Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

908results about "Windings insulation material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced dielectric strength mica tapes

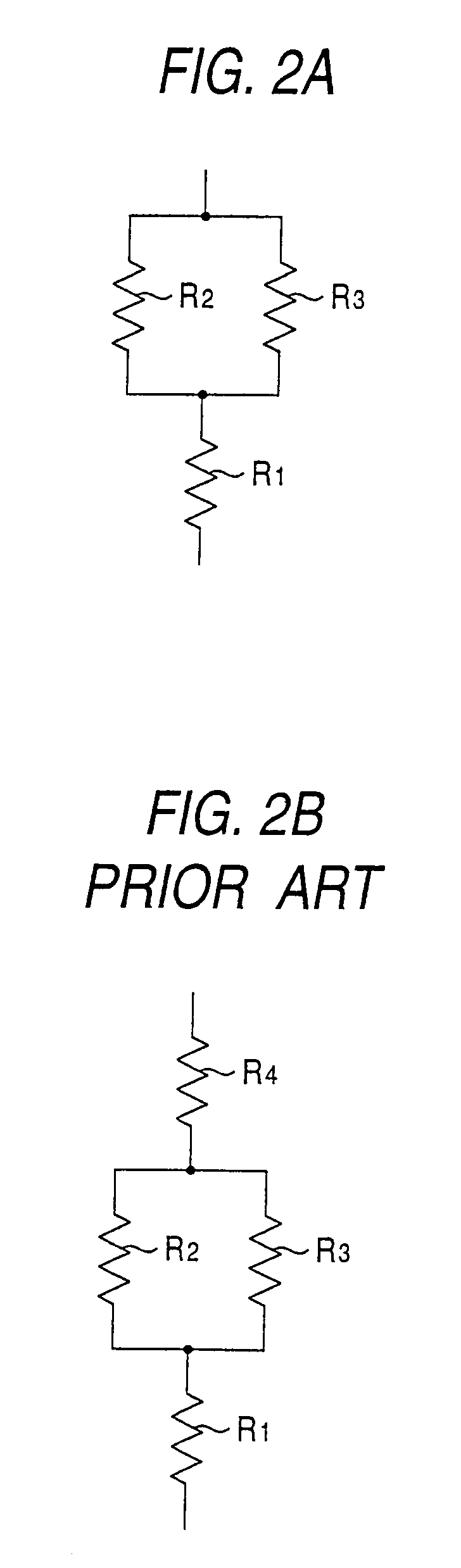

InactiveUS6190775B1Low costHigh voltageWindings insulation materialSynthetic resin layered productsDielectric strengthMetal

