Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11002results about "Manufacturing stator/rotor bodies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

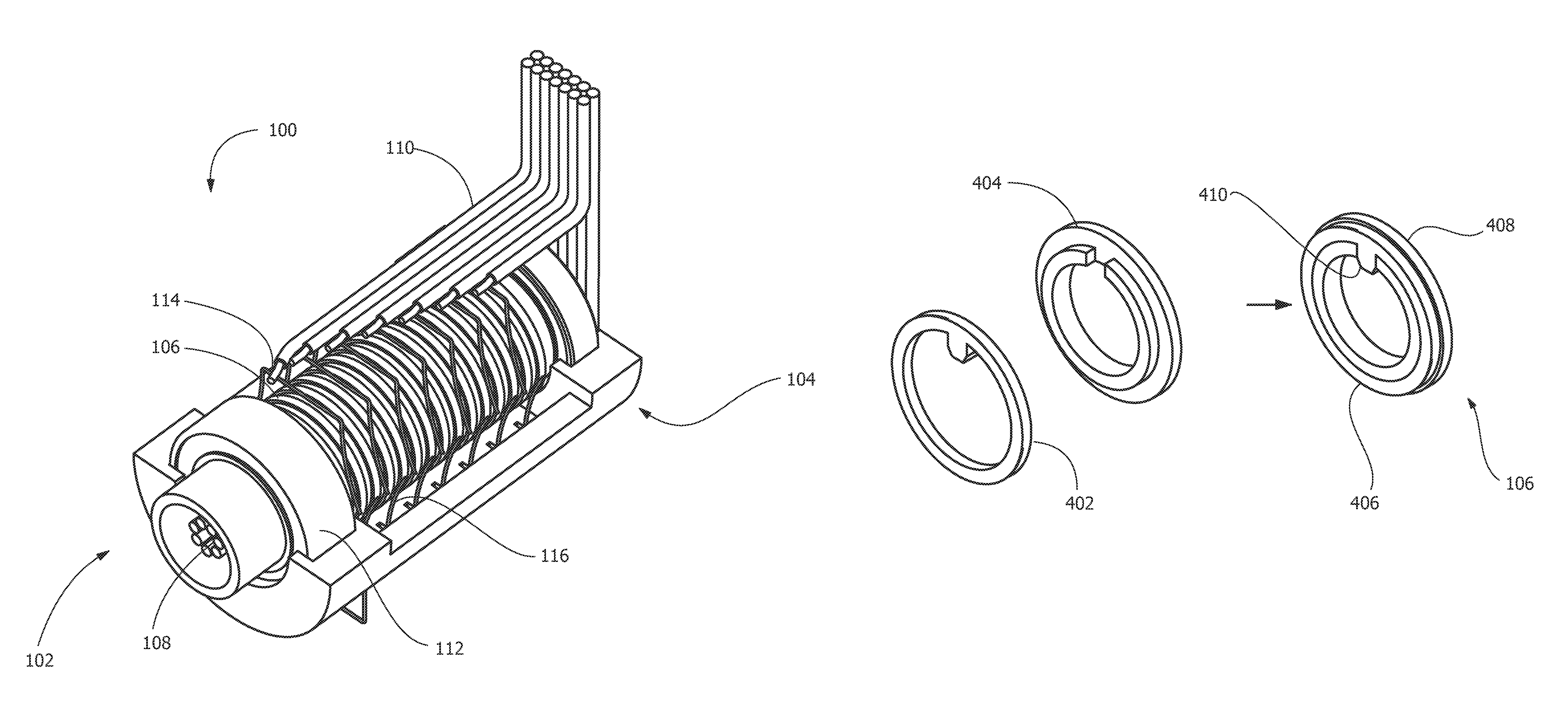

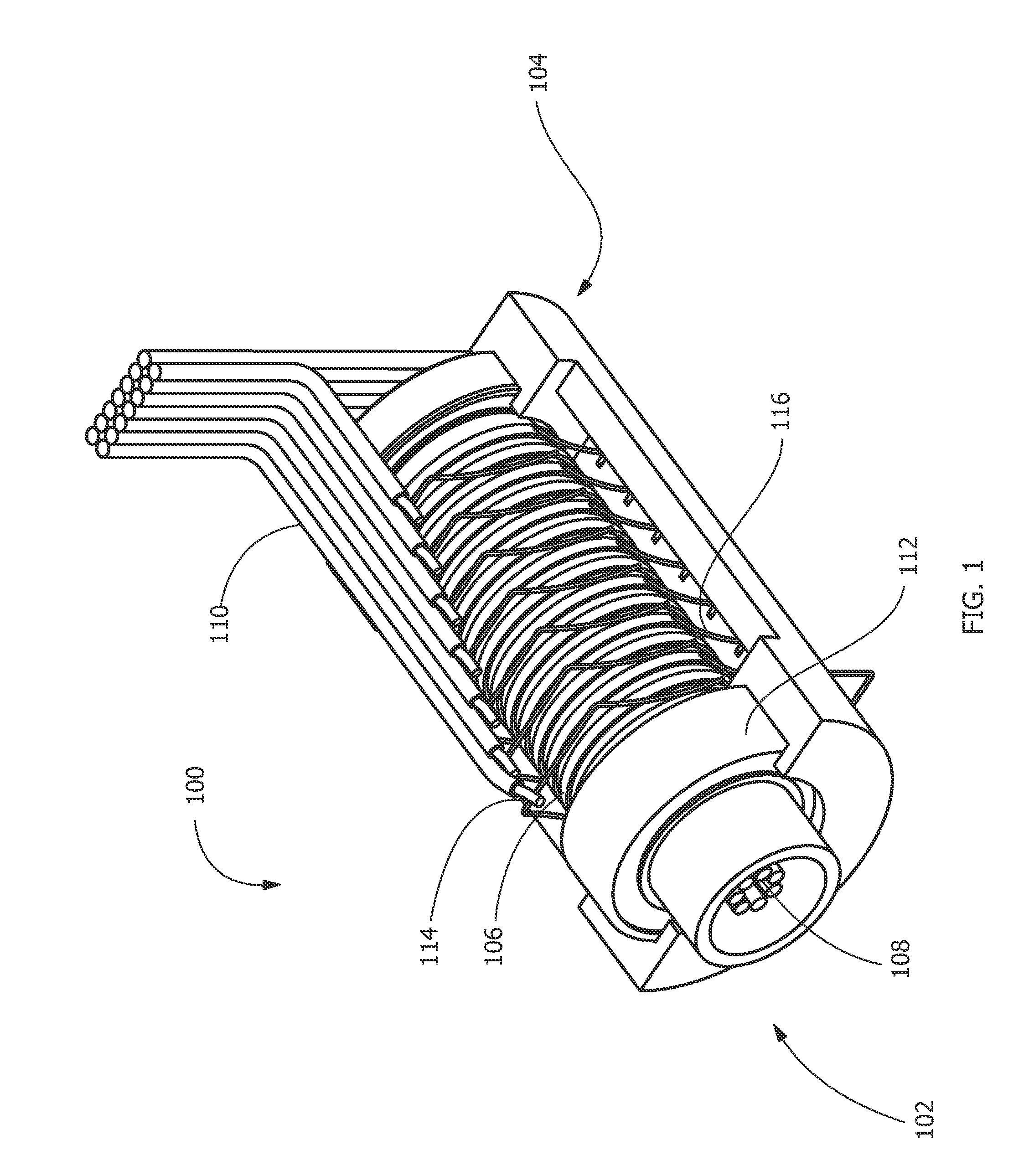

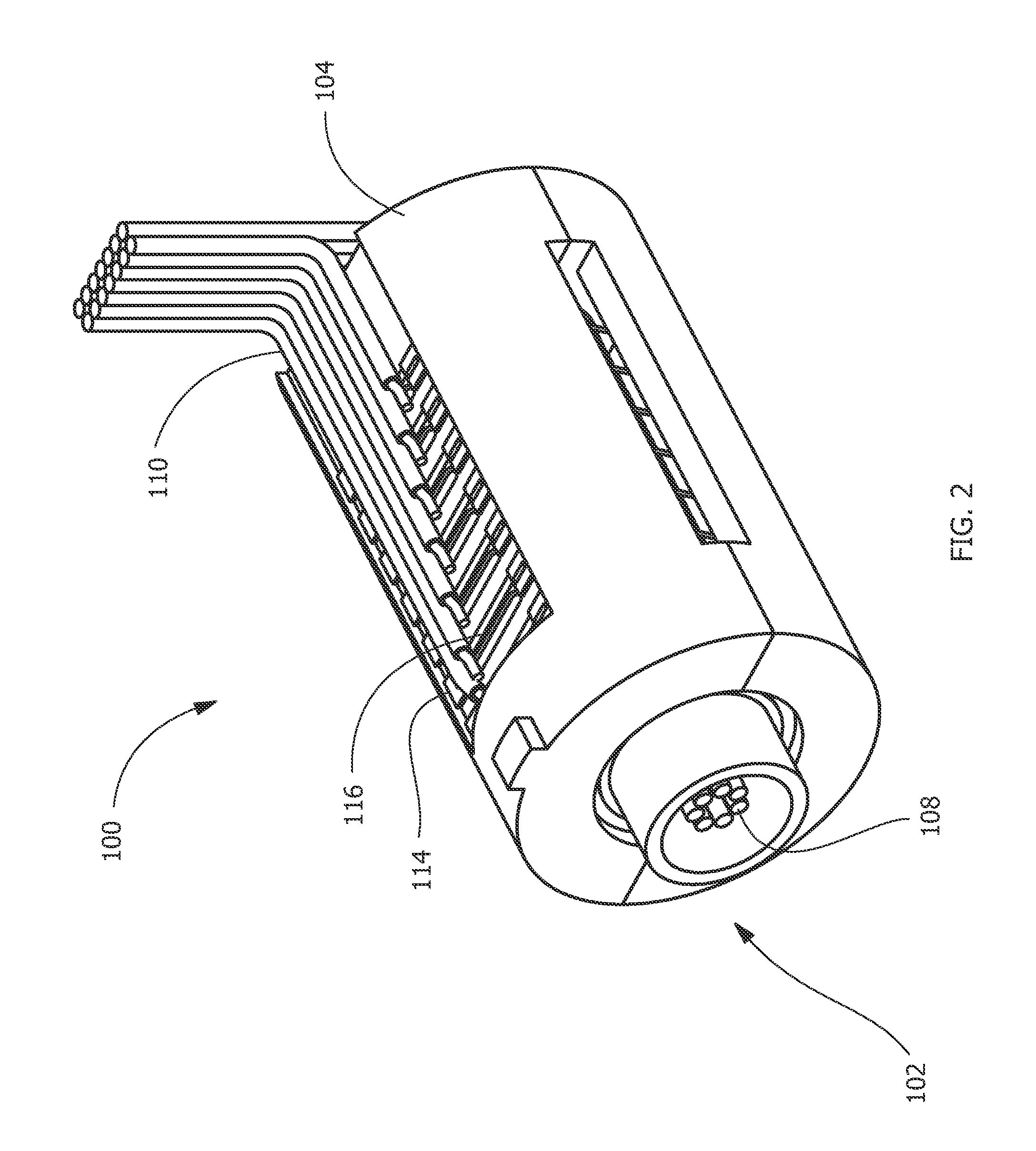

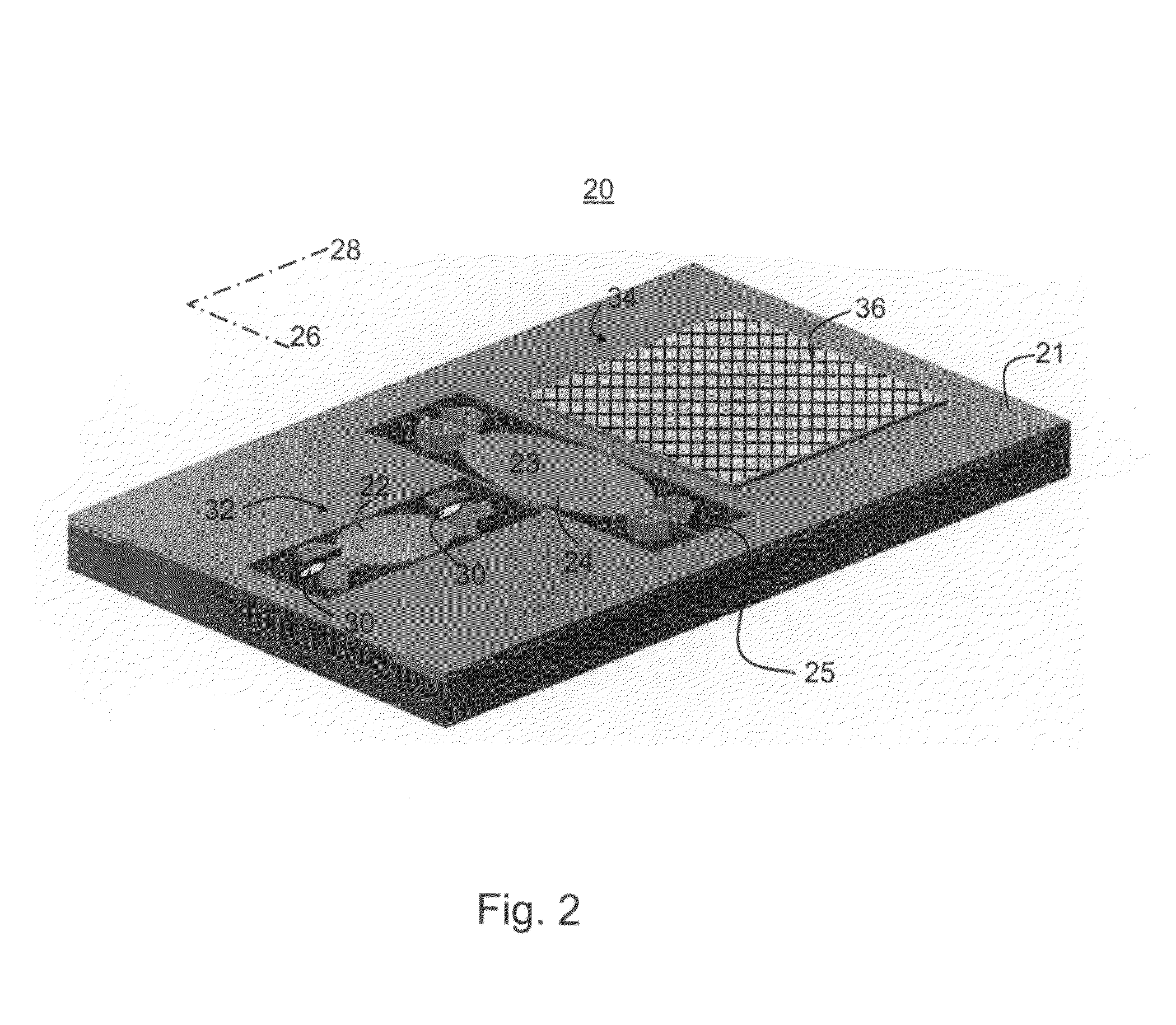

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

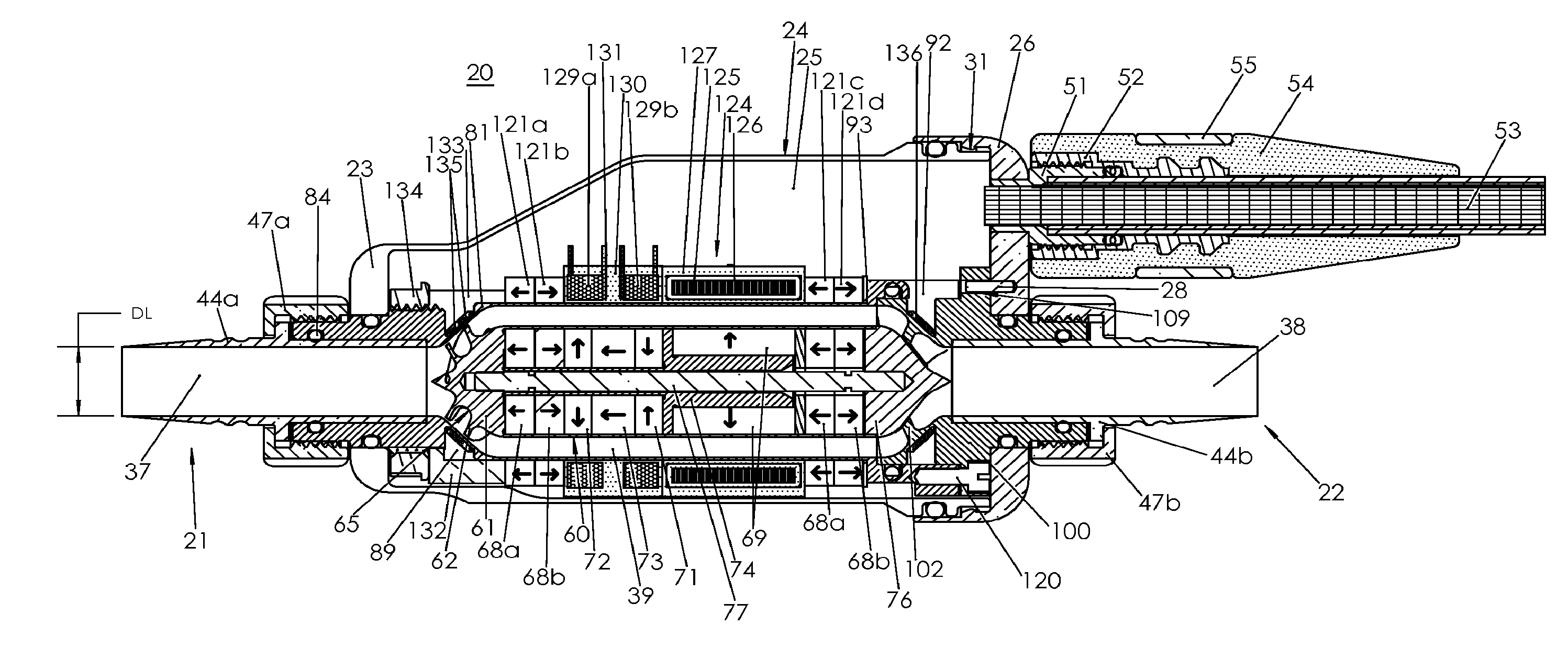

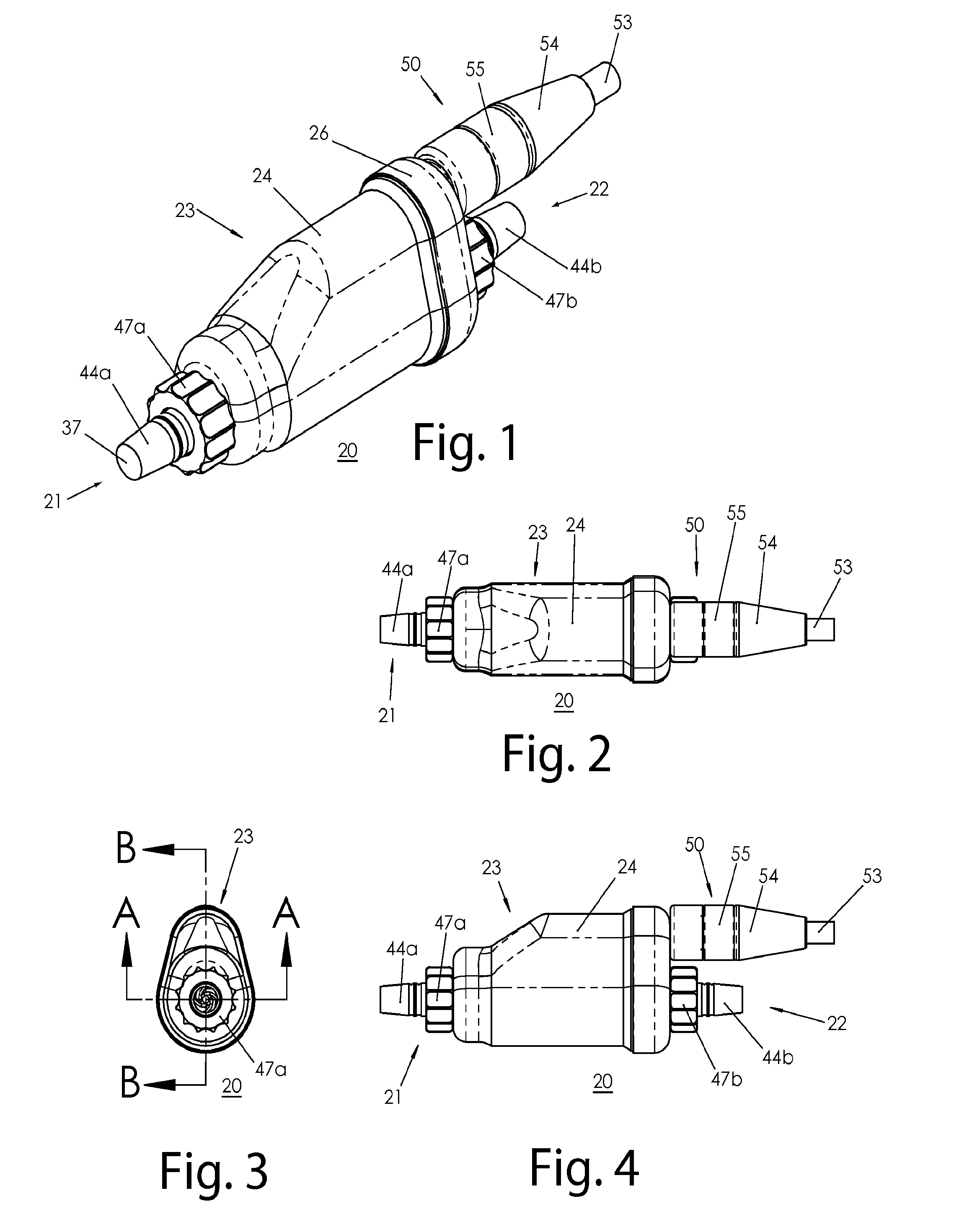

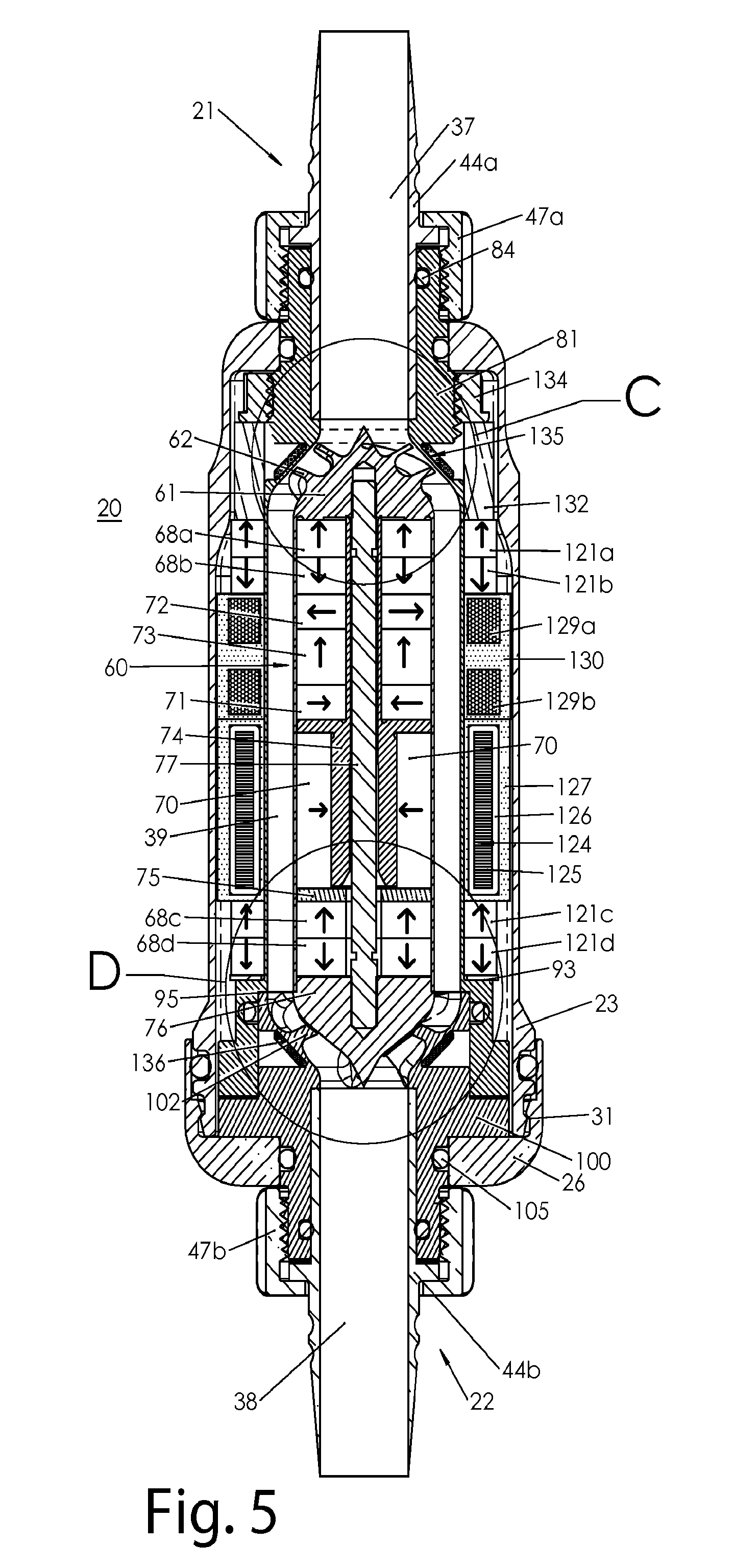

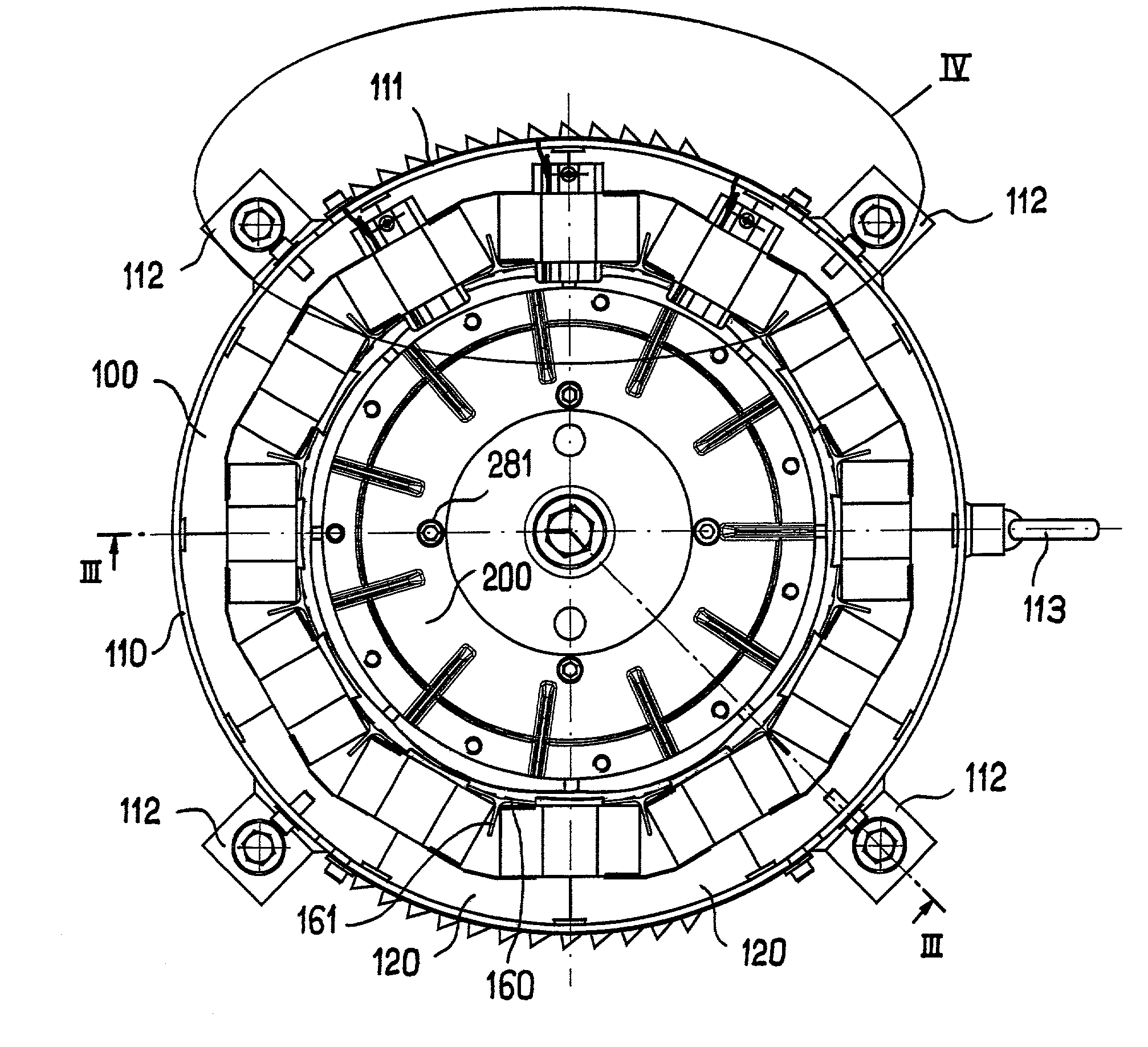

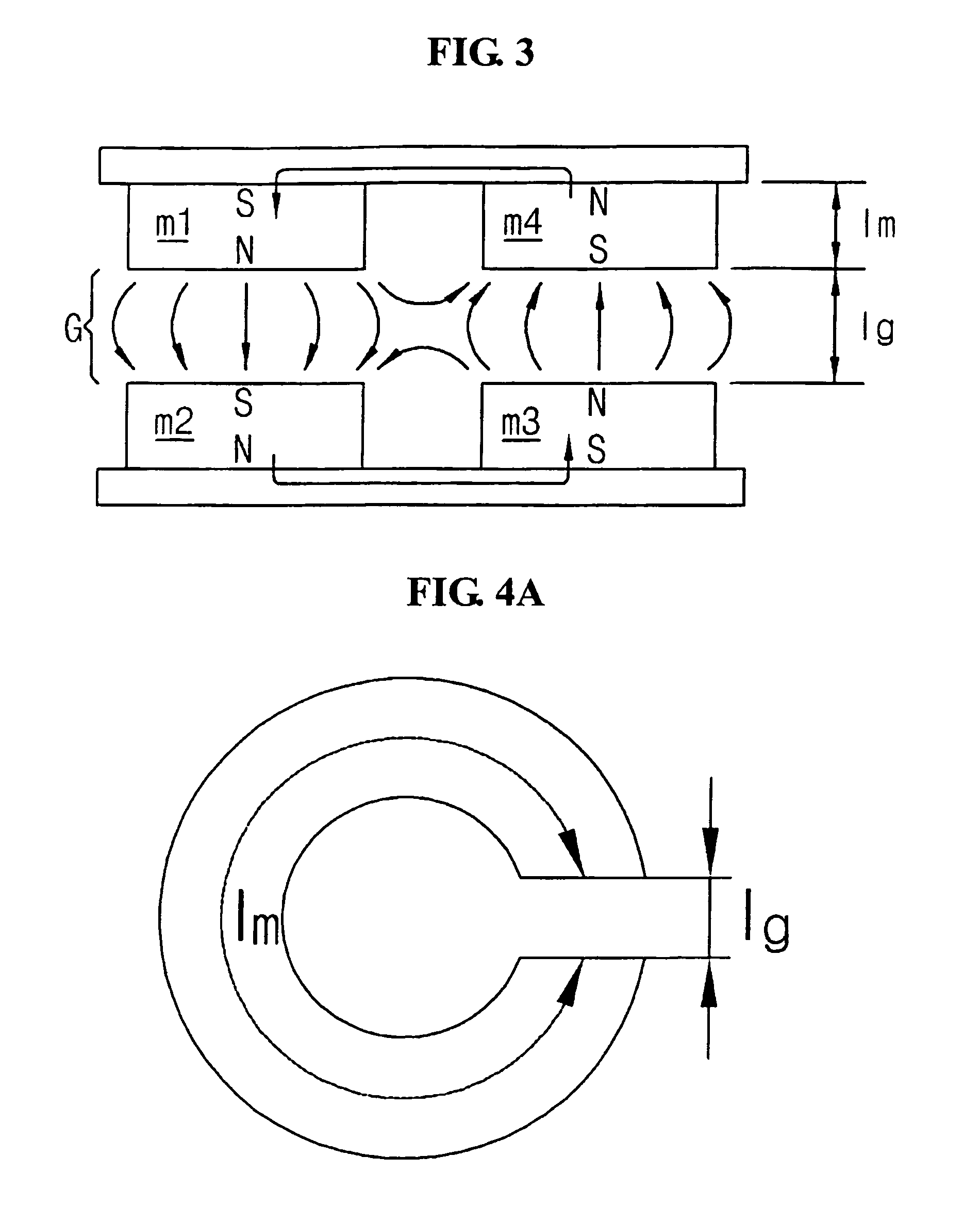

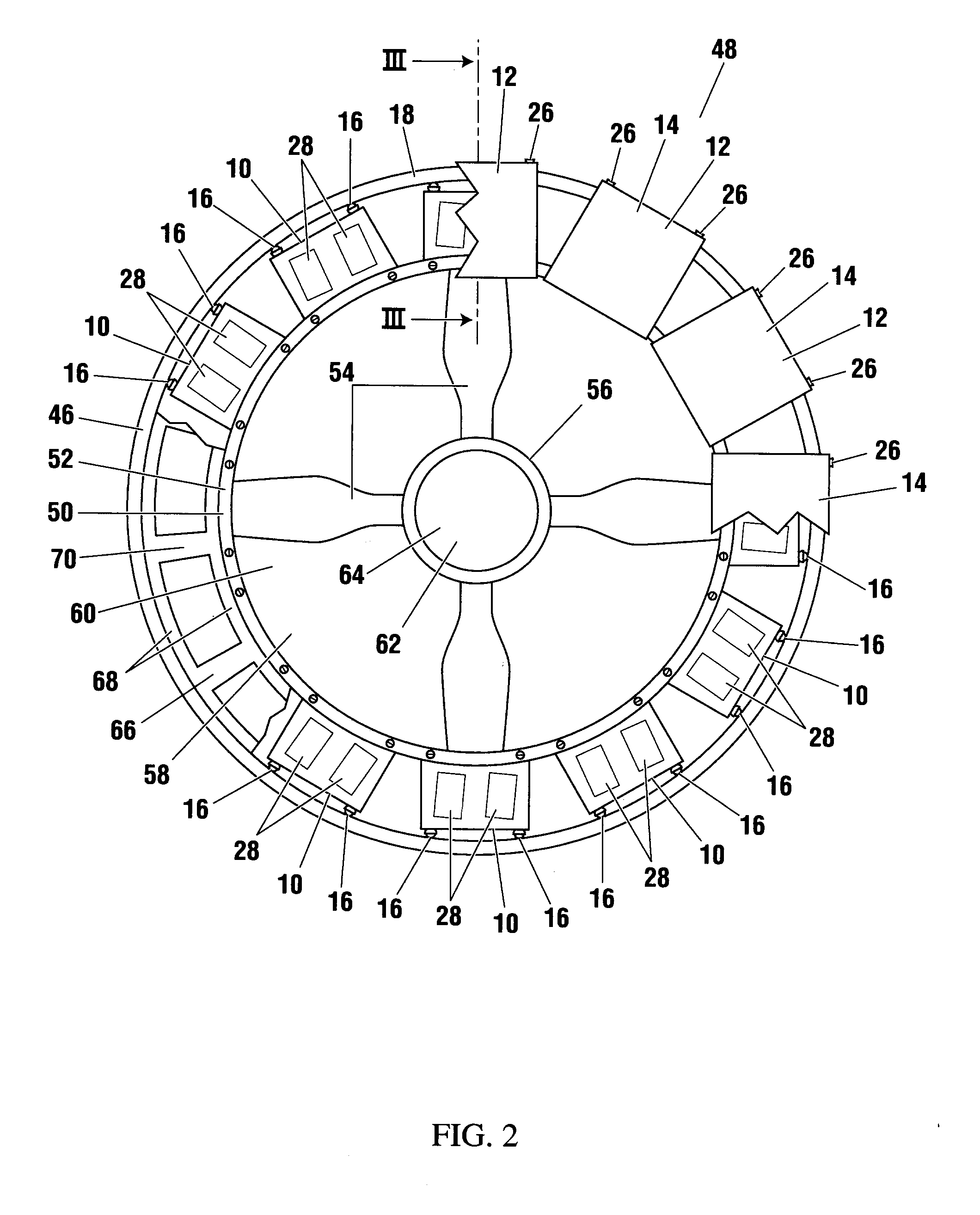

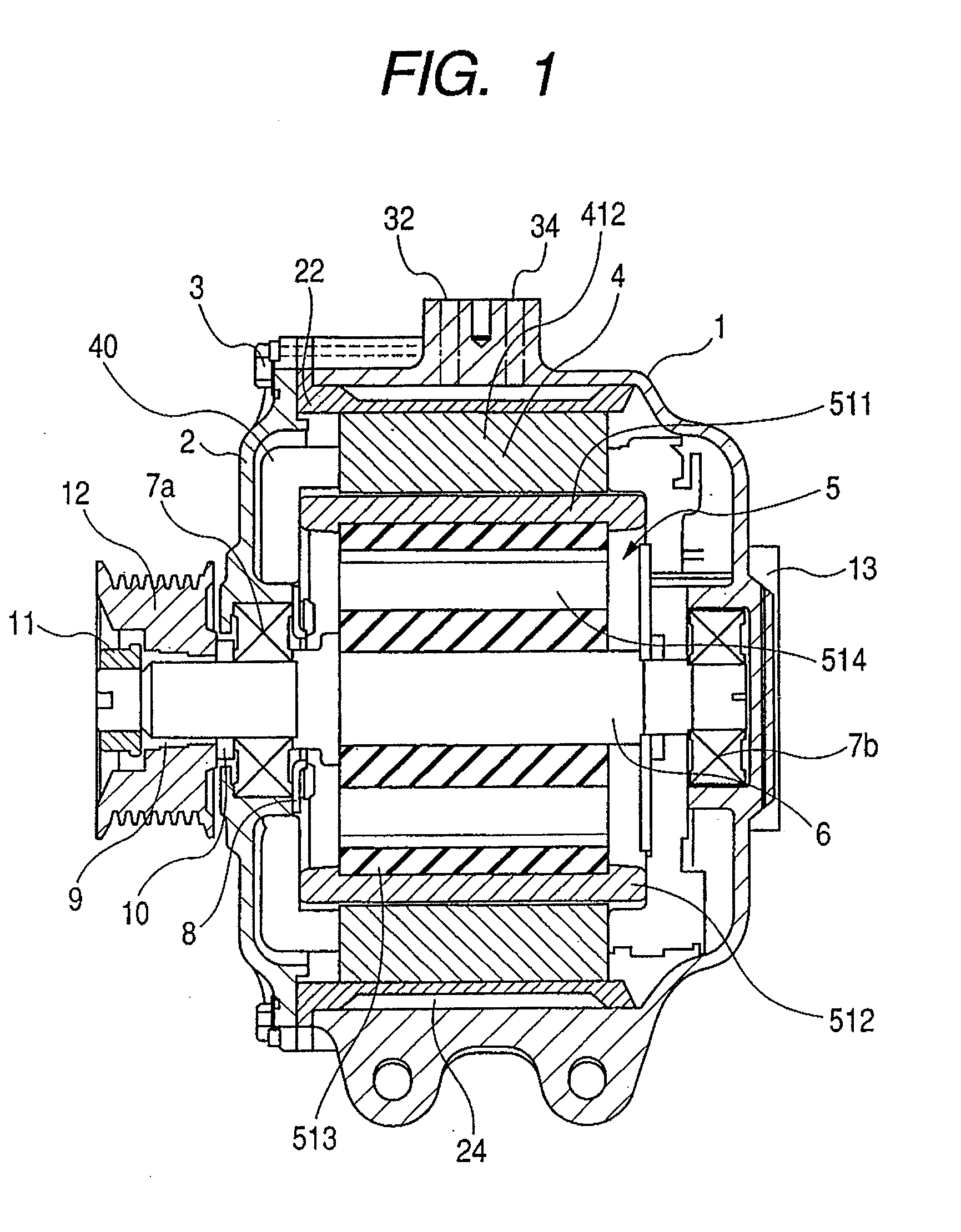

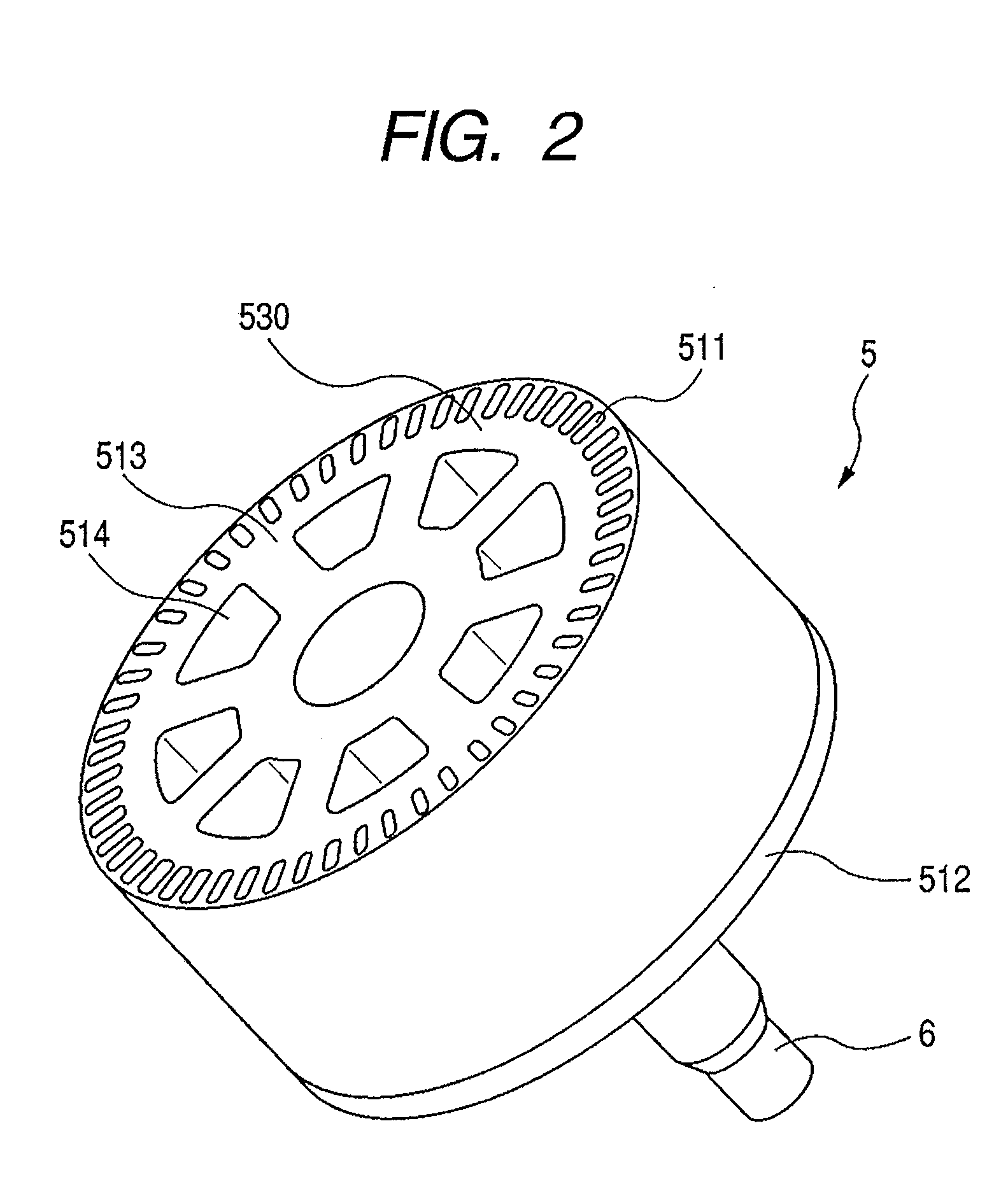

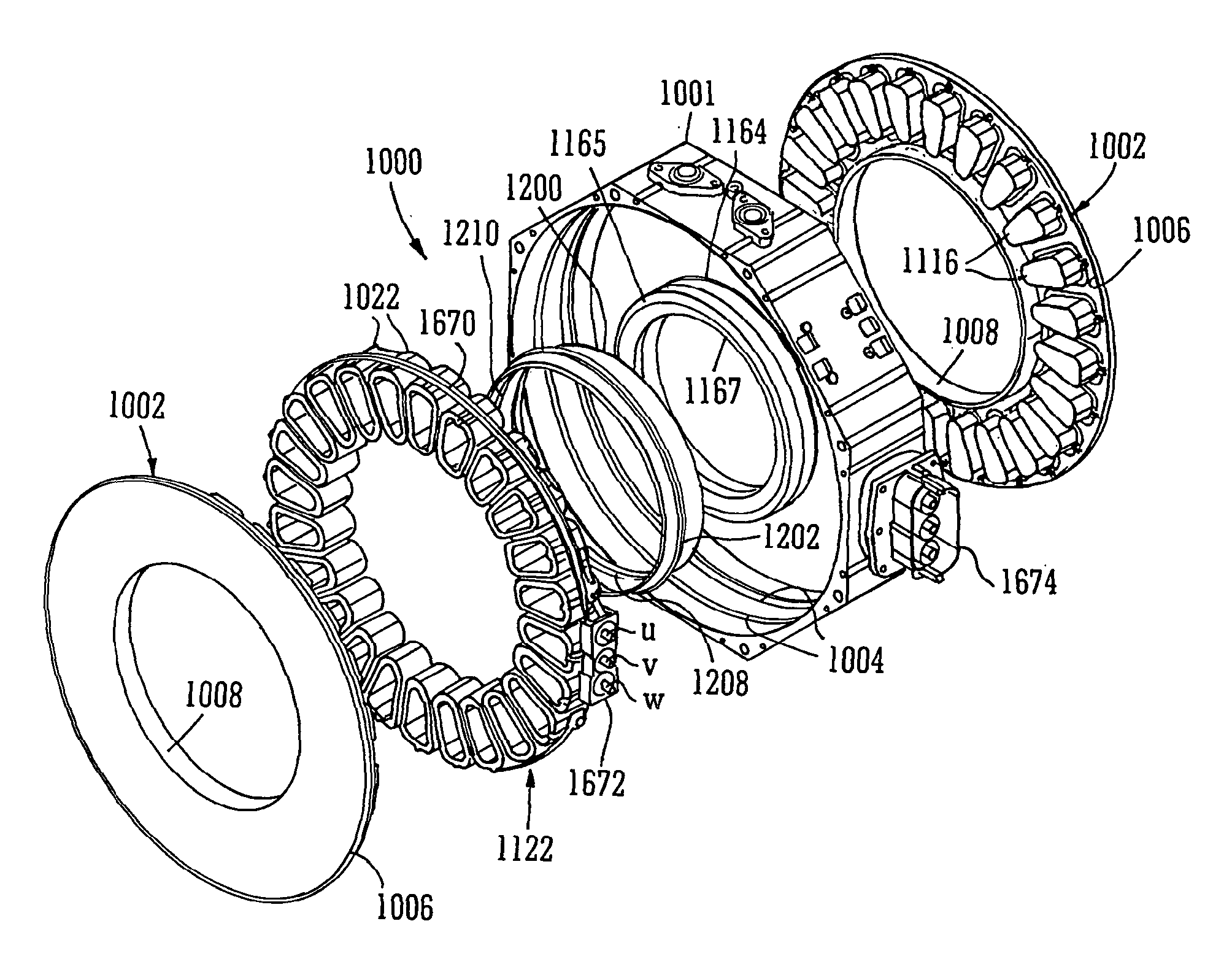

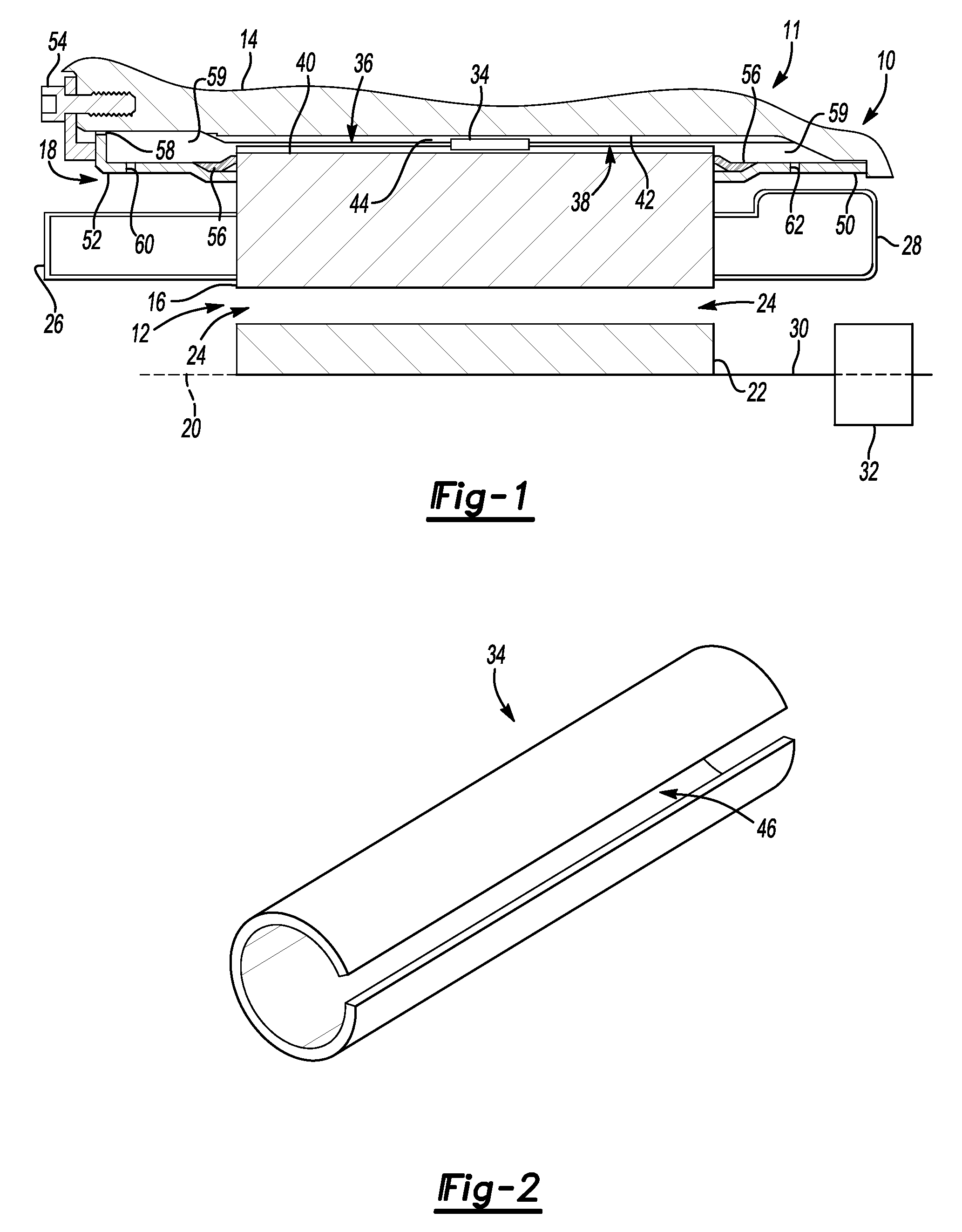

Magnetically-levitated blood pump with optimization method enabling miniaturization

ActiveUS20110237863A1Quality improvementReduce stiffnessControl devicesBlood pumpsBlood pumpMiniaturization

A magnetically-levitated blood pump with an optimization method that enables miniaturization and supercritical operation. The blood pump includes an optimized annular blood gap that increases