Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

567results about "Reciprocating/oscillating/vibrating magnetic circuit parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

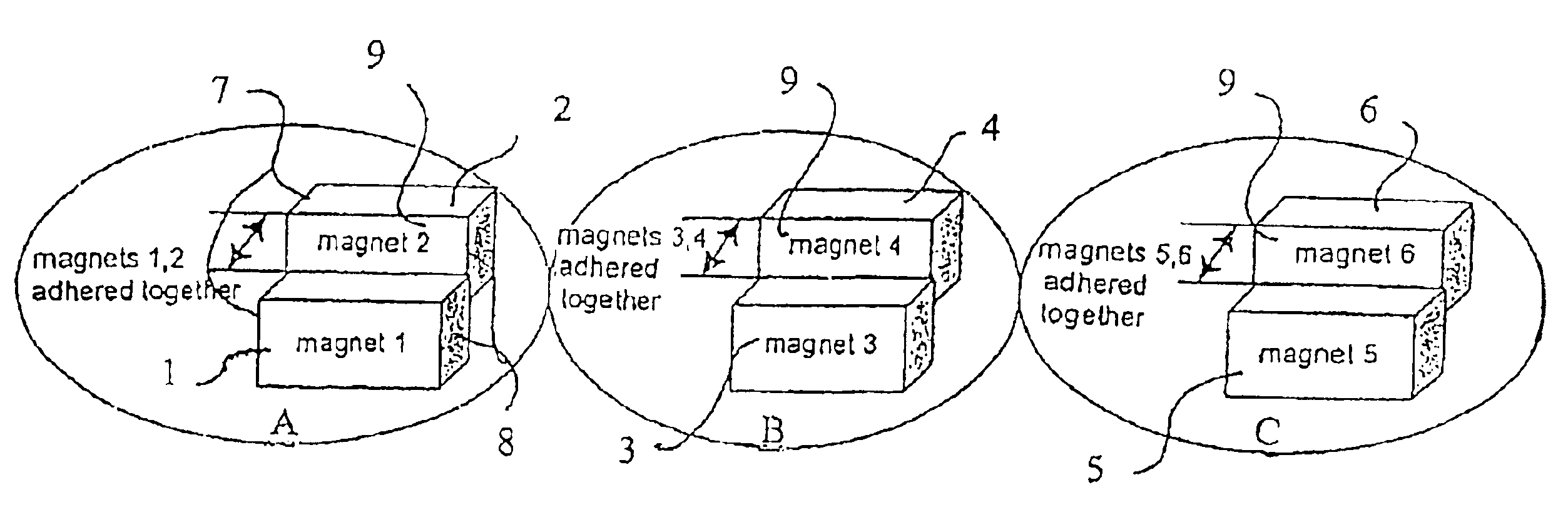

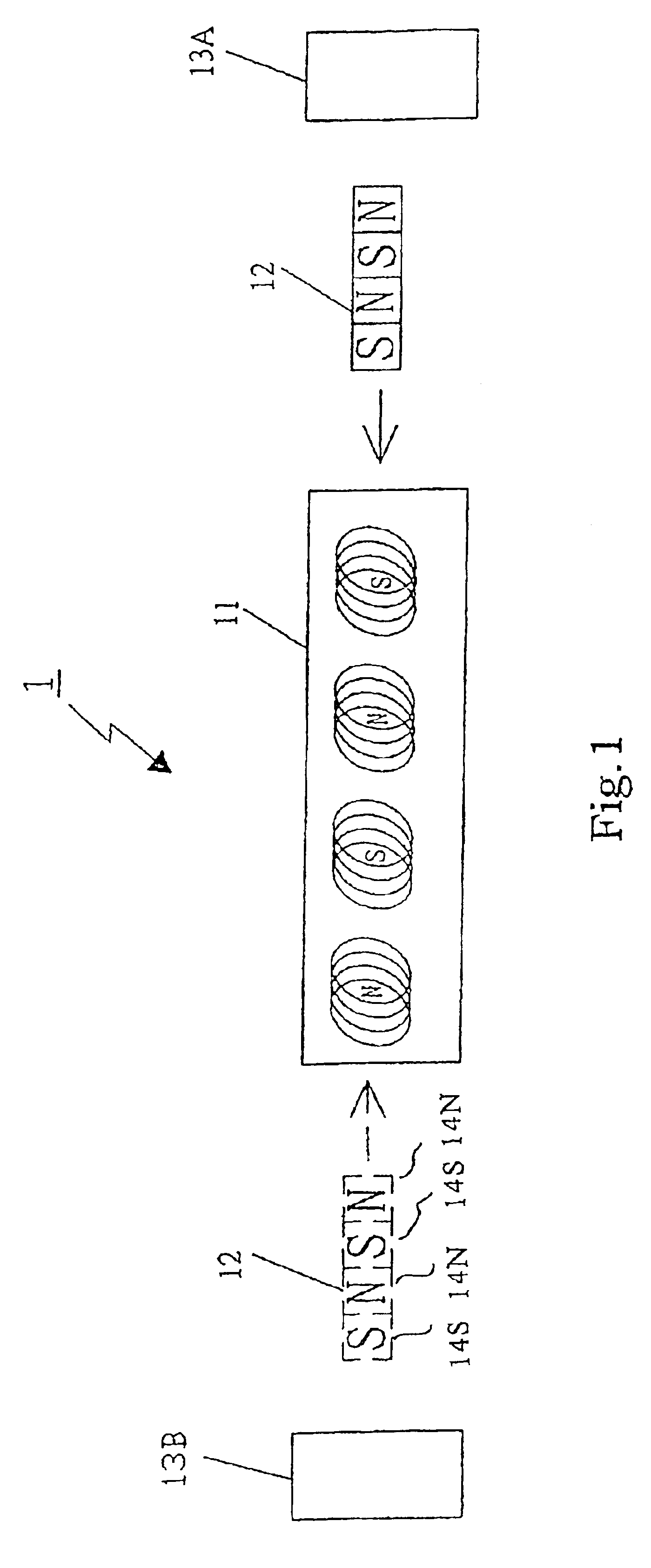

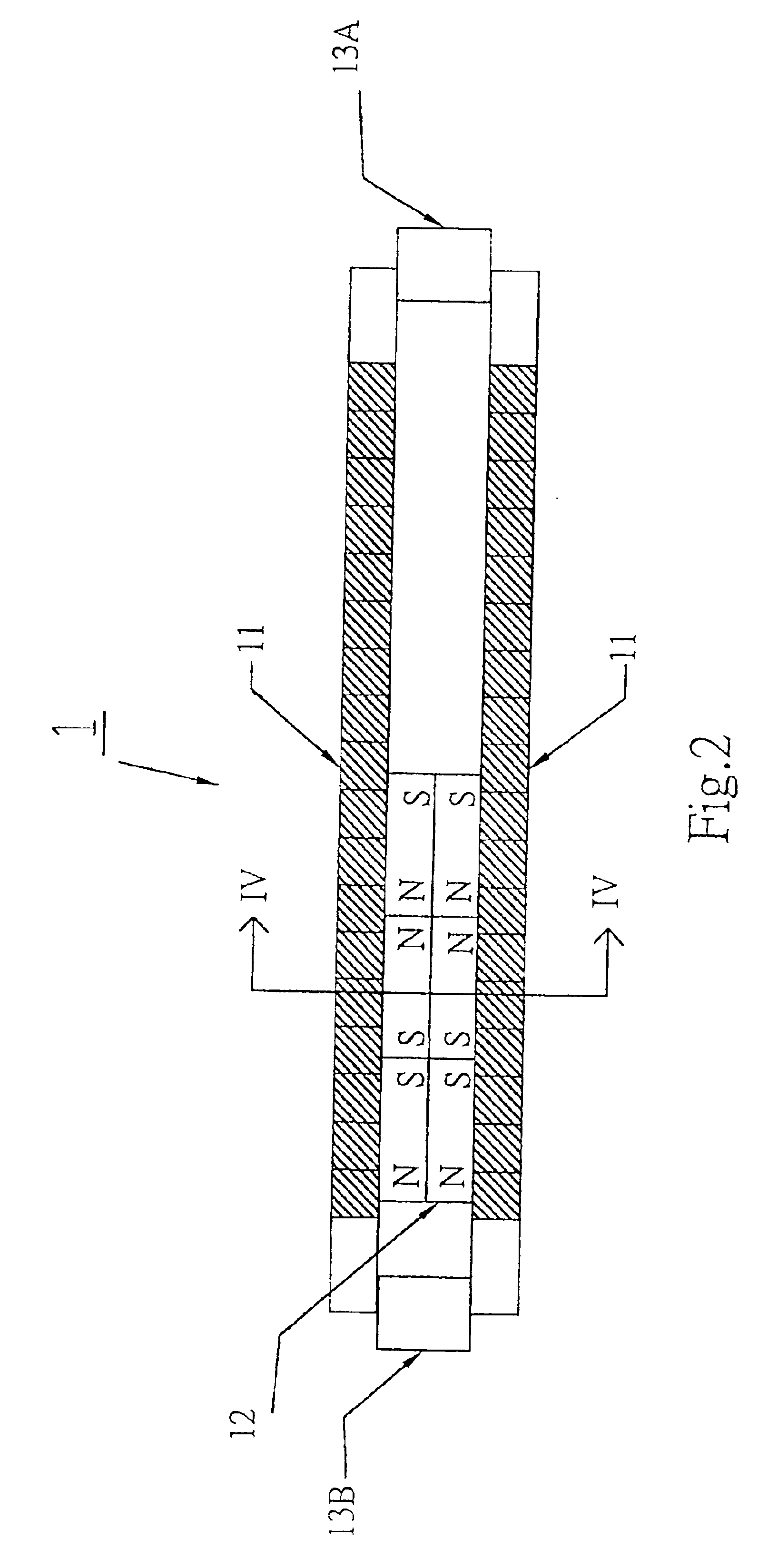

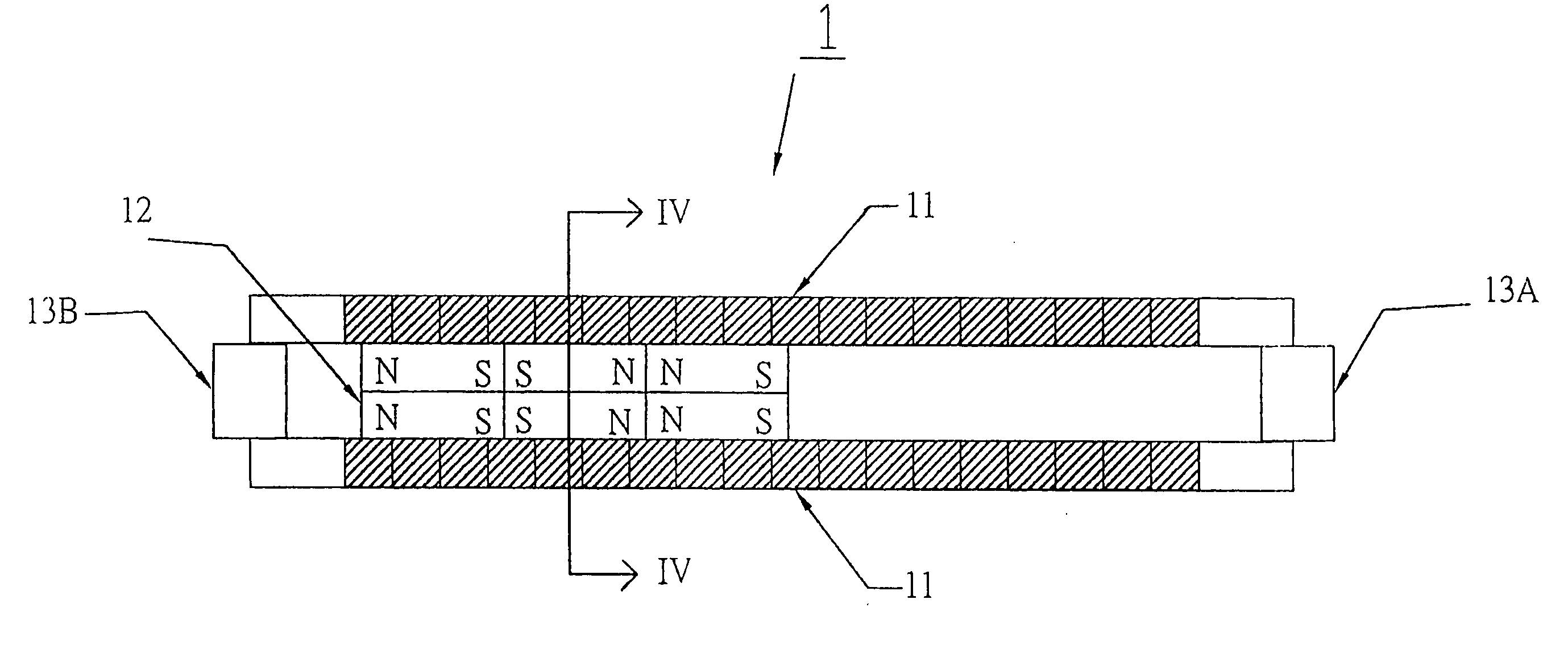

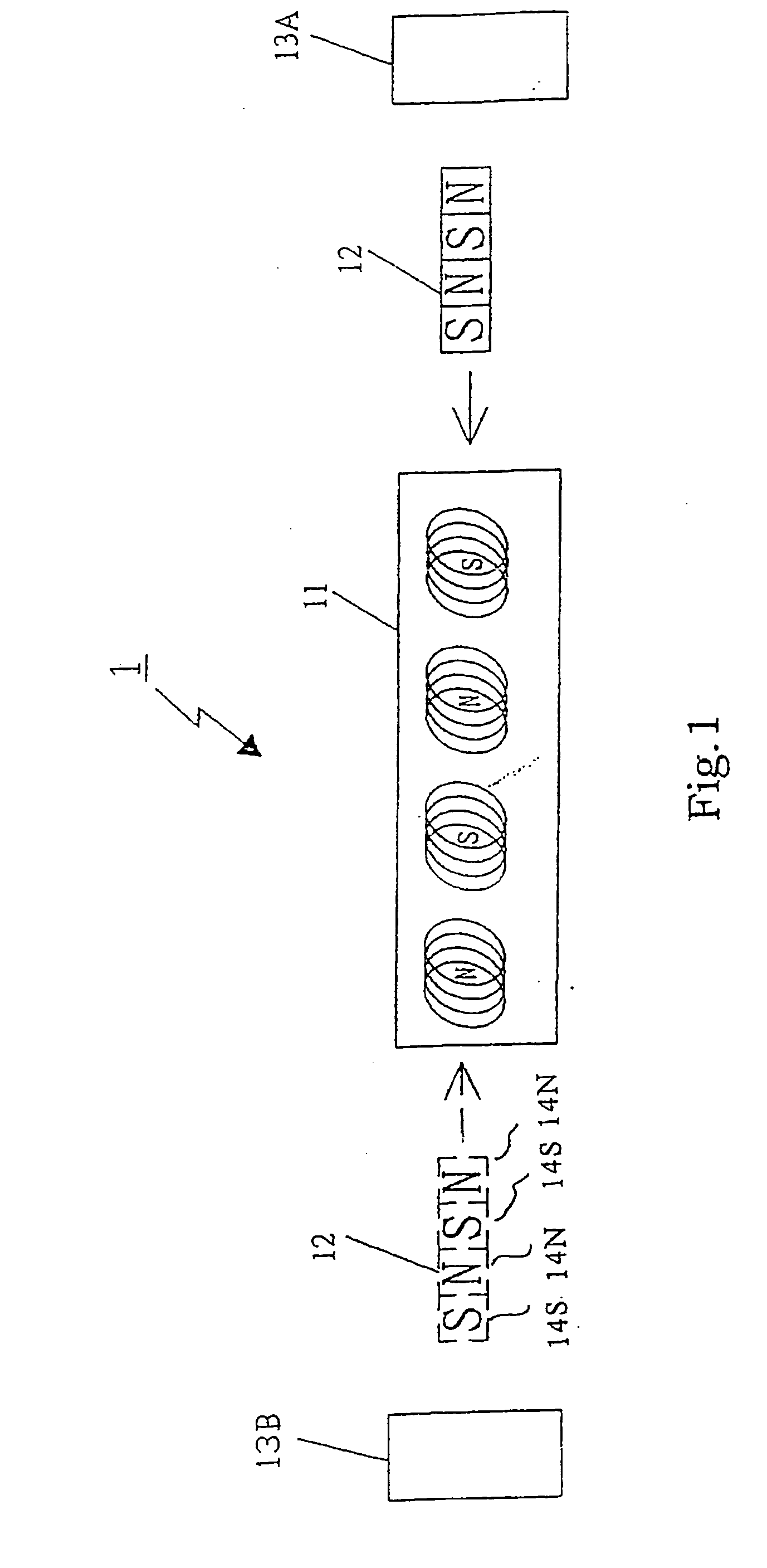

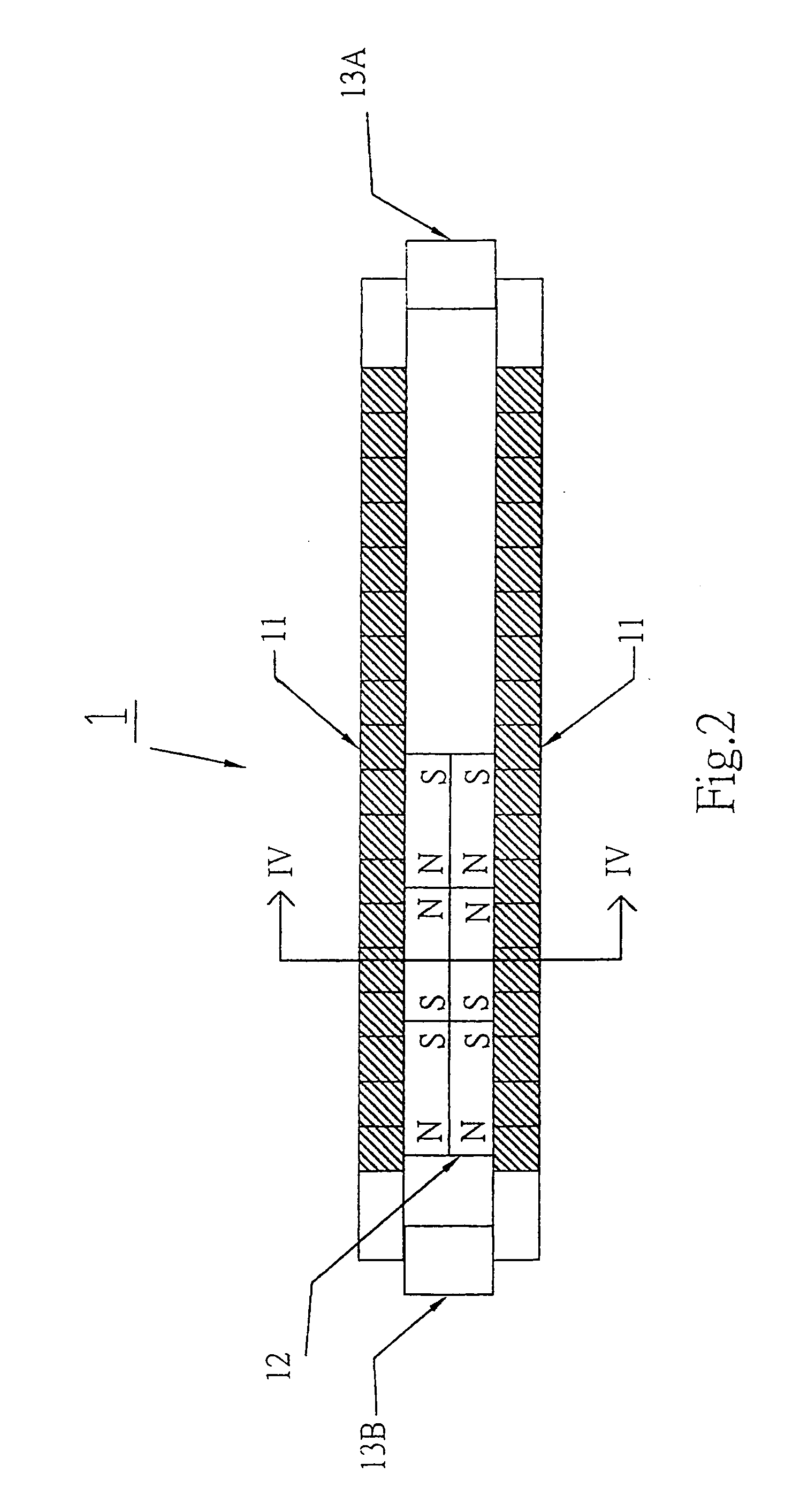

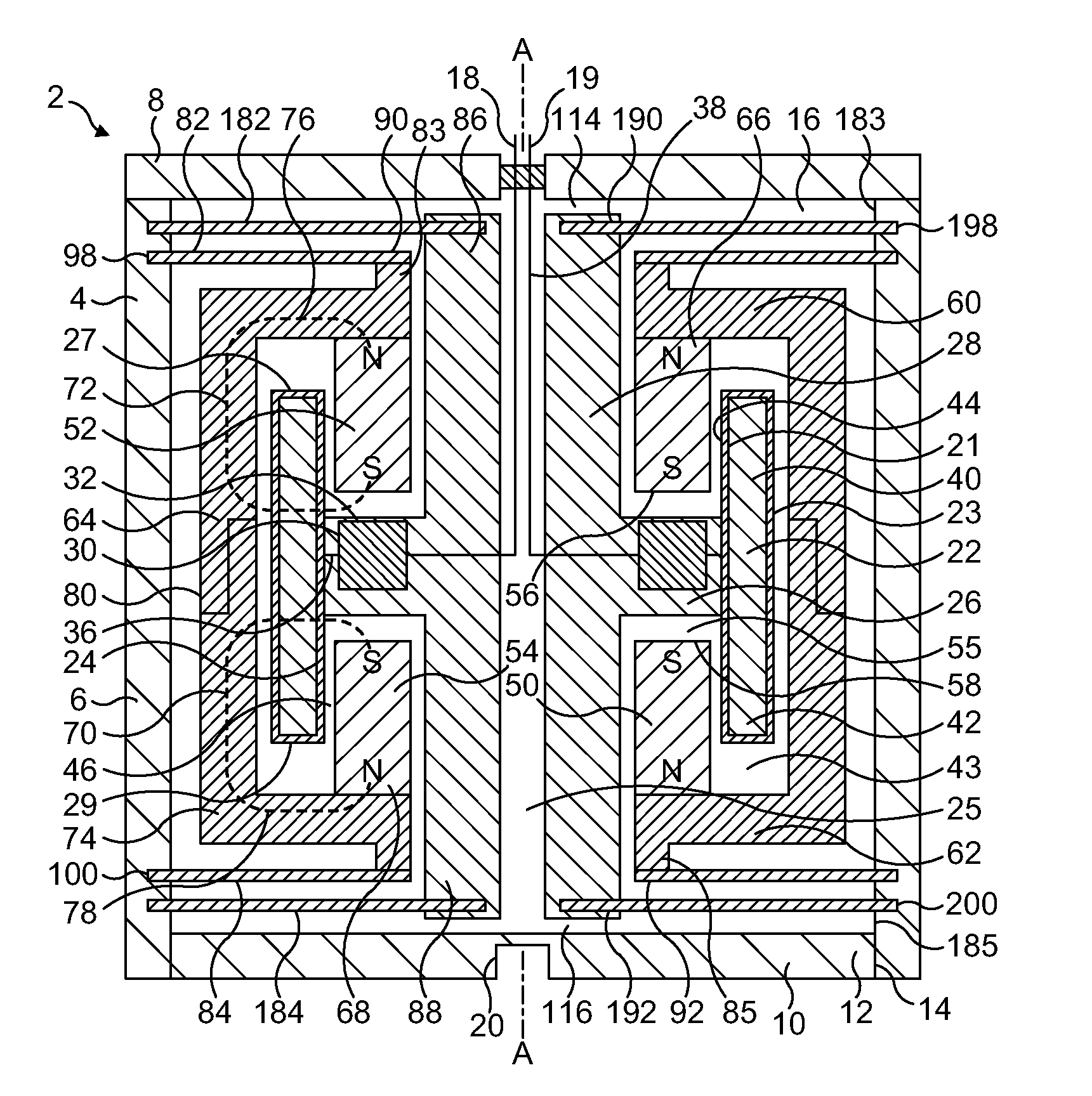

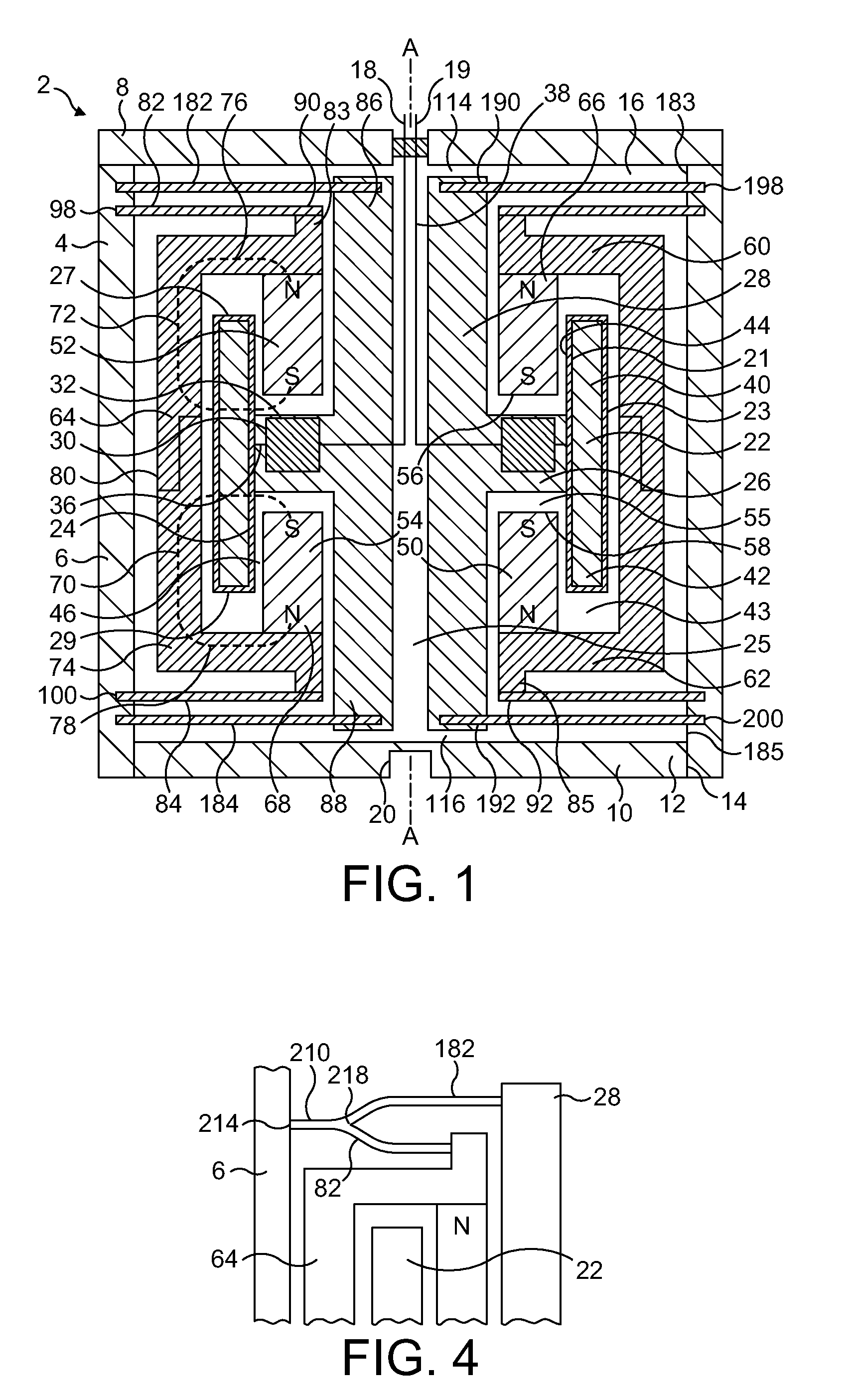

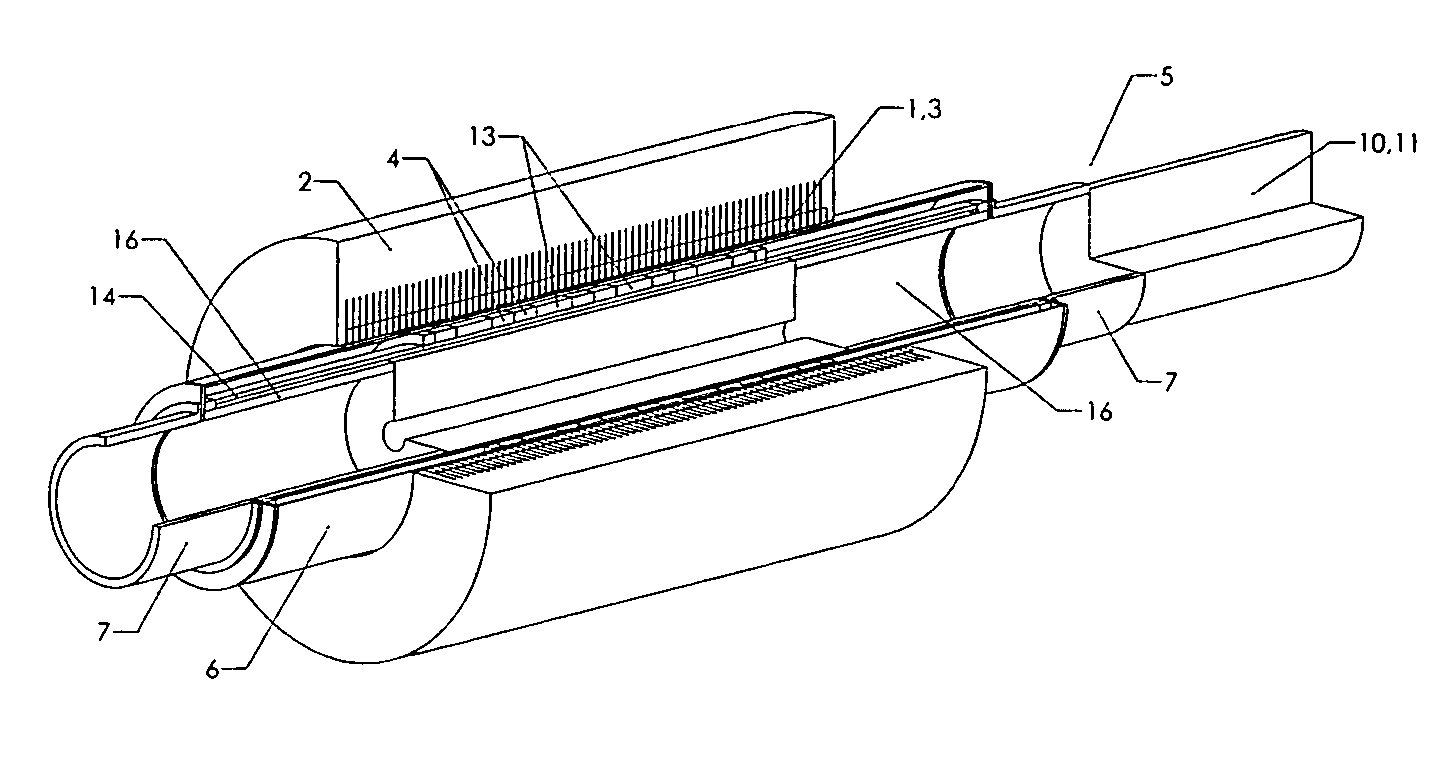

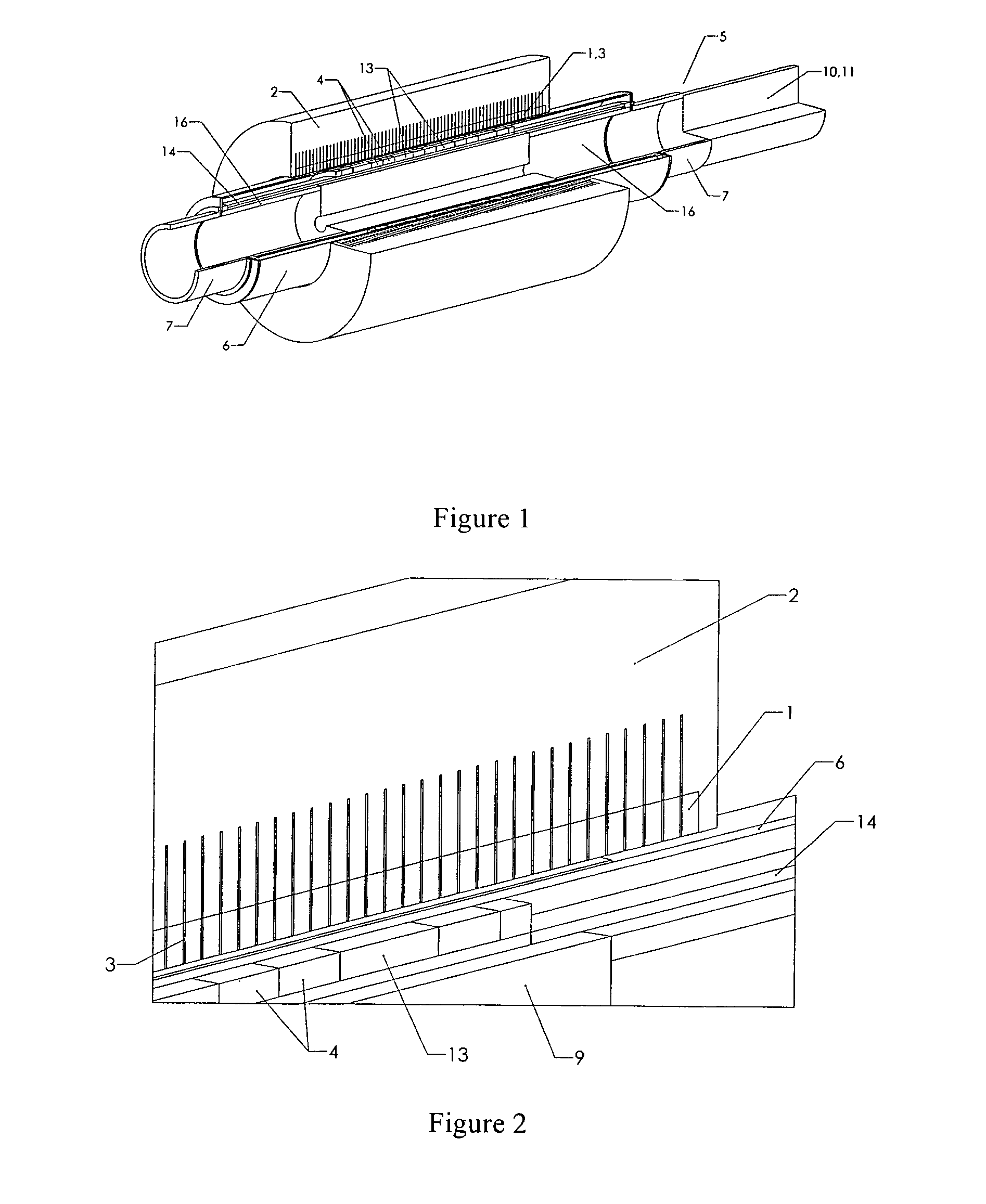

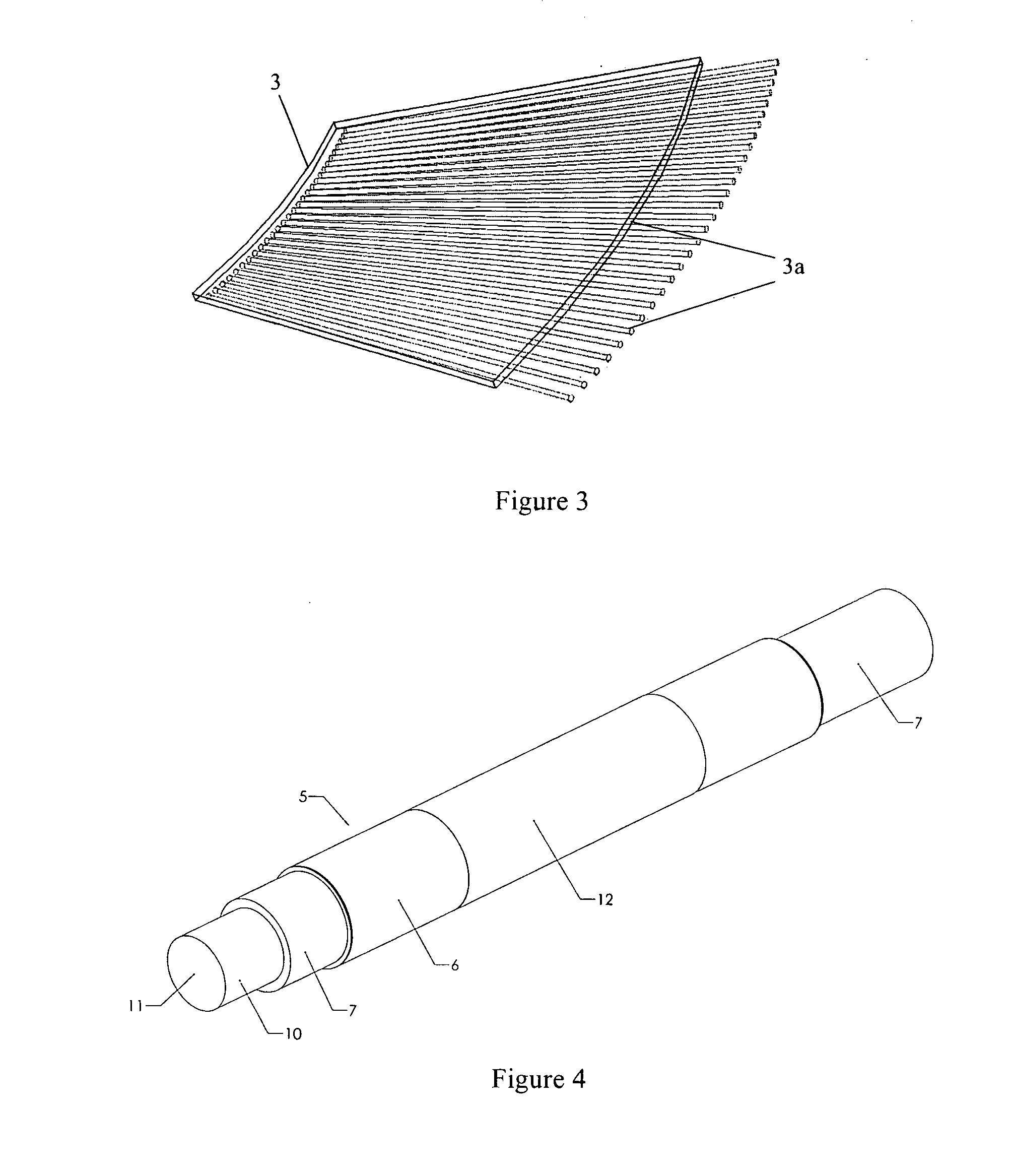

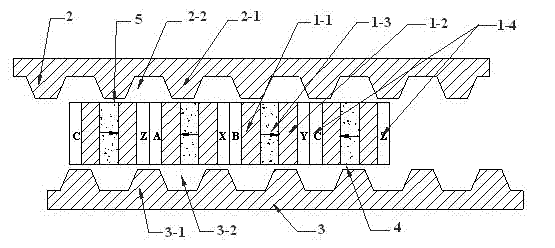

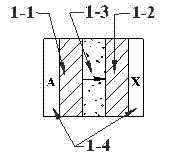

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS6936937B2Reduce demandIncrease demandWindingsMagnetic circuitReciprocating motionElectrical polarity

