Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1357 results about "Groove width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

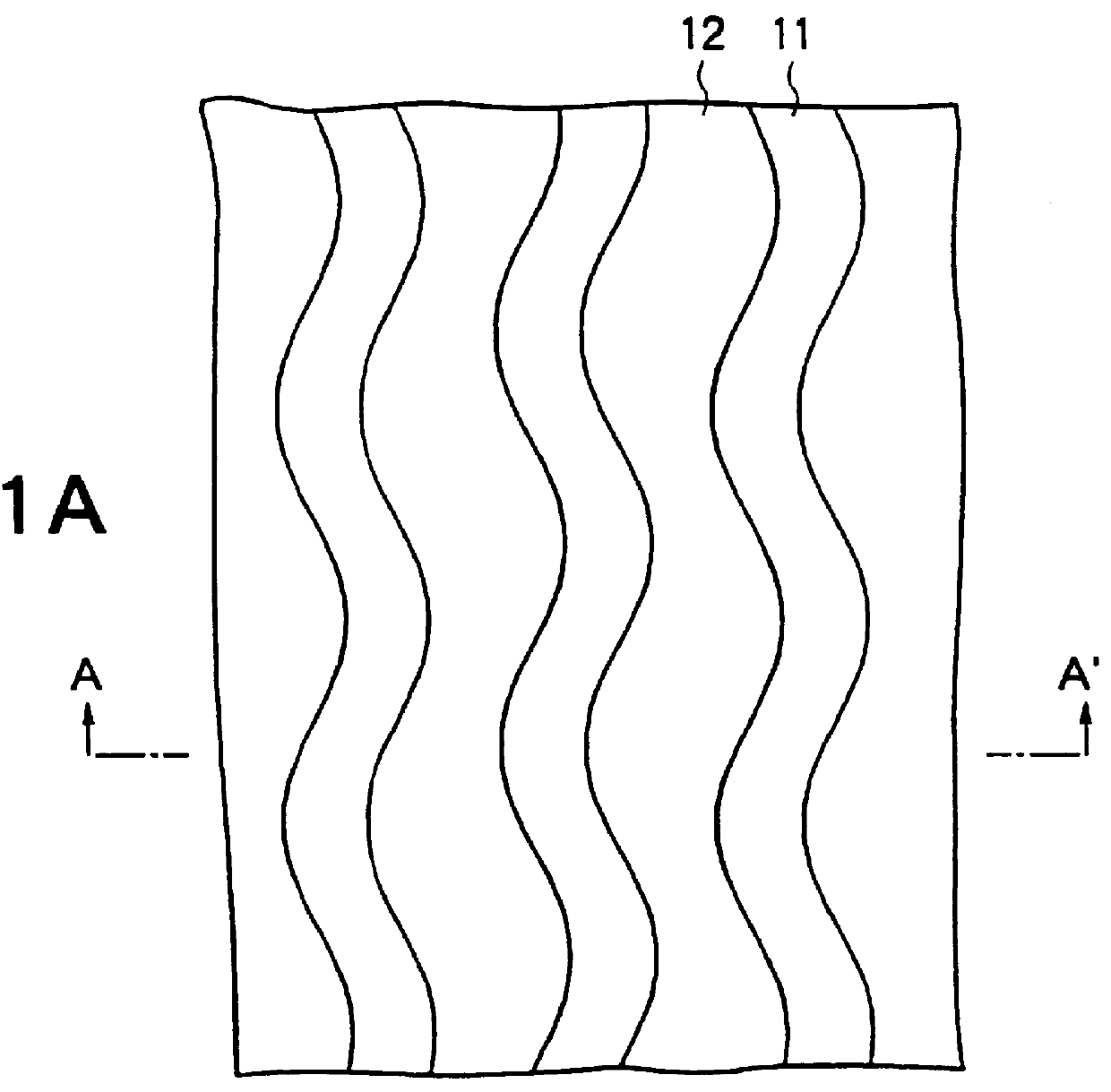

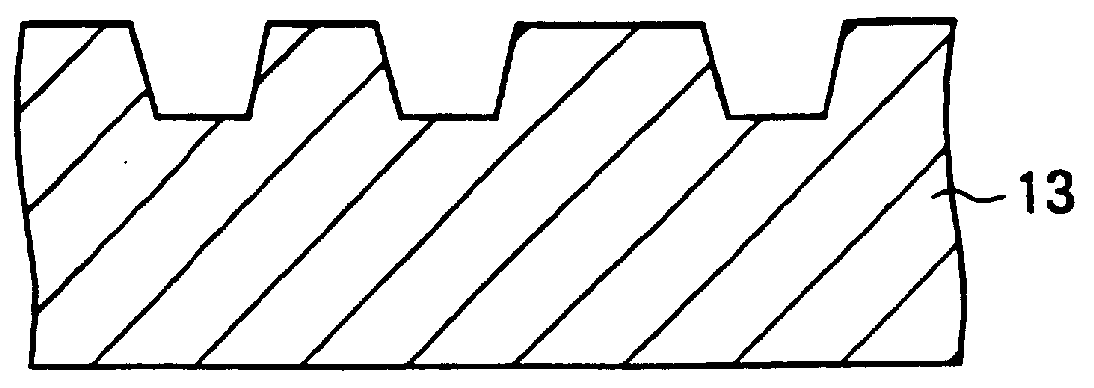

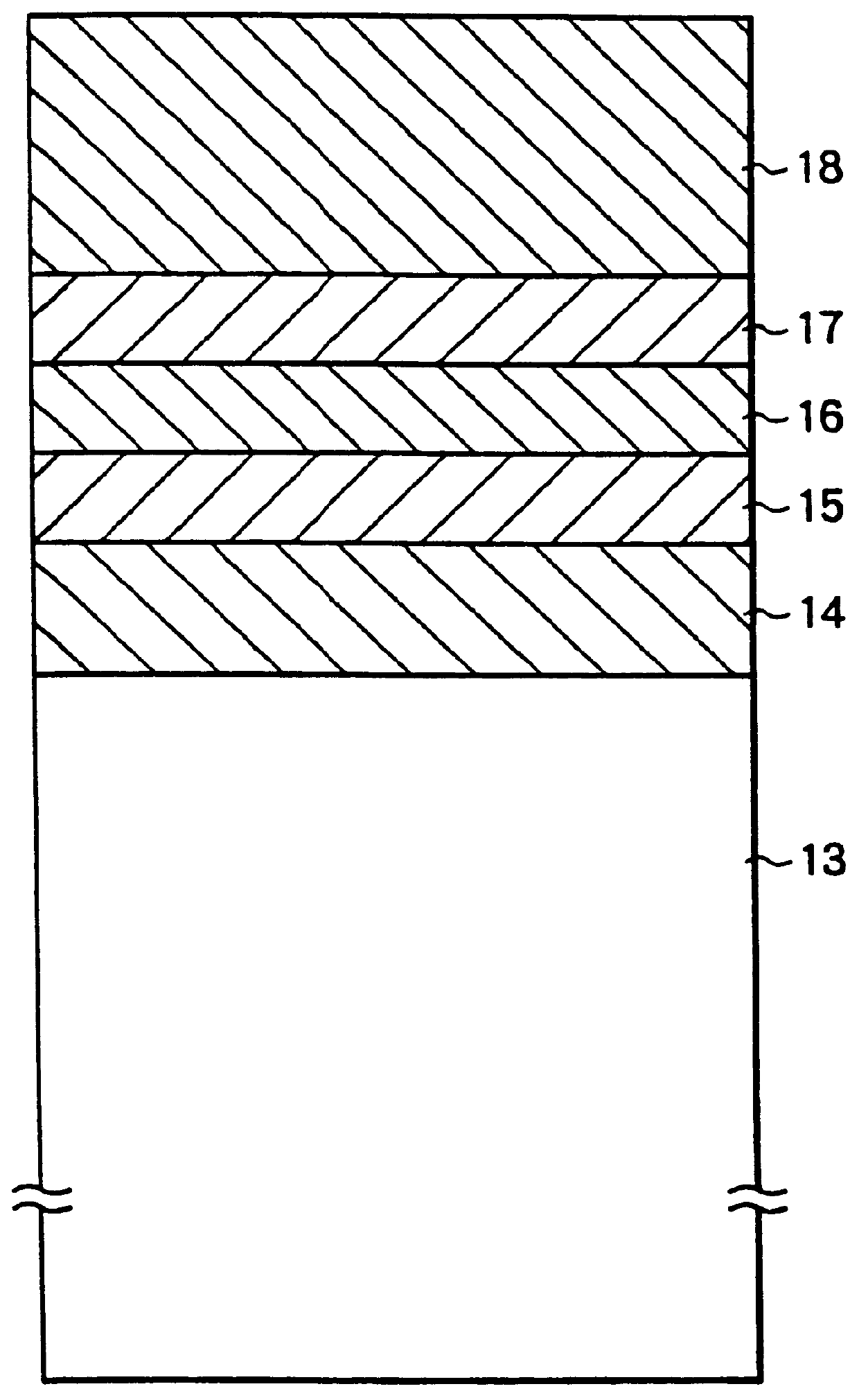

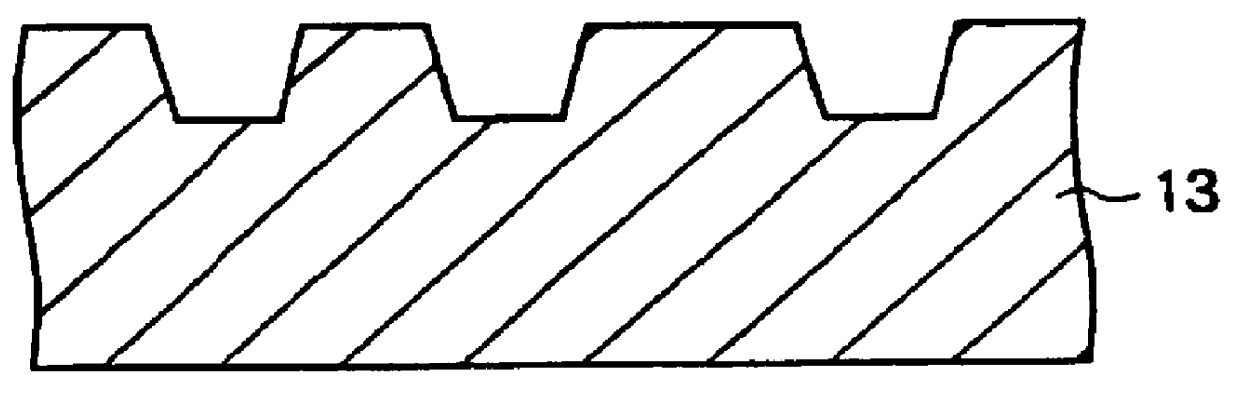

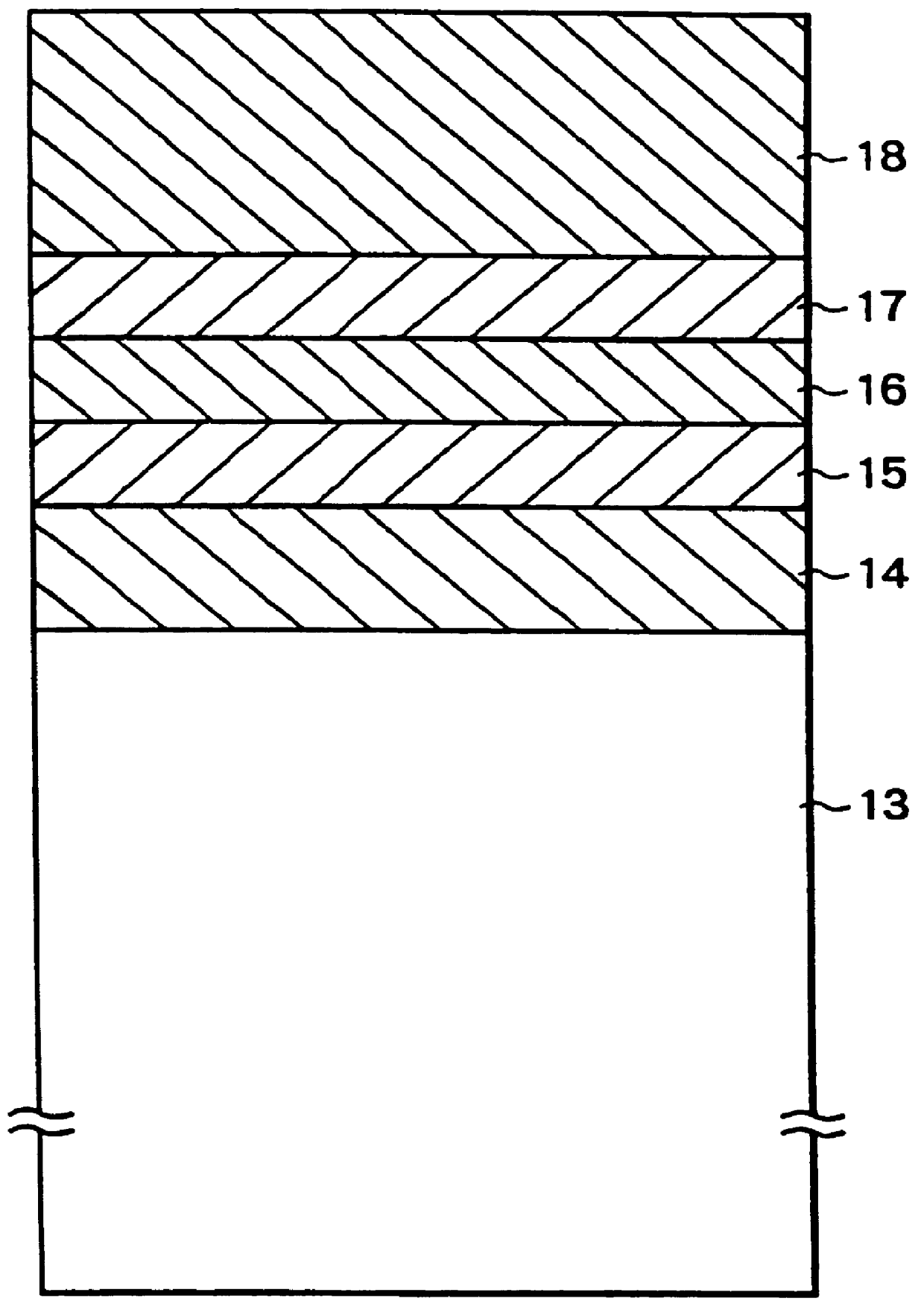

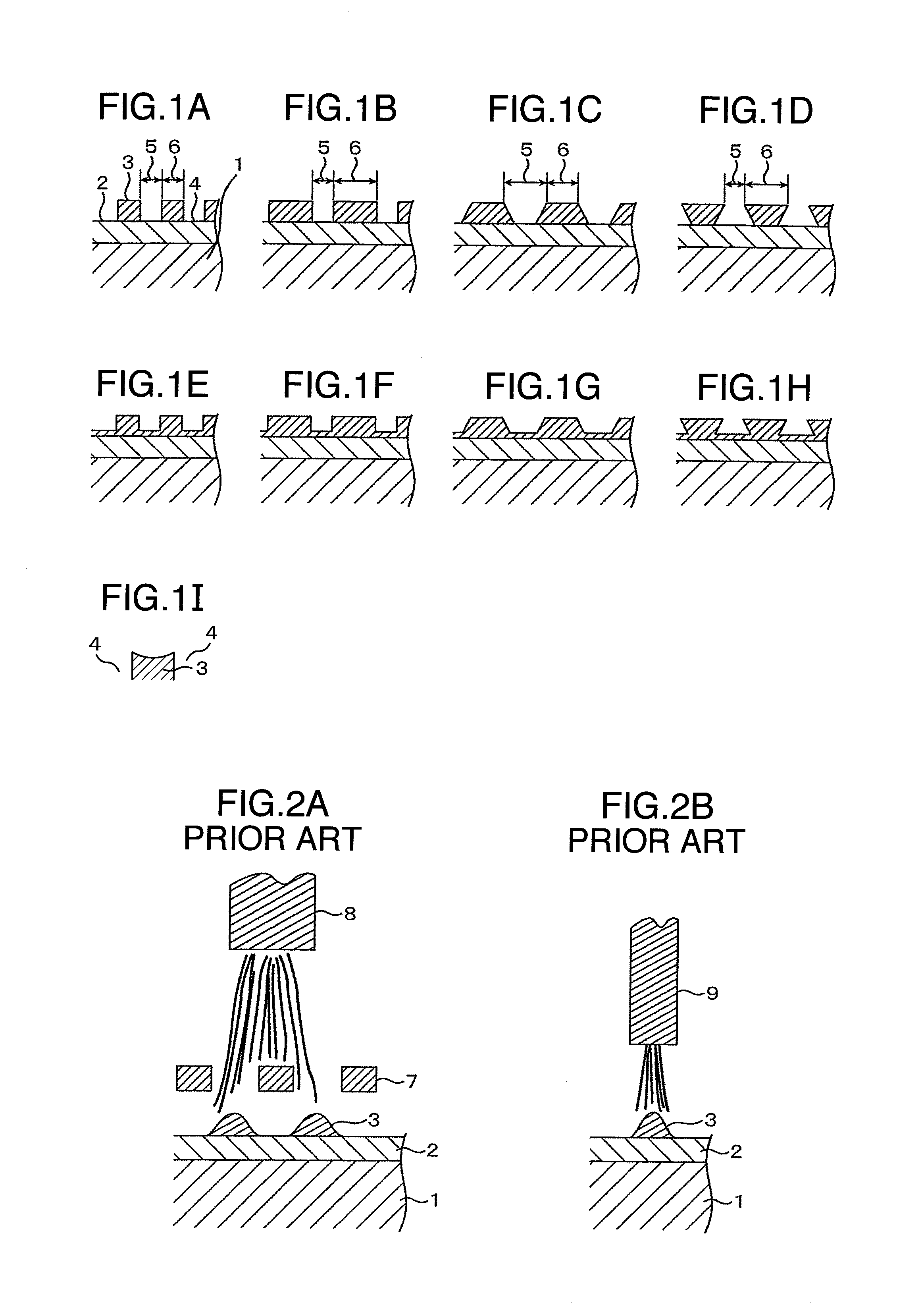

Optical phase-change disc

An optical phase-change disc comprises a substrate having thereon a spiral groove or concentric grooves for guiding a focused light beam, and a layer structure including a recording layer and protective layers sandwiching therebetween the recording layer. The groove has wobble for recording ATIP (absolute time information) or ADIP (address information). The following relationship between the groove width GW, beam diameter R0 and wobble amplitude aw: 0.25< / =GW / R0< / =0.45 or 0.65< / =GW / R0; and 0.03< / =aw / GW< / =0.08 hold for preventing distortion of the groove caused by repeated overwriting operation to improve reliability of the optical disc.

Owner:VERBATIM CORPORATION

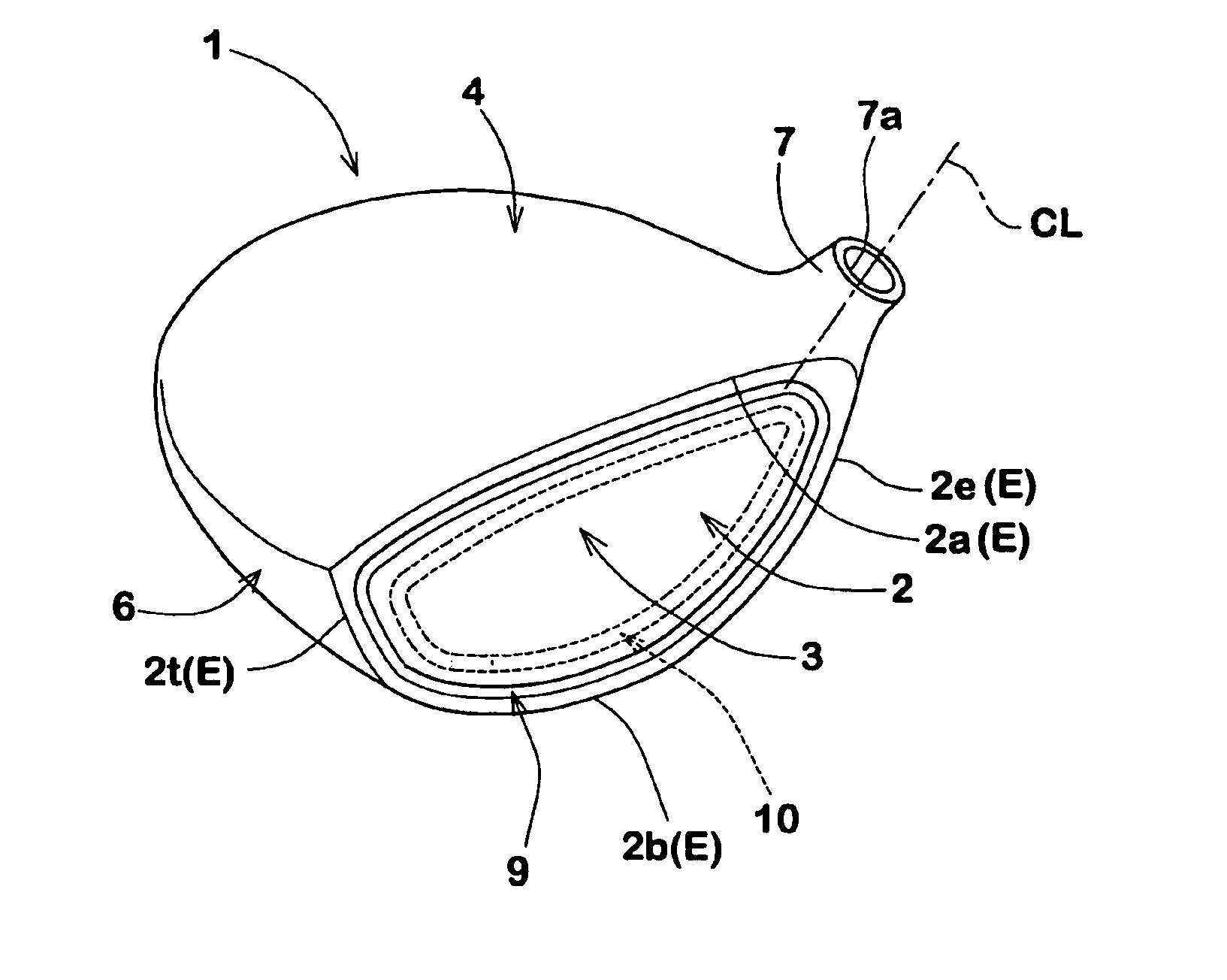

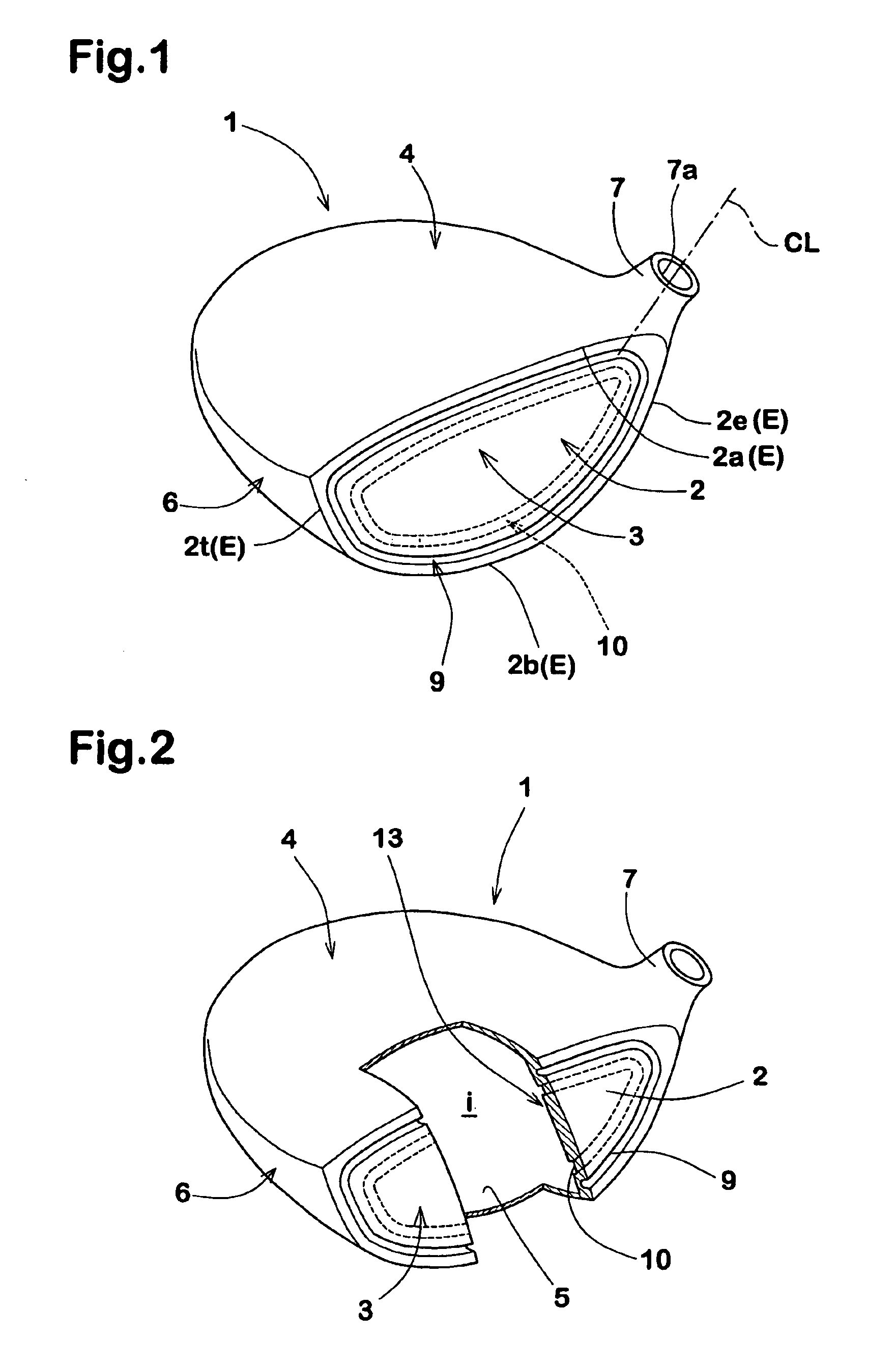

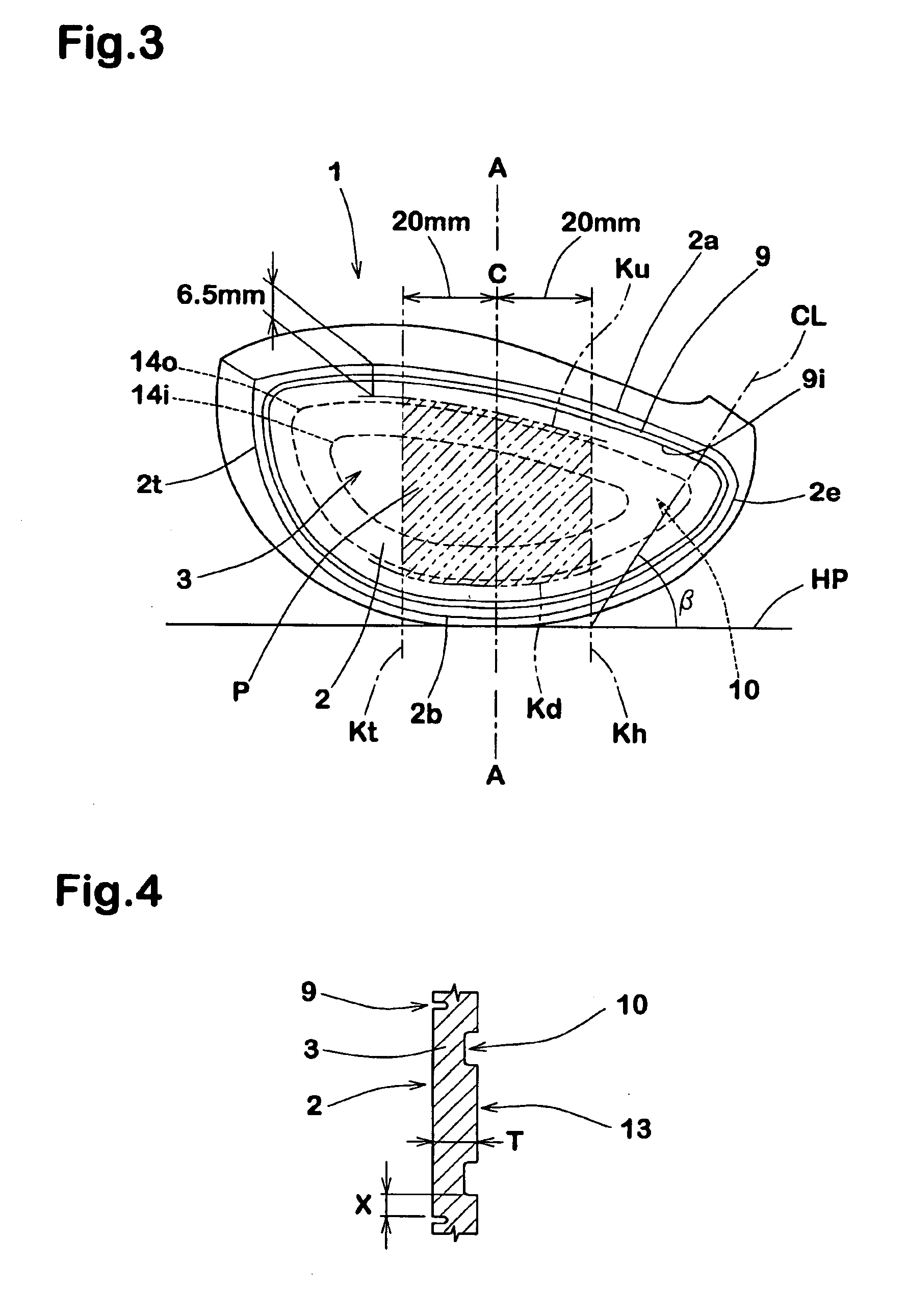

Golf club head

InactiveUS7066833B2Improve the overall coefficientWithout deteriorating durabilityGolf clubsStringed racketsGroove widthGolf Ball