blood flow and also provides a reduction in bearing stiffness among the permanent magnet bearings. Sensors are configured and placed optimally to provide space savings for the motor and magnet sections of the blood pump. Rotor mass is increased by providing permanent magnet placement deep within the rotor enabled by a draw rod configuration.

Owner:WORLD HEART +1

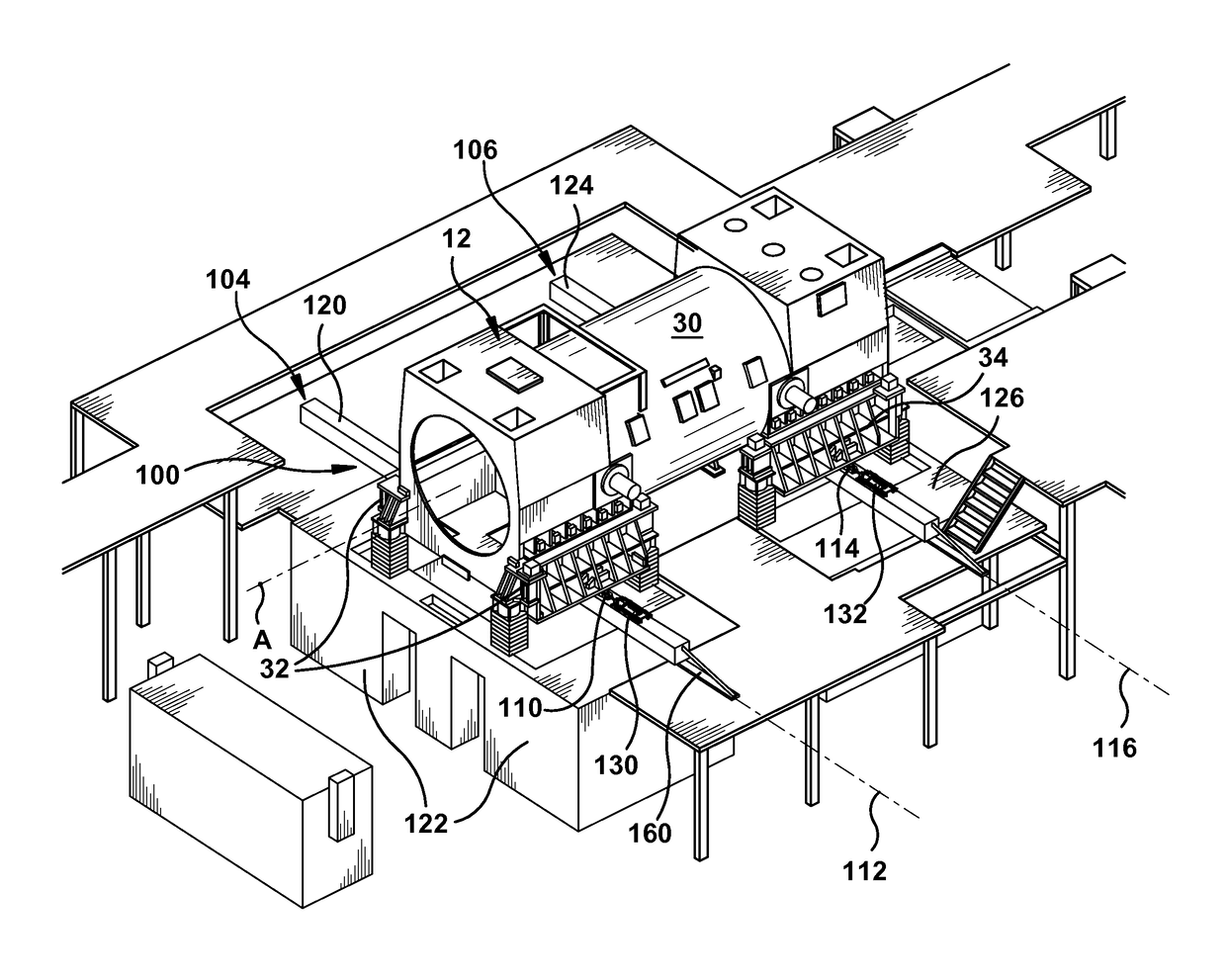

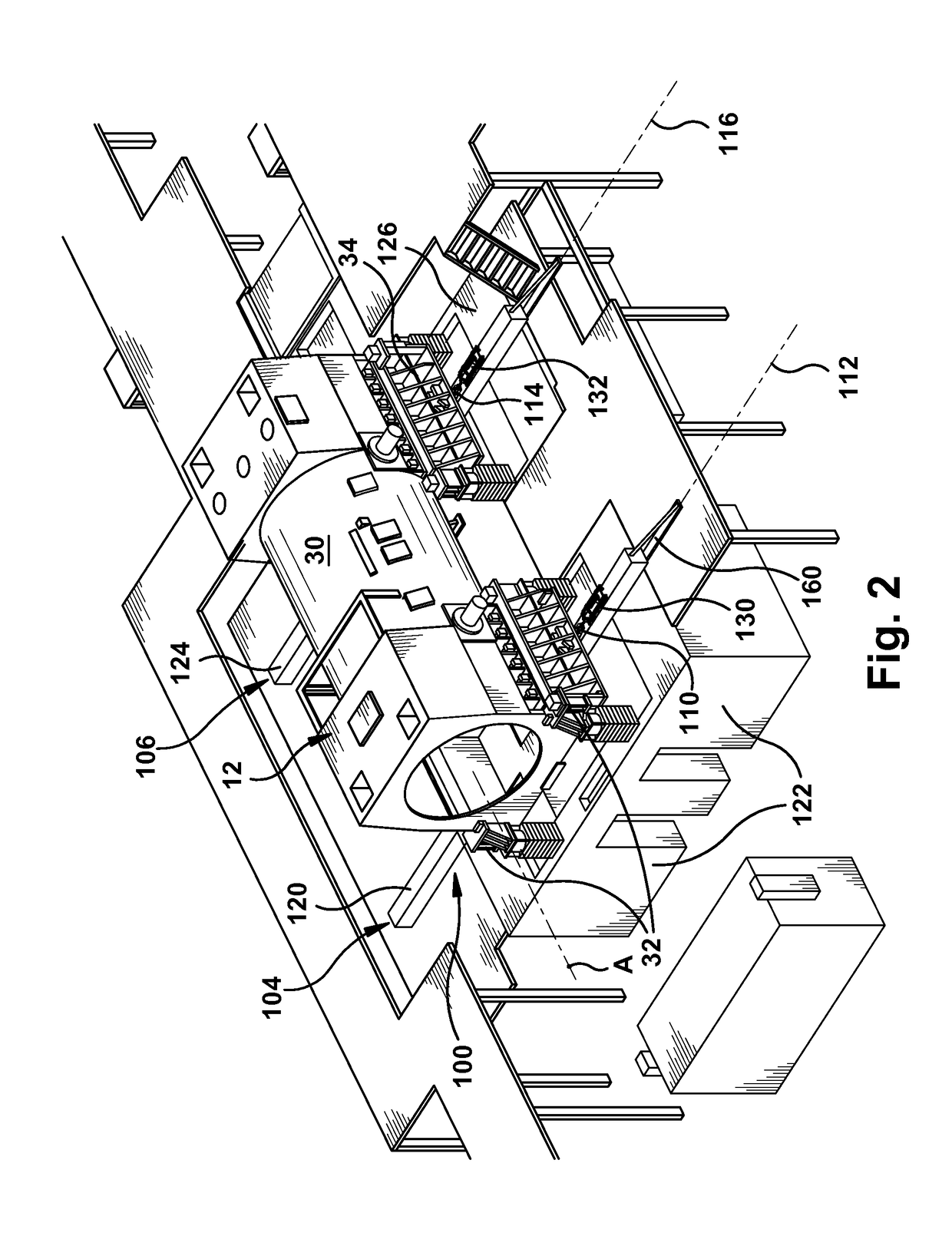

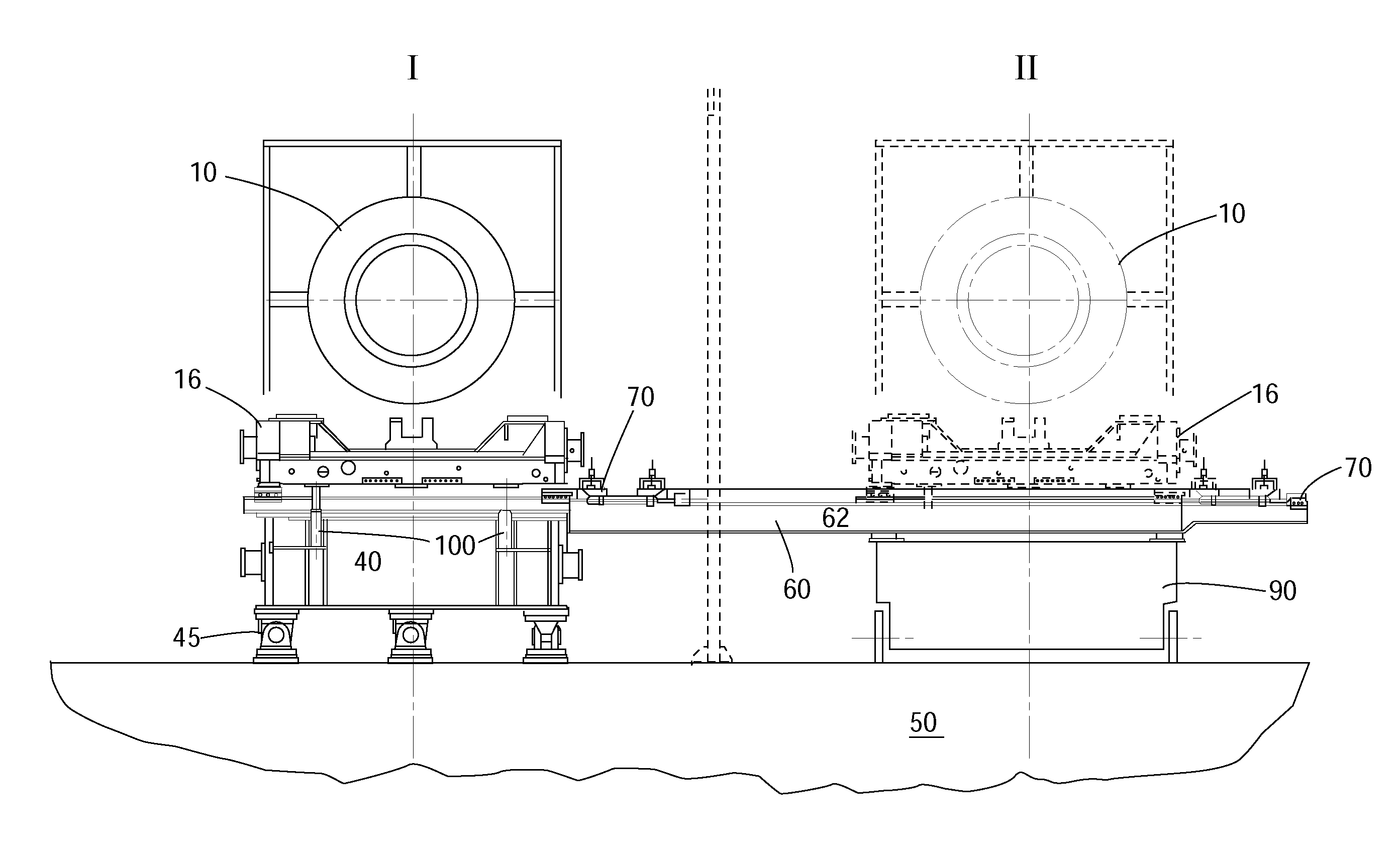

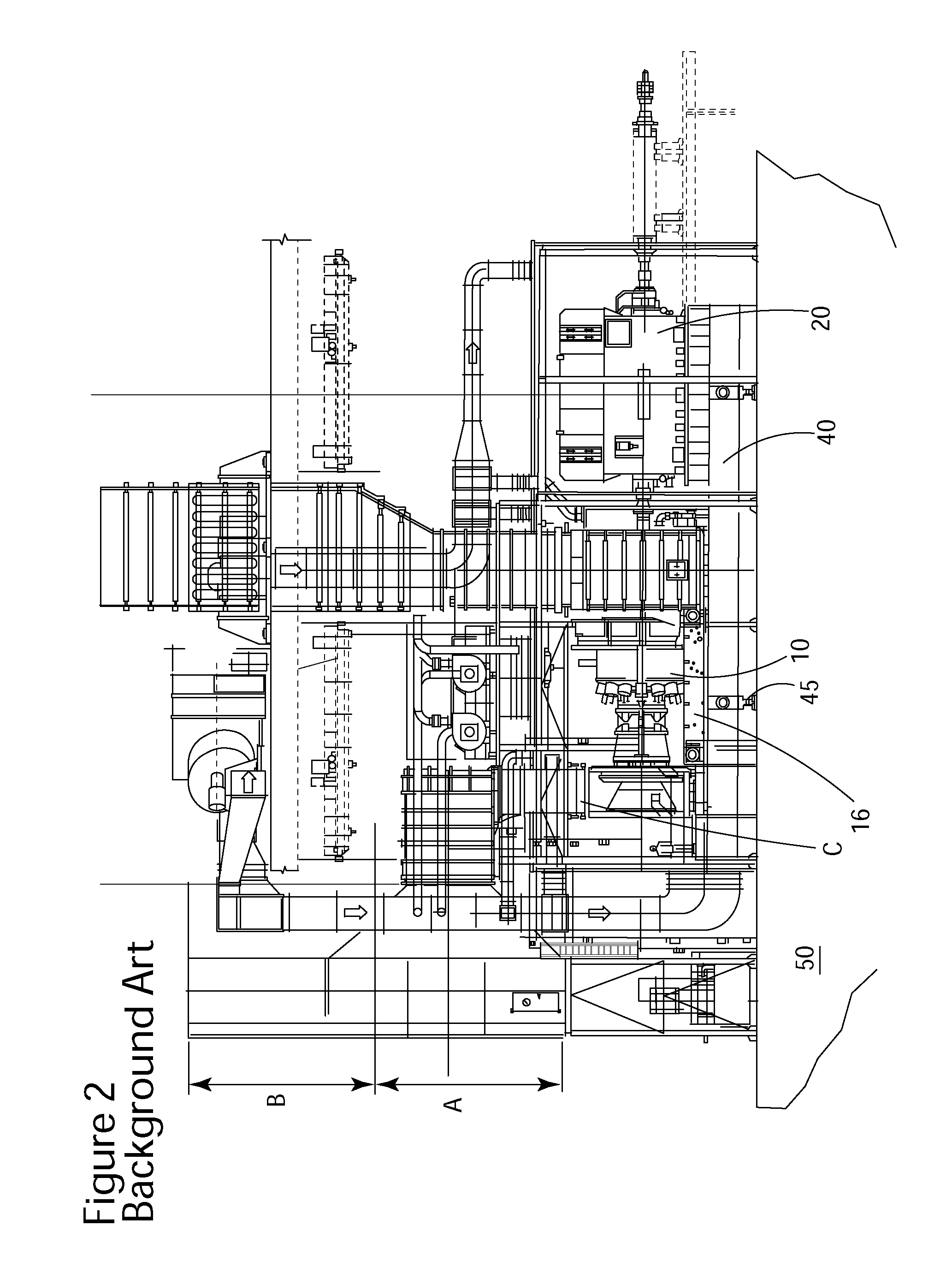

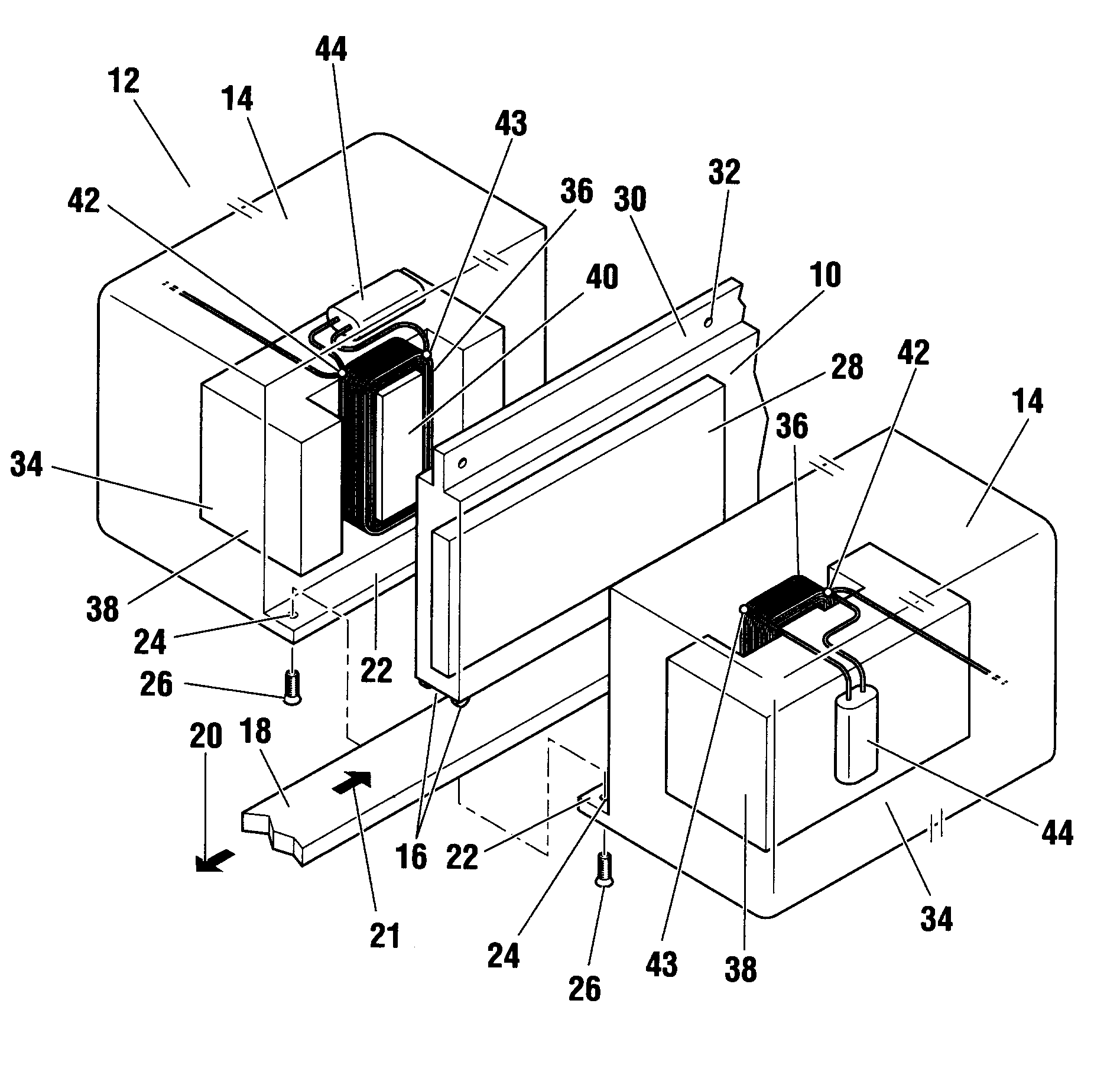

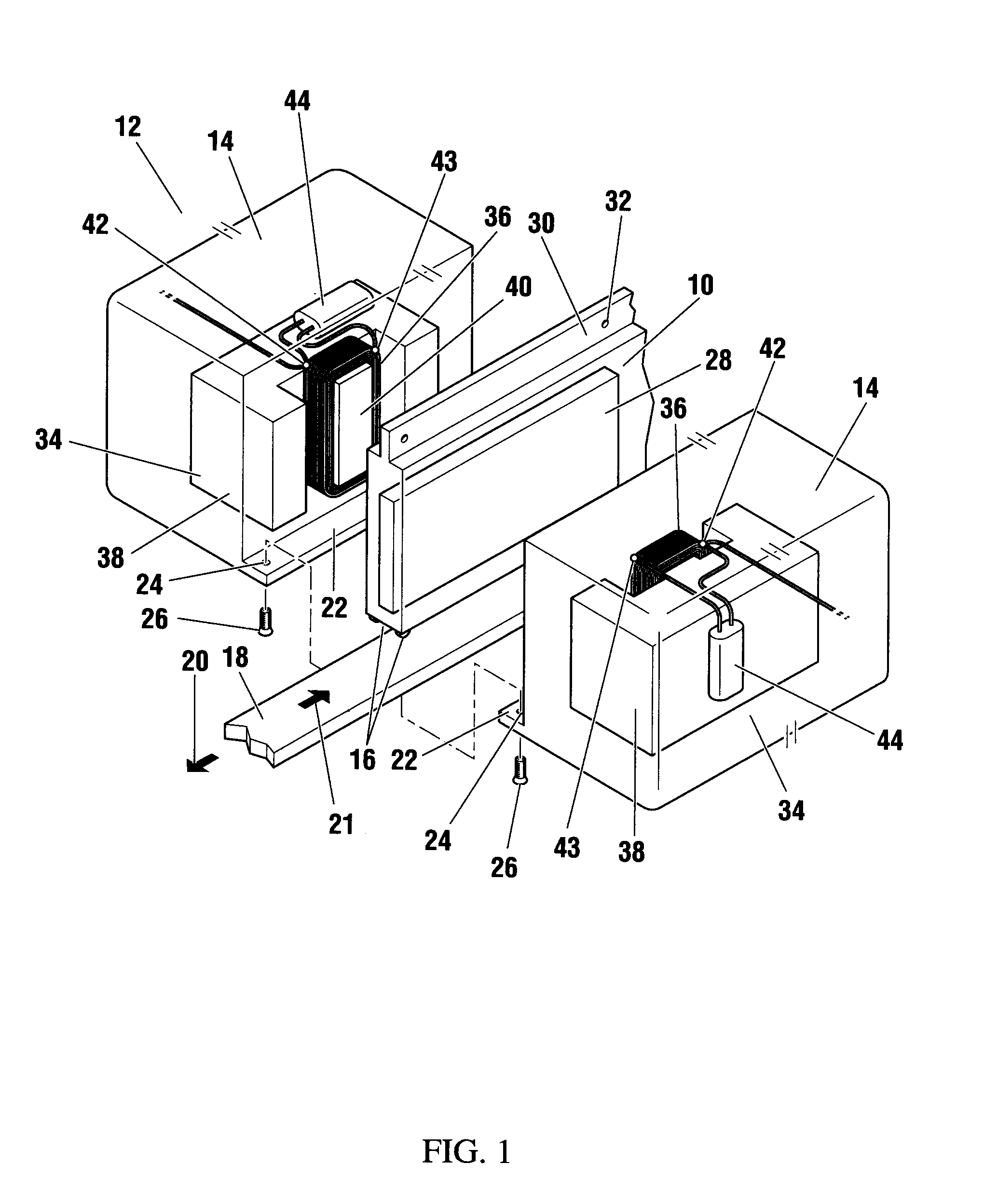

Method for laterally moving industrial machine

A method for laterally moving an industrial machine is provided. The method may include: supporting the industrial machine on a pair of rail elements configured to be positioned laterally below and support the industrial machine, the rail elements allowing the industrial machine to be moved laterally from a first operative position to a second, maintenance position. A pair of linear actuators configured to laterally move the industrial machine from the first, operative position to the second, maintenance position.