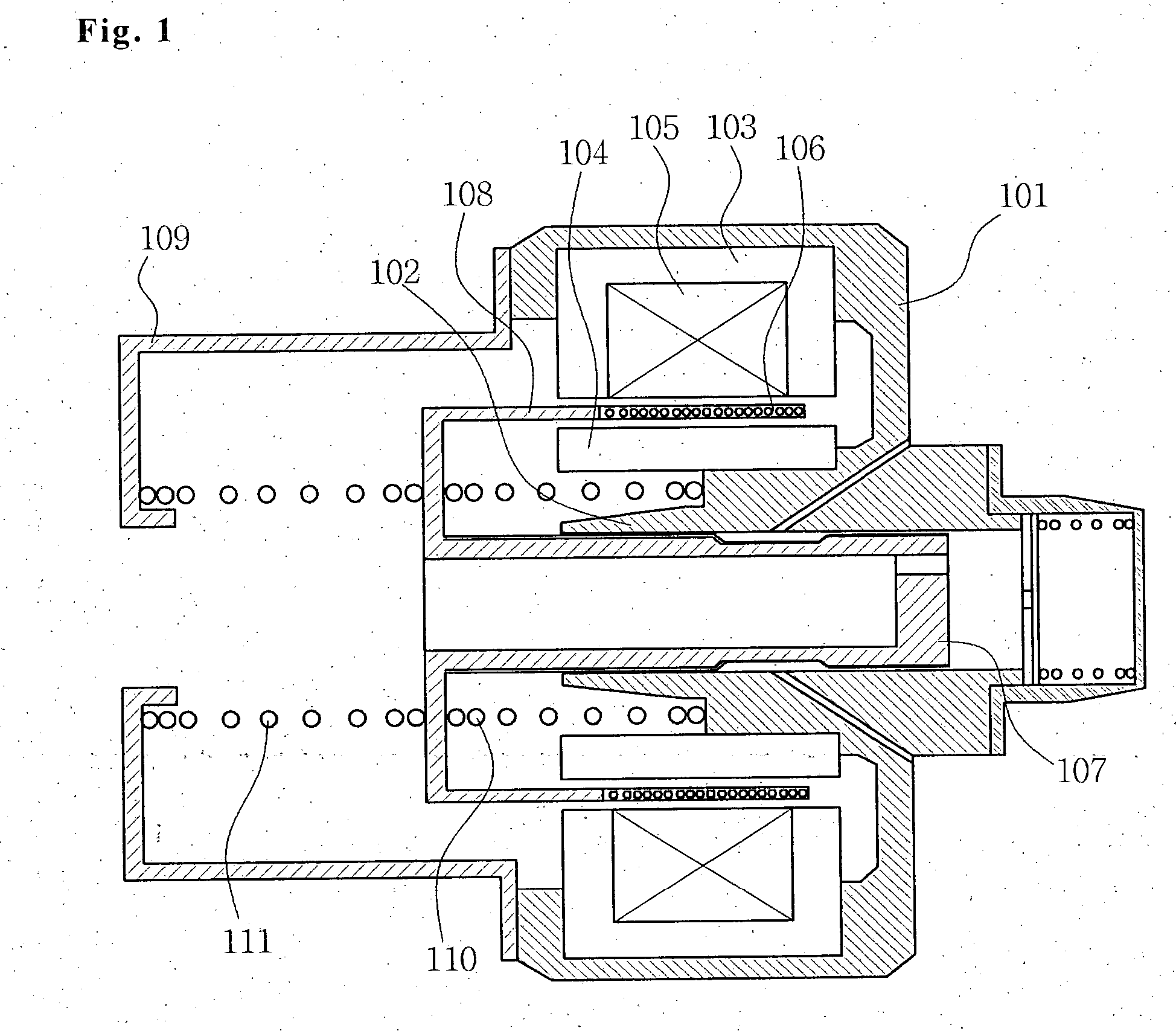

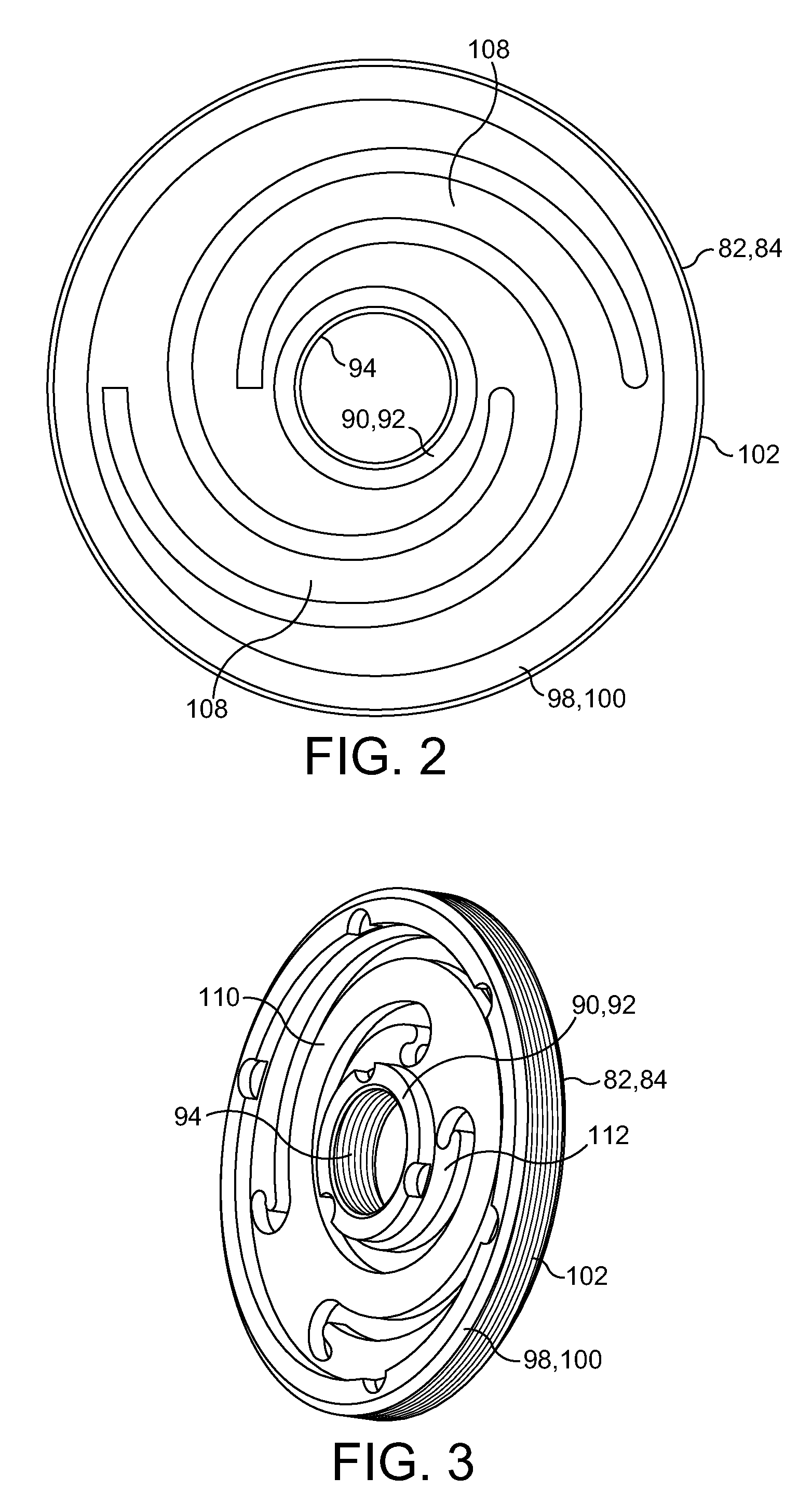

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

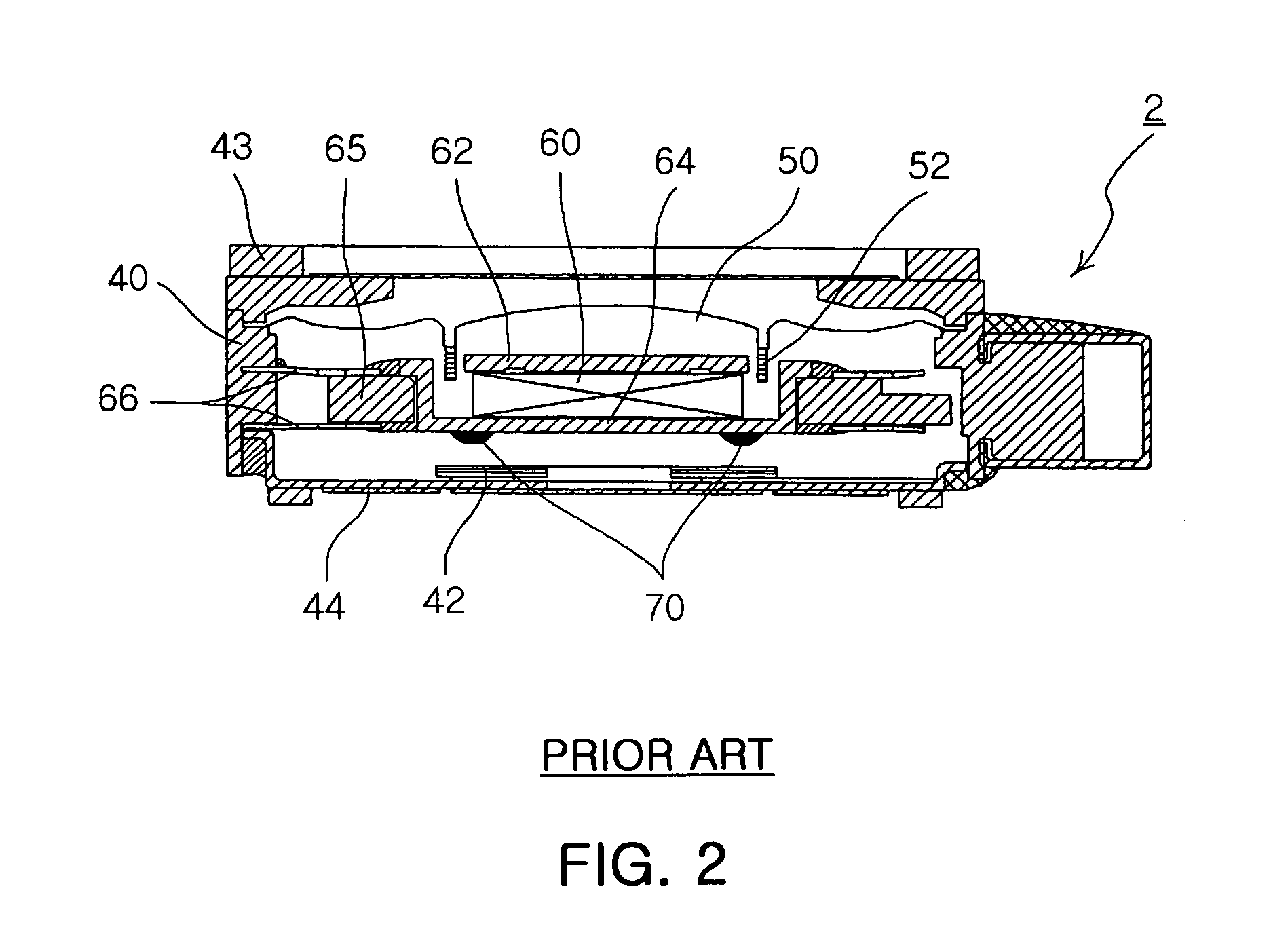

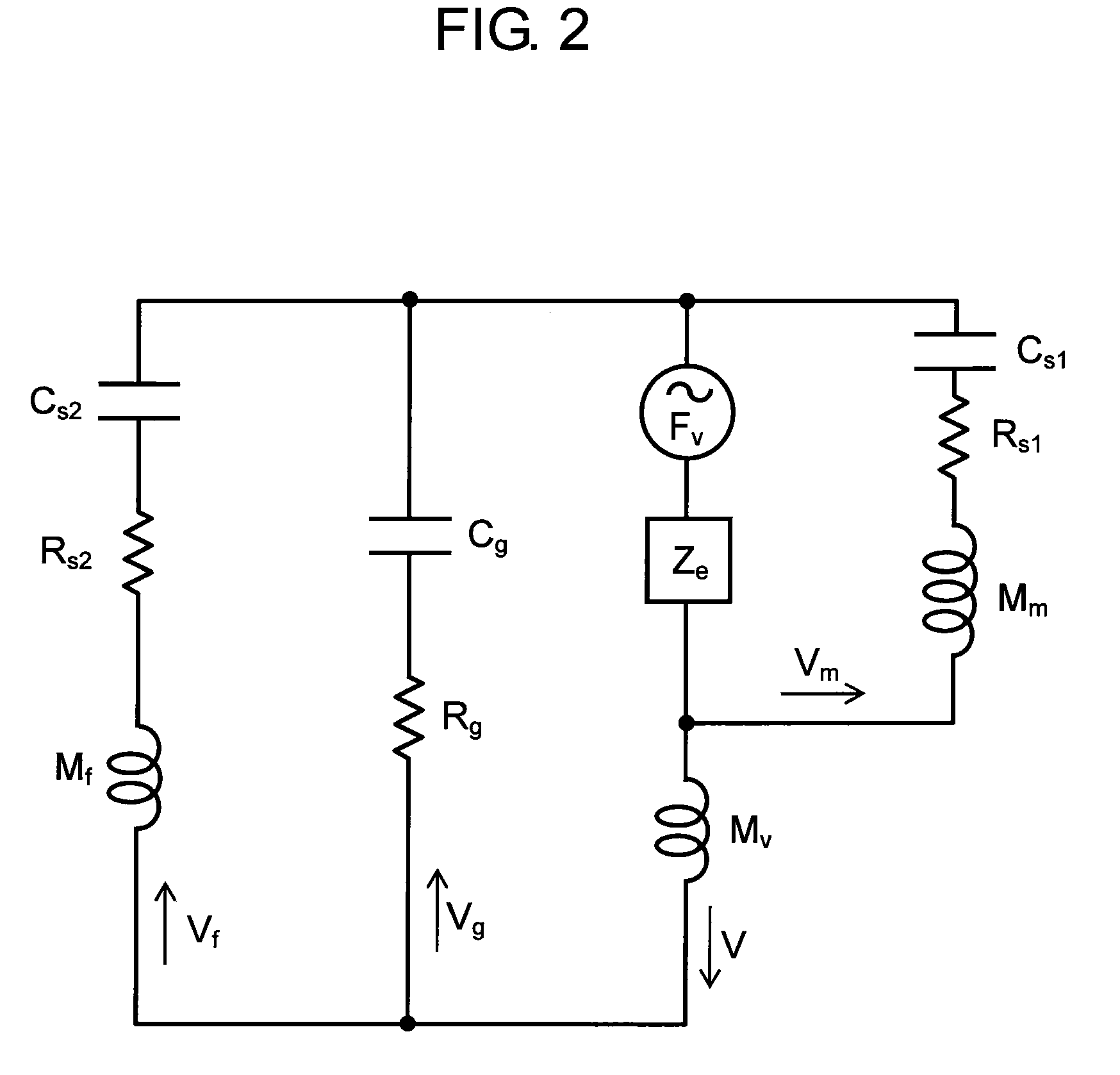

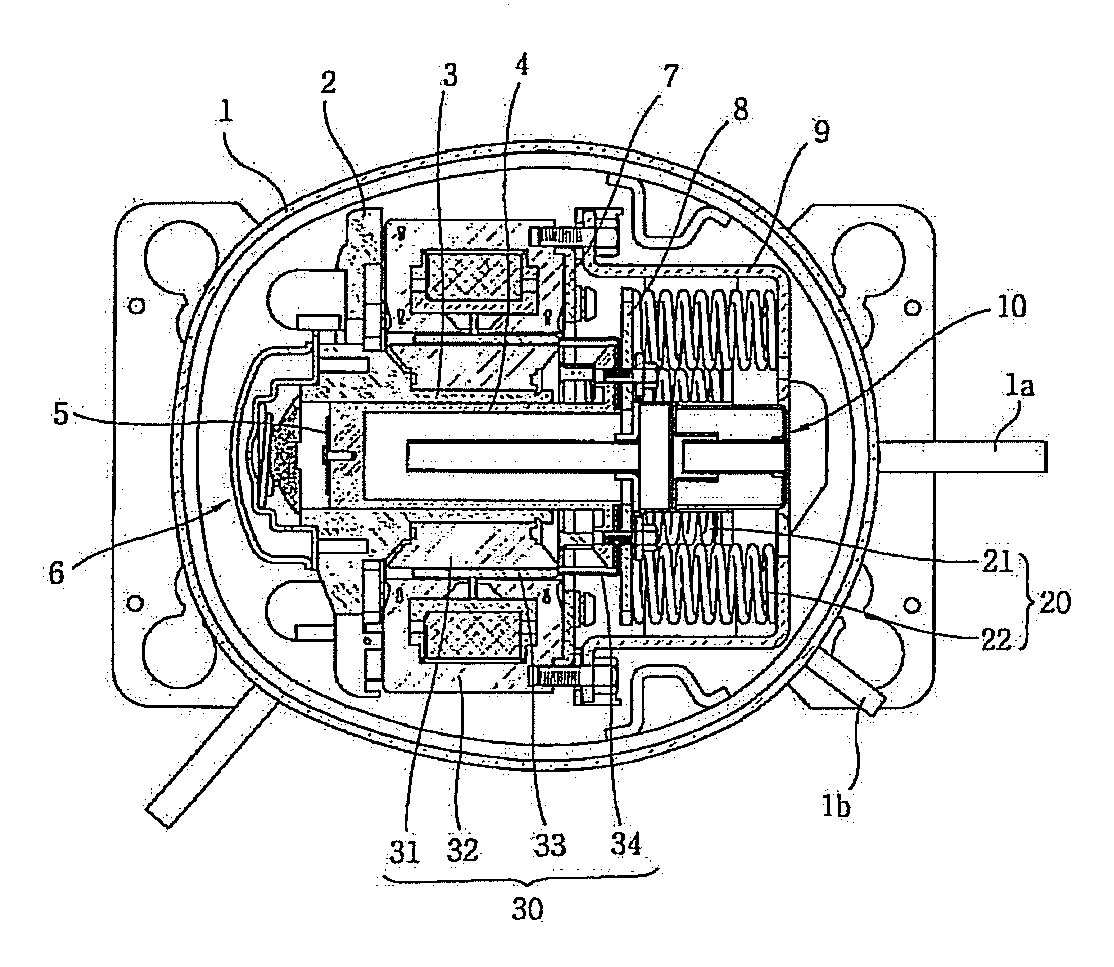

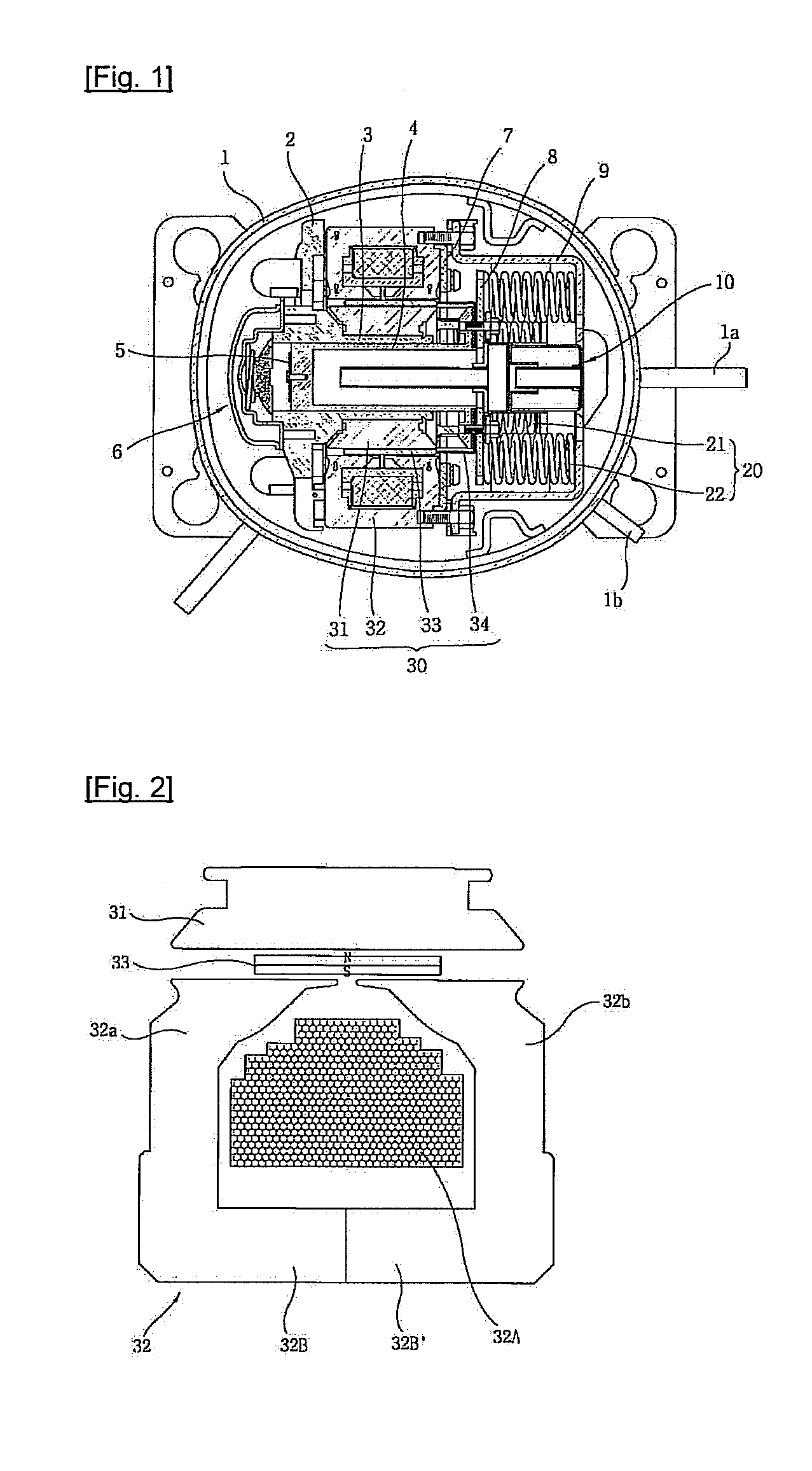

Electromechanical generator for converting mechanical vibrational energy into electrical energy

ActiveUS7586220B2Quality improvementSmall currentReciprocating/oscillating/vibrating magnetic circuit partsMachines/enginesFixed positionVibrational energy

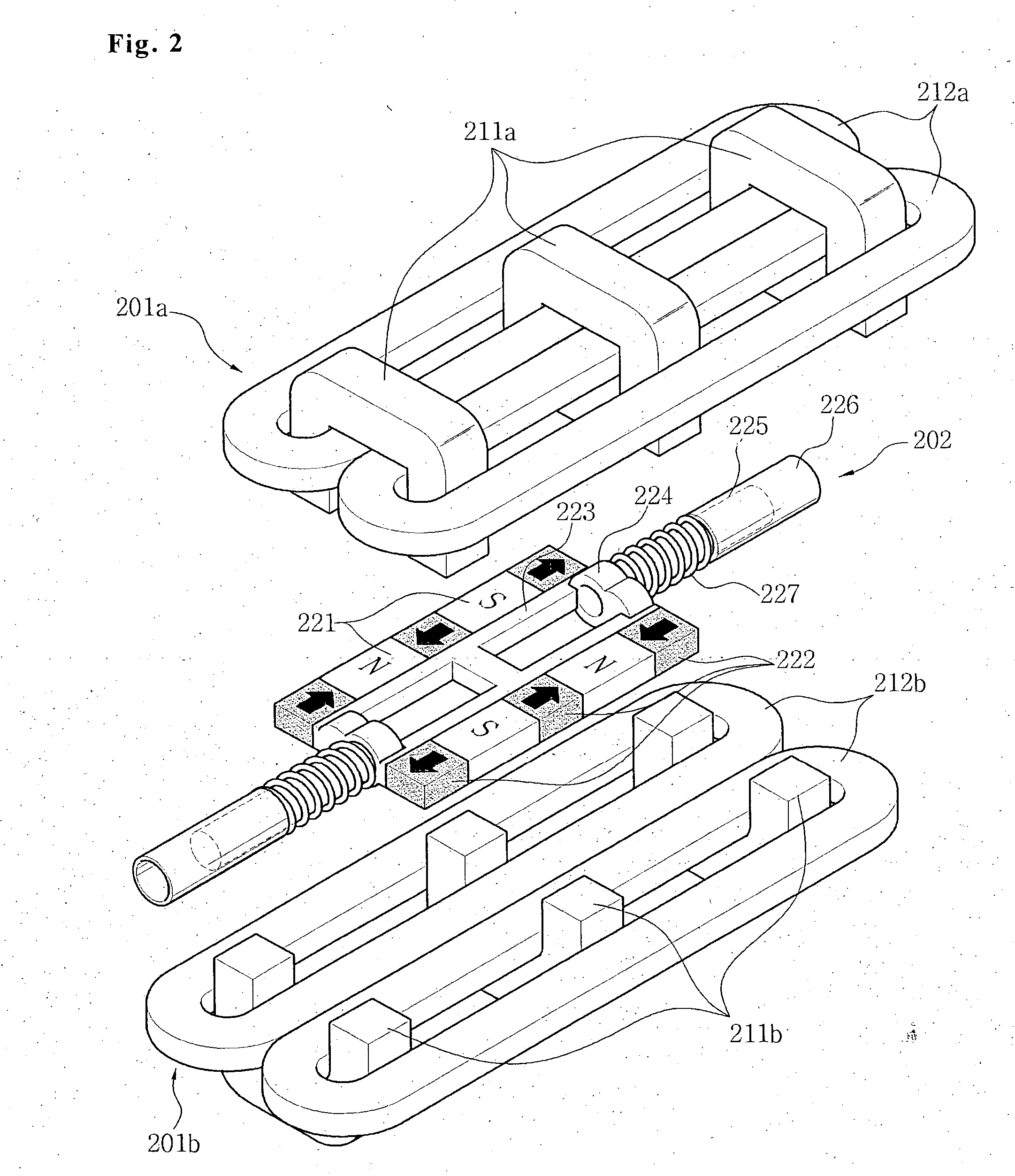

An electromechanical generator for converting mechanical vibrational energy into electrical energy, the electromechanical generator comprising a housing, an electrically conductive coil assembly fixedly mounted in the housing, the coil assembly having radially inner and outer sides, and upper and lower edges, thereof, a mount for the coil assembly extending inwardly of the radially inner side for fixing the coil assembly in a fixed position in the housing, a magnetic core assembly movably mounted in the housing for linear vibrational motion along an axis, and a biasing device mounted between the housing and the magnetic core assembly to bias the magnetic core assembly in opposed directions along the axis towards a central position, wherein the magnetic core assembly encloses the electrically conductive coil assembly on the radially outer side and on the upper and lower edges, and on a part of the radially inner side, the magnetic core assembly having a gap on a radially inner portion thereof through which the mount extends, and the radially inner portion including two opposed magnets spaced along the axis.

