Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1178results about "Alkali metal sulfites/sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

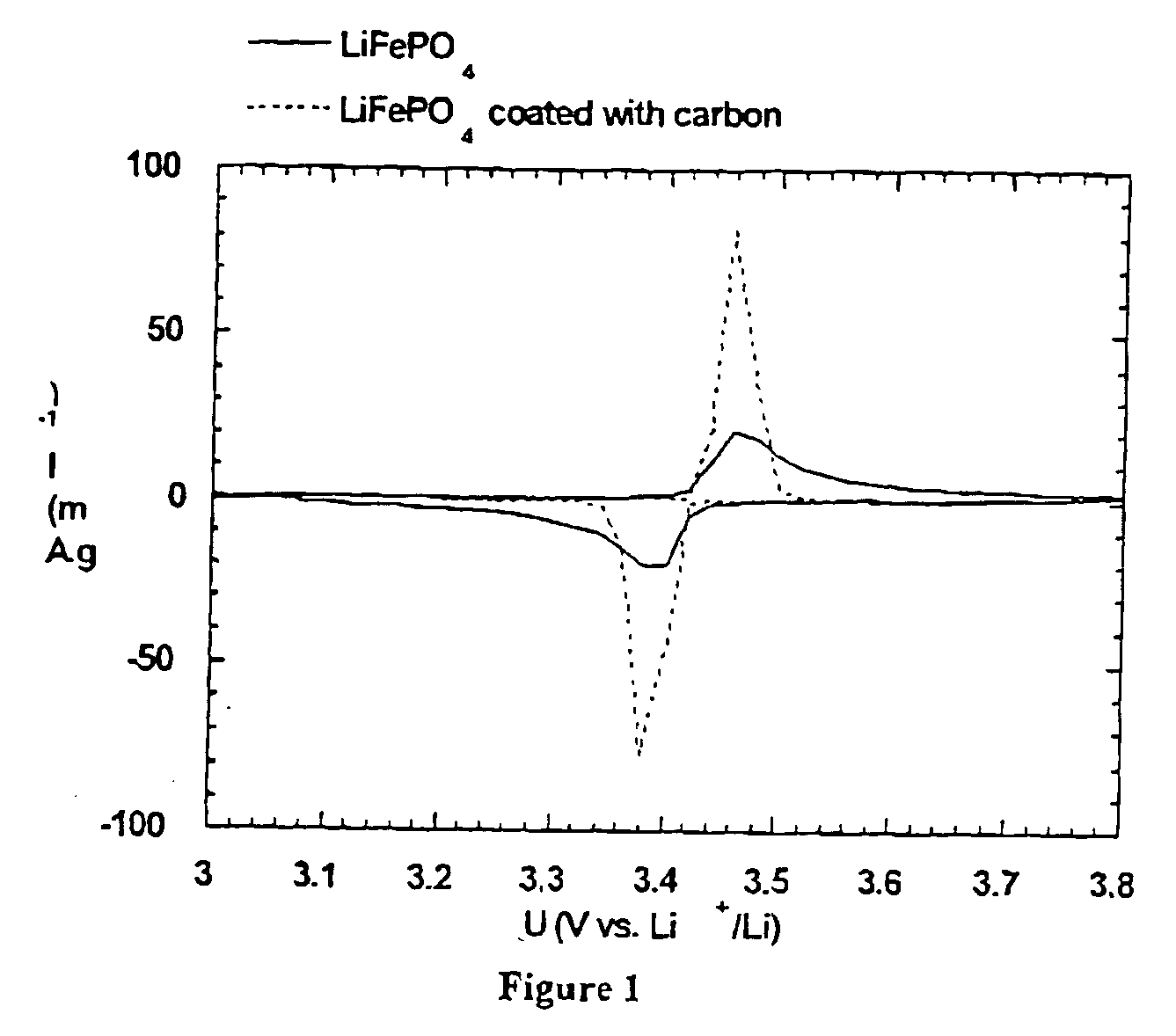

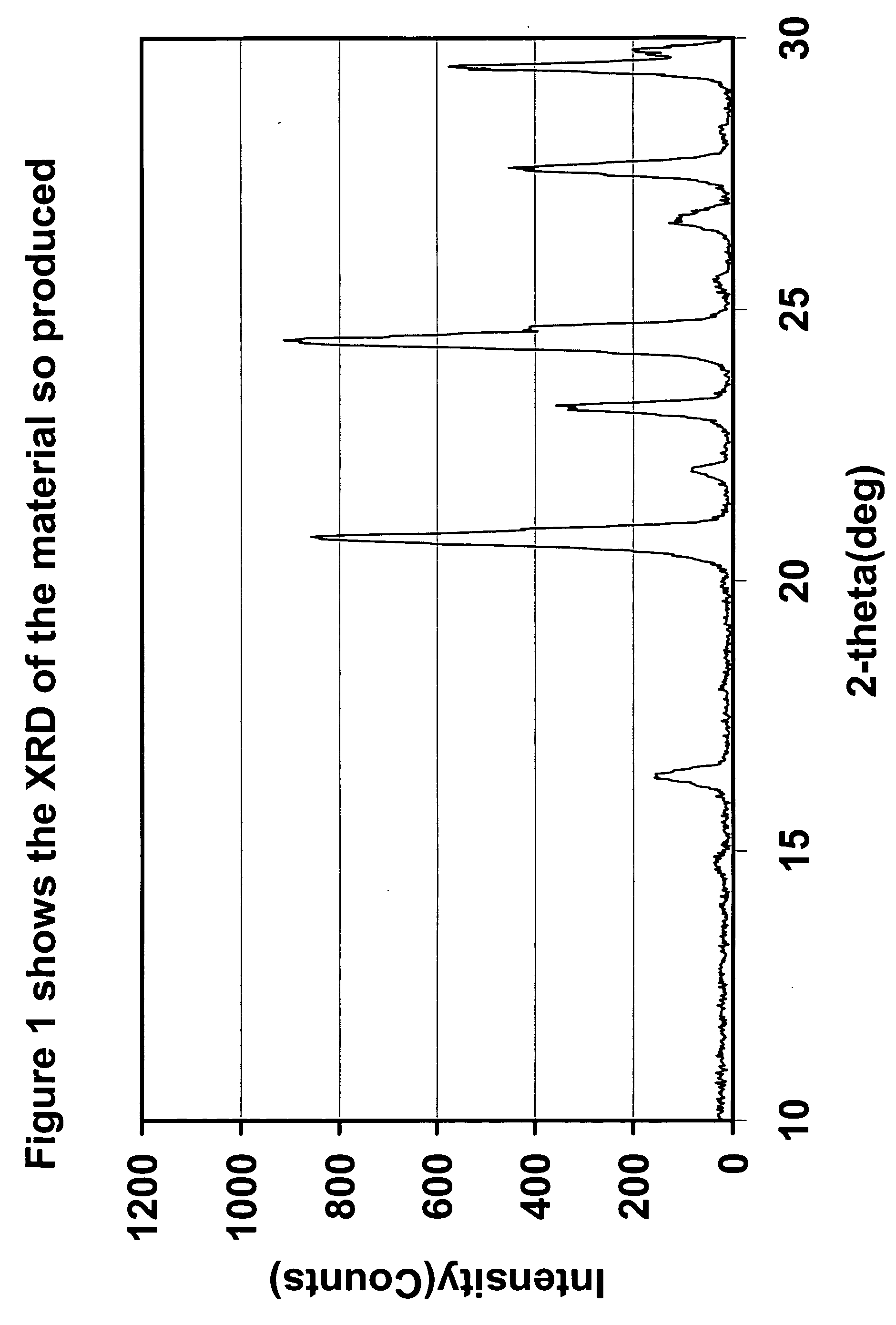

Method for synthesis of carbon-coated redox materials with controlled size

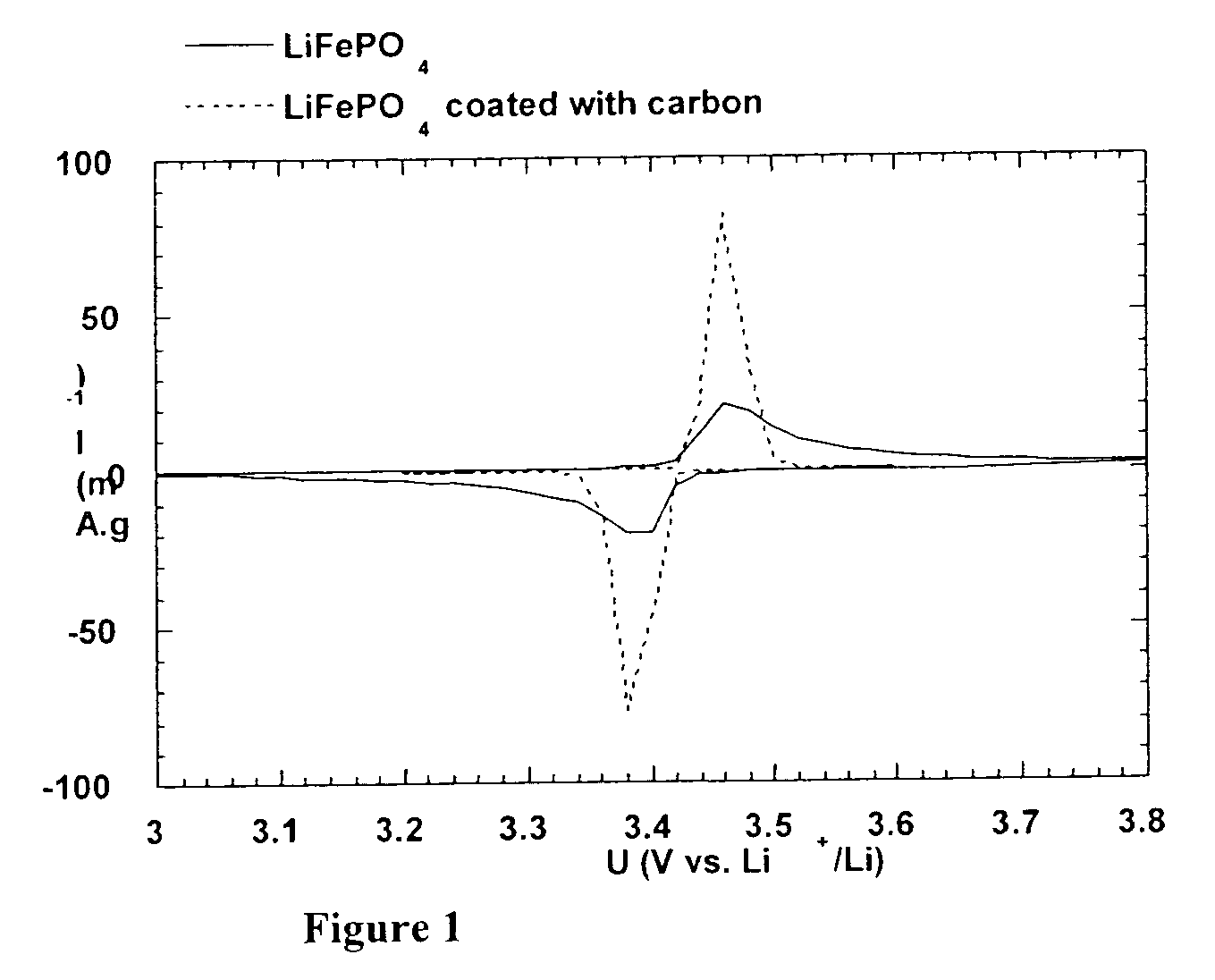

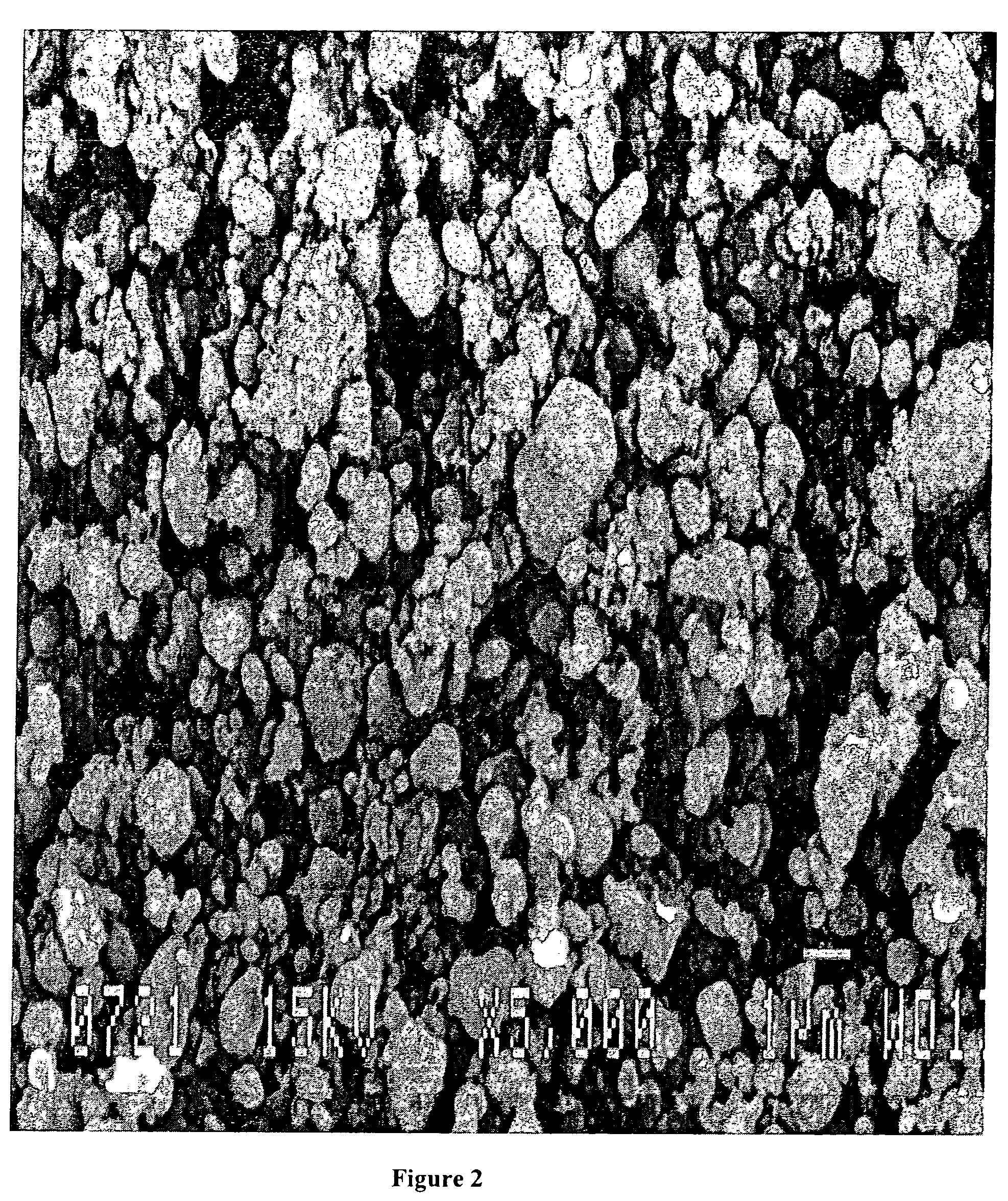

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

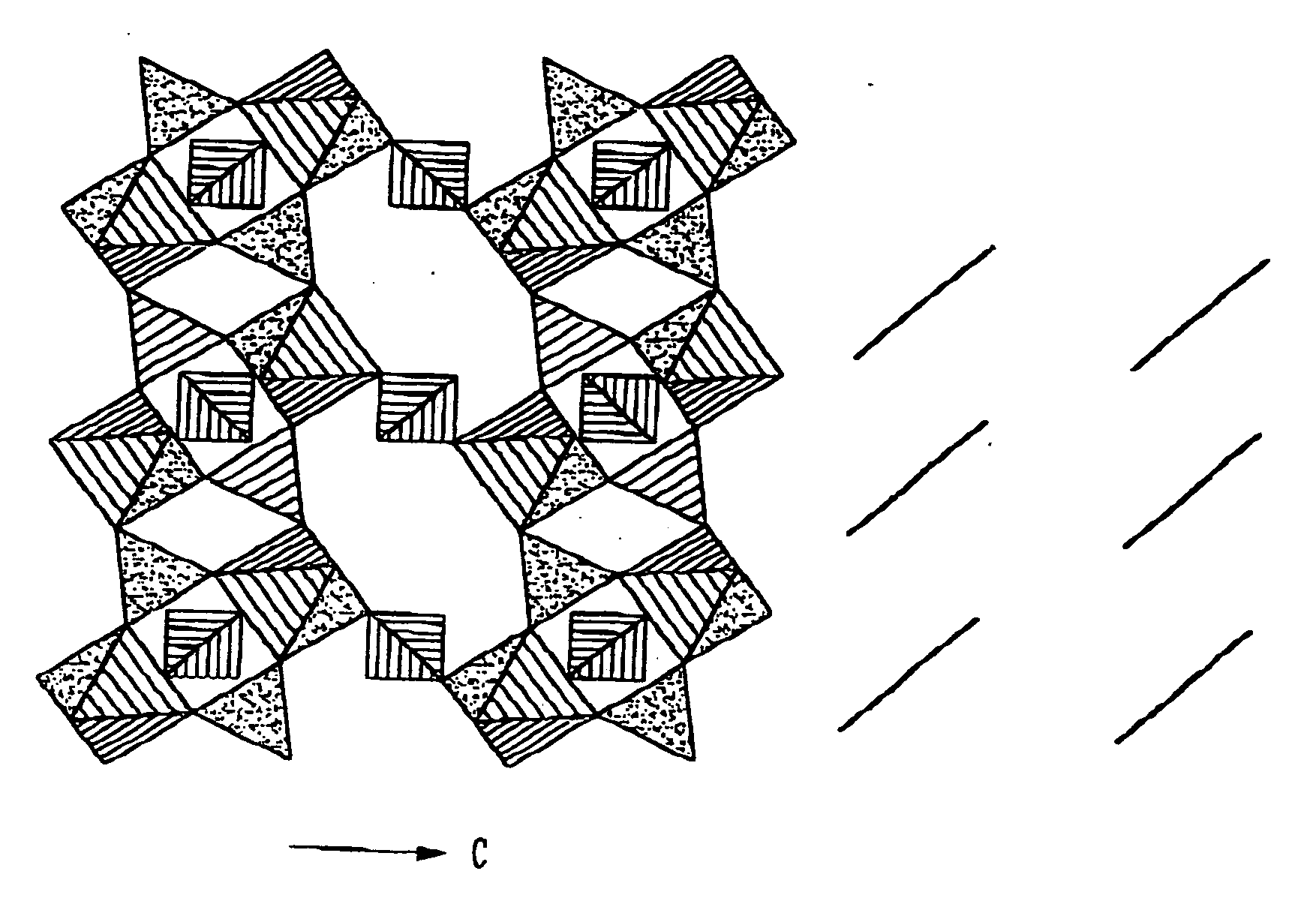

