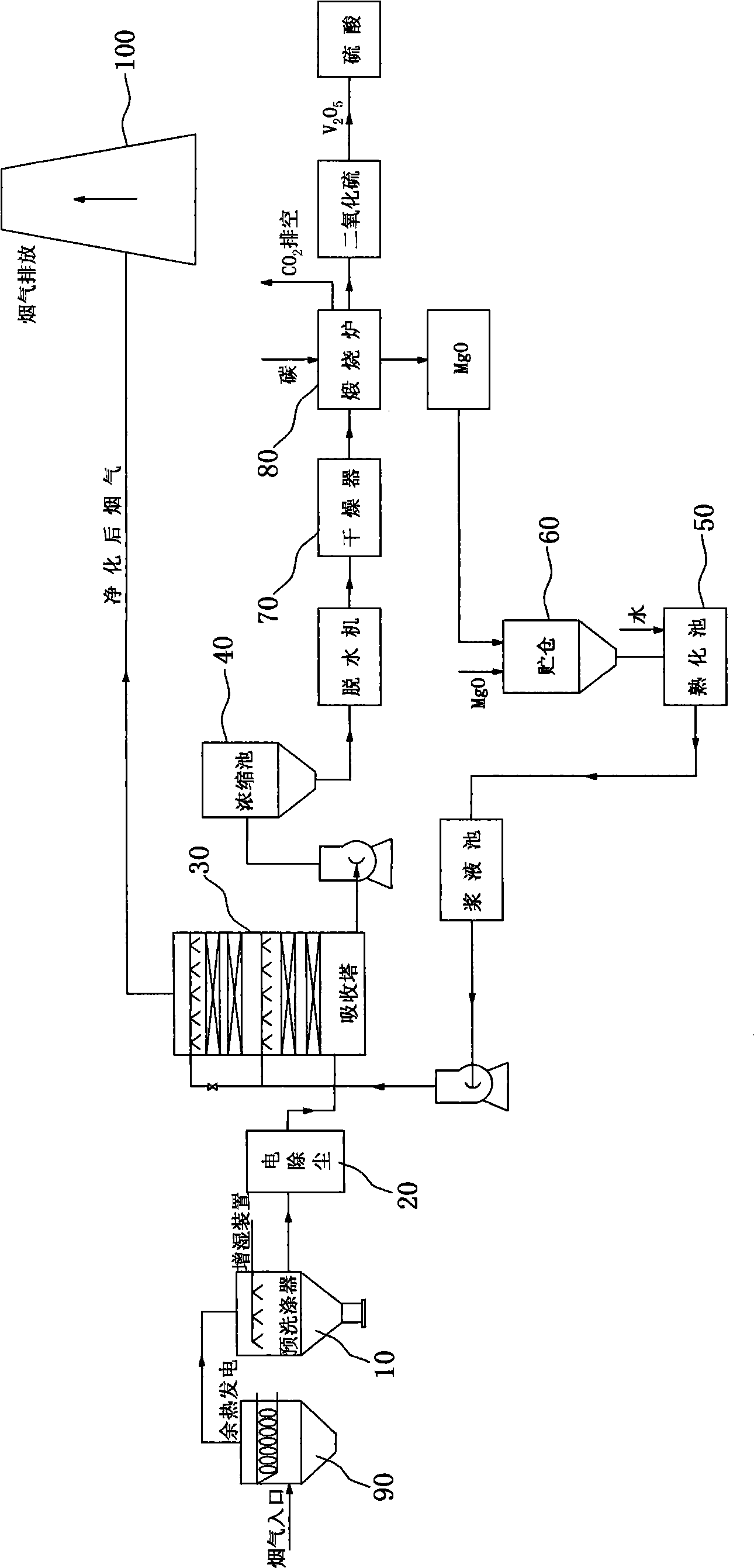

Fume desulfurizing and denitrifying device based on magnesia and method

InactiveCN102350197AEfficient recyclingSimple processDispersed particle separationMagnesium nitratesEngineeringSlurry

The invention relates to technology for treating fume pollutants and aims at providing a fume desulfurizing and denitrifying device based on magnesia and a method. The fume desulfurizing and denitrifying device based on the magnesia and the method are technically characterized in that SO2 is desorbed at the lower part of a desulfurizing and denitrifying tower by using magnesia slurry, a metal M2+ catalyst is added into circular absorption liquid, and air is also blown into the desulfurizing and denitrifying tower so as to quickly oxidize a desulfurized product of MgSO3 into MgSO4; ozone is introduced into the middle part of the desulfurizing and denitrifying tower so as to oxidize NO in fume into NOx; and the magnesia slurry is sprayed into the upper part of the tower, the NOx is absorbed, and magnesium nitrate is generated. Magnesium sulfate heptahydrate and magnesium nitrate hexahydrate can be respectively obtained by the conventional crystal separation of magnesium sulfate and the magnesium nitrate in the absorption liquid. According to the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing and denitrifying procedures are finished in one tower by using the magnesia, and the recycle of the by-products of the SO2 and the NO is also realized. The fume desulfurizing and denitrifying device based on the magnesia and the method have simple desulfurizing and denitrifying processes, low investment, low resistance and low running cost. By adopting the fume desulfurizing and denitrifying device based on the magnesia and the method, the desulfurizing rate of more than 96 percent and the denitrifying rate of more than 92 percent can be obtained.

Owner:EAST CHINA UNIV OF SCI & TECH

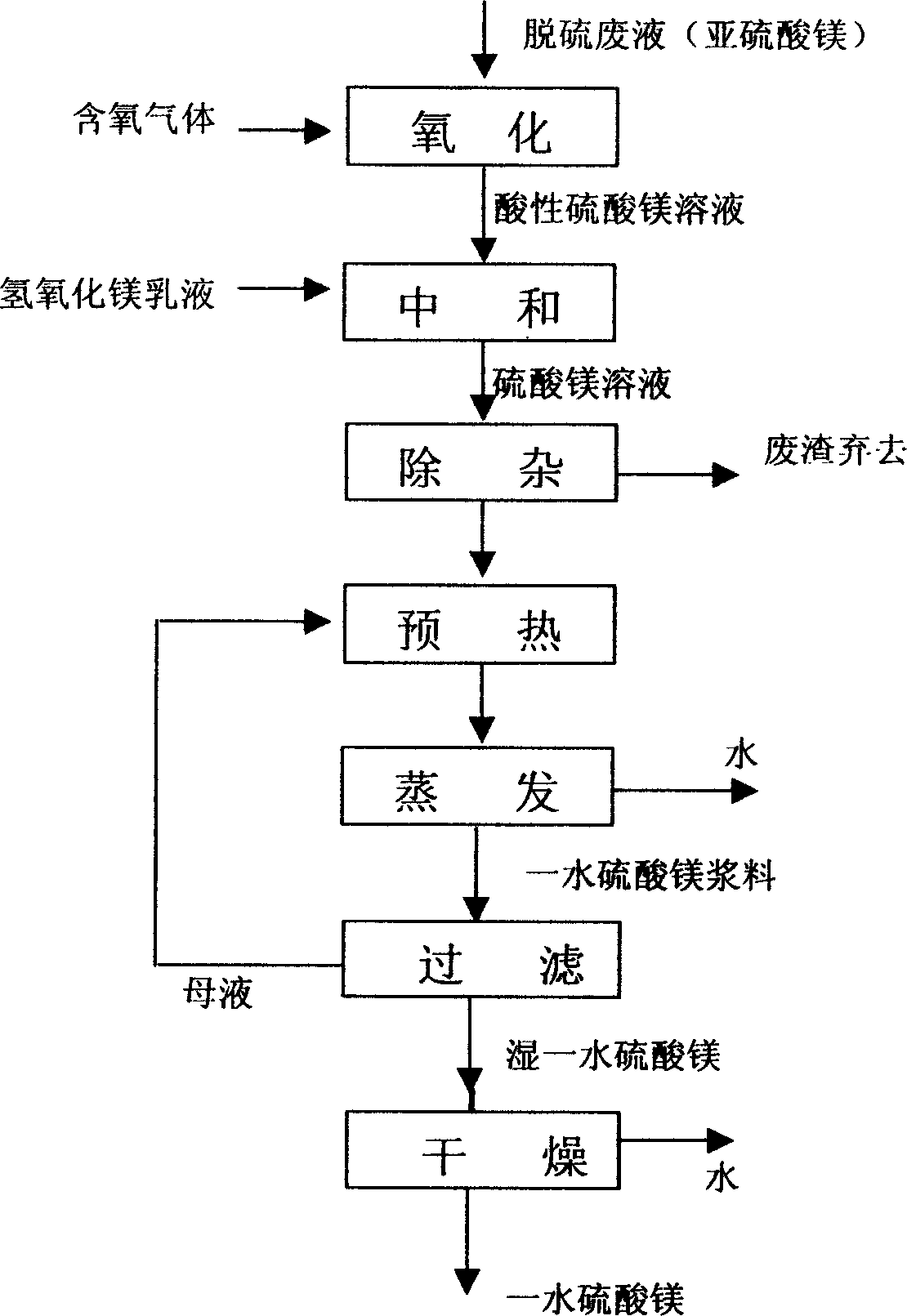

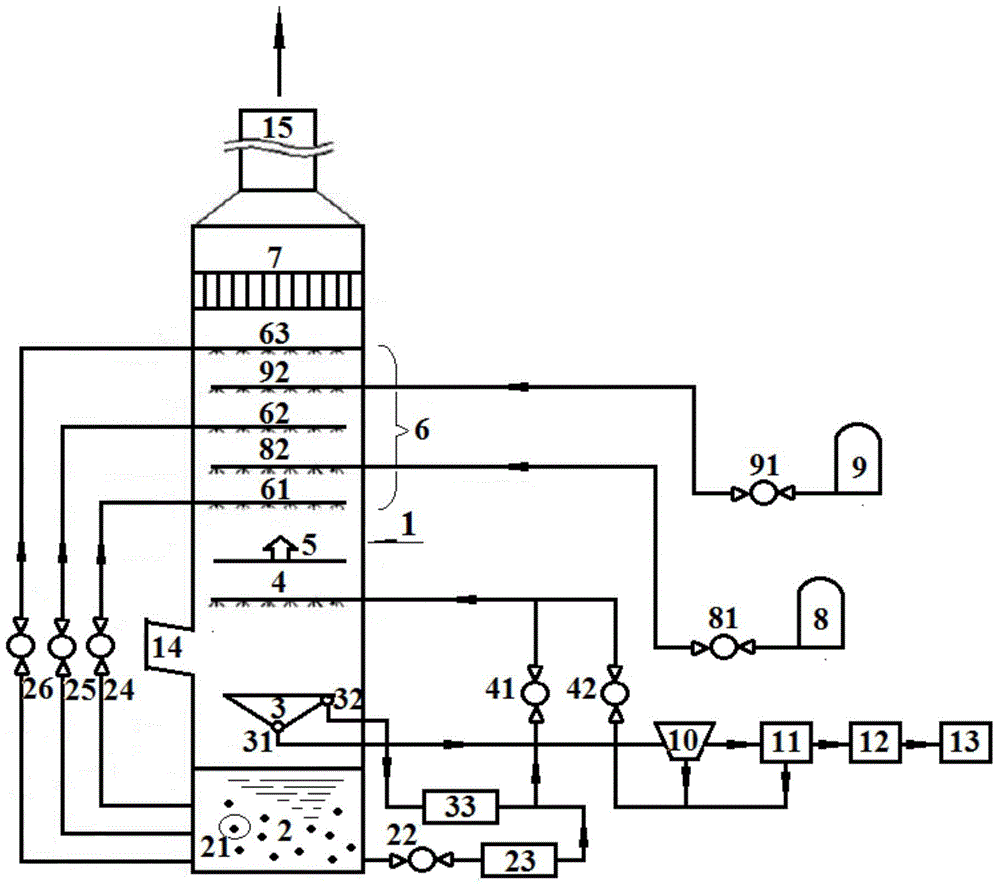

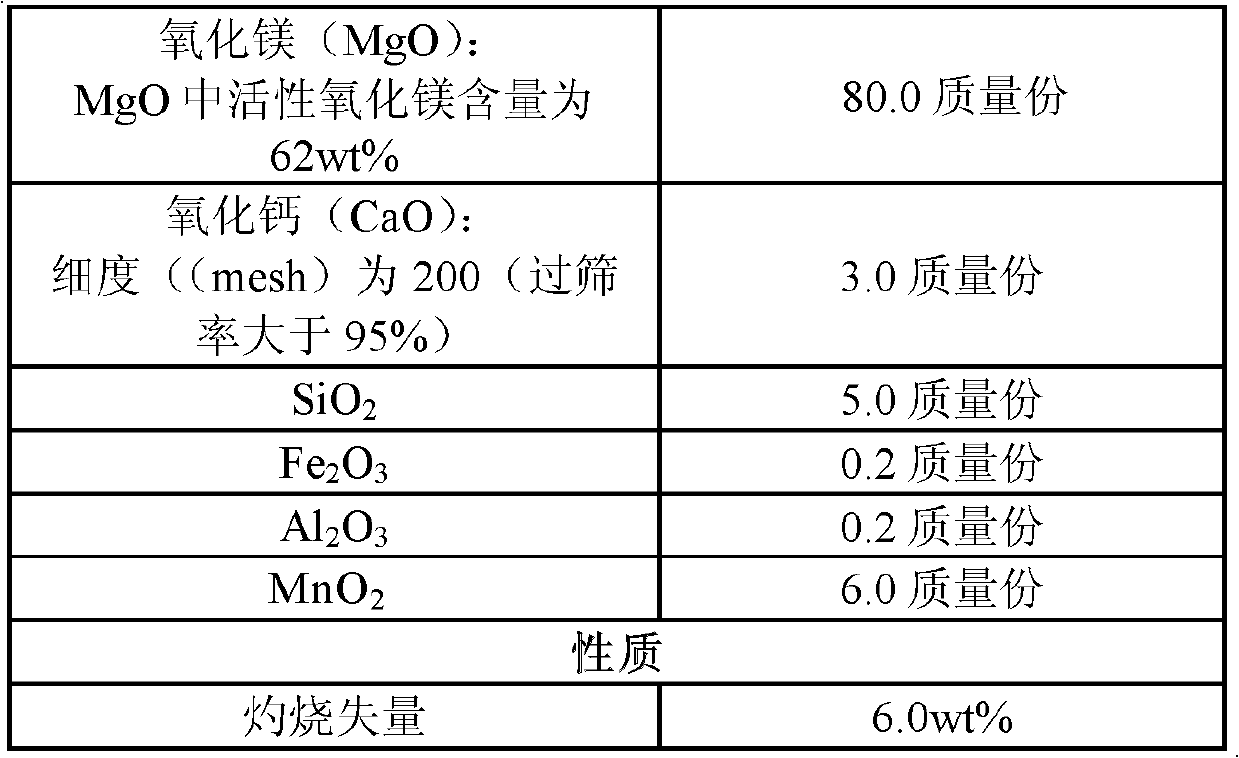

Magnesium sulfate production method using magnesium oxide and desulfurated waste fluid

InactiveCN1544331ASolve the problem of discharge into the seaExcellent energy consumptionDispersed particle separationWater/sewage treatmentLiquid wasteSulfur

The invention provides a process for preparing magnesium sulphate by utilizing magnesium oxide desulfurized exhausted liquid comprising the steps of oxidation step, neutralization step, edulcoration step, evaporation concentration, solid-liquid separation step, drying and packing step. By controlling different evaporation temperature, discharging condition and various equipment, kieserite and magnesium sulphate can be prepared respectively.