Owner:GE INFRASTRUCTURE TECH INT LLC

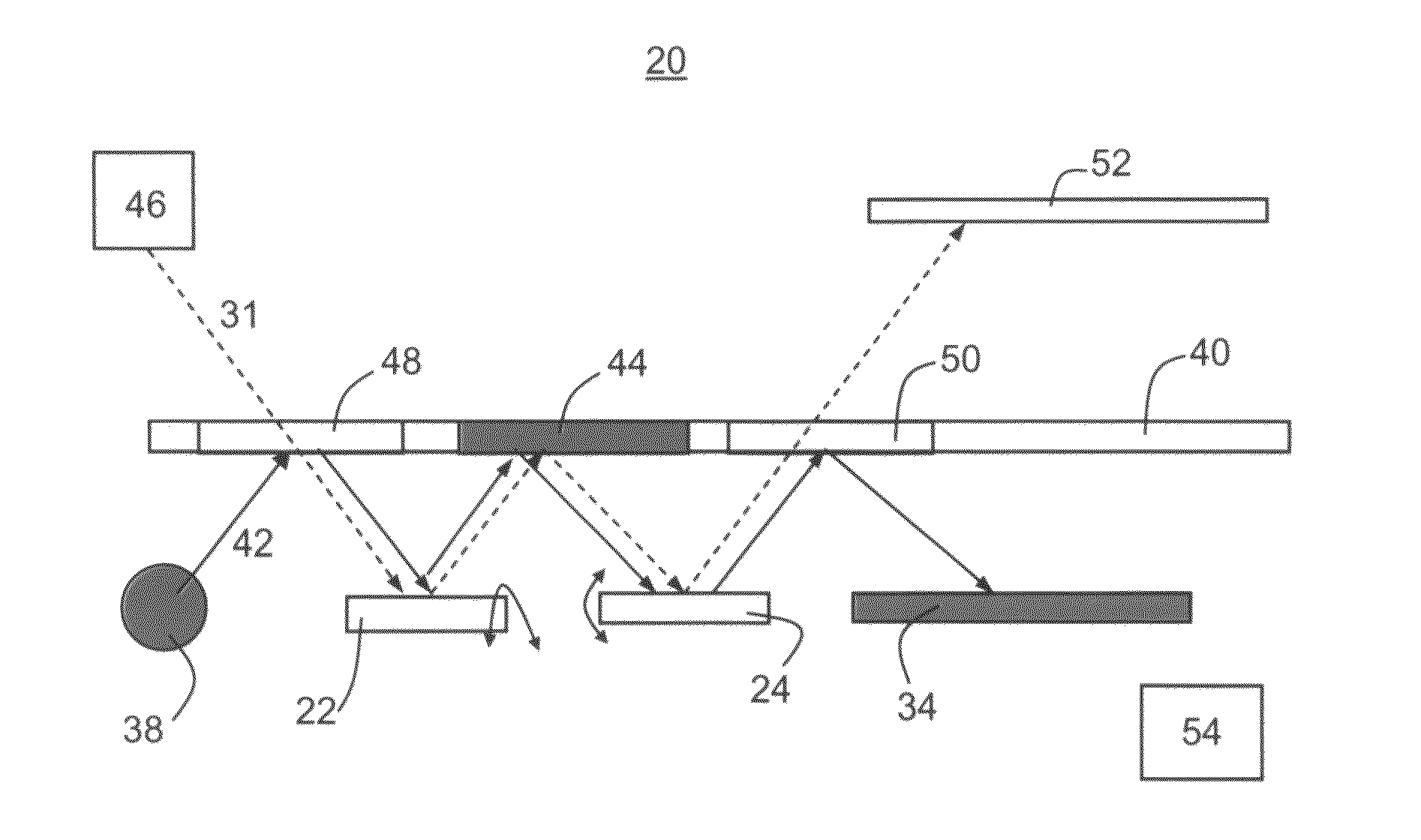

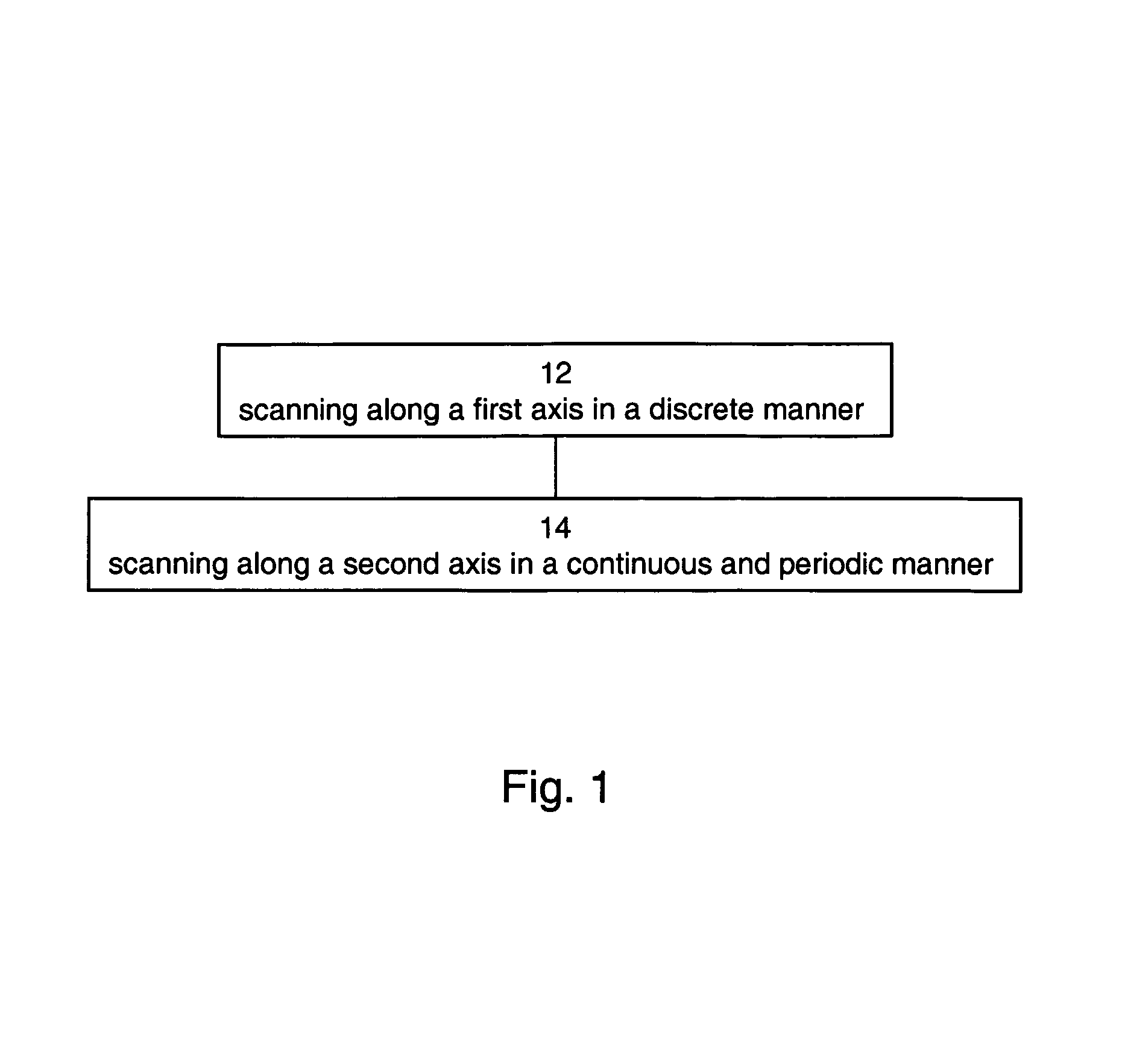

Method and device for scanning light

ActiveUS7952781B2Minimize moment-of-inertiaImprove reflectivityTelevision system scanning detailsManufacturing stator/rotor bodiesLight beamPhysics

A method of scanning a light beam is disclosed. The method comprises scanning the light beam along a first axis and scanning the light beam along a second axis, such that a functional dependence of the scanning along the first axis is substantially a step-wave, and a functional dependence of the scanning along the second axis is other than a step-wave.

Owner:APPLE INC

Method for moving and aligning heavy device

ActiveUS9032620B2Assembly machinesSemiconductor/solid-state device manufacturingEngineeringLift system

Method for laterally replacing a heavy component of a plant assembly, the method including disconnecting the heavy component from other components of the plant assembly and from a base plate to which the heavy component is fixed; lifting the heavy component above the base plate with a lifting system provided within the base plate; connecting at least a pair of rails to the base plate, under the lifted heavy component, such that the at least a pair of rails extends at substantially a right angle relative to a longitudinal axis of the heavy component; lowering the heavy component on crawling mechanisms disposed on the at least a pair of rails; and laterally replacing the heavy component from the base plate and the other components of the plant assembly by actuating the crawling mechanisms.

Owner:NUOVO PIGNONE TECH SRL

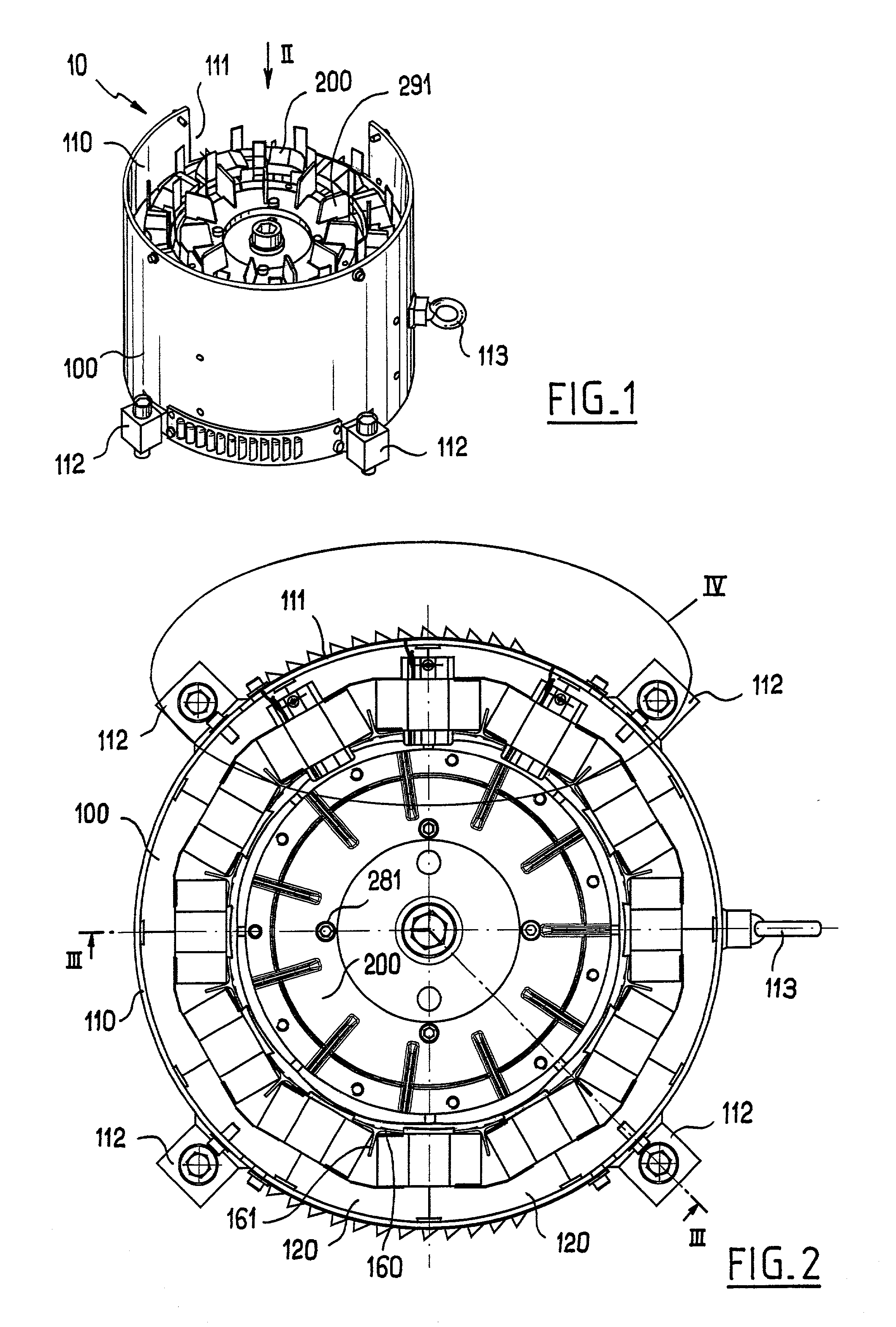

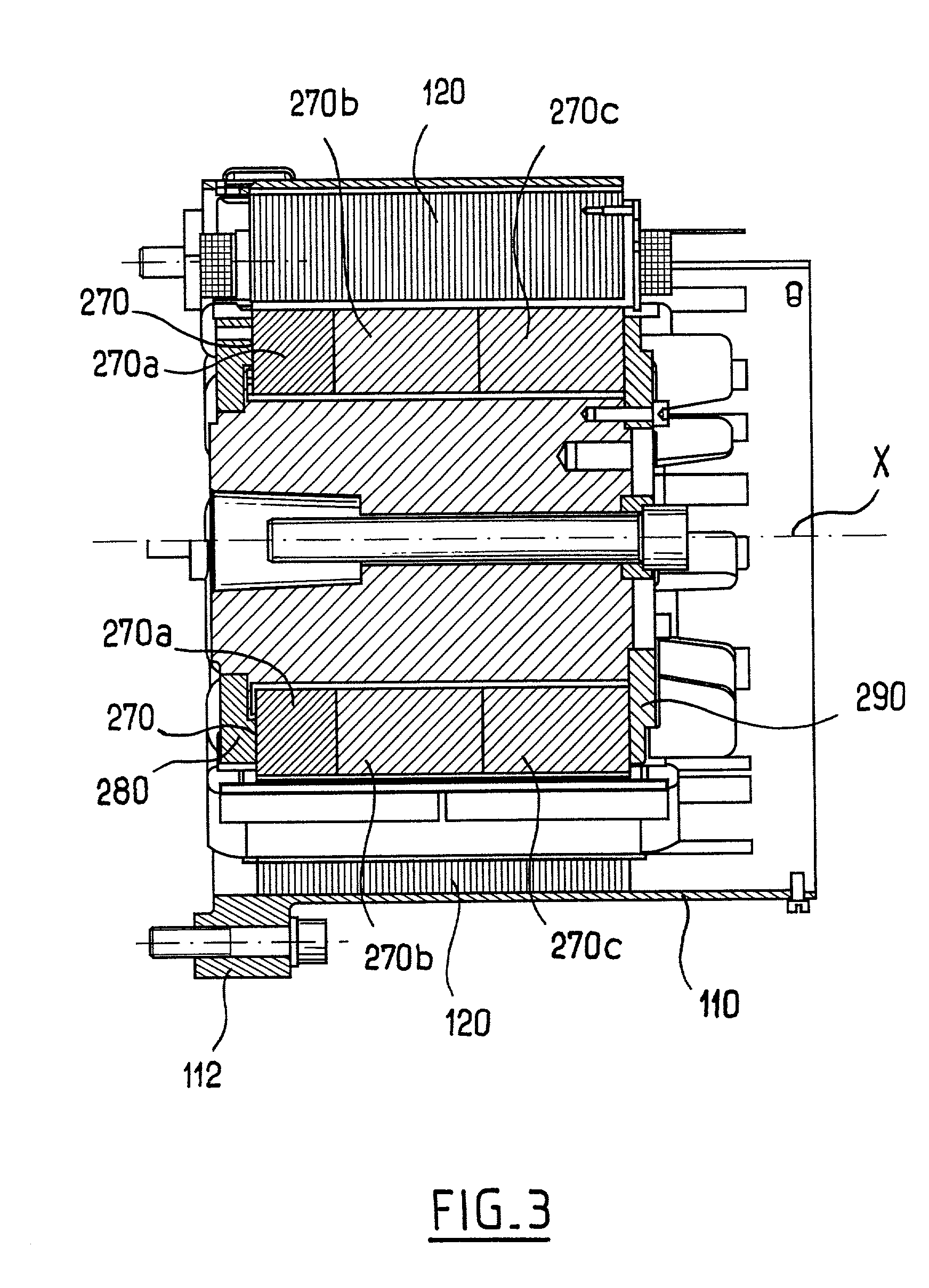

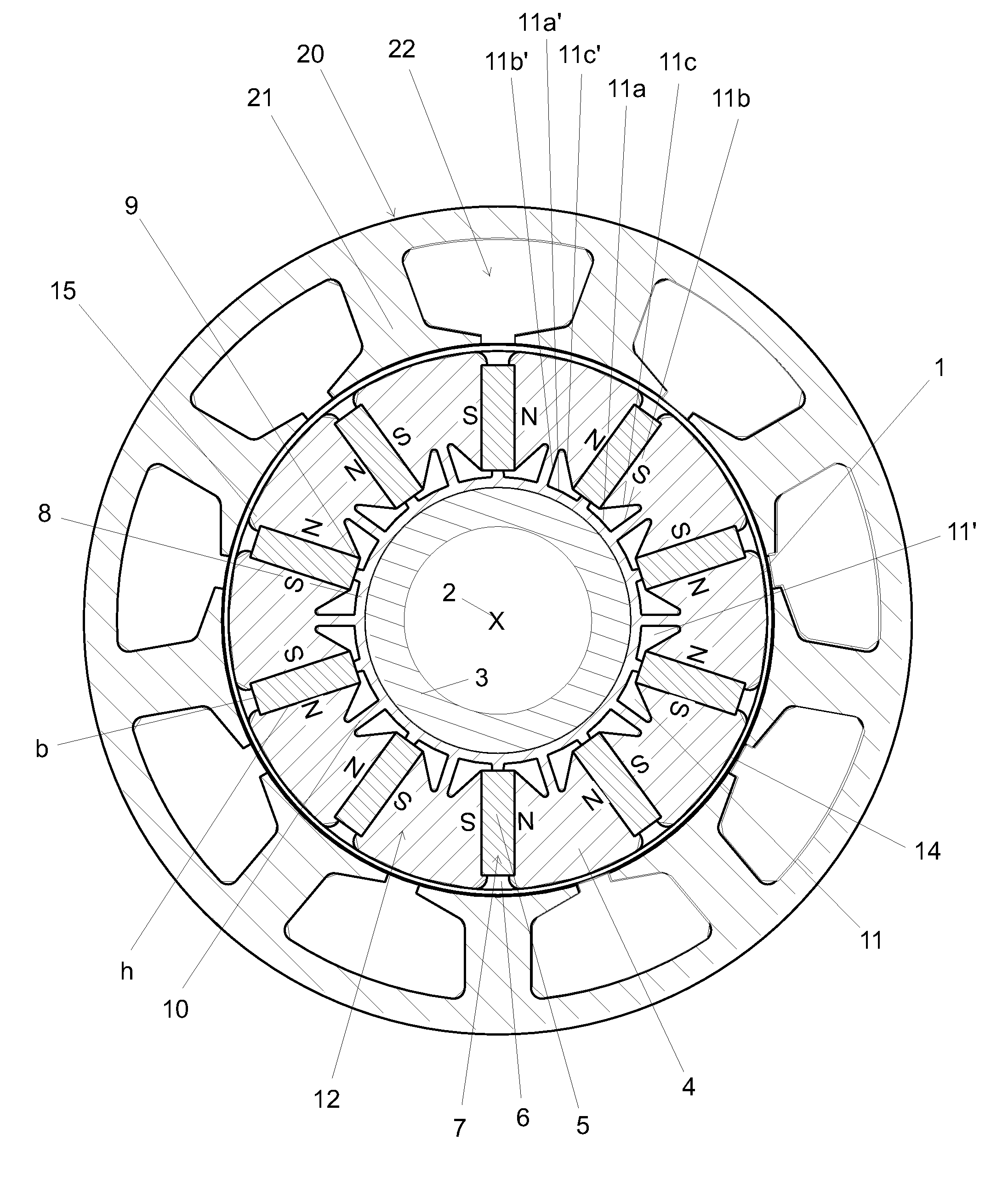

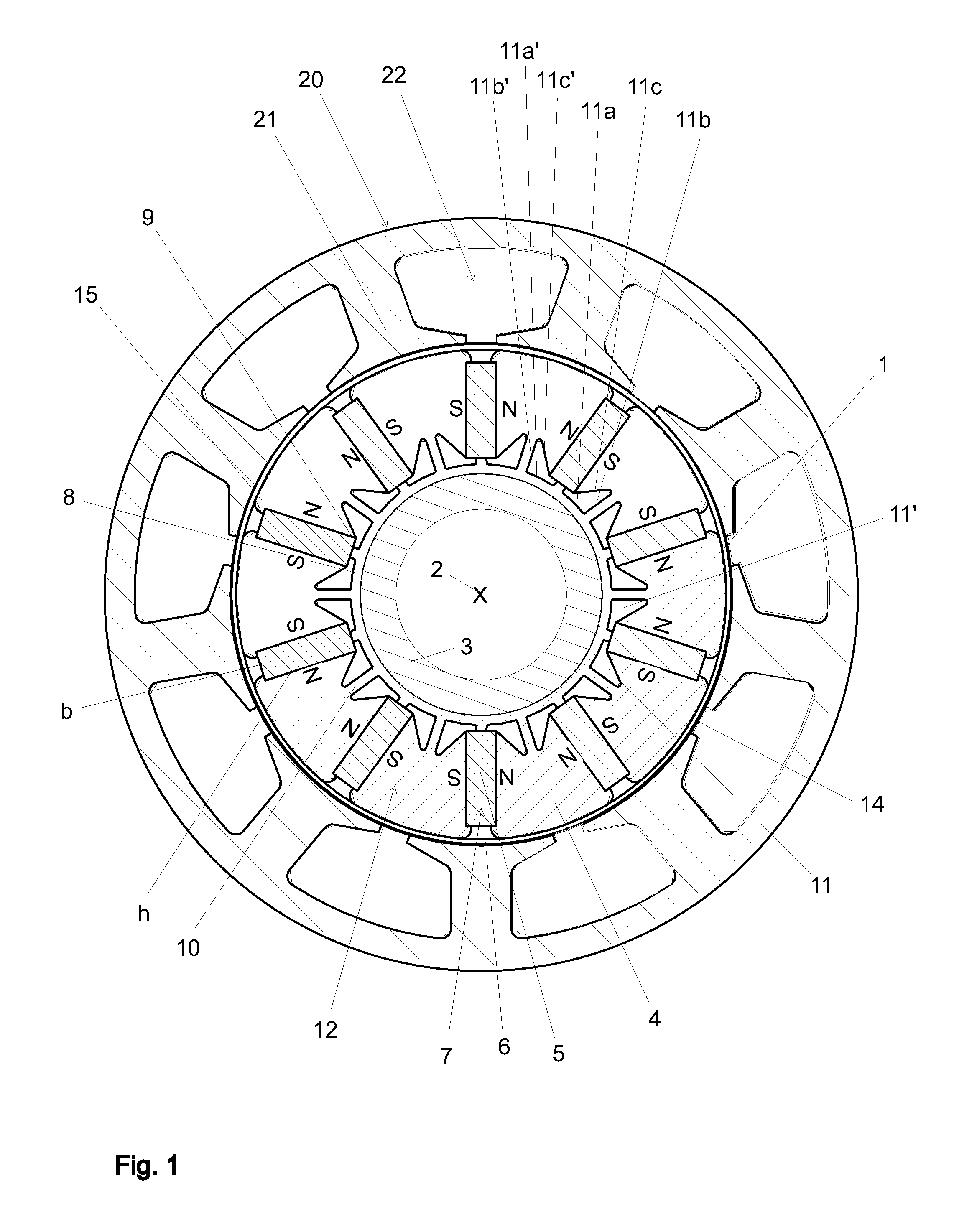

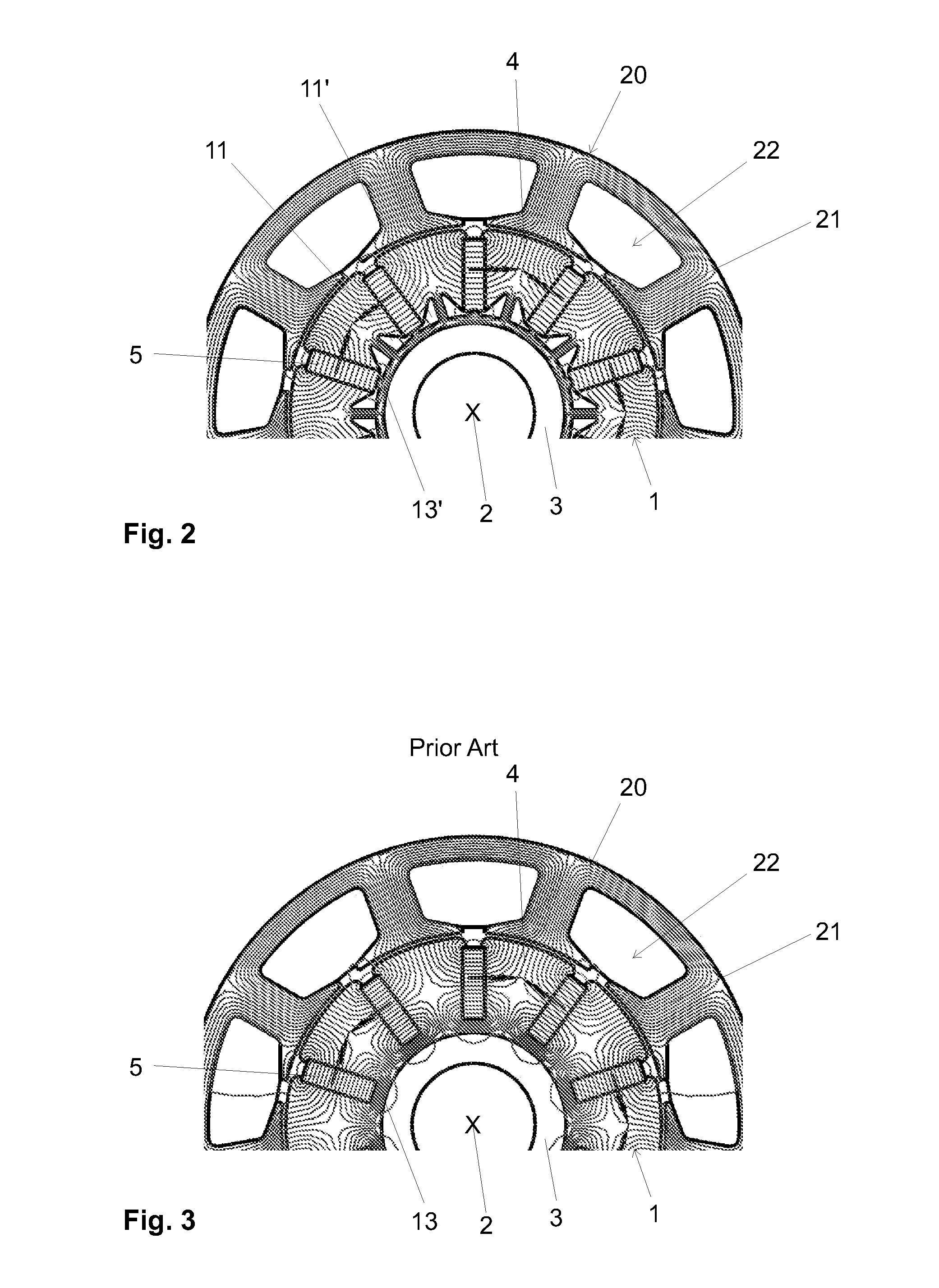

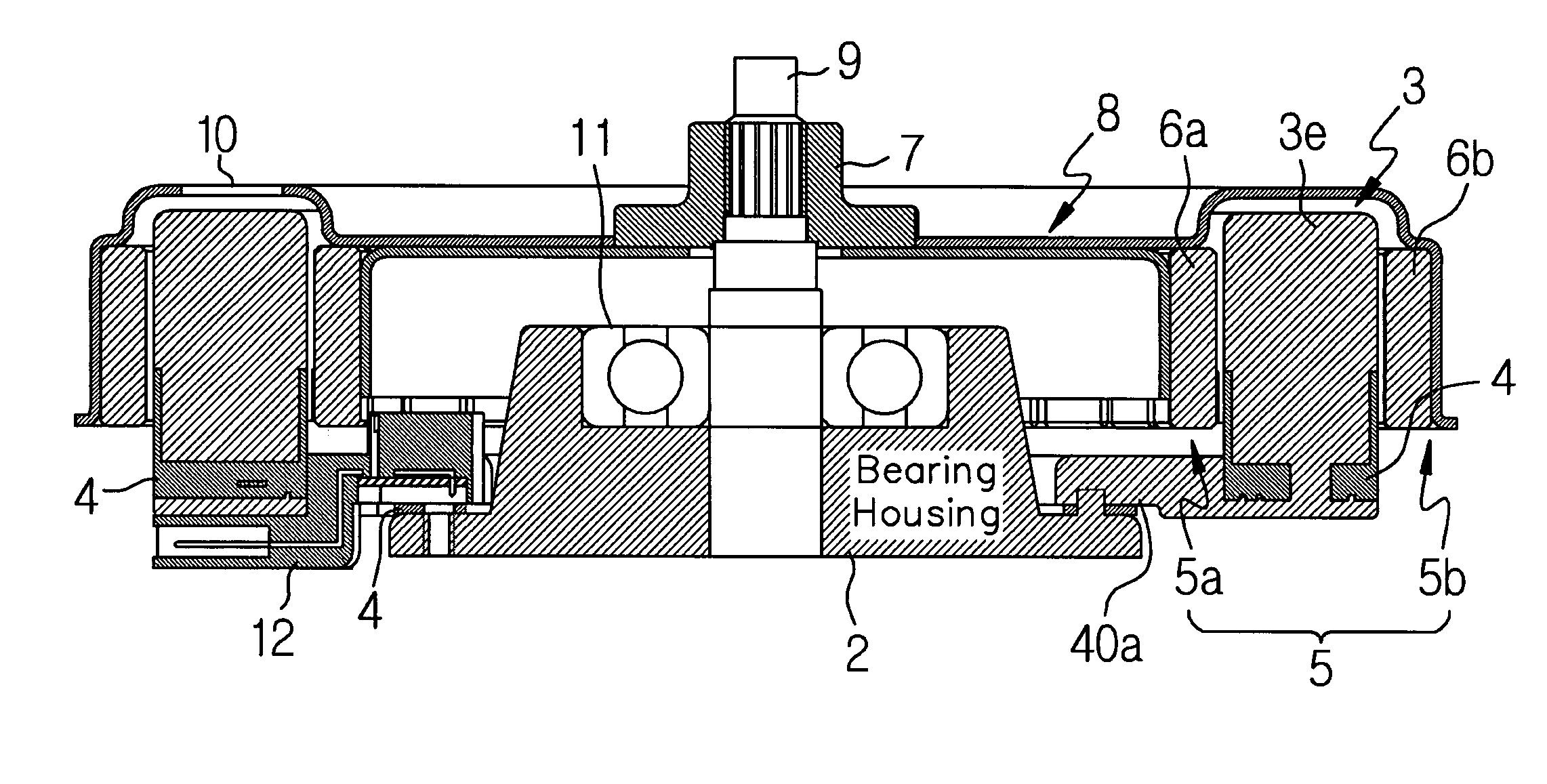

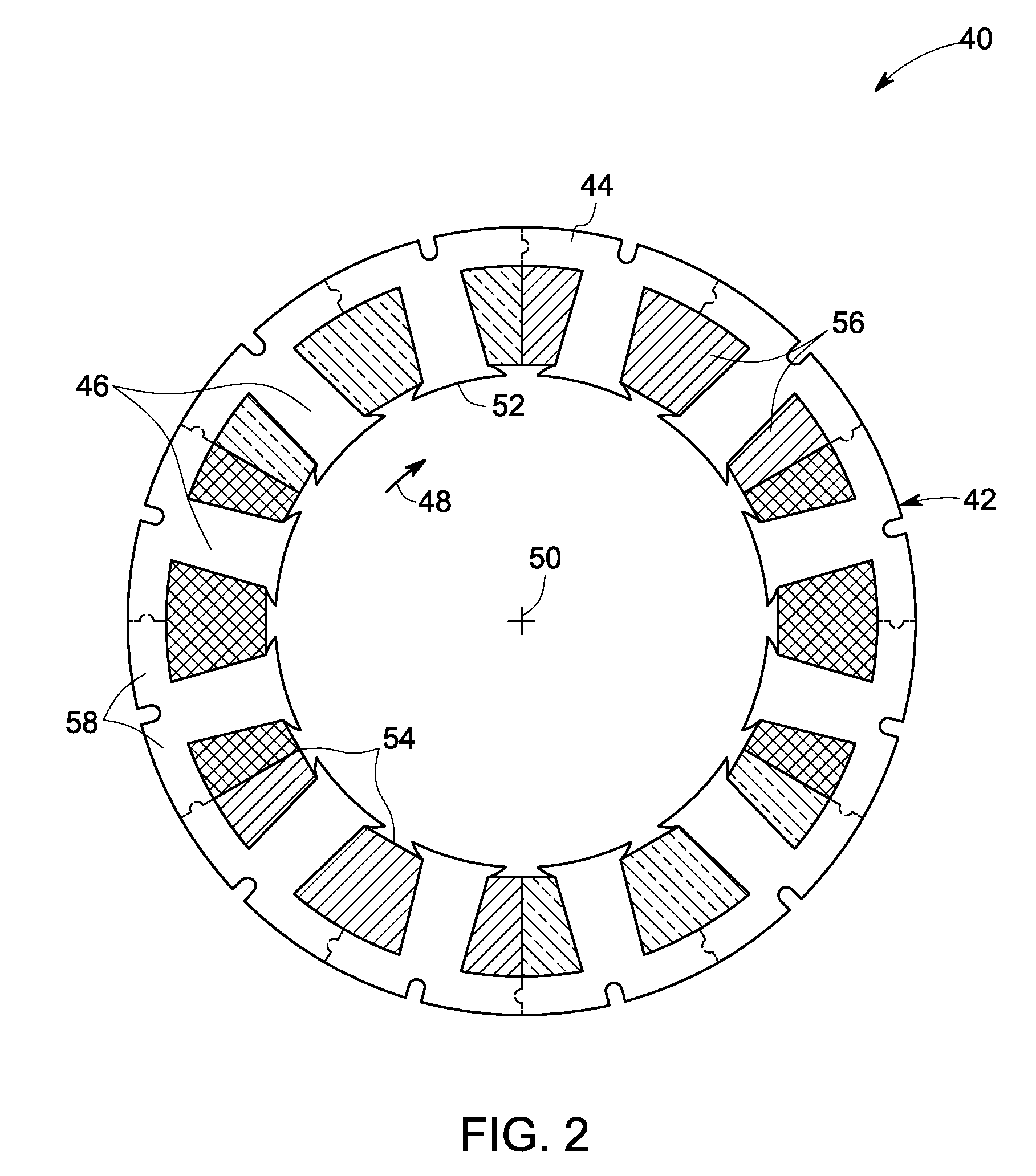

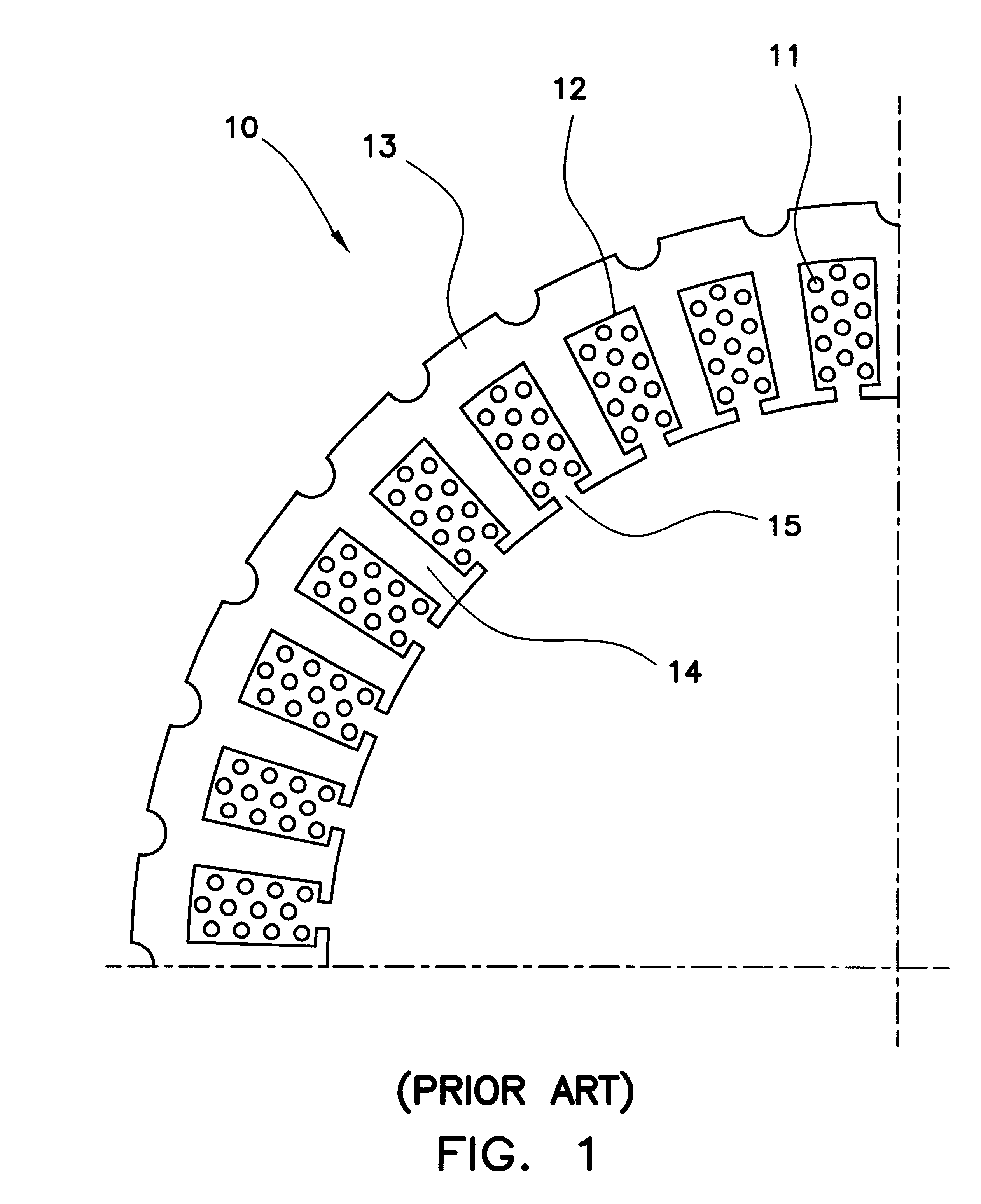

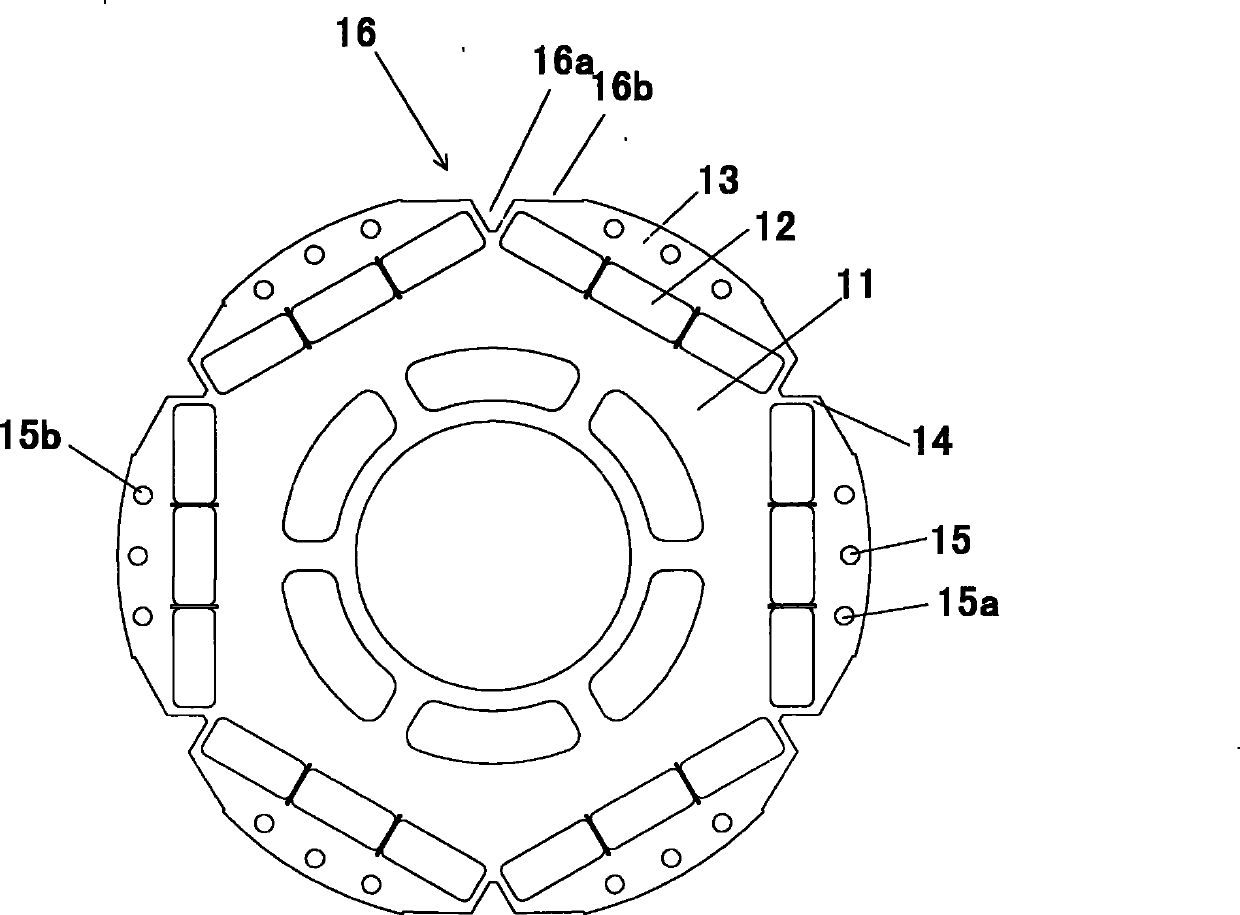

Rotary electric machine having a flux-concentrating rotor and a stator with windings on teeth

InactiveUS20020047425A1Increase powerReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePole piece

The invention relates to a rotary electric machine comprising a flux-concentrating rotor with permanent magnets disposed between pole pieces, and a stator with windings on teeth.

