Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about How to "Improve weavability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose-based masterbatch with improved breaking elongation, application thereof and method for preparing the same

ActiveUS8188164B2Good physical propertiesPrevents environmental risk and solvent recycling costCellulose coatingsArtificial filaments from cellulose derivativesMasterbatchFiber

Disclosed herein is a thermoplastic cellulosic composition for preparing a cellulose-based masterbatch and / or a fiber with an improved breaking elongation. In one example, the thermoplastic cellulosic composition includes an esterified cellulose present in a range of about 77 wt % to about 95 wt %, polyethylene glycol present in a range of about 4.5 wt % to about 15 wt %, a bifunctional reactant present in a range of about 0.01 wt % to about 3 wt %, an initiator present in a range of about 0.01 wt % to about 0.15 wt %, and a dispersing agent present in a range of about 0.01 wt % to about 5 wt %.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

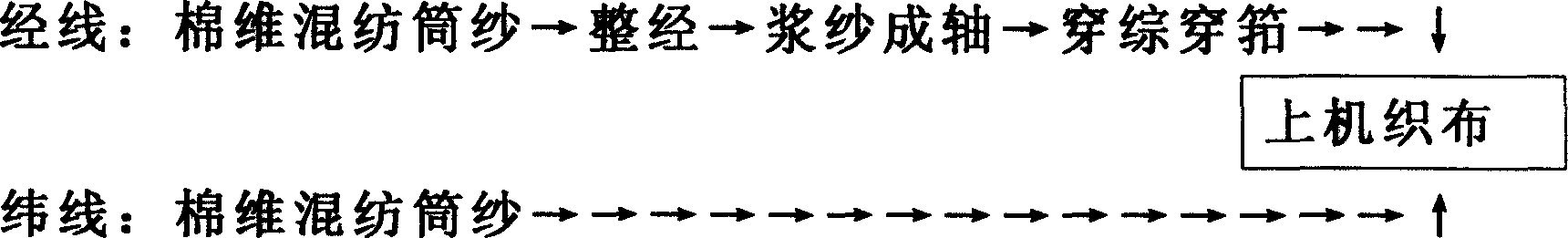

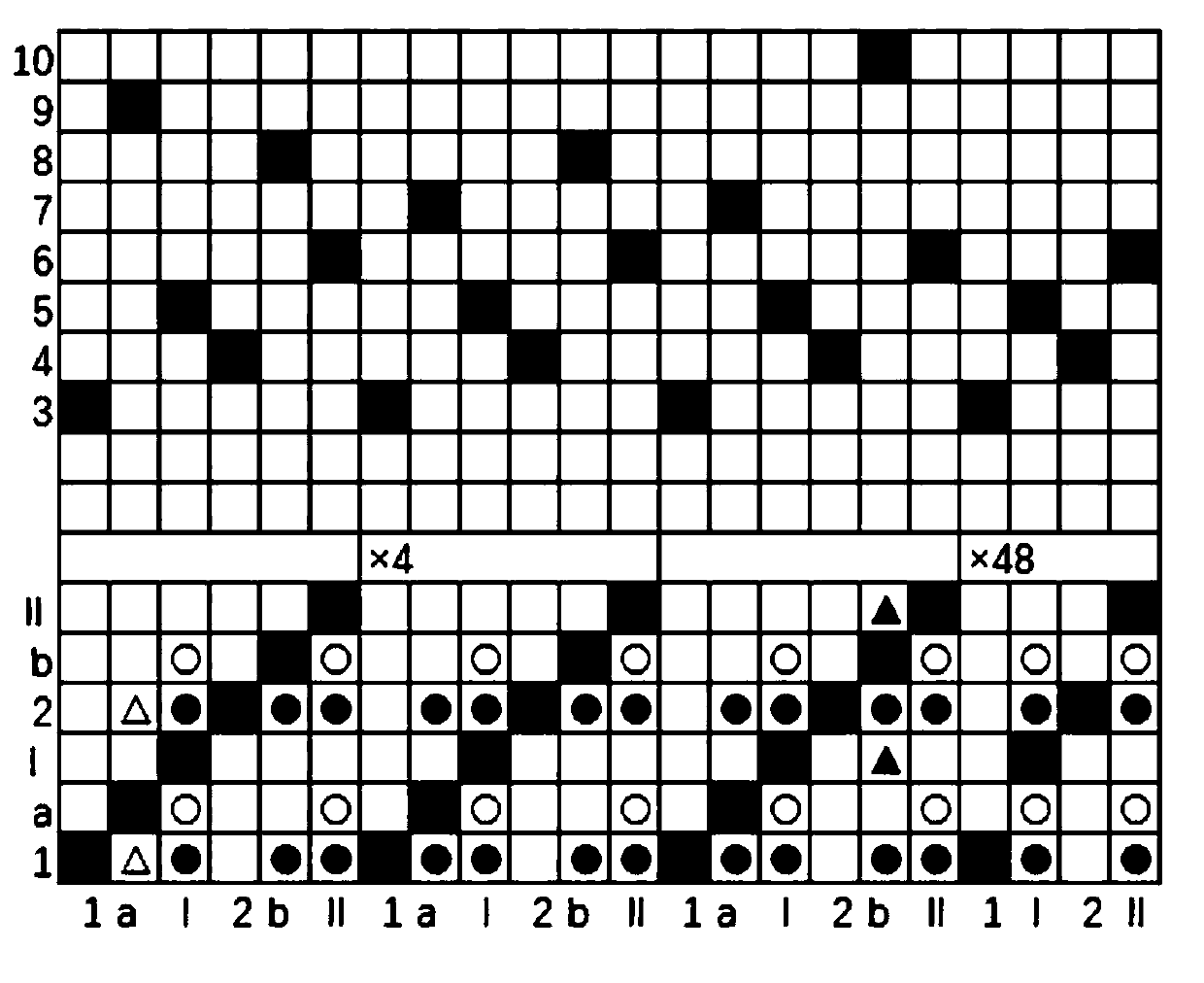

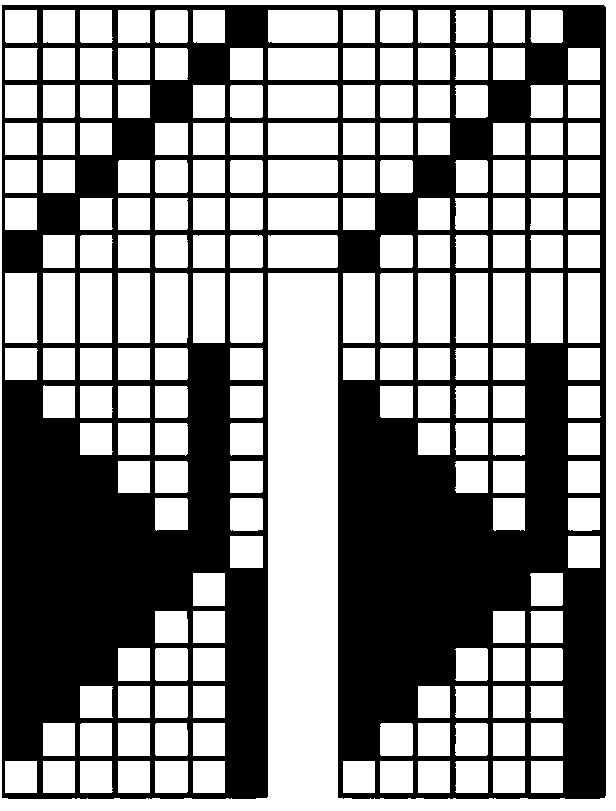

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

Preparation method of waterproof shell fabric

The invention discloses a preparation method of a waterproof shell fabric. The preparation method comprises the steps of examining precursor fiber, treating warp, weaving on a weaving machine and cropping; the warp treatment comprises six steps, namely hanging yarn, beaming, slashing, combining axles, leasing, as well as drafting and scrabbling reed. Starching is performed on warp, reasonable technological parameters are adopted, and specific sizing percentage control is performed, so that the inner layer of yarn is immersed in seriflux, cohesive force between fibers is increased, and breaking-resisting strength of yarn is improved; a layer of protective film is formed on the surface of the yarn, so that the yarn is smoother and wear-resisting, the warp can bear strong mechanical action of the weaving machine and repeated abrasion among yarns, the end breakage rate of the warp during weaving is reduced, and the weavability of the warp and the quality of the waterproof shell fabric are improved.

Owner:江苏晨越高新材料有限公司

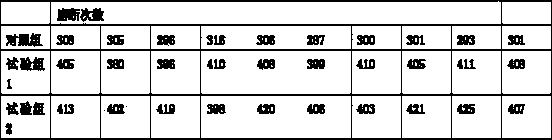

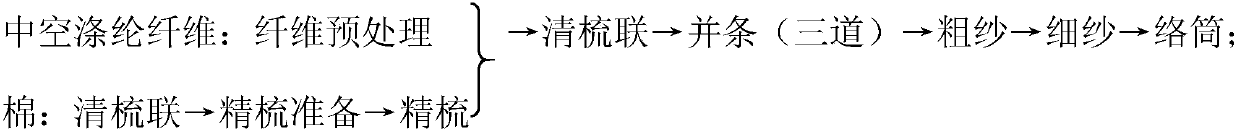

Design method and production technology of multi-layer heat preserving shell fabric

ActiveCN109537126AStrong three-dimensional structureAvoid breakingMulti-ply fabricsPolyesterSurface layer

The invention discloses a design method and a production technology of a multi-layer heat preserving shell fabric. The design method is characterized in that a woven fabric on the surface layer is prepared by blending polyimide fiber and hollow polyester fiber with compact sirospun yarn; the shell fabric is high in strength, high in friction resistance and high in heat preserving performance; warpyarn of the woven fabric on the intermediate layer is cotton and hollow polyester fiber blended yarn; weft yarn is OUTLAS phase-changed fiber and coffee carbon polyester fiber blended yarn; a relatively long floating line of the weft yarn is positioned between the woven fabrics on the surface layer and the inner layer, so that the yarn is in a loose state and supports the woven fabrics on the surface layer and the inner layer, and as a result, a heat preserving layer is formed; the yarn in the intermediate layer is relatively thick, the twisting coefficient is small, and heat absorbing and preserving fibers are adopted, so that the heat preserving performance of the woven fabrics can be ensured. The inner layer is the cotton and hollow polyester fiber blended yarn, so that the heat preserving effect is good; the shell fabric is skin friendly, can absorb moisture and is breathable, so that the problem of discomfort caused by that a woven fabric with too high moisture regain absorbs moisture and adheres to the body can be avoided.