Owner:HITACHI RAIL LTD +1

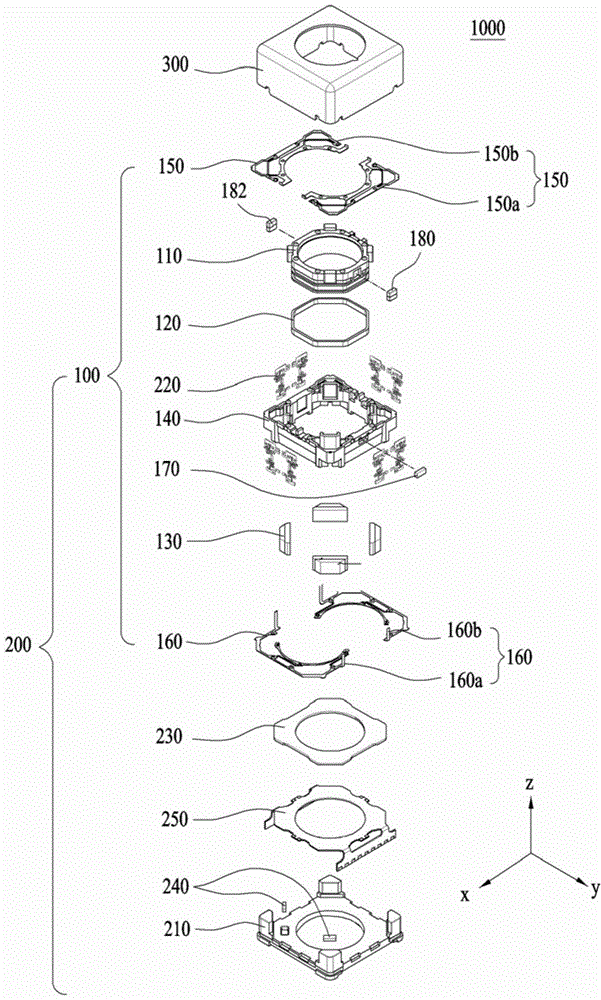

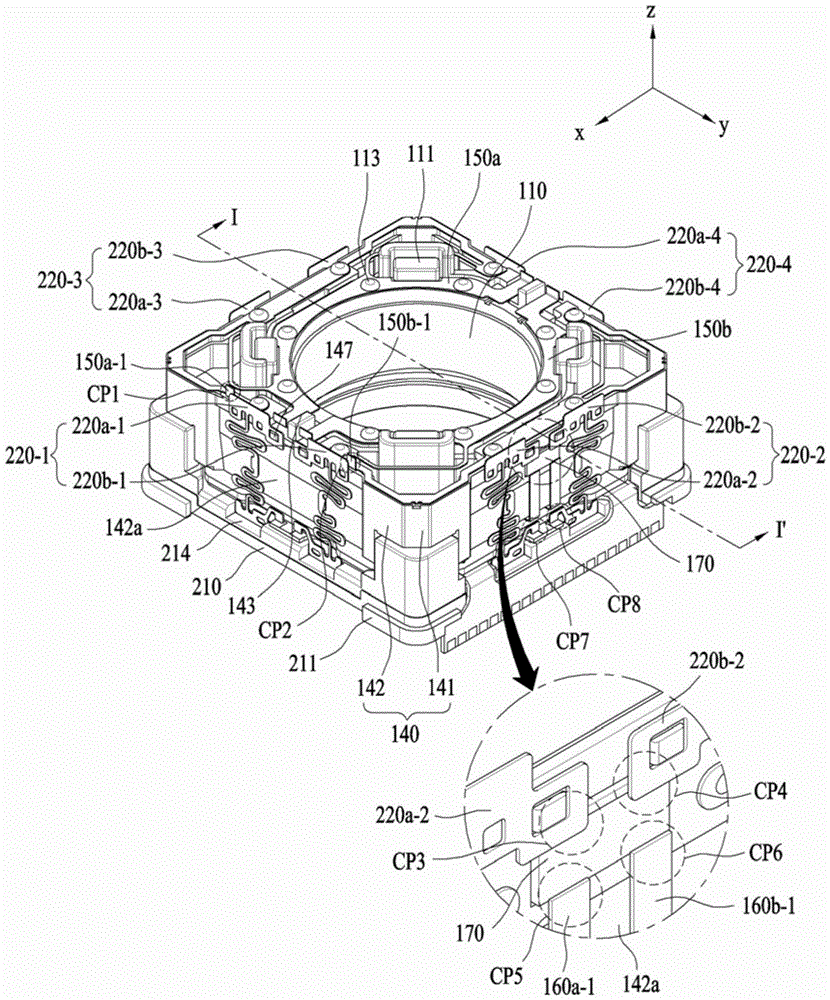

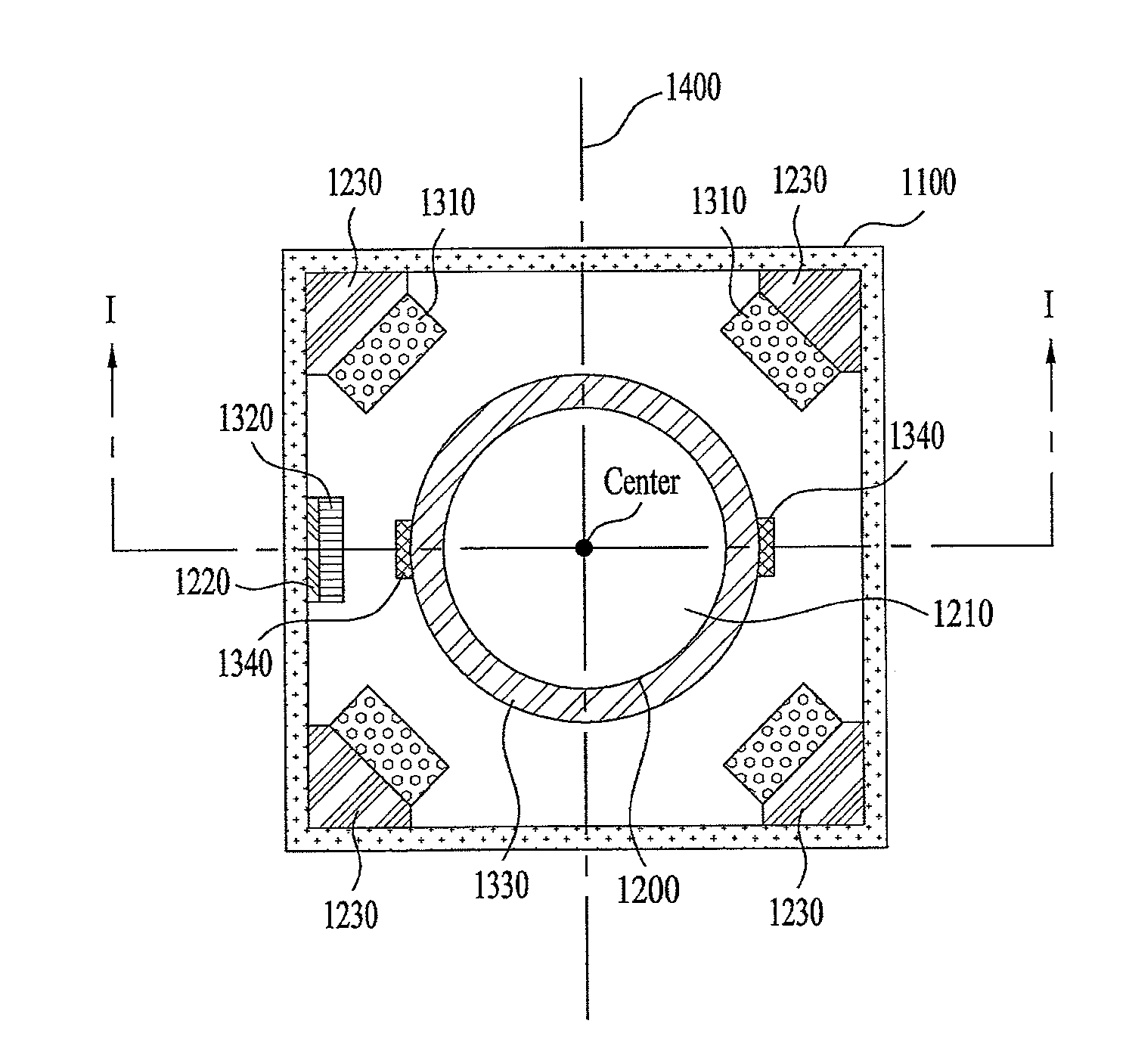

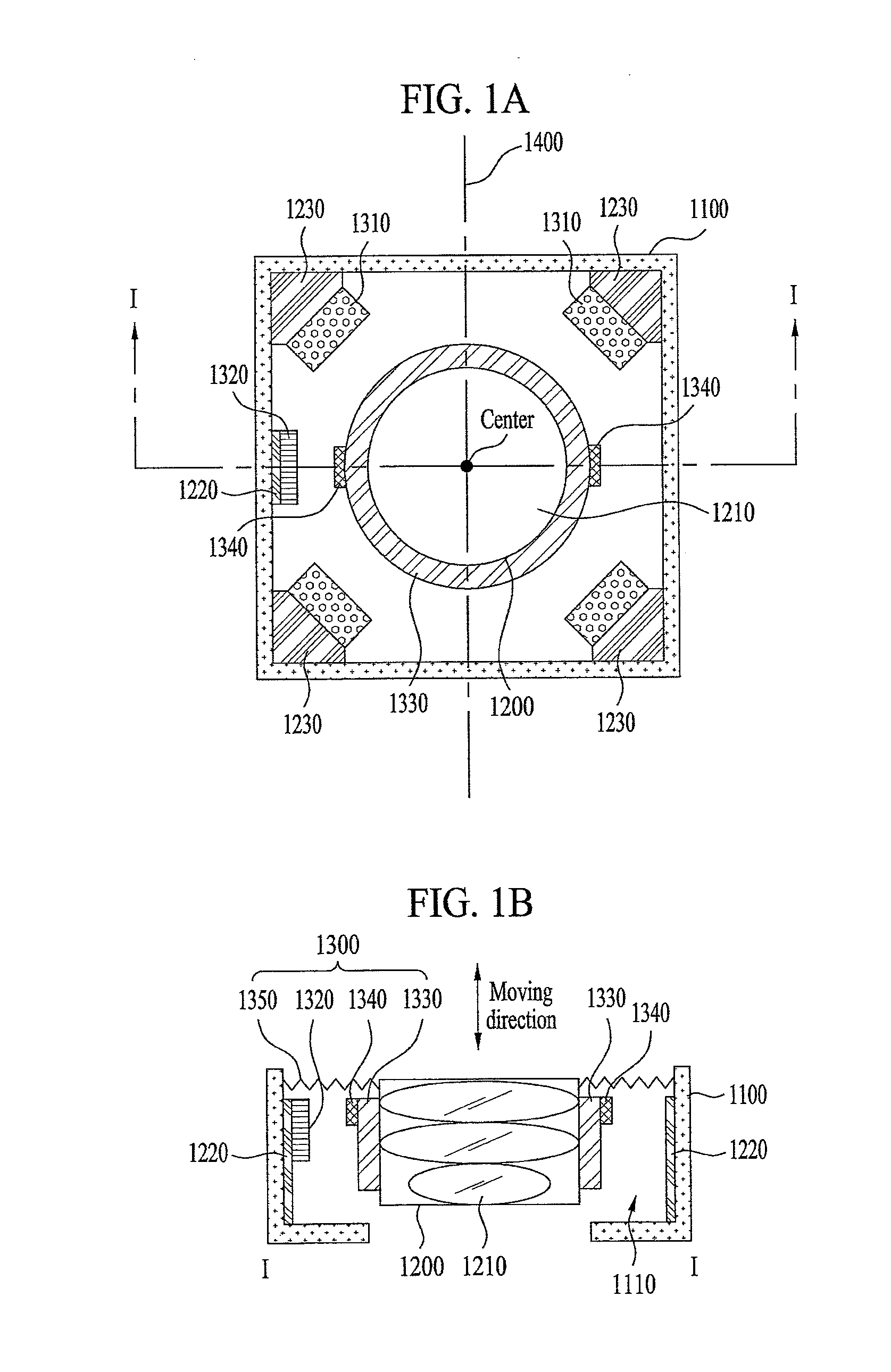

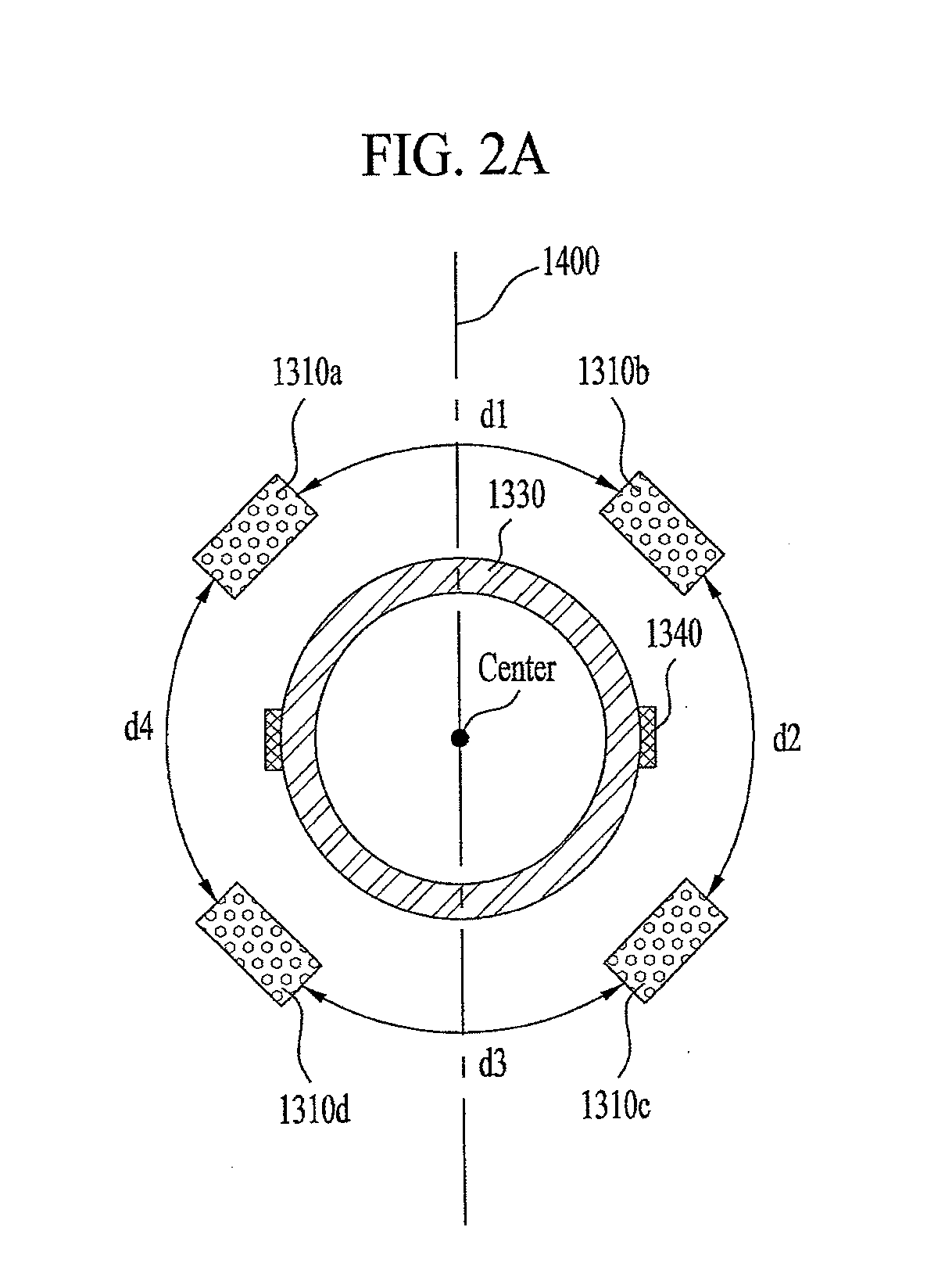

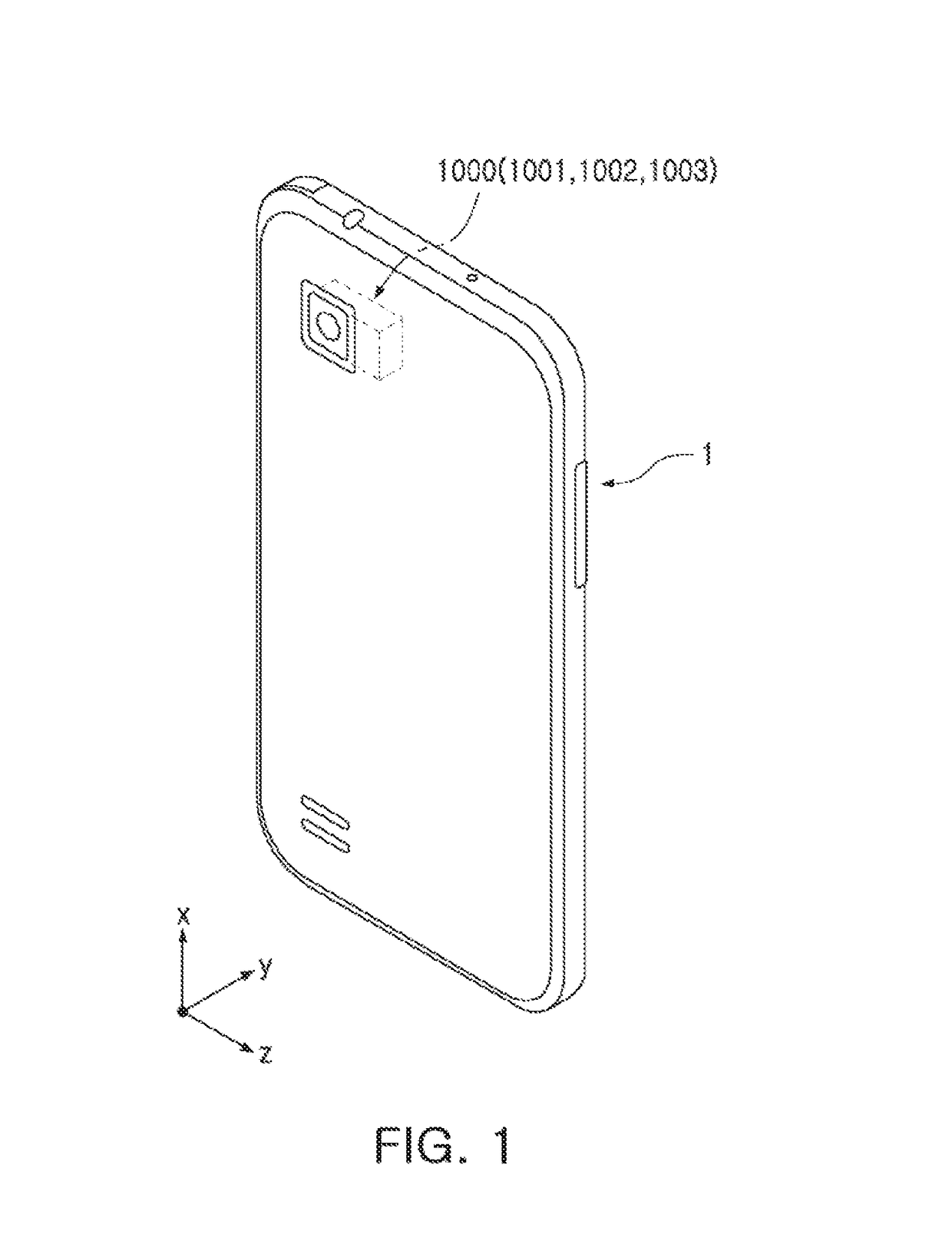

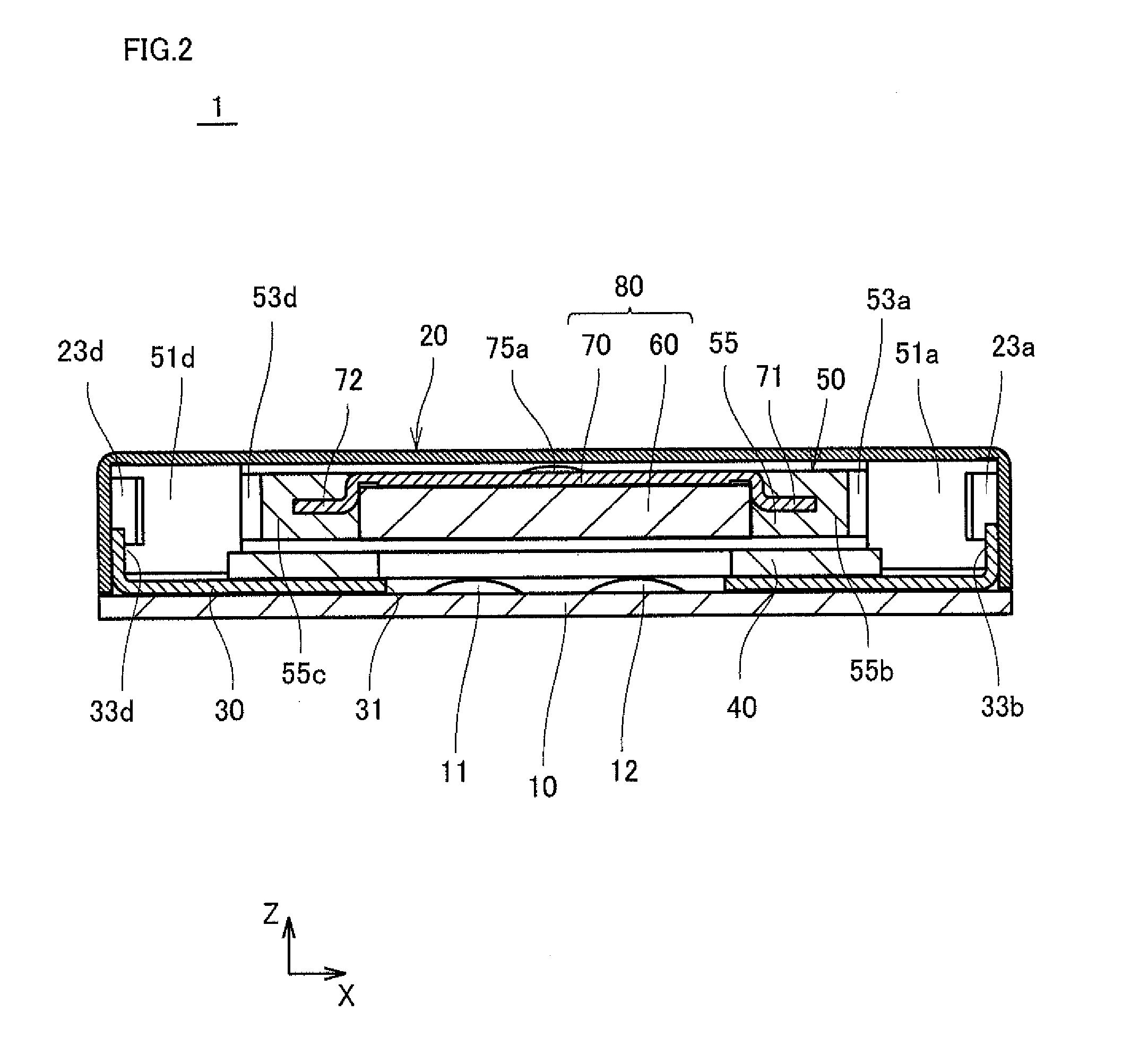

Lens moving unit and camera module having the same

ActiveCN104902149AReciprocating/oscillating/vibrating magnetic circuit partsTelevision system detailsBobbinEngineering

A lens moving apparatus includes a first lens moving unit including a bobbin having a first coil mounted at an outer circumference thereof, a first magnet being opposite to the first coil, and a housing for supporting the first magnet, and a second lens moving unit including a base, a plurality of support member pairs for supporting the housing such that the housing is movable relative to the base, and a second coil opposite to the first magnet, wherein each of the support member pairs includes first and second support members separated from each other, the first and second support members being disposed at the same side of the housing in a state in which the first and second support members are adjacent to each other, and power is supplied to the first coil through a first support member pair, which is one of the support member pairs.

Owner:LG INNOTEK CO LTD

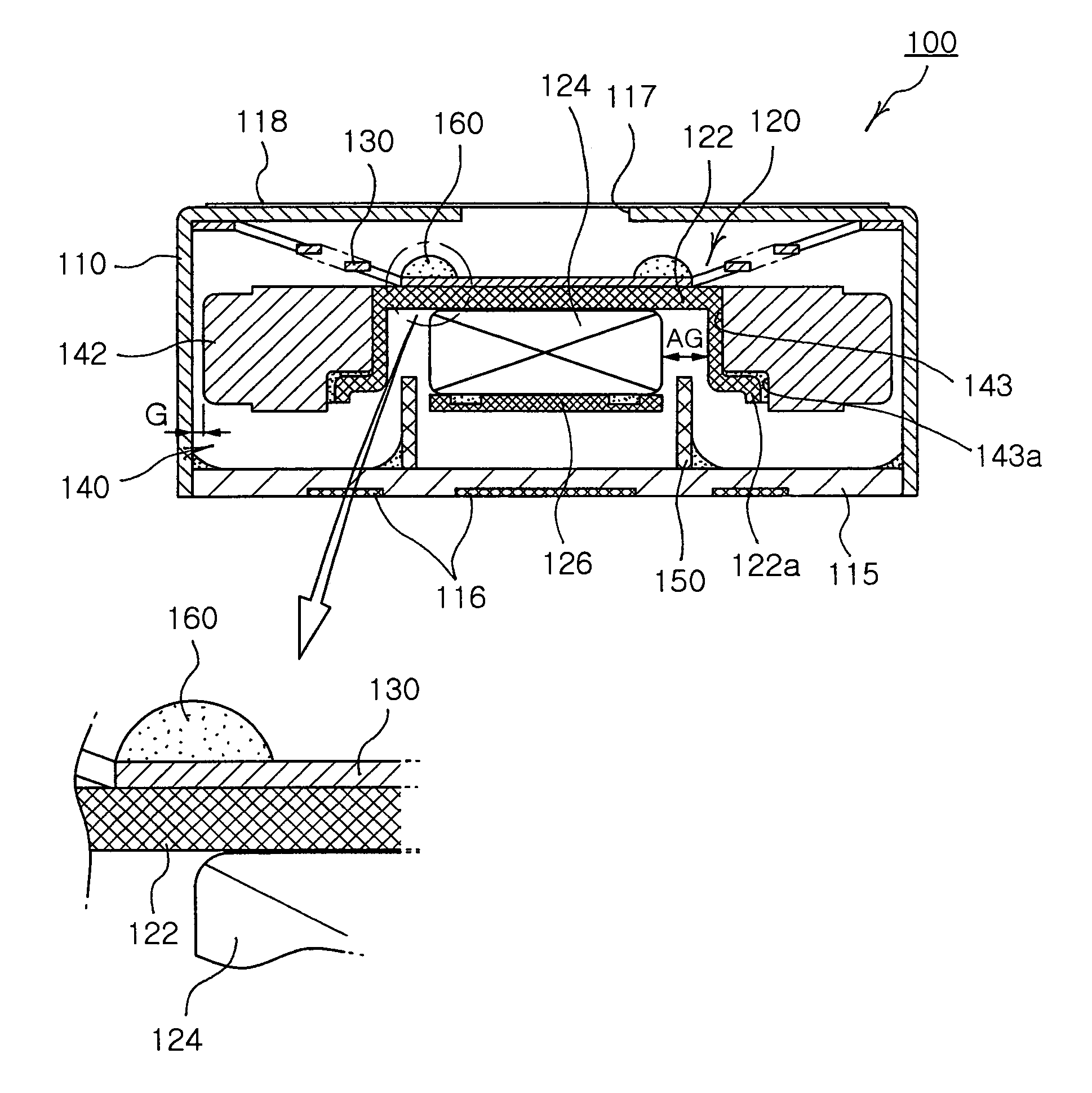

Camera module and method for auto focusing thereof

ActiveUS20150207983A1Reduce proper vibrationReciprocating/oscillating/vibrating magnetic circuit partsTelevision system detailsEngineeringCamera module

A camera module including a fixing unit including a hole formed therein a moving unit including at least one lens, and configured to linearly move in the hole of the fixing unit; and a driving unit configured to drive the moving unit. Further, the driving unit includes a corresponding magnet arranged in the inner surface of the hole of the fixing unit; a moving coil surrounding the outer surface of the moving unit; and a fixed coil arranged in the fixing unit and configured to receive from the moving coil a current or voltage variable based on a distance with the moving coil.

Owner:LG ELECTRONICS INC

Vertical vibrator

ActiveUS7038335B2Stable waveformConvenient positioningReciprocating/oscillating/vibrating magnetic circuit partsTransducer detailsVertical vibrationEngineering

A vertical vibrator is disclosed. The vibrator comprises a casing, a magnetic field part including a yoke and a magnet fixed to an inner surface of the yoke, a spring member fixed at one end to the casing and at the other end to the magnetic field part, a vibration part having a weight integrally mounted to the magnetic field part and vibrating together with the magnetic field part through the spring member, a vibration coil located below the magnetic field part for generating an electric field, and a magnetic fluid applied to an upper surface of the spring member corresponding to the magnet and fixed in position by a magnetic flux. The vibrator absorbs contact noise and impact caused by contact between the vibration part and the other members while ensuring convenient and appropriate positioning of the magnetic fluid, thereby having an extended life span.

Owner:MPLUS

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS20050225181A1Reduce demandIncrease demandReciprocating/oscillating/vibrating magnetic circuit partsMagnetsReciprocating motionElectrical polarity

