Method for recovering potassium elements from sintering ashes of steel and iron works and preparing potassium sulfate

A technology of sintered ash and potassium sulfate, applied in chemical instruments and methods, alkali metal sulfite/sulfite, potash fertilizer, etc., can solve the problem of increased energy consumption in device operation, increased specific resistance of dust particles, and excessive dust concentration and other problems, to achieve the effect of simple process flow, efficient recycling and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

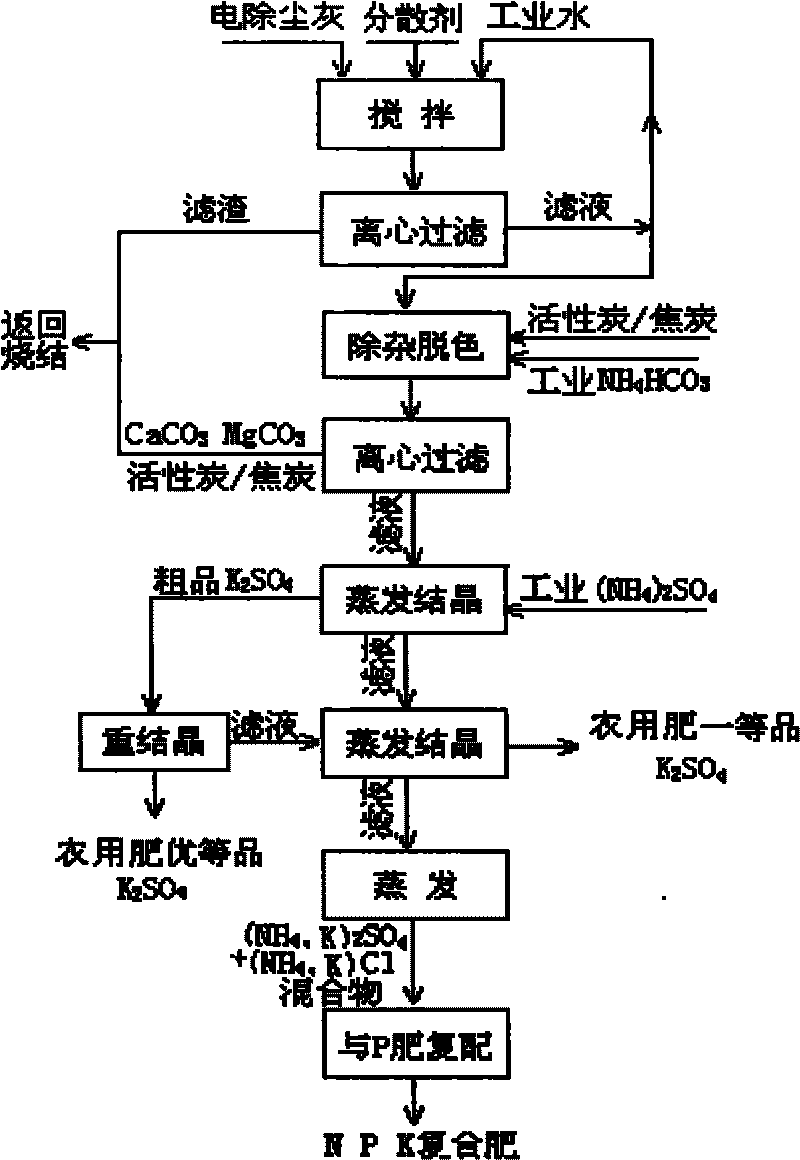

Method used

Image

Examples

Embodiment 1

[0014] Take 250 kg of sintered ash containing 8% potassium at room temperature, add it to 1000 L of water (solid-to-liquid ratio is 1:4), and add 0.50 kg of dispersant to it, and then stir for 30 min at a stirring speed of 80 r / min. After the stirring is completed, the sintered ash suspended mud is centrifugally filtered, and the obtained filtrate is used for circulating water to elute potassium twice according to the above method, and the obtained filter residue is mixed as iron ore sintering material. Extract the filtrate with a pH value of about 11.2, and add 6kg of industrial NH 4 HCO 3 , 0.5kg of powdered activated carbon, stirred at 80r / min for 15min, and added 0.60kgKOH to keep the pH of the system at about 8.5, so that the precipitation reaction is complete. After impurity removal and decolorization are completed, the suspension is centrifugally filtered, and the filter residue is returned as iron ore sintering ingredients, and 96kg of industrial (NH 4 ) 2 SO 4 , u...

Embodiment 2

[0017] Take 200kg of sintered ash containing 10% potassium at room temperature, add it to 800L water (solid-to-liquid ratio is 1:4), add 0.75kg dispersant to it, and stir at 80r / min for 20min. After the stirring is completed, the sintered ash suspended slurry is centrifugally filtered, and the obtained filtrate is used for circulating water to elute potassium three times according to the above method, and the obtained filter residue is mixed as iron ore sintering material. Extract the filtrate with a pH value of about 11.5, and add 8kg of industrial NH 4 HCO 3 1. 15 kg of industrial coke powder with a particle size of 60 mesh was stirred for 15 min at a speed of 80 r / min to remove impurities and decolorize the solution. During the stirring process, add 0.75kg of industrial KOH caustic soda to keep the pH of the system at about 8.5, so that the precipitation reaction is complete. The suspension is centrifugally filtered, and the filter residue is returned as iron ore sinterin...

Embodiment 3

[0019] Take 400kg of sintered ash containing 8% potassium at room temperature, add it to 2000L industrial water (solid-to-liquid ratio is 1:5), and add 2kg of dispersant therein, and then stir at 80r / min for 30min. After the stirring is completed, the sintered ash suspended slurry is centrifugally filtered, and the obtained filtrate is used for circulating water to elute potassium four times according to the above method, and the obtained filter residue is mixed as iron ore sintering material. Extract the filtrate with a pH value of about 10.5, add 15kg NH therein 4 HCO 3 , 40kg of industrial coke powder with a particle size of 70 mesh, stirred at 80r / min for 12min to remove impurities and decolorize the solution. Add 3.0kg of industrial KOH caustic soda with a content of 85% during the stirring process to keep the pH of the system at about 8.5, so that the precipitation reaction is complete. The suspension is centrifugally filtered, and the filter residue is returned as iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com