Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1611 results about "Coil structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

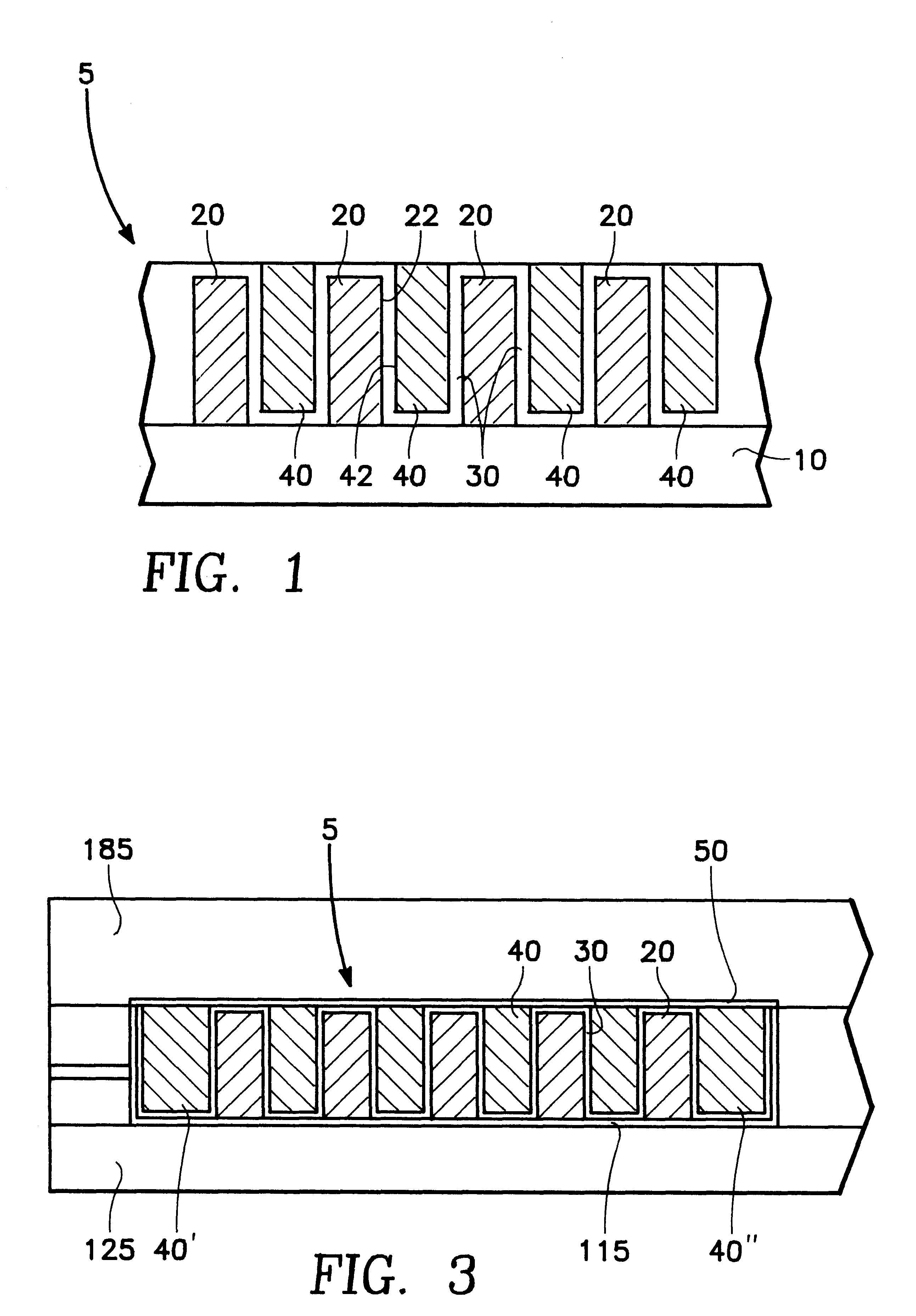

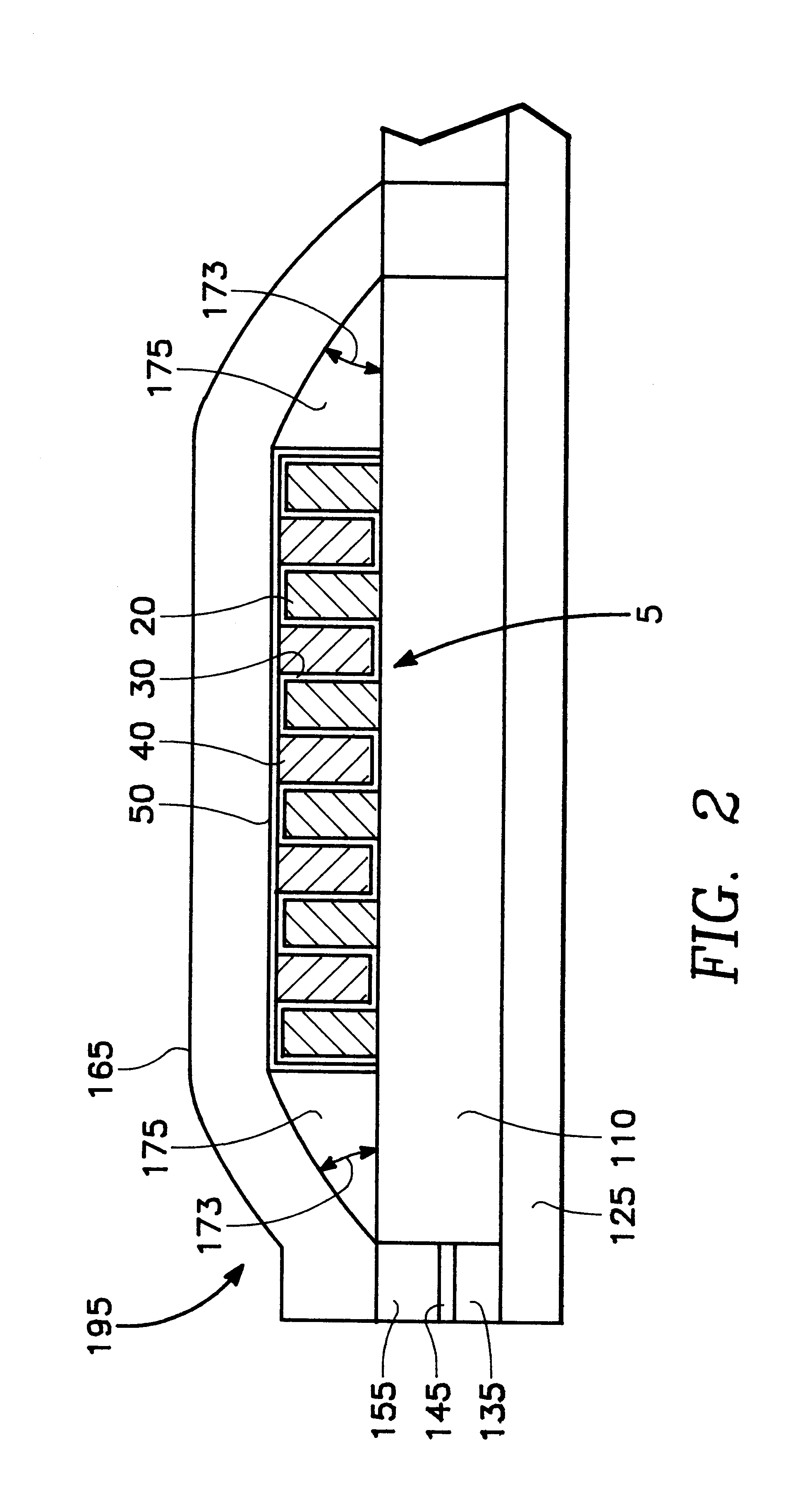

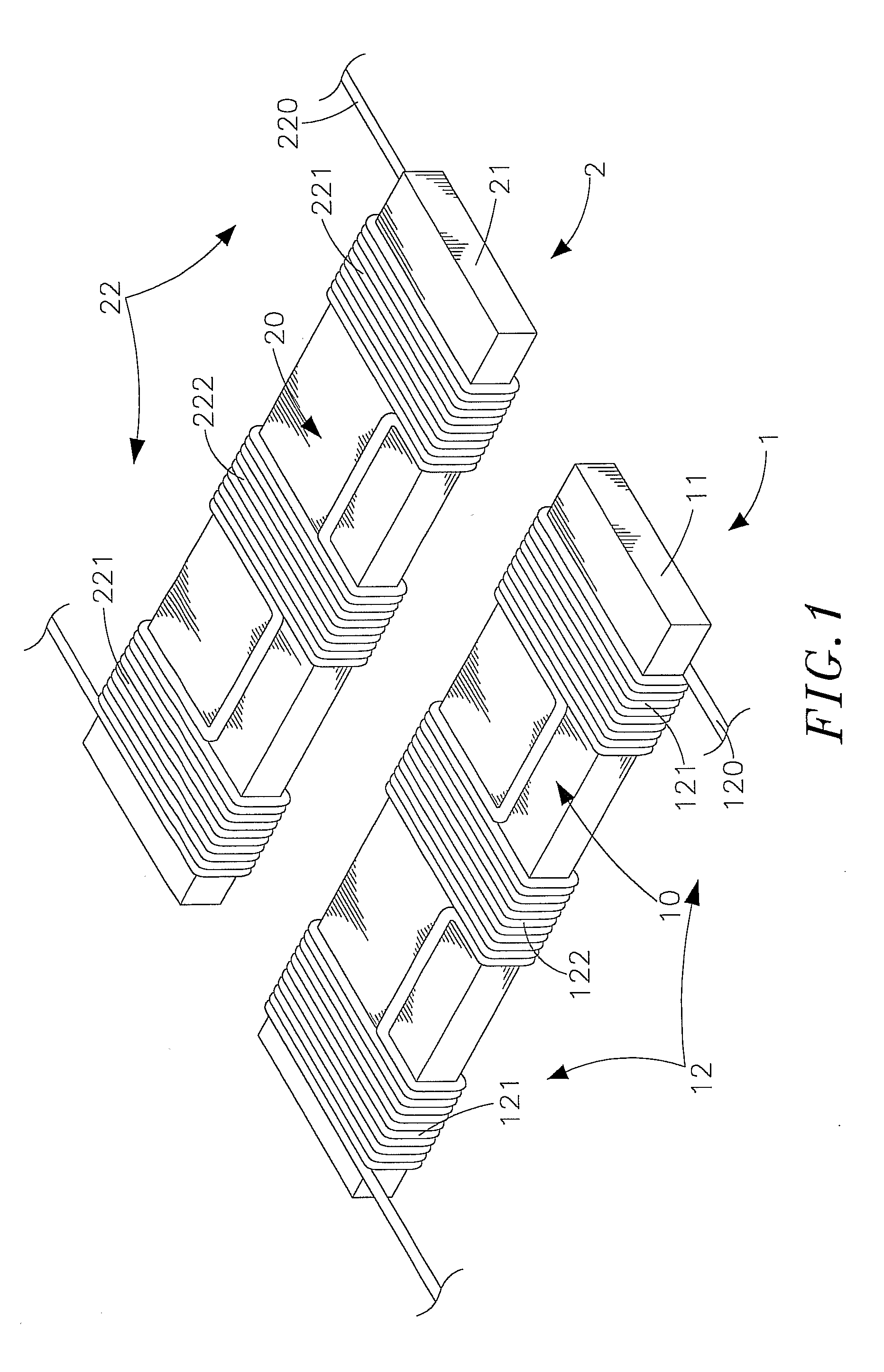

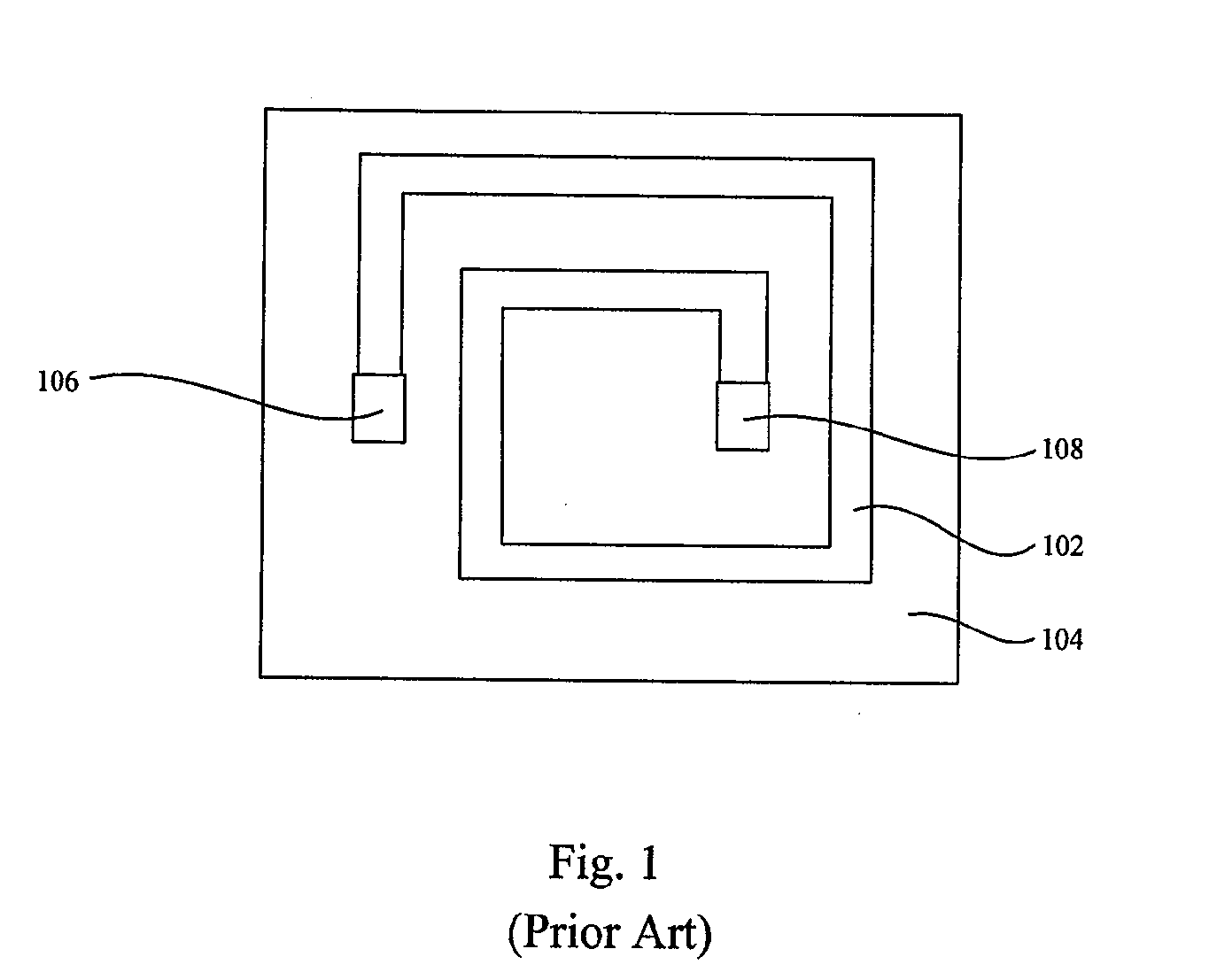

Thin film write head with interlaced coil winding and method of fabrication

InactiveUS6466401B1Increase working frequencySeparationConstruction of head windingsHeads using thin filmsResistConductive materials

The preferred embodiment of the present invention provides a write head having an interlaced conductor coil winding and method of fabrication. The interlaced winding of the present invention may have alternating turns of a first and a second coil. In the preferred embodiment, the side walls of successive coil turns are separated by an ultra thin inorganic insulation which defines the distance between successive turns of the first and second coil. In one method of fabrication, a conductive seed layer is deposited on a generally planar insulative surface, a resist mask is formed on the seed layer, and a conductive material deposited on the exposed seed layer to form the turns of the first coil. The masked portions of the seed layer are removed, after resist mask removal, to electrically isolate the turns of the first coil. The inorganic insulation may be formed in a layer conformal with the first coil. The second coil is formed between the turns of the first coil. A seed layer and mask may be used to facilitate second coil deposition. Etching, or planarization, may be used to electrically isolate the turns of the second coil. A capping layer may be formed over any exposed conductor material to insulate the winding from an upper pole structure or other overlying structure. Embodiments of the present invention may have multiple layers of conductor winding having some conventional, or all interlaced coil structure.

Owner:WESTERN DIGITAL TECH INC

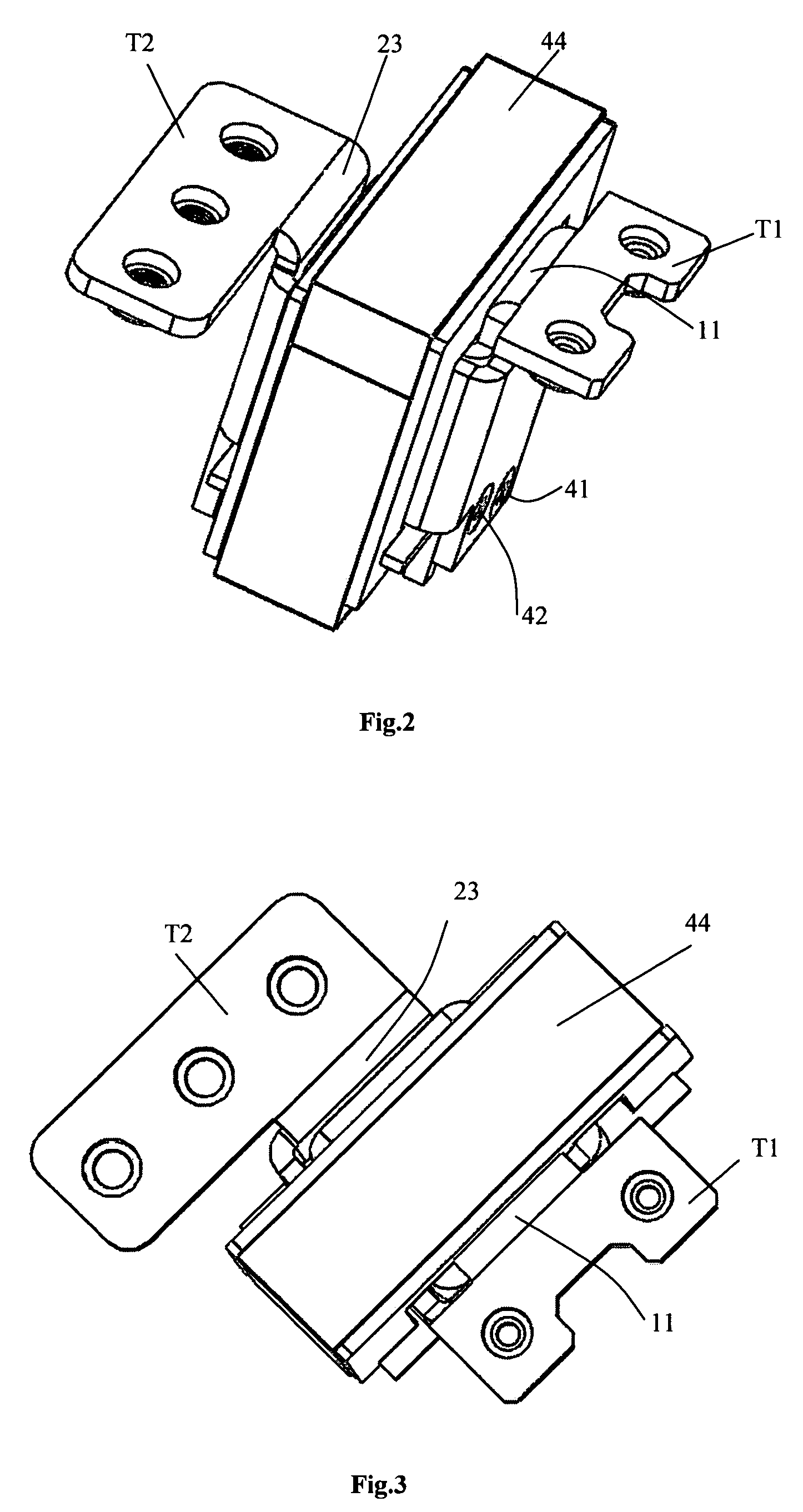

Complex Coil And Manufacturing Techniques

Owner:TERUMO KK

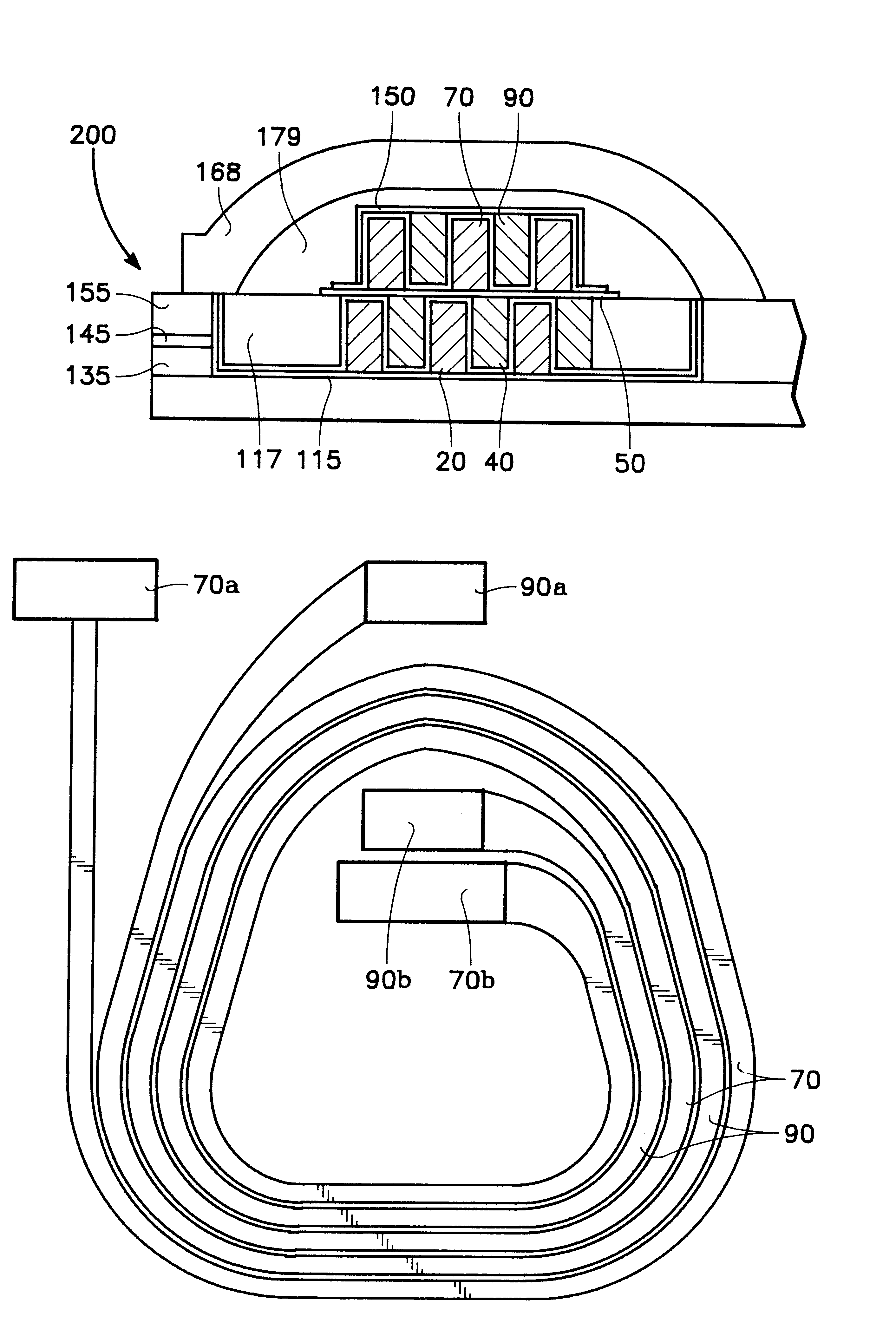

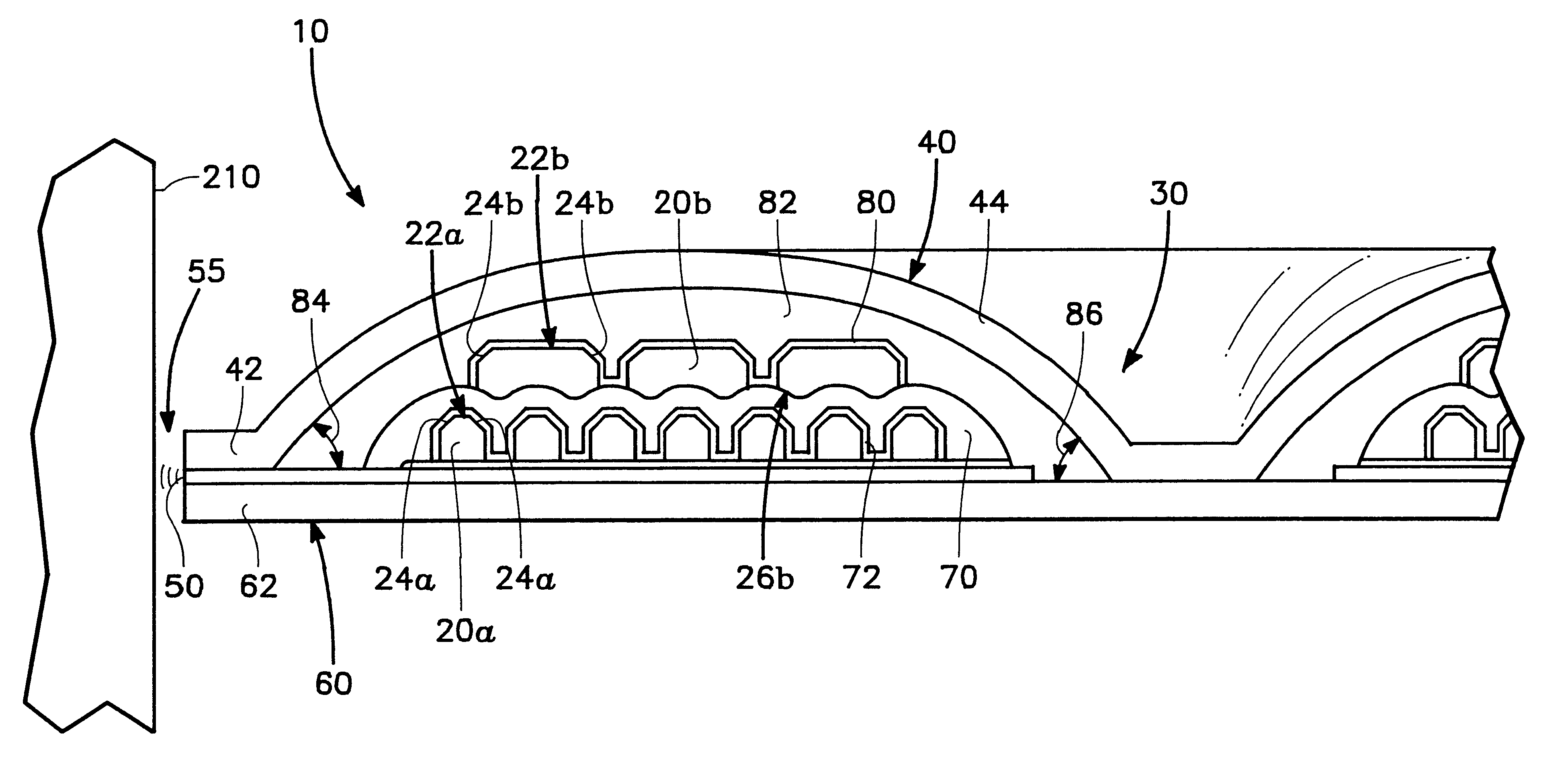

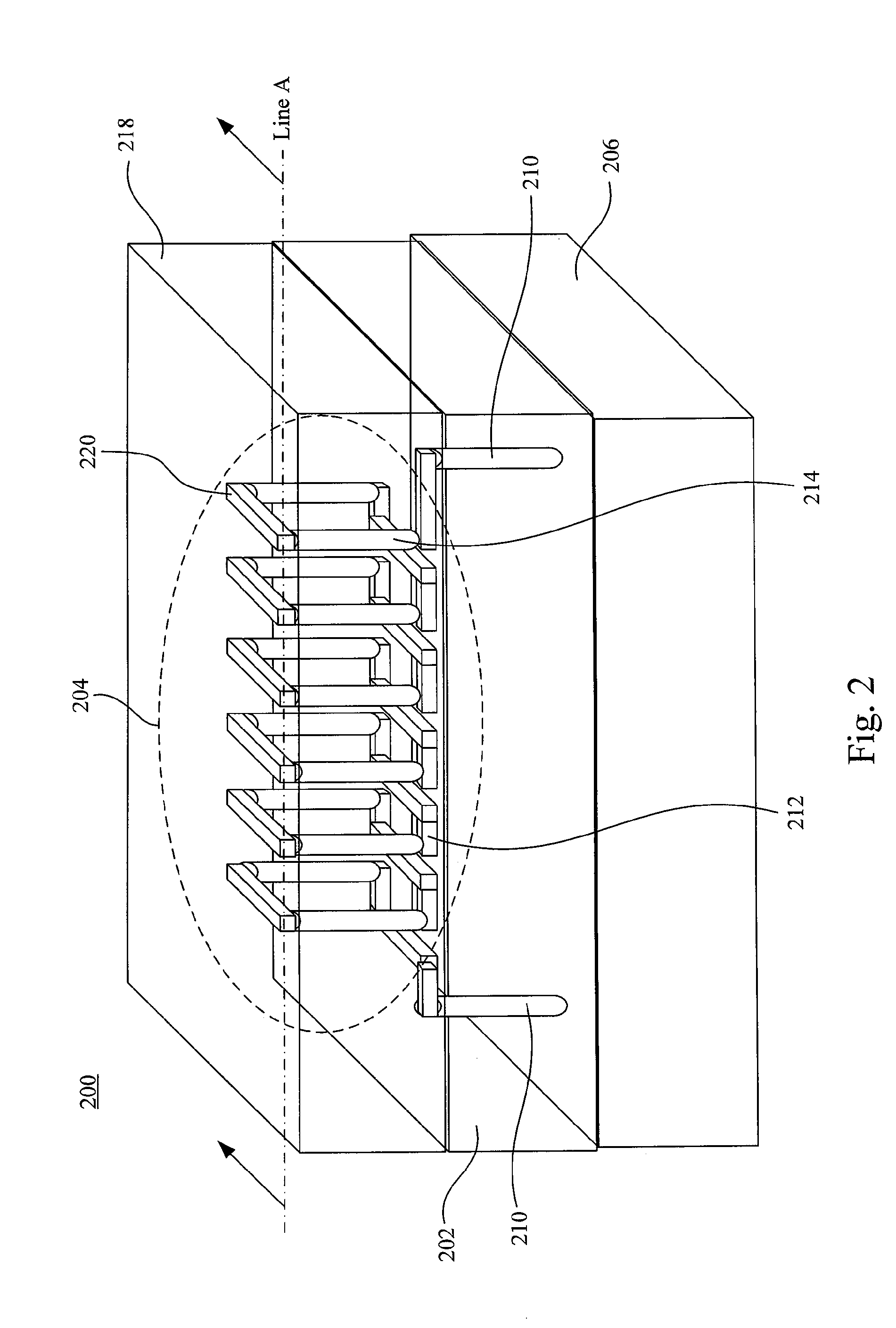

Low resistance coil structure for high speed writer

InactiveUS6333830B2Lower coil resistanceReduce dissipationConstruction of head windingsHeads using thin filmsElectrical conductorLower pole

The present invention provides a thin film write head having an upper and lower pole structures and conductor turns forming a winding for generating magnetic flux. The conductor is formed with a non-planar top surface. The winding of the present invention may be formed of lower and upper turns. The upper turns may be formed with a non-planar top surface, a non-planar bottom surface, or both. It is preferred that the bottom surface of the upper conductor turns be coherent with the non-planar top surface of the lower conductor turns. The non-planar top surface may be formed by removing corners formed during deposition between a generally planar top surface and abutting side walls. The corners may be removed by ion milling to form the non-planar top surface. The conductor may be copper with the non-planar top surface having sloping facets. The thin film write head of the present invention may be utilized to provide an improved data storage and retrieval apparatus. The preferred embodiment provides reduced coil resistance thereby reducing Johnson Thermal Noise and power dissipation. It also allows for reduced yoke length and reduced stack height while providing low apex angles to expand and improve yoke material deposition thereby improving head response and operational frequency.