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

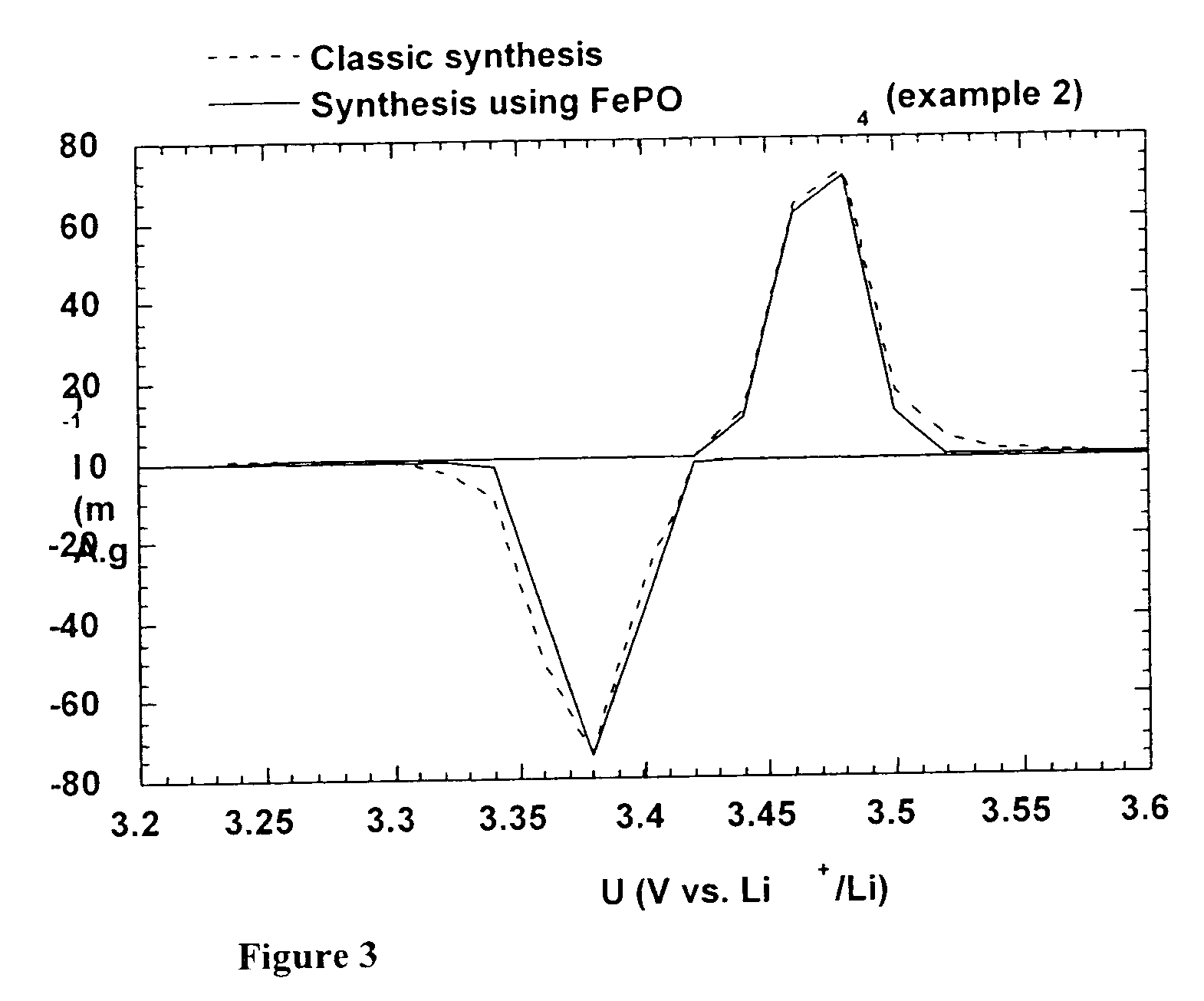

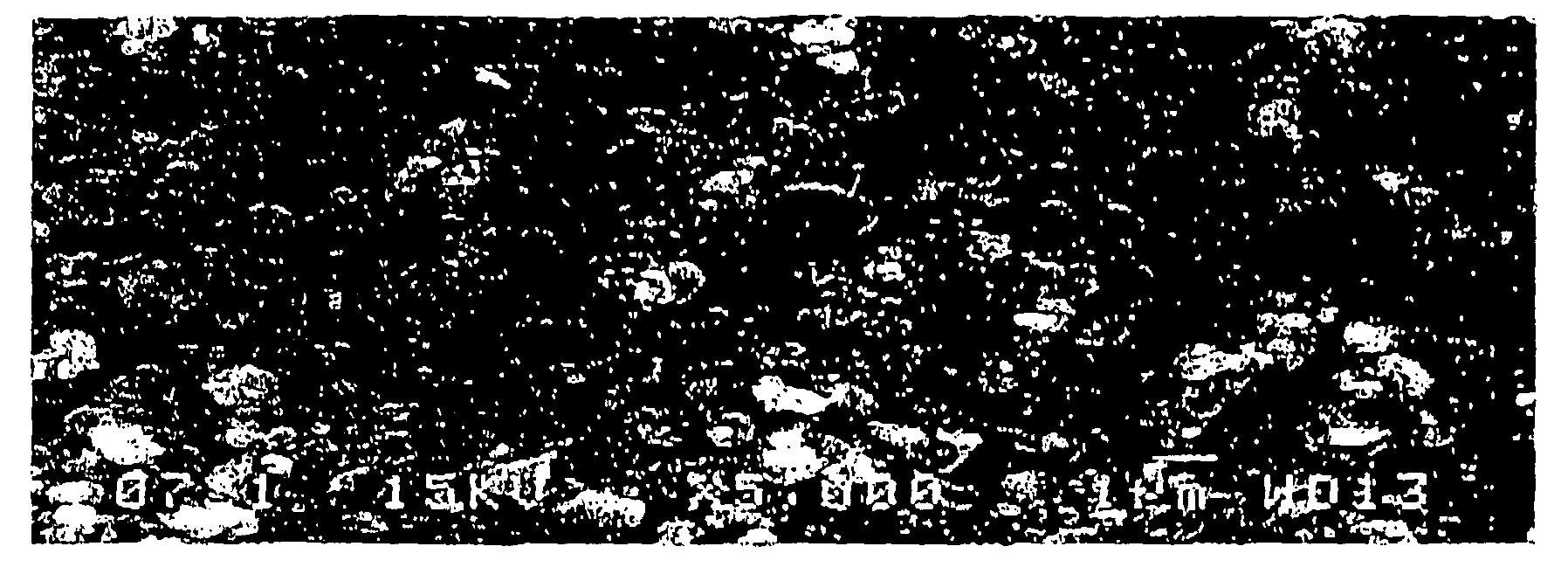

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

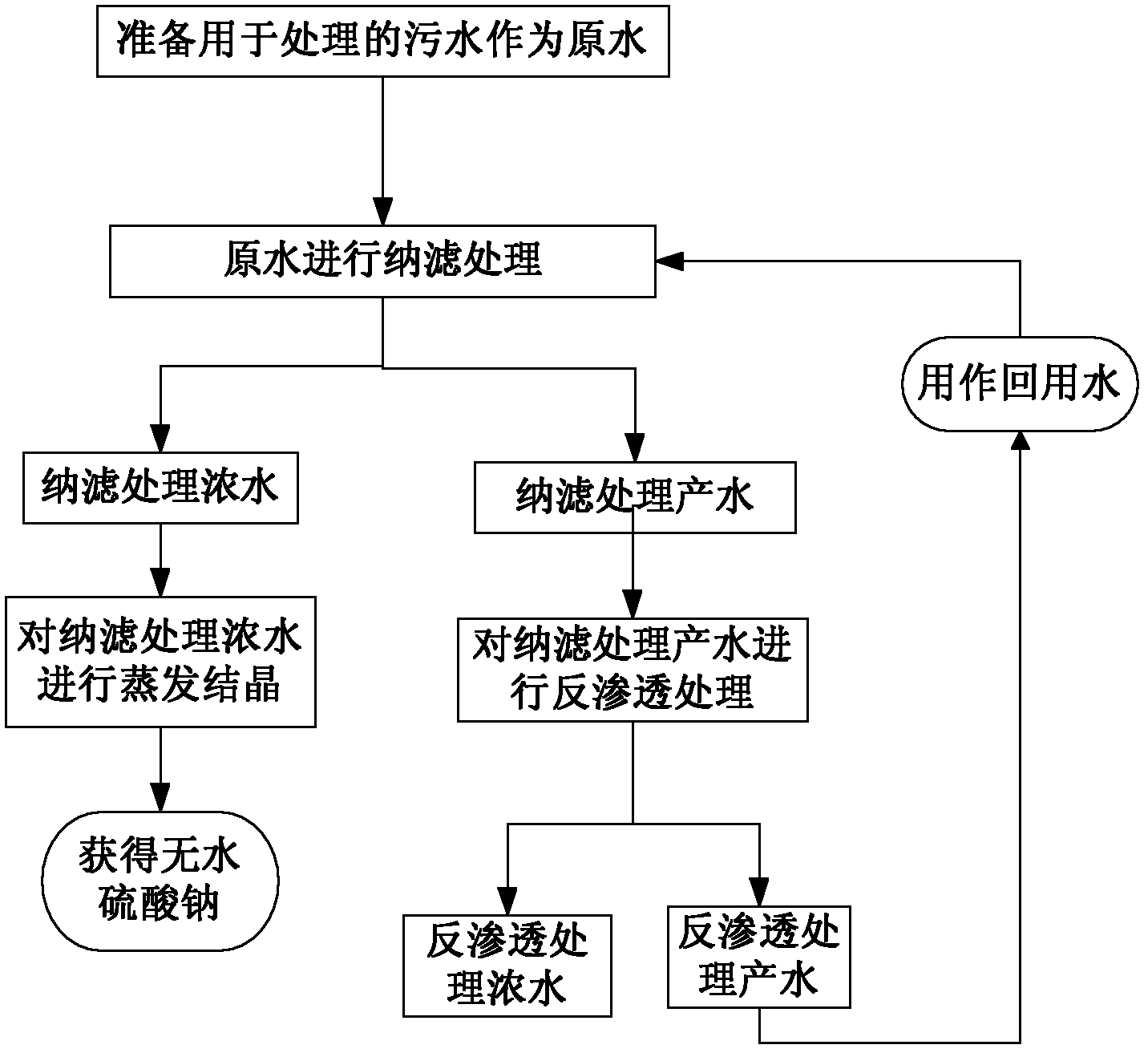

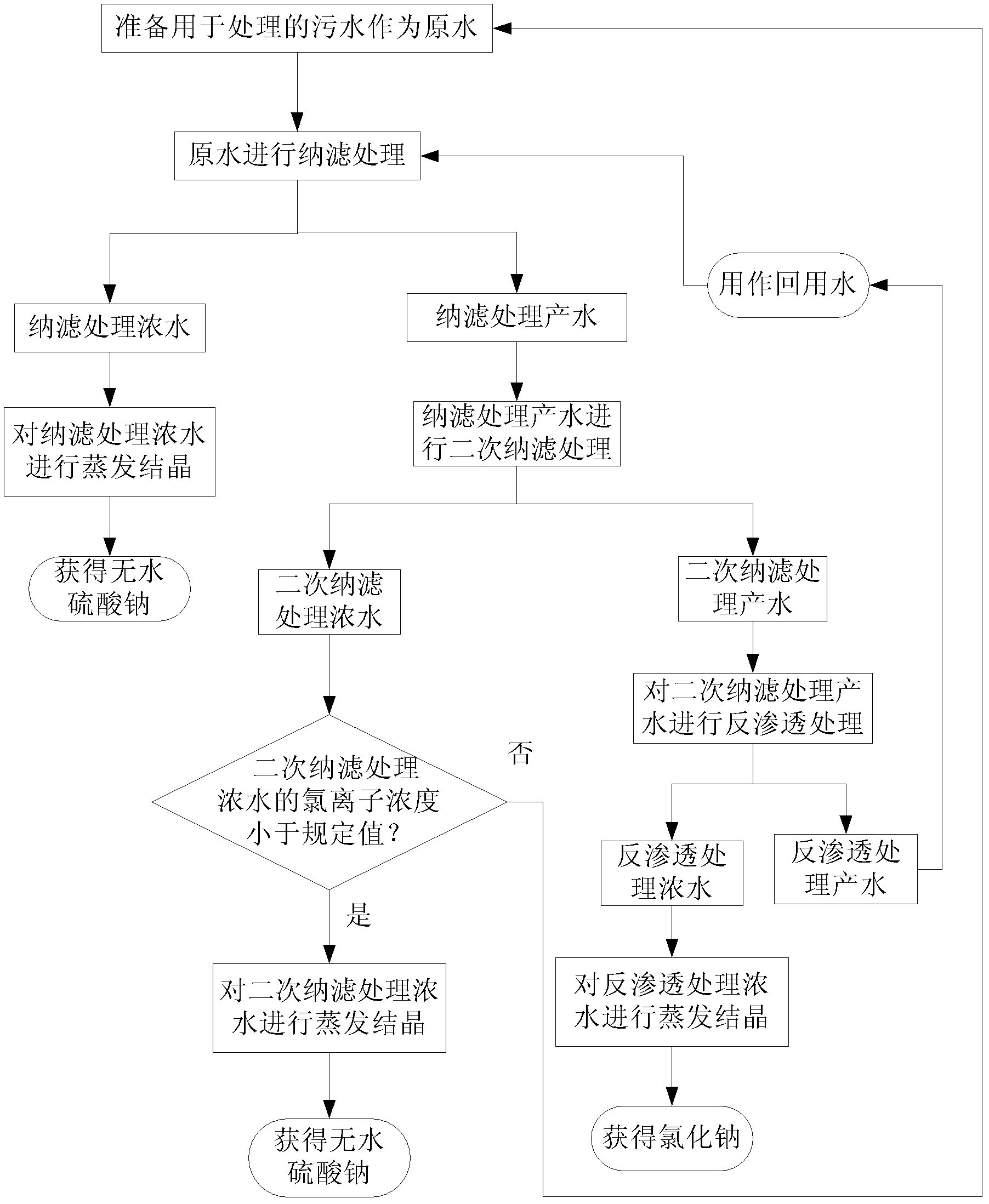

Treating method for sewage containing sodium sulfate and sodium chloride

ActiveCN102616891AEfficient separationNo pollution in the processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentReverse osmosisSewage

