Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1136results about How to "Guaranteed wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

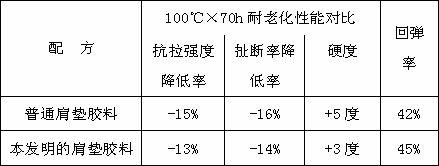

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

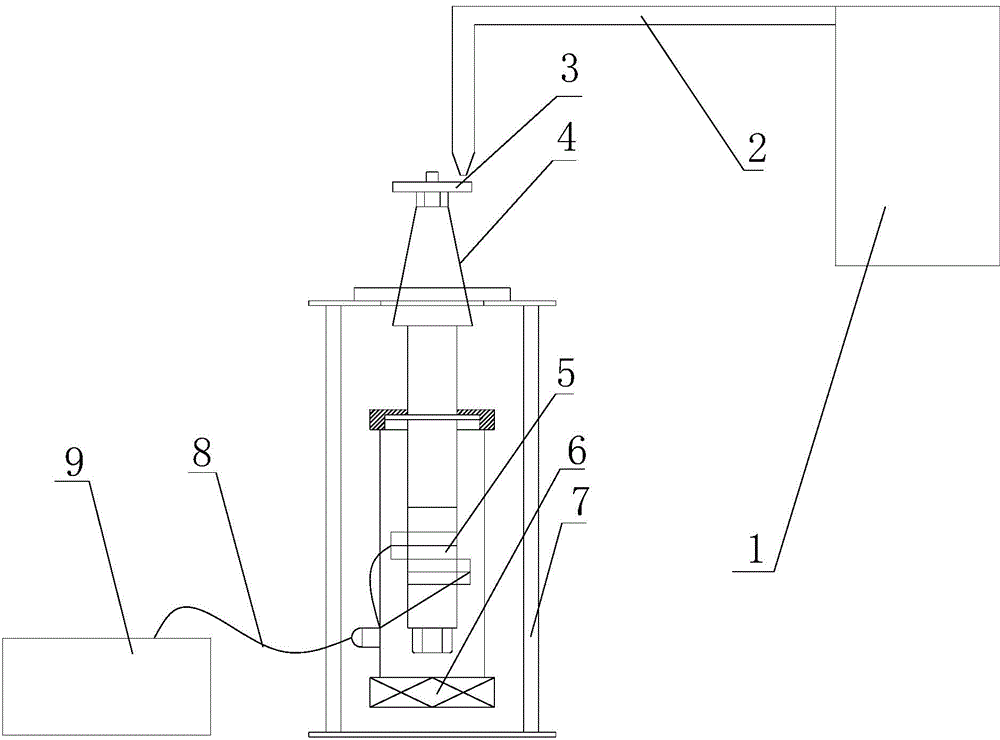

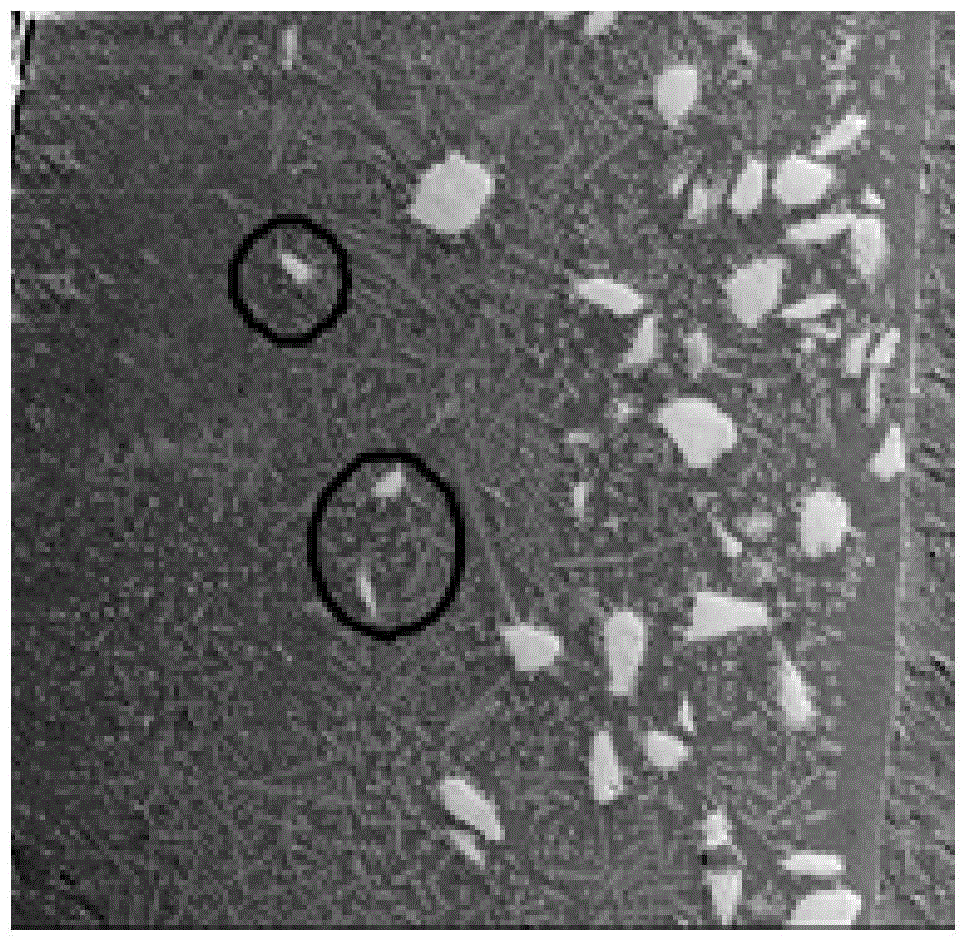

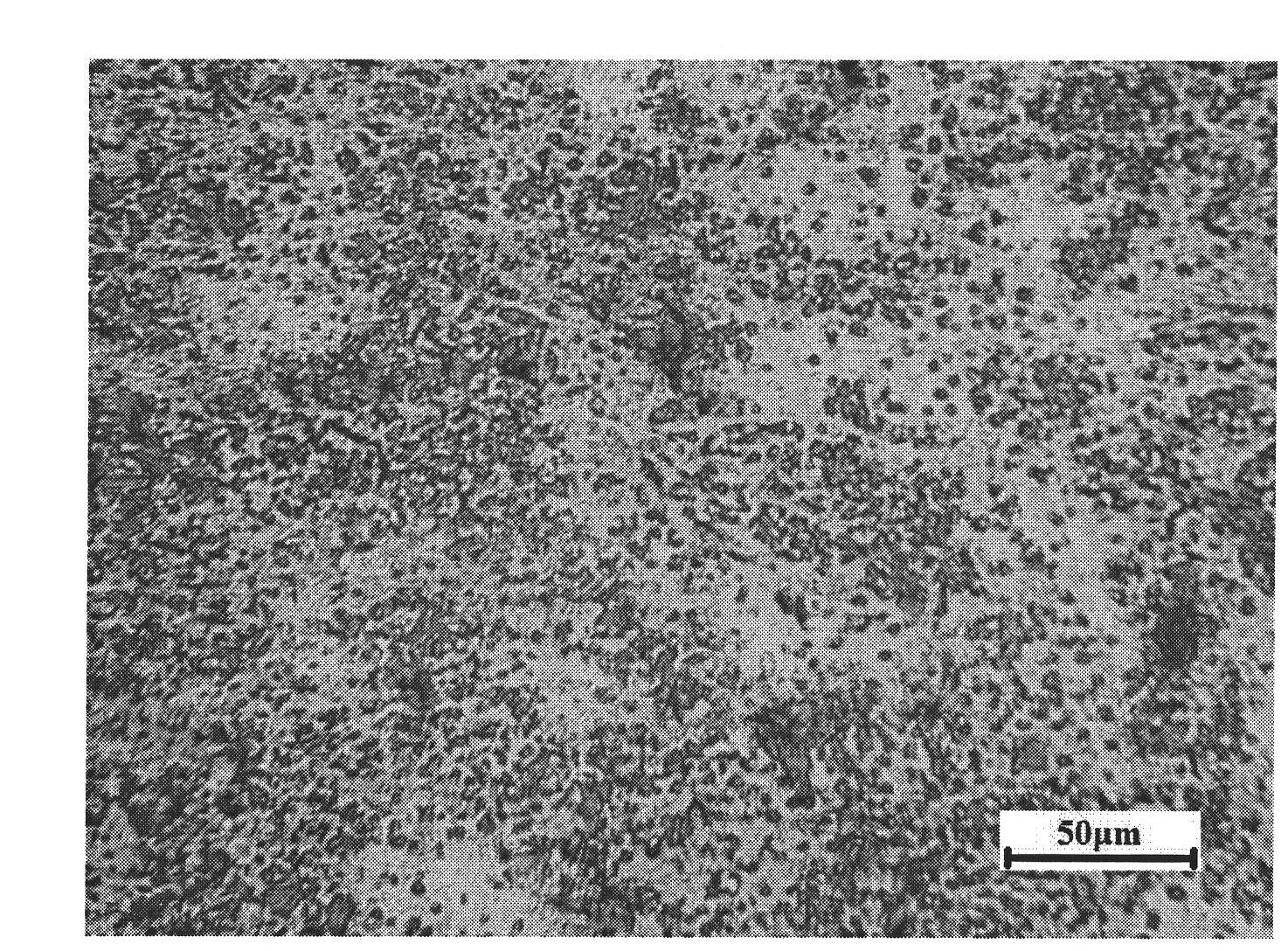

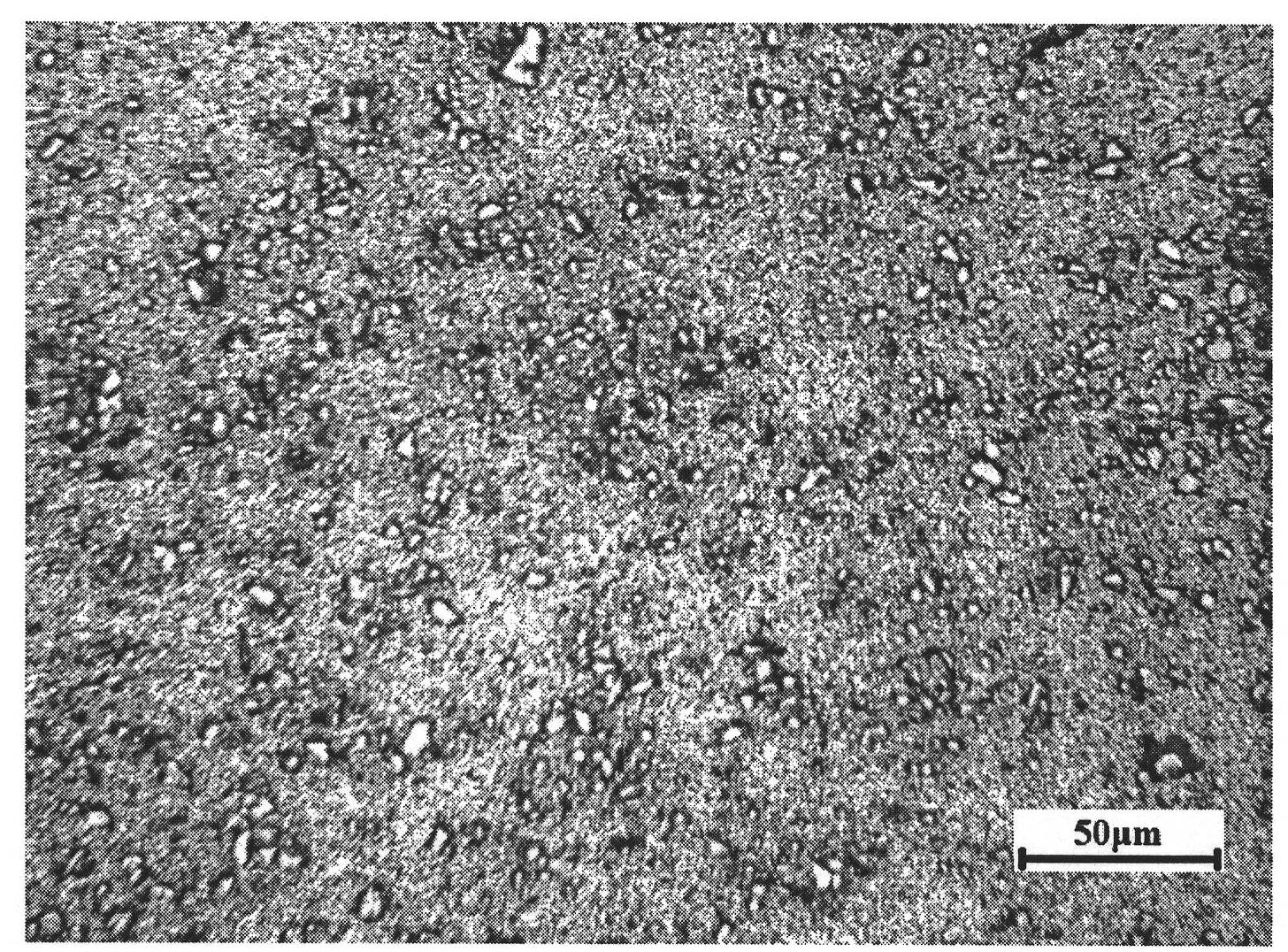

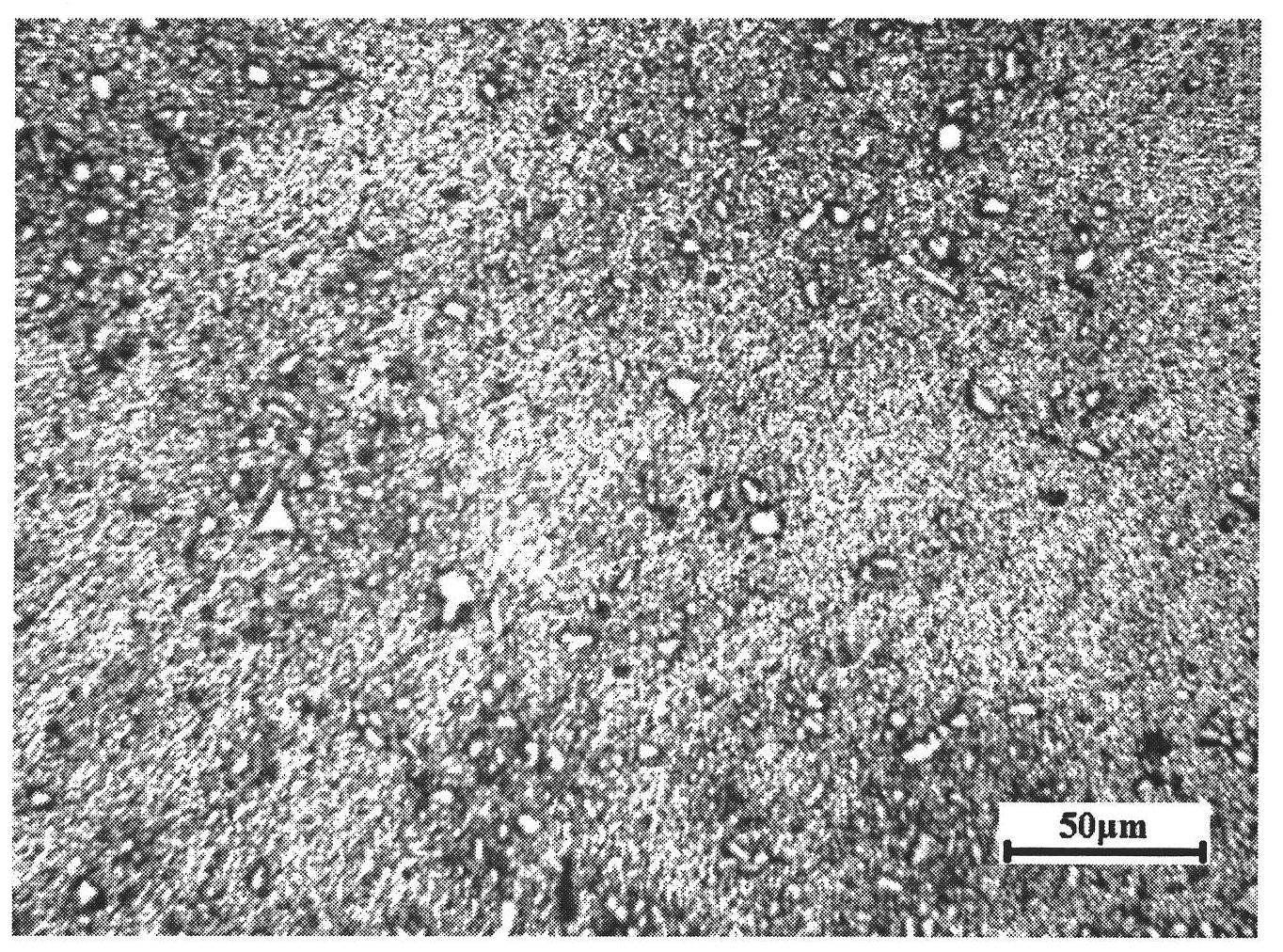

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-carbon steel multi-alloy wear-resisting ball and production method thereof

ActiveCN101736200AGuaranteed wear resistanceHigh hardnessFurnace typesHeat treatment furnacesChemical compositionHigh carbon

The invention discloses a high-carbon steel multi-alloy wear-resisting ball and a production method thereof. The wear-resisting ball comprises the main chemical compositions in percentage by weight: 1.0-1.2% of C, 1.2-1.6% of Si, 1.6-2.2 % of Mn, less than or equal to 0.05% of P, less than or equal to 0.25% of S, 1.5-2.5% of Cr, 0.2-0.3% of Mo, 0.005-0.01% of B, 0.025-0.05% of Ti, 0.08-0.15% of V and the balance of Fe. The production method comprises the steps of melting stock, modifying twice, pouring, quenching, tempering and obtaining finished products. The grinding ball produced with the production method of the invention has high hardness, high wear resistance, high toughness and high impact resistance; the production method of the grinding ball is easy and simple to operate.

Owner:安徽中建材开源新材料科技有限公司

Formula of sole material

InactiveCN102250407AGuaranteed wear resistanceGuaranteed compression performanceSolesElastomerPolyolefin

The invention discloses a formula of a sole material. The sole made of the sole material can be formed in one piece to save cost, and the sole does not contain heavy metal and is light and breathable. The sole material comprises the following substances in percentage by weight: 1, 11.6 to 52.4 percent of ethylene vinyl acetute (EVA); 2, 7 to 13 percent of polyolefin elastomer (POE); 3, 1.4 to 2.6percent of ethylene-propylene-diene monomer; 4, 12.6 to 23.4 percent of standard rubber; 5, 12.6 to 23.4 percent of cis-polybutadiene; 6, 3.5 to 6.5 percent of butylbenzene; 7, 2.8 to 5.2 percent of talc powder; 8, 2.1 to 3.9 percent of white carbon black; 9, 2.1 to 3.9 percent of stearic acid; 10, 0.7 to 1.3 percent of modifier; 11, 1.05 to 1.95 percent of zinc oxide; 12, 1.4 to 2.6 percent of cross-linking agent; and 13, 0.35 to 0.65 percent of sulfur.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

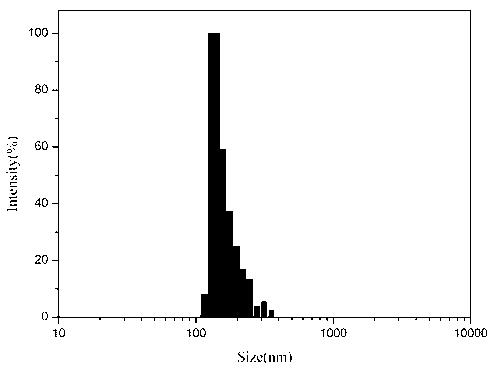

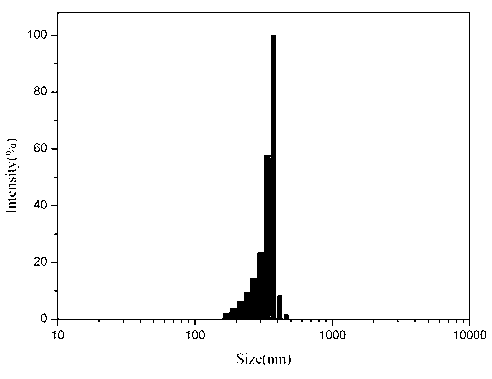

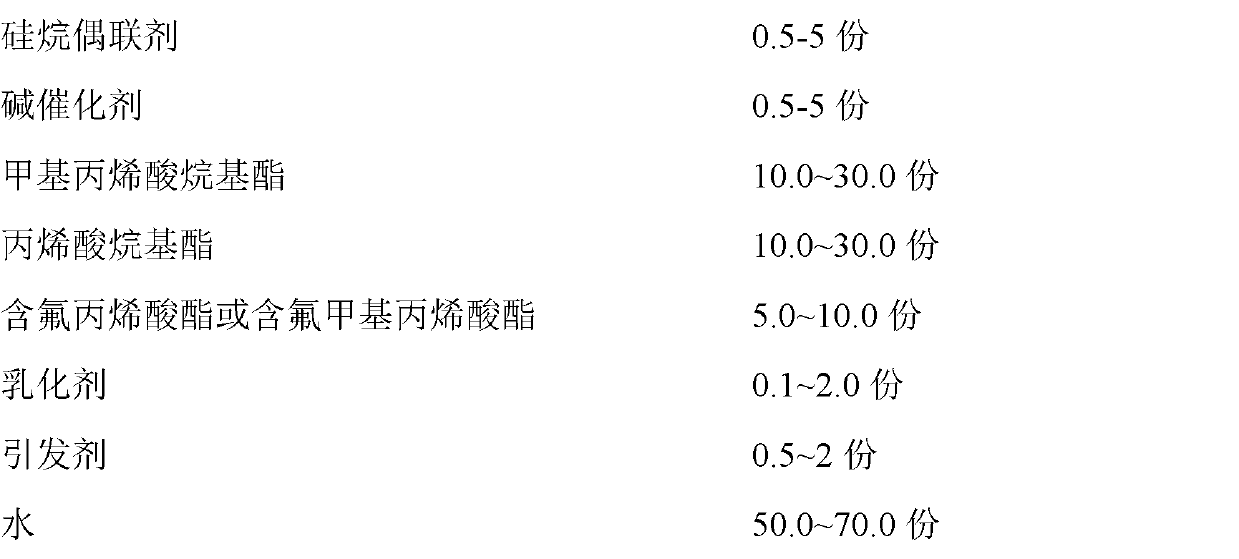

Waterborne organic and inorganic fluorosiloxane modified acrylate polymer emulsion and preparation method and application thereof