Owner:天津市昌昊化工股份合作公司

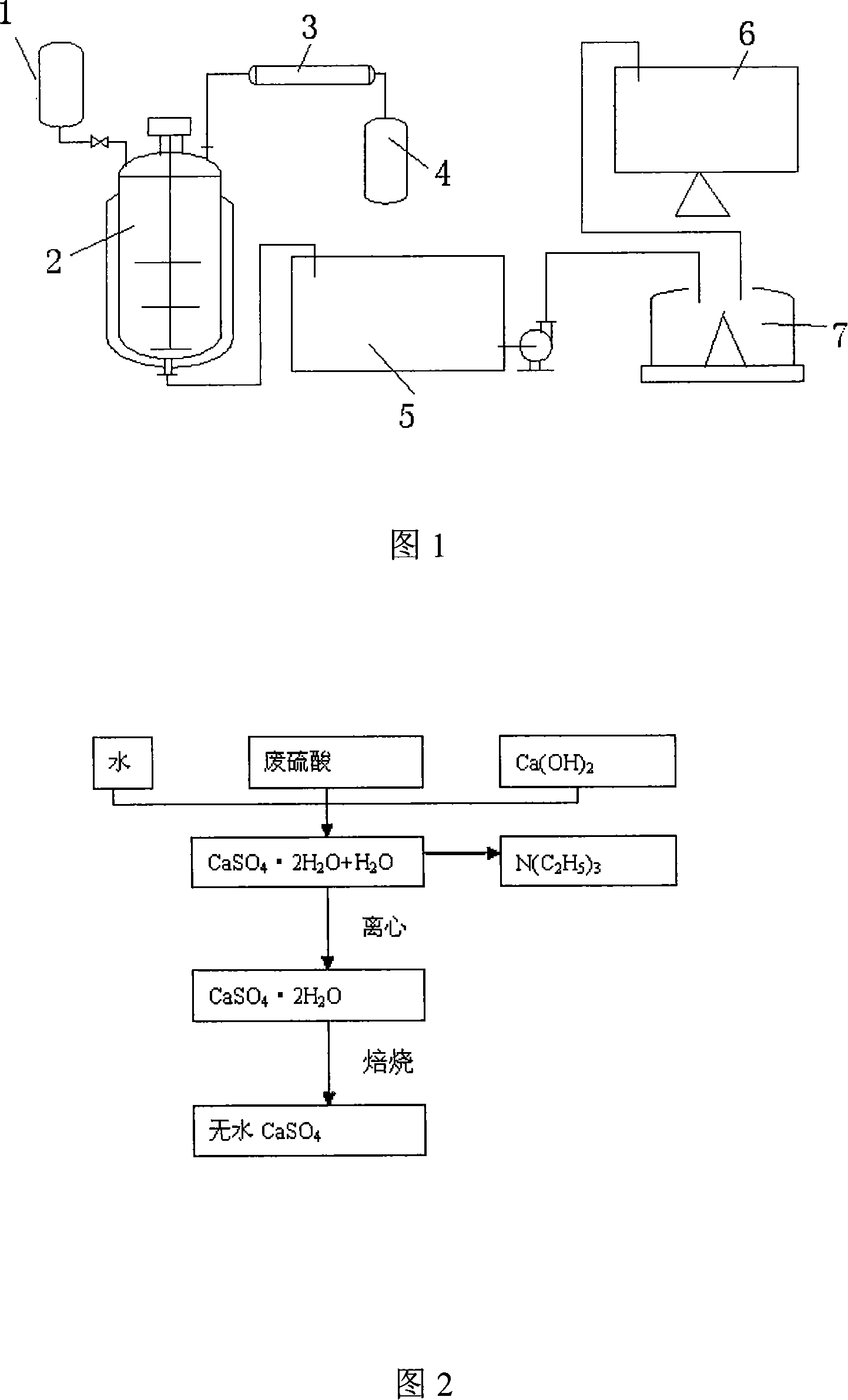

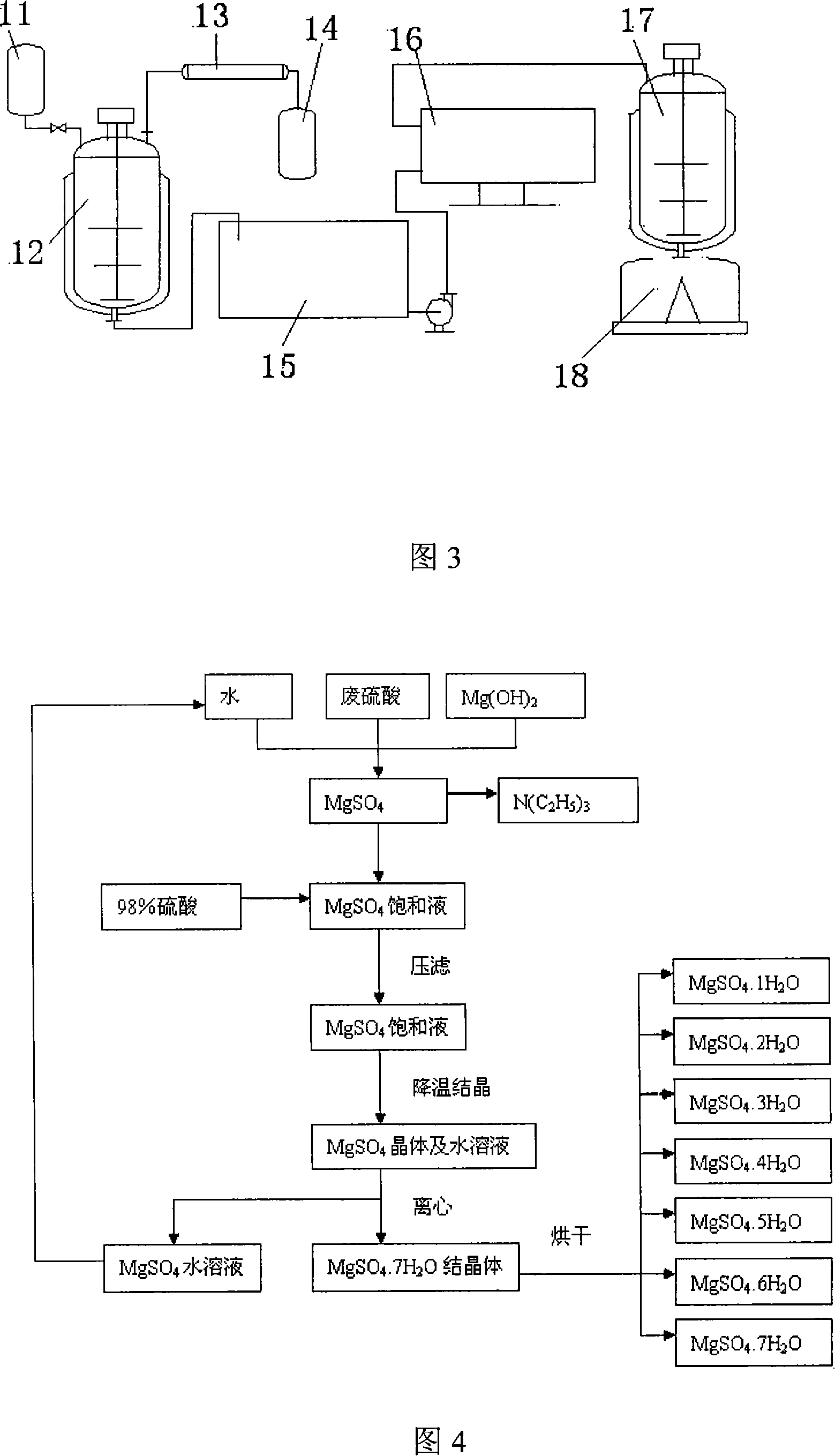

Waste acid treatment method and treatment system for acesulfame preparation technique by sulphuric anhydride cyclization method

ActiveCN101148300ASolve environmental problemsAchieve recyclingMagnesium sulfatesMultistage water/sewage treatmentSewageAcesulfame potassium

The present invention is process of treating waste acid solution from Acesulfame potassium preparing sulfuric anhydride cyclizing process. The process of treating waste acid solution includes the reaction of the waste acid solution and the mixture comprising Mg(OH)2 or MgO and water in a neutralizing reactor to produce triethylamine gas, cooling triethylamine gas in a cooler into triethylamine liquid and collecting in a tank, regulating the pH value of neutralizing reaction resultant in a regulating tank with 98 % concentration sulfuric acid solution into 5-7, filtering, cooling the filtrate in a MgSO4 cooling reactor to separate out MgSO4 hydrate. The present invention has MgSO4 yield up to 95 % and N(C2H5)3 recovering rate up to 95 % and can eliminate environmental pollution caused by Acesulfame potassium production.

Owner:ANHUI WEIDUO FOOD INGREDIENTS CO LTD

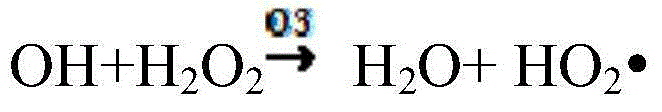

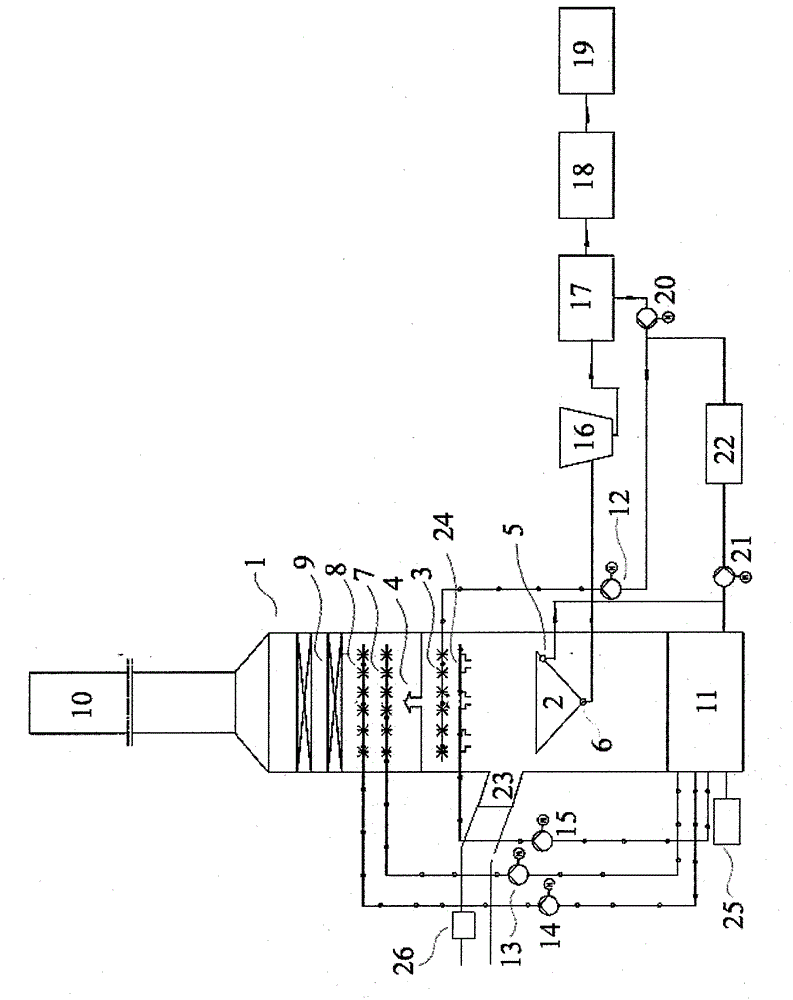

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

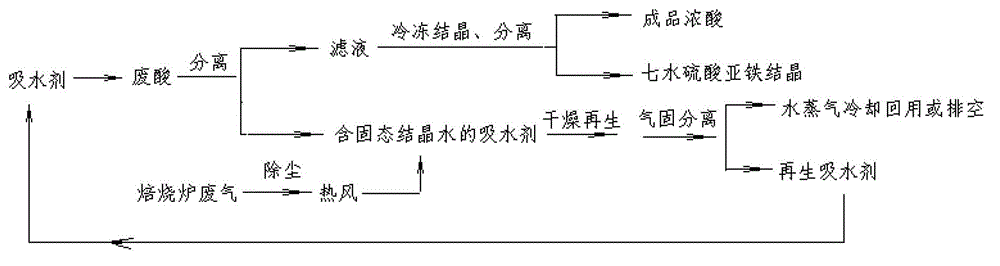

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

Environment-friendly separation and recovery method of fluorine in fluorine-containing waste liquid

InactiveCN105948083AAchieve separationAchieve recyclingMagnesium fluoridesHydrogen fluorideRecovery methodEnvironmental resistance

The invention discloses an environment-friendly separation and recovery method of fluorine in a fluorine-containing waste liquid. According to the invention, a magnesium-containing compound is added into the fluorine-containing waste liquid as a precipitation agent, such that fluorine in the waste liquid is selectively precipitated; filtering is carried out, and fluorine-removed liquid and magnesium fluoride precipitate are obtained; the fluorine-removed liquid is used in waste water recycling; the magnesium fluoride precipitate is decomposed with sulfuric acid, such that a series of compounds of fluorine are obtained; decomposition residue is subjected to a dissolution-crystallization treatment, such that magnesium sulfate crystals are obtained; the obtained magnesium sulfate crystals are returned and recycled in the fluorine selective precipitation process; the crystallization mother liquor of magnesium sulfate is returned to the dissolution-crystallization process or the magnesium fluoride precipitation decomposition process. The method has the advantages of simple process, simple operation, low production cost, and good fluorine-removing effect. With the method, fluorine resource utilization is realized. The method also has the advantages of no fluorine-containing waste production and no three-waste emission.

Owner:CENT SOUTH UNIV

Nanofiltration treatment method of desulfurization waste water

ActiveCN105236659AAchieve recyclingNovel processing methodMagnesium sulfatesMultistage water/sewage treatmentInorganic saltsWastewater

The invention provides a nanofiltration treatment method of desulfurization waste water. The method comprises the following steps that 1, pH of the desulfurization waste water is adjusted to range from 8.5 to 9.5, and TMT-15 and sodium carbonate are added to remove calcium ions and heavy metal elements; 2, the desulfurization waste water treated in the first step is filtered, and nanofiltration treatment is conducted on the filtered desulfurization waste water to obtain separation liquor and concentrated liquor; 3, crystallization treatment is conducted on the separation liquor to obtain NaCl solid salt, the concentrated liquor is treated according to the second step, nanofiltration treatment is repeatedly conducted on the concentrated liquor to make the recovery rate of NaCl in the desulfurization waste water treated in the first step reach above 80%, and MgSO4 solid salt is obtained through crystallization treatment. According to the nanofiltration treatment method of the desulfurization waste water, the treatment method is simple, the cost is low, operation is easy, the operation conditions are mild, the operation method is flexible, and recycling of various inorganic salt in the desulfurization waste water is achieved.

Owner:BEIJING WOTEER WATER TECH

Method for producing magnesium sulfate monohydrate by using desulfurization wastewater

ActiveCN102745725AQuality up to standardGuaranteed uptimeMagnesium sulfatesWastewaterCrystallization

The present invention discloses a method for producing magnesium sulfate monohydrate by using desulfurization wastewater. The method comprises the following steps: (1) pulping, (2) carrying out desulfurization, (3) discharging the pulp, (4) filtering, (5) carrying out concentration, and (6) carrying out crystallization. With the method of the present invention, high value byproducts can be synchronously produced during a flue gas desulfurization process by using a magnesium oxide method. In addition, with the method of the present invention, a stable running characteristic is provided, and quality of the produced magnesium sulfate monohydrate after desulfurization reaches standards.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