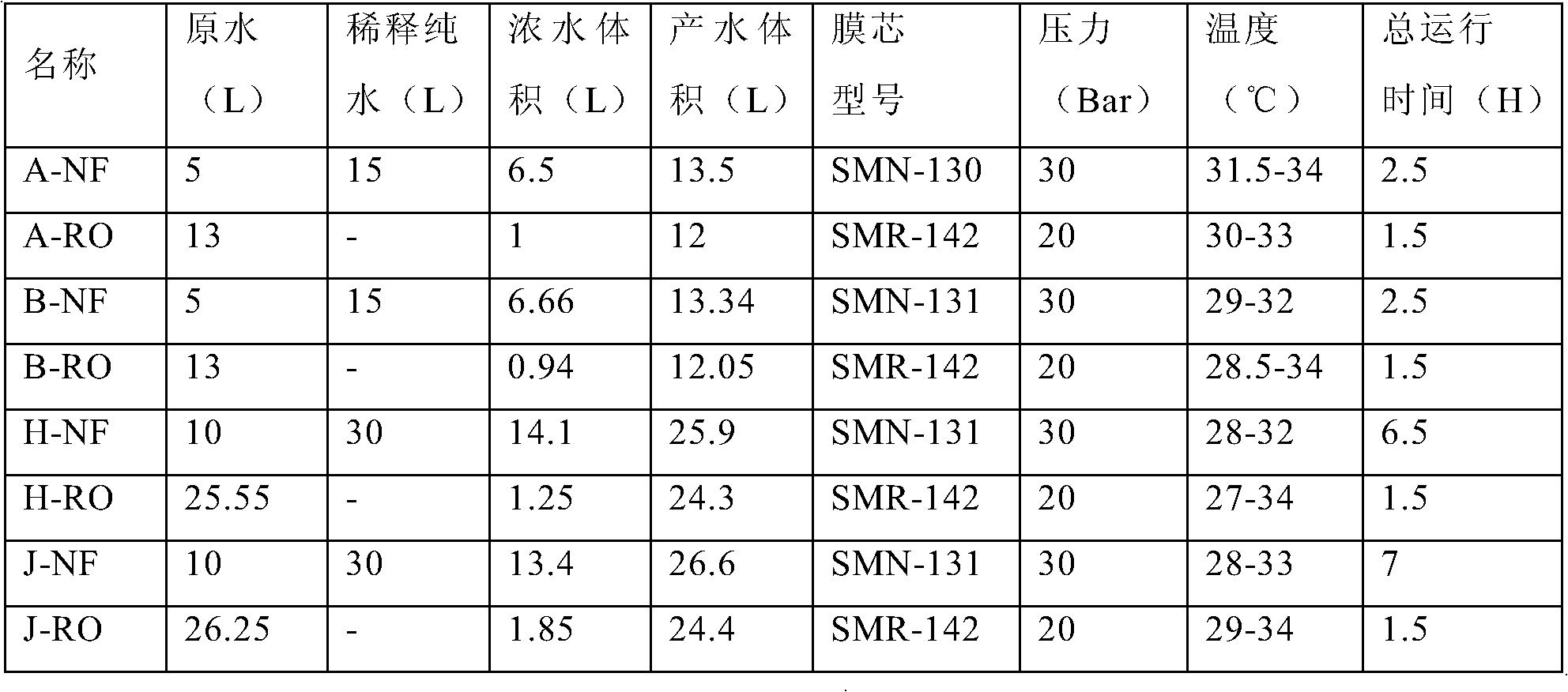

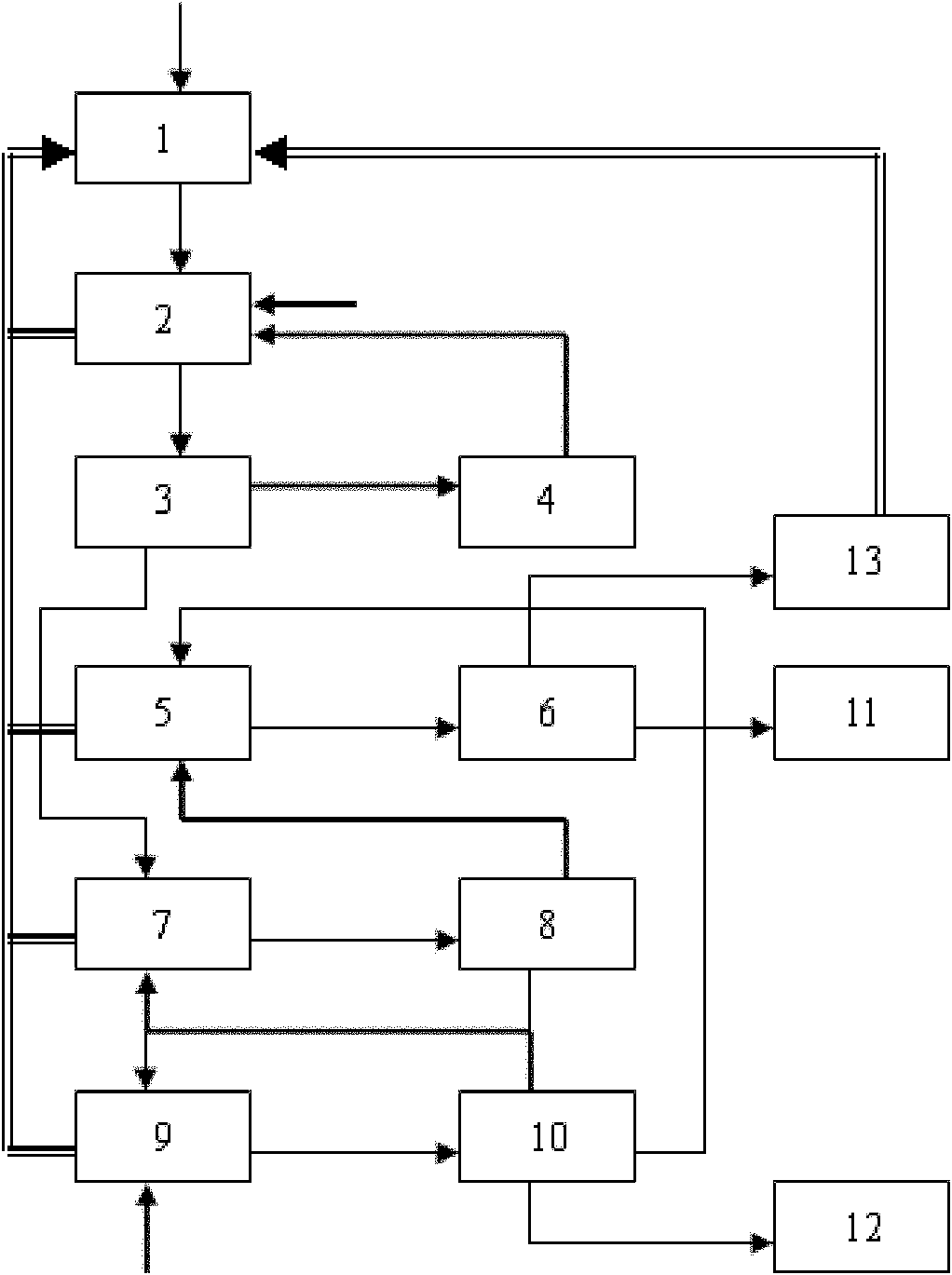

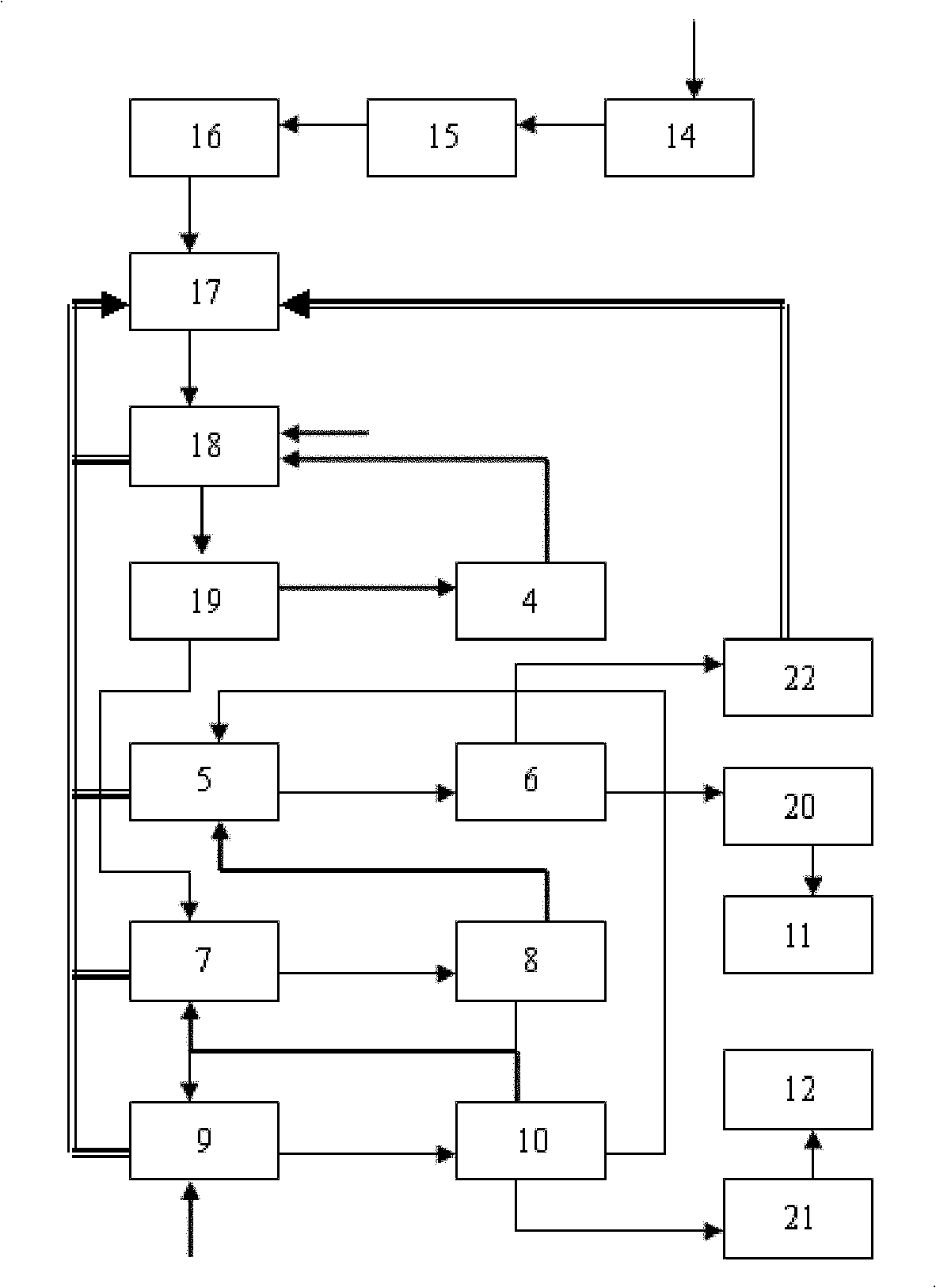

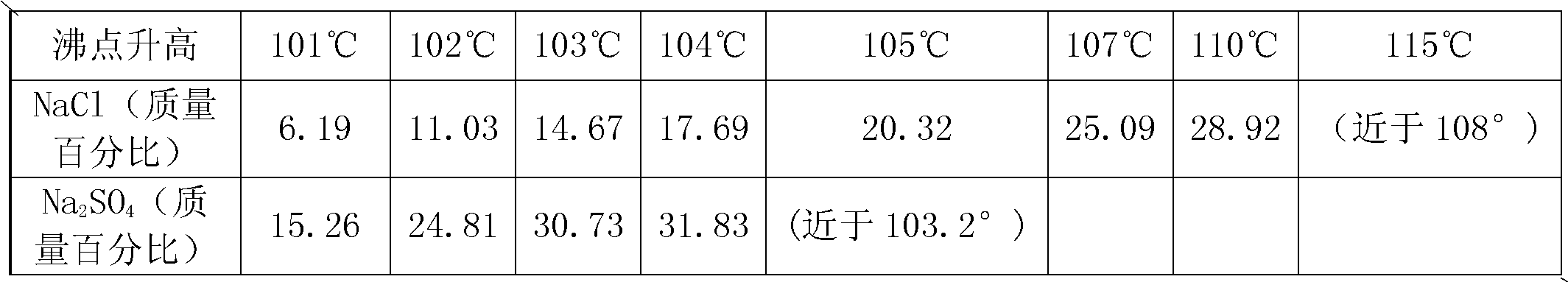

The invention provides a treating method for sewage containing sodium sulfate and sodium chloride. The method comprises a step of preparing sewage to be treated as raw water and a step of carrying out nanofiltration on the raw water. The method may also comprise a step of carrying out evaporative crystallization on concentrated water obtained after nanofiltration so as to obtain anhydrous sodium sulfate. The method may further comprise a step of carrying out reverse osmosis treatment on yielded water obtained after nanofiltration and using yielded water obtained after reverse osmosis treatment as diluting water in nanofiltration of the raw water. The method may also comprise a step of carrying out secondary nanofiltration on yielded water obtained after nanofiltration so as to obtain concentrated water and yielded water obtained after secondary nanofiltration, a step of carrying out reverse osmosis treatment on yielded water obtained after secondary nanofiltration and carrying out evaporative crystallization on concentrated water obtained after reverse osmosis treatment so as to obtain sodium chloride, a step of using yielded water obtained after reverse osmosis treatment as diluting water in nanofiltration of the raw water, and a step of carrying out evaporative crystallization on concentrated water obtained after secondary nanofiltration in the sequence of concentration so as to obtain anhydrous sodium sulfate or subjecting the concentrated water together with next batch of raw water to nanofiltration again . The method provided in the invention can be used for separating and purifying anhydrous sodium sulfate and sodium chloride and for purifying sewage.

Owner:昆明先导新材料科技有限责任公司

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

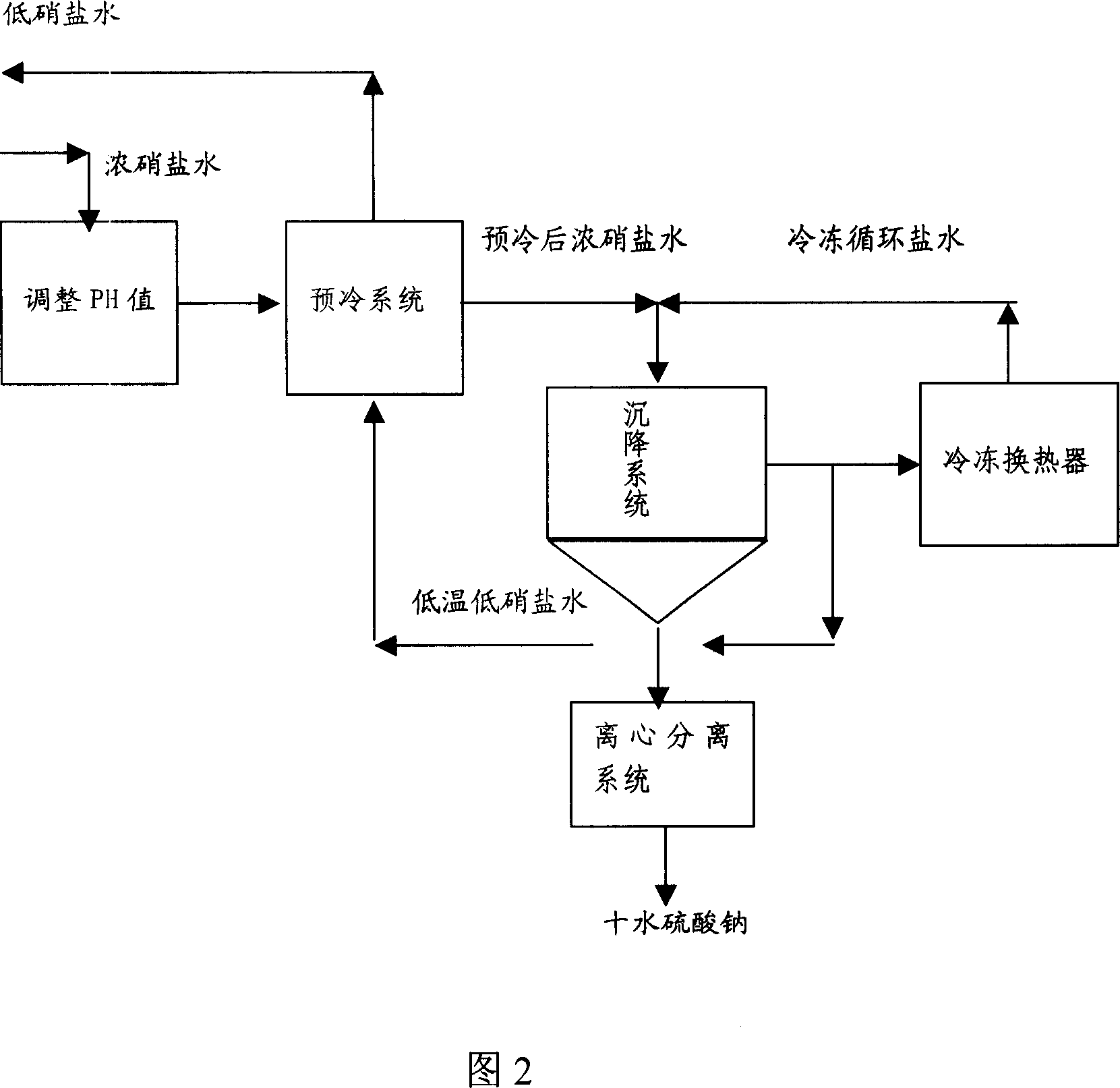

Method freezing separating mirabilite by brine solution

The invention discloses a method of cold separating mirabilite in salt water solution, which comprises the following steps: (1) adjusting pH value of armed salt cake solution as alkalify; (2) proceeding pre-cool in the precooling system; (3) mixing with low-temperature low-nitrate water of incorporating salt cake with lower temperature through demirabilite treatment; controlling temperature at -10-0 deg.c; proceeding solid-liquid separation in salt cake settler; getting ten water sodium sulfate crystal and low nitrate water; (4) lowering temperature of part low nitrate water through freezing heat exchanger; recycling as low temperature nitrate water of step (3); discharging the other part of low nitrate water as byproduct.

Owner:山东布莱恩化工技术有限公司

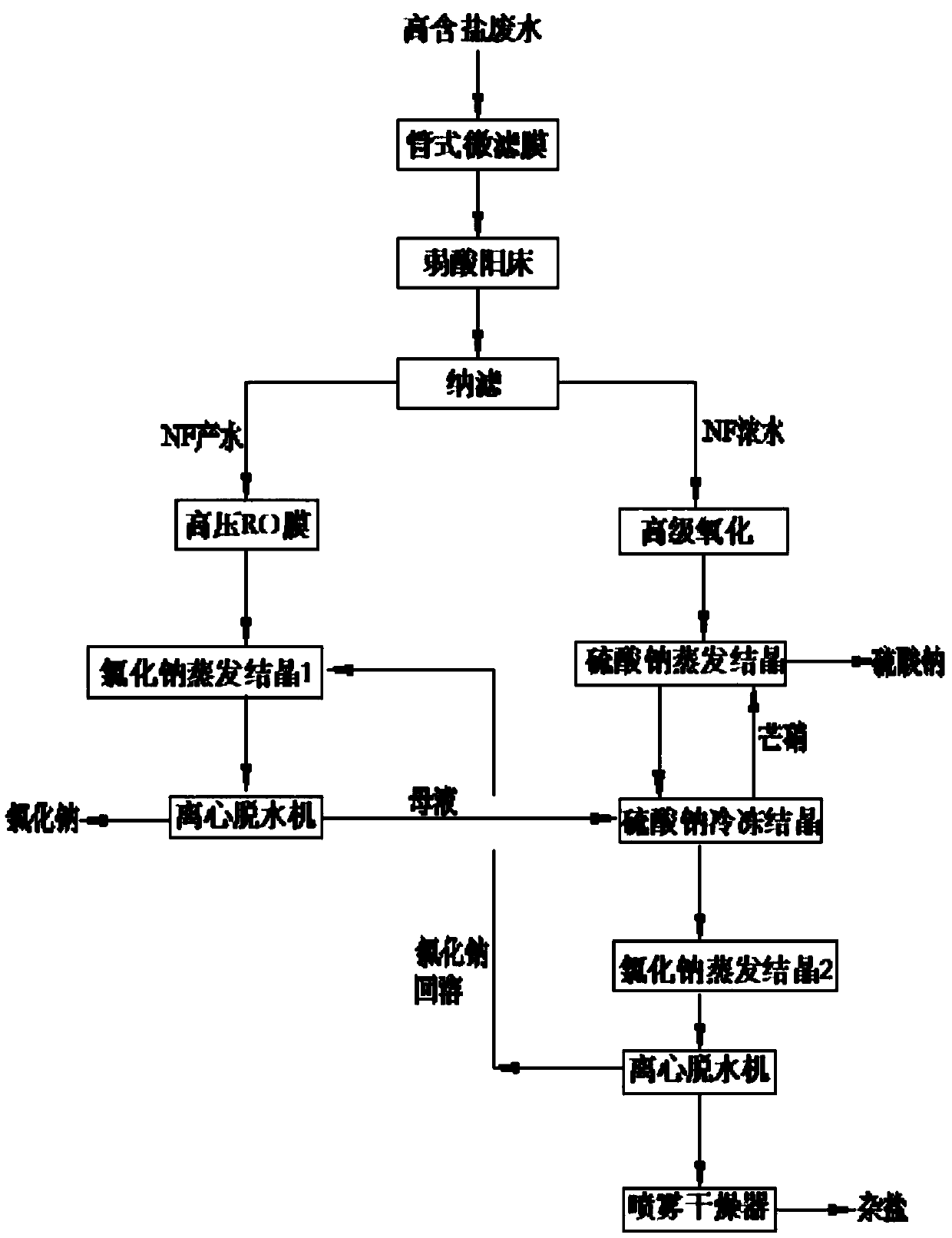

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

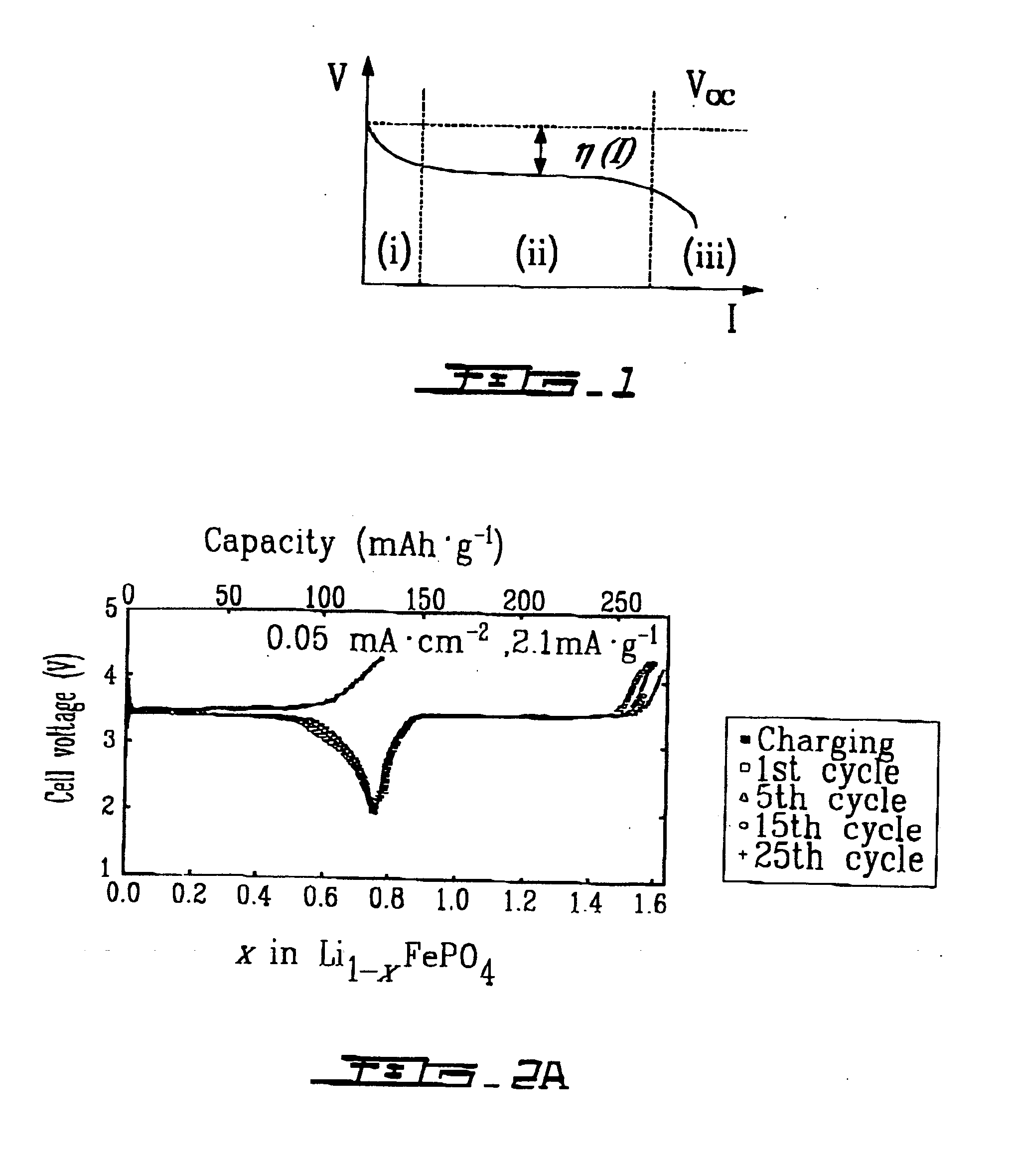

Cathode materials for secondary (rechargeable) lithium batteries

InactiveUS20050003274A1Cell electrodesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlkali ionsRechargeable cell

The invention relates to materials for use as electrodes in an alkali-ion secondary (rechargeable) battery, particularly a lithium-ion battery. The invention provides transition-metal compounds having the ordered-olivine, a modified olivine, or the rhombohedral NASICON structure and the polyanion (PO4)3− as at least one constituent for use as electrode material for alkali-ion rechargeable batteries.

Owner:HYDRO QUEBEC CORP

Process for production of gypsum/fiber board

ActiveUS20050161853A1Increase ratingsIncreased rehydration rateSolid waste managementWood working apparatusSlurryCellulose fiber

An improved process calcining a gypsum / cellulosic fiber slurry to produce a composite gypsum / cellulosic fiber product resides in adding a selected crystal modifier to the gypsum / cellulosic fiber slurry prior to the heating step to reduce the time necessary to carry out the calcination process, to reduce the temperature at which the calcination process is run or to increase the aspect ratio of the acicular calcium sulfate alpha hemihydrate crystals formed during the calcination process. Useful crystal modifiers include aluminum sulfate, aluminum chloride, chlorine, zinc sulfate, iron (III) sulfate, aluminum sulfate hexadecahydrate, iron (II) sulfate heptahydrate, iron (III) sulfate pentahydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, copper chloride dehydrate, manganese sulfate monohydrate and trisodium phosphate.