Owner:WESTERN DIGITAL TECH INC

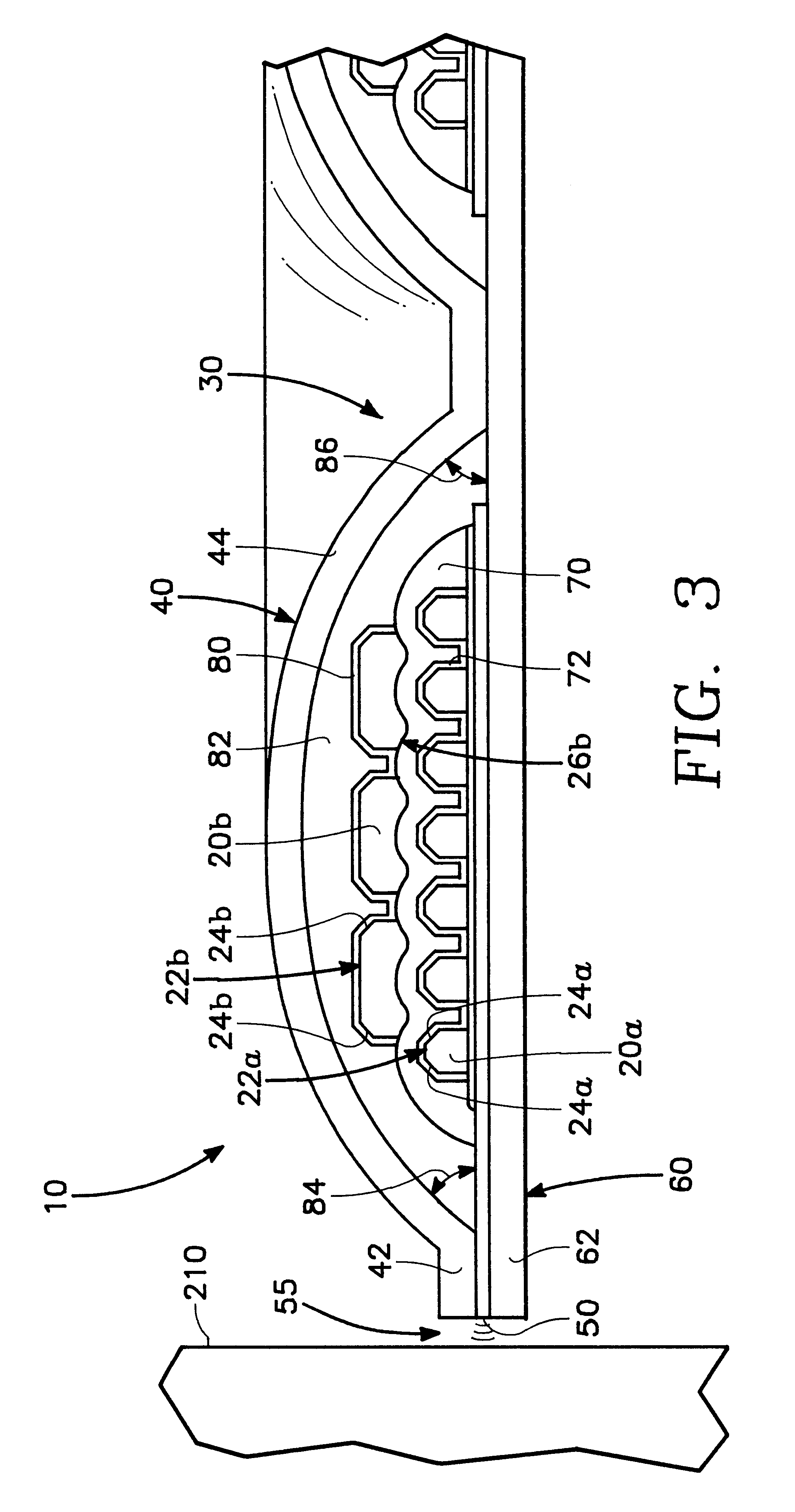

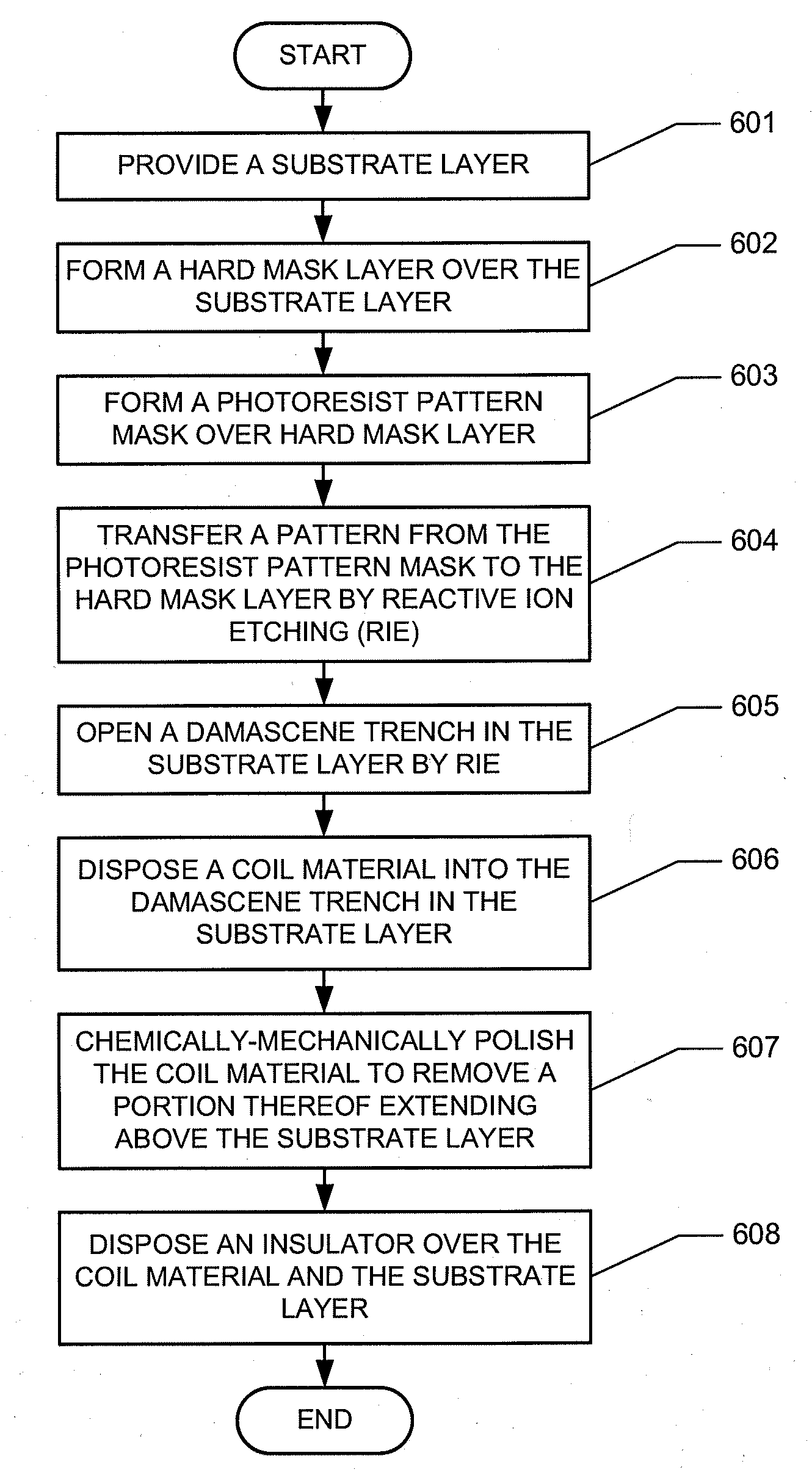

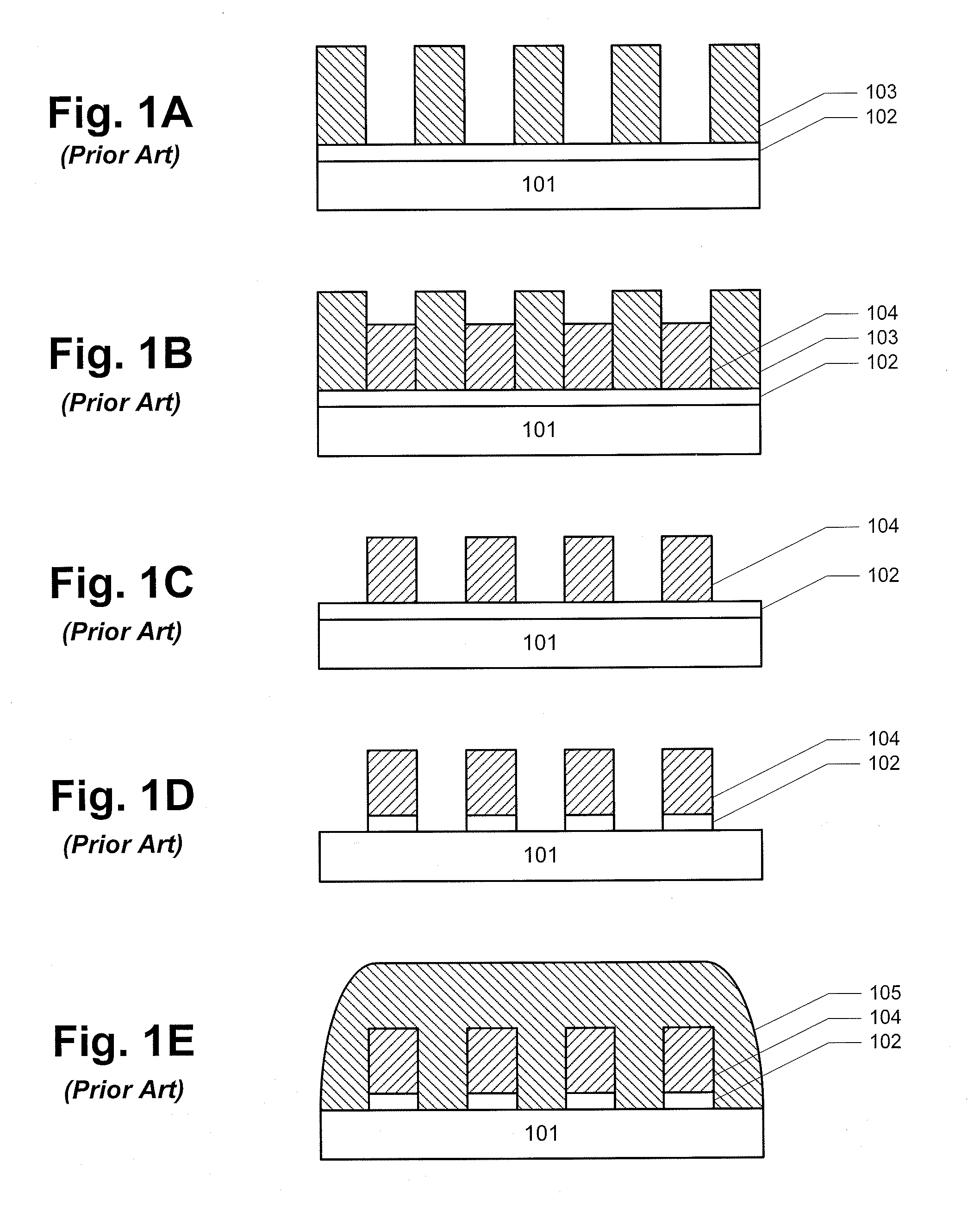

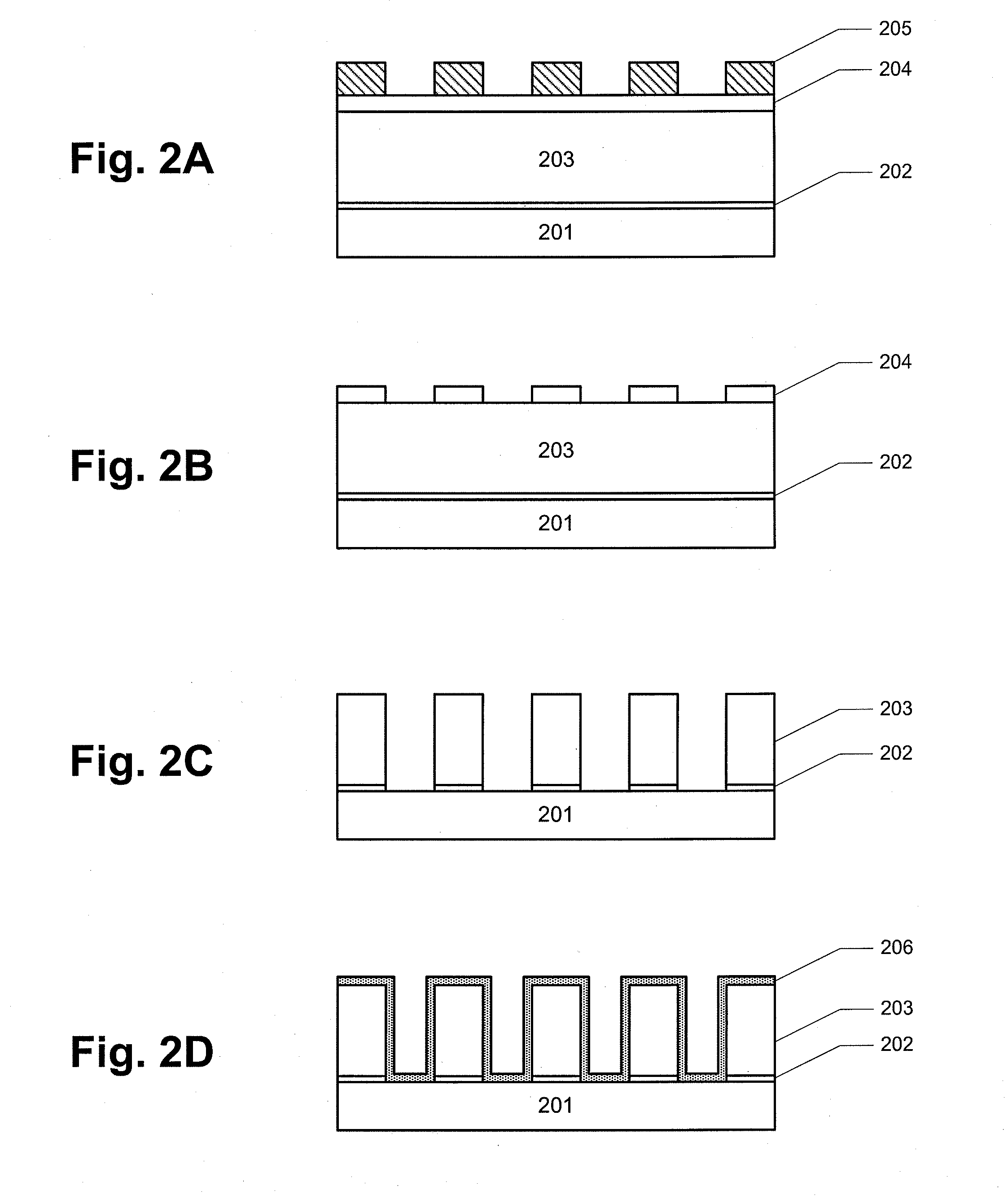

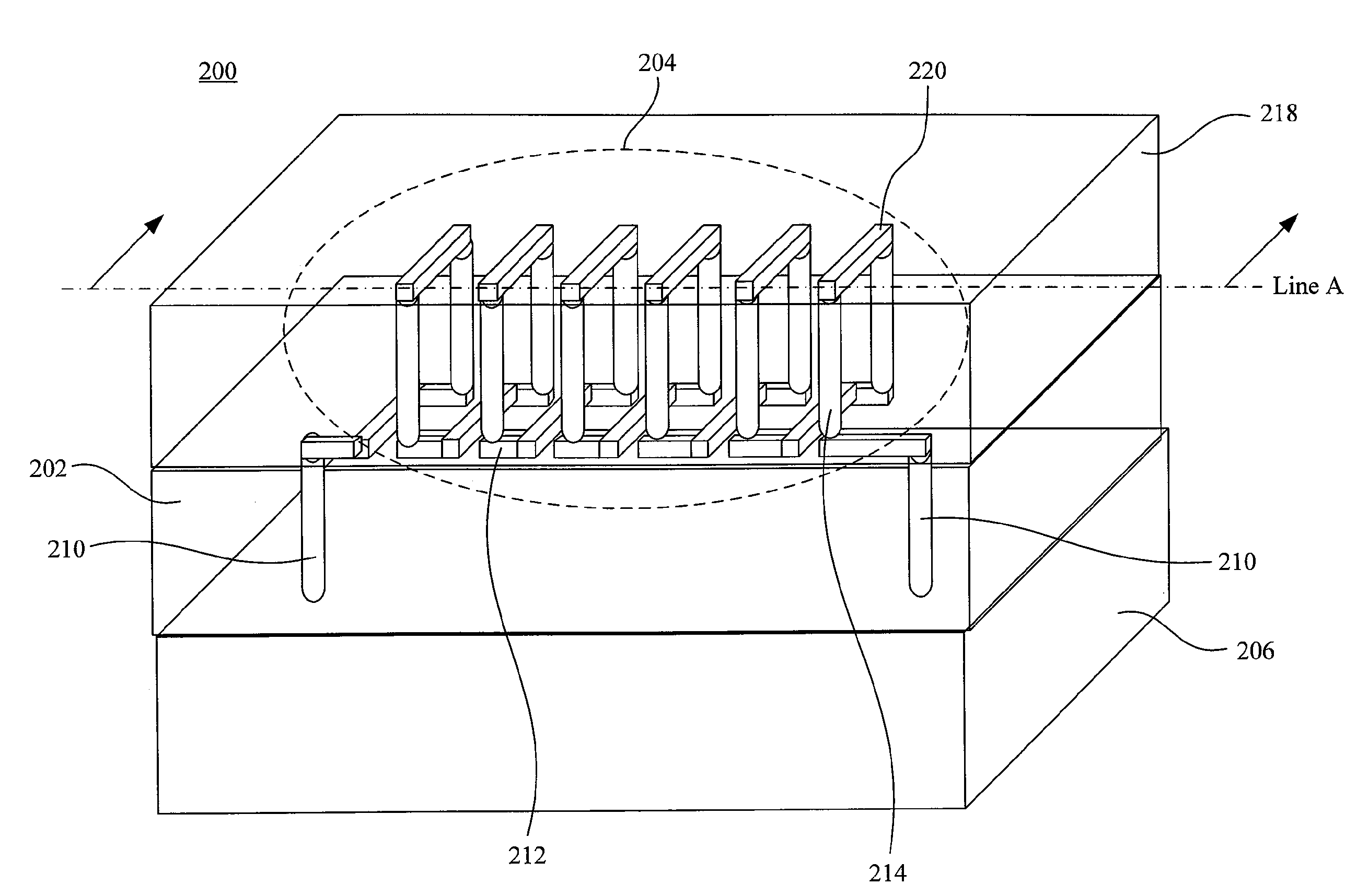

Damascene coil processes and structures

InactiveUS20100290157A1Eliminating insulation coverage problemEliminate needConstruction of head windingsDecorative surface effectsOptoelectronicsReactive-ion etching

A magnetic recording head is provided. The magnetic recording head comprises a write pole and a write coil structure configured to generate a magnetic field in the write pole. The write coil structure comprises a substrate layer and a coil material disposed within the substrate layer. The write coil structure is substantially free of photoresist. A method for forming a write coil structure is also provided. The method comprises the steps of providing a substrate layer, forming a photoresist pattern mask over the substrate layer, opening a damascene trench in the substrate layer by reactive ion etching, and disposing a coil material into the damascene trench in the substrate layer.

Owner:WESTERN DIGITAL TECH INC

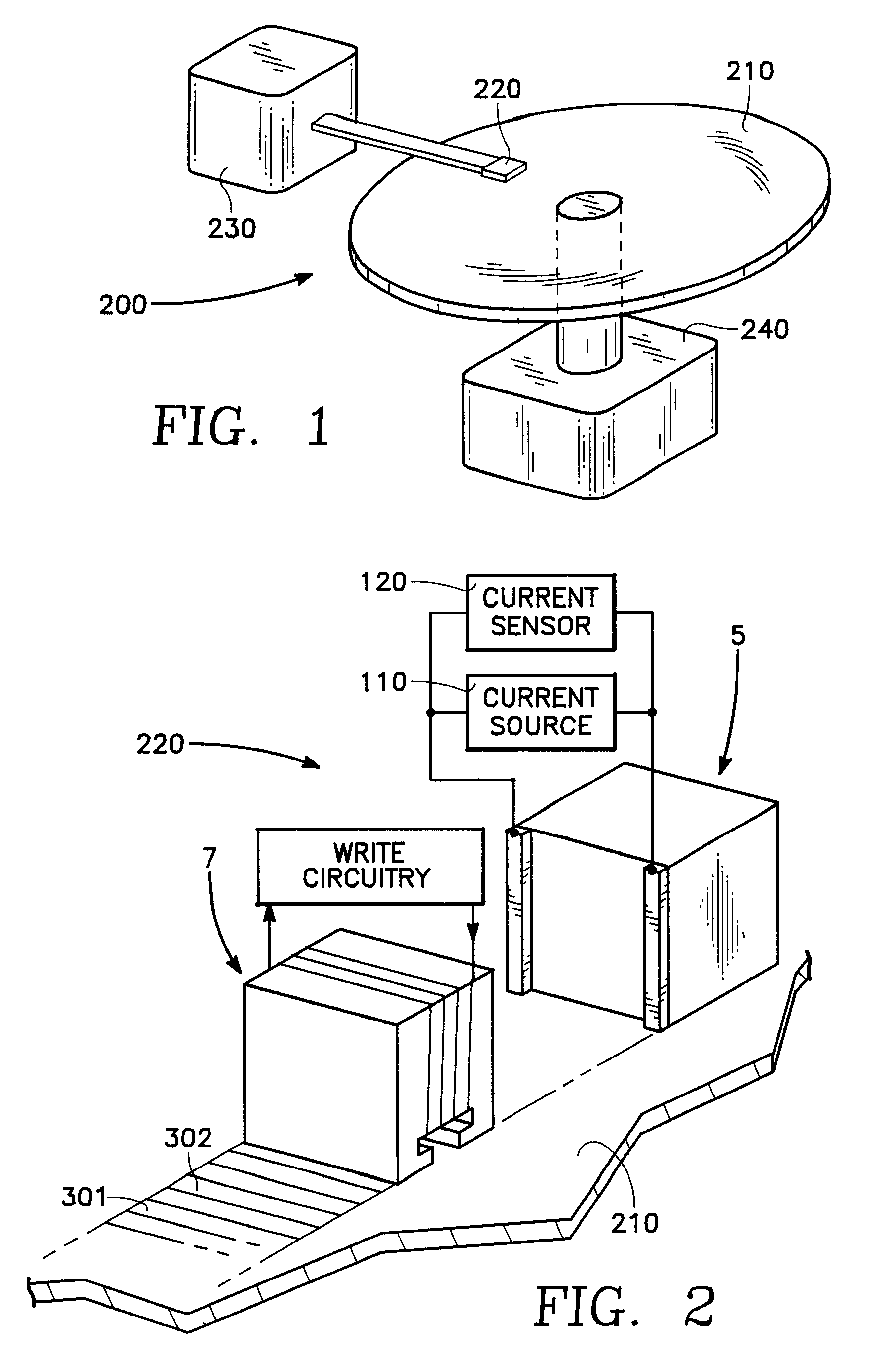

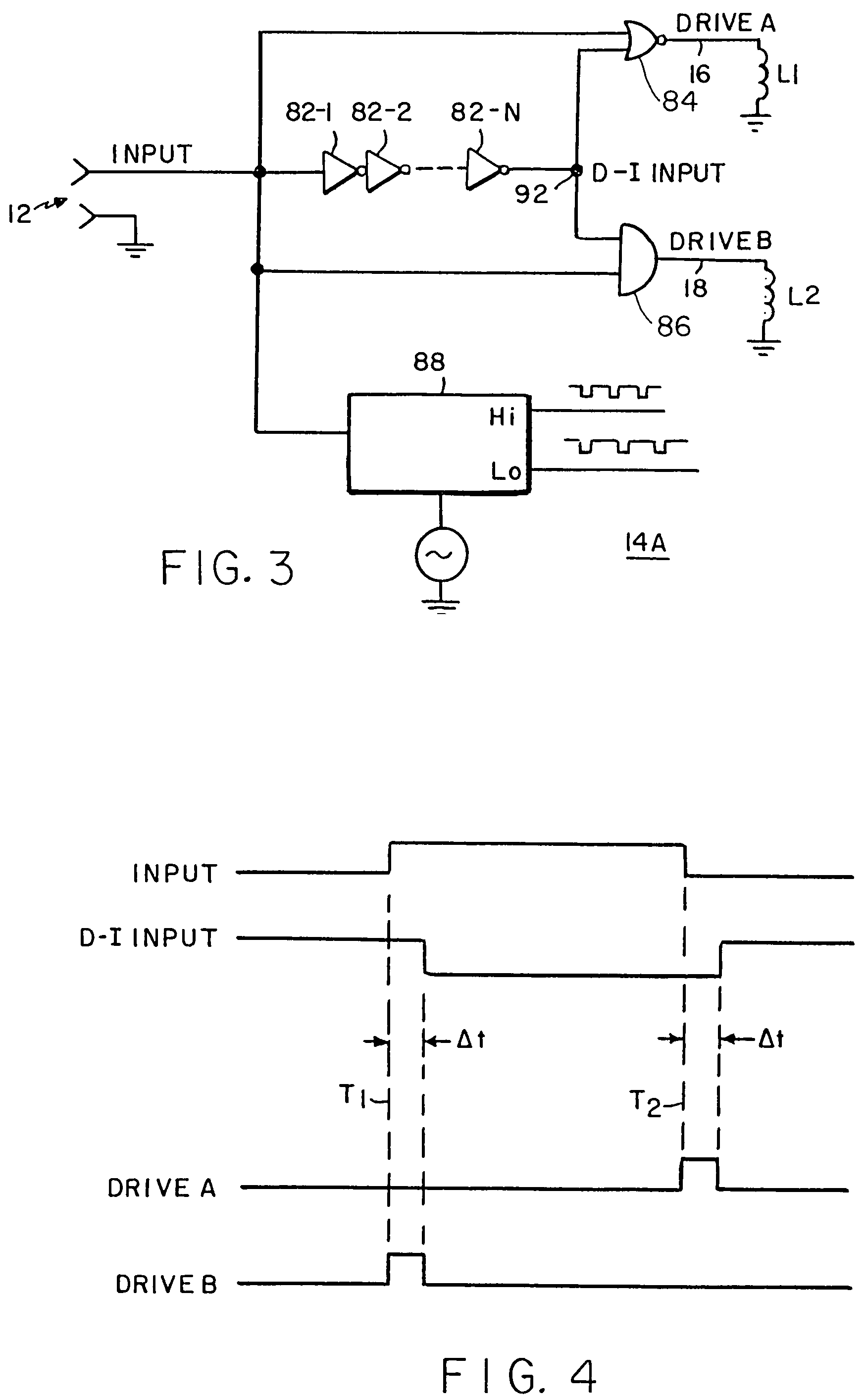

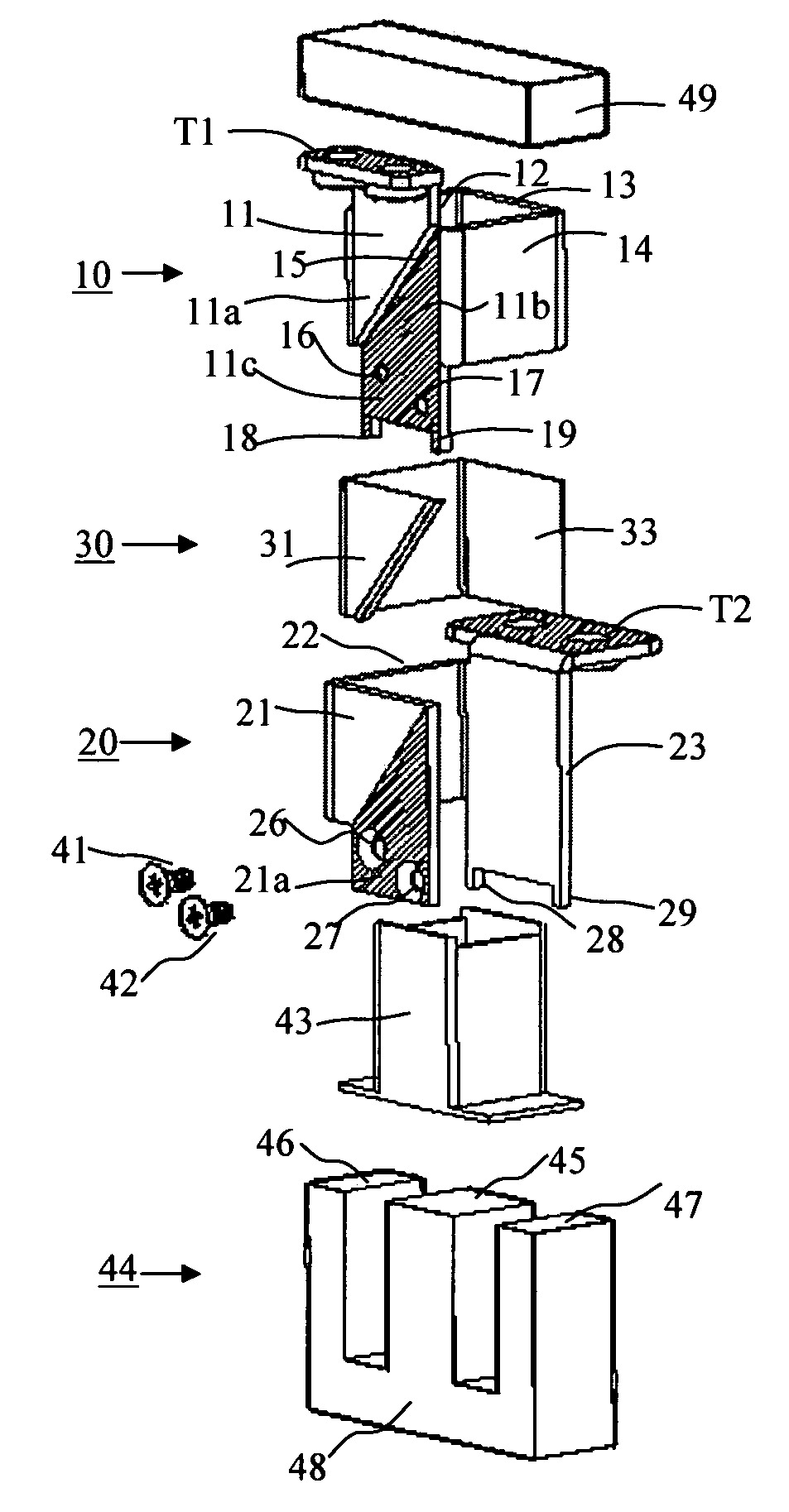

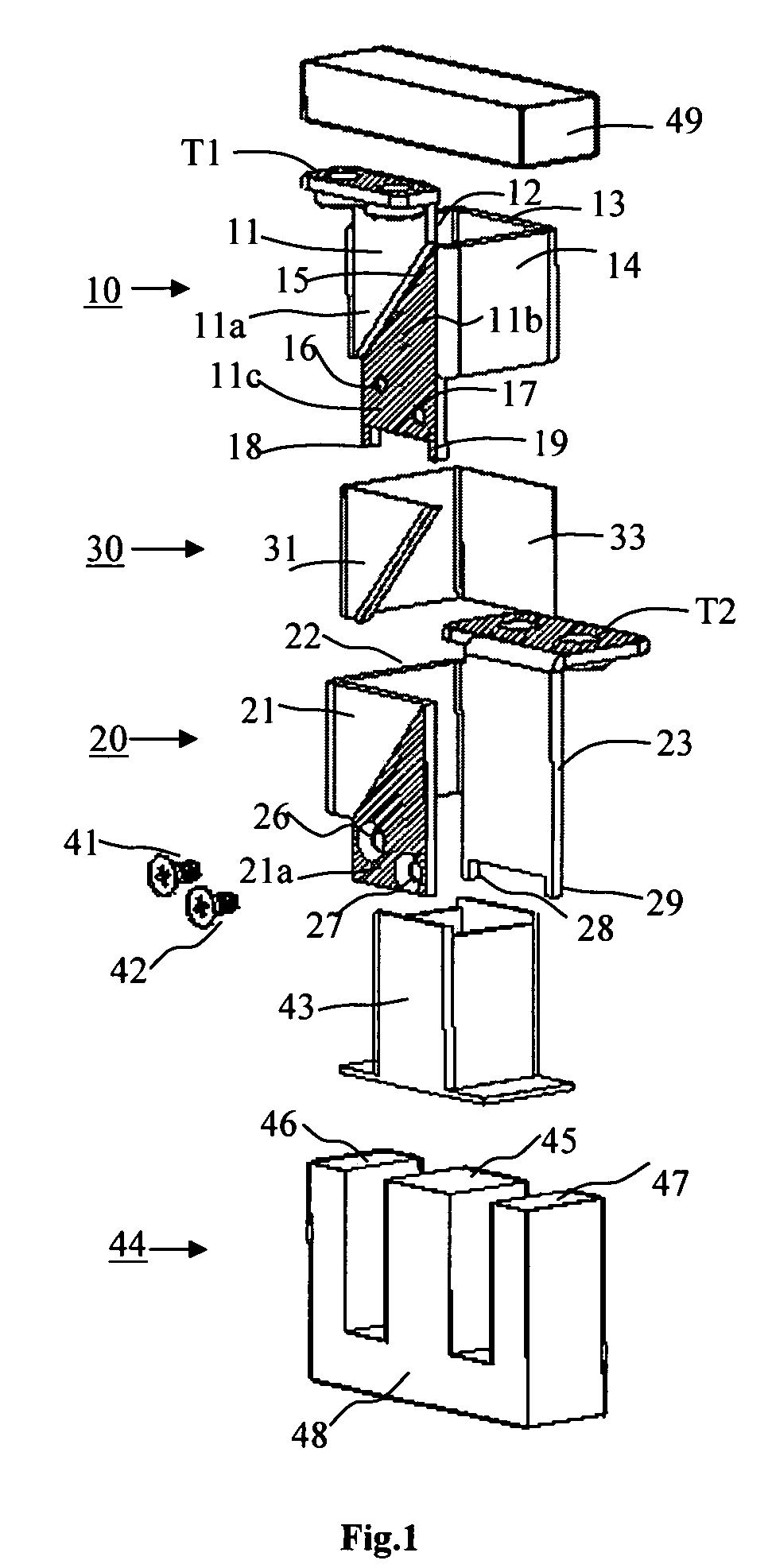

Apparatus and method for monitoring speaker cone displacement in an audio speaker

ActiveUS7961892B2Transducer casings/cabinets/supportsTone controlElectromagnetic couplingEngineering

An apparatus for monitoring speaker cone displacement in an audio speaker includes: (a) an electromagnetic coil structure; (b) a ferrous core structure; the ferrous core structure and the electromagnetic coil structure being mounted with the speaker to effect variable electromagnetic coupling between the ferrous core structure and the electromagnetic coil structure as the speaker cone moves; (c) a signal injecting circuit coupled with the electromagnetic coil structure for injecting a predetermined input signal into the electromagnetic coil structure; and (d) a signal monitoring circuit coupled with the electromagnetic coil structure; the signal monitoring circuit receiving an output signal from the electromagnetic coil structure and generating an indicating signal based upon the output signal; at least one signal characteristic of the indicating signal being related with the cone displacement.

Owner:TEXAS INSTR INC

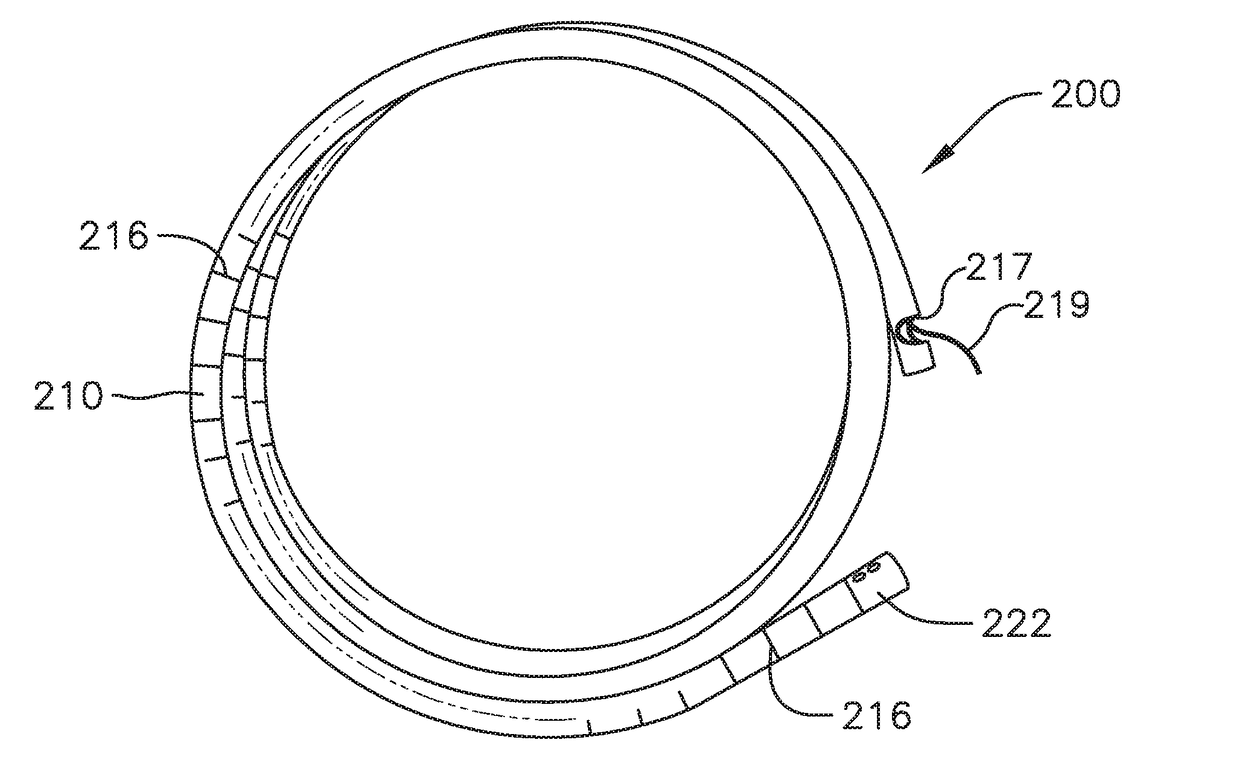

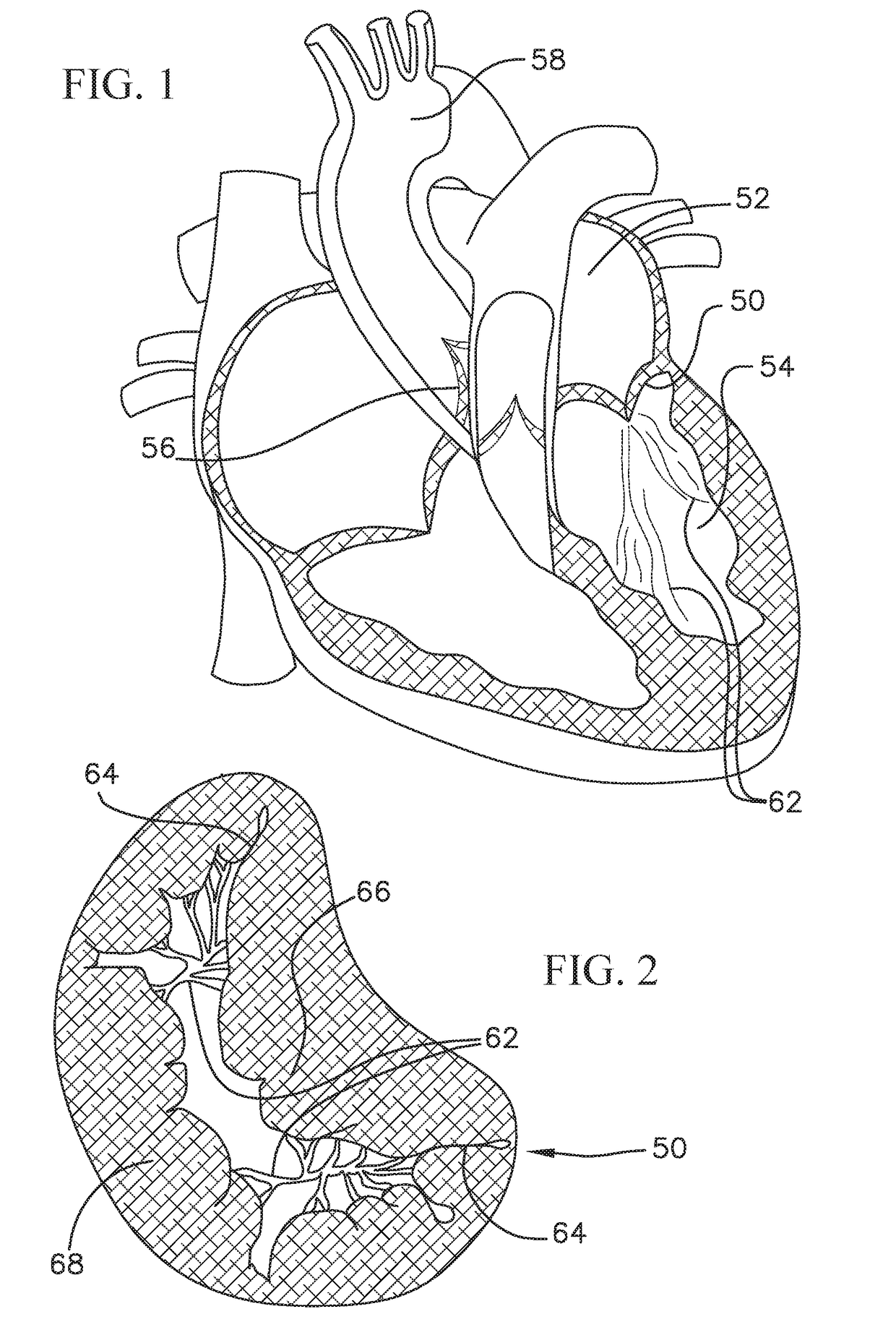

Heart valve docking coils and systems

Anchoring or docking devices configured to be positioned at a native valve of a human heart and to provide structural support for docking a prosthetic valve therein. The docking devices can have coiled structures that define an inner space in which the prosthetic valve can be held. The docking devices can have enlarged end regions with circular or non-circular shapes, for example, to facilitate implantation of the docking device or to better hold the docking device in position once deployed. The docking devices can be laser-cut tubes with locking wires to assist in better maintaining a shape of the docking device. The docking devices can include various features to promote friction, such as frictional cover layers. Such docking devices can have ends configured to more securely attach the cover layers to cores of the docking devices.

