Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about How to "Different thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

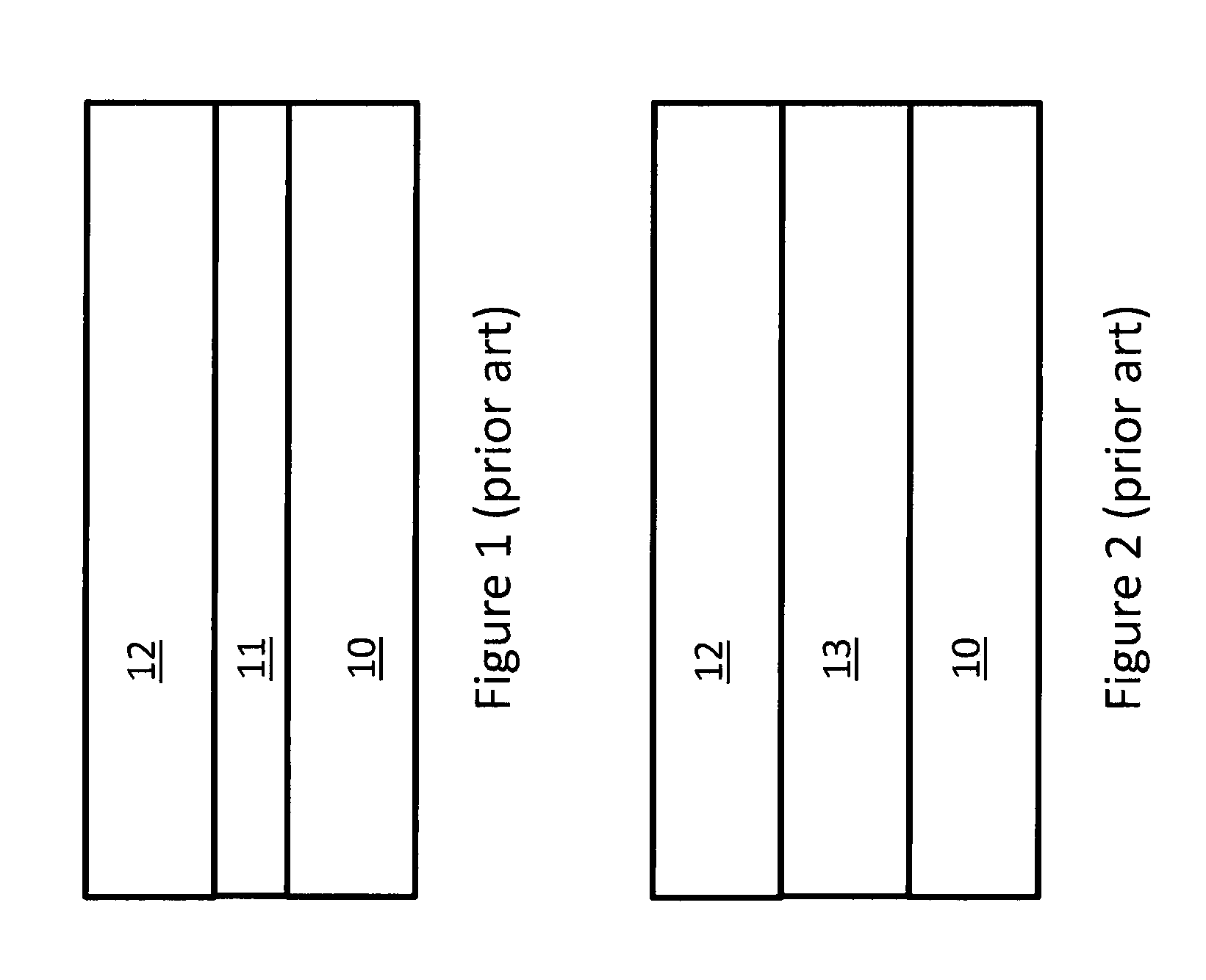

Ultra-thin Si channel MOSFET using a self-aligned oxygen implant and damascene technique

The present invention provides a thin channel MOSFET having low external resistance. In broad terms, a silicon-on-insulator structure comprising a SOI layer located atop a buried insulating layer, said SOI layer having a channel region which is thinned by the presence of an underlying localized oxide region that is located on top of and in contact with said buried insulating layer; and a gate region located atop said SOI layer, wherein said localized oxide region is self-aligned with the gate region. A method for forming the inventive MOSFET is also provided comprising forming a dummy gate region atop a substrate; implanting oxide forming dopant through said dummy gate to create a localized oxide region in a portion of the substrate aligned to the dummy gate region that thins a channel region; forming source / drain extension regions abutting said channel region; and replacing the dummy gate with a gate conductor.

Owner:GLOBALFOUNDRIES US INC

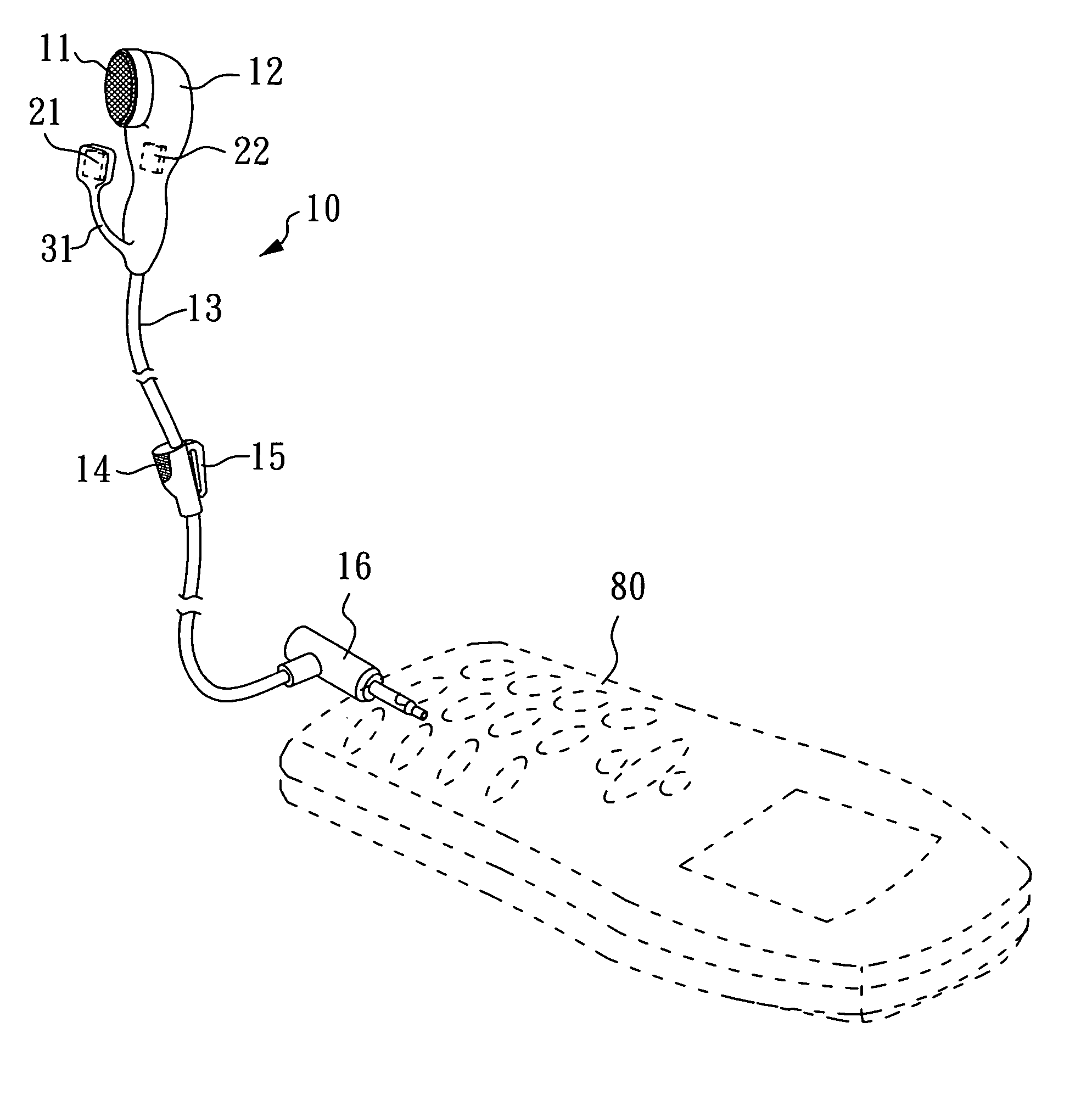

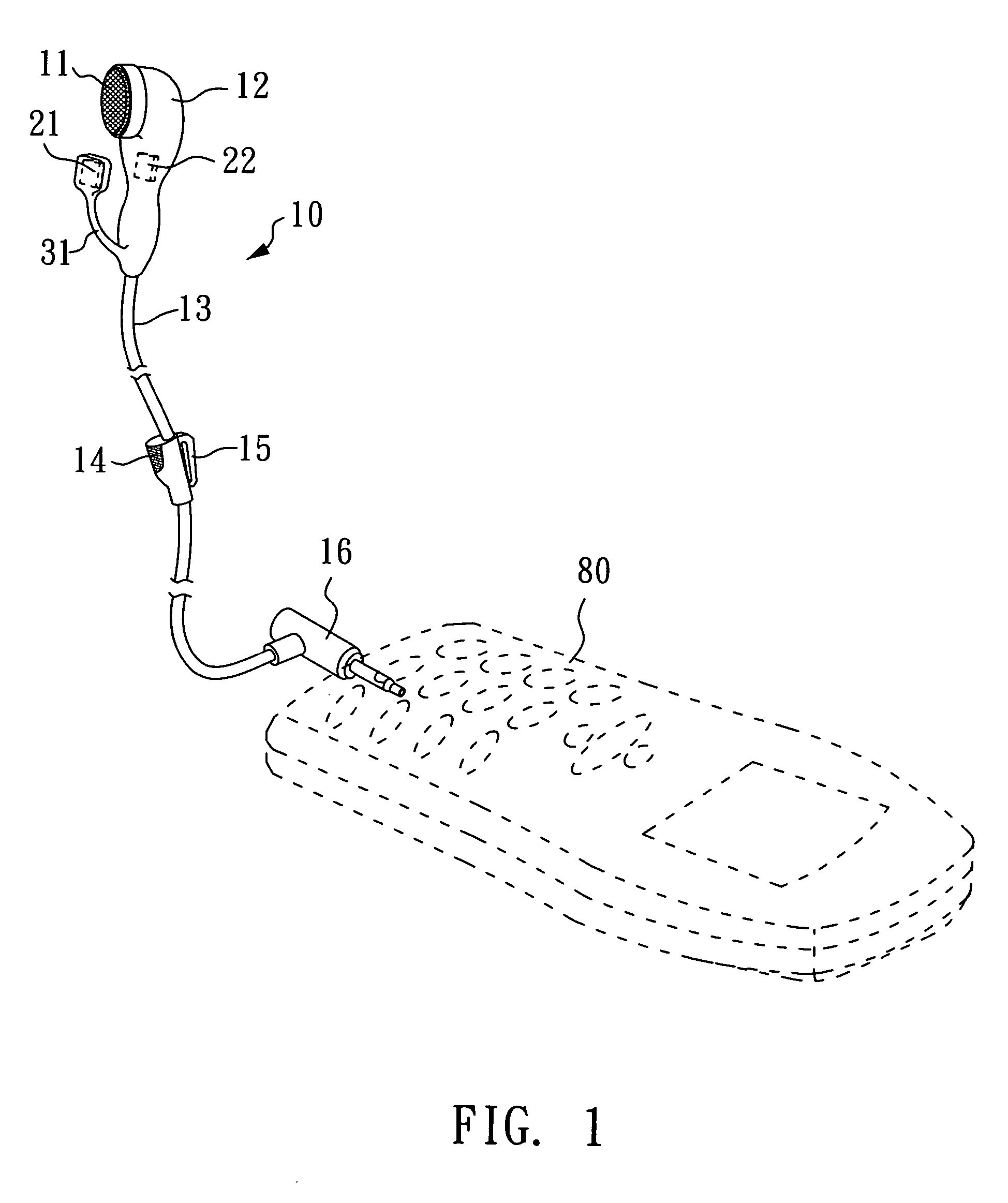

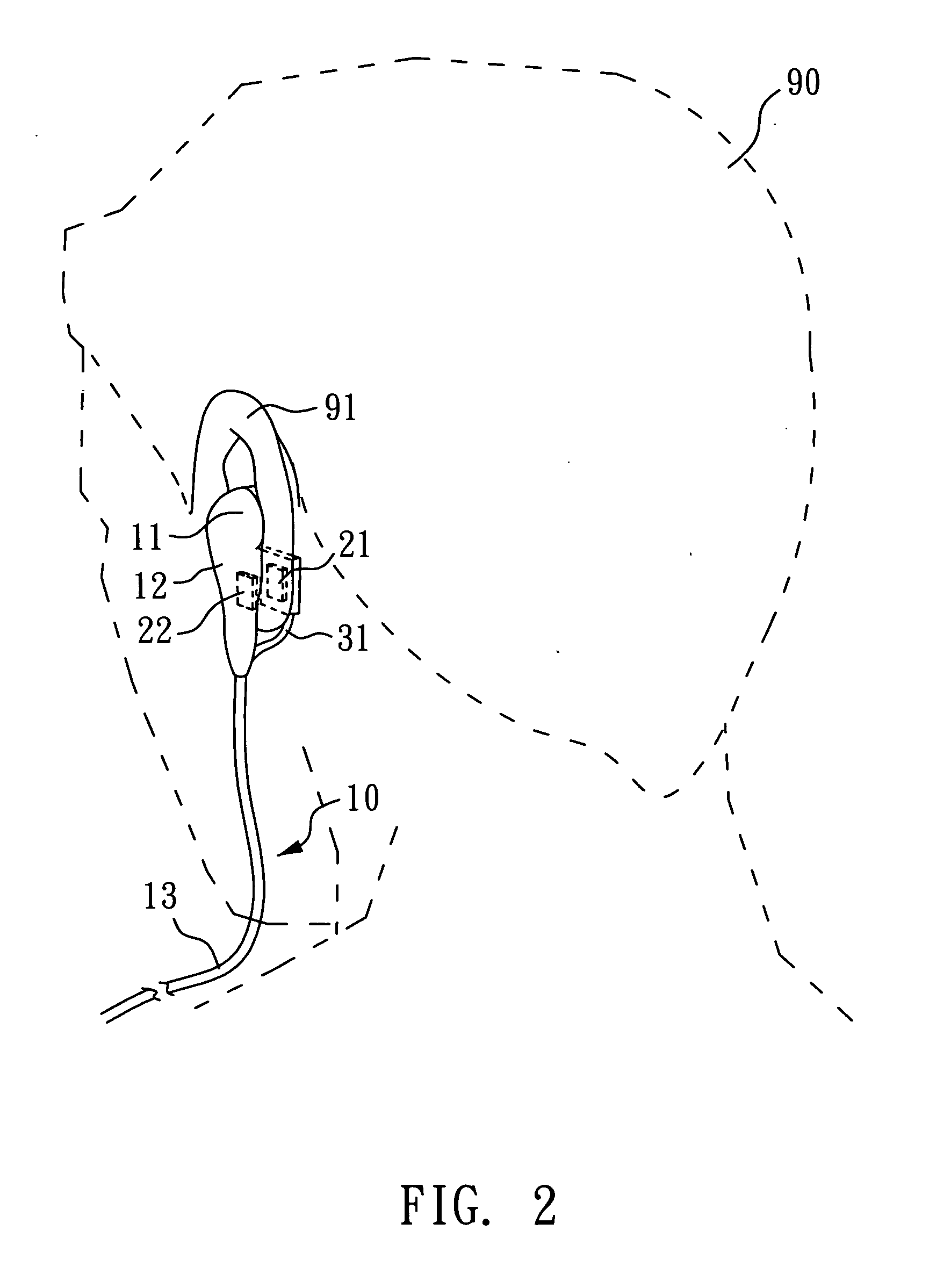

Earphone and earphone attachment

InactiveUS20050025329A1More comfortableSuitable shapeIntra aural earpiecesDeaf-aid setsEngineeringHeadphones

Owner:AMS RES CORP

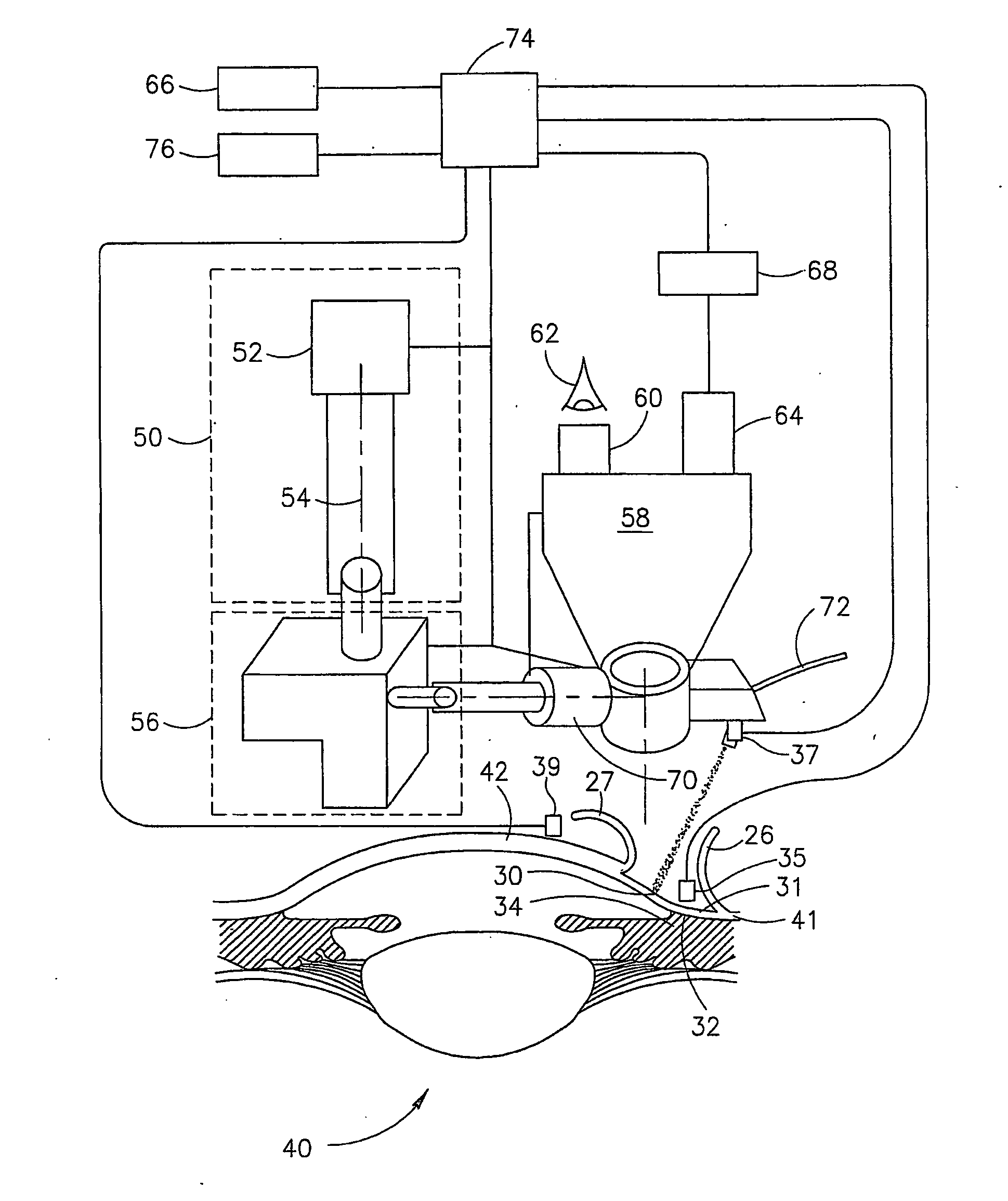

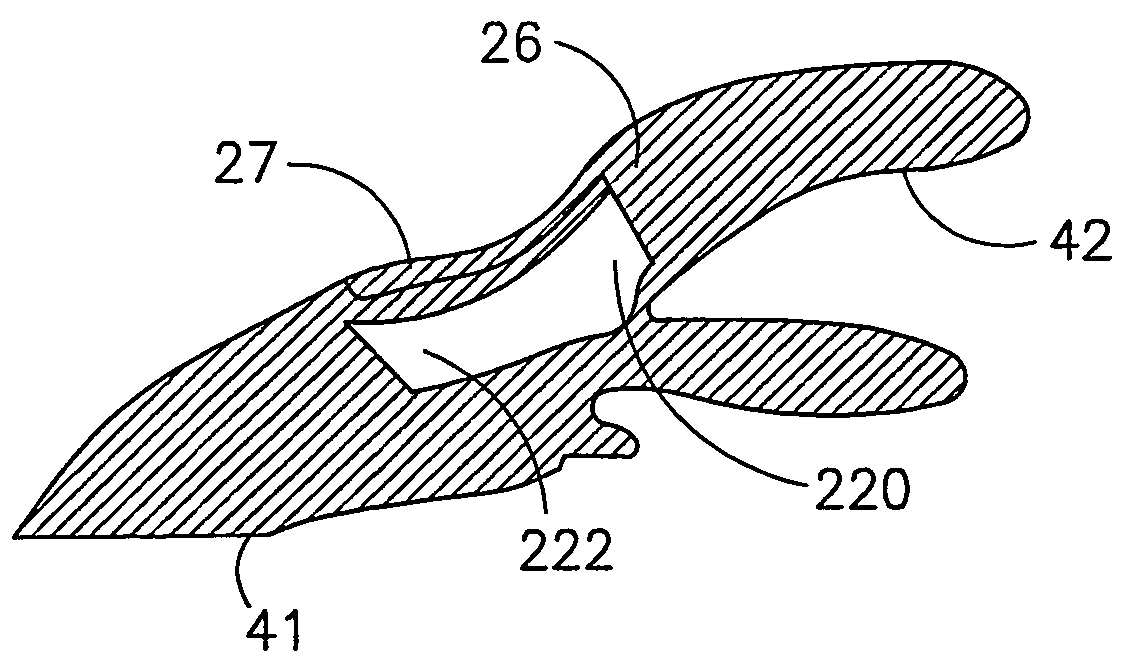

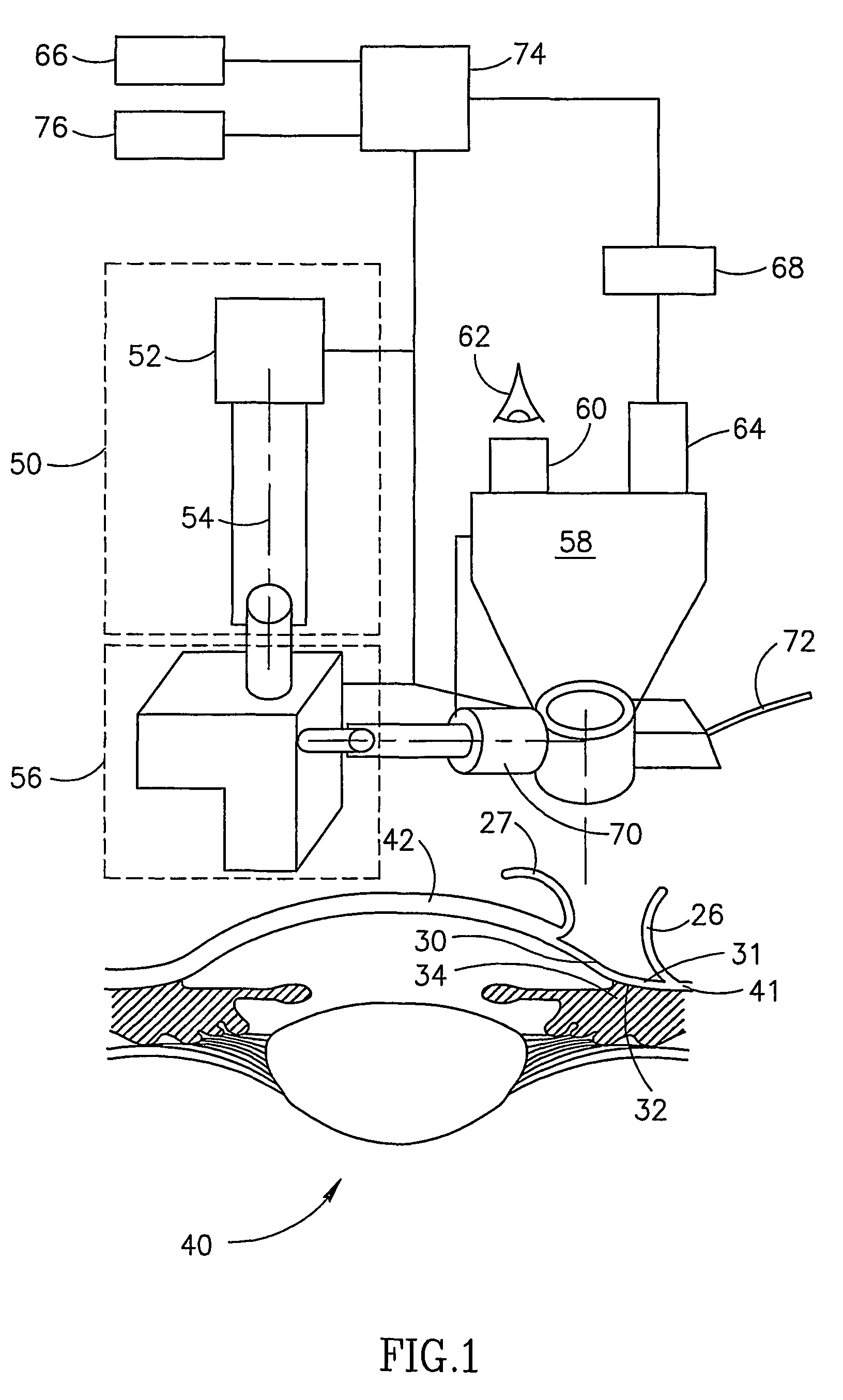

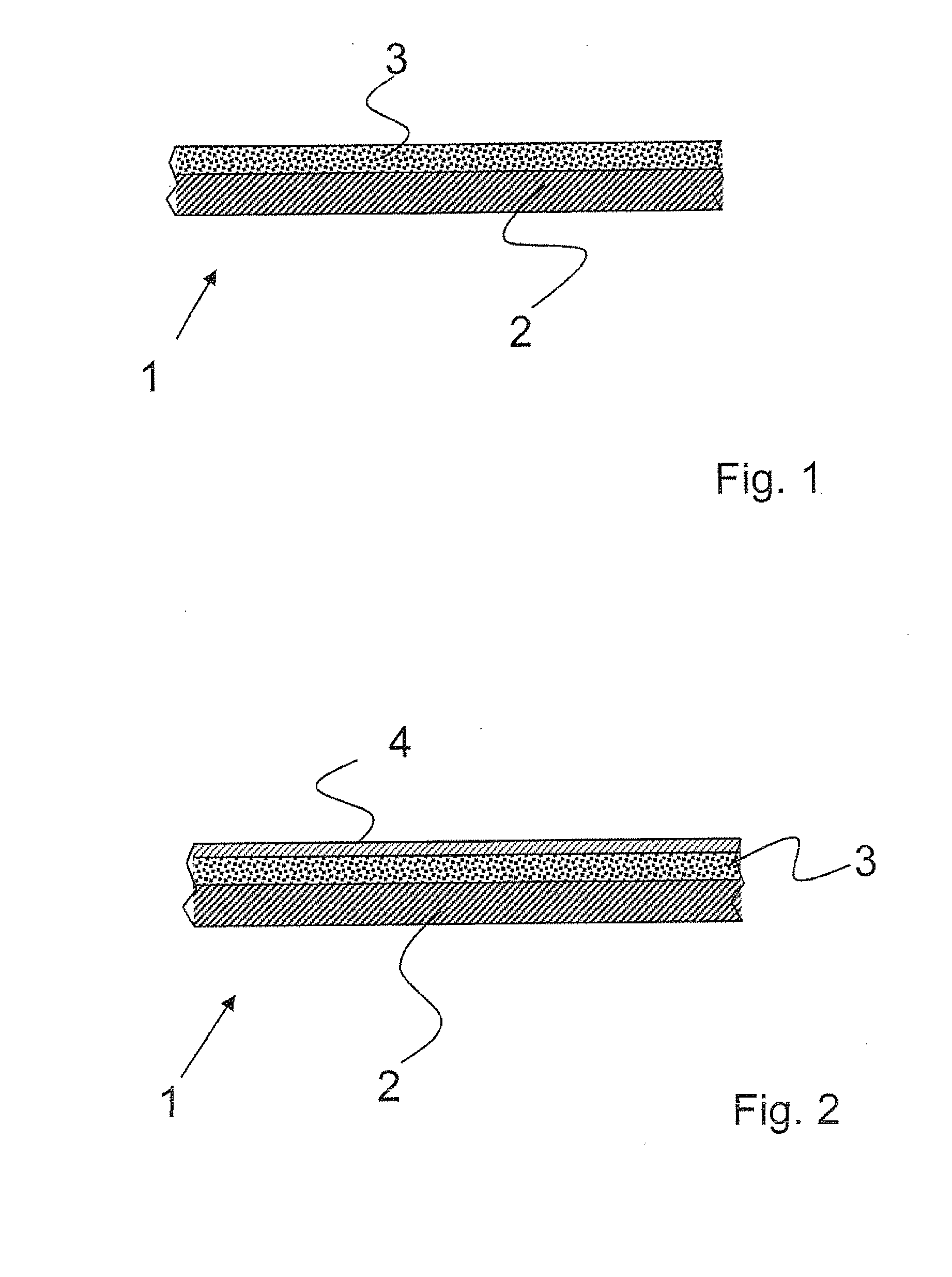

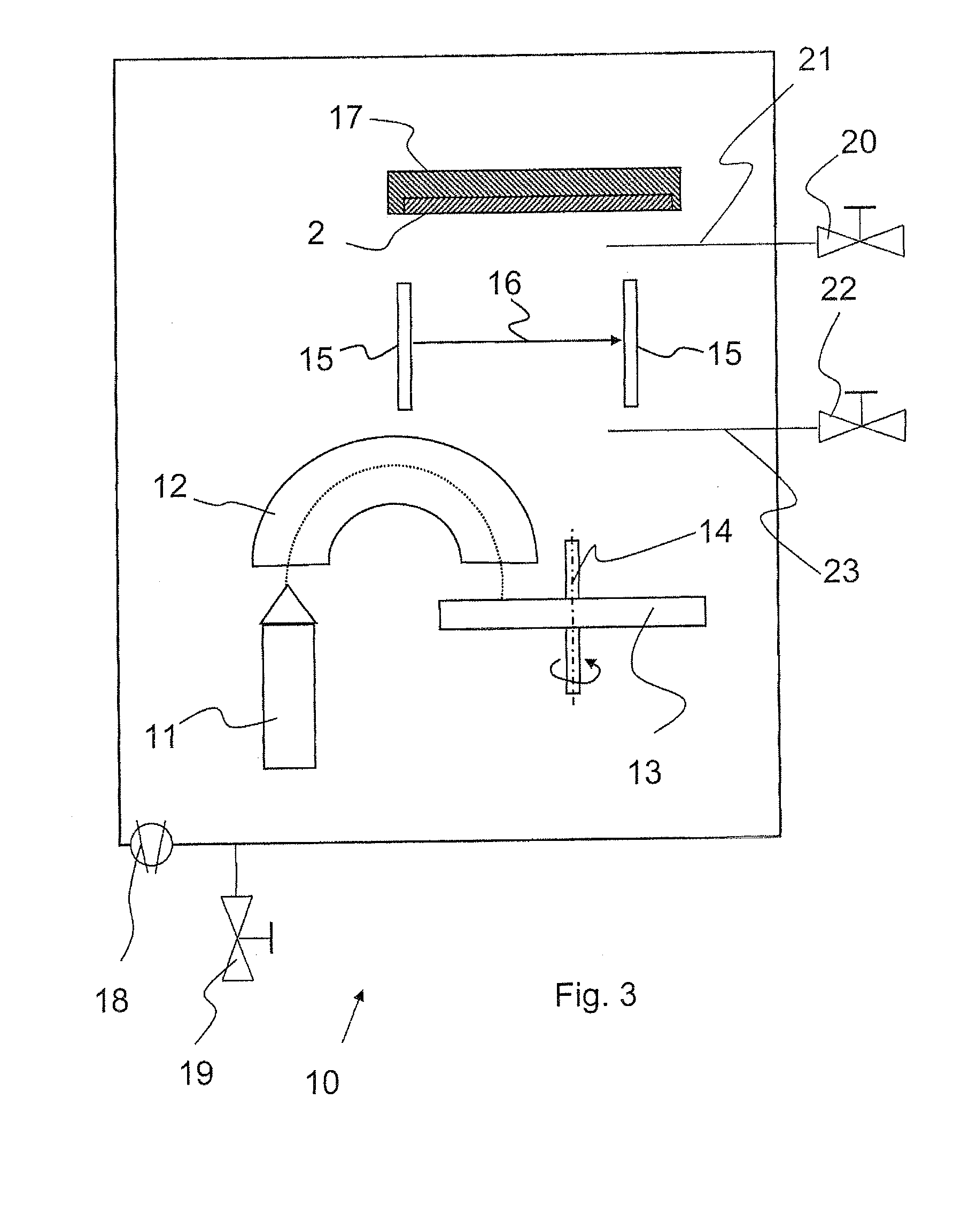

Non-penetrating filtration surgery

ActiveUS20050096639A1Raise security concernsReduce and eliminate scanningLaser surgeryDiagnosticsLight beamFiltration surgery

Apparatus for ophthalmic surgery, especially non-penetrating filtration surgery, comprising a laser source that ablates sclera tissue at steps of intermediate thickness. Optionally, the beam is scanned using a scanner and its results viewed using an ophthalmic microscope.

Owner:I OPTIMA LTD

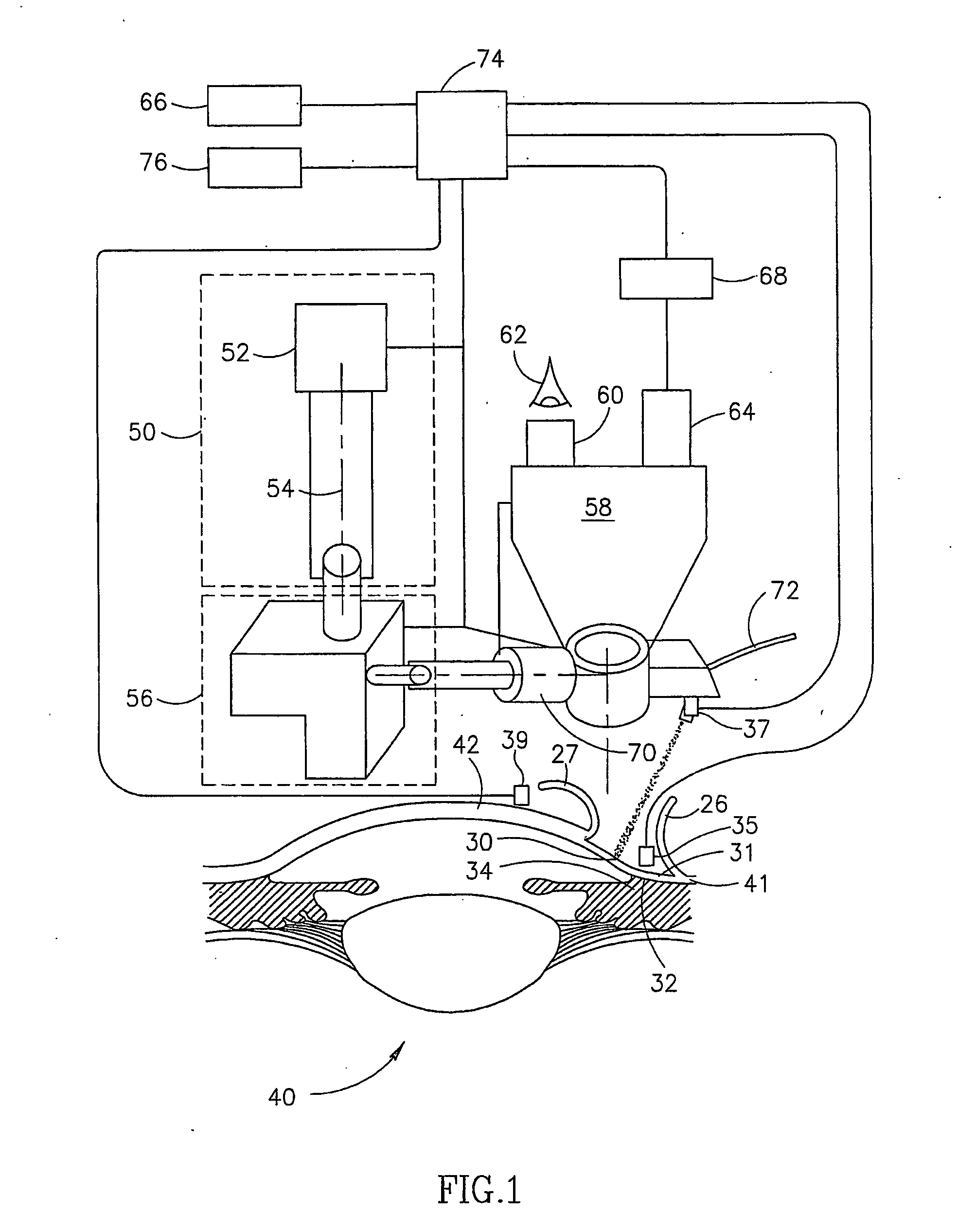

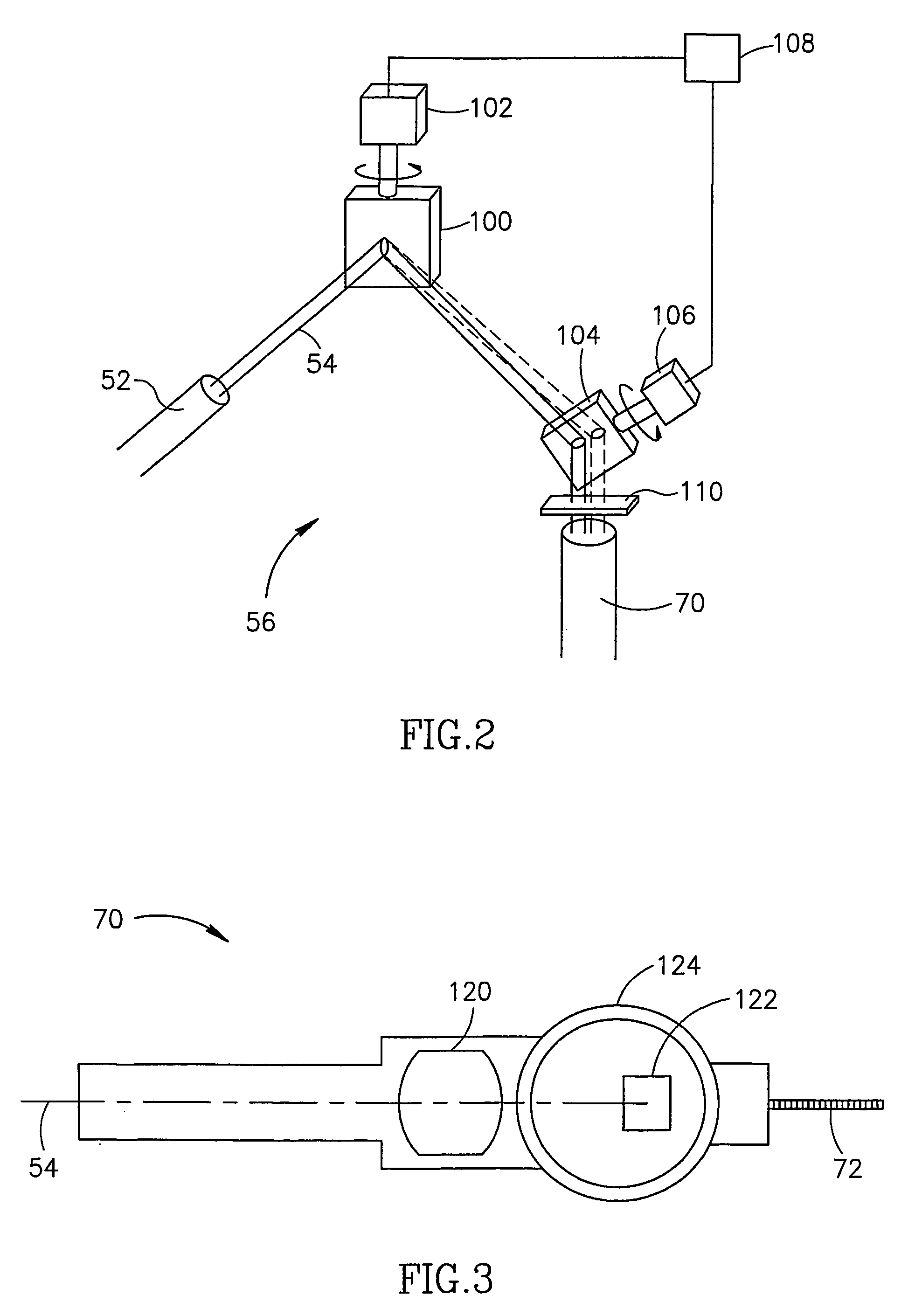

Non-penetrating filtration surgery

InactiveUS7135016B1Reduce penetrationDispersing heatLaser surgerySurgical instrument detailsPhysicsMicroscope

This invention is an apparatus for ophthalmic surgery comprising a laser source (52) that generates a laser beam (54); a scanner (56) comprising an input for said laser beam, and an output of a spatially scanned laser beam (54); controlling circuitry that drives said scanner (56) to remove tissue in a desired pattern on the eye (40); a microscope (58) for viewing said tissue removal; and a beam combiner (70) comprising a first input for a line of sight of said microscope (58) and second input for said spatially scanned beam (54).