Owner:UNITED STATES GYPSUM CO

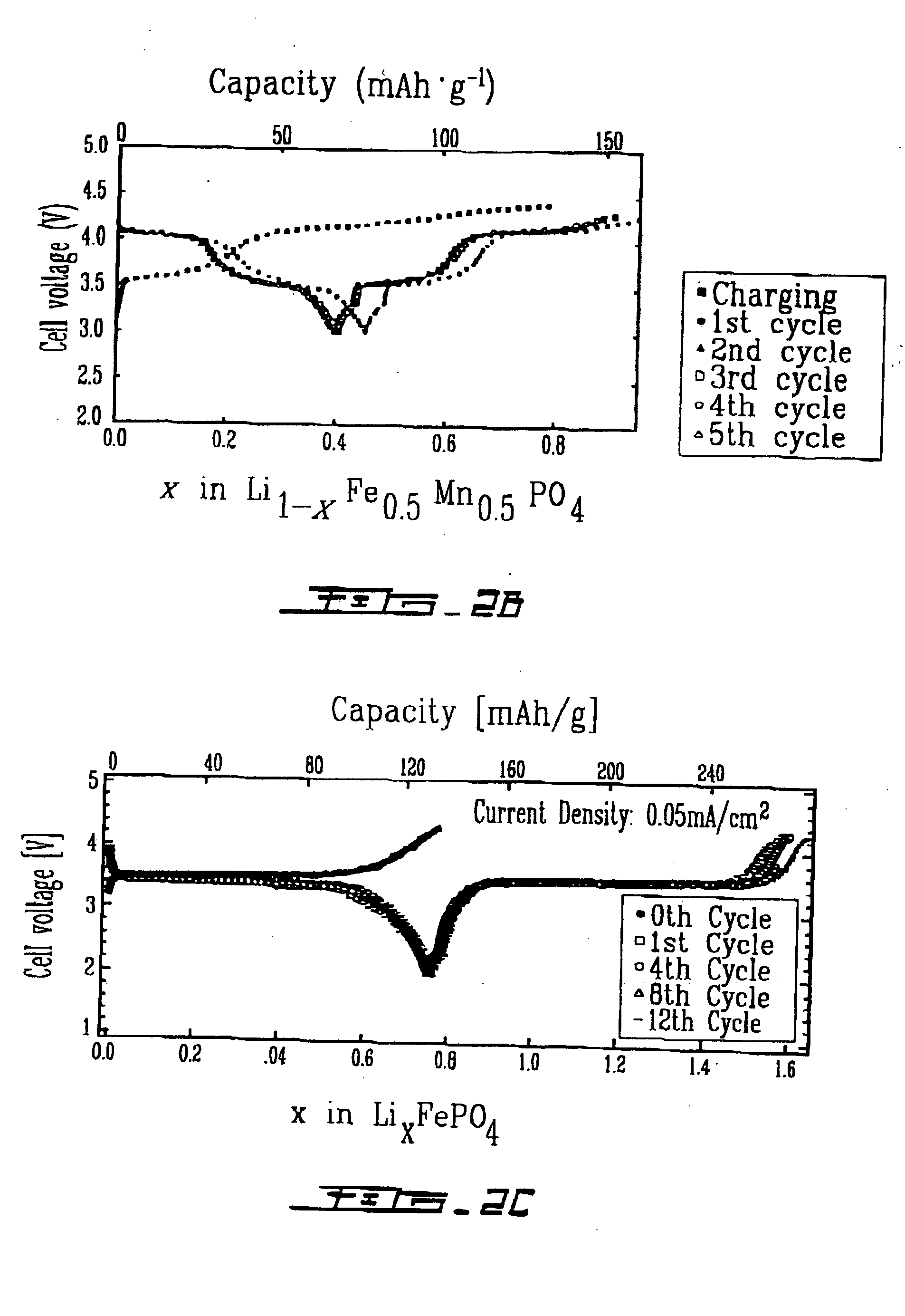

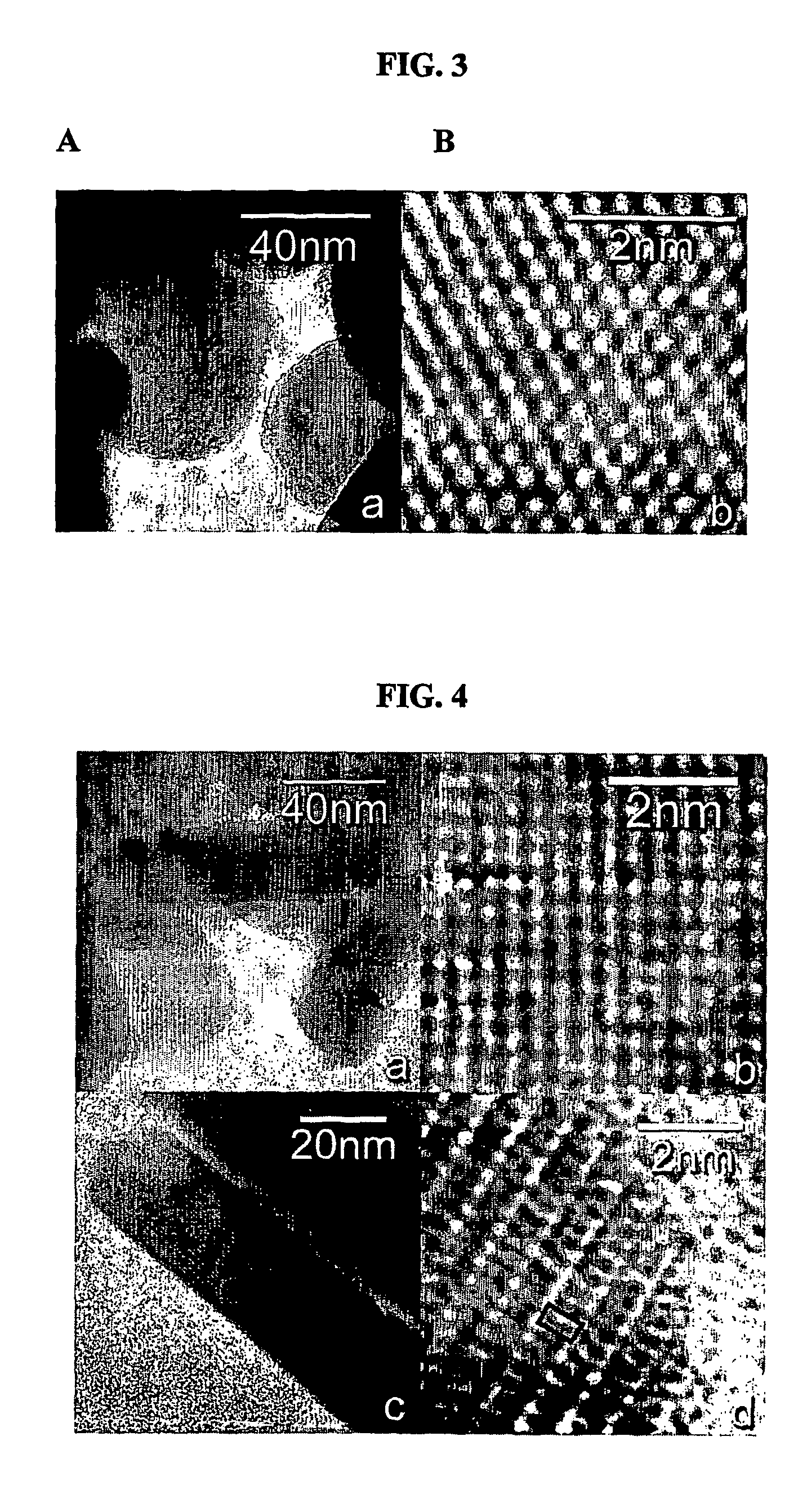

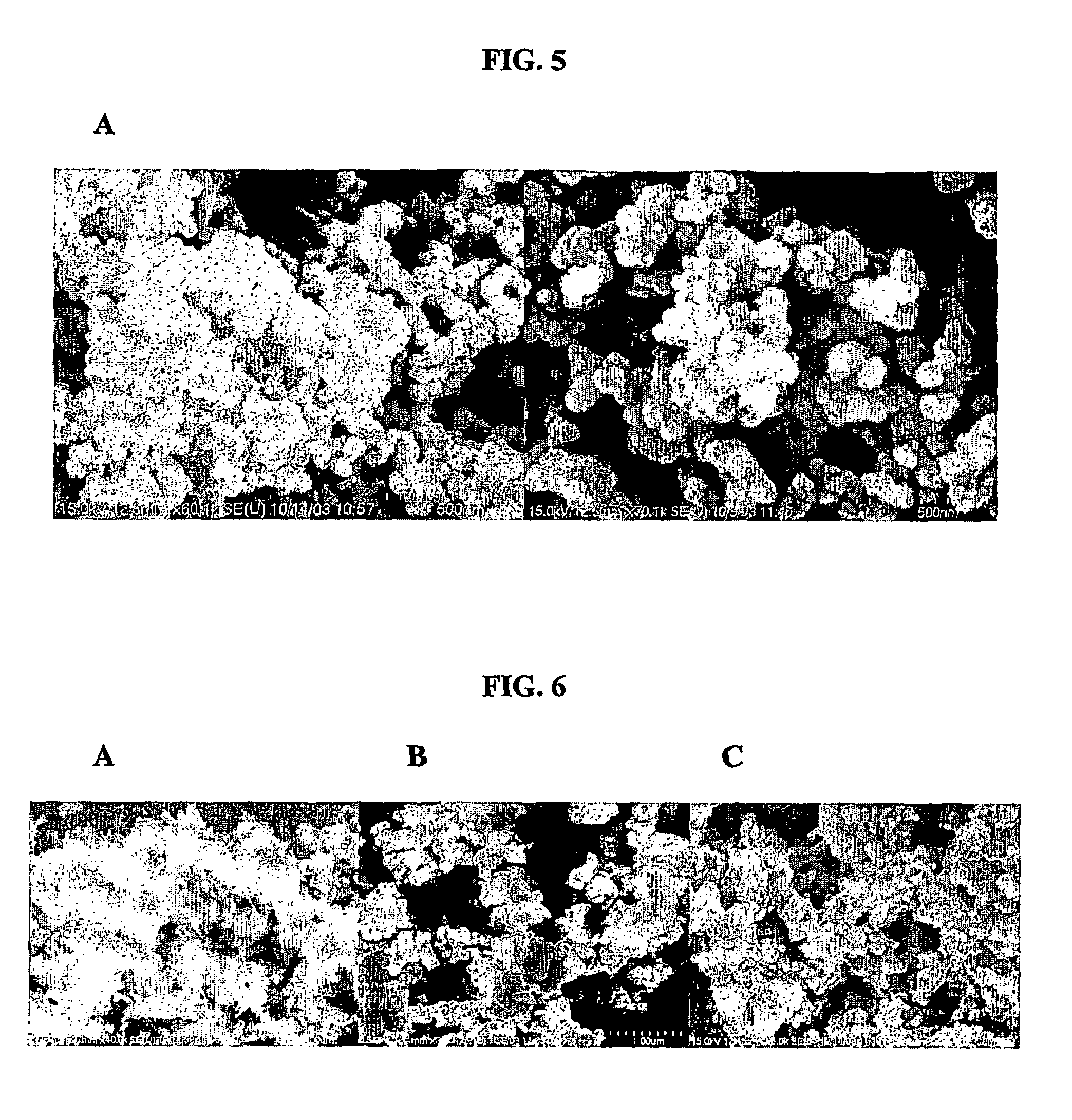

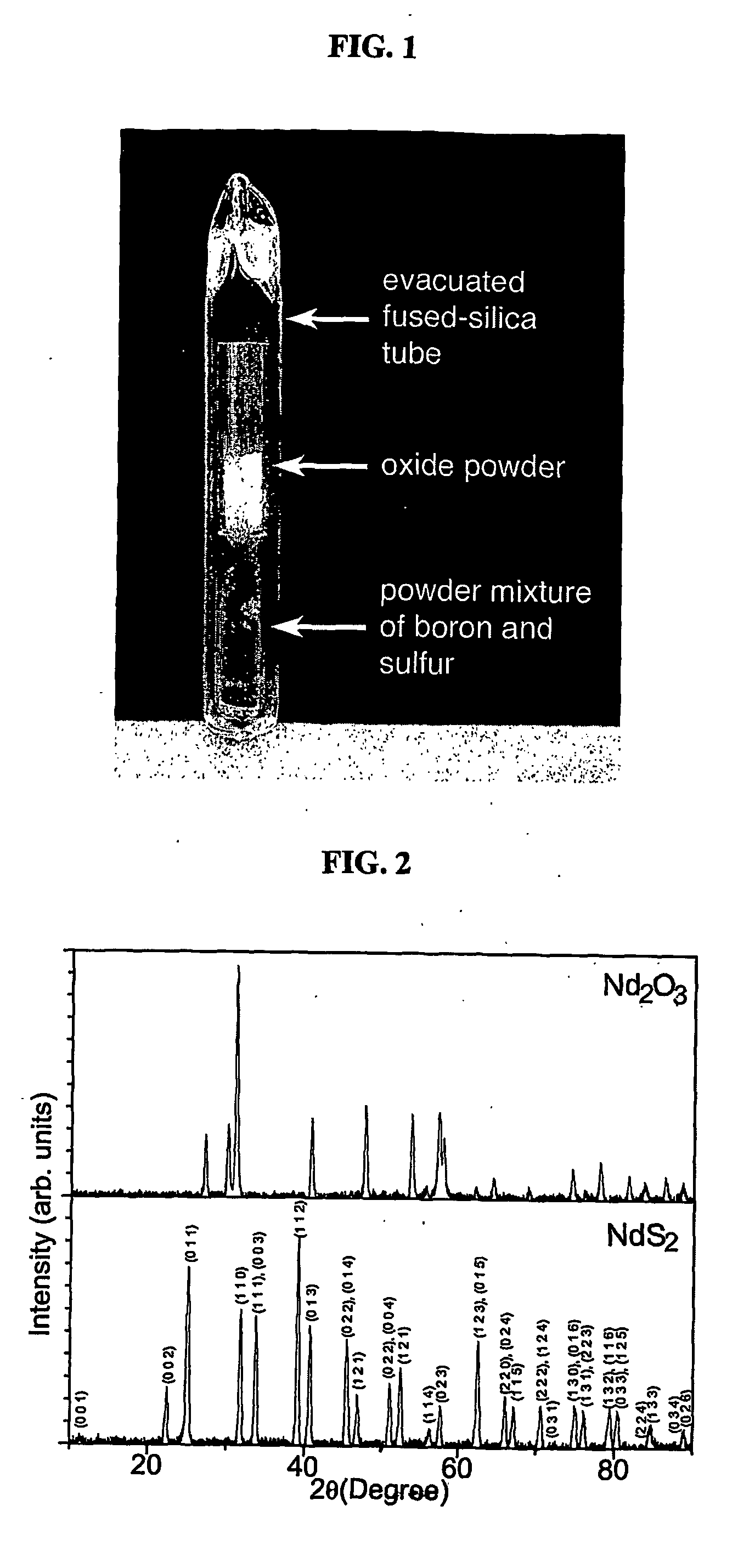

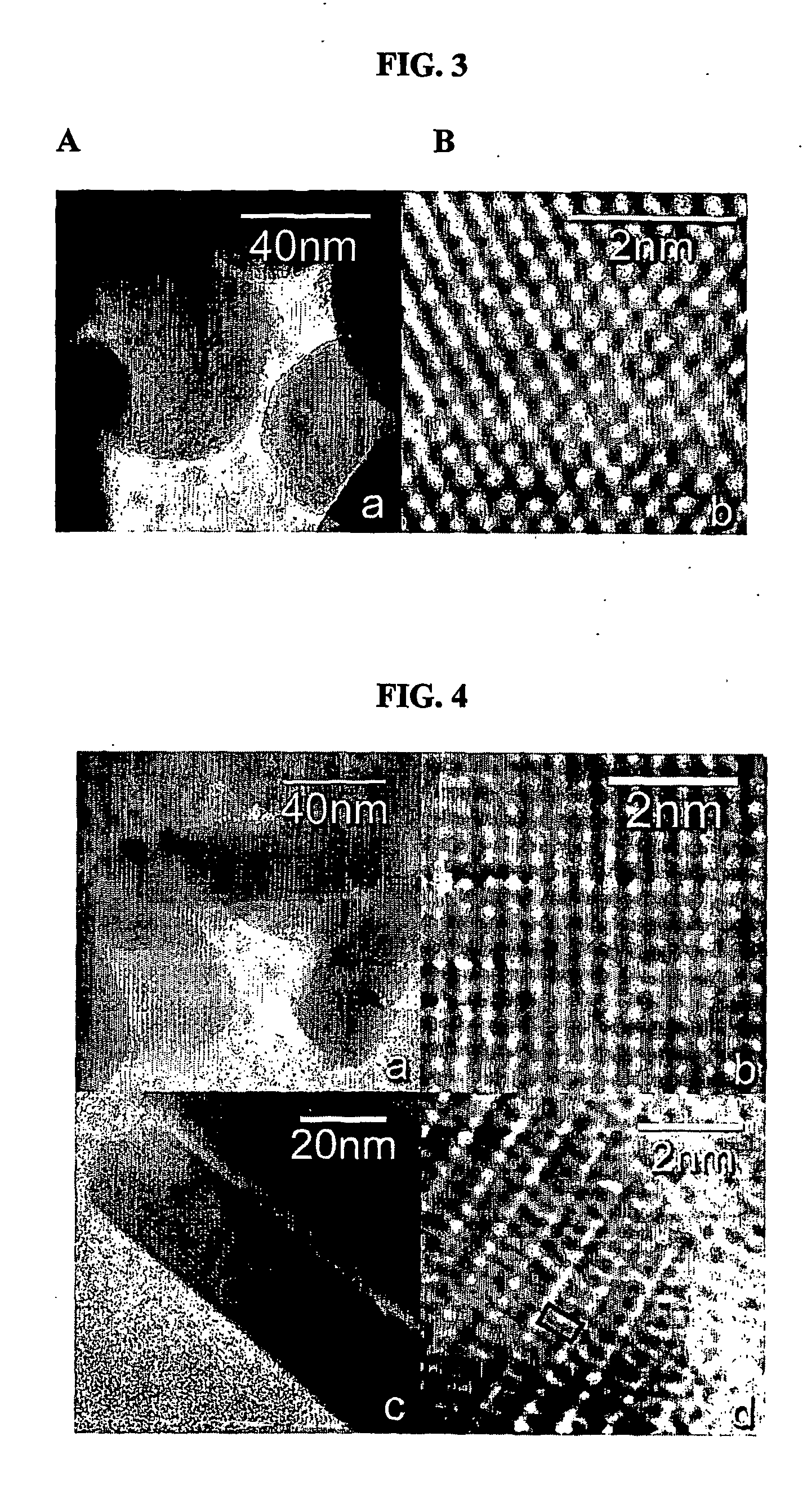

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

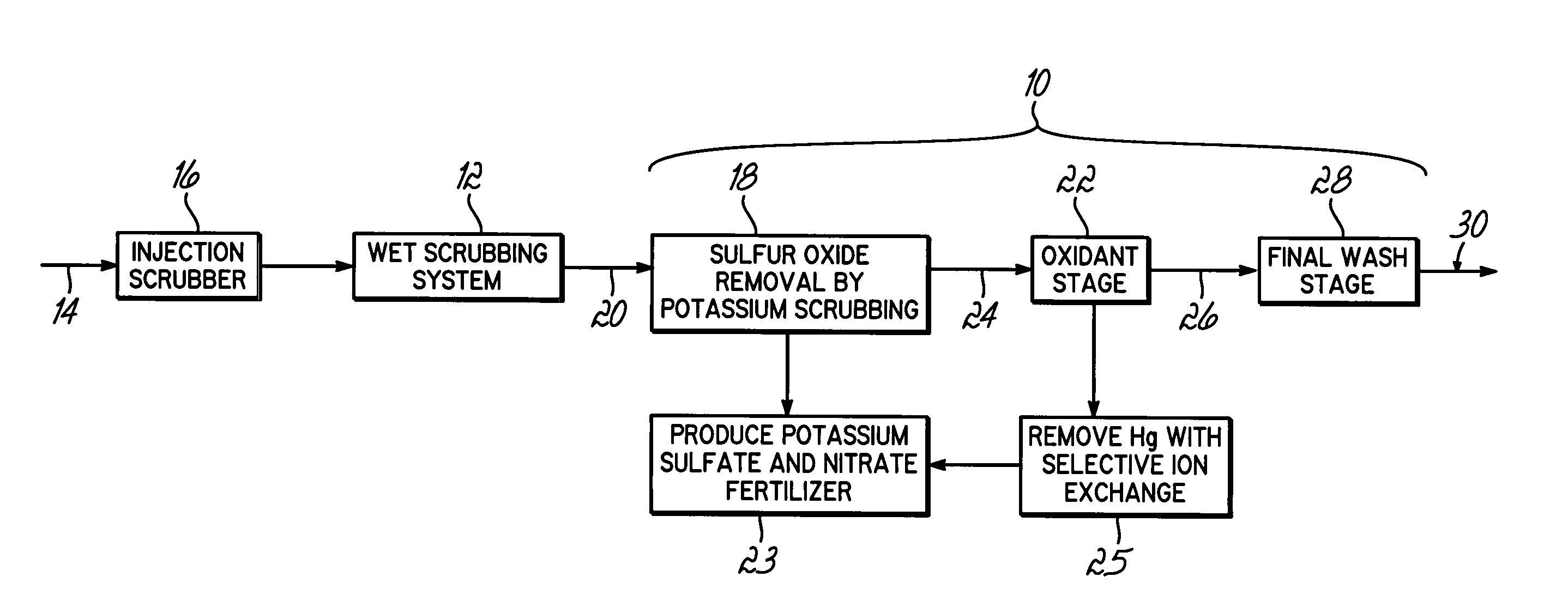

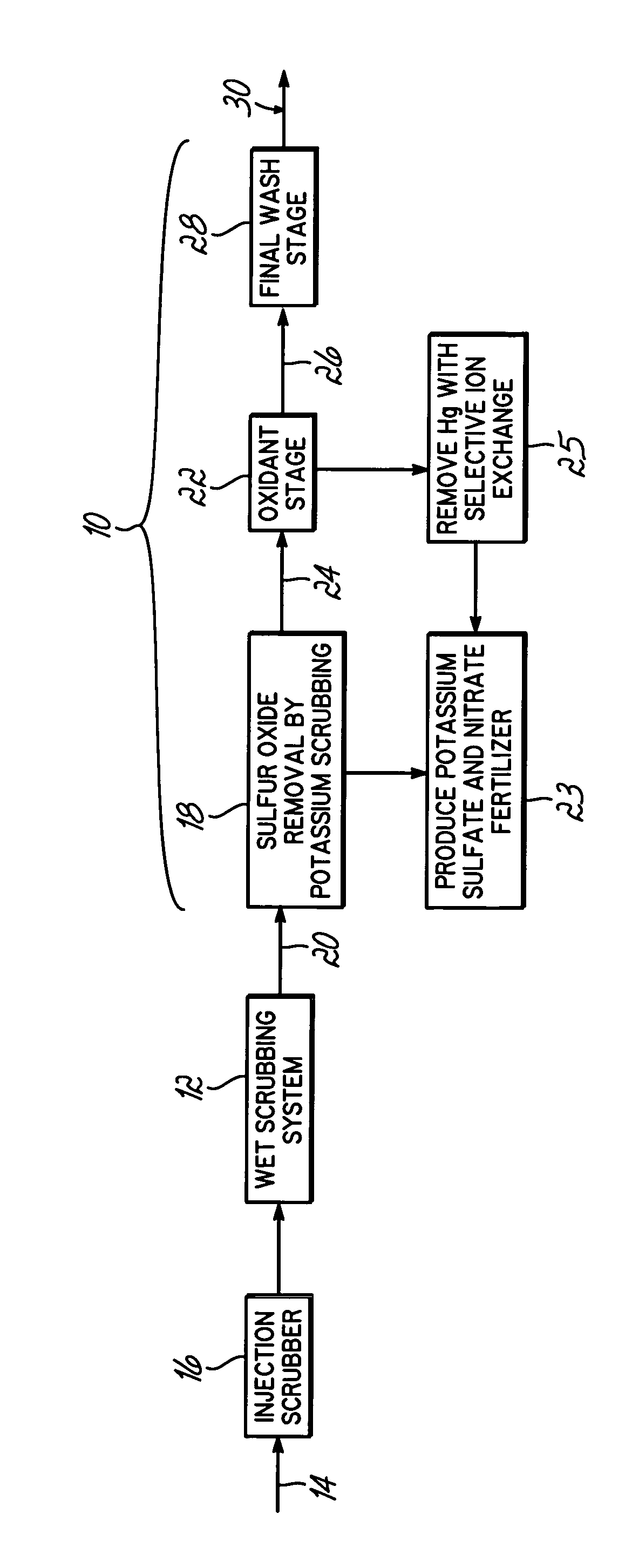

InactiveUS20060239877A1Low costImprove performanceAmmonium nitratesNitrogen compoundsSorbentPotassium

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

InactiveUS7514053B2Improve performanceAvoid pollutionAmmonium nitratesNitrogen compoundsNitrogen oxidesSorbent

