Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "High bonding strength between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

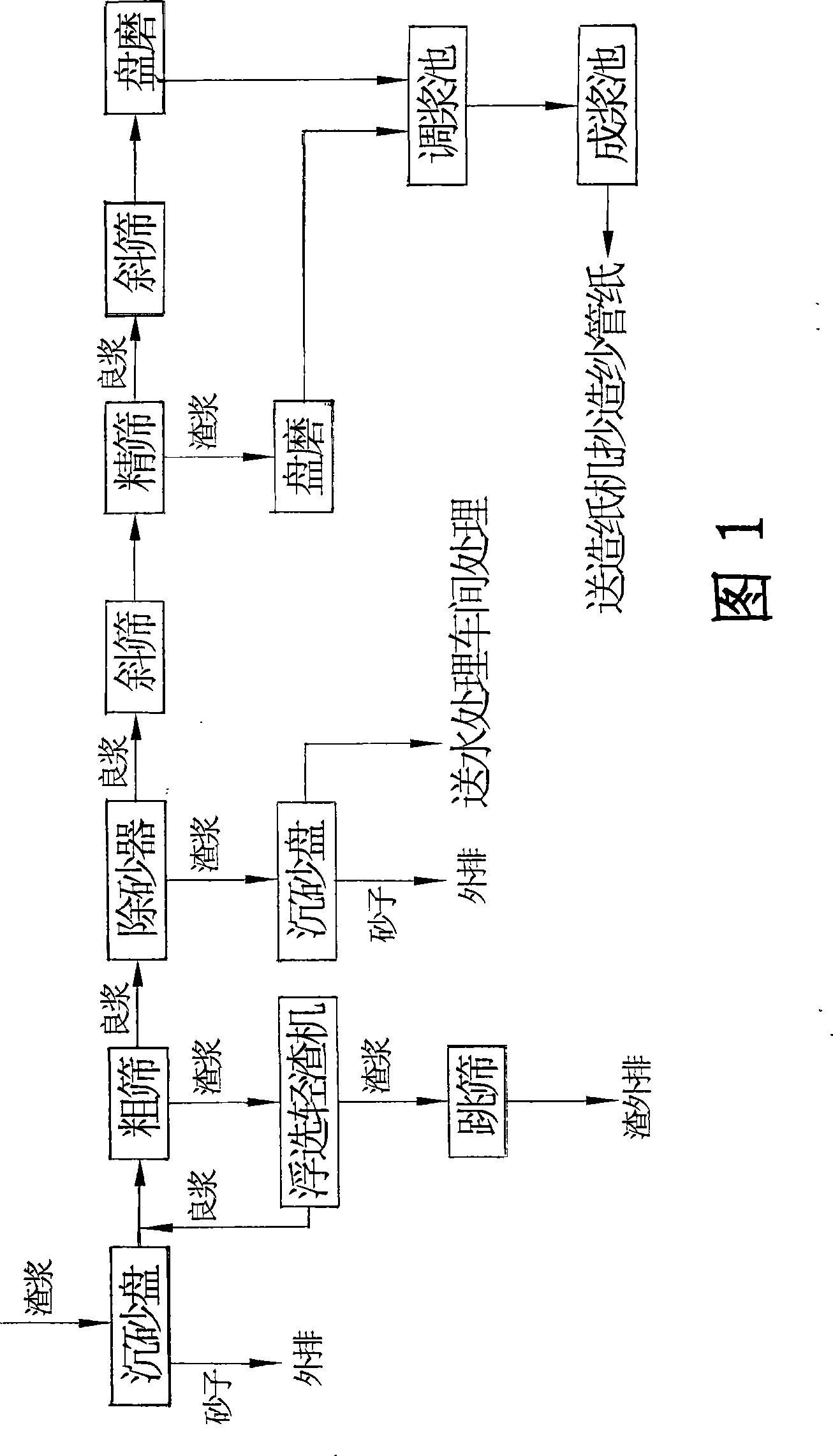

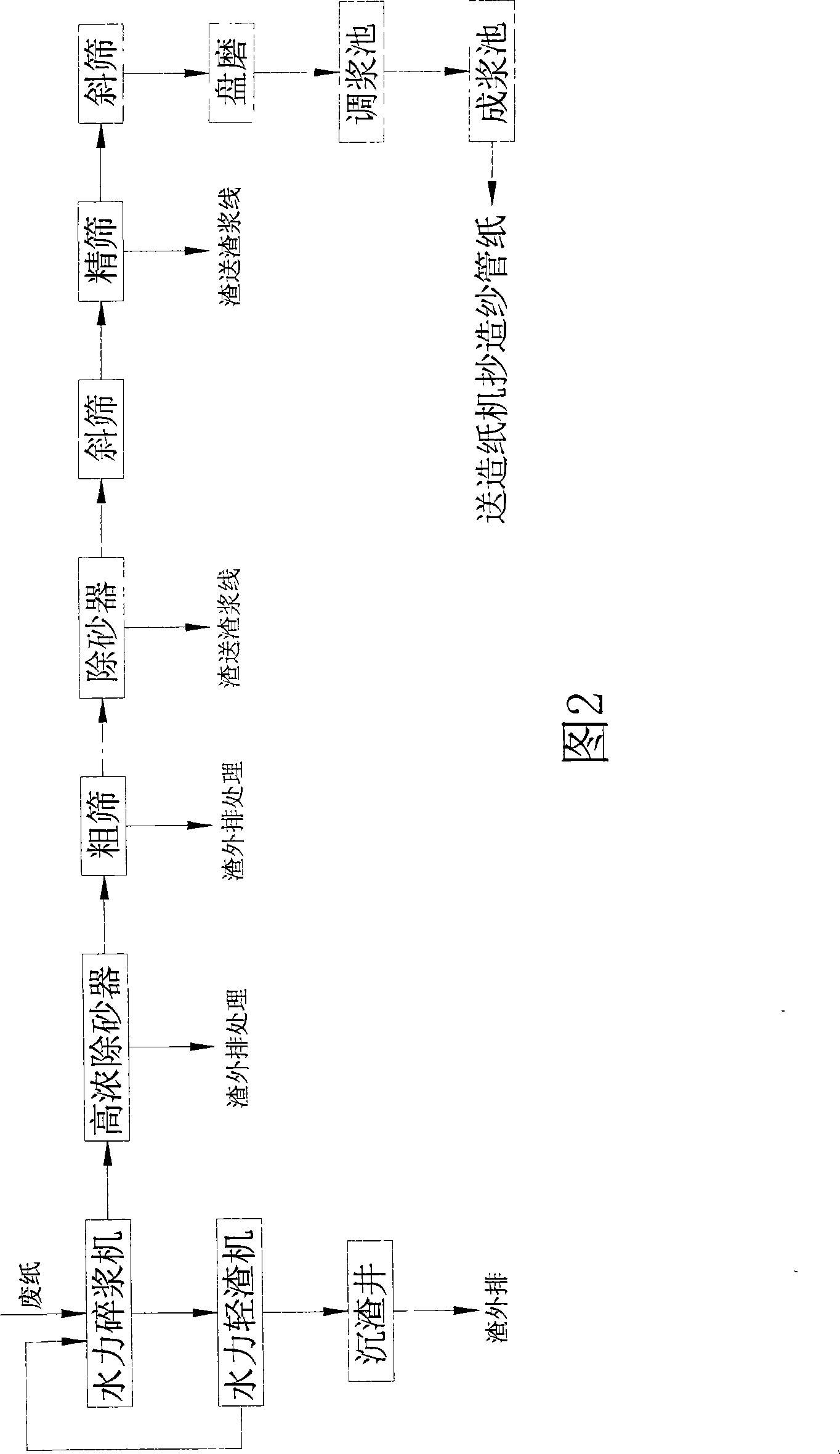

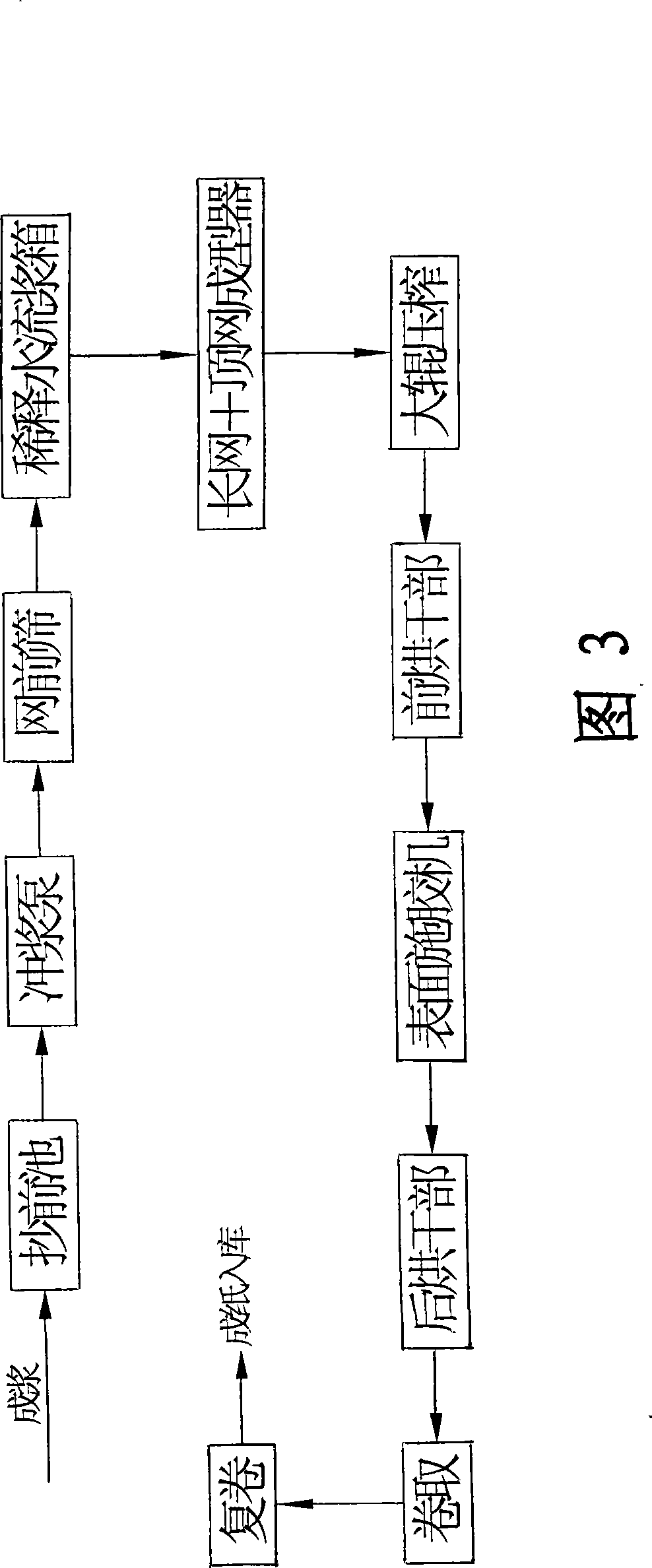

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

Delamination resistant multilayer containers

ActiveUS20110262668A1High bonding strength between layersAvoid layeringBottlesSynthetic resin layered productsPolyamideEngineering

The present invention provides a multilayer plastic bottle comprising layers of PET and a polyamide such as, for example, MXD6, that is free from occurrence of delamination upon dropping or upon exposure to impact. The present inventors have found that when forming a barrier layer containing an adhesion promoting agent according to the present invention, an impact energy applied to the barrier layer is well reduced and the resultant multilayer bottle is improved in interlaminar bonding strength and prevented from suffering from delamination upon dropping, etc.

Owner:GRAHAM PACKAGING CO LP

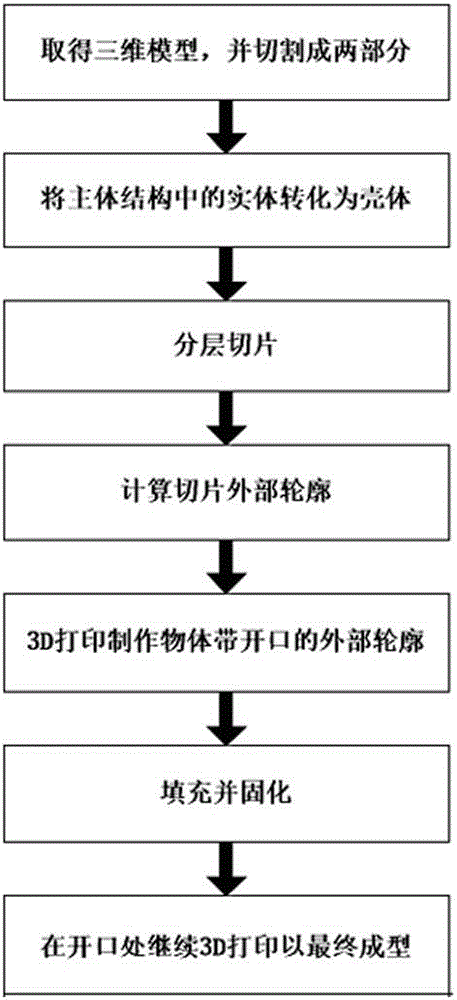

3D forming method based on outline injection molding

ActiveCN105172152AHigh bonding strength between layersSpeed up injection moldingAdditive manufacturing apparatusSoftwareInjection moulding

The invention discloses a 3D forming method based on outline injection molding. The method includes the following steps that a three-dimensional model is obtained and cut; a material is converted into a shell; layering and slicing are carried out; the outline of slices is calculated; the structure of the outline is subjected to 3D printing; filling and curing are carried out; final molding is achieved. The three-dimensional model of a printed object is obtained through 3D modeling software and converted so that the shell slices can be obtained, then the shell of the object is printed in a 3D mode, a sprue is reserved in the top or the bottom of the shell, one or more of a light curing liquid material, sealing glue, melted liquid and a meltable powder material are injected from the sprue to the interior for filling, curing and fusion are carried out, and the problem that an existing light curing technology is not high in layer-to-layer bond strength is solved. By means of the improvement, layer-to-layer bond strength is improved, and the injection molding speed is increased.

Owner:深圳晗竣雅科技有限公司

High-efficiency metal 3D printing equipment and method

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Carbon/carbon composite material flat plate preparation method

The invention discloses a carbon / carbon composite material flat plate preparation method, which comprises the following steps that 1) finely woven carbon fiber fabric and short carbon fiber nets are subjected to alternating lamination; 2) a carbon fiber needling integral felt is obtained in a needling mode; 3) resin dipping and curing are carried out; 4) graphitization treatment is carried out; and 5) chemical gas phase decomposition and density enhancement are carried out. The carbon / carbon composite material flat plate preparation method disclosed by the invention can be used for preparing carbon / carbon composite materials with good surface flatness and high interlayer combination degree.

Owner:湖南省鑫源新材料股份有限公司

Multi-layer structure with potassium ionomer

InactiveUS20060057318A1Easy to useHigh bonding strength between layersCovering/liningsSynthetic resin layered productsIonomerSurface layer

The present invention relates to a multi-layer structure constructed of two or more layers including a potassium ionomer layer (X) having a low surface resistivity and a layer (Y) comprising a polymer material having a high surface resistivity like LLDPE as a surface layer, where the static charge decay characteristics of the layer (Y) is improved. This type of two layer or three layer structure having the layer (X) as its intermediate layer or another surface layer gives good slip characteristics, abrasion resistance, and dust-free characteristics, and hence is useful for packaging materials, such as films, sheets and containers.

