Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1477 results about "Radial tire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A radial tire (more properly, a radial-ply tire) is a particular design of vehicular tire. In this design, the cord plies are arranged at 90 degrees to the direction of travel, or radially (from the center of the tire). Radial tire construction climbed to 100% market share in North America, following Consumer Reports finding the superiority of the radial design in 1968.

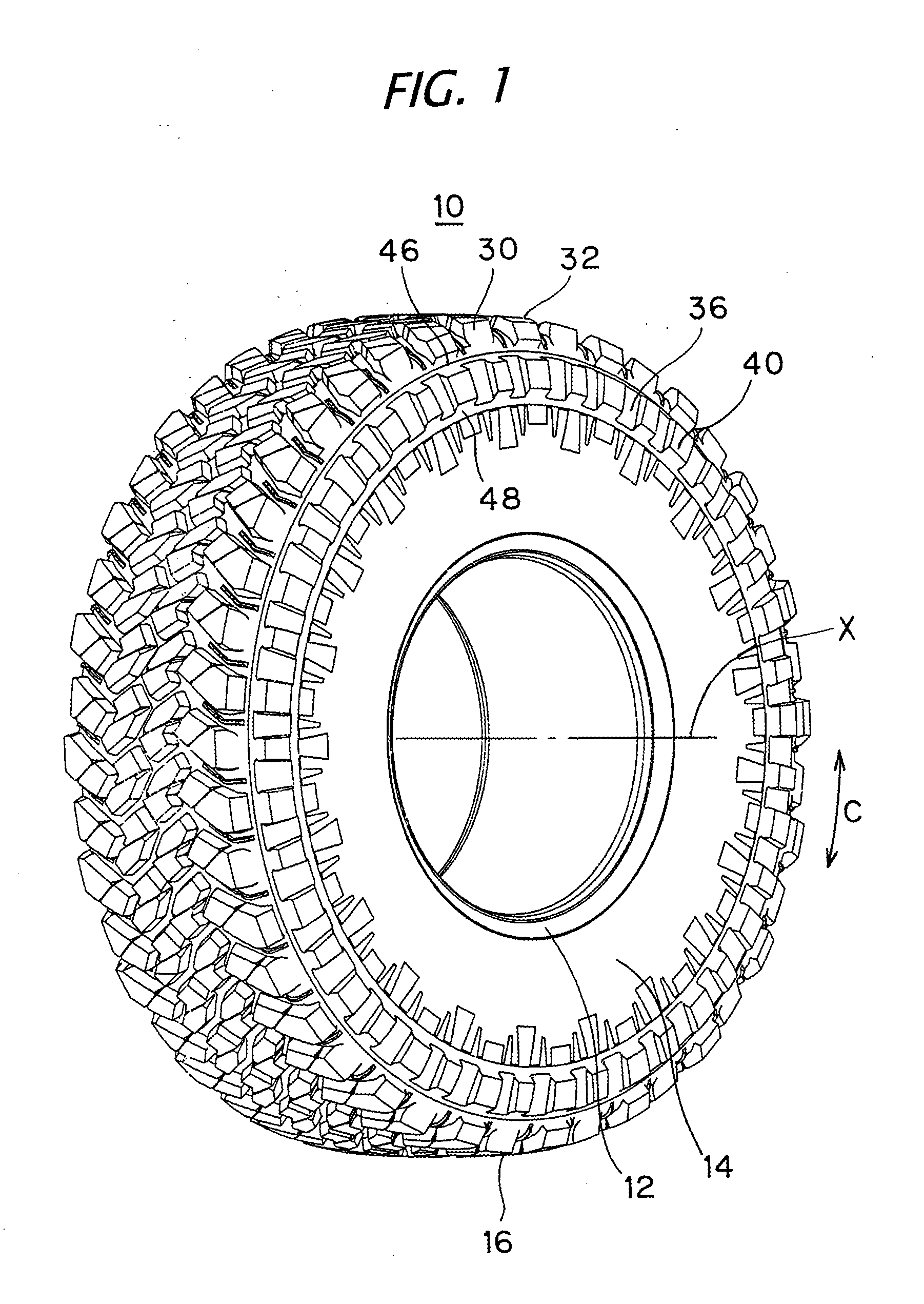

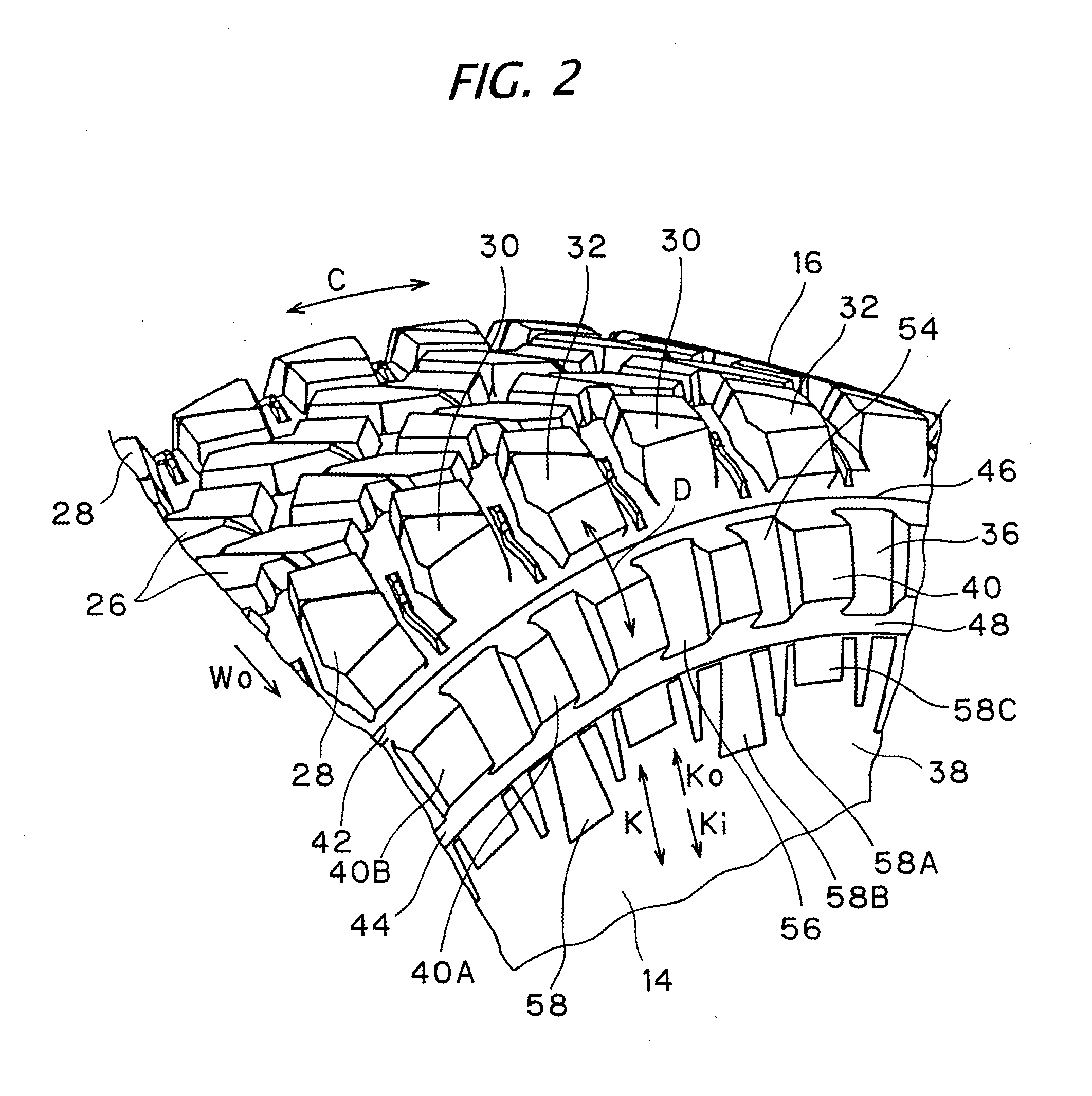

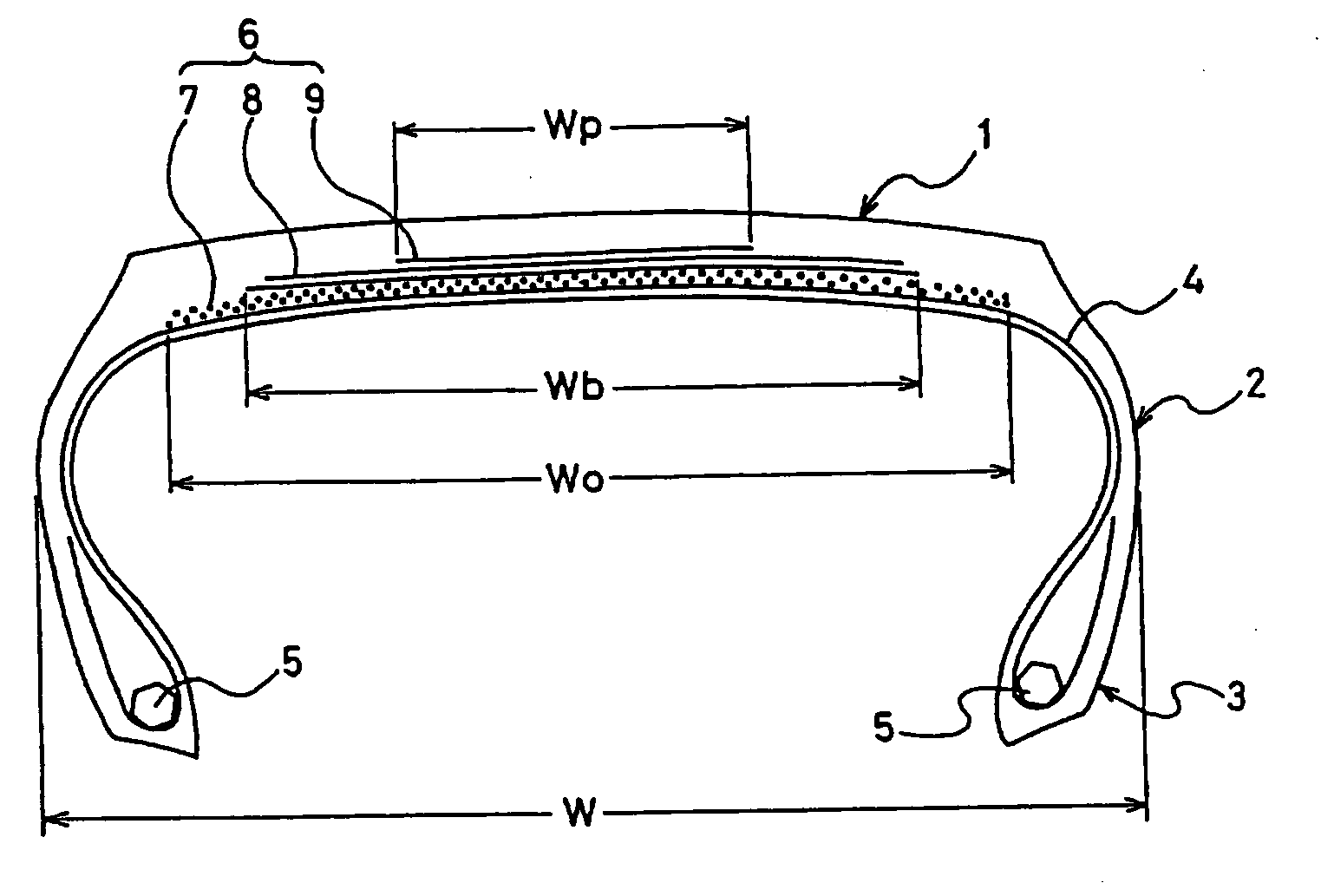

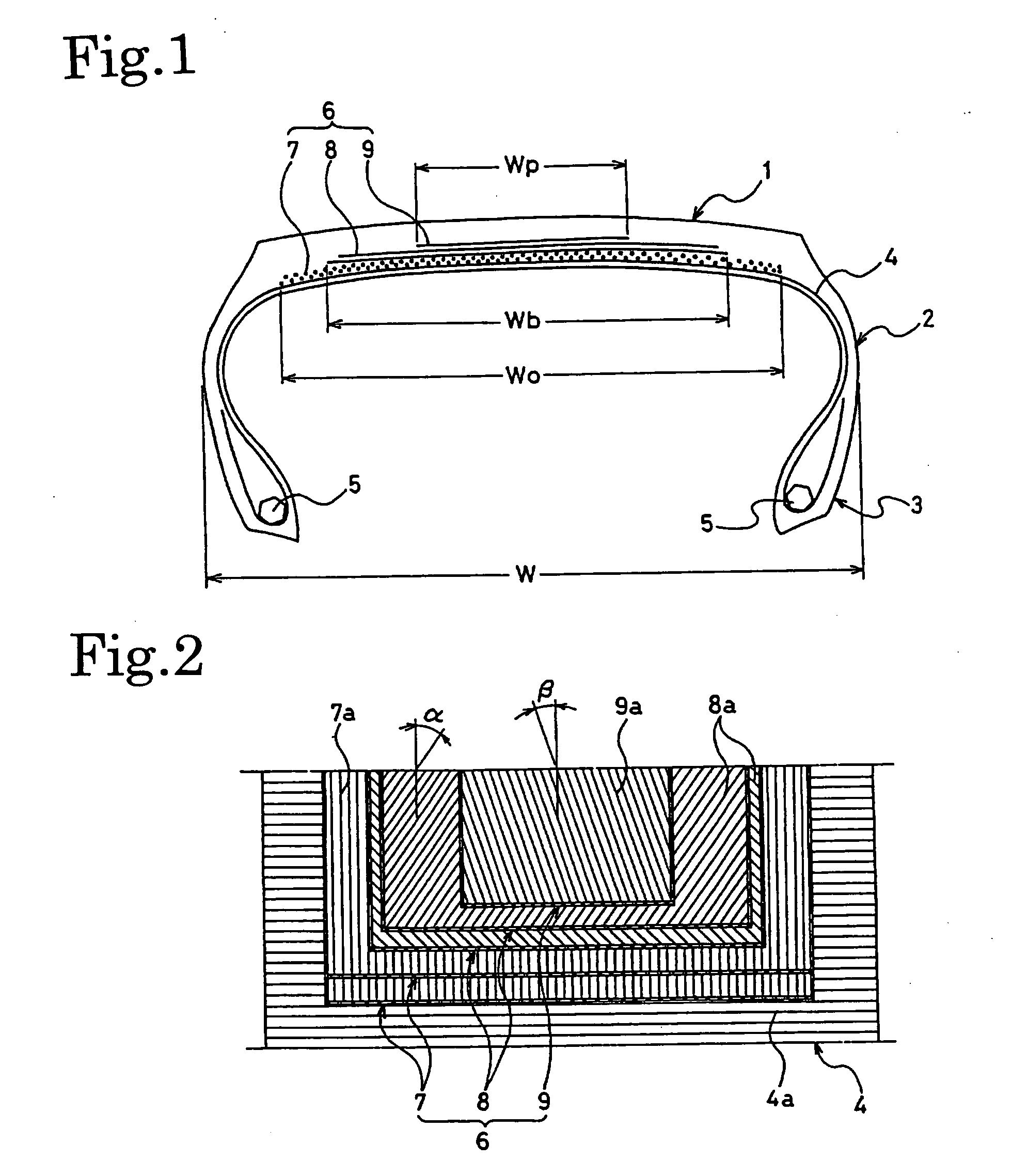

Pneumatic radial tire, and method of producing the same

ActiveUS20050194081A1Weight is lighterLower average tensionTyresPneumatic tyre reinforcementsForeign matterInternal pressure

In the pneumatic radial tire of the present invention, a total strength K0 of a belt layer 20 in a circumferential direction of the tire per unit of width at a tire equator surface position P0 is set greater than a total strength of the belt layer 20 in the circumferential direction of the tire per unit of width at a width position P2 corresponding to ⅔ of a maximum width of the belt layer having the tire equator surface CL as a center. In this way, it is possible to suppress the quantity consume of material in the belt layer 20, and to suppress the amount of expansion of tread rubber in a tread central region in the circumferential direction thereof when a standard internal pressure is charged and when the tire is rotated at high speed, thereby suppressing the growth of tire diameter. Since the expansion amount of the tread rubber in the circumferential direction is suppressed, the tension of the rubber is reduced. Therefore, it is possible to increase the resistance of the tread against the sticking of foreign matter, and even when foreign matter sticks in the tread, it is possible to suppress the growth of the crack.