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

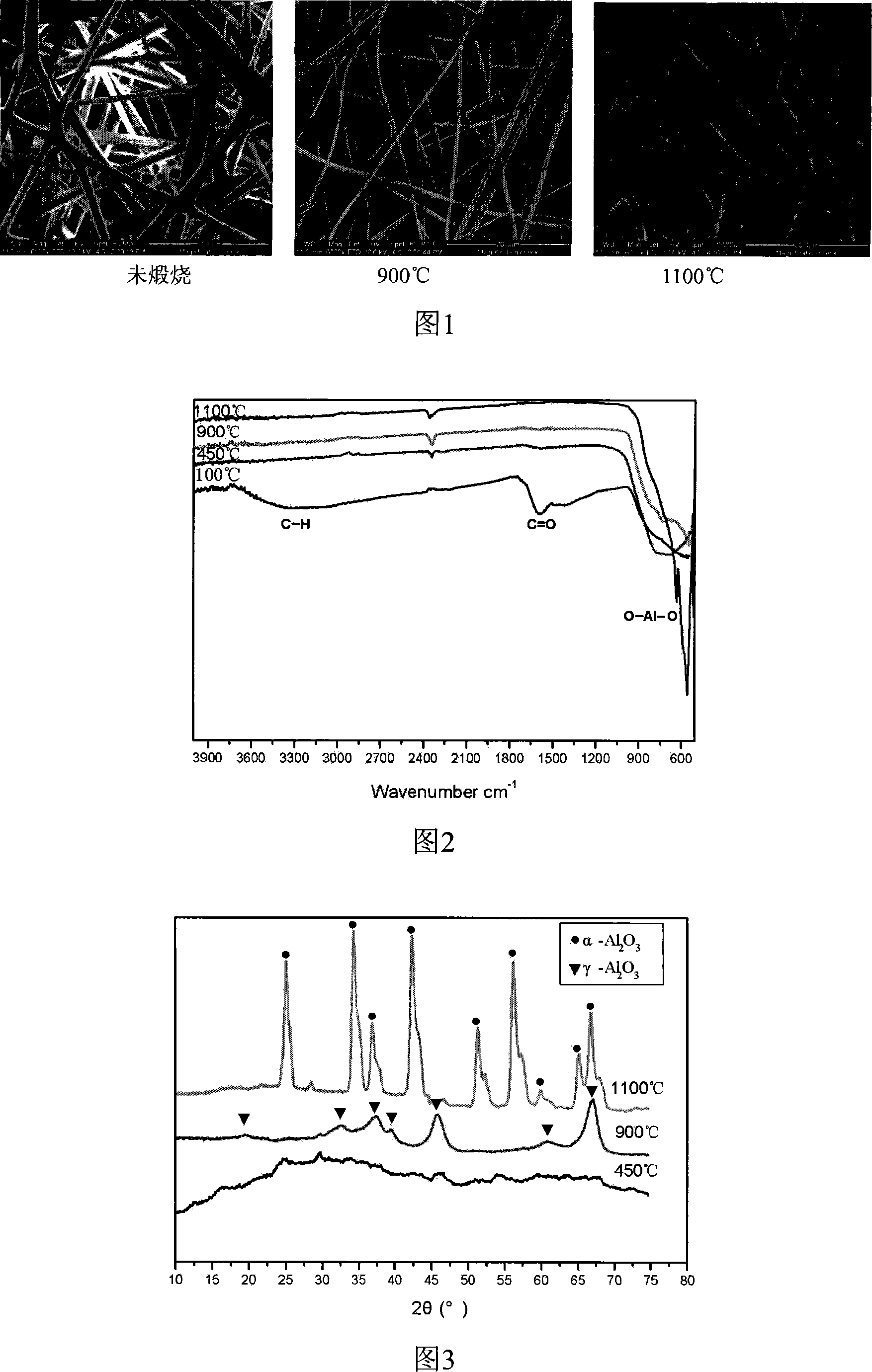

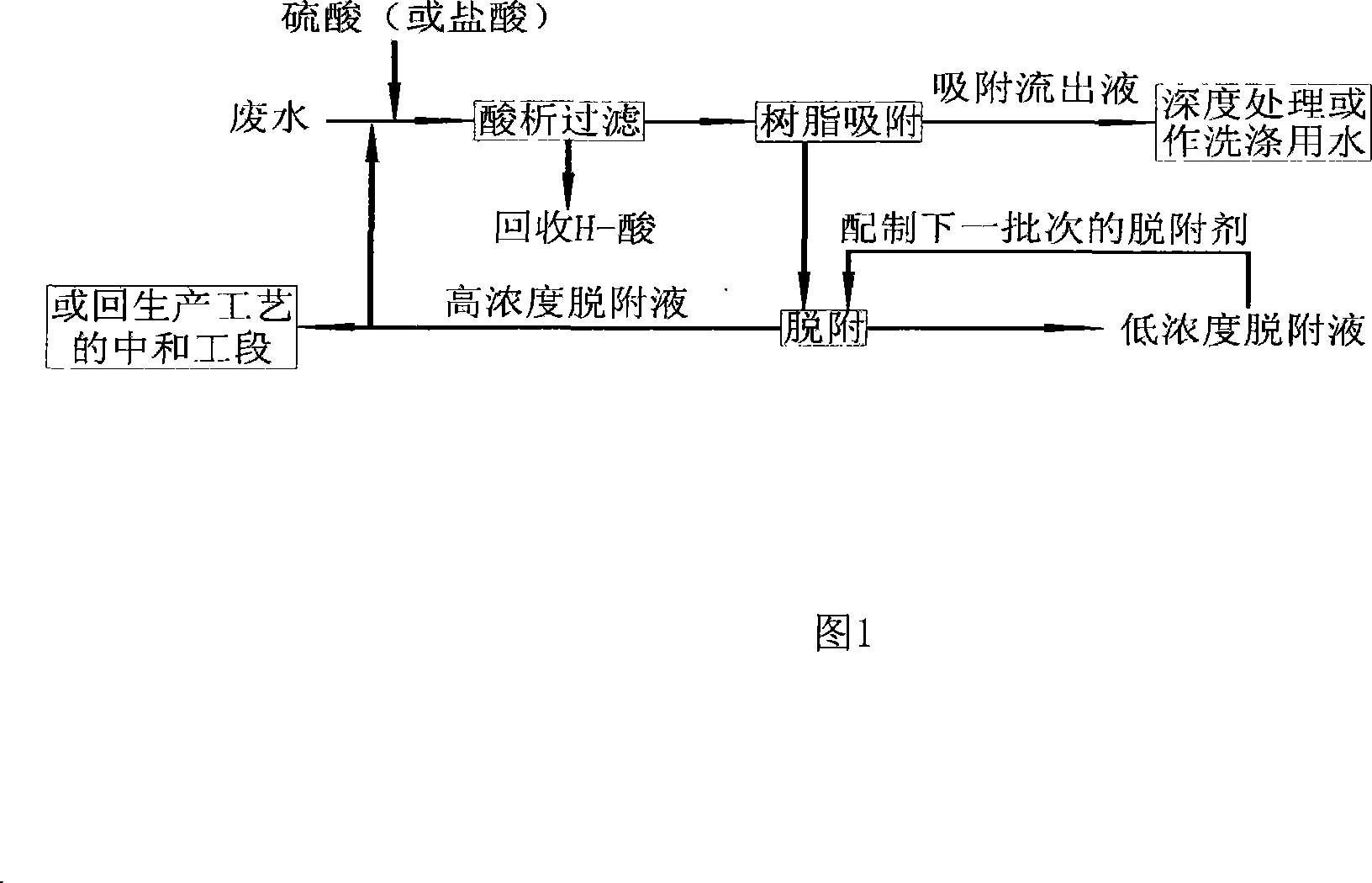

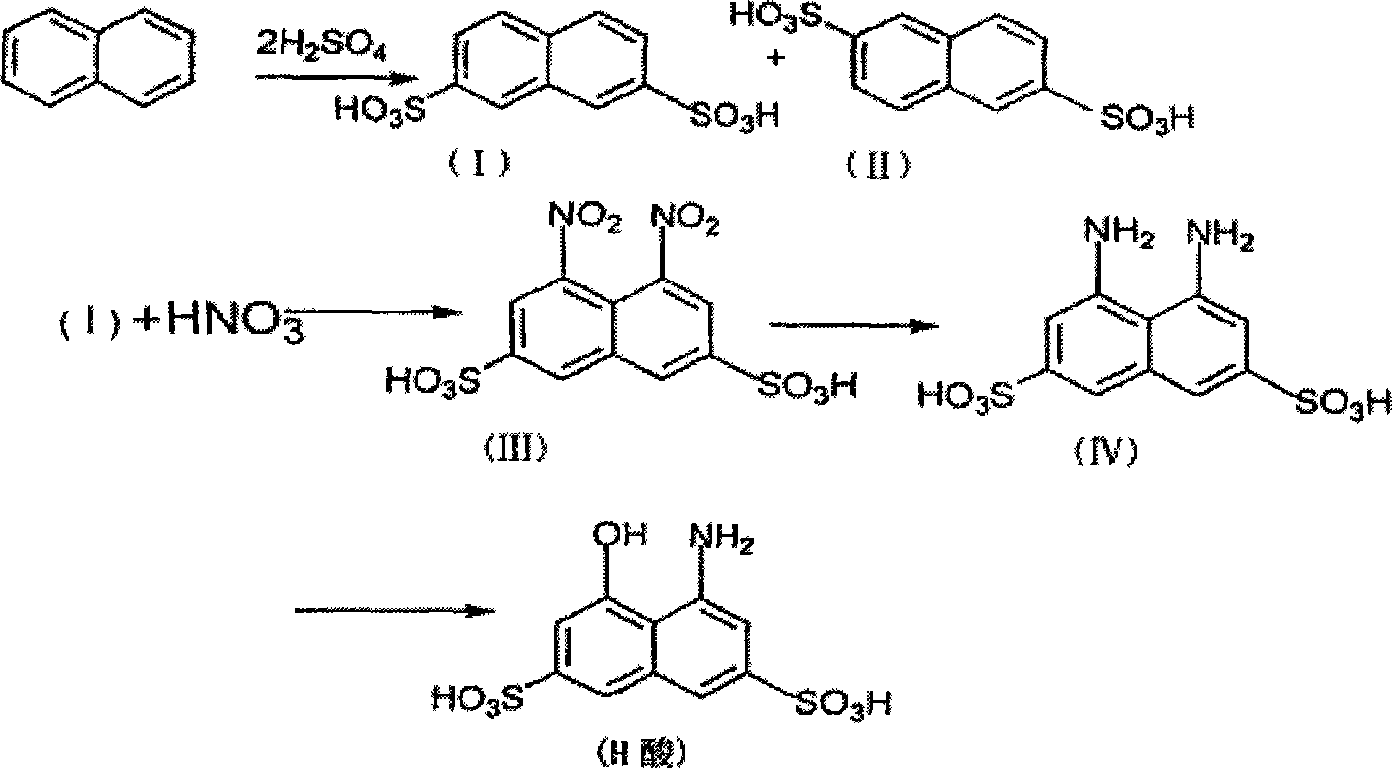

Method for preparing nano alumina fiber film material

The invention relates to a technology of preparing nano alumina fiber membrane material by electrostatic spinning, comprising: 1. the configuration of sol gel electrostatic spinning liquid. Pouring polyvinyl pyrrolidone into ethanol solvent and stirring thereof with high speed until completely dissolved; getting the polyvinyl pyrrolidone ethanol solution with the concentration of 5-8wt%, then, mixing the solution with the aluminum chloride solution with the concentration of 10-30wt%, wherein, the weight ratio between the polyvinyl pyrrolidone and the aluminum chloride is 3:1-1:1, stirring for one hour. 2. Electrostatic spinning. The prepared sol gel spinning liquid is injected into the electrostatic spinning device and electrostaticly spinning thereof is injected into aluminum chloride / polyvinyl pyrrolidone nano fiber membrane under the voltage of 25-35kv, the extrusion speed of 1-10ml / min and the reception distance of 10-20cm. 3. calcining. At last putting the prepared aluminum chloride / polyvinyl pyrrolidone nano fiber membrane into a muffle furnace and raising the temperature to 450-1100 DEG C with the speed of 50 DEG C / h, calcining for five hours and getting amorphous, Gamma type or Alpha type aluminum oxide fiber membrane. The nano aluminum oxide fiber membrane made by the invention is a catalyst and the carrier material of the catalyst and high temperature resistance filtration material with high specific surface area, good thermal stability and excellent mechanical properties. Furthermore, the material can be widely applied in fields such as the insulating materials and reinforced composites of space shuttle and high temperature boiler.

Owner:TIANJIN POLYTECHNIC UNIV

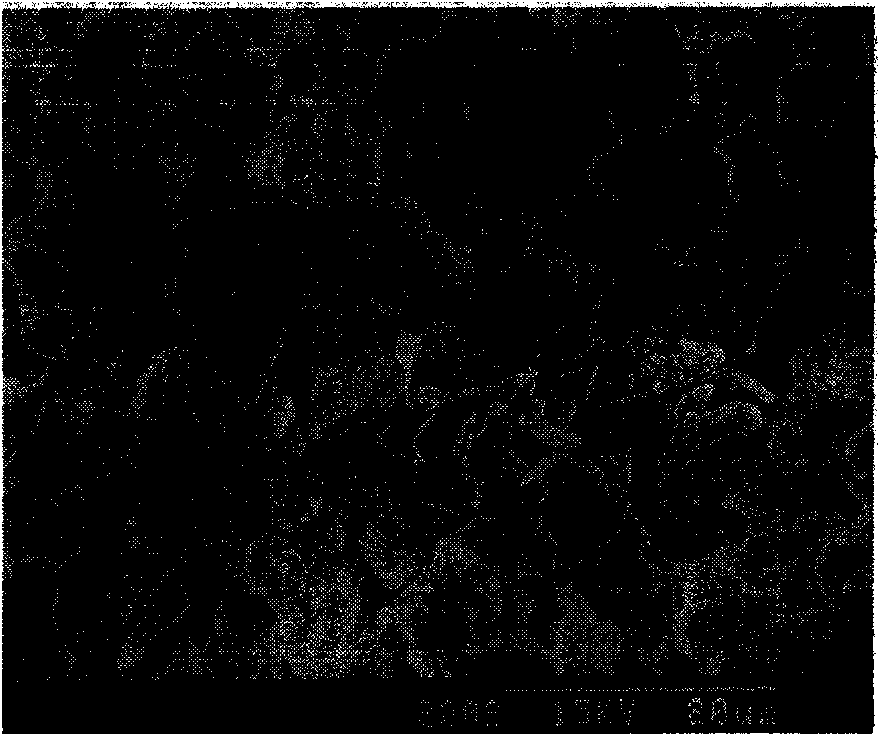

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

Method for separating magnesium from lithium and extracting lithium from brine

InactiveCN101538057ASolve the difficult technical problems of filtrationSimple technical processMultistage water/sewage treatmentSolution crystallizationFiltrationHigh energy

The invention provides a method for separating magnesium from lithium and extracting the lithium from high magnesium-lithium ratio brine (brine from a saline lake, from underground and from an oil-gas field). The method comprises: sodium salt and potassium and magnesium mixed salt are separated from the brine by evaporation of a saltpan; after boron extraction, sodium hydroxide is used for precipitating Mg<2+> from obtained old brine, and crystallized Mg(OH)2 is obtained by modification and precipitation condition control; filtration and separation are carried out to remove the Mg(OH)2 to realize separation of magnesium and lithium; after filtered mother solution is vaporized and concentrated for 2-4 times, Na2SO4 and NaCl are separated by crystallization, and pure caustic soda can be added to form lithium carbonate from lithium; or the operation of further evaporation is carried out until Na2SO4 and NaCl are separated by multiple times of natural evaporation or forced evaporation concentration and multiple times of cooling crystallization; the operations of evaporation and concentration are carried out until LiCl saturation, and LiCl products can be prepared after the operation of cooling crystallization is carried out. Compared with the prior art for separating the magnesium from the lithium and extracting the lithium from the brine, the method obtains the crystallized Mg(OH)2 by modification and precipitation condition control, solves the existing technical problem of hard filtration of Mg(OH)2, solves the defects of high energy consumption, complex process and high cost of the existing calcination method, and solves the fundamental defects of low Li<2+> recovery ratio and complex technical process of the traditional precipitation method. The Li<2+> recovery ratio ranges from 85-93%, Mg<2+> removal ratio is more than 99.5%, and the method solves the problem of extracting Li<+> and Mg<2+> from high-magnesium and low-lithium brine with Mg<2+> / Li<+>>=20 mass ratio.