Owner:SIEMENS ENERGY INC

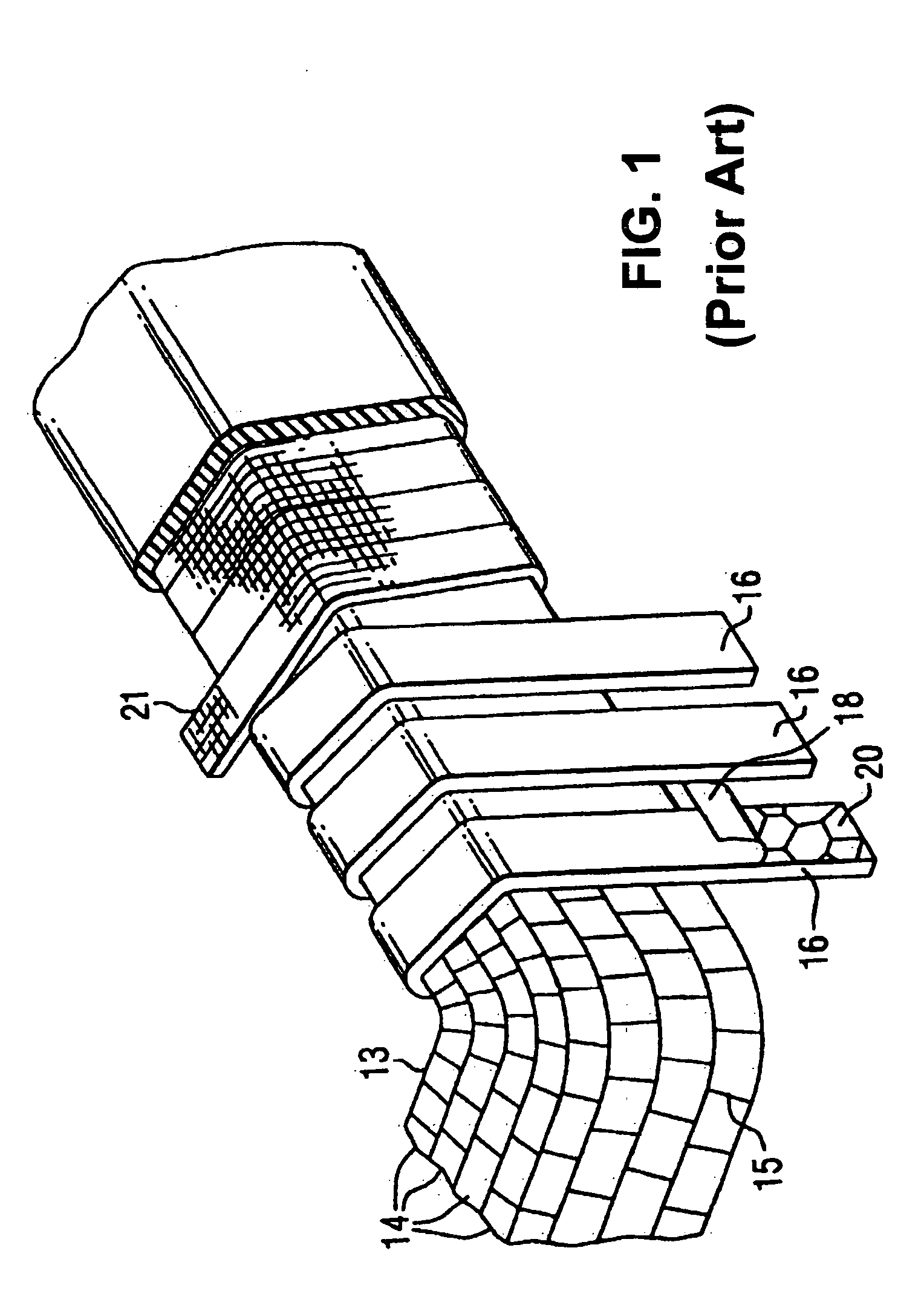

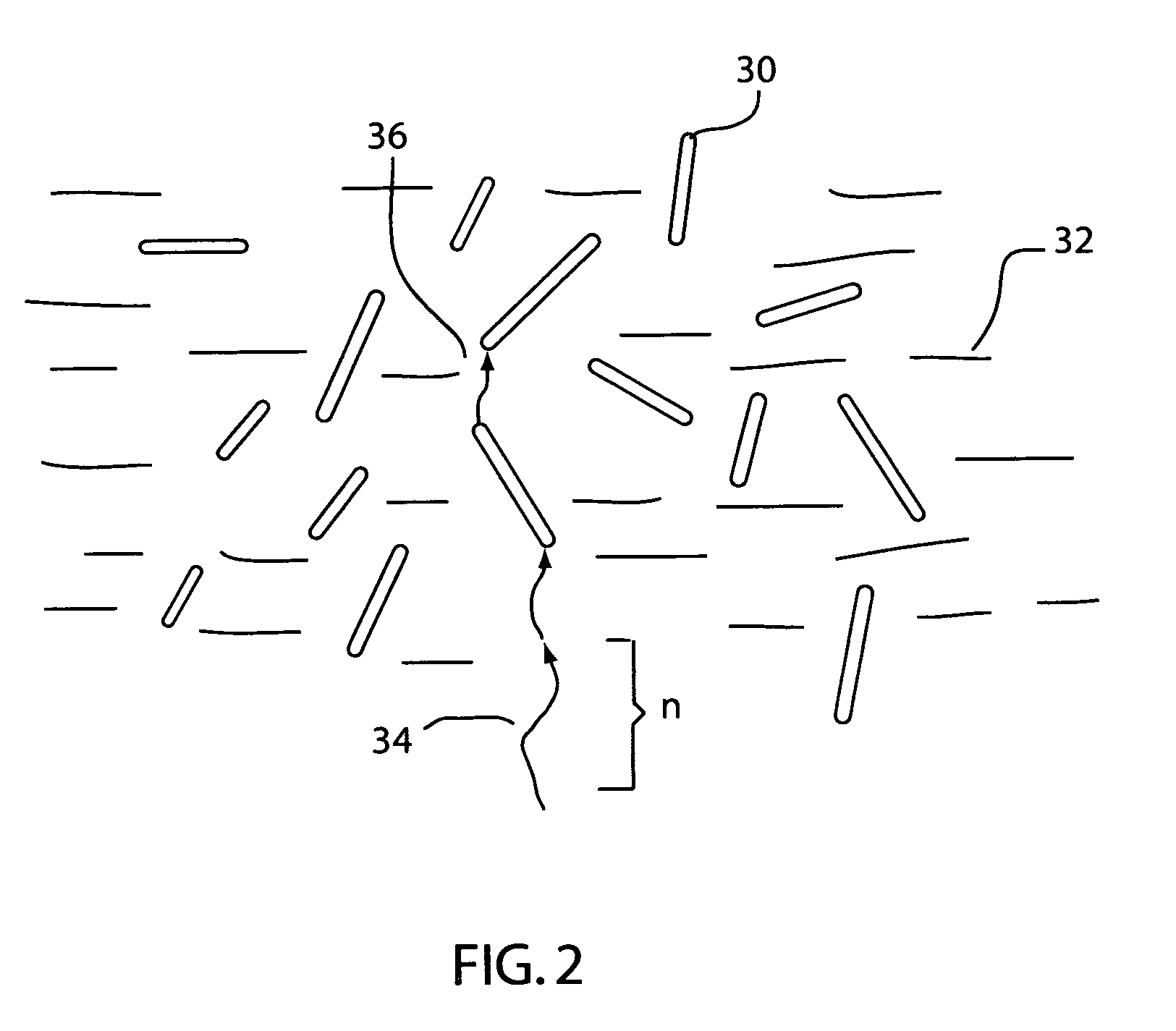

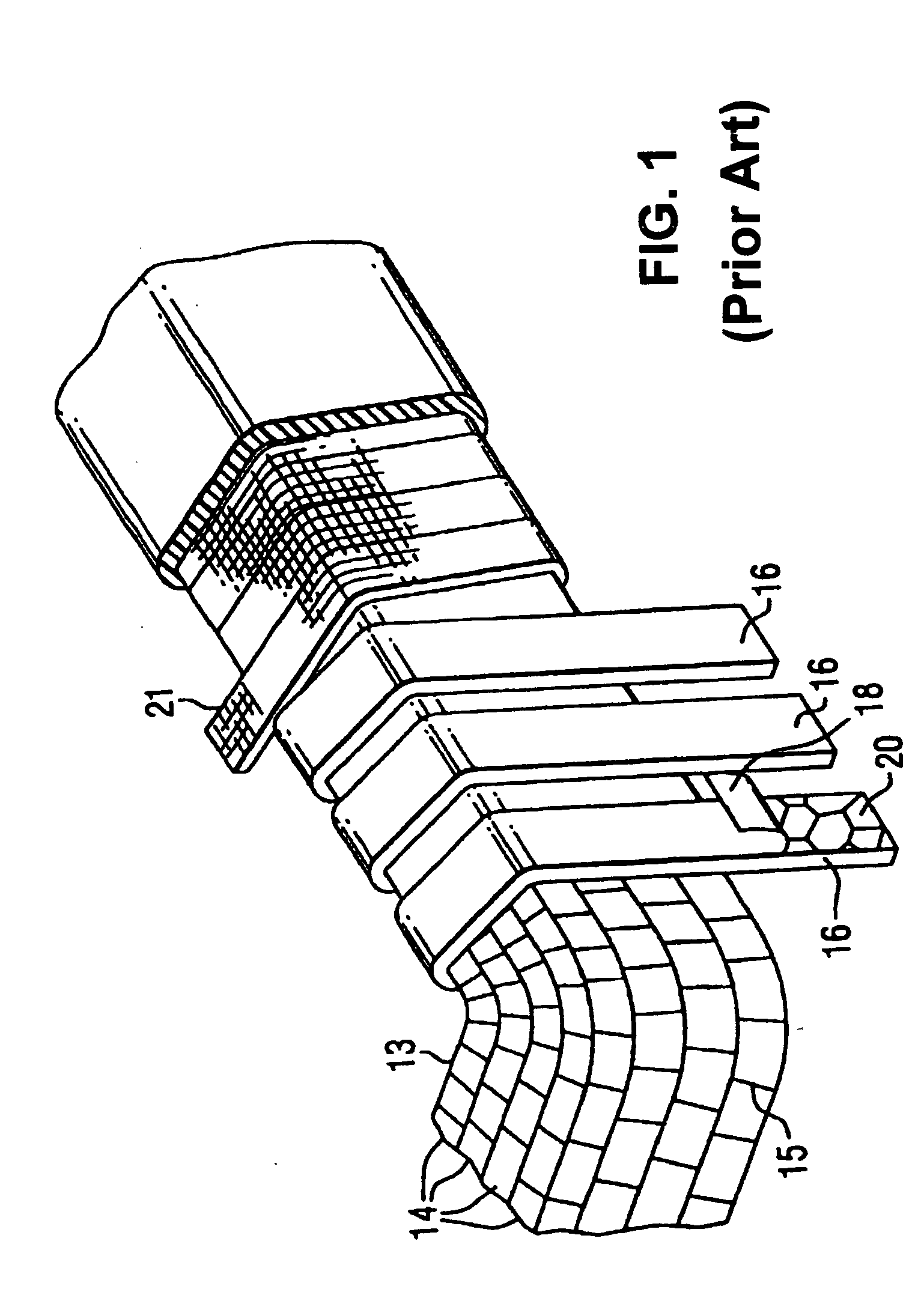

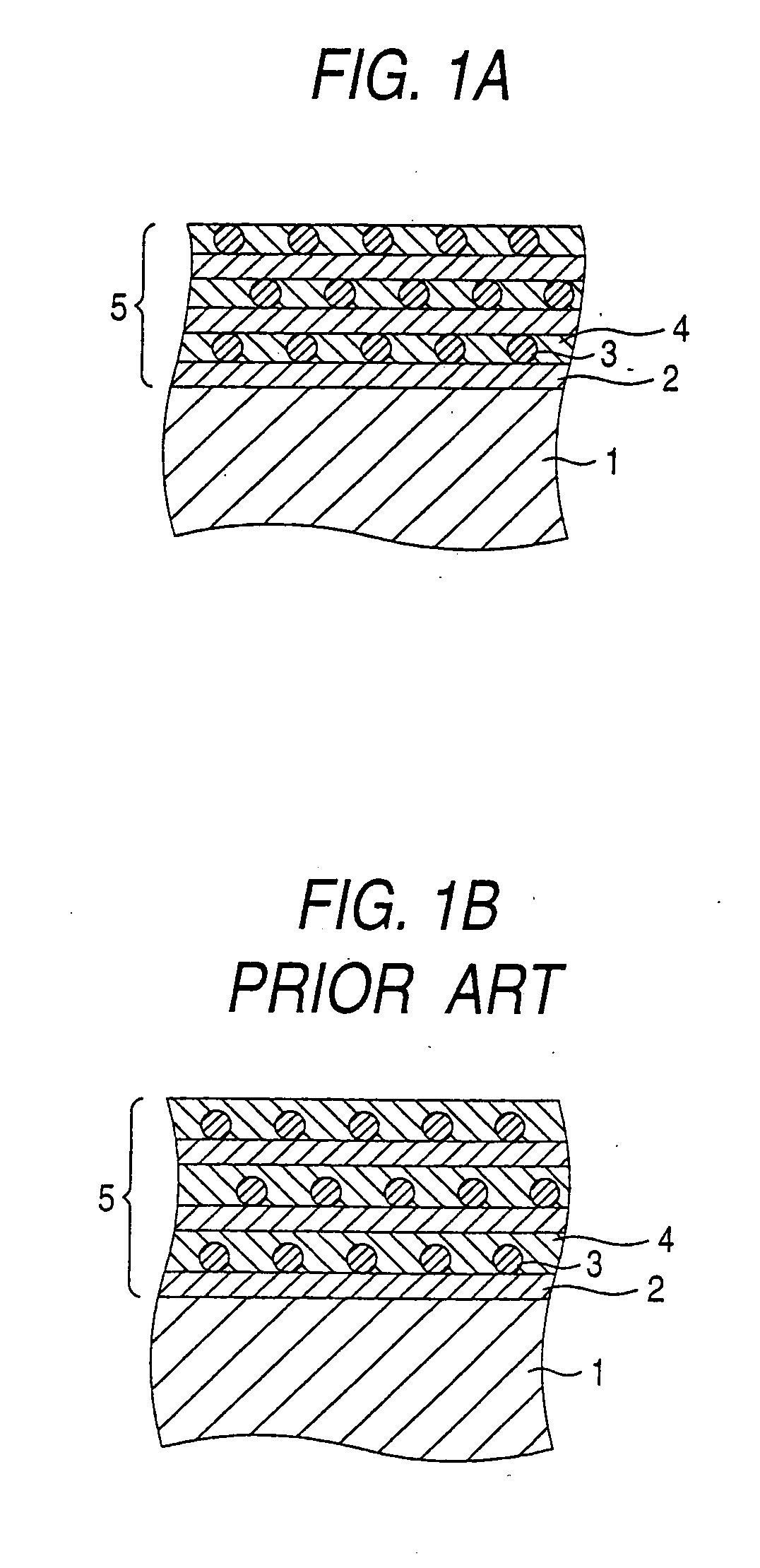

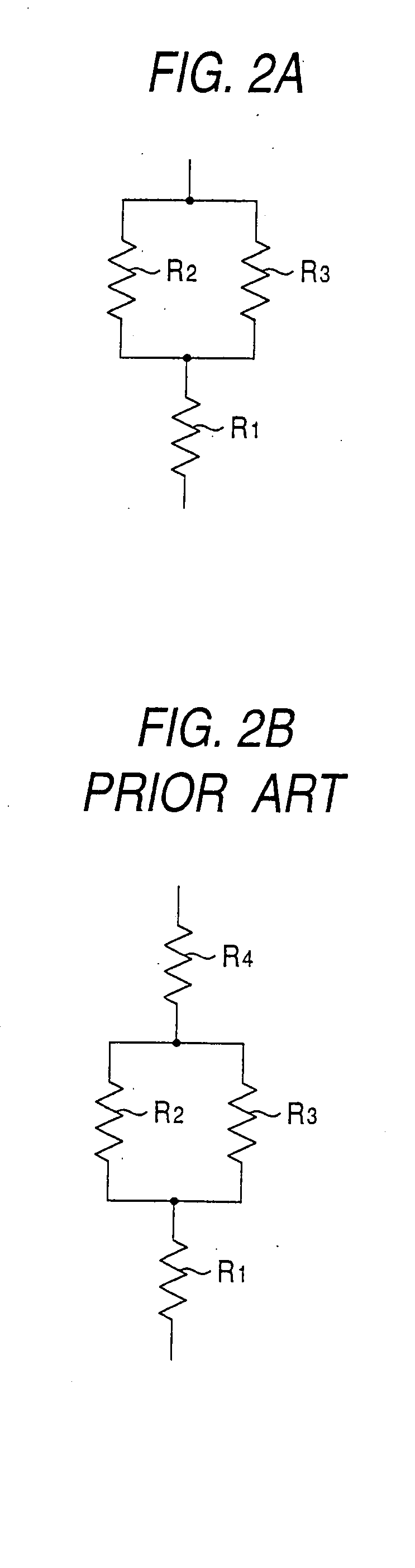

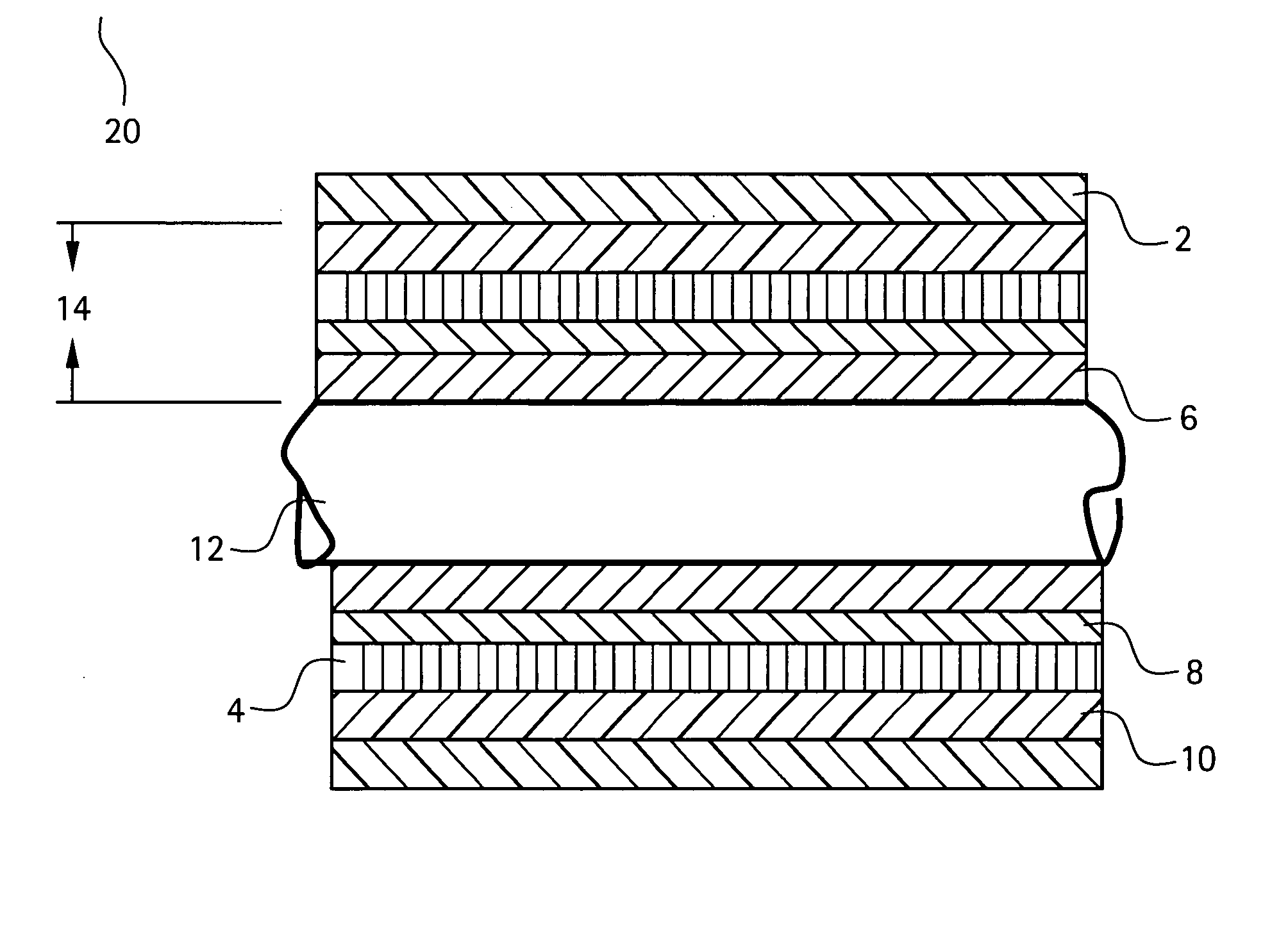

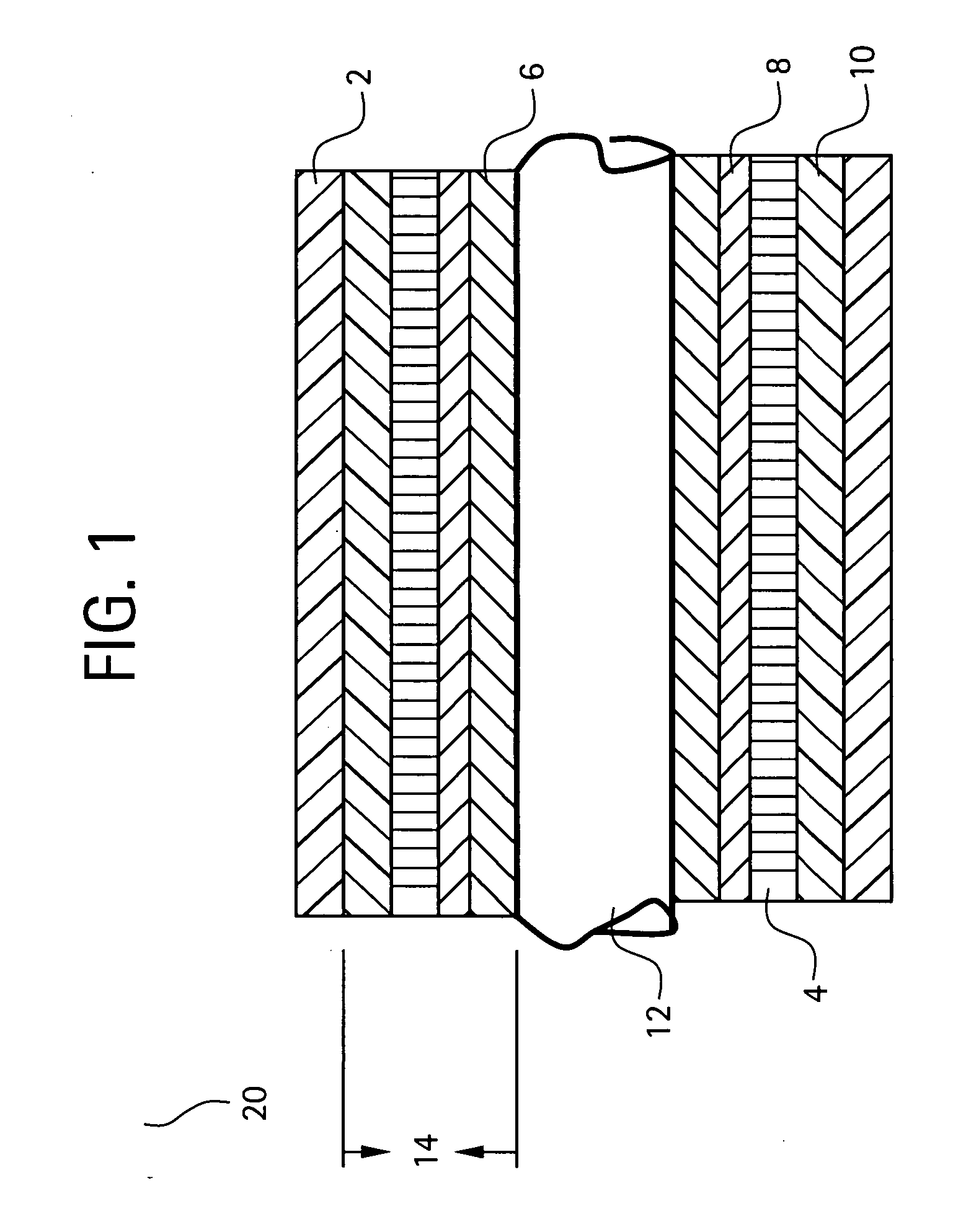

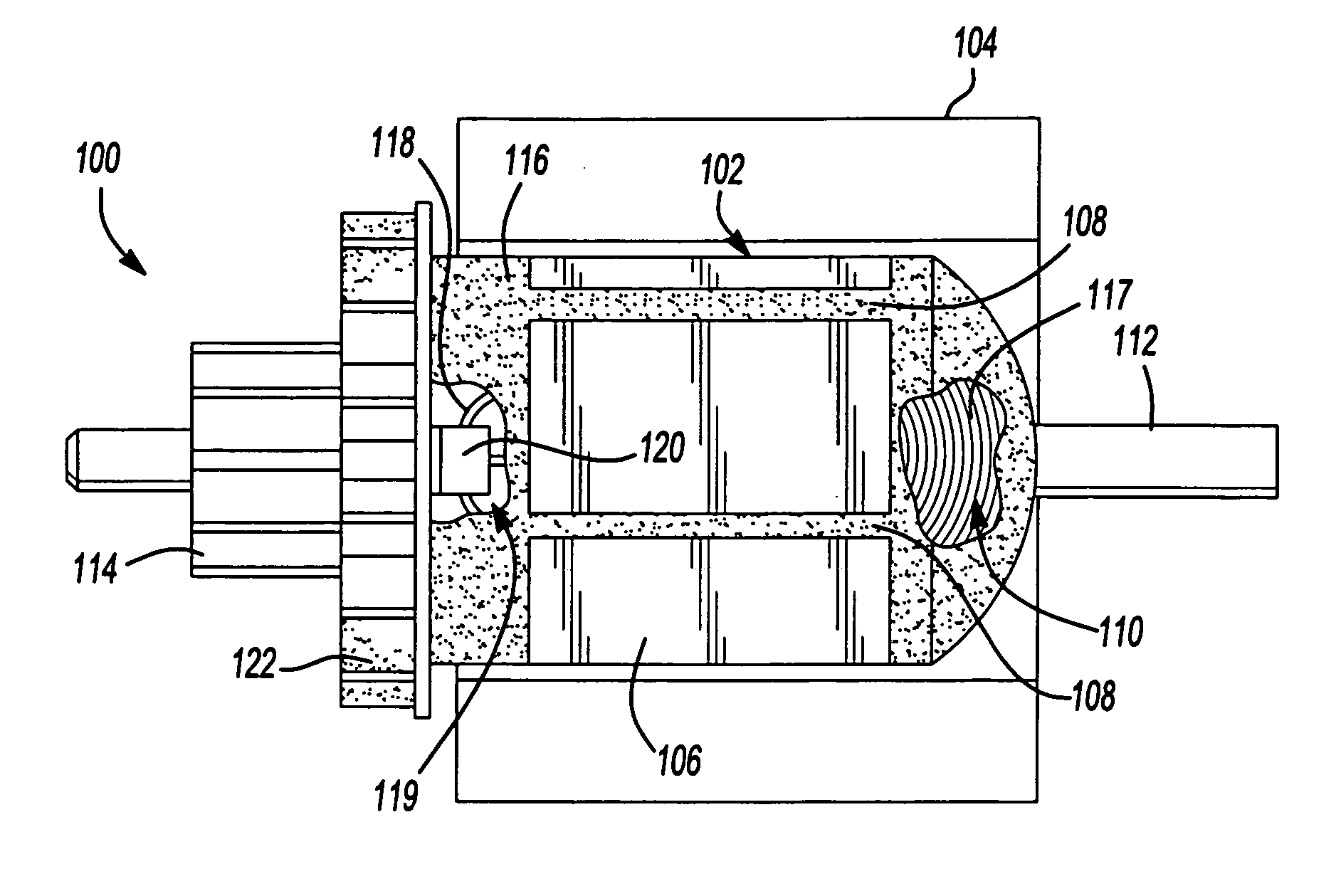

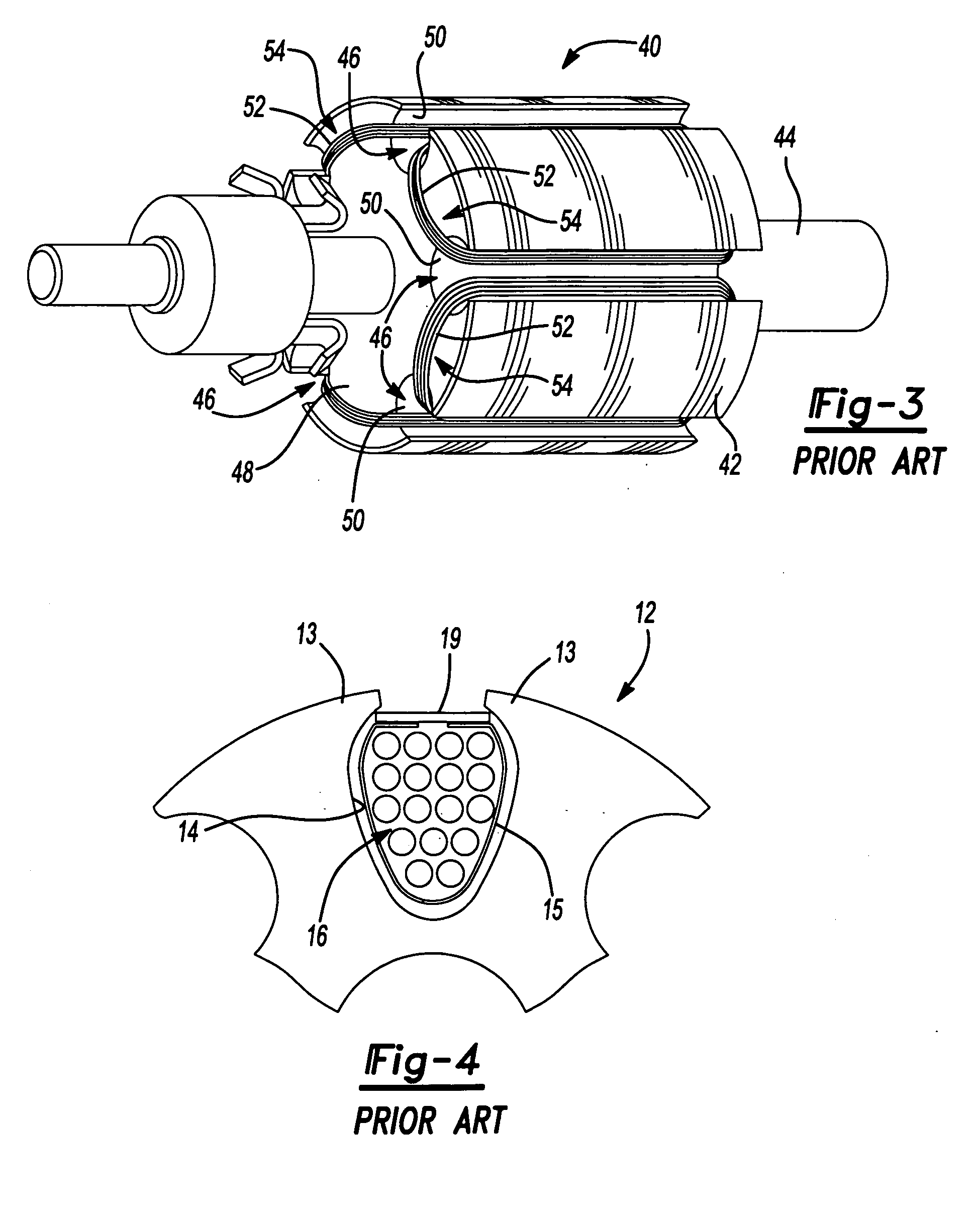

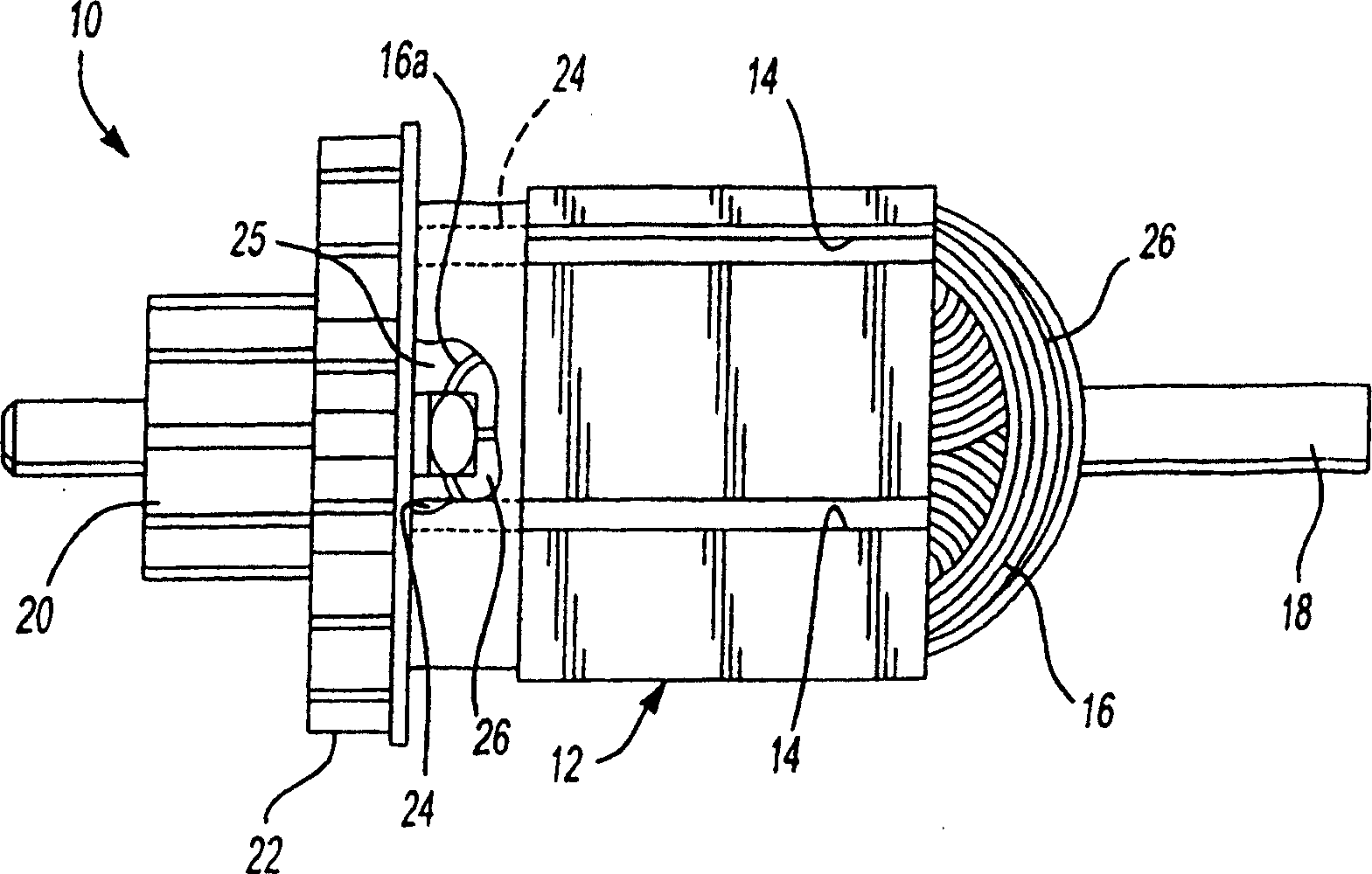

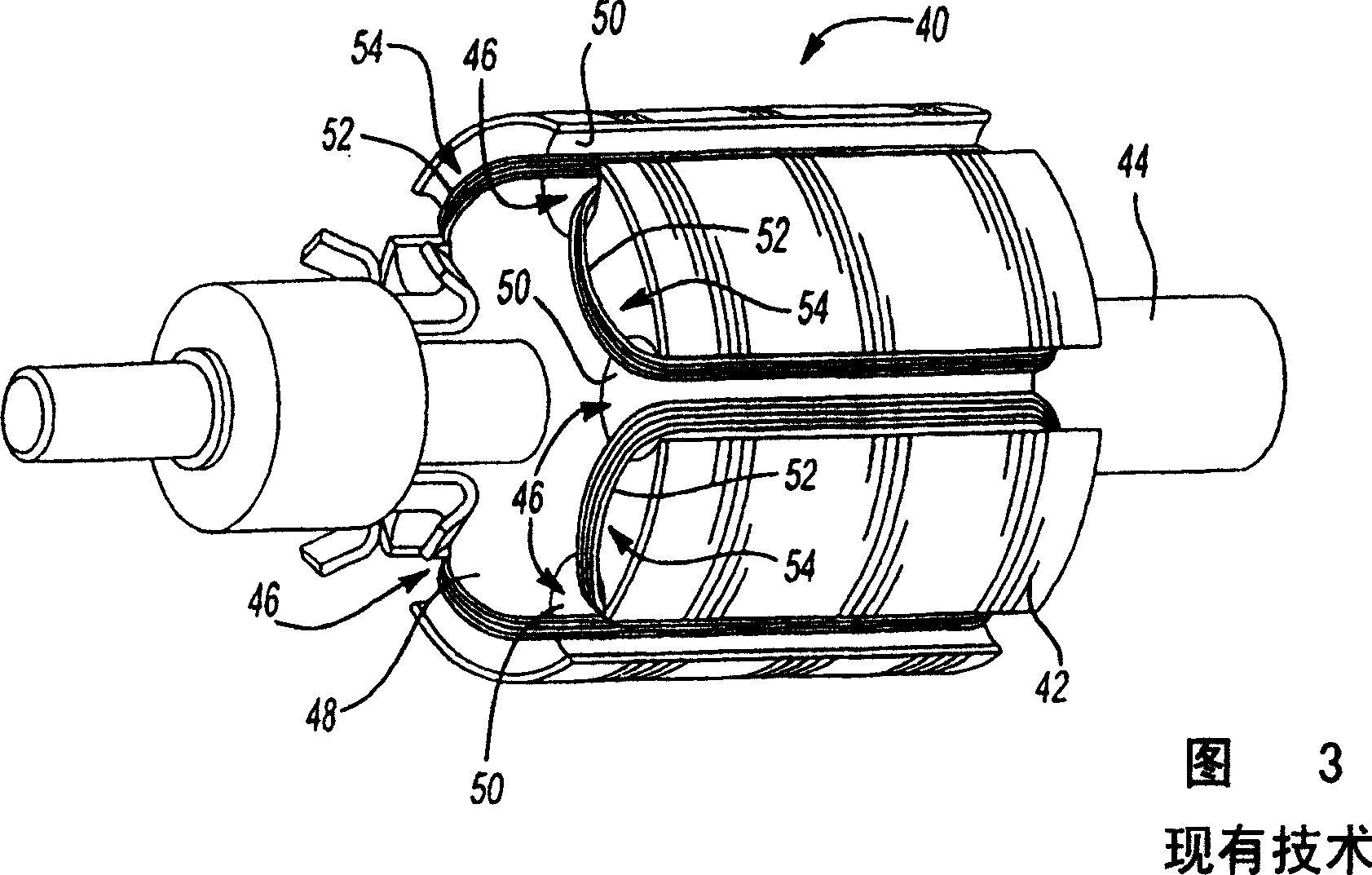

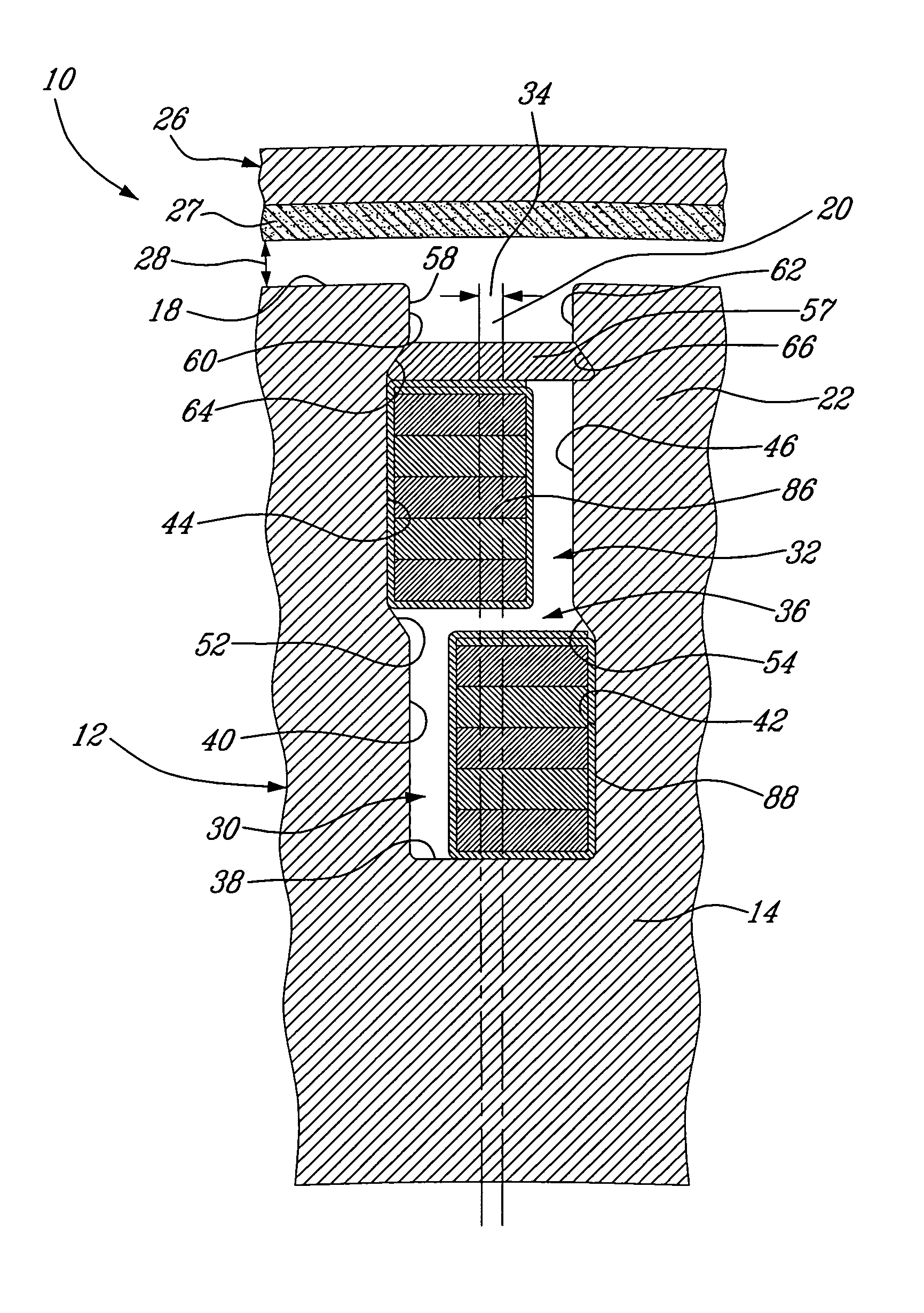

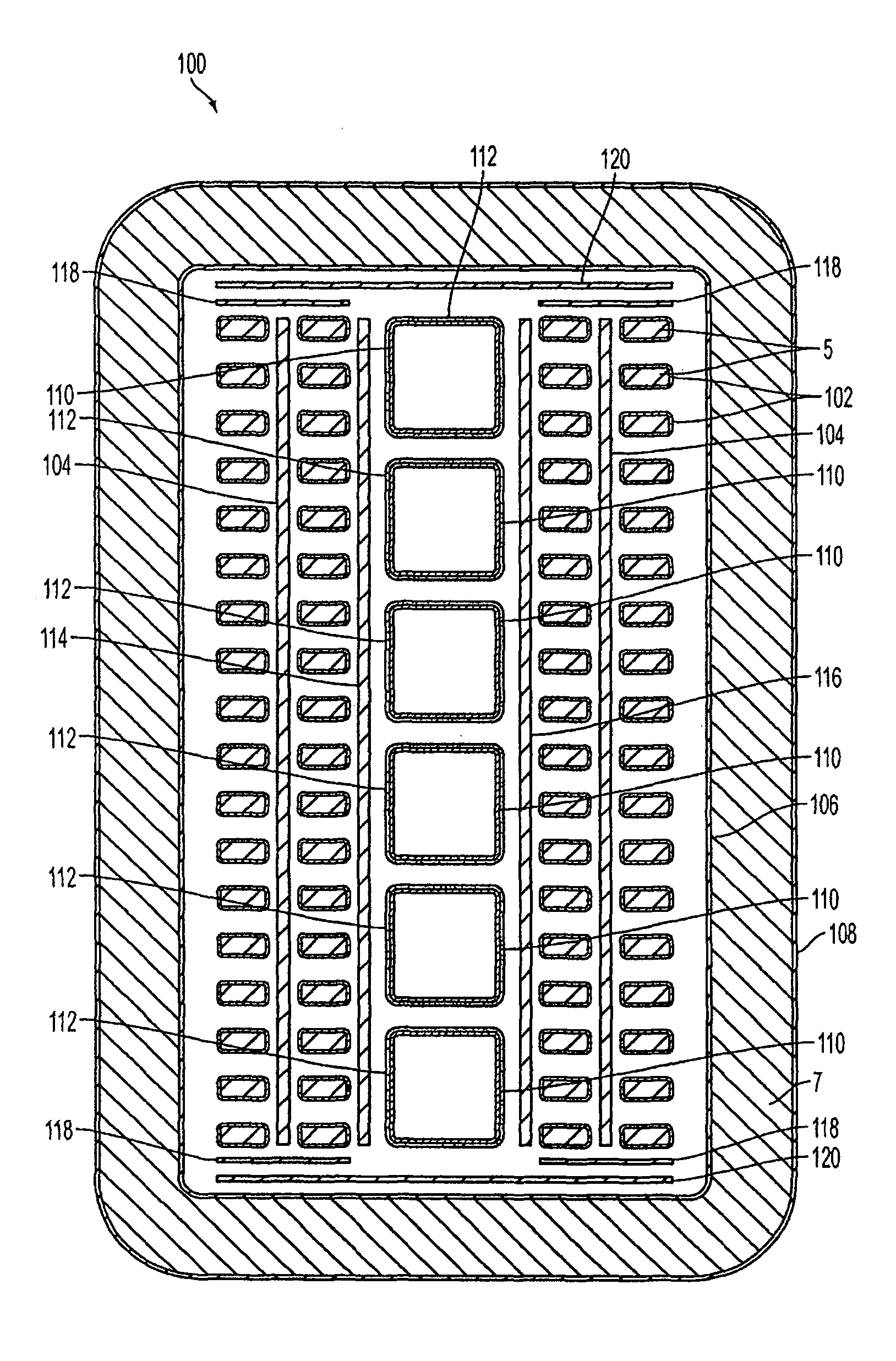

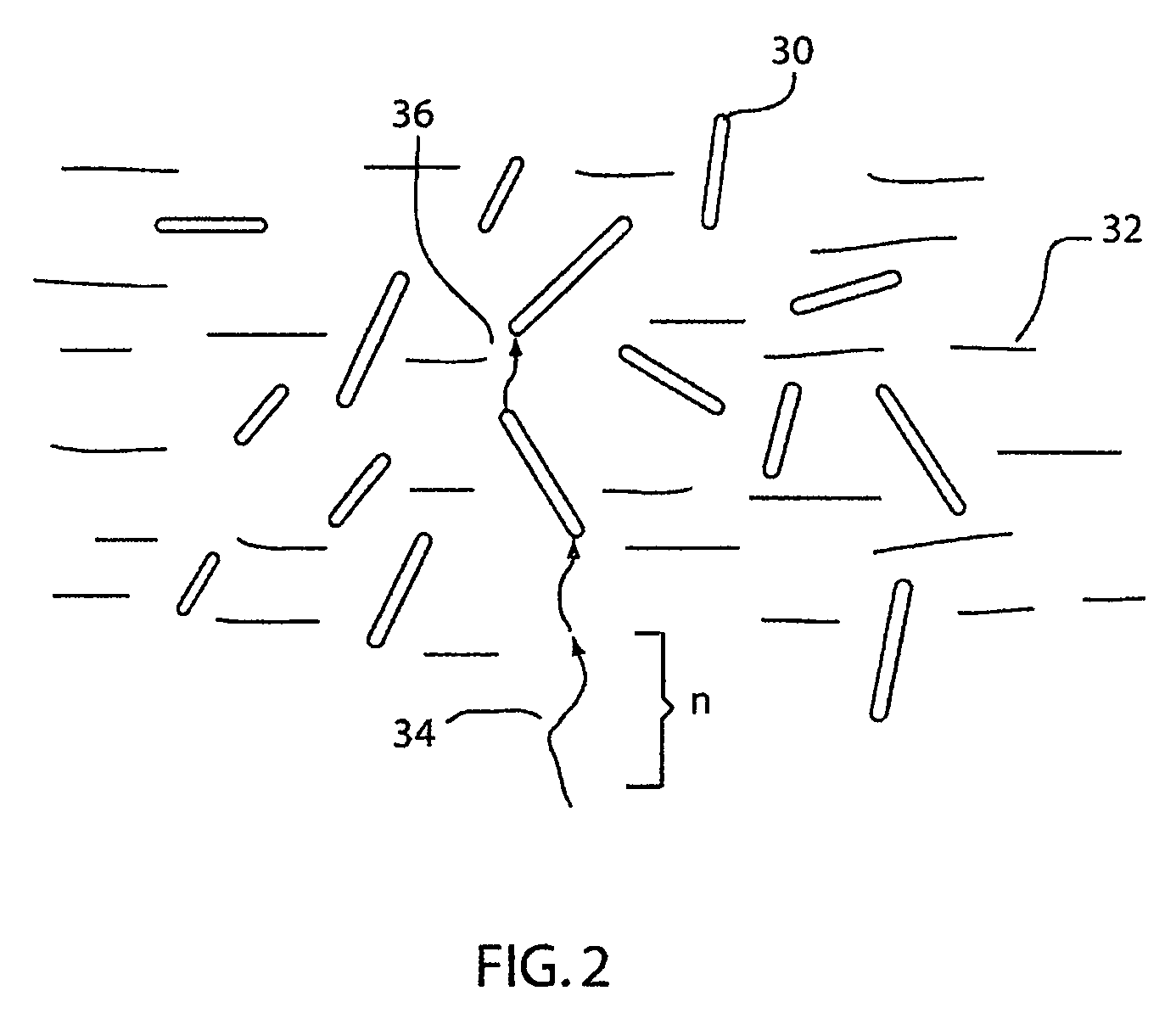

Compression of resin impregnated insulating tapes

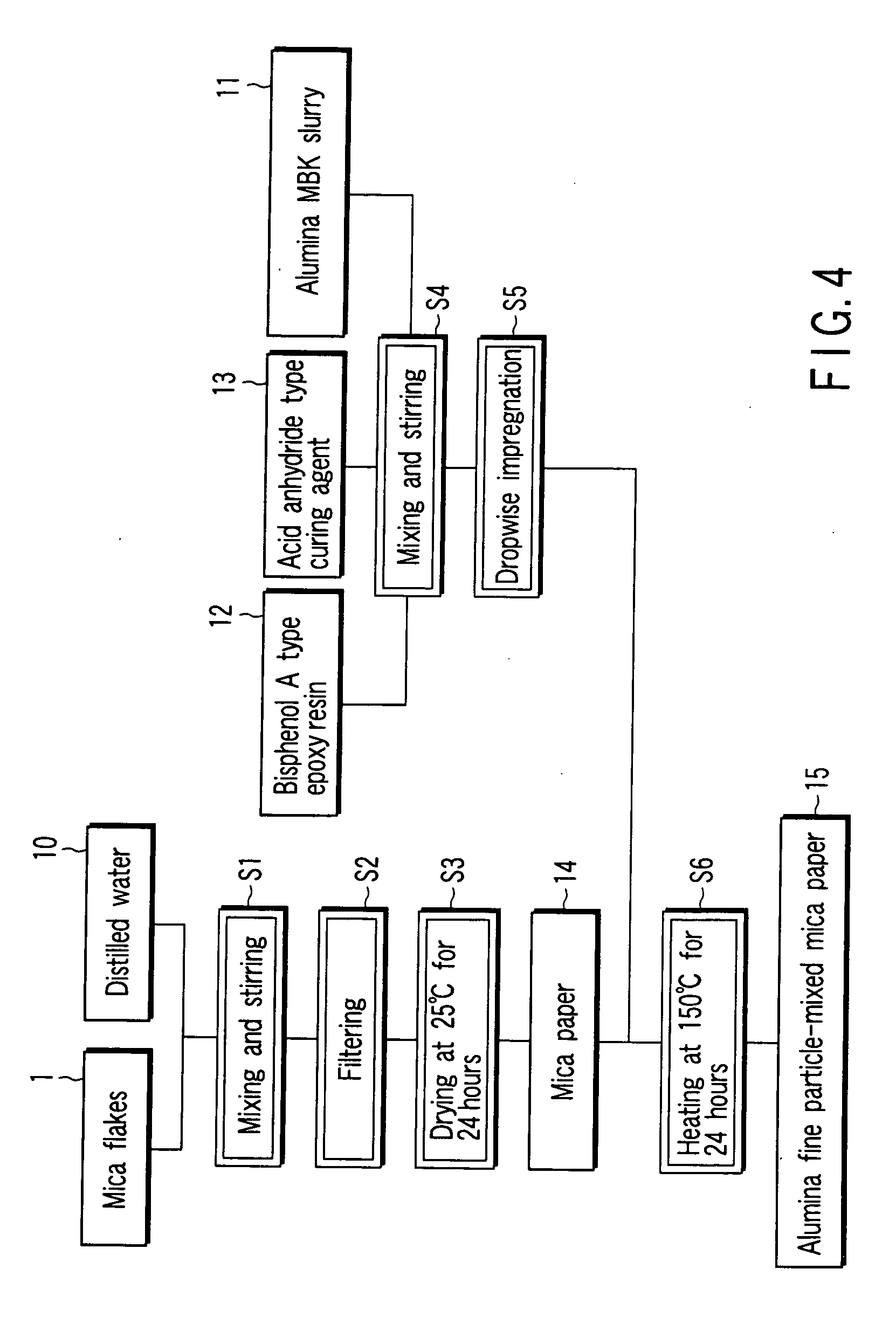

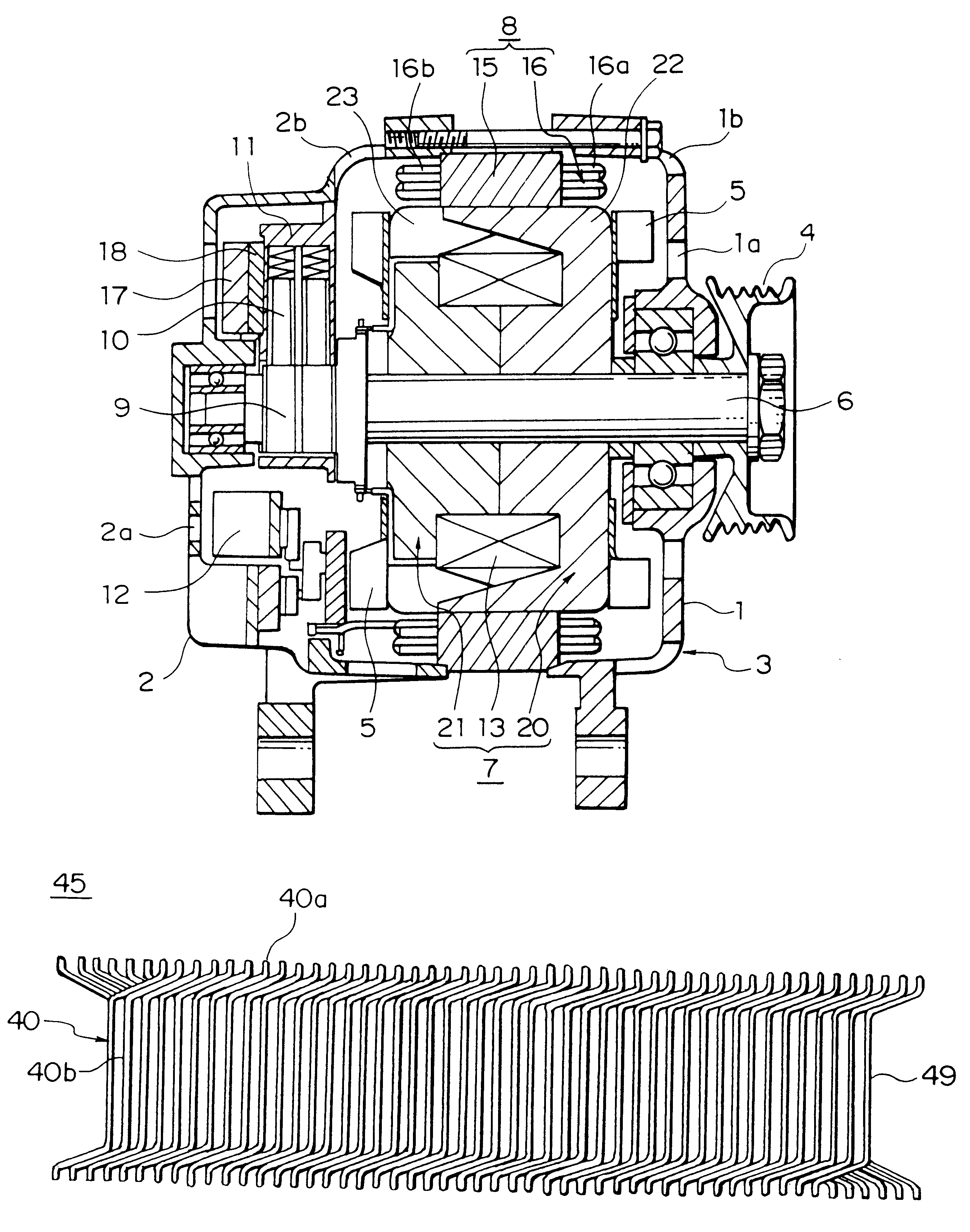

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

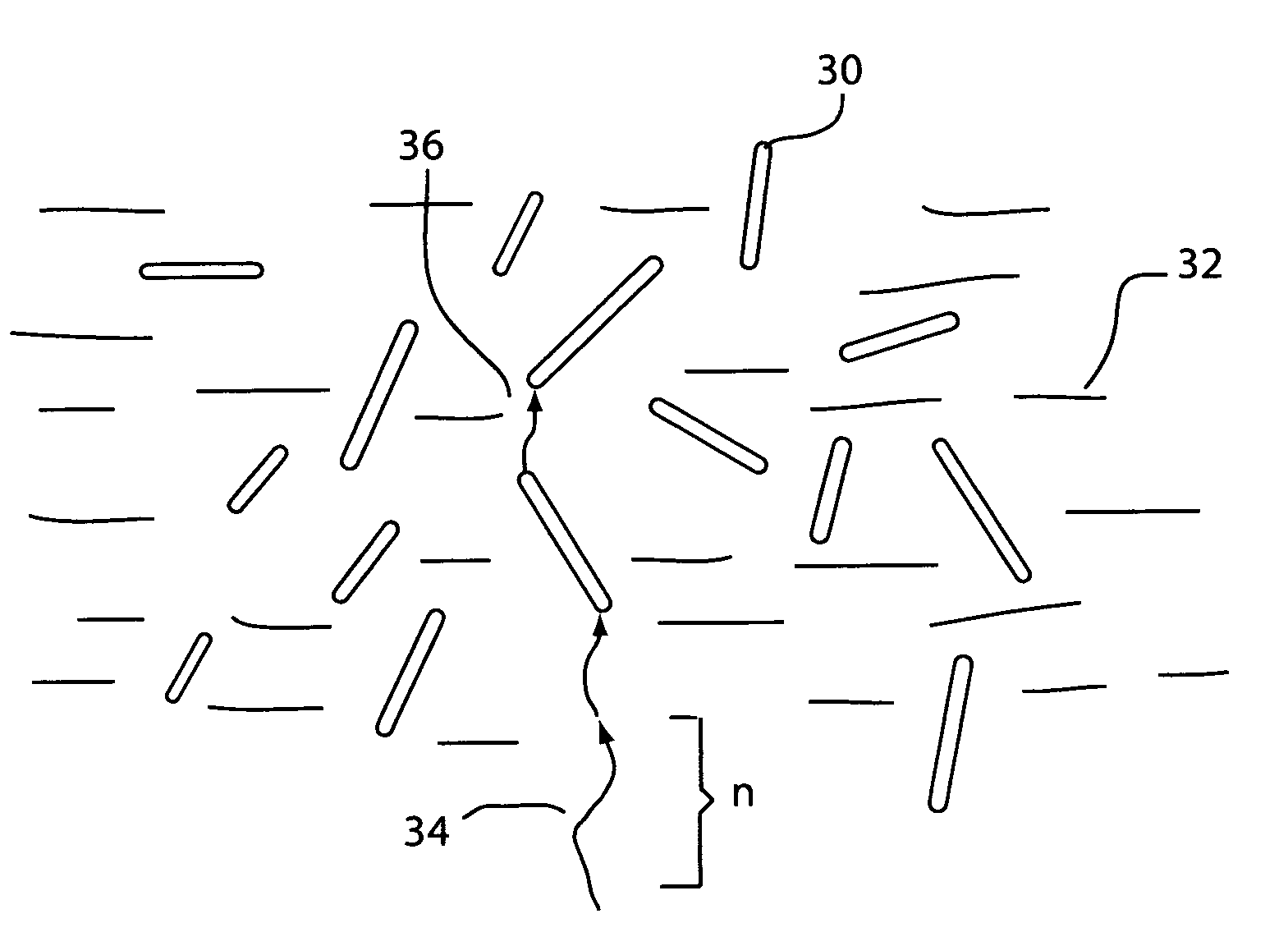

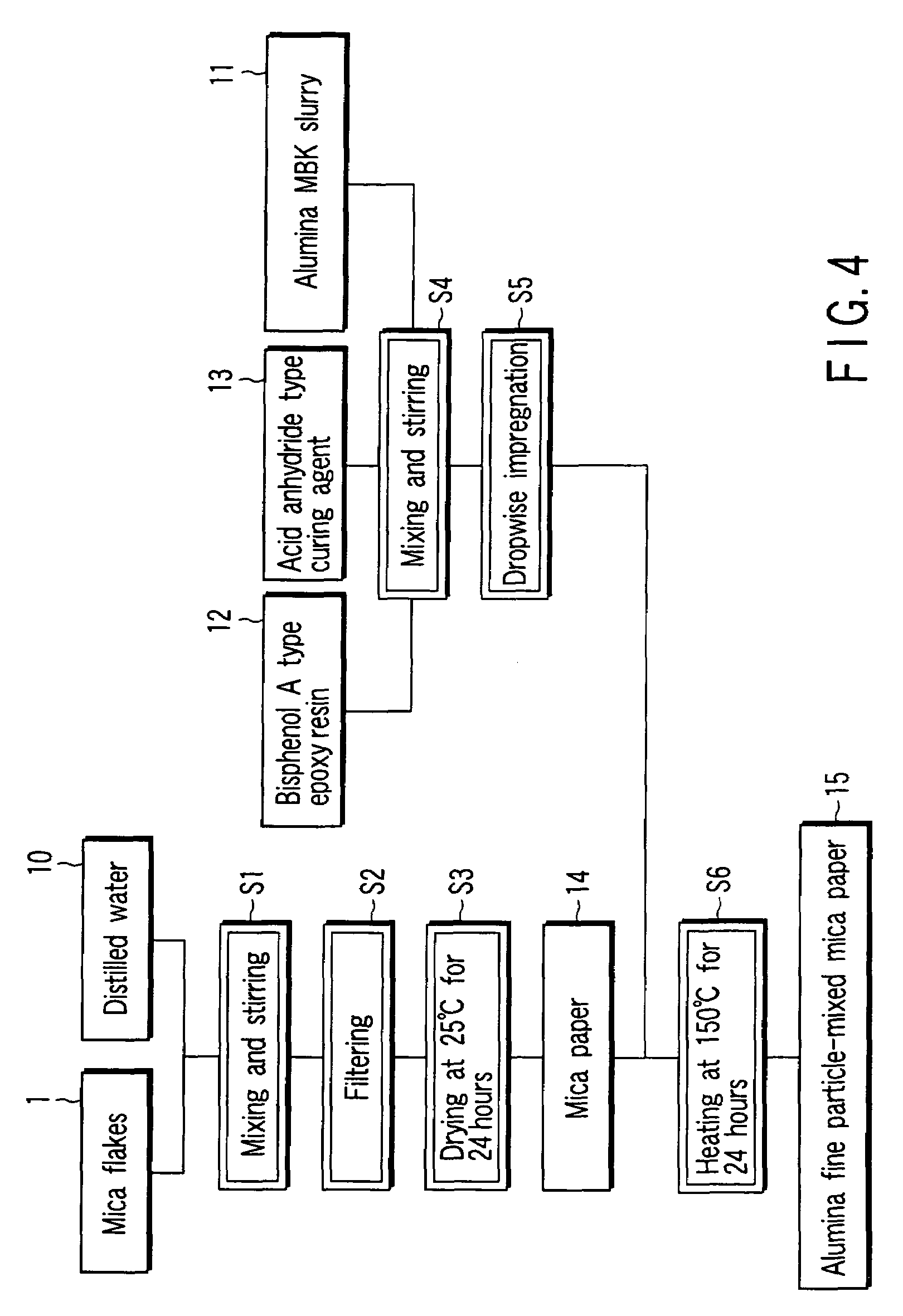