Owner:DUNLOP SPORTS CO LTD

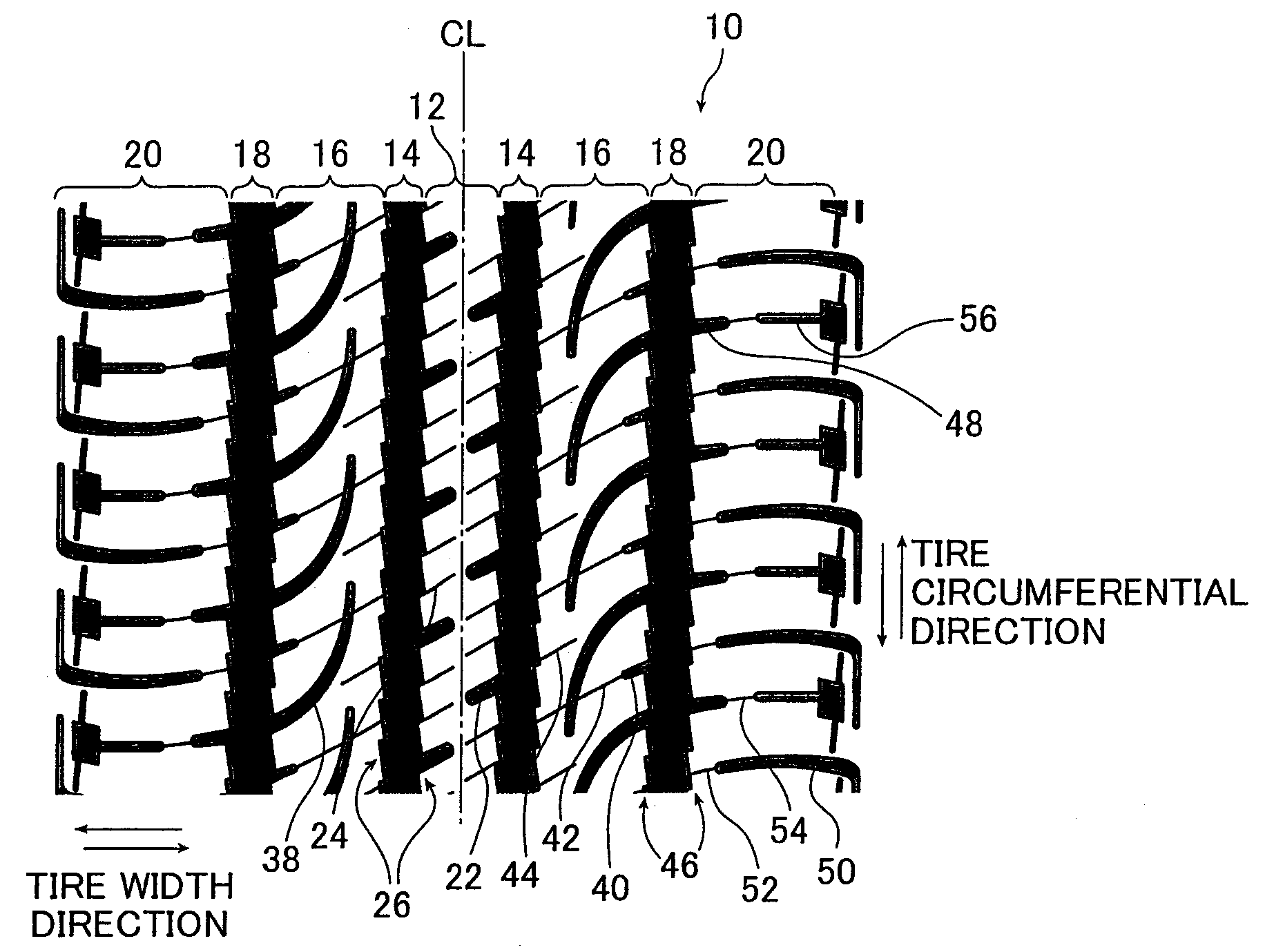

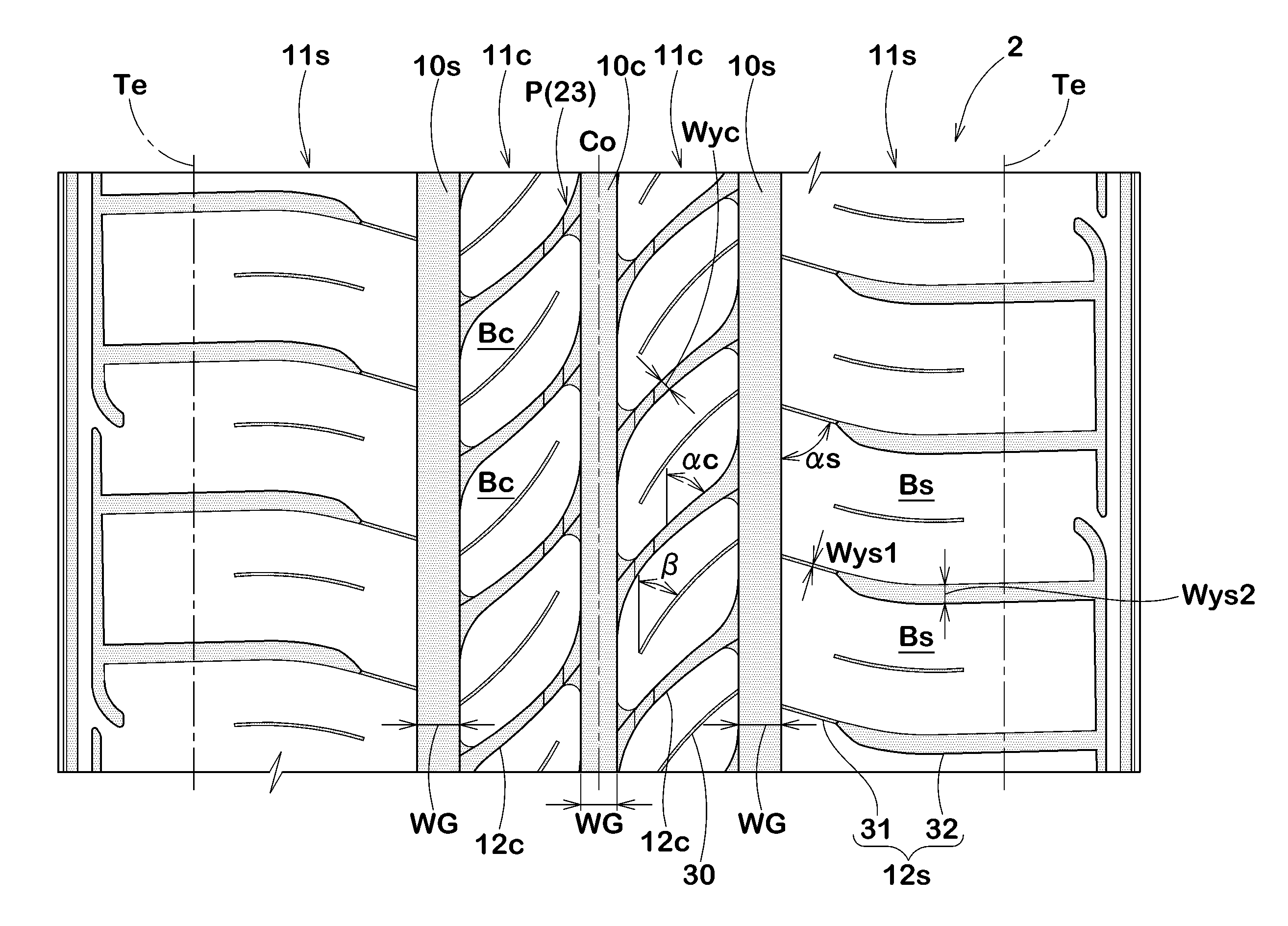

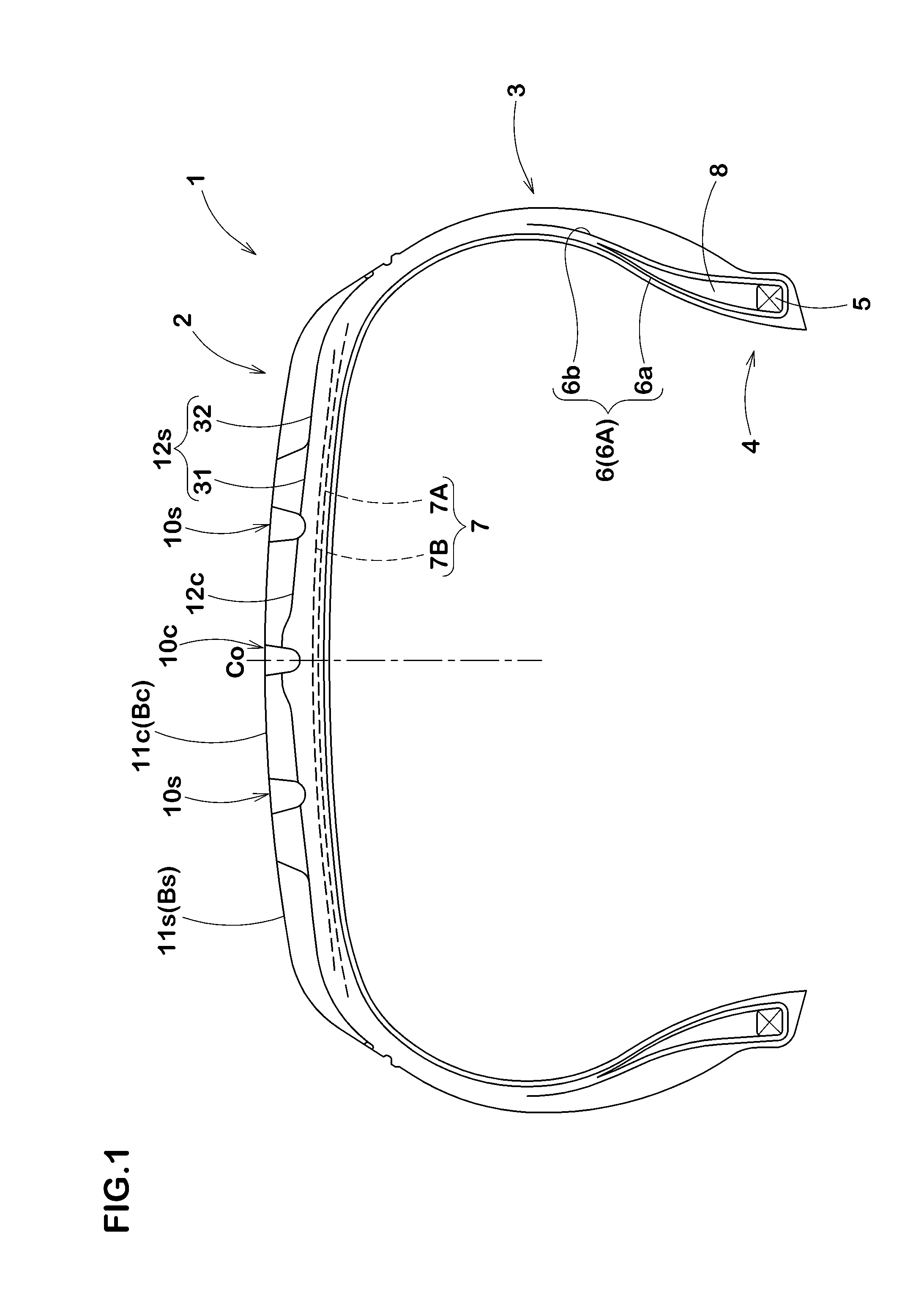

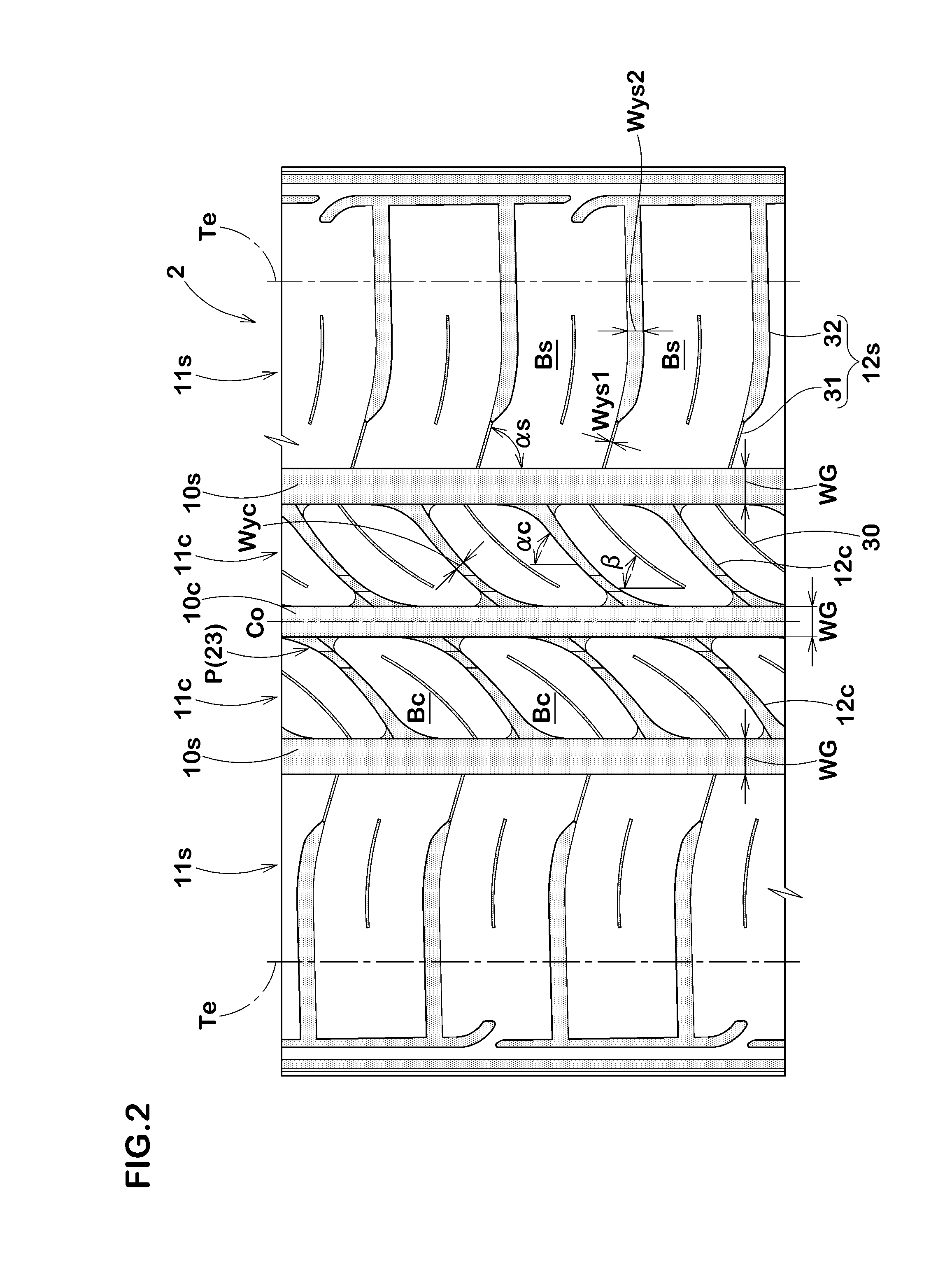

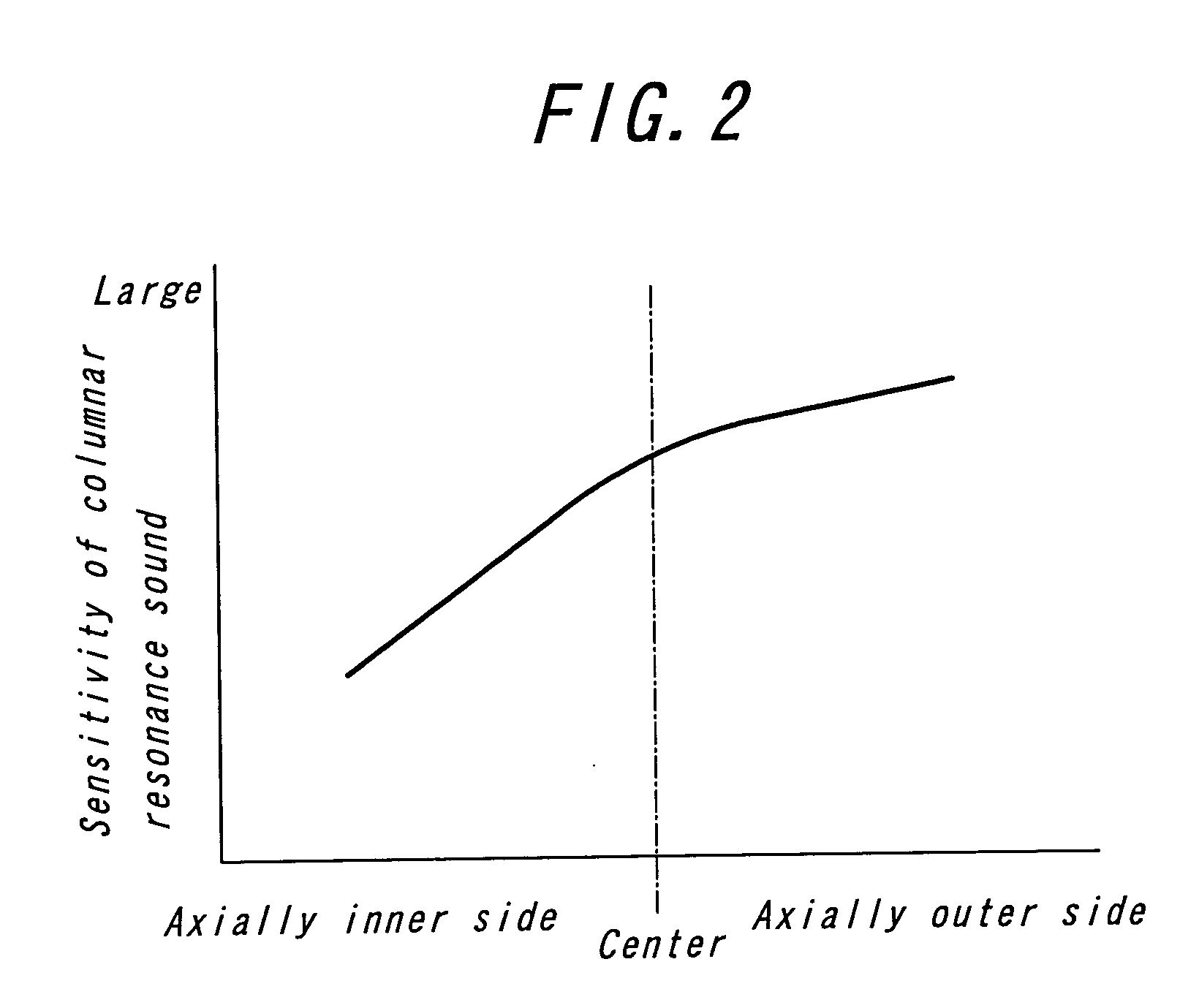

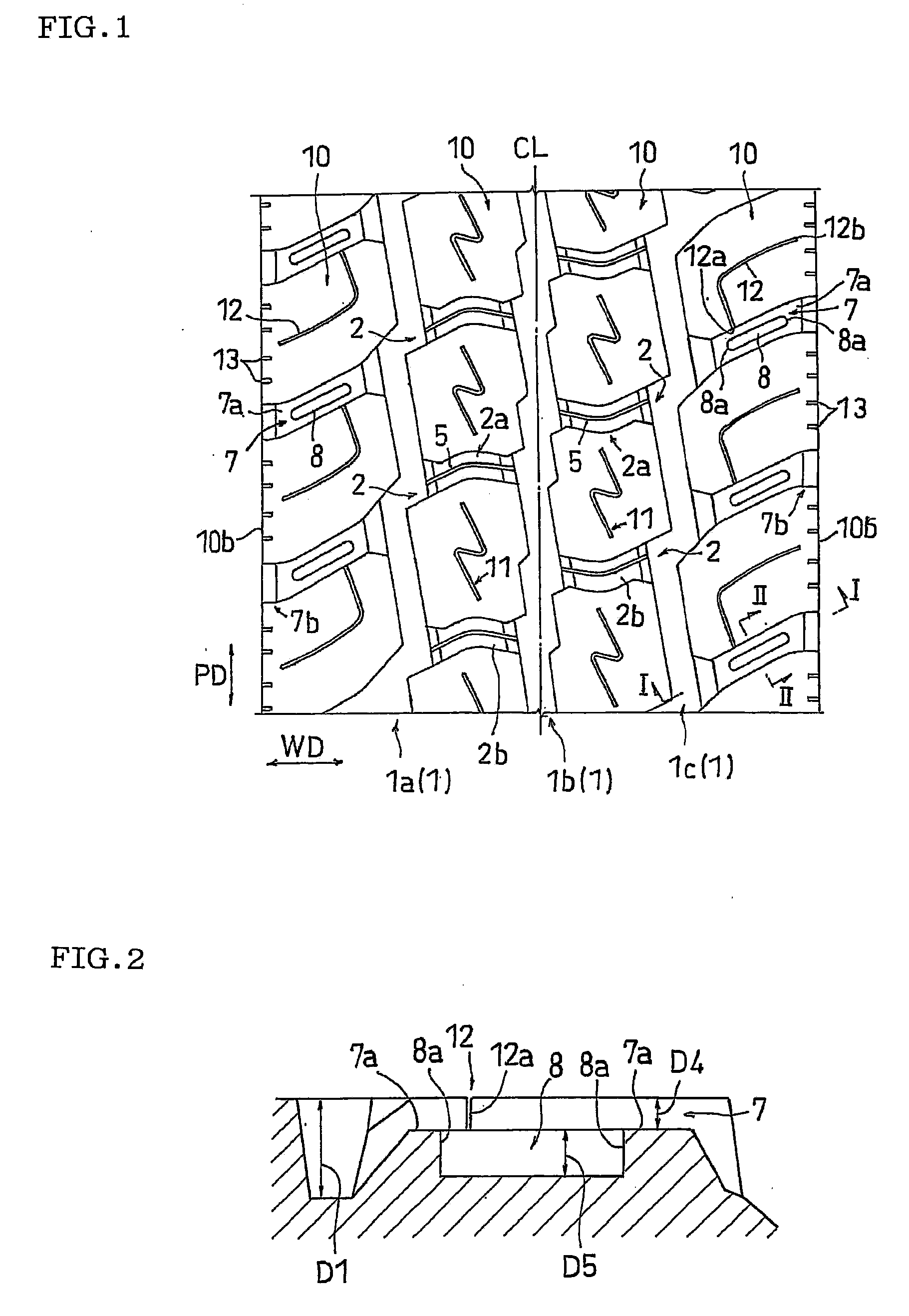

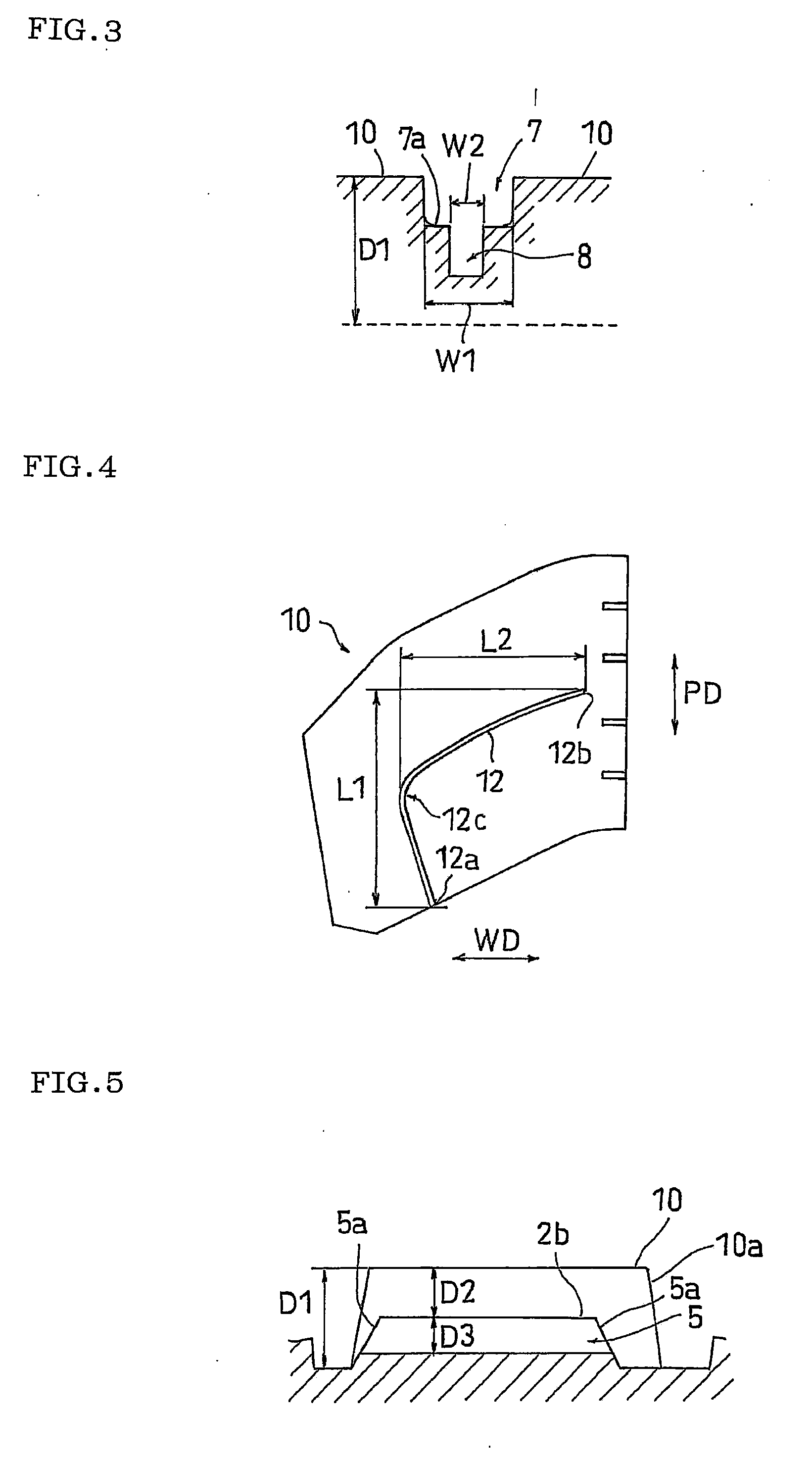

Pneumatic tire

ActiveCN101992658ASuppress resonanceReduce pass-by noiseTyre tread bands/patternsGroove widthEngineering

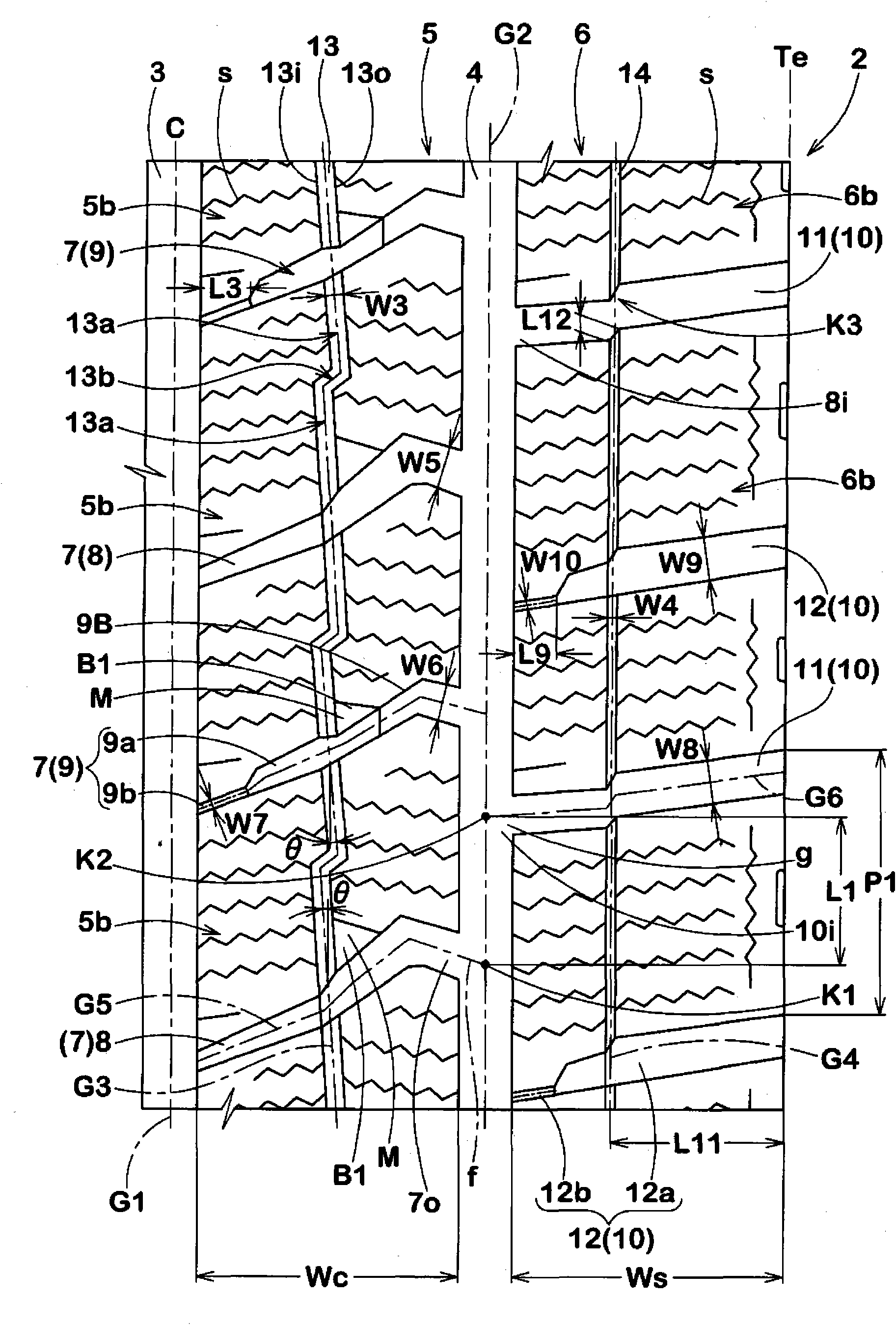

The present invention relates to a pneumatic tire capable of maintaining performance on snow, and improving operation stability and noise performance. A shoulder axial grove (10) comprises a first shoulder axial groove (11) having a groove width of not less than 3.5 mm.; a second shoulder axial groove (12) comprising an axially innermost sipe-like part (12b) having a groove width of 0.5 to 2.0 mm, and an axially outer main part (12a) having a groove width of not less than 3.5 mm. a crown axial groove (7) comprises a first crown axial groove (8) having a groove width of not less than 2.0 mm; and a second crown axial groove (9) comprising an axially innermost sipe-like part (9b) having a groove width of 0.5 to 2.0 mm, and an axially outer main part (9a) having a groove width of not less than 2.0 mm. In addition, the first and second shoulder axial grooves are formed on the tire circumference alternatively; the first and second crown axial grooves are alternatively formed on the tire circumference.

Owner:SUMITOMO RUBBER IND LTD

Optical phase-change disc having a grooved substrate, with the groove having specific wobbled and non-wobbled regions

An optical phase-change disc comprises a substrate having thereon a spiral groove or concentric grooves for guiding a focused light beam, and a layer structure including a recording layer and protective layers sandwiching therebetween the recording layer. The groove has wobble for recording ATIP (absolute time information) or ADIP (address information). The following relationship between the groove width GW, beam diameter R0 and wobble amplitude aw: 0.25< / =GW / R0< / =0.45 or 0.65< / =GW / R0; and 0.03< / =aw / GW< / =0.08 hold for preventing distortion of the groove caused by repeated overwriting operation to improve reliability of the optical disc.

