Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261results about "Slip-rings manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

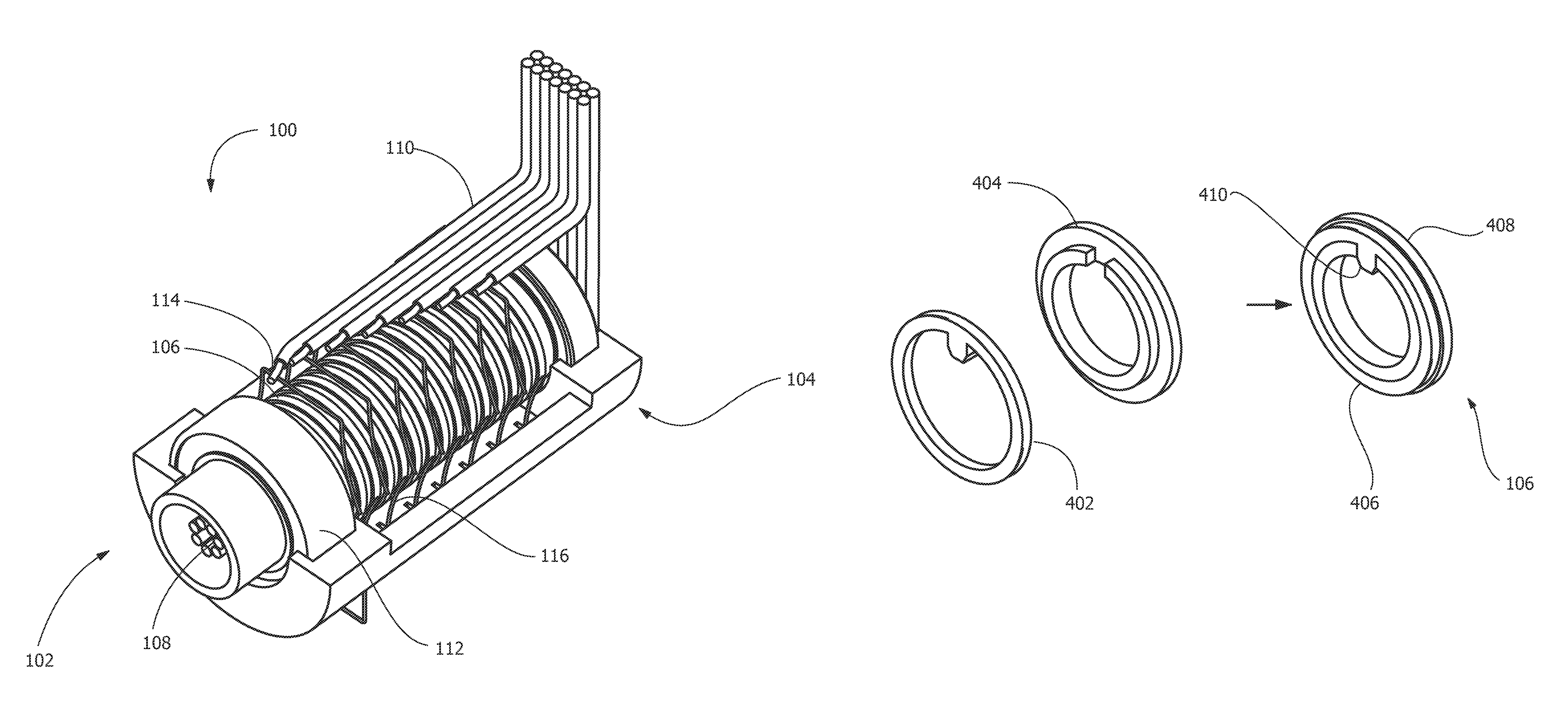

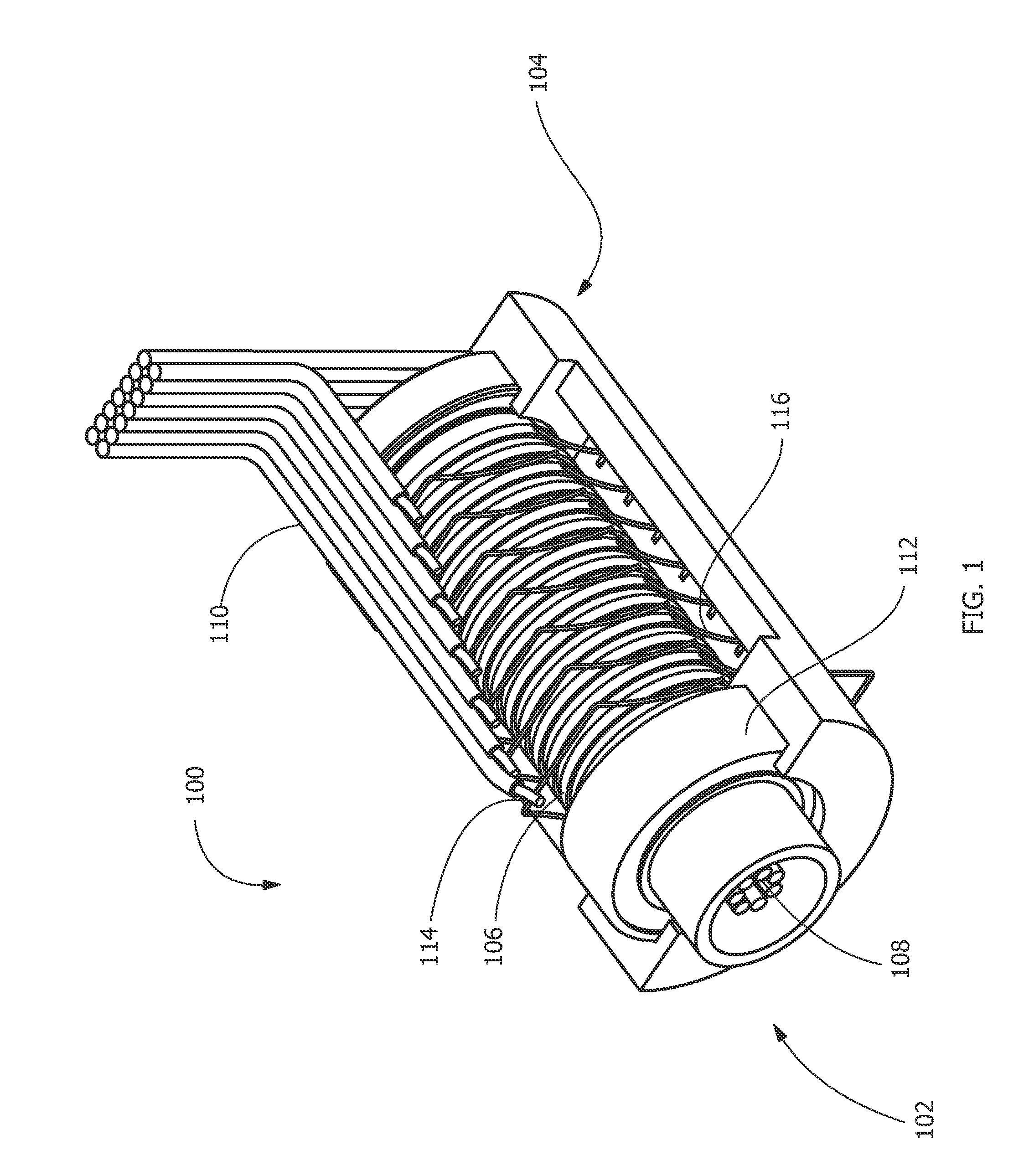

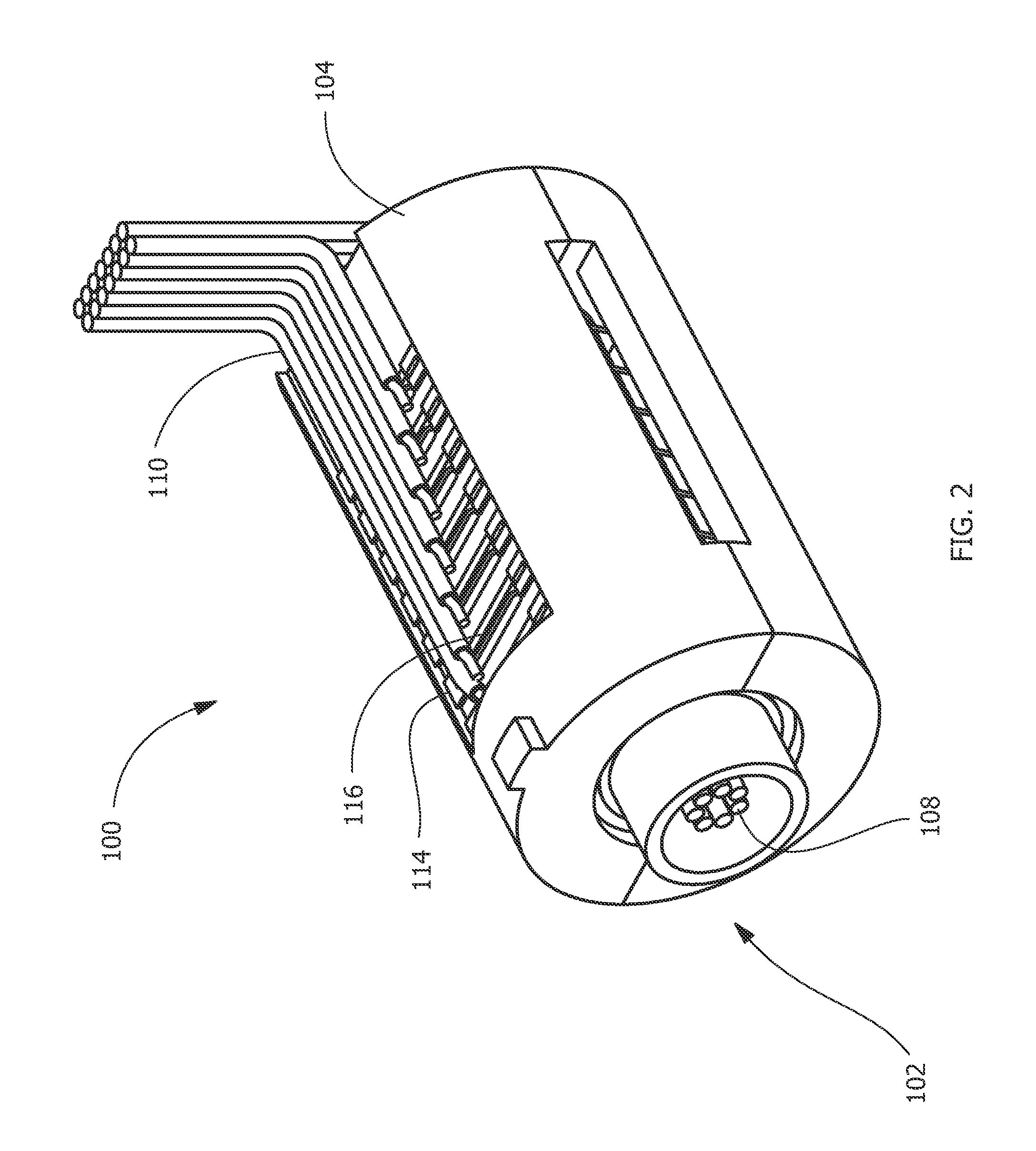

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

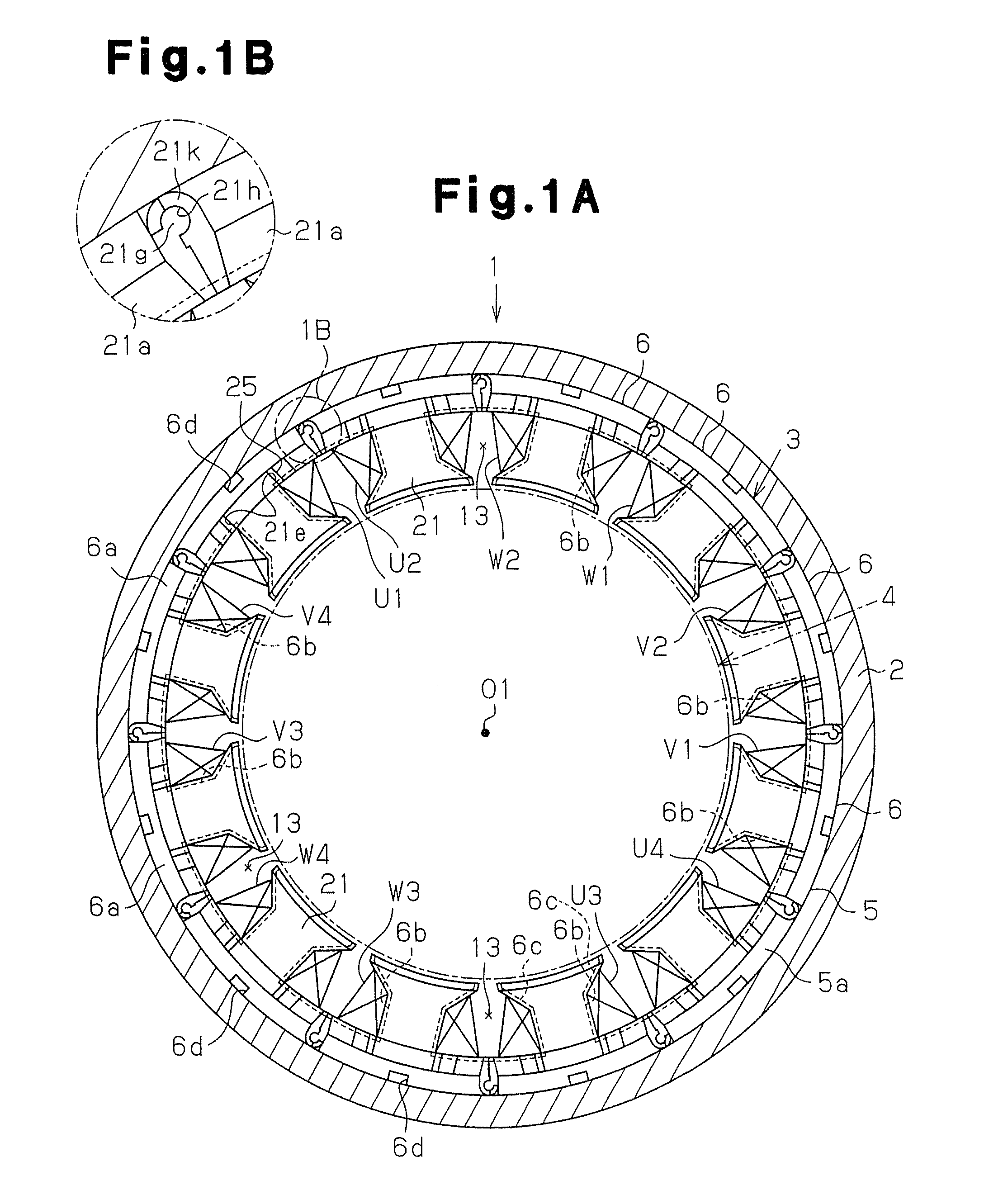

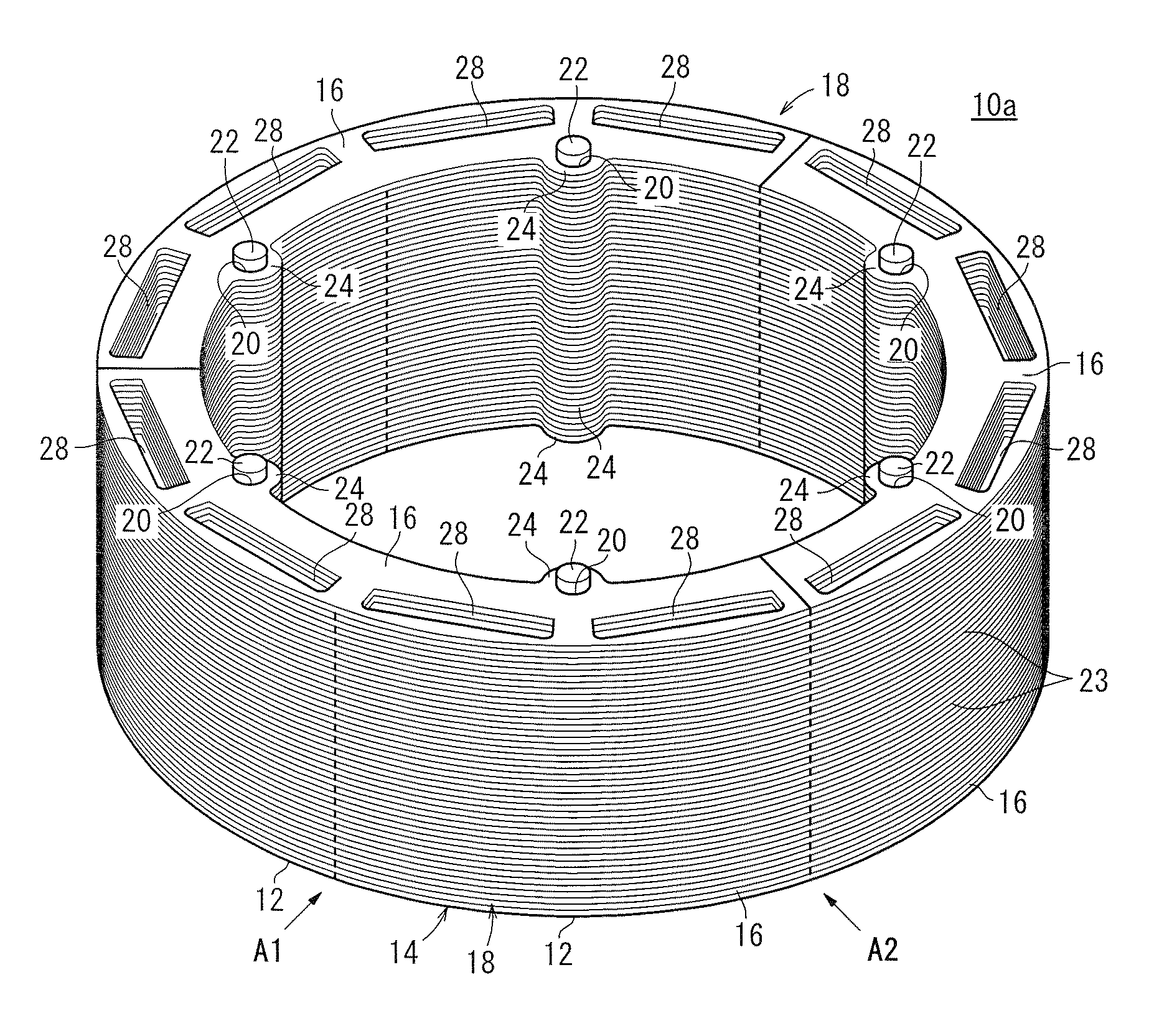

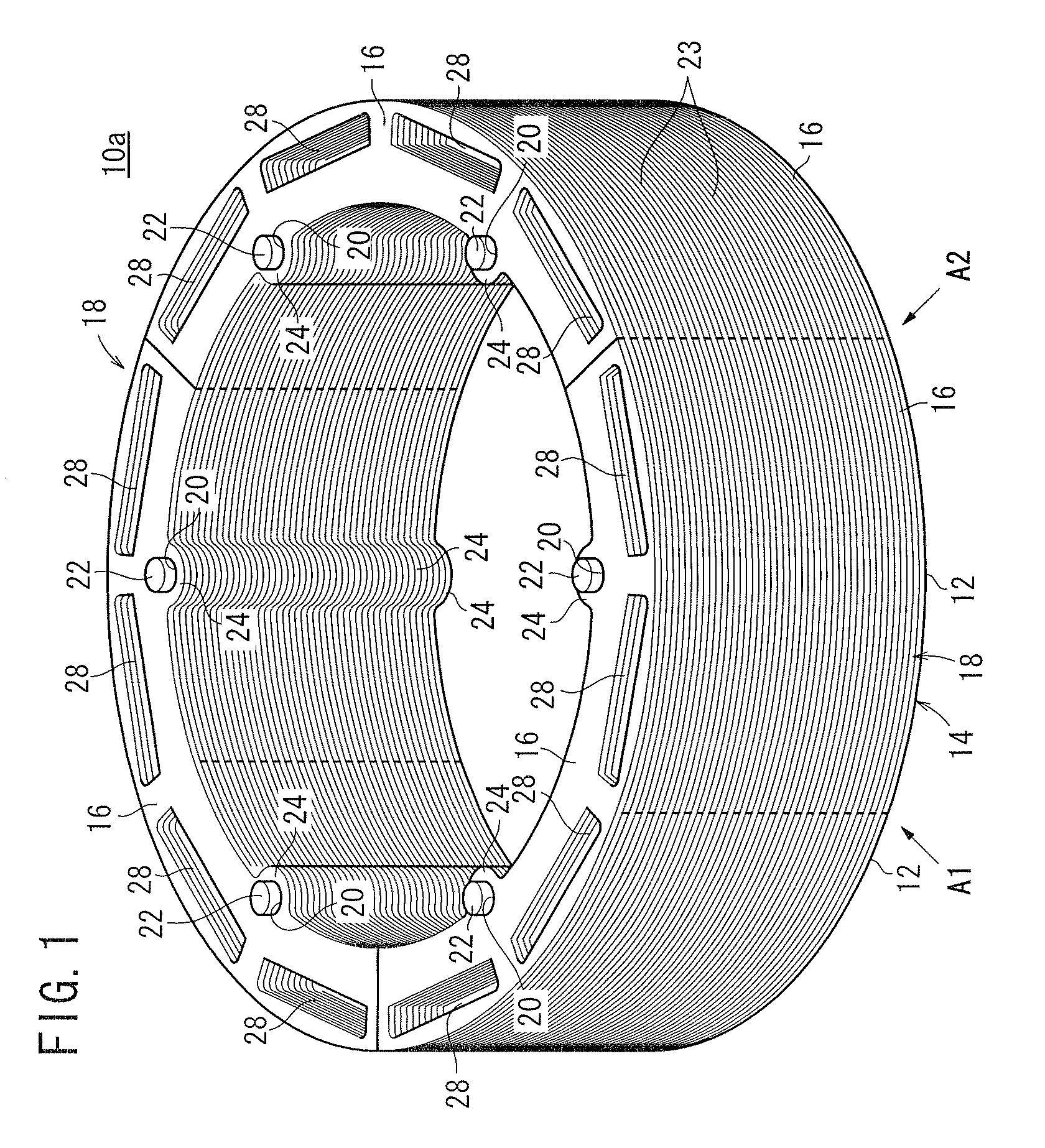

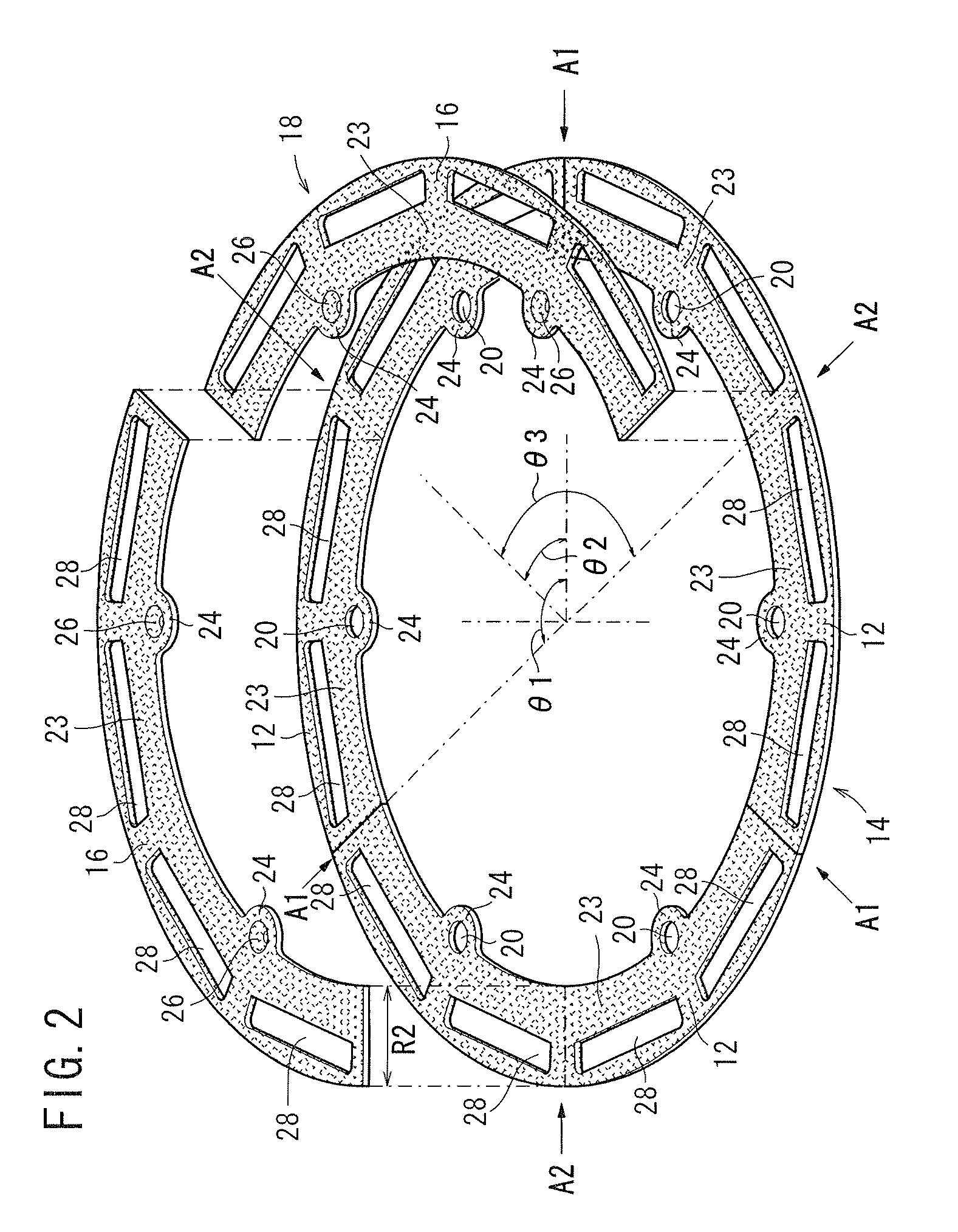

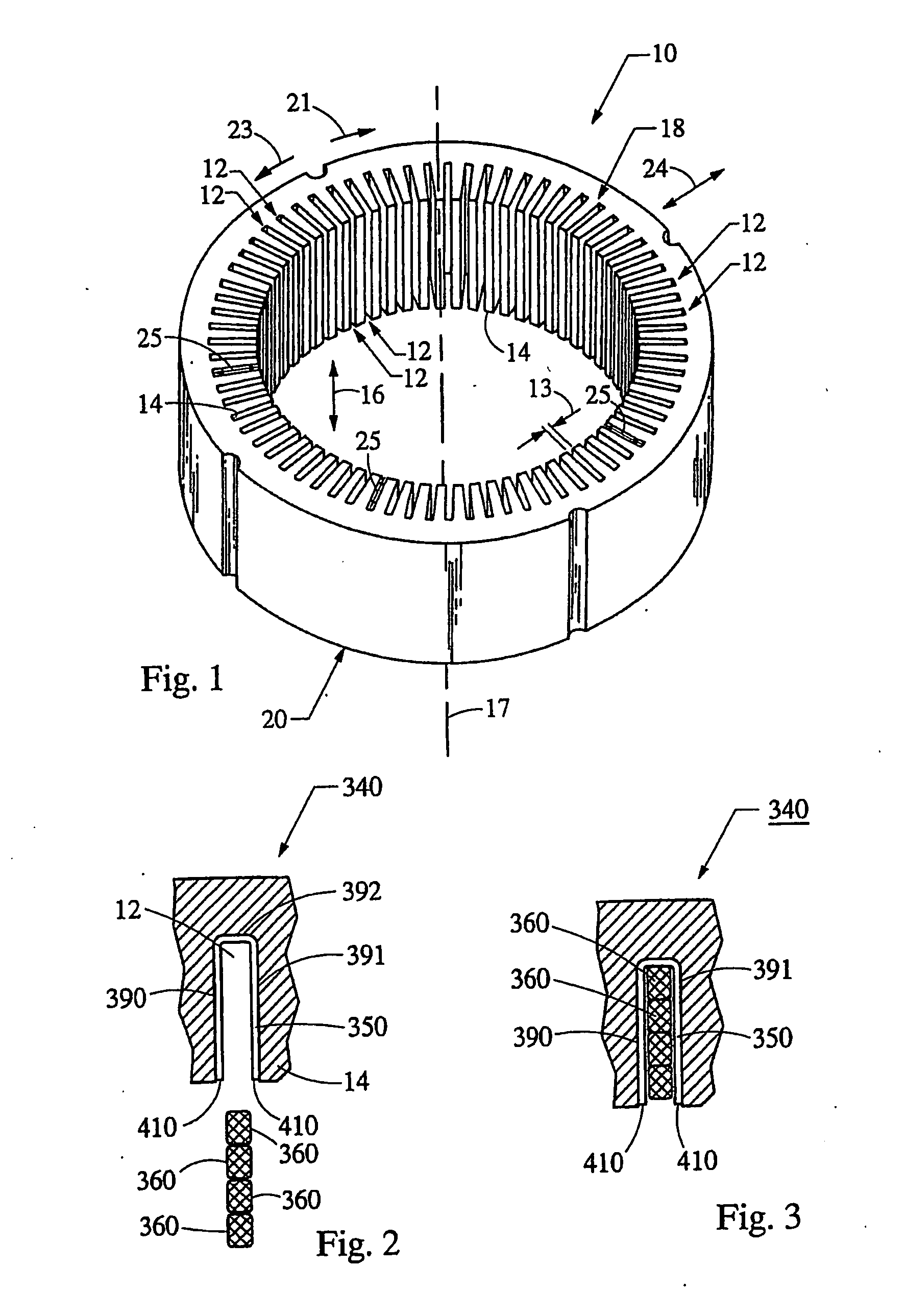

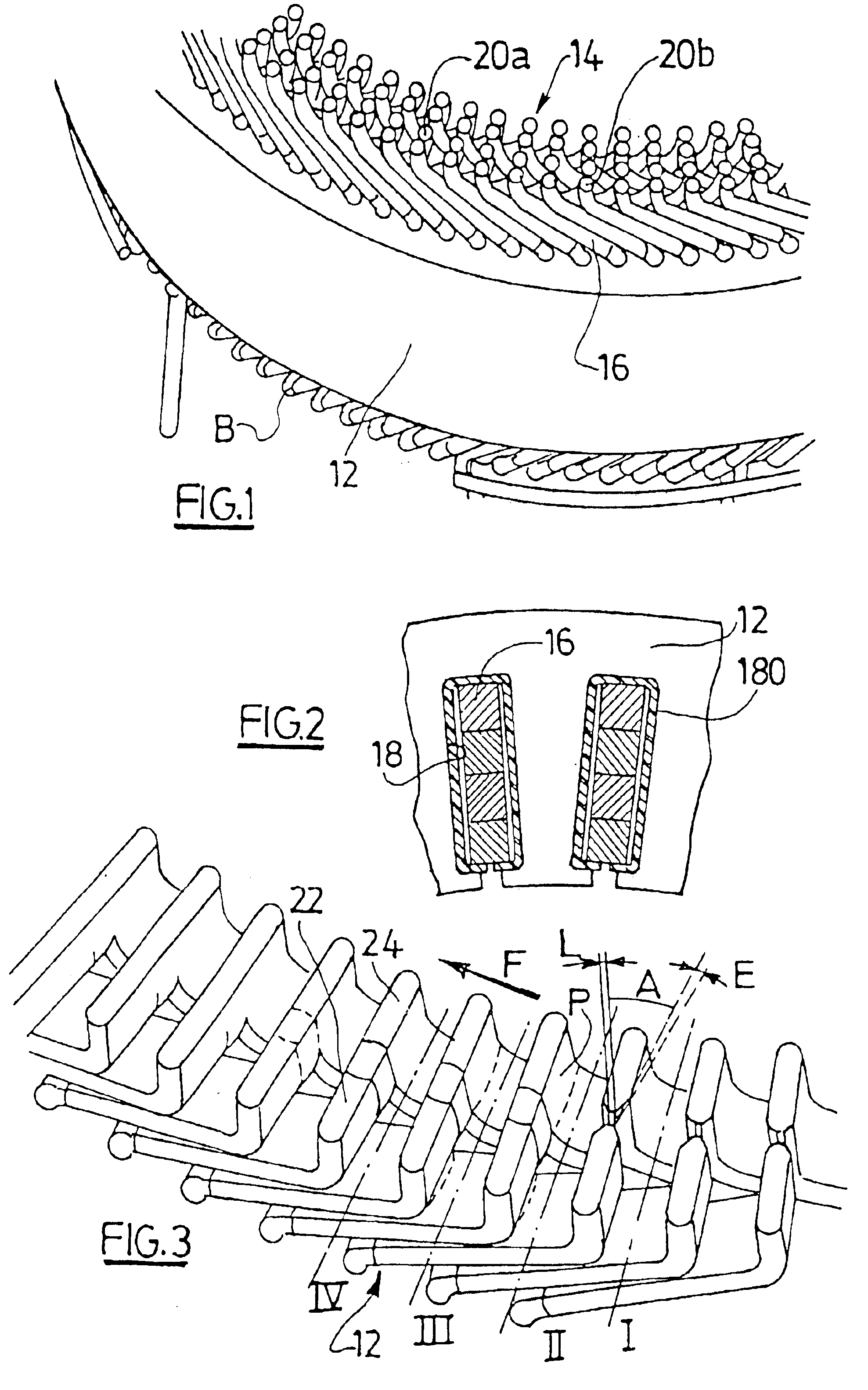

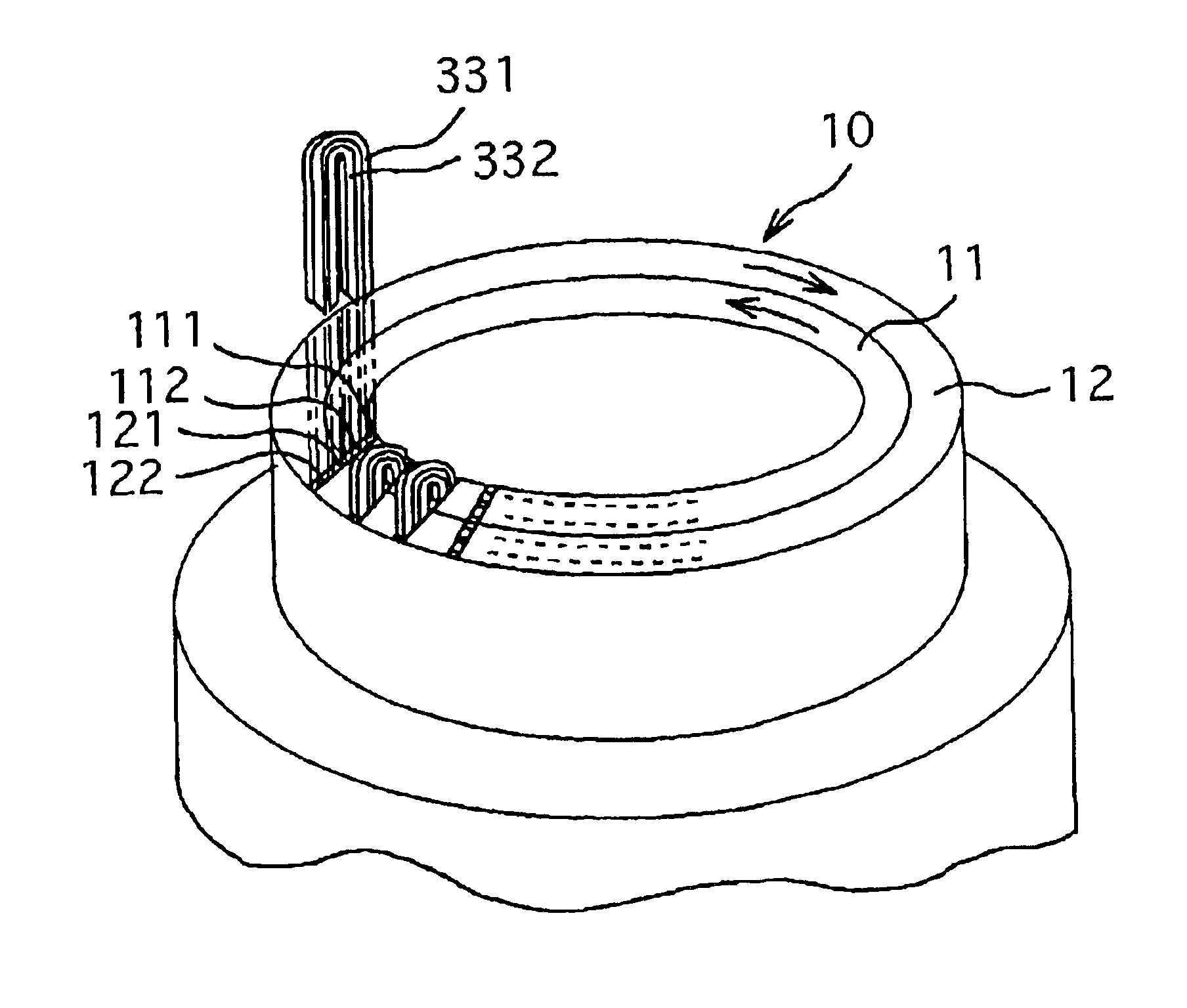

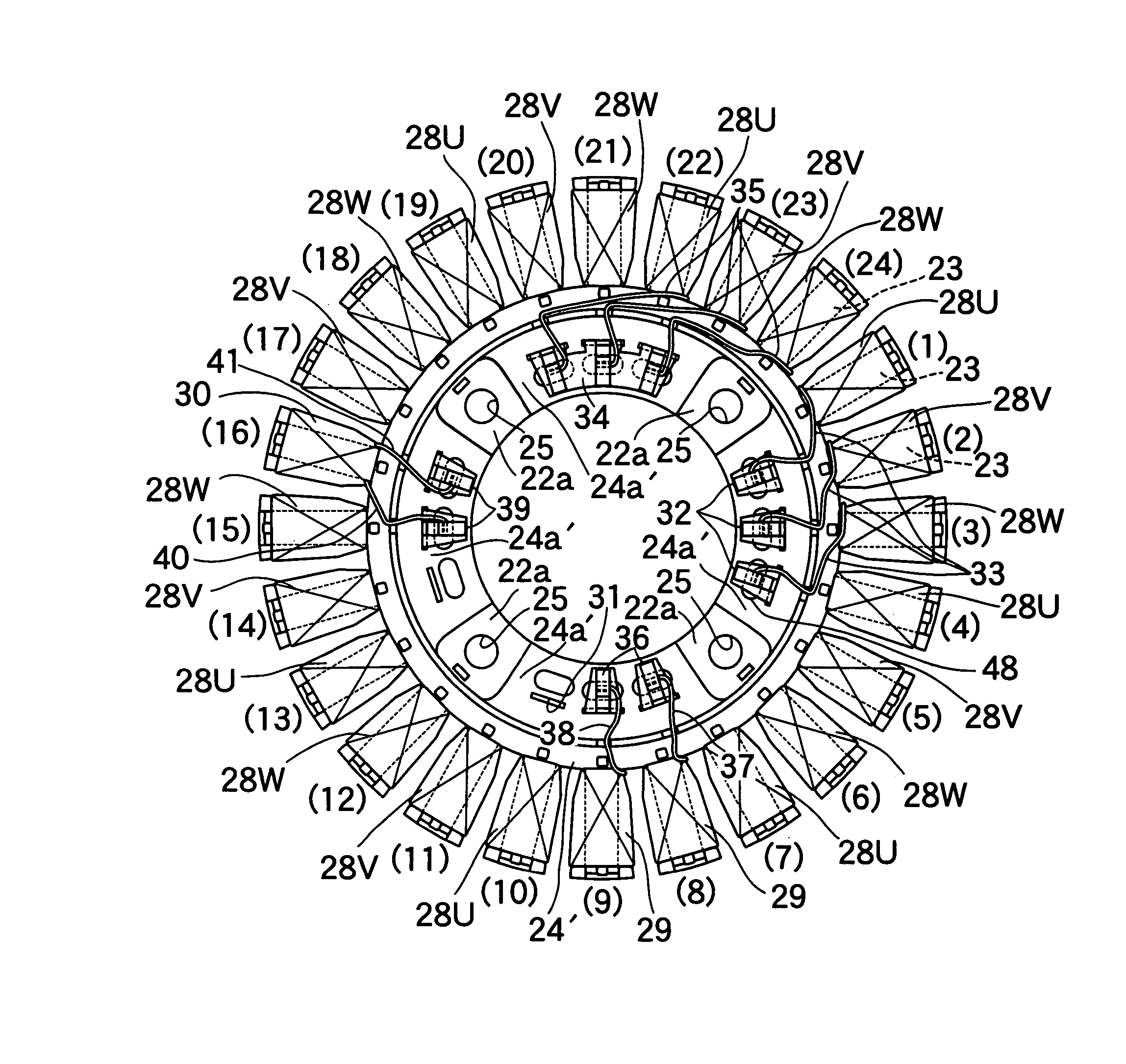

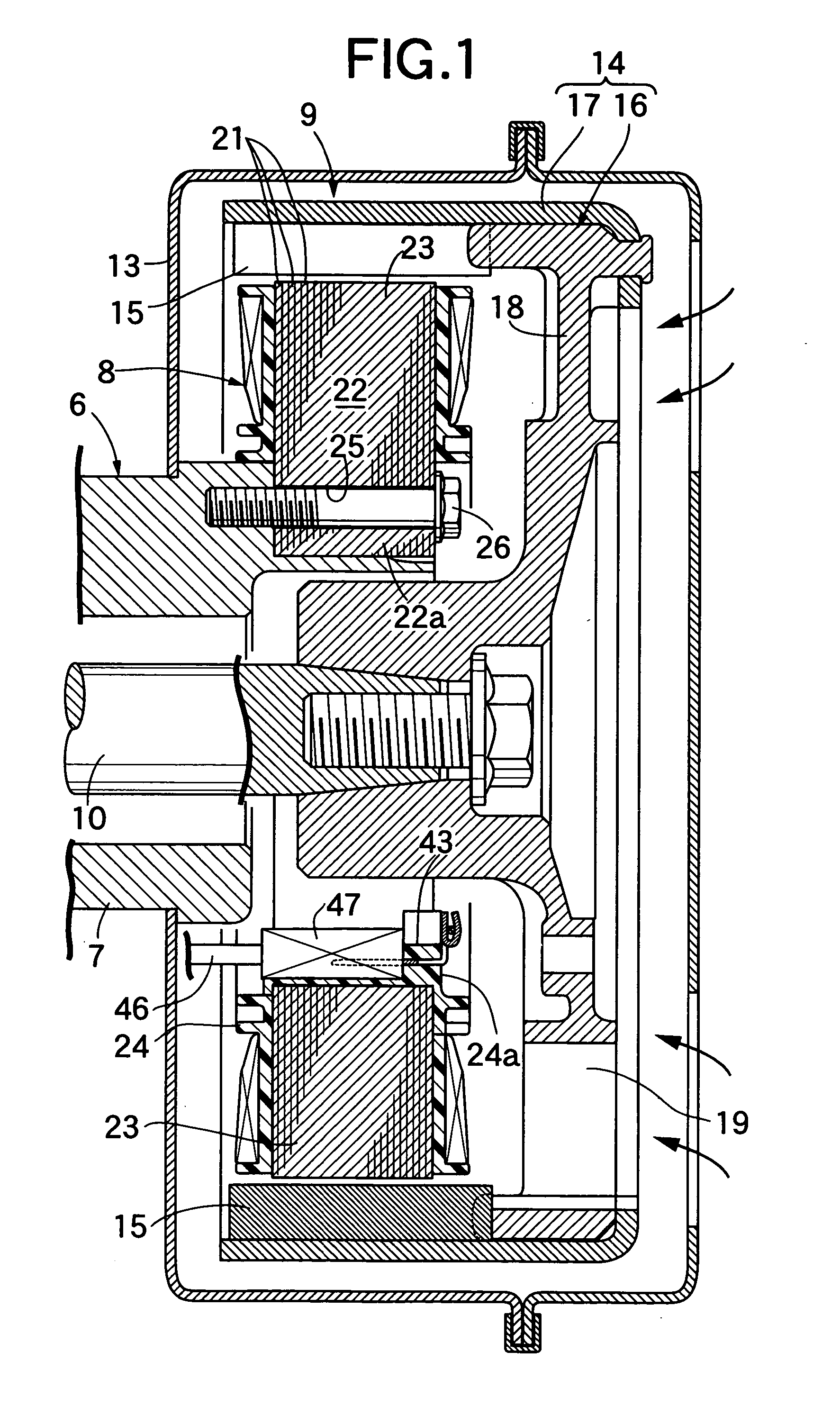

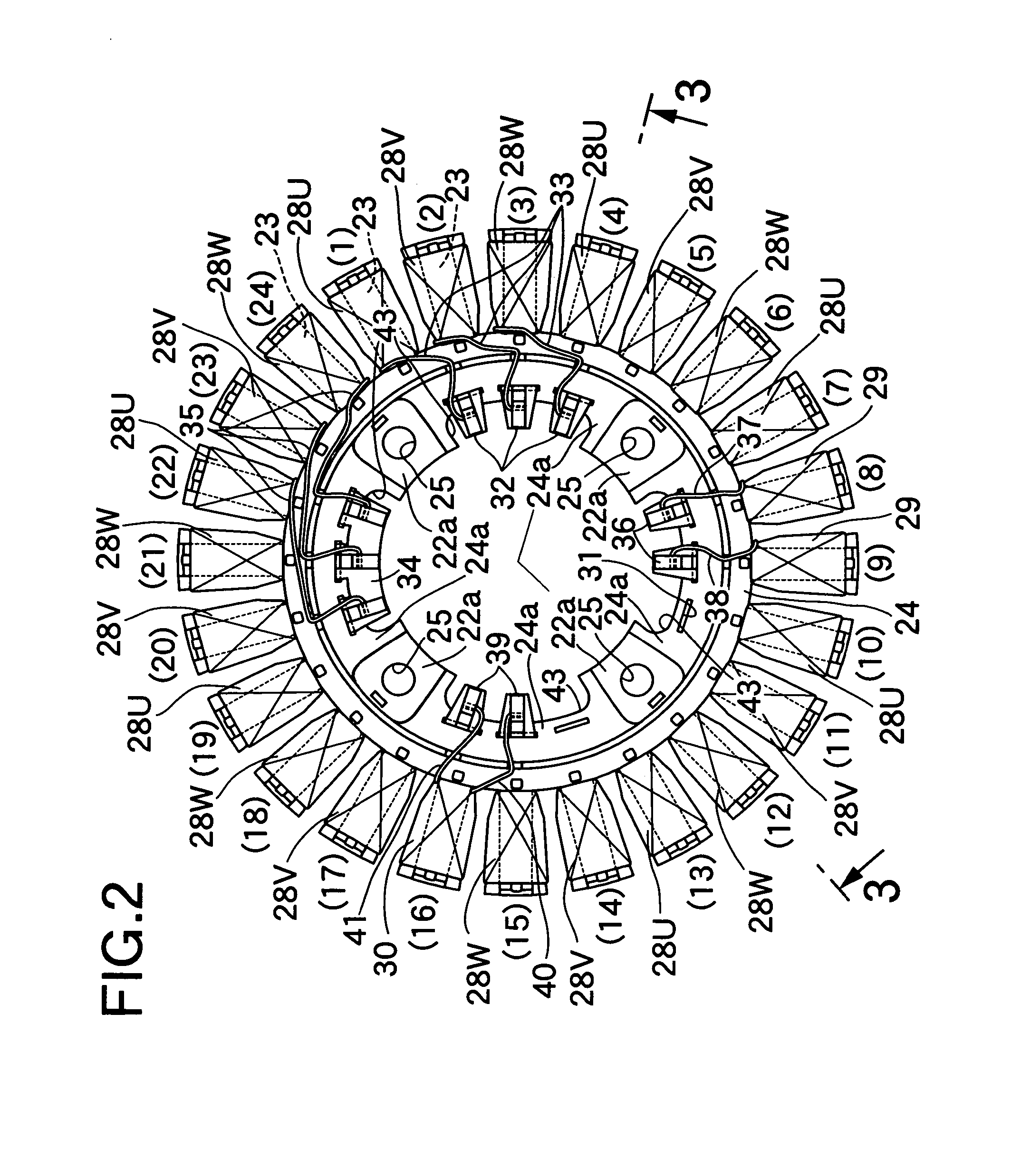

Manufacturing method of stator, and stator

ActiveUS20070182271A1Easy windingReduce connecting wiresSynchronous generatorsMagnetic circuit rotating partsState spaceEngineering

In a state in which a first divisional core and a second divisional core are arranged in a state spaced from each other and adjacent to each other, a first coil and a second coil are each wound around a tooth. The first coil and the second coil are in the same phase. In a state in which a plurality of divisional cores are arranged annularly so that their teeth are oriented in a radially inward direction, the first divisional core and the second divisional core are not adjacent to each other in the circumferential direction. A plurality of connection wires are shaped to converge at an end surface of a stator core. This facilitates the winding of the coils around the divisional cores. Further, the connection wires can be shortened.

Owner:DENSO CORP

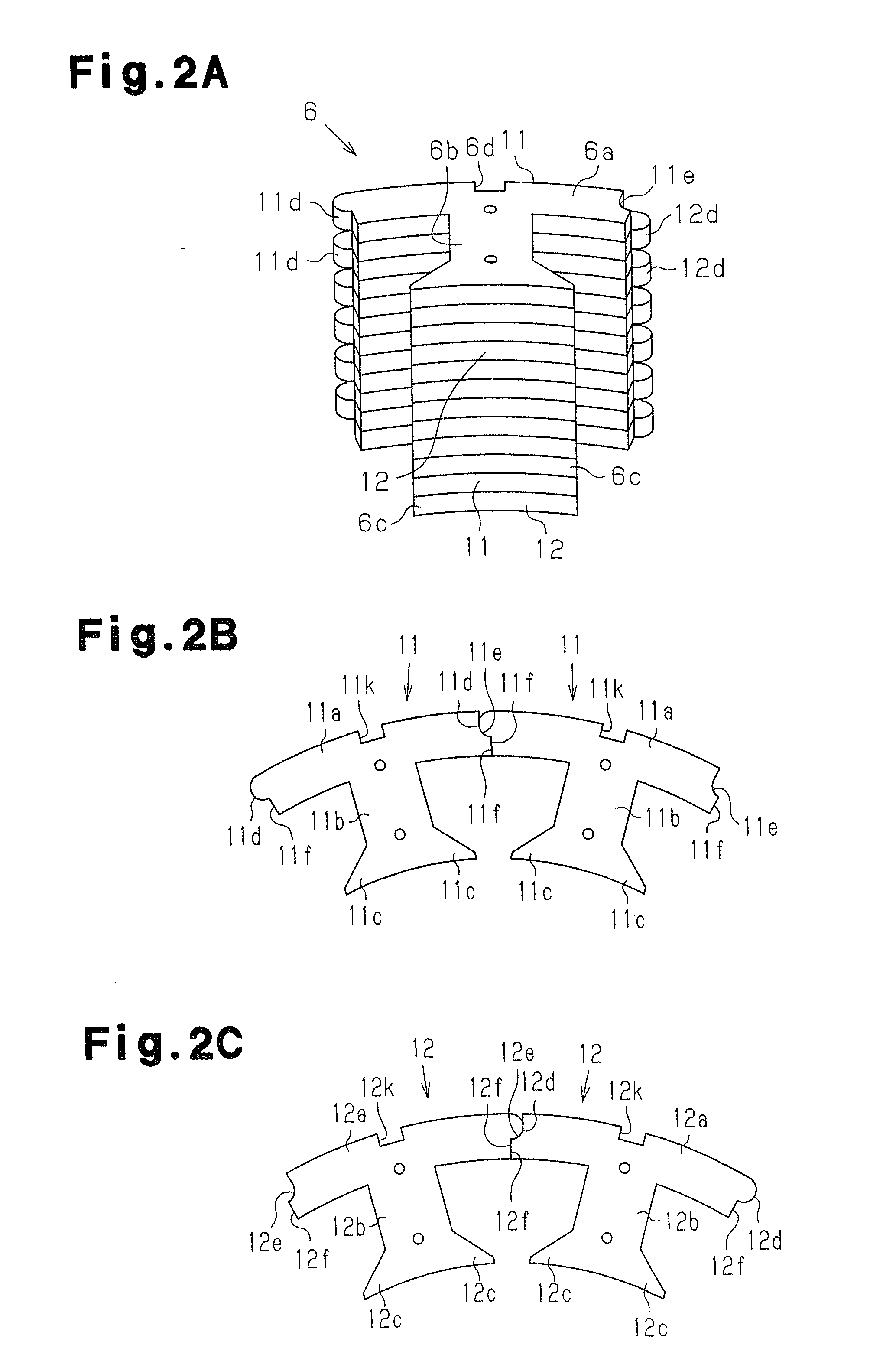

Method of making a composite electric machine component of a desired magnetic pattern

InactiveUS6889419B2More powerLow costManufacturing stator/rotor bodiesApplying solid insulationElectric machineNon magnetic

A method of making composite electric machine components. Magnetic segments and non-magnetic segments are separately formed to green strength, and then arranged adjacent to each other in a desired magnetic pattern. A small amount of powder material is added in-between the segments, and the whole assembly is then sintered to form a sinterbonded composite component of high structural integrity.

