Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1522results about "By zone-melting liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long persistent phosphors and persistent energy transfer technique

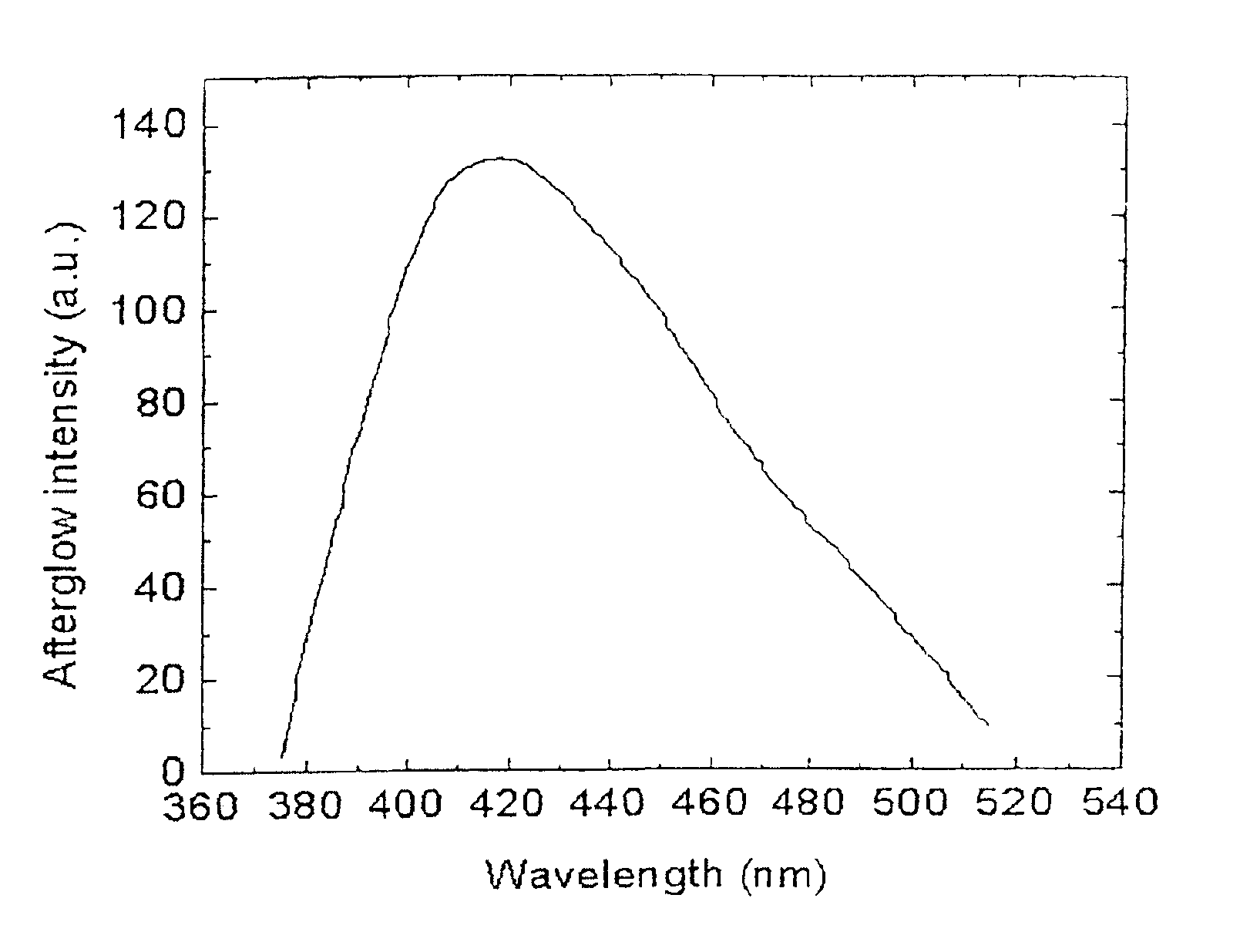

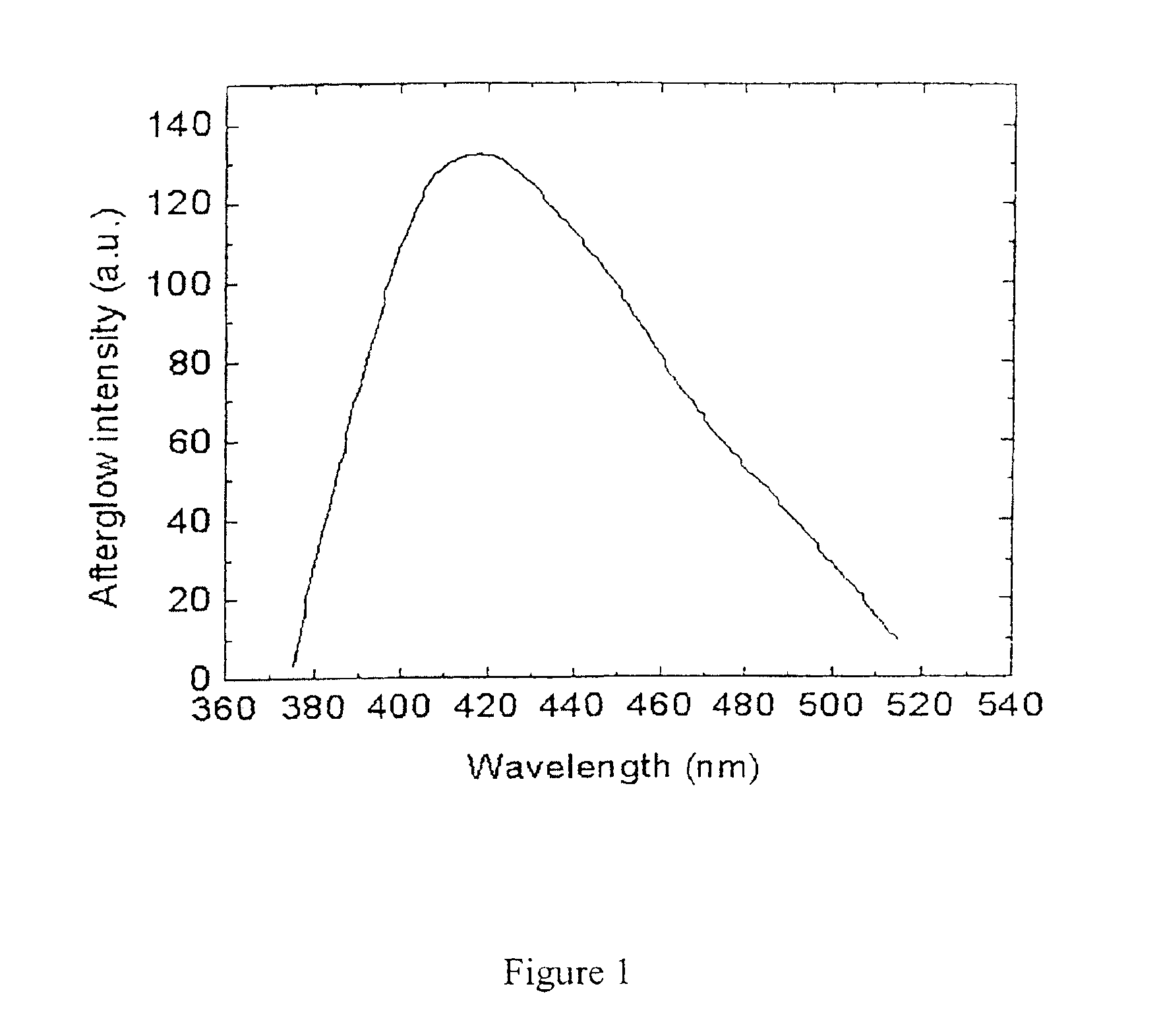

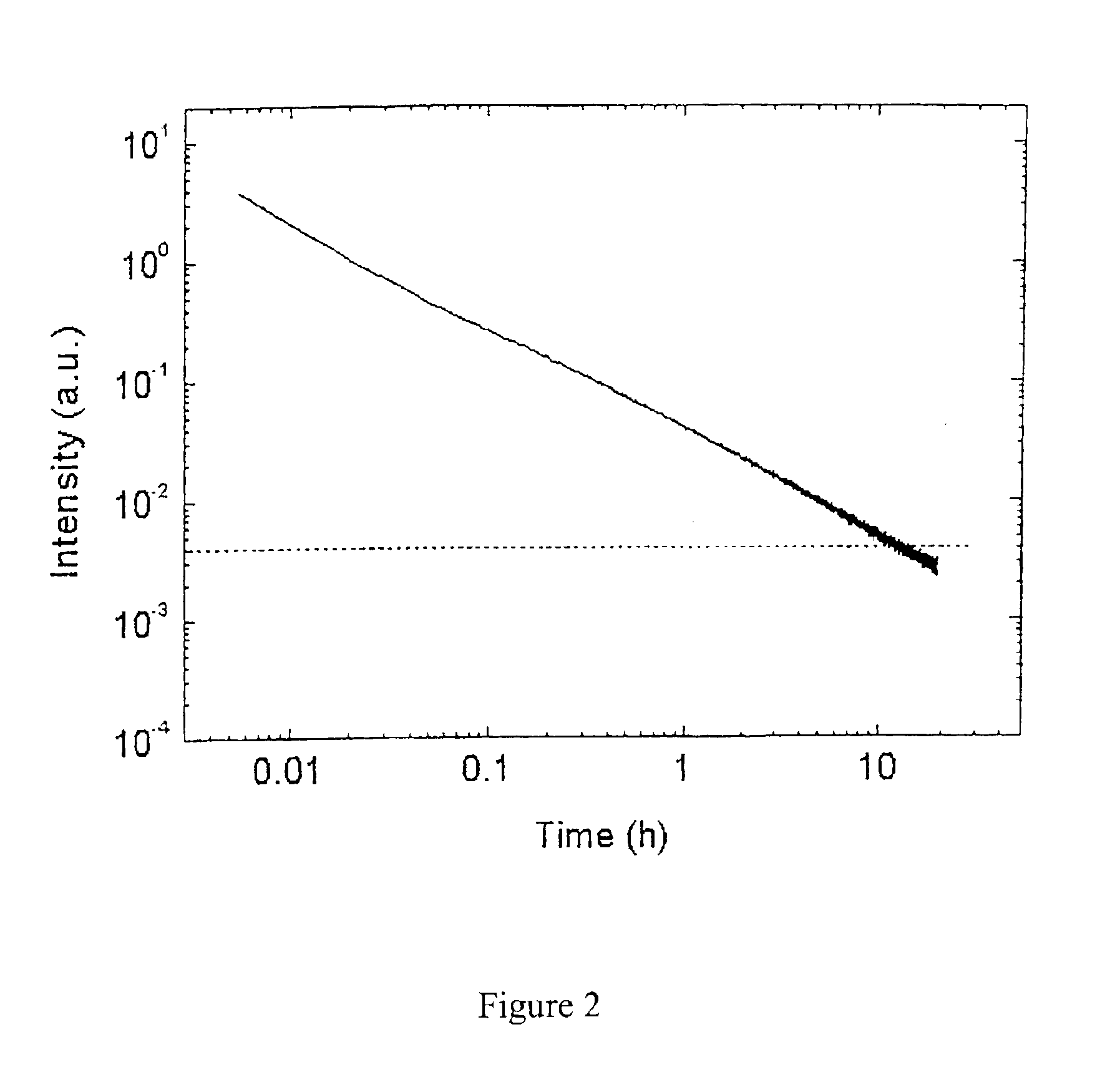

The invention provides long-persistent phosphors, methods for their manufacture and phosphorescent articles. The invention also provides a method for generating a long-persistent phosphorescence at a selected color. The phosphors of the invention may be alkaline earth aluminates, alkaline earth silicates, and alkaline earth aluminosilicates. The phosphors include those activated by cerium. The phosphors also include those in which persistent energy transfer occurs from a donor ion to an acceptor ion, producing persistent emission largely characteristic of the acceptor ion.