Owner:MITSUI LTD

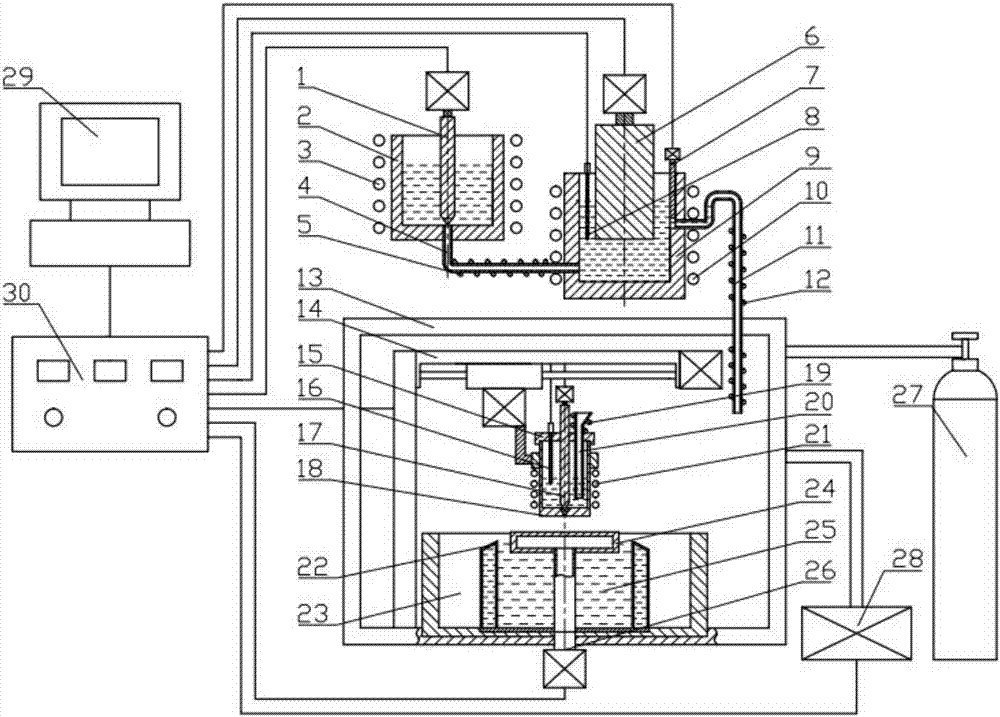

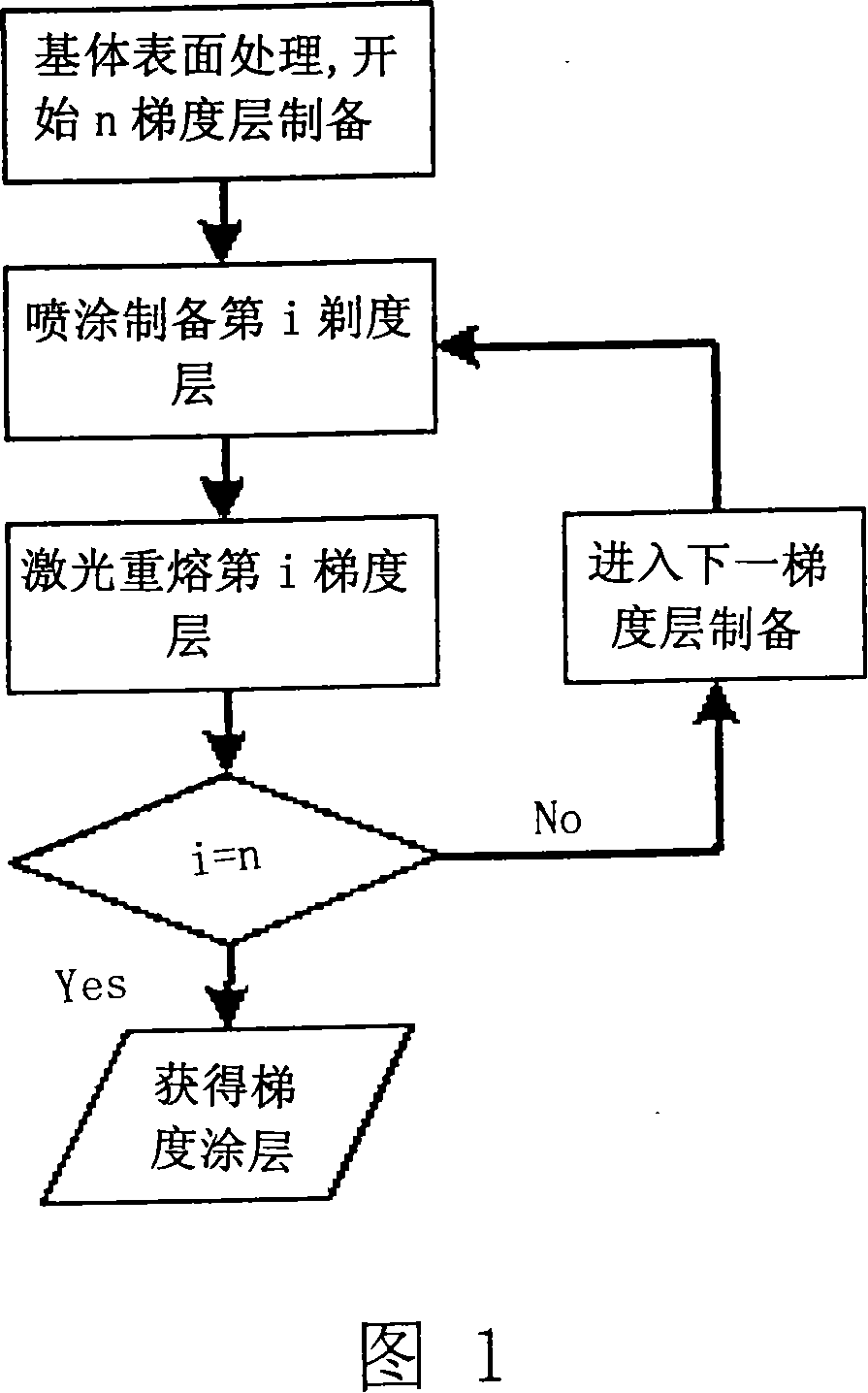

Processing method of hot sprayed gradient coatings based on time after time laser refusing

InactiveCN101112701AImprove bindingGood metallurgical bondPretreated surfacesCoatingsThermal sprayingOptoelectronics

A hot spray grads coat processing method based on multi-time laser remelting belongs to a novel material processing method. The method has a main innovative point that the multi-time laser remelting method is adopted for the composite process of the hot spraying grads coats, and the defects that not all sub-coat reaches the metallurgy combination, the grads structure in the coats is damaged and the hot spraying laminated organization can not be eliminated, etc. on the conditions of remelting without laser or one-time laser remelting are overcome. The detailed process is that the purification and activation disposal are firstly disposed to the base metal material, the first grads material is sprayed on the surface of the base and one-time laser remelting is sequentially carried out for the first grads layer, causing the first grads layer to form the metallurgy combination with the base; after that, the second grads material is sprayed on the surface of the first grads layer after remelting of laser and the secondary laser remelting is carried out, causing the metallurgy combination to be formed between the two grads oats; sequentially adopting the method, the hot spraying and laser remelting process are respectively carried out to all grads coats. The invention has the advantages of simple and reliable processing method and meeting the comprehensive performance requirements of coats.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

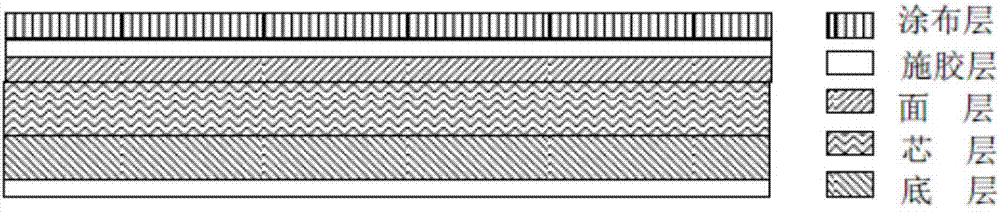

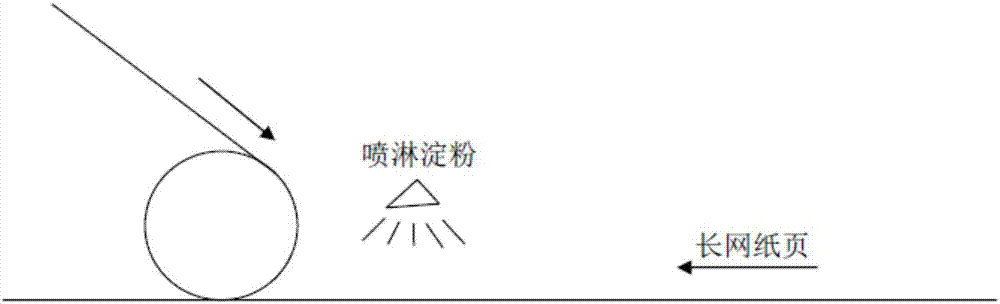

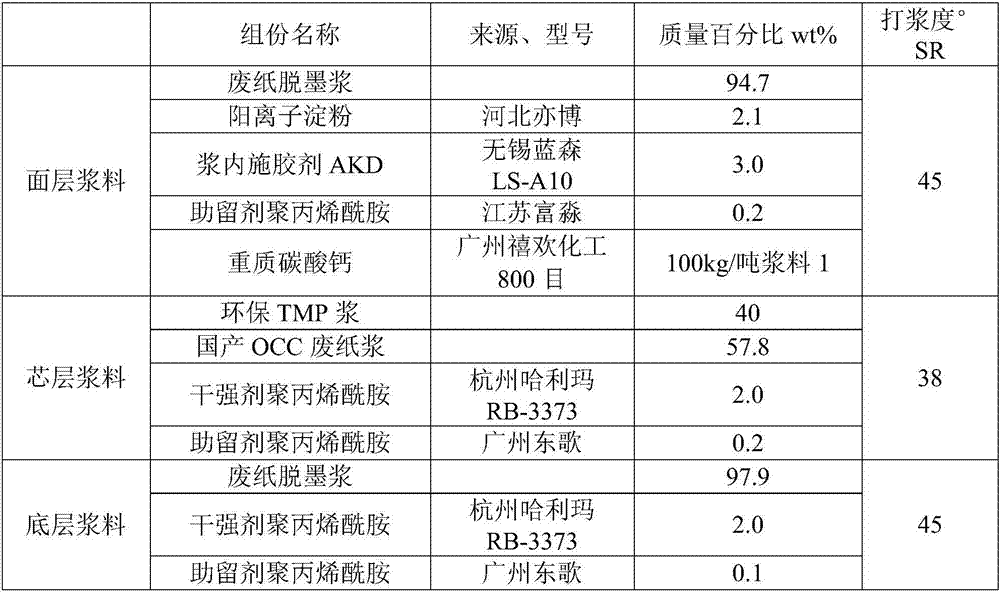

Environment-friendly low-basis-weight coated duplex board with grey back and preparation method thereof

The invention belongs to the technical field of papermaking and particularly relates to an environment-friendly low-basis-weight coated duplex board with grey back and a preparation method thereof. The environment-friendly low-basis-weight coated duplex board with grey back includes a coating layer, a front glue applied layer, a surface layer, a core layer, a bottom layer, and a back glue applied layer, all the layers being laminated by spraying a starch solution. In the invention, a mechanical thermal pulp TMP for producing medium-density polymeric plates is employed, wherein the mechanical thermal pulp is environment-friendly and low-cost, and has wide sources. In addition, the invention mainly provides a production technology of the low-basis-weight coated duplex board with grey back by applying the novel environment-friendly TMP pulp. The technology mainly includes three-layer mesh lamination shaping, spraying starch solution as interlayer adhesive and the like processes, so that the coated duplex board with grey back has excellent performance, is environment-friendly and energy-saving, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

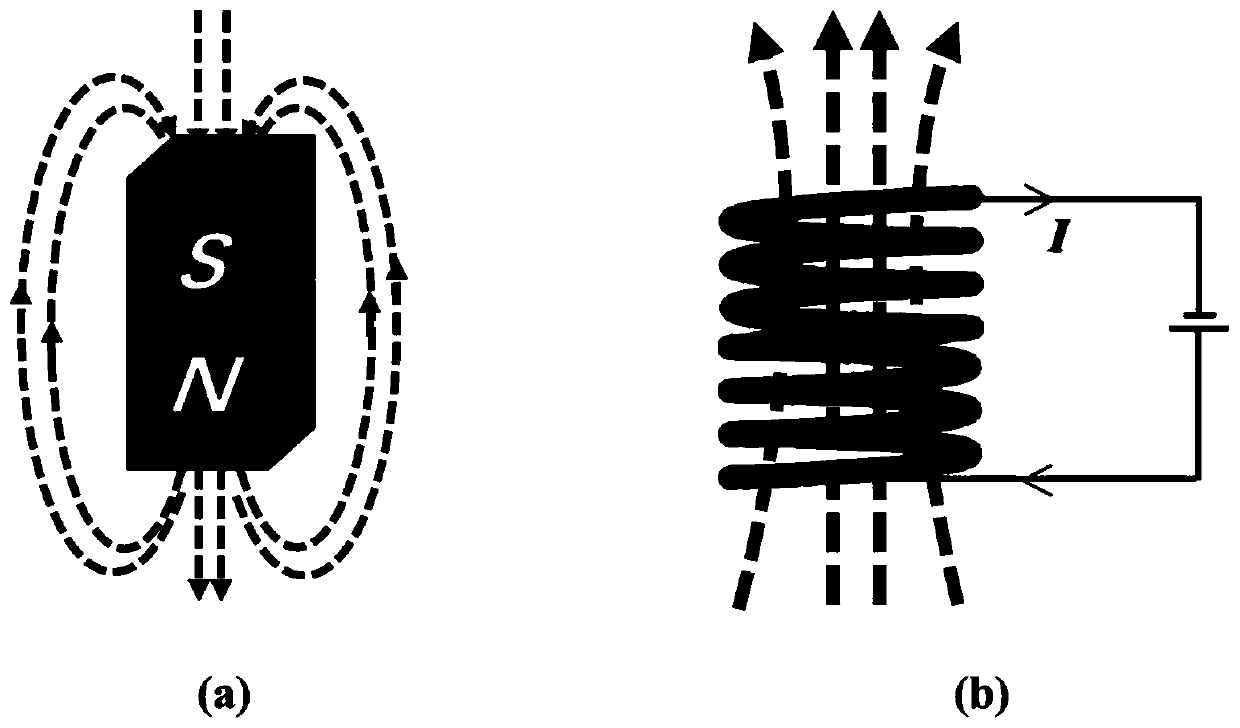

4D printing manufacturing method suitable for magnetic composite material

ActiveCN110600254AHigh bonding strength between layersImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sintering4d printing

The invention belongs to the related technical field of composite material 4D printing, and discloses a 4D printing manufacturing method suitable for the magnetic composite material. The method comprises the following steps: (1) mixing flexible polymer powder, strong magnetic powder and a rheological agent to obtain multiple kinds of composite powder, wherein the mass fractions of the strong magnetic powder in the multiple kinds of composite powder are in graded distribution; (2) forming a formed part of the to-be-manufactured gradient part by adopting a selective laser sintering process basedon the various composite powder and the three-dimensional model of the to-be-manufactured part; (3) magnetizing the formed part to enable the formed part to have permanent magnetism, and placing themagnetized formed part in a magnetic field to enable the formed part to deform, thereby completing 4D printing and manufacturing of the gradient part to be manufactured. According to the method, the performance of the part is improved, the flexibility is high, the mechanical property of the formed part is enhanced, the content of magnetic powder in the height direction of the formed part is distributed in a gradient mode, and the bending angle can be controlled.