Owner:DELPHI TECH INC

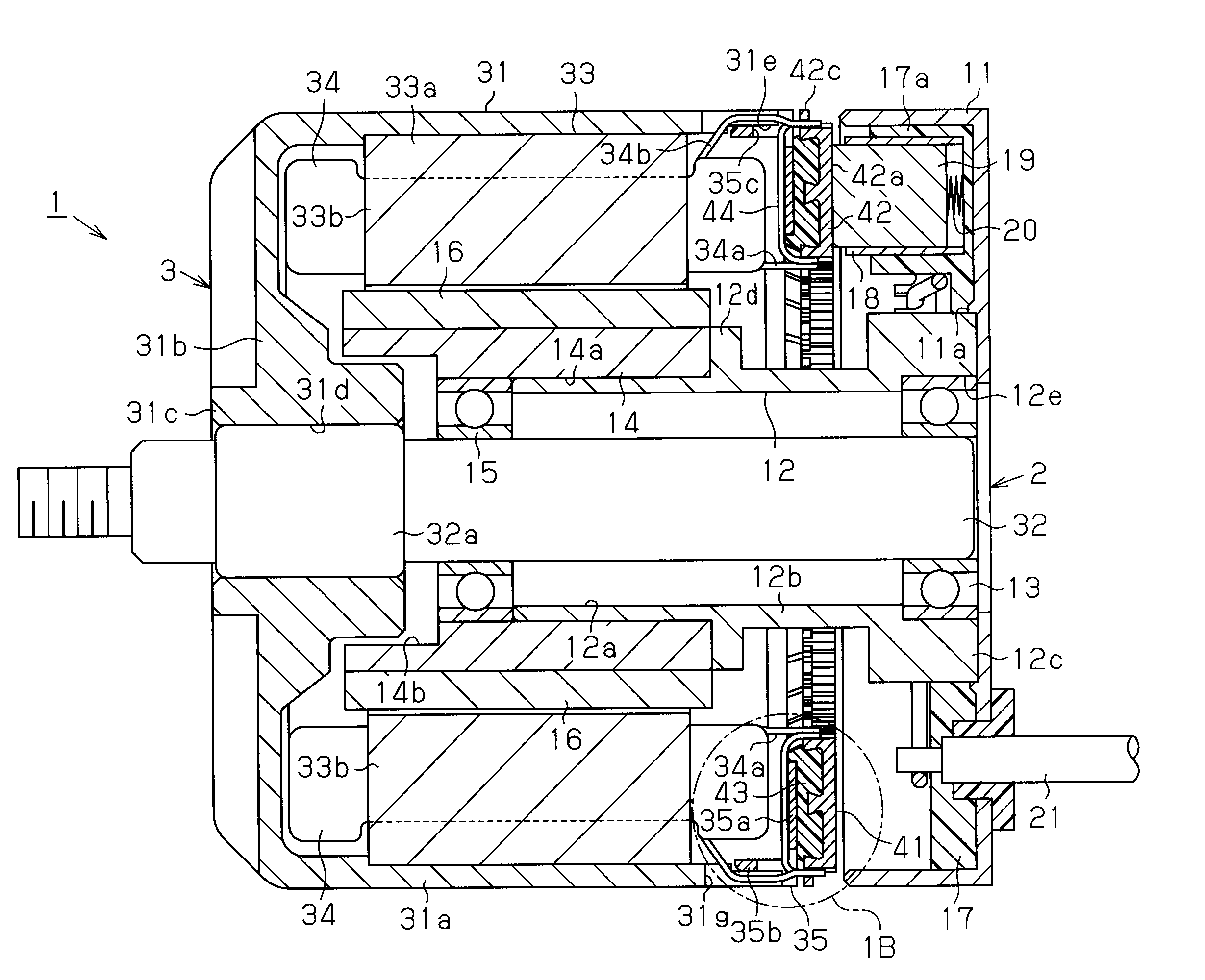

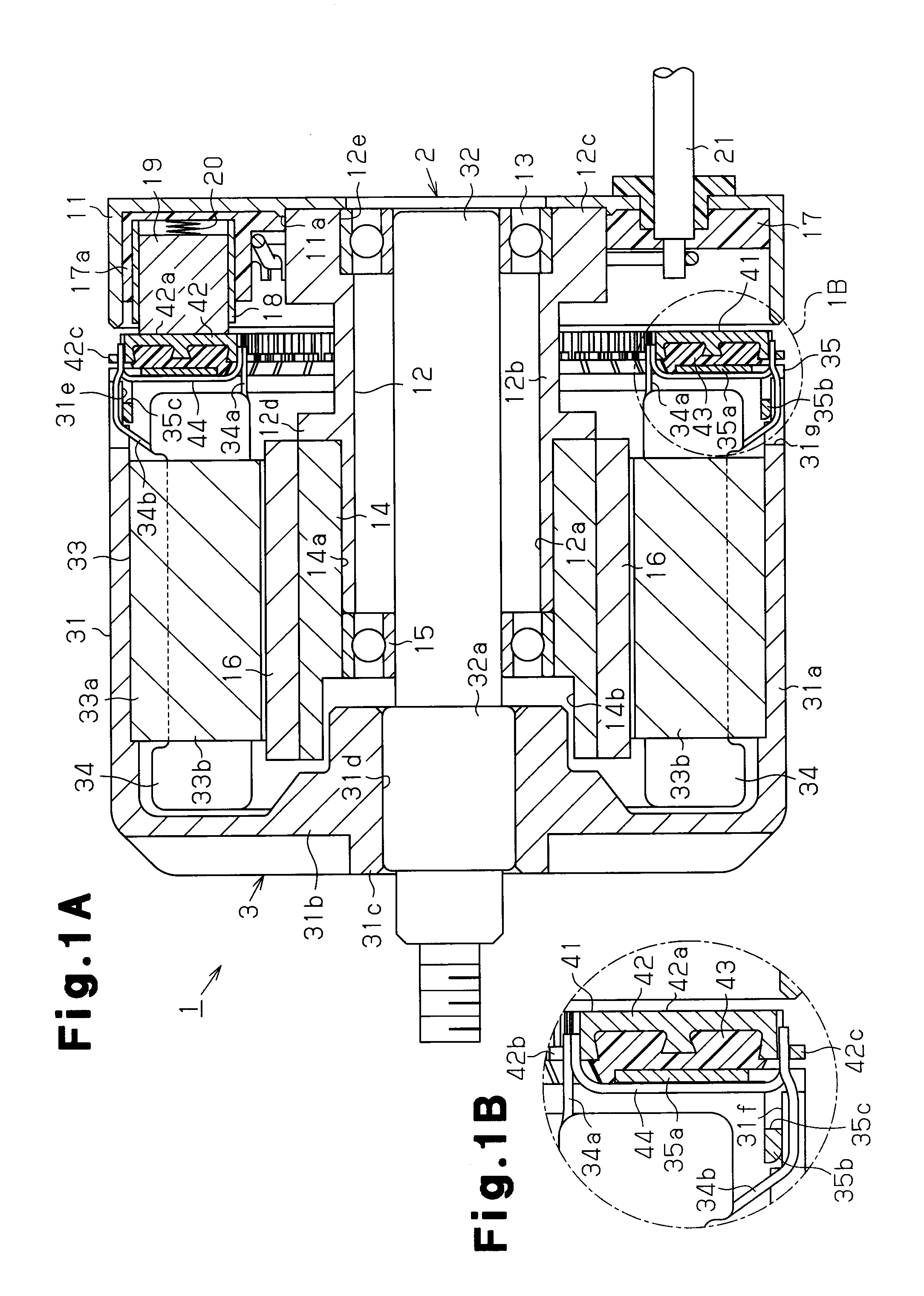

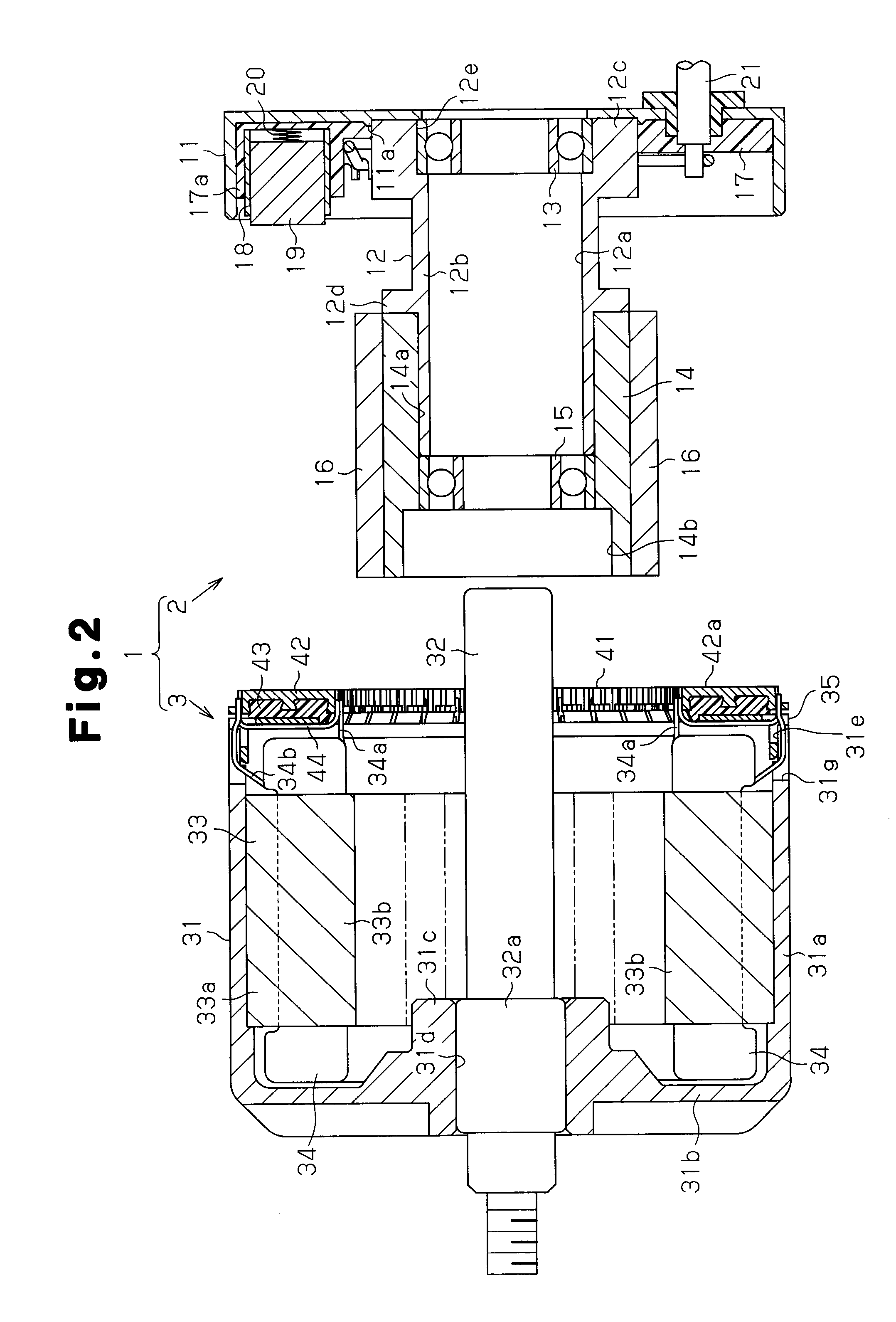

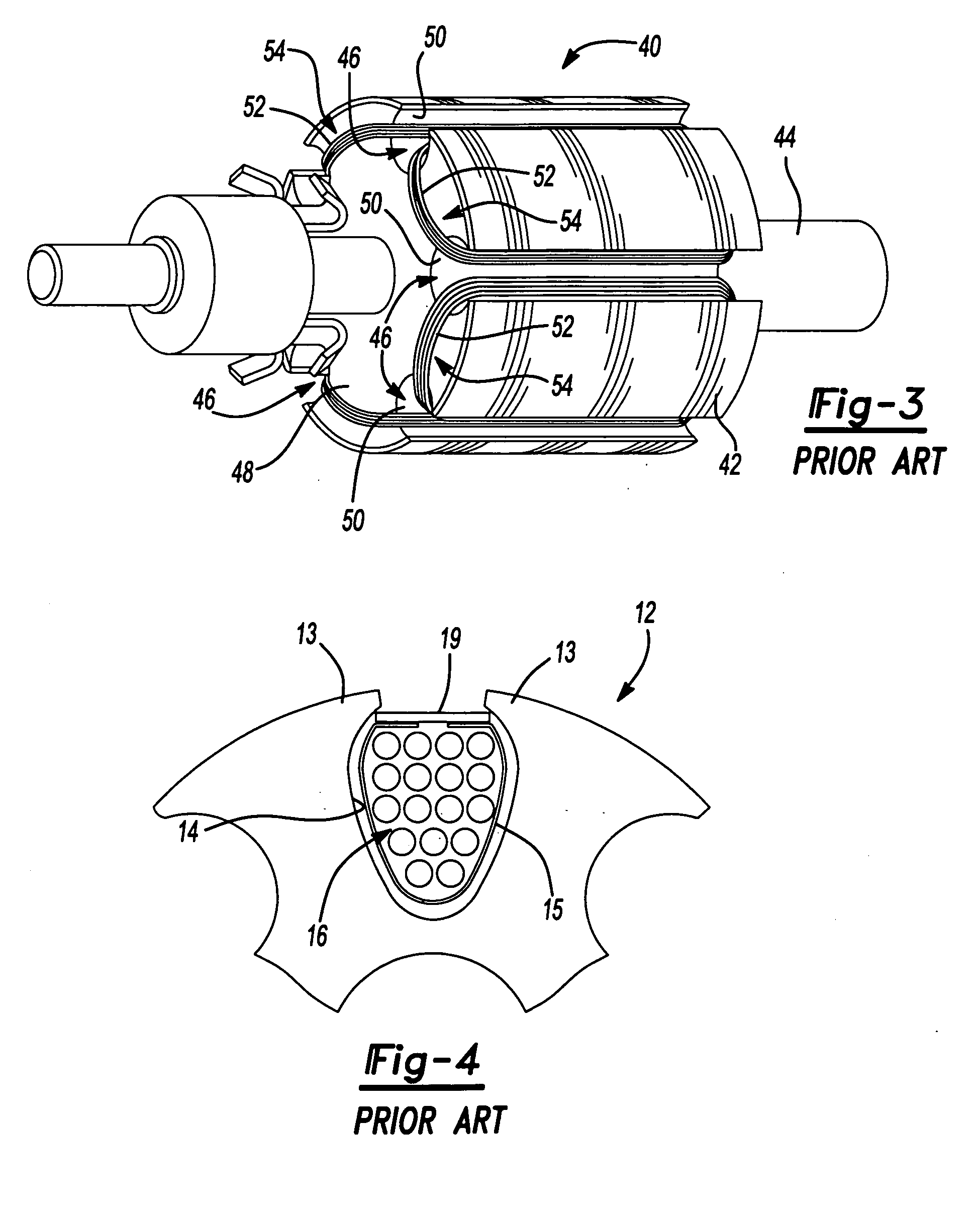

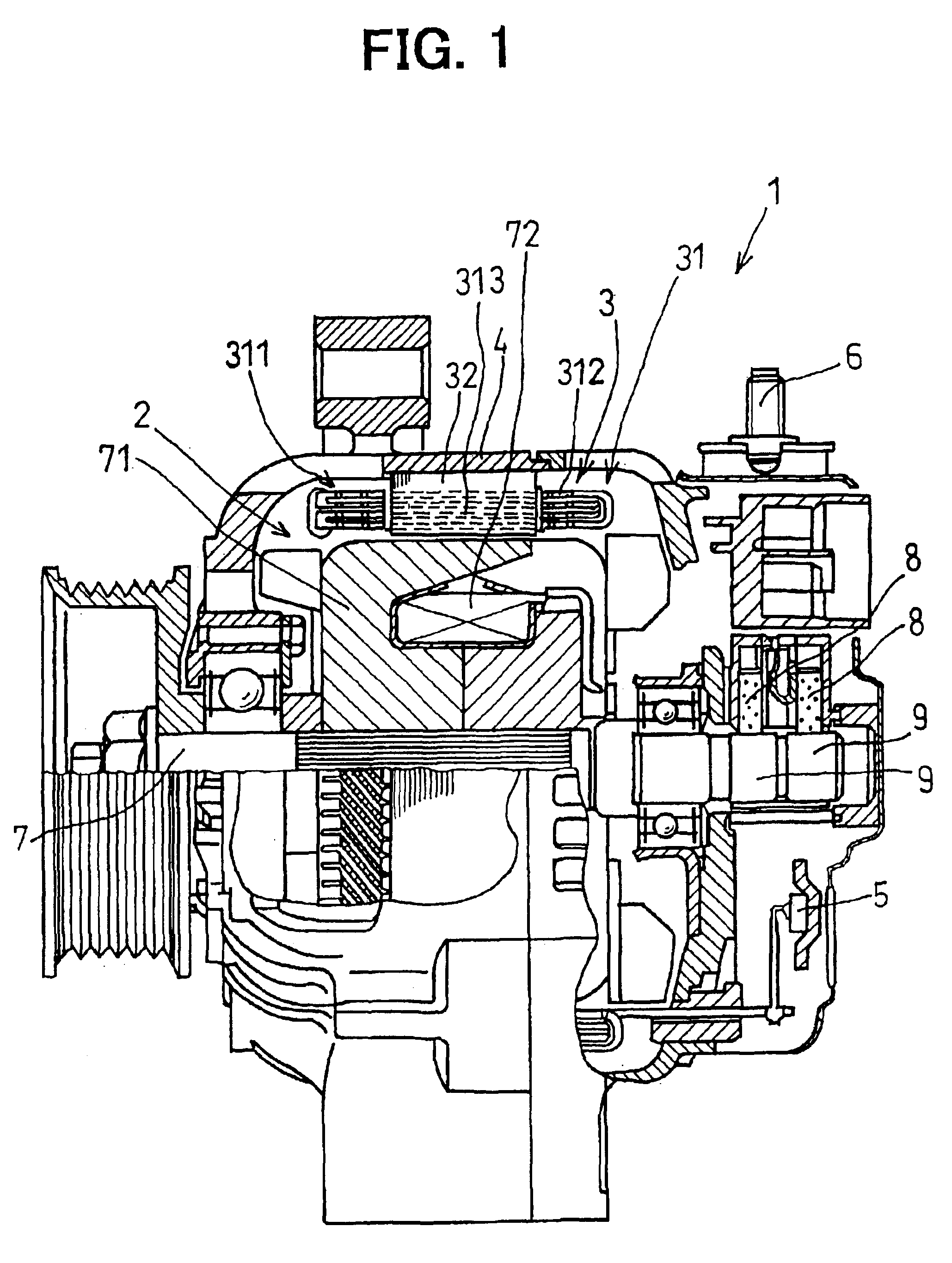

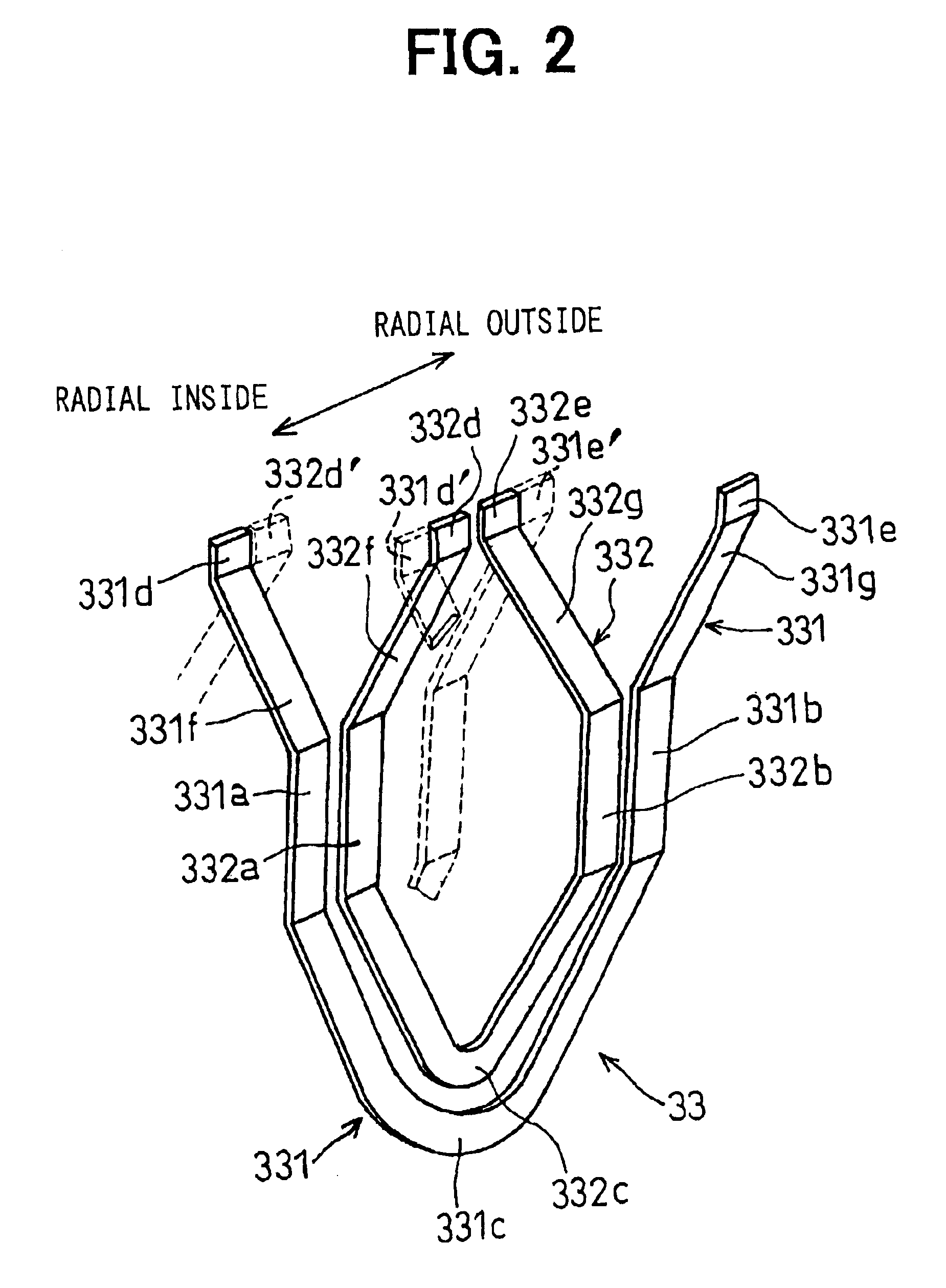

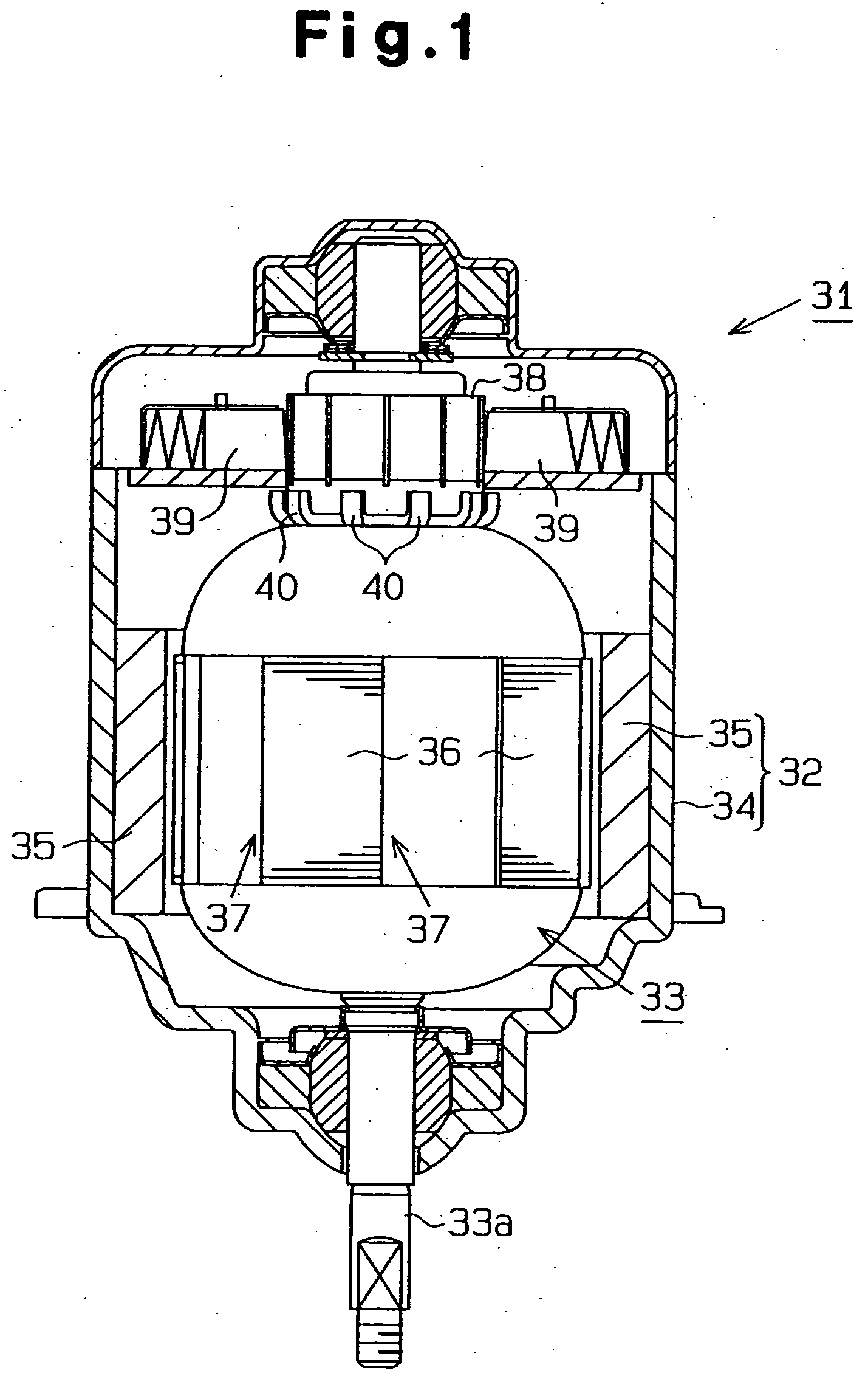

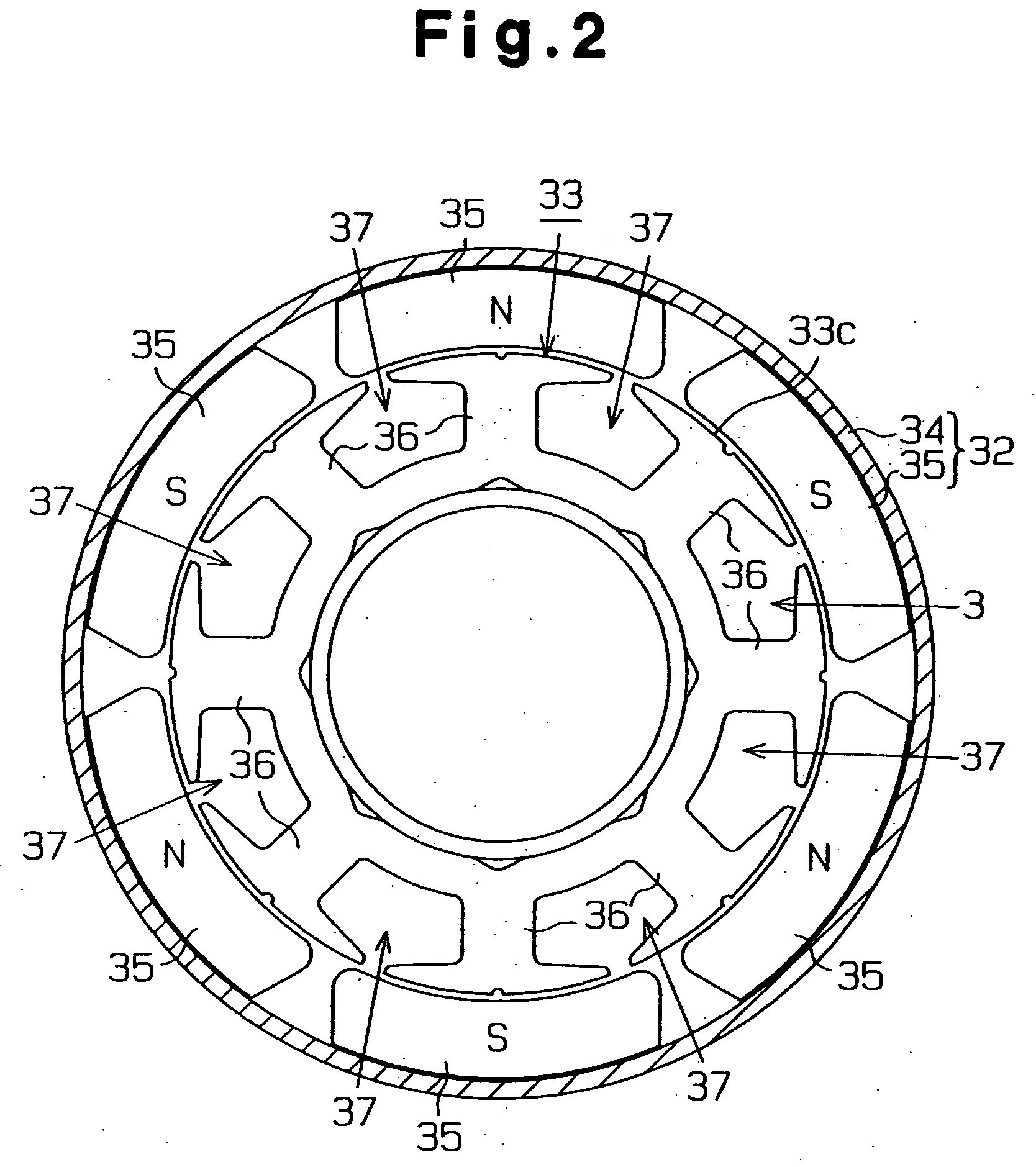

Direct-current motor and manufacturing method for the direct-current motor

InactiveUS20080122303A1Reduce vibrationRotary current collectorMagnetic circuit stationary partsEngineeringSliding contact

A direct-current motor includes a stator having a magnetic field system, a rotor disposed around the stator, a commutator which rotates together with the rotor, and power supply brushes which are urged in the axial direction by urging members so as to come into contact with the sliding contact surfaces. The rotor includes an armature core around which armature coils are wound, and a rotary shaft which rotates together with the armature core. The commutator has segments extending radially. The segments have sliding contact surfaces orthogonal to an axial line of the rotary shaft. At least a part of each power supply brush comes into contact with the sliding contact surface at a position further radially outward than the armature coil.

Owner:ASMO CO LTD

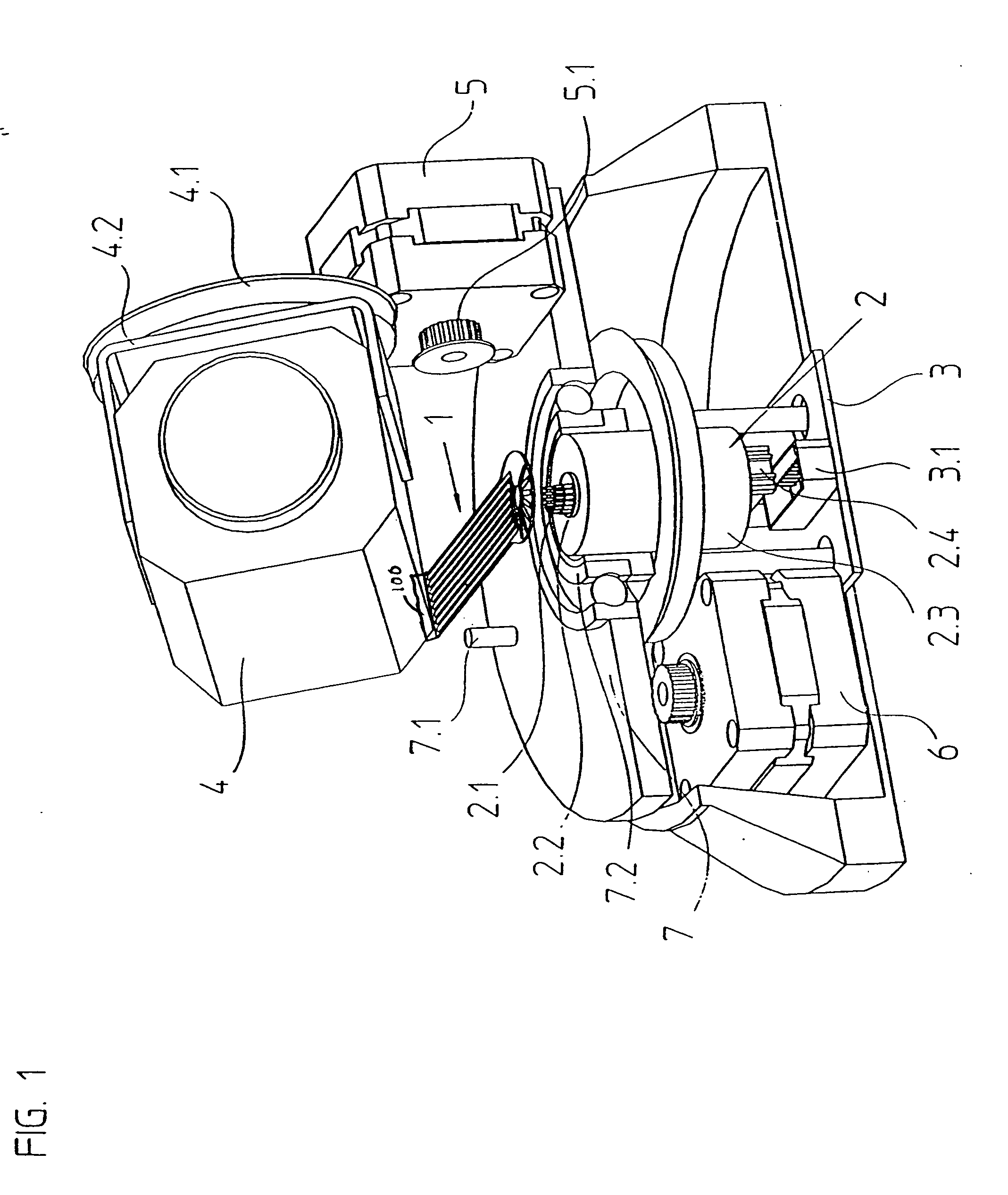

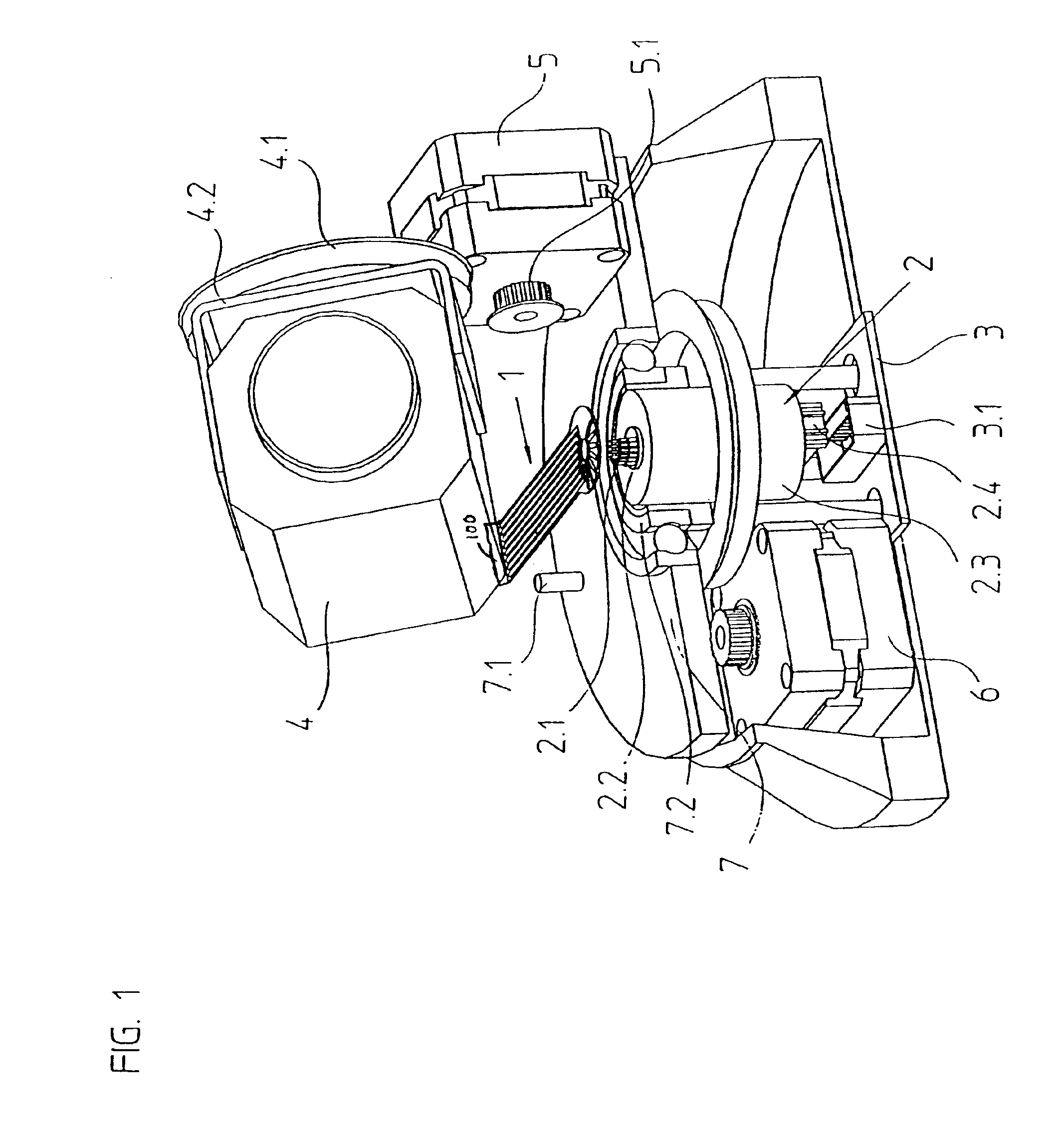

Slip ring unit with a printed circuit board