Owner:UNIV OF GEORGIA RES FOUND INC +1

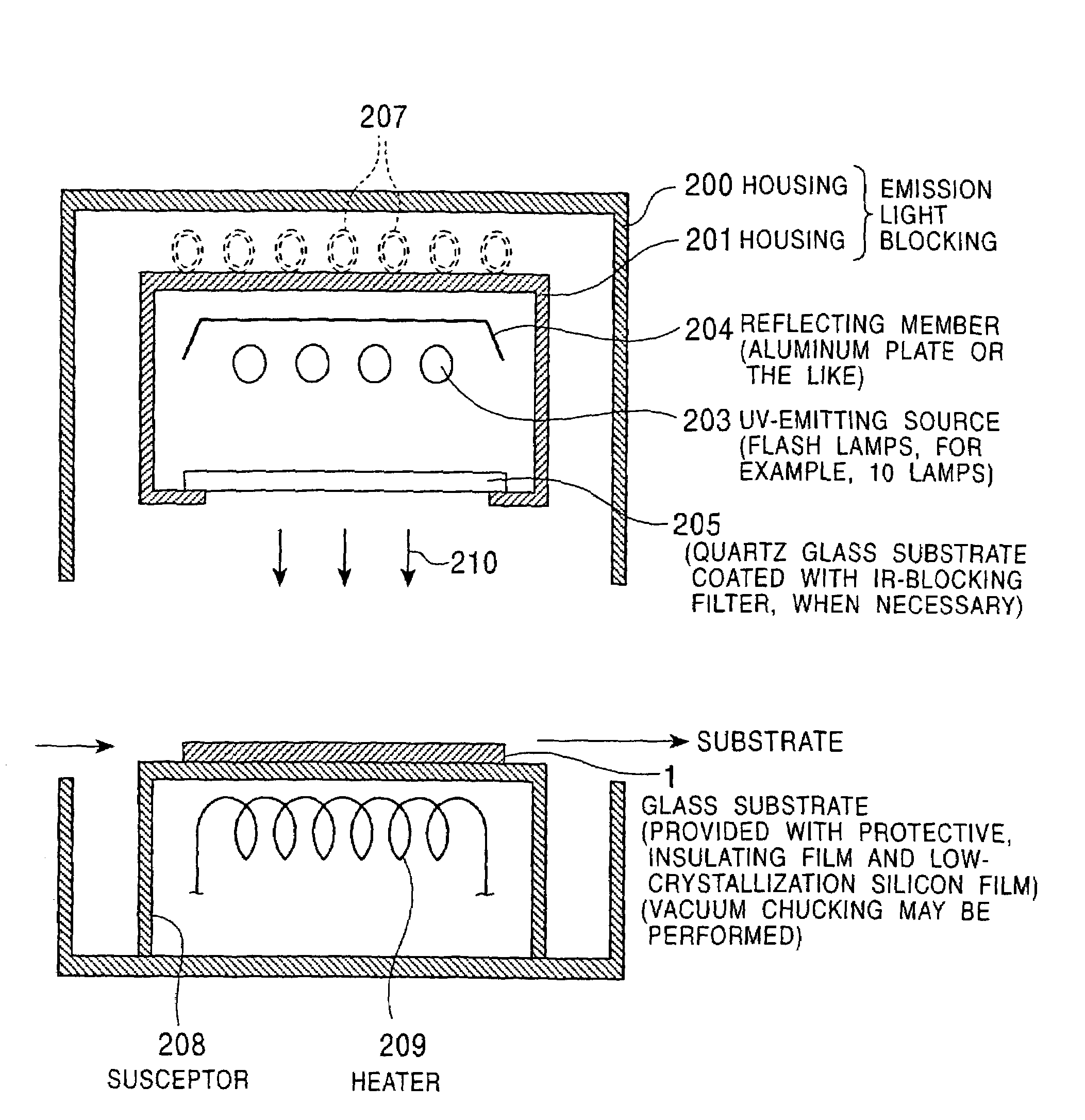

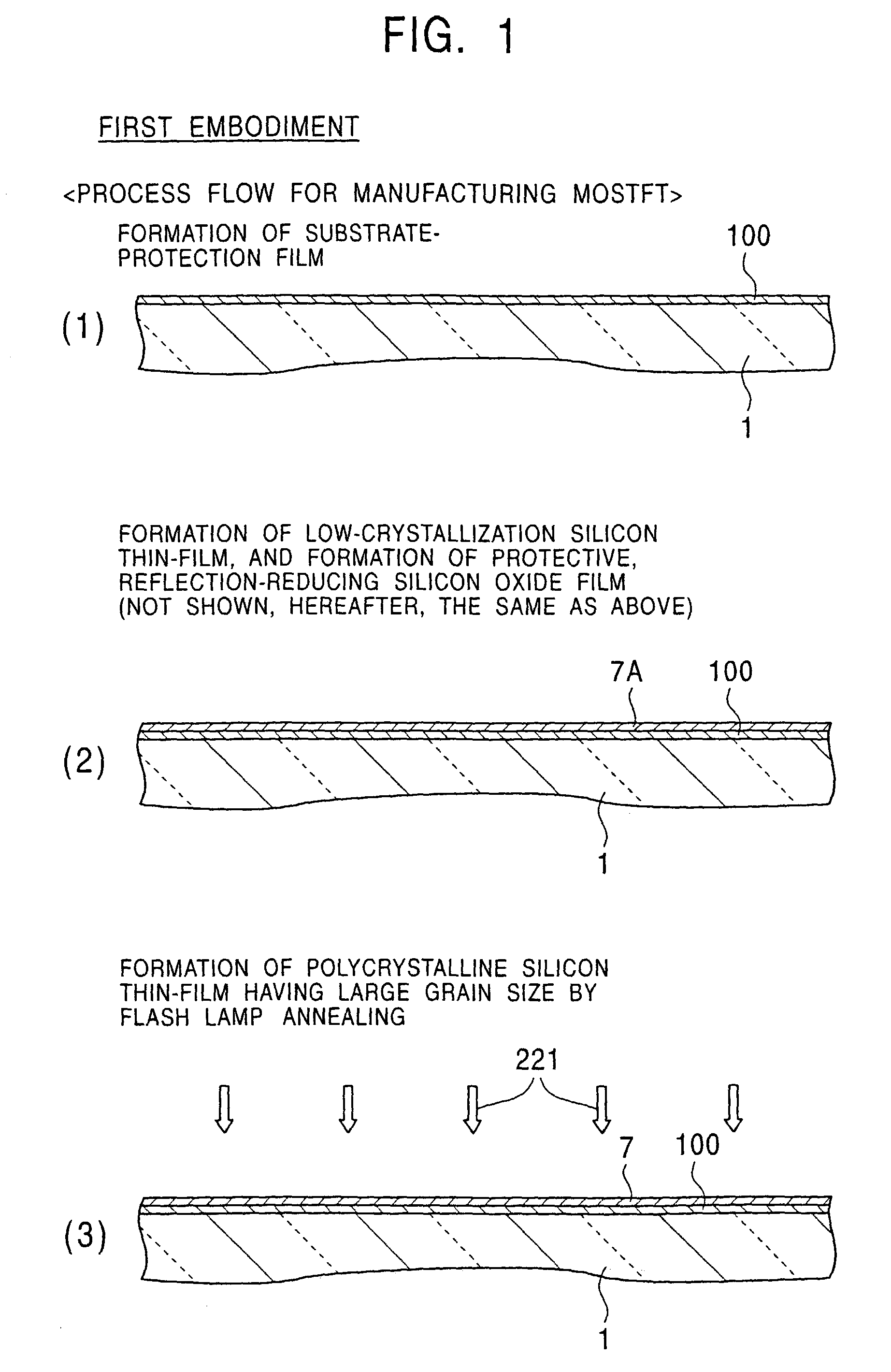

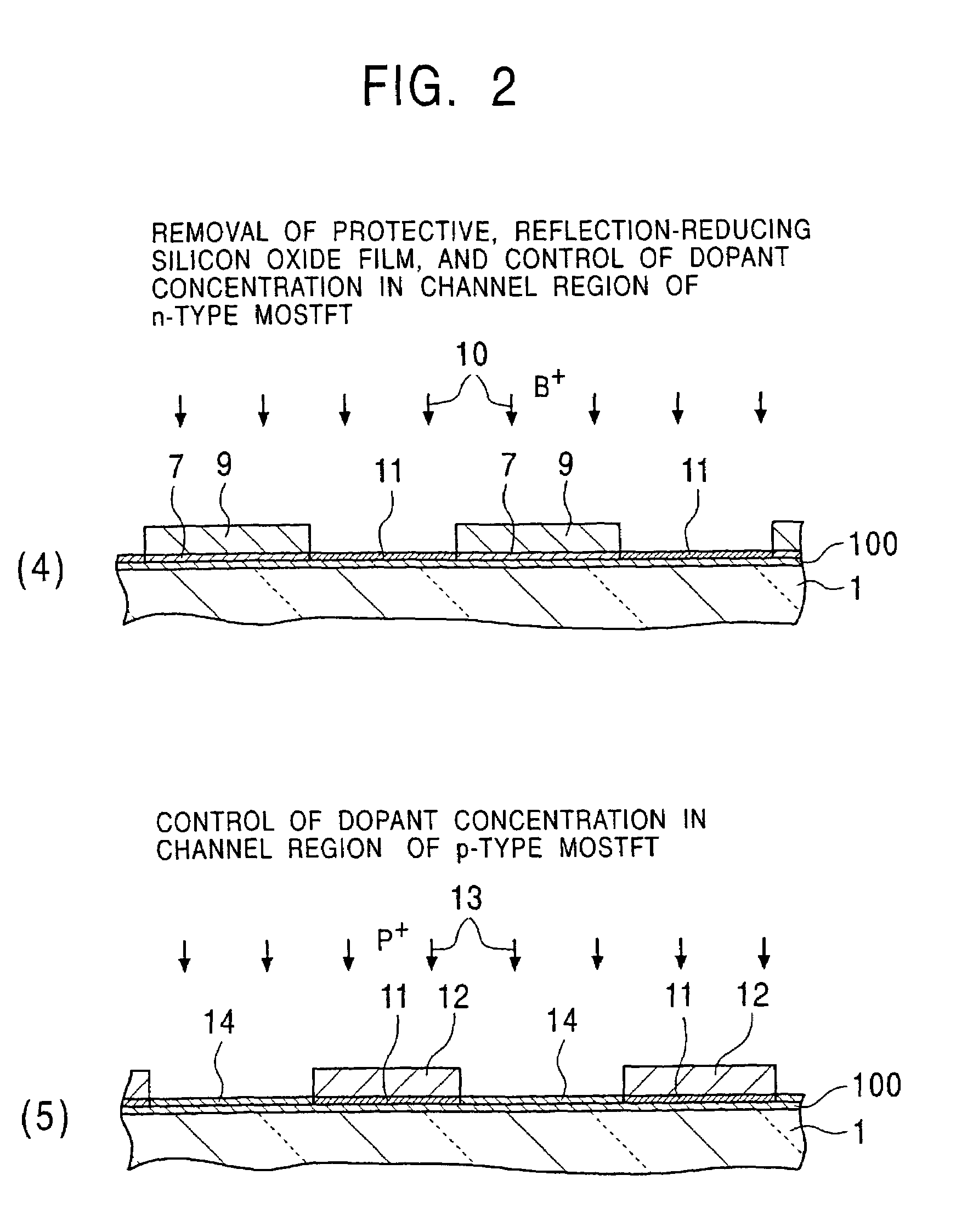

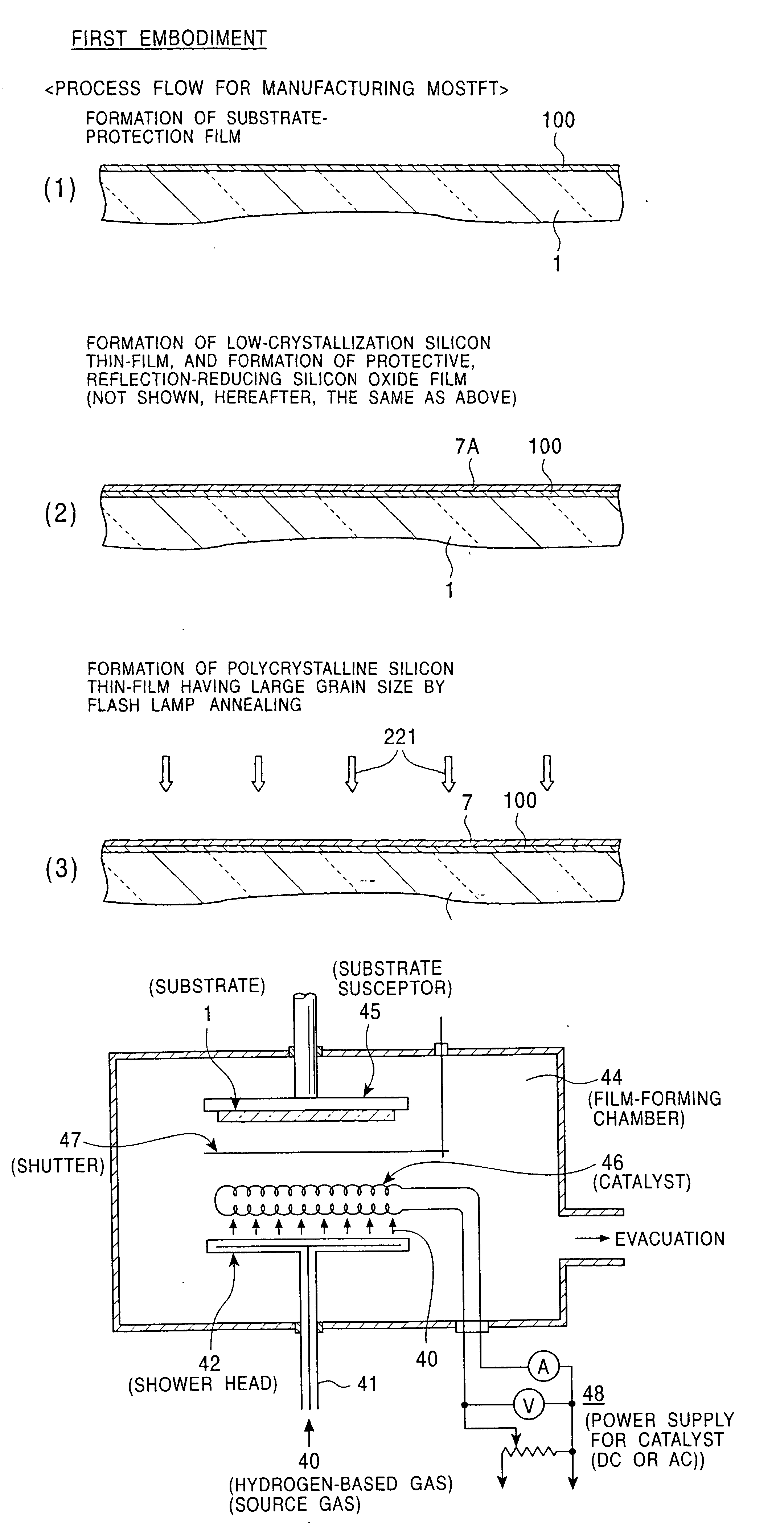

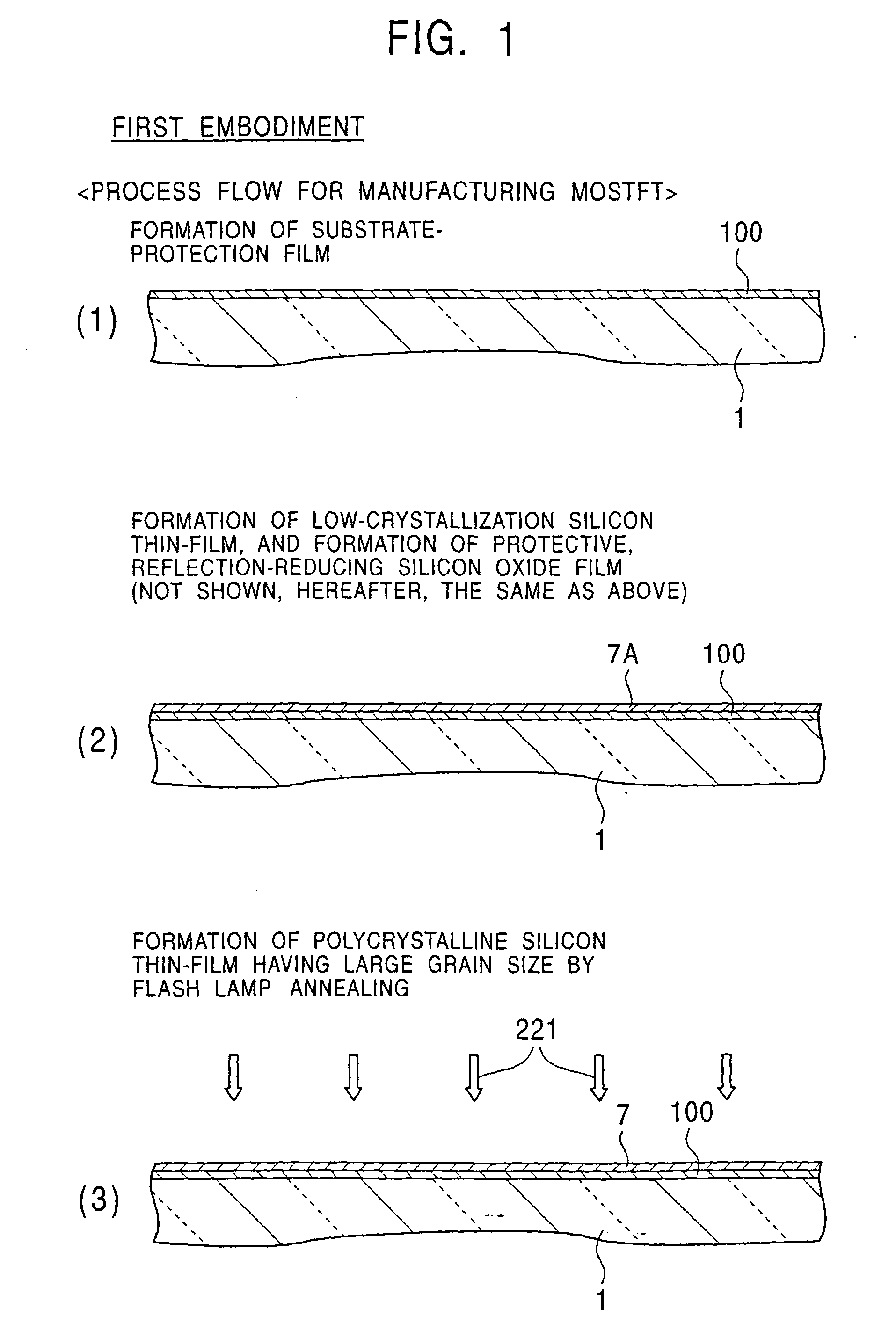

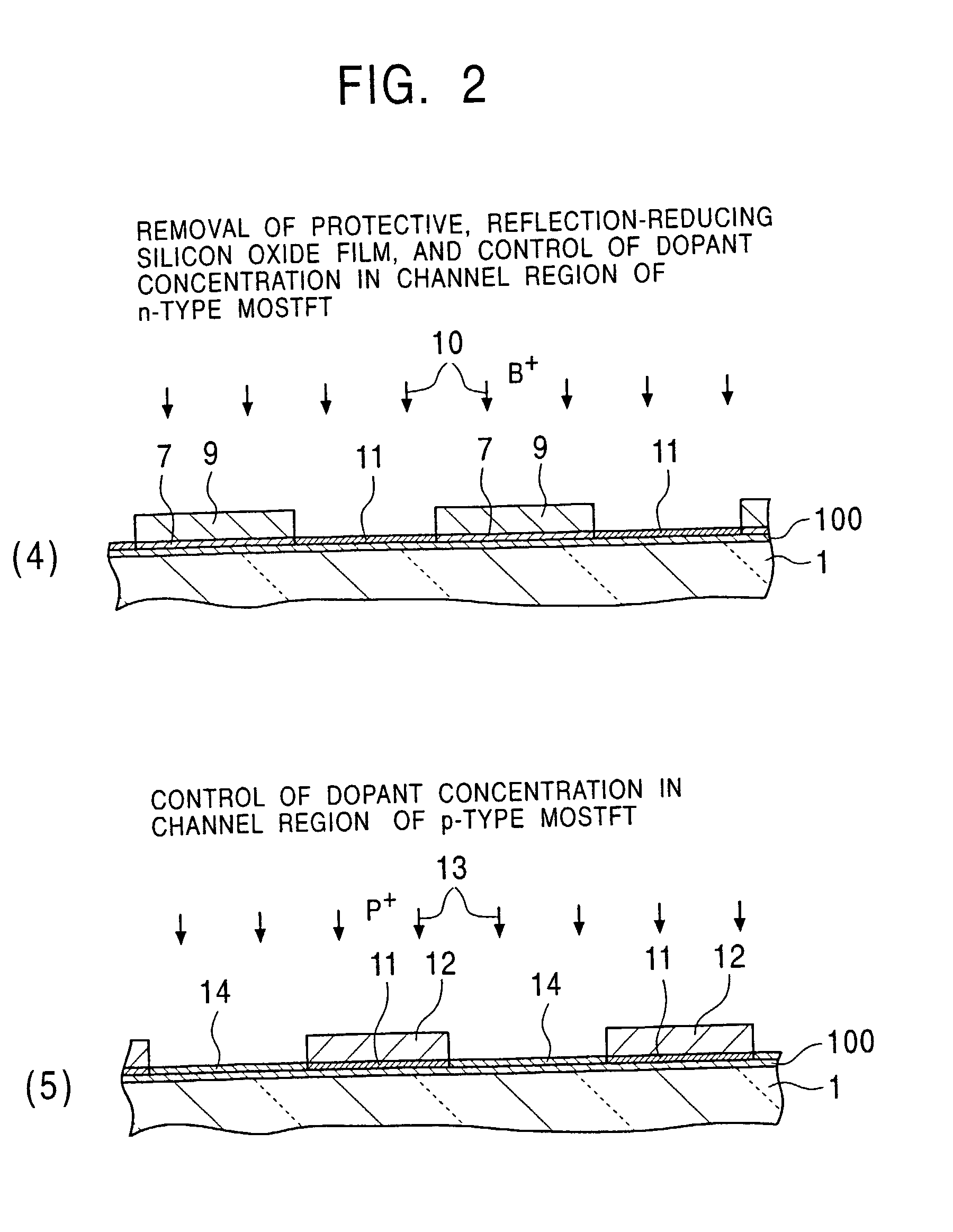

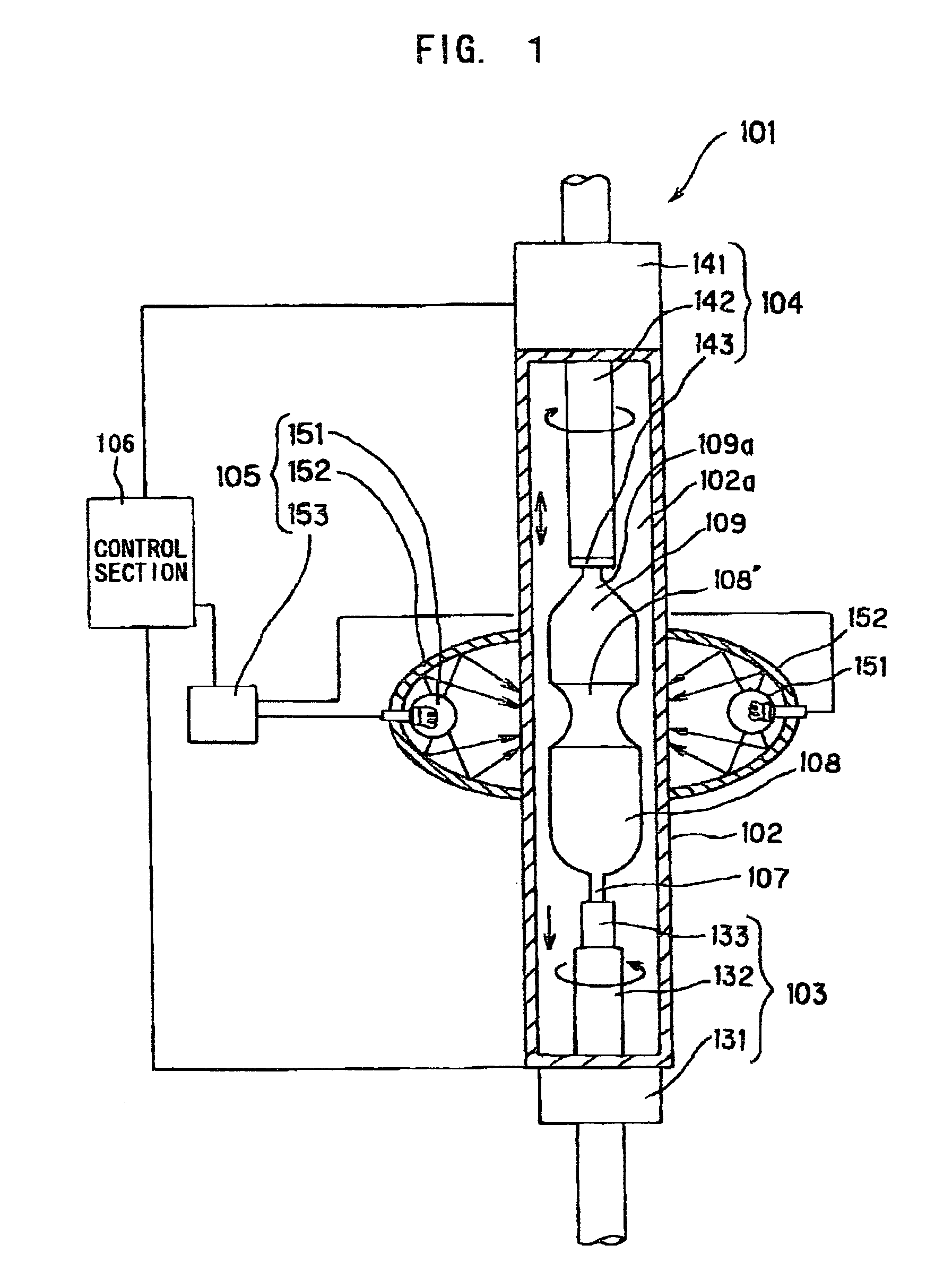

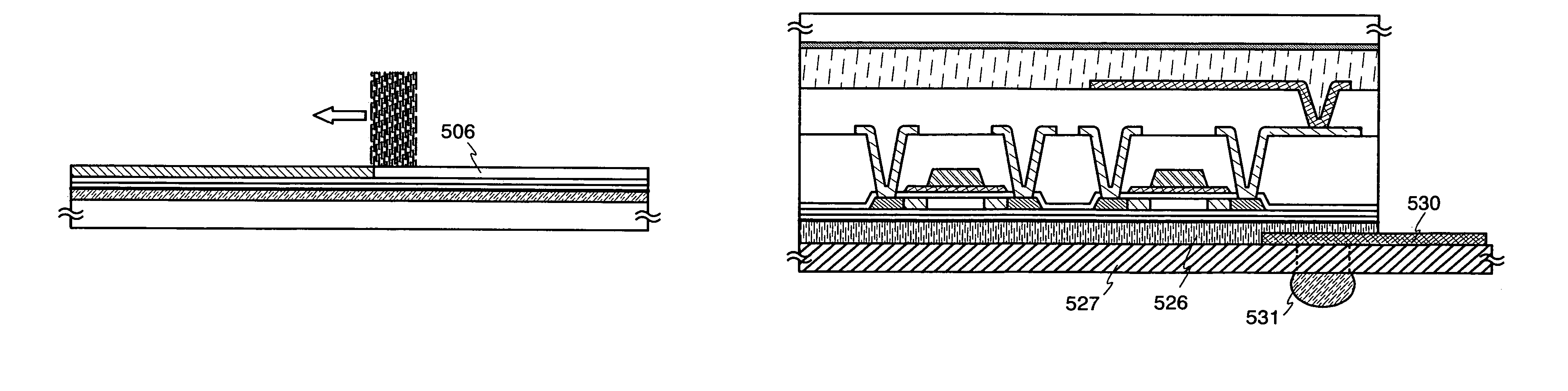

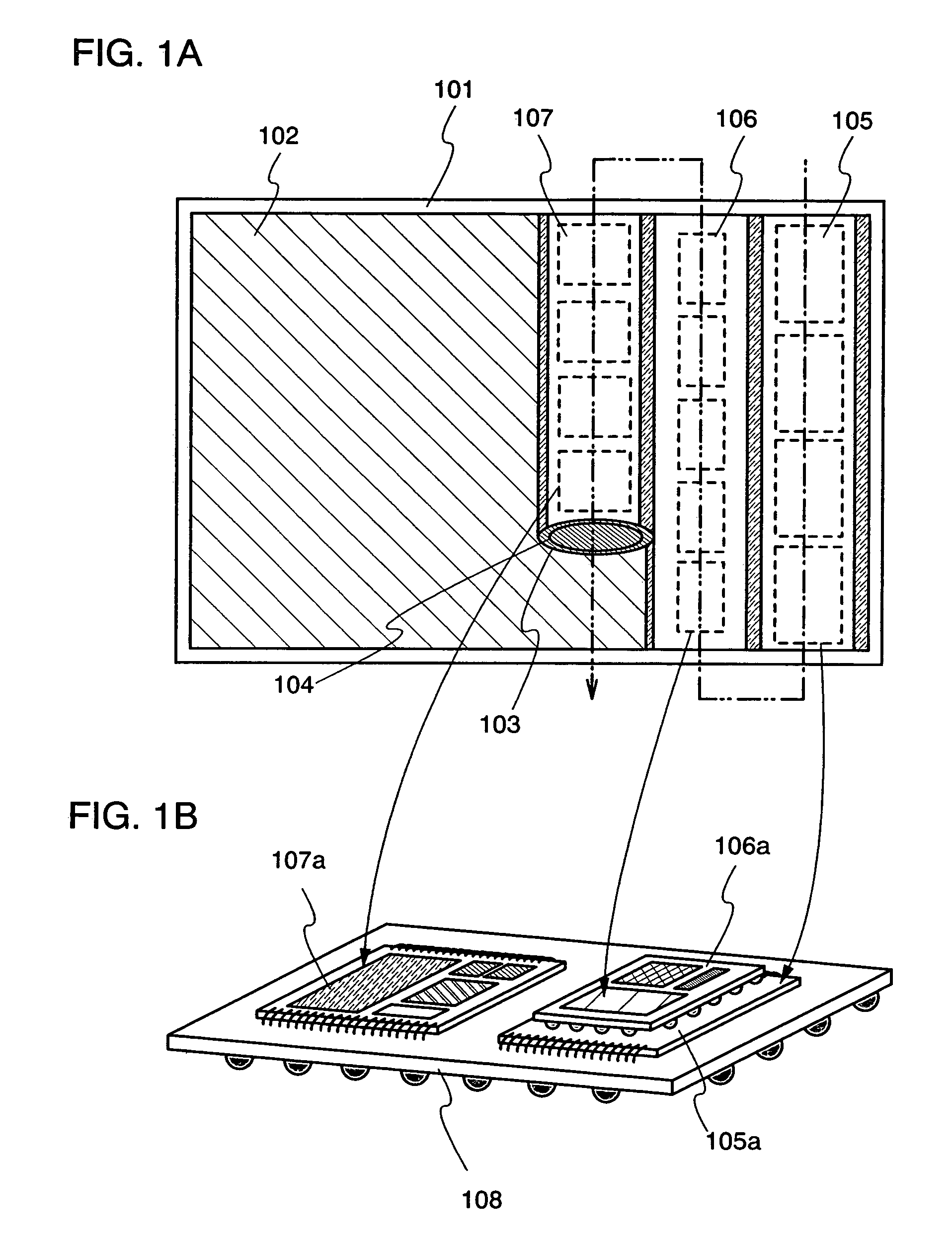

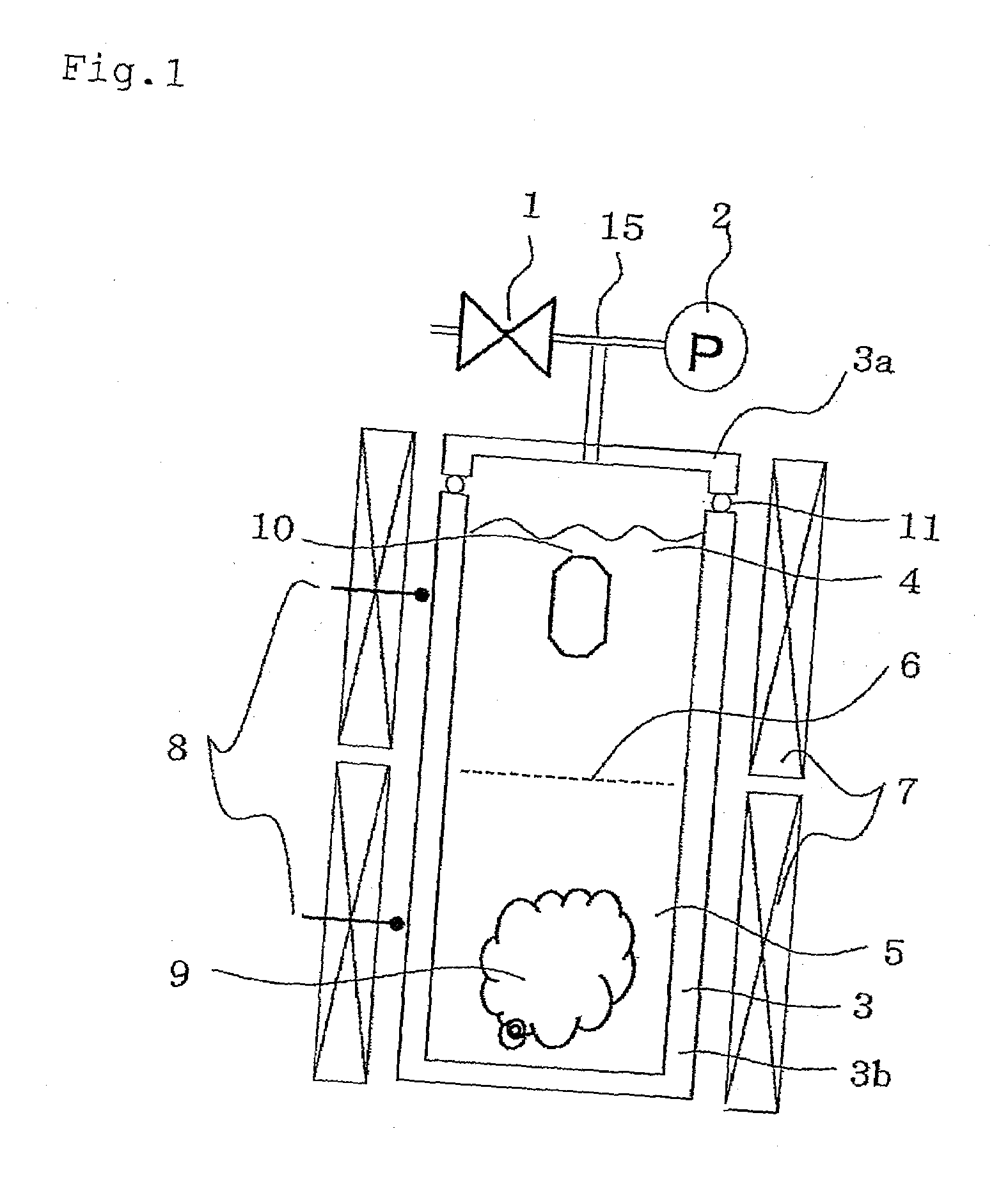

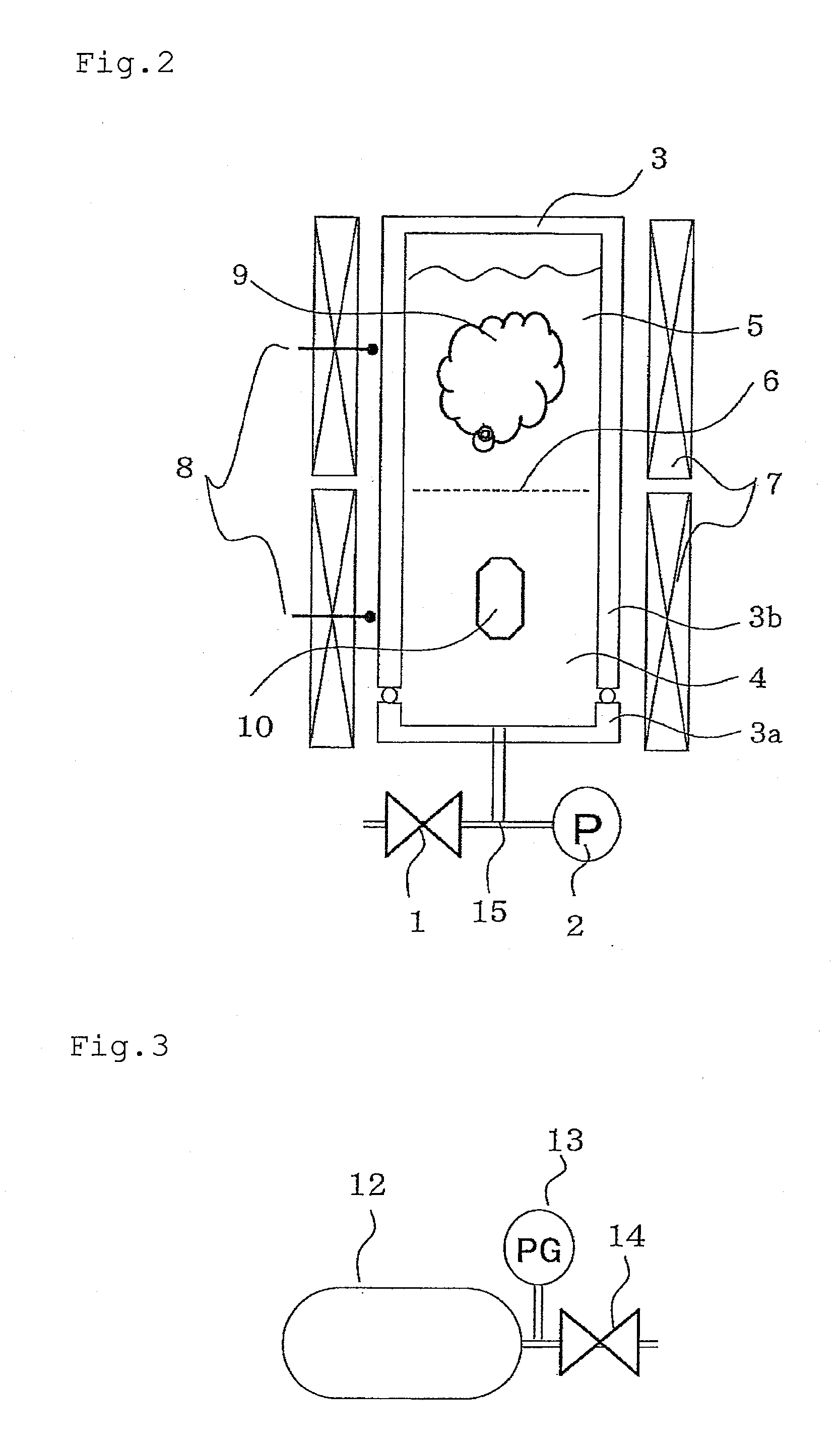

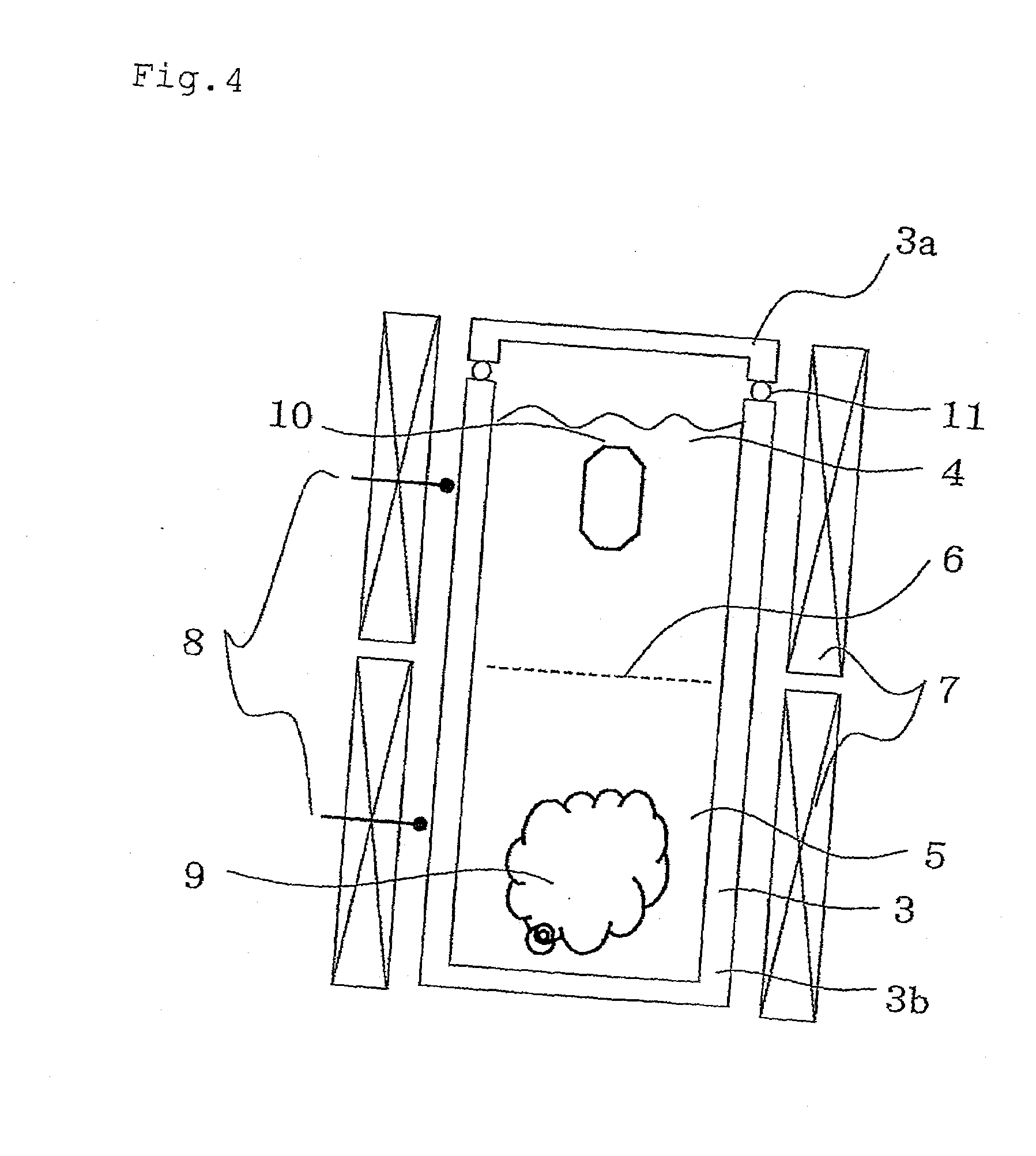

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

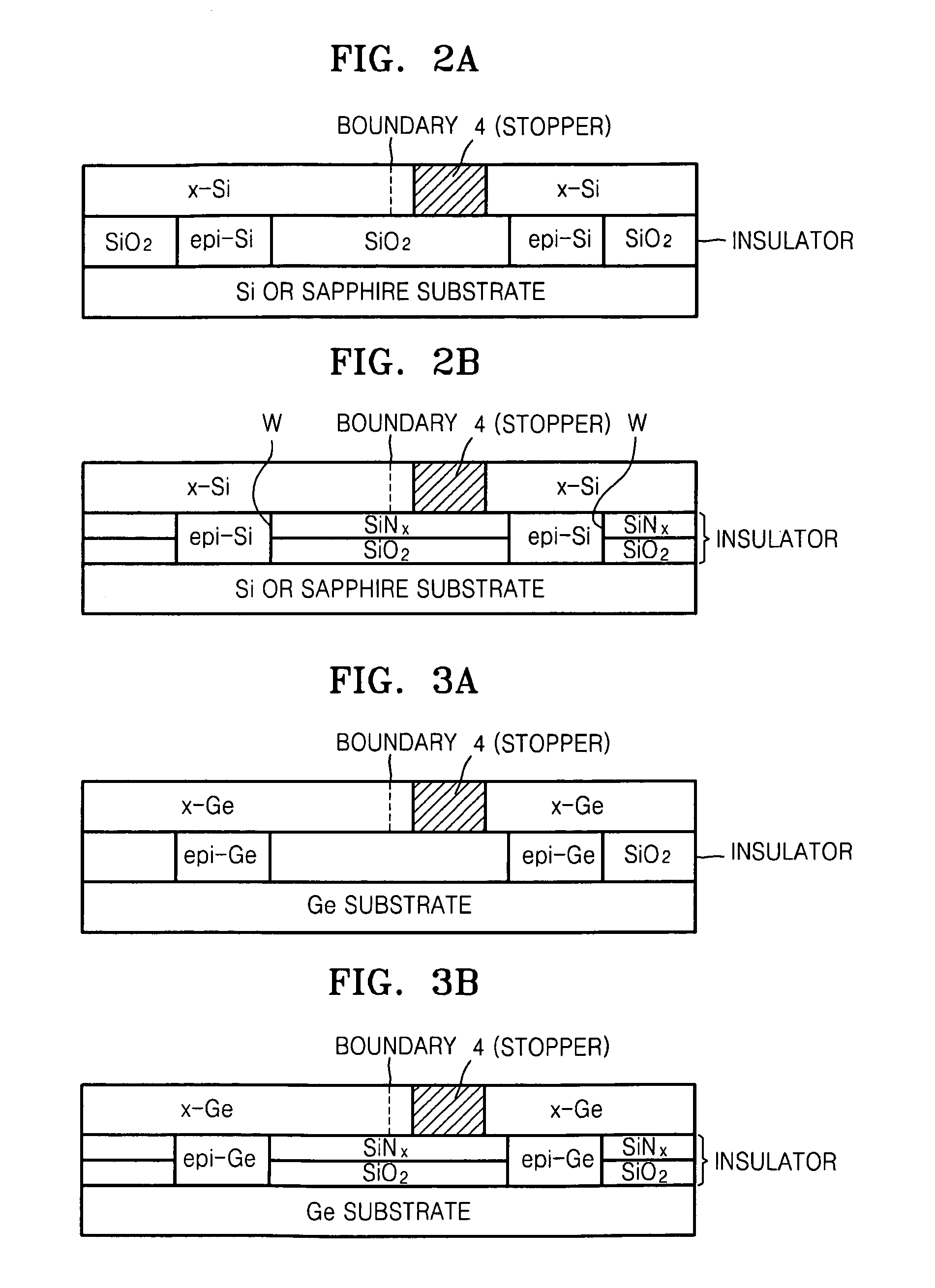

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

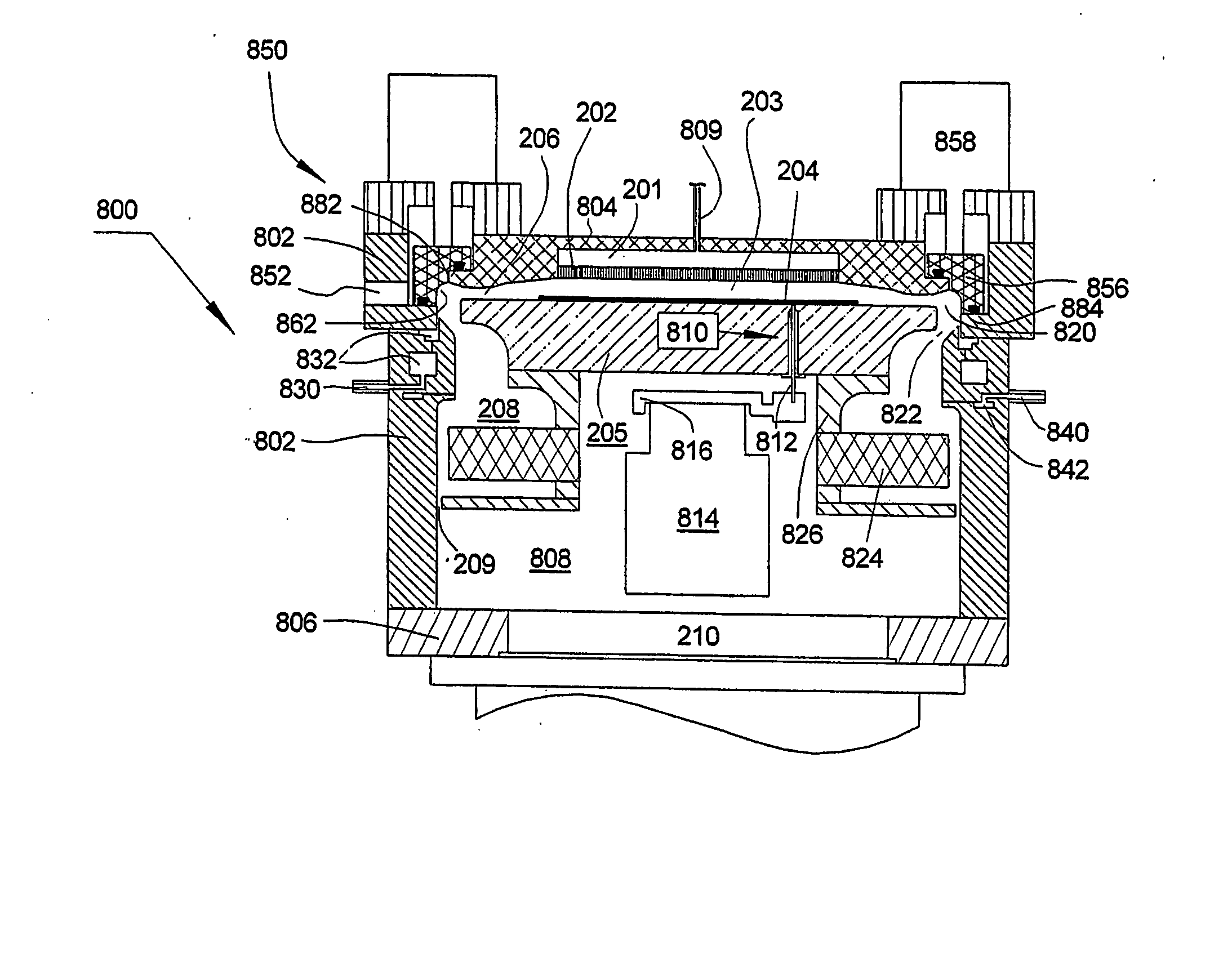

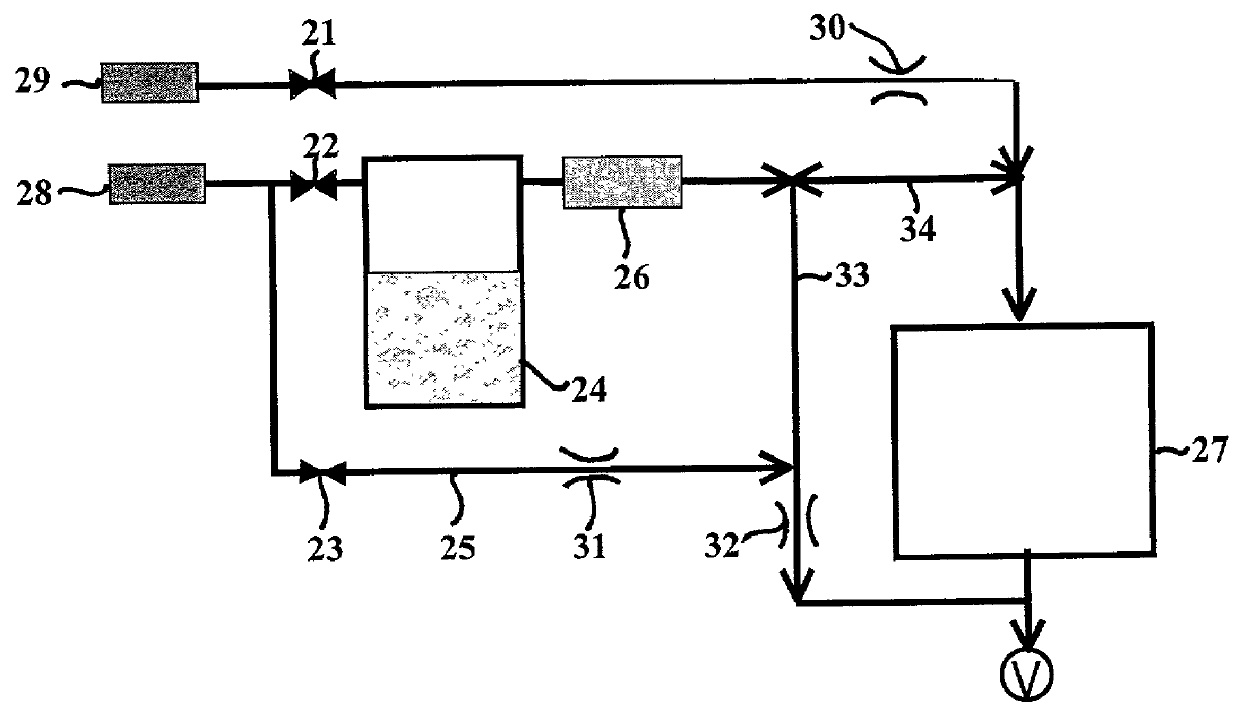

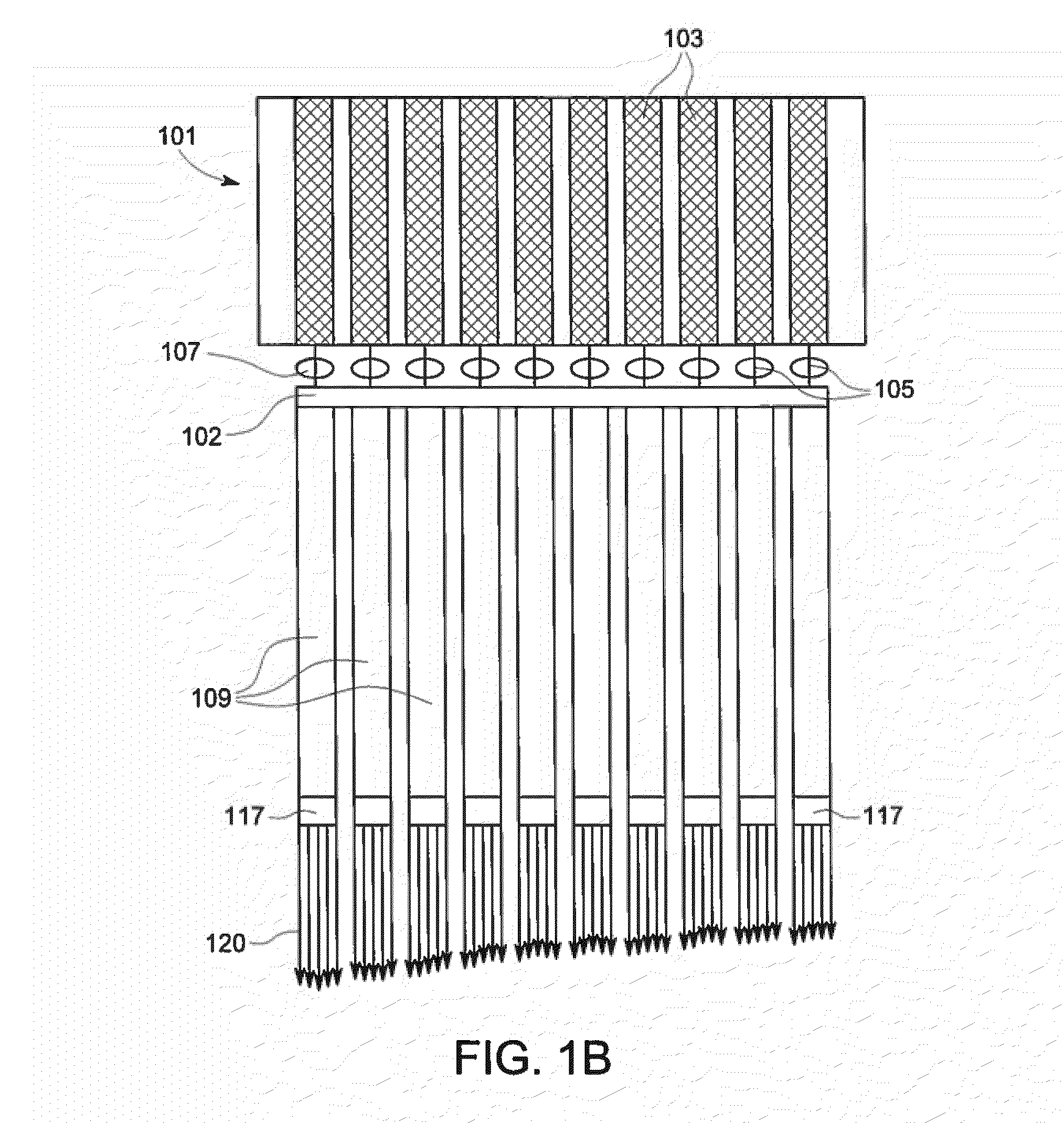

Ald Apparatus and Method

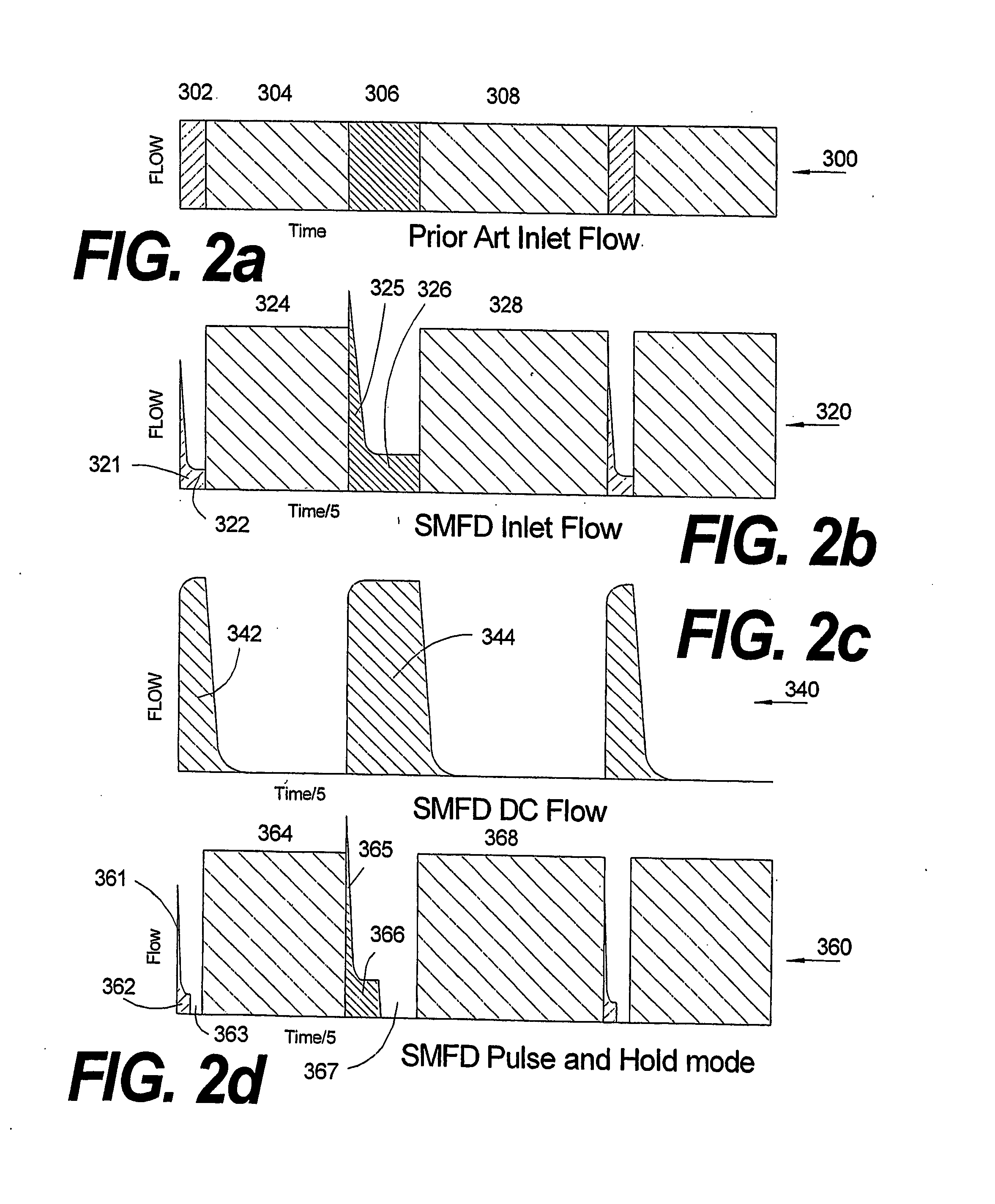

InactiveUS20070269983A1Enhanced advantageMaterial utilization efficiency is increasedLiquid surface applicatorsBy zone-melting liquidsCompound (substance)Engineering

Improved apparatus and method for SMFD ALD include a method designed to enhance chemical utilization as well as an apparatus that implements lower conductance out of SMFD-ALD process chamber while maintaining full compatibility with standard wafer transport. Improved SMFD source apparatuses (700, 700′, 700″) and methods from volatile and non-volatile liquid and solid precursors are disclosed, e.g., a method for substantially controlling the vapor pressure of a chemical source (722) within a source space comprising: sensing the accumulation of the chemical on a sensing surface (711); and controlling the temperature of the chemical source depending on said sensed accumulation.