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

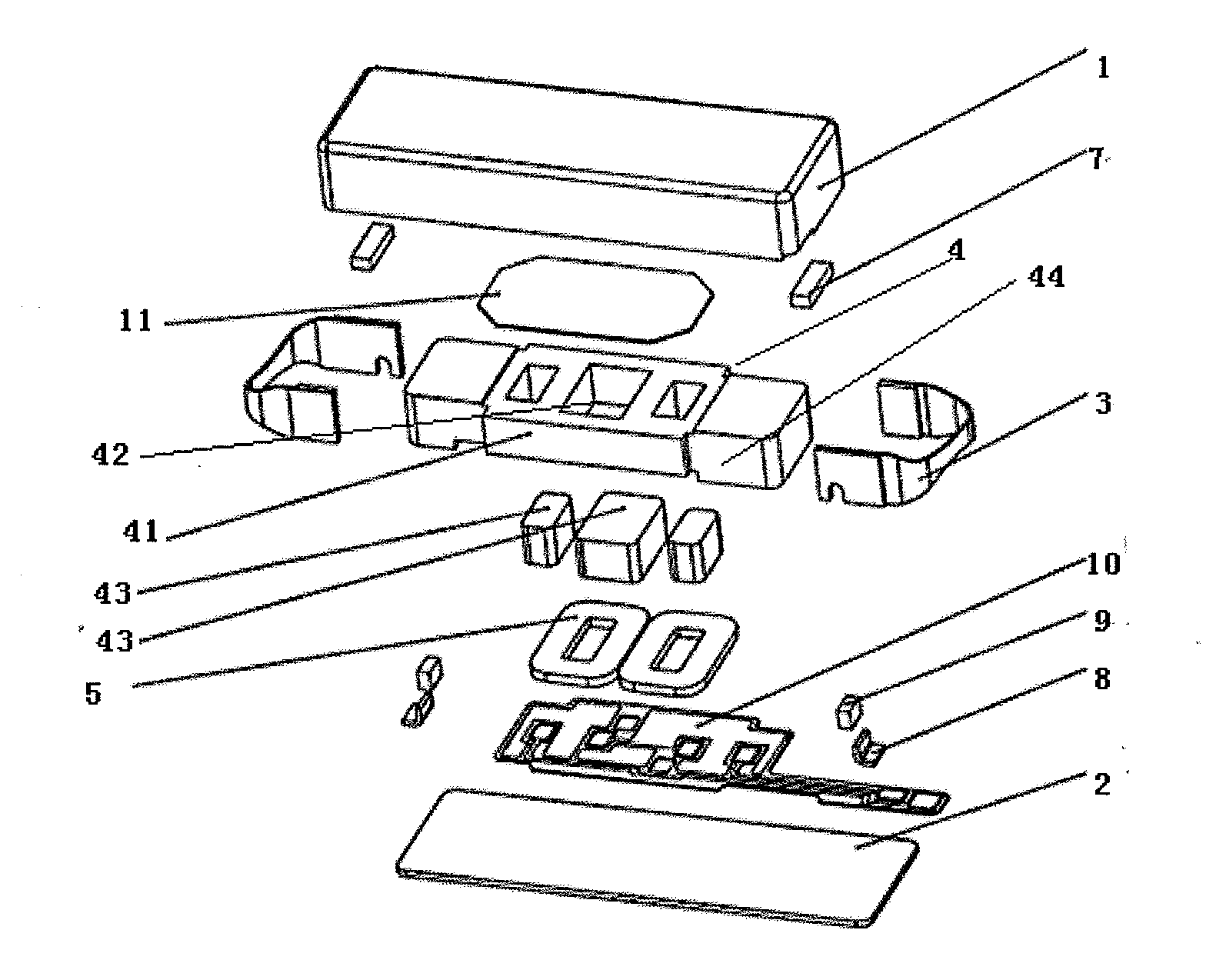

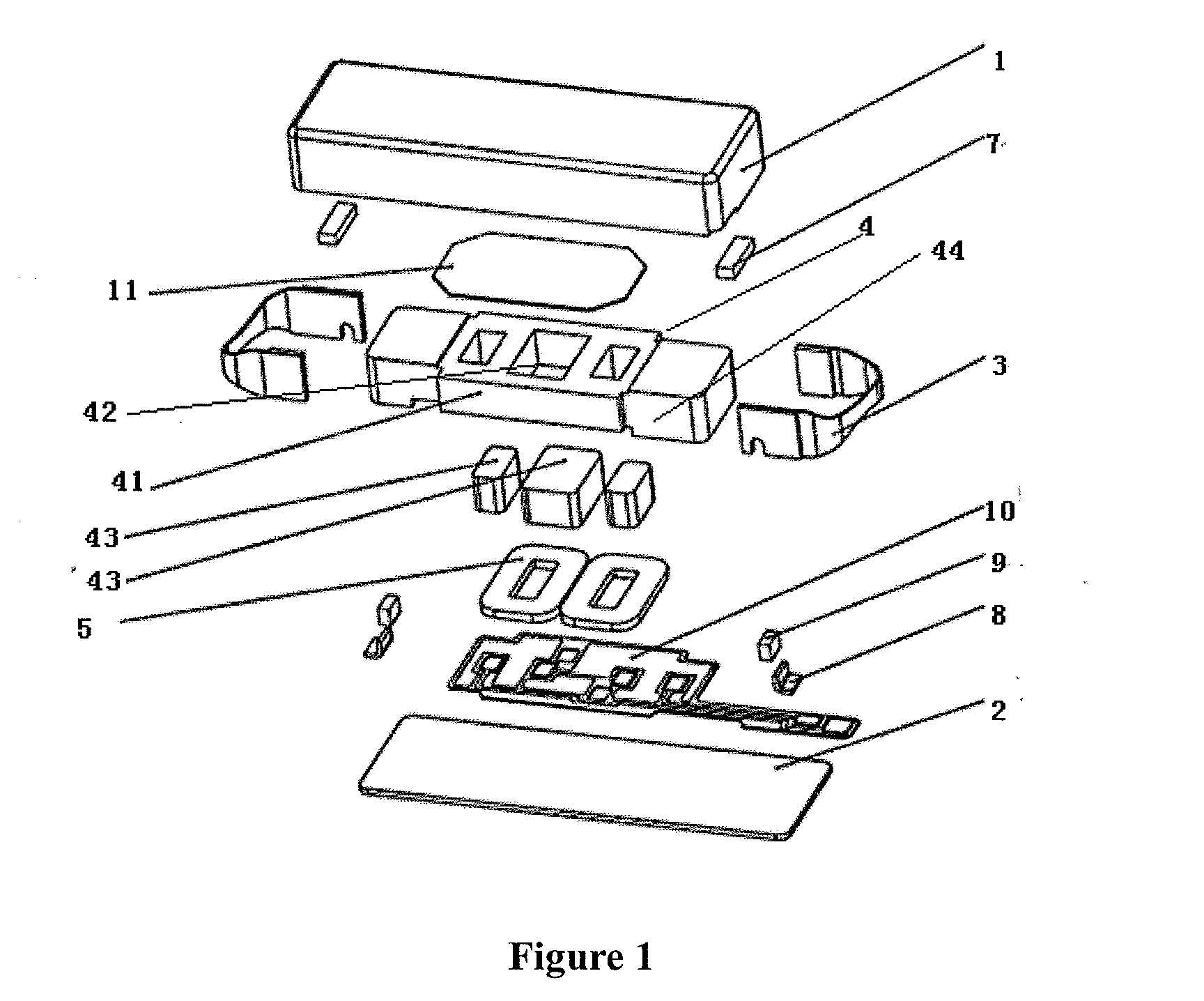

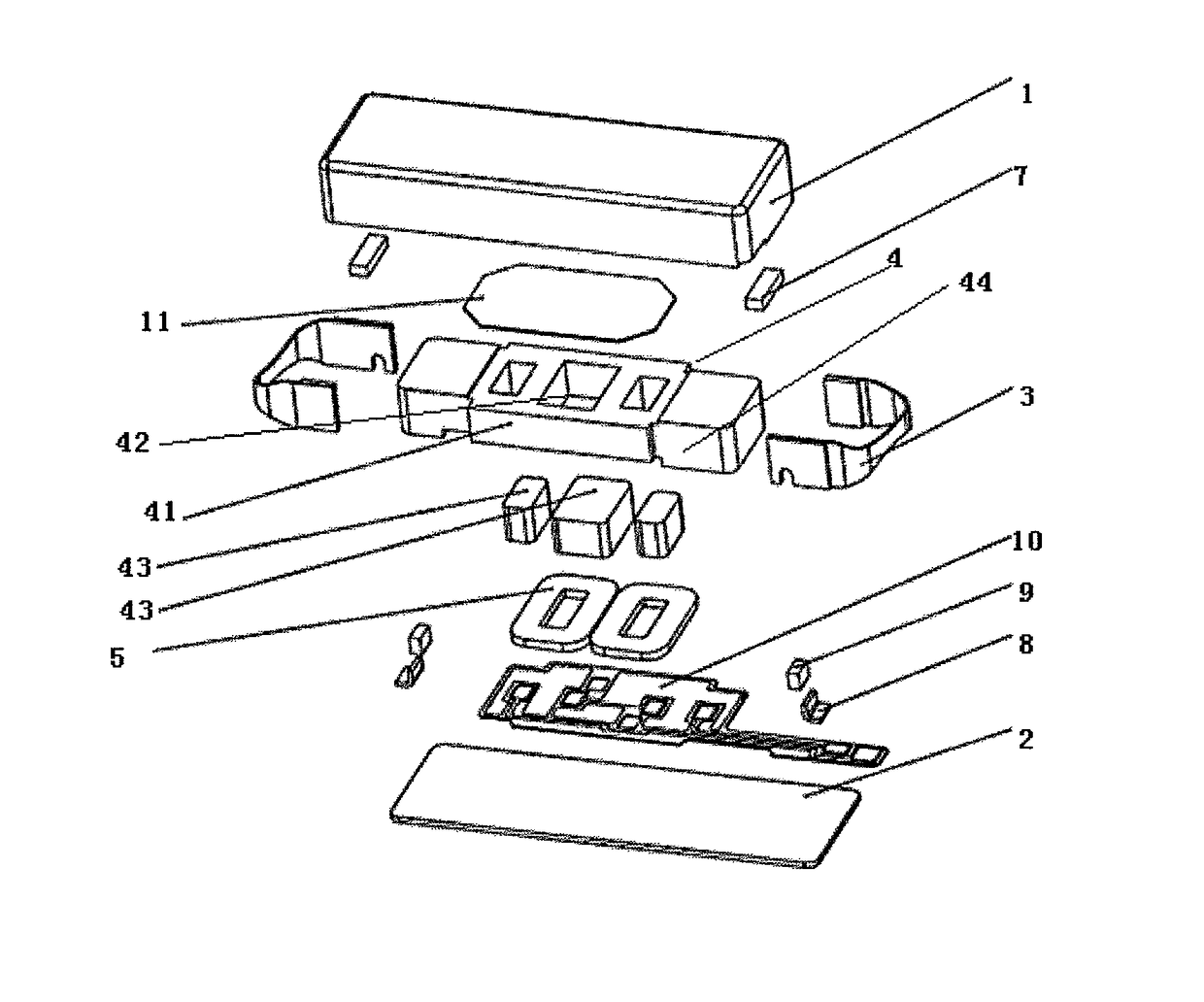

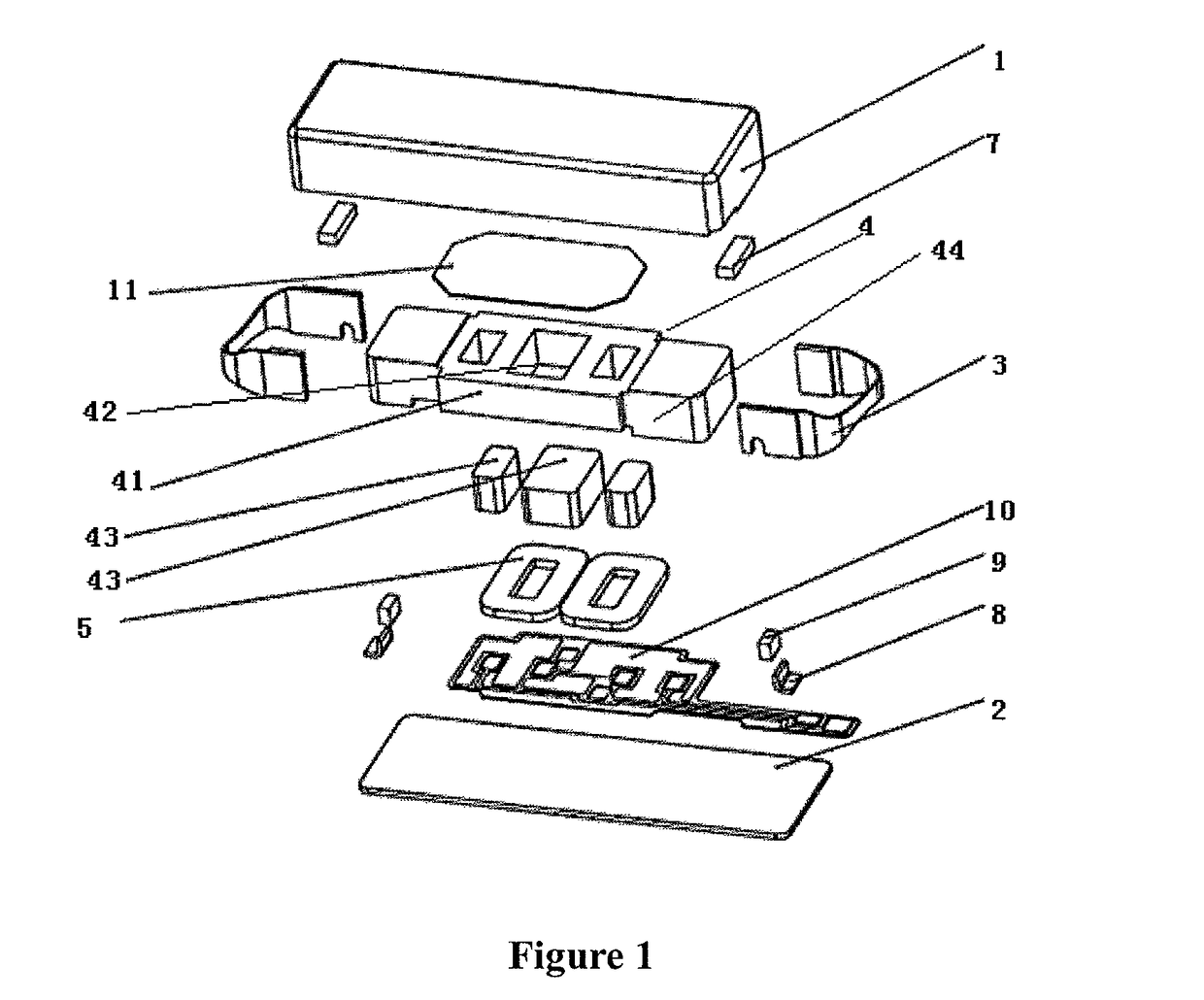

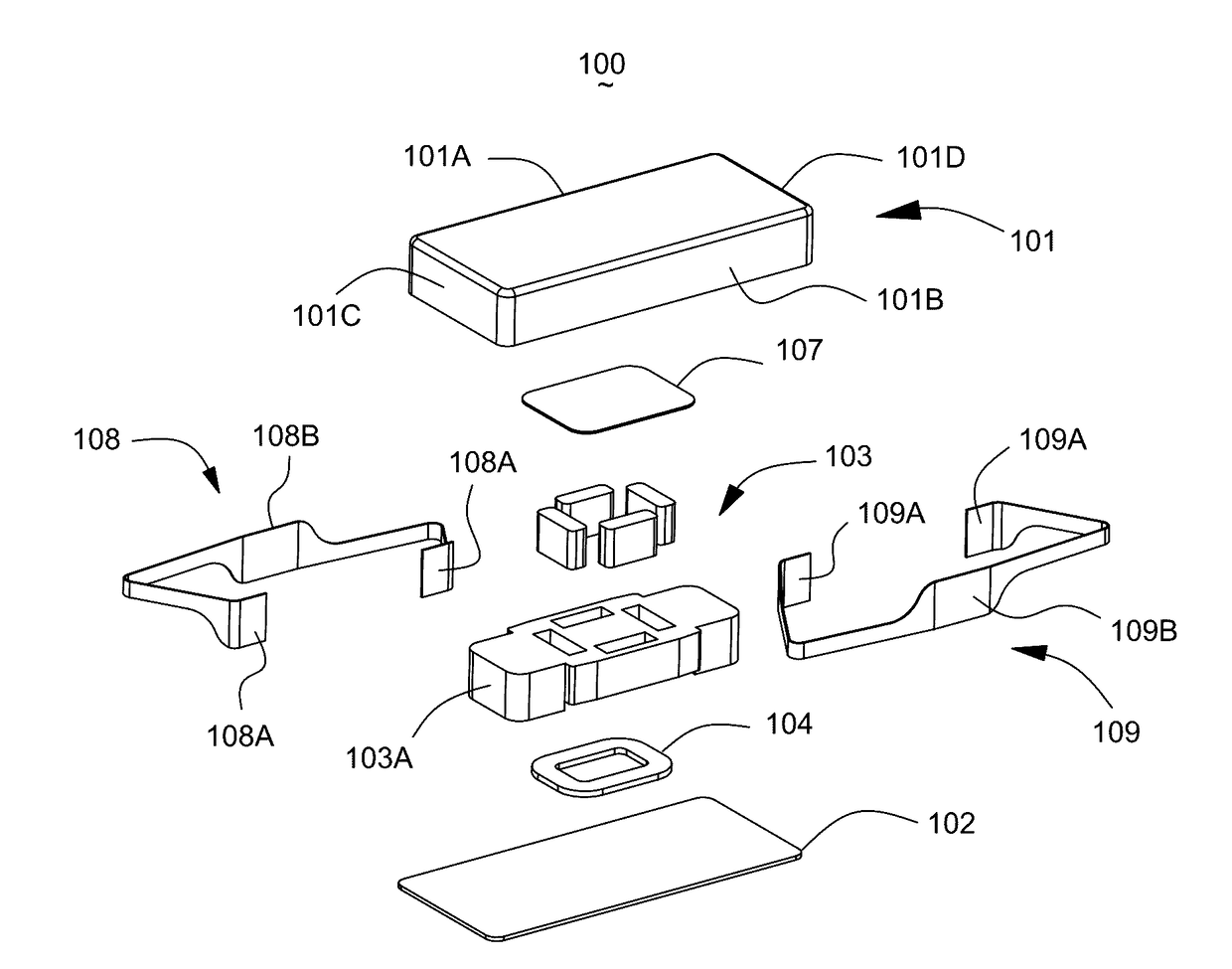

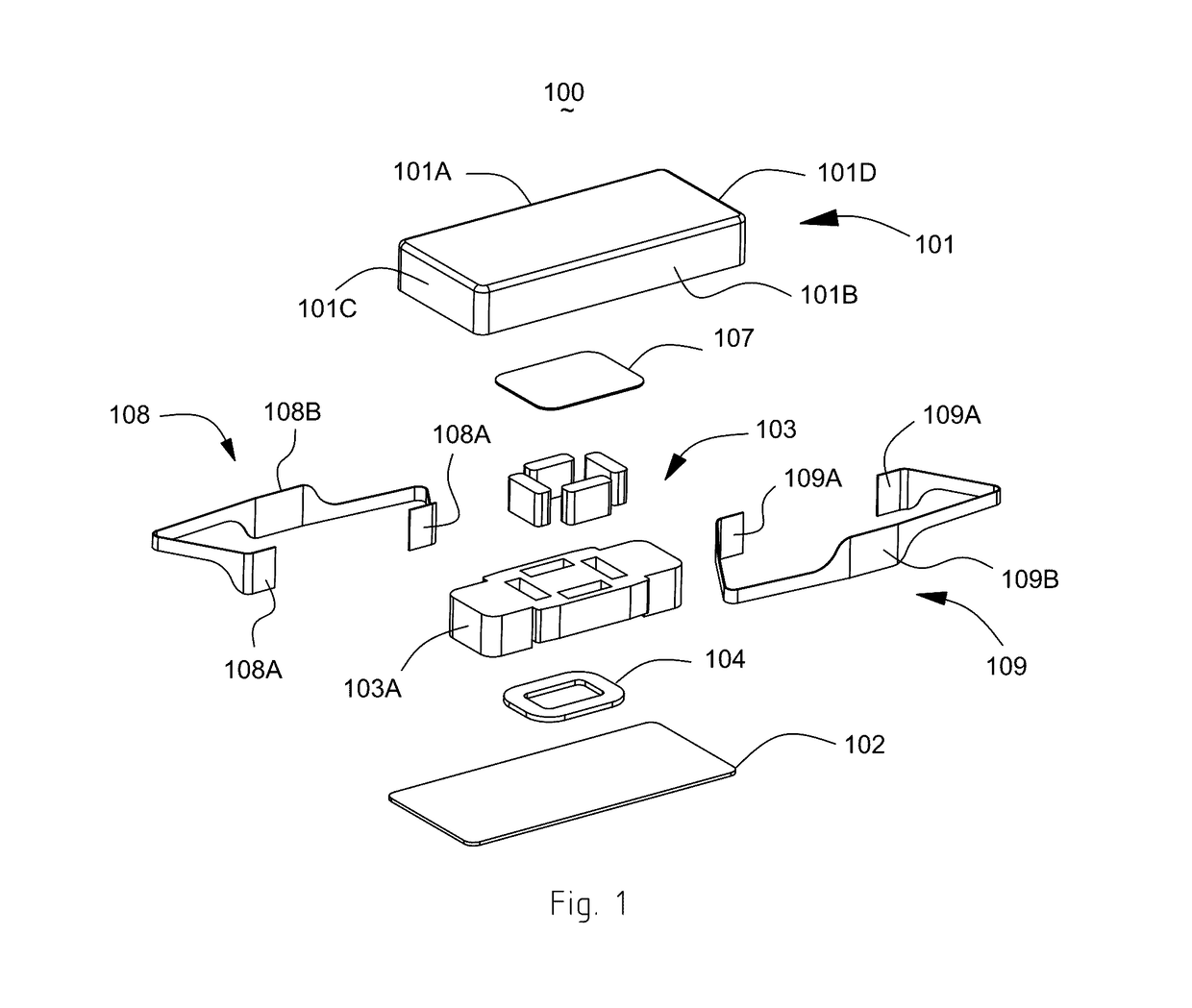

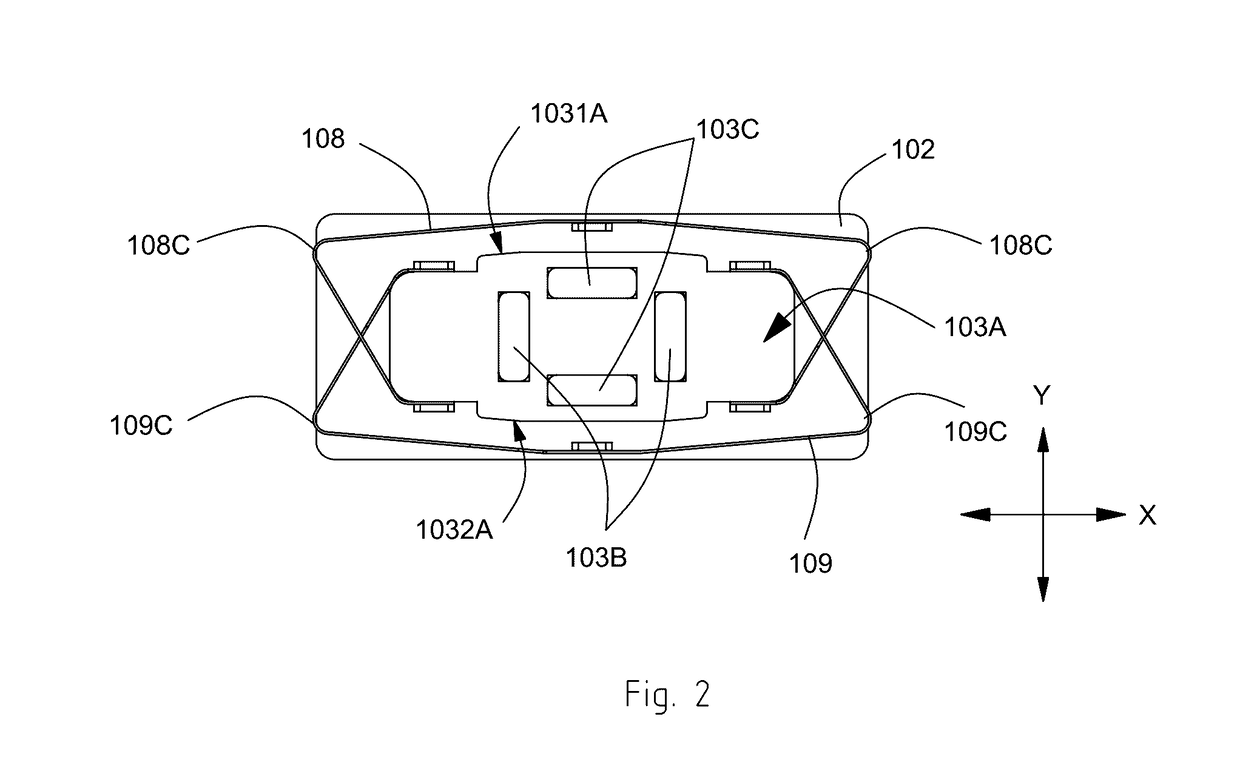

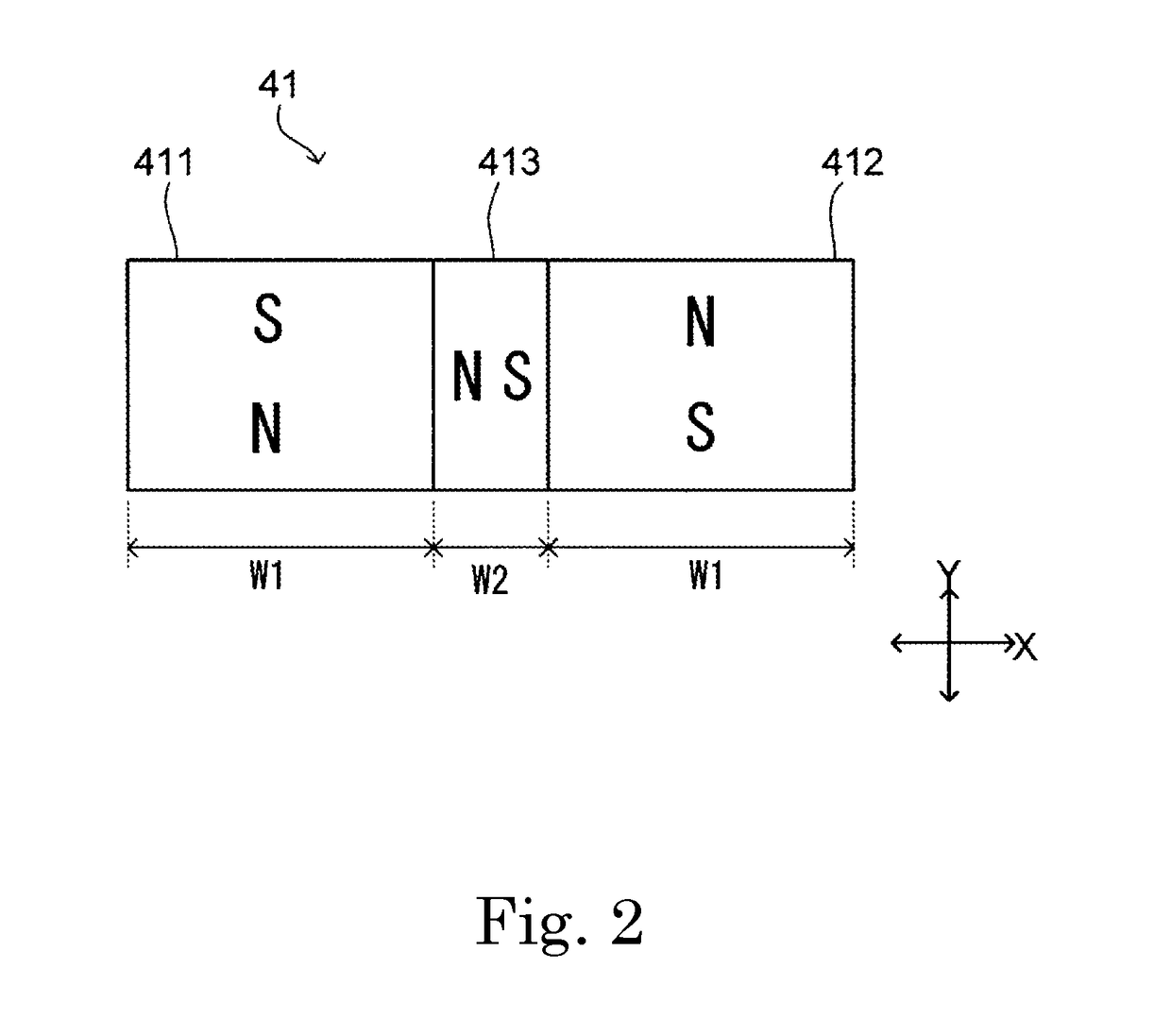

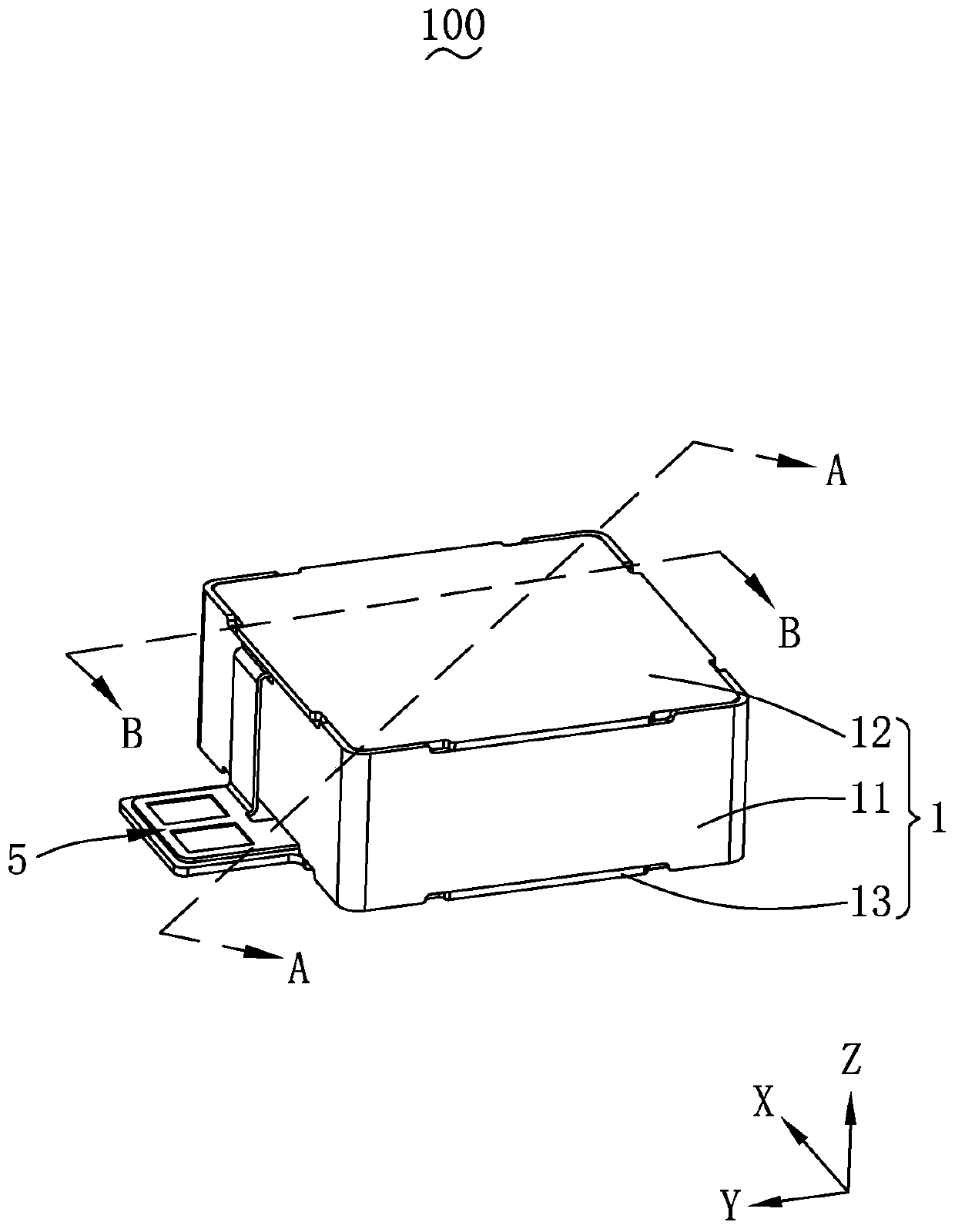

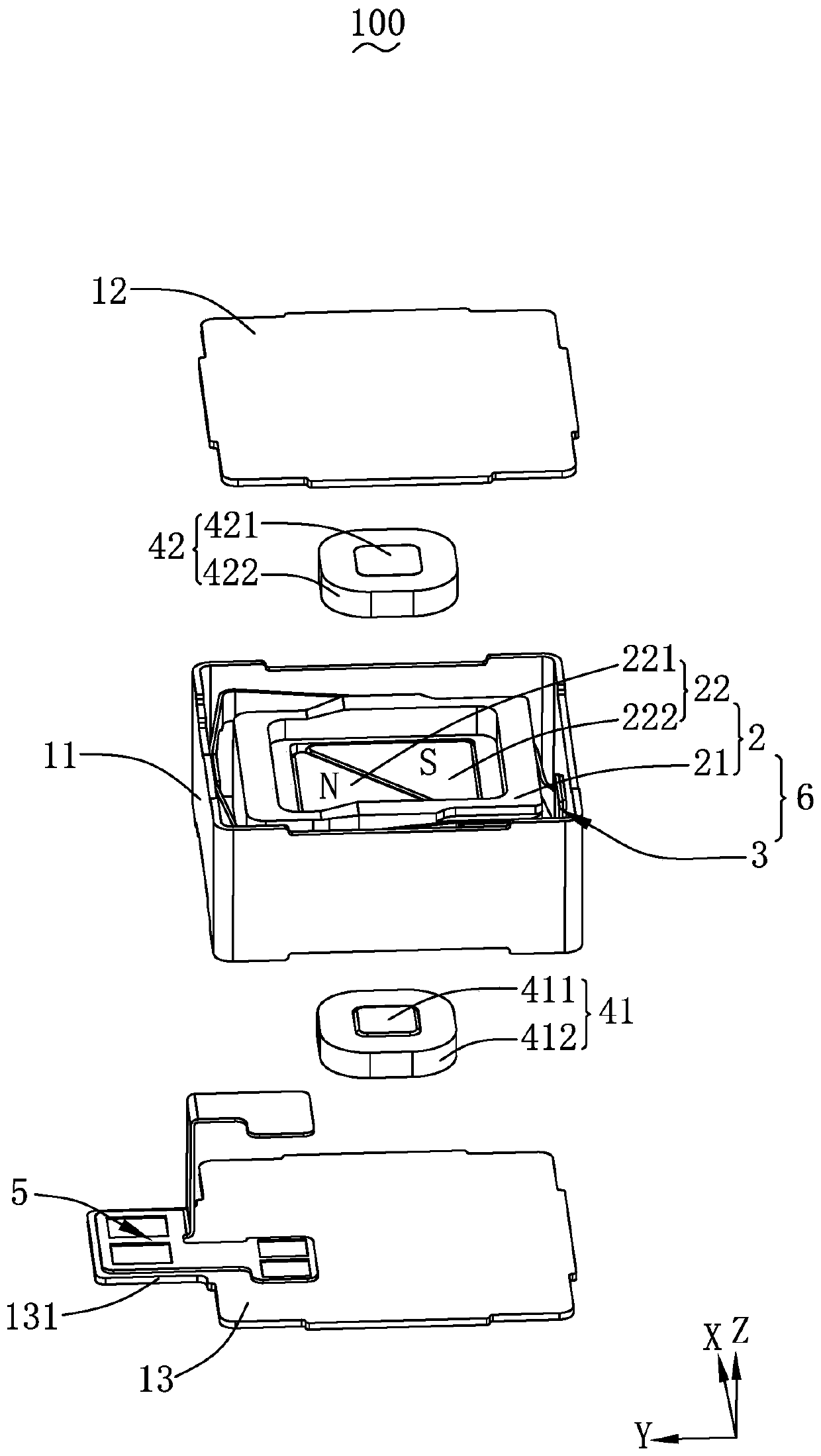

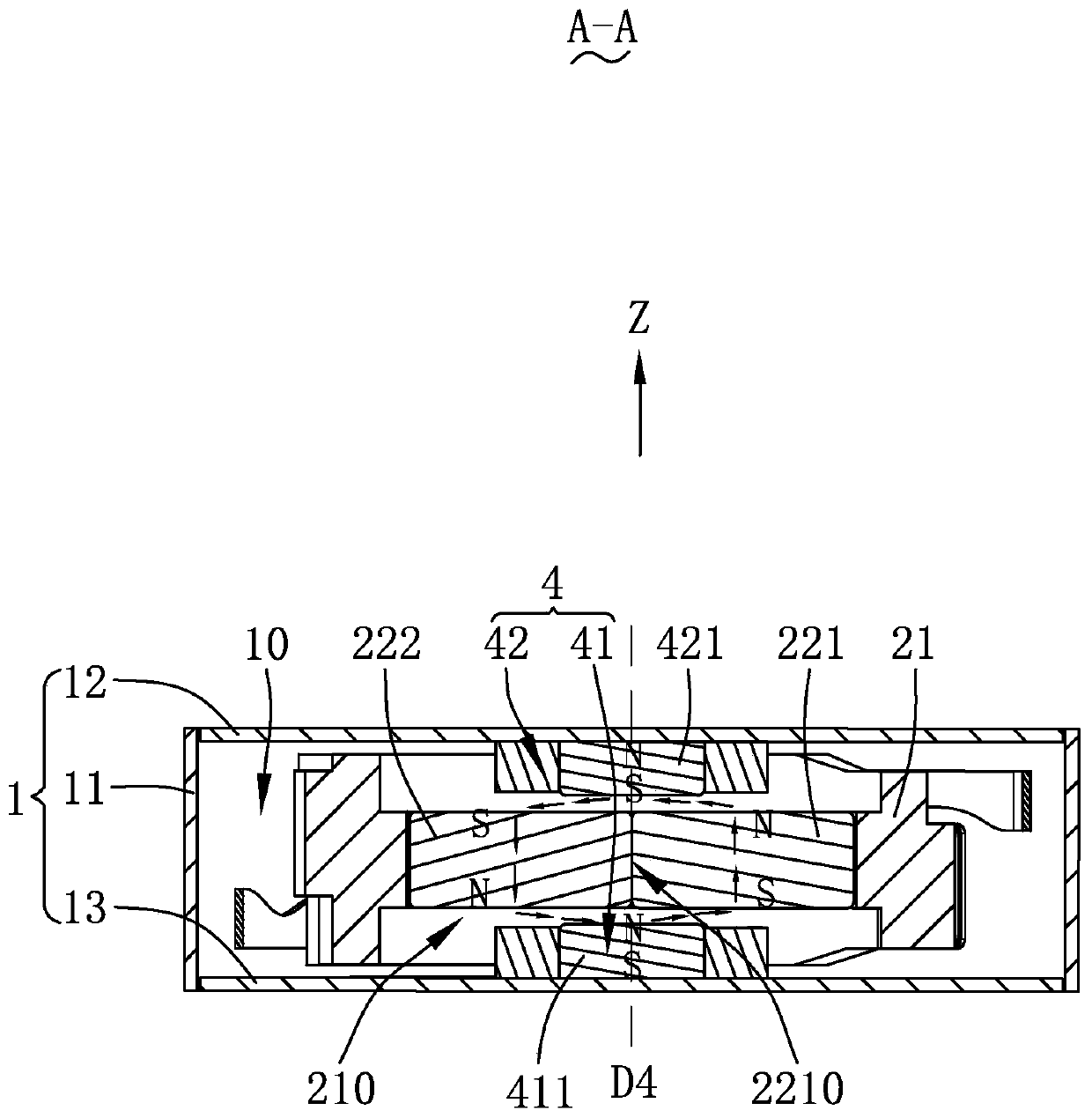

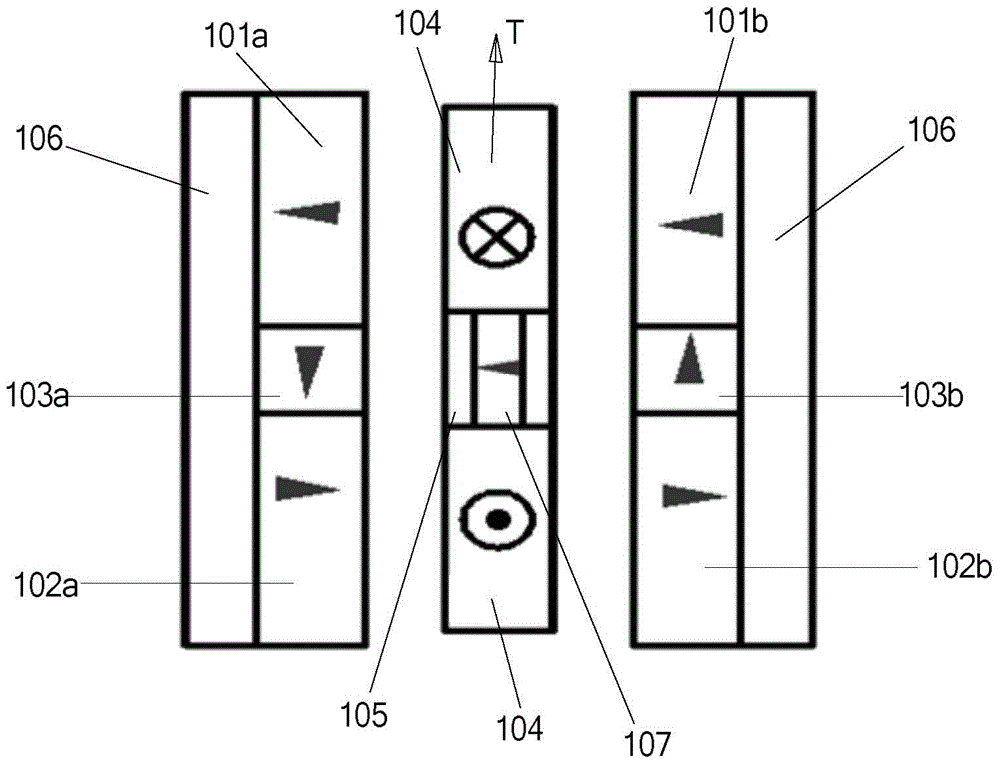

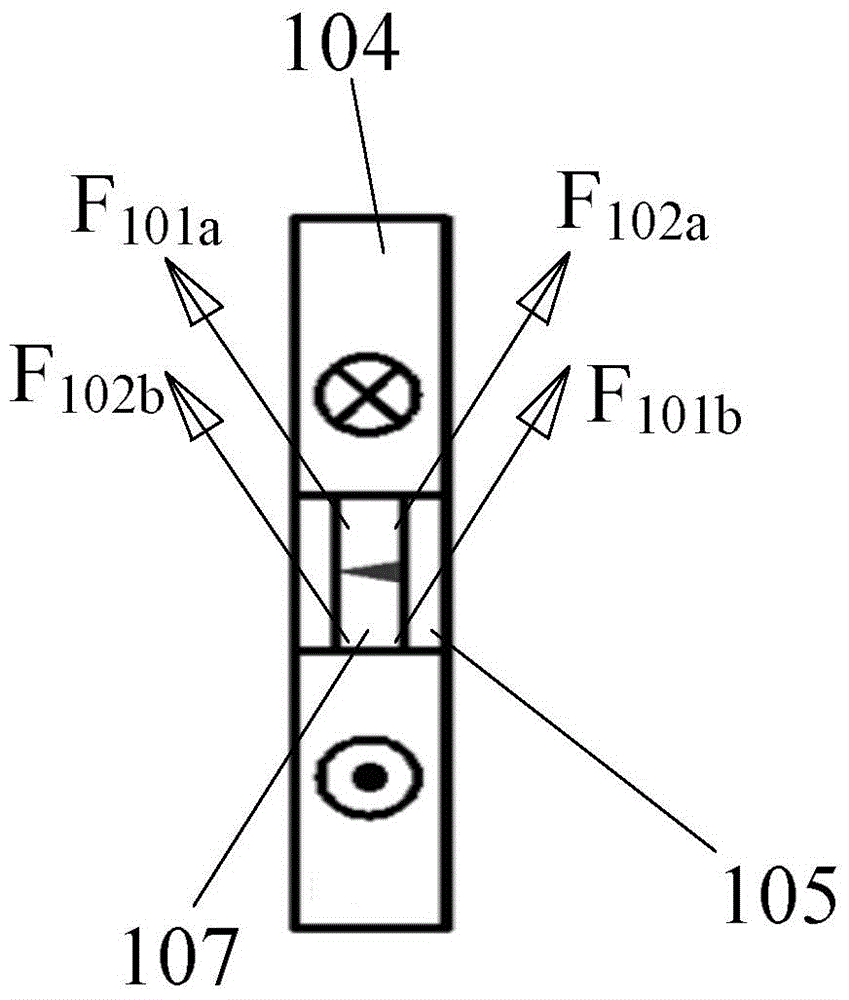

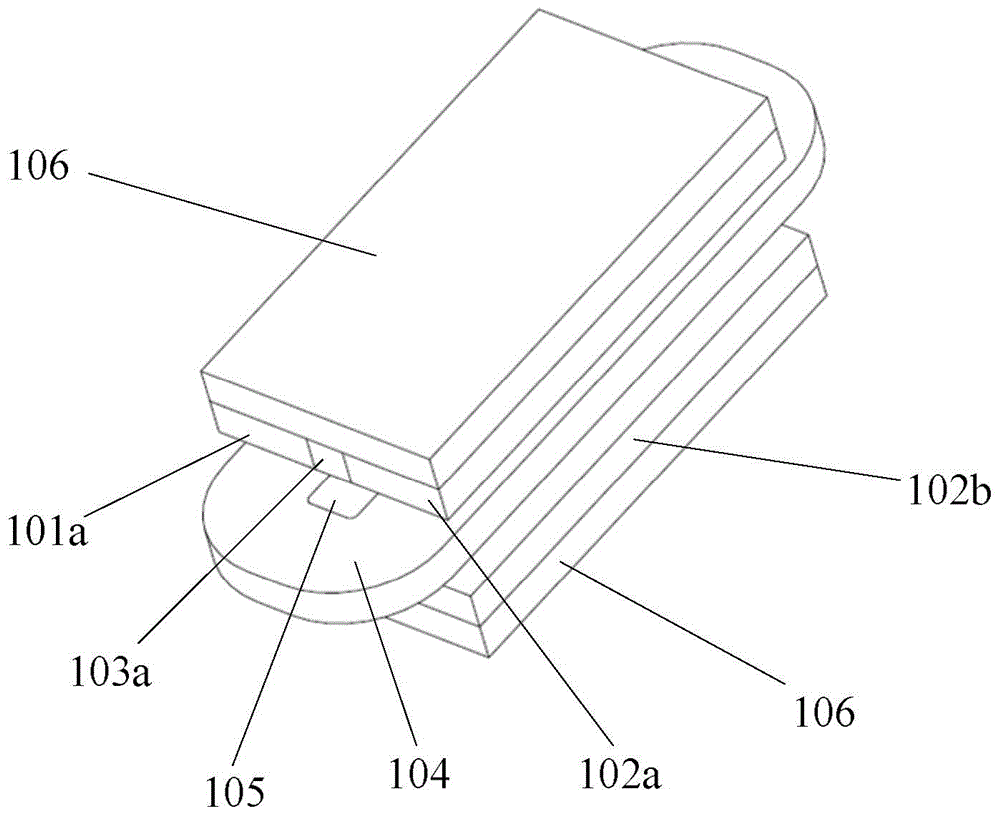

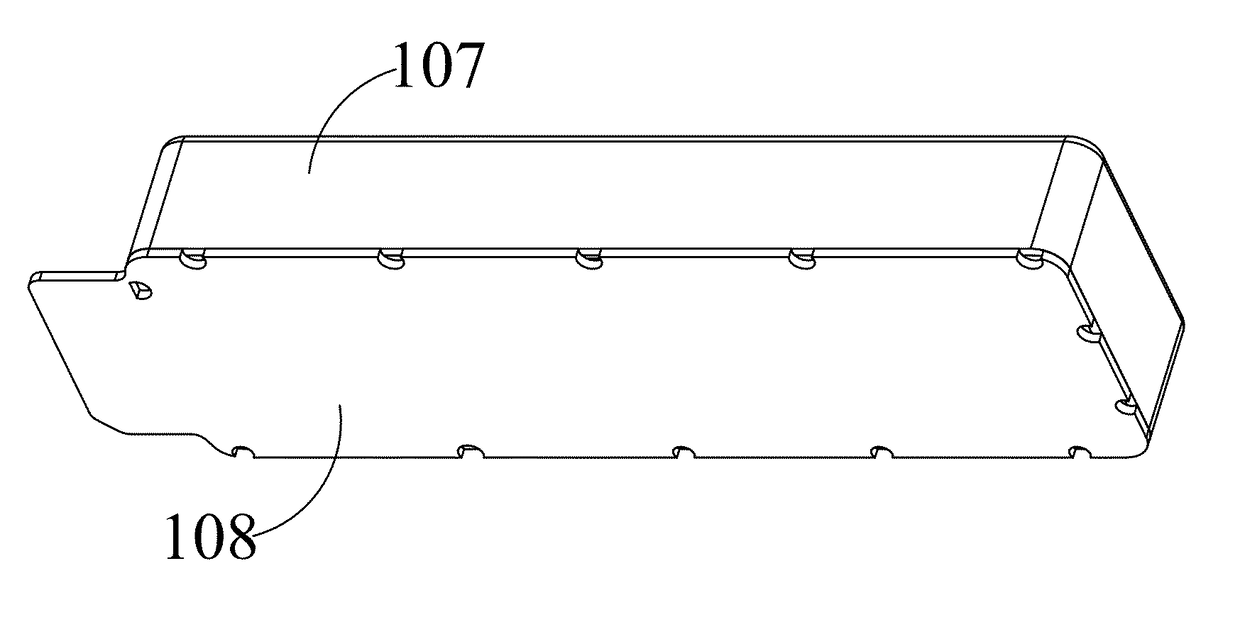

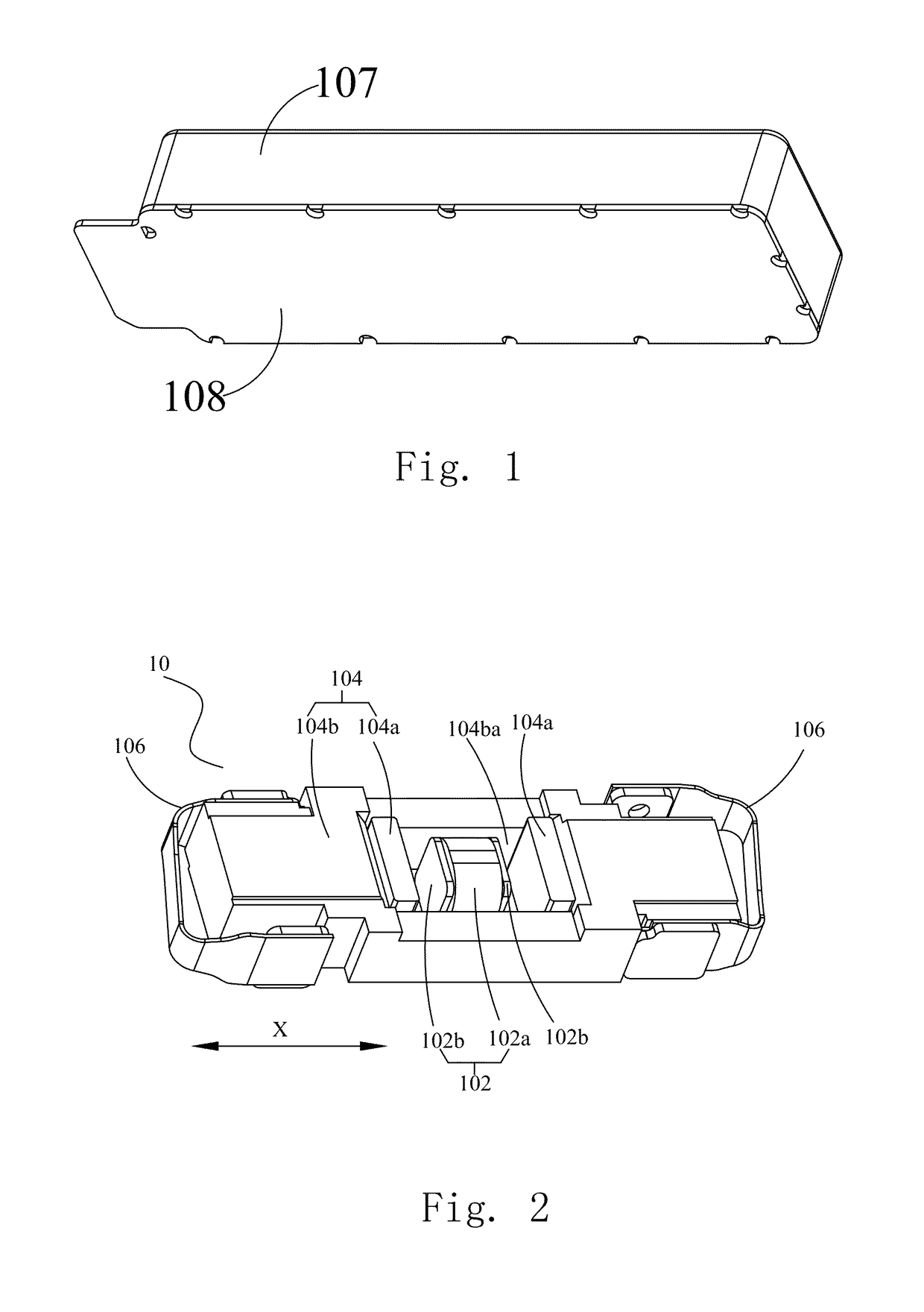

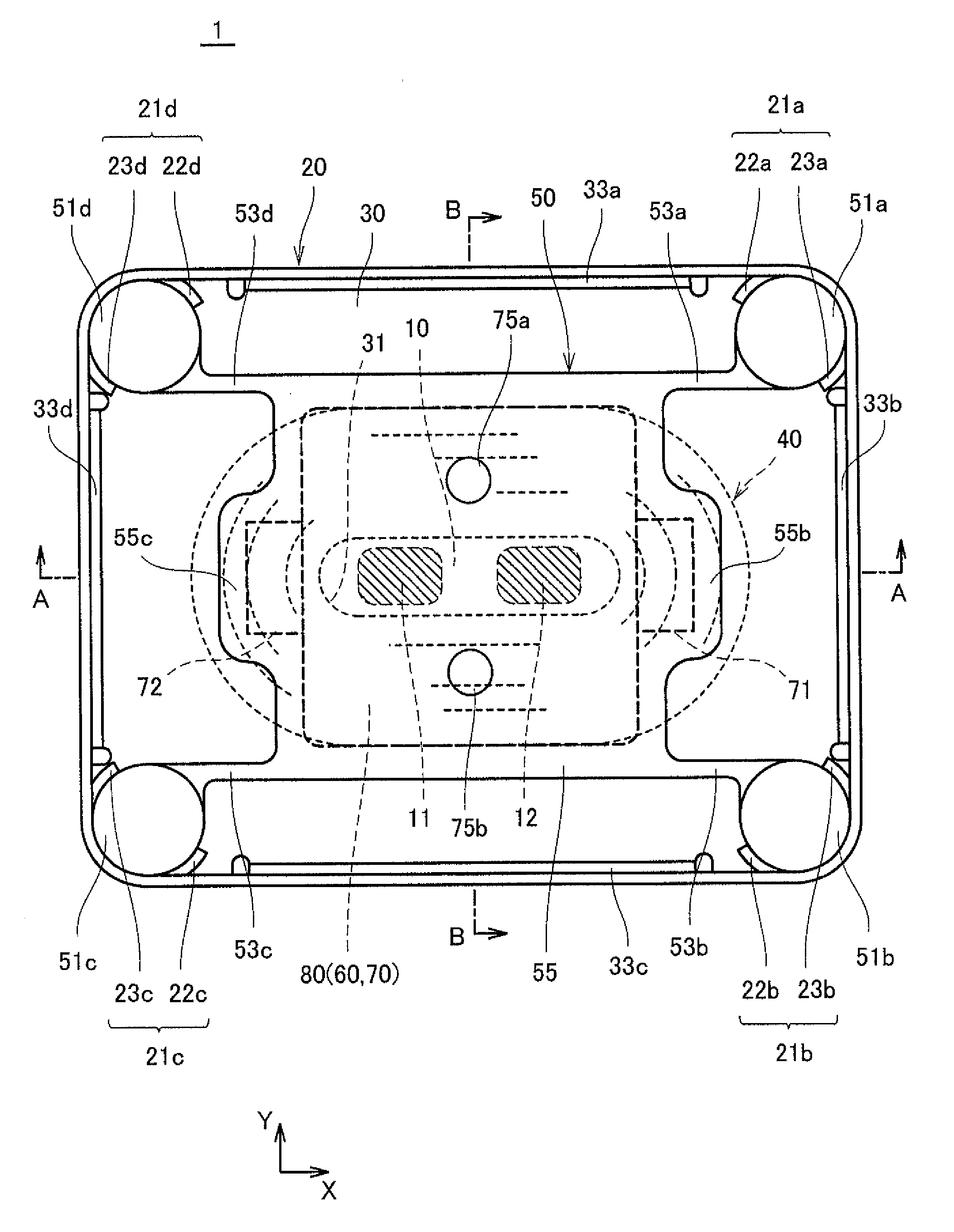

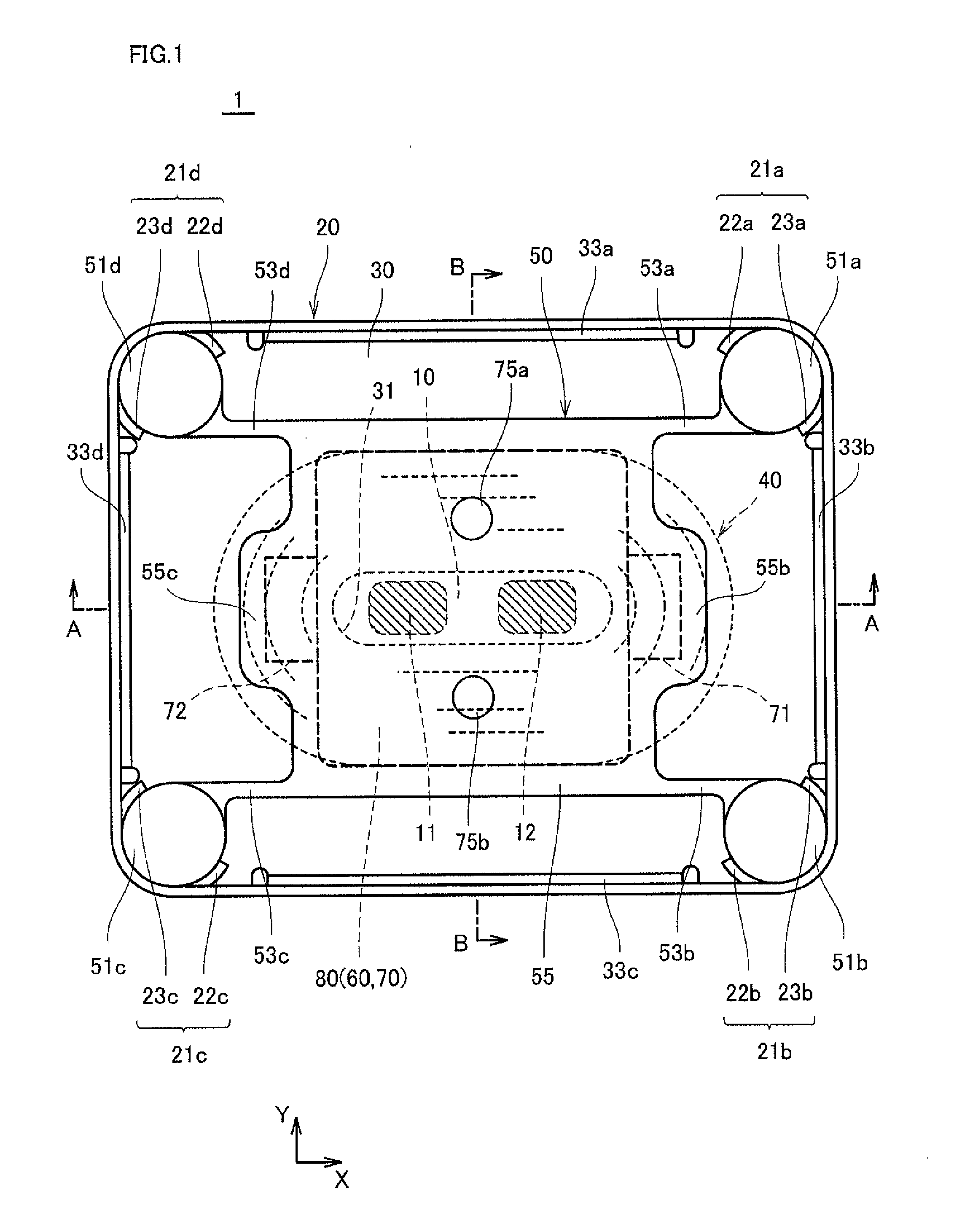

A fast-response horizontal vibration micro motor

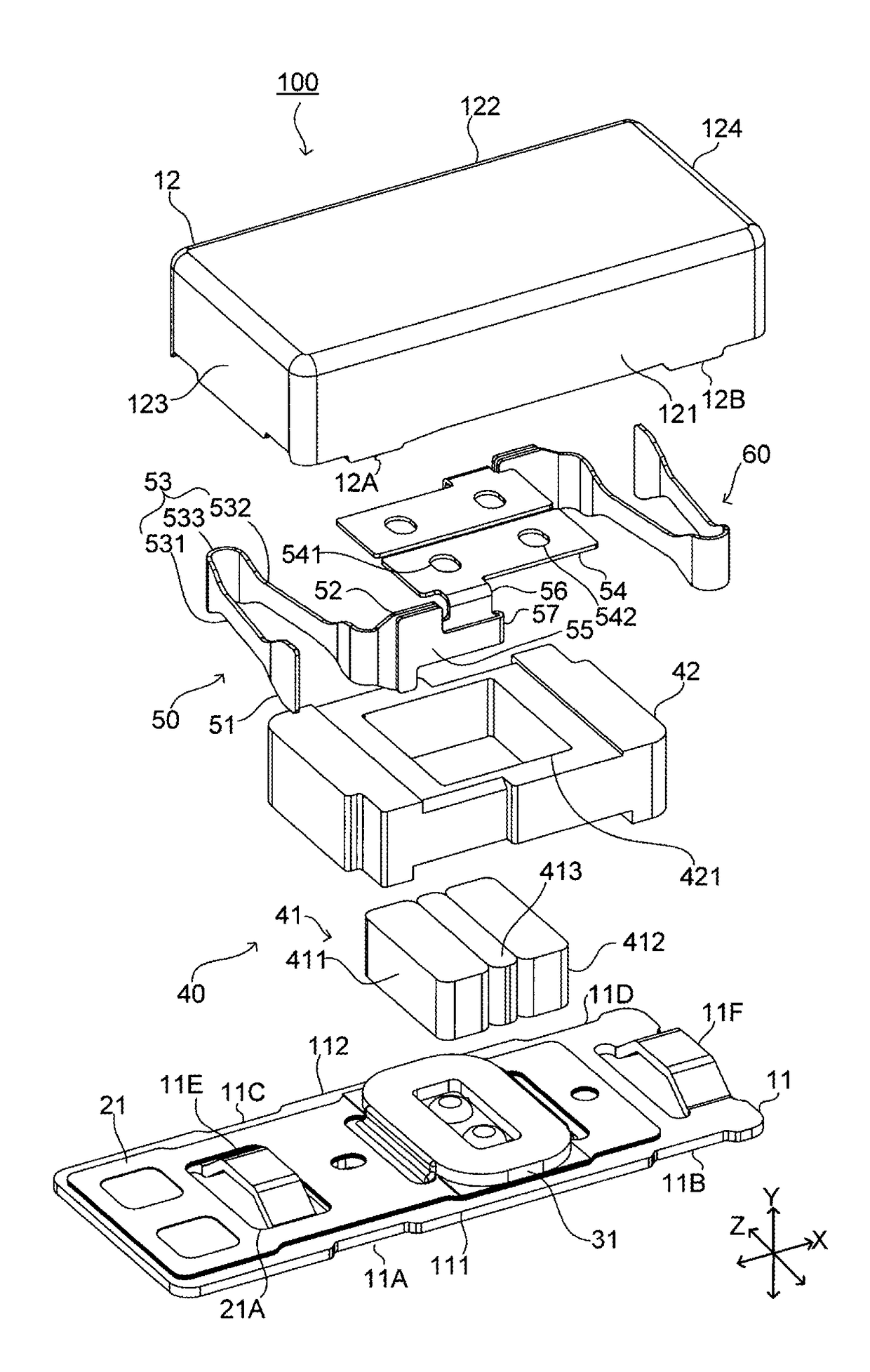

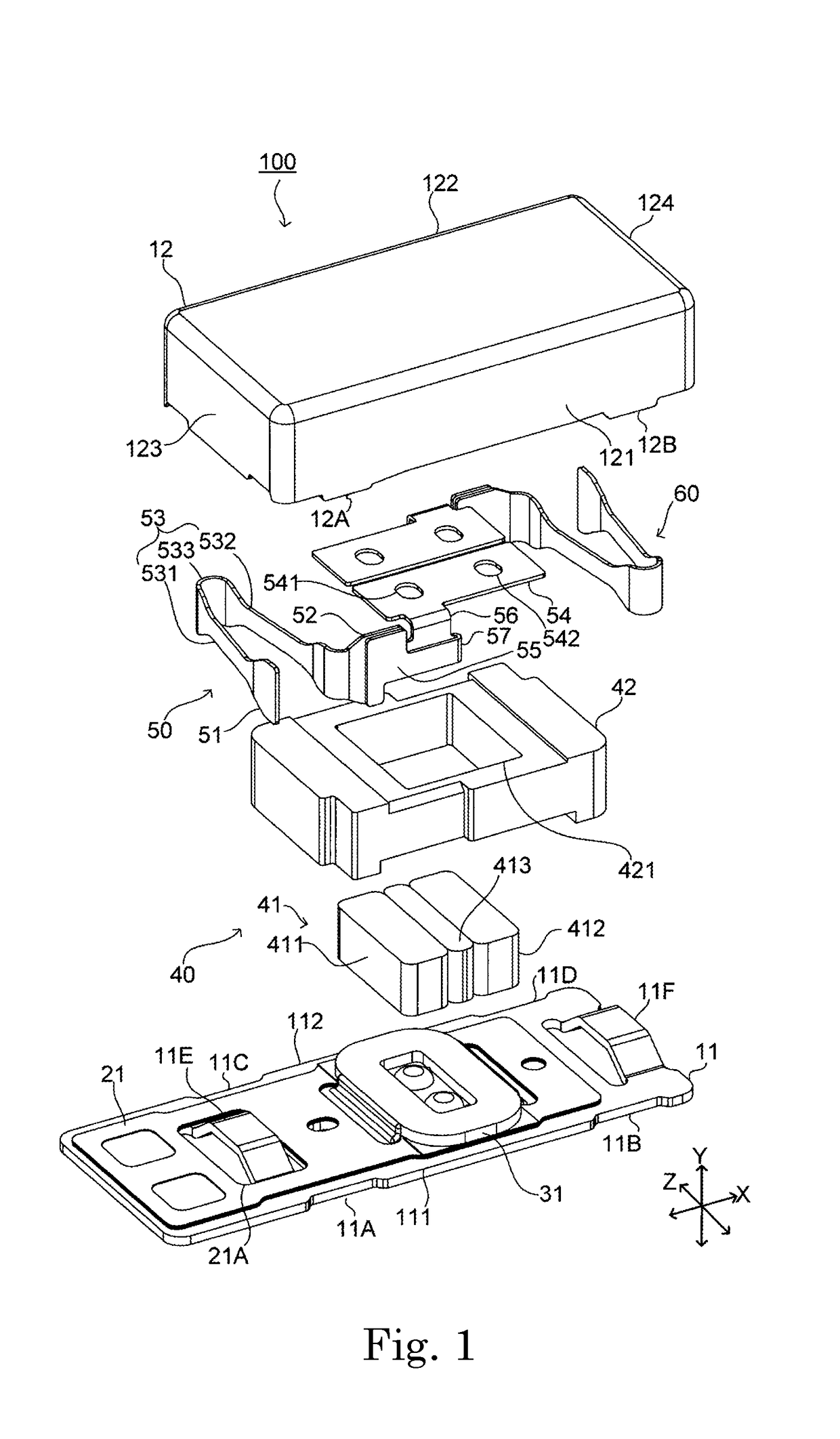

ActiveUS20160254736A1Extended service lifeLong heightReciprocating/oscillating/vibrating magnetic circuit partsEngineeringMicro motor

