Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

591 results about "Ferrite powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

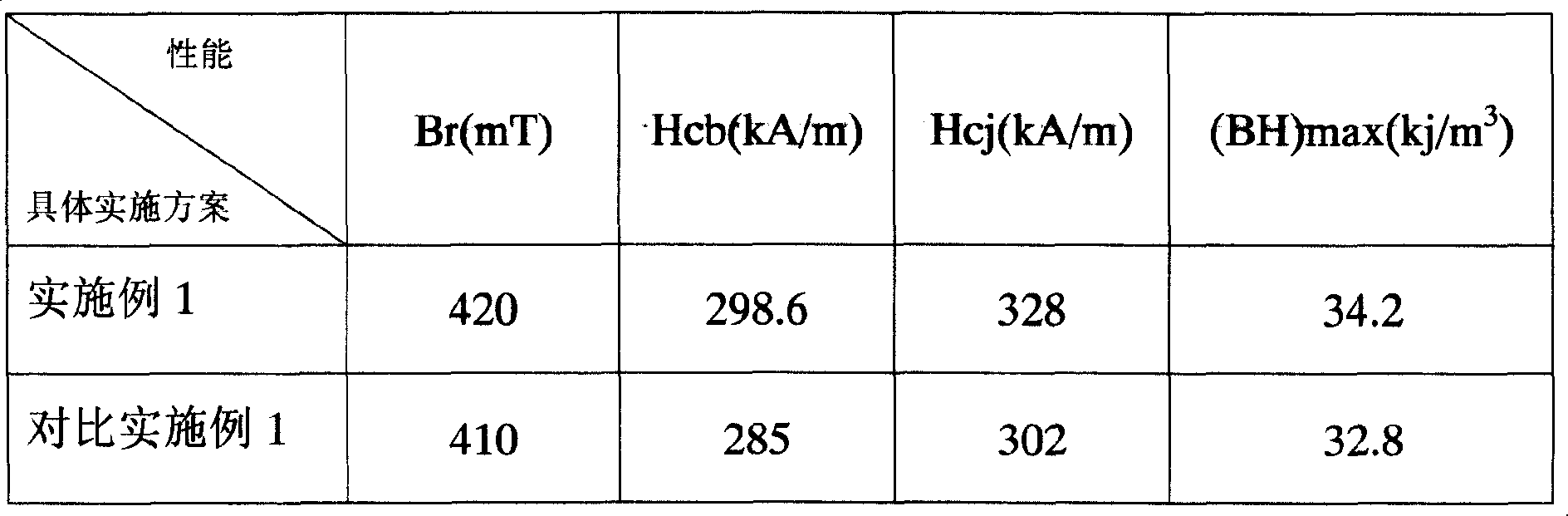

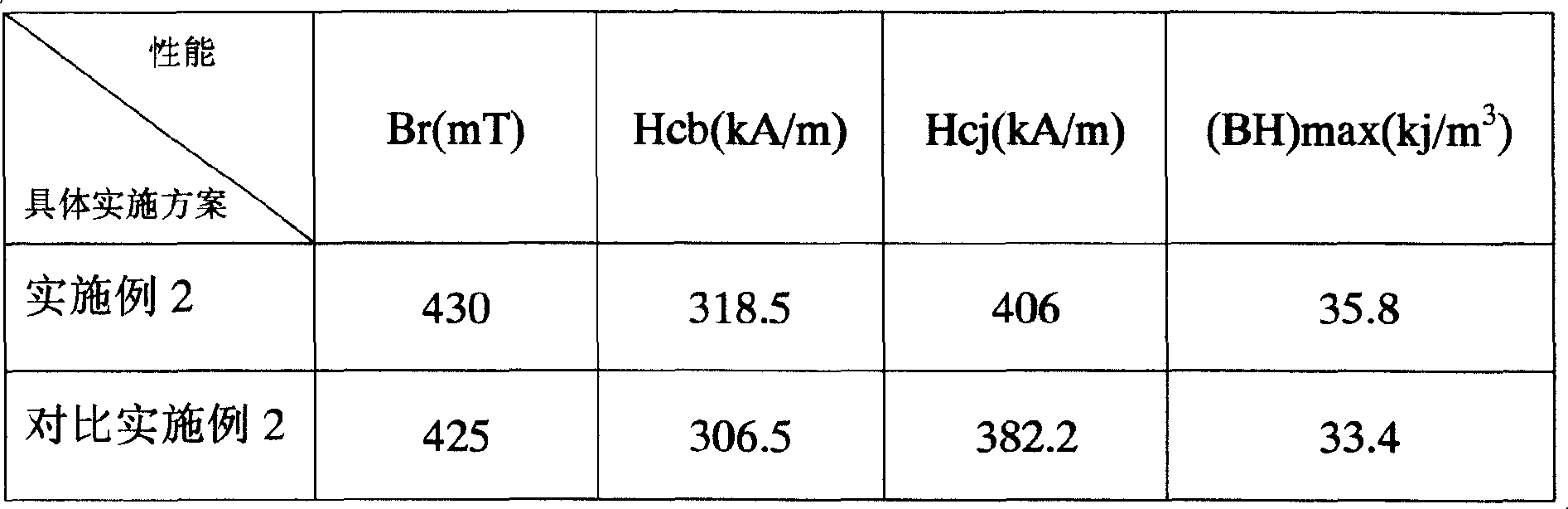

Magnetoplumbite permanent magnetic ferrite and method of producing the same

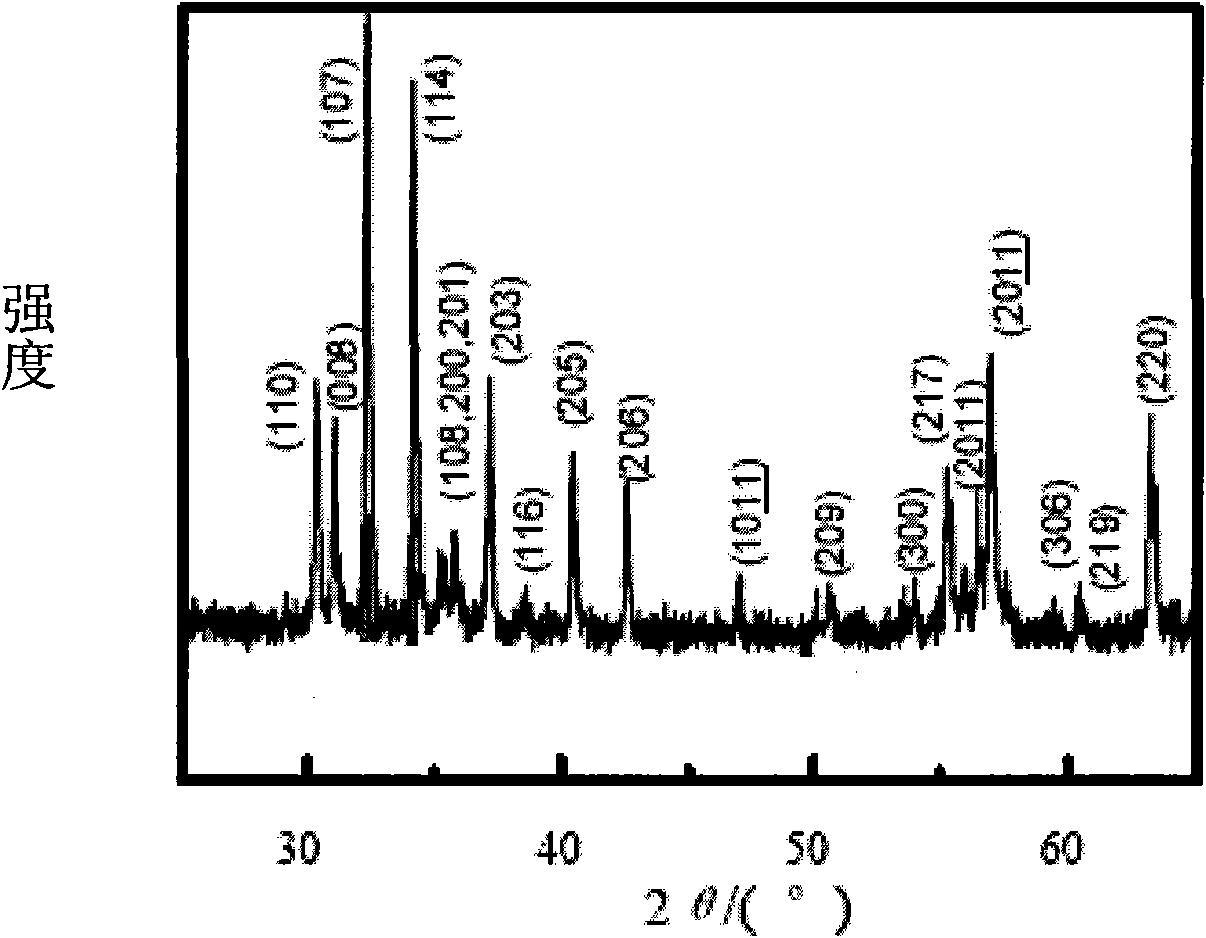

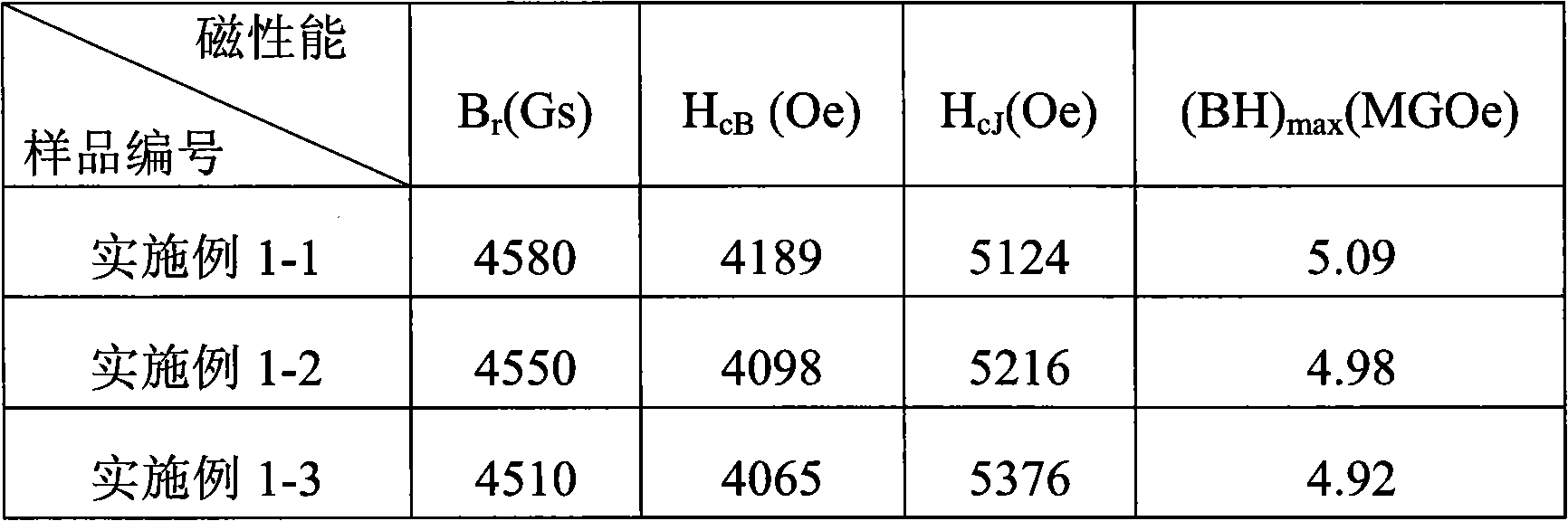

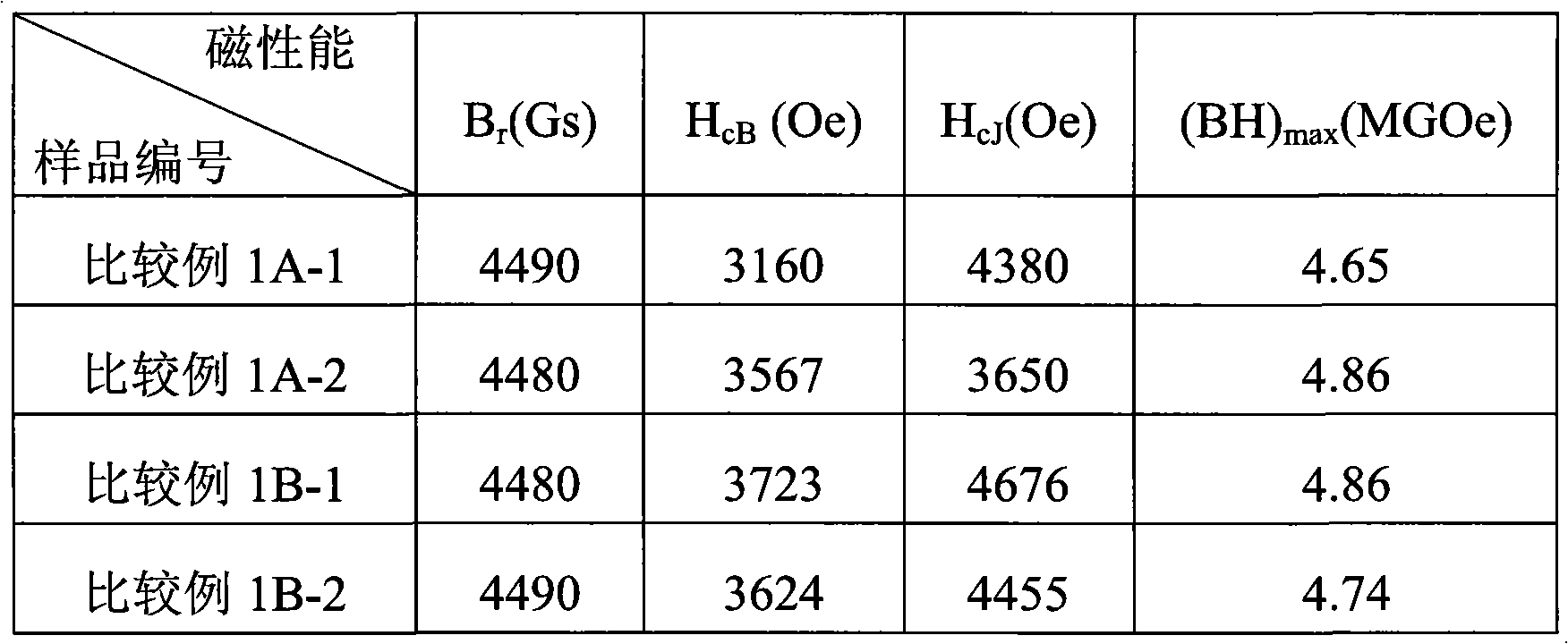

InactiveCN101552069AIncrease the degree of substitutionGuaranteed stabilityInorganic material magnetismInductances/transformers/magnets manufactureRemanenceMetallurgy

