Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1511results about How to "Improve drainage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

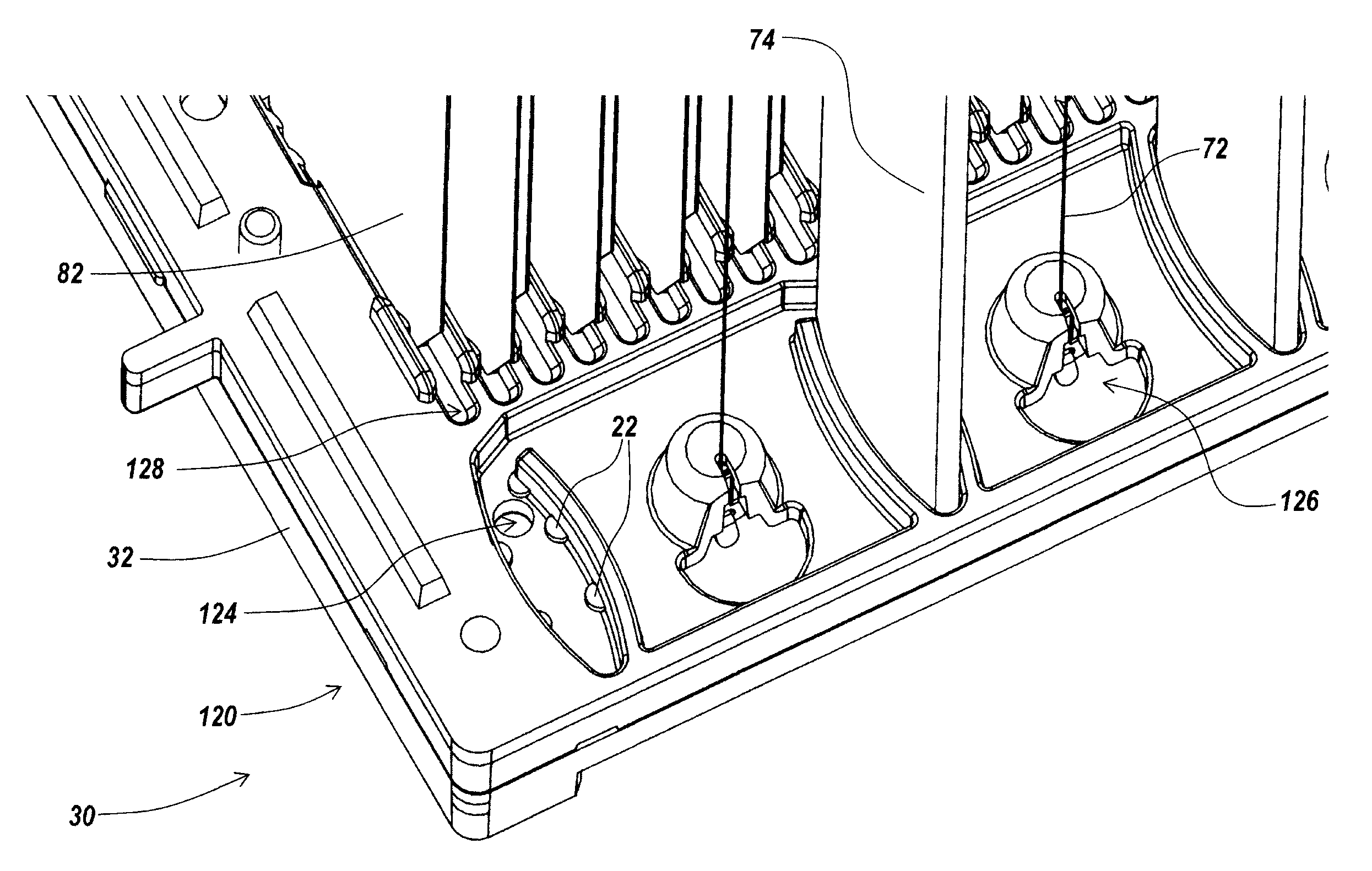

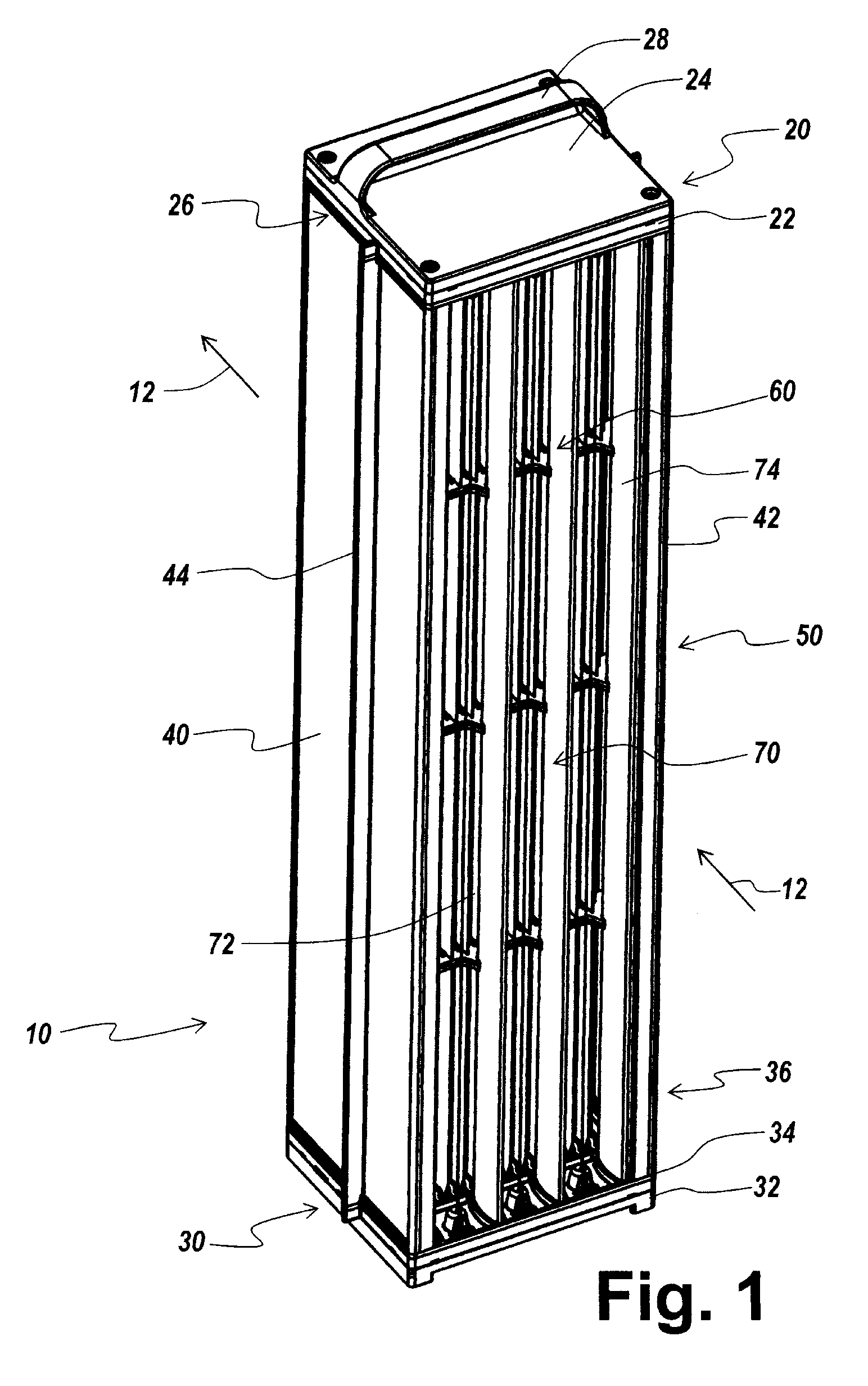

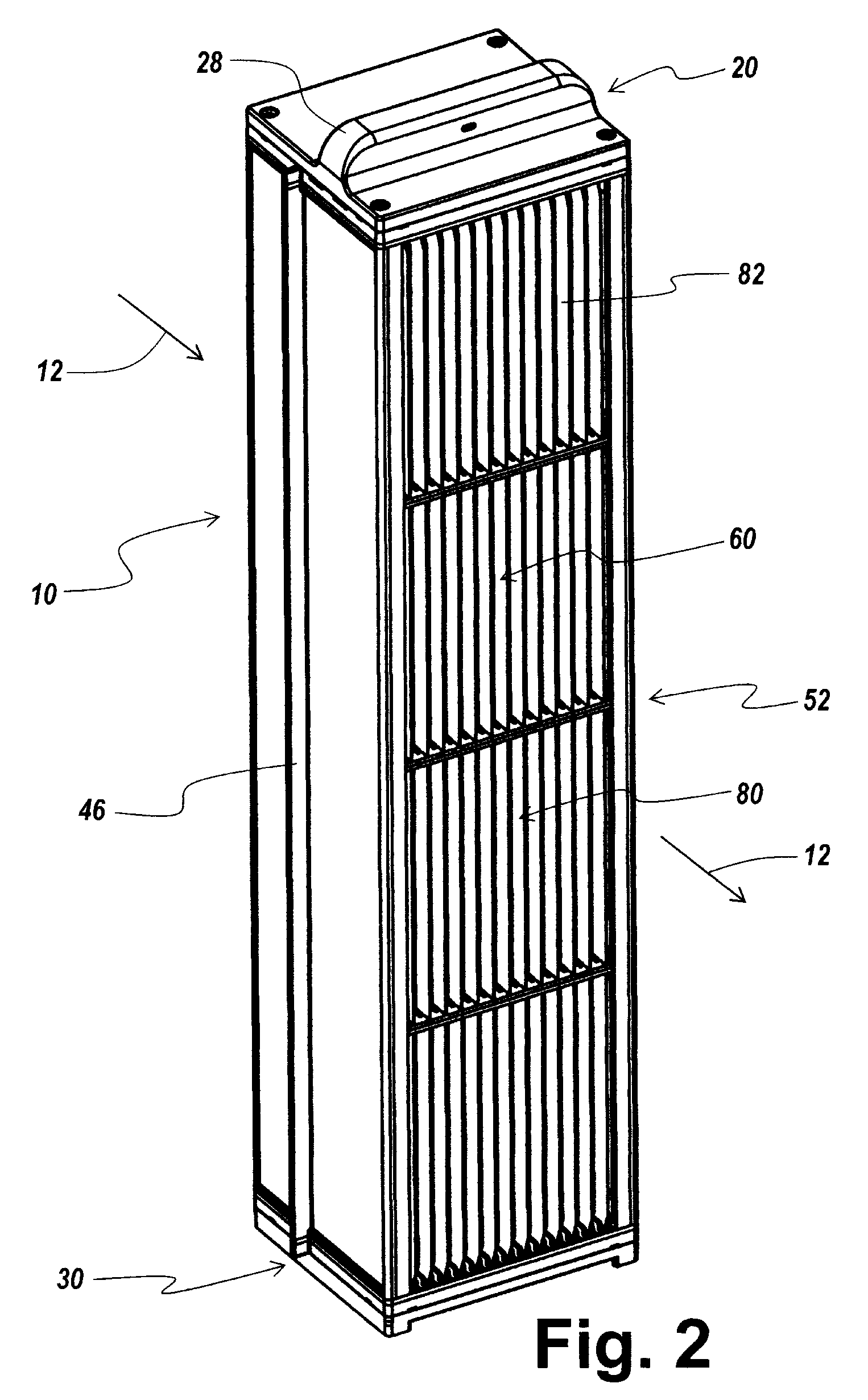

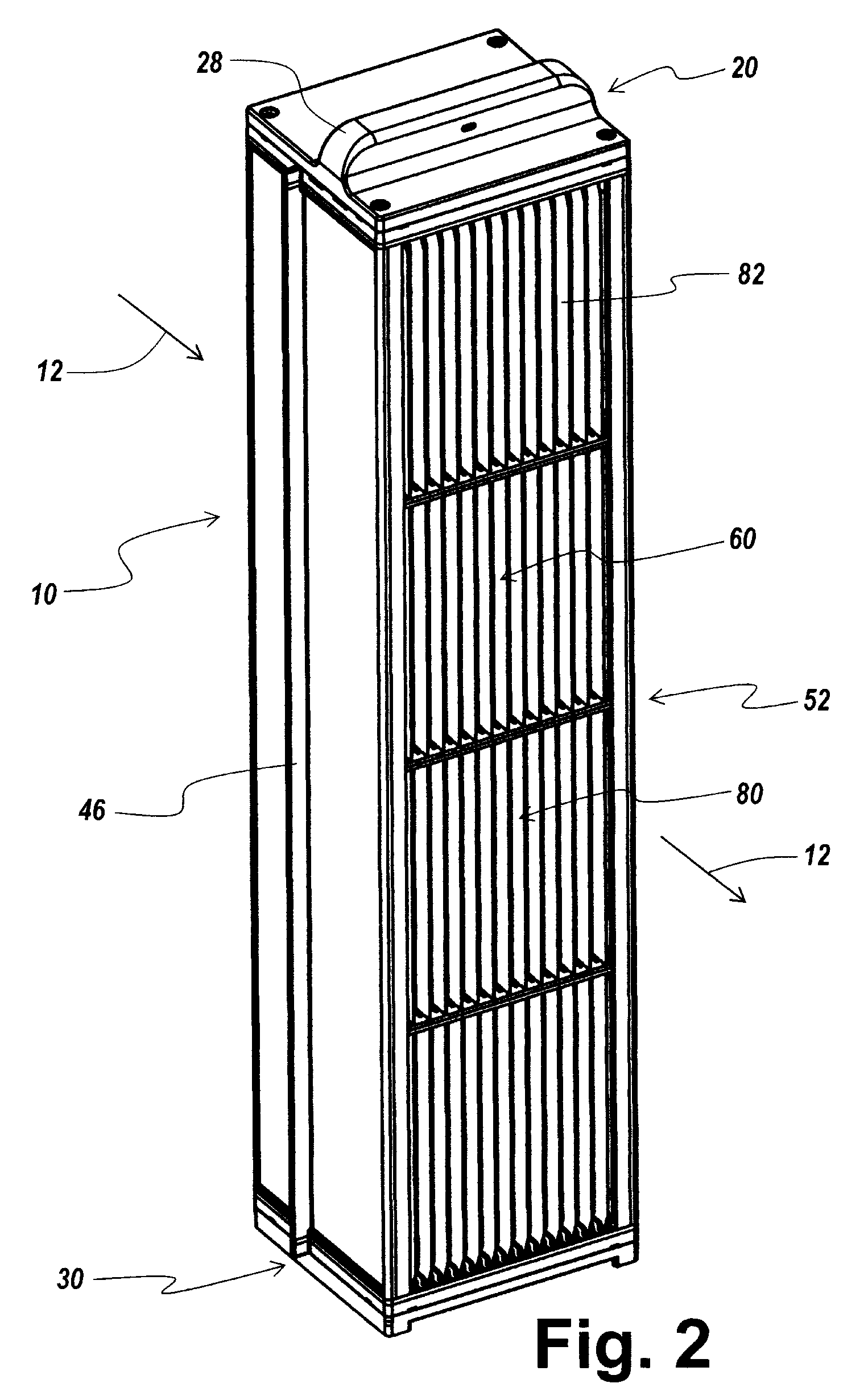

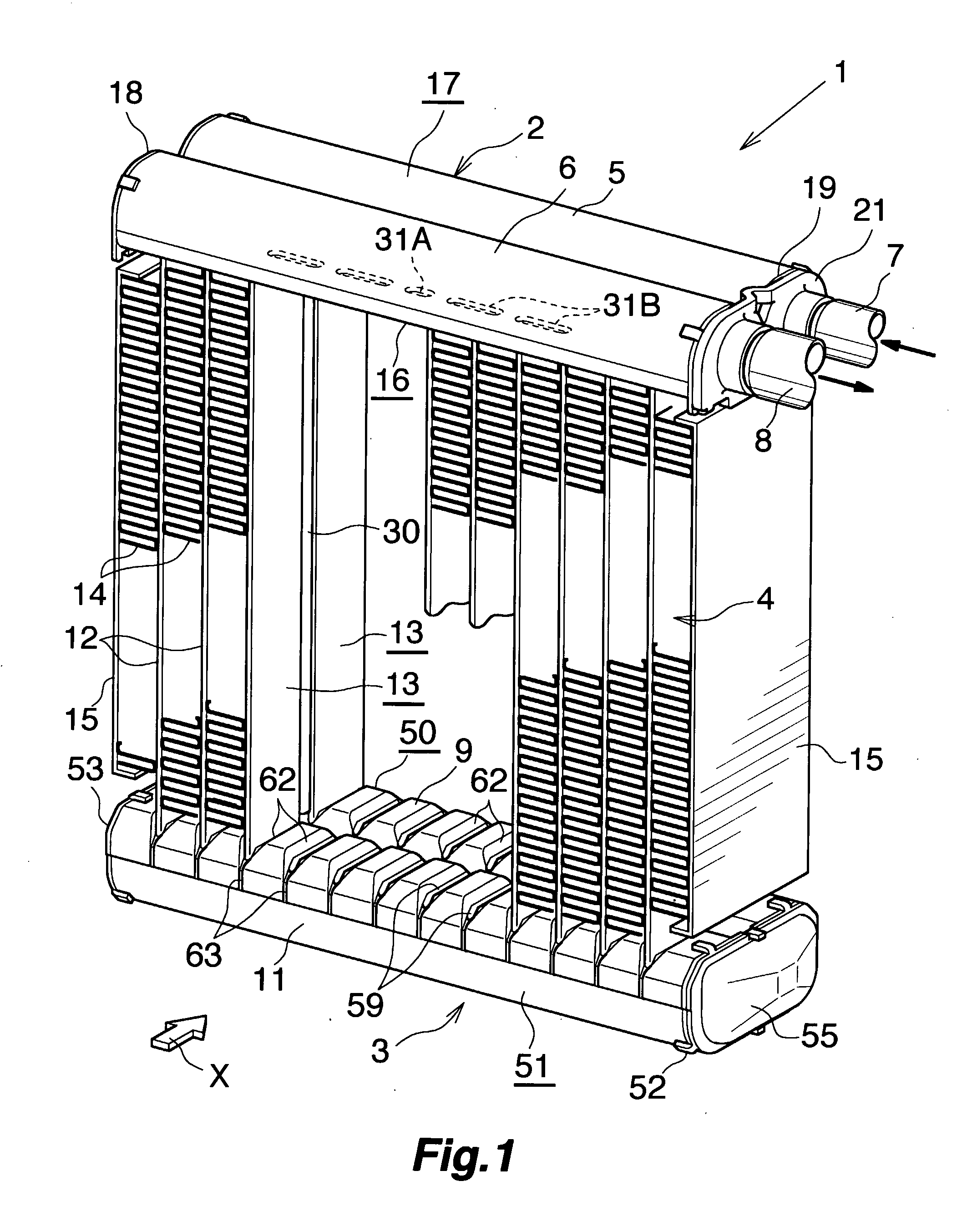

Electrostatic filter cartridge for a tower air cleaner

InactiveUS20080314250A1Improve removal efficiencyImprove drainage capacityHuman health protectionMagnetic separationParticulatesTower

The disclosed electrostatic precipitator cartridge for a tower air cleaner in accord with the present invention is low-cost, because constructed of injected molded plastics material and stamped and extruded metal components. It is easy to clean, not only because it's constitutive metal parts and plastic components are machine washable but also because the cartridge as a whole is machine washable, the pieces and components are designed and arranged to prevent intracartridge fluid buildup or retention after washing, thereby eliminating any electrical shorting or arcing or other undesirable phenomena resulting therefrom that could interfere with the operation of the electrostatic filter cartridge. It is mechanically stable and has high particulate collection efficiency because it's ionizer bars have a predetermined preferably air foil shape that provides improved ionization efficiency and that imparts improved torsion stability rendering it possible to provide taller electrostatic filter cartridges and / or greater cleaning power.

Owner:LASKO OPERATION HLDG LLC

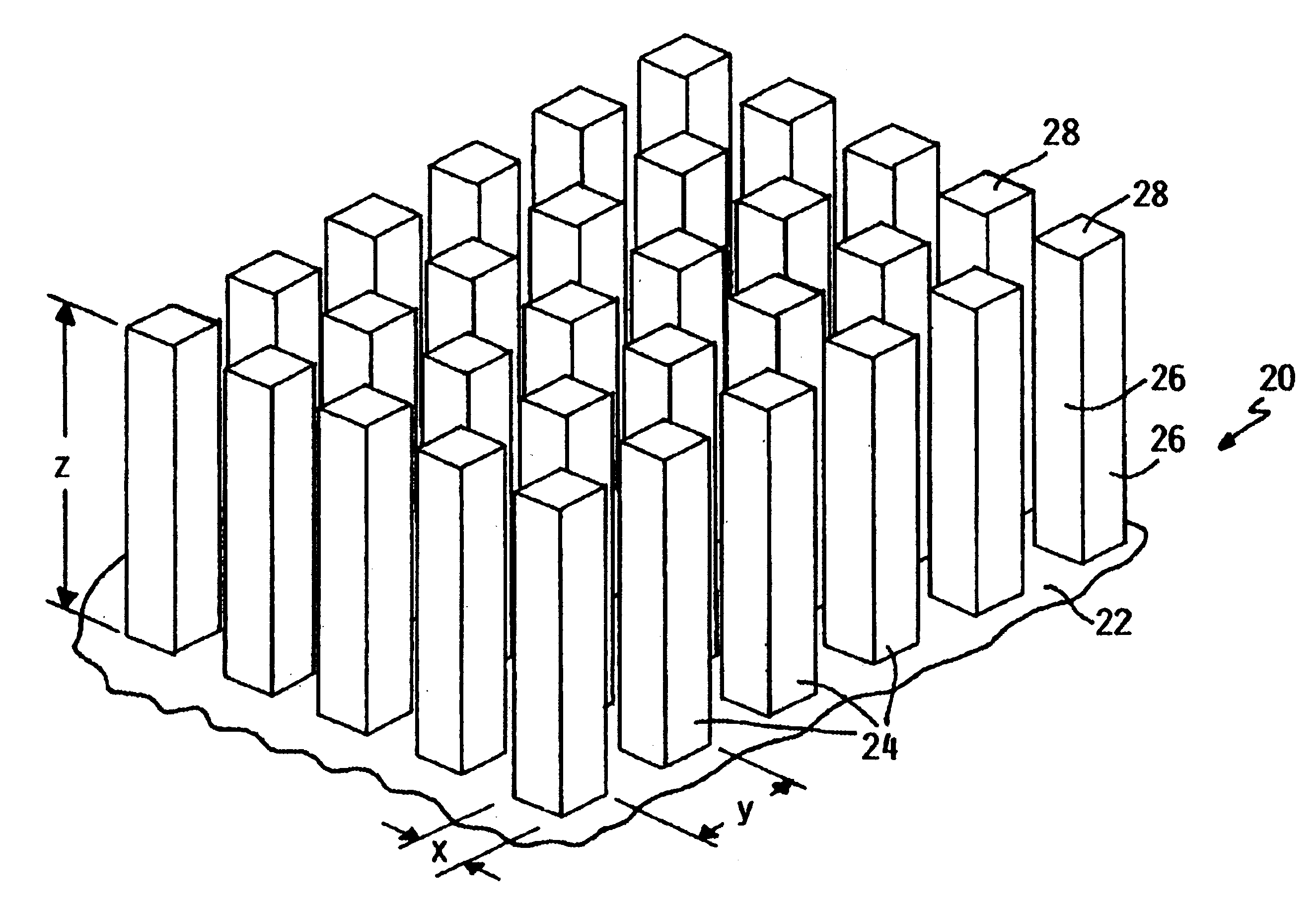

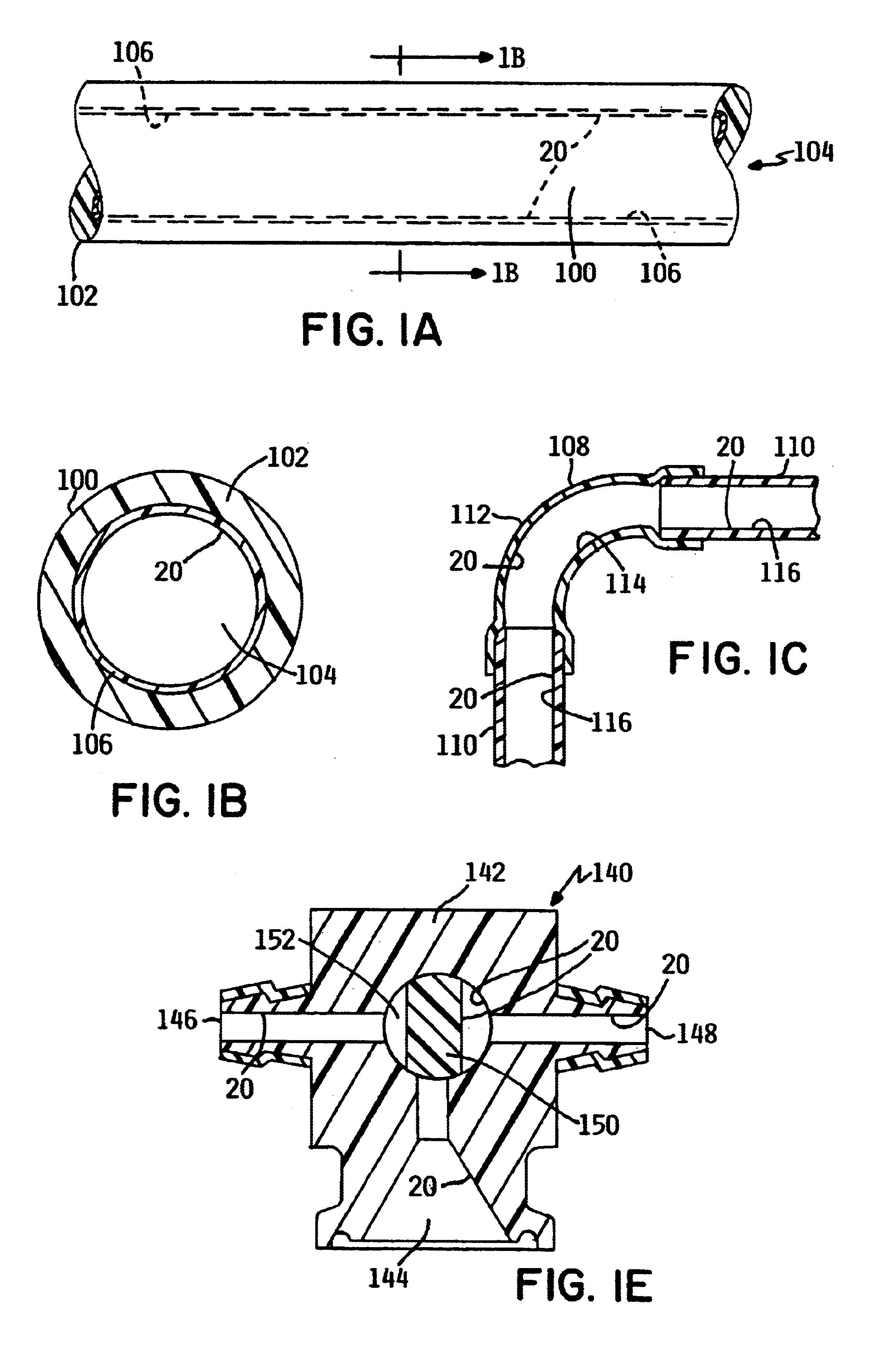

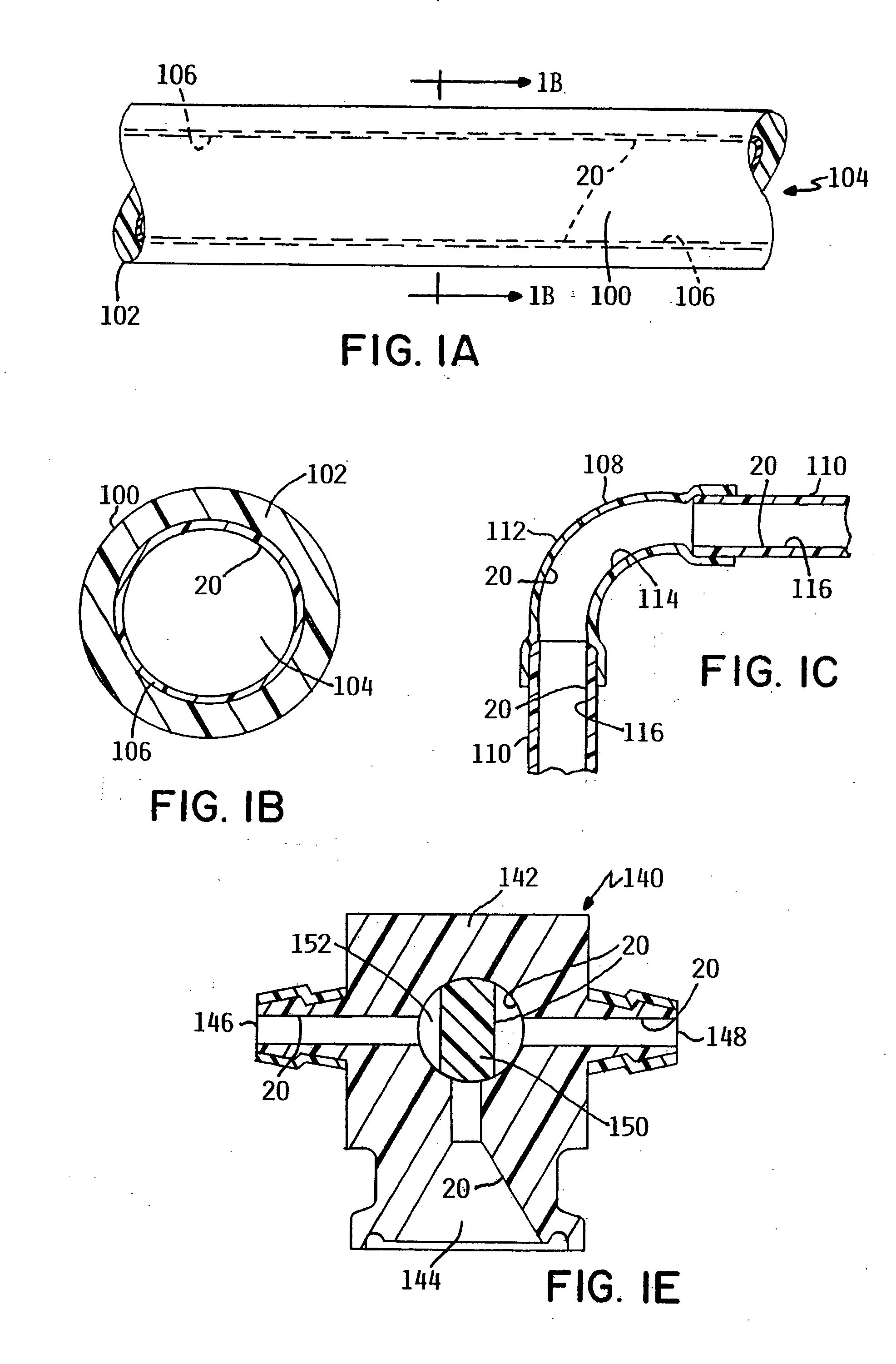

Fluid handling component with ultraphobic surfaces

InactiveUS6845788B2Reduce frictionImprove system efficiencyMaterial nanotechnologyFouling preventionVolumetric Mass DensityContact line