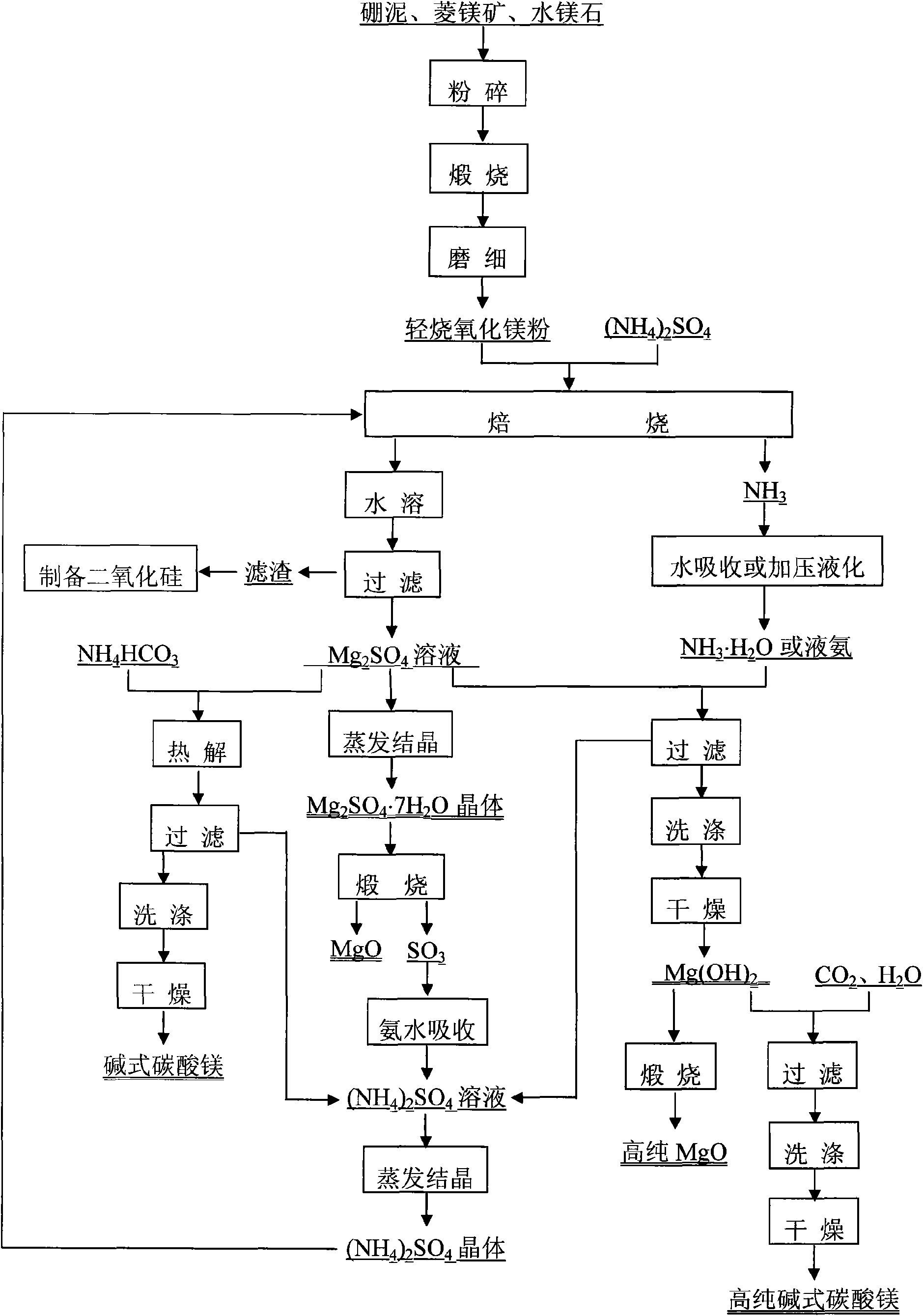

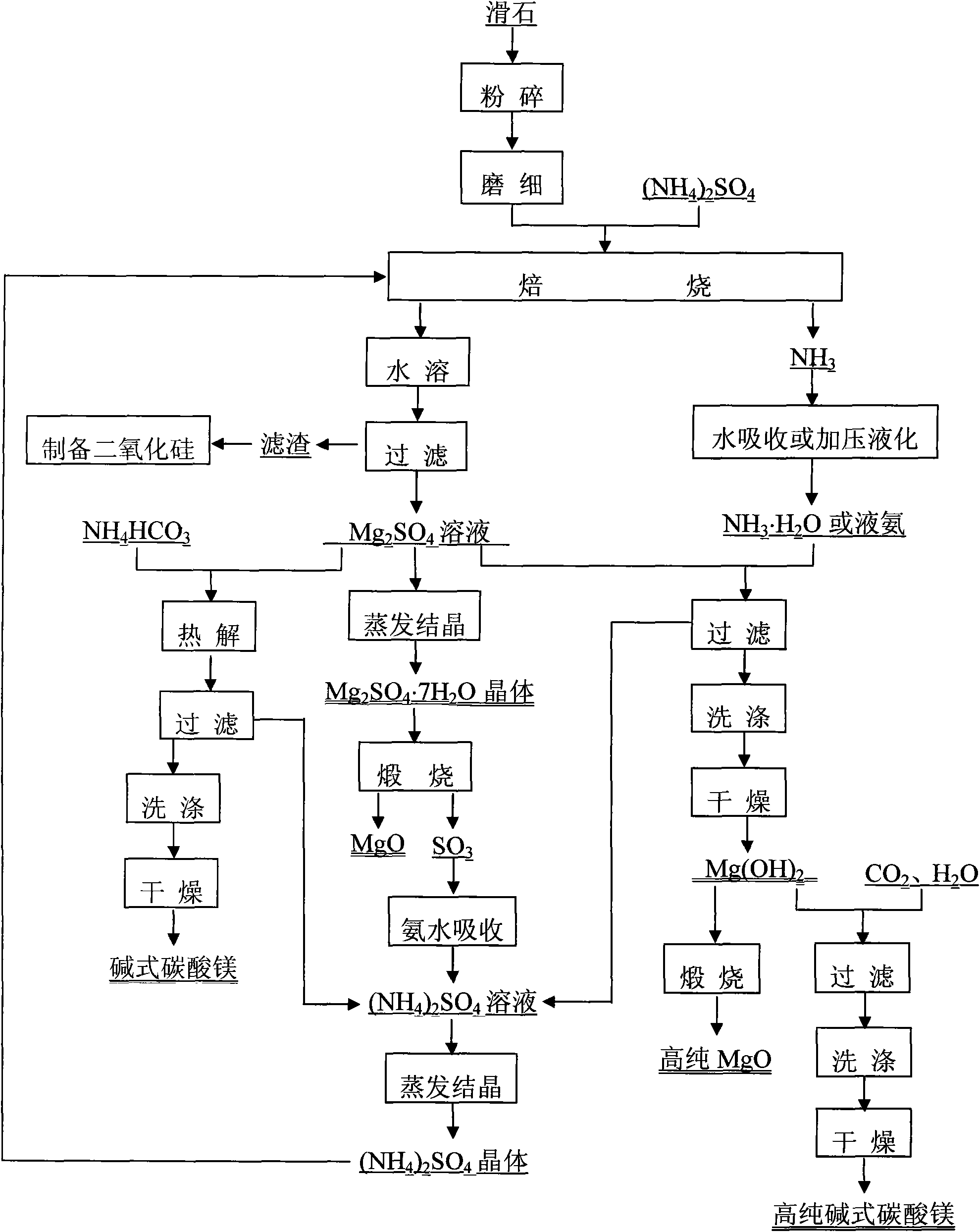

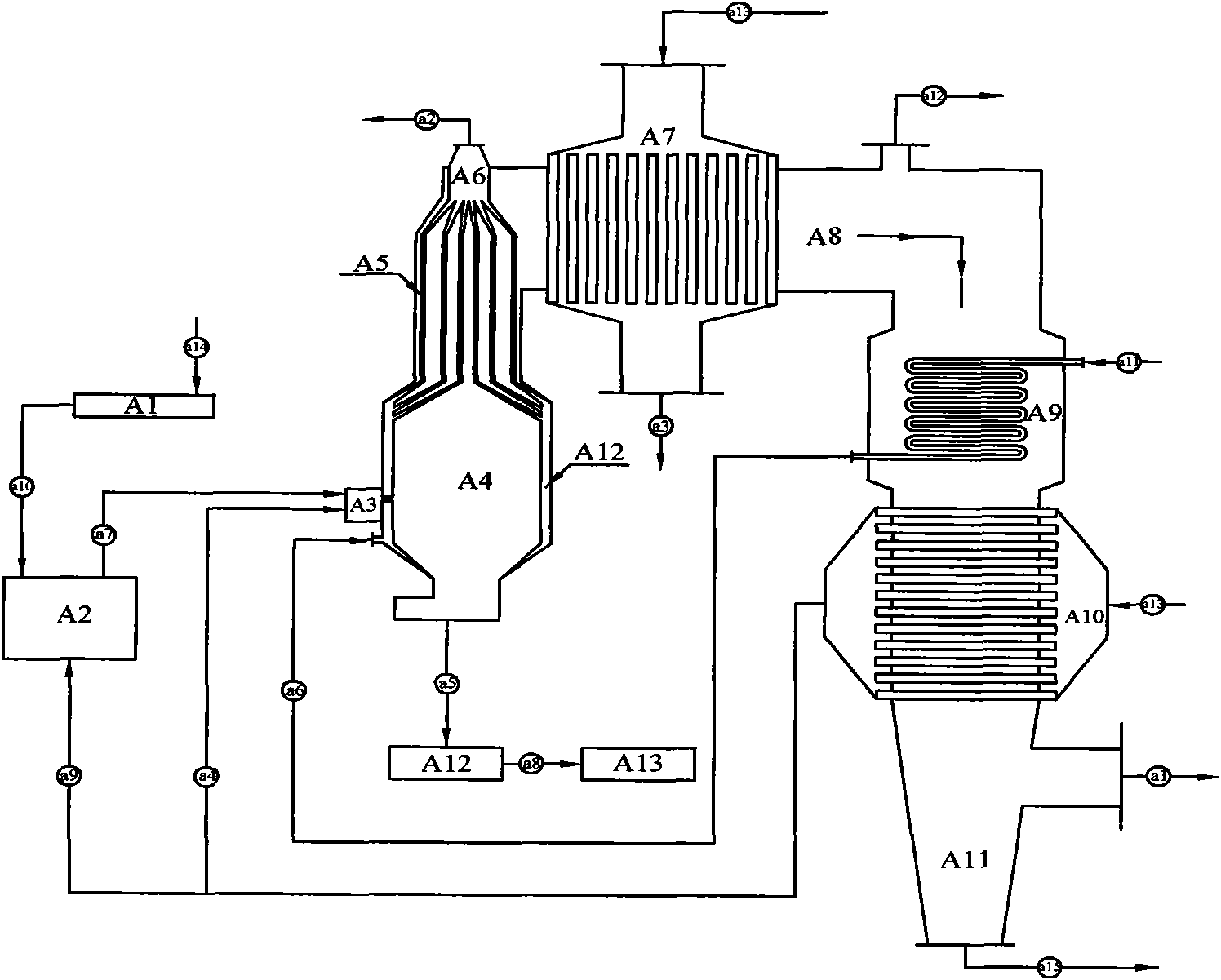

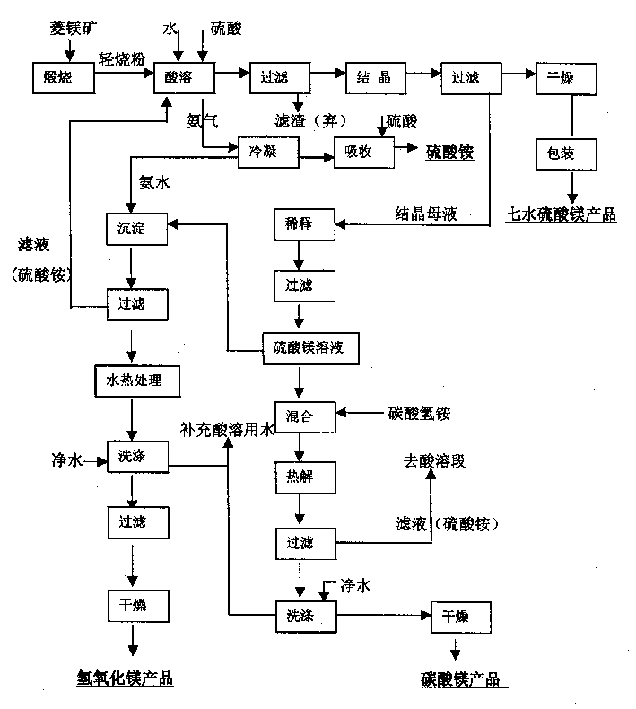

Method for producing series magnesia chemical products by using material containing magnesium

InactiveCN101683988ACause secondary pollutionSimple processMagnesium carbonatesMagnesium sulfatesSludgeChemical products

The invention relates to a method for producing a series of magnesia chemical products by using material containing magnesium. The method comprises the following steps: (1) crushing material (such asboric sludge, baudisserite and brucite) containing magnesium, calcining to obtain light calcinesia magnesia, and finely grinding or directly crushing and levigating the material containing (for example, soapstone) magnesium; (2) mixing the levigated materials containing magnesium with ammonium sulfate, and baking; (3) dissolving the baked product in water and filtering; (4) evaporating filtrate, concentrating and crystallizing to prepare magnesium sulfate; (5) dehydrating the magnesium sulfate, and calcining to prepare magnesium oxide; (6) mixing magnesium sulfate filtrate with an ammonium bicarbonate solution, and pyrolyzating to prepare basic magnesium carbonate; (7) adding ammonia water in a magnesium sulfate solution to prepare magnesium hydroxide; (8) carbonating and pyrolyzating themagnesium hydroxide to prepare high-purity basic magnesium carbonate; and (9) calcining magnesium hydroxide to prepare high-purity magnesium oxide. The high-purity magnesium oxide prepared by the method has high purity, good quality and high additional value, and the high-efficient and deep utility of the materials containing magnesium is realized. As byproducts, ammonia and ammonium sulfate are recycled, and the closed cycle is realized in the technological process which is an environment-firendly process flow. The method has simple process flow, less investment and easy realization of industrialized production.

Owner:NORTHEASTERN UNIV

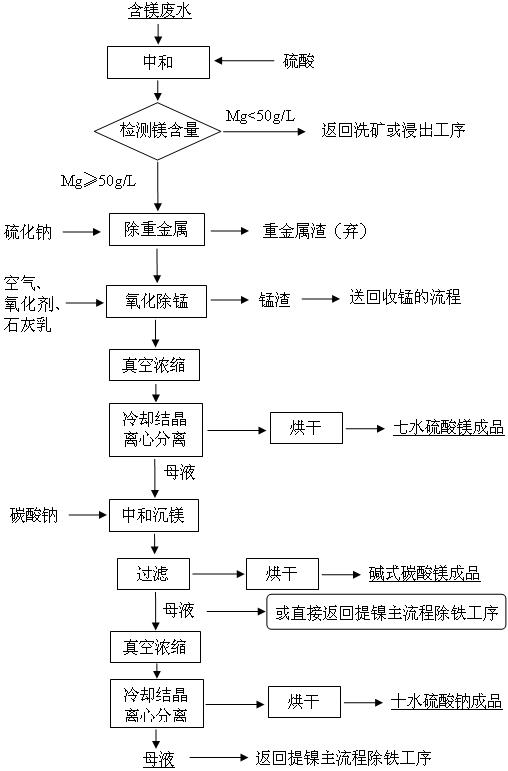

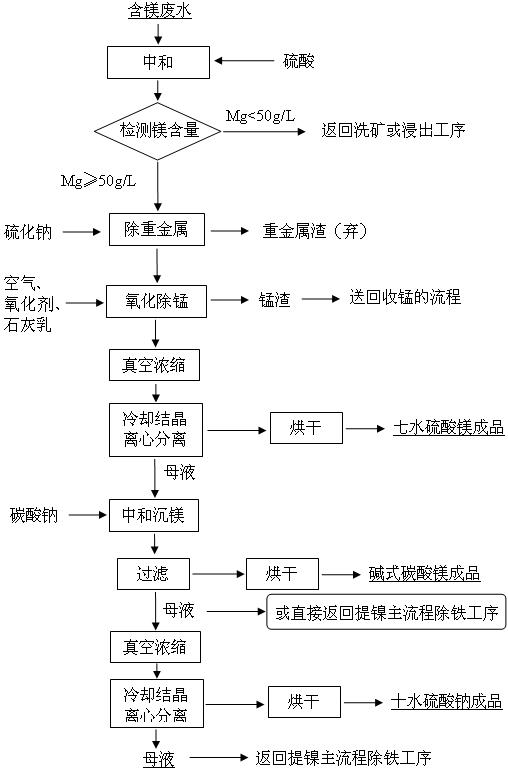

A comprehensive treatment method for laterite nickel ore hydrometallurgy wastewater

ActiveCN102276099ASolve the emission problemReduce manufacturing costMagnesium carbonatesMagnesium sulfatesManganeseEvaporation

The invention discloses a comprehensive treatment method of waste water from laterite-nickel ore wet smelting, which comprises the following steps: adjusting magnesium-containing waste water to be neutral so as to return the waste water to the ore-washing or leaching procedure for a process purpose, increasing the magnesium concentration of the waste water to above 50 g / L, performing heavy metal removal and manganese removal, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying to obtain magnesium sulfate heptahydrate, performing magnesium precipitation of the mother liquor after crystallization by sodium carbonate, separating basic magnesium carbonate, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying of the mother liquor after magnesium precipitation to obtain sodium sulfate decahydrate, or returning the mother liquor after magnesium precipitation directly to the iron-removing procedure of the nickel-extraction flow and to be used as a sodium source for iron removal by a sodium jarosite method. The method of the invention is simple and practical,has low cost, does not generate waste by-products, can both produce salable chemical products and reduce the production cost of the main flow for nickel recovery, and also prevents environment pollution.

Owner:广西银亿新材料有限公司

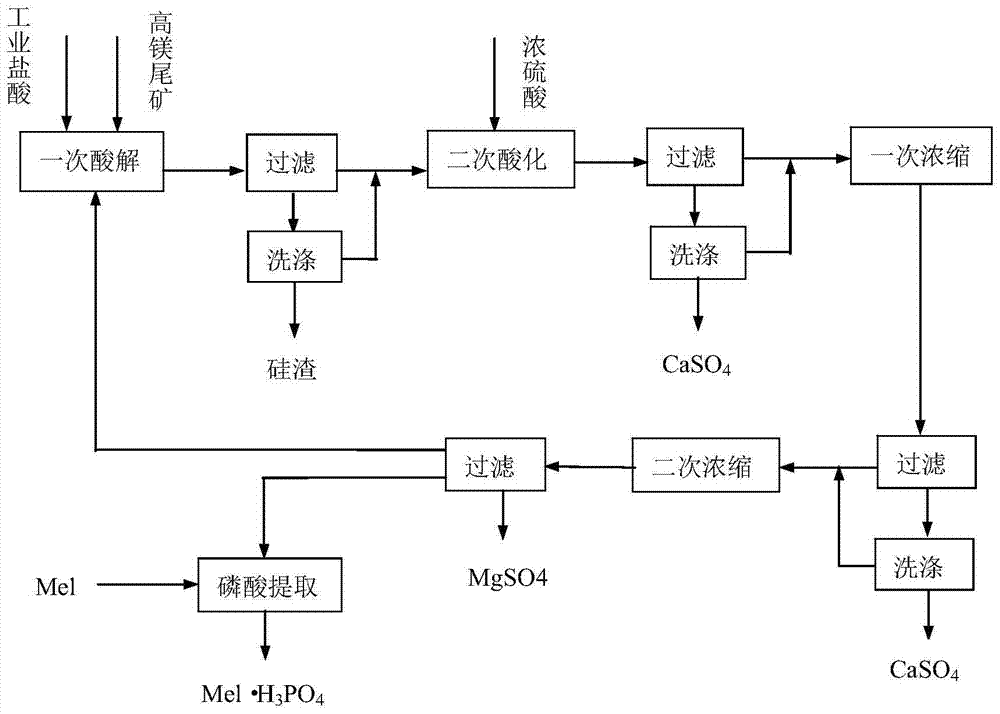

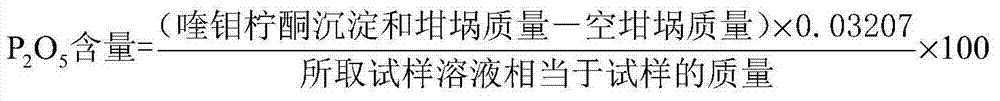

Method for recovering phosphorus in phosphate tailings with high magnesium content and preparing magnesium sulfate by adopting indirect sulfuric acid method

InactiveCN103922372AEfficient use ofEfficient recyclingPhosphorus oxidesSolid waste disposalSlagFiltration

The invention relates to a method for recovering phosphorus in phosphate tailings with high magnesium content and preparing magnesium sulfate by adopting an indirect sulfuric acid method. The method comprises the following steps: 1) mixing the phosphate tailings with high magnesium content with a hydrochloric acid to react, so as to obtain one-time acidolysis filtrate and silicon slag, carrying out insulated suction filtration and washing to obtain a one-time washing solution; 2) carrying out secondary acidification on obtained one-time acidolysis filtrate and a one-time washing solution by using a sulfuric acid, so as to obtain secondary acidified filtrate and calcium sulfate sediments, aging, carrying out suction filtration and washing; (3) concentrating the obtained secondary acidified filtrate and the one-time washing solution once to obtain one-time concentrated filtrate and one-time concentrated solid, carrying out suction filtration and washing after cooling; 4) concentrating the obtained one-time concentrated filtrate and one-time washing solution for the second time, so as to obtain secondary concentrated filtrate and secondary concentrated solid, carrying out suction filtration and drying after cooling, so as to obtain a magnesium sulfate product; 5) returning the secondary concentrated filtrate to be mixed with the hydrochloric acid, leaching the phosphate tailings with high magnesium content in cycle, and extracting after certain concentration is achieved. The method is short in flow, convenient to operate, and high in recovery rate of magnesium.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