ActiveCN103289021AGuaranteed wear resistanceGuaranteed scratch resistanceCoatingsEmulsionOrganic inorganic

The invention relates to the technical field of organic and inorganic hybrid materials. In order to solve the problems that organic and inorganic components of a waterborne organic and inorganic polymer emulsion are weakly bonded and easy to separate to affect the final performance of a coating, and the process of modifying the surfaces of the inorganic components to enhance the interfacial force between the organic and inorganic components is tedious to the disadvantage of industrialization and the like, the invention provides a waterborne organic and inorganic fluorosiloxane modified acrylate polymer emulsion, wherein the emulsion uses an inorganic part formed by hydrolysis of a silane coupling agent containing an alkene unsaturated group as a core, and alkyl methacrylate, alkyl acrylate, fluorinated acrylate or fluorinated methacrylate as a shell. The waterborne organic and inorganic fluorosiloxane modified acrylate polymer emulsion provided by the invention has the excellent performances of heat resistance, scraping resistance, wear resistance, high hardness and the like, and further has the performances of antiaging, scrubbing resistance, water resistance, contamination resistance and the like. The emulsion provided by the invention is simple in preparation method and suitable for industrialized production.

Owner:建德市新安有机硅新材料研究所

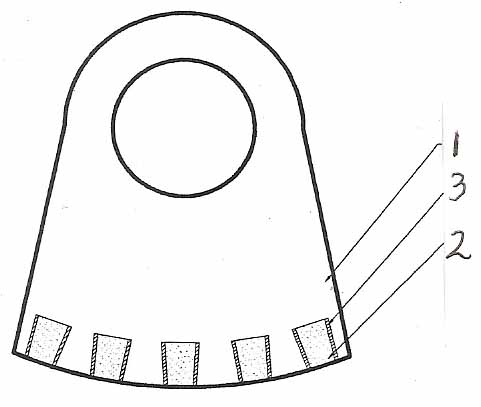

Ceramic reinforced metal matrix abrasion-resisting compound material and preparation method

The invention discloses a ceramic reinforced metal matrix abrasion-resisting compound material and a preparation method. The compound material comprises a metal matrix abrasion-resisting component body, wherein a plurality of blind holes are formed on the surface of the metal matrix abrasion-resisting component body, and self-fluxing alloy powder metallurgically bonded with the metal matrix abrasion-resisting component body and ceramic sintering bodies are arranged in the blinding holes. At a sintering temperature of a vacuum furnace, the self-fluxing alloy powder is fused and is metallurgically bonded with the abrasion-resisting component body while the abrasion-resisting component body and the ceramic are not deformed. The process is simple and the prepared material with a required hardness can be acquired without being subjected to the heat treatment. By using the preparation method, the problem that the ceramic is difficult to be bonded with a metal substrate is solved and the defect caused by a pouring process is avoided. The ceramic, alloy and metal on the surface of the abrasion-resisting component are regularly distributed, the abrasion resistance of the abrasion-resisting component is ensured and the shock resistance is also ensured.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