Owner:BRIDGESTONE CORP

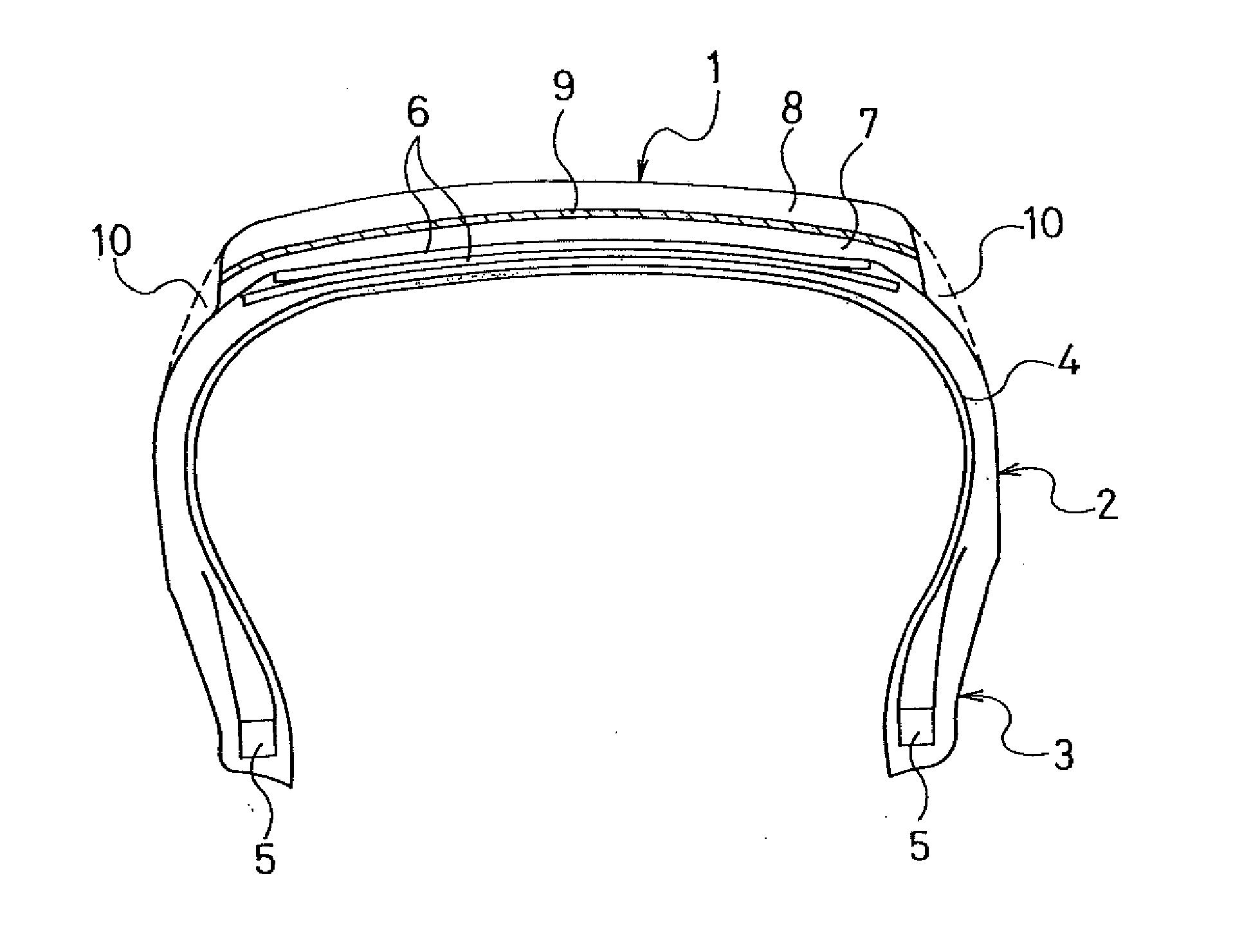

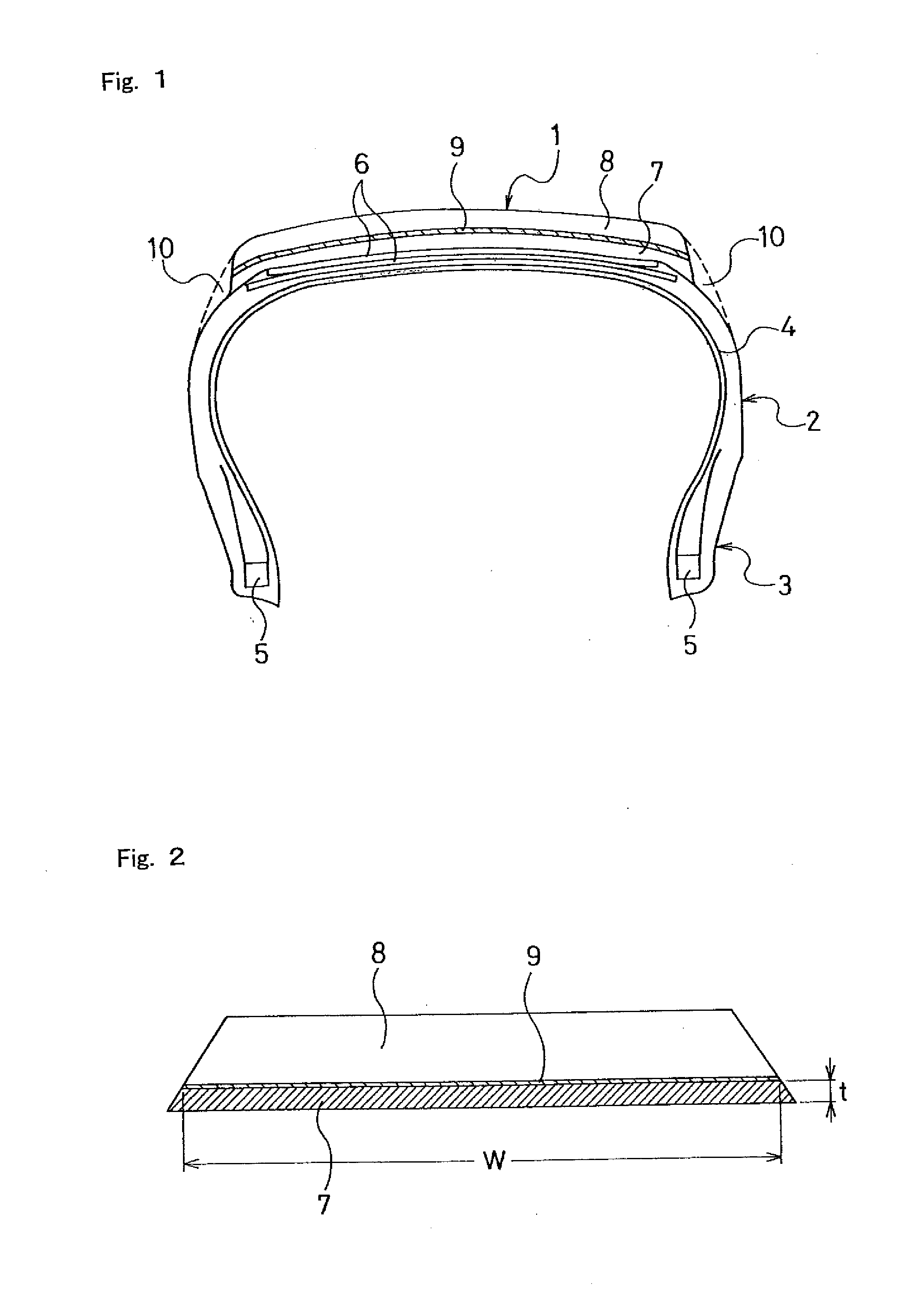

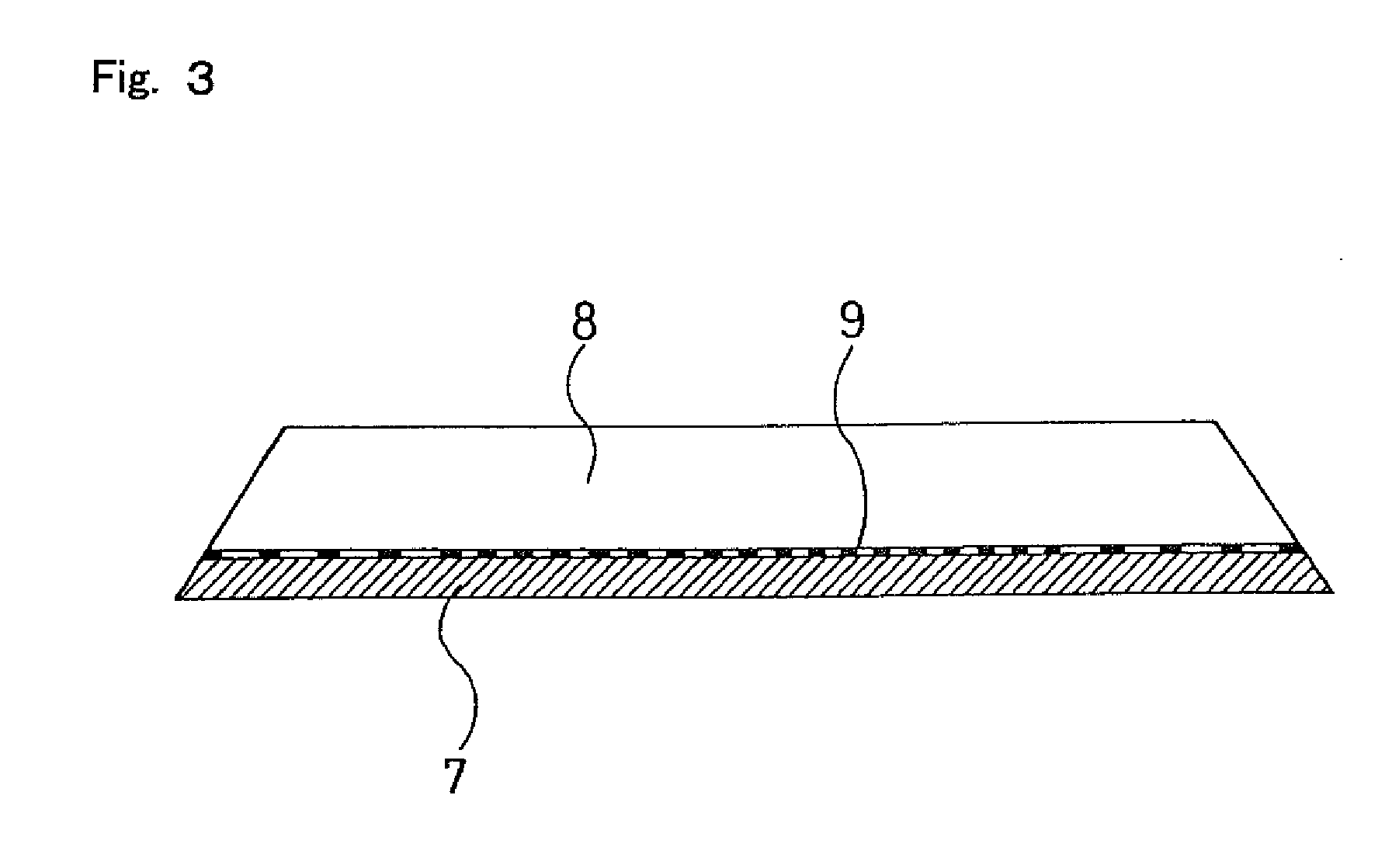

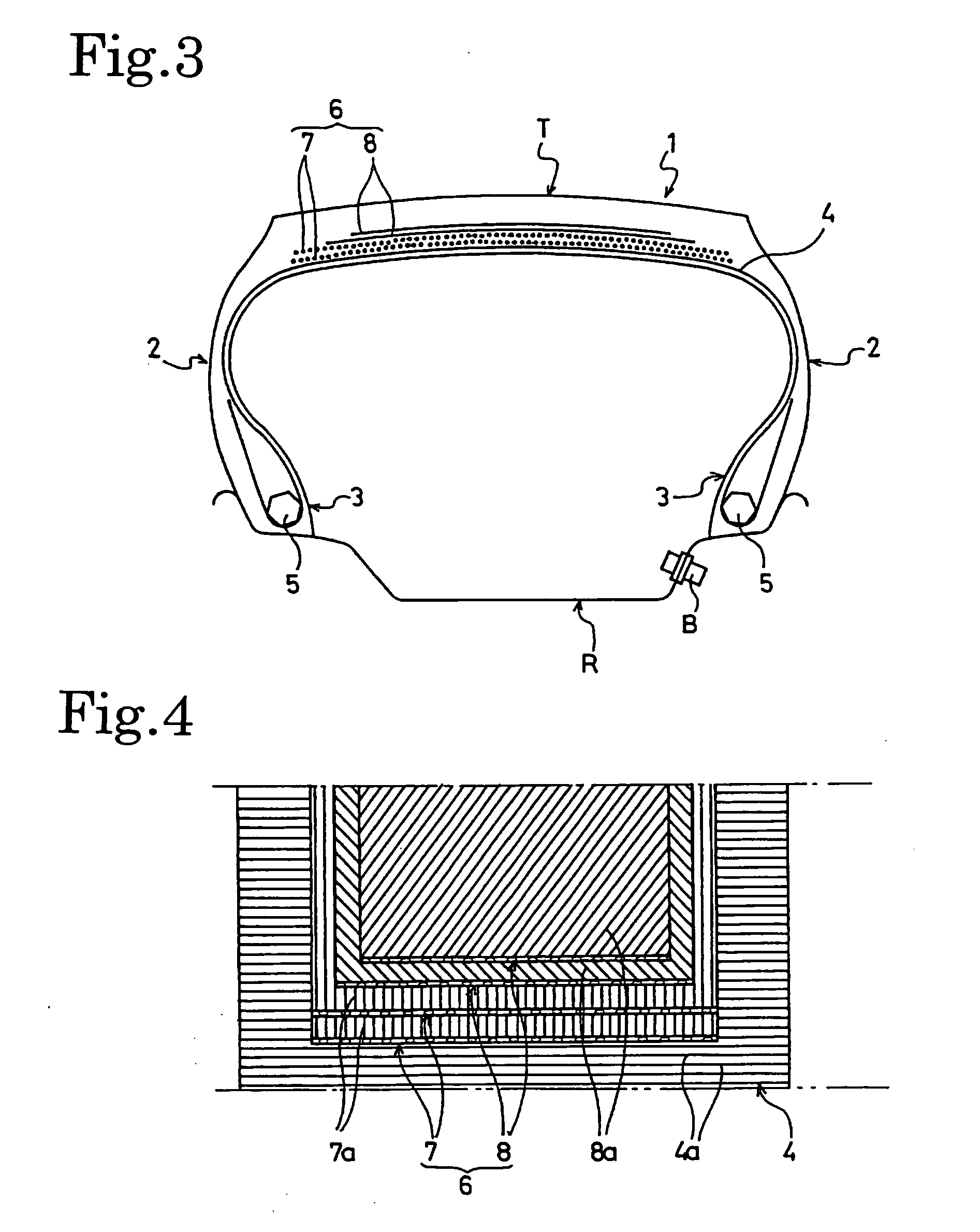

Pneumatic radial tire and process for producing retreaded tire

InactiveUS20110056603A1Easy to separateImprove productivityTyresInflatable tyresElastomerThermoplastic elastomer

A pneumatic radial tire includes: at least one carcass layer suspended across left and right bead parts; a belt layer arranged on an outer circumferential side of the carcass layer; and a tread arranged on an outer circumferential side of the belt layer. The tread has a laminated structure in which a thermoplastic film layer of a thermoplastic resin or a thermoplastic elastomer composition is interposed between a tread-side rubber layer and a belt layer-side rubber layer. The thermoplastic elastomer composition is obtained by blending an elastomer in a thermoplastic resin. A process for producing a retreaded tire includes the steps of: forming a base tire from the pneumatic radial tire by softening the thermoplastic film layer through heating so as to separate and remove the tread-side rubber layer, the pneumatic radial tire having the tread worn away; and subsequently bonding a new tread-side rubber layer onto the base tire.

Owner:YOKOHAMA RUBBER CO LTD

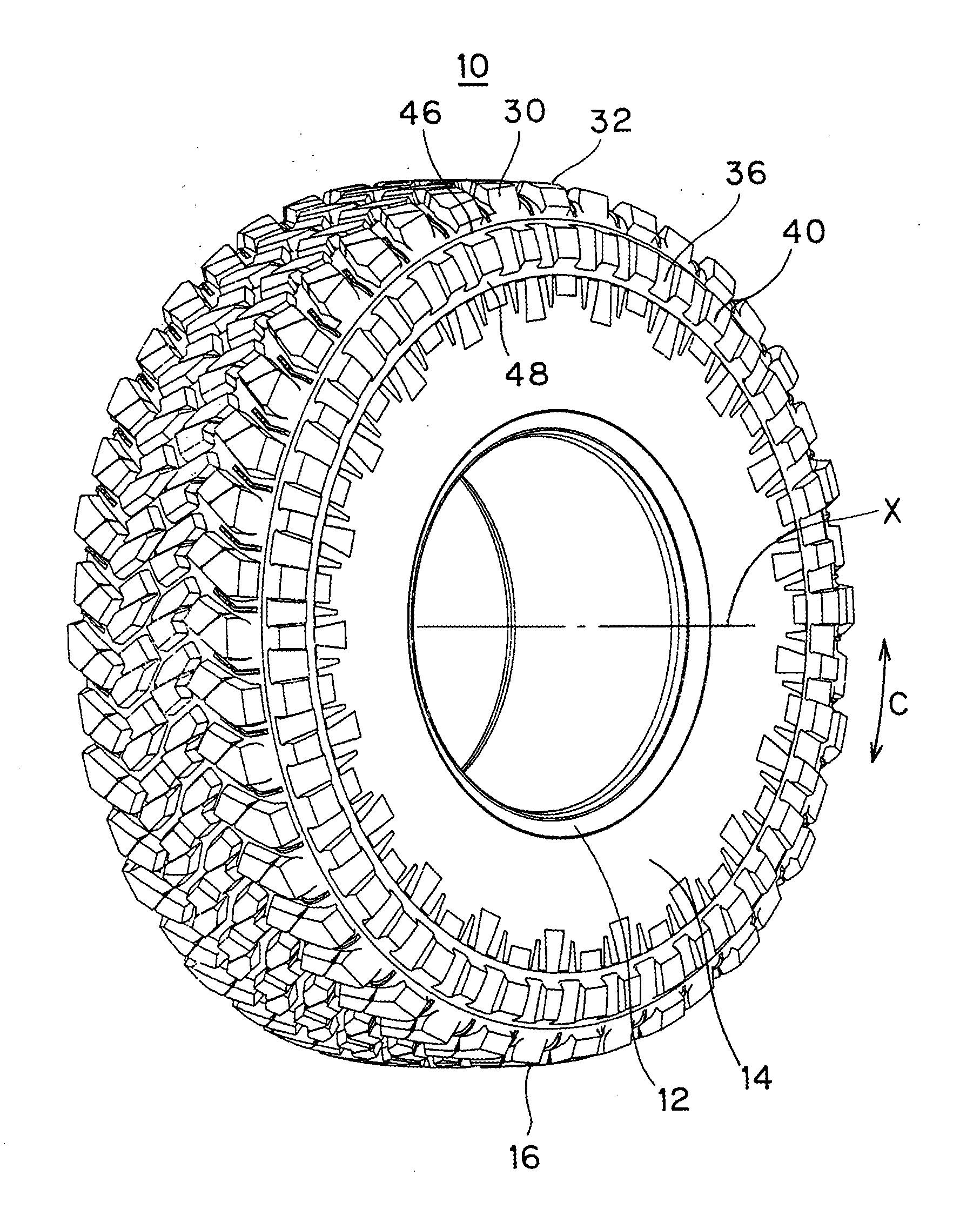

Pneumatic radial tire

ActiveUS20130139936A1Reduce stiffnessEasy to transformOff-road vehicle tyresPneumatic tyre reinforcementsMechanical engineeringThin walled

A pneumatic radial tire includes three or less steel belt layers, wherein a first block and a second block extending in an outer side than the first block are alternately provided in a tire circumferential direction on a ground edge region of a tread part. An annular region extending in a circumferential direction is provided on the outer surface of an outer side than a maximum width position in a side wall part, and plural projections are provided side by side on the annular region. An outer thin wall part continuing along an outer circumferential edge of the annular region and an inner thin wall part continuing along an inner circumferential edge of the annular region are provided, and the outer thin wall part is arranged adjacent to an inner radius height and inside of the inner radius height.

Owner:TOYO TIRE & RUBBER CO LTD

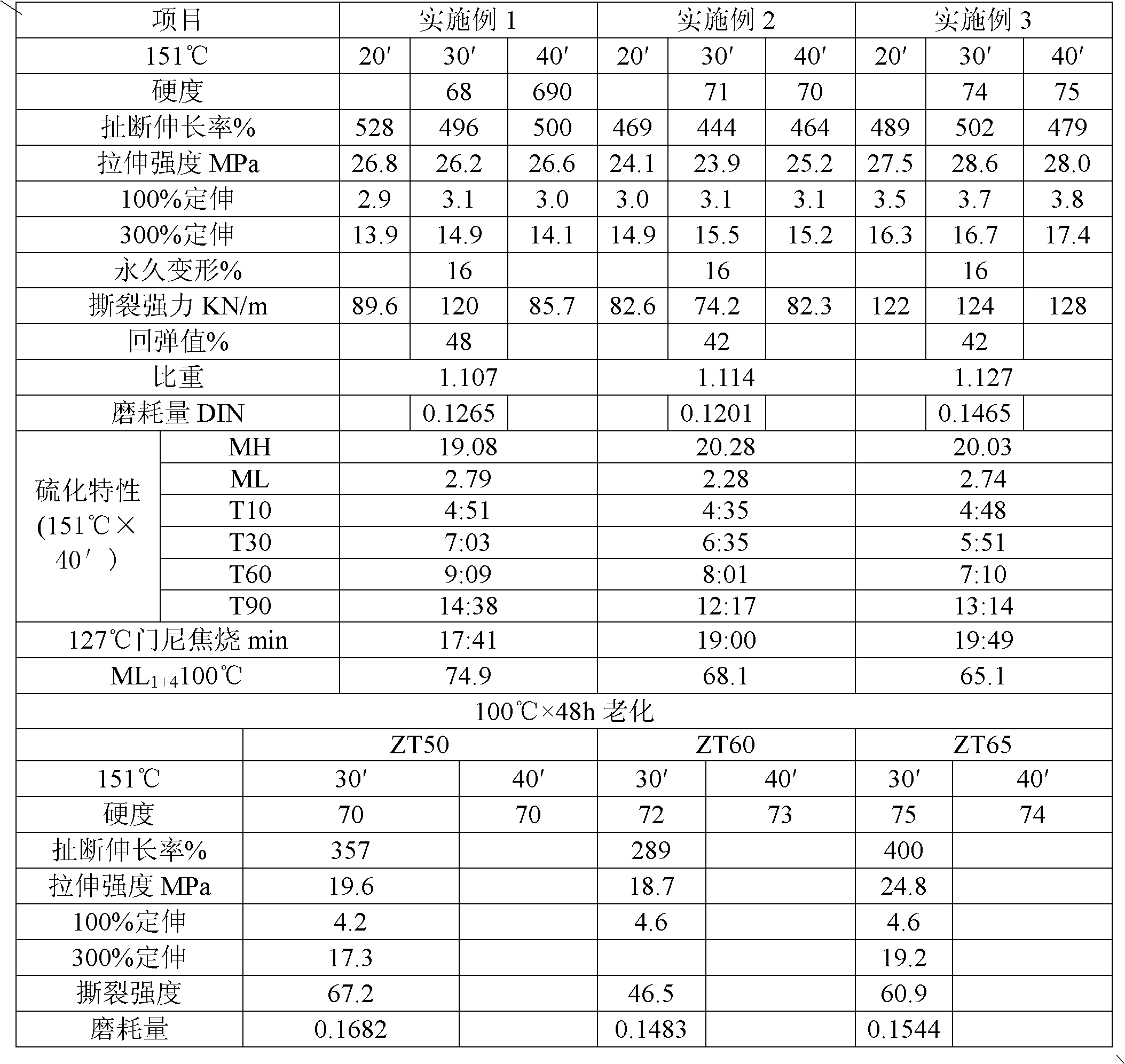

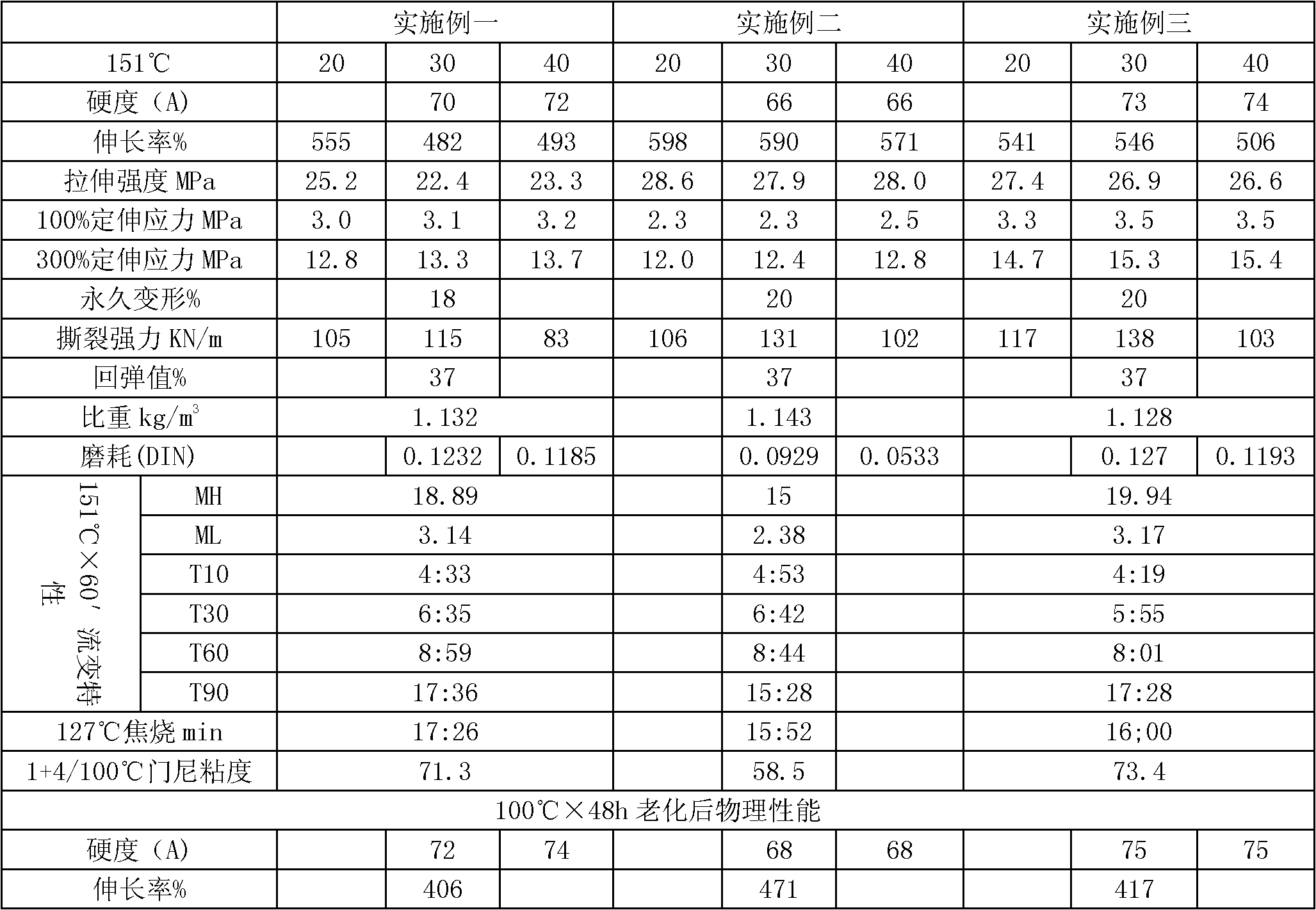

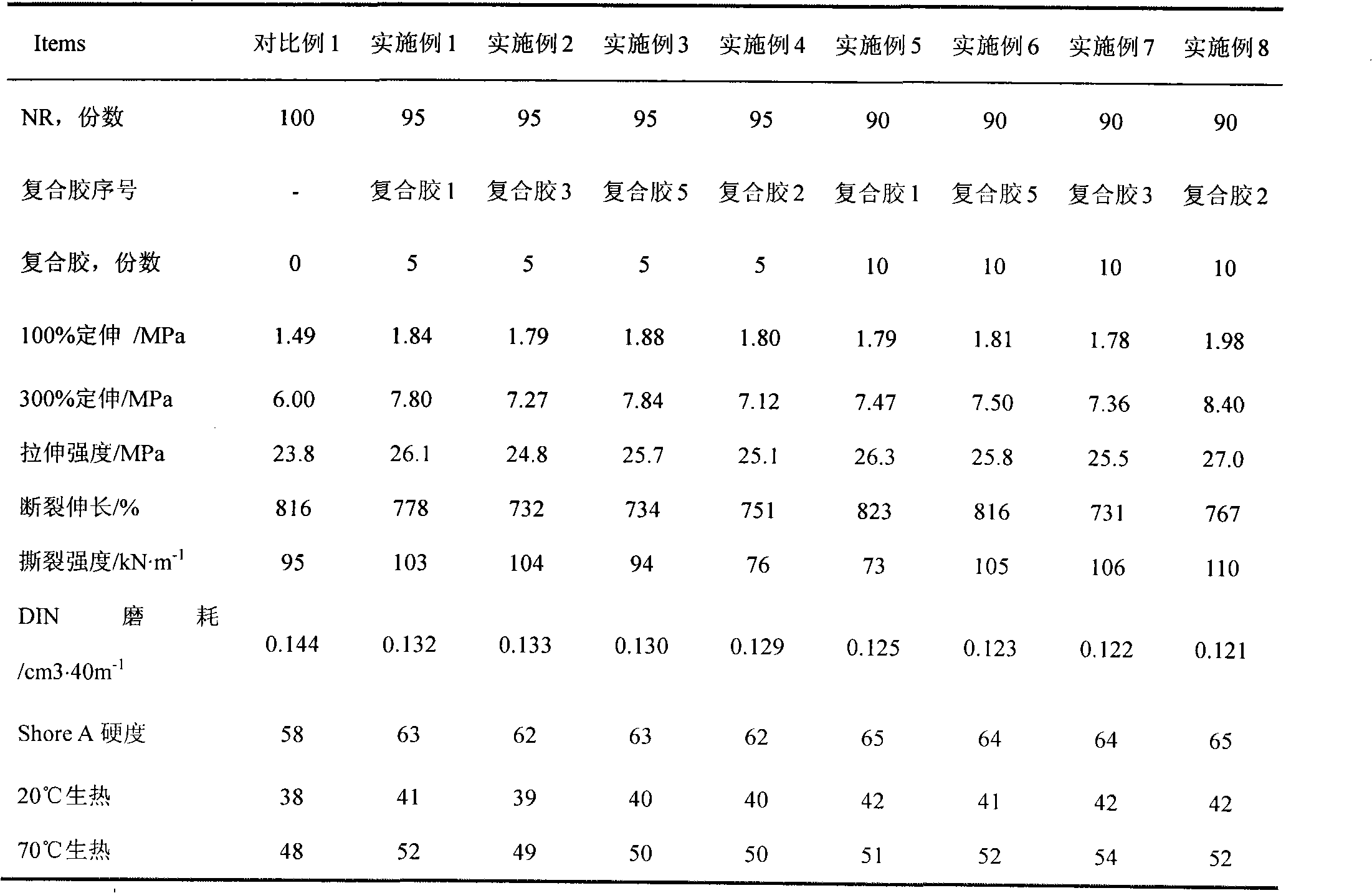

High abrasion-resistant tread rubber for middle and long distance highway transportation type radial tire and producing method thereof

ActiveCN102030926AImprove wear resistanceLower Mooney ViscositySpecial tyresMicrocrystalline waxEngineering

The invention relates to a high abrasion-resistant tread rubber for a middle and long distance highway transportation type radial tire and a producing method of the tread rubber, wherein the producing method comprises the following processing steps:(1) first-stage mixing: adding nature rubber SMR20,butadiene rubber, butadiene styrene rubber and peptizer into a mixing chamber for raw rubber plastication, then adding N234 carbon black, white carbon black, a silane coupling agent, zinc oxide, stearic acid, a dispersing agent and a plasticizer for mixing, finally adding N234 carbon black for mixing, and obtaining the first-stage original rubber by discharging rubber; (2) standing for first time; (3) second-stage mixing: adding first-stage original rubber, the N234 carbon black, an anti-aging agent RD, an anti-aging agent 4020 and microcrystalline wax into an internal mixer for mixing, and obtaining second-stage original rubber by discharging rubber after the mixing; (4) standing for second time; and (5) final mixing: adding the second-stage original rubber, sulphur, an accelerator NS and a scorch retarder CTP (cytidine triphosphate) into the mixing chamber for mixing, and obtaining the tread rubber by discharging rubber. In the invention, the abrasion resistance of middle and long distance highway transportation type radial tires can be greatly enhanced, the producing and working efficiency is enhanced, and energy is greatly saved.