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

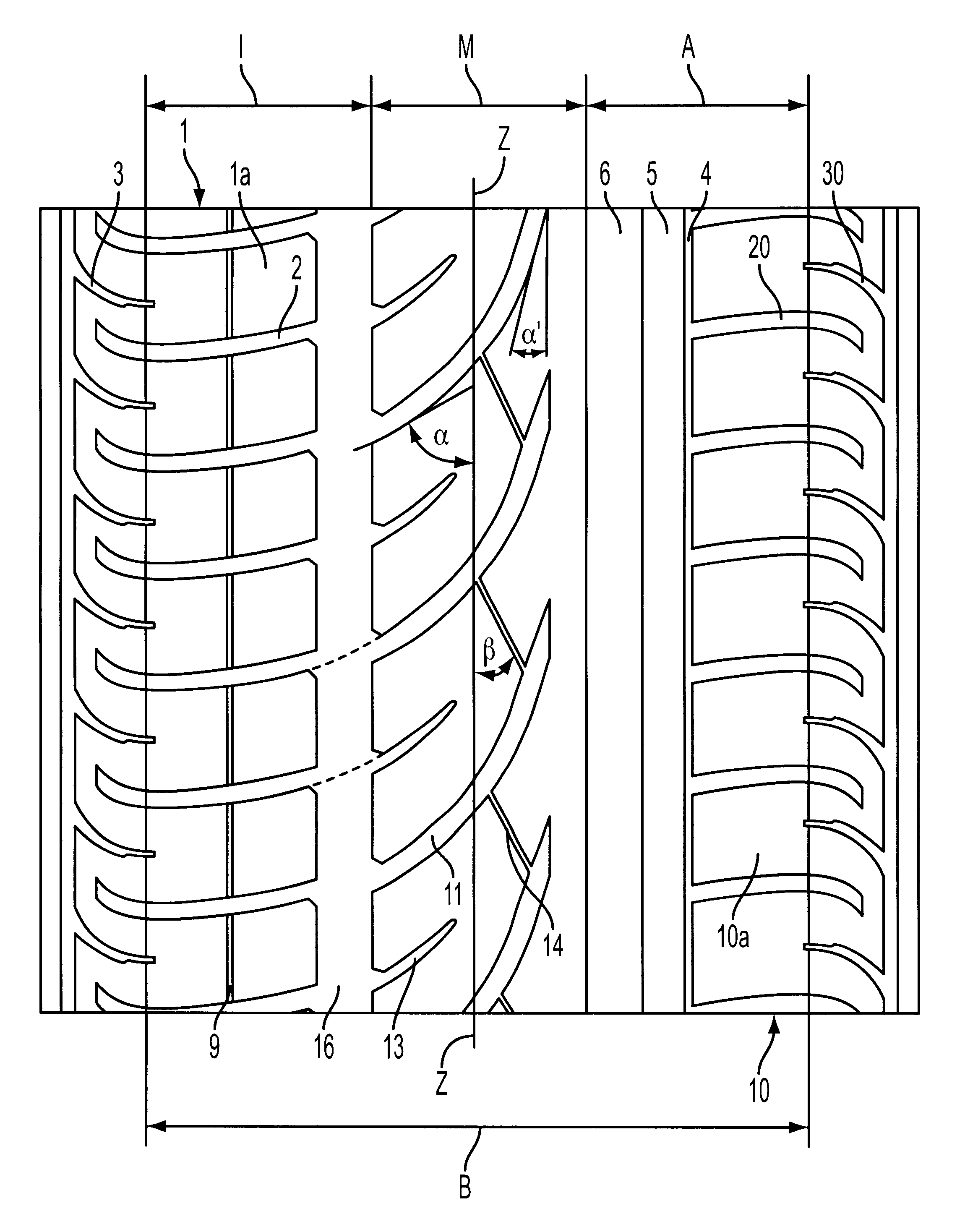

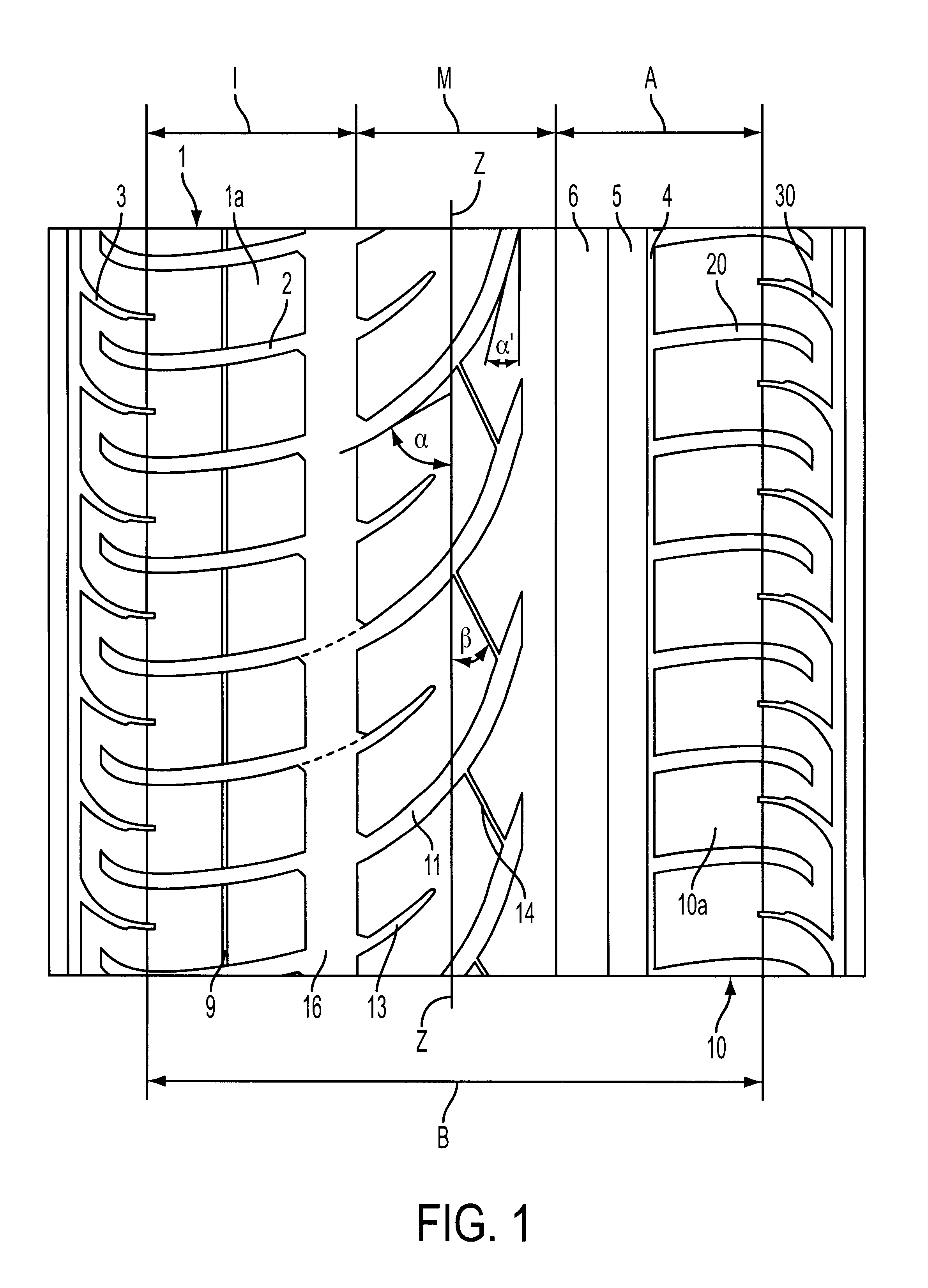

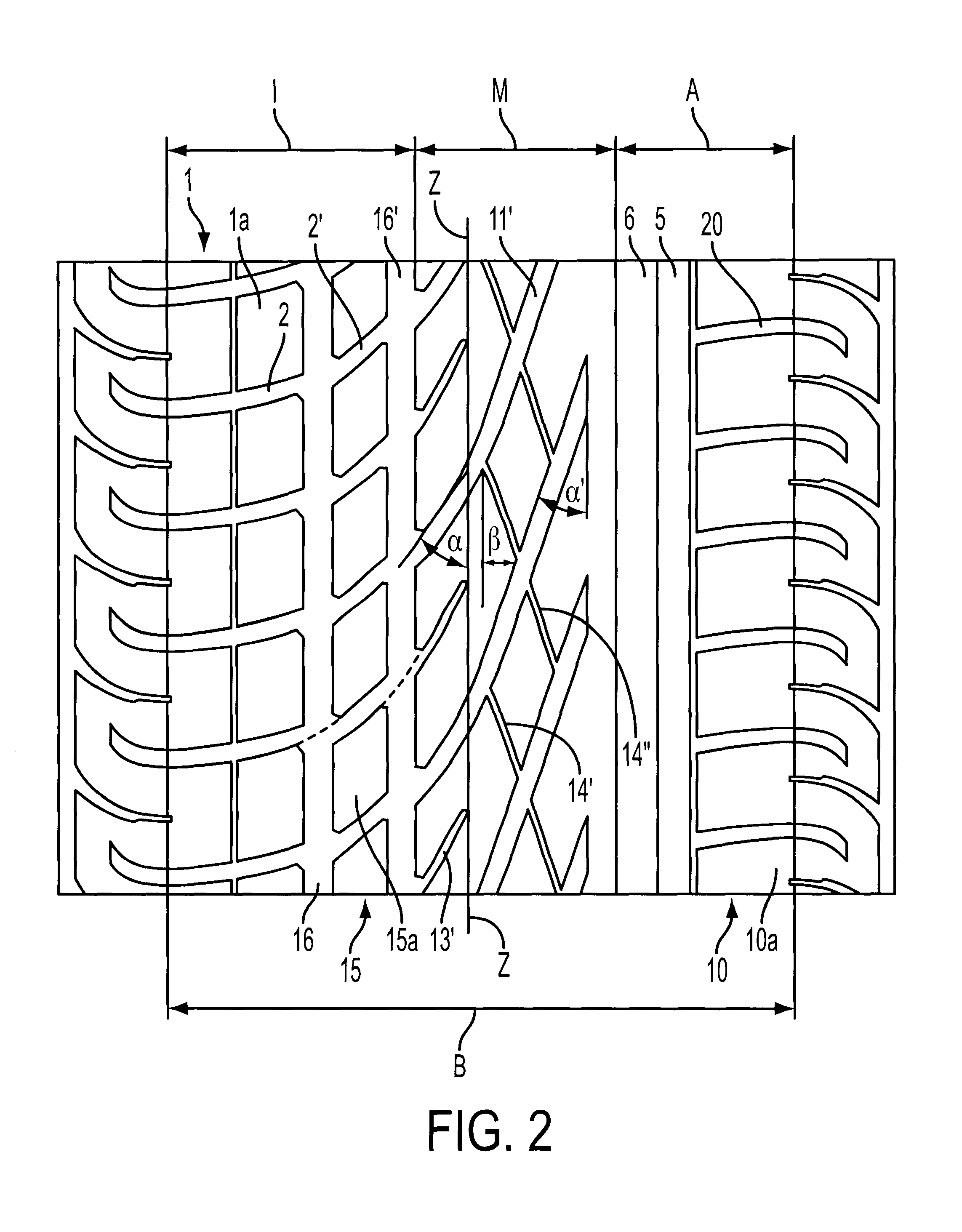

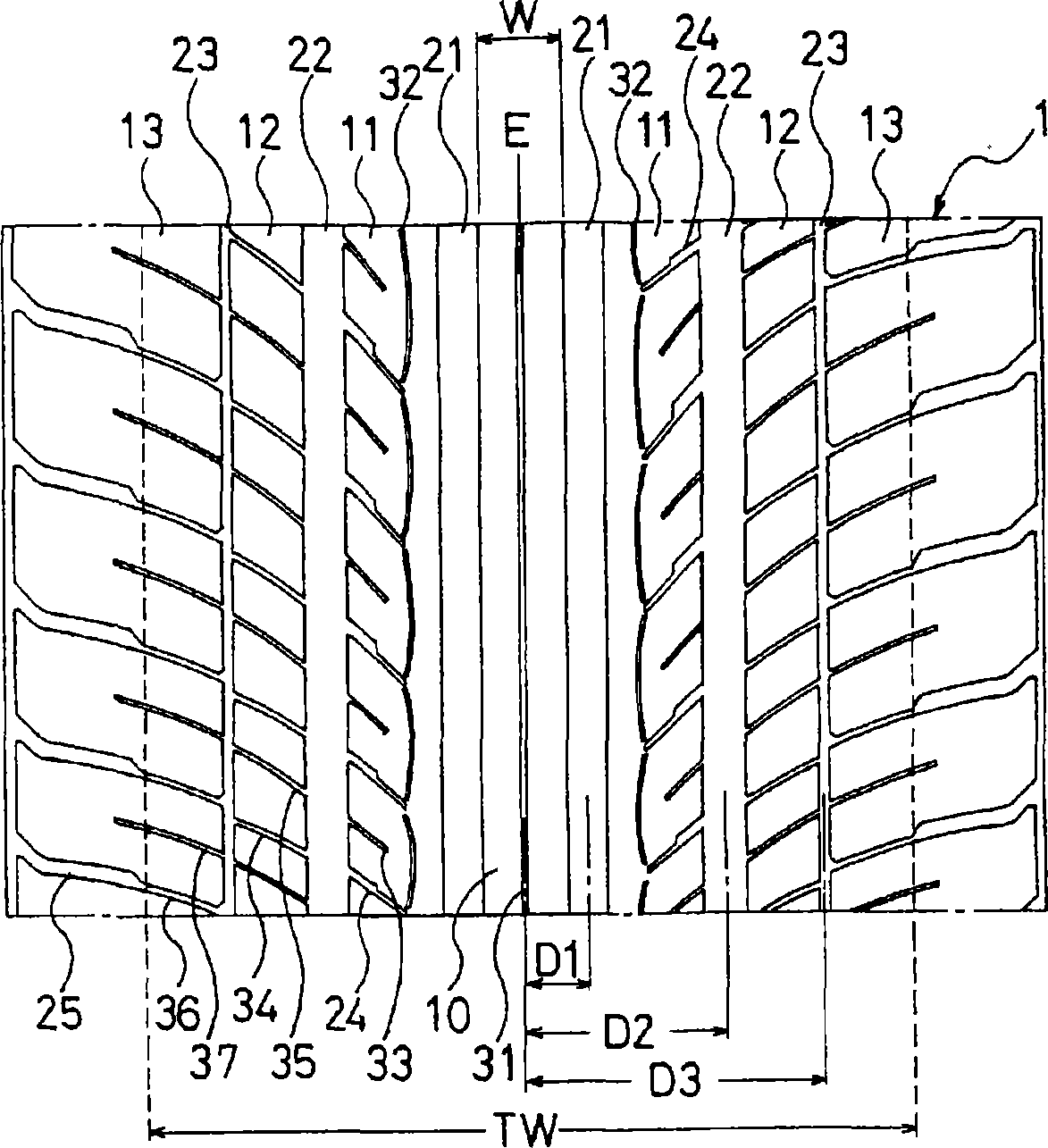

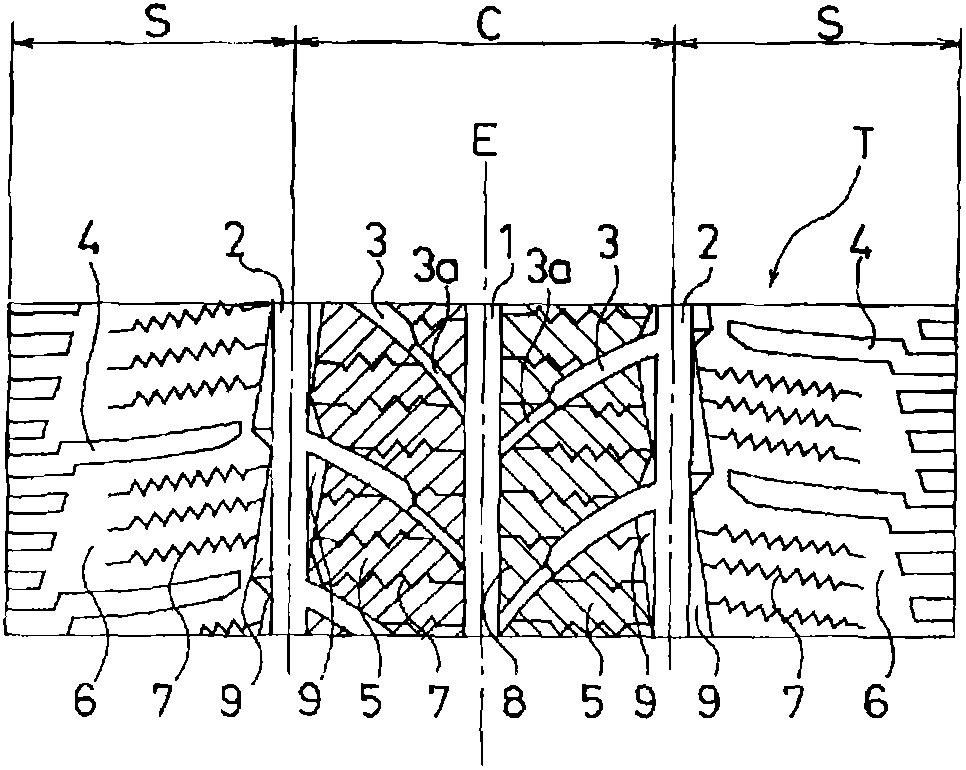

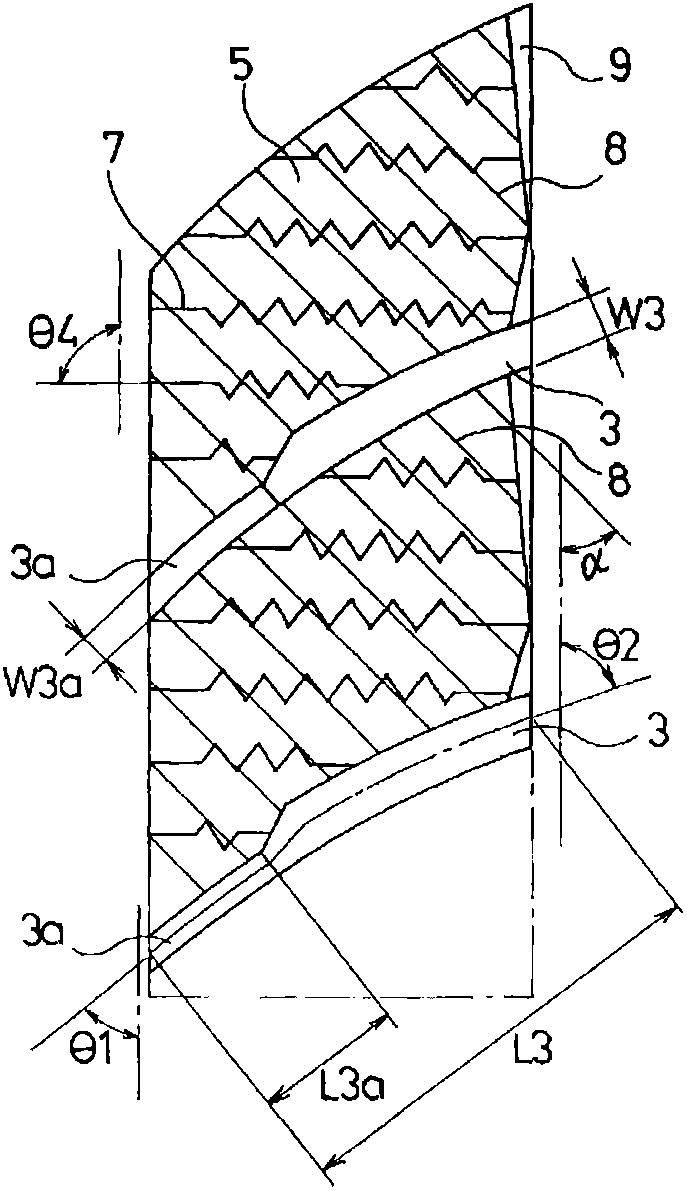

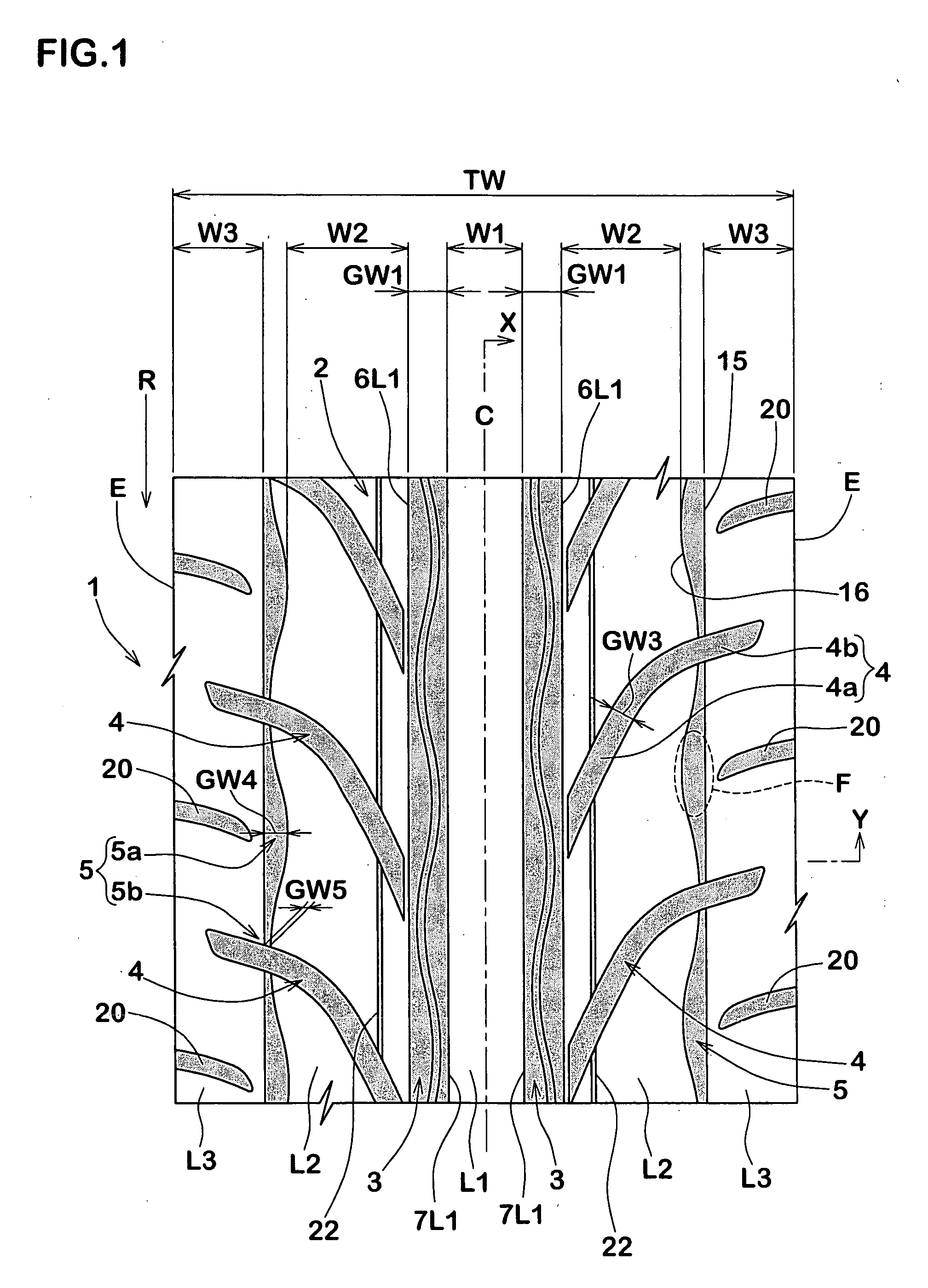

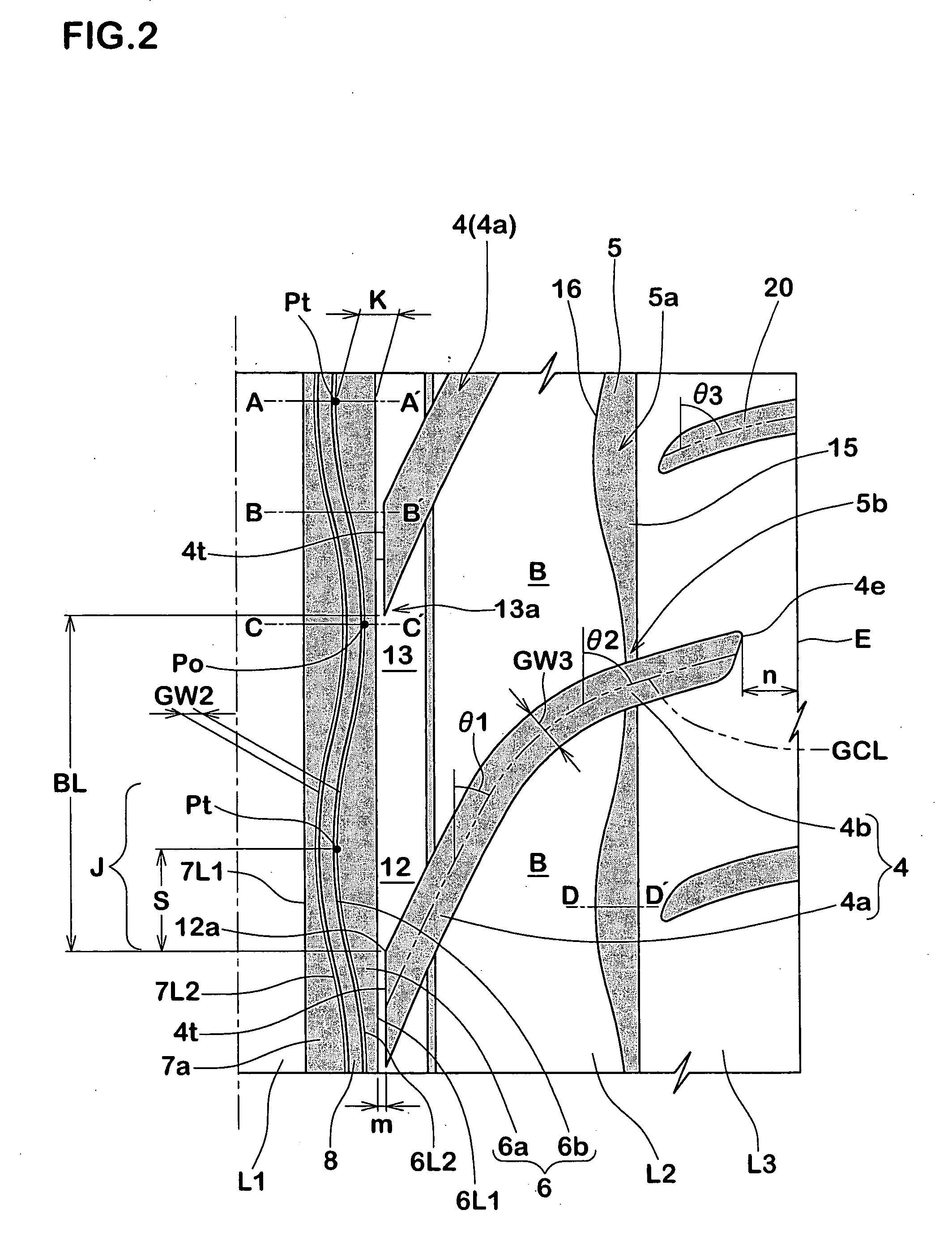

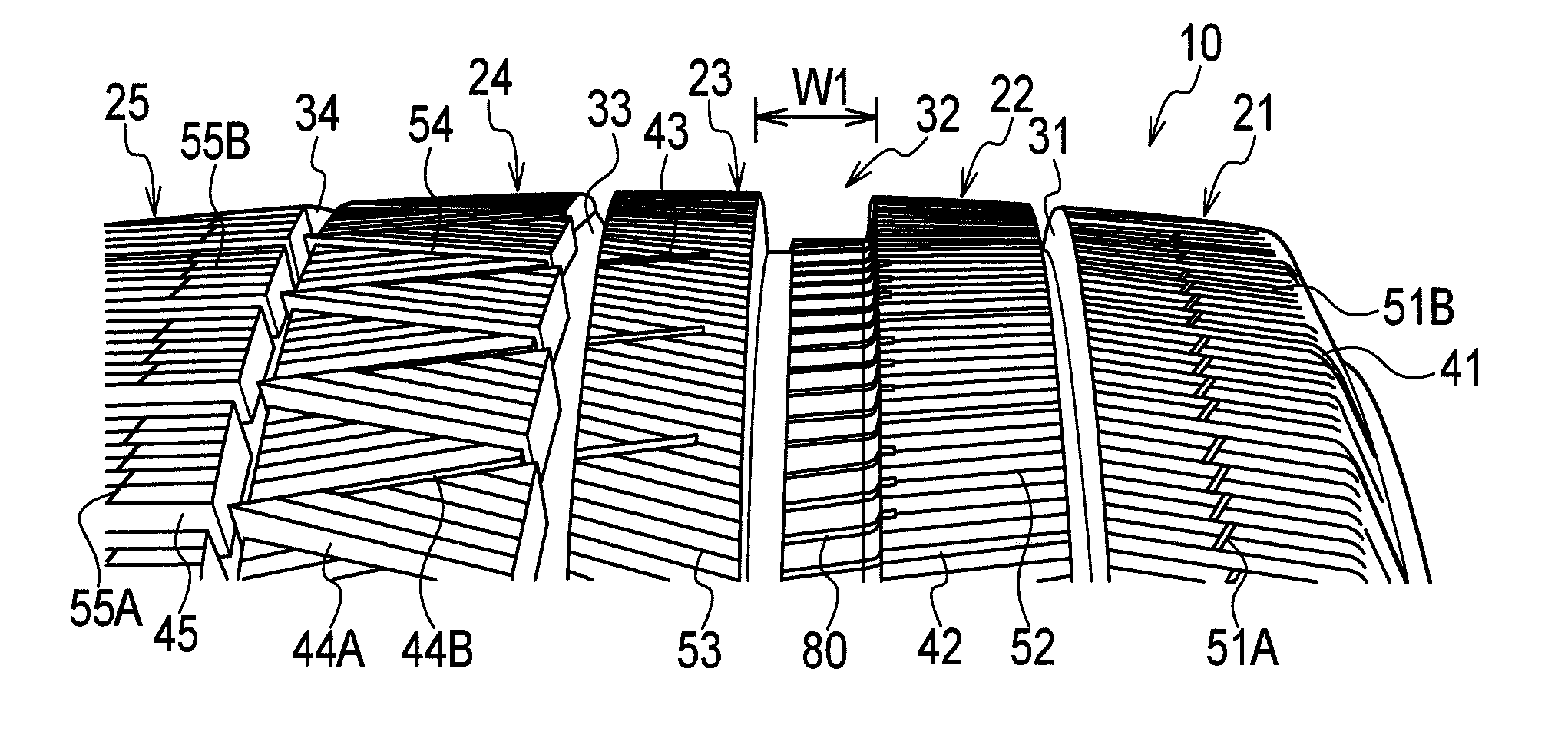

Vehicular pneumatic tire and process of making vehicular pneumatic tire

InactiveUS6439286B1Narrow profileAvoid impactTyresTyre tread bands/patternsTransverse grooveEngineering

Vehicular pneumatic tire having an asymmetric tread formed in relation to a circumference of a running surface and process of making vehicular pneumatic tire. The vehicular pneumatic tire includes an outside region that includes an outside shoulder block row and an outside circumferential groove, an inside region that includes an inside shoulder block row and an inside circumferential groove, and a center region that is laterally delimited by the outside circumferential groove and the inside circumferential groove. A plurality of transverse grooves are arranged within the inside shoulder block row, and the plurality of transverse grooves further are arranged to extend into the center region. No more than about one-half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions. The process includes forming an outside region to include an outside shoulder block row and an outside circumferential groove, forming an inside region to include an inside shoulder block row and an inside circumferential groove, and laterally delimiting a center region with the outside circumferential groove and the inside circumferential groove. The process further includes arranging a plurality of transverse grooves within the inside shoulder block row and to extend into the center region. No more than one half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

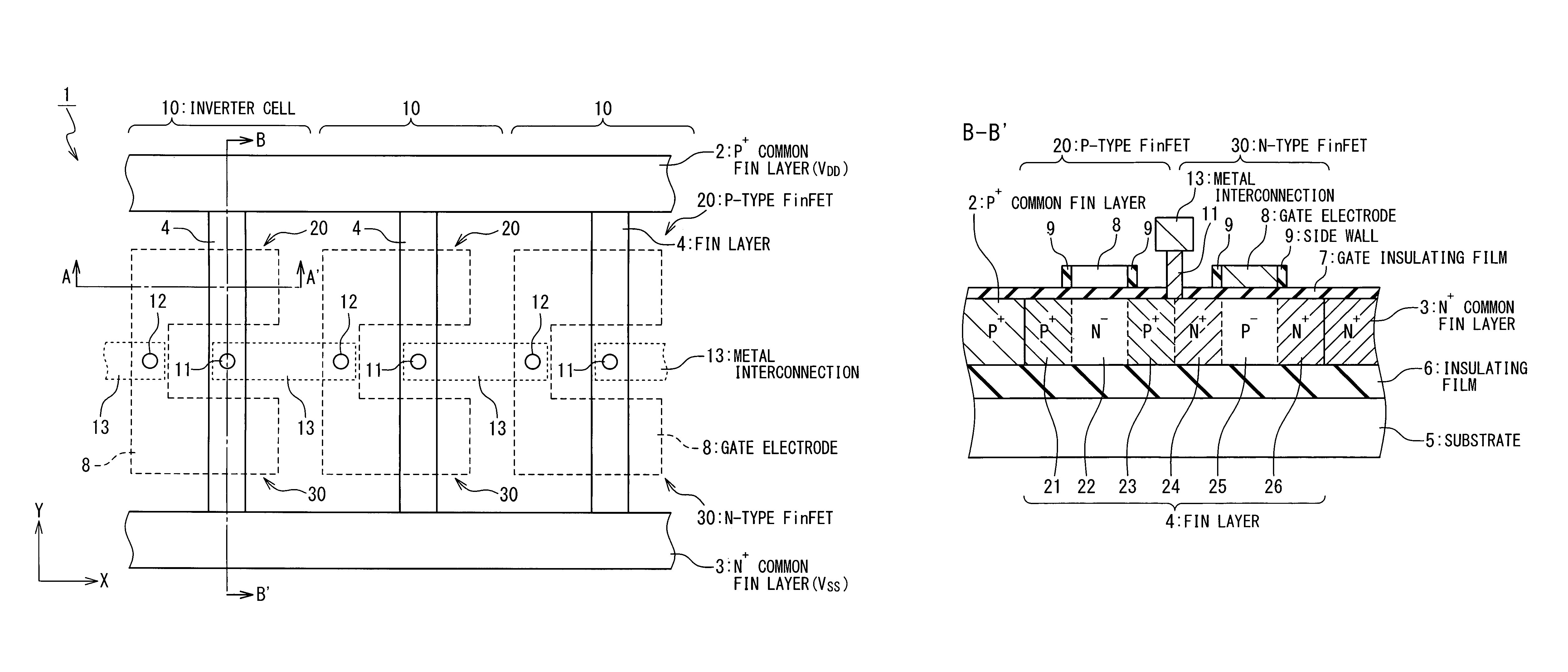

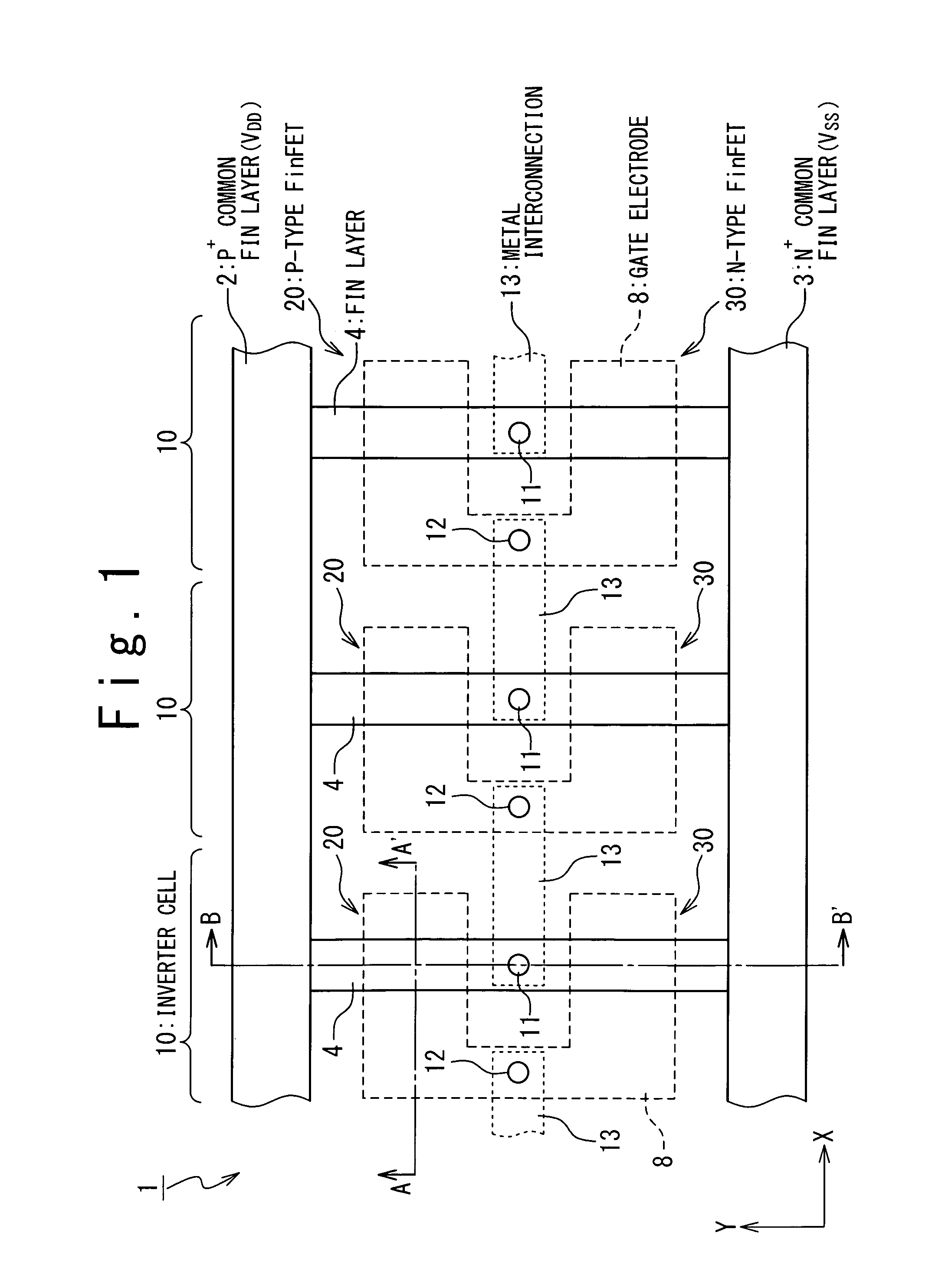

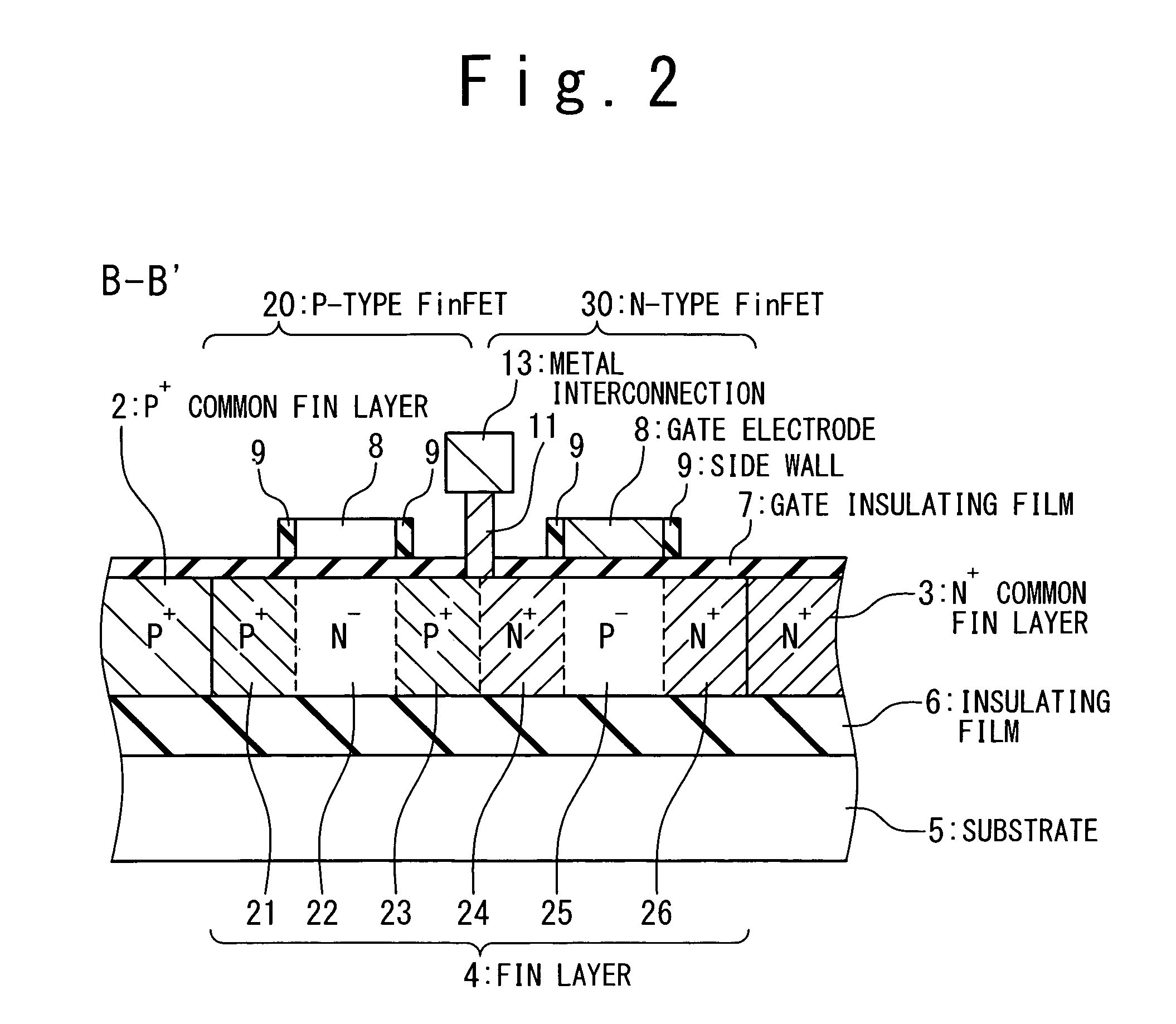

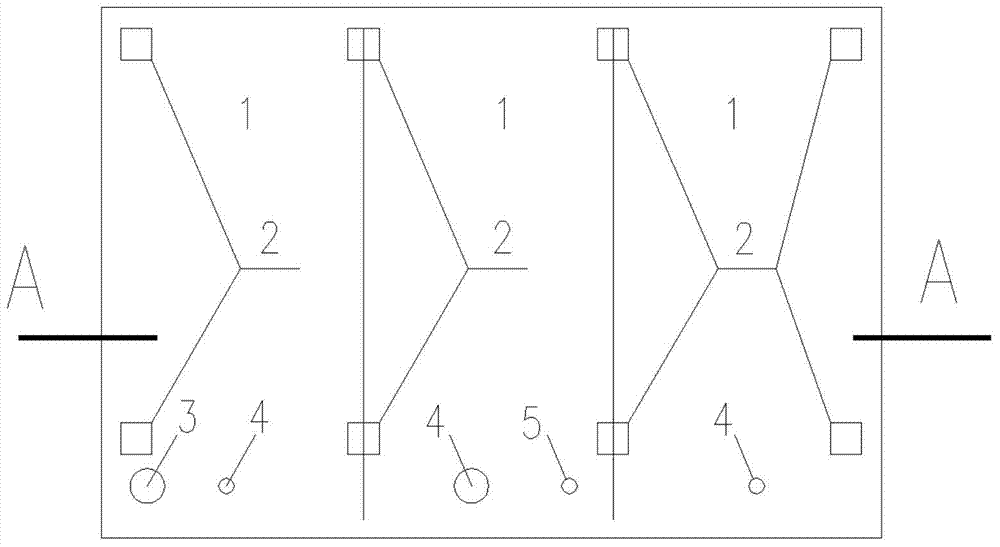

Semiconductor device with three-dimensional field effect transistor structure

InactiveUS7989846B2Improve drainage capacityIncrease the areaTransistorSolid-state devicesPower semiconductor deviceEngineering

The semiconductor device includes first and second common source semiconductor layers respectively extending in a first direction, first and second logic gate circuits respectively composed of at least one three-dimensional P-type FET and a three-dimensional N-type FET. The sources of the three-dimensional P-type FETs in the first and second logic gate circuits are joined to the first common source semiconductor layer. The sources of the three-dimensional N-type FETs in the first and second logic gate circuits are joined to the second common source semiconductor layer. The semiconductor layers of the three-dimensional P-type and N-type FETs in the first logic gate circuit are joined in their drain side, and The semiconductor layers of the three-dimensional P-type and N-type FETs in the second logic gate circuit are joined in their drain side. The dissipation of the FinFET can be improved.

Owner:RENESAS ELECTRONICS CORP

Fluid handling component with ultraphobic surfaces

InactiveUS20050145285A1Reduce frictionImprove system efficiencyMaterial nanotechnologyConveyorsVolumetric Mass DensityEngineering