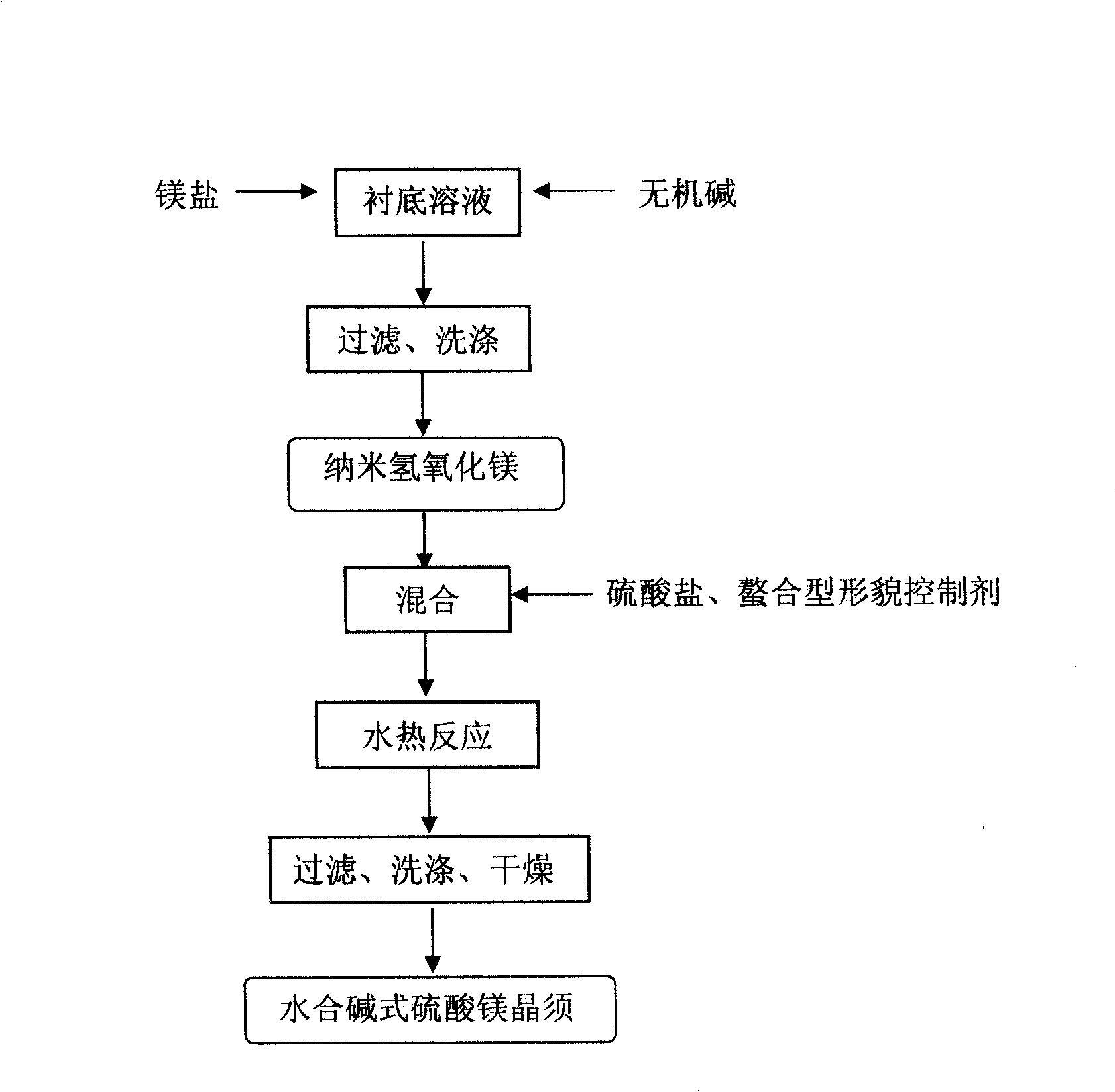

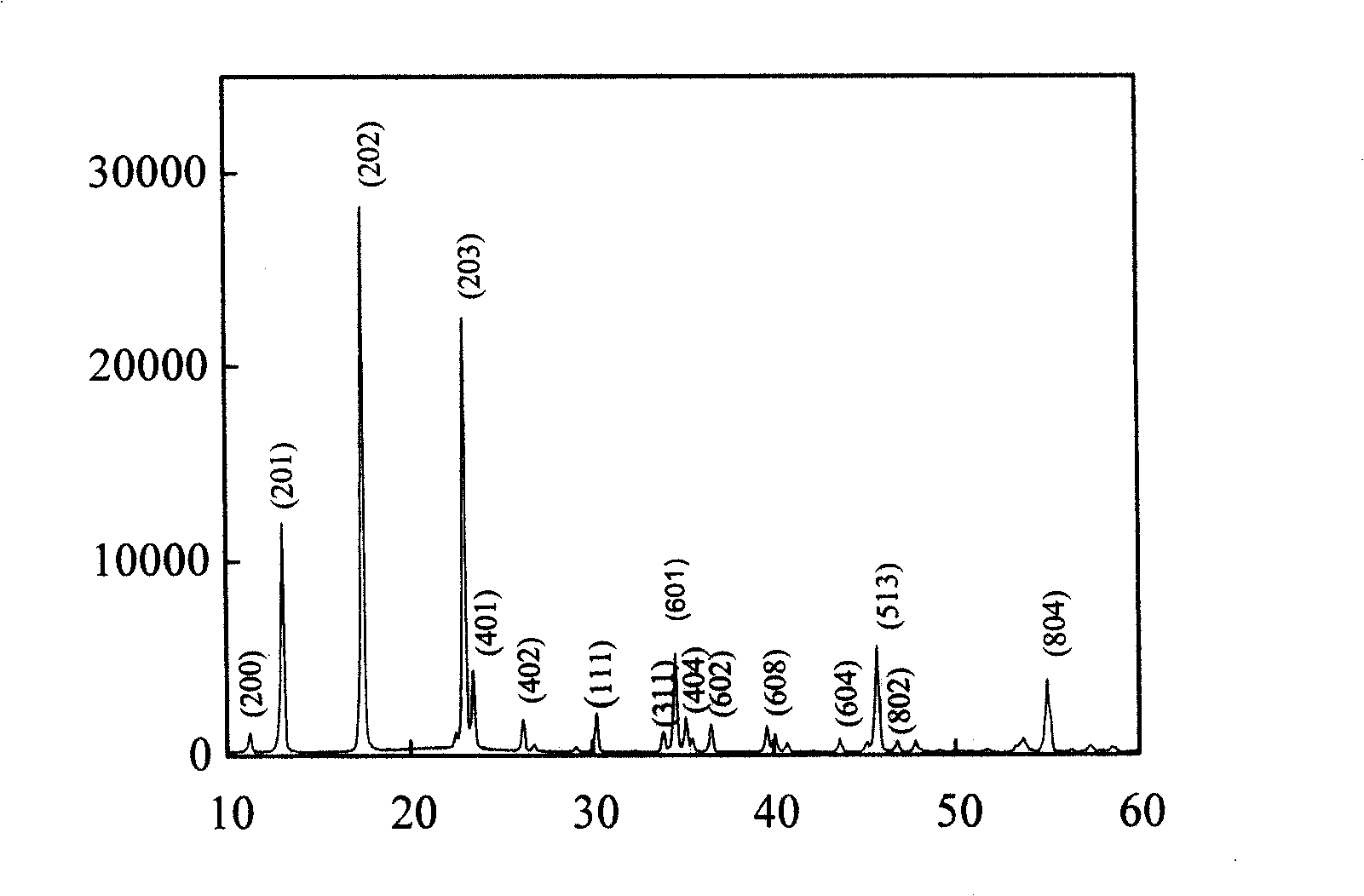

Preparation of high length-diameter ratio magnesium hydroxide sulfate hydrate whisker

InactiveCN101348937AReduce supersaturationHigh crystallinityPolycrystalline material growthFrom normal temperature solutionsMagnesium saltCrystallinity

A preparation method for hydrated basic magnesium sulfate crystal whisker with high-aspect ratio belongs to the technical field of inorganic chemical material preparation. The method comprises the following steps: water-soluble magnesium salt and inorganic base are taken as raw materials so as to prepare a precursor for nano magnesium hydroxide with better crystallinity and dispersivity in a substrate double-injection synthesis mode at a temperature between 10 and 90 DEG C; then the precursor is added into aqueous solution containing sulfate and micro chelated morphological control agent so as to carry out hydrothermal reaction at a temperature between 100 and 250 DEG C for 2 to 20 hours; and finally, one-dimensional growth of hydrothermal products is promoted by means of the selective adsorption and slow release action of the morphological control agent so as to prepare the hydrated basic magnesium sulfate crystal whisker with the average length of between 40 and 400mu m, the average diameter of between 0.05 and 0.2 mu m, the aspect ratio of between 200 and 2,000 and the main content more than 98 percent. The preparation method has the advantages of simple process, low cost, high added value of the product and easy industrial popularization; moreover, the product can be used in industries such as plastics, rubber, resin and ceramics as a reinforcing material.

Owner:TSINGHUA UNIV

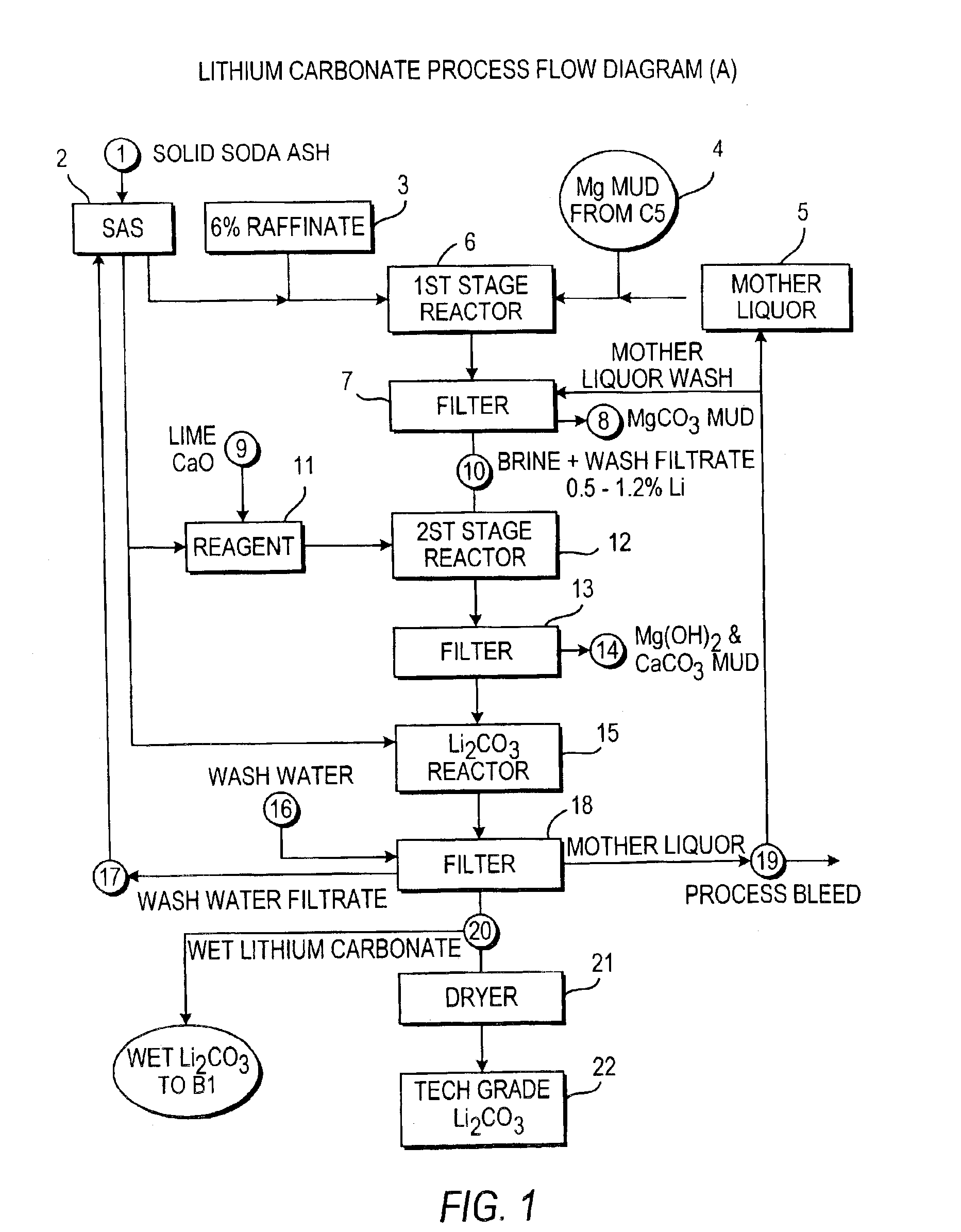

Production of lithium compounds directly from lithium containing brines

InactiveUS6921522B2Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Method for mining and machining water-soluble potassium salt mine

InactiveCN102251759APromote recoveryReduce collapseMagnesium chloridesFluid removalSodium saltPollution

The invention discloses a method for mining and machining a water-soluble potassium salt mine. The method disclosed by the invention comprises the following steps: firstly, exploiting the potassium salt mine by adopting a well drilling water soluble method; evaporating and crystallizing the exploited brine to sequentially precipitate a sodium salt and a potassium salt; refrigerating and crystallizing the residual feed liquid to further precipitate potassium chloride; and respectively filtering and drying the precipitated sodium salt and potassium salt to obtain finished sodium salt and potassium salt, wherein a part of mother liquor after the sodium salt and potassium salt are precipitated is used for preparing magnesium chloride, and the other part is used for preparing magnesium oxide. The method disclosed by the invention is particularly suitable for the exploitation of a potassium mine having the defects of complicated geological and hydrologic conditions, over-shallow or over-deep burial, poor quality and high carnallite content, can reduce ground collapse, improves the exploitation rate, can prepare a potassium fertilizer in a large scale and has the advantages of low energy consumption and little pollution and waste discharge.

Owner:CHINA NAT OFFSHORE OIL CORP +2

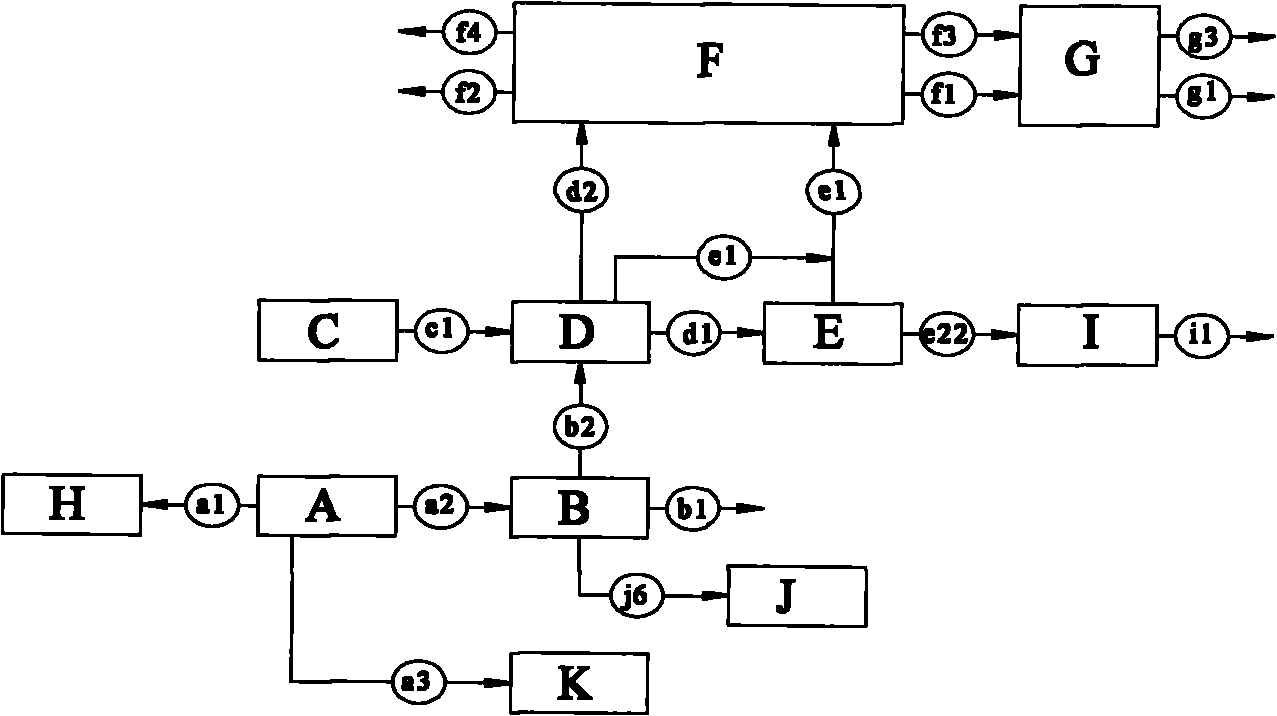

Method for integrated production of magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite

InactiveCN1401573AImprove protectionReduce manufacturing costMagnesium carbonatesMagnesium sulfatesAmmonium Hydrogen CarbonateCarbonate

A process for preparing magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite includes reaction of light-burned magnesium oxide powder obtained by calcining magnesite, the solution of ammonium sulfate as the by-product obtained by reaction with magnesium carbonate and magnesium hydroxide precipitate and industrial concentrated sulfuric acid, evaporating ammonia gas, dissolving in water, depositing to obtain magnesium hydroxide, controlling acidity and temp. filtering to remove impurities, cooling crystallizing to obtain magnesium sulfate heptahydrate, diluting the mother liquid, preparing alkaline magnetic carbonate by ammonium hydrogen carbonate method, and sulfuric acid absorption to residual ammonia water to obtain ammonium sulfate as by-product. Its advantage is no generation of gas and liquid pollutants.