Owner:SUNDEW TECH

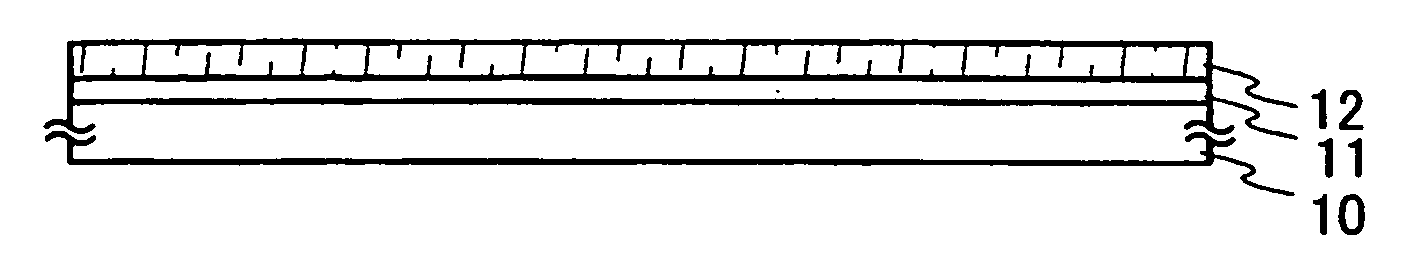

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

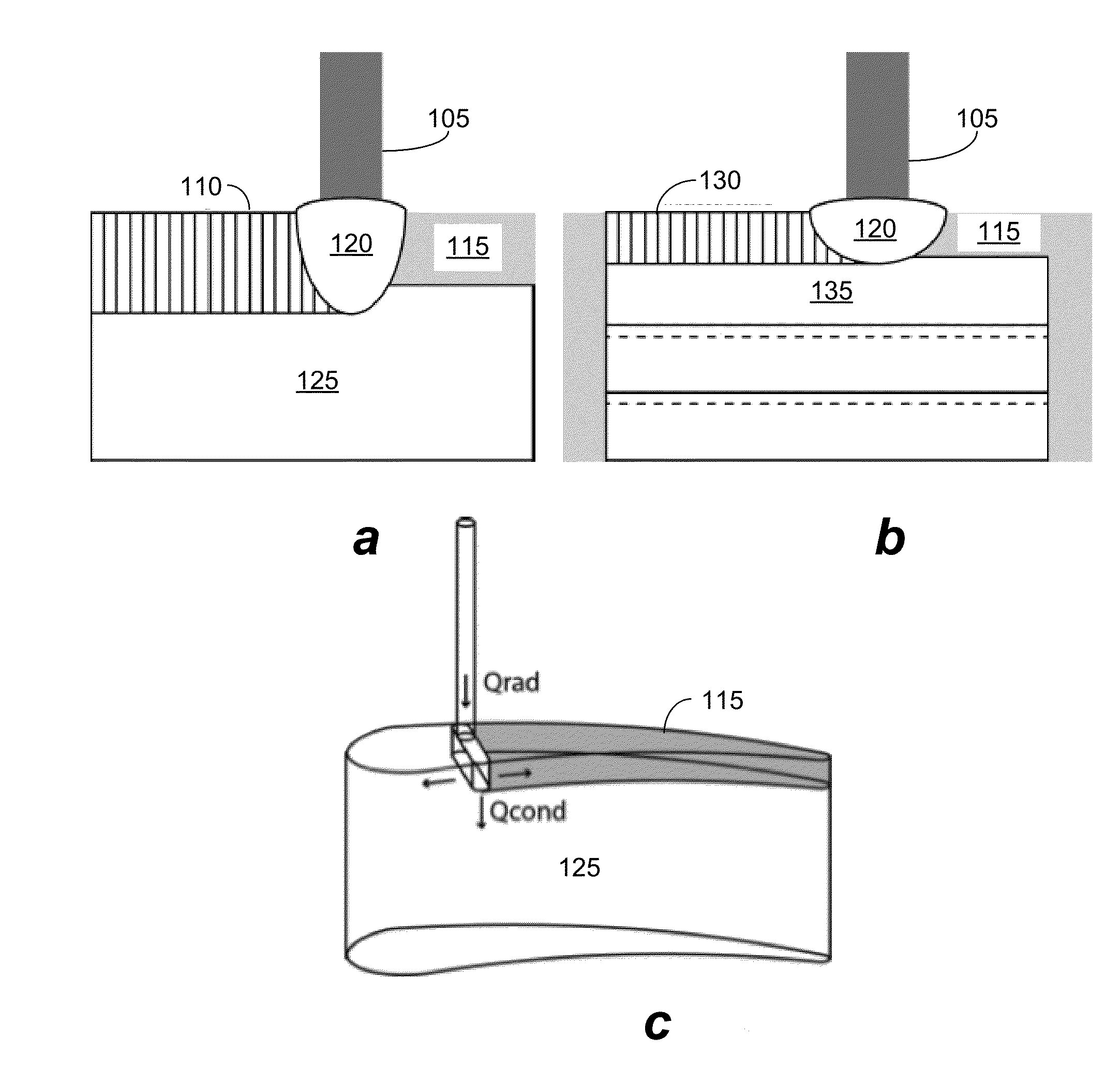

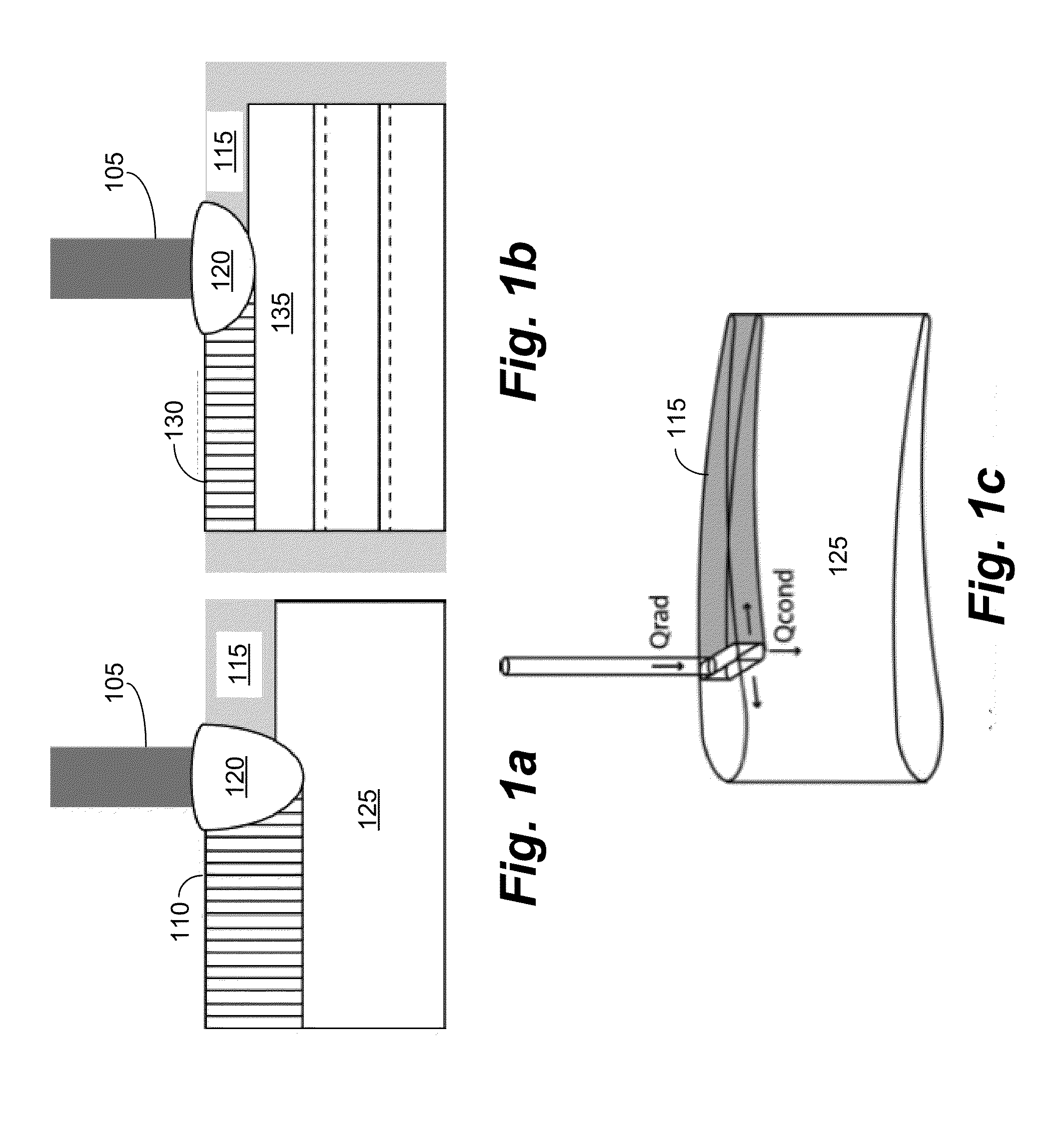

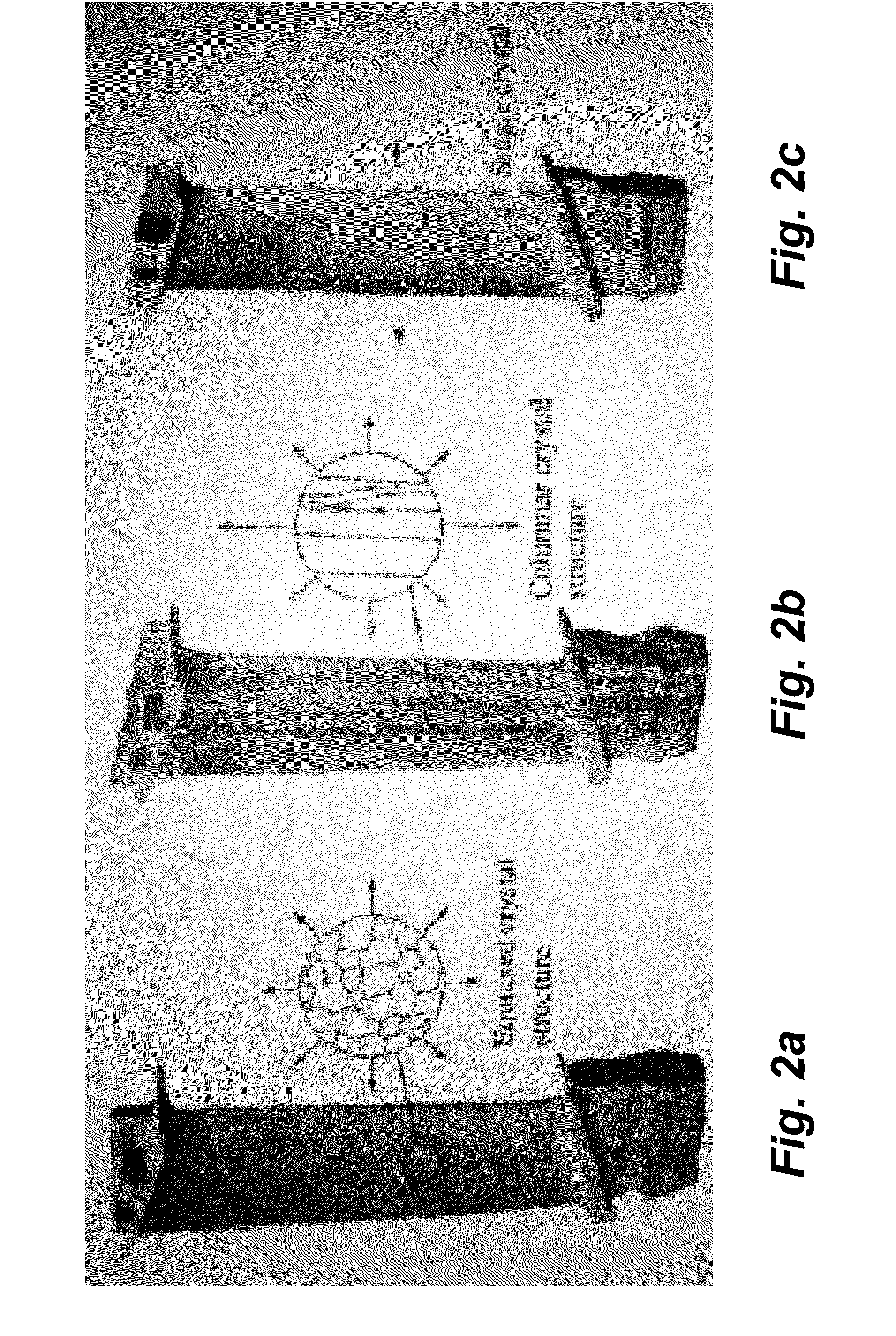

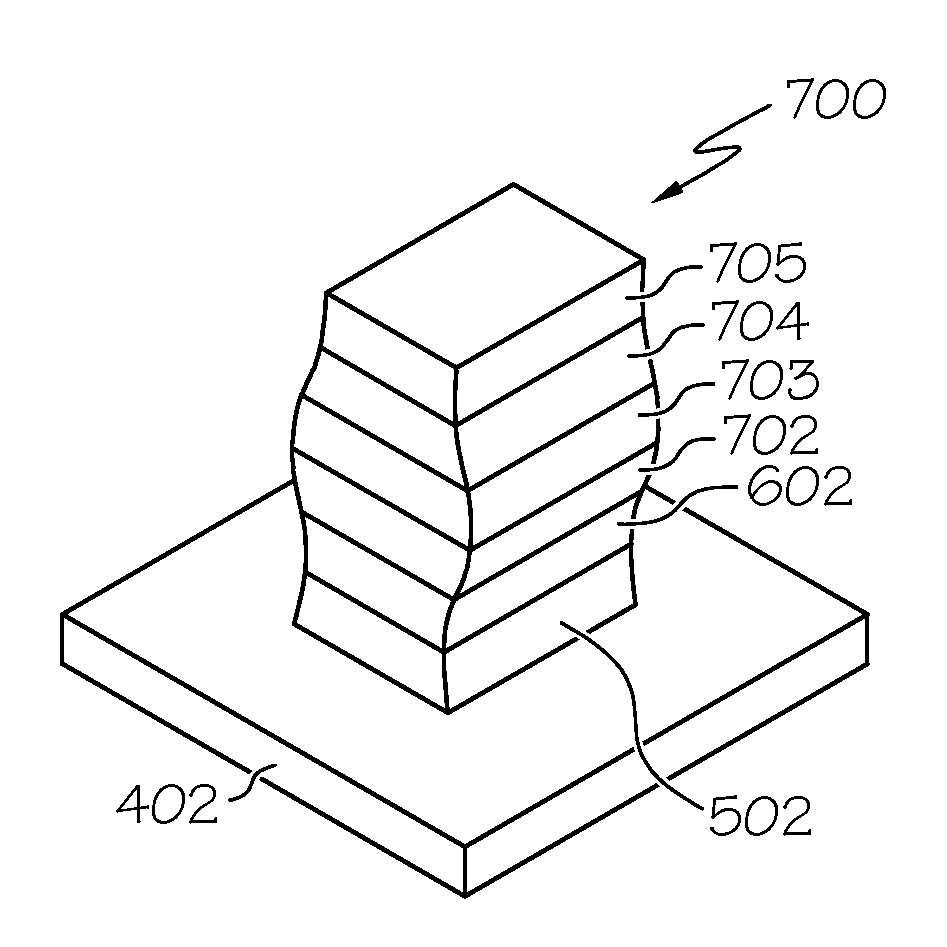

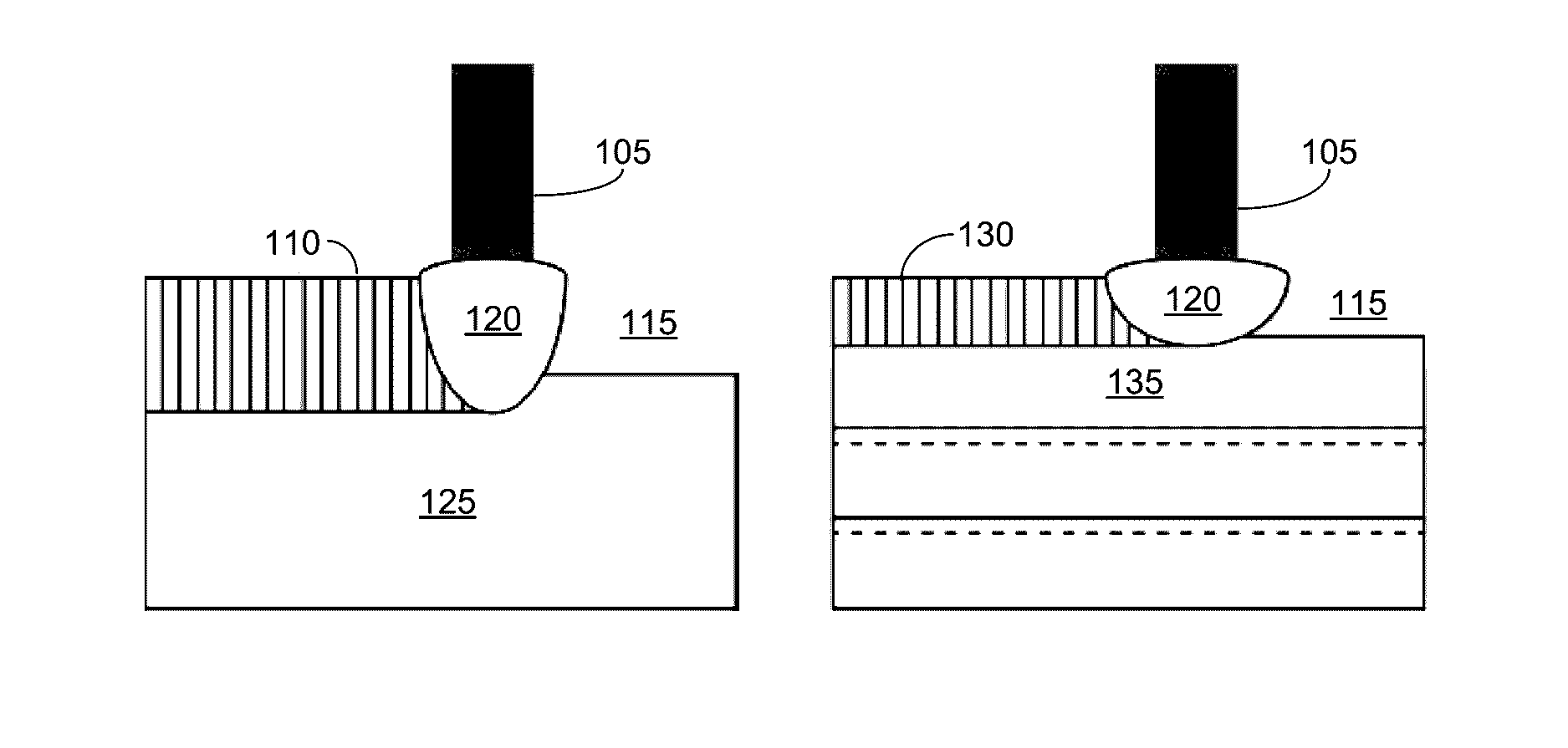

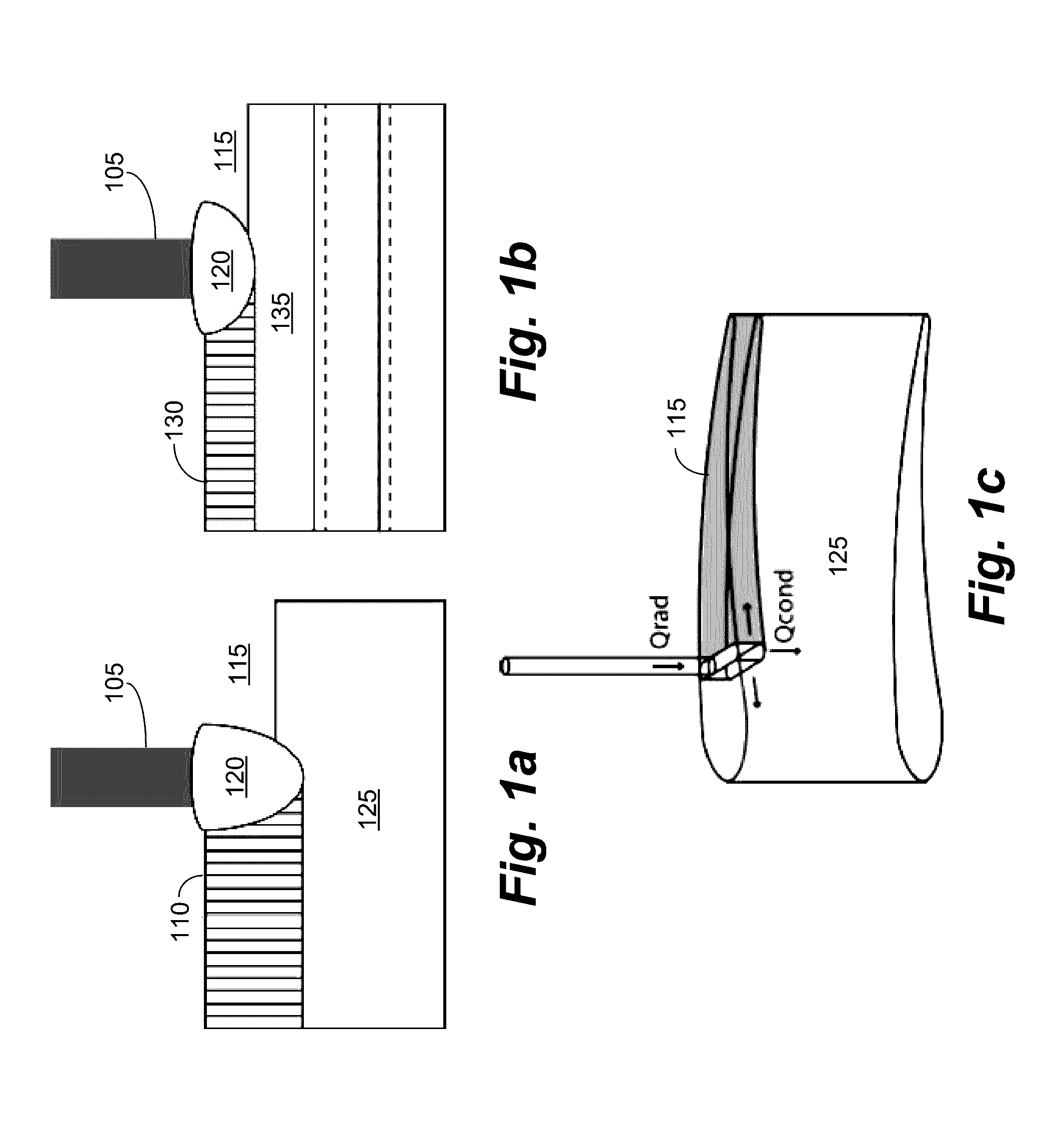

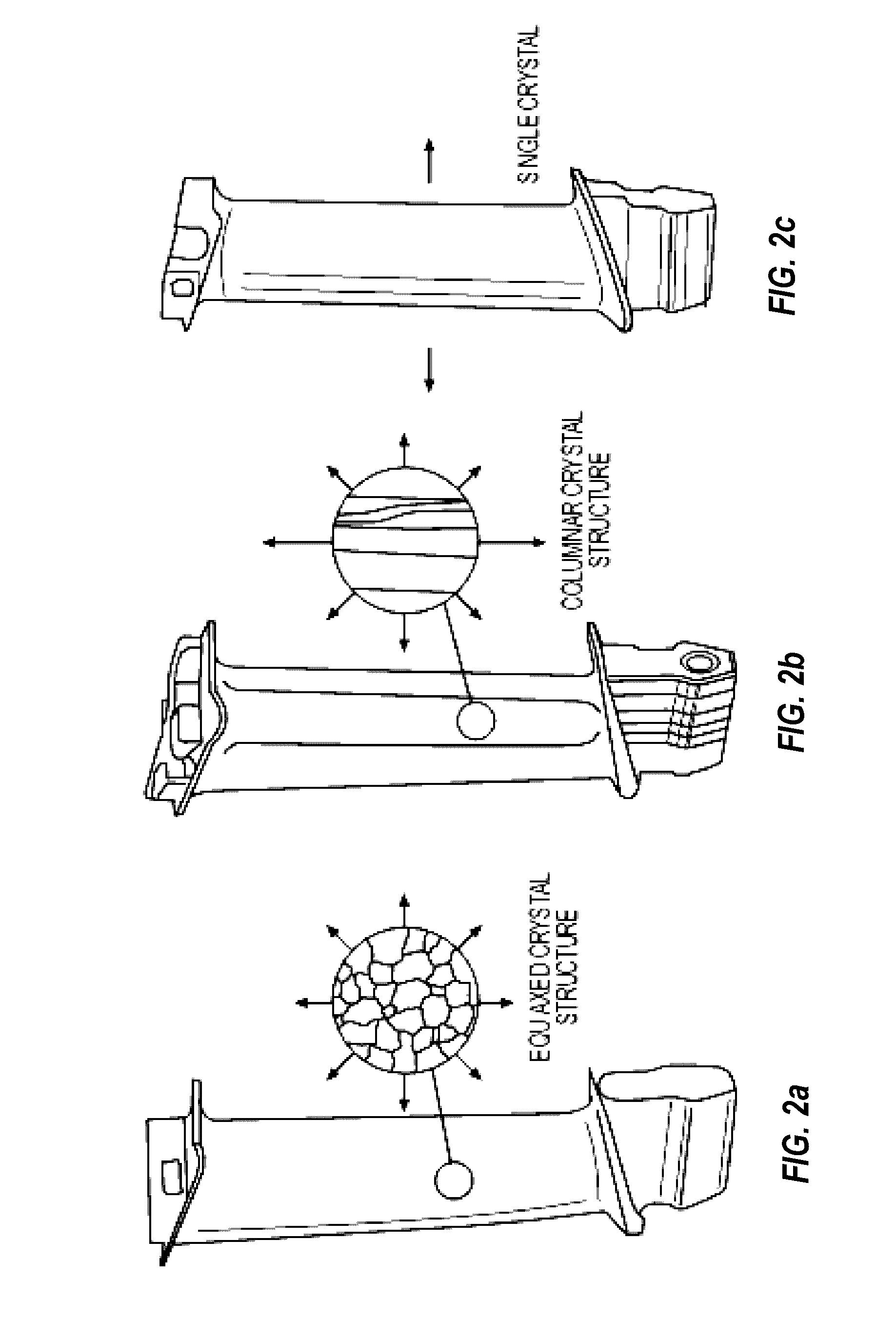

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

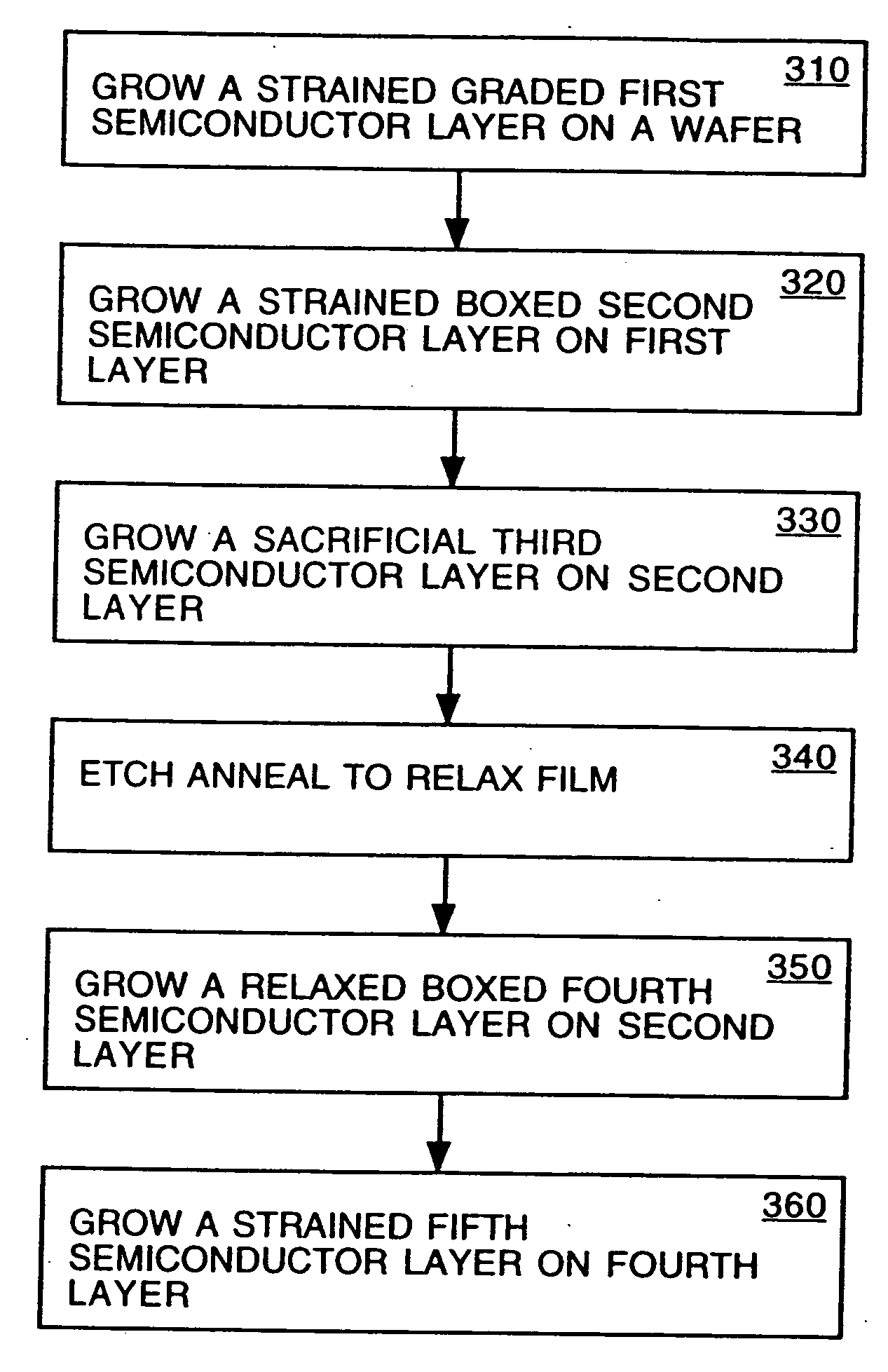

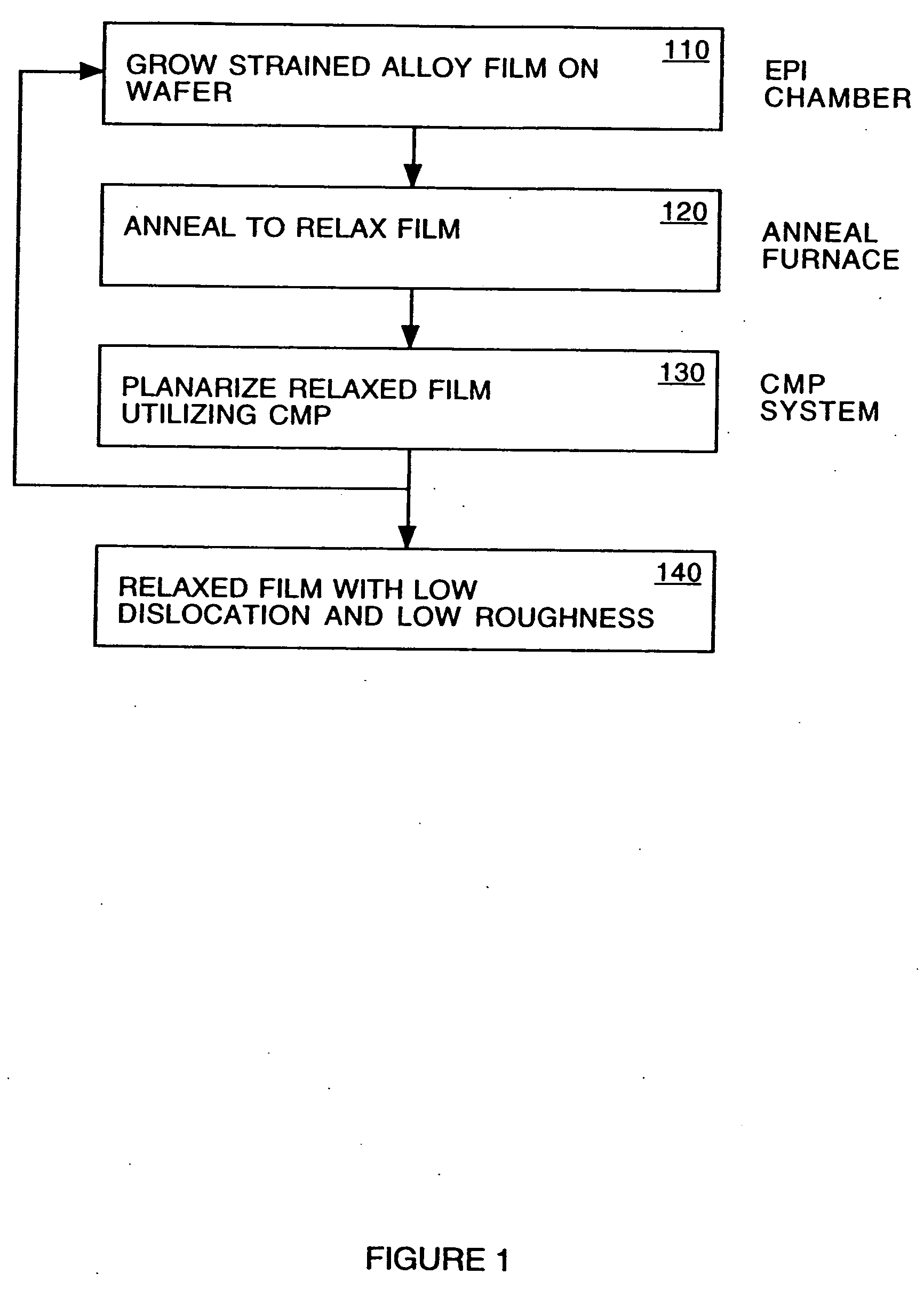

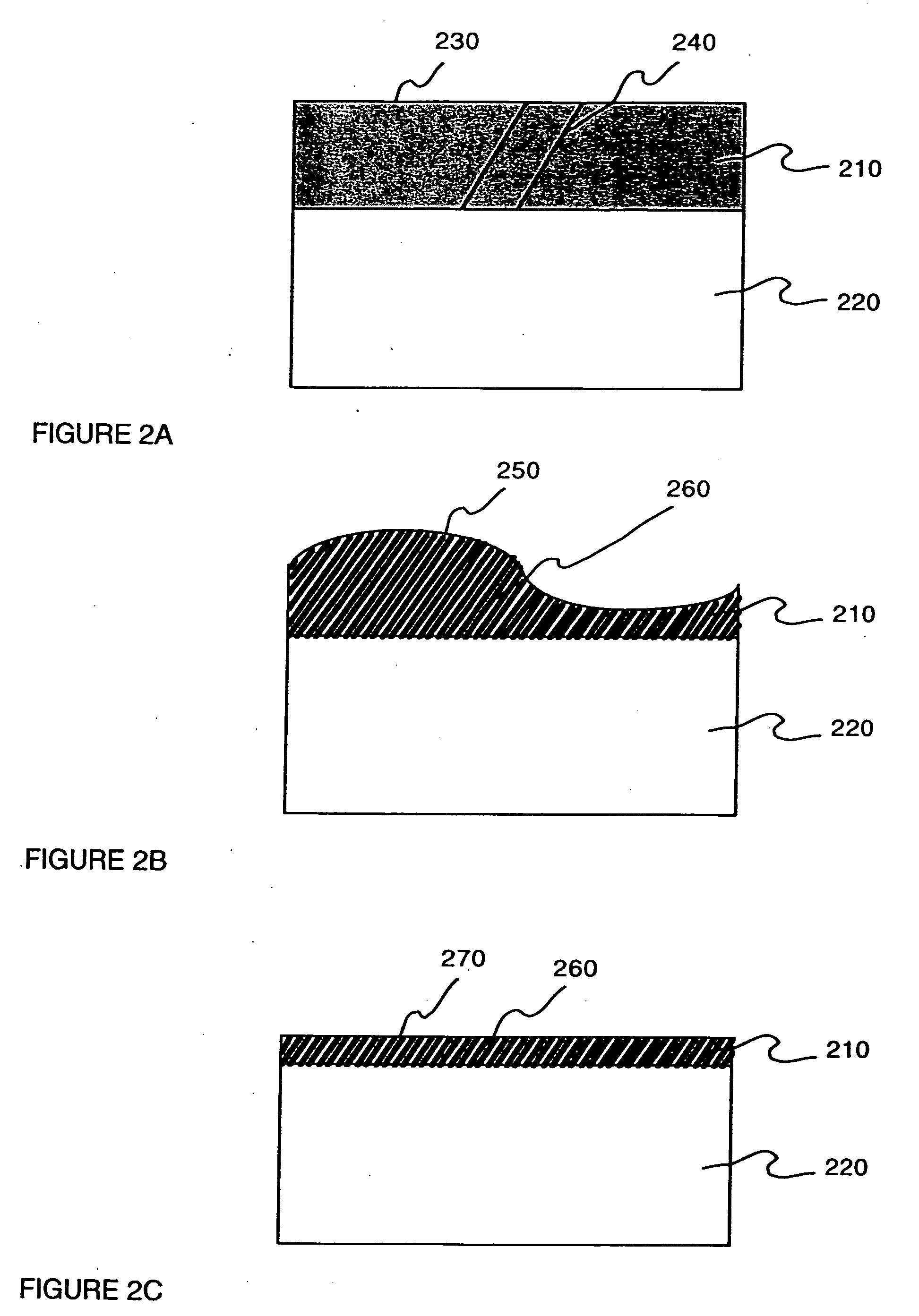

Non-contact etch annealing of strained layers

InactiveUS20070051299A1Reduce misalignmentReduce dislocation densityPolycrystalline material growthAfter-treatment detailsDopantElectrical conductor

The present invention provides a method of forming a strained semiconductor layer. The method comprises growing a strained first semiconductor layer, having a graded dopant profile, on a wafer, having a first lattice constant. The dopant imparts a second lattice constant to the first semiconductor layer. The method further comprises growing a strained boxed second semiconductor layer having the second lattice constant on the first semiconductor layer and growing a sacrificial third semiconductor layer having the first lattice constant on the second semiconductor layer. The method further comprises etch annealing the third and second semiconductor layer, wherein the third semiconductor layer is removed and the second semiconductor layer is relaxed. The method may further comprises growing a fourth semiconductor layer having the second lattice