Owner:JIANGSU GENERAL SCI TECH

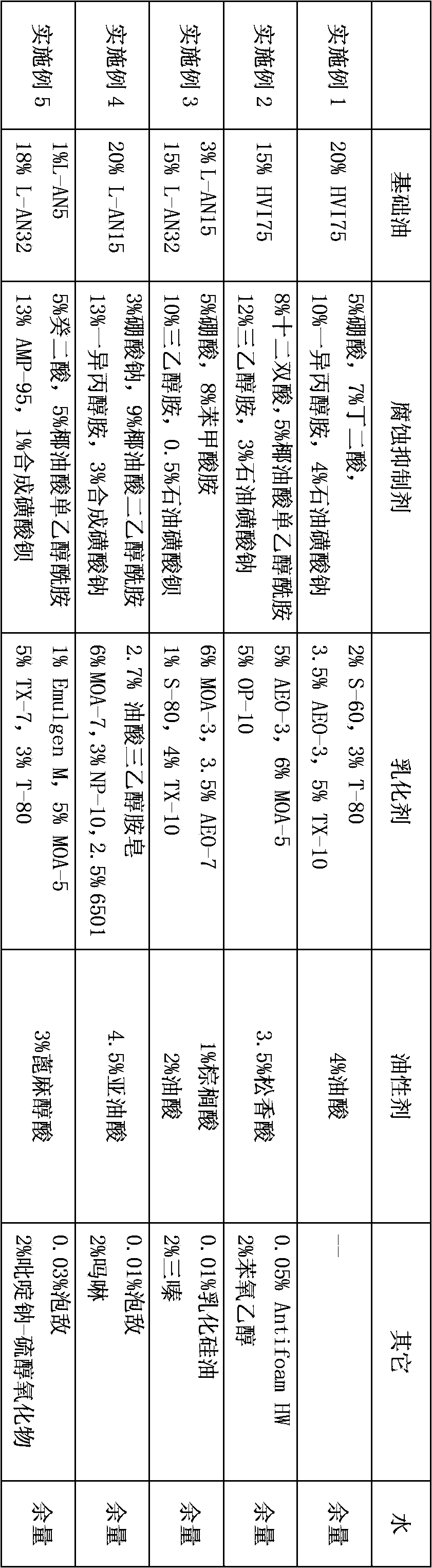

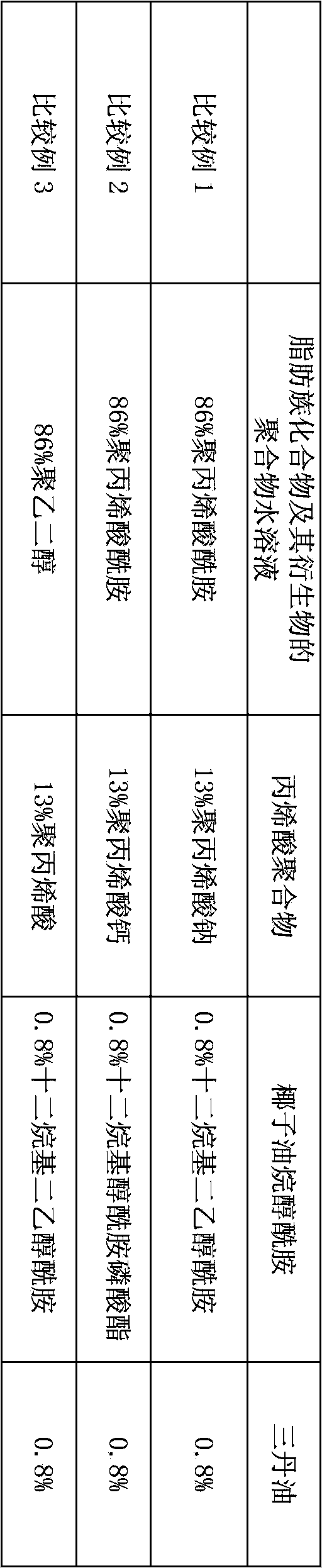

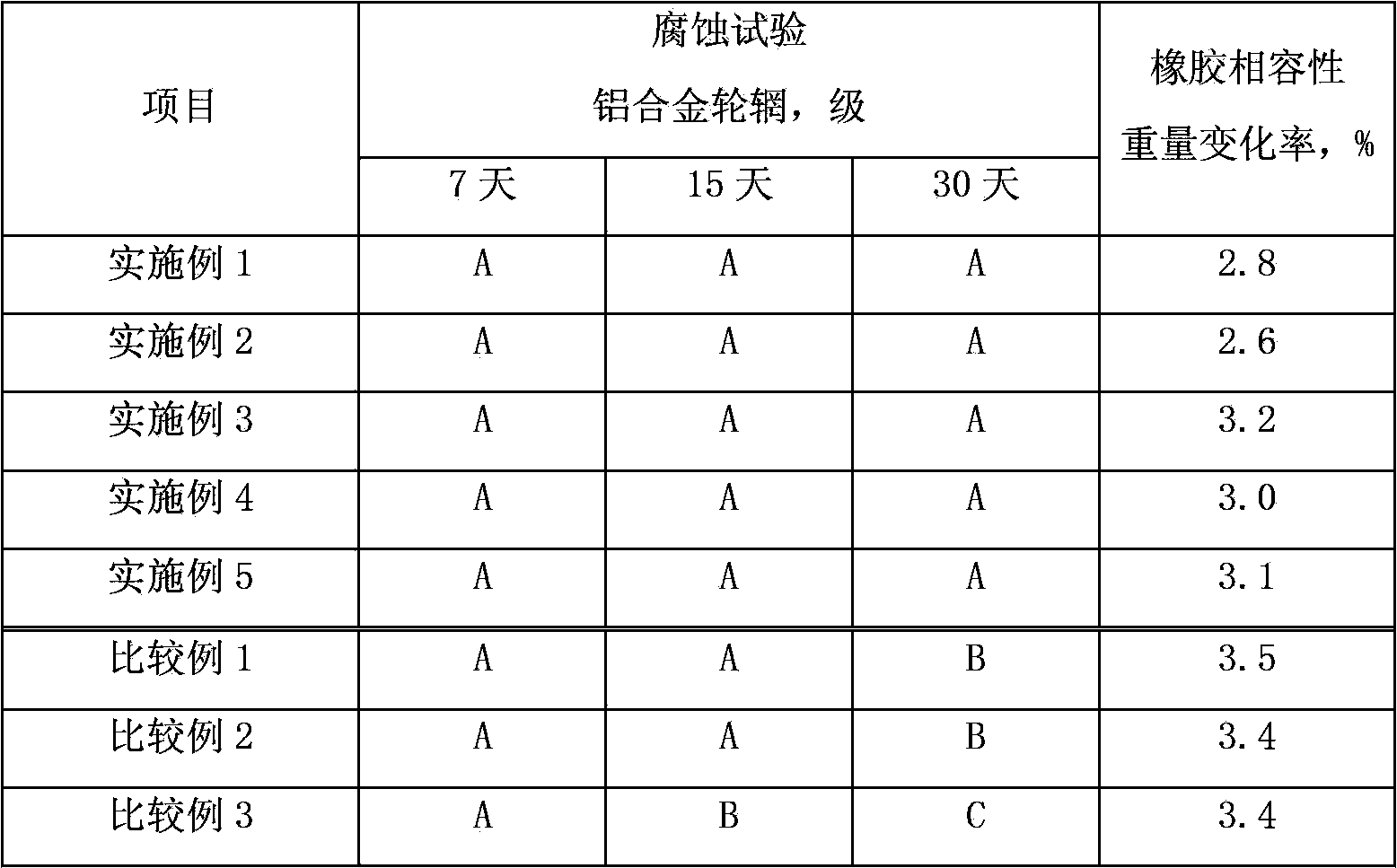

Application of lubricating oil composition in tire fitting

The invention relates to application of a lubricating oil composition in tire fitting, and is mainly used for solving the problem that polymer type fitting lubricating oil in the prior art has no anti-corrosive property to aluminum alloy rim. The problem is well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 10-30 parts of base oil, b) 15-35 parts of corrosion inhibitor, c) 8-20 parts of emulsifier, d) 1-6 parts of oil agent, and e) 5-40 parts of water. The lubricating oil composition can be applied to industrial production of automobile radial tire fitting.

Owner:CHINA PETROLEUM & CHEM CORP

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

All-steel radial ply tyre tread base and preparation method thereof

The invention discloses tread base for an all-steel radial tire and a preparation method thereof. The tread base for the all-steel radial tire comprises the following compositions in weight portion: 100 weight portions of natural gum SMR20, 0.1 to 0.5 weight portion of chemical peptizer, 30 to 45 weight portions of carbon black, 7 to 15 weight portions of white carbon black, 3 to 5 weight portions of zinc oxide, 1.5 to 3 weight portions of silane coupling agent Si-69, 1.5 to 3 weight portions of stearic acid, 1 to 2 weight portions of antiaging agent 4020, 0.5 to 2 weight portions of micro-crystalline wax, 0.5 to 2 weight portions of antiaging agent RD, 1 to 2 weight portions of fatigue protective agent G-108, 2 to 3 weight portions of oil-filled insoluble sulfur, 0.5 to 1 weight portion of accelerant NS, 0.5 to 1 weight portion of accelerant CZ and 0.1 to 0.5 weight portion of antiscorcher CTP. The tread base for the all-steel radial tire is prepared by one-stage mixing, standing for the first time, two-stage mixing, standing for the second time and final mixing.

Owner:JIANGSU GENERAL SCI TECH

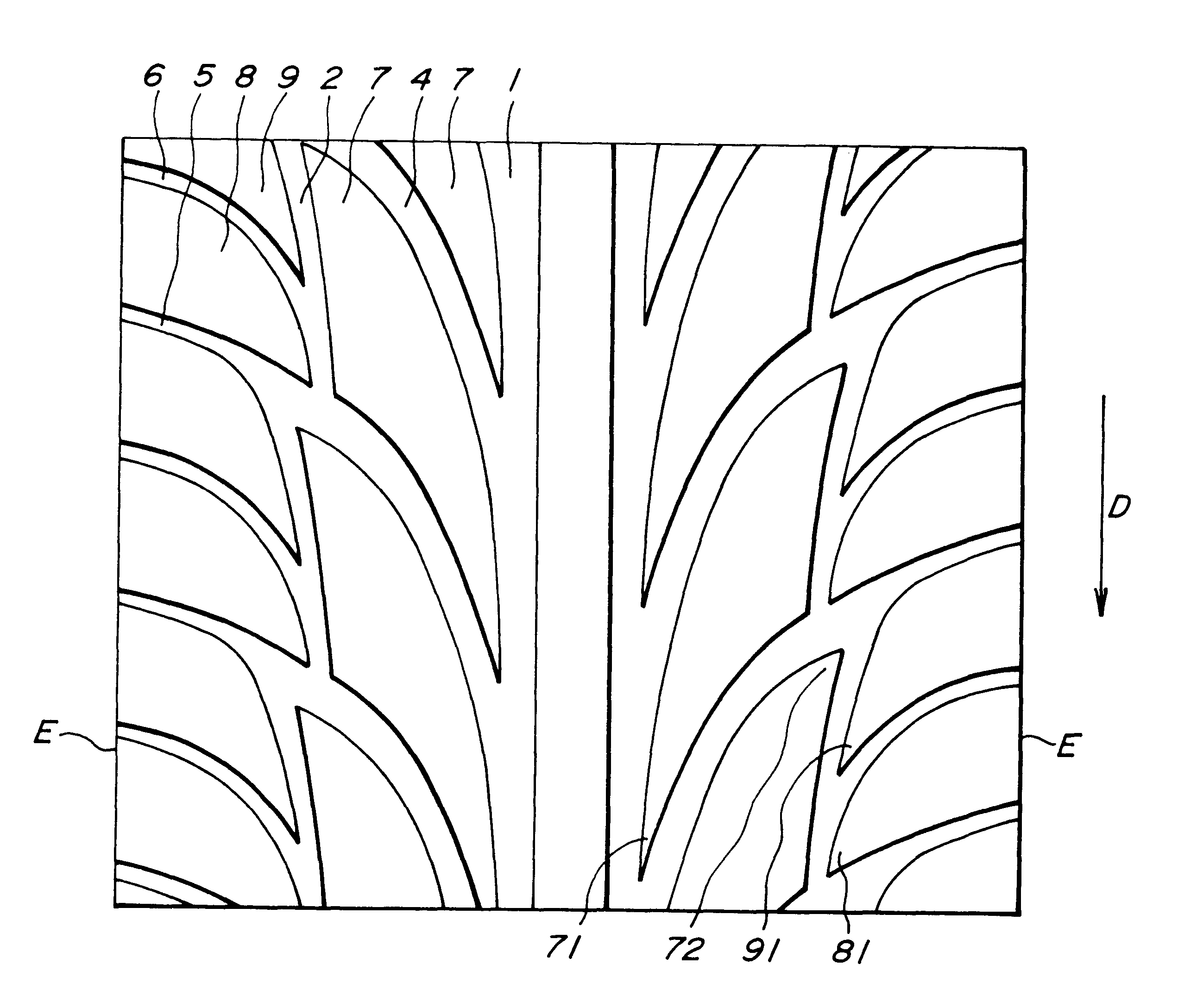

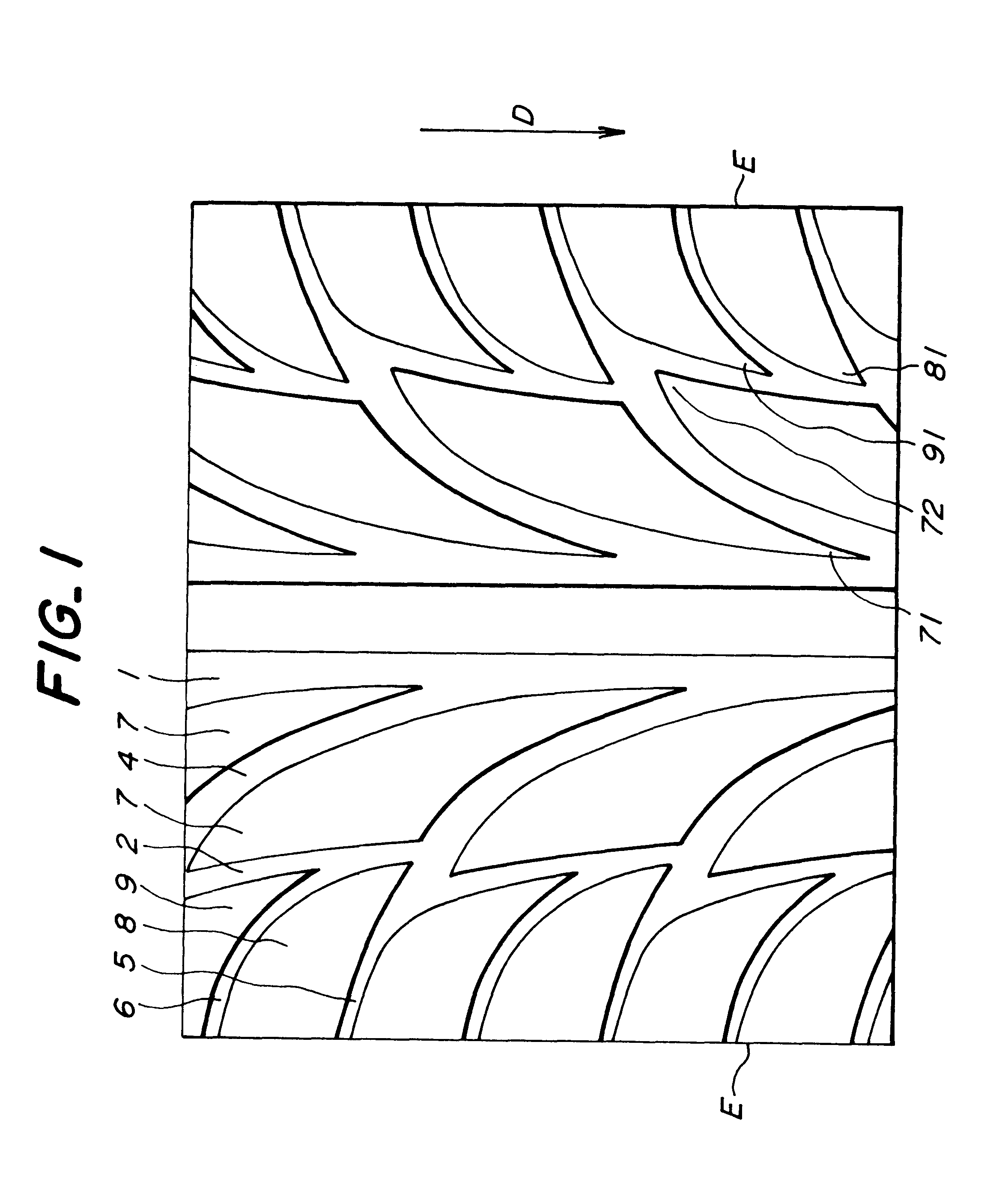

Pneumatic radial tire including beveled acute angle corner portions

A pneumatic radial tire for passenger car has a directional tread pattern comprising many blocks formed in a tread portion by a plurality of circumferential grooves extending in a circumferential direction of the tire and a plurality of directional slant grooves obliquely extending with respect to the circumferential direction, wherein at least a part of the directional slant grooves is branched from the circumferential groove near to the pattern center and extends toward and is opened at an end of a ground contact region of the tread, and at least a part of corner portions of each of the blocks forms an acute angle of 10-60° defined by the circumferential groove and the directional slant groove; and a surface of the corner portion of the block having an acute angle of 10-60° is beveled over a distance of 10-30 mm from a tapered end thereof in a longitudinal direction so as to gradually shallow from the tapered end toward a width widened portion of the block in both stepping-in and kicking-out sides of the block.