The present invention relates to a magnet powder formula of hexagonal type magnetoplumbite permanent magnetic ferrite, sintered magnet and method of producing the same. The invention provides a sintered permanent magnetic ferrite and magnet powder capable of acquiring remanence of more than 4500 Gs and Intrinsic coercivity of more than 5000 Oe at the same time, pointing to problems of unable to acquire high magnetic property and high Intrinsic coercivity at the same time in prior technology, and method of producing the same. major formula of the invention is a permanent magnetic ferrite powder containing hexagonal type magnetoplumbite permanent magnetic ferrite of the following formula as main phase: A[1-x-y]Ca[x]R[y]Fe[2n-z]M[z]O[19], A represents Sr or Sr and Ba, R represents at least one of La, Pr, Nd or Bi, and La is needed; M represents at least one of Co, Ni and Zn, and Co is needed; x, y, z represents addition percentage of each main metal elements.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Magnetic tape device and reproducing method employing TMR reproducing head and tape with characterized XRD intensity ratio

ActiveUS10546602B2Improve smoothnessImprove surface smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic tapeFerrite powder

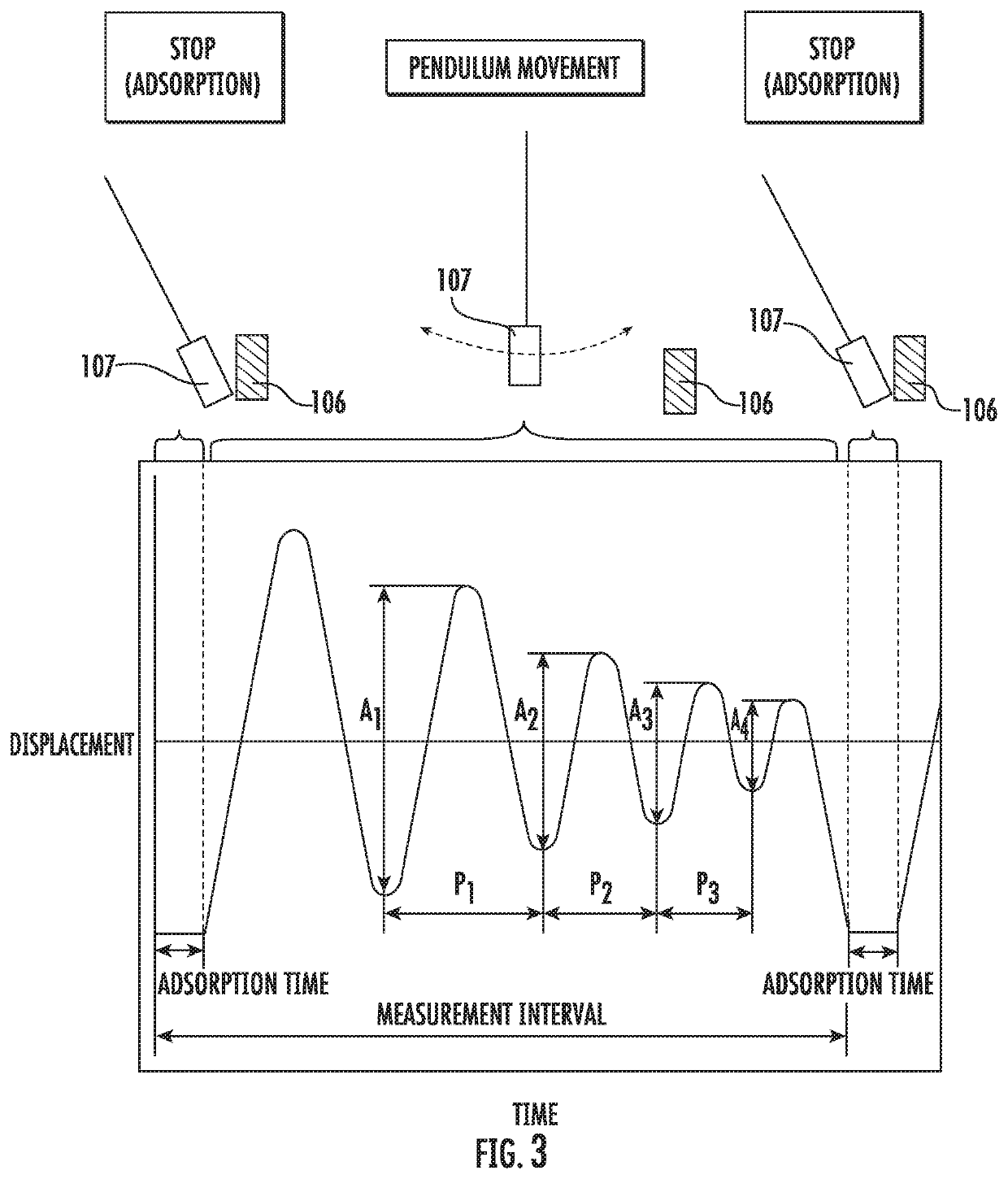

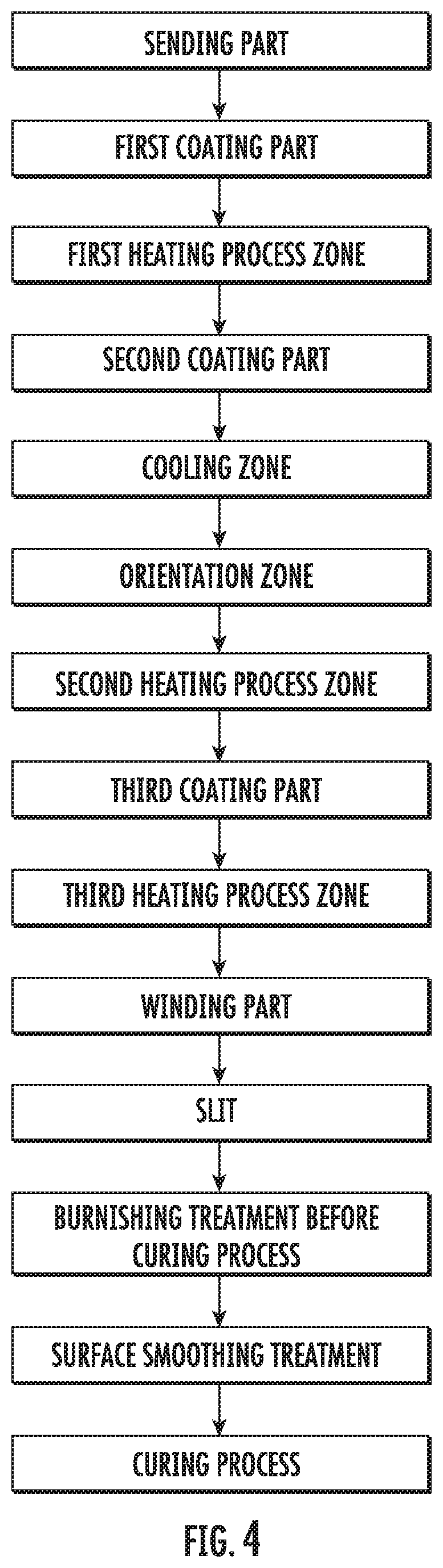

The magnetic tape device includes a Tunneling Magnetoresistive (TMR) head as a reproducing head; and a magnetic tape which includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent on the non-magnetic support, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

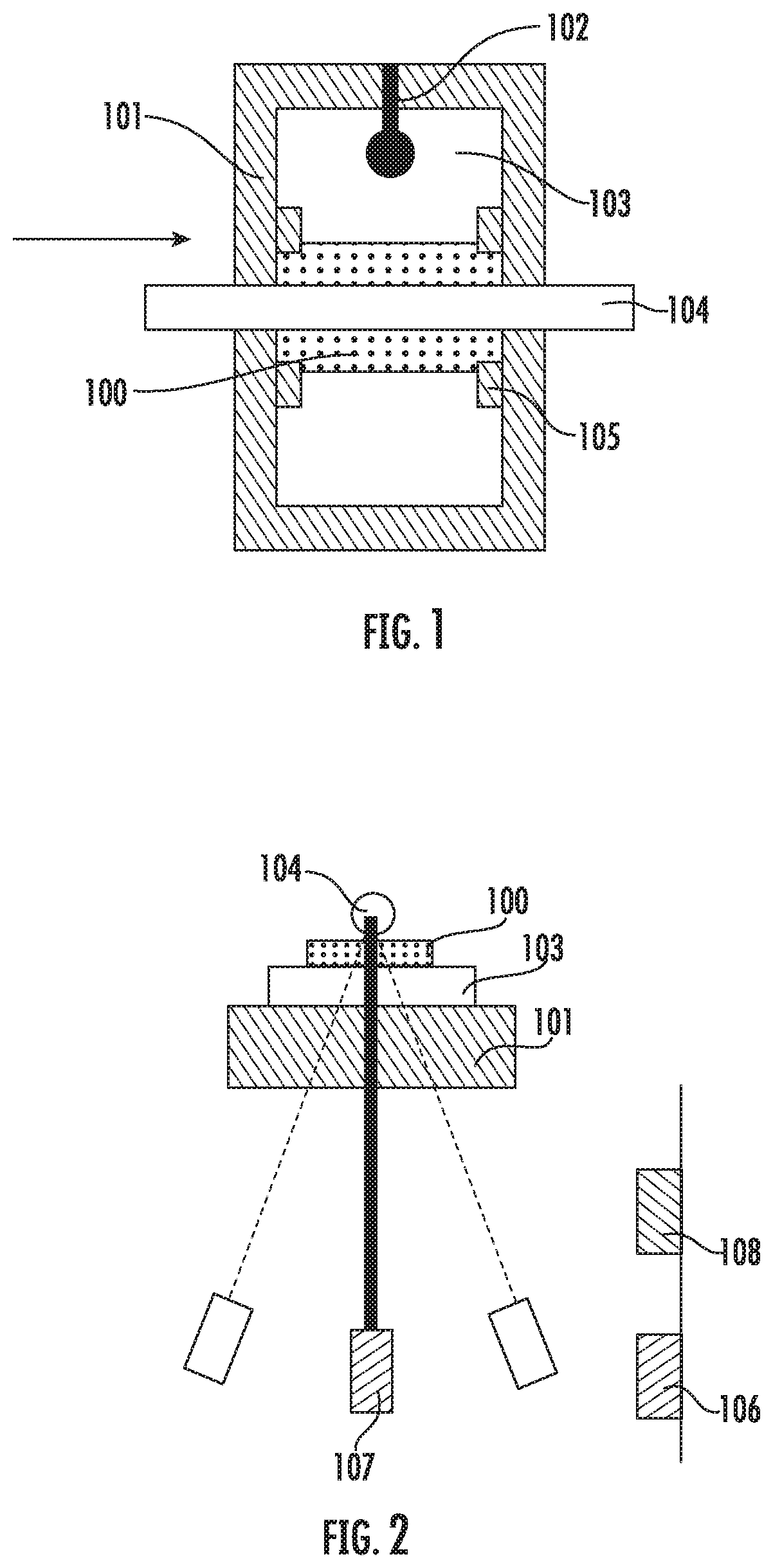

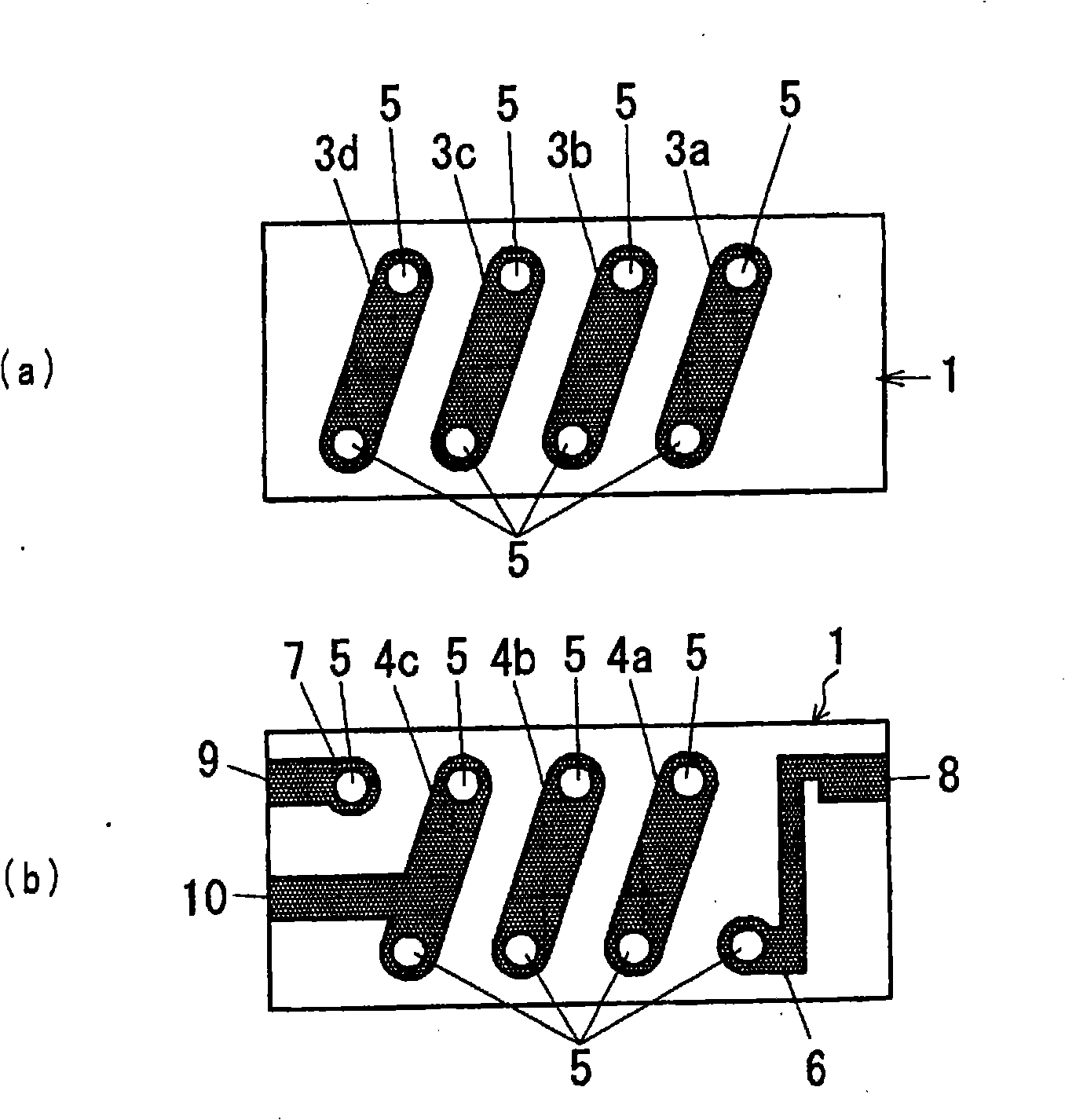

Electronic component

ActiveUS20100052838A1Smooth connectionImprove connectivityTransformers/inductances coils/windings/connectionsInductance with magnetic coreFerrite powderElectronic component

An electronic component is configured to include a laminate disposed between first and second magnetic substrates. The laminate is formed by laminating resin insulating layers, a coil pattern, and a lead pattern. The coil pattern is connected to external electrodes disposed on end surfaces of the laminate by using internal electrodes. The electronic component further includes expansion relaxation portions disposed in the inside of the resin insulating layers and located in the vicinity of connection regions of the internal electrodes and the external electrodes. The expansion relaxation portions are formed by using a magnetic powder resin in which a ferrite powder and a resin material are mixed.