Owner:I OPTIMA LTD

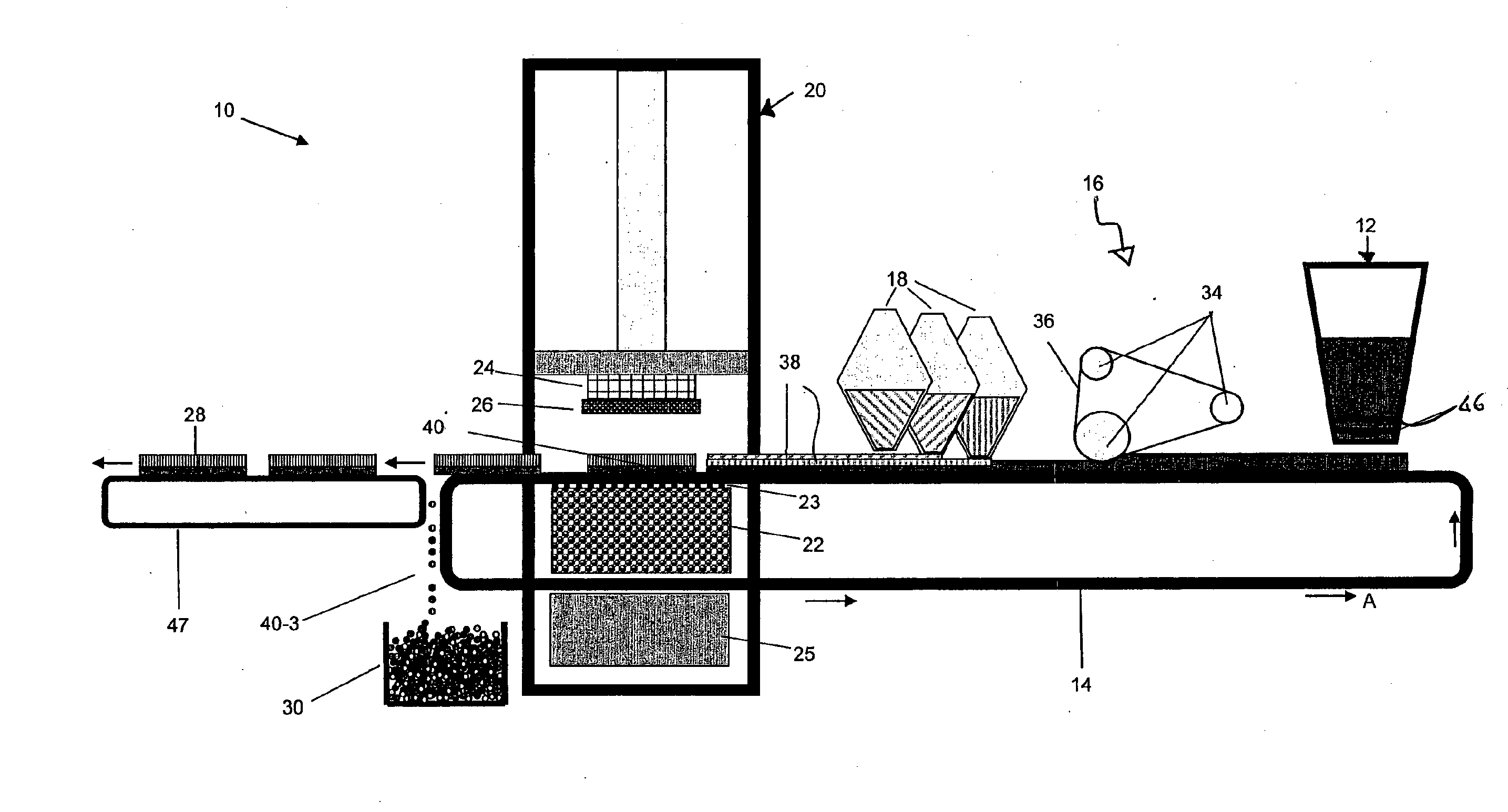

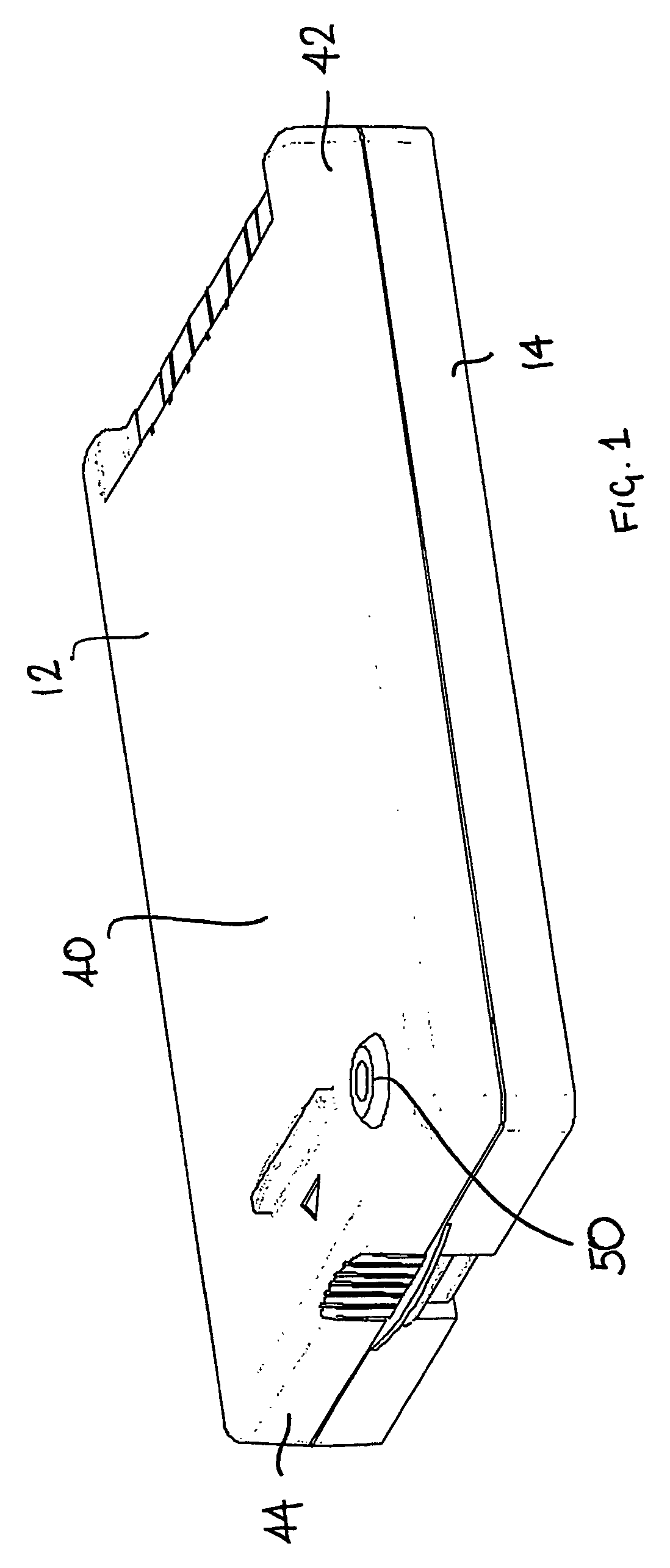

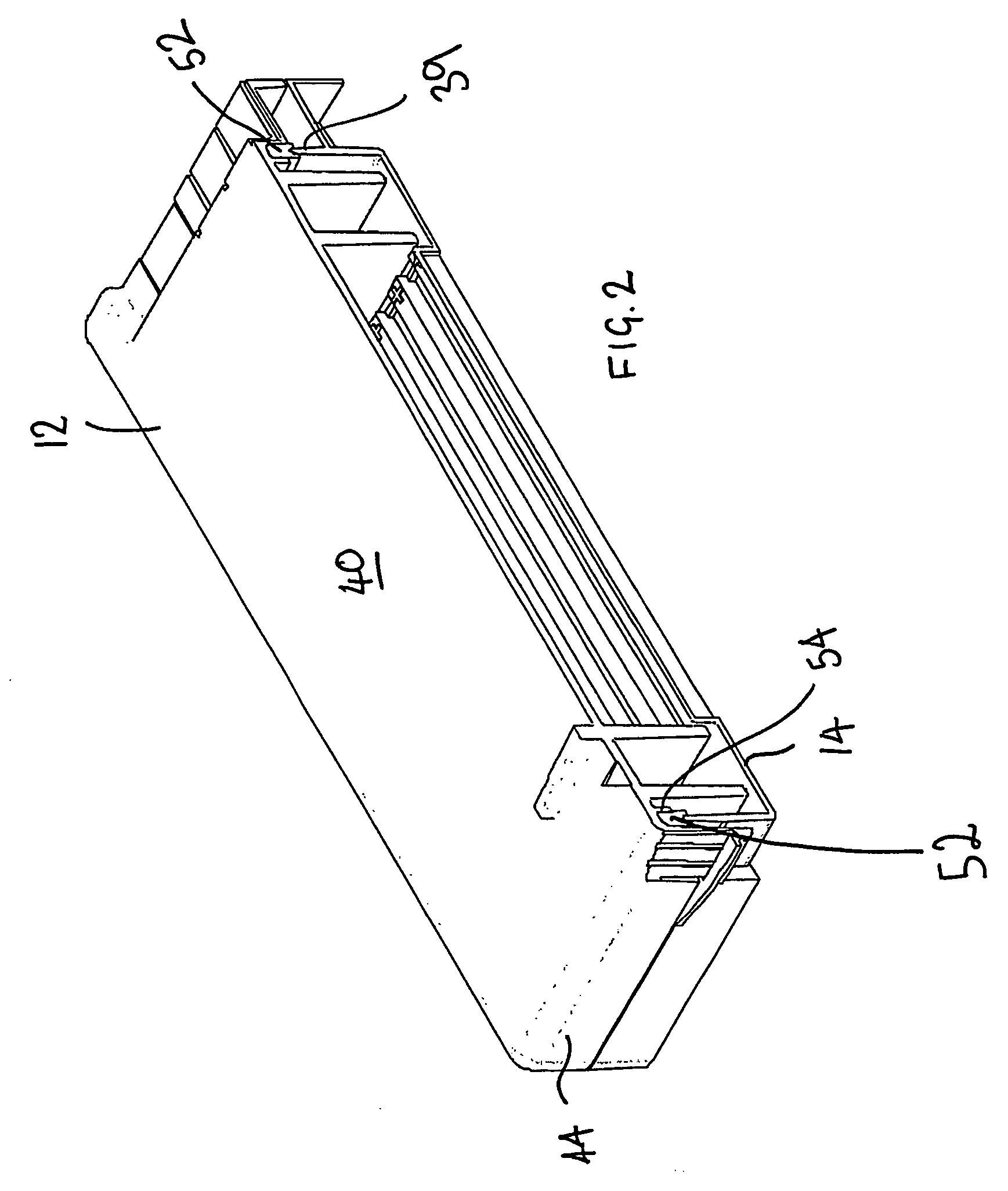

Apparatuses, system and methods for forming pressed articles and pressed articles formed thereby

ActiveUS20140141961A1Increase releaseHigh and consistent qualityConfectioneryPress rollersMechanical engineeringEngineering

The invention relates to a method and a system (10) for forming pressed articles by pressing powder or granules, the system comprising the following apparatuses: a powder discharge assembly (12); a no-cavity press assembly (20) including: an bottom plate (22) that is the same size or greater than the pressed articles, a constraining means to isolate a portion of powder, and a top punch (24); and a conveyor (14) to transport the powder and / or pressed articles.

Owner:MASS

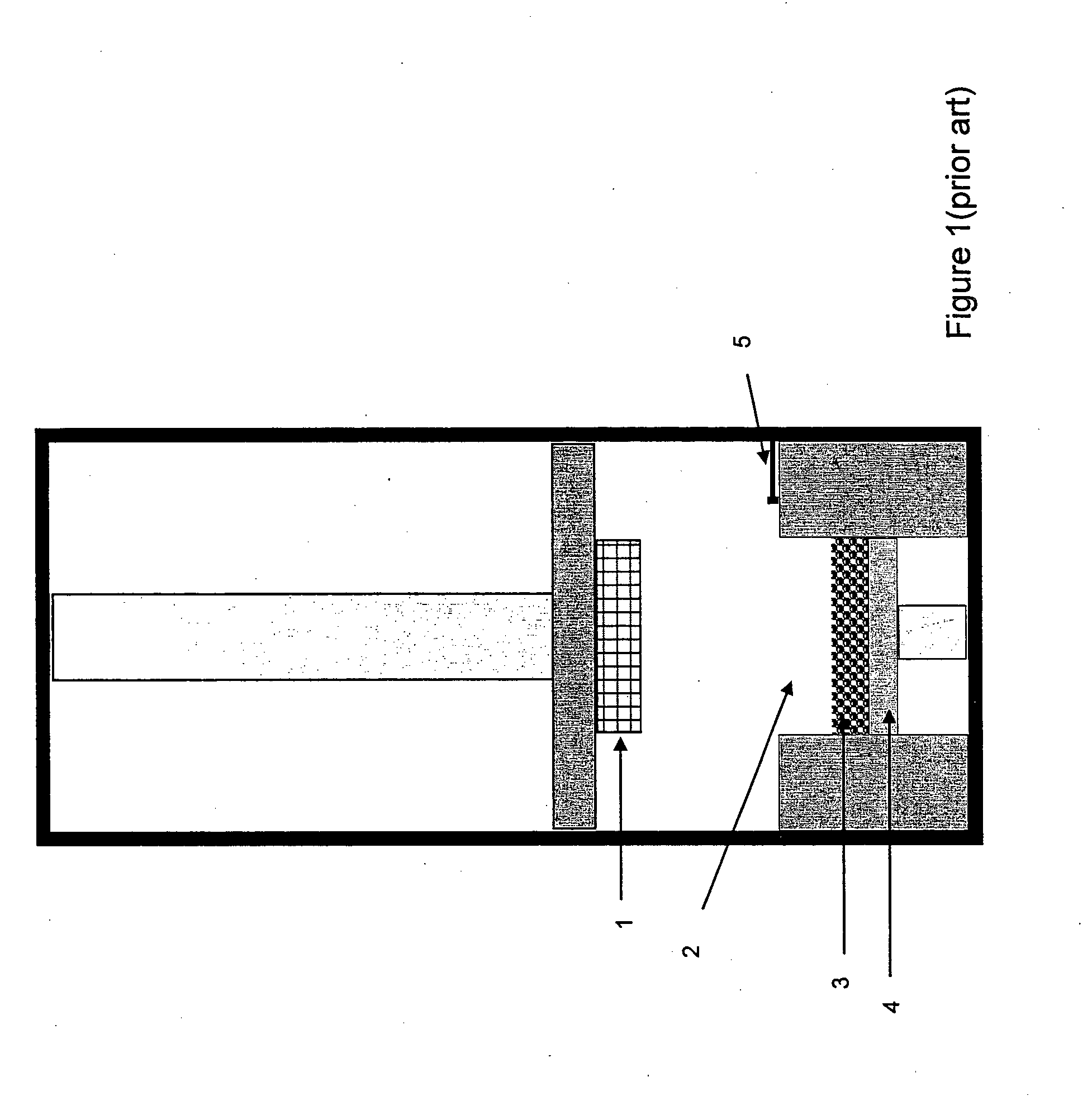

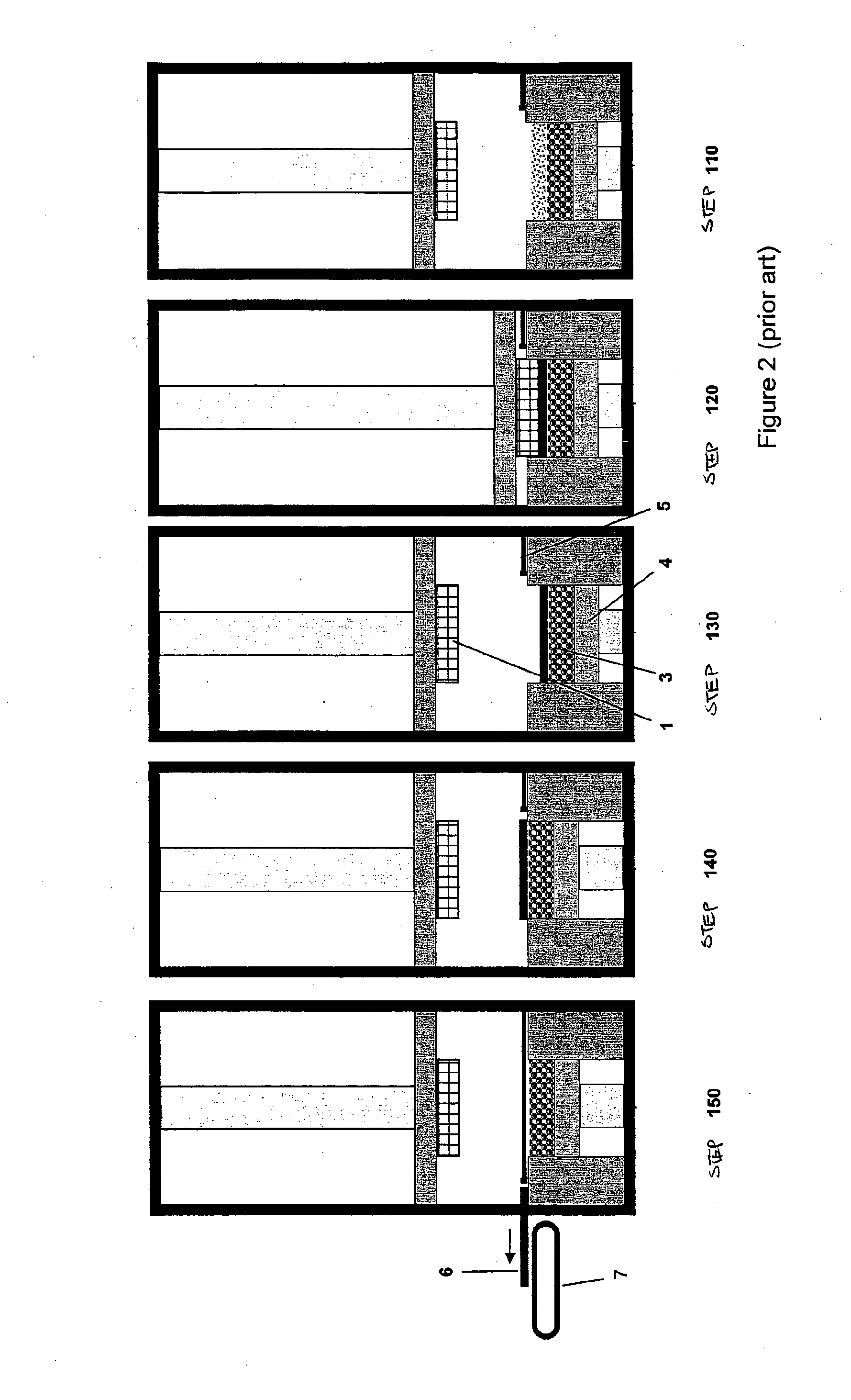

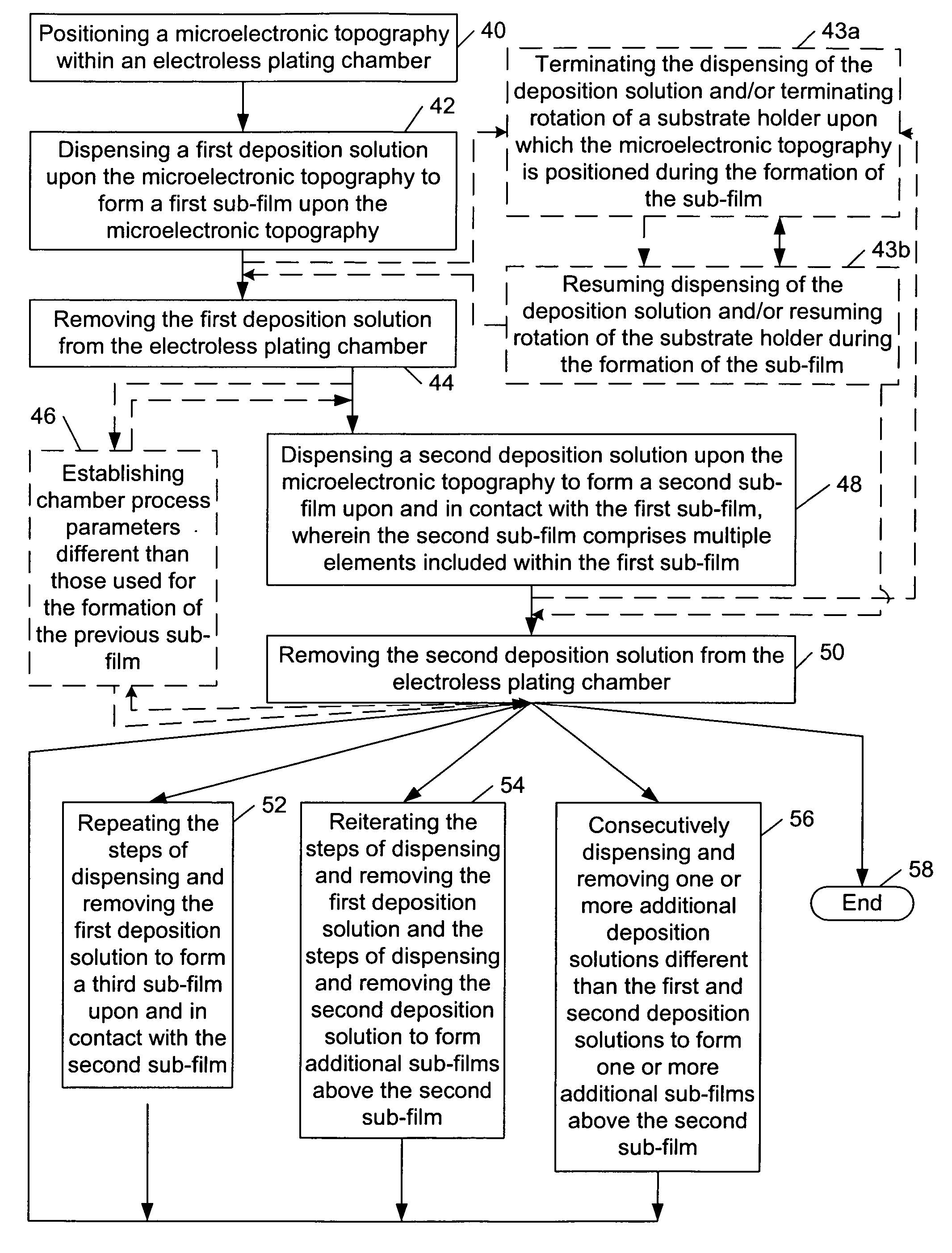

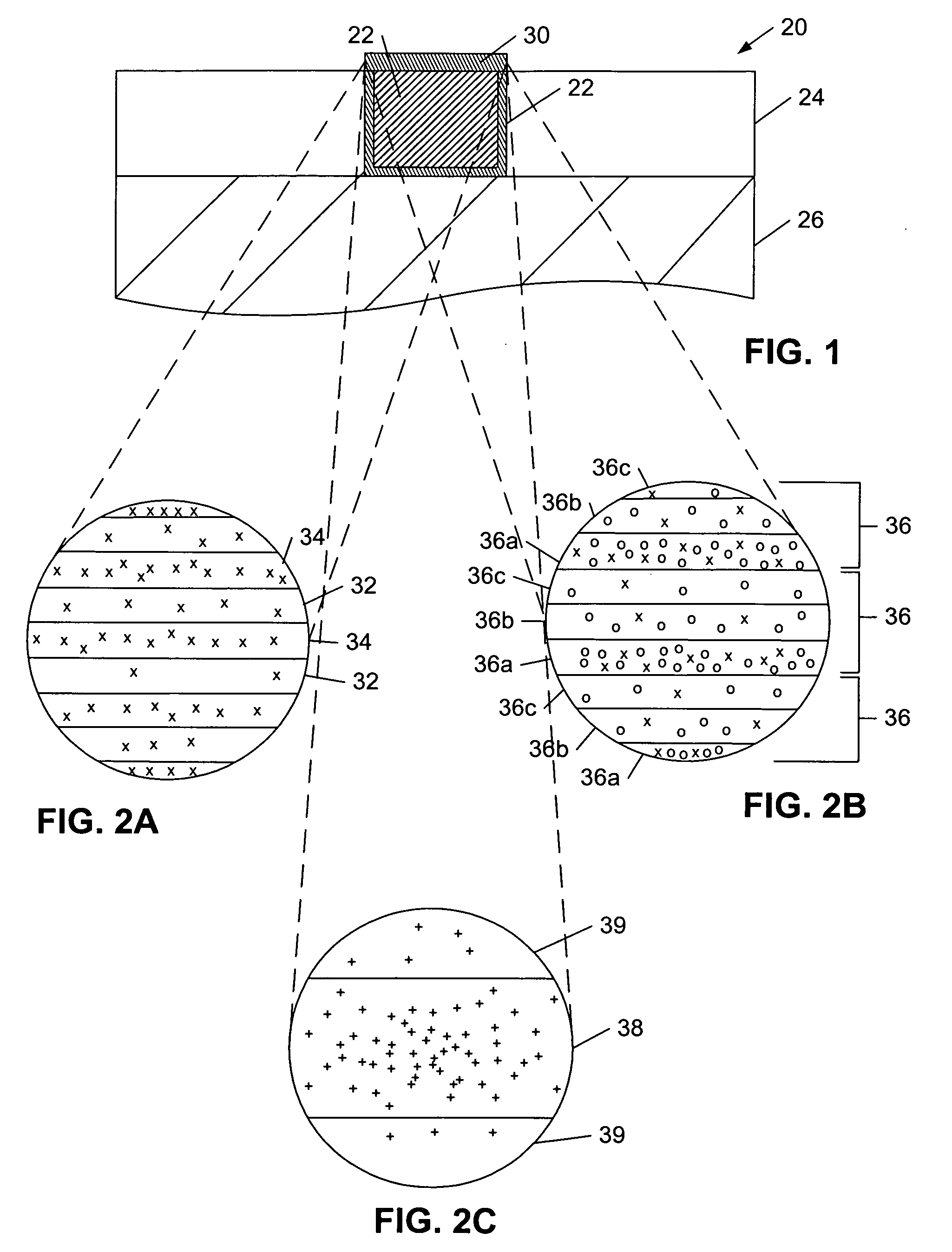

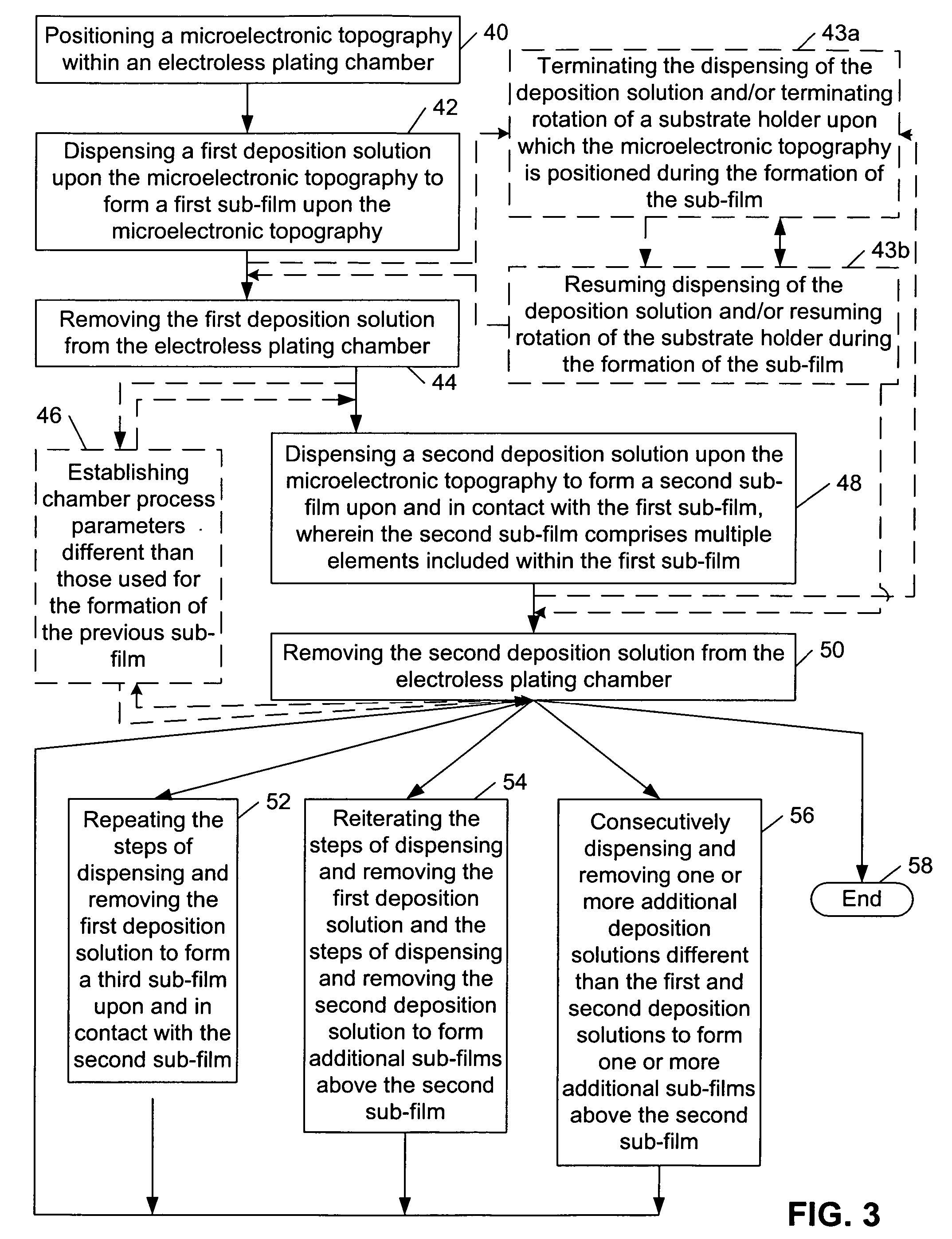

Systems and methods affecting profiles of solutions dispensed across microelectronic topographies during electroless plating processes

ActiveUS20060029727A1Different thicknessMaterial nanotechnologySemiconductor/solid-state device detailsProgram instructionElectroless plating

A method is provided which includes dispensing a deposition solution at a plurality of locations extending different distances from a center of a microelectronic topography each at different moments in time during an electroless plating process. An electroless plating apparatus used for the method includes a substrate holder, a moveable dispense arm, and a storage medium comprising program instructions executable by a processor for positioning the moveable dispense arm. Another method and accompanying electroless deposition chamber are configured to introduce a gas into an electroless plating chamber above a plate which is suspended above a microelectronic topography and distribute the gas to regions extending above one or more discrete portions of the microelectronic topography. An exemplary microelectronic topography resulting from the aforementioned methods and apparatuses includes a layer having distinct regions each including a comparatively different thickness and comparatively different concentrations of one of the one or more elements.