Owner:EDWARDS LIFESCIENCES CORP

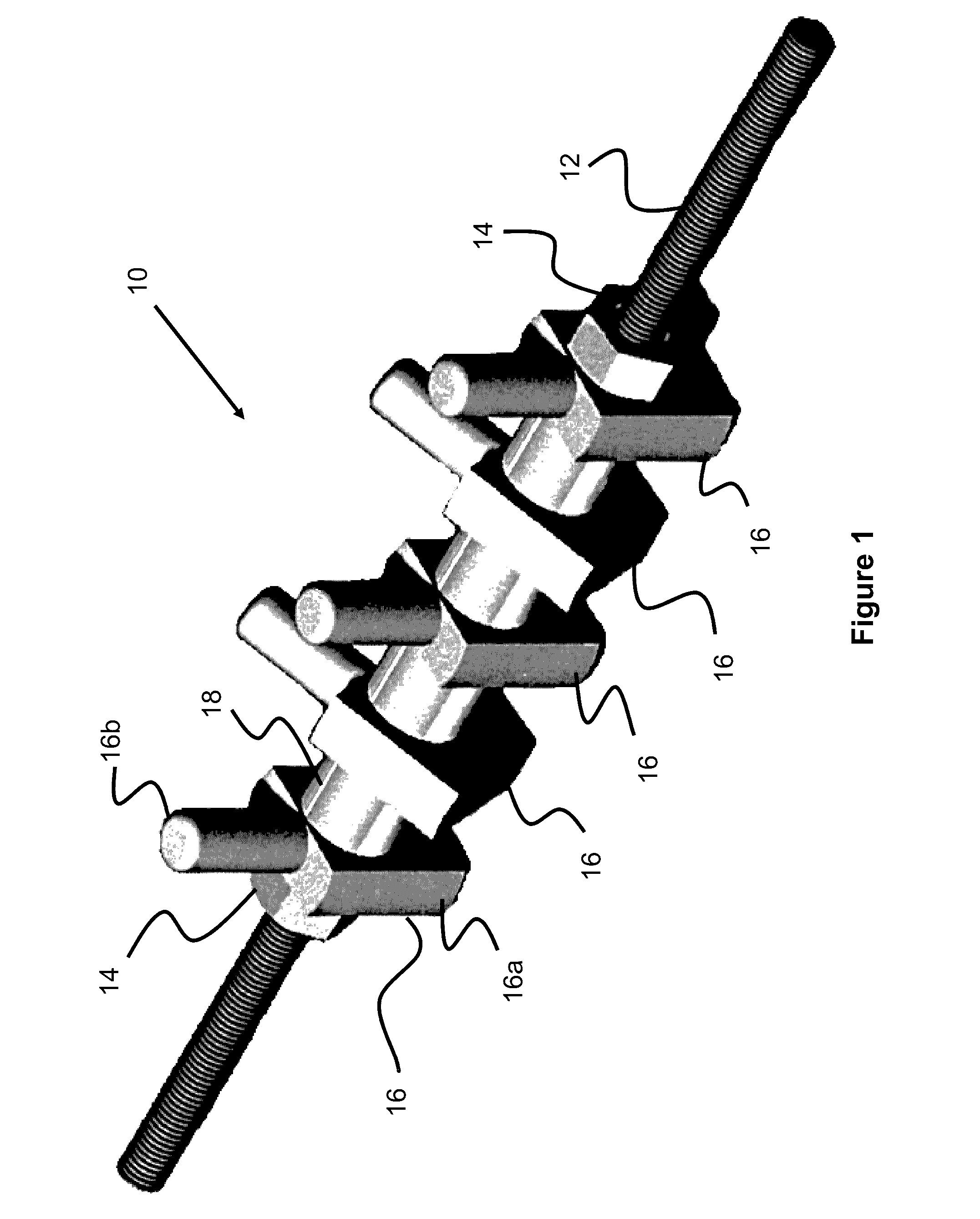

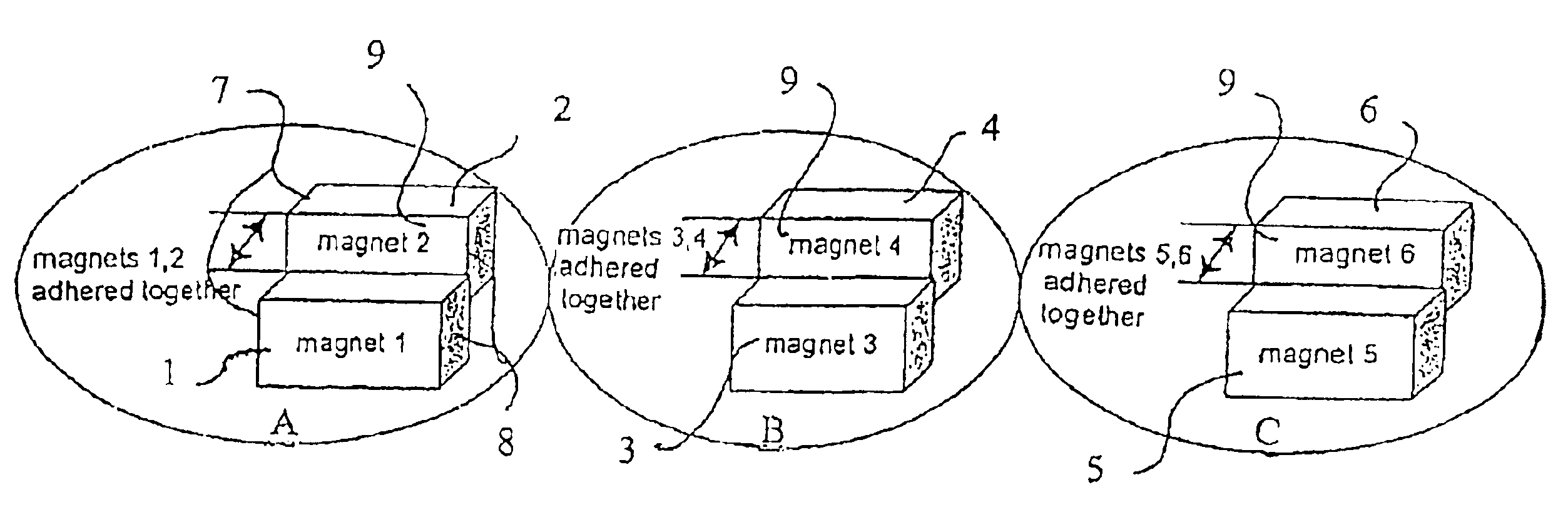

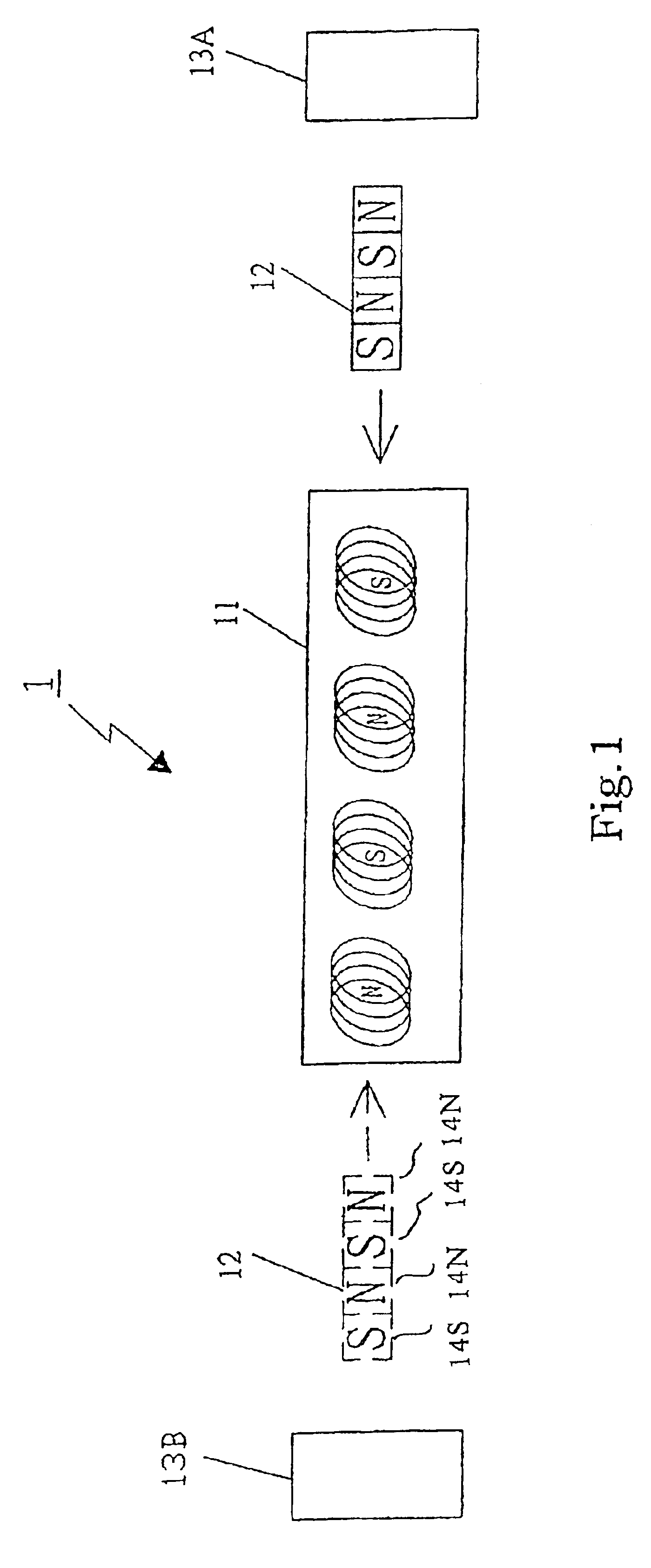

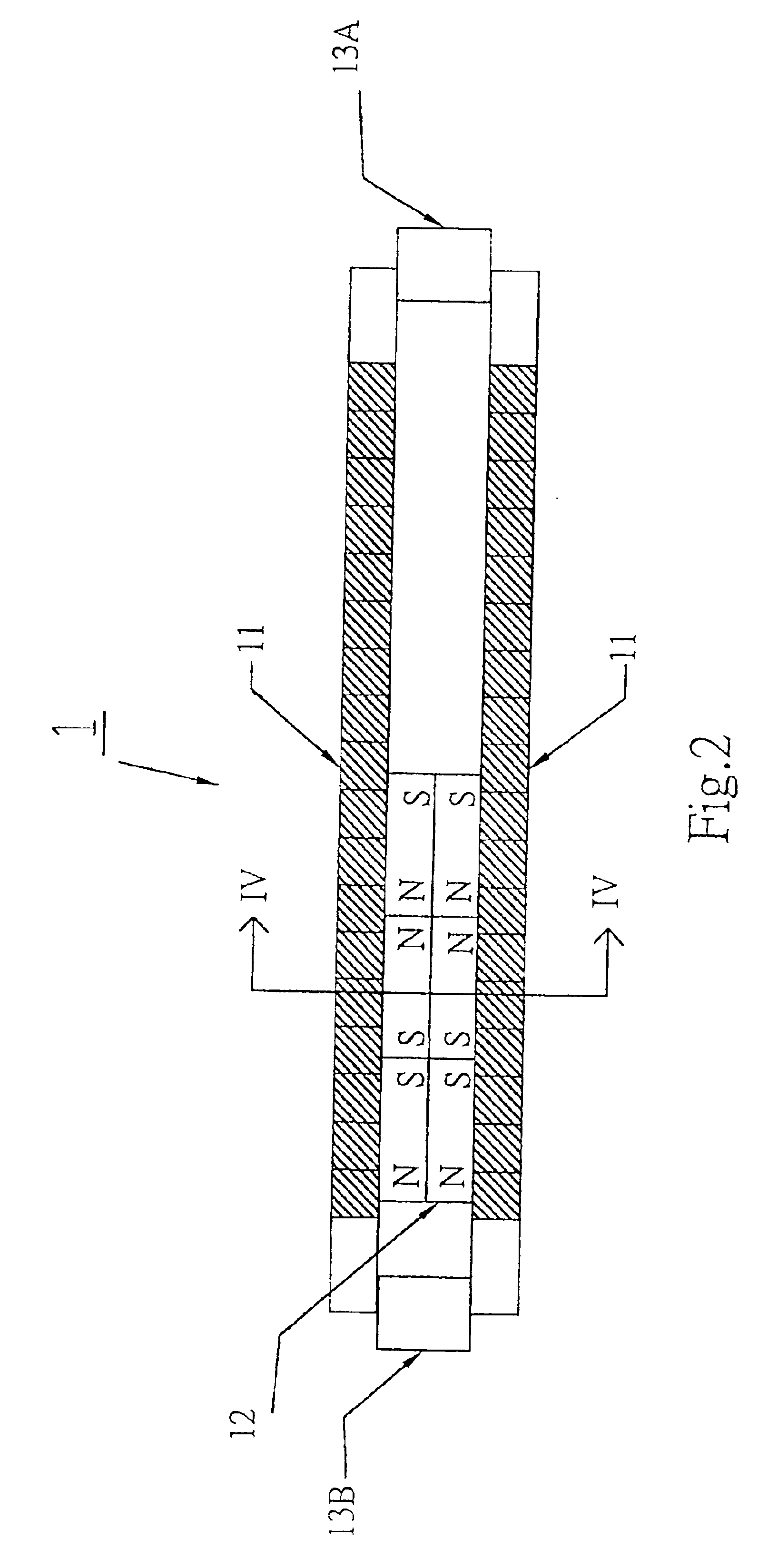

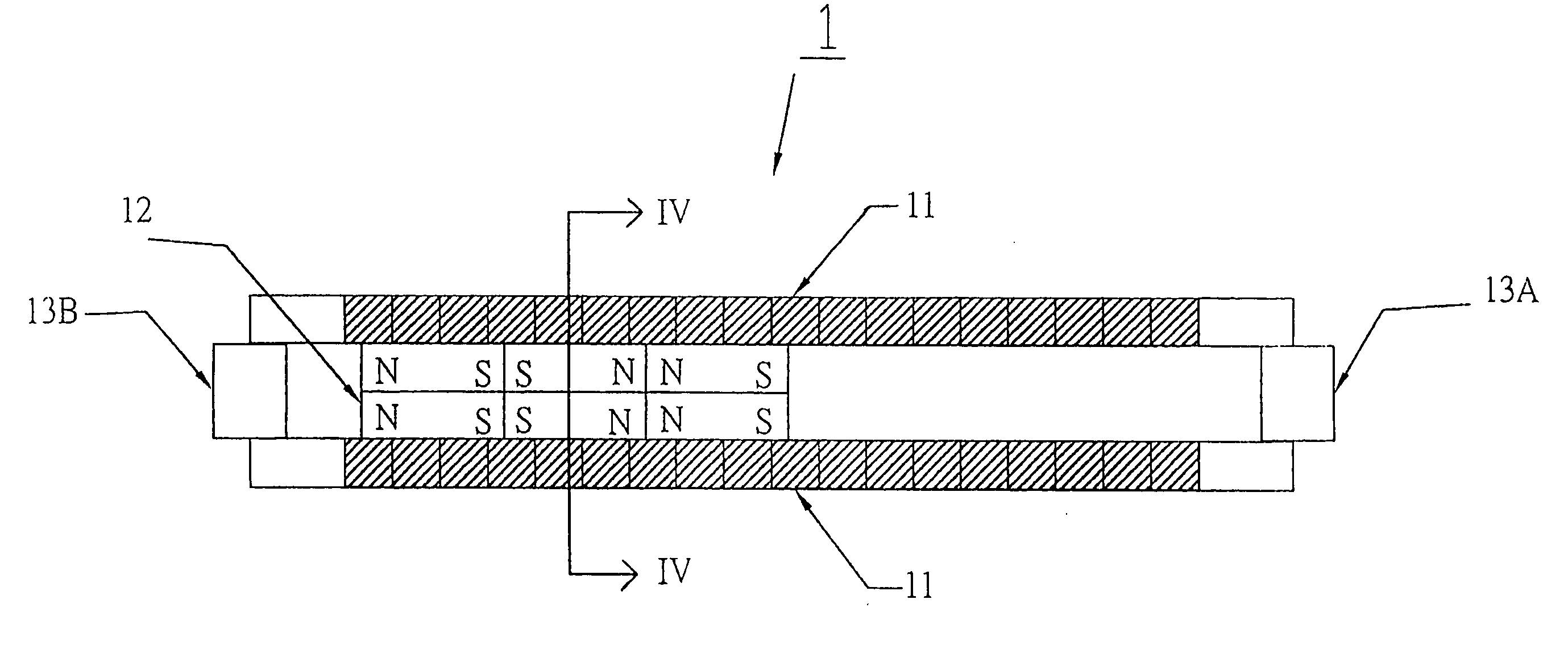

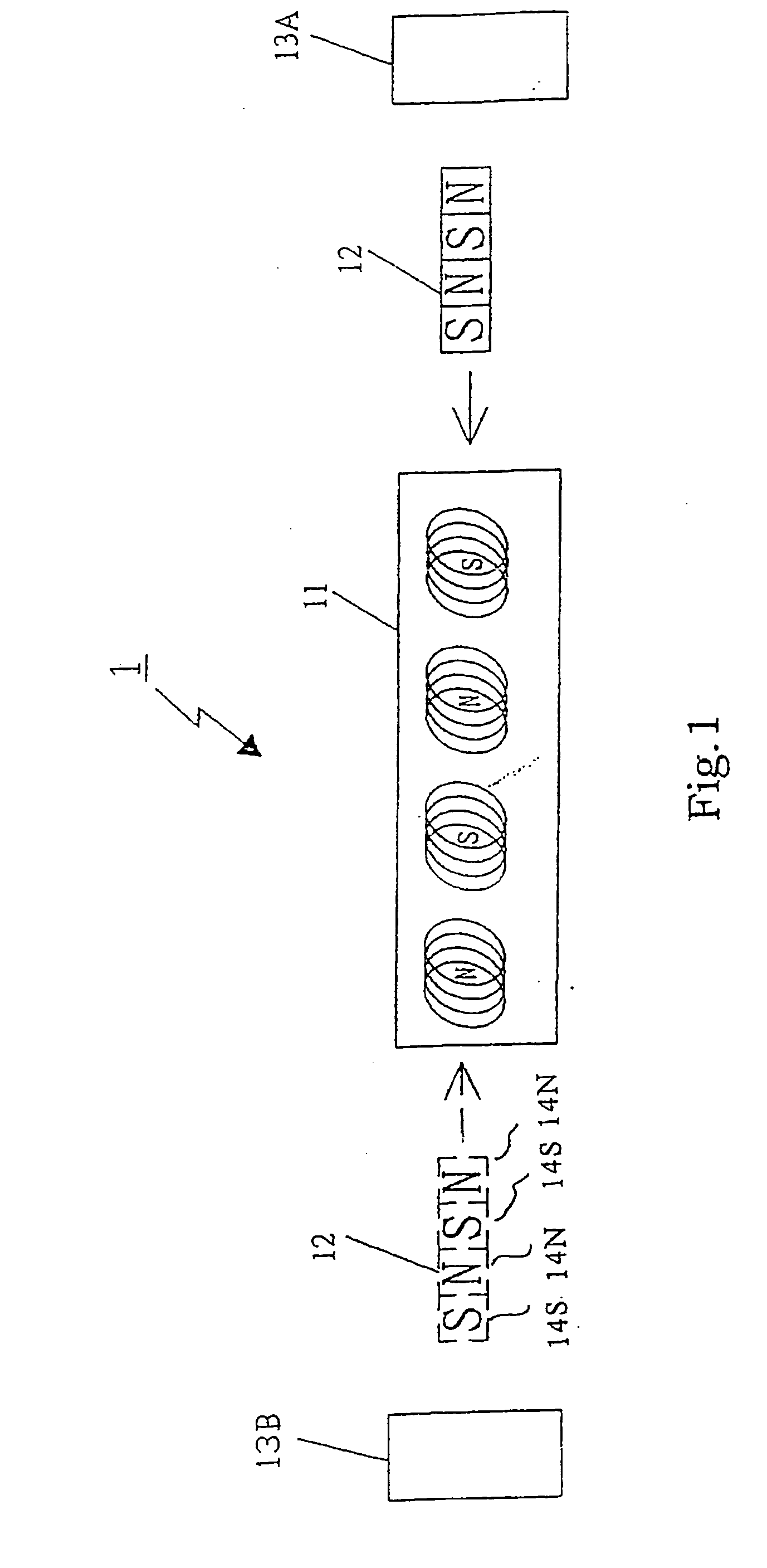

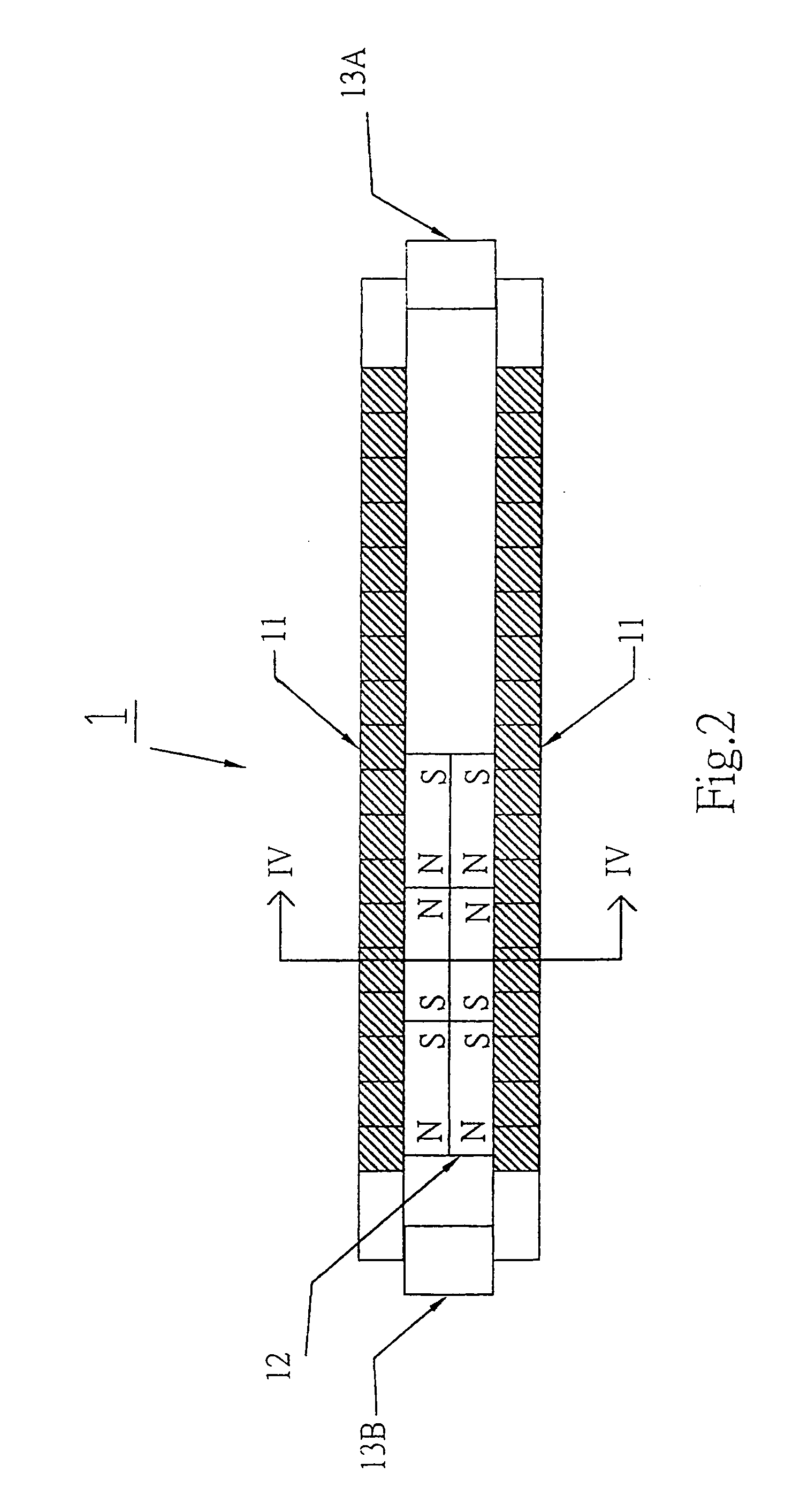

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS6936937B2Reduce demandIncrease demandWindingsMagnetic circuitReciprocating motionElectrical polarity

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

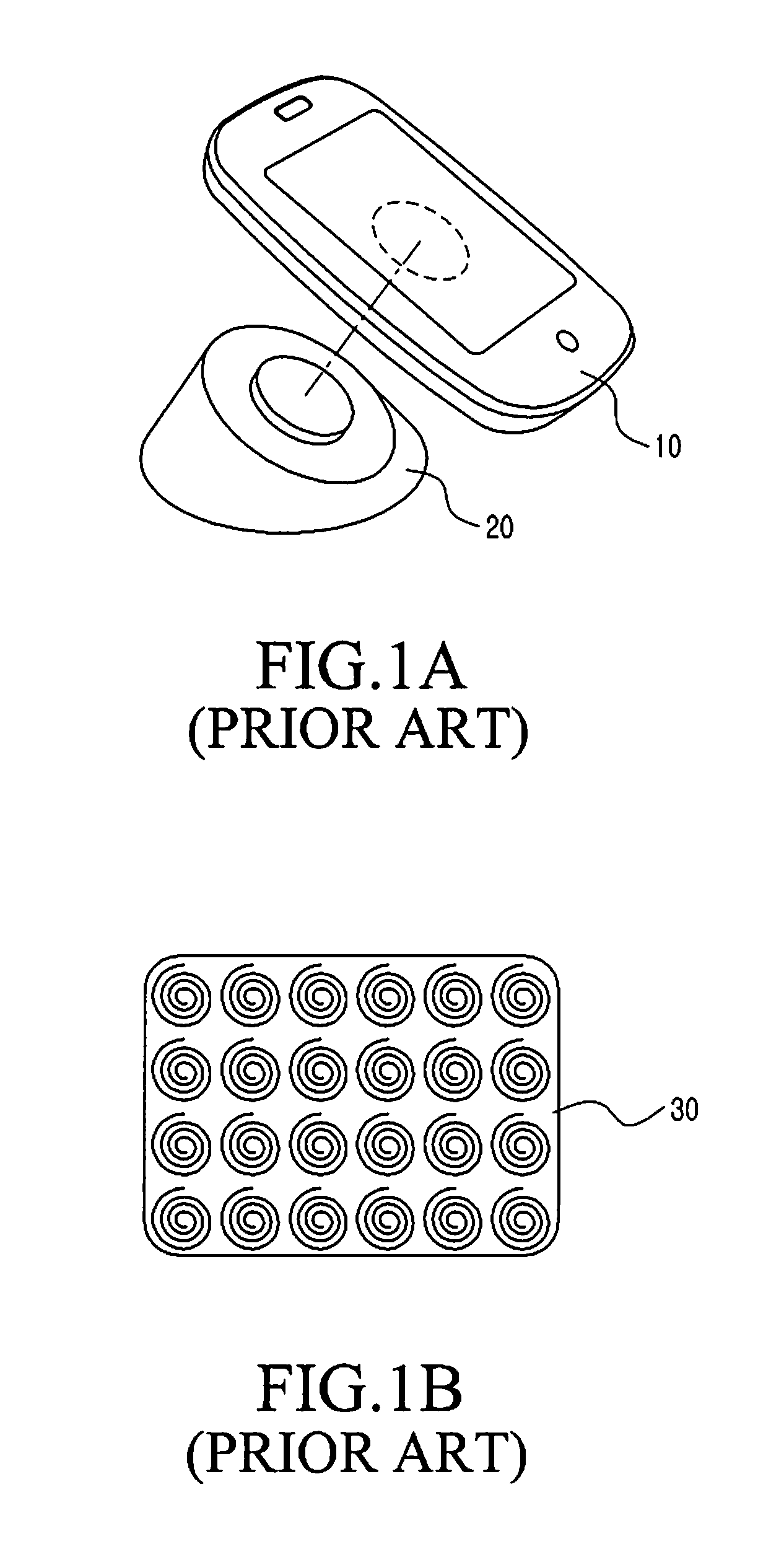

Wireless charging coil structure in electronic devices

ActiveUS20120074899A1Improve permeabilityPrevent electromagnetic emissionBatteries circuit arrangementsTransformersElectric power transmissionEngineering

The present inventions relates a wireless charging coil structure in electronic devices, comprising a PS coil module capable of emitting electromagnetic wave energy and a PR coil module capable of receiving power energy by electromagnetic induction. Each of the PS and PR coil modules includes a bar-shaped magnetic conductor, on which an insulated wire is wound into a first coil that is extended along the magnetic conductor to a given length and wound reversely into a second coil, thus producing an induction coil comprising at least the first and second coils. The induction range with given space formed between the first and second coils is used for electromagnetic induction to transmit signals and power energy. Such structure can be applied not only in planar handheld electronic devices, but also in other wireless power transmission systems that require narrow induction surface for power transmission.

Owner:FU TONG TECH

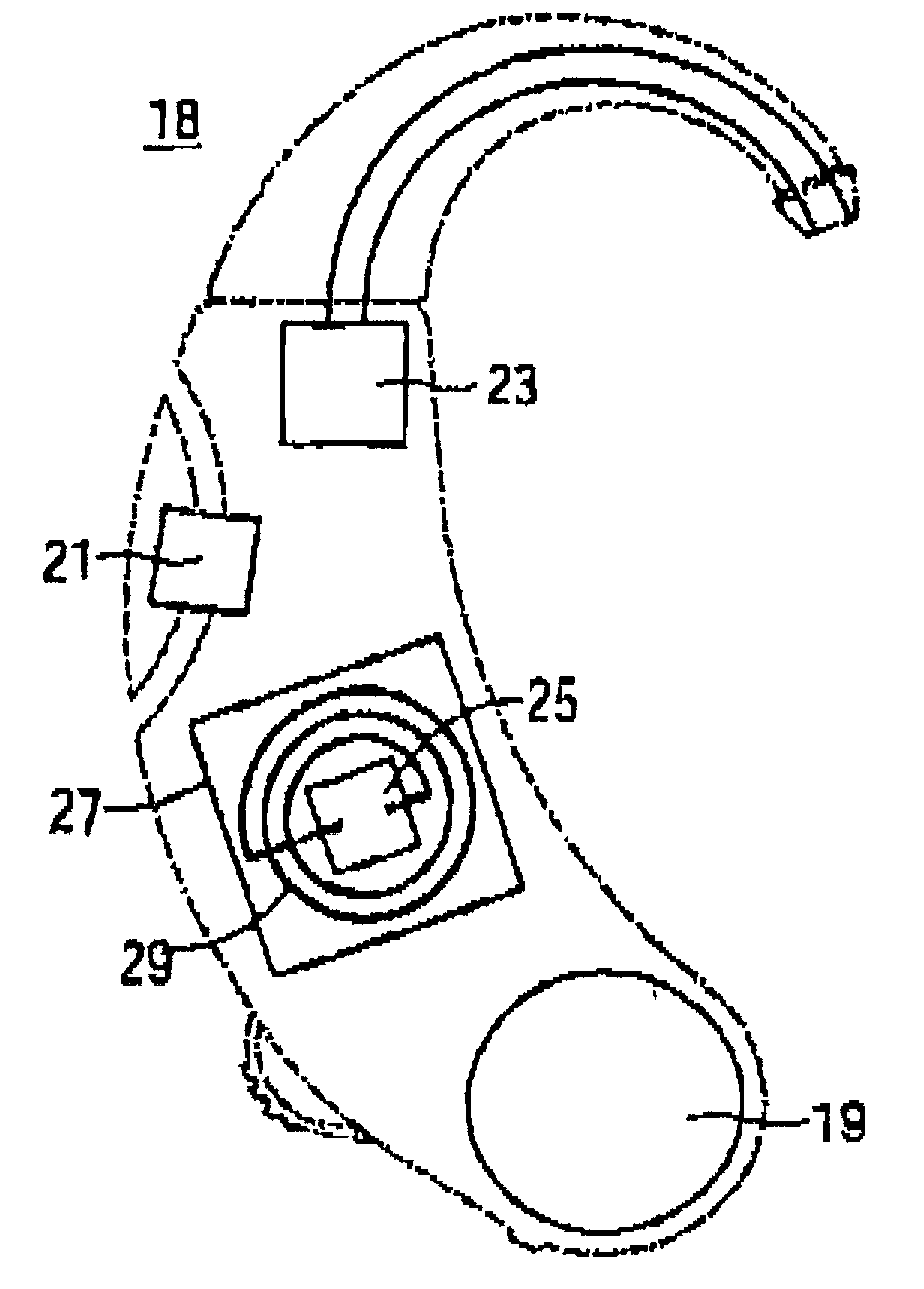

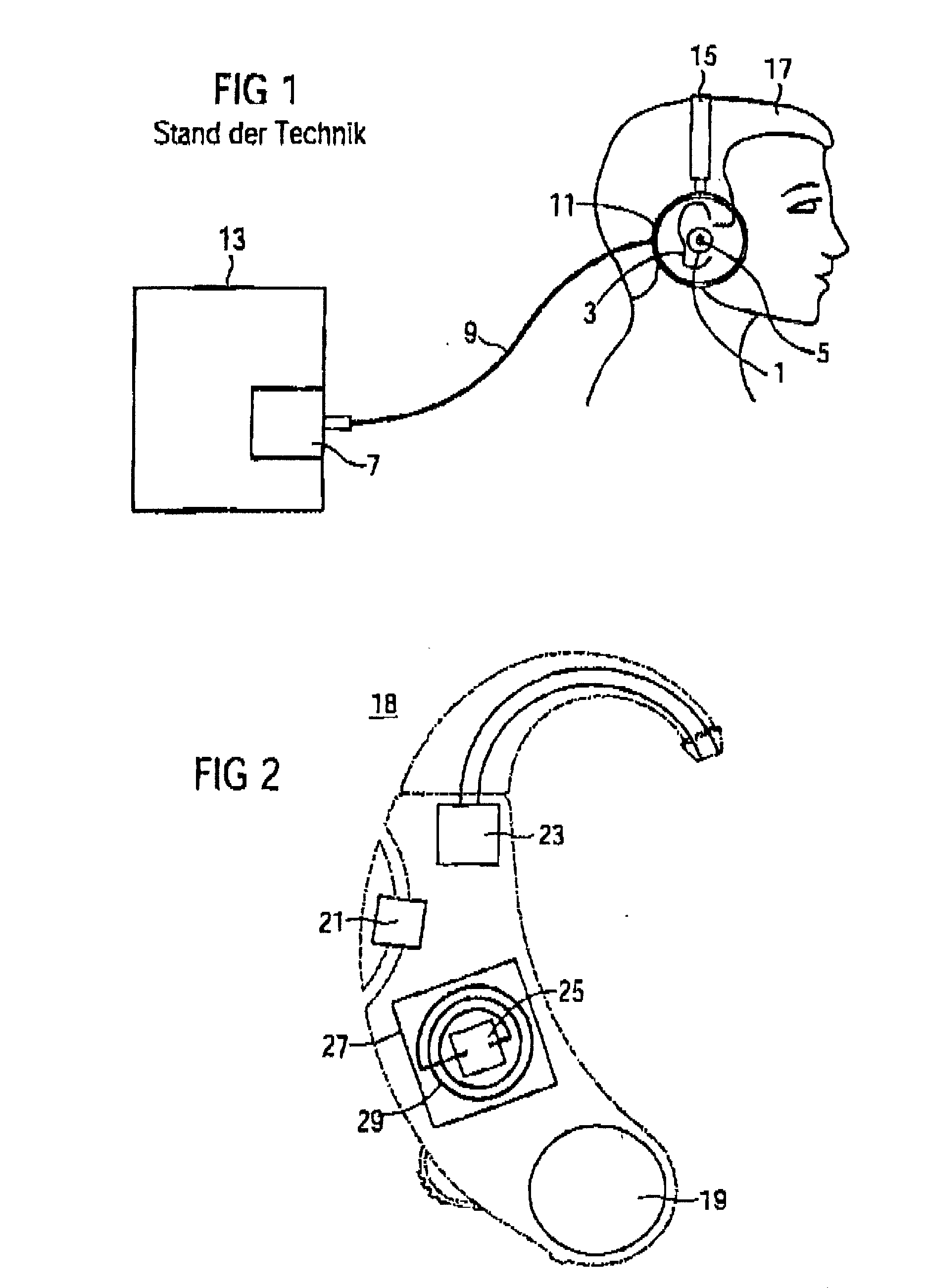

Wirelessly programmable hearing aid device

InactiveUS20080095387A1Easy to assembleMore compact constructionLoop antennasDeaf-aid setsEngineeringHearing aid

A hearing aid device that, for example, can be wirelessly programmed by an external transmission and / or receiving unit, includes a circuit chip in which is integrated with a coil in the form of a coil structure for the exchange of electromagnetic signals. The integration of the coil structure permits a greatly reduced space requirement for the coil structure which can be used as an antenna.

Owner:SIEMENS AUDIOLOGISCHE TECHN

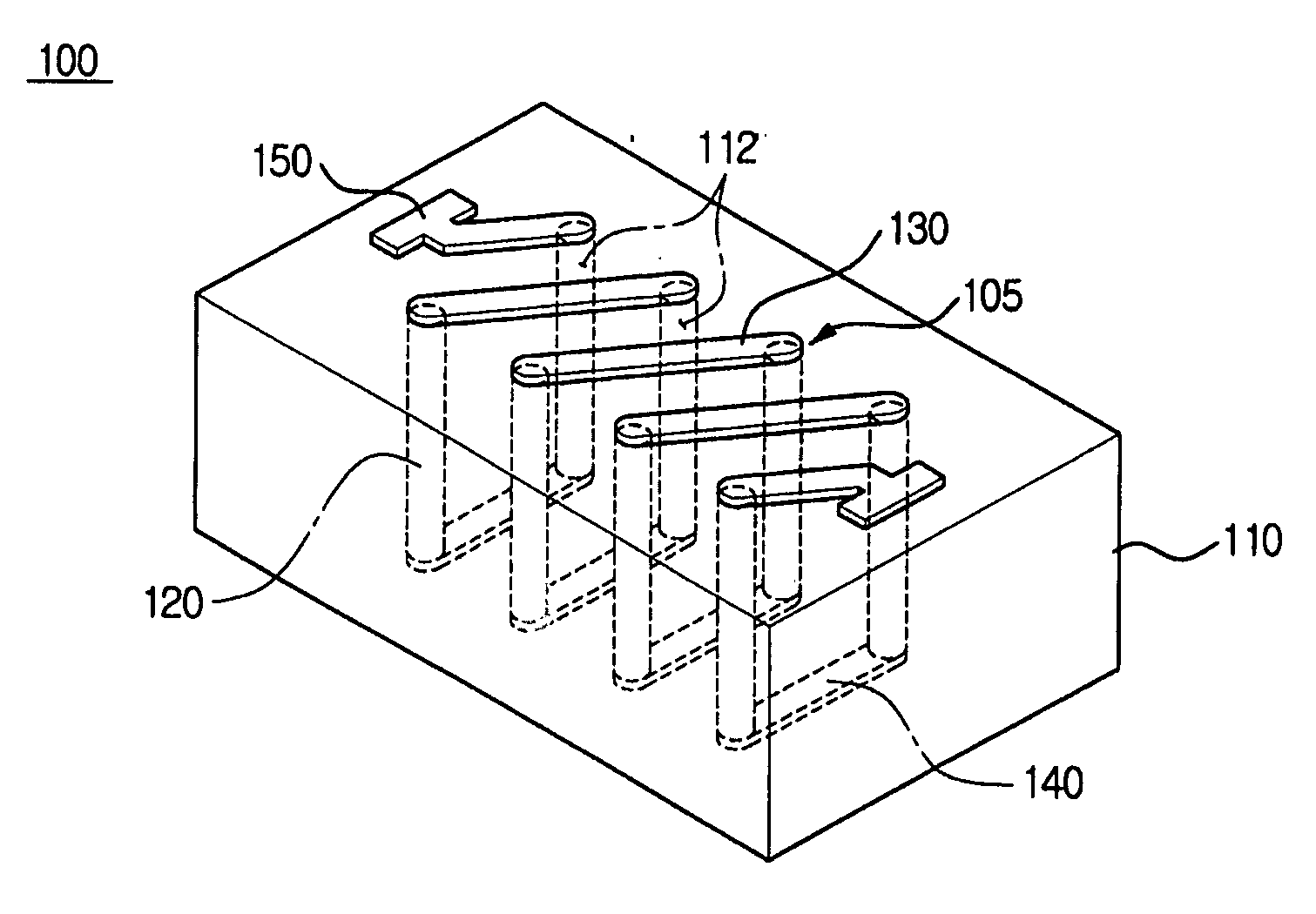

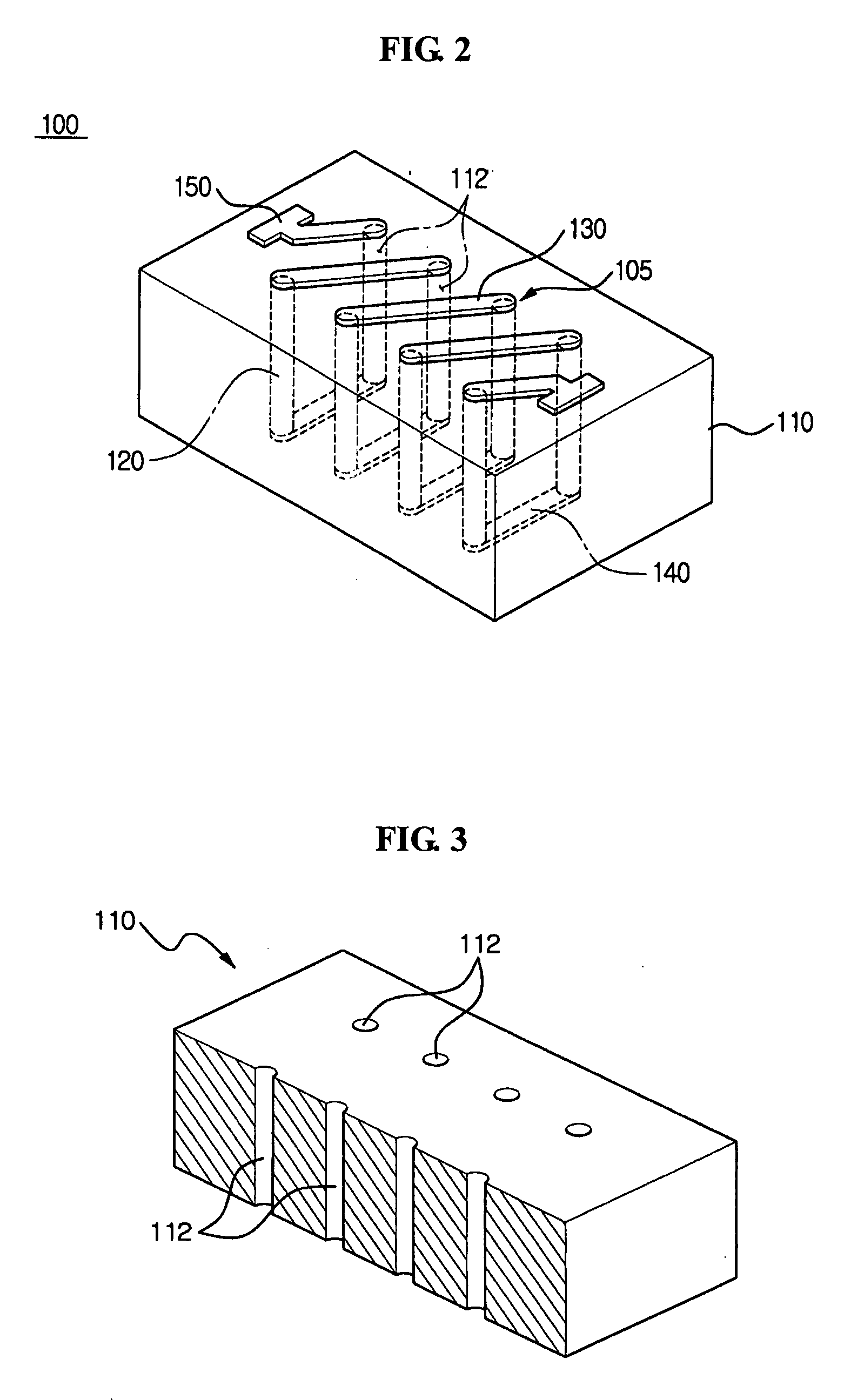

High efficiency inductor, method for manufacturing the inductor, and packaging structure using the inductor

ActiveUS20070085648A1Maintain good propertiesHigh quality factorTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringInductor

An inductor is provided which includes a plurality of via holes vertically passing through a substrate, the substrate having insulating properties, vertical conductive portions filling the via holes, and horizontal conductive portions connecting each individual vertical conductive portions at the top and the bottom of the substrate to form a single coil structure with the vertical conductive portions.