Owner:MURATA MFG CO LTD

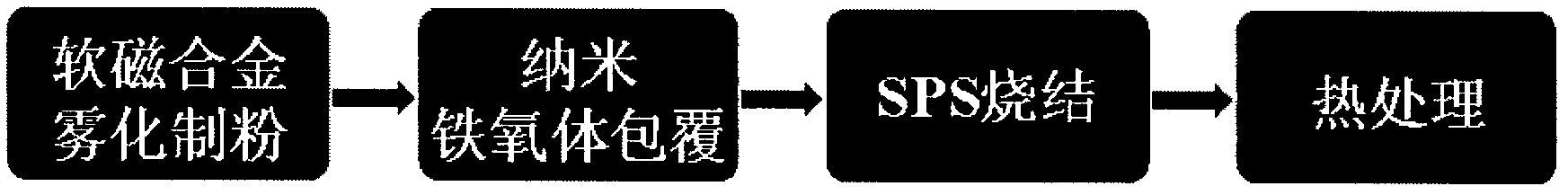

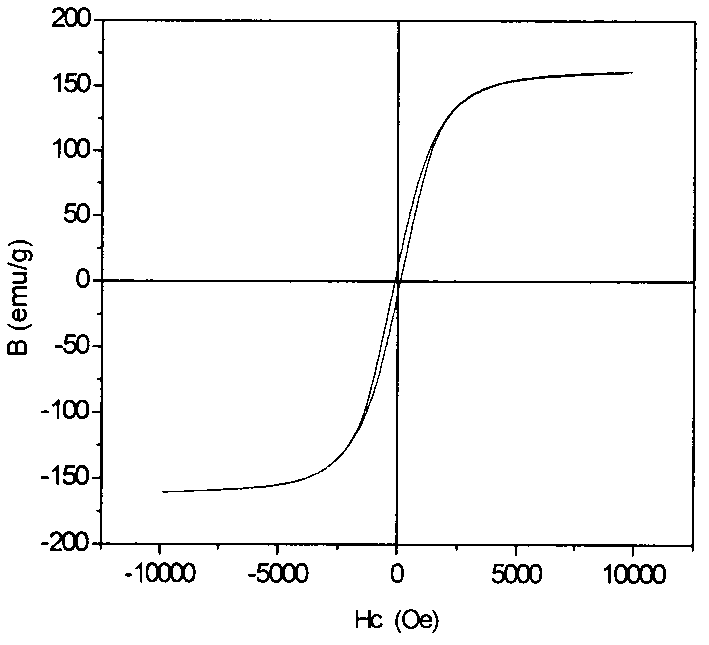

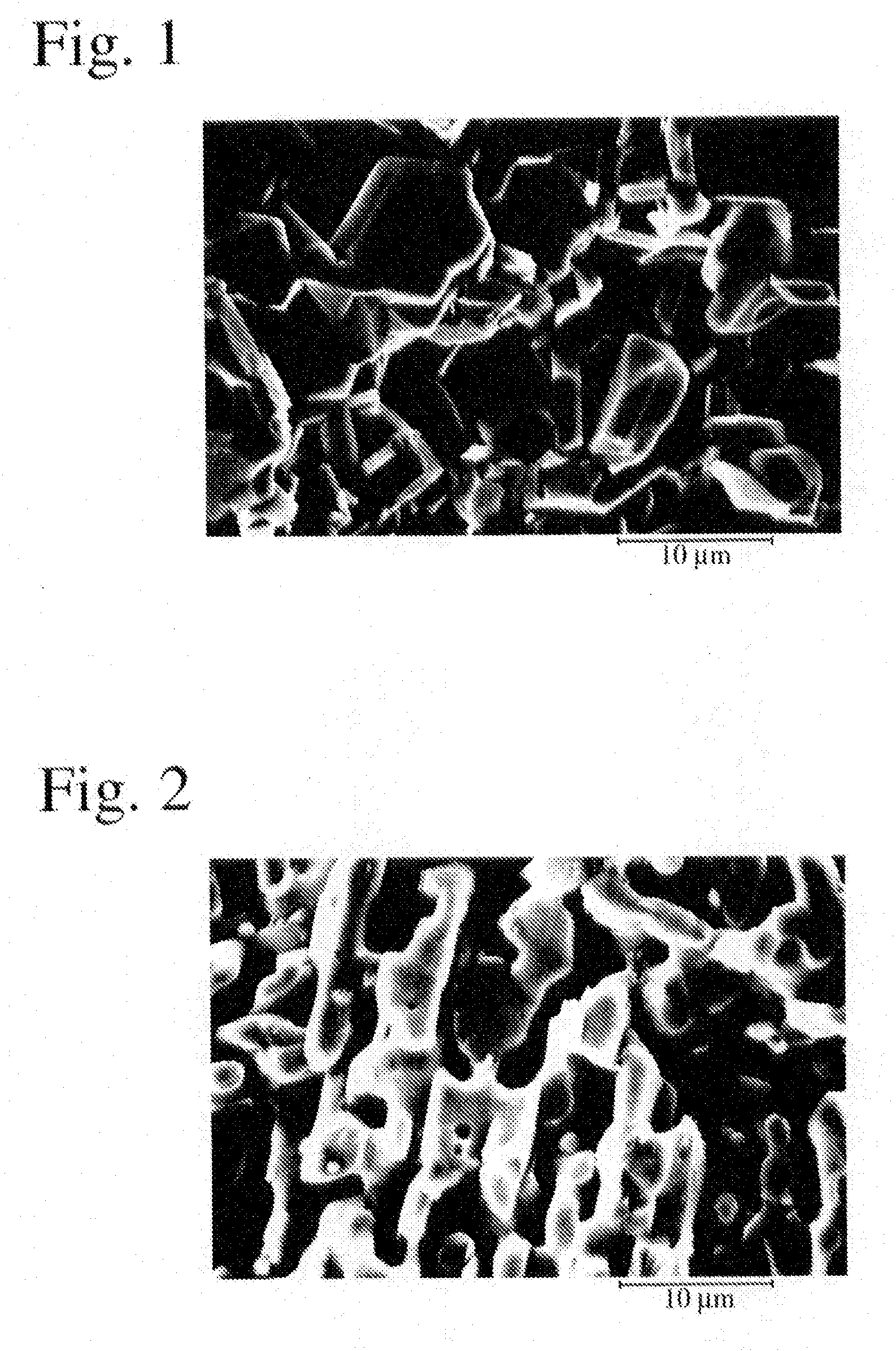

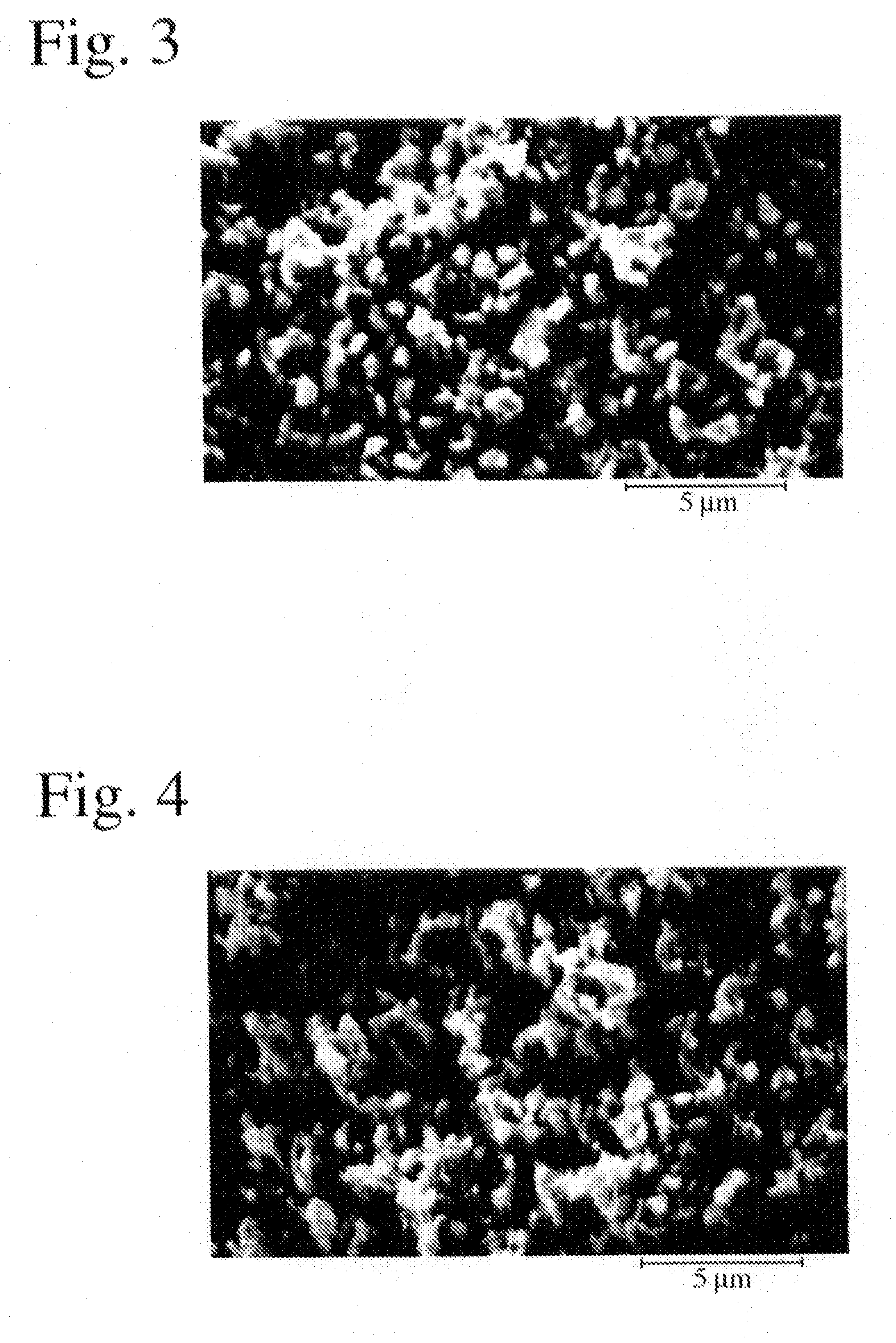

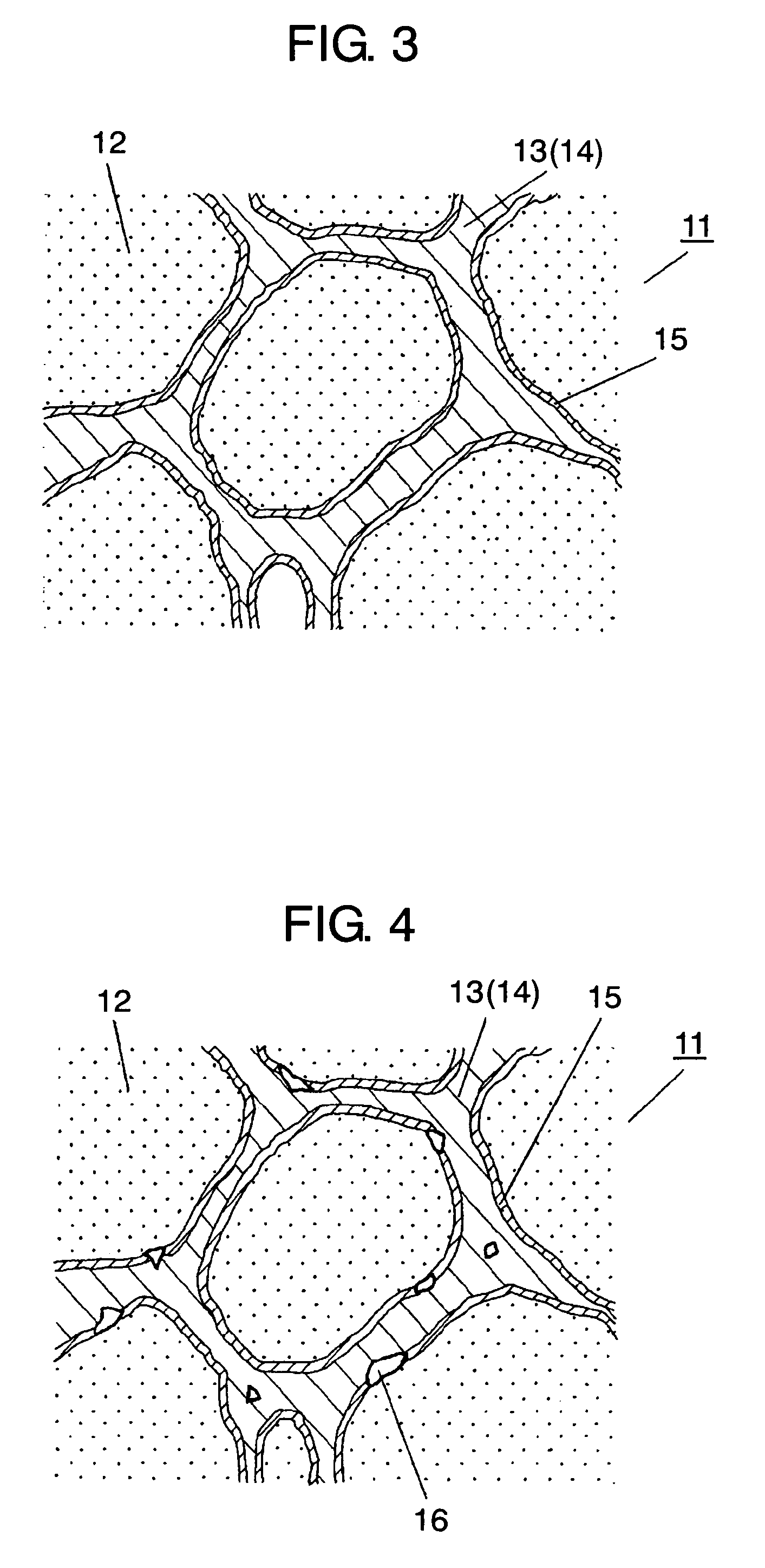

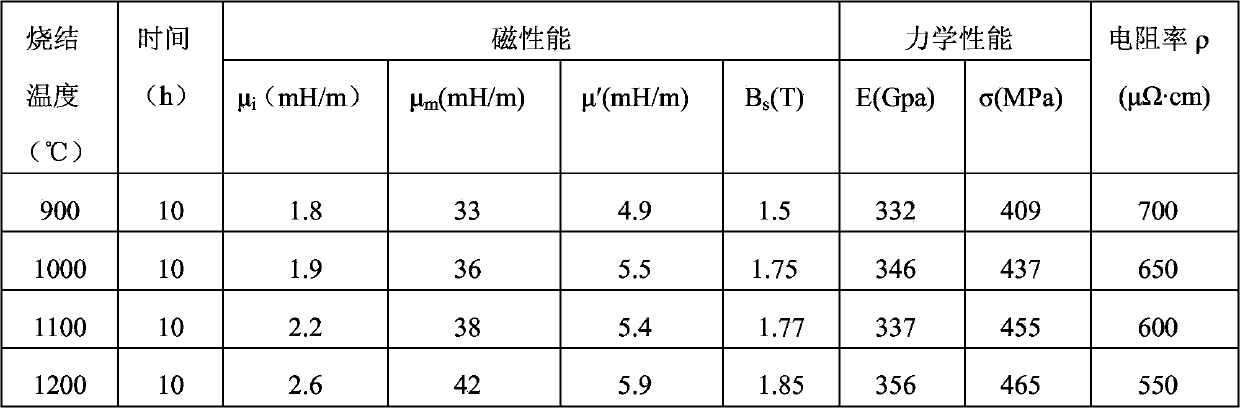

High-efficiency soft magnetic composite material and preparation method thereof

ActiveCN102136331AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseAlloy

The invention discloses a high-efficiency soft magnetic composite material and a preparation method thereof. The material is in a nest wall structure composed of soft ferrite of high electrical resistivity; the ferrite in the nest wall structure completely isolates the soft magnetic metal in the nest or an alloy particle soft magnetic phase to cause the soft magnetic metal in the nest or the alloy particle soft magnetic phase to mutually isolate; the content of the soft magnetic metal or the alloy particle is 50-99wt%; and the balance is the soft ferrite. The preparation method comprises the following steps: mixing the soft magnetic metal or alloy particles and the soft ferrite powder at a ratio; causing the soft ferrite powder to completely and evenly coat the surface of the soft magnetic metal or the alloy particles; complexly sintering and shaping by spark plasma sintering densification; and finally, carrying out stress removal annealing heat treatment. The high-efficiency soft magnetic composite material has the characteristics of high-saturation induction density, high resistivity, high magnetic conductivity, low coercive force, low magnetic core loss and excellent comprehensive mechanical property. The high-efficiency soft magnetic composite material can be applied to occasions with higher working efficiency, high magnetic field and high stress. The preparation method issimple and the technological operation is convenient.