Owner:HUAZHONG UNIV OF SCI & TECH

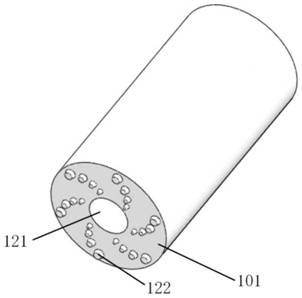

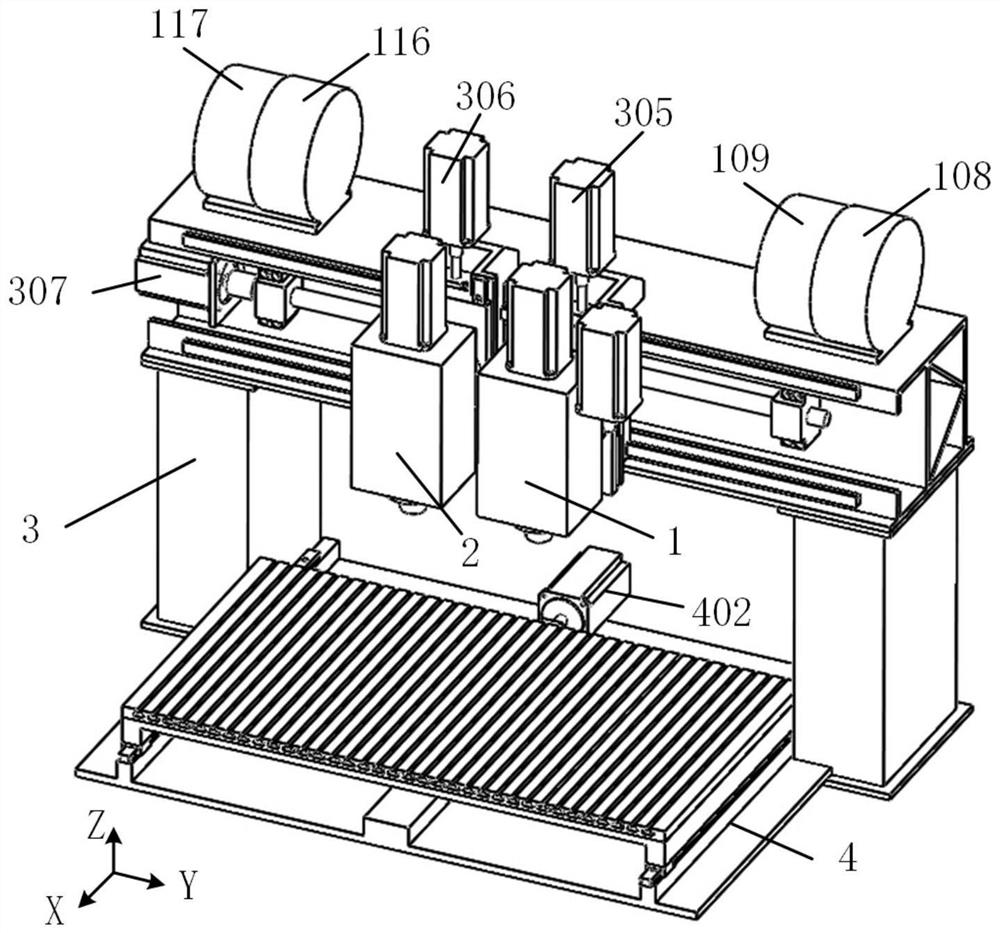

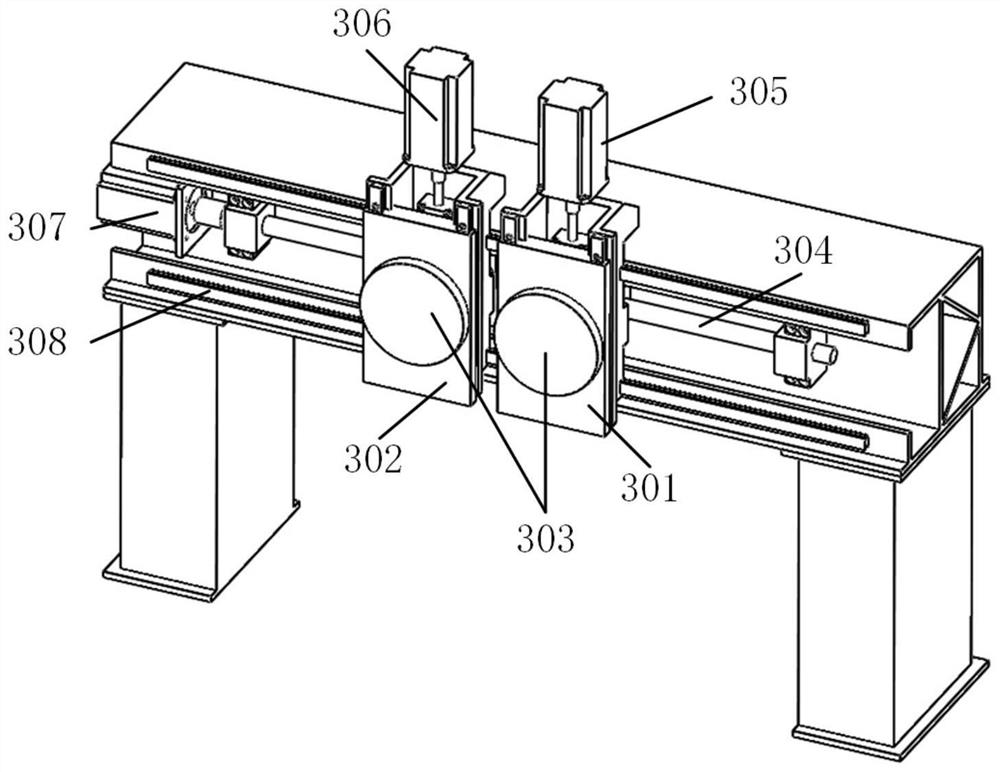

Stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials

ActiveCN111804910AImprove performanceEfficient Quality Additive ManufacturingAdditive manufacturing apparatusTransportation and packagingMaterial supplyIsothermal forging

The invention relates to a stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials. The device comprises four parts including a stirring friction additional material main shaft, an isothermal forging mechanism, a gantry type rack and a workbench; the stirring friction additional material main shaft is used for realizing mixing, preheating and supplying of powder or granular materials, conducting friction squeezing of materials output from a material supplying hole, and using friction heat and pressure to realize layer-by-layer additional material forming manufacturing; the isothermal forging mechanism is used for realizing isothermal forging and micro reshaping of an additional material layer; the gantry type rack is used for fixing the stirring friction main shaft and the isothermal forging mechanism and for realizing advancing as well as swaying angle adjustment of the stirring friction main shaft and the isothermal forging mechanism along the Y axis and the Z axis; and the workbench is used for fixing a substrate and realizing advancing of the substrate along the X axis. The method and the device can realize high-efficiency and high-quality additional material manufacturing of light alloy powder or granular materials, and have the advantages of higher efficiency, simple and convenient operation and lower energy consumption.

Owner:XI AN JIAOTONG UNIV

Method of producing tiny special-shaped composite connection point strip

ActiveCN101172314AHigh bonding strength between layersHigh bonding strengthWelding with roller electrodesContactsSeam weldingMetallurgy

The invention relates to a method for manufacturing a micro-shaped composite contact strip. In the method, the precious metal round wire and the matrix strip are directly composited by continuous rolling welding technology, and then the composited material is processed by precision rolling or rolling die drawing. Molding to prepare products of desired shape. The advantage of this method is that the precious metal is directly in the form of round wire, which not only increases the composite ratio of the precious metal and the base material, realizes the preparation of a micro-shaped composite contact strip with a large difference in width between the electrical contact layer and the base layer, but also improves the yield and Production efficiency, reducing production costs.

Owner:GRIKIN ADVANCED MATERIALS

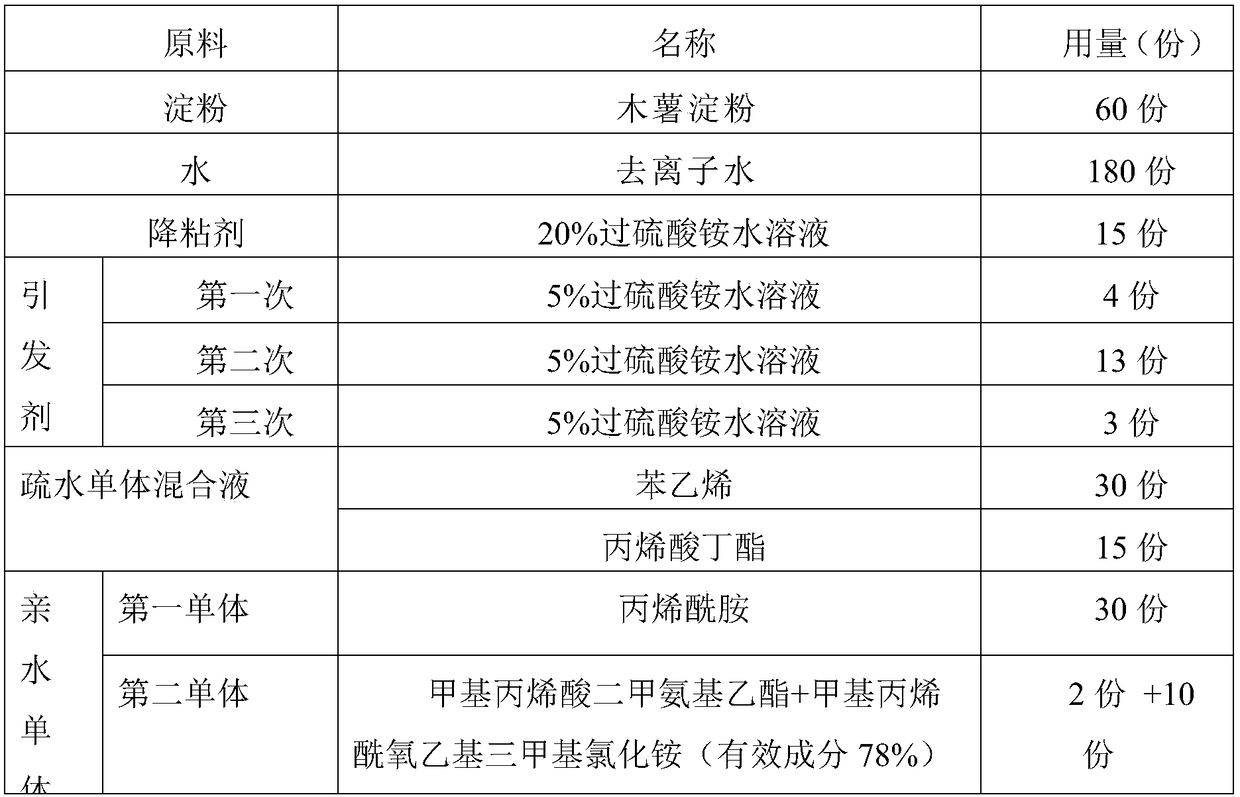

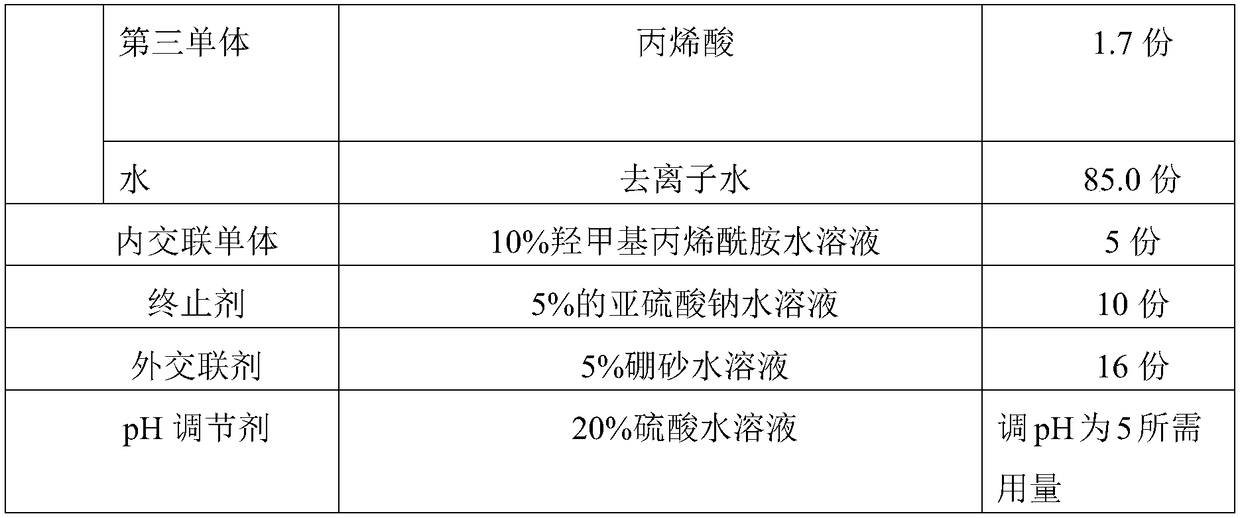

Preparation method of sizing enhancer

ActiveCN108341912APromote degradationSimple production processWater-repelling agents additionReinforcing agents additionHydrophilic monomerReflux

The invention discloses a preparation method of a sizing enhancer. The method is as follows: after cooking and viscosity reduction of starch, introducing nitrogen, cooling to 60-80 DEG C, adding an initiator, and reacting for 10 to 30 minutes; dropwise adding a hydrophobic monomer mixture, a hydrophilic monomer mixture solution, an internal crosslinking monomer solution and an initiator aqueous solution respectively, wherein the dropwise-adding time is controlled to 20 to 90 minutes, and the reaction temperature is controlled at 65 DEG C to 95 DEG C during the time; after the dropwise additionis completed, controlling the temperature at 80 DEG C-95 DEG C for reacting for 10 to 60 minutes, replenishing an initiator, continuing to react at 80 DEG C to 95 DEG C for 30 to 90 minutes, after areactor is free of reflux and the viscosity at 25 DEG C reaches 50 to 500 mPa.s, adding a terminator, cooling, adding an external crosslinking agent, and adjusting the pH to 4 to 6 to obtain the sizing enhancer. The sizing enhancer can be used for in-slurry sizing and surface sizing, and has the advantages such as good reinforcing effect, fast sizing and aging speed, and good resistance to moisture respiration.