Owner:LAM RES CORP

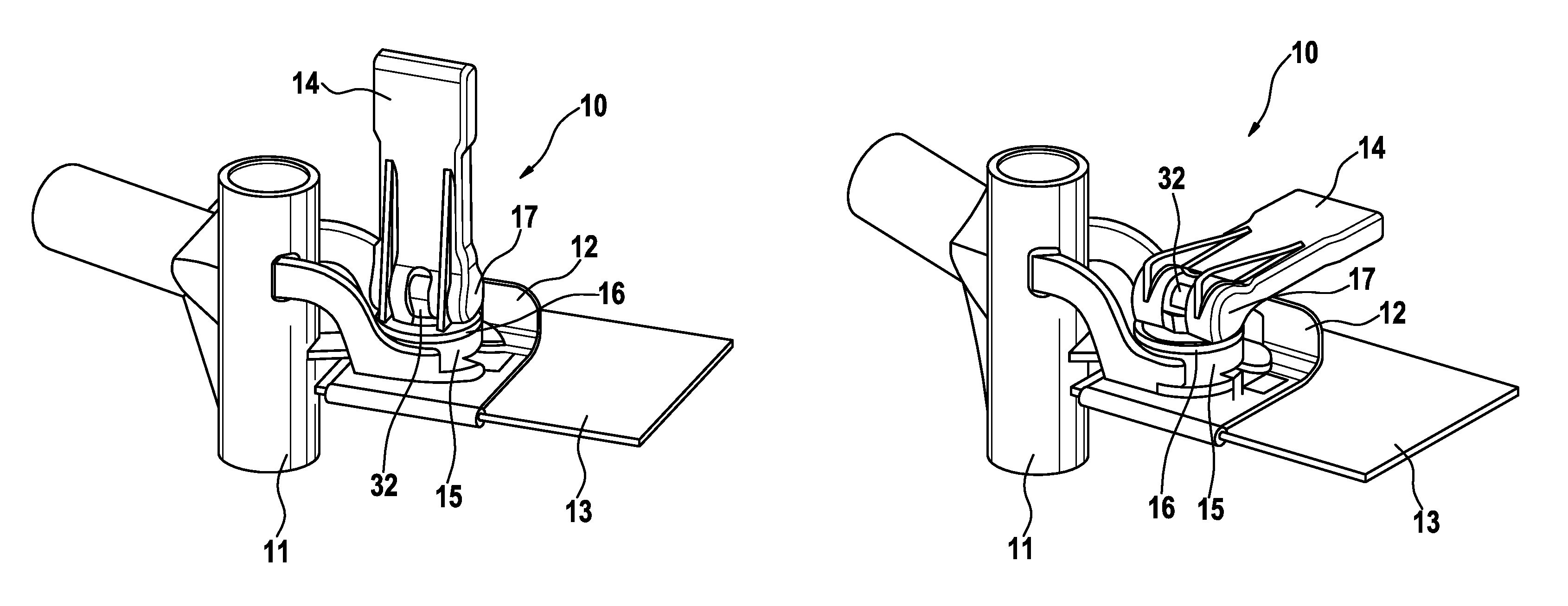

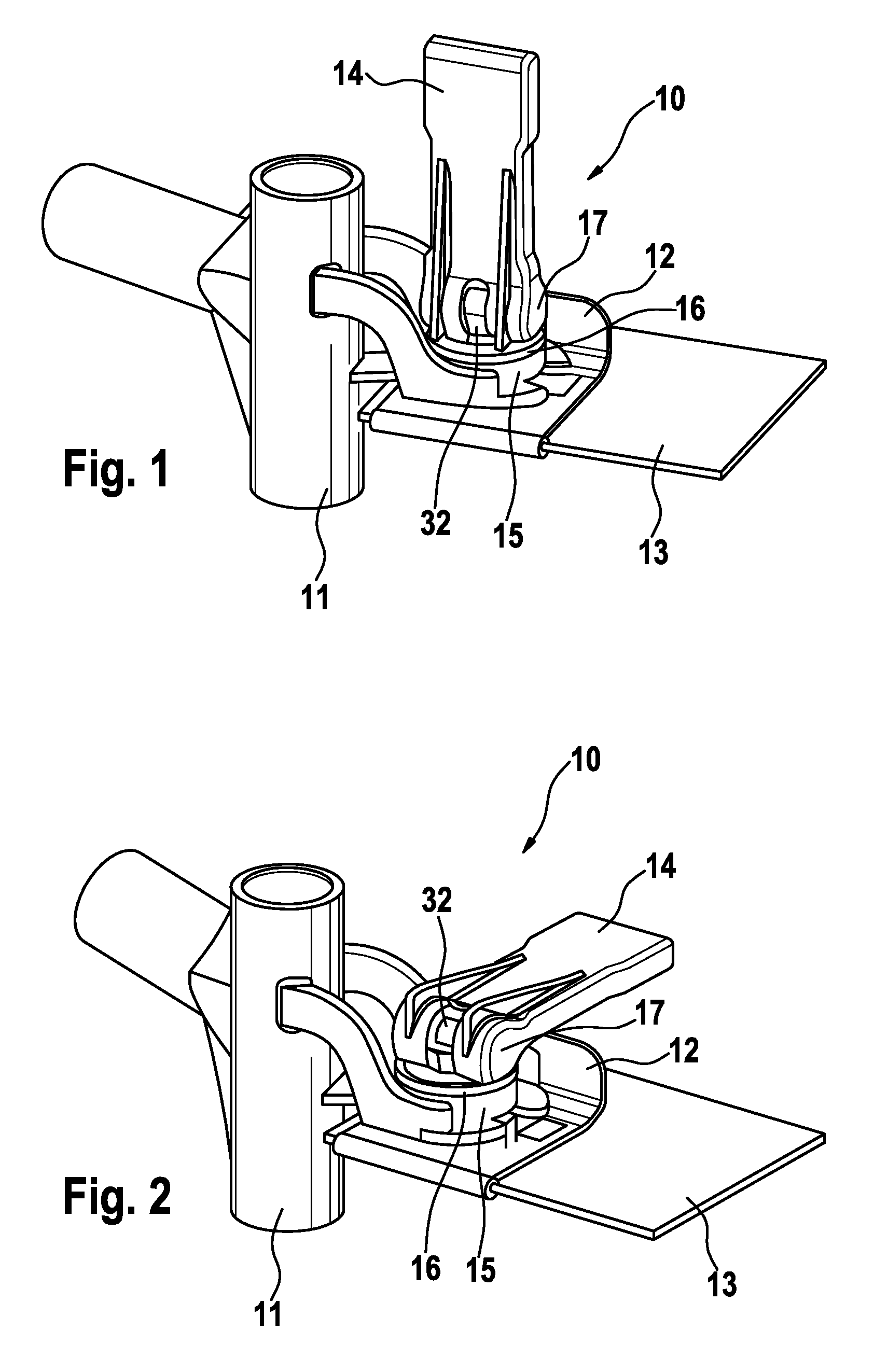

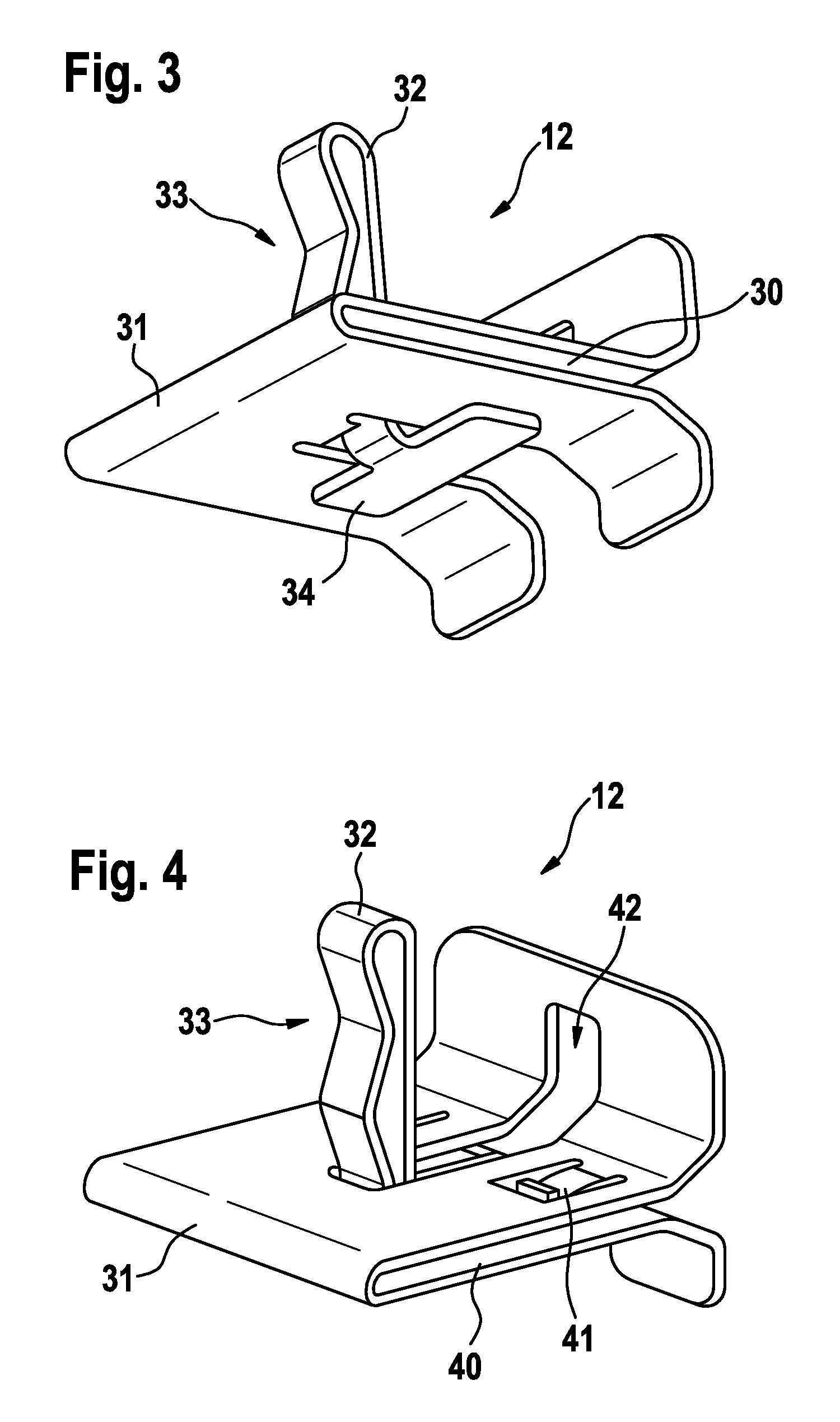

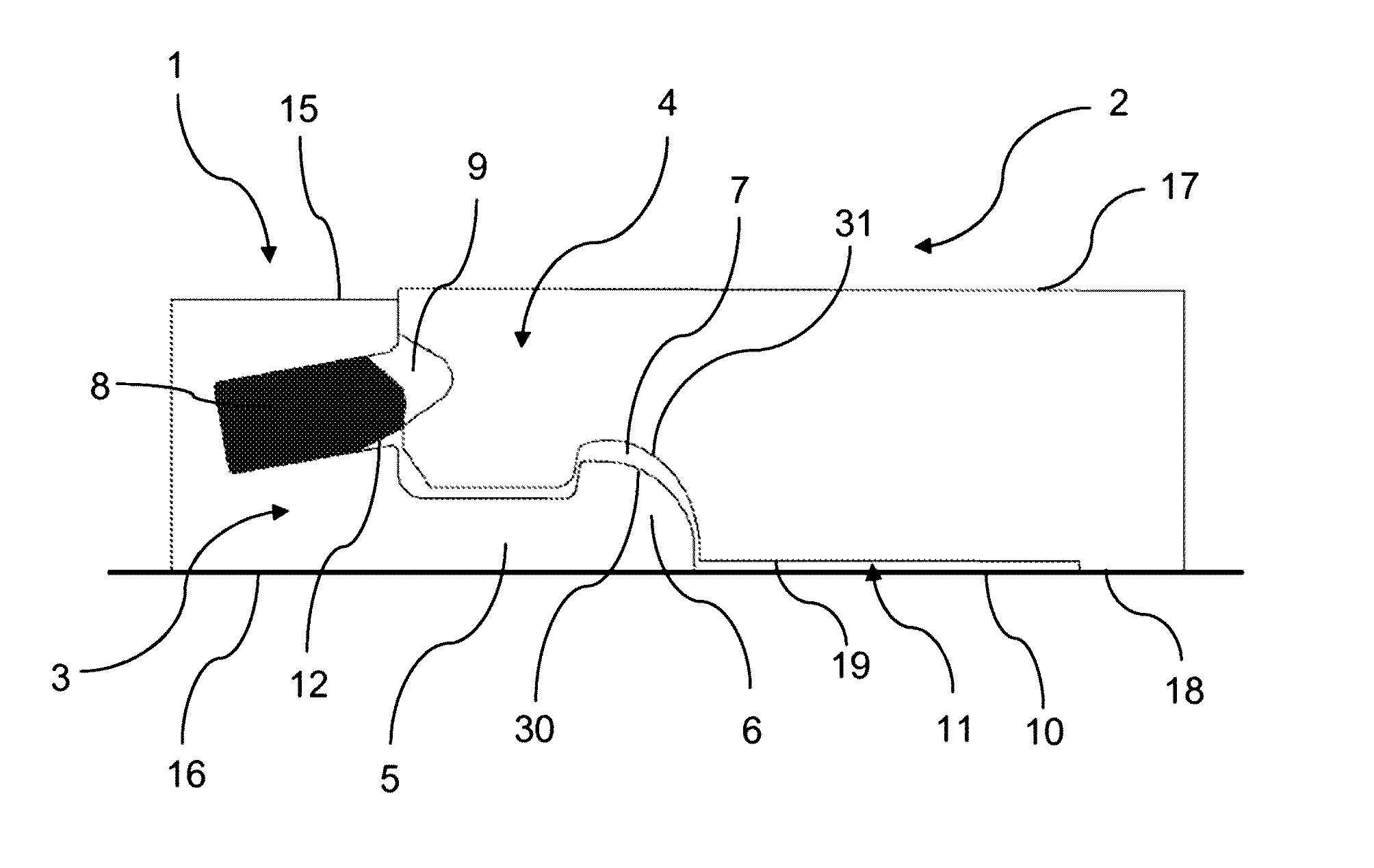

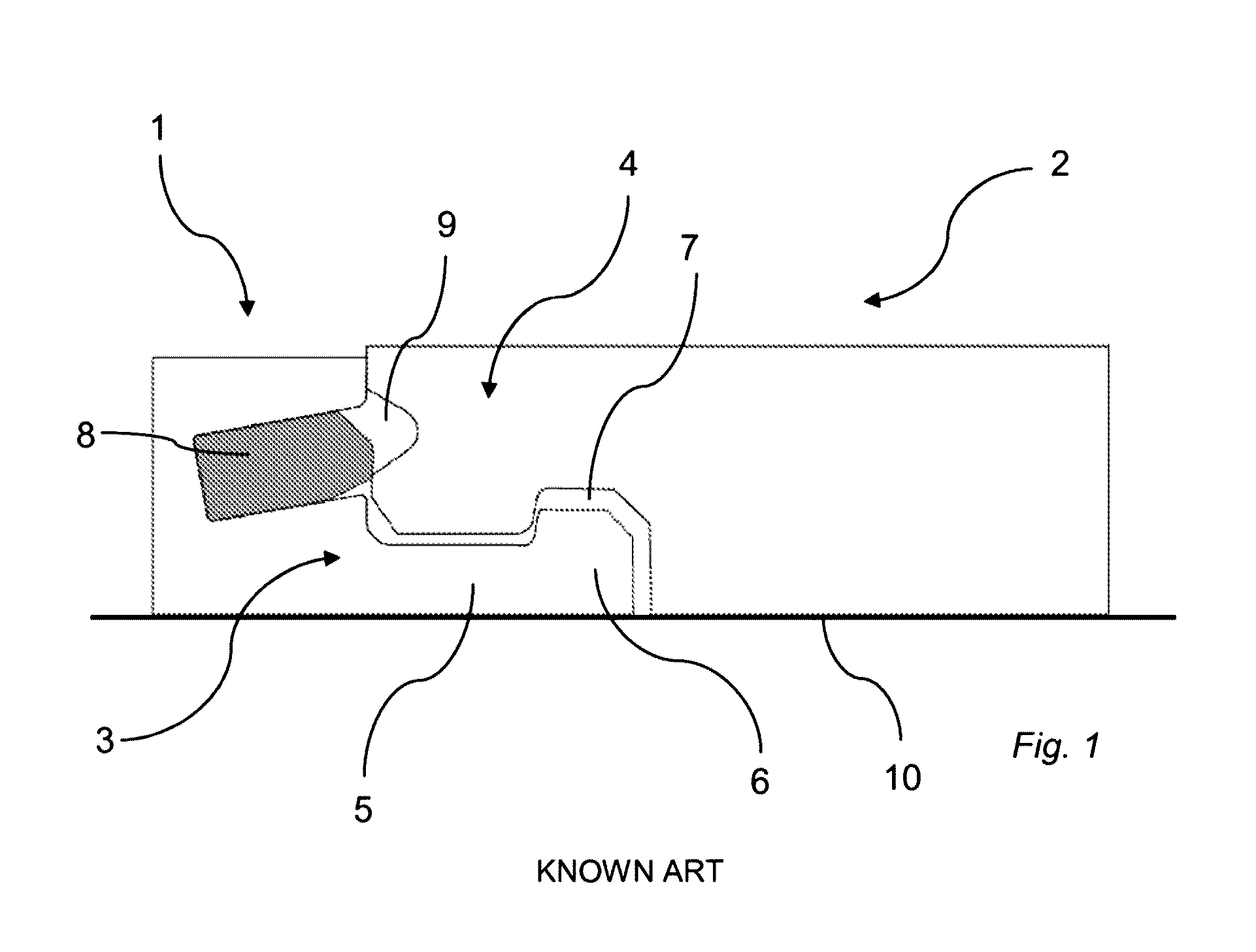

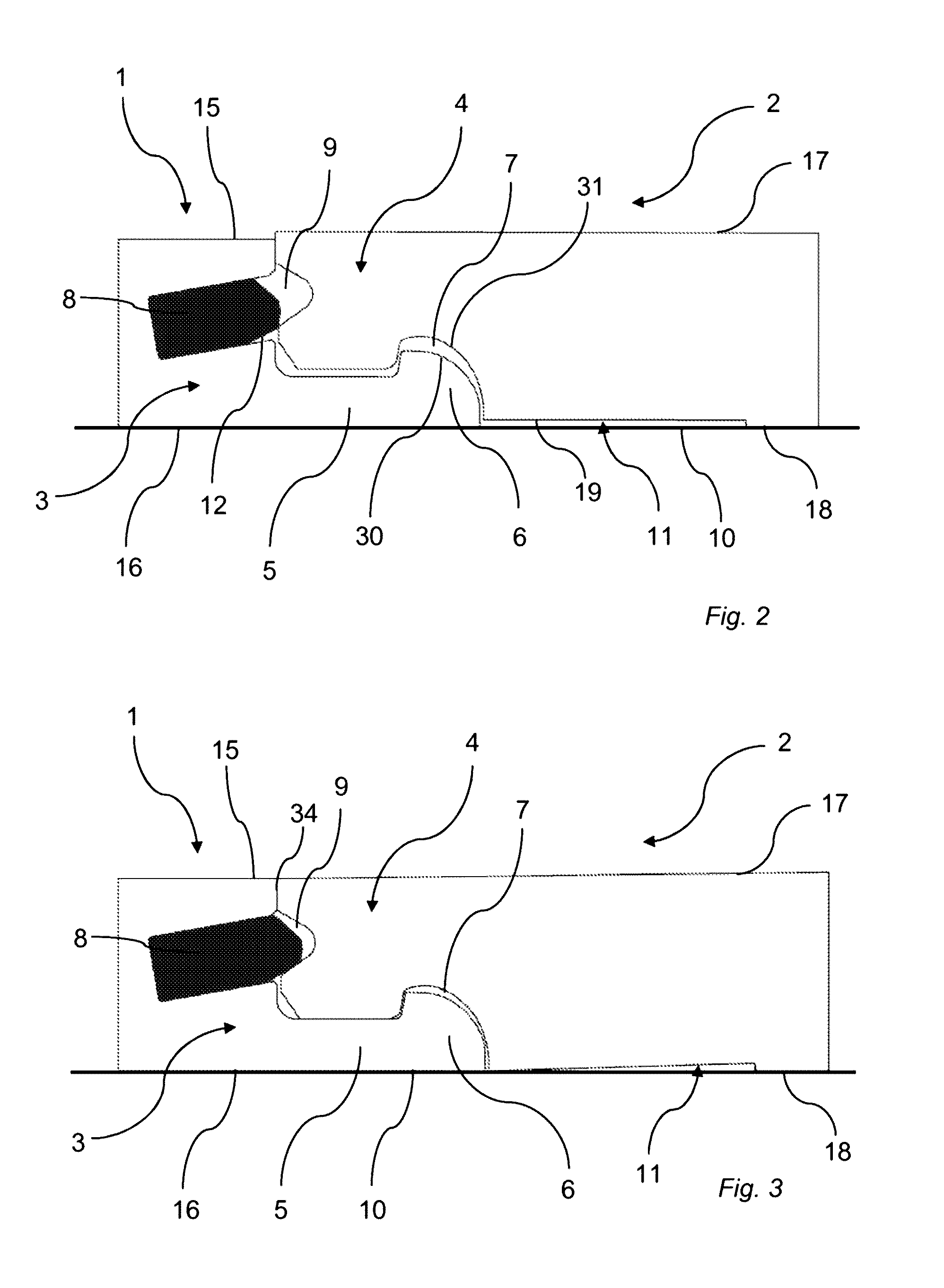

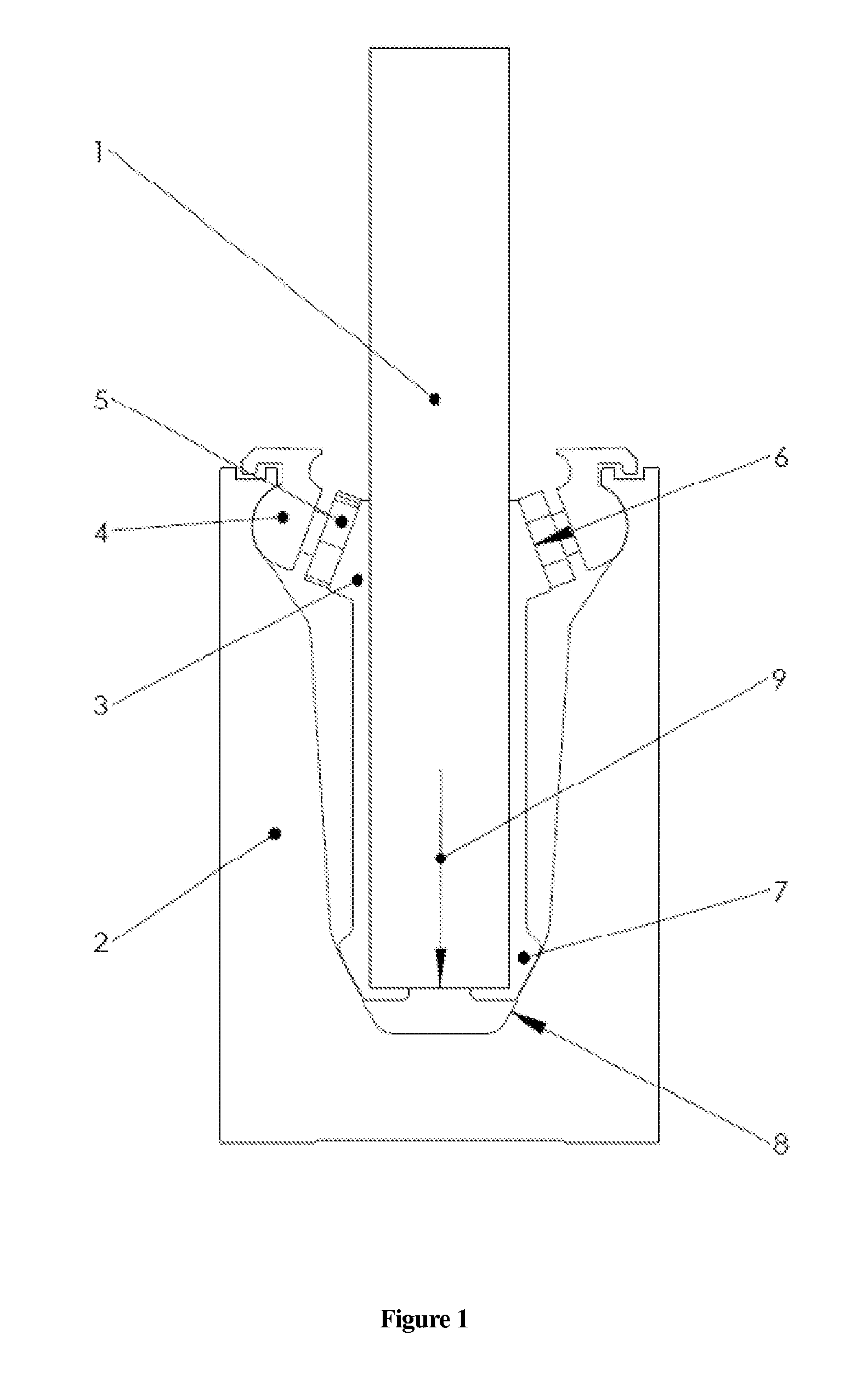

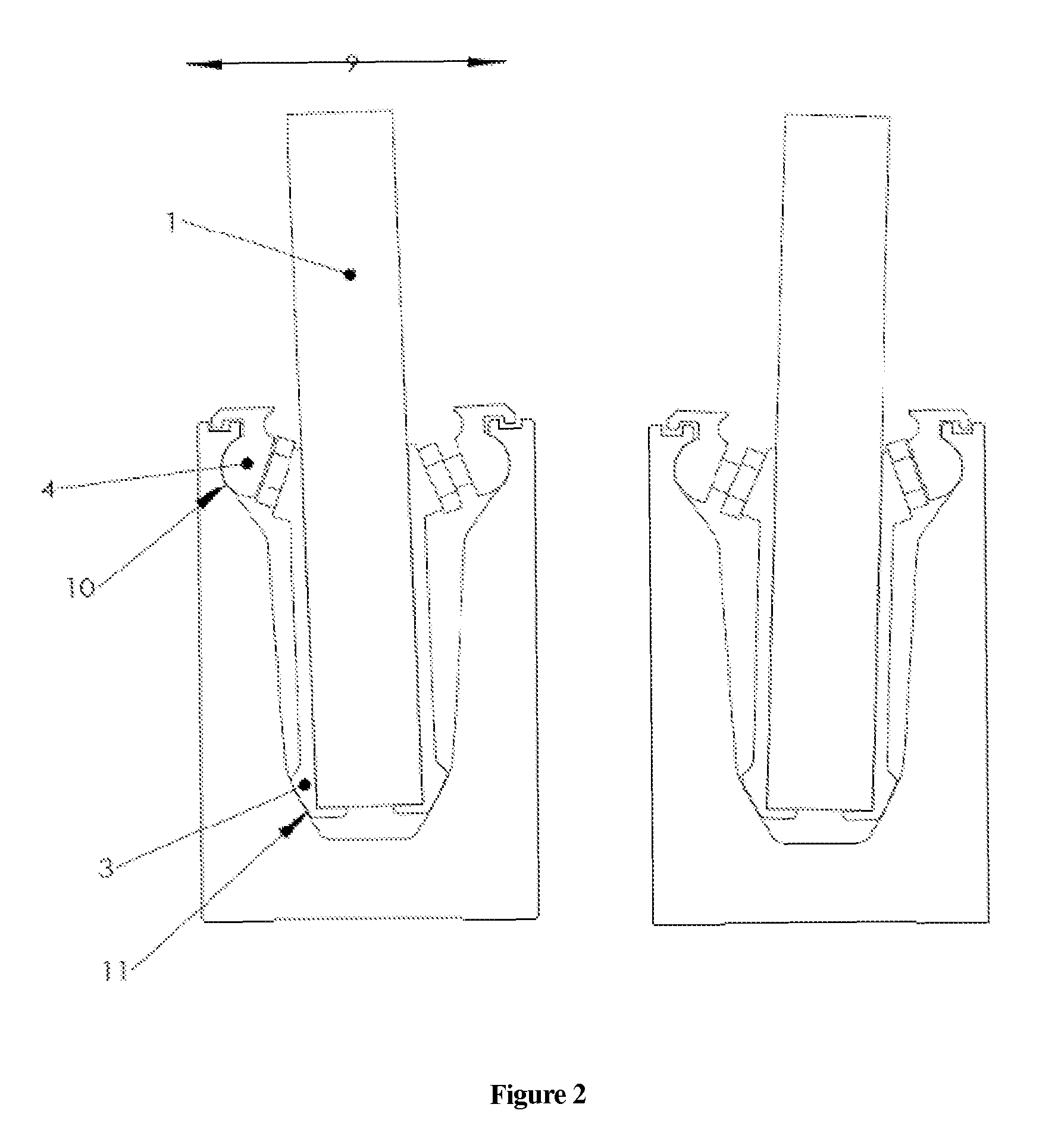

Windshield wiper device

InactiveUS8104134B2Less timeClamp firmlySnap fastenersCandle holdersMotorized vehicleMotor vehicle crash

The invention relates to a windshield wiper device, in particular for a motor vehicle, comprising a fastening device (10) for fastening the windshield wiper device to the motor vehicle. Until now windshield wiper devices were mainly fastened to the vehicle body by means of screwed connections and plugging locations. The objective of the invention is reducing the assembly effort for fastening the windshield wiper device to the vehicle body. As a result, the inventive windshield wiper device can be clamped firmly to a vehicle body panel (13) by the fastening device (10).

Owner:ROBERT BOSCH GMBH

Floorboards provided with a mechanical locking system

ActiveUS20170037642A1Easy to lockDifferent thicknessCovering/liningsFlooringEngineeringMechanical engineering

Owner:VÄLINGE INNOVATION AB

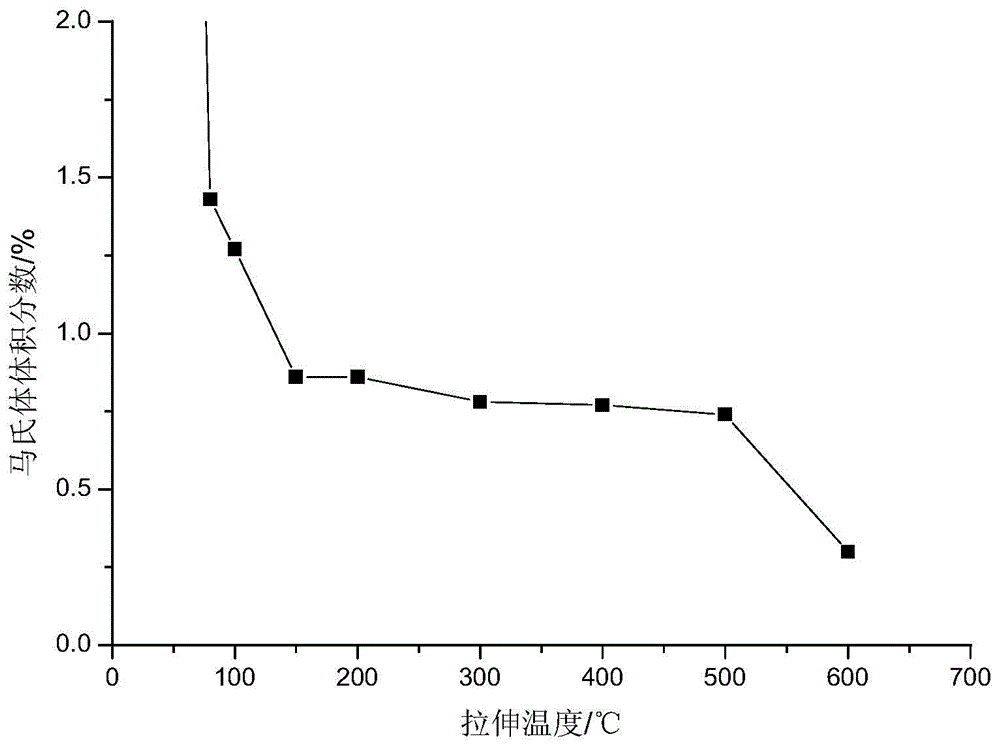

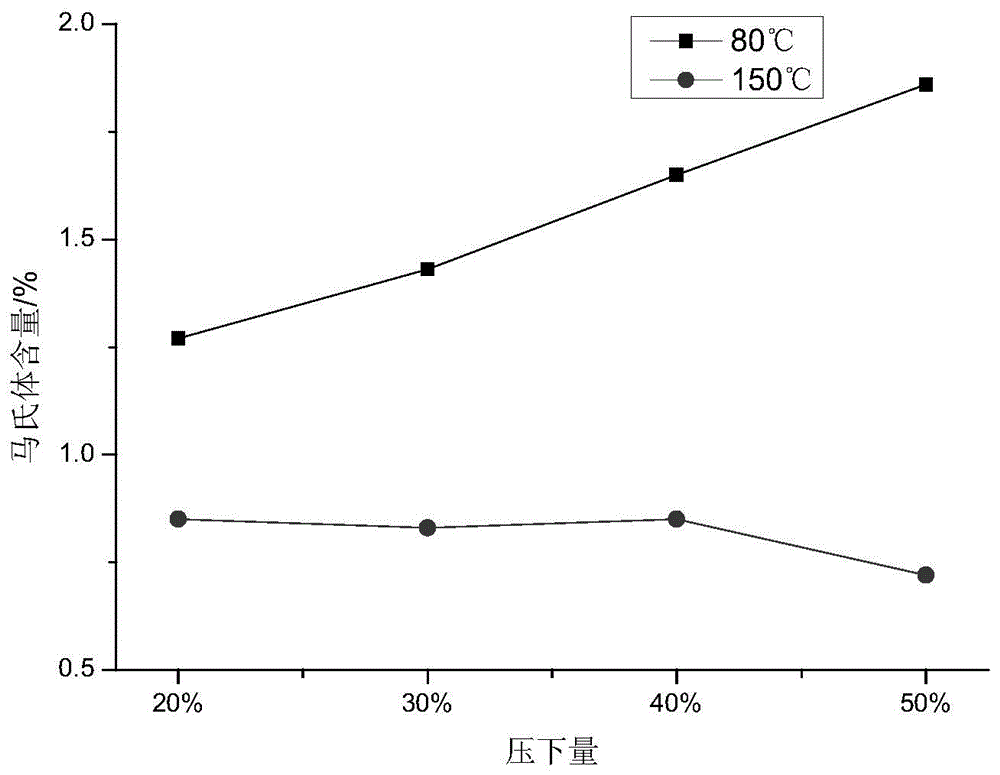

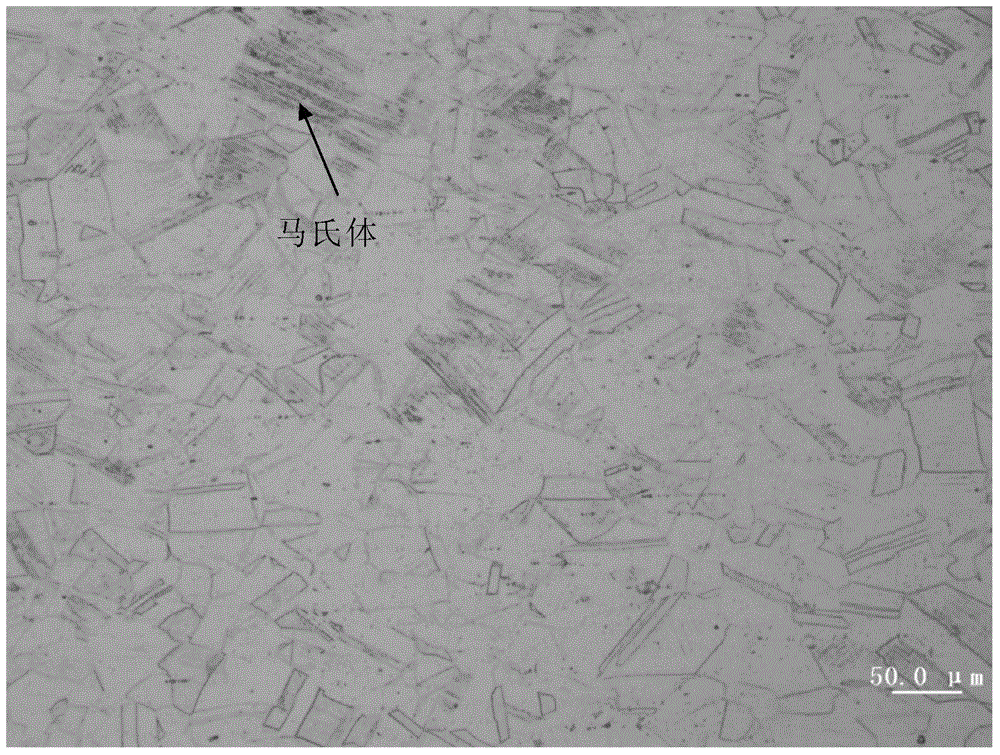

800-1,600 MPa grade high strength austenitic stainless steel, manufacturing method and warm forming method

The invention provides 800-1,600 MPa grade high strength austenitic stainless steel, manufacturing method and a warm forming method. The austenitic stainless steel comprises steel chemical components in weight of 0.04%-0.14% of C, 0.2%-0.6% of Si, 2%-12% of Mn, 12%-18% of Cr, 0.5%-6.5% of Ni, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 0.05%-0.25% of N, 0%-2% of Cu, one or more of Mo, Nb and Ti and the balance of Fe and inevitable impurities, and the condition that W(Ni)eq is larger than or equal to 20.5 and smaller than or equal to 25.5 is required to be met. The high strength austenitic stainless steel is obtained by controlling the rolling reduction to be 10%-40% in a rolling process, the tensile resistance is 800-1,600 MPa, and the extension is 13%-40%. At the same time, with the warm forming method, ultra-complex formed high strength stainless steel parts can be obtained, and the high strength austenitic stainless steel has excellent corrosion resistance, high strength and delayed cracking resistance.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

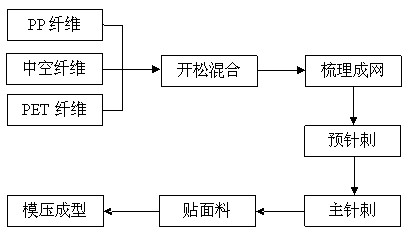

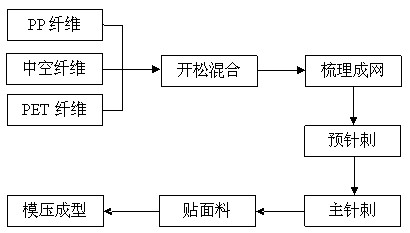

Heat-insulating and noise-reducing nonwoven composite material for automobile interior trim and preparation method thereof

ActiveCN102166864AImprove insulation performanceLow cost of preparationSynthetic resin layered productsLaminationHollow fibrePolypropylene

The invention discloses a heat-insulating and noise-reducing nonwoven composite material for automobile interior trim and a preparation method thereof. The composite material is prepared from certain proportions of PP (polypropylene) fiber, PET (polyester) fiber and hollow PET fiber, the mixed fiber is prepared into a composite felt by a certain acupuncture process, and an appropriate die pressing process is adopted to prepare a composite fiber felt. The composite material disclosed by the invention keeps lower surface density, good bending performance and good dimensional stability, can also meet the functional requirements for heat insulation and sound insulation, and can be used for preparing medium and high-grade automobile interior trim materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

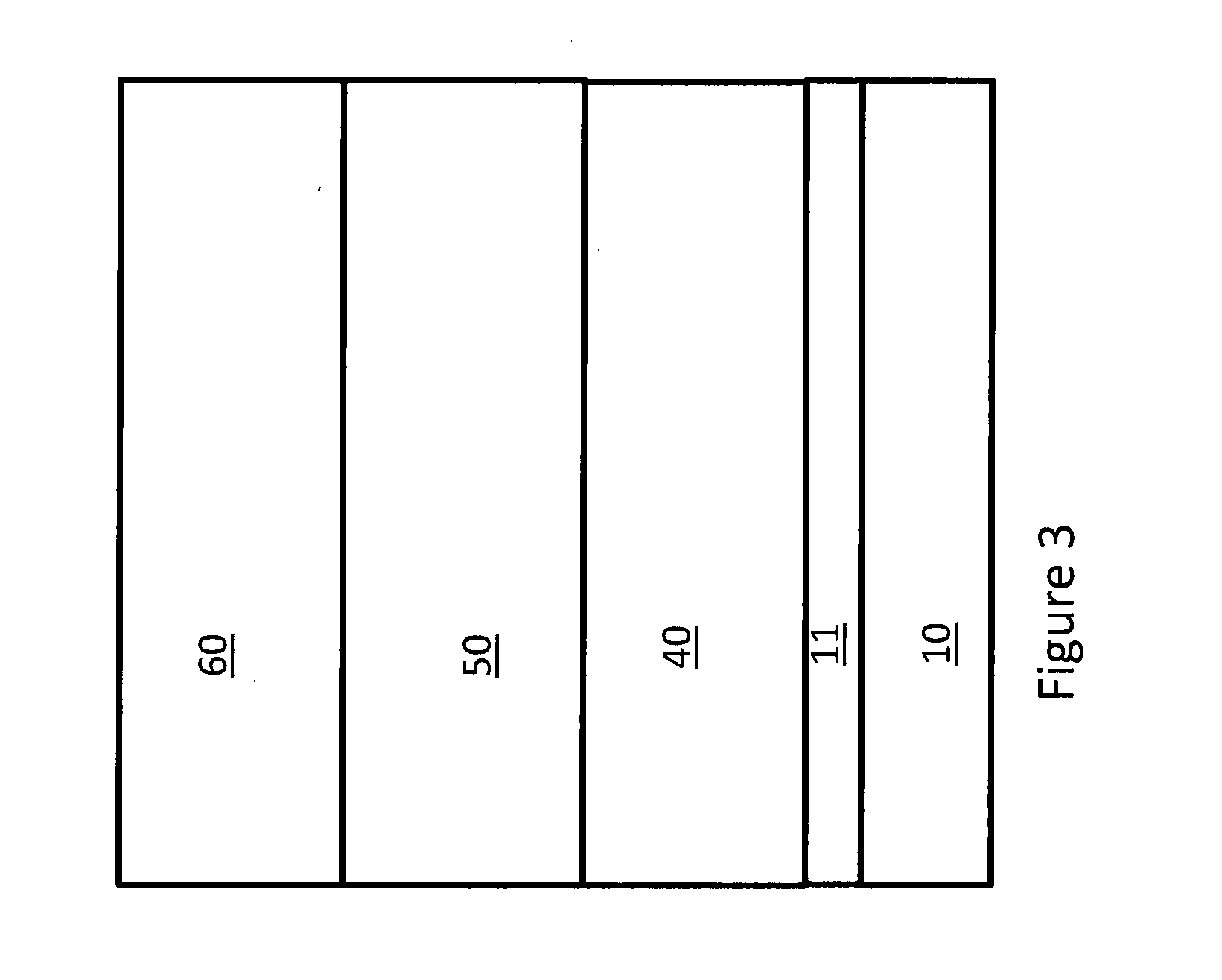

Layer structures for controlling stress of heteroepitaxially grown iii-nitride layers

InactiveUS20120126239A1Different thicknessMinimize impactSemiconductor/solid-state device manufacturingSemiconductor devicesNitridePhysics

A III-N layer structure is described that includes a III-N buffer layer on a foreign substrate, an additional III-N layer, a first III-N structure, and a second III-N layer structure. The first III-N structure atop the III-N buffer layer includes at least two III-N layers, each having an aluminum composition, and the III-N layer of the two III-N layers that is closer to the III-N buffer layer having the larger aluminum composition. The second III-N structure includes a III-N superlattice, the III-N superlattice including at least two III-N well layers interleaved with at least two III-N barrier layer. The first III-N structure and the second III-N structure are between the additional III-N layer and the foreign substrate.