InactiveUS20060003604A1Simple and cost-effective constructionReduce component countRotary current collectorSlip-rings manufactureEngineeringPrinted circuit board

A device for transferring electric currents that includes a slip ring unit that has a rotor with connecting wires and a stator and a printed circuit board fastened to the rotor, wherein the printed circuit board includes connectors in electrical contact with the connecting wires, wherein a torque required for rotary movement between the rotor and the stator is introduced via the printed circuit board.

Owner:ANGERPOINTNER LUDWIG

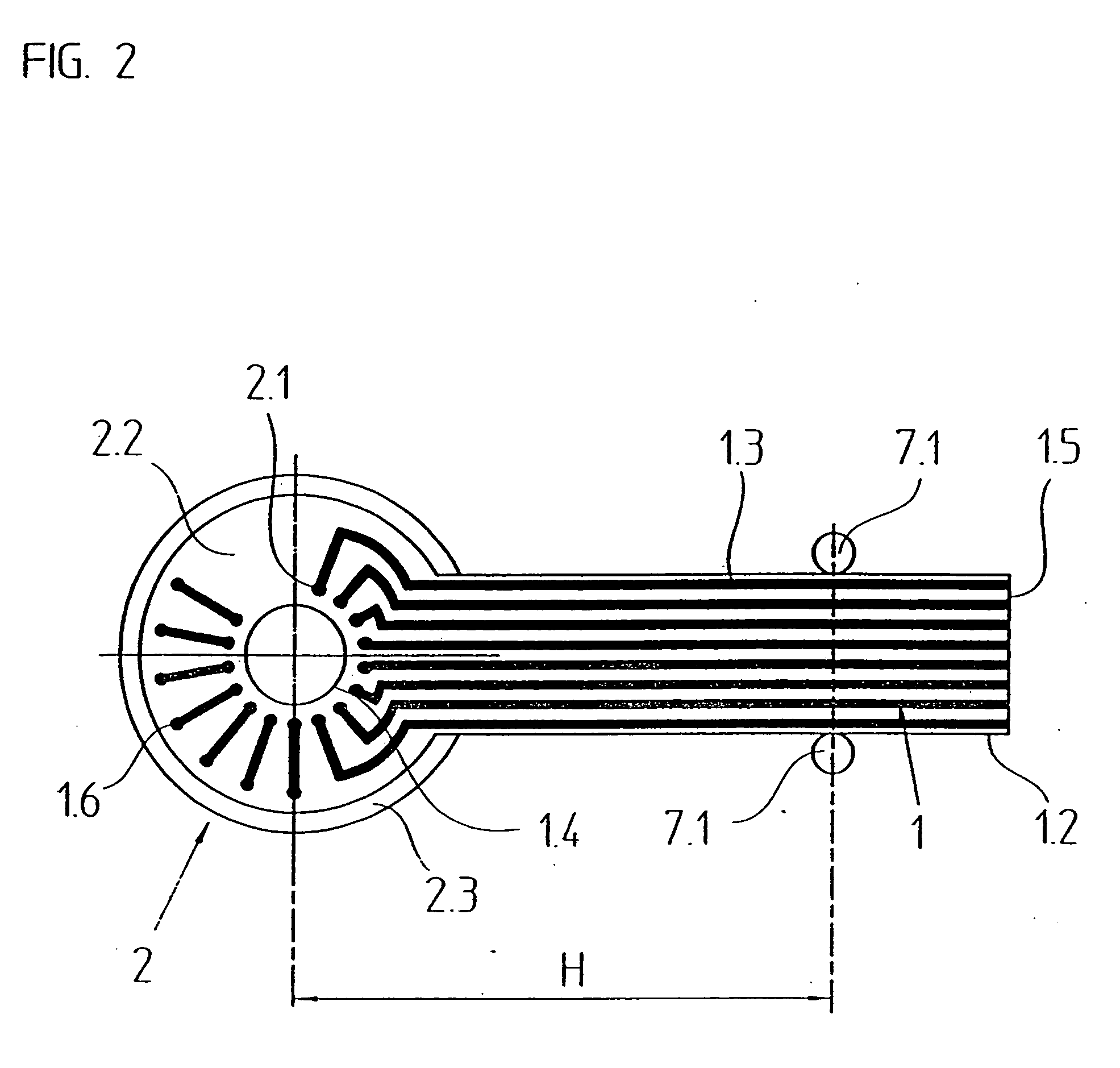

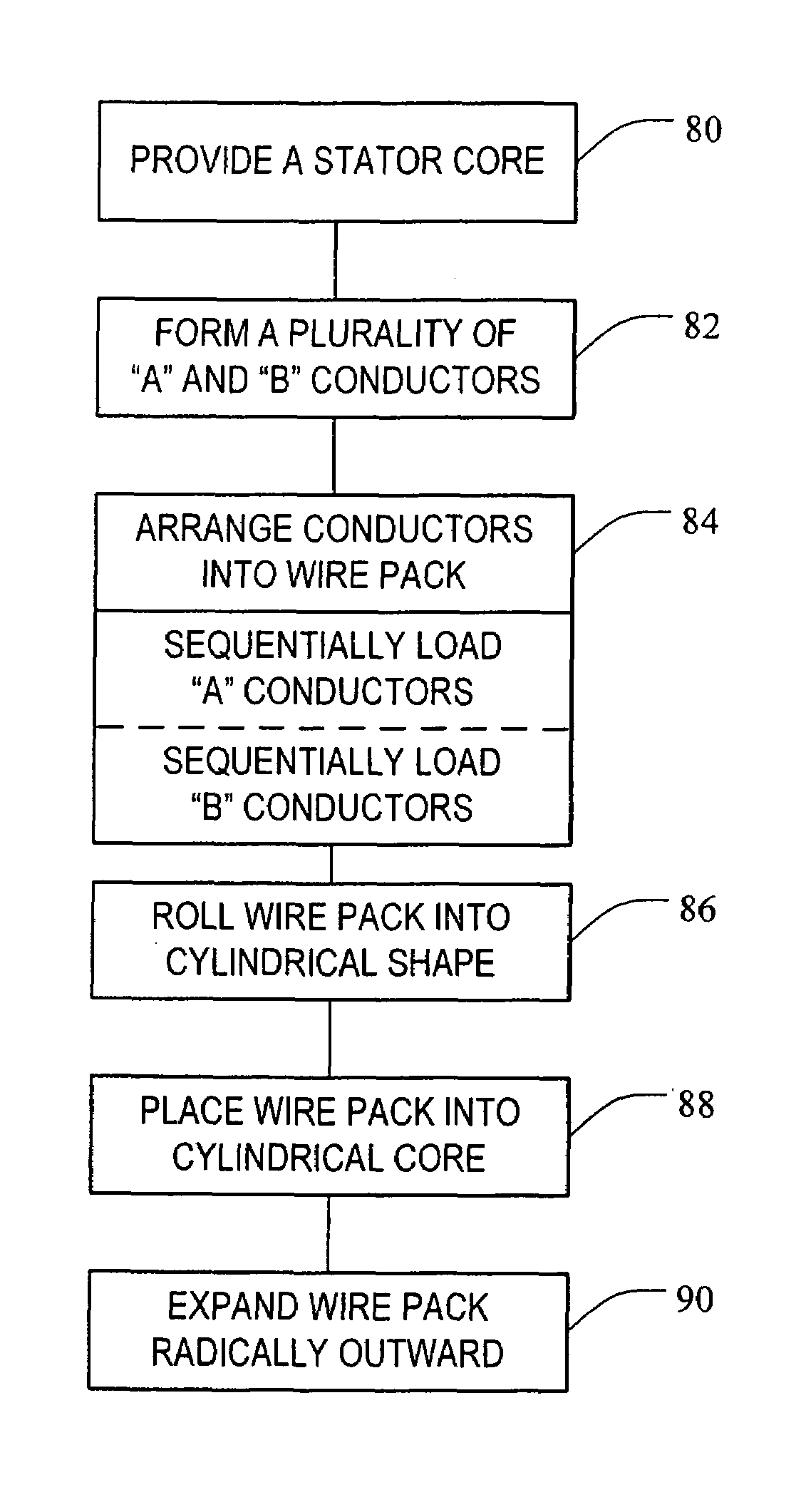

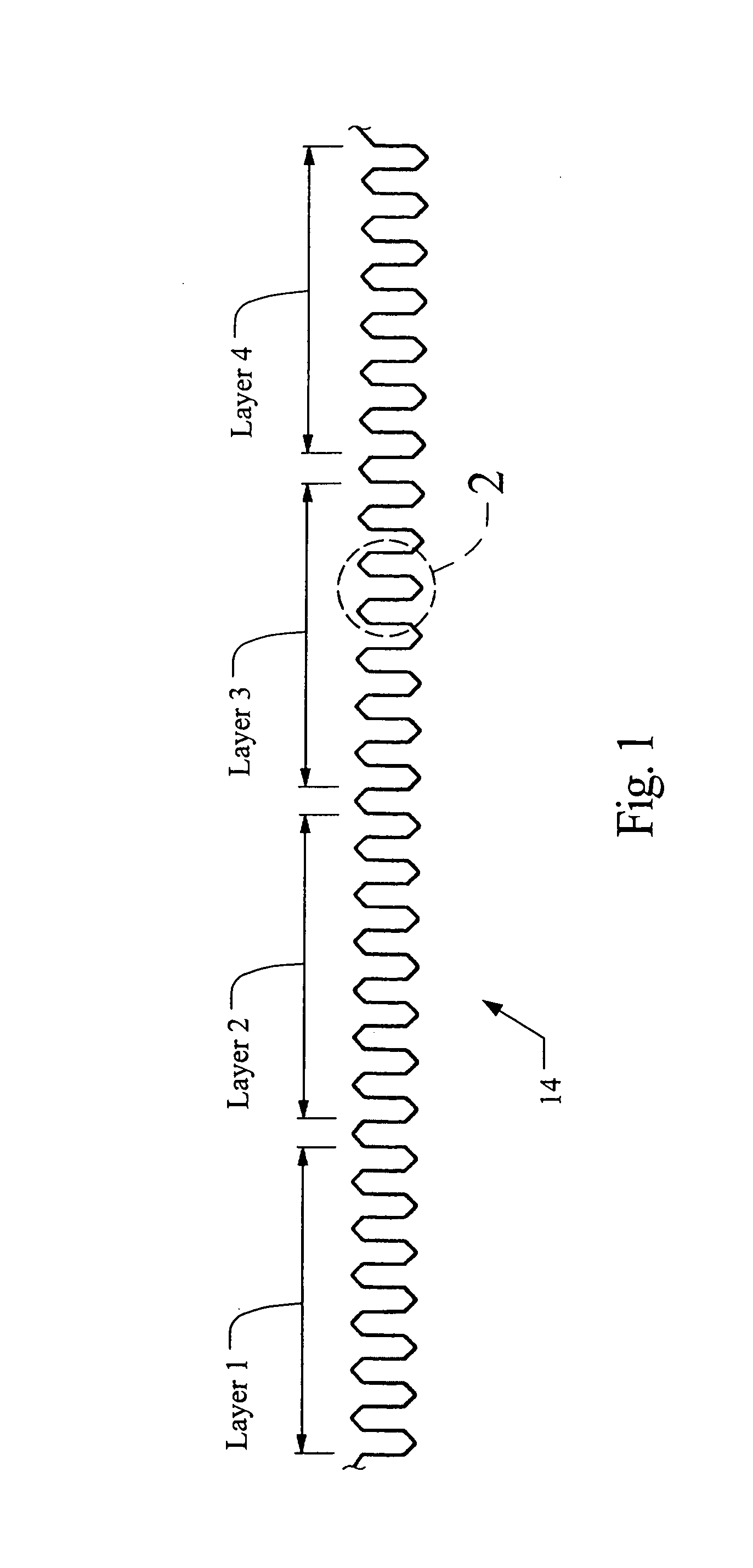

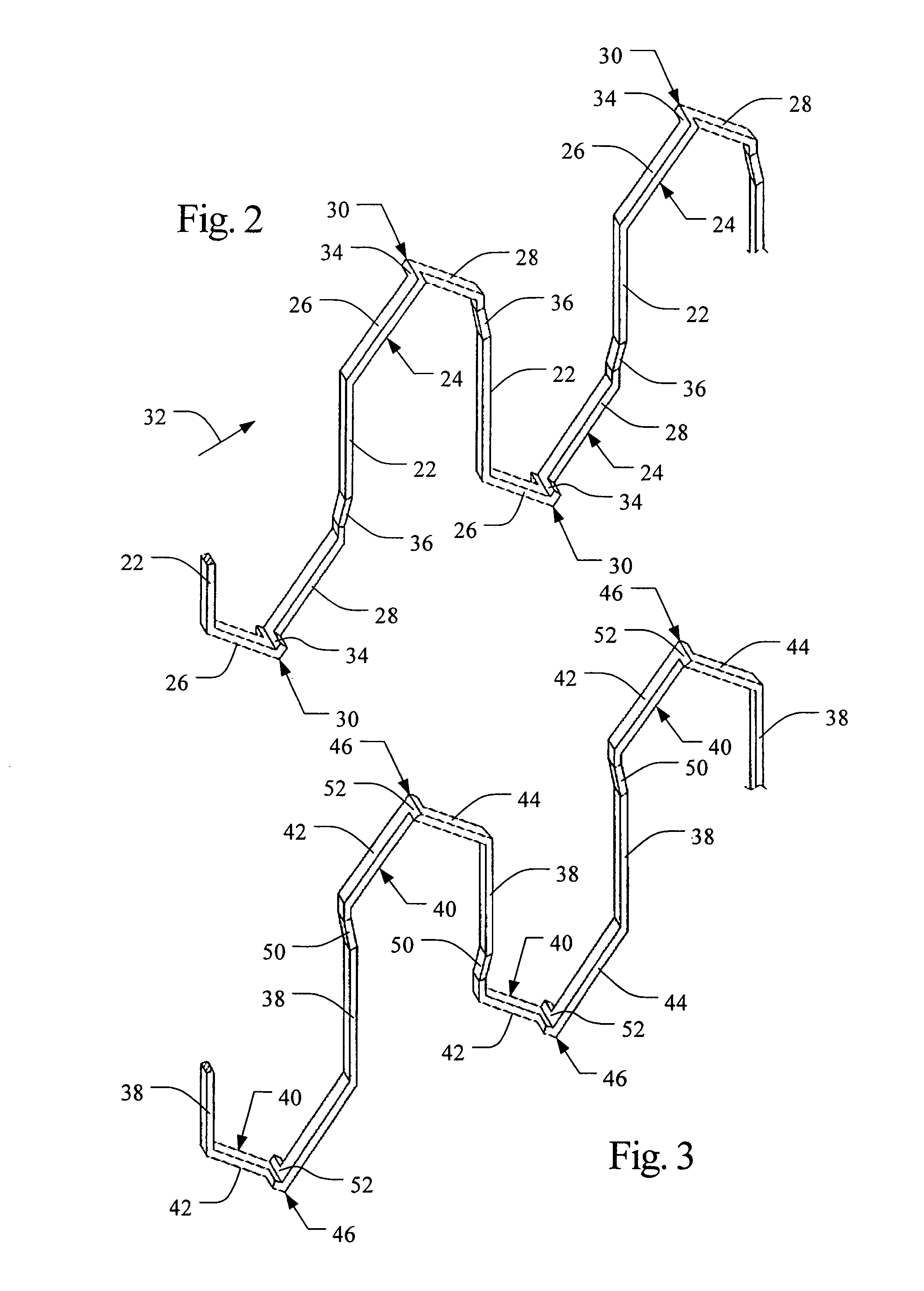

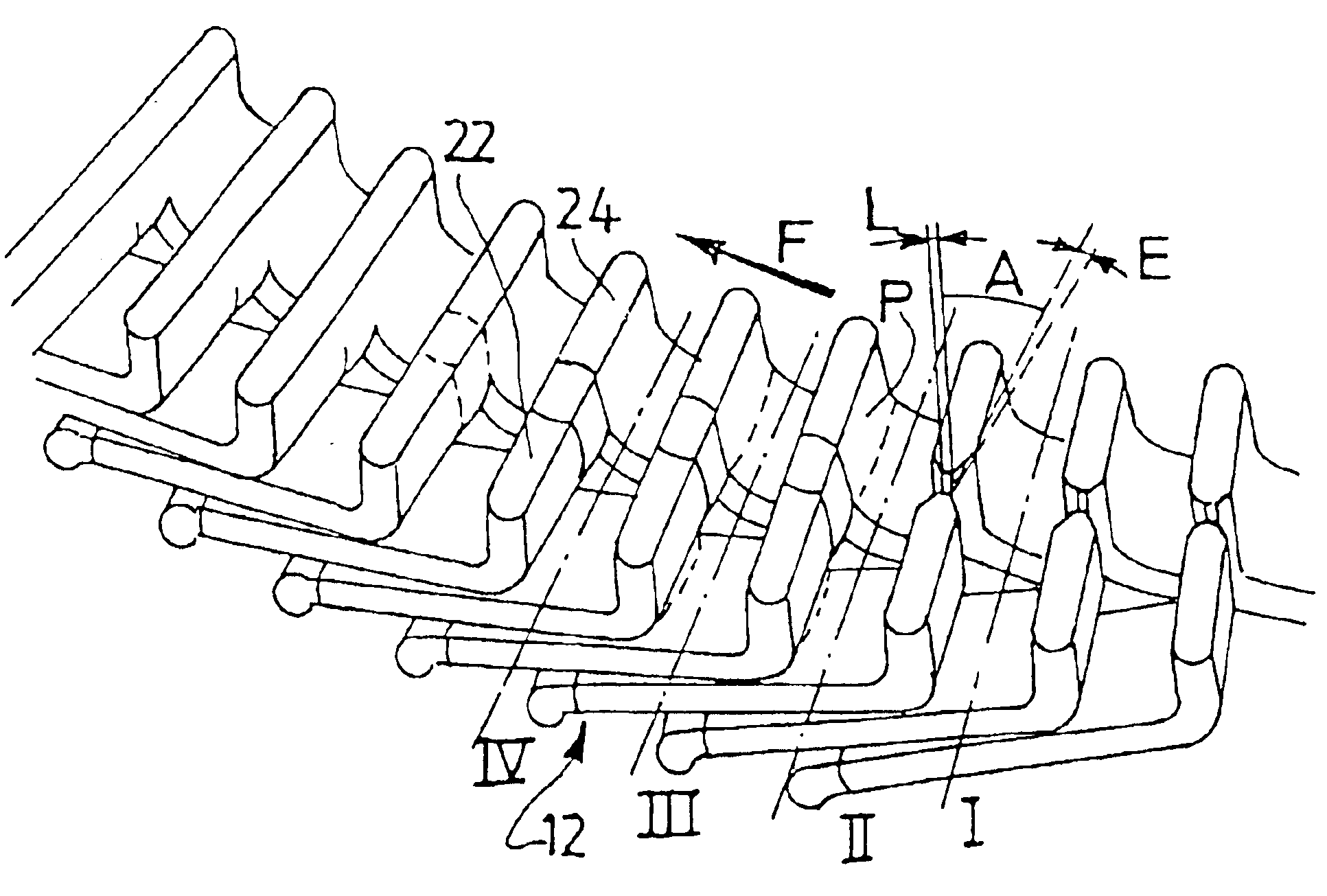

Method of forming cascaded stator winding

ActiveUS7386931B2Synchronous machinesAsynchronous induction motorsElectrical conductorElectric machine

A method of forming a stator for an electric machine having a cascaded winding includes the steps of: providing a stator core having a plurality of circumferentially spaced and axially-extending core slots in a surface thereof, forming a plurality of A conductors and a plurality of B conductors, arranging the A and B conductors into a wire pack, rolling the wire pack into a cylindrical shape and inserting the wire pack within the stator core, and expanding the wire pack radially outward such that the wire pack is inserted within the slots of the stator core.