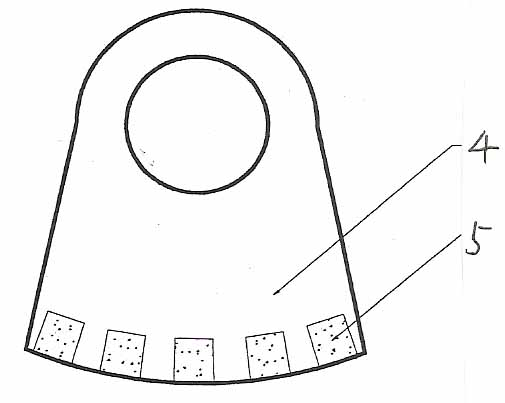

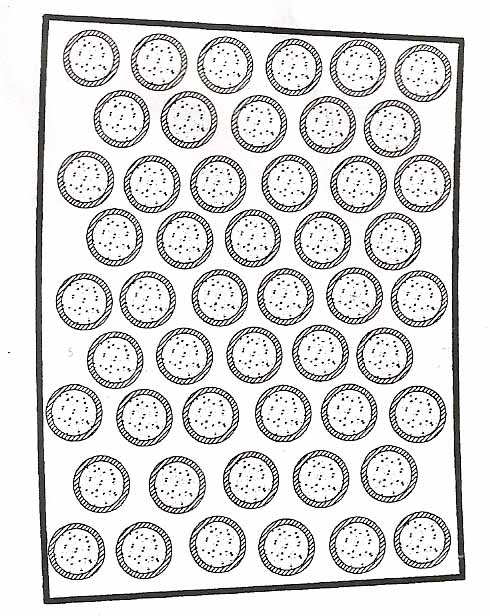

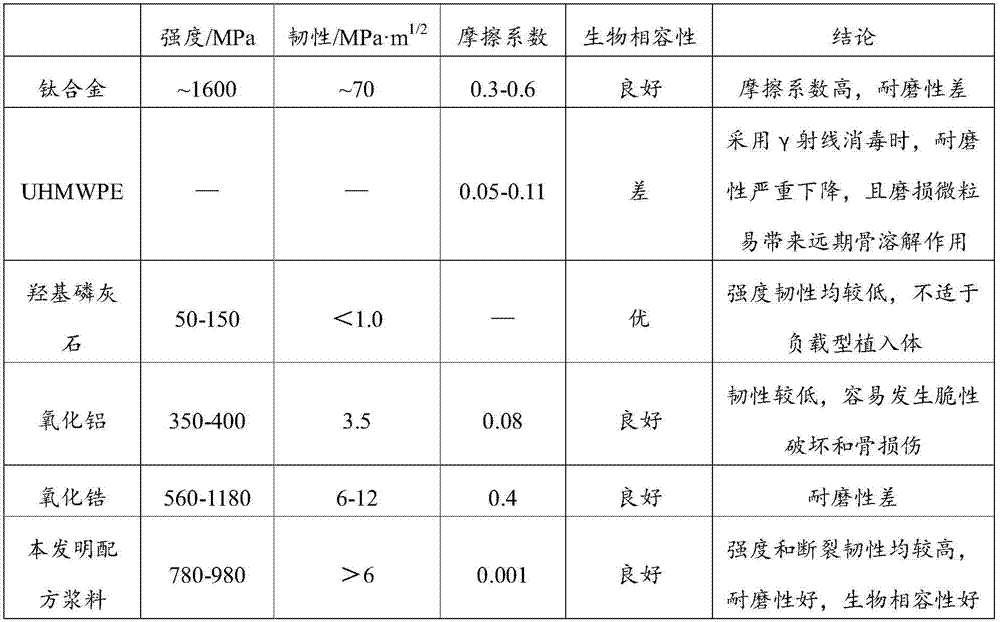

Slurry for photo-curing 3D-printing dental implant as well as preparation method and application of slurry

InactiveCN107158474AOvercome performance shortcomingsGuaranteed StrengthAdditive manufacturing apparatusProsthesisBiocompatibility TestingDiluent

The invention discloses slurry for a photo-curing 3D-printing dental implant as well as a preparation method and application of the slurry. The slurry contains the following raw material components: silicon nitride ceramic powder, photosensitive resin, a photoinitiator, an active diluent, a dispersing agent and an aid, wherein the volume ratio of the photosensitive resin to the silicon nitride ceramic powder is (3 to 7)-(1 to 9), the adding proportion of the photoinitiator is 0.1wt%-1.5wt% of the photosensitive resin, the adding proportion of the active diluent is 15wt%-30wt% of the photosensitive resin, the adding proportion of the dispersing agent is 0.1wt%-1.5wt% of the silicon nitride ceramic powder, and the adding proportion of the aid is 0.1%-1% of total mass of the slurry. The dental implant prepared from the slurry has good biocompatibility, and besides, the strength, breaking tenacity and wear resistance of the dental implant are greatly improved.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

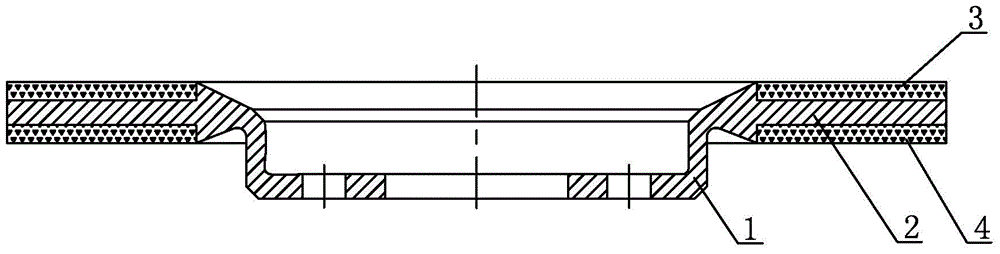

Automobile brake disc and manufacturing method thereof

ActiveCN105041921AImprove thermal conductivityReduce weightBraking discsMechanical engineeringBraking distance

The invention discloses an automobile brake disc which comprises a brake disc body. The brake disc body is made of aluminum alloy. The two work faces of the aluminum alloy brake disc body are each provided with an abrasion-resistant layer in a composite mode. The abrasion-resistant layers are made of a ceramic reinforcing material. The abrasion-resistant layers made of the ceramic reinforcing material are metallurgically combined with the aluminum alloy brake disc body through the squeeze casting technology. The brake disc is low in weight, good in abrasion resistance and cooling performance, long in service life, low in maintenance cost, and capable of reducing automobile oil consumption, improving the passage capacity of an automobile, shortening the brake distance and improving safety of the automobile. According to a manufacturing method of the brake disc, by means of selective local strengthening and the squeeze casting technology, the two work faces of the aluminum alloy brake disc body are each provided with one abrasion-resistant layer made of the ceramic reinforcing material in the composite mode, the abrasion-resistant layers made of the ceramic reinforcing material are metallurgically combined with the aluminum alloy brake disc body so that abrasion resistance of the work faces of the brake disc can be guaranteed, and raw material cost and machining cost of the brake disc are reduced.

Owner:NINGBO HIGHRISE NEW MATERIAL CO LTD

Wearable tubular welding rod made from tungsten carbide

InactiveCN1562550AGood welding performanceReduce burning lossWelding/cutting media/materialsSoldering mediaAdhesiveCarbide

An antiwear tubular welding tungsten carbide electrode for strengthening the surface of steel members, such as the surface of steel roller in roller bit, is composed of the welding tube and the filler consisting of sintered tungsten carbide particles, cast tngsten carbide particles, organic adhesive and powdered alloy containing Cr, Si, B, Mn and Ni.