Owner:CHANGCHUN UNIV OF TECH

Rotating machine, bonded magnet, magnet roll, and method for producing sintered ferrite magnet

ActiveUS20090218540A1Little temperature dependenceHigh Br and HcJMangetographic processPermanent magnetsRare-earth elementMetallurgy

A rotating machine comprising a sintered ferrite magnet having an M-type ferrite structure, comprising Ca, an R element that is at least one of rare earth elements and indispensably includes La, Ba, Fe and Co as indispensable elements, and having a composition represented by the formula: Ca1-x-yRxBayFe2n-zCoz, wherein (1−x−y), x, y, z and n represent the contents of Ca, the R element, Ba and Co, and a molar ratio, meeting 0.3≦1−x−y≦0.65, 0.2≦x≦0.65, 0.001≦y≦0.2, 0.03≦z≦0.65, 4≦n≦7, and 1−x−y>y; a bonded magnet comprising ferrite powder having the above composition and a binder, and a magnet roll, at least one magnetic pole portion of which is made of the above bonded magnet.

Owner:HITACHI METALS LTD

Method for making novel ferrite/iron-base composite material soft magnetic-powder core

ActiveCN1979698ALow shrinkageHigh bonding rateInorganic material magnetismInductances/transformers/magnets manufactureIron powderAdhesive

A preparation method for soft magnetic powder cores, a kind of new ferrite / ferreous-base compound material. Its power cores comprises the following materials with the given mass percentage: the 70~90% powder under 160 meshes, adhesive 1~30%; the powder materials comprises 10~100% ferreous powder and 0~90% MnZn ferrite powder, the adhesive is water glass adhesive and tetraethyl(ortho)silicate, which is made through mixing, molding, heat treatment, glue immersing, paint immersing and wrapping. The advantages of the invention are : (1) advanced formula design; (2) insulation adhesive is no toxin, no taste, less shrinkage rate, high bonding rate with powder; after immersing treatment, the quality coefficient value of powder cores is increased; (3) improves the integrated performance index parameter of magnetic powder cores, and the consistency of the performance parameter of product is guaranteed, the quality's conformity rate is improved too.

Owner:安徽众恒复合材料科技有限公司

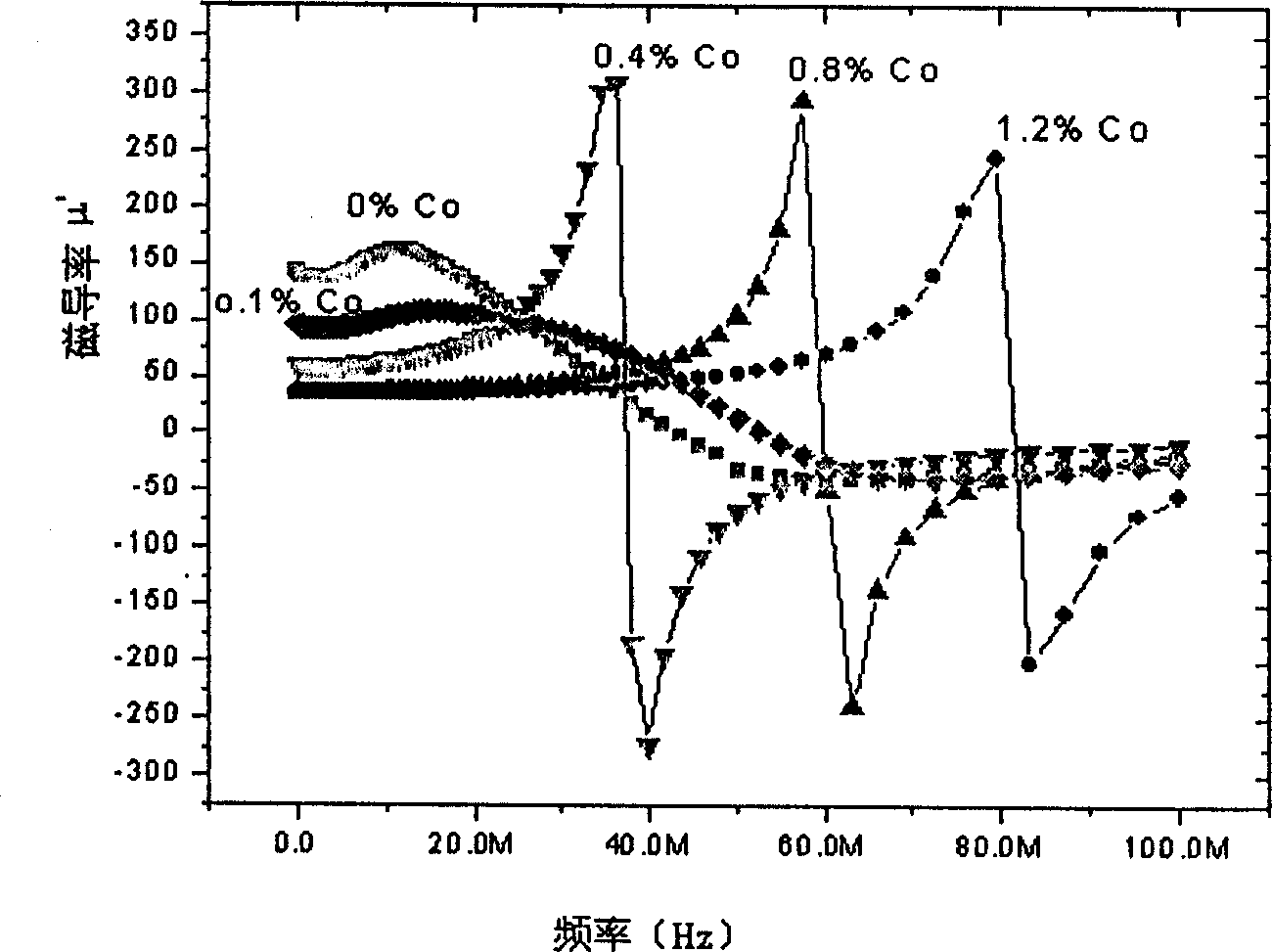

Hexagonal crystal system Y-type ferrite electromagnetic material and preparation method thereof

InactiveCN102674823AFacilitated DiffusionFully contactedInorganic material magnetismCrystal systemHexagonal crystal system

The invention provides a hexagonal crystal system Y-type ferrite electromagnetic material and a preparation method thereof. The material is a Ba2Co2-xZnxFeyO22 (x is more than or equal to 0 and less than or equal to 2, and y is more than or equal to 10 and less than or equal to 14) ferrite material with hexagonal flaky morphology, and is obtained by uniformly mixing reactants and a reaction medium and calcining, wherein the reactants at least comprise a barium source, an iron source and a cobalt source; the reaction medium is one kind of chlorate or a mixture of two kinds of chlorate; the molar ratio of various elements in the reactants is that the ratio of Ba to Fe is 2:(10-14), and the ratio of Ba to Co is 2:(0-2); and the ratio of the mass of the reaction medium to the total mass of the reactants is (1-4):1. The invention has the advantages that the morphology of ferrite powder particles can be well controlled; inorganic molten salt is taken as the reaction medium, and the reactants are quickly dispersed and fully contacted in the molten salt by utilizing the dissolution of the reactants in the molten salt so as to reduce reaction temperature and improve reaction rate; the molten salt runs through generated barium ferrite particles in the reaction process, so the mutual agglomeration among the particles can be stopped; and the process is simple, the product is high in purity, the resultant temperature is low, the mechanical ball milling is not required, the doping is avoided, and the particle size distribution is narrow.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

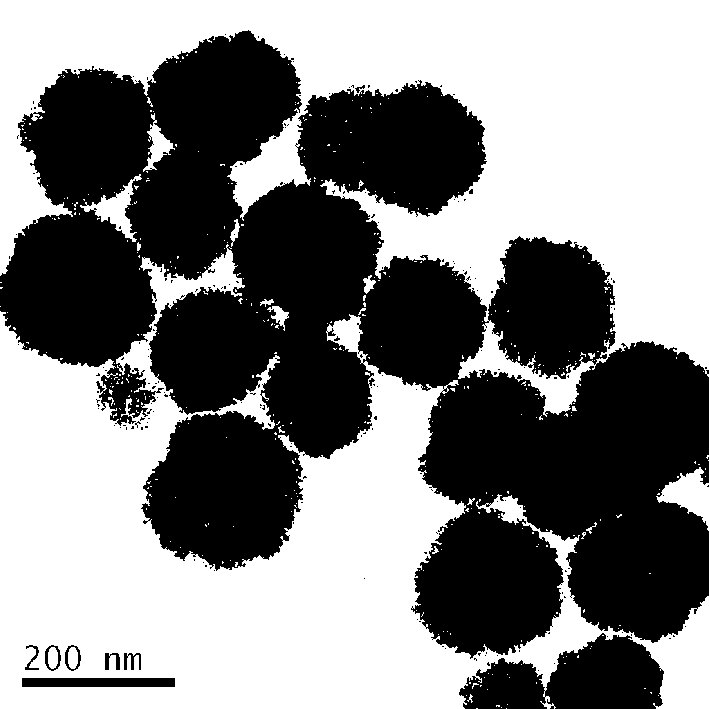

Block amorphous/ferrite soft magnetic composite material and preparation method thereof

ActiveCN102142309AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseFerrite powder

The invention discloses a block amorphous / ferrite soft magnetic composite material and a preparation method for the block amorphous / ferrite soft magnetic composite material. The soft magnetic composite material is the amorphous / ferrite soft magnetic composite material having a three-dimensional honeycomb structure; a honeycomb wall structure is formed by a high-resistivity soft magnetic ferrite; the honeycomb wall ferrite encloses and completely isolates amorphous alloy soft magnetic phases which are formed by soft magnetic amorphous alloy particles in the honeycomb, so that the amorphous alloy soft magnetic phases in the honeycomb are isolated from one another; and the amorphous / ferrite soft magnetic composite material comprises 50-99 weight percent of the soft magnetic amorphous alloy particles and the balance of the soft magnetic ferrite. The preparation method comprises the following steps of: firstly, mixing the soft magnetic amorphous alloy particles with soft magnetic ferrite powder in proportion, completely coating surfaces of the soft magnetic amorphous alloy particles with the soft magnetic ferrite powder; secondly, carrying out sintering densification compound moulding on the amorphous alloy particles without crystallization by employing a discharging plasma sintering technology; and finally, carrying out de-stressing and nanometre crystallization annealing heat treatment. Compared with an amorphous alloy soft magnetic material, the block amorphous / ferrite soft magnetic composite material has the advantages that: the resistivity is remarkably improved; and the working frequency of an amorphous alloy is improved.

Owner:CHANGCHUN UNIV OF TECH

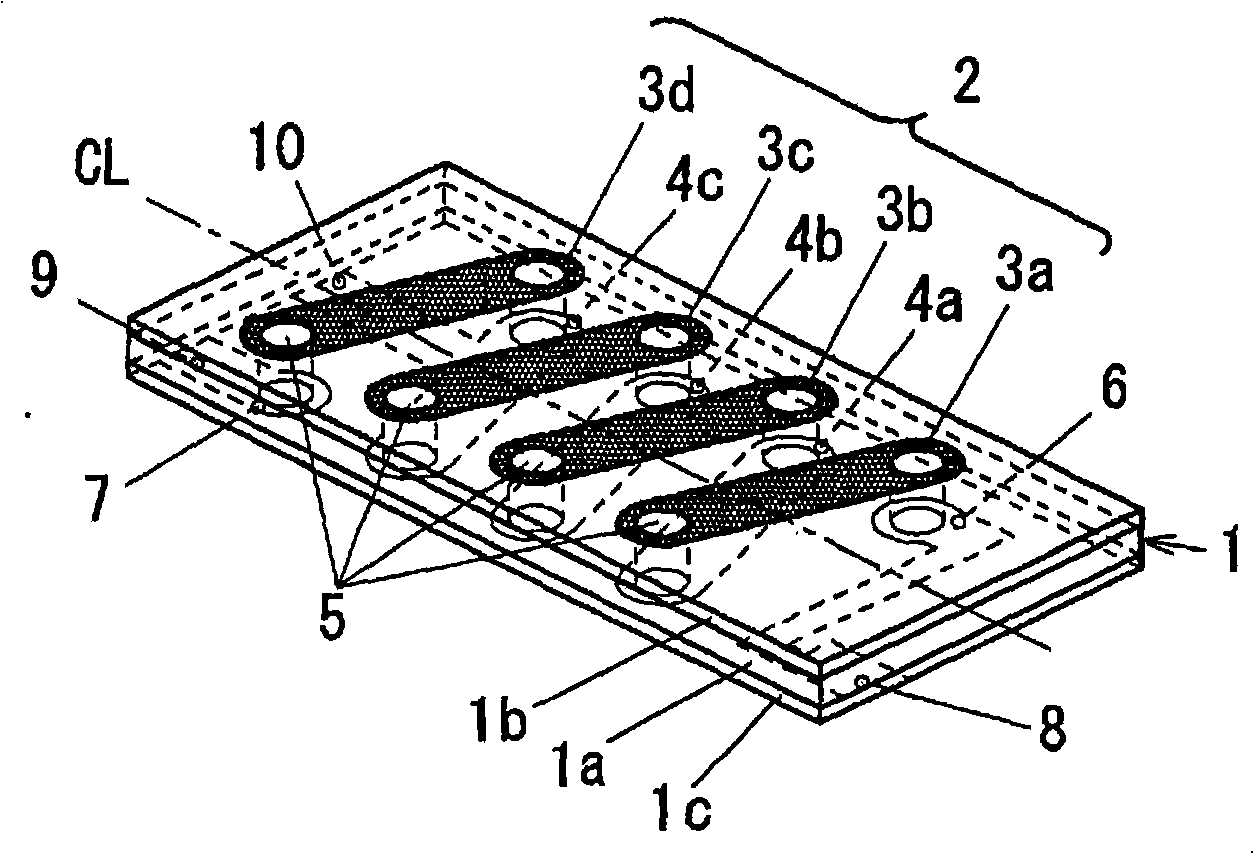

Antenna

InactiveCN101542832AHigh gainMiniaturizationLoop antennas with ferromagnetic coreRadiating elements structural formsPolymer resinFerrite powder

Owner:NOF CORP +2

Wide-temperature range low-loss Mn-Zn ferrite and its preparation method

Belonging to the fields of Mn-Zn ferrites and their preparation technologies, the invention relates to a wide-temperature range low-loss Mn-Zn ferrite and its preparation method. The ferrite comprises main components and auxiliary components, wherein, the main components include iron oxide, manganese oxide and zinc oxide. The ferrite is characterized in that, the main components have the following mole percent content calculated in their respective reference substances: 50 mol%- -56 mol% of Fe2)3, 0.36 mol%-42 mol% of MnO, and 5 mol%-10 mol% of ZnO. The auxiliary components consist of a titanium oxide, a cobalt oxide, a bismuth oxide and an ultrafine silicon oxide. Relative to the total amount of the main components, the titanium oxide, the cobalt oxide, the bismuth oxide and the ultrafine silicon oxide have a total weight percent content of 0.06-0.98 wt% calculated in their reference substances TiO2, CO2O3, Bi2O3 and ultrafine SiO2. The Mn-Zn ferrite powder of the invention has good mouldability, and has a wide atmosphere adaptation scope in the sintering process, and the sintered product can reach the expected technological indexes.