Owner:TSINGHUA UNIV

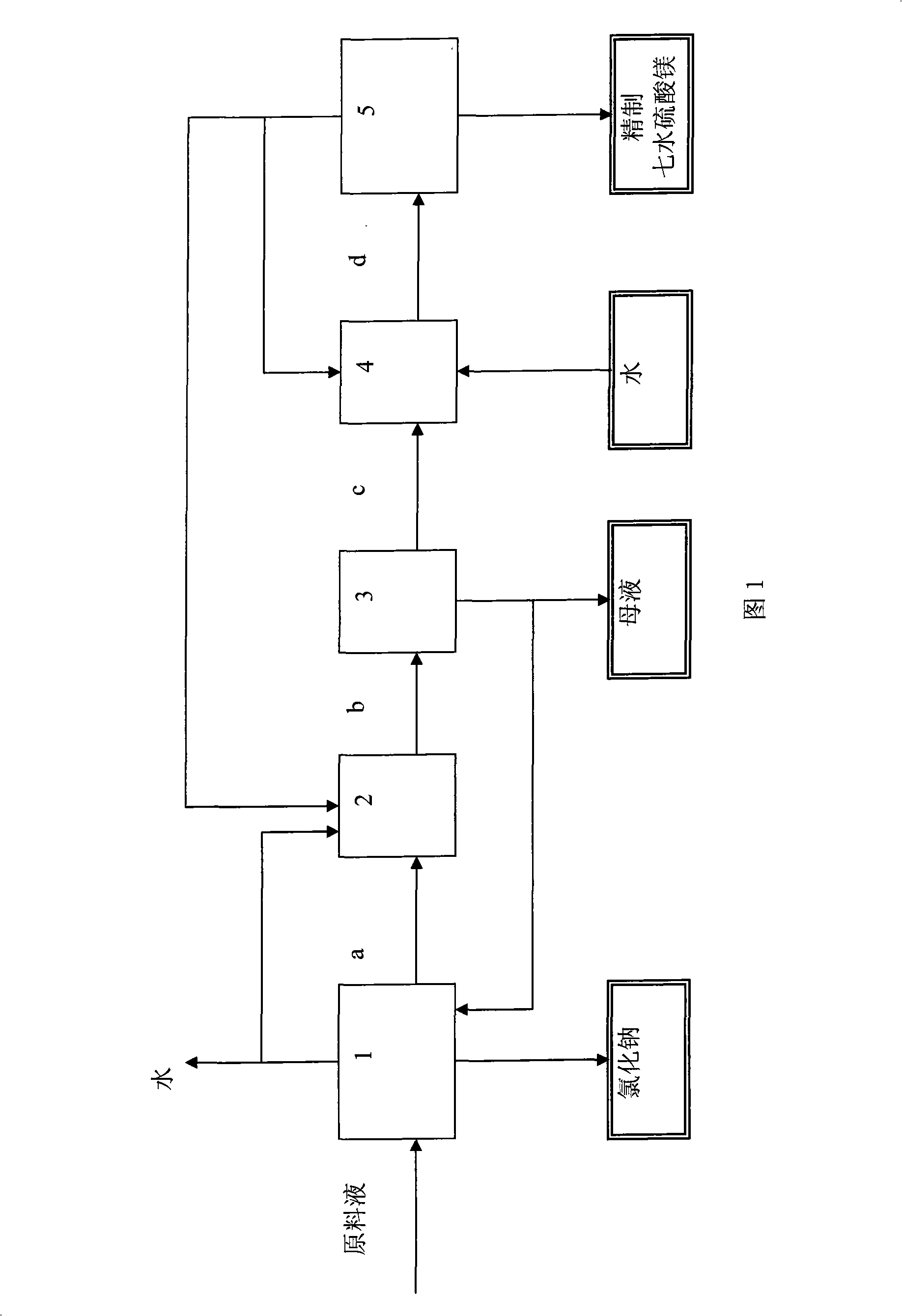

Method for preparing sodium chloride and magnesium sulphate heptahydrate with brine

InactiveCN101343071ASufficient precipitationHigh purityMagnesium sulfatesAlkali metal chloridesBoiling pointAqueous solution

The invention discloses a method for using brine to produce sodium chloride and heptahydrate magnesium sulfate, comprising the steps that: (1) brine is taken as a raw material, the molar ratio of SO4<2->:Mg<2+> in the brine is 0.1-0.8, and the molar ratio of SO4<2->:Na<+> is 0.025-1; and the pressure is decreased for boiling evaporation, the pressure is controlled to make the boiling temperature be 75 DEG C to 50 DEG C after the evaporation, and the molar ratio of SO4<2>:Na<+> in the solution is 0.4-2.5; (2) solid-liquid separation is implemented, and the solid phase is washed with saturated sodium chloride aqueous solution and is then dried for obtaining the sodium chloride; (3) a mother liquid of salt production is added with water to prepare a mixture; (4) the mixture is cooled and guided into a crystallizer, then crystals are separated out; and (5) solid-liquid separation is carried out for obtaining a crude product having a solid phase of heptahydrate magnesium sulfate. The method has advantages of simple equipment, simple process, complete separation of sodium chloride, high purity and yield of heptahydrate magnesium sulfate, having no miscellaneous salt removing link in the process, and realizable joint production of sodium chloride and heptahydrate magnesium sulfate.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

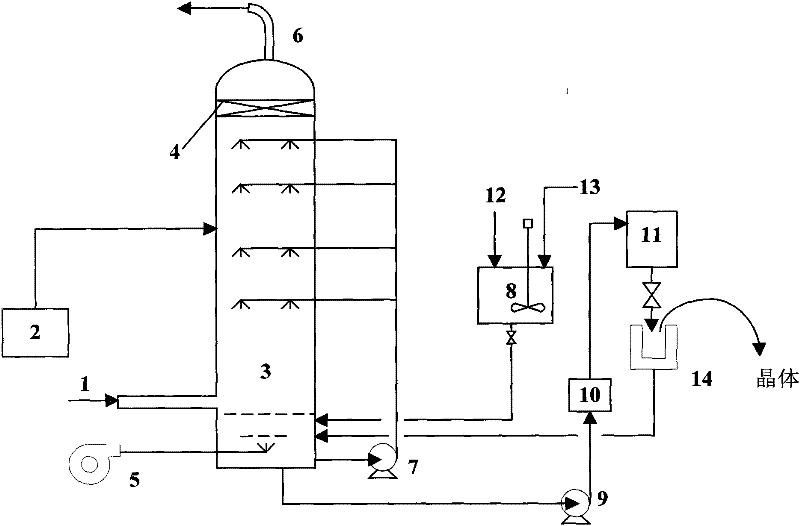

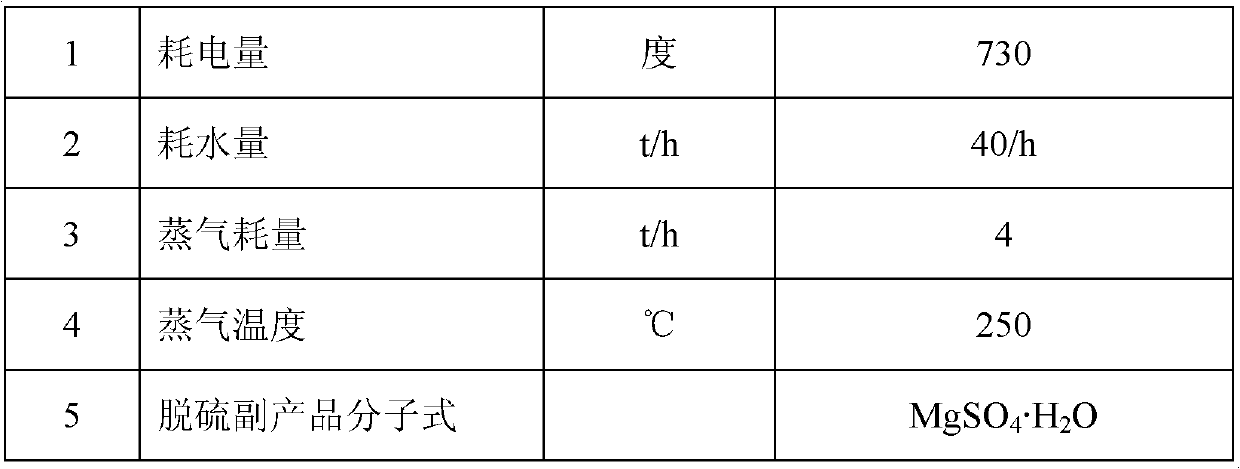

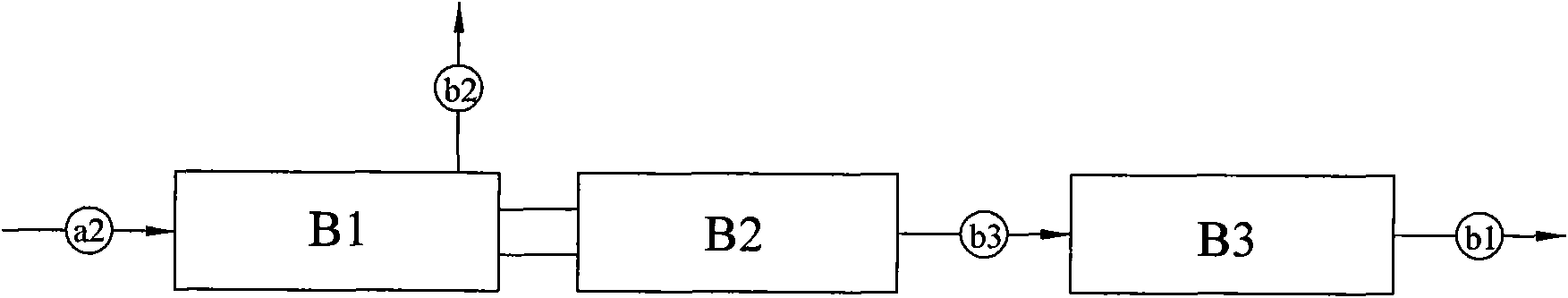

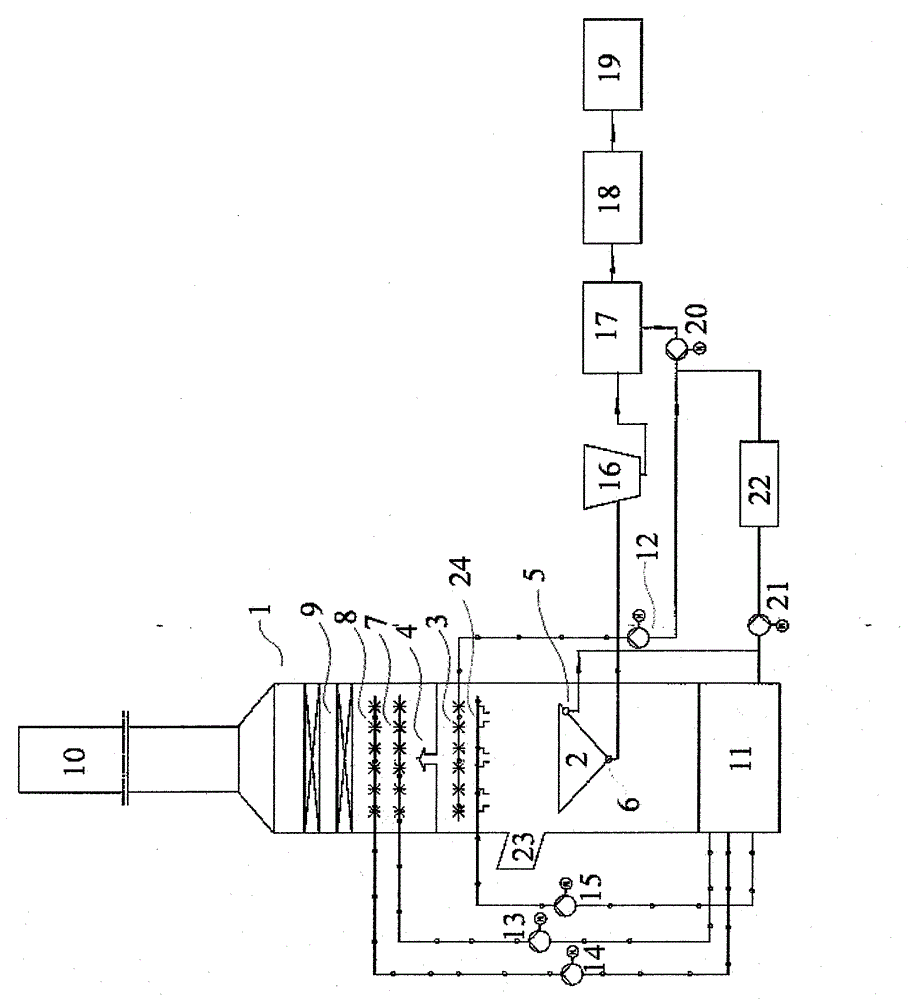

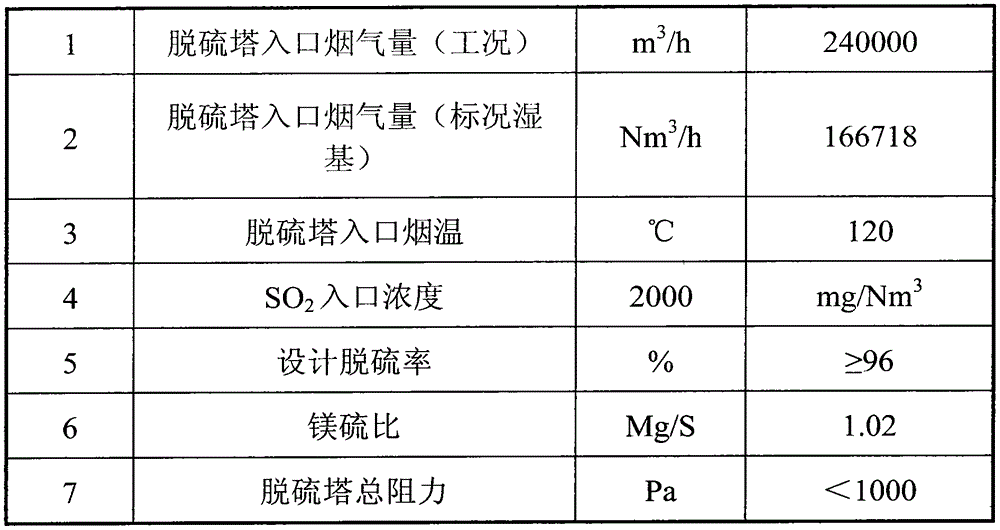

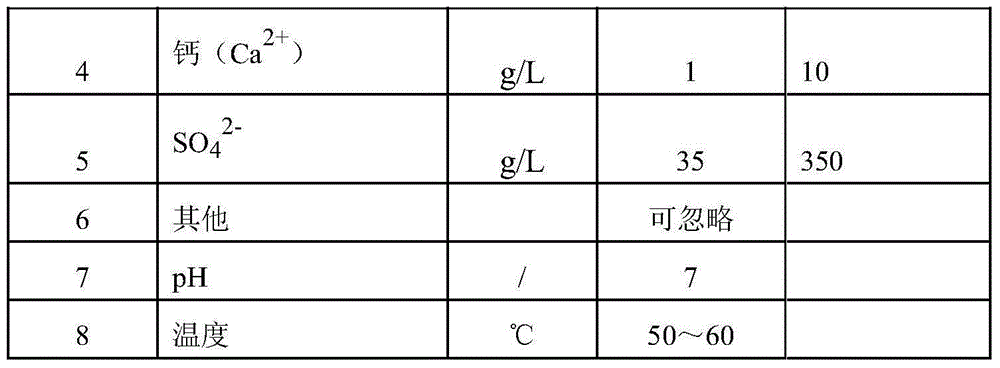

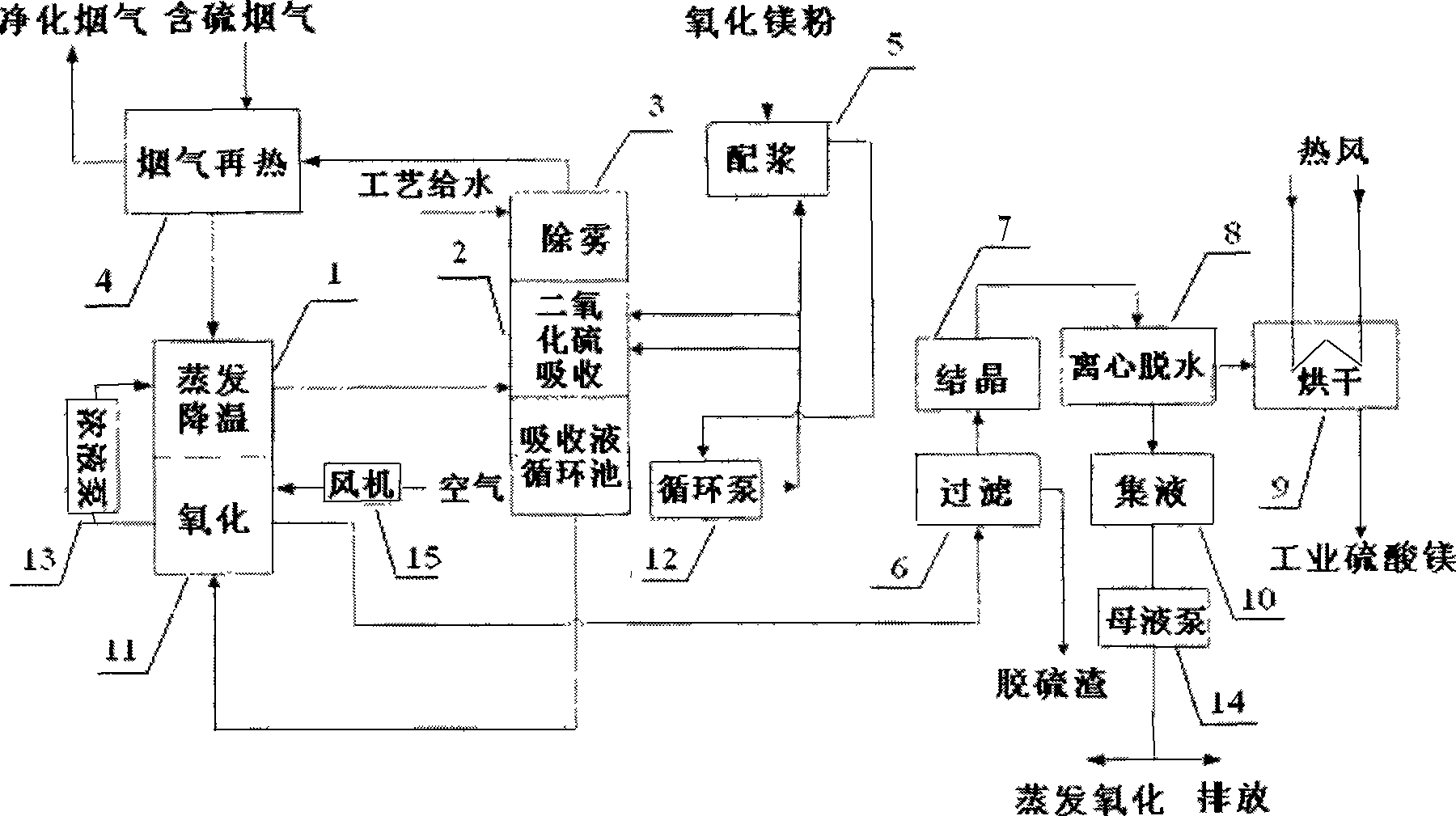

Magnesium sulfate production device and method by flue gas desulfurization

The invention a magnesium sulfate production device and method by flue gas desulfurization, particularly a device and method for producing magnesium sulfate by direct crystallization in a magnesium-oxide-process desulfurization waste liquid tower. The device comprises a flue gas desulfurization apparatus, a slurry circulating tank, an evaporative concentration region, a circulating settling apparatus, a crystallizing apparatus, a centrifugal apparatus, a drying apparatus and the like. The device and method provided by the invention can solve the problems of high steam consumption, higher production cost per ton of ores, and higher desulfurization operating cost when the magnesium-process desulfurization waste liquid is used for producing magnesium sulfate at present.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277-1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336-1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