Owner:TRANSPHORM INC

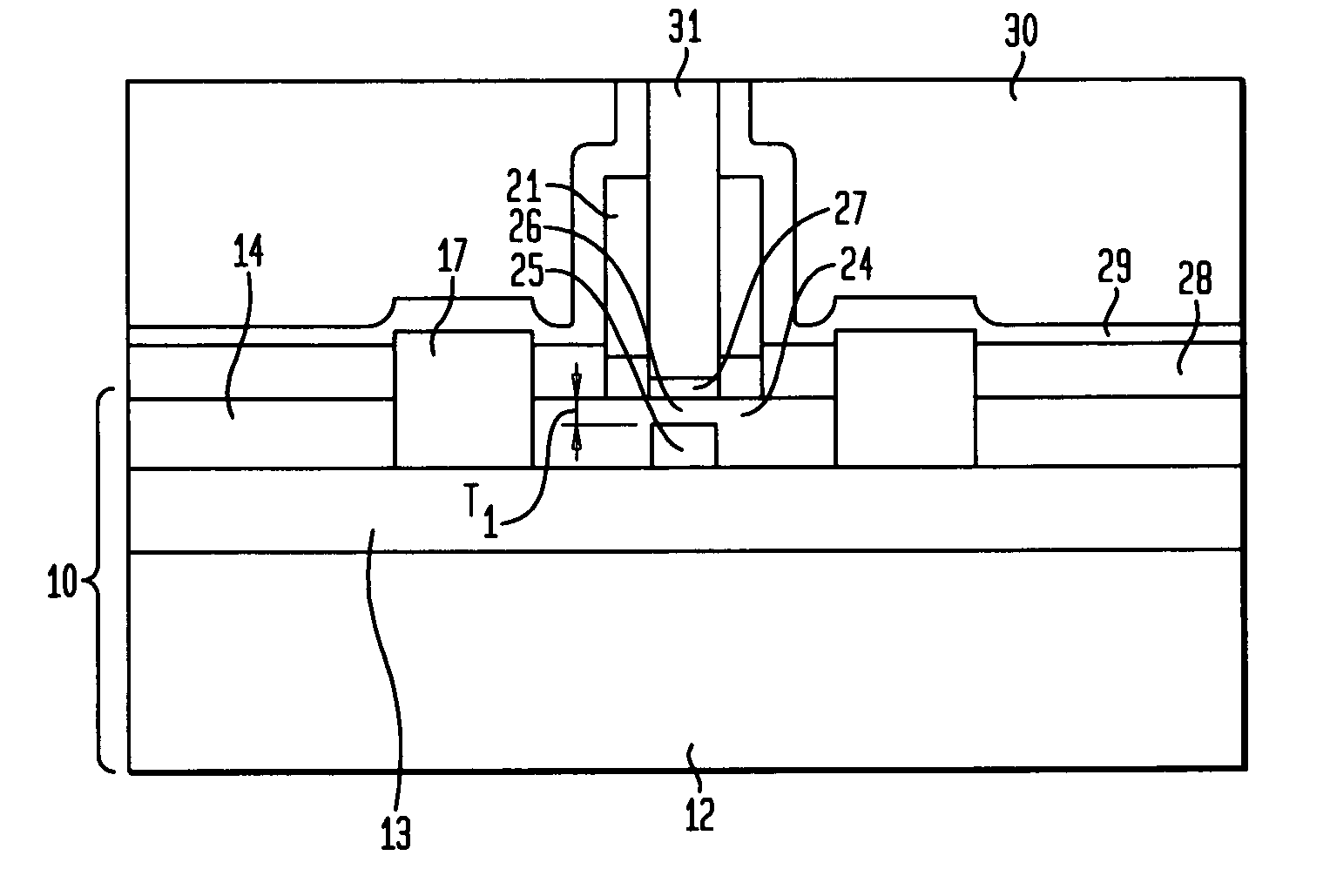

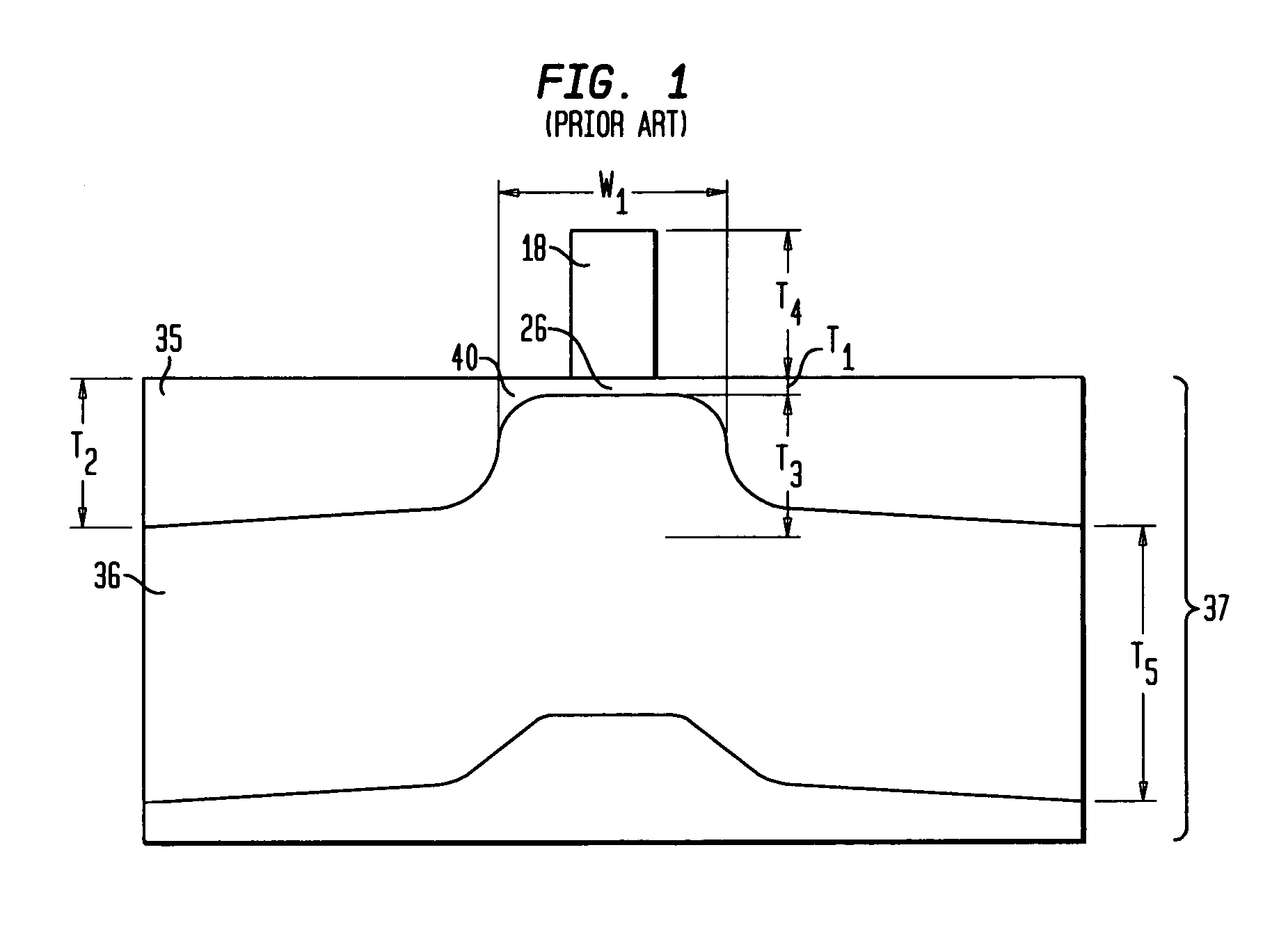

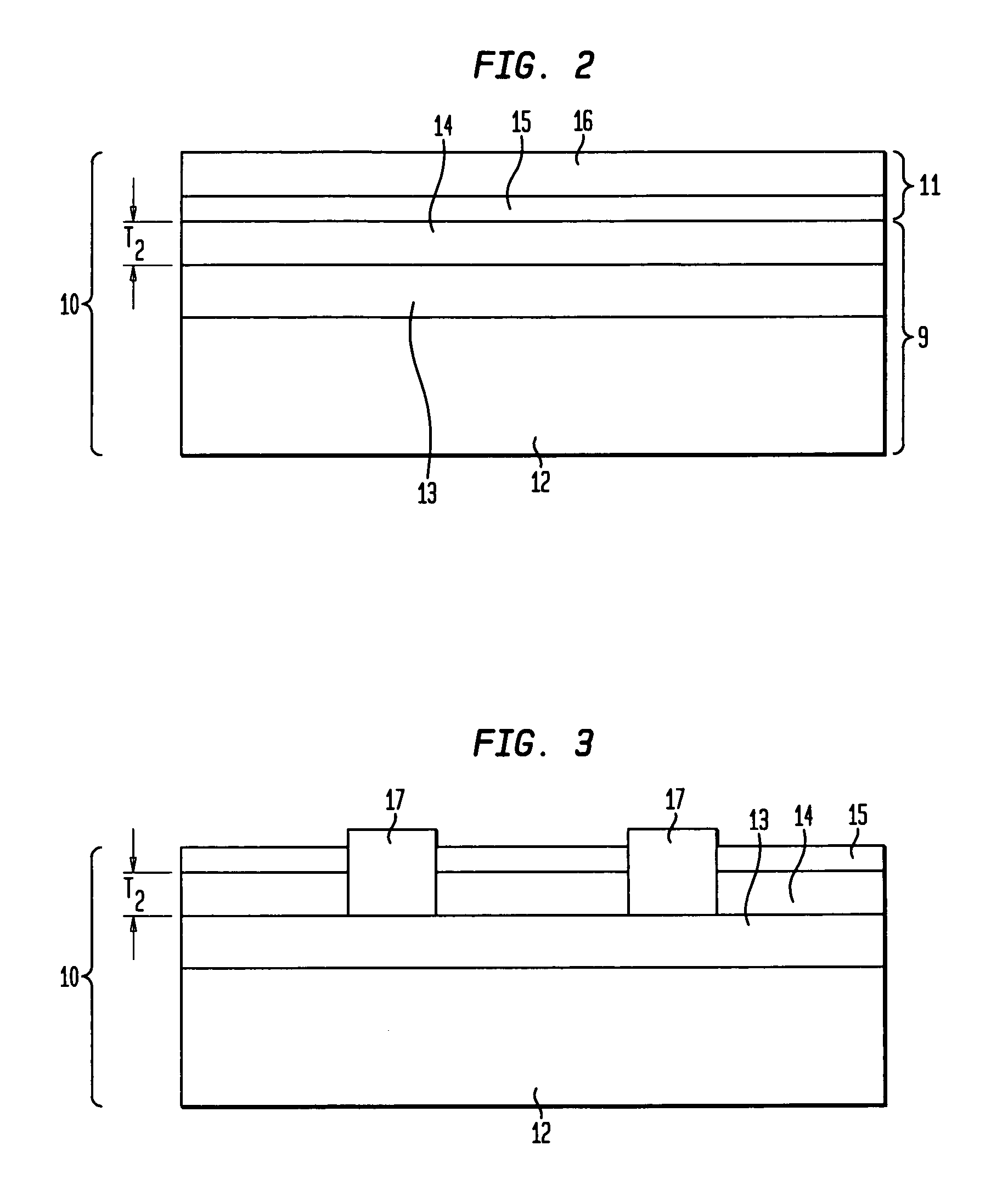

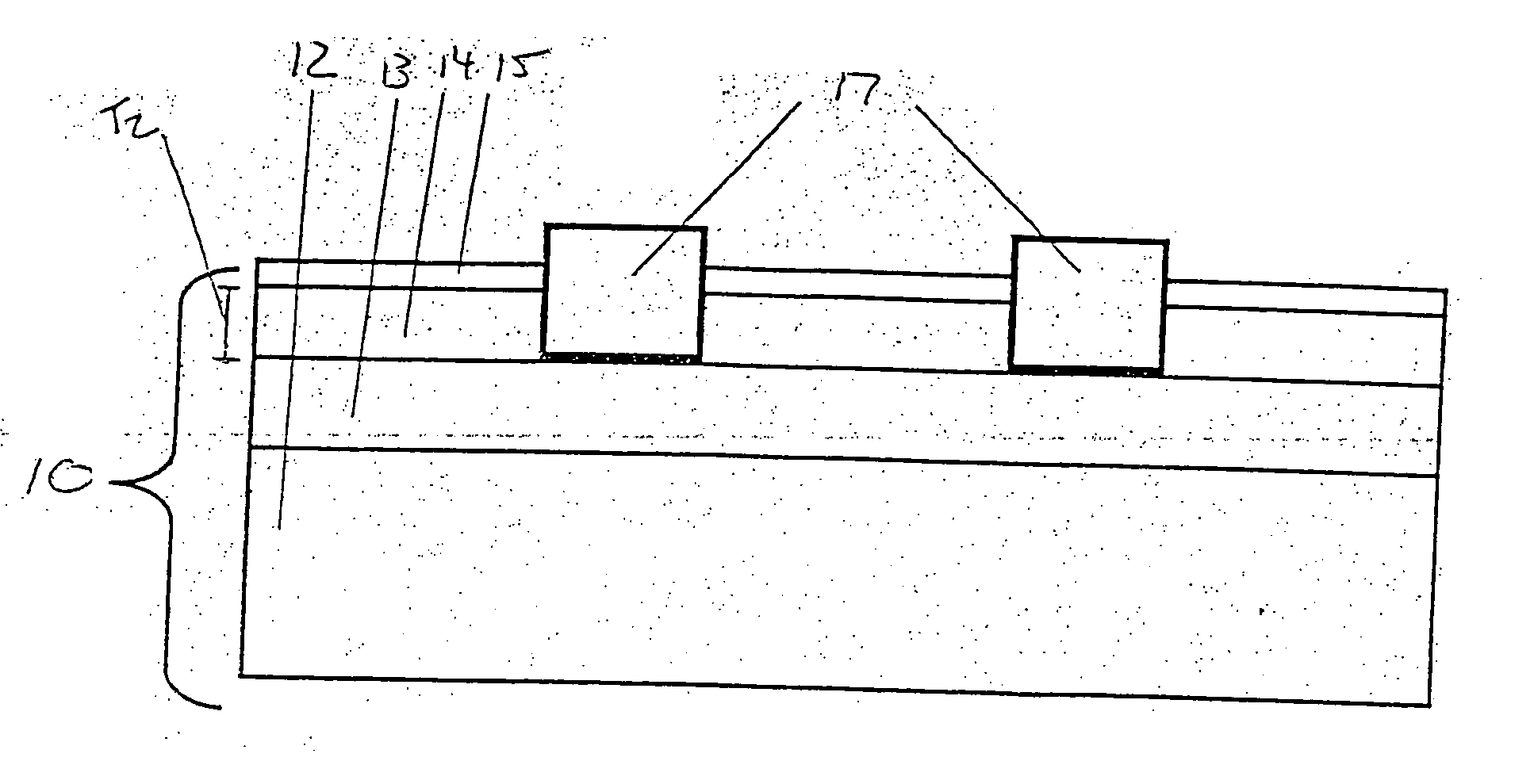

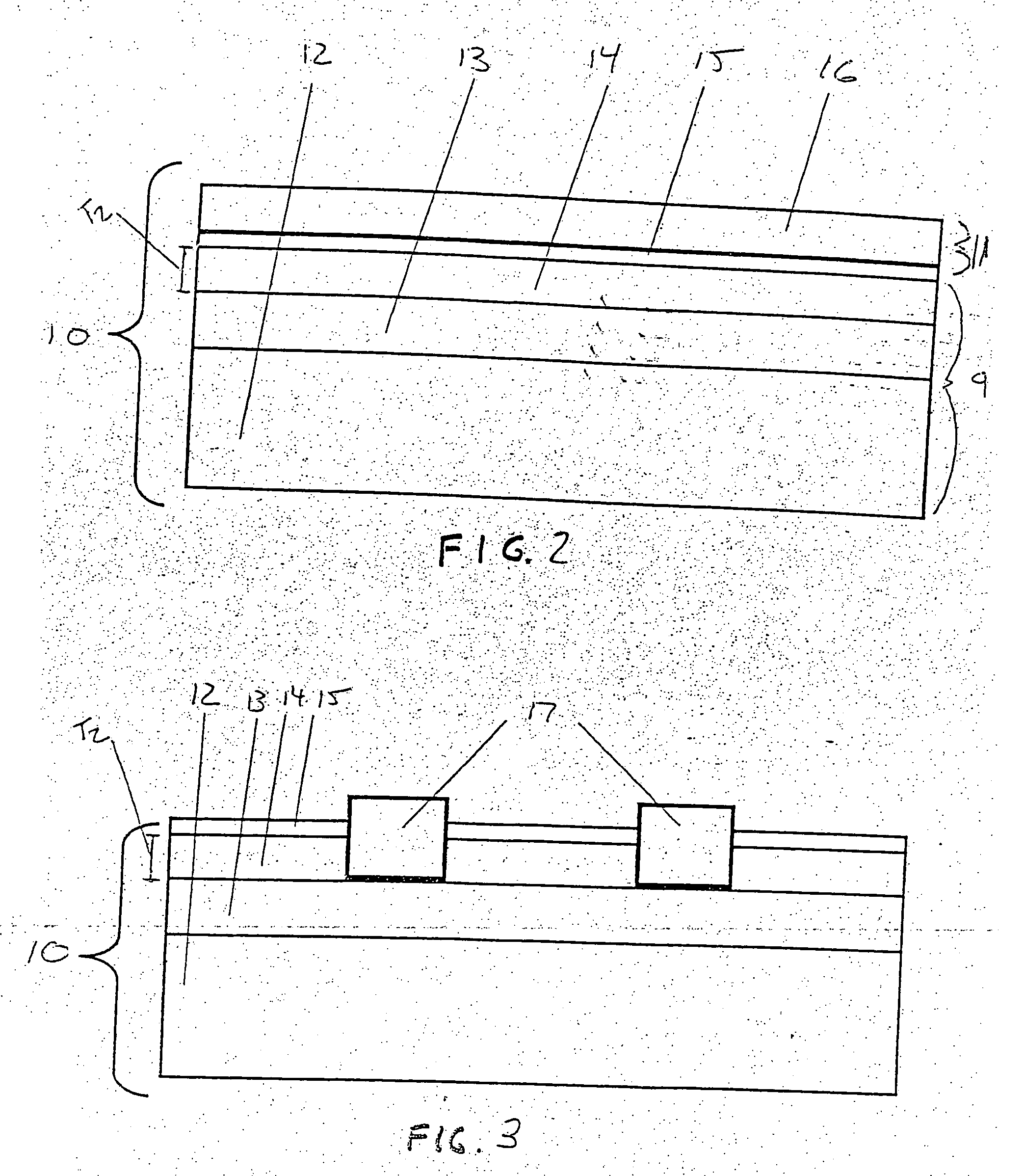

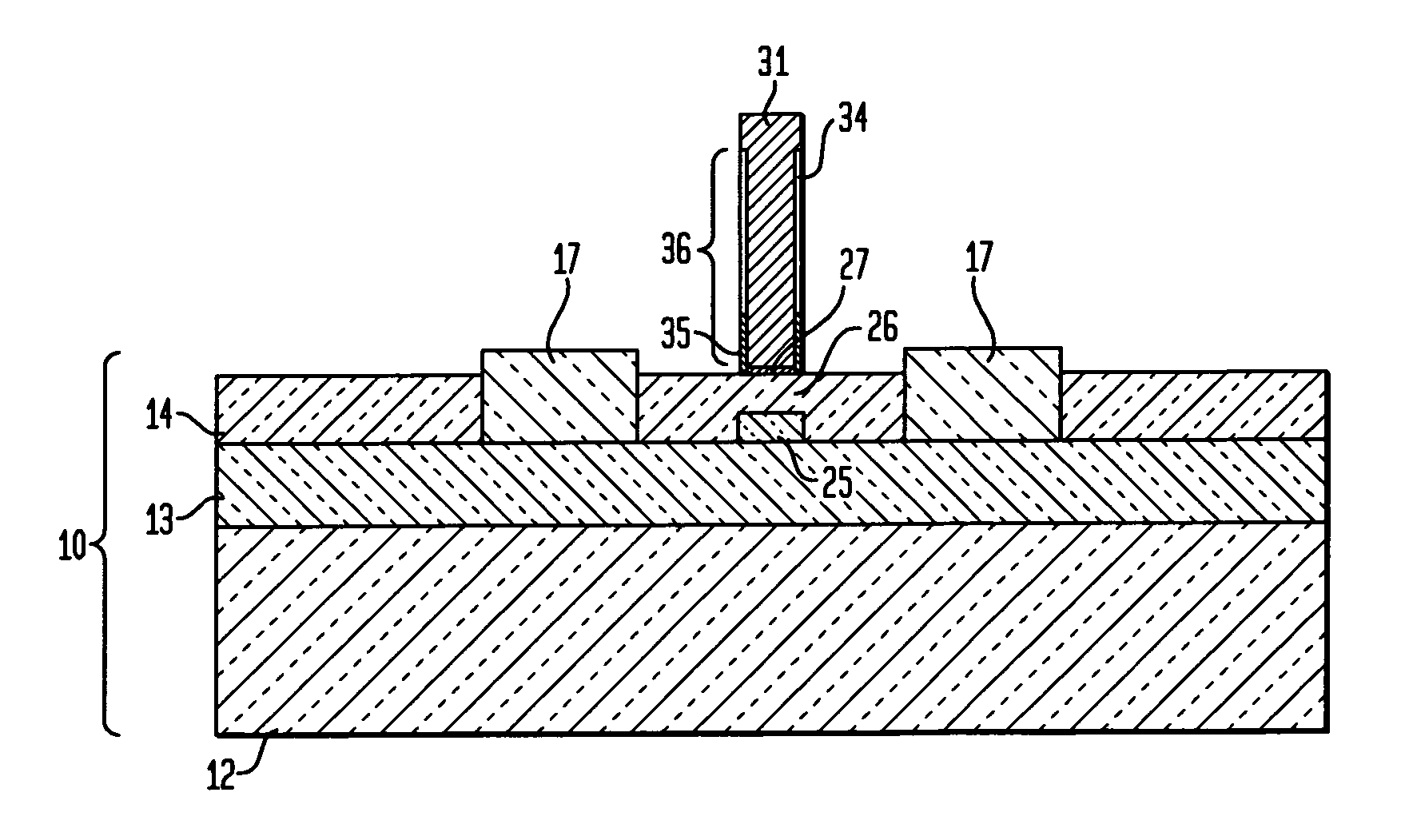

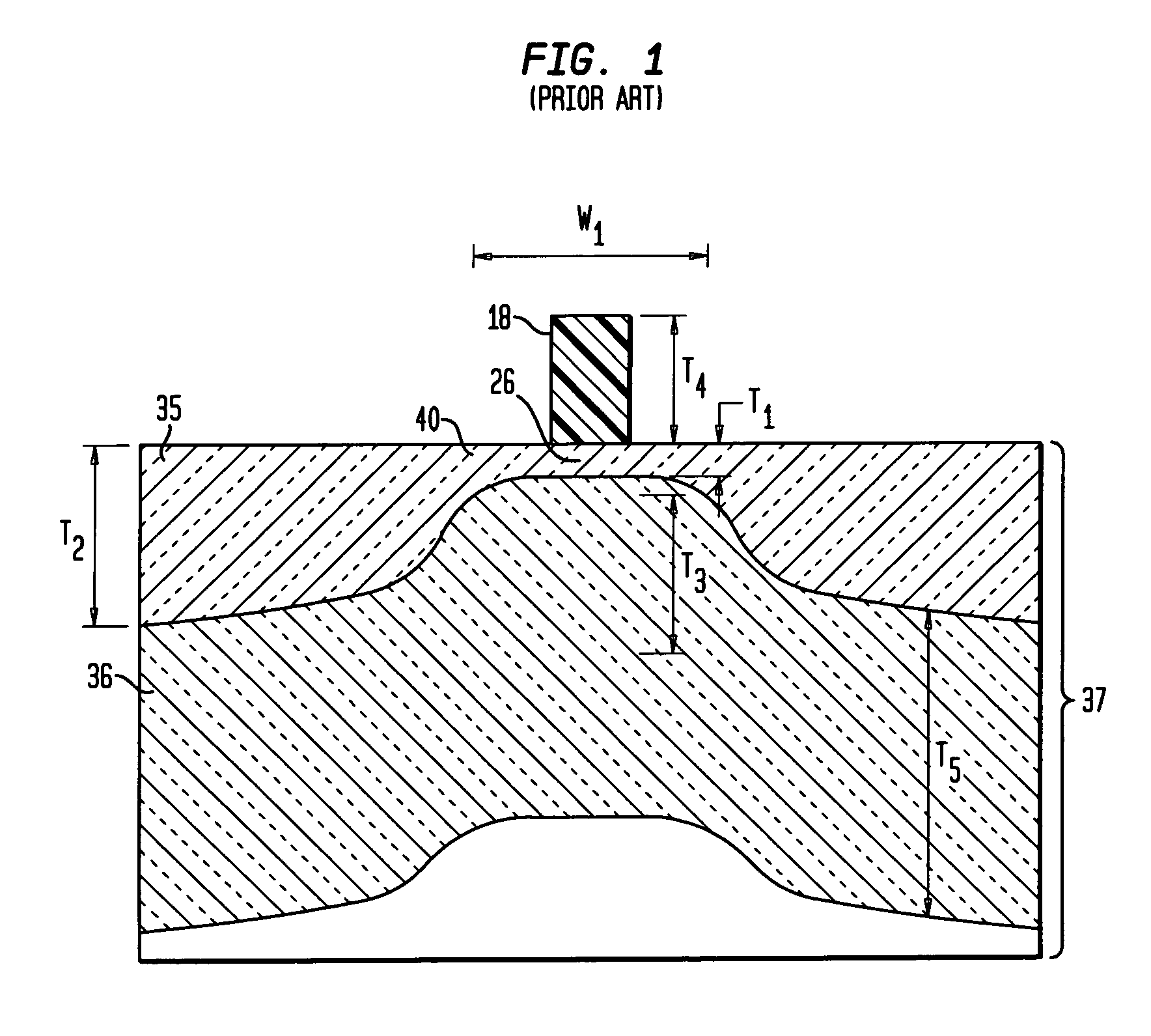

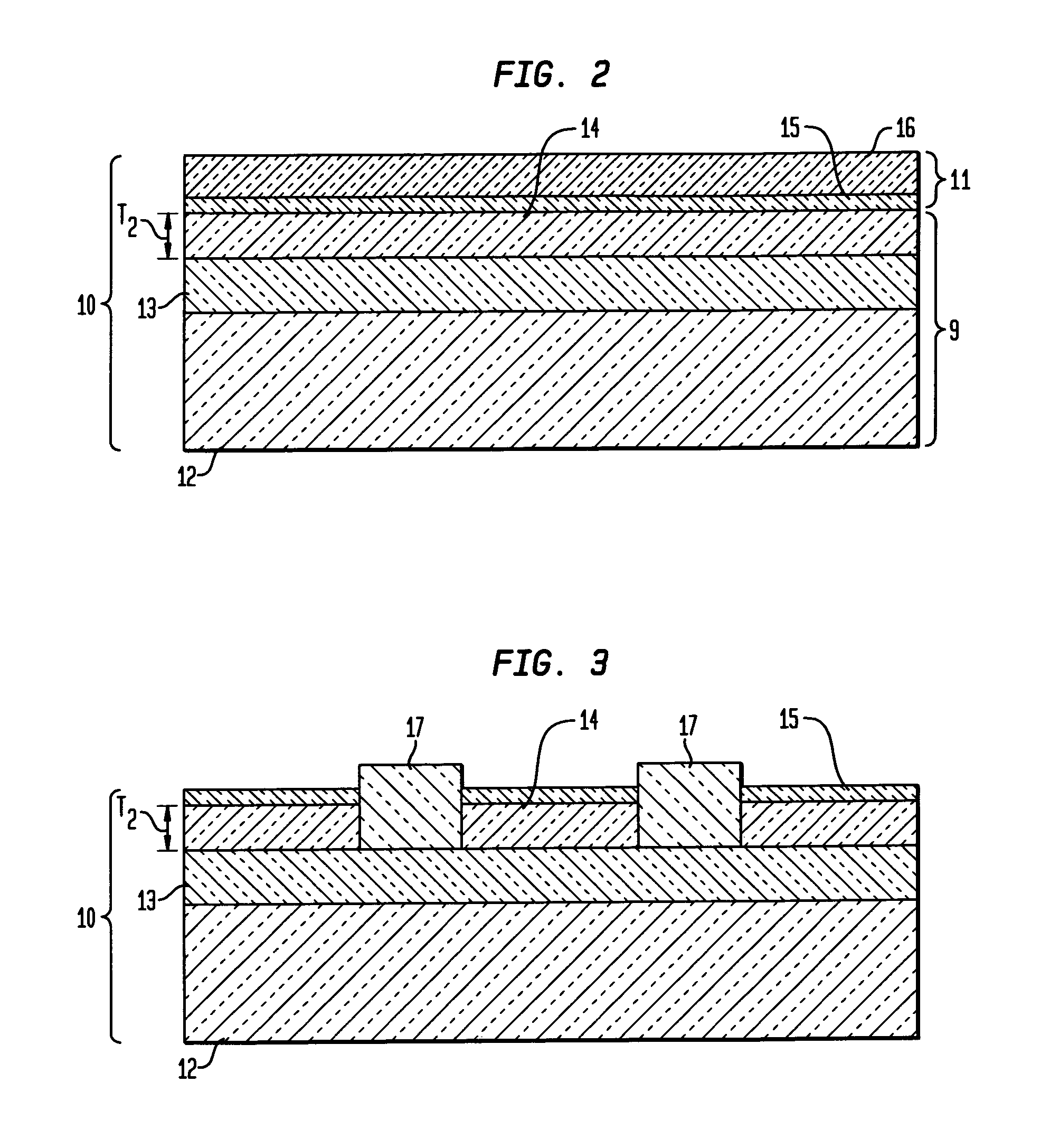

Ultra-thin Si MOSFET device structure and method of manufacture

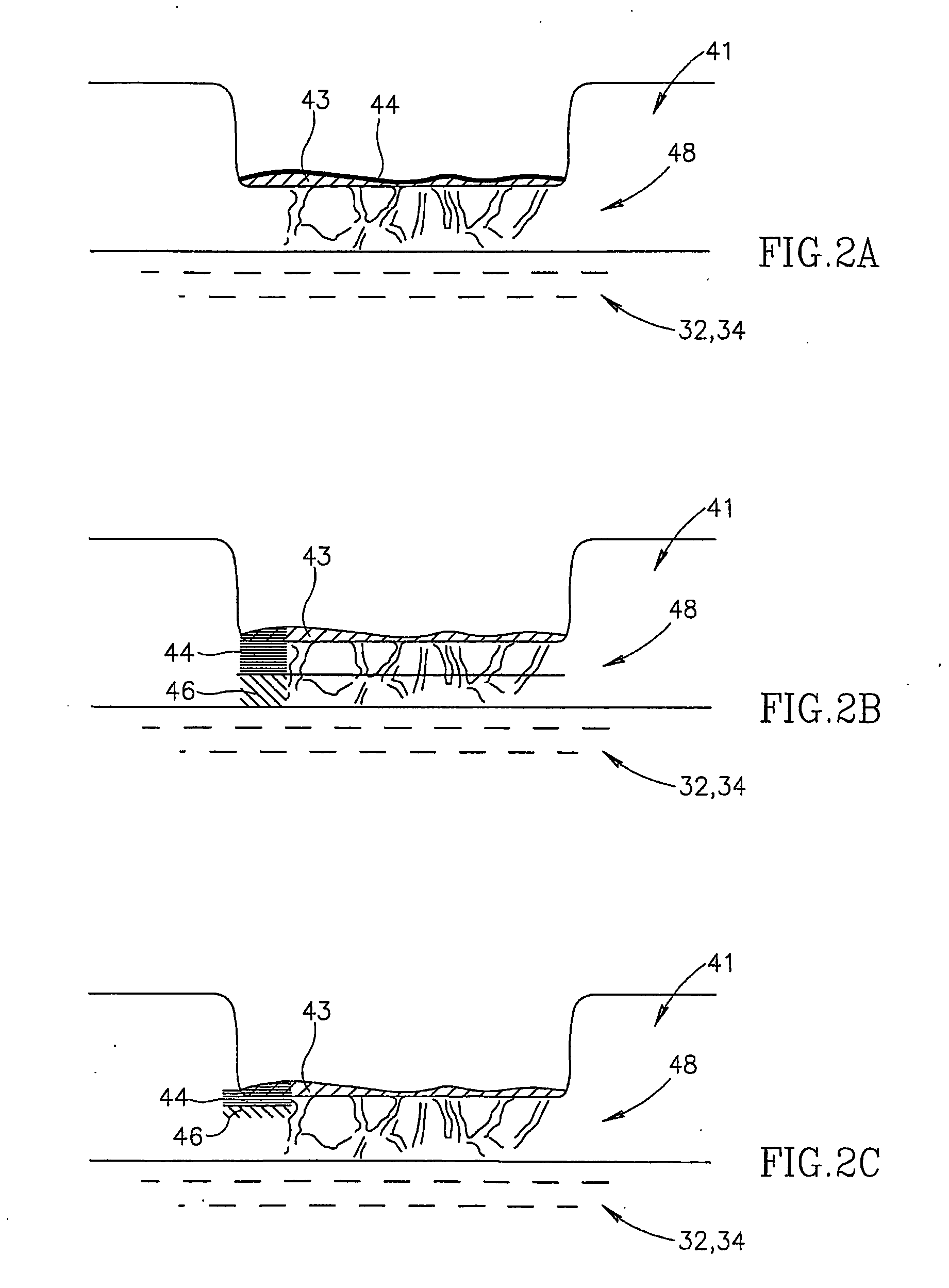

InactiveUS20050118826A1Slow circuit performanceIncrease parasitic capacitanceTransistorSolid-state devicesMOSFETOxide

The present invention comprises a method for forming an ultra-thin channel MOSFET and the ultra-thin channel MOSFET produced therefrom. Specifically, the method comprises providing an SOI substrate having a buried insulating layer underlying an SOI layer; forming a pad stack atop the SOI layer; forming a block mask having a channel via atop the pad stack; providing a localized oxide region in the SOI layer on top of the buried insulating layer thereby thinning a portion of the SOI layer, the localized oxide region being self-aligned with the channel via; forming a gate in the channel via; removing at least the block mask; and forming source / drain extensions in the SOI layer abutting the thinned portion of the SOI layer. Providing the localized oxide region further comprises implanting oxygen dopant through the channel via into a portion of the SOI layer; and annealing the dopant to create the localized oxide region.