Owner:MOTEURS LEROY SOMER

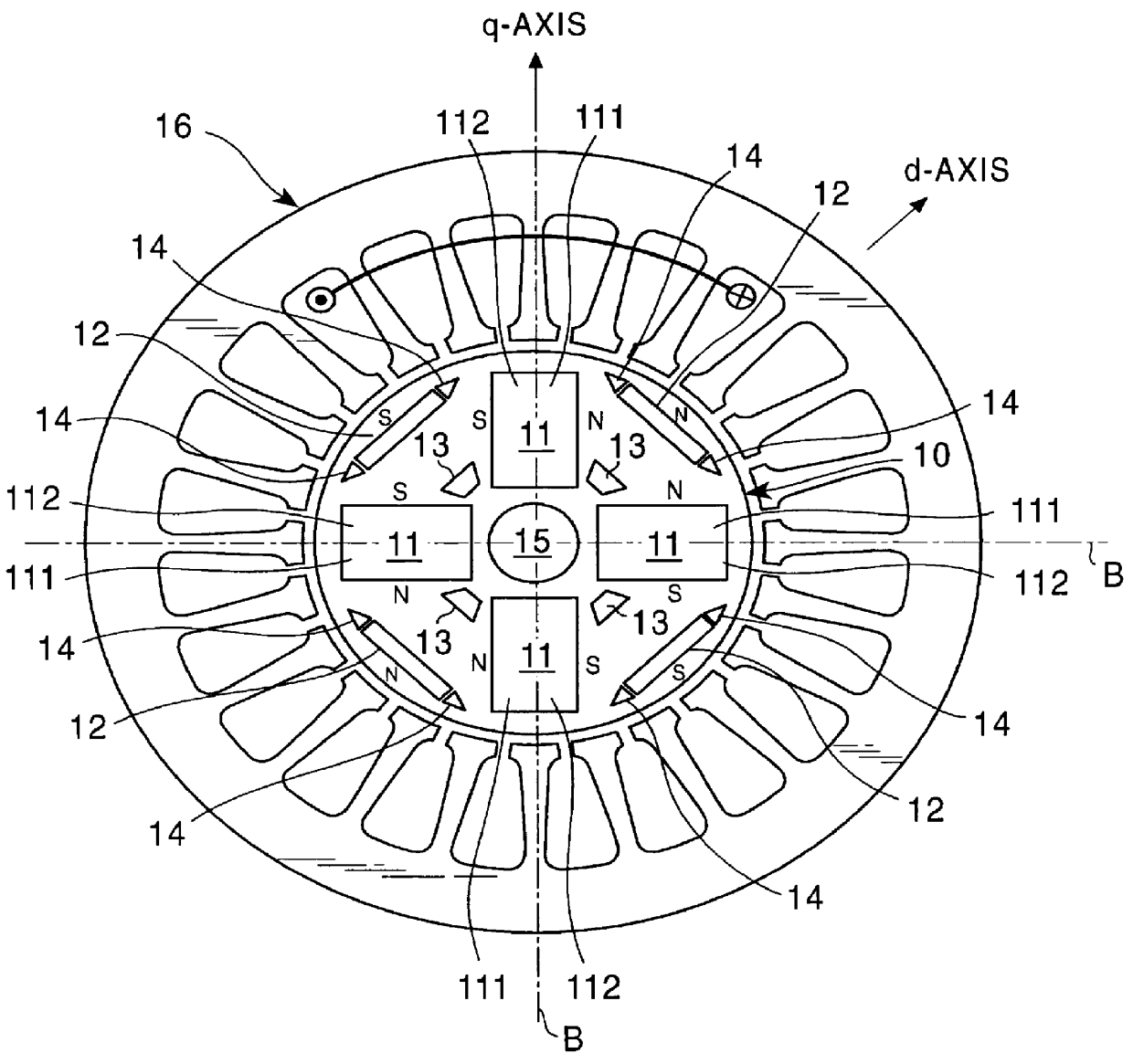

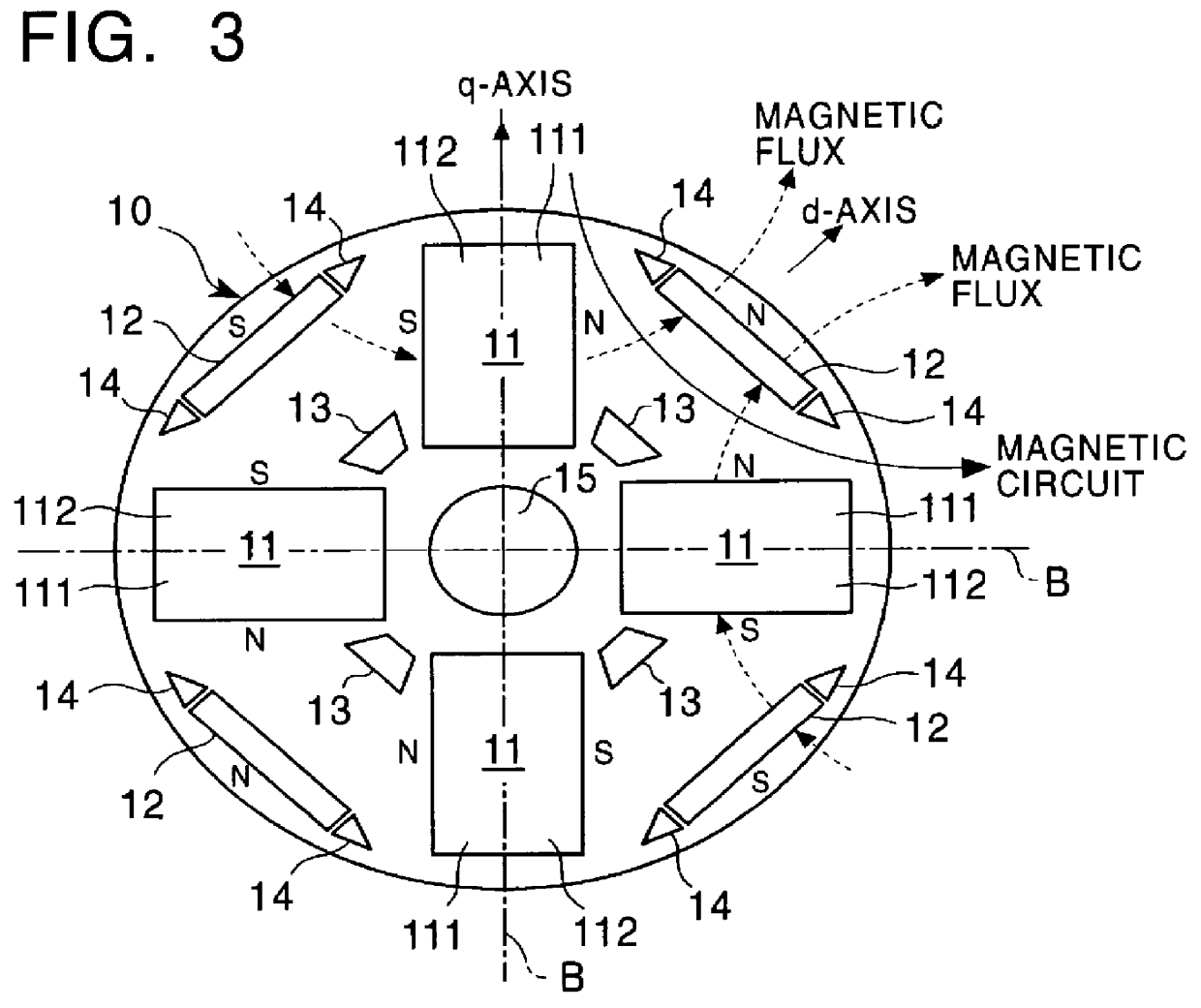

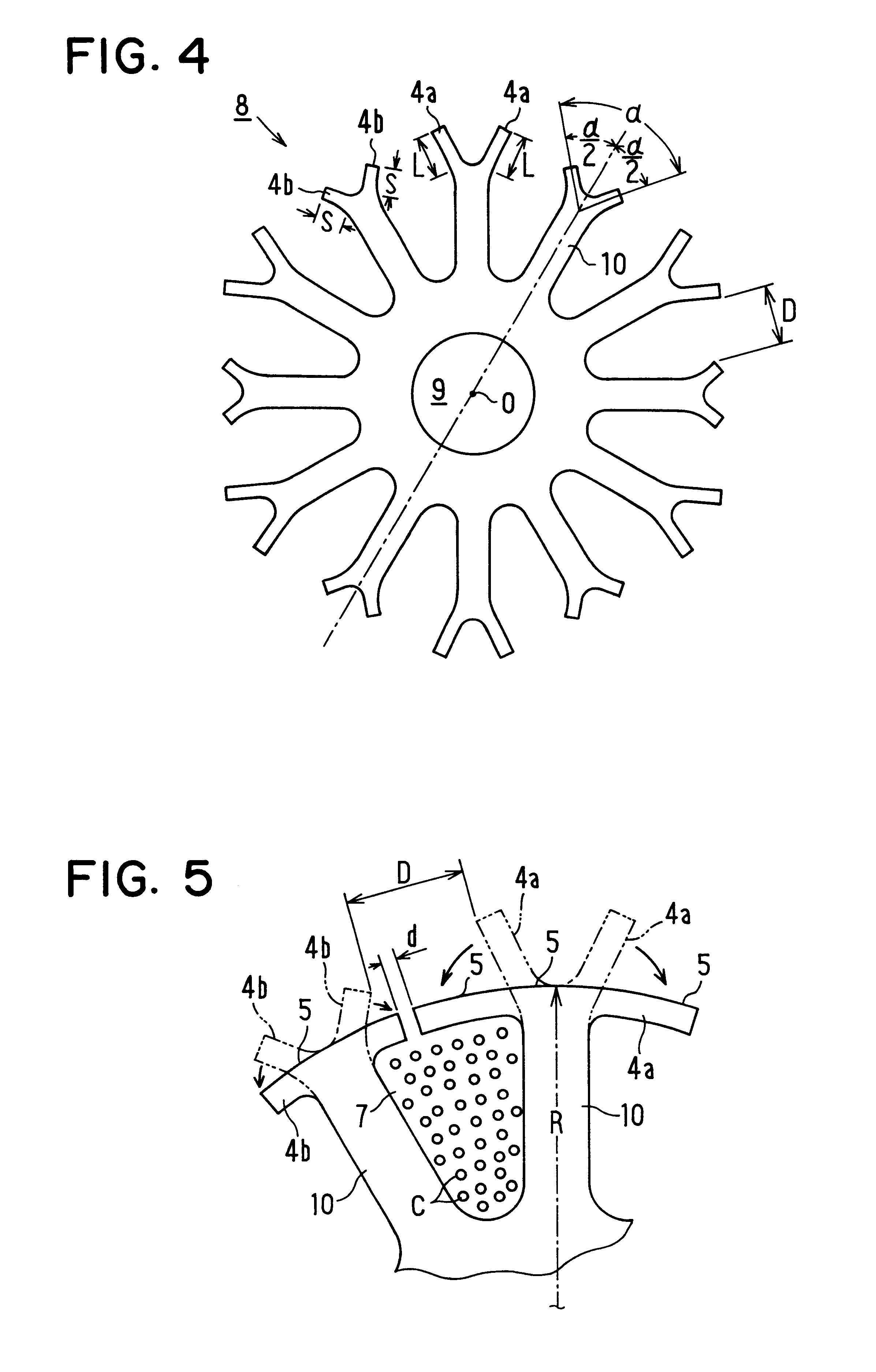

Permanent magnet rotor type electric motor with different permanent magnet materials

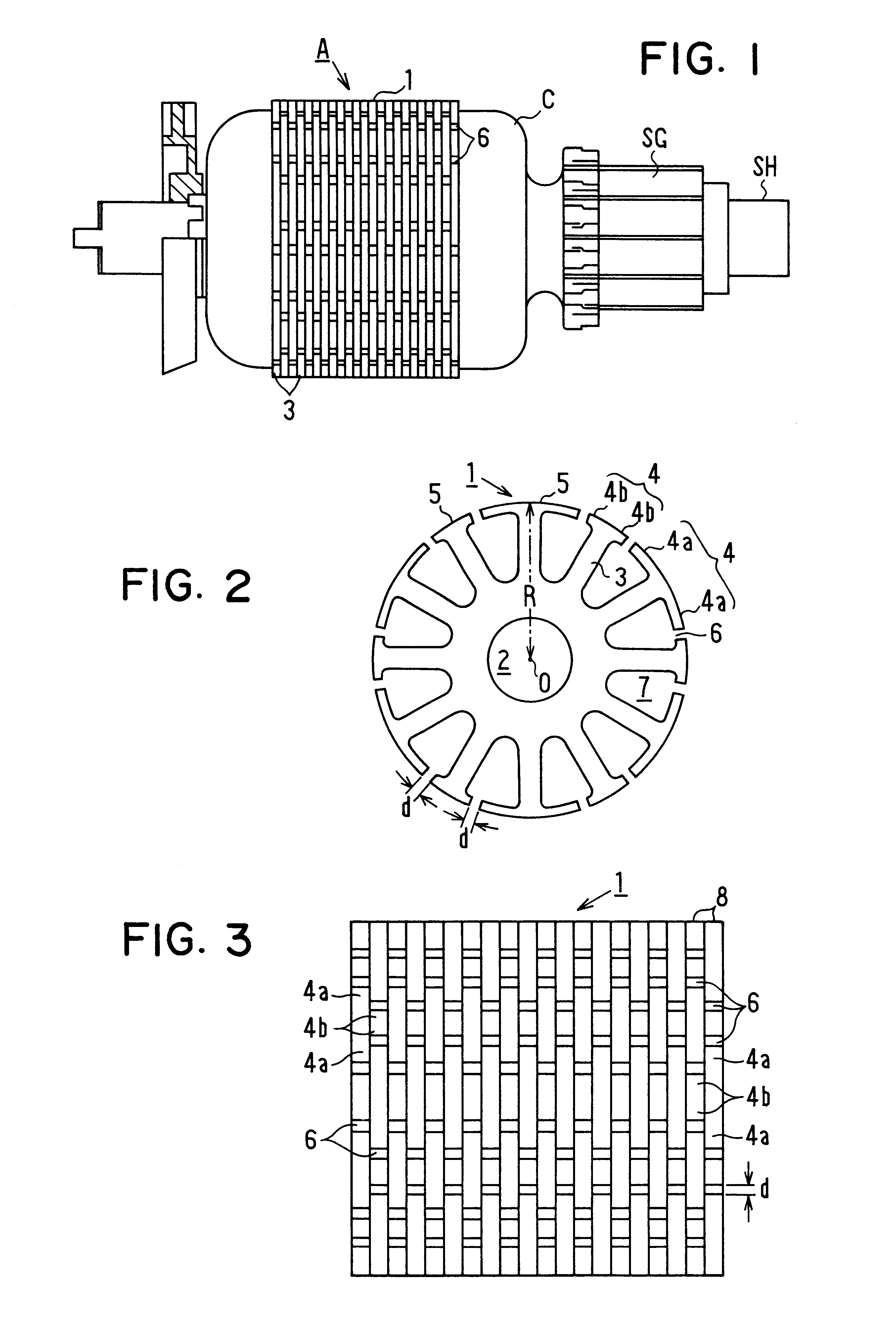

InactiveUS6025667AMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsPermanent magnet rotor

In an electric motor, such as a DC brushless motor or the like, having a permanent magnet in a rotor, each magnetic pole is formed of three permanent magnets, and the permanent magnets are made of at least two kinds of magnetic materials represented by ferrite magnet and rare-earth magnet. Thus, in a permanent magnet rotor type electric motor, a reluctance torque and a magnetic flux density can be selectively established, and cost is reasonable, corresponding to the quality.

Owner:FUJITSU GENERAL LTD

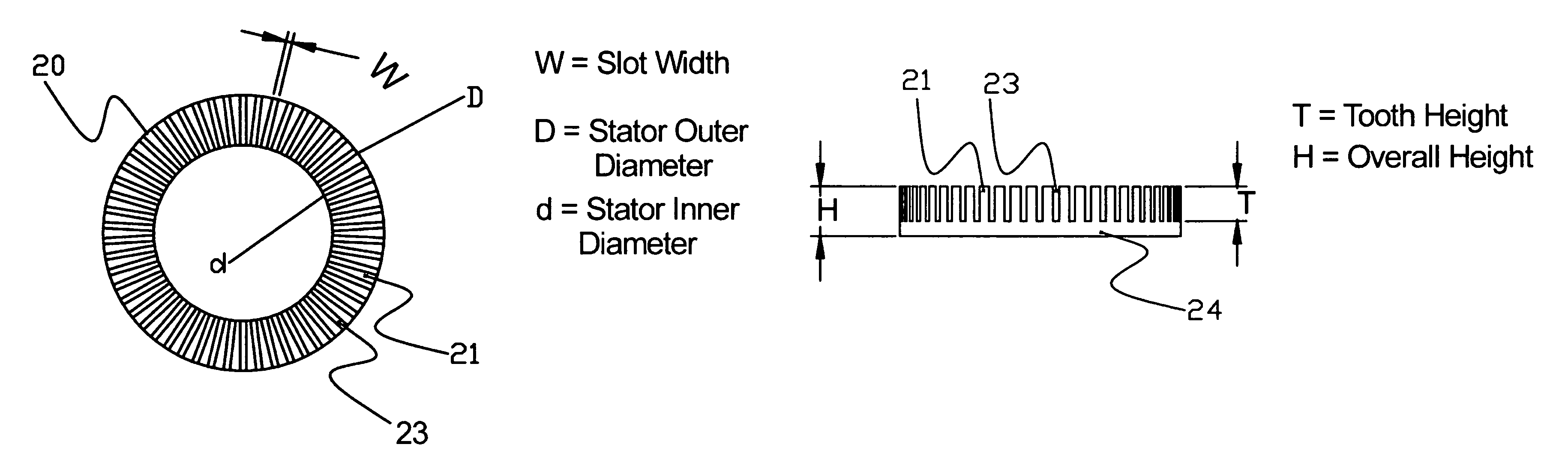

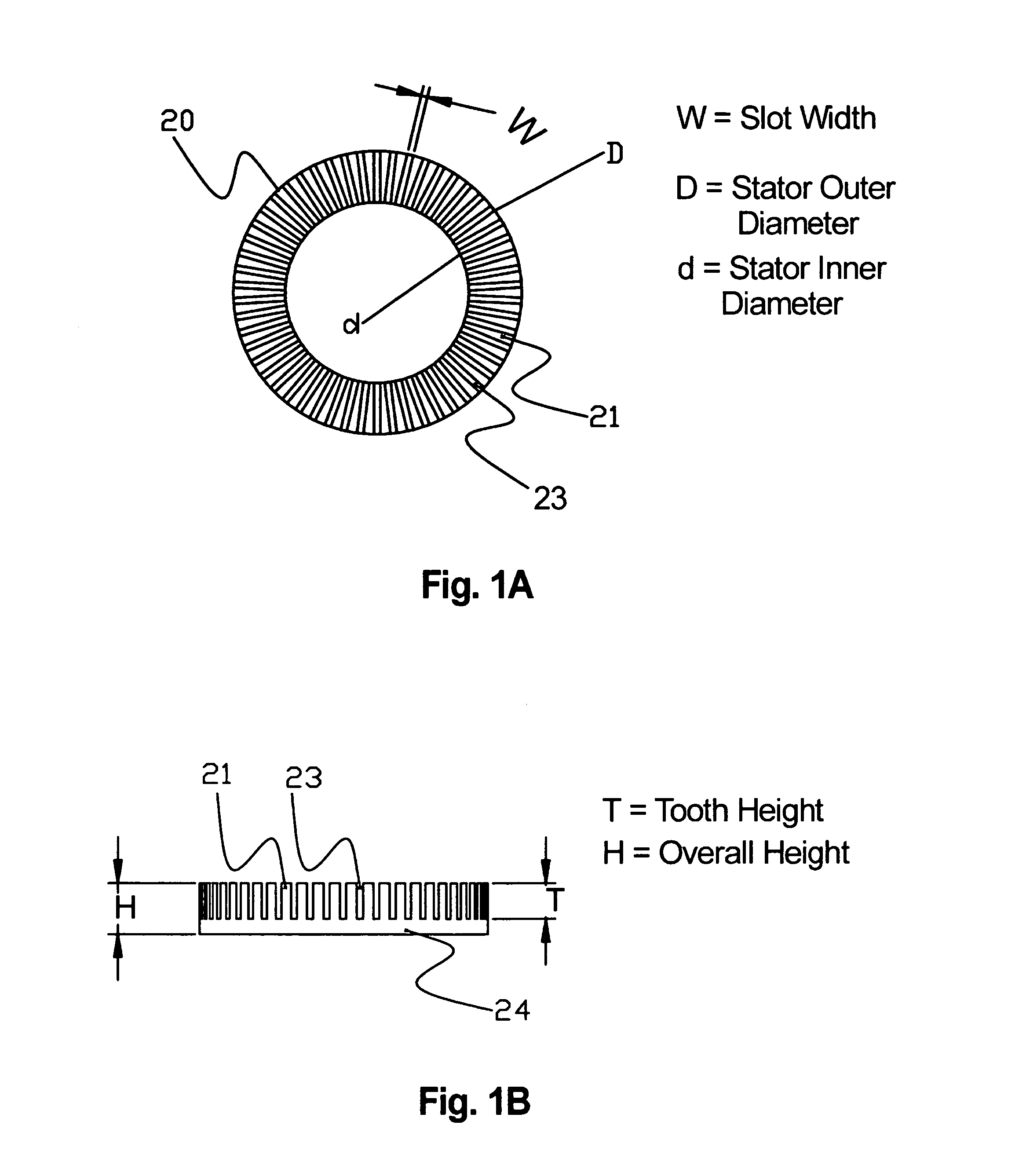

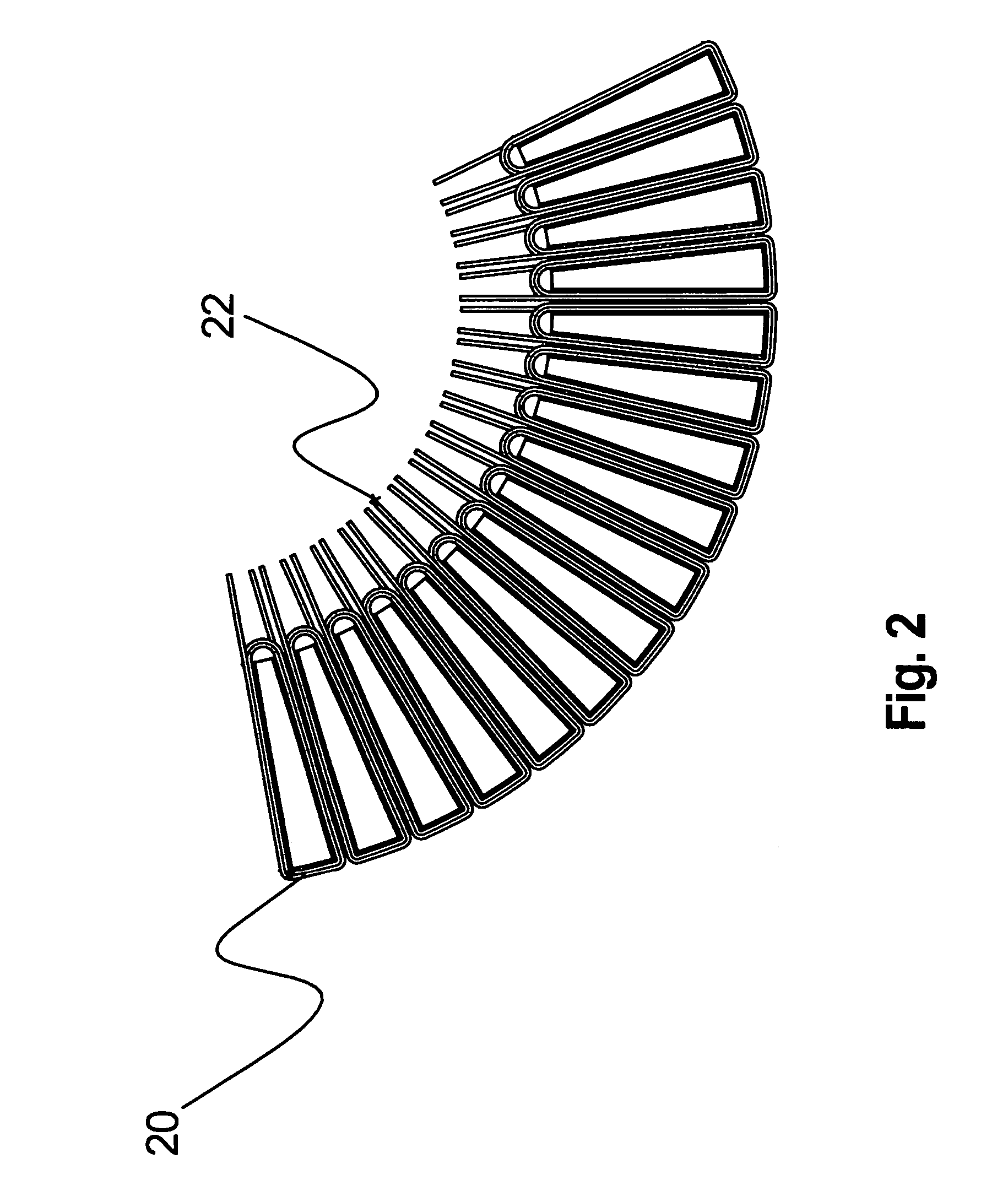

Efficient high-speed electric device using low-loss materials

InactiveUS7230361B2Reduce lossHigh frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringHigh torque

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

Rotary electric machine having a flux-concentrating rotor and a stator with windings on teeth

InactiveUS6891299B2Increase powerReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePole piece

A rotary electric machine including a flux-concentrating rotor with permanent magnets disposed between pole pieces, and a stator with teeth having a free end deprived of pole swellings and a concentrated winding. The pole pieces and the magnets are configured so as to minimize the difference Ld−Lq where Ld is inductance on a forward axis and Lq is inductance on a quadrature axis.

Owner:MOTEURS LEROY SOMER

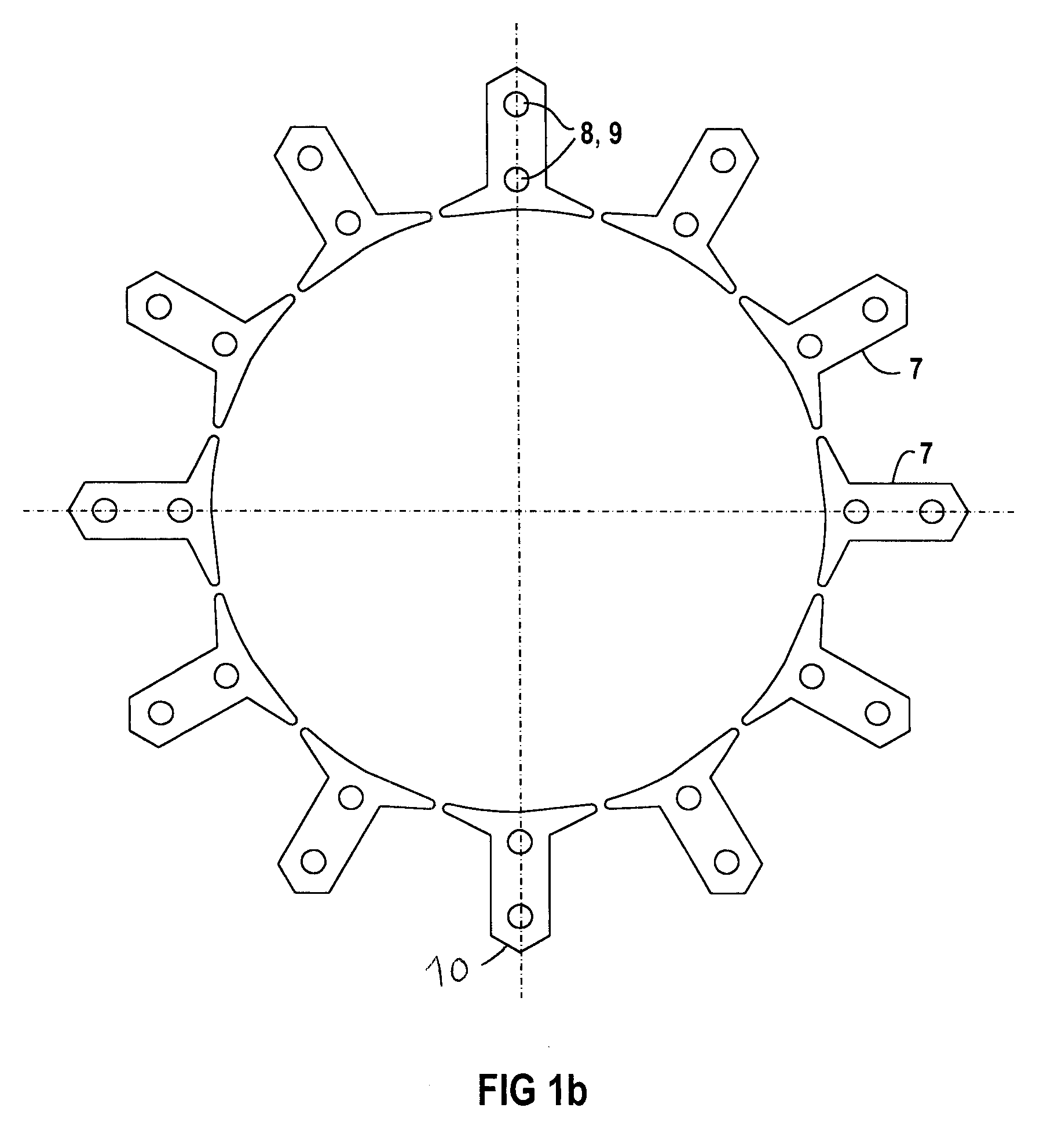

Rotor For Electric Motor

InactiveUS20090096308A1Improve efficiencyReduce manufacturing costMagnetic circuitManufacturing stator/rotor bodiesElectric machineMagnetic poles

An electric motor has an internal ferromagnetic rotor ring and an external stator. Circumferentially distributed cutouts in the rotor receive rectangular permanent magnets each having a width b and height h and the rotor ring is divided into rotor poles. The height h forms the longer side of each magnet and is radial to the motor axis. The magnets are magnetized in the width b direction with like poles oriented toward one another. A magnetic clearance is located between adjacent magnets for each inner portion of a rotor pole. The clearance does not contain magnetic material and in a center region of the rotor poles one support web connects an inner support ring with the particular rotor pole to provide mechanical support.

Owner:THYSSENKRUPP PRESTA AG

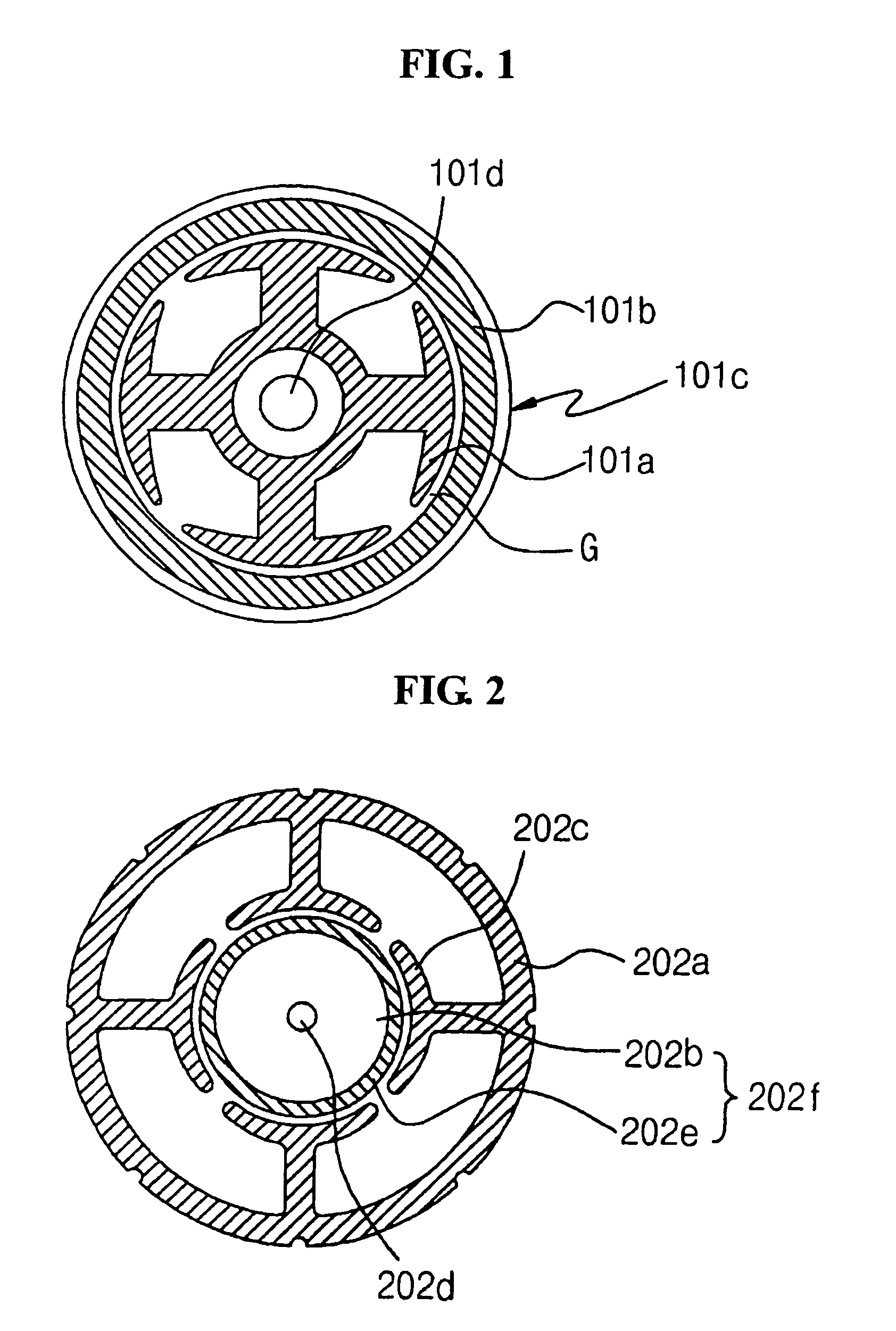

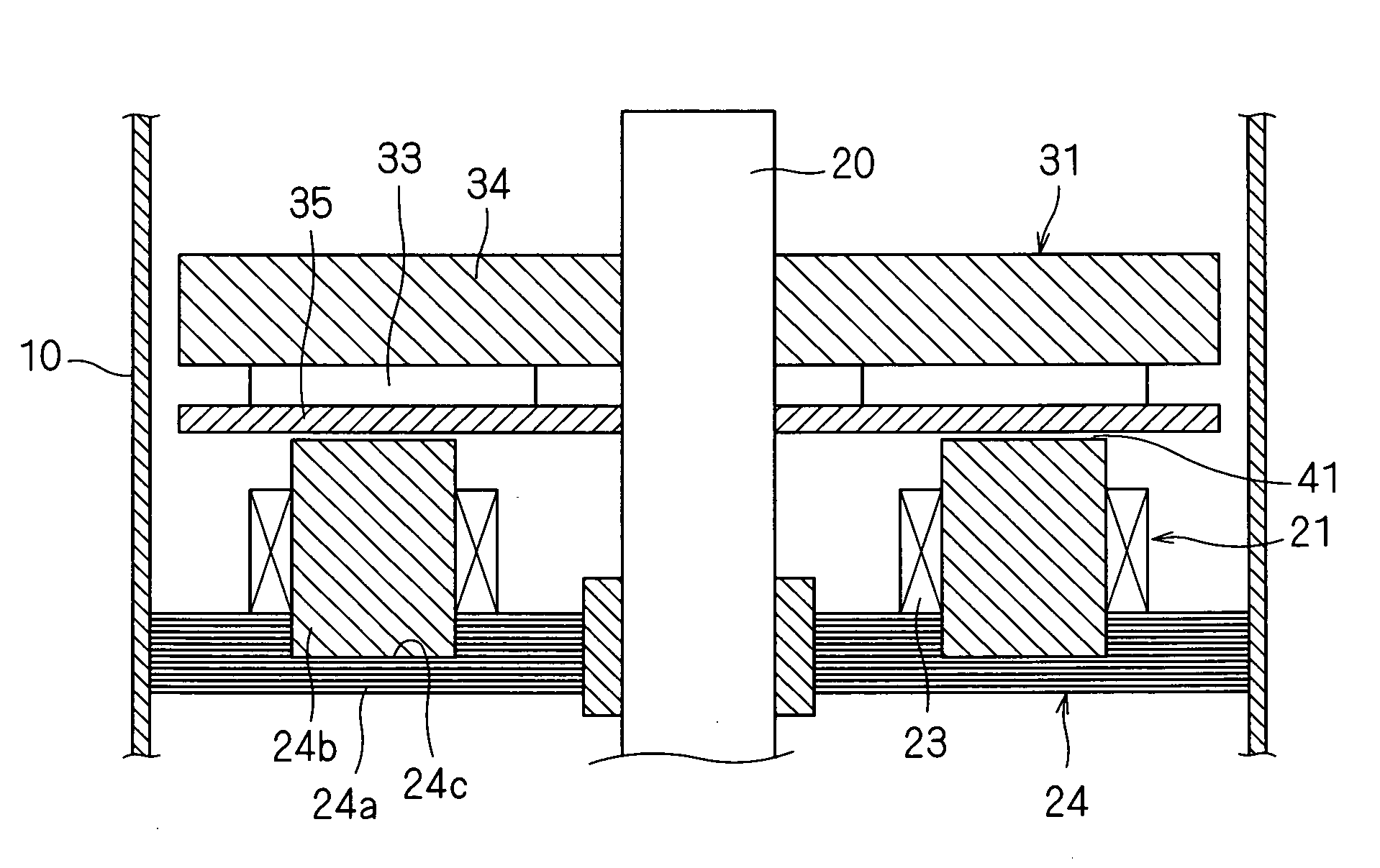

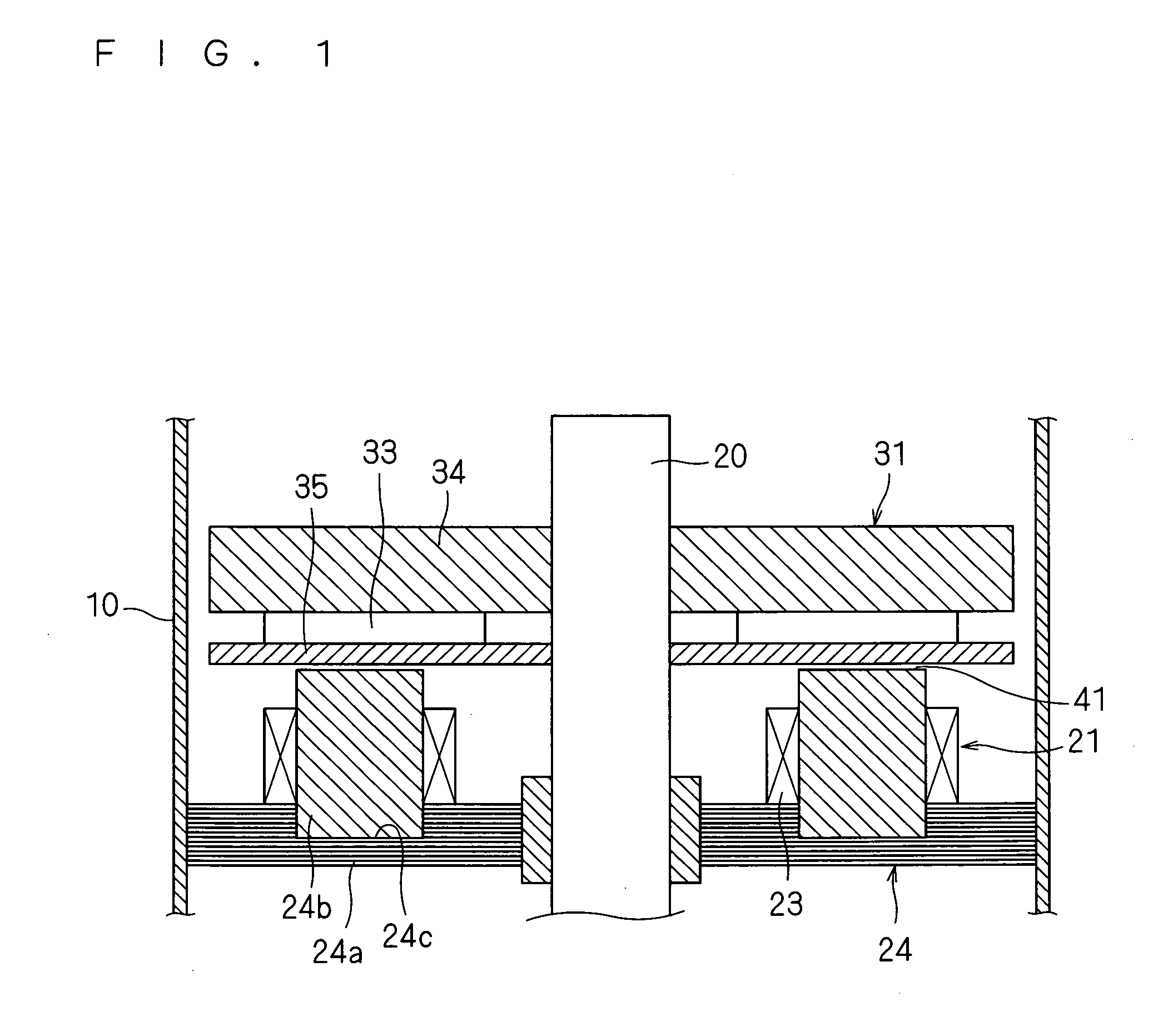

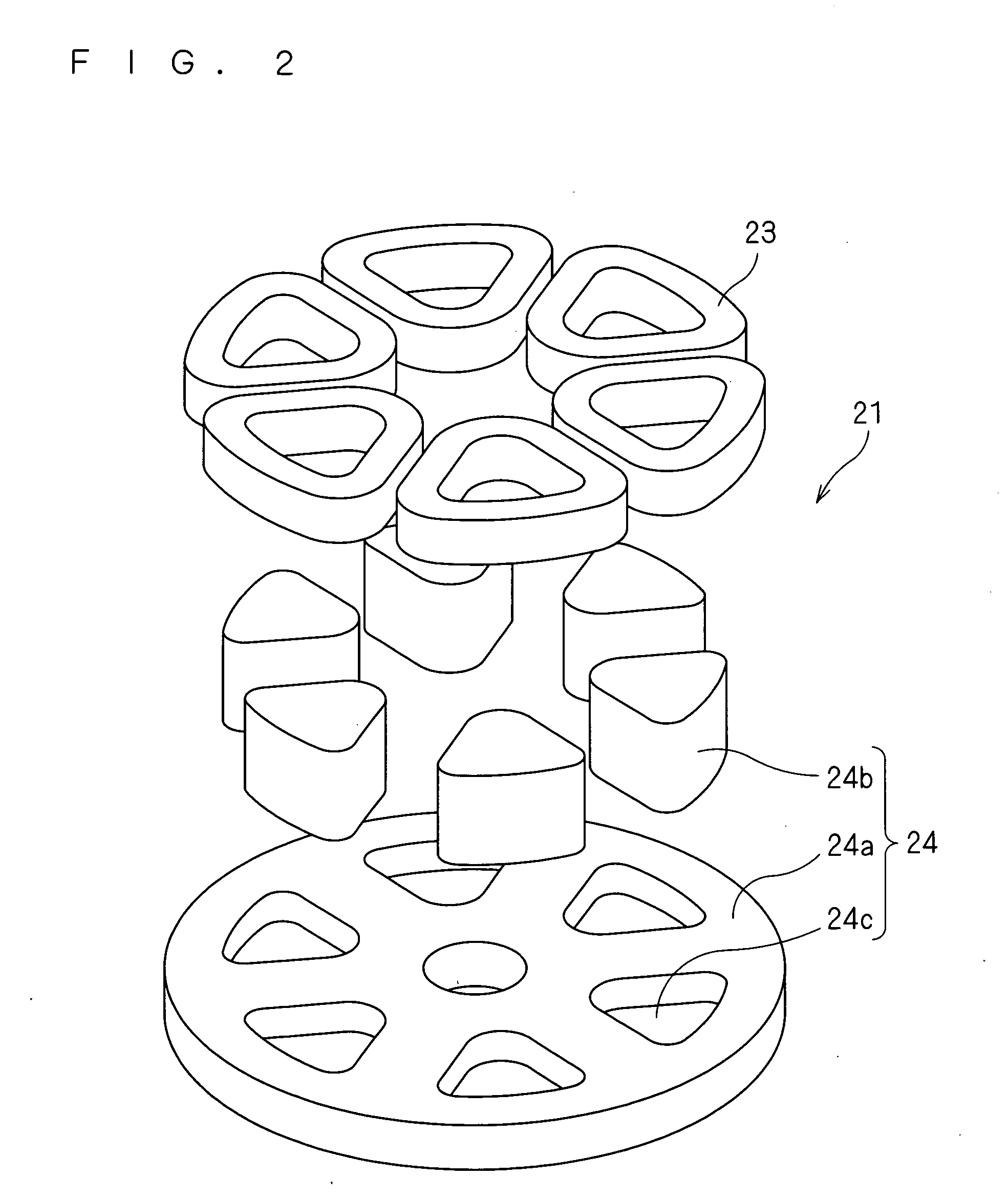

Brushless direct-current motor of radial core type having a structure of double rotors and method for making the same