Owner:泰州虹纬纺织有限公司

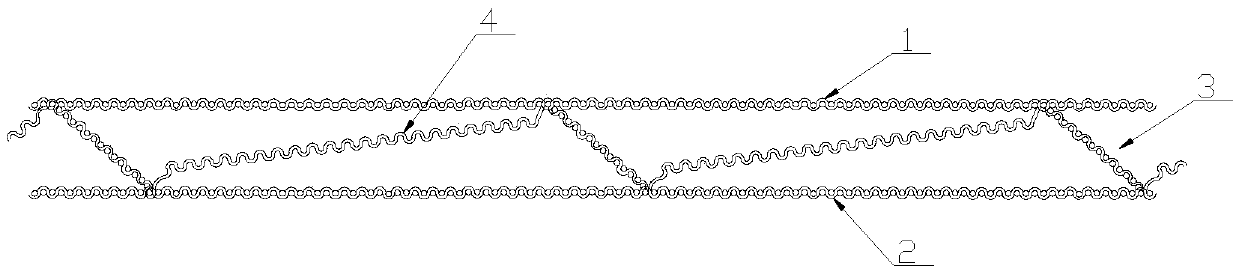

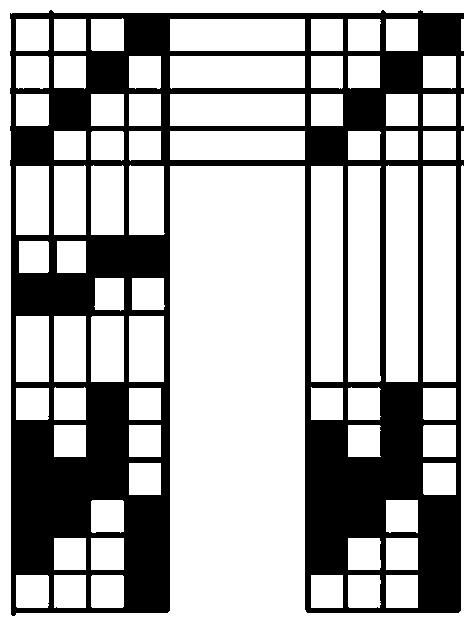

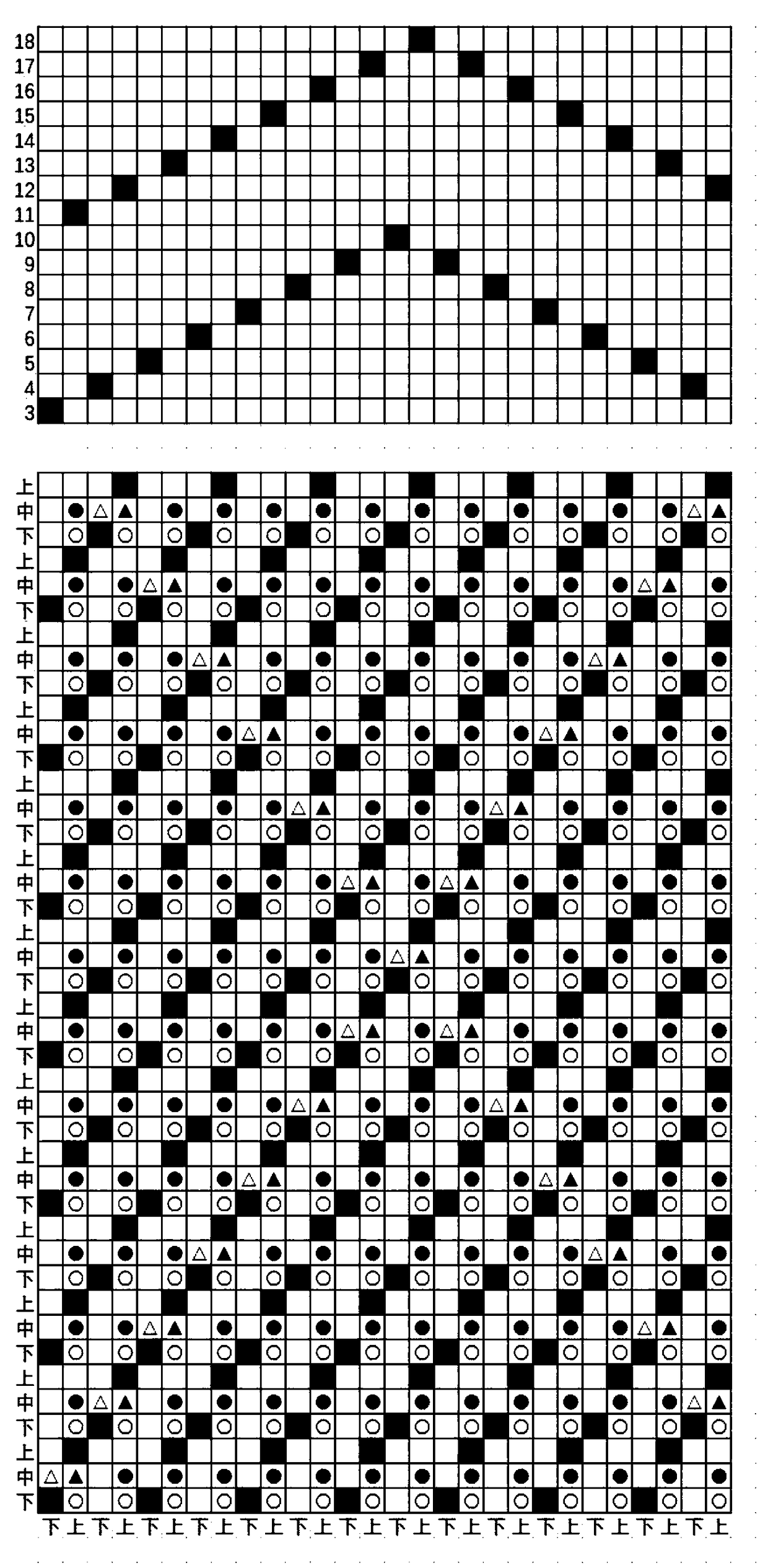

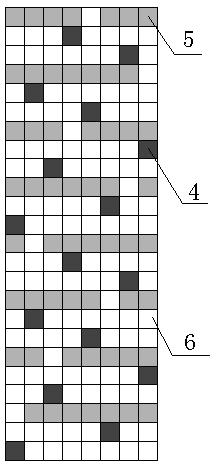

Weaving method of basalt fiber, glass fiber and polypropylene fiber woven fabric

The invention discloses a weaving method of a basalt fiber, glass fiber and polypropylene fiber woven fabric. The method includes, firstly, determining the interweaving rules of wefts and warps of every layer according to the number of interweaving layers of wefts and warps, drawing out a structure diagram of the basalt fiber, glass fiber and polypropylene fiber woven fabric; then drawing out an organizing diagram of the basalt fiber, glass fiber and polypropylene fiber woven fabric; lastly, obtaining the looming diagram of the basalt fiber, glass fiber and polypropylene fiber woven fabric. Basalt fiber and polypropylene fiber twisted yarns serve as the warps, and glass fiber and polypropylene fiber twisted yarns serve as the wefts; according to the looming diagram of the basalt fiber, glass fiber and polypropylene fiber woven fabric, the basalt fiber, glass fiber and polypropylene fiber woven fabric can be obtained through weaving process of a weaving machine. The basalt fiber, glass fiber and polypropylene fiber woven fabric obtained through the method has certain thickness and flexibility properties.

Owner:ZHEJIANG SCI-TECH UNIV

Liquid crystalline polyester fiber and process for production of the same

ActiveUS20100104870A1High elastic modulusHigh in strengthLayered productsOptical articlesPolyesterLiquid crystalline

A liquid crystalline polyester fiber which exhibits a half width of endothermic peak (Tm1) of 15° C. or above as observed in differential calorimetry under heating from 50° C. at a temperature elevation rate of 20° C. / min and a strength of 12.0 cN / dtex or more; and a process for production of the same. A liquid crystalline polyester fiber which is excellent in abrasion resistance and lengthwise uniformity and is improved in weavability and quality of fabric and which is characterized by a small single-fiber fineness can be efficiently produced without impairing the characteristics inherent in fabric made of liquid crystalline polyester fiber produced by solid phase polymerization, namely, high strength, high elastic modulus and excellent thermal resistance.

Owner:TORAY IND INC

Machining method of wrapped structural flax and polyester filament section color composite yarn and composite yarn

The invention provides a machining method of a wrapped structural flax and polyester filament section color composite yarn and a composite yarn. A section color effect principle of fusing and twistingtwo yarns with different colors, a specific false twisting effect of core yarns when a hollow ingot is subjected to wrap spinning of an externally-wrapped yarn and the core yarns are wound, a twist instability principle of the specific false twisting effect and an uneven distribution principle of a twist on a plucked yarn are comprehensively utilized; by enabling double core yarns to generate anirregular section color effect and adopting the colorless excellent-transparency filament (monofilament or less-number multifilament) externally-wrapped yarn to carry out wrapping consolidation, the flax composite yarn with section color characteristics is obtained. Wrinkle resistance of flax fabric can be effectively improved, yarn hairiness is reduced, hairiness regeneration is reduced, weavability is improved, section color appearance is given to the yarn and the fabric thereof, and the fabric is woven in a dyeing-free and sizing-free mode.

Owner:JIAXING UNIV

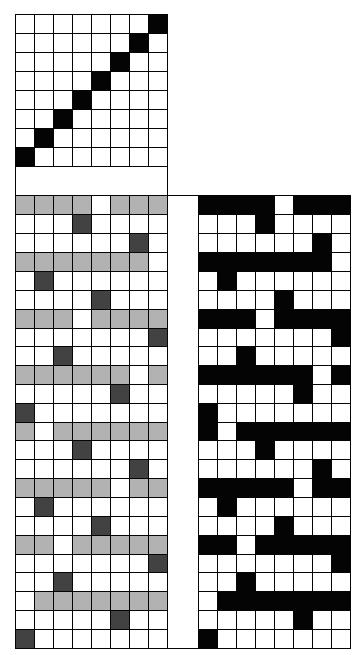

Composite material reinforced by hybrid fiber preform and preparation method of composite material

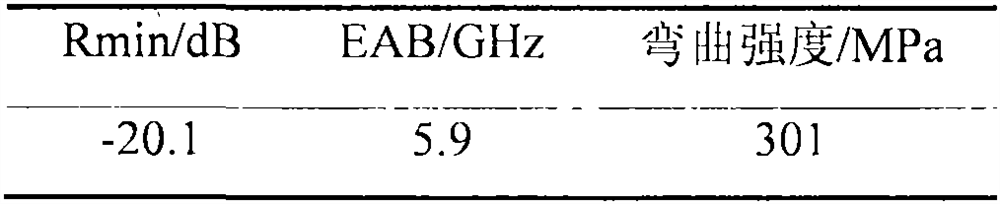

InactiveCN113912405ASolve the problem of easy hairImprove weavabilityCeramic layered productsFiber bundleUltimate tensile strength

The invention discloses a composite material reinforced by a hybrid fiber preform. The composite material is composed of the fiber preform, a composite material interface and a ceramic matrix, the fiber preform is a three-dimensional fabric formed by hybrid weaving of 2-5 kinds of high-performance inorganic fibers, and the matrix is resin, light alloy, carbon and ceramic. A preparation method of the composite material comprises the steps of ceramic slurry preparation, fiber bundle dipping treatment, fiber weaving, three-dimensional integral structure preform forming, preform heat treatment, interface preparation and matrix preparation. The weaving performance of the inorganic rigid fibers is improved, the prepared composite material is good in integrity, high in interlayer bonding strength and not prone to layering, meanwhile, the functions of wave transmission, wave absorption, high-temperature structural material, heat insulation and heat protection are achieved through combination of the hybrid fibers, and integration of the structure and the function is effectively achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing invisible slub mercerized cotton wool jeans fabrics

The invention involves a preparation method of stealth bamboo mercerized cotton or wool denim fabric. It is made of 6.7SB stealth bunchy yarn as warp yarn and 7.5S cotton and wool blended yarn as the weft yarn, warp yarn is darned with weft yarn through ball warping and after pencil dyeing and drafting, then singeing, desizing, drying, mercerising, water scrubbing and completing. Said stealth bunchy yarn is cotton yarn and its bamboo joint magnification is below 1.5 times; the cotton are 30% and wool 70% in weft yarn, cotton are 75.8%, wool 24.2% in face fabric. The process of pencil dyeing of warp yarn is: stealth bunchy yarn is affinaged in two affinaging grooves and scrubbed in two water grooves successively through ball warping and axis ball warping, then transported to the seventh groove to dyeing, the 32nd roll to high altitude airing oxygenating, the third groove to watering and the first groove to softening; then drying, dropping ingrain knitting yarns in barrels, opening warp beam, starching, drying, leasing and wrapping into weaver. The method can be organized well and the fabric color effect is fine.