Owner:SINOPEC OILFIELD EQUIP CORP

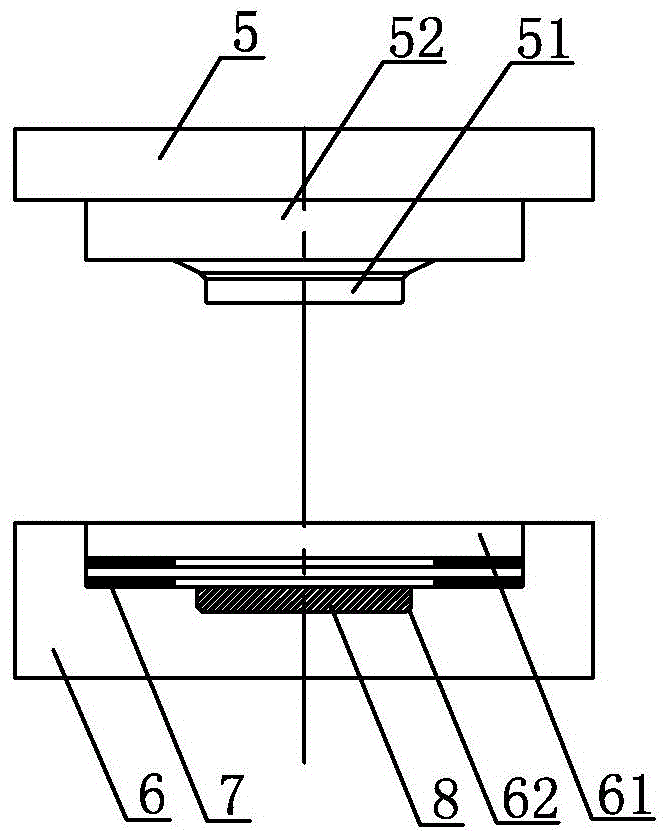

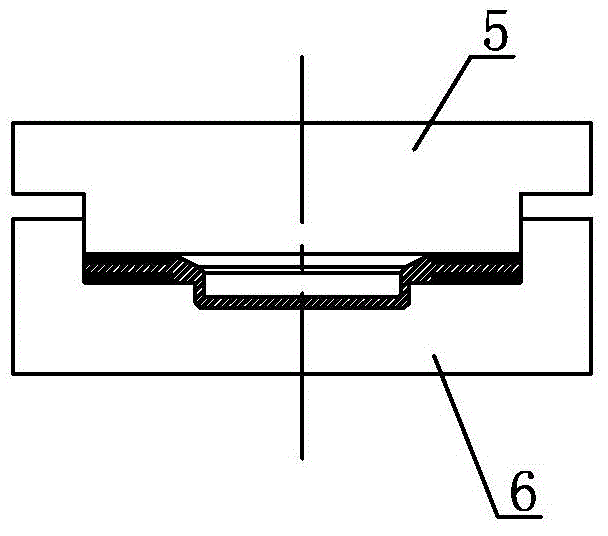

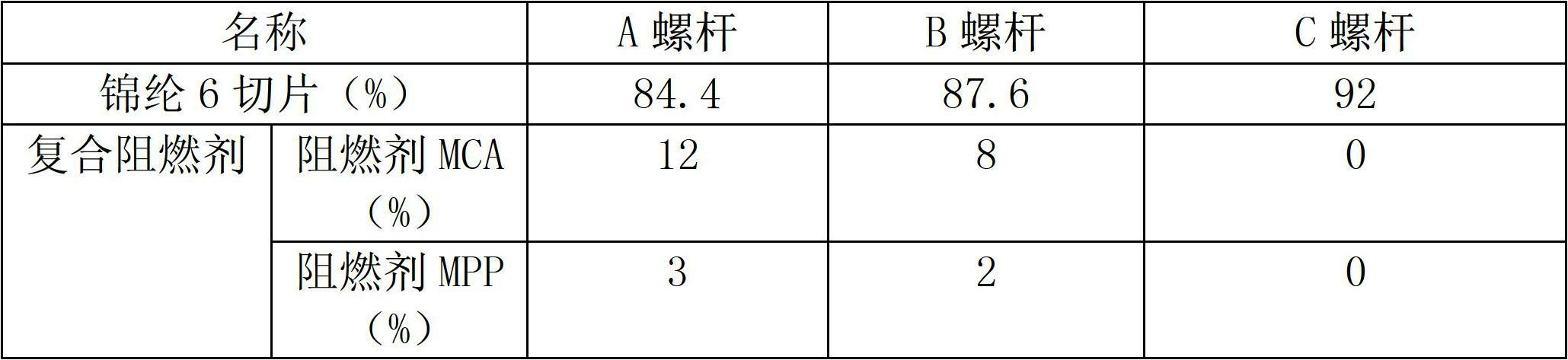

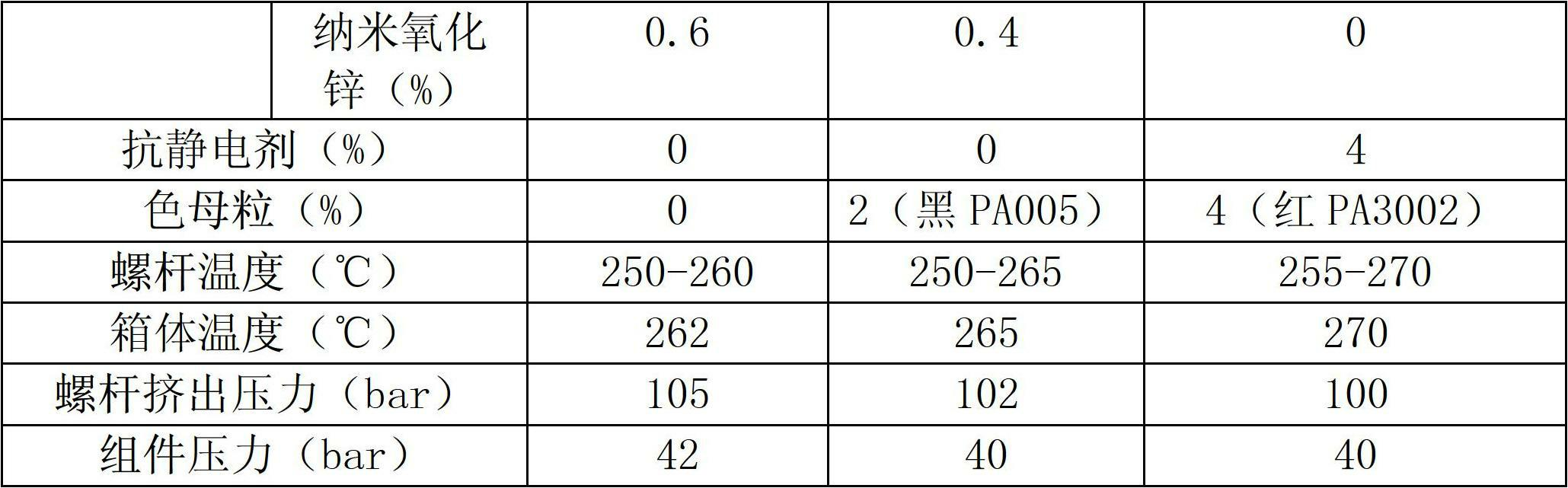

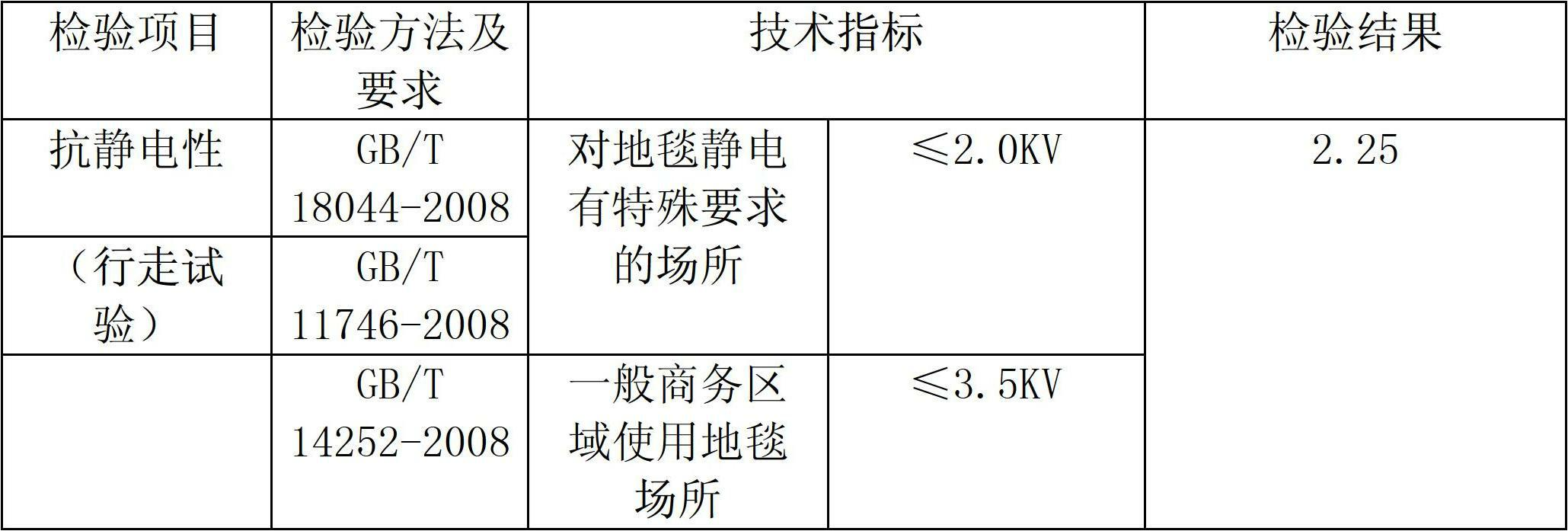

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

Antiwear lubricating paint for engine piston ring

The antiwear lubricating paint for engine piston ring is one kind of dry film lubricant. The paint consists of compoiste adhesive, antiseptic additive, antiwear additive, surfactant and dispersing medium. It is painted to the surface of piston and high temperature cured to form firm, compact and dense solid film with excellent antiwear resistance, high impact resistance and good sealing performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rubber composition taking natural rubber/carbon black and synthesized isoprene rubber/white carbon black as rubber master batch and preparation technique thereof

The invention relates to a rubber composition taking natural rubber / carbon black and synthesized isoprene rubber / white carbon black as rubber master batch and a preparation technique thereof. Natural rubber / carbon black and synthesized isoprene rubber / white carbon black are premixed to prepare rubber master batch, and then rubber aids are added according to the composition ratio to prepare rubber compound. The carbon black master batch of the compound is prepared from the following raw materials in parts by weight: 100 parts of natural rubber, 5-120 parts of carbon black, preferentially 20-80 parts of carbon black, the ratio of the natural rubber to the synthesized isoprene rubber is 1:3-5:1, a certain ratio of the carbon black to the white carbon black and a certain ratio of the natural rubber to the synthesized isoprene rubber are kept, and the ratio of the two fillers is consistent with the ratio of the two kinds of rubber. The rubber compound prepared by the preparation technique has the advantages of good abrasive resistance, high elasticity and low heat generation, and can be used in a tire formula and used for other rubber products.

Owner:EVE RUBBER RES INST

Wear-resistant coating and process for producing it

InactiveUS20080044646A1Guaranteed wear resistanceReduce coefficient of frictionValve arrangementsLayered productsFriction reductionCombustion

A process for producing a wear-resistant coating and a wear-resistant coating on a surfaces of machine or engine parts which are exposed to frictional wear. This has in particular use for internal combustion engines. The coating comprises at least one metal-free, amorphous hydrocarbon layer which includes sp2- and sp3-hybridized carbon applied to the surface of the machine part, for reducing friction and increasing the wear resistance of the surface of the machine or engine part.

Owner:INA SCHAEFFLER KG

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide compound castable used for a blast tuyere zone of an ironmaking blast furnace. The corundum, the silicon nitride, the silicon carbide, aluminate cement, aluminum powder, silicon metal, ultrafine silica powder, alumina powder and polypropylene fiber are mixed to form the castable. Residual brick of compound brown corundum refractory brick can be fast poured and repaired at the blast tuyere zone of the ironmaking blast furnace. When building a blast furnace, residual brick can be direct poured and formed to replace the compound brown corundum refractory forming brick and no high temperature is needed to fire during the production process; therefore, the invention is also an energy saving refractory for the blast tuyere zone of the ironmaking blast furnace and cast-place construction is not limited by space; fast pouring masonry is carried out and fast drying method is adopted, thereby being an inorganic nonmetal refractory applied to fast-drying quick furnace building and repairing during the blast furnace repairing and the tuyere zone of the newly-built blast furnace. The invention can normally furnace dry with the blast furnace.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Tyre

InactiveCN101450594AMaintain ice resistanceMaintain wet skid resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention discloses a tyre, which comprises (A) tread rubber, (B) tread basal rubber, (C) sidewall rubber, (D) rebate protective rubber, (E) carcass layer rubber, (F) lining layer rubber, (G) triangle rubber, (H) belted layer rubber, (I) air-tight layer rubber and (J) tyre bead steel wire rubber. The tyre components consist of rubber compositions, wherein the rubber compositions of the (A) tread rubber, the (B) tread basal rubber, the(C) sidewall rubber and the (D) rebate protective rubber adopt white carbon black and carbon black with high specific surface area as reinforcing fillers; and the rubber compositions of the (E) carcass layer rubber, the (F) lining layer rubber, the (G) triangle rubber, the (H) belted layer rubber, the (I) air-tight layer rubber and the (J) tyre bead steel wire rubber adopt white carbon black and carbon black with low specific surface area as reinforcing fillers. The tyre has the advantages of good puncture resistance and chunking resistance, low rolling resistance and heat generating performance, and greatly-reduced production cost. The full-steel giant engineering tyre is particularly suitable for an adverse road environment such as a large-scale mine yard.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