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γ cos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

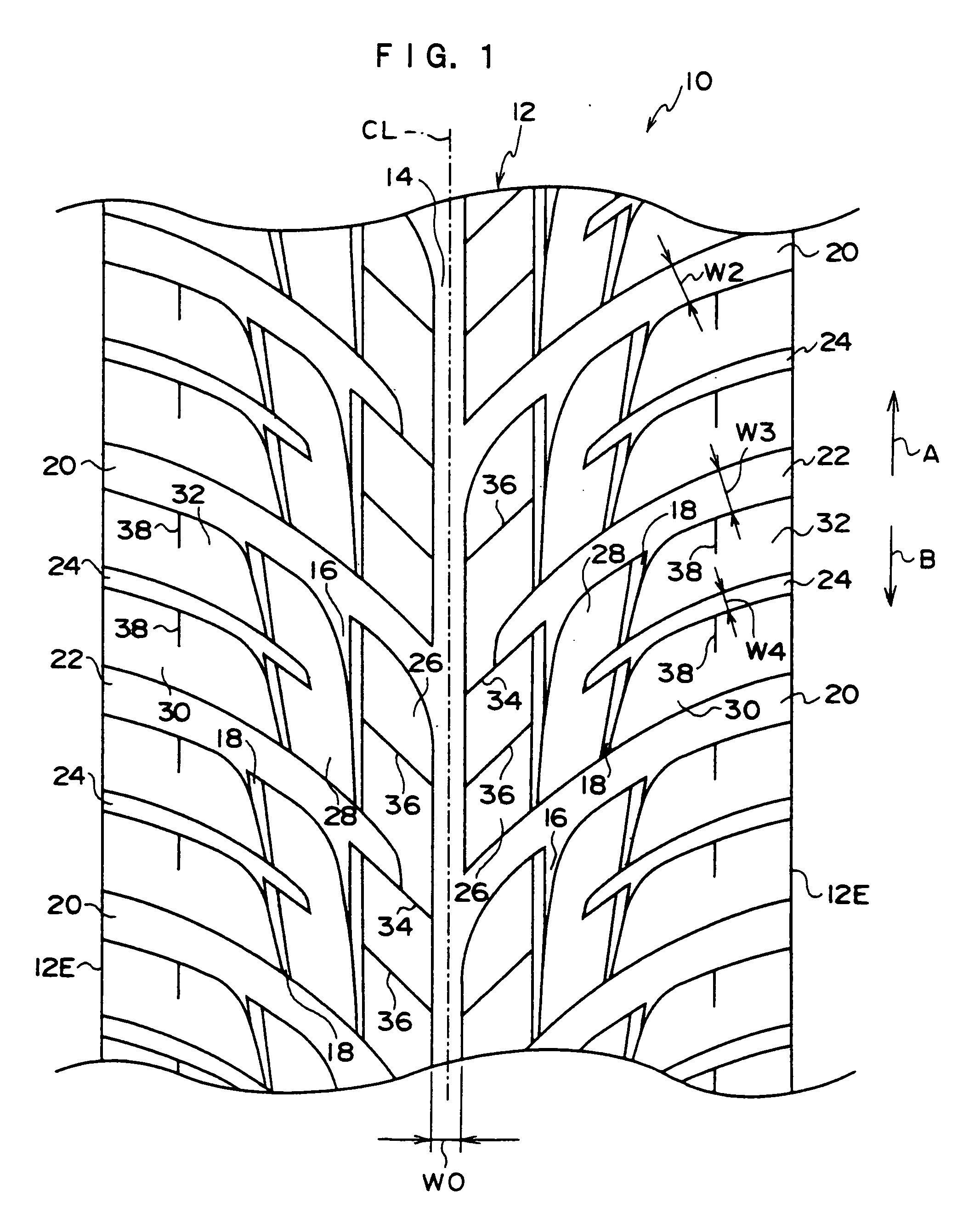

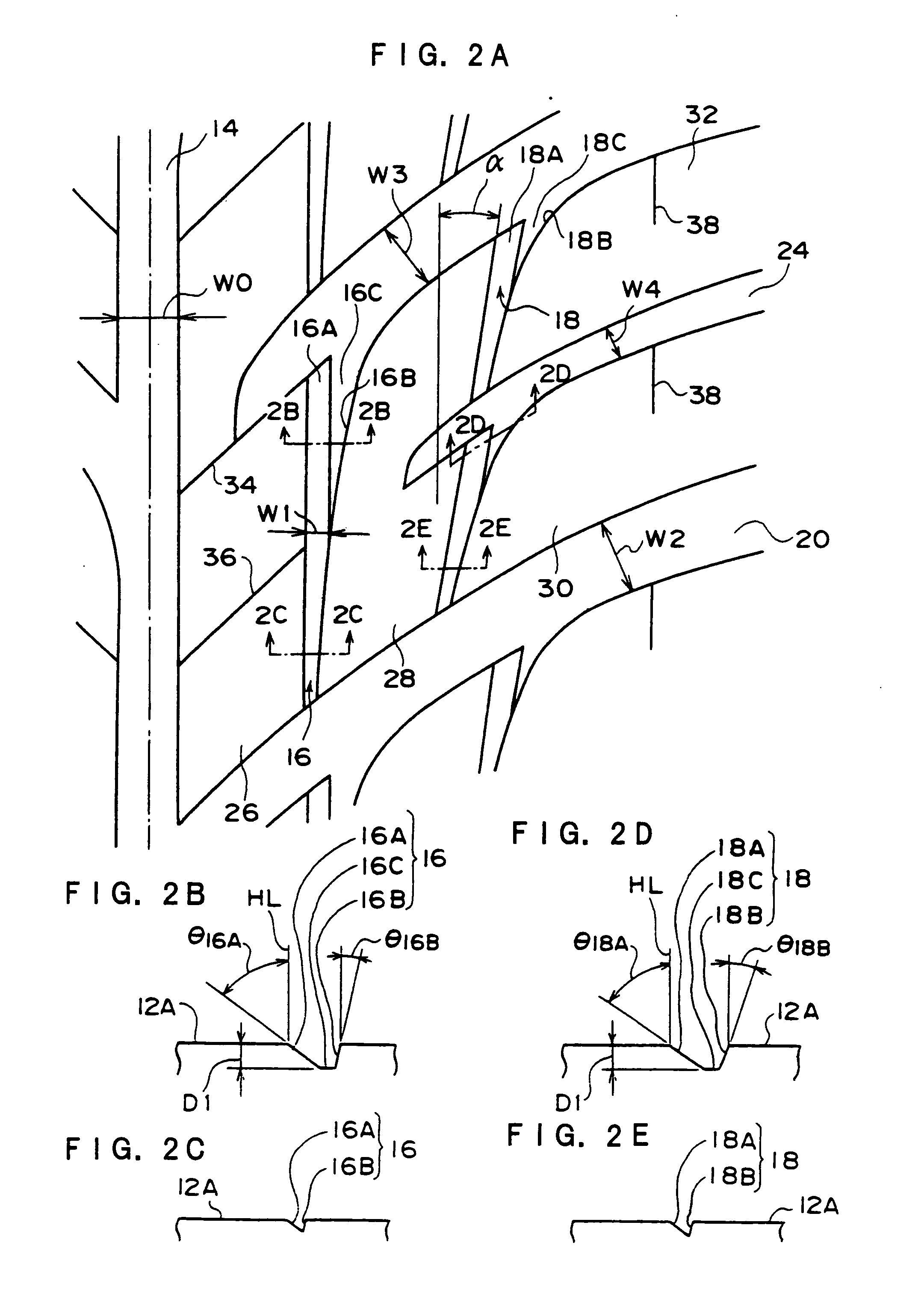

Pneumatic Tire

InactiveUS20070215258A1Good effectHigh wet drainage performanceTyre tread bands/patternsNon-skid devicesTransverse grooveWear resistant

The present invention provides a pneumatic tire which can obtain a high wet drainage performance, roadholding ability, and wear-resistant property without sacrificing other capabilities A directional pattern is formed by a circumferential wide major groove 14, a first narrow circumferential minor groove 16, a second narrow circumferential minor groove 18, a first transverse groove 20, a second transverse groove 22, and a third transverse groove 24. The circumferential wide major groove 14 is provided in a center region in a tire width direction of a tread 12. The first narrow circumferential minor groove 16 is arranged on the outside in a tire axis direction of the circumferential wide major groove 14. The second narrow circumferential minor groove 18 is arranged on the outside in the tire axis direction of the first narrow circumferential minor groove 16. The first transverse groove 20 is extended from a tread end 12E and coupled to the circumferential wide major groove 14. The second transverse groove 22 is arranged between the first transverse grooves 20, and the second transverse groove 22 is extended from the tread end 12E and terminated while not coupled to the circumferential wide major groove 14. The third transverse groove 24 is arranged between the first transverse groove 20 and the second transverse groove 22, and the third transverse groove 24 is extended from the tread end 12E and terminated between the first narrow circumferential minor groove 16 and the second narrow circumferential minor groove 18. Therefore, in wet road surface driving, the water between the pneumatic tire and a road surface flows efficiently into each groove to obtain high wet performance. Because the high wet performance is obtained while an increase in negative ratio is suppressed, a wheel tread area of a block is secured to improve a wear-resistant property. A circumferential length of a second block 28 becomes a substantial half of a first block 26, and circumferential lengths of a stepping-on side third block 30 and a kickout side third block 32 become a substantial half of the second block 28. Therefore, a wet drainage property can be improved on both sides of the tread while block rigidity is increased on a tread central region to improve traction performance, brake performance, and cornering performance. Furthermore, when the pneumatic tire of the invention is used in a front wheel, handling performance is improved by increasing the block rigidity in a central region in the tire axis direction. Widths and depths of the first narrow circumferential minor groove 16 and second narrow circumferential minor groove 18 are decreased from a kickout side toward a stepping-on side of the block in a range where the block is zoned by the first and second narrow circumferential minor grooves 16 and 18. Therefore, the block rigidity is increased on the stepping-on side of the blocks located on both sides of the first and second narrow circumferential minor grooves 16 and 18, and thereby the traction performance, brake performance, and cornering performance are improved.

