4D printing manufacturing method suitable for magnetic composite material

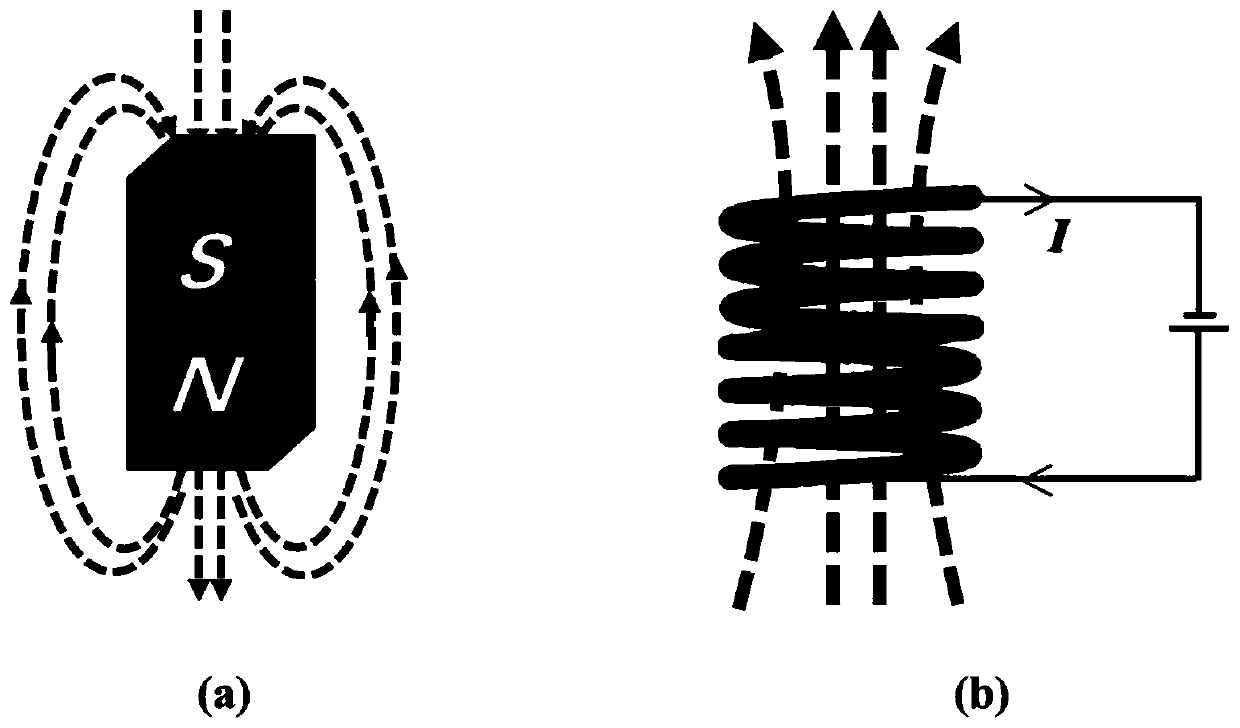

A magnetic composite material, printing and manufacturing technology, applied in the direction of inductance/transformer/magnet manufacturing, additive manufacturing, additive processing, etc., can solve the problems of inability to realize remote and controllable driving, inability to realize driving, and limitation of driving distance, and achieve Increase the amount of deformation, enhance the mechanical properties, and achieve the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] see image 3 , Figure 4 , Figure 5 and Figure 6 The 4D printing manufacturing method suitable for magnetic composite materials provided by the first embodiment of the present invention mainly includes the following steps:

[0042] (1) Select TPU powder, neodymium iron boron (NdFeB) powder and fumed silica powder, and the content of each component is shown in Table 1.

[0043] The quality of three kinds of powder materials in the embodiment 1 of table 1

[0044]

[0045] Dry the three kinds of powders separately, and then mix them in a mixer at a speed of 600 rpm to obtain composite powder materials with three kinds of NdFeB mass fractions.

[0046] (2) The laser selective sintering process is used to form the gradient magnetic composite material to obtain the formed part of the part to be manufactured. Among them, when the content of magnetic powder to be formed is 20wt%, the process parameters are: the laser scanning rate is 4000mm / s, the scanning distance i...

Embodiment 2

[0049] The 4D printing manufacturing method suitable for magnetic composite materials provided by the second embodiment of the present invention mainly includes the following steps:

[0050] (1) Select TPU powder, ferrite powder and castor oil derivative powder, and the content of each component is shown in Table 2.

[0051] The quality of three kinds of powder materials in the embodiment 2 of table 2

[0052]

[0053] Dry the three kinds of powders separately, and then mix them in a mixer at a speed of 600 rpm to obtain three kinds of composite powder materials with mass fractions.

[0054] (2) The laser selective sintering process is used to shape various magnetic composite materials with gradient magnetic powder content. When the content of magnetic powder to be formed is 20wt%, the process parameters are: the laser scanning rate is 3900mm / s, the scanning distance is 0.2mm, the laser power is 42W, the powder layer thickness is 0.1mm, and the temperature of the working c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com