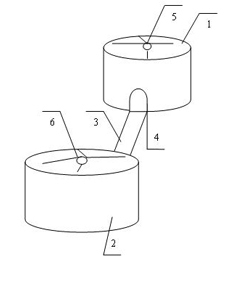

Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

The invention belongs to the field of aluminum-based composite material and preparation technology thereof and in particular discloses a ceramic particle reinforced aluminum-based gradient composite material, a preparation method thereof and a device used by the method. The composite material uses aluminum alloy as a matrix; the volume fractions of ceramic particles serving as a reinforcement material in the surface layer and the bottom layer are between 30 and 40 percent and between 0 and 5 percent respectively; the ceramic particles perform continuous gradient variation from the surface layer to the bottom layer; and the preparation method comprises the following steps: introducing the ceramic reinforced particles to a high-pressure airflow channel by a discharge amount regulation device to form a solid phase flow and a gas phase flow; atomizing molten aluminum alloy liquid, mixing the molten aluminum alloy liquid and the ceramic particles of the solid phase flow and the gas phase flow, and precipitating the mixture on a deposition matrix to prepare a deposition billet; and controlling the discharge amount regulation device and output air pressure through a programmable logic controller according to the height information of the deposition billet to obtain the ceramic particle reinforced aluminum-based gradient composite material. The preparation method of the invention has convenient operation and high automation degree; and the prepared composite material has the advantages of light weight, high wear resistance and anticorrosion of the surface and the like.

Owner:HUNAN UNIV

Belt conveyor rubber idler and production method thereof

The invention discloses a rubber idler of a belt conveyor, comprising an idle shaft and an idler steel pipe; a wear-resistant buffer layer with an arc outer surface consisting of more than one rubber rings of waste tires is sleeved on the idler shaft in the manner of interference. The invention also discloses a method for manufacturing the rubber idler of the belt conveyor. A wear-resistant idler, a buffer idler, a comb-shaped idler, a taper aligning idler, a friction aligning idler and a rubber aligning idler made of the rubber rings of waste tire are applied. Under the precondition of guaranteeing the sealing performance of the idler, the idler steel pipe or the shaft is sleeved by the wear-resistant idler, the buffer idler, the comb-shaped idler, the taper aligning idler, the friction aligning idler and the rubber aligning idler made of the rubber rings of waste tire. The idlers have comprehensive functions such as anti-corrosion, anti-tarnishing, abrasion resistance, compact resistance, aging resistance, tear resistance, light weight and large elastic force. In addition, the idlers can protect the belt and largely prolong the service life of the belt.

Owner:孙明昭

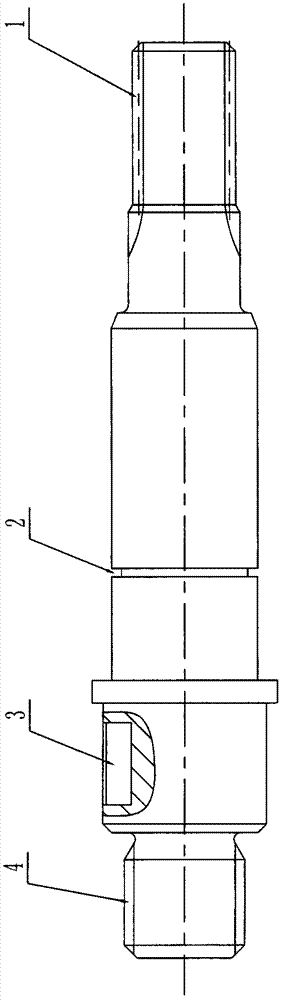

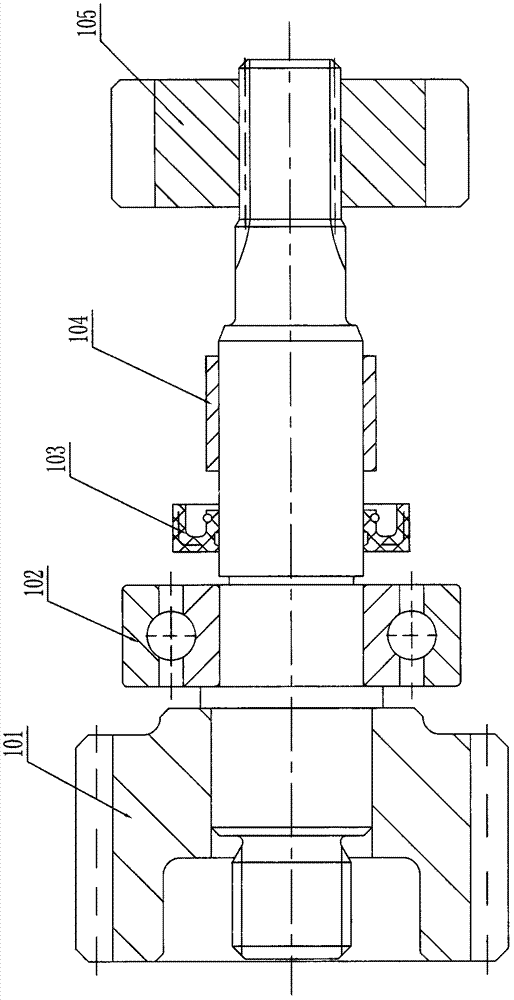

Oil pump shaft machining process

An oil pump shaft machining process includes steps of 1) feeding a blank; 2) turning two end faces and perforating a central hole; 3) roughly turning an outer circle with margin of 0.5 mm; 4) performing quenched-tempered heat treatment; 5) repairing and grinding the central hole; 6) finely turning an outer circle, grooving, turning a thread, and reserving grinding allowance of 0.3 mm after finely turning the outer circle; 7) milling a key slot; 8) cold rolling a spline; 9) locally quenching the outer circle surface at high frequency; 10) annealing at the low temperature, heating to 150-180 DEG C during annealing at the low temperature and preserving temperature for 2.5 hours; 11) repairing and grinding the central hole; 12) finely grinding the outer circles. By the oil pump shaft machining process, contact positions of a machined oil pump shaft with a deep groove ball bearing, an oil seal and a slide bearing are good in wear resistance, and the machined oil pump shaft is high in small-modulus spline machining efficiency, good in tooth form structure, resistant to impact and high in strength.

Owner:ZHEJIANG BODA TECH

High-carbon gray cast iron automobile brake disk and production method thereof

ActiveCN103225037AShorten the lengthConvenient lengthBraking discsFriction liningChemical compositionHigh carbon

The invention relates to a high-carbon gray cast iron automobile brake disk and a production method thereof. The high-carbon gray cast iron automobile brake disk comprises the following chemical components in percentage by weight: 3.7-3.8% of C, 0.5-0.8% of Mn, 0.3-0.5% of Cu, 0.1-0.2% of Cr, 0.2-0.4% of Mo, 1.6-2.0% of Si, 0.1-0.2% of N, 0.01-0.12% of P, 0.05-0.12% of S and the balance of Fe. The brake disk provided by the invention has the outstanding characteristics of small brake temperature rise, abrasion resistance, favorable heat fatigue resistance effect and the like; the performance of an automobile brake system can be obviously improved, and the service life can be obviously prolonged; and meanwhile, the potential safety hazard caused by ineffective brake due to high temperature can be effectively eliminated. Thus, the high-carbon gray cast iron automobile brake disk has high economic value.