Owner:九洲生物技术(苏州)有限公司

Polyether-ether-ketone/short-fiber composite filament material and preparation method thereof

InactiveCN107237002AAchieve recyclingRealize the use effectAdditive manufacturing apparatusMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a polyether-ether-ketone / short-fiber composite filament material for FDM (fused deposition modeling) and a preparation method thereof, belongs to fused deposition modeling materials and a preparation method of the fused deposition modeling materials, and solves the problems that pure PEEK (polyether-ether-ketone) is high in shrinkage rate, and bonding strength between layers is low in printing. According to the composite filament material, short fibers are short-cut inorganic fibers, surface oxidation treatment is performed on the short fibers, the treated short fibers and dispersing agents are added into ethanol solution, mixture is stirred and ultrasonically treated to form primary suspension liquid, polyether-ether-ketone powder is added into the primary suspension liquid, mixed materials of the primary suspension liquid and the polyether-ether-ketone powder are stirred and ultrasonically treated to form secondary suspension liquid, pressure reduction, extraction filtration, drying and ball-milling are performed on the secondary suspension liquid to obtain composite powder, and granulation and filament drawing are performed on the composite powder to obtain the composite filament material. The composite filament material is uniform in shape and good in chemical resistance and has better rigidity, toughness and abrasion resistance, the use temperature of the composite filament material can reach 260 DEG C or more, the shrinkage rate of the composite filament material is greatly reduced, and bonding strength between layers is improved when the composite filament material is used for FDM processes.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

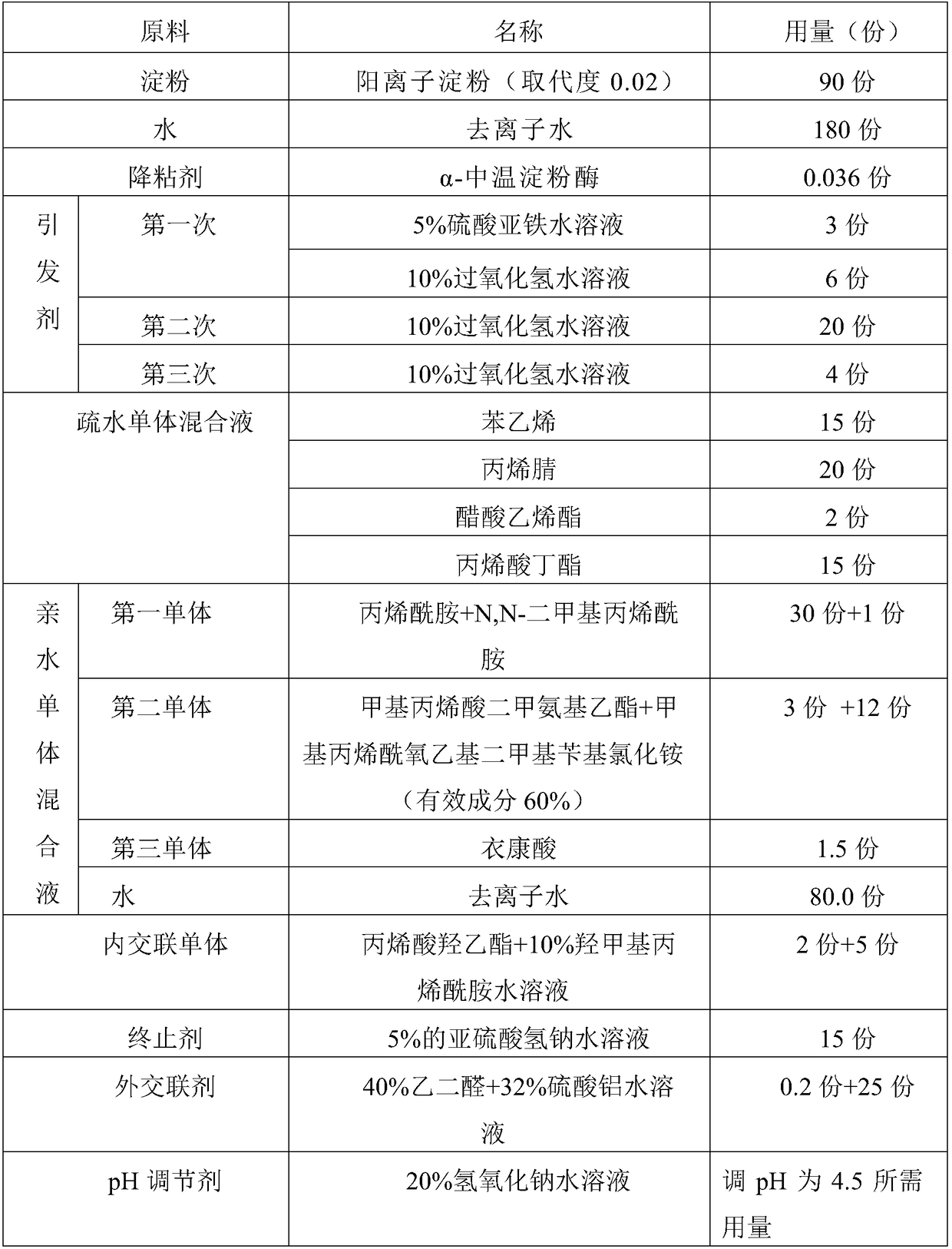

Composite material, preparation method and application thereof

InactiveCN108248170AEasy to prepareIncrease productivitySynthetic resin layered productsSpecial ornamental structuresFiberAdhesive

Relating to the field of composite materials, the invention discloses a composite material, a preparation method and application thereof. The preparation method of the composite material includes: gluing a fiber layer to at least one side surface of a thermoplastic sheet or metal sheet through an adhesive to form a preform, then employing two-component polyurethane resin for resin transfer moldingon the fiber layer surface of the perform so as to form a polyurethane-fiber layer together with the fiber layer. Specifically, the two-component polyurethane resin contains a polyol component and apolyisocyanate component. The preparation method for the composite material provided by the invention not only can ensure no springback of fiber cloth, but also can acquire good surface quality, and the obtained product has very high transparency, scratch resistance and interlayer bonding strength.

Owner:BYD CO LTD

Multilayer Bottle

ActiveUS20090277858A1The degree of freedom becomes largerLess bendingFlexible coversWrappersPolyamideCarboxylic acid

There is provided a multilayer bottle including an outermost layer and an innermost layer which are each made of a thermoplastic polyester resin, and at least one barrier layer interposed between the outermost layer and the innermost layer. The barrier layer contains at least two components including a polyamide obtained by polycondensing a diamine component containing m-xylylenediamine as a main component with a dicarboxylic acid component containing an α,ω-linear aliphatic dicarboxylic acid as a main component, and a thermoplastic resin having a lower molecular weight than that of the polyamide. The multilayer bottle hardly suffers from delamination upon impact or dropping and, therefore, is not required to have a shape with less irregularities or less bends for preventing the delamination, and further has a large freedom of design choice.

Owner:MITSUBISHI GAS CHEM CO INC

Composite material reinforced by hybrid fiber preform and preparation method of composite material

InactiveCN113912405ASolve the problem of easy hairImprove weavabilityCeramic layered productsFiber bundleUltimate tensile strength

The invention discloses a composite material reinforced by a hybrid fiber preform. The composite material is composed of the fiber preform, a composite material interface and a ceramic matrix, the fiber preform is a three-dimensional fabric formed by hybrid weaving of 2-5 kinds of high-performance inorganic fibers, and the matrix is resin, light alloy, carbon and ceramic. A preparation method of the composite material comprises the steps of ceramic slurry preparation, fiber bundle dipping treatment, fiber weaving, three-dimensional integral structure preform forming, preform heat treatment, interface preparation and matrix preparation. The weaving performance of the inorganic rigid fibers is improved, the prepared composite material is good in integrity, high in interlayer bonding strength and not prone to layering, meanwhile, the functions of wave transmission, wave absorption, high-temperature structural material, heat insulation and heat protection are achieved through combination of the hybrid fibers, and integration of the structure and the function is effectively achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