InactiveUS6992419B2Improve productivityImprove shortcomingsWindingsMagnetic circuit rotating partsElectrical polarityEngineering

A radial core type double rotor brushless direct-current motor is provided in which a double rotor structure is employed with inner and outer rotors which are doubly disposed and thus a stator core is completely divided. The motor includes a rotational shaft which is rotatably mounted on a housing of an apparatus, cylindrical inner and outer yokes which are rotatably mounted on the center of the housing, inner and outer rotors including a number of magnets which are mounted with the opposing polarities on the outer surface of the inner yoke and the inner surface of the outer yoke, and a number of cores assemblies which are installed between the inner and outer rotors in which a number of coils are wound around a number of division type cores, respectively.

Owner:AMOTECH

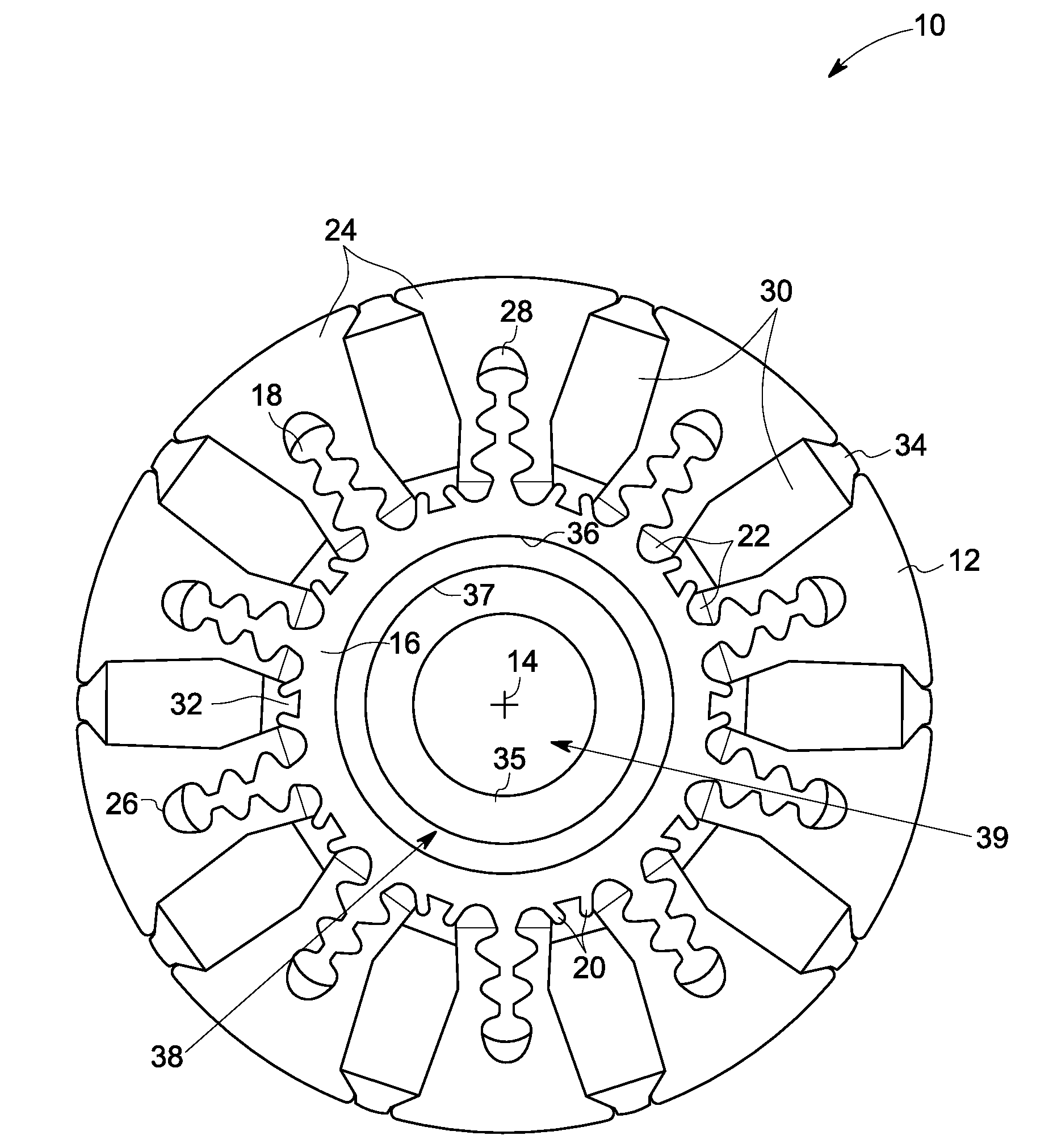

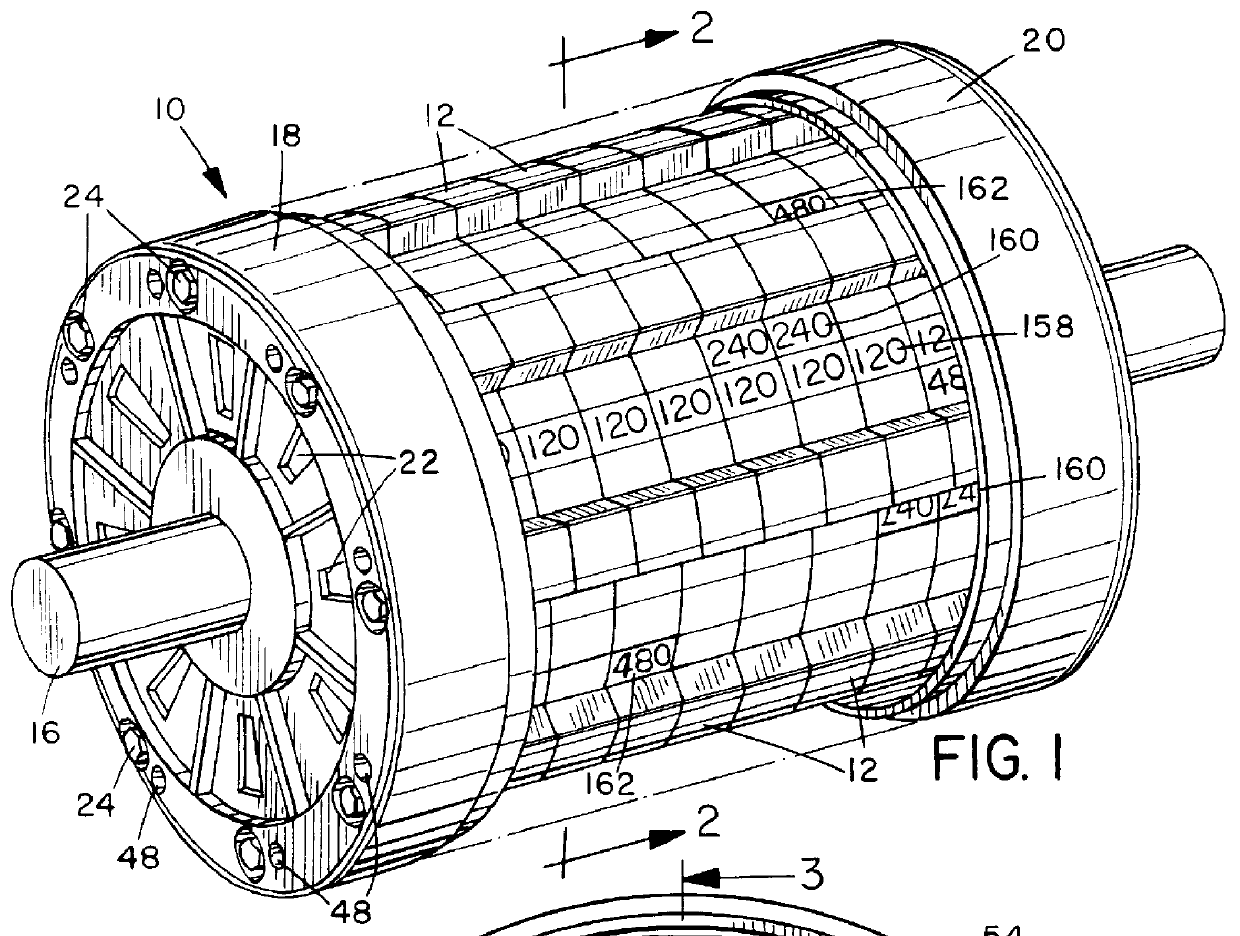

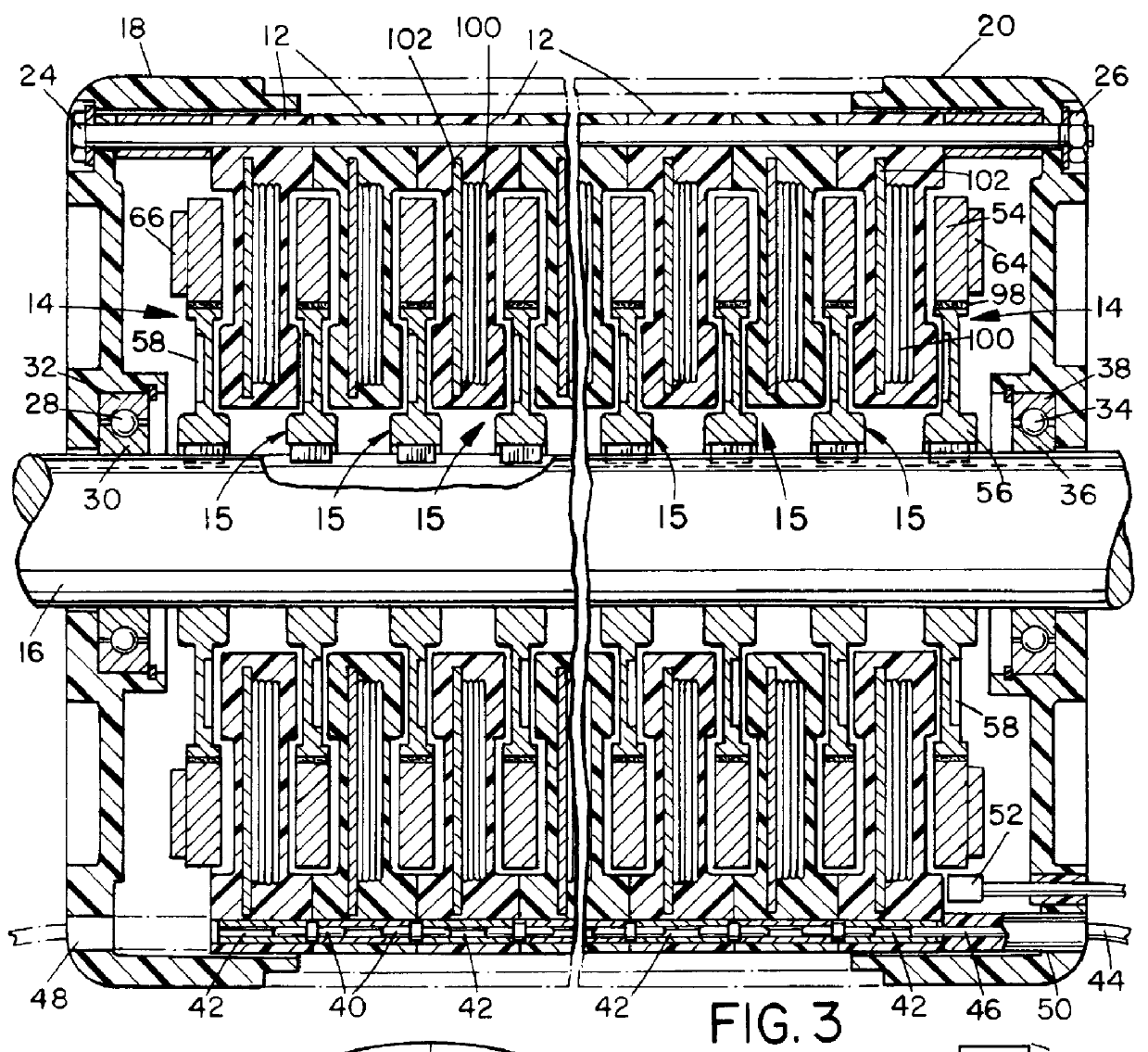

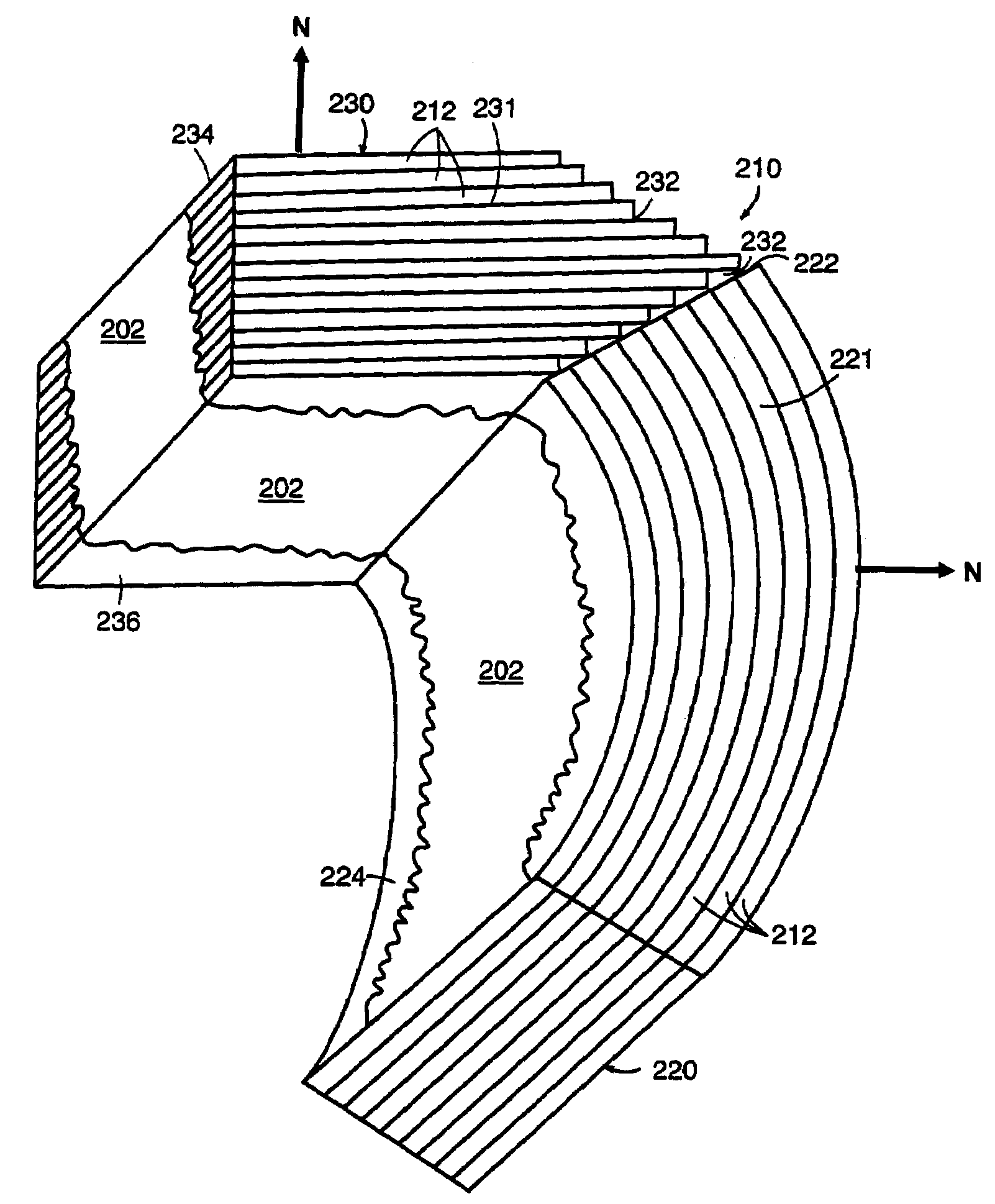

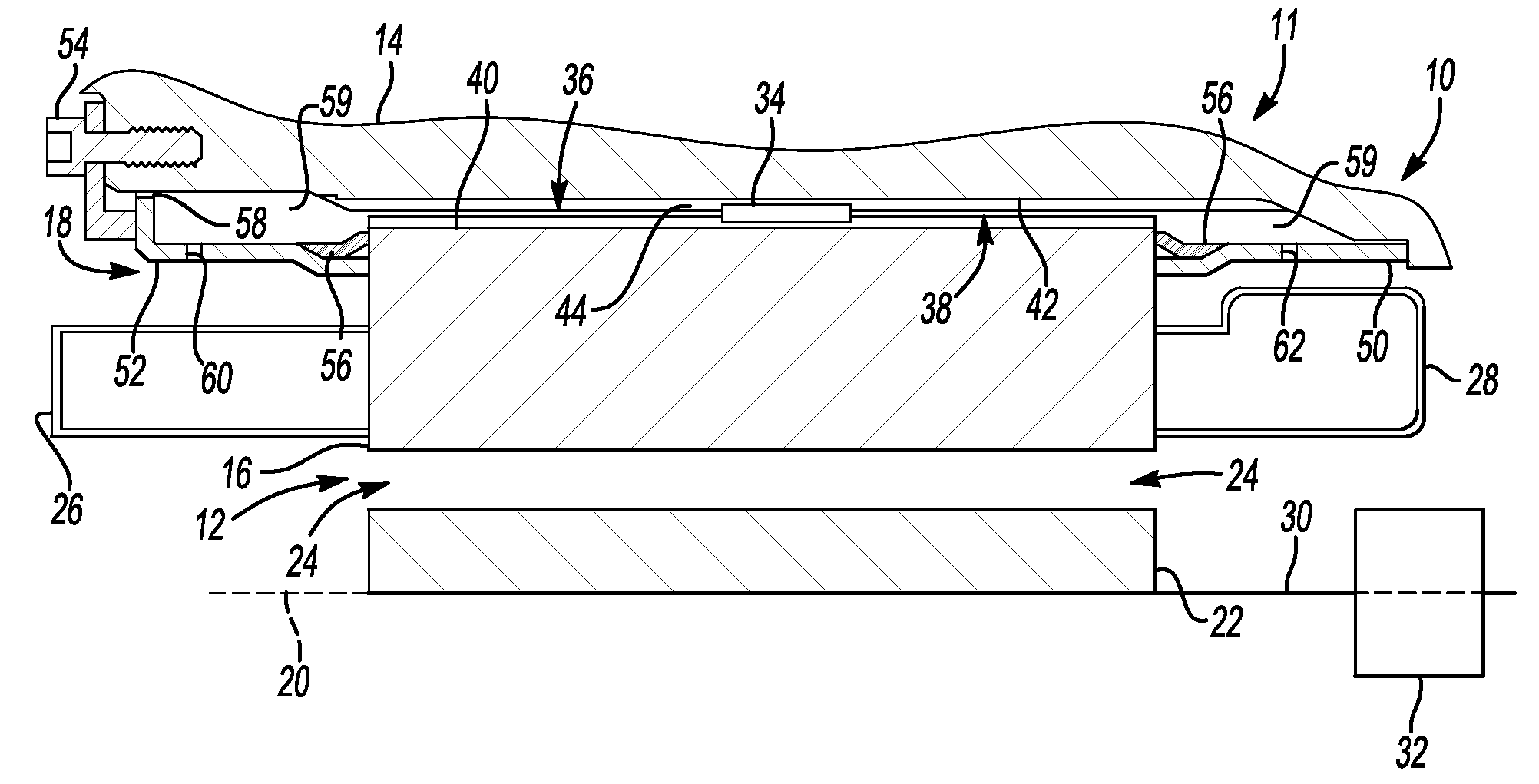

High speed internal permanent magnet machine

ActiveUS20100277028A1Magnetic circuit rotating partsManufacturing stator/rotor bodiesAlternating currentMagnet

An internal permanent magnet (IPM) machine is provided. The IPM machine includes a stator assembly and a stator core. The stator core also includes multiple stator teeth. The stator assembly is further configured with stator windings to generate a magnetic field when excited with alternating currents and extends along a longitudinal axis with an inner surface defining a cavity. The IPM machine also includes a rotor assembly and a rotor core. The rotor core is disposed inside the cavity and configured to rotate about the longitudinal axis. The rotor assembly further includes a shaft. The shaft further includes multiple protrusions alternately arranged relative to multiple bottom structures provided on the shaft. The rotor assembly also includes multiple stacks of laminations disposed on the protrusions and dovetailed circumferentially around the shaft. The rotor assembly further includes multiple permanent magnets for generating a magnetic field, which interacts with the stator magnetic field to produce torque. The permanent magnets are disposed between the stacks. The rotor assembly also includes multiple bottom wedges disposed on the bottom structures of the shaft and configured to hold the multiple stacks and the multiple permanent magnets.

Owner:GENERAL ELECTRIC CO

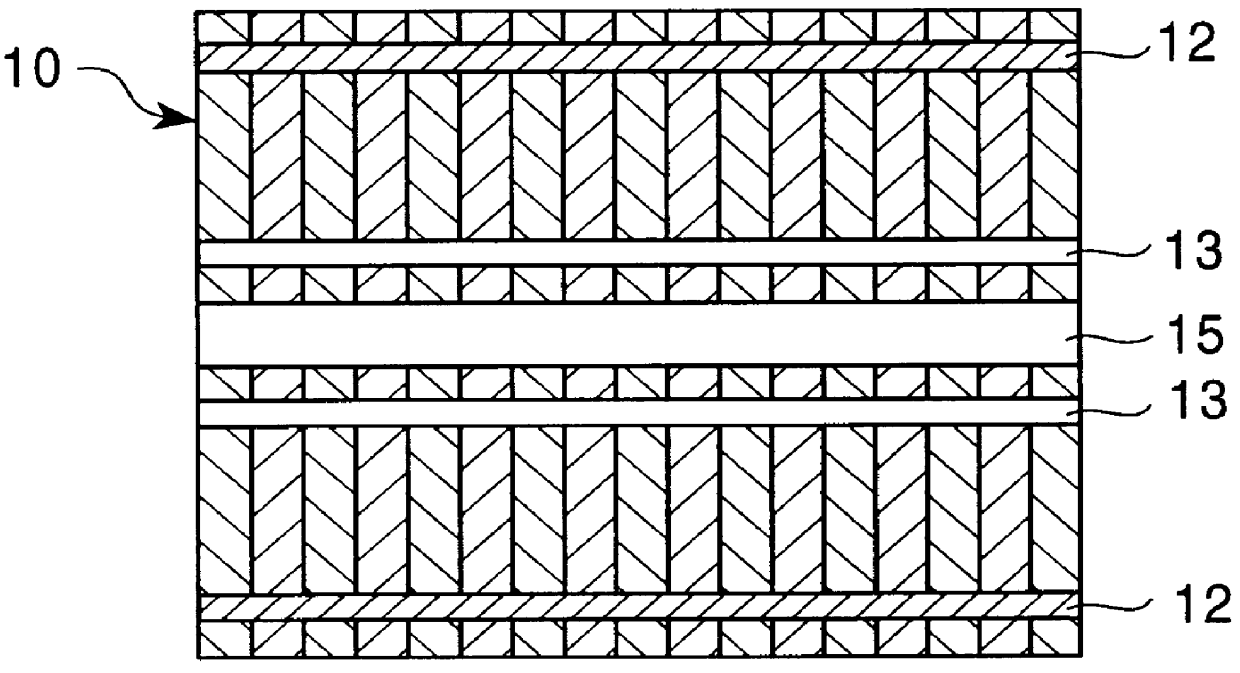

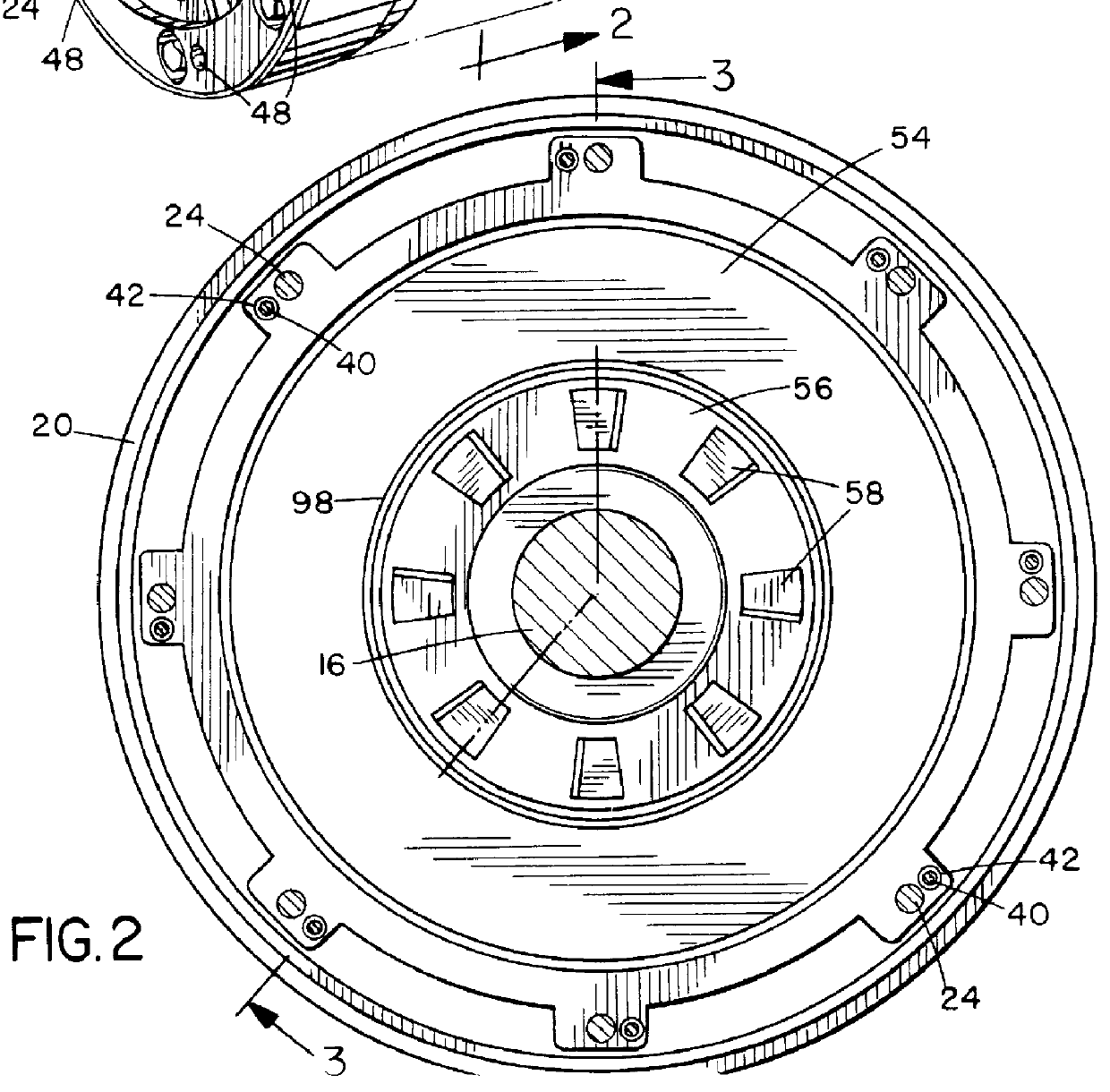

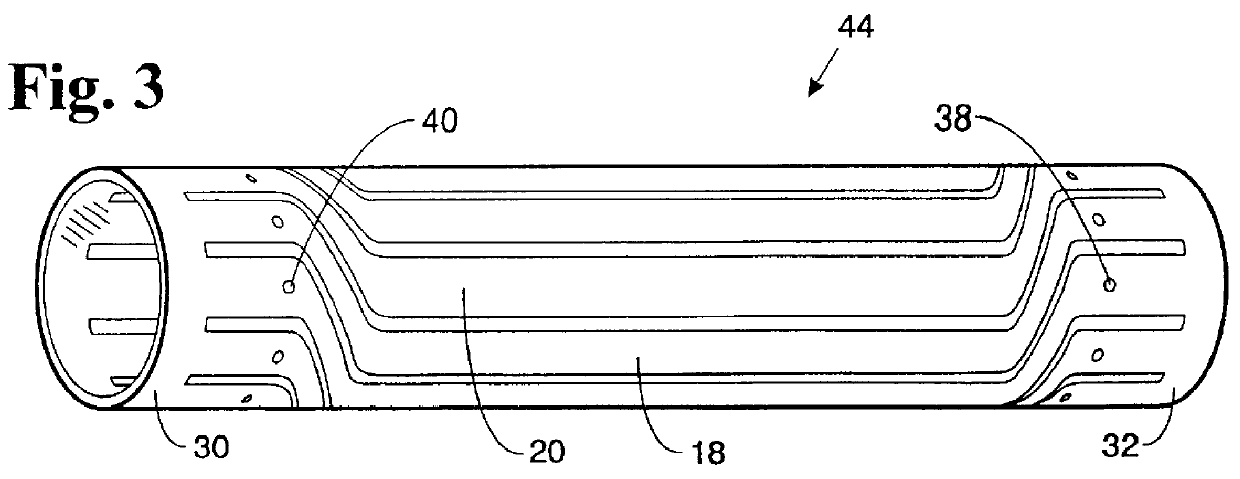

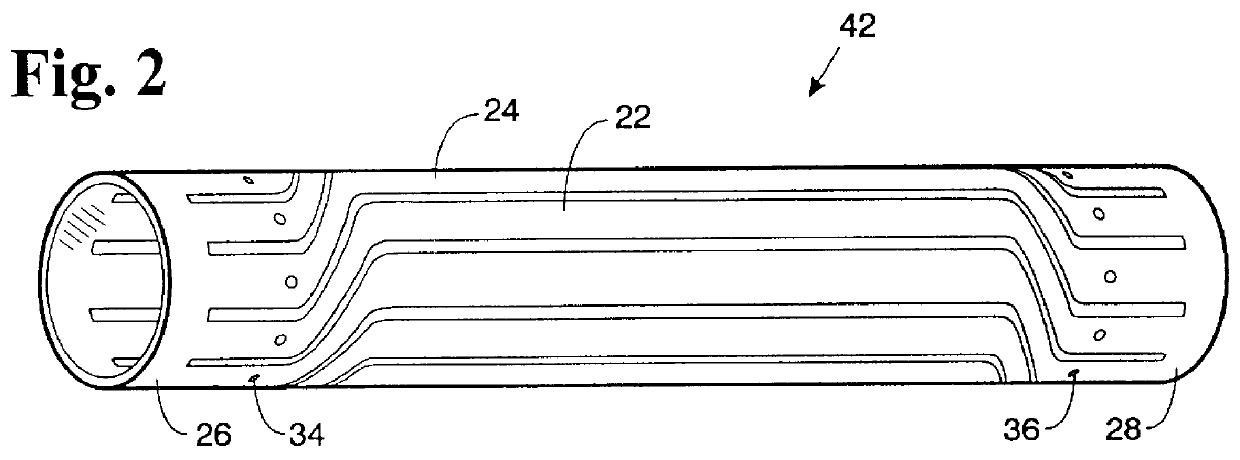

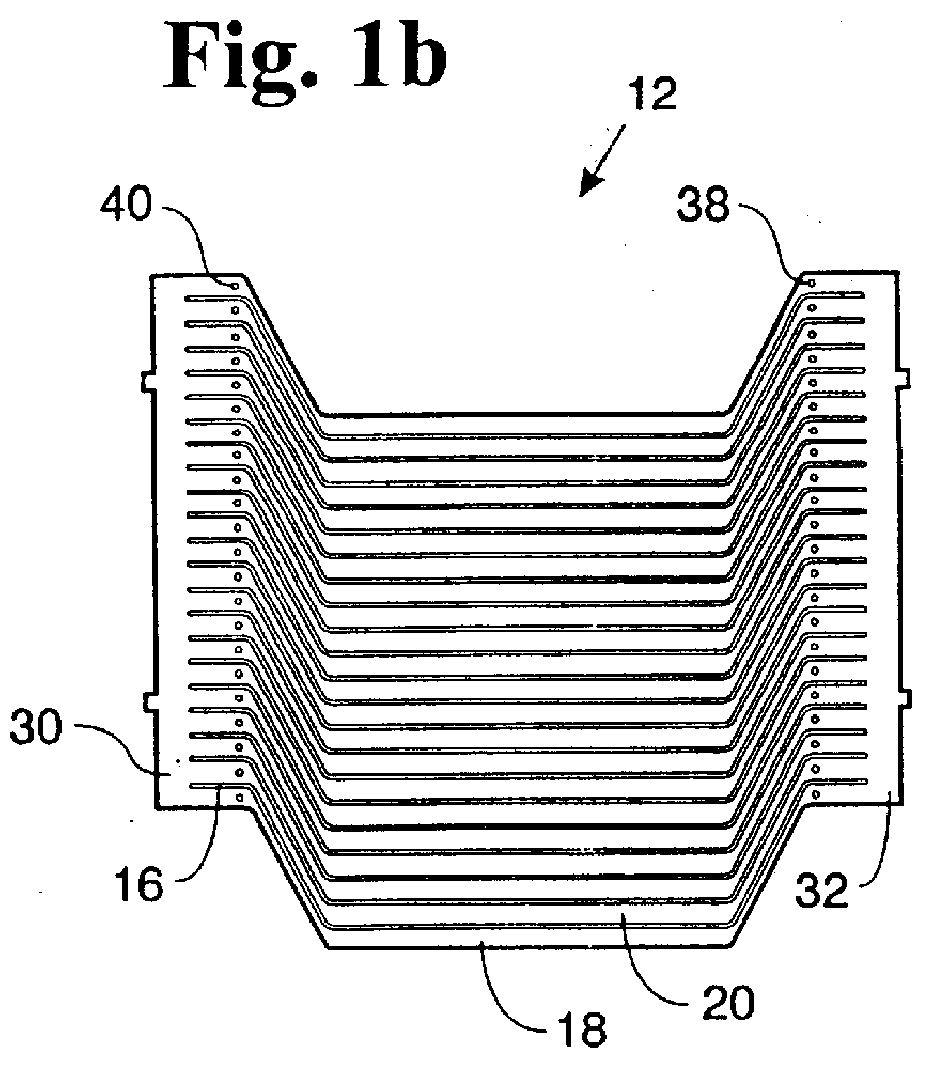

Motor generator including interconnected stators and stator laminations

InactiveUS6163097AMaximization of overall densityShort gapWindings insulation shape/form/constructionAsynchronous induction motorsCross-linkElectrical conductor

An axial field motor / generator having a rotor that includes at least three annular discs magnetized to provide multiple sector-shaped poles. Each sector has a polarity opposite that of an adjacent sector, and each sector is polarized through the thickness of the disc. The poles of each magnet are aligned with opposite poles of each adjacent magnet. Metal members adjacent the outermost two magnets contain the flux. The motor / generator also has a stator that includes a stator assembly between each two adjacent magnets. Each stator assembly includes one or more conductors or windings. Although the conductors may be formed of wire having a round, uniform cross-section, they may alternatively be formed of conductors having a tapered cross-section that corresponds to the taper of the sectors in order to maximize the density of the conductor in the gap between axially adjacent poles. The conductors may also alternatively be formed of traces in a printed circuit, which may have one or more layers. Each stator assembly may be removably connectable to another stator assembly to provide modularity in manufacturing and to facilitate selection of the voltage at which the motor / generator is to operate. Electrical contacts, such as pins extending from the casing, may removably connect the conductors of adjacent stator assemblies. A magnet may be dynamically balanced on the shaft by hardening a thin ring of cross-linked resin between the magnet and the shaft while the shaft is spun, using ultraviolet light to polymerize the resin.