Owner:河南淮海精诚工业科技有限公司

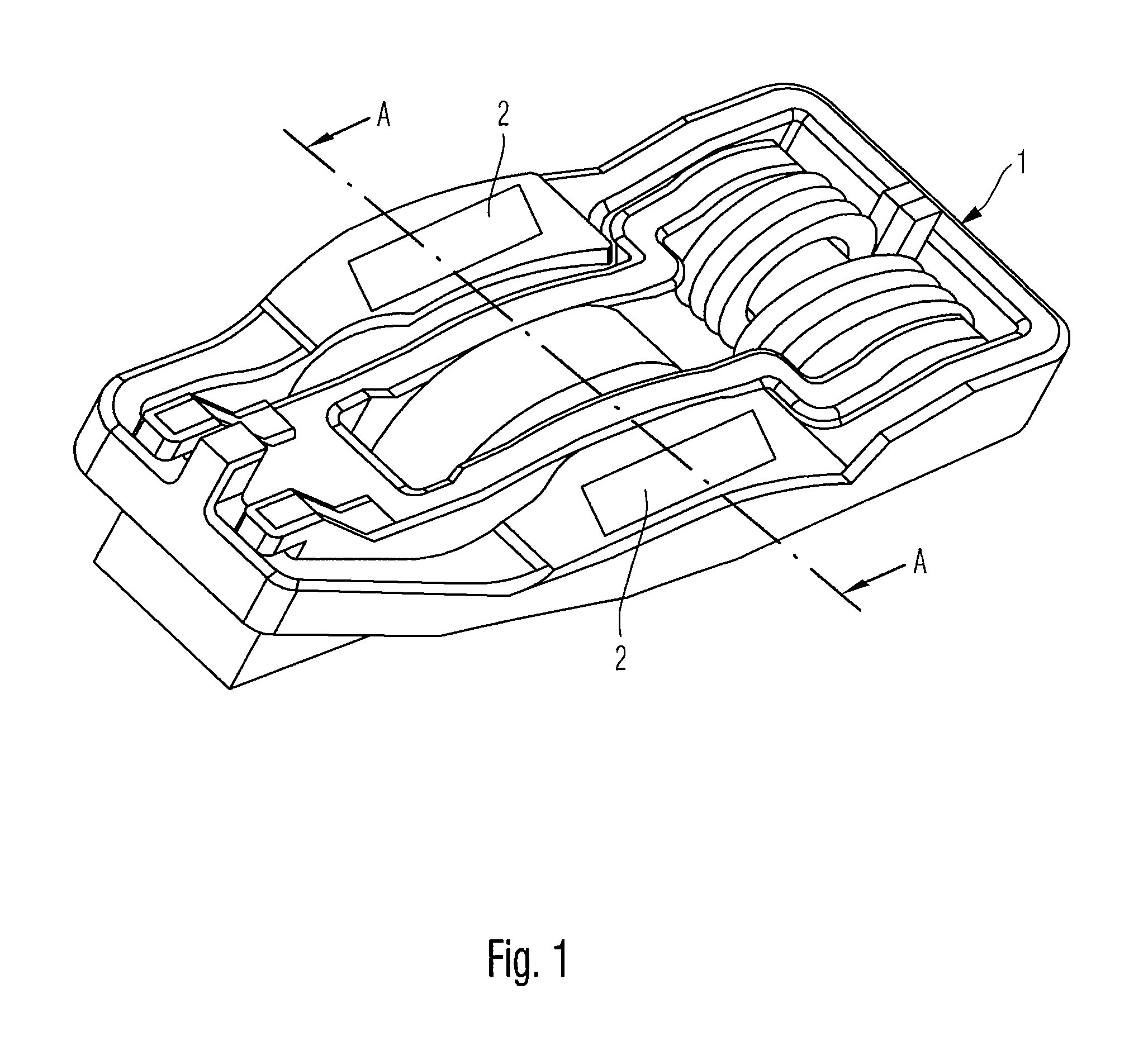

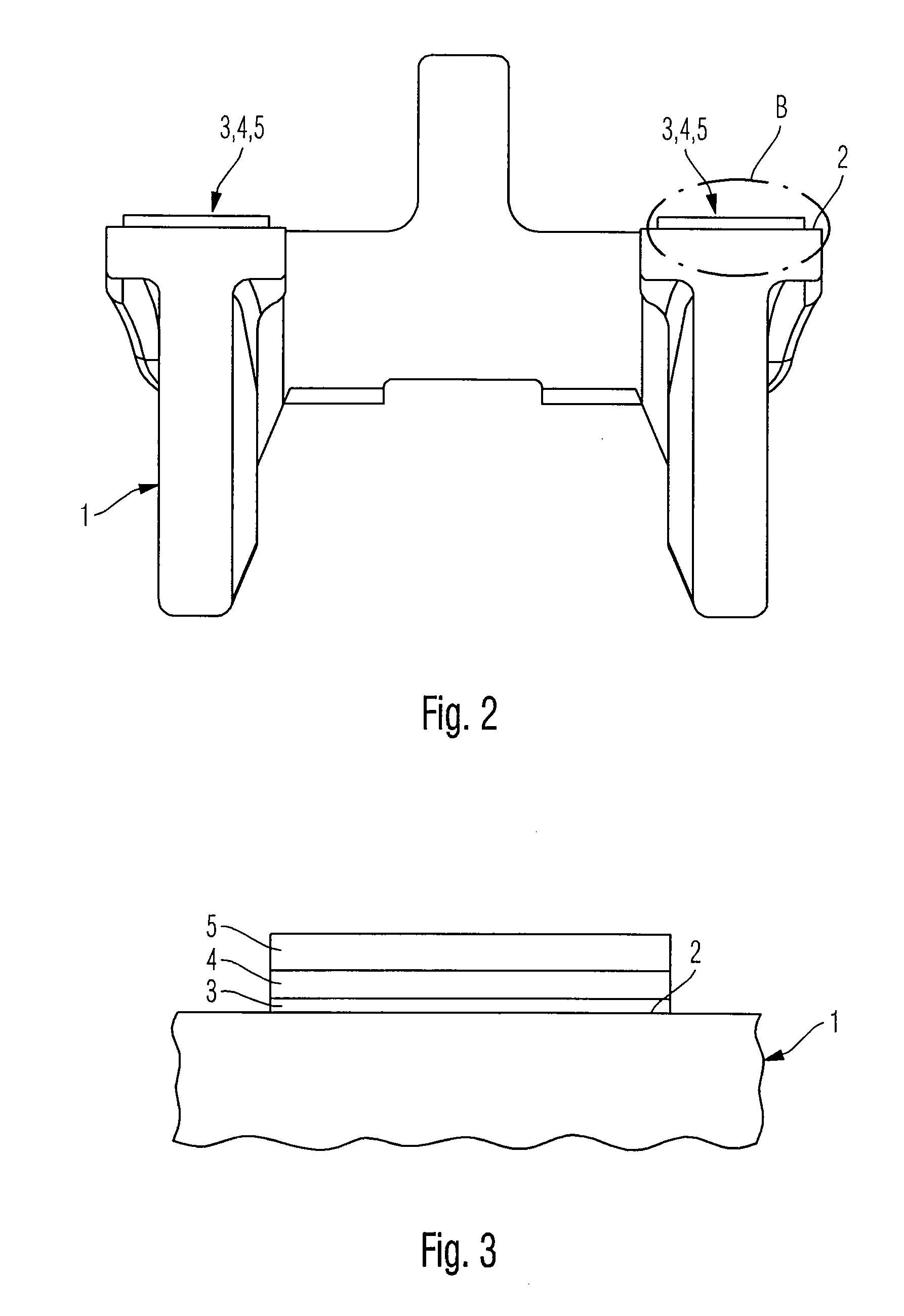

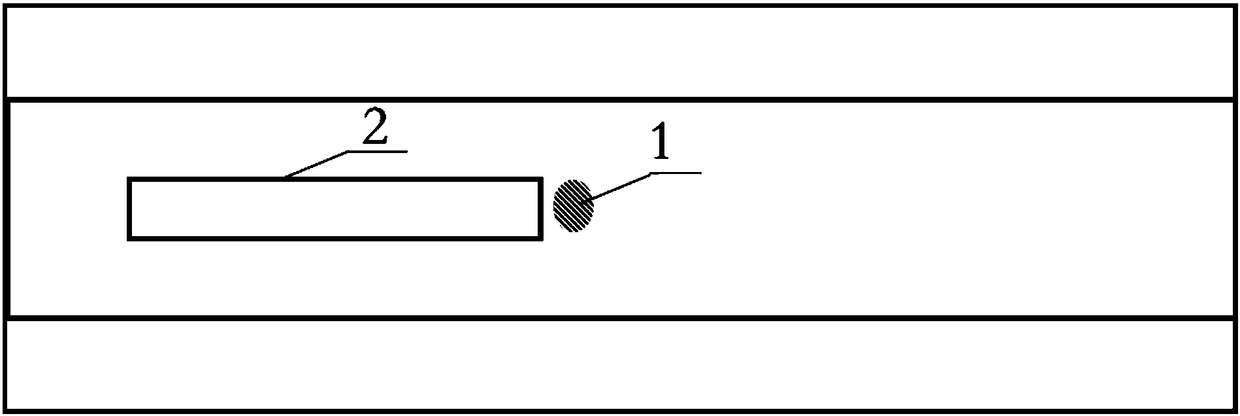

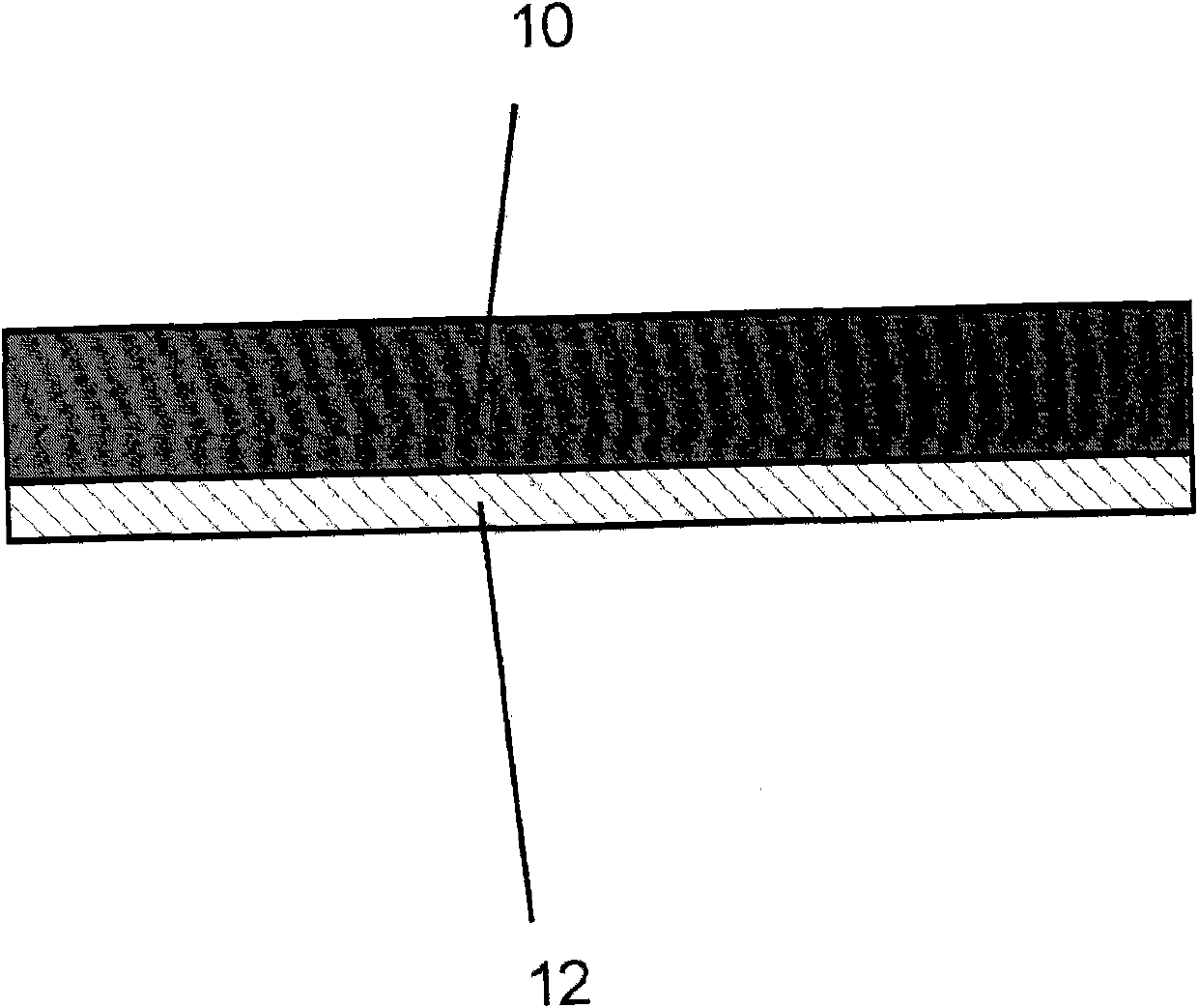

Wear-resistant fabric adhesive tape

ActiveCN102020945AGuaranteed wear resistanceLow flexural stiffnessLayered productsFilm/foil adhesivesPolyesterWear resistant

The invention relates to an adhesive tape composed of a carrier and of an adhesive layer applied on at least one side, the carrier being a woven fabric, preferably a woven polyester fabric, characterized in that the ratio of the linear density per unit length of the transverse threads to the linear density per unit width of the longitudinal threads is between 2.2 and 6 and the carrier has a basis weight of greater than or equal to 110 g / m2.