Owner:NANTONG GUANYOUDA MAGNET

Antenna

InactiveUS20090128437A1Reduce adverse effectsHigh gainLoop antennas with ferromagnetic coreRadiating elements structural formsInter layerPolymer resin

There is provided an antenna whose outside shape can be miniaturized while maintaining a gain at a desired level with respect to a radio wave of a wide frequency range. The antenna is configured by using a core of a laminate structure. The core is a plate of a rectangular outside shape, configured to have a laminate structure including each of first, second and third resin layers. The first resin layer has magnetic powder mixed therein and formed as a middle layer, and the second resin layer and the third resin layer made of resin only without magnetic powder mixed therein are formed to sandwich the first resin layer therebetween. In the core of the laminate structure, it is preferable to use a polymer resin for each of the resin layers, and to use soft ferrite powder as the magnetic powder.

Owner:NOF CORP +2

Coil component

InactiveUS20140333404A1Avoid performanceDecrease productivityTransformers/inductances coils/windings/connectionsCoilsFerrite powderWavelength

Disclosed herein is a coil component including: an insulating layer containing a ferrite powder and a coil electrode embedded in the insulating layer, in which a particle diameter of the ferrite powder is smaller than a wavelength of light which is used during an exposure process, thereby increasing permeability and improving an impedance characteristic.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

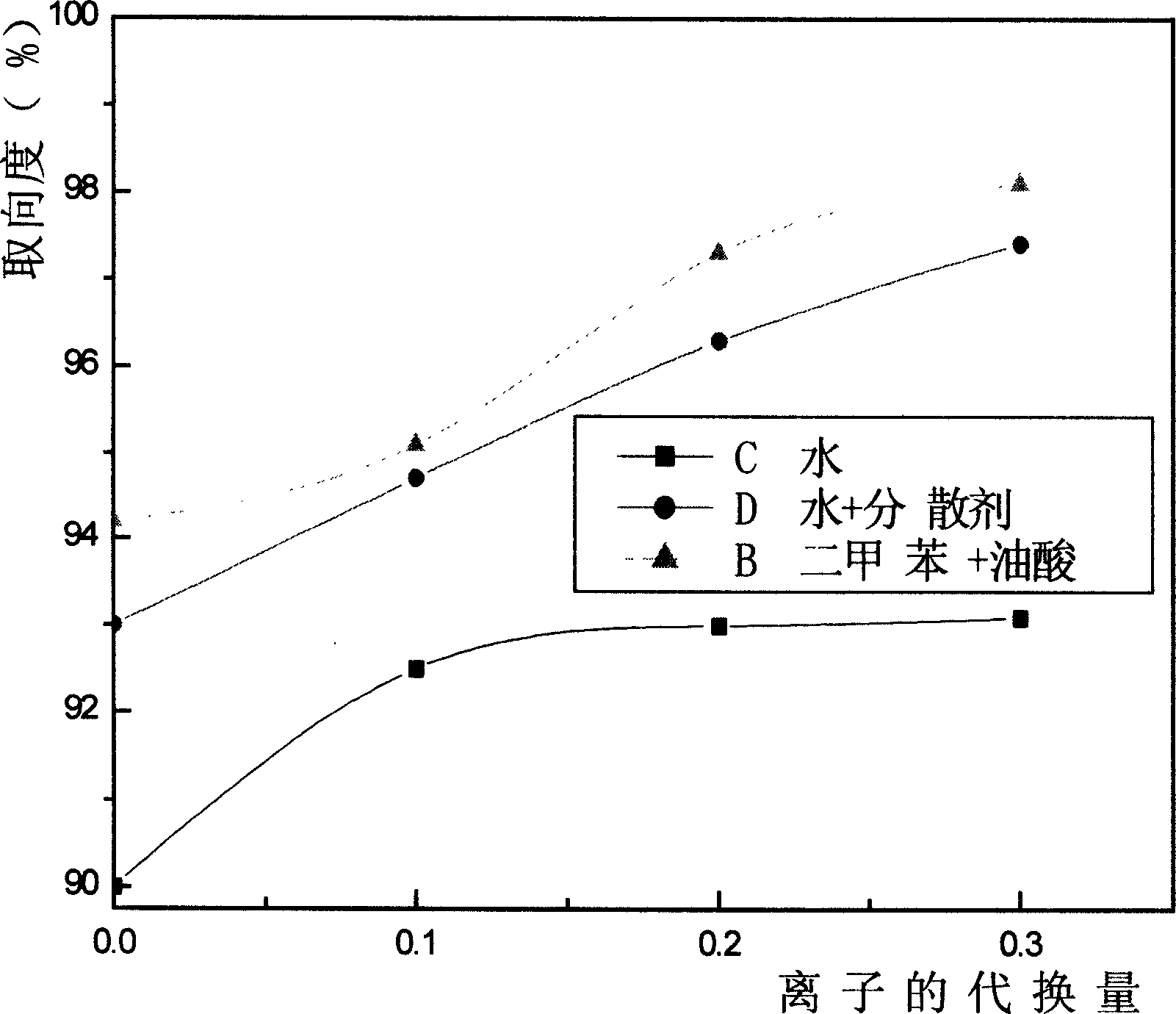

Process for preparing magnetic powder and sintered magnet and product produced thereby

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

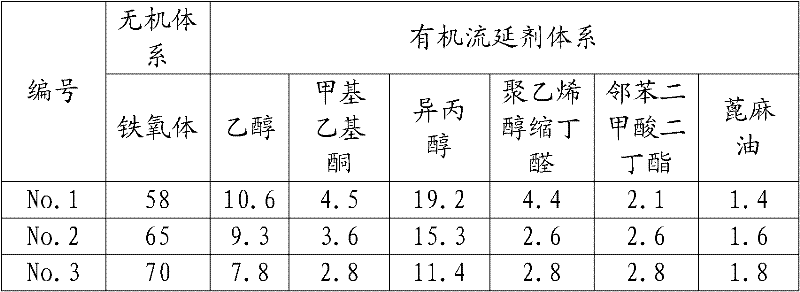

Slurry for NFC (Near Field Communication) magnetic sheet and NFC magnetic sheet

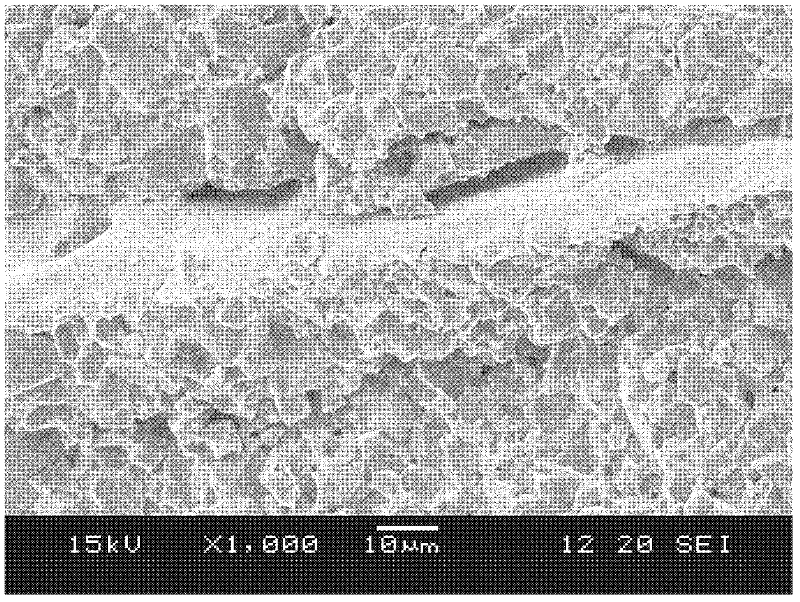

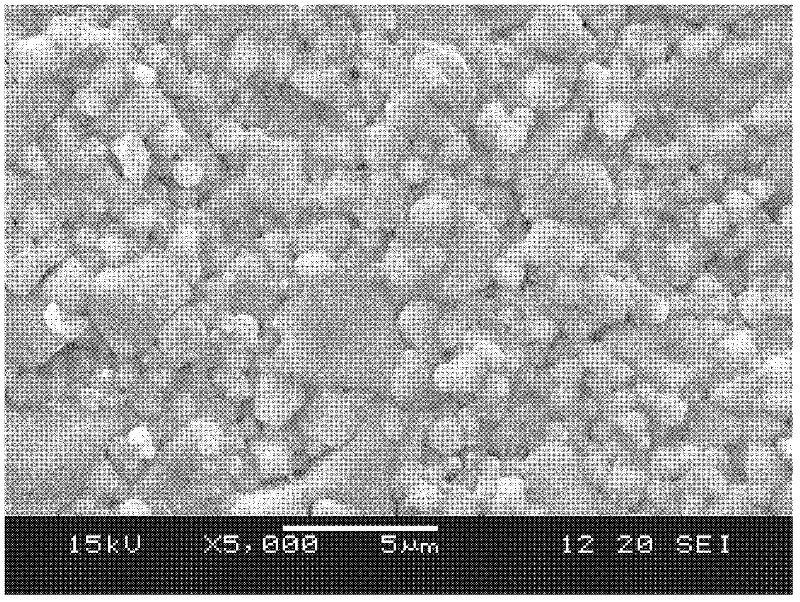

ActiveCN103833340AImprove performanceSolve the problem of sintering warpagePermanent magnetsMagnetic materialsOrganic solventPlasticizer

The invention provides slurry for a NFC (Near Field Communication) magnetic sheet. The slurry for the NFC magnetic sheet comprises ferrite powder and an organic system. The slurry is prepared by the following steps: sequentially adding a dispersant, an organic solvent and the ferrite powder into a ball-milling tank for primary ball-milling; then, sequentially adding a plasticizer and a bonder for secondary ball-milling; and selectively adding or not adding an assistant, and defoaming in vacuum to obtain the slurry for the NFC magnetic sheet. The invention further provides the NFC magnetic sheet prepared from the slurry for the NFC magnetic sheet by tape casting. The slurry for the NFC magnetic sheet provided by the invention can effectively solve the problem that the thin magnetic sheet is sintered and warped by optimizing types and adding sequence of components and technical conditions in the organic system in the tape casting formula, thereby greatly enhancing the product yield.

Owner:BYD CO LTD

Method for preparing low-power loss manganese-zinc ferrite based on core-shell structure grains

The invention provides a method for preparing low-power loss manganese-zinc ferrite based on core-shell structure grains. Through adding of high-resistance low-melting point oxide, the core-shell structure grains are formed, so that the power loss of the manganese-zinc ferrite is reduced. The innovativeness of the invention is that the higher pre-sintering temperature is adopted, so that pre-sintered powder obtains a higher ferrite percentage; through ball milling, the size of ferrite powder is reduced below the single domain size; and then, the low-melting point oxide is added, and an additive is molten on the ferrite particle surface during sintering, so that the grains with high-resistivity shells are formed, and the hysteresis loss and the eddy current loss of the manganese-zinc ferrite are simultaneously and greatly reduced.

Owner:ZHEJIANG UNIV

Broadband and high-magnetic-permeability ferrite teflon tape and production method thereof

The invention relates to a broadband and high-magnetic-permeability ferrite teflon tape and a production method thereof. The teflon tape comprises pre-burned ferrite powder and an organic tape casting system, wherein the pre-burned ferrite powder comprises ferric oxide, nickel oxide, copper oxide, zinc oxide, bismuth oxide and an additive, and the organic tape casting system comprises a solvent, a dispersant, a binder and a plasticizer. The LTCF (Low Temperature Cofired Ferrite) teflon tape prepared in the invention has a flat surface, is sintered at 900 DEG C for compactness, and a sintered body has an excellent performances: the initial permeability is not smaller than 450H / m at 100kHz, and the resistivity is not smaller than 109 ohm.cm. A chip inductor element manfauctured by using theteflon tape has high inductance and high quality factors, meanwhile, a low-temperature glass protective coating is coated in a silver paste circuit printing process of the inductor element, so that adevice failure caused by Ag diffusion when the device is used is prevented. Therefore, the broadband and high-magnetic-permeability ferrite teflon tape and the production method thereof have huge application prospect.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

Prepn of doped magnetic ferrite material

InactiveCN1486958AEvenly dispersedSkip the ball milling processInorganic material magnetismMetal nitrateNitrate