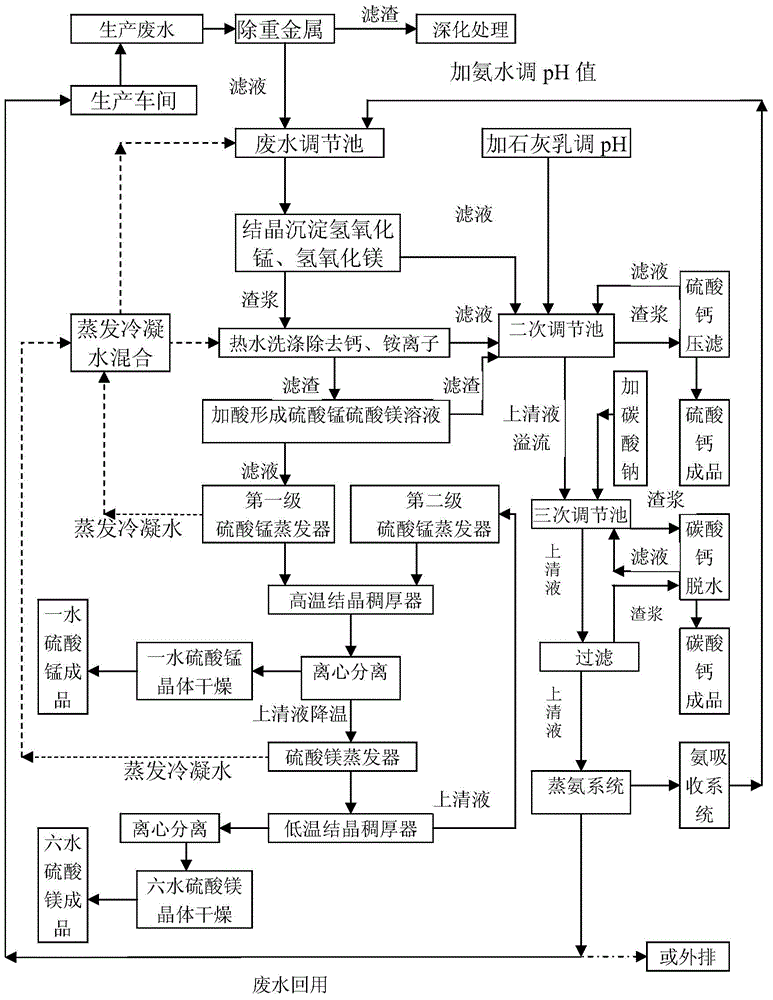

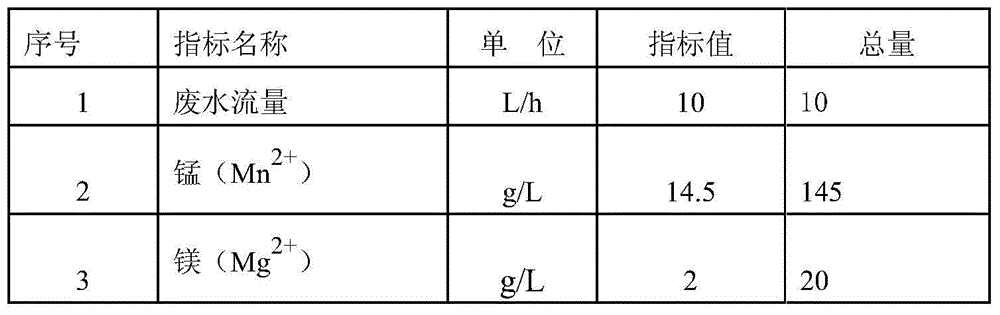

Comprehensive utilization method for separating, concentrating and purifying manganese sulfate, magnesium sulfate and calcium sulfate in high-salt waste water

ActiveCN103553138AAchieving circular economy goalsImprove energy savingCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesSulfateEvaporation

The invention relates to a comprehensive utilization method for separating, concentrating and purifying manganese sulfate, magnesium sulfate and calcium sulfate in high-salt waste water. The method is characterized by comprising the following steps of maintaining the temperature of mother liquor of waste water at 50DEG C to 60DEG C, utilizing ammonia water or liquid ammonia to adjust the pH value of the waste water to 10 to 1.5, collecting separating manganese ions and magnesium ions in the waste water in a form of manganese hydroxide and magnesium hydroxide, adding sulfuric acid into the separated manganese hydroxide and magnesium hydroxide to prepare a manganese sulfate solution and a magnesium sulfate solution, and adopting a segmented evaporation crystallization method to realize the separation to produce manganese sulfate monohydrate and magnesium sulfate hexahydrate; adding lime milk into the waste water after the manganese hydroxide and magnesium hydroxide are separated to adjust the pH value, crystallizing calcium sulfate, precipitating the calcium sulfate, and press filtering the calcium sulfate to produce calcium sulphate dehydrate. After being treated by utilizing the method, the waste water can reach the emission standard and can be externally discharged or recycled by the enterprise, and solid wastes in the waste water can be completely recycled. The investment is low, and the annual net investment return rate is more than 15 percent.

Owner:中诚和易(北京)国际科技有限公司

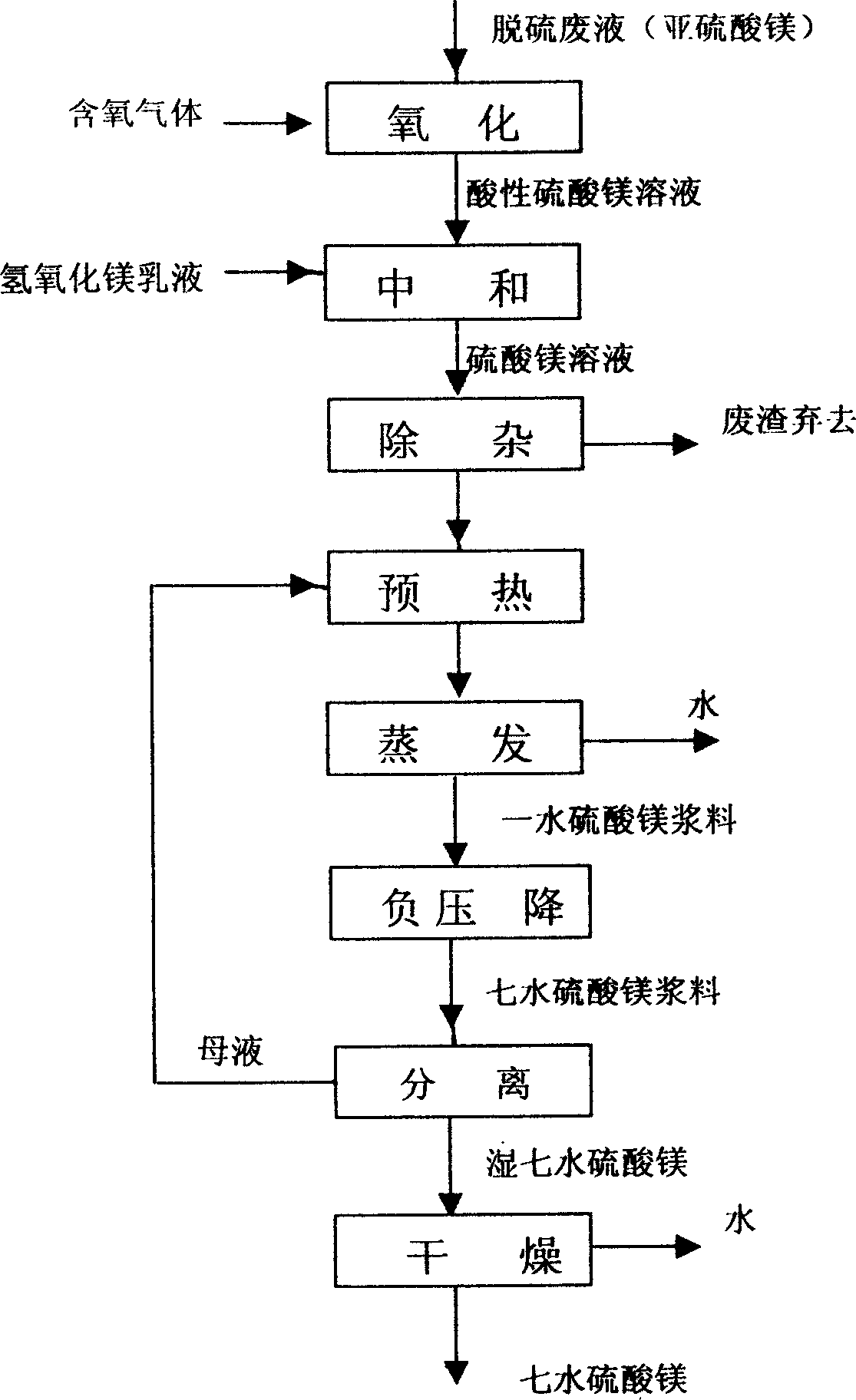

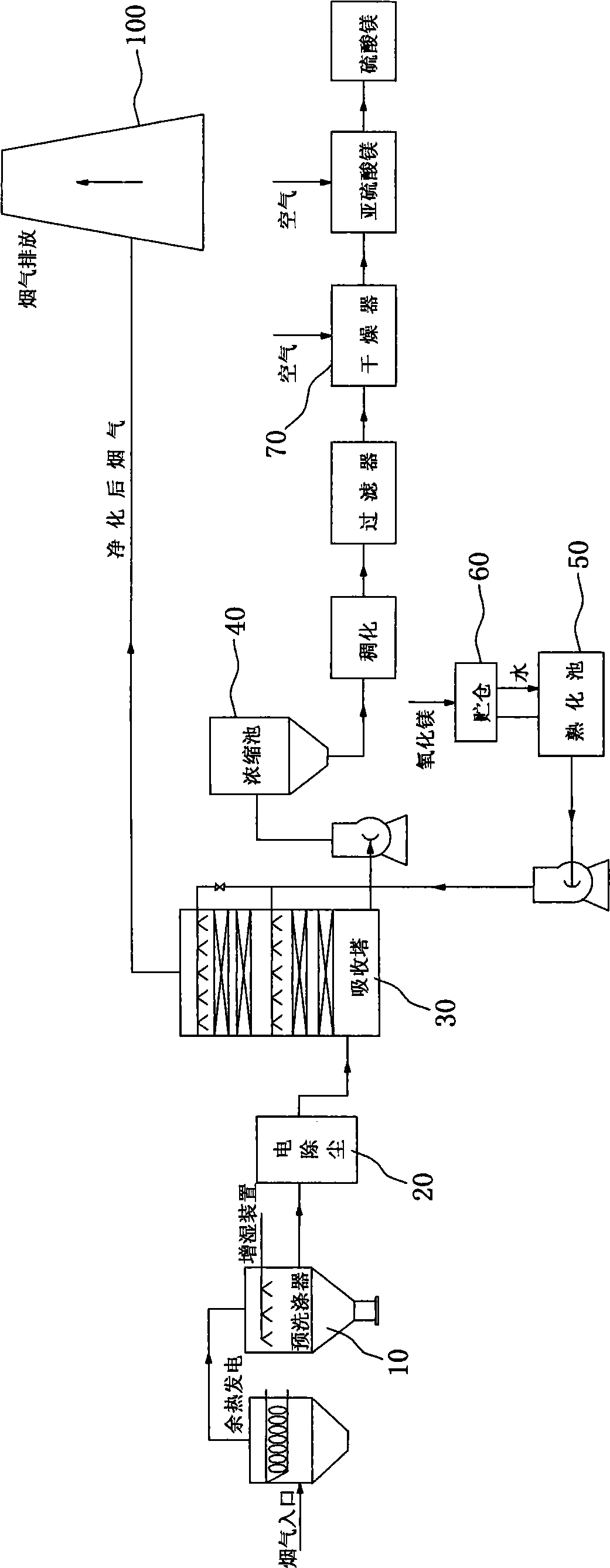

Flue gas desulfurization by magnesia wet method and recovering process of automatic concentration of product

ActiveCN101530725AAvoid intensive external energy consumptionAvoid external energy consumptionDispersed particle separationMagnesium sulfatesFiltrationSlurry

Flue gas desulfurization by the magnesia wet method and a recovering process of automatic concentration of the product relates to the improvement of the existing flue gas desulfurization by the magnesia wet method and product recovering process by the thick slurry process, belonging to the technical field of flue gas desulfurization and product recycling. The process is technically characterized in that the thick slurry is shunted in the process of recyclable absorption and desulfurization; spray cooling is carried out to cool flue gas; inspissation liquid is oxidized to generate MgSO4; then filtration, crystallize and the like are carried out to generate mm level MgSO4. 7H2O or MgSO4. H2O crystal grain. The invention not only features in low cost, but also has low spray flow rate and power consumption as well as outstanding water conservation effect; what is more, the invention avoids external power consumption of the concentration of the desulfurized product, can remarkably improve stability and economical efficiency of recovery. All steps of automatic concentration are linked with one and another, as a result, the application range of the invention is expanded to high-sulphur coal and technical support is provided for more economical, effective and direct recovery of magnesium sulfate monohydrate.

Owner:TSINGHUA UNIV

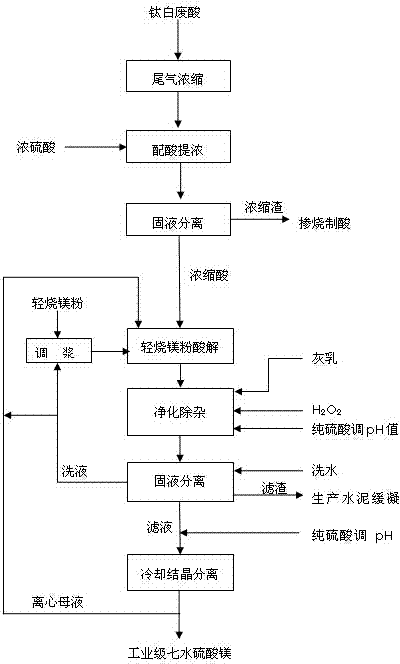

Method for producing industrial-grade magnesium sulfate by using titanium white waste acid

ActiveCN104118893AReduce processing difficultyInhibitory concentrationMagnesium sulfatesFerrous sulfate ironSulfate

The invention relates to a method for producing industrial-grade magnesium sulfate by using titanium white waste acid. According to the method, the titanium white waste acid is purified by using a manner of preparing acid and concentrating, so that the influence of salts such as ferrous sulfate in the titanium white waste acid on preparation of industrial-grade magnesium sulfate heptahydrate is reduced; purified and concentrated acid reacts with caustic-burned magnesia powder; the purification treatment is carried out by adjusting pH value by using acetylene sludge or lime milk; impurities in the magnesium sulfate can be effectively removed by using a manner of oxidizing by using hydrogen peroxide and re-adjusting the pH value by using pure sulfuric acid under alkaline conditions; the titanium white waste acid is used for preparing acid and concentrating so as to react with the caustic-burned magnesia powder, so that the concentration process for preparing magnesium sulfate by using titanium white waste acid is cancelled, the application range of the titanium white waste acid is expanded; and the method for producing industrial-grade magnesium sulfate by using titanium white waste acid is simple in production process, small in investment, low in cost, high in yield and high in product purity. The overall process is free of waste and byproduct, remarkable in social benefit and great in economic benefit.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

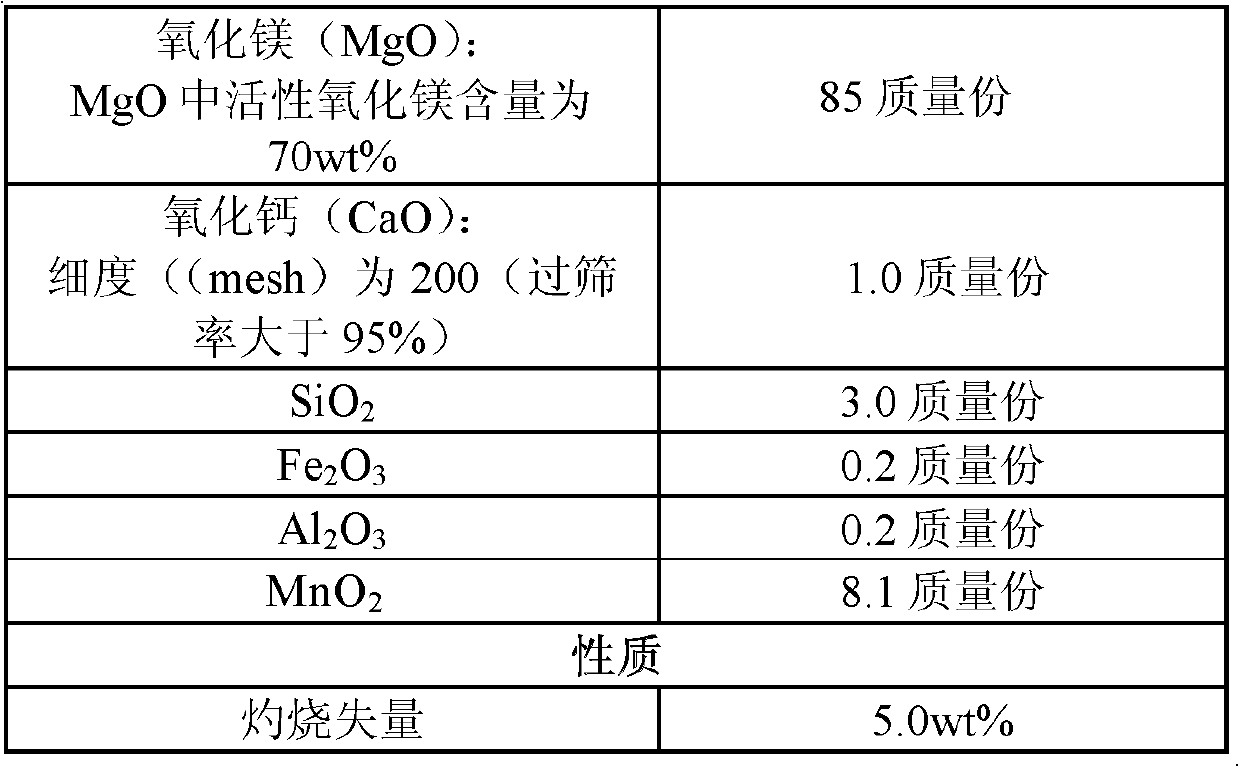

Method for preparing magnesium sulfate and magnesium silico calcium sulfur fertilizer by utilizing alkylated waste sulfuric acid