Owner:TESA SE

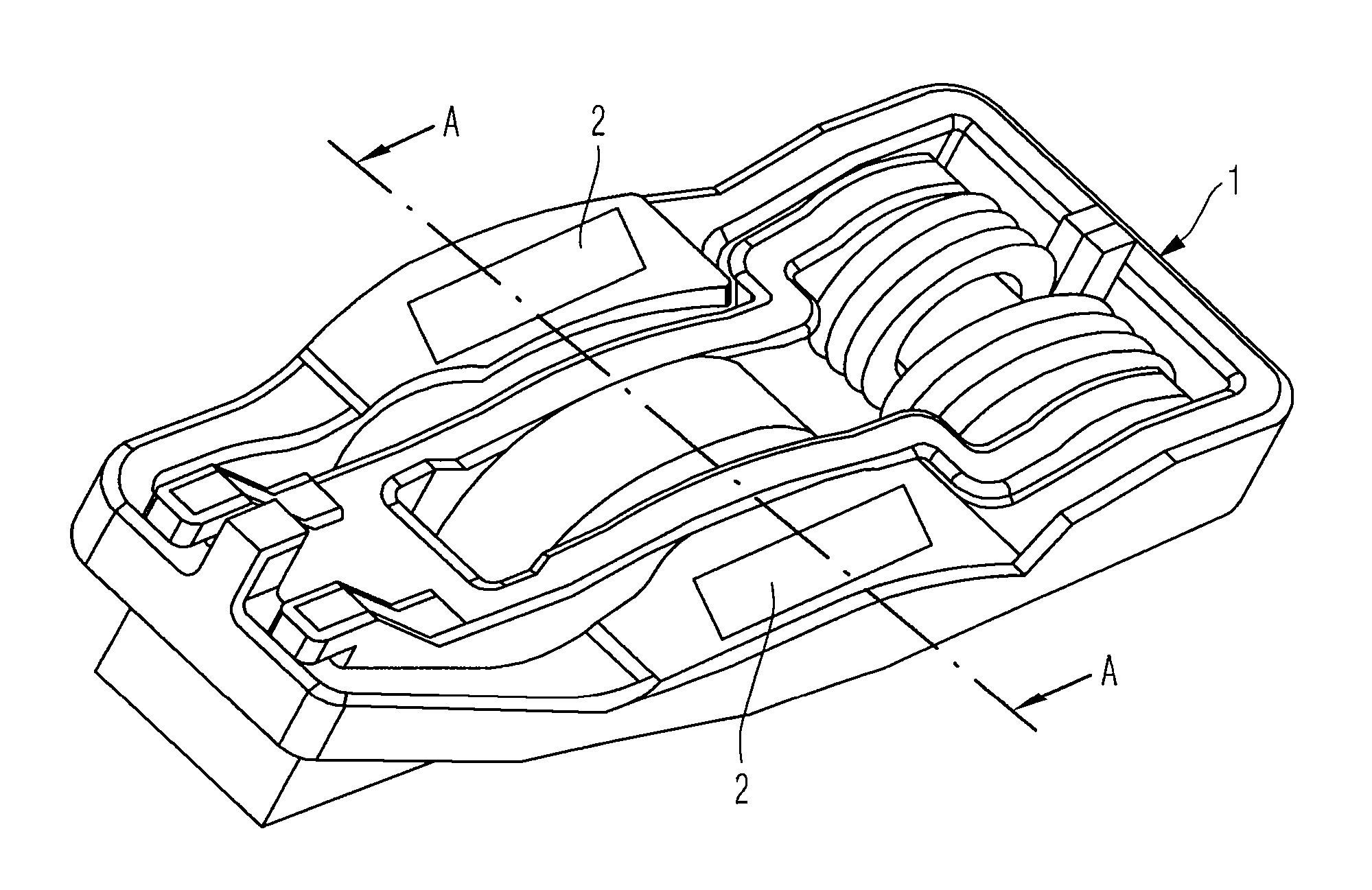

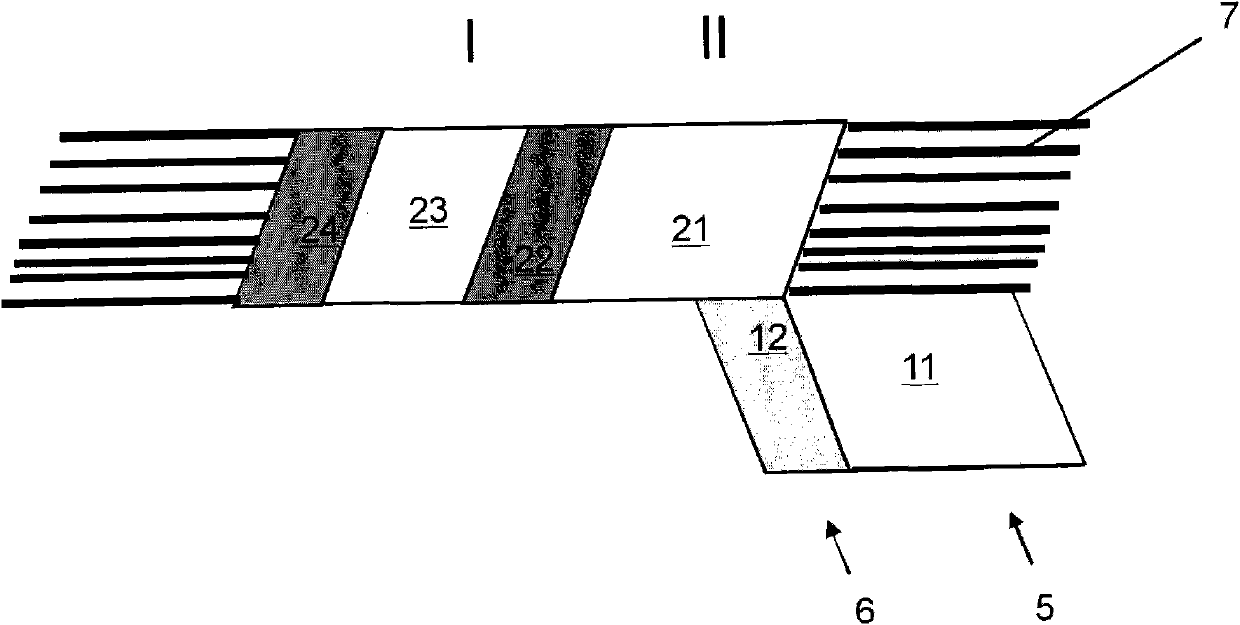

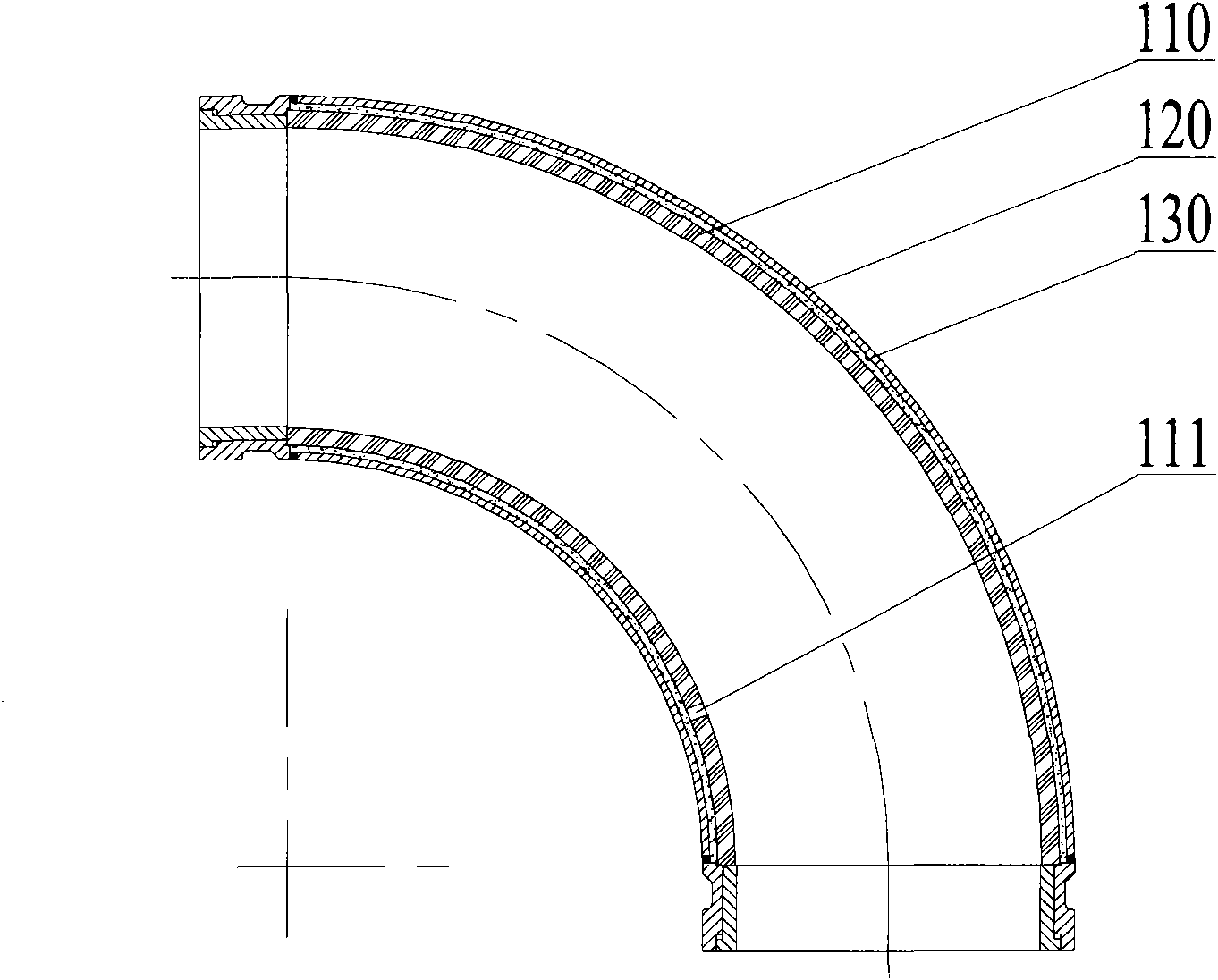

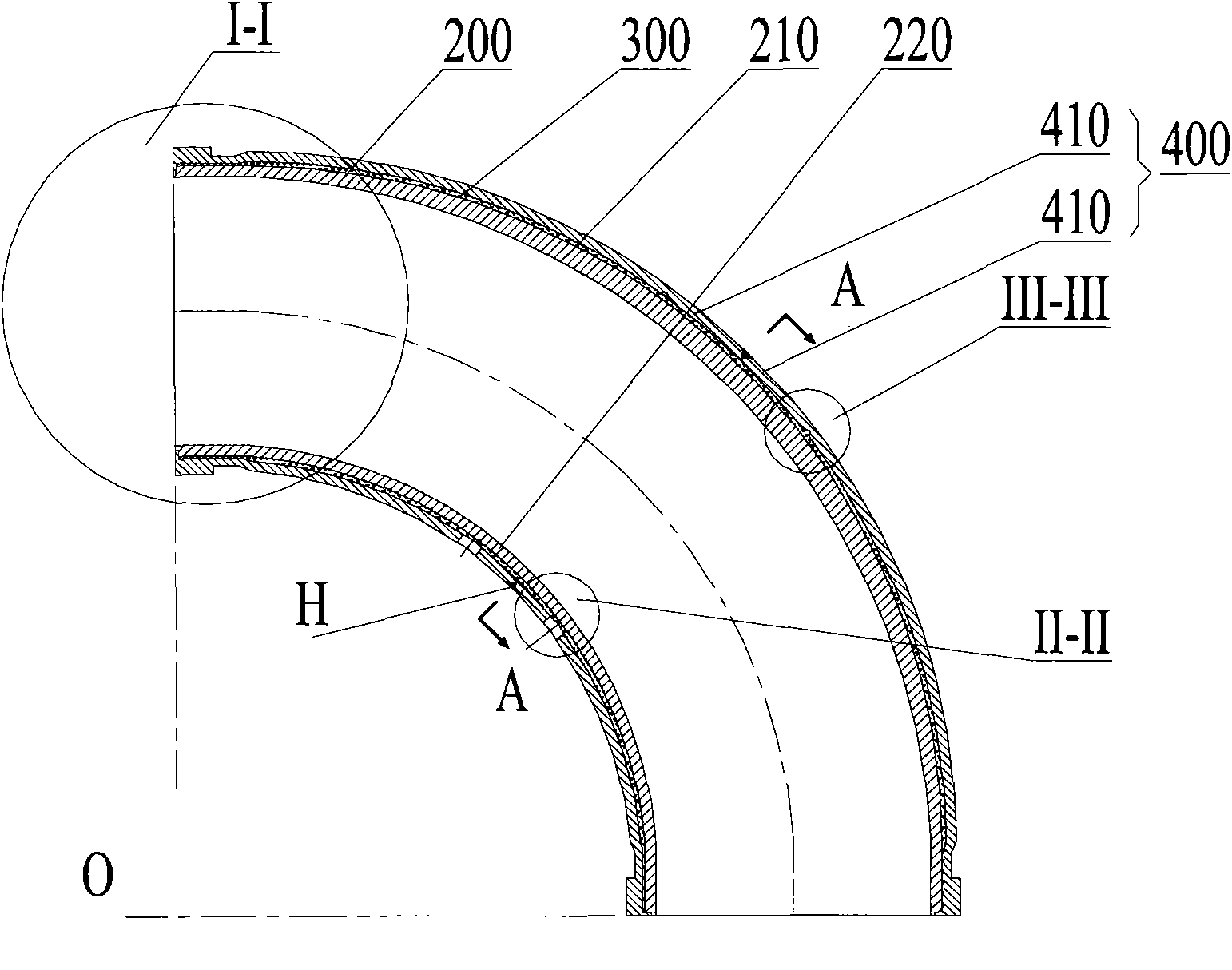

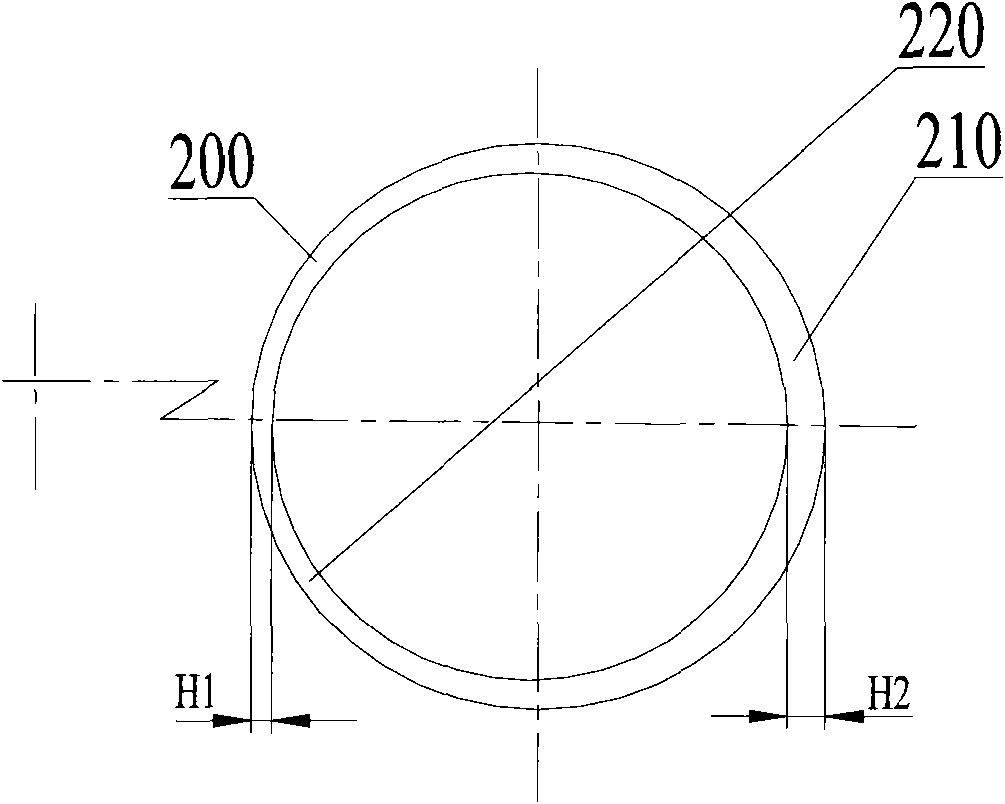

Conveying bent pipe, concrete conveyer and manufacturing method of same

InactiveCN101625060AReduce manufacturing costEasy to processBulk conveyorsRigid pipesManufacturing technologyEngineering

The invention discloses a conveying bent pipe, a concrete conveyer and a manufacturing method of the conveying bent pipe. The disclosed sequentially comprises an inner pipe, an outer pipe and a filling layer, and the outer pipe at least comprises two supporting pipes which are sequentially connected; the outer pipe of the conveying bent pipe has a split type structure and comprises two or more than two supporting pipes, thereby reducing the cost of the conveying bent pipe under the condition that the wearing resistance, the strength, the high toughness and the impact resistance are ensured. In an optimized technical scheme, the inner pipe and outer pipe are fixed by an adhesive layer to transfer the acting force of the inner pipe to the outer pipe, the supporting and protecting function of the inner pipe by the outer pipe is ensured, and safety of the conveying bent pipe can be increased. Because the inner pipe and the outer pipe can be mutually positioned by matching with an inner convex body and an inner notch, the manufacturing method of the conveying bent pipe not only can simplify a manufacturing technology in a conveying bent pipe manufacturing process, but also can reduce auxiliary mechanisms and reduce the manufacturing cost of the conveying bent pipe.

Owner:SANY HEAVY IND CO LTD (CN)

Method for preparing super-flat glaze-polished ceramic tile from coal gangue

ActiveCN106810206ALower melting temperatureGuaranteed wear resistanceCeramic materials productionClaywaresBrickResource utilization

The invention discloses a method for preparing a super-flat glaze-polished ceramic tile from coal gangue. By adopting a double-layer green body and reasonable green body formula and grain size gradation, the coal gangue is used as a main production raw material of the green body to the maximum extent; meanwhile, by raising the initial melting temperature of a ground coat layer, gas in the green body is exhausted as much as possible; in addition, a wear-resisting fritted glaze is adopted in a cover coat layer, so that the melting temperature of the glaze is reduced, and the abrasive hardness of the glaze is guaranteed; finally, the strength of a brick body and the flatness of the glaze are improved by adopting a high-temperature and heat-insulating mode. According to the method disclosed by the invention, by using the coal gangue as the main raw material and the wear-resisting fritted glaze, resource utilization of wastes is effectively realized, the sintering temperature is greatly lowered, the sintering period is shortened, and the production cost is remarkably reduced, so the method has a broad market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Rubber composition for producing color tyre

InactiveCN102492192AAchieve productionGuaranteed wear resistanceSpecial tyresMasterbatchPolymer science

The invention provides a rubber composition for producing a color tyre. The color tyre comprises a rubber composition of tyre surface, a rubber composition of tyre sidewall, an outer protective rubber composition and sealing layer rubber composition. In a primary color glue of the rubber composition of tyre surface, the rubber composition of tyre sidewall and the outer protective rubber composition, black carbon black is substituted by white carbon black; 1574 color masterbatch, 2507 color masterbatch and titanium dioxide in a certain proportion are added to realize coloration of the rubber composition of tyre surface, the rubber composition of tyre sidewall and the outer protective rubber composition; in the sealing layer rubber composition, black carbon black is substituted by white carbon black; and black masterbatch and titanium dioxide in a certain proportion are added to avoid blackening tendency of the sealing layer, so as to realize production of the color tyre as well as guarantee wear resistance of the color tyre. The produced color tyre can satisfy national test standard.

Owner:双星东风轮胎有限公司

High-silicon aluminum alloy and preparation method thereof

The invention discloses a high silicon-aluminum alloy and a method for preparation, in particular to the high-silicon aluminum alloy with excellent wear resistance and a method for preparation. The invention comprises 10.5-11.2 percent of silicon powder, 2.2-2.7 percent of copper clad aluminum alloy, 0.2-0.5 percent of magnesium, 85.6-87.1 percent of aluminum, which are made through melting, mixing, first refining, second refining and casting. The high silicon-aluminum alloy has excellent wear resistance, high tensile strength and high tensile strength, and is capable of meeting the performance requirements of an air conditioner of an automobile.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