Owner:BRIDGESTONE CORP

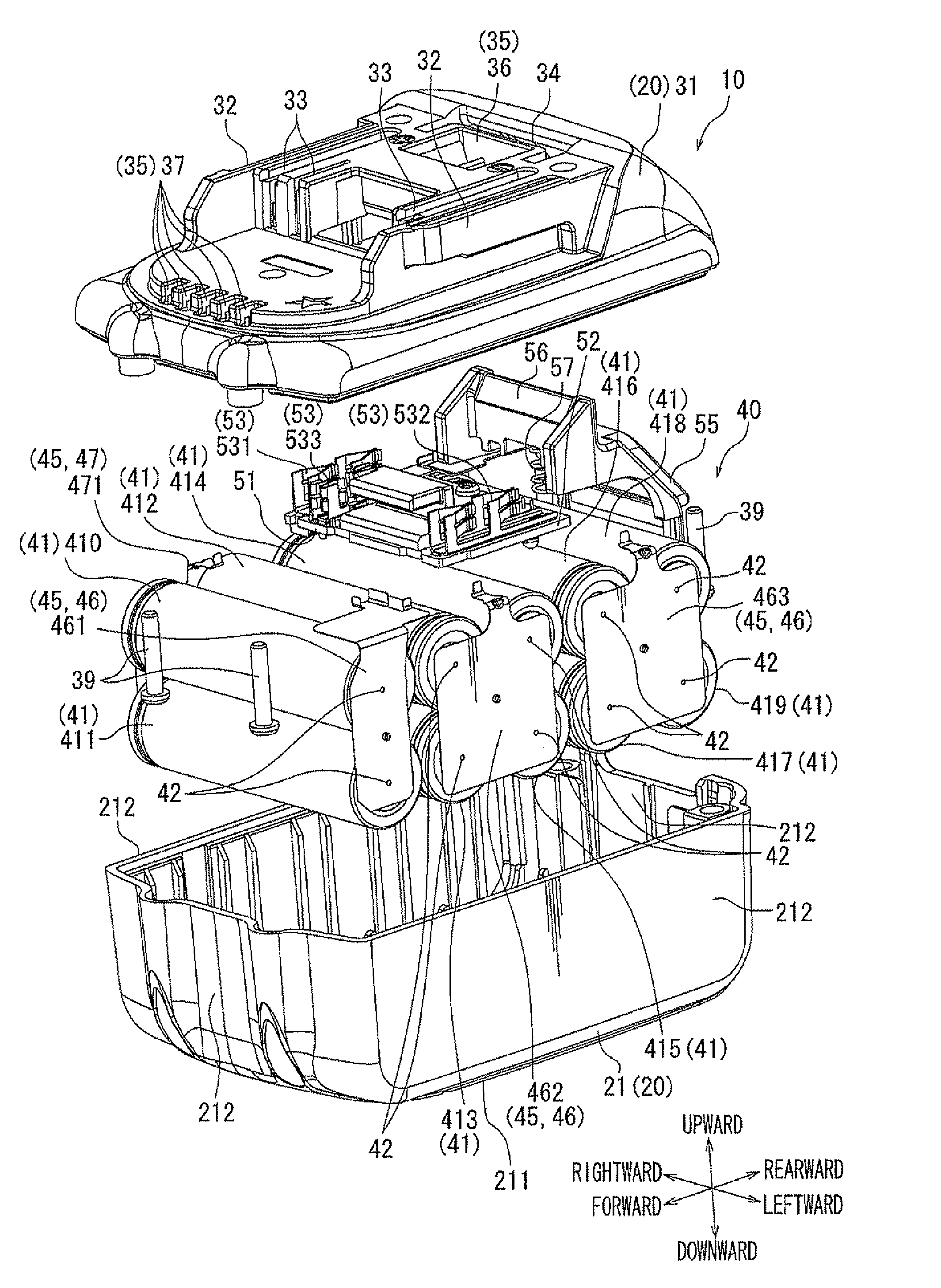

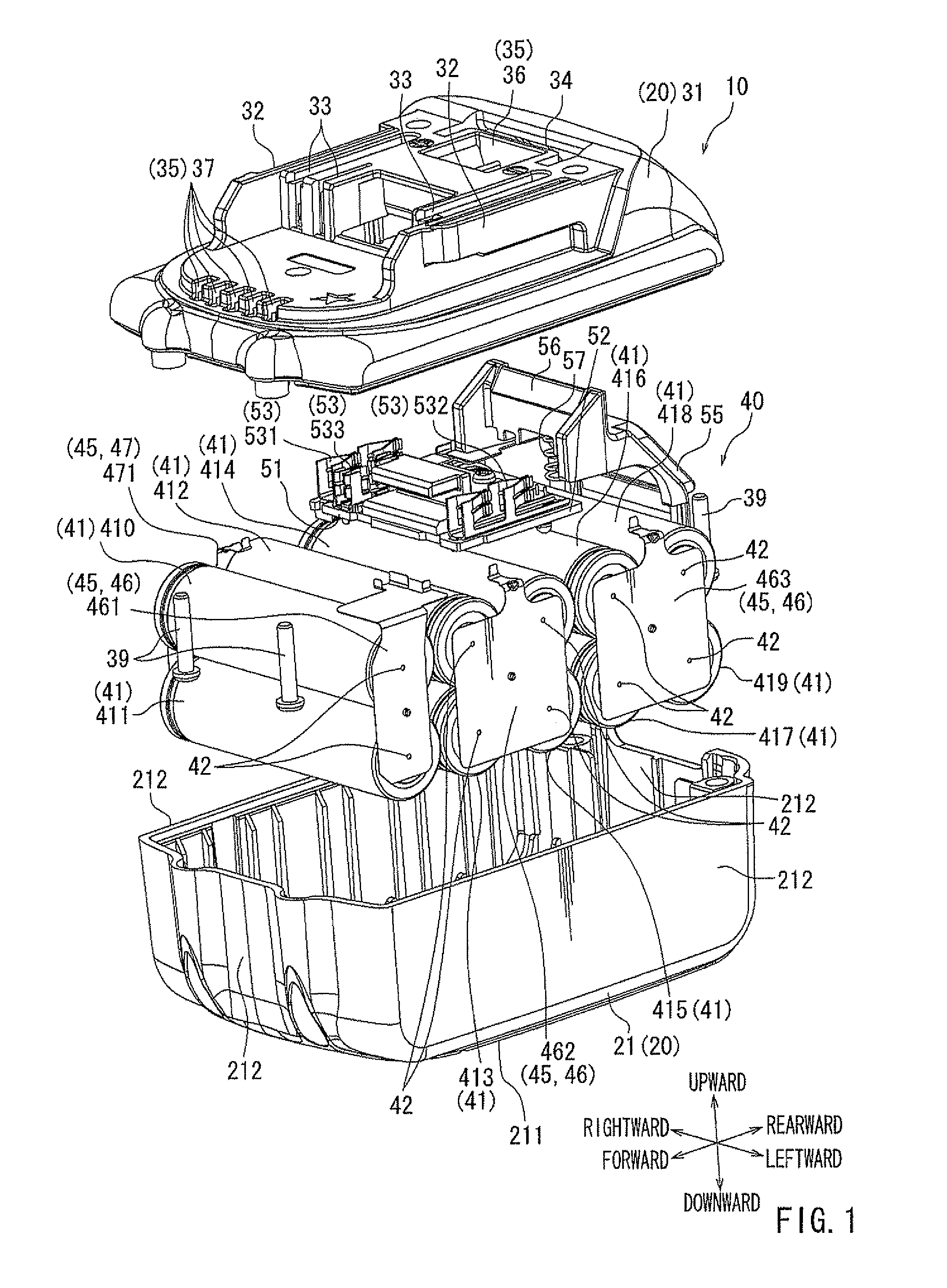

Battery pack

ActiveUS20130224539A1Prevent leakageReduce the numberBattery isolationBatteriesEngineeringBattery cell

A battery pack may include a drainage device provided at a bottom portion of the housing case. The drainage device may include a drain hole communicating between the inside and the outside of the housing case, so that water introduced into the housing case is discharged to the outside of the housing case. The drainage device may be disposed between two of the terminal members that are connected to electrodes of the battery cells.

Owner:MAKITA CORP

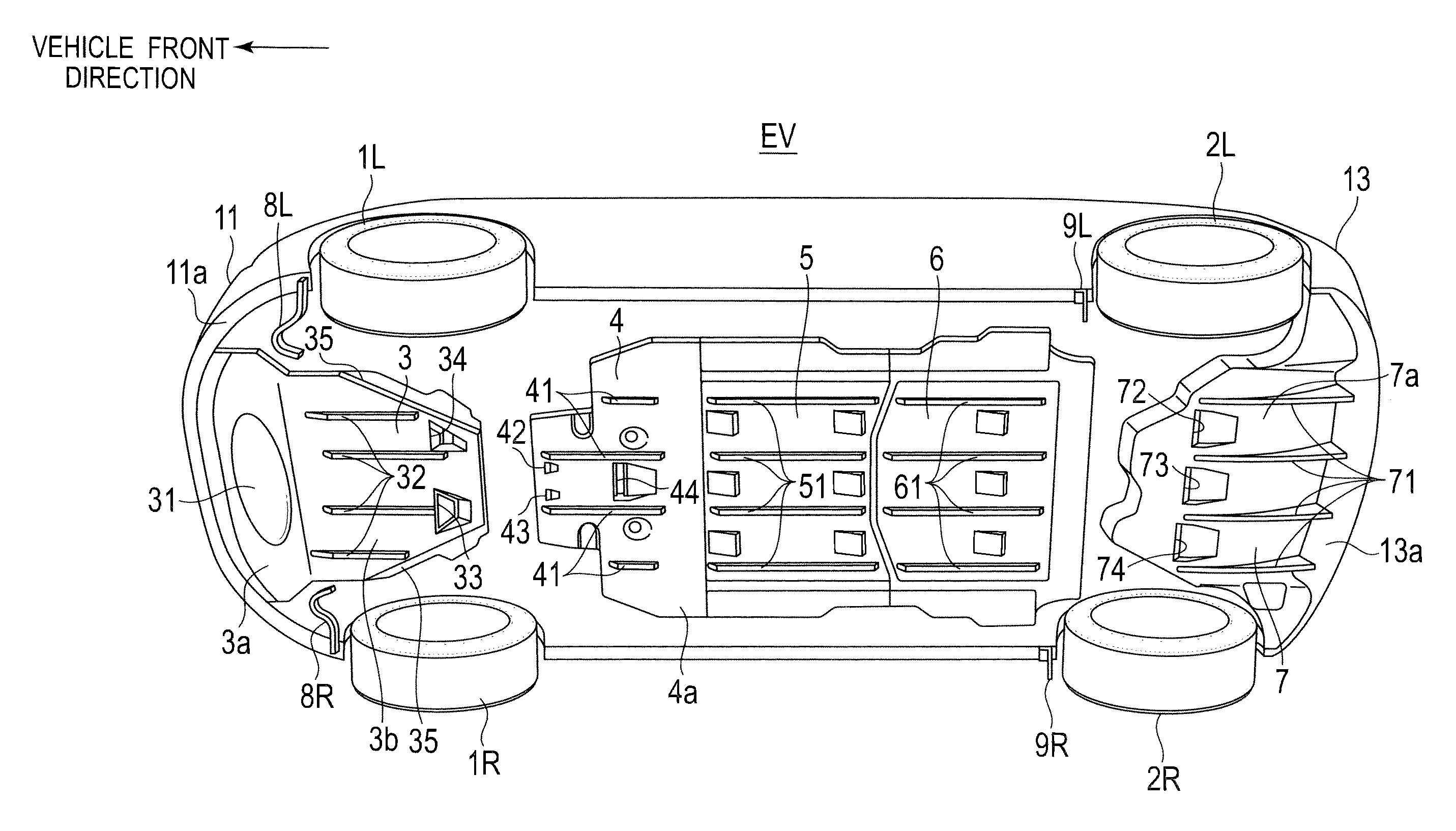

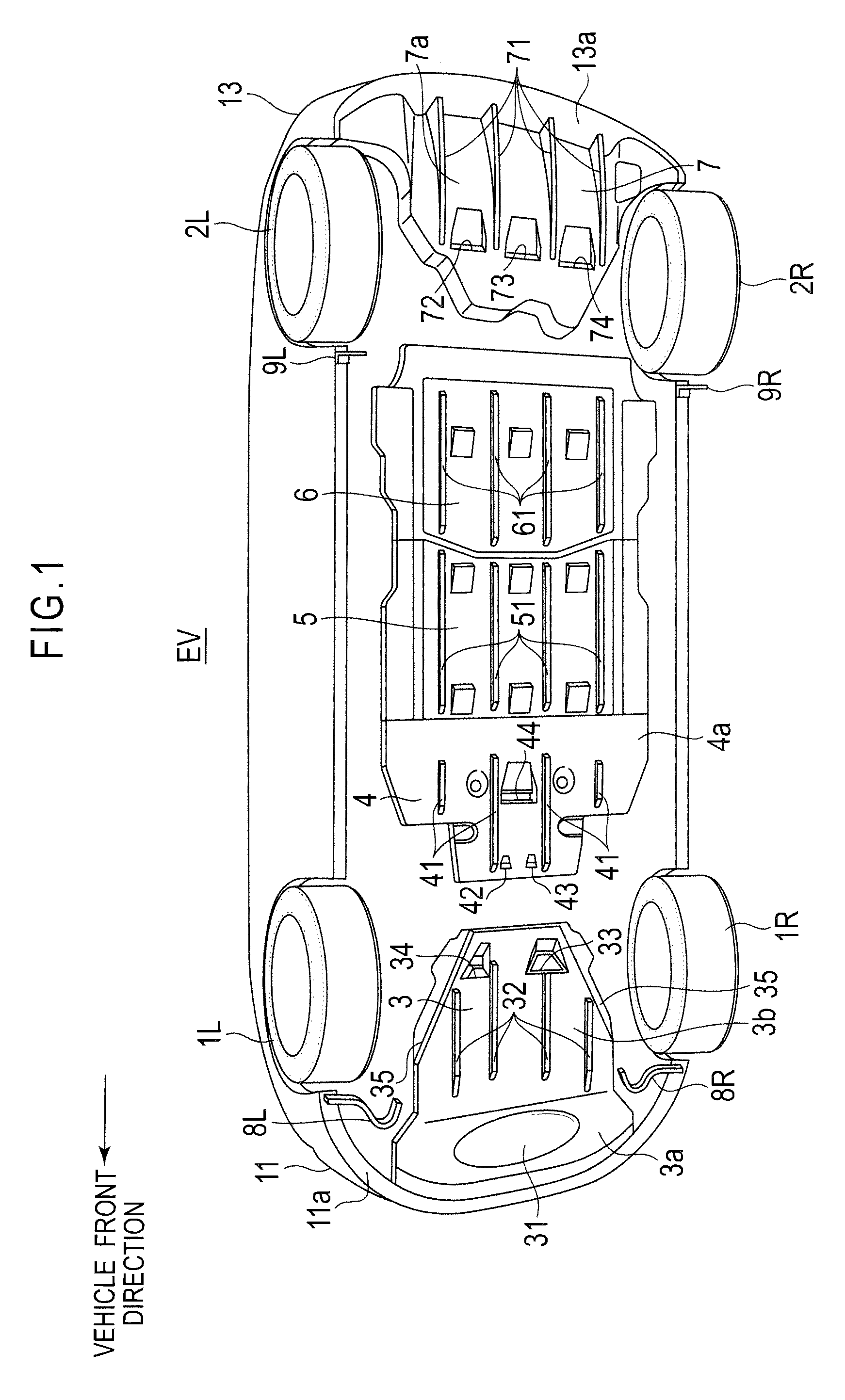

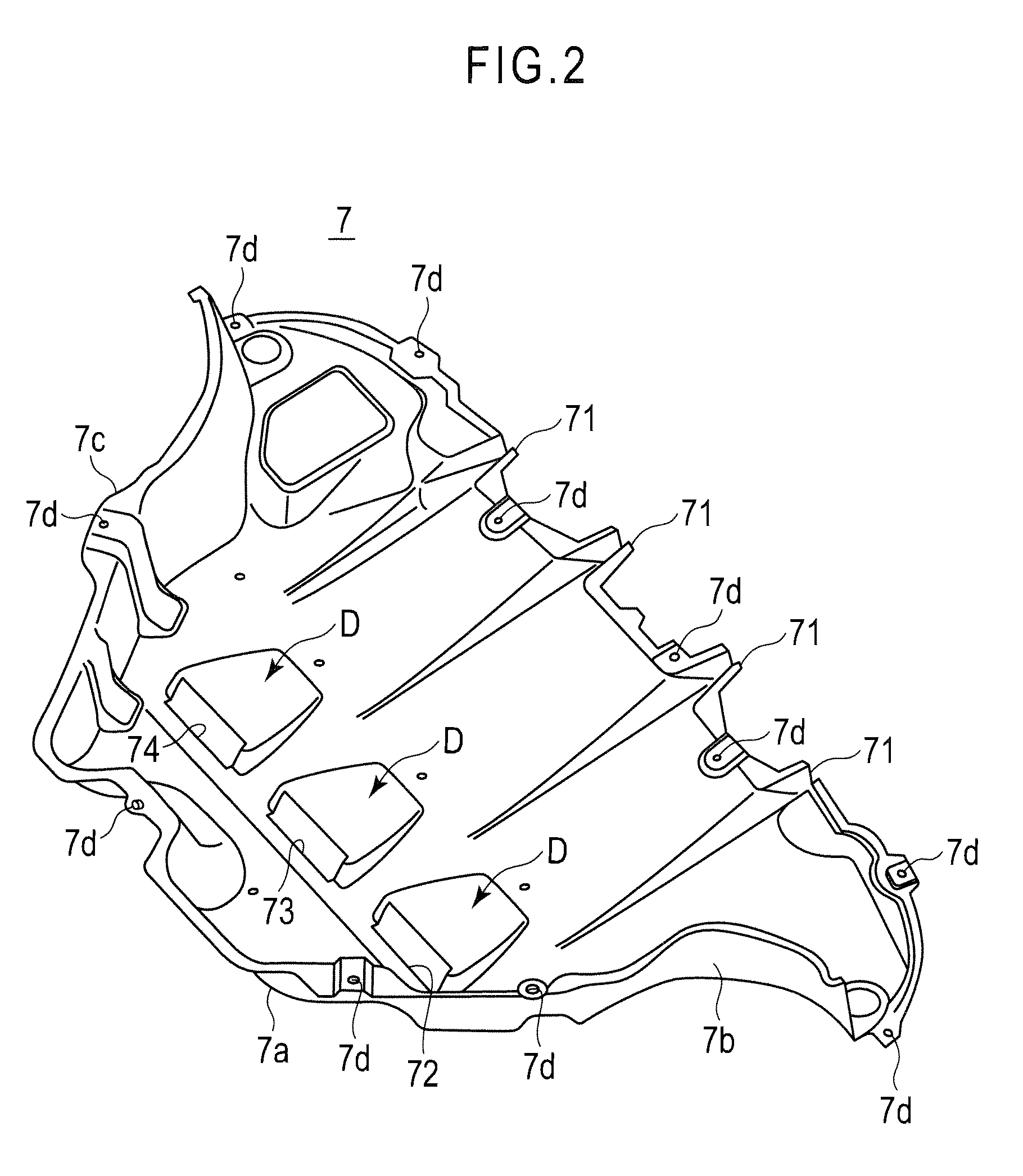

Vehicle underfloor structure

ActiveUS20130026797A1Increase resistanceImprove drainage capacityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD

Dryer section

InactiveUS6189233B1Improve drainage capacityKeep dryDryer sectionDrying machines with non-progressive movementsEngineeringSupport belt

Dryer section of a machine for at least one of producing and processing a web of material. The dryer section includes at least one heatable drying cylinder having a circumference, at least a part the circumference adapted to be surrounded by the material web, at least one support band arranged to surround the at least a part of the circumference, and a sealing band arranged to surround the at least a part of the circumference. An overpressure cap is arranged to receive one of a liquid and gaseous medium and is adapted to apply a pressurized one of the liquid and gaseous medium on the at least one drying cylinder. A temperature of the medium is lower than a temperature on an outside of the part of the circumference. At least one second support band is arranged around the at least one drying cylinder and is positioned between the at least one support band and the sealing band, wherein the at least one second support band has a coarser structure than the at least one support band.

Owner:VOITH SULZER PAPIERMASCHEN GMBH

Pneumatic tire

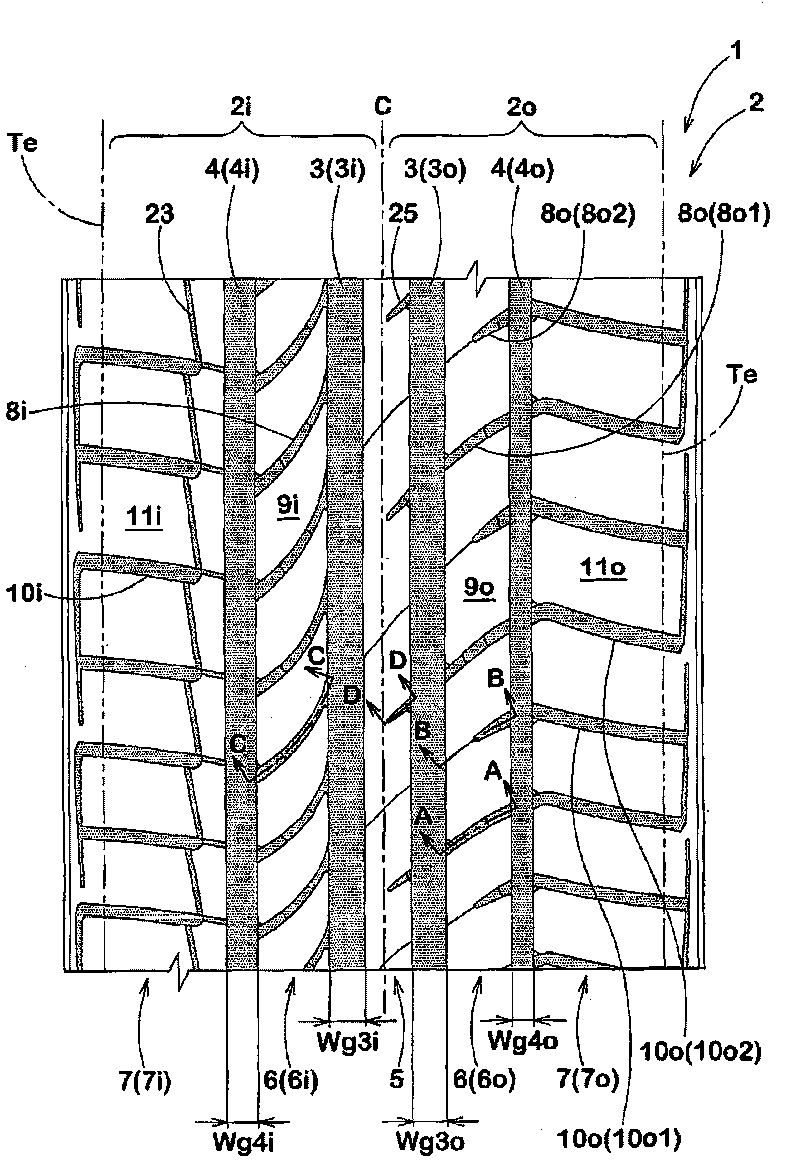

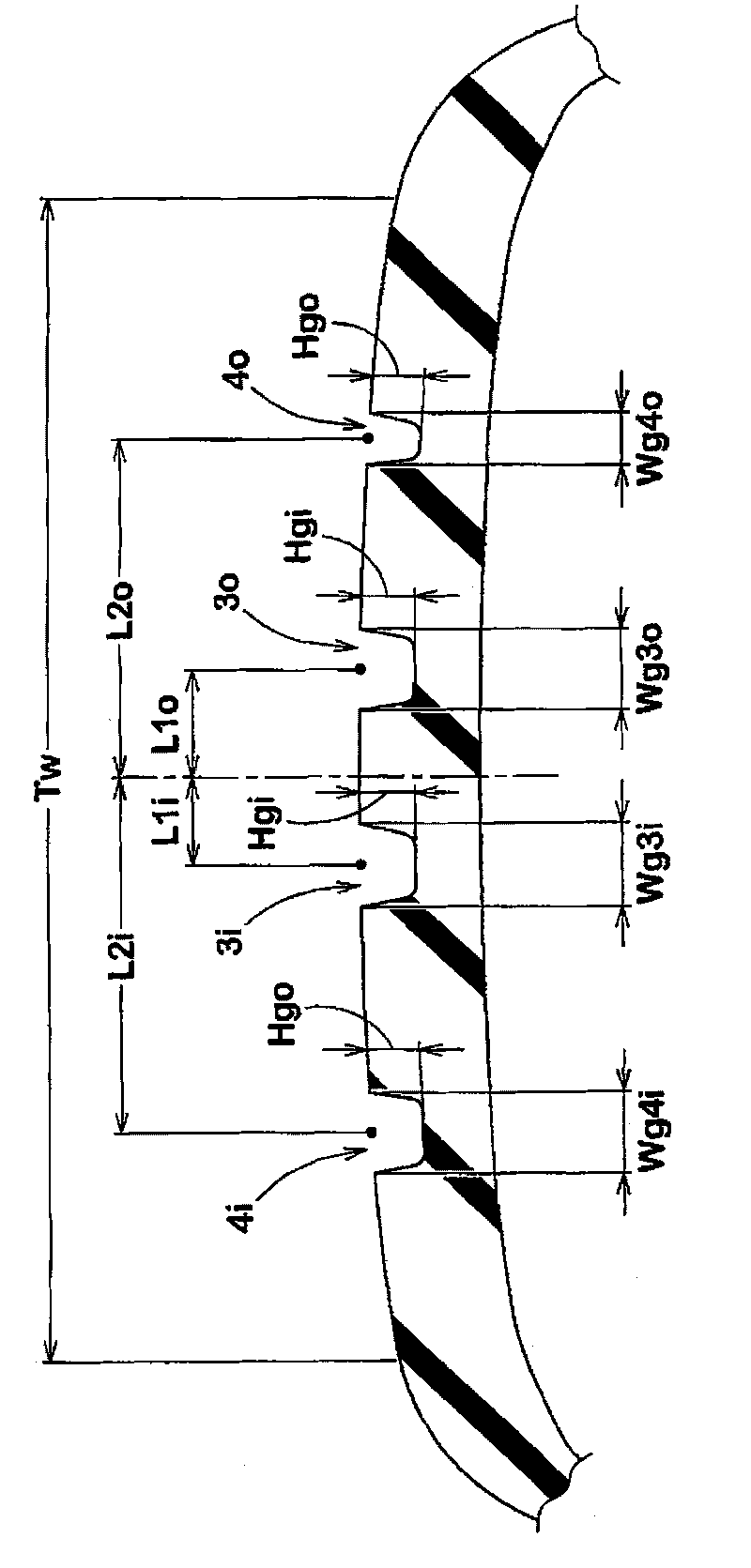

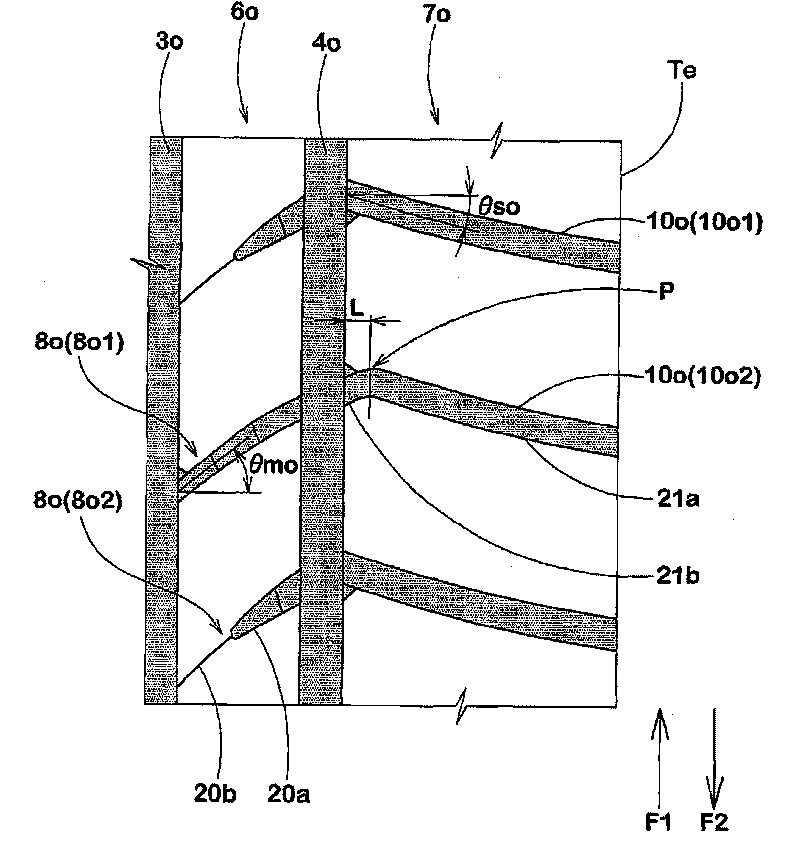

ActiveCN101746223AEnsure normal drainageSuppression of poor drainage performanceTyre tread bands/patternsEngineeringTread

A tire having an asymmetric tread pattern that land proportion of outer side area is larger than inner side area, but having a reduced difference in drainage performance between tires on right and left wheels, the tire having tread surface (2) divided by four circumferential grooves (3 and 4) into center (5), middle (6,6) and shoulder lands (7,7), wherein middle (6o) and shoulder land (7o) in the outer side area (2o) are divided respectively by outer middle lateral grooves (8o) and outer shoulder lateral grooves (10o) into blocks (9o and 11o), inclination direction of the middle lateral grooves (8o) is opposite to that of the shoulder lateral grooves (10o) with respect to tire axial direction, and the lateral grooves (8o and 10o) are inclined at an angle mo between 5 DEG and 45 DEG and at an angle so between more than 0 DEG and not more than 40 DEG , respectively.