Owner:VERBATIM CORPORATION

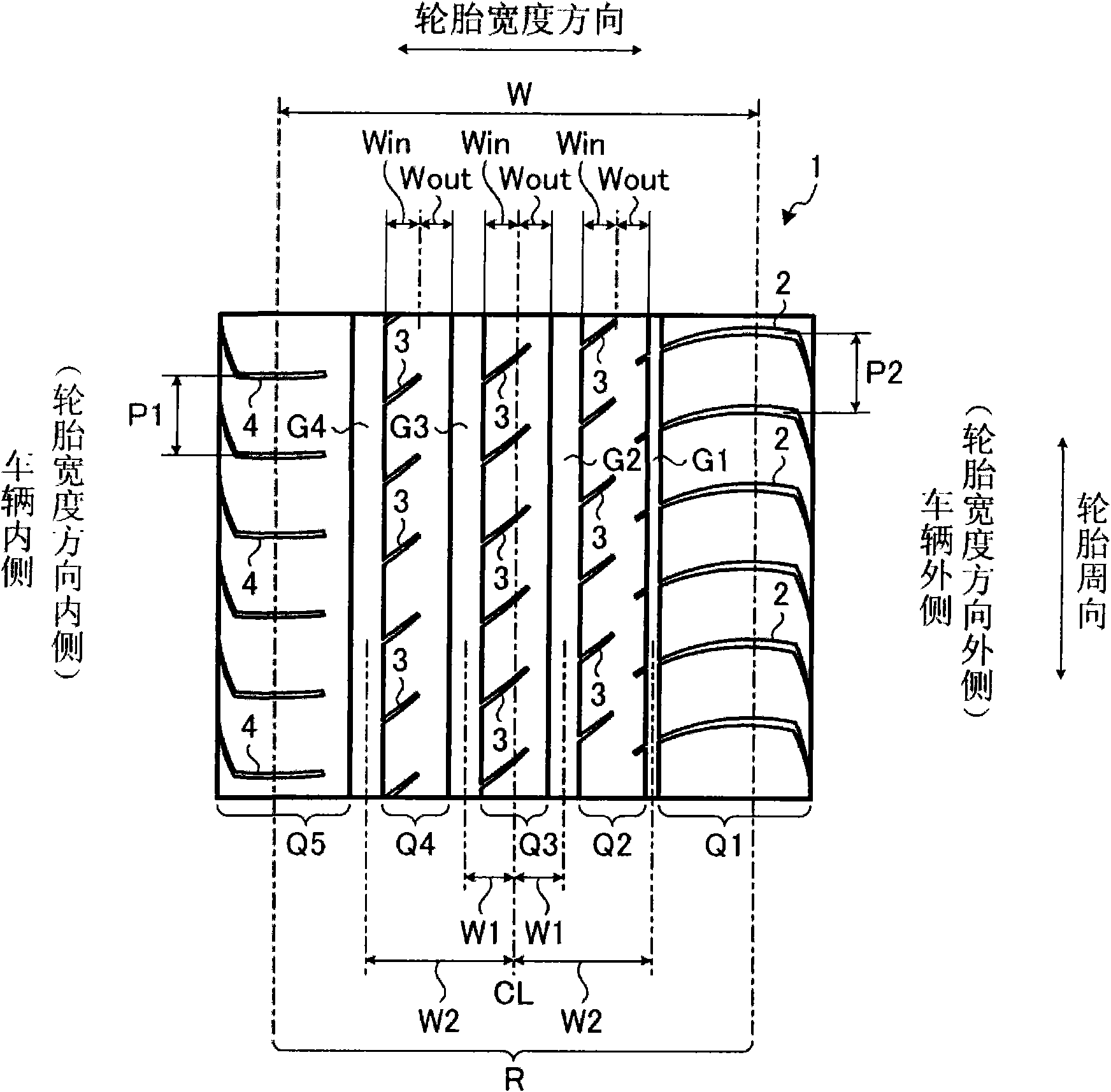

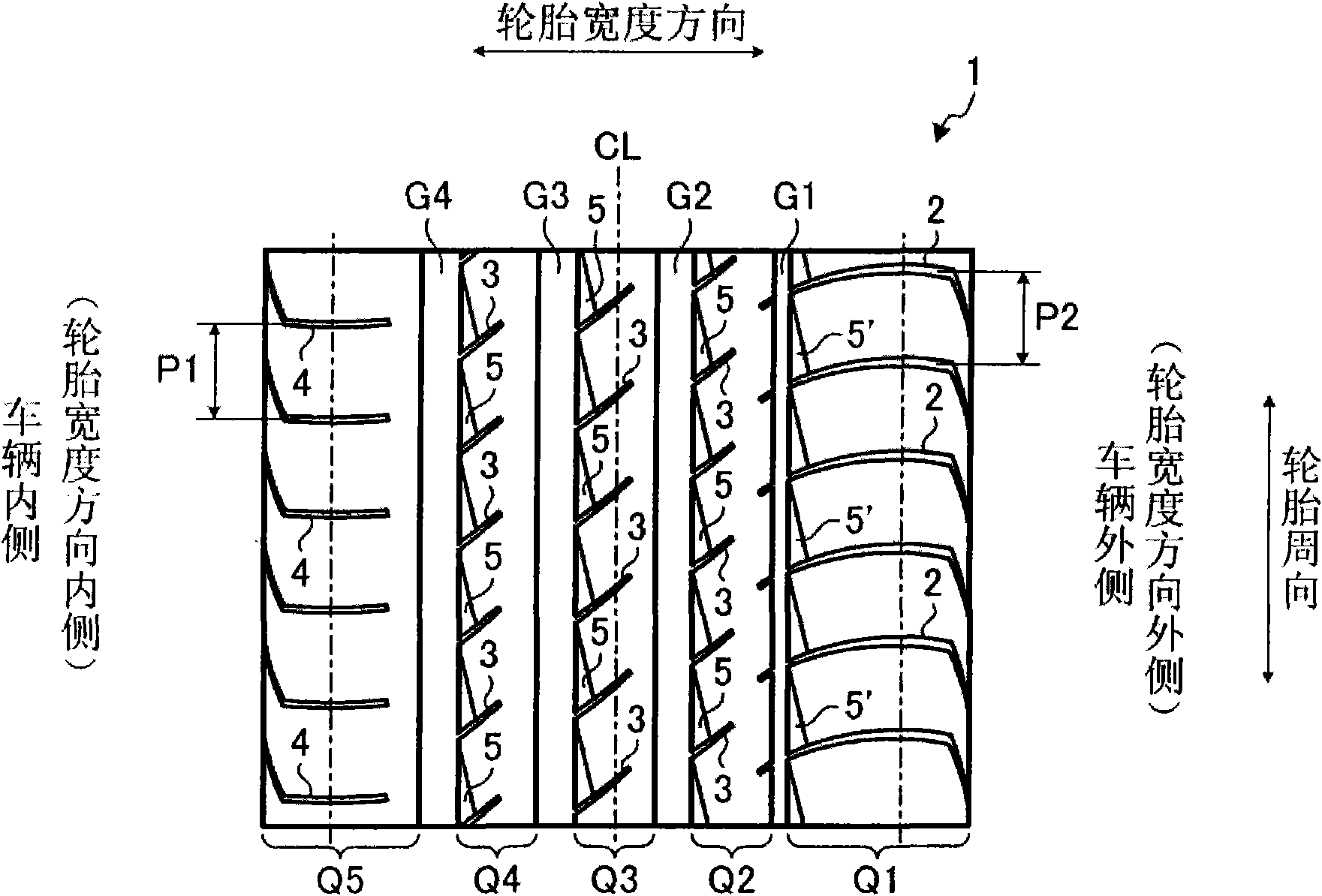

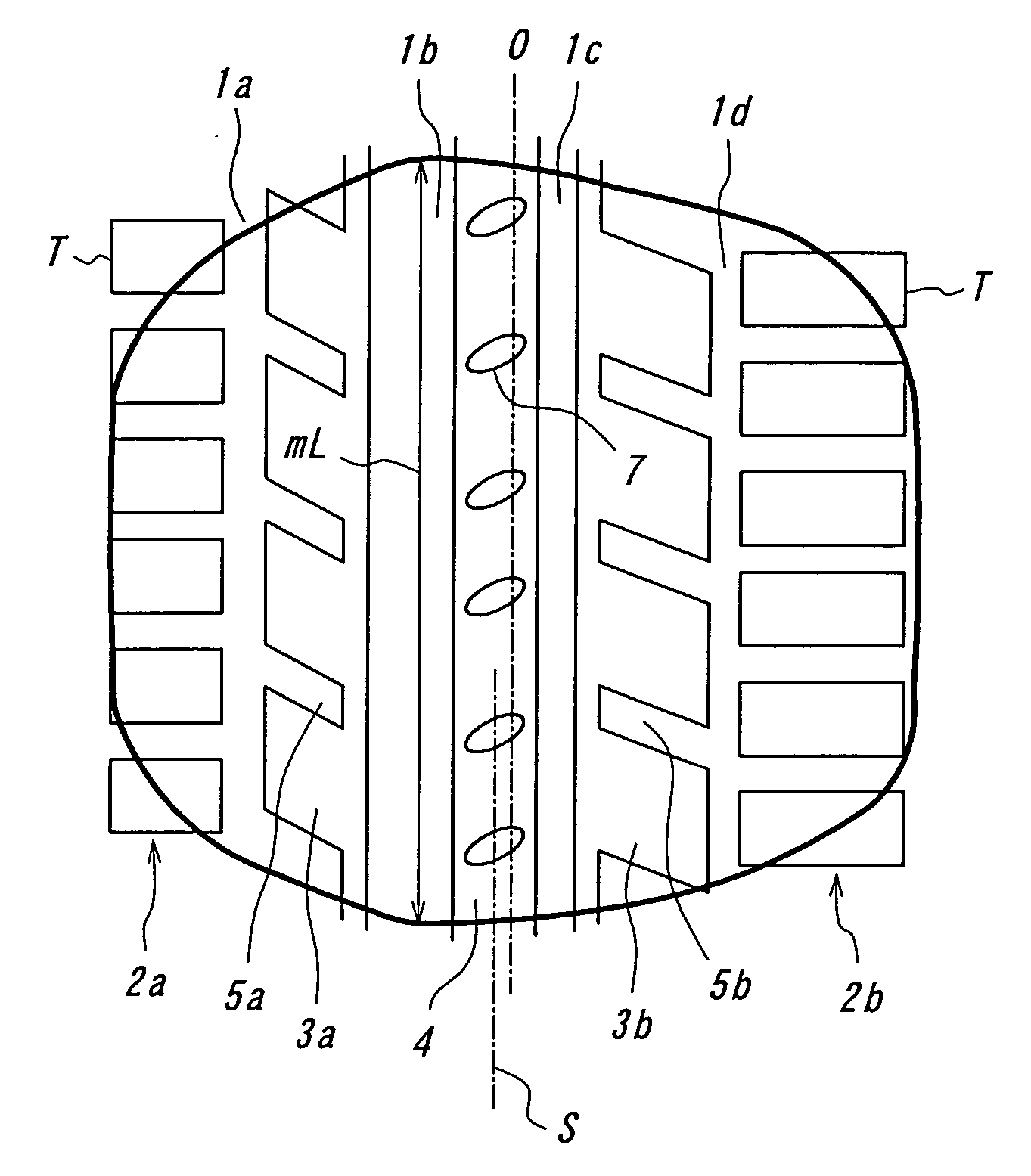

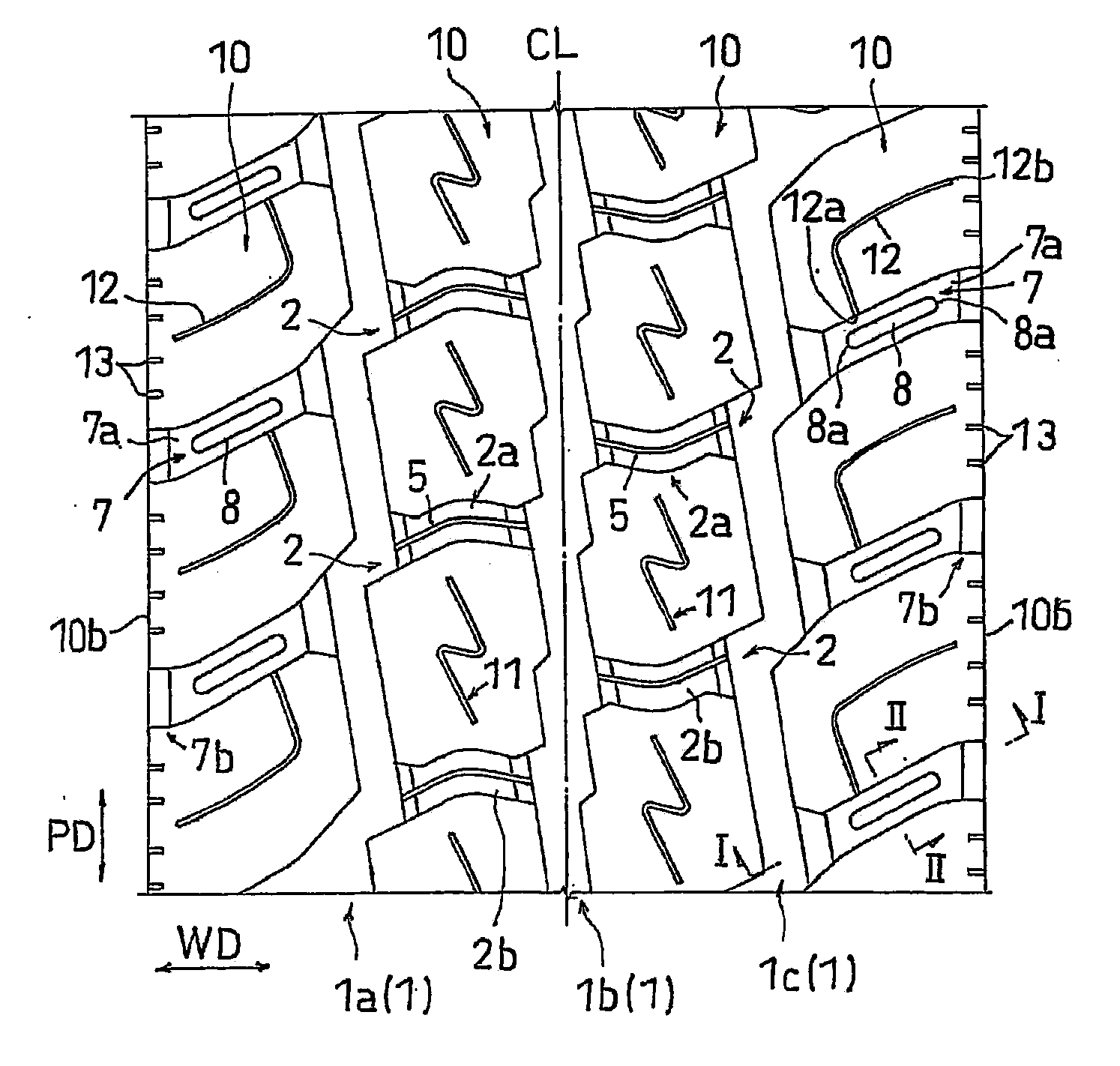

Pneumatic tire

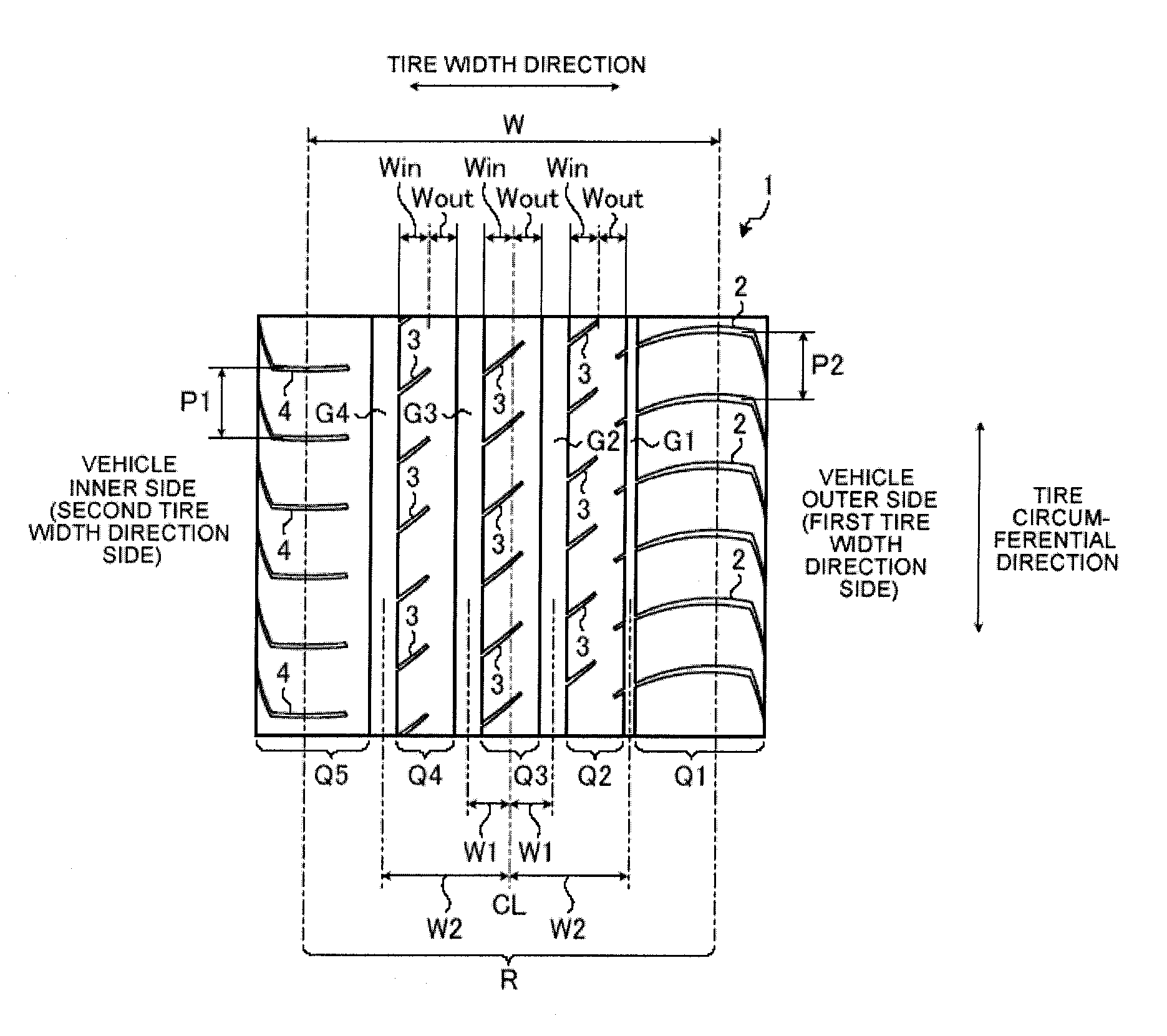

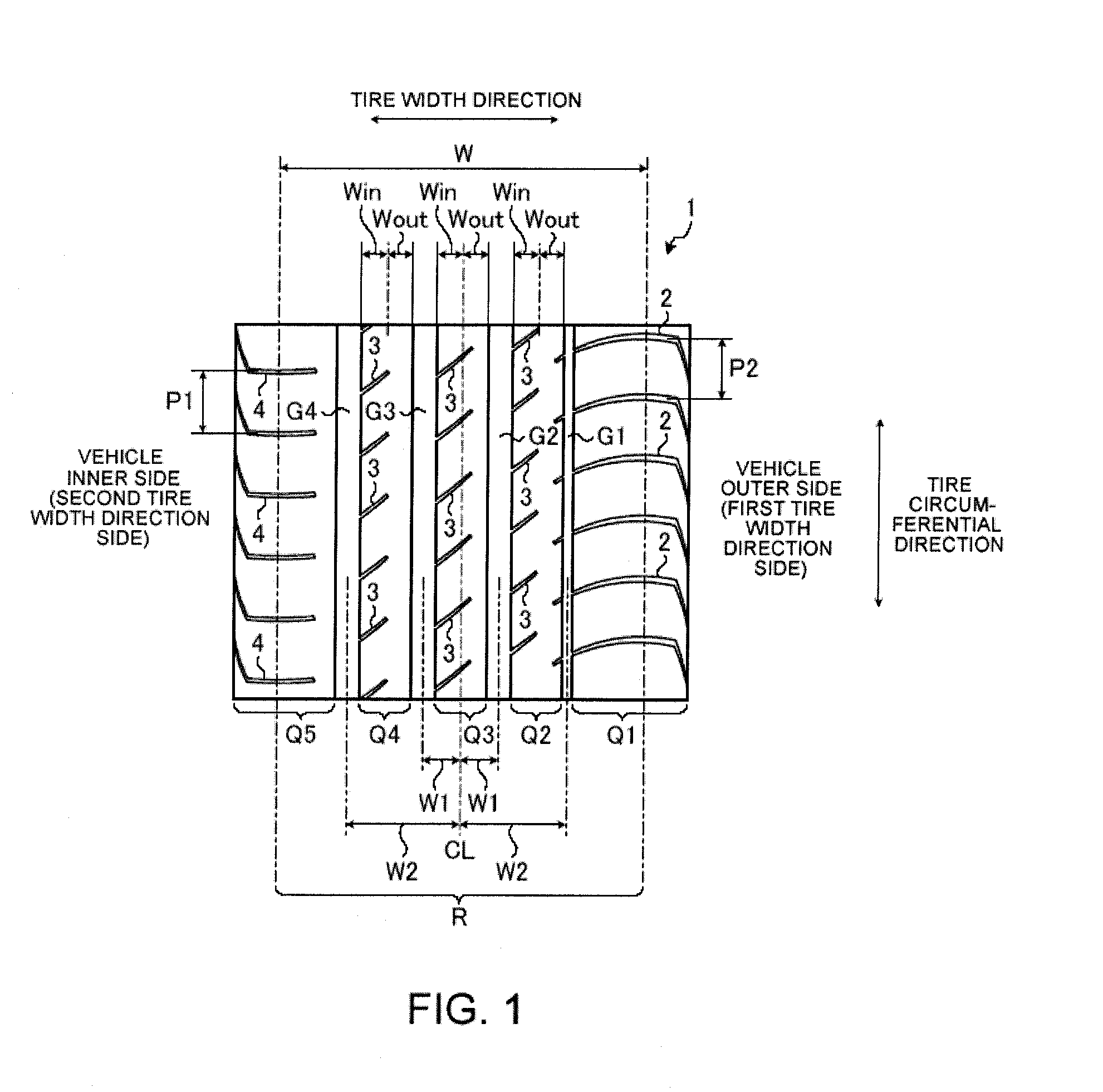

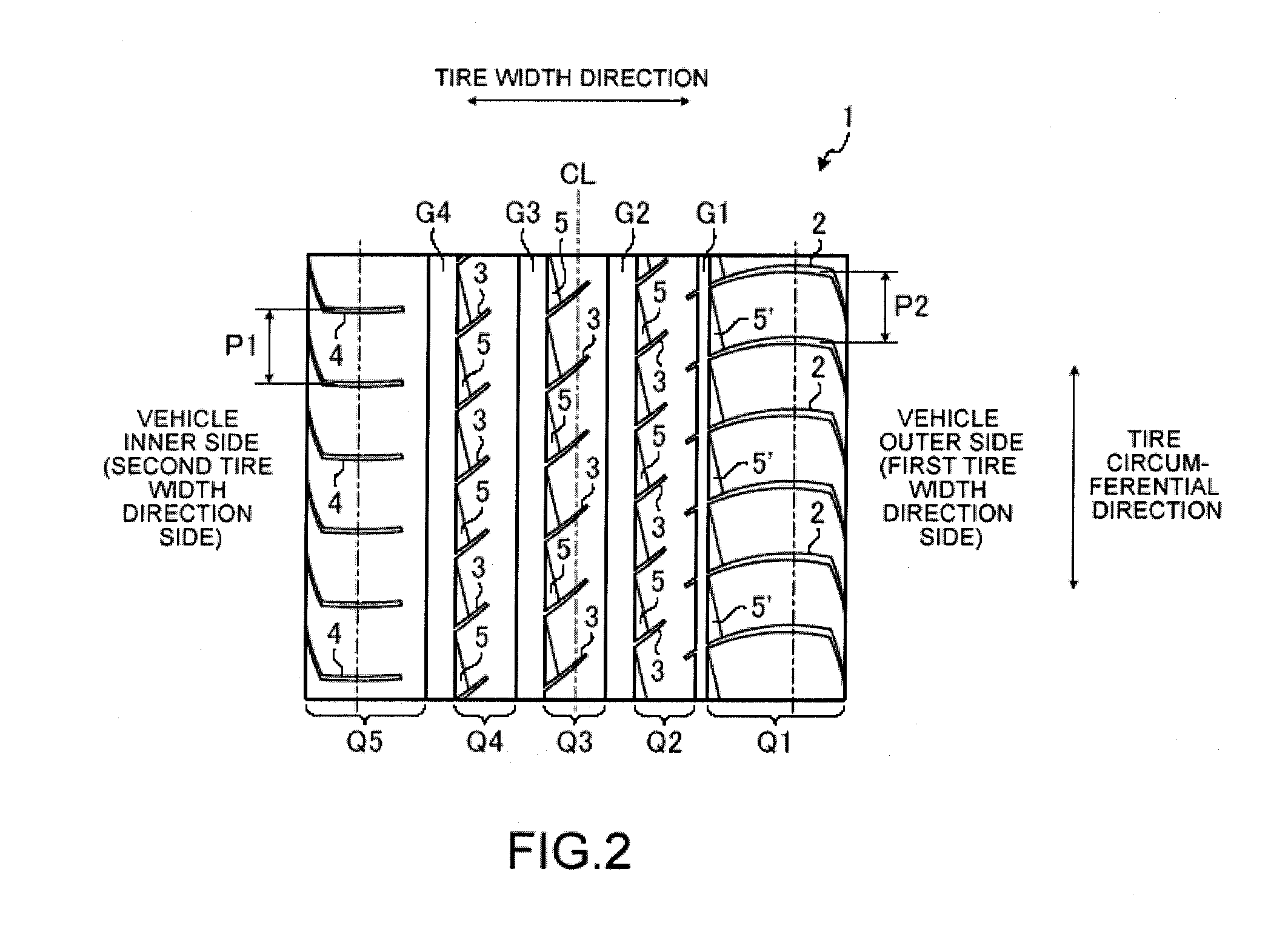

ActiveUS20100212792A1Improve steering stabilityGuaranteed rigidityTyre tread bands/patternsNon-skid devicesGround contactGroove width

A pneumatic tire including five land portions Q1, Q2, Q3, Q4, Q5 in a tread surface 1 by providing four main grooves G1, G2, G3, and G4 in a ground contact region R of the tread surface 1, wherein positions and groove widths of the main grooves G1, G2, G3, and G4 are specified together with only the land portion Q1 positioned outermost on a vehicle outer side when mounted on a vehicle being formed into a block row, and the other land portions Q2, Q3, Q4, and Q5 being formed into ribs, and a groove area proportion of the tread surface 1 is larger on a vehicle inner side than the vehicle outer side with a tire equator CL and center lines of the land portions Q2, Q3, Q4 as boundaries.

Owner:YOKOHAMA RUBBER CO LTD

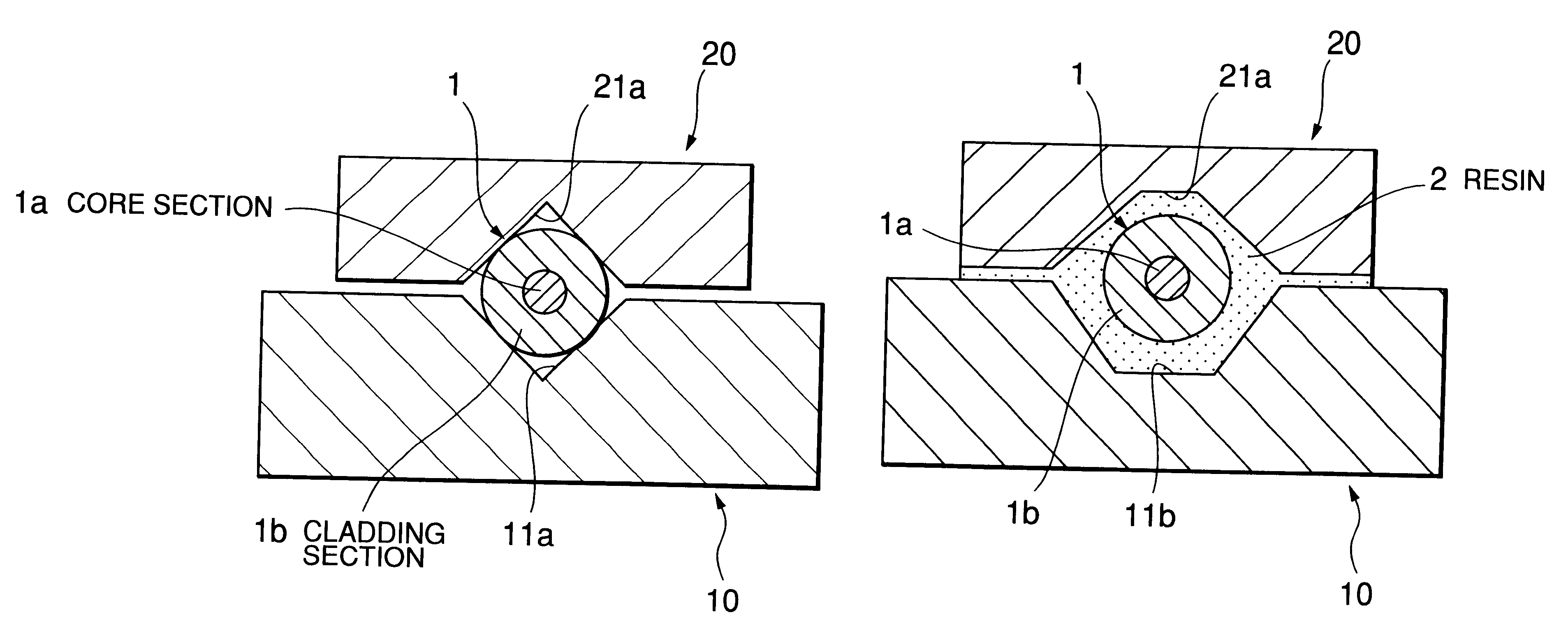

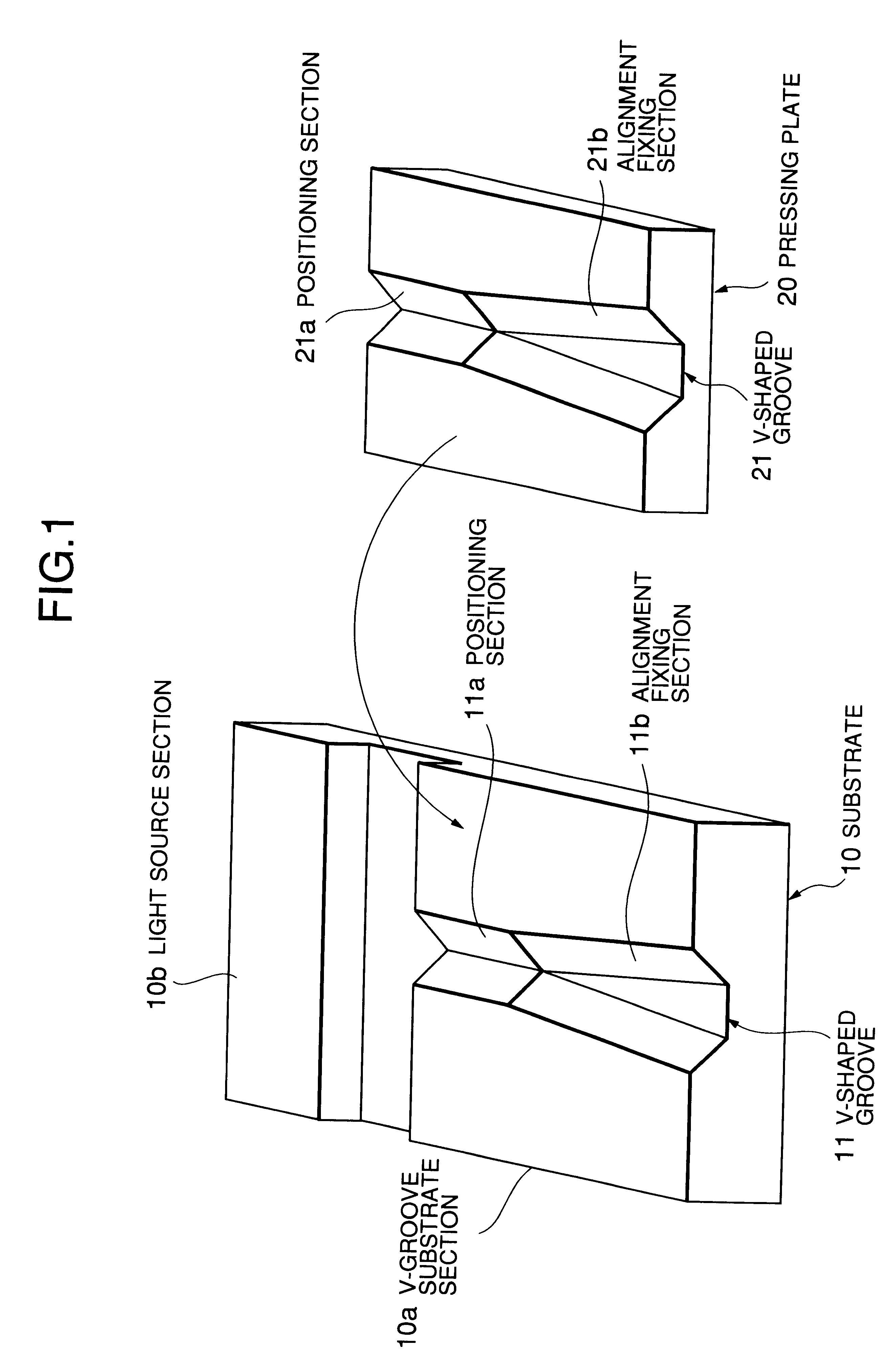

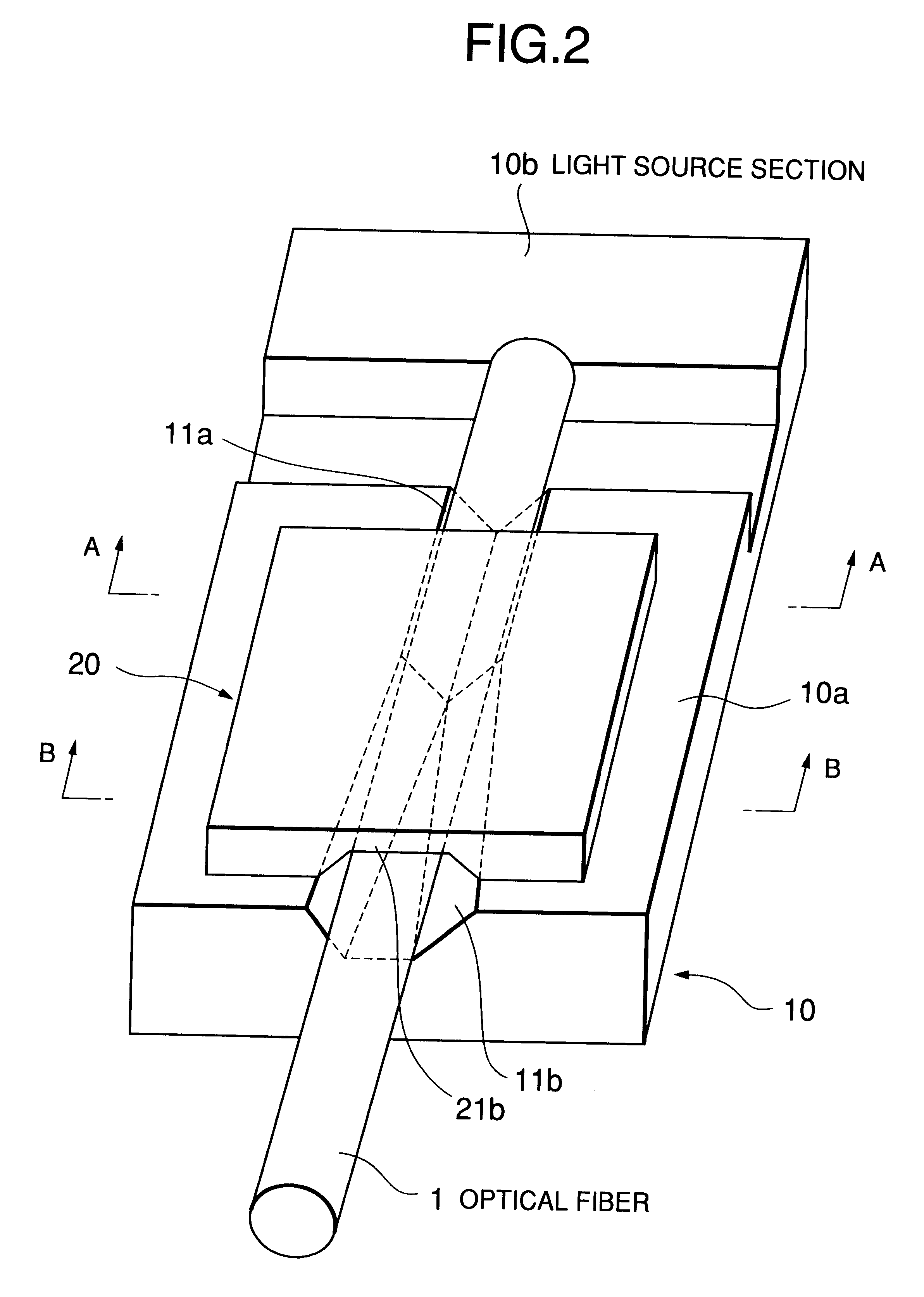

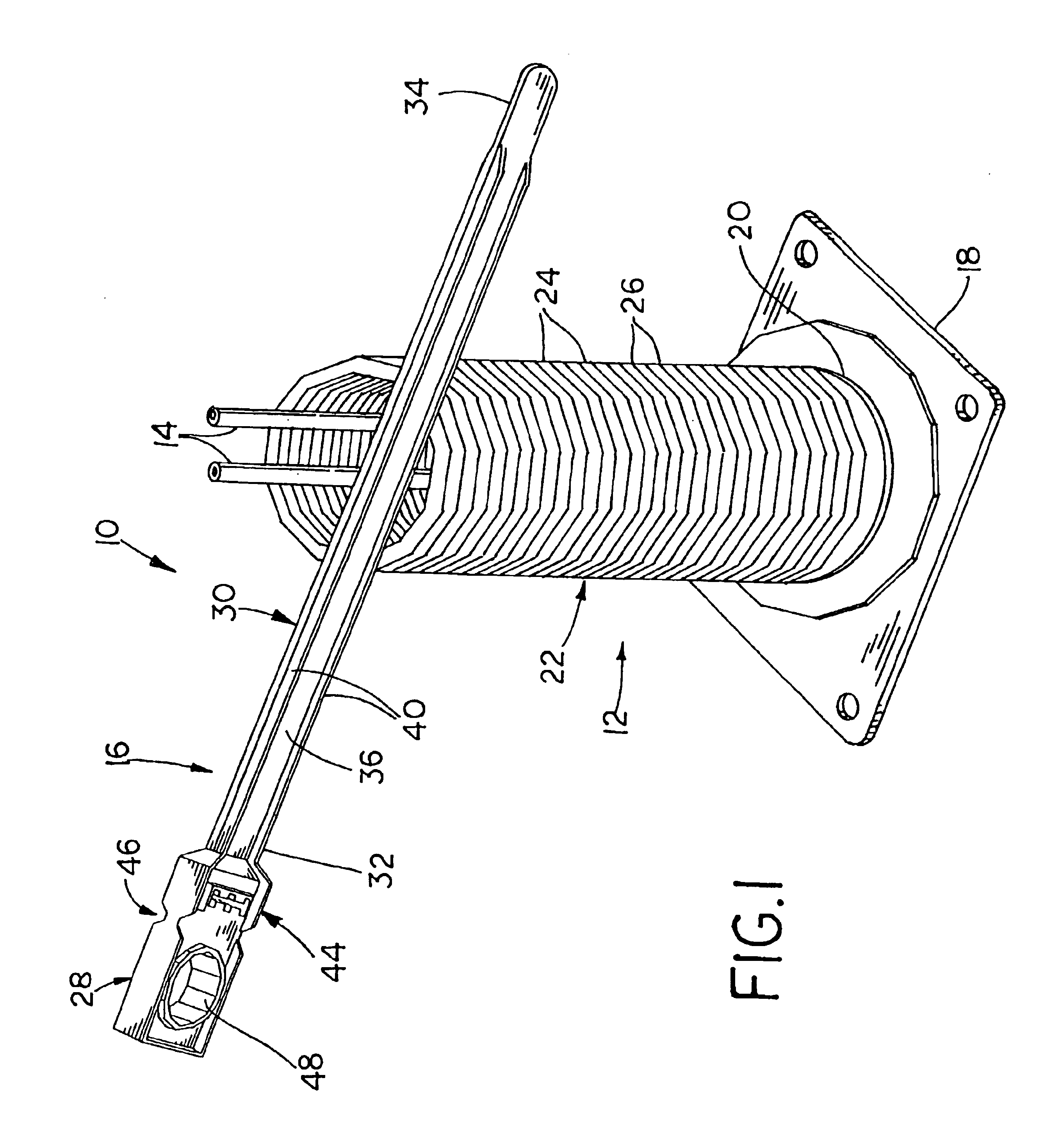

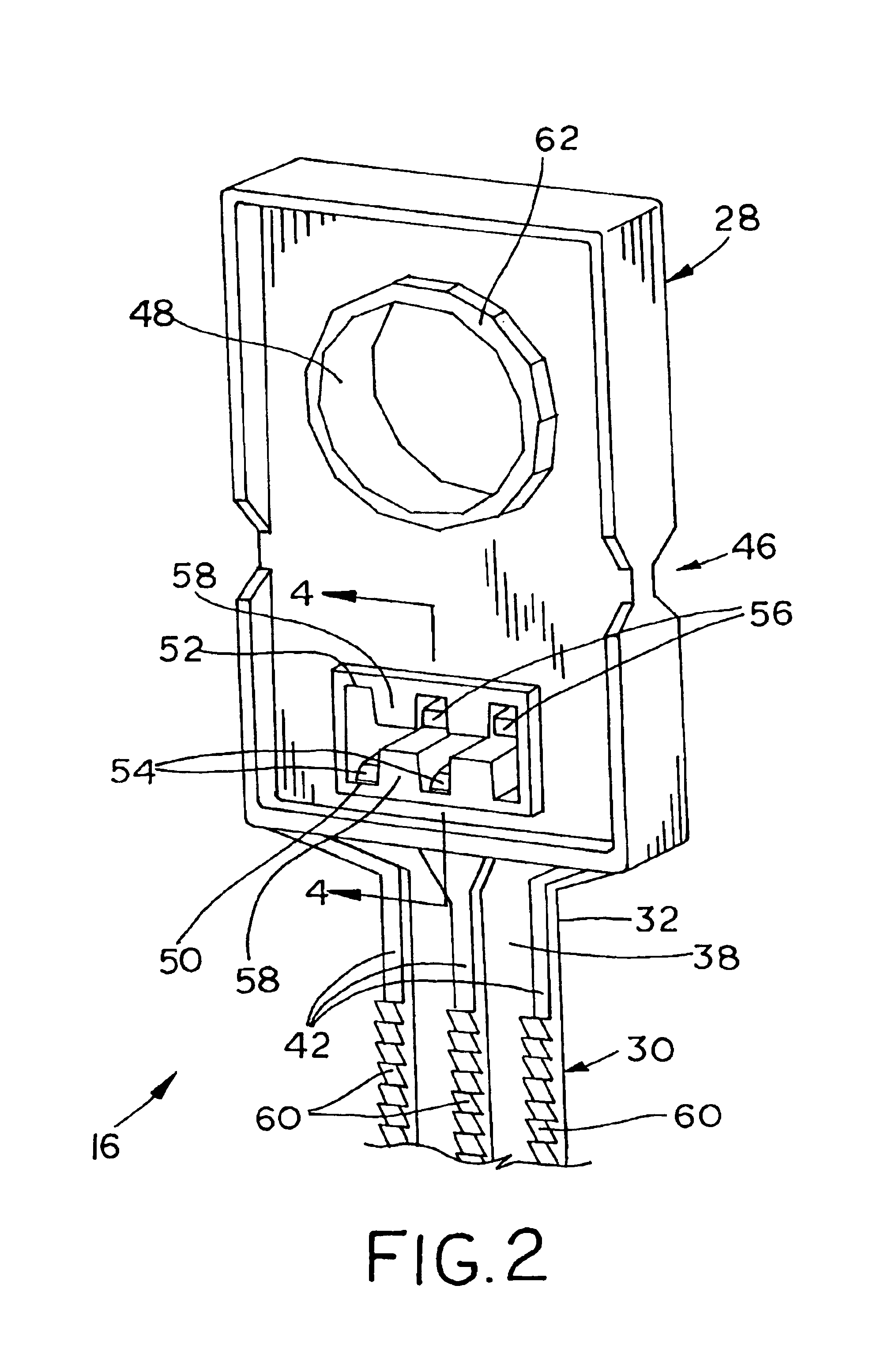

Installation structure for optical fiber

InactiveUS6553173B1Suppress floating and bendingImprove accuracyCoupling light guidesGroove widthEngineering

An installation structure for positioning and holding an optical fiber by means of a V-shaped groove formed on a substrate is disclosed. The V-shaped groove is divided into a positioning section and an alignment fixing section. The positioning section has groove width and depth for allowing the optical fiber to have a contact therewith. The alignment fixing section has groove width and depth larger than those of the positioning section to an extent for not allowing the optical fiber to have a contact therewith, when the optical fiber is disposed on the V-shaped groove.

Owner:NEC CORP

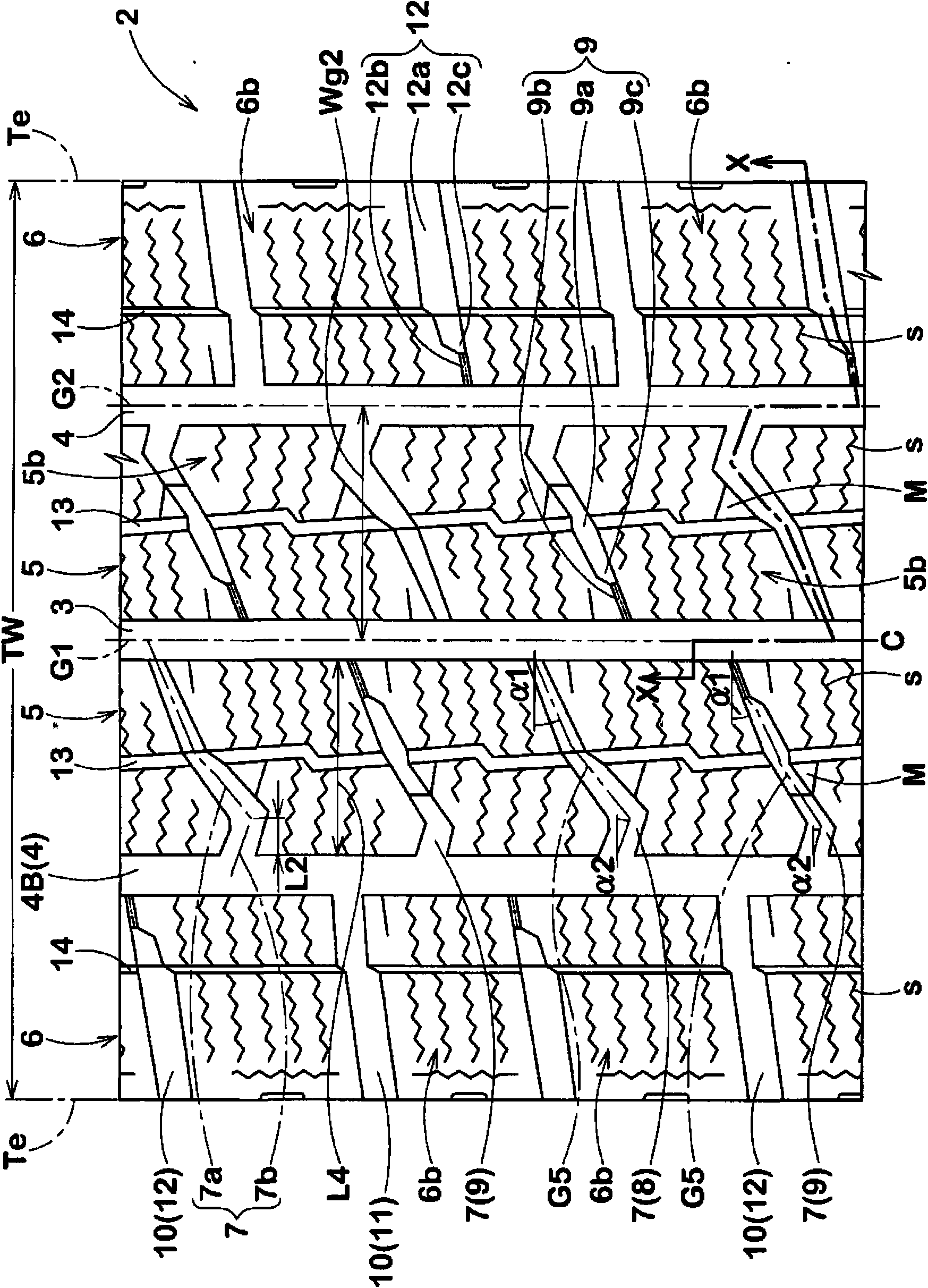

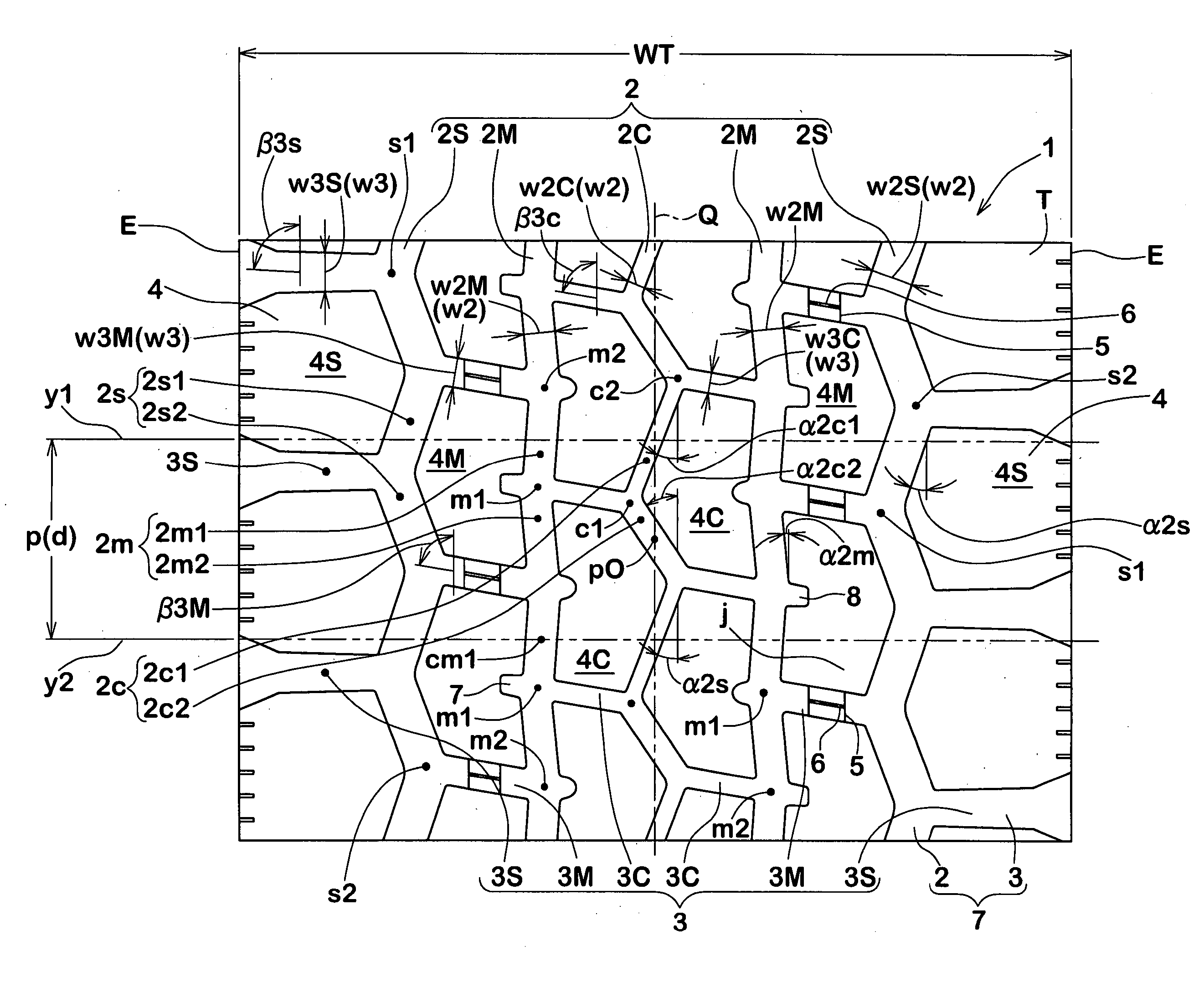

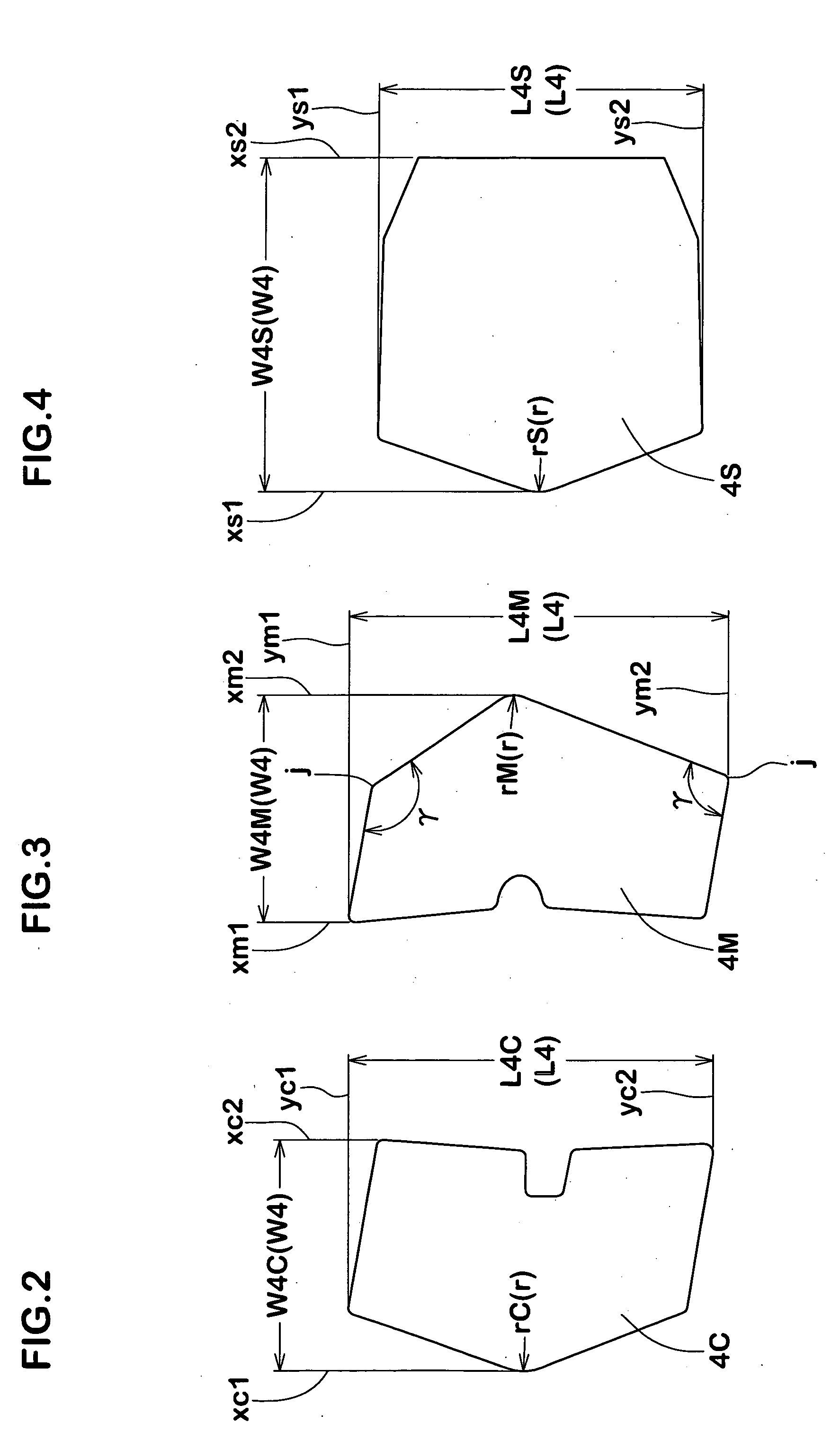

Heavy duty pneumatic tire

InactiveUS20060102267A1Improve performanceSacrificing wet grip performance and on-snow performanceTyre tread bands/patternsNon-skid devicesGroove widthEngineering

It aims to provide a heavy duty pneumatic tire with block patterns and capable of improving deflected wear resisting performances without sacrificing wet grip performances or on-snow performances and that can particularly be favorably used for all seasons. The present invention comprises block patterns employing at least three types of blocks 4 comprised of central blocks 4C delimited by the central longitudinal groove 2M, the intermediate longitudinal grooves 2M, and the central lateral grooves 3C, intermediate blocks 4M delimited by the intermediate longitudinal grooves 2M, the outer longitudinal grooves 2S and the intermediate lateral grooves 3M, and outer blocks 4S that are delimited by outer longitudinal grooves 2S, outer lateral grooves 3S that extend from this outer longitudinal grooves 2S to the tread ends E, and wherein longitudinal length ratios (L4 / W4) of blocks 4, groove width ratios of longitudinal grooves and lateral grooves (w2 / w3), maximum widths of blocks, minimum widths of blocks and ratios thereof (W4max / W4min), and circumferential edge components and tire axial edge components and ratios thereof (EC / EL) at respective stages of wear are defined to be within specified ranges.