Owner:钟辉

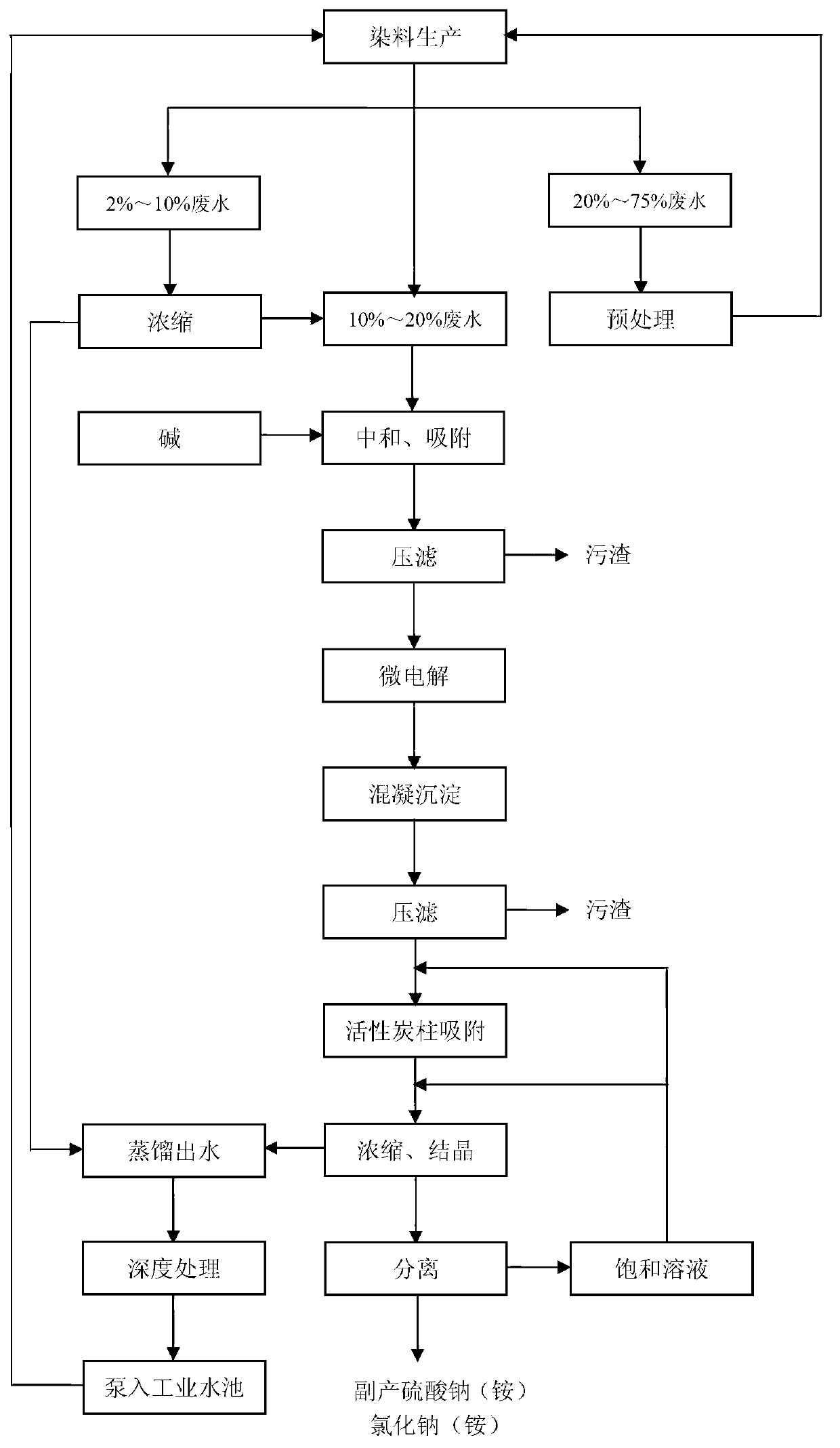

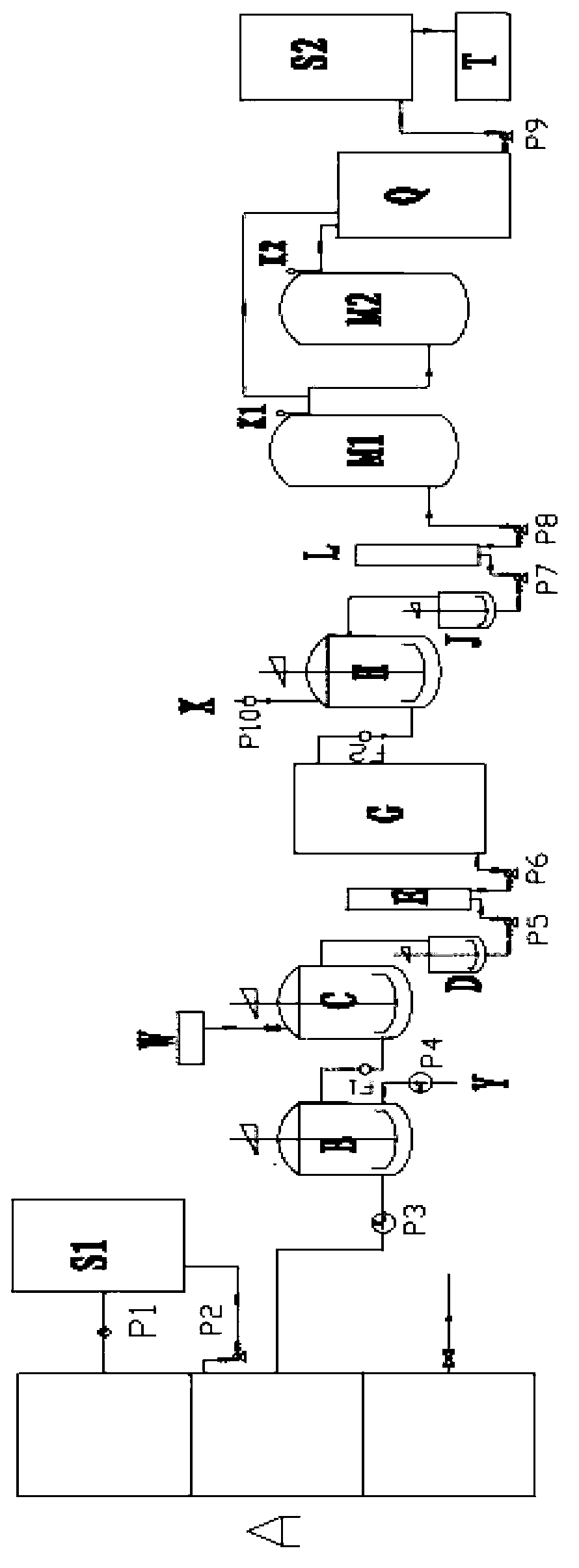

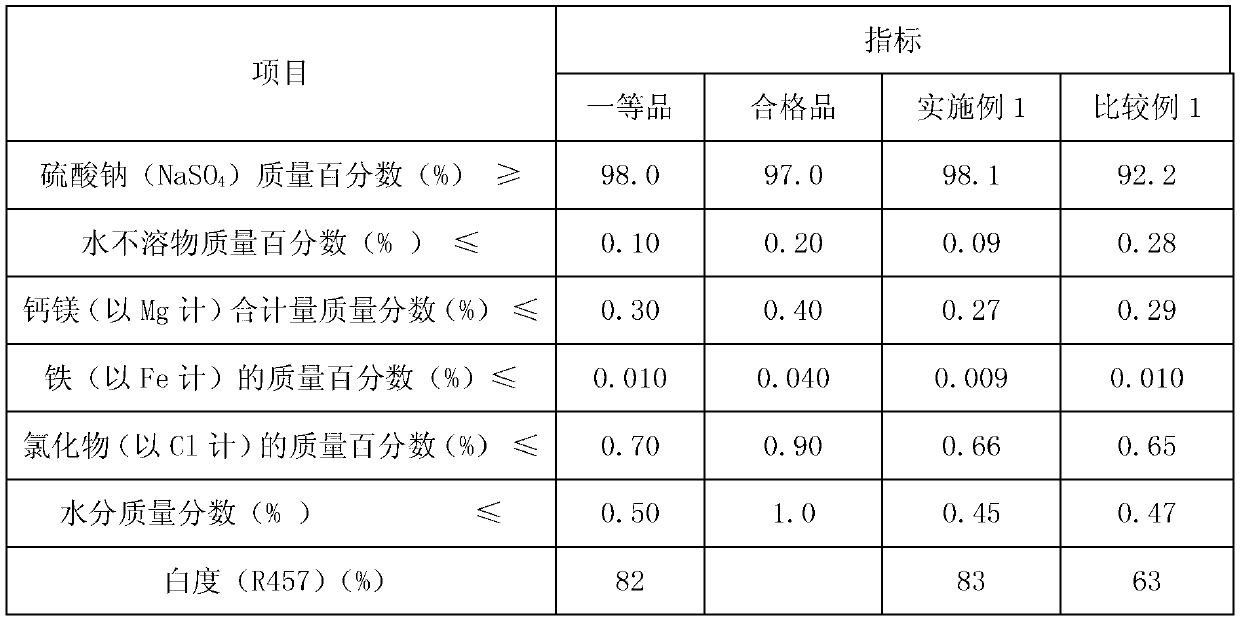

Dye acidic waste water treatment method and device

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

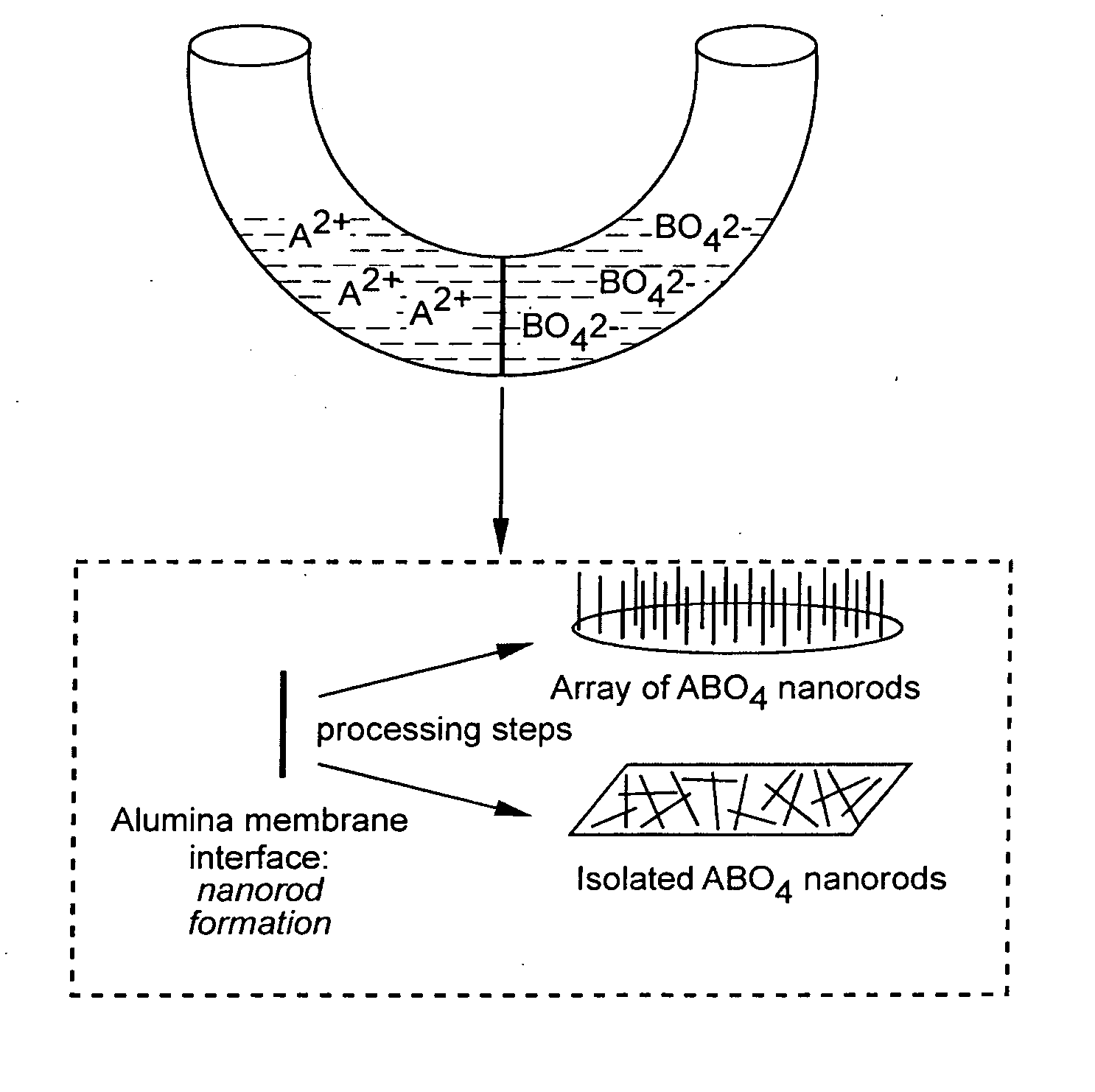

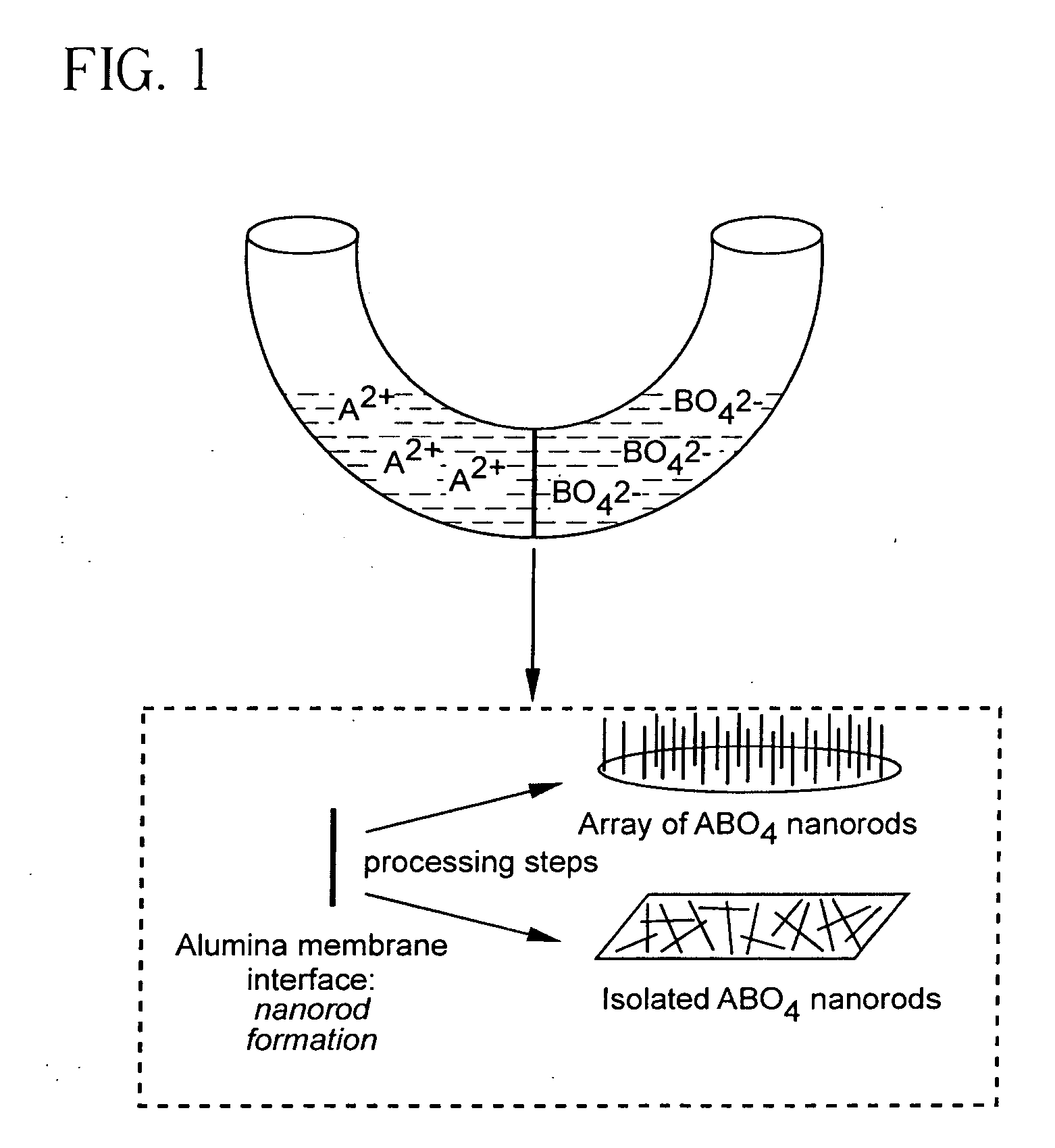

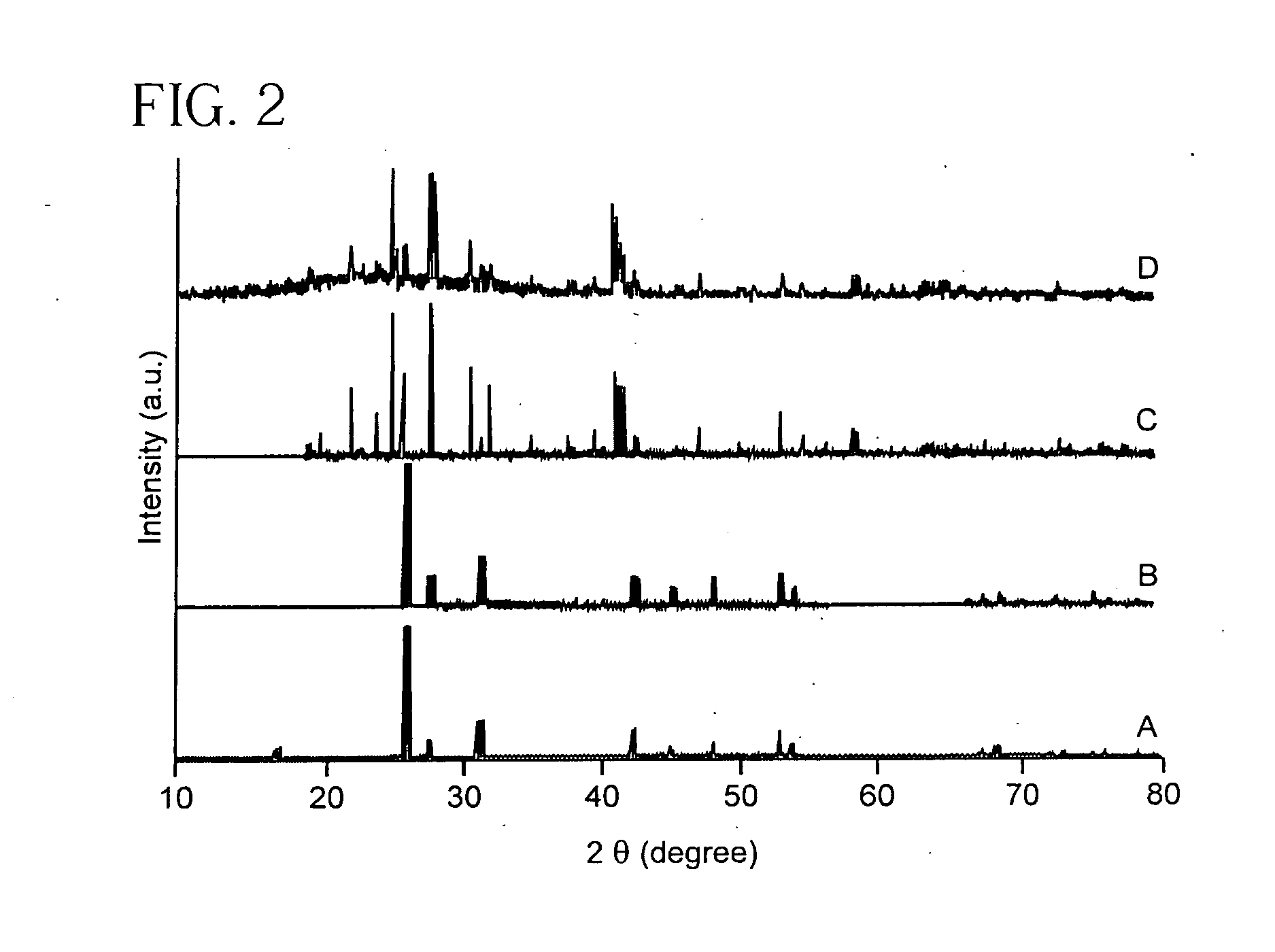

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

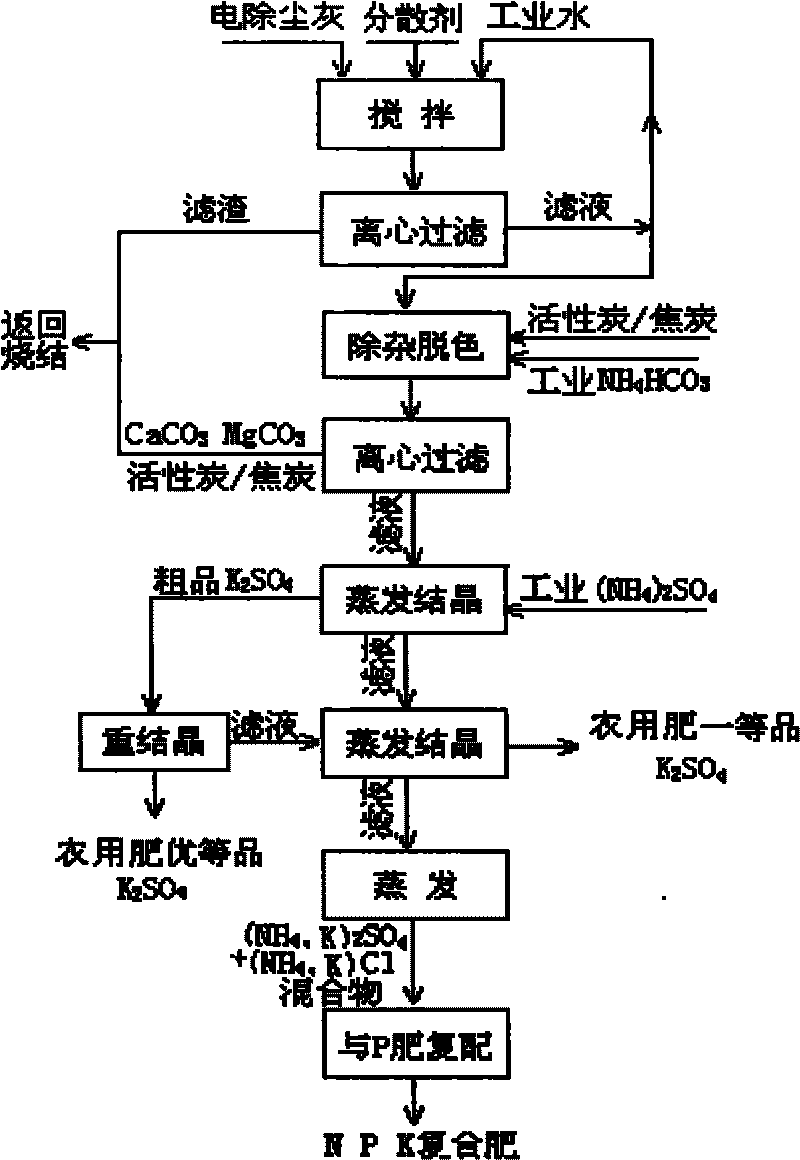

Method for recovering potassium elements from sintering ashes of steel and iron works and preparing potassium sulfate

ActiveCN101723410AEliminate erosionExtended service lifeAlkali metal sulfites/sulfatesPotassium fertilisersEvaporationImpurity

The invention discloses a method for recovering potassium elements from sintering ashes of steel and iron works and preparing potassium sulfate. The method comprises the following main steps of: A. removing potassium by adopting a circulating industry washing leaching solution mode, and carrying out solid-liquid separation on suspension liquid by adopting a centrifugal filtration or centrifugal precipitation mode; B. adding NH4HCO3 into the potassium removing solution for removing impurities, and adding active carbon or industrial coke powder for decoloration; and C. adding industrial (NH4)2SO4 for evaporation and crystallization to prepare the potassium sulfate. The invention can completely eliminate corrosion caused by circulating gathering of alkali metal of potassium, sodium and the like in the iron-making blast furnace and the adverse effects on sintering electric dedusting system efficiency and the like when the sintering ashes are reused as ingredients directly, and simultaneously realize high-efficiency recycling of the potassium resource.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

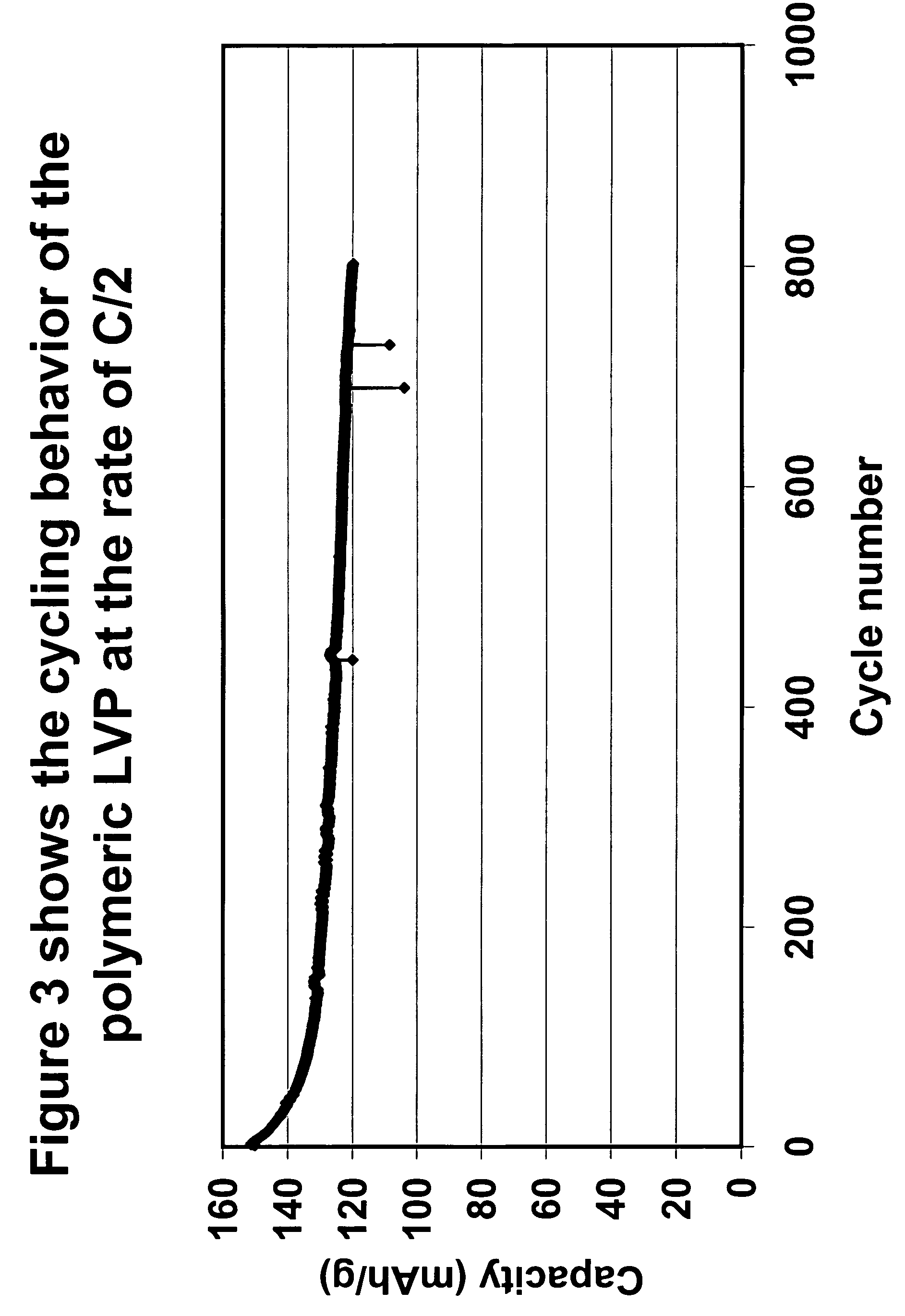

Synthesis of cathode active materials

The present invention relates to a method for preparing an electroactive metal polyanion or a mixed metal polyanion comprising forming a slurry comprising a polymeric material, a solvent, a polyanion source or alkali metal polyanion source and at least one metal ion source; heating said slurry at a temperature and for a time sufficient to remove the solvent and form an essentially dried mixture; and heating said mixture at a temperature and for a time sufficient to produce an electroactive metal polyanion or electroactive mixed metal polyanion. In an alternative embodiment the present invention relates to a method for preparing a metal polyanion or a mixed metal polyanion which comprises mixing a polymeric material with a polyanion source or alternatively an alkali metal polyanion source and a source of at least one metal ion to produce a fine mixture and heating the mixture to a temperature higher than the melting point of the polymeric material, milling the resulting material and then heating the milled material. It is another object of the invention to provide electrochemically active materials produced by said methods. The electrochemically active materials so produced are useful in making electrodes and batteries.