Owner:李国良

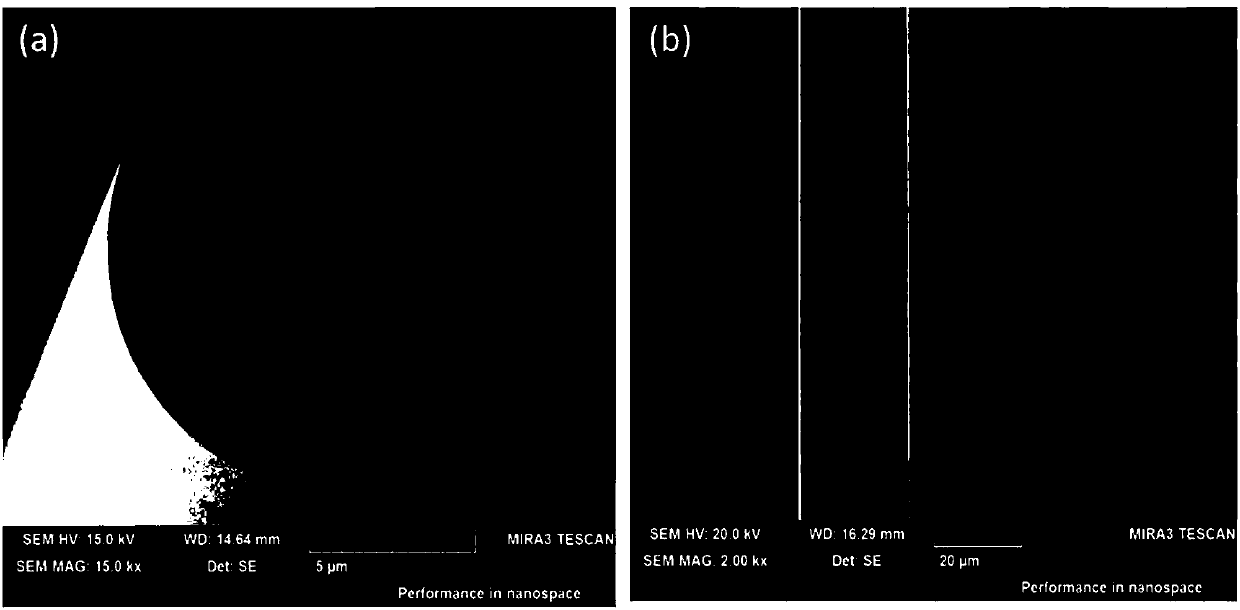

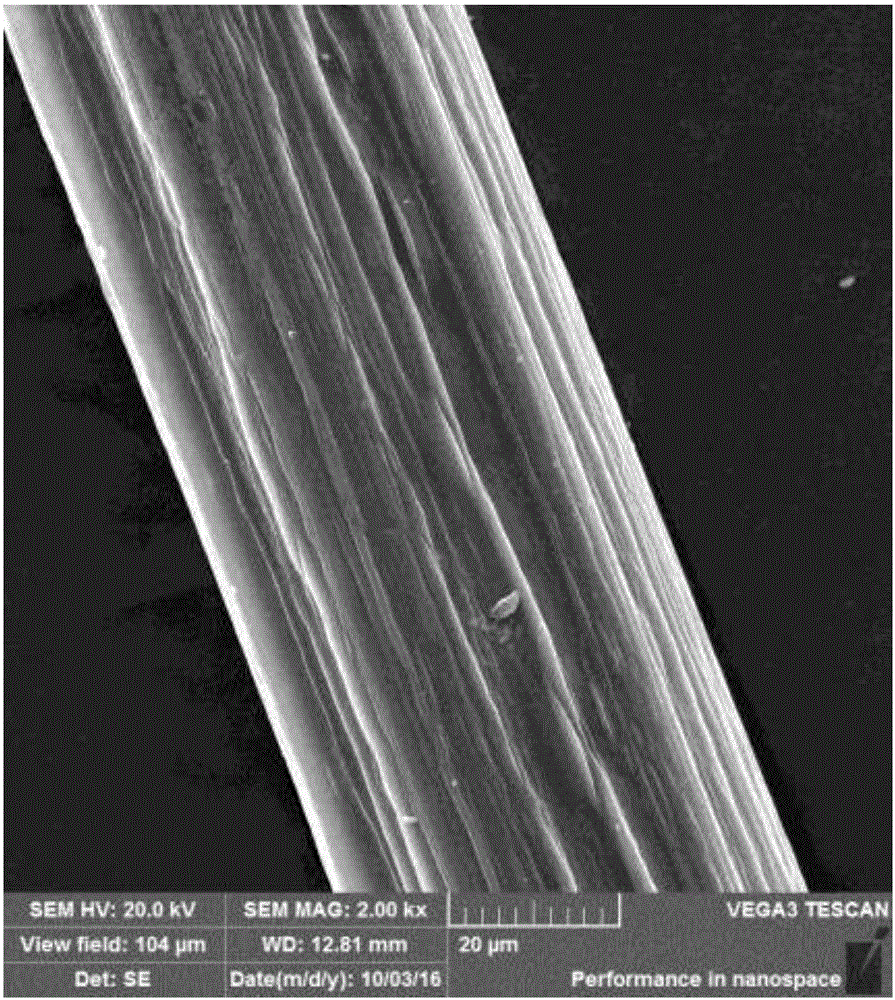

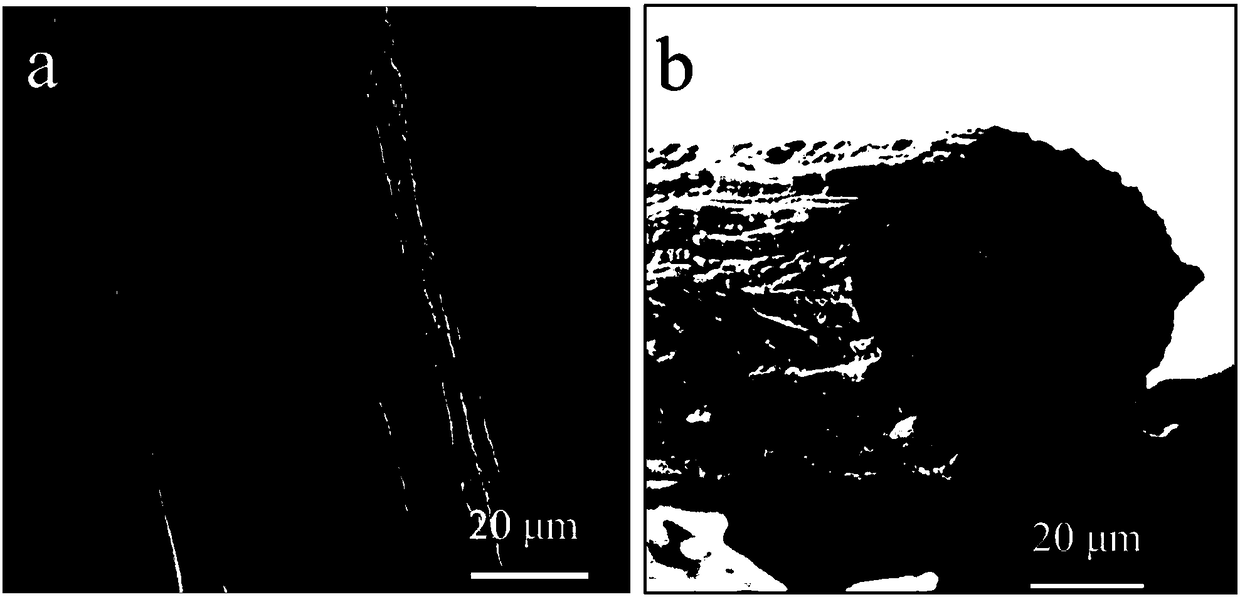

Carbon fiber surface modified treatment method

InactiveCN106192407AImprove surface propertiesImprove monofilament tensile strengthCarbon fibresFiberCarbon fibers

The invention provides a carbon fiber surface modified treatment method. The method comprises the following steps that firstly, carbon fiber is steeped into a compatilizer solution, then, under the vacuum condition, a sulfuric acid solution of potassium permanganate is used for performing oxidation etching treatment on CF-1, after treatment is completed, natural cooling is performed to reach room temperature, washing is performed till pH is 6-8, drying is performed, CF-2 is obtained, then, lithium borohydride is used for reduction in diethyl ether, an alcohol-water solution of the silane coupling agent for the reduced CF-3 is subjected to treatment to obtain CF-4. According to the method, the surface activity of the fiber is improved, and meanwhile the fiber body is not damaged.