Owner:SUMITOMO RUBBER IND LTD

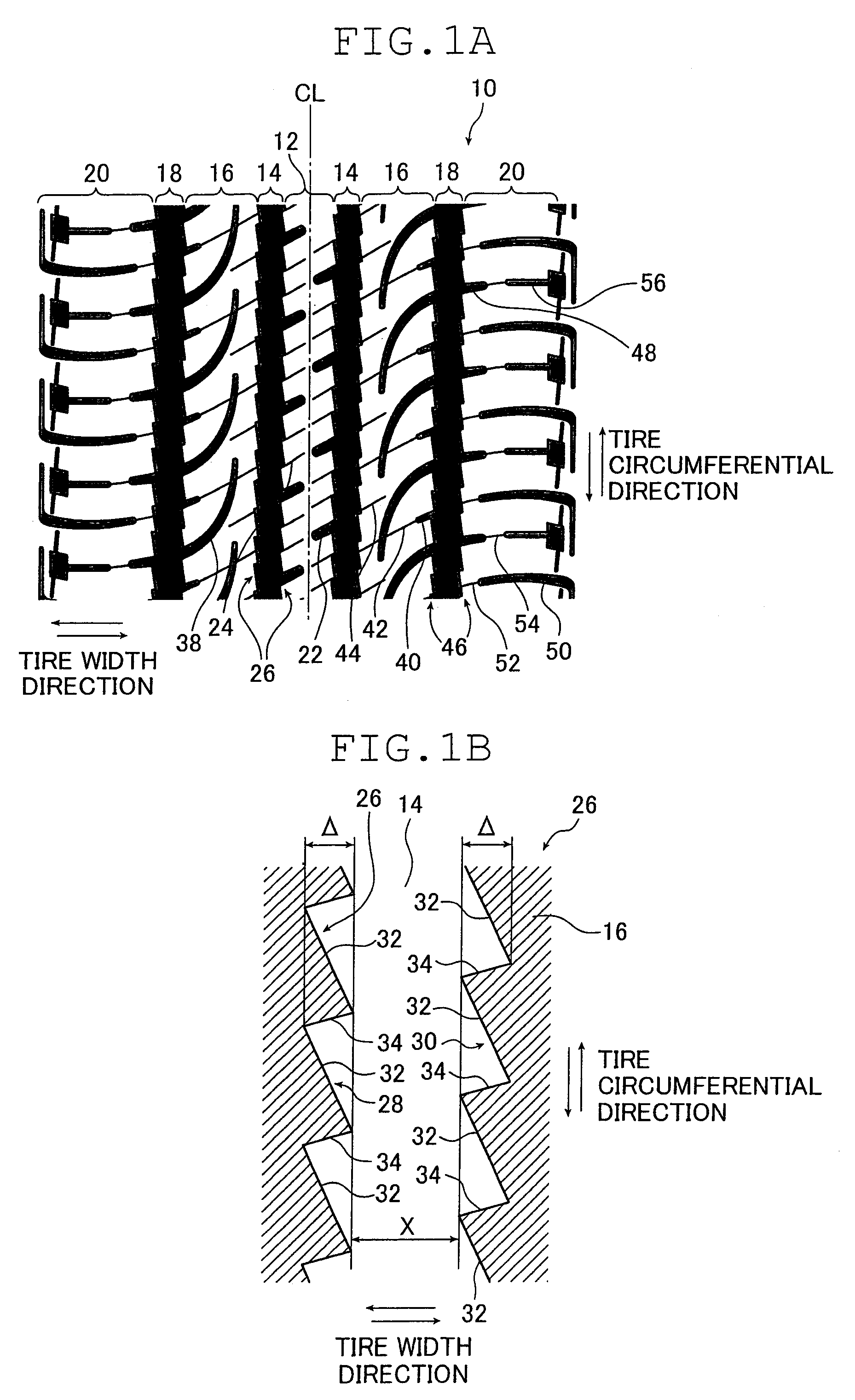

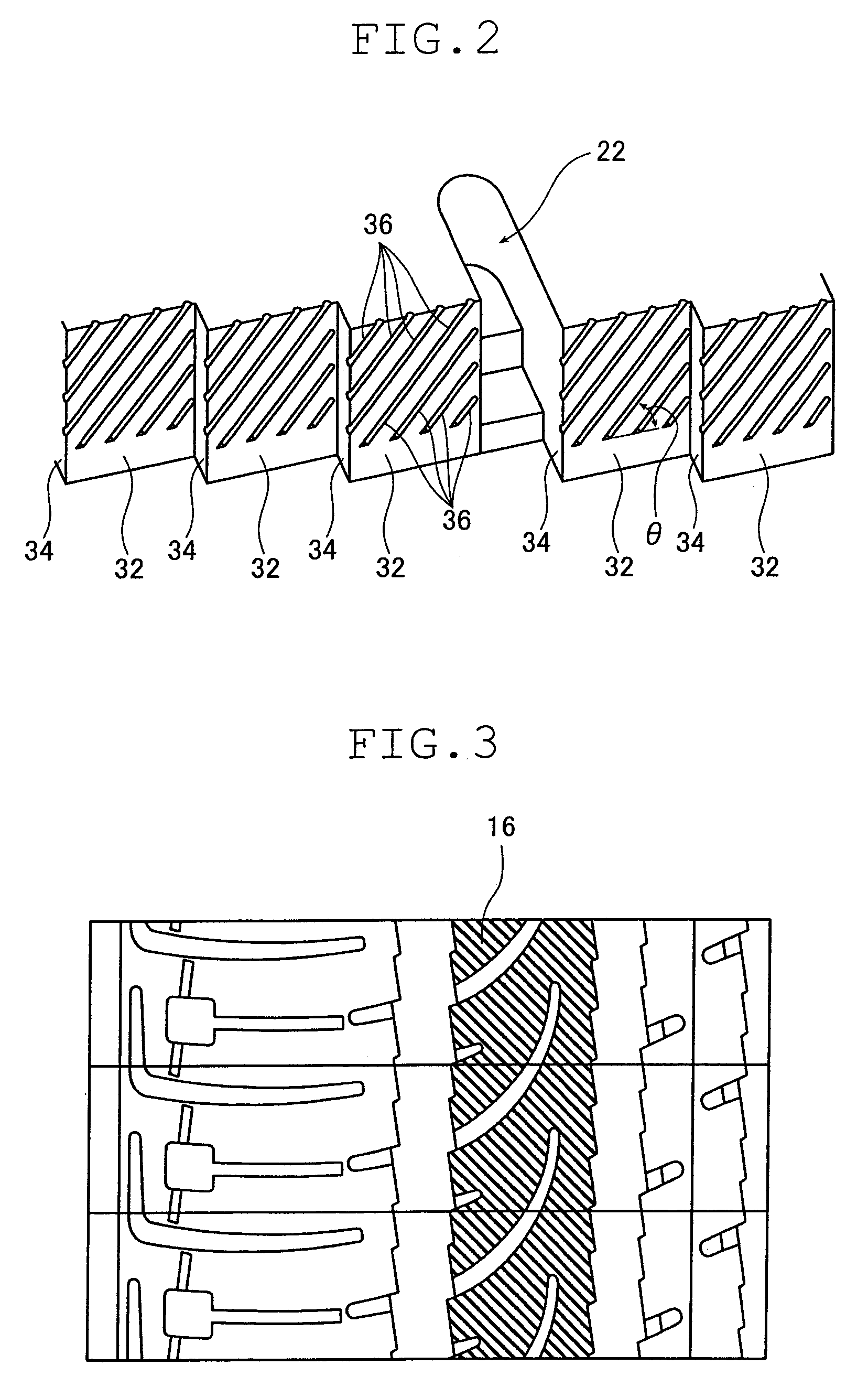

Pneumatic tire

A pneumatic tire has a tread pattern which comprises at least three circumferential grooves with a groove width of 6 to 18 mm and a groove depth of 6.0 to 16.0 mm extending in a tire circumferential direction, wherein, on groove walls on both sides forming the at least three circumferential grooves, first inclined walls inclined by an inclination angle of 5 to 20 degrees with respect to the tire circumferential direction and second inclined walls inclined by an inclination angle of 0 to 45 degrees with respect to a tire width direction are provided so as to be successively connected in the tire circumferential direction so that positions of groove ends in the tire width direction vary in the tire circumferential direction.

Owner:THE YOKOHAMA RUBBER CO LTD

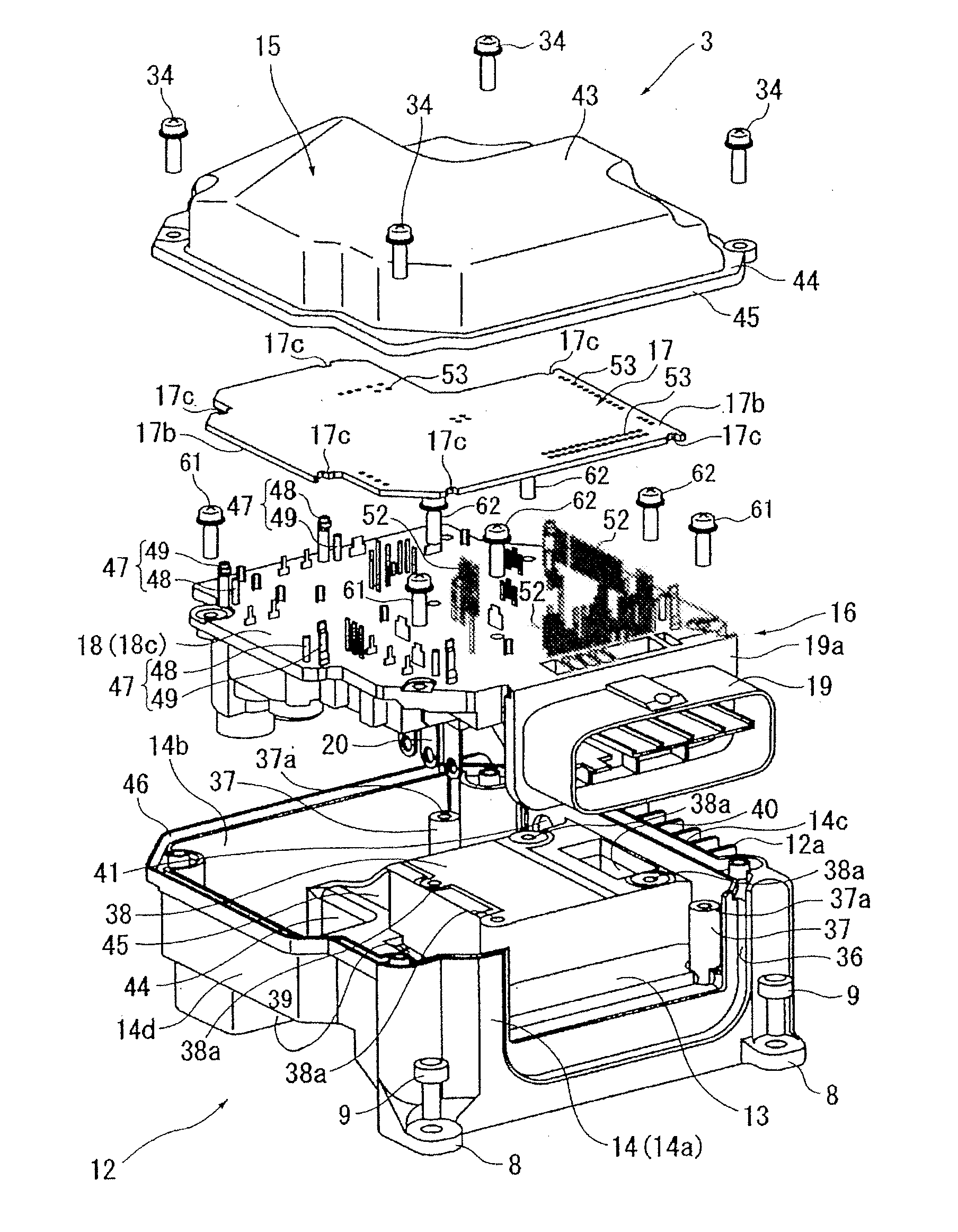

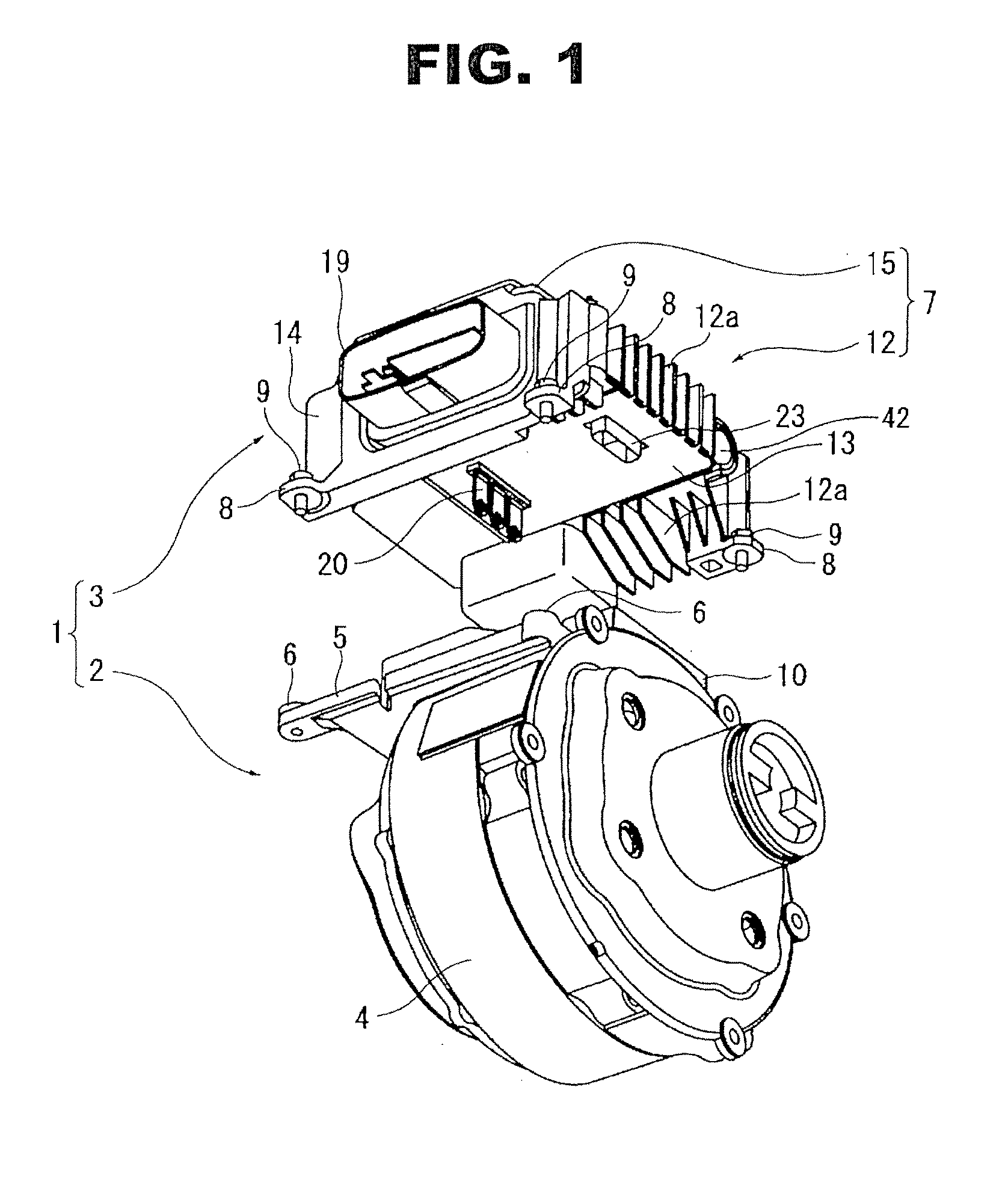

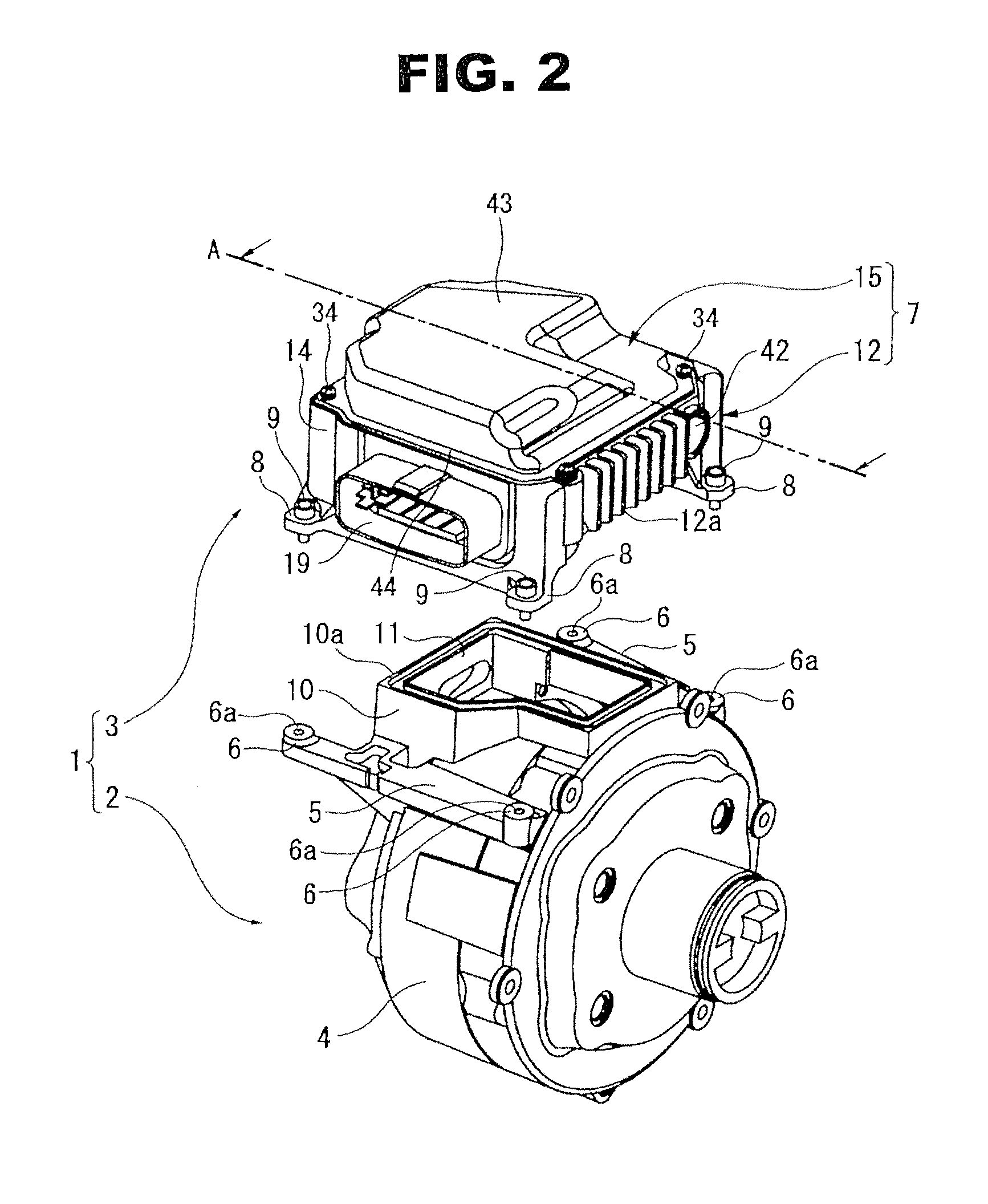

Electronic control device

InactiveUS20140085839A1Suppress relative position shiftImprove assembly workabilityClosed casingsHermetically-sealed casingsGroove widthSealant

An electronic control device has an enclosure accommodating therein a circuit board and having (a) a first enclosure member which is provided at a connecting part thereof with a seal groove and (b) a second enclosure member which is provided at a connecting part thereof with a convex line that is fitted into the seal groove of the first enclosure member; a protrusion formed on either one of an inner wall surface in the seal groove or an opposing surface, which faces the inner wall surface of the seal groove, of the convex line so as to protrude toward the other surface. The protrusion limits a movement, in a seal groove width direction, of the convex line fitted into the seal groove. The seal groove and the convex line are sealed with a sealant.

Owner:HITACHI AUTOMOTIVE SYST LTD

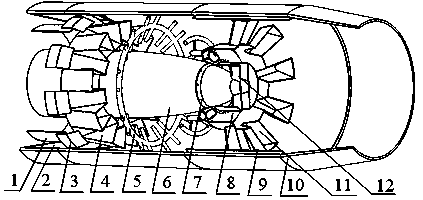

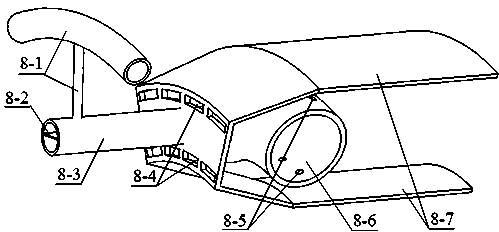

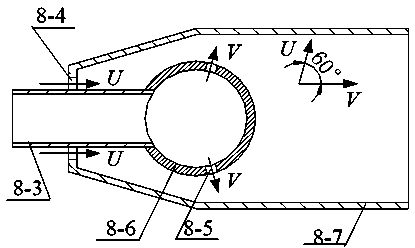

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

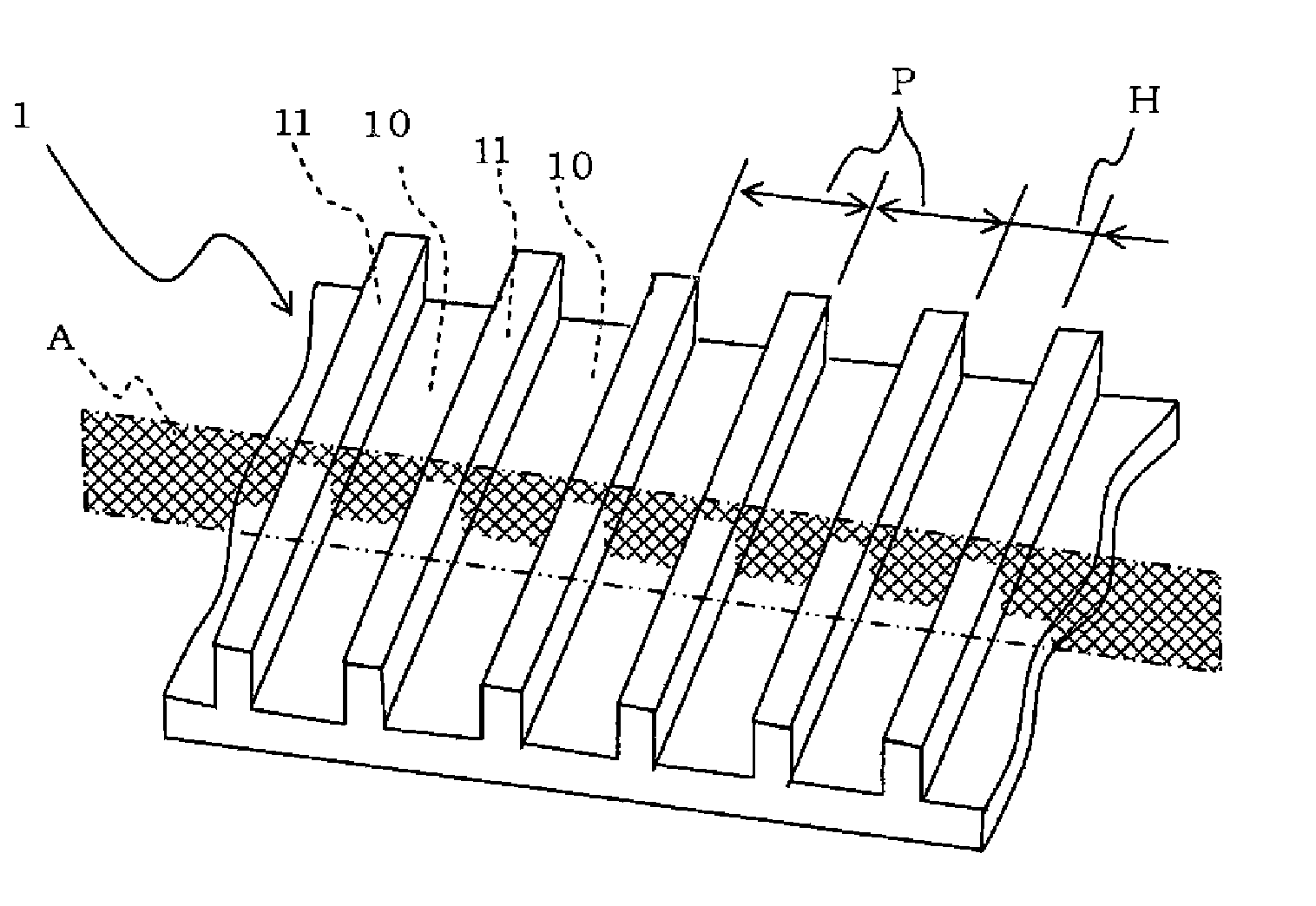

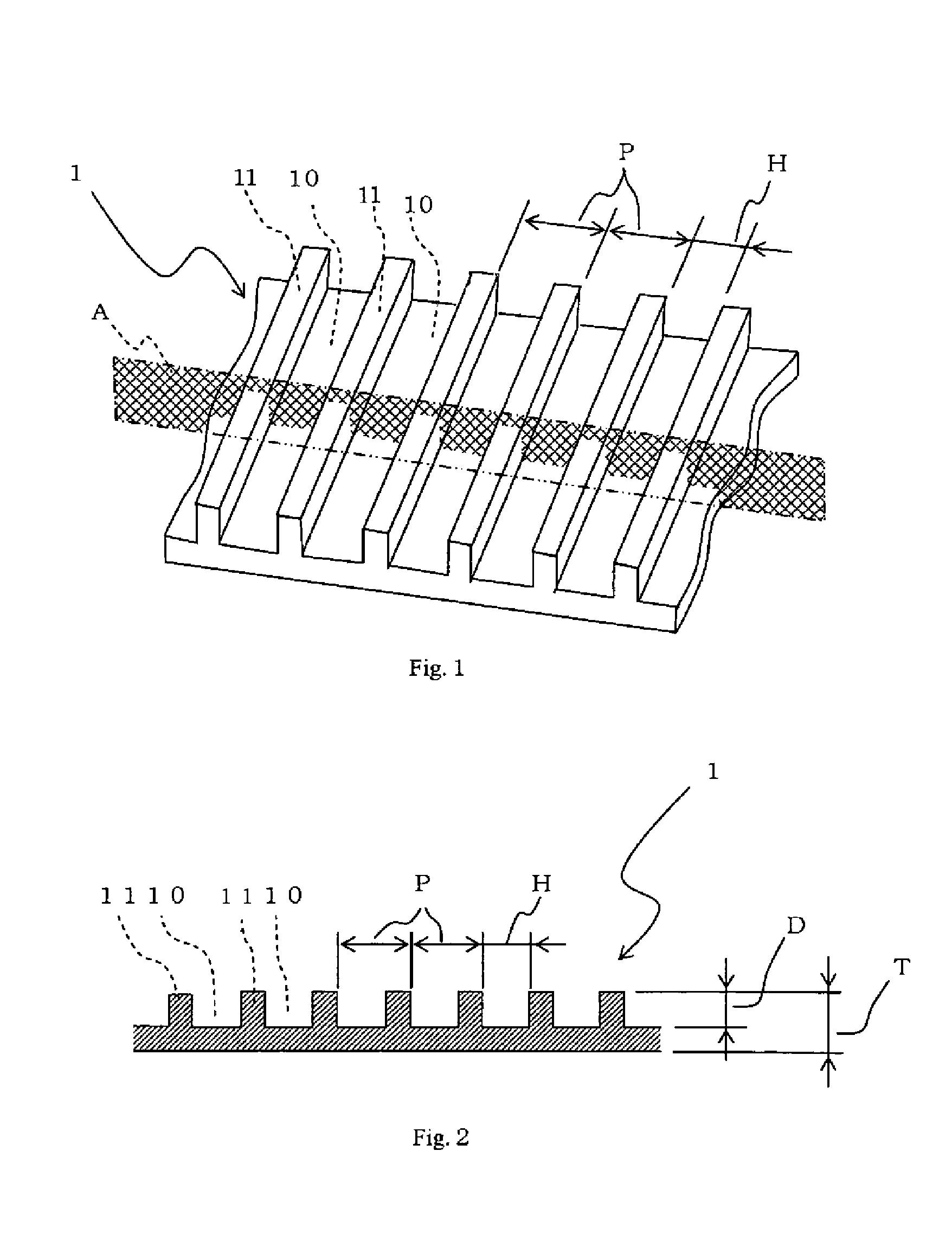

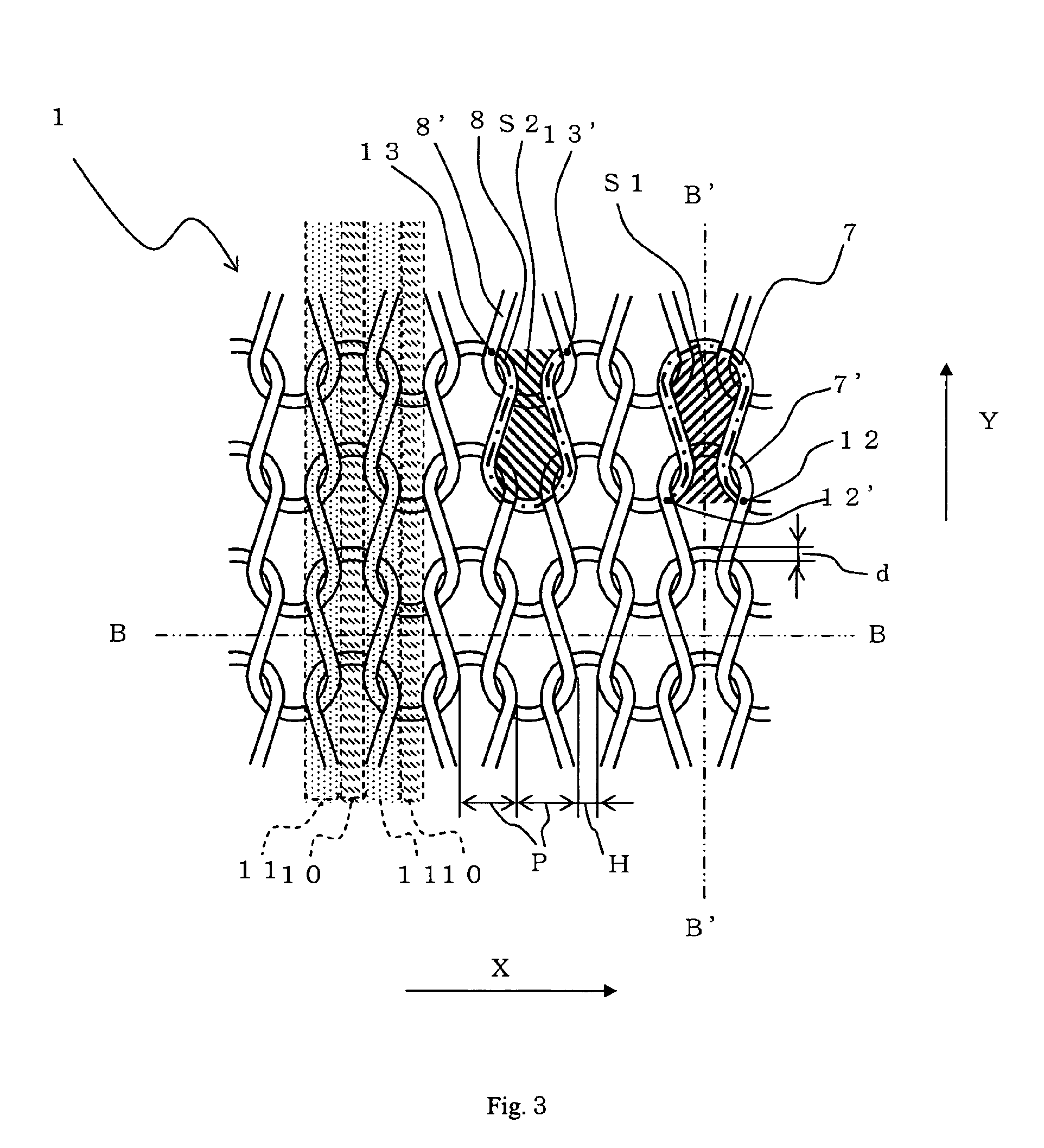

Liquid separation device, flow channel material and process for producing the same

InactiveUS8388848B2Additional drawbackNarrow widthMembranesGeneral water supply conservationGroove widthFiltration

A liquid separation device is provided, and is capable of suppressing the lowering of filtration function due to an increase in flow channel resistance of permeated liquid which results in a separation membrane falling in a groove of a permeated liquid flow channel material along with accompanied breakage of the separation membrane surface. A permeated liquid flow channel material is disposed on the back side of a separation membrane composed of a sheet-like material having a linear groove and a linear crest alternately arrayed on one surface or both surfaces, wherein a groove width of the linear groove in the sheet-like material is 10 to 200 μm, and a ratio of the groove width of the linear groove to the pitch of the linear groove is 0.45 or more.