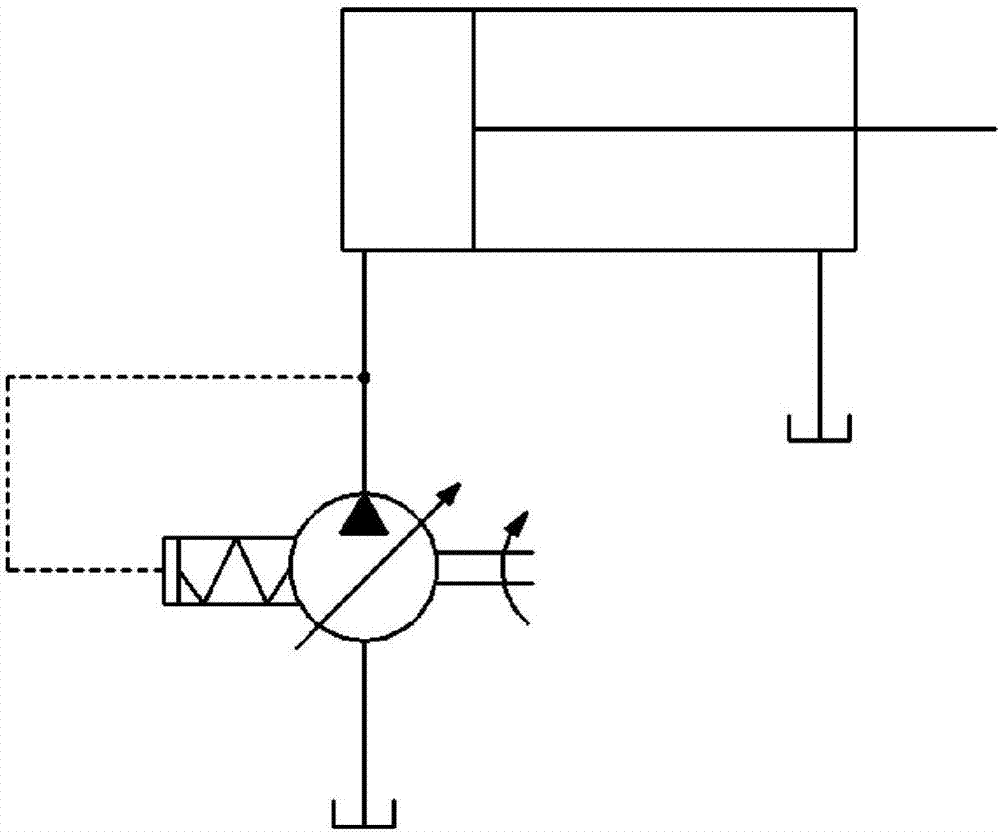

Multicomponent atmosphere controllable spraying method and apparatus

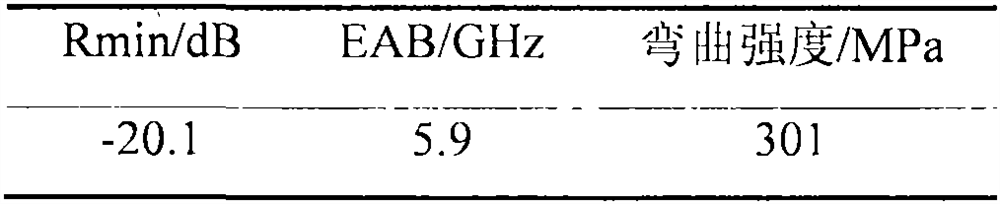

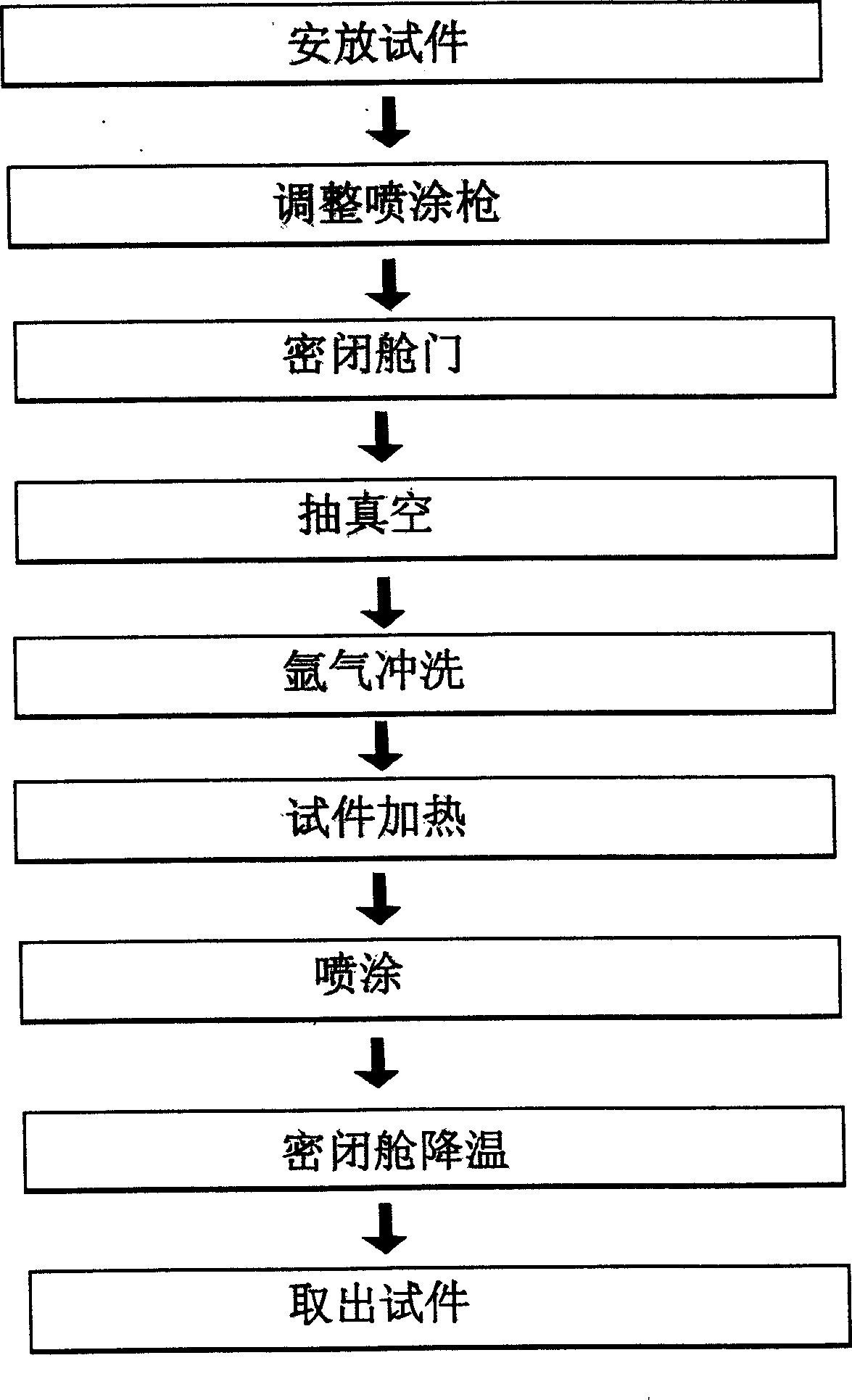

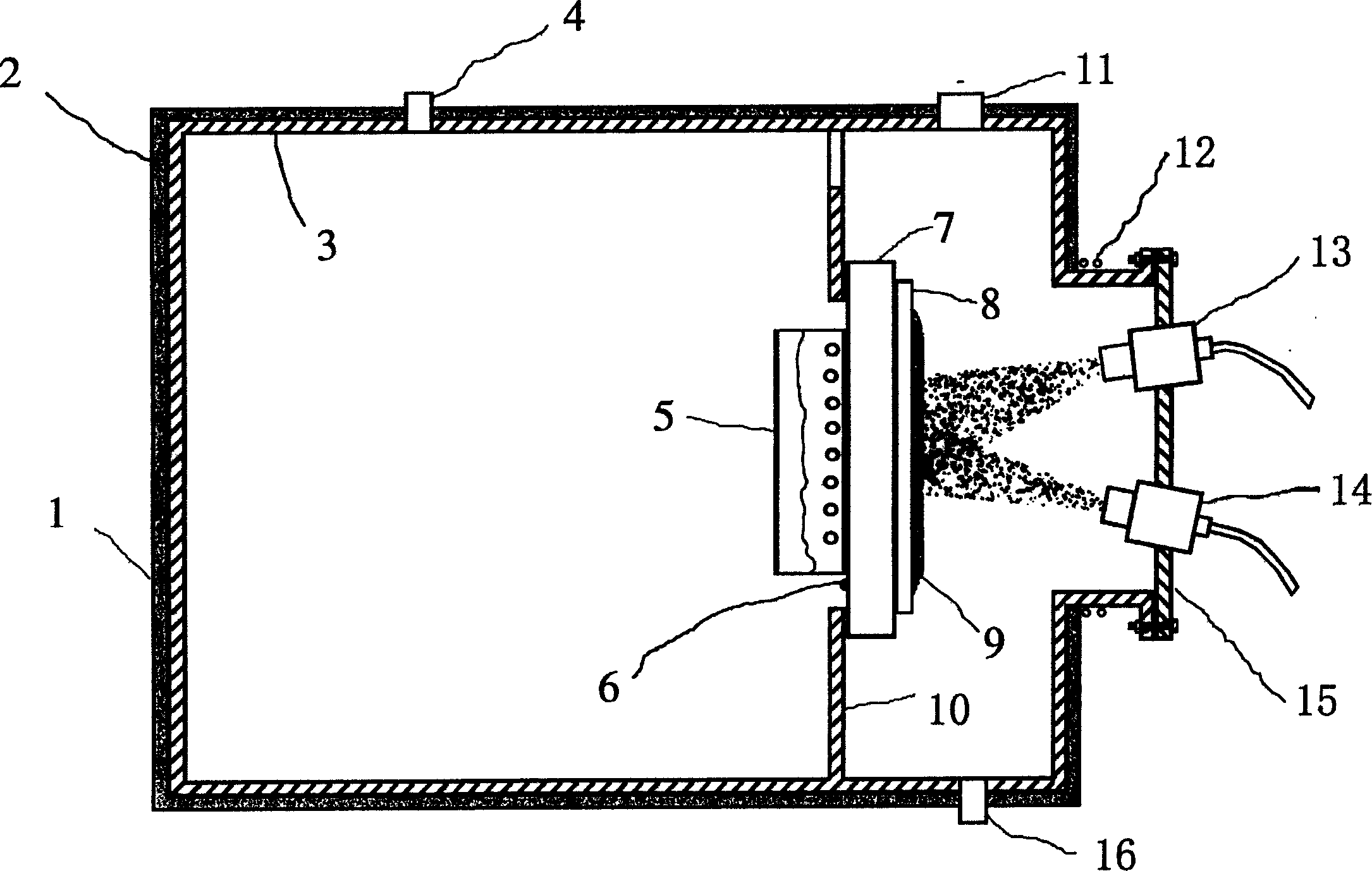

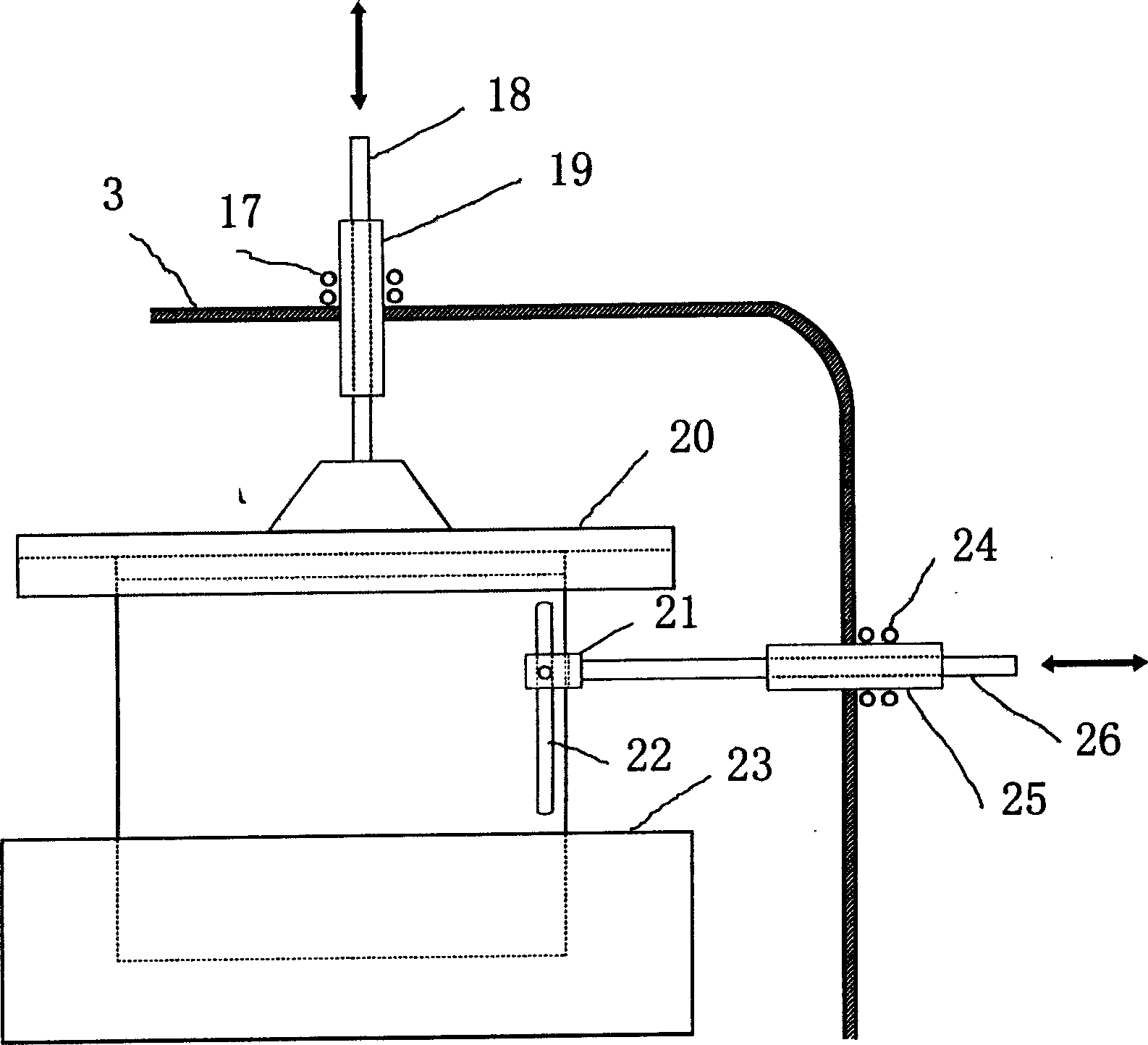

InactiveCN1583283AHigh bonding strength between layersNo porosityLiquid spraying plantsElectric arc sprayingEngineeringPlasma sprayed

A multi-element atmosphere controllable spray method includes such steps as installing a sample on carrier table, regulating spray distance, sealing door, vacuumizing, filling inertial gas, heating sample, using arc and plasma guns for spaying, holding its temp, and cooling. Its apparatus is composed of case, supporting plate, movable carrier table, heating plate and arc and plasma guns.

Owner:SHENYANG POLYTECHNIC UNIV

Preparation method of carbon/carbon composite material flat plate with carbide coating on surface

InactiveCN103232255AGood surface smoothnessHigh bonding strength between layersCarbon compositesFiber

The invention discloses a preparation method of a carbon / carbon composite material flat plate with a carbide coating on the surface. The preparation method is characterized by comprising the following steps of: A, alternately superposing plain carbon cloth or twilled carbon cloth with a short carbon fiber net blank and needling on a knitting machine to form quasi-three-dimensional needled integrated felt; B, performing warm-pressing preforming on the integrated felt on a flat plate machine to obtain a flat plate preformed body with the density of 0.50 to 0.75 g / cm<3>; C, placing the flat plate preformed body into a chemical vapor deposition furnace and densifying to obtain a carbon / carbon composite material flat plate with the density of 1.35 to 1.55 g / cm<3>; D, placing the densified flat plate into a high-temperature graphitization furnace and performing treatment at 2,200 DEG C for 2 hours; E, placing the flat plate subjected to high-temperature graphitization treatment on a lathe and cutting into a flat plate with the designed size; and F, placing the cut flat plate into the chemical vapor deposition furnace and depositing one layer of carbide on the surface of the flat plate to obtain the finished product. The method is mainly used for preparing the carbon / carbon composite material flat plate with the carbide coating on the surface.

Owner:HUNAN YOUYUAN MATERIALS

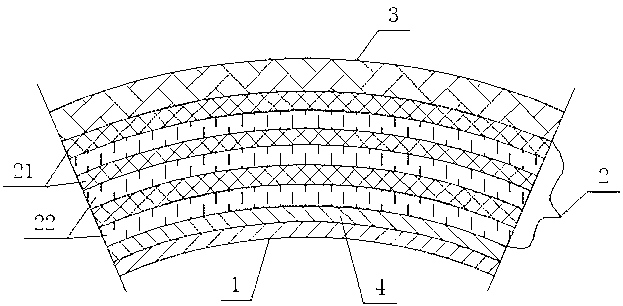

Glass steel tube produced in continuous winding process

The invention discloses a glass steel tube produced in a continuous winding process. The glass steel tube comprises an inner liner layer, a structural layer and an outer protection layer. The structural layer is formed by multiple long fiber layers and multiple short fiber layers at intervals in the vertical direction in a staggered and combined mode. Each long fiber layer comprises long cut glass fibers and resin, and each short fiber layer comprises short cut glass fibers, quartz sand and resin. The glass steel tube is manufactured in the continuous winding process with the resin serving as a substrate, the glass fibers as reinforced materials and the quartz sand as stuffing. Meanwhile, due to the facts that the structural layer is formed by the multiple long fiber layers and short fiber layers in a staggered mode and combination strength between the layers is high, the overall strength and rigidity of the glass steel tube are strong. Meanwhile, the glass steel tube has strong corrosion resistance and flexibility, stretching strength is much more excellent than that of an existing product, and service life of the glass steel tube can be more than 50 years.

Owner:QUANZHOU LUTONG PIPELINE TECH

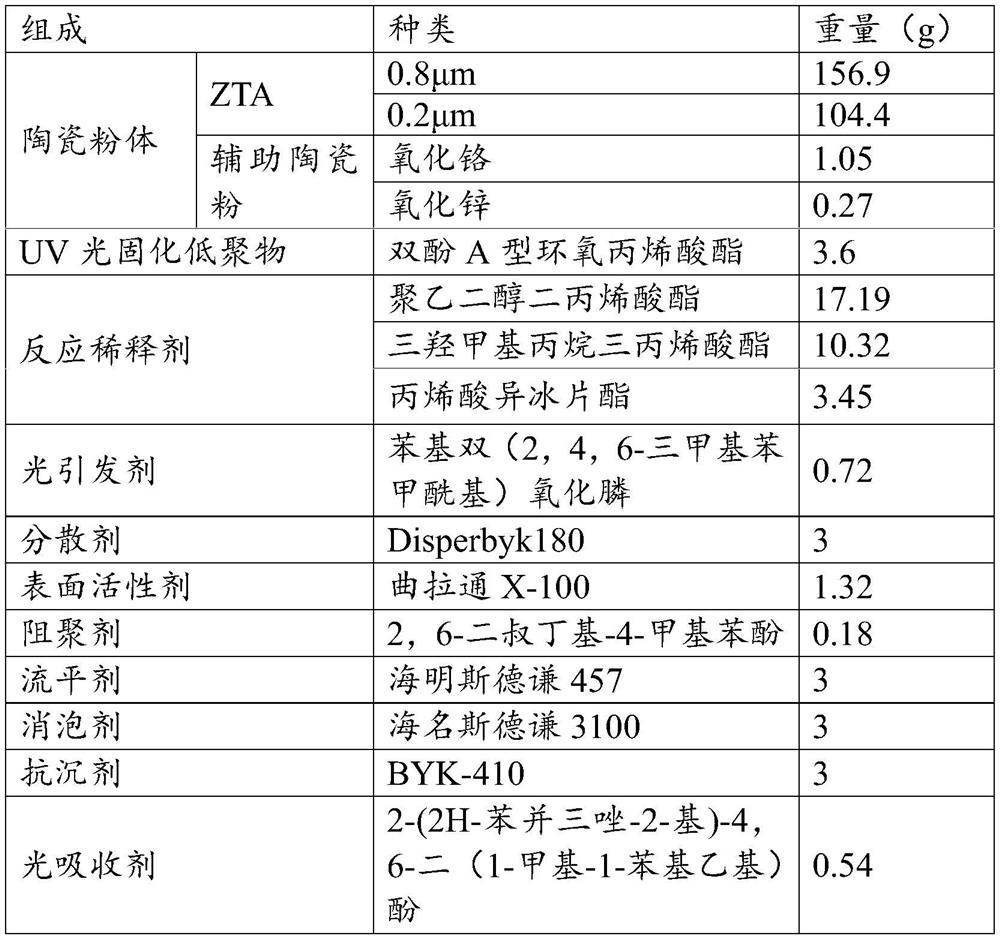

Preparation method of ceramic material

ActiveCN114380583AHigh hardnessHigh densityAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicAluminum Ion

The invention belongs to the technical field of ceramics, and provides a preparation method of a ceramic material, which comprises the following steps: degumming a zirconium oxide toughened aluminum oxide ceramic blank, pre-sintering, soaking in steeping liquor and sintering, wherein the impregnation liquid comprises a zirconium ion salt solution, an aluminum ion salt solution and urea. According to the preparation method of the ceramic material, the mixed solution of the zirconium ion salt solution, the aluminum ion salt solution and the urea is adopted as the steeping liquor to carry out post-treatment on the zirconium oxide toughened aluminum oxide ceramic green body, the compactness of the ceramic material is improved, and the defect that a ceramic product prepared through a traditional 3D printing technology is low in hardness is overcome.