Owner:SAMSUNG ELECTRONICS CO LTD

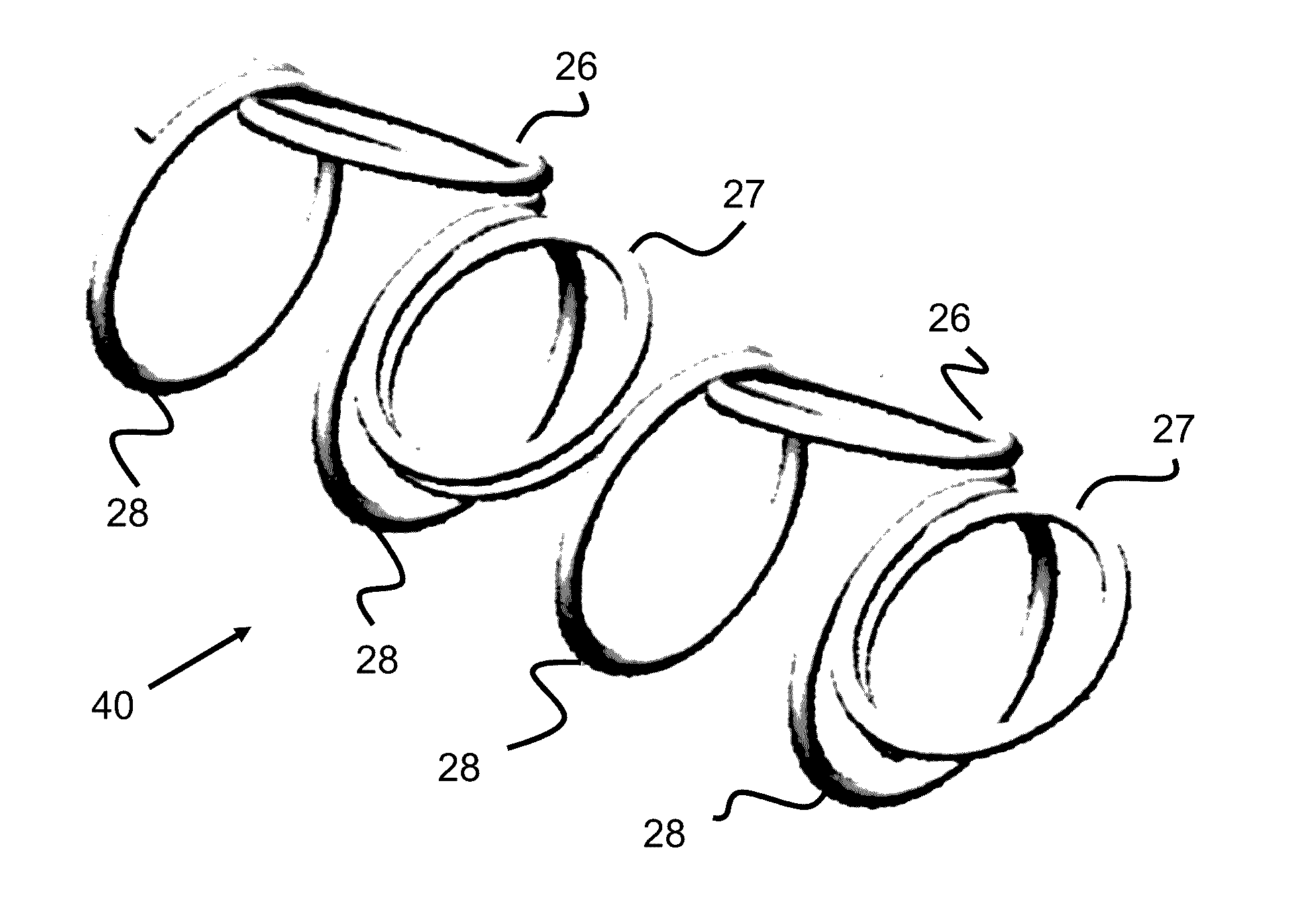

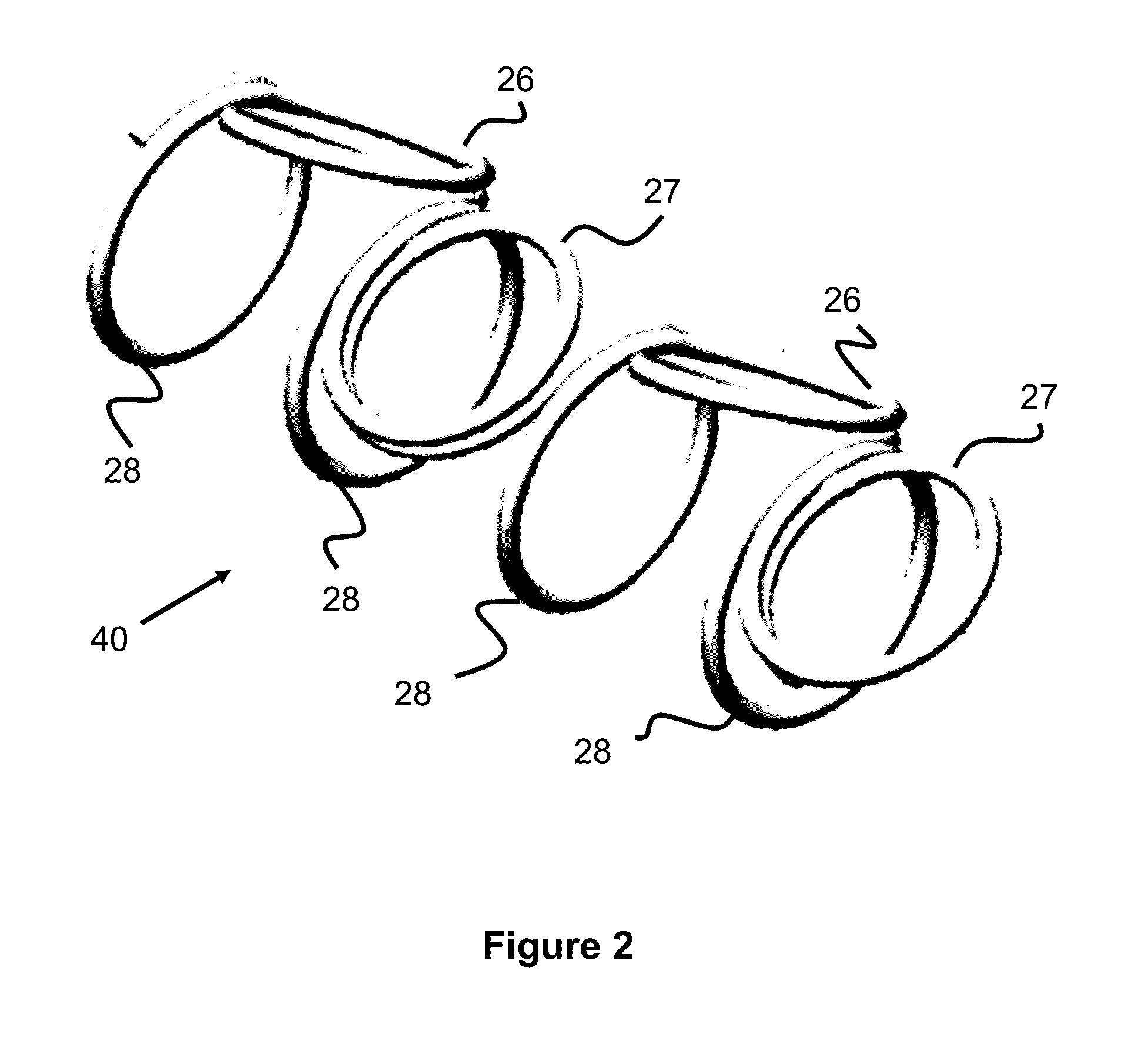

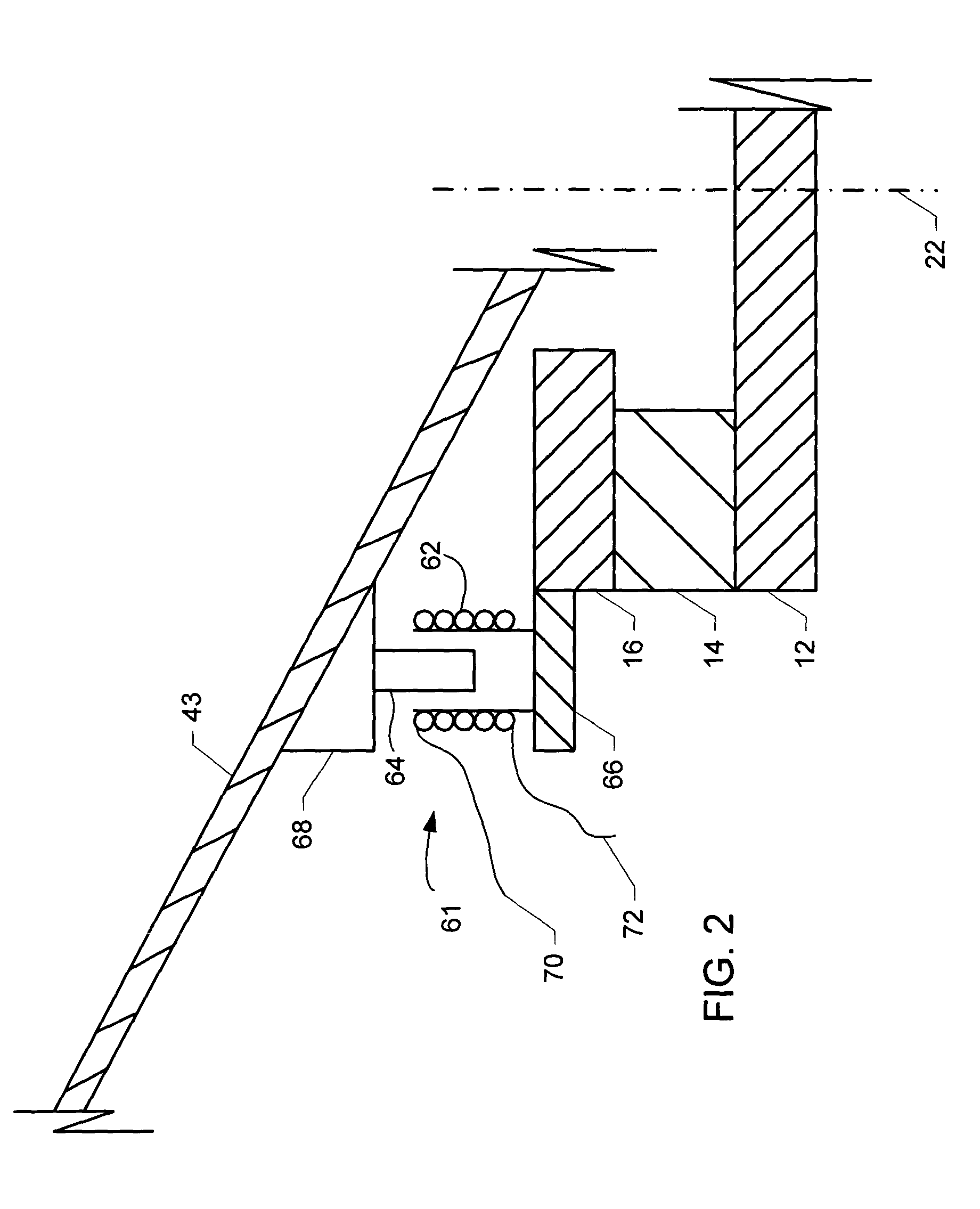

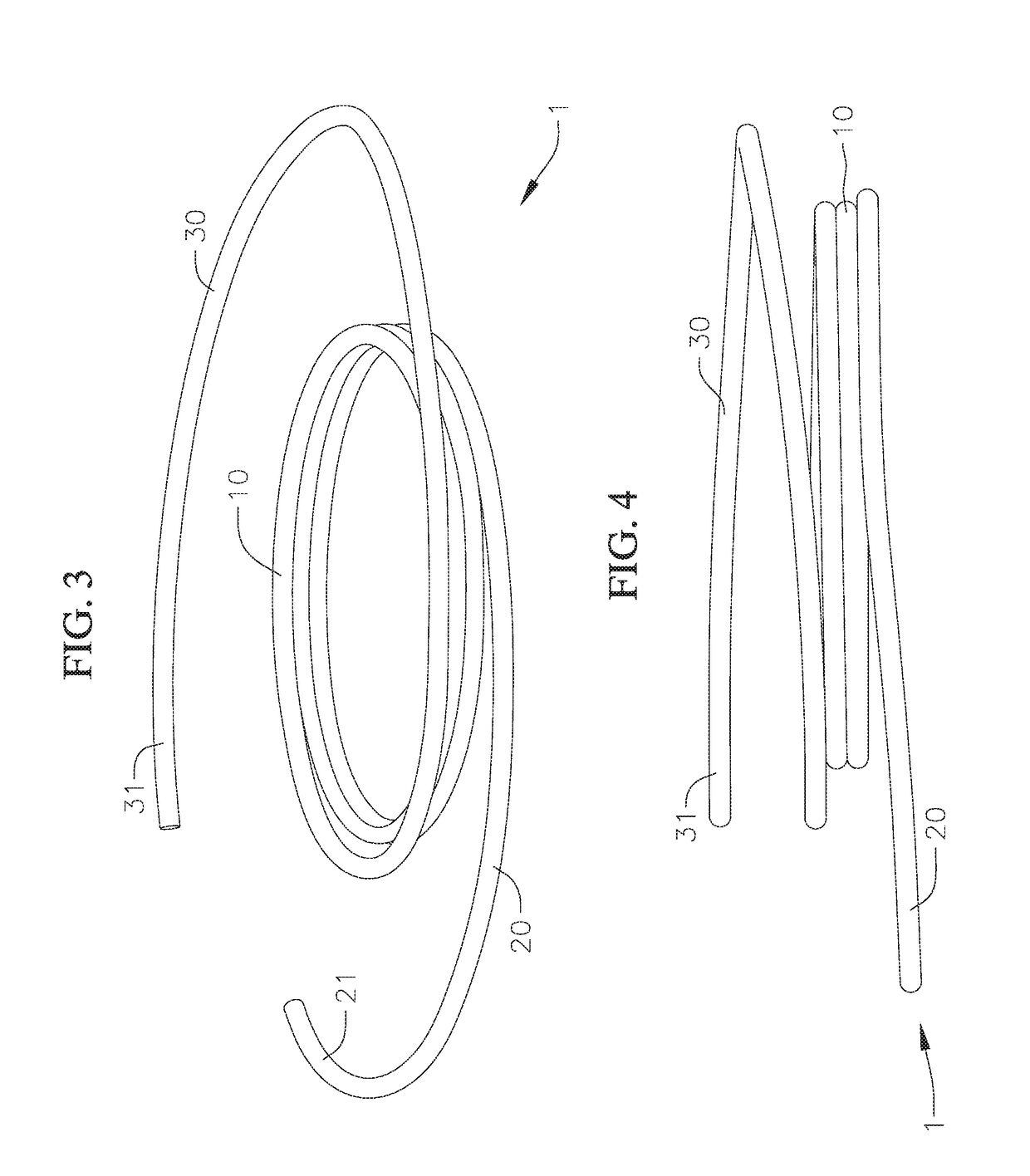

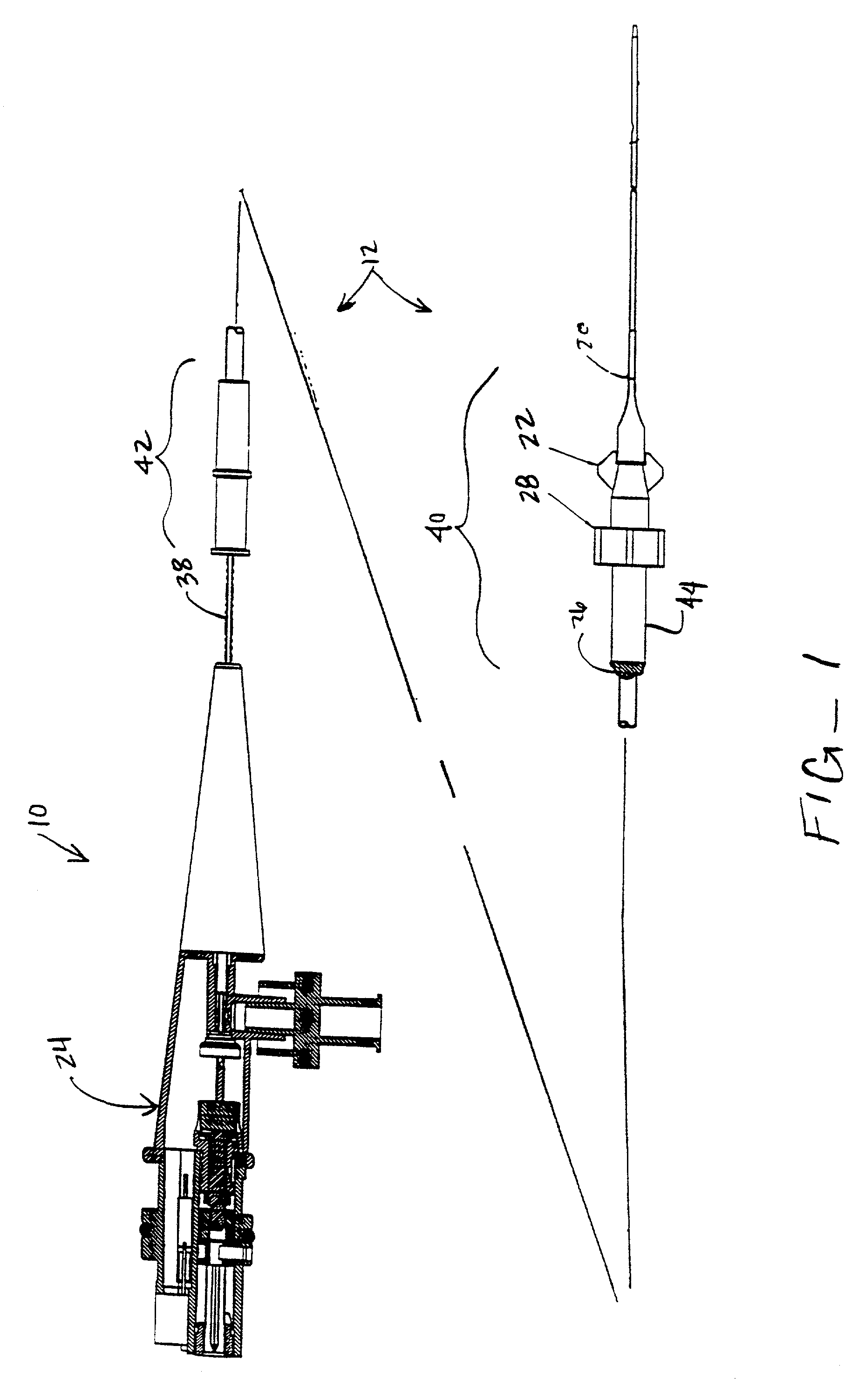

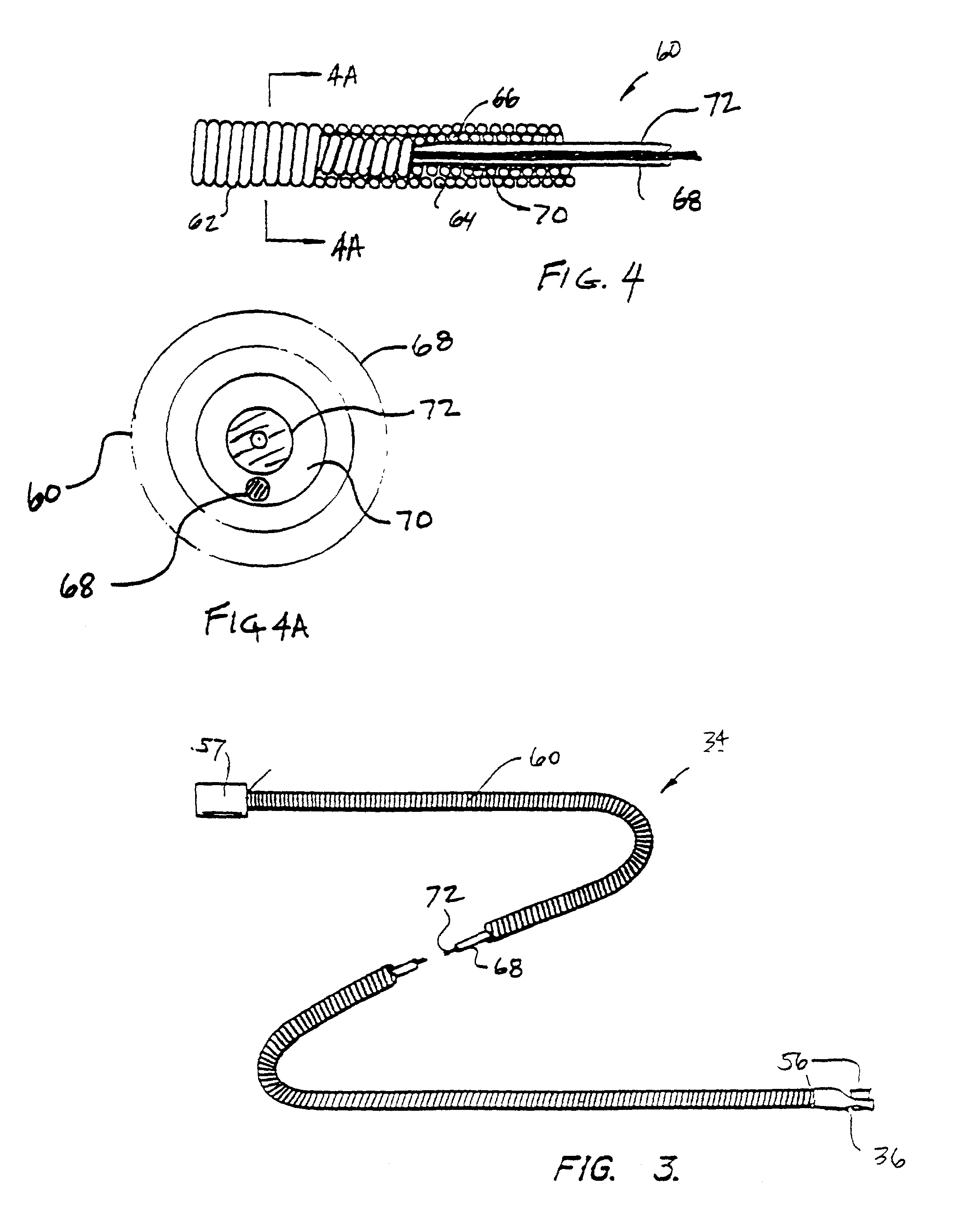

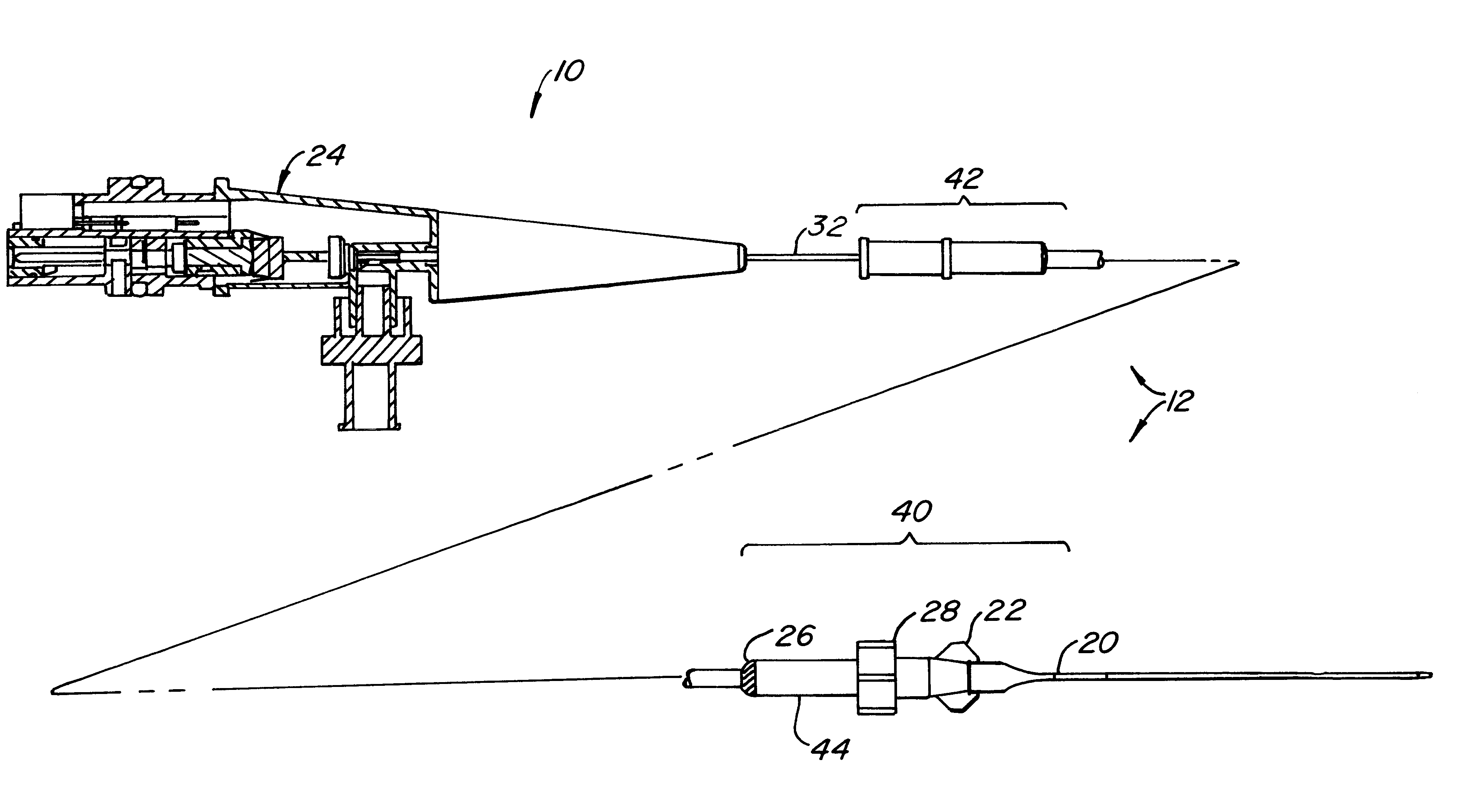

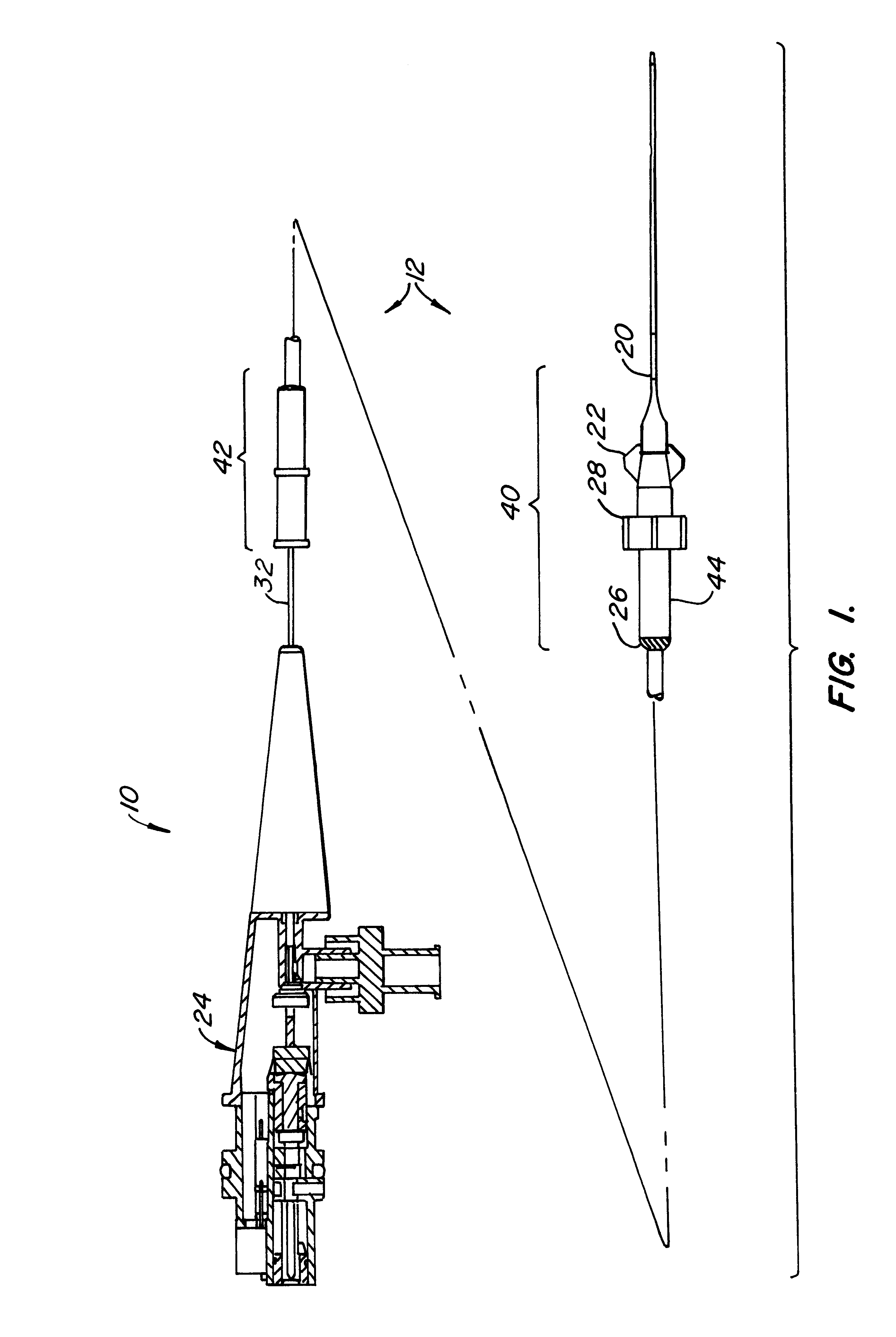

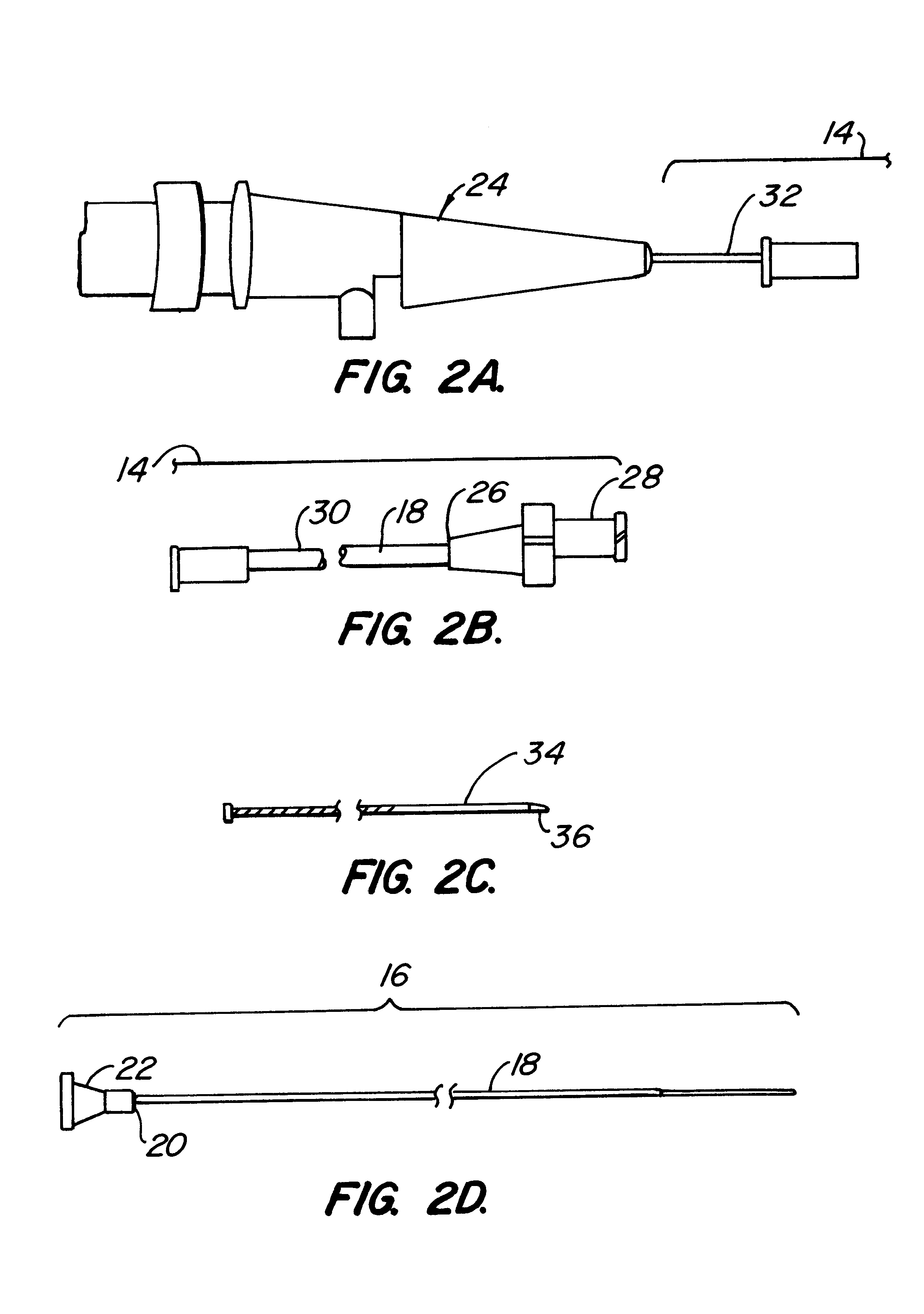

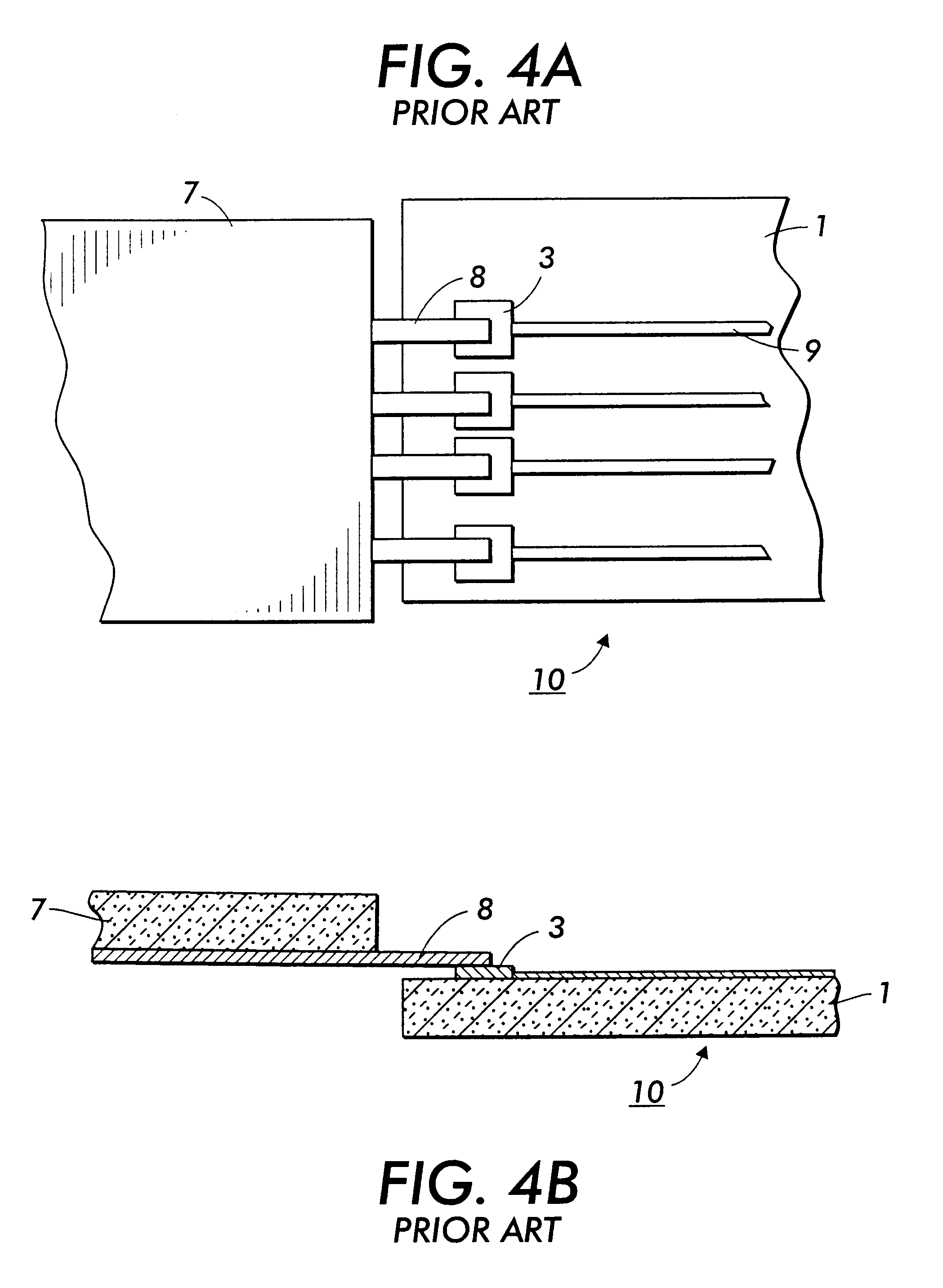

System and method for intraluminal imaging

InactiveUS20010037073A1Reduce gapLess precisionUltrasonic/sonic/infrasonic diagnosticsSurgeryElectricityUltrasonic imaging

An improved catheter system having an ultrasonic imaging transducer coupled to a drive cable disposed within a lumen of a flexible tubular catheter body. An improvement including a reconfiguration of the ferrites in the hub assembly, such that the need for the gap between the ferrites is removed. A strain relief member is provide to increase the strength of the electrical transmission lines to enable them to withstand the tensile forces caused by either flushing and / or pull-back operations. A device which allows the electrical transmission lines to extend their length when placed in tension may also be employed to provide strain relief to the electrical transmission lines. Another improvement includes a counter-wound coil structure, which may either expand or contract as the drive cable is being rotated to strengthen the drive cable. The distal tip of the catheter body may be redesigned to provide a lumen which allows for the release of flushing fluids through a distal port in the guidewire lumen.