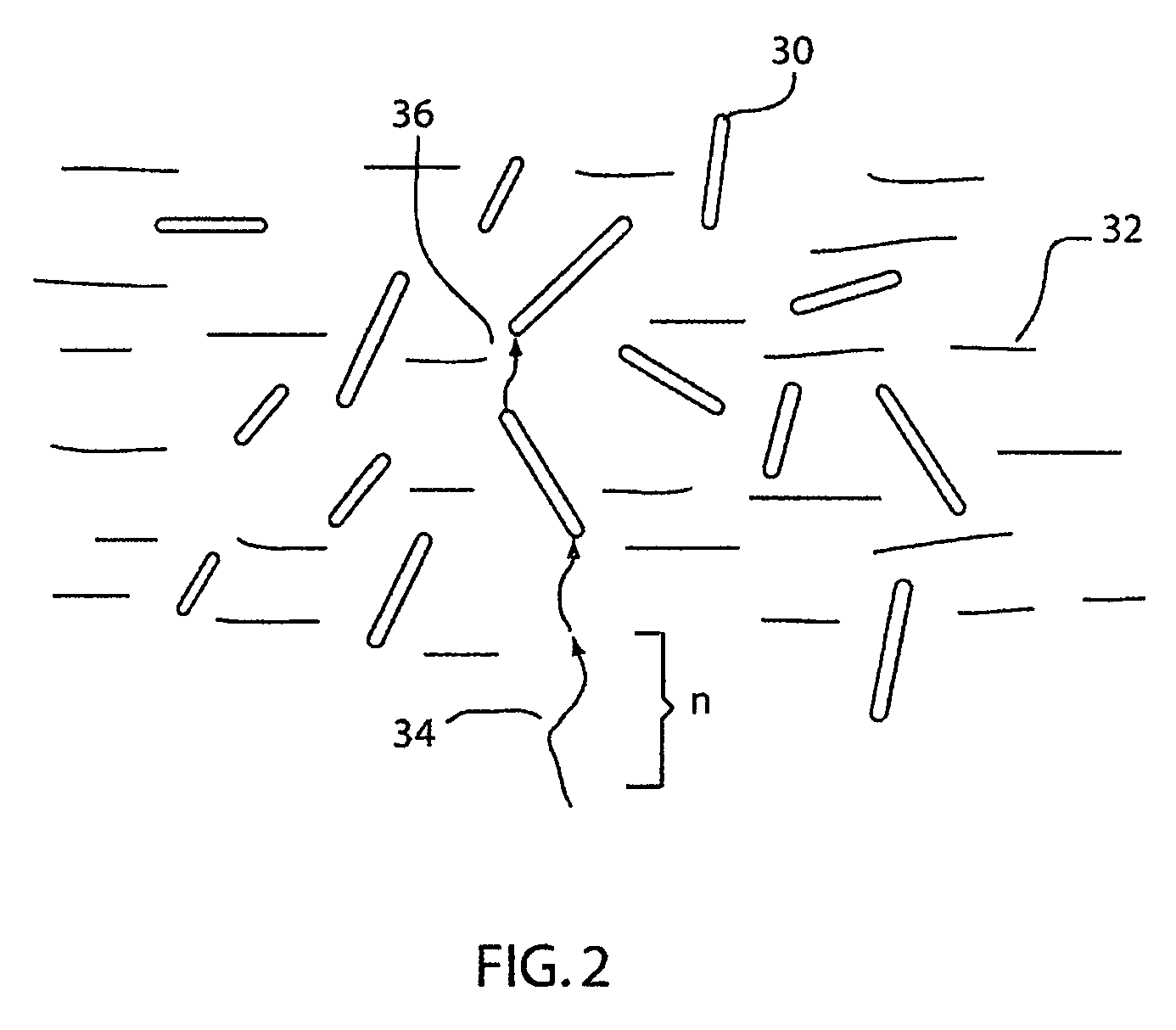

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

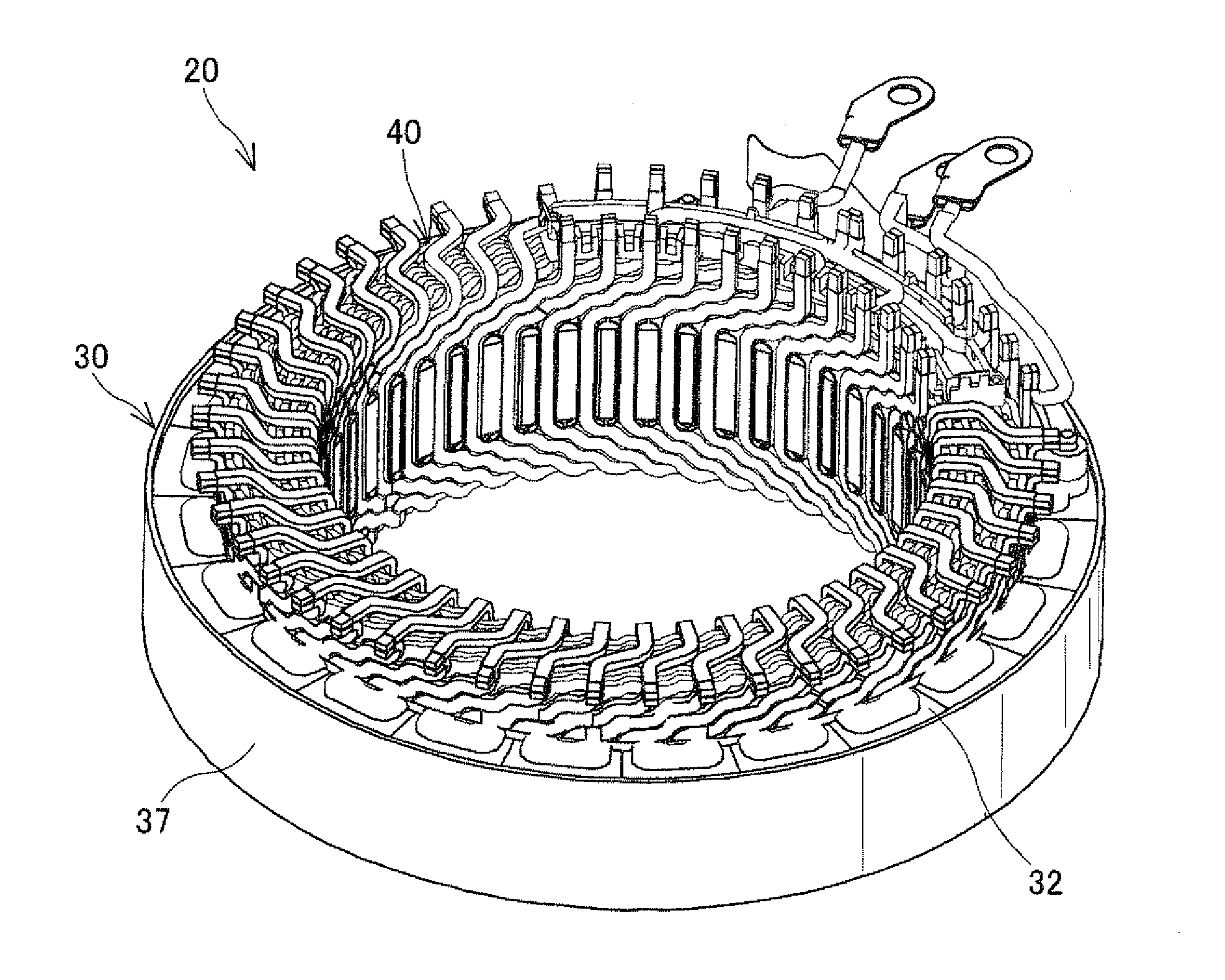

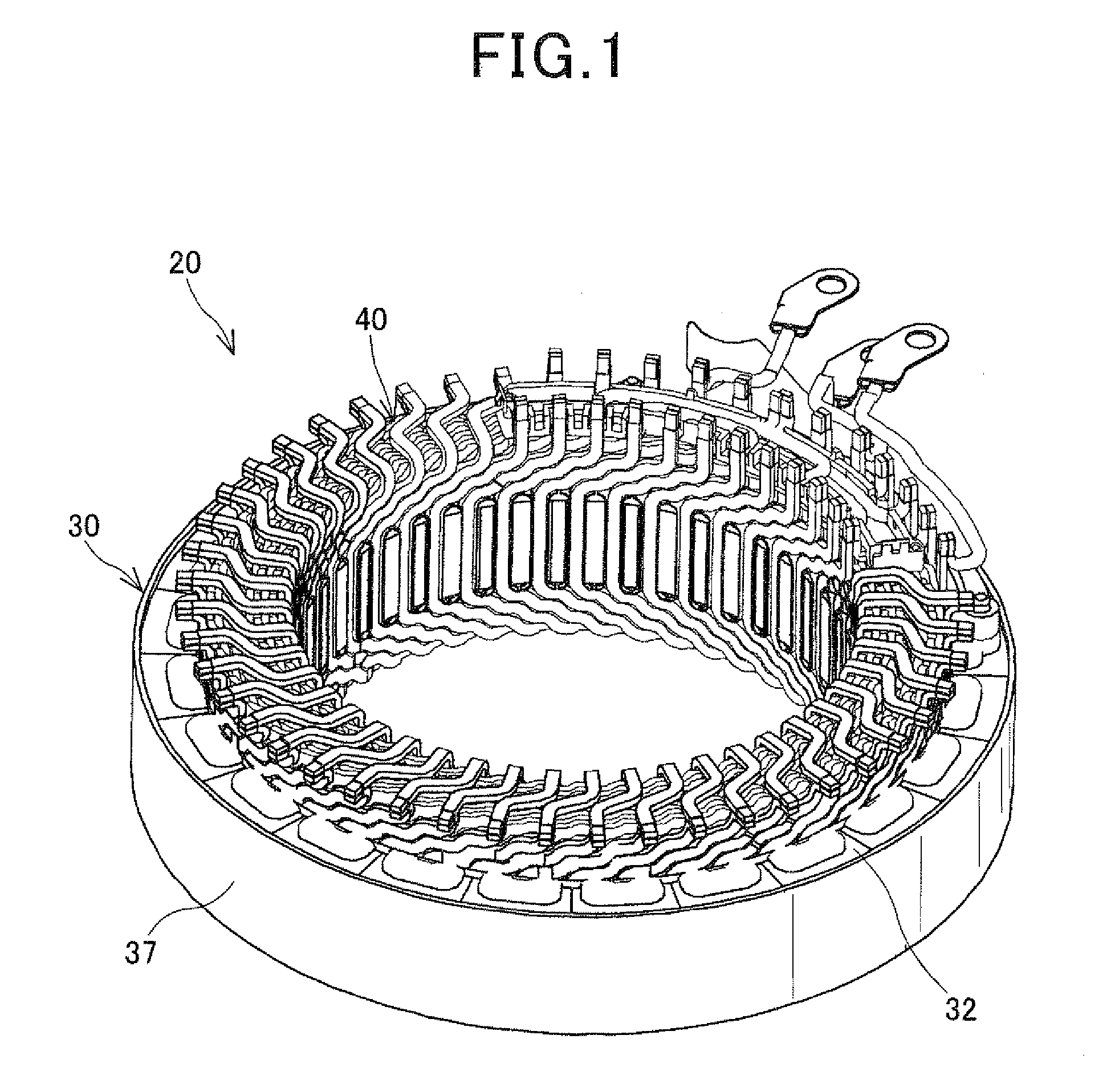

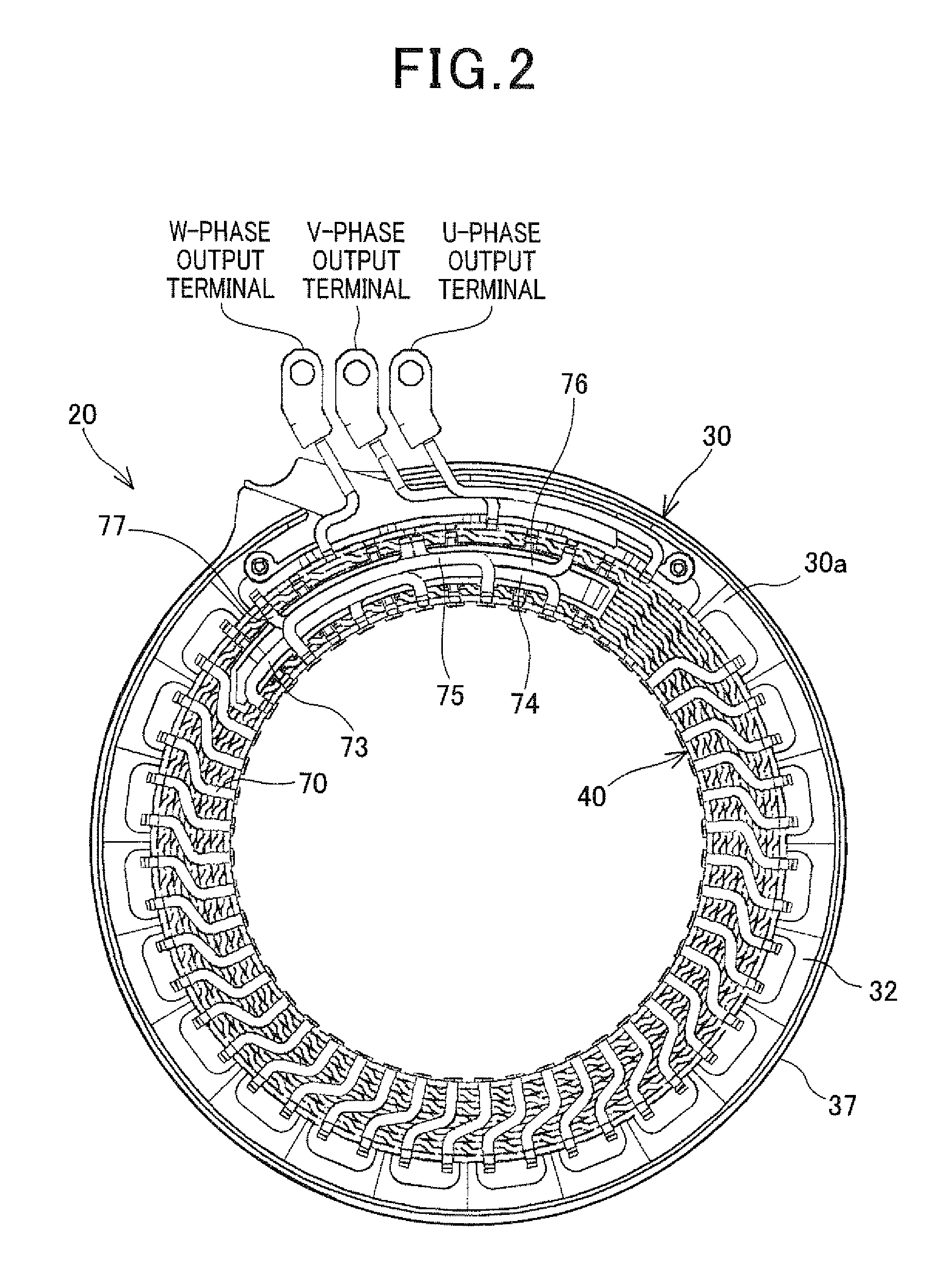

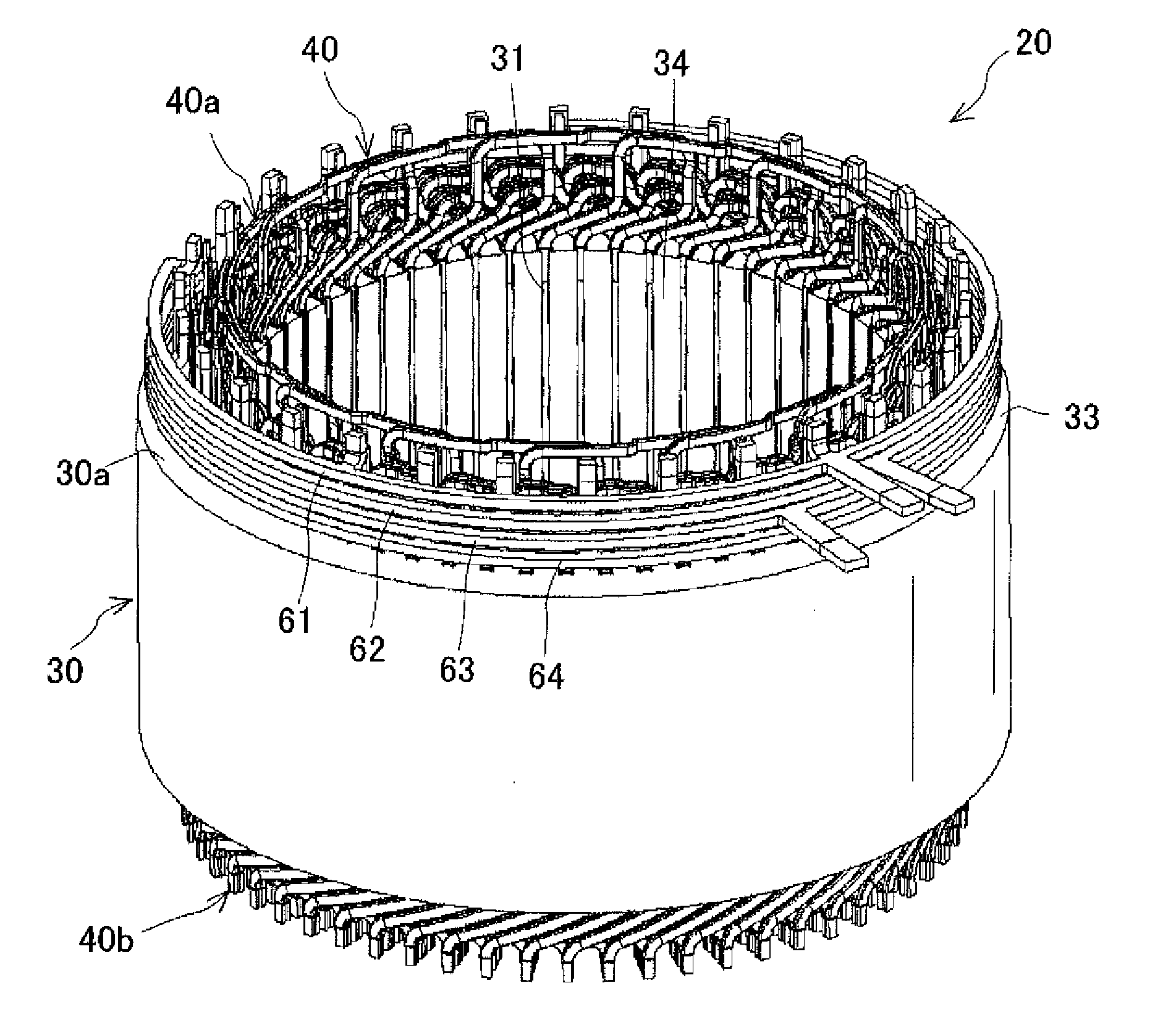

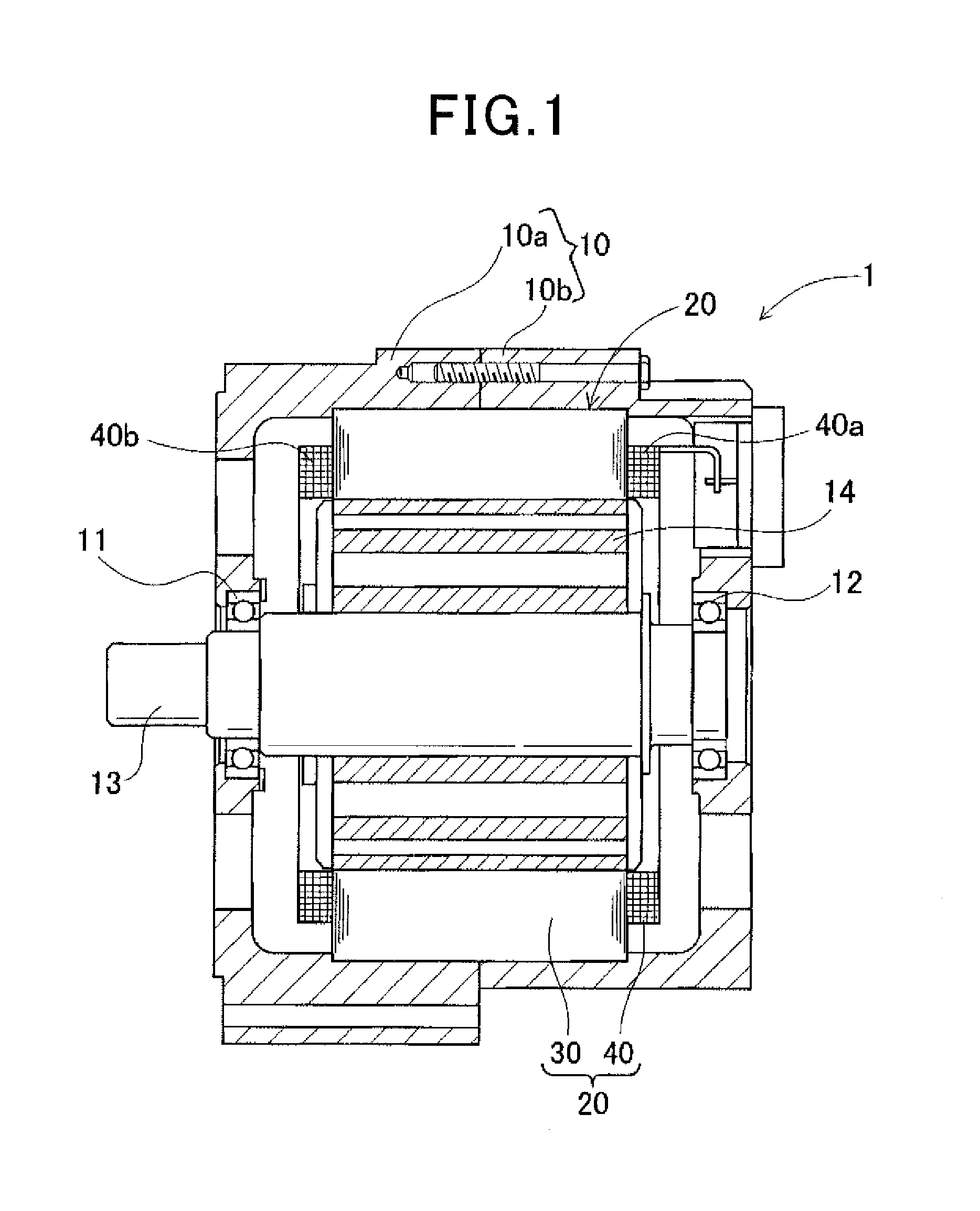

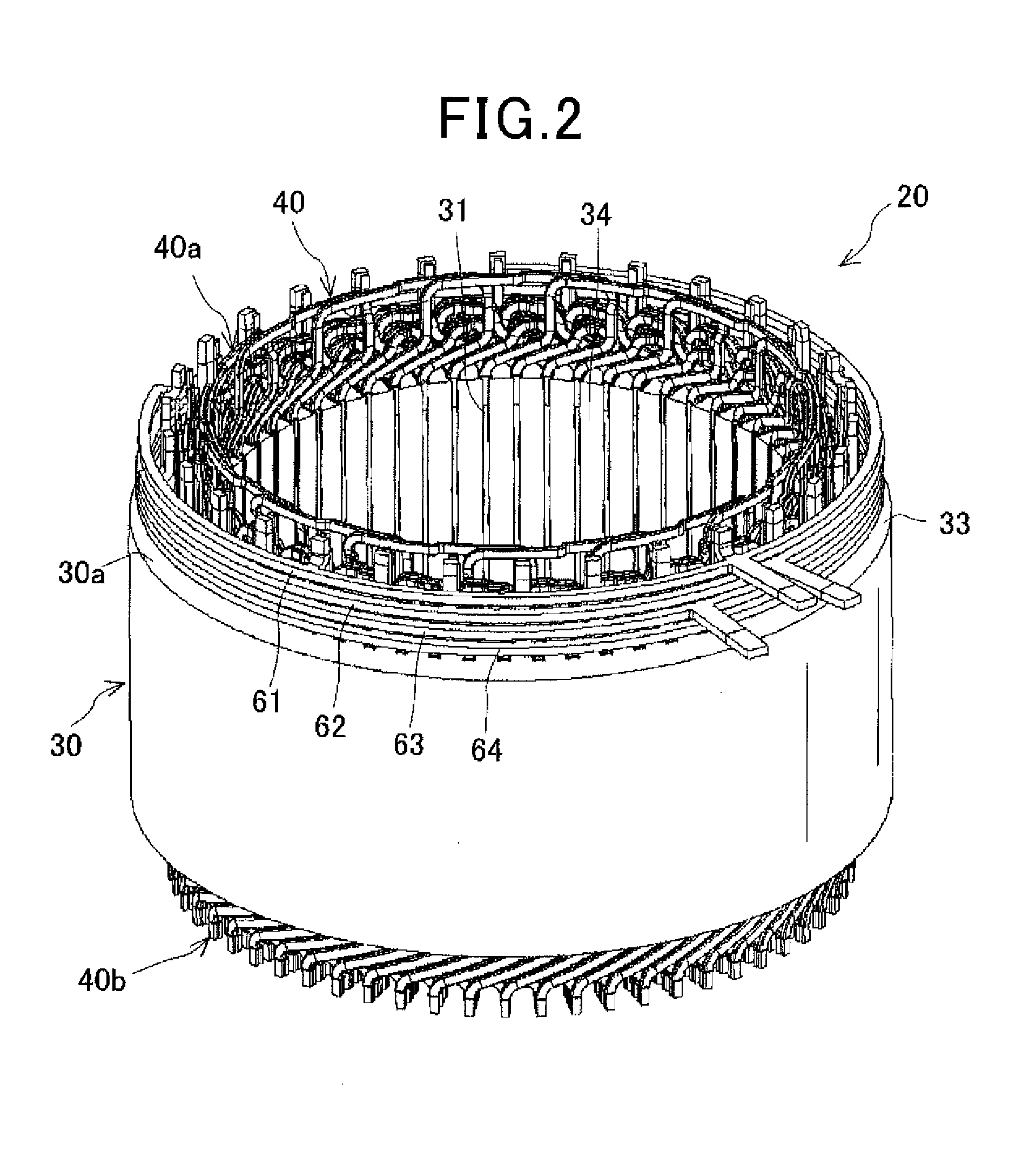

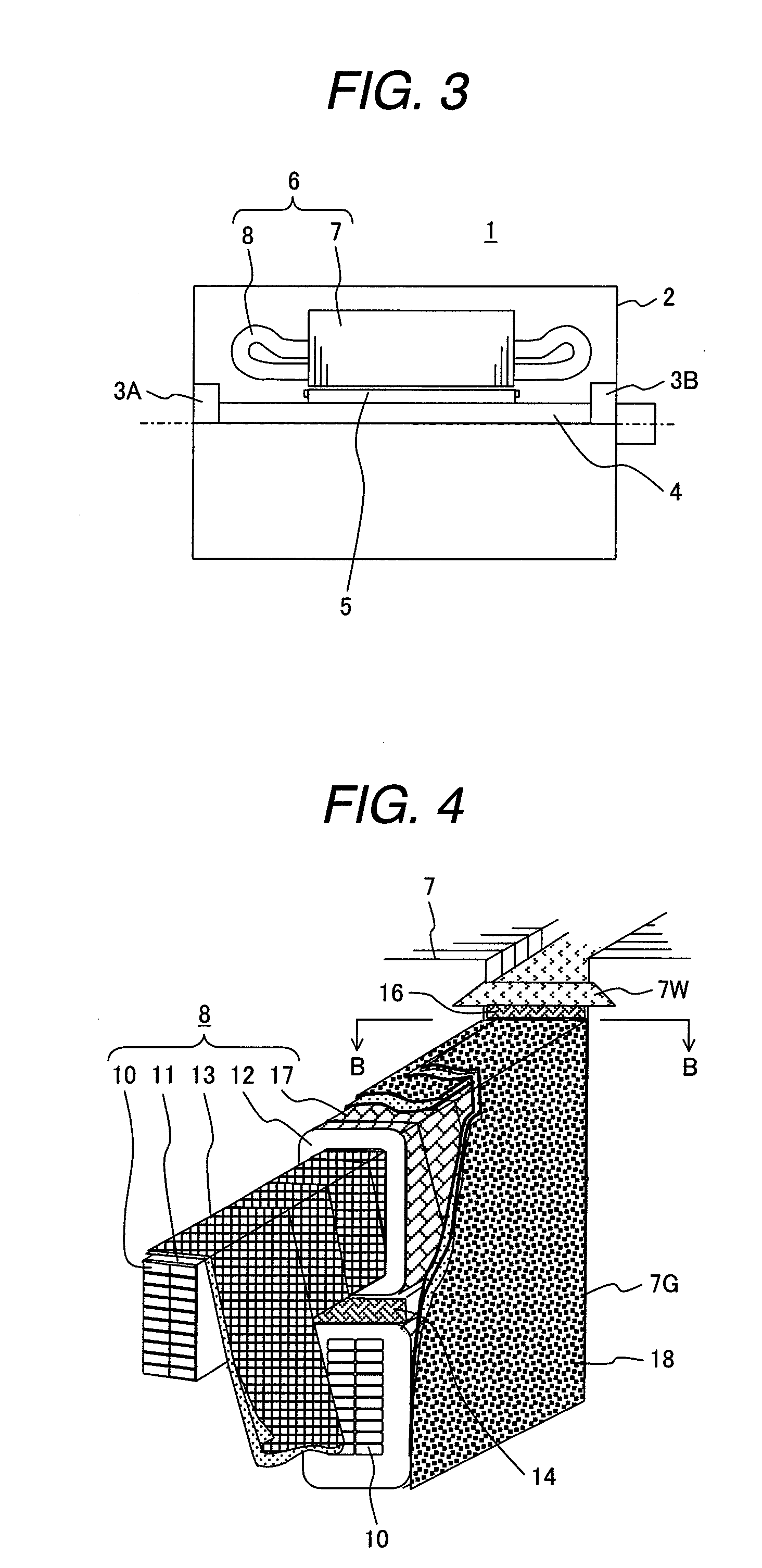

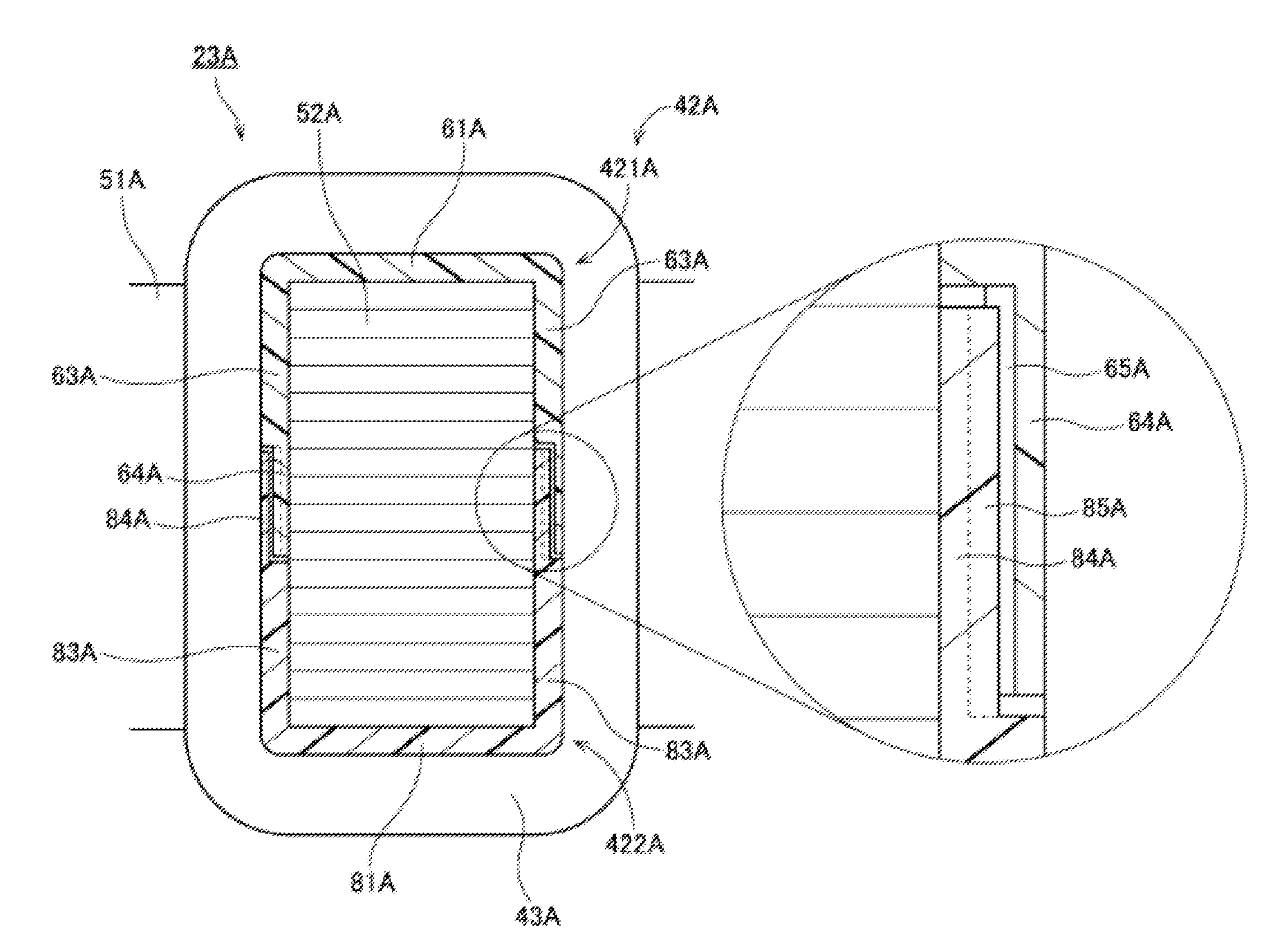

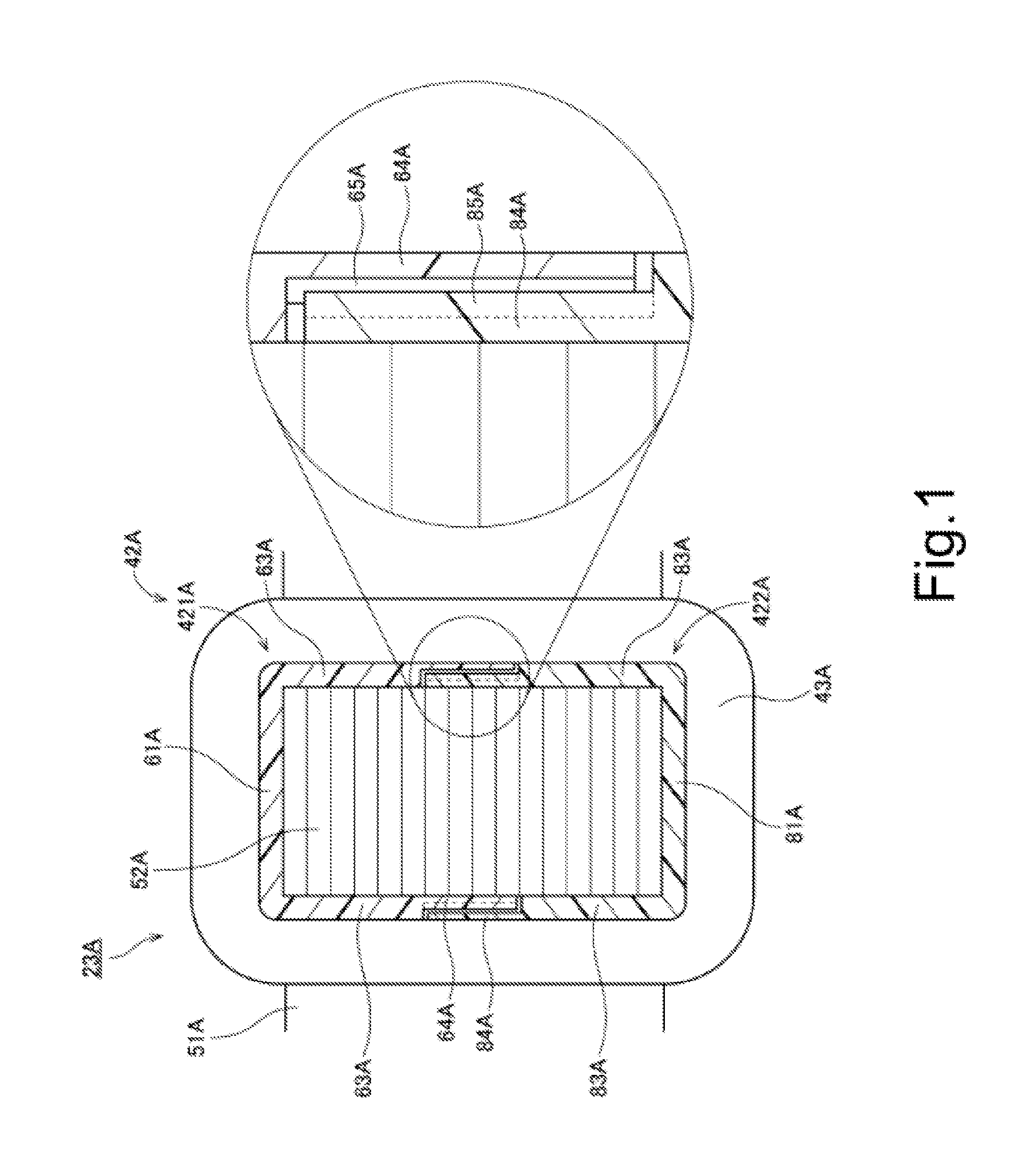

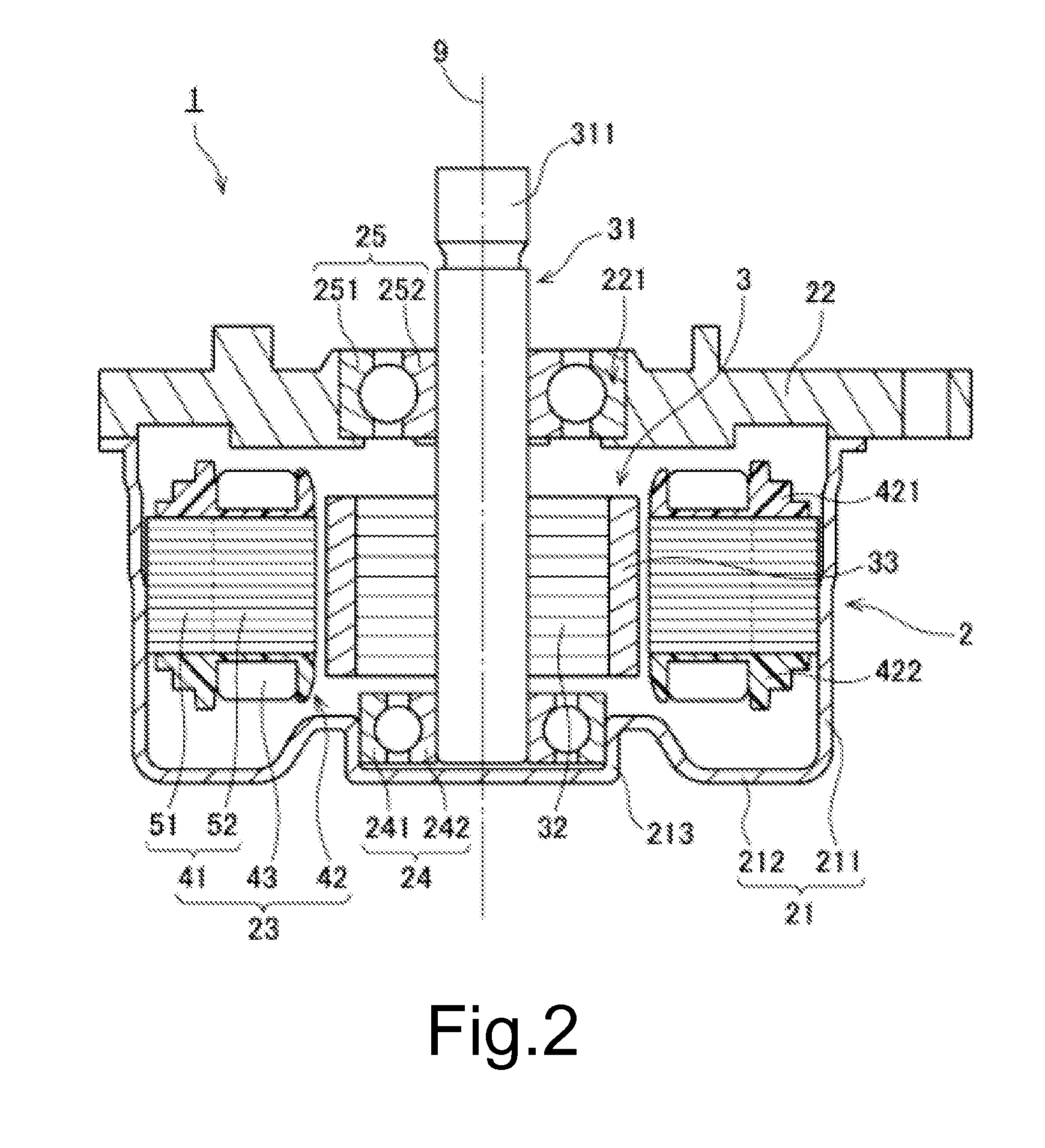

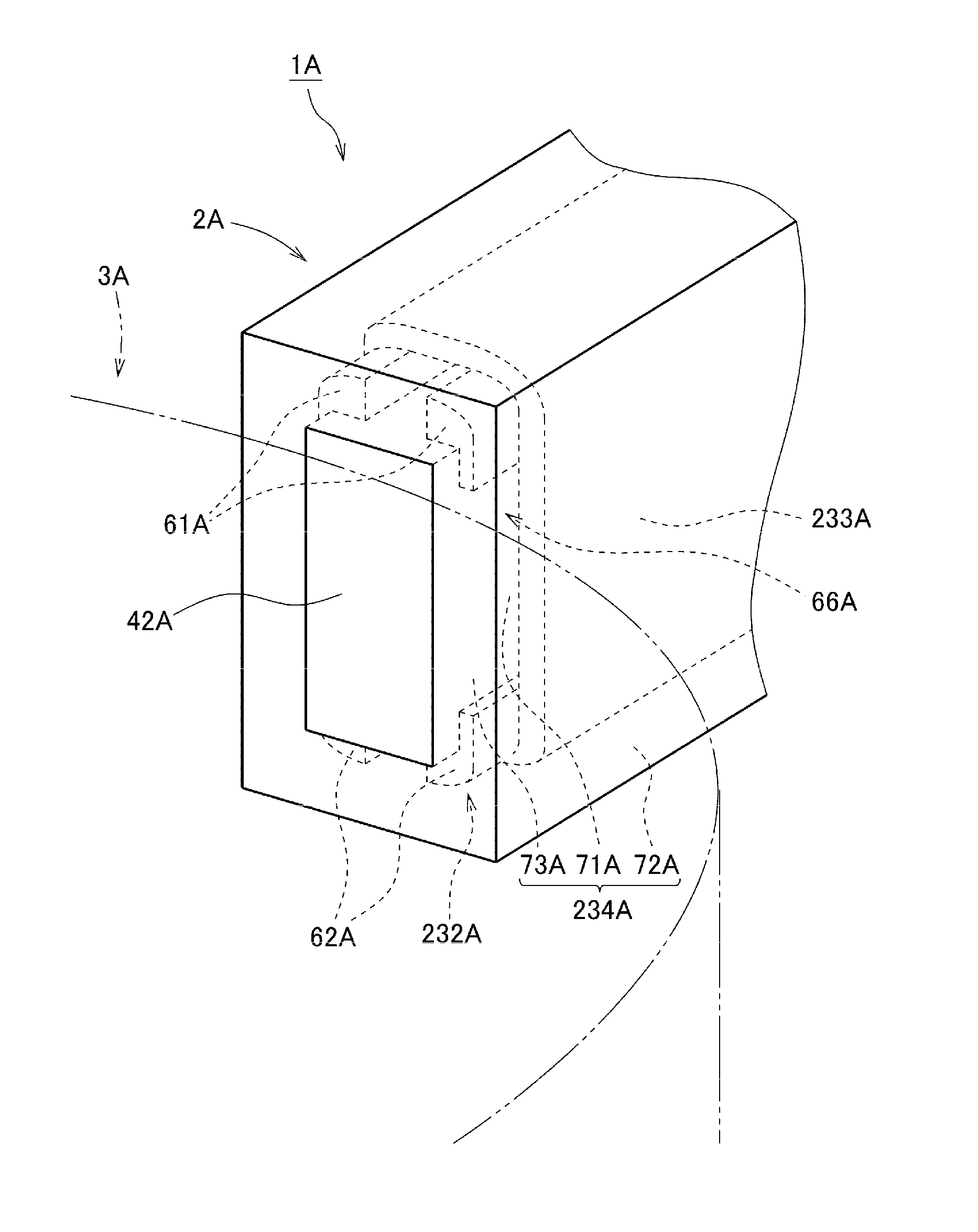

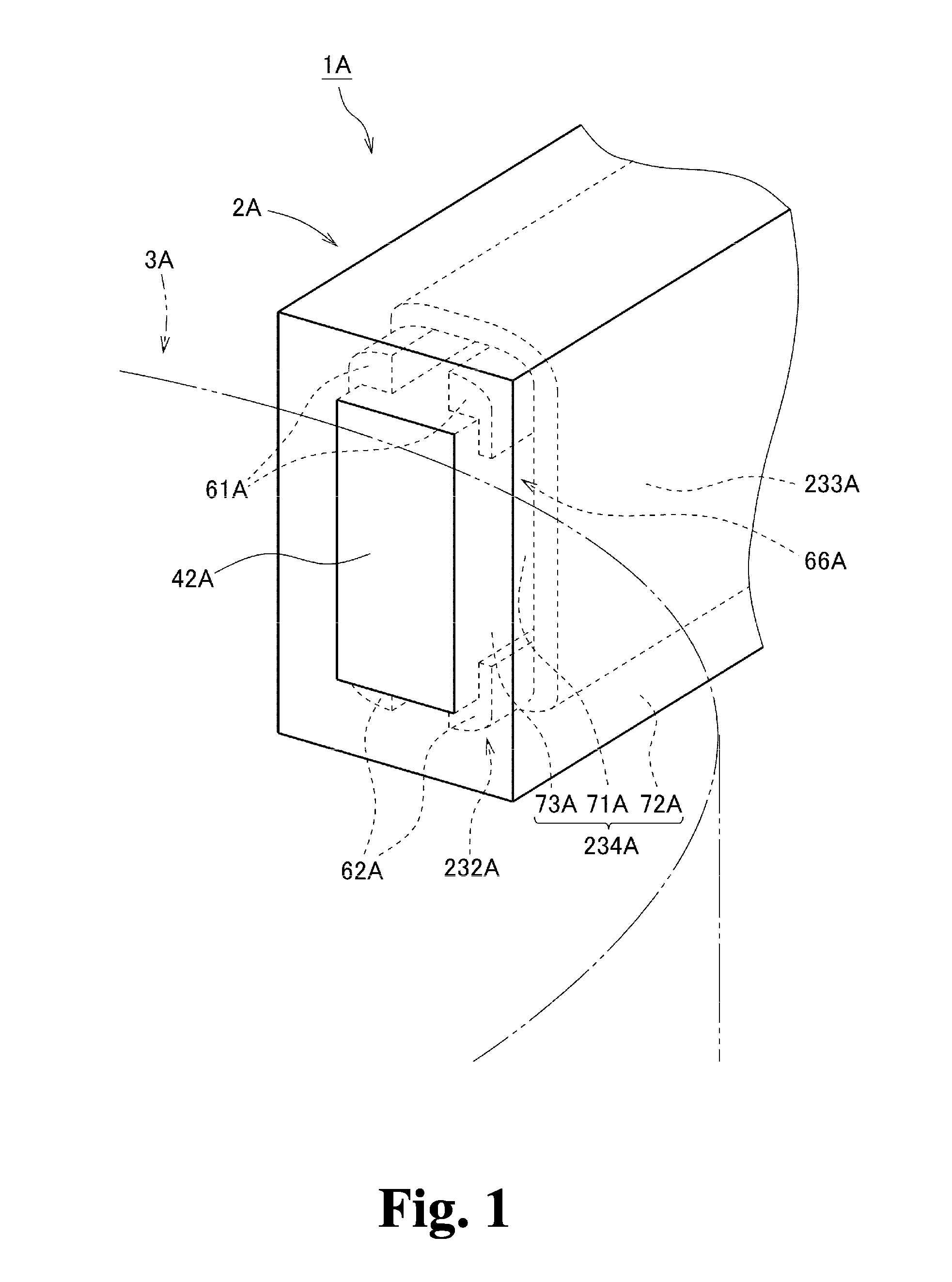

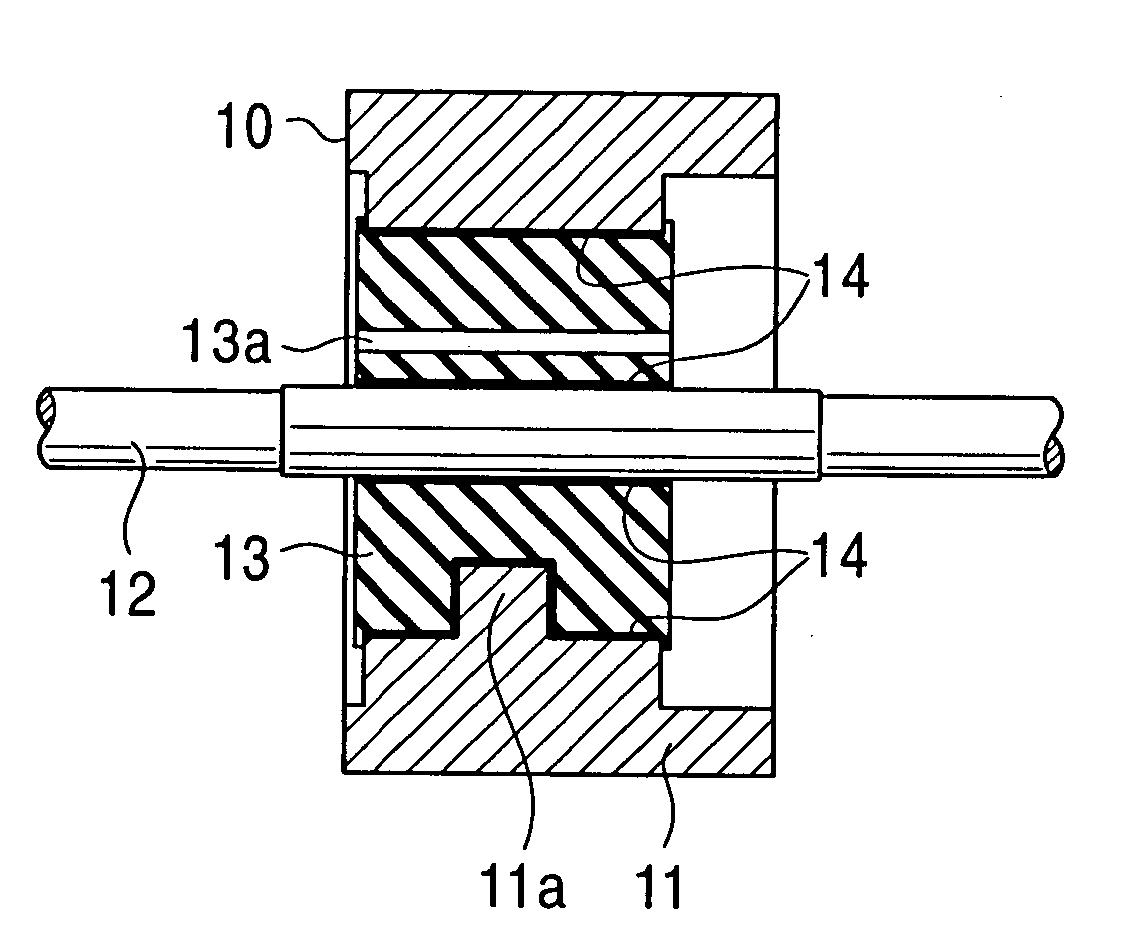

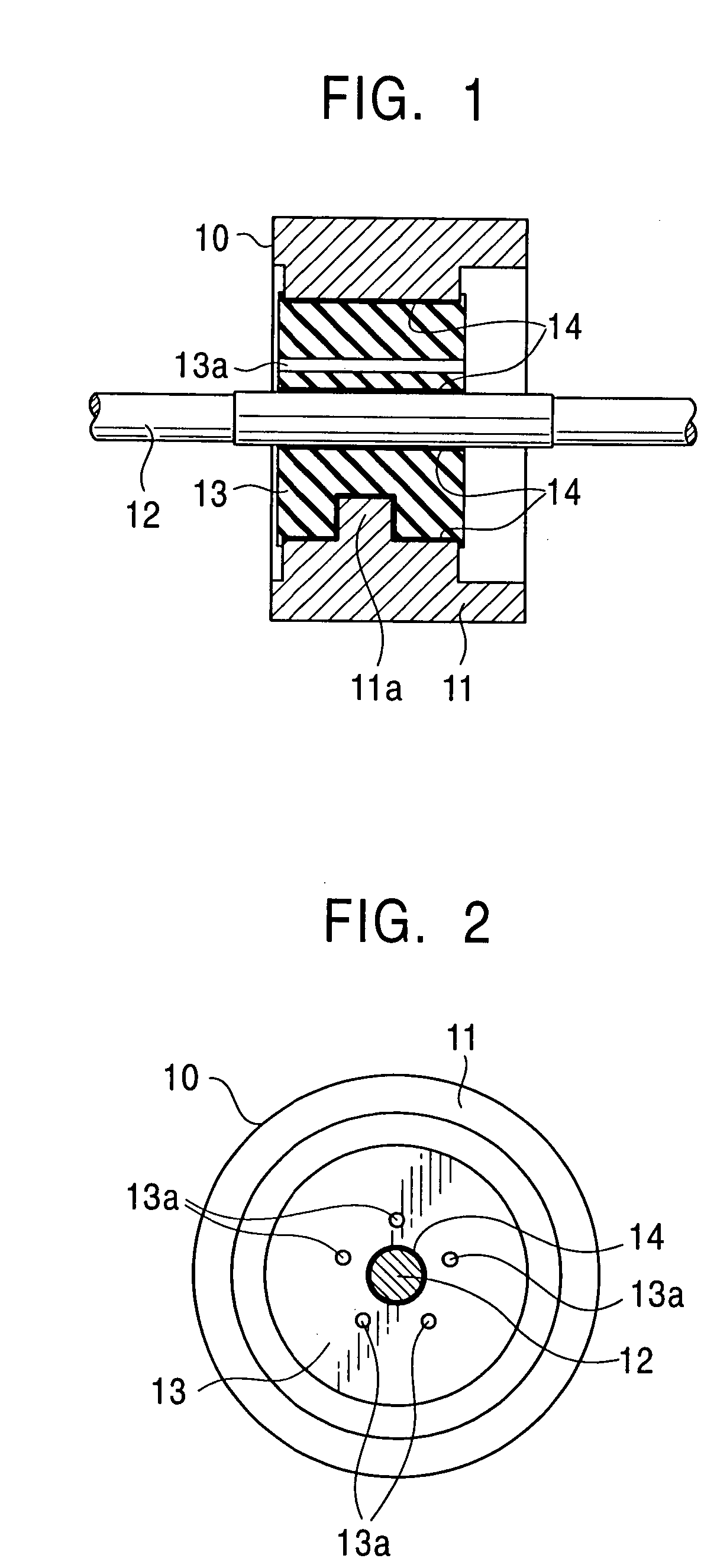

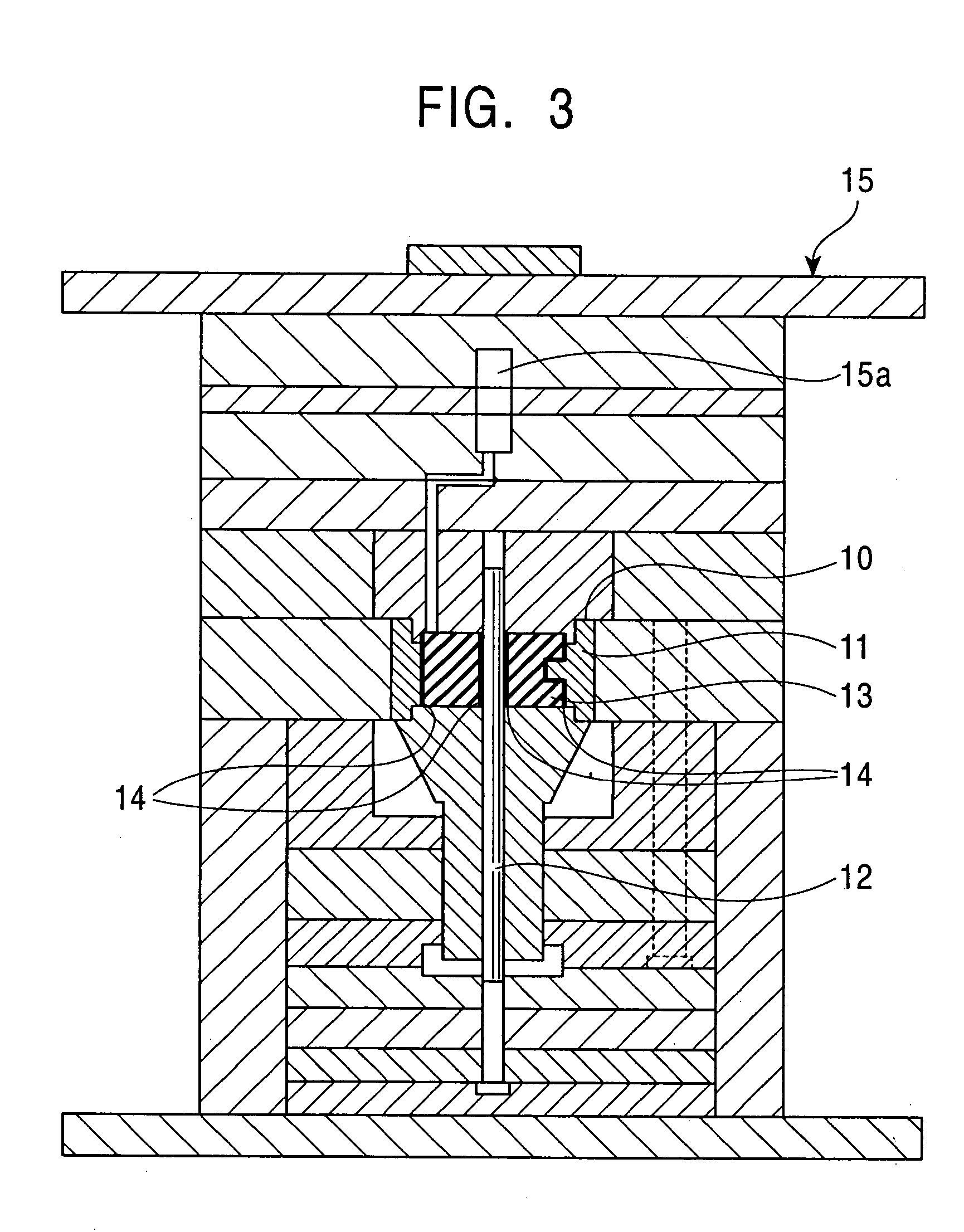

Stator for electric rotating machine

InactiveUS20120019081A1Avoid displacementImprove insulation performanceWindings insulation materialManufacturing dynamo-electric machinesElectric machineStator coil

A stator includes an annular stator core and a stator coil. The stator coil is formed of a plurality of electric wires mounted on the stator core. The stator coil has a coil end part that protrudes from an axial end face of the stator core so as to be located outside slots of the stator core. The electric wires forming the stator coil are grouped into a plurality of electric wire sets. Each of the electric wire sets consists of a predetermined number of the electric wires which are electrically connected to one another. The stator coil further includes a plurality of bridging wires. Each of the bridging wires extends, on an axially outer periphery of the coil end part of the stator coil, to electrically connect a corresponding pair of the electric wire sets. Further, at least two of the bridging wires are fixed to one another.