Owner:SMITH TECH DEV LLC +1

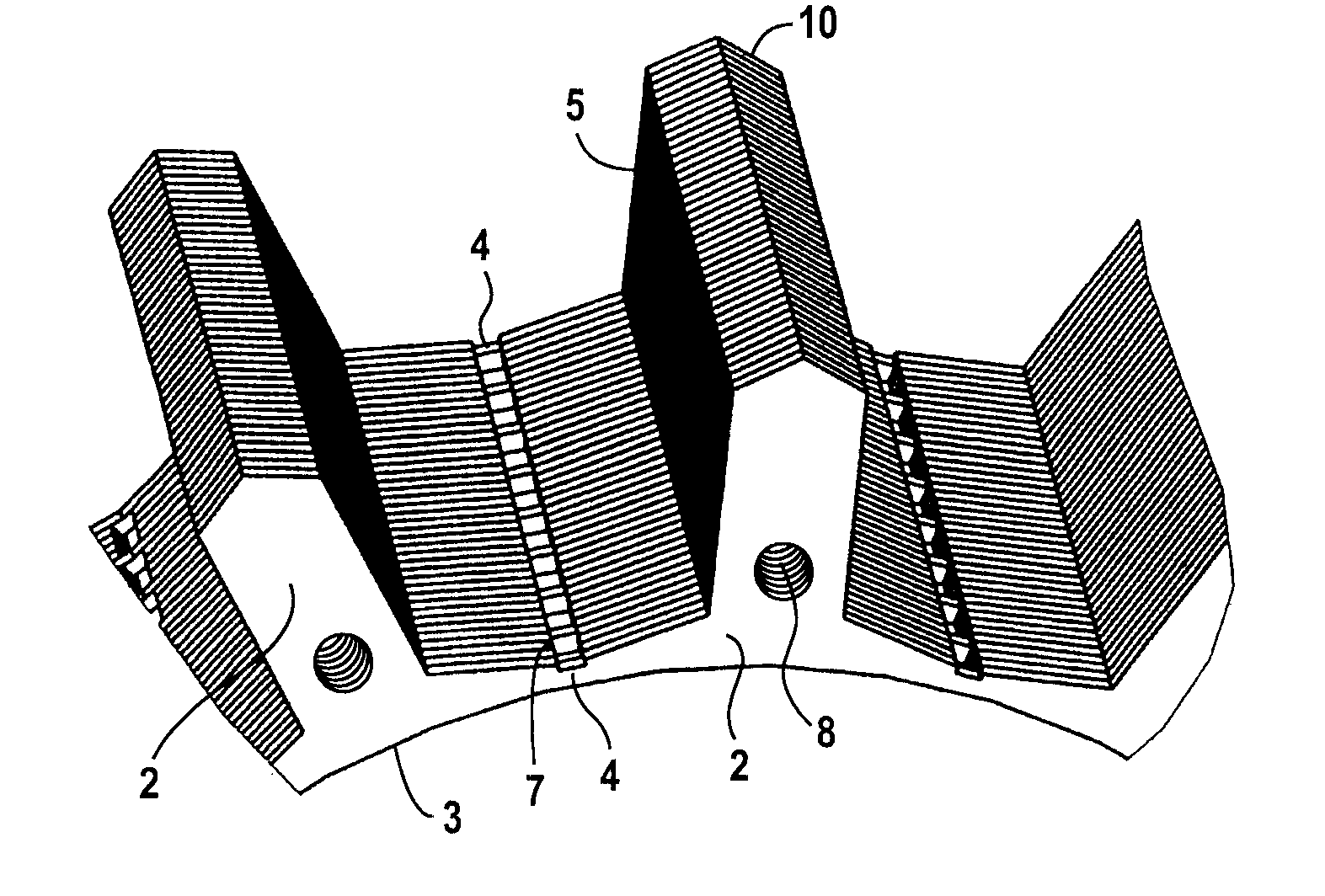

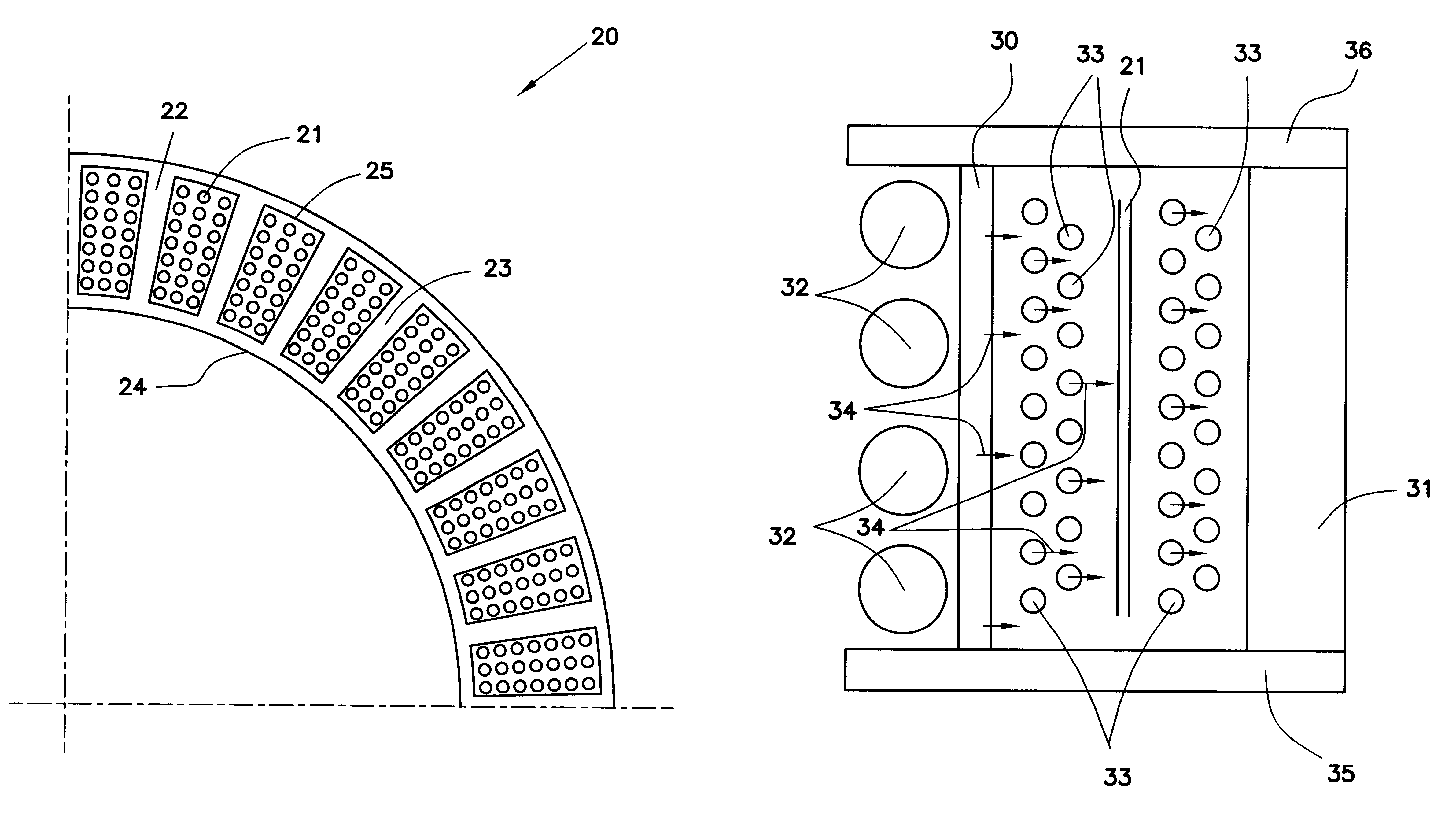

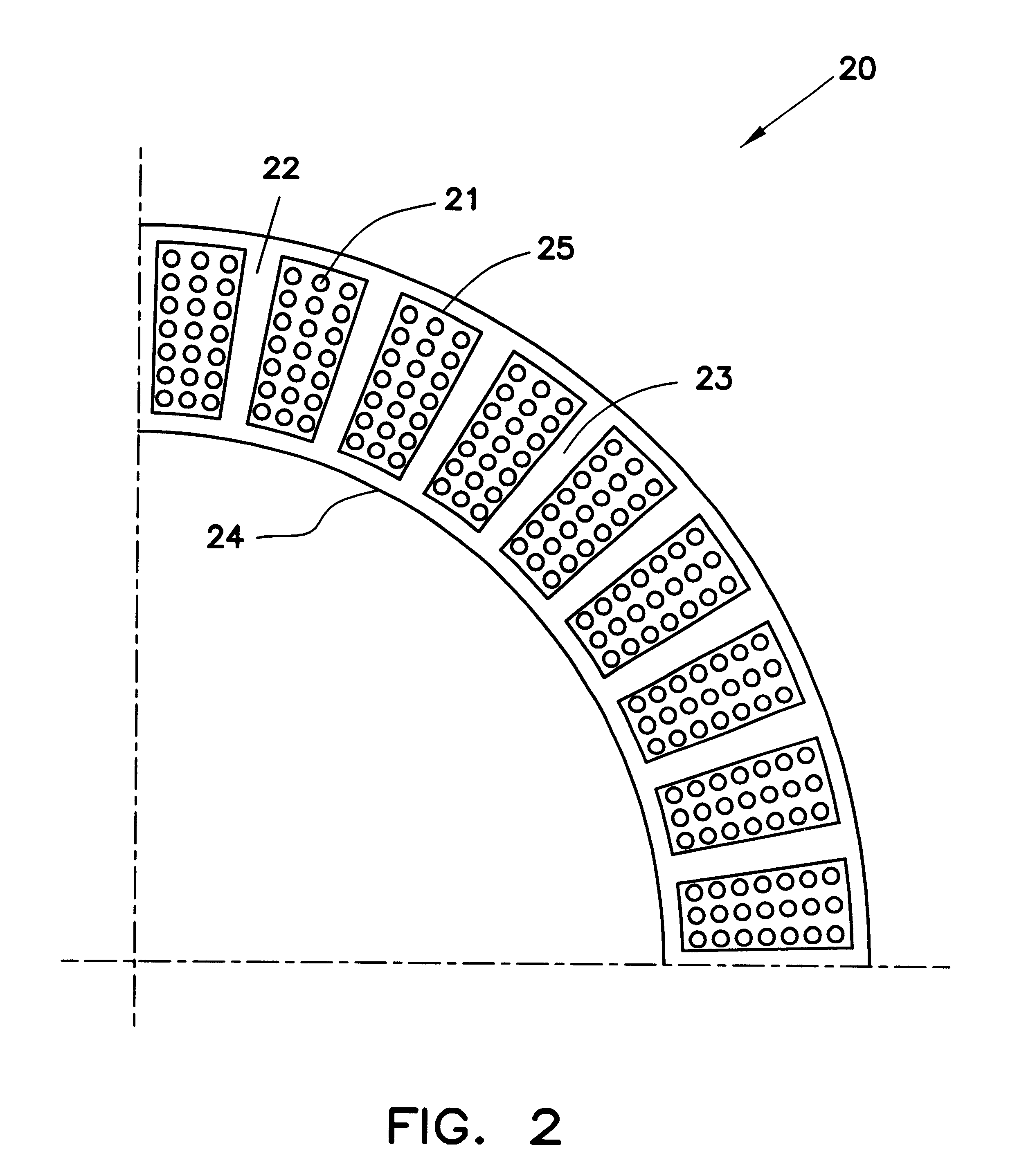

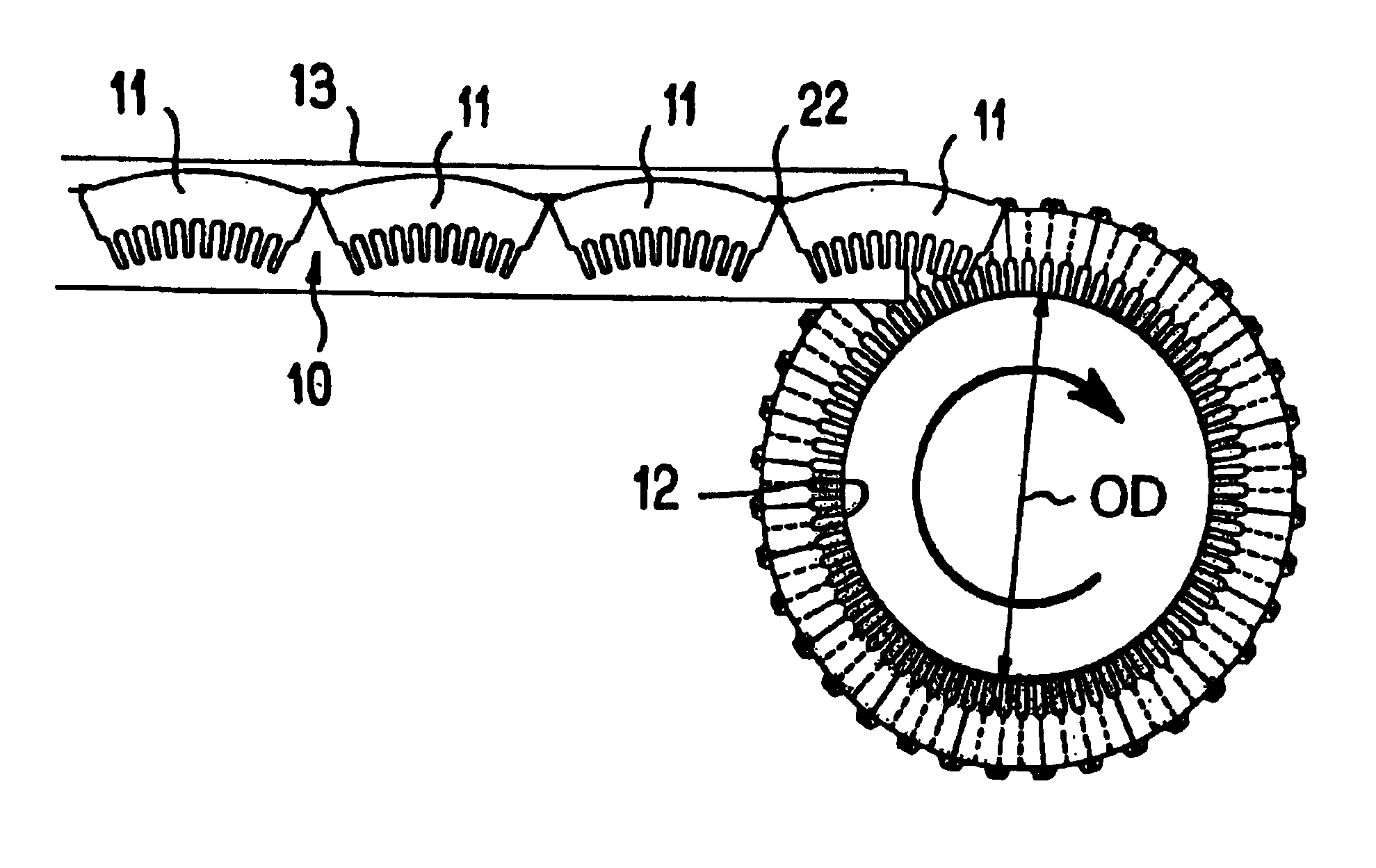

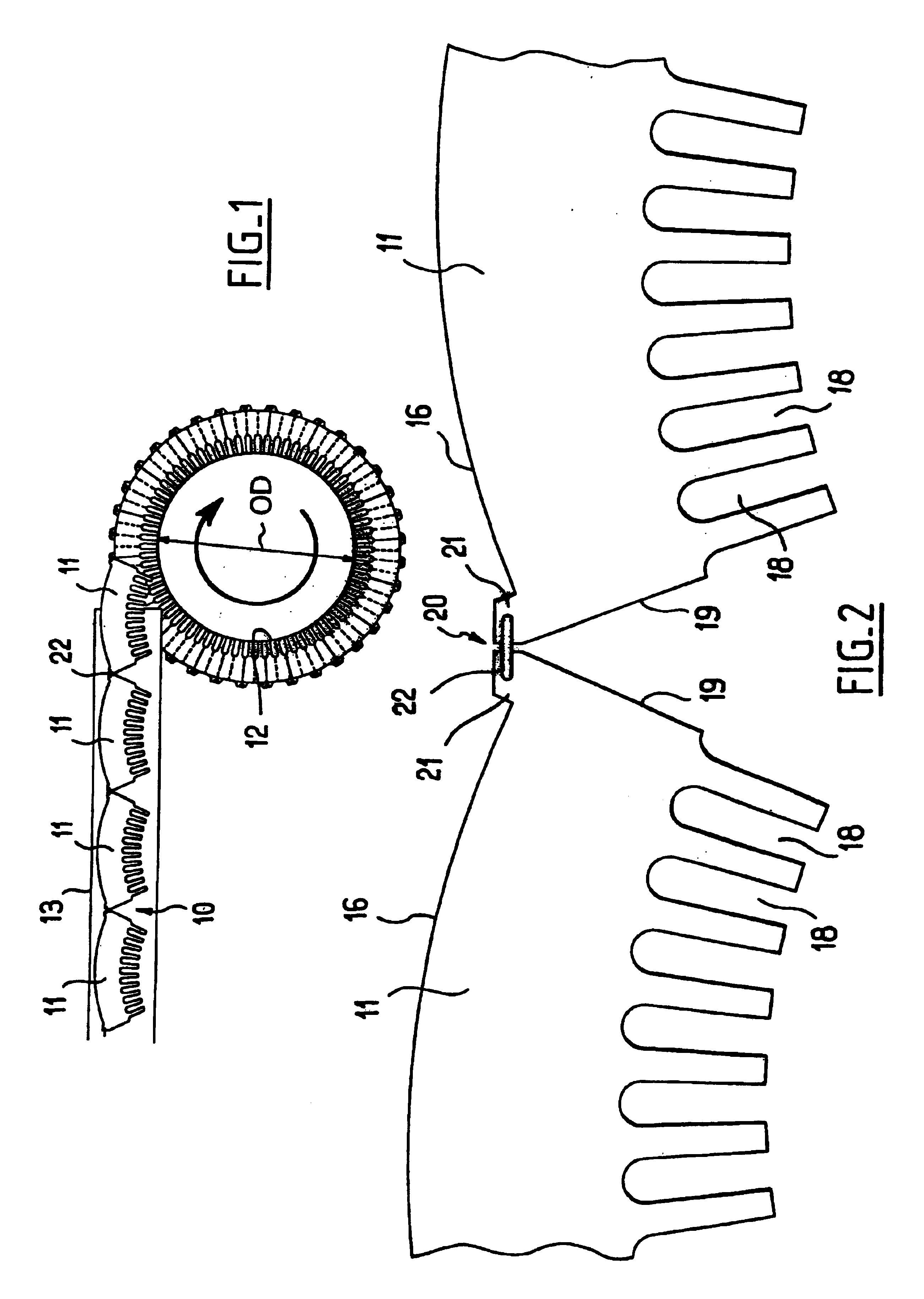

Axial air gap machine having stator and rotor discs formed of multiple detachable segments

InactiveUS20100007225A1Improve fault tolerancePossible to useMagnetic circuit rotating partsMagnetic circuit stationary partsPower factorSupercapacitor

A generator or motor apparatus having a stator formed of a plurality of pairs of parallel stator segments is provided The pairs of parallel segments are connected together to form a channel in which an annular rotor moves The annular rotor also comprises a plurality of detachable segments connected together to form an annular tram operable to move through said channel Each stator segment comprises a stator winding set and each rotor segment comprises a magnet dimensioned to fit between the parallel spaced apart stator segments The apparatus may include a support structure, the rotor segments being slidably coupled to the support structure and the stator segments being attached the support structure The apparatus may be a rim generator, wind turbine generator or other electrical machine The stator winding set includes a winding, and may include other electrical or electronic components, including possibly a power factor capacitor, direct current filtering capacitor, supercapacitor, and one or more diodes The stator winding set nay be encapsulated within the stator segment

Owner:CLEAN CURRENT PARTNERSHIP

Electric motor

InactiveUS6483221B1Simplify and reduce costsProduction be simplified and reducedMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringMetal

A method of producing a laminated core of a stator of an electric motor, includes at least one laminated core of a stator formed by stacked sheet-metal laminates, which have mechanical individual poles and of poles connected in the circumferential direction of the stator, at least one pole shank and at least one pole shoe facing a rotor. The sheet-metal laminates are configured with indentations and protrusions and, as a result, the sheet-metal laminates form the laminated core of the stator by interengagement of the indentations and protrusions. The mechanical poles of the laminated core of the stator have windings, and webs are provided between the poles to connect the connected mechanical poles in the circumferential direction. The axial set-up of the sheet-metal laminates of the laminated core of the stator has a predeterminable alternating succession of poles with a connecting web and poles without a connecting web.

Owner:SIEMENS AG

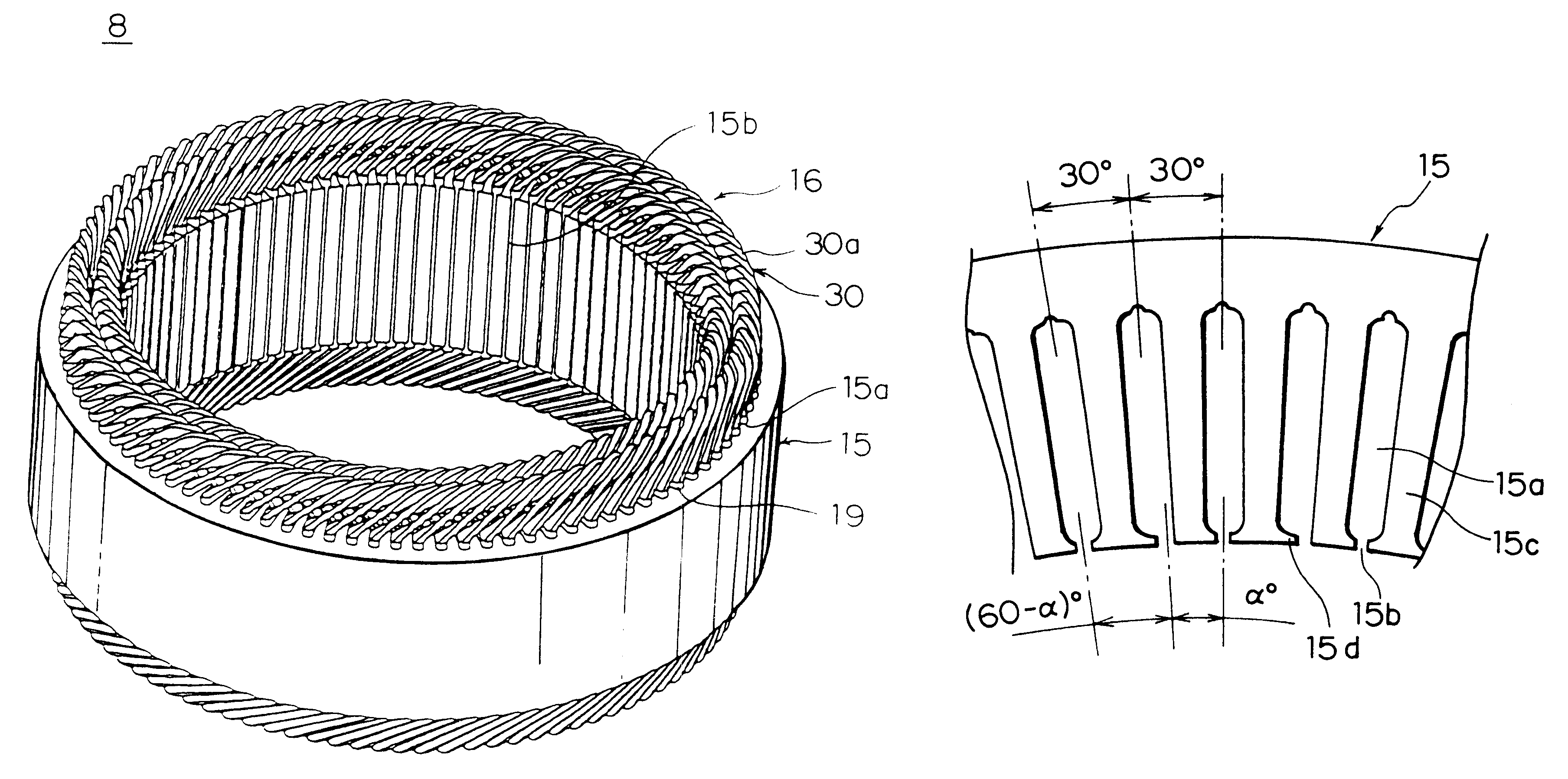

Amorphous metal stator for a radial-flux electric motor

InactiveUS6960860B1Improve motor efficiencyLow core lossMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesEngineering

An amorphous metal stator for a high efficiency radial-flux electric motor has a plurality of segments, each of which includes a plurality of layers of amorphous metal strips. The plural segments are arranged to form a generally cylindrical stator having a plurality of teeth sections or poles protruding radially inward from the inner surface of the stator. In a first embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator crosses just one air gap when traversing each segment of the stator. In a second embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator traverses each segment without crossing an air gap.

Owner:METGLAS INC

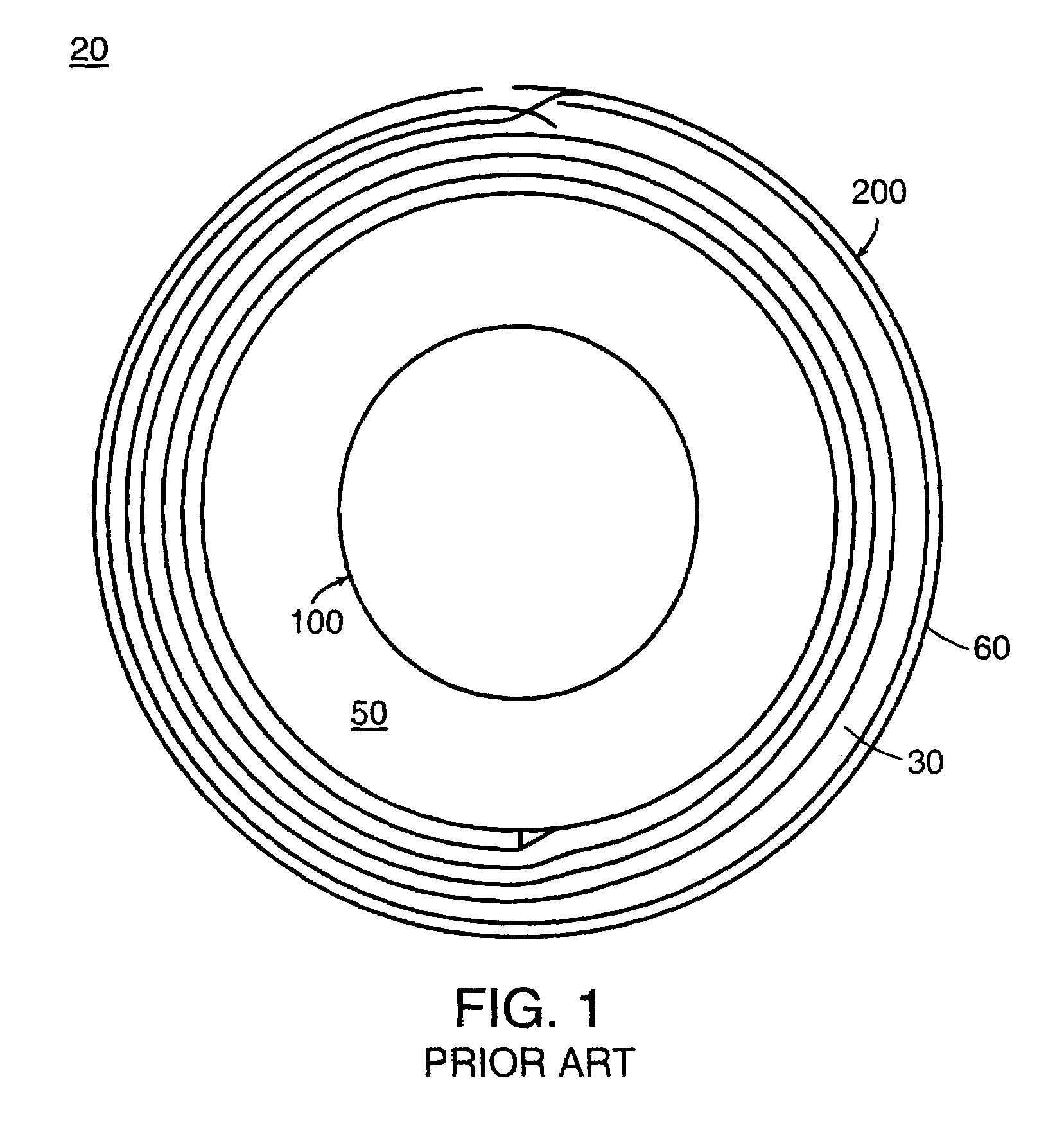

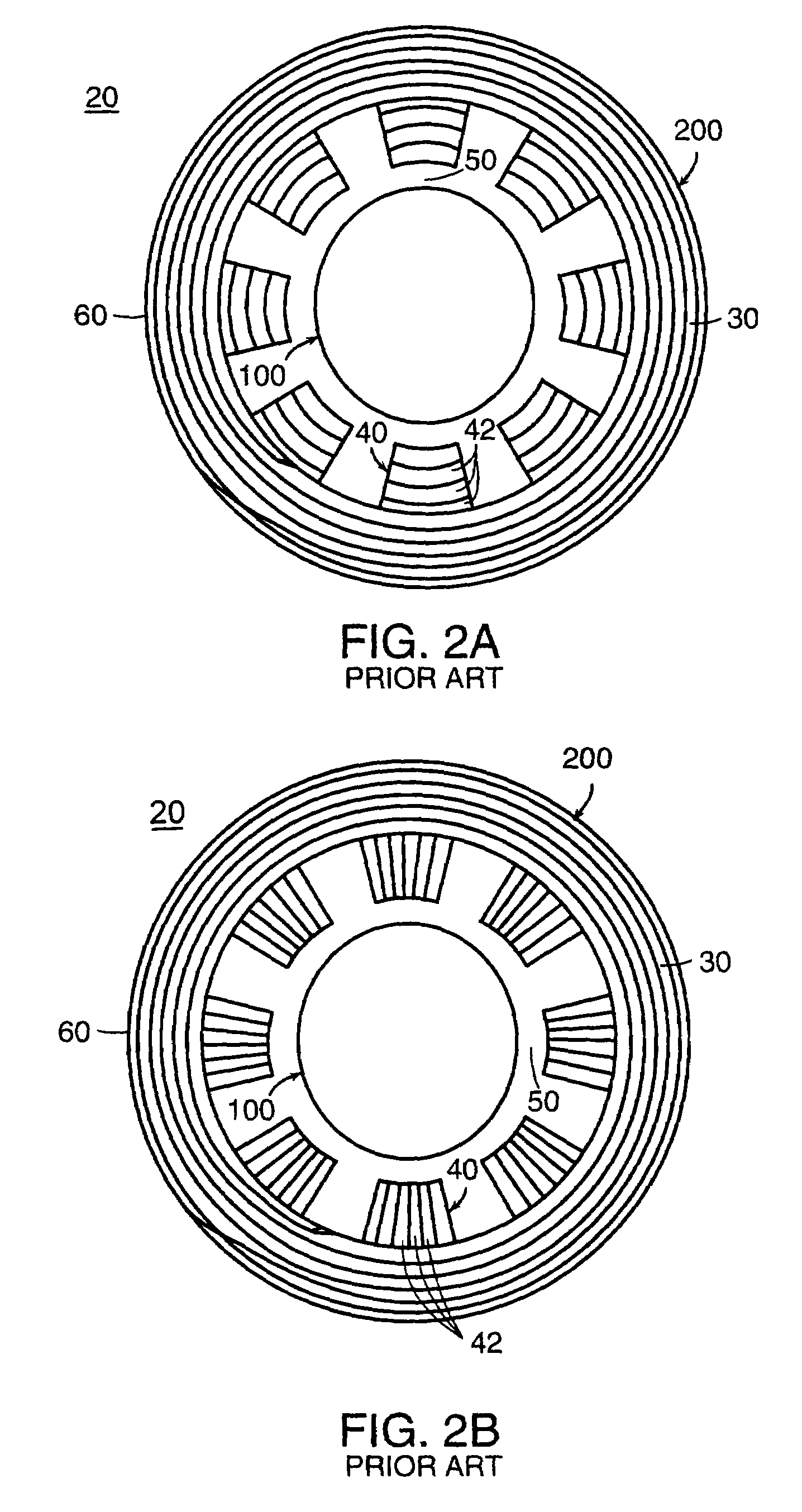

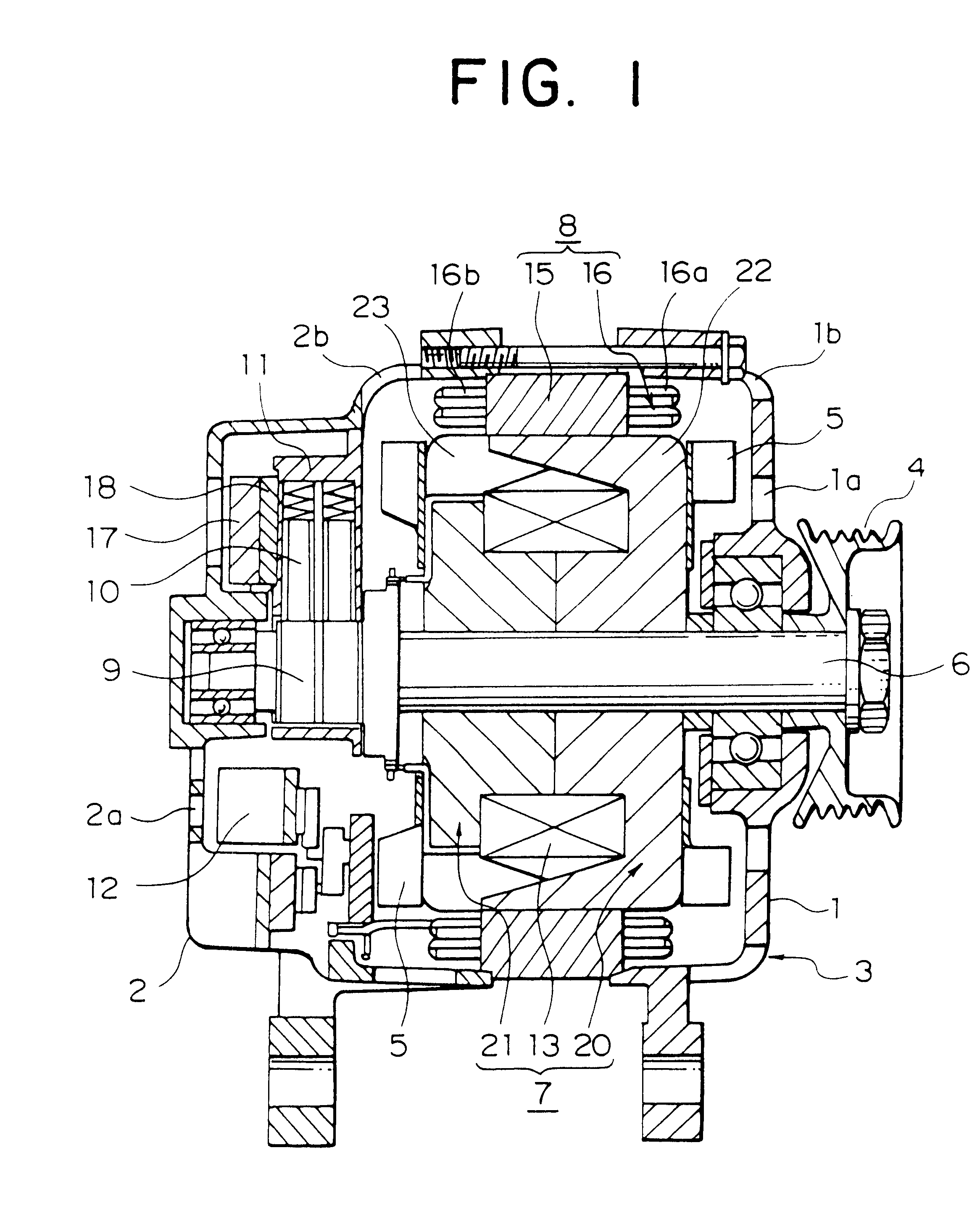

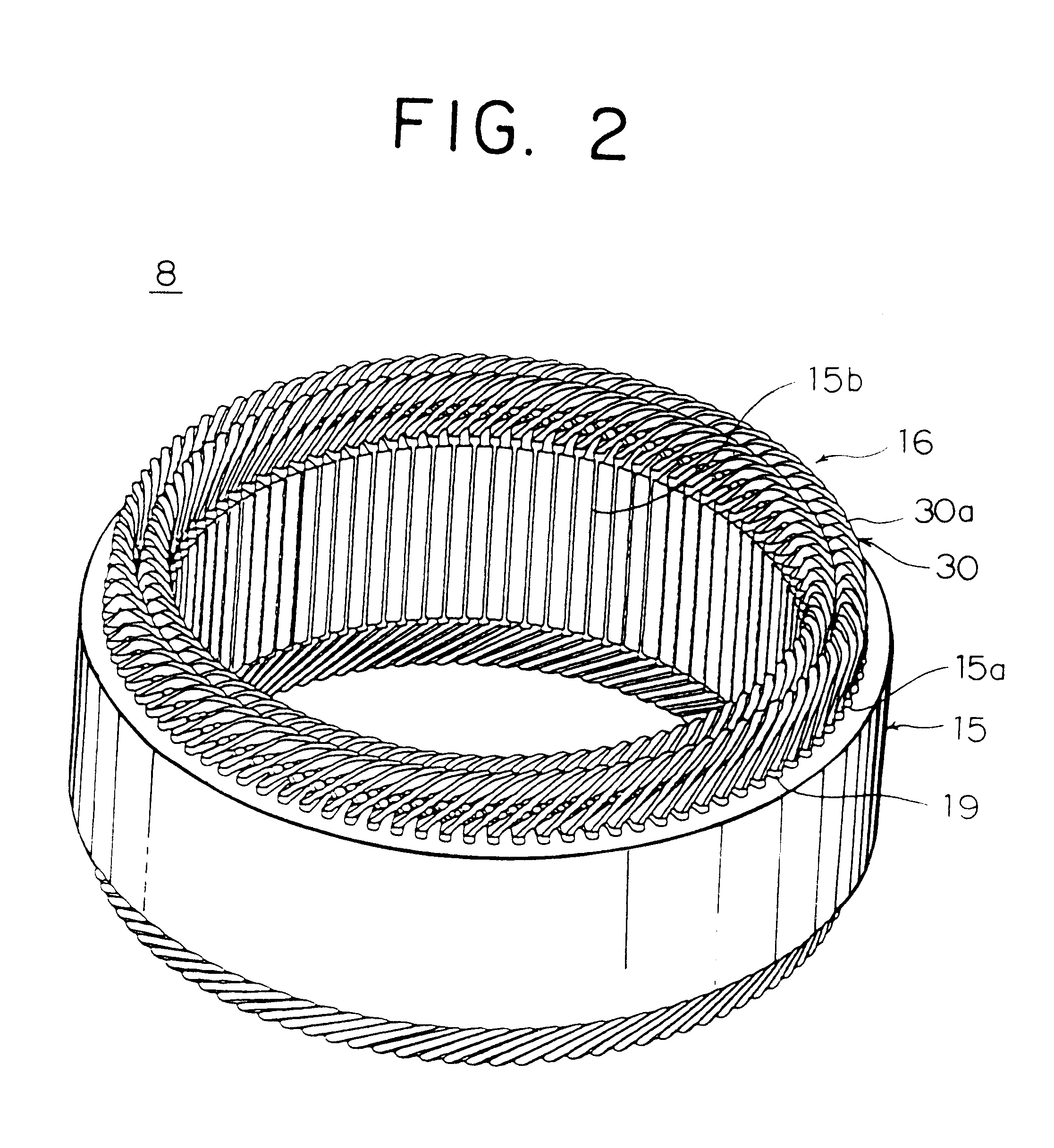

Alternator

InactiveUS6504283B1Reduce noise levelComponent with highSynchronous generatorsAsynchronous induction motorsAlternatorStator coil