A fast-response horizontal vibration micro motor that includes a housing, a cover plate, a vibration assembly and coils. The cover plate is installed on the housing; the vibration assembly is suspended in the installation space; the coils are located at positions a certain distance above the vibration assembly; the vibration assembly can perform reciprocating vibration in a direction substantially parallel to the bottom surface of the housing, and also enables the two elastic supporting members located on the two opposite sidewalls to be correspondingly stretched and compressed during vibration; the vibration assembly includes a vibration block, and the vibration block is provided with at least three installation through holes and permanent magnets installed in the installation through holes. The arrangement of the three permanent magnets increases the response speed of the motor, and the arrangement of the two serially-connected coils also increases the response speed of the motor.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

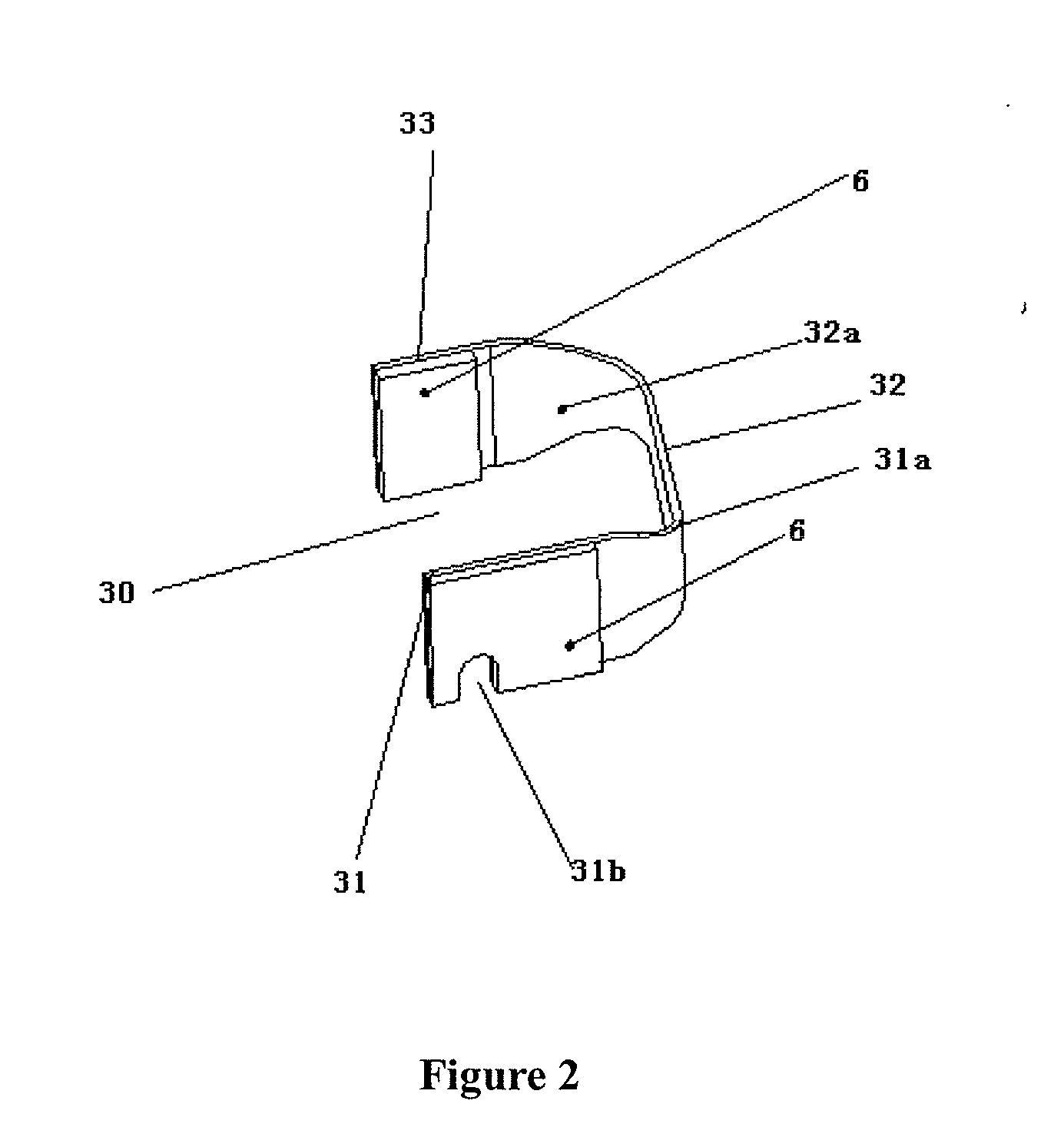

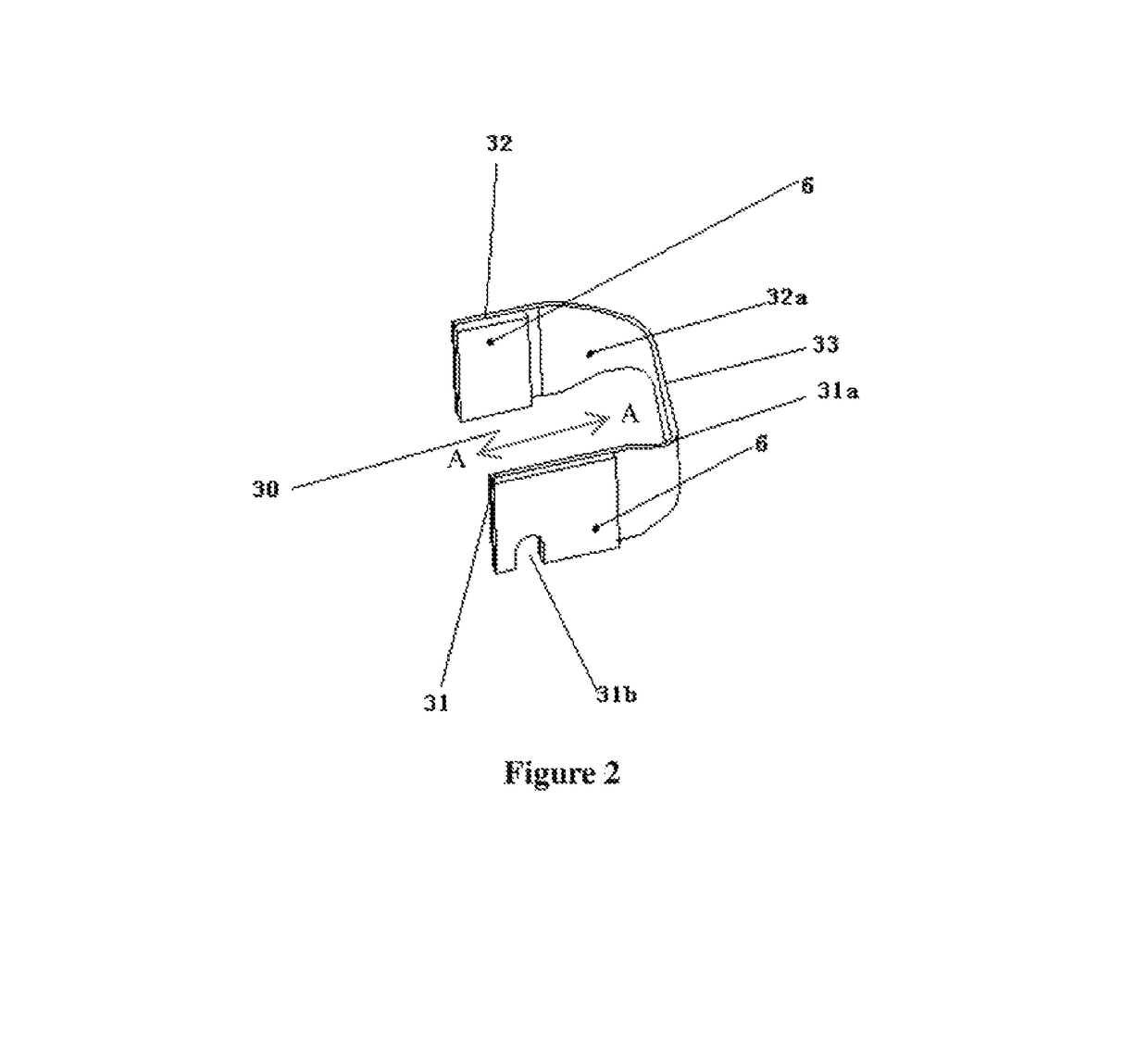

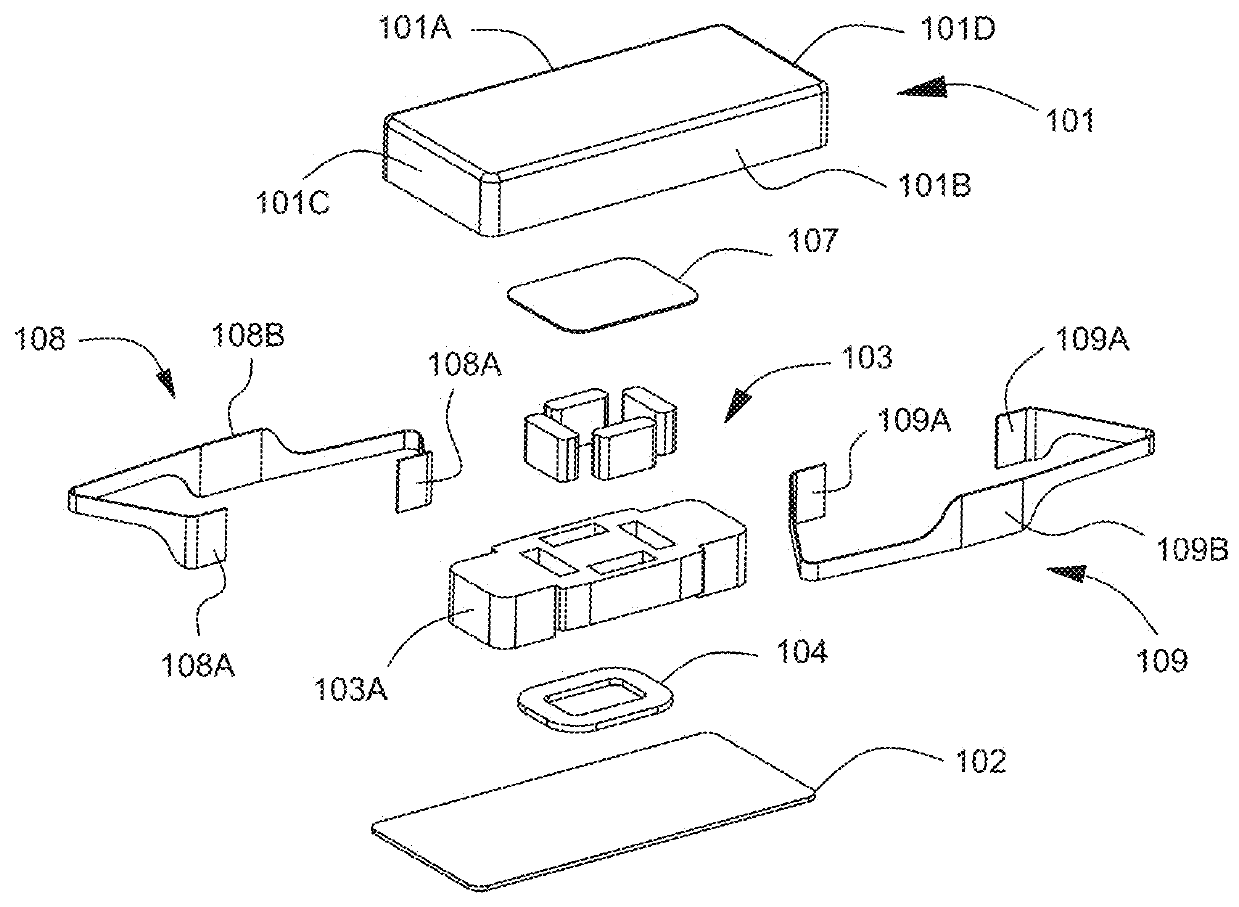

Vibration generator moving vibrator by magnetic field generated by coil and holder used in vibration-generator

ActiveUS20130076178A1Easy to buildReciprocating/oscillating/vibrating magnetic circuit partsMechanical vibrations separationEngineeringMagnetic field

A holder is used while attached to a chassis of a vibration generator that moves a vibrator to generate a vibration. The holder includes a vibrator retention unit retaining the vibrator, a fixed unit fixed to the chassis, and an arm. The arm connects the fixed unit and the vibrator retention unit, and the arm supports the vibrator retention unit while the vibrator retention unit can be displaced with respect to the fixed unit. The fixed unit, the arm, and the vibrator retention unit are integrally formed using resin.