Owner:重庆恩辰新材料科技有限责任公司 +1

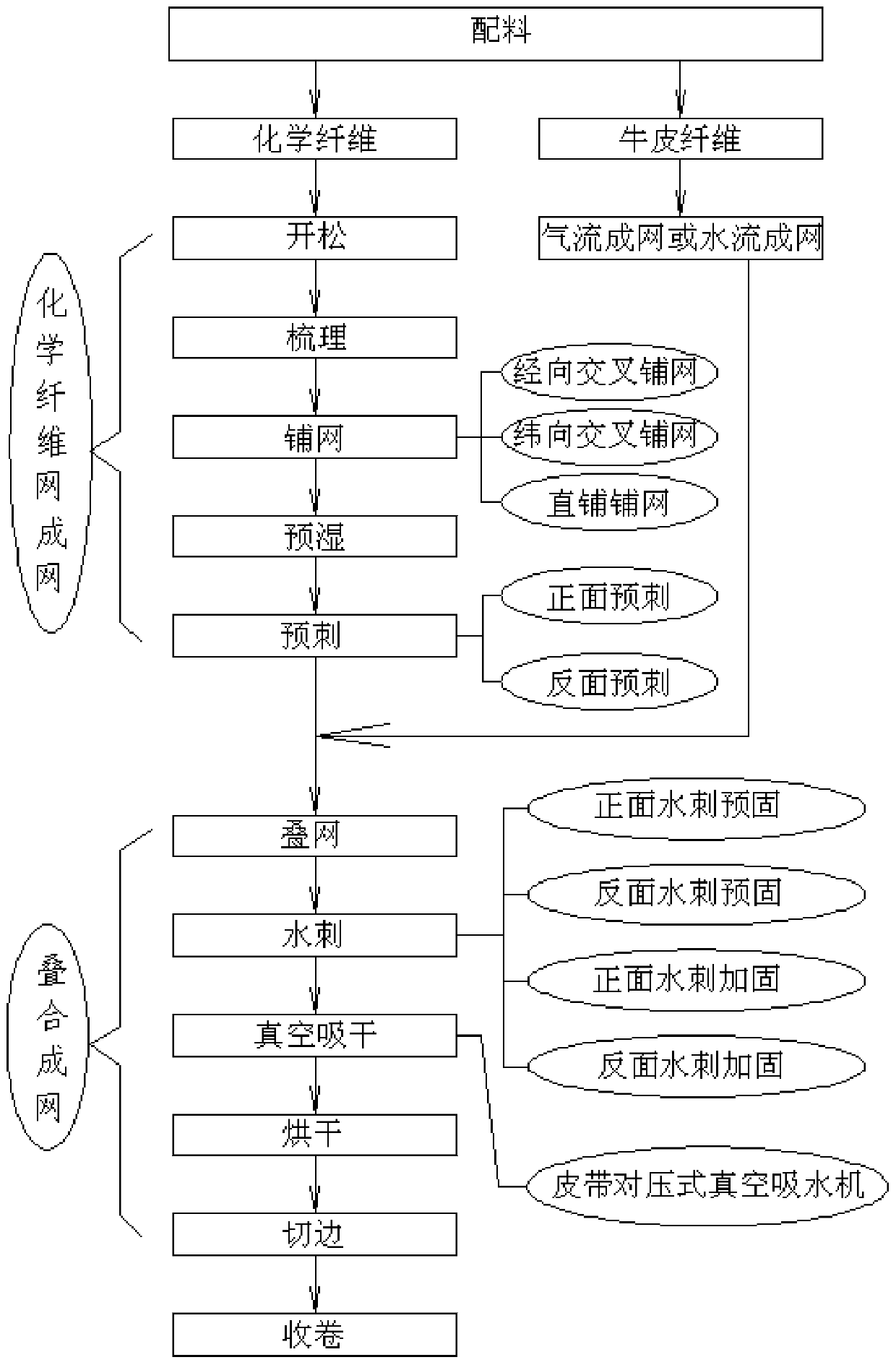

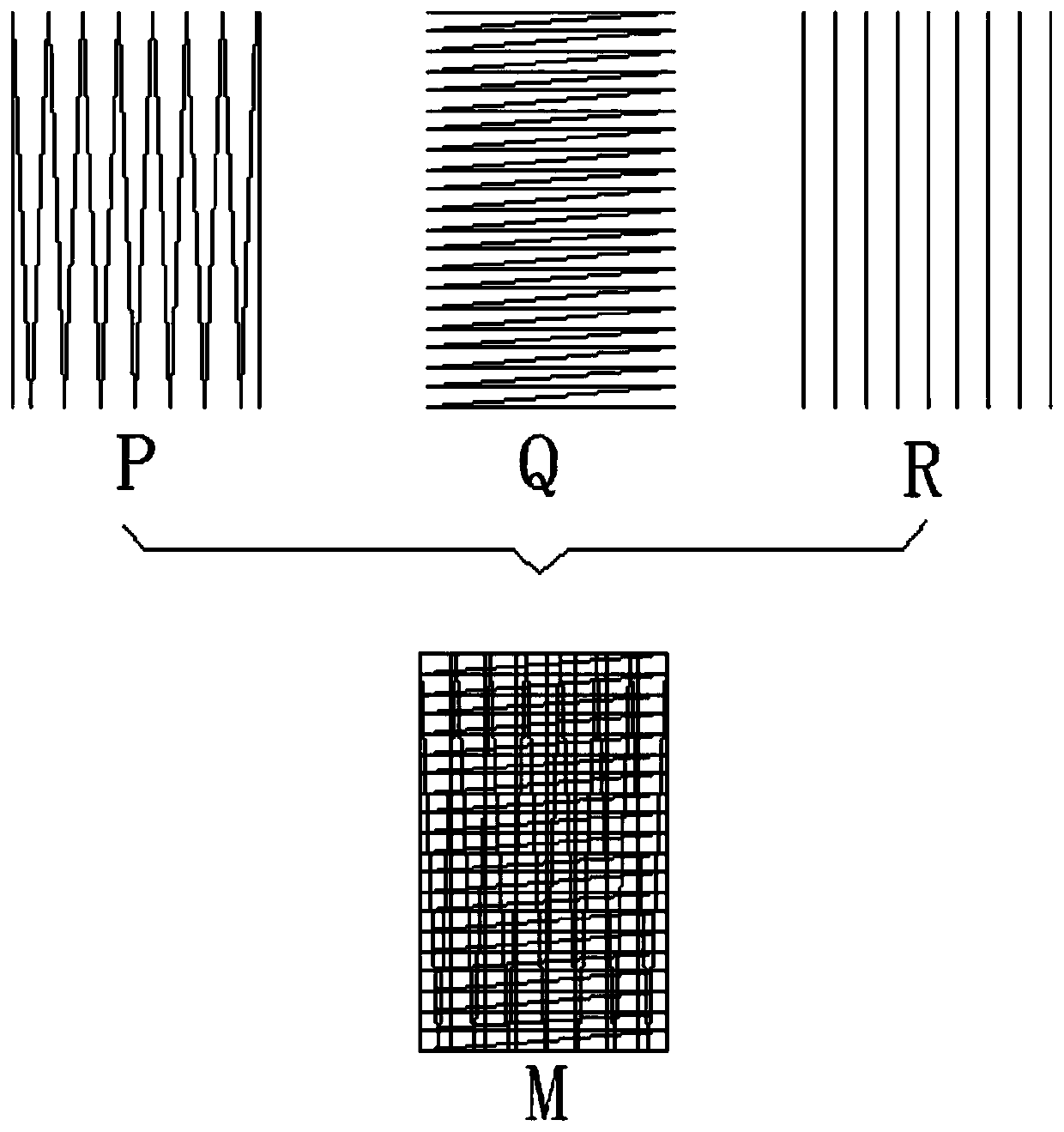

Preparation process of fully-penetrated cow fiber leather base cloth

ActiveCN110258023ASolve the disadvantages that are not easy to penetrateHigh tensile strengthDrying solid materials without heatNon-woven fabricsFiberManufacturing technology

The invention relates to the technical field of leather manufacturing, and discloses a preparation process of fully-penetrated cow fiber leather base cloth. The preparation process includes a batching process, a chemical fiber net forming process, a cow leather fiber net forming process, and a process of laminating the chemical fiber net and the cow leather fiber net into a net, wherein the batching process includes taking chemical fibers and cow leather fibers as raw materials for preparing fully-penetrated cow fiber leather base cloth, and batching according to a proportion; the chemical fiber net forming process sequentially includes the working procedures of opening, carding, net laying, pre-wetting and pre-penetrating: in the cow leather fiber net forming process, making cow leather fiber raw materials into a cow leather fiber net by adopting airflow net forming or water flow net forming; and the process for laminating the chemical fiber net and the cow leather fiber net into a net sequentially includes the working procedures of laminating the net, spunlacing, vacuum suction and drying, and the net laying working procedure includes warp cross laying and weft cross laying. The preparation process improves the physical properties of the cow fiber leather base cloth and reduces the production cost.

Owner:JIANGYIN JUNHUA TEXTILE TECH

NbTiAl series laminate structure intermetallic compound composite material and its preparation method

InactiveCN1962257AHigh bonding strength between layersGood room temperature toughness and high temperature performanceMetallic material coating processesLaser beam welding apparatusMetal alloyIntermetallic

The invention relates to a laminated metal composite of NbTiAl group, and relative production, wherein said composite is formed by one layer of Nb group flexible metal alloy layer, above one layer of Nb group metal compound, and above one layer of Nb group flexible metal alloy. The invention is made from laser deposition method, while the metal compound layer is directly composed on the flexible metal alloy layer via said method; the flexible metal layer and metal compound layer are smelt, while their thickness and ratio can be controlled. The invention has high flexibility in room temperature and high temperature.