Owner:TOYOTA JIDOSHA KK

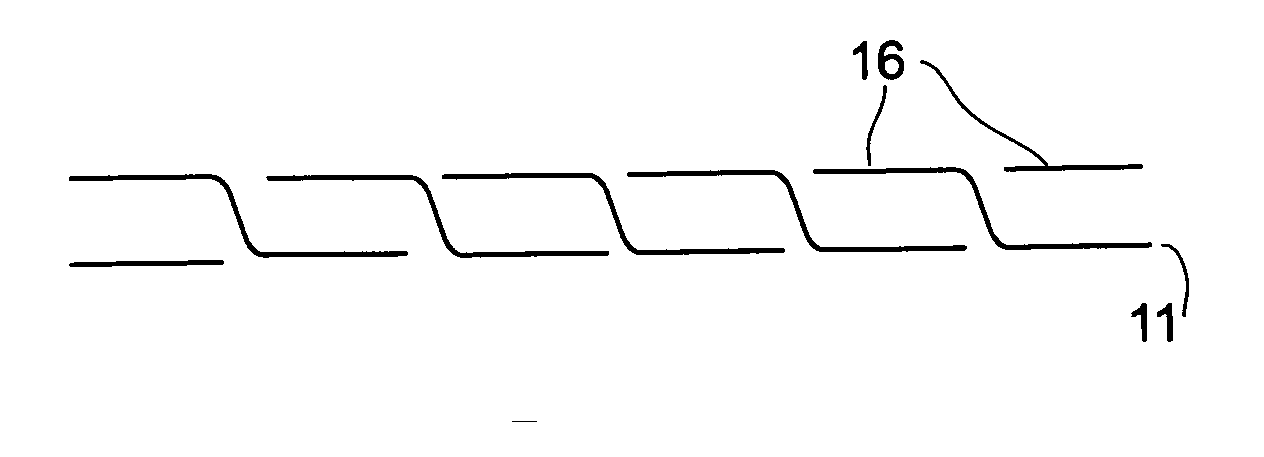

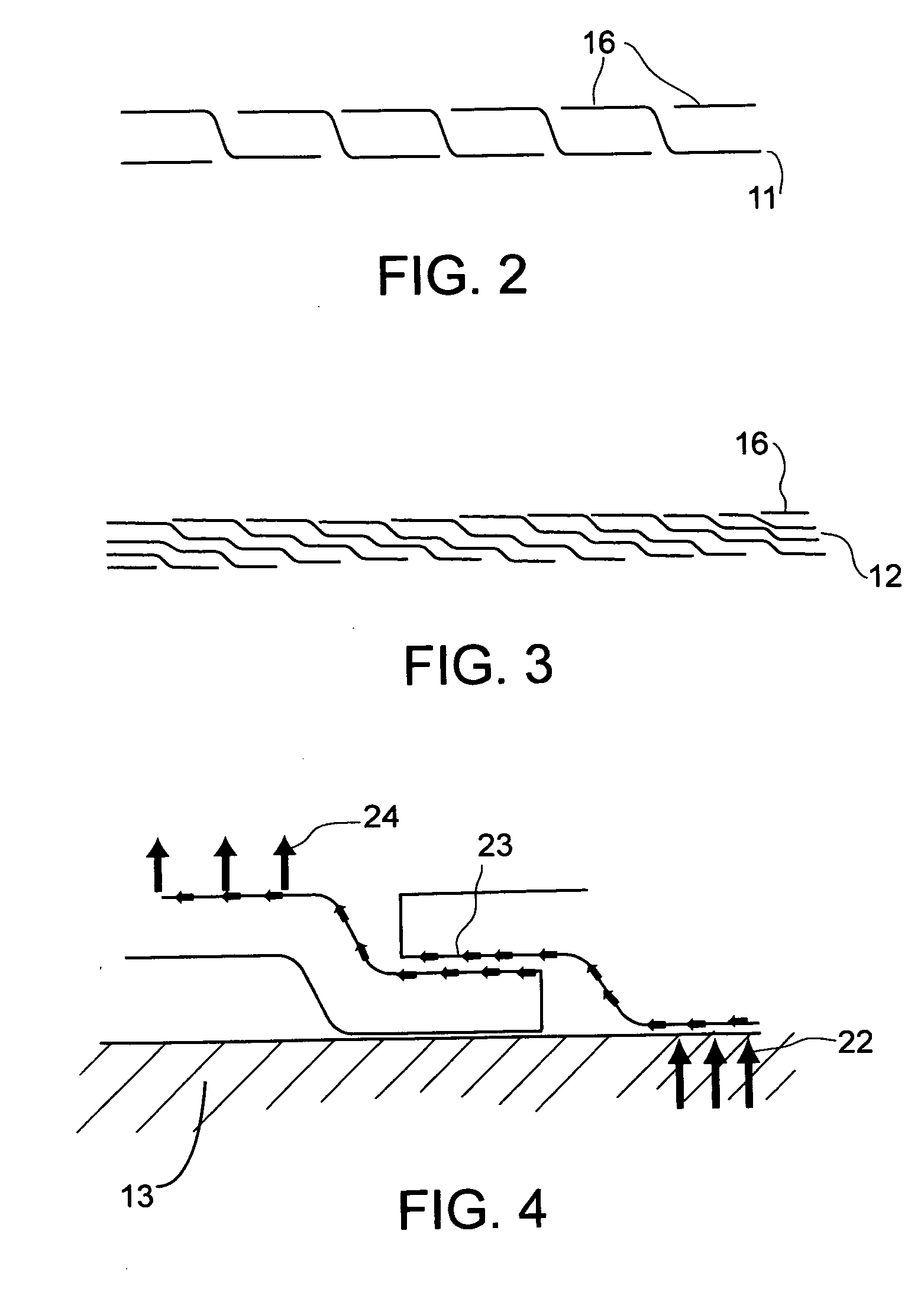

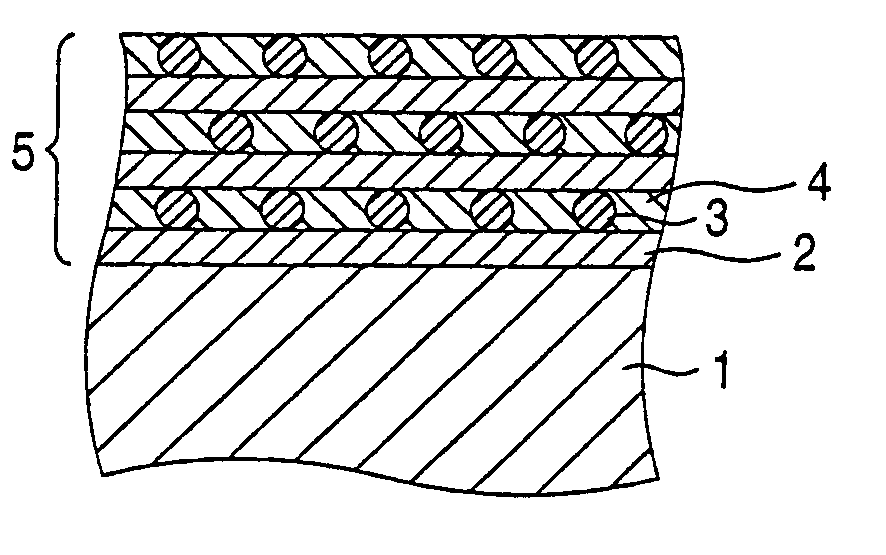

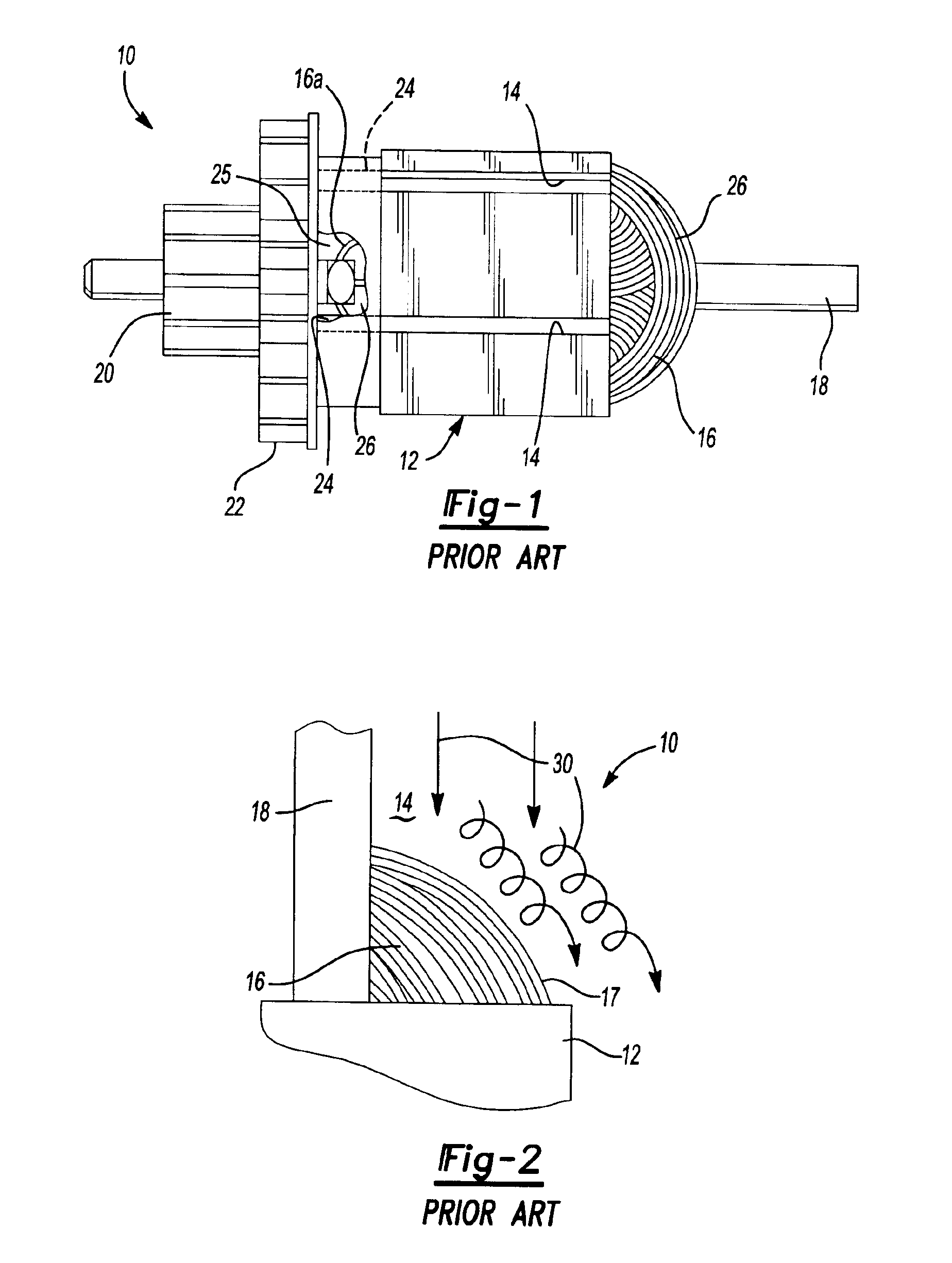

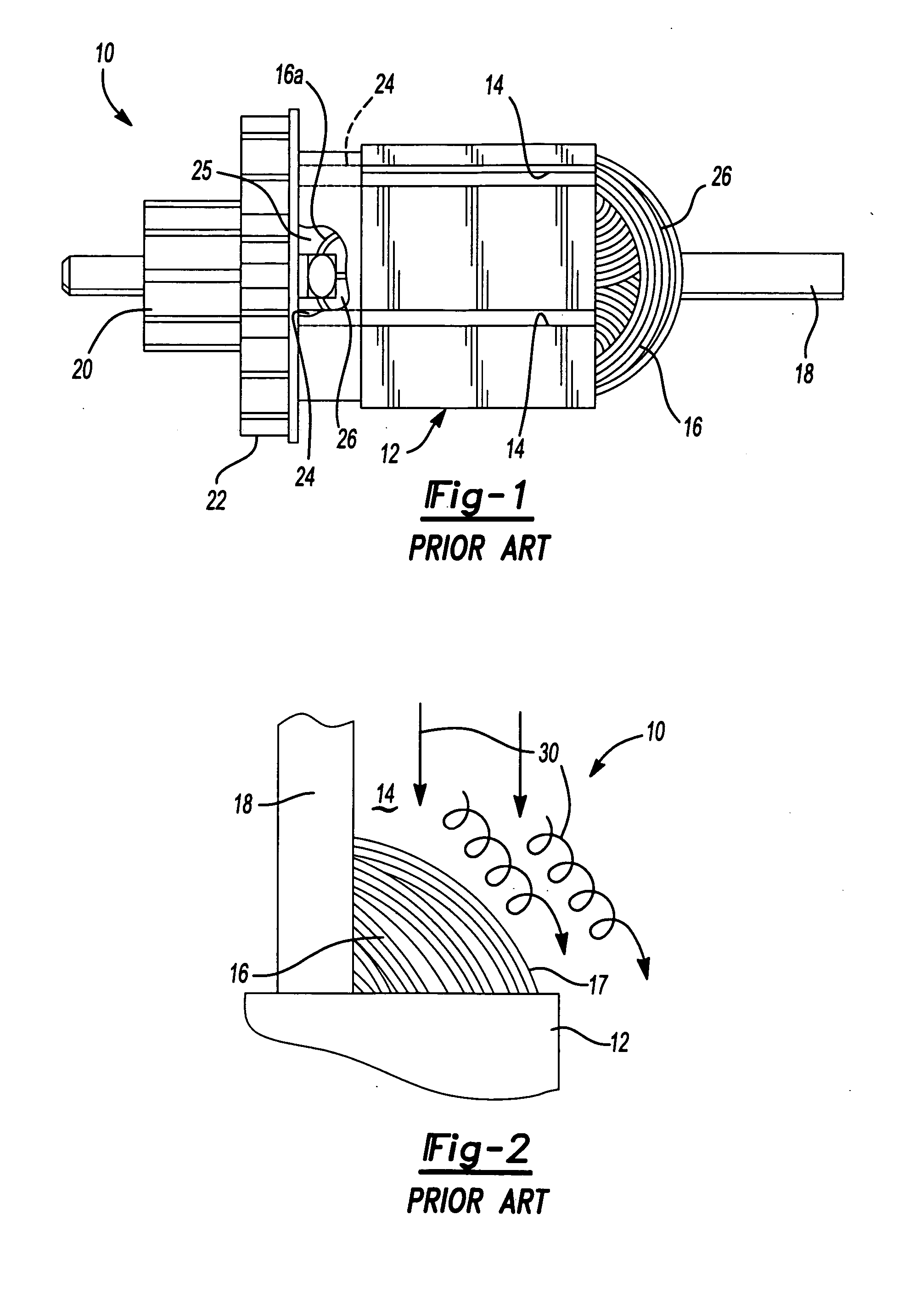

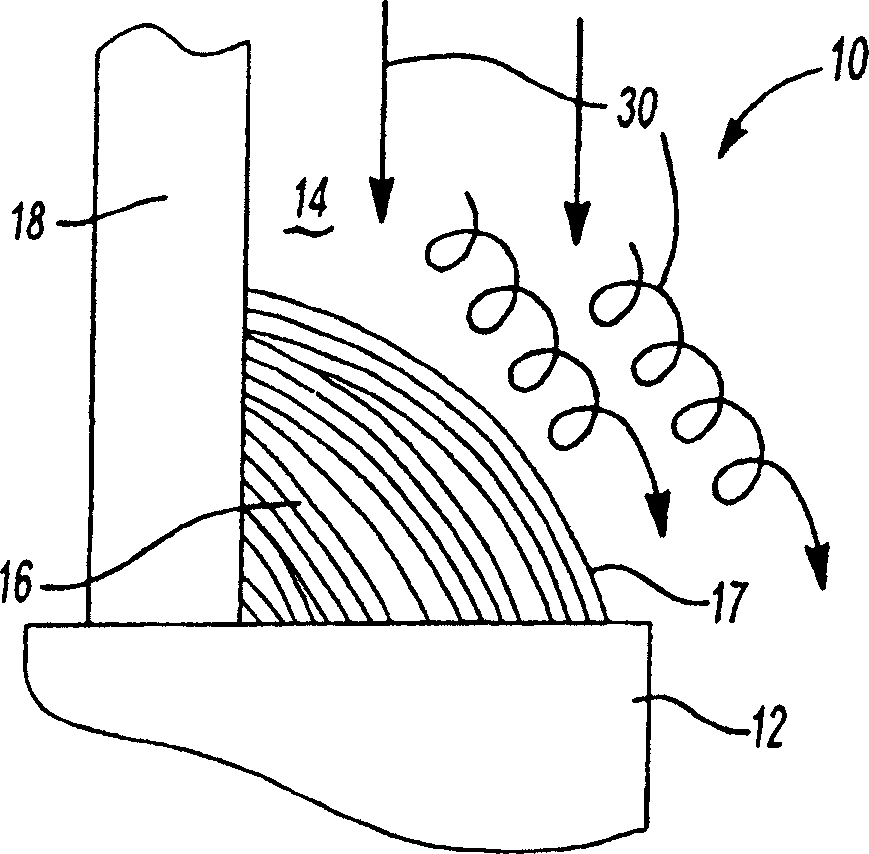

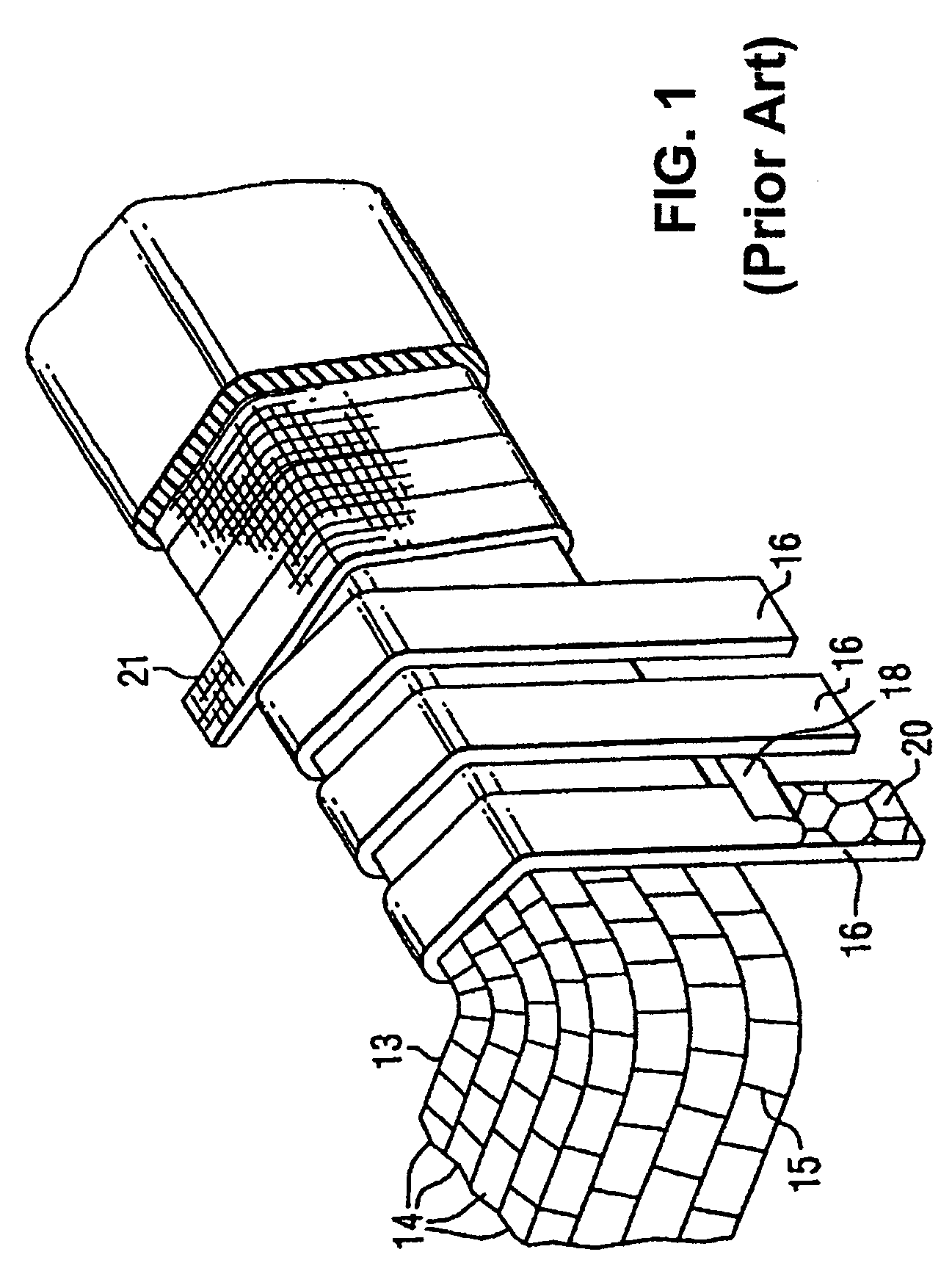

Surface coating of lapped insulation tape

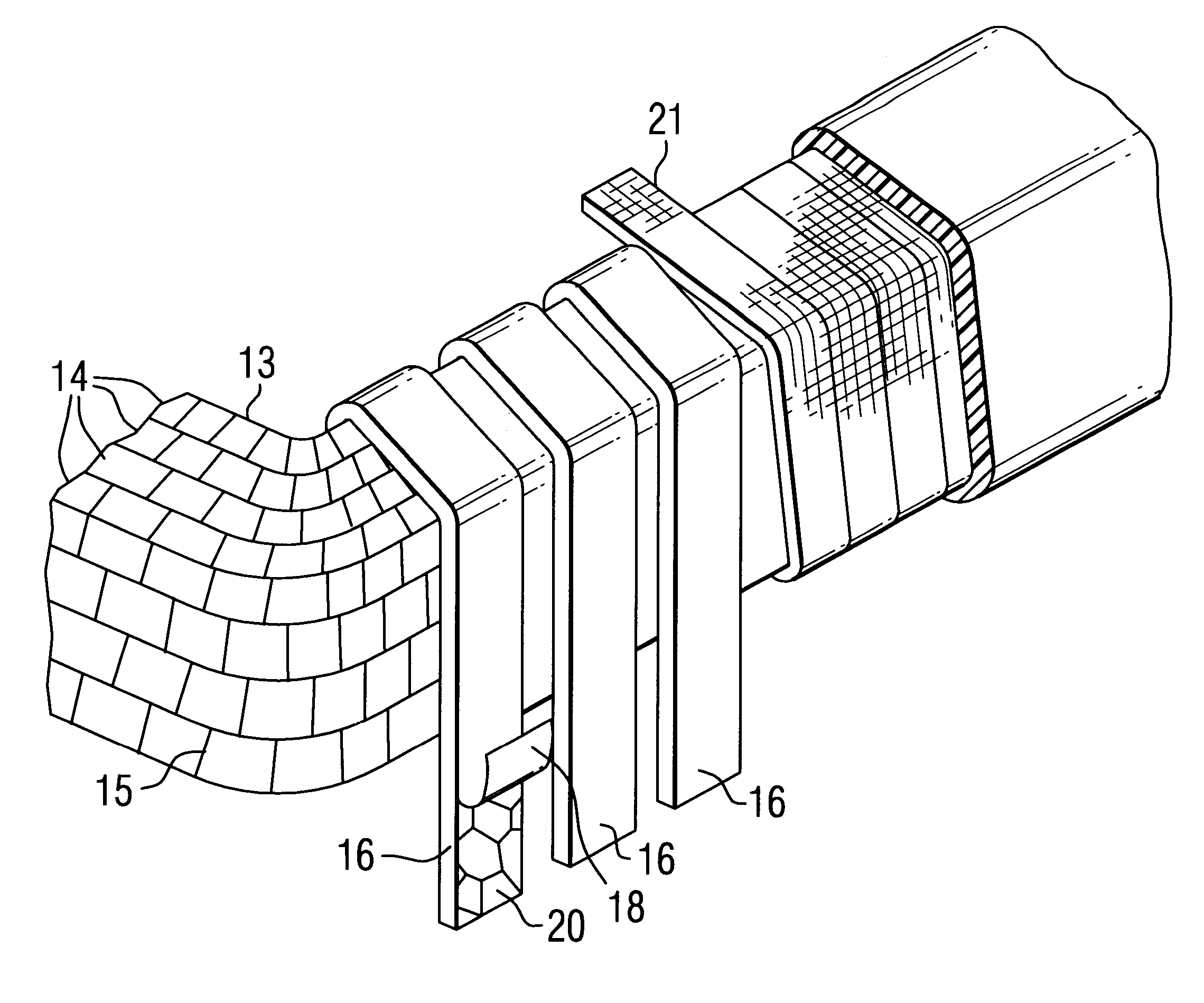

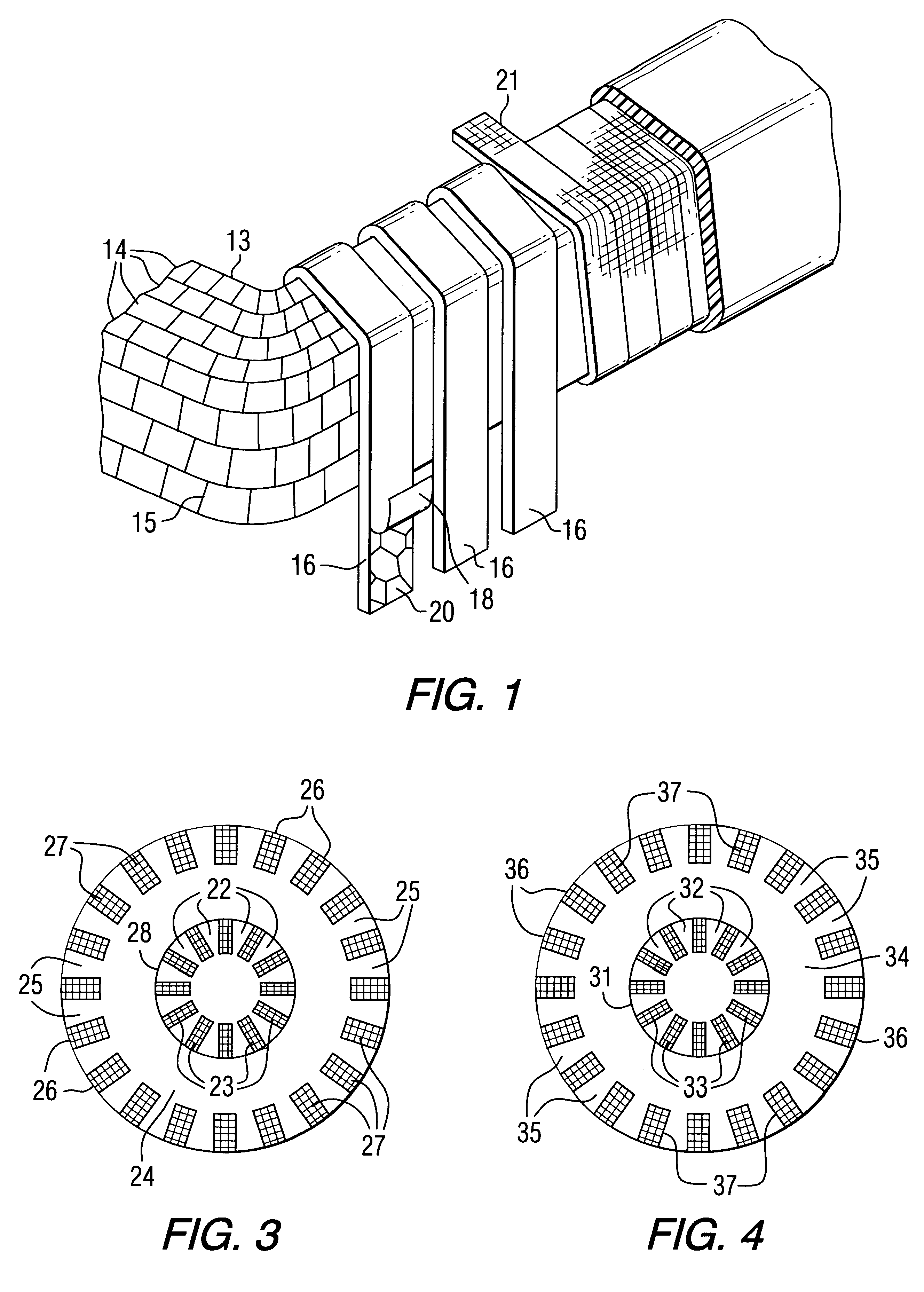

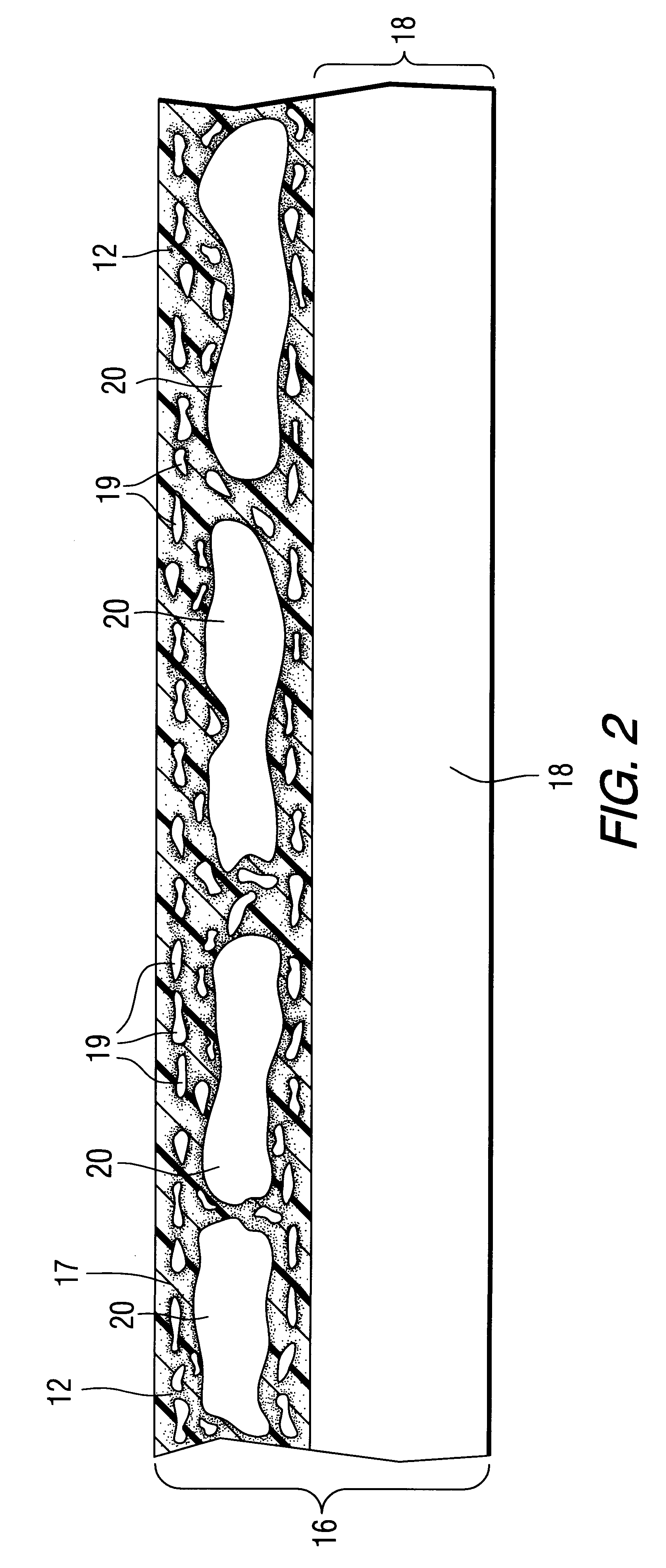

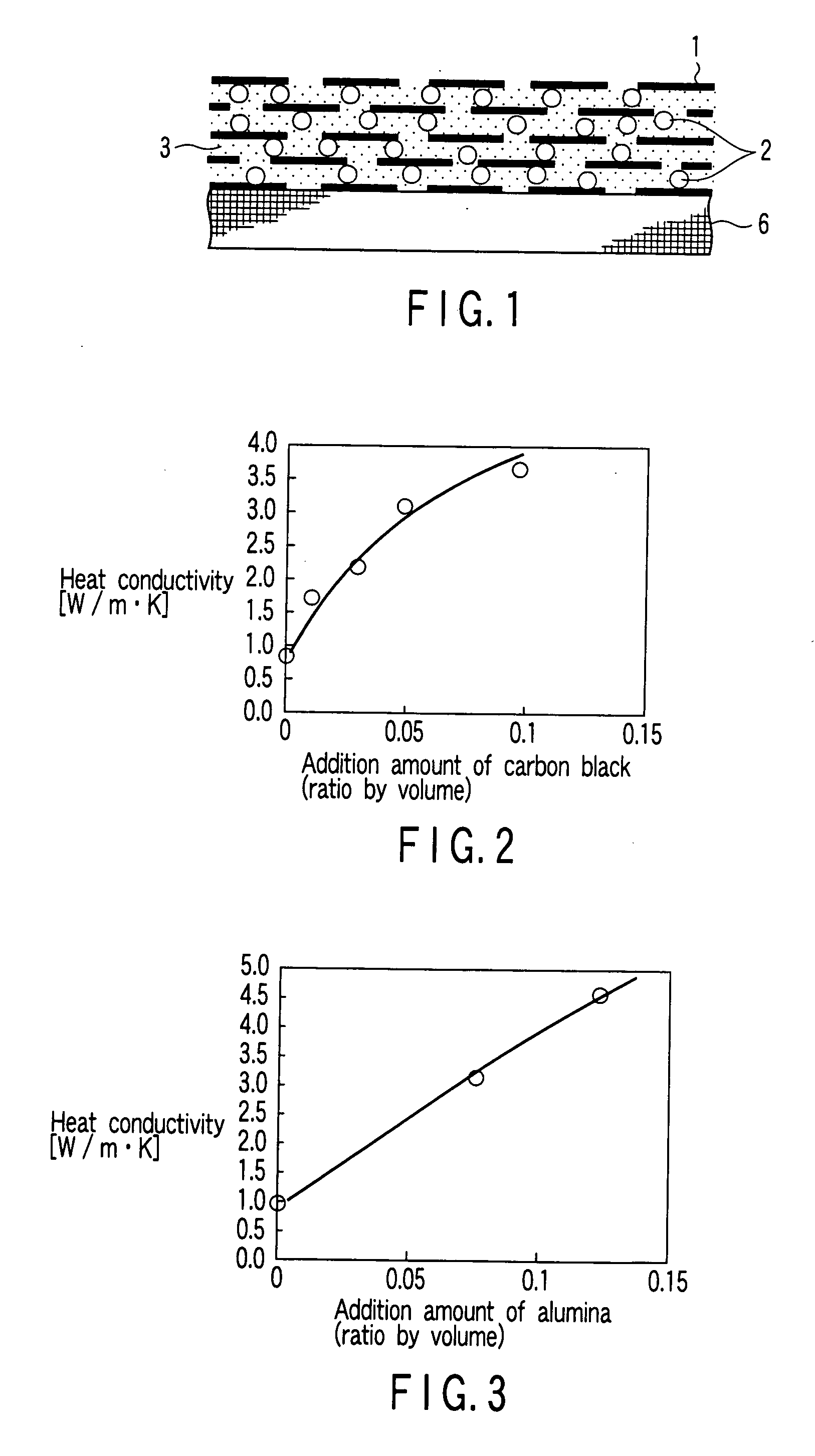

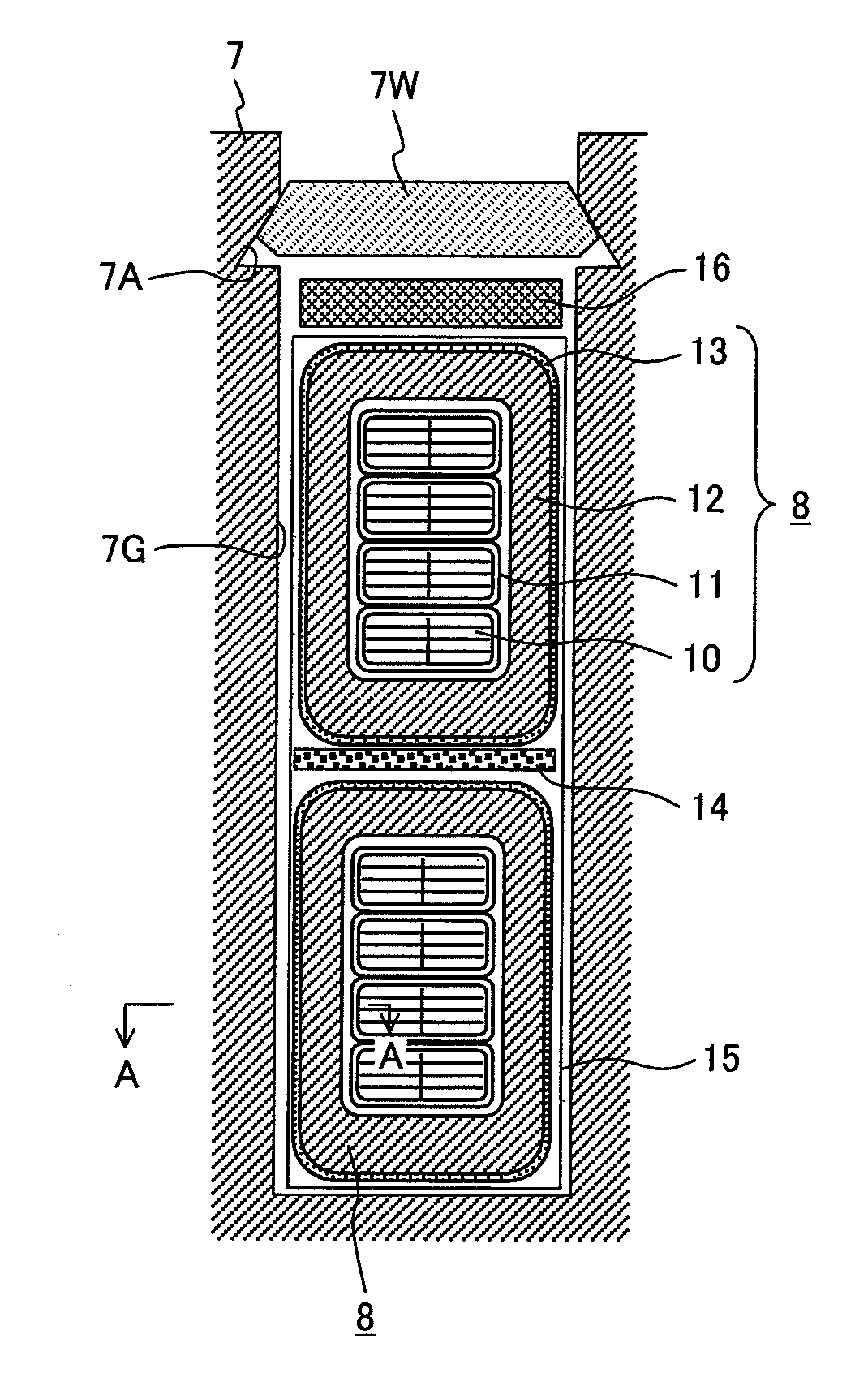

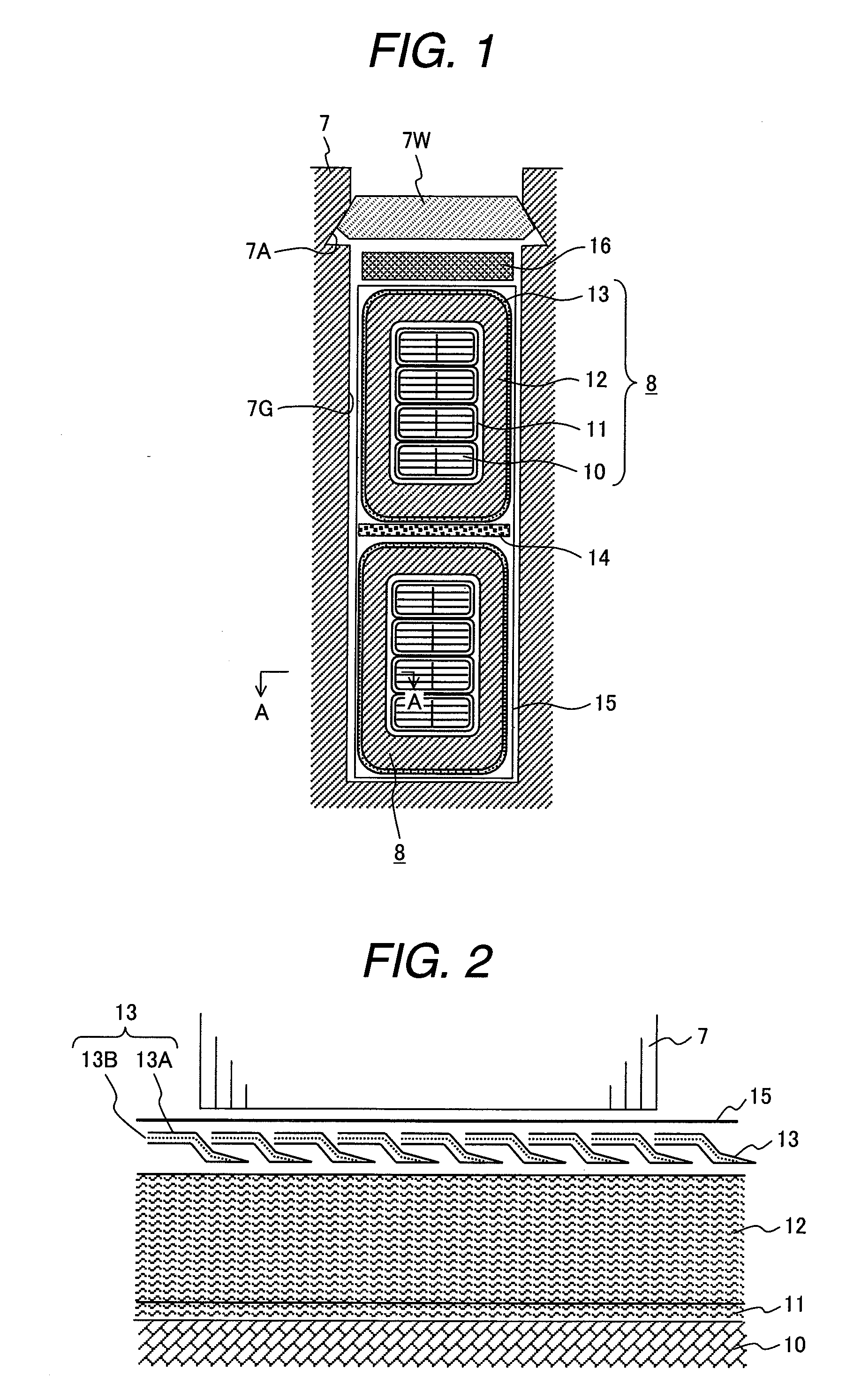

ActiveUS20050274540A1Facilitates surface coatingImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionHeat flowMagnetic tape

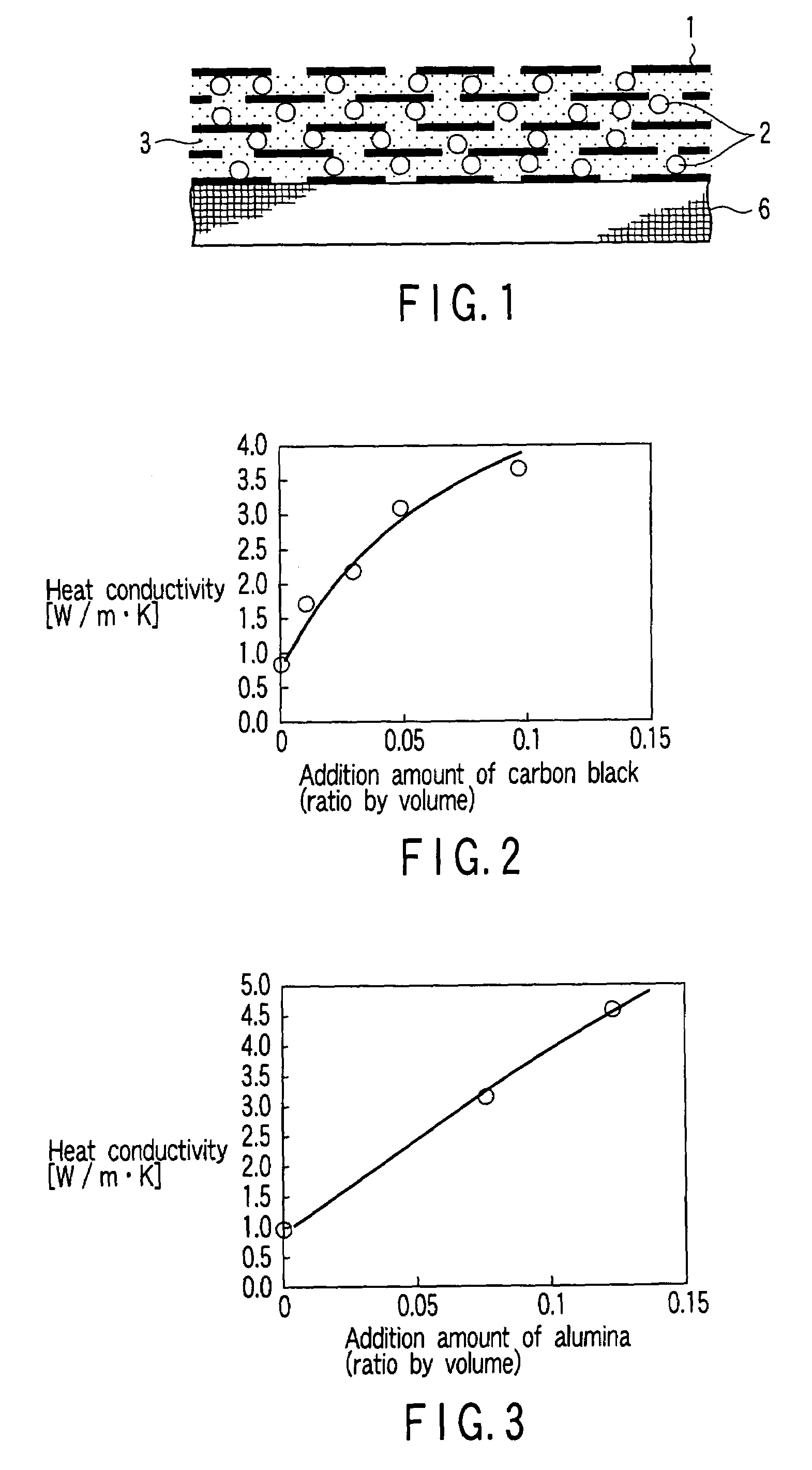

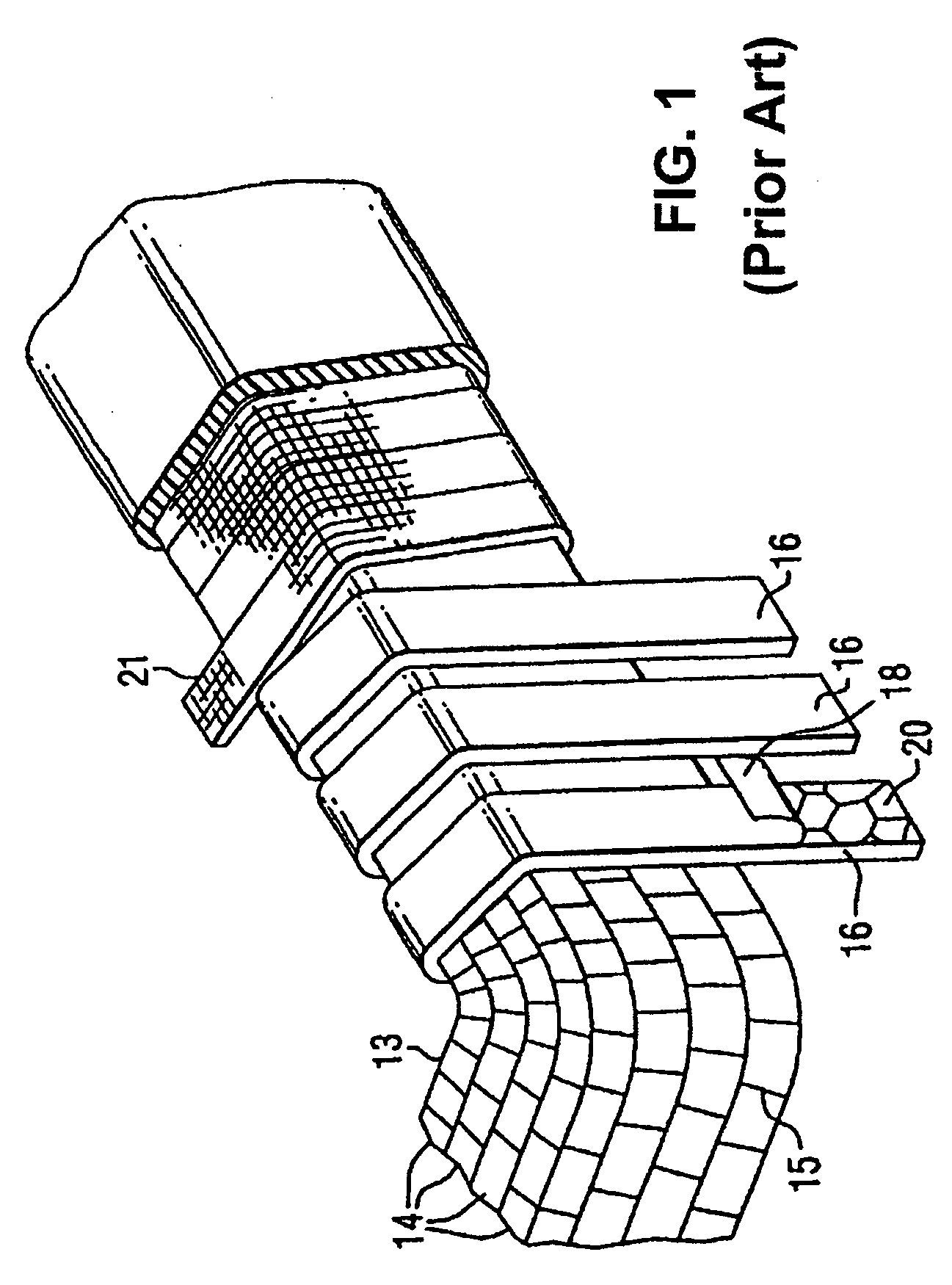

In one embodiment the present invention improves the heat flow from an electrically insulated object 13 by providing an enhanced conduit at the interface between the layers of insulating tape 16. The tape 16 has been surface coated with a high thermal conductivity (HTC) material, so that the interface between the layers of tape 23 provides a pathway for the heat to reach the environment 24. The radiation of heat through the tape layers is also increased by the surface coatings.

Owner:SIEMENS ENERGY INC

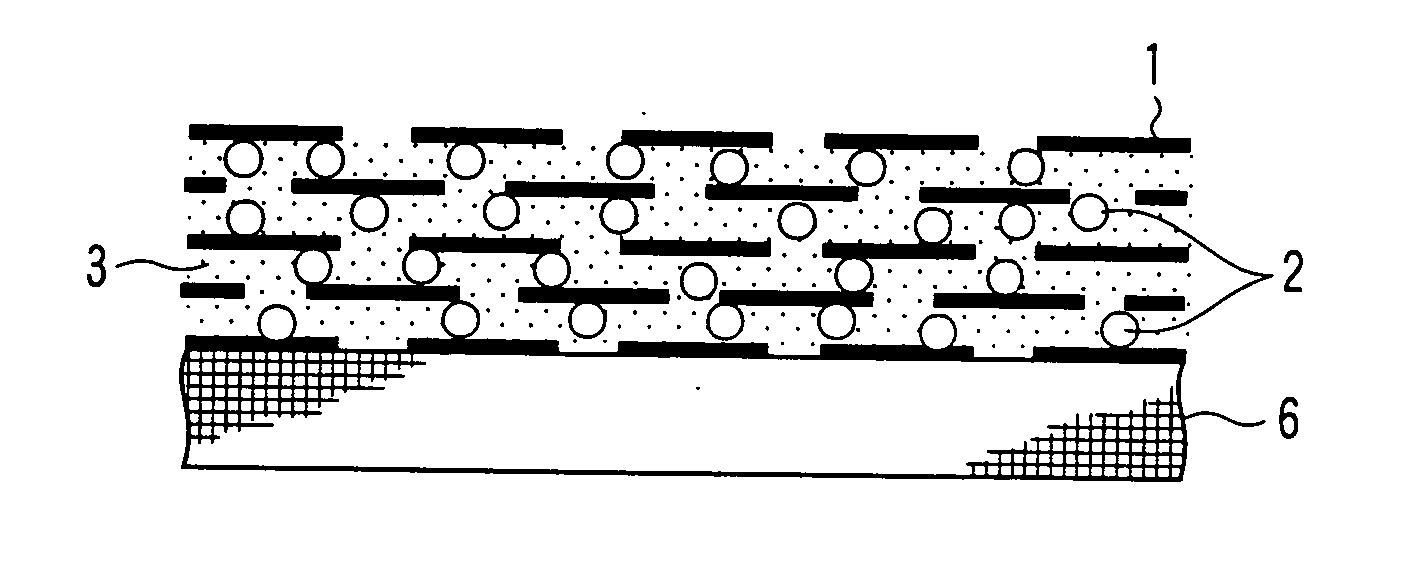

Tape member or sheet member, and method of producing tape member or sheet member

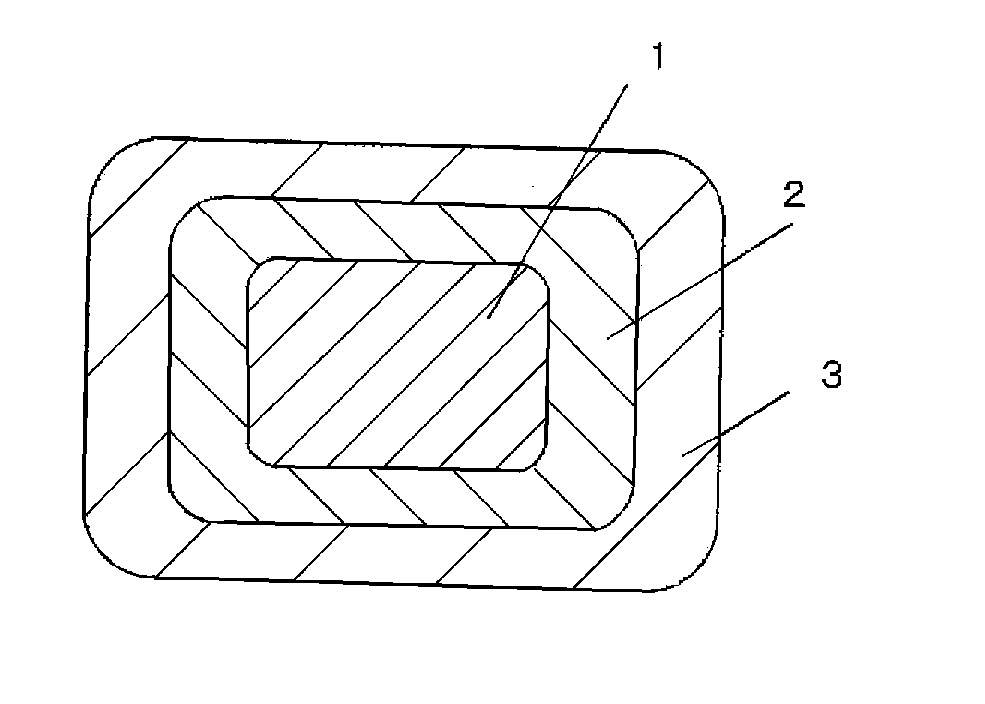

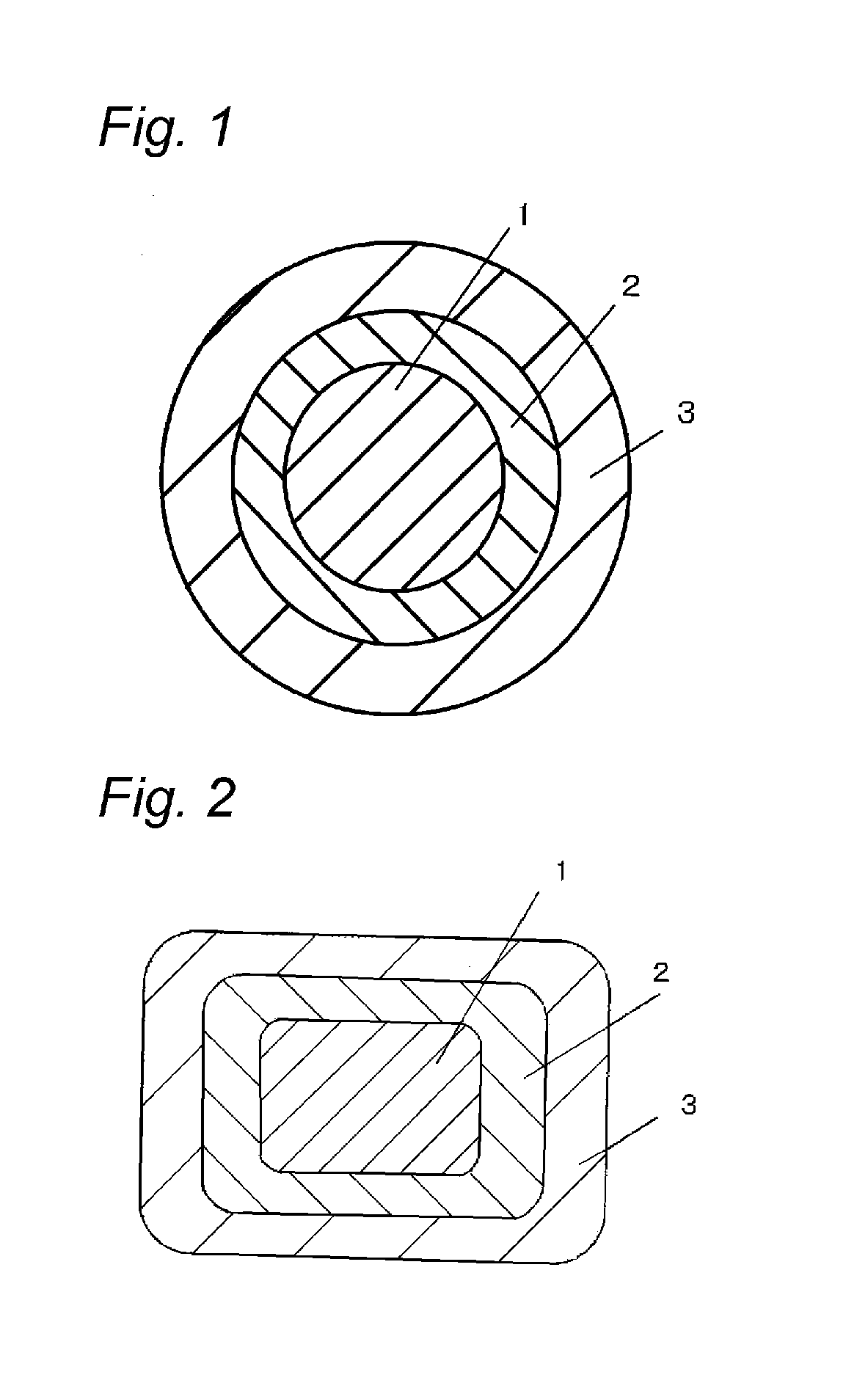

InactiveUS7425366B2Easy to produceImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionEngineeringThermal transmittance