Owner:SCI MED LIFE SYST

System and method for intraluminal imaging

InactiveUS6419644B1Reduce gapLess precisionUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic imagingCatheter

An improved catheter system having an ultrasonic imaging transducer coupled to a drive cable disposed within a lumen of a flexible tubular catheter body. An improvement including a reconfiguration of the ferrites in the hub assembly, such that the need for the gap between the ferrites is removed. A strain relief member is provide to increase the strength of the electrical transmission lines to enable them to withstand the tensile forces caused by either flushing and / or pull-back operations. A device which allows the electrical transmission lines to extend their length when placed in tension may also be employed to provide strain relief to the electrical transmission lines. Another improvement includes a counter-wound coil structure, which may either expand or contract as the drive cable is being rotated to strengthen the drive cable. The distal tip of the catheter body may be redesigned to provide a lumen which allows for the release of flushing fluids through a distal port in the guidewire lumen.

Owner:BOSTON SCI SCIMED INC

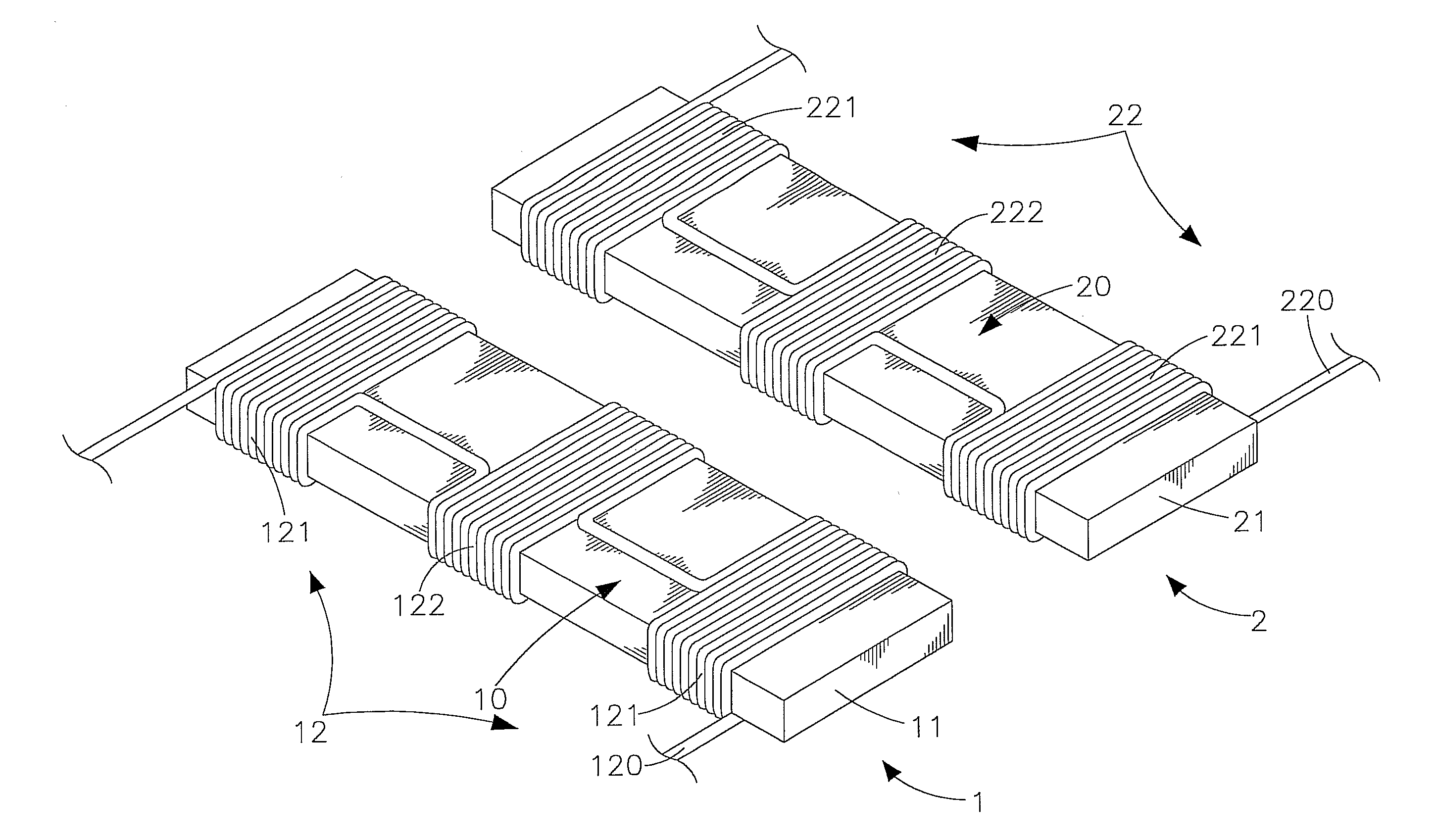

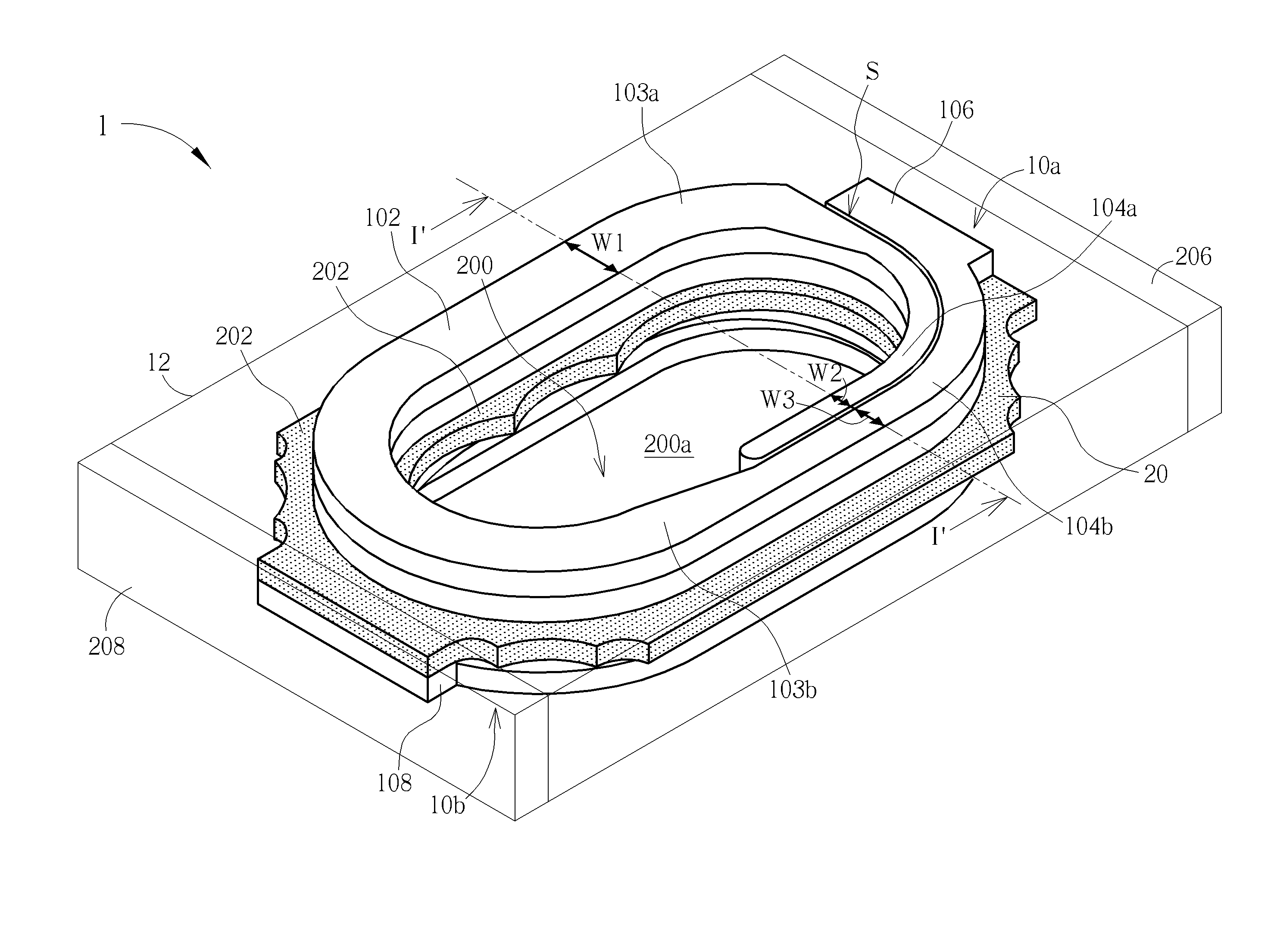

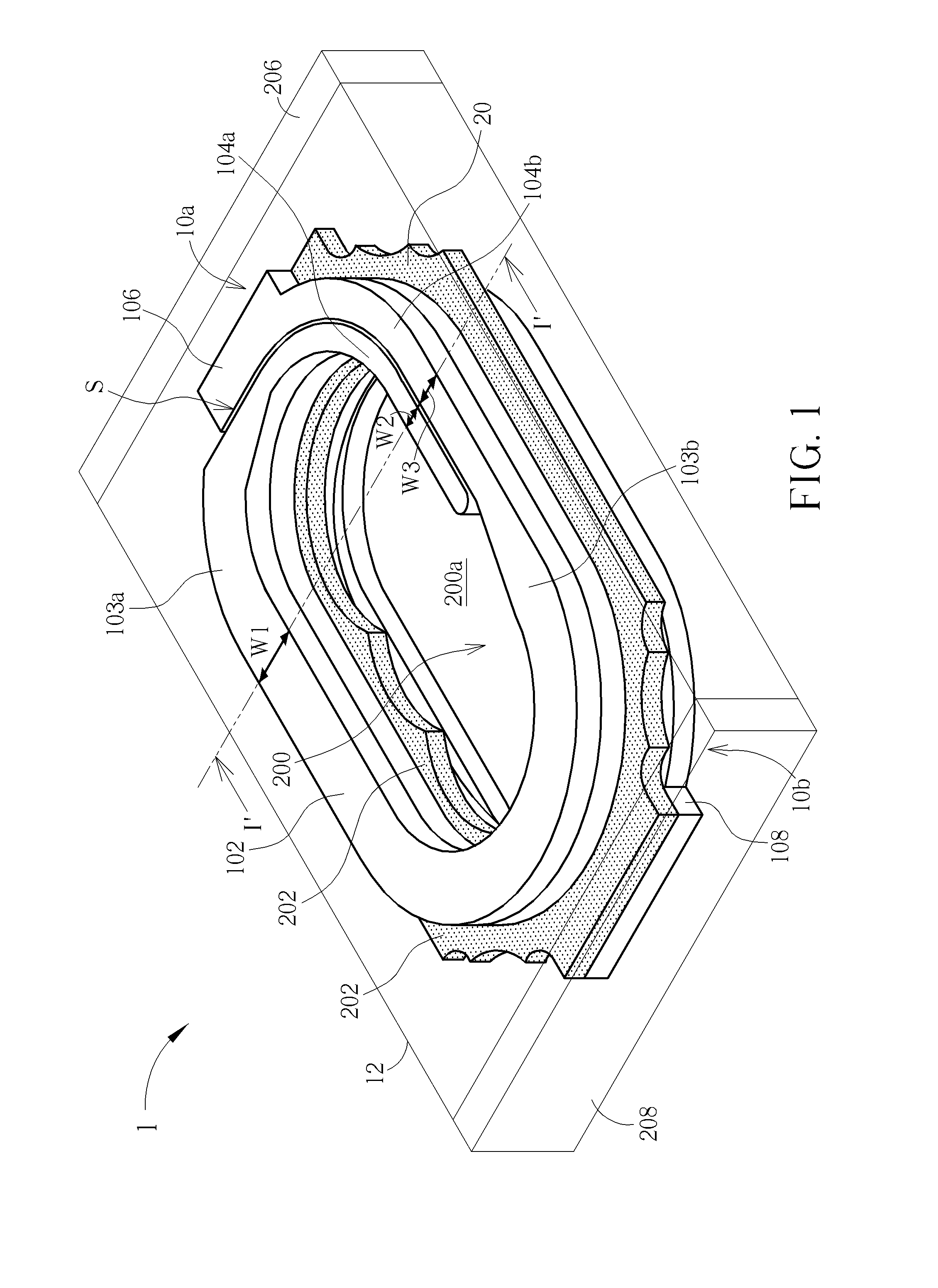

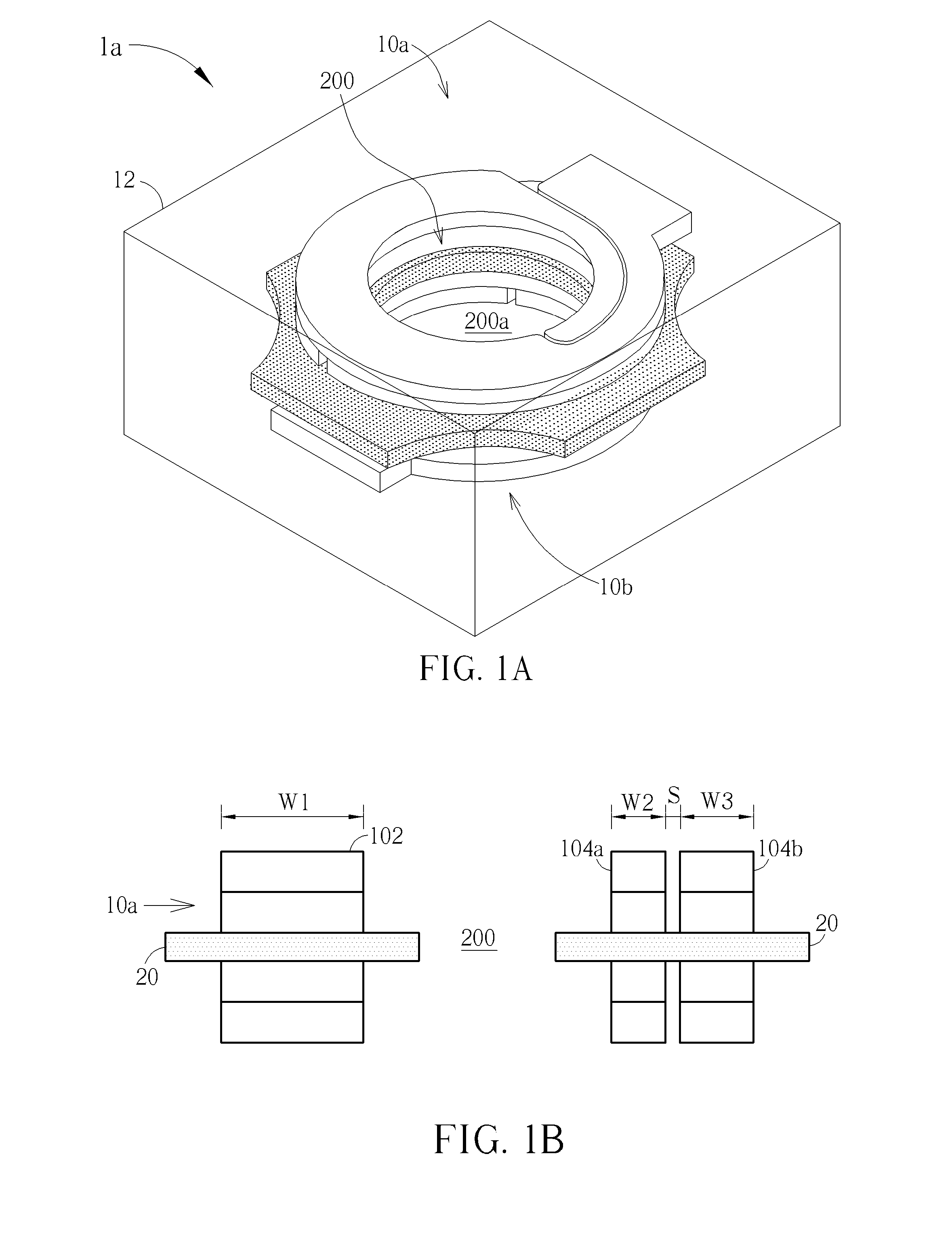

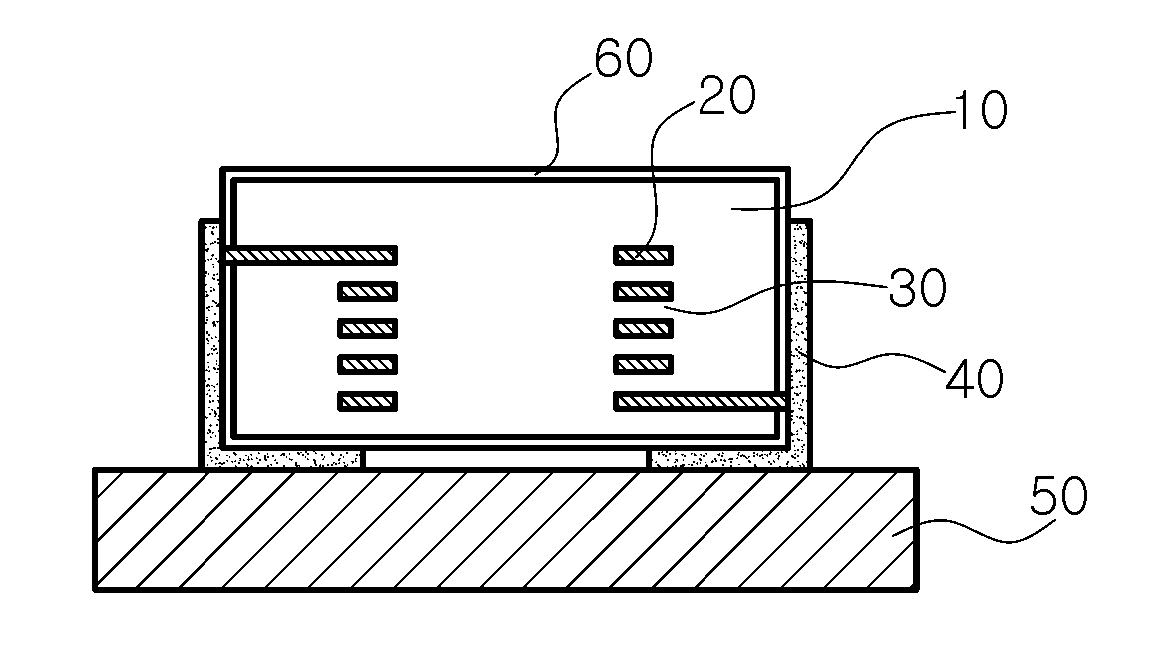

Coil structure and electromagnetic component using the same

InactiveUS20130300529A1Small sizeHigh yieldTransformersTransformers/inductances detailsEngineeringConductor Coil

An electromagnetic component including a multi-layer, spiral coil structure embedded in a molded body is disclosed. Each layer of the coil structure makes approximately one and a quarter turns of a winding. Each layer of the coil structure has a loose middle segment, two slim end segments overlapping each other with a spacing therebetween, and tapered neck segments respectively connecting the loose middle segment with the two slim end segments.

Owner:CYNTEC

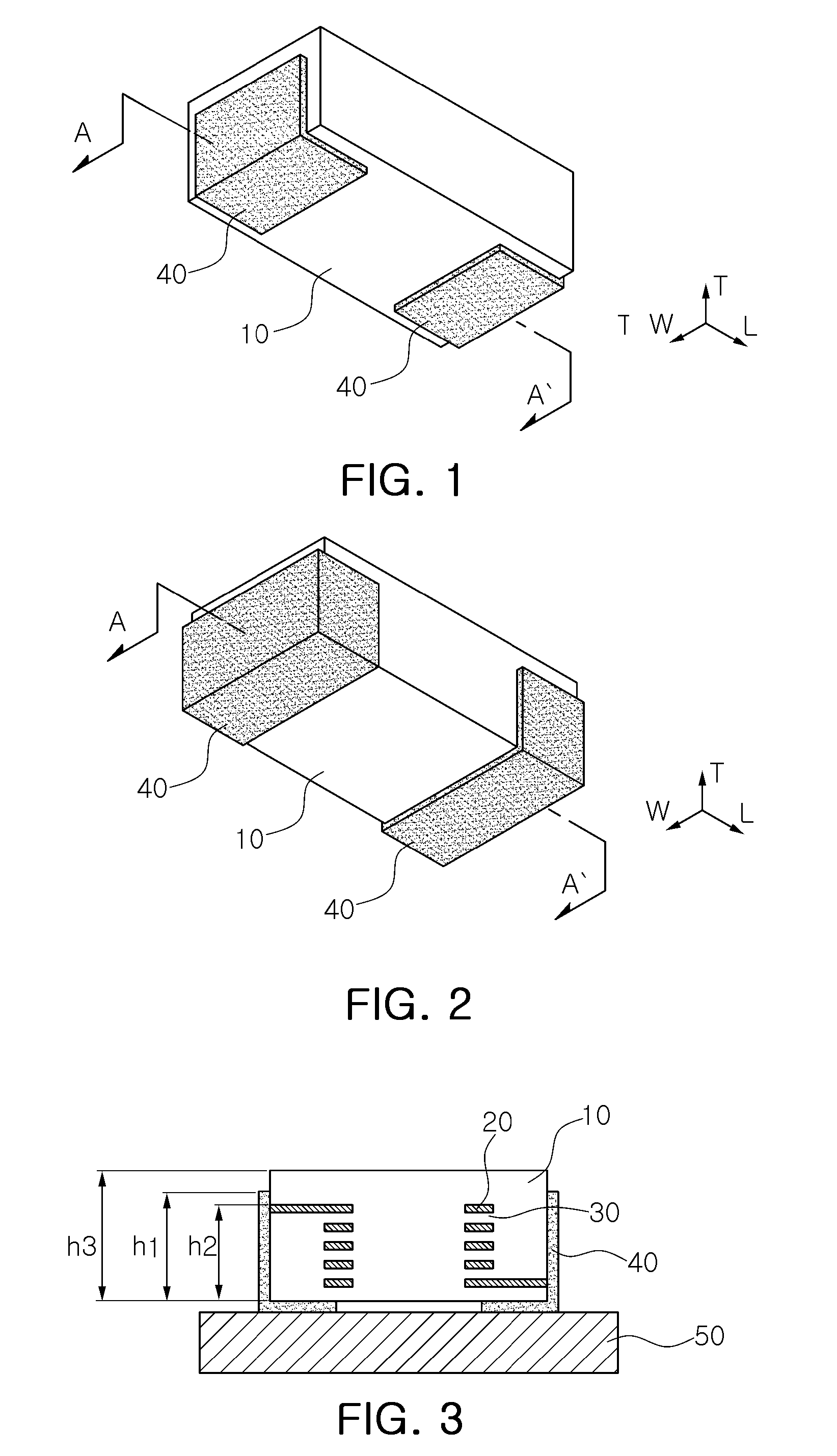

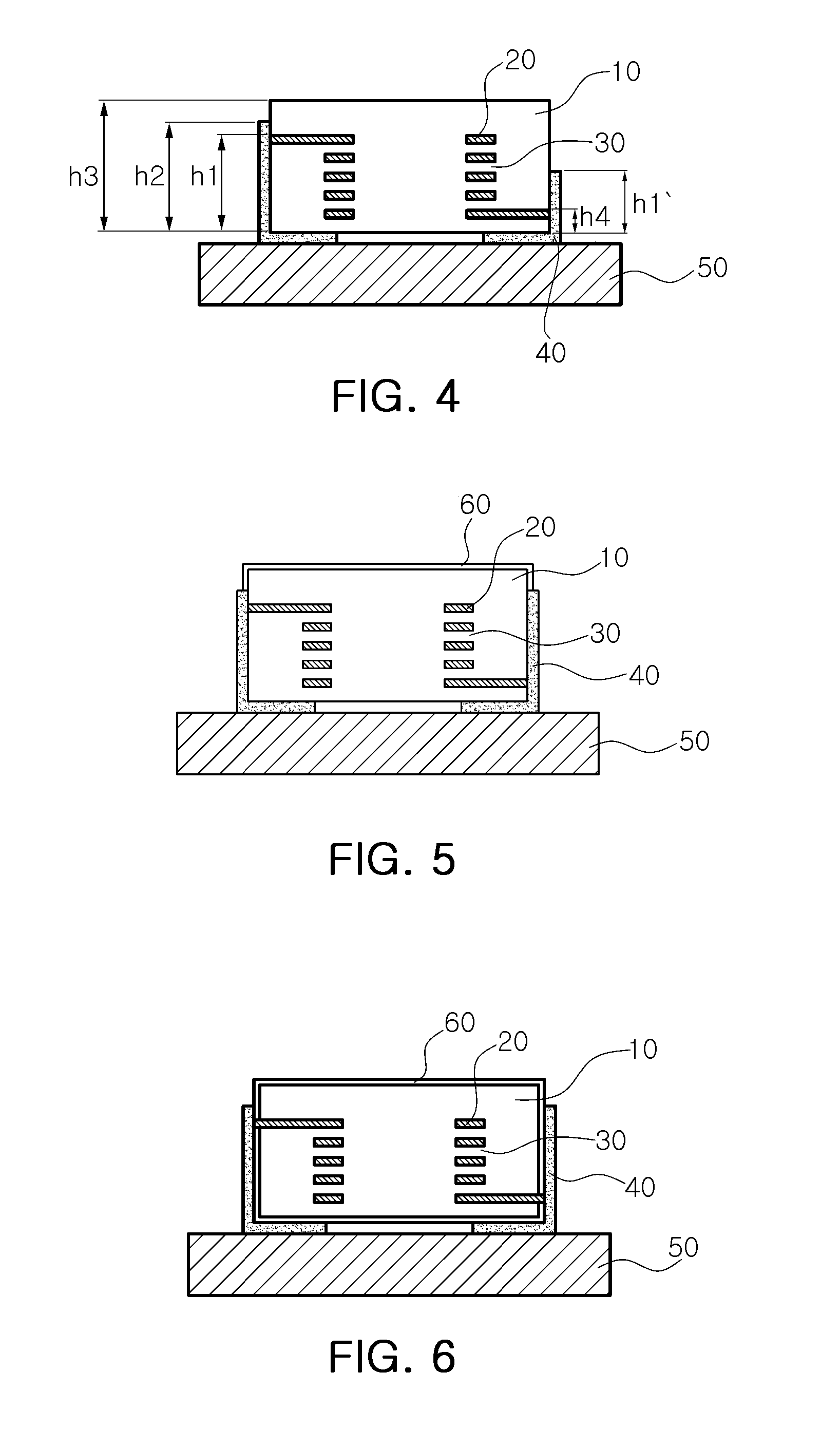

Chip-type coil component

ActiveUS20120274432A1Improve reliabilityTransformers/inductances coils/windings/connectionsCoilsCoil structureMetal

The chip-type coil component includes: a body; conductive patterns connected to each other so as to have a coil structure; and external electrodes formed on the bottom surface and the two surfaces in the length direction; wherein a height of the external electrodes in a thickness direction of the body is greater than a height from the bottom surface to a farthest conductive pattern therefrom among the conductive patterns and is less than a height from the bottom surface of the body to the top surface thereof. According to embodiments of the present invention, even in a case in which a chip-type coil component set contacts a metal can, interference such as short-circuits does not occur, and as a result, a chip-type coil component having excellent reliability can be acquired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

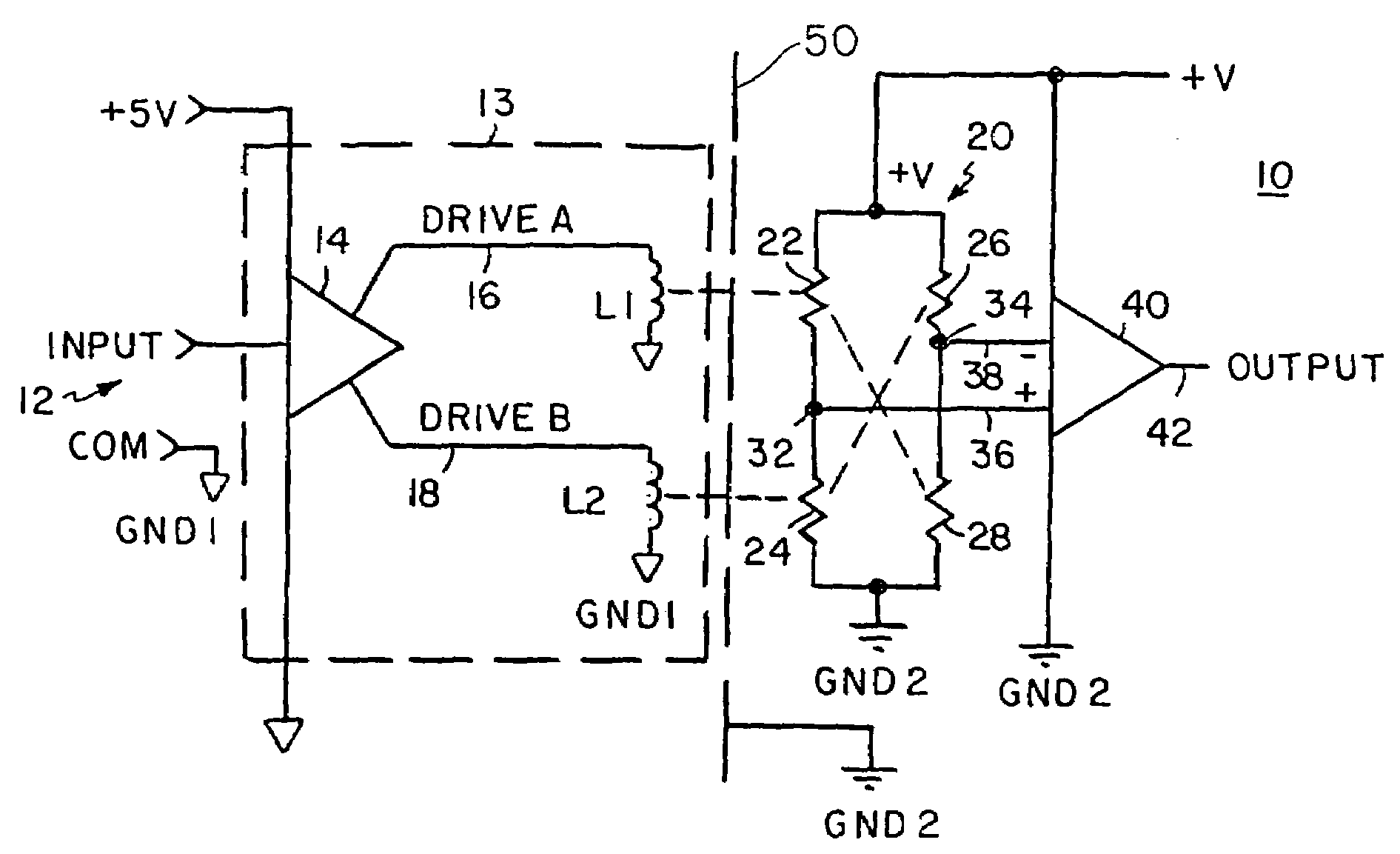

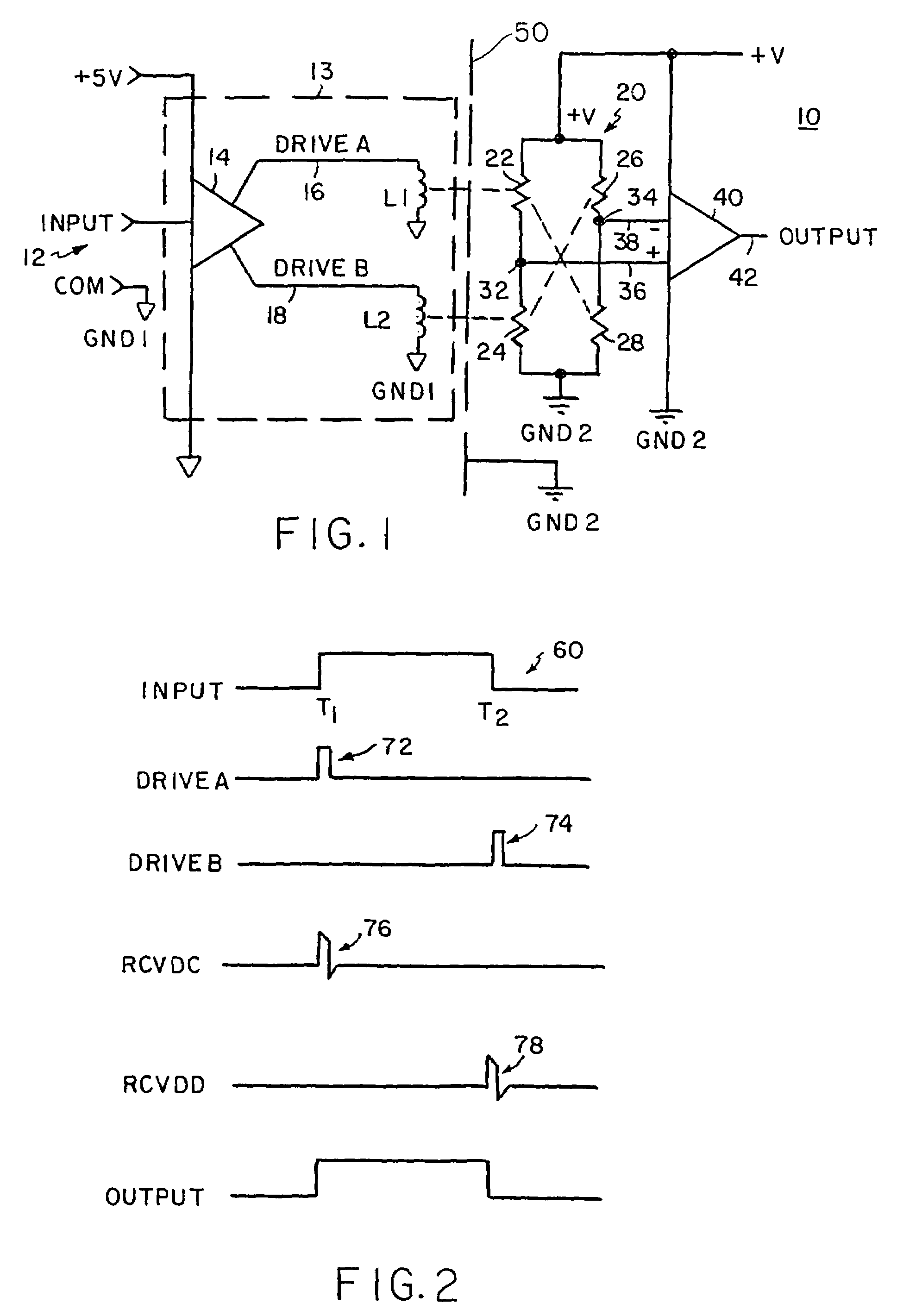

Chip-scale coils and isolators based thereon

InactiveUS7545059B2Improve performanceReduce capacitanceMultiple-port networksNear-field transmissionTransformerEngineering

Coil structures and isolators using them. A coil(s) is (are) used as a magnetic field-generating element(s) paired with another coil(s) or other magnetic field-receiving element(s). The coil(s) is(are) formed in or on a substrate which does not include some or all of the driver (i.e., input) or receiver (i.e., output) circuits. The coil(s) and magnetic field-receiving element(s) thus can be manufactured separately from the driver and / or receiver circuitry, using different processes, instead of subjecting the chip areas containing both input and output circuits to post processing to form the coil(s). Isolators can be assembled using such coils with a resultant lower cost. Isolators also can be assembled using transformers made from such coils wherein the transformers can be driven on either of their windings in order to provide bi-directional isolation with a single transformer.