constant on the second semiconductor layer, wherein the fourth semiconductor layer is relaxed, and growing a strained fifth semiconductor layer having the first semiconductor lattice constant on the fourth semiconductor layer. The method controls the surface roughness of the semiconductor layers. The method also has the unexpected benefit of reducing dislocations in the semiconductor layers.

Owner:SILICON GENERAL CORPORATION

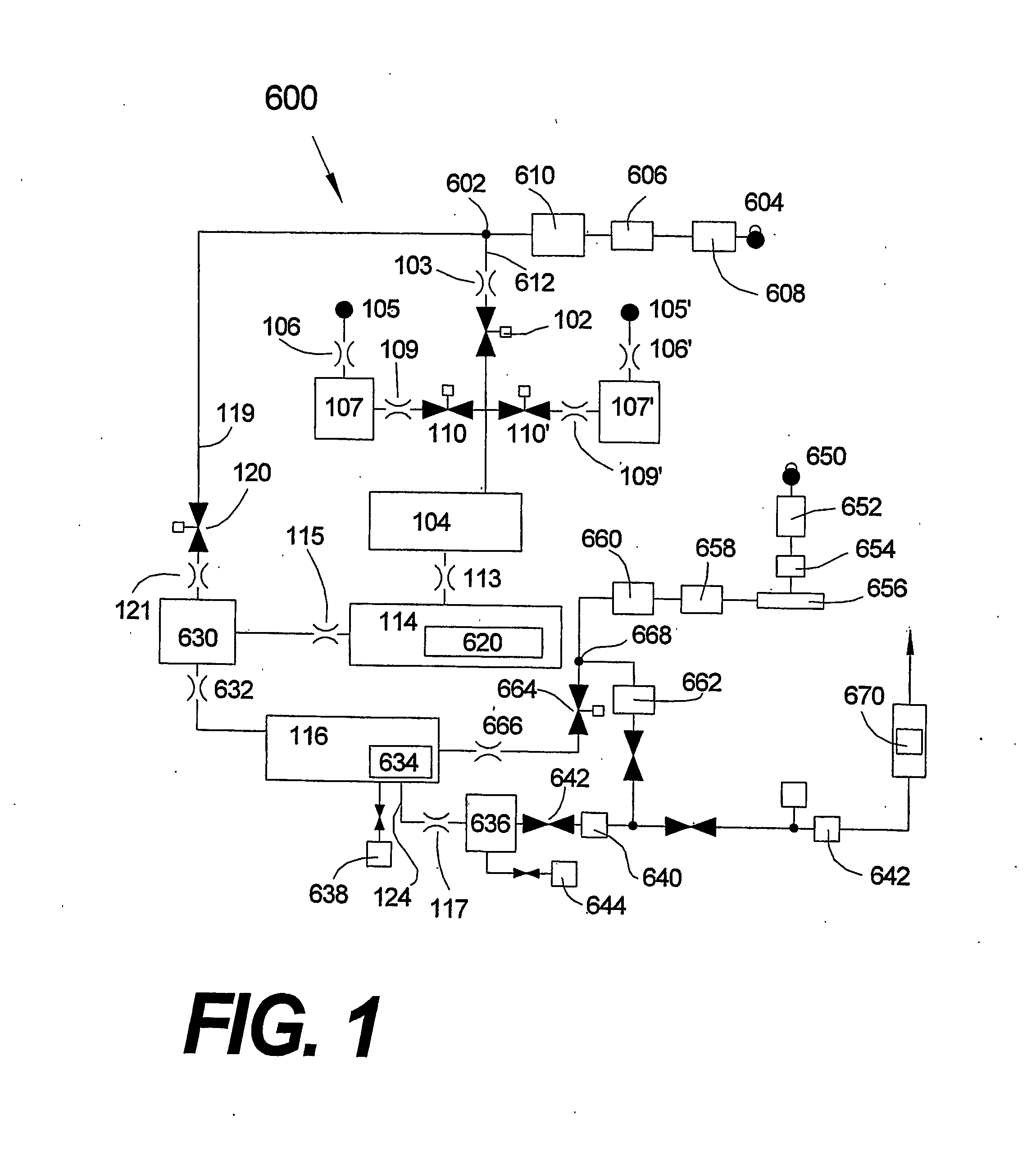

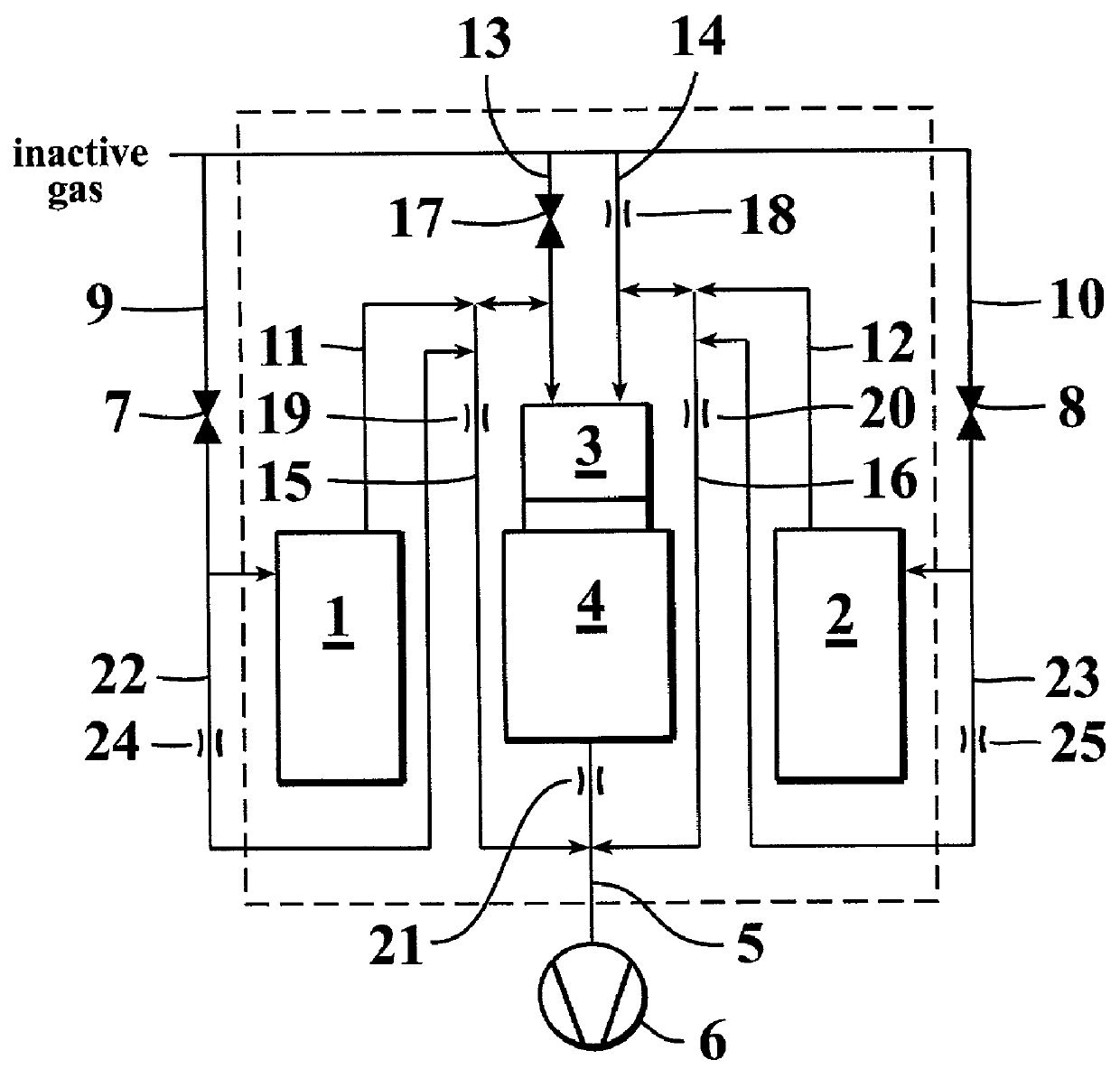

Method of growing a thin film onto a substrate

InactiveUS20010054377A1Reduce wasteGuaranteed uptimePressurized chemical processPolycrystalline material growthSurface reactionGas phase

A method of growing a thin film onto a substrate placed in a reaction chamber according to the ALD method by subjecting the substrate to alternate and successive surface reactions. The method includes providing a first reactant source and providing an inactive gas source. A first reactant is fed from the first reactant source in the form of repeated alternating pulses to a reaction chamber via a first conduit. The first reactant is allowed to react with the surface of the substrate in the reaction chamber. Inactive gas is fed from the inactive gas source into the first conduit via a second conduit that is connected to the first conduit at a first connection point so as to create a gas phase barrier between the repeated alternating pulses of the first reactant entering the reaction chamber. The inactive gas is withdrawn from said first conduit via a third conduit connected to the first conduit at a second connection point.