Owner:GLOBALFOUNDRIES INC

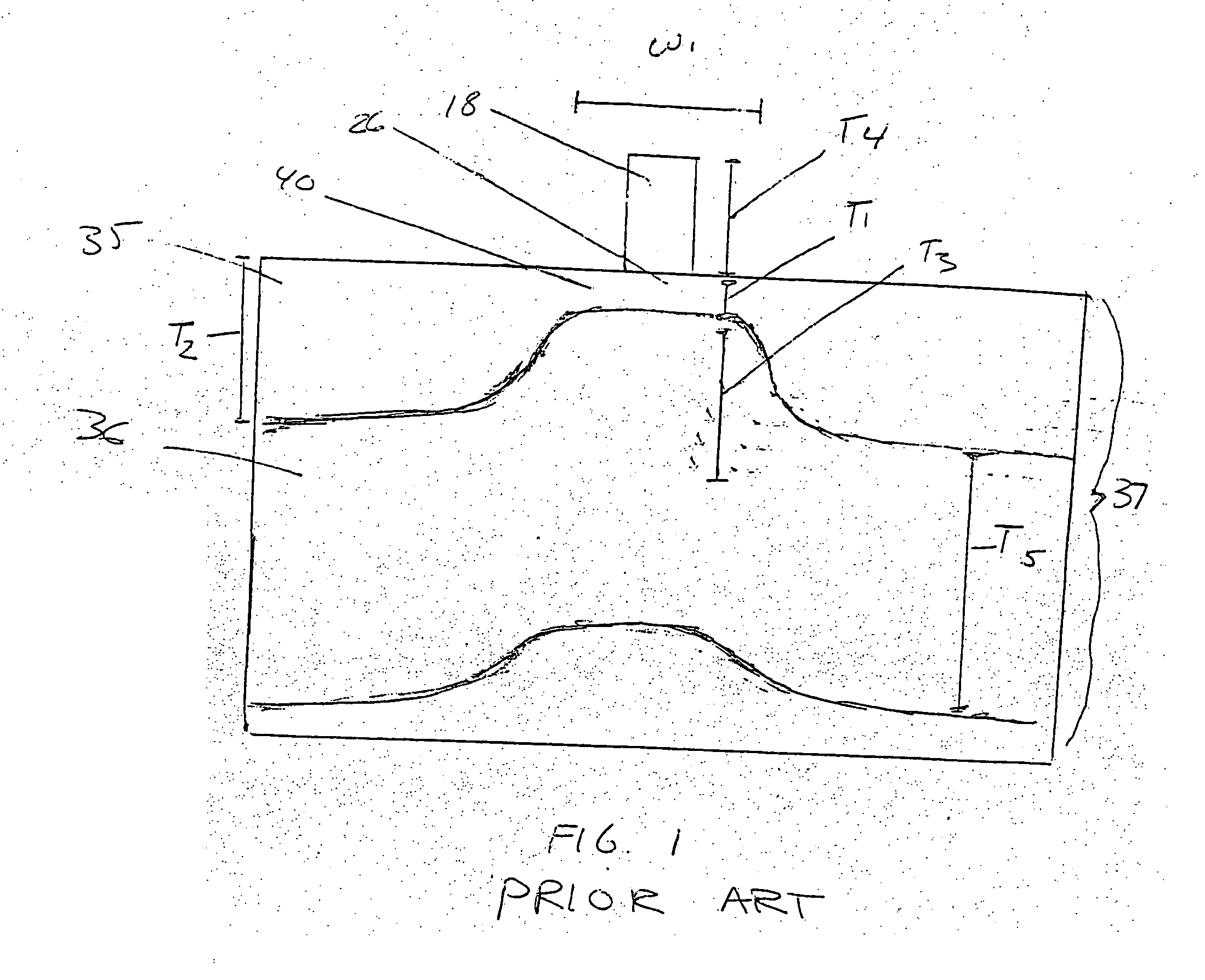

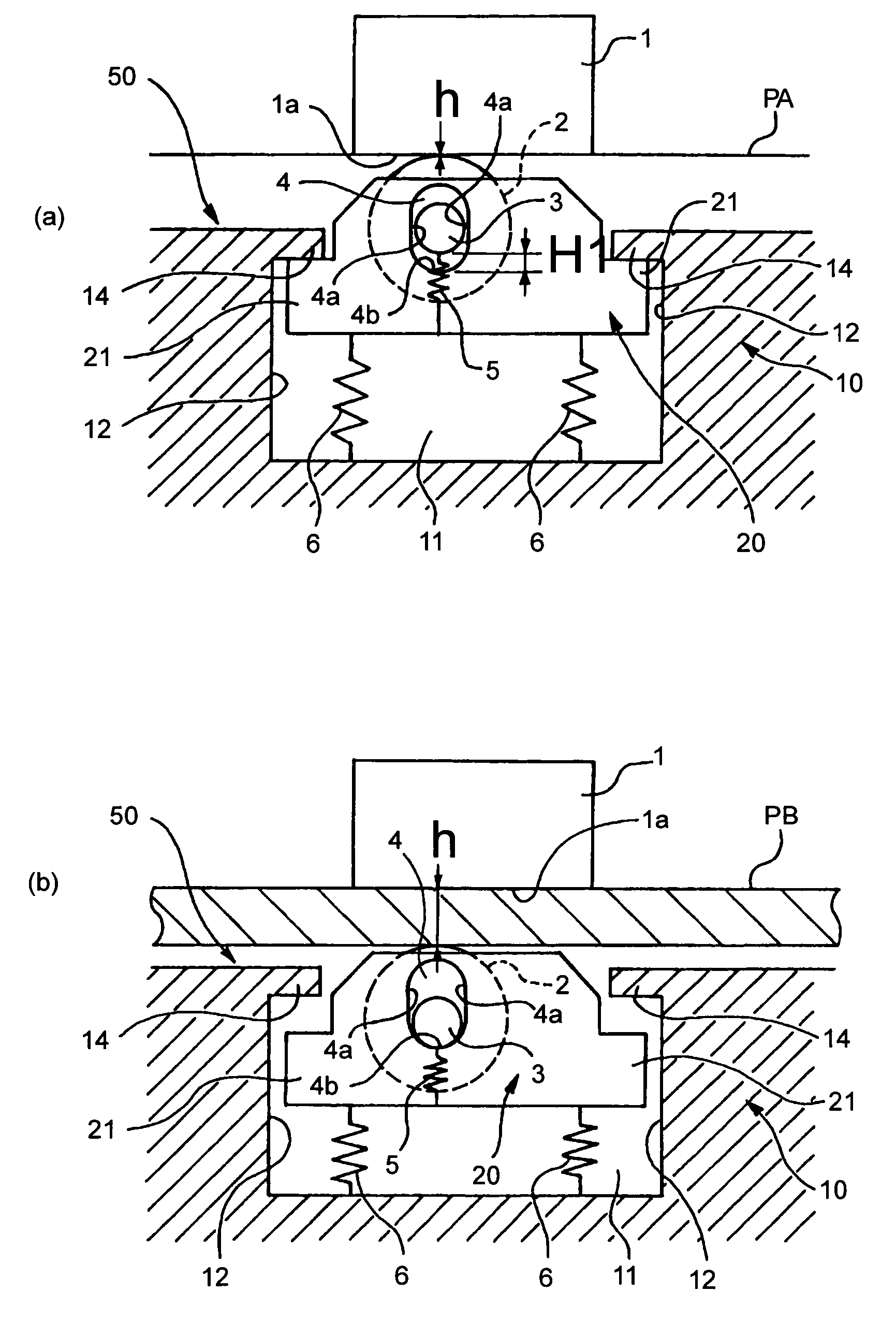

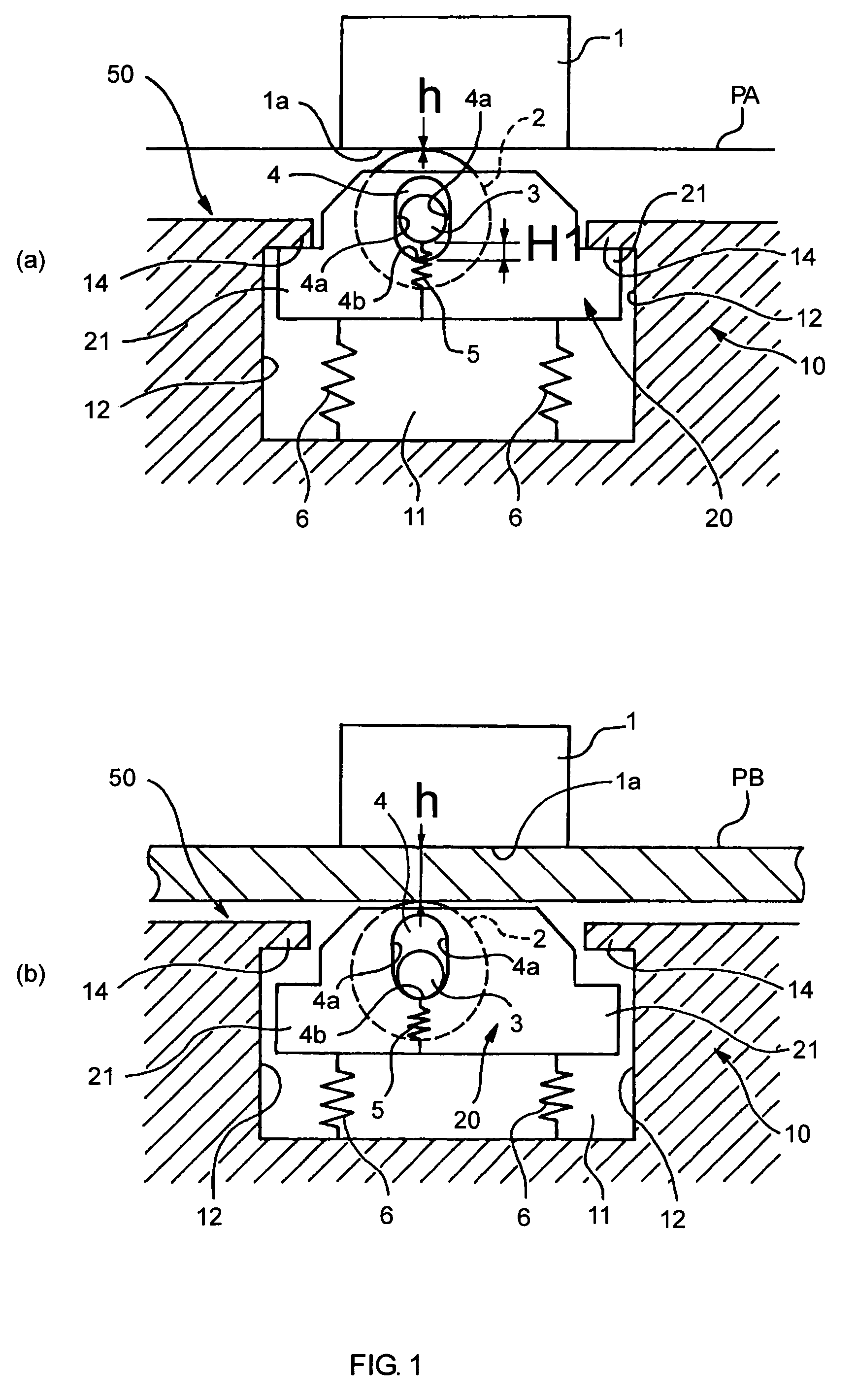

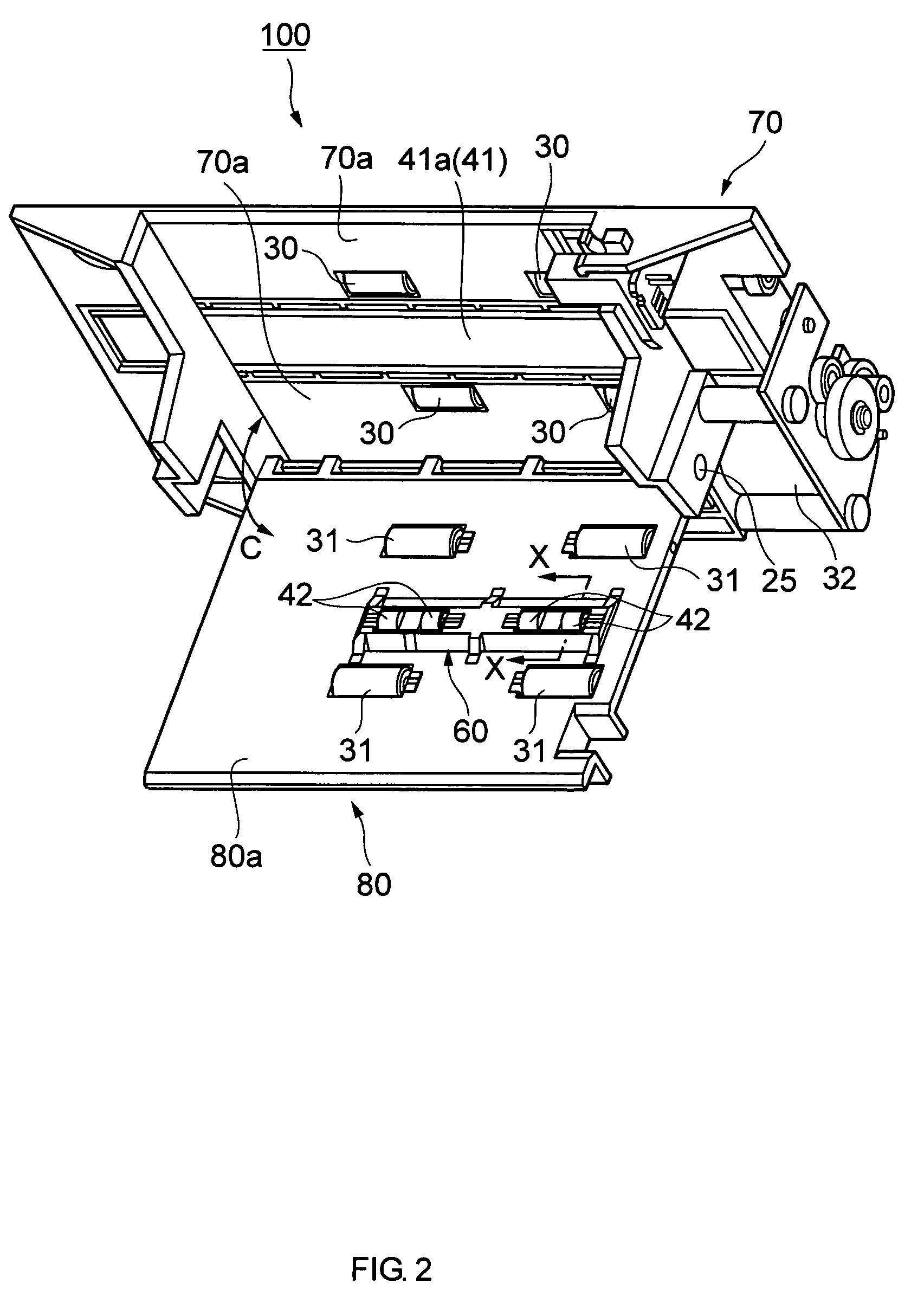

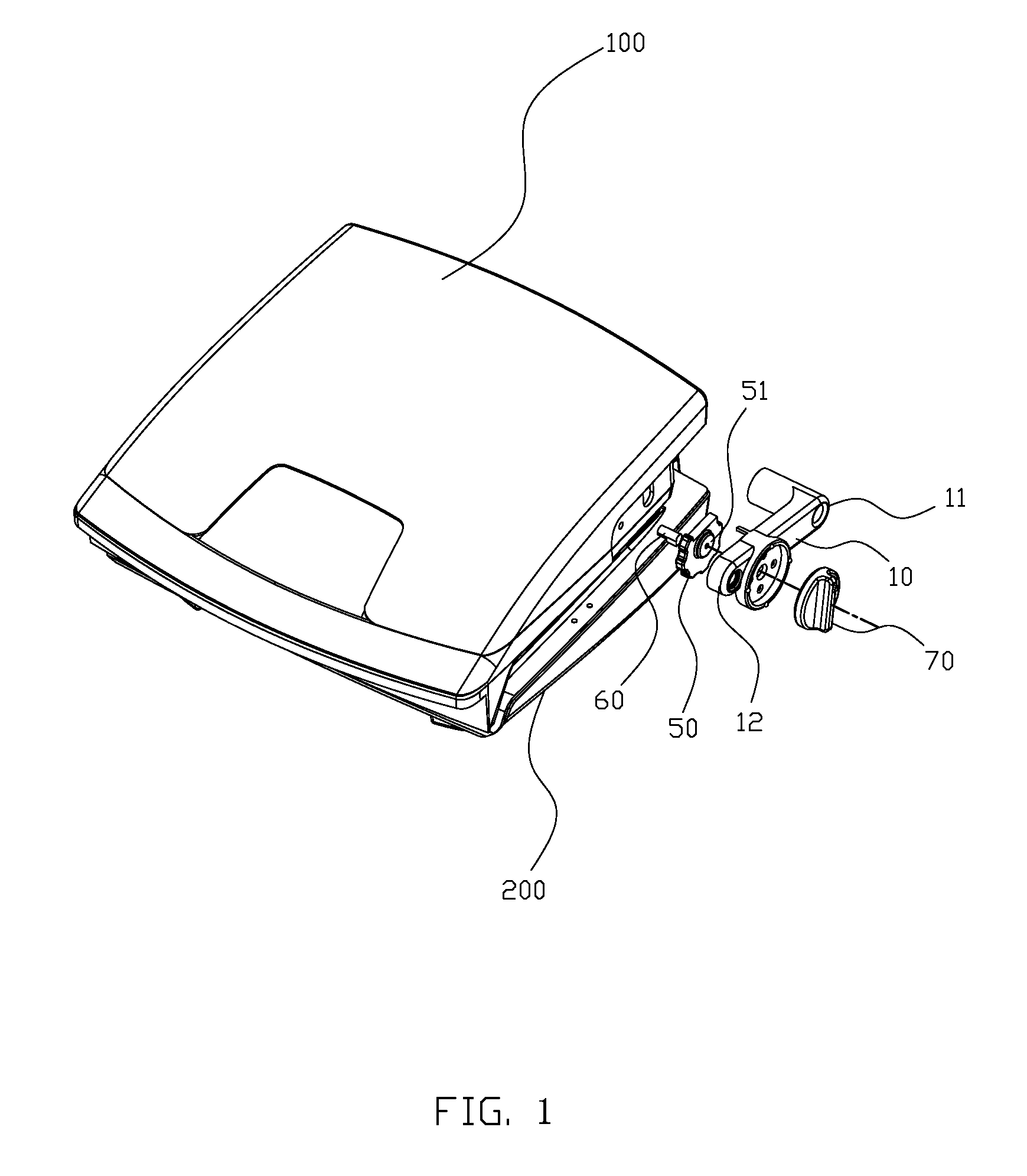

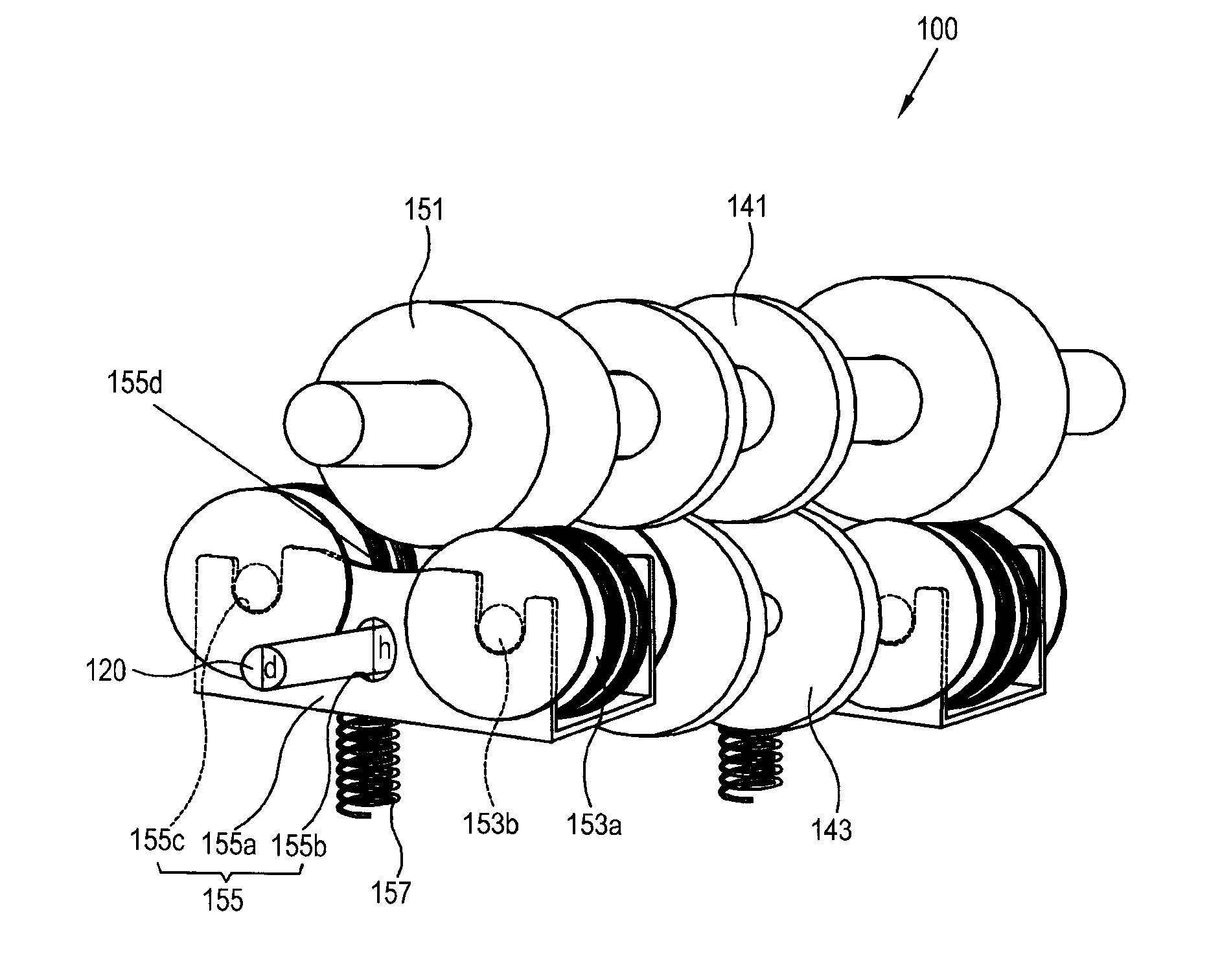

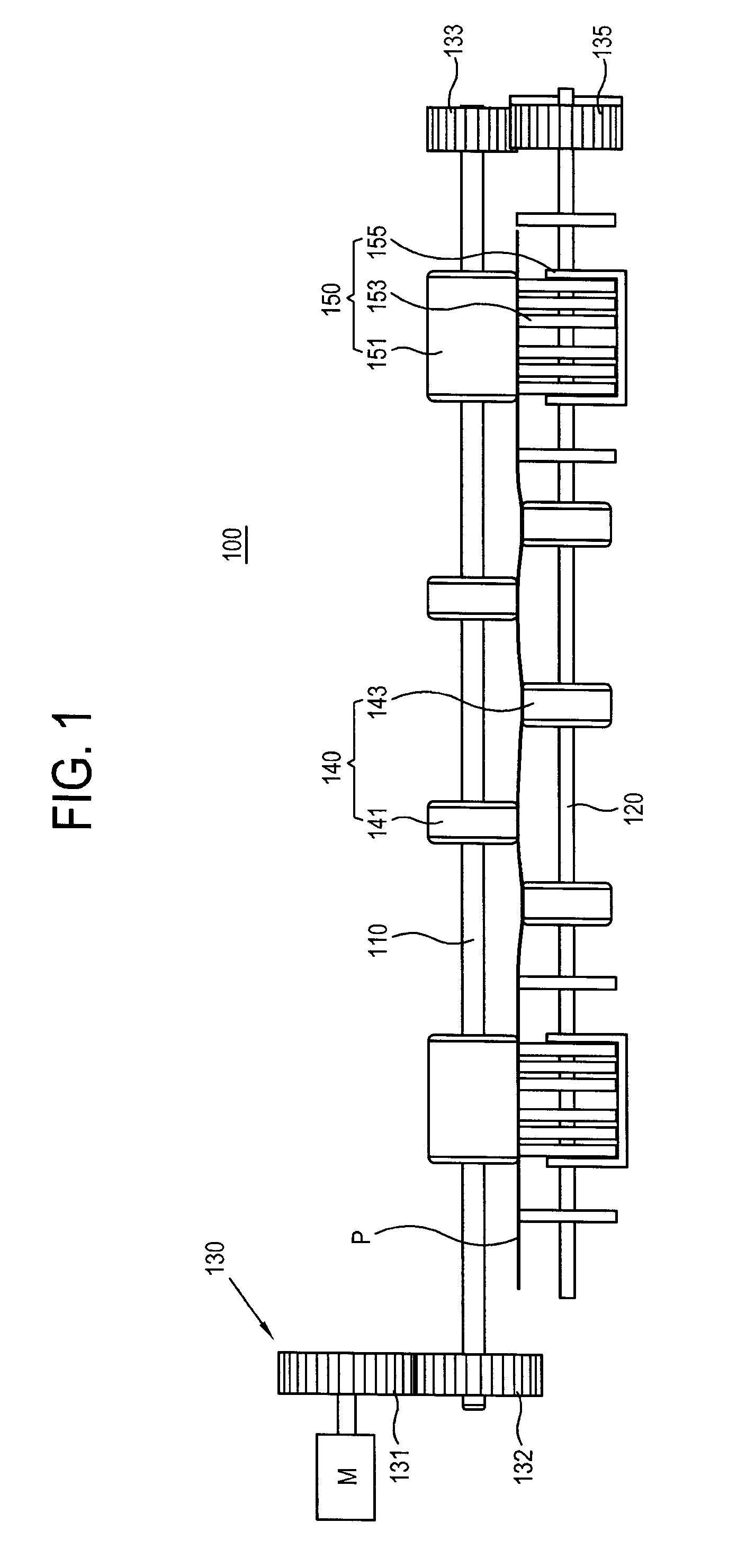

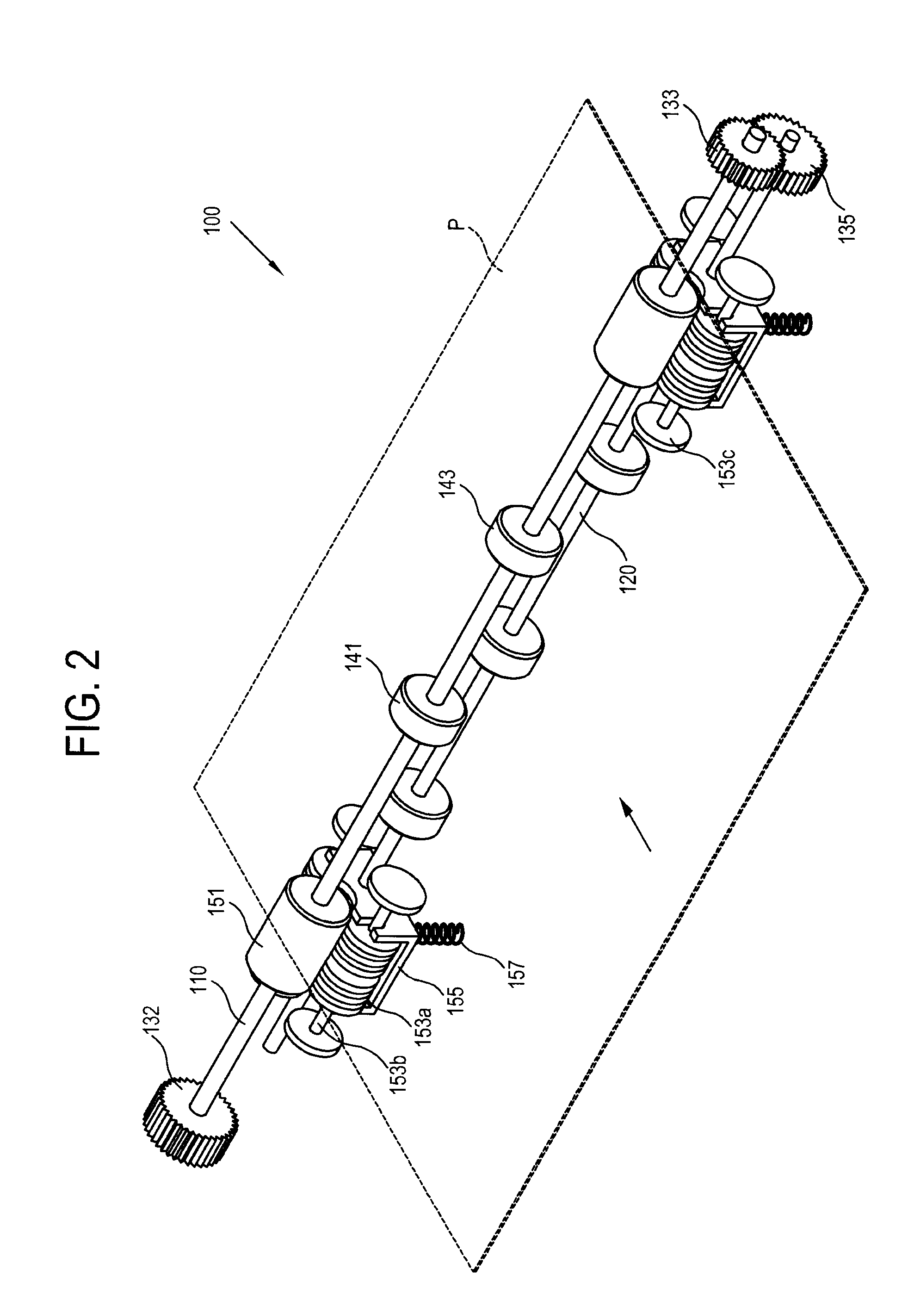

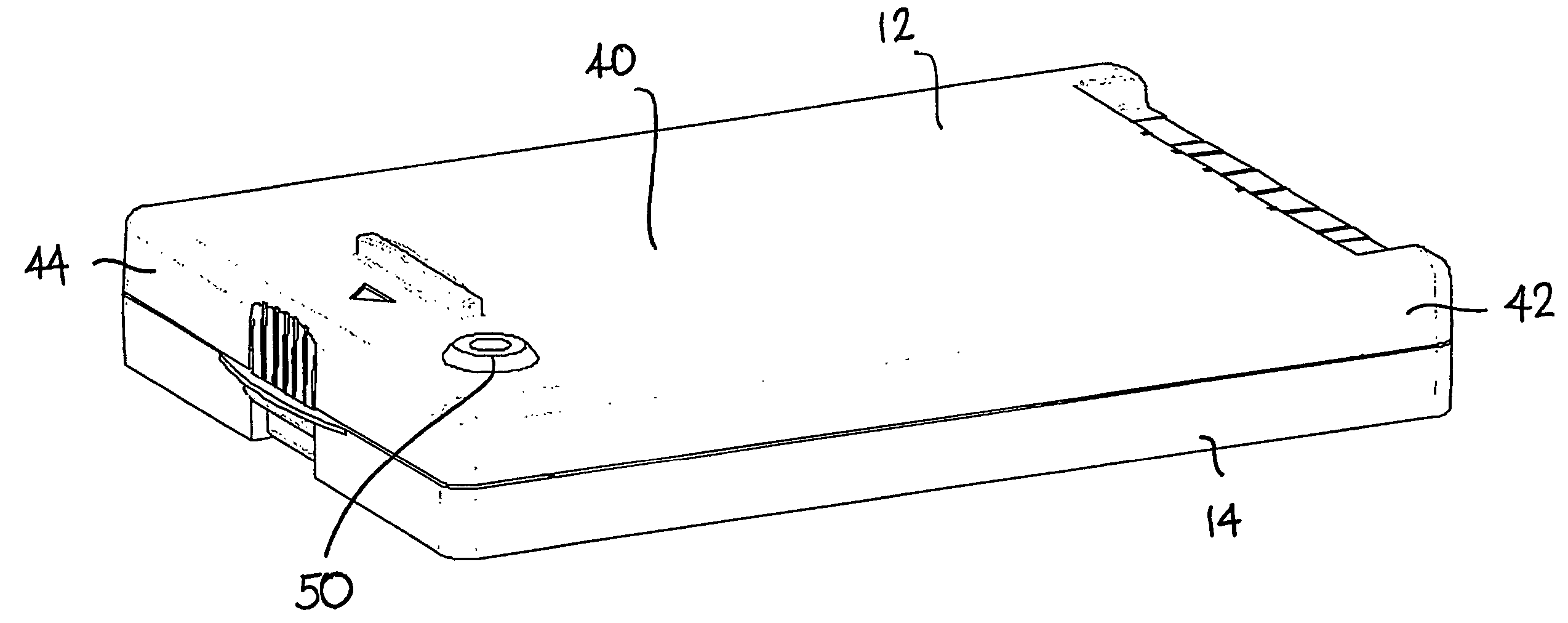

Image scanning apparatus, method and business machine using the same

ActiveUS7355763B2Avoid mistakesDifferent thicknessPaper-money testing devicesCharacter and pattern recognitionElastomerSpring force

Scanning errors and document feed errors are prevented by pressing originals, including thin originals and thick originals of greatly different thicknesses, to the scanning surface (1a) of an image sensor (1) with pressure appropriate for the respective original. A pressure-generating mechanism (50) is used to press the original against the scanning surface (1a) by selecting different elastic bodies with different spring forces to produce a different elastic force in accordance with the thickness of the original document.