Owner:ANALOG DEVICES INC

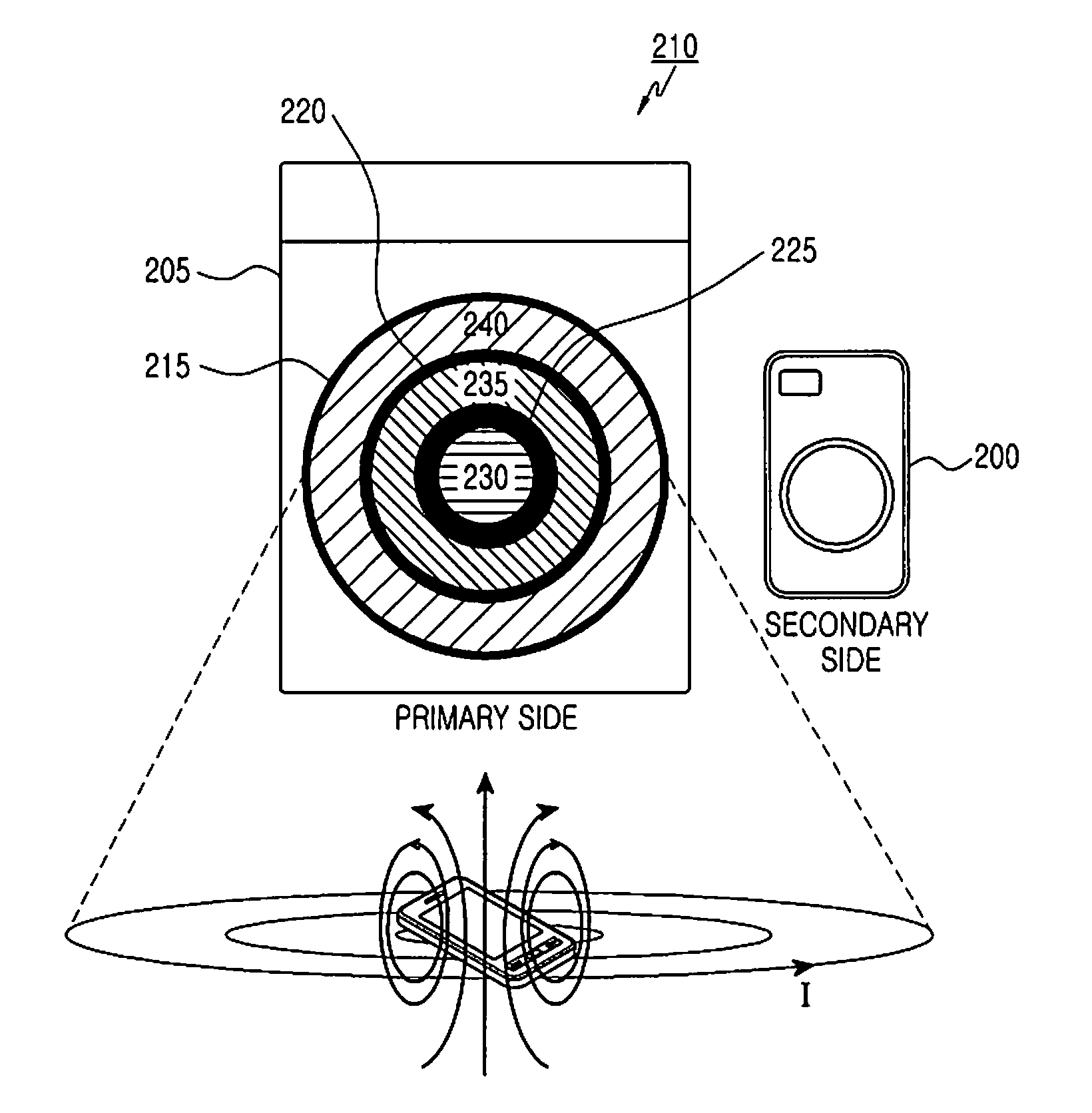

Wireless charger for charging control and charging control method therefor

ActiveUS20110115433A1Excellent electromotive forceBatteries circuit arrangementsTransformersCharge controlEngineering

A coil structure and a charging control method in a wireless charger having a primary coil are provided to supply an induced electromotive force suitable for a charging target having a secondary coil. Concentric coils having different radii are arranged in a wireless charger, and a coil suitable for the location of a charging target placed on the wireless charger is selected. An input power corresponding to the selected coil is determined, and the determined power is applied to the selected coil. Then the same charging efficiency can be provided irrespective of a location of a charging target placed on the wireless charger.

Owner:SAMSUNG ELECTRONICS CO LTD

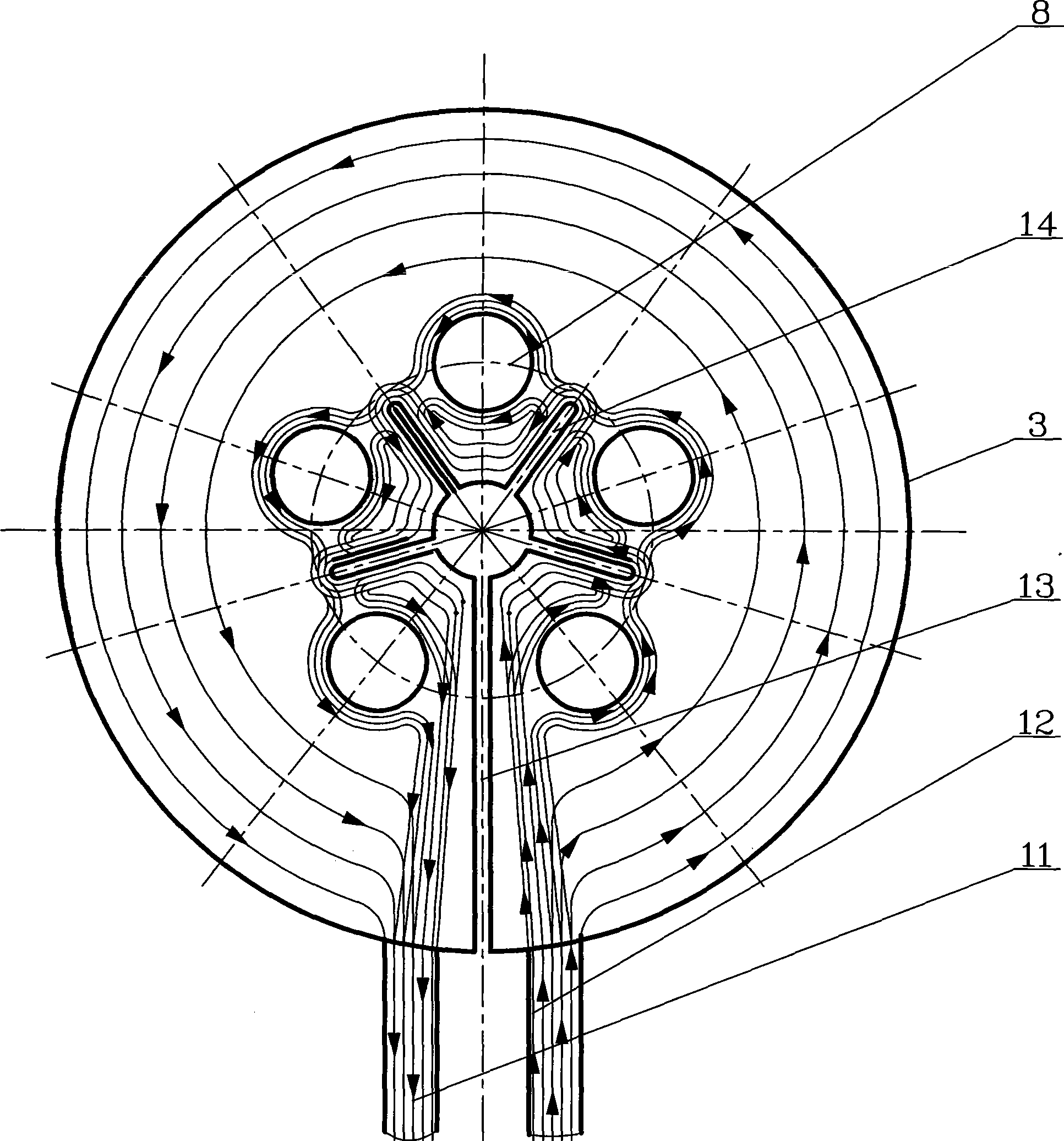

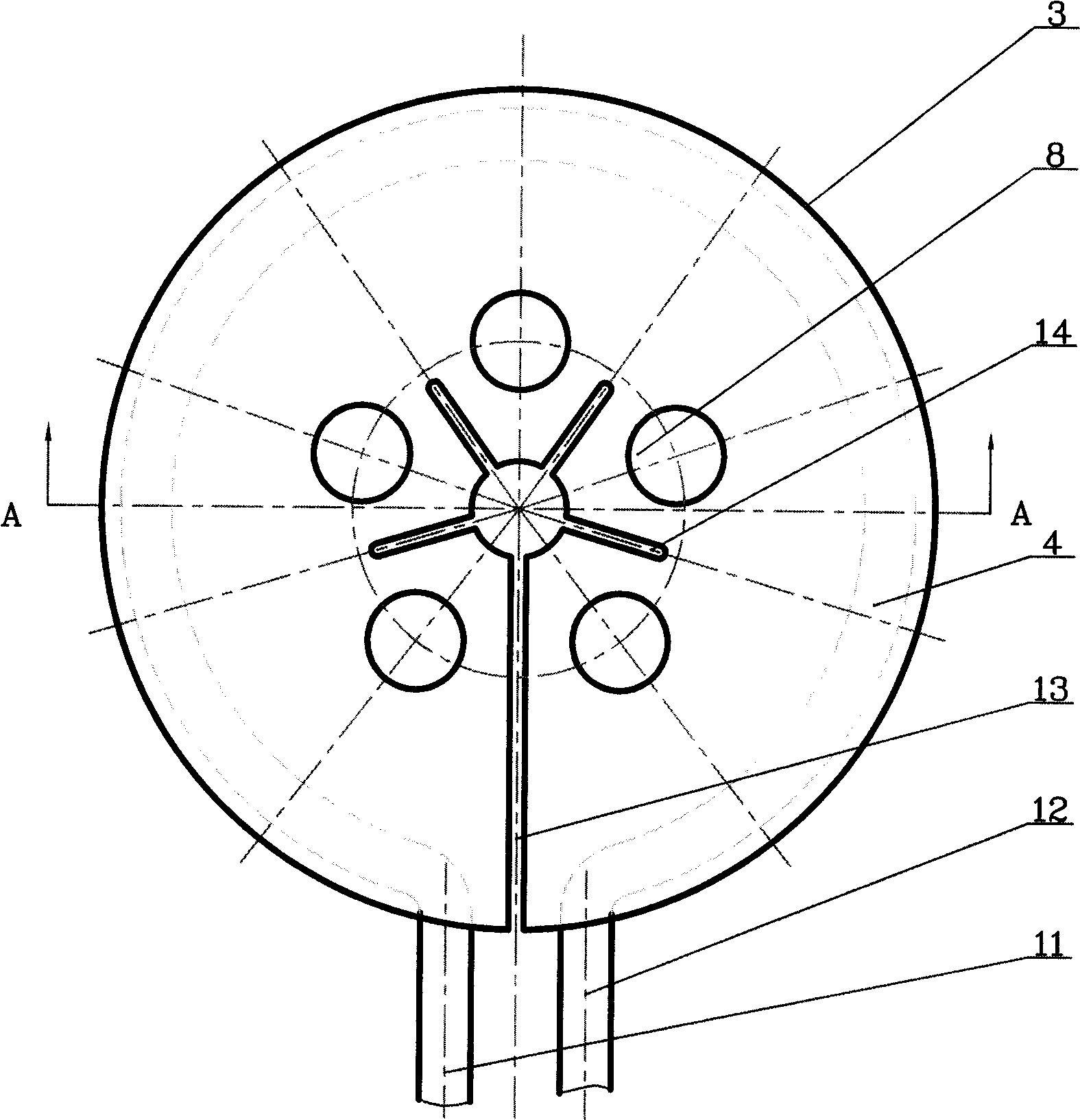

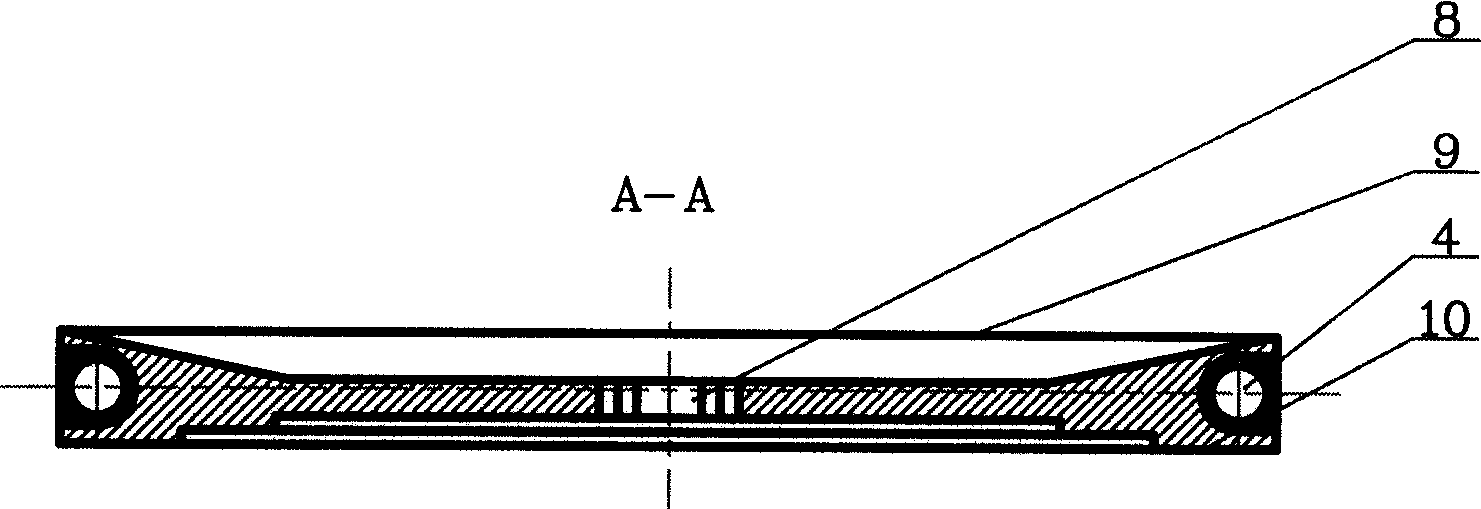

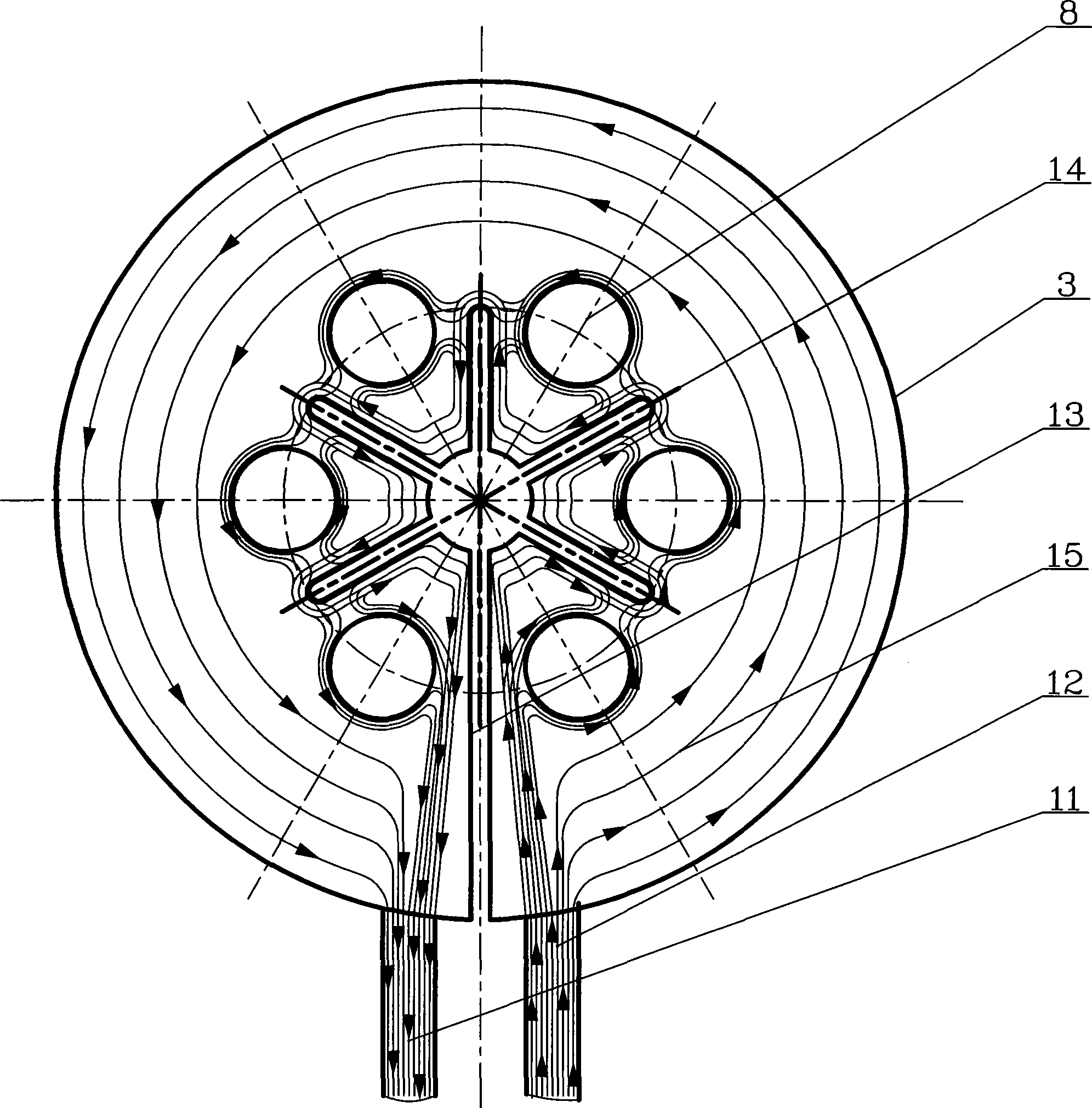

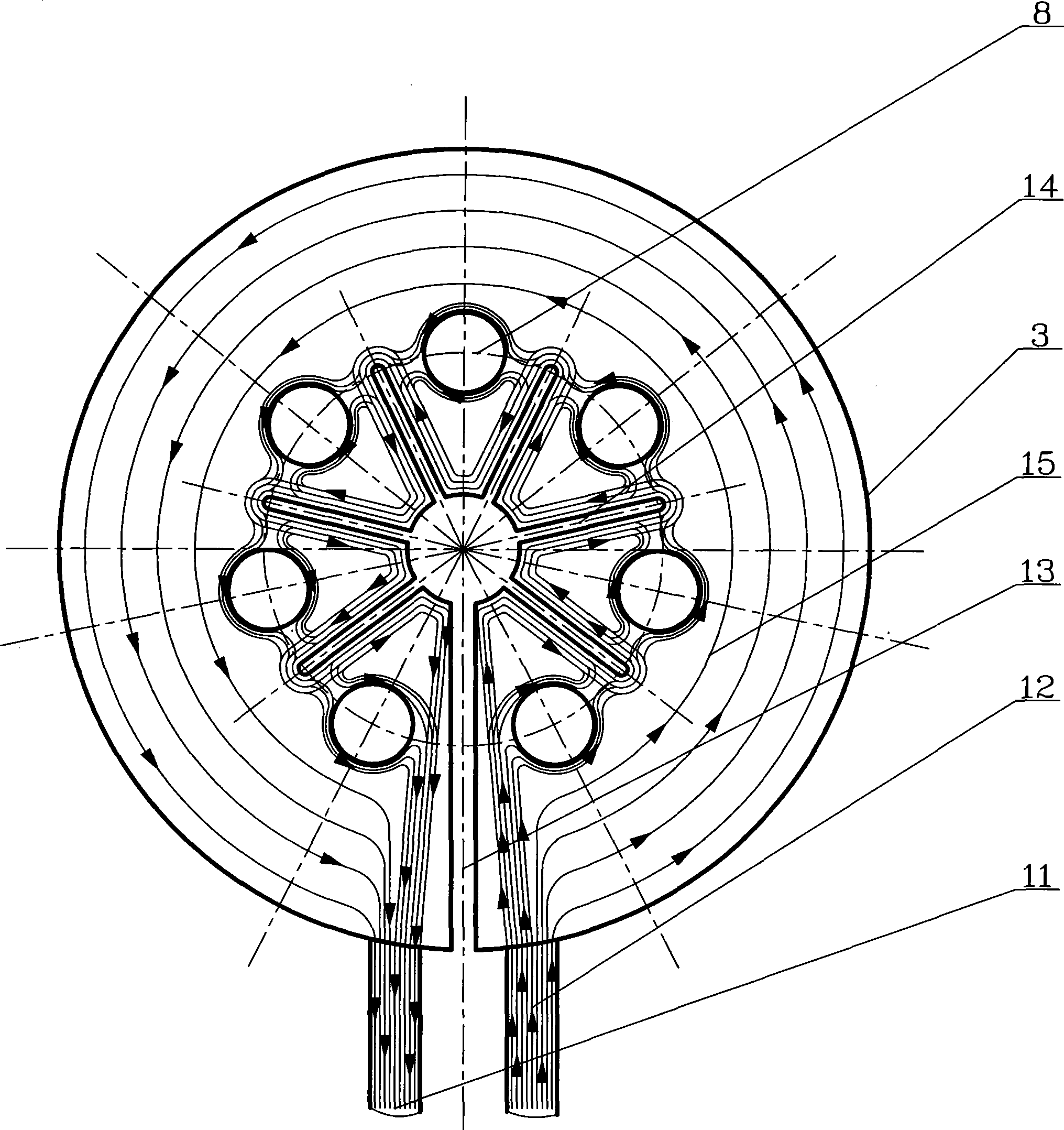

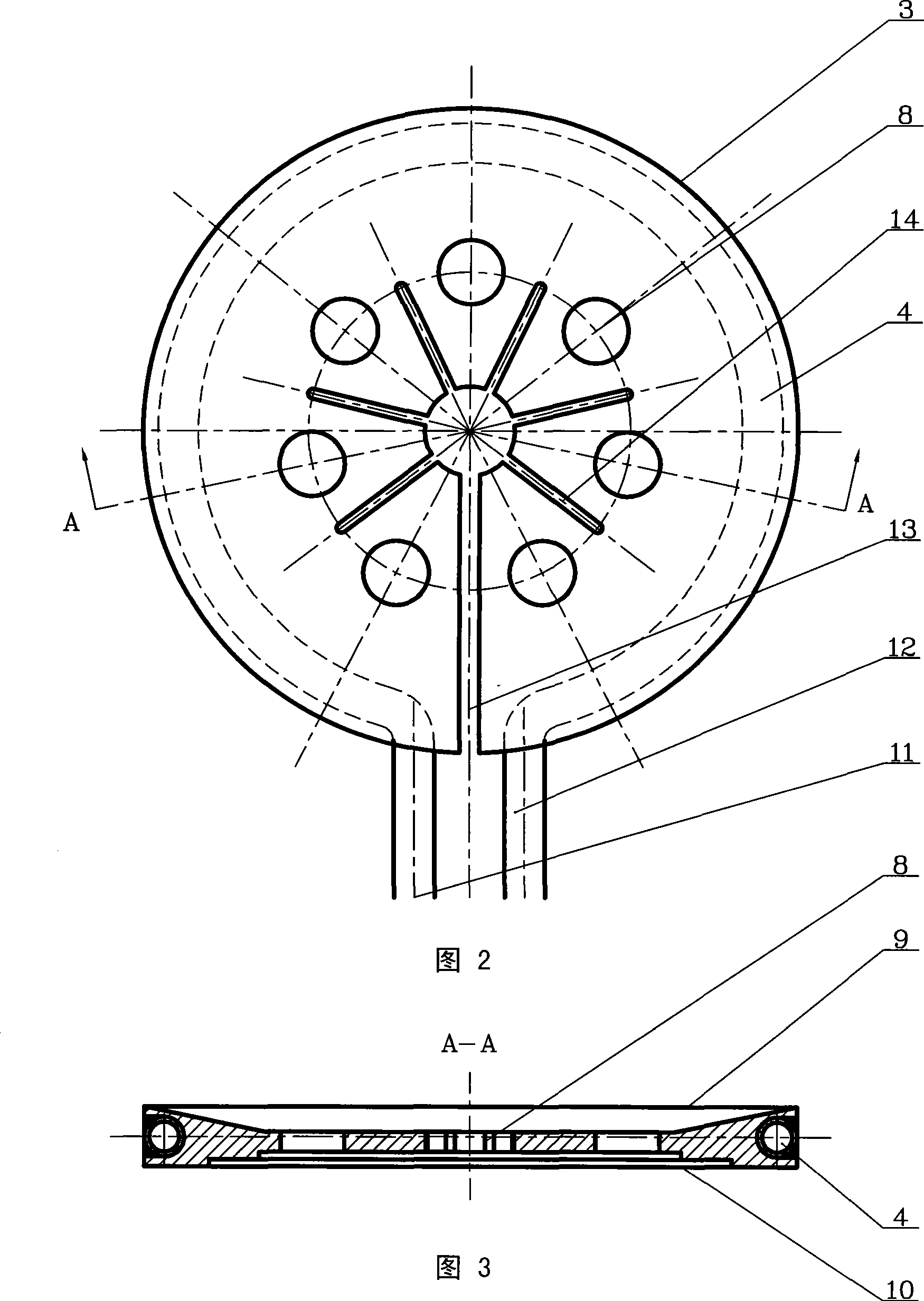

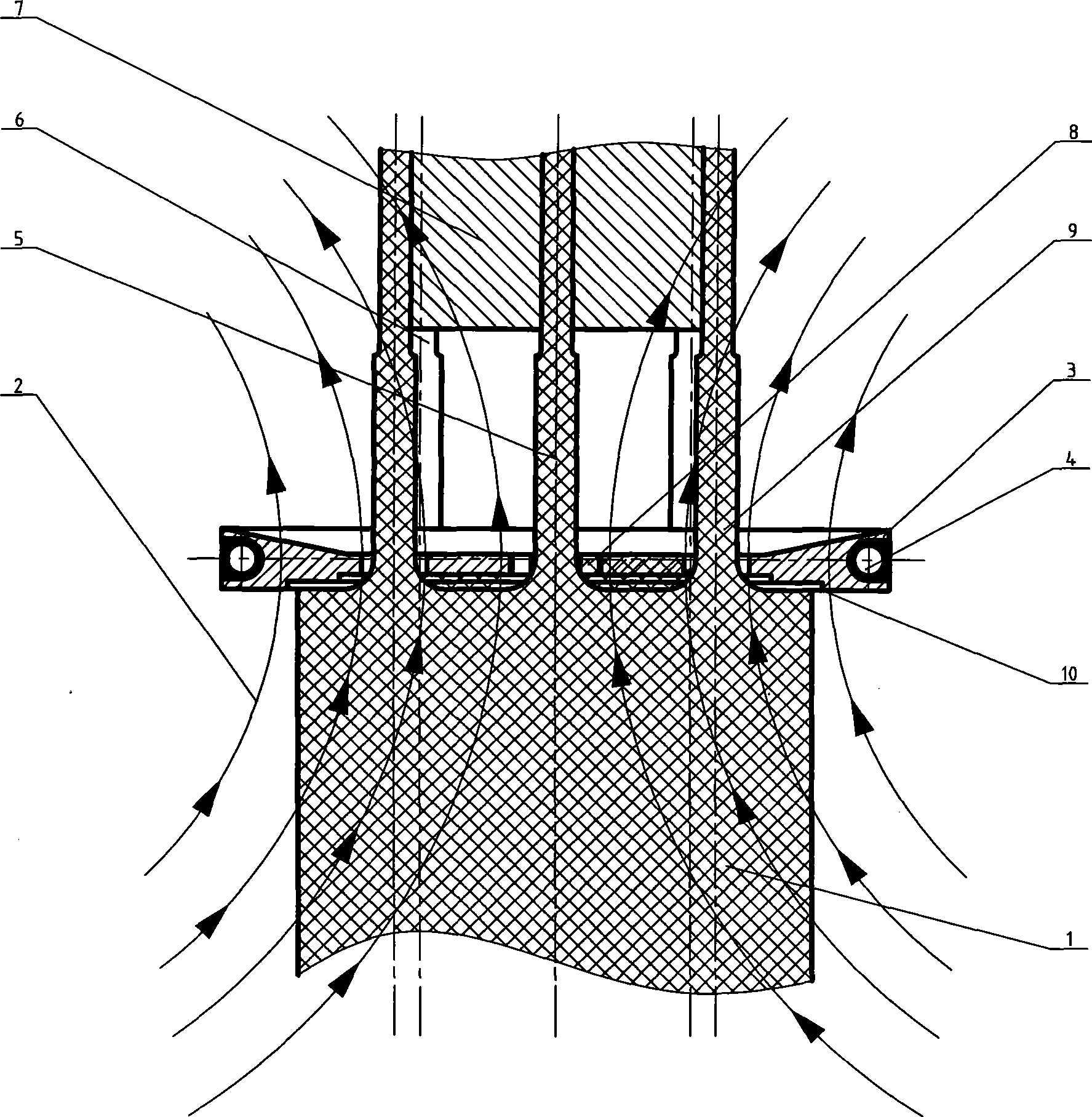

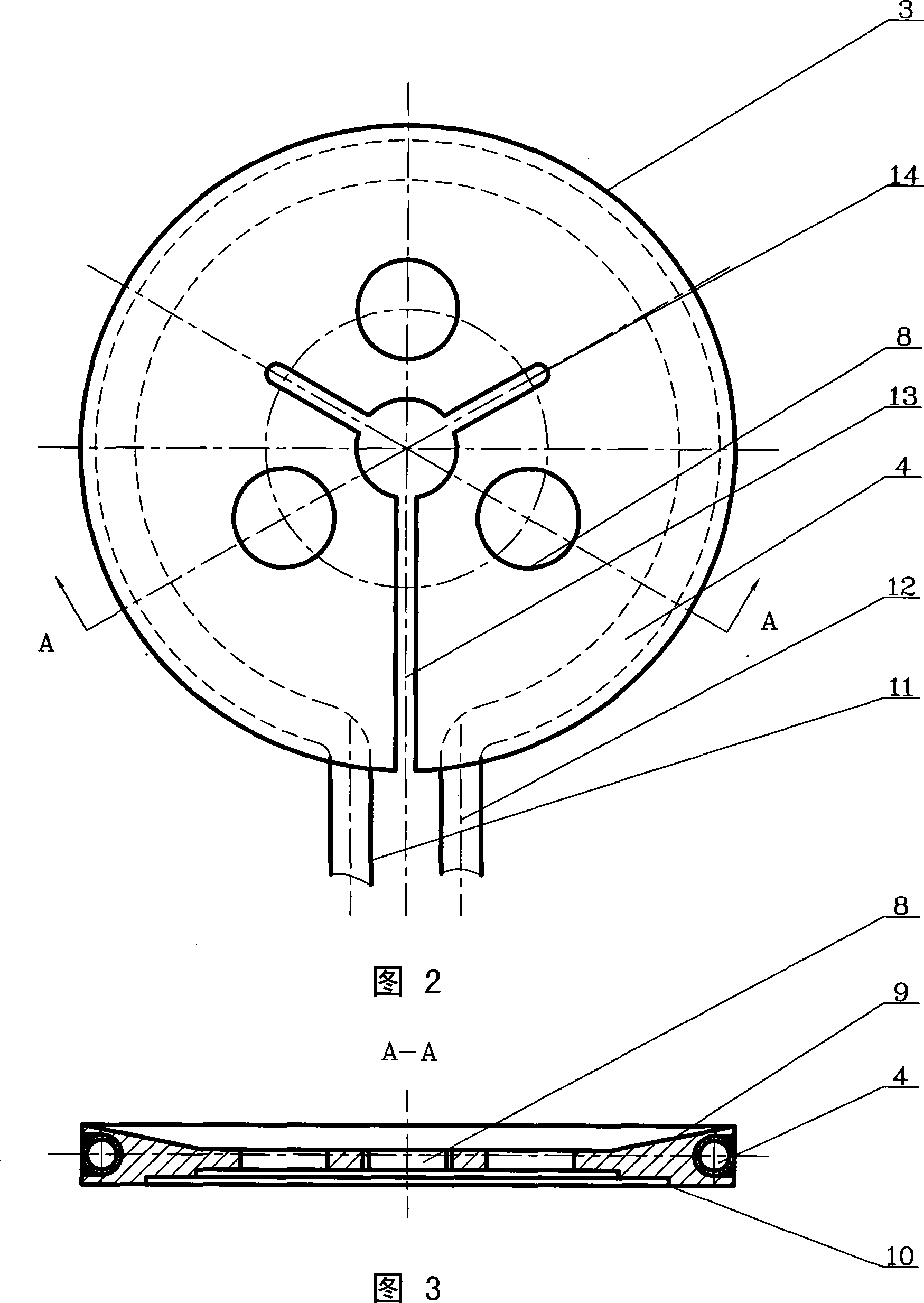

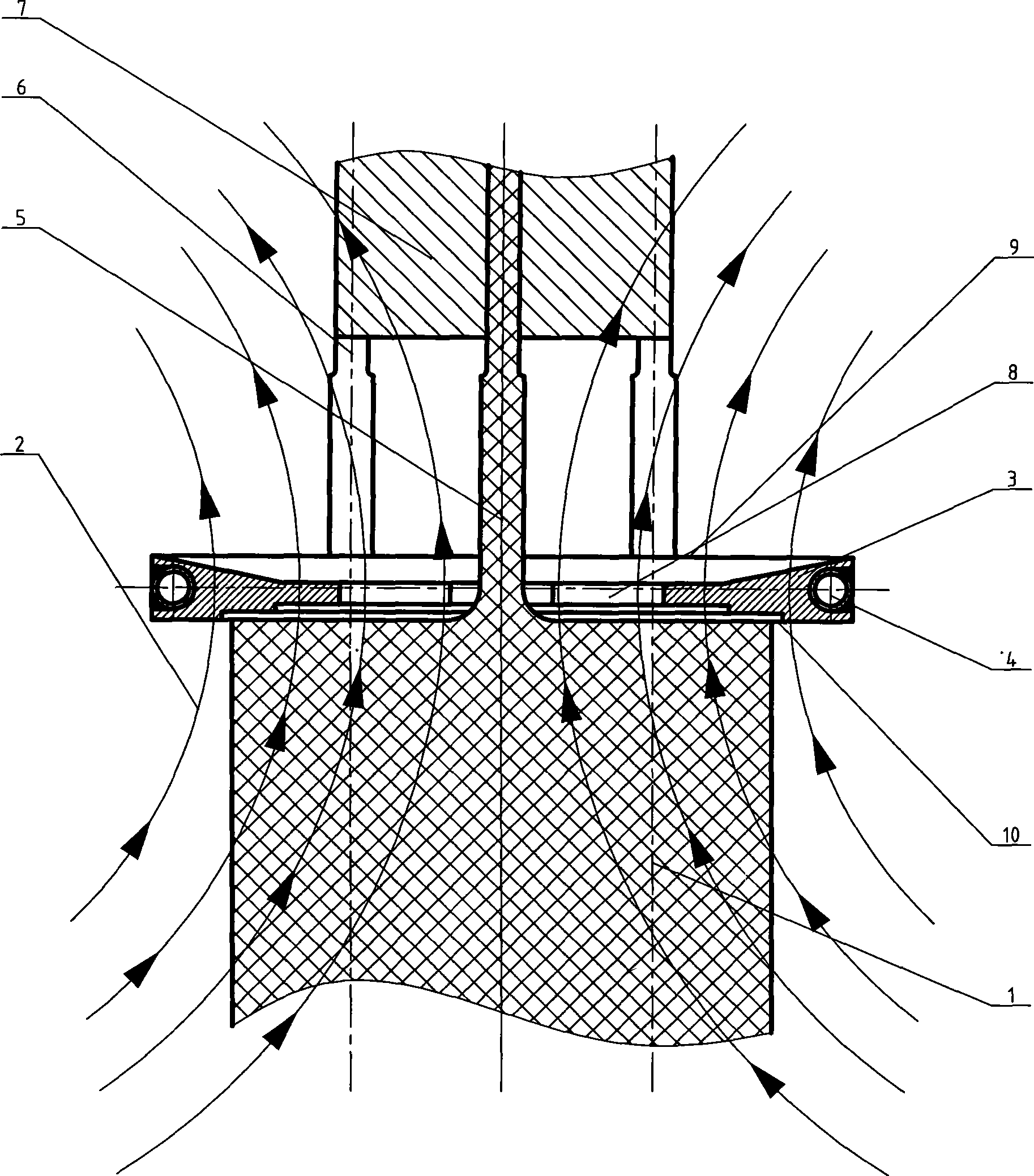

High-frequency coil structure capable of producing six silicon cores and other crystal material at the same time

ActiveCN101487136AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsEngineeringCopper

The invention provides a high-frequency coil structure which can produce six silica cores and other crystal materials simultaneously, relating to the technical field of high-frequency coils. The high-frequency coil structure comprises a radial shunt trough (14) which is used for diversion of current (15), and six internal holes (8), wherein, one internal hole is arranged at the middle part and other five internal holes are uniformly distributed around the middle internal hole in a petal-shape; an inclined opening (13) at one side of a copper pipe A(11) for conveying current and cooled water and a copper pipe B(12) for conveying current and cooled water is connected and communicated with the middle internal hole; the radial shunt trough extends out from the middle internal hole to a position between every two internal holes except the inclined opening; the inclined opening is connected with the middle internal hole; and the radial shunt trough is radially distributed between every two peripheral internal holes by the middle internal hole, thus leading the current to uniformly run by surrounding the six internal holes under the shunt effect of the shunt trough during the running process and achieving the objects that the current is uniformly distributed around the six internal holes.