Owner:郑州峰泰纳米材料有限公司

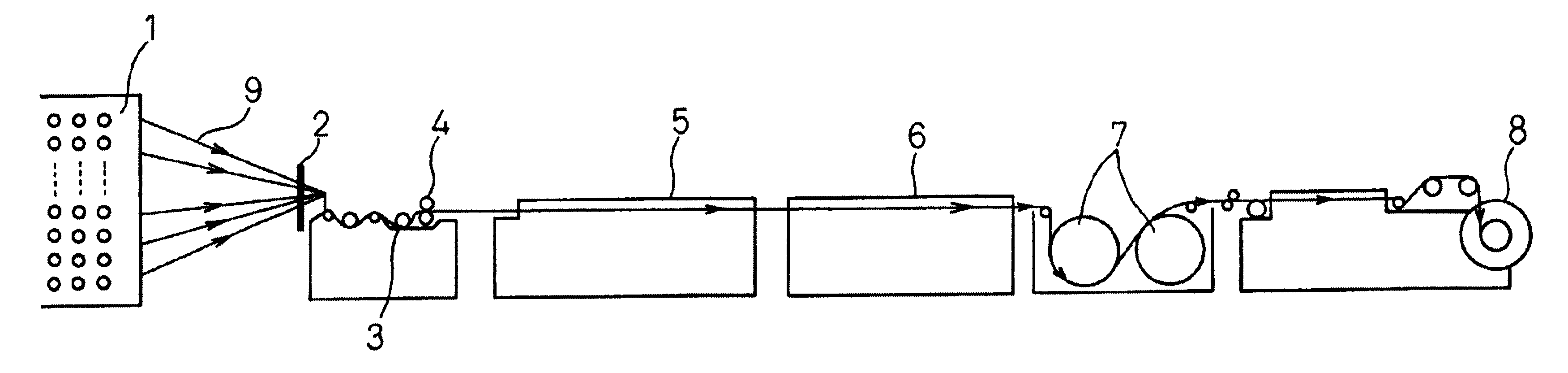

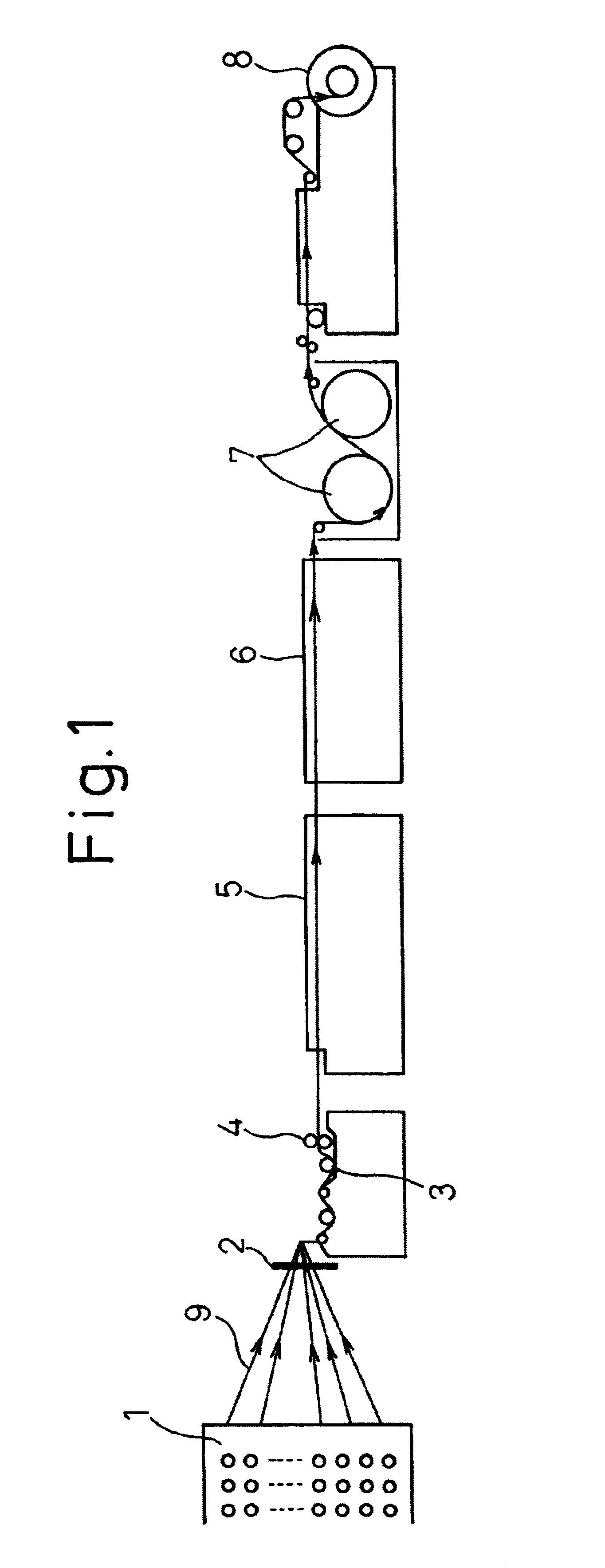

Beam for weaving and sizing method

To provide a method for sizing polytrimethylene terephthalate fiber yarns and a warp beam improved in mutual stickiness of the yarns and excellent in weavability,The sizing method according to the present invention is characterized in that the yarns are dried while controlling a stretch ratio S (%) between a squeeze roll and a drying cylinder in a range from -9 to -3% or from -1 to +4%. From the sized yarns thus obtained, a warp beam is formed at a winding tension in a range from 0.09 to 0.22 cN / dtex to have hardness in a range from 65 to 90 degrees.

Owner:ASAHI KASEI KK

Preparation method of SiC continuous fiber reinforced titanium-based composite, and product

The invention discloses a preparation method of a SiC continuous fiber reinforced titanium-based composite, and a product. The preparation method comprises the following steps that a SiC continuous fiber with the diameter being 10-15 [mu]m is placed in the air environment to be subjected to heat treatment, then, with the SiC continuous fiber as a base material, Al2O3 is sputtered on the surface ofthe SiC continuous fiber through magnetron sputtering, and thus the SiC continuous fiber covered with an Al2O3 coating is obtained; a titanium or titanium alloy base body is heated to be melted, andthus a melted titanium or titanium alloy solution is obtained; the SiC continuous fiber covered with the Al2O3 coating is placed in a mould, preheating is conducted, and the mould is vacuumized; and the melted titanium or titanium alloy solution is pressed into the mould, heat preservation and cooling are conducted, and thus the SiC continuous fiber reinforced titanium-based composite is obtained.The filament SiC continuous fiber is adopted as the reinforcing base material, and the magnetron sputtering technology and a vacuum pressure impregnation method are combined, so that the prepared SiCcontinuous fiber reinforced titanium-based composite has the advantages that the structure is compact, the mechanical property is high, the interface stable property is good, and the service life islong.