Owner:LITHIUM WERKS TECH BV +1

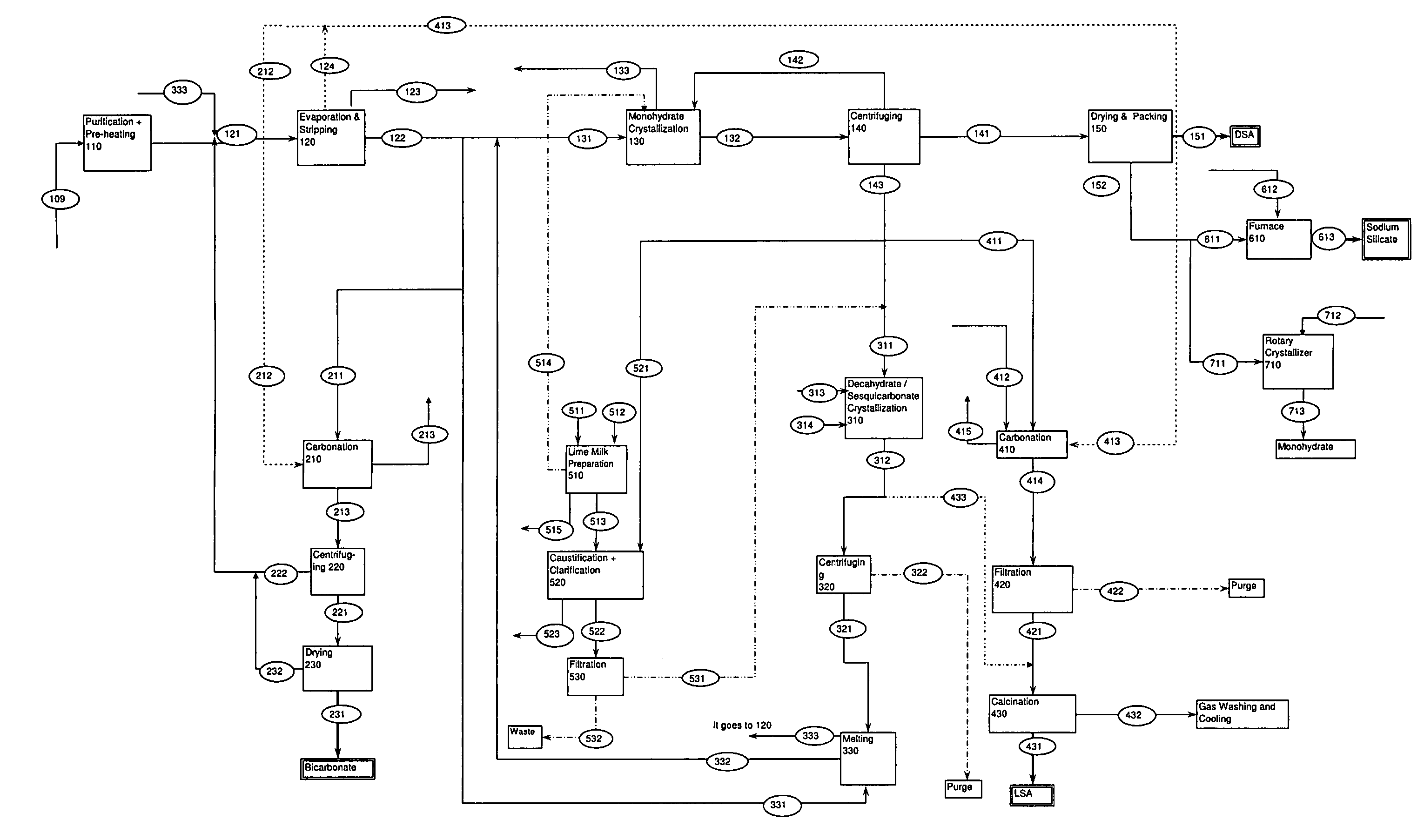

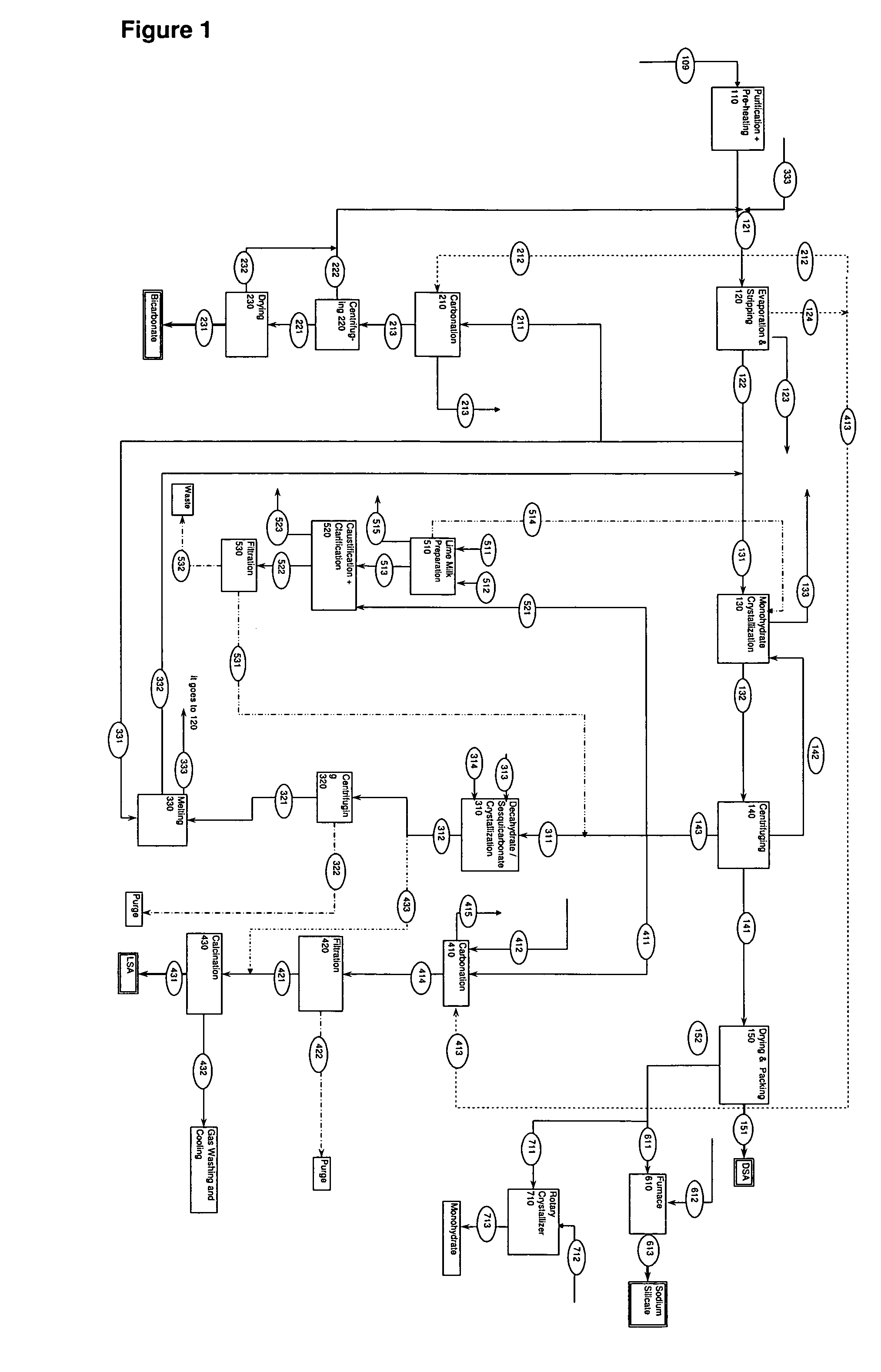

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

ActiveUS7507388B2Processing requirementLow production costCrystallization separationAlkali metal silicatesSodium bicarbonateEvaporation

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

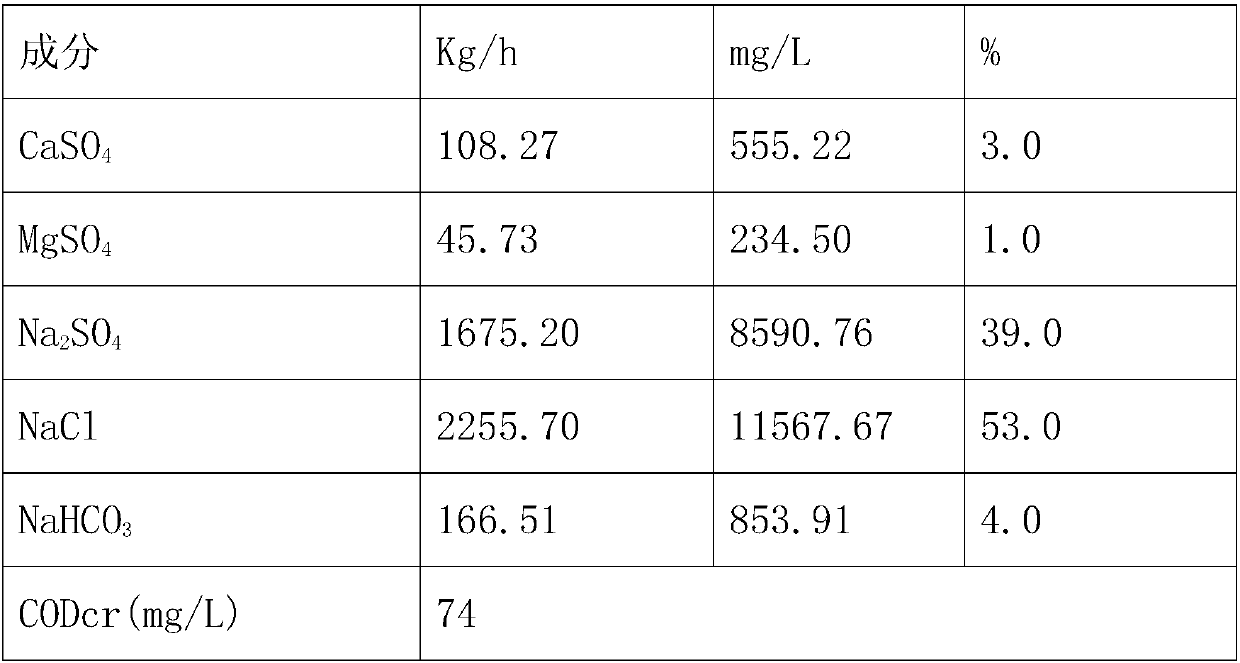

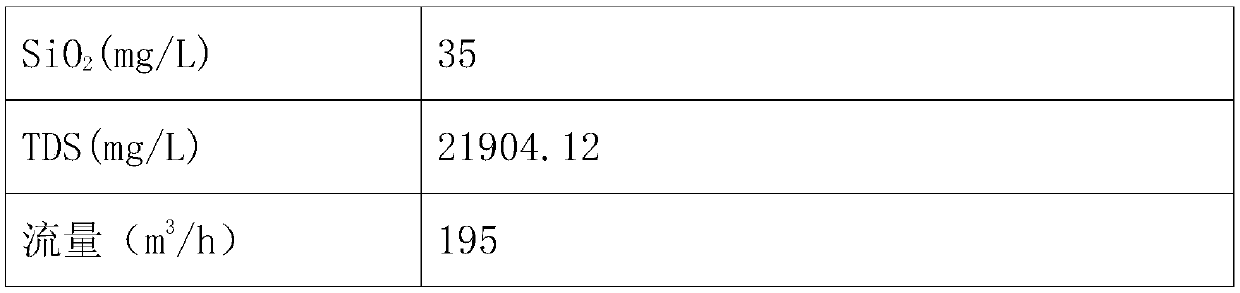

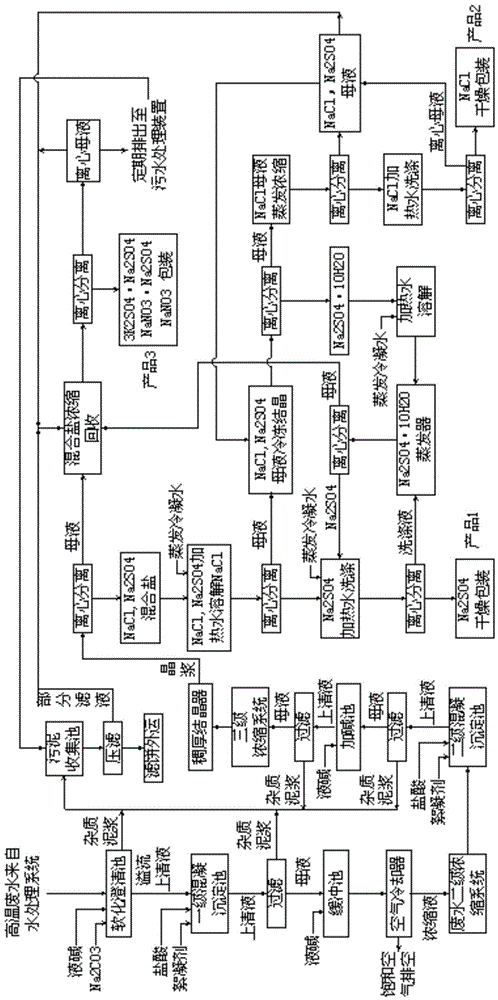

Comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in coal chemical industry

ActiveCN105585194AReduce consumptionReduce evaporative loadChemical industryTreatment involving filtrationHigh concentrationChemical oxygen demand

The invention relates to a comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in the coal chemical industry. After the high-concentration waste saline water is subjected to softening for impurity removal and subjected to coagulation sedimentation to remove COD (chemical oxygen demand), the water is concentrated by 20%-30% through an air cooler; then, the water enters second and third concentration systems and a salt mixture recovery system, and sodium sulfate, sodium chloride and sodium nitrate and potassium sulfate mixed salt are concentrated and separated with a multi-effect negative pressure evaporation method; condensed water is recycled. The purity of separated sodium chloride and the purity of separated sodium sulfate are higher than 99%, and sodium chloride and sodium sulfate can be directly sold. The method has remarkable economic benefits and social benefits, is environment-friendly, comprehensively reaches the standard and can be used for comprehensive treatment and utilization of similar high-concentration saline water in other industries, so that the environment-friendly and energy-saving requirements for full utilization of resources are met.