Owner:TORAY IND INC

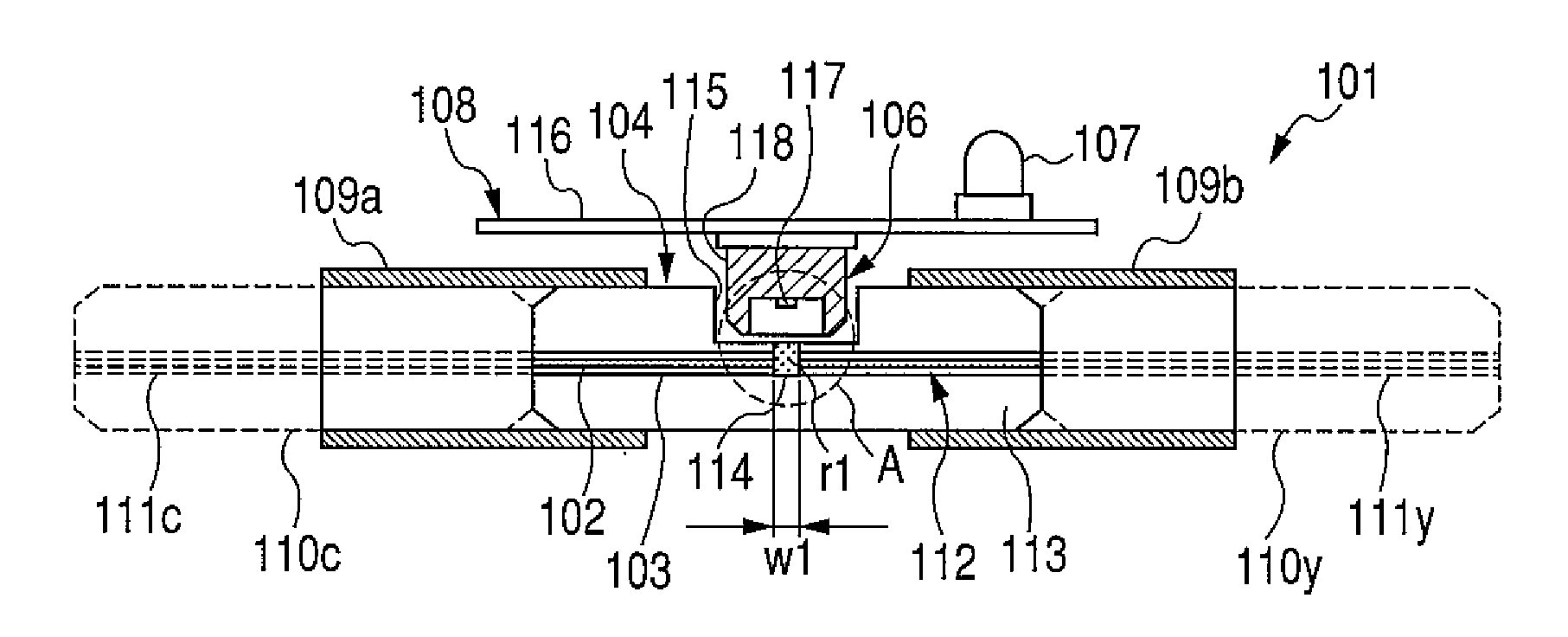

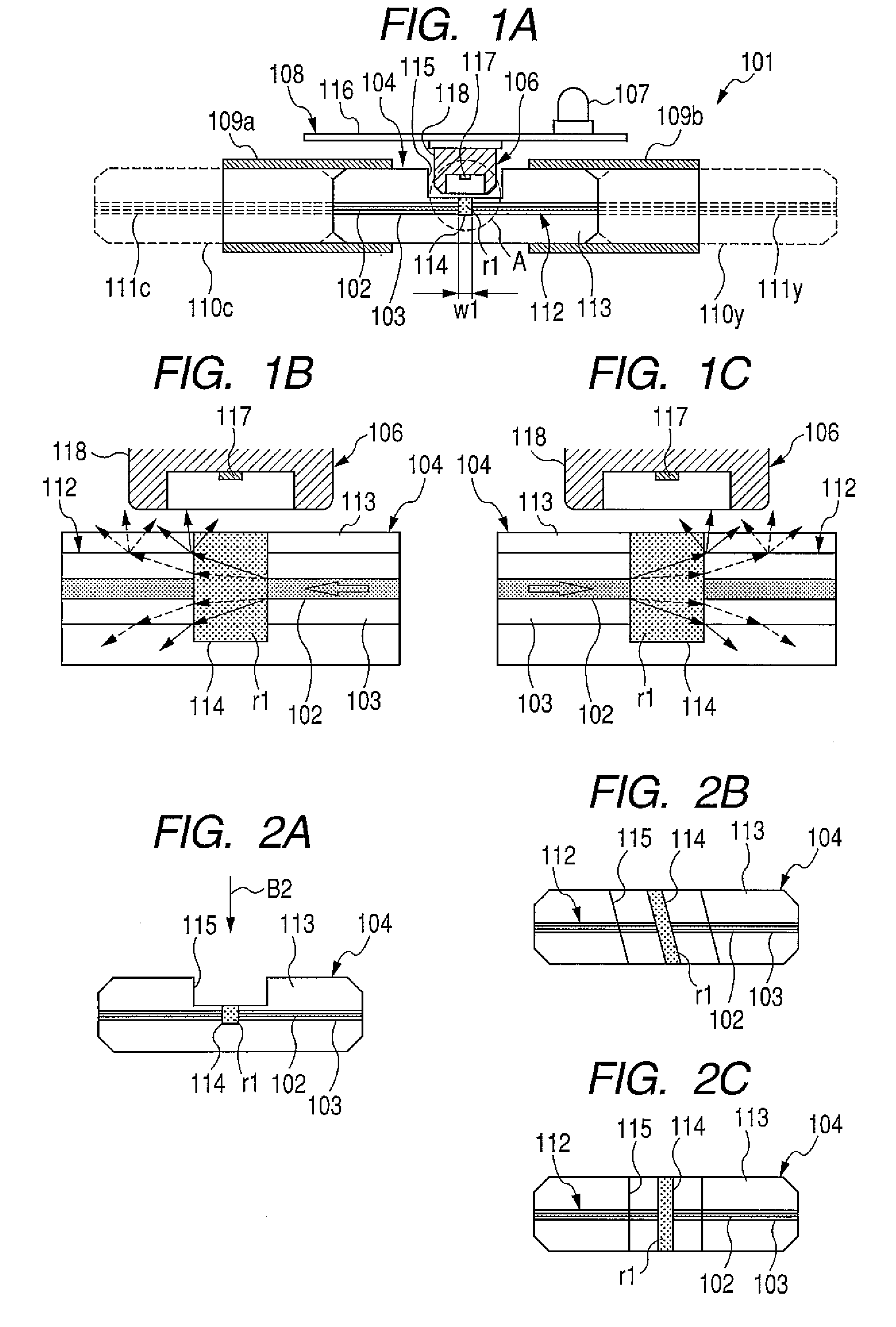

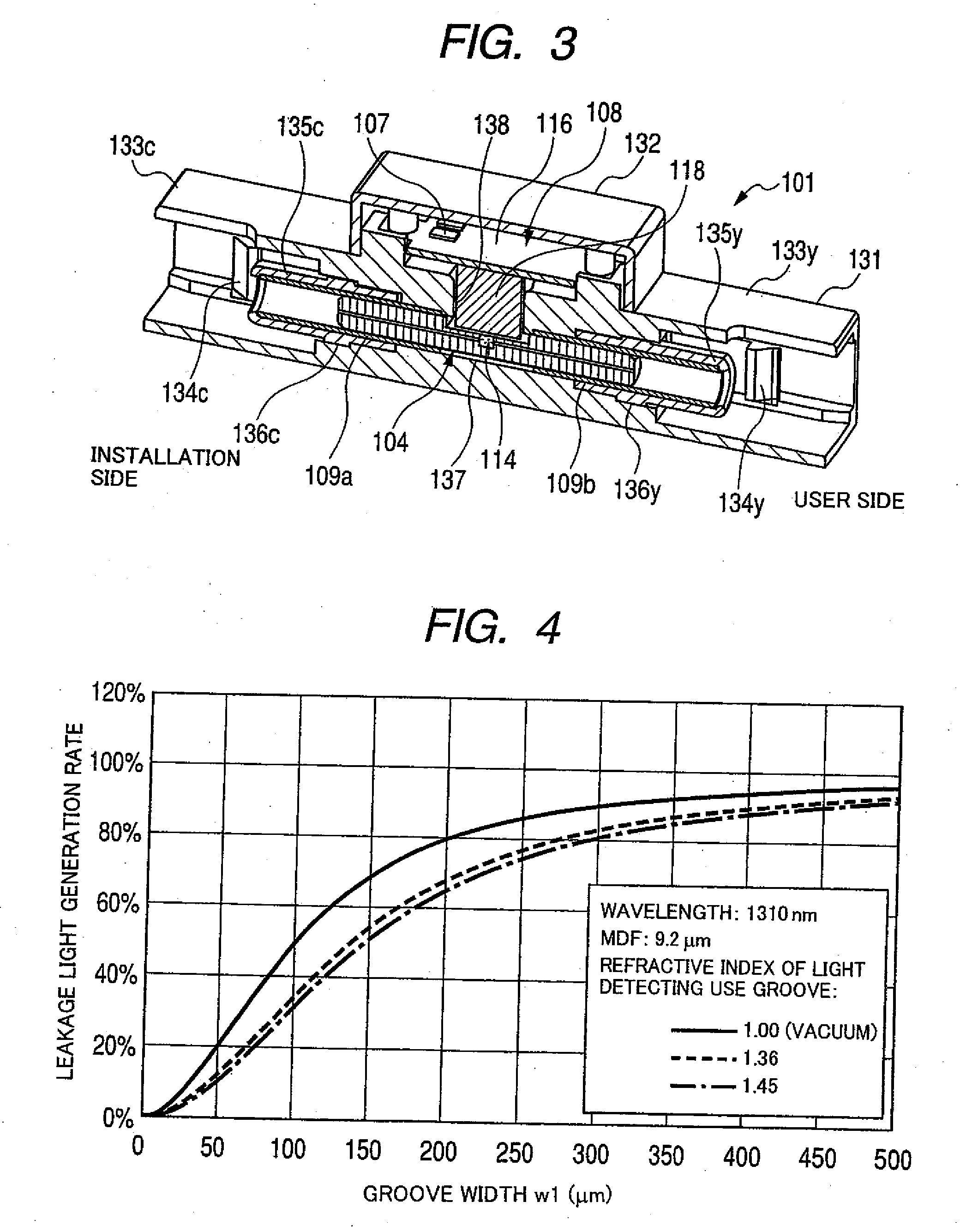

Communication Light Detecting Device

ActiveUS20100008676A1Efficient extractionSimple structureTransmission monitoringTransmission monitoring/testing/fault-measurement systemsGroove widthRefractive index

A communication light detecting device interconnecting light transmission paths and collocated therebetween, comprises: an optical coupling body including a core portion for photo coupling with the light transmission paths, and a light extracting portion for extracting a part of the communication light as a leakage light; and a light detecting portion having a light receiving member for receiving the leakage light. The light extracting portion is preferable to possess a lower refractive index than that of the core portion. Besides, the light extracting portion is preferable to include a light detecting use groove with a groove width of 50 μm or more and 140 μm or less formed by cutting and separating the core portion. Besides, the light extracting portion is preferable to be the optical coupling body in which outer diameter of the core portion is different from the outer diameter of a core of the light transmission path.

Owner:HITACHI METALS LTD +2

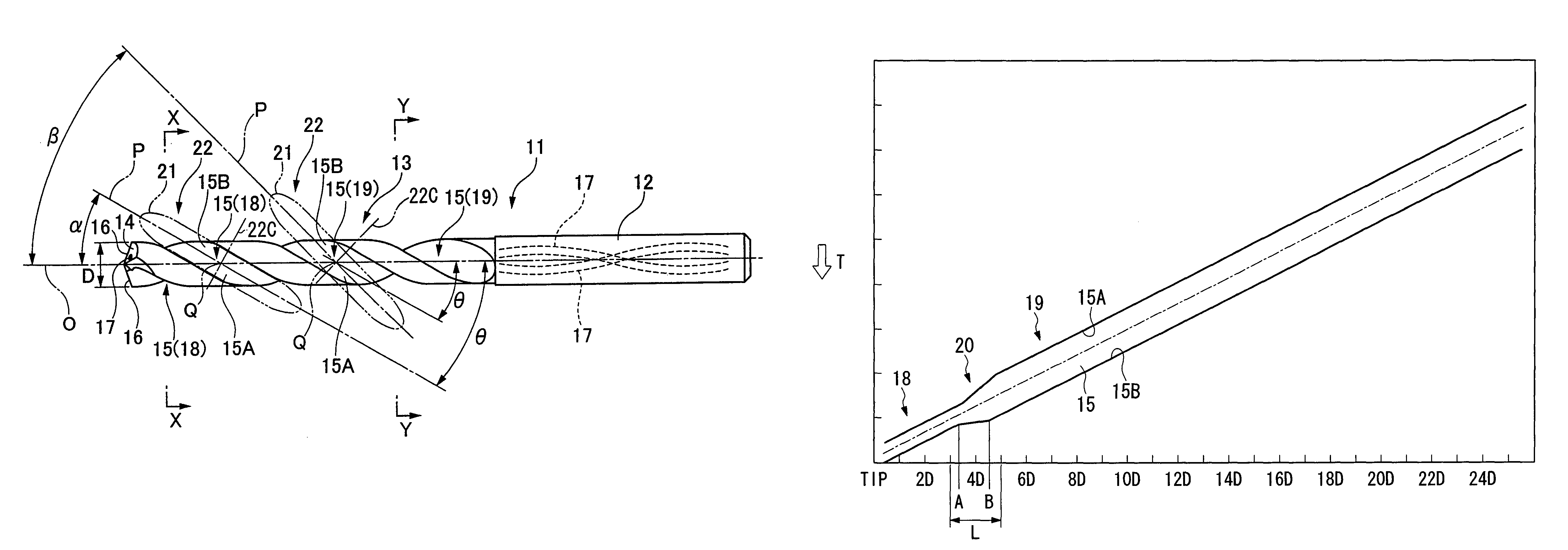

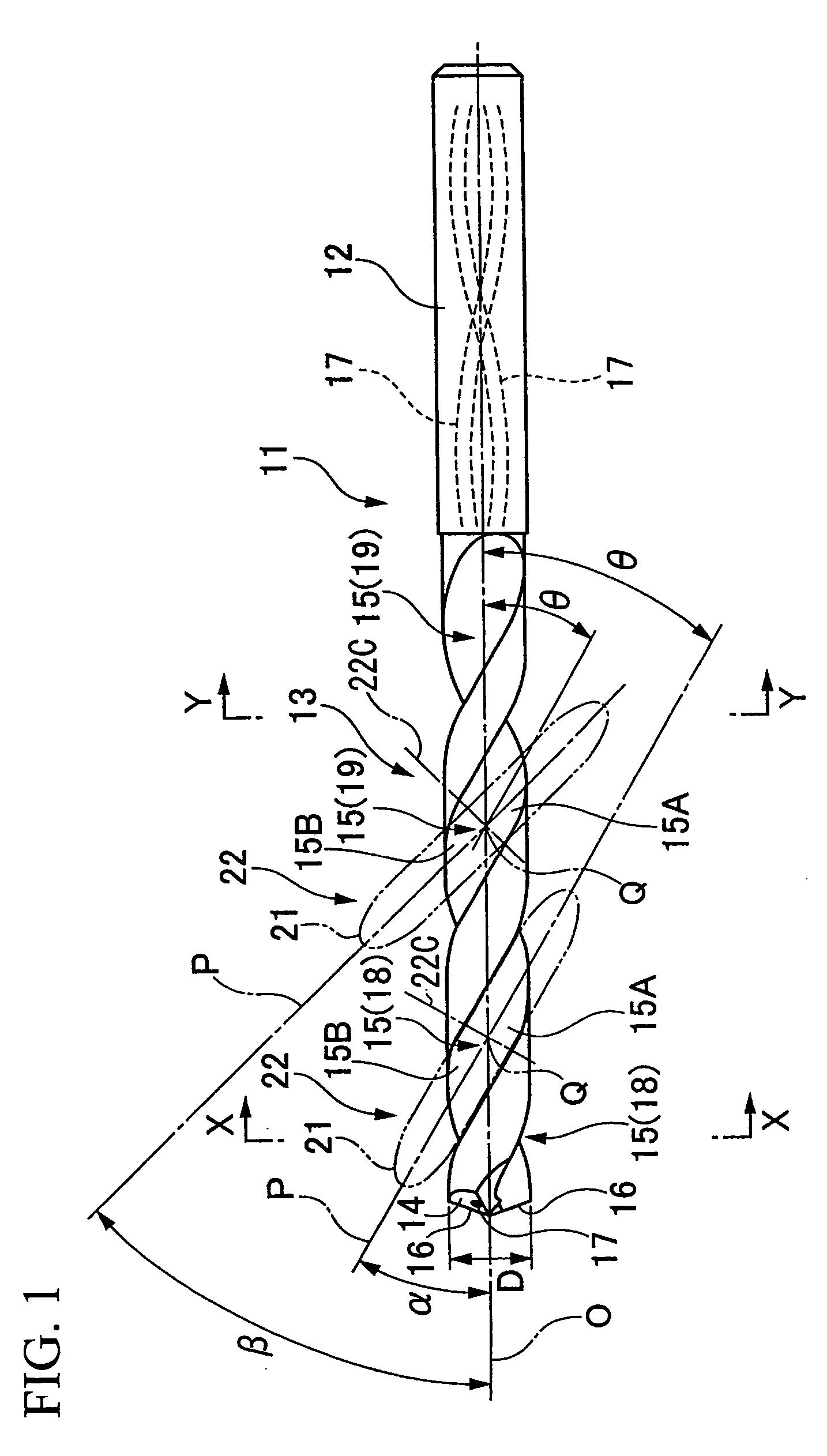

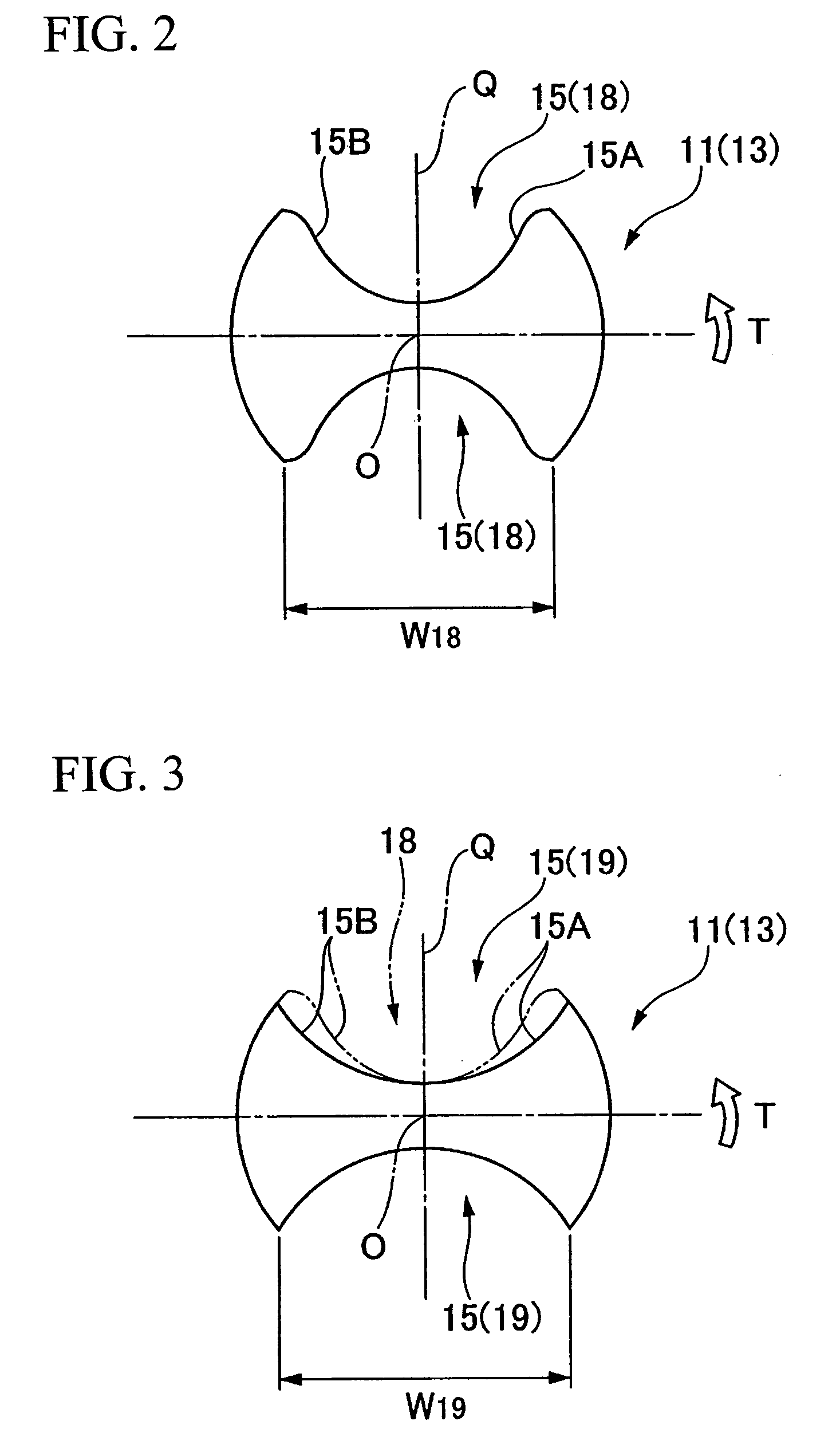

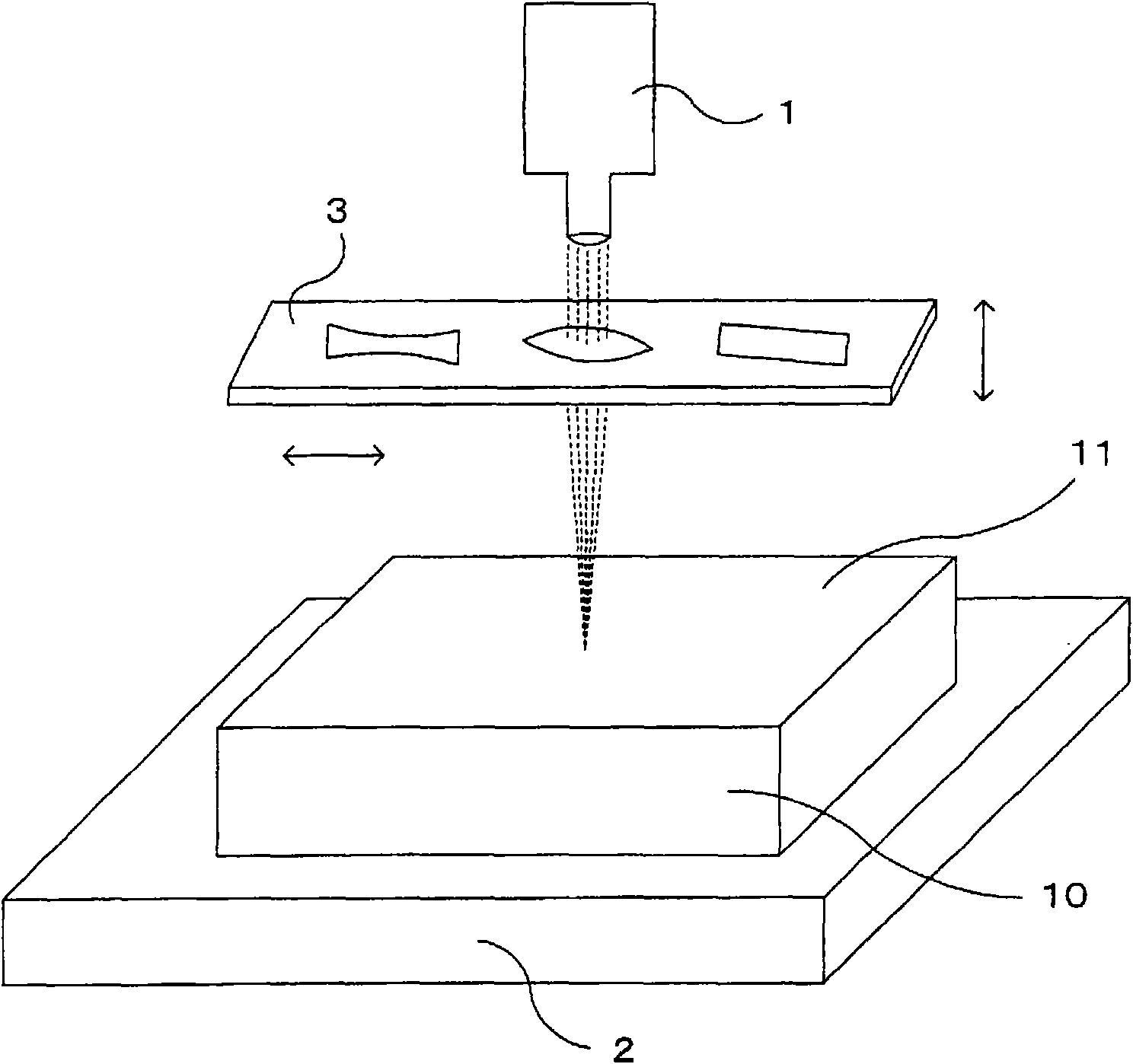

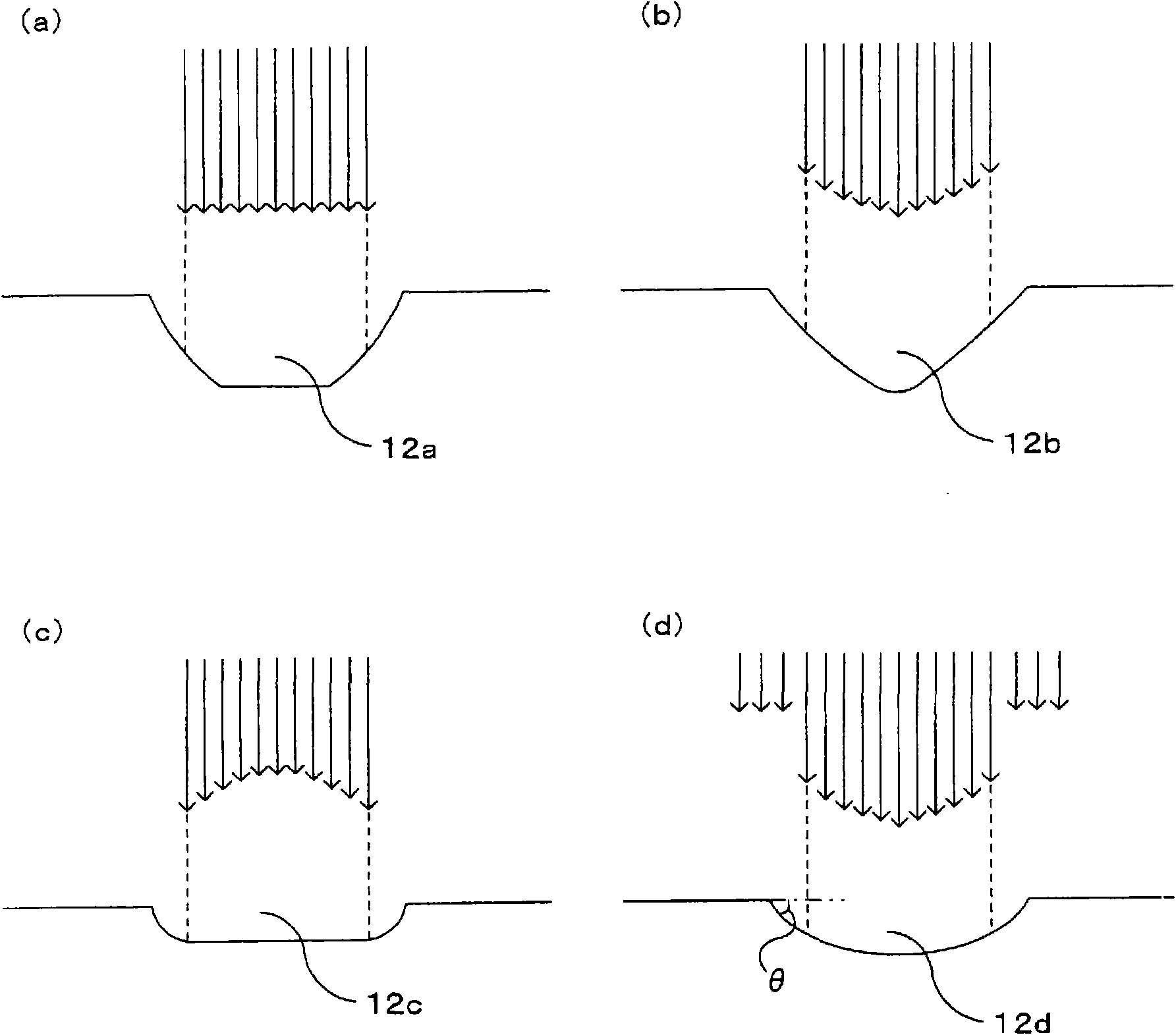

Drill with groove width variation along the drill and double margin with a thinning section at the tip

InactiveUS7306411B2Reliable dischargeImprove surface roughnessWood turning toolsTransportation and packagingGroove widthEngineering

Owner:MITSUBISHI MATERIALS CORP

Method of machining u-shaped groove of substrate of fragile material, removal method, boring method and chamfering method using the same method

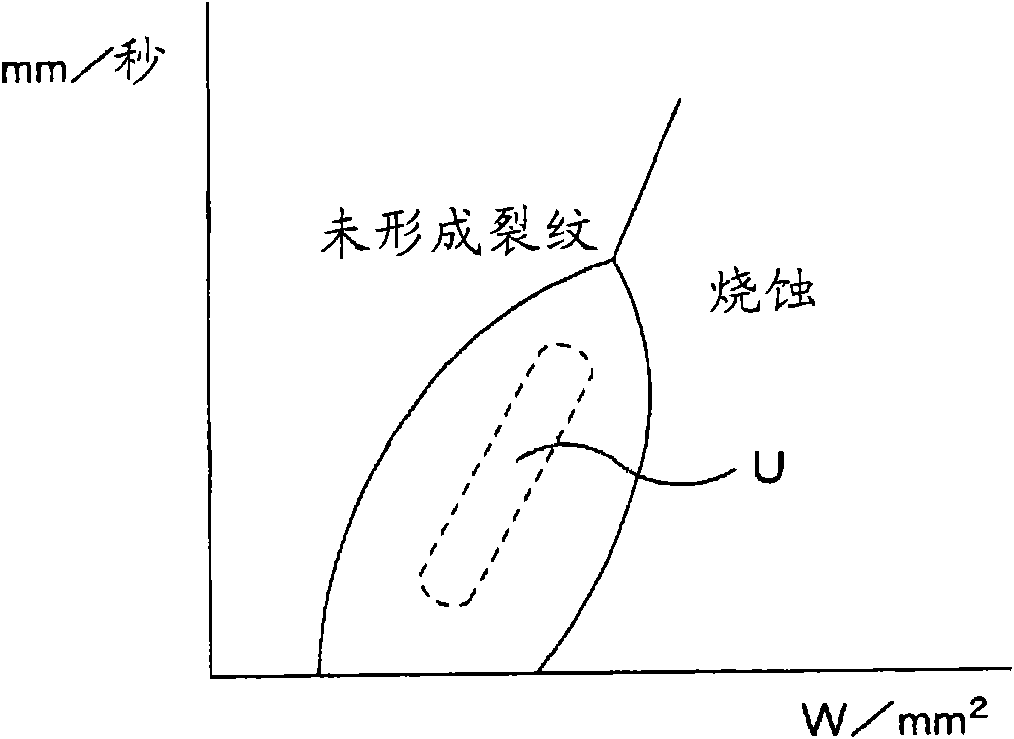

A method of easily forming a linear or curved continuous or discontinuous U-shaped groove on a substrate surface, and a chamfering method using the same. Part of the surface of a substrate made of a fragile material is rapidly heated under laser irradiation conditions for forming the U-shaped groove consisting of a predefined combination of laser power, a laser irradiation area and scanning speed according to a substrate material to be machined, a groove width of the U-shaped groove to be formed, a depth and a shape of a groove surface, thereby exfoliating part of the substrate from the surface and forming the U-shaped groove. A chamfered face comprising a groove surface constituted of part of the U-shaped groove formed between an end surface segmented from an expected segmentation line and the substrate surface is formed by a method of scribing from an initial end of the expected segmentation line set on the bottom of the groove toward a terminal end by means of laser crack growth, a method of scribing by means of a cutter wheel or the like.

