Composite material reinforced by hybrid fiber preform and preparation method of composite material

A composite material and preform technology, applied in chemical instruments and methods, ceramic layered products, layered products, etc., can solve the problems of lack of products, high temperature resistance, ablation resistance, wave absorption and other performance studies are less, etc. Achieve the effects of high interlayer bonding strength, integration of structure and function, and short densification period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

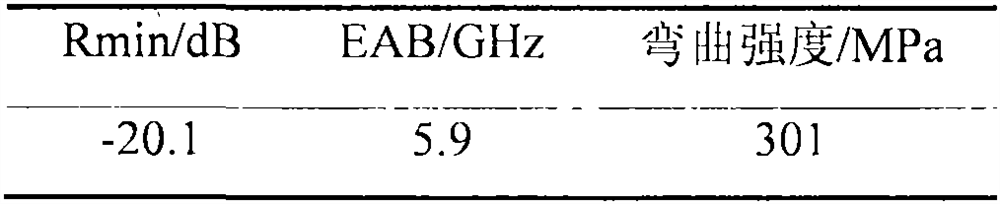

Embodiment 1

[0022] A composite material reinforced by a mixed fiber prefabricated body, composed of a fiber prefabricated body, a composite material interface and a matrix, characterized in that the fiber prefabricated body is a three-dimensional fabric woven from three kinds of fibers, and the fiber volume fraction in the prefabricated body is The number of fiber cloth layers in the prefabricated body is 3 layers, and the three-dimensional overall structure is formed by adding yarns between the layers. The fibers are woven by loom temples during the weaving process; the outer layer of the wave-absorbing composite material It is a glass fiber wave-transparent layer with a fiber volume fraction of 10% and a thickness of 5mm. It adopts plain weave and its impedance is about 400Ω. The middle layer is a silicon carbide fiber loss layer with a fiber volume fraction of 15% and a thickness of 3mm. Plain weave, resistivity 1~10Ω·cm, dielectric loss tangent value 0.6, inner layer is carbon fiber re...

Embodiment 2

[0036]A composite material reinforced by a mixed fiber prefabricated body, composed of a fiber prefabricated body, a composite material interface and a matrix, characterized in that the fiber prefabricated body is a two-dimensional three-dimensional fabric woven from two kinds of fibers, and the fiber volume in the prefabricated body The score is 45%. The number of layers of fiber cloth in the prefabricated body is 2 layers. The layers are stitched together to form a three-dimensional overall structure. The fibers are woven with loom temples during the weaving process; the outer layer of the high-temperature structural material is Silicon carbide fiber, the volume fraction of silicon carbide fiber in the preform is 15%, the thickness is 8mm, the inner layer is carbon fiber volume fraction is 20%, and the thickness is 12mm; the fiber cloth used is respectively composed of silicon carbide fiber, carbon fiber and a ceramic powder Composition, the volume fraction of ceramic powder ...

Embodiment 3

[0048] A composite material reinforced by a mixed fiber prefabricated body, composed of a fiber prefabricated body, a composite material interface and a matrix, characterized in that the fiber prefabricated body is a three-dimensional fabric woven from five kinds of fibers, and the fiber volume fraction in the prefabricated body is 65%, the number of layers of fiber cloth in the prefabricated body is 5 layers, and the thickness of each layer is 10-50mm. The layers are bonded by resin to form a three-dimensional overall structure. The fibers are woven by loom temples during the weaving process; 1400 The outer layer of the heat-resistant composite material above ℃ is carbon fiber, the fiber volume fraction is 15%, and the thickness is 10mm. The middle layer is silicon carbide fiber, alumina fiber, and quartz fiber in sequence. %, the thickness is 8mm, 8mm, 8mm respectively, the inner layer is high silica fiber, the volume fraction of the fiber is 20%, and the thickness is 10mm; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com