Owner:SEIKO EPSON CORP

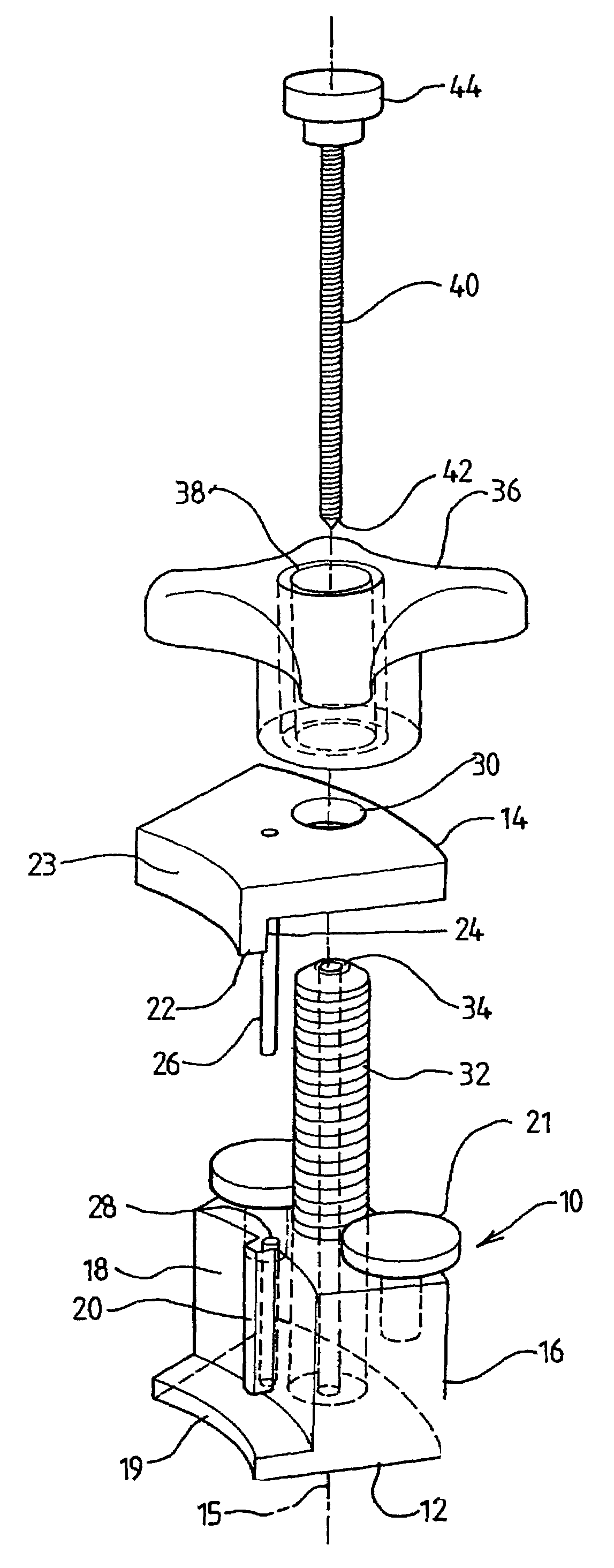

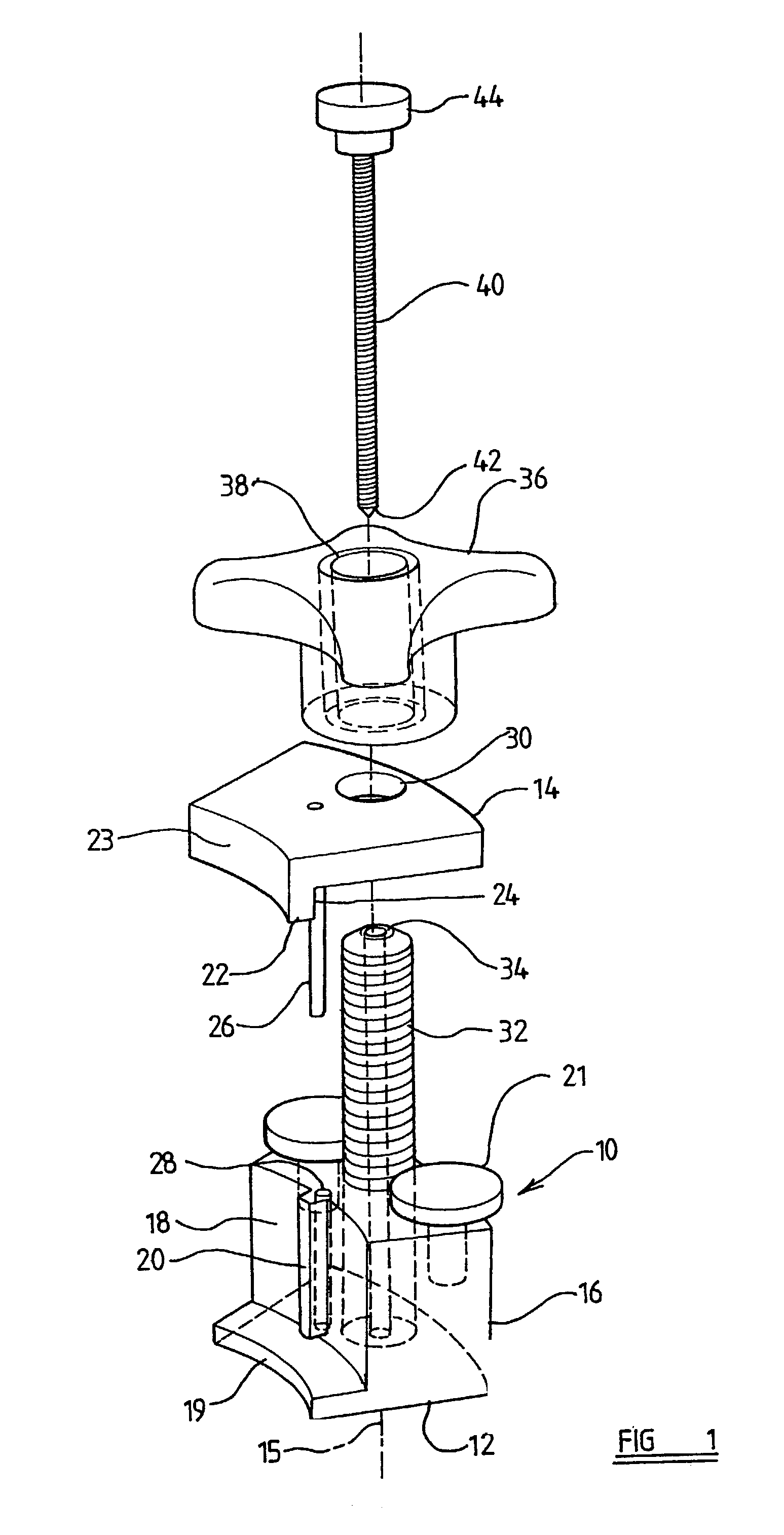

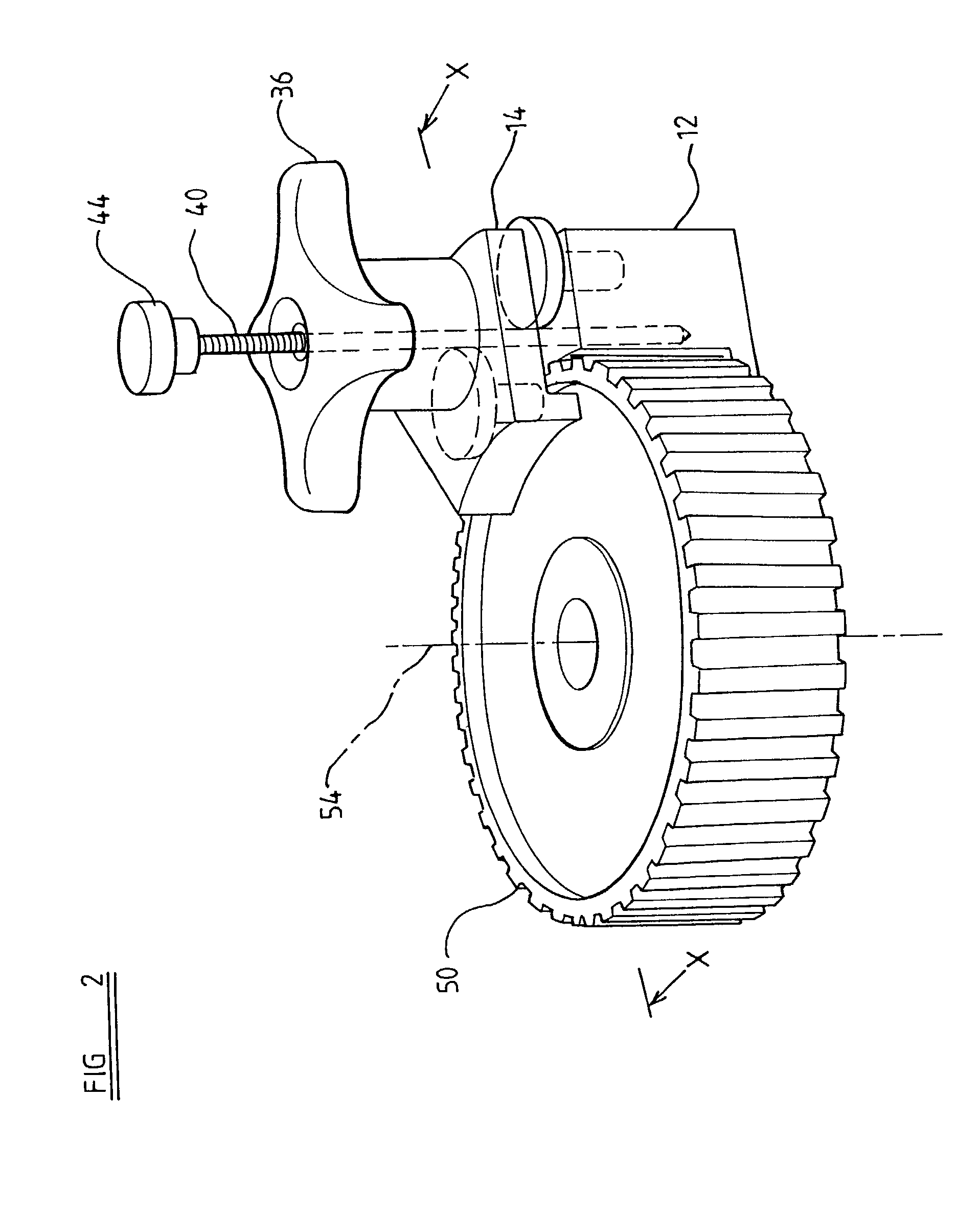

Holding device

InactiveUS7047610B2Sufficient forceDifferent thicknessGearingFriction grip releasable fasteningsFixed position

A device for holding a rotary element stationary relative to a fixed body, the device comprising at least one element, adapted to engage with the rotary element to hold the device in a fixed position relative to the rotary element; and an engaging member, adapted to engage with the body to hold the device relative to the body.

Owner:AUTO SERVICE TOOLS

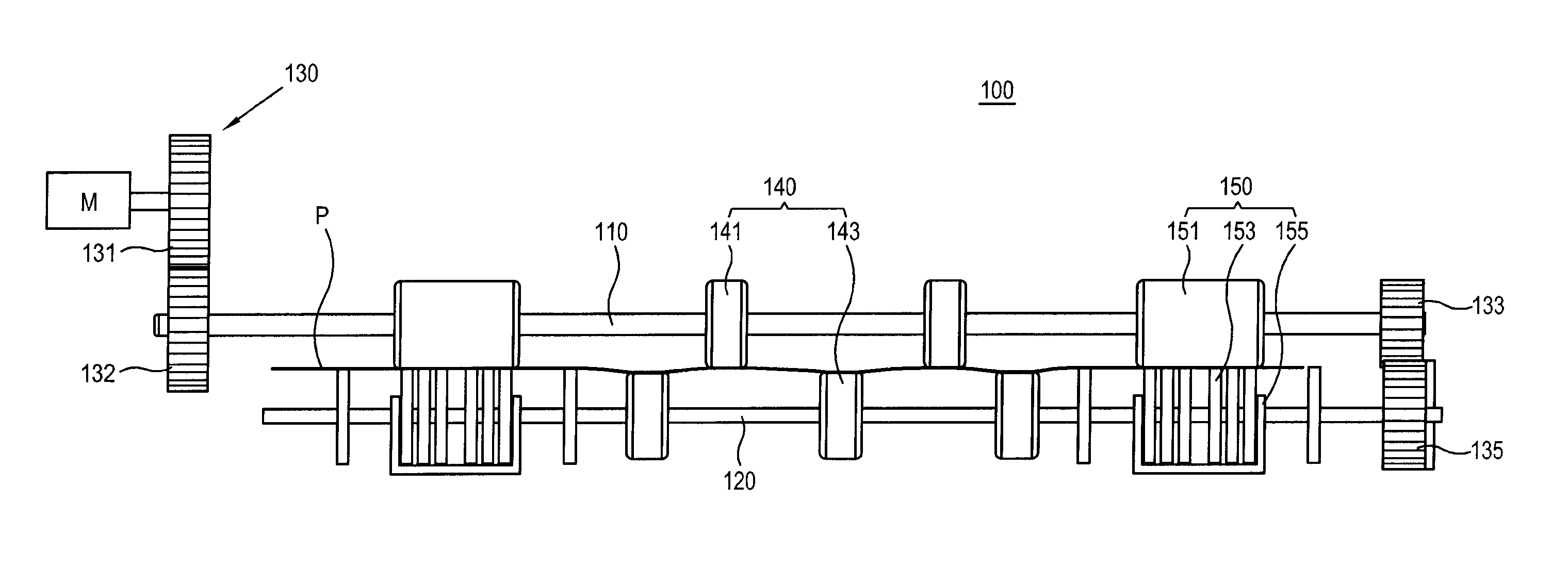

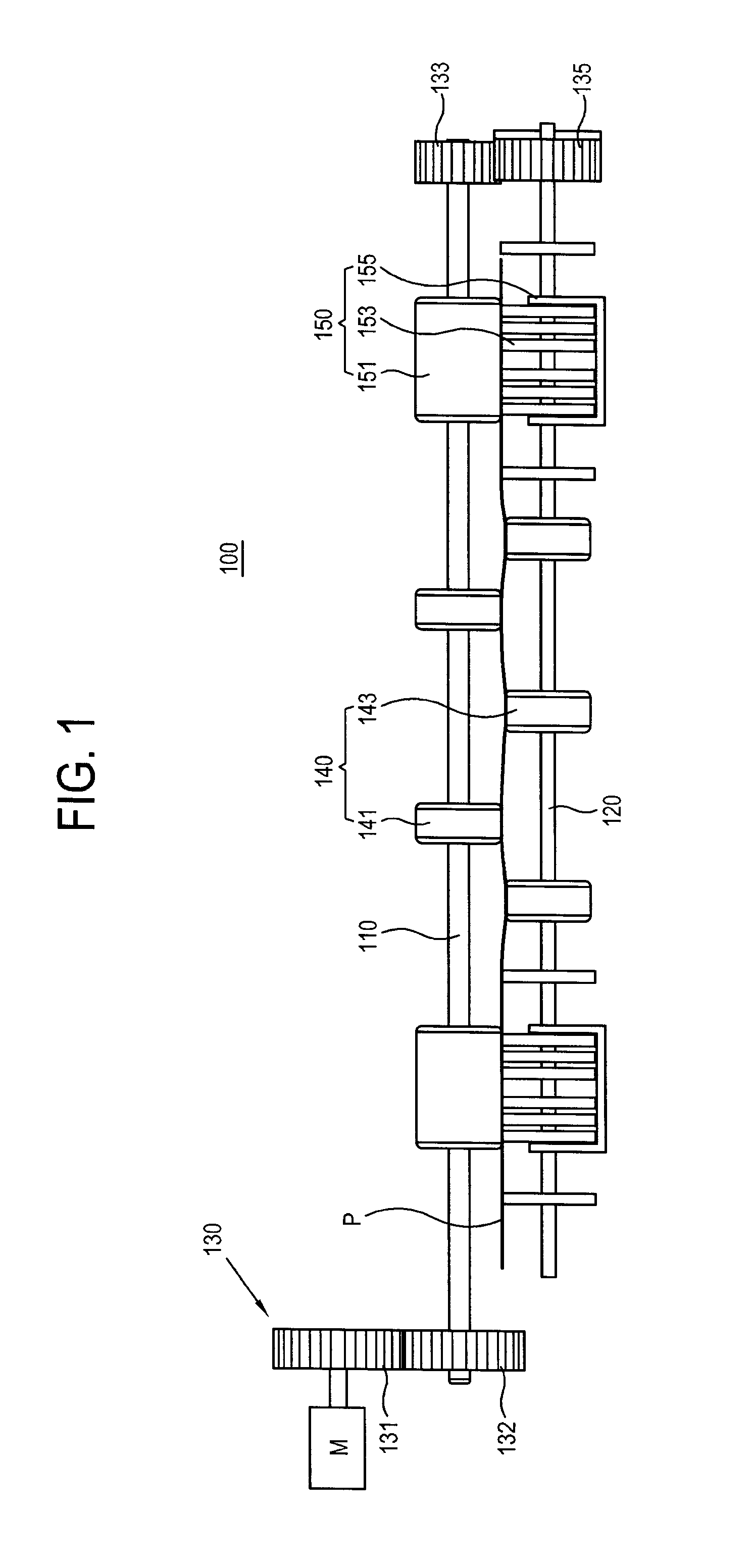

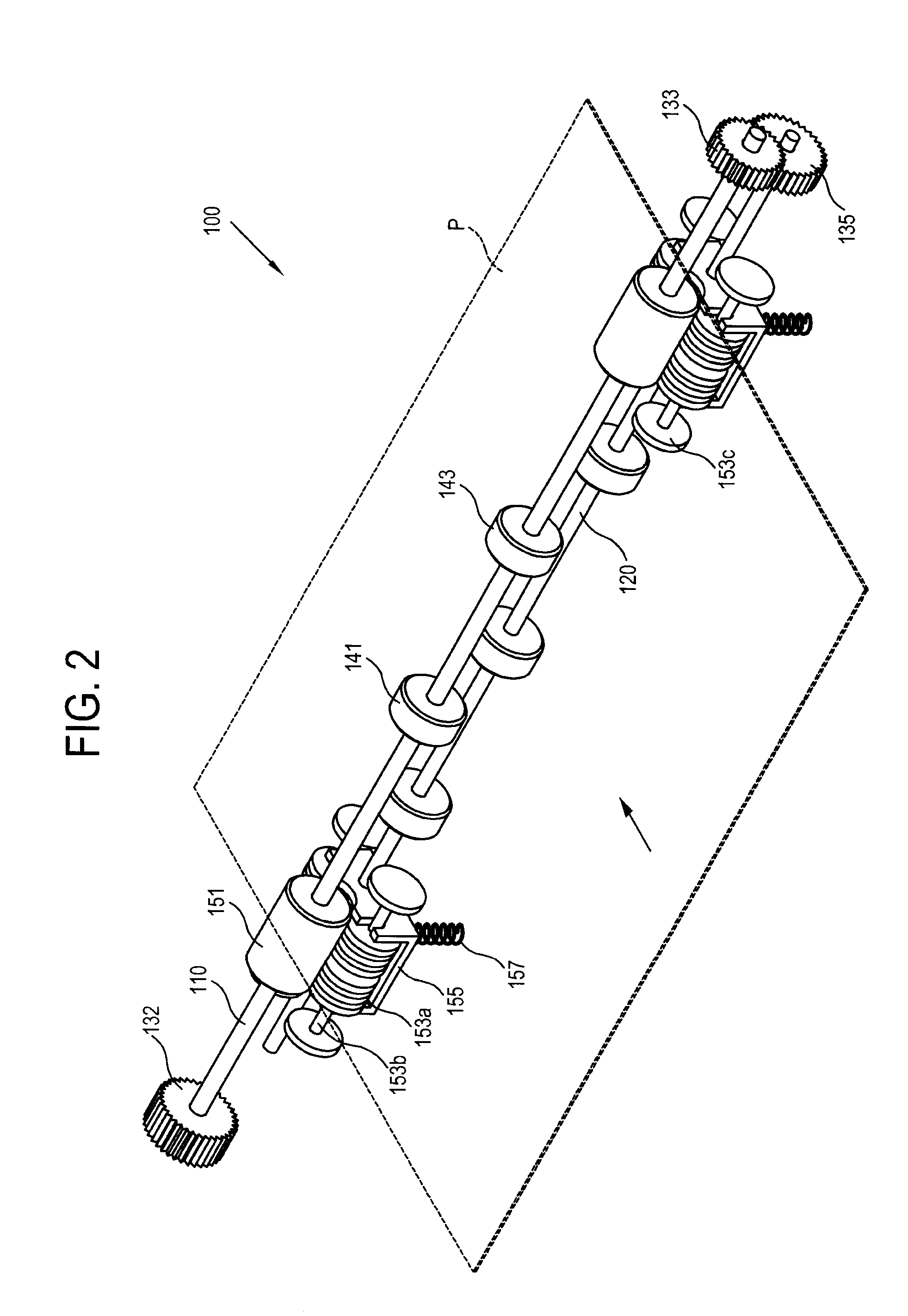

Discharging unit and image forming apparatus having the same

ActiveUS20080310900A1Less frizzDifferent thicknessElectrographic process apparatusOther printing apparatusImage formationMechanical engineering

A discharging unit for discharging a printing medium from an image forming apparatus includes an elastic roller and a curl preventing roller to oppose each other in a pressing relationship forming a nip therebetween to reduce curling of a print medium passing through the nip. At least one of the elastic roller and the curl preventing roller is allowed to move towards or away from the other roller so that the nip can be adjusted to accommodate different thicknesses of varying types of printing medium.

Owner:HEWLETT PACKARD DEV CO LP

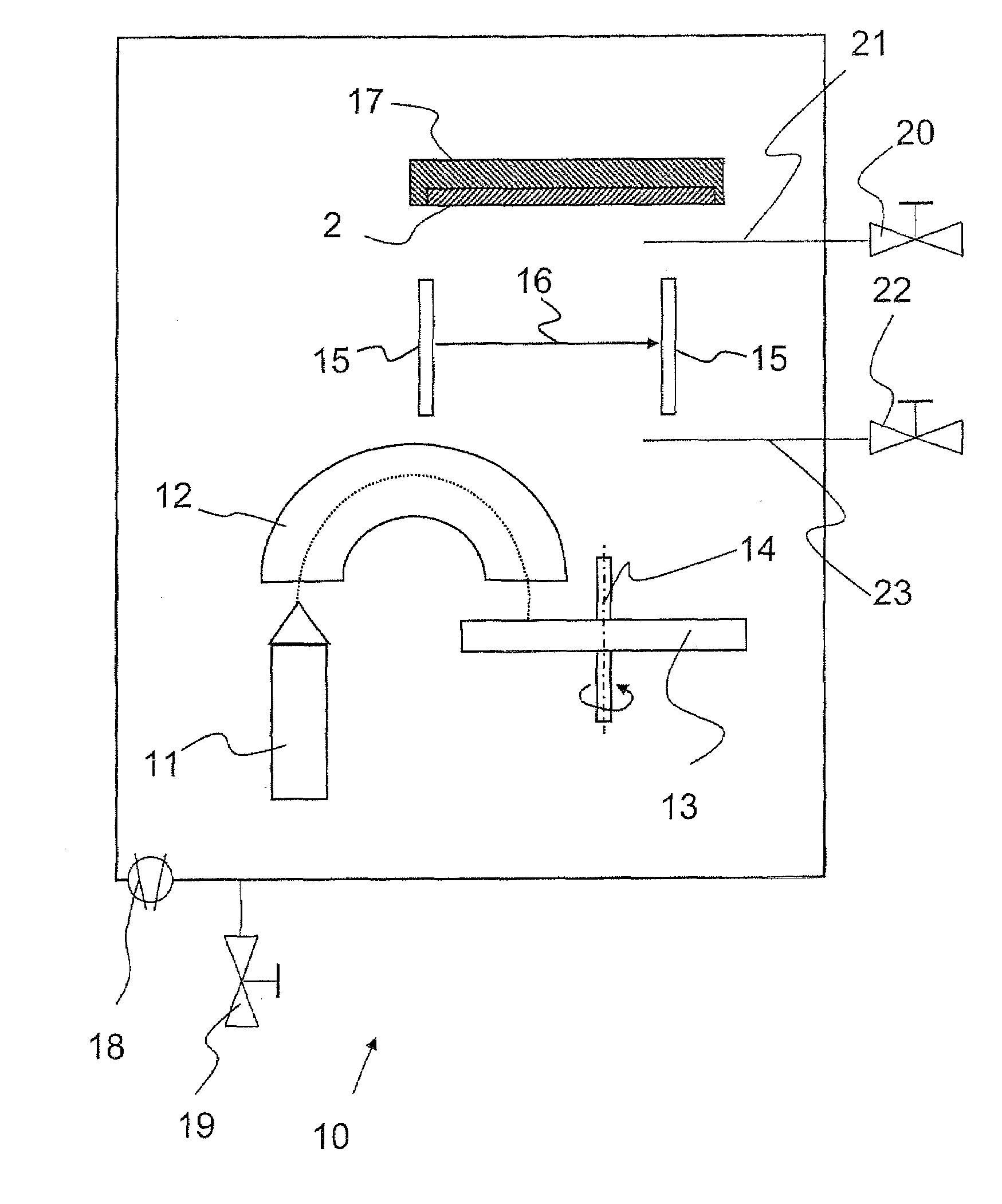

Method for applying a porous glass layer

InactiveUS20090011217A1Simple and economicalEconomical and simpleLayered productsVacuum evaporation coatingPorous glassDeposition rate

The invention relates to a method for applying a porous glass layer. It is proposed to apply a porous glass layer by means of a PVD method. Porosity factor and average pore size can be varied by means of the process parameters such as pressure and deposition rate, as well as by deliberate addition of extrinsic substances.