Owner:MITSUBOSHI DIAMOND IND CO LTD

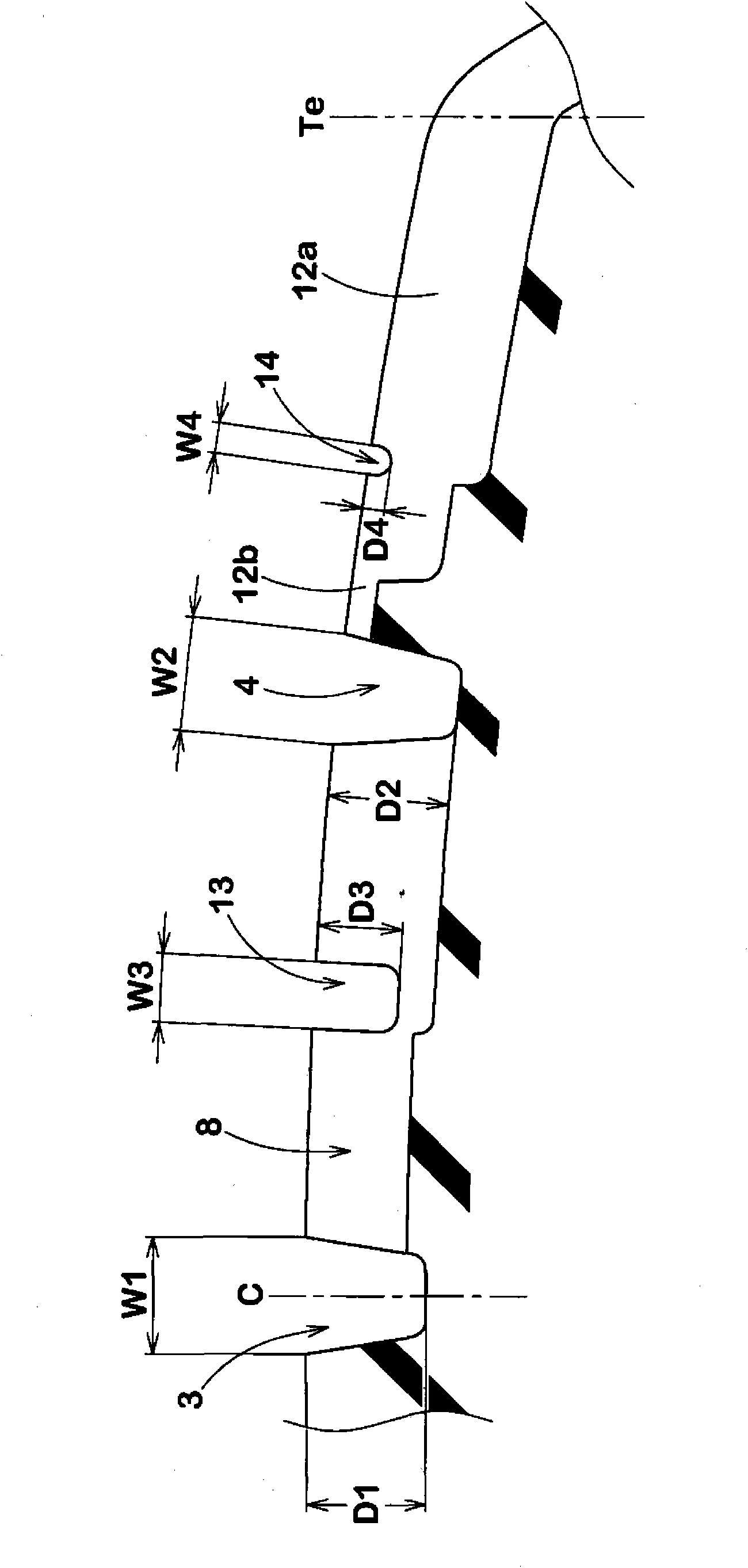

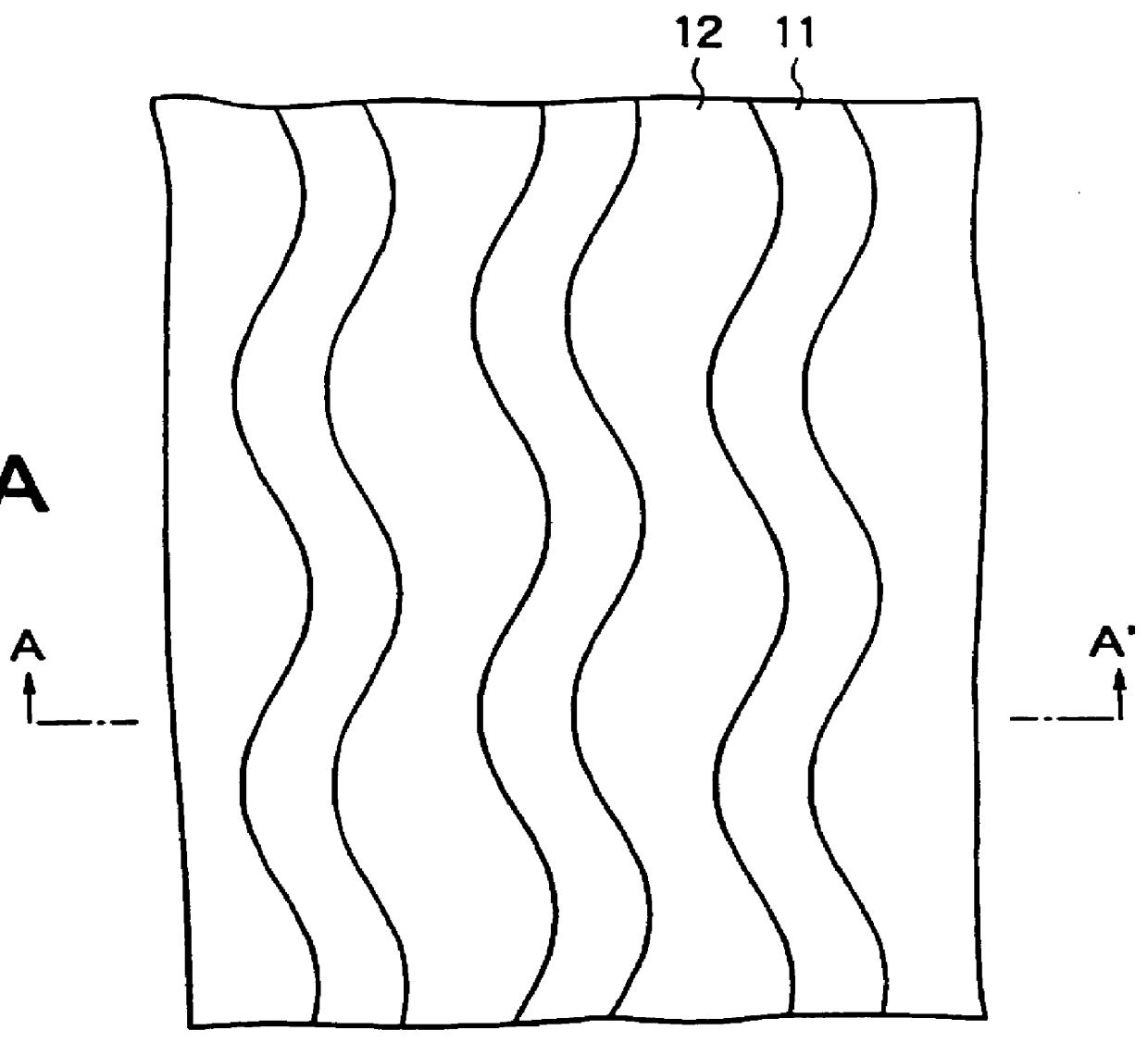

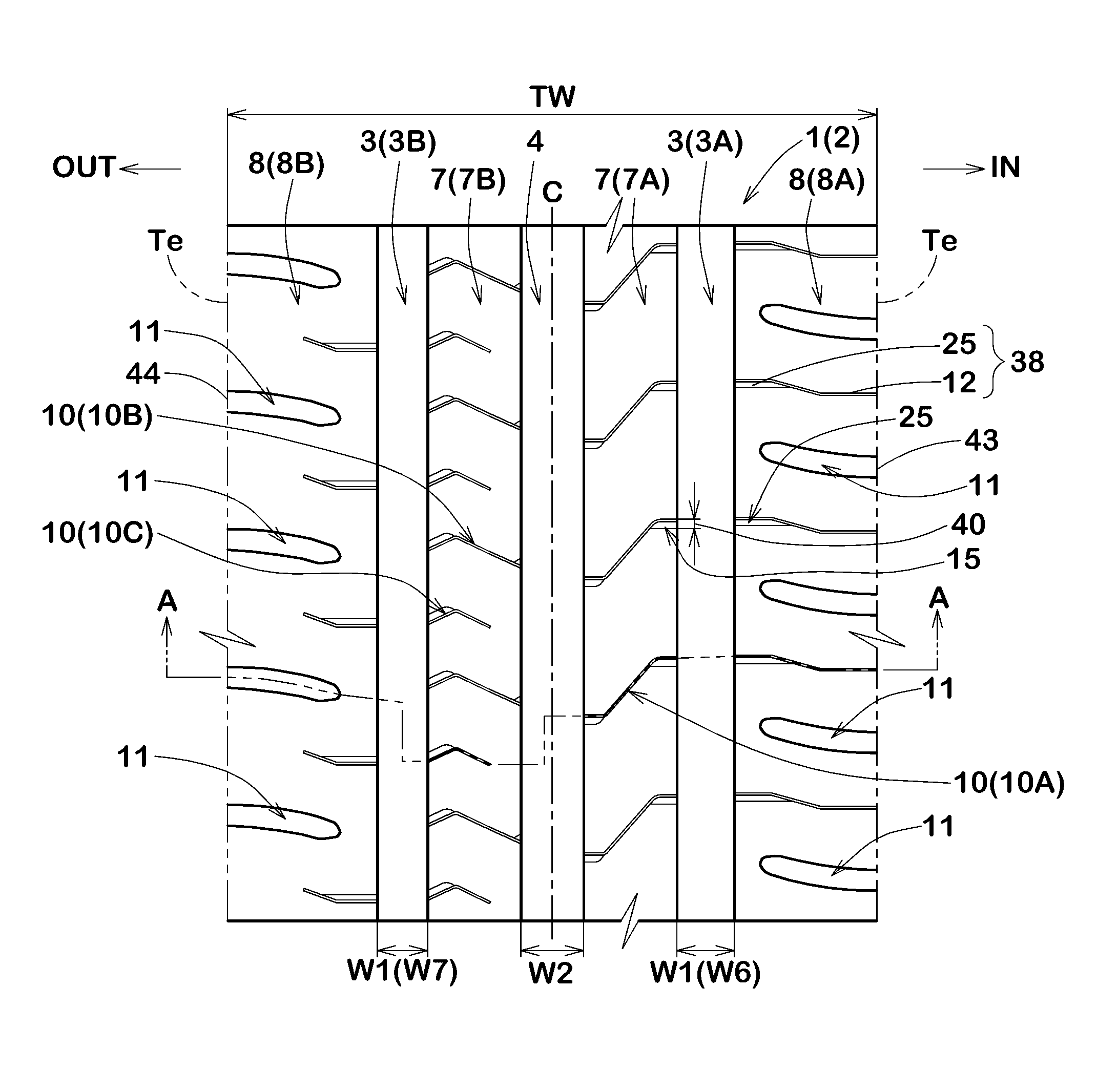

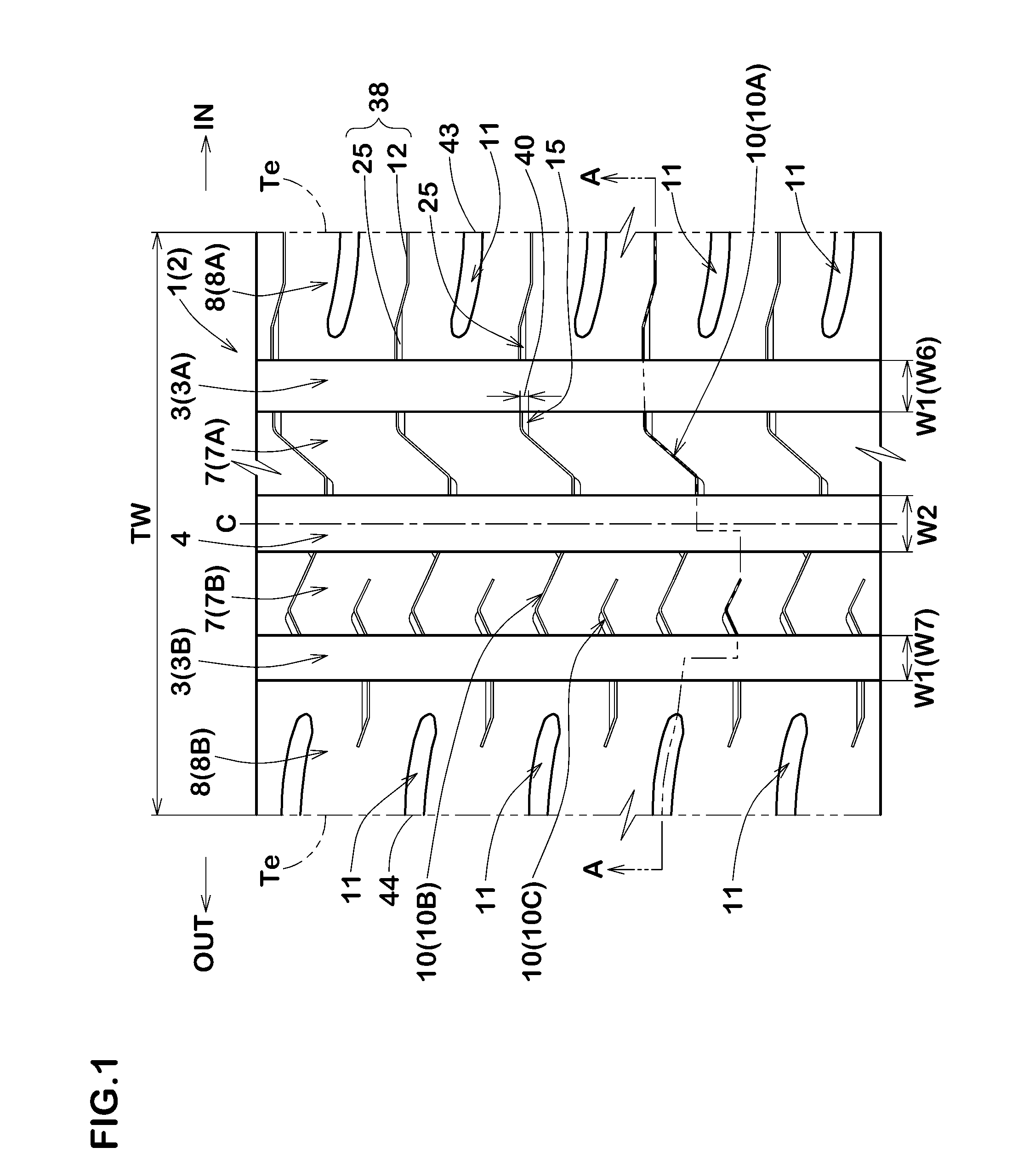

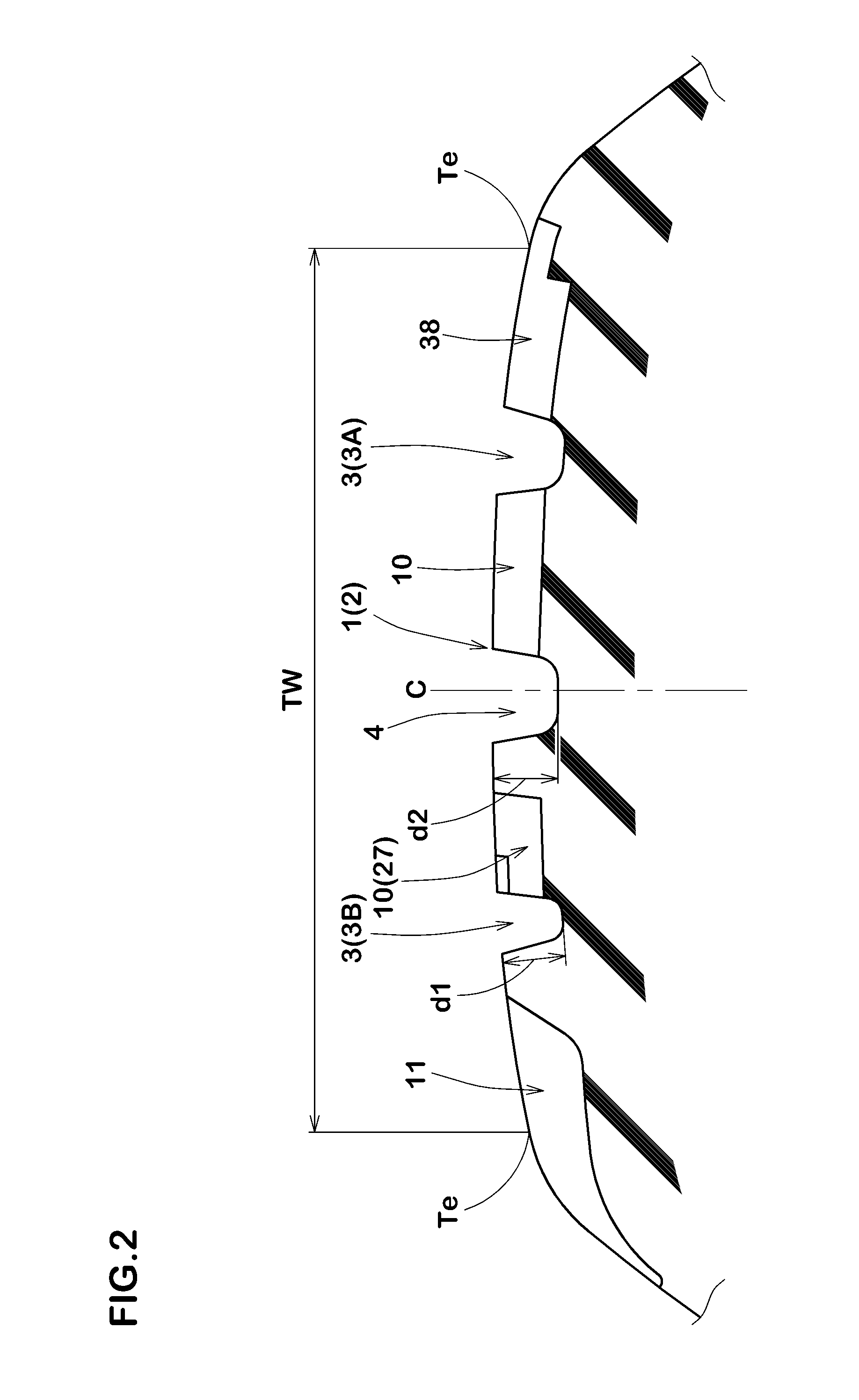

Pneumatic tire

ActiveUS20160152090A1Constant groove widthImprove steering stabilityTyre tread bands/patternsNon-skid devicesGroove widthLanding zone

A pneumatic tire comprises a tread portion 2 provided with two shoulder main grooves 3, a crown main grooves 4, two shoulder land zones 8, and two middle land zones 7. The shoulder land zones 8 are each provided with shoulder lateral grooves 11. The middle land zones 7 are each provided with middle narrow grooves 10. Each of the middle narrow grooves 10 comprises a sipe-like narrow portion 12 whose groove width is less than 2 mm, and a wide portion 14 whose groove width is not less than 2 mm. The wide portion 14 includes an axially outer wide portion 15 formed at the axially outer end of the middle narrow groove 10.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20140238566A1Suppressing increase in driving noiseInhibitionTyre tread bands/patternsNon-skid devicesGroove widthEngineering

A pneumatic tire includes a tread having at least one main groove and a plurality of ribs extending in the tire-circumferential direction. At least one of the ribs has a plurality of narrow grooves formed at intervals in the tire-circumferential direction. At least one intermittent sipe is formed corresponding to at least one of the narrow grooves. The narrow grooves are grooves each having a portion extending substantially along the tire-circumferential direction and having a groove width smaller than the at least one main groove. The at least one intermittent sipe has a plurality of holes that are intermittently formed, and at least one solid part located between adjacent two of the holes. The holes and the solid part are arranged in a direction intersecting the narrow grooves. The intermittent sipe intersects the corresponding narrow groove in the at least one solid part.

Owner:TOYO TIRE & RUBBER CO LTD

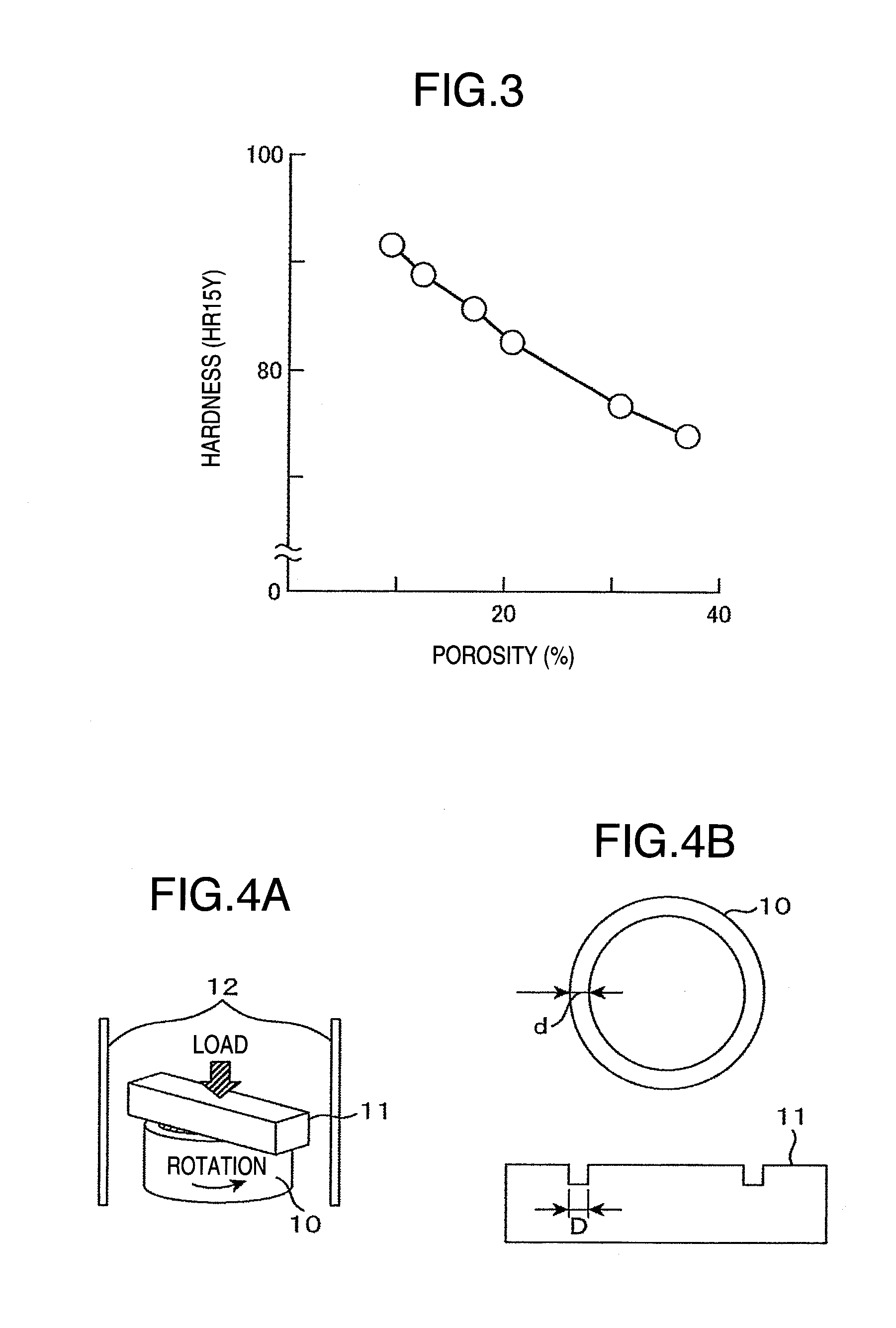

Gas turbine shroud with ceramic abradable layer

InactiveUS20120107103A1High operating requirementsEasy to operatePump componentsBlade accessoriesGroove widthWear resistance

A gas turbine shroud includes a ceramic abradable coating superior in abradable property and durability. The gas turbine ceramic abradable coating of the present invention is configured by an abradable metal layer and a porous ceramic abradable layer (hardness RC15Y: 80±3), the porous ceramic abradable layer is provided with slit grooves by machining work, and a slit groove width is 0.5 to 5 mm. Thereby, the abradable property, and durability against a thermal cycle and high-temperature oxidation are improved.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Pneumatic tire

ActiveCN101890881AGuaranteed rigidityImprove driving stabilityTyre tread bands/patternsGround contactGroove width

A pneumatic tire including five land portions Q1, Q2, Q3, Q4, Q5 in a tread surface 1 by providing four main grooves G1, G2, G3, and G4 in a ground contact region R of the tread surface 1, wherein positions and groove widths of the main grooves G1, G2, G3, and G4 are specified together with only the land portion Q1 positioned outermost on a vehicle outer side when mounted on a vehicle being formed into a block row, and the other land portions Q2, Q3, Q4, and Q5 being formed into ribs, and a groove area proportion of the tread surface 1 is larger on a vehicle inner side than the vehicle outer side with a tire equator CL and center lines of the land portions Q2, Q3, Q4 as boundaries.

Owner:THE YOKOHAMA RUBBER CO LTD

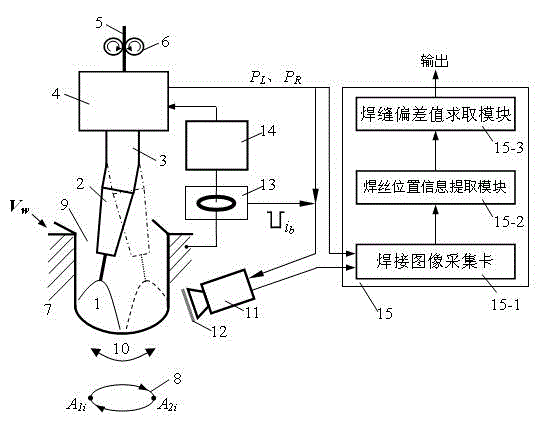

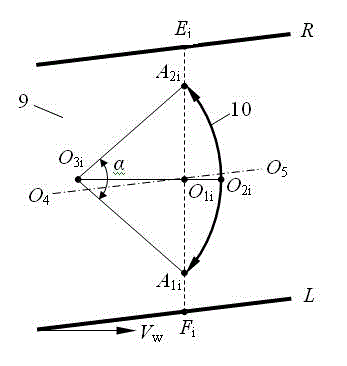

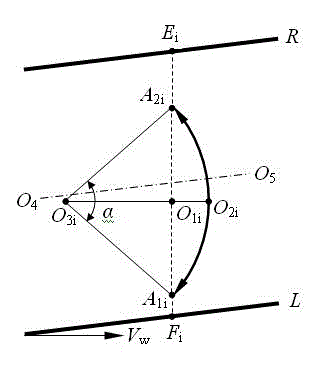

Infrared vision sensing detection method and device for narrow-gap weld seam deviation

ActiveCN104551347AImprove environmental adaptabilityImprove real-time performanceImage enhancementImage analysisCurrent sensorComputer image

The invention discloses an infrared vision sensing detection method and an infrared vision sensing detection device for narrow-gap weld seam deviation. The device comprises a shaking (or rotating) electric arc narrow-gap welding torch, an electric arc current sensor, a computer image processing system and an infrared photographing system, wherein an infrared camera acquires an infrared image of a welding region in an external touch mode when an electric arm shakes (or rotates) to a position closest to the left side wall or the right side wall of a groove; after the infrared image is subjected to computer image processing, welding wire position and groove edge information is extracted in real time, and a weld seam deviation output is calculated according to changes of a welding wire relative to the left side wall and the right side wall of the groove; when a pulse electric arc is welded, the current sensor is used for detecting a signal in the base value period of electric arc current pulse, thus realizing welding image acquisition synchronized with the current period of a pulse electric arc base value. The system is simple in constitution, wide in application range, high in weld seam deviation detection precision, high in environment adaptability and high in interference capacity and is suitable for shaking (or swinging) and rotating electric arc narrow-gap welding occasions with groove width change.

Owner:JIANGSU UNIV OF SCI & TECH

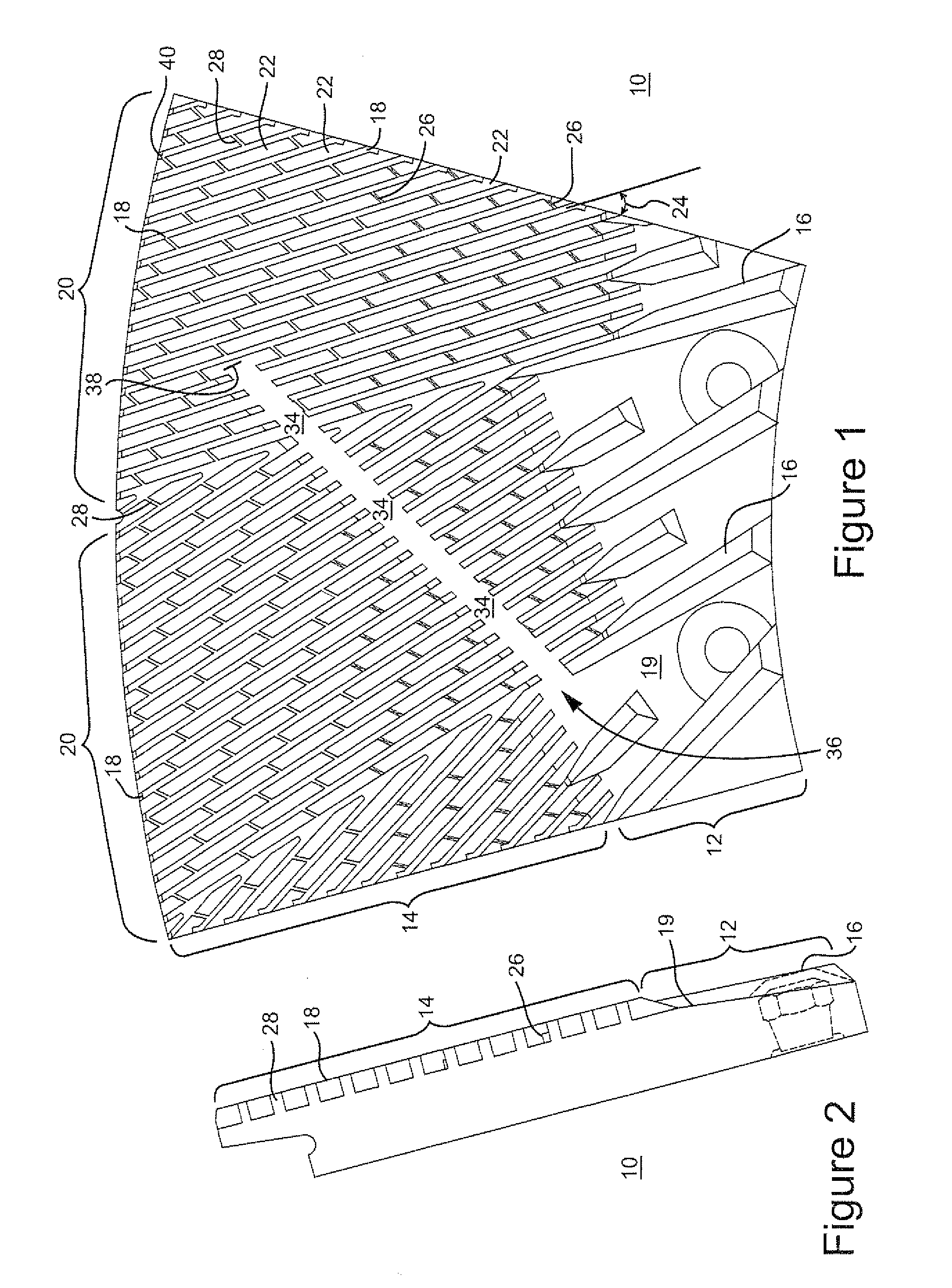

Refiner plates having steam channels and method for extracting backflow steam from a disk refiner

ActiveUS20080296419A1Reduce the amount requiredHigh energy costReed/straw treatmentCocoaGroove widthMechanical engineering

A refining plate for refining lignocellulosic material including: a radially outer peripheral edge and a substrate surface; a refining zone having a plurality of substantially radially disposed bars and grooves between the bars, wherein the bars protrude upward from the substrate surface and the grooves each have a groove width, and a steam channel traversing the bars and grooves of the refining zone, wherein the steam channel has a radially outer end radially inward of the outer peripheral edge of the plate and the steam channel has a width substantially greater than the groove width.

Owner:ANDRITZ INC

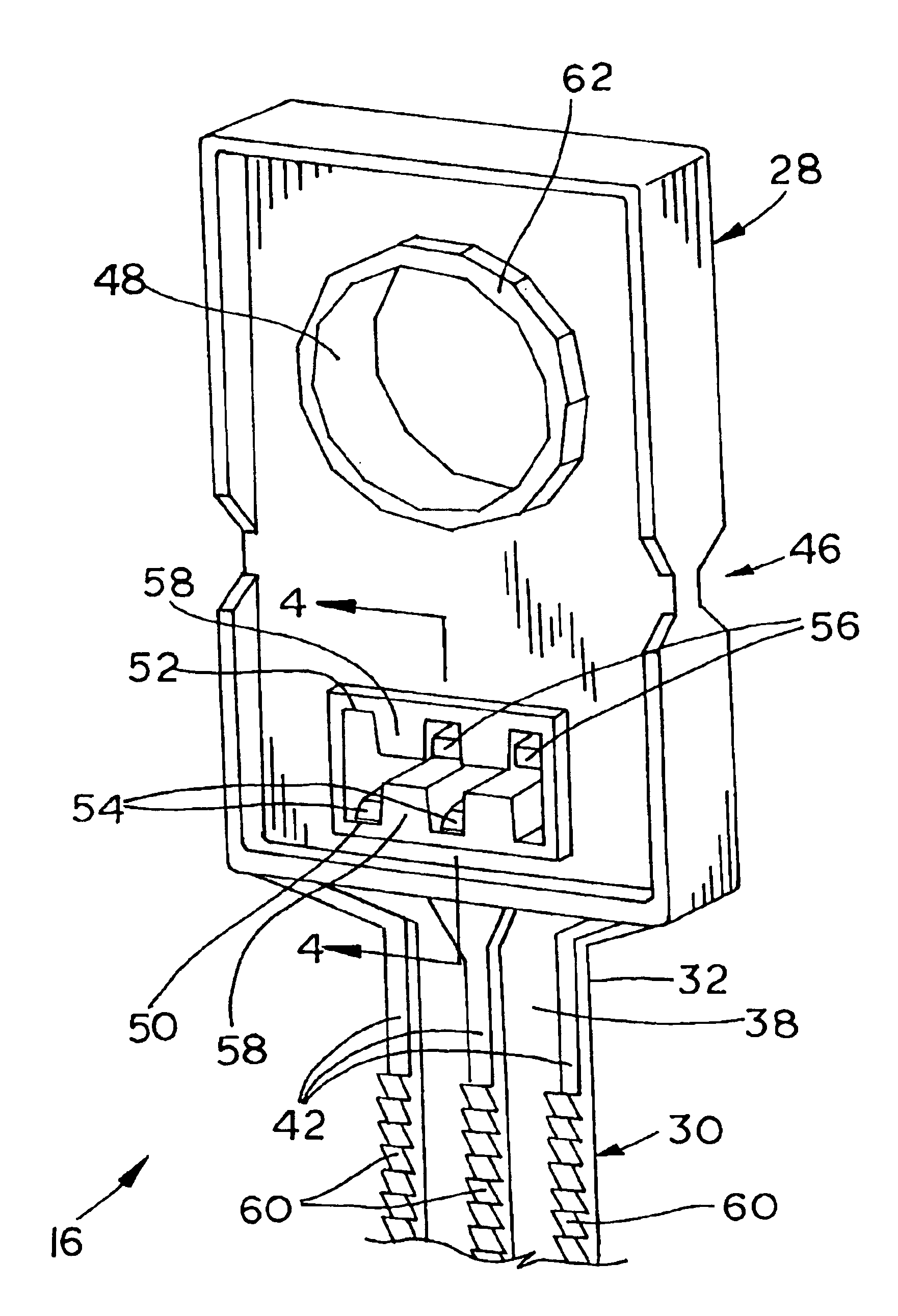

Electrical assembly including an electrical tie

InactiveUS6938305B2Prevent movementEasy to fixFlexible elementsHose connectionsGroove widthElectrical conductor

An electrical assembly includes an electrical convoluted tubing, at least one electrical conductor and an electrical tie. The electrical convoluted tubing includes an outer surface having a plurality of generally parallel, annular convolutions defining respective grooves therebetween. Each groove has a width. The at least one electrical conductor is positioned within the tubing. The electrical tie is positioned around the tubing and includes a head and an elongate strap. The elongate strap has opposing sides and an end. The end is attached to the head. At least one of the sides has at least one longitudinally extending rib, with each rib having a width which is less than the groove width.

Owner:GROUP DEKKO

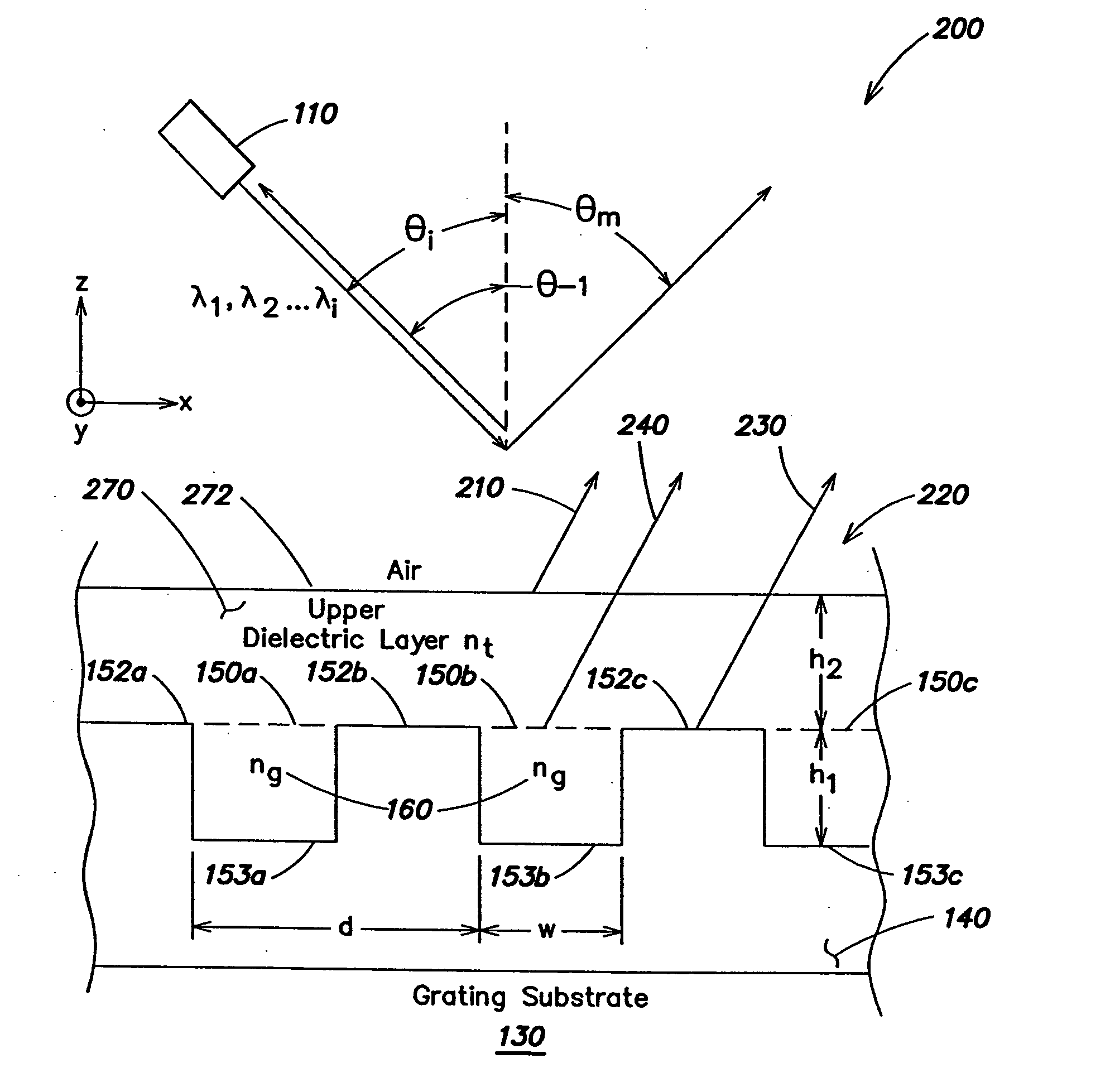

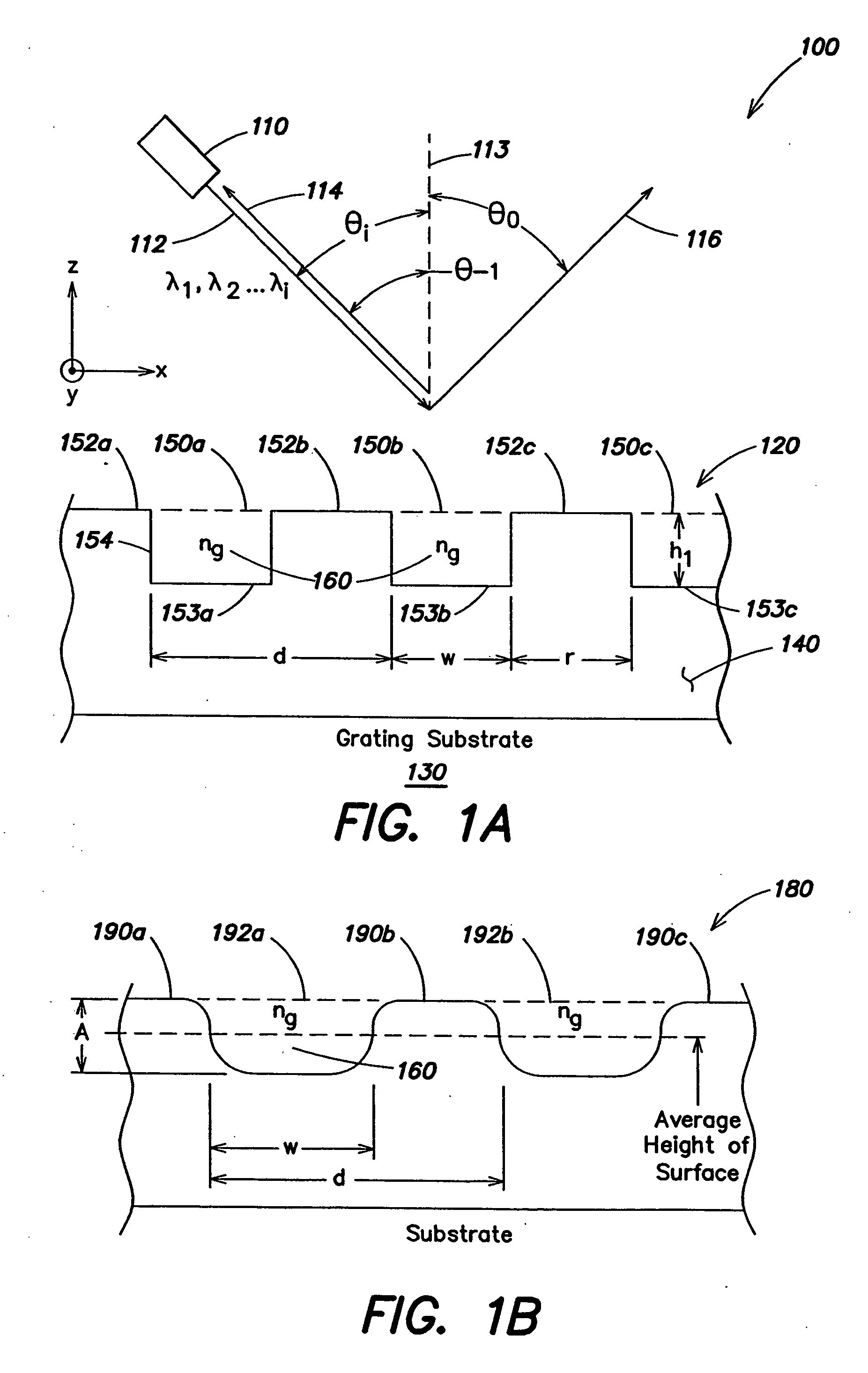

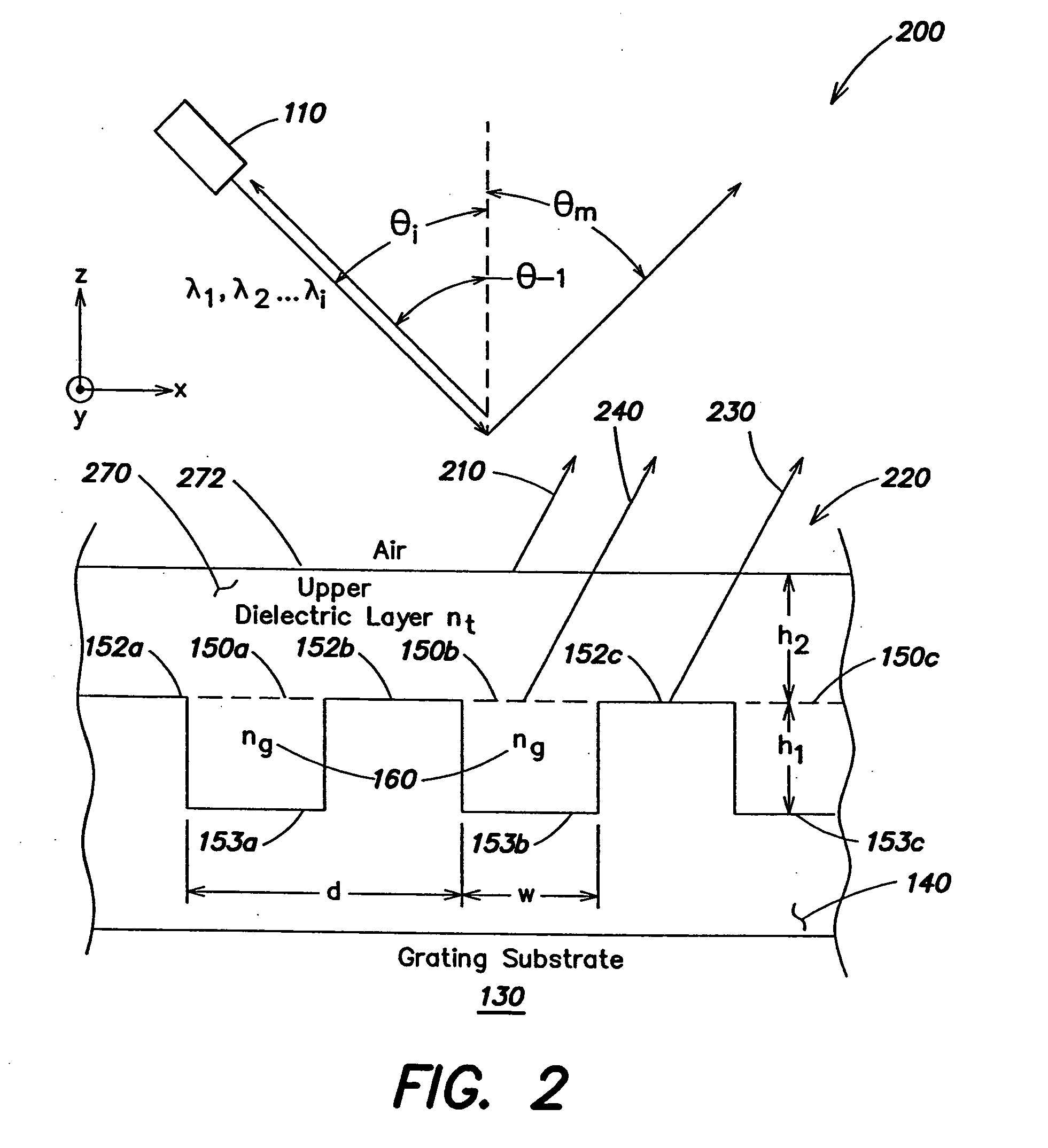

Diffraction grating having high throughput efficiency

A reflective diffraction grating having grooves and ridges and providing high throughput efficiency in the minus-first diffraction order. All but the zeroth diffraction order and the minus-first diffraction order may be prevented from existence by directing the radiation onto the grating at an appropriate angle. The radiation having a TM polarization is eliminated from the zeroth order by destructive interference by appropriate selection of a the groove width of the grating, and radiation having a TE polarization is eliminated from the zeroth order by destructive interference by depositing an overcoat of an appropriate thickness. A dielectric material may be deposited in the grooves.