Owner:REMY TECHNOLOGIES LLC

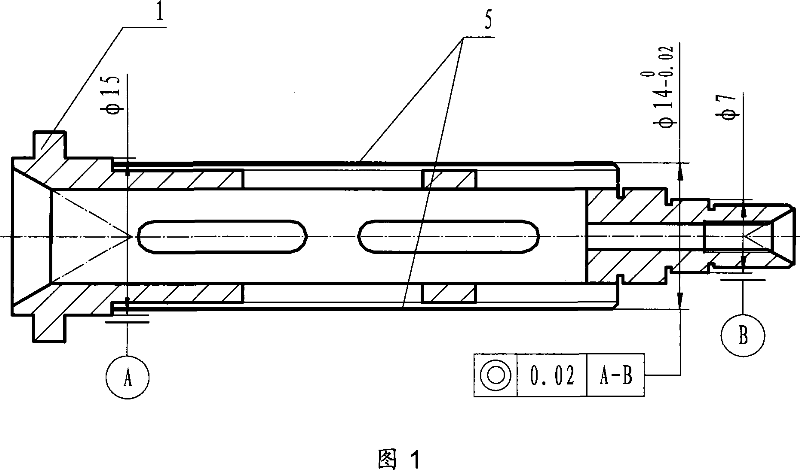

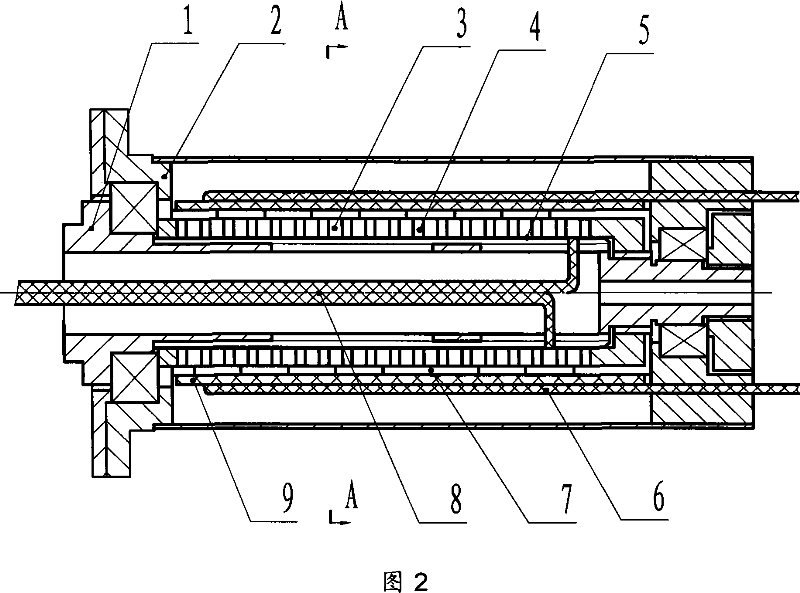

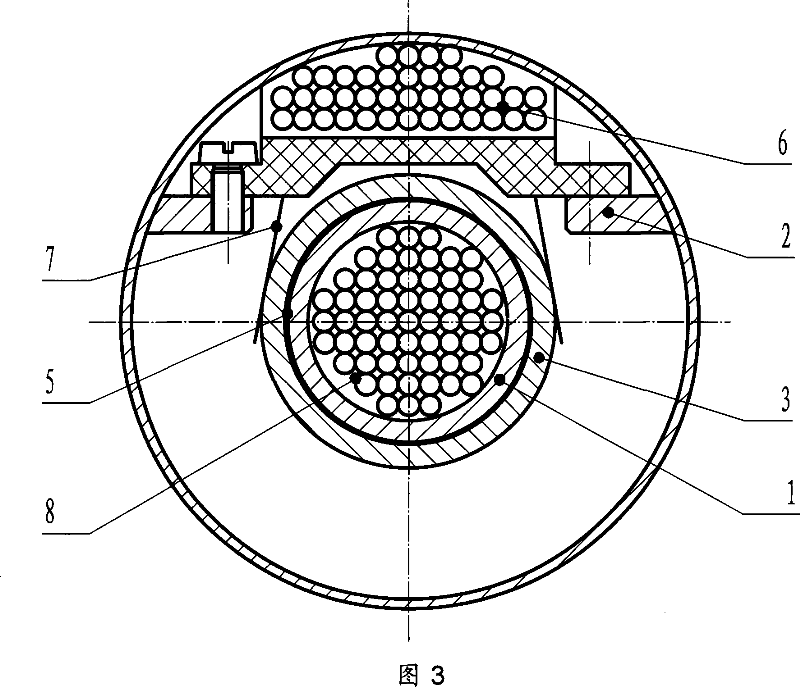

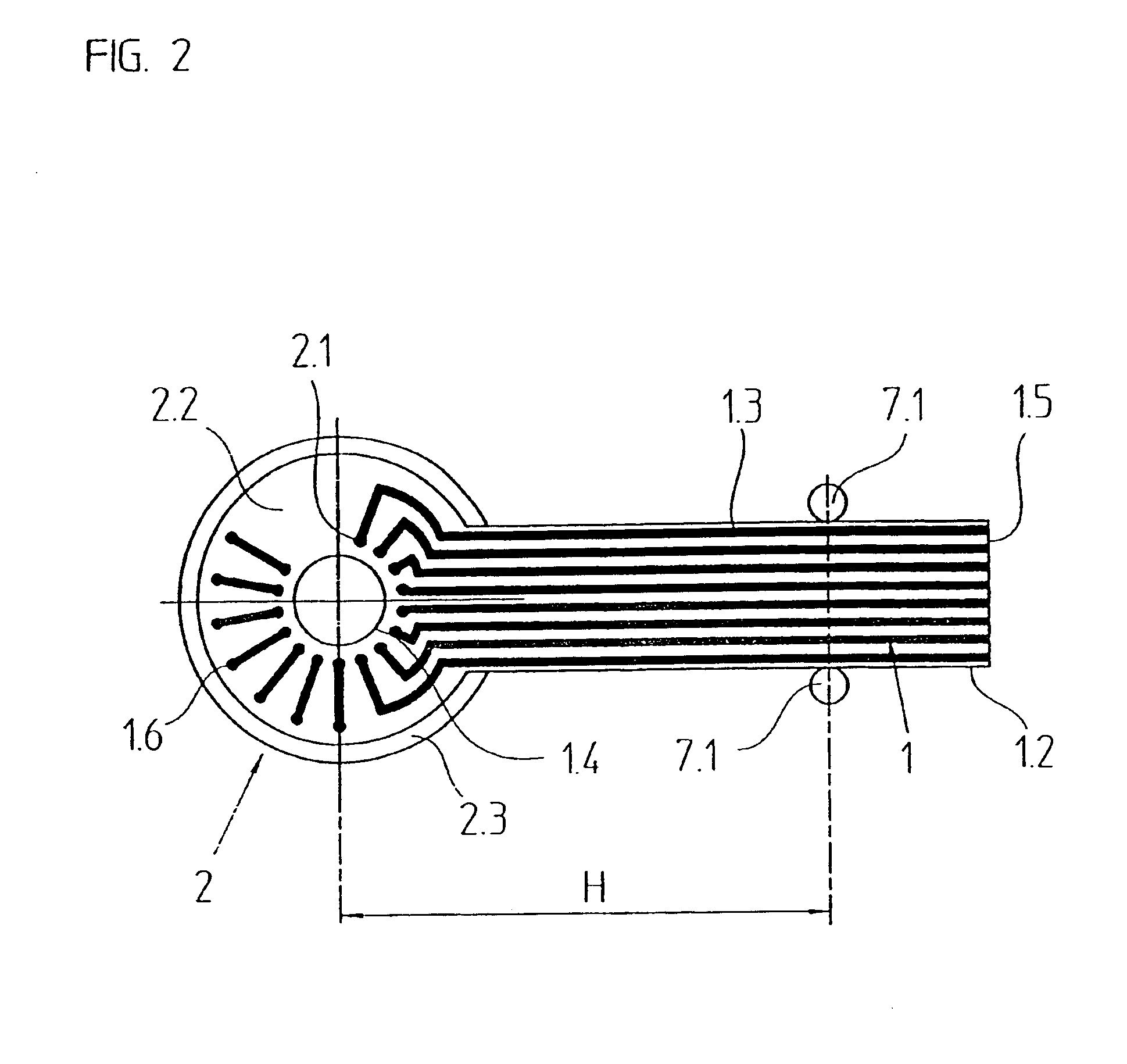

Radial insulation laminated conductive retractor collar

ActiveCN101039008AAvoid precision machiningSimple processRotary current collectorSlip-rings manufactureThermal insulationPolymer insulation

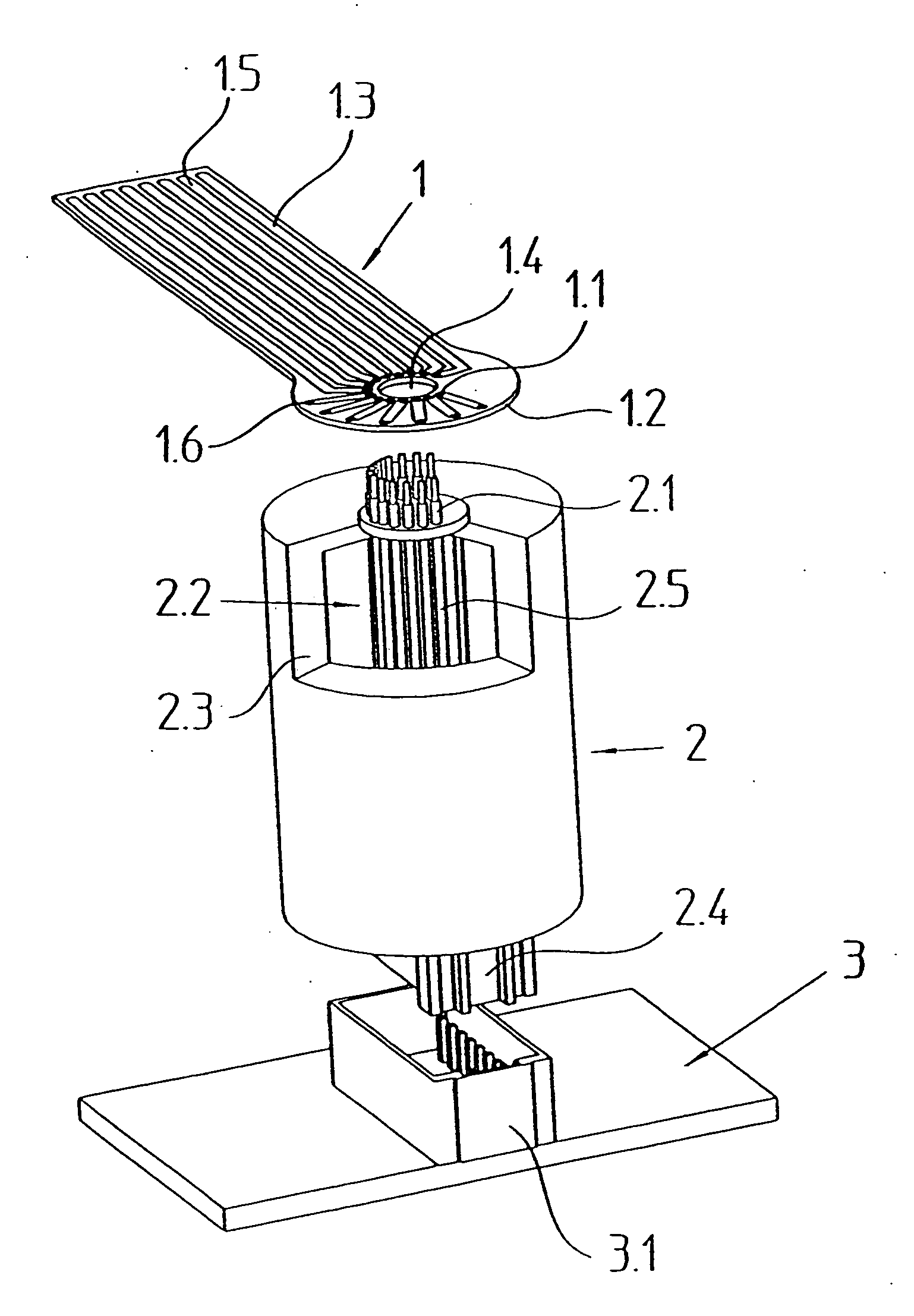

The invention provides a radial insulation laminated conductive slip ring which belongs to electrical rotary adapter. Conductive ring sheets 3 and insulation sheets 4 are interval arranged on a slip ring shaft 1, and a section of the slip ring shaft 1 surface for mounting the conductive ring sheet is coated with polymer insulation material to guarantee the insulation between the slip ring shaft 1 and the conductive ring sheet 3. A brush 7 mounted on a brush bracket 9, which is mounted on a shaft sleeve 2, tightly contacts with the conductive ring sheet 3, rolling bearings are disposed between the slip ring 1 and the shaft sleeve 2 for supporting, when the slip ring 1 rotates relative to the shaft sleeve 2, the transmission for multi-channel electrical signals between the relative rotating parts can be realized via conductive ring sheet lead-out wires 8 and brush lead-out wires 6. The invention effectively simplifies the production procedure, and reduces the radial size of the slip ring, and increases the stiffness of the shaft.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

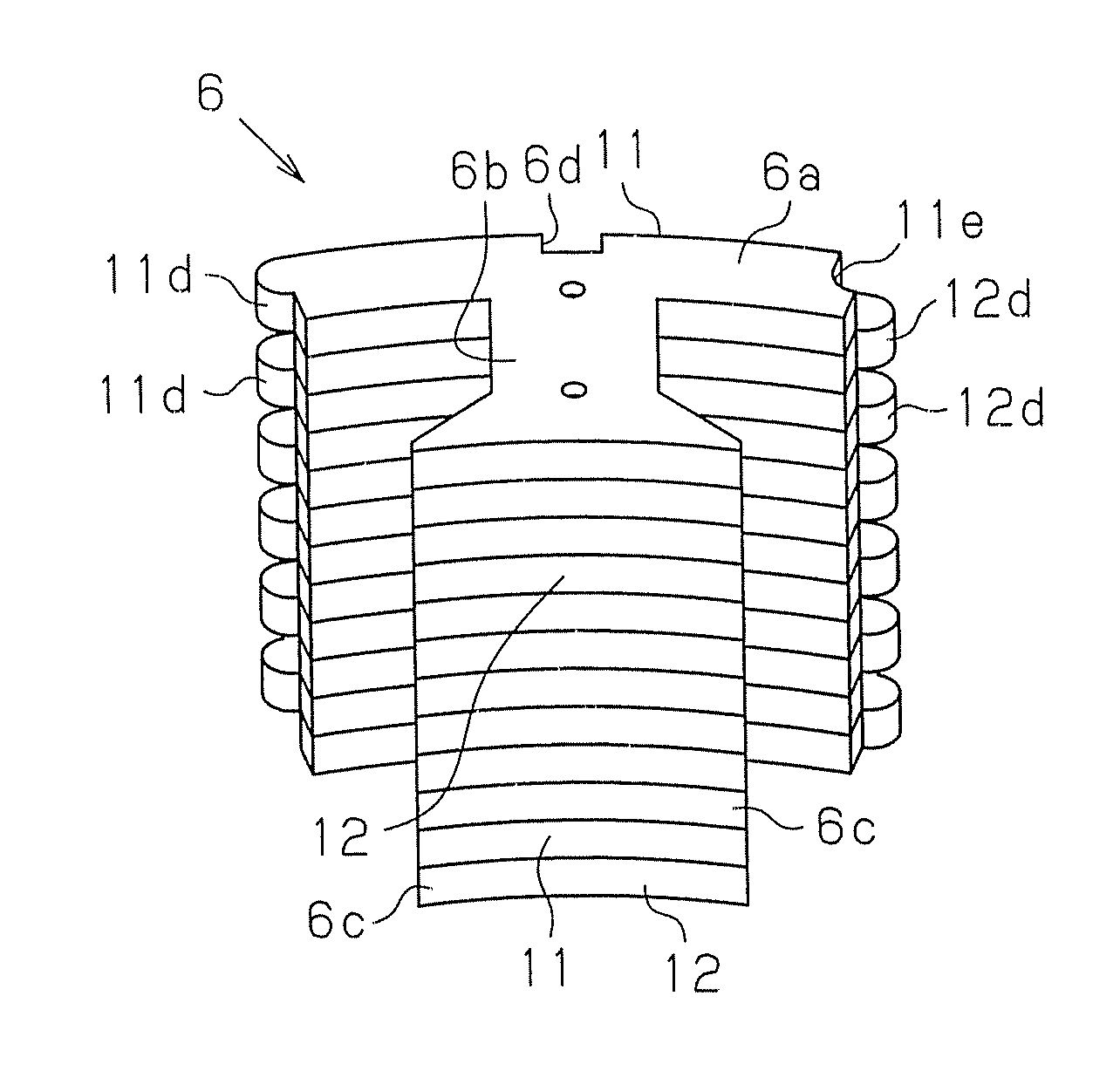

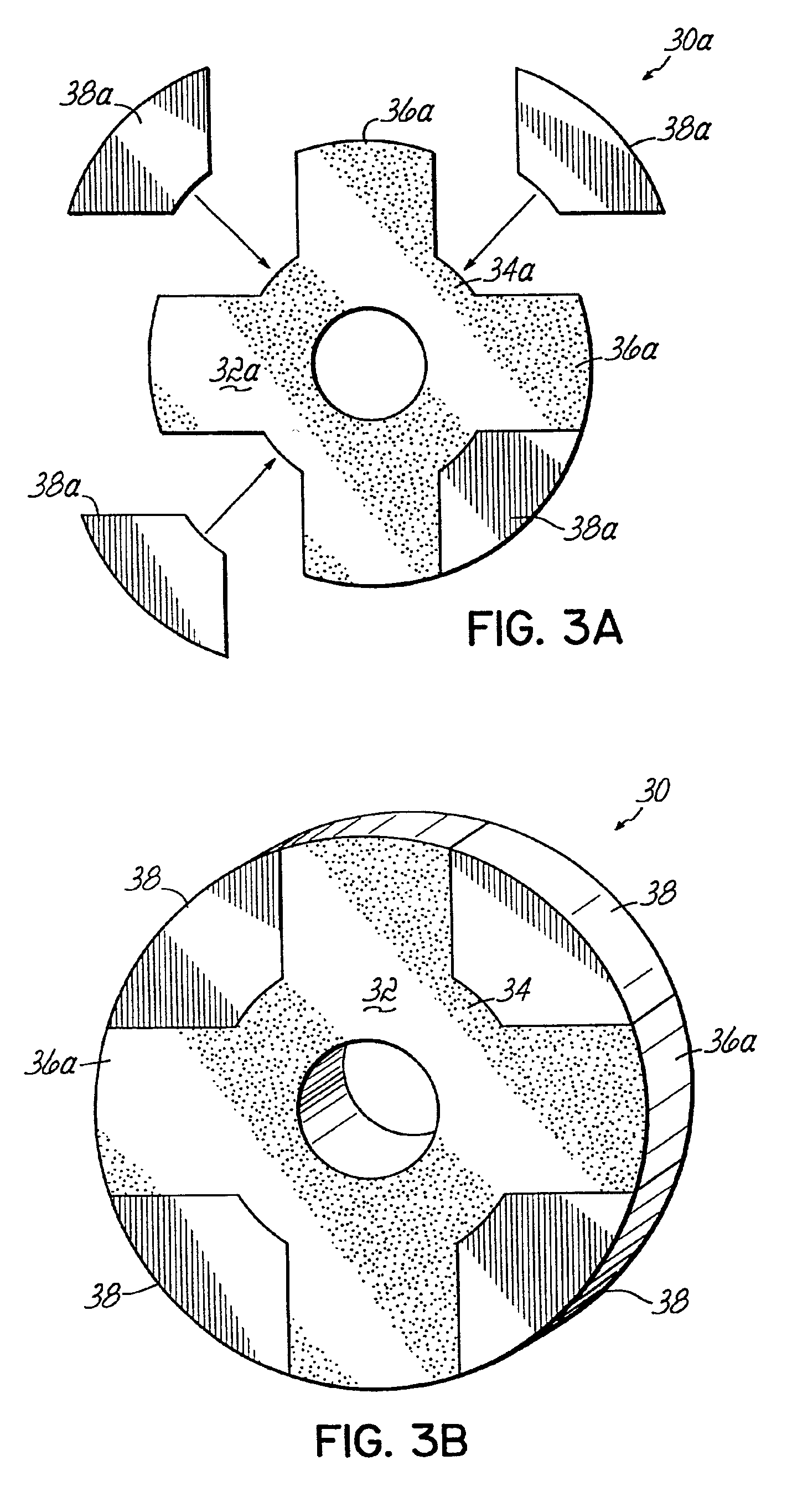

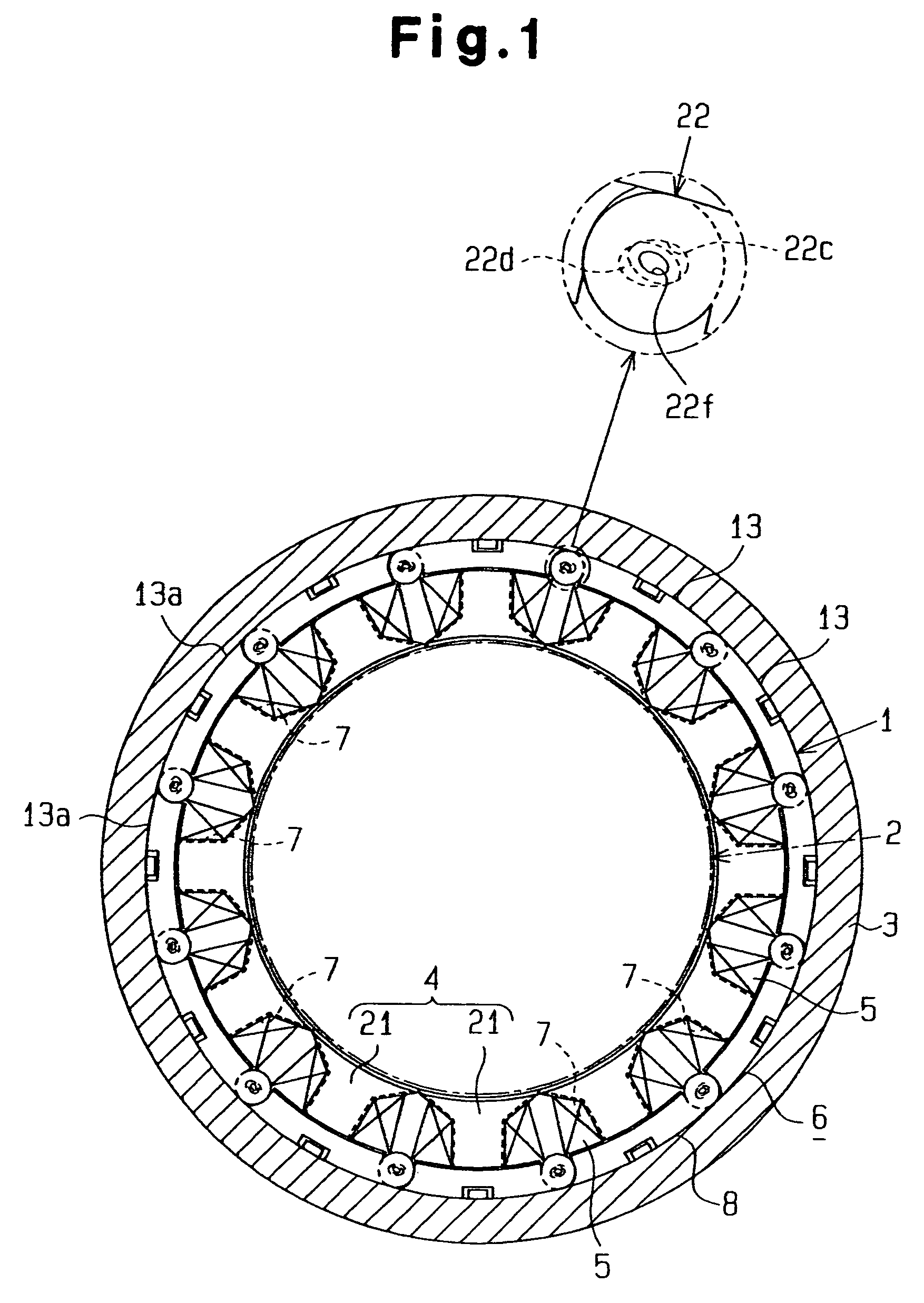

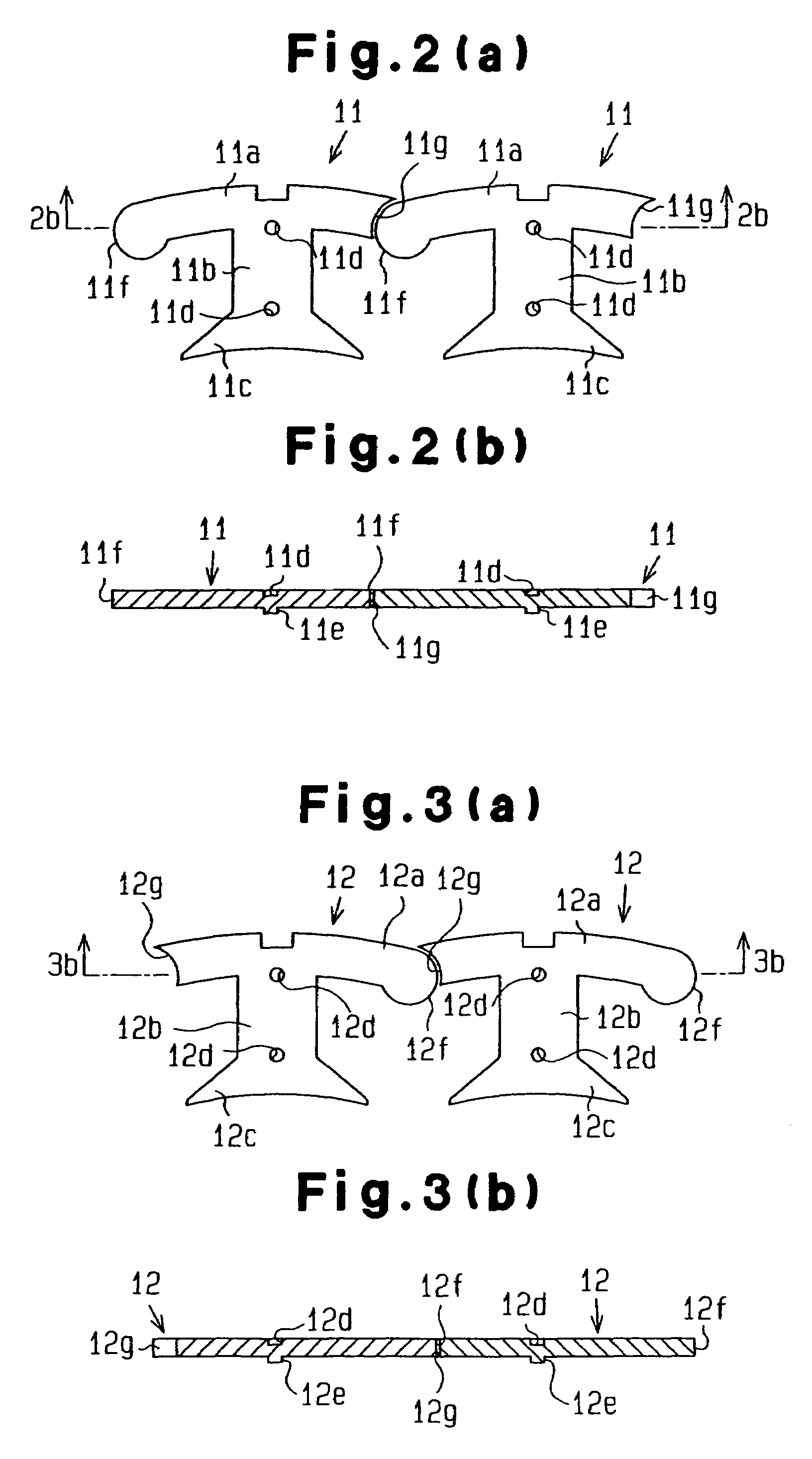

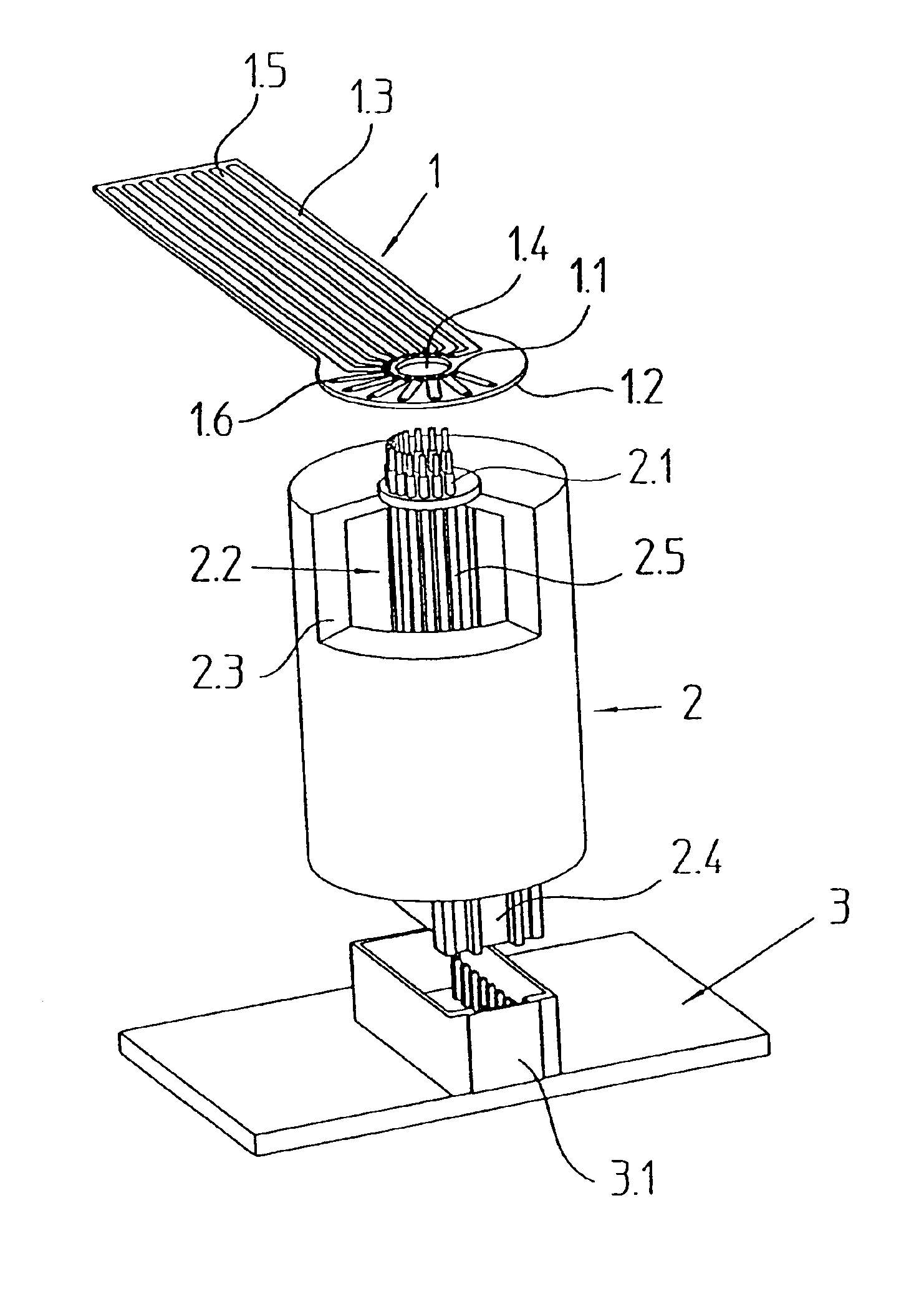

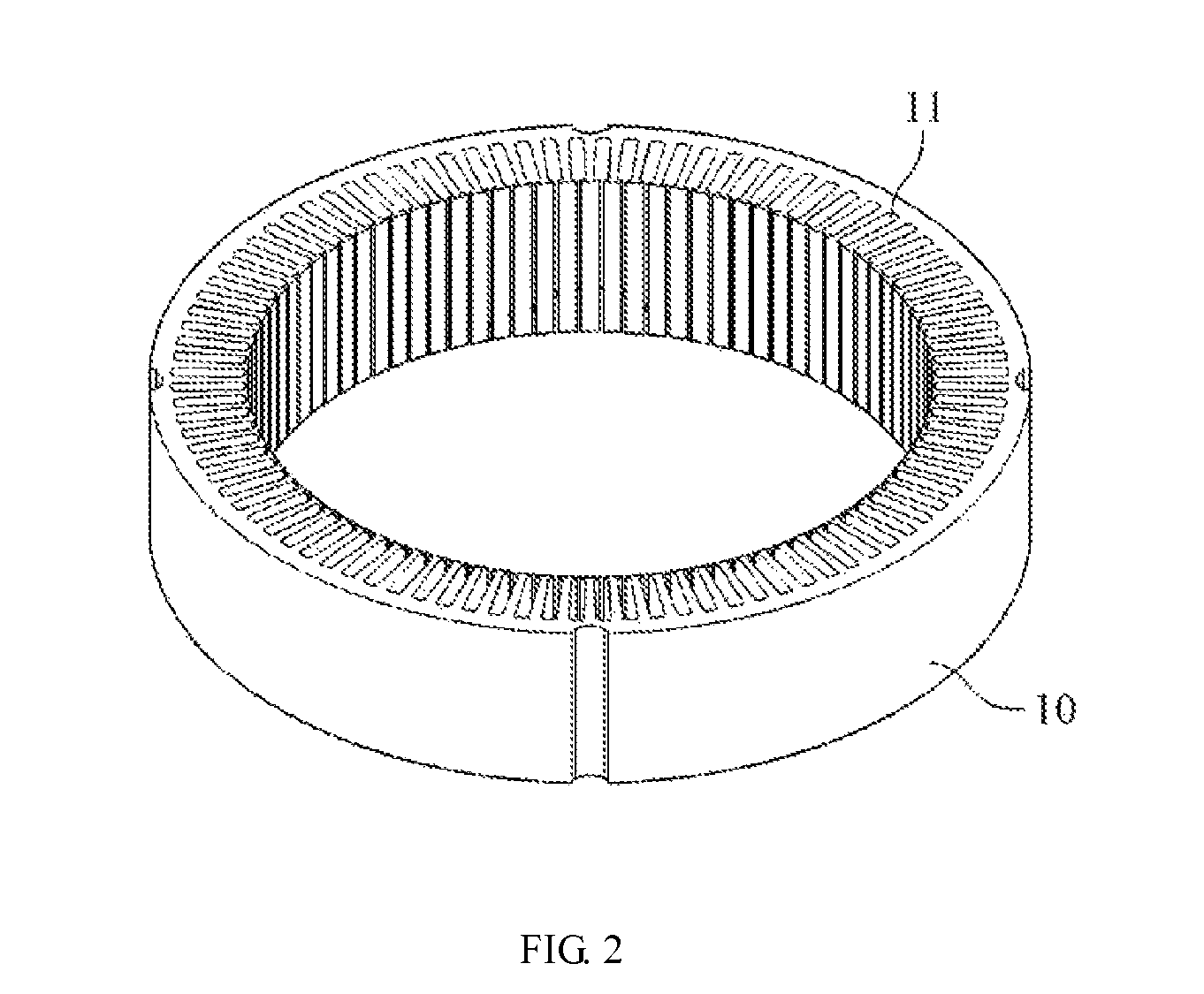

Device for producing ring core, method for producing ring core and ring core produced by that method

InactiveUS20100052463A1High strengthMagnetic circuitManufacturing stator/rotor bodiesProduction lineEngineering

In the device for producing a ring core, a drop-through blanking die (46) constituting a rotor core production line (30) is used to mold a ring core by laminating a plurality of split core plates (12, 16) while arranging them in a ring shape. The drop-through blanking die (46) consists of a rotary mechanism (55) for rotating the split core plates (12, 16) thus laminated through a predetermined angle, an inner guide member (62) being arranged on the inner circumferential side of the split core plates (12, 16) laminated in a ring shape, and an outer guide member (58) being arranged on the outer circumferential side of the split core plates (12, 16). While the split core plates (12, 16) are supported by any one of the inner guide member (62) and the outer guide member (58), a pressure is imparted to the split core plates (12, 16) by the other.

Owner:HONDA MOTOR CO LTD

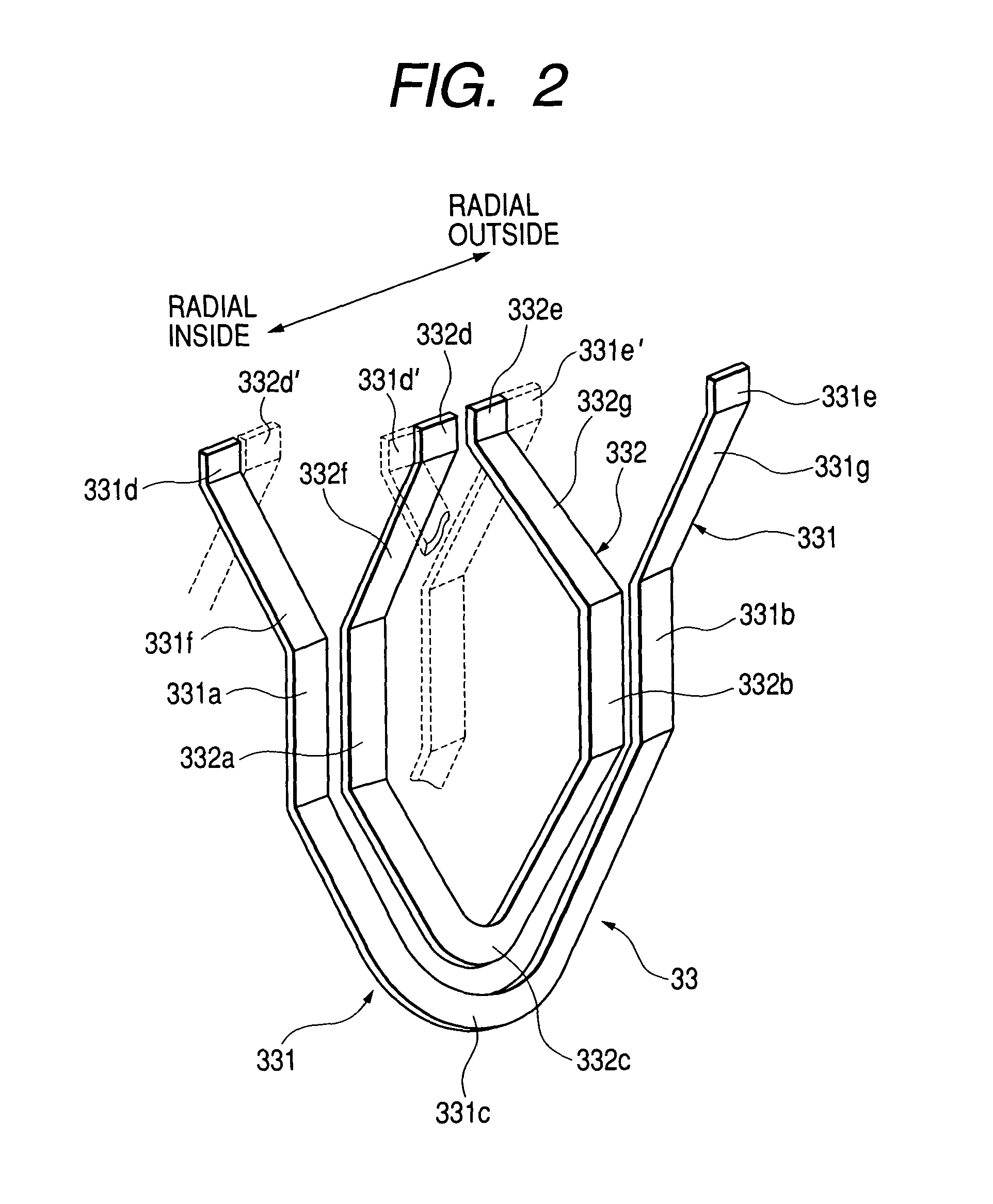

Insulator and manufacturing method thereof, and stator for electric rotating machine

A stator for a motor includes a stator core, an insulator, and coils. The stator core includes an annular portion and teeth, which extend radially from the annular portion. The stator core is divided into core segments in the circumferential direction. Each core segment has an arcuate portion and one of the teeth, which extends from the arcuate portion. The insulator insulates each coil wound around one of the teeth from the stator core. The insulator includes coupling portions at positions corresponding to the circumferential ends of the arcuate portions. Each coupling portion couples the adjacent core segments to be rotatable relative to each other. The insulator facilitates manufacture of the stator.