Owner:LUOYANG JINNUO MECHANICAL ENG

High-current electrical coil construction

InactiveUS7248139B1Improve current carrying capacityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMechanical engineeringCoil structure

Owner:TDK LAMBDA CORP

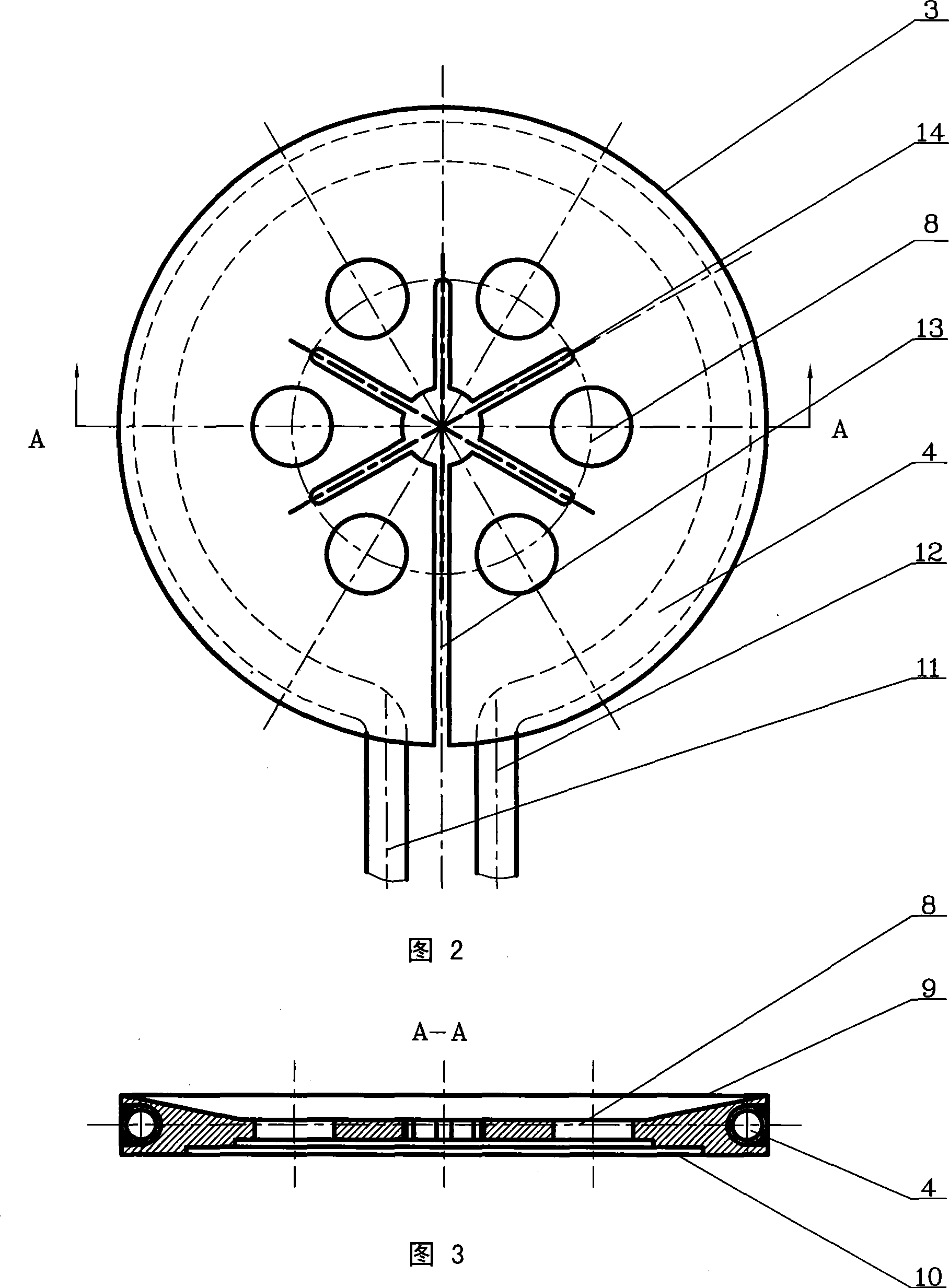

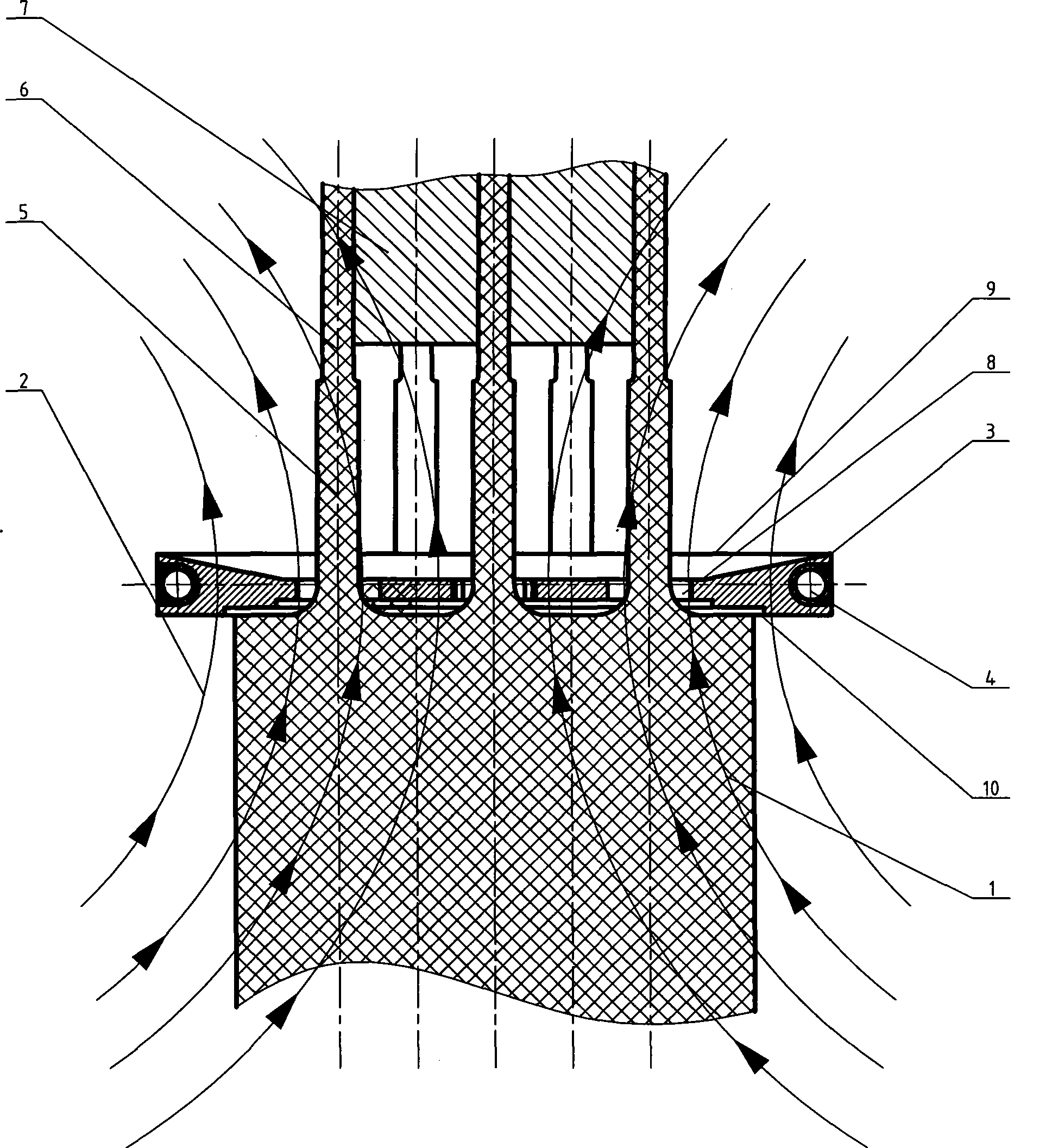

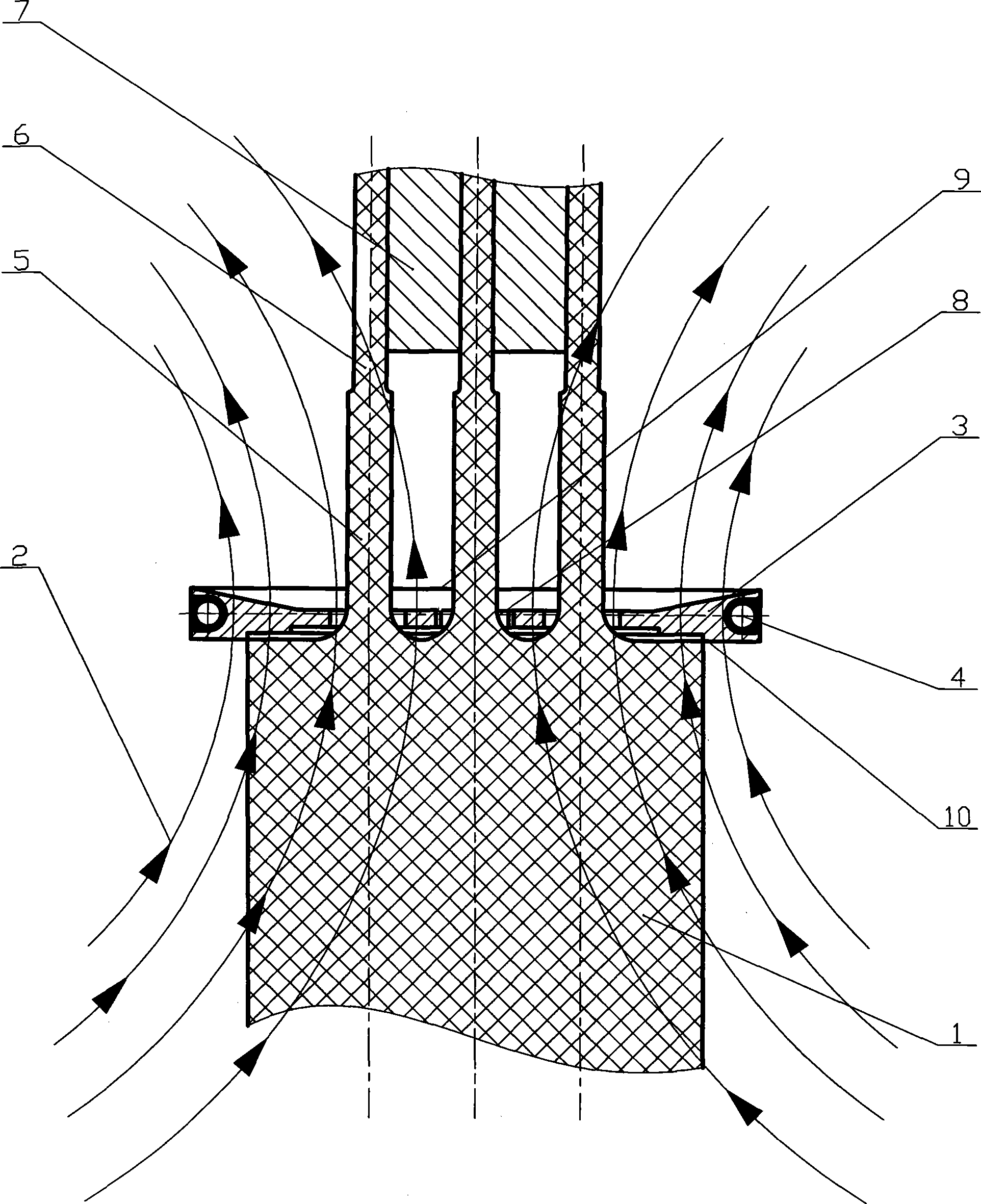

High-frequency coil structure capable of simultaneous producing seven silicon cores and other crystal material

ActiveCN101457389AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing seven silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and seven inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and six inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the seven inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the seven inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

High-frequency coil structure capable of simultaneous producing eight silicon cores and other crystal material

ActiveCN101457390AEvenly distributedDistributed between every two peripheral inner holes to make the current run evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing eight silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a radial splitter box (14) for guiding current (15), and eight inner bores (8) one inner bore of which is arranged at the middle part of the high-frequency coil and seven inner bores of which are evenly distributed around the inner bore at the middle part in a petaline shape, an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the radial splitter box extends outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the radial splitter box is radially distributed at the position between every two peripheral inner bores by the inner bore at the middle part, which causes the current to evenly surround the eight inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the eight inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

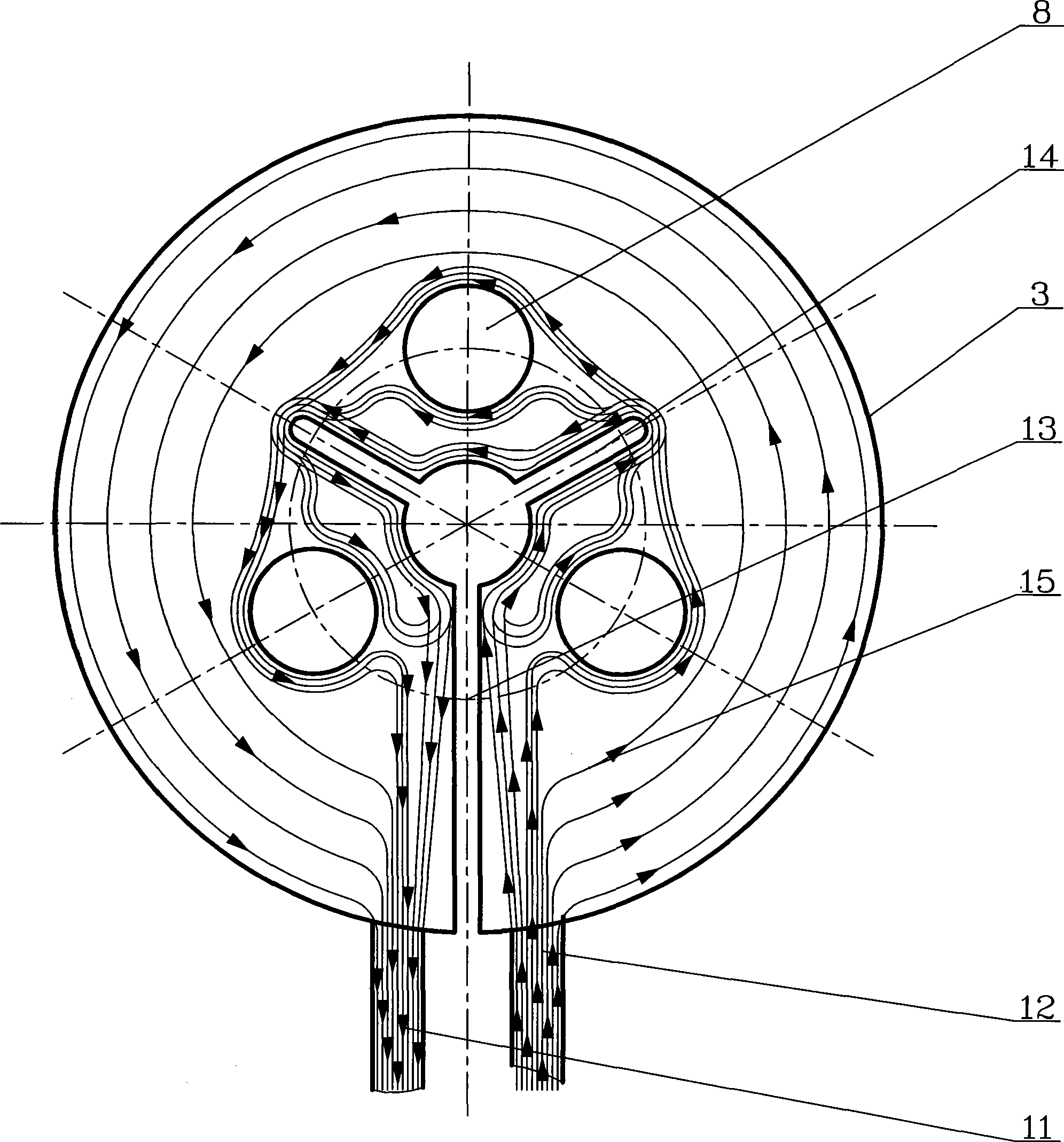

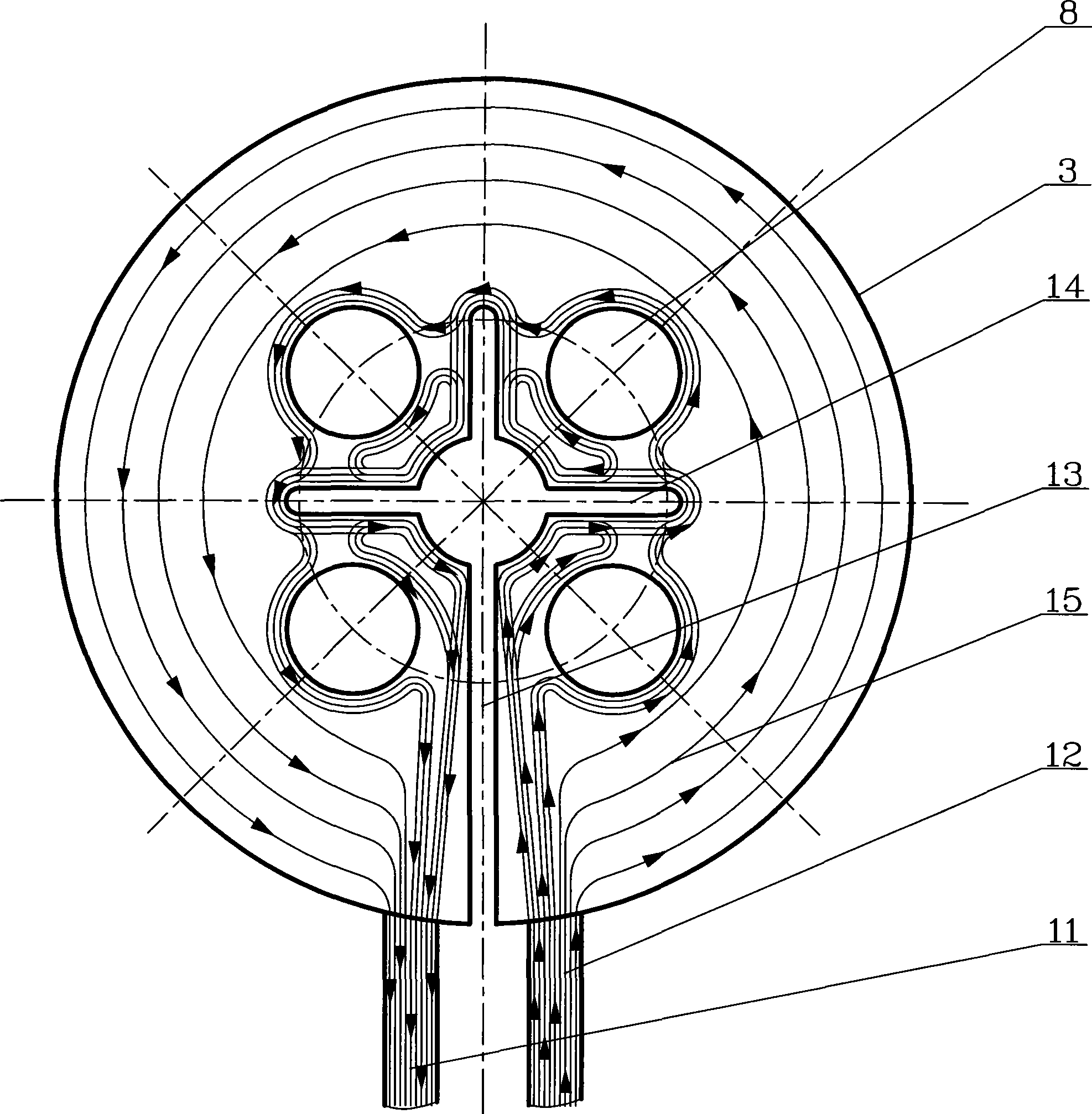

High-frequency coil structure capable of simultaneous producing four silicon cores and other crystal material

InactiveCN101457391AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing four silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises splitter boxes (14) for guiding current (15), and four inner bores one inner bore (8) of which is arranged at the middle part of the high-frequency coil and three inner bores of which are evenly distributed around the inner bore at the middle part; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore at the middle part; and the splitter boxes extend outwards to the position between every two inner bores except for the oblique opening from the inner bore at the middle part. The oblique opening is connected with the inner bore at the middle part, and the two splitter boxes extend upwards to the position between two inner bores without the oblique openings from the inner bore at the middle part, which causes the current to evenly surround the four inner bores for running under the current splitting action of the splitter boxes while the current is running, thus realizing the purpose that the current is evenly distributed around the four inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

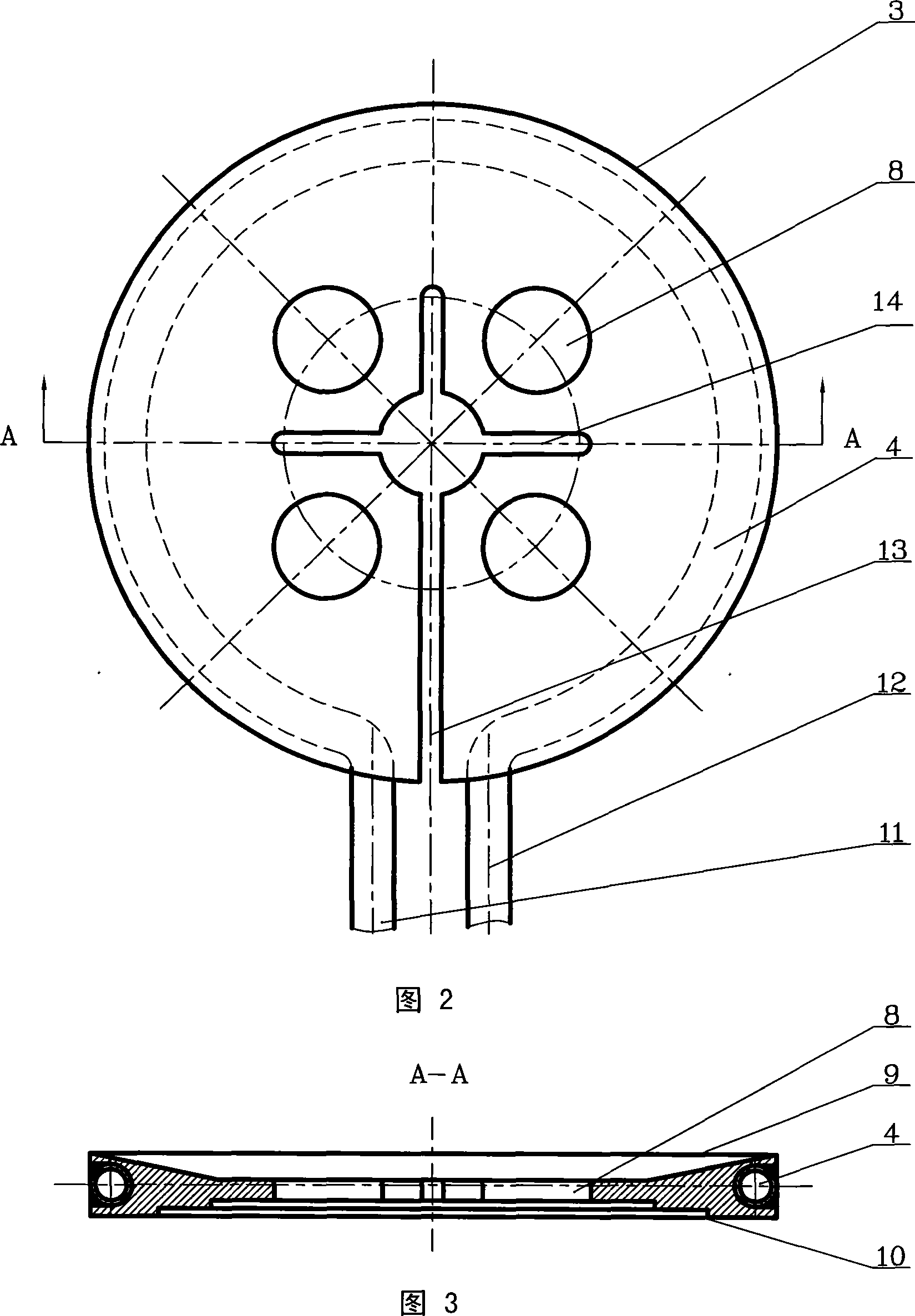

High-frequency coil structure capable of simultaneous producing five silicon cores and other crystal material

InactiveCN101457392AEvenly distributedHeating evenlyCoil arrangementsBy zone-melting liquidsCrystalline materialsCopper

The invention discloses a high-frequency coil structure capable of simultaneously producing five silicon cores and other crystalline materials, and relates to the technical field of the high-frequency coils. The high-frequency coil structure comprises a splitter box (14) for guiding current (15), and five inner bores (8) one inner bore (8) of which is arranged at the middle part of the high-frequency coil and four inner bores (8) of which are evenly distributed around the inner bore at the middle part in a 'cross' shape; an oblique opening (13) arranged on one side of a current delivery and cooling water delivery copper pipe A(11) and a current delivery and cooling water delivery copper pipe B(12) is in through connection with the inner bore (8) at the middle part; and the splitter box (14) extends outwards to the position between every two inner bores (8) except for the oblique opening (13) from the inner bore (8) at the middle part. The high-frequency coil structure can cause the current to evenly surround the five inner bores for running under the current splitting action of the splitter box while the current is running, thus realizing the purpose that the current is evenly distributed around the five inner bores.

Owner:LUOYANG JINNUO MECHANICAL ENG

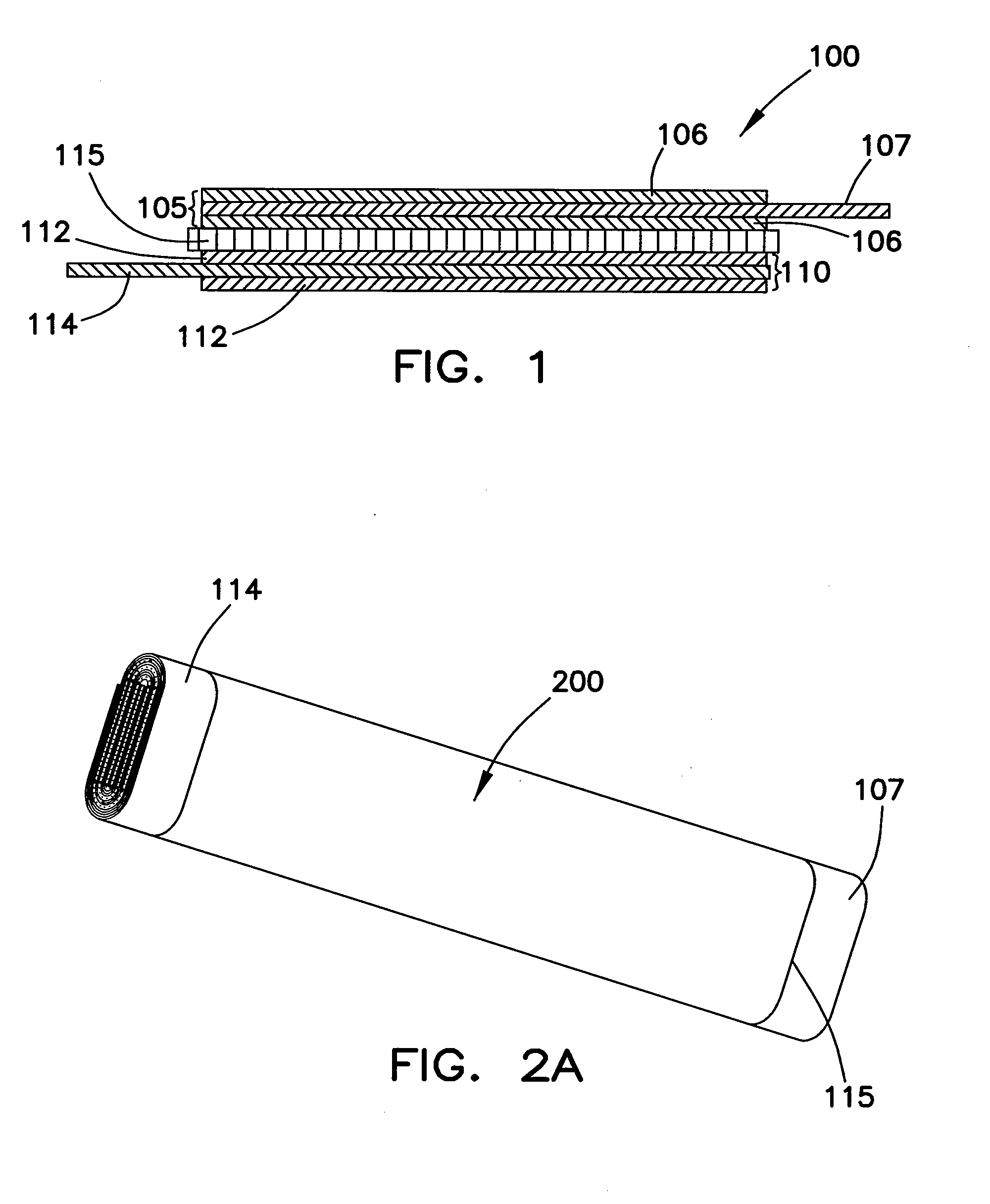

Electrochemical cell having a coiled core

There is disclosed a core for an electrochemical cell that comprises an anode sheet, a cathode sheet, and a separator sheet disposed between the anode sheet and cathode sheet. The anode sheet, cathode sheet, and separator sheet are wound to form a flattened coil structure. The flattened coil structure has opposed flattened sides and opposed arcuate sides. The anode and cathode sheets terminate at the same or different arcuate sides. Further, the separator sheet may terminate at one of the arcuate sides.

Owner:BYD CO LTD

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS20050225181A1Reduce demandIncrease demandReciprocating/oscillating/vibrating magnetic circuit partsMagnetsReciprocating motionElectrical polarity

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

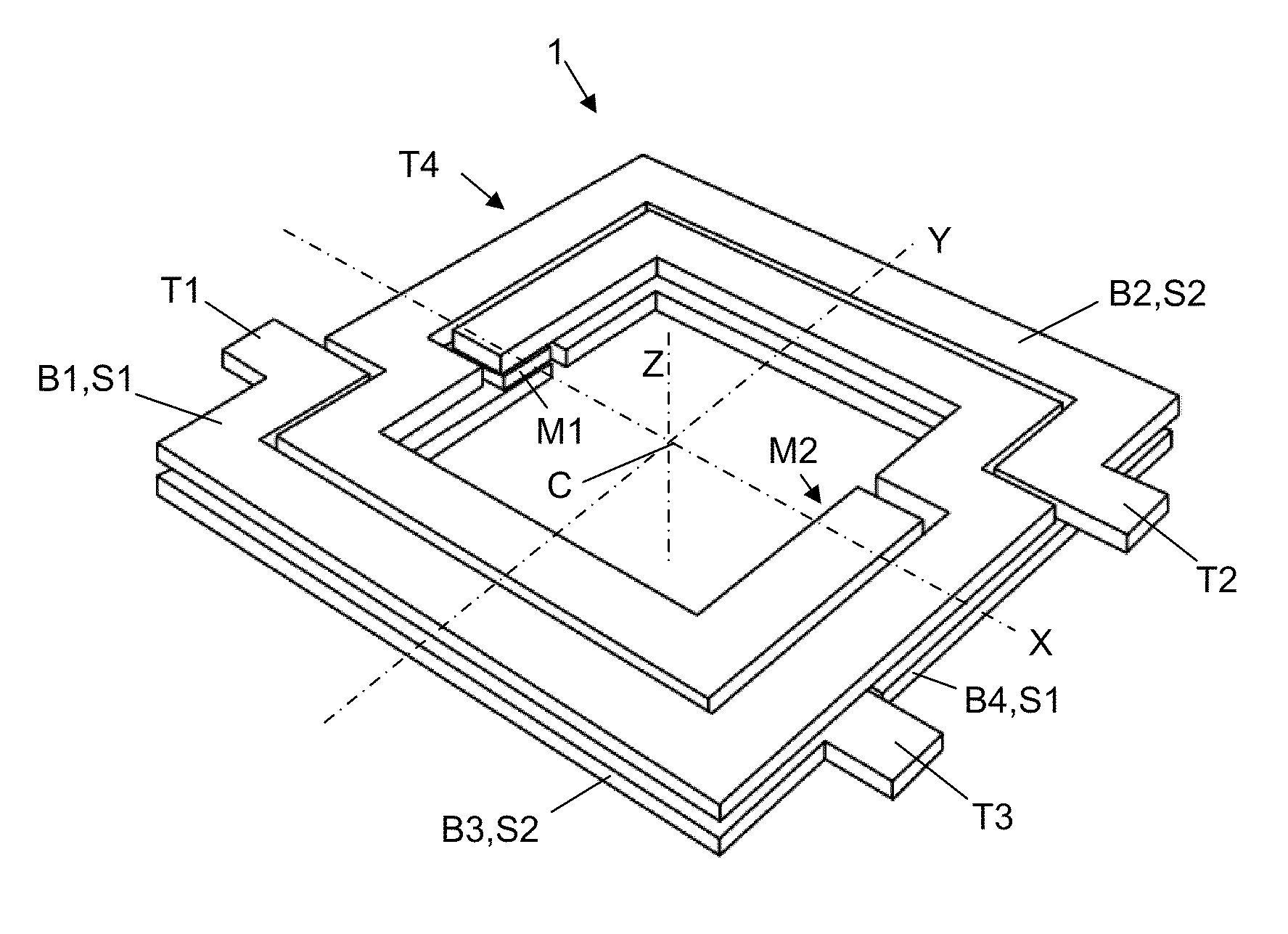

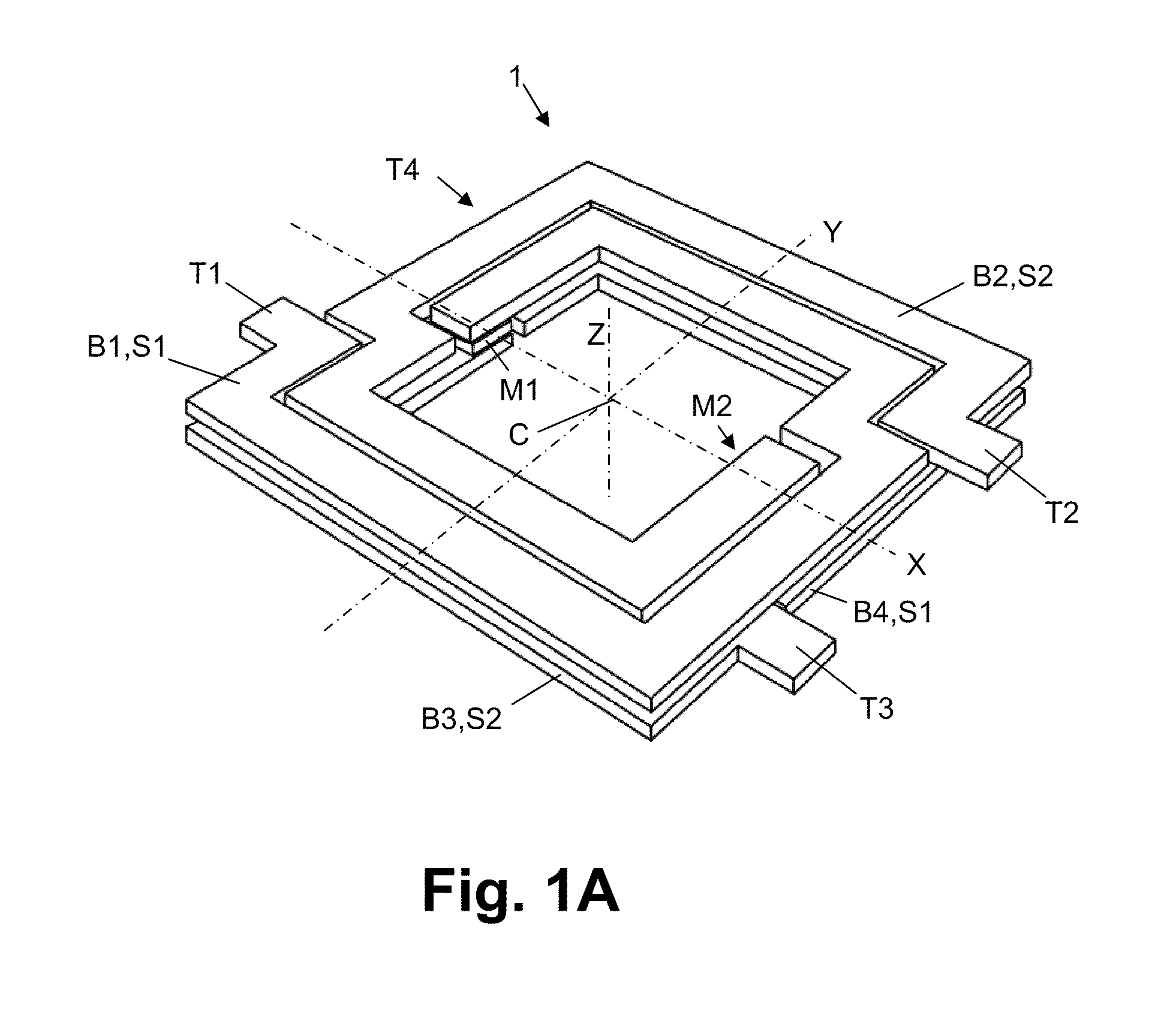

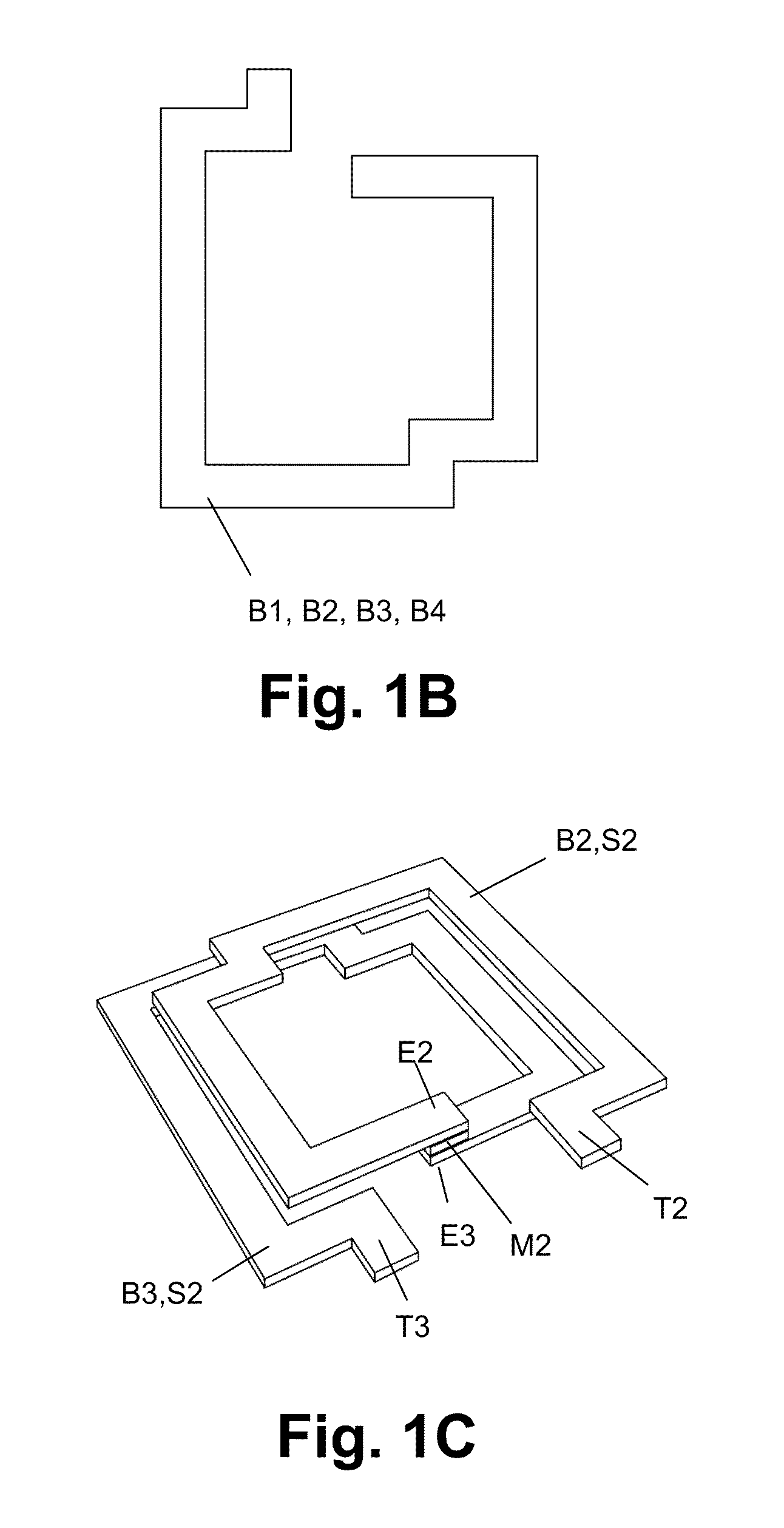

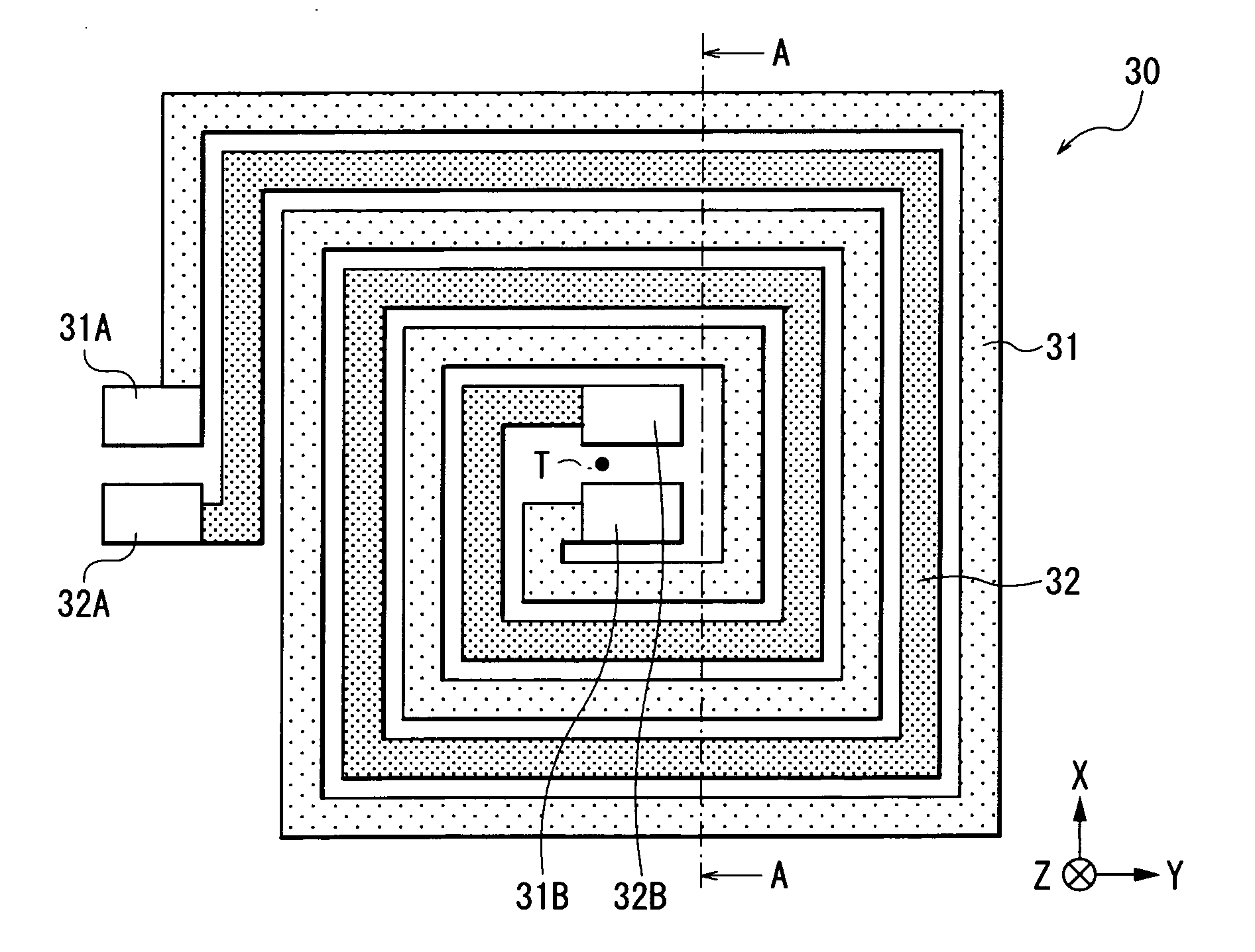

Two Layer Transformer

ActiveUS20110032065A1Increase the inner areaImprove electrical performanceMultiple-port networksSemiconductor/solid-state device detailsTransformerEngineering