Owner:SUMITOMO RUBBER IND LTD

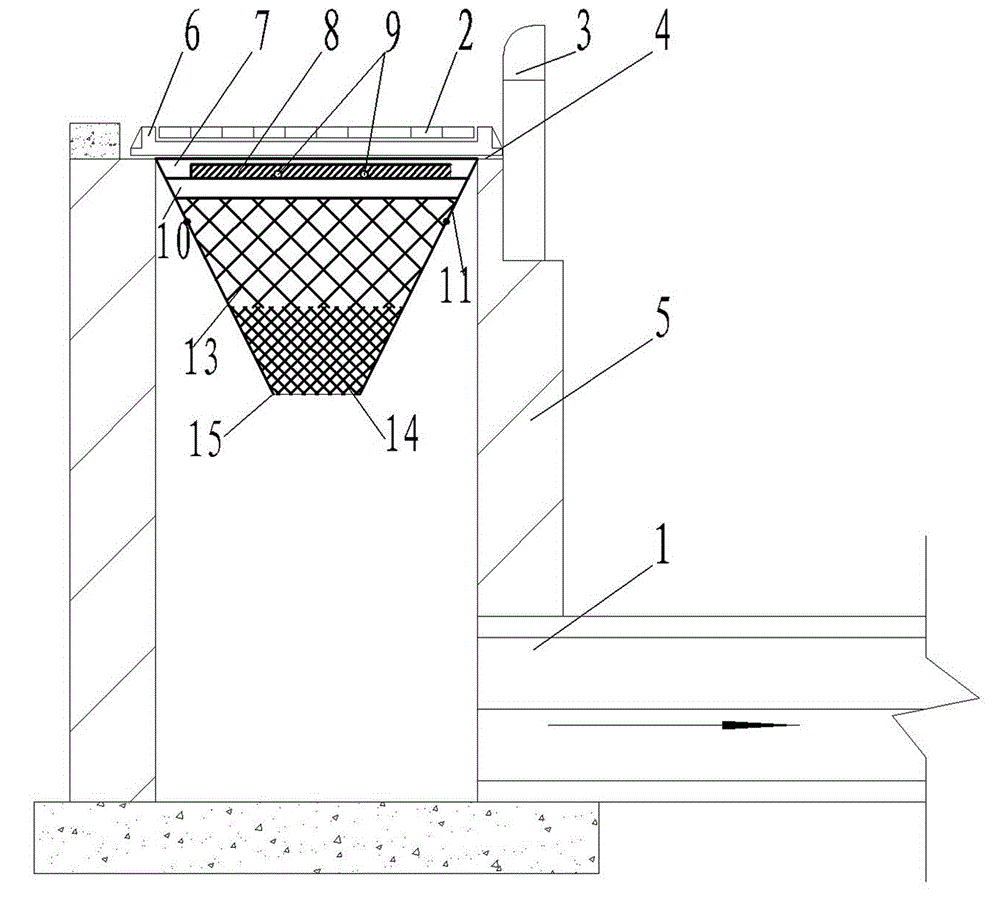

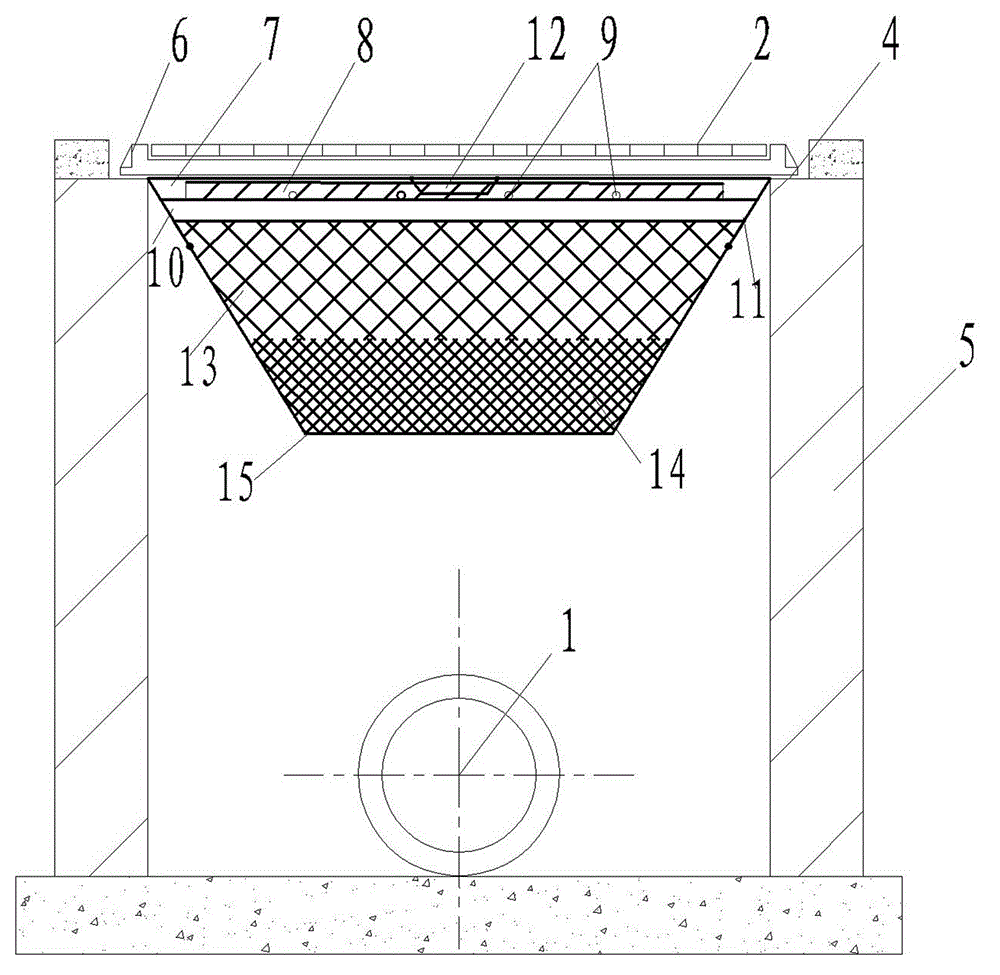

Gutter inlet automatic overflow pollutant intercepting device

ActiveCN103334486AMeet pollution interceptionSatisfy functionFatty/oily/floating substances removal devicesPipeflowEconomic benefits

A gutter inlet automatic overflow pollutant intercepting device comprises a clamping seat. At least one extensible rod is connected with the portion below the clamping seat. The lower end of the extensible rod is connected with a metal support. The metal support and the extensible rod are sleeved by a filter screen. The gutter inlet automatic overflow pollutant intercepting device is characterized in that the clamping seat comprises a grease absorbing cable clamping groove. According to the gutter inlet automatic overflow pollutant intercepting device, pollutants entering a gutter inlet is intercepted through the pollutant intercepting filter screen, so that the gutter inlet and a rainwater pipeline are prevented from being blocked, and the water discharging capacity of a rainwater pipeline network is improved; the pollutants are controlled from a source through the rainwater pipeline network, so that disposing pressure of a sewage disposal plant and pollution to city water by runoff pollution are reduced. Grease type pollutants in runoff rainwater can be effectively controlled through the arrangement of a grease absorbing cable, so that the following disposing cost of the sewage disposal plant and the pollution of city water are reduced, and the gutter inlet automatic overflow pollutant intercepting device has obvious environment and economic benefits. According to the gutter inlet automatic overflow pollutant intercepting device, the structure of an existing gutter inlet is not changed, the improving cost of the gutter inlet is reduced, and the gutter inlet automatic overflow pollutant intercepting device is simple in structure, practical and low in production cost.

Owner:BEIJING ORIENT LANDSCAPE

Carbon Substrate For Gas Diffusion Layer, Gas Diffusion Layer Using The Same, And Electrode For Fuel Cell, Membrane-Electrode Assembly And Fuel Cell Comprising The Gas Diffusion Layer

ActiveUS20140011118A1Improved water discharge abilityImprove mechanical strengthNon-fibrous pulp additionActive material electrodesEngineeringPorosity

Owner:JNTC +1

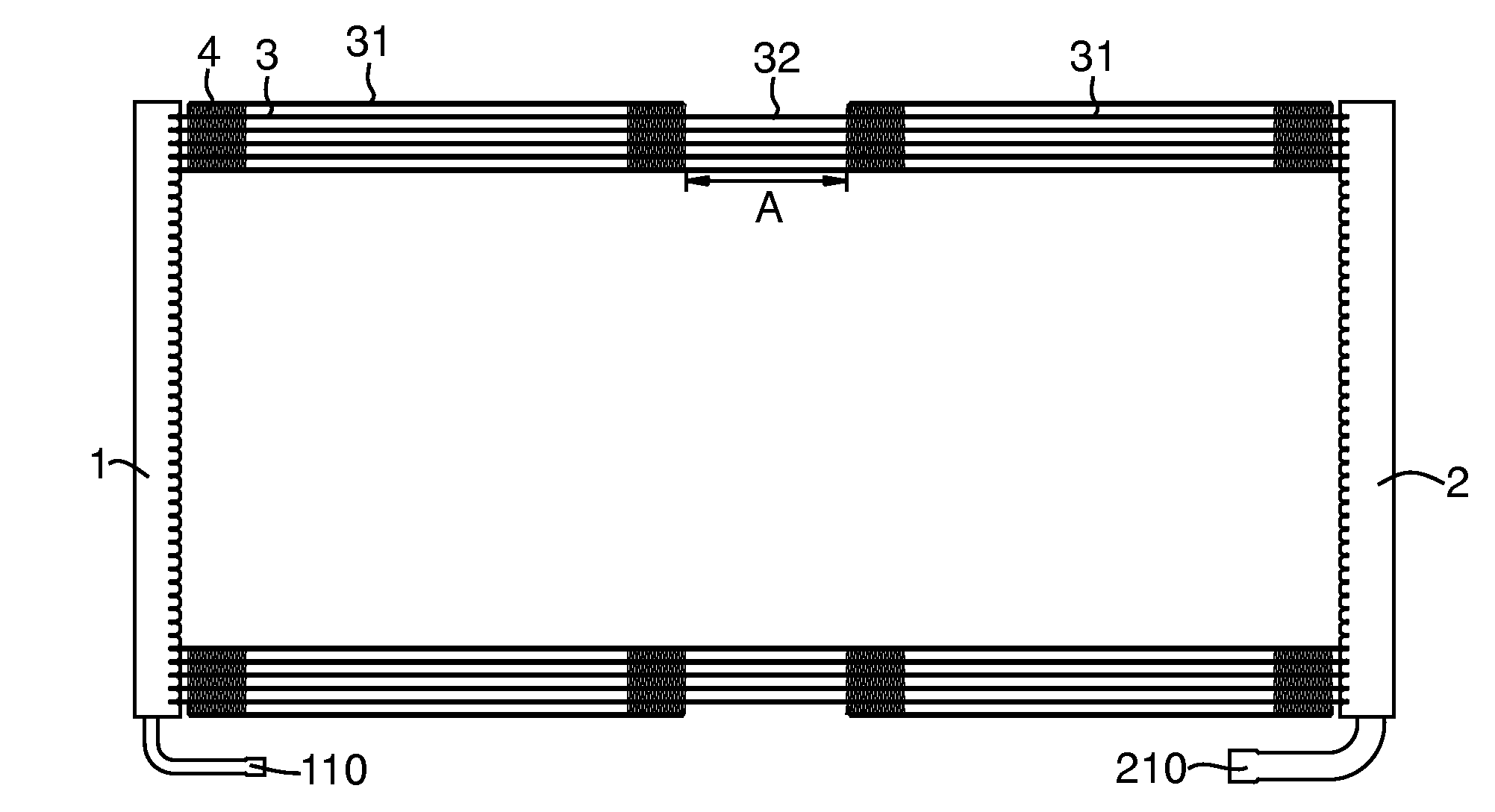

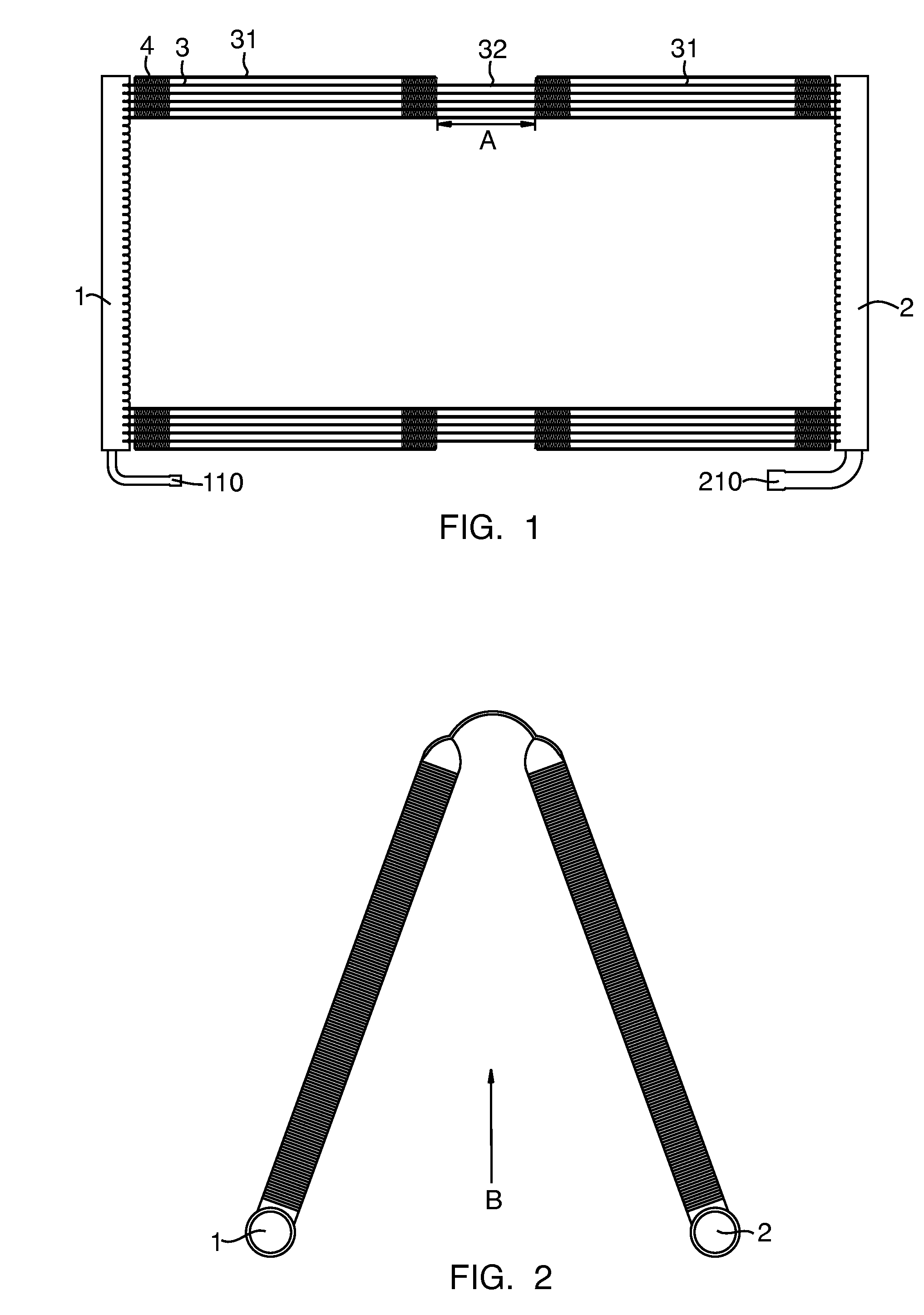

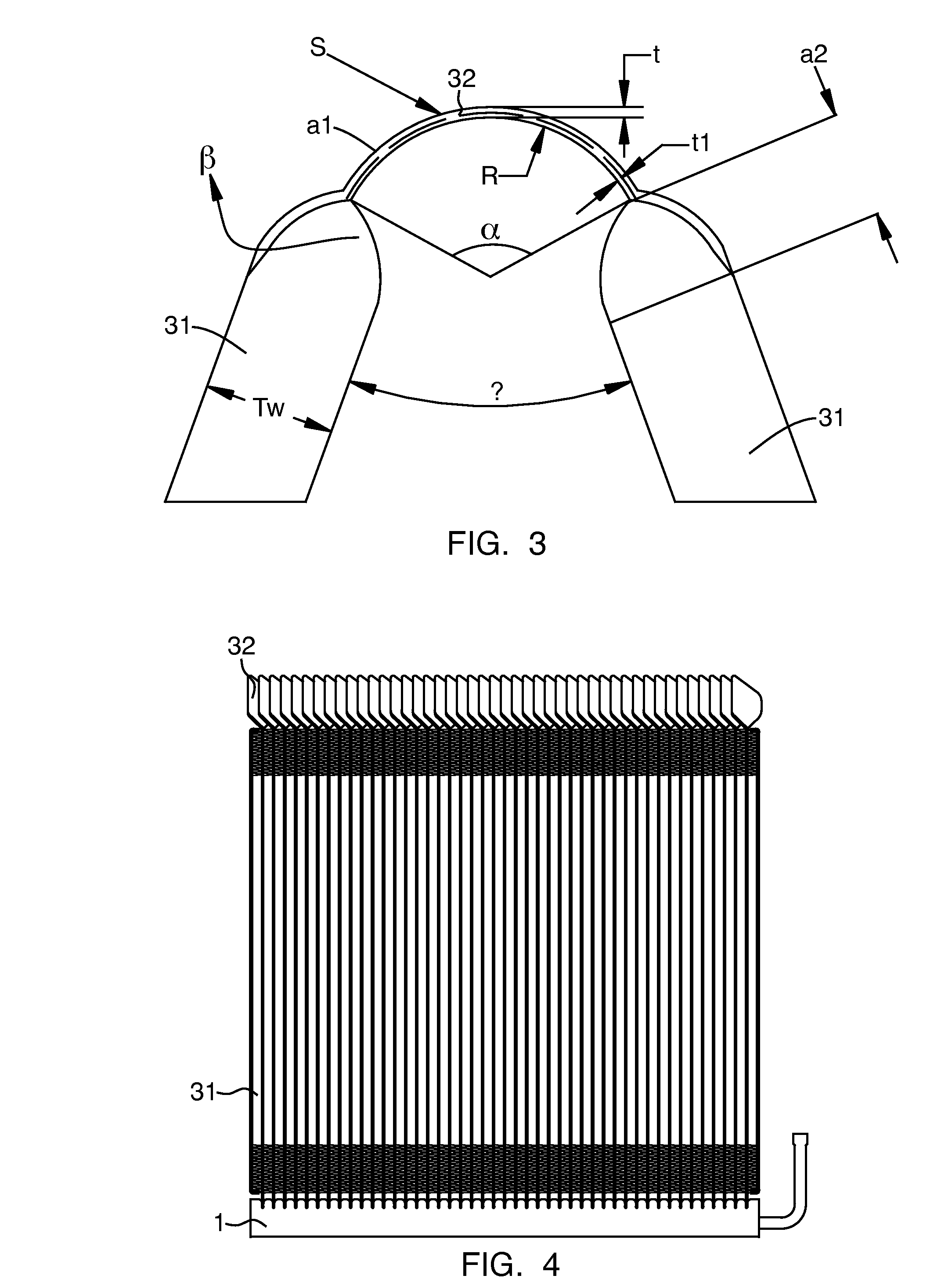

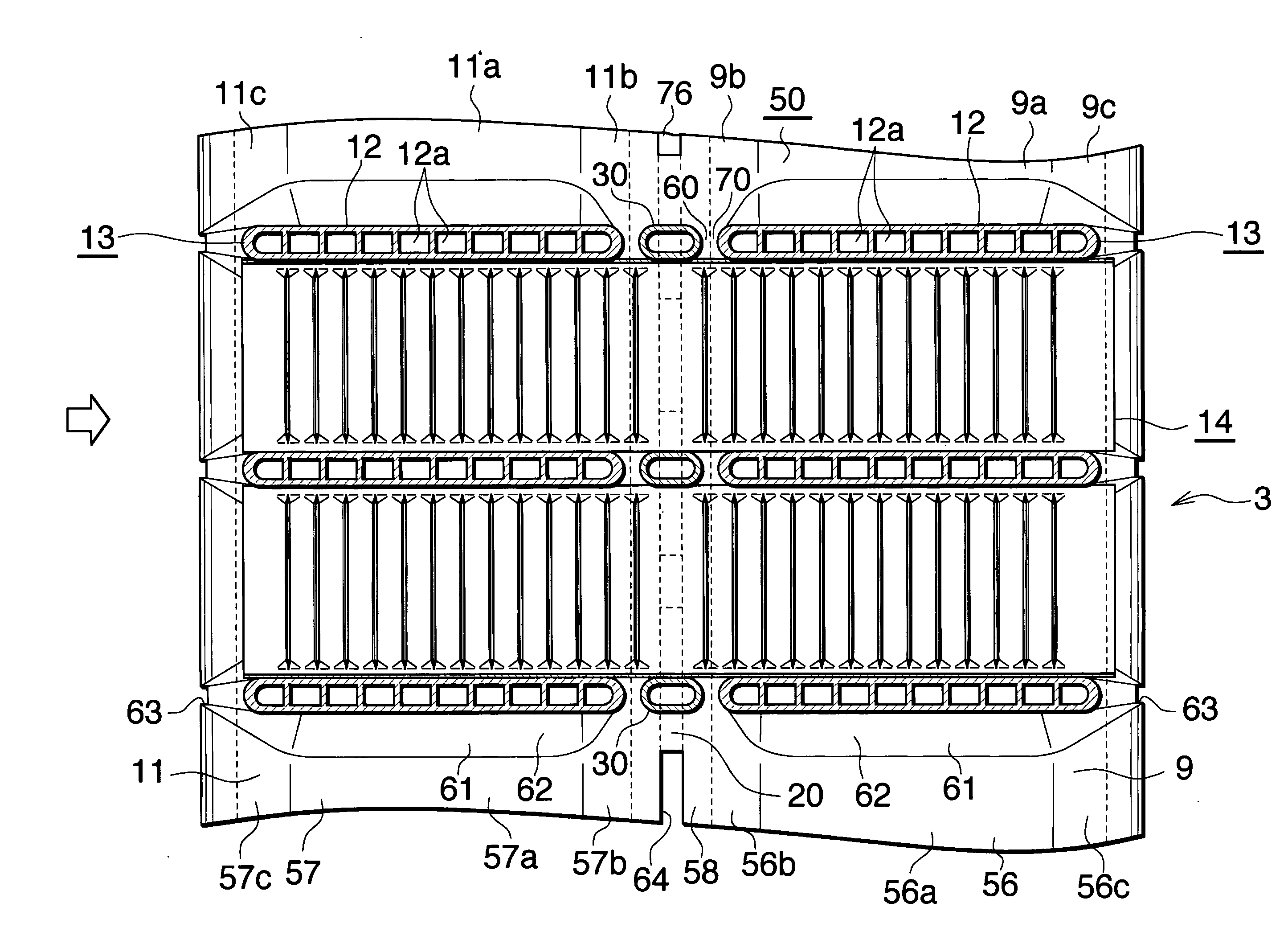

Heat exchanger

ActiveUS20110247791A1Easy to bendConveniently manufacturedStationary conduit assembliesHeat exchanger casingsEngineeringStraight segment

A heat exchanger comprises first and second headers; a plurality of tubes each defining two ends connected to the first and second headers respectively. Each tube comprises a bent segment and straight segments connected to first and second ends of the bent segment respectively, the bent segment being twisted relative to the straight segments. A plurality of fins are interposed between adjacent straight segments. A length of the bent segment before bending satisfies a formula: 5tπ(180−θ) / 180+2Tw≦A≦30tπ(180−θ) / 180+8Tw , where: A is the length of the bent segment before bending, t is a wall thickness of the tube, Tw is a width of the tube, θ is an intersection angle between the straight segments of the tube, and π is circumference ratio. The heat exchanger of embodiments of the present invention is easy to bend and convenient to manufacture without reducing the heat exchange efficiency.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER +1

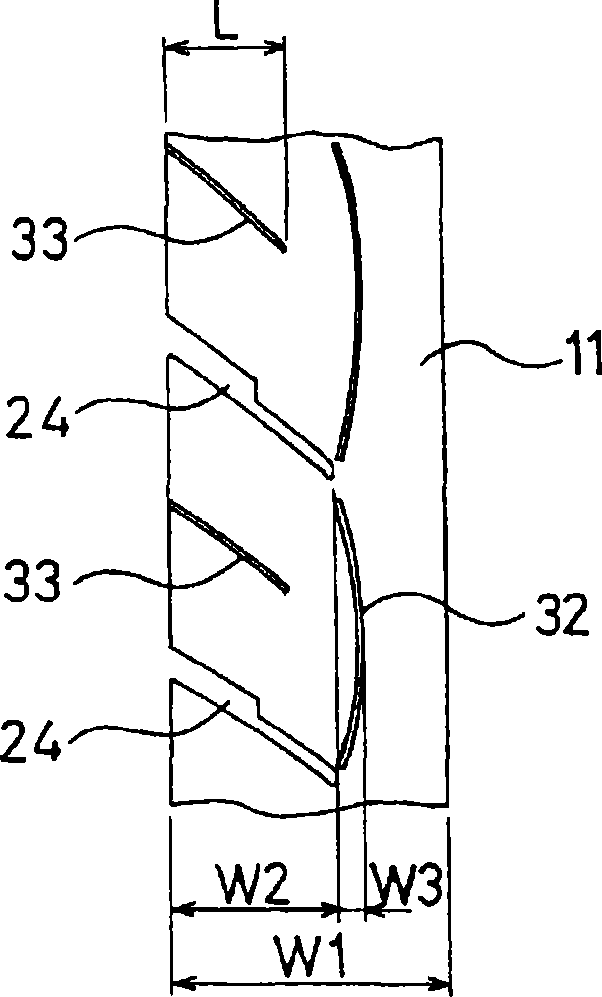

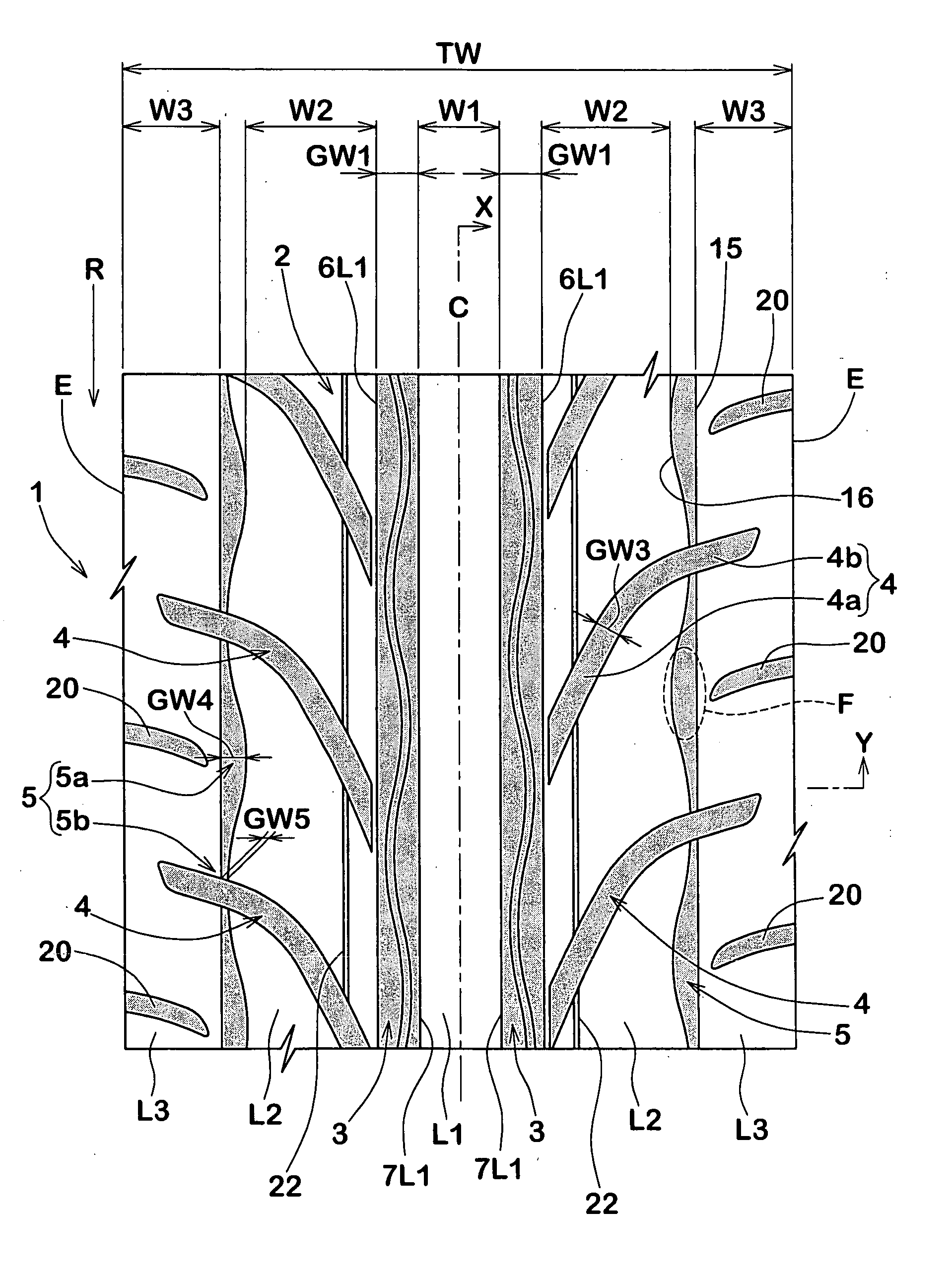

Pneumatic tire

InactiveCN1867464AImprove wetting performanceImprove noiseTyre tread bands/patternsEngineeringOperational stability

A pneumatic tire capable of simultaneously achieving wet performance and noise performance while enhancing driving stability. The pneumatic tire has a rib-like land portion extending in the circumferential direction of the tire, in the central portion of the tread; a left and right pair of first grooves extending in the circumferential direction of the tire while being next to both sides of the rib-like land portion; and a left and right pair of first land portions extending in the circumferential direction of the tire while being next to the outsides of the first grooves. Narrow grooves extending in the circumferential direction of the tire are provided in the rib-like land portion. Further, lug grooves and zigzag narrow grooves are provided in the first land portions, where the lug grooves do not communicate with the first grooves and incline relative to the tire equator, and the undulating or zigzag narrow grooves extend in the tire circumferential direction. The minimum distance (W2) between an undulating or zigzag narrow groove and the outer side wall of a first land portion is set 60-70% of the width (W1) of the first land portion, and the amplitude (W3) of the undulating or zigzag narrow groove is set 5-12% of the width (W1) of the first land portion.

