Knitting method for warp-knitted spacer fabric with different thicknesses

A technology of warp-knitting spacer fabrics and fabrics, which is applied in warp knitting, knitting, textiles and papermaking, and can solve problems such as inability to produce free-form objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

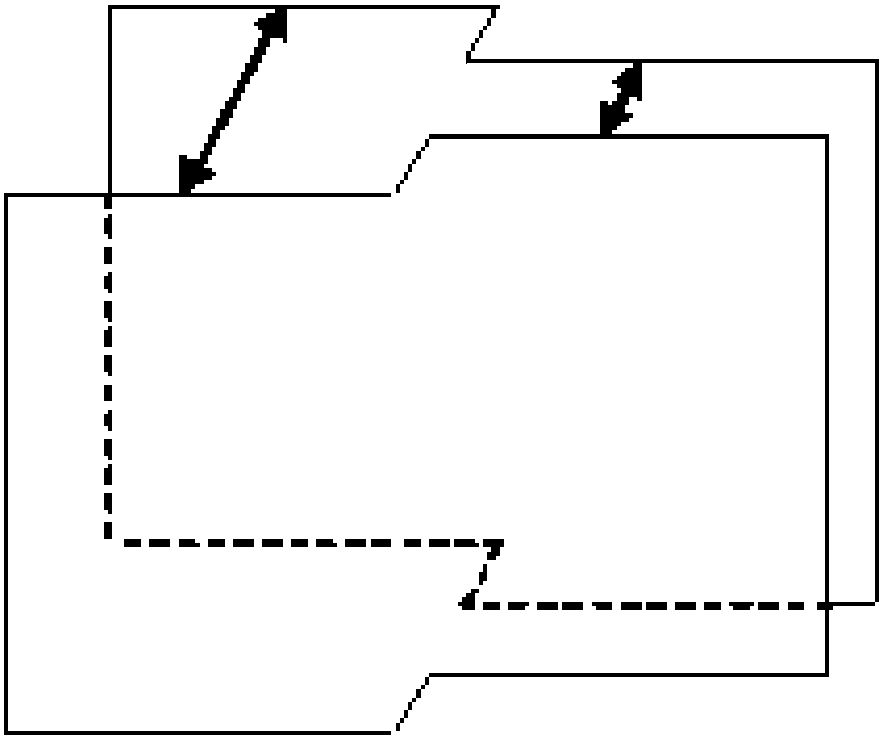

[0038] Example 1: Concave-convex effect formed laterally

[0039] On the E22 double-needle bed warp knitting machine, six bars are used for knitting, and the distance between the knockout plates is 16mm. The fabric structure, yarn threading and warp let-off are shown in Table 1:

[0040] Table 1

[0041]

[0042]When the distance between the stripping plate is 16mm, the spacer yarn of GB3 has 2 rows of normal knits on the front and rear needle beds, and the let-off amount during knitting is 17327mm / rack, but at this time, the spacer yarns of GB4 are on the same front and rear needle beds. 2. When knitting in rows, the let-off amount is greater than the normal let-off amount of 24000mm / rack. Both GB3 and GB4 have 10 rows of missing pads, that is, the 10 rows, the spacer yarns do not connect the fabrics of the front and rear needle beds, but in order to achieve the thickness of the connecting yarn area of GB4 greater than the thickness of the connecting yarn area of GB3,...

Embodiment 2

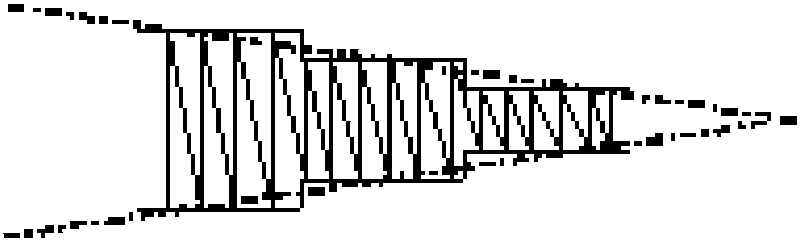

[0043] Example 2: Concave-convex effect is formed vertically

[0044] Five bars were used to knit on the E18 double-needle bed warp knitting machine, and the distance between the knockout plates was 16mm. The fabric texture, yarn threading and warp let-off are shown in Table 2:

[0045] Table 2

[0046]

[0047] When the distance between the stripping plate is 30mm, the spacer yarn of GB3 has 2 rows of normal loops on the front and rear needle beds, and the let-off amount when the loops are formed is 31679mm / rack, and the let-off amount when 8 rows are missing pads is 29341mm / rack rack, the warp let-off of spacer wires in the first 200 rows remains unchanged. The let-off of the last 200 rows changes, the let-off of 2 rows is 42000mm / rack, and the let-off of 8 rows is 40000mm / rack. Finally, after the surface material is compounded and filled on the surface of the fabric, the thickness of the last 200 rows is greater than that of the first 200 rows, such as Figure 5-1 , ...

Embodiment 3

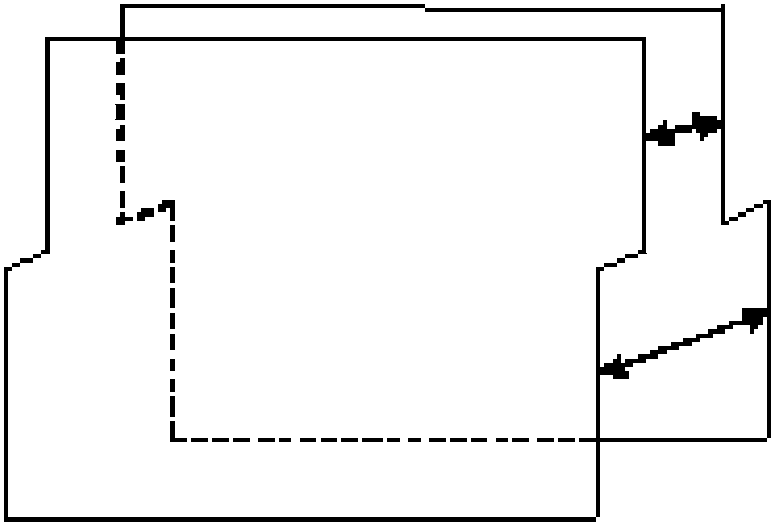

[0048] Example 3: Simultaneous formation of concave and convex effects horizontally and vertically

[0049] On the E22 double-needle bed warp knitting machine, six bars are used for knitting, and the distance between the knockout plates is 30 mm. The fabric structure, yarn threading and warp let-off are shown in Table 3:

[0050] table 3

[0051]

[0052]

[0053] When the distance between the stripping plate is 30mm, the spacer yarn of GB3 has 2 rows of normal loops on the front and rear needle beds, and the let-off amount when forming the loops is 17327mm / rack, and the let-off amount when there are 8 rows of missing pads is 6000mm / rack. Rack, the warp let-off of spacer wires in the first 100 rows remains unchanged. The warp let-off of 2 rows of GB4 during normal loop formation is changed to 24000mm / rack, the warp let-off of 8 rows when the pad is missing is changed to 9000mm / rack, and the warp let-off of the first 100 rows remains unchanged. GB3 and GB4 change the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com