Owner:DENSO CORP

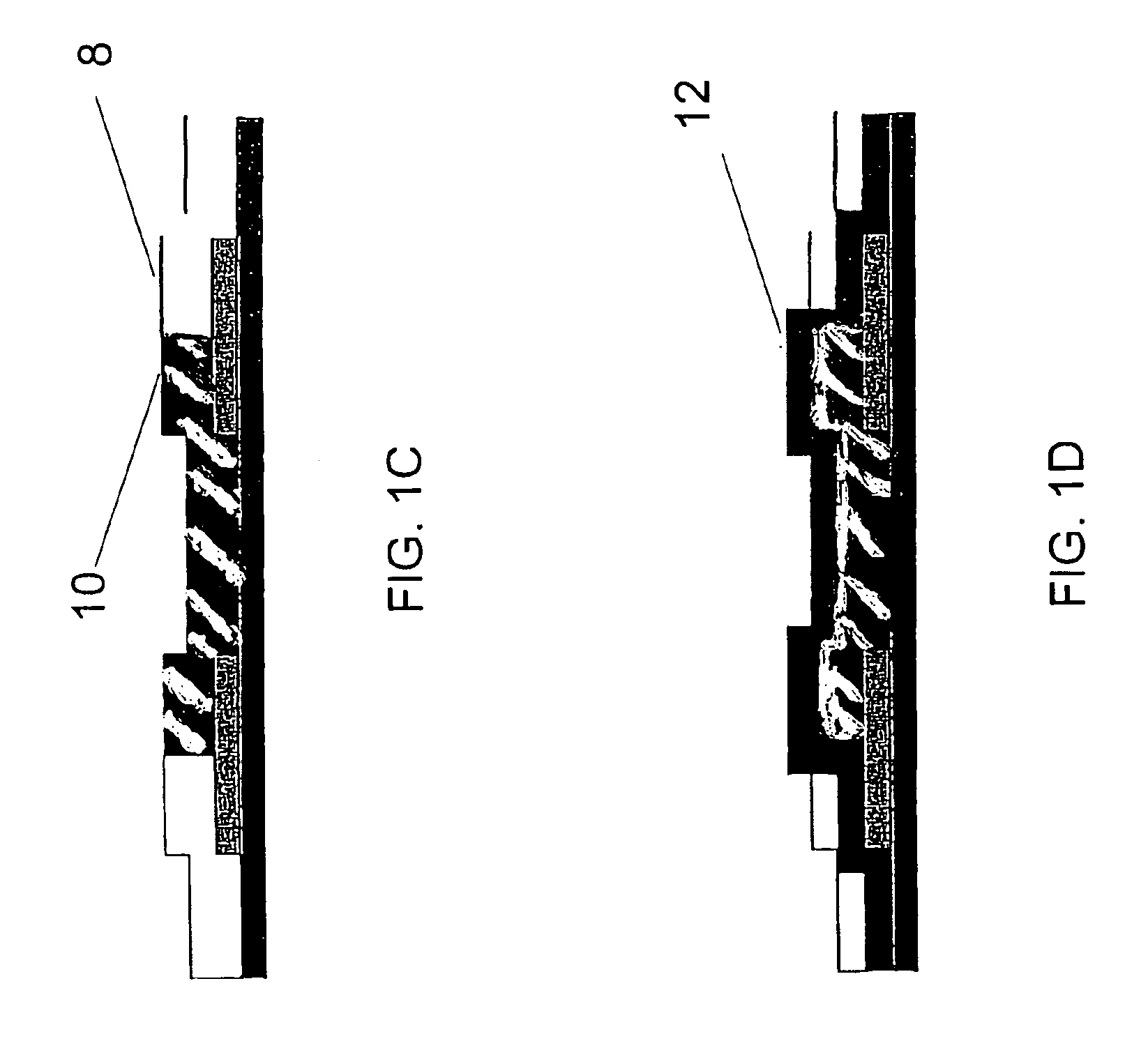

Electric motor and method of making same and method of making a power tool

InactiveUS20060255678A1Speed up the processWindings insulation materialRotary current collectorPower toolMagnet wire

Owner:BLACK & DECKER INC

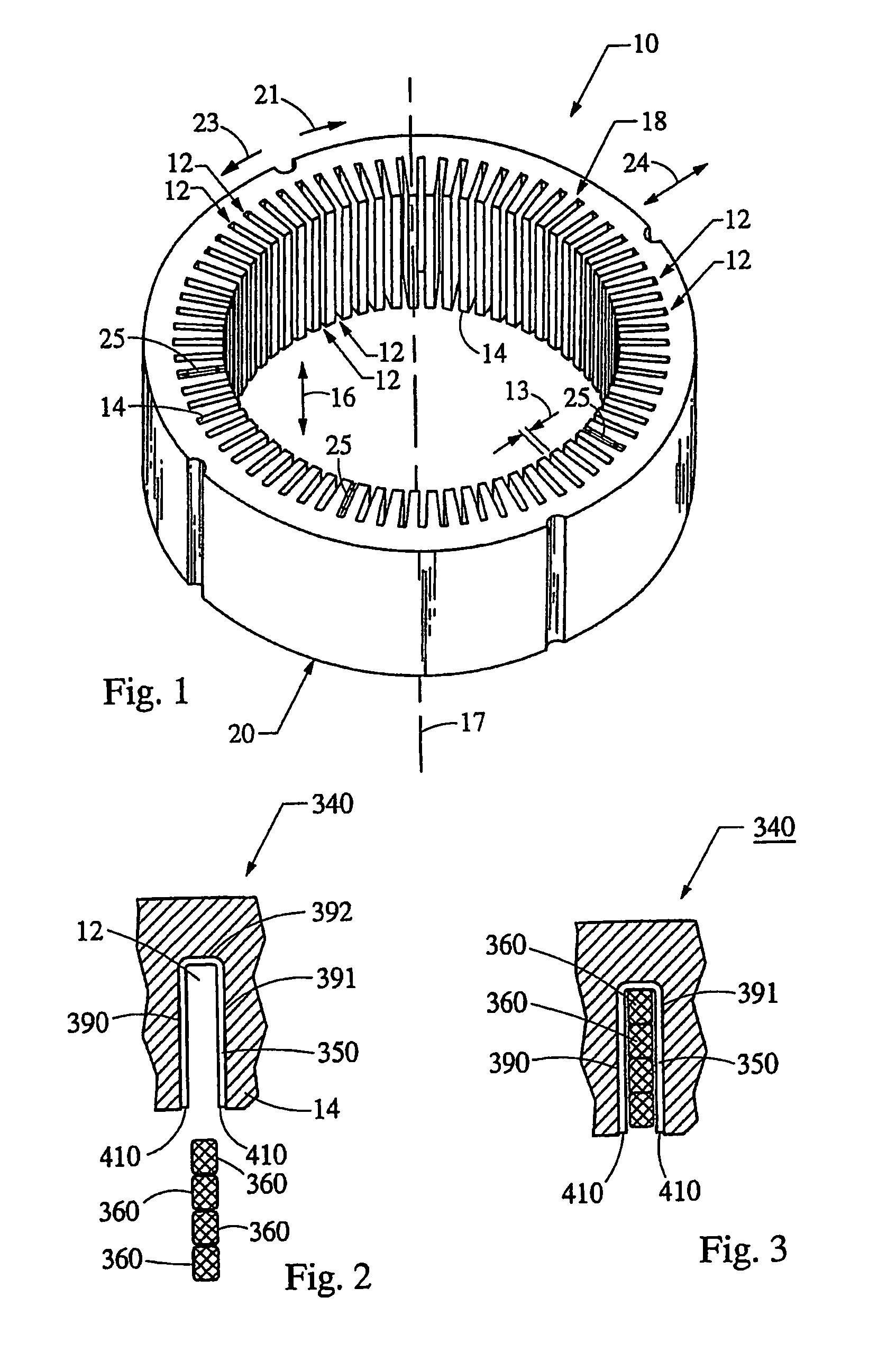

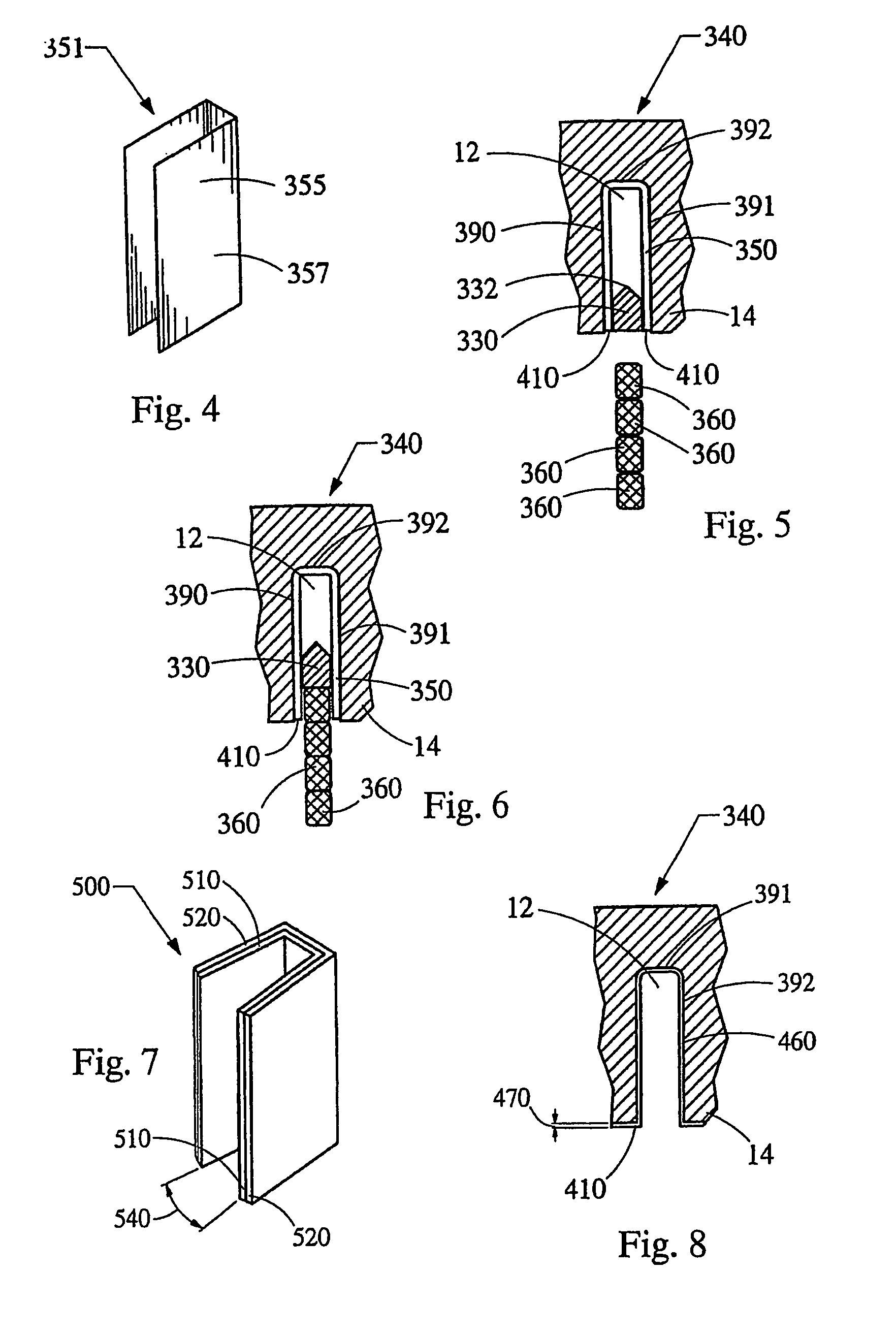

Method for forming a stator core

ActiveUS7788790B2Potential for this defect to occur is increasedLess spring forceSynchronous generatorsWindings insulation shape/form/constructionElectric machineEngineering

Owner:BORGWARNER INC

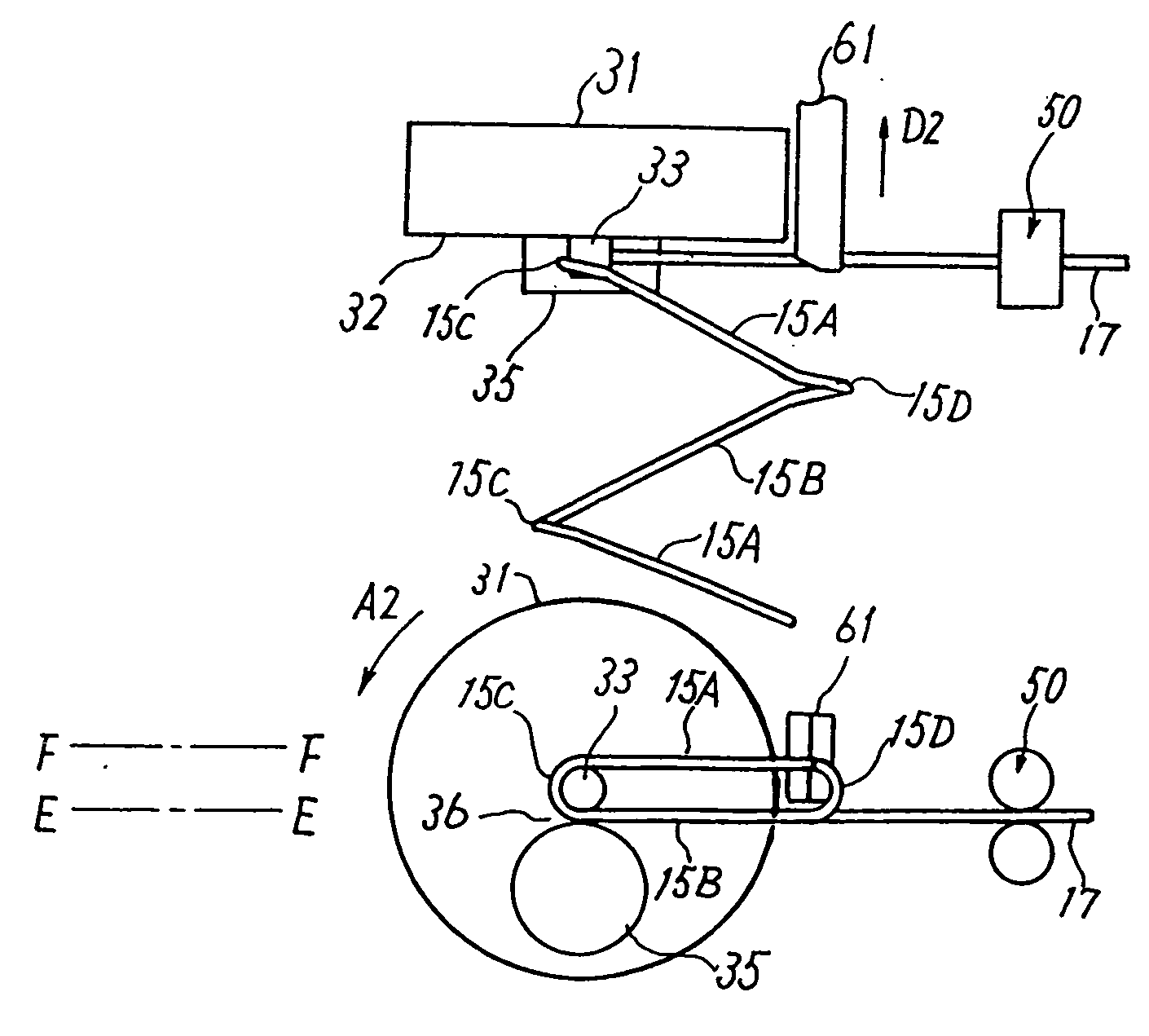

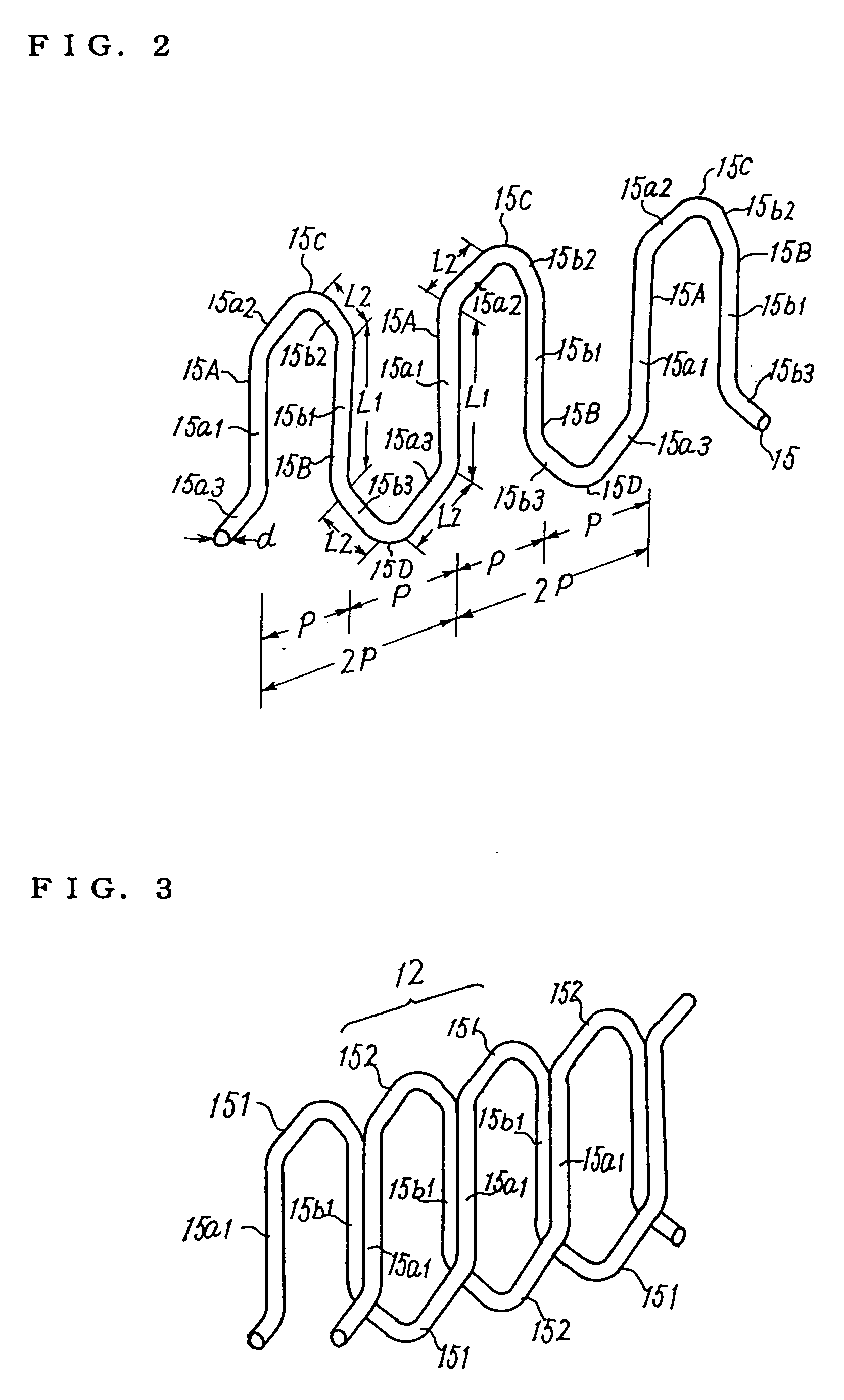

Manufacturing method of a coil assembly

InactiveUS20060005376A1Easily adjust pitch and lengthEasy to adjustManufacturing dynamo-electric machinesCommutators manufactureMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

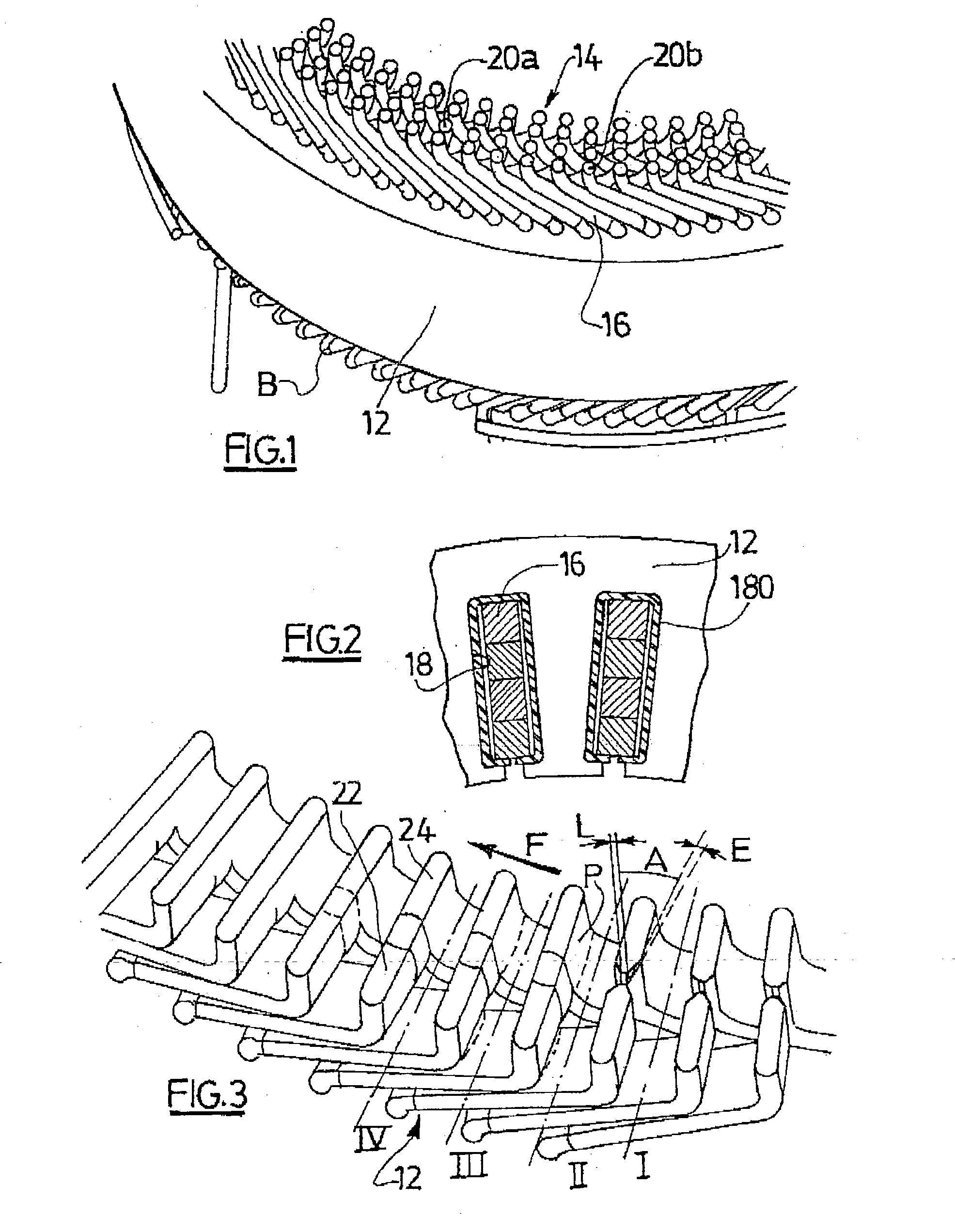

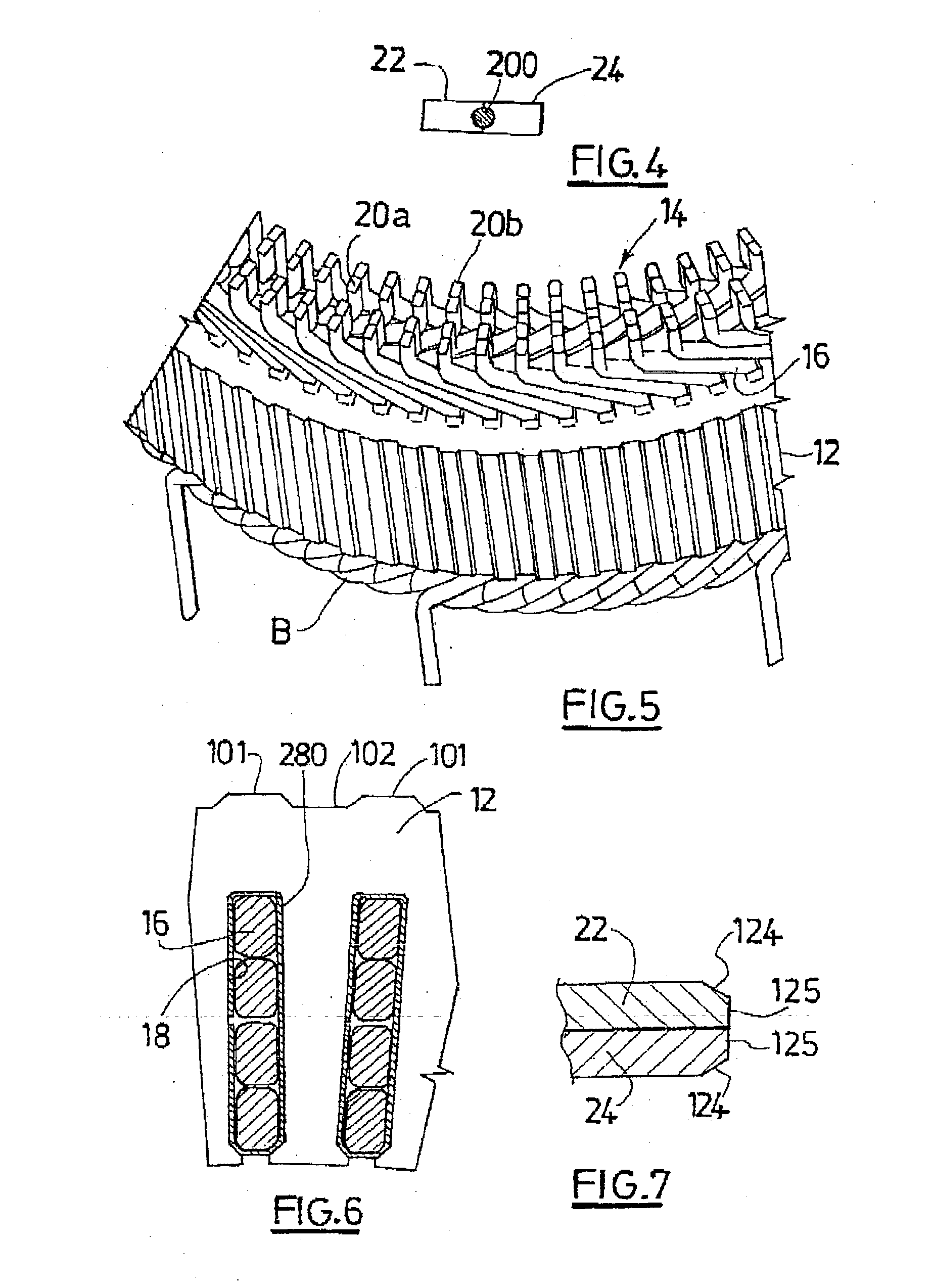

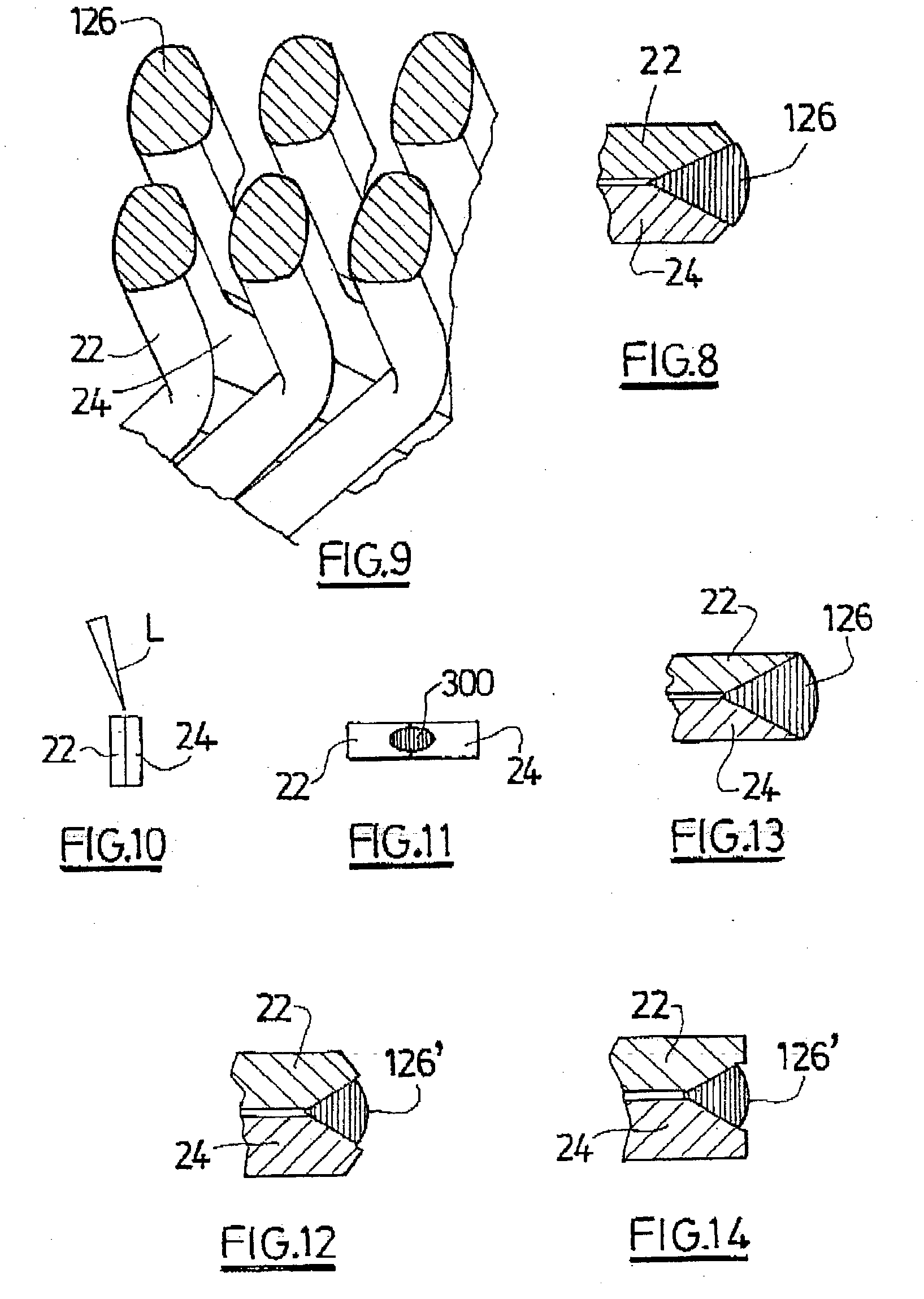

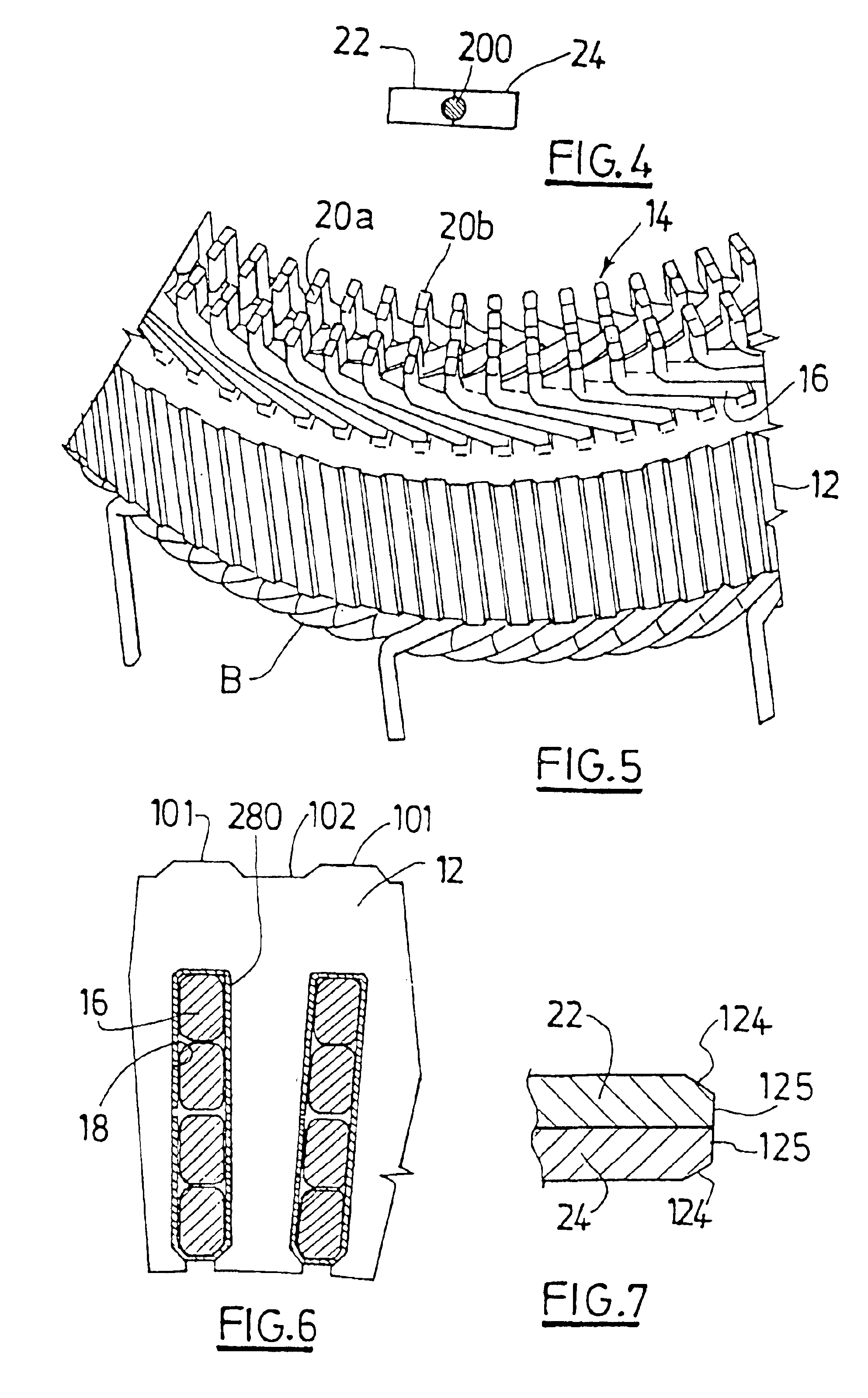

Method for assembling conductive segments of a rotor winding or stator winding in a rotary electric machine

InactiveUS20030159269A1Reduce assemblyRapid and simple and economicalMagnetic circuitSynchronous machinesElectrical conductorAlternator

The inventive method of assembling conductive segments (16) of a rotor winding or a stator winding in a rotary electric machine comprises the following stages: insertion of the conductive segments (16) into slots made in a core (12) of the rotor or stator, whereby the free ends of the conductive segments protrude beyond the latter, and welding of the free ends of the conductive segments in groups of two in order to form a winding (14) around the rotor or stator. The conductor statements are both made of wire which is electrically conductive and coated with an electrically insulating material. The coating of electrically insulating material is removed in the welding zone of the conductive segments by the means used for welding the latter. The invention can be used for conducting segments of a rotor or stator winding in an alternator in a motor vehicle.

Owner:VALEO EQUIP ELECTRIC MOTEUR

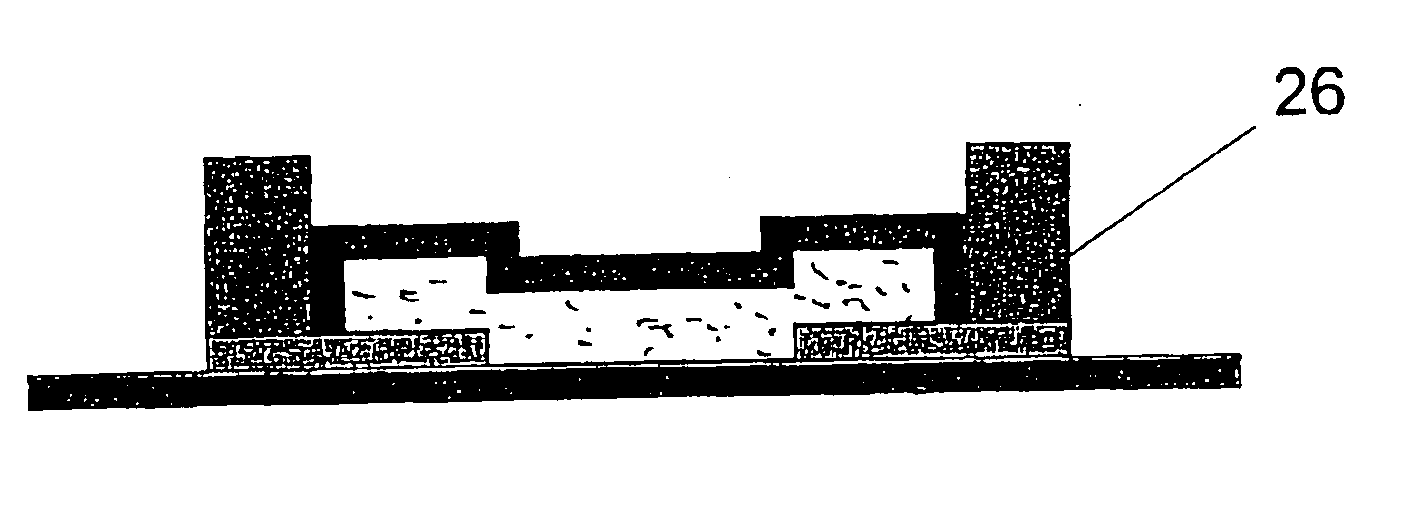

Method for sealing an active area of a surface acoustic wave device on a wafer

InactiveUS6877209B1Readily apparentPiezoelectric/electrostriction/magnetostriction machinesThermometers using material expansion/contactionAcoustic waveEngineering

One embodiment disclosed relates to a method for sealing an active area of a surface acoustic wave (SAW) device on a wafer. The method includes providing a sacrificial material over at least the active area of the SAW device, depositing a seal coating over the wafer so that the seal coating covers the sacrificial material, and replacing the sacrificial material with a target atmosphere. Another embodiment disclosed relates to an SAW device sealed at the wafer level (i.e. prior to separation of the die from the wafer). The device includes an active area to be protected, an electrical contact area, and a lithographically-formed structure sealing at least the active area and leaving at least a portion of the electrical contact area exposed.

Owner:SILICON LIGHT MACHINES CORP

Slip ring unit with a printed circuit board

InactiveUS7002269B2Simple and cost-effective constructionReduce component countTelevision system detailsRotary current collectorPrinted circuit boardElectrical contacts

A device for transferring electric currents that includes a slip ring unit that has a rotor with connecting wires and a stator and a printed circuit board fastened to the rotor, wherein the printed circuit board includes connectors in electrical contact with the connecting wires, wherein a torque required for rotary movement between the rotor and the stator is introduced via the printed circuit board.

Owner:LTN SERVOTECHN

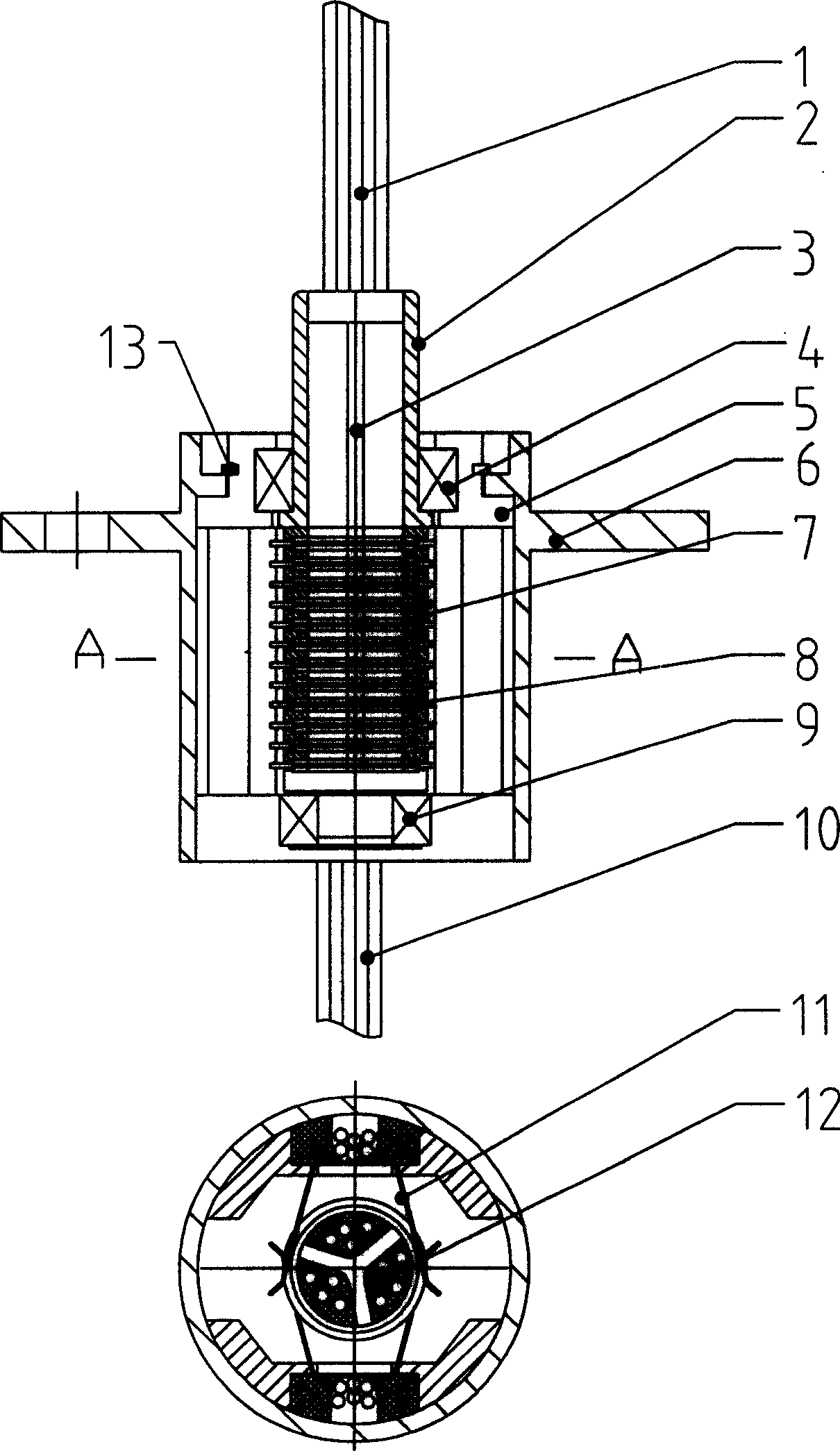

Laminated conductive rotary slip ring and producing process

InactiveCN1614830AReform processNot prone to displacement contactRotary current collectorSlip-rings manufactureEngineeringInjection moulding

The invention relates to a revolving and slip ring type circuit connector. It consists of spindle, insulating piece, conducting ring, bearing shell. The insulation piece and conducting ring with wire each sleeves on the triangle major axis. Then the bearing shell is sleeved and the dung is injected. The conducting revolving axis is easily made. The invention divides the conducting revolving axis into several individual component parts and changes the injection mould technology into lamination adhesive bonding technology.