Owner:THE YOKOHAMA RUBBER CO LTD

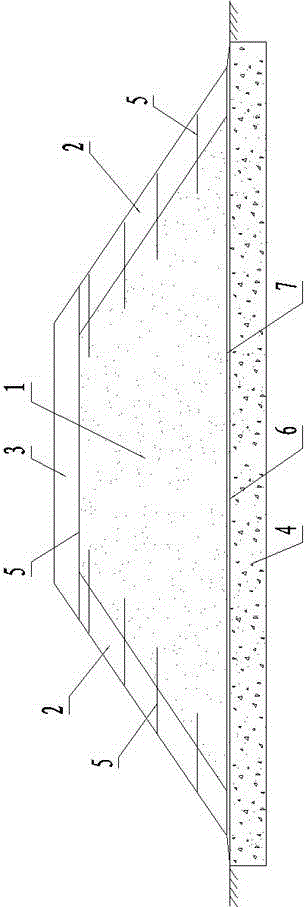

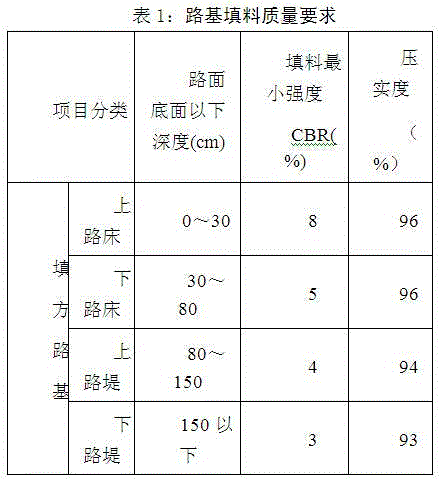

Construction method of geogrid reinforced clay edge-covered tailing subgrade

ActiveCN104631254AImprove overall strengthImproved deformation and failure characteristicsRoadwaysCapillary waterSubgrade

The invention discloses a construction method of a geogrid reinforced clay edge-covered tailing subgrade and belongs to the technical field of subgrades in the civil engineering. The construction method comprises the following steps: foundation treatment, sand gravel underlayer construction, laying of a two-way geogrid and water-permeable geotechnical cloth, feeding laying operations of clay edge-covering layers on the two sides of the subgrade and a tailing subgrade main body layer by layer, rolling construction, one-way geogrid construction between the tailing subgrade main body and the edge-covering clay to a designed elevation, and finally, the construction of an ash doped clay sealing layer. As the one-way geogrids are laid between the clay edge-covering layers on the two sides of the subgrade and the tailing subgrade main body, the defects such as differential settlement, poor subgrade stability and the like between the two fillers, namely the clay and the tailings, are reduced. The construction method has the advantages of simple structure, low cost and convenience for construction; besides, the consumption of the tailings and the overall stability of the subgrade can be increased, the differential settlement and the usage of the earthwork of the subgrade are reduced, rainfall infiltration and capillary water rise are decreased, and the internal drainage performance of the section of the subgrade is improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

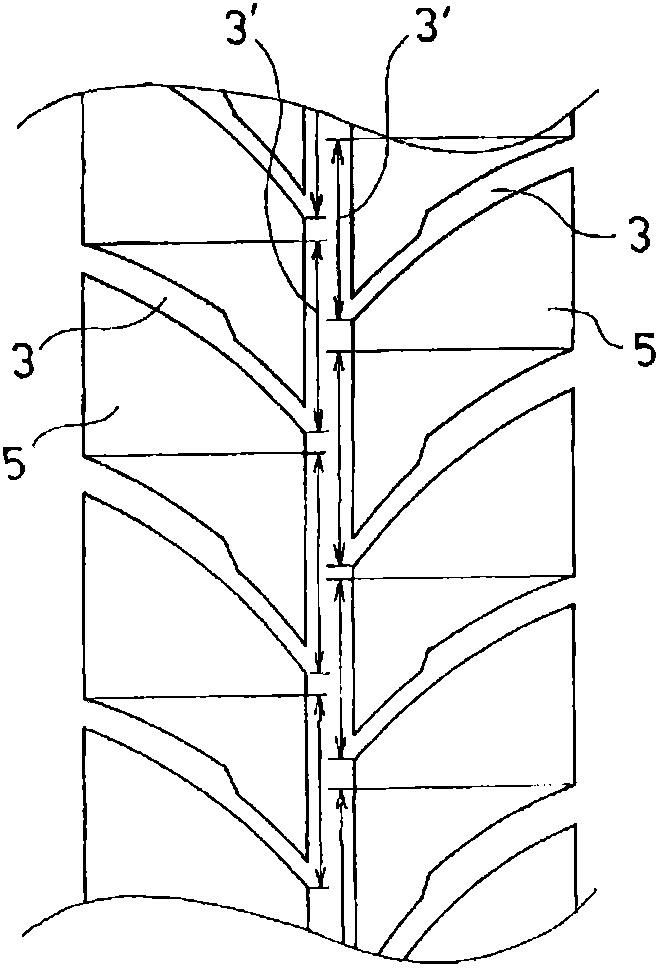

Pneumatic tire

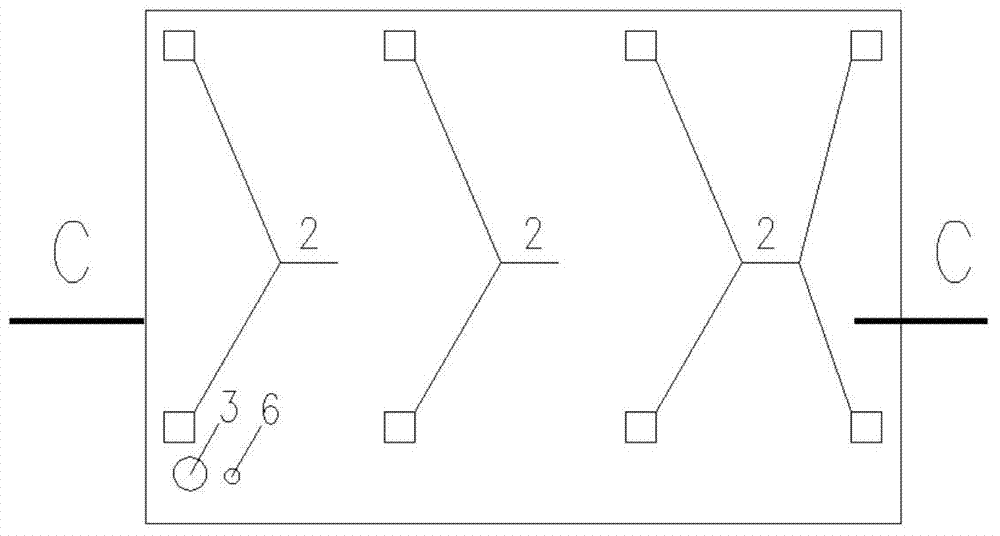

ActiveCN102310723AImprove wetting performanceImprove snow performanceSpecial tyresTyre tread bands/patternsAcute angleTransverse groove

The invention provides a pneumatic tire, which has directional patterns and achieves improved wet performance, snow performance and nonuniform wear resistance. The central portion (C) of the pneumatic tire is divided into multiple pattern blocks (5) via a central main groove (1), outer main grooves (2) and transverse grooves (3). Meanwhile, the strip-shaped patterns (5) at the tire shoulder portion (S) is provided with shoulder pattern grooves (4). The patterns of the pneumatic tire are directional patterns. The transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and is reversely inclined relative to the tire equator, wherein the central inclined angle Theta1 of the transverse grooves (3) is an acute angle. Meanwhile, the transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and the tire circumferential direction in a staggered manner such that the circumferential portion (3') formed by upward projection of the transverse grooves (3) in the tire circumferential direction is provided at the periphery of the tire. In addition, sipes (7) are provided at the pattern blocks (5) and the strip-shaped patterns (6).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20060130950A1Improve rigidityImprove performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire is provided with a pair of circumferential grooves (3) arranged in both sides of a tire equator (C), and a plurality of oblique grooves (4) having a steep decline portion (4a) extending to an outer side in a tire axial direction at an angle (q1) between 15 and 45 degree with respect to a tire circumferential direction from a position near the circumferential groove (3), in a tread surface (2). A land portion (B) surrounded by the circumferential groove (3) and the steep decline portion (4a) has an acute corner portion (12) and an obtuse corner portion (13), each being formed between the circumferential groove (3) and the steep decline portion (4a). An outer groove wall surface (6) of the circumferential groove (3) includes a gentle decline wall (6a) in the tread surface side, and a steep decline wall (6b) in the groove bottom side.

Owner:SUMITOMO RUBBER IND LTD

Electrostatic filter cartridge for a tower air cleaner

InactiveUS7621984B2Improve removal efficiencyImprove drainage capacityHuman health protectionMagnetic separationParticulatesElectricity

The disclosed electrostatic precipitator cartridge for a tower air cleaner in accord with the present invention is low-cost, because it is constructed of injected molded plastics material and stamped and extruded metal components. It is easy to clean, not only because it's constitutive metal parts and plastic components are machine washable but also because the cartridge as a whole is machine washable, the pieces and components are designed and arranged to prevent intracartridge fluid buildup or retention after washing, thereby eliminating any electrical shorting or arcing or other undesirable phenomena resulting therefrom that could interfere with the operation of the electrostatic filter cartridge. It is mechanically stable and has high particulate collection efficiency because it's ionizer bars have a predetermined preferably air foil shape that provides improved ionization efficiency and that imparts improved torsion stability rendering it possible to provide taller electrostatic filter cartridges and / or greater cleaning power.

Owner:LASKO OPERATION HLDG LLC

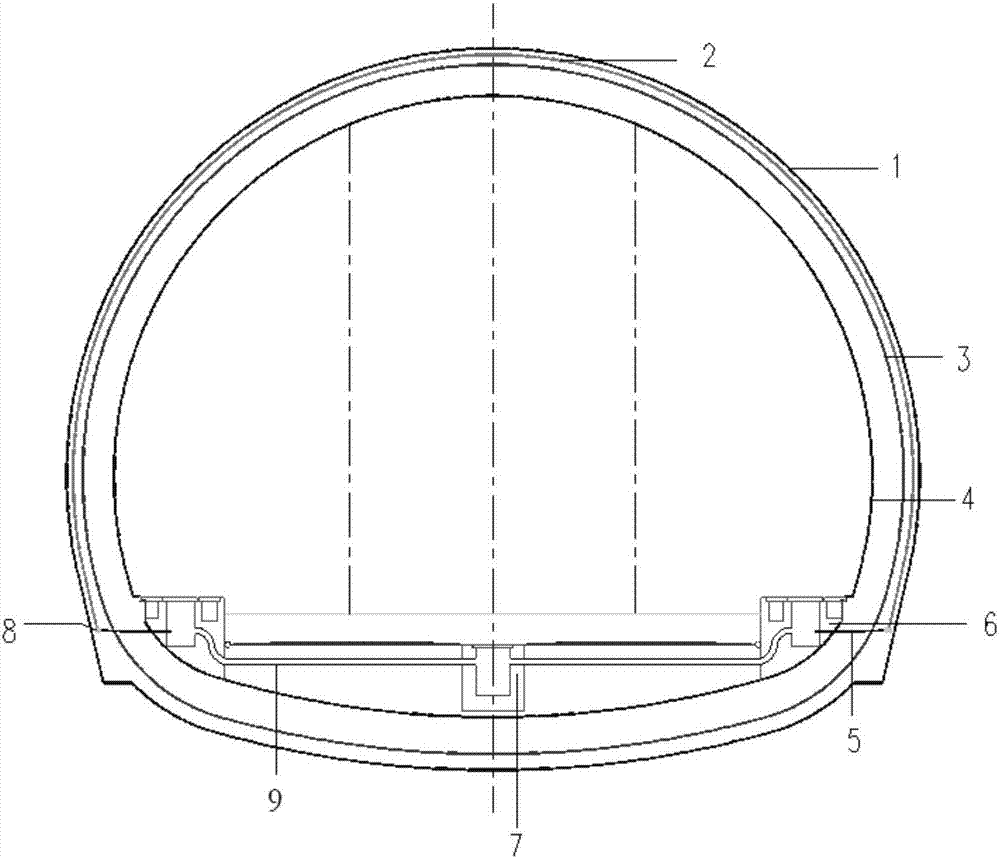

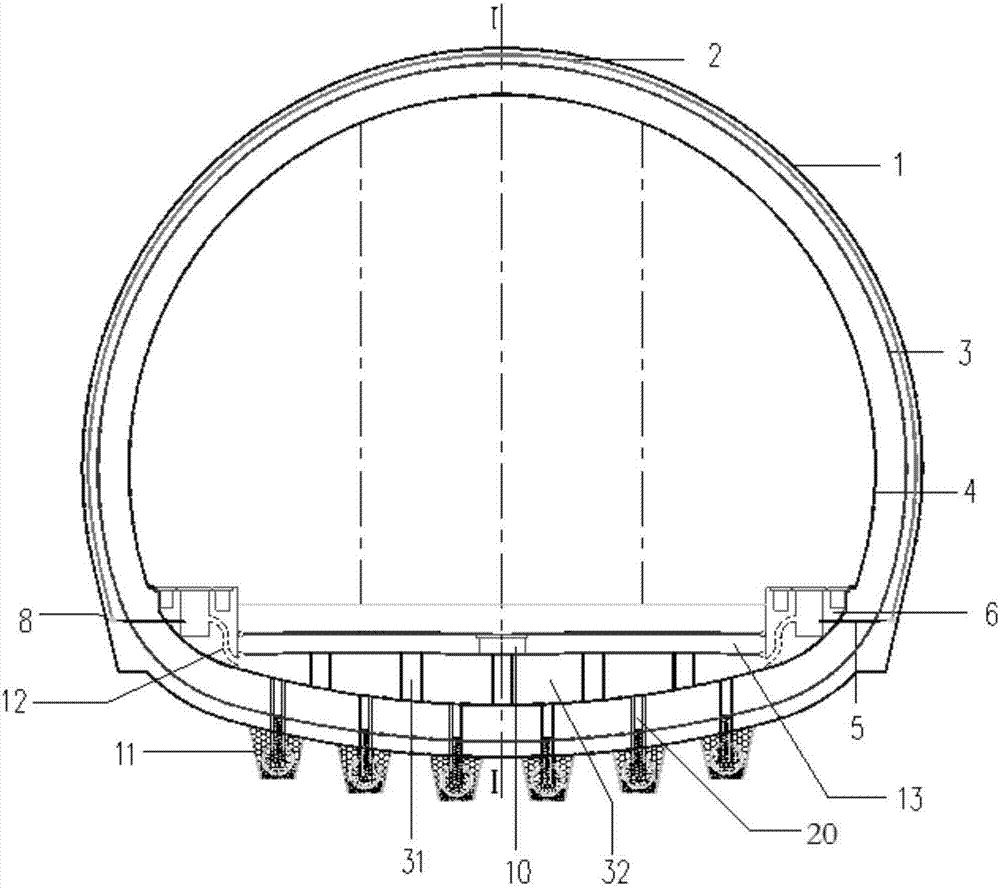

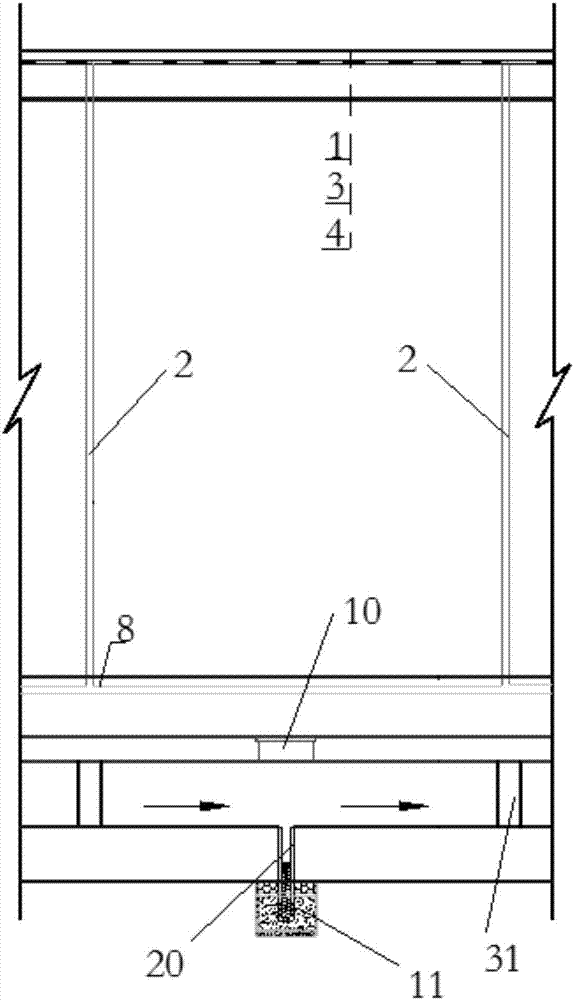

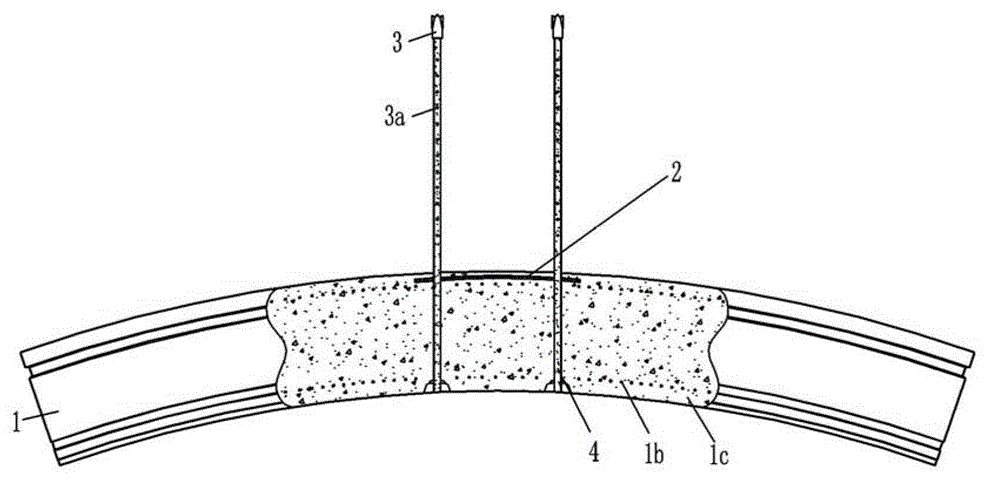

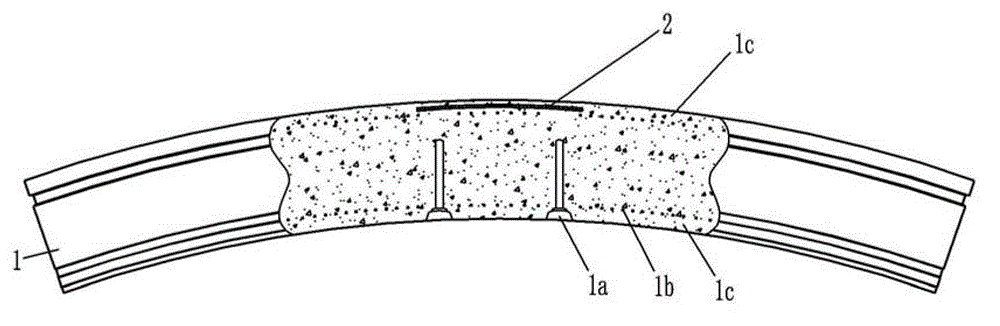

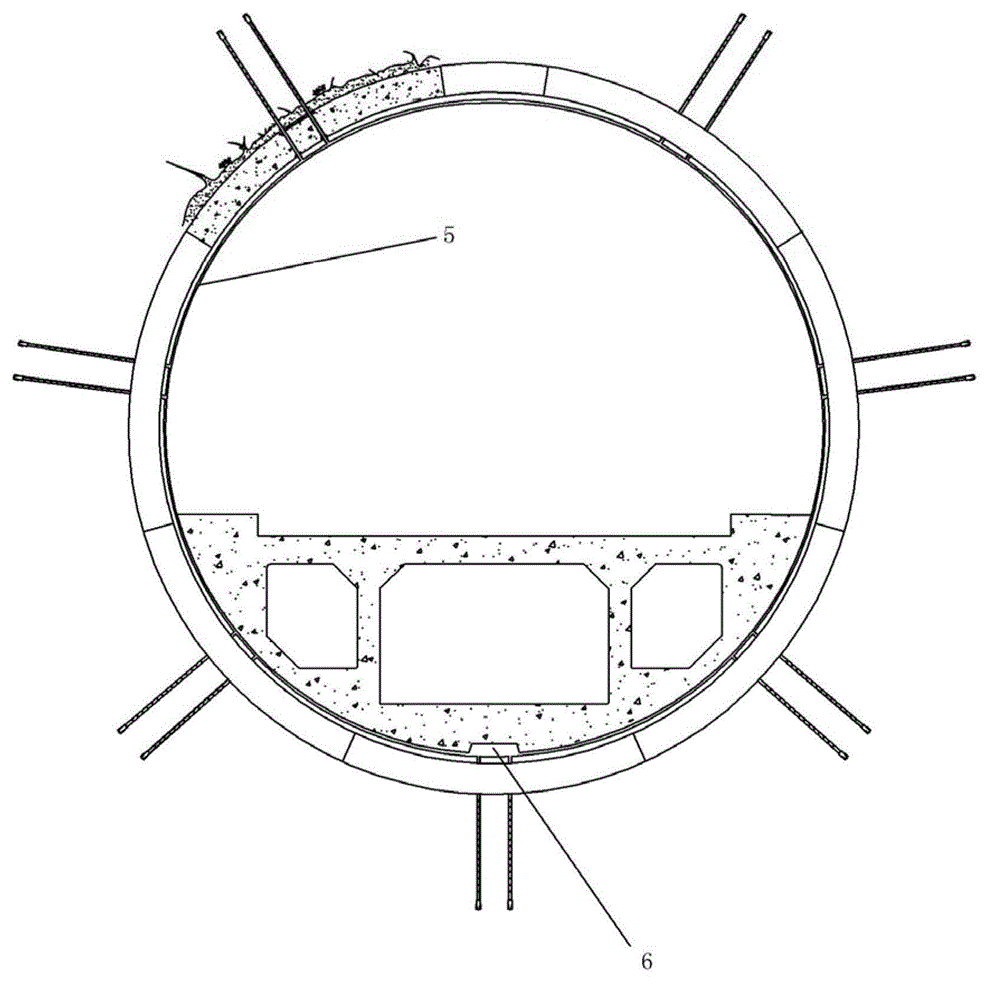

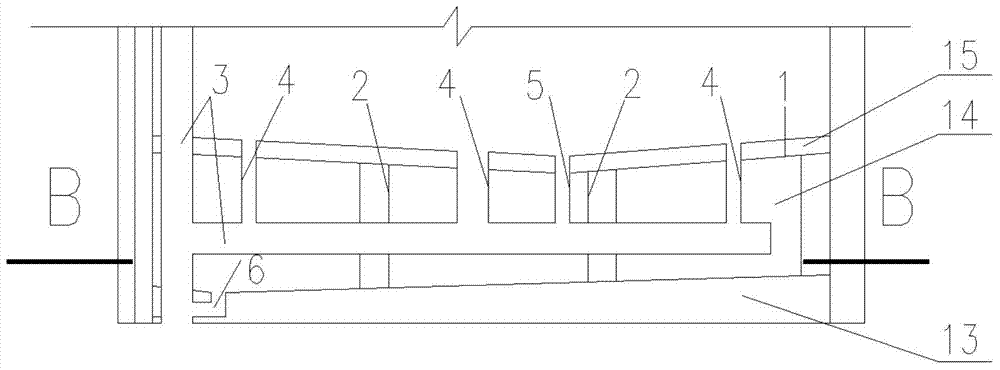

Water-rich stratum tunnel bottom drainage structure and construction method thereof

ActiveCN106968712AReduce water pressureImprove drainage capacityUnderground chambersTreatment involving filtrationDrainage tubesWater well

The invention relates to a water-rich stratum tunnel bottom drainage structure and a construction method thereof. A ballast bed base plate is arranged above an inverted arch in a spaced mode; bearing piles are arranged between the ballast bed base plate and the inverted arch; water passing culverts of the tunnel bottom are formed between the ballast bed base plate and the inverted arch; drainage side ditches communicate with the water passing culverts through side ditch drainage pipes; water collecting wells are arranged on the bottom faces of the water passing culverts; the lower ends of the water collecting wells penetrate through the inverted arch to extend into filtering water collecting devices under the inverted arch; water releasing holes are formed in the bottoms and the side walls of the water collecting wells, and filtering layers are arranged on the outer sides of the water releasing holes; and one-way drainage devices are arranged in the water collecting wells. An inverted arch filling part in the prior art is replaced with the ballast bed base plate and the bearing piles; on the basis of guaranteeing tunnel structure safety, the water passing cross section area of a tunnel drainage system is increased, and the tunnel drainage capacity is improved; and meanwhile, underground water under the water-rich stratum tunnel inverted arch is drained, tunnel bottom water pressure is reduced, and preventing of damage such as upheaval of the tunnel inverted arch and frost boiling and mud pumping of a ballast bed is facilitated.

Owner:SOUTHWEST JIAOTONG UNIV

Anti-blocking water absorption manhole cover

ActiveCN111305363AAffect drainage efficiencyPrevent splashSewerage structuresClimate change adaptationMarine engineeringAirbag

The invention discloses an anti-blocking water absorption manhole cover which comprises a manhole cover body. Multiple water inlets are formed at the upper end of the manhole cover body in the circumferential direction of the manhole cover body at equal distance. Cavities are symmetrically formed in the manhole cover body. A first telescopic airbag is fixedly connected to the inner wall of each cavity, and a second telescopic airbag is arranged on the outer side of each first telescopic airbag in a sleeving manner. A dredging device used for dredging the water inlets is mounted on the manholecover body. According to the anti-blocking water absorption manhole cover, through the arrangement of an elastic plate, a vertical rod, first cross rods, second cross rods and sliding plugs, when a vehicle passes through the elastic plate, the vertical rod can drive the first cross rods to move through the second cross rods, the sliding pugs drive the first telescopic airbags and the second d telescopic airbags to be stretched, so that ejector rods move downwards, and the process that rainwater enters the water inlets is accelerated; and the situation that when the vehicle fast runs on the manhole cover body, rainwater on the manhole cover body is drained away, and the water drainage efficiency of the manhole cover body is influenced is avoided.