The invention discloses a method for preparing magnesium sulfate and a magnesium silico calcium sulfur fertilizer by utilizing alkylated waste sulfuric acid. The method comprises the steps of consuming sulfuric acid by producing magnesium sulfate, adsorbing and separating acid-soluble oil waste residues by virtue of suspended matters of silicon, calcium and the like in a mineral powder, calcining the waste residues by virtue of an external heat source with the assistance of the heat of oil-containing residues and the heat of waste activated carbon, carbonizing an organic matter, and preparing the fertilizer containing magnesium silico calcium sulfur. The method has the beneficial effects that the method is simple in process and easy to operate, is easy to implement, is little in equipment investment, is low in the cost, is large in the market need for the magnesium silico calcium sulfur fertilizer as a by-product and is remarkable in the economic and social benefits without secondary pollution. With the adoption of the method, all resources are used in an optimization way, so that the method is an ideal process for treating the alkylated waste sulfuric acid with low cost.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

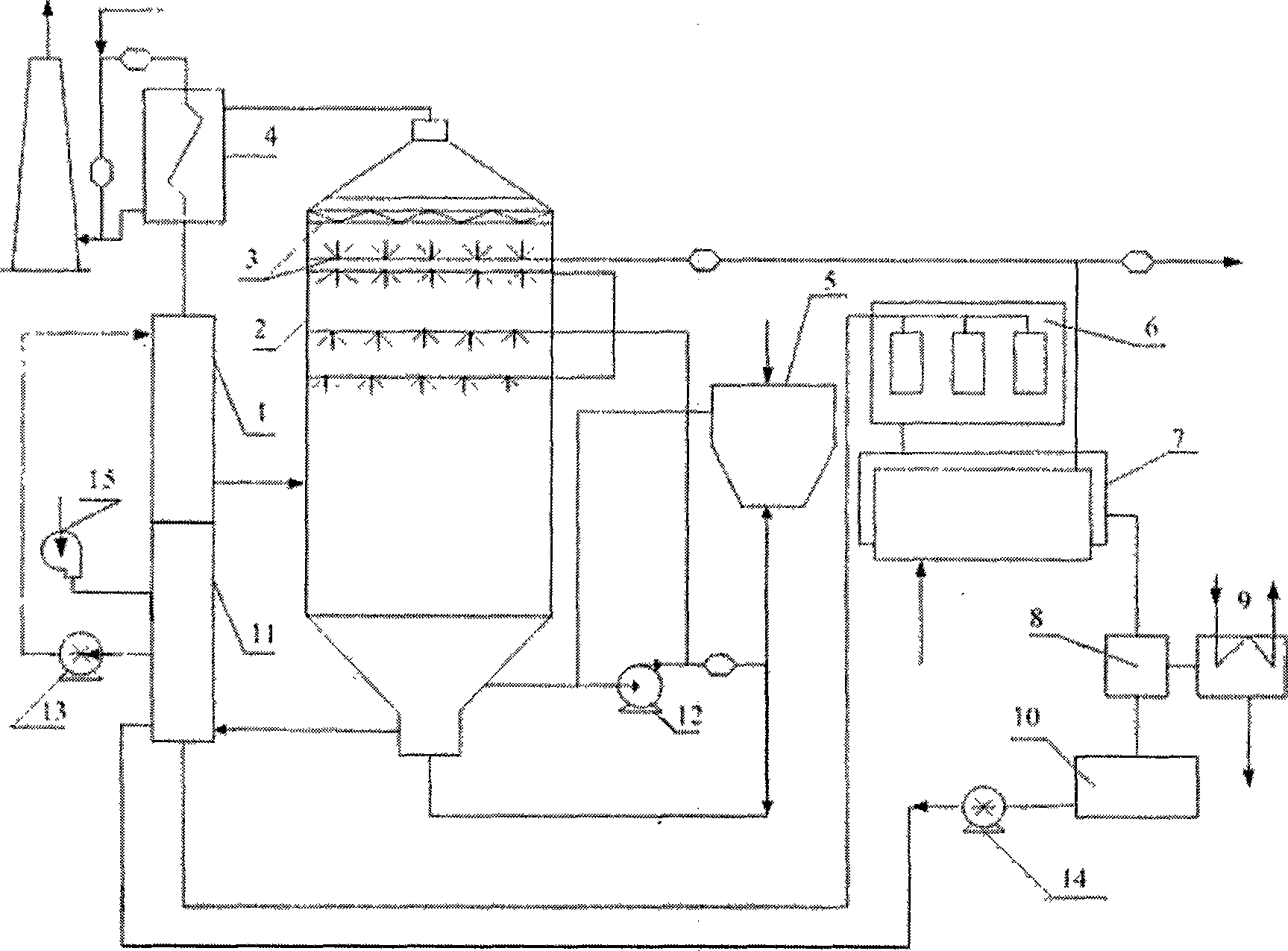

Device and method for producing magnesium sulfate by using flue gas of coal-fired boiler

ActiveCN104477952AReduce power consumptionReduce consumptionGas treatmentMagnesium sulfitesEvaporationSlurry

The invention provides a device and a method for producing magnesium sulfate by using flue gas of a coal-fired boiler, and particularly provides a device and a method for producing the magnesium sulfate by direct crystallization in a magnesium oxide-process waste desulfurization liquid tower by using the flue gas, low in oxygen content, of the coal-fired boiler. The device comprises oxygenation equipment, flue gas desulfurization equipment, slurry circulating equipment, evaporation and concentration equipment, cyclic sedimentation equipment, oxidization equipment, crystallization equipment, centrifugation equipment, drying equipment and the like. By adopting the device and the method disclosed by the invention, the desulfurization efficiency and the quality of a side product magnesium sulfate can be guaranteed under a condition that the wind power consumption and steam consumption of an oxidization fan are greatly reduced, the operating cost of a magnesium sulfate production system is greatly lowered, and the desulfurization operation cost is lowered.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

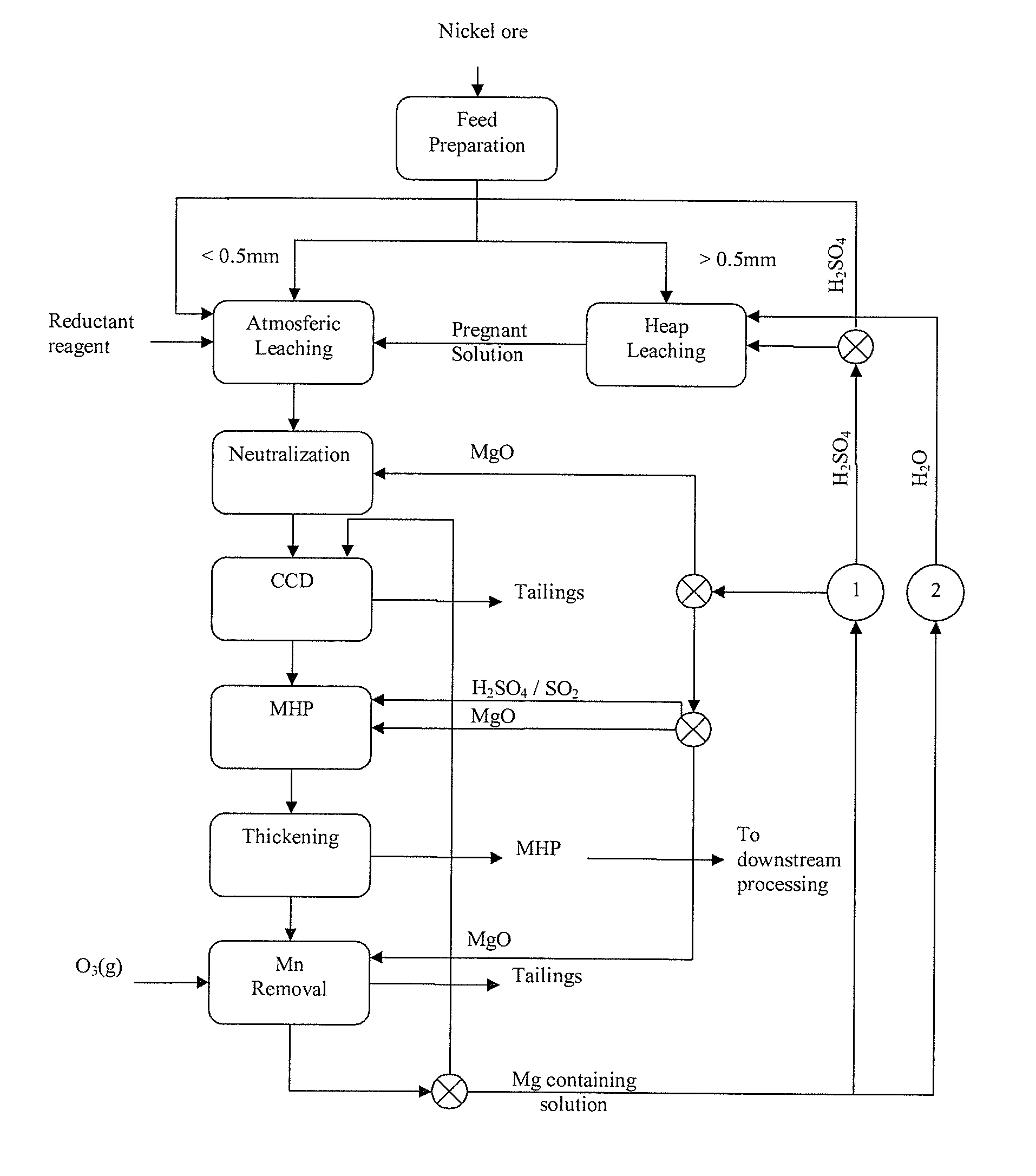

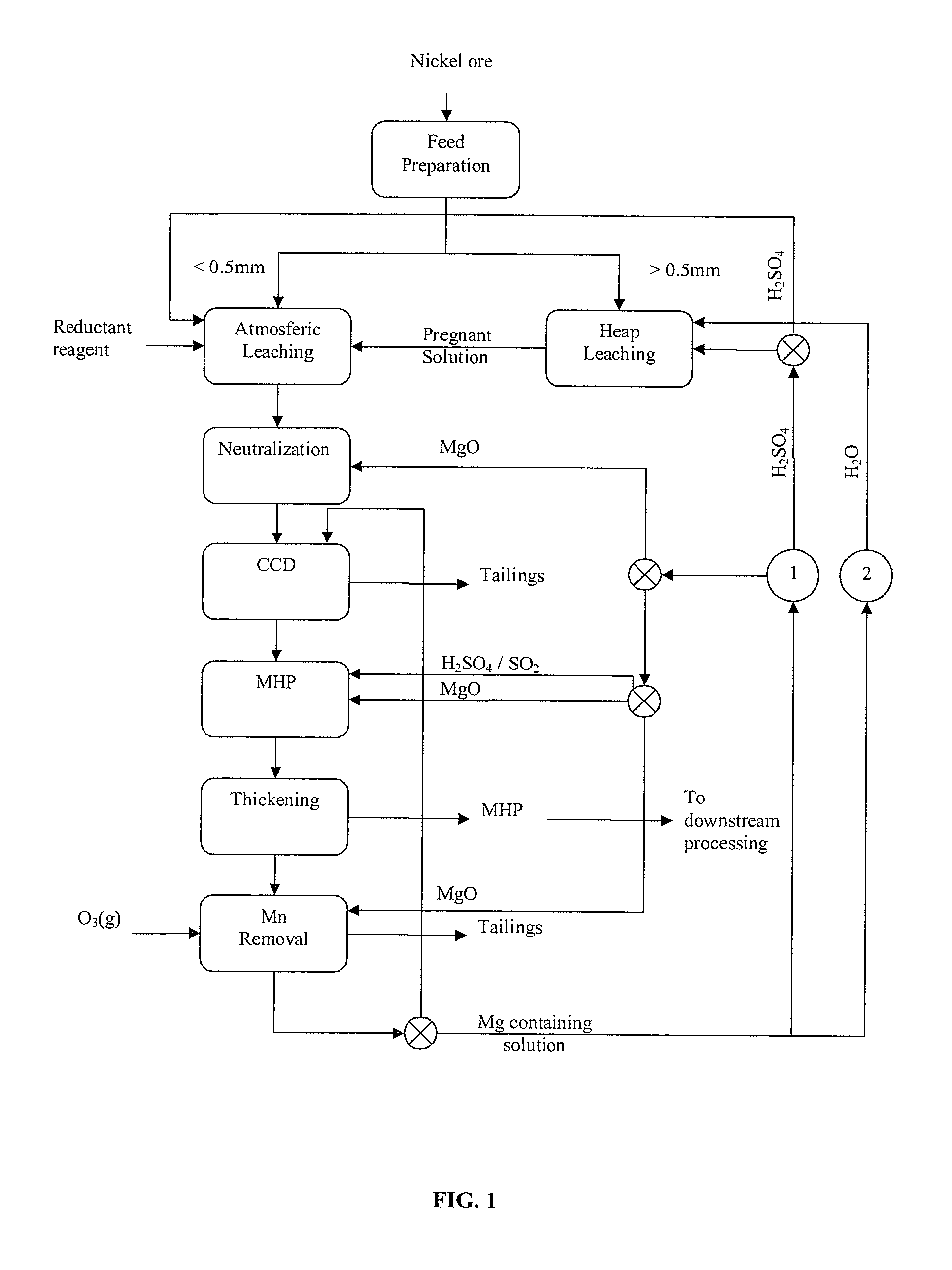

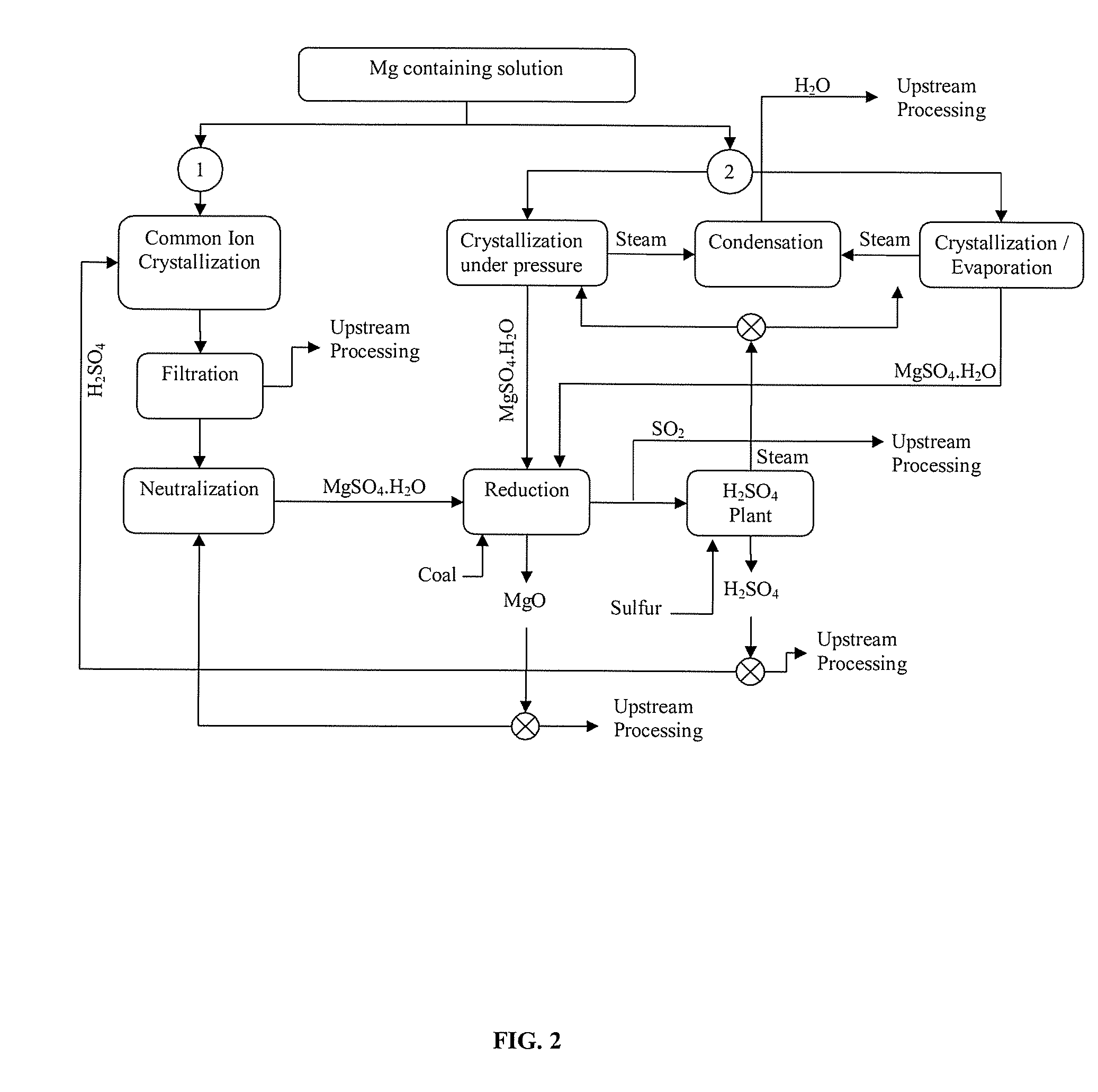

Magnesium recycling and sulphur recovery in leaching of lateritic nickel ores

ActiveUS20110110832A1Simplified logisticsReduce the amount requiredCalcium/strontium/barium sulfatesMagnesium sulfatesHigh magnesiumSulfur

The present invention resides in a process of recovering nickel and cobalt, regenerating the main raw materials, said process including the steps of: granulometric separation; leaching; neutralization; MHP production in only one stage and the pressure crystallization of magnesium sulphite.The process proposes a way to recovery nickel and cobalt from laterite ores through the atmospheric and heap leaching with staged addition of ore—by size separation—and H2SO4, decreasing the nickel losses and simplifying the neutralization circuit and producing a more purified MHP.The present process route is employed for nickel extraction, including the one from high magnesium containing lateritic ores.