Owner:ASM IP HLDG BV

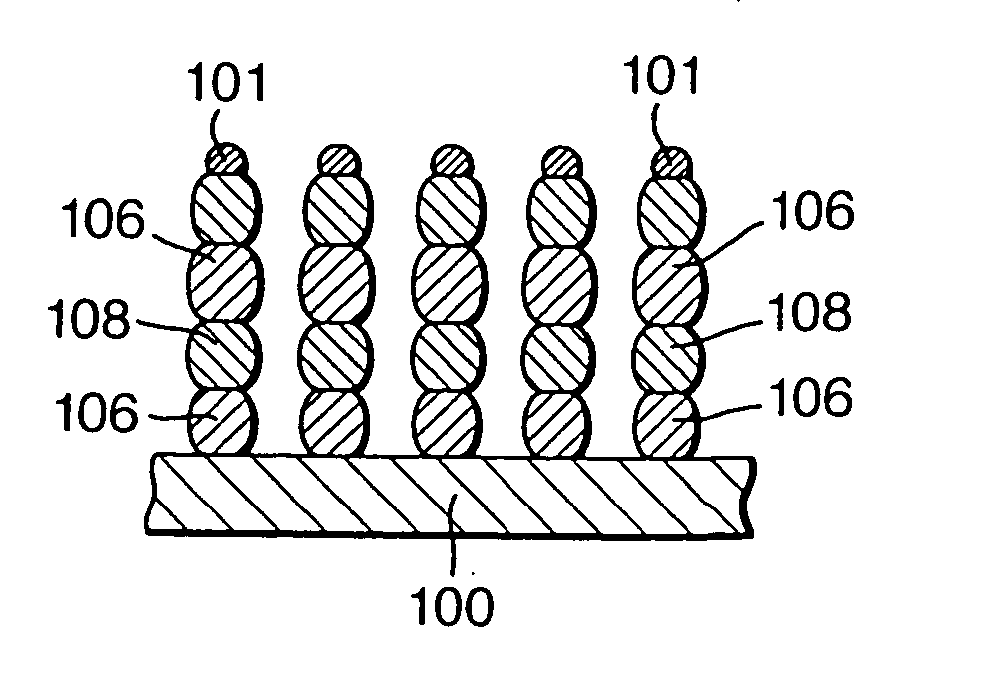

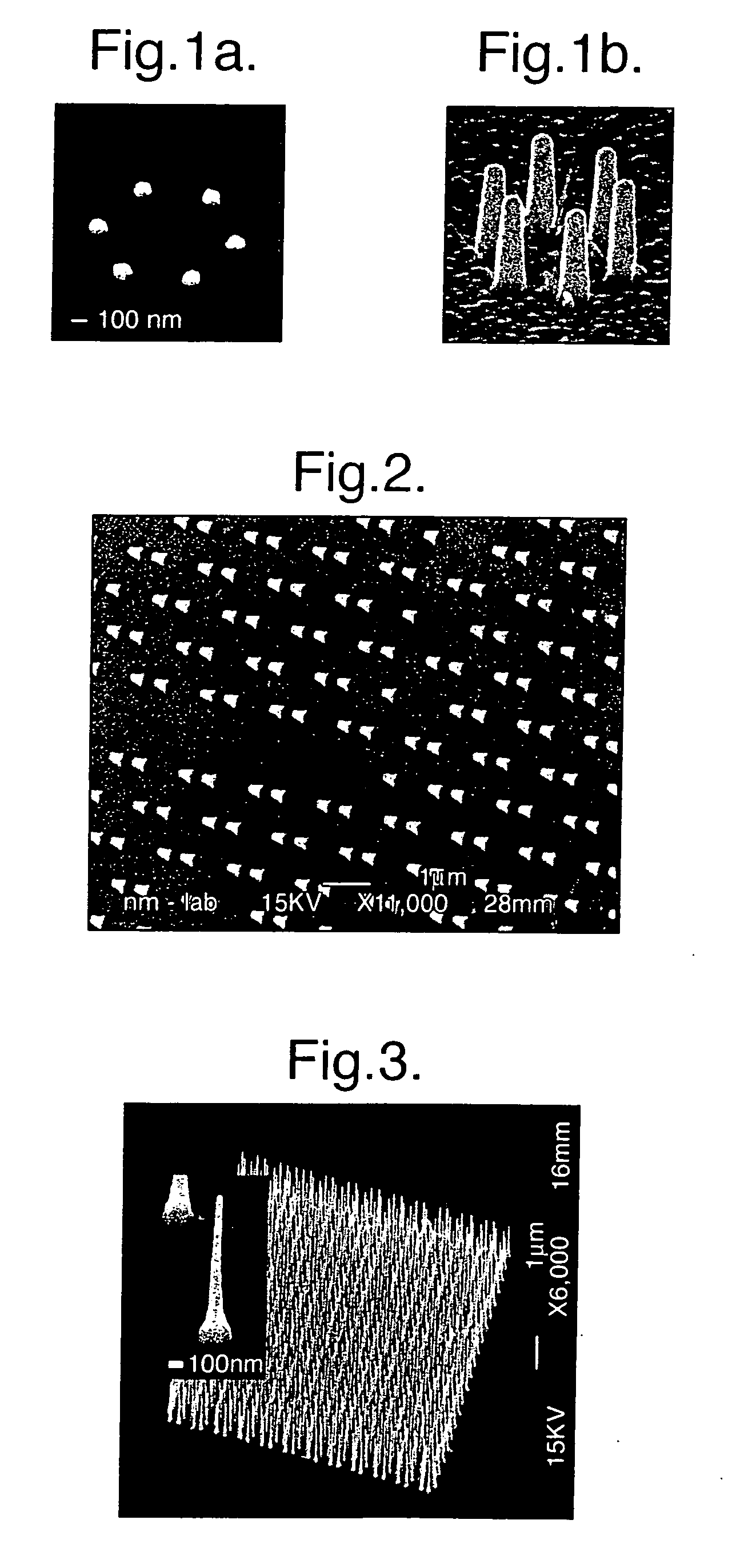

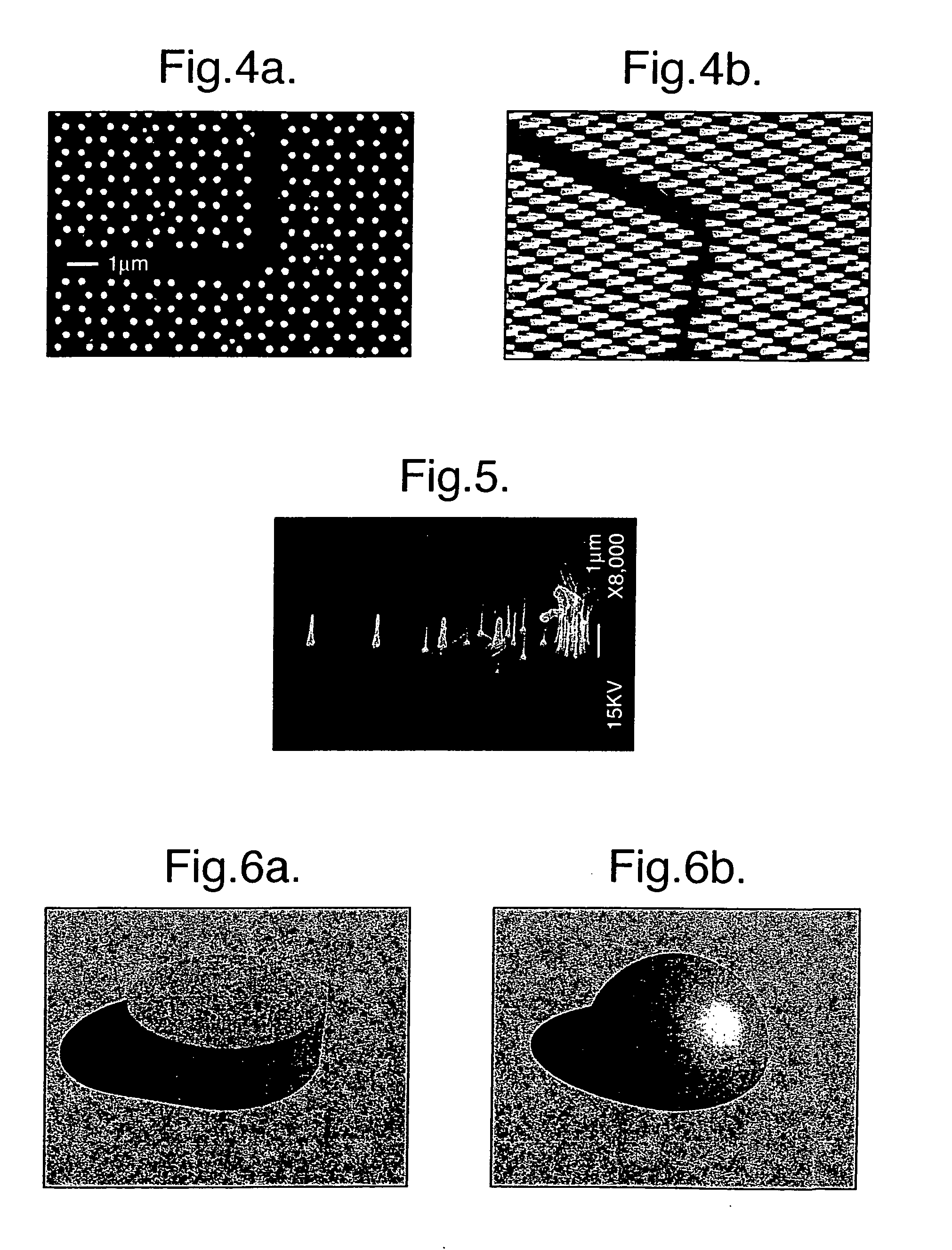

Precisely positioned nanowhiskers and nanowhisker arrays and method for preparing them

InactiveUS20050011431A1Increase forceImprove stabilityMaterial nanotechnologyPolycrystalline material growthPhotonic bandgapAdemetionine

A nanoengineered structure comprising an array of more than about 1000 nanowhiskers on a substrate in a predetermined spatial configuration, for use for example as a photonic band gap array, wherein each nanowhisker is sited within a distance from a predetermined site not greater than about 20% of its distance from its nearest neighbour. To produce the array, an array of masses of a catalytic material are positioned on the surface, heat is applied and materials in gaseous form are introduced such as to create a catalytic seed particle from each mass, and to grow, from the catalytic seed particle, epitaxially, a nanowhisker of a predetermined material, and wherein each mass upon melting, retains approximately the same interface with the substrate surface such that forces causing the mass to migrate across said surface are less than a holding force across a wetted interface on the substrate surface.

Owner:QUNANO

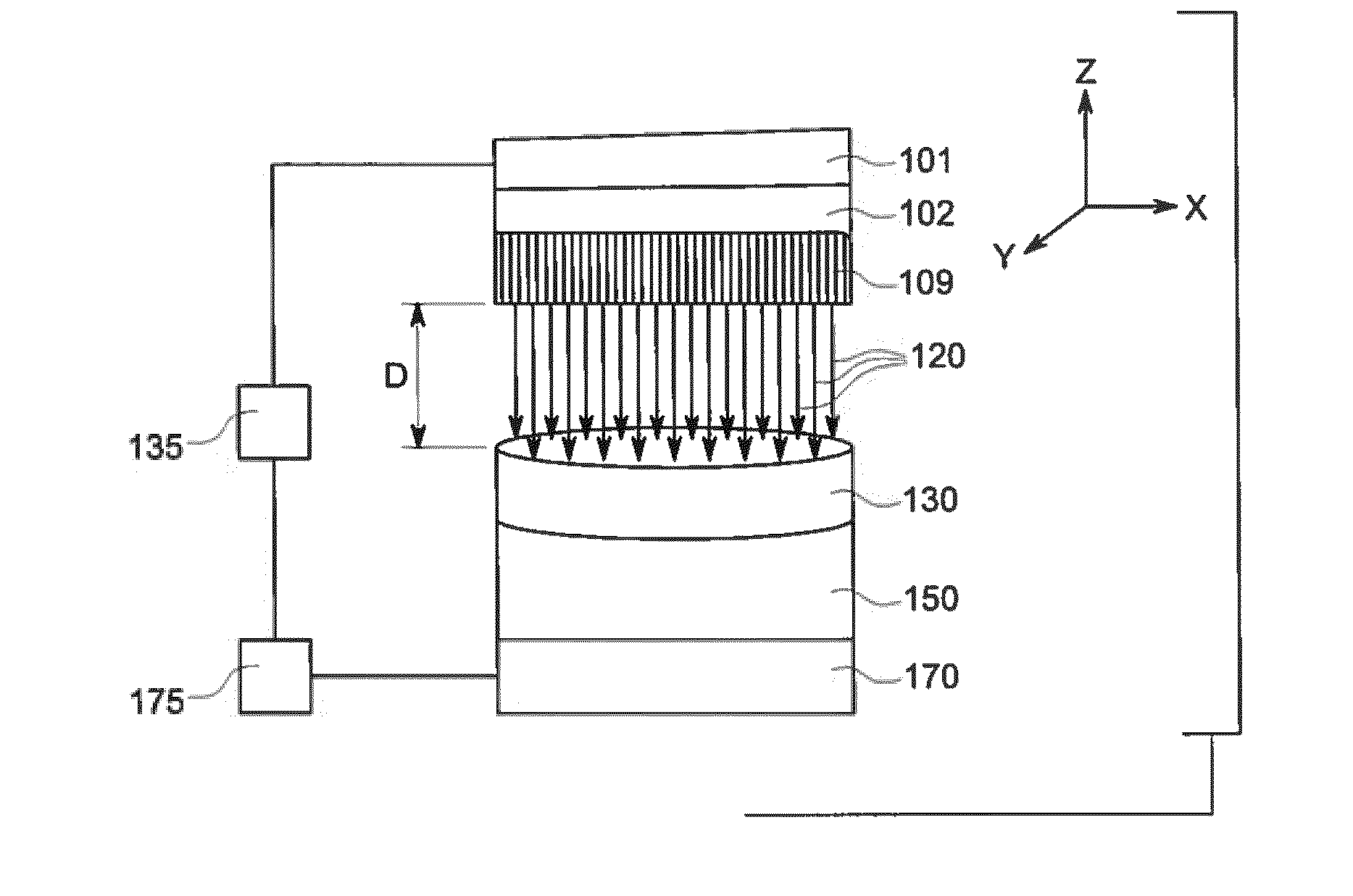

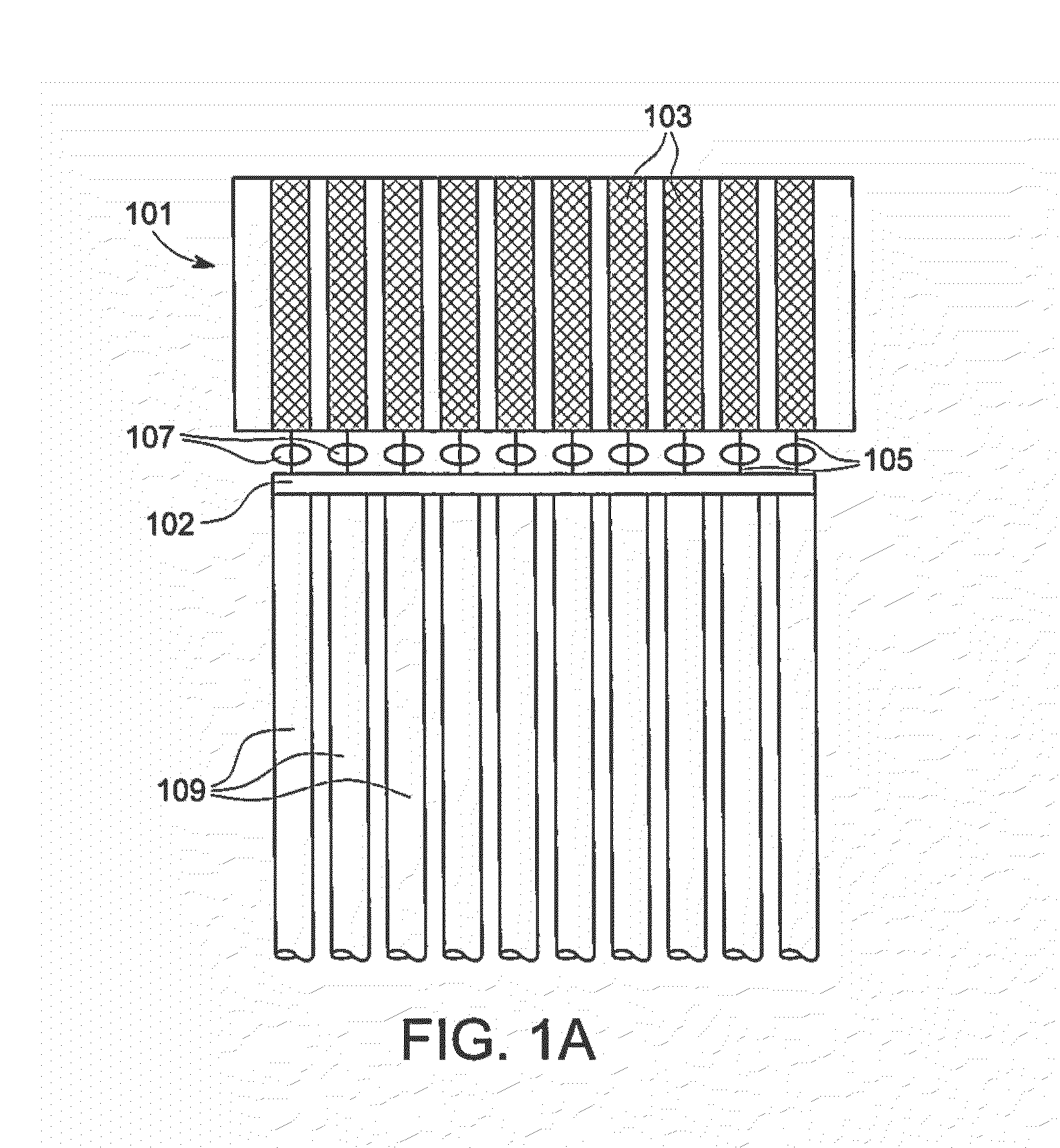

Control of solidification in laser powder bed fusion additive manufacturing using a diode laser fiber array

A method of method of forming or repairing a superalloy article having a columnar or equiaxed or directionally solidified or amorphous or single crystal microstructure includes emitting a plurality of laser beams from selected fibers of a diode laser fiber array corresponding to a pattern of a layer of the article onto a powder bed of the superalloy to form a melt pool; and controlling a temperature gradient and a solidification velocity of the melt pool to form the columnar or single crystal microstructure.

Owner:GENERAL ELECTRIC CO

Turbine components for engines and methods of fabricating the same

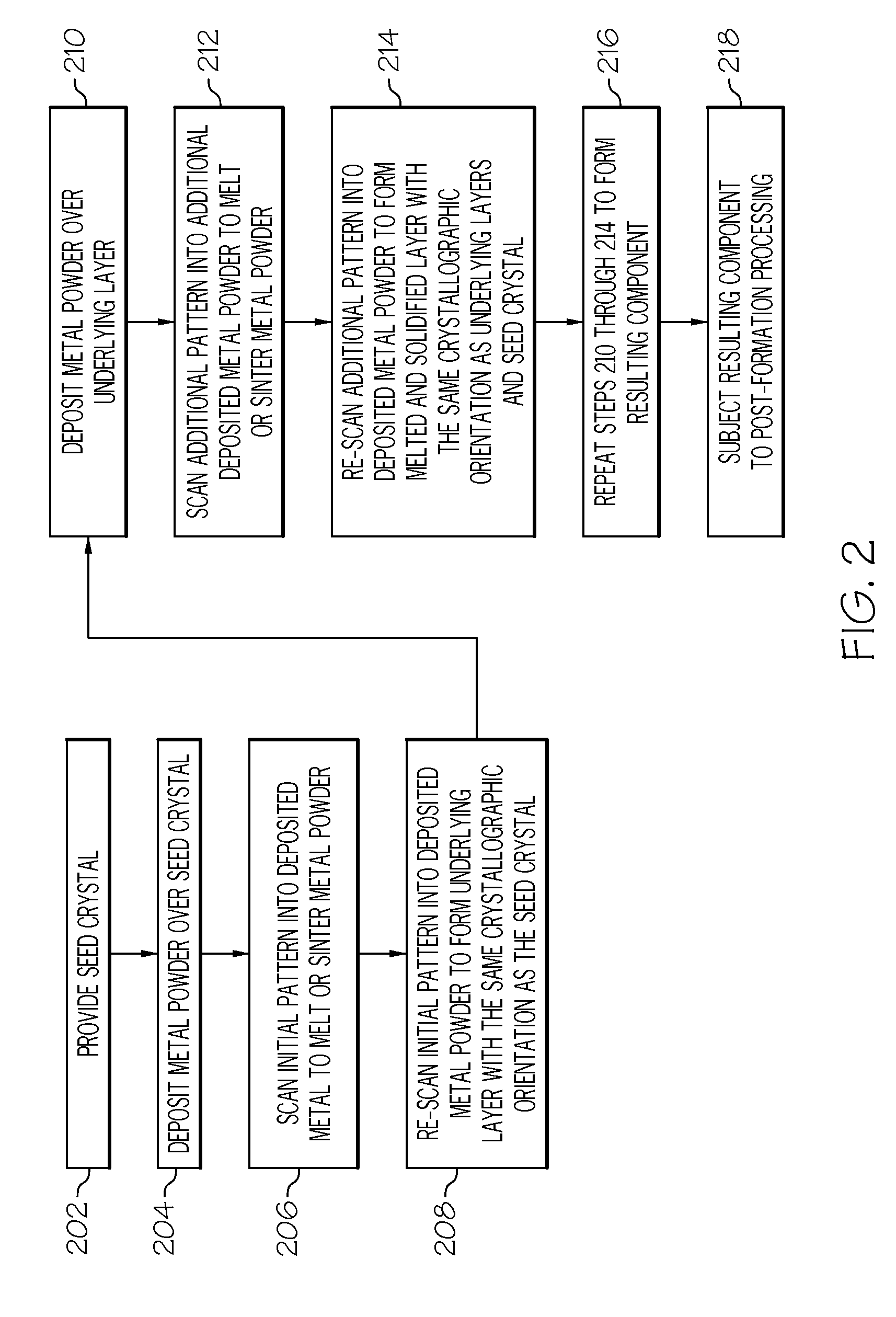

A method is provided that includes depositing metal powder over a seed crystal having a predetermined primary orientation, scanning an initial pattern into the metal powder to melt or sinter the deposited metal powder, and re-scanning the initial pattern to re-melt the scanned metal powder and form an initial layer having the predetermined primary orientation. The method further includes depositing additional metal powder over the initial layer, scanning an additional pattern into the additional metal powder to melt or sinter at least a portion of the additional metal powder, re-scanning the additional pattern to re-melt a portion of the initial layer and the scanned deposited additional metal powder to form a successive layer having the predetermined primary orientation, and repeating the steps of depositing additional metal powder, scanning the additional pattern, and re-scanning the additional pattern, until a final shape of the component is achieved.