Owner:MINEBEAMITSUMI INC

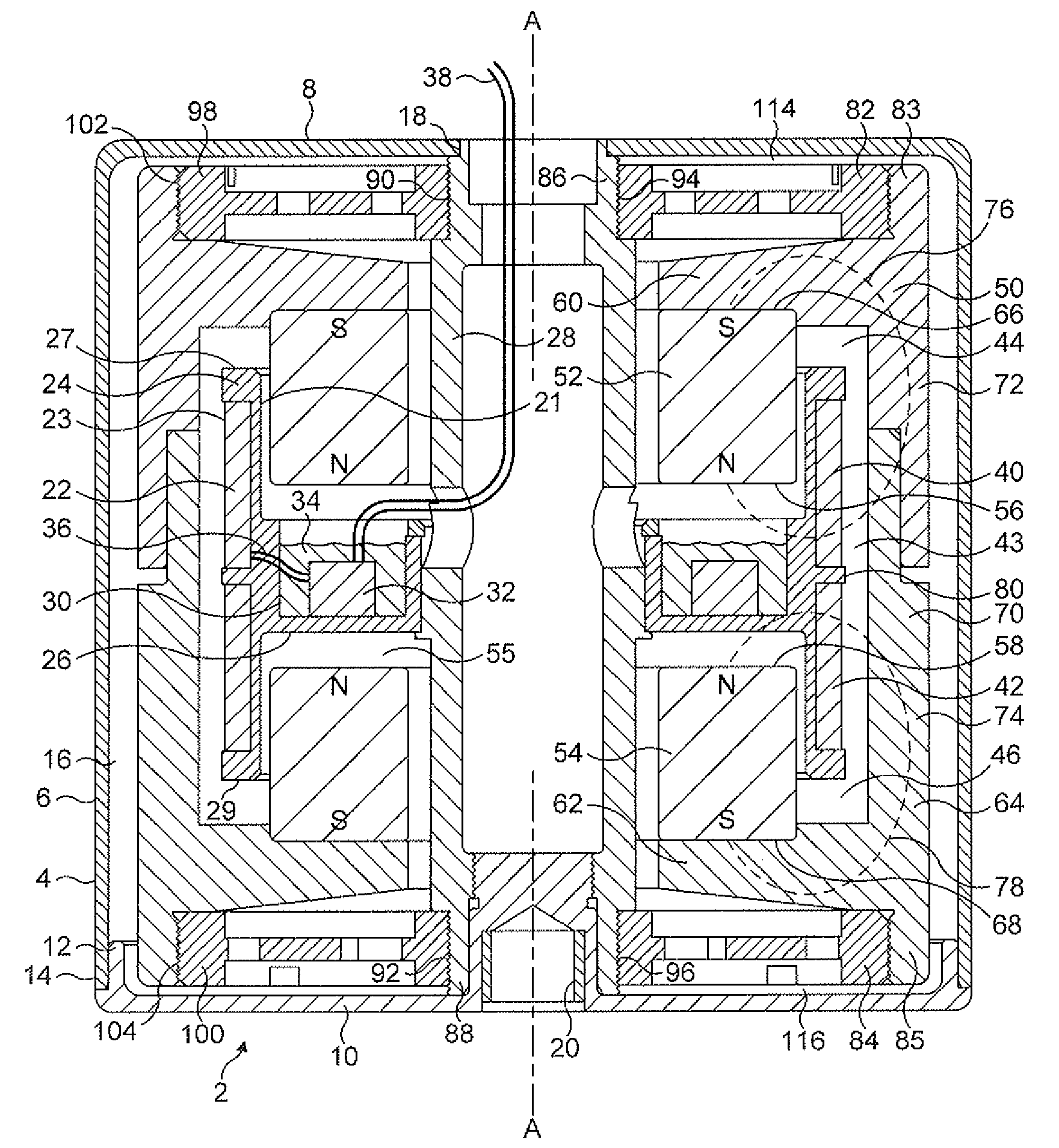

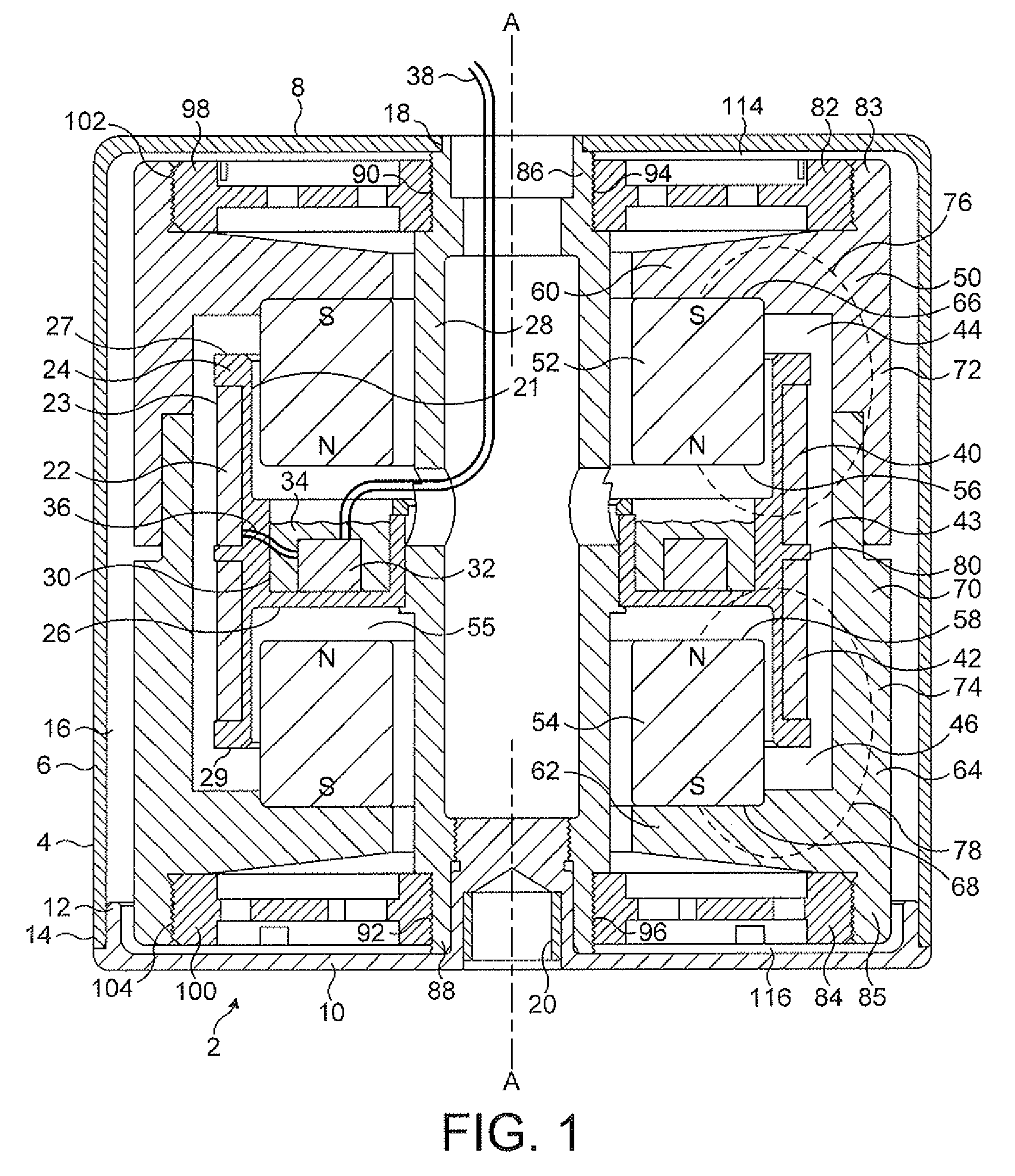

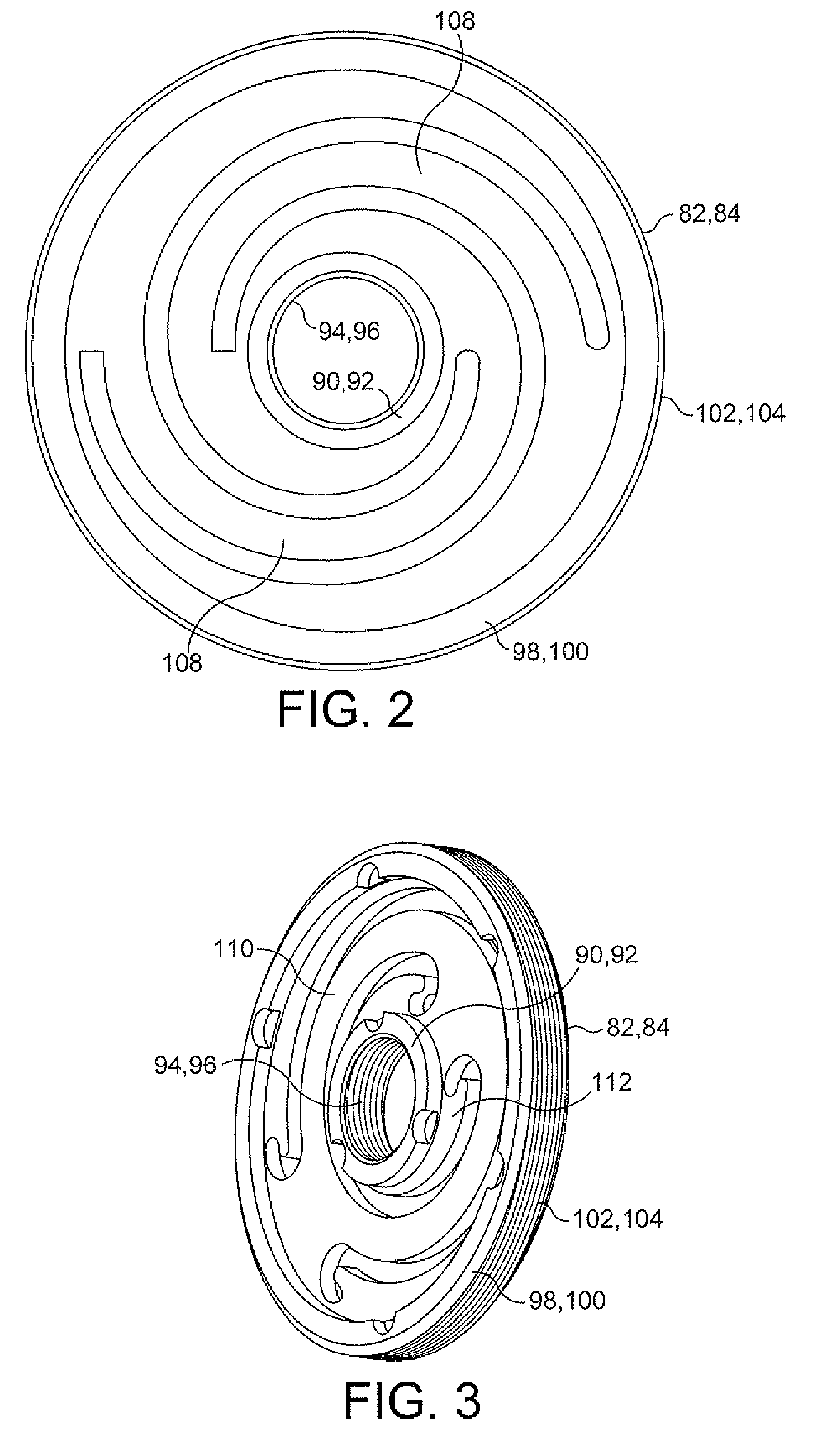

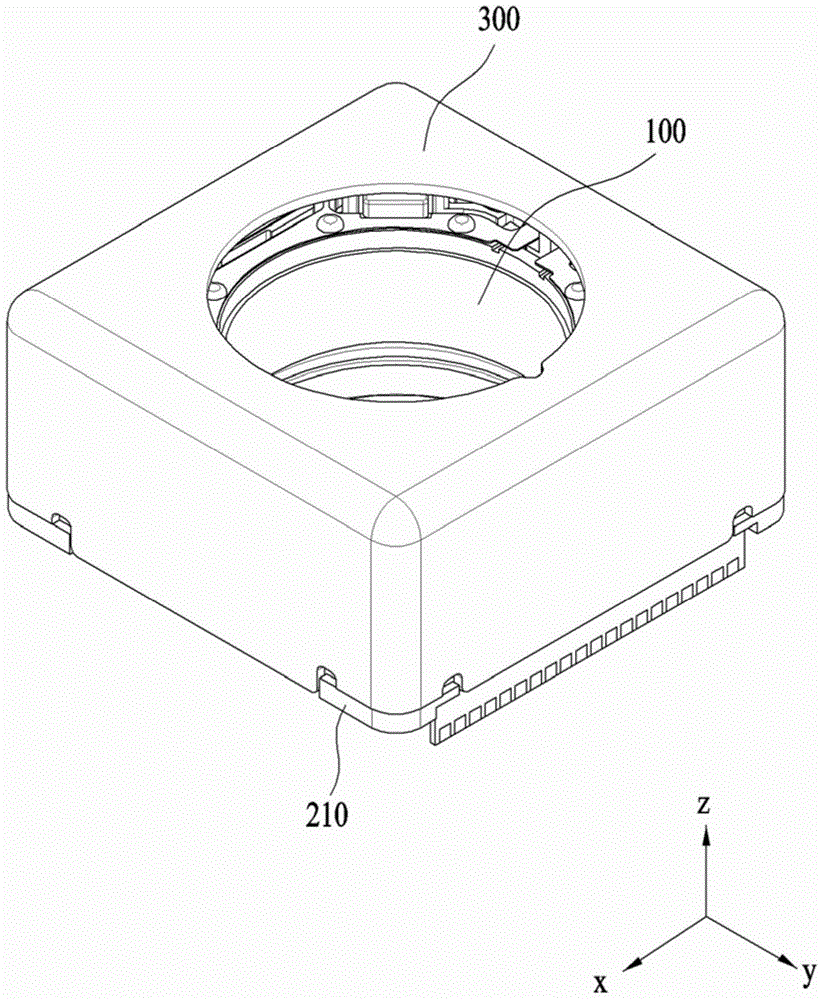

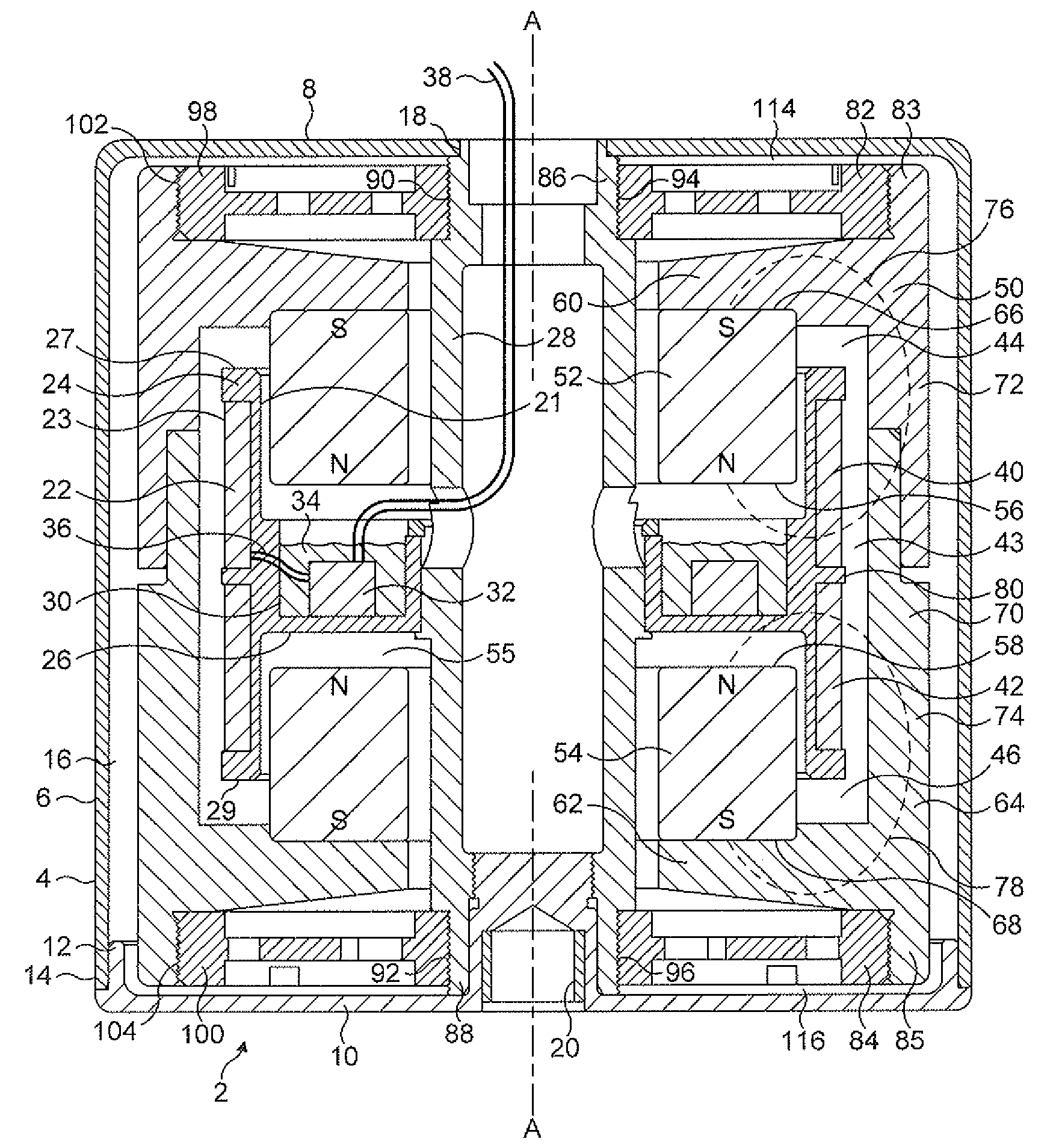

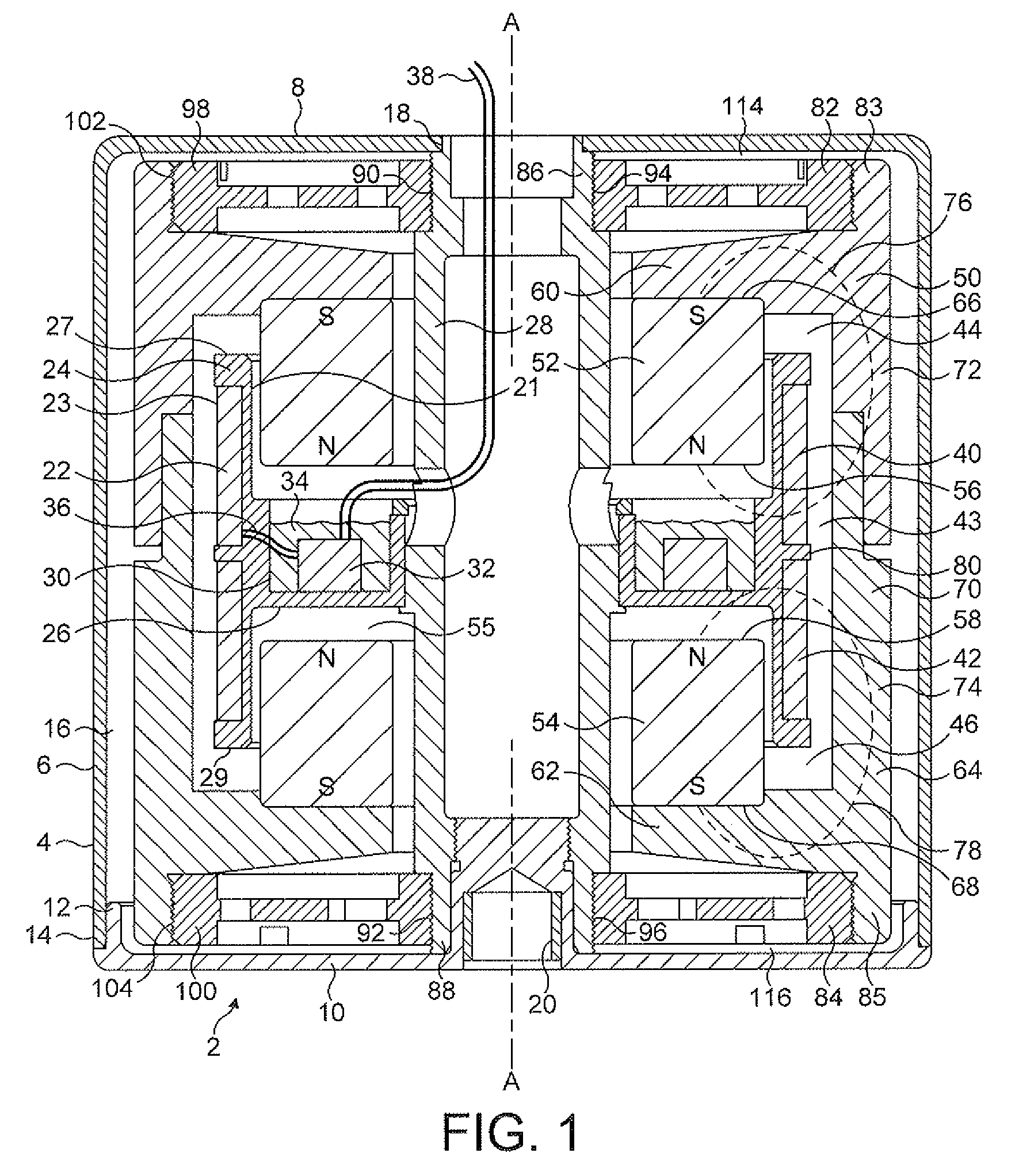

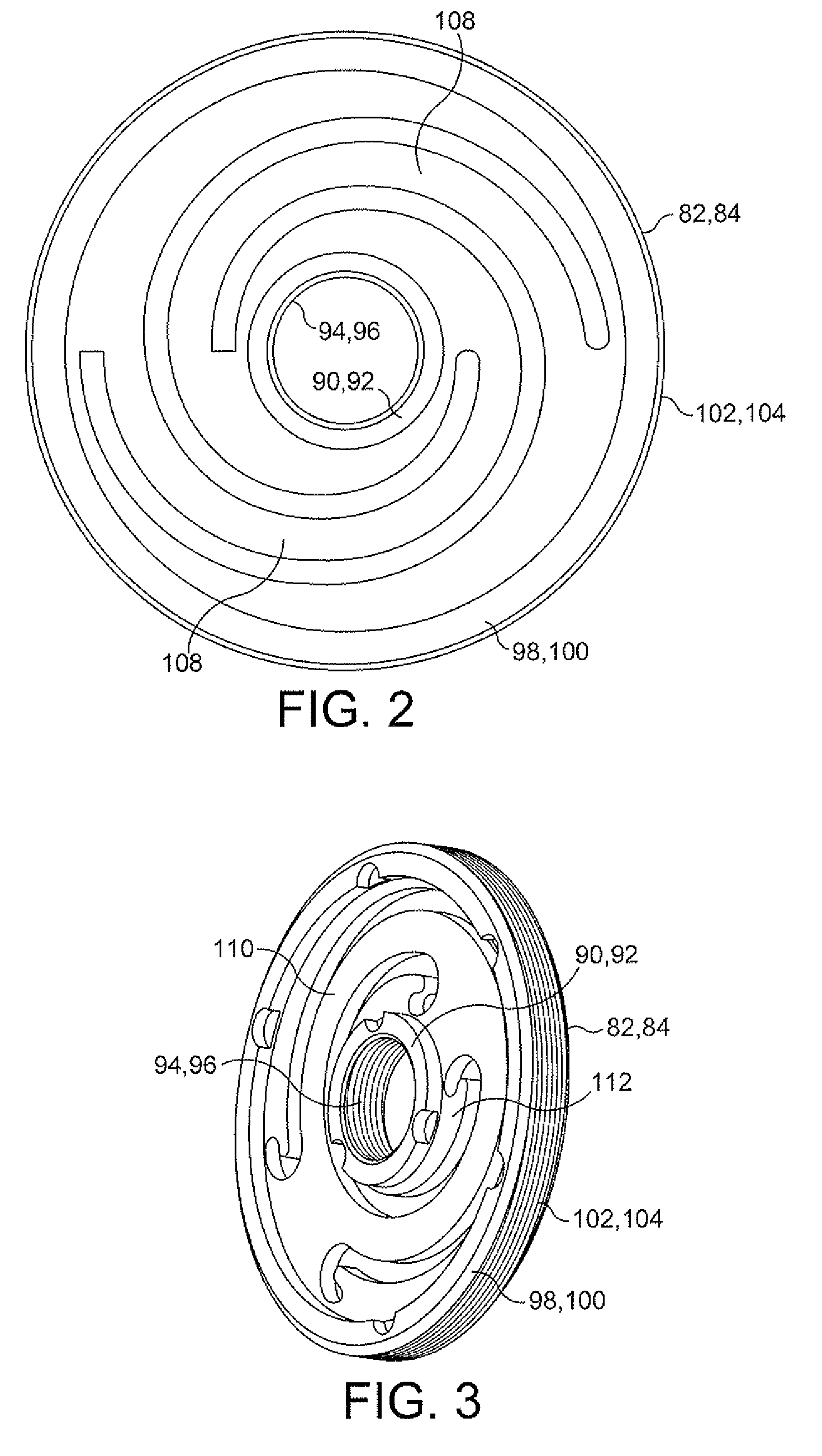

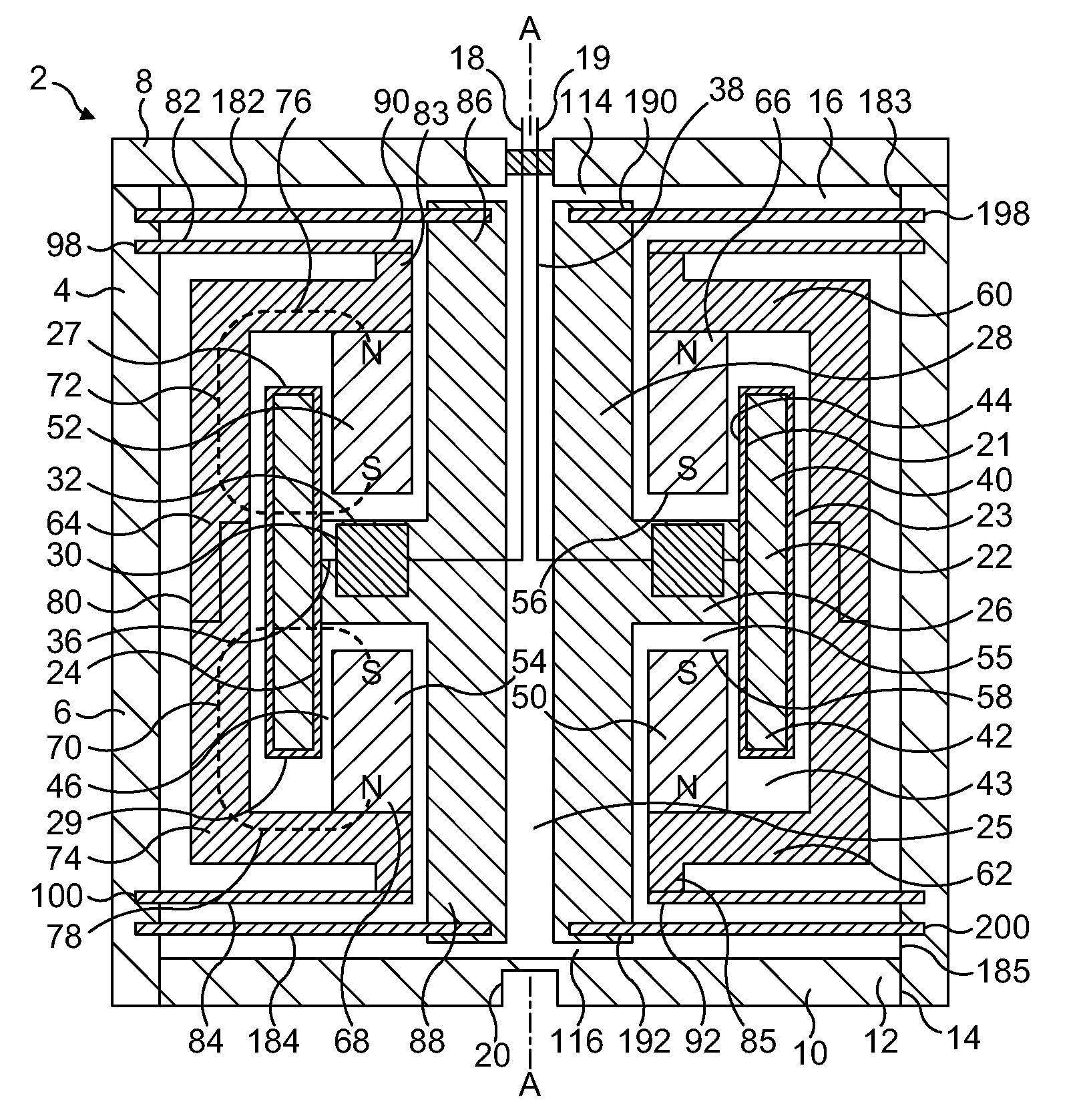

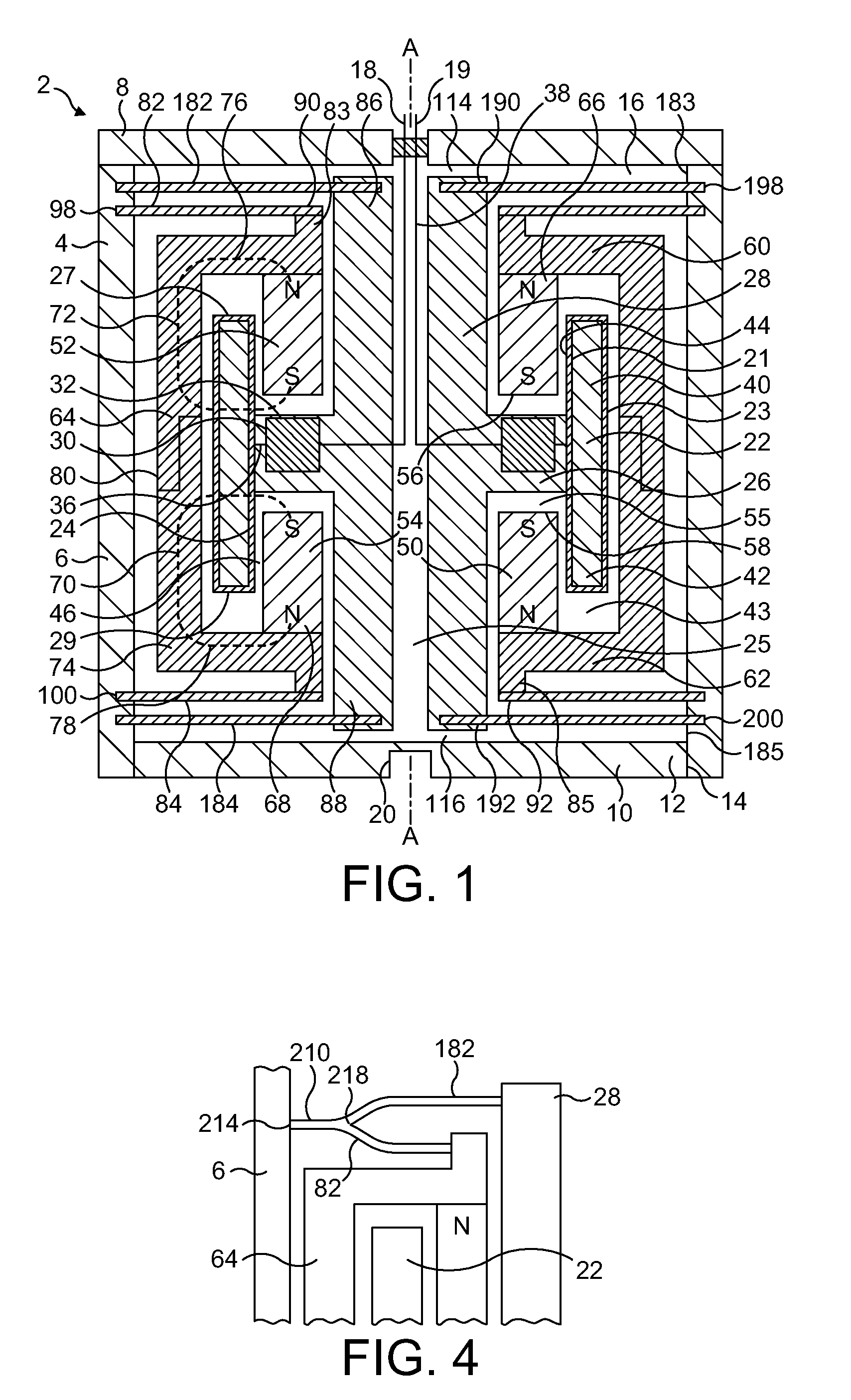

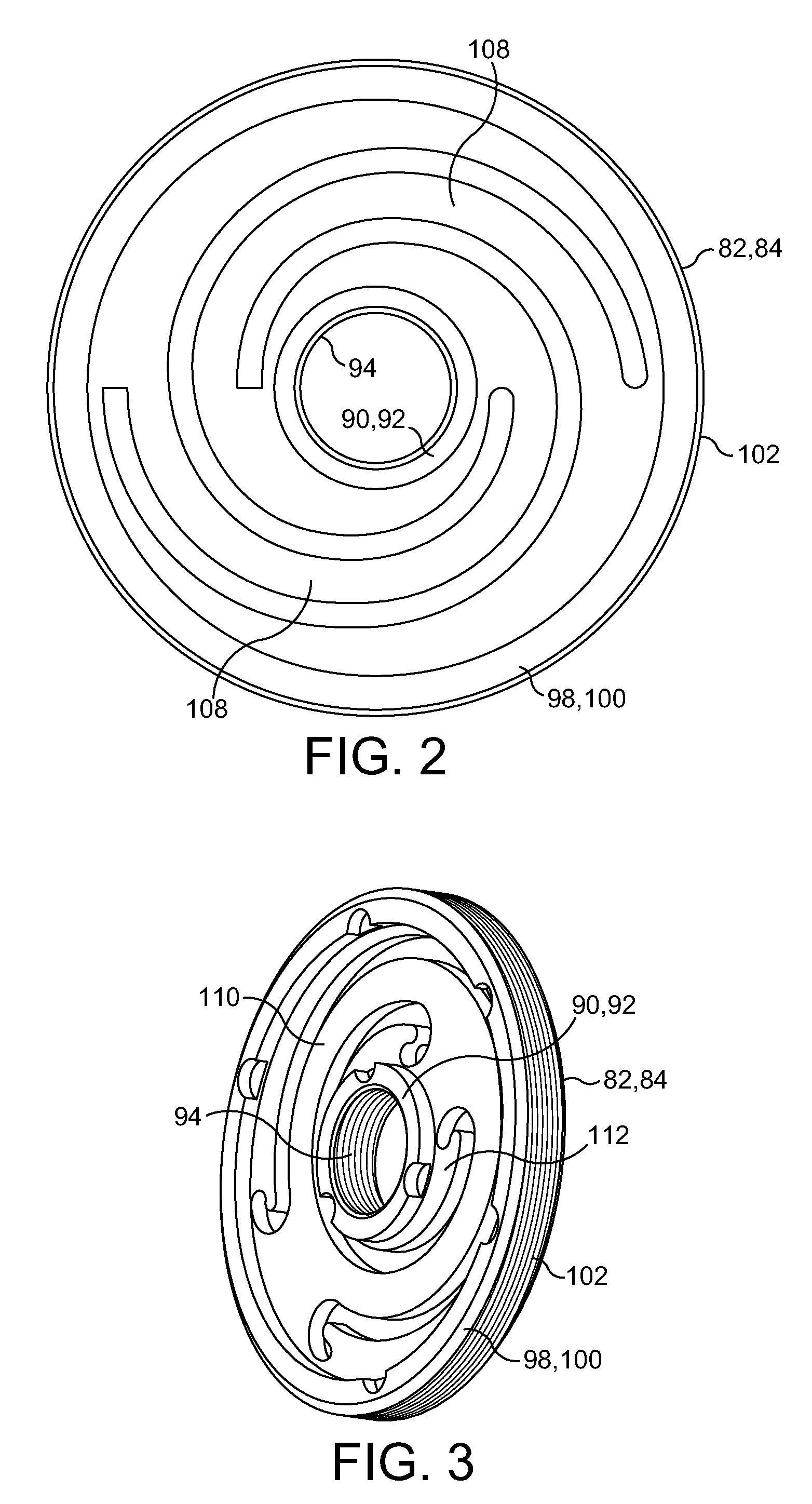

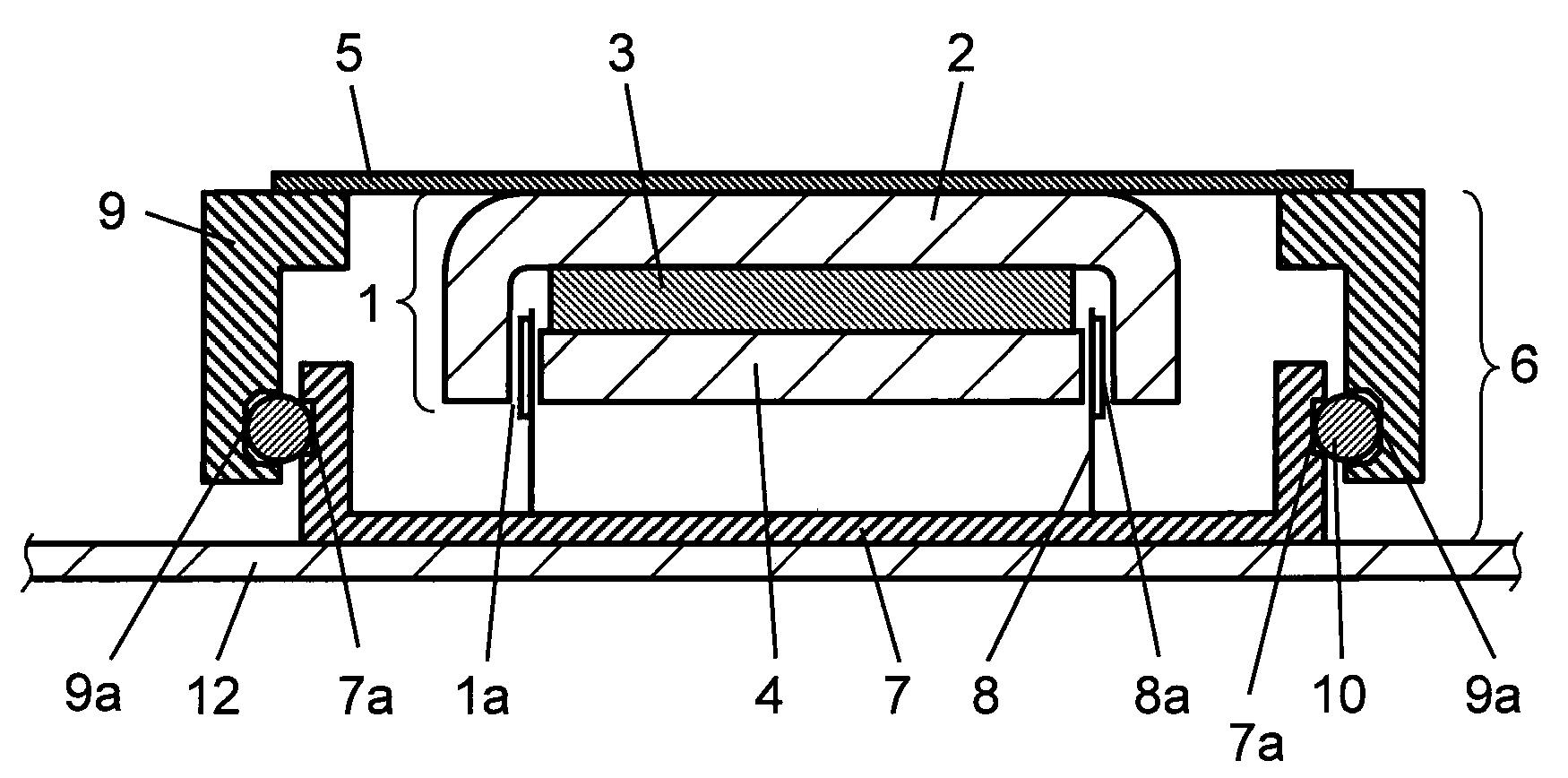

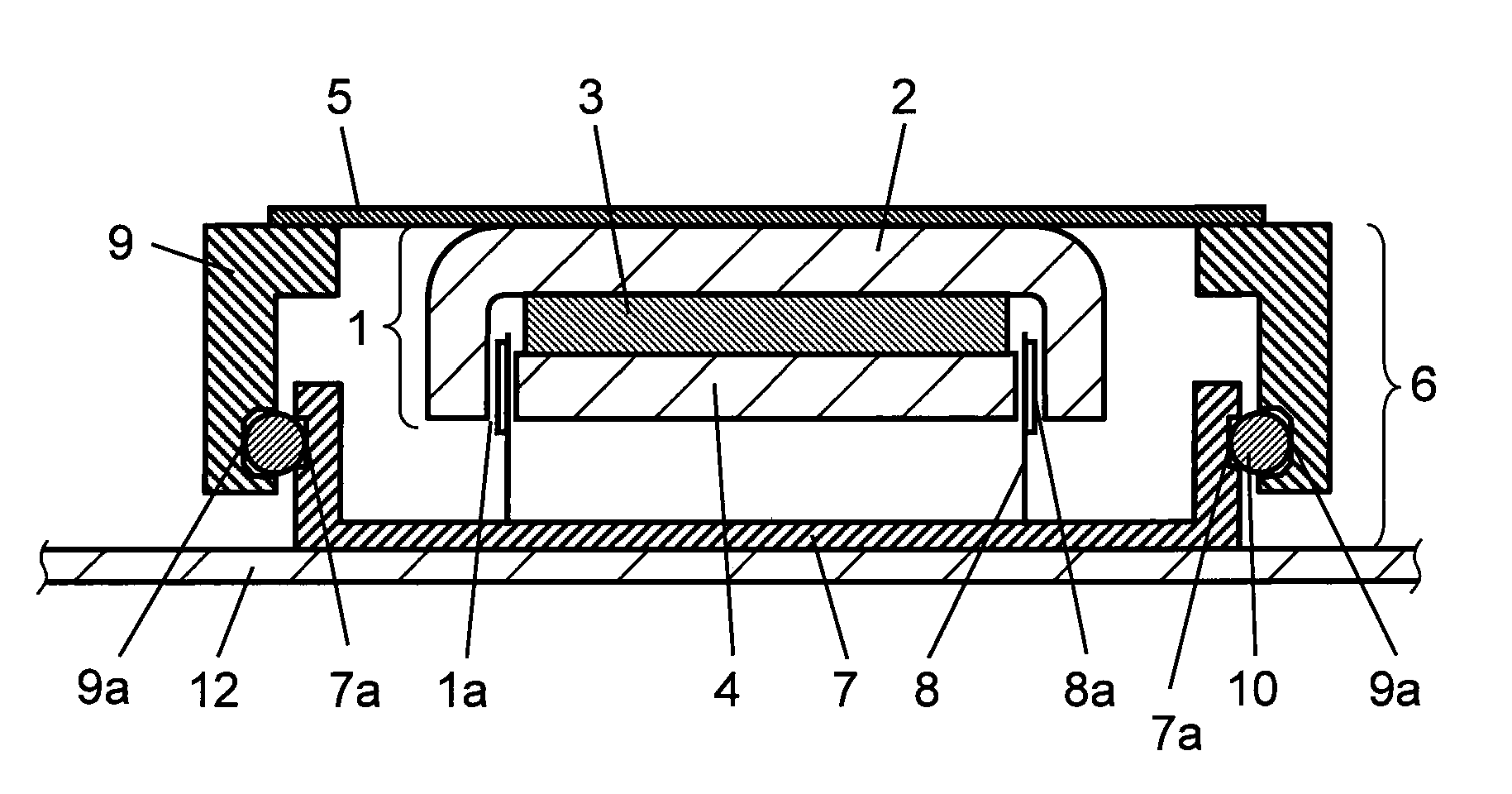

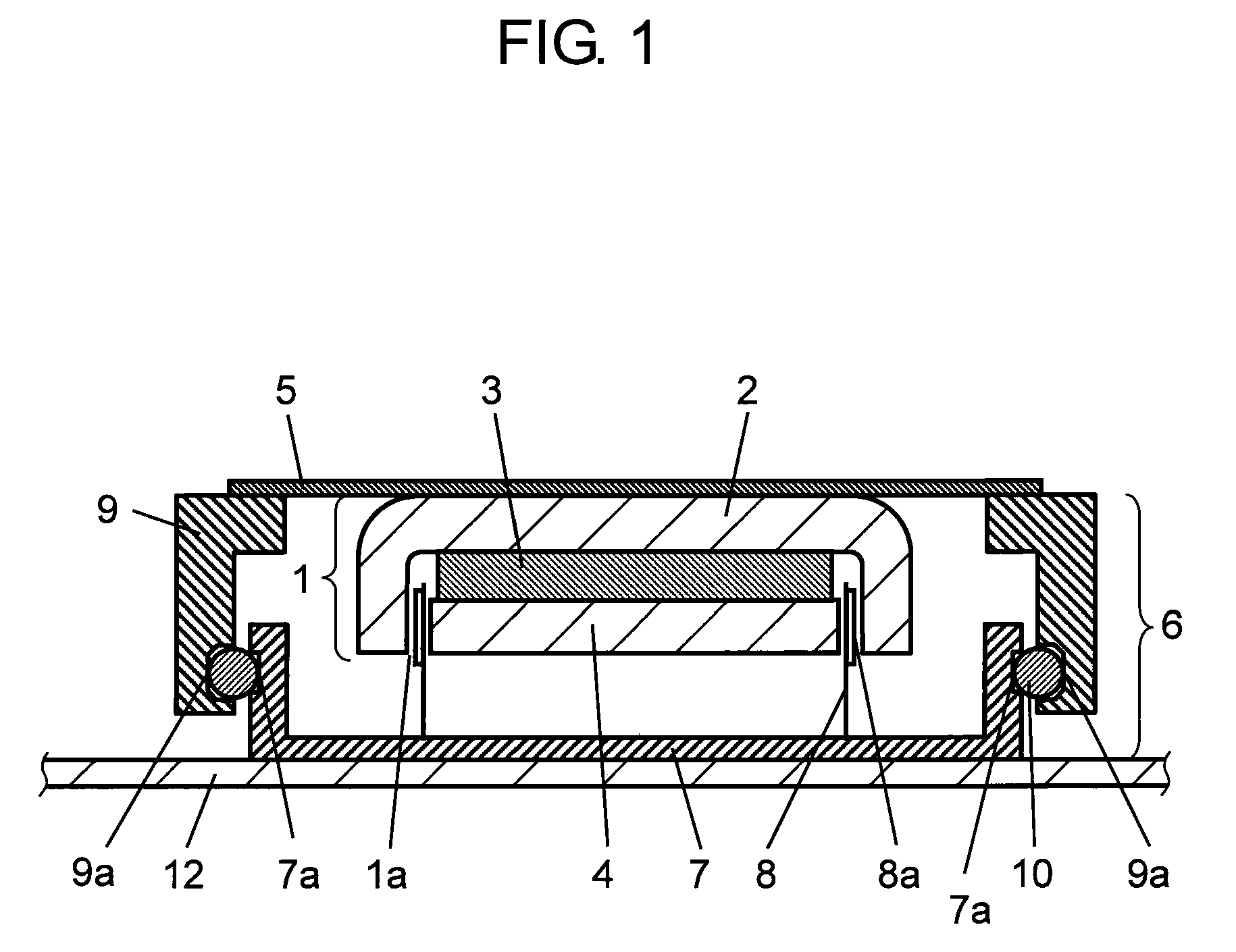

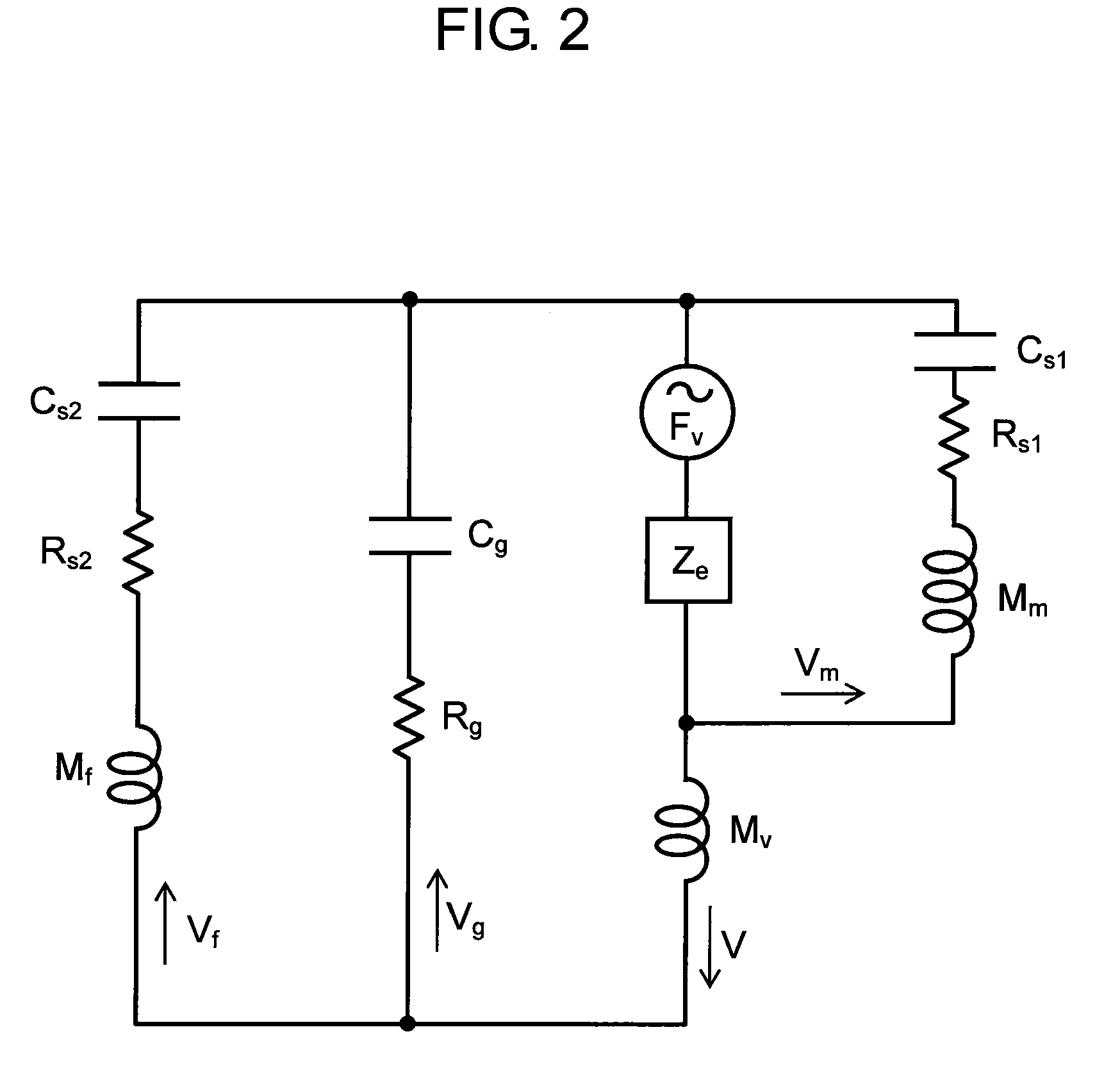

Electromechanical Generator for Converting Mechanical Vibrational Energy Into Electrical Energy

ActiveUS20080265692A1High moving massSmall currentReciprocating/oscillating/vibrating magnetic circuit partsMechanical energy handlingEngineeringFixed position

An electromechanical generator for converting mechanical vibrational energy into electrical energy, the electromechanical generator comprising a housing, an electrically conductive coil assembly fixedly mounted in the housing, the coil assembly having radially inner and outer sides, and upper and lower edges, thereof, a mount for the coil assembly extending inwardly of the radially inner side for fixing the coil assembly in a fixed position in the housing, a magnetic core assembly movably mounted in the housing for linear vibrational motion along an axis, and a biasing device mounted between the housing and the magnetic core assembly to bias the magnetic core assembly in opposed directions along the axis towards a central position, wherein the magnetic core assembly encloses the electrically conductive coil assembly on the radially outer side and on the upper and lower edges, and on a part of the radially inner side, the magnetic core assembly having a gap on a radially inner portion thereof through which the mount extends, and the radially inner portion including two opposed magnets spaced along the axis.

Owner:HITACHI RAIL LTD +1

Fast-response horizontal vibration micro motor

ActiveUS9614425B2Guaranteed smooth progressImprove noiseReciprocating/oscillating/vibrating magnetic circuit partsEngineeringMicro motor

A fast-response horizontal vibration micro motor that includes a housing, a cover plate, a vibration assembly and coils. The cover plate is installed on the housing; the vibration assembly is suspended in the installation space; the coils are located at positions a certain distance above the vibration assembly; the vibration assembly can perform reciprocating vibration in a direction substantially parallel to the bottom surface of the housing, and also enables the two elastic supporting members located on the two opposite sidewalls to be correspondingly stretched and compressed during vibration; the vibration assembly includes a vibration block, and the vibration block is provided with at least three installation through holes and permanent magnets installed in the installation through holes. The arrangement of the three permanent magnets increases the response speed of the motor, and the arrangement of the two serially-connected coils also increases the response speed of the motor.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

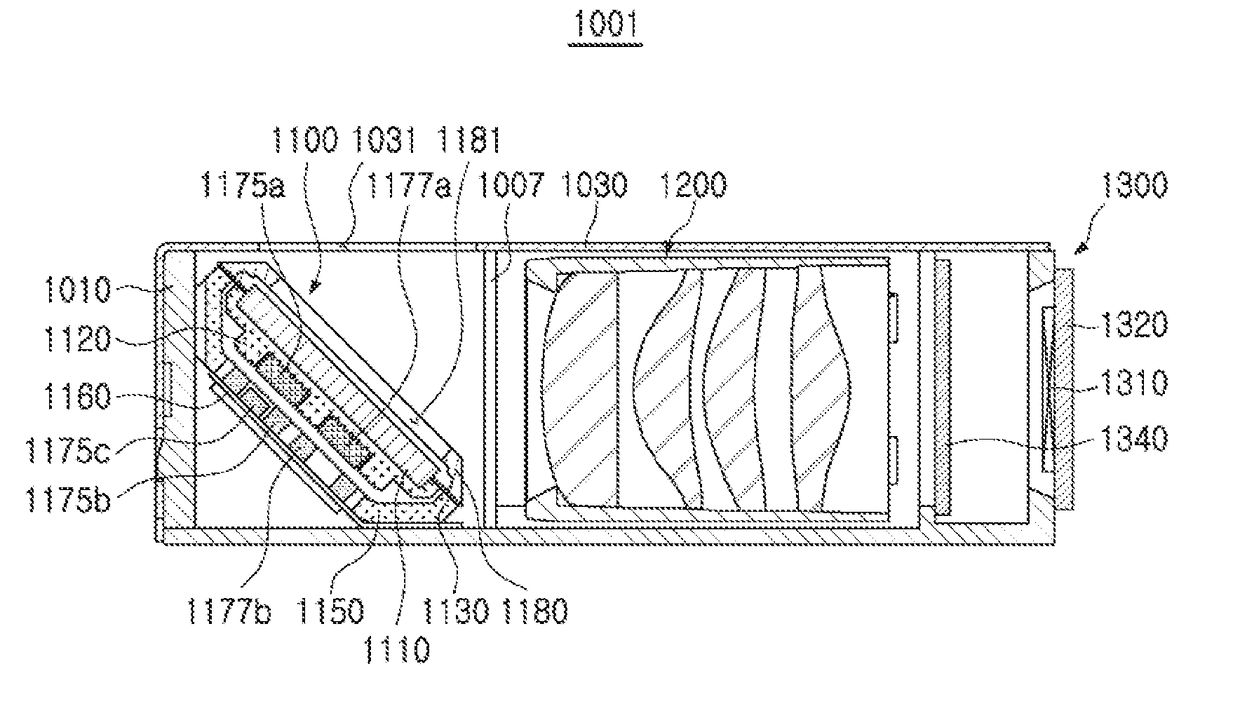

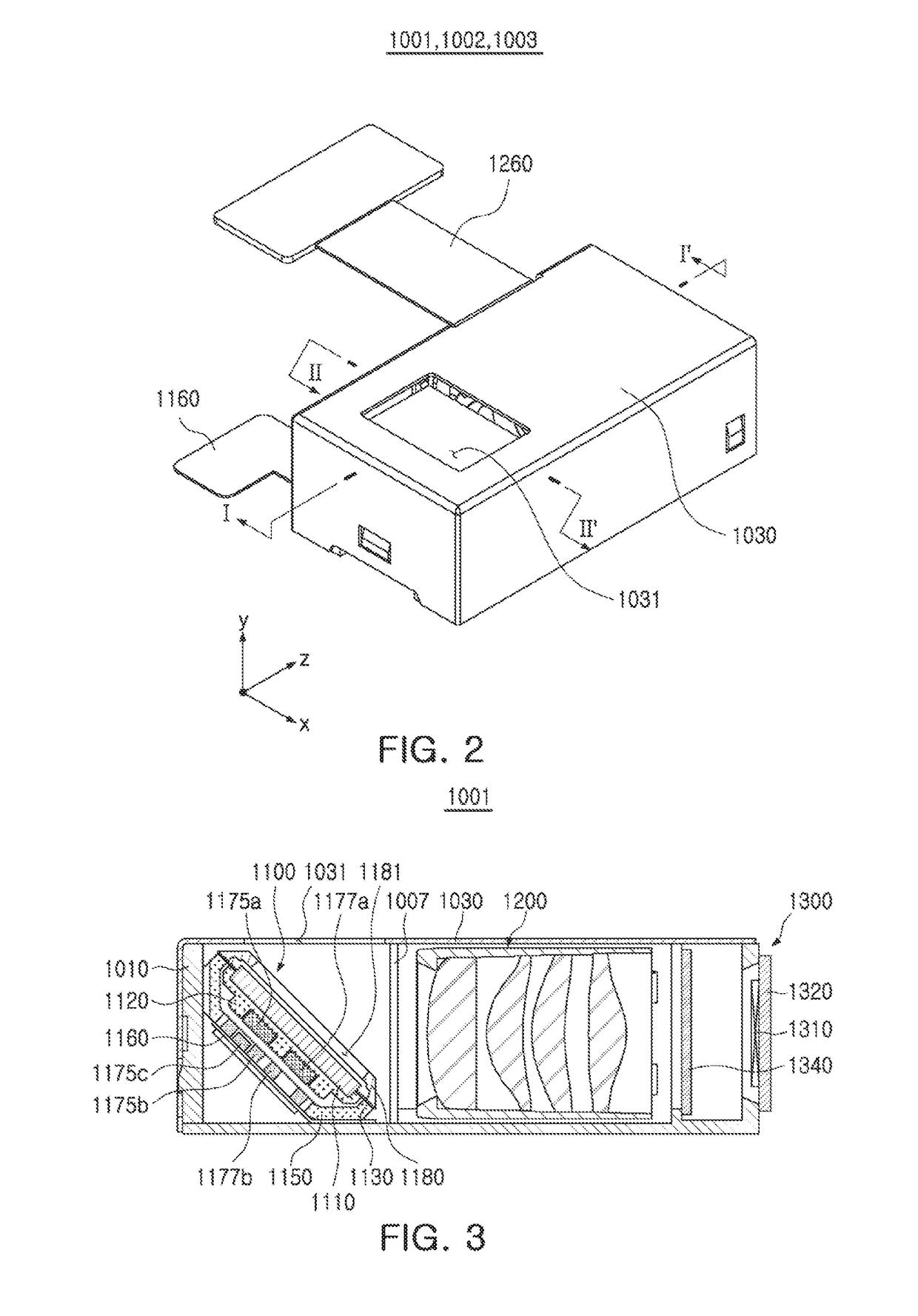

Reflecting module for ois and camera module including the same

ActiveUS20180231793A1Well formedSimple structureReciprocating/oscillating/vibrating magnetic circuit partsProjector focusing arrangementCamera moduleEngineering

There are provided a reflecting module for optical image stabilization (OIS) and a camera module including the same. The reflecting module for OIS includes: a housing including an internal space; a movable holder supported in the internal space of the housing by an elastic member; a reflecting member disposed on the movable holder; and a driving part configured to provide driving force to the movable holder so that the movable holder is moved relative to the housing, wherein the elastic member includes a fixed frame fixed to the housing, a movable frame provided in the fixed frame, and a spring connecting the fixed frame and the movable frame to each other and, the movable frame is movable in relation to two axes perpendicular to each other.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