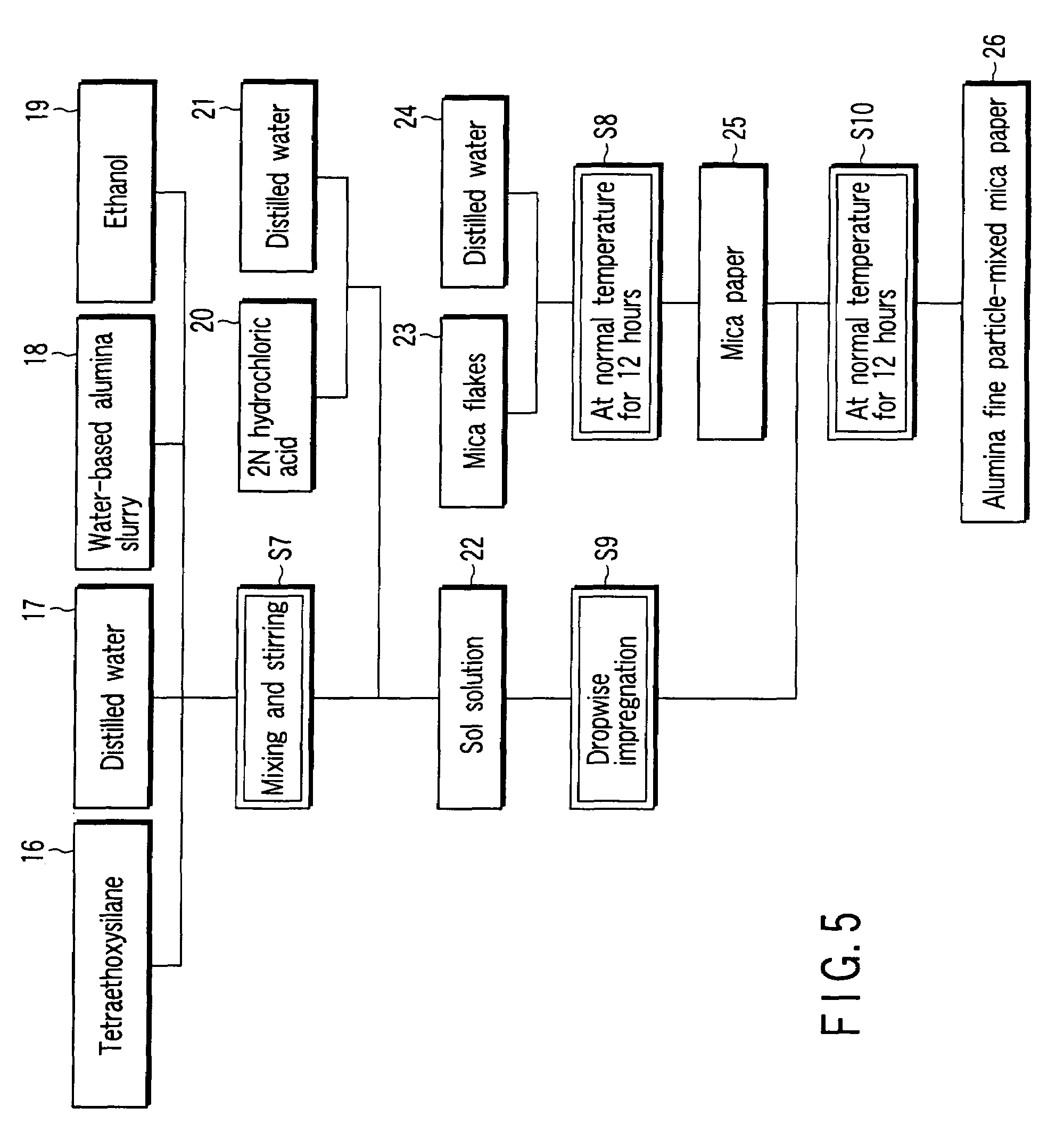

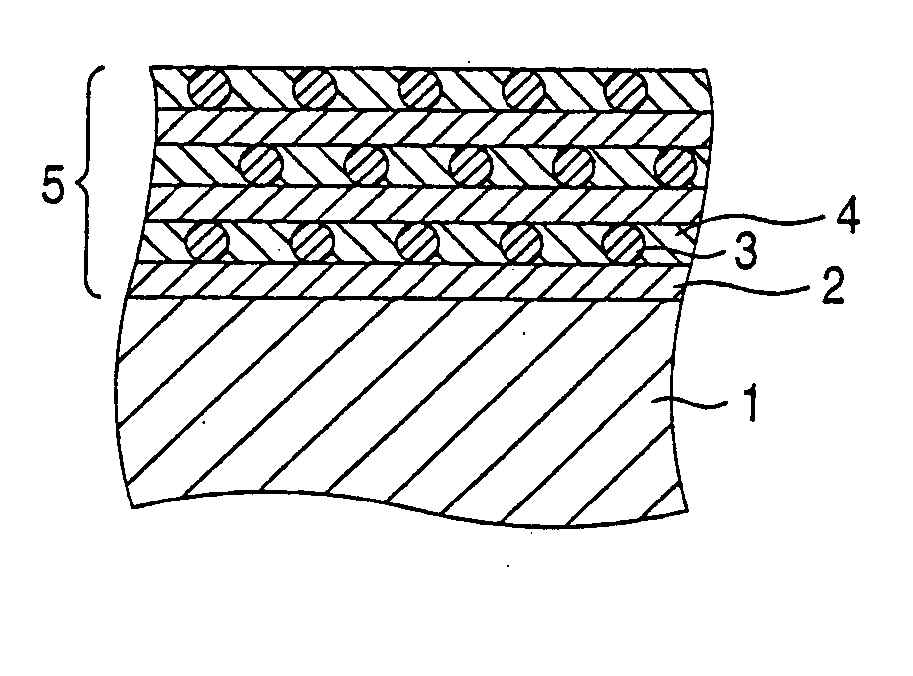

The invention aims to provide a highly heat conductive tape member or sheet member and a method for easily producing a highly heat conductive tape member or sheet member. The mica tape member or mica sheet member of the invention includes a mica-containing layer and a lining material, and the mica-containing layer contains scaly particles, particles having a heat conductivity of 0.5 W / mK or higher and a size of 1 μm or smaller, and a binder.

Owner:KK TOSHIBA

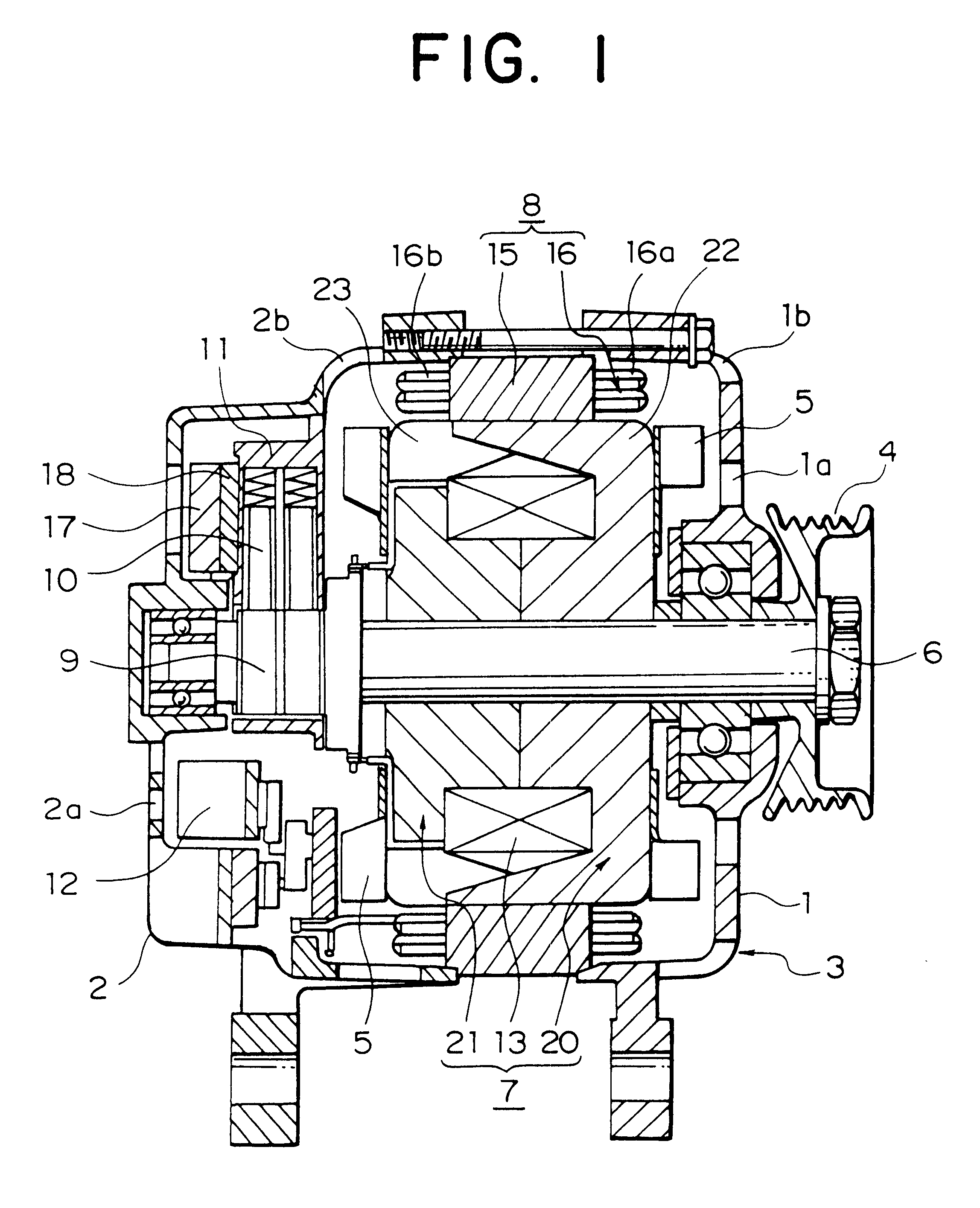

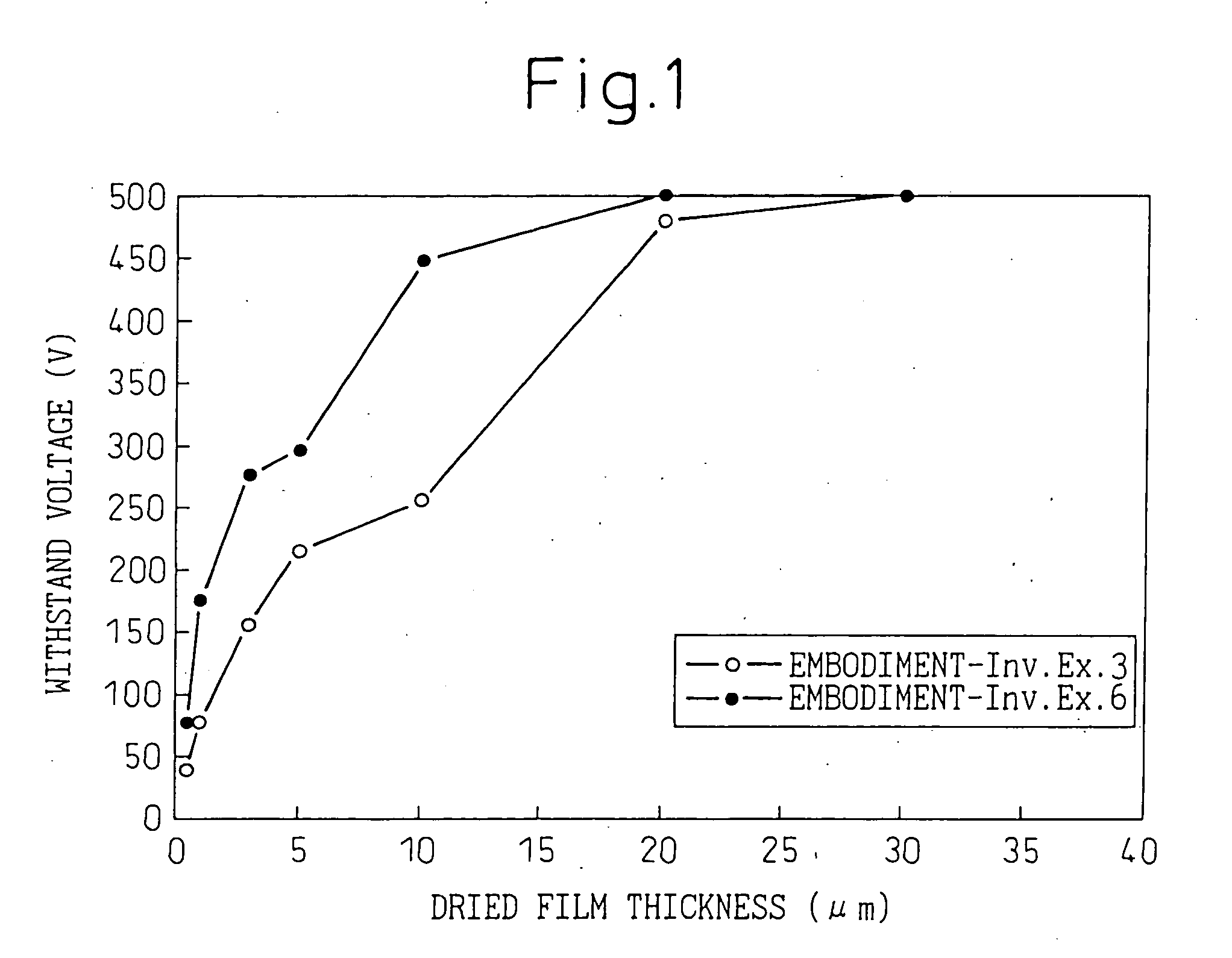

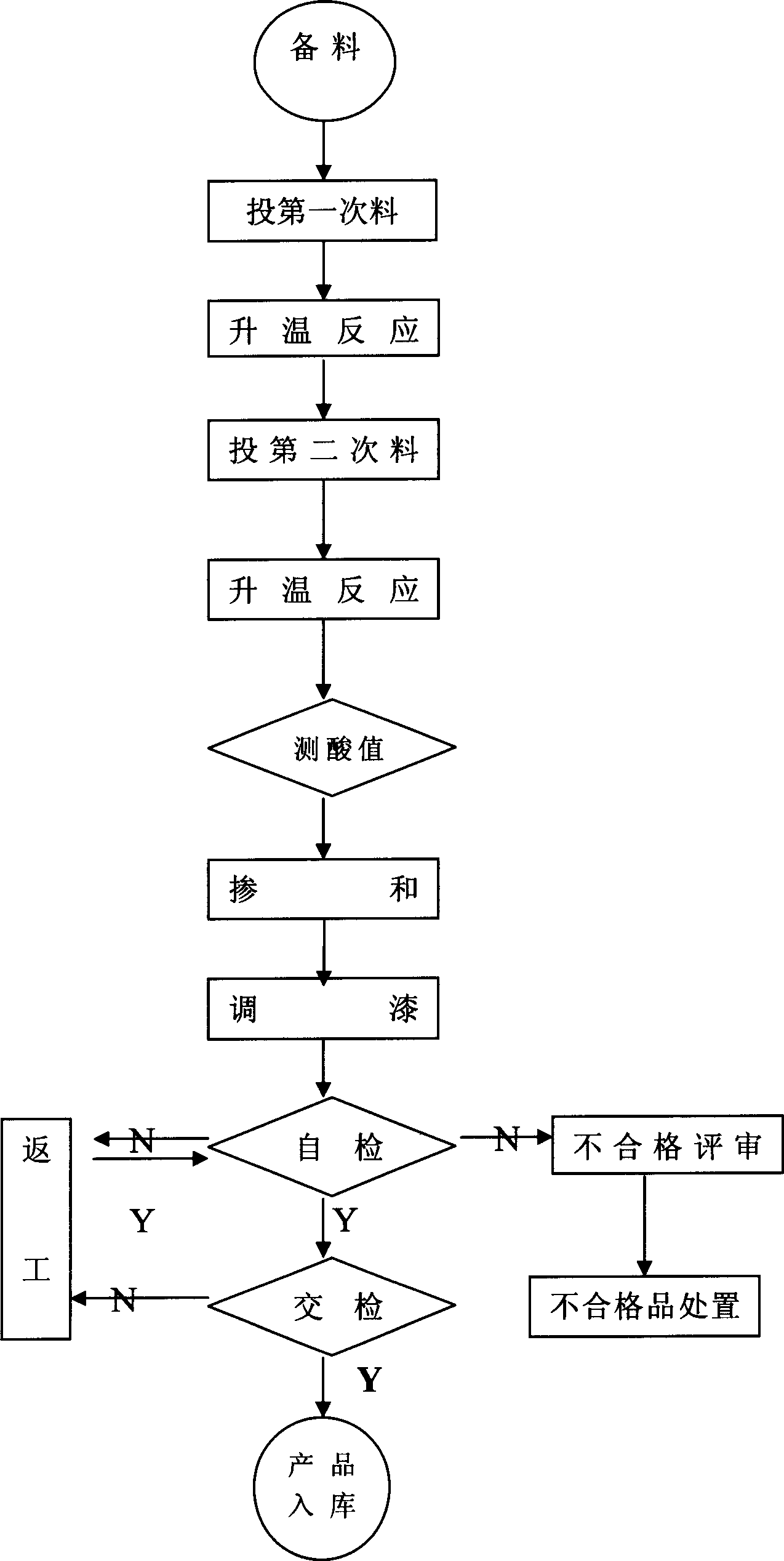

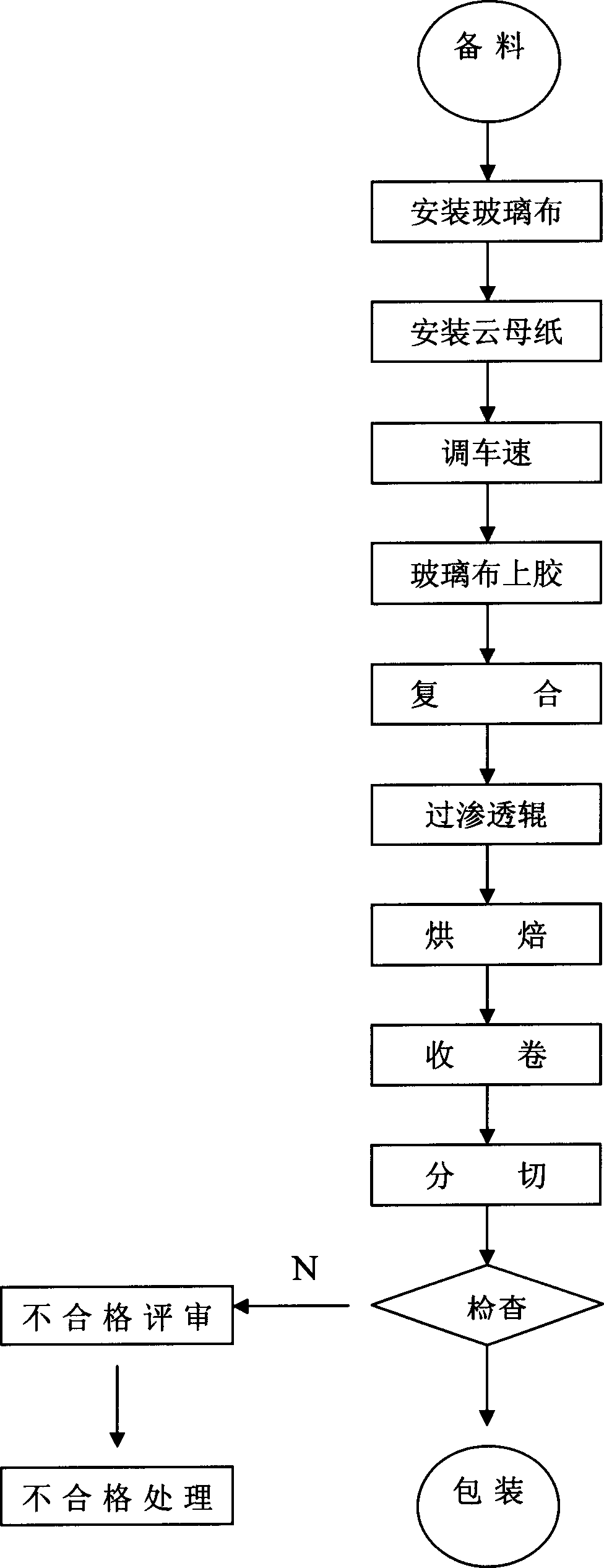

Manufacturing method of insulation coil

ActiveUS20050097726A1Good pressure characteristicsImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionElectrical conductorInorganic particle

On a surface of a glass cloth adhered a mica layer sheet, a mixture of inorganic particles having a thermal conductivity of at least 5 W / mK, a resin, and a solvent is applied to form a layer of the mixture of the inorganic particles, the resin, and the solvent; the layer of the mixture is reduced in thickness using a doctor blade, followed by pressurizing to form a high thermally conducting layer; the mica layer sheet on which the high thermally conducting layer is disposed is cut to obtain a mica insulating tape; and the mica insulation tape is wound around a coil conductor. As a result, an insulated coil that is excellent in the voltage endurance characteristics and has a high thermal conductivity is manufactured.

Owner:MITSUBISHI ELECTRIC CORP

Method of manufacturing insulated coil

ActiveUS7120993B2Good pressure characteristicsImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionElectrical conductorInorganic particle

On a surface of a glass cloth adhered a mica layer sheet, a mixture of inorganic particles having a thermal conductivity of at least 5 W / mK, a resin, and a solvent is applied to form a layer of the mixture of the inorganic particles, the resin, and the solvent; the layer of the mixture is reduced in thickness using a doctor blade, followed by pressurizing to form a high thermally conducting layer; the mica layer sheet on which the high thermally conducting layer is disposed is cut to obtain a mica insulating tape; and the mica insulation tape is wound around a coil conductor. As a result, an insulated coil that is excellent in the voltage endurance characteristics and has a high thermal conductivity is manufactured.

Owner:MITSUBISHI ELECTRIC CORP

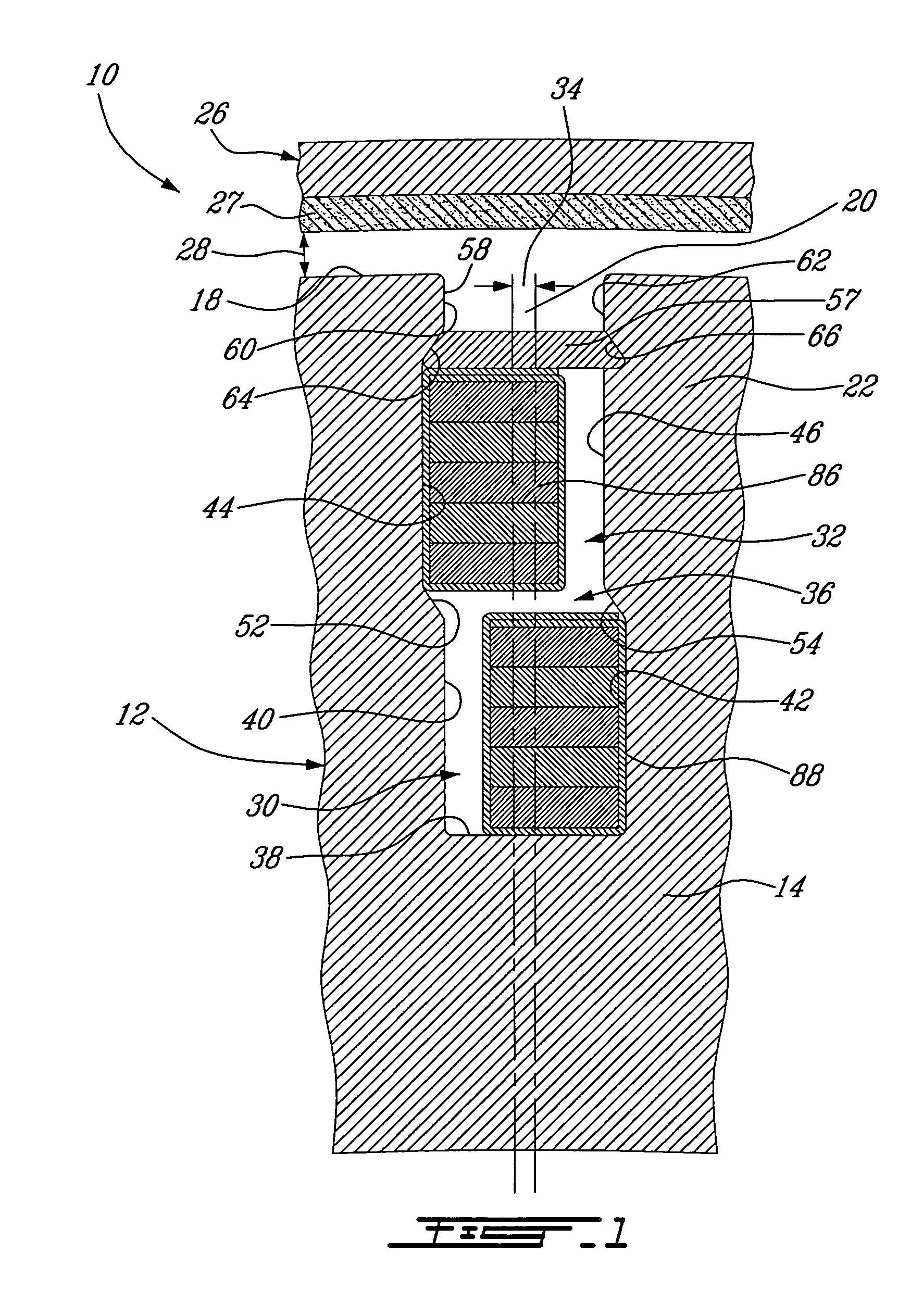

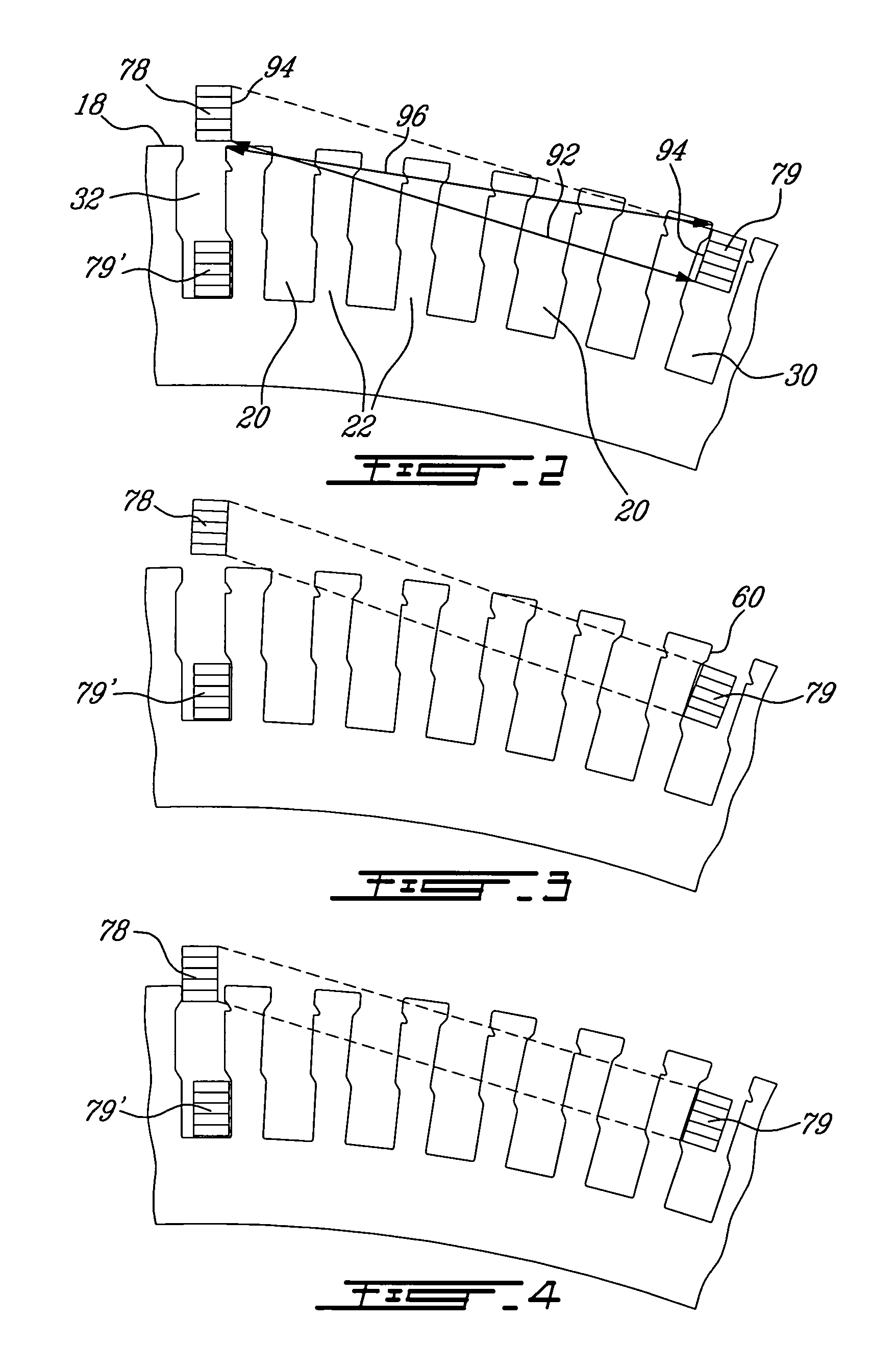

Stator coil with improved heat dissipation

ActiveUS20080284262A1Improve heat transfer performanceImprove thermal conductivityWindings insulation materialMagnetic circuitStator coilCopper

A stator coil includes a plurality of copper strands and a layer of high thermal conductivity polymer disposed adjacent at least one of the copper strands. The high thermal conductivity polymer includes a host polymer and a high thermal conductivity filler. The high thermal conductivity polymer improves heat transfer from the plurality copper strands.