Owner:HONEYWELL INT INC

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

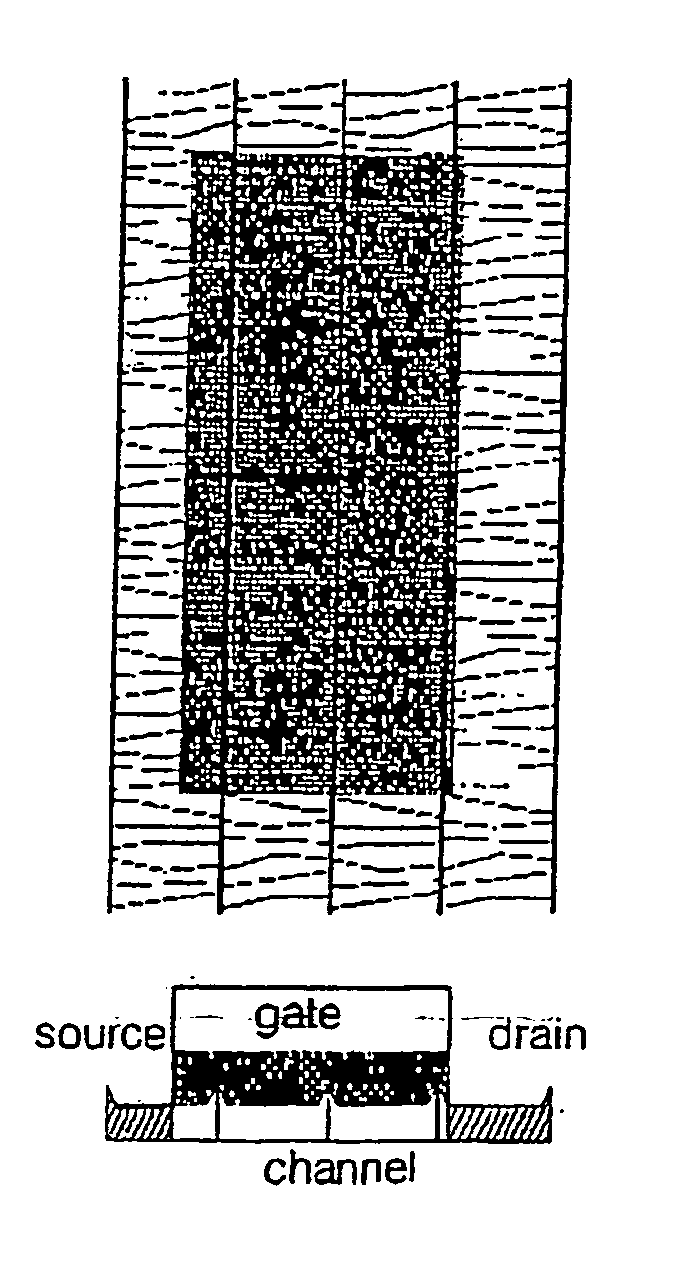

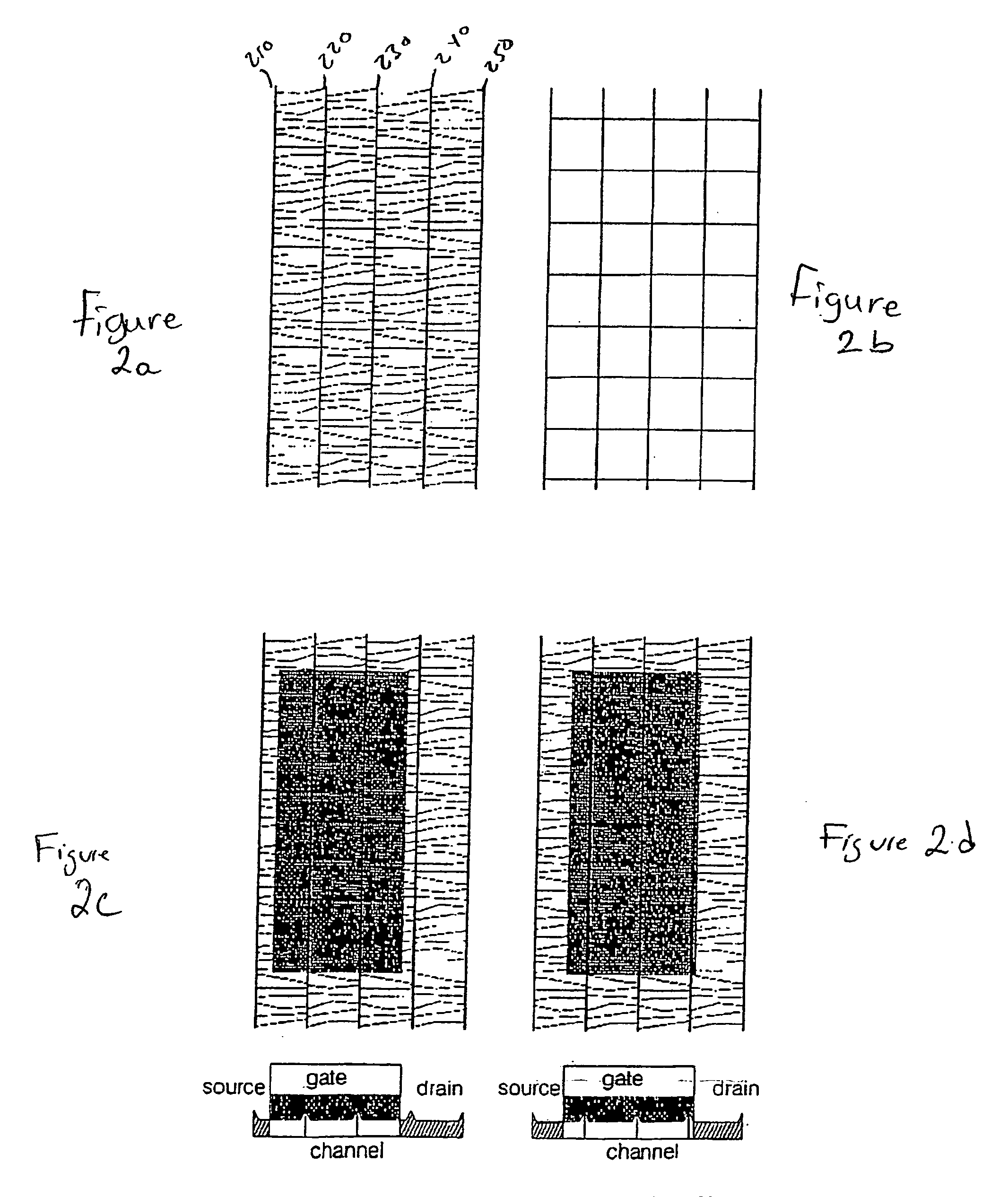

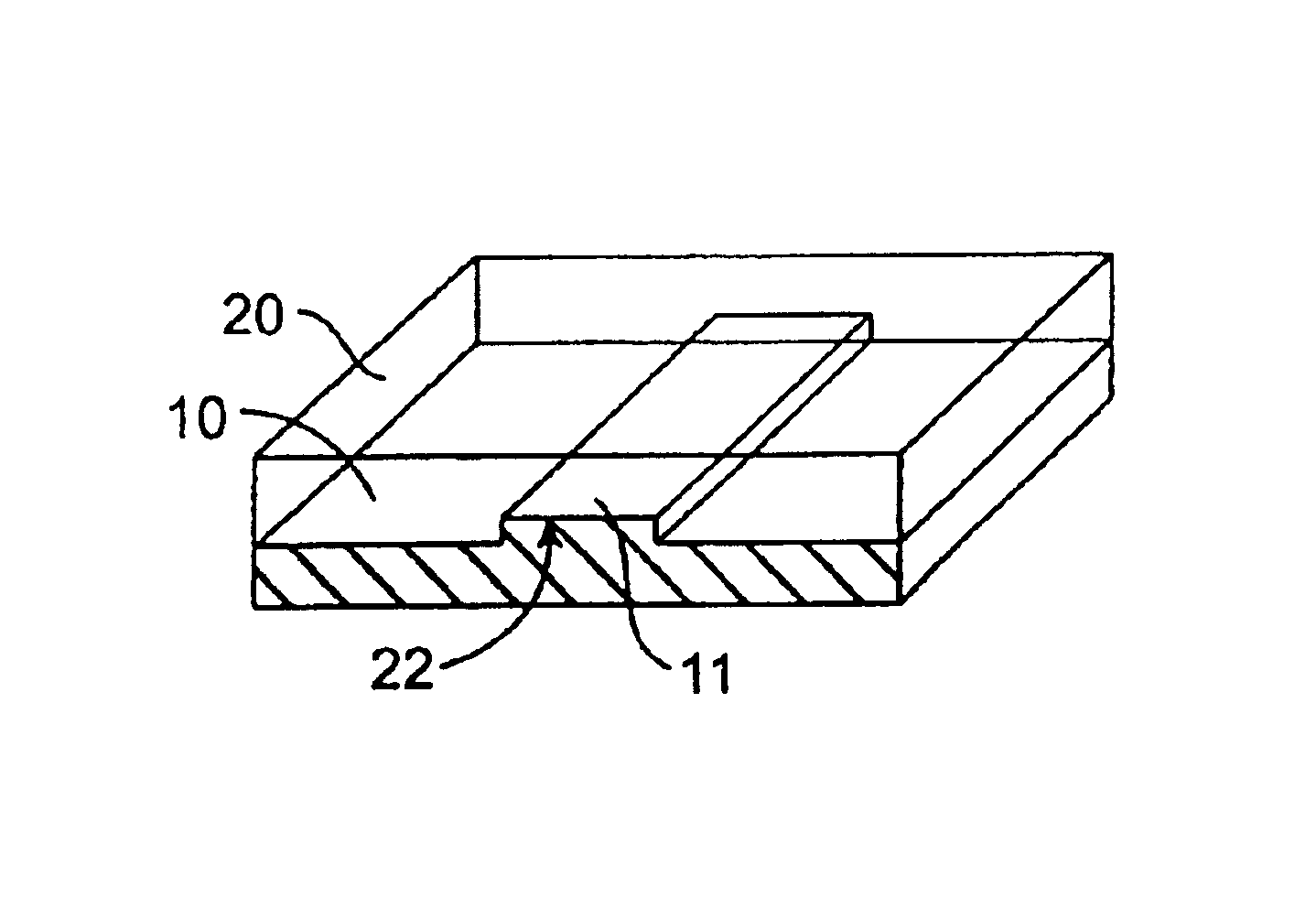

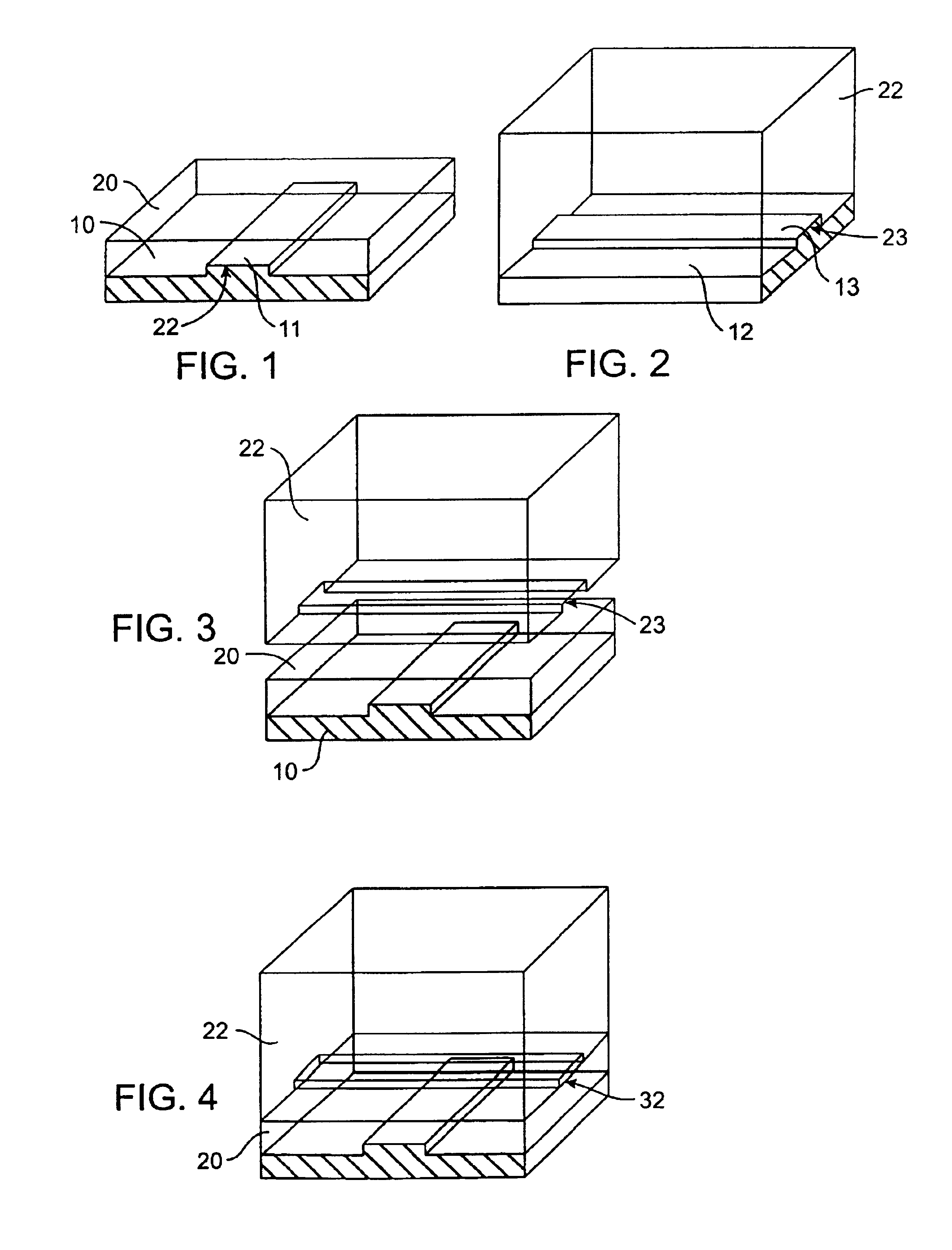

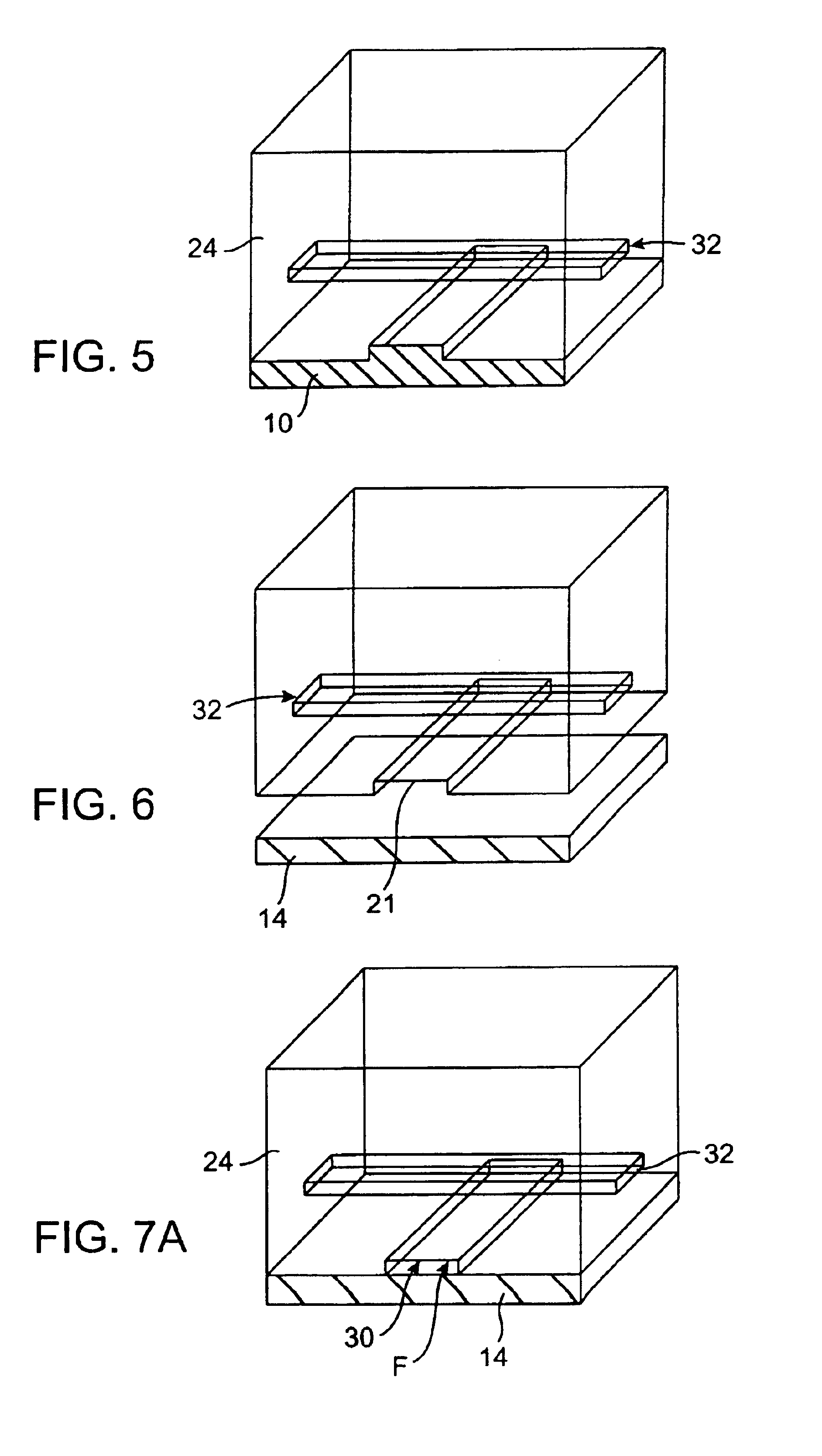

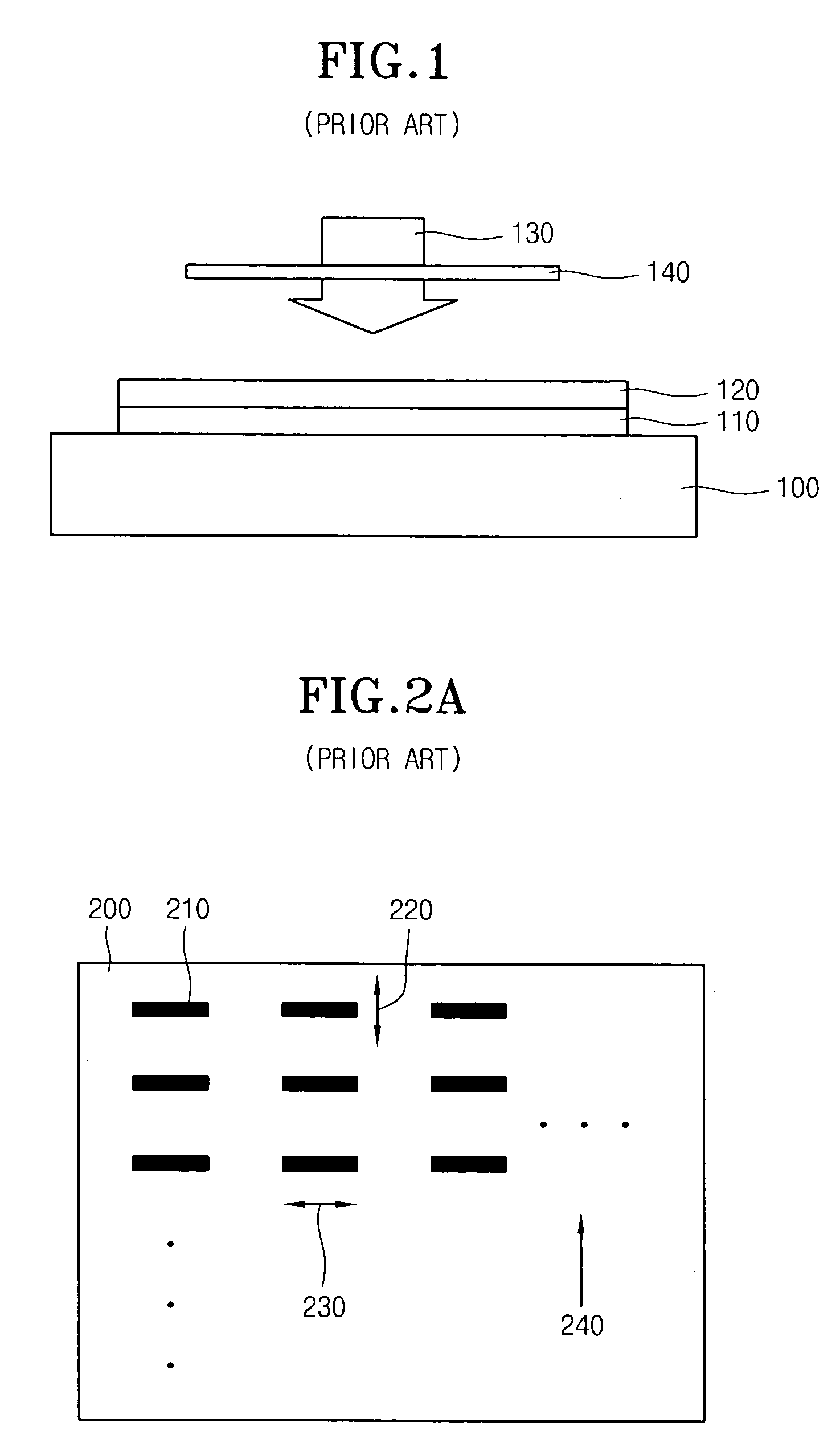

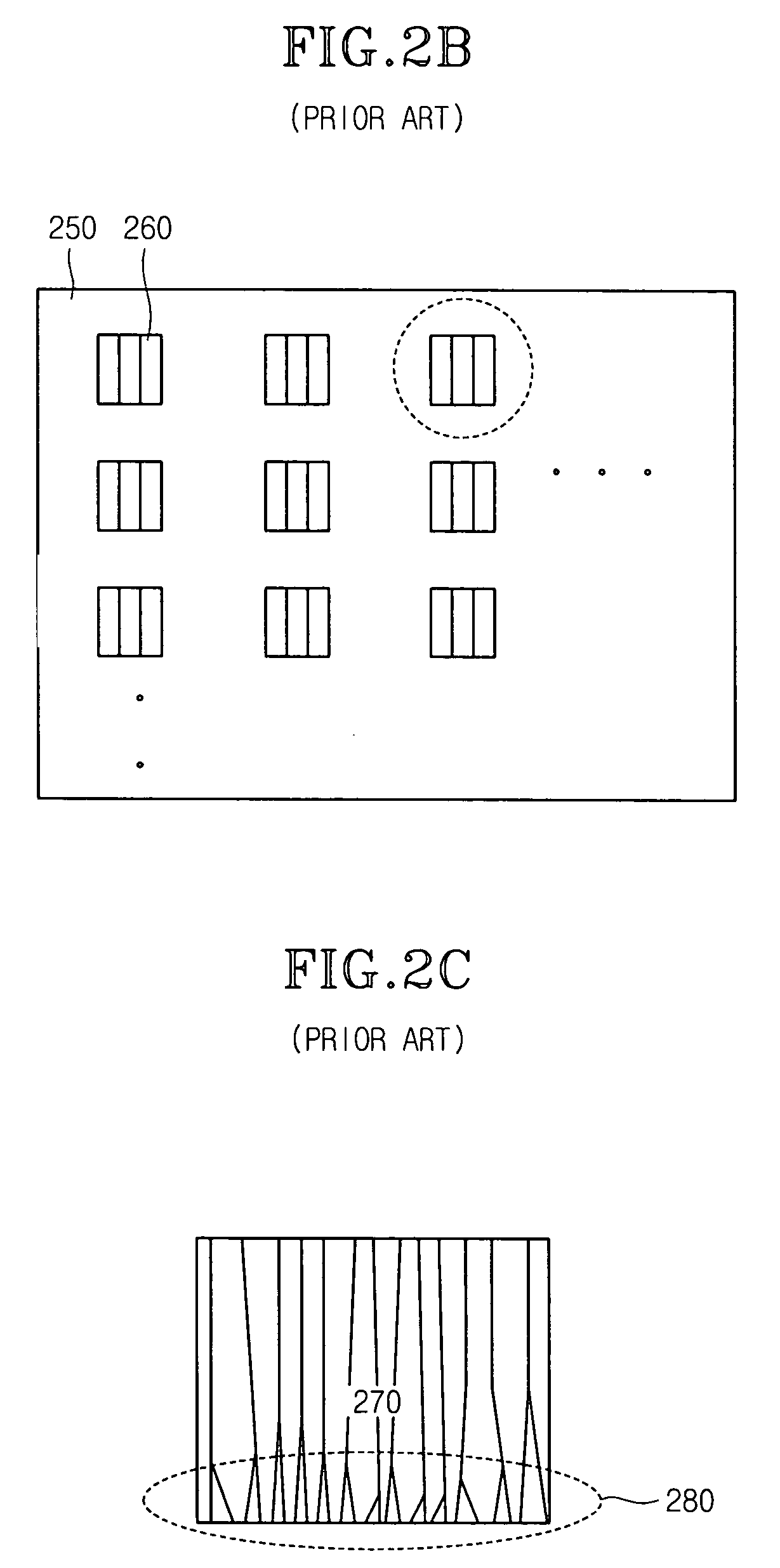

Polycrystalline tft uniformity through microstructure mis-alignment

InactiveUS20050034653A1Provide uniformityUniformityTransistorPolycrystalline material growthOptoelectronicsGrain structure

Methods of making a polycrystalline silicon thin-film transistor having a uniform microstructure. One exemplary method requires receiving a polycrystalline silicon thin film having a grain structure which is periodic in at least a first direction, and placing at least portions (410, 420) of one or more thin-film transistors on the received film such that they are tilted relative to the periodic structure of the thin film.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

