Slurry for photo-curing 3D-printing dental implant as well as preparation method and application of slurry

A technology of dental implants and 3D printing, applied in the direction of prosthesis, medical science, additive processing, etc., can solve the problems of inability to realize product manufacturing, increase production cost, prolong manufacturing cycle, etc., and achieve guaranteed strength, high reliability, Rapidly produced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

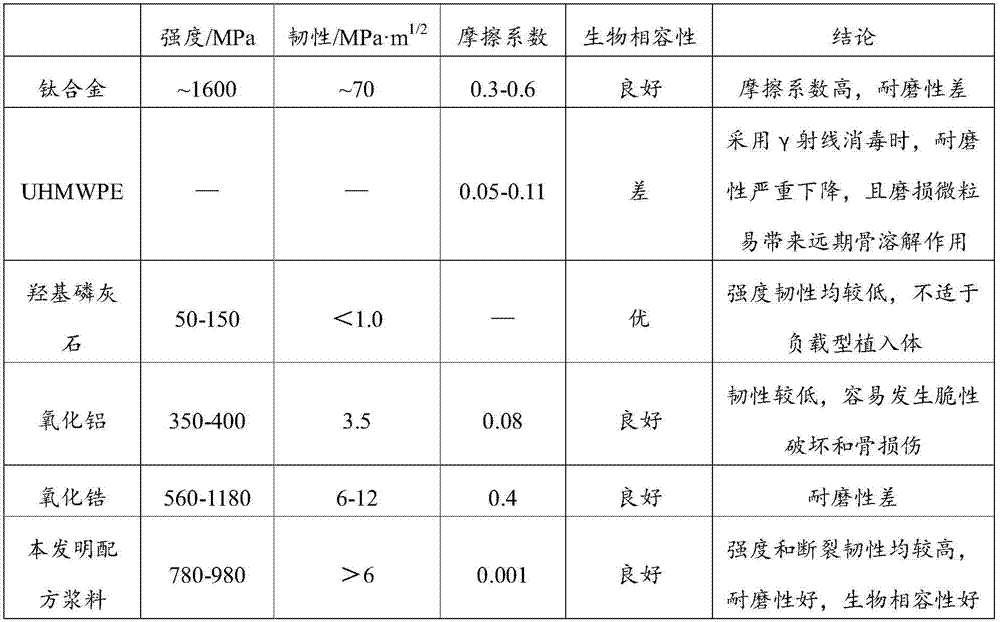

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Preparation of silicon nitride ceramic powder: Weigh α-silicon nitride, β-silicon nitride, and additives according to the proportions, and stir them through a ball mill for 4 hours until they are evenly mixed and set aside;

[0025] Step 2: Weigh a certain amount of photosensitive resin, photoinitiator, and reactive diluent according to the ratio, and mix for 5 minutes by heating in a 60°C water bath + magnetic stirring to obtain a photosensitive resin system;

[0026] Step 3: Add silicon nitride ceramic powder, dispersant, and other additives into the above photosensitive resin system in two batches, and perform ball mill dispersion to obtain a ceramic slurry with a viscosity of 3500 mPa·s.

[0027] Step 4: Add the ceramic slurry into the trough of the light-curing 3D printer, adjust the exposure parameters: exposure time 20ms, scanning speed 2500mm / s, open the dental implant CAD model that has been sliced, and complete the dental implant under the control of th...

Embodiment 2

[0032] Step 1: Preparation of silicon nitride ceramic powder: Weigh α-silicon nitride, β-silicon nitride, and additives according to the proportions, and stir them through a ball mill for 3 hours until they are evenly mixed and set aside;

[0033] Step 2: Weigh a certain amount of photosensitive resin, photoinitiator, and reactive diluent according to the proportion, and mix them for 7 minutes by heating in a water bath at 60°C + magnetic stirring to obtain a photosensitive resin system;

[0034]Step 3: adding silicon nitride ceramic powder, dispersant, and other additives into the above photosensitive resin system in 3 batches, and performing ball mill dispersion to obtain a ceramic slurry with a viscosity of 2000 mPa·s.

[0035] Step 4: Add the ceramic slurry into the trough of the light-curing 3D printer, adjust the exposure parameters: exposure time 10ms, scanning speed 4000mm / s, open the dental implant CAD model that has been sliced, and complete the dental implant under t...

Embodiment 3

[0040] Step 1: Preparation of silicon nitride ceramic powder: Weigh α-silicon nitride, β-silicon nitride, and additives according to the proportions, and stir them through a ball mill for 5 hours until they are evenly mixed and set aside;

[0041] Step 2: Weigh a certain amount of photosensitive resin, photoinitiator, and reactive diluent according to the ratio, and mix them for 8 minutes by heating in a water bath at 55°C + magnetic stirring to obtain a photosensitive resin system;

[0042] Step 3: Add silicon nitride ceramic powder, dispersant, and other additives into the above photosensitive resin system in 3 batches, and perform ball mill dispersion to obtain a ceramic slurry with a viscosity of 5000 mPa·s.

[0043] Step 4: Add the ceramic slurry into the trough of the light-curing 3D printer, adjust the exposure parameters: exposure time 30ms, scanning speed 1000mm / s, open the dental implant CAD model that has been sliced, and complete the dental implant under the control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com