Owner:SCHOTT AG

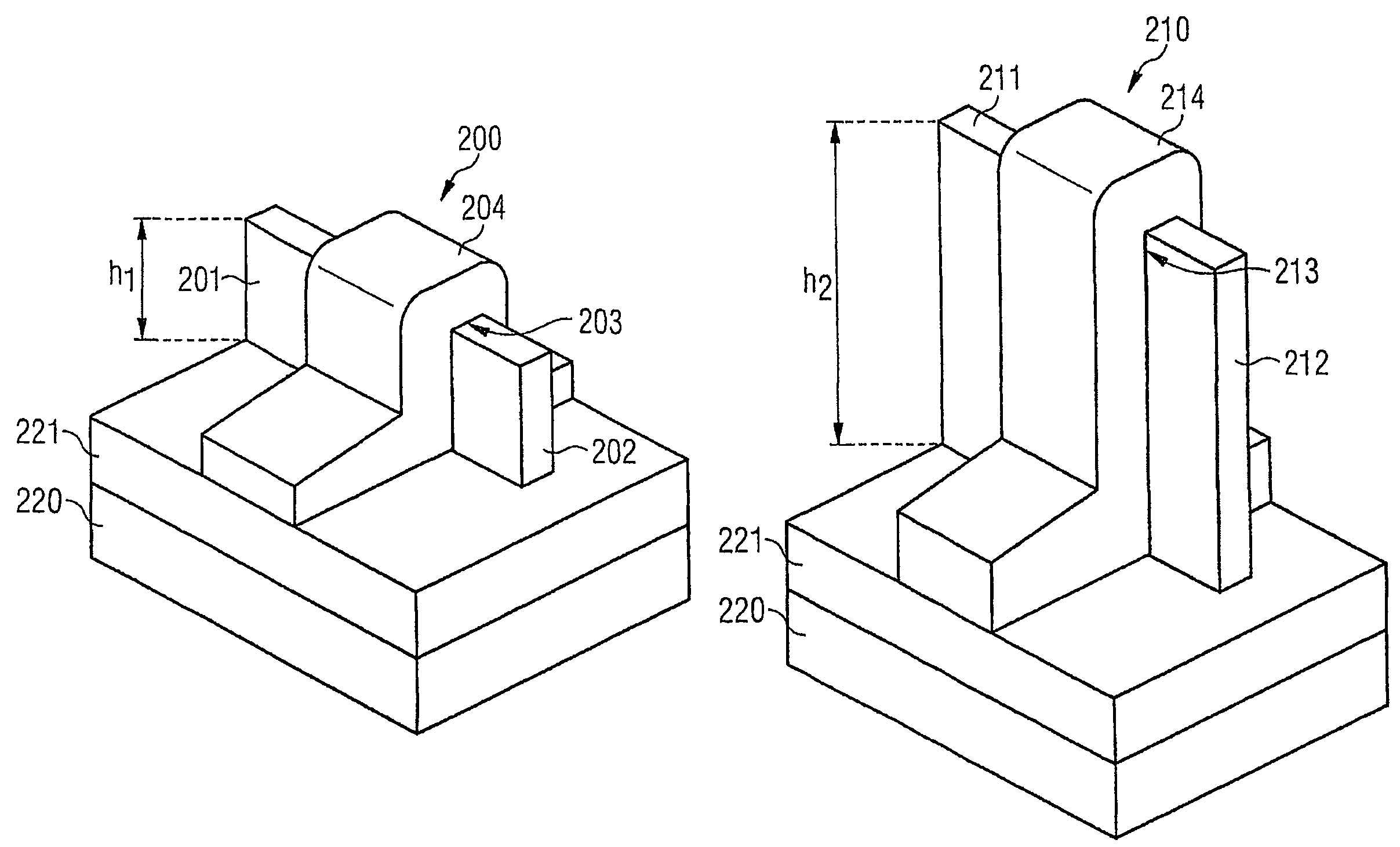

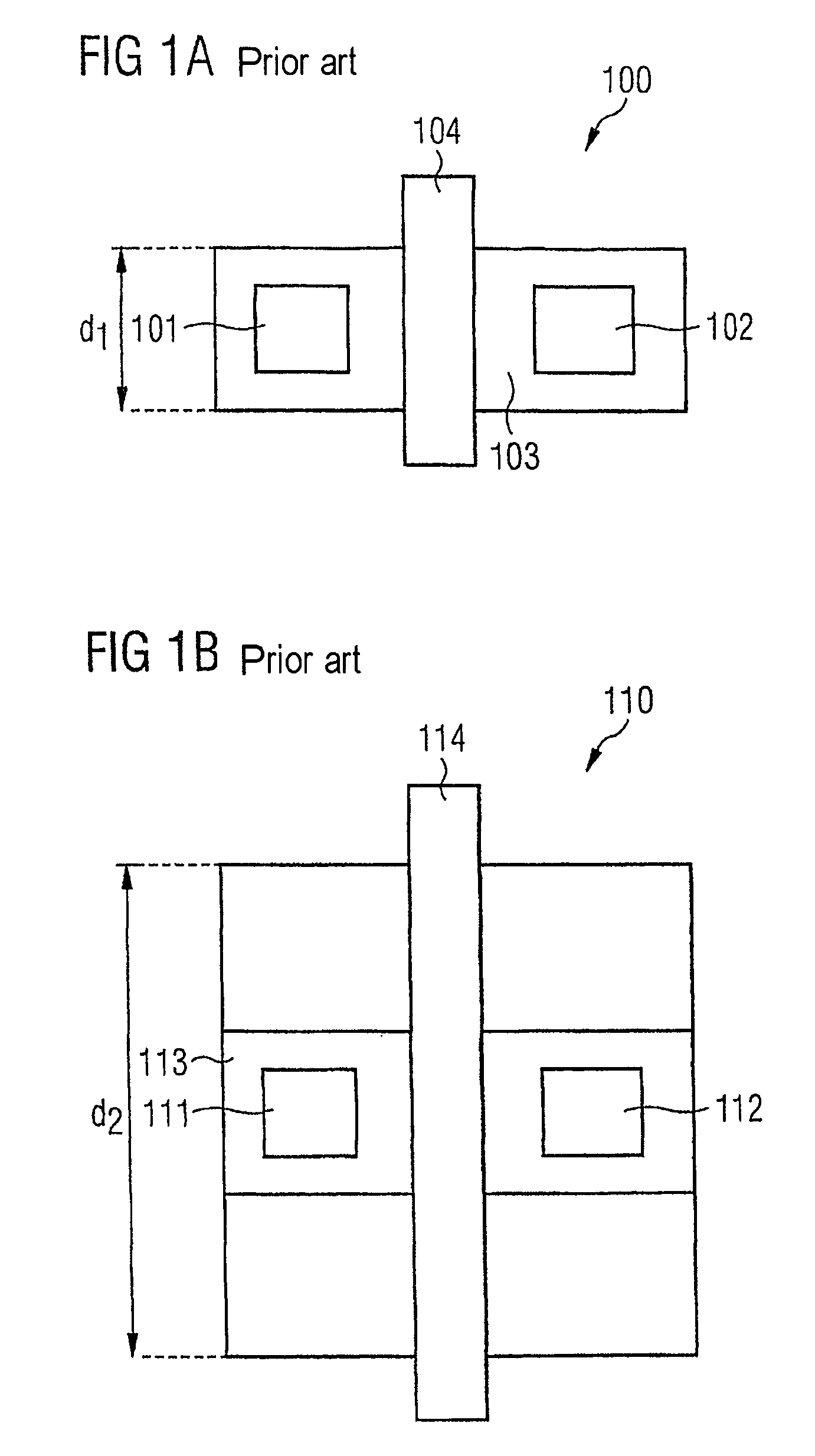

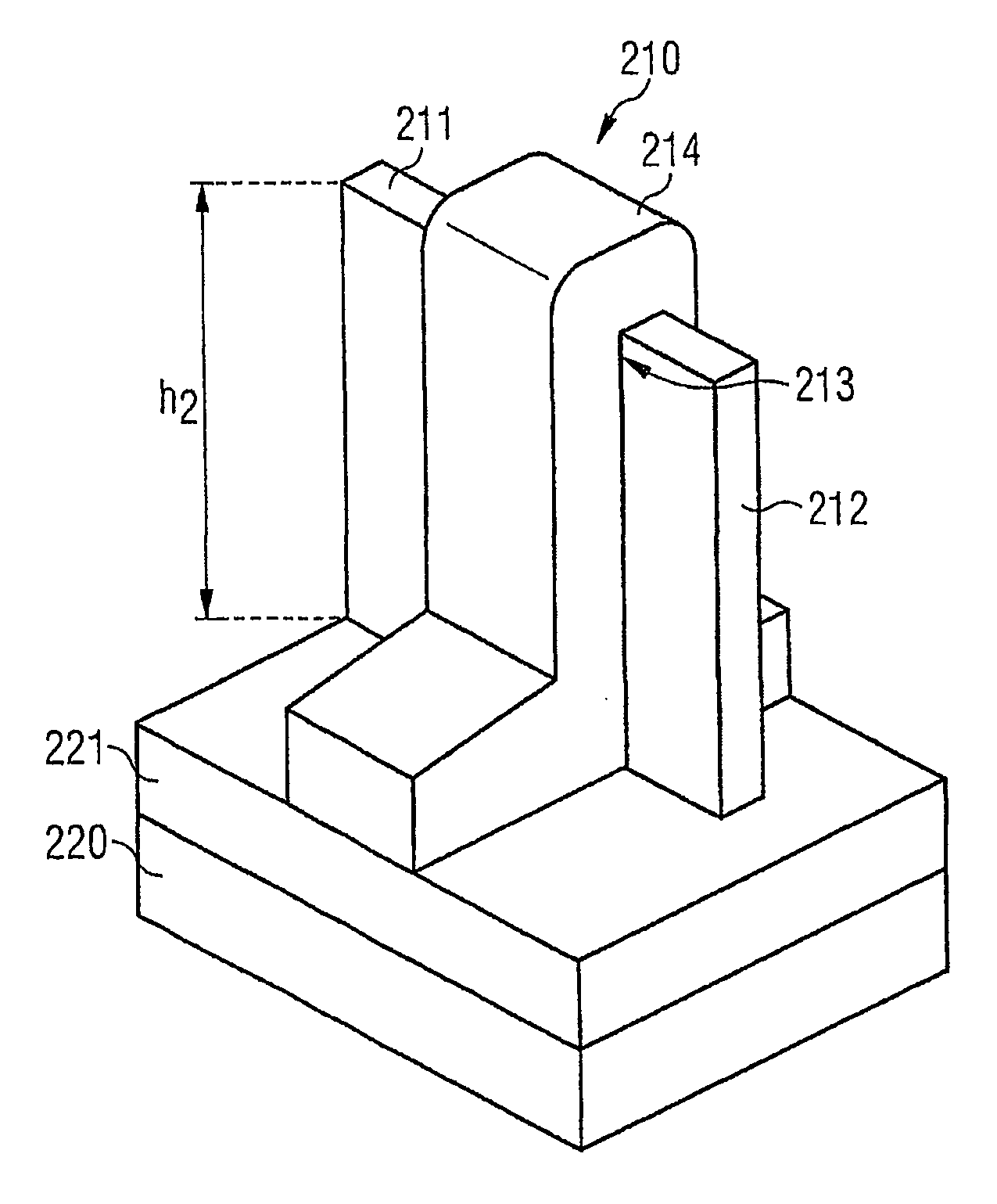

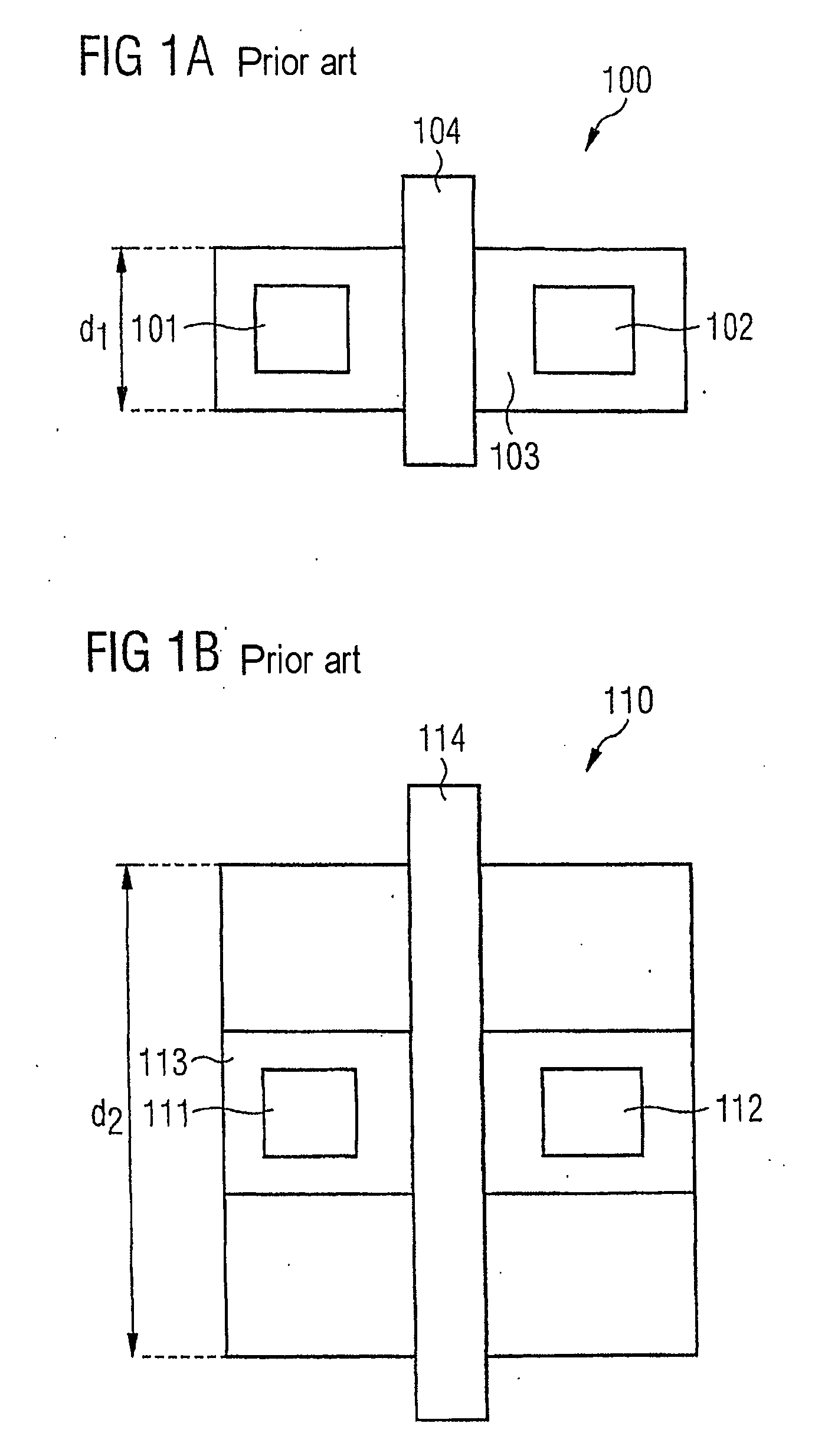

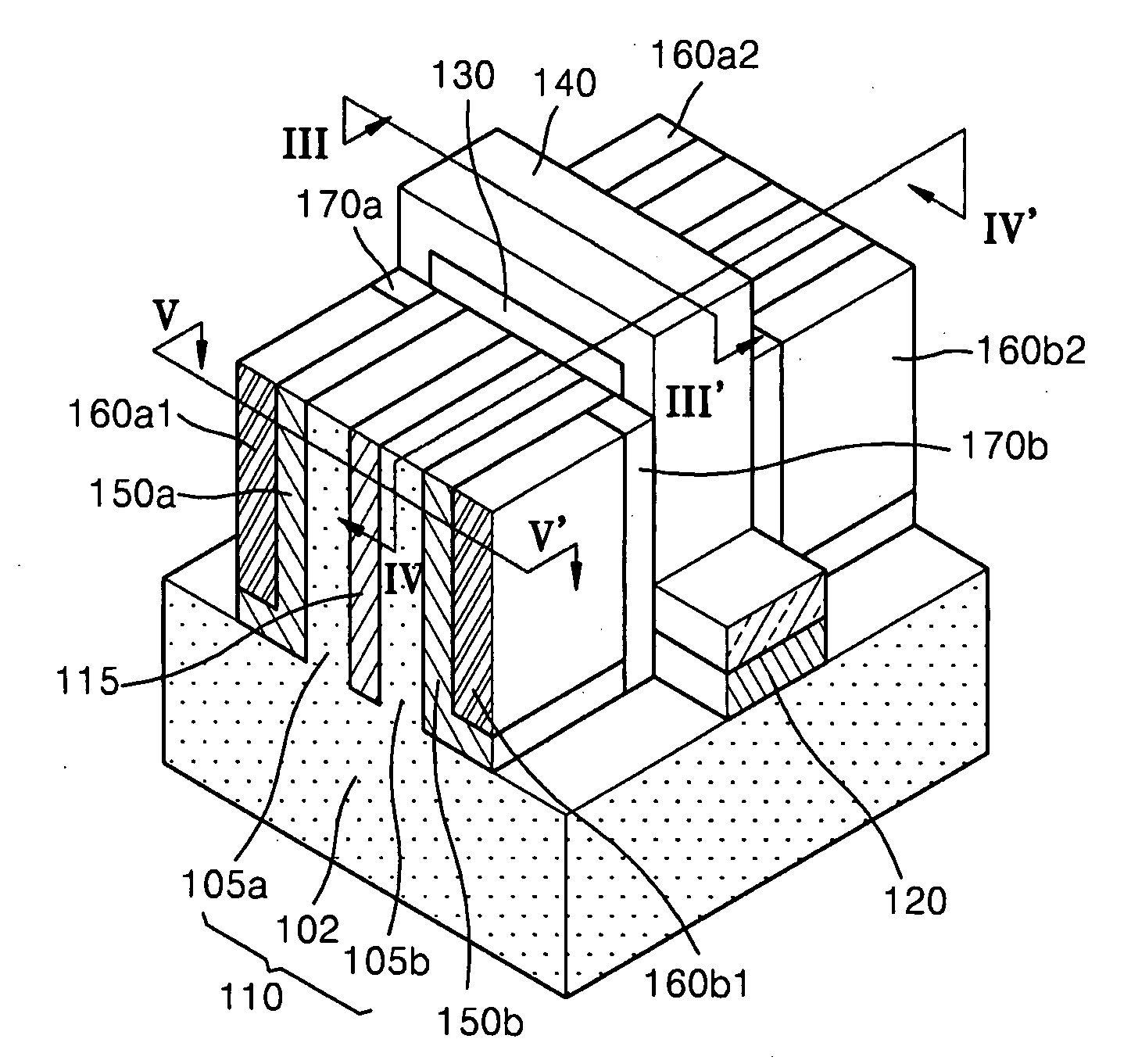

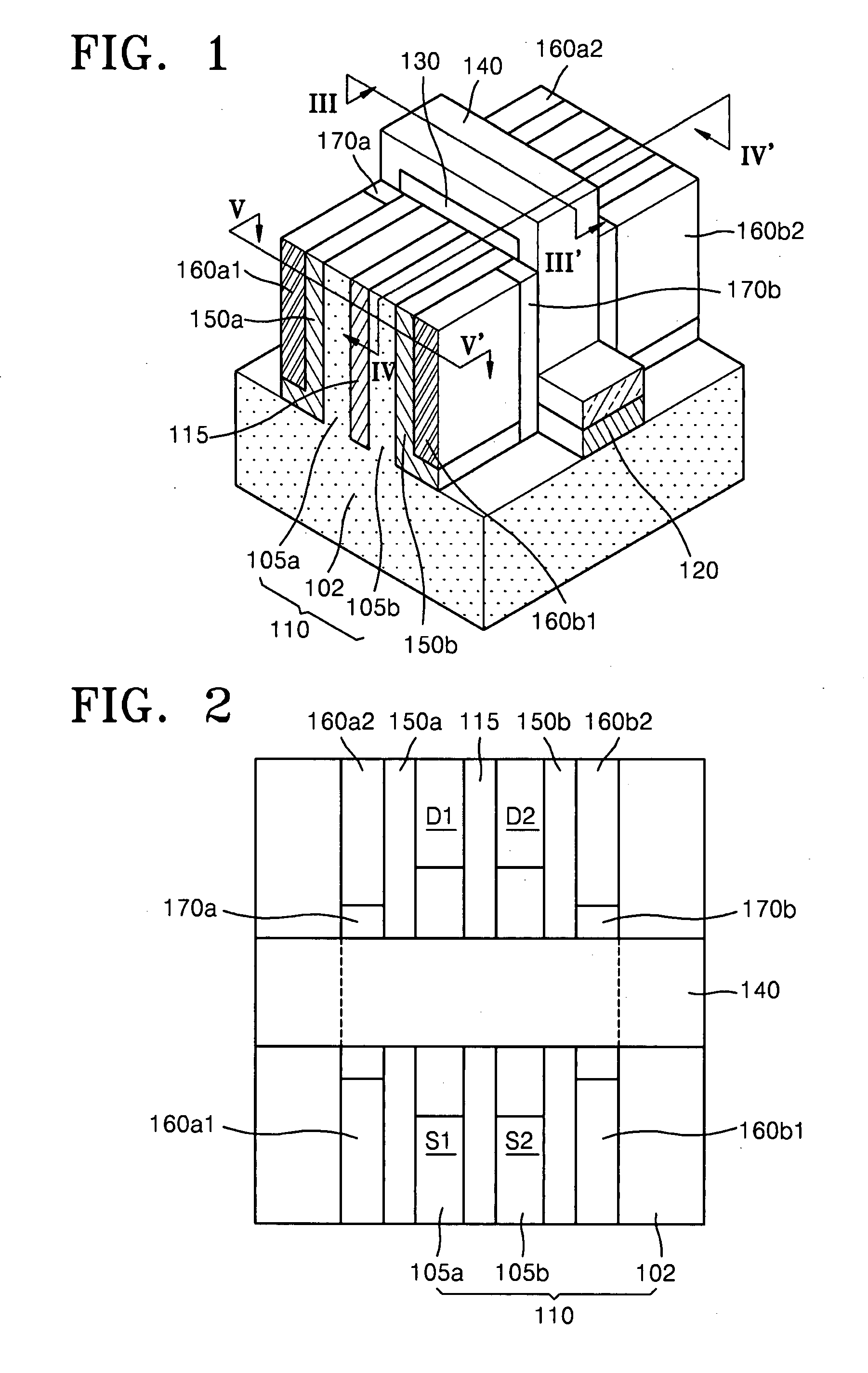

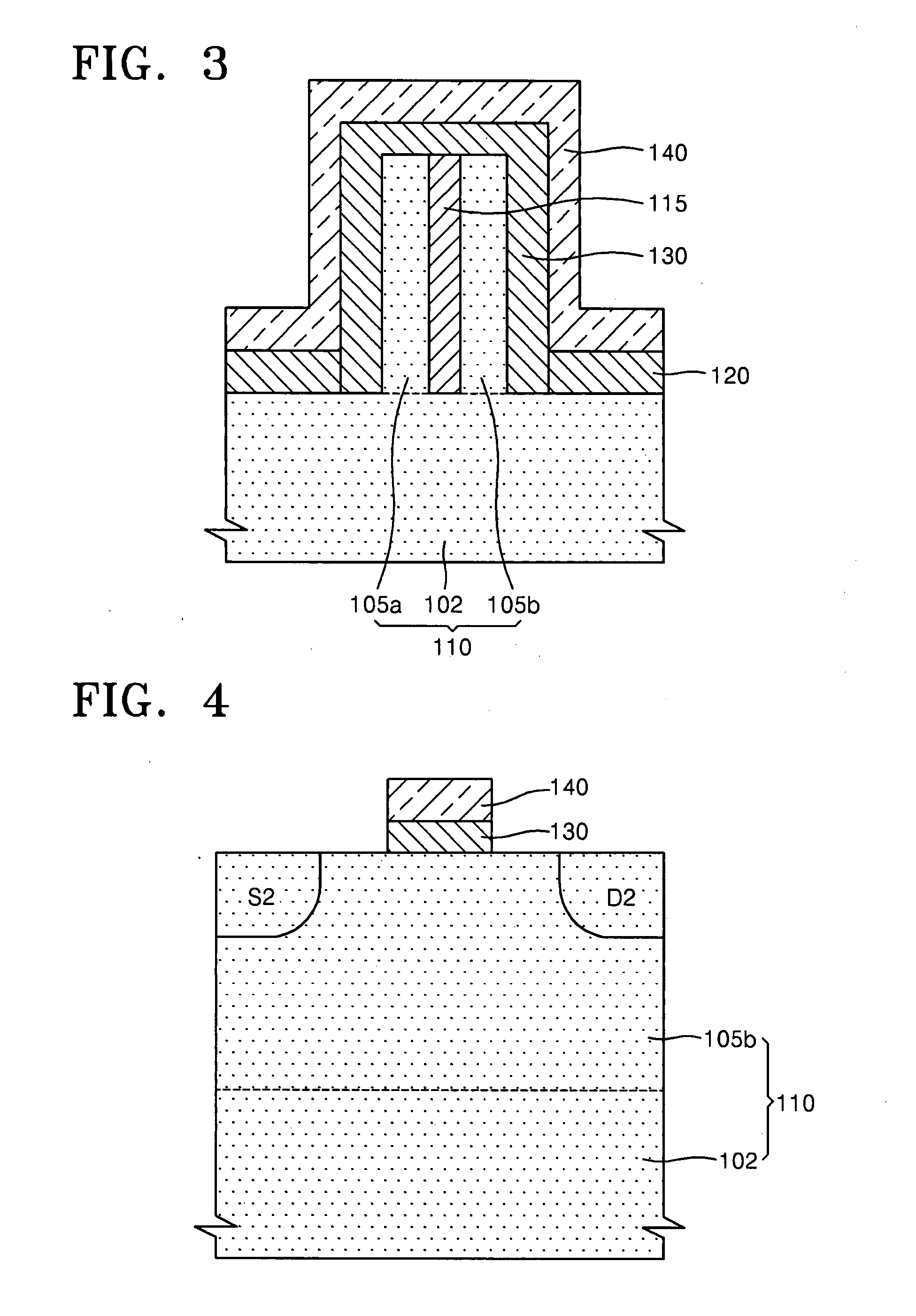

Fin field effect transistor arrangement and method for producing a fin field effect transistor arrangement

InactiveUS7719059B2Quality improvementDifferent thicknessTransistorSolid-state devicesField-effect transistorPhysics

A fin field effect transistor arrangement comprises a substrate and a first fin field effect transistor on and / or in the substrate. The first fin field effect transistor includes a fin in which a channel region is formed between a first source / drain region and a second source / drain region and above which a gate region is formed. A second fin field effect transistor is provided on and / or in the substrate including a fin in which a channel region is formed between a first source / drain region and a second source / drain region and above which a gate region is formed. The second fin field effect transistor is arranged laterally alongside the first fin field effect transistor, wherein a height of the fin of the first fin field effect transistor is greater than a height of the fin of the second fin field effect transistor.

Owner:INFINEON TECH AG

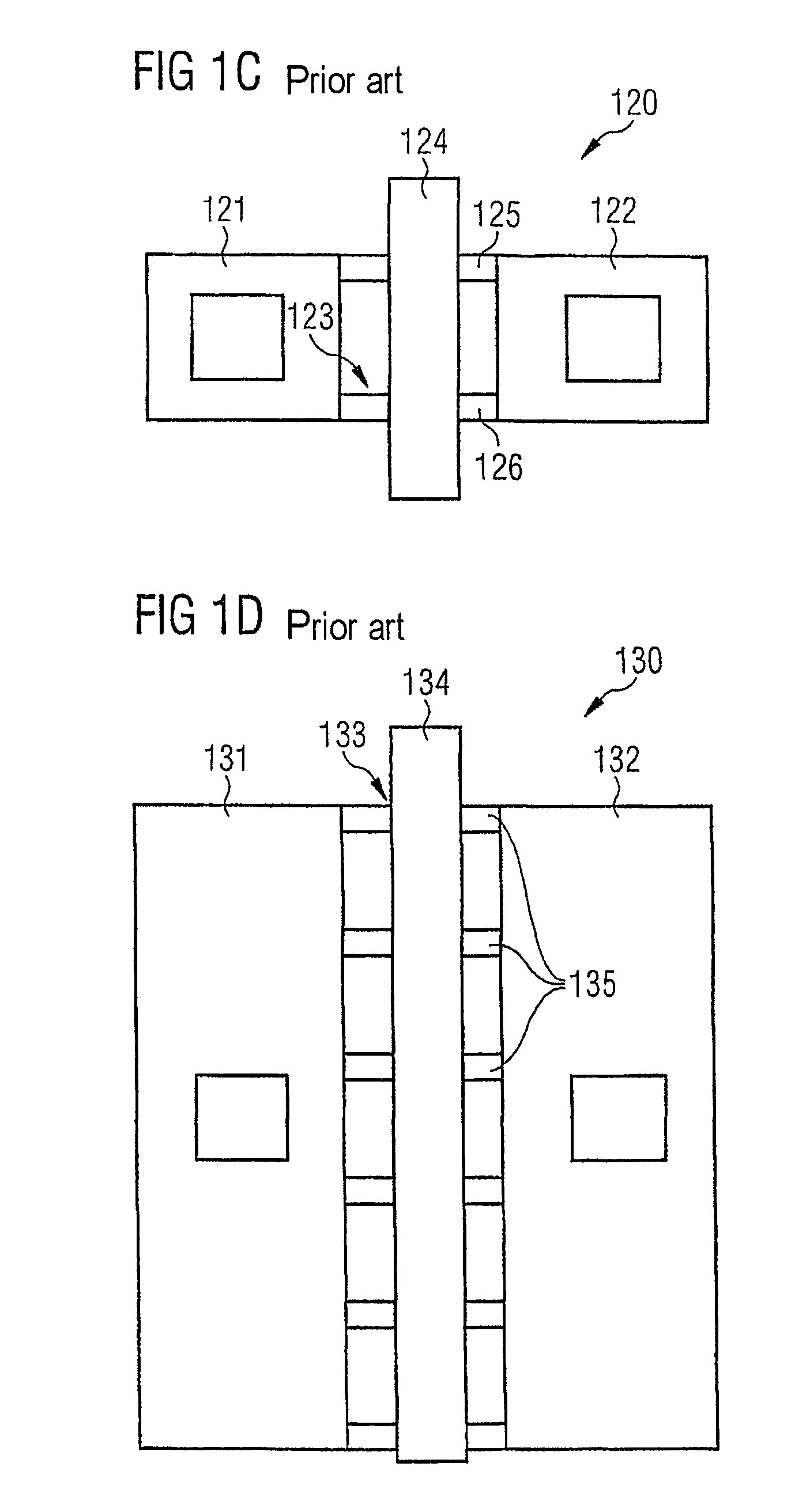

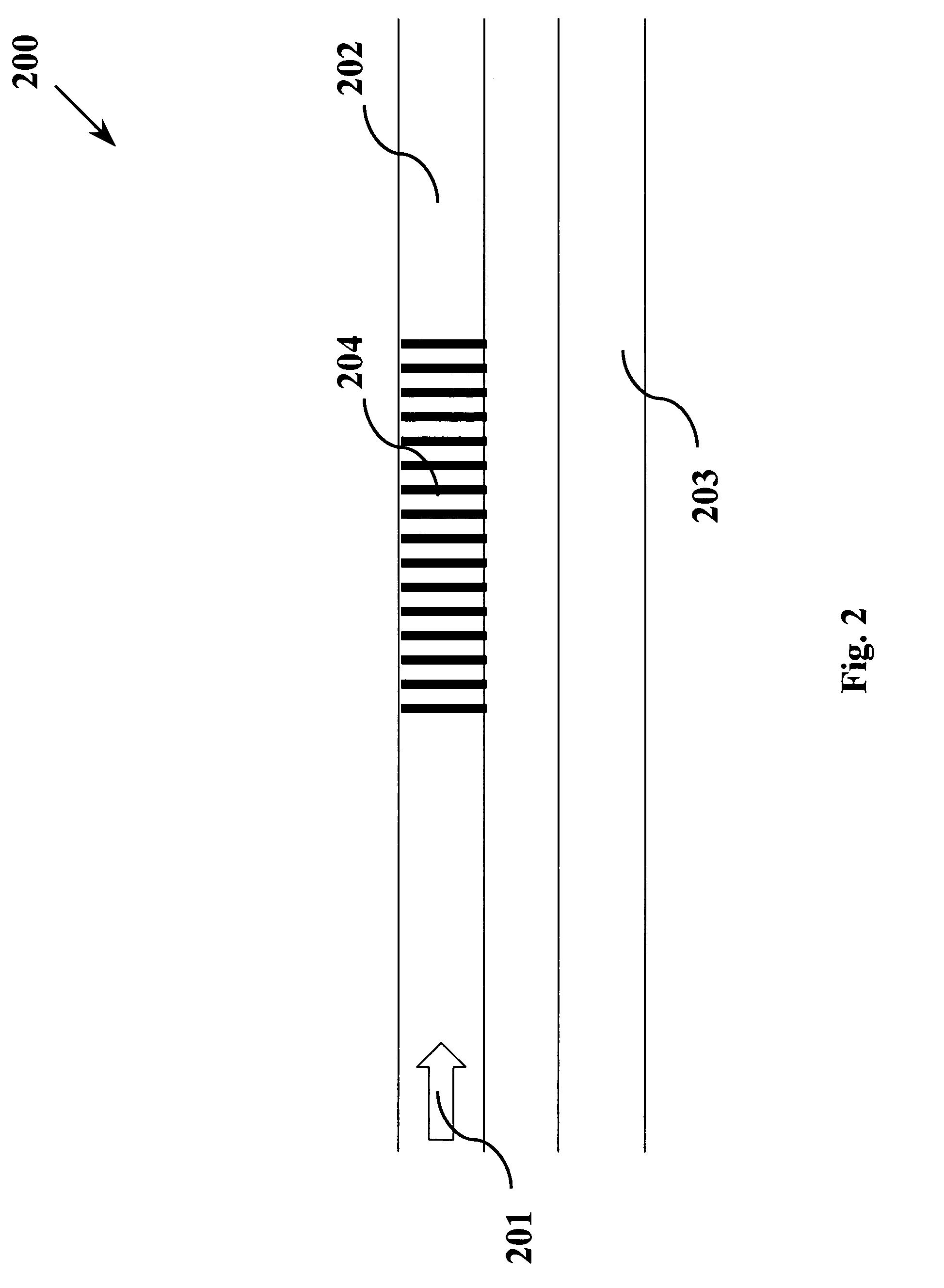

Grating-based wavelength selective switch

The present invention is a wavelength-selective optical transmission system that includes a first waveguide for transmitting a multiplexed optical signal therethrough. The system further includes a second waveguide coupled to the first waveguide wherein a least one of the first and second waveguides have a set of wavelength-selective Bragg gratings disposed near a coupling section between the first and second waveguides to reflect a reflecting optical signal back to the first waveguide and for transmitting a contra-directional optical signal and a co-directional optical signal having respectively a contra-directional selected wavelength and a co-directional selected wavelength corresponding to the Bragg gratings. One of the contra-directional and co-directional wavelengths is chosen as a designated wavelength, and the reflecting optical signal and one of the contra-directional or co-directional optical signals are outside of a predefined range surrounding the designated wavelength.

Owner:INTEGRATED OPTICS COMM

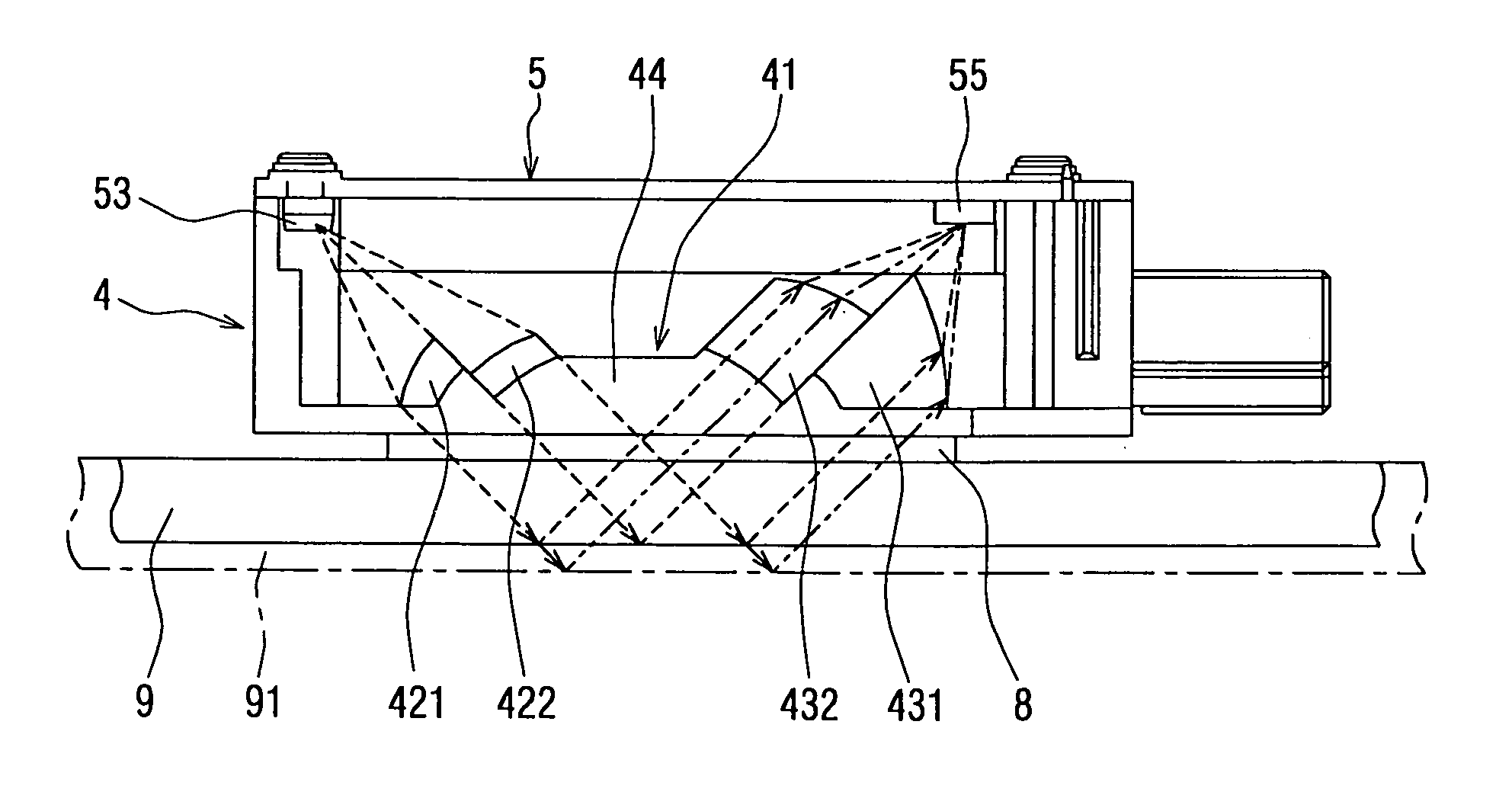

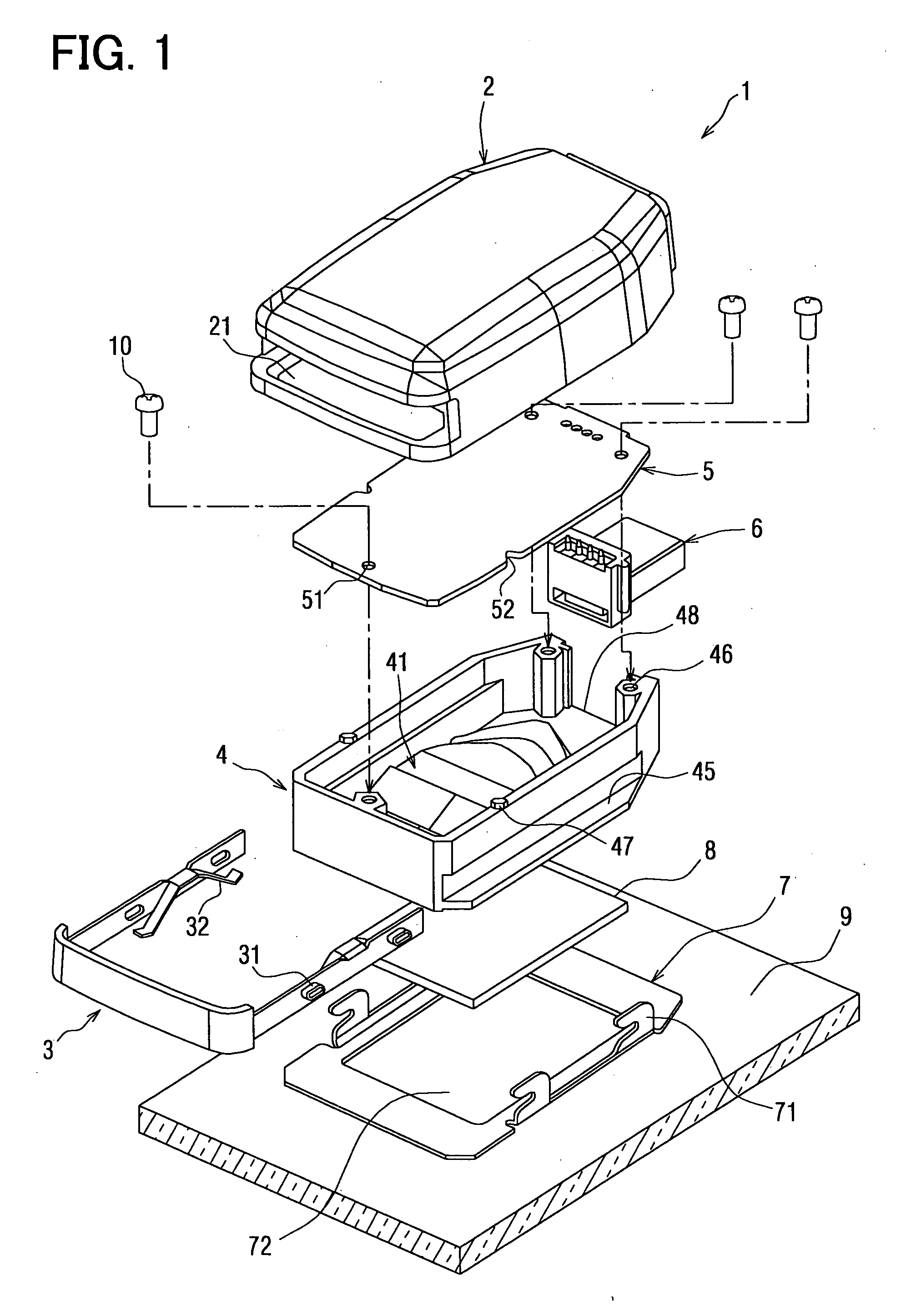

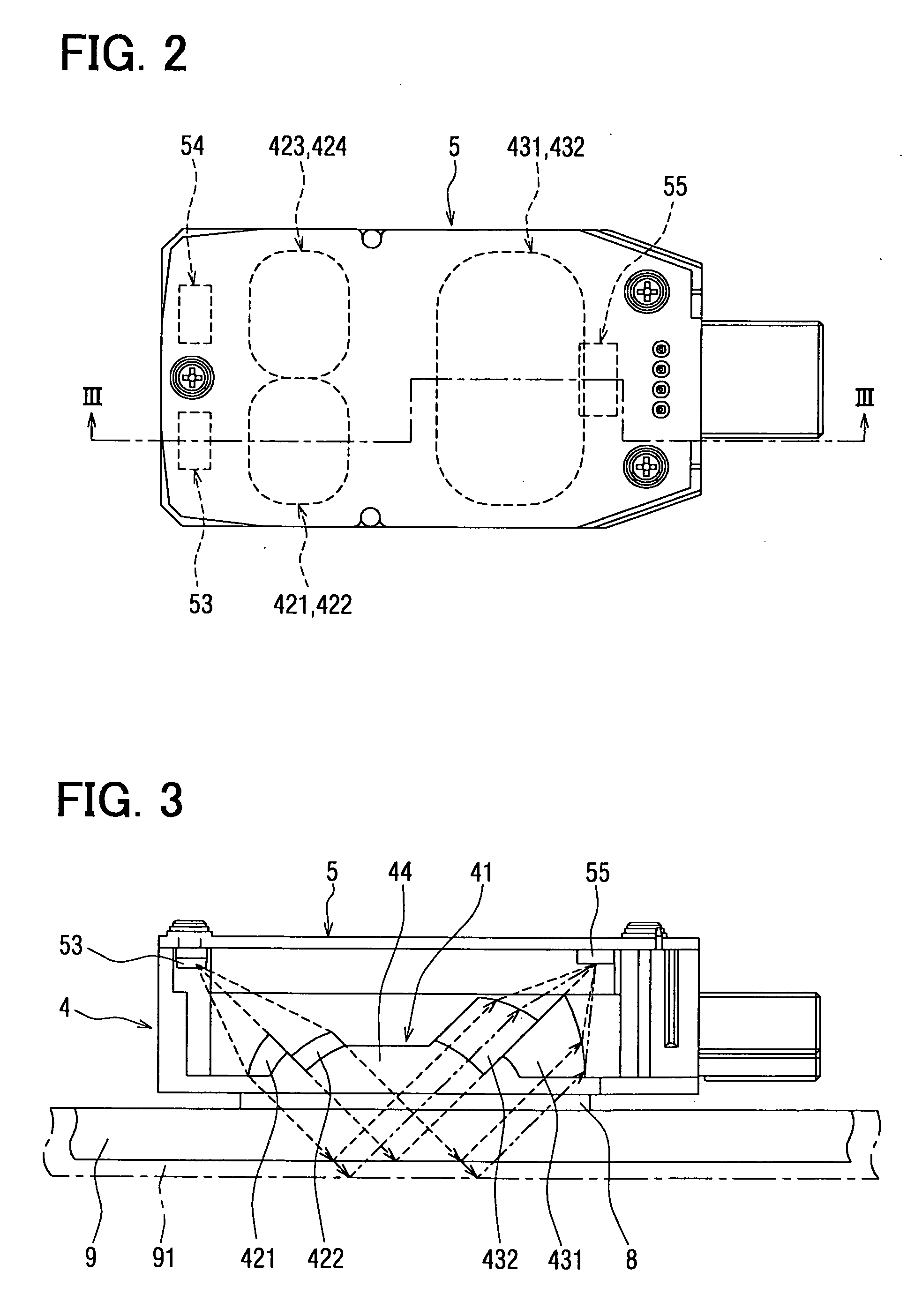

Raindrop detection apparatus

ActiveUS20060076477A1Reduce manufacturing costReduce the overall heightInvestigating moving fluids/granular solidsScattering properties measurementsOptoelectronicsWindshield

A raindrop detection apparatus includes a light emitting unit for emitting light to an inner side of a windshield, a light receiving unit for receiving the light reflected by an outer surface of the windshield, a first lens unit which is arranged between the windshield and the light emitting unit to convert the light from the light emitting unit into parallel light, and a second lens unit which is arranged between the windshield and the light receiving unit to converge the reflected light at the light receiving unit. The second lens unit is larger than a radial cross section of the reflected light. An amount of raindrop landed on the outer surface of the windshield is detected based on an intensity of the light received by the light receiving unit.

Owner:DENSO CORP

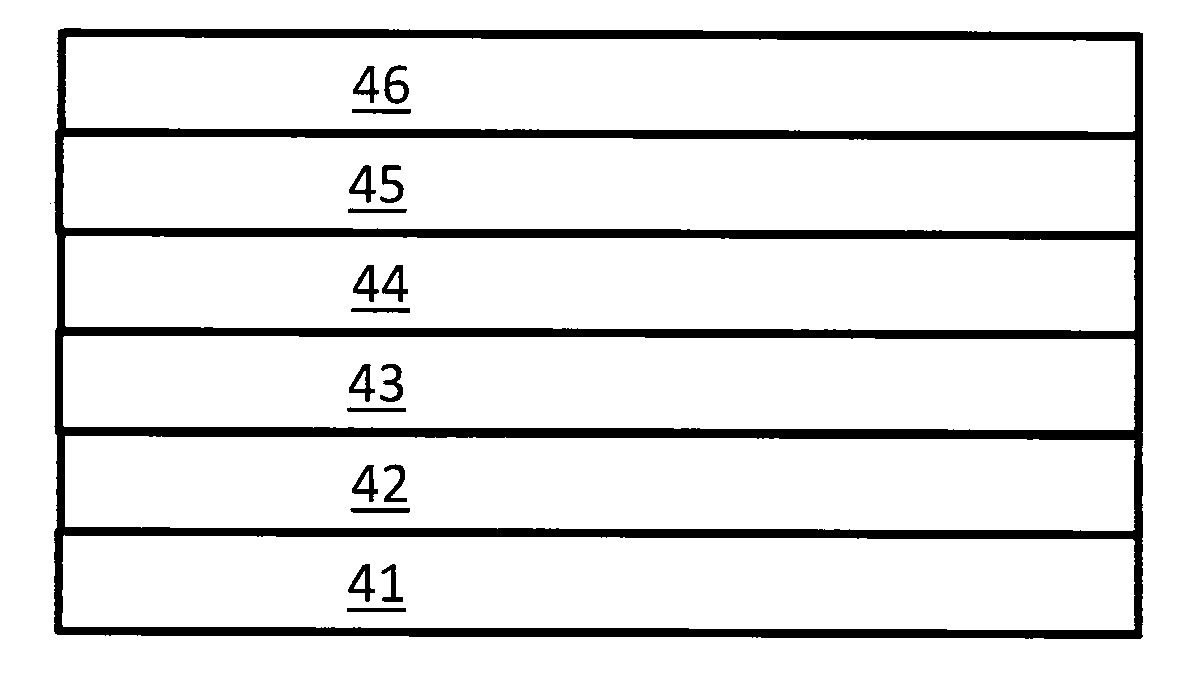

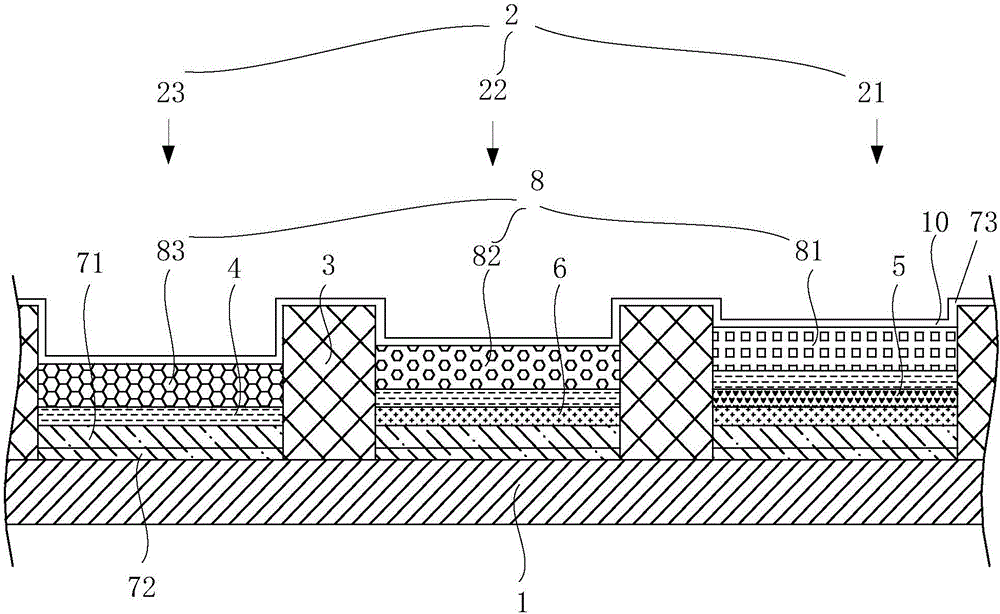

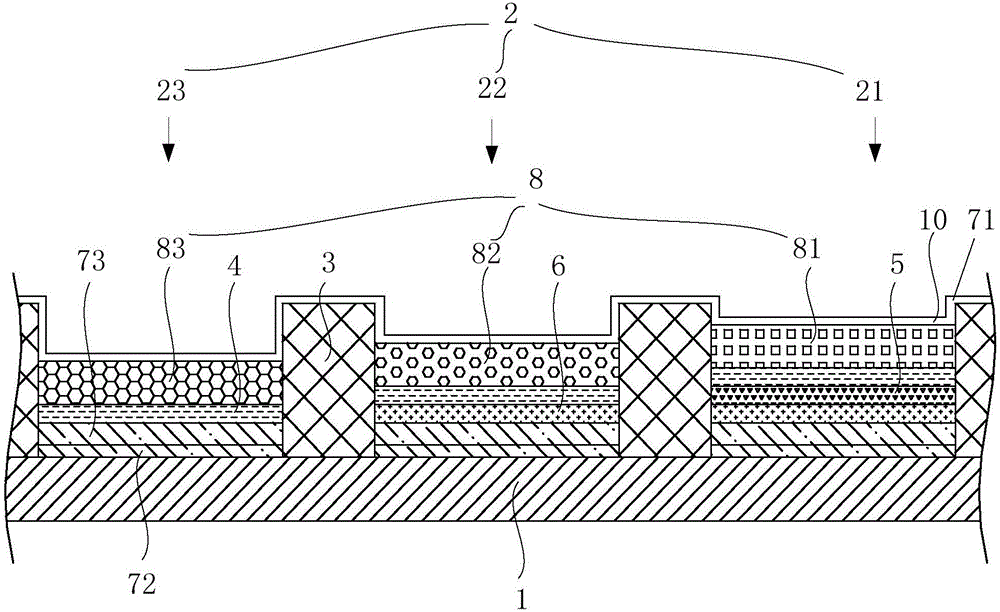

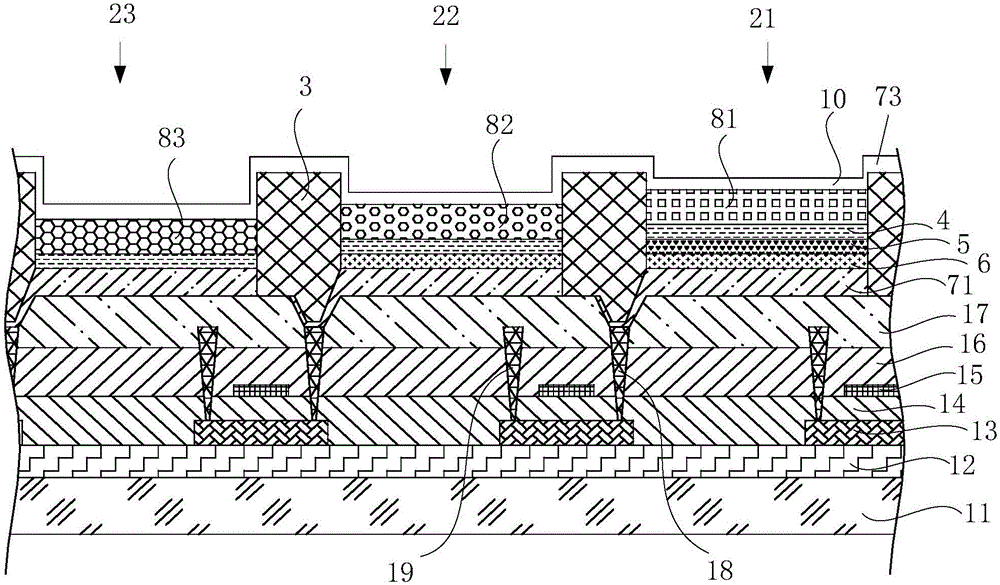

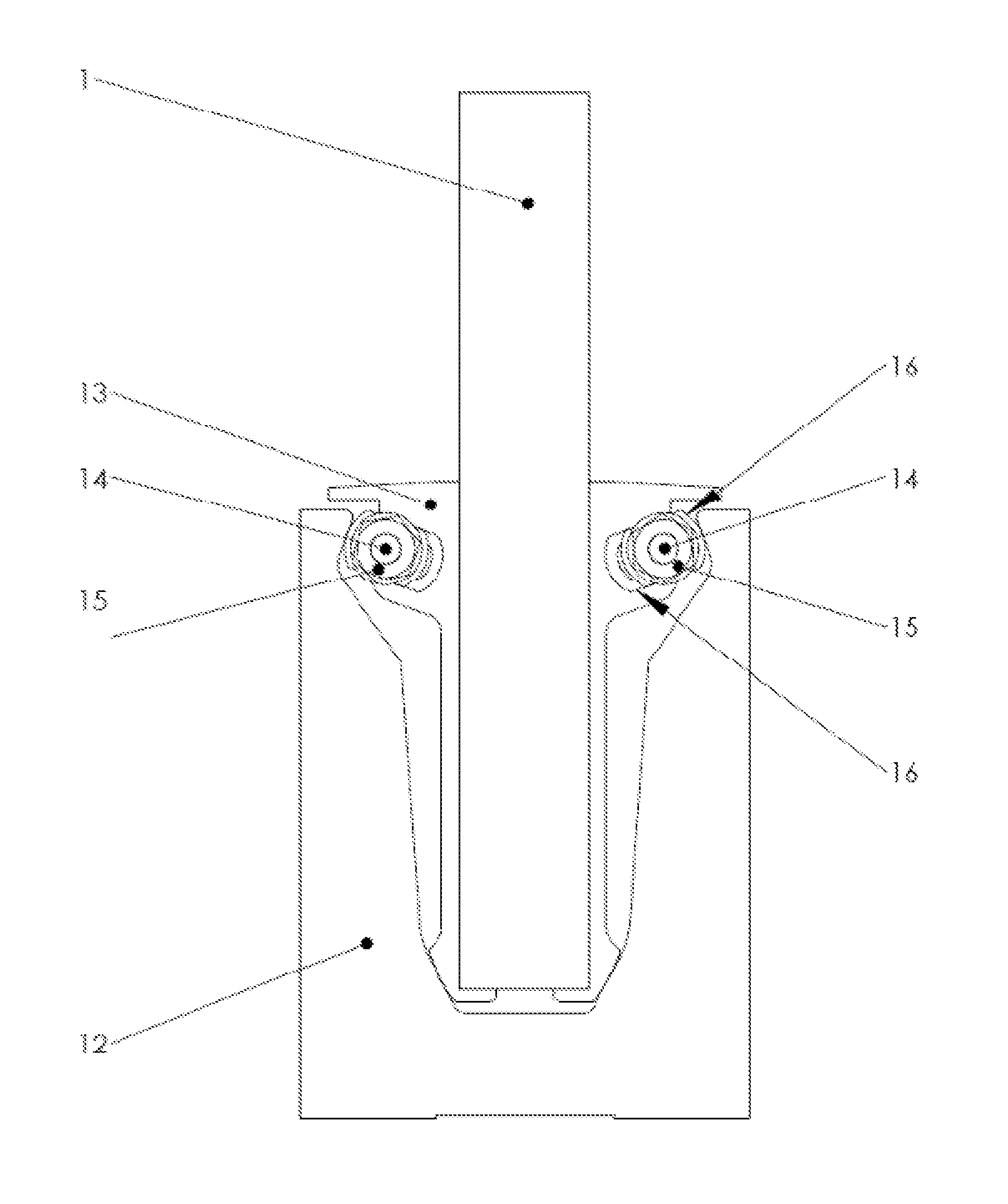

Organic light-emitting diode array substrate, display device and manufacturing method

ActiveCN105720081ASimple preparation processDifferent thicknessSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyComposite electrode

The invention discloses an organic light-emitting diode array substrate, a display device and a manufacturing method, and belongs to the field of processing of displays. The array substrate comprises a substrate and a plurality of sub-pixel units, wherein the plurality of sub-pixel units are arranged on the substrate; each sub-pixel unit comprises a composite electrode, an organic material functional layer and a first electrode, which are sequentially arranged on the substrate; the composite electrodes included by different types of sub-pixel units are different in thickness; and the composite electrode, the organic material functional layer and the first electrode included by the same sub-pixel unit form a micro-cavity structure. The plurality of sub-pixel units are arranged on the substrate; and the composite electrodes included by different types of sub-pixel units in the plurality of sub-pixel units are different in thickness, so that the micro-cavity structures of different types of sub-pixel units are different in thickness; the manufacturing technology of the micro-cavity structures is simple and convenient to implement in process; the manufacturing cost is reduced; and the manufacturing efficiency and yield are improved.