Owner:SHANGHAI UNIV

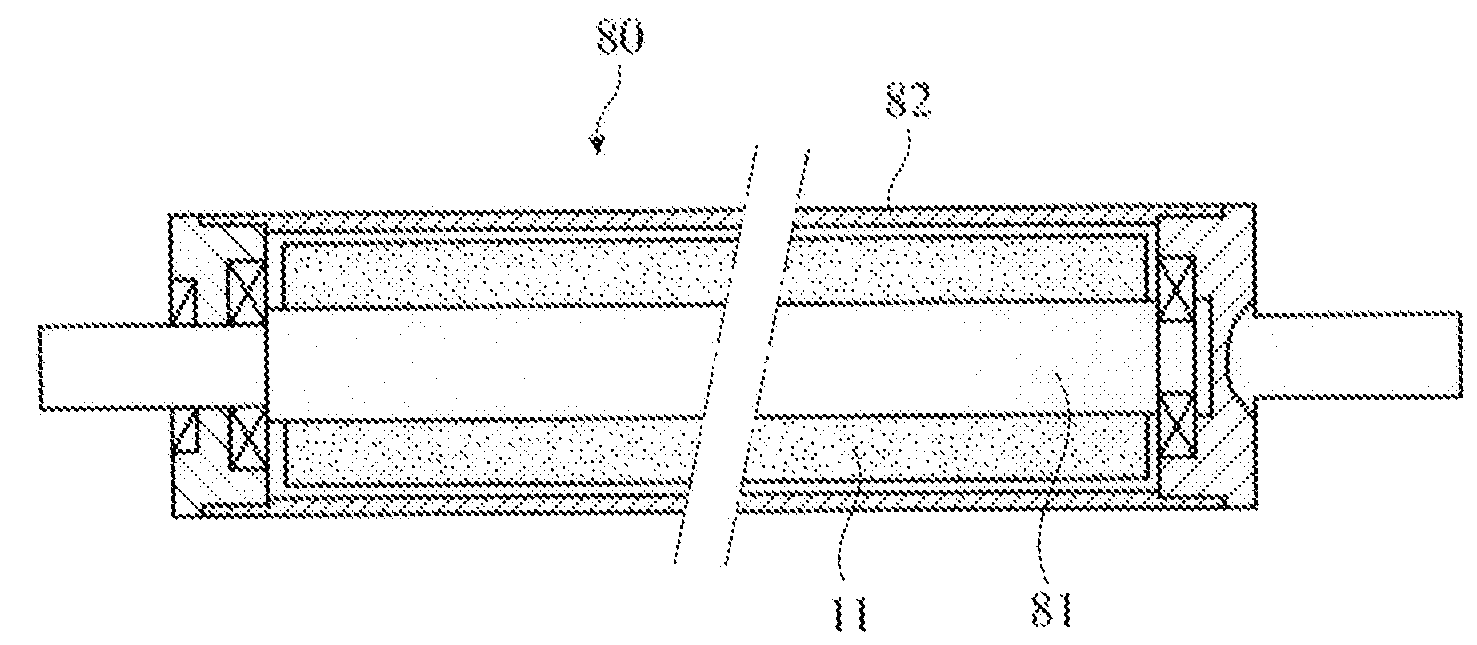

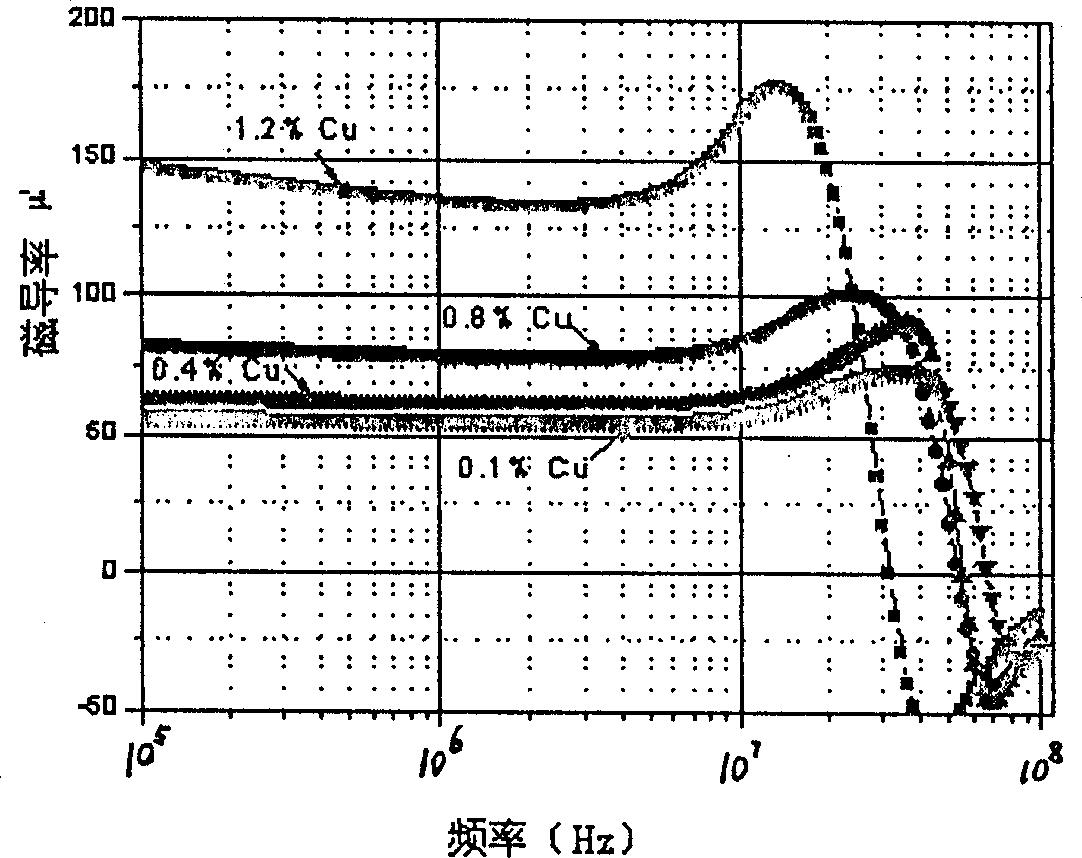

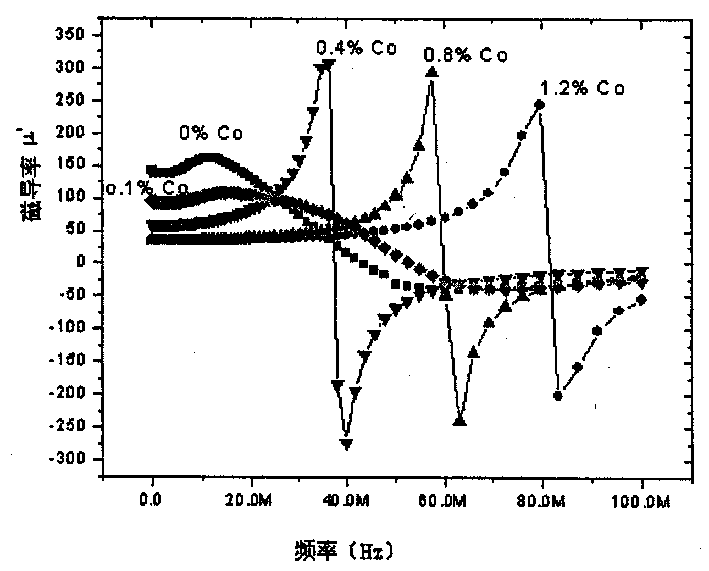

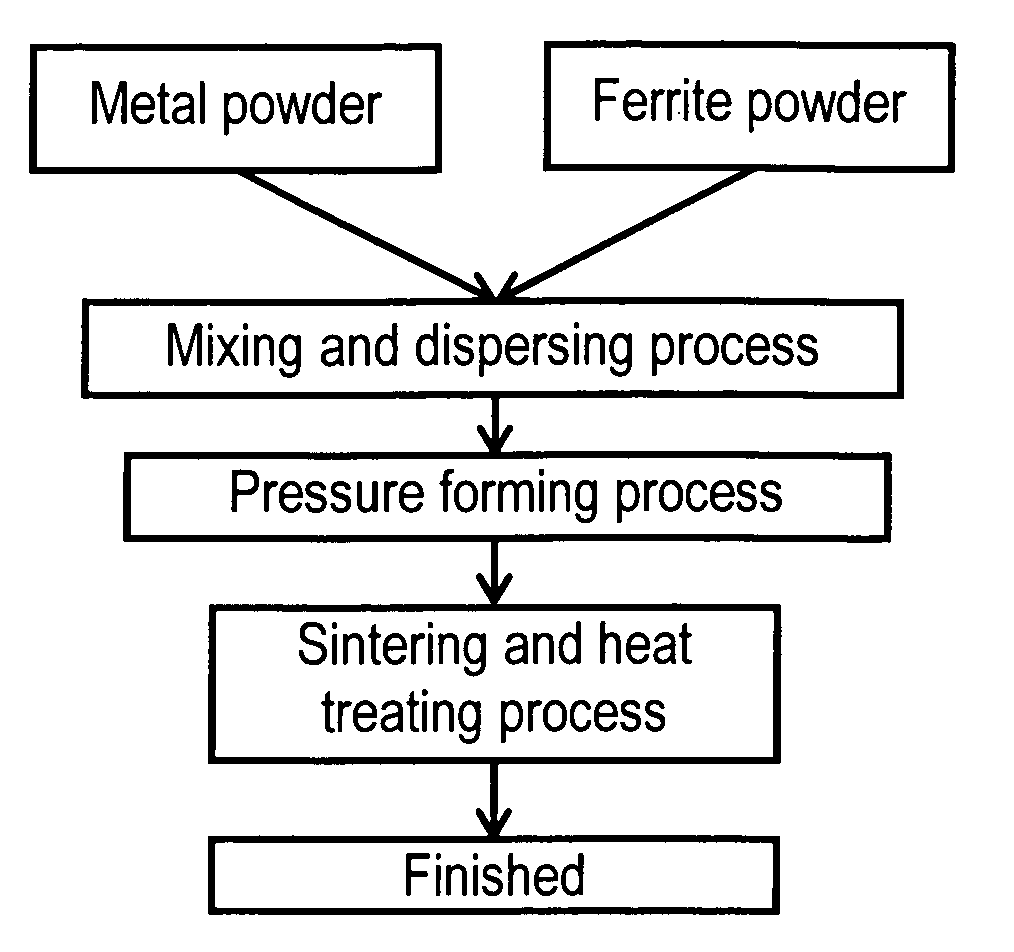

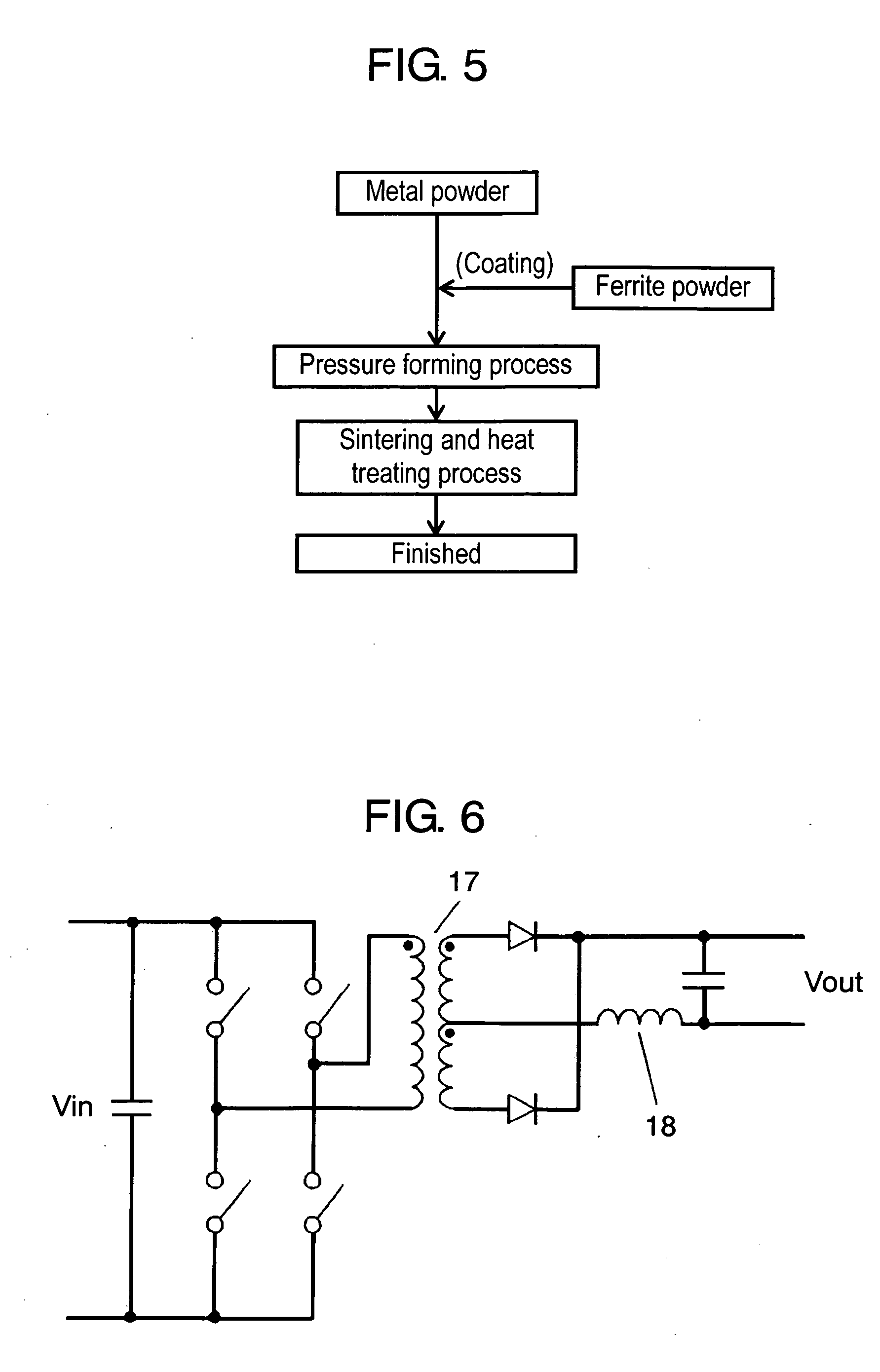

Composite sintered magnetic material, its manufacturing method, and magnetic element using composite sintered magnetic material

A composite sintered magnetic material comprises a kind of metal powder at least one selected from the group consisting of Fe, Fe—Si type, Fe—Ni type, Fe—Ni—Mo type, and Fe—Si—Al type, and a ferrite layer formed from a kind of ferrite powder at least one selected from the group consisting of Ni—Zn type, Mn—Zn type, and Mg—Zn type, wherein a diffusion layer is formed by sintering between both of these to integrates the both.

Owner:PANASONIC CORP

Tape casting slurry for laminated sheet type electronic component and preparation method for tape casting slurry

The invention discloses tape casting slurry for a laminated sheet type electronic component and a preparation method for the tape casting slurry. The tape casting slurry comprises 45 to 55 weight percent of ceramic or ferrite powder, 0.1 to 1.0 weight percent of dispersing agent, 30 to 48 weight percent of solvent, 3 to 8 weight percent of adhesive, 3 to 5 weight percent of plasticizer, 0.1 to 0.5 weight percent of 2-methyl-2,4-pentendiol serving as an addition agent a and 0.1 to 0.5 weight percent of silane coupling agent serving as an addition agent b. The 2-methyl-2,4-pentendiol is added, so that the problems that the viscosity of the slurry is rapidly increased, and the performance of a membrane is rapidly deteriorated because boric is added are solved; the silane coupling agent is added, so that the slurry is low in viscosity and high in dispersing performance, the green density of the membrane is increased, and the ductility is enhanced; and the finally prepared slurry is uniform, stable and suitable for large-scale production.

Owner:SHENZHEN GUDIAN ELECTRONICS

Preparation of polyurethane wave-absorbing gel material

The invention discloses preparation of a polyurethane wave-absorbing gel material. The wave-absorbing material is prepared through polymerization reaction by taking polyether polyol, isocyanate, silicon dioxide aerogel particle, deionized water, a halogen-free flame retardant, graphitized carbon black, ferrite powder, an inflaming retarding smoke suppressor, a composite catalyst, a foam stabilizer, and a physical foaming agent as raw materials. The gel material has the advantages of good wave-absorbing performance, simple molding technology, good inflaming retarding performance, and excellent environmental performance.