Owner:AHURA SCI

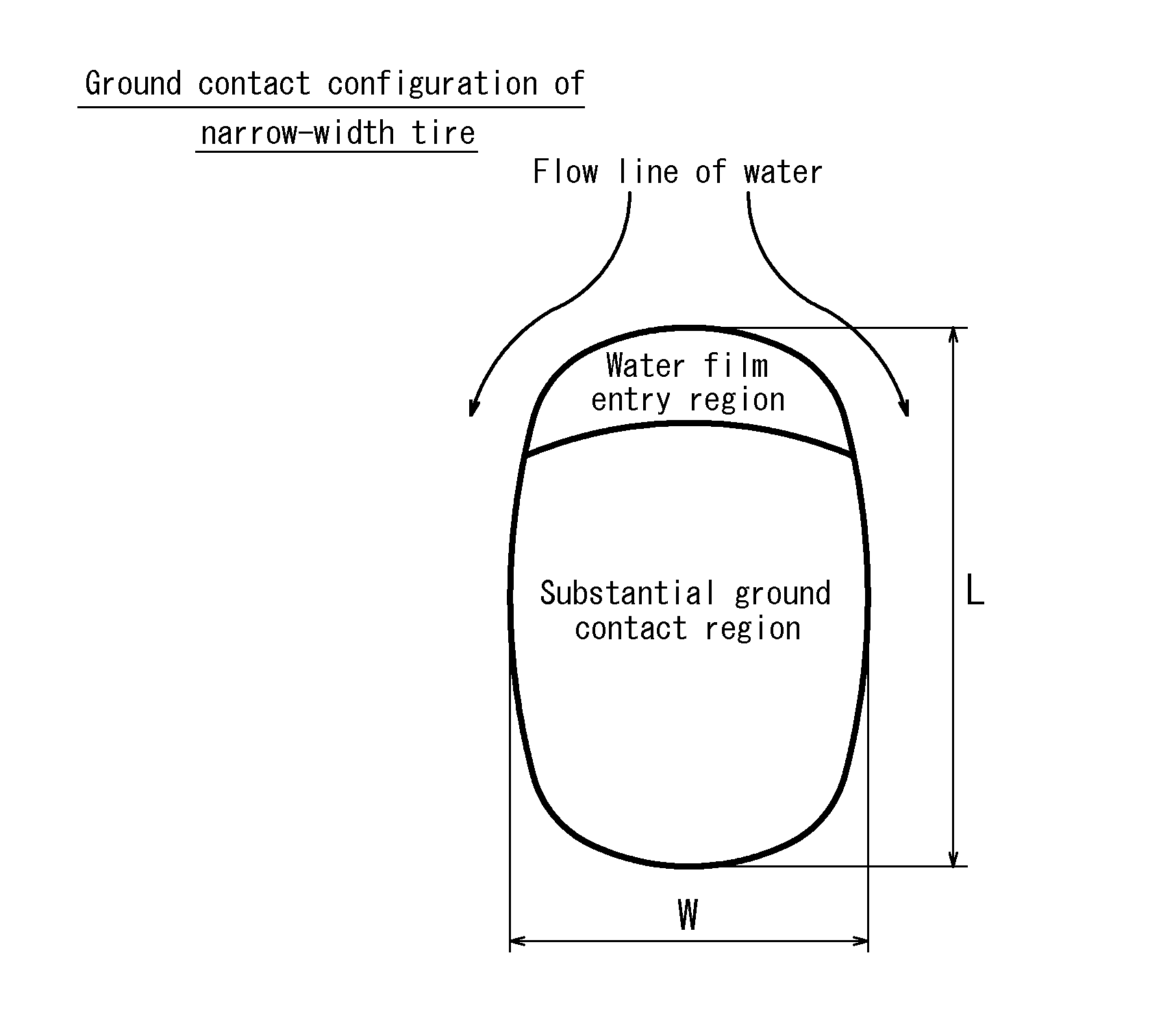

Pneumatic radial tire for passenger vehicle and method for using the same

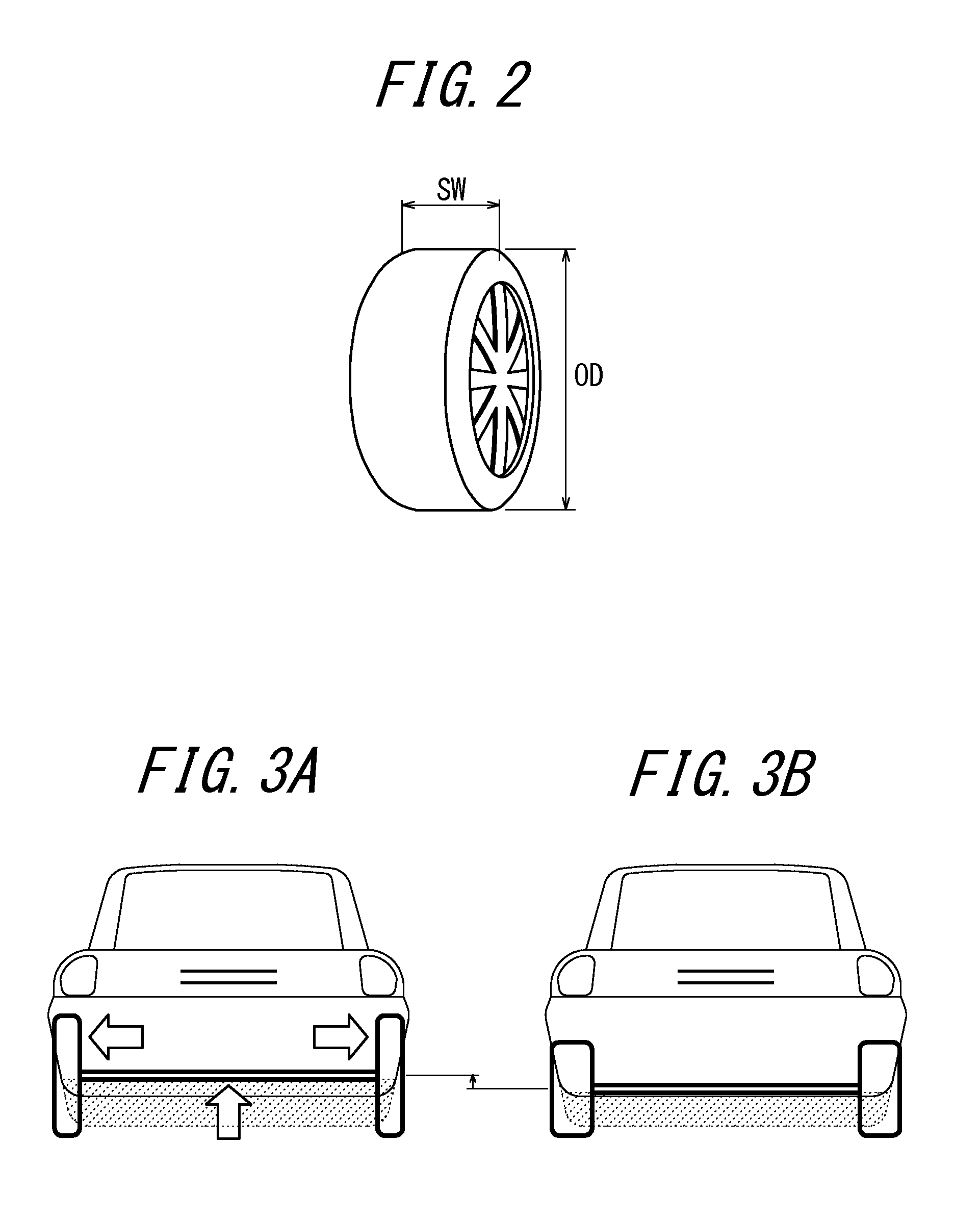

ActiveUS20140290820A1Wide spaceGuaranteed uptimeSpecial tyresInflatable tyresGroove widthGround contact

An object of the present invention is to adequately control relationship between a cross sectional width SW and an outer diameter OD of a pneumatic radial tire for a passenger vehicle. Specifically, a ground contact surface 1 of the tread of the pneumatic radial tire for a passenger car of the present invention is provided with either, as a groove, only at least one main groove 2a extending in the tread circumferential direction or, as grooves, only the main groove 2a and at least one auxiliary groove 2b other than the main groove, wherein the auxiliary groove has a groove width≦2 mm in a tread widthwise region and a negative ratio of the main groove 2a is in the range of 12% to 20% (inclusive of 12% and 20%).

Owner:BRIDGESTONE CORP

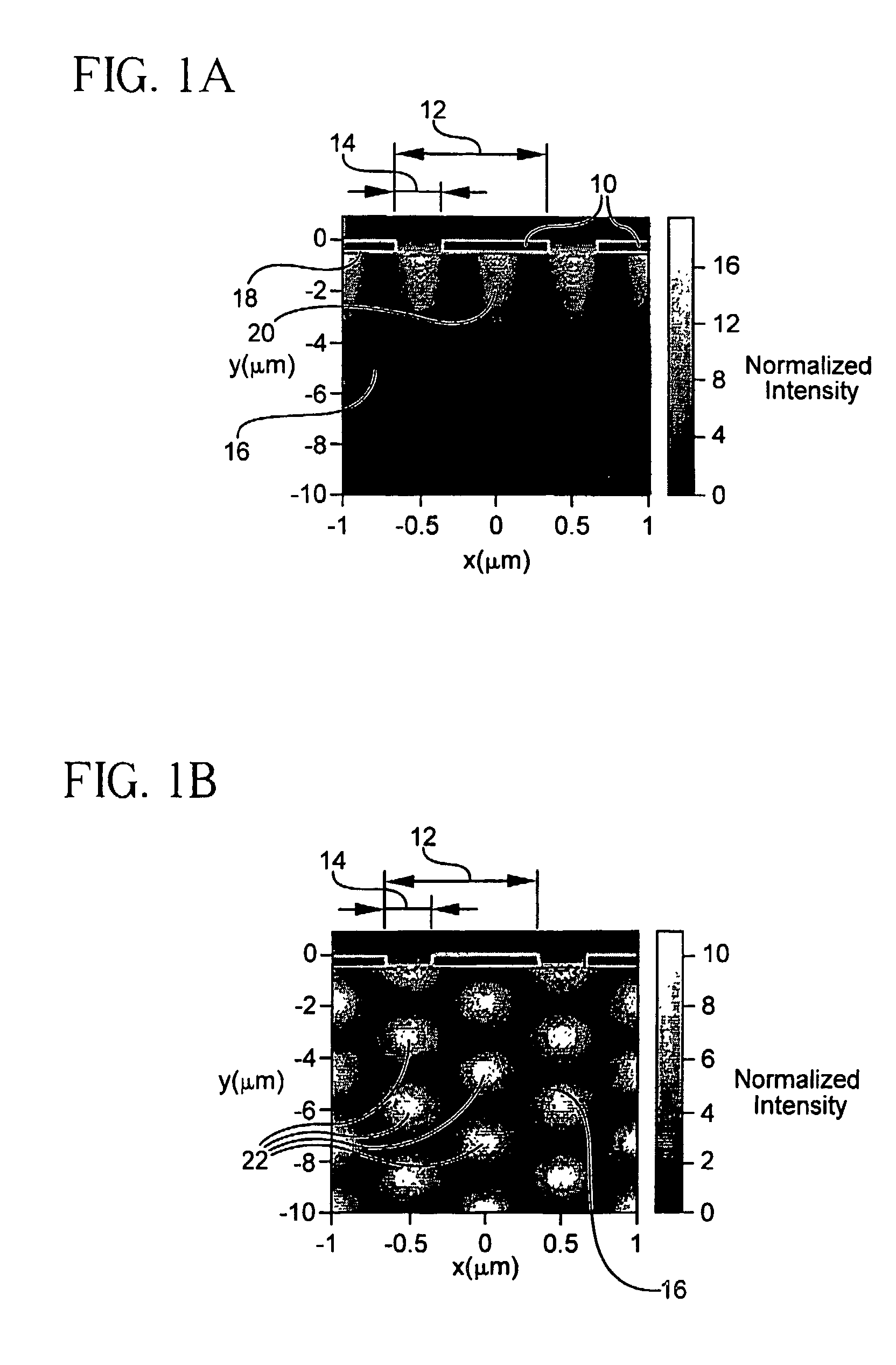

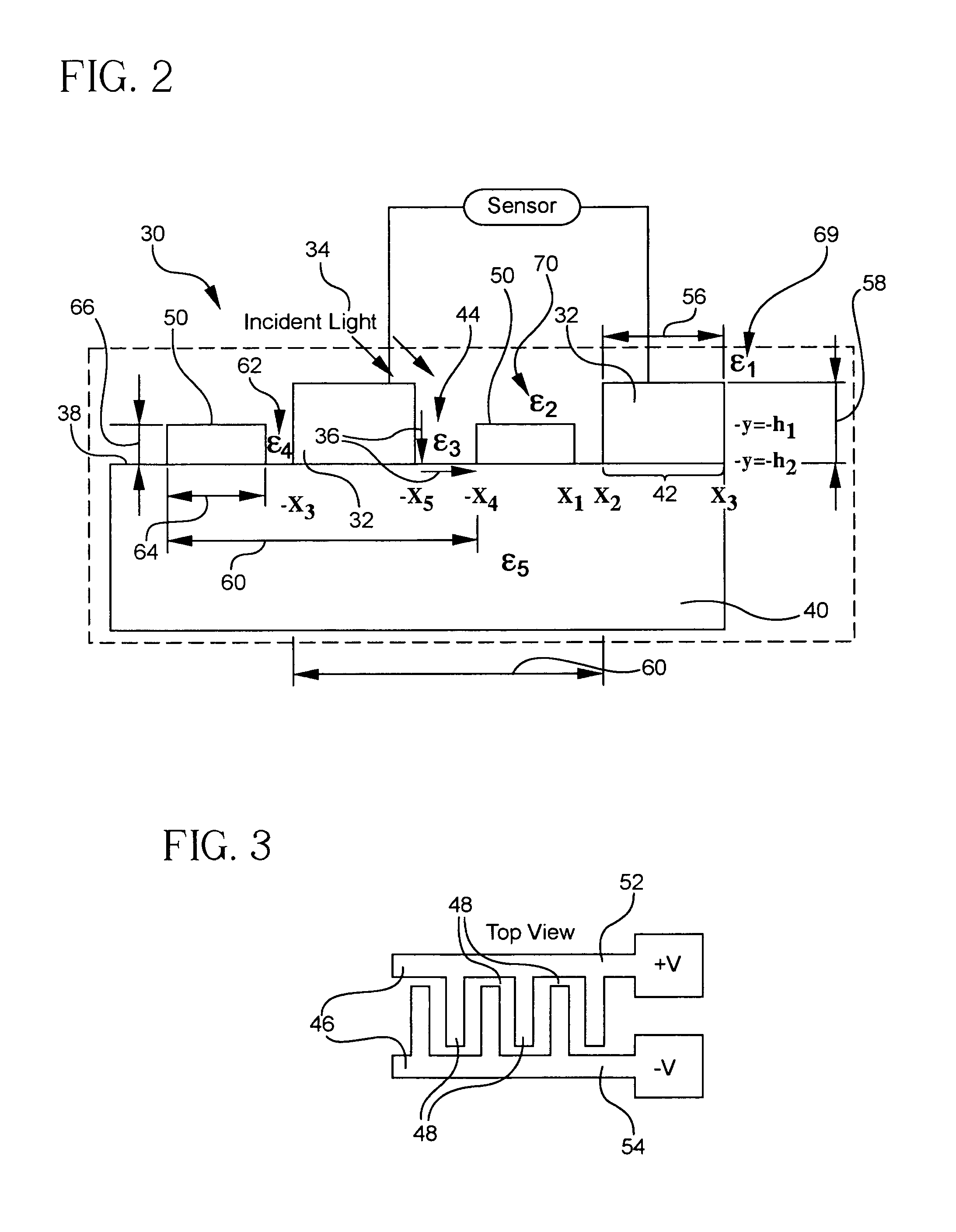

High responsivity high bandwidth metal-semiconductor-metal optoelectronic device

InactiveUS7423254B2Improve responsivenessSolid-state devicesMaterial analysis by optical meansDielectricSilicon oxide

An optical device for sensing an incident optical wave within a wavelength range includes a first array and a second array of electrodes superposed on a substrate, and a sensor connected to the contacts. The arrays are interdigitated. Each array includes its own parameters: contact width, contact thickness, groove width, and a groove dielectric constant. A structure associated with the arrays resonantly couples the incident wave and a local electromagnetic resonance or hybrid mode including at least a surface plasmon cavity mode (CM). For coupling the CM, an aspect ratio of contact thickness to spacing between electrodes is at least 1. A preferred structure for coupling a hybrid mode for high bandwidth and responsivity includes a higher dielectric constant in alternating grooves. The substrate may include silicon, including silicon-on-insulator (SOI). An SOI device having a alternating grooves with a higher dielectric, e.g., silicon oxide, provides 0.25 A / W and 30 GHz bandwidth.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