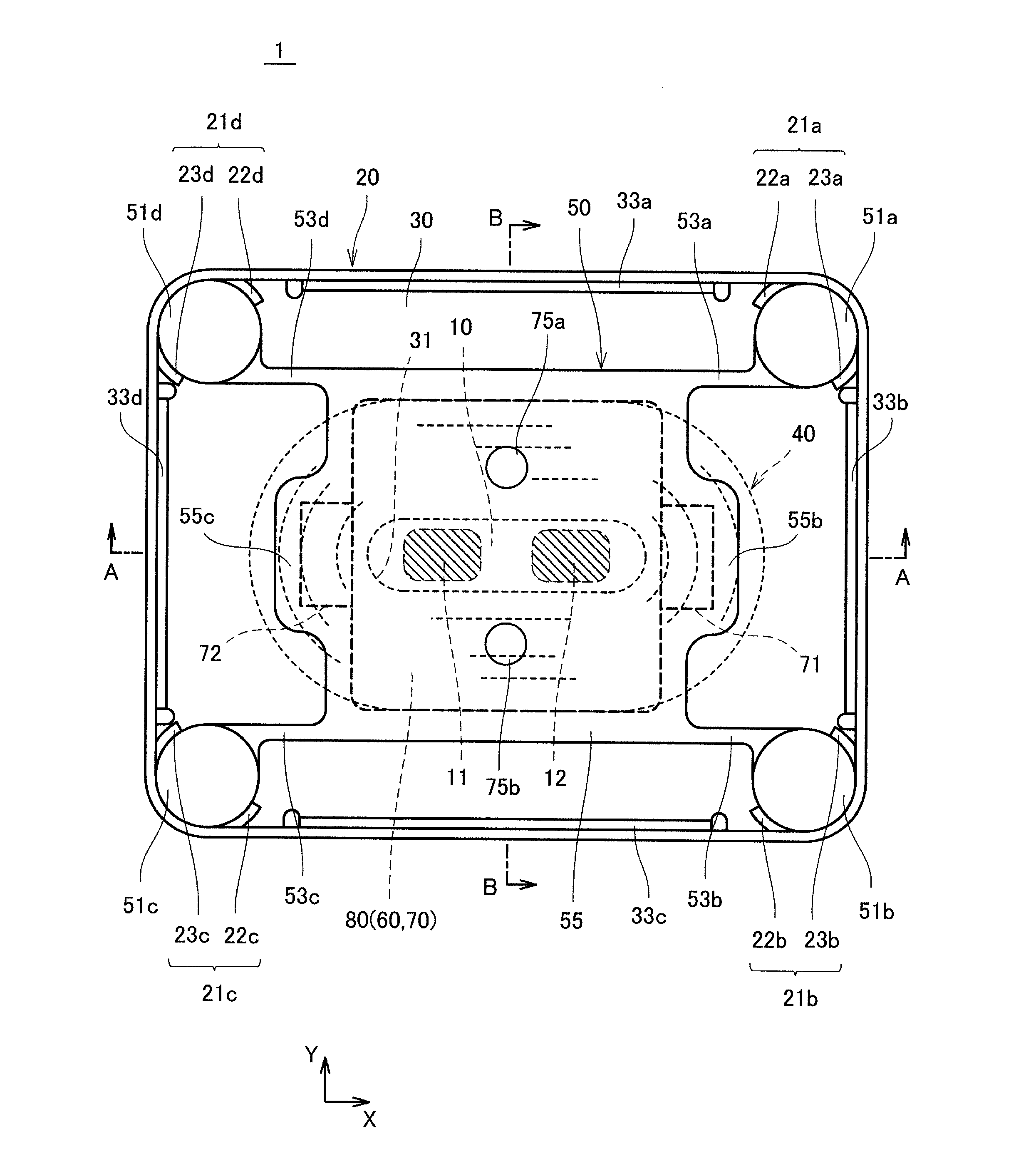

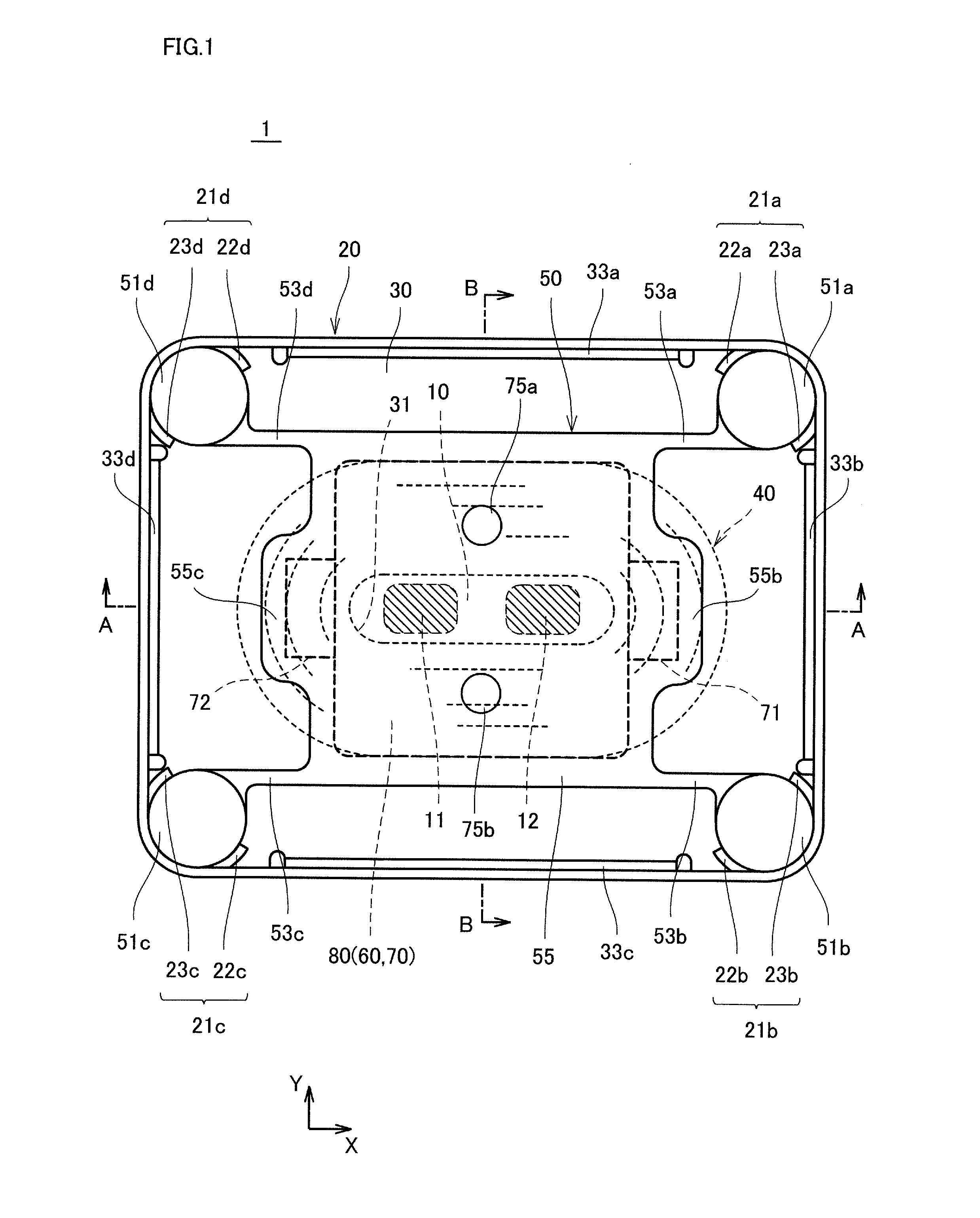

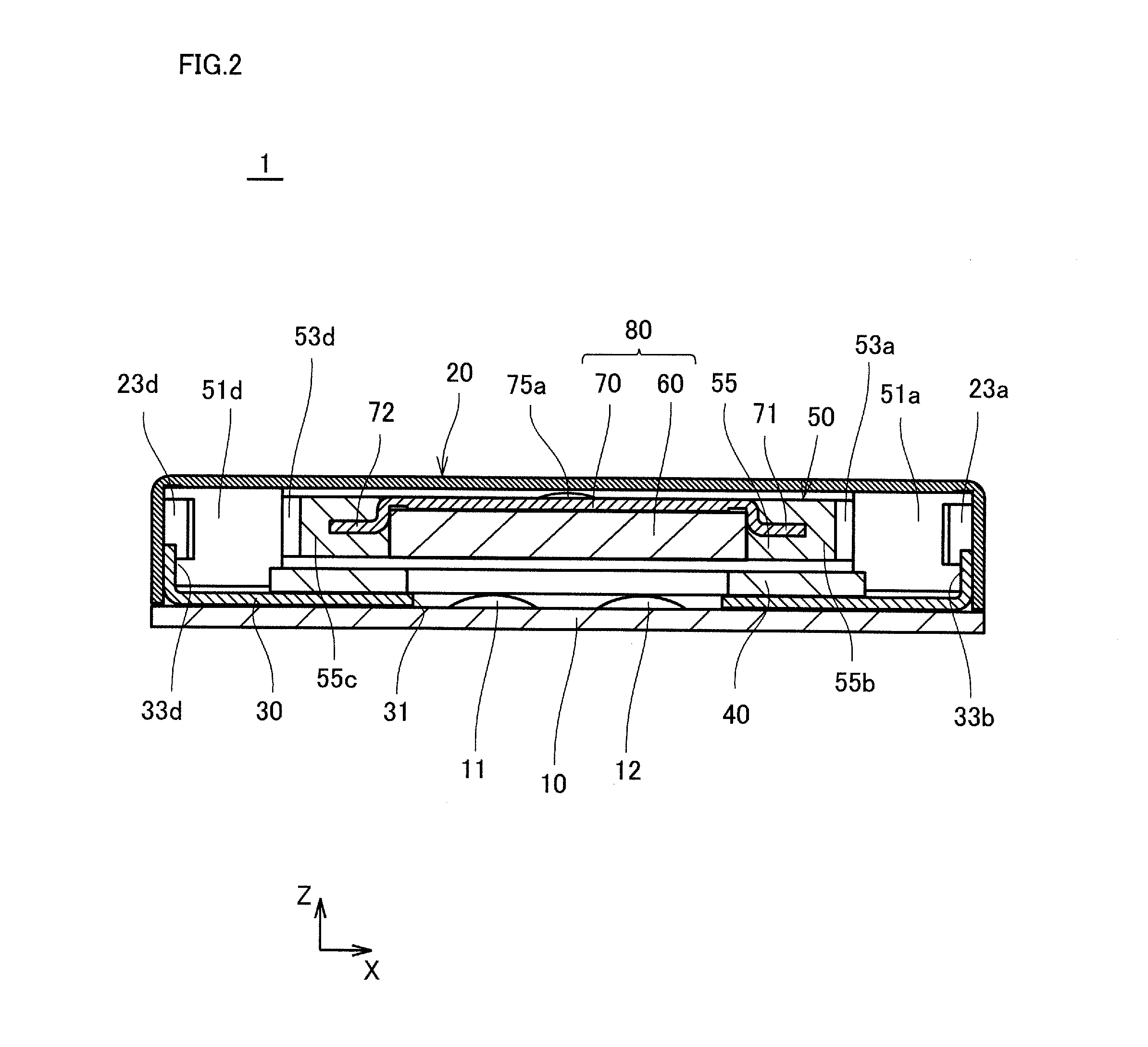

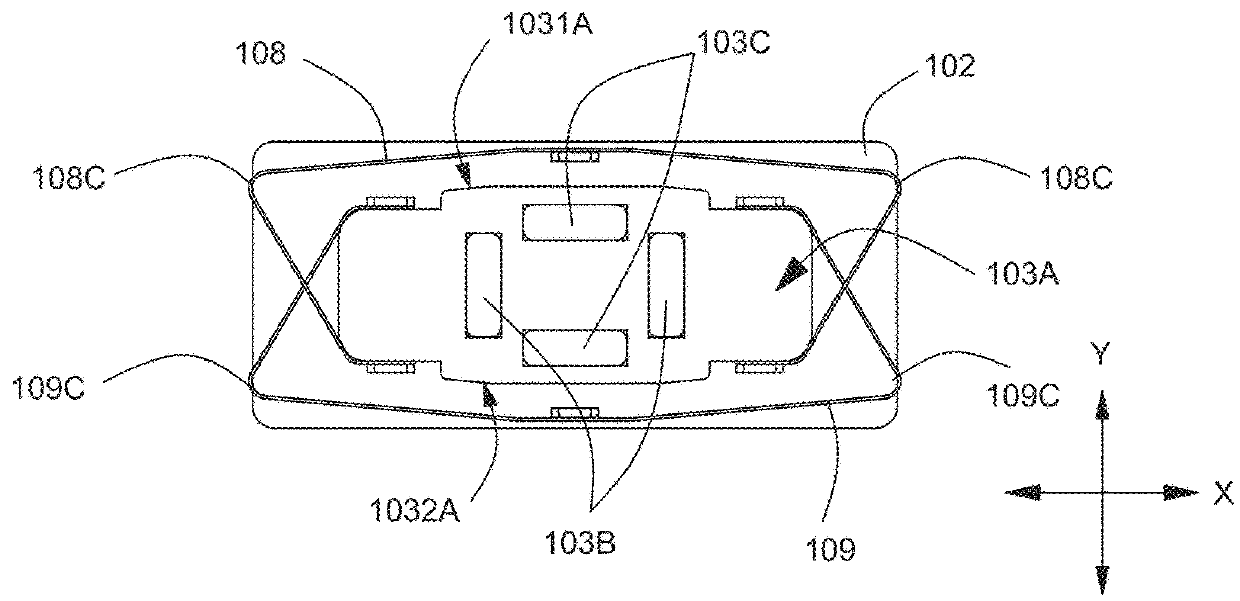

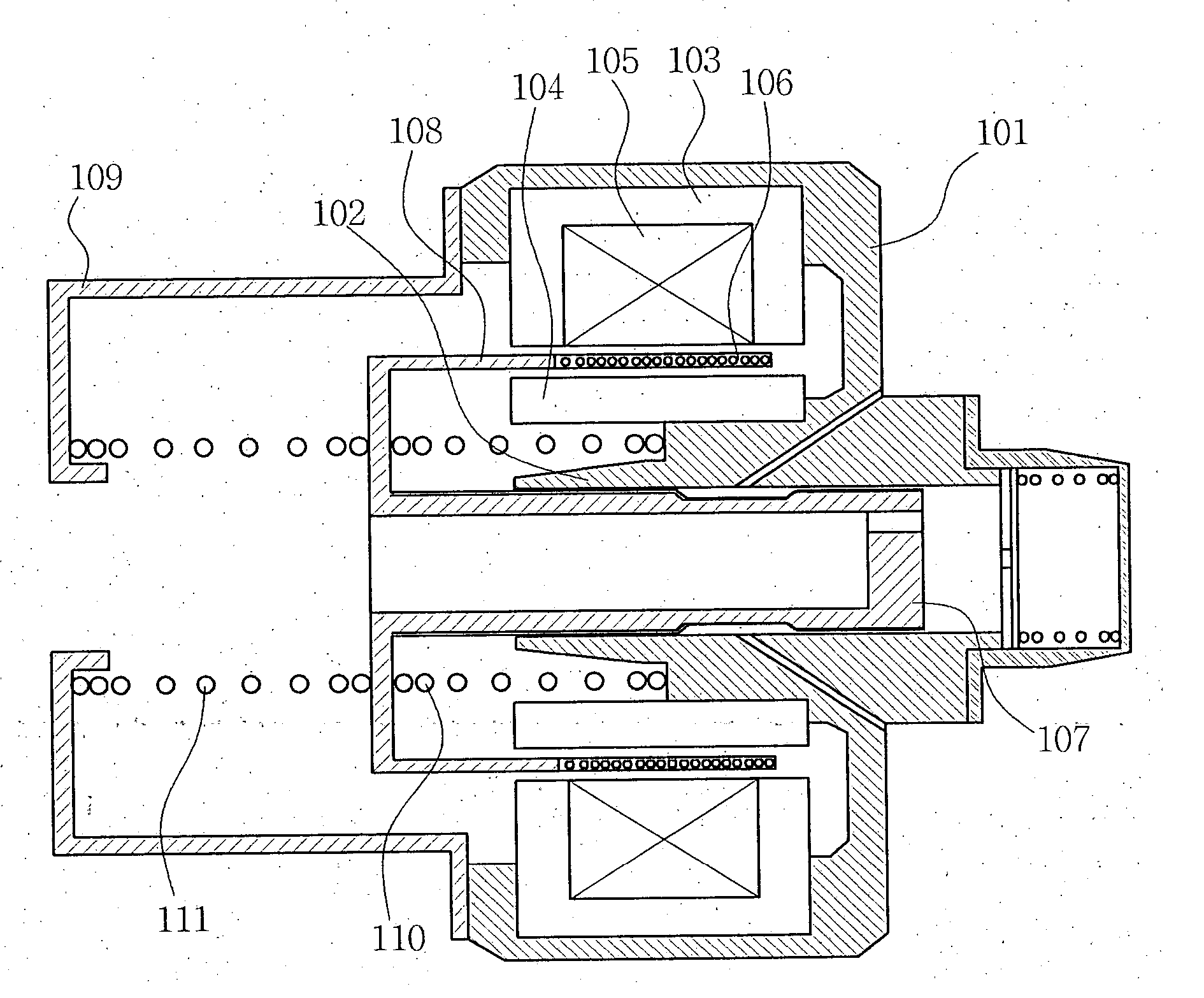

Double resonance vibration motor

ActiveUS10008894B2Simple structureImprove stabilityReciprocating/oscillating/vibrating magnetic circuit partsWindingsEngineeringResonance vibration

A double resonance vibration motor includes a housing, vibration parts in the housing, a coil fixed in the housing, and elastic connectors to support elastically the vibration part. The vibration parts include a mass block, a first magnet group and a second magnet group installed in the mass block. The coil is opposite to the first magnetic group and the second magnetic group. The driving force generated by the first magnetic group and the coil makes the vibration motor vibrate along the first direction. The driving force of the second magnet group and the coil makes the vibration motor vibrate along the second direction. The first direction and the second direction intersect. Two different directions have respectively one resonance frequency. Two different resonant frequencies can vibrate alone or at the same time, to realize the control in different vibration directions.

Owner:AAC TECH PTE LTD

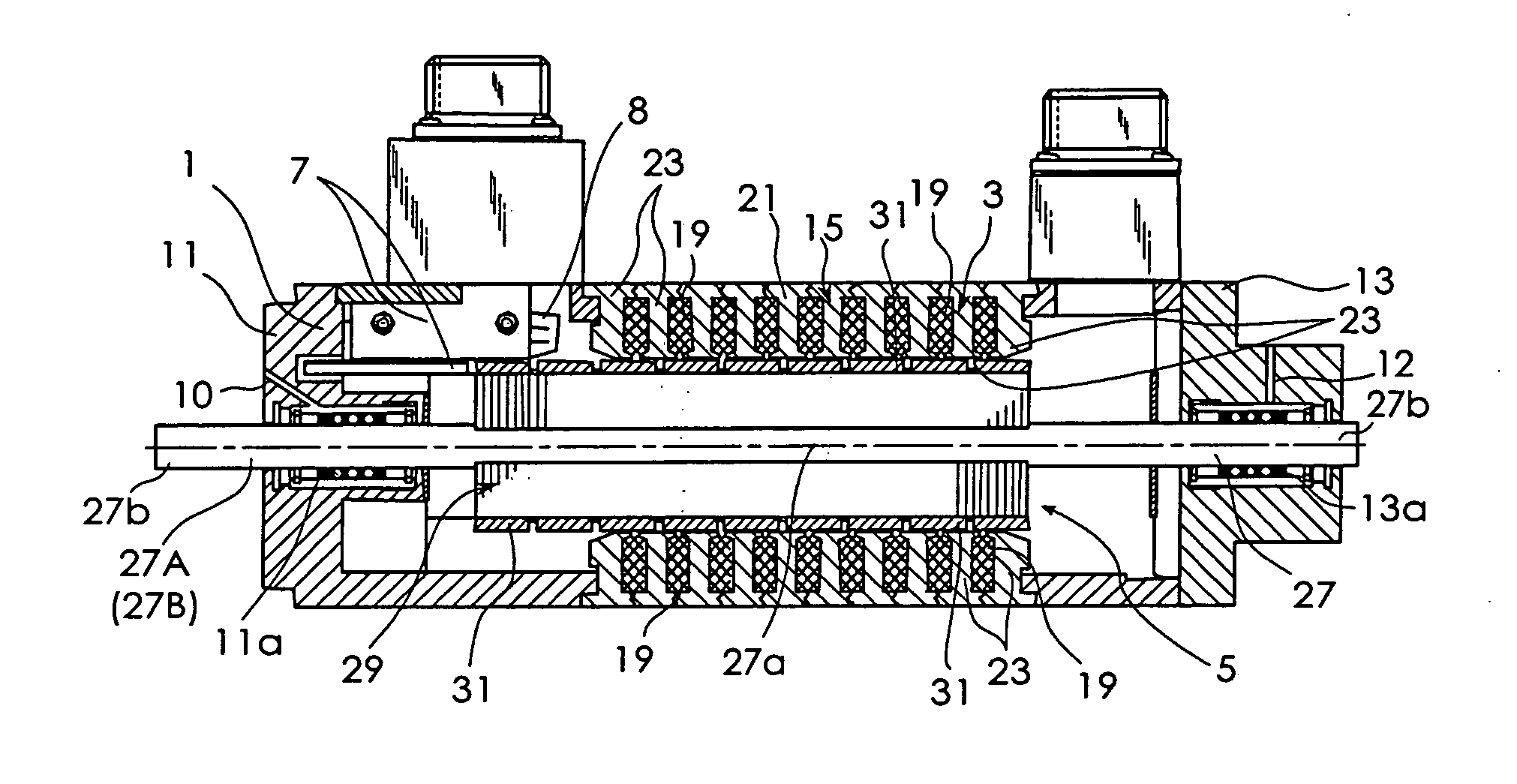

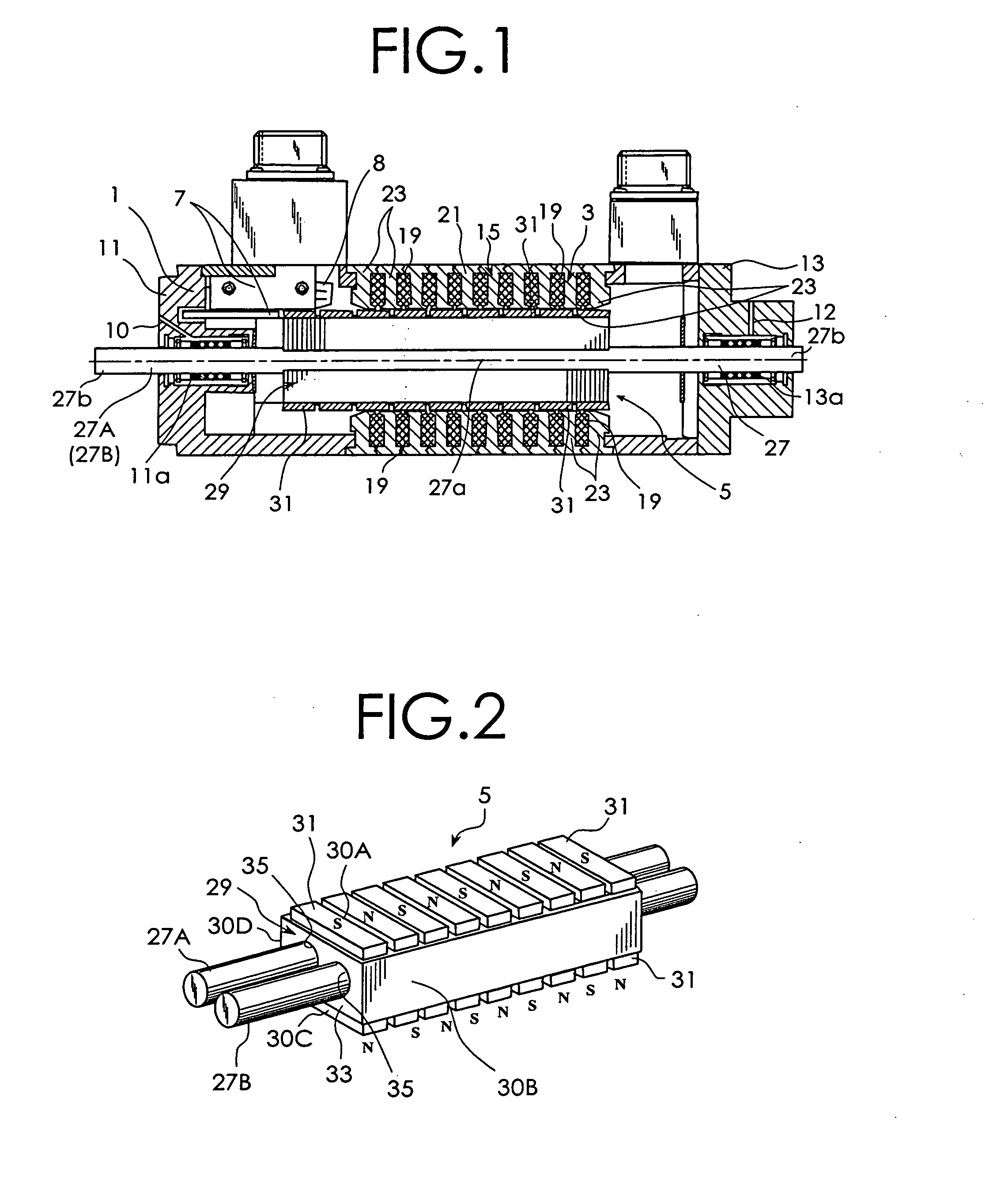

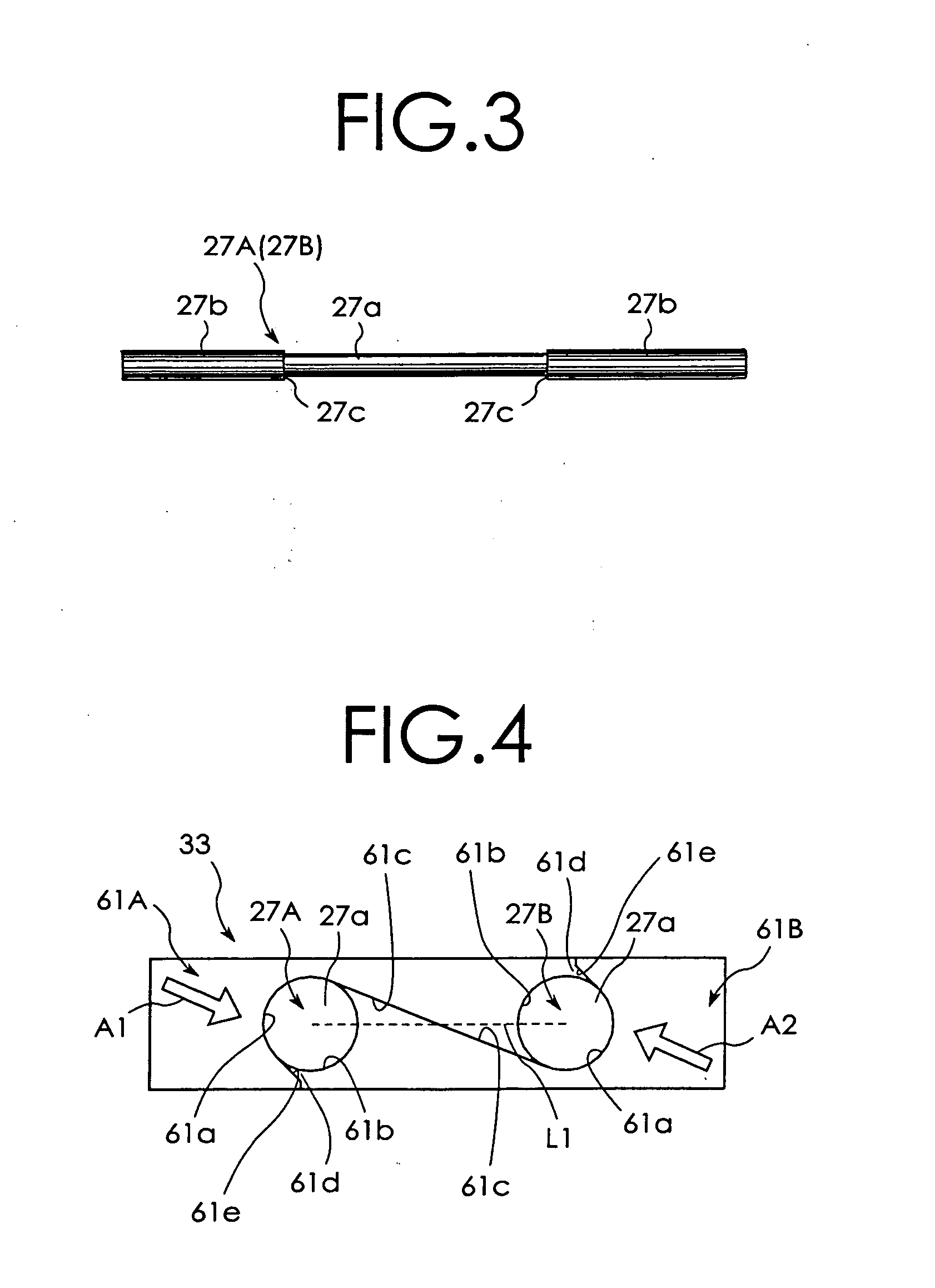

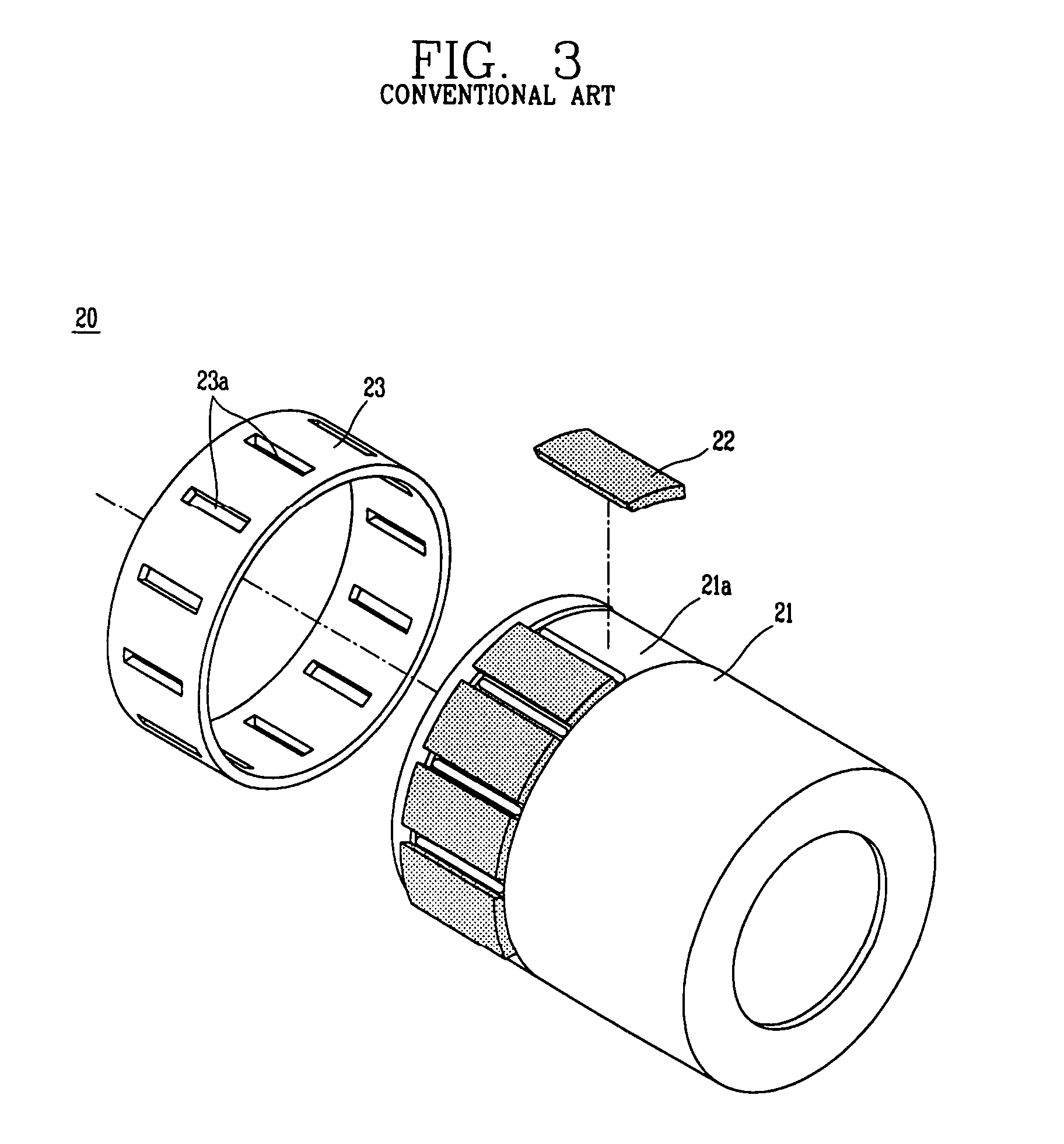

Movable assembly for cylinder type linear motor

InactiveUS20050046282A1Possible damageReduce magnetic resistanceReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsSteel platesDrive shaft

A movable assembly used in a cylinder type linear motor is provided which can be manufactured at low cost without requiring a cutting process while preventing its magnetic characteristics from deteriorating. The movable core is constructed of a laminated yoke which is formed of a plurality of electromagnetic steel plates laminated in an axial direction of the first and second direct drive shafts. A plurality of permanent magnets 31 fixed to the laminated yoke 29 are arranged in such a manner that the polarity appearing on the outer surface of the two permanent magnet 31 opposing each other through the laminated yoke 29. The first and second direct drive shafts each have a yoke mounting portion and paired supported portions at both axial ends of the yoke mounting portion. The first and second direct drive shafts are so shaped that the cross section of the yoke mounting portion orthogonal to the axial direction is smaller than that of the supported portions. Each of the electromagnetic steel plates is made up of first and second divided electromagnetic steel plate pieces of the same shape.

Owner:SANYO DENKI CO LTD

Reciprocating motor

ActiveUS7288862B2Improve productivityLow costReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsReciprocating motionEngineering

Owner:LG ELECTRONICS INC

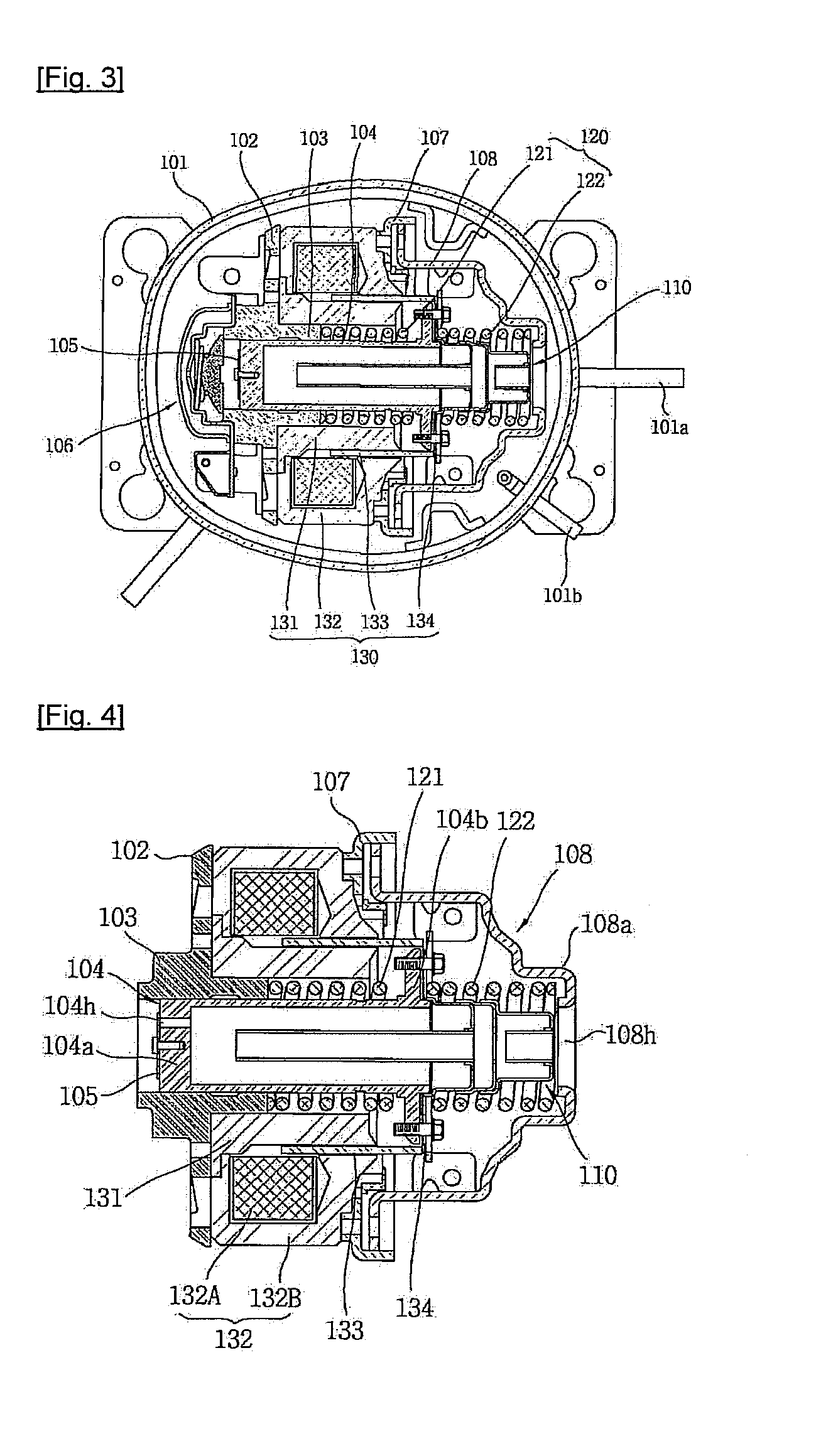

Electromechanical Generator for Converting Mechanical Vibrational Energy into Electrical Energy

ActiveUS20100327672A1Quality improvementHigh QReciprocating/oscillating/vibrating magnetic circuit partsVibrational energyMagnet

An electromechanical generator for converting mechanical vibrational energy into electrical energy, the electromechanical generator comprising a housing, an electrically conductive coil assembly movably mounted in the housing, the coil assembly having radially inner and outer sides, and upper and lower edges, thereof, a mount for the coil assembly extending inwardly of the radially inner side for mounting the coil assembly for linear vibrational motion along an axis about, a first biasing device mounted between the housing and the mount to bias the electrically conductive coil assembly in opposed directions along the axis towards a central coil position, a magnetic core assembly movably mounted in the housing for linear vibrational motion along the axis, and a second biasing device mounted between the housing and the magnetic core assembly to bias the magnetic core assembly in opposed directions along the axis towards a central magnet position, wherein the magnetic core assembly encloses the electrically conductive coil assembly on the radially outer side and on the upper and lower edges, and on a part of the radially inner side, the magnetic core assembly having a gap on a radially inner portion thereof through which the mount extends, and the radially inner portion including two opposed magnets spaced along the axis.

Owner:HITACHI RAIL LTD +1

Double resonance vibration motor

ActiveUS20170110920A1Simple structureImprove stabilityReciprocating/oscillating/vibrating magnetic circuit partsWindingsEngineeringResonance vibration

A double resonance vibration motor includes a housing, vibration parts in the housing, a coil fixed in the housing, and elastic connectors to support elastically the vibration part. The vibration parts include a mass block, a first magnet group and a second magnet group installed in the mass block. The coil is opposite to the first magnetic group and the second magnetic group. The driving force generated by the first magnetic group and the coil makes the vibration motor vibrate along the first direction. The driving force of the second magnet group and the coil makes the vibration motor vibrate along the second direction. The first direction and the second direction are intersected. Two different directions have respectively one resonance frequency. Two different resonant frequencies can vibrate alone or at the same time, to realize the control in different vibration directions.

Owner:AAC TECH PTE LTD

Bi-directional operating compressor using transverse flux linear motor

InactiveUS20060087180A1Reciprocating/oscillating/vibrating magnetic circuit partsSpringsPistonMagnet

Disclosed herein is a bi-directional operating compressor using a transverse flux linear motor, the compressor comprising: a pair of stators including a plurality of U-shape upper stator iron cores and a plurality of U-shape lower stator iron cores, and a pair of neighboring circular winding coils; a rotor placed between the pair of stators including a plurality of permanent magnets connected to iron cores, a rotor center installed between a pair of structures facing each other, a pair of supports connected to both sides of the center, and a pair of pistons connected to one side of the support respectively; and a pair of cylinders provided facing the pistons at both side ends of the rotor, for compressing air in response to the reciprocating motion of the pistons.

Owner:KOREA ELECTROTECH RES INST

Vibration motor

ActiveUS20180021812A1Enhanced magnetic forceImprove responsivenessReciprocating/oscillating/vibrating magnetic circuit partsMechanical vibrations separationMagnetPhysics

A vibration motor includes a stationary portion including a casing and a coil; a vibrating body including a weight and a magnet, the vibrating body being supported so as to be vibratable in one direction relative to the stationary portion; an elastic member located between the stationary portion and the vibrating body; and a top plate portion that is disposed above the vibrating body in an up-down direction that is perpendicular to the one direction. The magnet is disposed above the coil, and the top plate portion faces the magnet in the up-down direction. The magnet includes a set of first magnets that generate magnetic forces that are opposite to each other in the up-down direction and one or more second magnets that are interposed between the first magnets and each generate a magnetic force in the one direction.

Owner:SANYO SEIMITSU

Vibration motor

ActiveCN110266171AAchieve vibrationImprove the vibration effectReciprocating/oscillating/vibrating magnetic circuit partsElectric machineMagnetization

The invention provides a vibration motor, which comprises a base, a vibration unit, an elastic member and a coil assembly, wherein the vibration unit comprises a mass block and magnetic steel; the vibration unit comprises the mass block supported on the elastic element and the magnetic steel fixed on the mass block and arranged opposite to the coil assembly; the magnetization direction of the magnetic steel is a thickness direction; a drive signal is applied to the coil assembly; the elastic member supports vibration of the vibration unit along the direction vertical to the magnetization direction; and the vibration unit vibrates along any one of a first vibration direction vertical to the magnetization direction, a second vibration direction vertical to the magnetization direction and vertical to the first vibration direction and a third direction in a plane in which the first vibration direction and the second vibration direction are located through adjusting the drive signal. Compared with the related technology, the vibration motor provided by the invention has the advantages that multidirectional vibration is achieved and the vibration effect is good.

Owner:AAC TECH PTE LTD

Flat plate voice coil motor

ActiveCN104682656AWill not affect the amperageImprove feverReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsElectric machineMagnetic poles

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

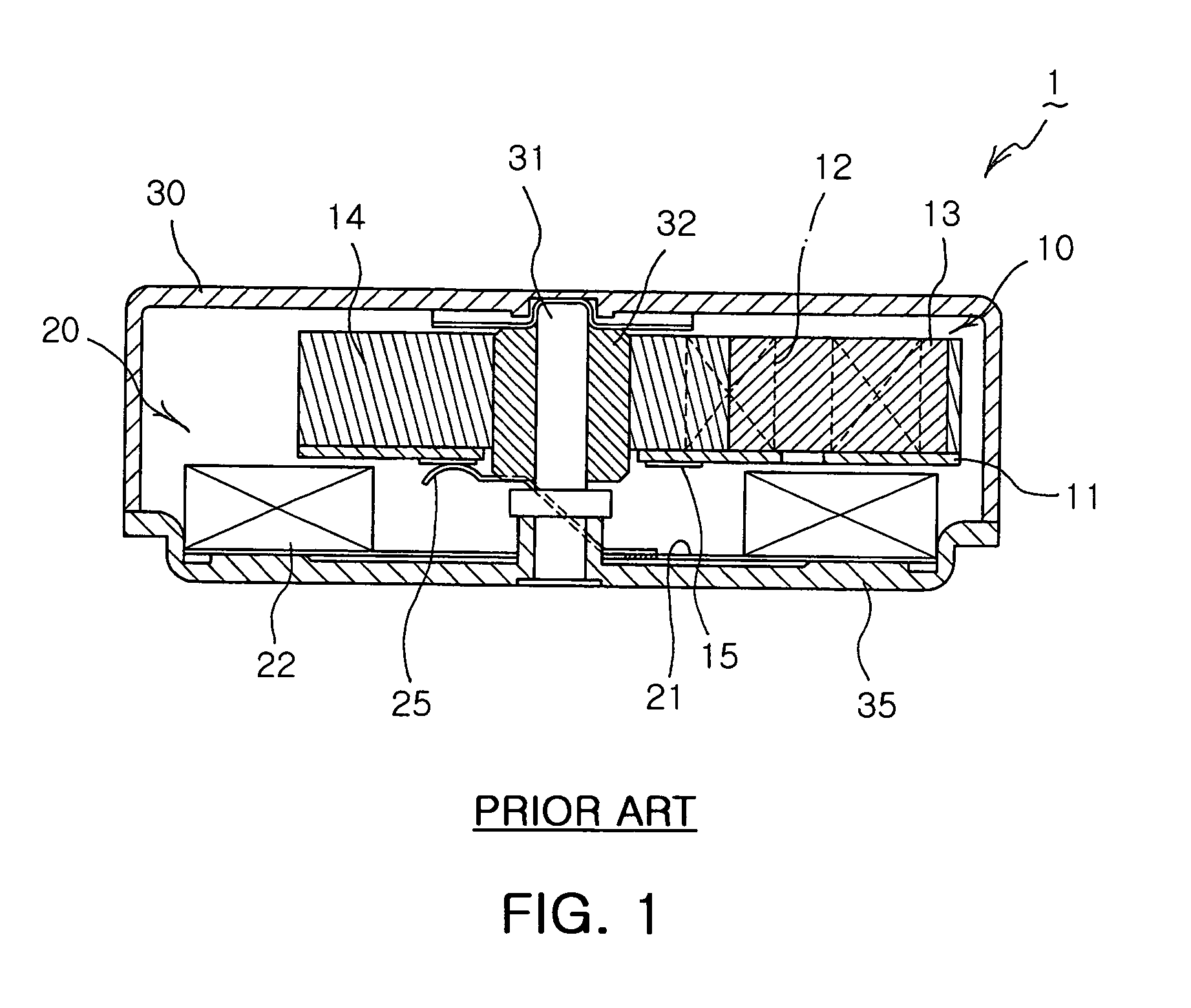

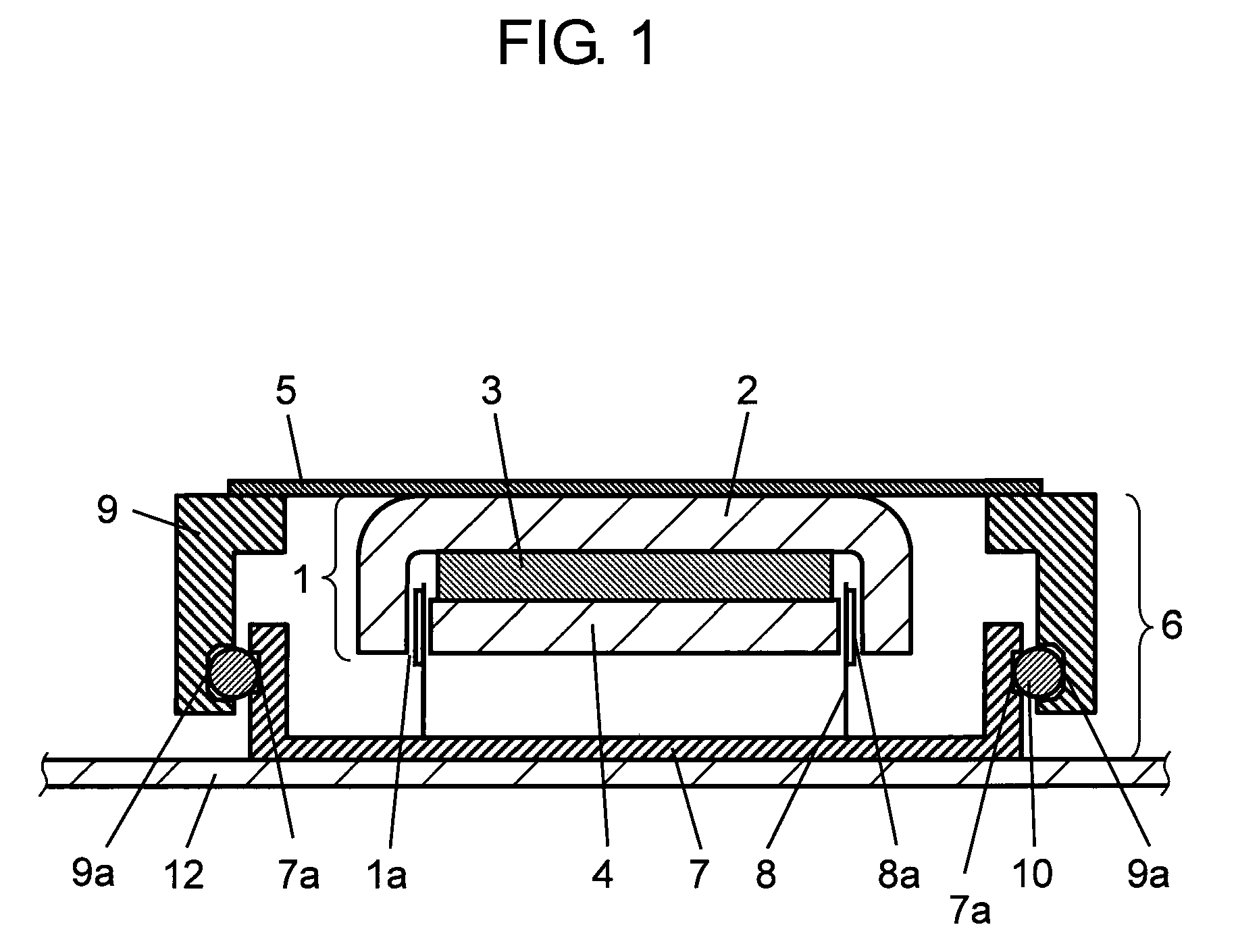

Acoustic exciter and speaker using it

ActiveUS20090184589A1Broad sound reproduction rangeReduce decreaseReciprocating/oscillating/vibrating magnetic circuit partsLoudspeakersElastomerEngineering

An acoustic exciter comprises a suspension made of an elastic material, which is coupled to the opening part of a frame, and a vibrator to which a voice coil disposed in the magnetic gap of a magnetic circuit connected to the suspension is coupled. An elastic body is so disposed between the frame and the vibrator as to be pressed against the frame and the vibrator. Thereby, the exciting efficiency of the vibrator can be increased, and the performance and tone quality of the acoustic exciter can be improved.