Owner:刘磊 +1

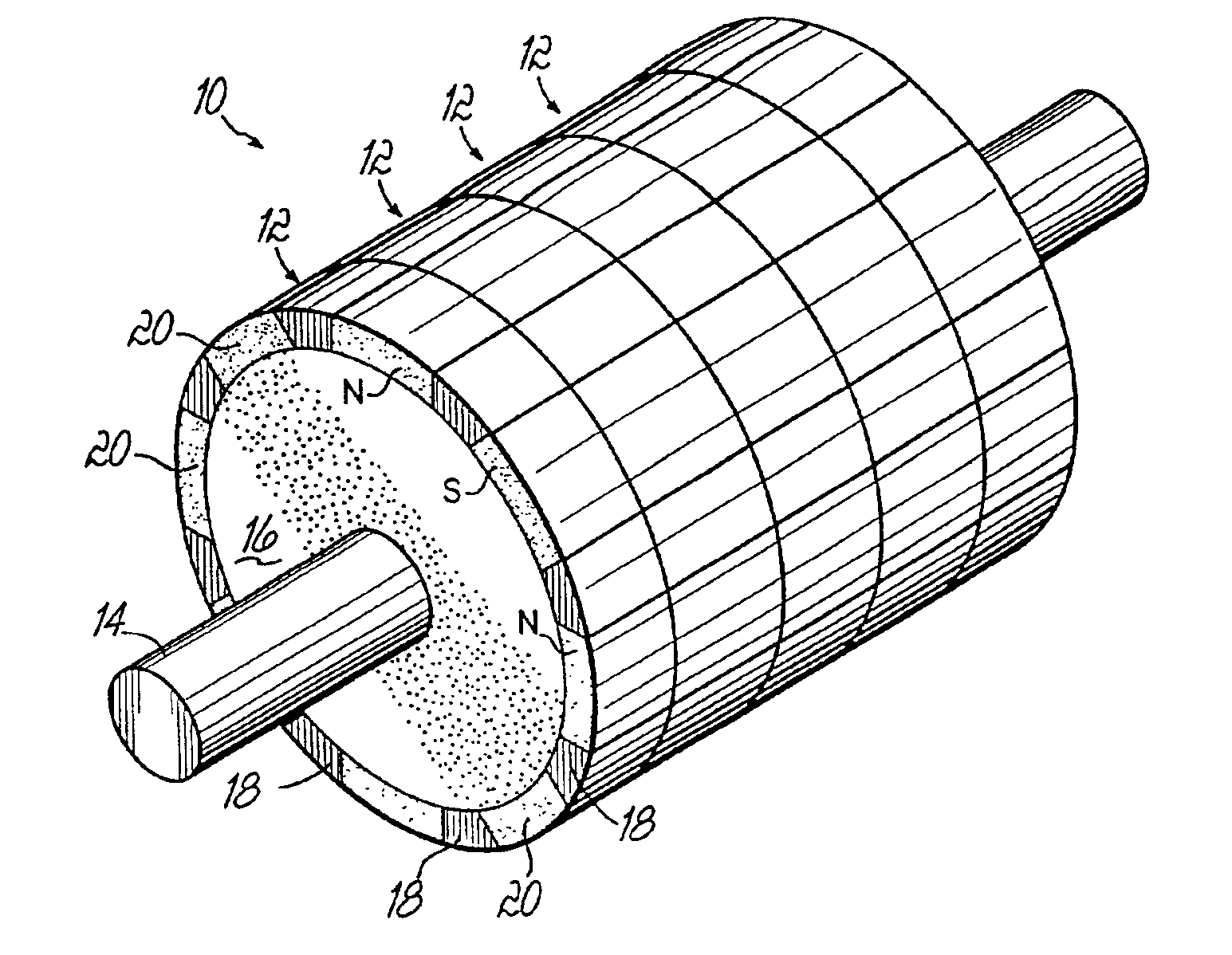

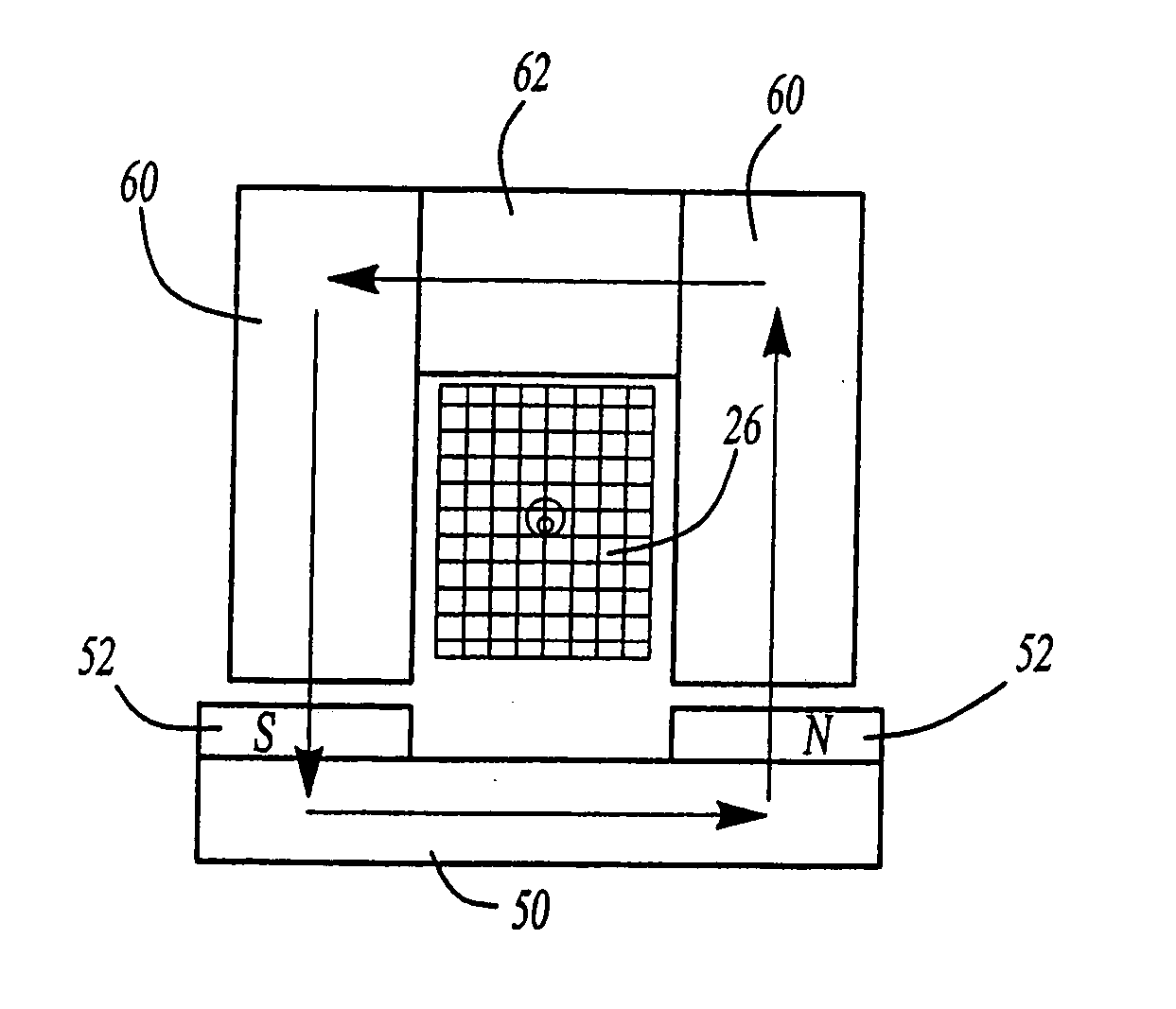

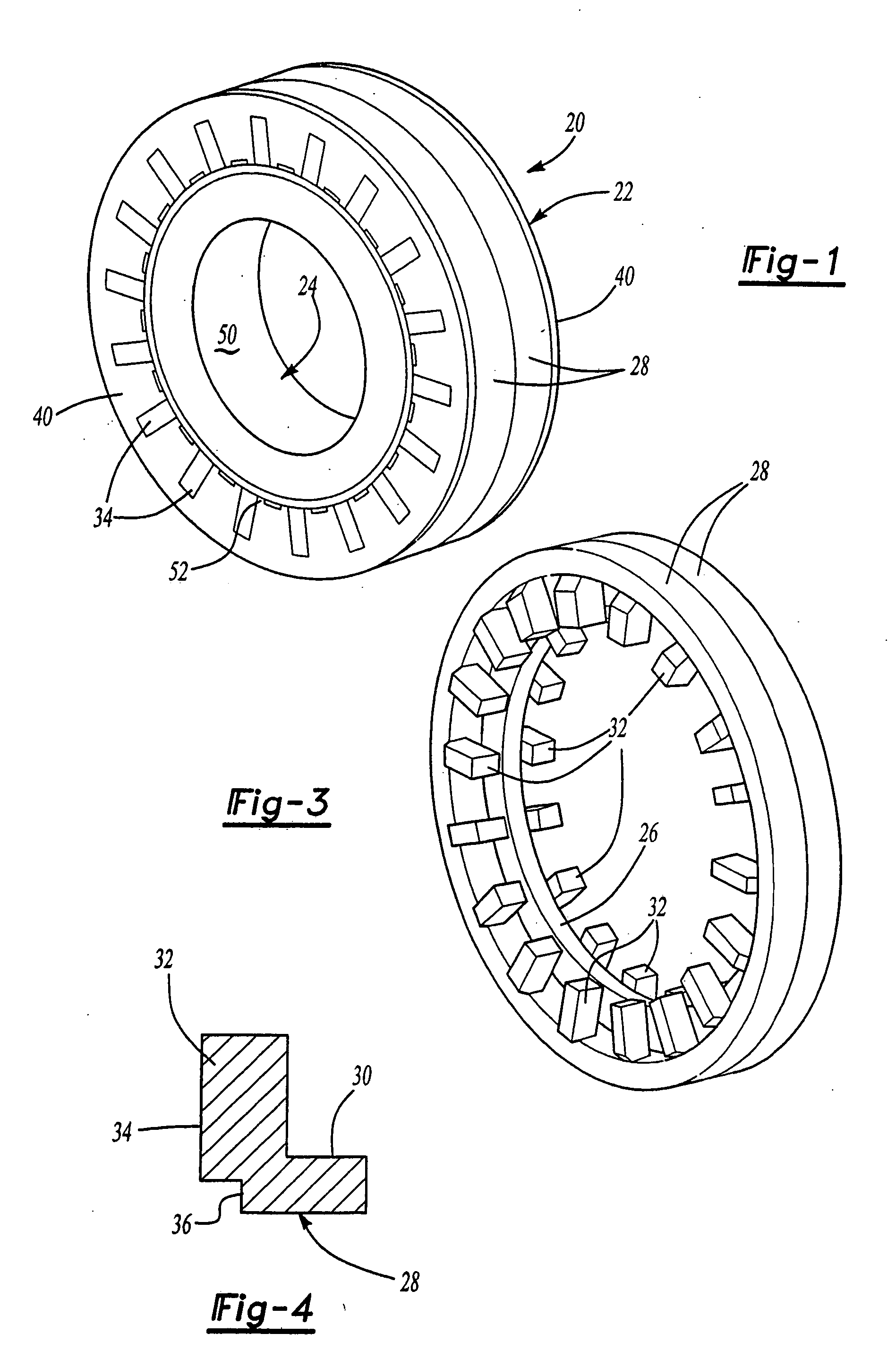

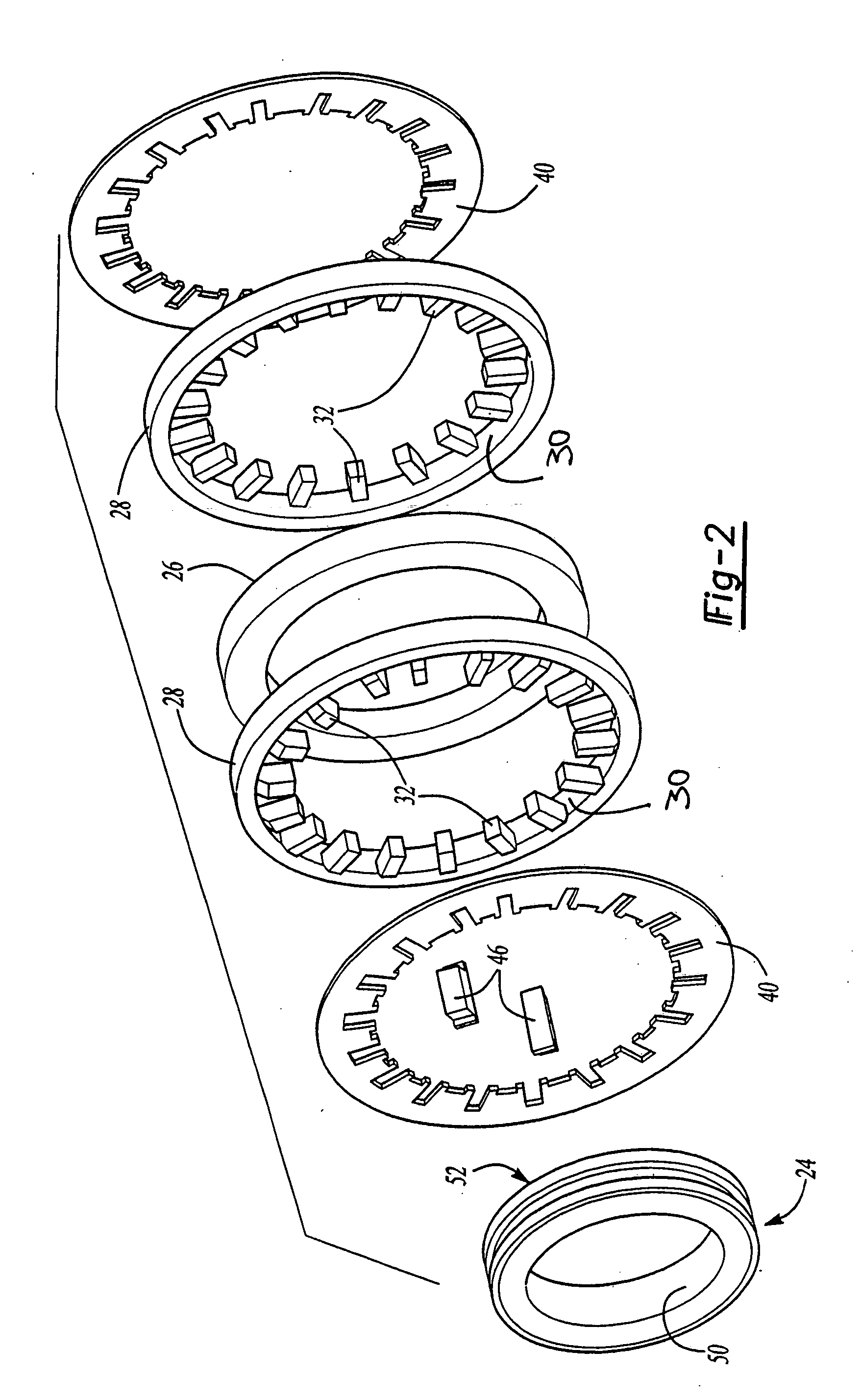

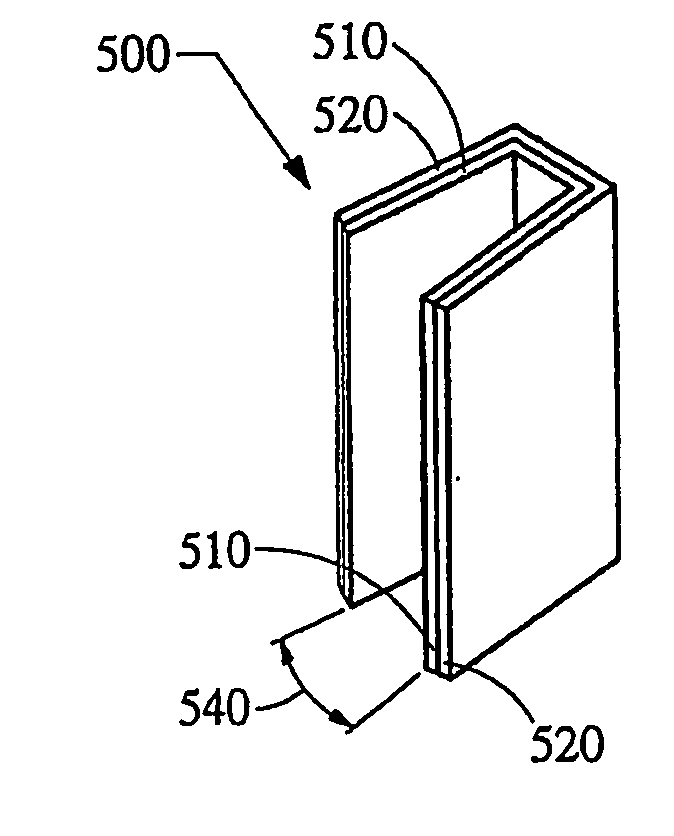

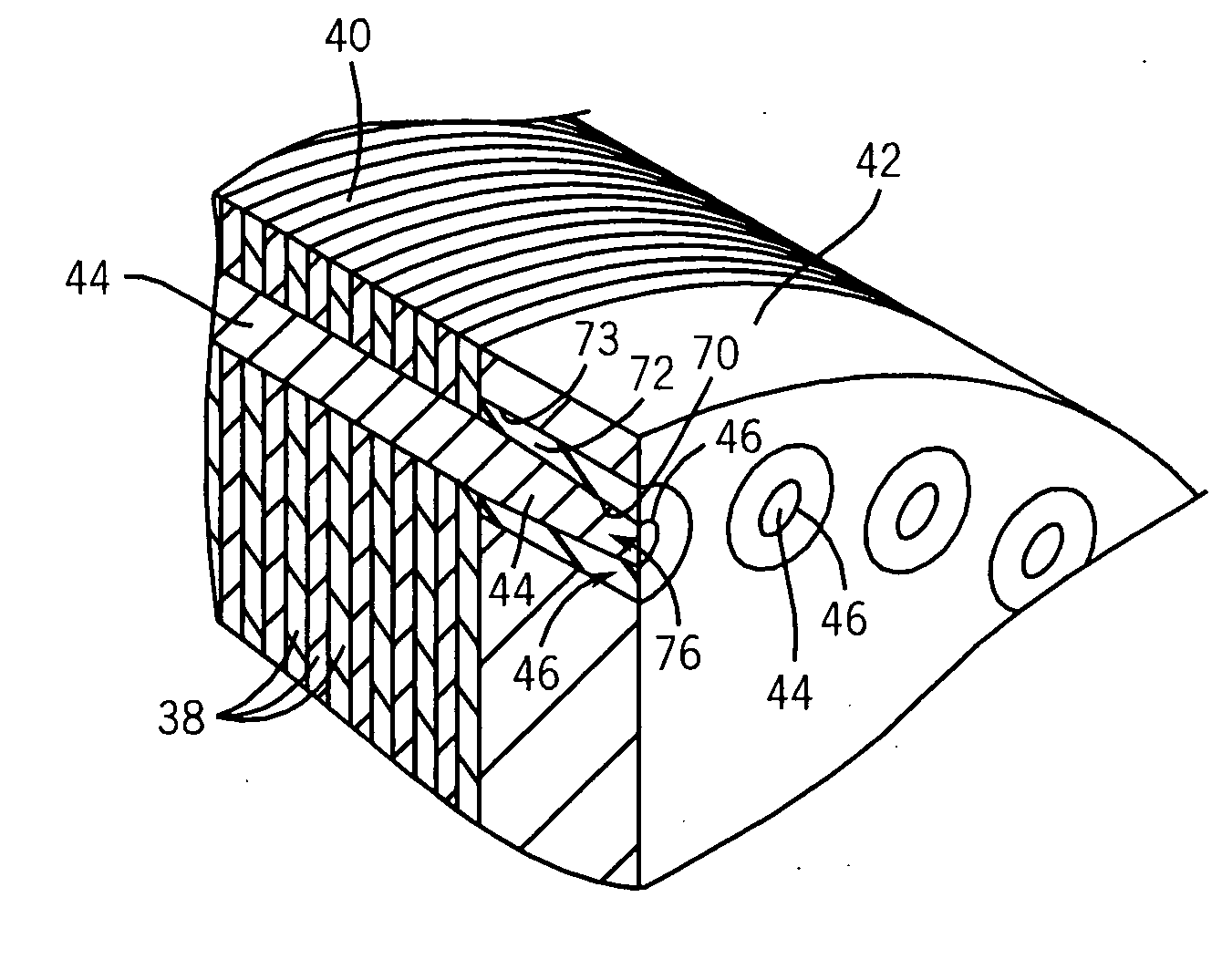

Fabricated components of transverse flux electric motors

InactiveUS20050204545A1Improve performanceRaise transfer toSynchronous machine detailsMagnetic circuit stationary partsTransverse fluxEngineering

Transverse flux electric motors are made using a unique process where individual components are premade and then assembled together. A stator portion is made by nesting a coil between two stator core portions. The stator core portions are made from laminations or sintered powder materials. A separate rotor portion is provided with a core and two permanent magnets that interact with projections on the stator core portions. In one example, the stator includes support members that support additional magnetic core portions to magnify the magnet flux density in the air gap between the stator and the rotor.

Owner:OTIS ELEVATOR CO

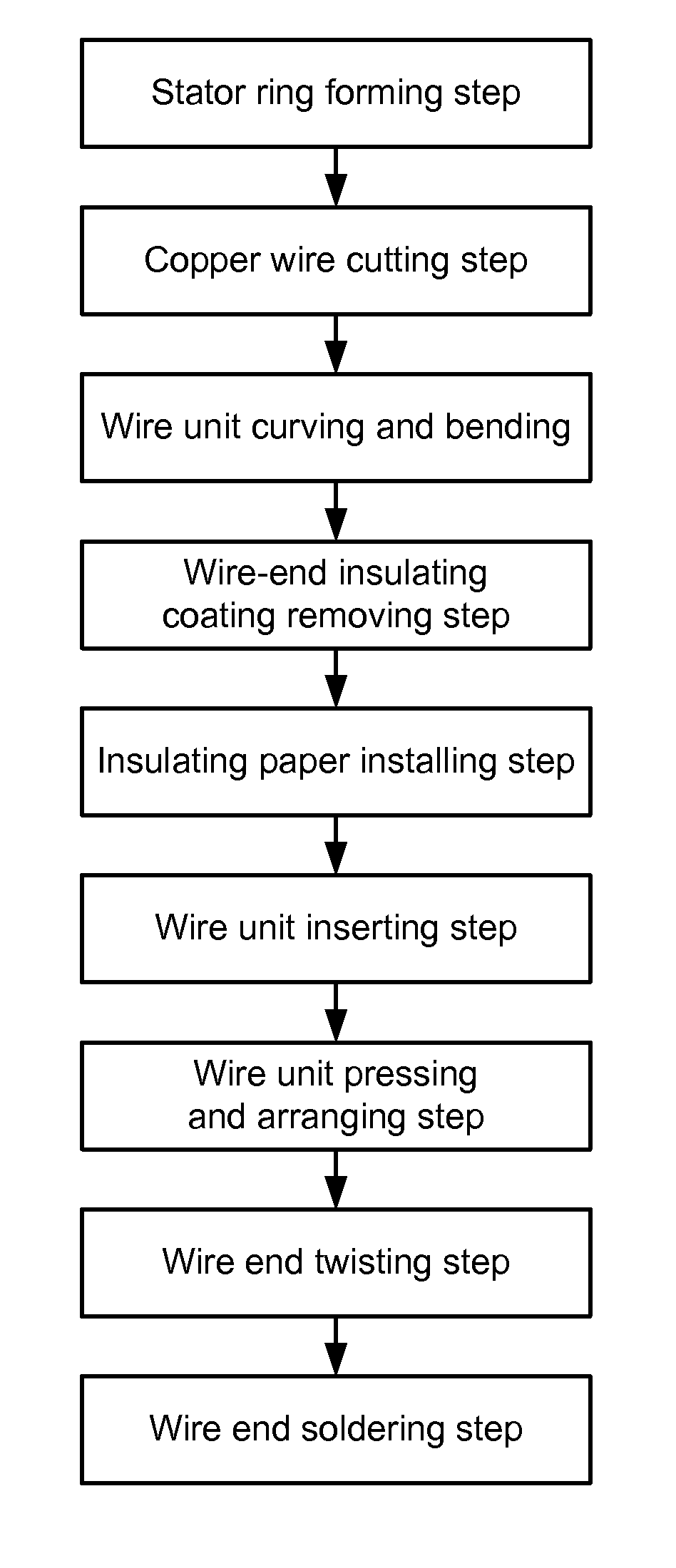

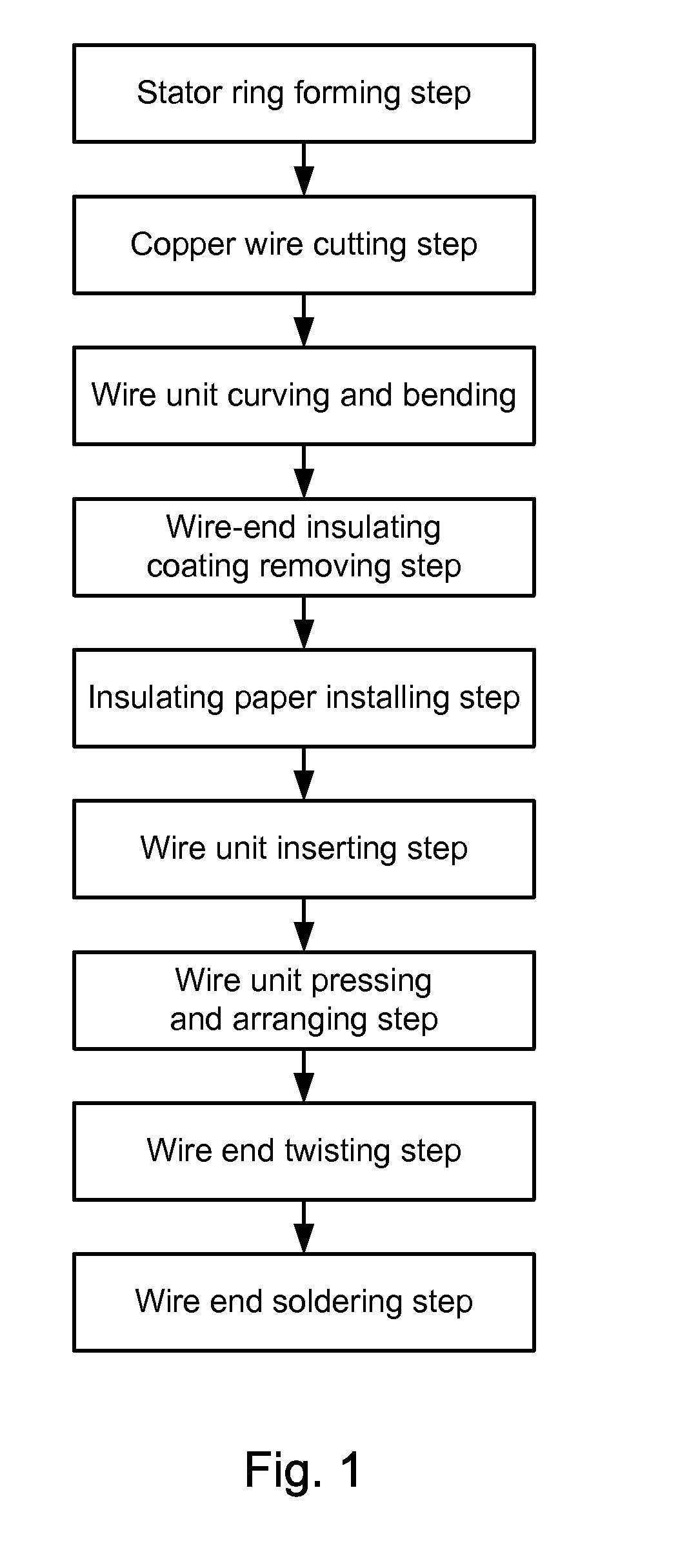

Method for making wound stator of automotive generator

InactiveUS8296926B2Efficiency problemEffective controlManufacturing dynamo-electric machinesMetal working apparatusCopper wireEngineering

A method for making a wound stator of an automotive generator is provided for replacing the conventional winding technique. The method includes: forming a stator ring provided with a plurality of annularly arranged radial through slots; cutting a copper wire into a plurality of wire units each having a rectangular cross section; inserting the wire units into the through slots in an interlacing manner; and soldering wire ends of the wire units sequentially so as to form a connected loop.

Owner:VICTORY IND CORP

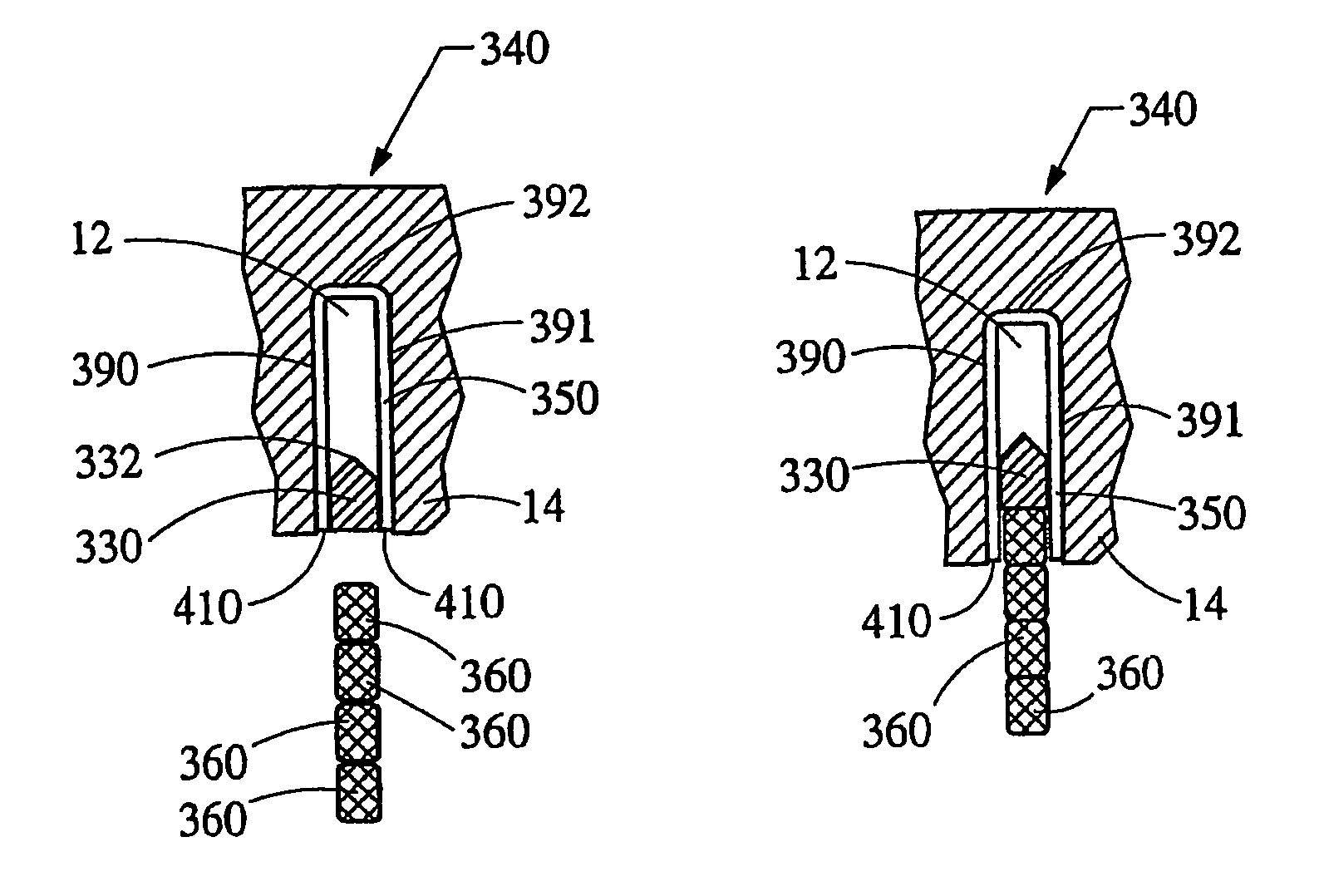

Stator of a rotary electric machine having secured core slot insulators

ActiveUS20070222323A1Less spring forceLess secureSynchronous generatorsWindings insulation shape/form/constructionElectric machineEngineering

A stator of a rotary electric machine having secured core slot insulators includes a multi-phase stator winding, having a plurality of slot segments that are adapted to be radially inserted into a plurality of circumferentially spaced axially-extending core slots in a surface of a cylindrically-shaped stator core. The stator winding includes the plurality of slot segments alternately connected at the first and second ends of the stator core by a plurality of end loop segments to form the winding. The plurality of core slots house an insulator to electrically isolate the slot segments from the core slots. The insulator is secured to the sides of the core slot prior to the process of radial inserting the plurality of slot segments into the plurality of core slots of the cylindrically-shaped stator core.

Owner:BORGWARNER INC

Method for assembling conductive segments of a rotor winding or stator winding in a rotary electric machine

InactiveUS6915556B2Reduce assemblyRapid and simple and economicalMagnetic circuitSynchronous machinesAlternatorElectric machine

This process for assembling conductive segments (16) of a rotor or stator winding of a rotary electrical machine comprises the stages consisting in inserting the conductive segments (16) in slots arranged in a core (12) of the rotor or of the stator in such a way that the conductive segments project beyond the latter by their free ends, and in welding the conductive segments in pairs by their projecting free ends to form a winding (14) around the rotor or the stator.The conductive segments each being formed by a wire of electrically conductive material covered with a layer of electrically insulating material, the layer of electrically insulating material is eliminated, in the zone in which the conductive segments are welded, by the means used to weld the latter.Application to the assembly of conductive segments of a rotor or stator winding of a motor-vehicle alternator.