Owner:CENT SOUTH UNIV

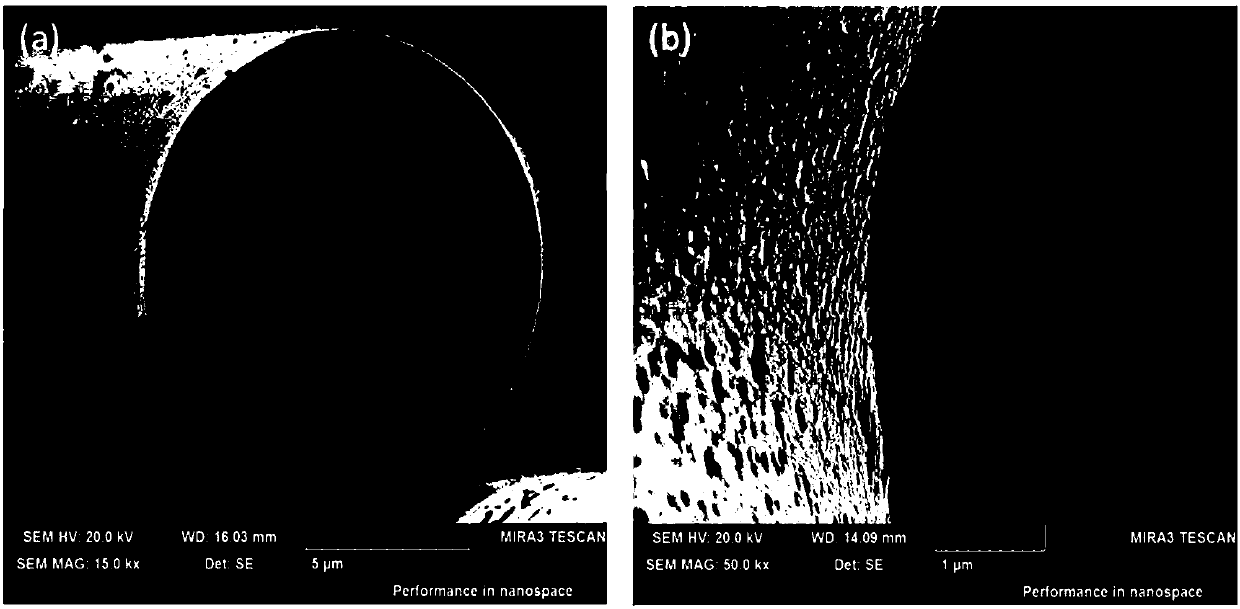

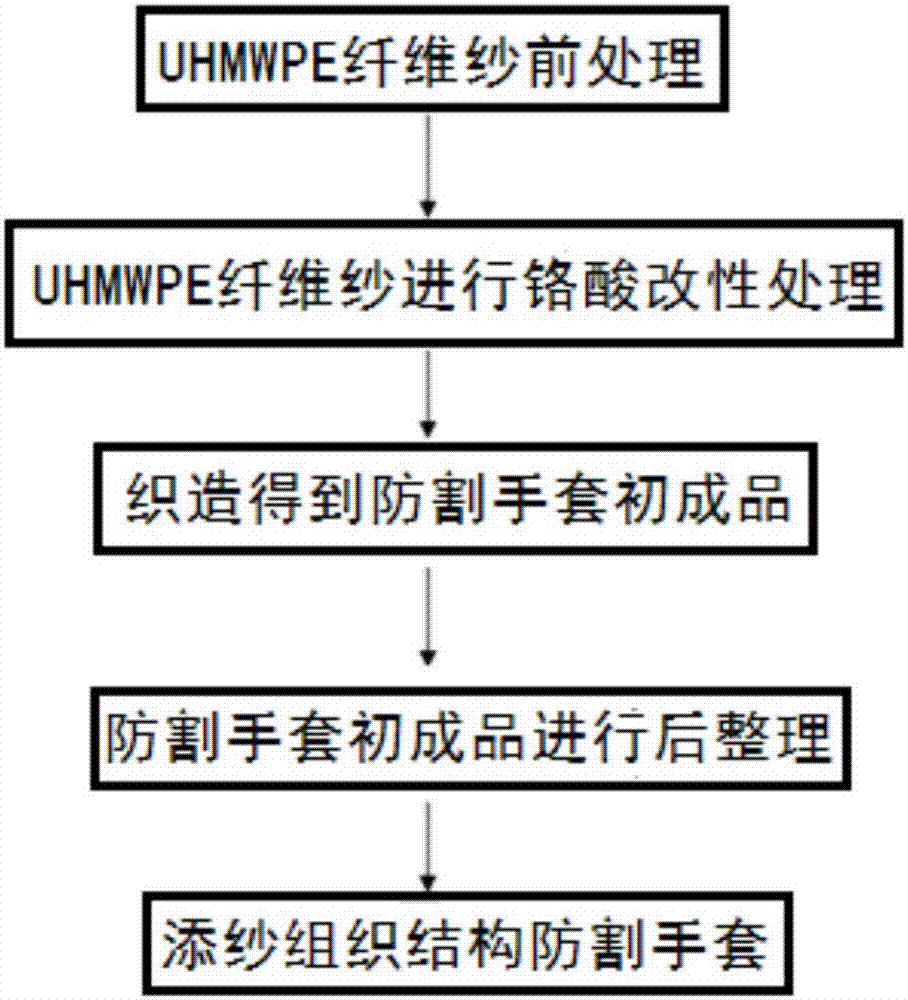

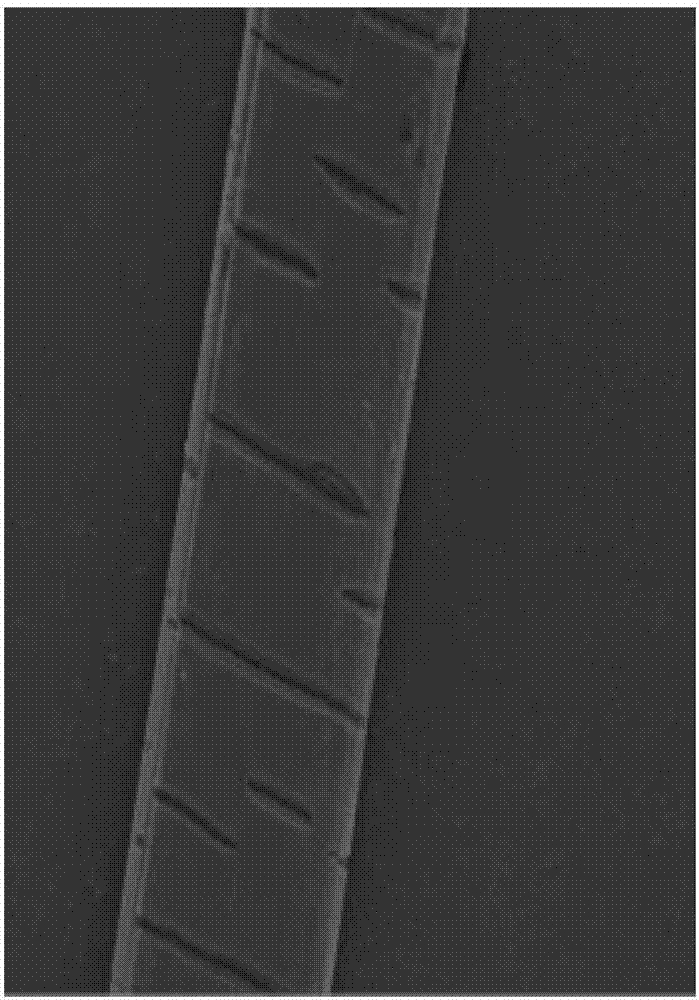

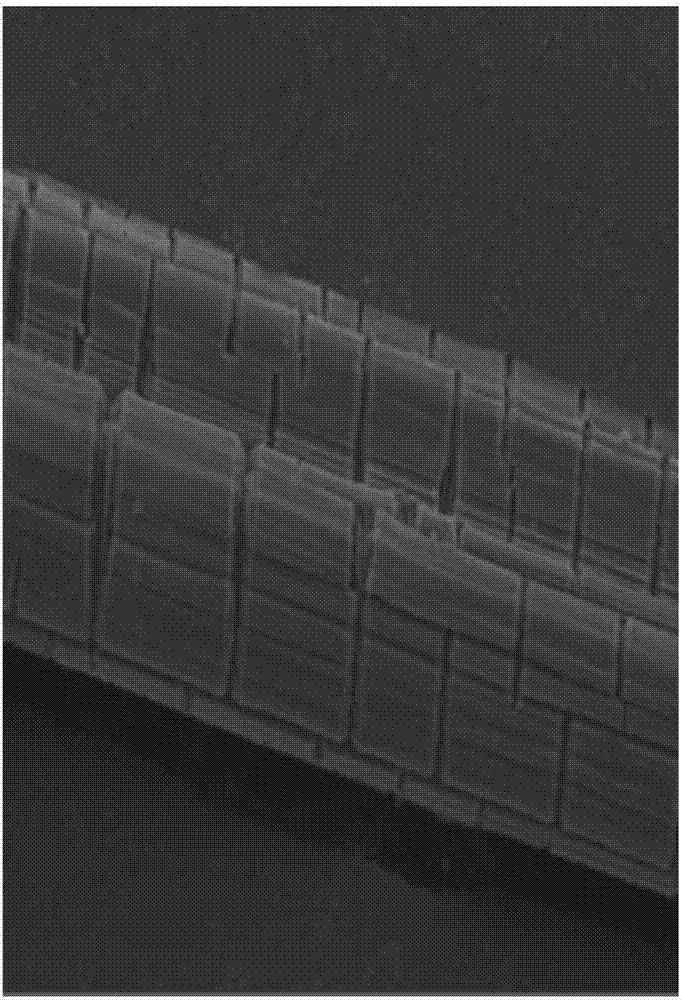

Method for preparing anti-cutting glove with plating structure

The invention discloses a method for preparing an anti-cutting glove with a plating structure. The method specifically includes the following steps that 1, UHMWPE fiber yarn is obtained and pre-processed; 2, the UHMWPE fiber yarn obtained after pre-processing is subjected to modification by using chromic acid; 3, the UHMWPE fiber yarn obtained in the step 2 serves as a veil of the plating structure, normal cotton yarn serves as ground yarn of the plating structure, weaving is conducted on a glove machine, and a semi-finished anti-cutting glove product is obtained; 4, the semi-finished anti-cutting glove product obtained in the step 3 is subjected to after-finishing, and the anti-cutting glove with the plating structure is obtained. The method for preparing the anti-cutting glove with the plating structure solves the problem that yarn is easily tangled in the manufacturing process of an ultra-high-molecular-weight polyethylene anti-cutting glove, and can effectively improve the wearing comfort of the anti-cutting glove.