Owner:TSINGHUA UNIV

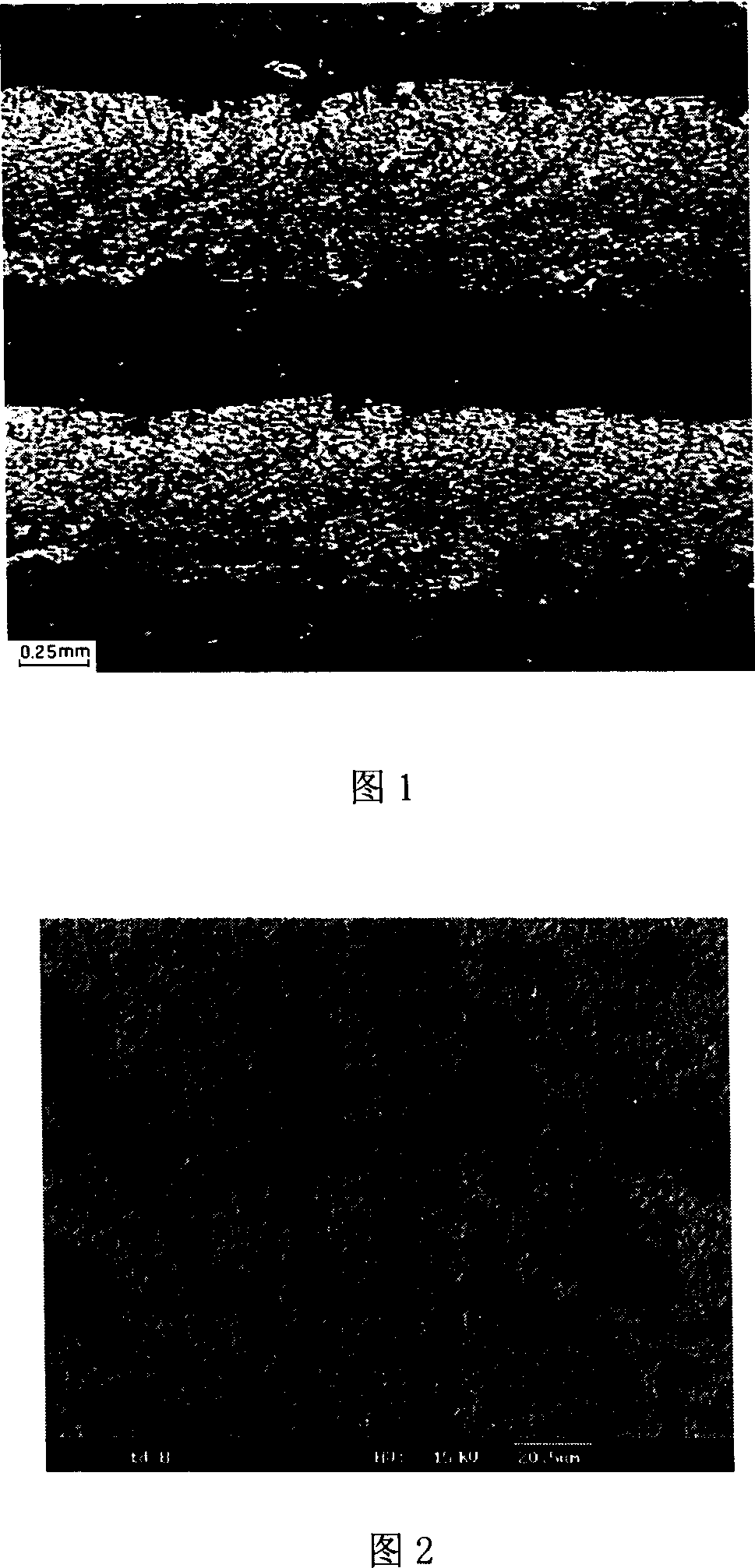

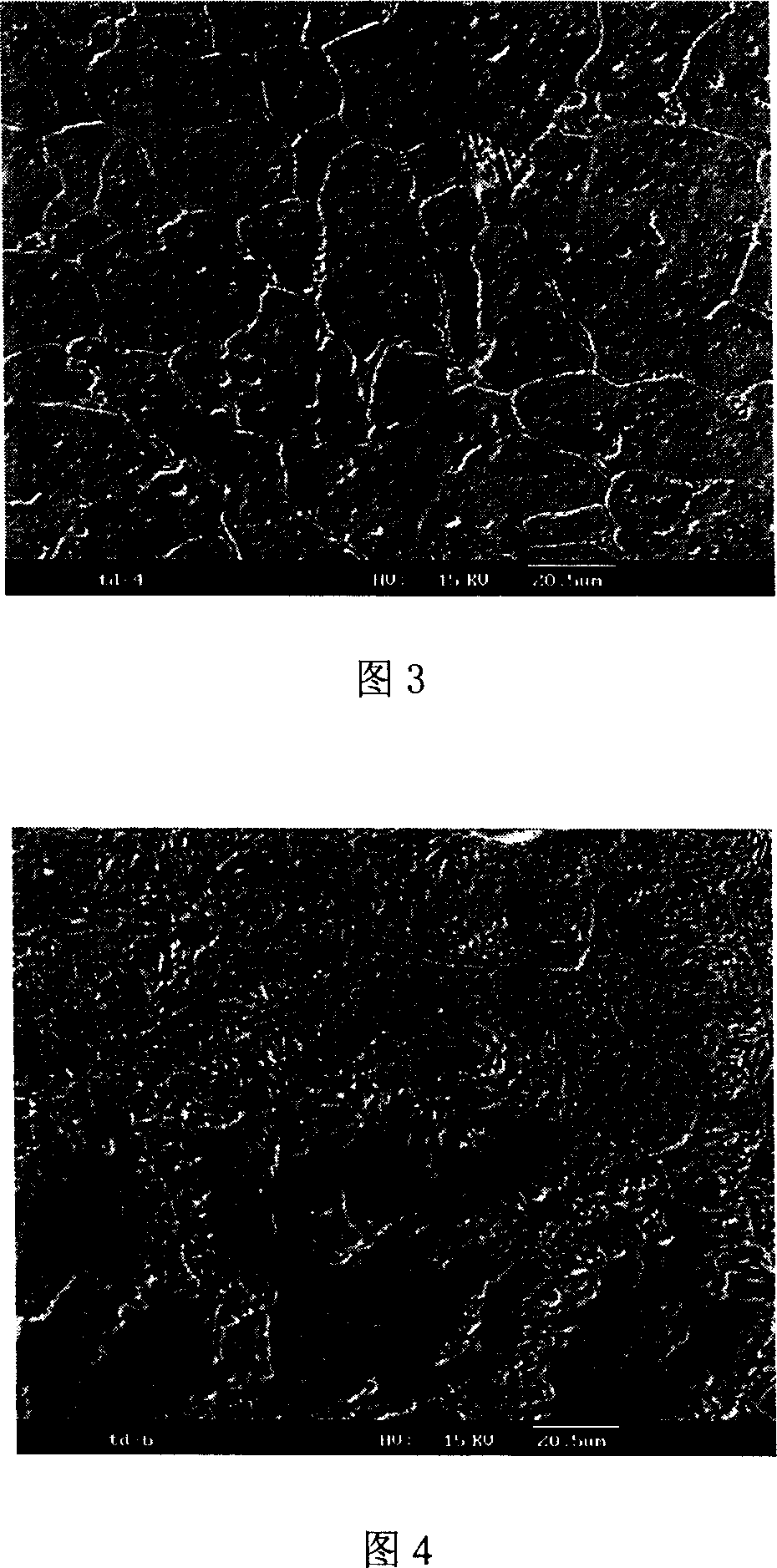

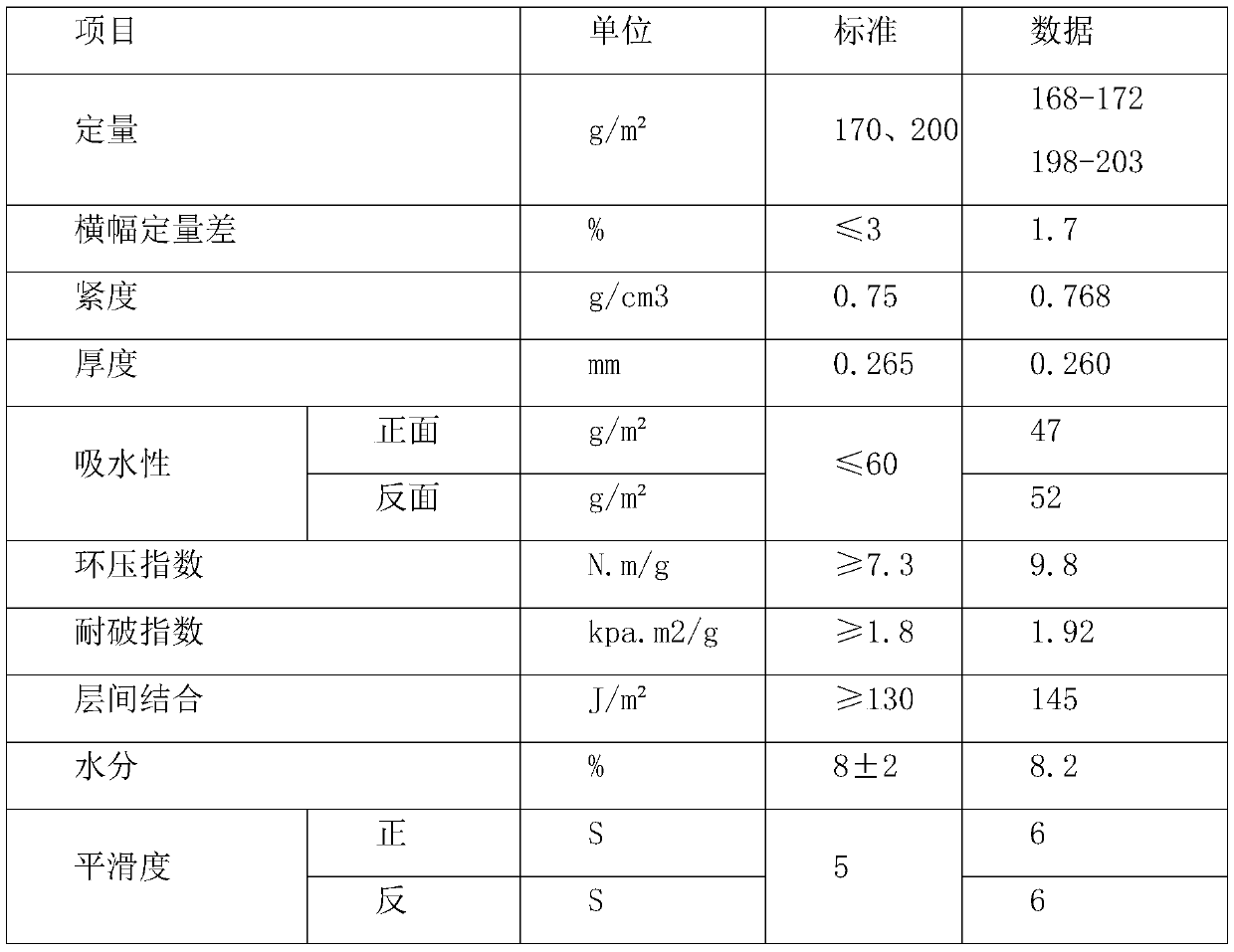

ML kraft paperboard and preparation process thereof

ActiveCN110373945AImprove tightnessHigh strengthWrappersWater-repelling agents additionCardboardPapermaking

The invention discloses an ML kraft paperboard and a preparation process thereof, and mainly relates to the technical field of papermaking. According to the ML kraft paperboard, basis weight is 170, 200g / m<2>, the banner quantitative difference is less than or equal to 3%, tightness is greater than or equal to 0.75 g / cm<3>, smoothness is greater than or equal to 5s, a lateral ring pressure index is greater than or equal to 7.3N.m / g, interlayer bonding strength is greater than or equal to 130J / m<2>, a bursting index is greater than or equal to 1.8kpa. M<2> / g, transverse folding strength is greater than or equal to 4 times and paper moisture is 8+ / -2%. The preparation process of the ML kraft paperboard comprise the steps that preparation, pulping, mixing, paper forming and rewinding are carried out to obtain the paperboard, and then packaging is carried out; and pulp is ground during pulping, spray starch and fillers are added during paper making, and a dyeing agent is added for dyeing.The ML kraft paperboard has the advantages of low cost, high interlayer bonding, high water resistance, high smoothness and clean front appearance. The ML kraft paperboard is mainly used in a surfacelayer and an inner layer of an industrial paper tube, the ''angle-rising'' problem does not occur when the paper tube is cut in sections due to low basis weight; and the problems of surface blisteringand paper tube layering are solved due to the fact that the interlayer bonding strength of the ML kraft paperboard is higher than that of a general kraft paperboard and cardboard paper.

Owner:汇胜集团平原纸业有限公司

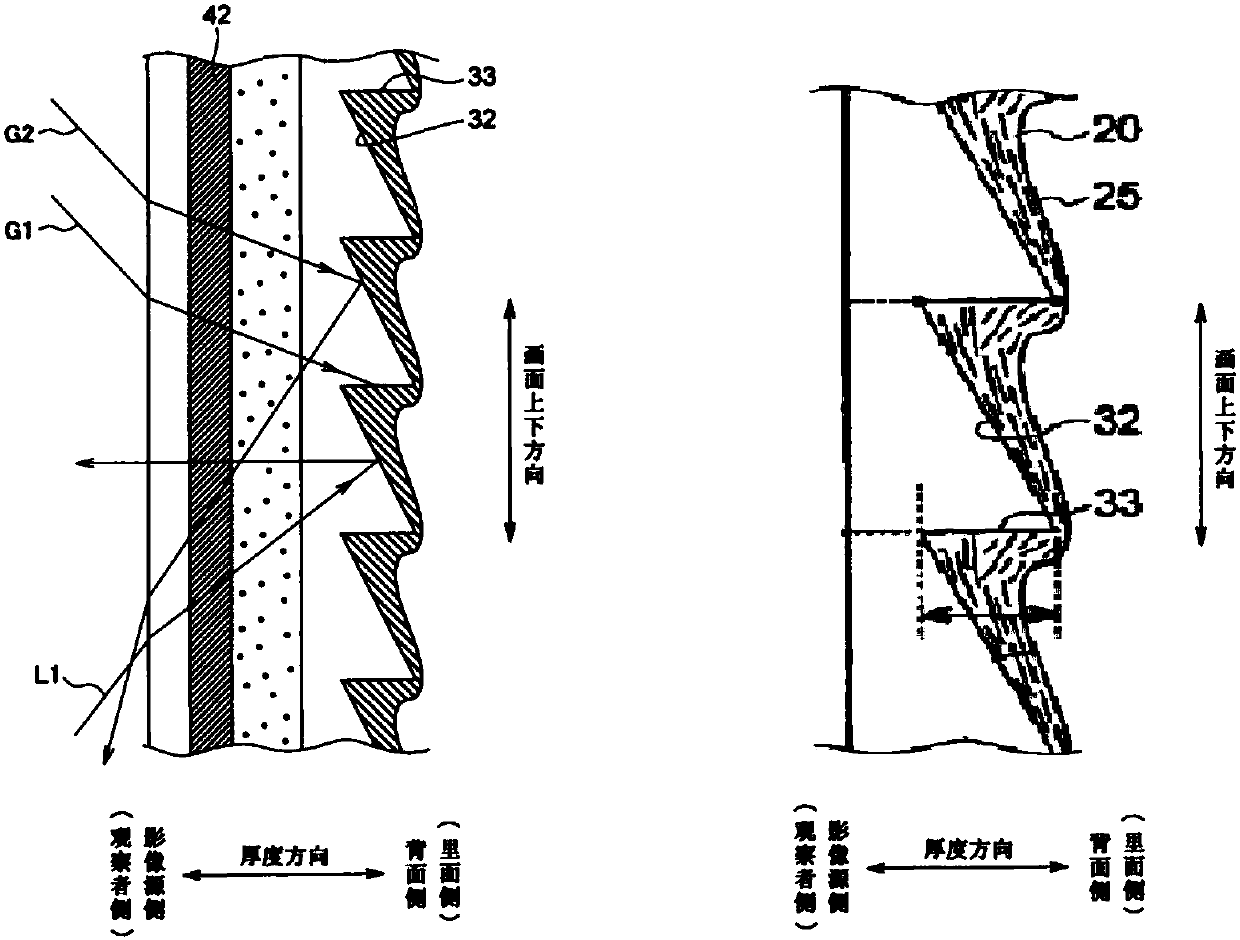

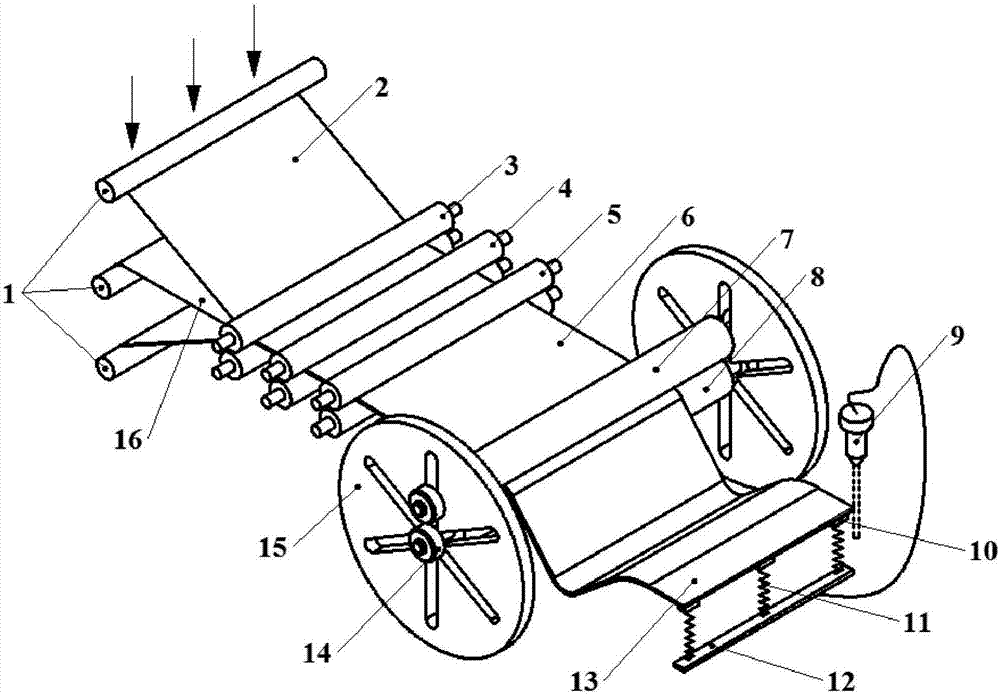

Screen and preparation method of light-absorbing film

The invention discloses a screen with a light absorption layer and a preparation method of the light absorption film for the light absorption layer. The screen comprises a first transparent base material layer, an optical function layer, an adhesive glue layer and the light absorption layer, which are sequentially stacked from the incident side of the projection light. The light absorption layer receives and absorbs light which passes through the adhesive layer and reaches the light absorption layer. The optical function layer comprises a plurality of microstructure units, and the plurality ofmicrostructure units form a sawtooth structure. The optical function layer can enable at least a part of projection light to be emitted after total reflection and to transmit at least a part of ambient light. According to the invention, the screen gain can be improved while the high contrast is obtained, the processing technology can be simplified, and the cost can be reduced.