Owner:SIEMENS ENERGY INC

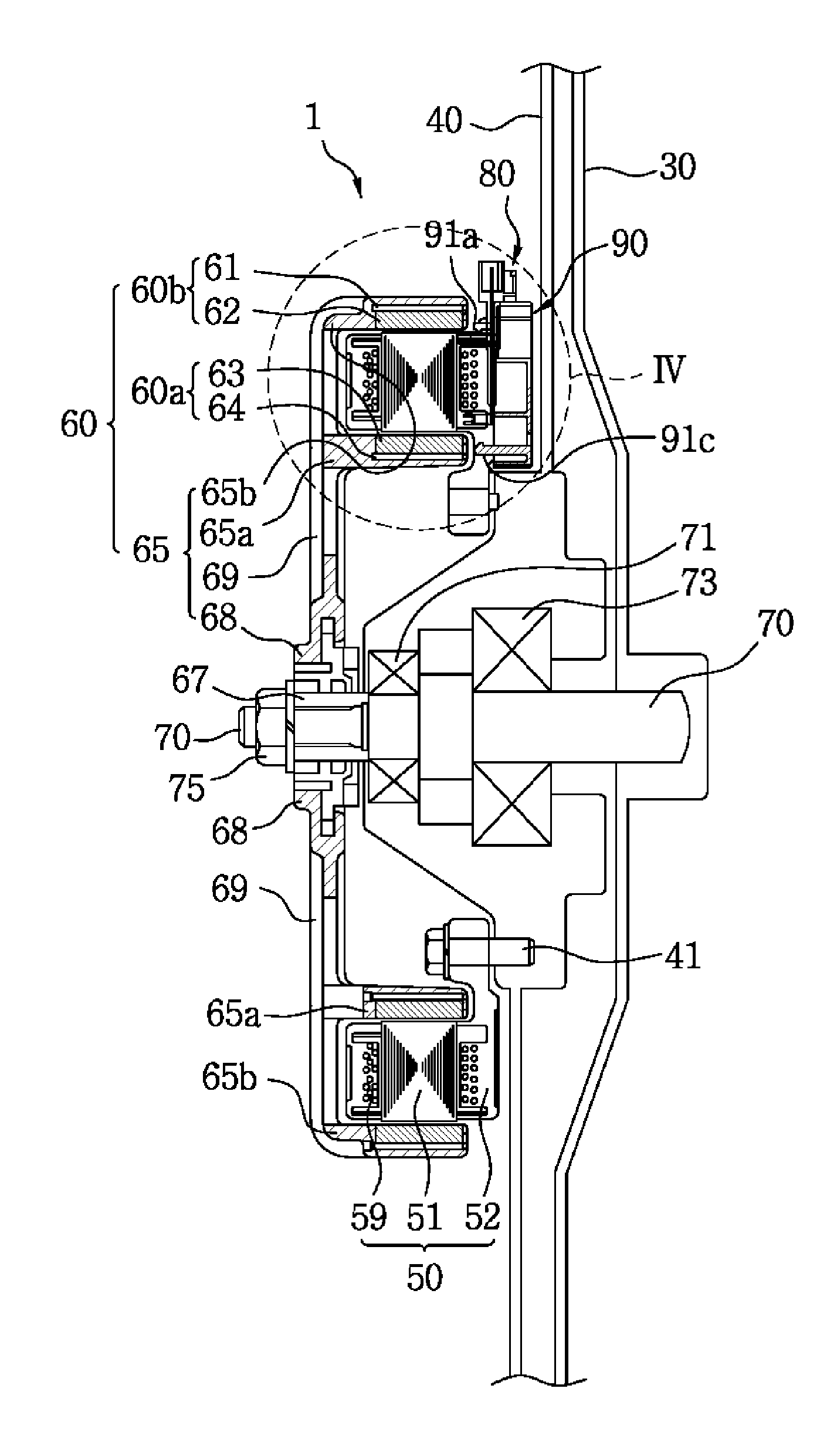

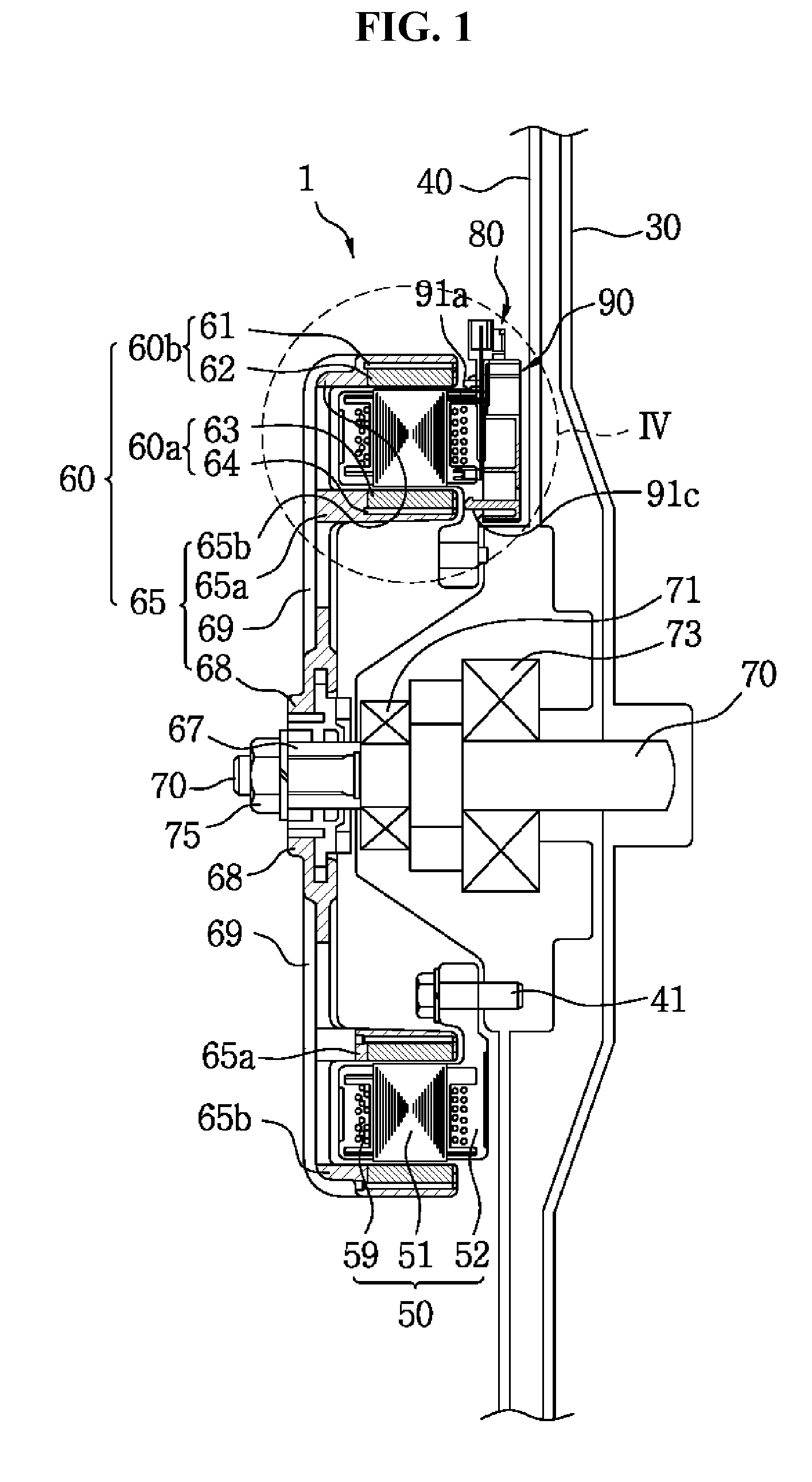

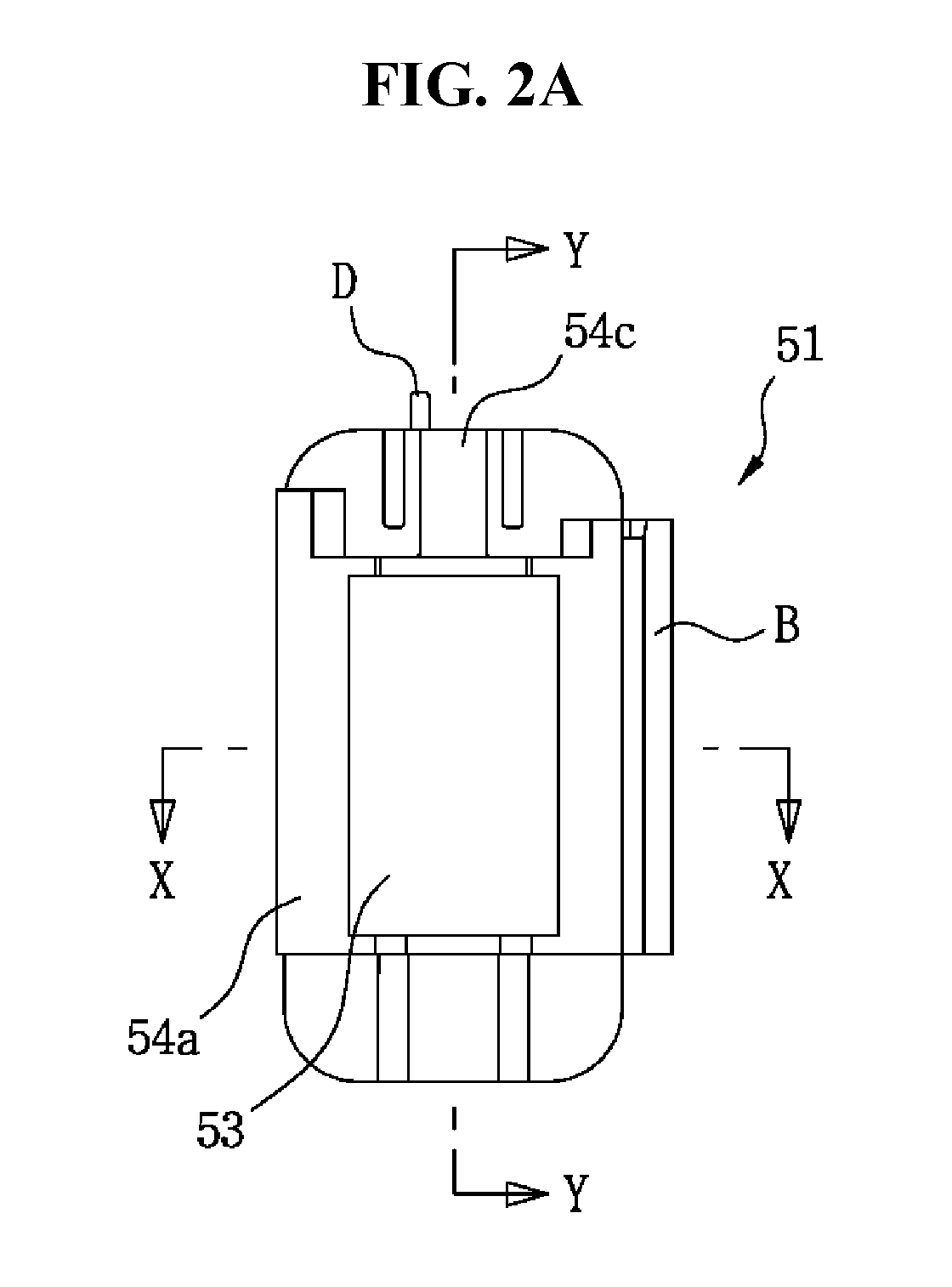

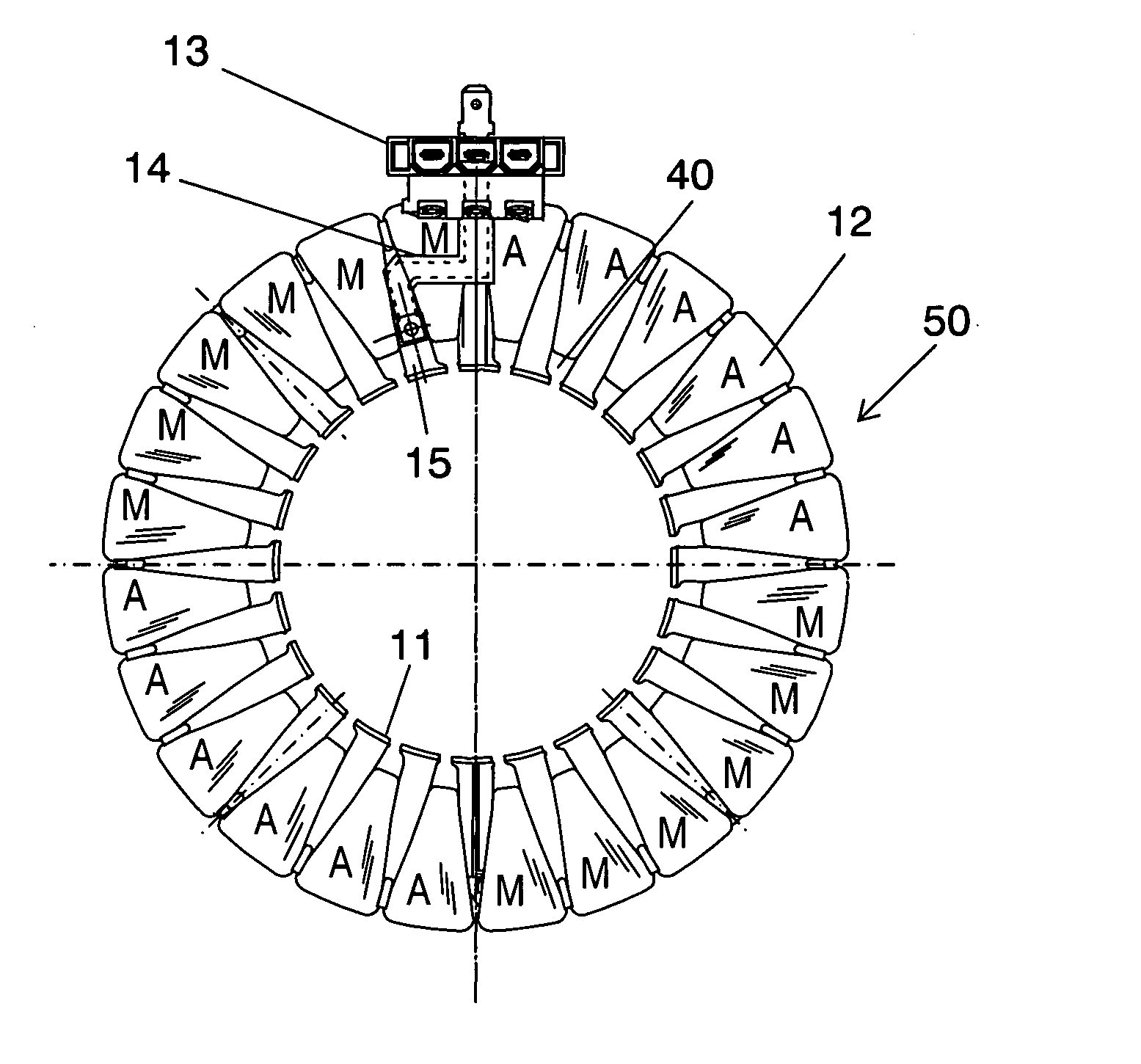

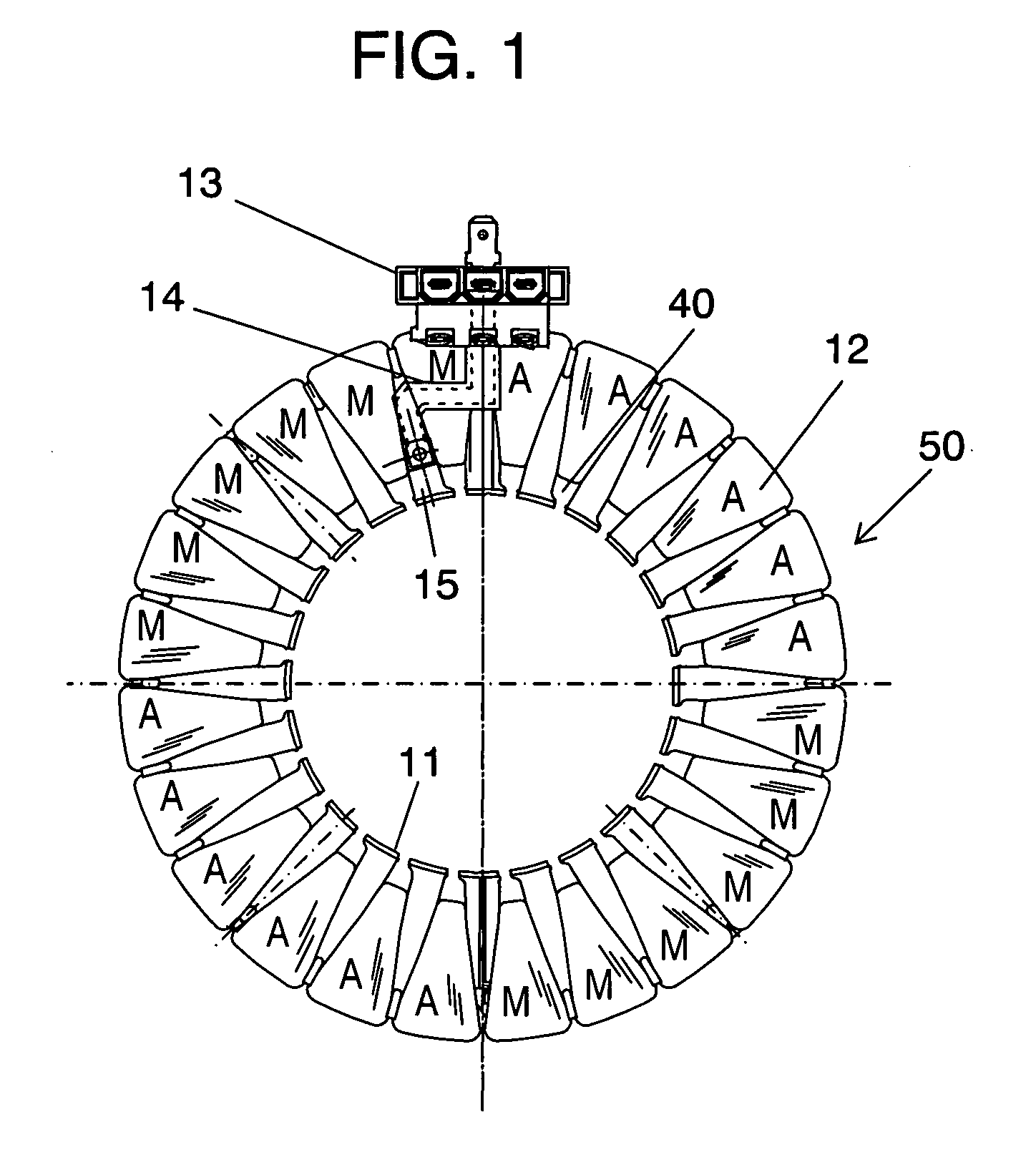

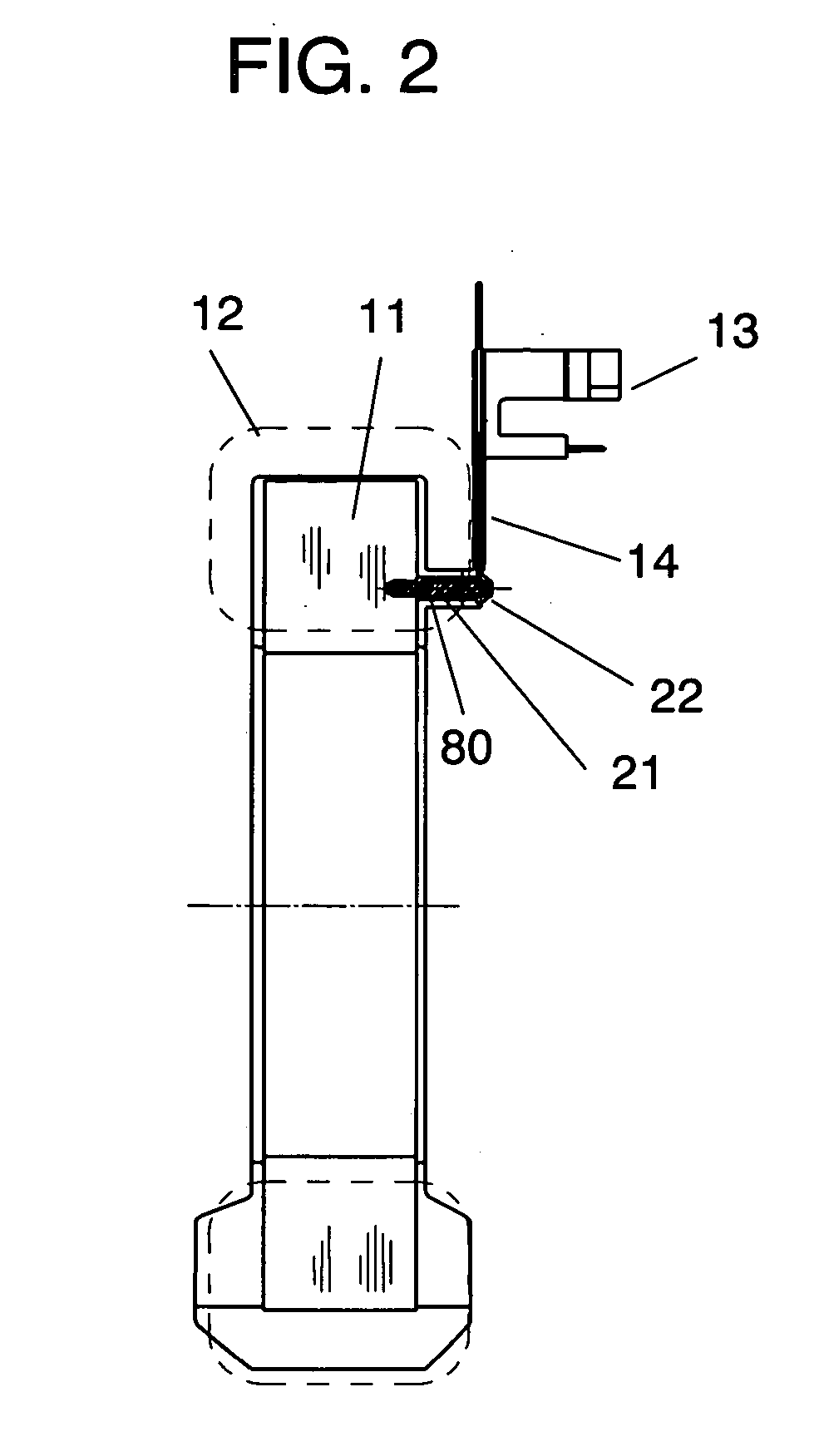

Slim type stator and method of making the same, slim type motor having the stator, and direct drive apparatus for drum-washing machine

ActiveUS20110316365A1Process stabilityImprove workabilityWindings insulation materialMagnetic circuit stationary partsBobbinStator coil

Provided is a stator for use in a brushless direct-current (BLDC) that is used for a direct drive (DD) apparatus for drum-washing machines that is mounted in an allowable space without reducing size of a tub related to a laundry capacity in a drum-washing machine, to thereby make a basket in the inside of the tub rotationally driven in a direct drive method. The slim type stator includes: a number of division cores; a number of bobbins that partially surrounds the number of the division cores; an electric power terminal block on the outer portion of which a connector is provided in which external electric power is applied through the connector and that has terminal pins that are extended to the inside of the stator from the connector; a wiring box that is integrally formed with each bobbin and that mutually connects a stator coil with the terminal pins per phase; and a stator holder that mutually connects a number of division stator cores around which coils are wound with the outer circumference of the bobbins and supports the number of division stator cores.

Owner:AMOTECH

Tape member or sheet member, and method of producing tape member or sheet member

InactiveUS20060258791A1Easy to produceImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionThermal conductivityElectrical and Electronics engineering

The invention aims to provide a highly heat conductive tape member or sheet member and a method for easily producing a highly heat conductive tape member or sheet member. The mica tape member or mica sheet member of the invention includes a mica-containing layer and a lining material, and the mica-containing layer contains scaly particles, particles having a heat conductivity of 0.5 W / mK or higher and a size of 1 μm or smaller, and a binder.

Owner:KK TOSHIBA

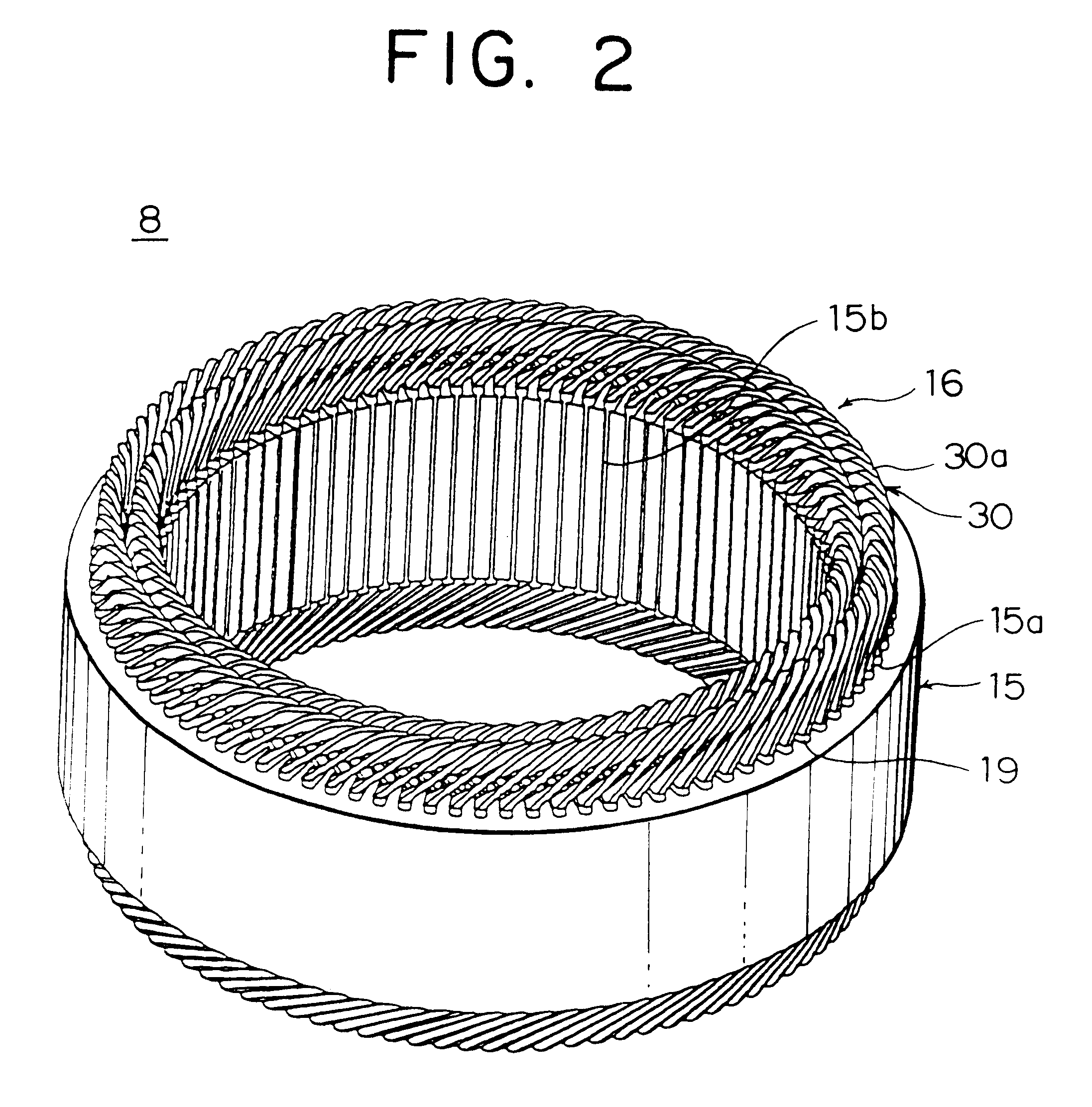

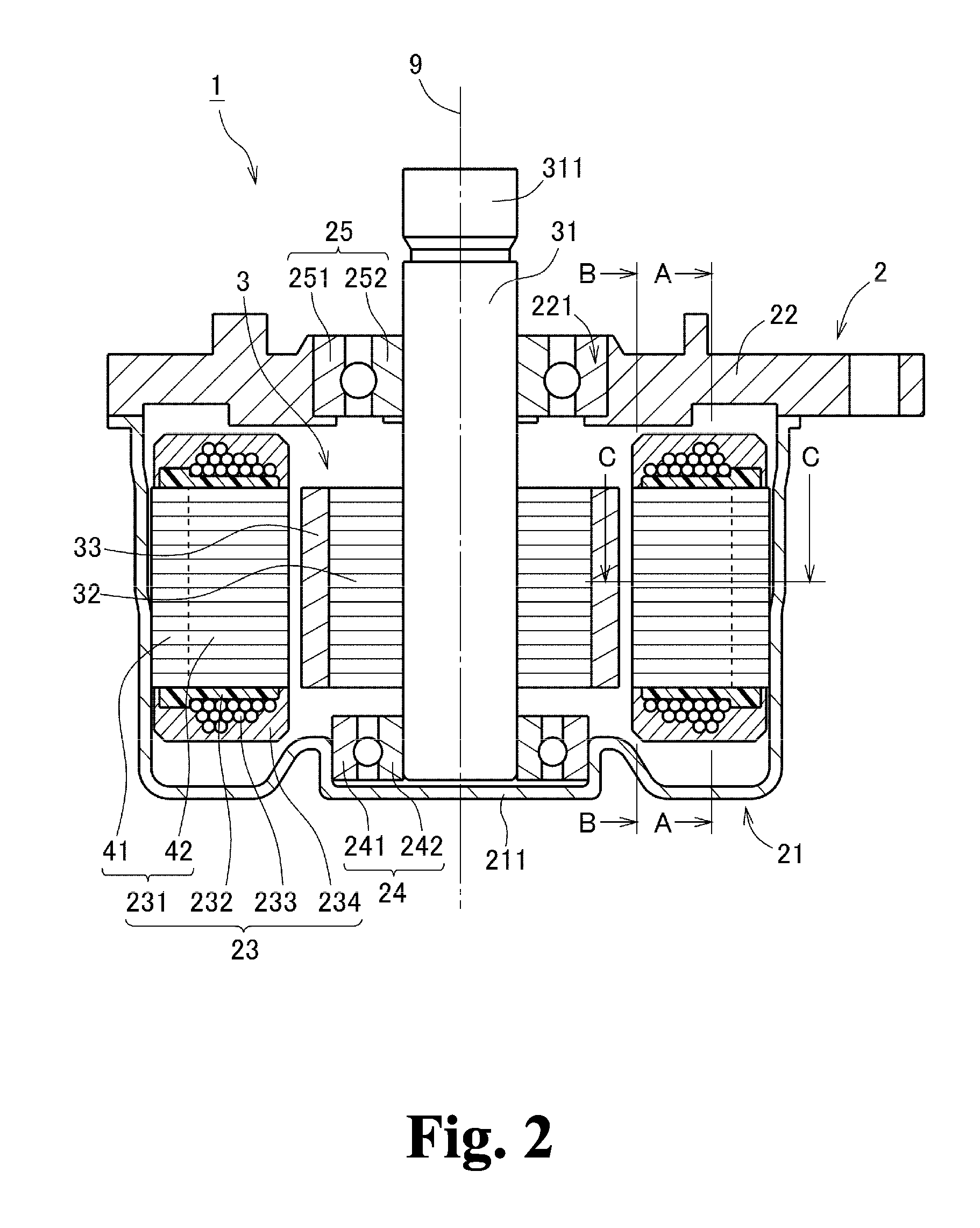

Alternator

InactiveUS6396185B1Improve serviceabilityIncrease productivitySynchronous generatorsWindings insulation materialAlternatorDepth direction

An alternator includes a rotor for forming north-seeking (N) and south-seeking (S) poles about a rotational circumference, a stator having a stator core disposed facing the rotor and a polyphase stator winding installed in the stator core, and a bracket supporting the rotor and the stator, wherein the stator core comprises a laminated iron core formed with a number of slots extending axially at a predetermined pitch in a circumferential direction, the polyphase stator winding comprises a number of winding sub-portions in each which a long strand of wire is wound so as to alternately occupy an inner layer and an outer layer in a slot depth direction within the slots at intervals of a predetermined number of slots, the strand of wire folding back outside the slots at axial end surfaces of the stator core to form turn portions, the turn portions align in a circumferential direction to constitute coil end groups at both axial end portions of the stator core, and the turn portions at both axial end portions of the stator core are provided with an insulative coating.

Owner:MITSUBISHI ELECTRIC CORP

Stator for rotating electric machine

ActiveUS20170033630A1Reduce potential differenceAvoid it happening againWindings insulation materialMagnetic circuit stationary partsBusbarElectric machine

A stator includes a stator core having slots, a stator coil comprised of three phase windings, phase busbars each electrically connecting a corresponding one of the phase windings to an inverter, and a neutral busbar star-connecting the phase windings to define a neutral point therebetween. In each of the slots of the stator core, there are arranged K in-slot portions of the phase windings of the stator coil in K layers so as to be radially aligned with each other, where K is an even number. The phase and neutral busbars are electrically connected with those in-slot portions of the phase windings of the stator coil which are arranged at the radially outermost layer or the radially innermost layer in the respective slots of the stator core so as to be circumferentially spaced from one another by M slot-pitches or more, where M is a slot multiplier number.

Owner:DENSO CORP

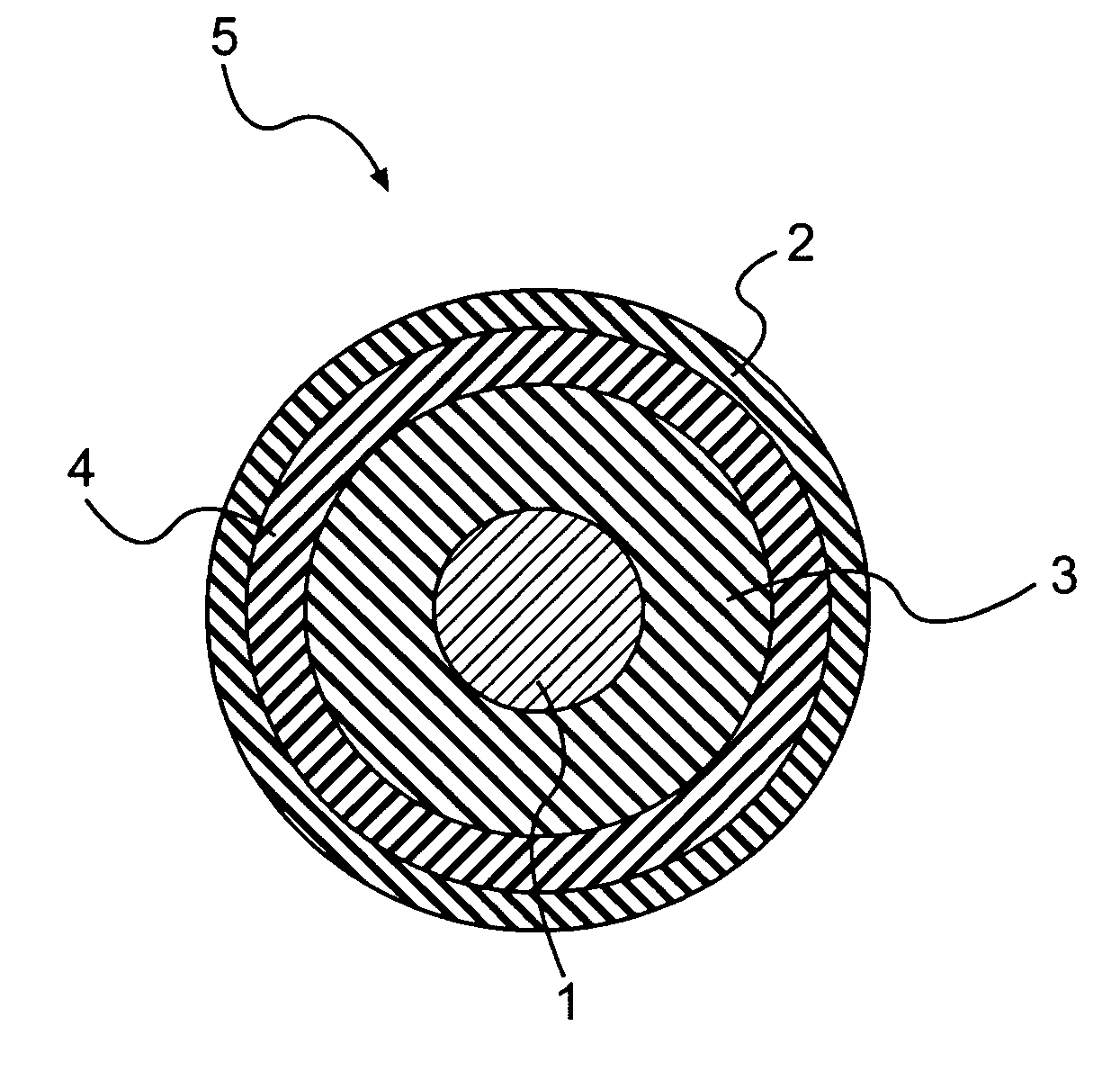

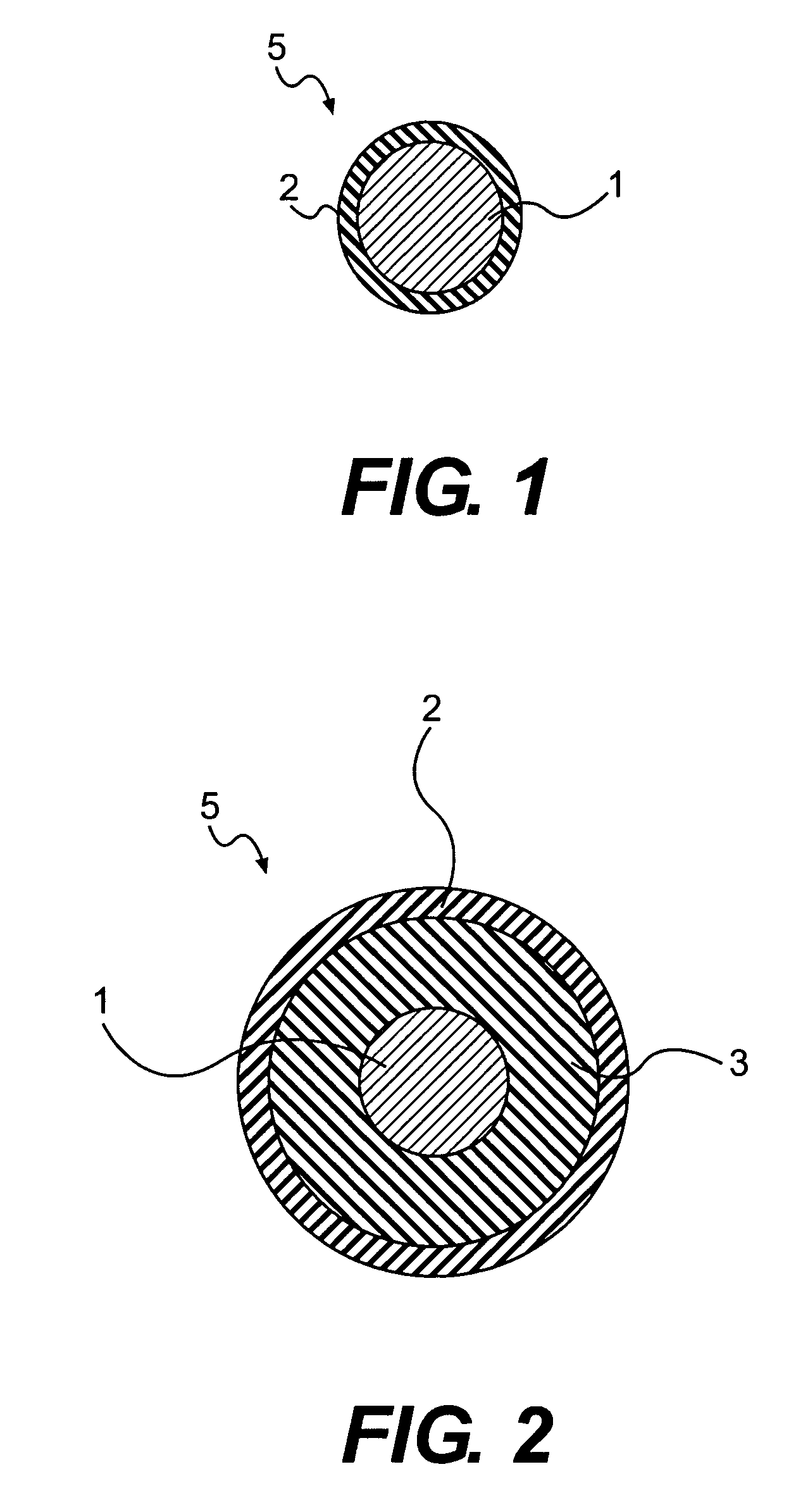

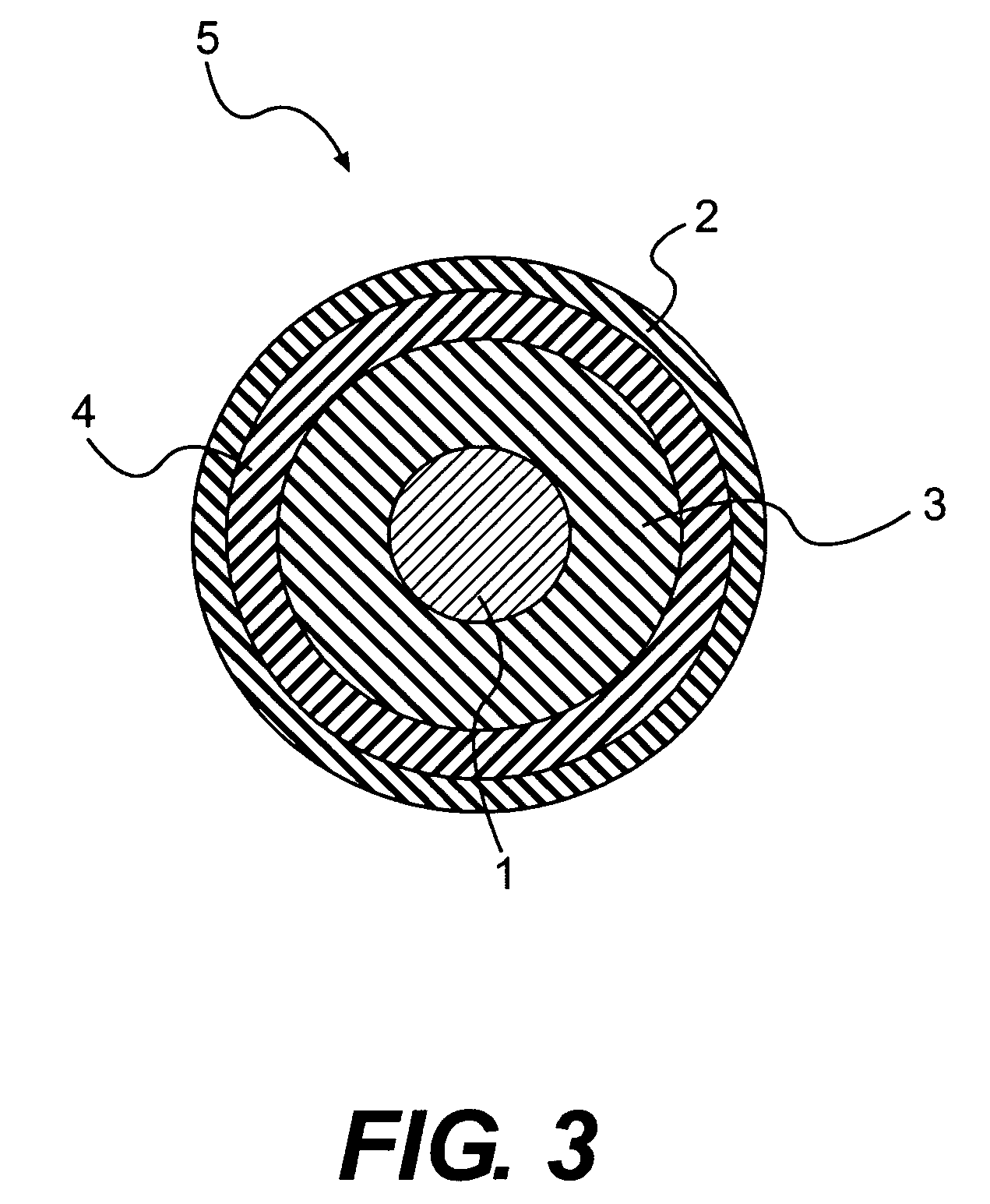

Inverter surge-resistant insulated wire

ActiveUS20150021067A1High partial discharge inception voltageImprove insulation performanceWindings insulation materialPlastic/resin/waxes insulatorsDielectricInsulation layer

An inverter surge-resistant insulated wire, having at least one baked enamel layer around the outer periphery of a conductor, and an extrusion-coated resin layer at the outside of the baked enamel layer, wherein a total thickness of the baked enamel layer and the extrusion-coated resin layer is 50 μm or more, a thickness of the baked enamel layer is 60 μm or less, and a thickness of the extrusion-coated resin layer is 200 μm or less, wherein the minimum of tensile elastic modulus of the extrusion-coated resin layer at a range of 25 to 250° C. is 100 MPa or more, wherein a dielectric constant of an insulation layer having a combination of the baked enamel layer and the extrusion-coated resin layer is 3.5 or less at 25° C. and 5.0 or less at 250° C., and wherein a relation between dielectric constant (∈1′) of the baked enamel layer at 250° C. and dielectric constant (∈2′) of the extrusion-coated resin layer at 250° C. satisfies (∈2′ / ∈1′)>1.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Rotating electrical machine winding, rotating electrical machine, and semiconductive insulating component used therein

ActiveUS20080106157A1Firm supportWindings insulation materialWindings insulation shape/form/constructionEngineeringStress relaxation

When a rotating electrical machine winding is inserted into a slot with a protective insulation intervening between them, a semiconductive insulating layer is lap-wound between an interlayer insulating layer of the rotating electrical machine winding and the protective insulation, the semiconductive insulating layer being formed by center-folding a continuous semiconductive sheet in the longitudinal direction. A thermal stress relaxation layer is provided inside the center-folded continuous semiconductive sheet so that thermal stress exerted in thickness direction of the insulating layers is absorbed.