Owner:台州友驿科技有限公司

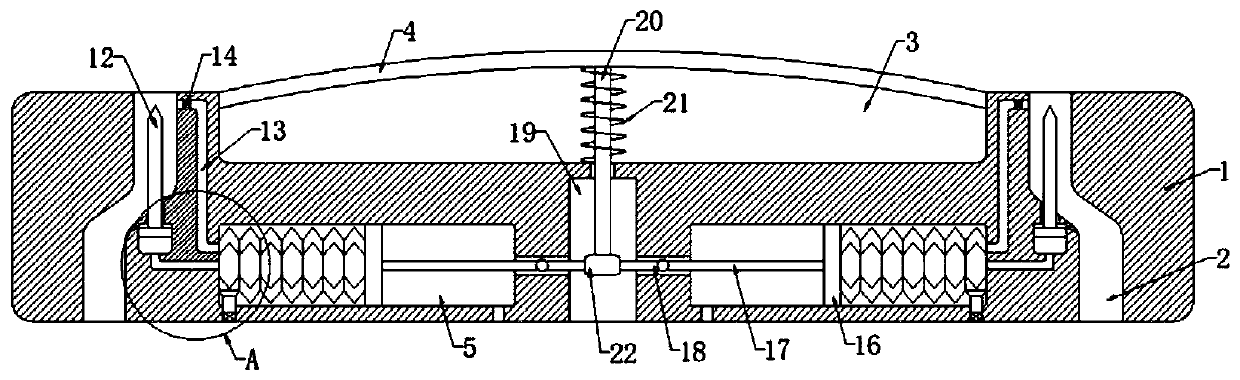

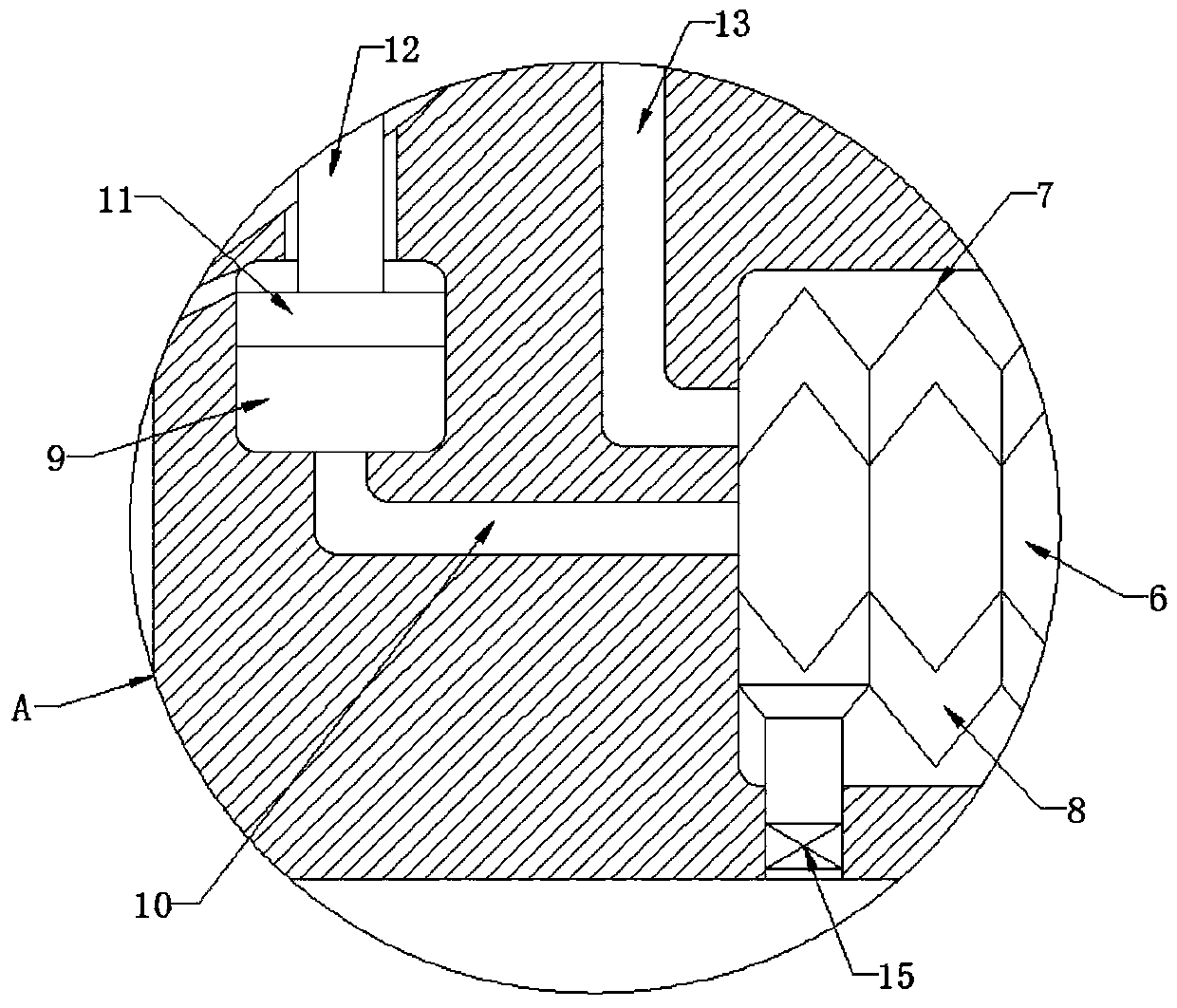

Drain-type pipe piece for tunnel lining

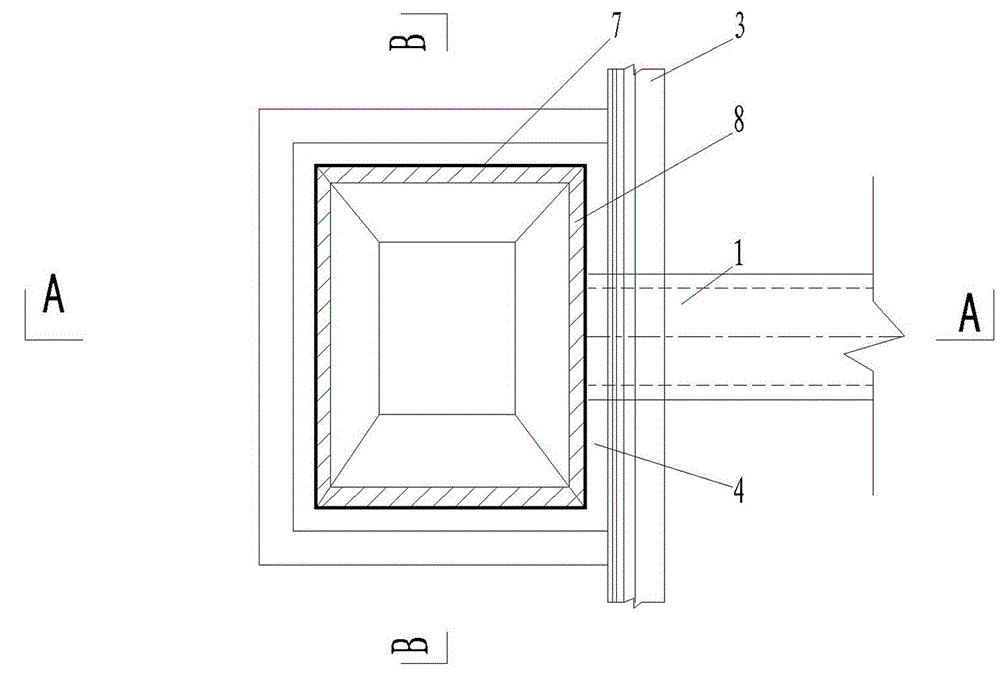

ActiveCN102979535ANo need to increase intensityEnsure safetyUnderground chambersDrainageReinforced concreteSlurry

The invention discloses a drain-type pipe piece for tunnel lining. The drain-type pipe piece comprises a reinforced concrete pipe piece (1), a slurry injection hole (or a hoist hole) (1a) in the pipe piece (1), a load bearing steel bar (1b), and a concrete protective layer (1c) on the outer side; a water stop rubber block (2) capable of being expanded when being in contact with water is preburied in the concrete protective layer (1c) right opposite to one or two slurry injection holes (1a) of the pipe piece (1); a self-advancing type hollow anchor rod (3) is inserted in the slurry injection holes (or the hoist hole) (1a) of the pipe piece (1), then penetrates the water stop rubber block (2), and shoots out of the concrete protective layer (1c); and drain holes (3a) are formed in the rod wall of the outer end of the self-advancing type hollow anchor rod (3), and a filter column (4) used for filtering sand is plugged in the inner cavity of the self-advancing type hollow anchor rod (3). Lining built with the pipe pieces has a reliable drain function, and can reduce water pressure around the structure to ensure tunnel safety; and construction is convenient, small damage is caused to the pipe piece lining structure, and construction cost of the pipe piece lining is low.

Owner:SOUTHWEST JIAOTONG UNIV

Pneumatic tire

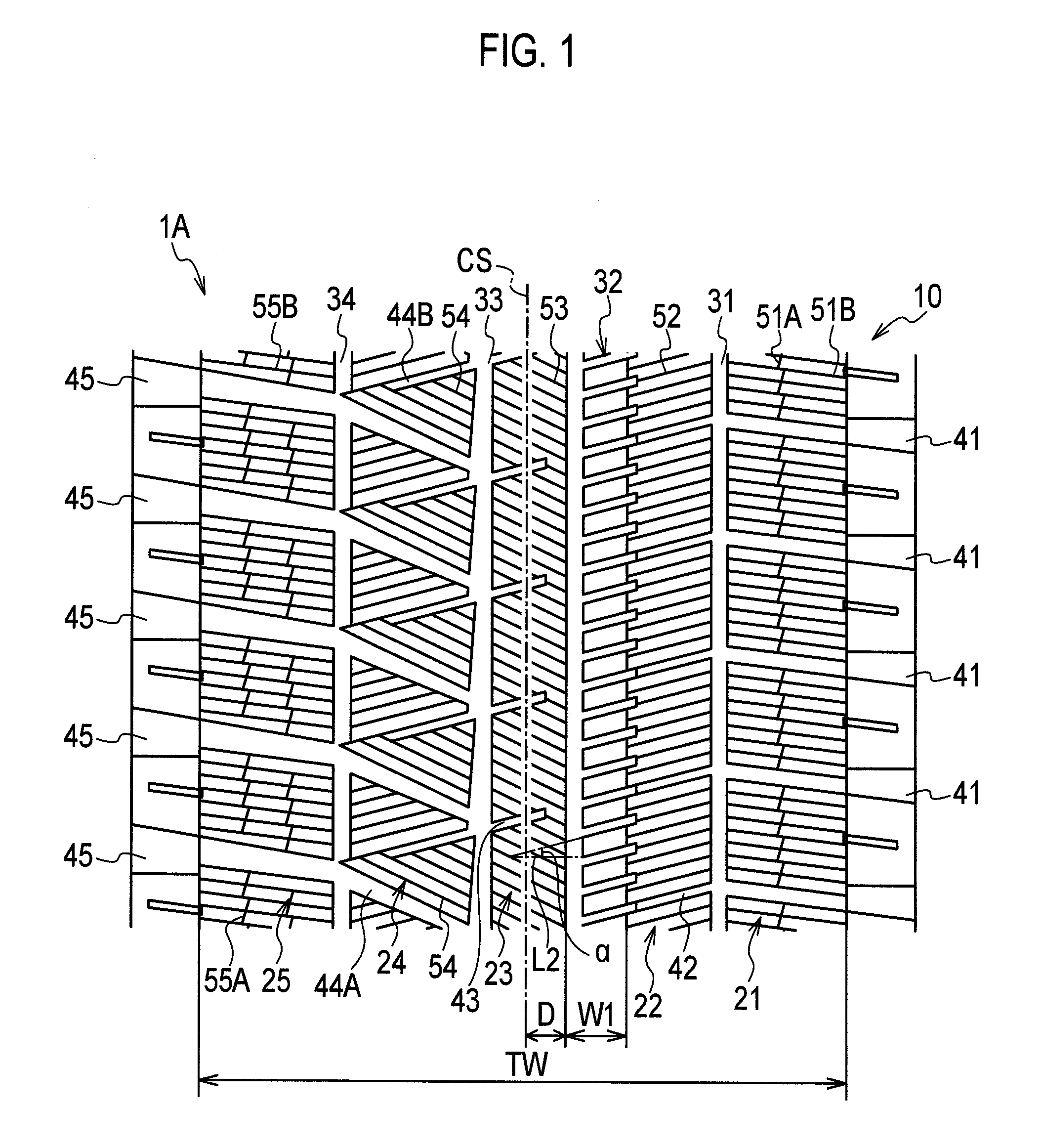

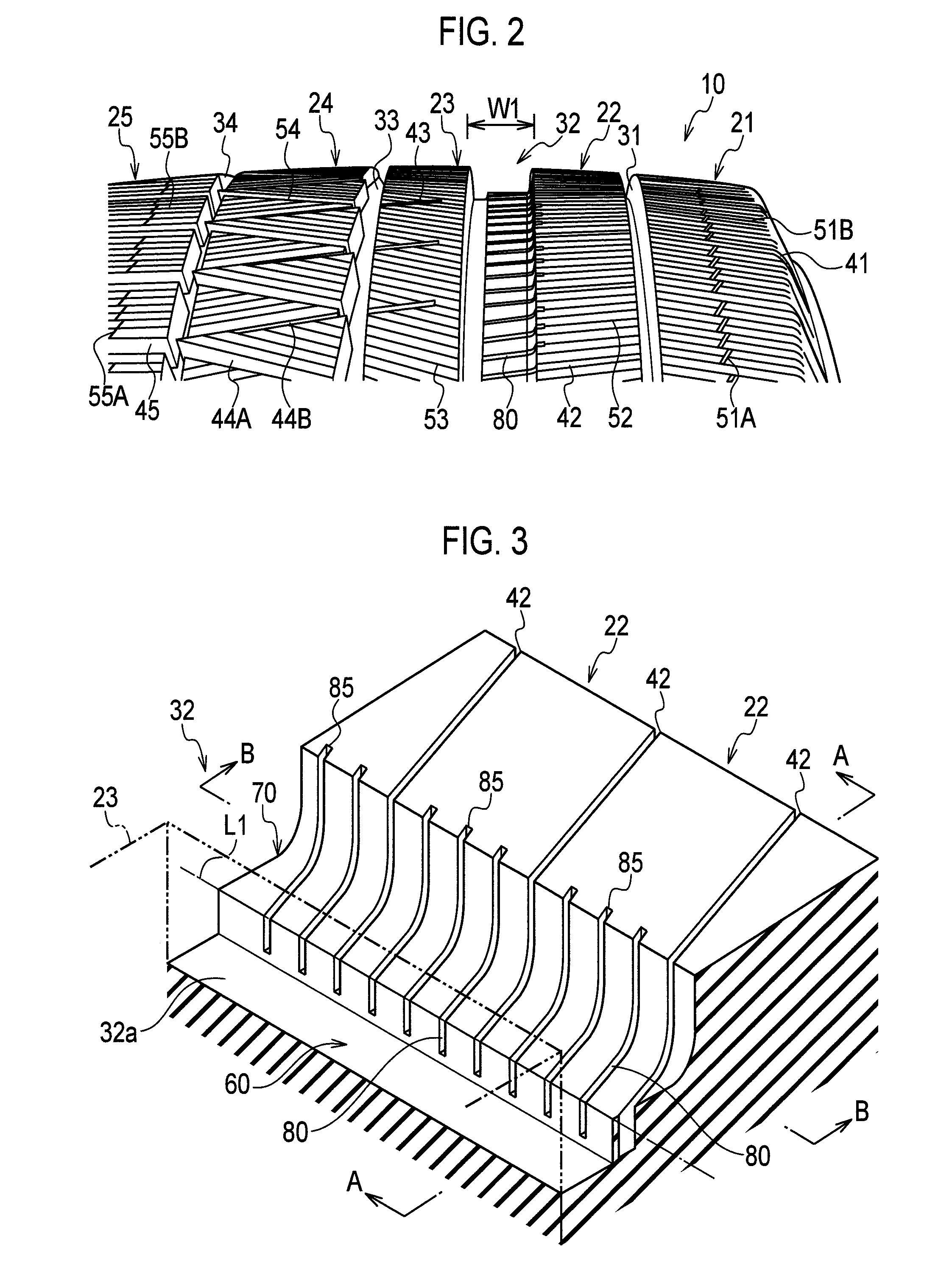

ActiveUS20110146863A1Prevent skidEasily drainTyre tread bands/patternsNon-skid devicesEngineeringGroove width

In a present invention, in a pneumatic tire 1A, a circumferential groove 32 extending in a tire circumferential direction is formed by land portions 20 constituting a tread surface 10 coming into contact with a road surface. A flat groove portion 60 and an in-groove land portion 70 are formed in the circumferential groove 32. The flat groove portion 60 is a flat surface of a groove bottom 32a of the circumferential groove 32. The in-groove land portion 70 is raised toward the tread surface 10 side from the groove bottom 32a of the circumferential groove 32. Multiple narrow grooves 80 extending in a tread width direction are formed in the in-groove land portion 70. A wide-groove width W1 of the circumferential groove 32 in the tread width direction is 5 to 30% of a tread width TW of the tread surface in the tread width direction.

Owner:BRIDGESTONE CORP

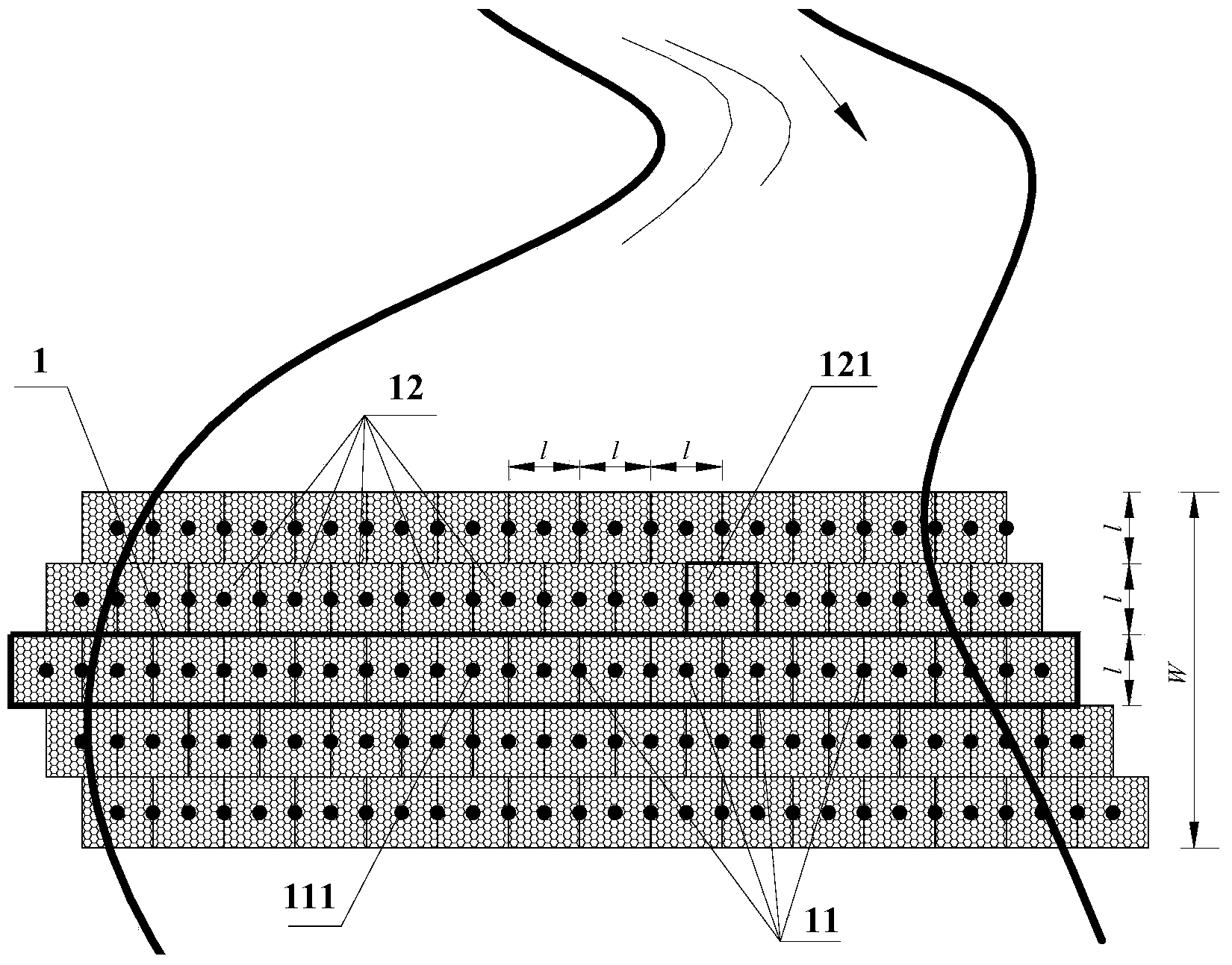

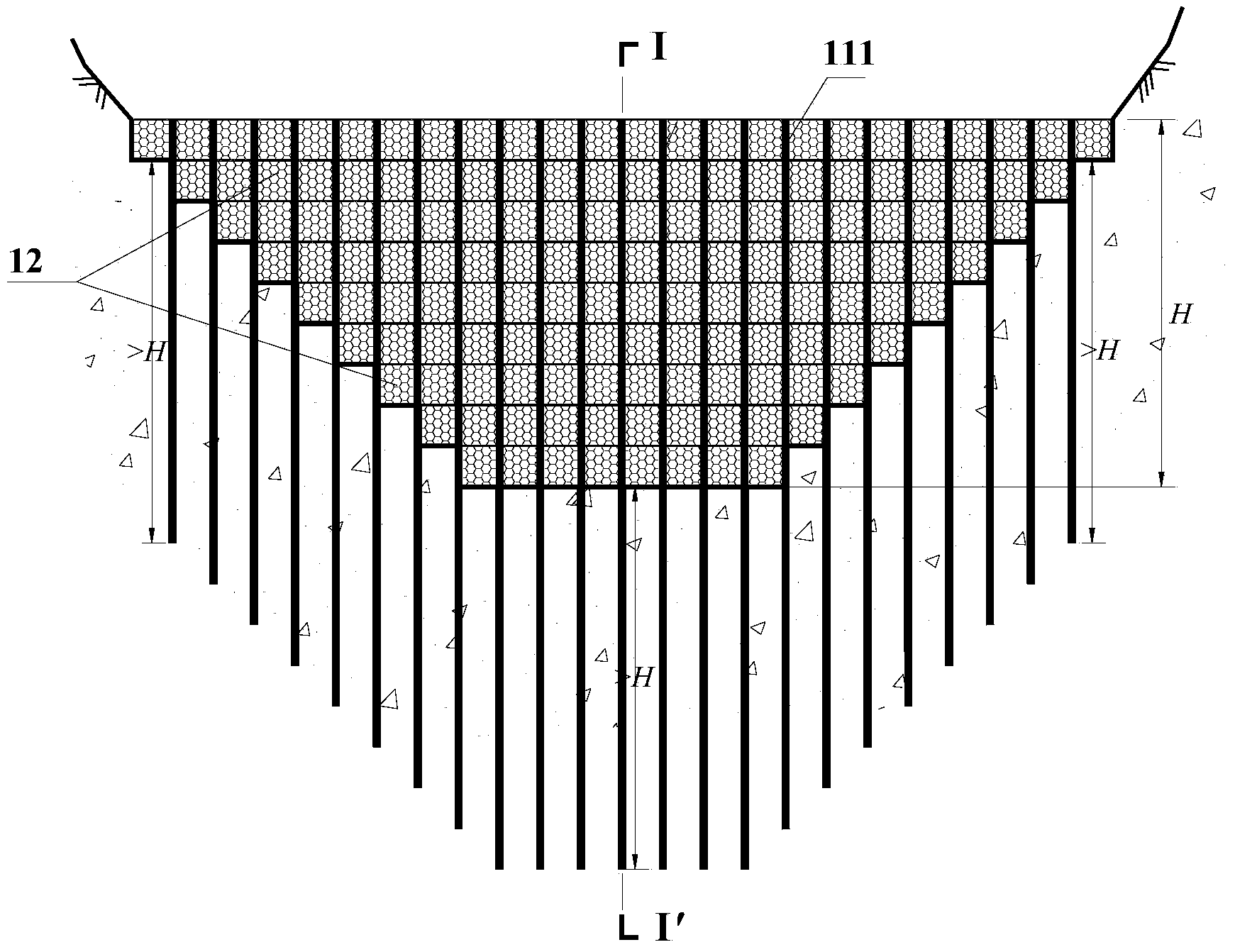

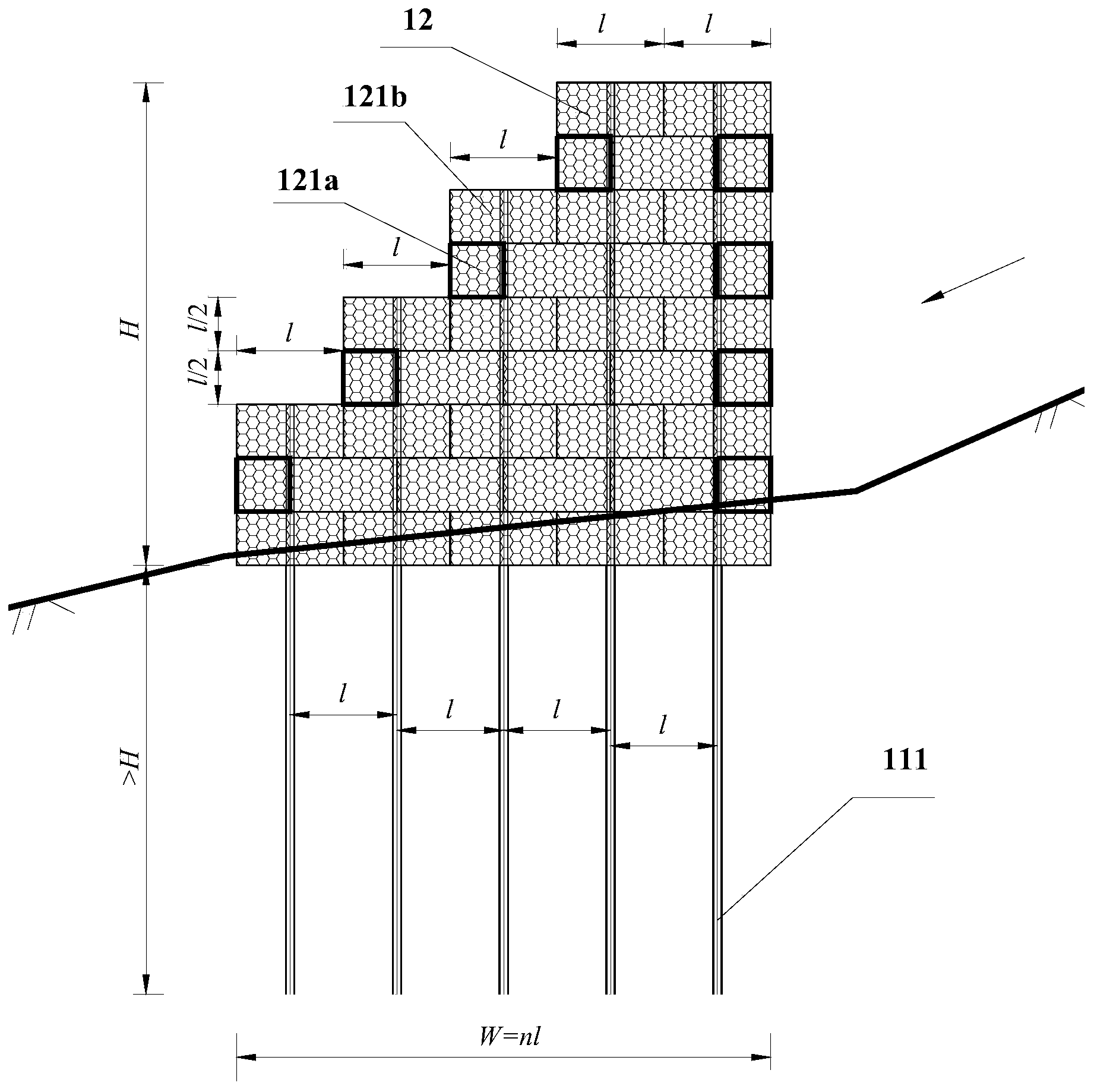

Debris flow gabion prevention and control structural body and design method thereof

InactiveCN103526722AImprove impact resistanceReduce operating and maintenance costsDamsClimate change adaptationEngineeringGabion