Owner:BRIDGESTONE CORP

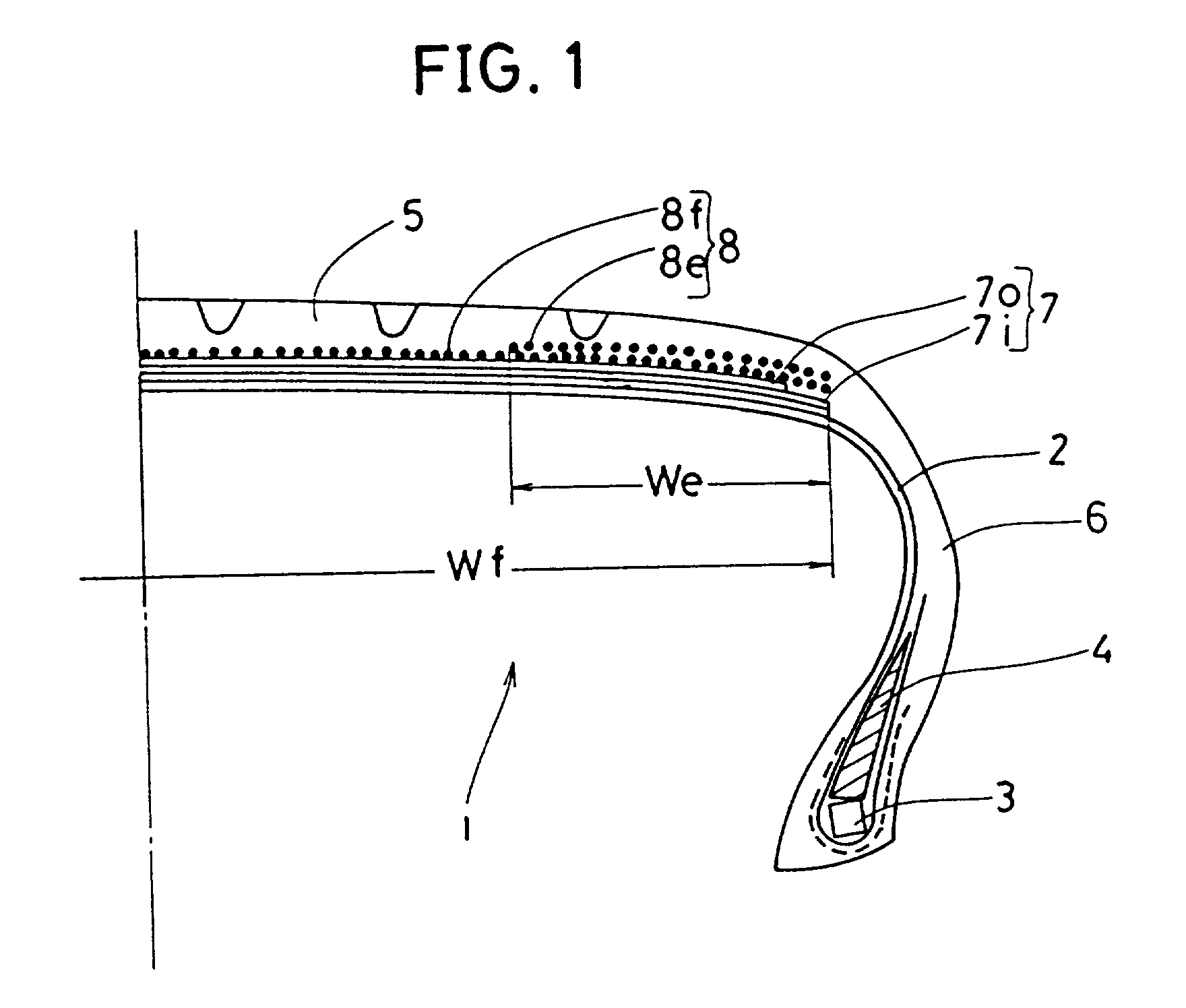

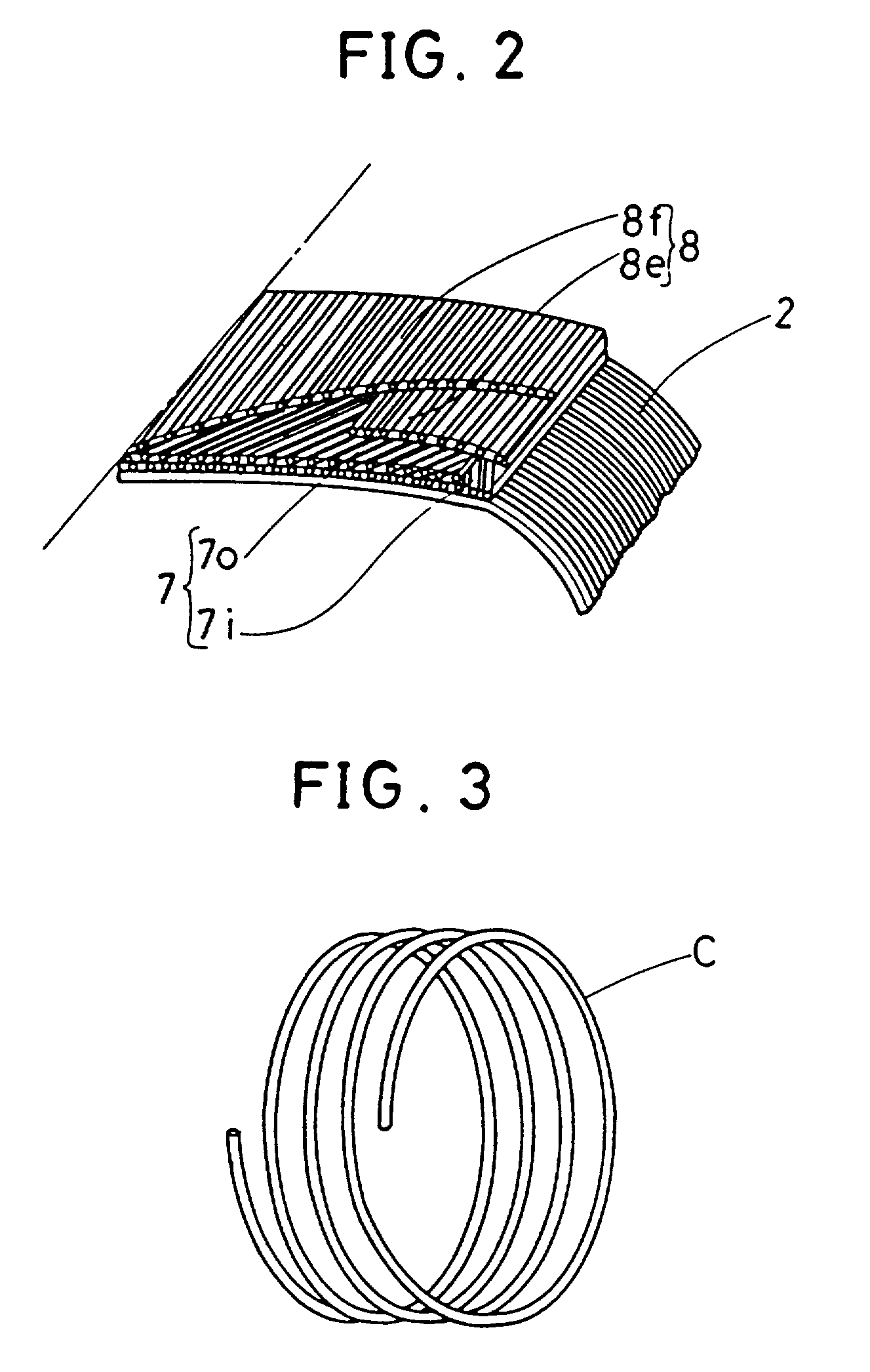

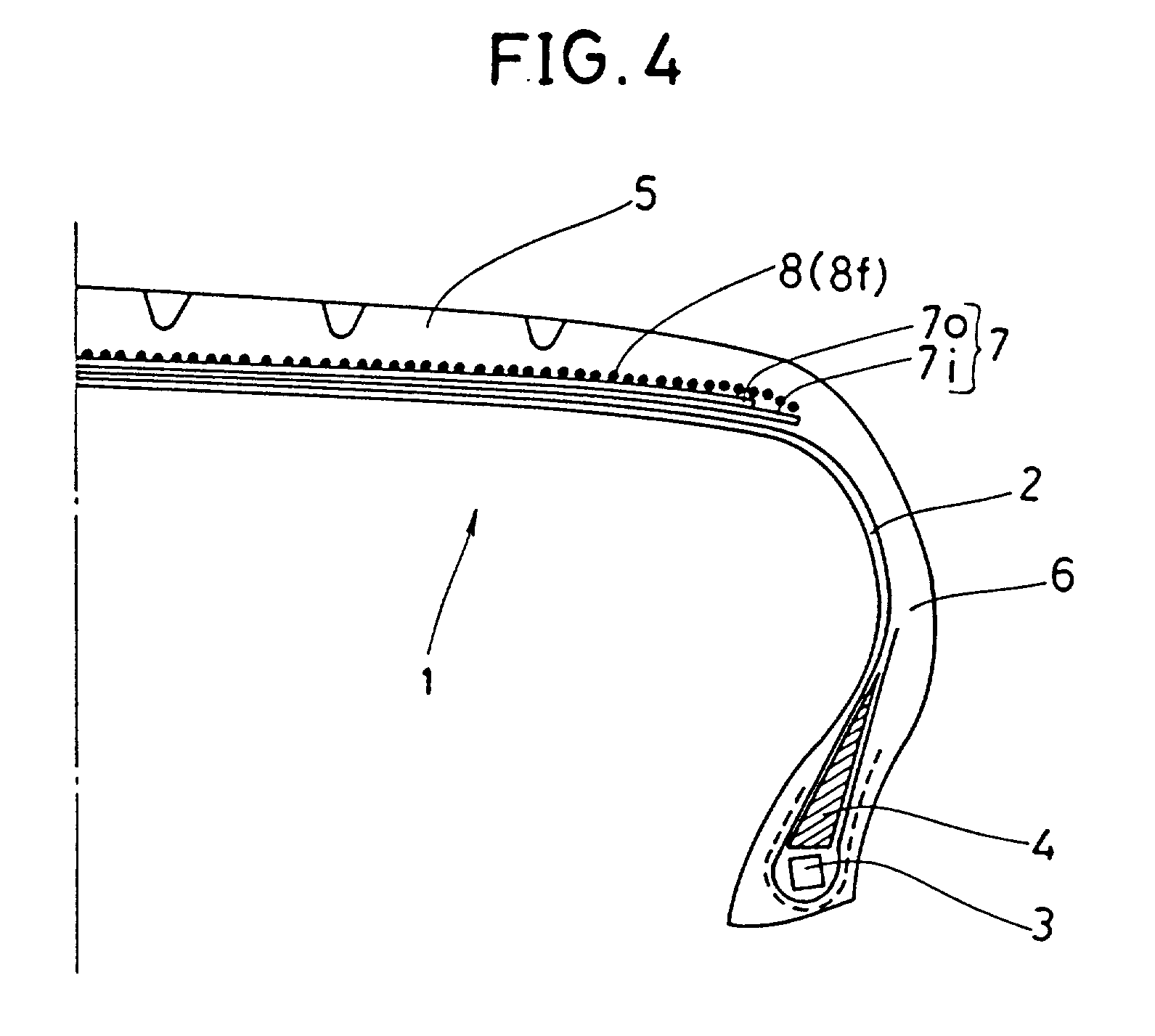

Pneumatic radial tire and method for manufacturing same

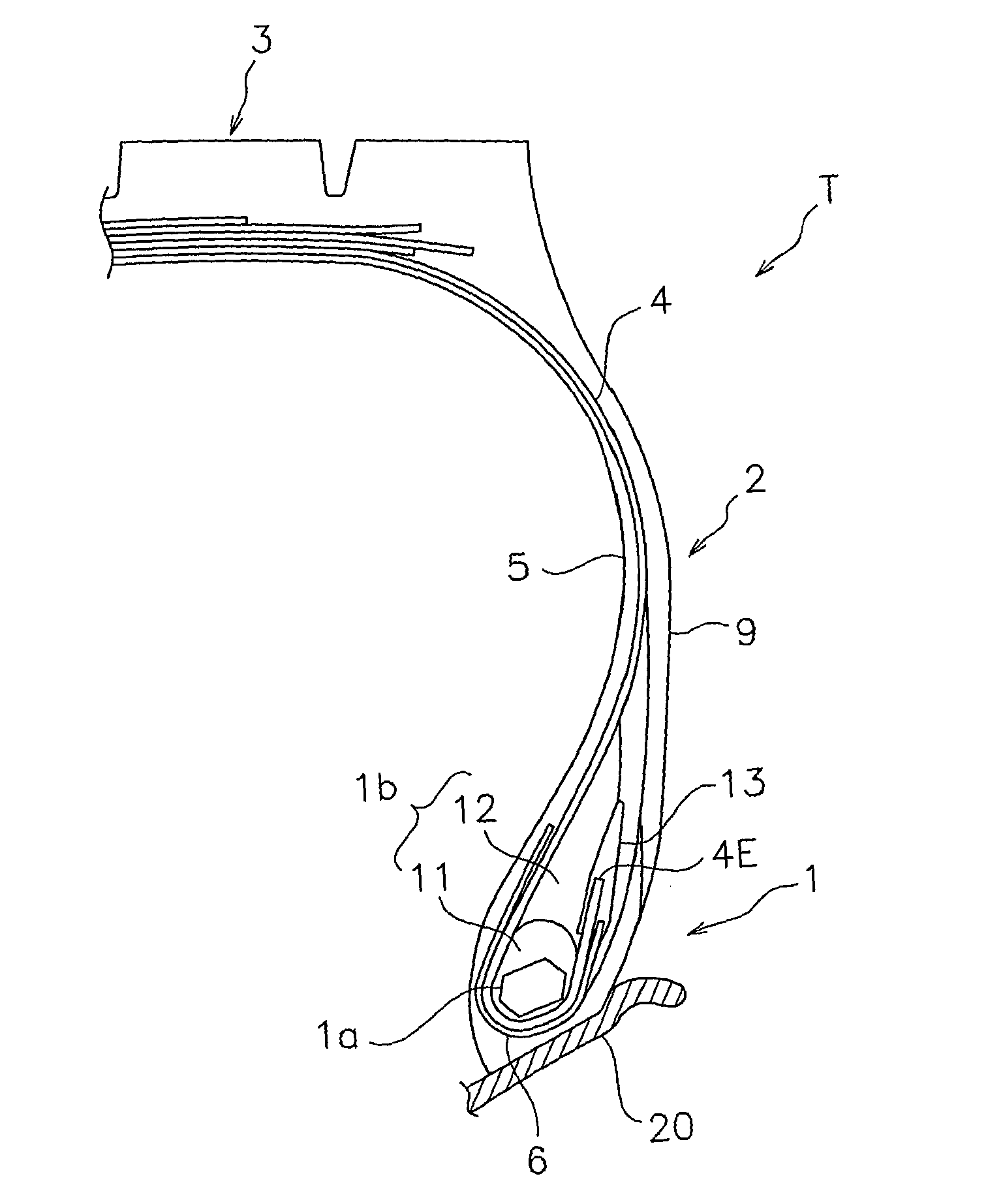

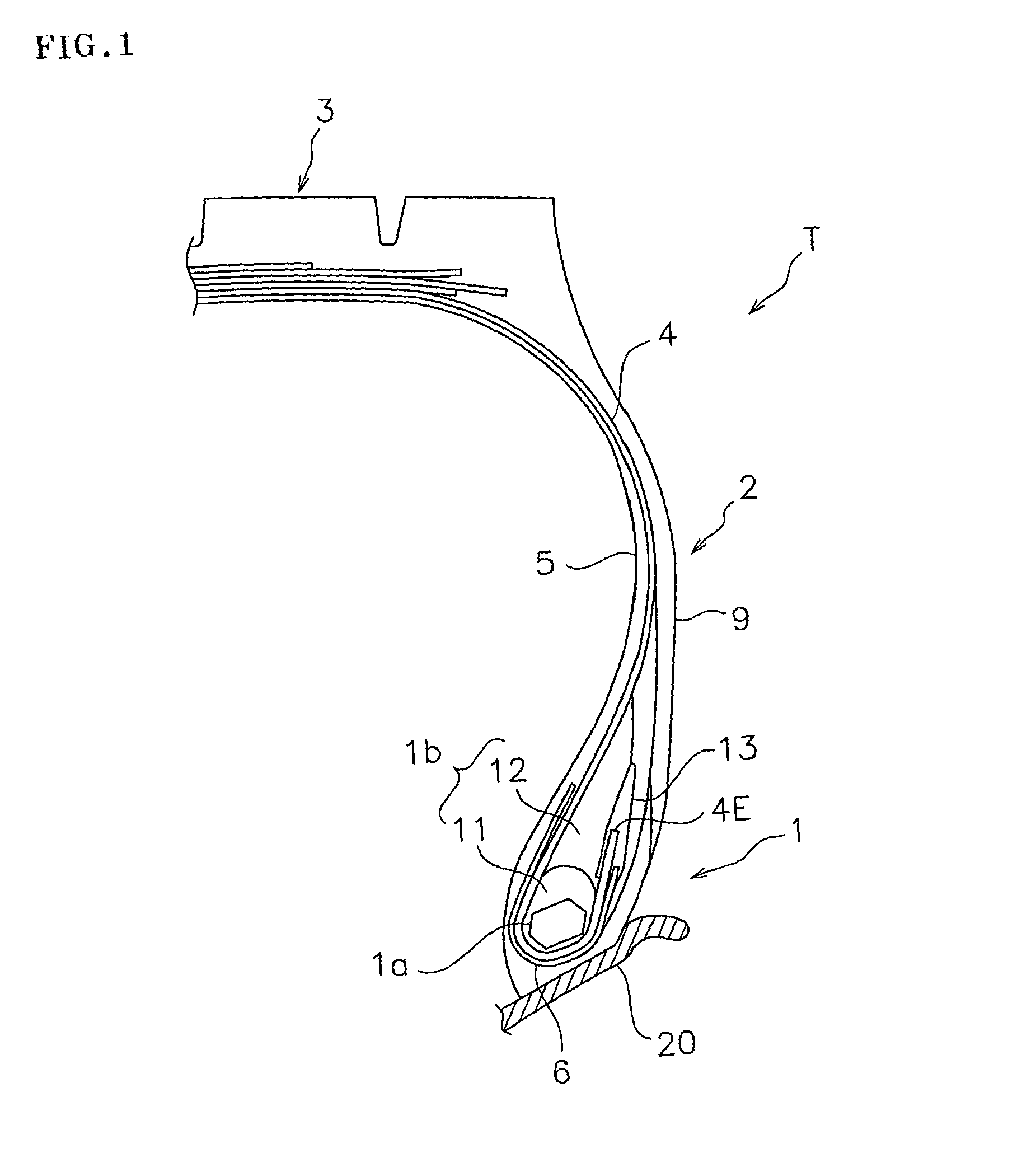

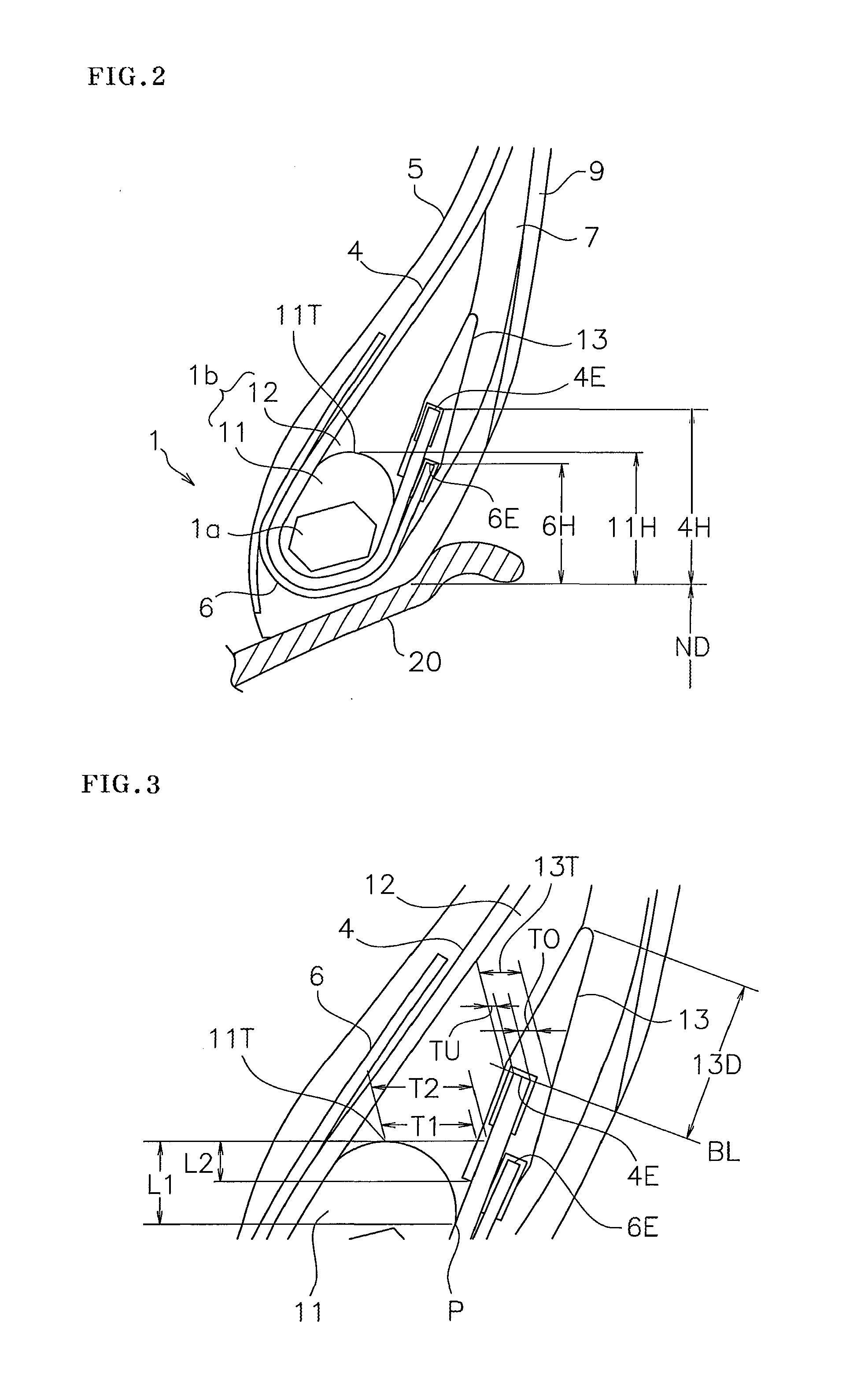

InactiveUS20010008158A1Inhibition effectAvoid separationTyresPneumatic tyre reinforcementsFiberElastomer

A pneumatic radial tire and a method for manufacturing the same, a device for forming a band of radial tire, and a method of and device for forming a belt-band-tread rubber assembly. The pneumatic tire including a belt arranged on the radially outer side or a carcass, and a band arranged on the radially outer side of the belt and composed of continuous one to several organic fiber cords wound spirally and approximately parallel to the circumferential direction of the tire. The radial tire manufacturing method including the steps of laminating the predetermined number of belt plies on a belt drum or belt ring for forming a belt, and winding one to several organic fiber cords continuously and spirally in the cicumferential direction of the belt on the outer surface of the formed belt in order to form a band. The band forming device including a means for drawing out a cord to be wound, a means for traversing the letting-off means in the widthwise direction of the belt, and a means for controlling the traverse of the letting-off means. The method of forming belt-band-tread rubber assemblies comprising a step of expanding the diameter of belt drum so that the shape in axial section of belt drum becomes the same or approximately the same as the finished shape of the band in vulcanization mold. The assembly forming device including a diameter-variable belt drum comprising a stretchable forming annular body made of an elastomer, and a means for expanding and contracting the diameter of the annular body, wherein the shape in axial section of the circumferential surface of the annular body in the diameter.