Owner:VALE LIMITED

Stabilizing agent for peroxide-bleaching procedure and methods of bleaching a fiber material by using same

InactiveUS6120556AImprove bleaching effectImprove efficiencyOrganic/inorganic per-compounds compounding agentsBleaching apparatusFiberBleach

A stabilizing agent for peroxide-bleaching procedure includes (A) a component including a homopolymer or copolymer of alpha -hydroxyacrylic acid or water soluble salt or polylactone of the homo- or co-polymer, (B) a component including a homopolymer or copolymer of acrylic acid, methacrylic acid and / or maleic acid and water-soluble salt of the homo- or co-polymer, (C) a component including DTPA, TTHA or water-soluble salt thereof and optionally (D) a component including a water-soluble inorganic Mg salt and is used to pretreat a fiber material with a pretreating liquid containing the stabilizing agent before bleaching with peroxide, or to bleach the fiber material by a bleaching liquid containing a peroxide bleaching agent and the stabilizing agent.

Owner:NIPPON PEROXIDE

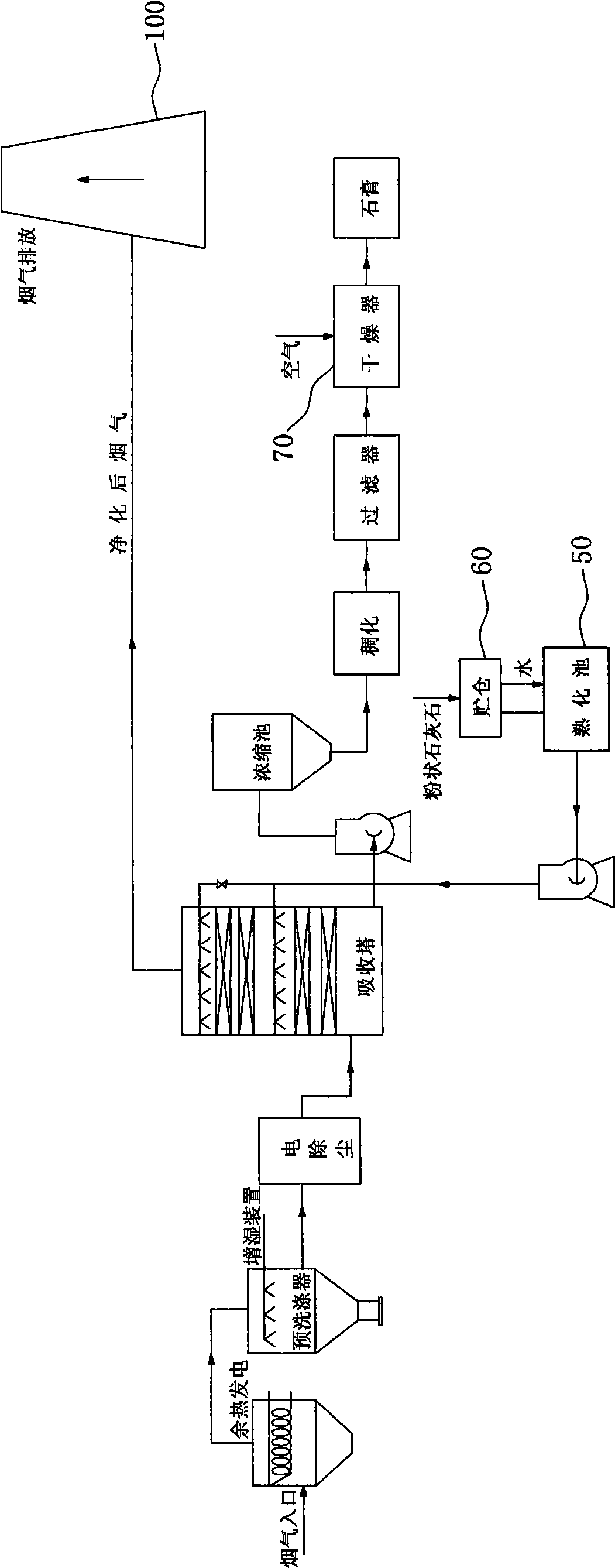

Large flue gas desulfurization dust-removal system

The invention relates to a boiler flue gas desulfurization and dust removal system and energy-saving comprehensive utilization technology, which avoid secondary pollution and resource waste. The boiler flue gas desulfurization and dust removal system comprises a pre-washer for reducing the temperature and increasing the humidity for flue gas, wherein the flue gas after pretreatment and fly ash removal enters an absorption tower, and contacts circulatory serum in the absorption tower, and SO2 in the flue gas reacts with an absorbent so as to be removed from the flue gas; and the flue gas after desulfurization is exhausted out from an exhaust pipe. The SO2 in the flue gas treated by the system reacts with the absorbent so as to be removed from the flue gas; the partial serum can be recycled through aftertreatment; and the flue gas after desulfurization is exhausted out from the exhaust pipe and does not have harm to the environment.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Seawater desalination, resource comprehensive utilization and zero discharge processing system

InactiveCN103253818ASave energyCreate pollutionGeneral water supply conservationSeawater treatmentUF - UltrafiltrationSeawater

The invention discloses a seawater desalination, resource comprehensive utilization and zero discharge processing system. The system comprises an ultrafiltration (UF) system, a seawater reverse osmosis (SWRO) system, a deionized water processing system, namely an UPW system, a mechanical compression system capable of preventing scaling and a salt manufacturing and salt chemical engineering system, wherein the UF system is used for generating pure seawater; the SWRO system is used for generating desalted water and concentrated seawater; the concentrated seawater can be produced into calcium sulfate, sodium chloride, potassium chloride, magnesium sulfate, bromine, magnesium chloride and steam condensed water by virtue of the mechanical compression system and the salt manufacturing and salt chemical engineering system; and the steam condensed water and a part of desalted water flow into the UPW system to generate deionized water. According to the processing system, the relevant projects of seawater desalination, energy source utilization, industrial salt manufacturing and salt chemical engineering are organically combined, so that reasonable allocation and utilization of resources are realized, and the aims of energy conservation, emission reduction, circular economy and zero discharge are fulfilled.

Owner:金逹行有限公司

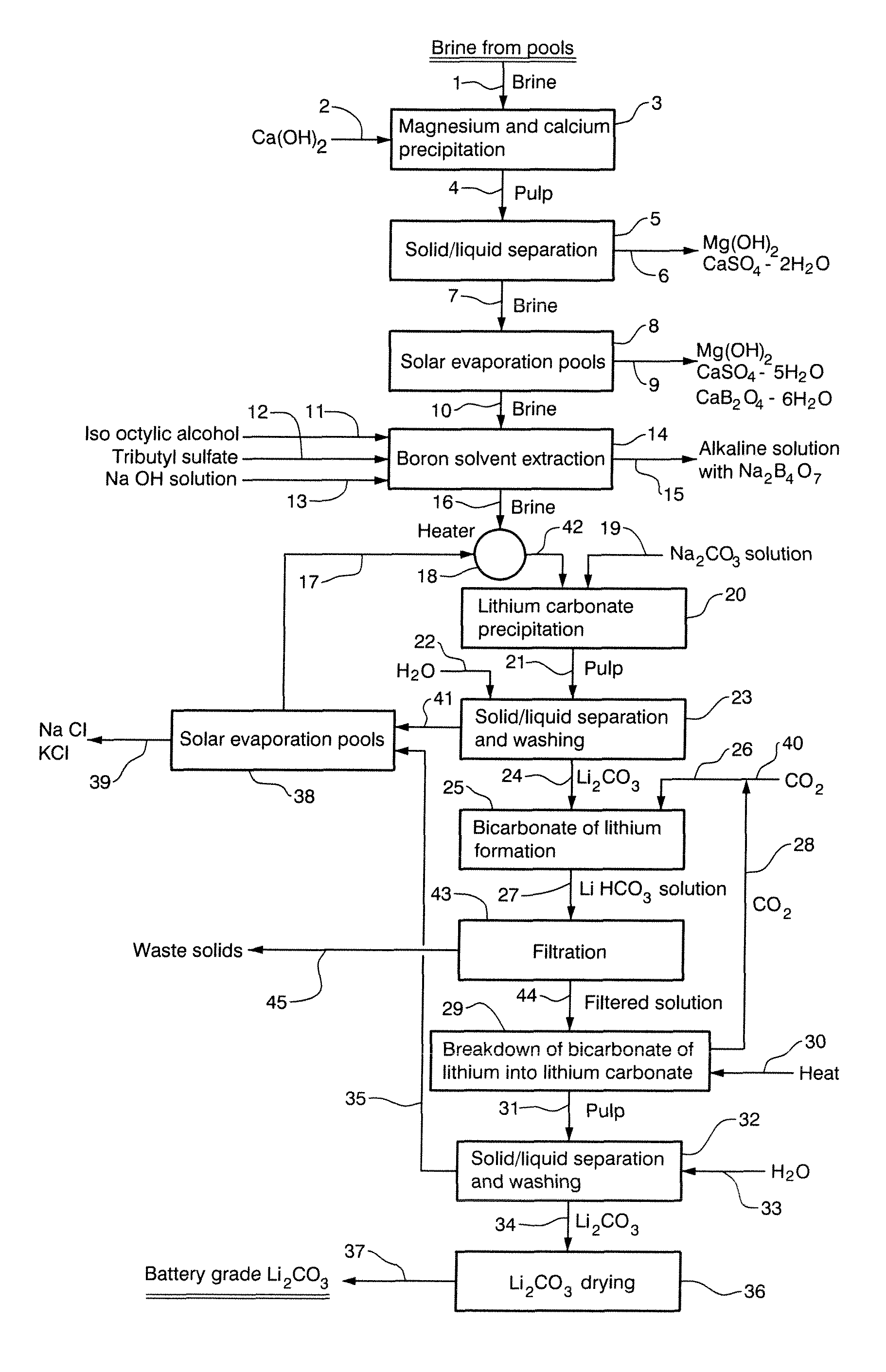

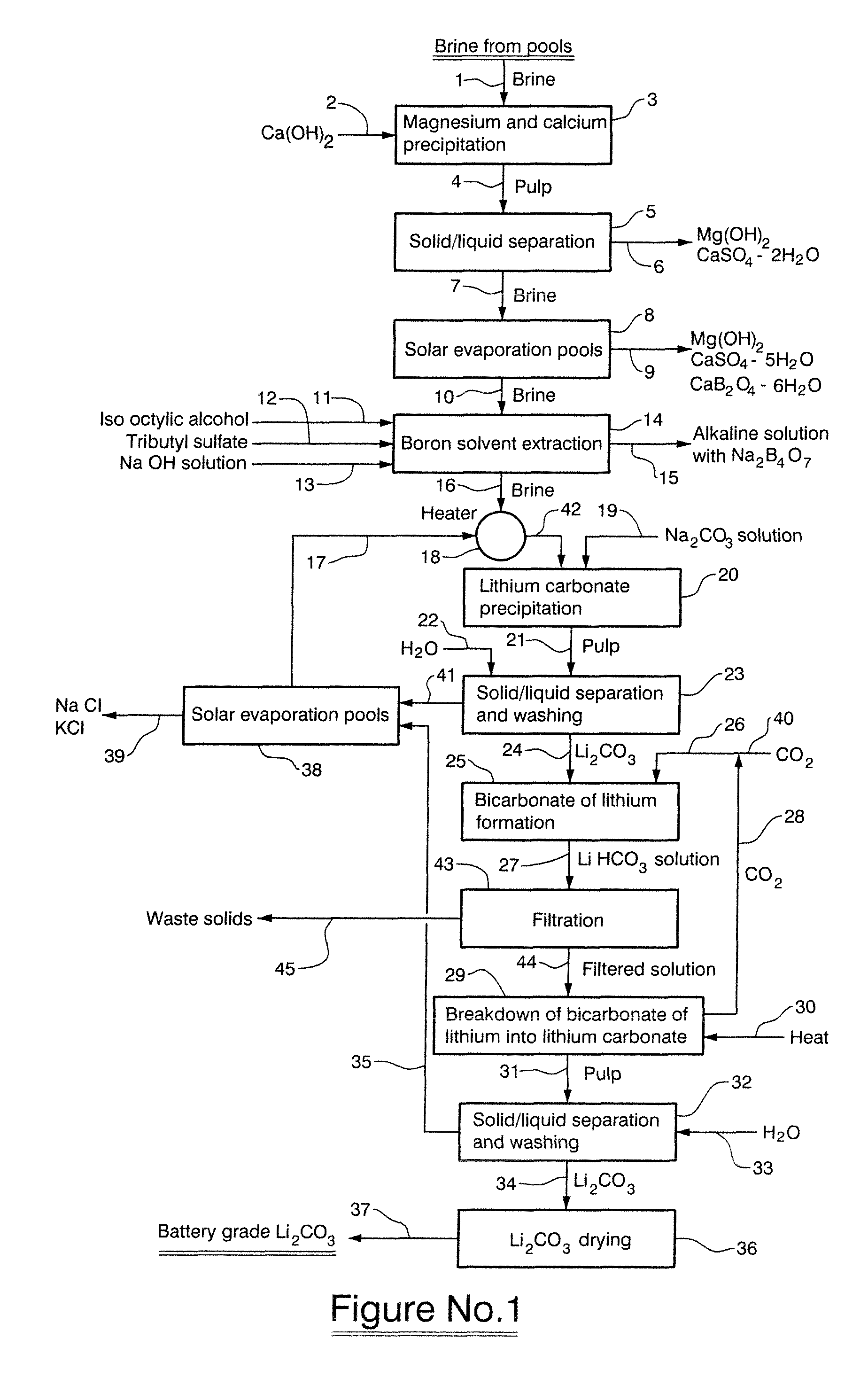

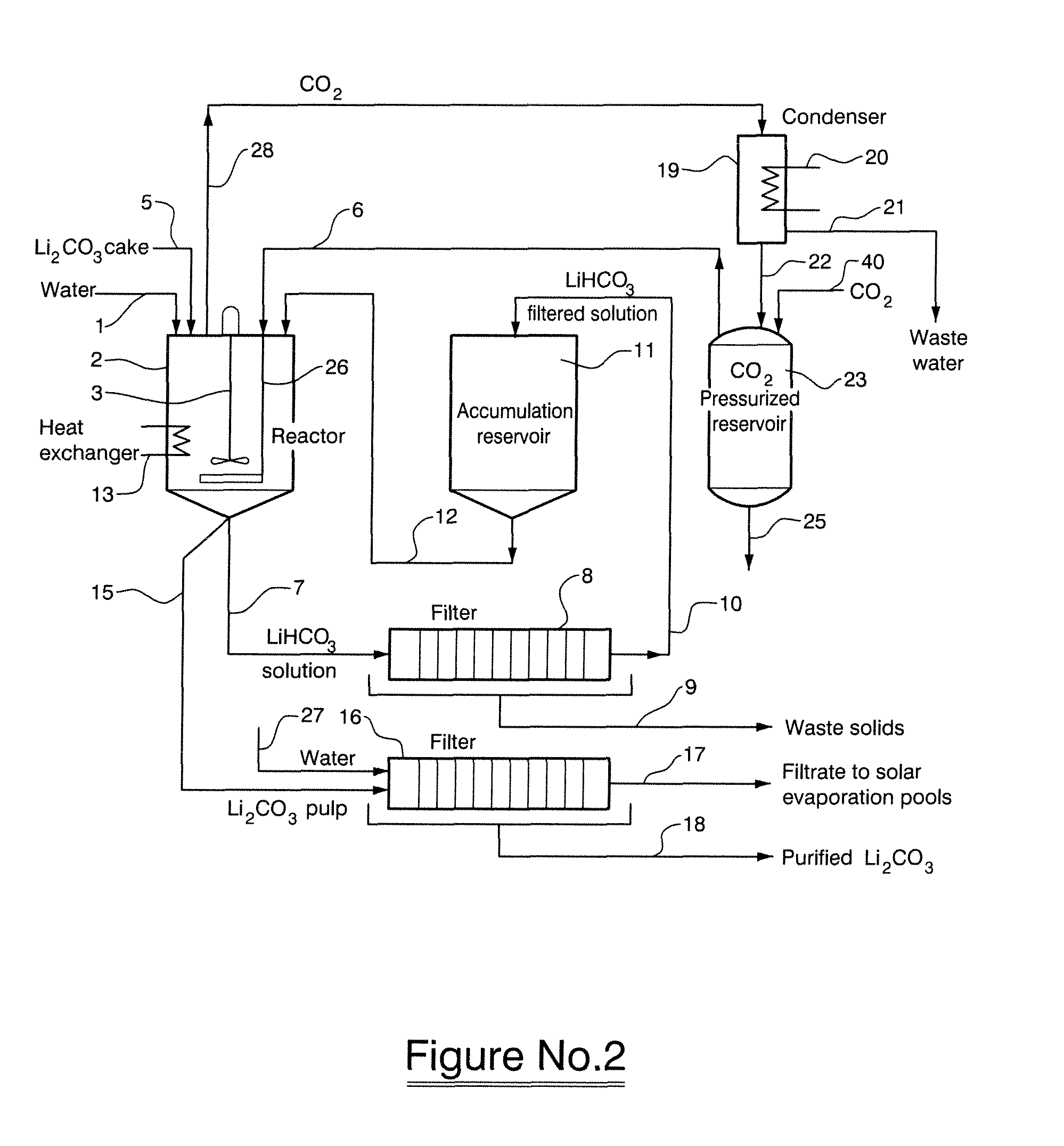

Method for the production of battery grade lithium carbonate from natural and industrial brines

InactiveUS8691169B2Avoid lostCalcium/strontium/barium sulfatesMagnesium sulfatesMetallic lithiumCalcium hydroxide

It is possible to produce battery grade metallic lithium from naturally occurring or industrial brine by a process comprising the following steps: (i) precipitating magnesium with calcium hydroxide; (ii) removal of boron via extraction of solvents; (iii) precipitation of lithium with sodium carbonate; (iv) transformation of lithium carbonate to bicarbonate of lithium with carbonic acid; (v) decomposition of bicarbonate of lithium into high purity lithium carbonate as a result of heating of the solution.Re-precipitation of lithium carbonate by the formation of bicarbonate of lithium allows for the removal of the majority of contaminants which co-purify with lithium carbonate and yield battery grade highly purified lithium carbonate.

Owner:MINERA EXAR

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com