Pneumatic tyre

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of reducing the handling stability on dry roads, reducing drainage performance and traction performance, and may not be able to achieve it. Achieve the effects of improving handling stability, increasing rigidity, and suppressing front-to-back and sideways skidding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

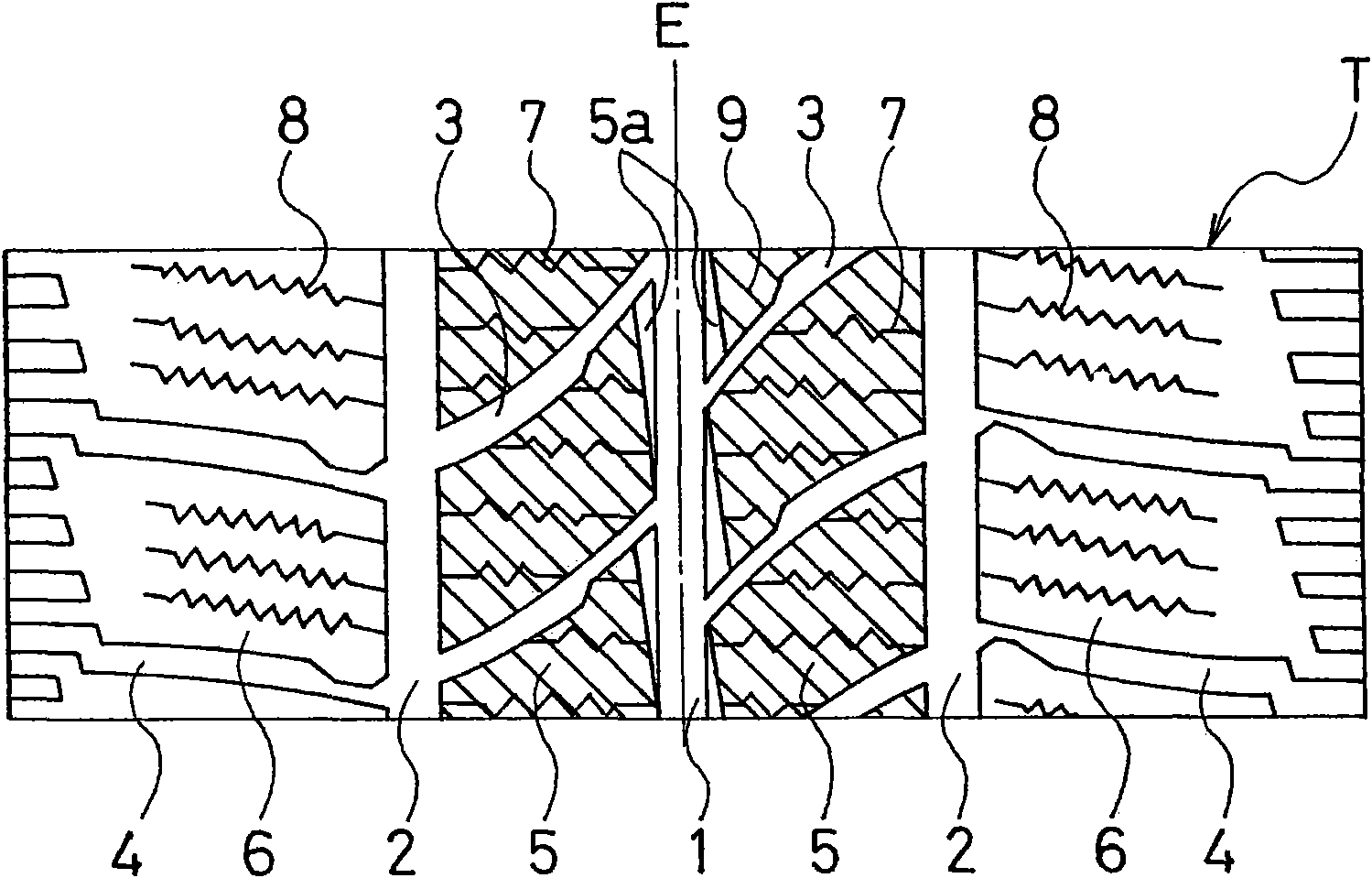

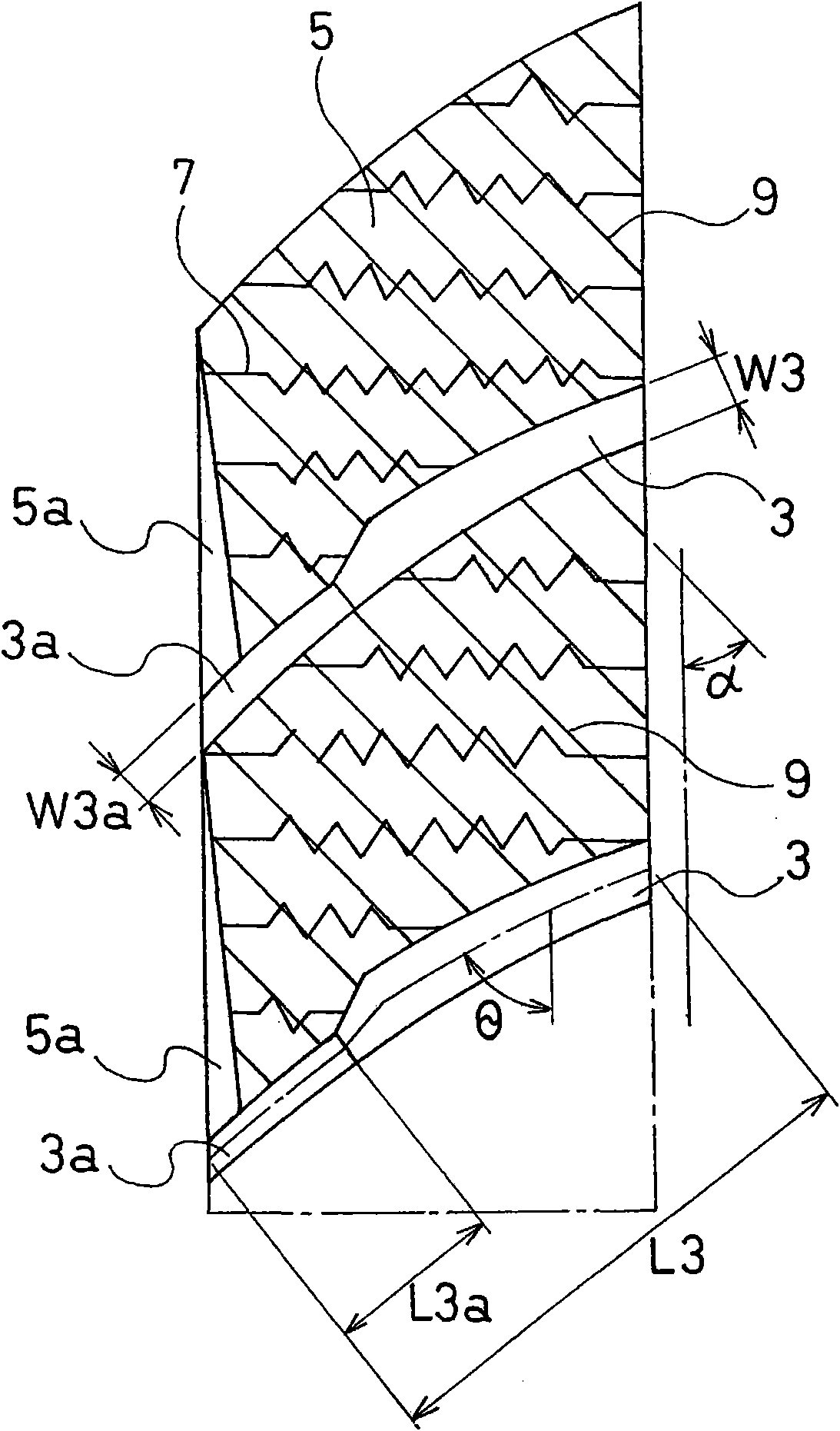

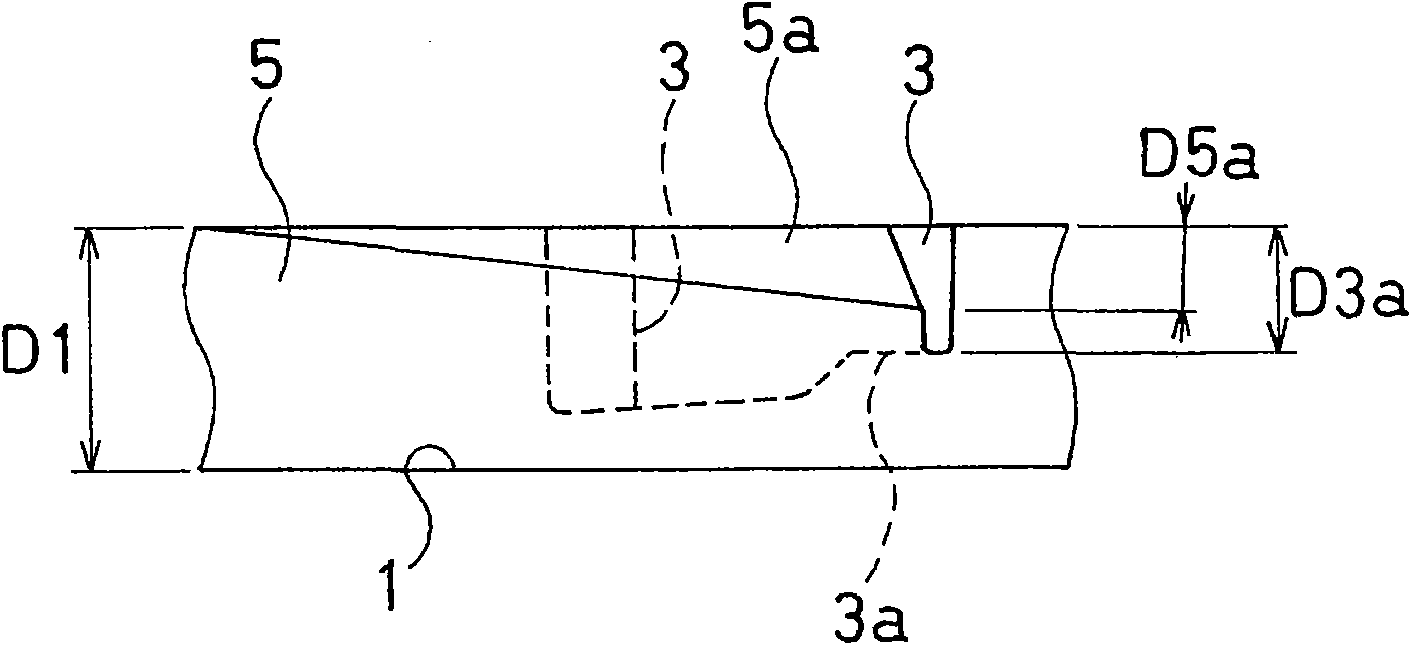

[0042] The tire size of the pneumatic tire is 195 / 75R16C, 107 / 105R, and the tread part is provided with three main grooves extending linearly in the tire circumferential direction and a plurality of transverse grooves extending in the tire width direction. The groove is divided into a plurality of pattern blocks, and a plurality of sipe patterns are arranged on each pattern block. As shown in Table 1, the inclination angle formed by the transverse groove and the tire circumferential direction, whether the transverse groove has a riser, whether there is a Chamfering, presence or absence of fine grooving, ratio of the minimum and maximum groove width of the transverse groove (W3a / W3×100%), ratio of the groove depth of the transverse groove in the ascending part to the groove depth of the central main groove (D3a / D1×100%), the ratio of the length of the rising portion to the length of the lateral groove (L3a / L3×100%), tires of Conventional Example, Comparative Examples 1-3 and Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com