Owner:KOJIMA YOSHIHIDE +4

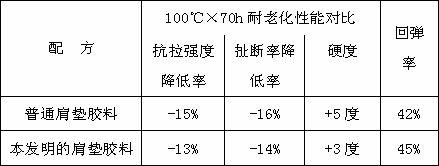

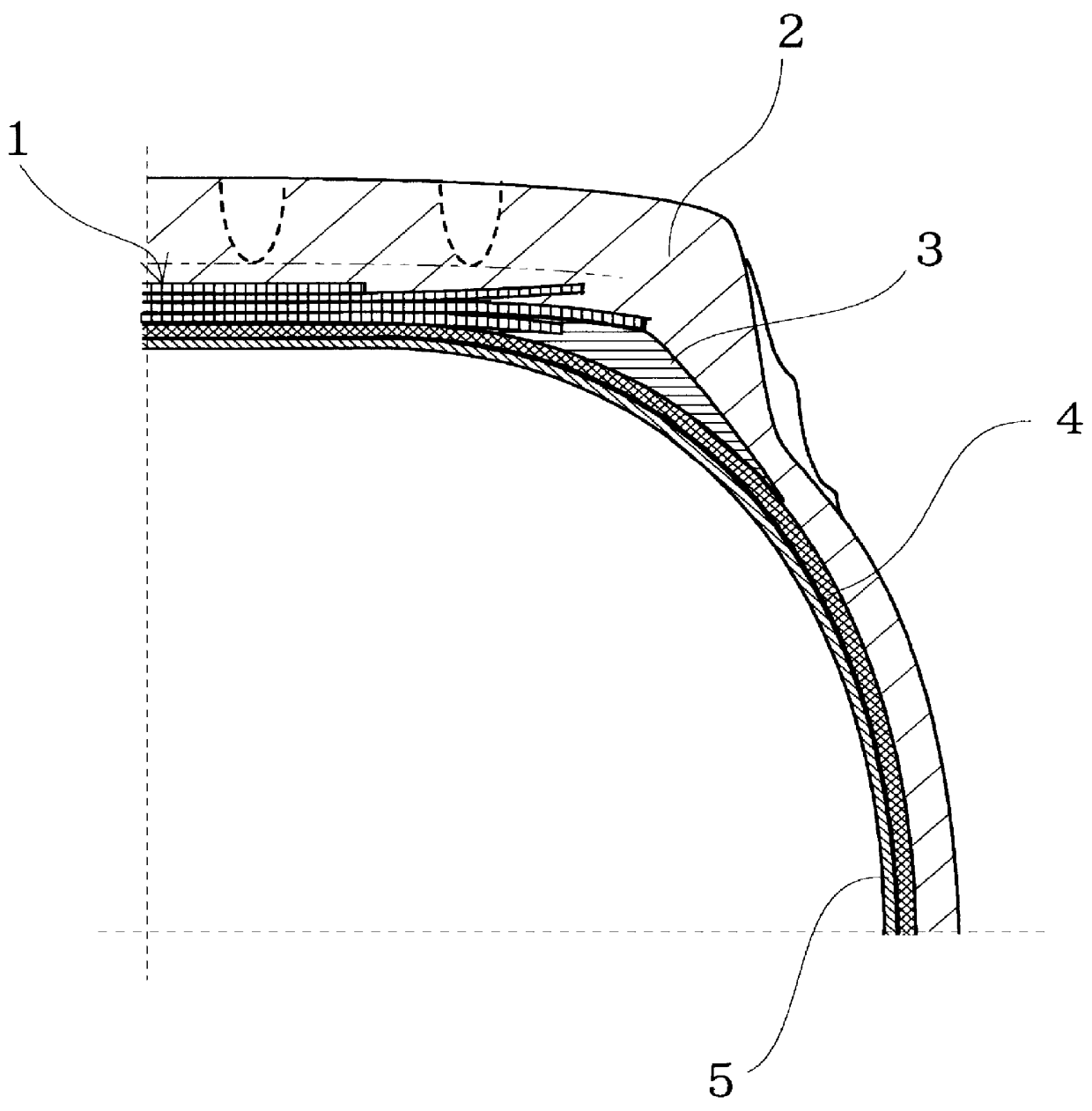

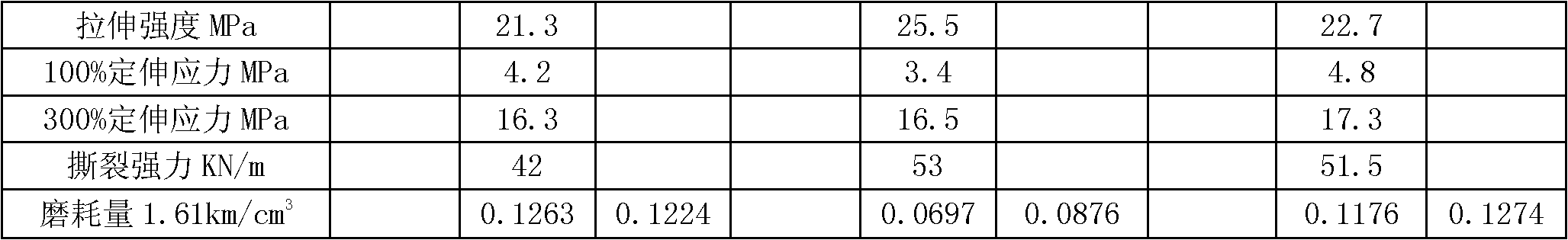

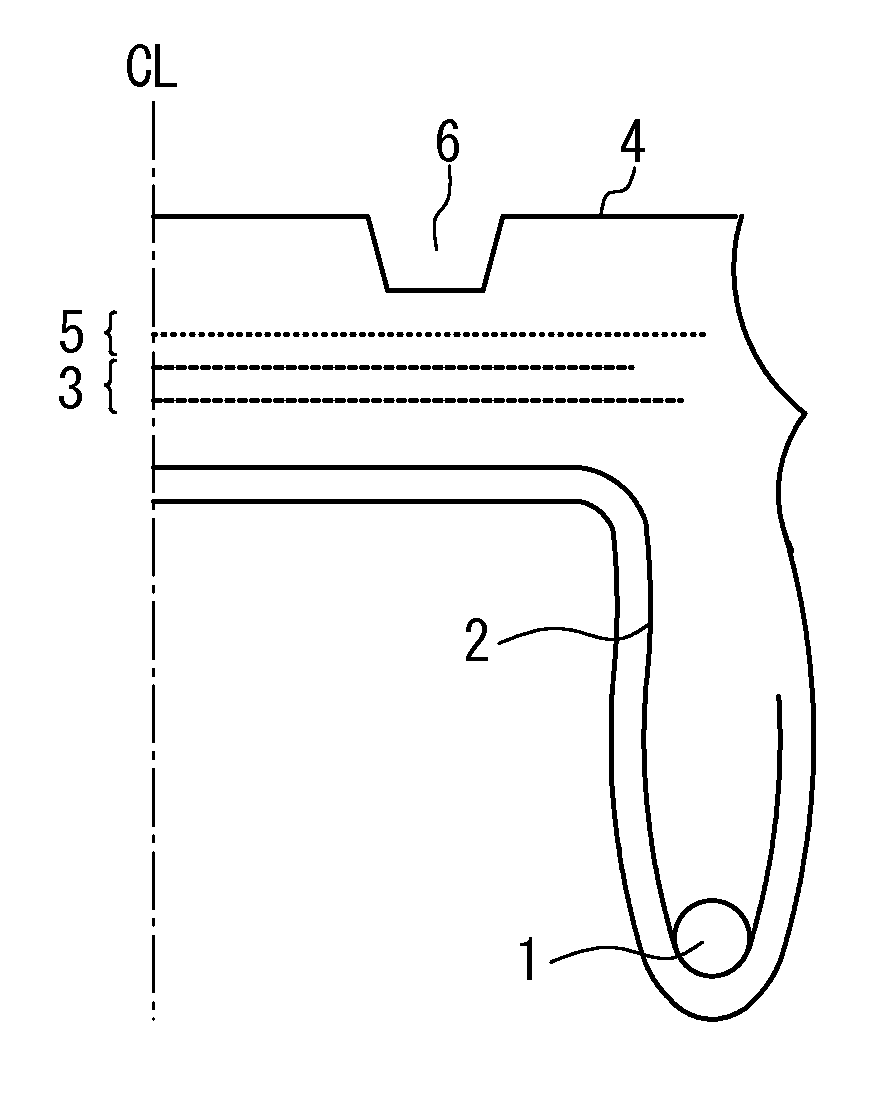

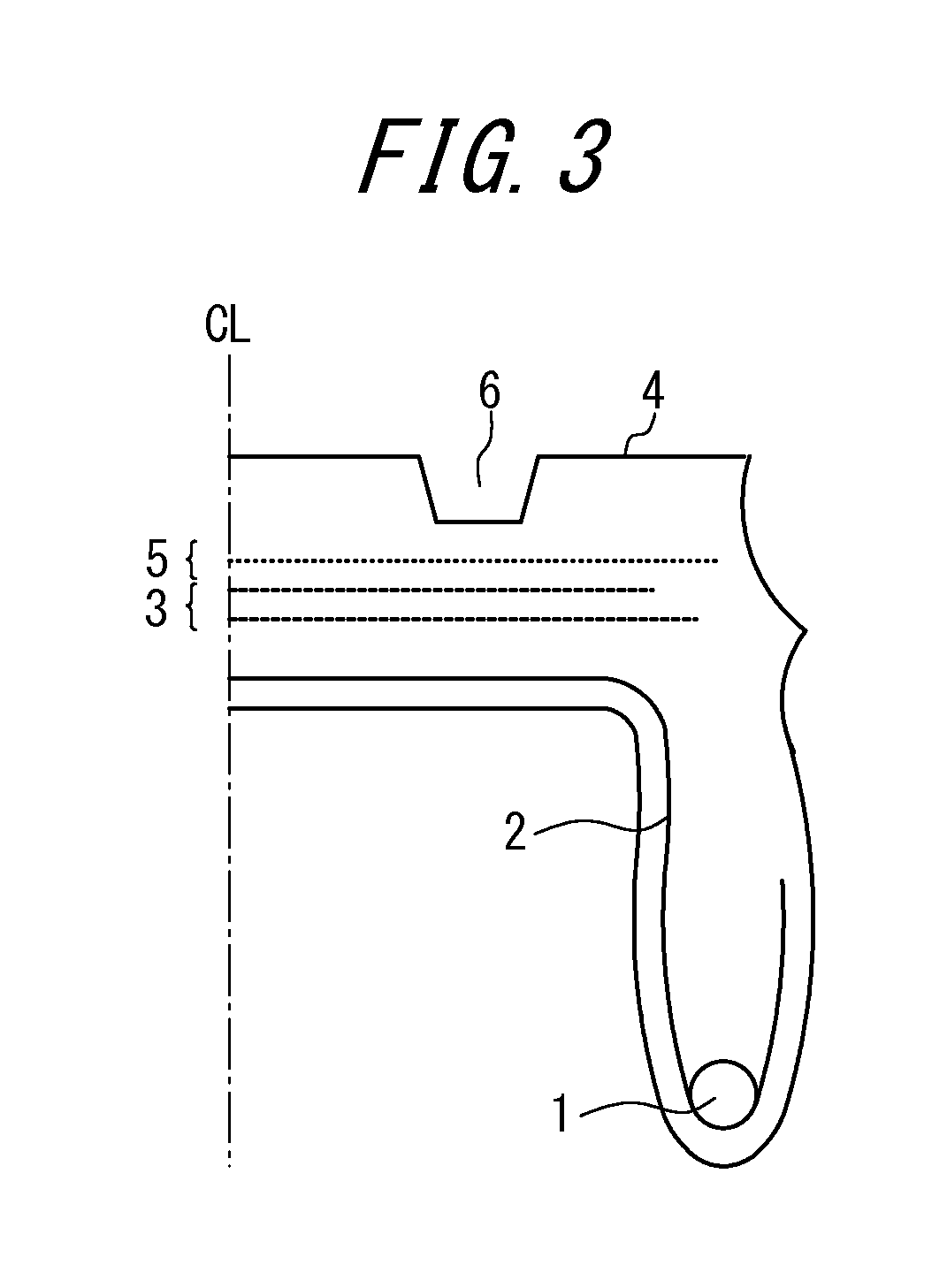

Pneumatic radial tire with specified under-belt pad rubber compound

A pneumatic radial tire is provided which comprises an under-belt pad (3) provided circumferentially between edge portions of a belt (1) and a carcass in a shoulder portion thereof, the under-belt pad (3) being of a rubber compound containing 10 to 60 parts by weight of carbon black and 3 to 30 parts by weight of silica with a total amount of carbon black and silica being 20 to 65 parts by weight, 2 to 5 parts by weight of sulfur and 0.5 to 3 parts by weight of resorcin or a resorcin derivative all relative to 100 parts by weight of rubber, and 0.5 to 2 parts by weight of hexamethylene tetratine or a melamine derivative as a methylene donor relative to 1 part by weight of the resorcin or the resorcin derivative, and having a dynamic viscoelasticity E' of 5 MPa to 10 MPa, a loss tangent tan delta of 0.10 to 0.18 and a 300% modulus of 11 MPa to 15 MPa.

Owner:TOYO TIRE & RUBBER CO LTD

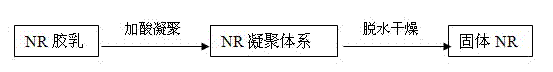

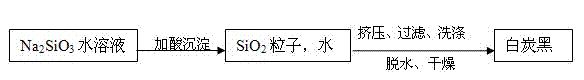

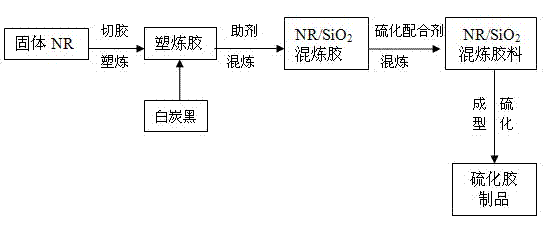

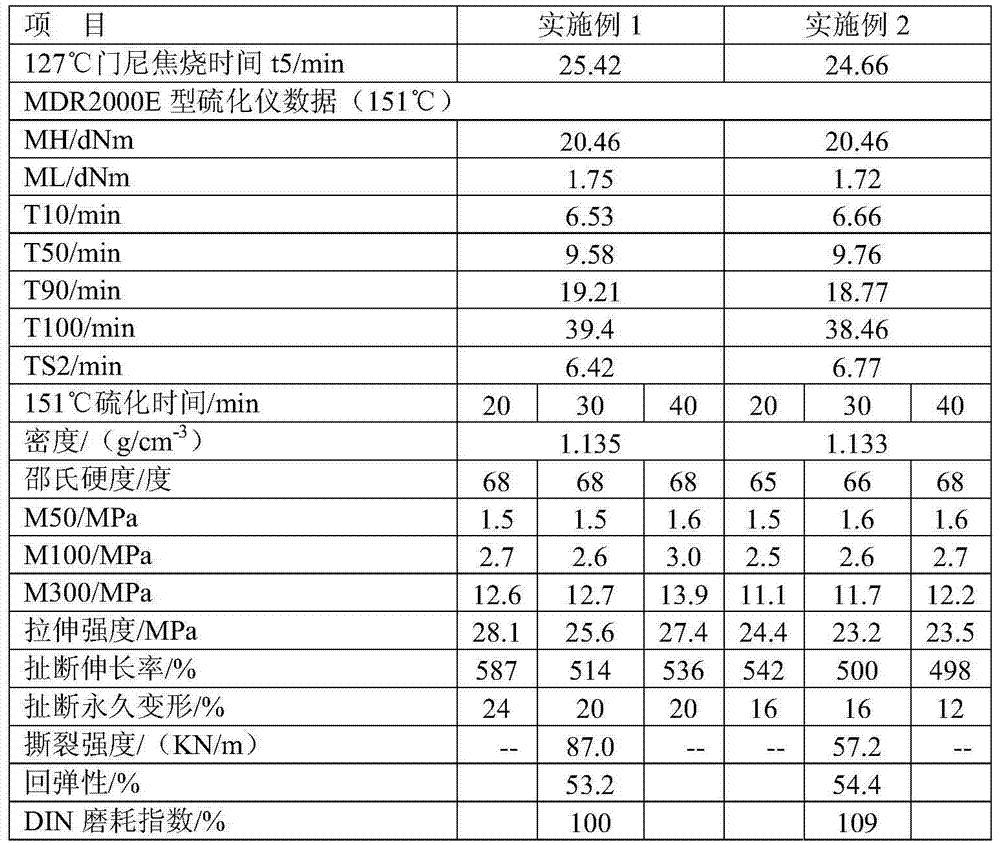

Wet smelting method for preparing natural rubber/nanometer silicon dioxide rubber compound

ActiveCN102775618AGrowth inhibitionImprove adsorption capacityRolling resistance optimizationRolling resistanceEmulsion

The invention discloses a wet smelting method for preparing a natural rubber / nanometer silicon dioxide rubber compound, which comprises the following steps of: mixing natural rubber latex with silicon sol solution to form a wet smelting system; heating the silica sol to generate condensation reaction to generate the SiO2 gel with properties, heating the wet smelting system to generate the silica sol into nanometer silicon dioxide particles in situ and uniformly dispersing the nanometer silicon dioxide particles into NR (Natural Rubber) emulsion to form the NR / nanometer silicon dioxide rubber compound after condensation and co-precipitation; and mixing the natural rubber latex with a nanometer silicon dioxide dispersing body to form the NR / nanometer silicon dioxide rubber compound after condensation and co-precipitation. The wet smelting method has the beneficial effects that the mass ratio of natural rubber / nanometer silicon dioxide prepared by the wet smelting method is 100 / 30-90, and vulcanized rubber of the nanometer silicon dioxide has excellent physical and mechanical properties and is high-quality rubber for preparing truck radial tire tread rubber with high wet skid resistance and low rolling resistance, i.e. green tire.

Owner:SOUTH CHINA UNIV OF TECH

Rubber composition for tread of truck radial tire with low hysteresis loss

ActiveCN104119578AMeet the use requirementsGuaranteed wear resistanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

The invention discloses a rubber composition for a tread of a truck radial tire with low hysteresis loss and belongs to the technical field of rubber tires. The rubber composition comprises the following components in parts by weight: 100 parts of matrix rubber, 5-7 parts of active agent, 15-30 parts of carbon black, 25-40 parts of white carbon black, 2-5 parts of silane coupling agent, 1-3 parts of white carbon black dispersant, 1-3 parts of plasticizer, 1.5-3 parts of accelerant, 3-6 parts of anti-aging agent, 1-2 parts of vulcanizing agent, 0.1-0.3 part of scorch retarder, 0-2 parts of antifatigue and 0-0.6 part of environment-friendly peptizer, wherein the matrix rubber is composed of natural rubber or natural rubber and rare earth cis-polybutadiene, the white carbon black is prepared by a high dispersing precipitation method, and the white carbon black dispersant is a higher aliphatic acid metallic soap mixture. The rubber composition disclosed by the invention has low hysteresis loss and can reduce the rolling resistance of the tire in use, so that the energy consumption of the vehicle is reduced.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Low rolling-resistance high abrasion-resistance recap vulcanized tread rubber compound and preparation method thereof

ActiveCN105367831AImprove wear performanceSolve mixingSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention relates to a low rolling-resistance high abrasion-resistance recap vulcanized tread rubber compound. The low rolling-resistance high abrasion-resistance recap vulcanized tread rubber compound comprises the following components in parts by weight: 40-60 parts of natural rubber, 40-60 parts of butadiene rubber, 25-32 parts of carbon black, 20-30 parts of white carbon black, 4-6 parts of a silane coupling agent TESPT, 0.1-0.4 parts of an environmentally friendly peptizer, 2-3 parts of stearic acid, 4-6 parts of zinc oxide, 0-2 parts of a carbon black dispersing agent, 0.5-2 parts of an antioxidant RD, 1-3 parts of an antioxidant 4020, 1-2 parts of protection wax, 1-3 parts of sulphur S-80, 1-2.5 parts of a promoter CZ-80, and 0.2-0.4 parts of a scorch retarder CTP-80. A mixing technology of the above rubber compound employs first-stage mixing and primary rubber mixing at low temperature, the produced tread can be used for retreading the tires, compared with conventional retreaded tires, the gasoline consumption during a driving process of the vehicle is reduced by more than 3%, an Akron abrasion index is obviously better than that of the conventional low rolling-resistance load-carrying radial tire tread rubber compound, the total formula cost for recap is reduced.

Owner:SAILUN GRP CO LTD

Pneumatic radial tire including false dividing groove

A pneumatic radial tire for passenger car has a directional tread pattern (with respect to a rotating direction of tire) defined by a circumferential center groove, a plurality of directional slant grooves disposed at intervals in the circumferential direction of the tire, and a plurality of blocks formed at intervals in both circumferential and axial directions of the tire, in which these blocks form a pair of central block rows and a pair of side block rows, and surfaces of acute corner portions of blocks constituting the central block row and the side block row located outward and inward in the axial direction of the tire at given length, and chamfered acute corner portions of blocks constituting the central block row and the side block row are connected to each other at their chamfered shallowest tips.

Owner:BRIDGESTONE CORP

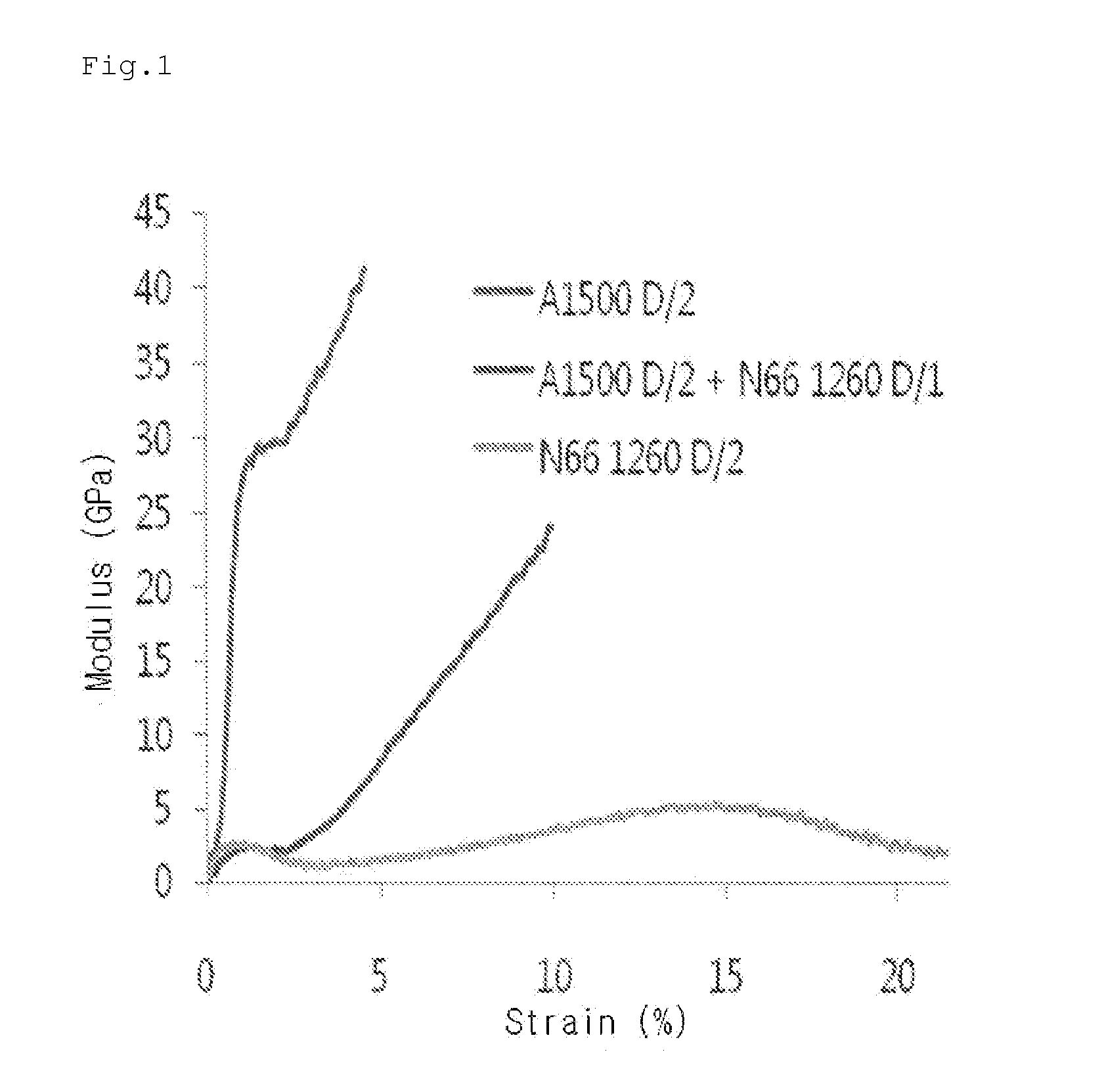

Hybrid cord composed of aramid cord and nylon 66 cord, and pneumatic tire using the same as reinforcing cord

InactiveUS20130025758A1High speed durabilityImprove steering stabilityPneumatic tyre reinforcementsYarnNylon 66Engineering

Provided is a high-performance pneumatic radial tire for passenger cars which uses a hybrid cord composed of an aramid cord and a Nylon 66 cord having different twist counts for the first twist and different twist counts for the second twist, as a reinforcing belt, and thereby has improved high speed durability and steering stability.