Owner:和易中诚环保科技有限公司

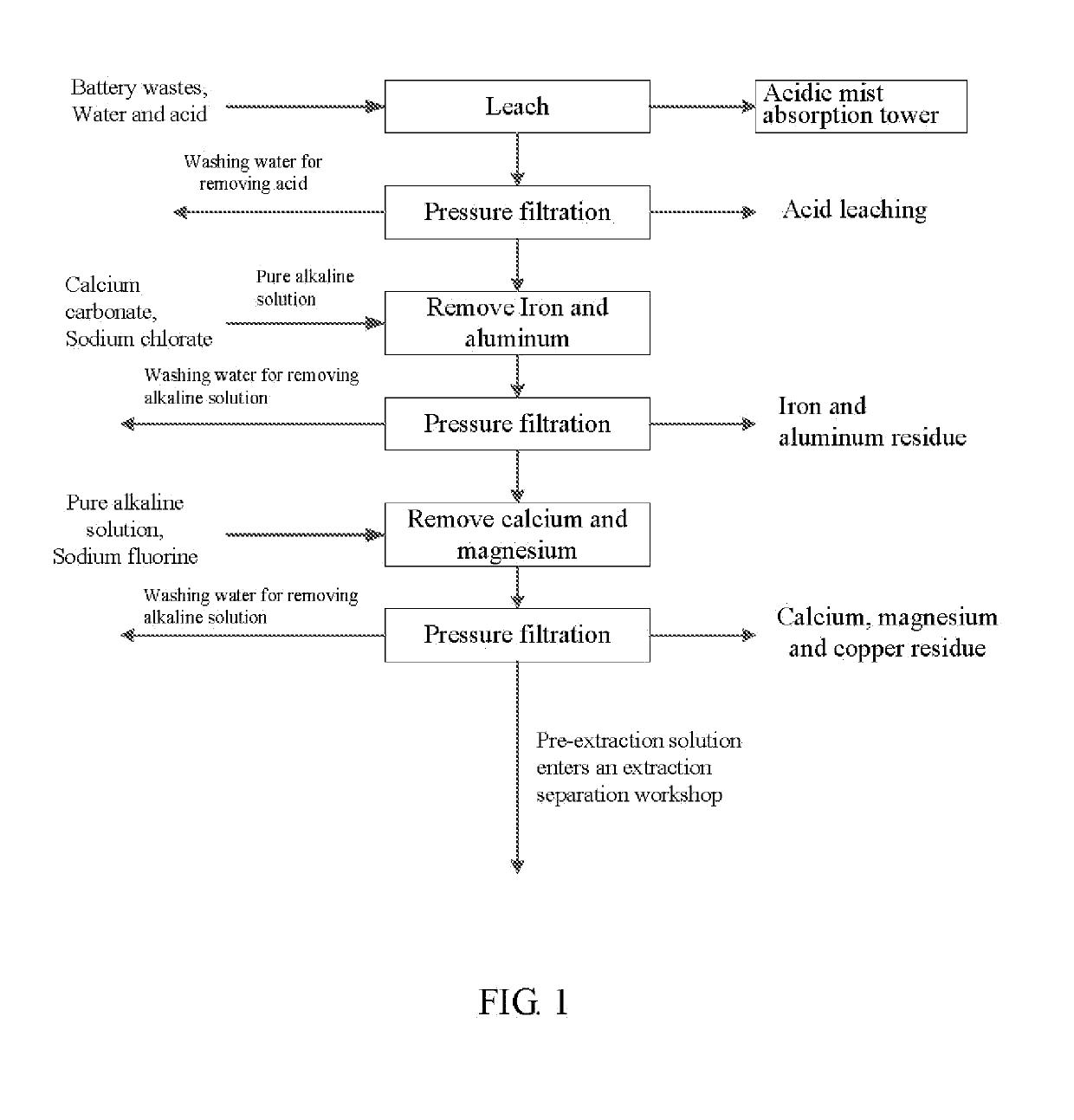

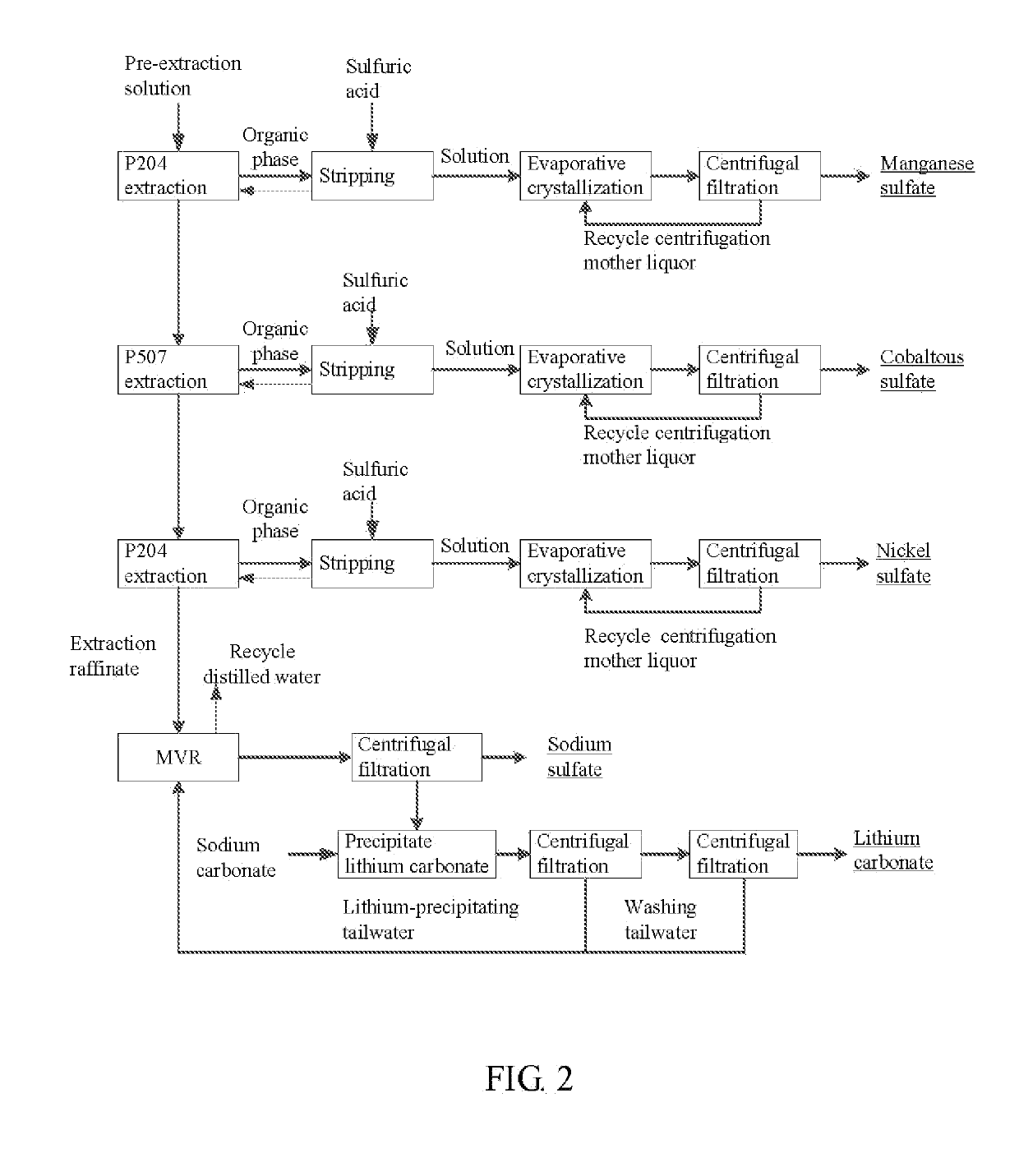

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

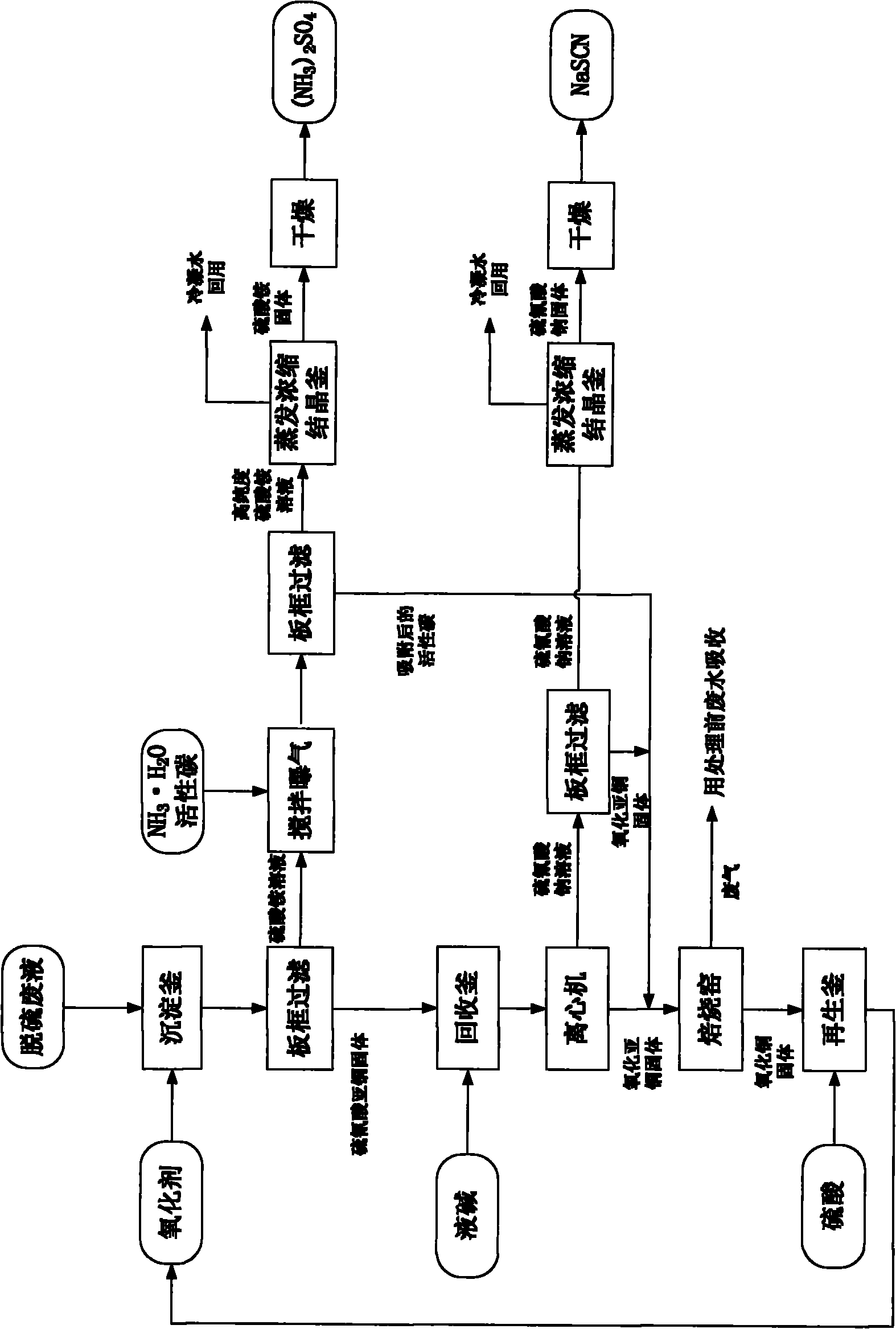

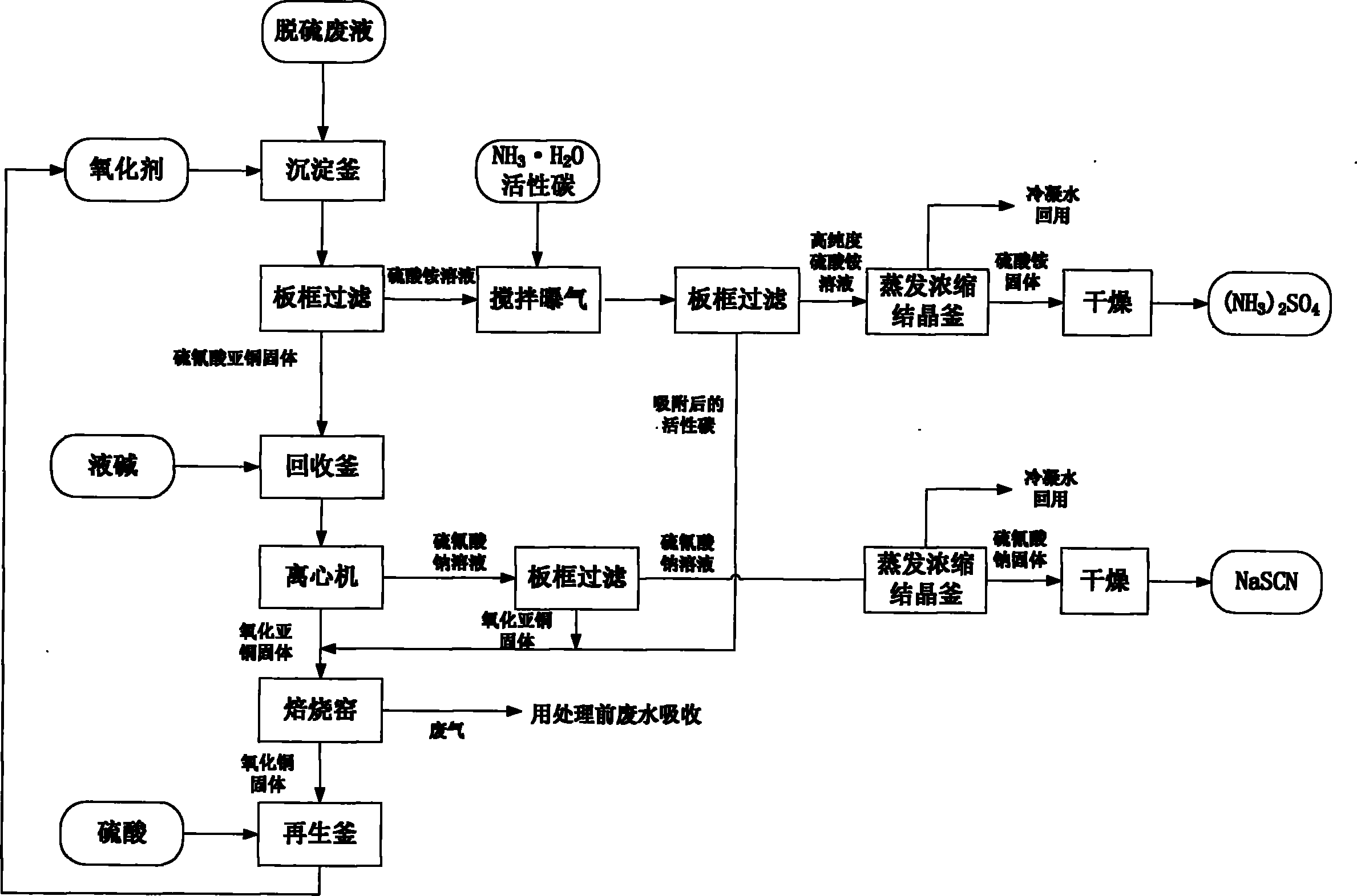

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Coking wastewater membrane concentration salt separation zero-emission treatment system and coking wastewater membrane concentration salt separation zero-emission treatment method

InactiveCN110734178AAvoid foulingGuaranteed uptimeSpecific water treatment objectivesChemical industryFiltrationReverse osmosis

The invention belongs to the technical field of water treatment, and particularly relates to a coking wastewater membrane concentration salt separation zero-emission treatment system and a coking wastewater membrane concentration salt separation zero-emission treatment method. The method comprises: coking wastewater pretreatment, wherein the coking wastewater pretreatment comprises full-automaticsand filtration, active carbon adsorption regeneration, ultra-filtration and softening; membrane salt separation and concentration treatment, wherein the membrane salt separation and concentration treatment comprises low-pressure nano-filtration, high-pressure nano-filtration, purification nano-filtration and reverse osmosis treatment; and concentration treatment, fluorine and silicon removal, electrodialysis concentration and evaporative crystallization, wherein an industrial-grade sodium chloride product with a purity of more than 92% is obtained, a sodium sulfate concentrated solution enters a freezing crystallization device to generate mirabilite, the mirabilite is heated and melted and then enters an evaporation crystallization, centrifugation and drying system, and an industrial-grade sodium sulfate product with a purity of more than 95% is obtained. According to the invention, with the system and the method, the zero discharge of coking wastewater is achieved, and the process technology is an innovative coking wastewater zero discharge process at home and abroad.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

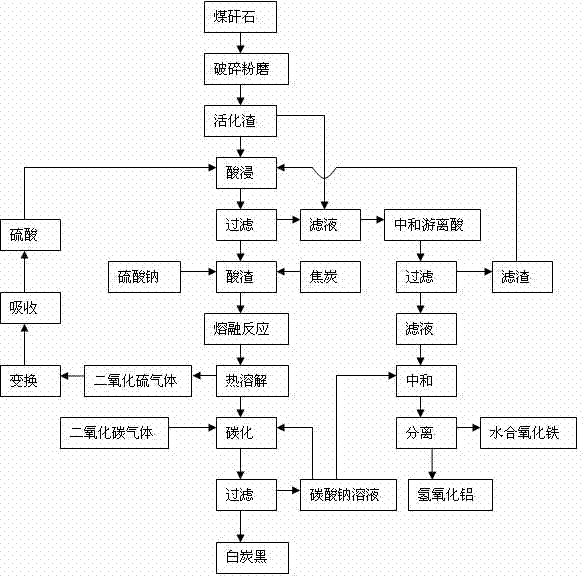

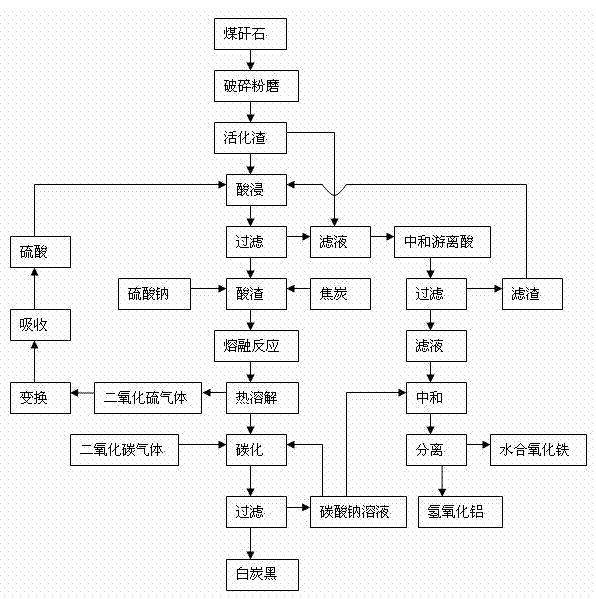

Comprehensive extraction method of ferro-silico-aluminum in gangue

ActiveCN102515279AGood slag activityMeet operating conditionsSilicaIron oxides/hydroxidesAluminium hydroxideSlag

The invention discloses a comprehensive extraction method of ferro-silico-aluminum in gangue, comprising the following steps of: using gangue as a raw material, crushing, grinding, activating, carrying out acid leaching, filtering, neutralizing free acid in the acid leaching filtered solution by the use of active slag, filtering to obtain a neutralized acid leaching solution, adding a sodium carbonate solution into the neutralized acid leaching solution, adjusting pH value, separating iron and aluminium to obtain hydrous iron oxide, aluminium hydroxide and a by-product sodium sulphate, adding sodium sulphate and coke into the acid leaching slag which has undergone acid leaching and filtration, carrying out a high-temperature melt reaction to recover silicon so as to prepare soluble glass, simultaneously recovering sulfur dioxide to prepare sulfuric acid, reusing sulfuric acid for the acid leaching treatment, diluting the soluble glass by the use of a sodium carbonate solution, carrying out carborization to obtain white carbon black, and reusing the carbonating solution for iron-aluminium separation. The method provided by the invention has characteristics of wide application range of the raw material gangue, high comprehensive recovery rate, no output of by-products, less residue amount and the like, provides a novel technological process for high-efficiency recovery of ferro-silico-aluminum from gangue, and expands the ways of gangue application.

Owner:KUNMING UNIV OF SCI & TECH +1

Sodium sulfate and sodium chloride mixed wastewater separation method and separation apparatus thereof

InactiveCN105967208AAchieve separationAchieve purificationAlkali metal chloridesAlkali metal sulfites/sulfatesWastewaterEvaporation

The invention relates to a sodium sulfate and sodium chloride mixed wastewater separation method and a separation apparatus thereof. The separation method comprises the following steps: increasing the sodium chloride content of sodium sulfate and sodium chloride mixed wastewater to precipitate parts of sodium sulfate, evaporating the mixed wastewater to increase the concentration in order to respectively crystallize the evaporated wastewater to precipitate sodium chloride and sodium sulfate mixed crystals, returning the obtained wastewater, mixing and dissolving the returned wastewater in the new sodium chloride content of sodium sulfate and sodium chloride mixed wastewater, and precipitating sodium sulfate crystals and sodium chloride crystals step by step to finally realize sodium sulfate and sodium chloride separation. The quantity of energy consumed in the evaporation mode treatment of wastewater in the method is same to the quantity of energy consumed in the evaporation mode treatment of wastewater in the prior art. The method and the apparatus avoid the problem of generation of a large amount of solid wastes after wastewater evaporation in the prior art, realize sodium sulfate and sodium chloride separation and purification without adding other reagents, truly realize zero discharge, and allow separated sodium sulfate and sodium chloride to be highly pure and to be directly used and sold as industrial products.

Owner:上海亿华科技有限公司 +2

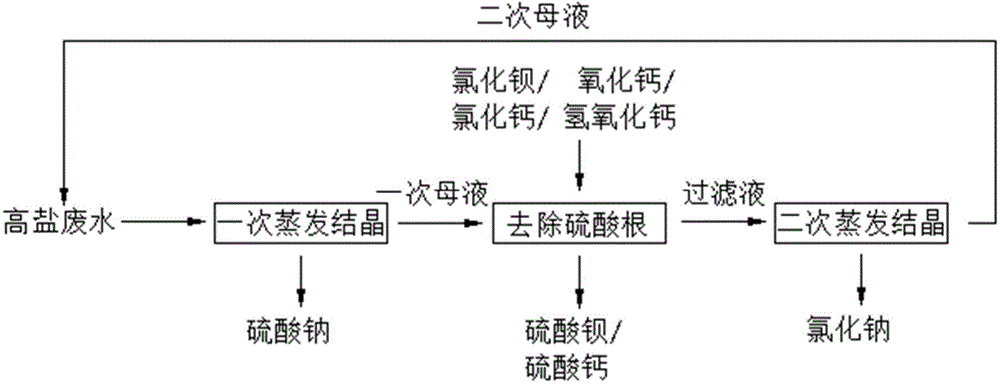

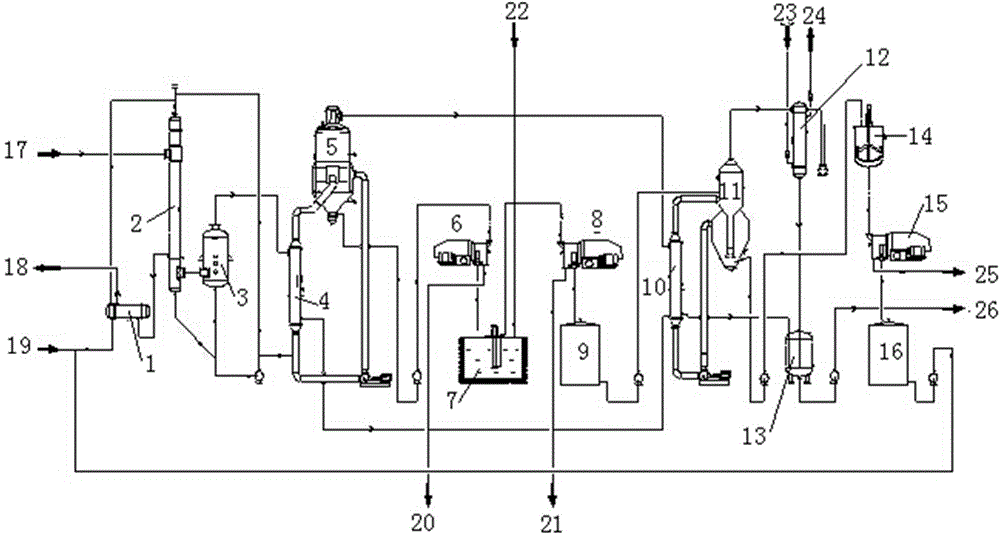

Recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN104973726AHigh purityMeet quality requirementsEnergy based wastewater treatmentMultistage water/sewage treatmentResource utilizationSULFATE ION

The invention discloses a recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate, and belongs to the field of industrial wastewater treatment. According to the recovery processing method, sodium chloride and sodium sulfate are recycled via primary evaporative crystallization, removing of sulfate ions via adding of materials and generation of precipitations, and secondary evaporative crystallization. The recovery processing method can be used for effective recovery of sodium chloride and sodium sulfate in coal chemical industry high salinity wastewater; process conditions are simple and stable; the recovery processing method is convenient for industrialized popularization; recovered sodium chloride and sodium sulfate are capable of satisfying quality requirements of industrial-grade products, and can be recycled and reused directly or be sold as by-products; processing of high salinity wastewater is realized; environmental requirements are satisfied; waste is changed into valuables; salt resource utilization is realized; and factory income is increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Aqueous borohydride compositions

InactiveUS6866689B2Use minimizedHigh catalytic efficiencyOther chemical processesMonoborane/diborane hydridesHydrogenSodium borohydride

An aqueous fuel for generating hydrogen includes alkaline aqueous composition of about 17 to 37 mole percent of a sodium borohydride, and from about 0.001 to 1 mole percent of sodium hydroxide.

Owner:MONTGOMERY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com