Owner:XI'AN POLYTECHNIC UNIVERSITY

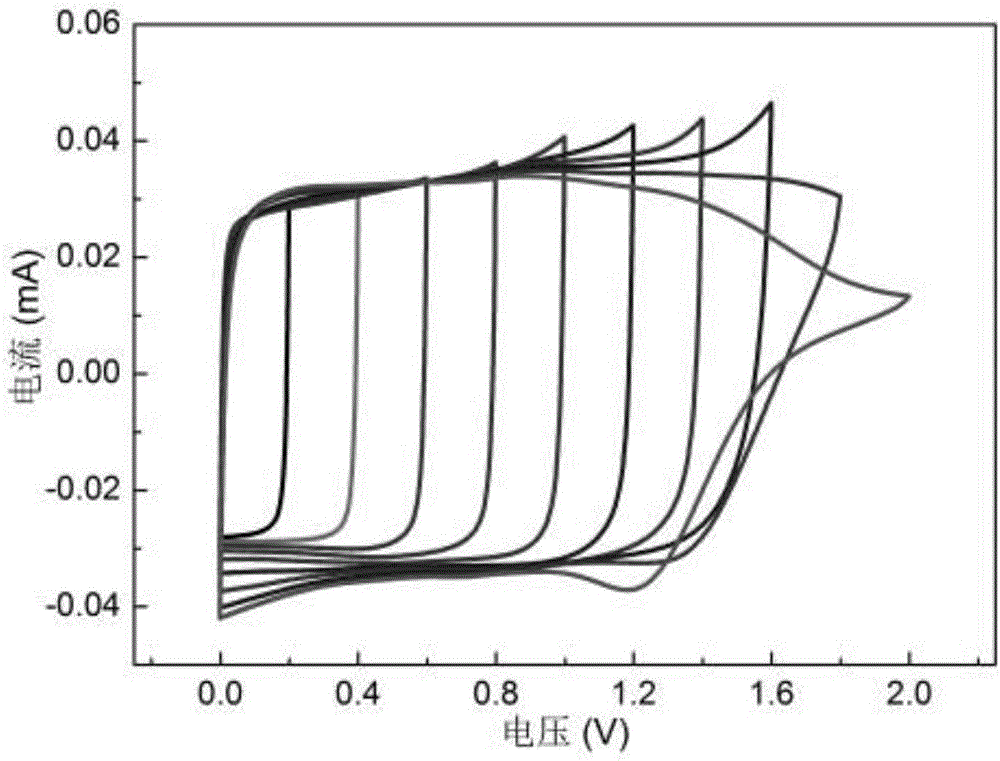

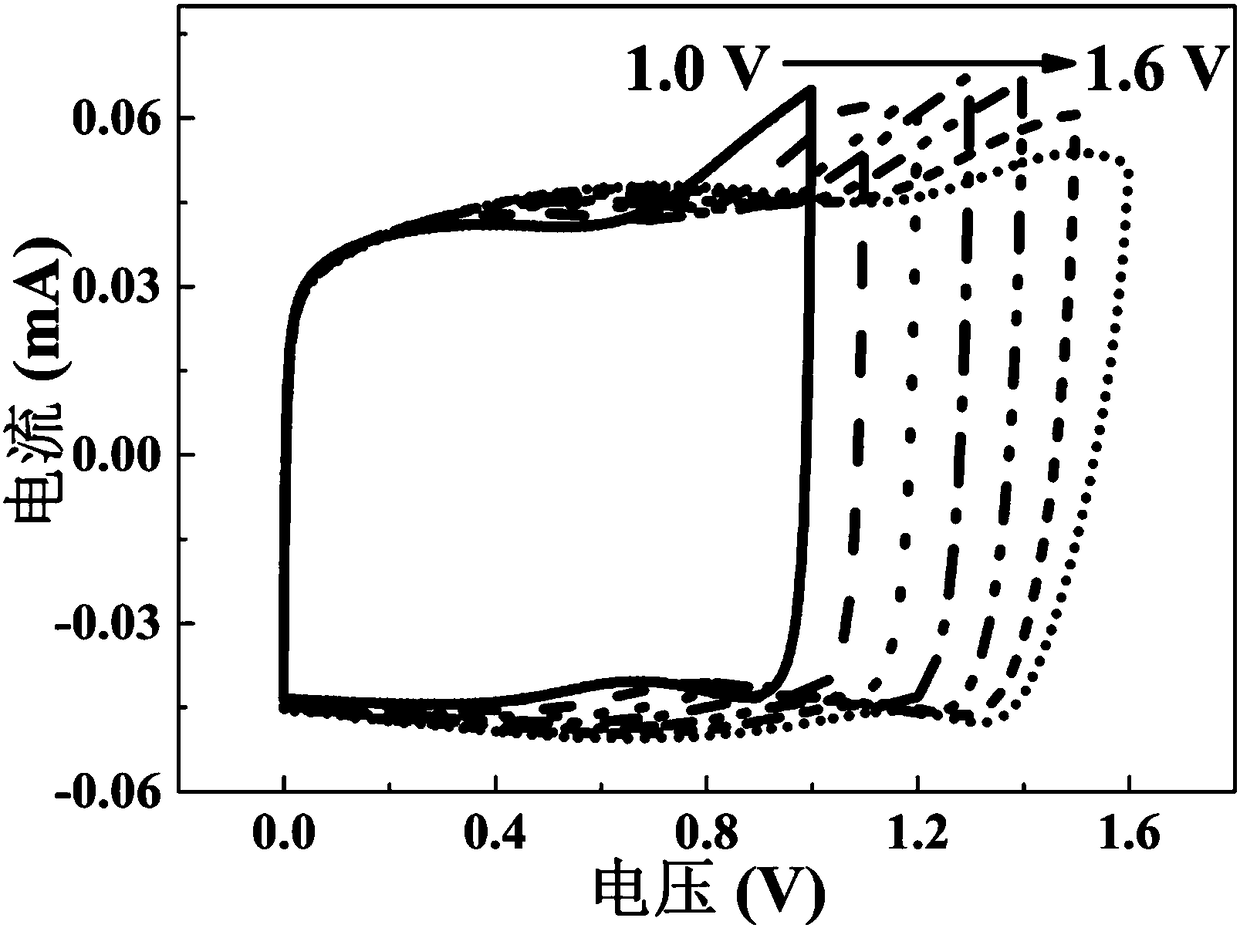

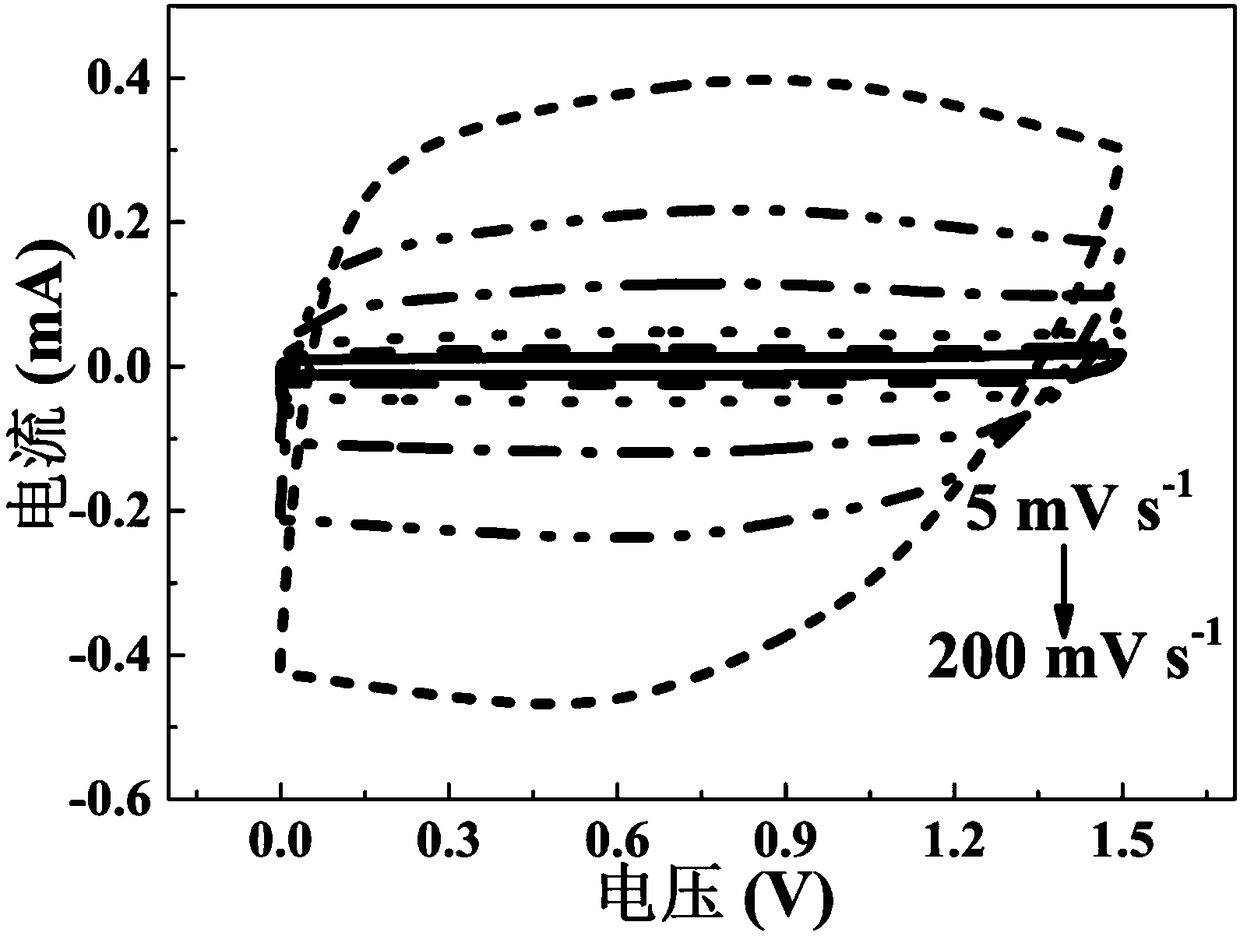

Ultra high conductivity polymer fiber and linear super capacitor set and preparation method thereof

ActiveCN106592009AEasy to operateGood flexibilitySynthetic fibresHybrid capacitor electrodesFiberPolymer science

The invention discloses ultra high conductivity polymer fiber and a linear super capacitor set and a preparation method thereof. A wet spinning method is used for preparing flexible polymer fiber form a conductive polymer, and the flexible polymer fiber is processed in an inorganic solution to obtain the ultra high conductivity polymer fiber; the ultra high conductivity polymer fiber is spirally wound on elastic lines and used respectively as super capacitor inner and outer electrodes and wires, the inner and outer electrodes are coated with a gel electrolyte, and the adjacent two super capacitors are connected in series by the wire. By using different spiral winding methods to adjust the position relationship between the inner electrode and the outer electrode, an upper-lower two-layer linear super capacitor set integrated device and a synchronous single-layer linear super capacitor set integrated device can be obtained. The preparation method is simple in operation, the product has good flexibility and high knittability, by integrated series or parallel connection of a plurality of super capacitors, voltage and current can be respectively improved, special equipment is not needed, and scaled production can be achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Waterproof conductive yarn

InactiveCN111254536AImprove flexibilityAchieve waterproof effectYarnEngineeringElectrically conducting yarn

The invention discloses a waterproof conductive yarn. The waterproof conductive yarn is of a three-layer structure which is provided with a conductive layer, a waterproof layer and a wrapping layer from inside to outside correspondingly; wherein the conductive layer is located on the innermost layer, the outer layer of the conductive layer is coated with the waterproof layer, and the outer layer of the waterproof layer is wrapped with the wrapping layer. The waterproof conductive yarn has the beneficial effects that the conductive layer can be made into a conductive layer yarn with good flexibility; the waterproof layer can achieve a waterproof effect and provide certain physical strength; the warping layer can improve the overall weavability of the conductive yarn, improve the wear resistance of the yarn, well prevent the waterproof layer from being damaged in the weaving and using processes and improve the performance stability of the waterproof layer; the three-layer conductive yarnis simple in structure, convenient in manufacturing method and high in applicability.