Owner:HANKOOK TIRE WORLDWIDE

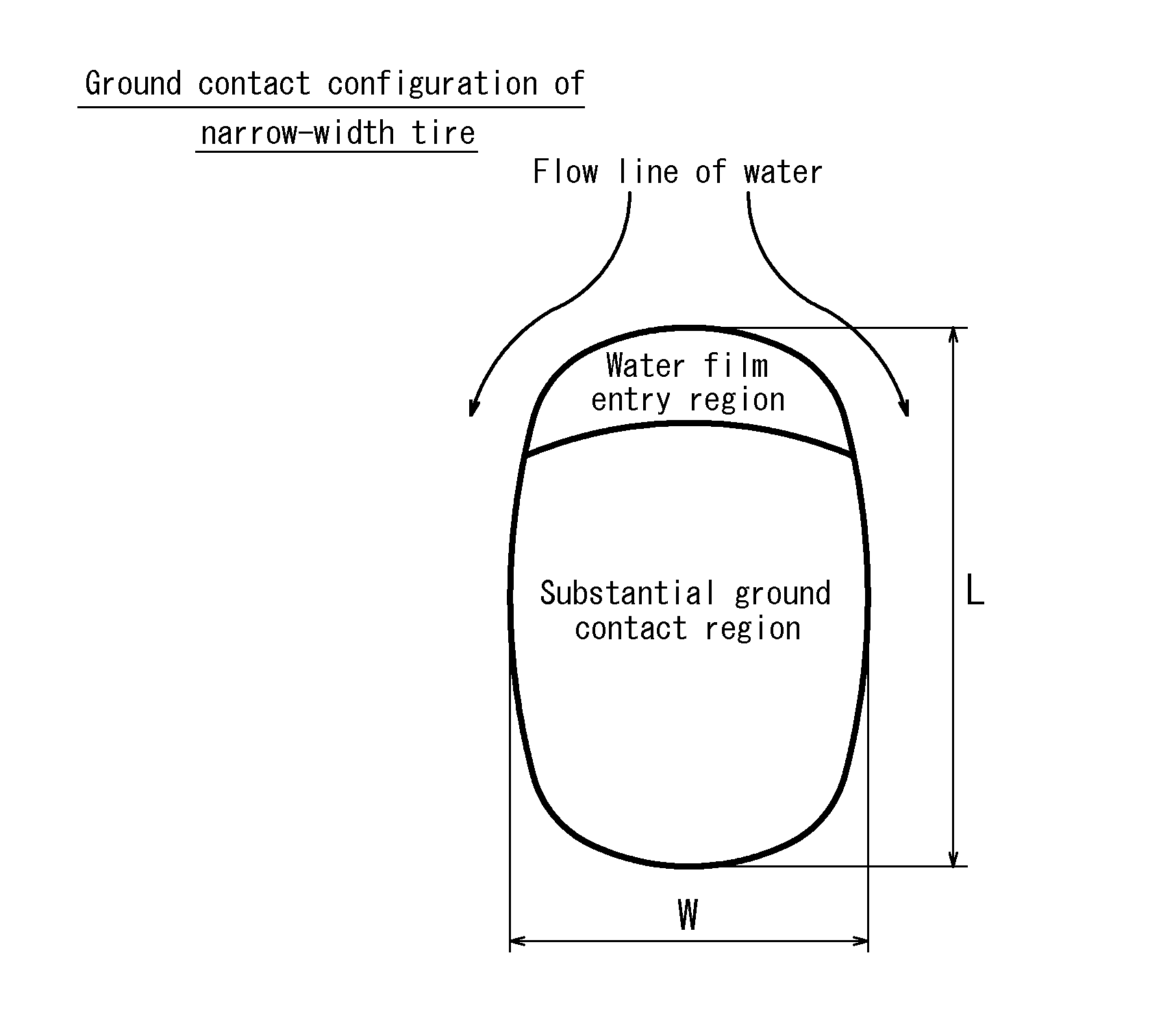

Pneumatic radial tire for passenger vehicle and method for using the same

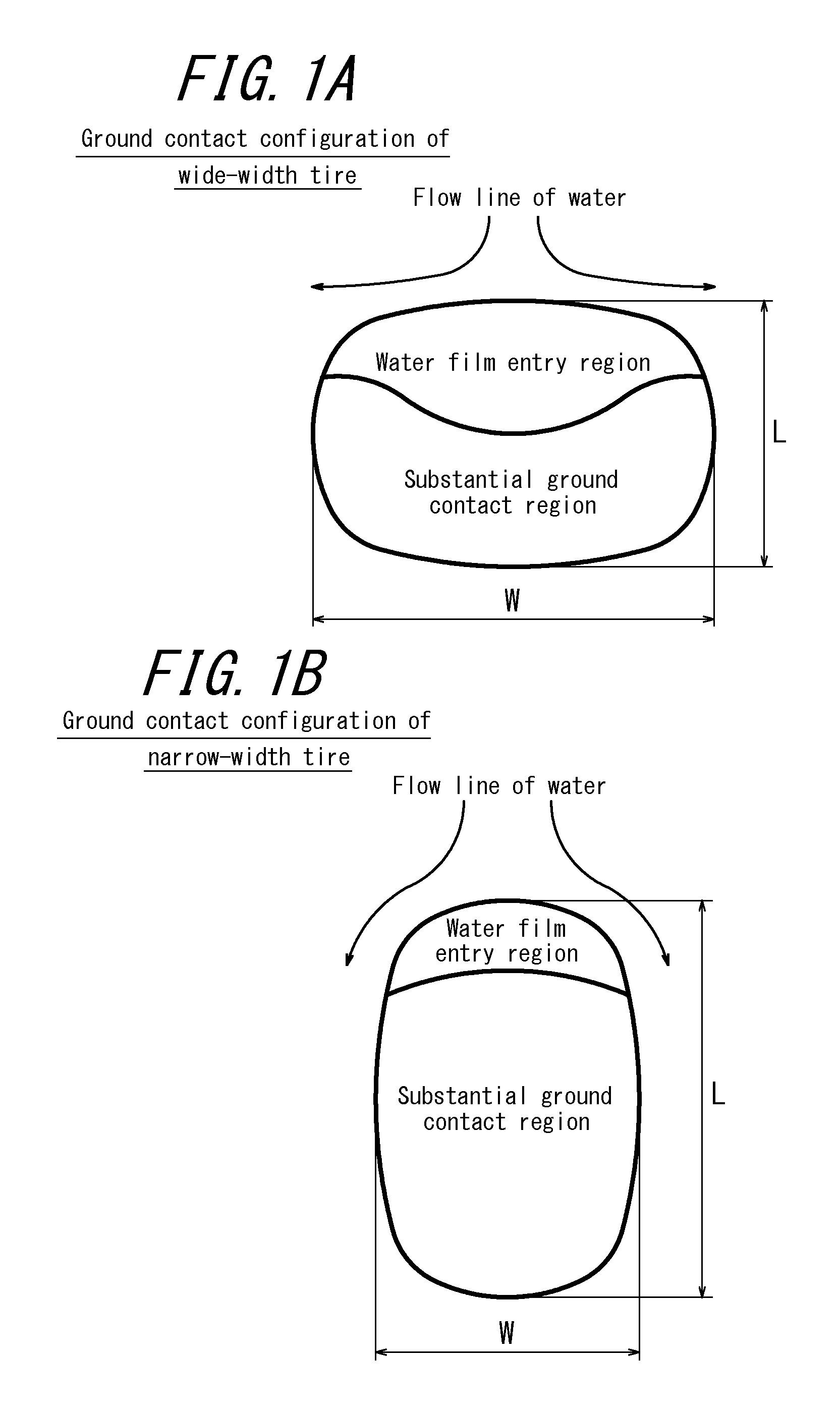

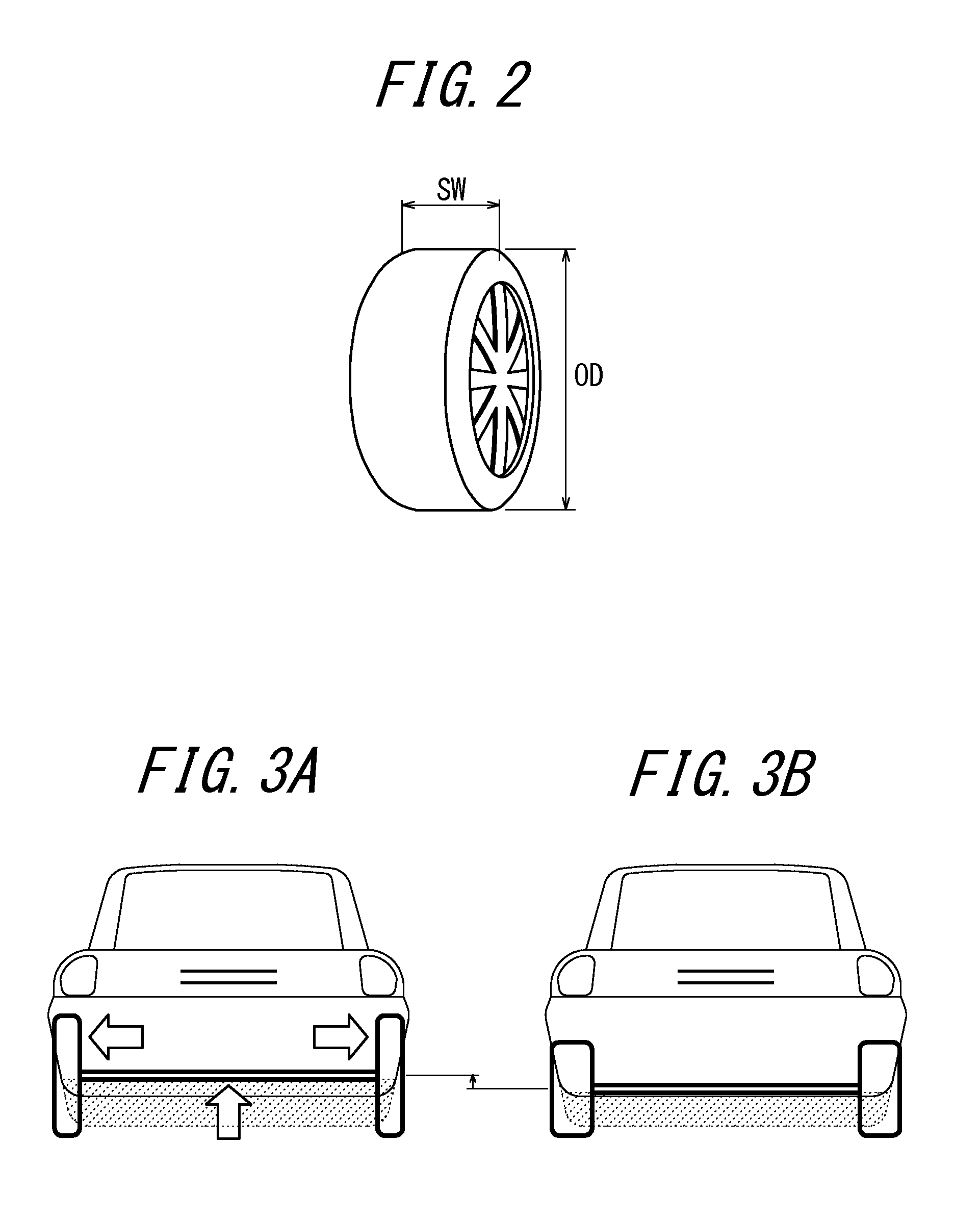

ActiveUS20140290820A1Wide spaceGuaranteed uptimeSpecial tyresInflatable tyresGroove widthGround contact

An object of the present invention is to adequately control relationship between a cross sectional width SW and an outer diameter OD of a pneumatic radial tire for a passenger vehicle. Specifically, a ground contact surface 1 of the tread of the pneumatic radial tire for a passenger car of the present invention is provided with either, as a groove, only at least one main groove 2a extending in the tread circumferential direction or, as grooves, only the main groove 2a and at least one auxiliary groove 2b other than the main groove, wherein the auxiliary groove has a groove width≦2 mm in a tread widthwise region and a negative ratio of the main groove 2a is in the range of 12% to 20% (inclusive of 12% and 20%).

Owner:BRIDGESTONE CORP

Semi-steel wire radial tire undertread calendering sizing compound

The invention relates to calendering belt compound in a semi-steel wire radial tyre. The main points are as follows: the belt glue stuff is prepared from various materials which comprise natural rubber (code: SMR20), carbon black N326, carbon black N660, white carbon black, a silane coupling agent, zinc oxide, an antioxidant 4020, an antioxidant RD, resorcinol-80, a binding agent RA-65, an accelerator DZ, insoluble sulfur IS-7020 and a scorch retarder CTP.

Owner:SICHUAN TYRE & RUBBER CO LTD

Flat Heavy-Duty Pneumatic Radial Tire and Method of Manufacturing the Same

InactiveUS20090211685A1Improving its durability and partial-wear resistance and its driving stabilityIncrease stiffnessPneumatic tyre reinforcementsWood working apparatusShell moldingEngineering

A flat heavy-duty pneumatic radial tire having a 0-degree belt layer formed of steel cords and increased in durability, wherein multiple plies of steel cord belt layers (6) are disposed on the outer periphery of a carcass layer (4). The steel cord belt layers (6) includes at least one ply of the 0-degree belt layer with a cord angle of substantially 0° relative to the circumferential direction of the tire and at least two plies of bias belt layers (8) with a cord angle substantially equal to an equilibrium angle of within a range of 45° to 65° relative to the circumferential direction of the tire. The tire is manufactured as follows. The tire cured and molded in a mold is released from the mold, assembled with a rim to be inflated while the tire is hot, and then cooled to normal temperature under the inflated condition.

Owner:THE YOKOHAMA RUBBER CO LTD

Mine-type all-steel radial truck tire tread rubber and preparation method thereof

InactiveCN102276881AImprove crack resistanceImprove fracture resistanceMicrocrystalline waxCrack resistance

The present invention relates to a kind of preparation method of mine-type all-steel radial truck tire tread rubber, which comprises the following process steps: (1) masticating natural rubber, styrene-butadiene rubber and peptizer in a mixing chamber, and then adding charcoal black, silica, silane coupling agent, zinc oxide, stearic acid, plasticizer and anti-crack resin, continue mixing, then add carbon black for mixing, and finally inject aromatic oil for mixing, and carry out mixing after mixing Glue removal to obtain one section of masterbatch; (2) cooling one section of masterbatch to normal temperature; (3) mixing one section of masterbatch with carbon black, antioxidant A, antioxidant B and microcrystalline wax in the mixing chamber, mixing After refining, carry out debinding to obtain the second-stage masterbatch; (4) cool the second-stage masterbatch to normal temperature; (5) mix the second-stage masterbatch and sulfur, accelerator and anti-scorch agent in the mixing chamber, mix After the rubber is discharged, the finished tread rubber is obtained. The invention can improve the crack resistance, fracture resistance, fatigue resistance and impact resistance of the radial tire tread.

Owner:JIANGSU GENERAL SCI TECH

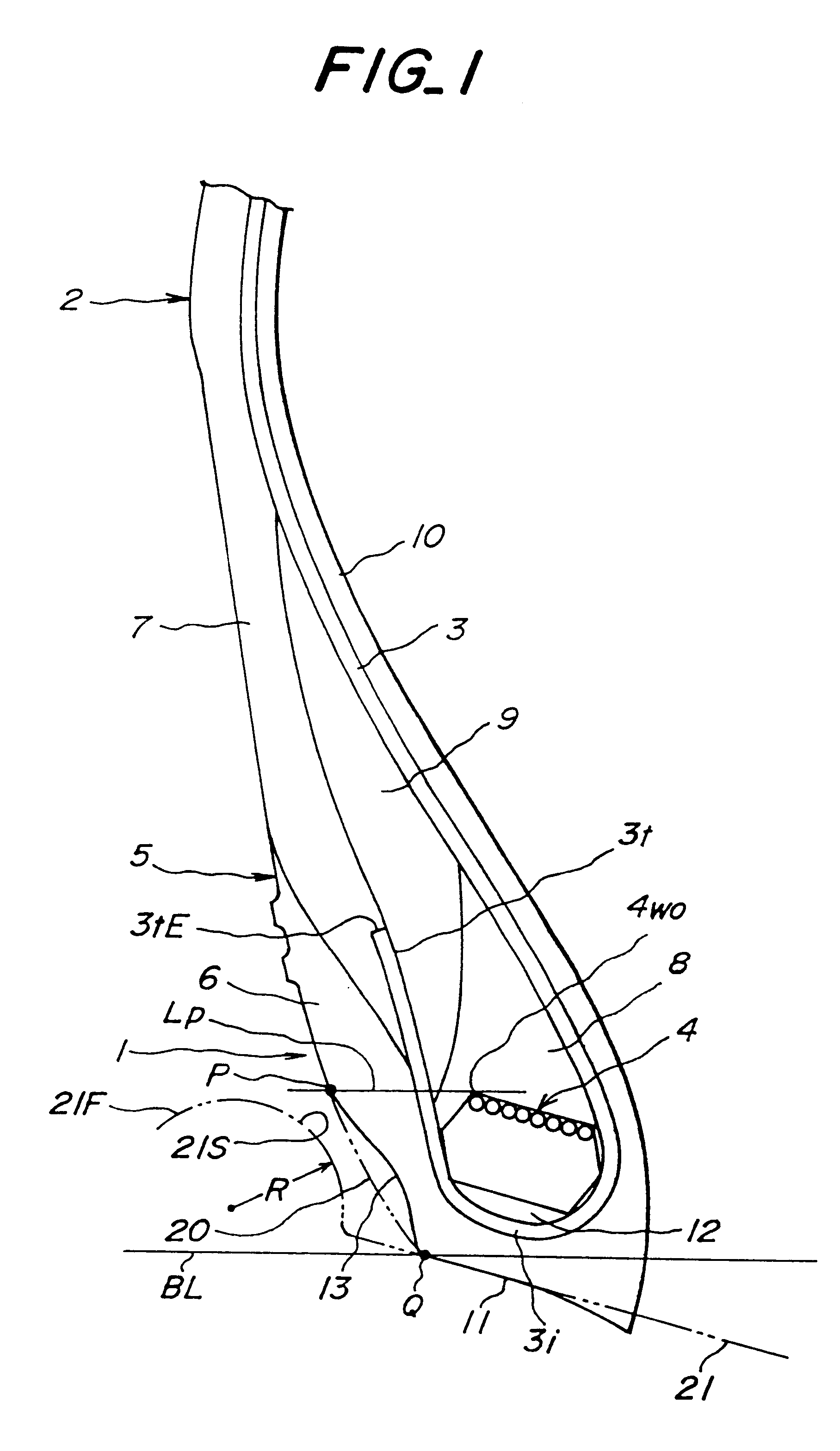

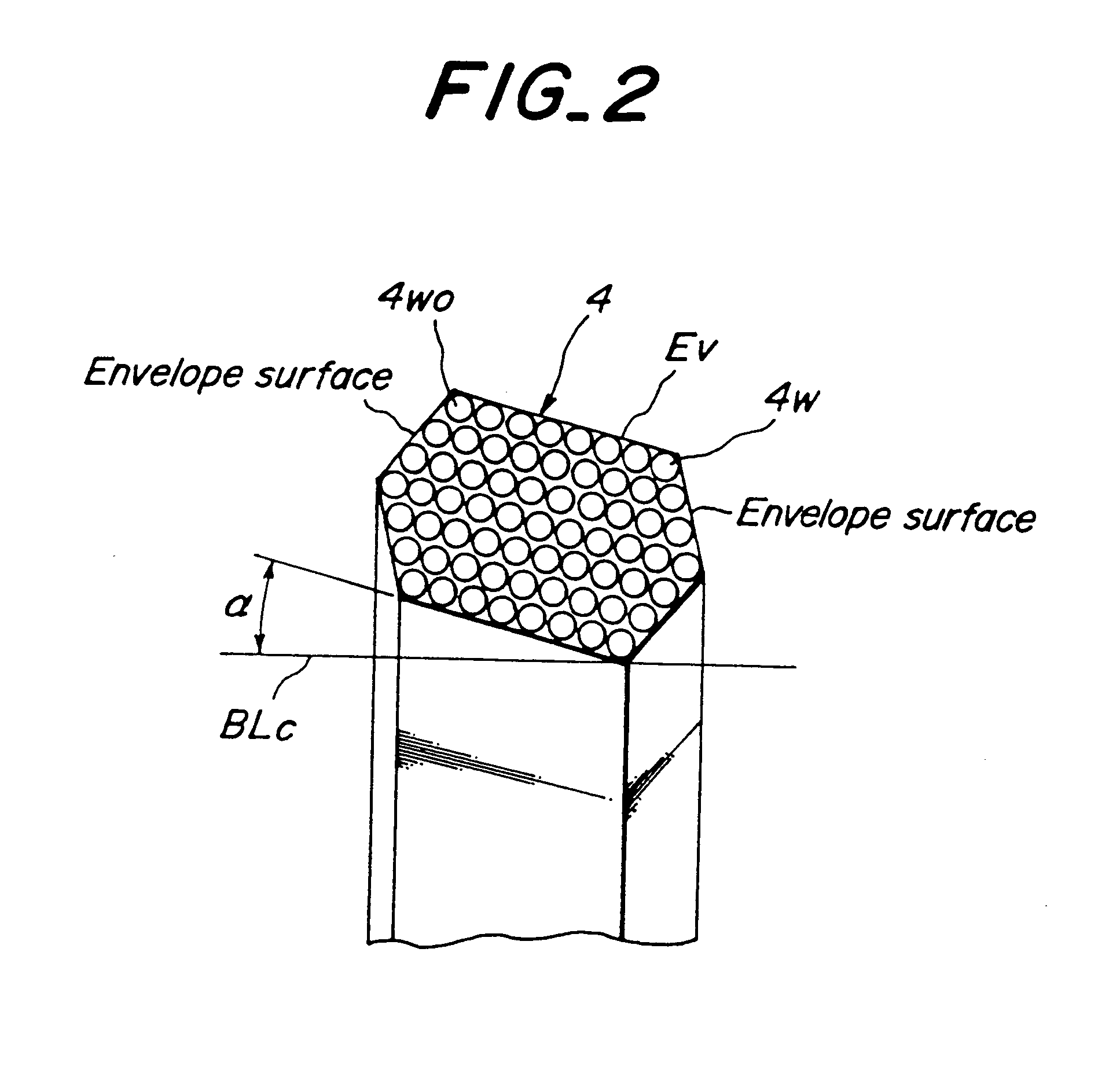

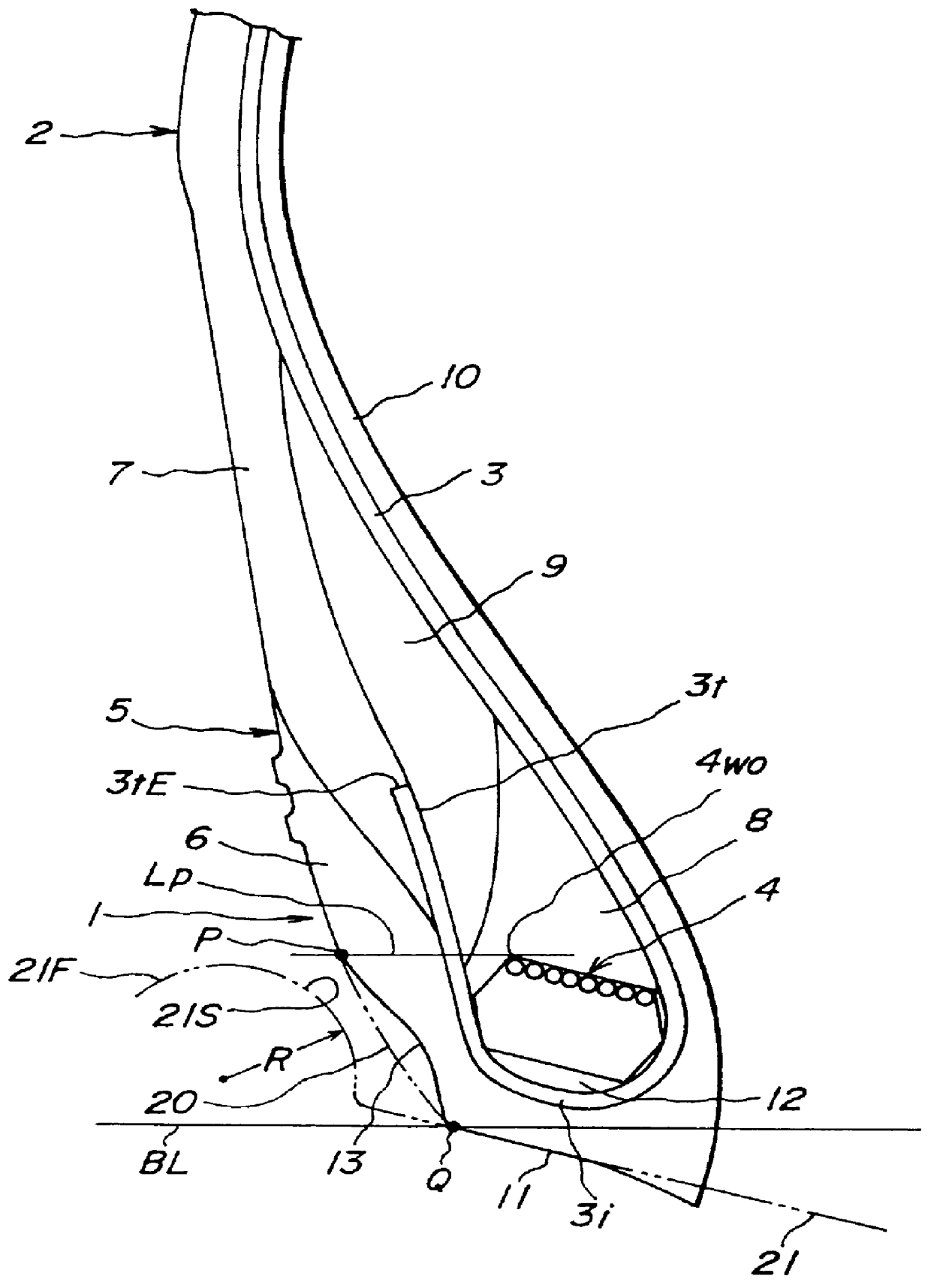

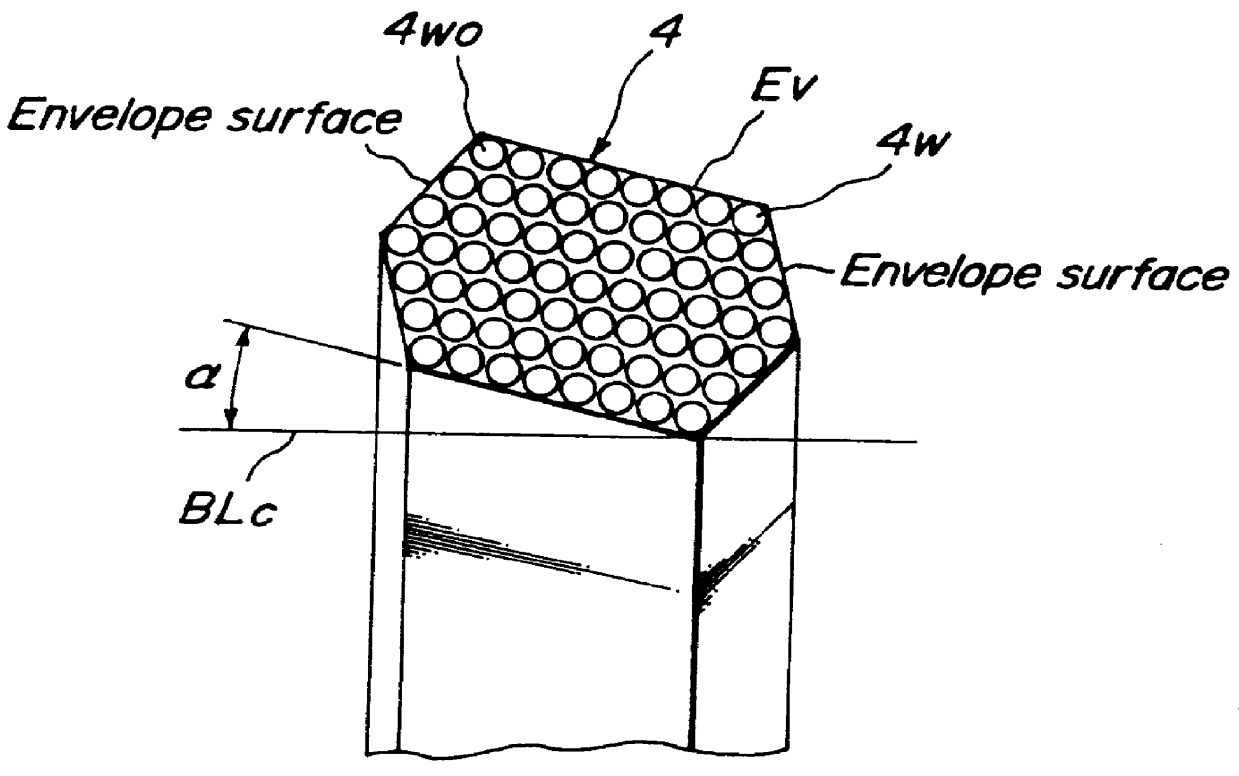

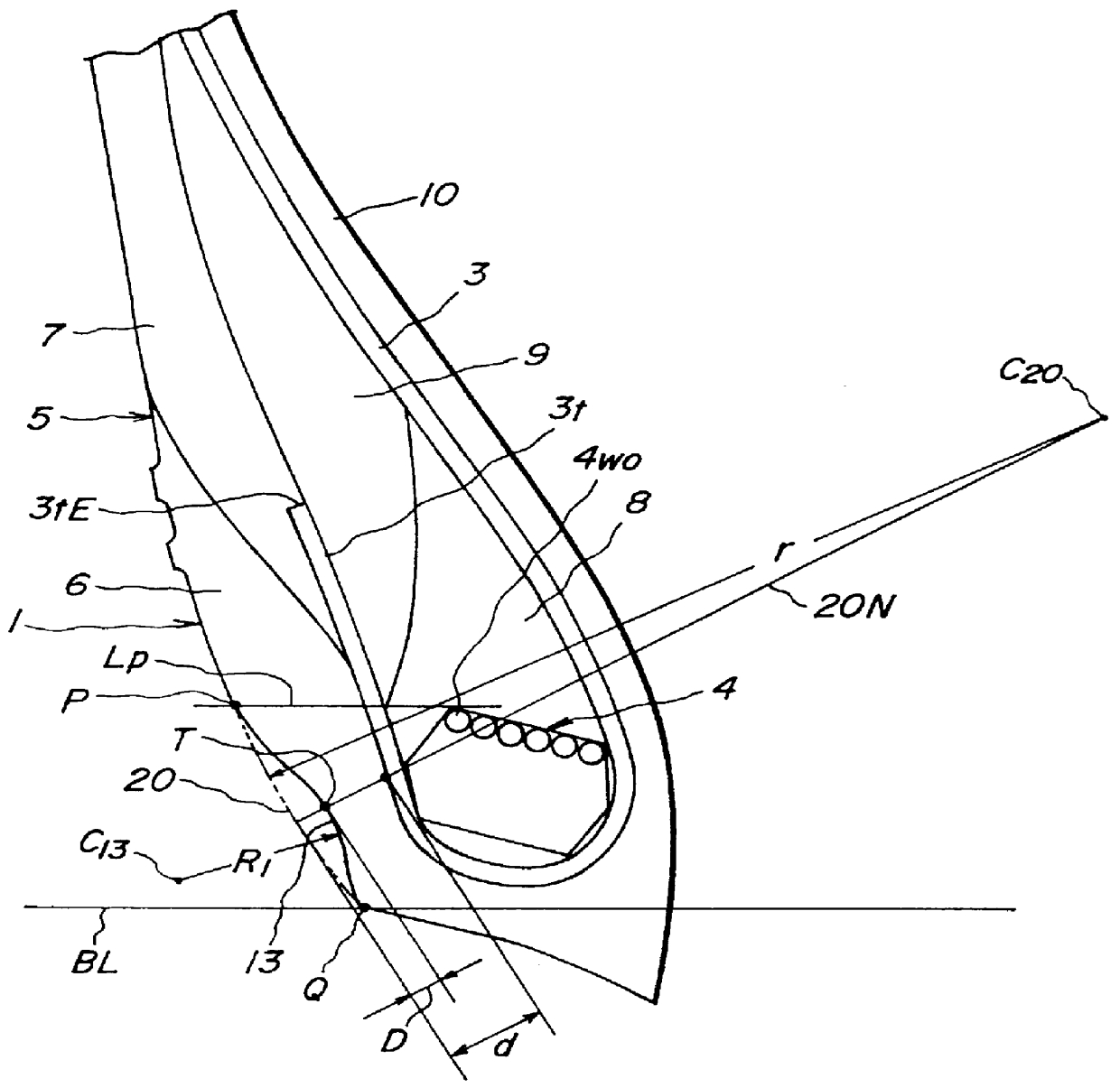

Pneumatic radial tires for trucks and buses mounted on 15 degree drop center rim

InactiveUS6345657B1Water treatment parameter controlFatty/oily/floating substances removal devicesCurve shapeEngineering

In a pneumatic radial tire for trucks and buses mounted on an approved 15° drop center rim, an outer surface portion of a composite side-rubber and / or an envelope surface of the bead core among members constituting the bead portion of the tire has a curved shape concavedly directed toward the outside of the tire at a region opposite to an inner curved surface of a slantly rising portion in a flange of the approved rim.