Owner:江苏瑞丰科技实业有限公司

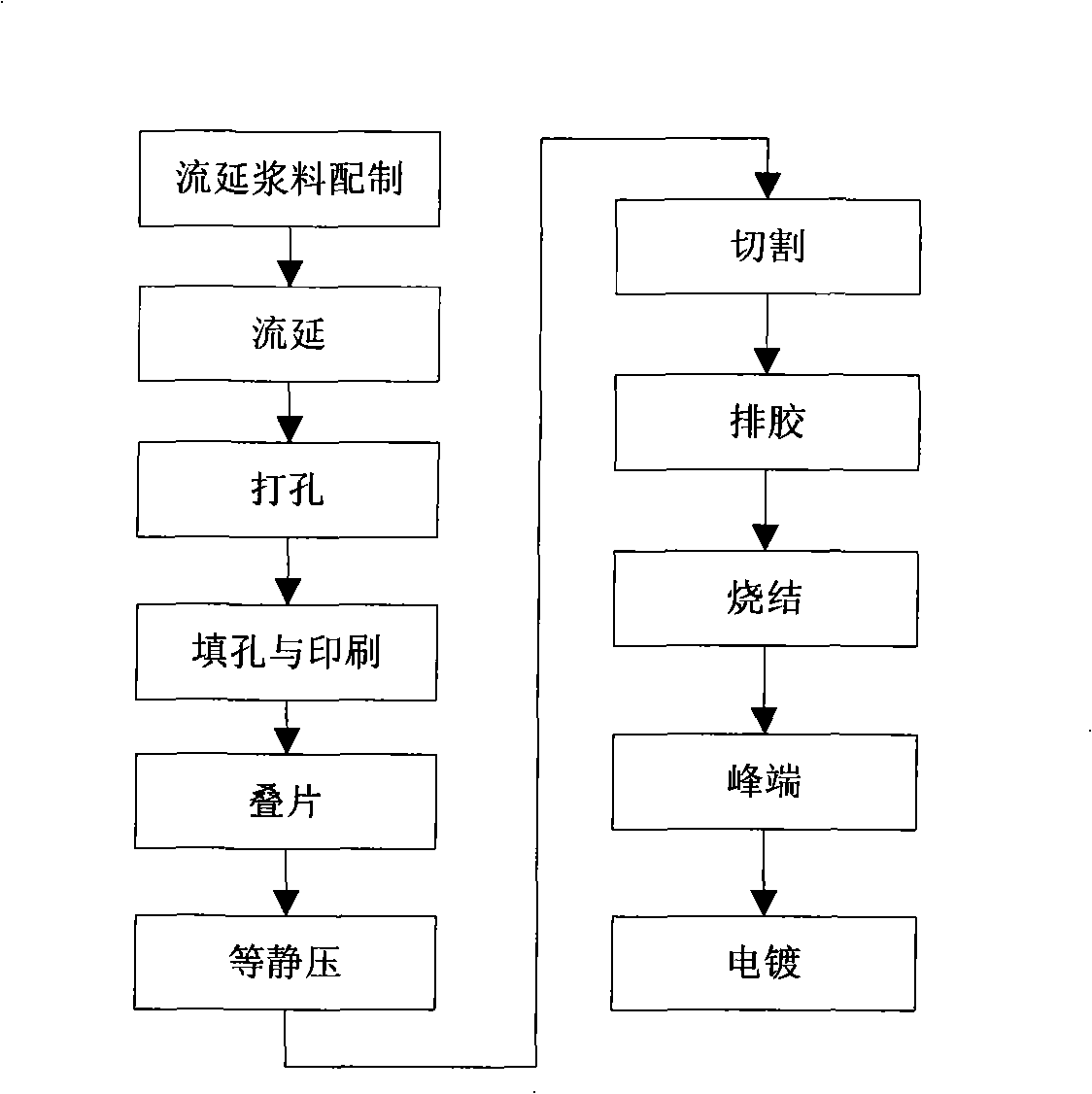

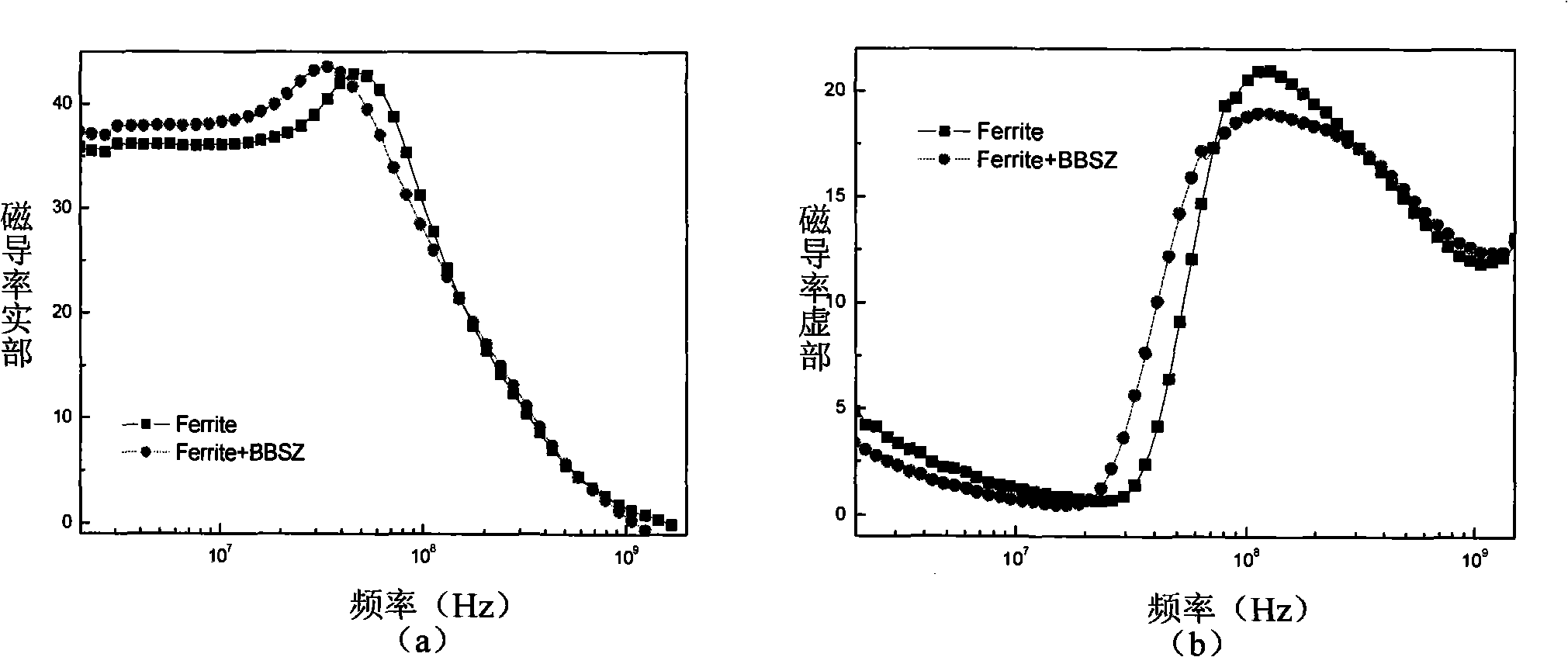

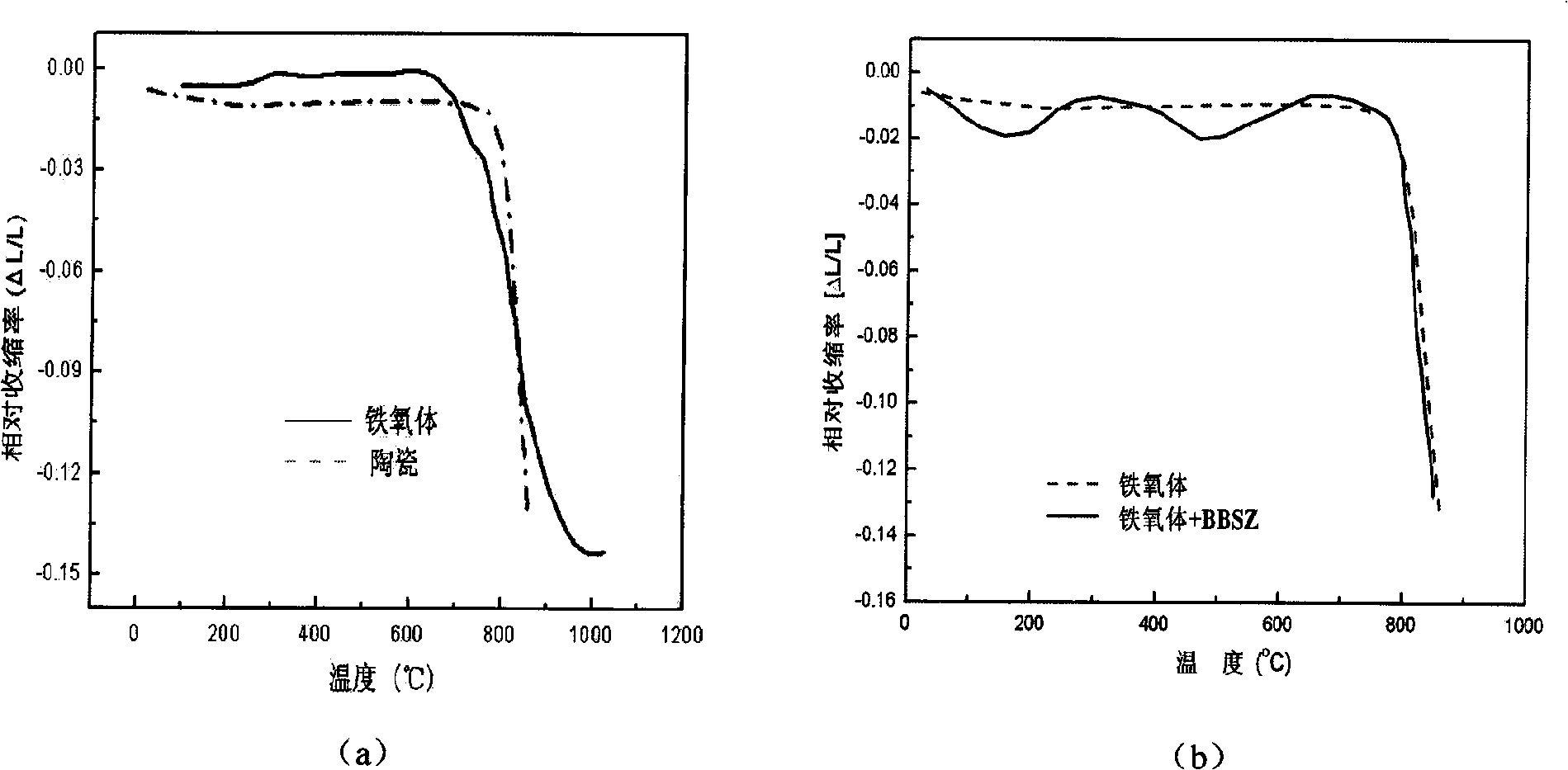

Low-temperature matching co-firing method of ferrite and ceramic material

InactiveCN101514102AAchieve matching cofiringImproving the characteristic parameters of low temperature sintering densificationFerrite powderSlurry

A low-temperature matching co-firing method of ferrite and ceramic material belongs to the technical field of electronic components and relates to the low-temperature co-firing method (LTCC technology) of ceramics and the ferrite, in particular to the method for eliminating stress in the LTCC technology and realizing the matching co-firing of heterogeneous materials. The method controls the consistency of sintering densification characteristic parameters between the heterogeneous materials by adding BBSZ glass which is equal to 5 percent by weight of ferrite powder material in a tape-casting slurry formula of the ferrite as a matching co-firing assist agent, thereby realizing the matching sintering during the co-firing process. The method can effectively improve the low-temperature sintering densification characteristic parameters of the materials and realize the matching co-firing of the heterogeneous materials; meanwhile, the method has little effect on the electromagnetic property of the ceramics or the ferrite powder material. The method is characterized by simplicity, good operability, cheap prices, obvious effect and the like, thereby being capable of being widely used in the LTCC technology for producing various electronic components.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Medium and low-dielectric constant low-temperature cofired ceramic material and preparation method thereof

The invention provides a medium and low-dielectric constant low-temperature cofired ceramic material. A ceramic principal phase comprises 20%-40% of ZnO, 10%-27% of TiO2, 1%-15% of BaO, 1%-10% of ZrO2, 1%-8% of La2O3 and the balance of Sm2O3; and a fluxing agent comprises 10%-25% of SiO2, 1%-10% of B2O3 and 3%-15% of aluminoborosilicate glass powder. A preparation method of the material comprises the steps of: 1) preparing a ceramic material principal phase mixture ; 2) firstly grinding; 3) roasting; 4) preparing a mixture of the fluxing agent and the ceramic principal phase roasting material; 5) re-roasting; and 6) regrinding. The sintering temperature is as low as 830-900 DEG C, and the sintering contractibility rate can be controlled at 10%-20%; the adjusting range of dielectric constant is 5-25, and a dielectric constant attrition rate is less than 0.001; the temperature coefficient of resonance frequency is -10-10ppm; and the material can be compositely and jointly sintered with a ferrite powder magnetic film and silver entoplasm.