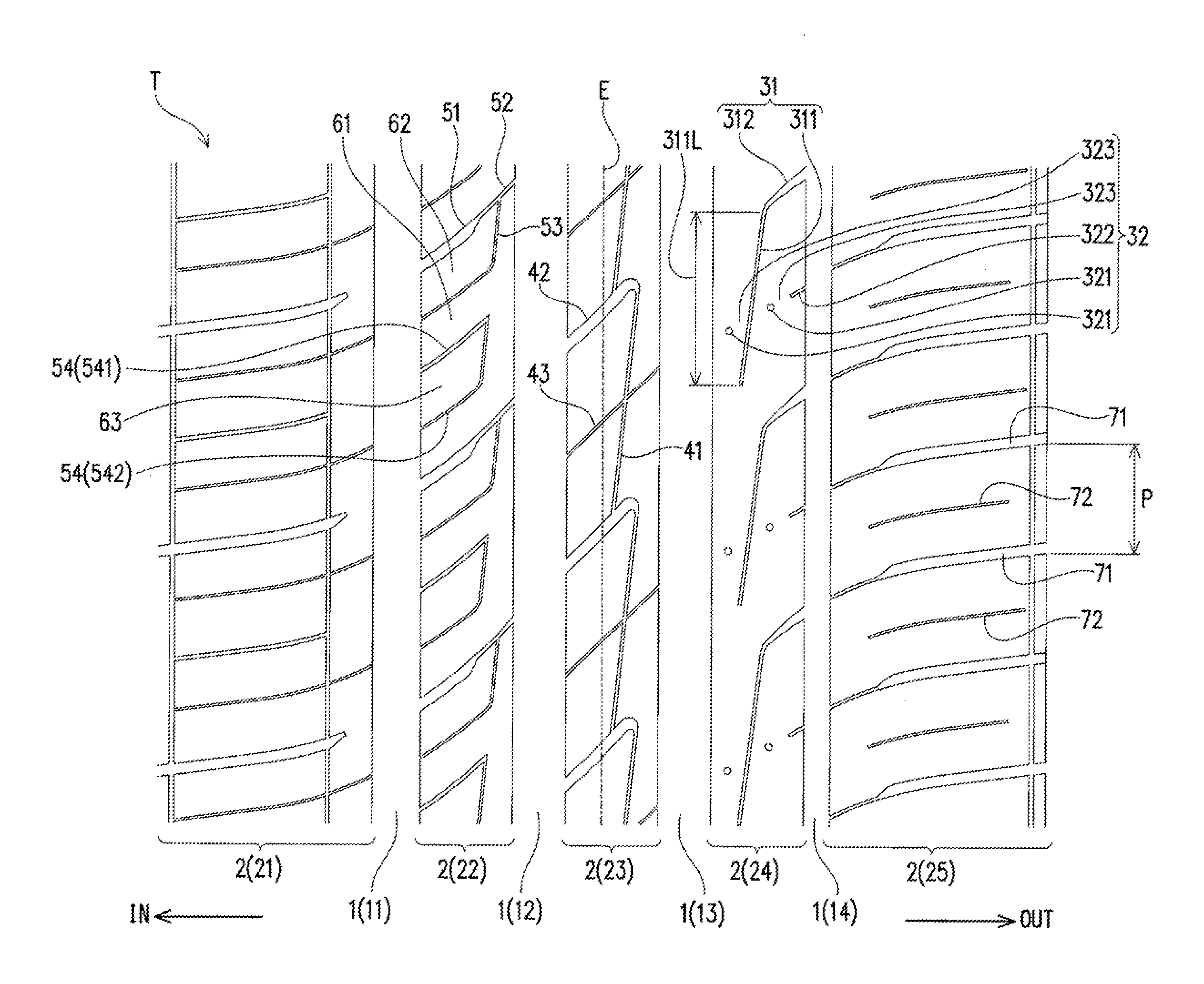

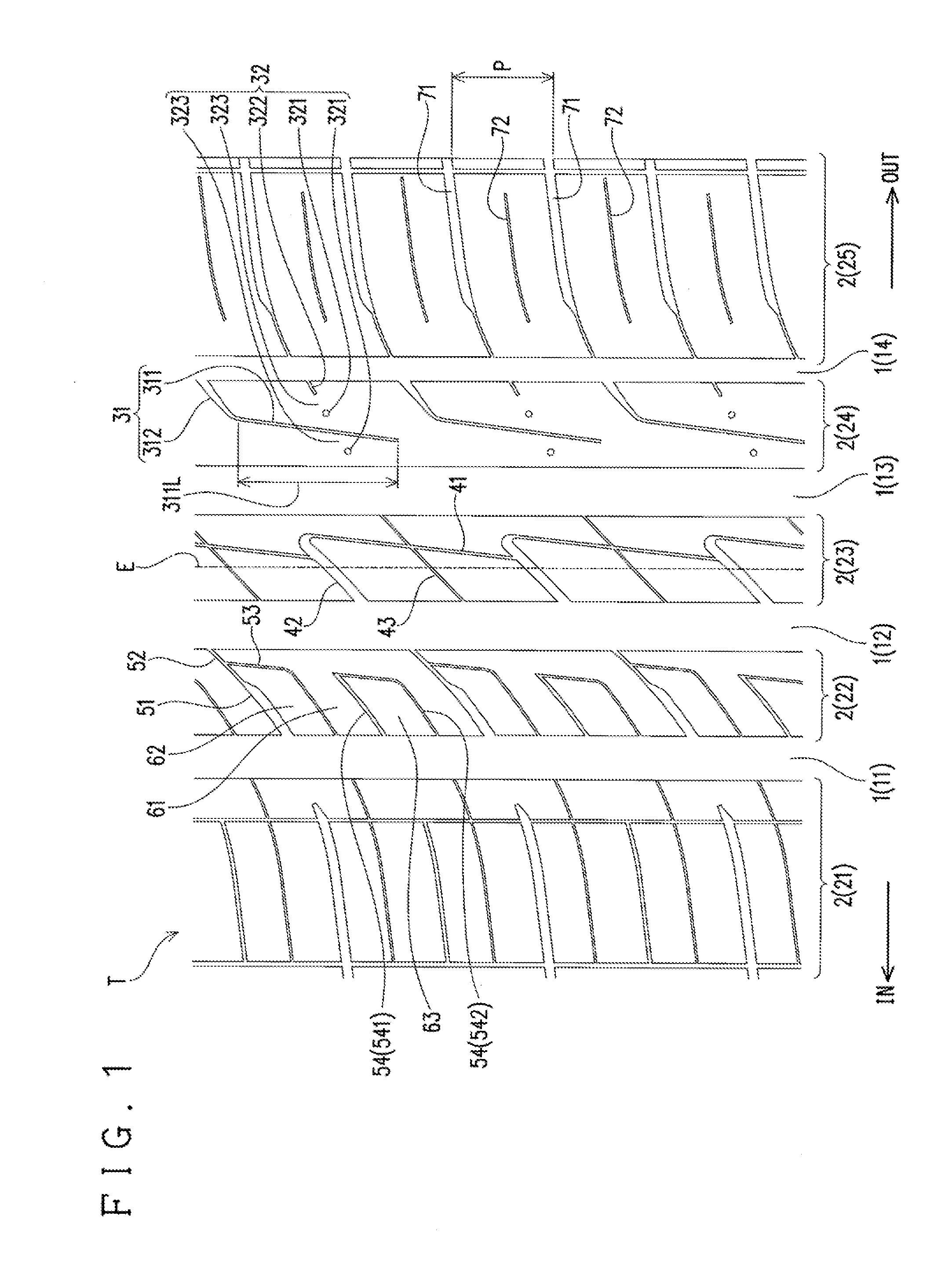

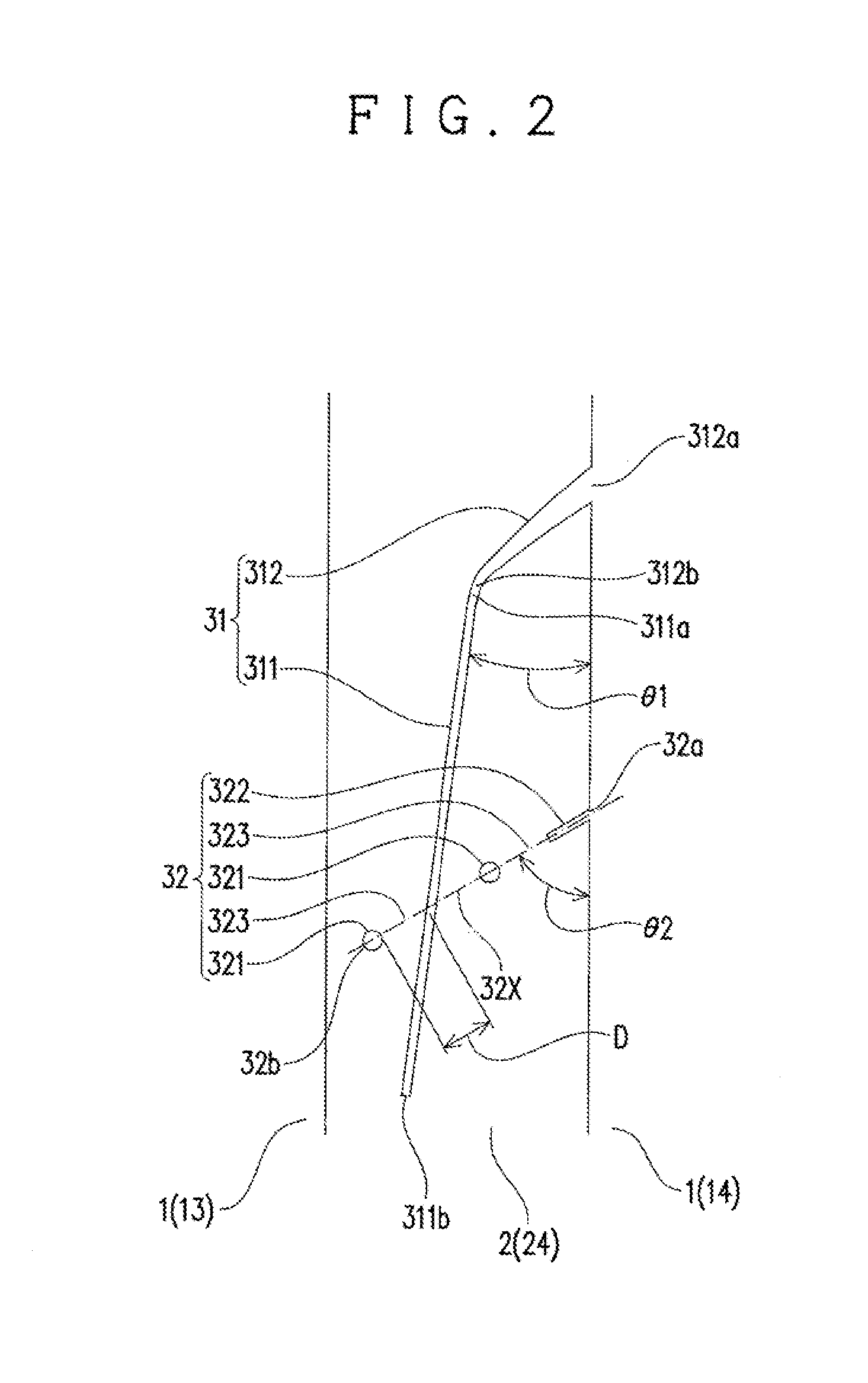

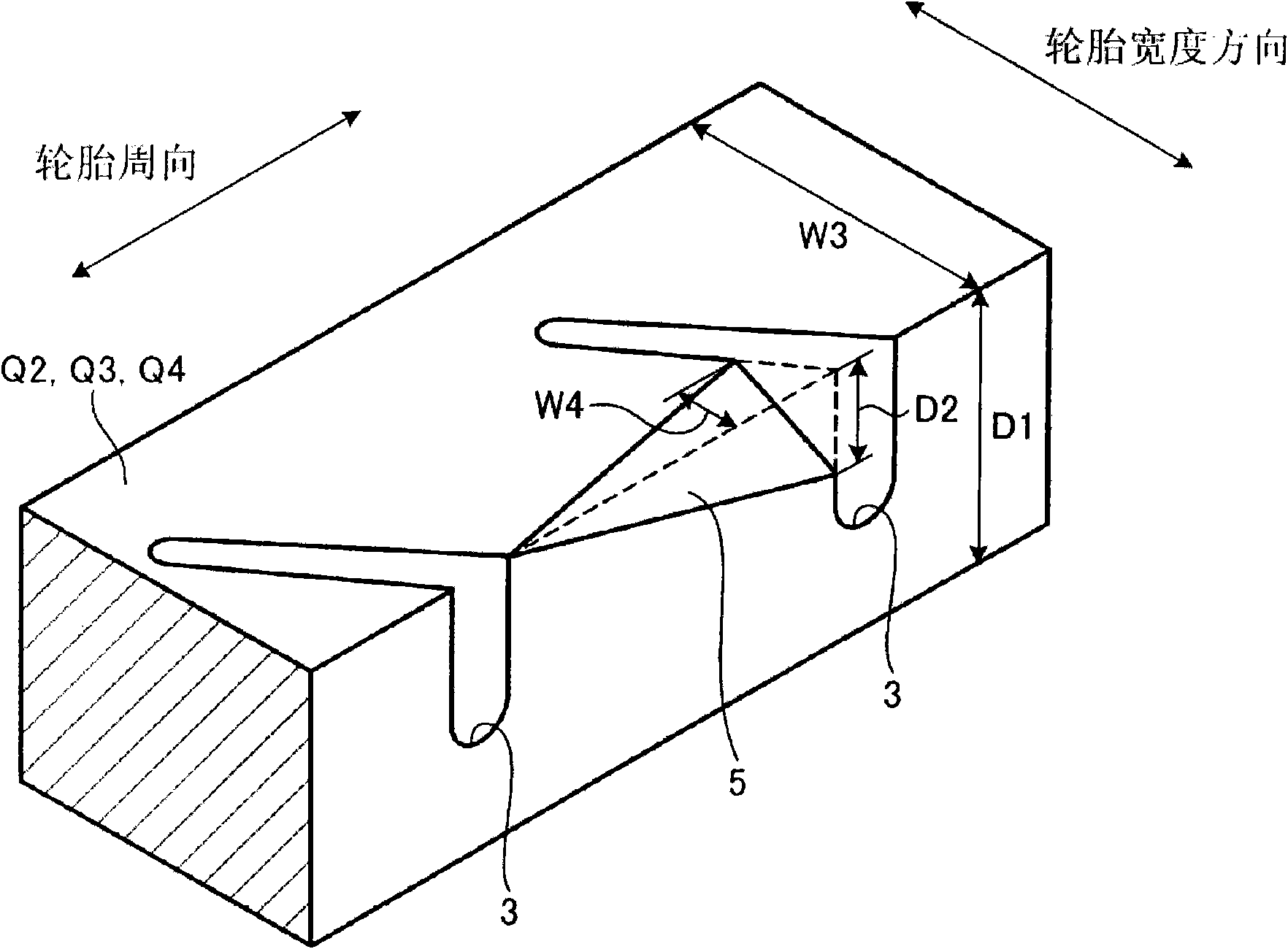

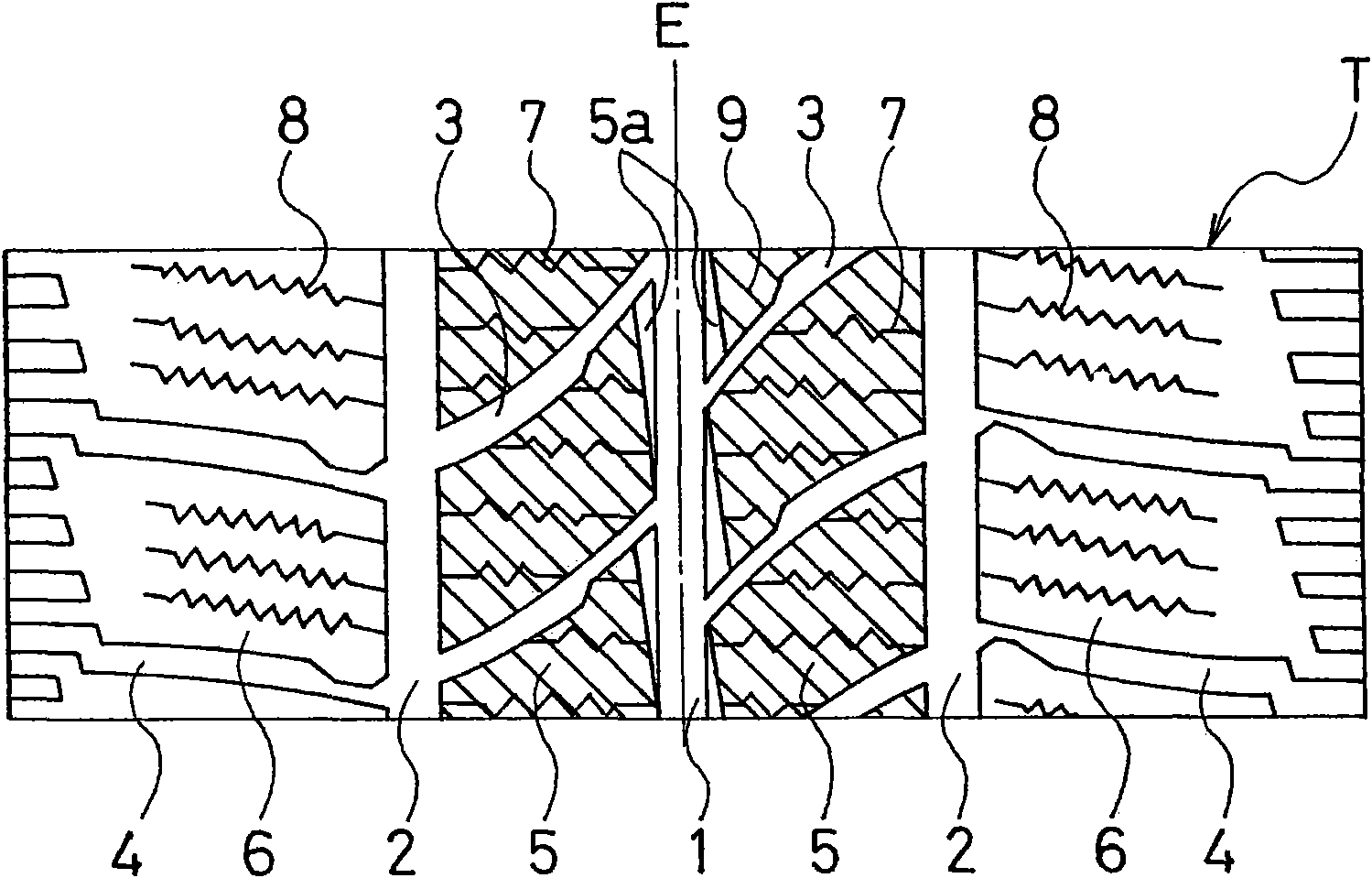

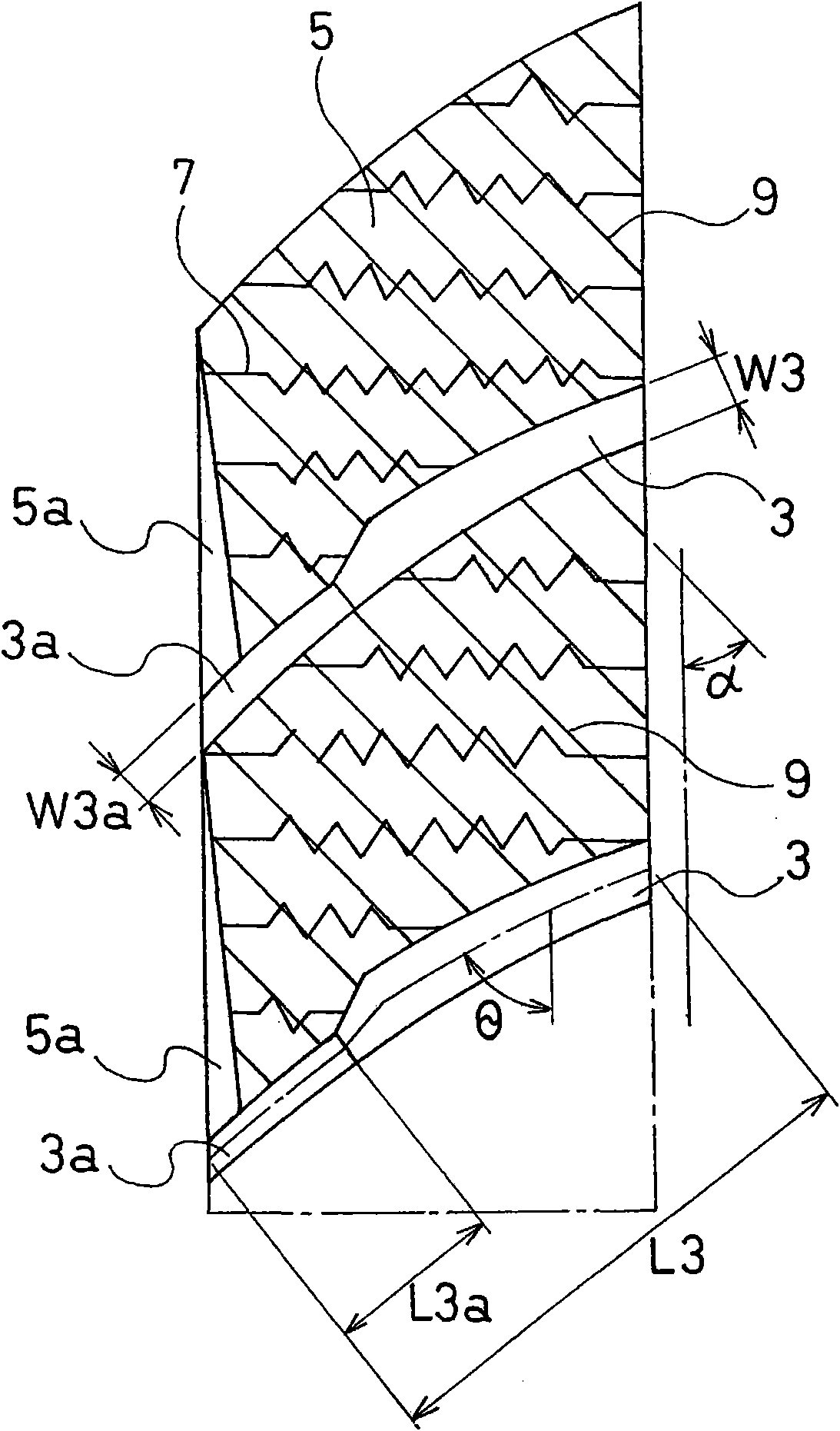

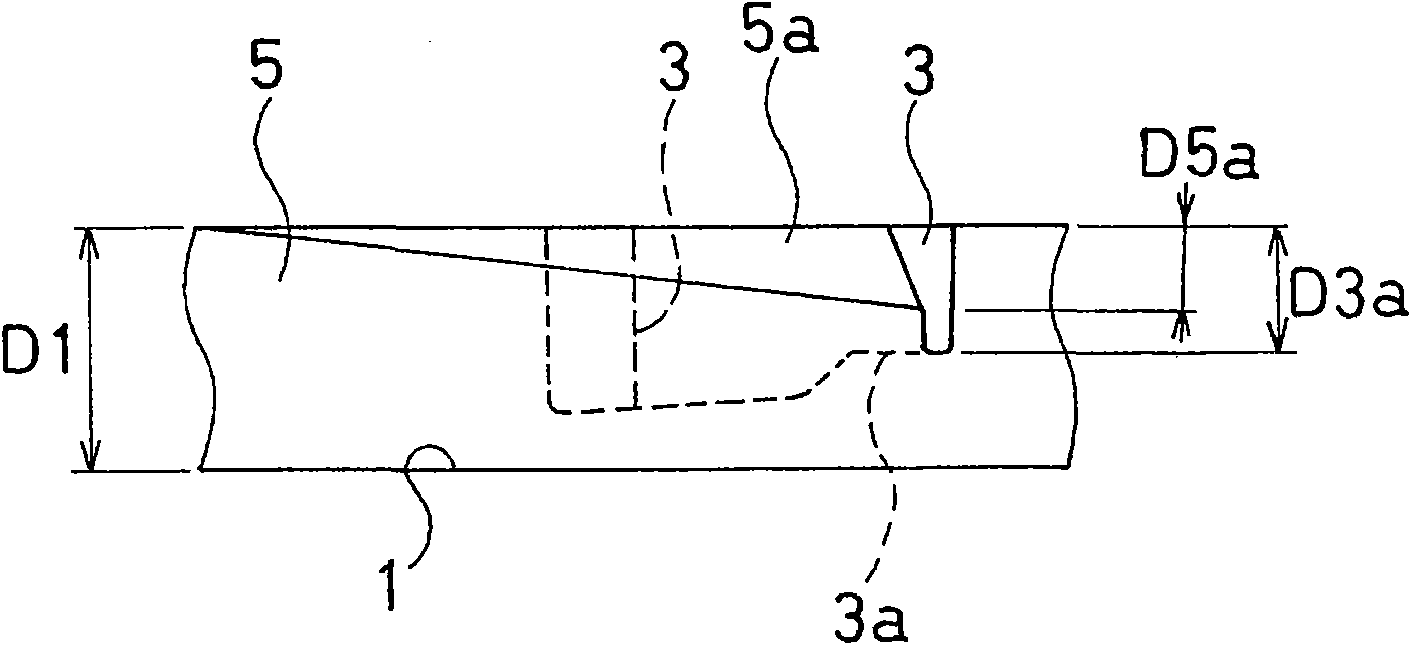

Pneumatic tyre

The invention relates to a pneumatic tyre. At least three main grooves (1,2) extending towards the perimeter of the tyre and a plurality of horizontal grooves (3) extending towards the width direction of the tyre and communicating between the main grooves are mounted on a tyre tread part (T) and a plurality of pattern blocks (5) are divided using the main grooves (1,2) and the horizontal grooves (3), characterized in that: a central main groove (1) on a tyre equator (E) is formed into a straight line shape and the horizontal groove (3) is arranged and inclined by 40-60degree relative to the tyre perimeter and an ascending part (3a) is formed at the part of the horizontal groove (3) communicated with the central main groove (1) to make the groove width and the groove depth of the horizontal groove (3) proportionally change and the groove depth (D3a) of the horizontal groove (3) is 40-60% of the groove depth (D1) of the central main groove (1) and the minimum groove width (W3a) of the horizontal groove (3) is 30-50% of the maximum groove width (W3). The pneumatic tyre well keeps the wet road and simultaneously improves the operation stability during driving on the snow road and the dry road.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

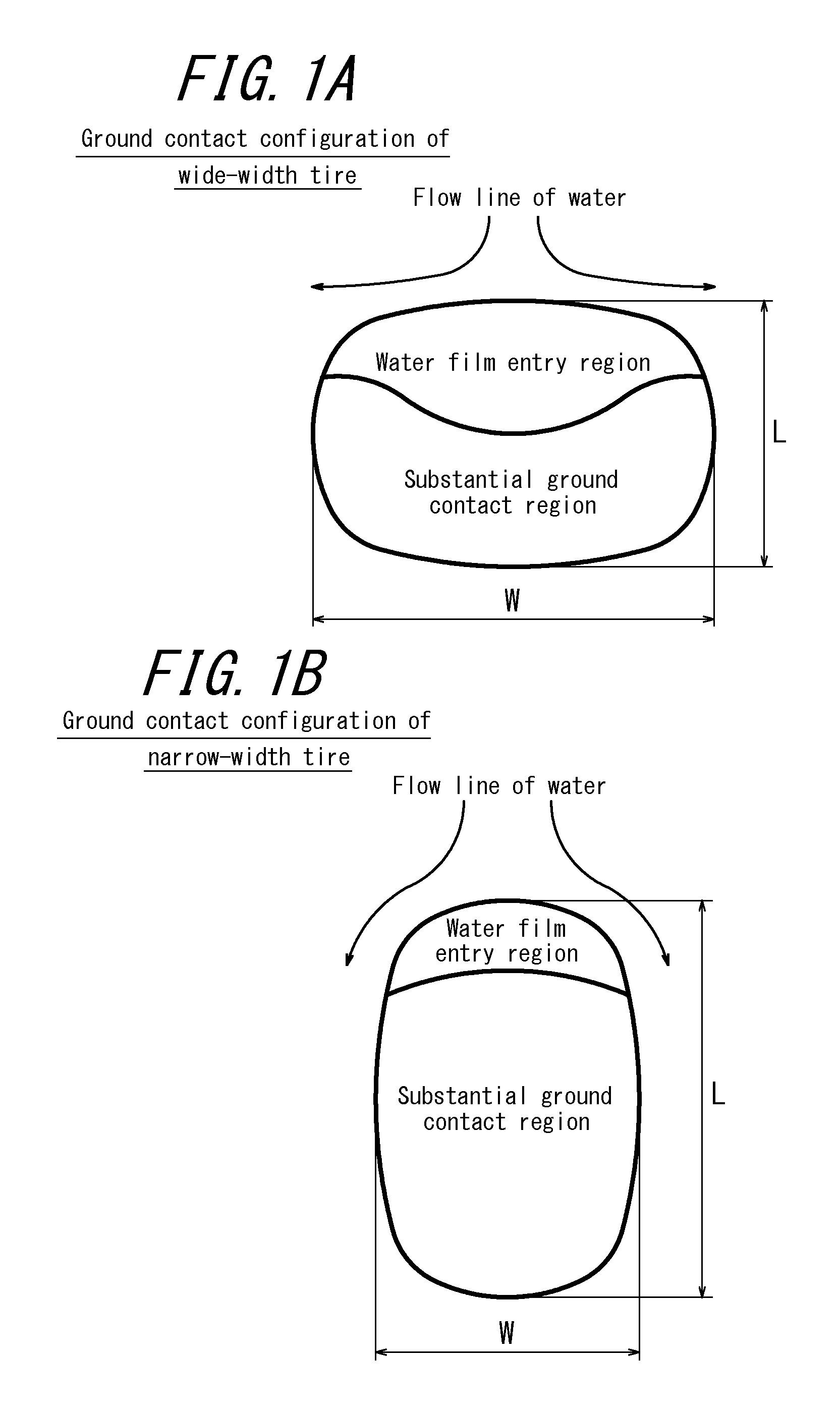

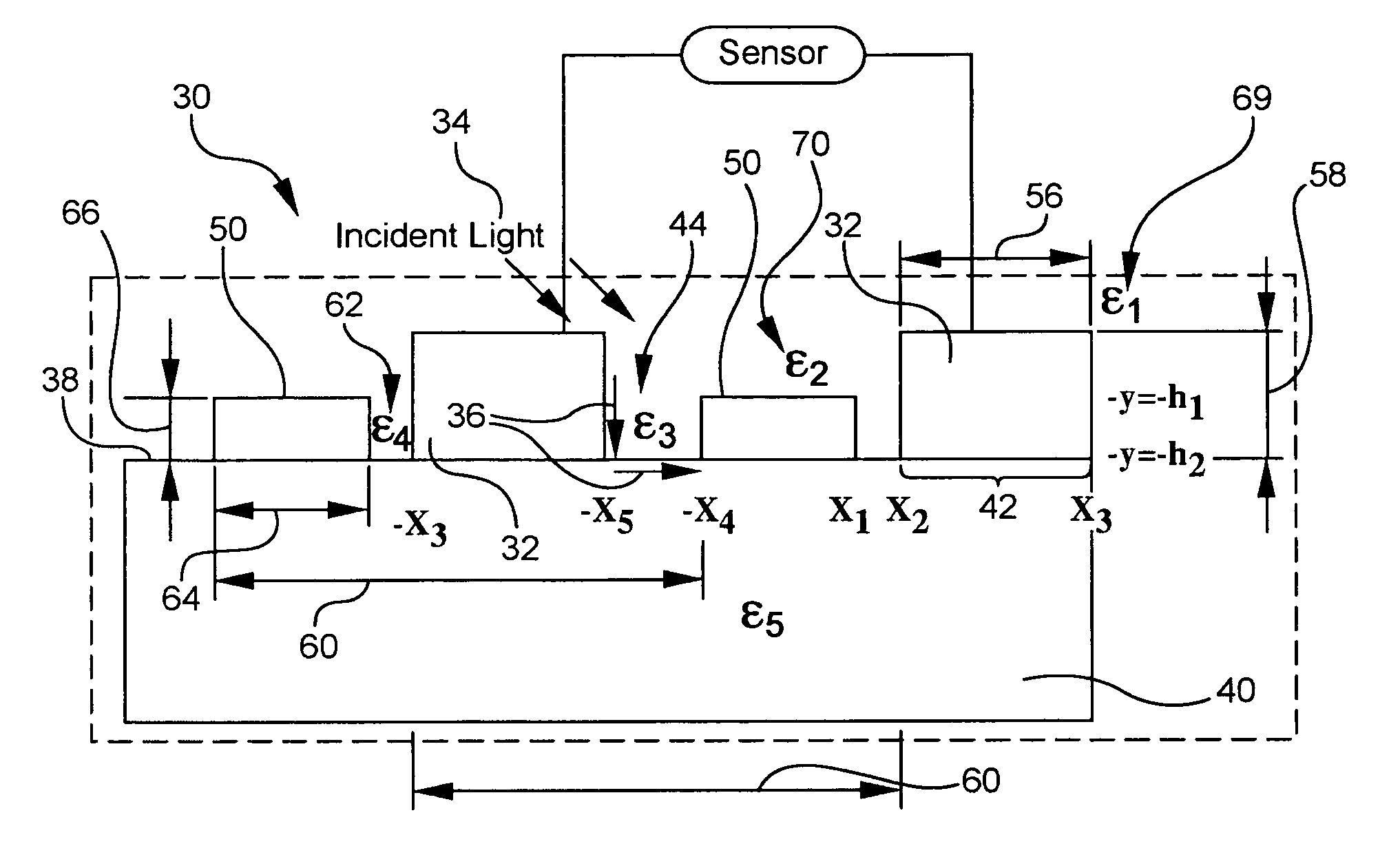

ActiveUS20120160385A1Improve anti-hydroplaning performanceImprove Noise PerformanceTyre tread bands/patternsNon-skid devicesGround contactGroove width

Owner:SUMITOMO RUBBER IND LTD

Tire with asymmetric tread pattern and method of mounting the tire

InactiveUS20050247388A1Improve steering stabilityPromote generationSubsonic/sonic/ultrasonic wave measurementMetal-working apparatusGroove widthEngineering

This invention relates to a tire suitable in a passenger car, particularly a tire being high in the resistance to hydroplaning on a wet road surface and low in the tire noise and having an asymmetric tread pattern. In such a tread pattern that at least two circumferential grooves extending along an equatorial plane of the tire are formed in a region of a tread surface at an axially inner side with respect to the equatorial plane in the mounting on the vehicle and at least one circumferential groove is formed in a region at an axially outer side thereof, a circumferential groove nearest to the equatorial plane of the tire among the circumferential grooves arranged in the axially inner side region has a width wider by 20% or more than an average groove width of the tire and a circumferential groove arranged toward a side of a tread end at the axially inner side region has a width corresponding to 90-110% of the average groove width, and the circumferential groove nearest to the equatorial plane of the tire at the axially outer side region has a width narrower by 10% or more than the average groove width, whereby the resistance to hydroplaning and the controllability of tire noise, which have a conflicting relation in the prior art, are established in a higher level.

Owner:BRIDGESTONE CORP

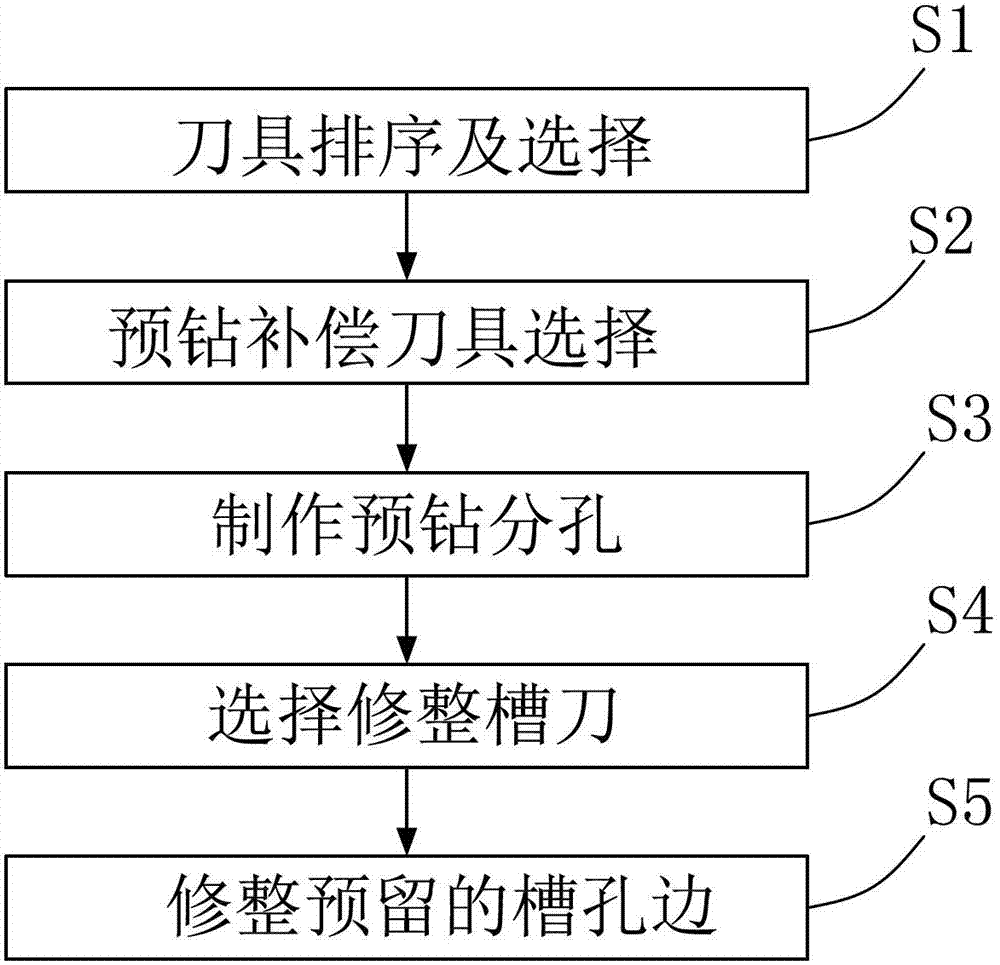

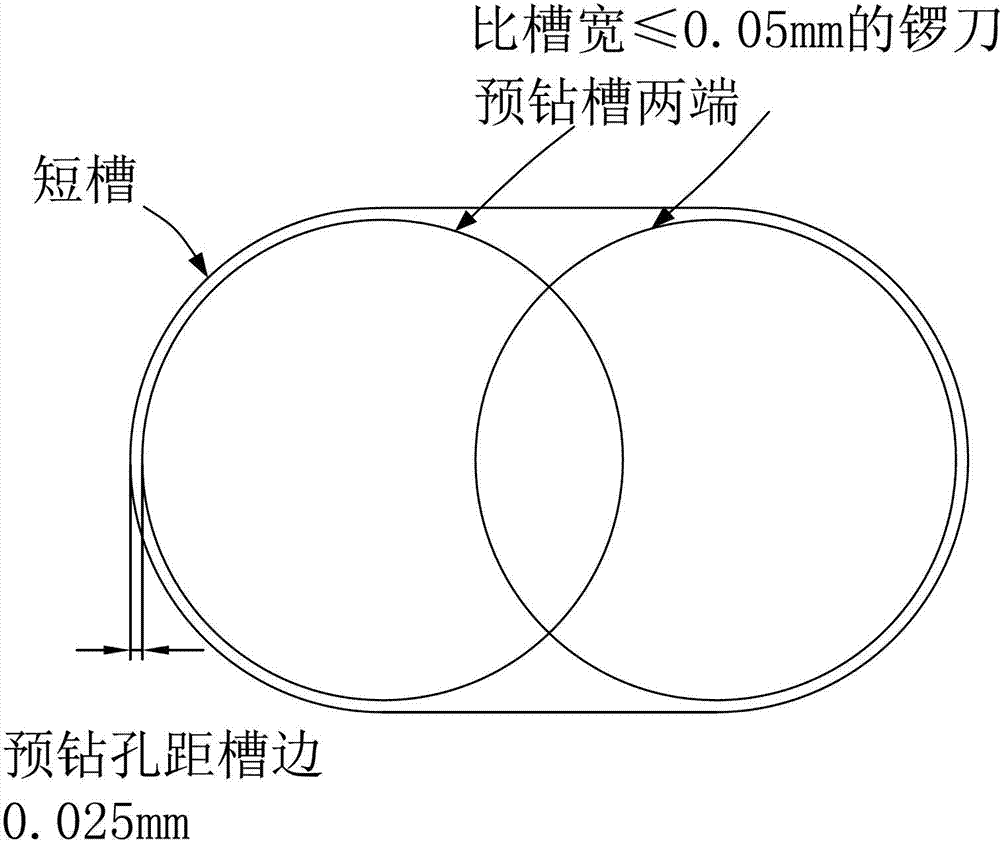

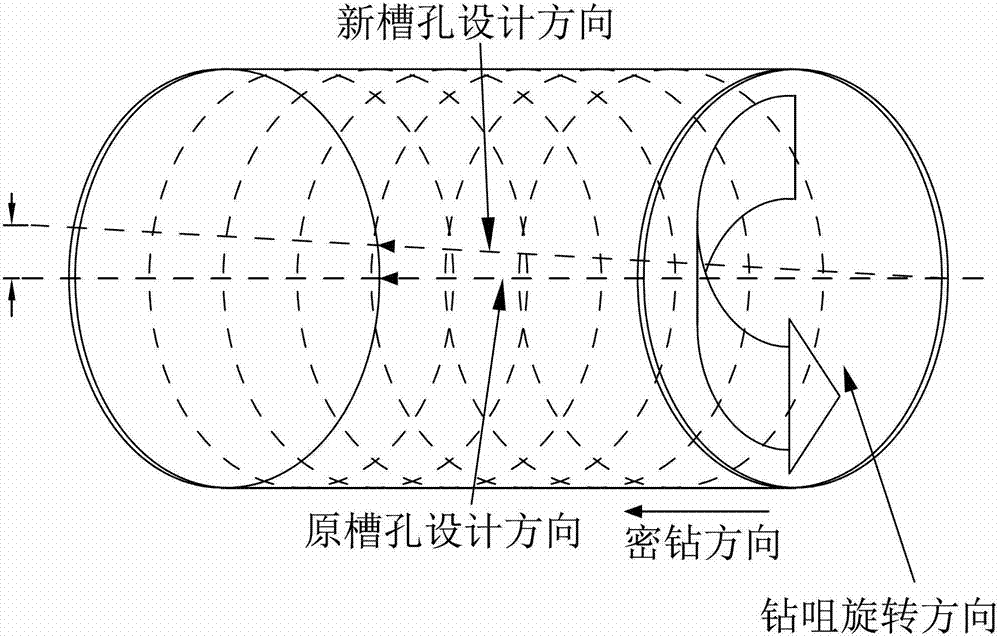

Manufacture method of short slotted hole for printed circuit board

The invention discloses a manufacture method of a short slotted hole for a printed circuit board, aiming at solving the problems of size deviation and deformation when the short slotted hole is machined. The manufacture method comprises the following steps of: S1, carrying out sequential cutter arrangement on a slotted hole which needs to be manufactured by setting the length and the width of a slot in combination with a preset standard according to the shape of the slotted hole, and selecting a proper cutter according to the size of the slotted hole; S2, respectively setting subsidiary slots arranged at two sides of a pre-drilling slot for the designed slot width in a milling way, and setting an adding and amplifying size X on the basis of the normal compensation of a finished product along the length direction of the slot; S3, setting a compensation distinguishment of pre-drilled subsidiary holes arranged at two ends of the slotted hole, wherein a pre-drilling mouth selects a milling cutter of which the ratio groove width is less than or equal to 2X, and reserving the adding and amplifying size X at pre-drilling holes arranged at two ends of the slot from the edge of the slot; S4, carrying out compensating finishing on the whole slotted hole by the milling cutter of which the ratio groove width is less than or equal to 2X; and S5, thickly drilling by the milling cutter from one pre-drilling hole to another pre-drilling hole at a fixed displacement, so that the deformation quantity of the short slotted hole can be reduced.

Owner:梅州五株电路板有限公司

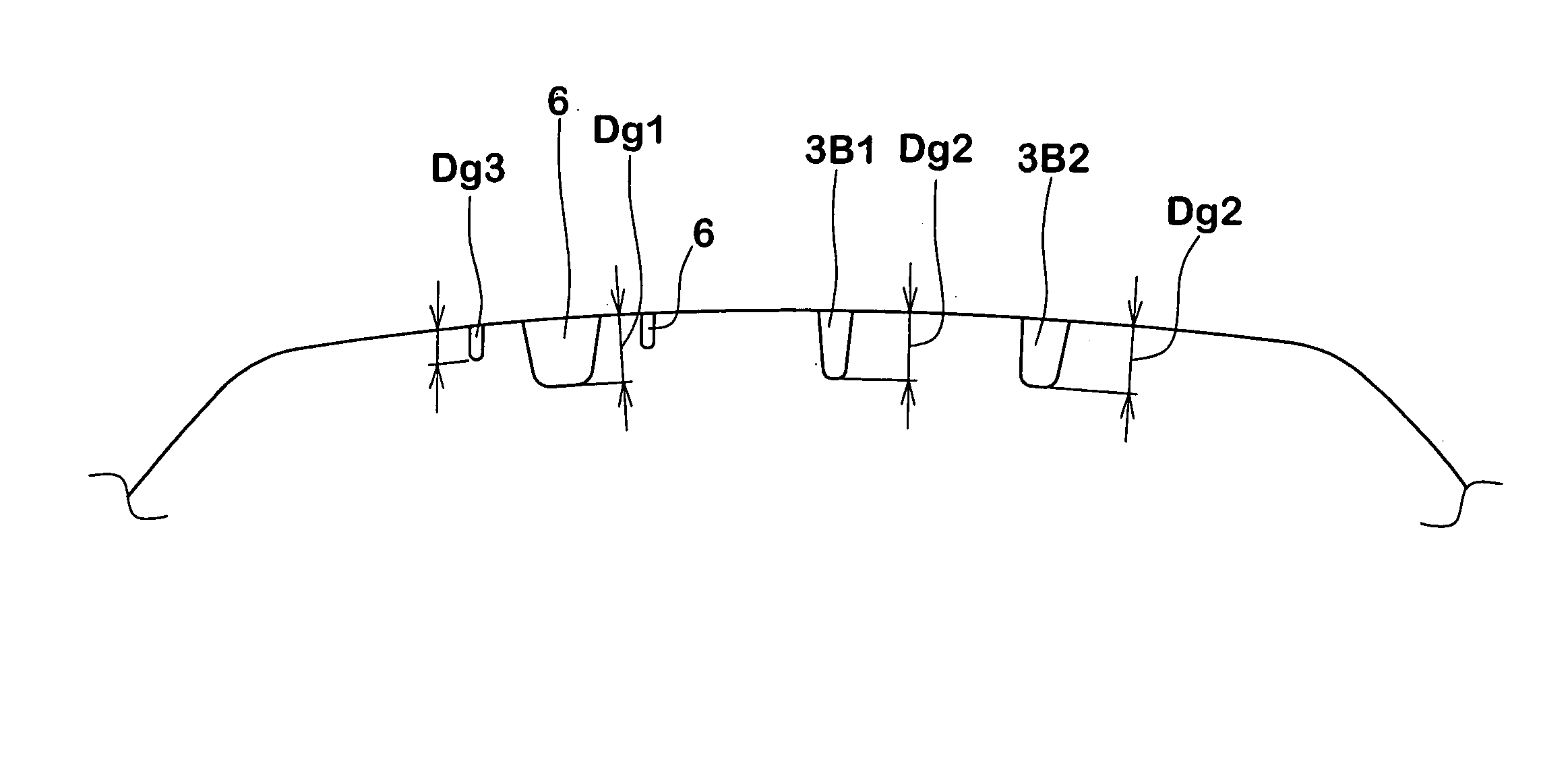

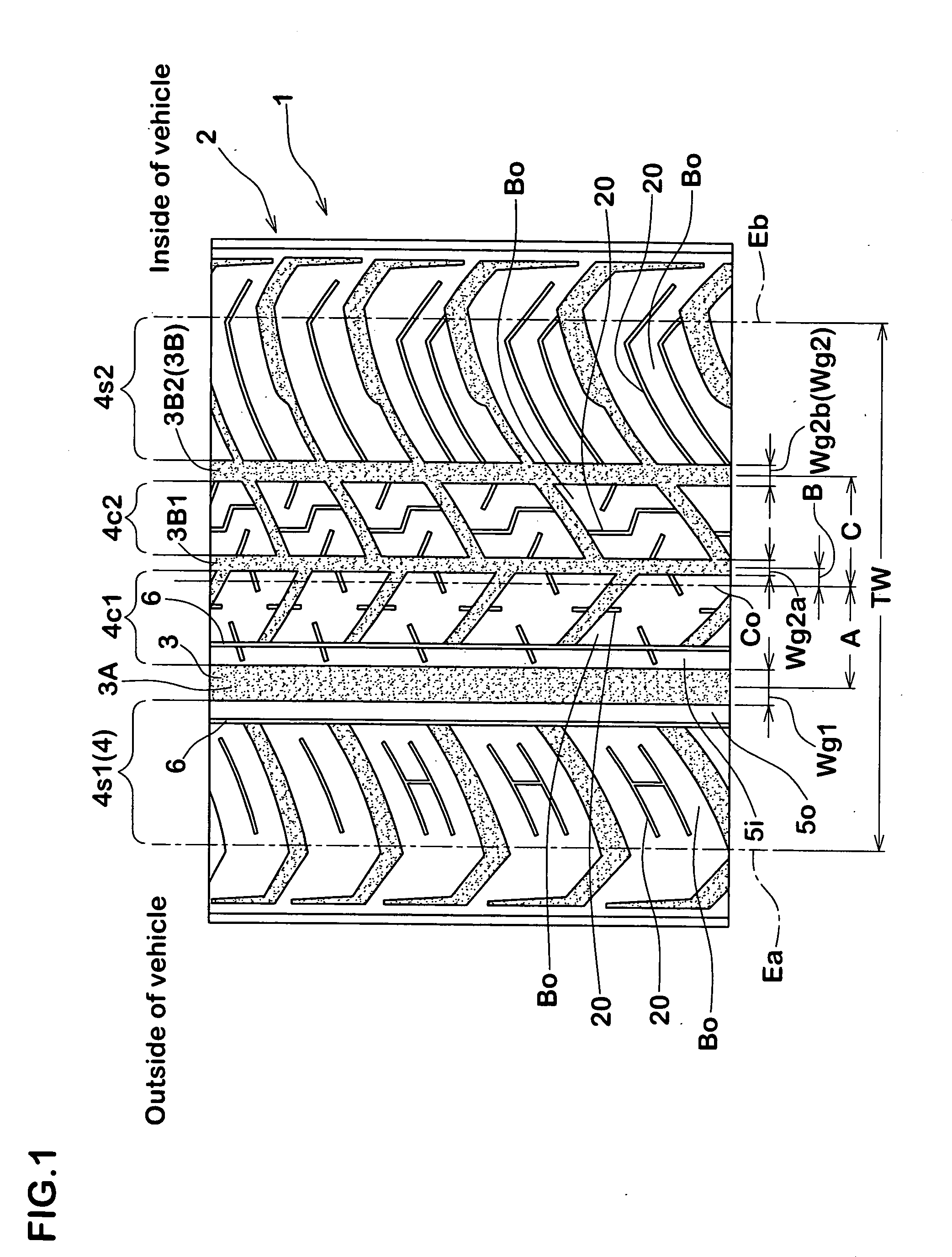

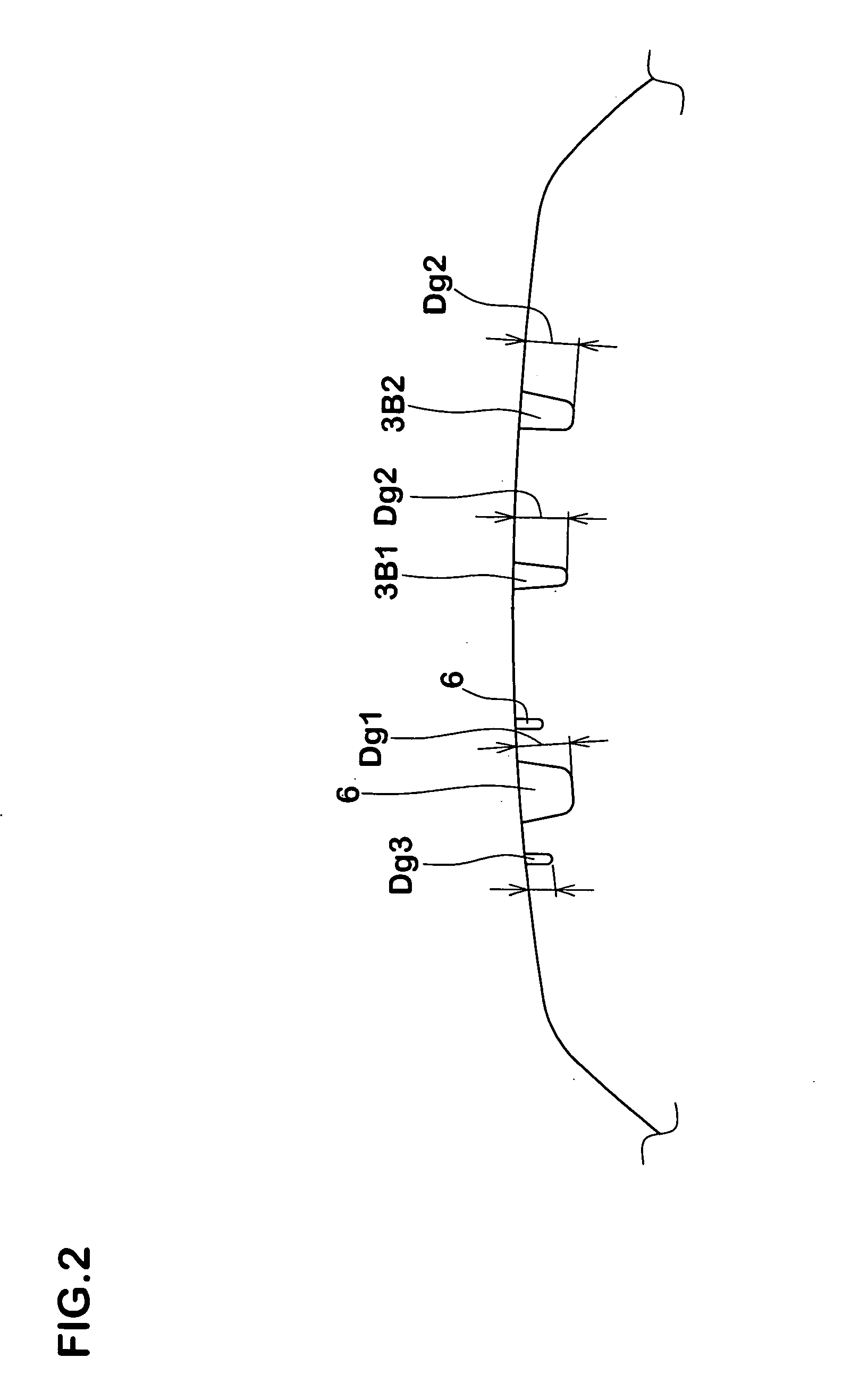

Pneumatic tire

InactiveUS20050121123A1Improve Noise PerformancePrevent degradationTyre tread bands/patternsNon-skid devicesGroove widthEngineering

It is a subject to improve wet performances and noise performances while restricting degradations in dry performances, and for solving this subject, the pneumatic tire is comprised of a tread grounding surface that is partitioned into four to five block regions by three to four main grooves that extend successively in the tire circumferential direction. The main grooves are comprised of one large width main groove which groove width comprises 4 to 20% of a tread grounding width and which is apart from the tire equator by a distance corresponding to 5 to 30% of the tread grounding width further to one grounding end side, and small width main grooves that are disposed between the large width main groove and the other grounding end and which groove width is larger than 2.0 mm but smaller than that of the large width main groove. Both groove side edges of the large width main groove extends in a successive and linear manner in the tire circumferential direction without being interrupted. A ratio ST / SY between a front and rear rigidity ST of the tread grounding surface and a lateral rigidity SY is set to be larger than 0.9 but smaller than 1.1. The lateral rigidity SYs is set to be larger than the front and rear rigidity STs for the shoulder block regions 4s1, 4s2 on both sides. As for the central block region (when the number of main grooves is three, crown block regions 4c1, 4c2, and when the number of main grooves is four, the crown block region 4c2), the lateral rigidity SYc is smaller than the front and rear rigidity STc.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveUS20080053585A1Sufficient edge effectImprove driving effectTyre tread bands/patternsNon-skid devicesGroove widthMechanical engineering

A pneumatic tire provided with a tread pattern on which a plurality of blocks are formed with circumferential grooves which extend along a circumferential direction of the tire and lateral grooves which traverse the circumferential grooves, wherein the lateral groove disposed between the blocks on the endmost tread edge region has a depth from 10 to 50% of a depth of the circumferential groove to be traversed and has a groove bottom concave portion whose both ends in a longitudinal direction are disposed inside the groove bottom, and a width of the groove bottom concave portion, which is determined on the basis of the bottom plane of the groove bottom, is from 25 to 45% of a groove width of the lateral groove.

Owner:TOYO TIRE & RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com