Owner:BRIDGESTONE CORP

Meridian tyre belted layer component and preparation technology thereof

InactiveCN101613493AReduce pollutionImprove surface Green intensitySpecial tyresPneumatic tyre reinforcementsVulcanizationThree stage

The invention discloses a meridian tyre belted layer component and a preparation technology thereof. Base material rubber, an aging-proof system, a reinforcing system, an adhesion system, a softener, a vulcanization system and a radiosensitizer are mixed at a ratio to form a mixture; the mixture is performed with three-stage mixing to prepare mixed rubber; a steel wire tire cord is made into a meridian tyre belted layer component by coating and calendaring; on a transmission device below a constant tension traction beam below an electron accelcrator, the tyre belted layer component is performed with radiation processing by adjusting the beam current energy of the electron accelcrator; under the condition of limited-oxygen radiation, the preparation of the meridian tyre belted layer component is finished. The radiated belted layer glue stock of the invention has high Green strength, stable structure size and performance, lowered belted layer thickness, small amount of rubber, high production efficiency and energy saving, lowers investment cost and protection cost, is favourable for environment protection, and can improve the quality of meridian tyres.

Owner:BEIJING RADIATION APPL RES CENT

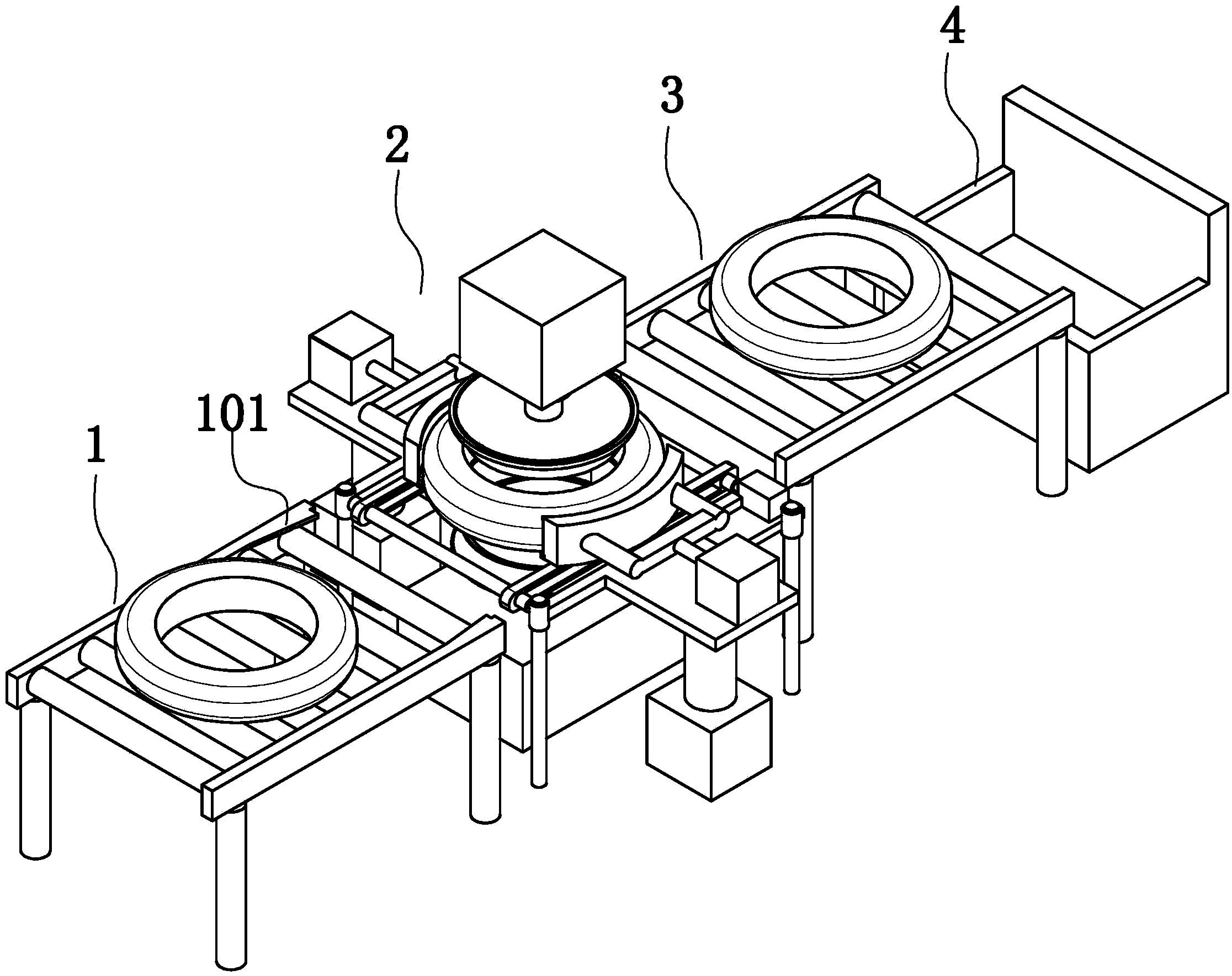

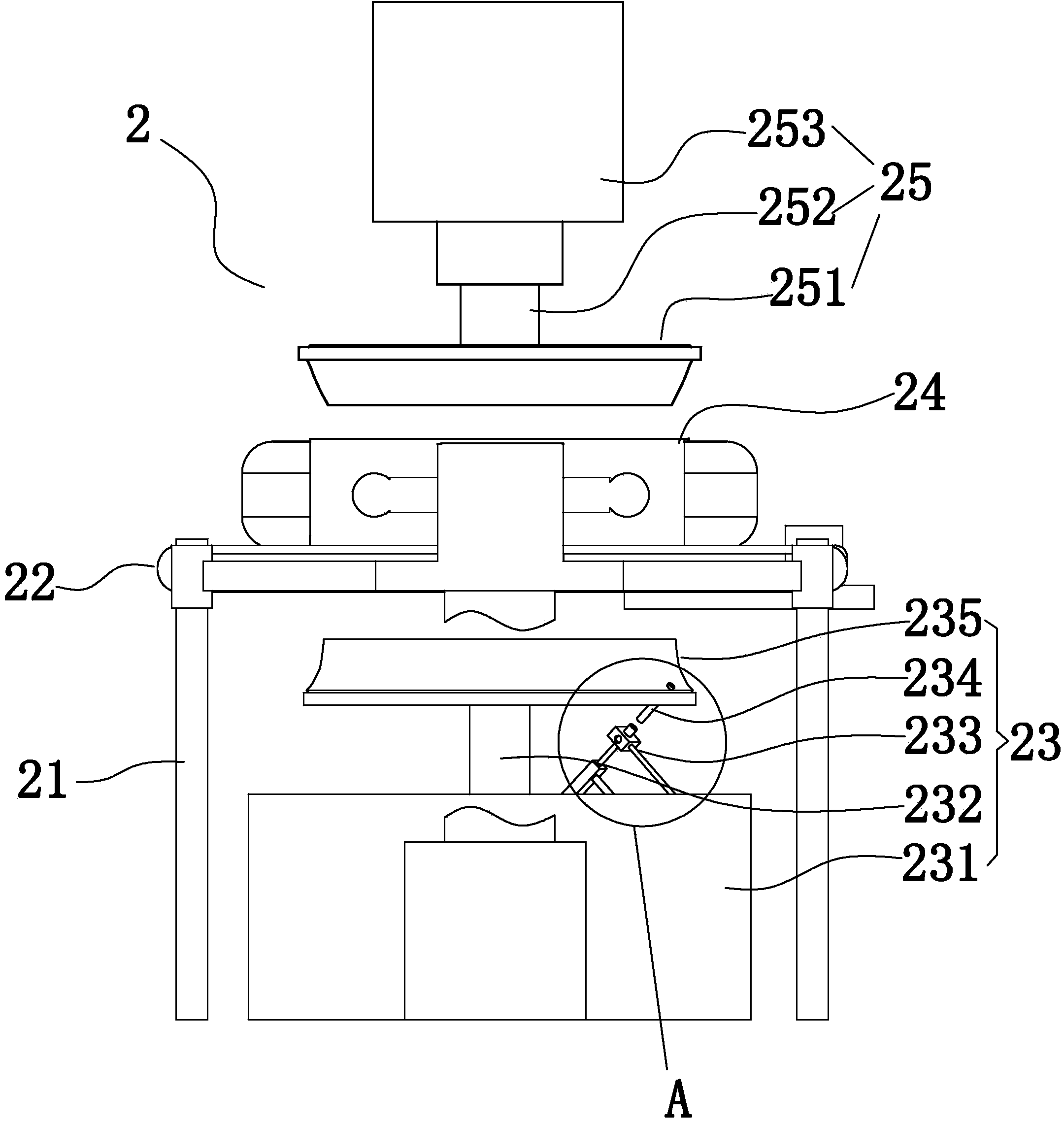

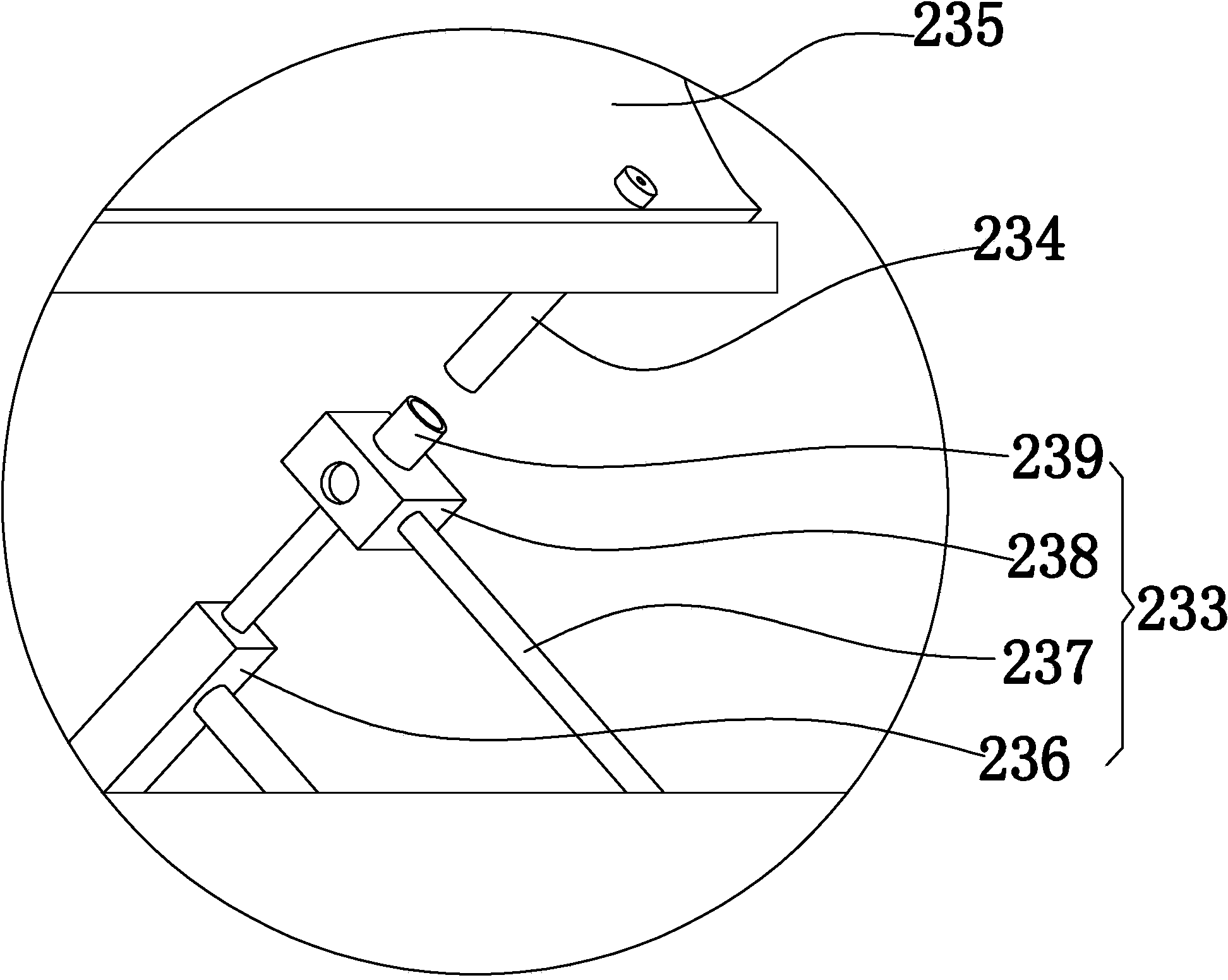

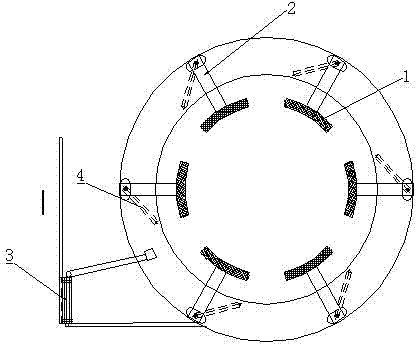

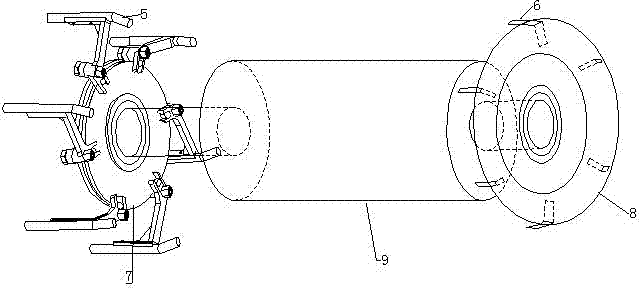

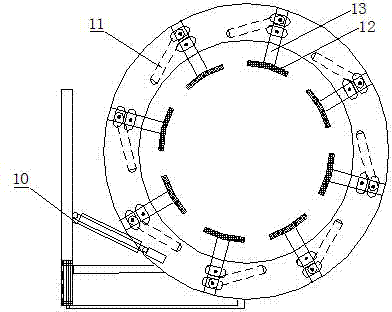

Radial tire dynamic balance intelligent detection device

ActiveCN104142211AHigh degree of automationImprove work efficiencyStatic/dynamic balance measurementDrive shaftDynamic balance

The invention discloses a radial tire dynamic balance intelligent detection device which is high in automation degree and working efficiency and capable of automatically detecting the dynamic balance of a tire. The radial tire dynamic balance intelligent detection device comprises a front-segment conveying line, a dynamic balance detection platform and a rear-segment conveying line, wherein the front-segment conveying line, the dynamic balance detection platform and the rear-segment conveying line are arranged in sequence. The dynamic balance detection platform comprises supporting columns, a lifting platform capable of ascending and descending along the supporting columns, a power base located below the lifting platform and a driven device located above the lifting platform. The power base comprises a power shaft, a driving device and a lower half rim arranged at the upper end of the power shaft. The driven device comprises a driven shaft, a second lifting mechanism used for driving the driven shaft to ascend and descend and an upper half rim capable of rotating around the driven shaft. The upper end face of the lower half rim and / or the lower end face of the upper half rim is provided with a sealing gasket / sealing ring. The lifting platform is provided with a pair of parallel conveying belts and a transverse clamping mechanism located above the conveying belts.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

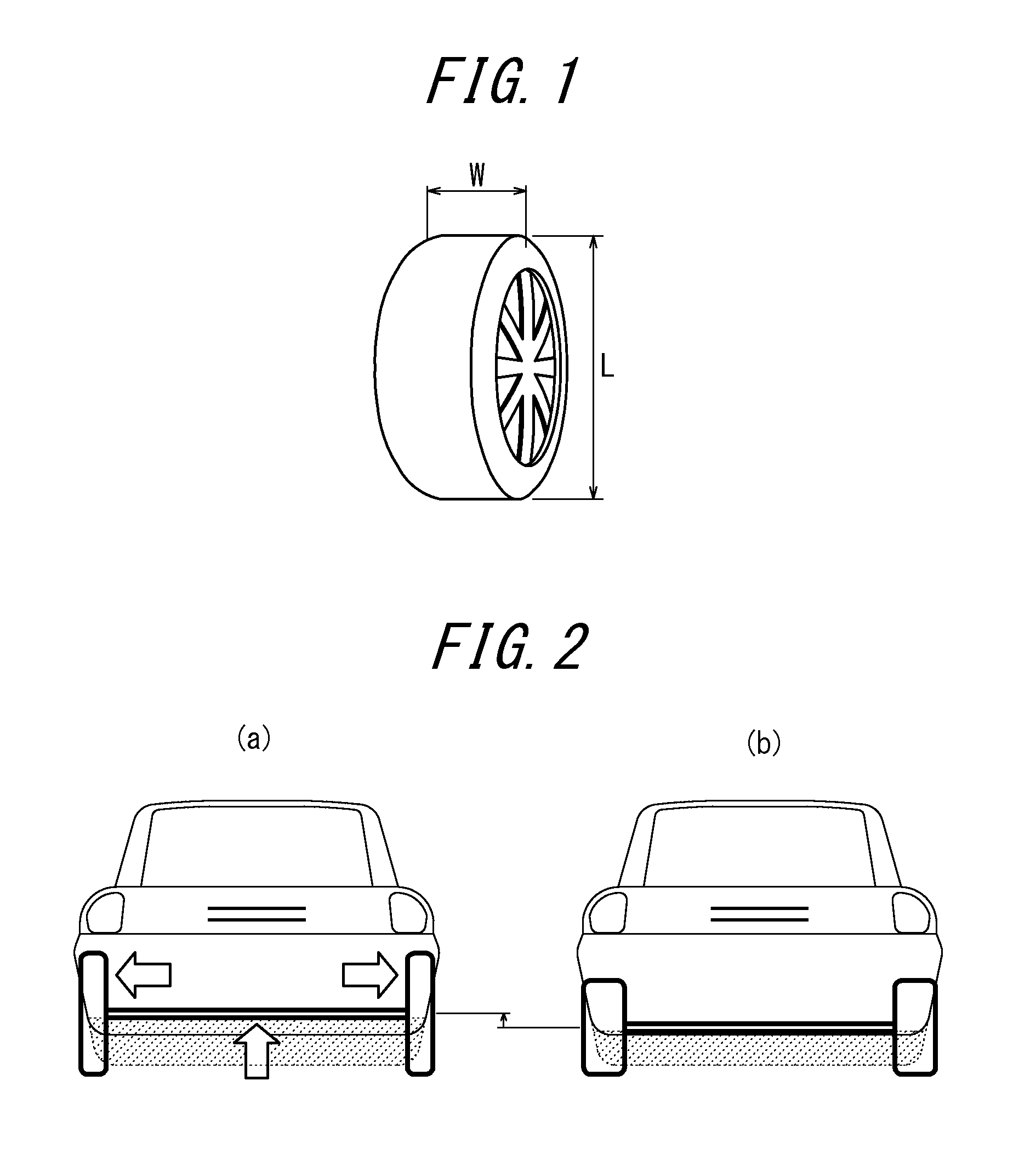

Pneumatic radial tire for passenger vehicles

InactiveUS20130042953A1Improve fuel efficiencyReduction factorSpecial tyresPneumatic tyre reinforcementsFlat tireRun-flat tire

A run-flat tire of the present invention is a pneumatic radial tire for passenger vehicles which has a carcass composed of plies of radially arranged cords toroidally extending between a pair of bead portions, and the a W / L ratio of the section width W to the outer diameter L of the tire is 0.25 or less.

Owner:BRIDGESTONE CORP

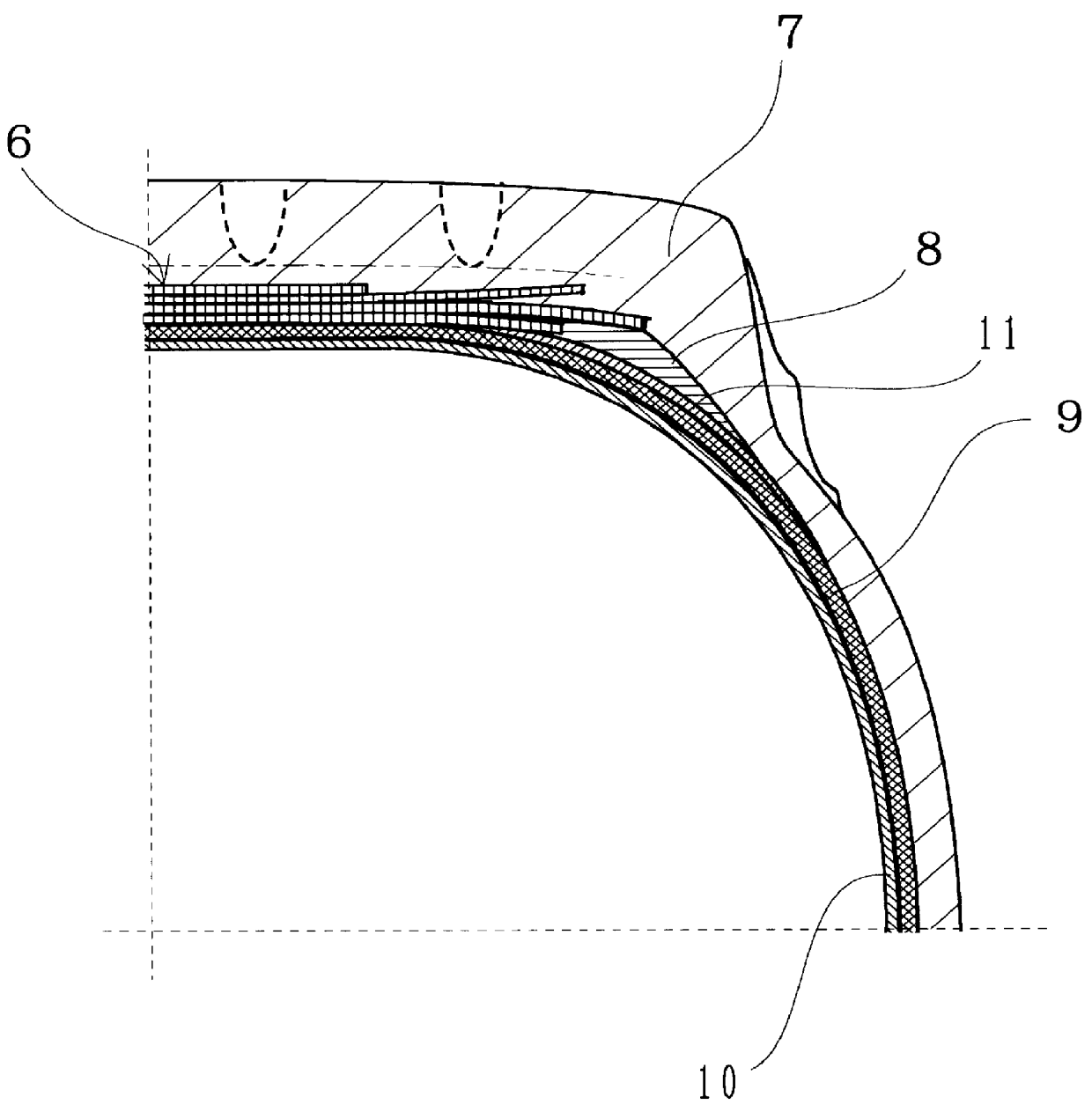

Pneumatic radial tire

InactiveUS20120318427A1Increased durabilityAvoid separationHeavy duty tyresHeavy duty vehicleTire beadPolymer science

A pneumatic radial tire has a rubber filler includes a lower filler and an upper filler. The lower filler surrounds a bead core and has a round cross sectional shape. The upper filler has a lower rubber hardness than the lower filler. A chafer is wound up around the bead core outside of a carcass ply and includes a metal cord. A wound-up end of the carcass ply is arranged radially outside of an upper end of the lower filler and a wound-up end of the chafer. A rubber pad has a higher rubber hardness than the upper filler and sandwiches the wound-up end of the carcass ply. The rubber pad extends to radially inside of the upper end of the lower filler and contacts with an inside of a wound-up portion of the carcass ply.