Owner:DONGHUAJINGYUE SUZHOU TEXTILE TECH RES CO LTD

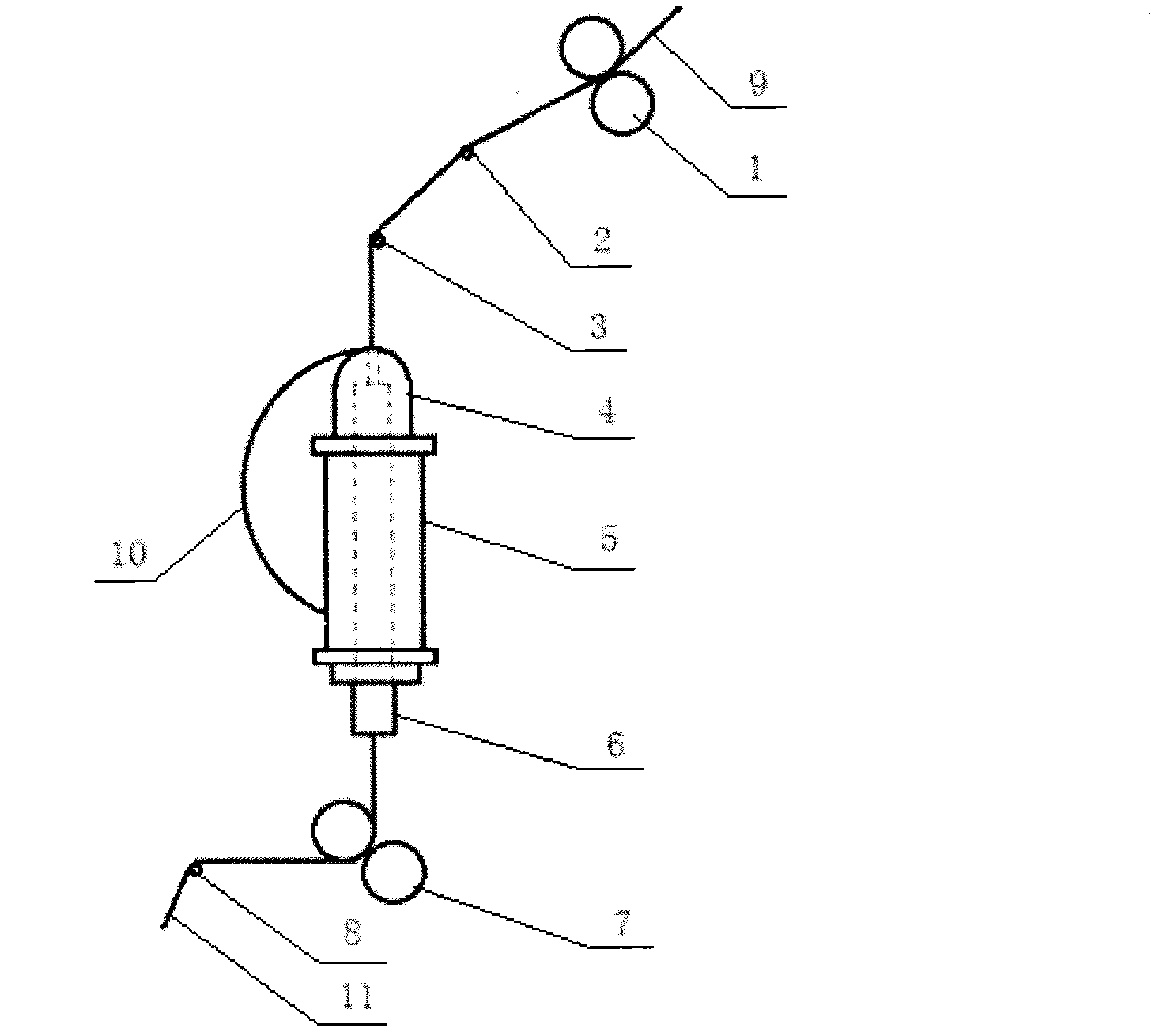

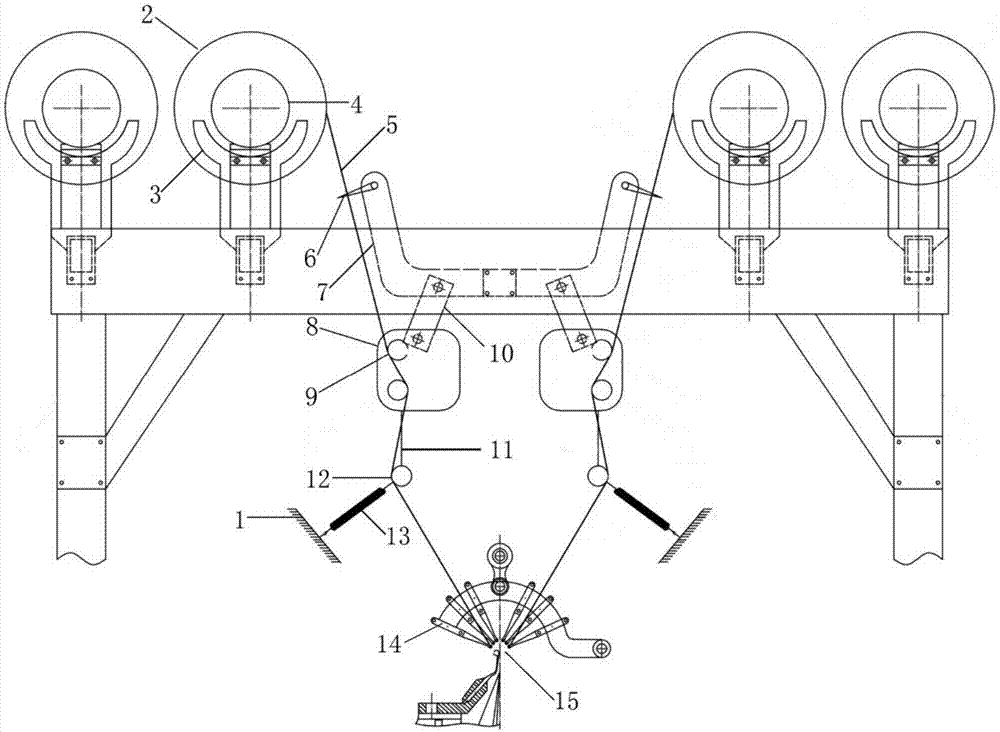

Method for preparing three-dimensional thermoplastic composite material based on improved wrapped yarn structure

InactiveCN103215706AEvenly distributedGood physical and mechanical propertiesWoven fabricsYarnYarnEngineering

The invention discloses a method for preparing a three-dimensional thermoplastic composite material based on an improved wrapped yarn structure. A wrapping device adopted by the improved wrapped yarn is characterized in that a gathering device is added on the original wrapping device. The preparation method comprises the following steps of preparation of wrapped yarn, weaving of three-dimensional orthogonal linen woven fabric fabrication and forming of composite materials. The invention provides a process for preparing three-dimensional orthogonal woven fabric enhanced-thermoplastic composite materials based on the improved wrapped yarn structure, and the distribution problem of thermoplastic resin on the fabrication can be effectively improved. The method has the advantages of simple process, low cost, high efficiency, energy saving, environmental protection and wide application.

Owner:DONGHUA UNIV

Design method and production process of multifunctional bed sheet fabric

The invention discloses a design method and production process of multifunctional bed sheet fabric. The multifunctional bed sheet has a three-layer structure. The inner layer of the bed sheet is madeof yarns woven by cool fibers; the surface of the bed sheet is made of yarns woven by ultra-hollow warm-keeping fibers, so that the two surfaces of the bed sheet have different touch feelings including a cooling feeling and a warm feeling; and a yarn laying layer is made of wefts in the intermediate layer, so that the bed sheet feels soft and thus the comfortable level of the bed sheet is enhanced. With connection crossing points, diamond patterns are formed on the two sides of the bed sheet.

Owner:IANGSU COLLEGE OF ENG & TECH

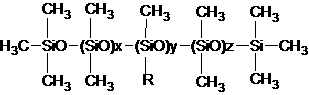

Sizing agent applied to constant SiC (Silicon Carbide) fiber and preparation method and application thereof

ActiveCN103132327AImprove bundle tensile strengthImprove weavabilityFibre treatmentFiberPolyvinyl alcohol

The invention discloses a sizing agent applied to a constant SiC (Silicon Carbide) fiber, and a preparation method and an application of the sizing agent. The sizing agent applied to the constant SiC fiber comprises the following raw materials in parts by weight: 0.15-0.6 part of polyvinyl alcohol, 0.1-1 part of modified organic silicon oil, 0.8-3.0 parts of polyoxyethylene nonyl phenol ether, 0.1-0.8 part of potassium peroxodisulfate and 100 parts of distilled water. The invention further discloses the preparation method of the sizing agent applied to the constant SiC fiber. By utilizing the sizing agent disclosed by the invention to carry out sizing treatment on the constant SiC fiber, the beam tension strength of the SiC fiber can be effectively improved, the broken filaments and the broken heads of the fiber can be effectively wrapped, and the softness of the fiber is improved, so that the stitchability of the fiber is greatly improved; the raw materials are easily accessed; and the sizing agent is simple to prepare, low in cost, stable in property and simple in use, equipment and process, and is easy to implement on a practical constant SiC fiber production line.

Owner:NAT UNIV OF DEFENSE TECH

Process for manufacturing super-high-count ramie fabric and the fabric

ActiveUS8375537B2Improve cohesionHigh strengthSevering textilesDrying machines with progressive movementsYarnWater soluble

The present invention relates to a process for manufacturing a ramie fabric and the fabric. The process comprising the following steps: blend spinning a high-count ramie fiber such as a ramie fiber of 2500Nm or higher with a water-soluble fiber as carrier to form a yarn; sizing the yarn at a low temperature; weaving the yarn to form a gray fabric; then removing the water-soluble fiber from the gray fabric by deweighting the gray fabric during a printing and dyeing finishing process to obtain a super-high-count ramie fabric with a ramie yarn fineness of 160Nm or higher.

Owner:HUNAN HUASHENG ZHUZHOU CEDAR

Environment-friendly sorghum fiber fabric

InactiveCN104562367AImprove product qualityImprove combing effectCarding machinesHeating/cooling textile fabricsFiberYarn

The invention relates to an environment-friendly sorghum fiber fabric, and belongs to the technical field of fabrics. The environment-friendly sorghum fiber fabric is made of 100% of sorghum fibers in percentage by weight by using a spinning technology, a weaving technology and a printing and dyeing technology. Damage on the fibers is reduced in blowing and cotton carding processes in the spinning technology, carding degree can be improved, a carding effect is high, slashing speed is maintained in a slashing process in the weaving technology, reasonable yarns are selected, the weavability of the yarns is improved, the quality and the grade of the produced sorghum fiber fabric are high, the sorghum fiber fabric feels soft and smooth, cloth grains are clear, and the sorghum fiber fabric has wool sense, is high in dangling property, absorbs moisture, is breathable and is suitable for follow-up processing of high-grade products completely.

Owner:QINGDAO XINYIFA IND & TRADE

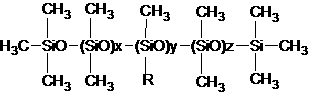

Symmetric warp let-off method and device of single needle bed warp knitting machine

ActiveCN107059237AConsistent tensionOvercoming Weaving EffectsWarp knittingYarn tensionWarp knitting

The invention relates to a symmetric warp let-off method and device of a single needle bed warp knitting machine. Yarns are conveyed to a weaving portion from a front side and a back side of a machine body of the single needle bed warp knitting machine respectively; and let-off paths of yarns at two sides of the machine body are mutually symmetrical, i.e., a symmetrical axis of the let-off paths is perpendicular to a central cross beam. The warp let-off device includes an even number of warp let-off systems which are horizontally symmetrical and positioned on the two sides of the machine body of the warp knitting machine; each warp let-off system includes a yarn unfolding mechanism, a yarn tension adjustment mechanism, and a looping mechanism; yarns are unfolded by the yarn unfolding mechanism, the tension of the yarns is adjusted by the yarn tension adjustment mechanism, and the yarns are conveyed to the looping mechanism. The influence of yarn tension difference on knitting can be avoided, the knittability of the yarns can be improved; a plurality of rows of yarn division needles and yarn guide needles can disperse extreme fine metal wires, tangled metal wires can be reduced, broken ends can be reduced, and the quality and the production efficiency of fabrics can be improved.

Owner:DONGHUA UNIV

Aluminum silicate/nickel-chromium stainless steel wire fireproof rolling curtain cloth and manufacturing method thereof

InactiveCN102002789AImprove fire resistancePlay a supporting roleWoven fabricsAluminum silicateFire resistance

The invention discloses aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth and a manufacturing method thereof. Aluminum silicate yarns and nickel-chromium stainless steel wires are taken as raw materials to form a fabric through a weft backed weave structure. The warp yarns of the fabric are aluminum silicate / nickel-chromium stainless steel wire doubled wires, and weft yarns are two groups of aluminum silicate yarns and nickel-chromium stainless steel wire yarns, wherein the positive weft yarns are aluminum silicate yarns, and the reverse weft yarns are nickel-chromium stainless steel wires. The gram per square meter of the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth is 800 to 1,200g / m<2>, the total tightness of the fabric is more than or equal to 115 percent, and the fire resistance temperature is 1,100 DEG C. The manufacturing method comprises the following steps of: (1) doubling the aluminum silicate yarns with the nickel-chromium stainless steel wires; (2) performing spooling, beaming, slashing and drawing processes on the doubled aluminum silicate / nickel-chromium stainless steel wires for weaving; (3) respectively quilling the aluminum silicate yarns and the nickel-chromium stainless steel wires for weaving; and (4) weaving the prepared warp yarns and weft yarns on a shuttle loom with a double-side multi-shuttle box mechanism according to the designed looming draft so as to prepare the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth.

Owner:SICHUAN UNIV

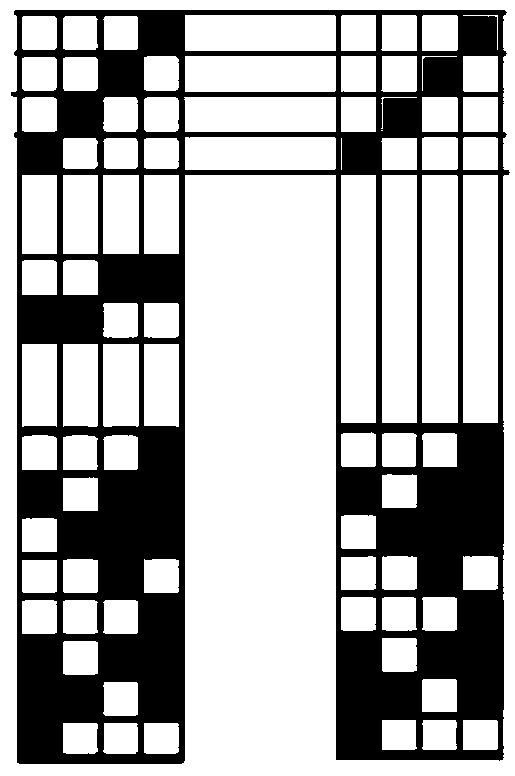

Production technology of corn fiber environmental-friendly fabric

InactiveCN103306007ASmooth and soft textureClear cloth textureHeating/cooling textile fabricsWoven fabricsCardingEngineering

The invention discloses a production technology of corn fiber environmental-friendly fabric which is made through spinning technology, weaving technology and dyeing technology by taking corn fiber with the mass percent being of 100 percent as raw material. The spinning technology comprises blowing, cotton carding, drawing, roving, spinning and spooling; the weaving technology comprises beaming, slashing, denting and weaving; and the dyeing technology comprises fabric turning, sewing up, fuzzing, preheating setting, atmospheric overflow scouring, dyeing, cleaning, drying, setting, ironing, shearing and forming. The production technology has the advantages that the technology improves the fabric weavability, and the corn fiber fabric produced has high product quality grade, soft and smooth texture, clear face grain, wool-like sensation and hanging performance, is moisture-retentive and breathable, and can be completely applicable to the subsequent processing of high-grade products.