Owner:APPOTRONICS CORP LTD

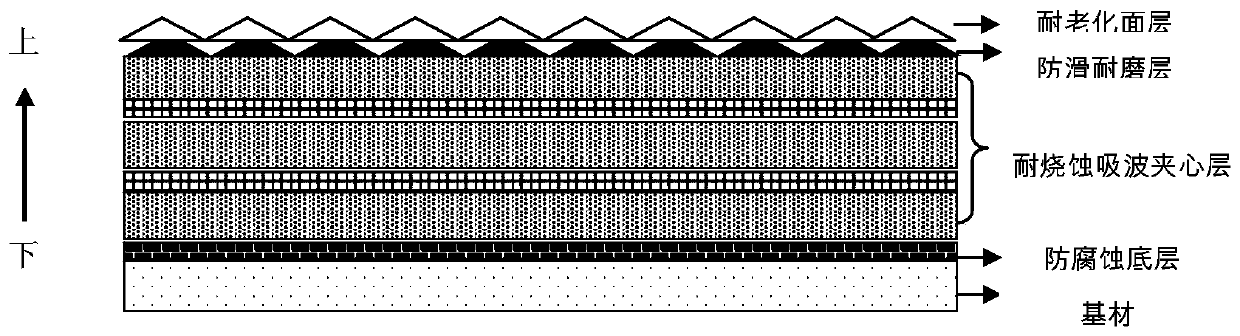

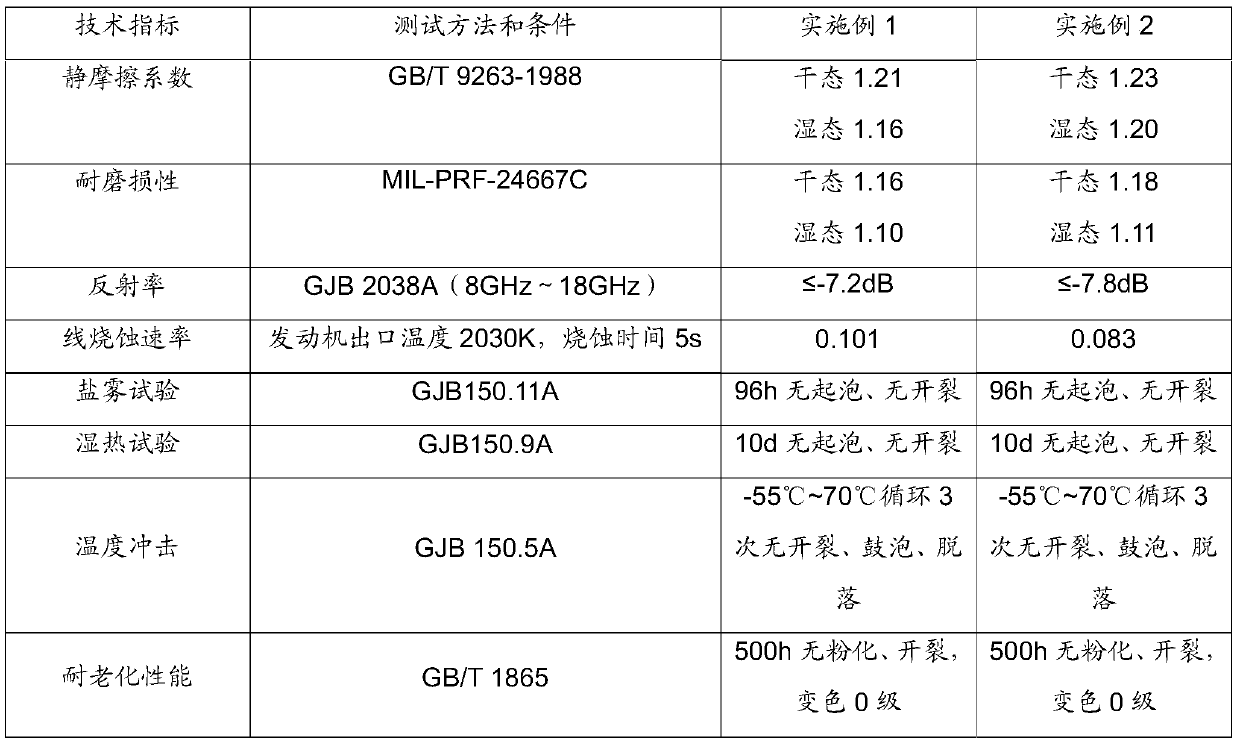

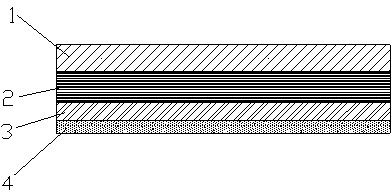

Ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and preparation method thereof

ActiveCN110885583AThe need for multifunctional integrationReduced viewing distanceFireproof paintsAnti-corrosive paintsStatic friction coefficientComposite coating

The invention provides an ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and a preparation method thereof, and belongs to the field of special functional coatings. The composite coating comprises an anticorrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an antiskid and wear-resistant layer and an anti-aging surface layer, and the composite coating is designed through collaborative matching of interlayer thickness to form a multifunctional compatible integrated coating. Compared traditional antiskid coatings, the coating of the invention has the following advantages: the process is simple, the reflectivity of the composite coating is smaller than or equal to -7 dB in a frequency band of 8-18 GHz, the composite coating has a low linear ablation rate and a good anti-aging performance, the static friction coefficient before and after abrasion is larger than or equal to 1.10, the composite coating can pass GJB150 environment testassessment, and the coating design scheme has remarkable technical advancement.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High-abrasion-proof tangential belt

InactiveCN102991051AHigh bonding strength between layersReasonable structural designSynthetic resin layered productsRubber layered productsAdhesiveEngineering

The invention discloses a high-abrasion-proof tangential belt. The tangential belt comprises an outer elastic layer, a strengthening layer, an inner elastic layer and an abrasion-proof layer, wherein the outer elastic layer and the inner elastic layer are adhered to two sides of the strengthening layer by using an adhesive, the outer elastic layer is arranged on the outer side, the abrasion-proof layer is formed on one side of the inner elastic layer, and the abrasion-proof layer is an adhered abrasion-proof coating. The high-abrasion-proof tangential belt disclosed by the invention is reasonable in structure design and high in interlayer bonding strength, and a body has good strength and flexibility; and meanwhile, because the bottom of the tangential belt is additionally provided with an abrasion-proof coating, the tangential belt shows the excellent application performance on high-speed textile equipment, and is long in service life.

Owner:SUZHOU XUNXIAN TEXTILE TECH CO LTD

Method for Filling Into Multilayer Bottle

ActiveUS20100180979A1High bonding strength between layersAvoid layeringSynthetic resin layered productsLarge containersGlass transition pointEngineering

There is provided a method for filling a multilayer bottle including outermost and innermost layers and at least one barrier layer interposed between the outermost and innermost layers, with a material to be stored therein. In the filling method, the material to be stored is filled in the multilayer bottle having the barrier layer satisfying a specific glass transition point (Tg) and a specific water content as measured by a Carl-Fisher method at 230° C. for 30 min. The multilayer bottle obtained by the filling method of the present invention hardly undergoes delamination between the layers owing to dropping or impact, and is applicable to a filling method such as hot filling.

Owner:MITSUBISHI GAS CHEM CO INC

Multilayer bottle

ActiveUS7927678B2The degree of freedom becomes largerLess bendingFlexible coversWrappersPolymer sciencePolyamide

There is provided a multilayer bottle including an outermost layer and an innermost layer which are each made of a thermoplastic polyester resin, and at least one barrier layer interposed between the outermost layer and the innermost layer. The barrier layer contains at least two components including a polyamide obtained by polycondensing a diamine component containing m-xylylenediamine as a main component with a dicarboxylic acid component containing an α,ω-linear aliphatic dicarboxylic acid as a main component, and a thermoplastic resin having a lower molecular weight than that of the polyamide. The multilayer bottle hardly suffers from delamination upon impact or dropping and, therefore, is not required to have a shape with less irregularities or less bends for preventing the delamination, and further has a large freedom of design choice.

Owner:MITSUBISHI GAS CHEM CO INC

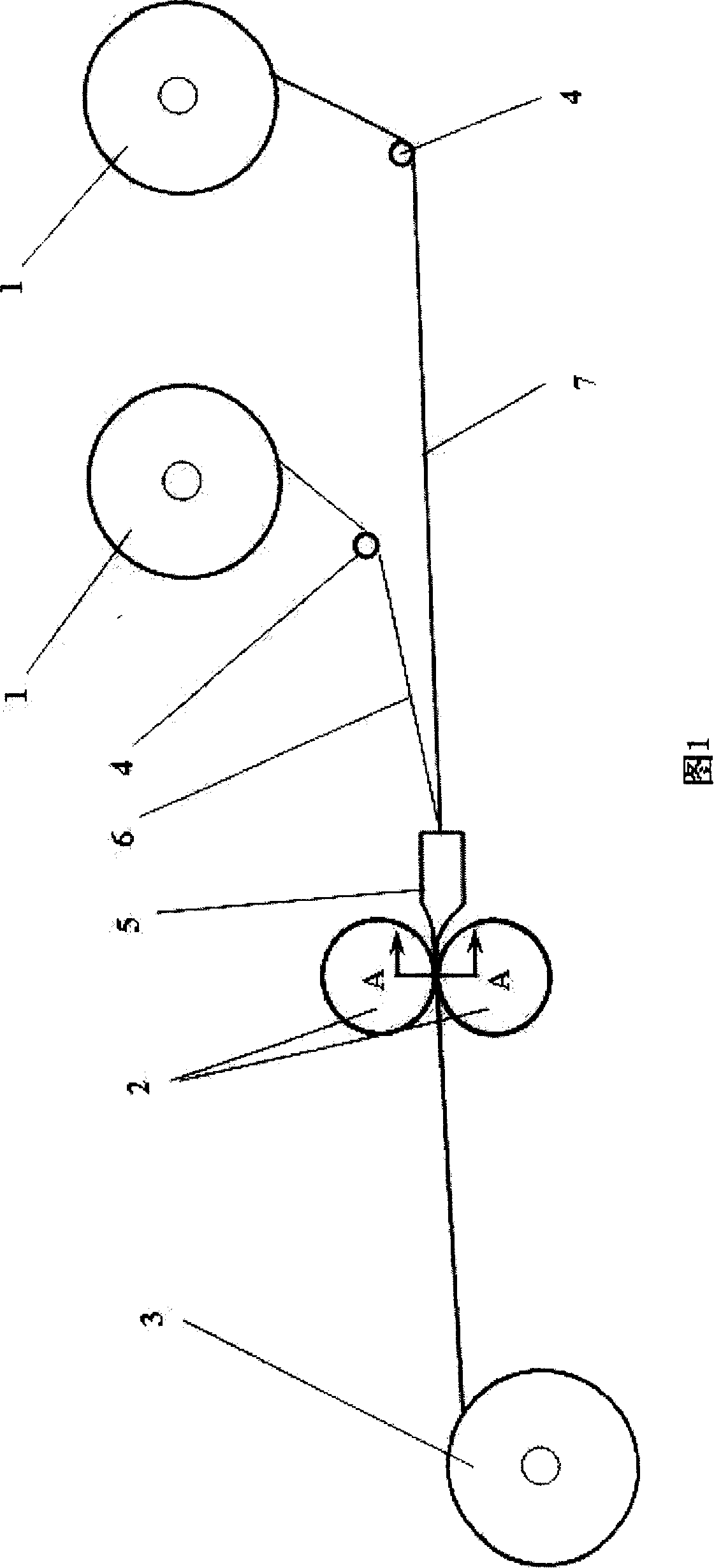

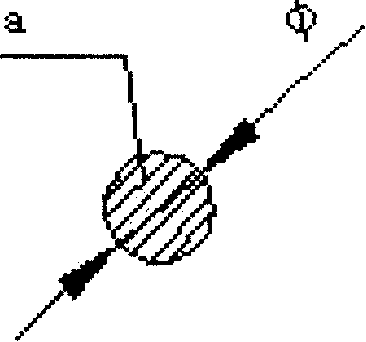

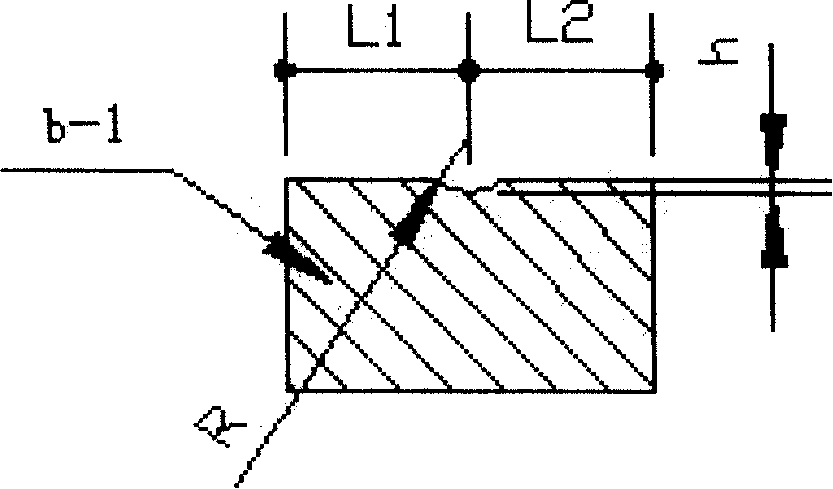

Free roll bending equipment for super-hybrid composite layer plates and forming method

ActiveCN107379572AReduce manufacturing costShorten production timeMetal working apparatusRoom temperatureResin-Based Composite

The invention discloses a free roll bending equipment for super-hybrid composite layer plates and a forming method. The super-hybrid composite layer plates are of lamination structures of metal layers and fiber reinforced resin base composites, and the forming method comprises six procedures, namely spraying glue and feeding, hot rolling, free roll bending, water cutting and pressure maintaining cooling; the free roll bending operation is achieved by rotating of a bending roll shaft and revolving around an fixing roll shaft of the bending roll shaft, the bending curvature is determined by the radius of the fixing roll shaft, and the bending angle is determined by the revolution angle of the bending roll shaft; and after an bending component is subjected to free roll bending, the bending component is placed in a closed container with a constant pressure to conduct heat insulation and is cooled to a room temperature. According to the free roll bending equipment for the super-hybrid composite layer plates and the forming method, preparation and bending formation of the super-hybrid composite layer plates are integrated, manufacturing cost and time is reduced by a large margin, and the free roll bending equipment for the super-hybrid composite layer plates and the forming method have the advantages of being high in interlayer combination strength, high in forming precision, high in degree of automation and high in designability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multi-Layer Bottle

ActiveUS20100233401A1Excellent gas barrier performanceLarge freedom of design choiceSynthetic resin layered productsThin material handlingPolyamideCarboxylic acid

There is provided a multilayer bottle including outermost and innermost layers each made mainly of a polyester (A) and at least one barrier layer interposed between the outermost and innermost layers. The polyester (A) is a thermoplastic resin obtained by polymerizing a dicarboxylic acid component containing 80 mol % or more of terephthalic acid with a diol component containing 80 mol % or more of ethylene glycol. The barrier layer is composed of a polyamide (B) and a polyamide (C). The polyamide (B) is obtained by polycondensing a diamine component containing 70 mol % or more of m-xylylenediamine with a dicarboxylic acid component containing 70 mol % or more of an α,ω-linear aliphatic dicarboxylic acid having 4 to 20 carbon atoms. The polyamide (C) has a higher saturation water content than that of the polyamide (B) as measured at 23° C. and 50% RH under 1 atm, and a content of the polyamide (C) in the barrier layer is 20% by weight or less on the basis of a weight of the barrier layer. The multilayer bottle hardly suffers from delamination upon dropping or upon exposure to impact and, therefore, is not required to have a shape with less irregularities or less bends for preventing the delamination, and further has a large freedom of design choice.

Owner:MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com