Dynamoelectric machine having an encapsulated coil structure

A technology of coil and lamination structure, applied in the manufacture of motor generators, magnetic circuit shape/style/structure, coils, etc., can solve the problem of large armature and achieve the effect of increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

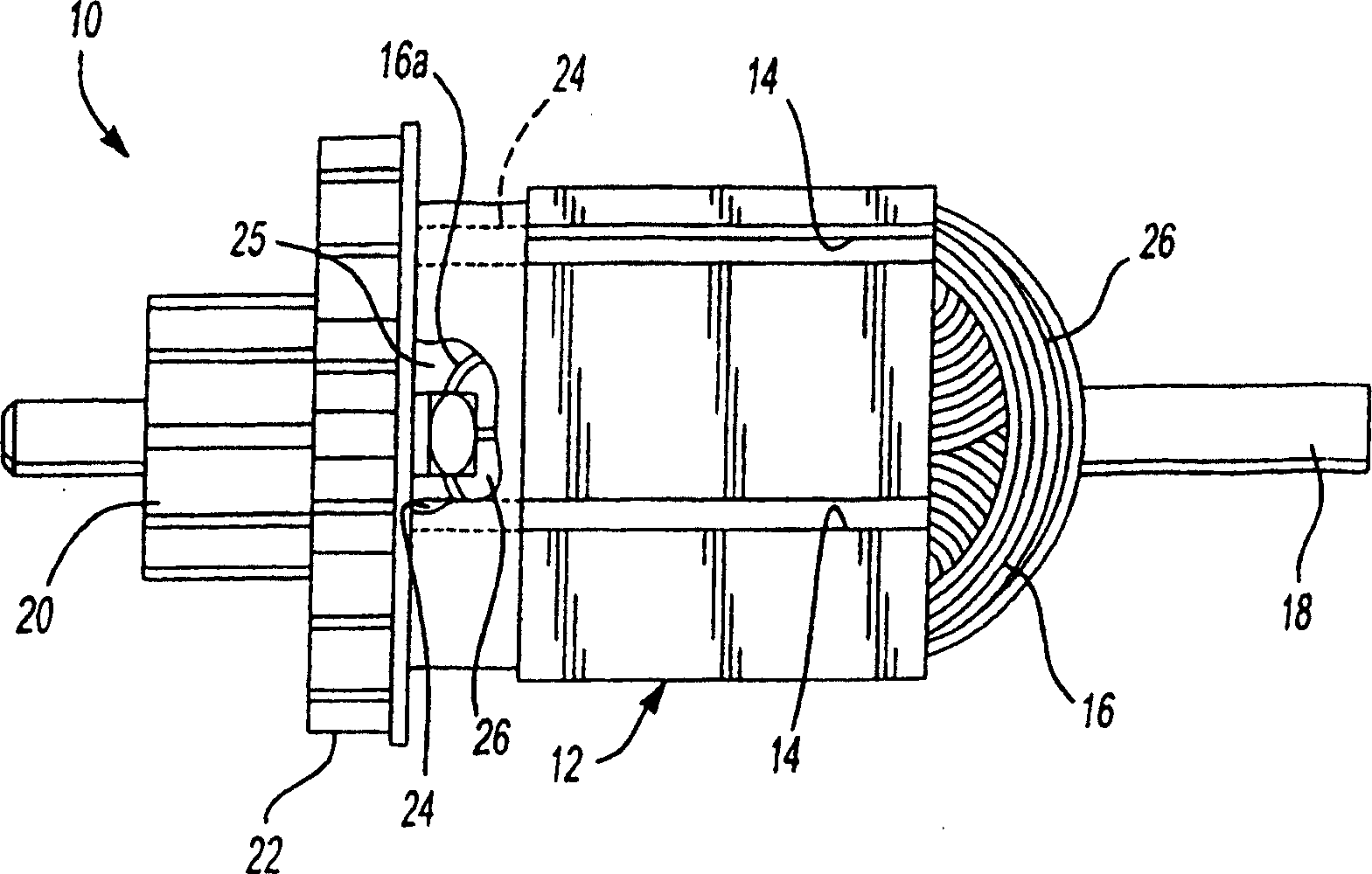

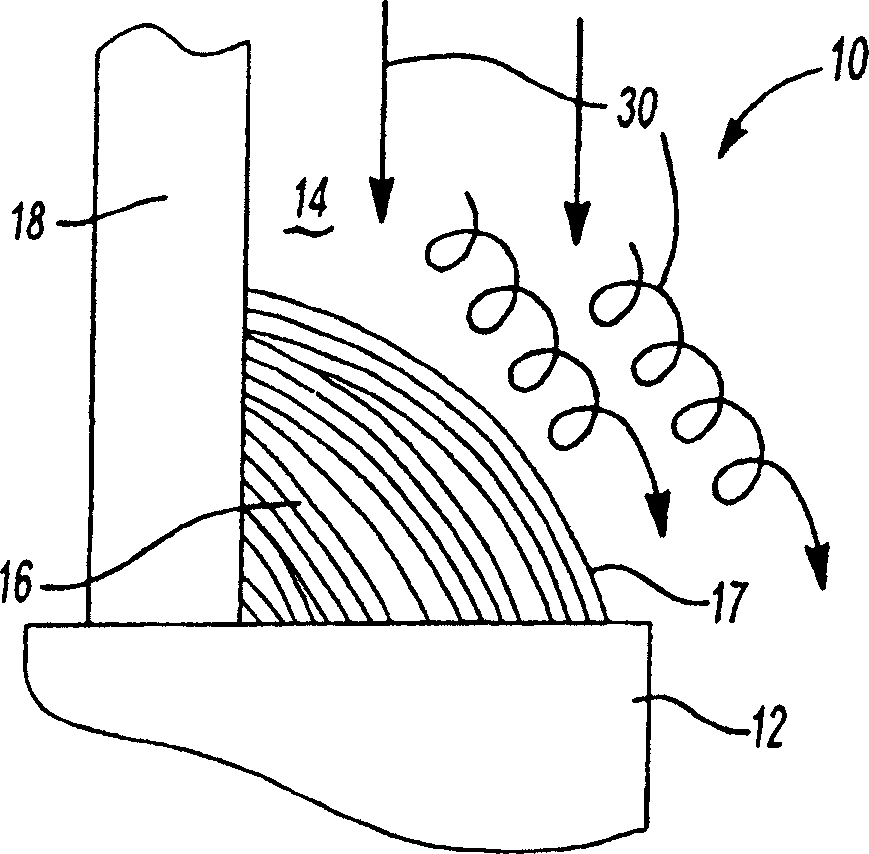

[0077] see now Figure 5 , discloses a motor 100 according to a preferred embodiment of the present invention. The electric machine 100 includes an armature 102 and a stator 104, which is shown in a very simplified manner. The armature 102 includes a laminated structure 106 having a plurality of longitudinal slots 108 circumferentially disposed thereabout. A plurality of magnet wires 110 are wound in slots 108 to form a plurality of coil windings with end coils 117 . An armature shaft 112 extends coaxially through the laminated core 106 and carries a commutator 114 at one end thereof. Thermally conductive plastic 116 is injection molded onto armature 102 such that the plastic flows into and through each slot 108 . The thermally conductive plastic 116 is applied by placing the armature 102 in a suitable injection molding tool and then injecting the thermally conductive plastic 116 into the molding tool at a suitable high pressure. The thermally conductive plastic 116 prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com