Owner:VALEO EQUIP ELECTRIC MOTEUR

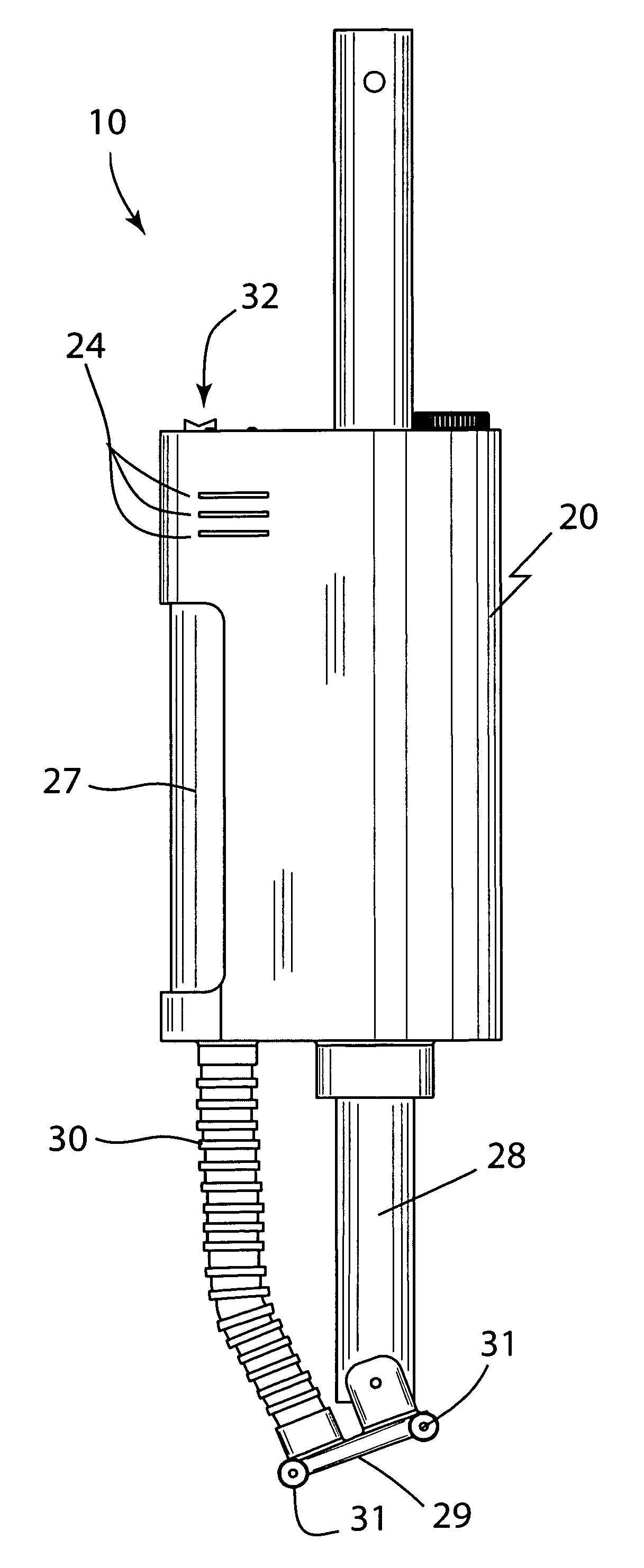

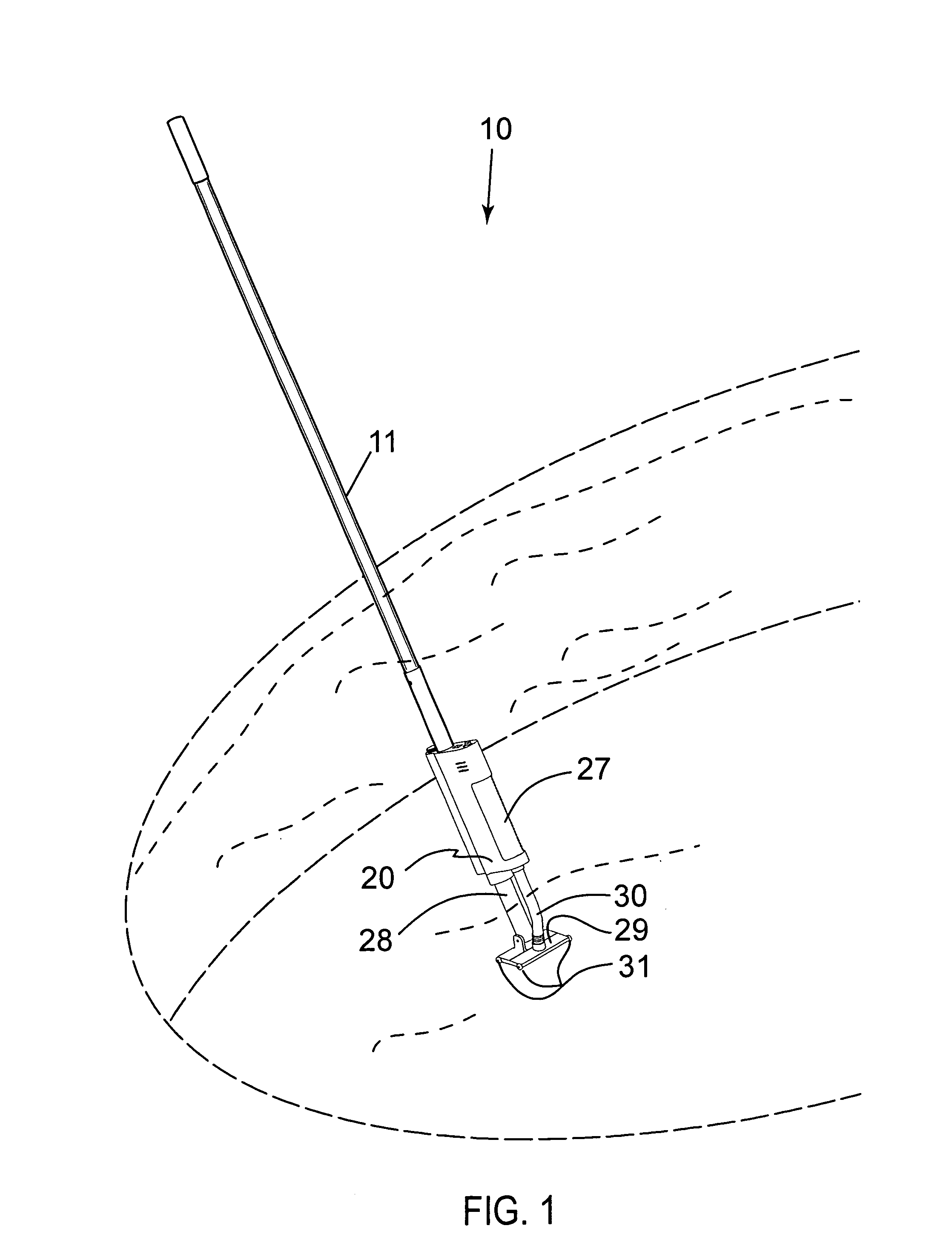

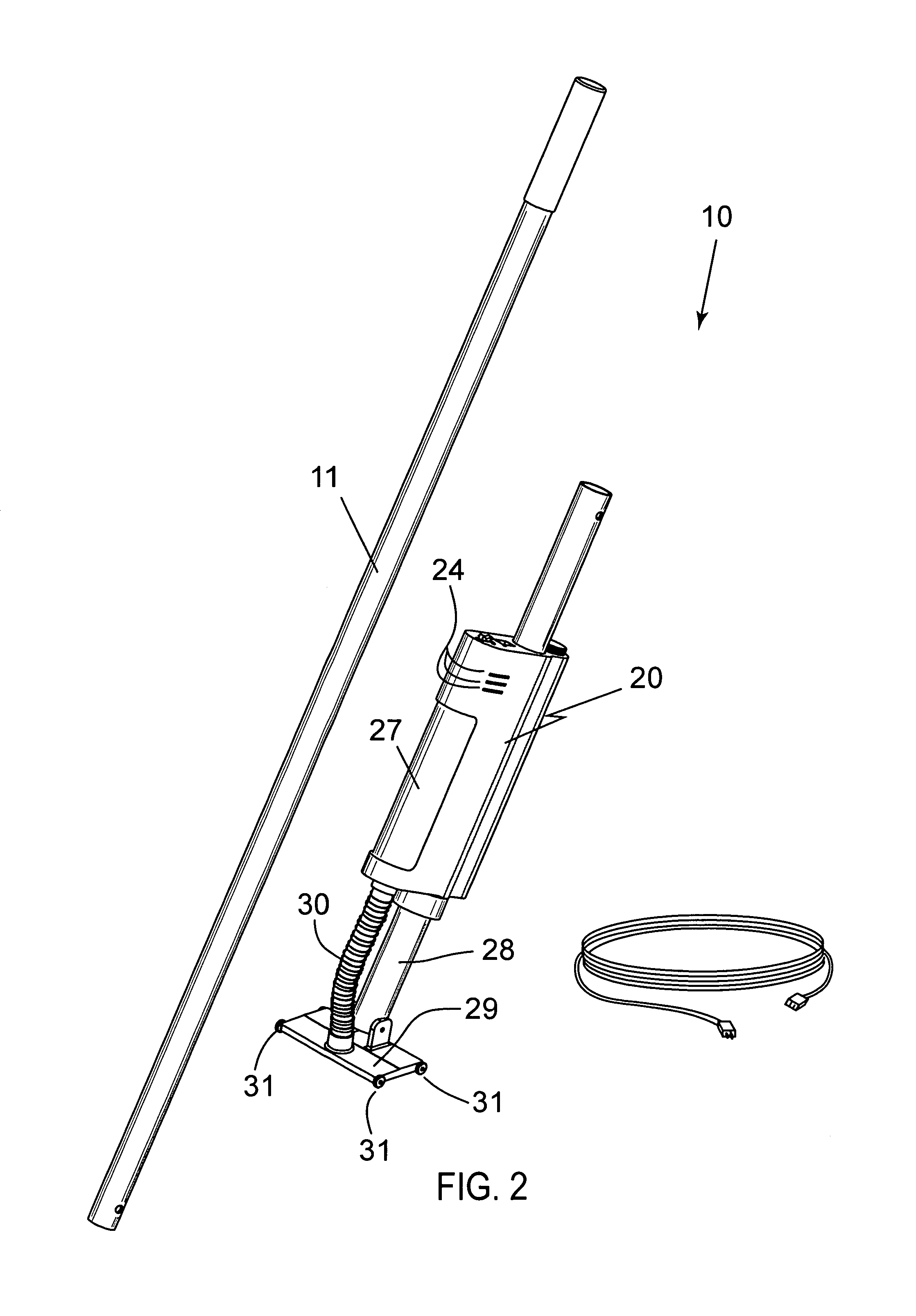

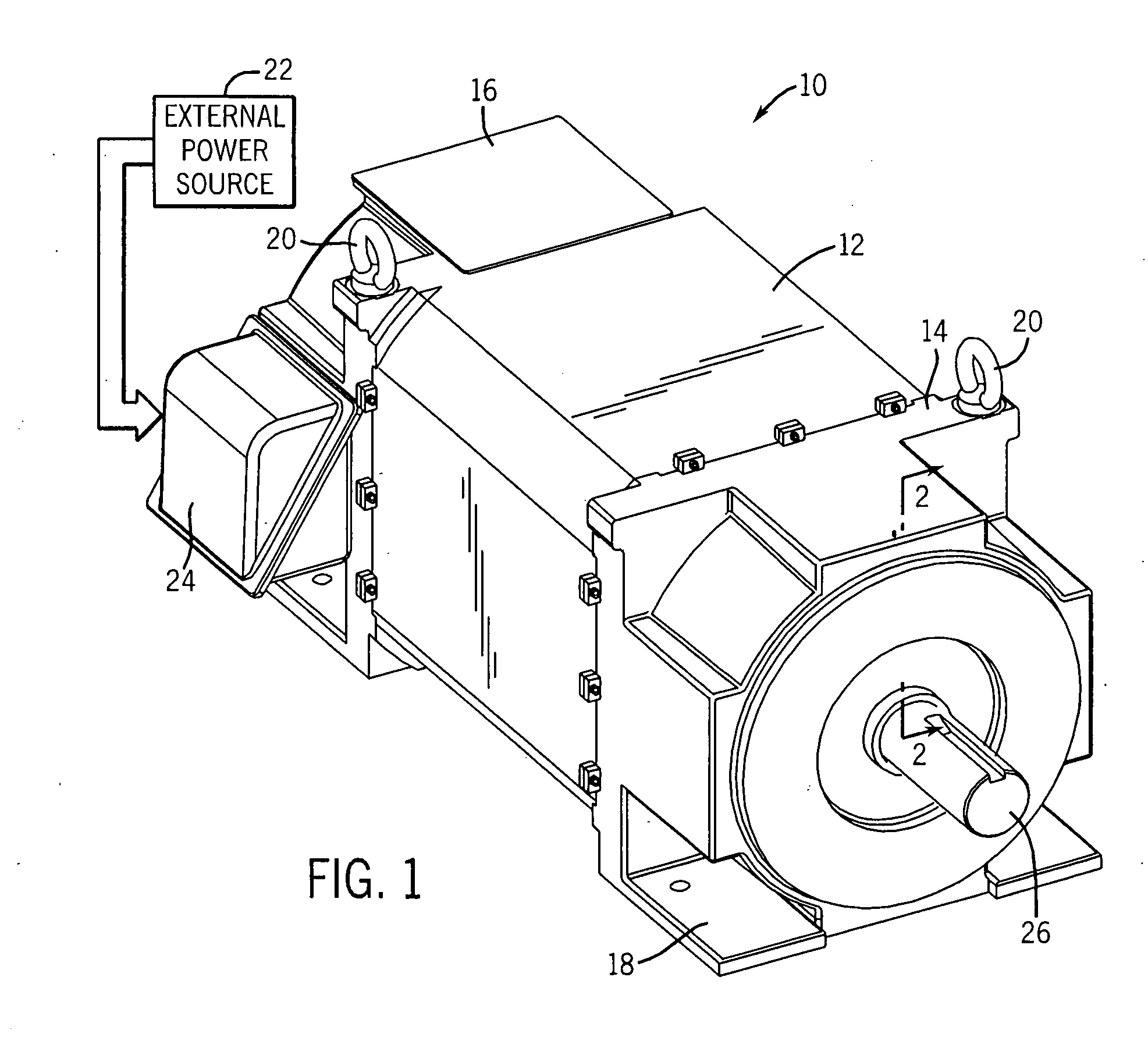

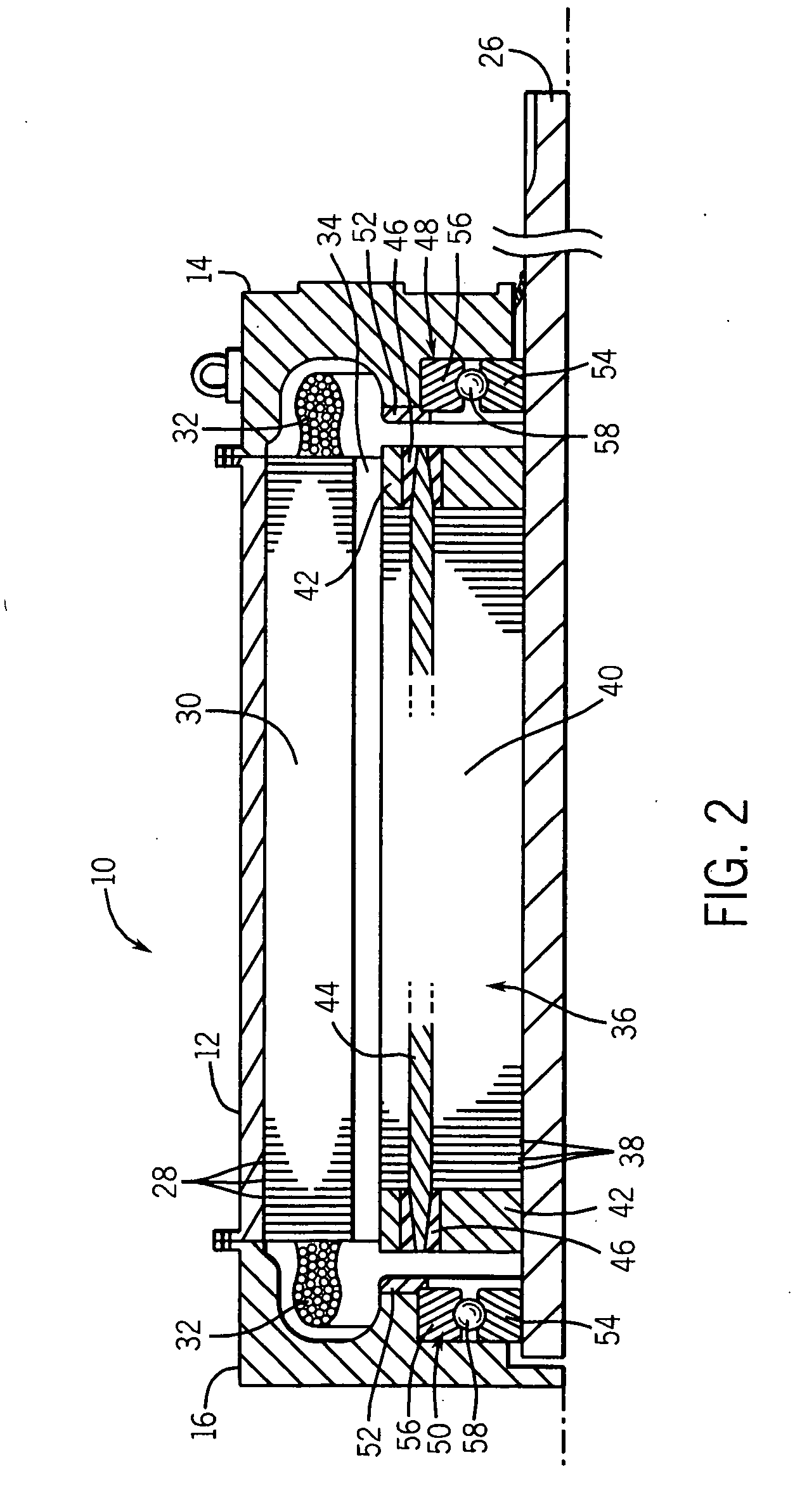

Pool cleaning vacuum employing multiple power supply sources and associated method

InactiveUS7437790B1Effective guidanceContinuous operationCleaning filter meansSuction filtersEngineeringElectrical and Electronics engineering

A pool cleaning vacuum employing multiple power supply sources and associated method includes a body including first, second and third vertically juxtaposed chambers formed therein. The chambers share a wall with the second chamber wherein the third chamber is isolated therefrom. A motor assembly and a filter section are housed within the first chamber. The filter section is located downstream of the motor assembly, and has an open lateral face exposed to the aqueous environment. An anchor shaft is seated within the second chamber and extends through an entire longitudinal length of the body. A vacuum head is pivotally attached to the anchor shaft. The vacuum head includes a conduit in communication with the filter section, and a plurality of wheels rotatably coupled to opposed corners thereof. A mechanism transmits a predetermined quantity of power to the motor assembly.

Owner:AJELLO MIKE

Method of manufacturing stator coil of rotary electric machine

InactiveUS6938323B2Improved and simplified methodSimple manufacturing processFilament handlingManufacturing stator/rotor bodiesAlternatorElectric machine

A stator coil of a rotary electric machine such as an alternator for use in an automobile is composed of a plurality of U-shaped conductor segments inserted into slots formed in a stator core. Each segment has a head portion and two legs extending from the head portion. The plurality of segments include regular segments each having a regular distance between two legs (a regular slot-pitch) and special segments each having a special slot-pitch different from the regular slot-pitch. The head portions of both the regular and the special segments are simultaneously twisted to form the respectively required slot-pitches after a preliminary twist is given to the special segments. In this manner, a process of manufacturing the stator coil is simplified.

Owner:DENSO CORP

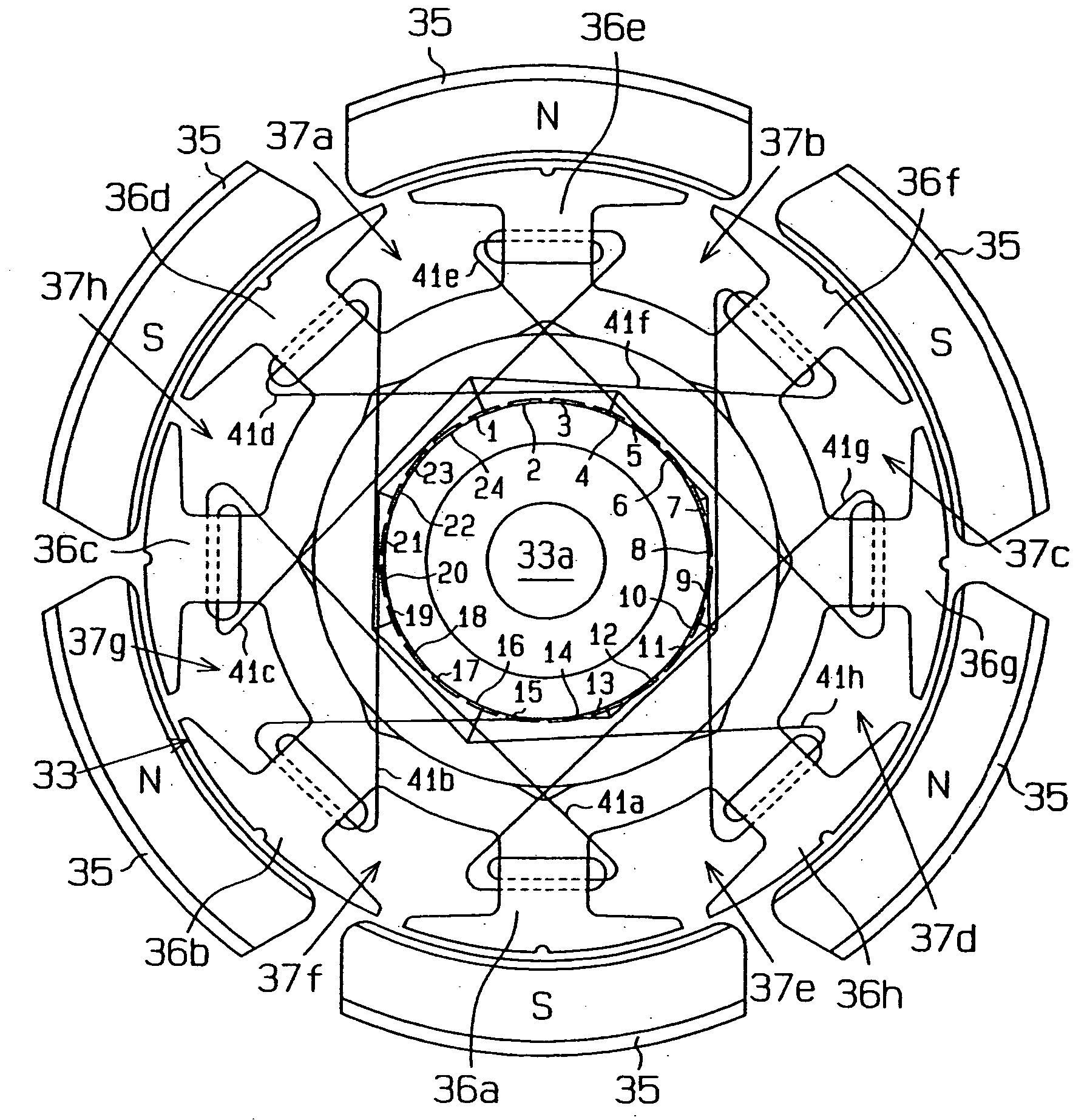

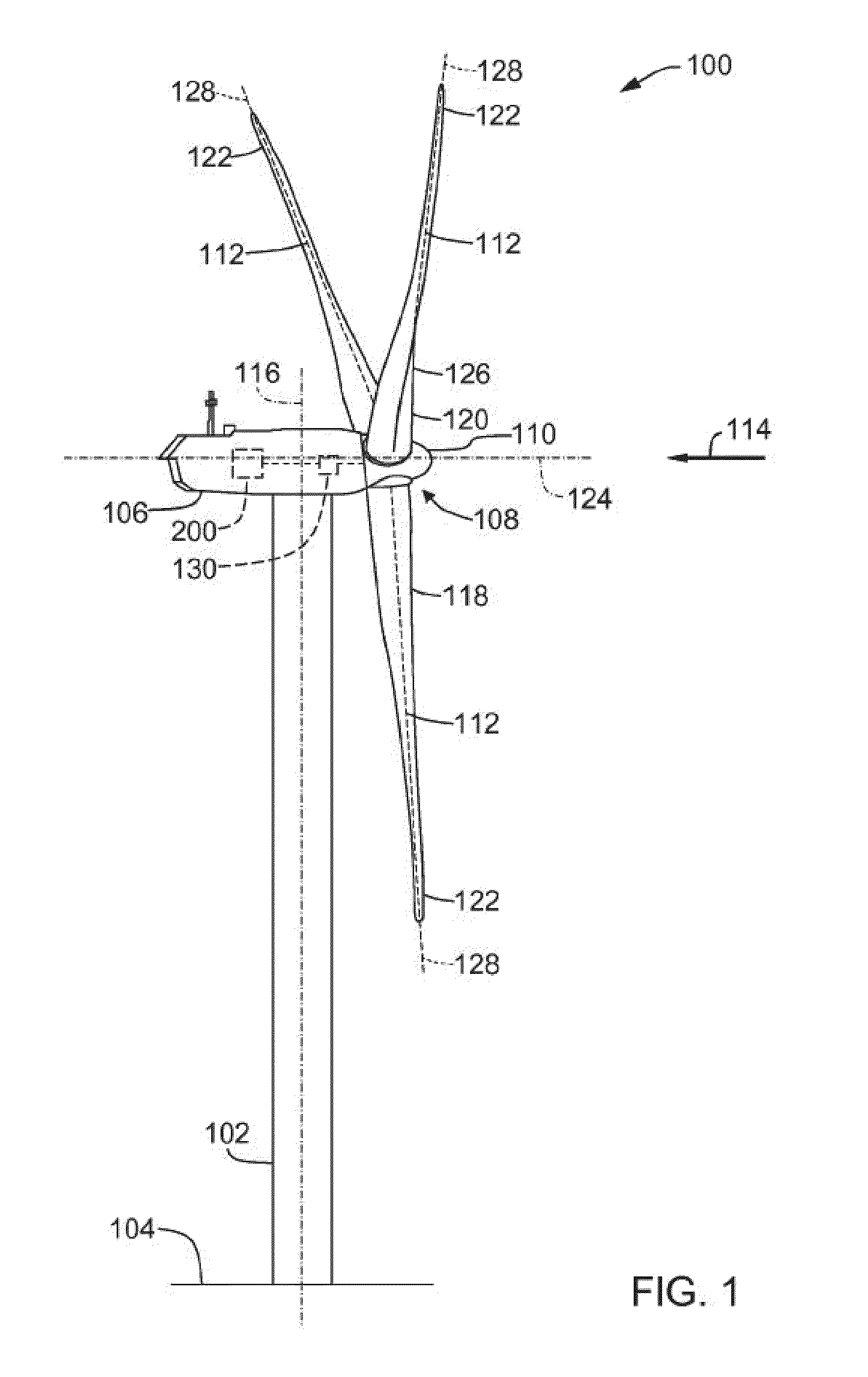

Core of rotation apparatus, method for manufacturing core, and rotation apparatus

A motor includes a stator having magnets, a rotor having teeth, a commutator secured to the rotor, and brushes. A coil is wound about each tooth. The commutator is connected to the coils. The brushes slidably contact the commutator. The number of the magnets and the number of the teeth are determined such that the resultant of torque vectors that act on the teeth is zero. For example, the number of the magnet is six, and the number of the teeth is eight. As a result, the rotor is prevented from vibrating.

Owner:DENSO CORP

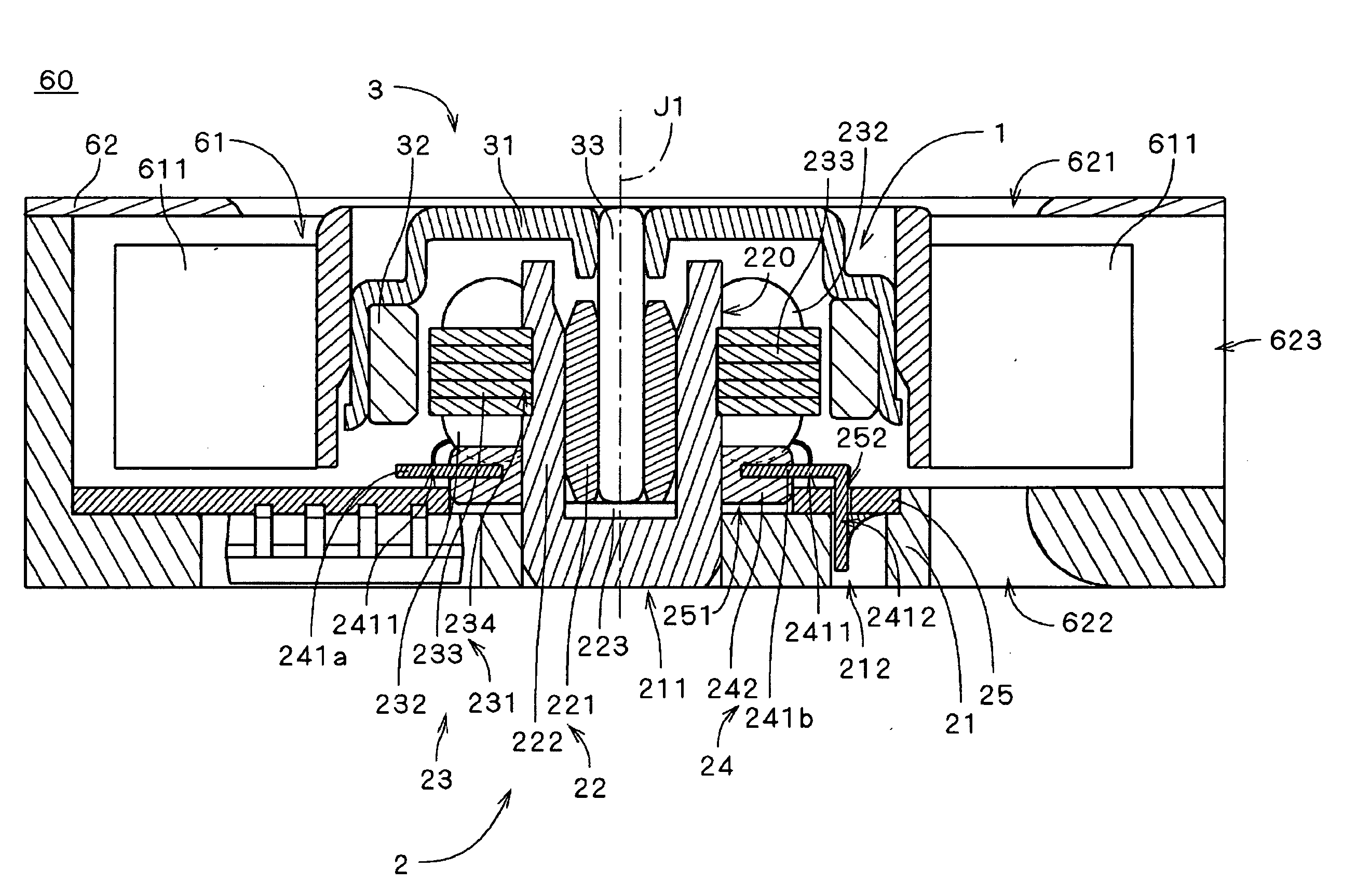

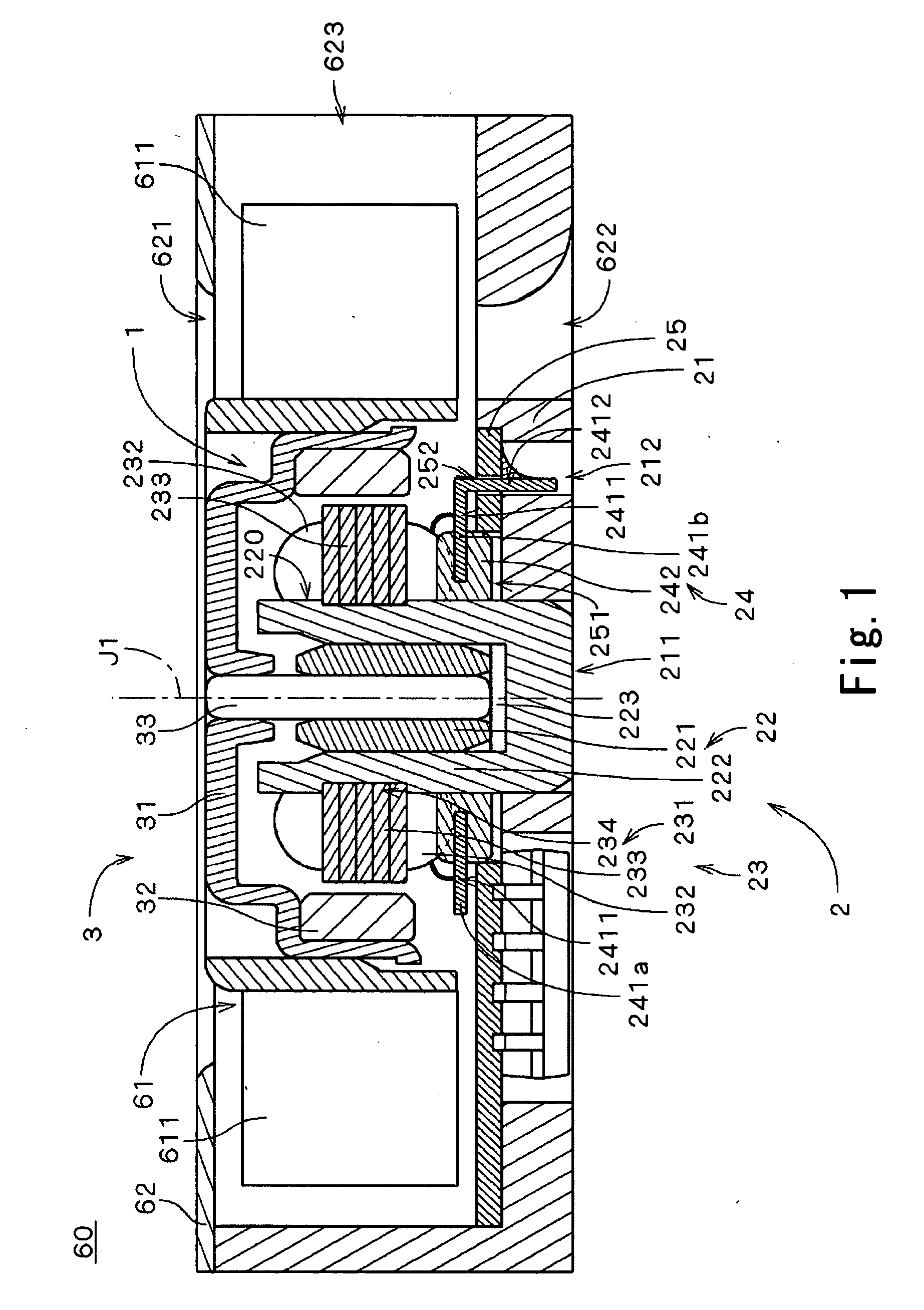

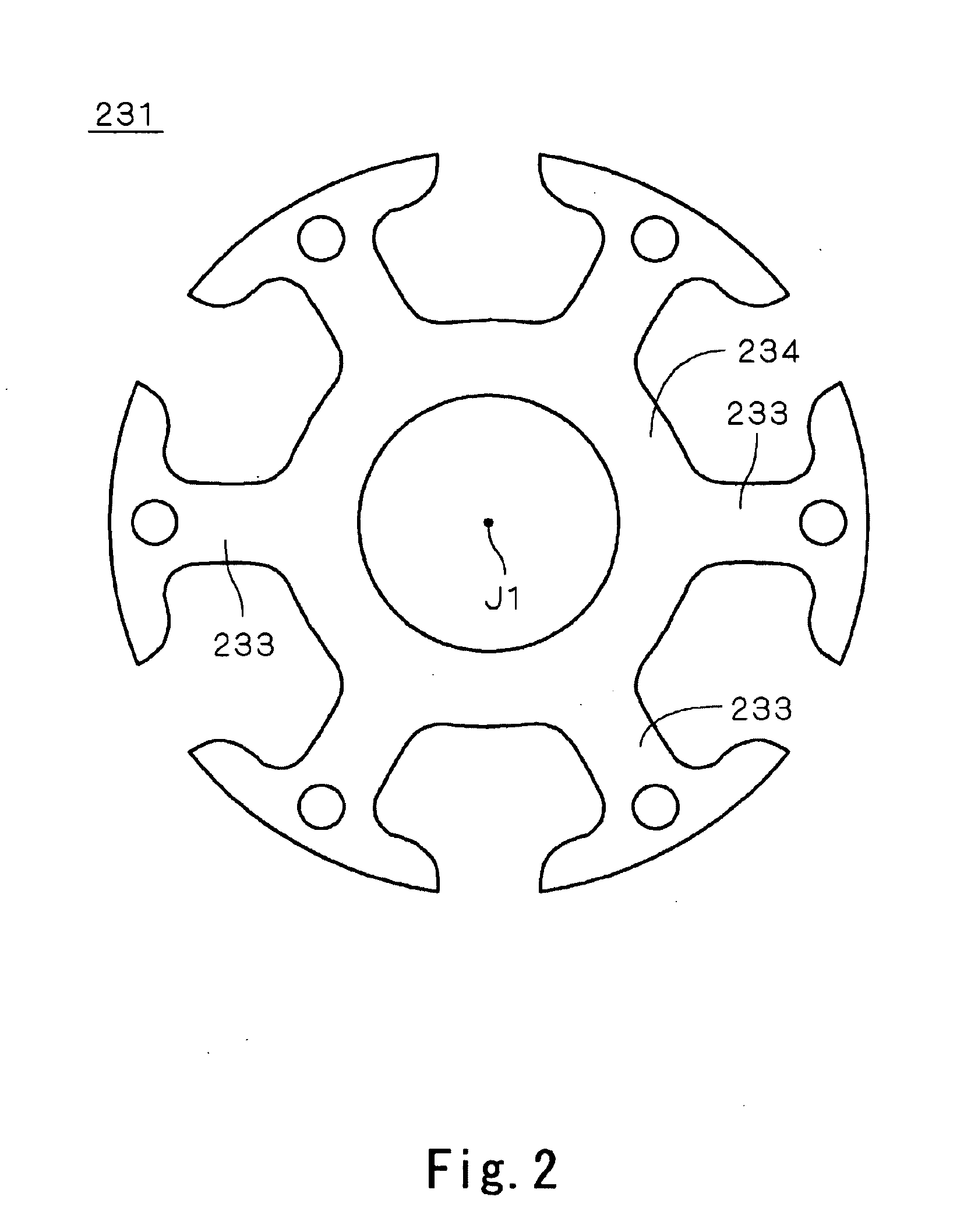

Method of manufacturing stator unit, and motor using the stator

ActiveUS20070007834A1Easy to manufacturePreventing open circuitWindingsMagnetic circuitEngineeringElectric motor

In manufacturing of the stator unit 2 according to one preferred embodiment of the present invention, a plurality of terminal pins are arranged in an axially spaced manner from a plurality of the coils during a twining process of the wires from the coils 232 to the terminal pins 241. Then, after the wire is twined to the terminal pins, the terminal pins connected to the coils are moved along the outer side face of the sleeve housing, functioning to as a guide portion for the terminal pins. By virtue of the configuration, the terminal pins 241 may be approximated to the coils without applying the tension on wire, and the stator unit may be made thin with preventing the open circuit of the wires.