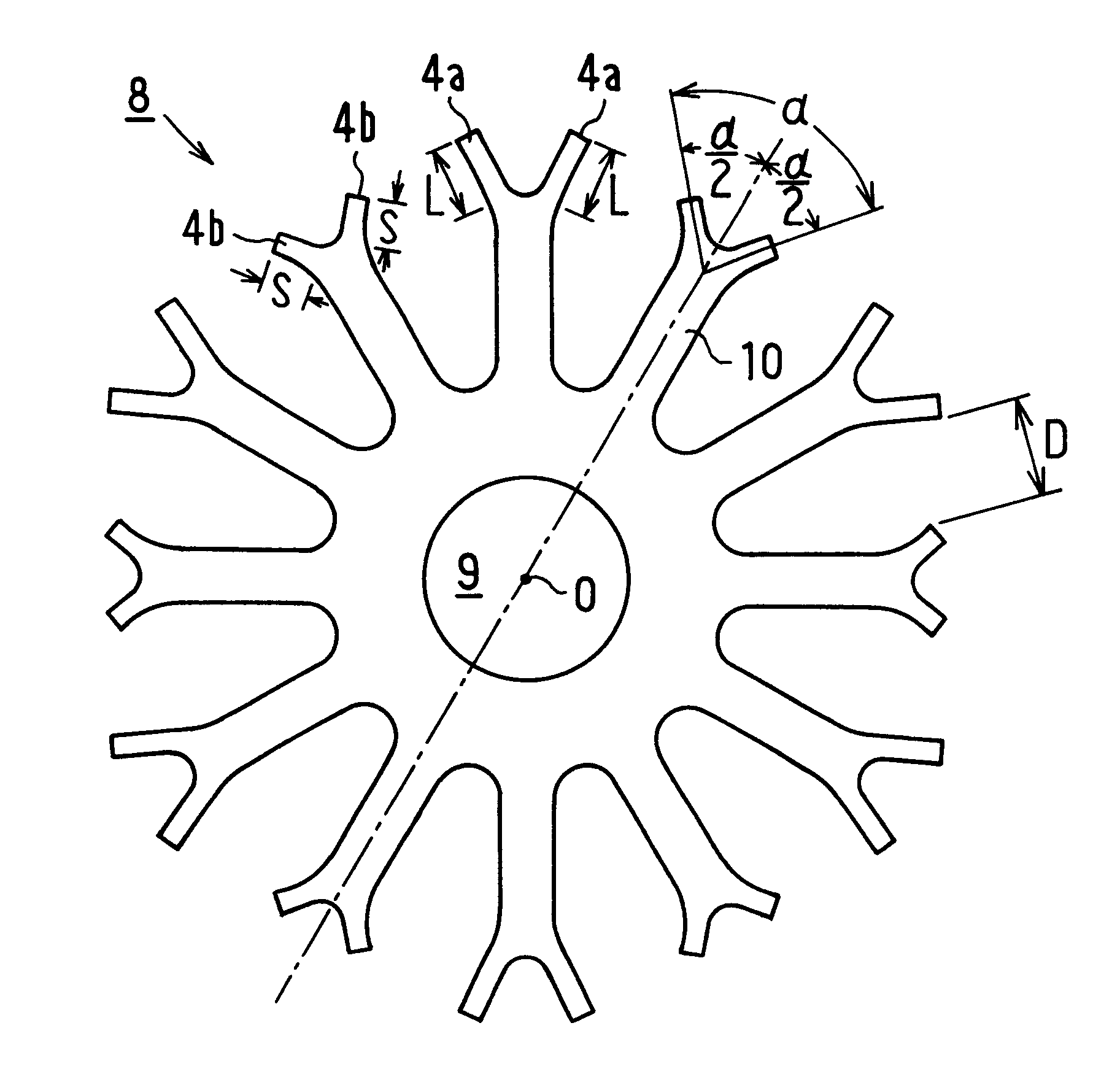

An alternator includes a stator having an annular stator core provided with a number of slots extending axially disposed in lines circumferentially so as to open on an inner circumferential side and a stator coil wound into the stator core so as to be installed in the slots, a rotor having a number of claw-shaped magnetic poles for alternately forming north-seeking (N) and south-seeking (S) poles about a rotational circumference, the rotor being rotatably disposed on the inner circumferential side of the stator core, a bracket supporting the rotor and the stator, and a rectifier disposed at a first axial end of the stator and connected to end portions of the stator coil, the rectifier converting alternating current from the stator coil into direct current, wherein a number of slots is two per phase per pole, and the stator coil comprises a number of winding sub-portions in each of which a long strand of wire is wound so as to alternately occupy an inner layer and an outer layer in a slot depth direction within the slots at intervals of a predetermined number of slots by folding back the strand of wire outside the slots at axial end surfaces of the stator core.

Owner:MITSUBISHI ELECTRIC CORP

Manufacturing Method for Rotary Electric Machine and Stator

InactiveUS20080201935A1Improve productivityManufacturing stator/rotor bodiesApplying solid insulationElectrical conductorElectric machine

A manufacturing method for a rotary electric machine according to the present invention comprises steps of: (1) preforming a coil including a plurality of element coils of an insulated conductor; (2) inserting a first side of a first element coil of the element coils into a first slot of a stator core through an opening of the first slot; (3) inserting a second side of the first element coil into a second slot in which a first side of a second element coil of the element coil has been already inserted; (4) electrically connecting coil ends of a plurality of the coils to each other; and (5) rotatably mounting a rotor inside the stator core.

Owner:HITACHI LTD

Preparing method for amorphous alloy stator iron core of high-speed electric machine

ActiveCN101286676ASimple processShort processing timeInductances/transformers/magnets manufactureManufacturing stator/rotor bodiesElectric machineAlloy

The invention aims at providing a method for preparing a noncrystalline alloy stator core with low loss and regular and complete appearance which is applied to high-speed electrical machines. The preparation method comprises the following steps of incising noncrystalline alloy belt material to form a plurality of noncrystalline alloy sheets with preset length, laminating the noncrystalline alloy sheets to form laminated rods of the noncrystalline alloy sheets with preset thickness, annealing the laminated rods, soaking the annealed laminated rods in a binder, solidifying the laminated rods after being soaked, and cutting the laminated rods according to preset shape and size to form the stator core with needed shape and size. Therefore, the noncrystalline stator core can be prepared needing one-time final cutting only.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

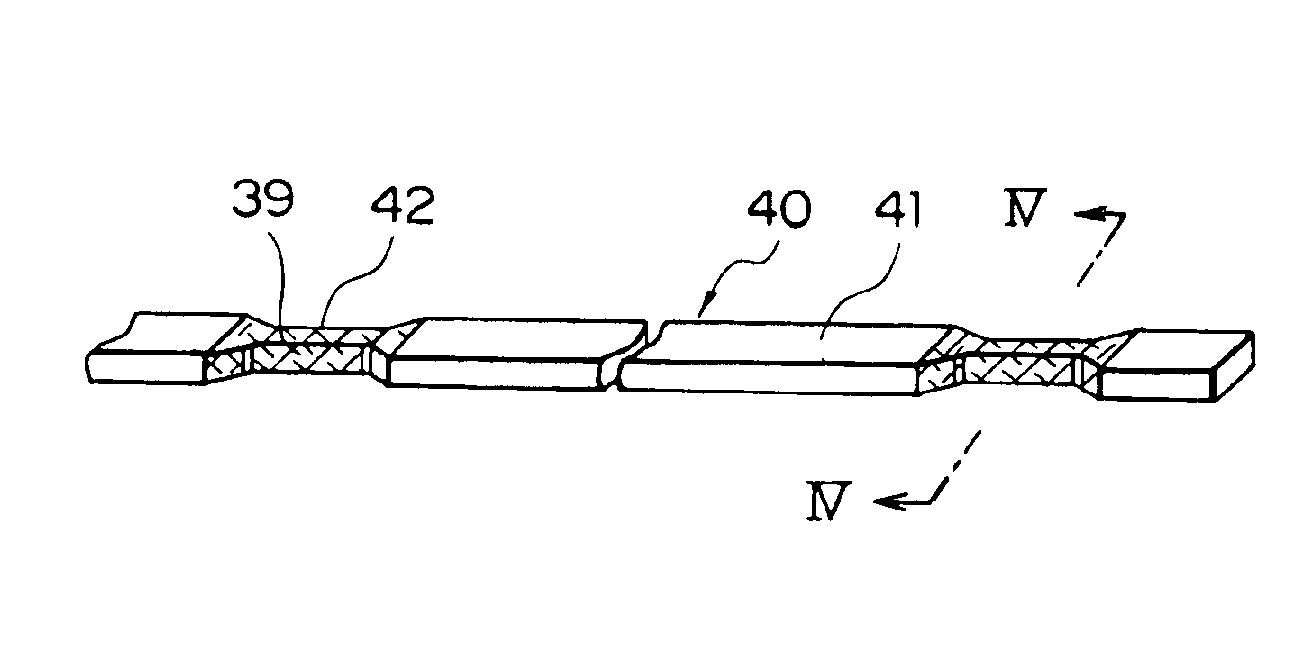

Method of manufacturing a stator for an alternator with reduced conductor portions

InactiveUS6865796B1Improve reliabilityImprove productivityWindings insulation shape/form/constructionManufacturing winding connectionsElectrical conductorAlternator

Coil members are obtained by forming width-reduced portions in a wire material over a predetermined longitudinal range generally centered on cutting positions, then removing an insulation coating from the width-reduced portions, and thereafter cutting the wire material at the width-reduced portions. Coil segments are prepared by bending the coil members into a general U shape. Then the coil segments are inserted into the slots in a stator core, and a stator is obtained by welding together the free end portions of the projecting coil segments.

Owner:MITSUBISHI ELECTRIC CORP

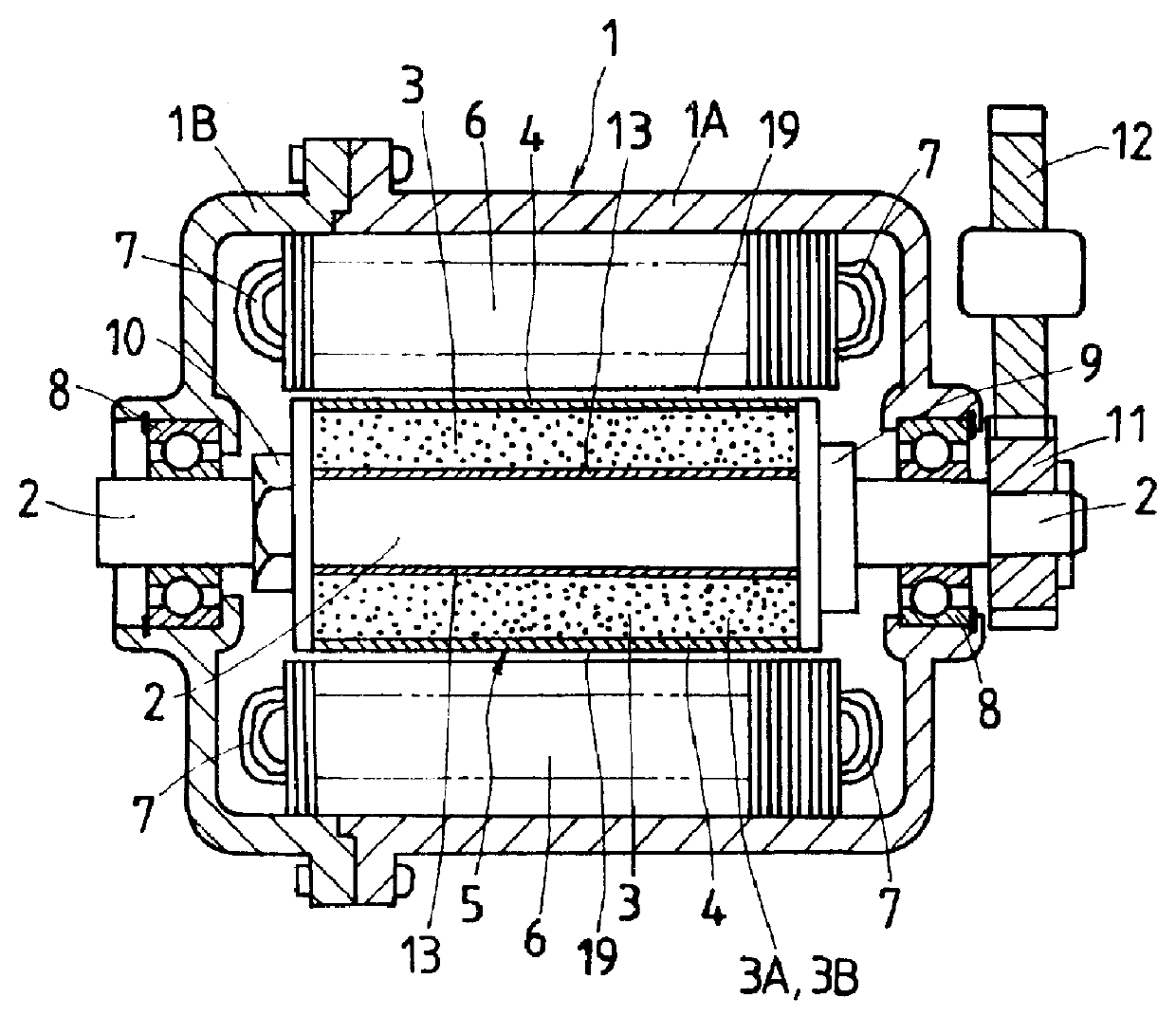

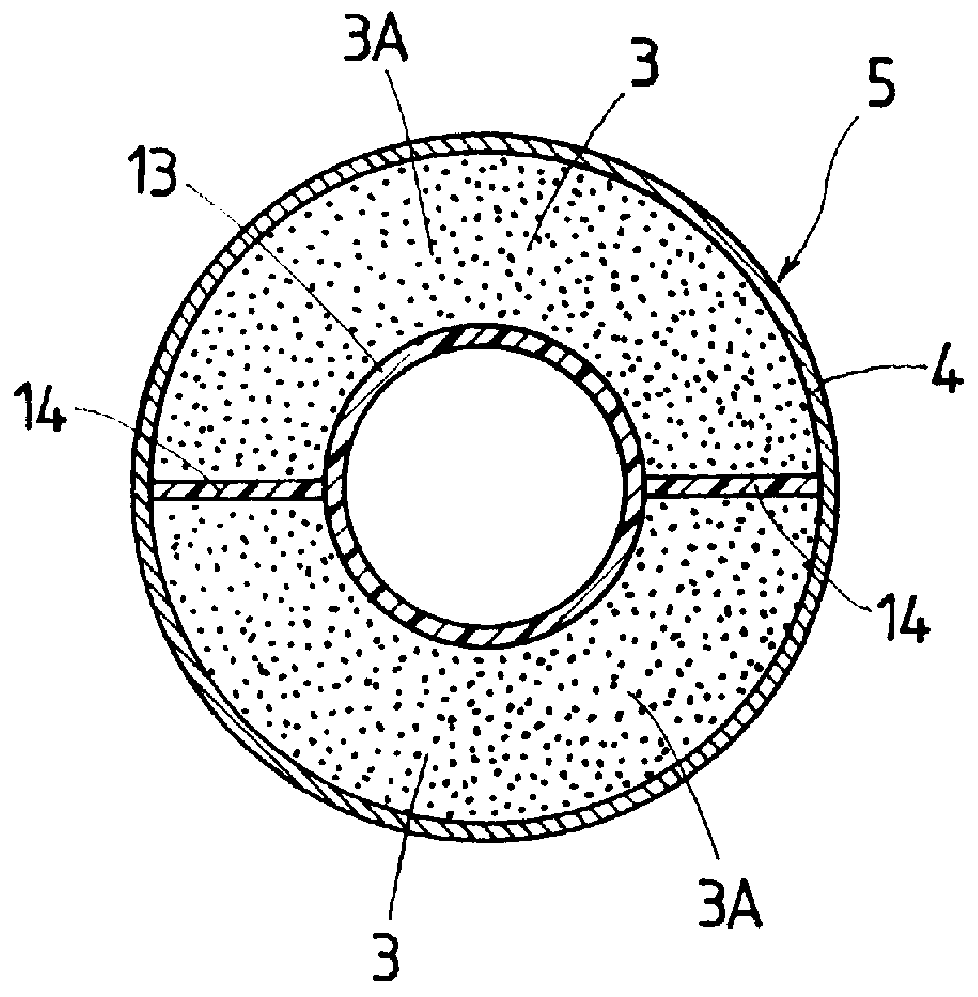

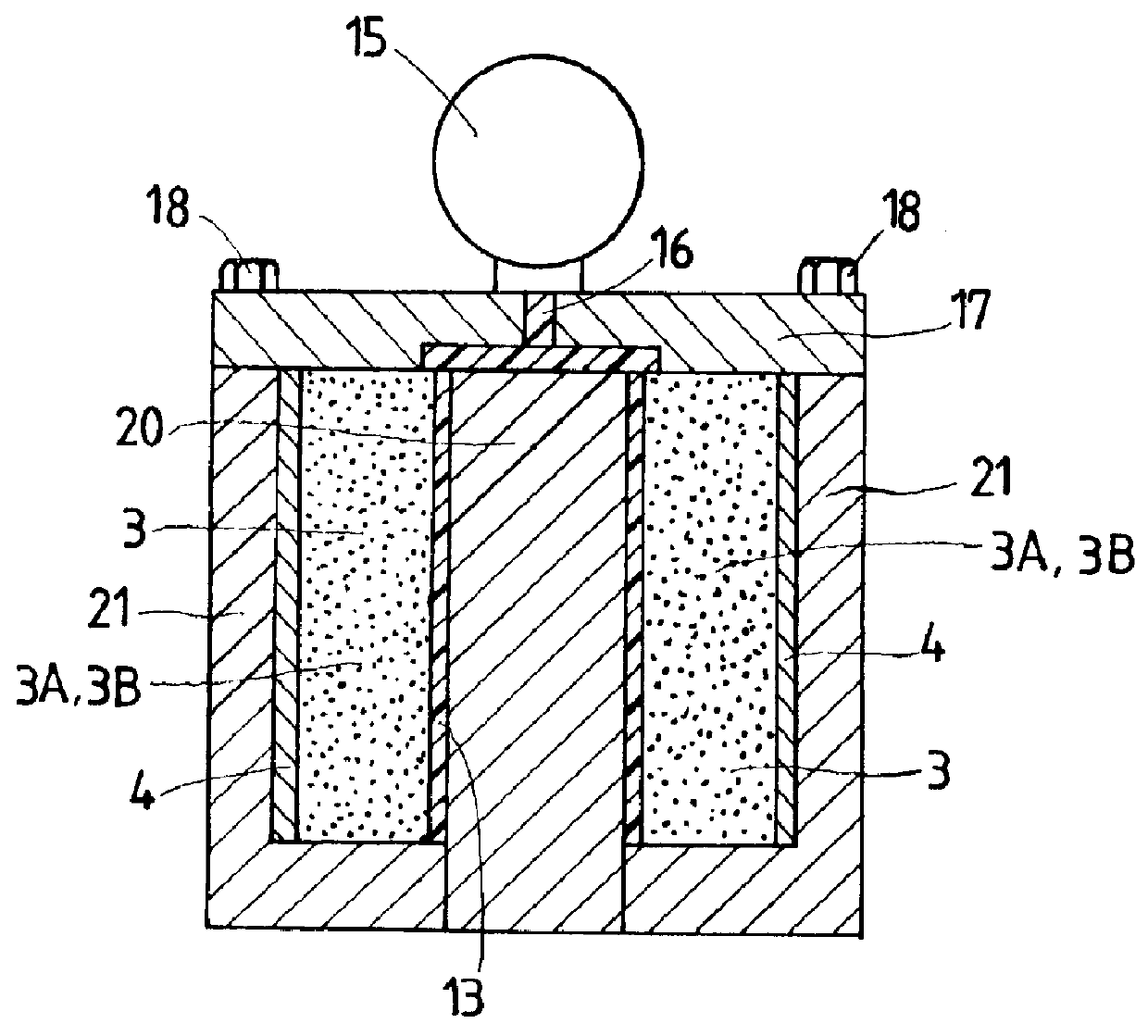

Electromagnetic device with embedded windings and method for its manufacture

InactiveUS6232681B1Maximize electromagnetic couplingGap minimizationSynchronous machinesMagnetic circuit stationary partsReduced sizeConductor Coil

A powdered magnetic material stator core with embedded stator windings and a method for its manufacture. Embedding the windings within a radially compacted powdered magnetic material stator core enables equivalent or better electromagnetic performance in a significantly reduced size. Radial compaction of the powdered magnetic material minimizes the distortion of the stator windings during compaction.

Owner:REMY TECHNOLOGIES LLC

Armature for an electromotive device

InactiveUS6111329AMaximize conductor-packing factorMaximize conductor volume to gap ratioWindings insulation shape/form/constructionMagnetic circuit rotating partsGlass fiberEngineering

An armature for an electric motor is constructed from a pair of precision machined copper plates cut in a pattern to produce a series of axially extending surface conductive bands with each band separated from the other by an insulated cutout. The precision machined plates are rolled to form two telescoping, hollow cylinders with each cylinder having a pattern of conductive bands representing a half-electric circuit. The outer surface of the inner cylinder is wrapped with several layers of fiberglass strands for structural stability and insulation. The fiberglass wrapped inner cylinder is telescoped inside the outer cylinder. The outer surface of the telescoped structure is also wrapped with several layers of fiberglass strands for structural stability. The conductive bands from the outer cylinder being the near mirror image of the conductive bands of the inner cylinder are helically coupled to form a complete electrical circuit. The resulting tubular structure is encapsulated in a potting material for further structural stability and insulation. The result is a freestanding ironless core inductive armature coil for a DC motor with brushes. The armature also has a commutator, which is mounted at one end of the coil and is in electrical contact with the helically coupled conductive bands. An insulated flywheel and shaft assembly is mounted inside the coil with the flywheel behind the commutator for motor mounting and operation.

Owner:THINGAP

Structure of rotor for generators and method of manufacturing the same rotor

InactiveUS6144130AReduce manufacturing costImprove permeabilityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsFiberEngineering

Owner:ISUZU MOTORS LTD

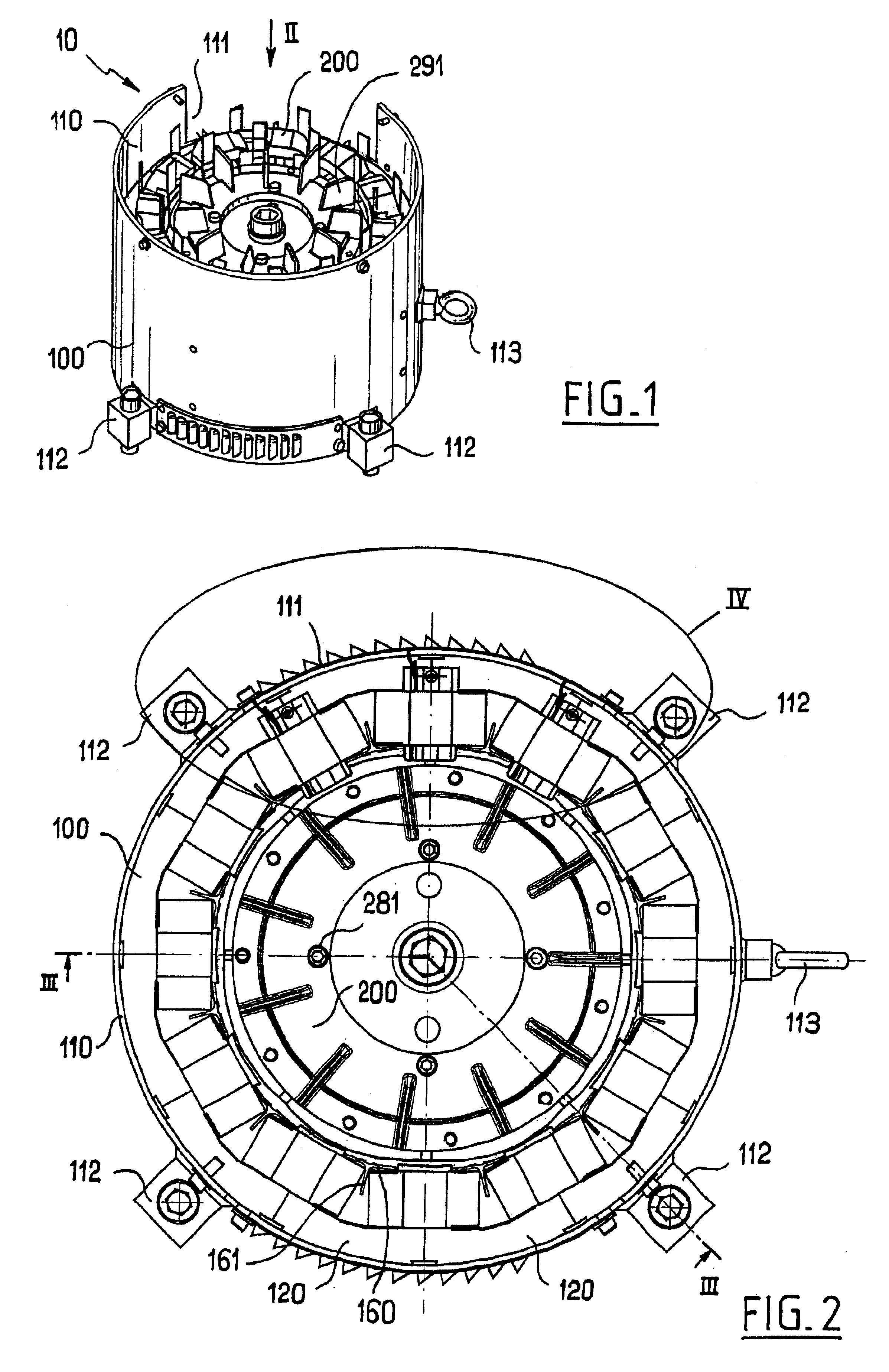

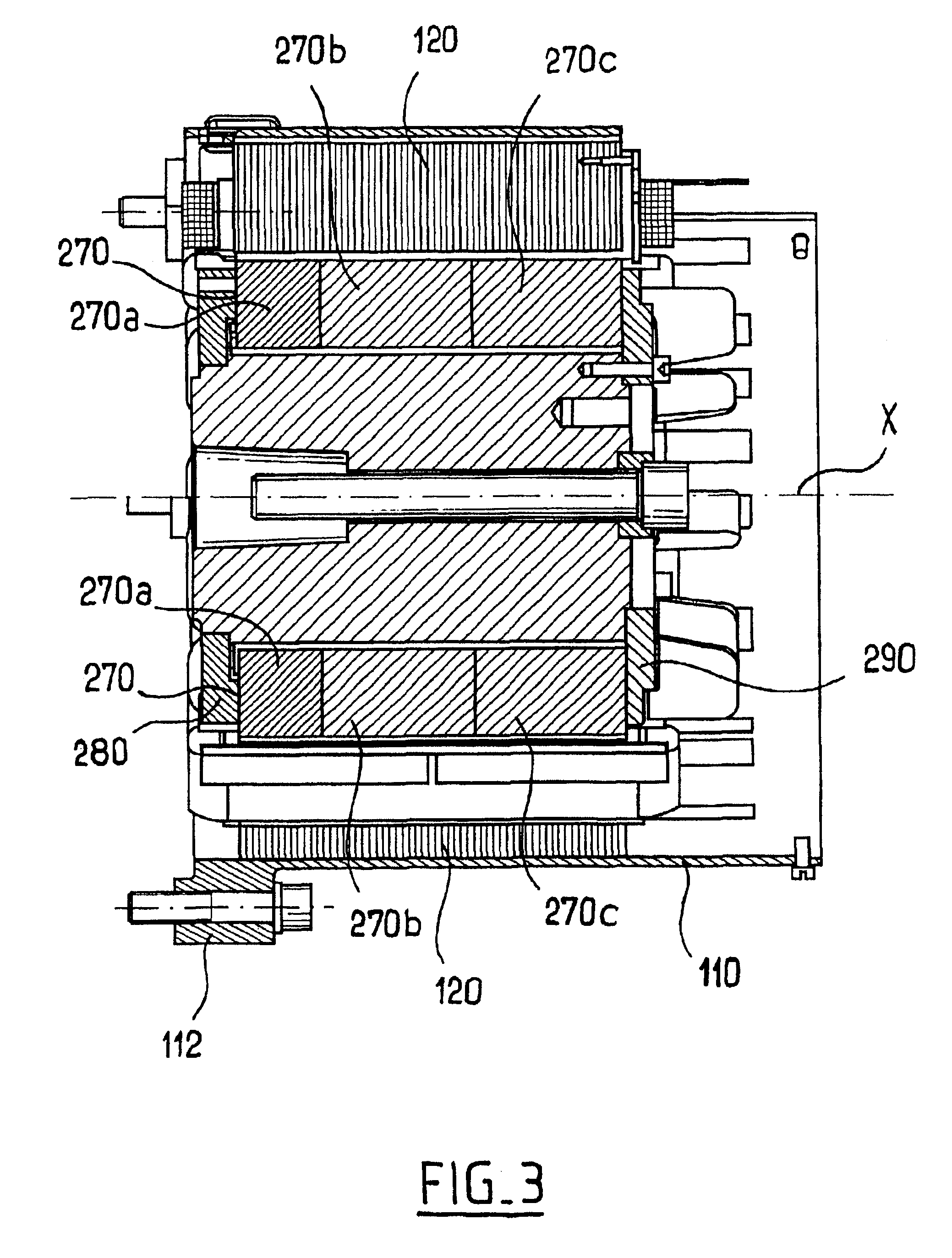

Electric machine - over-moulding construction

ActiveUS20130147291A1Gap minimizationImprove machine efficiencyMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineStator coil

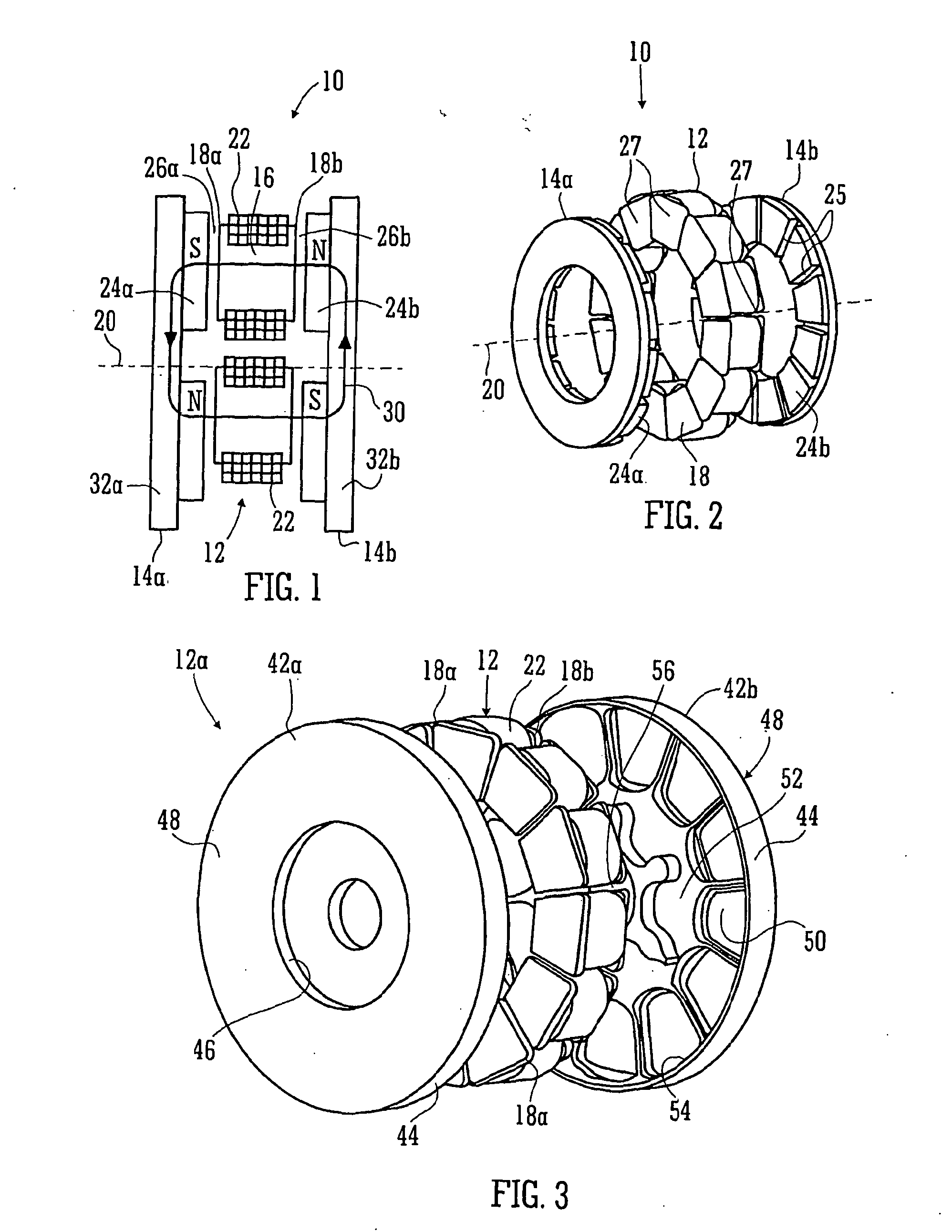

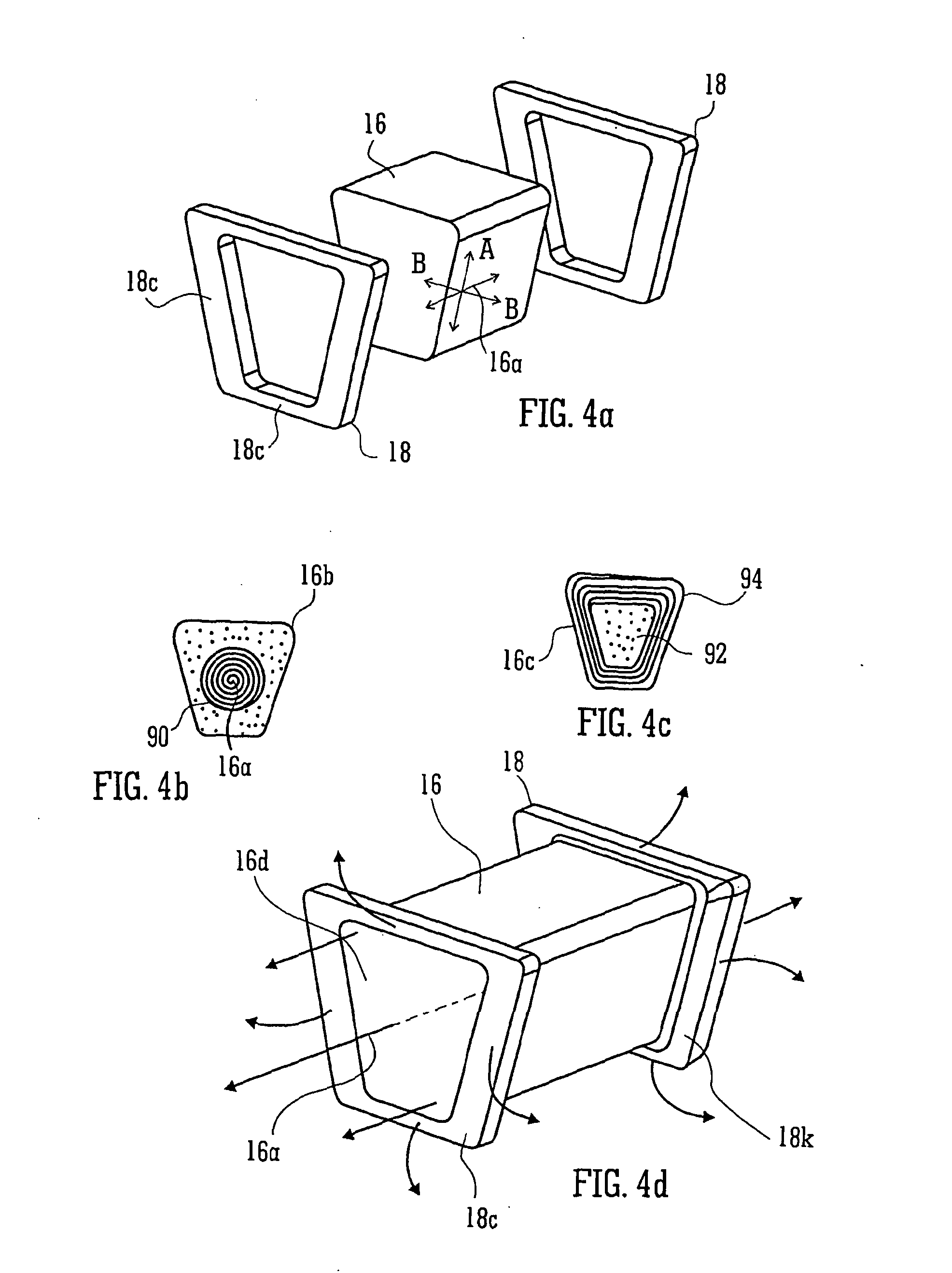

An electric machine (10) comprises a rotor (14a, b) having permanent magnets (24a, b) and a stator (12) having coils (22) wound on stator bars (16) for interaction with the magnets across an air gap (26a, b) defined between them. The bars (16) and coils (22) are enclosed by an annular stator housing (42a, b) that extends between the air gap. A chamber (52, 54, 56) is defined that incorporates cooling medium to cool the coils. The stator housing comprises two mating clamshells (42a, b) that mount the stator bars and coils in the machine. Each clamshell is moulded from reinforced plastics and interconnected (optionally through one or more intermediate components). At least one clamshell has over-moulded therein stator bar shoes that form part of said radial wall, and optionally one or more of the following components: cylindrical boss supports extending along the cylindrical outer wall part; connection studs that communicate electrically the chamber externally; stator coils; coolant inlet and outlet ports; and an outer race of a rotor bearing.