Owner:BOE TECH GRP CO LTD

Panel support and adjustment mechanism

Owner:PURE VISTA

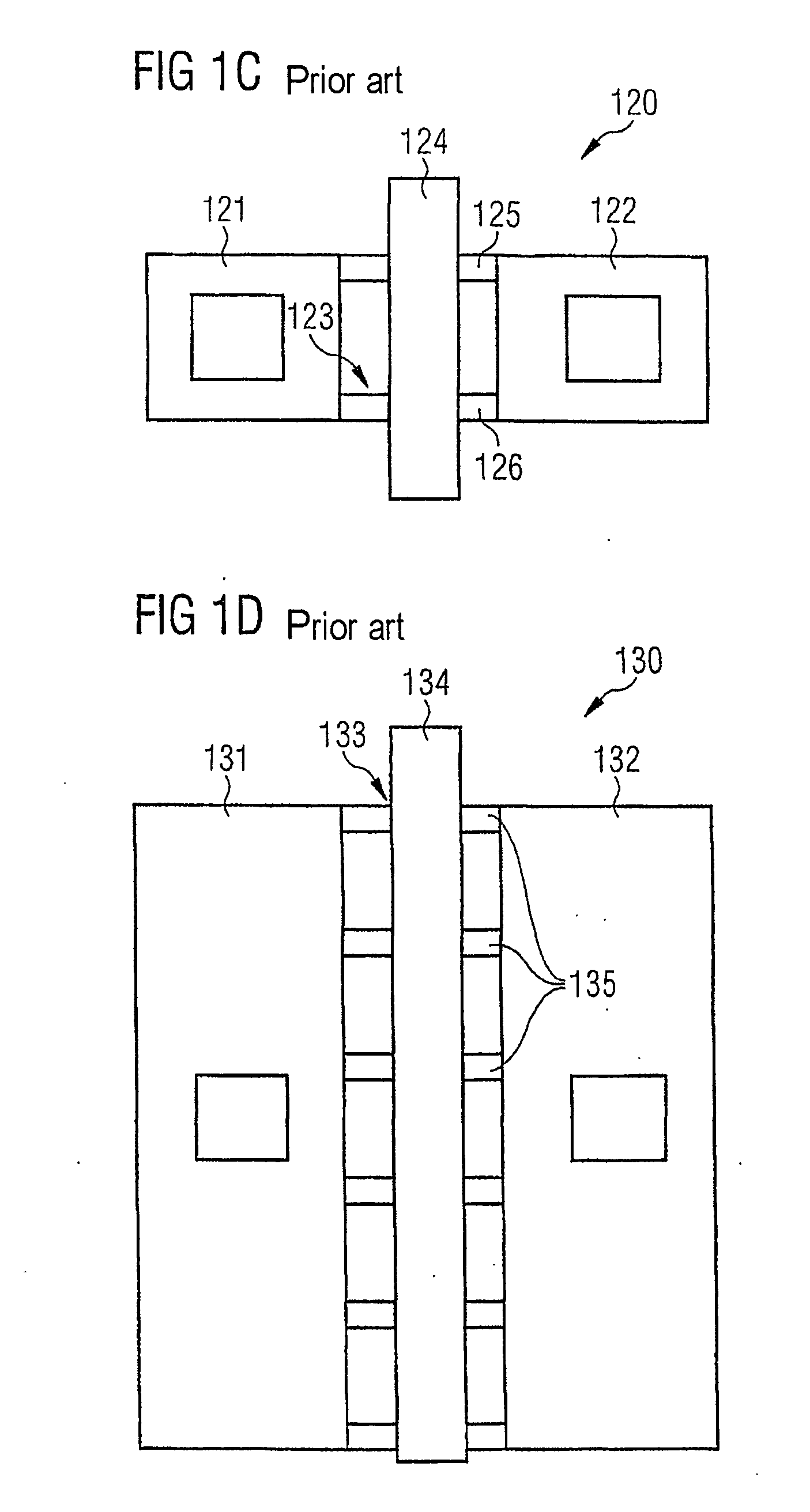

Fin field effect transistor arrangement and method for producing a fin field effect transistor arrangement

InactiveUS20070096196A1Quality improvementDifferent thicknessTransistorSolid-state devicesPhysicsFin field effect transistor

A fin field effect transistor arrangement comprises a substrate and a first fin field effect transistor on and / or in the substrate. The first fin field effect transistor includes a fin in which a channel region is formed between a first source / drain region and a second source / drain region and above which a gate region is formed. A second fin field effect transistor is provided on and / or in the substrate including a fin in which a channel region is formed between a first source / drain region and a second source / drain region and above which a gate region is formed. The second fin field effect transistor is arranged laterally alongside the first fin field effect transistor, wherein a height of the fin of the first fin field effect transistor is greater than a height of the fin of the second fin field effect transistor.

Owner:INFINEON TECH AG

Non-volatile memory device having four storage node films and methods of operating and manufacturing the same

InactiveUS20070296033A1Different thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A nonvolatile memory device that may operate in a multi-bit mode and a method of operating and manufacturing the nonvolatile memory device are provided. The nonvolatile memory device may include a first source region and a first drain region that are respectively in first fin portions on both sides of a control gate electrode and respectively separated from the control gate electrode, a second source region and a second drain region that are respectively formed in second fin portions on both sides of the control gate electrode and respectively separated from the control gate electrode, first and second storage node layers that are formed with the control gate electrode therebetween and on the side of the first fin opposite to a buried insulating layer between first and second fins, and third and fourth storage node layers that are formed with the control gate electrode therebetween and on the side of the second fin opposite to the buried insulating layer. The nonvolatile memory device may further include a semiconductor substrate including the first and second fins, a control gate electrode on the sides of the first and second fins opposite to the buried insulating layer and extending onto the buried insulating layer and a gate insulating layer between the first and second fins and the control gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Ultra-thin Si MOSFET device structure and method of manufacture

The present invention comprises a method for forming an ultra-thin channel MOSFET and the ultra-thin channel MOSFET produced therefrom. Specifically, the method comprises providing an SOI substrate having a buried insulating layer underlying an SOI layer; forming a pad stack atop the SOI layer; forming a block mask having a channel via atop the pad stack; providing a localized oxide region in the SOI layer on top of the buried insulating layer thereby thinning a portion of the SOI layer, the localized oxide region being self-aligned with the channel via; forming a gate in the channel via; removing at least the block mask; and forming source / drain extensions in the SOI layer abutting the thinned portion of the SOI layer. Providing the localized oxide region further comprises implanting oxygen dopant through the channel via into a portion of the SOI layer; and annealing the dopant to create the localized oxide region.

Owner:GLOBALFOUNDRIES INC

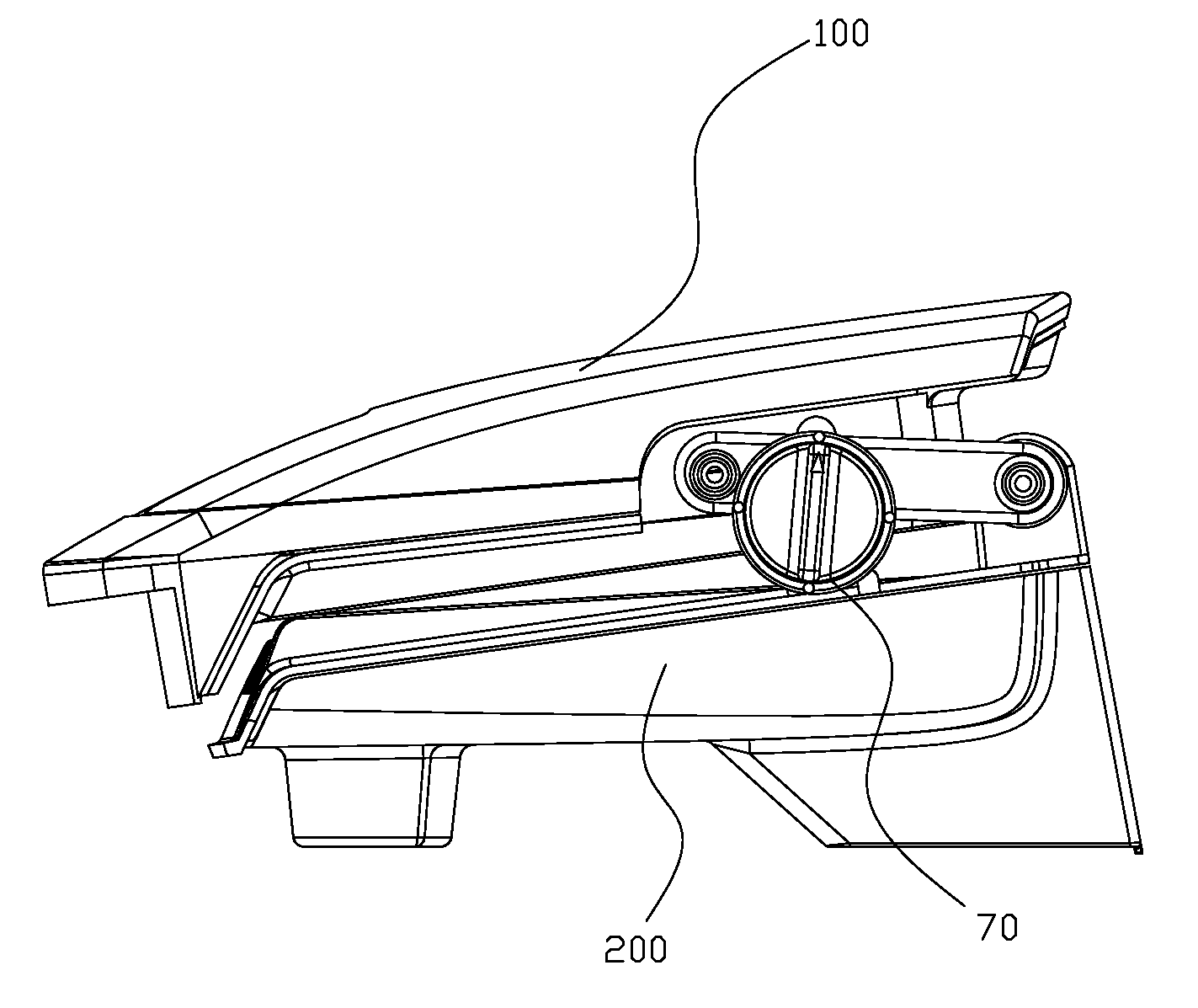

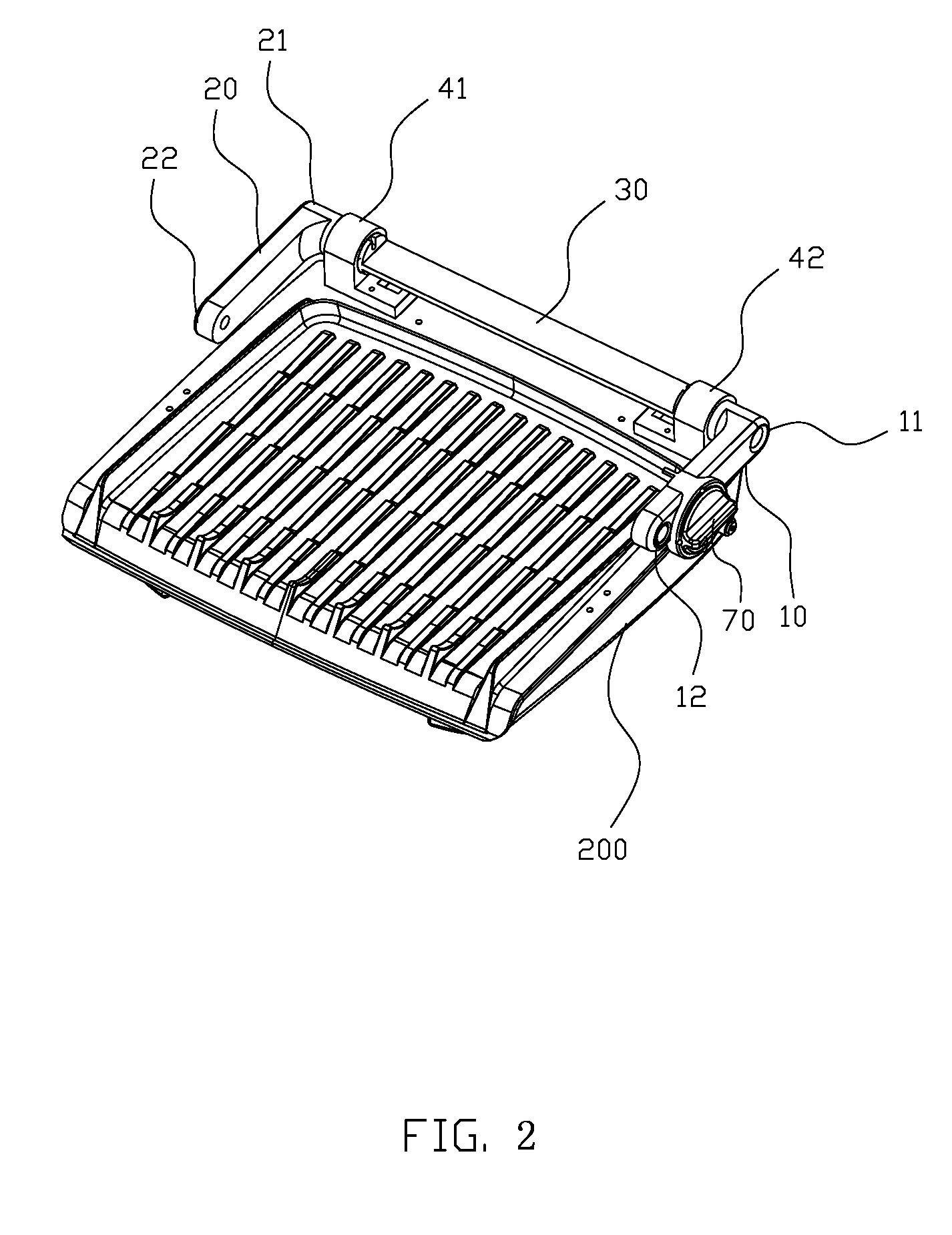

Height regulating mechanism of grill pan

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

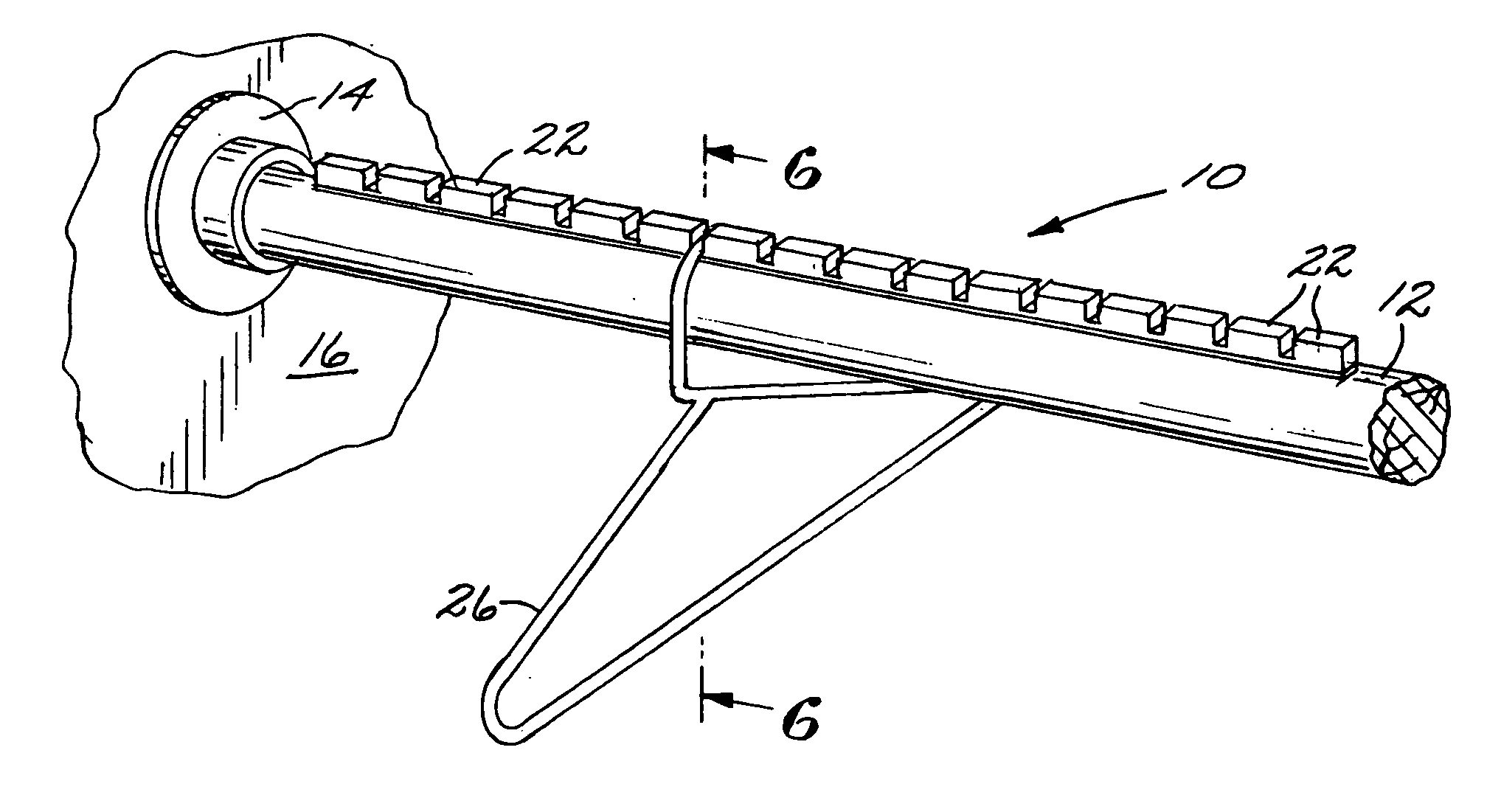

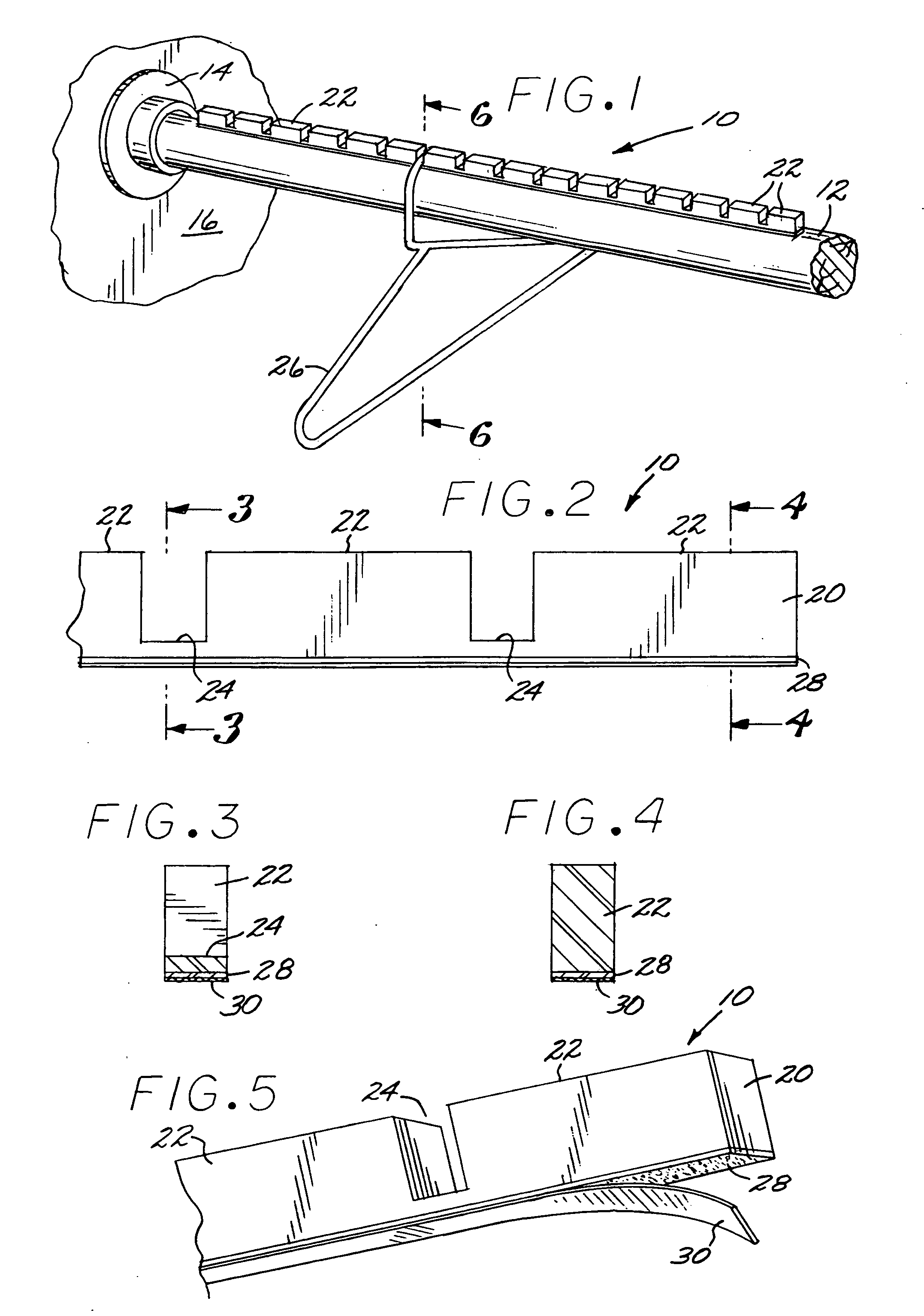

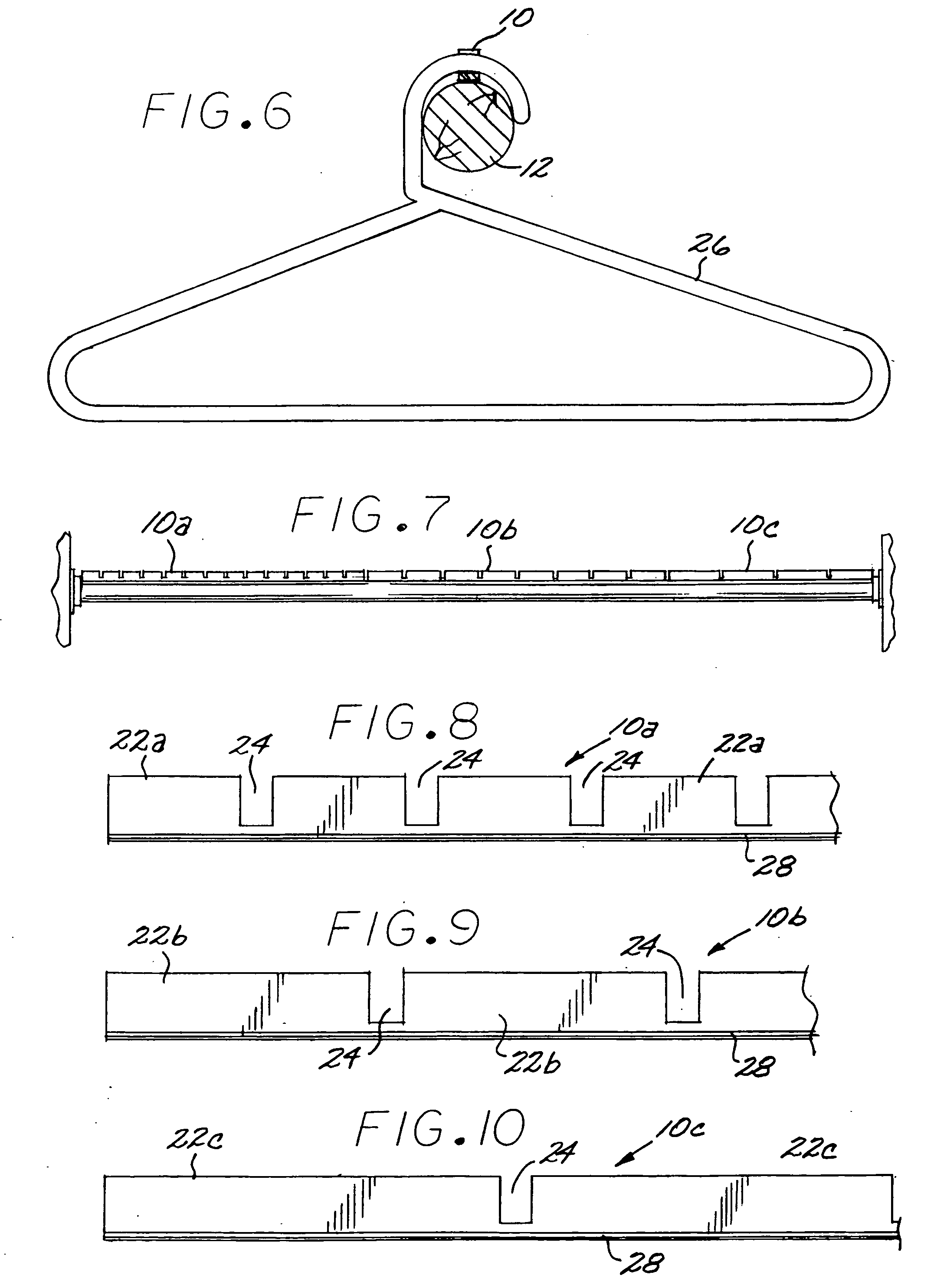

Closet hanger spacer

InactiveUS20060278594A1Susceptibility to wrinkling and creasingDifferent thicknessWardrobesApparel holdersEngineeringMechanical engineering

A closet hanger spacing device includes an elongate body having a series of spaced-apart spacing elements arranged along its length on a first side, and an adhesive element applied on a second side opposite the first side, whereby the spacing device can be adhesively attached to a hanger rod in a closet. The spacing elements define notches between them, in each of which the hook of a clothing hanger is received, while the spacing elements themselves maintain the desired degree of spacing between adjacent hangers and thus the clothing items hung on them. The spacing interval between the notches may be a fixed constant, or the device may have two or more portions with different spacing intervals. The adhesive element comprises a strip of double-sided tape or a strip of adhesive material.

Owner:MACON STEPHEN E

Discharging unit and image forming apparatus having the same

ActiveUS7865128B2Less frizzDifferent thicknessElectrographic process apparatusOther printing apparatusImage formationEngineering

A discharging unit for discharging a printing medium from an image forming apparatus includes an elastic roller and a curl preventing roller to oppose each other in a pressing relationship forming a nip therebetween to reduce curling of a print medium passing through the nip. At least one of the elastic roller and the curl preventing roller is allowed to move towards or away from the other roller so that the nip can be adjusted to accommodate different thicknesses of varying types of printing medium.

Owner:HEWLETT PACKARD DEV CO LP

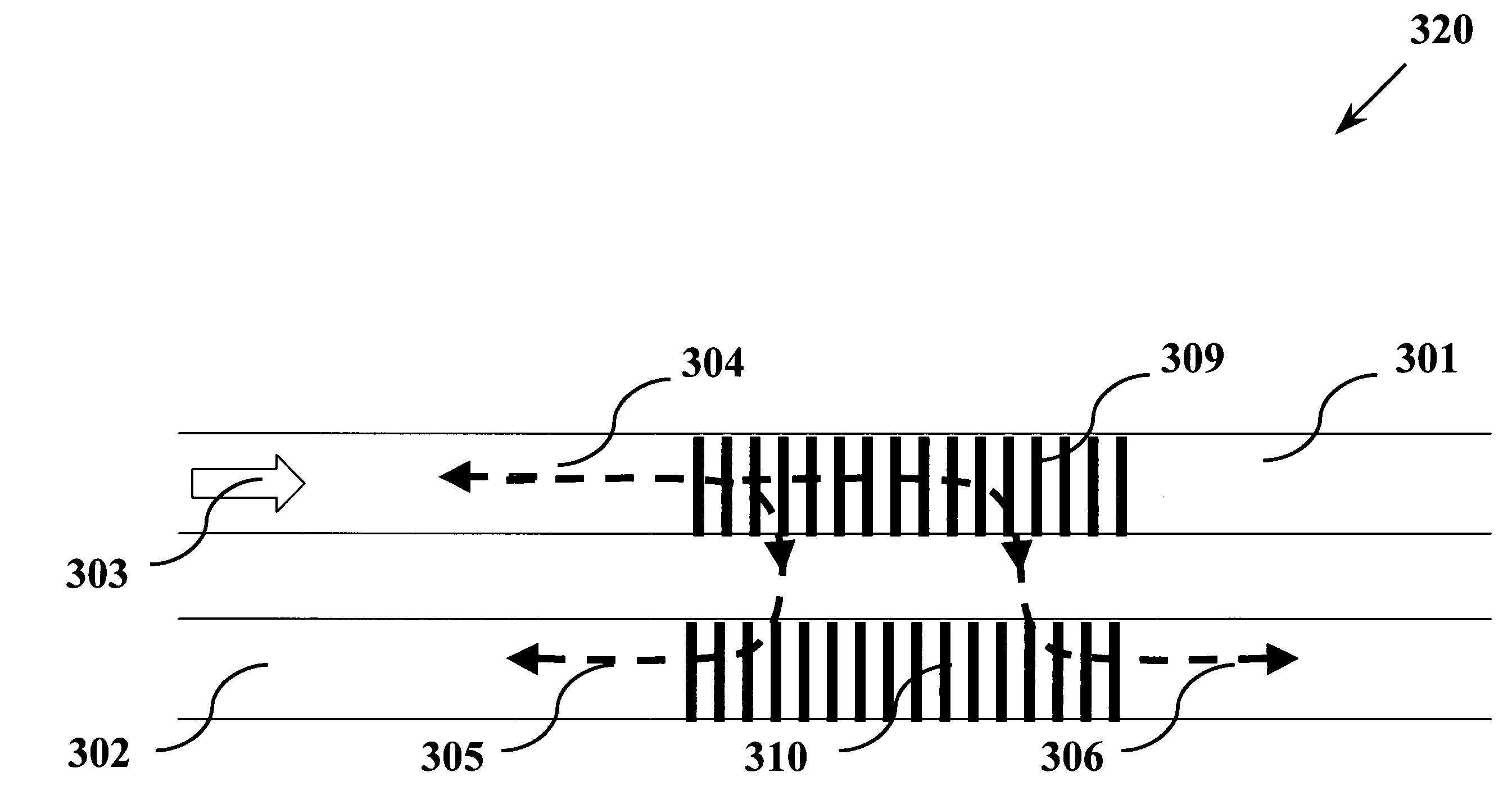

Knitting method for warp-knitted spacer fabric with different thicknesses

The invention relates to a knitting method for a warp-knitted spacer fabric with different thicknesses. The warp-knitted spacer fabric is knitted by adopting six guide bars on a double-needle bar warp knitting machine, and the knitting method is characterized by comprising the following steps: (1) penetrating an upper surface layer yarn into guide bars GB1 and GB2, penetrating a lower surface layer yarn into guide bars GB5 and GB6, and penetrating a spacer yarn into guide bars GB3 and GB4, wherein the upper surface layer of the fabric is knitted by the guide bars GB1 and GB2, the lower surface layer of the fabric is knitted by the guide bars GB5 and GB6, and the spacer yarn is knitted by the guide bars GB3 and GB4; (2) when the thickness is changed in the transverse direction, penetrating the yarn by the guide bars GB3 and GB4 complementarily, wherein the yarn penetrating amounts of the guide bars GB3 and GB4 are equal, the guide bar GB3 penetrates the yarn first and then is spaced, and the guide bar GB4 is spaced first and then penetrates the yarn; the warp feeding amount of the guide bar GB3 is set to be smaller than that of the guide bar GB4; (3) when the thickness is changed in the longitudinal direction, setting the set warp feeding amount of part transverse area in the longitudinal row of the guide bar GB3 or the guide bar GB4 to be great, and setting the set warp feeding amount of part transverse area in the longitudinal row of the guide bar GB3 or the guide bar GB4 to be small. According to the knitting method for the warp-knitted spacer fabric with different thicknesses, the transverse cross section and the longitudinal cross section of the fabric can have different thicknesses by controlling the yarn penetrating amount and the warp feeding amount.

Owner:JIANGNAN UNIV

Apparatus for electrophoresis

InactiveUS20050072678A1Good reproducibilityDifferent thicknessCellsFatty/oily/floating substances removal devicesElectrophoresisElectrode pair

An apparatus for electrophoresis comprises a base incorporating an integral or separable tray defining a plurality of parallel troughs into which IPG strips may be placed is disclosed. The apparatus further includes a lid. The lid has a top and depending sides and is configured to fit over the base. The lid defines at least one opposed pair of depending electrodes, and also, spaced inwardly of the electrodes relative to the sides of the lid, a pair of opposed depending members for applying pressure to IPG strips located in use, in troughs of the tray. In a variant the lid provides individually addressable electrodes for each of the grooves in the tray wherein the lower edge of the depending electrode bars and the IPG holder bars are all crenellated. In this manner, the lid of the cassette provides an individual pair of opposed electrodes for each of the IPGs running in the tray, and the voltage between each of the pairs of electrodes can be controlled independently of the voltage between other opposed electrode pairs.

Owner:PROTEOME SYSTEMS INTELLECTUAL PROPERTY PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com