Owner:MITSUBISHI HEAVY IND LTD

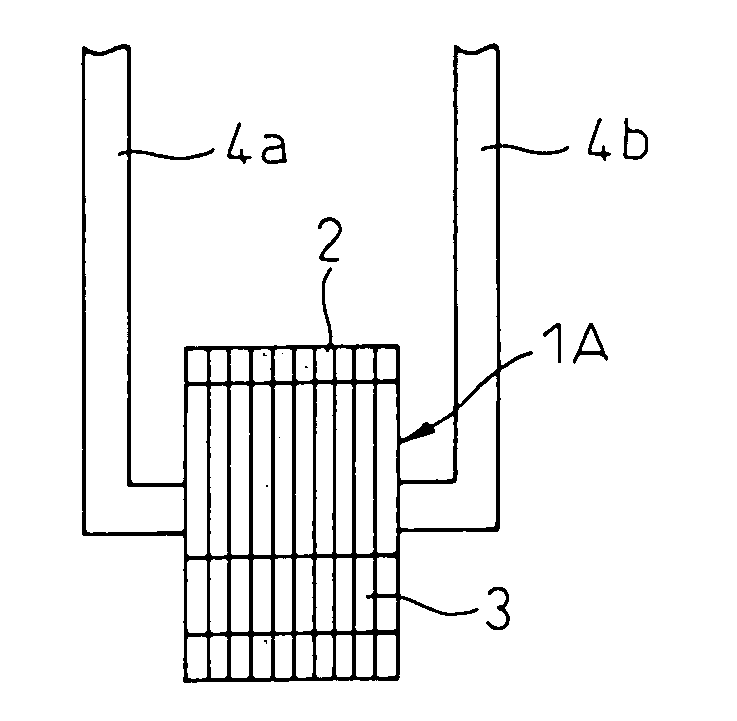

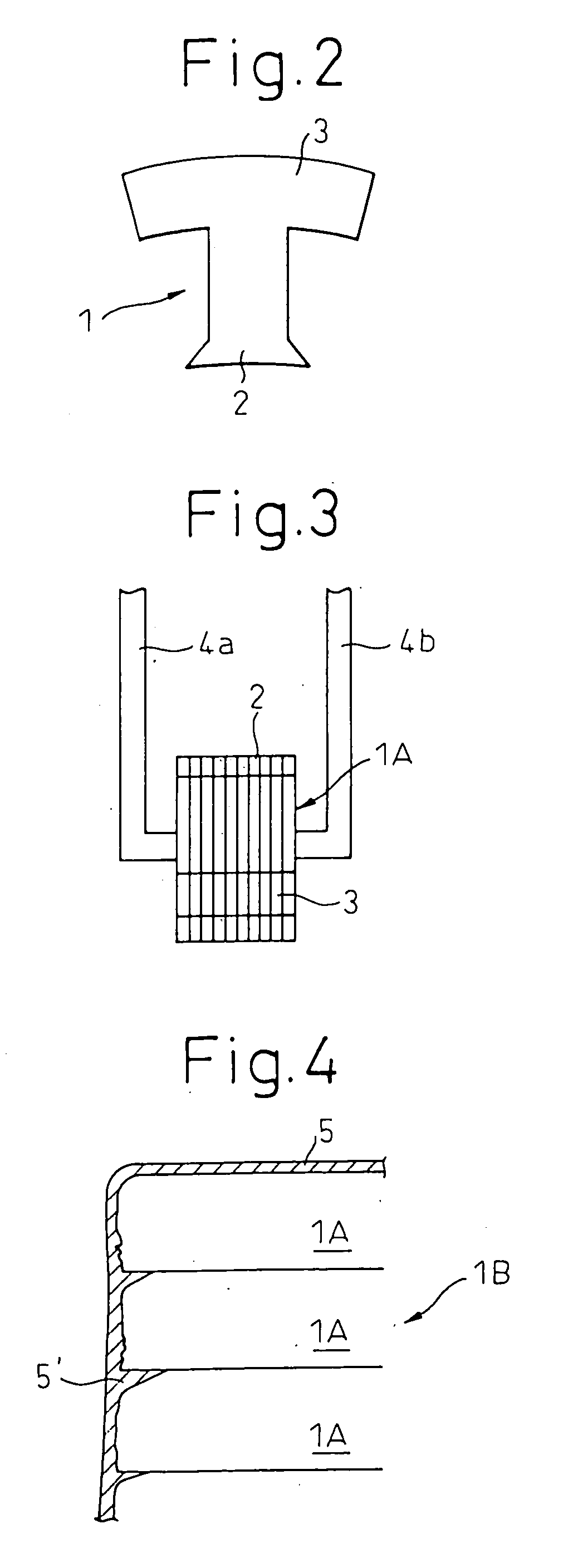

Iron core exhibiting excellent insulating property at end face, and method for coating end face of iron core

InactiveUS20040046632A1Improve bindingIncrease powerWindings insulation materialPretreated surfacesPunchingHeat resistance

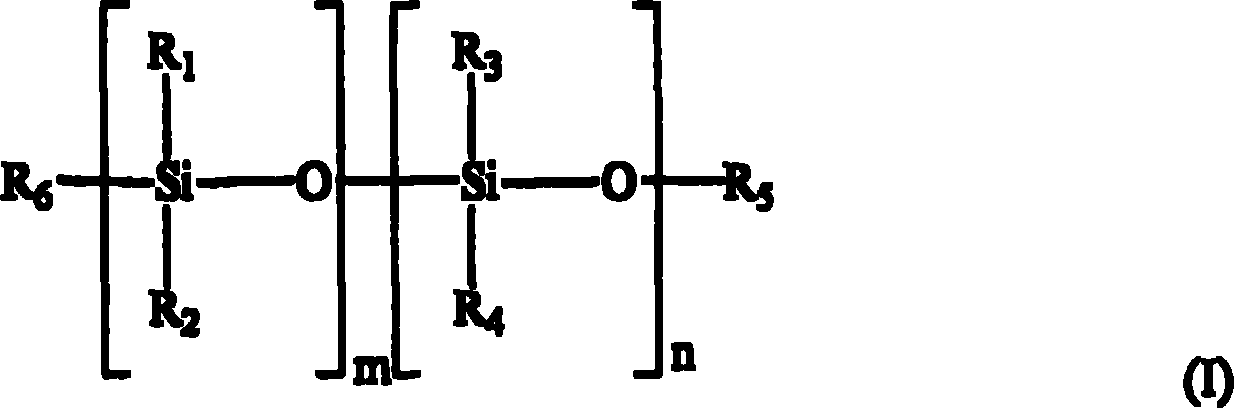

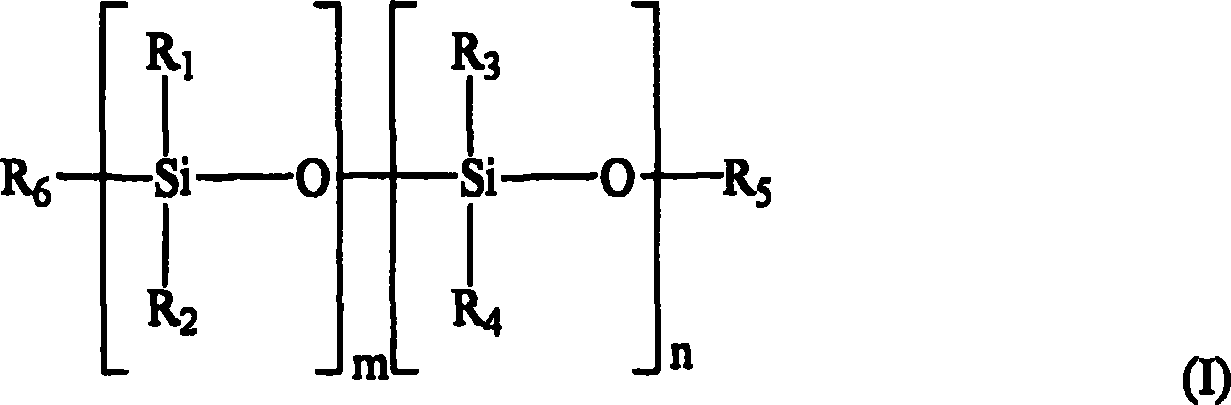

A means for treating the end faces of a core which is used for an electrical apparatuses and etc., to give insulation extremely superior in effect of improvement of the insulation, corrosion resistance, adhesiveness, heat resistance, and magnetic properties at a low temperature in a short time without cleaning for removing punching oil, annealing, or other pre-treatment; a core having an insulation coating comprised of a dry film of a pure silicone polymer, modified silicone polymer, and / or mixed silicone polymer as a silicone compound on the core end faces and having an average film thickness of at least 0.5 mum, a breakdown voltage of at least 30V, and a heat resistance in the air of at least 400° C.; and a method of production comprised of forming a core, then dipping it in or spraying it by one or more types of a pure silicone polymer, modified silicone polymer, and / or mixed silicone polymer as an insulation coating.

Owner:NIPPON STEEL CORP +1

Pulsed voltage surge resistant magnet wire

InactiveUS7253357B2Increase resistanceEasy to slideWindings insulation materialPlastic/resin/waxes insulatorsPulse voltageEngineering

A magnet wire including at least one conductor and at least one insulating layer. The insulating layer includes (a) at least a polymeric resin; (b) at least a fluorinated organic filler; and (c) at least a non-ionic fluorinated surfactant. The magnet wire is endowed with high resistance to pulsed voltage surges.

Owner:PPE FIOS ESMALTADOS

Motor having a highly reliable grounding construction and electric device having this motor mounted thereon

ActiveUS20060175917A1Highly reliable grounding structureWindings insulation materialAssociation with grounding devicesElectric motorBuilding construction

This motor has a stator formed by integrally molding a stator core, a stator winding wound around the stator core and a grounding terminal mounted on the stator winding by insulating resin. The motor has a rotor provided with a shaft, a bracket mounting a bearing for supporting the shaft, and a conductive pin press fit in at least one hole having a predetermined diameter provided in teeth of the stator core. The pin and the grounding terminal are electrically connected to each other.

Owner:PANASONIC CORP

Composite coatings for ground wall insulation in motors, method of manufacture thereof and articles derived therefrom

InactiveUS20050016658A1Windings insulation materialWindings insulation shape/form/constructionBobbinSilicone coating

An article comprises a bobbin wire; an electrically insulating backing disposed upon the bobbin wire; a mica paper disposed upon the electrically insulating backing and wound around the backing; and a silicone coating disposed upon the electrically insulating backing. A method of manufacturing an article comprises disposing an electrically insulating backing upon a bobbin wire; disposing mica paper upon the electrically insulating backing; and coating the mica paper with a silicone coating.

Owner:GENERAL ELECTRIC CO

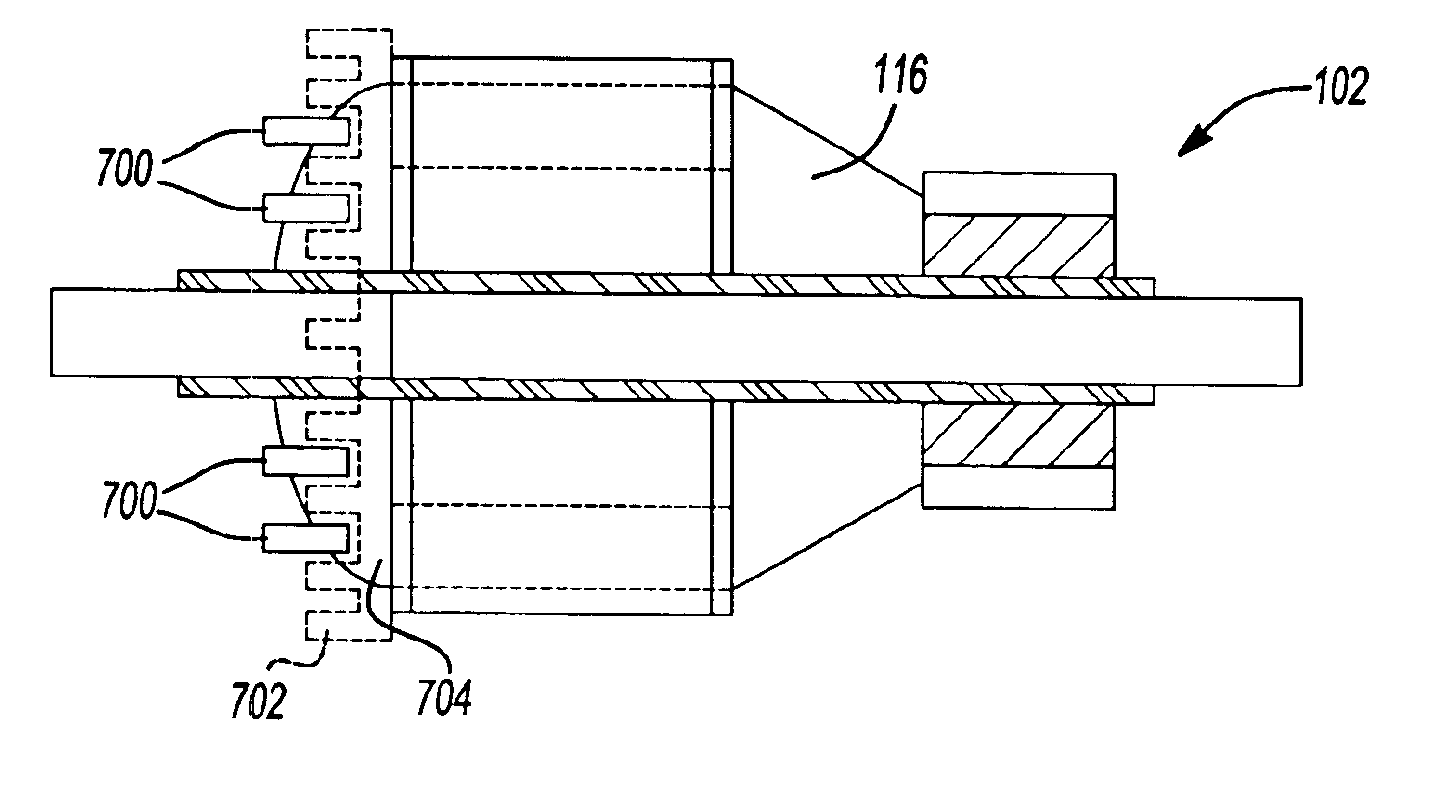

Dynamoelectric machine having encapsulated coil structure with one or more of phase change additives, insert molded features and insulated pinion

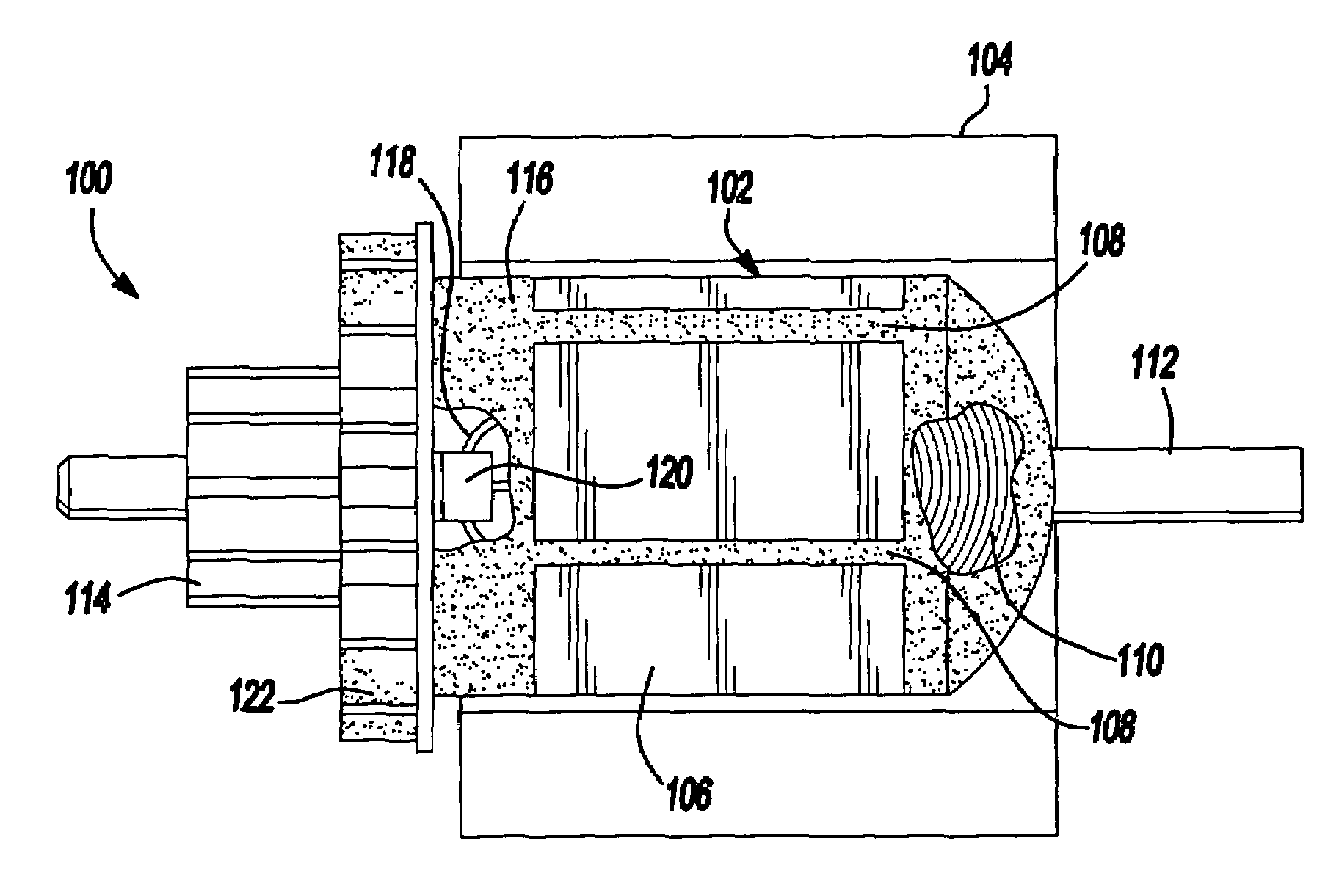

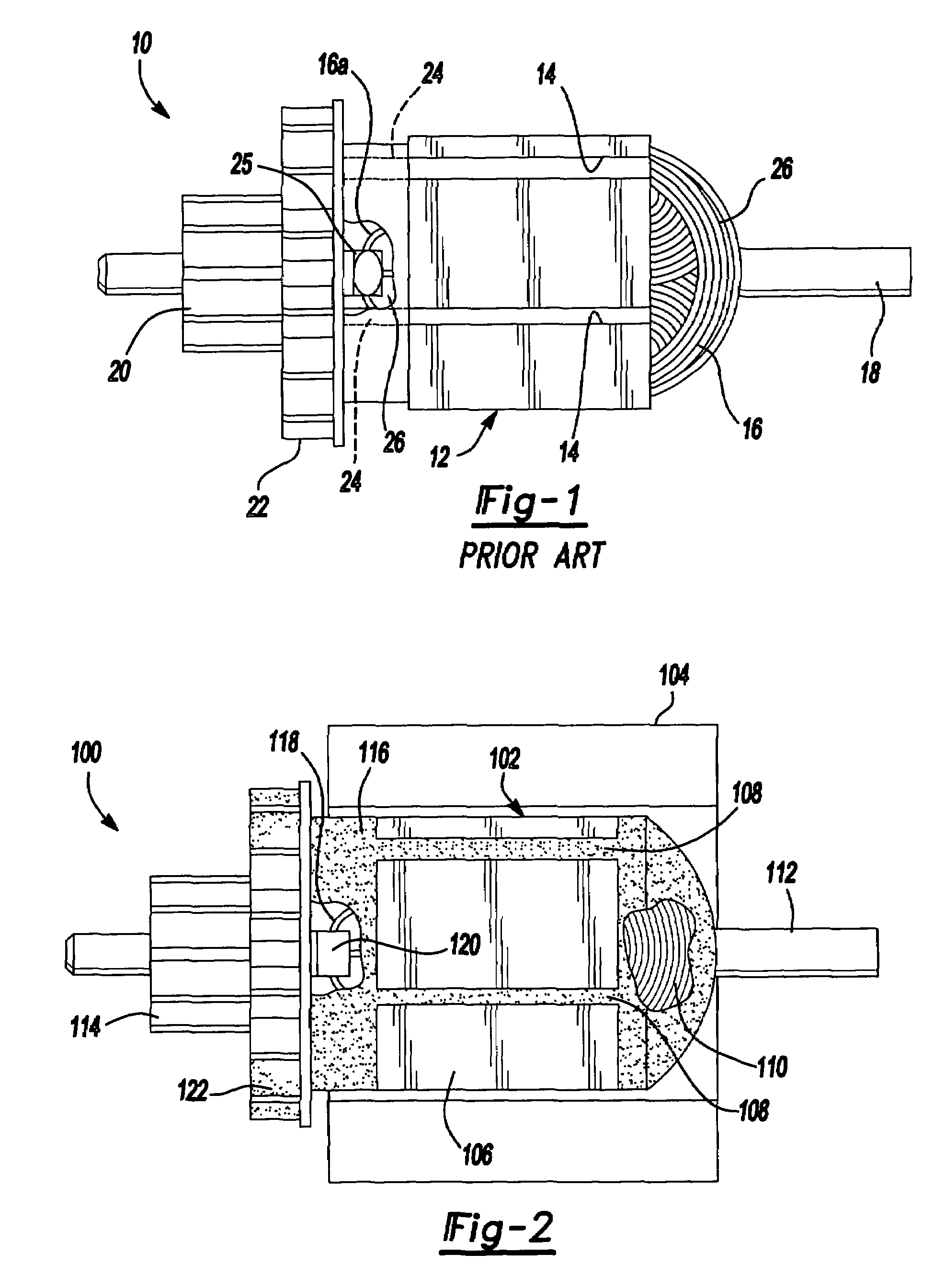

InactiveUS6946758B2Increase stiffnessIncrease critical speedWindings insulation materialWindings insulation shape/form/constructionAdhesivePinion

Magnet wires wound in slots in a lamination stack of a dynamoelectric machine are encapsulated, in whole or in part, with thermally conductive plastic. Pre-formed features having a thermal conductivity higher than the thermally conductive plastic are insert molded when the plastic is molded. The pre-formed features may include a finned end cap and a fan. Alternatively, end domes of the plastic over end coils of the wound magnet wires have a metallic layer on them, such as by being metallized. The end domes can be formed with features which are also metallized. The thermally conductive plastic can have a phase change additive in it. The magnet wires can have a layer of heat activated adhesive that is activated when the plastic is molded. Slots in the lamination stack can include slot liners formed of thermally conductive plastic. A fan can be formed when the thermally conductive plastic is molded to encapsulate the magnet wires.

Owner:BLACK & DECKER INC

Composite coatings for groundwall insulation, method of manufacture thereof and articles derived therefrom

InactiveCN1992100AWindings insulation materialMaterial nanotechnologyNanoparticleThermosetting polymer

Disclosed herein is an article comprising an electrical component and an electrically insulating layer disposed upon the electrical component, wherein the electrically insulating layer comprises a thermosetting polymer and a nanosized filler, wherein the nanosized filler comprises metal oxide and diamond nanoparticles that have an average largest dimension of less than or equal to about 200 nanometers.

Owner:GENERAL ELECTRIC CO

Strand cross-section for high fill-factor electric machine windings

InactiveUS20160036277A1Maximizes slot fill factorFacilitate filling slotWindings insulation materialWindings insulation shape/form/constructionElectrical conductorElectric machine

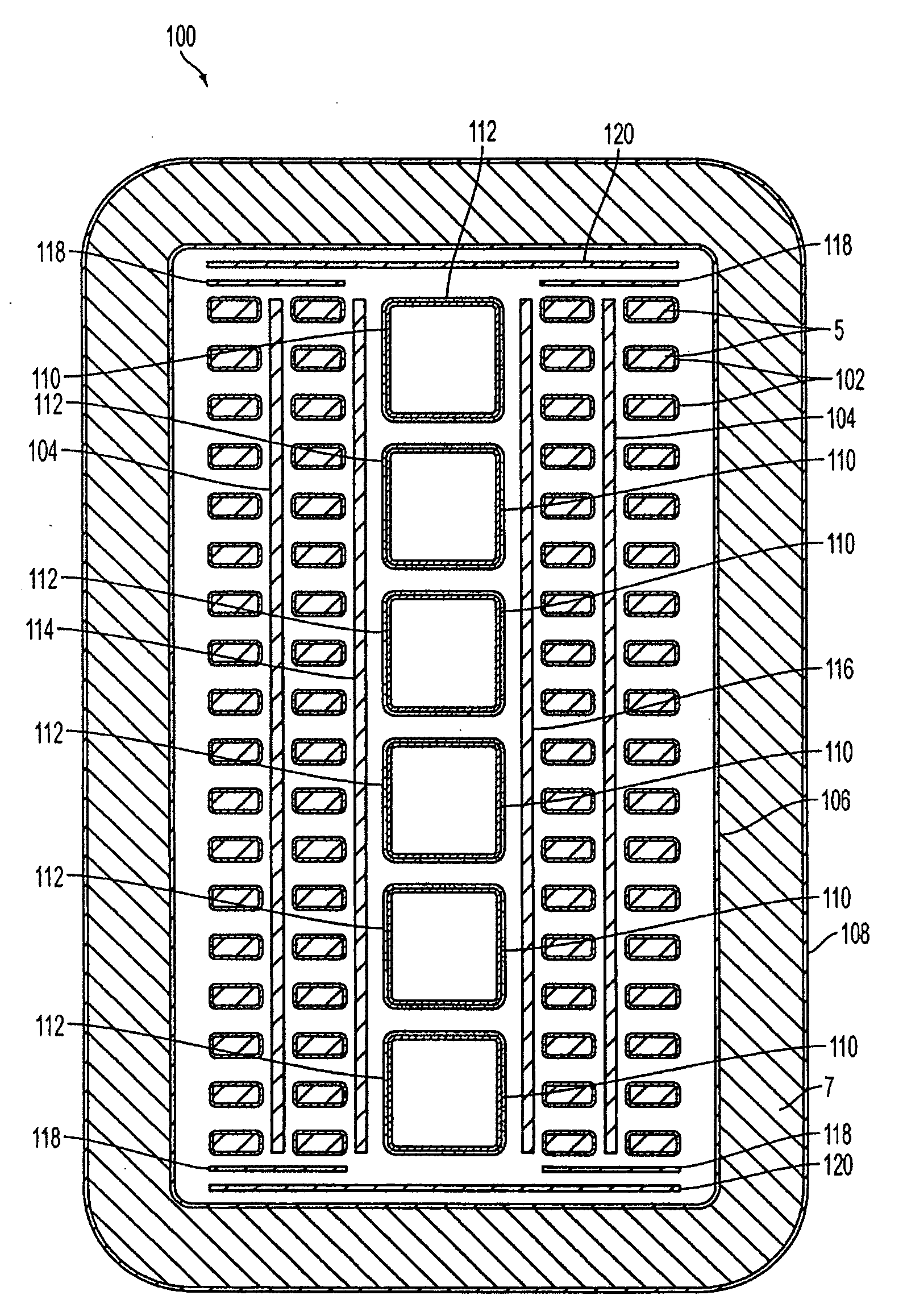

A winding configuration for an electric machine includes a stator core with a plurality of winding slots, a plurality of conductor strands distributed in a winding slot of the plurality of winding slots, and an insulation matrix that surrounds each of the plurality of the conductor strands. The winding slot includes a slot cavity with a cross-section area and the plurality of distributed conductor strands are configured to maximize slot fill factor.

Owner:HAMILTON SUNDSTRAND CORP

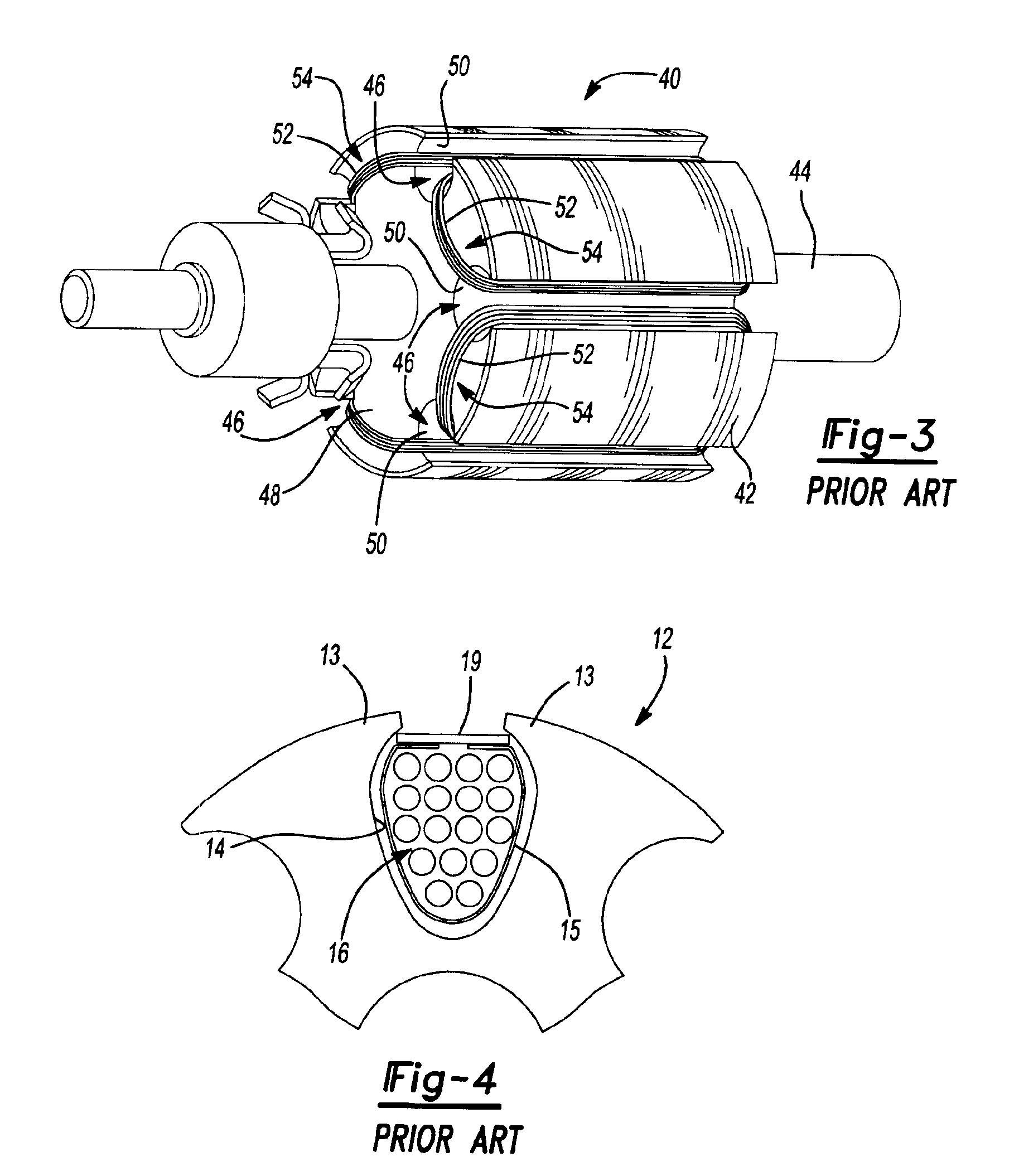

Method for forming an armature for an electric motor for a portable power tool

InactiveUS7013552B2Resists extreme temperatureHeat dissipationWindings insulation materialManufacturing stator/rotor bodiesAdhesiveEngineering

An electric motor having an armature which includes a coating of thermally conductive plastic applied in a conventional injection molding process. The armature also includes a fan which is integrally formed from the thermally conductive plastic applied to the armature. This completely eliminates the need to apply one or more coatings of a trickle resin to the armature. It also eliminates the need to separately form and secure a fan by a suitable adhesive to the armature, which together significantly simplifies the manufacturing and cost of the armature. The plastic coating also better fills the spaces between the magnet wires, thus promoting even more efficient cooling and better holding of the magnet wires stationary relative to one another. The thermally conductive plastic coating may be mixed with other suitable materials to provide a density approximately equal to the magnet wires. This eliminates the need to balance the armature after the injection molding step.

Owner:BLACK & DECKER INC

Insulating structure and production for vacuum-pressure immersing process of high-voltage motor

ActiveCN1819408AWindings insulation materialWindings insulation shape/form/constructionProduction lineVacuum pressure

The invention adopts a dry mica tape whole impregnation type VPI (vacuum pressure impregnation) insulation process for stator. It comprises: binding up with dry mica tape; after cog leaves the production line, the whole rotator is impregnated with solventliss epoxy in vacuum pressure condition to form a composite insulation structure of VPI process. It features: the epoxy of the insulation structure contains unsaturated bond, and after adding reactive diluent, the whole impregnation insulation epoxy with low viscosity, hypertonicity and wide adaptation is obtained.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Electric motor and method of making same and method of making a power tool

InactiveUS20060255678A1Speed up the processWindings insulation materialRotary current collectorPower toolMagnet wire

Owner:BLACK & DECKER INC

Dynamoelectric machine having an encapsulated coil structure

InactiveCN1669203AIncrease torqueIncrease powerWindings insulation materialWindings insulation shape/form/constructionCritical speedMagnet

Magnet wires wound in slots in a lamination stack of a dynamoelectric machine are encapsulated, in whole or in part, with plastic. The plastic may be thermally conductive and have features molded therein that enhance heat transfer. The plastic may stiffen the armature and increase its critical speed. Characteristics of the plastic, its geometry and its distribution may be varied to adjust spinning inertia and resonant frequency of the armature. The magnet wires may be compressed into the slots, by application of iso-static pressure or by the pressure of the plastic being molded around them. Larger magnet wire can then be used which increases the power of the electric motor using the armature having the larger magnet wire. A two or three plate mold may be used to mold the plastic around the armature. Balancing features can be molded in place. The plastic can have a base polymer that is a blend of two or more polymers and various thermally conductive fillings.

Owner:BLACK & DECKER INC

Armature and motor

InactiveUS20130193800A1Avoid damagePrecise cuttingWindings insulation materialWindings insulation shape/form/constructionStructural engineeringDecreased thickness

An insulator of an armature includes an upper resin member and a lower resin member. Each of the upper and lower resin members includes decreased thickness portions. Axial positions of the decreased thickness portions of the upper and lower resin members are arranged to overlap at least partially with each other. Each of the upper and lower resin members further includes a rib arranged to project from a corresponding one of the decreased thickness portions. The rib improves the strength of the corresponding decreased thickness portion and reduces the likelihood that any of the decreased thickness portions of the upper and lower resin members will be damaged when the two members are fitted to each other.

Owner:NIDEC CORP

Motor and method of manufacturing motor

ActiveUS20150008769A1Improve cooling effectIncrease the areaWindings insulation materialWindings insulation shape/form/constructionEngineeringMechanical engineering

Owner:NIDEC CORP

Dynamoelectric machine stator and method for mounting prewound coils thereunto

InactiveUS7049725B2Reduce risk of damageReduce riskWindings insulation materialWindings insulation shape/form/constructionElectrical conductorRadial position

A dynamoelectric machine stator core for receiving a pre-formed stator winding includes a core body defining a cylindrical core main peripheral surface. A plurality of axially extending stator slots are circumferentially spaced in the core body. Each of the stator slots defines a slot first section extending radially from the slot base to a slot intermediate radial position and a slot second section extending radially from the slot intermediate radial position towards the core main peripheral surface. The slot first and second sections communicate with each other and are circumferentially offset relative to each other. The slot first and second sections are positioned, configured and sized to facilitate insertion therein of a corresponding conductor section of the stator winding with reduced needs for deforming the latter.

Owner:TM4 INC

Method of manufacturing rotor of electric motor

InactiveUS7120986B2Low costEasy to takeWindings insulation materialManufacturing stator/rotor bodiesHardnessMagnet

In a method of manufacturing a rotor of an electric motor to be arranged inside a stator, a permanent magnet is formed in a ring-shape, and a rotating shaft and the permanent magnet are concentrically arranged in a mold. Then, a rubber material in a fluid state is poured into a space between the permanent magnet and the rotating shaft to vulcanize and mold a cushioning member having predetermined hardness. The permanent magnet and the rotating shaft are integrally coupled through the cushioning member.

Owner:FUJITSU GENERAL LTD

Stator coil with improved heat dissipation

InactiveUS8030818B2Improve thermal conductivityImprove heat transfer performanceWindings insulation materialWindings insulation shape/form/constructionStator coilCopper

A stator coil includes a plurality of copper strands and a layer of high thermal conductivity polymer disposed adjacent at least one of the copper strands. The high thermal conductivity polymer includes a host polymer and a high thermal conductivity filler. The high thermal conductivity polymer improves heat transfer from the plurality copper strands.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com