Owner:YASA LIMITED

Core sheet, core and method of manufacturing an armature

InactiveUS6242835B1Improve space factorLess cogging in the torqueWindingsMagnetic circuit rotating partsEngineeringConductor Coil

Owner:ASMO CO LTD

Armature Core, Motor Using It, and Its Manufacturing Method

InactiveUS20100225195A1High magnetic flux densityPrevents impairment of motor characteristicMagnetic circuit rotating partsPositive displacement pump componentsMagnetic fieldElectric motor

An object is to enable simple manufacture of a motor, especially, a stator core or a field without impairment of motor characteristics. The motor includes a shaft, a rotor fixed to the shaft, and a stator including a stator core that faces the rotor with a certain space therebetween and coils that are attached to the stator core. The stator includes a back yoke, and the stator core having a plurality of teeth that are circumferentially placed in an axial end face of the back yoke so as to stand upright axially of the back yoke, and that are formed of a dust core made of pressed magnetic powder. The above-mentioned teeth are buried axially to a certain depth in the back yoke.

Owner:DAIKIN IND LTD

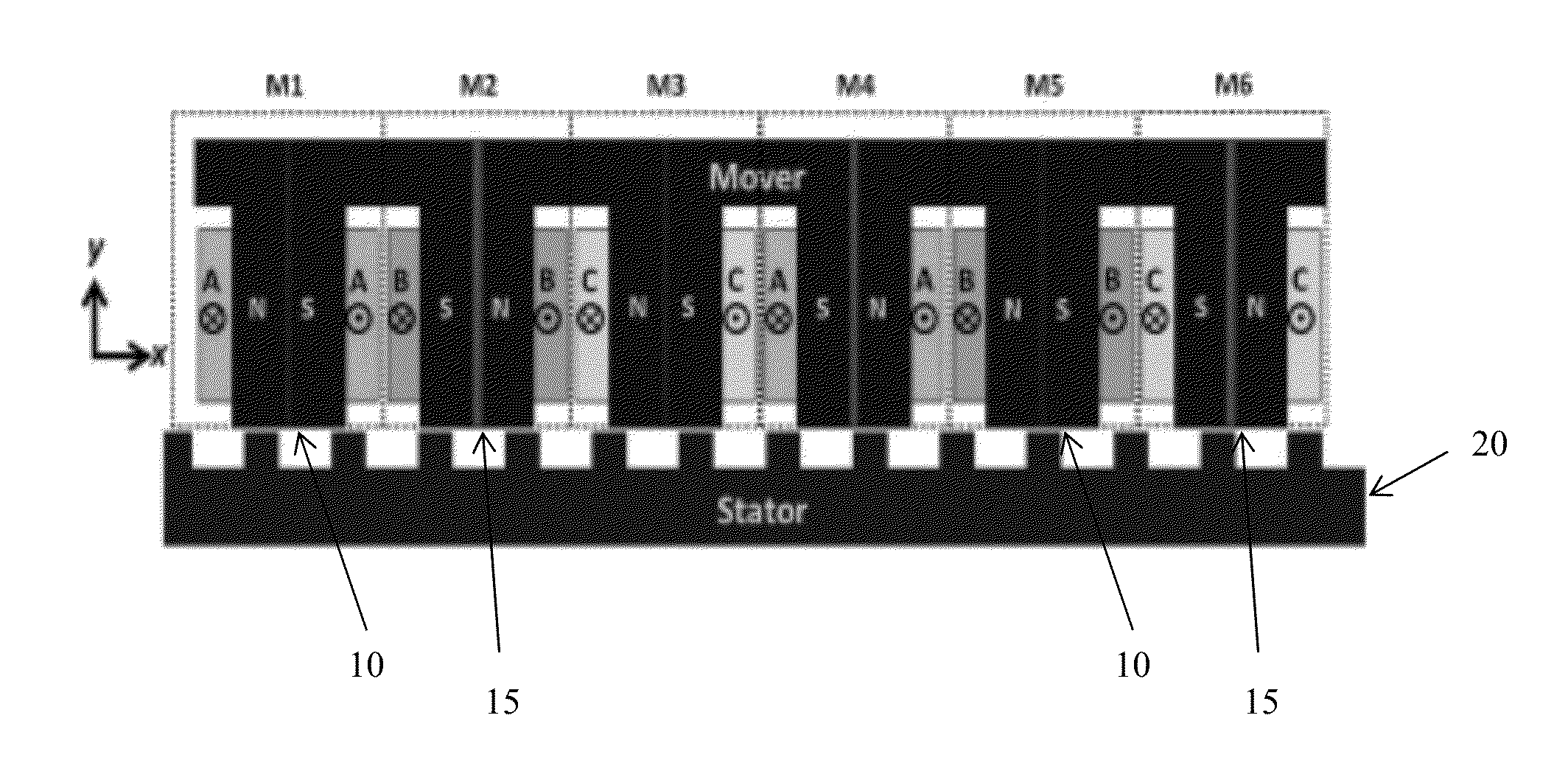

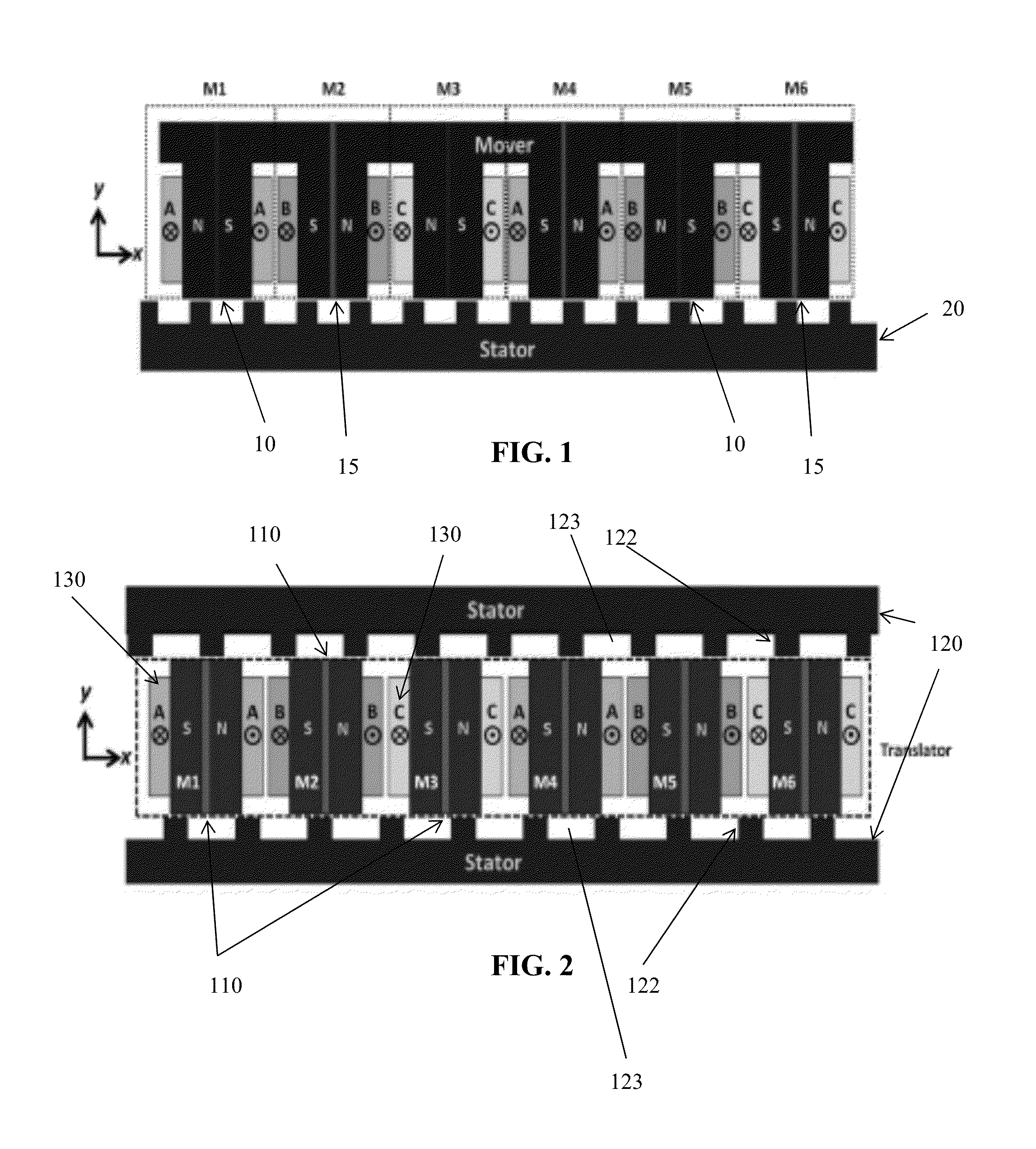

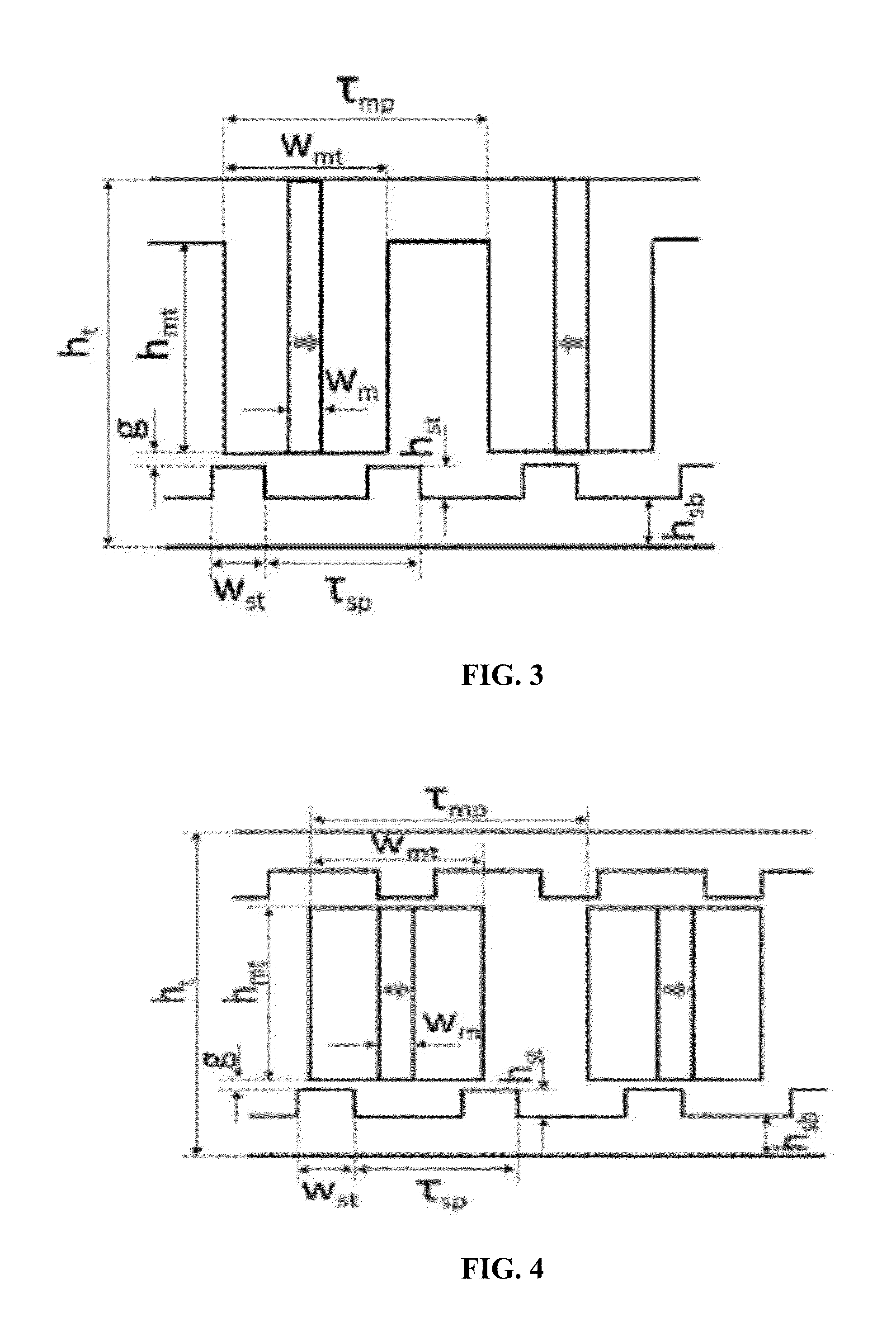

Flux-switching linear permanent magnet machine with yokeless translator

ActiveUS20130249324A1Manufacturing stator/rotor bodiesPropulsion systemsCost effectivenessSynchronous motor

Advantageous motors, such as flux-switching linear synchronous motors (FSLSMs) are provided. In an FSLSM, all magnets can be magnetized in the same direction. In addition, an FSLSM can be yokeless and can have two stators displaced from one another by half a pole pitch. FSLSMs of the subject invention are cost-effective and provide high thrust, and can operate well even under fault conditions.

Owner:RENESSELAER POLYTECHNIC INST

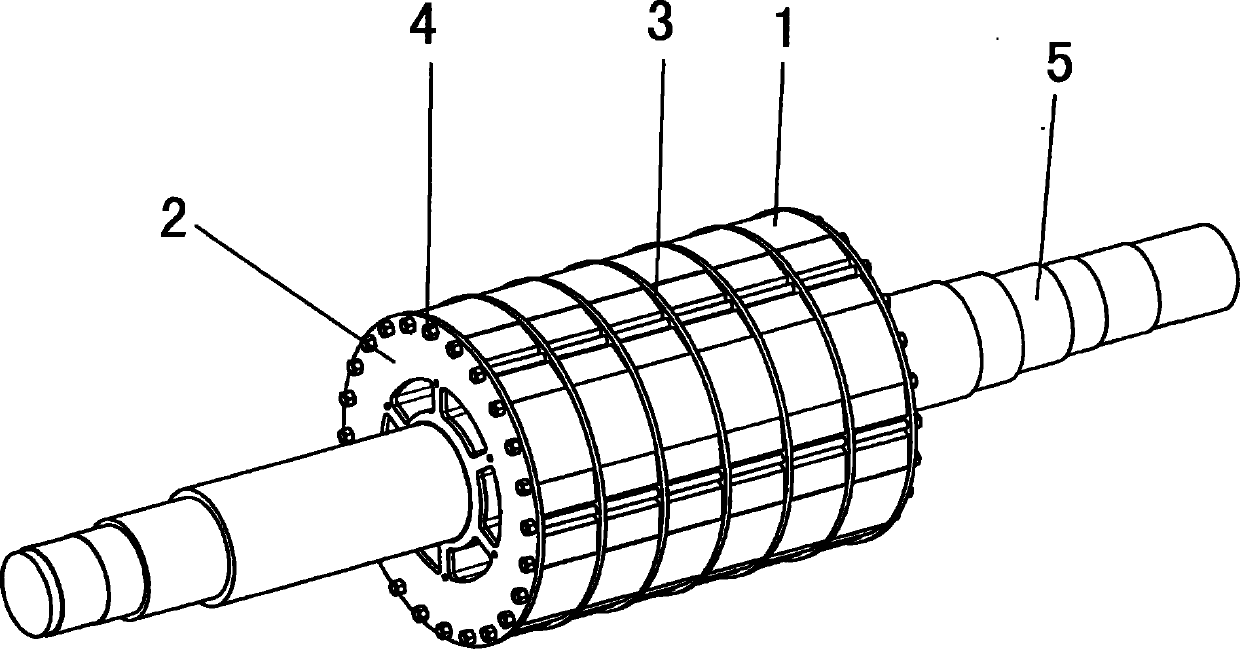

High-power permanent-magnet motor rotor, installation method of rotor and method for magnetizing rotor permanent magnet

ActiveCN102005838AEasy to producePlay a supporting roleMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet motorMagnetic isolation

Owner:东元总合科技(杭州)有限公司

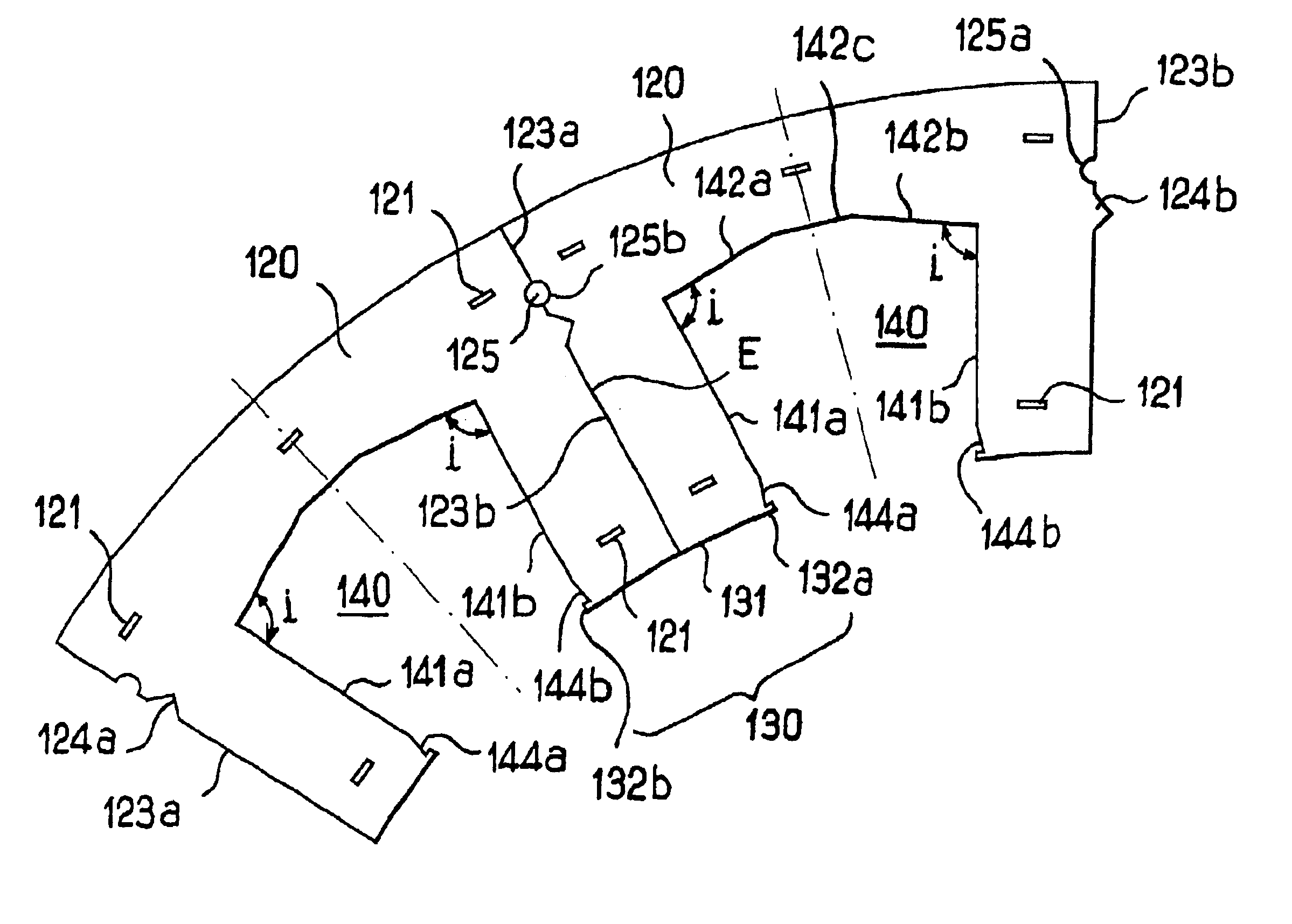

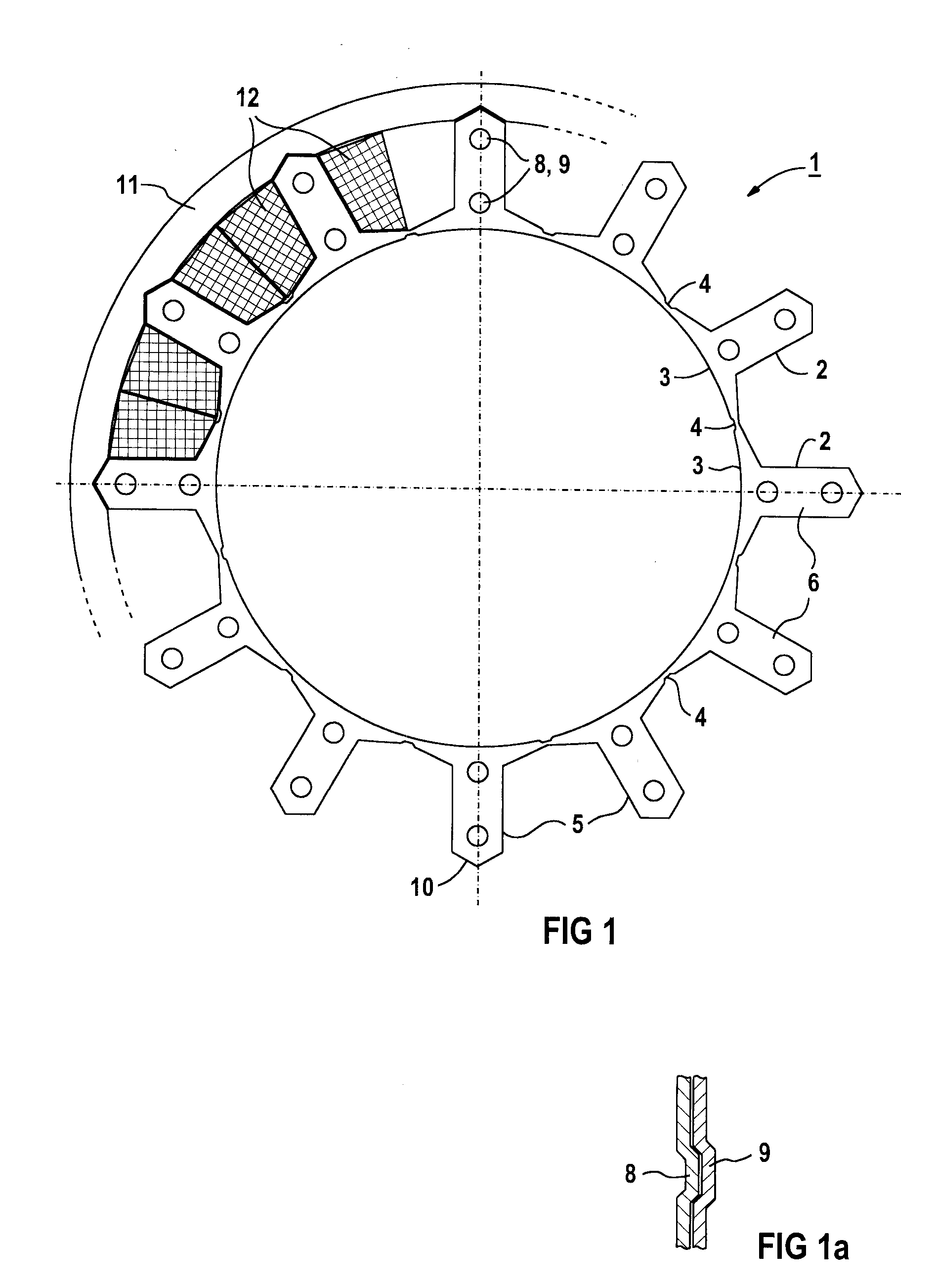

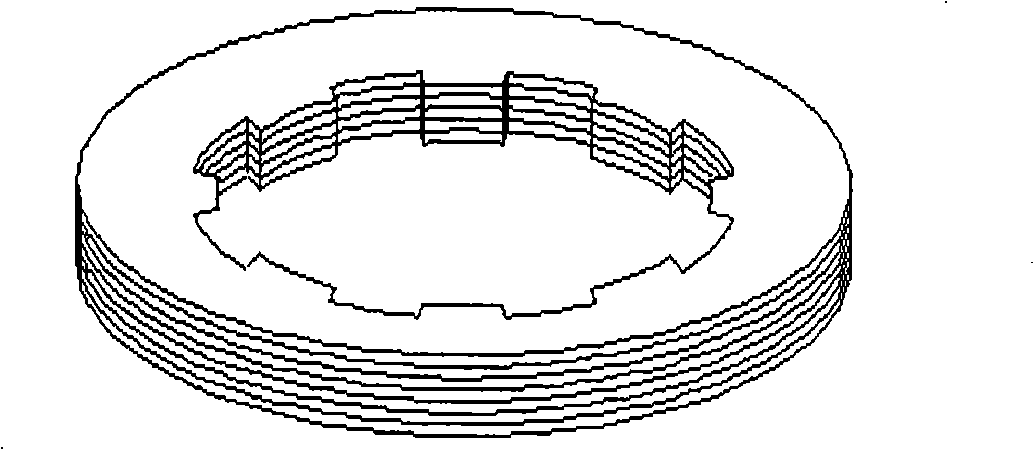

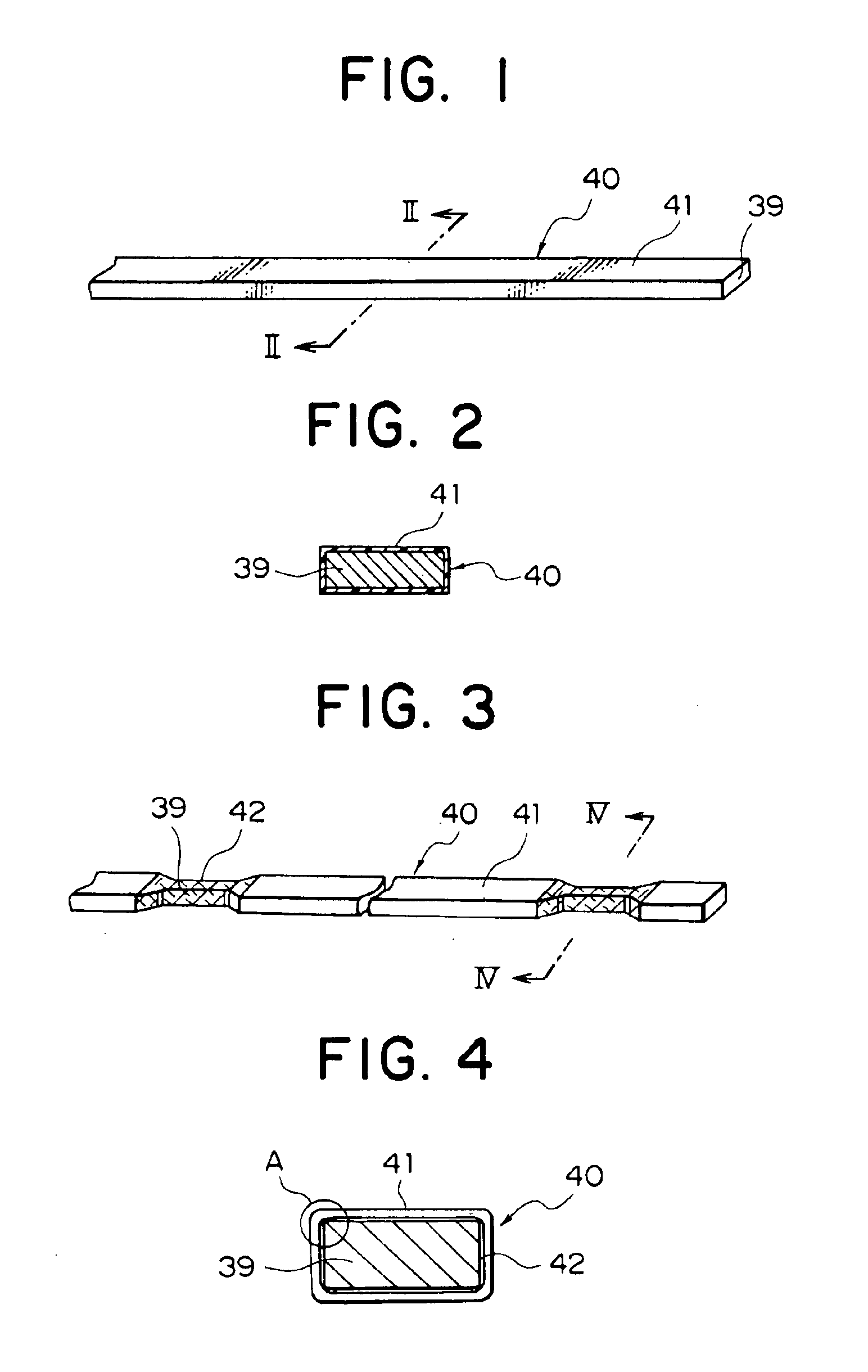

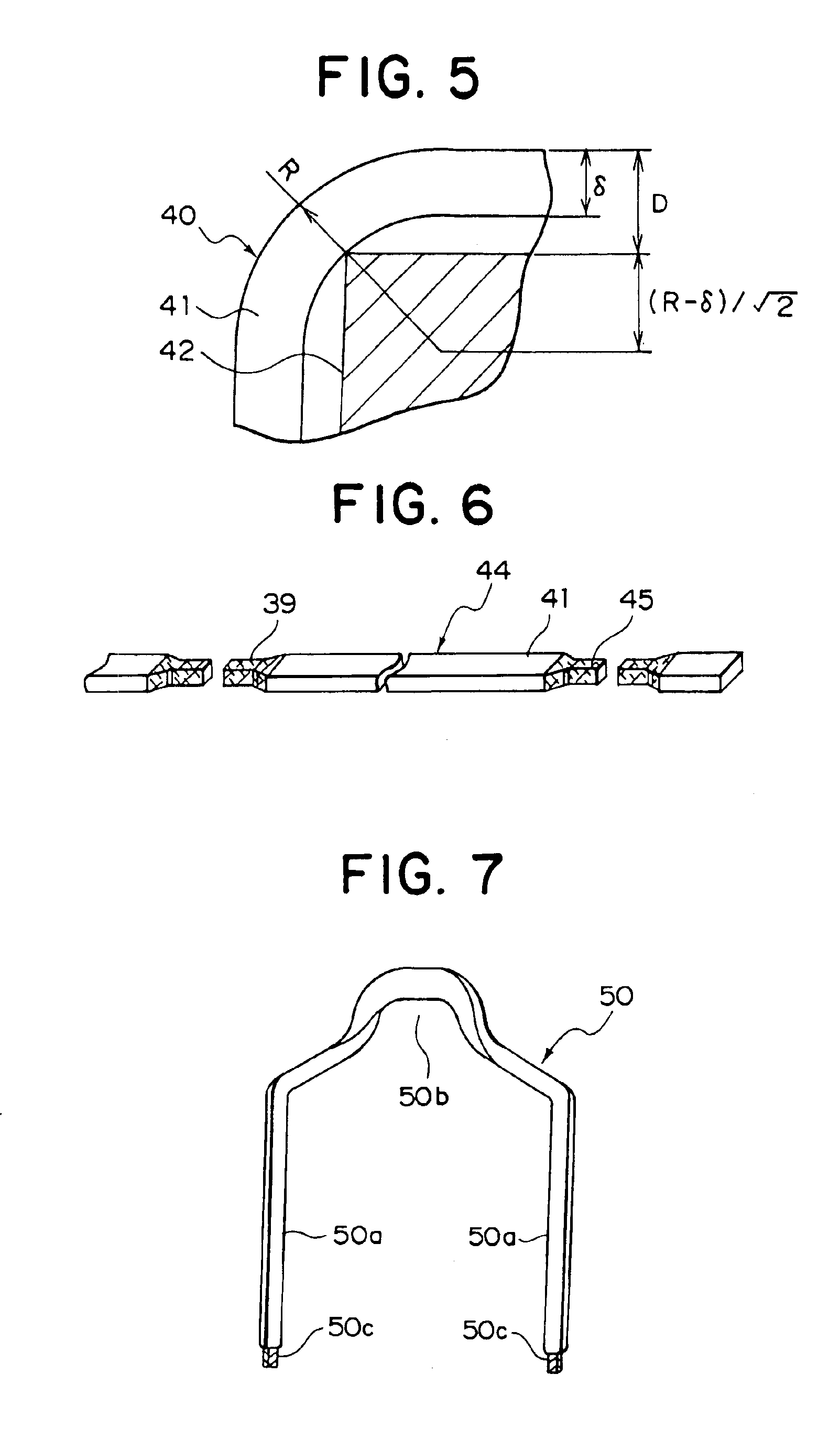

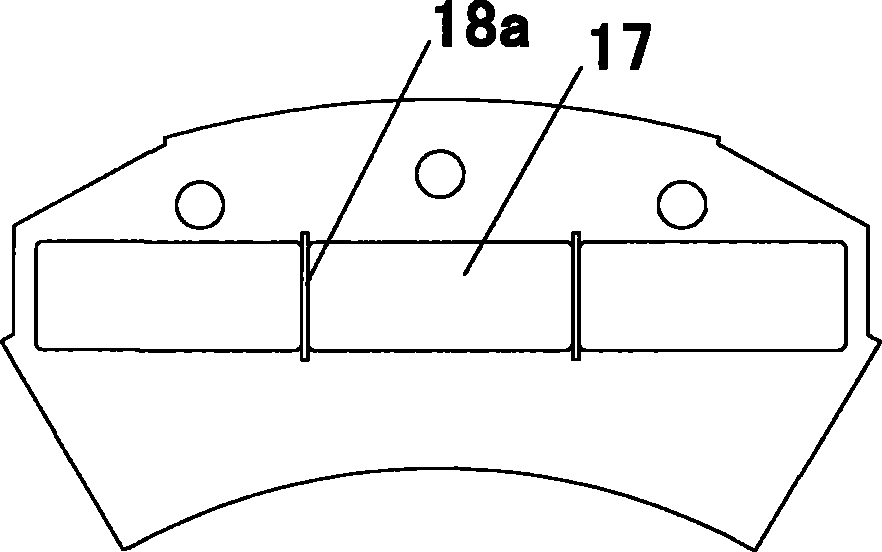

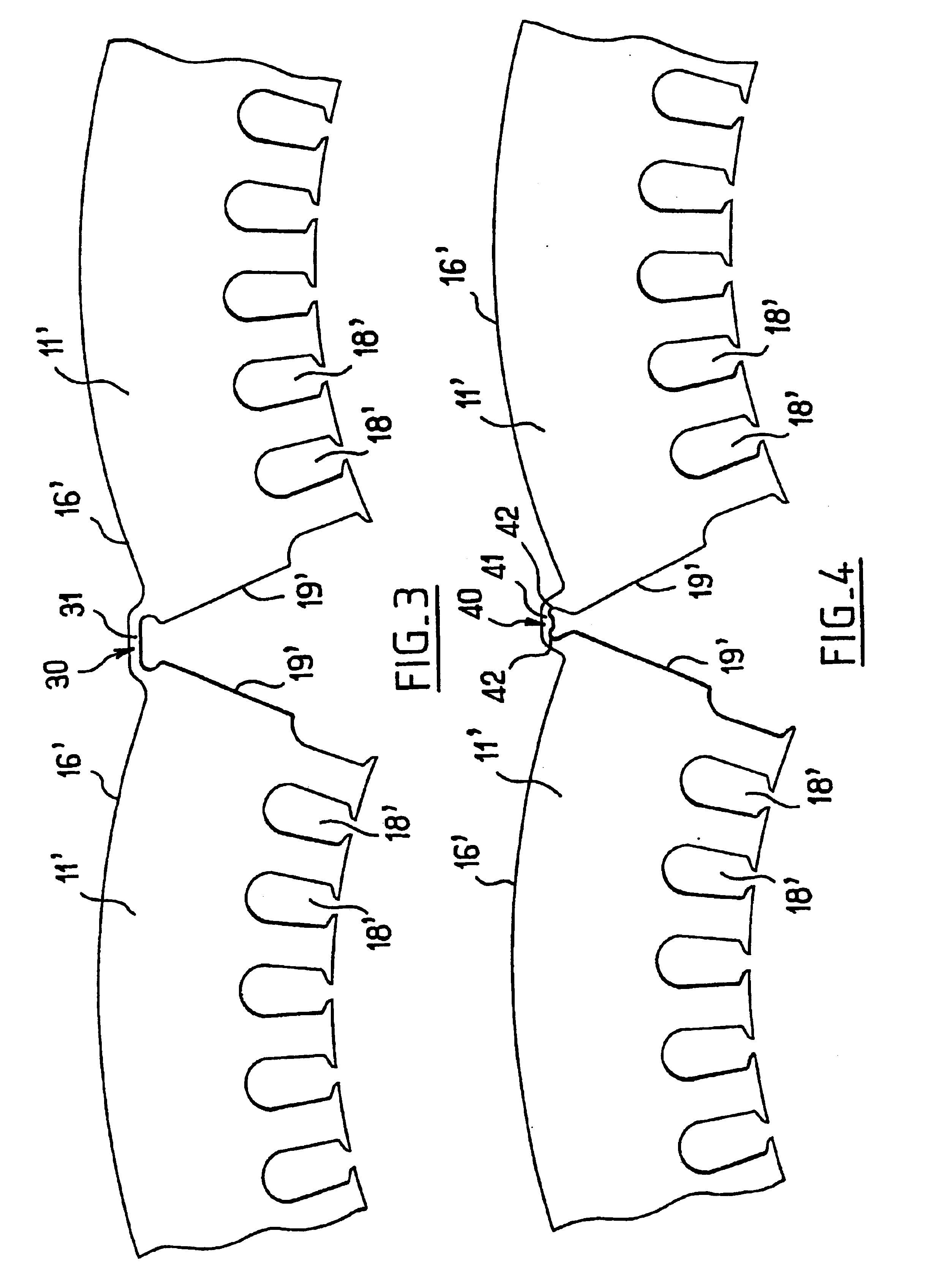

Strip of lamination sectors and a method of manufacturing a magnetic circuit for an electrical machine

InactiveUS6741005B2Smooth connectionAvoid breakingMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringElectrical and Electronics engineering

The invention relates to a strip of lamination sectors for making a magnetic circuit of an electrical machine, the sectors are interconnected by links, and the strip is for winding on a mandrel to form a stack of layers of sectors. Said links lie outside the sectors.

Owner:MOTEURS LEROY SOMER

Electric motor assembly with stator mounted in vehicle powertrain housing and method

ActiveUS20090212649A1Avoid relative motionMagnetic circuit stationary partsManufacturing stator/rotor bodiesIn vehicleEngineering

An electric motor assembly in a vehicle powertrain is provided with a generally annular stator fit within an interior cavity of the powertrain defined by a housing. Roll pins are fit between the housing and the stator. The stator may have a plurality of first geometric features and the housing a plurality of second geometric features. The first geometric features are be configured to align with the second geometric features when the stator is fit within the cavity, with the roll pins fit between the housing and the stator at the aligned first and second geometric features. A method of assembling the electric motor assembly is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com