Owner:NIDEC CORP

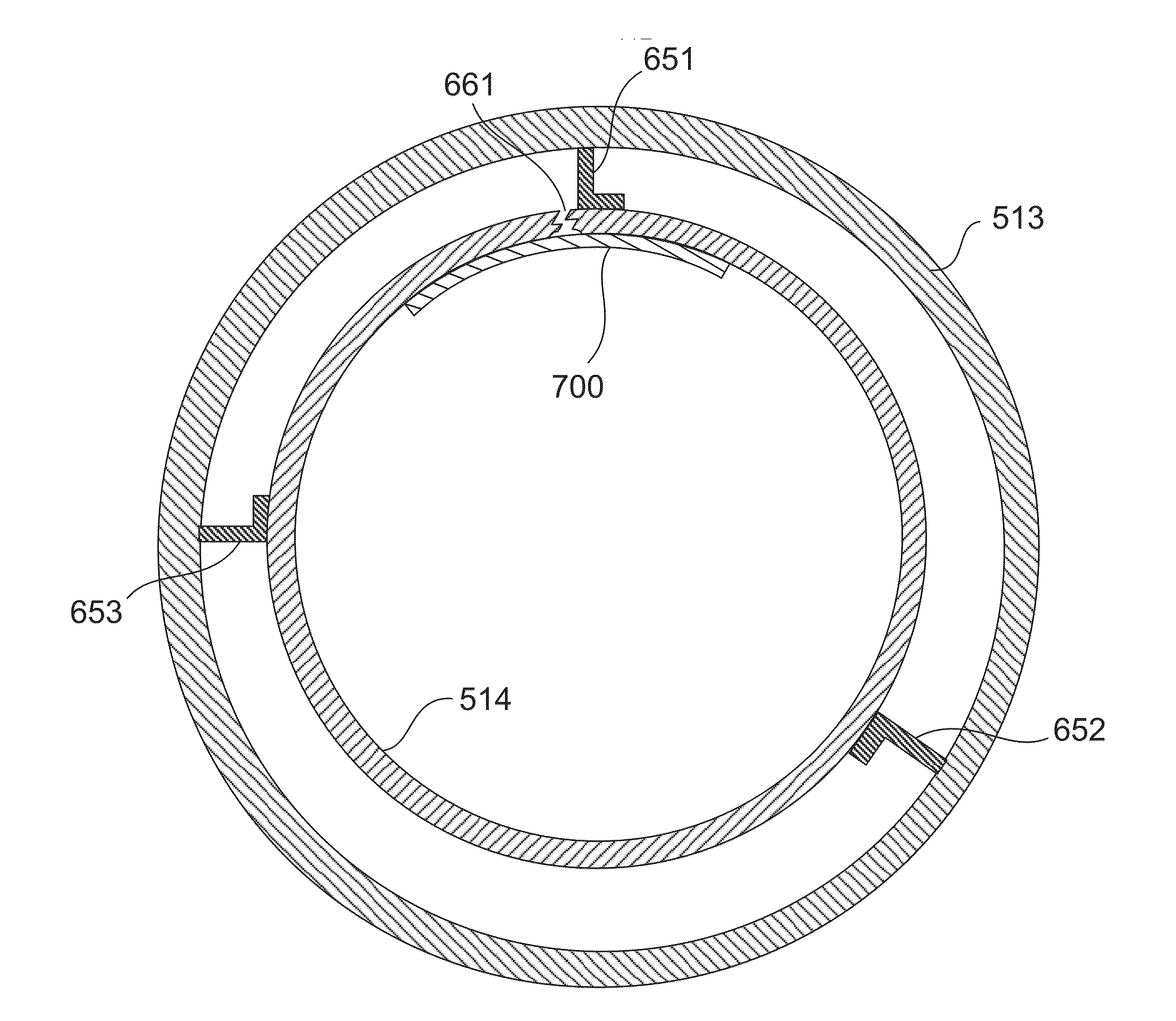

Method and system for repairing or servicing a wye ring

A method for repairing or servicing a wye ring of a generator includes the steps of, dismantling the generator to gain access to the wye ring, determining a fault location in the wye ring; and attaching a patch to the wye ring in an area of the fault location. The patch provides an electrical path around the fault location so that the generator is repaired.

Owner:GENERAL ELECTRIC CO

Production method of a sequentially joined-segment stator coil of a rotary electrical machine

InactiveUS6910257B1Reduce variationRelieve pressureFilament handlingManufacturing stator/rotor bodiesElectric machineStator coil

A production method of a polyphase sequentially joined-segment coil of a rotary electric machine and a product produced by the same are provided. A production machine includes pairs of tines working to catch heads of conductor segments when they are twisted using rings. The tines are designed to be rotatable about an axis of the rings following rotation of the rings to absorb stress acting on insulating coating on the heads of the segments to minimize rubbing of the insulating coatings, thereby ensuring a desired degree of electrical insulation of the stator coil.

Owner:DENSO CORP

Stator for outer rotor multipole generator and method of assembling the stator

InactiveUS20060103247A1Improve efficiencyEfficient assemblyWindingsMagnetic circuitElectrical conductorBobbin

An outer rotor type multi-pole generator stator is provided in which a lead wire extending from a coil is connected by fusing to a connecting terminal fitted into and fixed to a bobbin wherein, in order to avoid the lead wire becoming slack after connection by fusing and enable assembly of the stator to be carried out efficiently, the connecting terminal (32) is formed from an external conductor connection terminal portion (32a) that is fitted into and fixed to a fitting hole (31), a connecting plate portion (32b) having one end thereof connected at right angles to the external conductor connection terminal portion (32a) and extending toward the radially inner side of the stator, and a clamping plate portion (32c) provided so as to be connected to the connecting plate portion (32b) so that the lead wire (33) can be held between the clamping plate portion (32c) and the other end portion of the connecting plate portion (32b) and connected by fusing, and the bobbin (24) is provided on the inner periphery thereof with a channel (43) having one end thereof facing the other end of the connecting plate portion (32b) and opposite ends thereof open so that one electrode of a pair of electrodes (44, 45) for connecting by fusing can be inserted through the channel (43).

Owner:SAWAFUJI ELECTRIC COMPANY

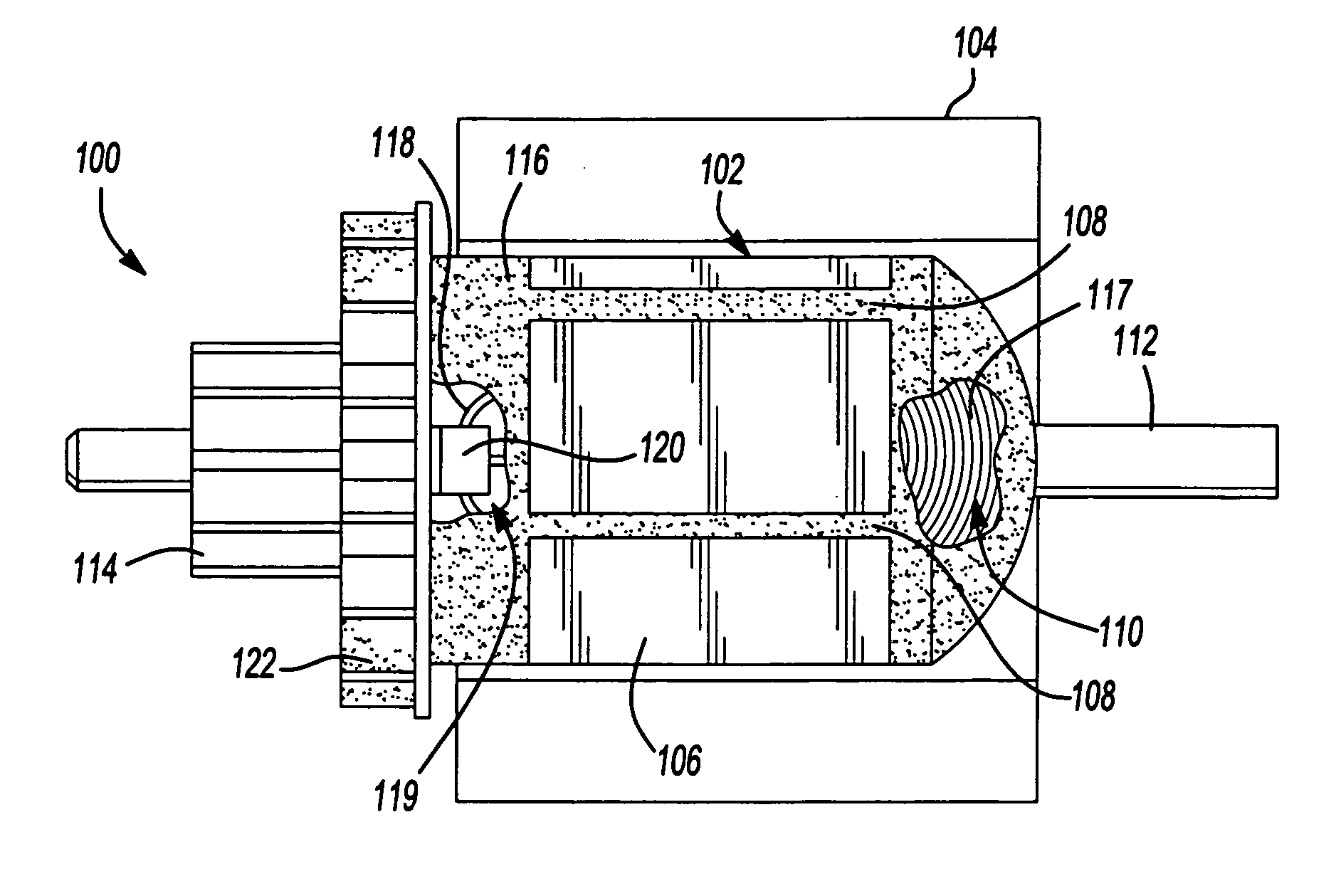

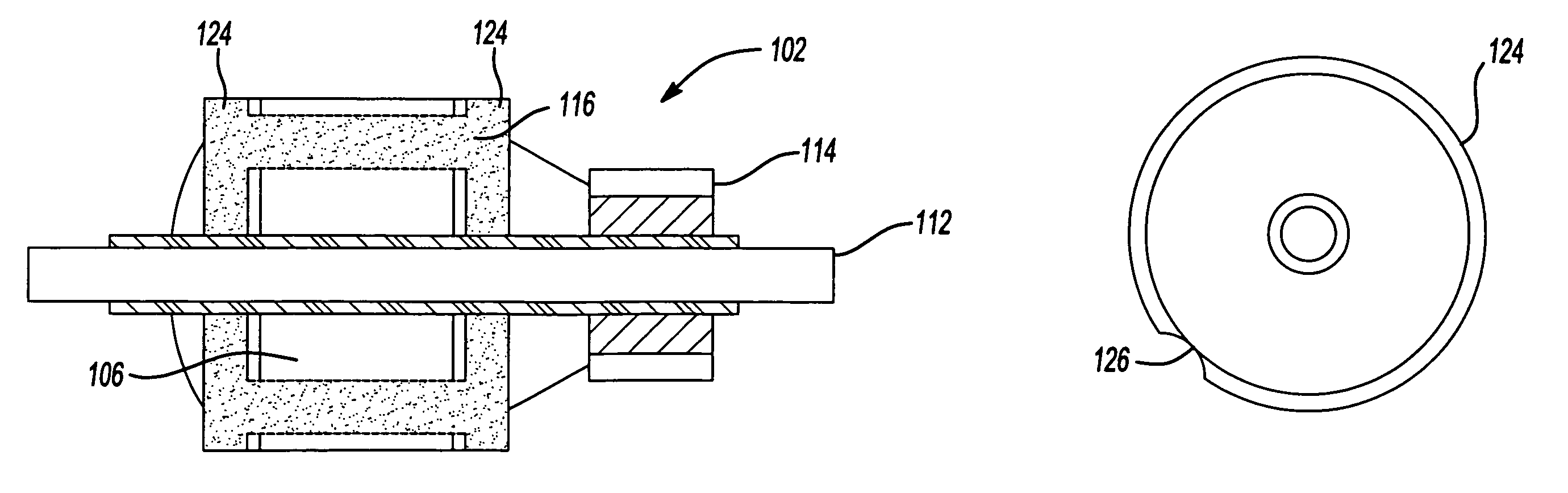

Fabricated rotor assembly fixture and method

InactiveUS20070062026A1Improving rotor performanceEasy constructionMagnetic circuit rotating partsSynchronous motorsMechanical engineeringPiston

In accordance with one embodiment, the present technique provides an apparatus for assembling a rotor. The exemplary apparatus includes a base that has a central aperture and a seating surface for receiving the rotor. An arbor then extends through the central aperture, the arbor having a longitudinal axis that is substantially orthogonal to the seating surface, and including threaded ends opposite with respect to one another. The exemplary apparatus also includes at least one member of a family of fixtures coupleable to the arbor, the family including a pressure fixture that has first and second piston assemblies disposed at diametrically opposite locations to one another, the family also including a support fixture coupleable the arbor and having members extending axially therefrom, the members being configured to support securing members of the rotor. Advantageously, the exemplary apparatus provides for a mechanism through which a securing member may be symmetrically installed with respect to the rotor core, thus improving rotor performance and construction.

Owner:RELIANCE ELECTRIC TECH

Method of forming a power tool

InactiveUS7814641B2Increase stiffnessIncrease critical speedWindings insulation materialRotary current collectorEngineeringPower tool

A method of forming a power tool includes forming and balancing an armature by securing a lamination stack having slots therein on an armature shaft securing a commutator on one end of the armature shaft, winding magnet wires in the slots in the lamination stack and securing ends of the magnet wires to the commutator, and molding plastic to at least partially encase the magnet wires in plastic and forming a balancing feature. Plastic is removed from the balancing feature during dynamic balancing of the armature. The armature is then disposed in a stator to form an electric motor and the electric motor is disposed in a power tool.

Owner:BLACK & DECKER INC

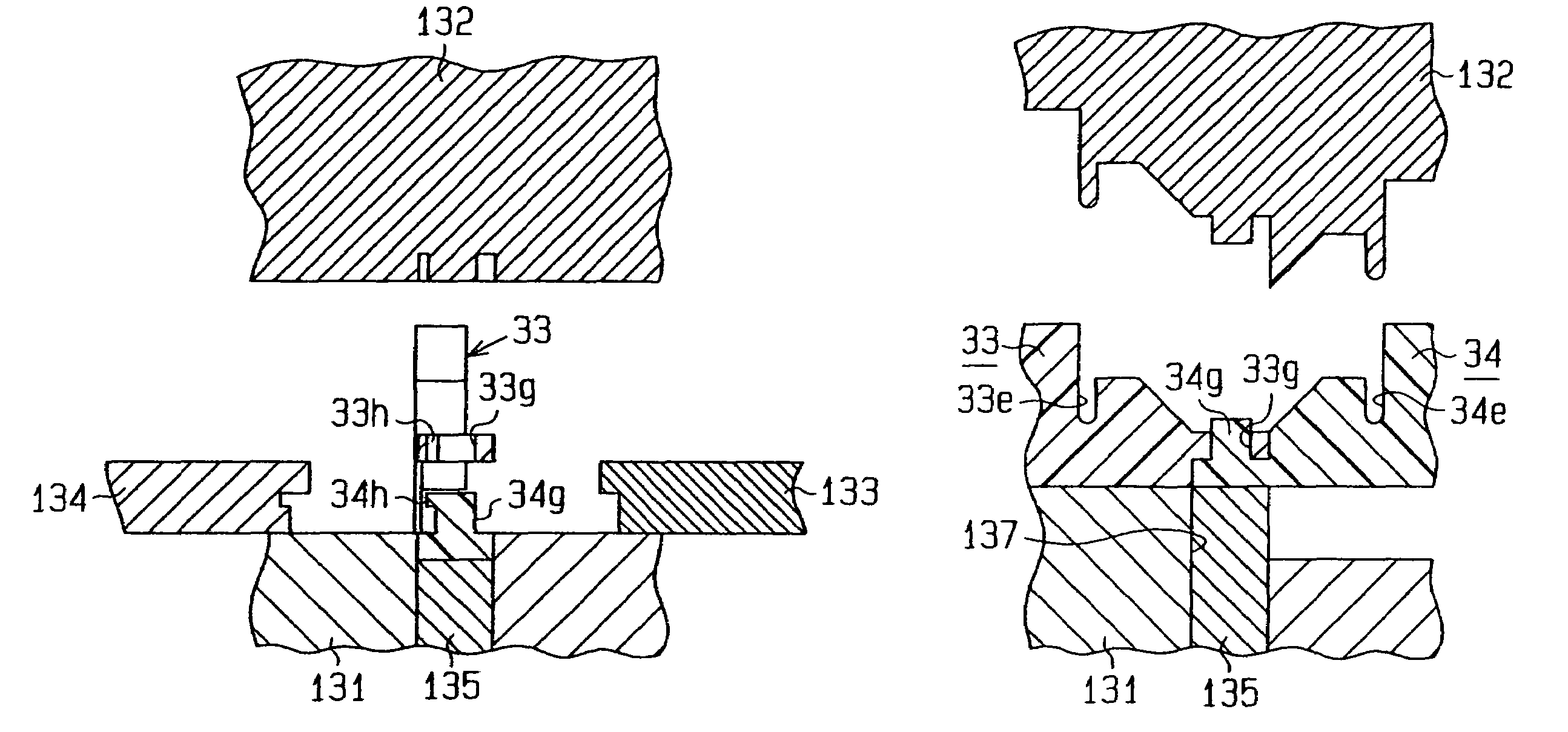

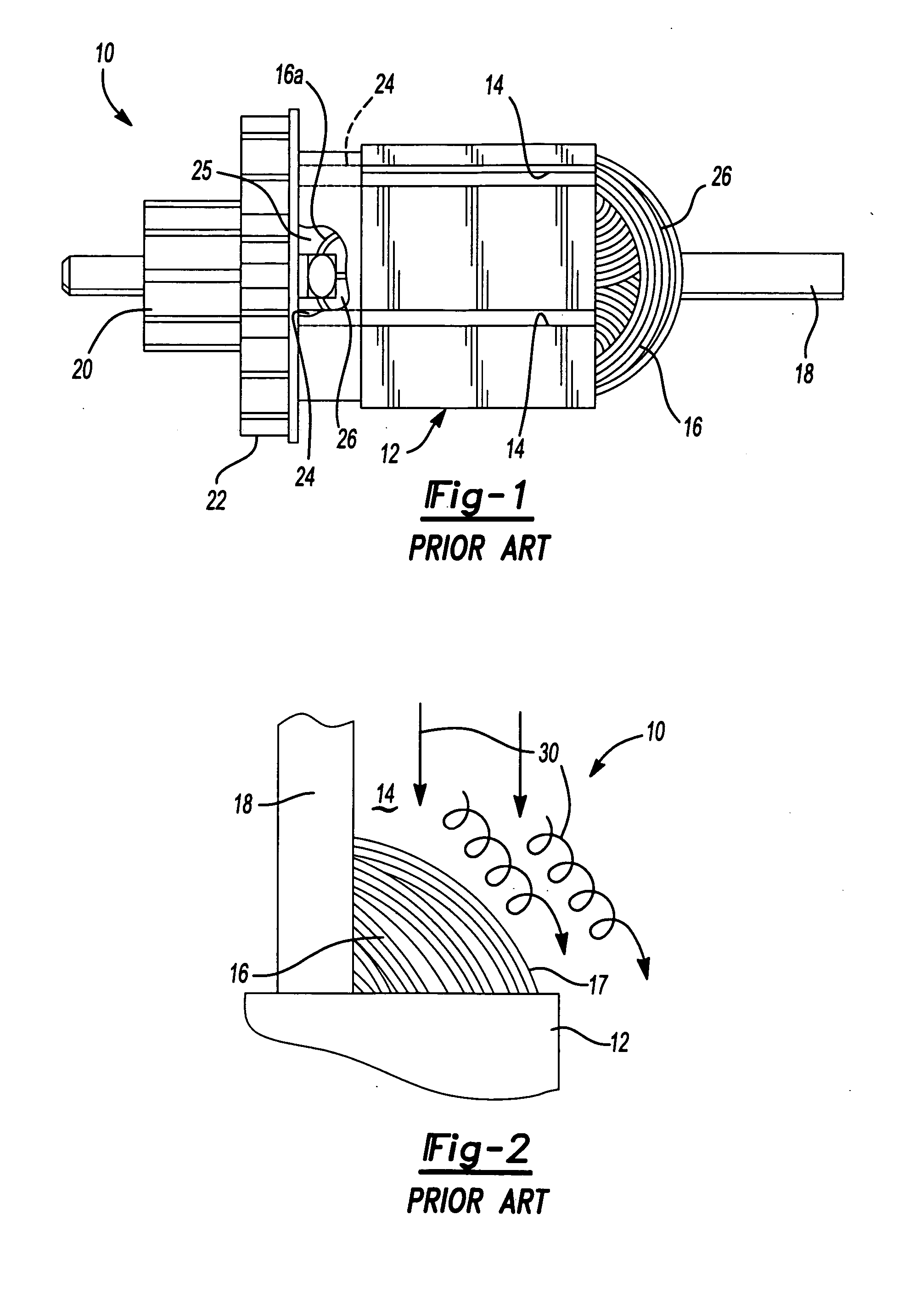

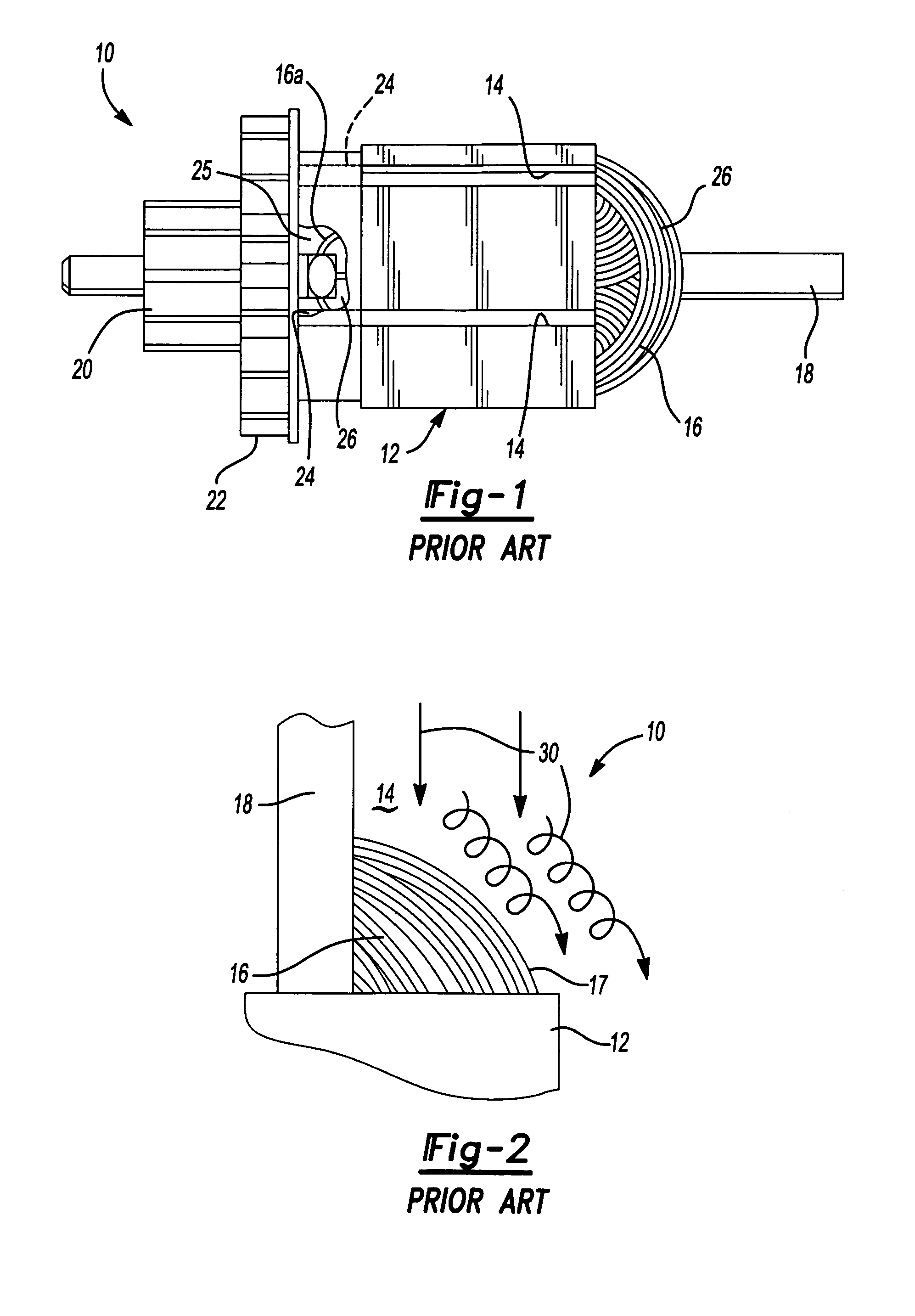

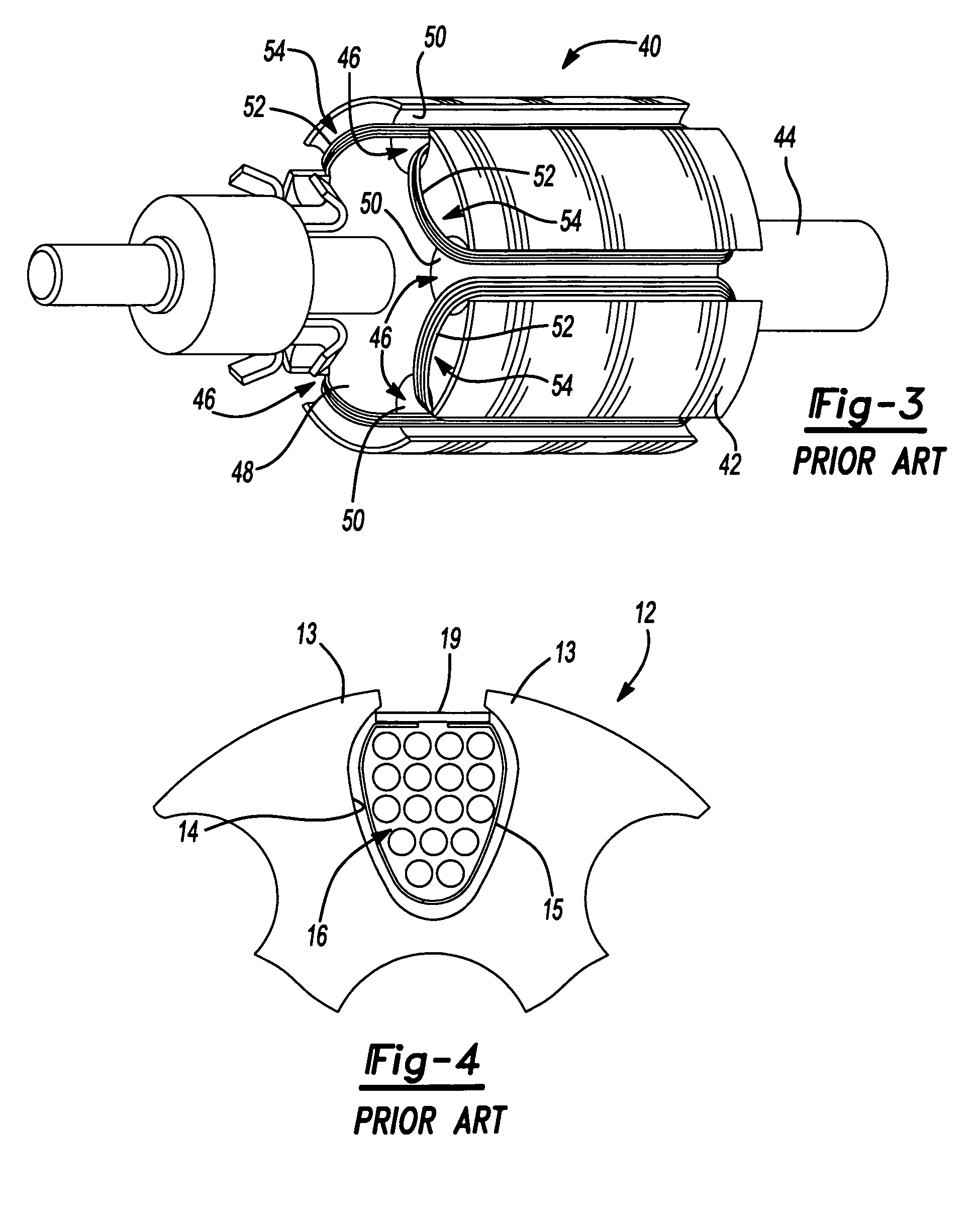

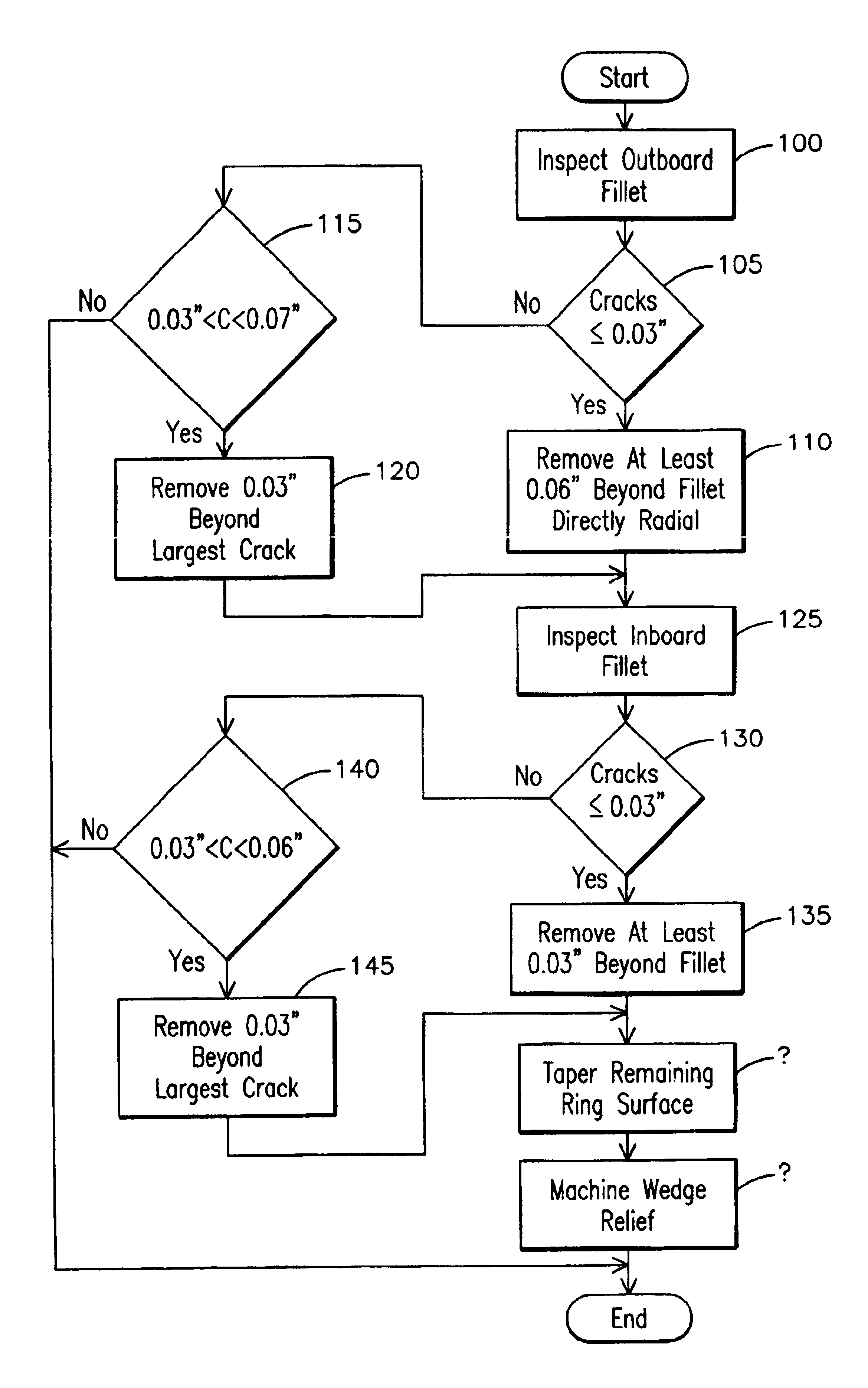

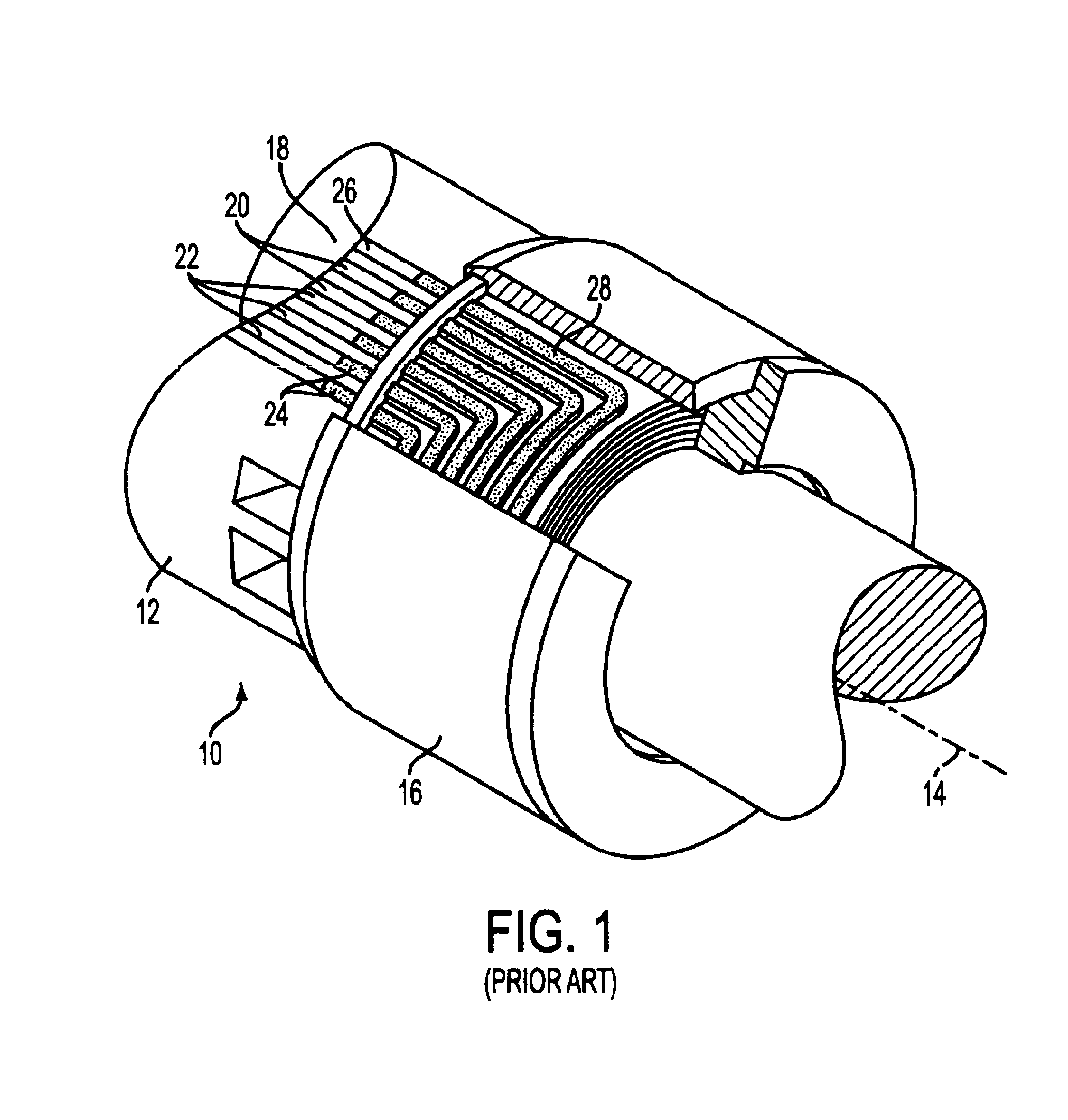

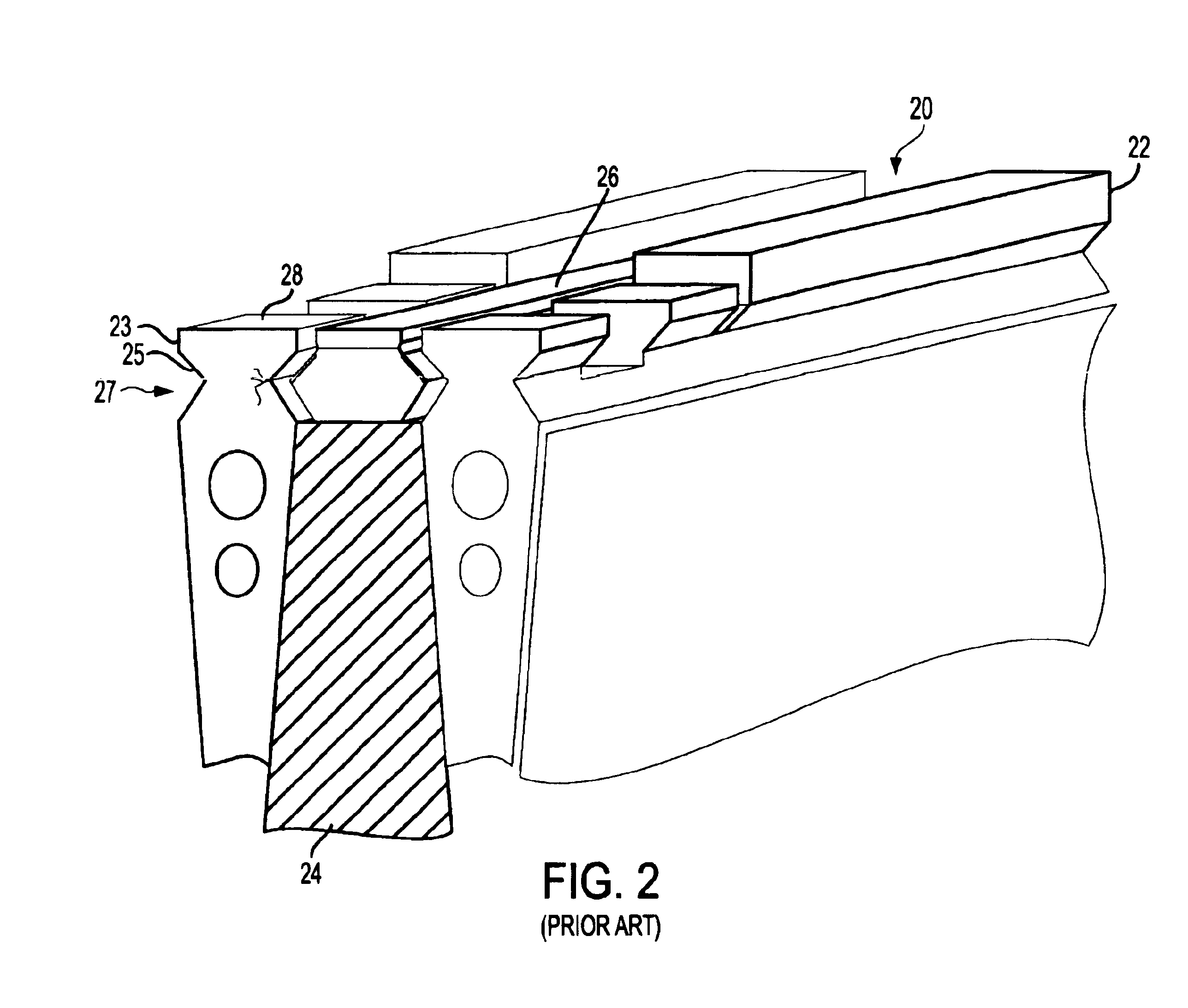

Method for repairing generator rotor

InactiveUS6941639B2Windings insulation shape/form/constructionMagnetic circuit rotating partsStress inducedEngineering

An improved generator rotor (30) and a method of repairing an existing generator rotor (12) are disclosed. Methods consistent with the present invention provide techniques for repairing existing stress-damaged rotors (12) to remove stress-induced cracks (29), without requiring new retaining rings (16), to significantly extend the useful life of a generator without the cost and complexity of conventional repair techniques. Improved generator rotors (30) consistent with the present invention provide a tooth-top design that is more resistant to stress-induced cracking than conventional designs, resulting in new generators with longer useful lives.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com