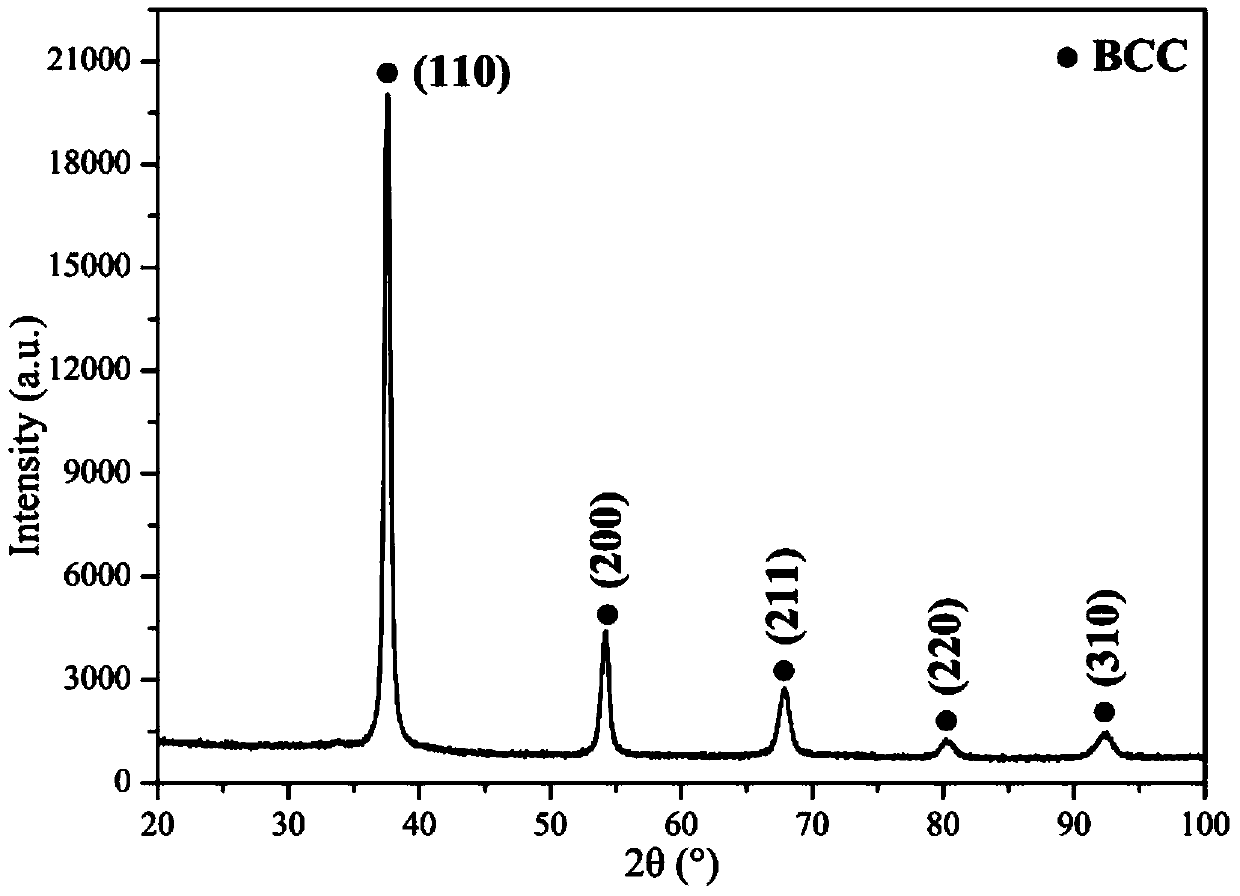

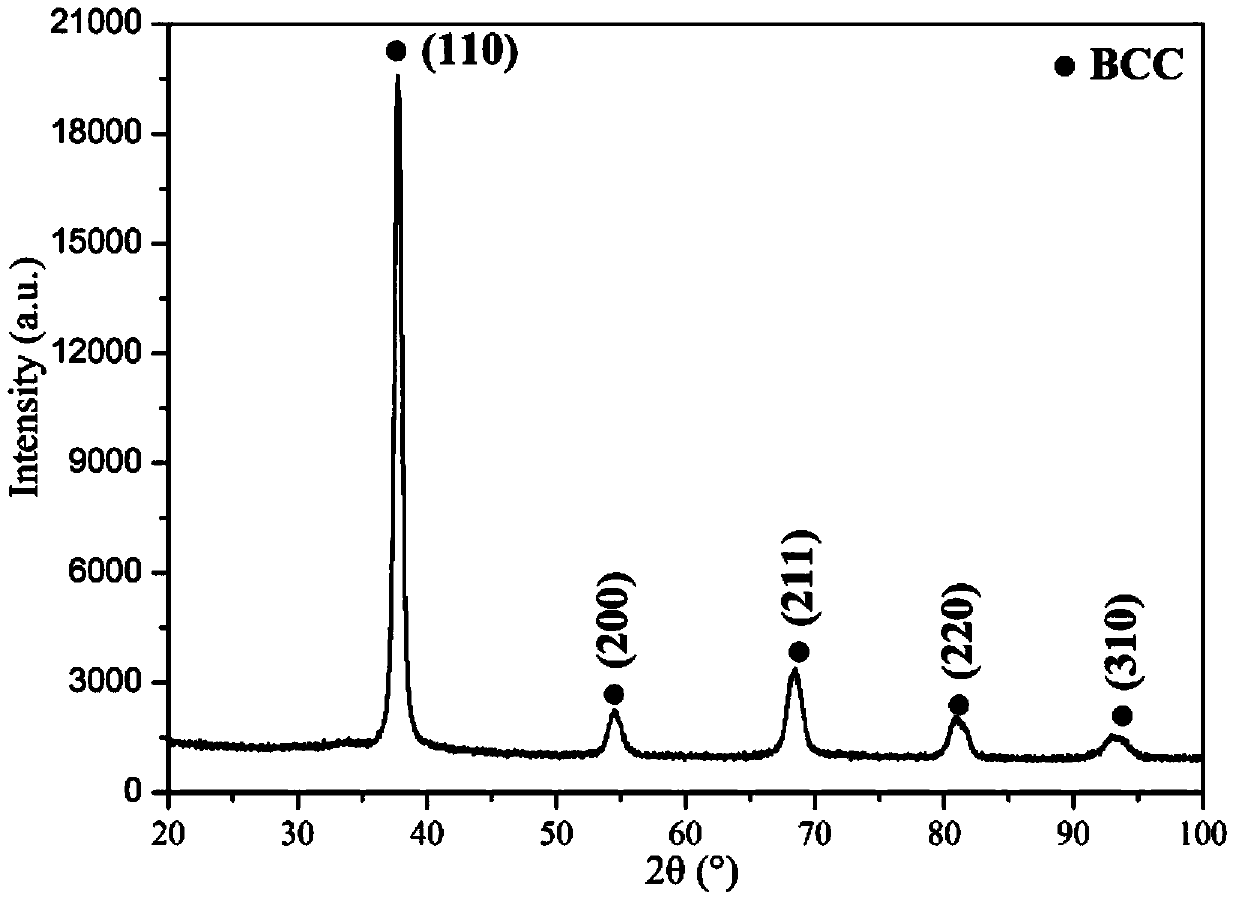

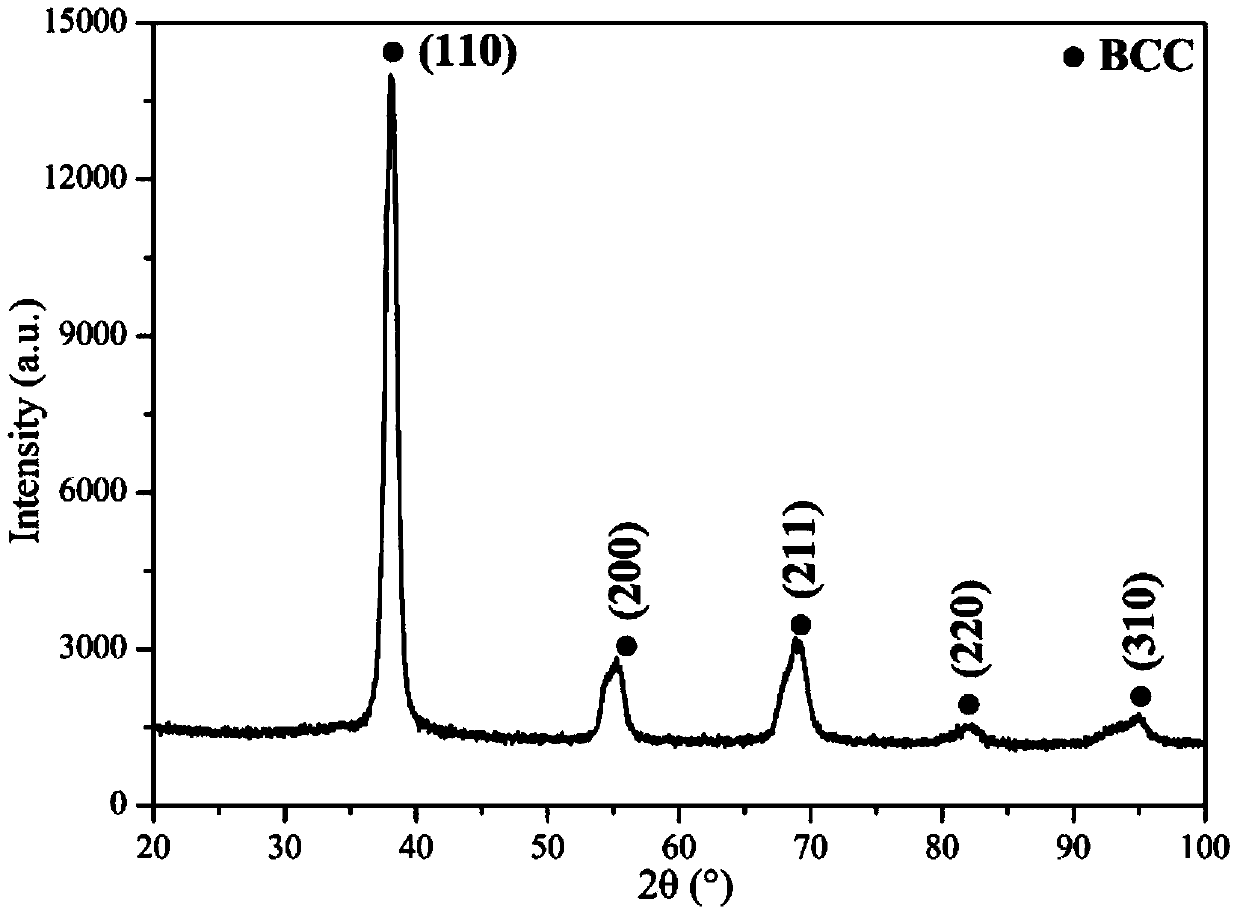

TiZrNbMoxHfy multi-principal component high temperature alloy and preparation method thereof

Owner:HARBIN INST OF TECH

Low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for bullet train and preparation method of polyolefin cable material

ActiveCN104231394ASmall mechanical propertiesLow elongation at breakPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention discloses a low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for a bullet train. The polyolefin cable material is prepared from the following raw materials in parts by weight: high-density polyethylene, linear low-density polyethylene, a flame retardant, silicon dioxide, ethylene-vinyl acetate graft maleic anhydride copolymer, an elastomer, an antioxidant and a lubricant. The invention further discloses a preparation method of the polyolefin cable material. The preparation method comprises the following steps: adding prepared polyolefin and an assistant into a high-speed mixer, mixing at the speed of 1,000-1,500r / min for 5-10 minutes, and mixing and granulating by virtue of a double-screw extruder at 150-170 DEG C to obtain the polyolefin cable material. The polyolefin cable material has the advantages of high elongation rate, low smoke, no halogen, flame retardancy, no toxics and the like, and specifically can be used for manufacturing wires and cables for the bullet train with the speed of 350km / h.

Owner:ANHUI HUALING CABLE GRP

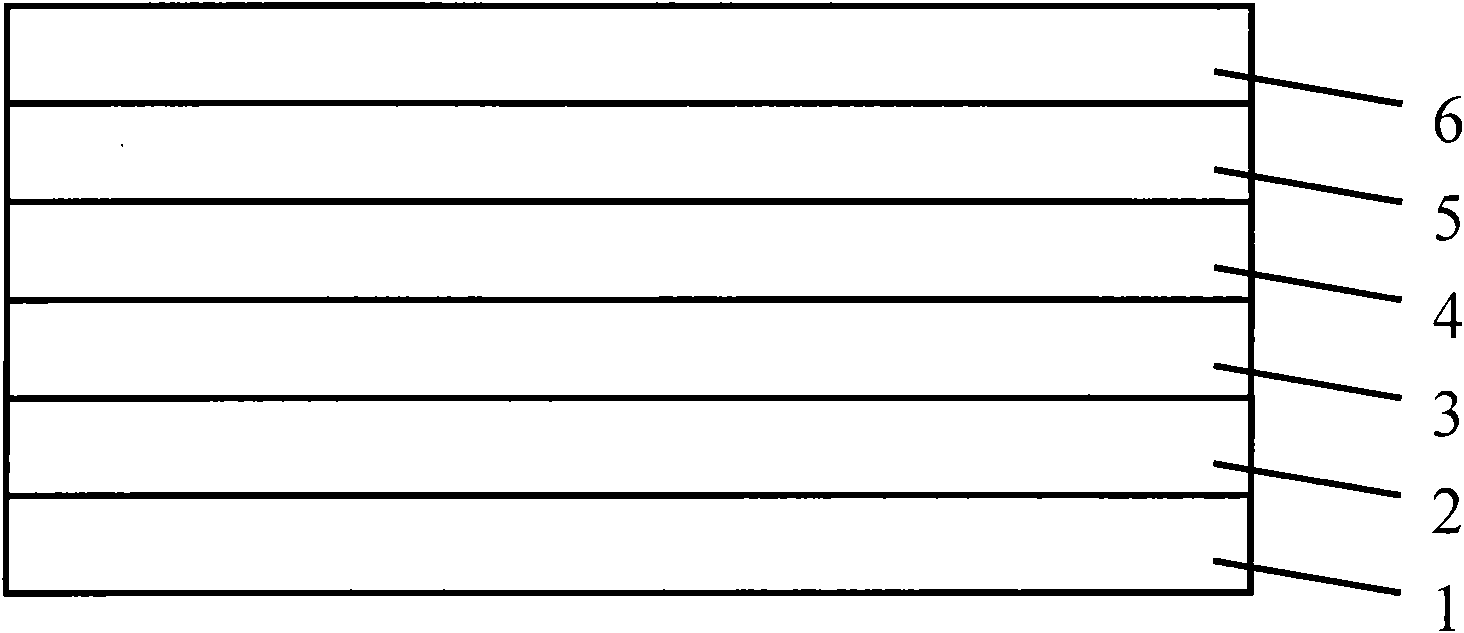

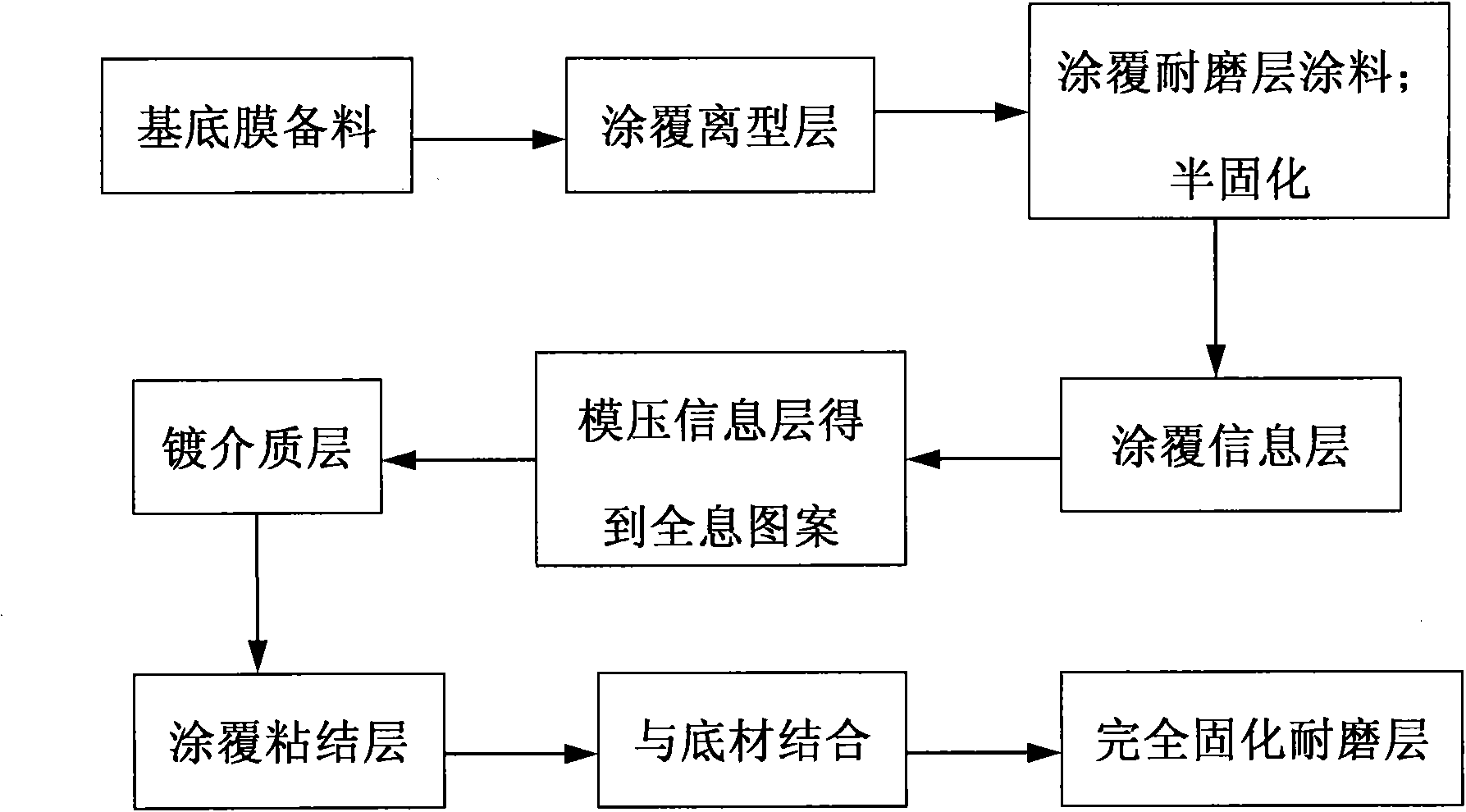

Method for preparing material with holographic patterns

InactiveCN101614954AGuaranteed wear resistanceGuaranteed CorrosionDecorative surface effectsPhotomechanical apparatusInformation layerWear resistance

The invention discloses a method for preparing a material with holographic patterns, which comprises the following steps: forming a releasing layer, an abrasion-resistant layer, an information layer and a dielectric layer on a basement membrane in turn to obtain a holographic transfer membrane, and combining the holographic transfer membrane and a base material at one side of the dielectric layer, wherein the abrasion-resistant layer is formed by coating an abrasion-resistant layer paint on the surface of the releasing layer and then semi-curing the abrasion-resistant layer paint; and fully curing the abrasion-resistant layer after the holographic transfer membrane is combined with the base material to obtain the material with the holographic patterns. The material with the holographic patterns prepared by the method avoids the deformation of the abrasion-resistant layer paint during curing on the premise of ensuring the abrasion resistance and corrosion resistance of the material so as to improve the quality of a product.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com