Owner:KAISHENG TEXTILE

Textile sizing agent for polyester fabric

The invention discloses a textile sizing agent for a polyester fabric. The textile sizing agent comprises the following components in parts by mass: 28-32 parts of acrylate modified silicone oil, 39-41 parts of crylic acid, 18-22 parts of methacrylic acid, 2.8-3.2 parts of a methacrylate compound, 2.9-3.1 parts of glycerinum, 2.9-3.2 parts of emulsified oil, 0.25 part of 2-naphthol, 3 parts of methyl methacrylate, 15-23 parts of vicat flax, 10-12 parts of a durable drainage polymer, 11-18 parts of long stapled cotton, 4-8 parts of a hot melt adhesive, 5-10 parts of polyester fibers, 2-6 parts of nanometer titania powder, 3-8 parts of waterproof resin slurry and 3-8 parts of rosin. Through the formula, sizing is performed on a textile fabric, so that the enhancement rate, the stretch reduction rate, the hairiness reduction rate and the abrasion degree increase rate can be increased, the weavability is improved, the breakage rate of warps meets the successful weaving requirement, a prepared clothing material is comfortable and soft, can keep warm, and is resistant to water, the manufacture is simple and convenient, the cost is low, and a certain market value is achieved.

Owner:NANTONG ZHONGRUN TEXTILE PRINTING & DYEING CO LTD

Textile size and preparation method thereof

InactiveCN109403035AModerate viscosityModerate viscosity, moderate sizing stabilityAbrasion resistant fibresYarnEthyl acrylate

The invention discloses textile size and a preparation method thereof. The textile size is prepared from the following components in parts by weight: 40-50 parts of PE liquid, 60-70 parts of methacrylic acid, 65-90 parts of butyl acrylate, 45-60 parts of ethyl acrylate, 400-600 parts of methyl acrylate, 150-200 parts of methyl methacrylate, 5-7 parts of an emulgator, 7-9 parts of ammonium persulfate, 10-15 parts of a defoaming agent, 3-5 parts of an antistatic agent, 10-15 parts of penetrant and 80-120 parts of ammonium hydroxide. The textile size has the following beneficial effects: (1) thetextile size prepared through the preparation method is moderate in viscosity and good in sizing stability; and (2) after yarn is treated through the textile size, the sizing performance of the yarn is improved obviously, the breaking strength and abrasion performance are improved obviously, and thus the weavability of the yarn treated through the size is also improved obviously.

Owner:浙江佳润新材料有限公司

Method for weaving blended yarn branched twisted yarn

The invention discloses a method for weaving blended yarn branched twisted yarn. The method comprises the steps of wool yarn making, stranding and doubling, twisting and yarn steaming. Through the design of processes and parameters, the processed branched twisted yarn is wrapped tightly, the bright yarn has fewer broken ends, the high break rate during direct wool spinning processing of metallic yarn is overcome, exposed shining points of the twisted yarn are continuous, the shining is strong, the yarn is smooth, the brute force is high, the product weavability is high, and the method is suitable for marketing applications.

Owner:JIANGYIN HAITE NETWORK TECH CO LTD

Preparation method of health-care summer sleeping mat

InactiveCN106213908AGood moisture absorption and air permeabilitySignificant anti-mite performanceBed linenMechanical fibre separationYarnTextile fiber

The invention discloses a preparation process of a health-care summer sleeping mat. The preparation process comprises the steps of cutting, scraping linen, cleaning, drying in the air, degumming, cutting fibers, preparing fibers, splitting fibers, combing fibers, drawing, twisting yarns, obtaining warp yarns and knitting, wherein fiber raw materials consist of pineapple leaf fibers and other textile fibers, the percentage of the pineapple leaf fibers is 40 to 60 percent, the percentage of pineapple head disordered fibers is 30 to 45 percent, and the percentage of textile filler is 10 to 20 percent. The summer sleeping mat prepared by selecting the pineapple leaf fibers as one raw material has the functions of coolness, moisture absorption and discharge, ventilation property, softness, comfortableness, no prodding and itching feeling and the like, has a better effect of repelling and preventing mites, and has the advantages of higher softness, smoothness, washing resistance, storage resistance and durability; the detected summer sleeping mat has the efficacy of naturally resisting bacteria, inhibiting bacteria, repelling mites, removing odor, deodorizing and the like; a sleep environment can be remarkably improved.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI +1

Sub-micron filament belt spun yarn forming device and method for covering surface hairness of yarn body

The invention relates to a sub-micron filament belt spun yarn forming device and method for covering the surface hairiness of a yarn body. An electrospun sub-micron filament film belt roll disposed atthe upper end of a ring spinning machine is unwound by an active unwinding frame to produce a sub-micron filament film belt; the sub-micron filament film belt justly fits to the edge fiber of a spinning triangular zone by the limiting and adjustment of a guide wheel, and the upward transfer of the twist enables the surface of a staple fiber ring spun yarn to be tightly coated with the sub-micronfilament film belt with a smooth surface, so that a ring spun yarn with less hairiness or free of hairiness can be processed. The technical bottleneck of difficulty in reducing the hairiness of the ring spun yarn is broken through by coating the short fiber yarn body with the flexible sub-micron filament film belt, the processing of the ring spun yarn which can be woven without sizing is expectedto be realized, the problems of environmental pollution and energy consumption caused by sizing can be solved, and the device and the method have broad application prospects.

Owner:DONGHUA UNIV

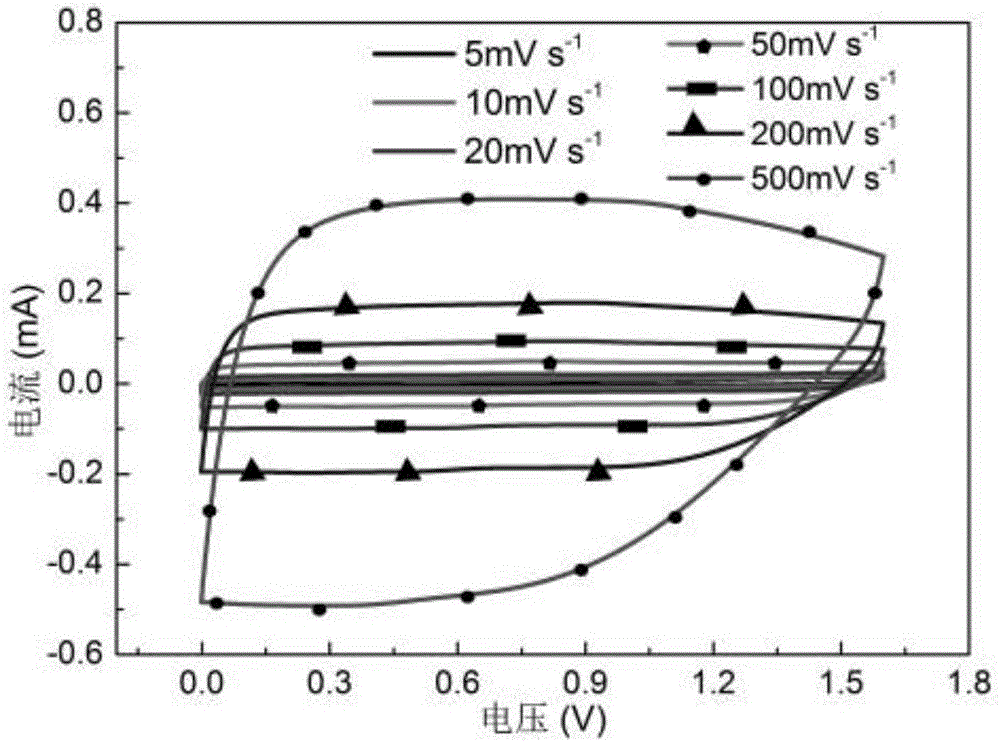

High and low temperature flexible fibrous supercapacitor and preparation method and application thereof

InactiveCN108447701AEasy to operateGood flexibilityHybrid capacitor electrodesHybrid/EDL manufactureHigh energyAdhesive

The invention provides a preparation method of a high and low temperature flexible fibrous supercapacitor, two conductive polymer composite fiber electrodes are parallelly arranged at a certain interval, two ends are fixed on a PET film by use of a conductive adhesive tape and conductive silver adhesive, surfaces are coated with aqueous gel electrolytes, and thus a high and low temperature flexible fibrous supercapacitor integrated device is prepared. The invention also provides a high and low temperature flexible fibrous supercapacitor and application thereof. The high and low temperature flexible fibrous supercapacitor still maintains high energy density in a wide-temperature range environment from 60 to 100 DEG C, and has ultrahigh safety performance, and the performance is not affectedwhen the supercapacitor is bent at an arbitrary angle.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Formula of textile fabric sizing agent

The invention discloses a formula of a textile fabric sizing agent. The textile fabric sizing agent is prepared from components in parts by mass as follows: 28-32 parts of PVA, 39-41 parts of grafted starch, 18-22 parts of amide, 2.8-3.2 parts of an antistatic agent, 2.9-3.1 parts of glycerin, 2.9-3.2 parts of emulsified oil, 0.25 parts of 2-naphthol, 3 parts of wax flakes, 15-23 parts of vicat flax, 10-12 parts of a durable drainage polymer, 11-18 parts of long stapled cotton, 4-8 parts of hot melt glue, 5-10 parts of polyester fibers, 2-6 parts of nanometer titanium dioxide powder, 3-8 parts of waterproof resin slurry and 3-8 parts of rosin. The textile fabric is subjected to sizing with the formula, so that enhancement rate, elongation decreasing rate, hairiness decreasing ratio and abrasion degree growth ratio of the textile fabric can be increased, weavability of the textile fabric is improved, end breakage rate of warp yarn meets the smooth weaving requirement, and a prepared material for clothing is comfortable, soft, warm-keeping and waterproof, is simple and convenient to prepare and low in cost and has certain market value.

Owner:NANTONG SANJIANG TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com