Owner:SHENZHEN SUNLORD ELECTRONICS

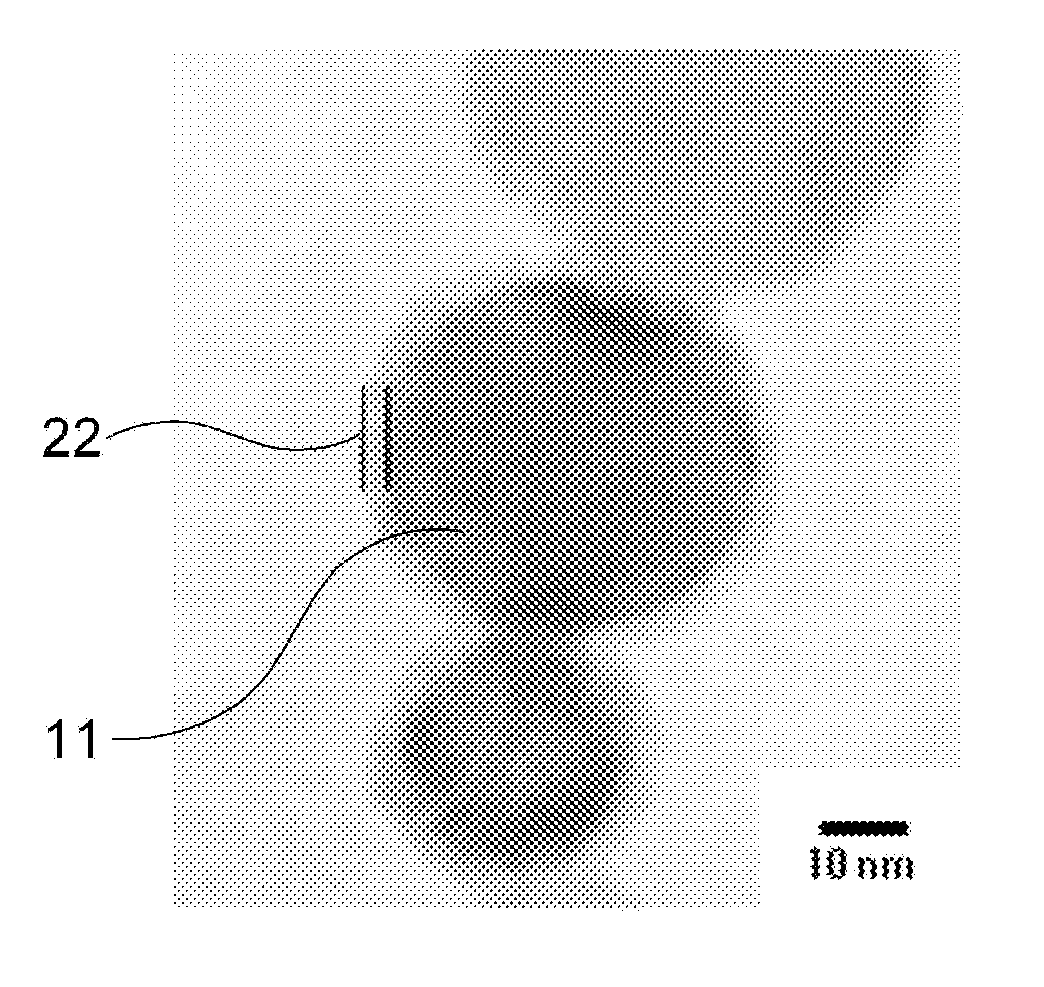

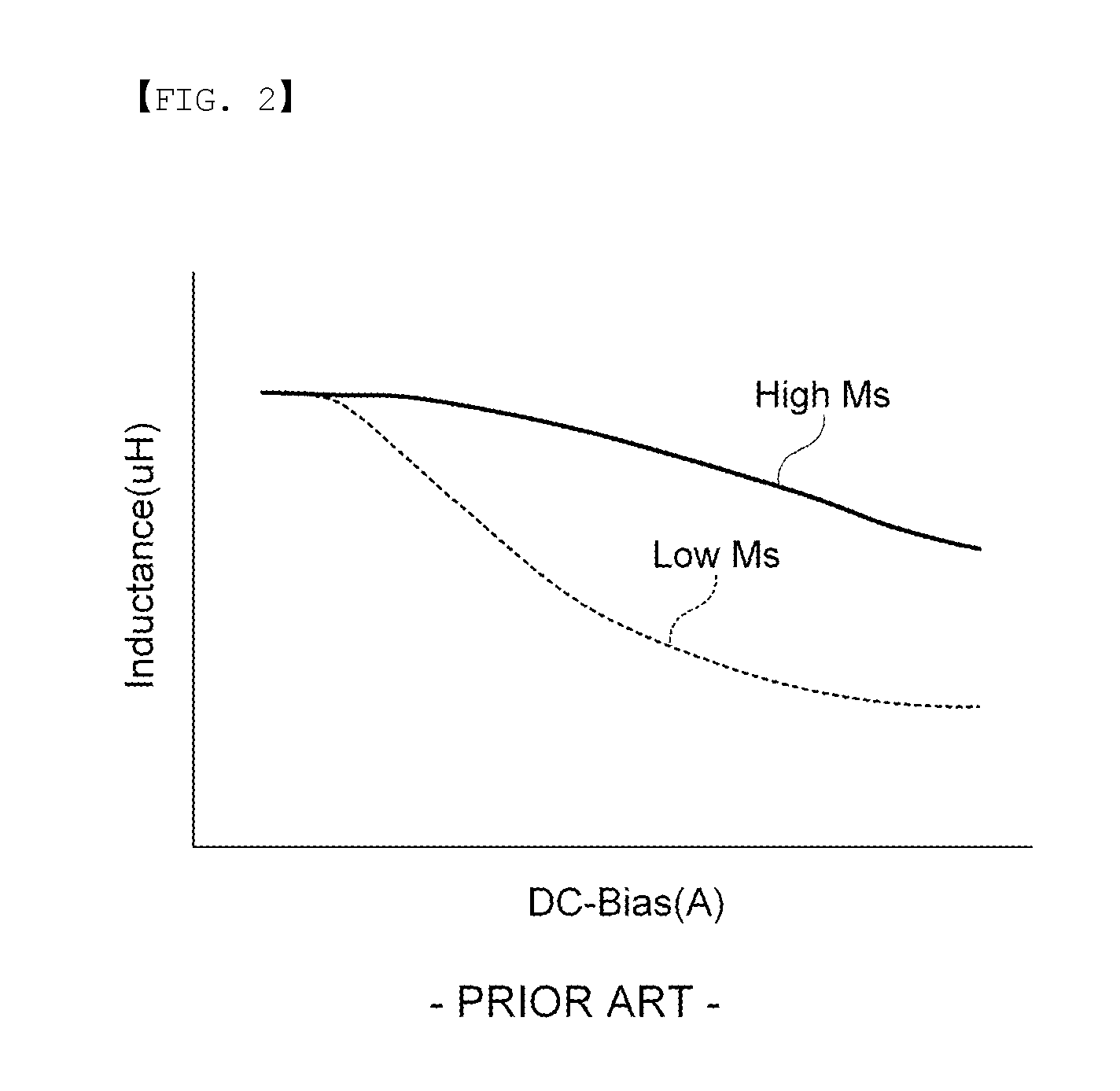

Ferrite powder of metal, ferrite material comprising the same, and multilayered chip components comprising ferrite layer using the ferrite material

InactiveUS20130033354A1Reduce the chance of changeInorganic material magnetismFerroso-ferric oxidesFerrite layerMagnetization

Disclosed herein are a ferrite powder having a core-shell structure, the core being made of iron (Fe) or iron-based compounds comprising iron (Fe) and the shell being made of metal oxides, a ferrite material comprising the ferrite powder and the glass, and multilayered chip components including the ferrite layer using the ferrite material, inner electrodes, and outer electrodes. According to the exemplary embodiments of the present invention, it is possible to provide the ferrite material capable of improving the change in the inductance L value in response to applied current by suppressing magnetization at high current. The multilayered chip components including the ferrite material according to the exemplary embodiment of the present invention can also be used in a band of MHz.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

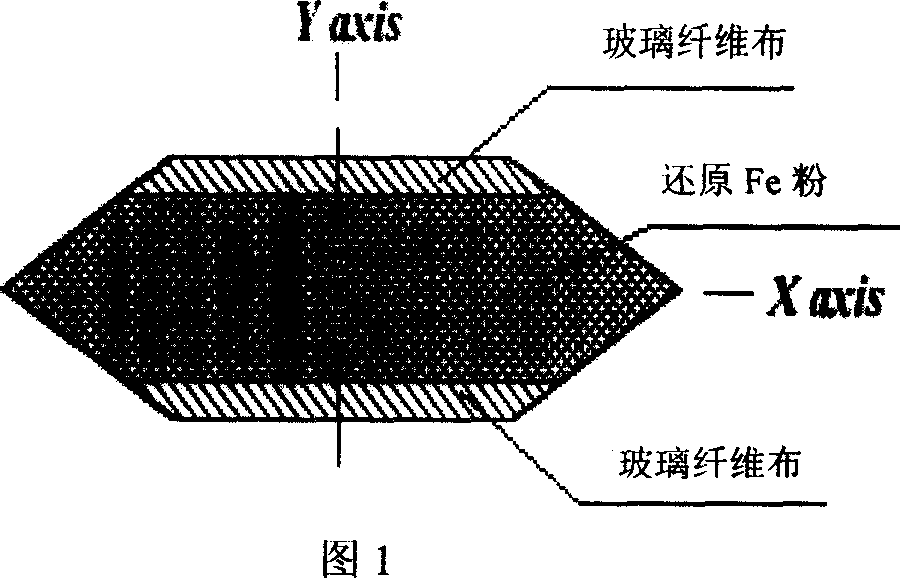

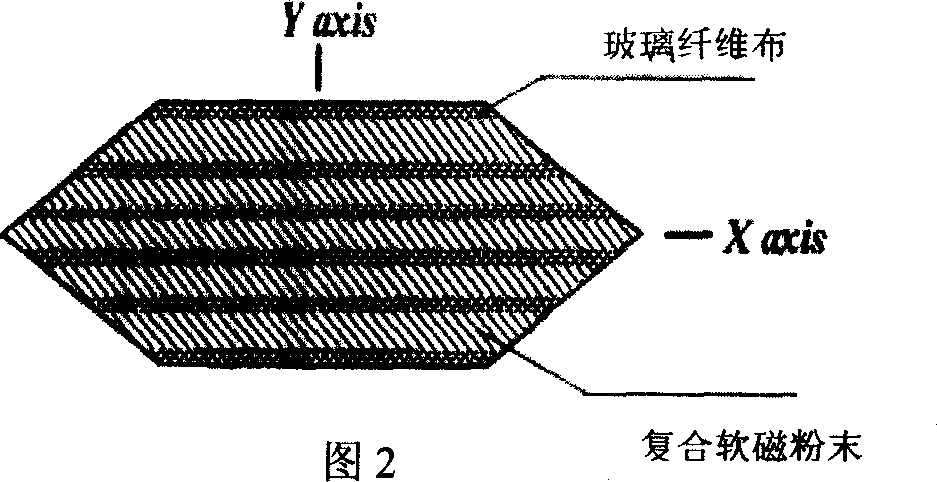

Composite soft magnetic powder magnetic conducting material for slot wedge of electric machine and preparation thereof

InactiveCN1949406AHas a relative magnetic permeabilityImprove insulation performanceWindingsInorganic material magnetismHigh resistivityLoad loss

The invention relates to a dynamo using slot wedge using compound soft magnetic powder magnetic conductance material. The powder is the compound soft magnetic powder compounded from MnZn ferrite powder and reduced iron powder or carbonyl iron dust. The radio is 10-90wt% high resistivity magnetic powder, and 10-90wt% high magnetic permeability magnetic powder. Adding certain quantity glass fiber into compounded magnetic powder layer, separating structure would be formed. The invention could decrease supplementary load loss of dynamo, as well as eddy current loss, and improve efficiency of dynamo.

Owner:SICHUAN UNIV

Method for manufacturing sintered permanent ferrite powder

InactiveCN101205138AIncrease surface areaGood dispersionInorganic material magnetismMetallurgyGranularity

The invention relates to a manufacturing method for sintering permanent magnetism ferrite powder. The method comprises following working procedures: A. Preparing materials; B. Mixing; C. Concentrating; D. Dispersing; E. Balling; F. Sintering. 1. The surface area of the powder produced with the manufacturing method of sintering permanent magnetism ferrite powder of the invention is increased, the dispensability is good, and the sintering permanent magnetism ferrite powder with high magnetism performance can be gained; 2. The granularity of powder which is produced with the manufacturing method of sintering permanent magnetism ferrite powder of the invention is well-proportioned, the consumption of the energy is small and the productivity effect is high; 3. The manufacturing method of powder which is produced with the manufacturing method of sintering permanent magnetism ferrite powder of the invention is simple, the operation is easy, no pollution is generated and the demand of mass production can be realized.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation process of neodymium-iron-boron /ferrite composite magnet body for permanent magnet alternating current synchronous motor

InactiveCN102324814AHigh densityImprove performanceManufacturing stator/rotor bodiesSynchronous motorFerrite powder

The invention discloses a preparation process of a neodymium-iron-boron / ferrite composite magnet body for a permanent magnet alternating current synchronous motor, which comprises the steps that: (1) neodymium-iron-boron powder and ferrite powder are uniformly mixed, put into coupling agent solution, decentralized, soaked and dried; (2) binder and curing agent solution are blended and granulatedwith magnetic powder which is dried in step (1); (3) the mixture which is obtained in step (2) is melted, cast into sheets, broken in hydrogen and ground by air into material powder with the grain size of 3mu m to 4mu m; (4) the material powder is arranged in a mould, oriented, compressed, shaped and demagnetized, a raw blank is taken out, vacuumized and packaged, the packaged blank is put into an isostatic pressing machine to be pressurized to 18MPa to 25MPa, pressure is maintained and the blank is taken out; and (5) the raw blank which is shaped in step (4) is arranged in a high vacuum furnace to be sintered, and is aged in two stages. The preparation process manufactures the high-density and high-performance permanent magnet body for the permanent magnet alternating current synchronousmotor with lower cost.

Owner:邓上云

Composite sintered magnetic material, its manufacturing method, and magnetic element using composite sintered magnetic material

InactiveUS20050072955A1Inorganic material magnetismCeramic shaping apparatusFerrite layerFerrite powder

A composite sintered magnetic material comprises a kind of metal powder at least one selected from the group consisting of Fe, Fe—Si type, Fe—Ni type, Fe—Ni—Mo type, and Fe—Si—Al type, and a ferrite layer formed from a kind of ferrite powder at least one selected from the group consisting of Ni—Zn type, Mn—Zn type, and Mg—Zn type, wherein a diffusion layer is formed by sintering between both of these to integrates the both.

Owner:PANASONIC CORP

Preparation method of multiaperture ferrite

InactiveCN103101980AEasy to prepareThe reaction raw materials are simple and cheapIron compoundsCobalt compoundsFluid phaseFerrite powder

The invention provides a method for preparing multiaperture spherical magnetic ferrite (zinc ferrite, nickel ferrite, cobalt ferrite and manganese ferrite) by taking dodecylamine as a precipitator by a solvothermal method. The preparation method is characterized in that an ethylene glycol solution of ferric trichloride and chloride is used as a reaction solution; dodecylamine is used as the precipitator; and the ethylene glycol solution and the dodecylamine are stirred and mixed uniformly at the room temperature to form a liquid phase reaction solution; and the liquid phase reaction solution is transferred to a reaction kettle for hydrothermal reaction at 180-250 DEG C. Products are separated, washed and dried to obtain corresponding multiaperture ferrite powder after reaction. The preparation method has the characteristics of being low in raw materials, simple in process, convenient in operation, controllable in shape, and the like.

Owner:LUDONG UNIVERSITY

High-efficiency superparamagnetic ferrite nano arsenic adsorbent and preparation process thereof

InactiveCN102527319ALarge specific surface areaLow costOther chemical processesAlkali metal oxides/hydroxidesSorbentSuperparamagnetism

The invention belongs to the field of nano adsorption materials and in particular relates to a high-efficiency superparamagnetic ferrite nano arsenic adsorbent and a preparation process thereof. The prepared nano ferrite can well remove harmful ions (such as arsenic) from water and has strong magnetic recovery capacity, so that the problems of excessive harmful ions in the water and incapability of recovery of the adsorbent at present are solved. The adsorbent consists of superparamagnetic spinel ferrite phase nanoparticles and is nanopowder with the grain size of 3 to 8 nm, wherein the specific surface area is 100 to 500 m<2> / g. According to the process, pure crystallized nano ferrite powder is prepared by using anhydrous metal chloride, absolute ethanol and sodium hydroxide as reaction precursors and performing solvent thermal reaction. The prepared superparamagnetic ferrite nanoparticles are high in purity, small in grain size, high in specific surface area and high in hydrophilicity and more new selectable materials are provided for reducing the harmful ion (such as arsenic) content of water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite soft magnetic material and method for preparing material

ActiveCN103632794AHigh saturation magnetic inductionImprove permeabilityInorganic material magnetismLiquid/solution decomposition chemical coatingFerrite powderMetal

The invention discloses a composite soft magnetic material and a method for preparing the material. The composite soft magnetic material is composed of soft magnetic ferrite powder and a soft magnetic alloy film, wherein the particle size of the soft magnetic ferrite powder ranges from 10 microns to 120 microns, the soft magnetic alloy film wraps the surface of the soft magnetic ferrite particles, and the thickness of the soft magnetic alloy film ranges from 0.01 micron to 10 microns. According to the composite material, due to the fact that the metal soft magnetic film wraps the surface of the soft magnetic ferrite powder particles, the obtained composite soft magnetic particles are sintered to obtain the composite soft magnetic material. The material not only has high saturation induction intensity, but also has high magnetic permeability. The material has the features of both soft magnetic ferrite and metal soft magnetic material, and meanwhile the material has good mechanical performance and is mainly applied to the medium-high frequency field.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com