Owner:TOYO TIRE & RUBBER CO LTD

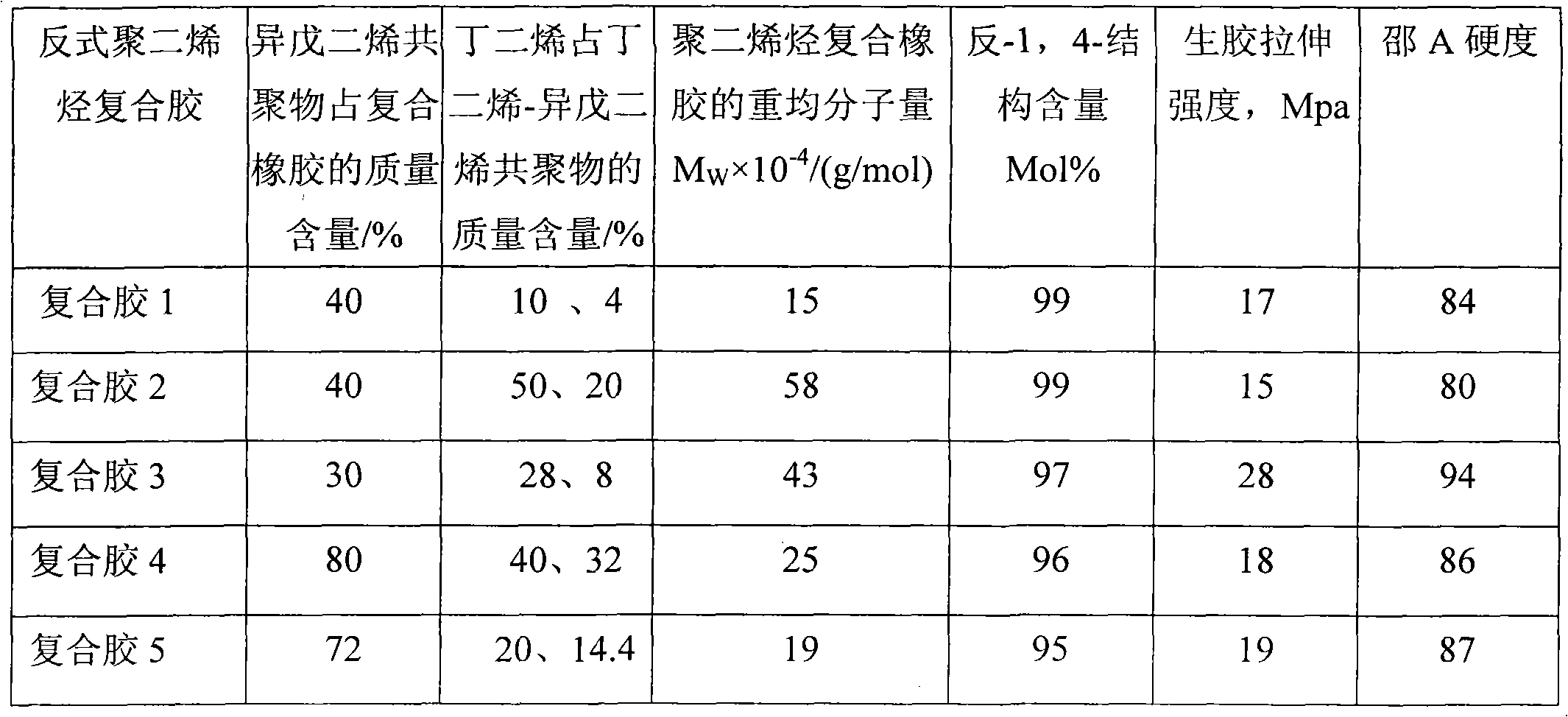

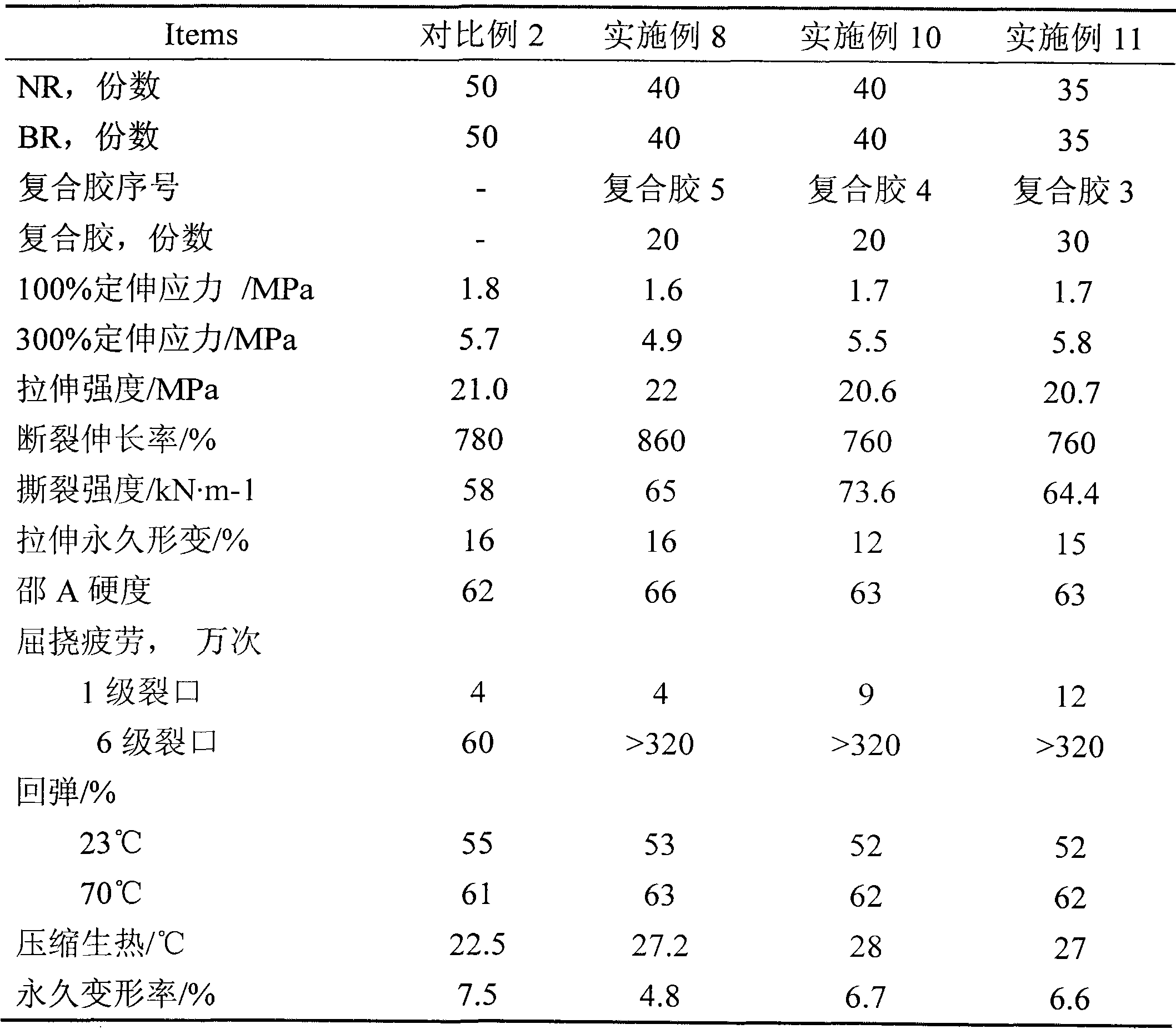

Application of trans-1,4-polydiene composite rubber in rubber products

The invention discloses a use of a trans-1,4-polydiene composite rubber, and an application formula of the trans-1,4-polydiene composite rubber. The composite rubber is composed of 10-80% by mass of trans-1,4-polyisoprene and 20-90% by mass of a trans-1,4-butadiene-isoprene copolymer, and the copolymer is composed of 0.1-99.9mol% of a butadiene unit and 0.1-99.9mol% by mole of an isoprene unit. The substitution of natural rubber and / or styrene-butadiene rubber and / or butadiene rubber in a tire surface rubber by 5-30 parts of the composite rubber obviously improves the wear resistance of a tire and reduces the rolling resistance. The substitution of natural rubber and / or butadiene rubber in the sidewall rubber of the tire by 5-50 parts of the composite rubber obviously improves the crack increasing resistance of the tire, reduces the rolling resistance and heat generation, and makes the good traction performance of the tire be maintained, so the composite rubber is especially suitable for dynamic use rubber products comprising tires, damping materials and the like, especially tire surface rubber of all-steel radial tires or high duty tires.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

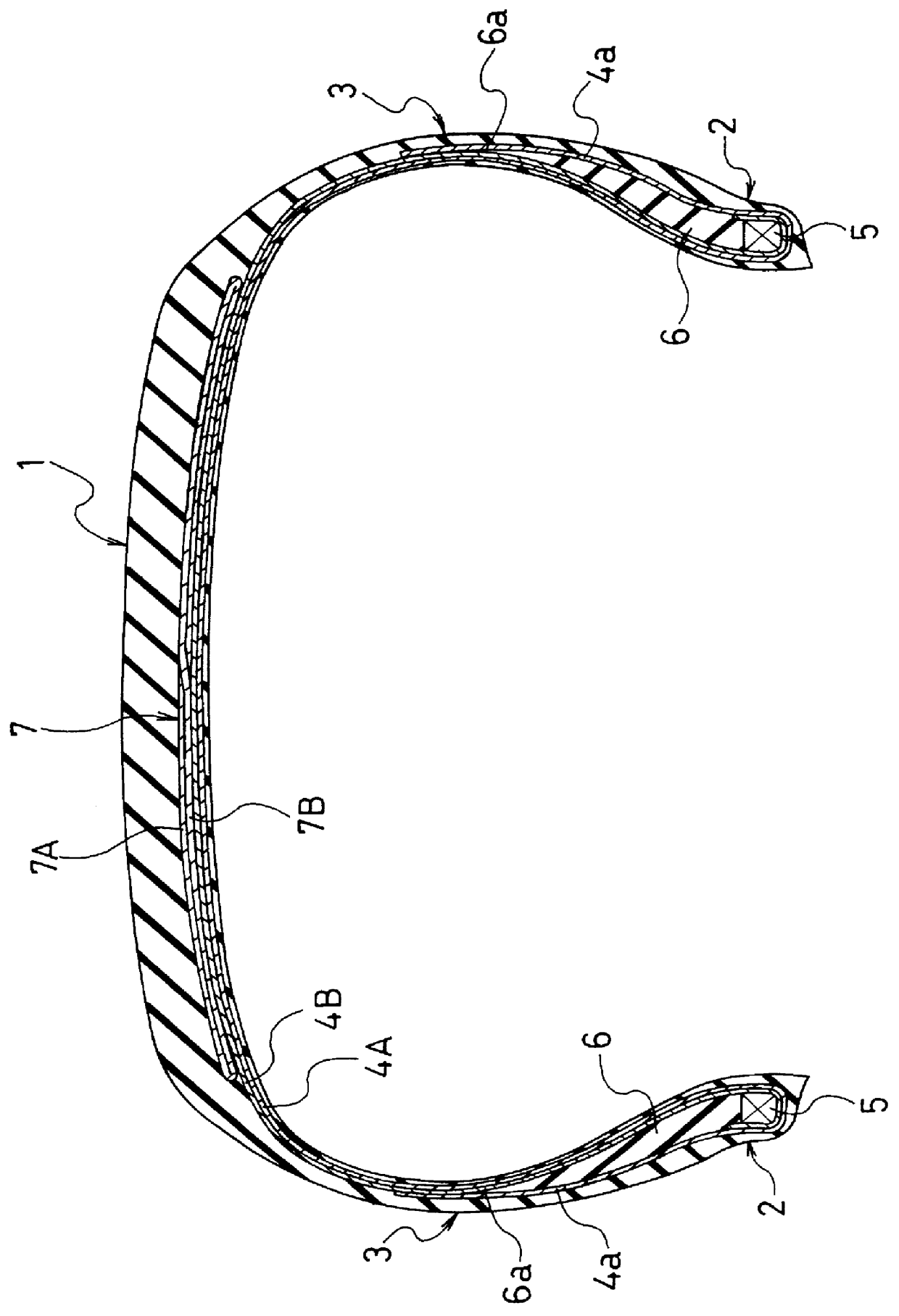

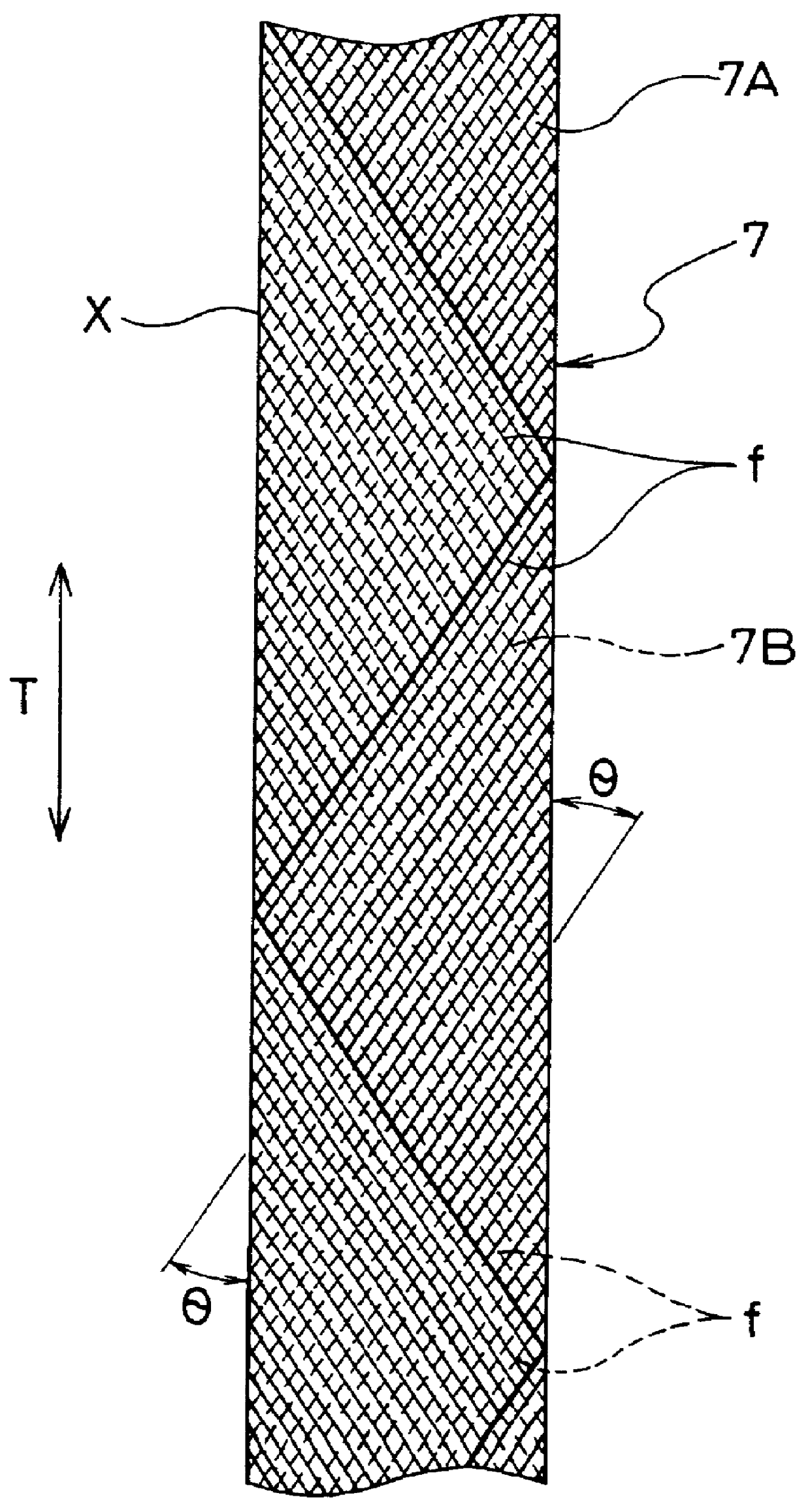

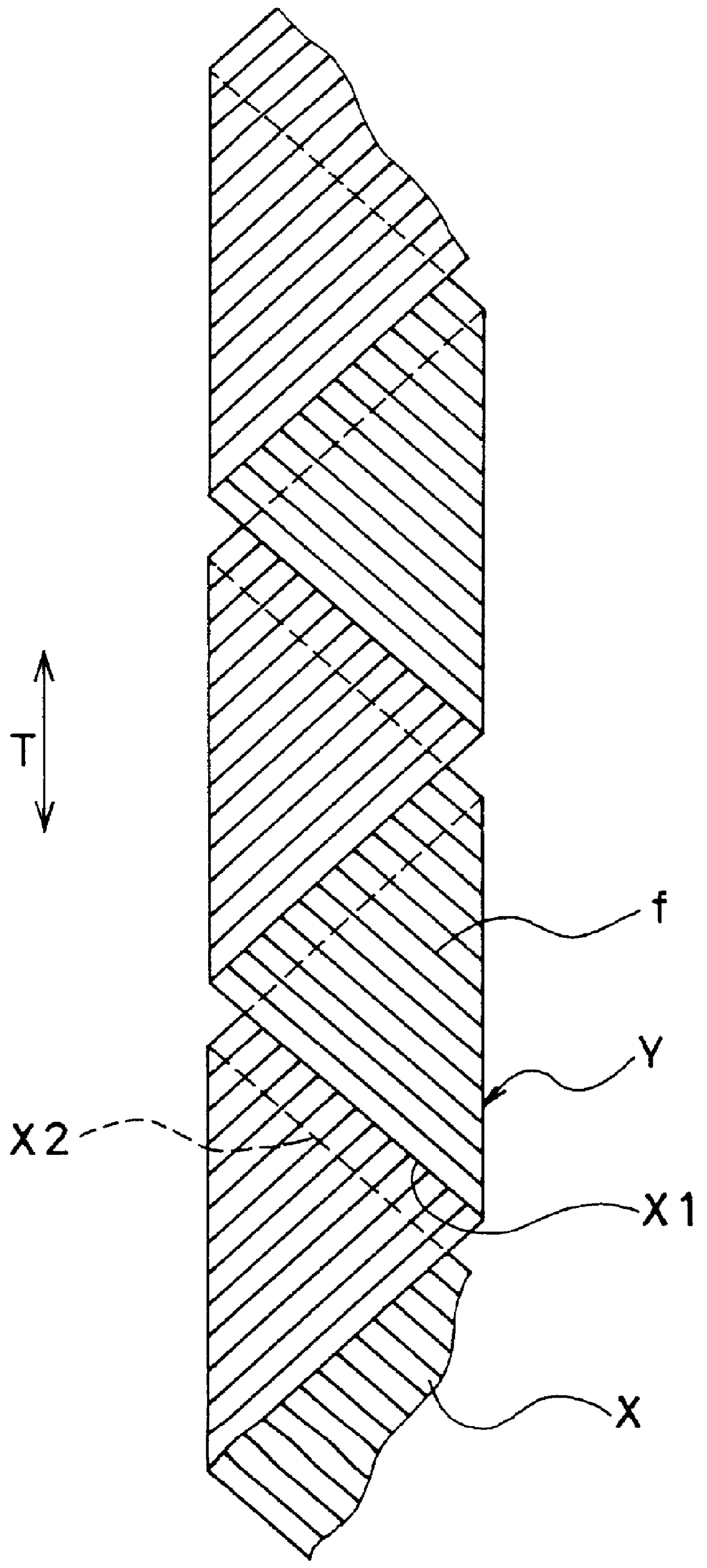

Pneumatic radial tire having at least two zigzag belt layers

InactiveUS6058997AImprove driving stabilityIncreased edge separationPneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

PCT No. PCT / JP97 / 02587 Sec. 371 Date Feb. 25, 1998 Sec. 102(e) Date Feb. 25, 1998 PCT Filed Jul. 25, 1997 PCT Pub. No. WO98 / 04424 PCT Pub. Date Feb. 5, 1998A pneumatic radial tire has at least two belt layers disposed at a tread portion thereof, wherein the two belt layers are constituted by inclining a strip formed by aligning a plurality of reinforcing cords to a tire circumferential direction and extending it zigzag in the tire circumferential direction so that the strip is turned back from the lower belt layer to the upper belt layer at both end portions of the two belt layers, and zone portions in which the reinforcing cords incline to the right in the tire circumferential direction and the zone portions in which the reinforcing cords incline to the left in the tire circumferential direction are alternately arranged.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic radial tires for trucks and buses mounted on 15 DEG drop center rim

In a pneumatic radial tire for trucks and buses mounted on an approved 15 DEG drop center rim, an outer surface portion of a composite side-rubber and / or an envelope surface of the bead core among members constituting the bead portion of the tire has a curved shape concavedly directed toward the outside of the tire at a region opposite to an inner curved surface of a slantly rising portion in a flange of the approved rim.

Owner:BRIDGESTONE CORP

Zero degree belt compound of all-steel radial tire

InactiveCN102086275AMeet processing performance requirementsSolve quality defectsSpecial tyresCyclohexylthiophthalimideAlkylphenol

The invention relates to a zero degree belt compound of all-steel radial tire, which is characterized by being prepared from a plurality of raw materials. The raw materials in formula comprises 10# natural rubber, carbon black N375, carbon black N660, hydrated silica, zinc oxide, modified alkylphenol- formaldehyde resin TKM-M, N-(1,3-dimethylbutyl)-N'-phenyl p phenylenediamine, resorcinol formaldehyde resin, cobalt boroacylate, hexamethoxy methyl melamine, N-t butyl-2-benzothiazolesulfenamide, insoluble sulfur HD OT20 and N-cyclohexylthiophthalimide. The invention is used as zero degree belt compound in all-steel radial tire production. The rubber compound of the invention has the advantages of reducing extrusion temperature of the zero degree belt, improving extrusion speed, increasing surface viscosity of the zero degree belt, prolonging holding time of viscosity, improving rubber-coating effect, and effectively solving the quality problems of point-like copper exposition and poor surface viscosity.

Owner:SICHUAN TYRE & RUBBER CO LTD

Three-drum forming method of full steel wire loading radial tire via one-time method

ActiveCN102371696AAchieve precise positioningIncrease the level of automationTyresTire beadMechanical engineering

The invention relates to a three-drum forming method of a full steel wire loading radial tire via a one-time method, belonging to the manufacturing technical field of a tire. A tire bead is located by a magnet absorption ring, a tire cord joint adopts an automatic seaming type joint, an inclined angle between an lining layer / a tire-side composite component joint and a tire cord is more than or equal to 6 degrees, the joint adopts automatic lamination, and weighing control of each tire blank is implemented by adopting a device which repairs the tire in the front and dismounts the tire at the back for a material feeding frame. In such a forming process, an automatic level and production efficiency of the forming are improved, a labor intensity of operators and a quality defect caused by human factors are reduced, a forming storage space and a transportation line are optimized, and the quality and the cost control level of products are improved.

Owner:TRIANGLE TIRE

Airtight rubber of all-steel radial tyre and preparation method thereof

The invention discloses an air-barrier glue for all-steel-wire truck radial tires, as well as a preparation method thereof. The glue comprises the following components in weight portion: 60 to 80 portions of natural glue, 20 to 40 portions of butadiene-styrene rubber, 40 to 65 portions of carbon black N660 as a reinforcing agent, 3 to 7 portions of zinc oxide as an activator, 1 to 4 portions of stearic acid, 2.5 to 5 portions of 204 resin as a tackifier, 2 to 5 portions of homogenizing agent UB4000 or 2 to 5 portions of homogenizing agent 40MSF, 0.5 to 2 portions of antiager 4020, 0.5 to 2 portions of antiager RD, 1 to 3 portions of protective wax, 2 to 4 portions of aromatic oil as a softening plasticizer, 0.5 to 1.0 portions of sulfur as a vulcanizing agent and 1.0 to 3.0 portions of accelerator NS or 1.0 to 3.0 portions of accelerator TBBS.

Owner:JIANGSU GENERAL SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com