Owner:PANASONIC CORP

Electromechanical generator for converting mechanical vibrational energy into electrical energy

ActiveUS8492937B2Quality improvementHigh QReciprocating/oscillating/vibrating magnetic circuit partsMechanical energy handlingVibrational energyElectric generator

An electromechanical generator for converting mechanical vibrational energy into electrical energy, the electromechanical generator comprising a housing, an electrically conductive coil assembly movably mounted in the housing, the coil assembly having radially inner and outer sides, and upper and lower edges, thereof, a mount for the coil assembly extending inwardly of the radially inner side for mounting the coil assembly for linear vibrational motion along an axis about, a first biasing device mounted between the housing and the mount to bias the electrically conductive coil assembly in opposed directions along the axis towards a central coil position, a magnetic core assembly movably mounted in the housing for linear vibrational motion along the axis, and a second biasing device mounted between the housing and the magnetic core assembly to bias the magnetic core assembly in opposed directions along the axis towards a central magnet position, wherein the magnetic core assembly encloses the electrically conductive coil assembly on the radially outer side and on the upper and lower edges, and on a part of the radially inner side, the magnetic core assembly having a gap on a radially inner portion thereof through which the mount extends, and the radially inner portion including two opposed magnets spaced along the axis.

Owner:HITACHI RAIL LTD +1

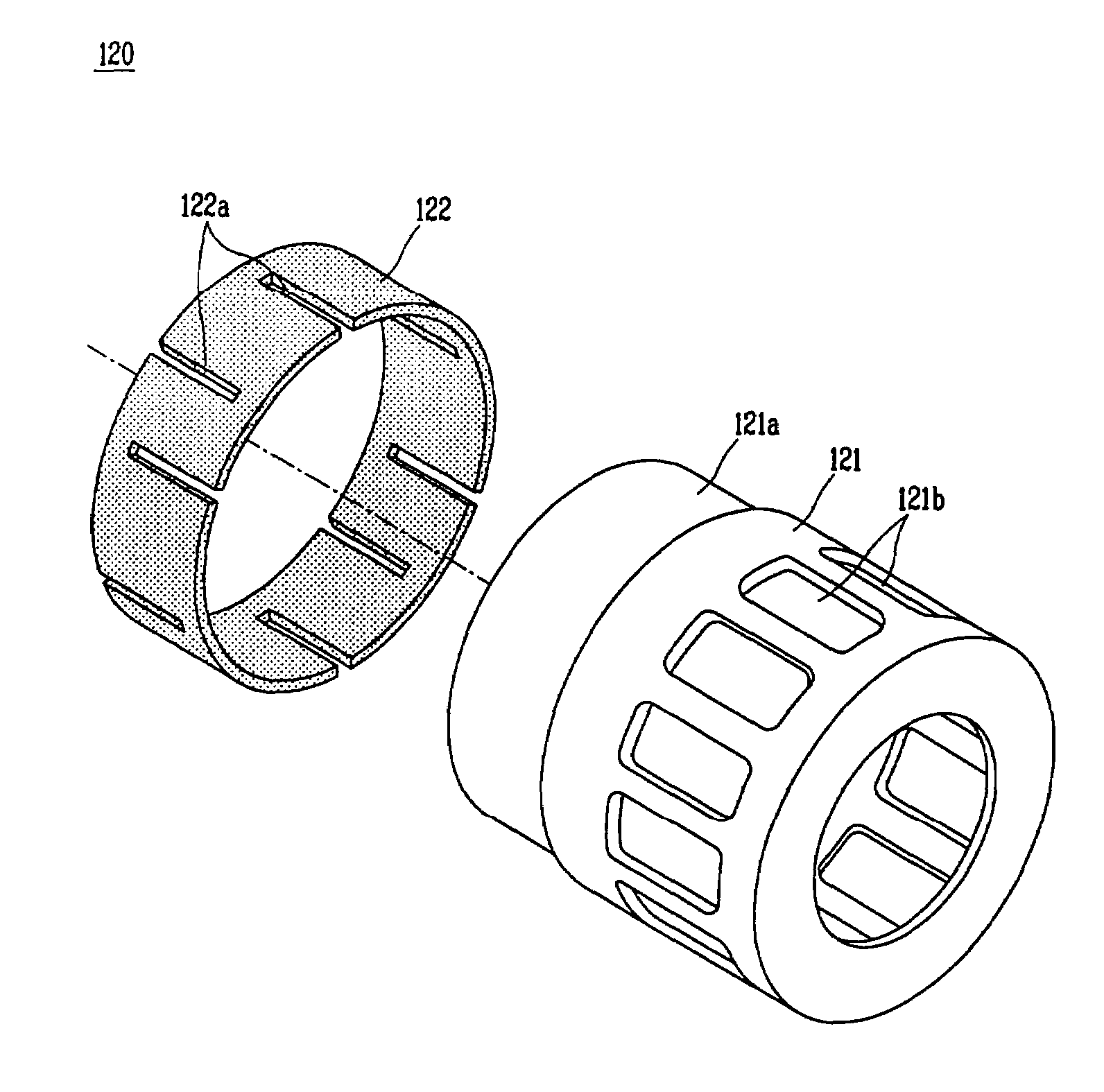

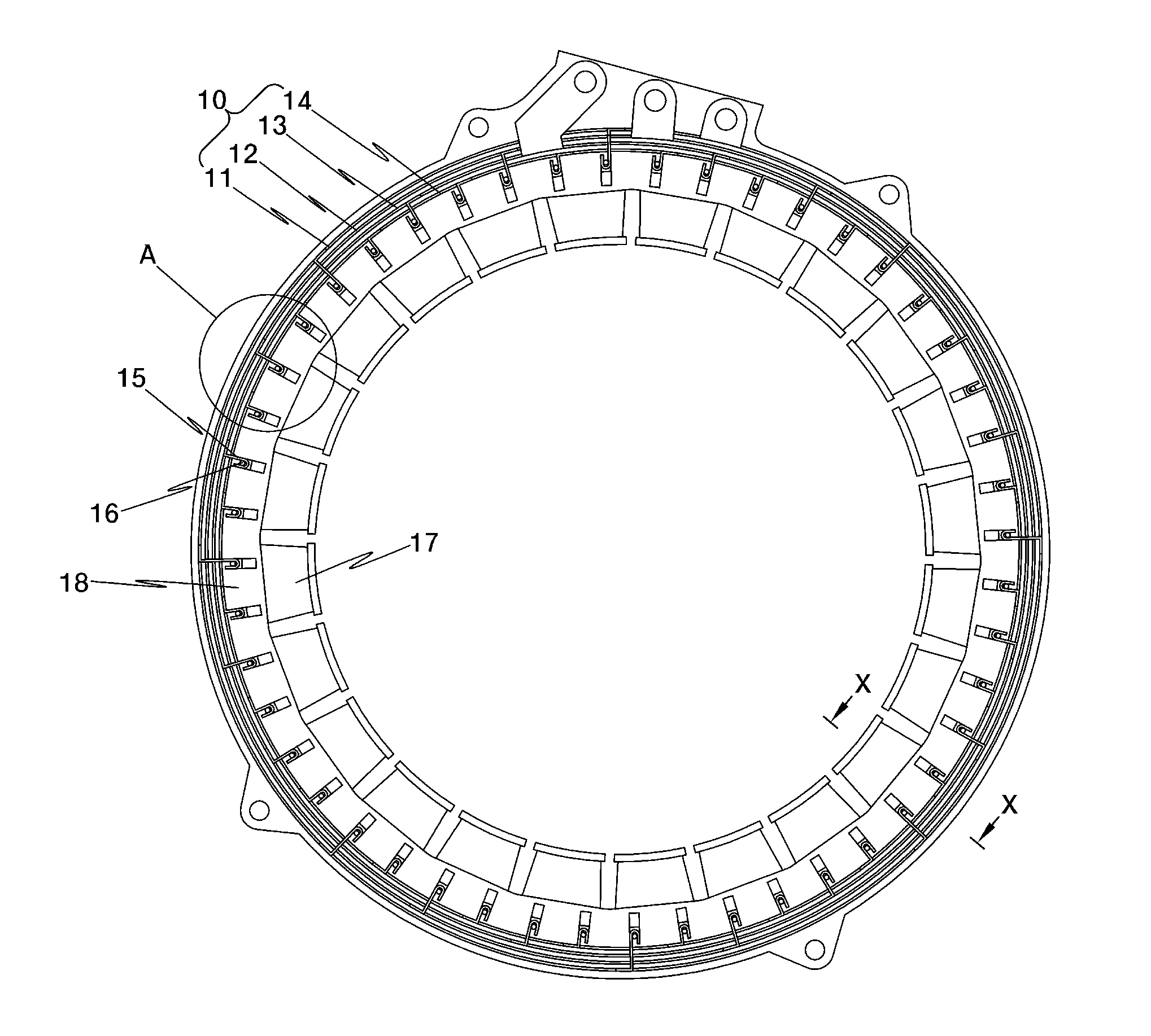

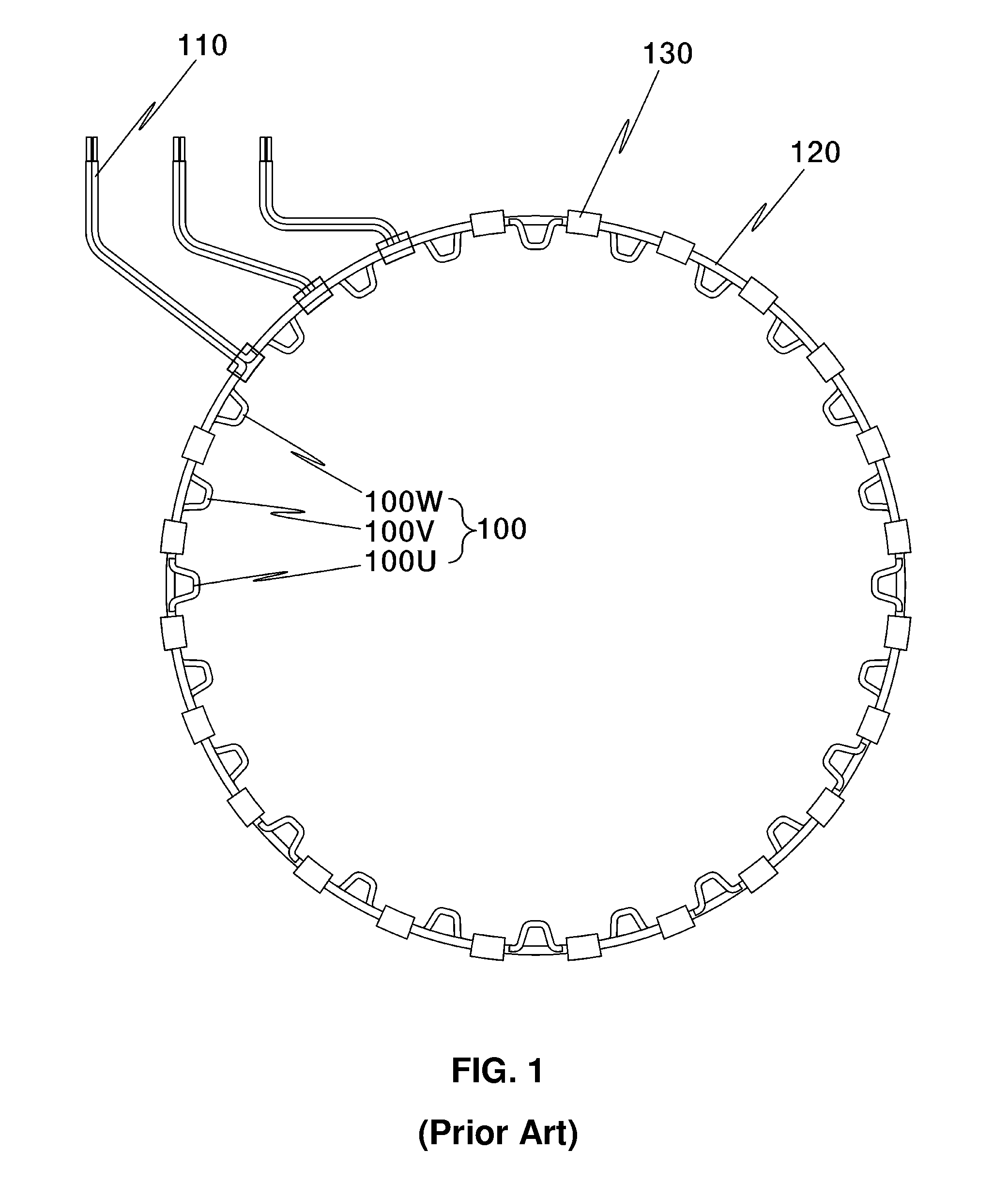

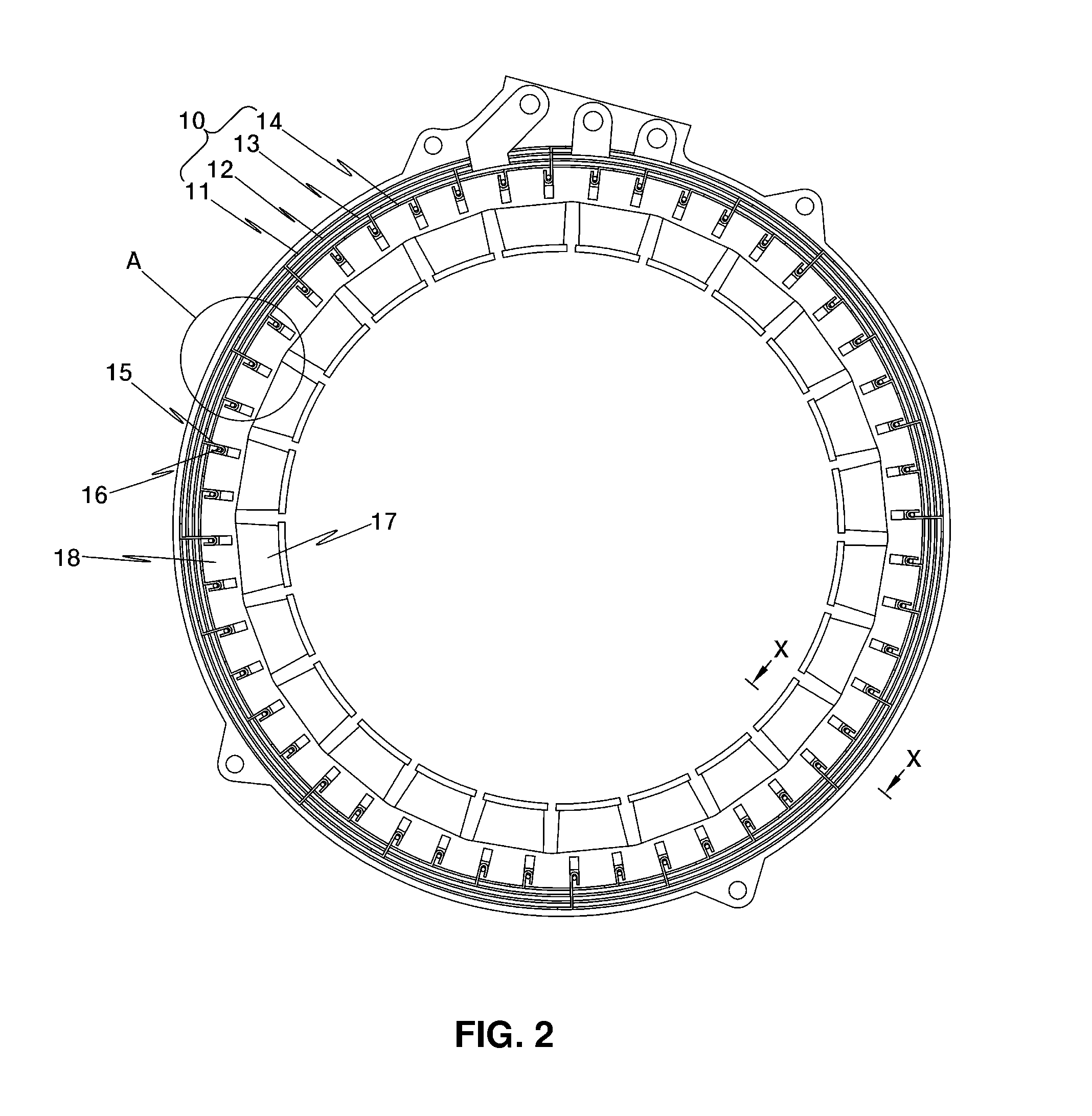

Concentrated winding type driving motor for vehicle

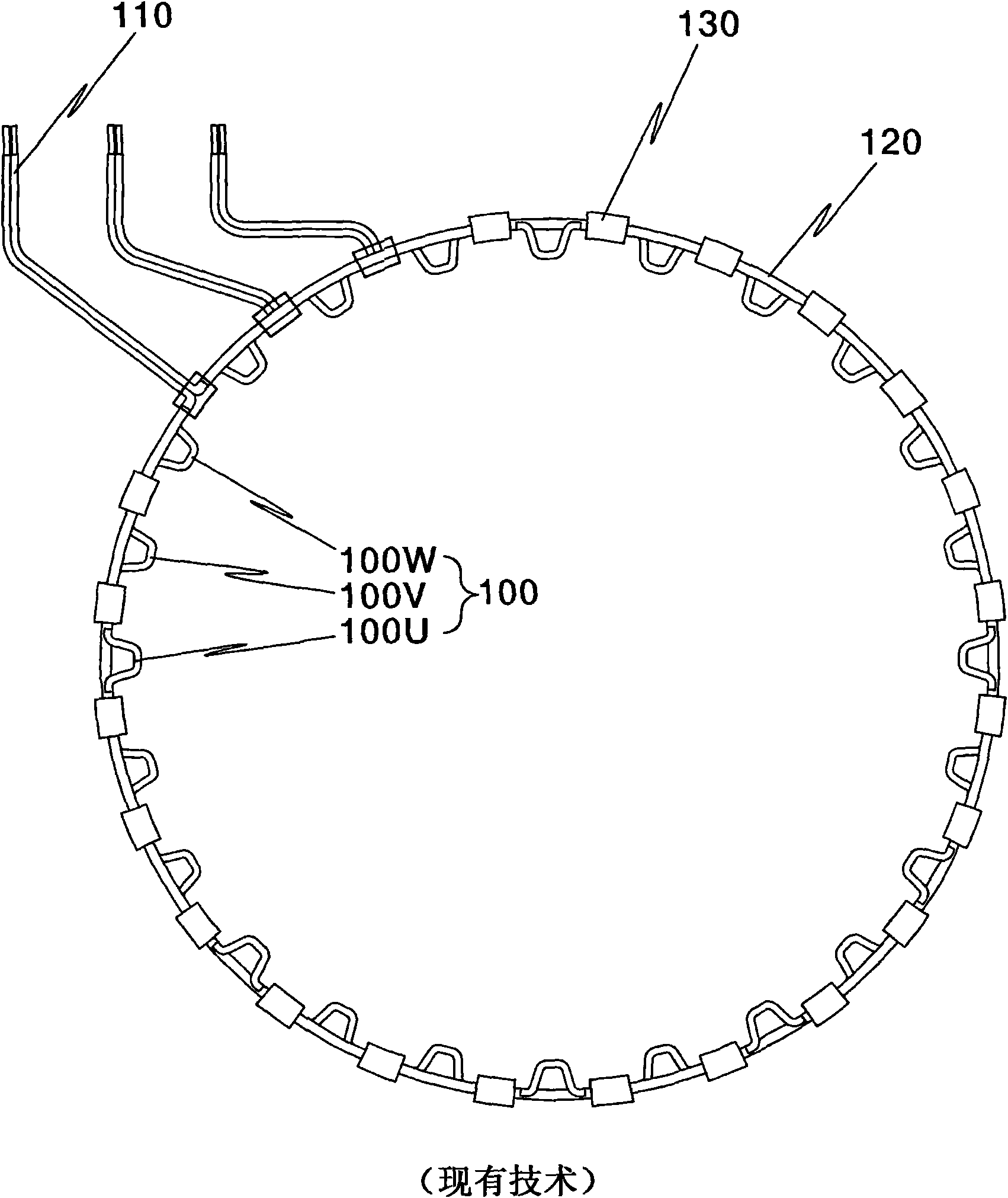

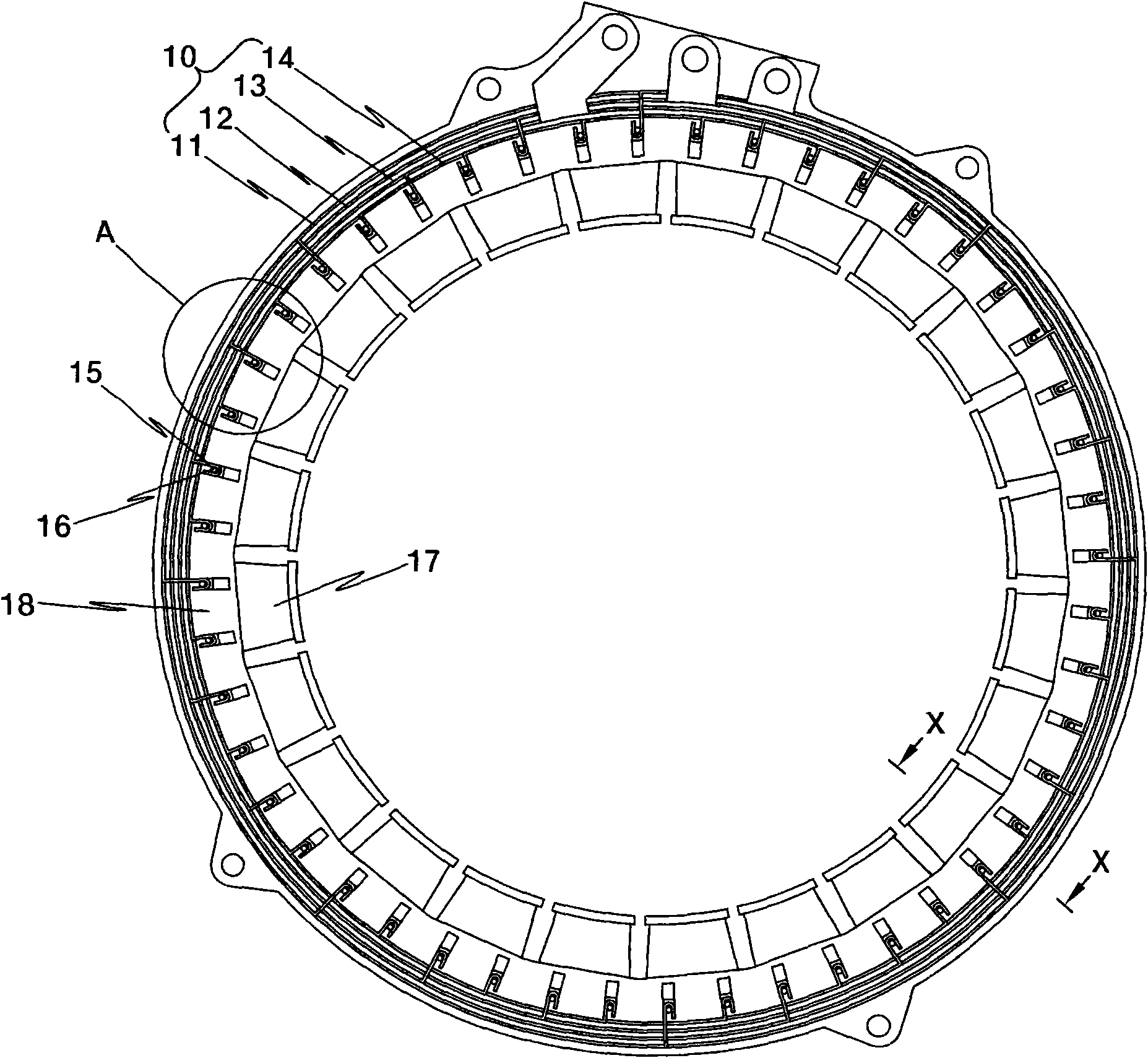

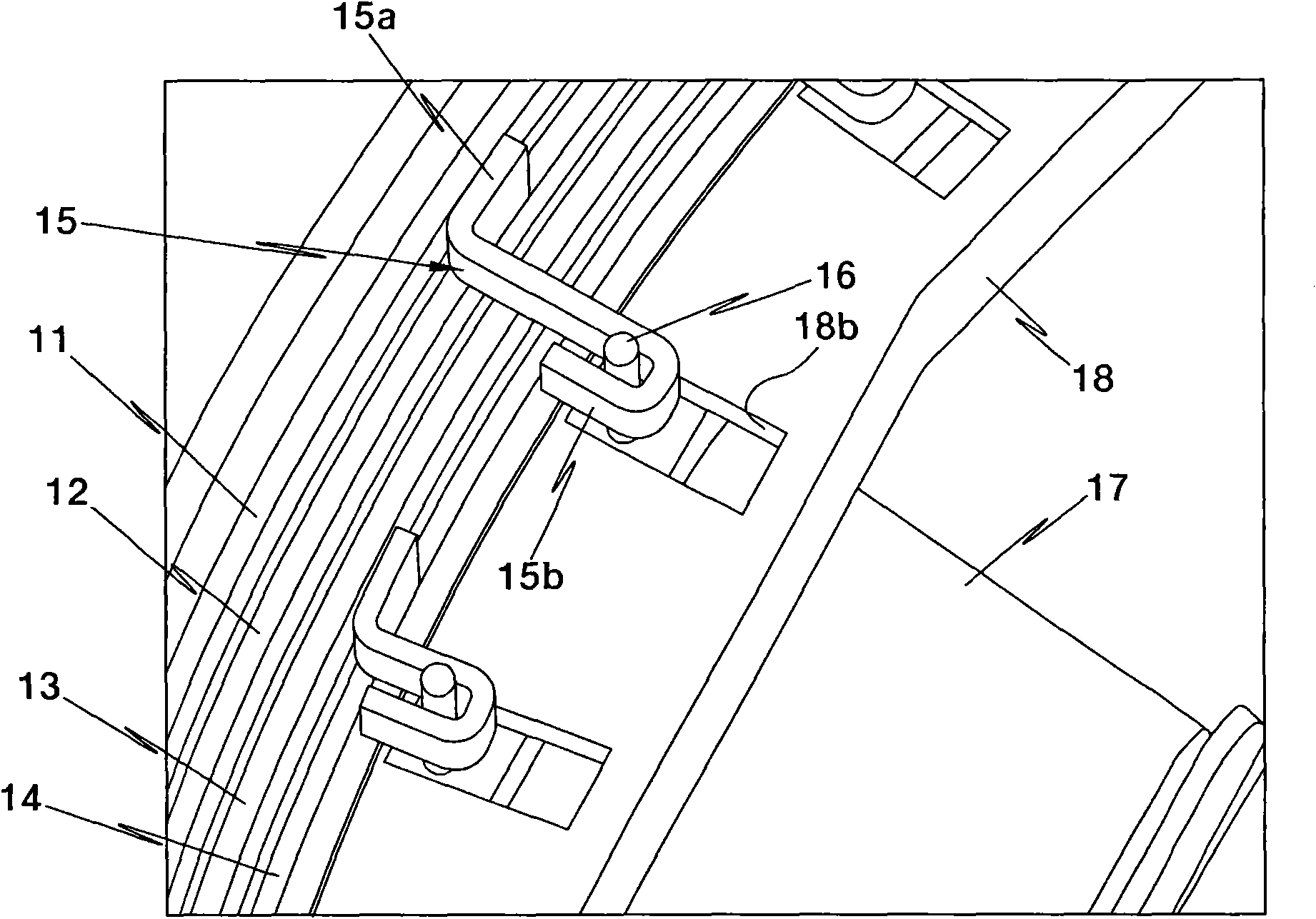

InactiveCN102088219AAvoid interferenceFirmly connectedReciprocating/oscillating/vibrating magnetic circuit partsWindingsElectrical conductorEngineering

Disclosed herein is a concentrated winding type coil connecting structure of a driving motor for a hybrid vehicle. A protrusion protrudes upwards (the axial direction of the motor) from each of U- / V- / W- / N-phase conducting plates concentrically inserted into receiving grooves of a conductor holder, and a bent part is bent from the upper end of the protrusion in a radial direction of the motor, and a curved groove is formed in an end of the bent part to surround the circumferential surface of each of the coils, so that a connector integrally having the protrusion, the bent part and the groove allows each conducting plate and the coil to be firmly joined to each other, thus maintaining a strong force of connection between the conducting plate and the coil, and providing high workability and durability.

Owner:HYUNDAI MOTOR CO LTD +1

Acoustic exciter and speaker using it

ActiveUS8247930B2Broad sound reproduction rangeReduce decreaseReciprocating/oscillating/vibrating magnetic circuit partsLoudspeakersElastomerEngineering

An acoustic exciter comprises a suspension made of an elastic material, which is coupled to the opening part of a frame, and a vibrator to which a voice coil disposed in the magnetic gap of a magnetic circuit connected to the suspension is coupled. An elastic body is so disposed between the frame and the vibrator as to be pressed against the frame and the vibrator. Thereby, the exciting efficiency of the vibrator can be increased, and the performance and tone quality of the acoustic exciter can be improved.

Owner:PANASONIC CORP

Linear vibration motor

InactiveUS10079531B2Enhanced magnetic forceImprove the forceReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsEngineeringLinear vibration

A linear vibration motor is disclosed. The linear vibration motor, includes a housing provided with an accommodation space; a vibrator accommodated in the accommodation space; and an electromagnet accommodated in the accommodation space. The vibrator includes a weight having a through-hole and a plurality of permanent magnets engaging with an inner wall of the through-hole. A number of elastic connecting parts are accommodated in the accommodation space, one end of the elastic connecting part connected with the housing and the other end connected with the weight for suspending the vibrator in the accommodation space. The electromagnet includes an iron core and a coil around the iron core for producing magnet fields interacting with the permanent magnets further for producing attracting and repelling force to drive the vibrator to vibrate.

Owner:AAC TECH PTE LTD

Concentrated winding type driving motor for vehicle

InactiveUS20110133581A1Easily fusion weldedAvoid interferenceReciprocating/oscillating/vibrating magnetic circuit partsWindingsElectrical conductorElectric machine

Disclosed herein is a concentrated winding type coil connecting structure of a driving motor for a hybrid vehicle. A protrusion protrudes upwards (the axial direction of the motor) from each of U- / V- / W- / N-phase conducting plates concentrically inserted into receiving grooves of a conductor holder, and a bent part is bent from the upper end of the protrusion in a radial direction of the motor, and a curved groove is formed in an end of the bent part to surround the circumferential surface of each of the coils, so that a connector integrally having the protrusion, the bent part and the groove allows each conducting plate and the coil to be firmly joined to each other, thus maintaining a strong force of connection between the conducting plate and the coil, and providing high workability and durability.

Owner:HYUNDAI MOTOR CO LTD +1

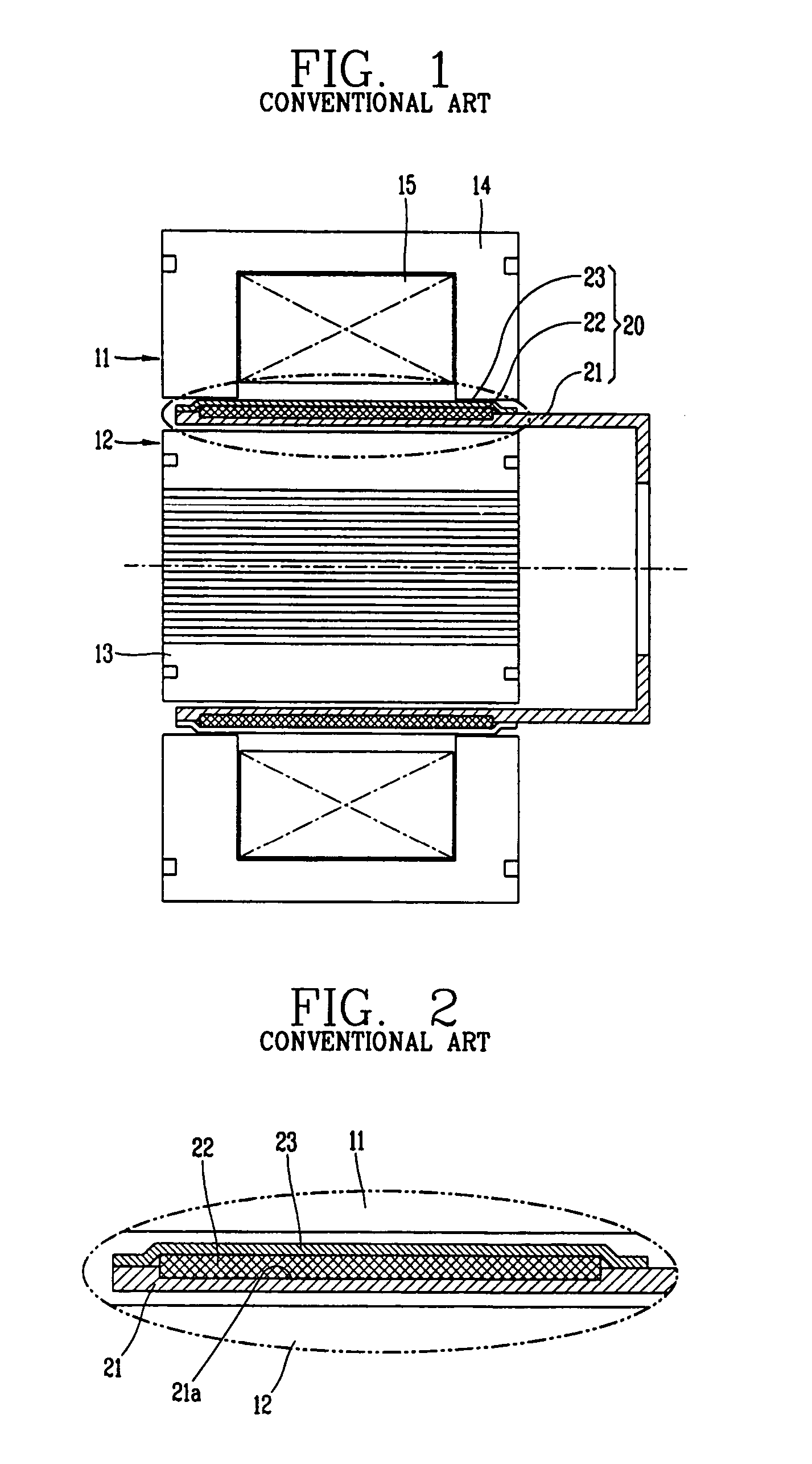

Linear compressor

ActiveUS20130129540A1Light weightSmall sizeReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsLinear motionLinear compressor

A linear compressor according to the present invention can prevent leakage of a magnetic force by changing the construction of a linear motor. As the construction of the linear motor is changed, a mechanical spring constant is set smaller in consideration of a magnetic spring constant, so that the size of springs supporting a piston in the reciprocal linear motion direction can be reduced and components supporting the springs can be removed. Therefore, the linear compressor achieves a small size / a light weight. With the characteristics of the linear motor construction, the linear compressor can suppress a stroke spreading influence and easily expand a compression capacity according to a load.

Owner:LG ELECTRONICS INC

Tubular electrical machines

InactiveUS20070164615A1Heat dissipationEliminate the problemReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsSuperconducting CoilsMagnet

An improved synchronous tubular electrical machine comprises a radially outer member that has a substantially cylindrical inner surface and radially inner member that is substantially cylindrical and is coaxially disposed within the outer member such that it may move reciprocally relative to the outer member in the axial direction. A plurality of axially spaced circumferential armature coils are electrically insulated from one another and are formed as part of one of the outer member and the inner member. A plurality of axially spaced circumferential superconducting coils are formed as part of the other of the outer member and the inner member. During operation of the tubular machine, each superconducting coil is maintained in a superconducting state and an electrical current is supplied to each superconducting coil in such a manner that the current flowing around each coil is in the opposite direction to the current flowing around the coils adjacent to it. Such tubular machines may be significantly more efficient, have higher peak-mean power ratios and be much smaller than current permanent magnet based synchronous tubular electrical machines.

Owner:GE POWER CONVERSION

Vibration generator moving vibrator by magnetic field generated by coil and vibrator-mounted holder used in vibration-generator

ActiveUS20140202252A1Reciprocating/oscillating/vibrating magnetic circuit partsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringMagnet

A vibrator-mounted holder is attached to a casing of a vibration generator which moves a vibrator to generate a vibration when used. The vibrator-mounted holder includes a vibrator, a vibrator retention unit retaining the vibrator, a fixing unit fixed to a casing, and an arm. The vibrator includes a magnet having a plate shape parallel to a horizontal surface and a yoke arranged on the magnet. The arm connects the fixing unit to the vibrator retention unit, and supports the vibrator retention unit in a manner that the vibrator retention unit is displaceable with respect to the fixing unit. The yoke has a projecting portion which is projected downward and fixed to the vibrator retention unit. The arm is connected to a portion, at which the projecting portion is arranged, within the vibrator retention units.

Owner:MINEBEAMITSUMI INC

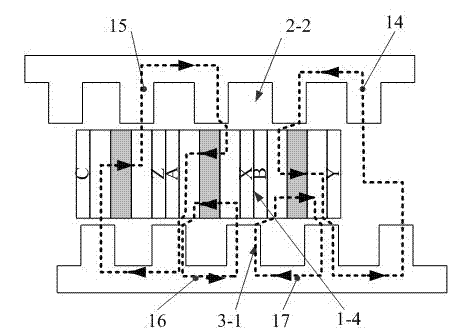

Double-edge staggered teeth flat type flux switching permanent magnet linear motor

InactiveCN103296857AIncrease thrust densityIncrease profitReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsSecondary toothMagnet

The invention provides a double-edge staggered teeth flat type flux switching permanent magnet linear motor and belongs to the technical field of motors. The double-edge staggered teeth flat type flux switching permanent magnet linear motor comprises a primary part and two secondary parts. In the primary part, a permanent magnet body is arranged between two magnet guiding primary iron core teeth to form a sandwich structure, magnetizing directions of the permanent magnet bodies on two adjacent sandwich structures are opposite, through grooves are formed between the sandwich structures, and armature windings are arranged in the through grooves. The two secondary parts are arranged on two sides of the primary part and are both magnet guiding iron cores of tooth socket structures. Secondary teeth on one side of the primary part and opposite secondary teeth on the other side of the primary part are staggered in position to form a structure with teeth of one secondary part corresponding to grooves of the other secondary part. During work of the double-edge staggered teeth flat type flux switching permanent magnet linear motor, along with changing of the relative positions of the primary part and the secondary parts on two sides, a flux changes the path, and the maximum flux with a winding turn chain in each groove is generated by three adjacent permanent magnets. The double-edge staggered teeth flat type flux switching permanent magnet linear motor can improve utilization rate of the permanent magnet bodies, improves thrust density and removes one-side magnetic pull.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com