The invention discloses a debris flow gabion prevention and control structural body and a design method of the debris flow gabion prevention and control structural body. The flexible debris flow blocking structural body aims to overcome the defects that an existing permeable dam is limited in water permeability and is cracked and destroyed easily by over large instantaneous impact force. The debris flow gabion prevention and control structural body comprises at least one gabion dam prevention and control structural single body. Each single body comprises a lower steel pipe pile group and an upper gabion dam, wherein the steel pipe pile group is formed by arranging a plurality of steel pipe piles in the transverse direction of a debris flow channel, the lower pile bodies of the steel pipe piles are embedded into a debris flow gulley bed, and the upper portions of the steep pipe piles are exposed out of the gulley surface and are connected with the gabion dam in a penetrating mode. The multiple gabion dam prevention and control structural single bodies are arranged adjacently in the longitudinal direction of the debris flow channel. Through the optimization design, the gabion dam is of a multi-layer structure, each layer of the gabion dam is composed of a plurality of gabion nets, and the gabion nets of each layer are arranged in a staggered mode. The invention further provides the design method of the debris flow gabion prevention and control structural body. The debris flow gabion prevention and control structural body can fully utilize the water permeability of the gabion combined structure and deformation feedback of the gabion combined structure on the impact to achieve a good prevention and control effect.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

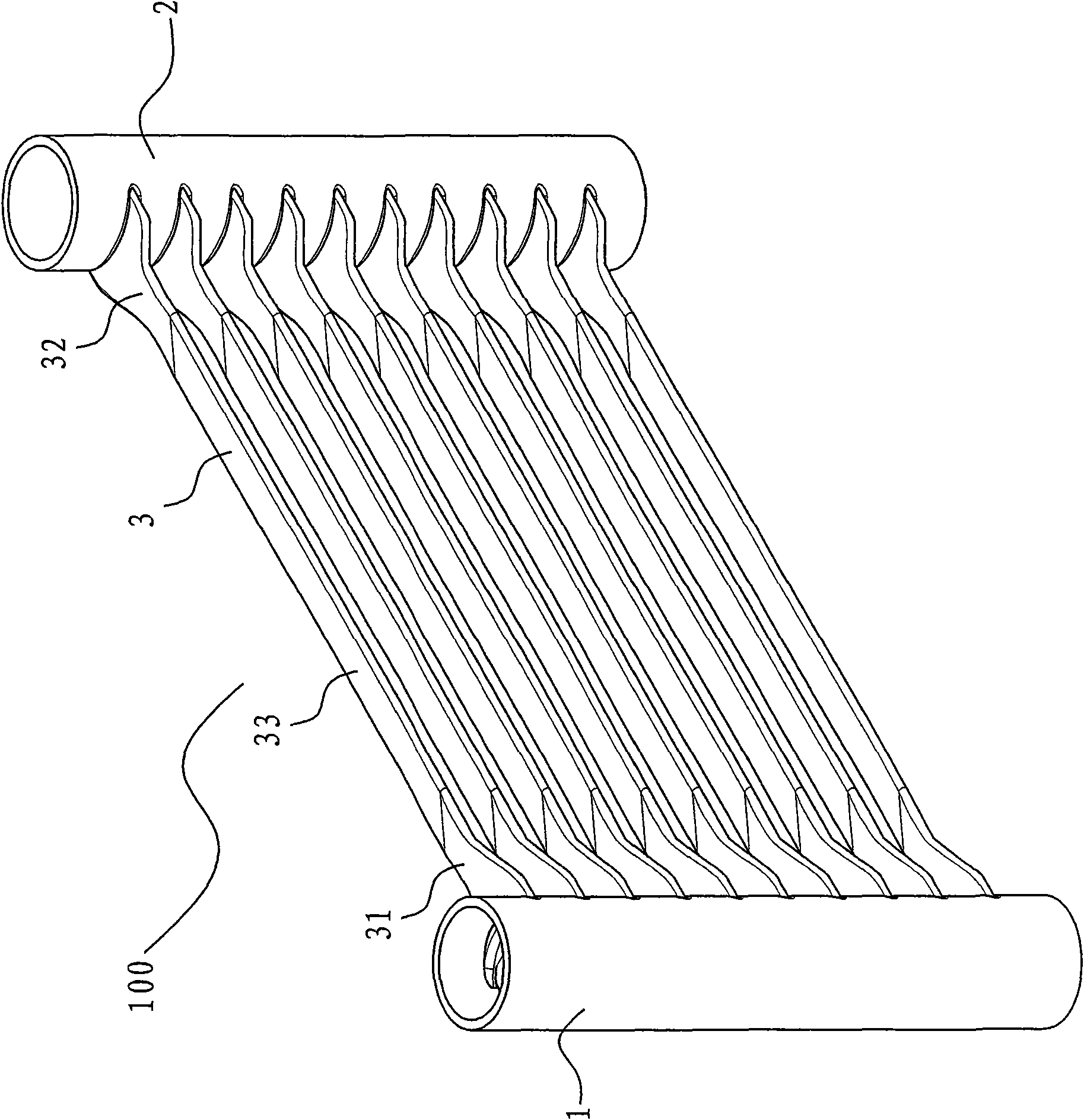

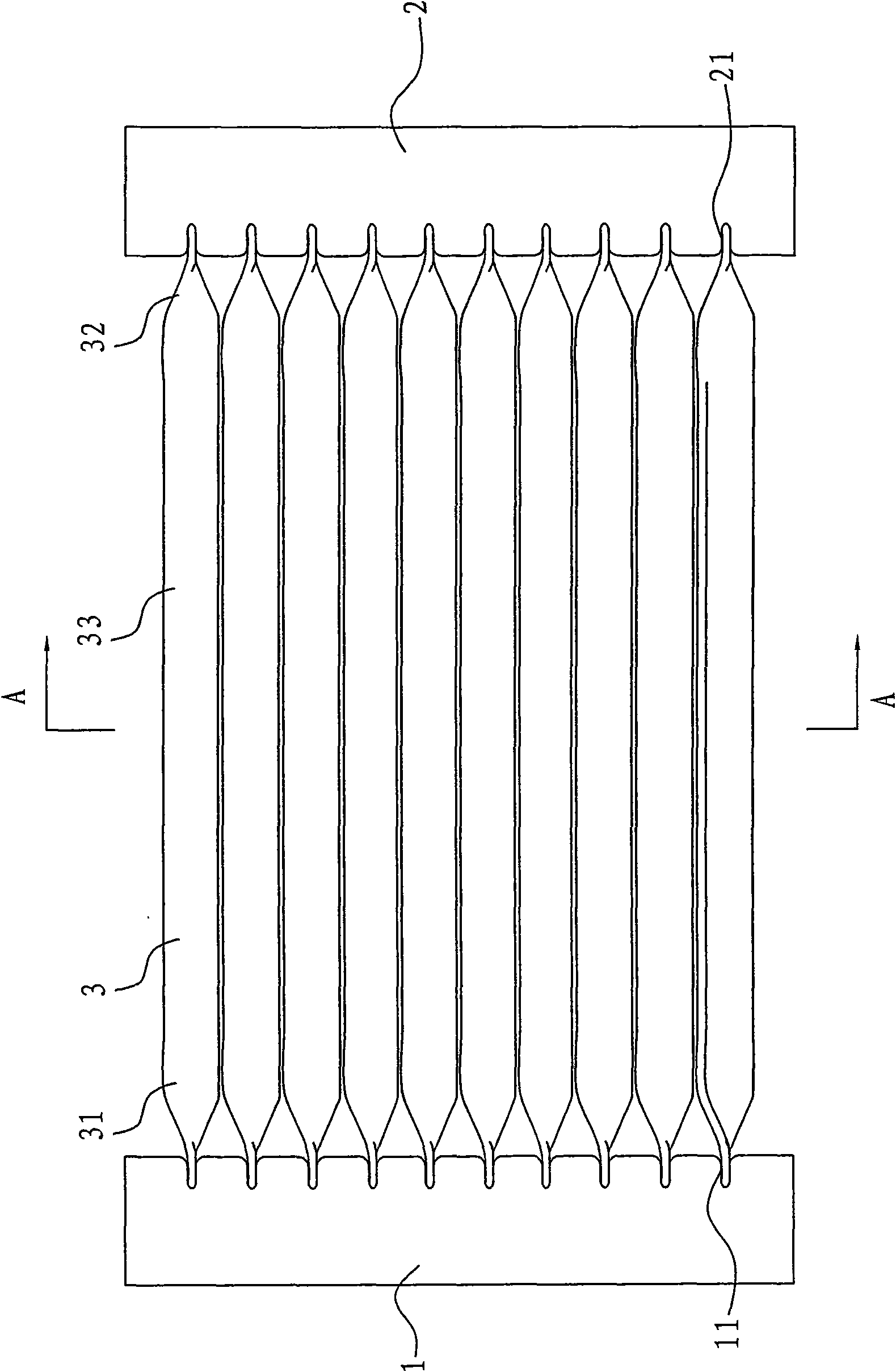

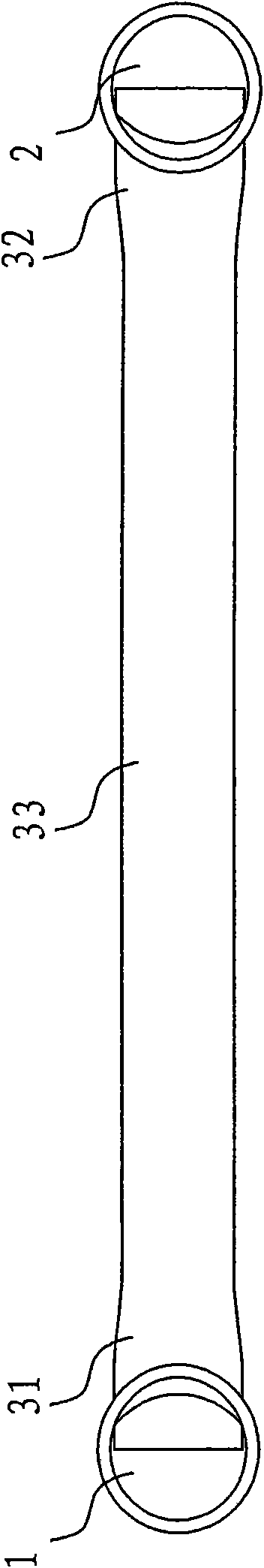

Heat exchanger

ActiveCN101619939AImprove drainage capacityImprove heat transfer effectEvaporators/condensersStationary conduit assembliesEngineeringGravitation

The invention discloses a heat exchanger which comprises a first collecting pipe, a second collecting pipe, a plurality of flat pipes and fins, wherein the second collecting pipe and the first collecting pipe are positioned in a first plane and spaced with a preset distance; the first end and the second end of each flat pipe are respectively connected with the first collecting pipe and the second collecting pipe so as to communicate the first collecting pipe and the second collecting pipe through fluid; an included angle between the plane of the flat pipes and a second plane being orthogonal to the first plane is alpha, wherein alpha is larger than 0 degree and smaller than 90 degrees; and the fins are arranged between adjacent flat pipes. When the heat exchanger is used as a single cooling evaporator or a heat pump type heat exchanger, condensed water flows downwards along inclined surfaces of the flat pipes or the fins under the action of self gravity to leave the surface of the heat exchanger and cannot be gathered on the flat pipes and the fins, thereby improving the draining effect and improving the heat exchange performance.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

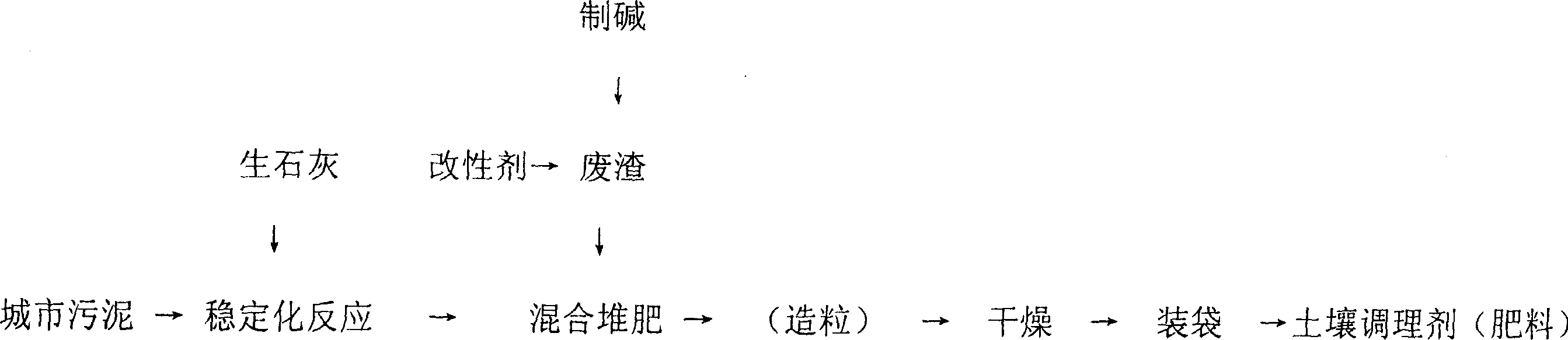

Method of producing polyacidic soil regulating agent using offscum in alkali manufacturing and city sludge

InactiveCN1868930AReduce contentReduce absorptionBio-organic fraction processingSludge treatmentSludgeCompost

A process for preparing a multi-element acidic soil conditioning agent from the alkali dregs and city sludge includes such steps as adding calcium lime to city sludge for stabilizing and disinfecting it, modifying the alkali dregs by (NH4)2HPO4, mixing them together, stacking to obtain compost, drying and breaking.

Owner:广东省农业科学院土壤肥料研究所 +1

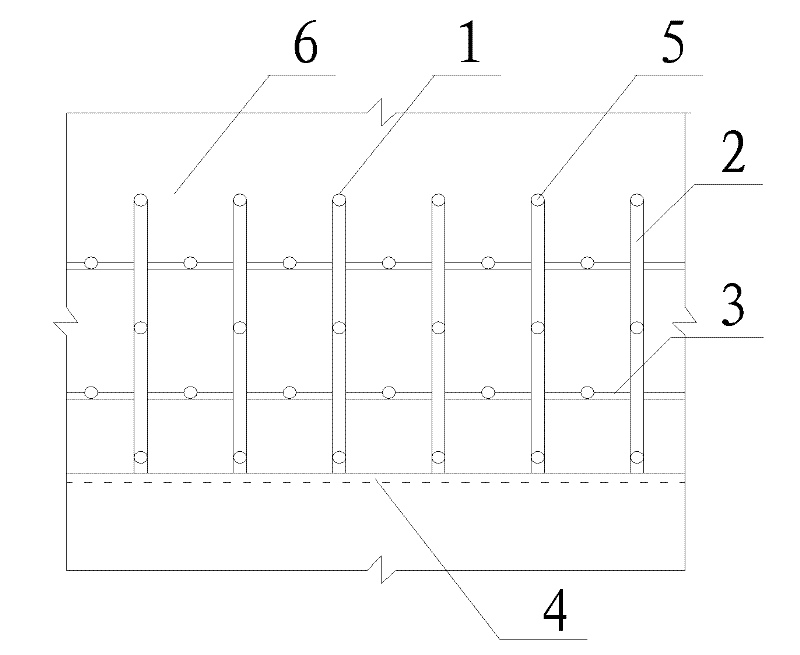

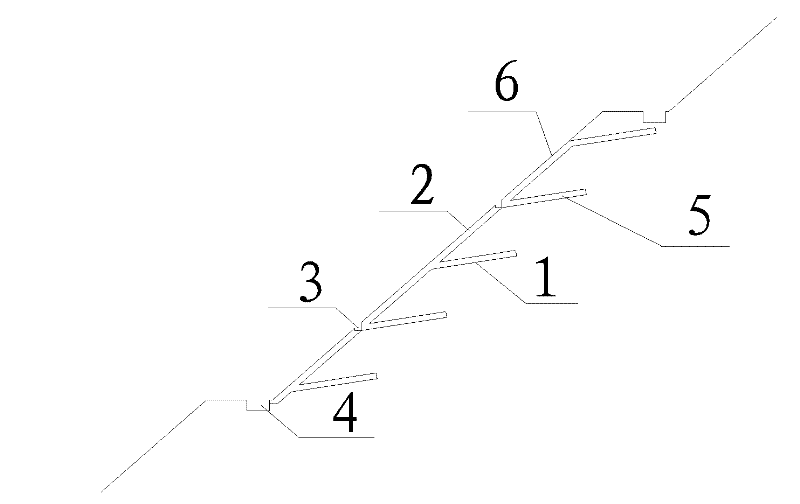

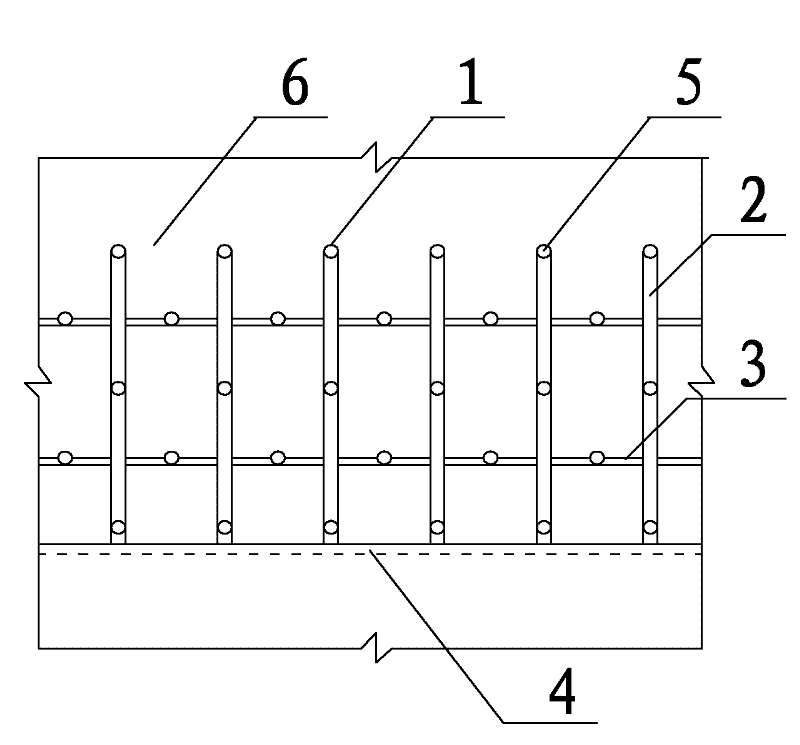

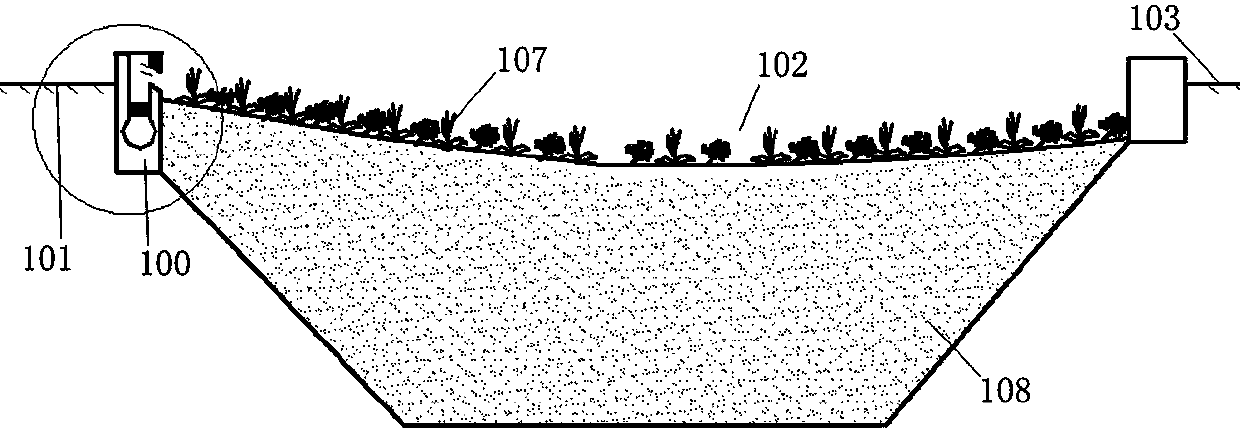

A slope shallow drainage system

The invention discloses a side slope shallow drainage system. The bottom platform of the side slope (6) is provided with drainage ditches (4), and multiple rows and rows of drainage boreholes are densely arranged on the side slope (6). (1), the distance between the drainage boreholes (1) is 2-3m, the depth is 3-4m, and the elevation angle is 0-10°, each of the drainage boreholes (1) is provided with Drainage pipe, the slope of the slope (6) is arranged with a longitudinal micro-drainage ditch (2) and / or a transverse micro-drainage ditch (3) docked with the outlet of each of the drainage pipes, the The longitudinal miniature water collection ditch (2) and / or the horizontal miniature water collection ditches (3) communicate with the drainage ditch (4). The invention is a side slope shallow layer drainage system for quickly and efficiently discharging the groundwater infiltrated by rainfall into the shallow layer soil of the side slope.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

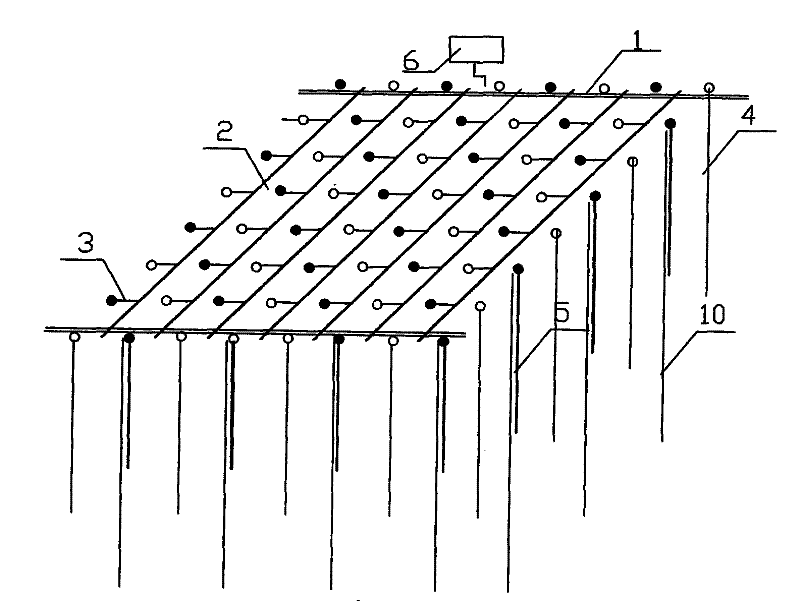

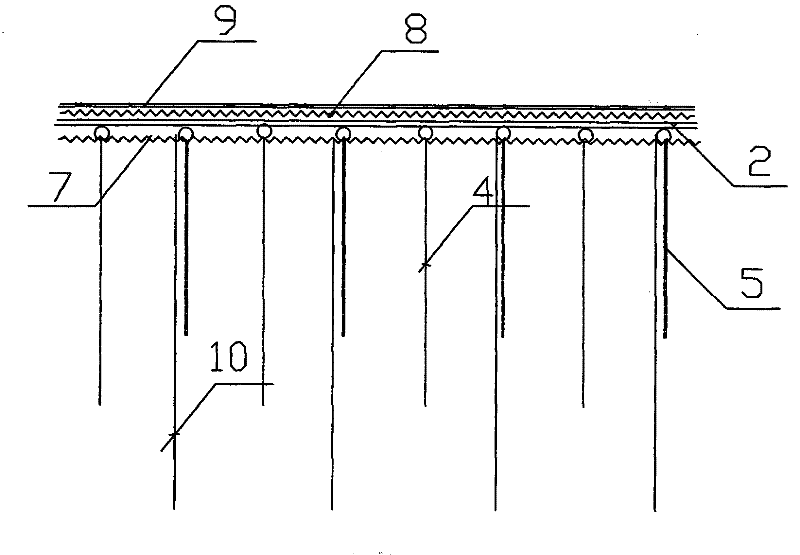

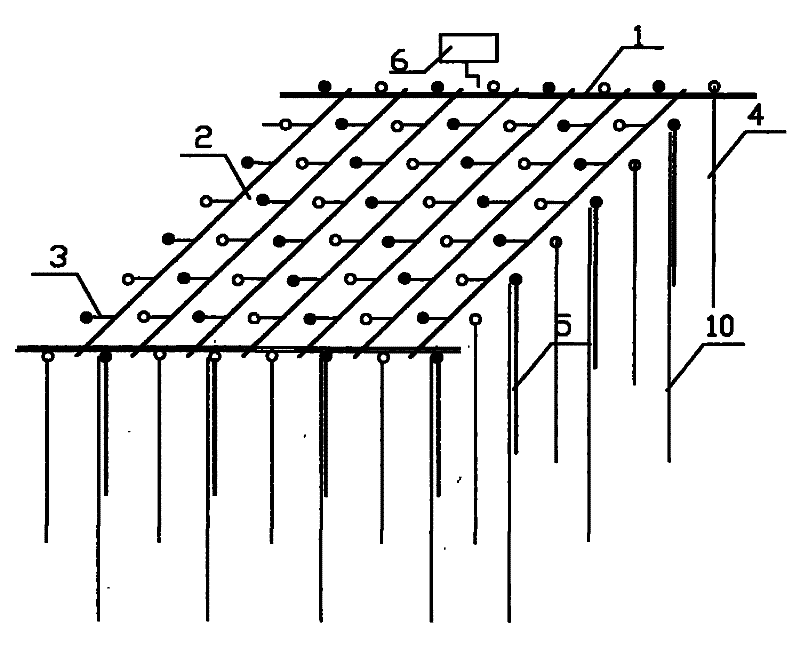

Large-area soft soil foundation duplex negative pressure consolidation processing method

InactiveCN101748721AEnhanced transfer processAccelerated dissipationSoil preservationDynamic compactionProcess region

The invention relates to a large-area soft soil foundation duplex negative consolidation processing method, comprising the following processes of: step 1, negative pressure consolidation: (a) paving plastic woven cloths in an area to be processed, driving a vertical plastic drainage board and a vertical plastic soak-away trench; (b) paving a main pipe and a branch pipe, wherein the vertical plastic drainage board and a transverse plastic drainage board are connected with the branch pipe; (c) paving a geo-membrane, and paving two to three sealing membranes on the geo-membrane; (d) excavating a side ditch pressing membrane; (e) installing a vacuum pump to vacuumize for negative pressure precipitation, wherein the main pipe is connected with the vacuum pump; step 2, well point dynamic arrangement: (a) inserting a well point pipe in a hole inserted by a vertical plastic soak-away trench or nearby the hole; (b) paving the branch pipe, the main pipe and the vacuum pump, carrying out the well point dynamic arrangement; and step 3, dynamic consolidation: a) precipitating and dynamically compacting in the first and second times, carrying out precipitation and dynamic compaction processes on the area to be processed for several times, carrying out multiple rounds of point compactions and finally carrying out a full compaction. According to the large-area soft soil foundation duplex negative consolidation processing method, the bearing capacity of the processed field is higher, the hard crust is thicker and the post-construction settlement is less.

Owner:曾国海 +3

Kerb with drainage function and pollutant intercepting function

InactiveCN104005316AFunctionalWith drainage capacityFatty/oily/floating substances removal devicesSewerage structuresGratingWater treatment system

The invention relates to the technical field of urban road rainwater treatment, in particular to a kerb with the drainage function and the pollutant intercepting function in an urban road rainwater treatment system. The kerb comprises a water inlet, an overflow port, a drainage channel, an overflow channel and a rainwater grating. The rainwater grating is arranged at the water inlet, the included angles between grating bars of the rainwater grating and the inflow direction of the rainwater runoff ranges from 108 degrees t 135 degrees, and the drainage channel is arranged at the bottom of the overflow channel and communicated with a catch basin. The kerb has certain drainage capacity, can make excessive rainwater flow into the greenbelt so as to effectively delay occurrence of the peak value, and can effectively improve the overall drainage capacity of an urban road and reduce the occurrence frequency of urban inland inundation. The kerb further achieves hierarchical control over rainwater runoff pollutants, effectively improves the quality of discharged rainwater and reduces rainwater runoff pollution loads. The kerb can be produced through a modular unit and thus is convenient to construct, install, clean and maintain.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Evaporator

InactiveUS20080202153A1Preventing drop in cooling performanceImprove drainage capacityCompression machines with non-reversible cycleEvaporators/condensersEngineeringEvaporator

An evaporator includes a plurality of heat exchange tubes extending vertically and arranged in rows spaced apart from each other in a front-rear direction. A drainage acceleration member extending vertically is disposed between the adjacent front and rear heat exchange tubes. A gap is present between each of the adjacent front and rear heat exchange tubes, and the drainage acceleration member disposed between the front and rear heat exchange tubes. The gaps serve as drain channels. The evaporator exhibits excellent drainage of condensed water.

Owner:KEIHIN THERMAL TECH CORP

Waterproof structure manufacturing method of caisson-type toilet

InactiveCN103485509AEffectively drainAvoid springsSewerage structuresFlooring insulationsWater dischargeEngineering

A waterproof structure manufacturing method of a caisson-type toilet includes manufacturing of a basic layer, an overhead layer and a ground layer, has the advantages of being capable of effectively preventing the common problems that pipelines are broken, water is leaked due to the fact that connectors are not firm and water is accumulated through two-time waterproof structuring and two-time water-discharging structuring, avoiding the spring water phenomenon of the ground of the toilet, facilitating air drying of the toilet and preventing the toilet from being under a wet environment for a long time, and is suitable for the caisson-type toilet with a caisson which is 35-50cm deep.

Owner:BEIJING SHOUGANG CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com