One aspect of the invention relates to a symmetrical transformer with a stacked coil structure comprising two coils each having at least two turns, said coils being located in two conductive planes. The structure comprises four identical basic elements, each basic element providing a conductive path for part of said coils. The terminals of the transformer are located at opposite sites of the structure so that the structure can be easily connected in a chain.The invention also relates to a semiconductor device comprising such a structure.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

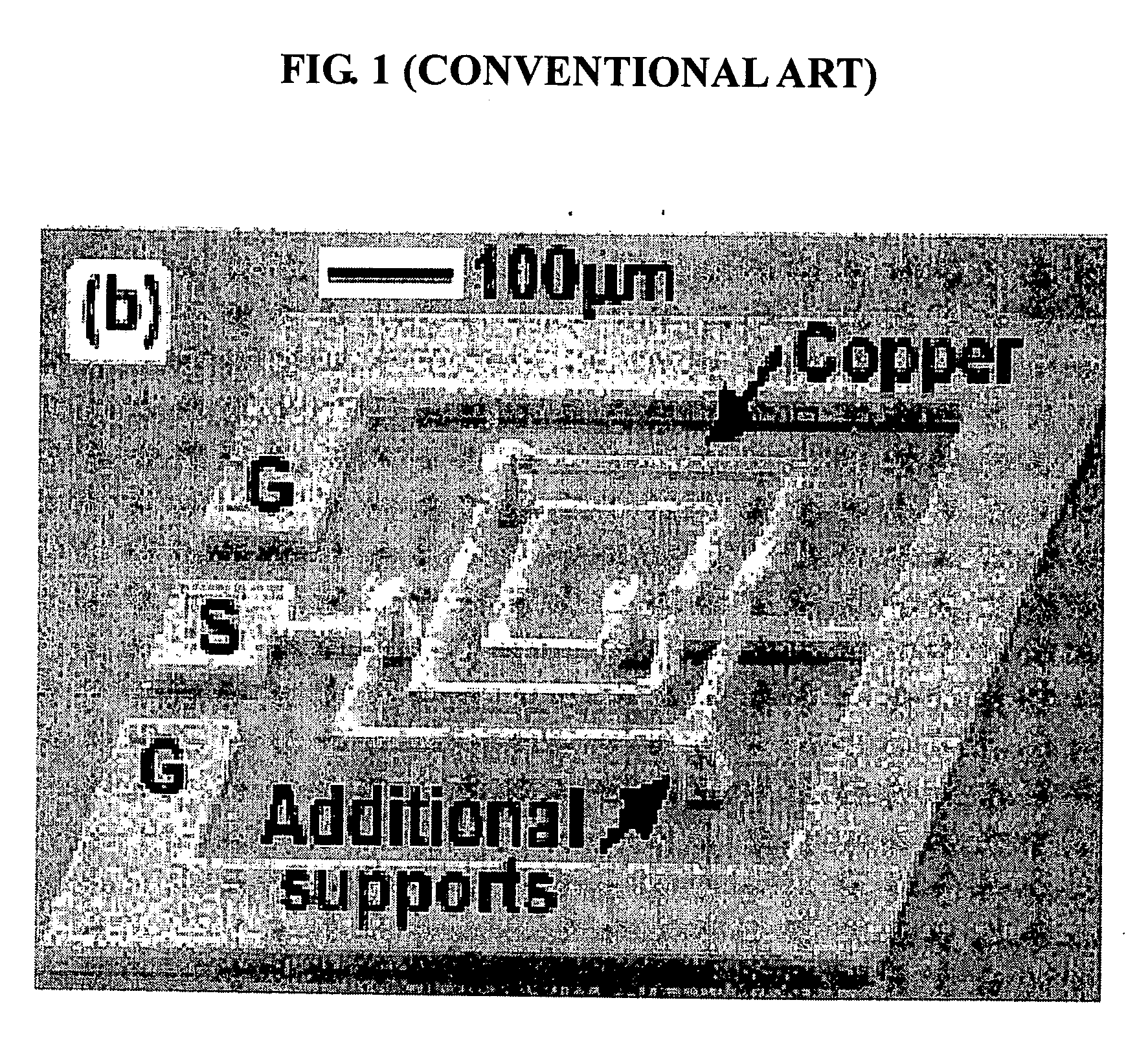

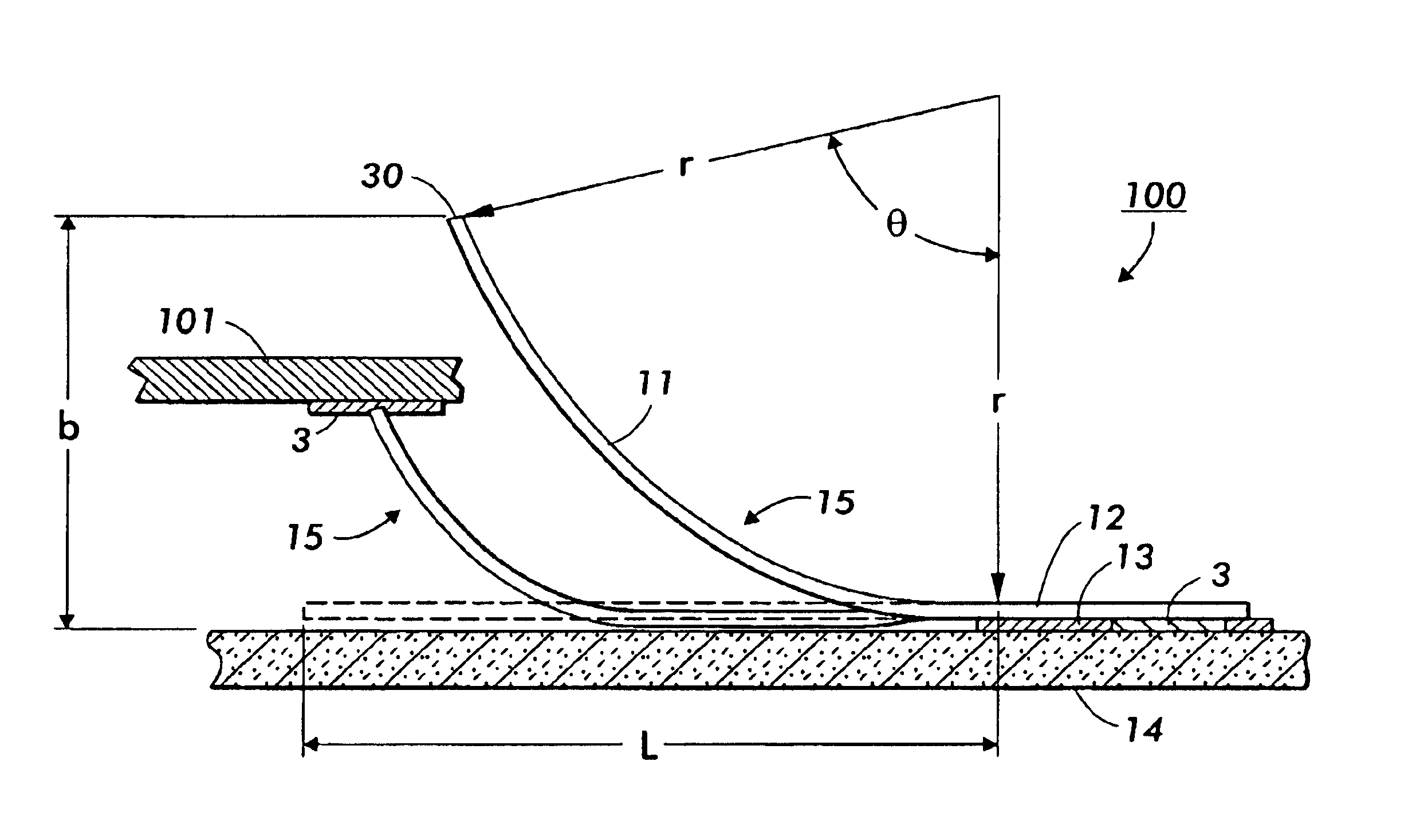

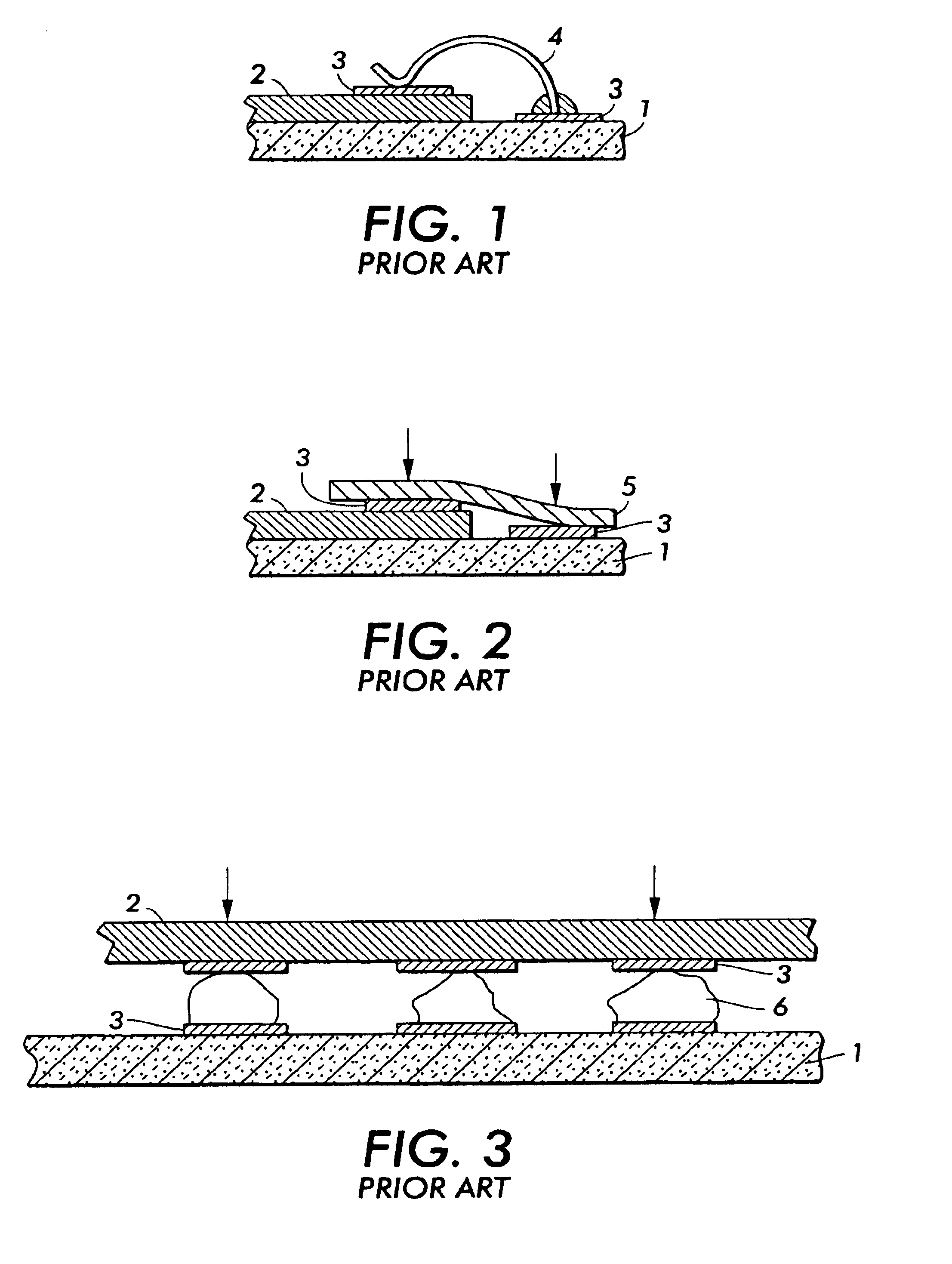

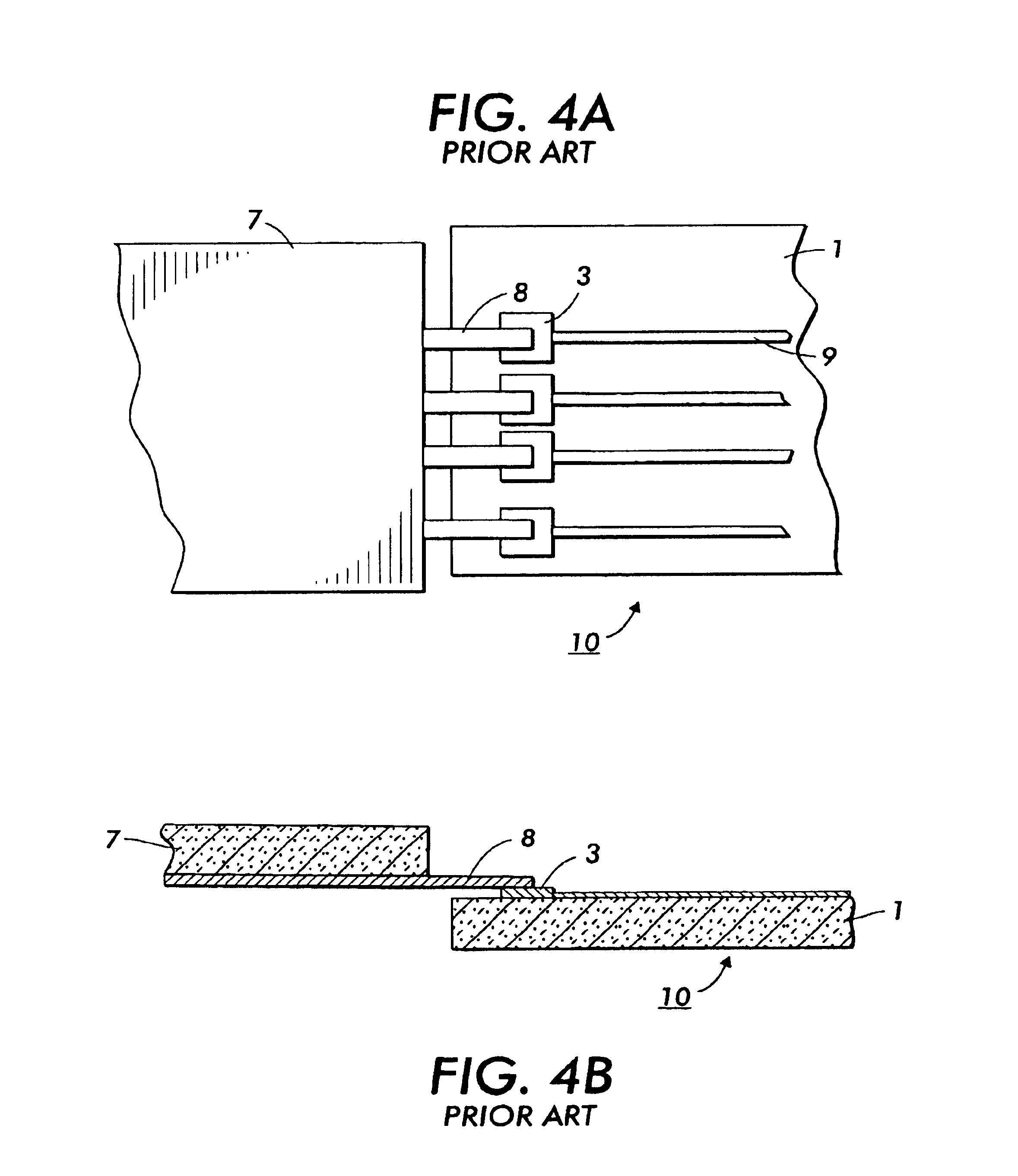

Photolithographically-patterned out-of-plane coil structures and method of making

InactiveUS6856225B1Reduce speedEliminate needSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsMicro structureTransformer

An out-of-plane micro-structure which can be used for on-chip integration of high-Q inductors and transformers places the magnetic field direction parallel to the substrate plane without requiring high aspect ratio processing. The photolithographically patterned coil structure includes an elastic member having an intrinsic stress profile. The intrinsic stress profile biases a free portion away from the substrate forming a loop winding. An anchor portion remains fixed to the substrate. The free portion end becomes a second anchor portion which may be connected to the substrate via soldering or plating. A series of individual coil structures can be joined via their anchor portions to form inductors and transformers.

Owner:XEROX CORP

Method of Manufacturing a Coil Inductor

ActiveUS20090188104A1Total current dropSemiconductor/solid-state device manufacturingCoils manufactureCoil inductanceInductor

A method of manufacturing a coil inductor and a coil inductor are provided are provided. A plurality of conductive bottom structures are formed to be lying on a first dielectric layer. A plurality pairs of conductive side structures are then formed, wherein each pair of the conductive side structure stand on top surface of a first end and a second end of each conductive bottom structure respectively; a second dielectric layer is formed on the first dielectric layer, coating the bottom and side structures; and a plurality of conductive top structures are formed to be lying on the second dielectric layer, wherein each conductive top structure electrically connects each pair of the conductive side structures, wherein the conductive bottom structures, the conductive side structures and the conductive top structures together form a conductive coil structure.

Owner:TAIWAN SEMICON MFG CO LTD

Photolithographically-patterned out-of-plane coil structures and method of making

InactiveUS6582989B2Capacitor with electrode distance variationSolid-state devicesMicro structureTransformer

An out-of-plane micro-structure which can be used for on-chip integration of high-Q inductors and transformers places the magnetic field direction parallel to the substrate plane without requiring high aspect ratio processing. The photolithographically patterned coil structure includes an elastic member having an intrinsic stress profile. The intrinsic stress profile biases a free portion away from the substrate forming a loop winding. An anchor portion remains fixed to the substrate. The free portion end becomes a second anchor portion which may be connected to the substrate via soldering or plating. Alternately, the loop winding can be formed of two elastic members in which the free ends are joined in mid-air. A series of individual coil structures can be joined via their anchor portions to form inductors and transformers.

Owner:XEROX CORP

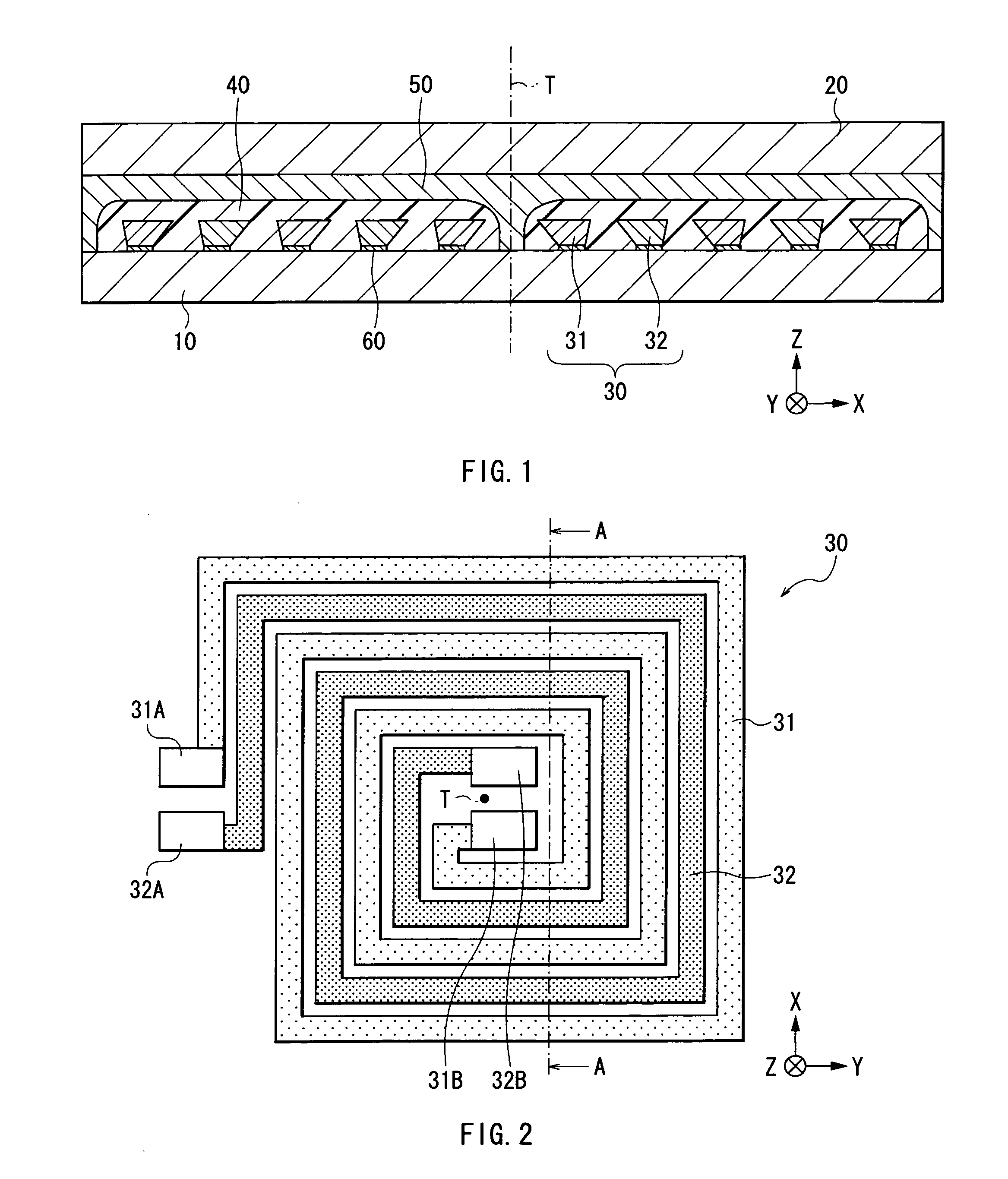

Thin film coil, method of manufacturing the same, coil structure, and method of manufacturing the same

InactiveUS20060001520A1Improve featuresReduce capacitanceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureCapacitanceDifferential transmission

The present invention provides a coil structure capable of improving a differential transmission characteristic by reducing capacitance as much as possible. A common mode choke coil is constructed so that a section of each of two coil patterns constructing a thin film coil has an inverted trapezoid shape which is bilaterally asymmetrical. Because of the structural characteristic that the section of each of the two coil patterns has an inverted trapezoid shape which is bilaterally asymmetrical, the facing area of the two coil patterns contributing to capacitance is minimized. Thus, the capacitance of the thin film coil can be reduced as much as possible.

Owner:TDK CORPARATION

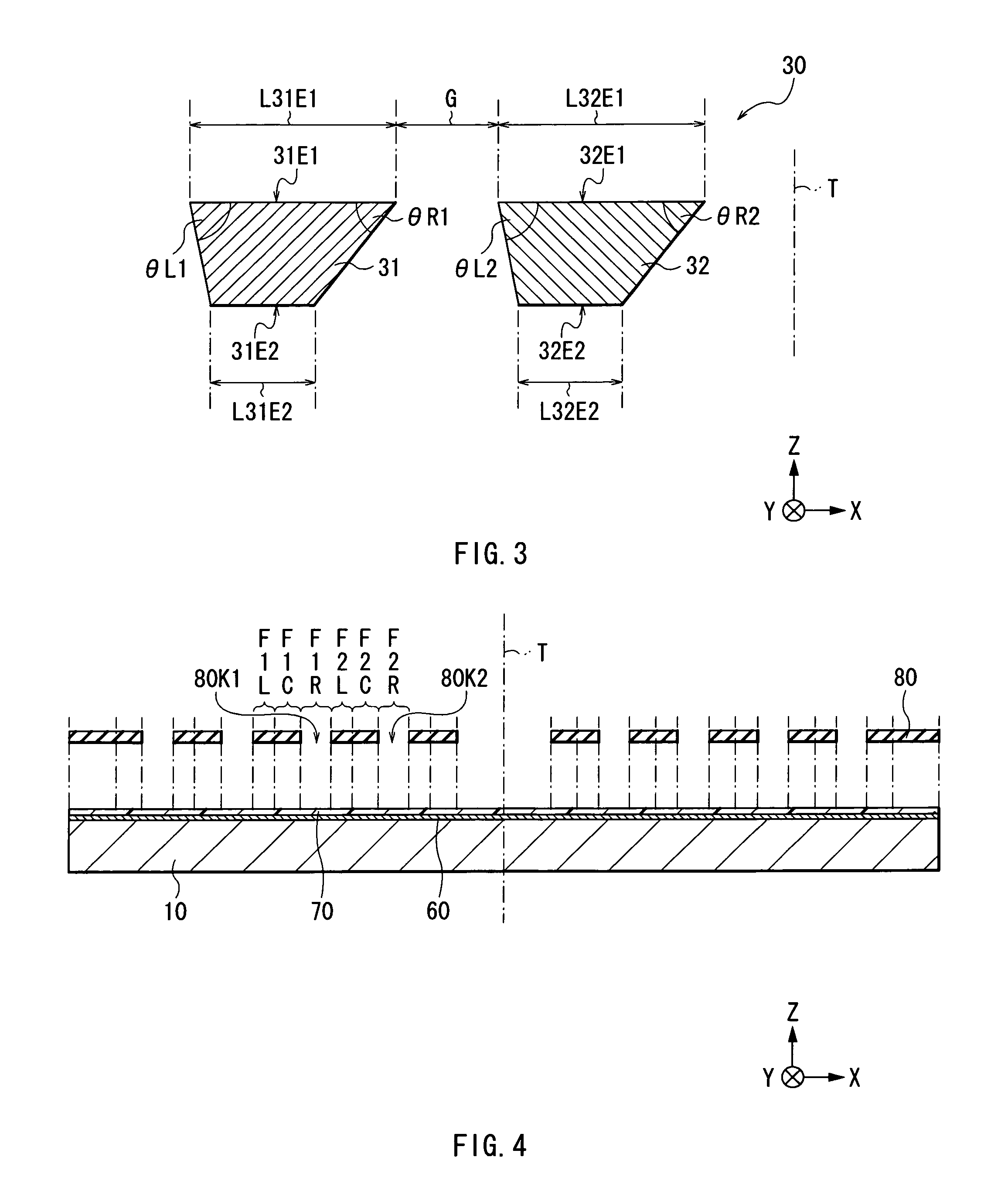

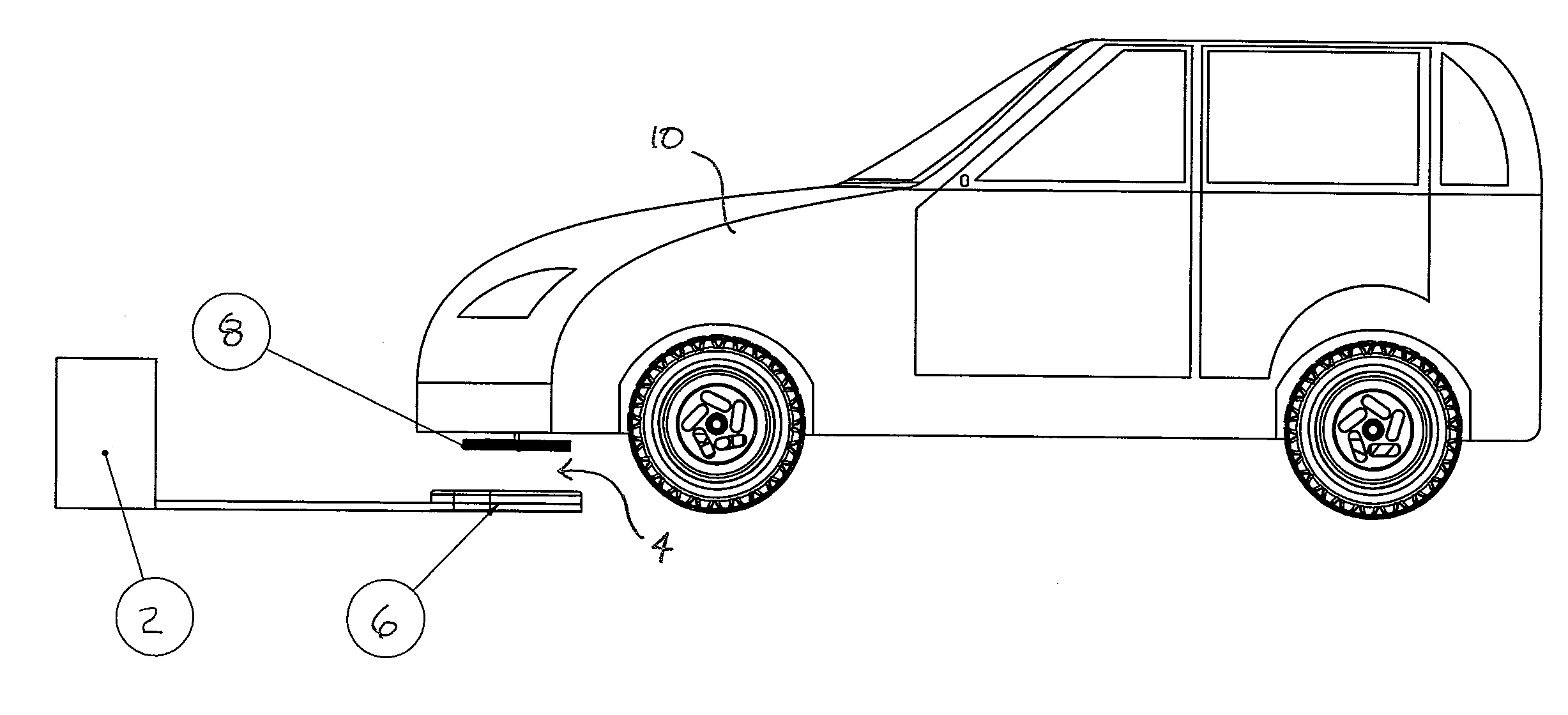

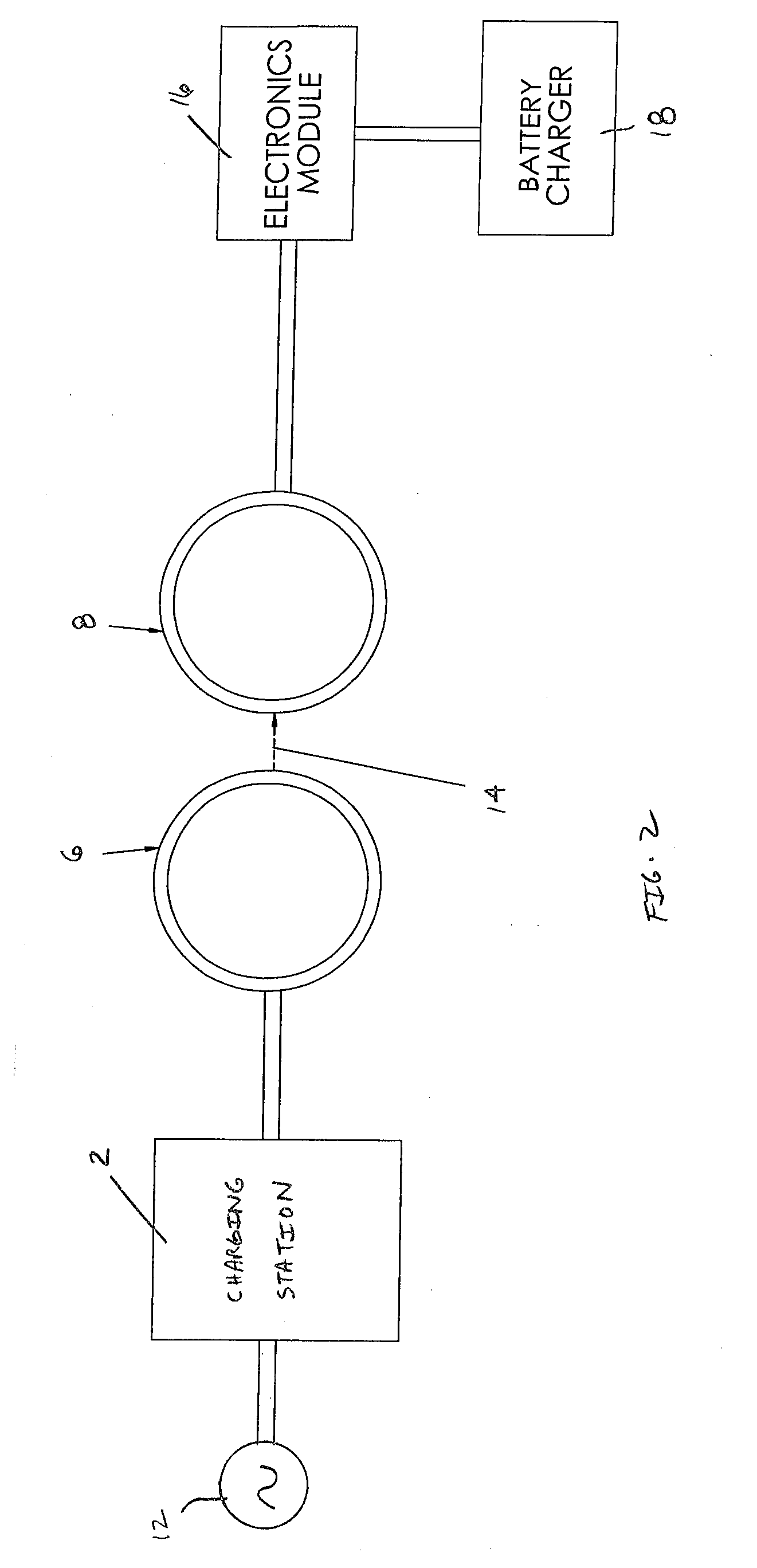

Secondary coil structure of inductive charging system for electric vehicles

InactiveUS20130038276A1Low heat generationBatteries circuit arrangementsCharging stationsPlastic materialsElectric vehicle

A secondary coil structure for an electric vehicle charging system is characterized by a flexible sheet of synthetic plastic material which acts as a substrate for a coil connected with the top surface of the sheet. The coil has an axis generally normal to the sheet. A second sheet of material is connected with the first sheet with the coil arranged between the sheets. The secondary coil may be configured to match the configuration of a component of the vehicle with which the secondary coil is connected. When electric current is introduces into the coil, the coil generates an elongated magnetic field with a lower maximum value in the vicinity of the vehicle components than that created by a conventionally wound coil, thereby minimizing heat generated in steel components of the vehicle body.

Owner:PLUGLESS POWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com