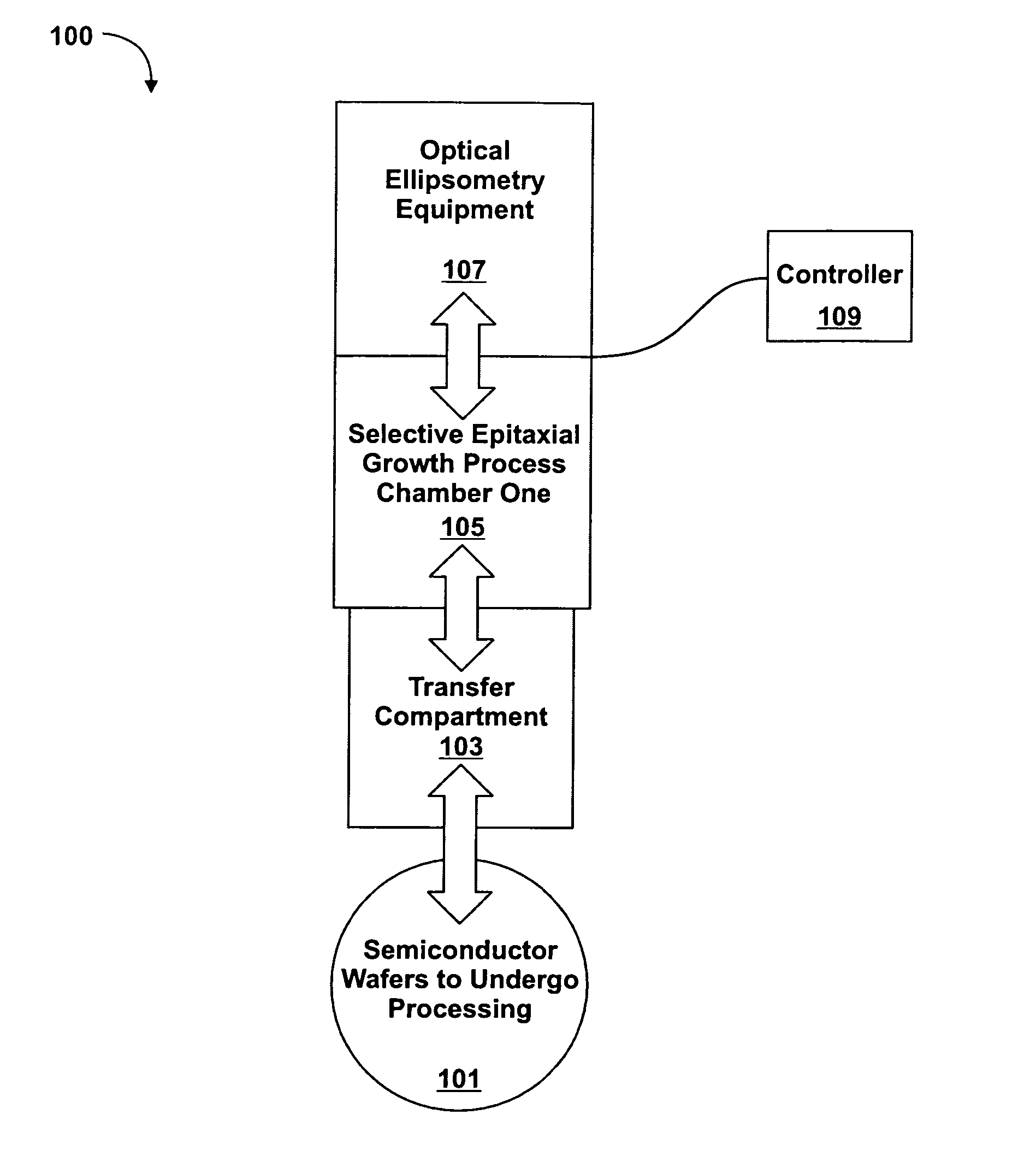

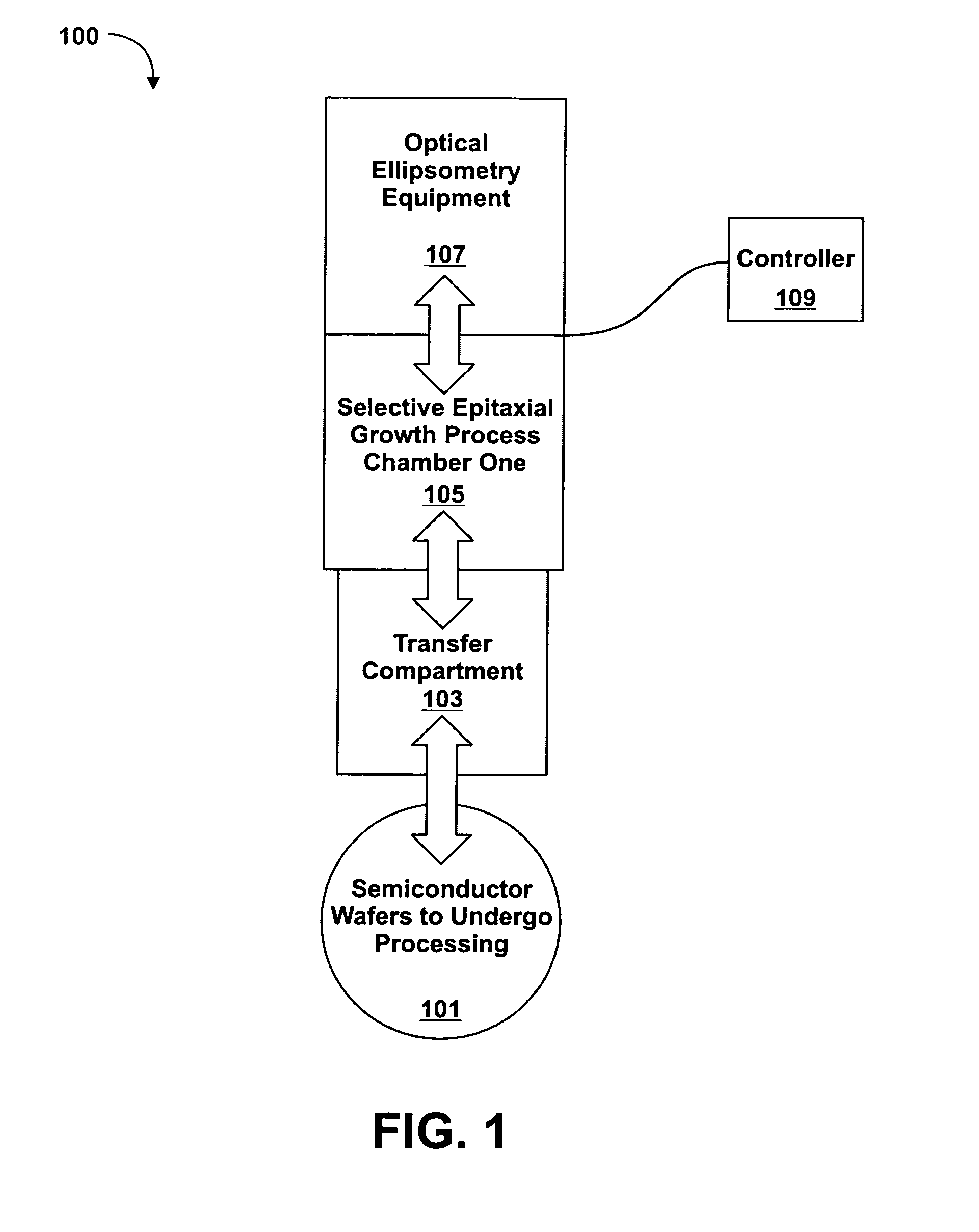

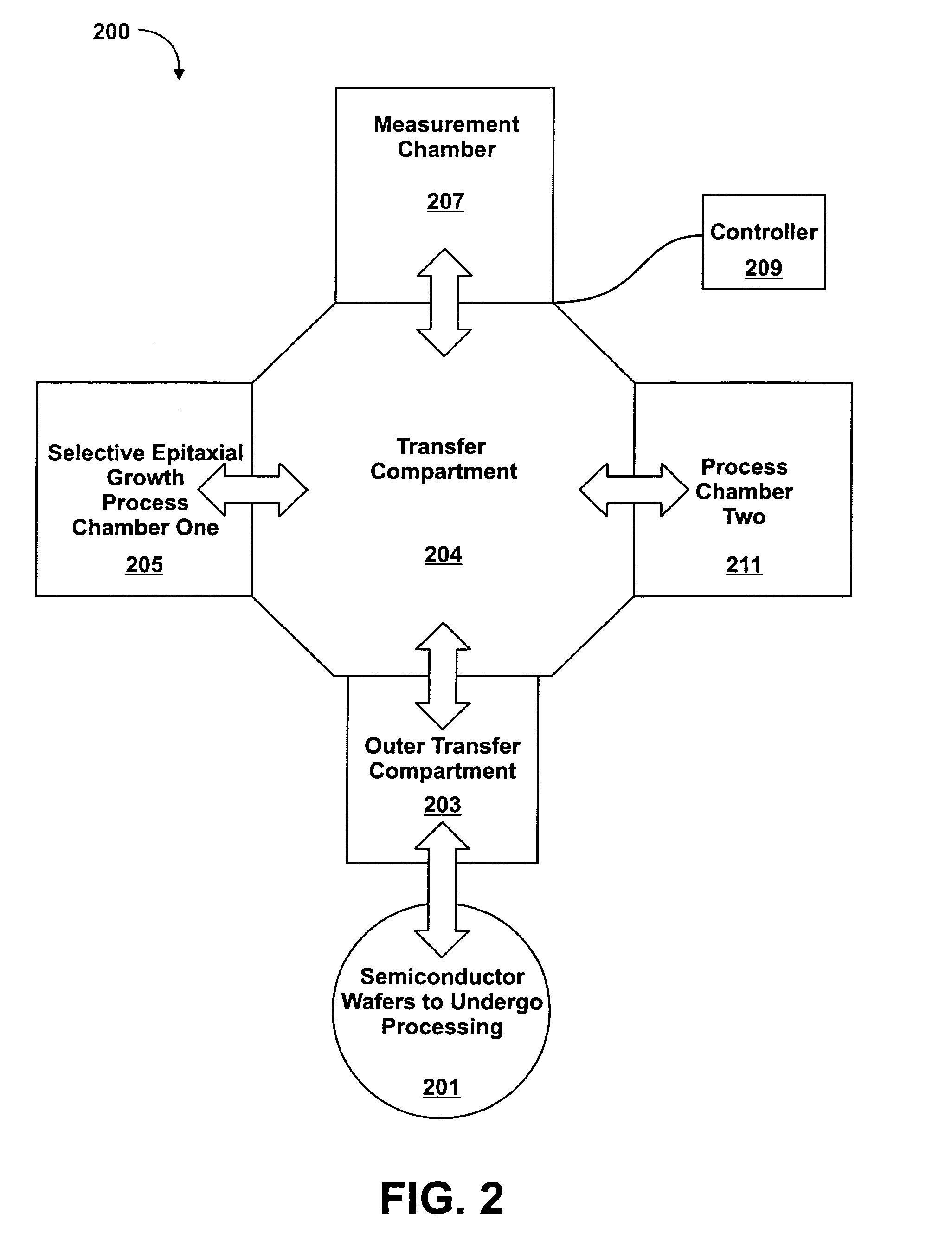

Method and apparatus for controlling the thickness of a selective epitaxial growth layer

Methods and systems for permitting thickness control of the selective epitaxial growth (SEG) layer in a semiconductor manufacturing process, for example raised source / drain applications in CMOS technologies, are presented. These methods and systems provide the capability to measure the thickness of an SEG film in-situ utilizing optical ellipsometry equipment during or after SEG layer growth, prior to removing the wafer from the SEG growth tool. Optical ellipsometry equipment can be integrated into the SEG platform and control software, thus providing automated process control (APC) capability for SEG thickness. The integration of the ellipsometry equipment may be varied, dependent upon the needs of the fabrication facility, e.g., integration to provide ellipsometer monitoring of a single process tool, or multiple tool monitoring, among other configurations.

Owner:ADVANCED MICRO DEVICES INC

Method of forming three-dimensional nanocrystal array

InactiveUS20040079278A1Material nanotechnologyPolycrystalline material growthPhotonic bandgapQuantum dot

A method of forming an assembly of isolated nanowires of at least one material within a matrix of another material is provided. The method comprises: providing a substrate; forming a catalyst array on a major surface of the substrate; growing an array of the nanowires corresponding with the catalyst array, the nanowires, each comprising at least one material; and forming a matrix of another material that fills in spaces between the nanowires. The method is useful for producing a variety of structures useful in a number of devices, such as photonic bandgap structures and quantum dot structures.

Owner:HEWLETT PACKARD DEV CO LP

Method for reducing defect concentration in crystals

ActiveUS20060096521A1Reduce defect concentrationRelieve pressureAfter-treatment detailsUltra-high pressure processesDiamond crystalHigh pressure cell

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:SLT TECH

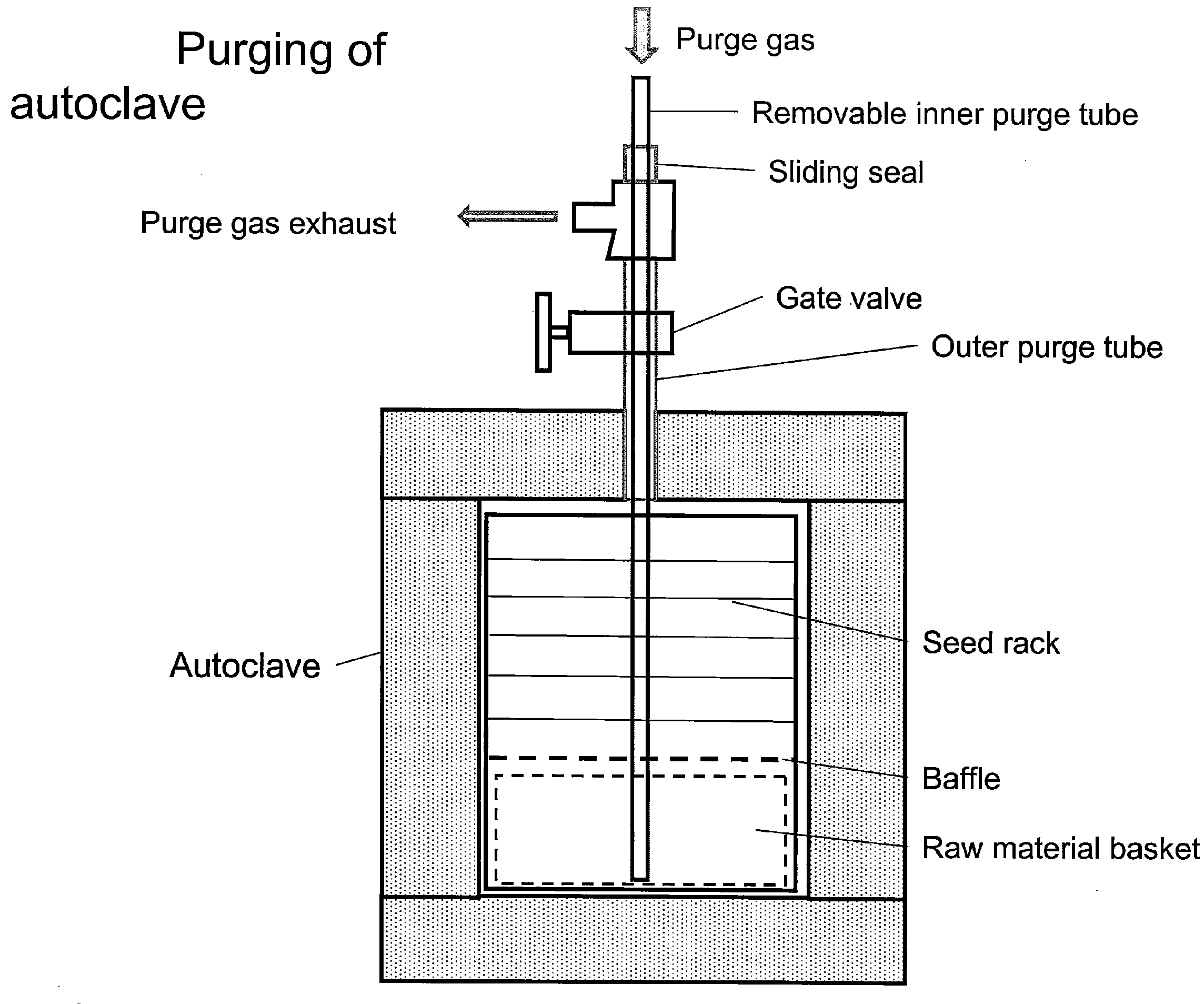

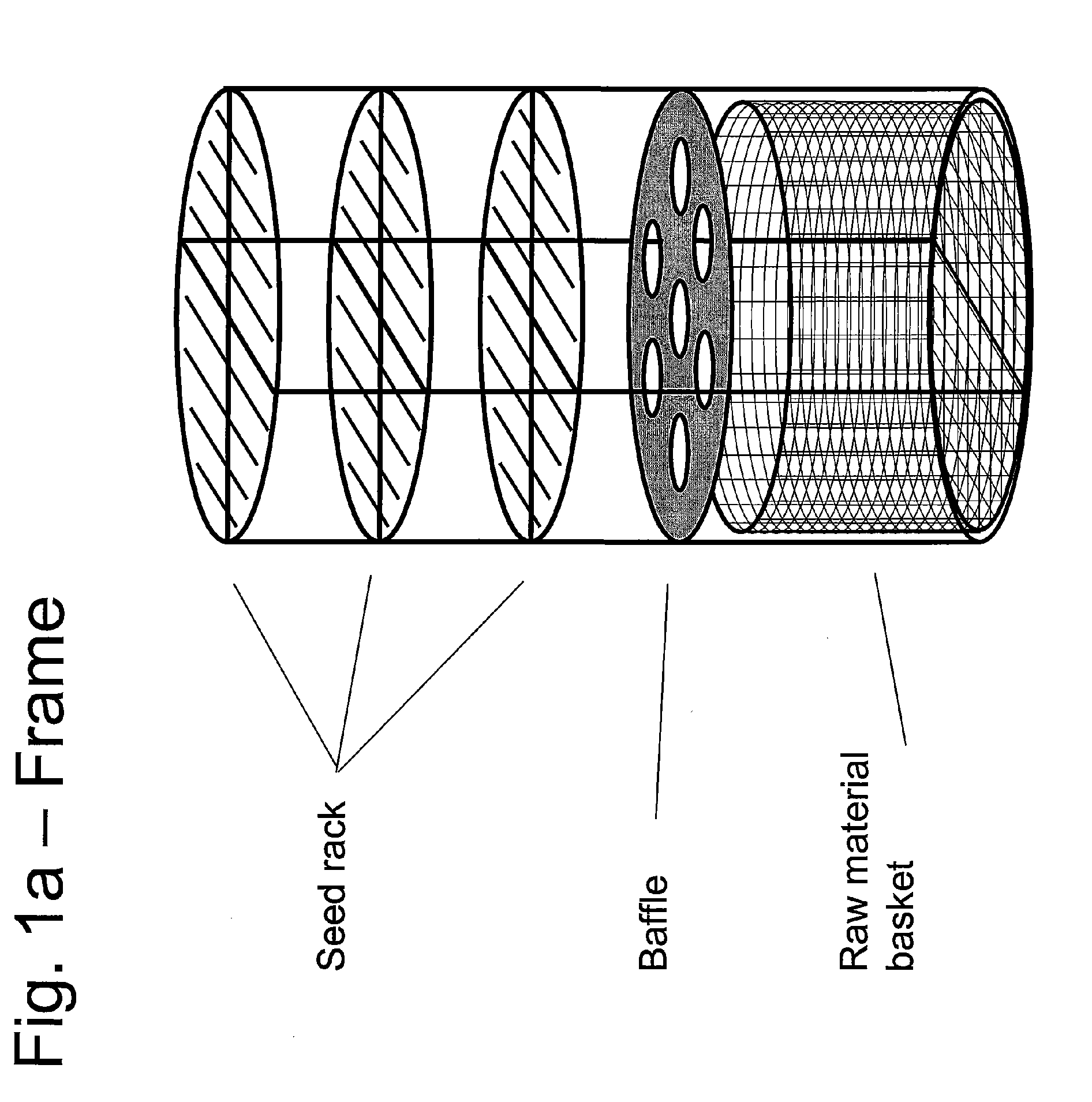

Process and apparatus for large-scale manufacturing of bulk monocrystalline gallium-containing nitride

ActiveUS20100031876A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessSingle crystal

A method for large-scale manufacturing of gallium nitride includes a process for reducing and / or minimizing contamination in the crystals, for solvent addition to an autoclave, for improving or optimizing the solvent atmosphere composition, for removal of the solvent from the autoclave, and for recycling of the solvent. The method is scalable up to large volumes and is cost effective.

Owner:SLT TECH

Microvolume crystallization method employing multiple lumens

InactiveUS6872250B2Facilitates the device being rotatedMaterial crystallisationPolycrystalline material growthCrystallizationCrystal

A method for determining crystallization conditions for a material, the method comprising: taking a microfluidic device comprising one or more lumens having microvolume dimensions and a plurality of different crystallization samples within the one or more lumens, the plurality of crystallization samples comprising a material to be crystallized and crystallization conditions that vary among the plurality of crystallization samples; transporting the plurality of different crystallization samples within the lumens; and identifying a precipitate or crystal formed in the one or more lumens.

Owner:TAKEDA SAN DIEGO

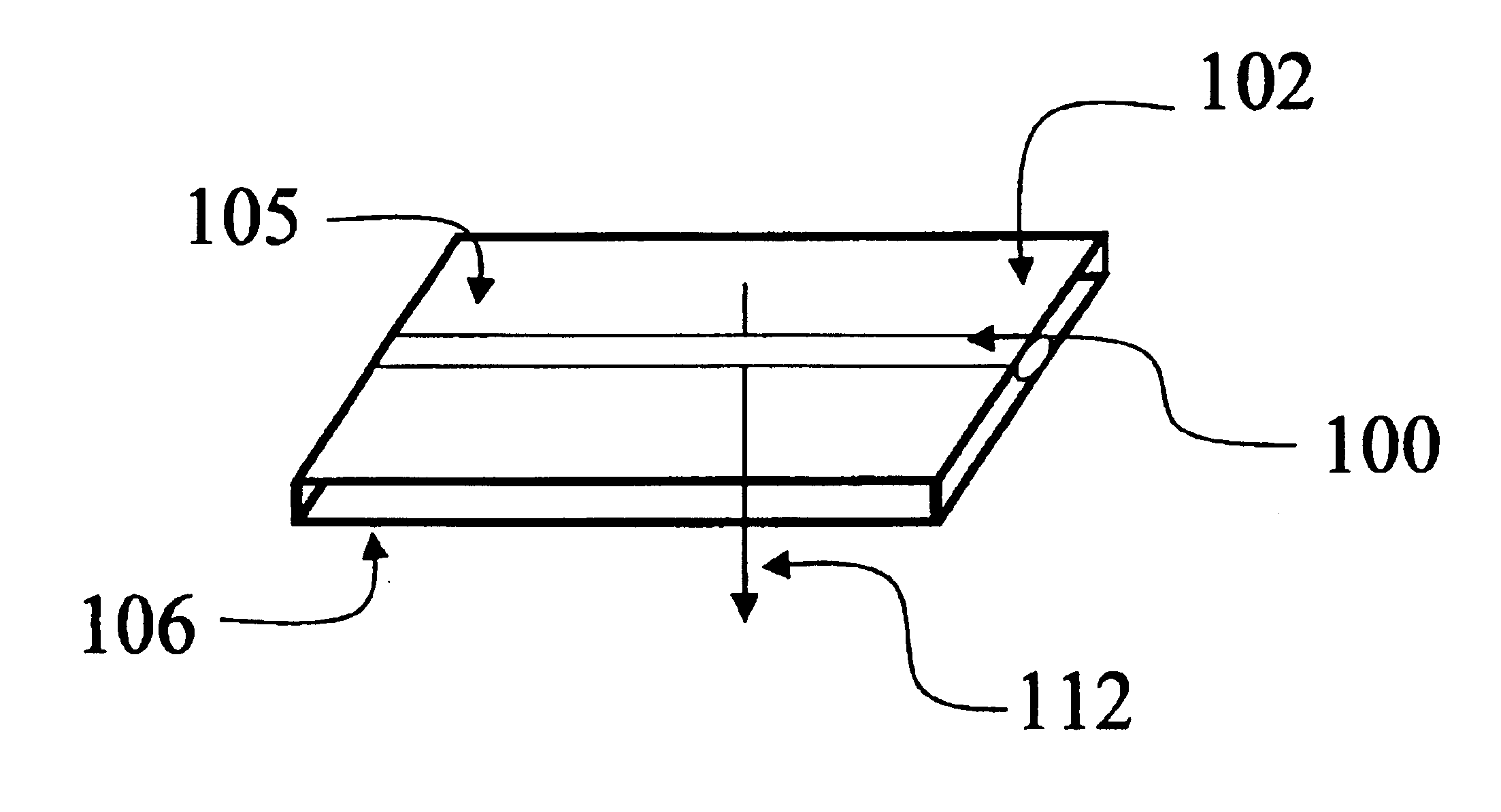

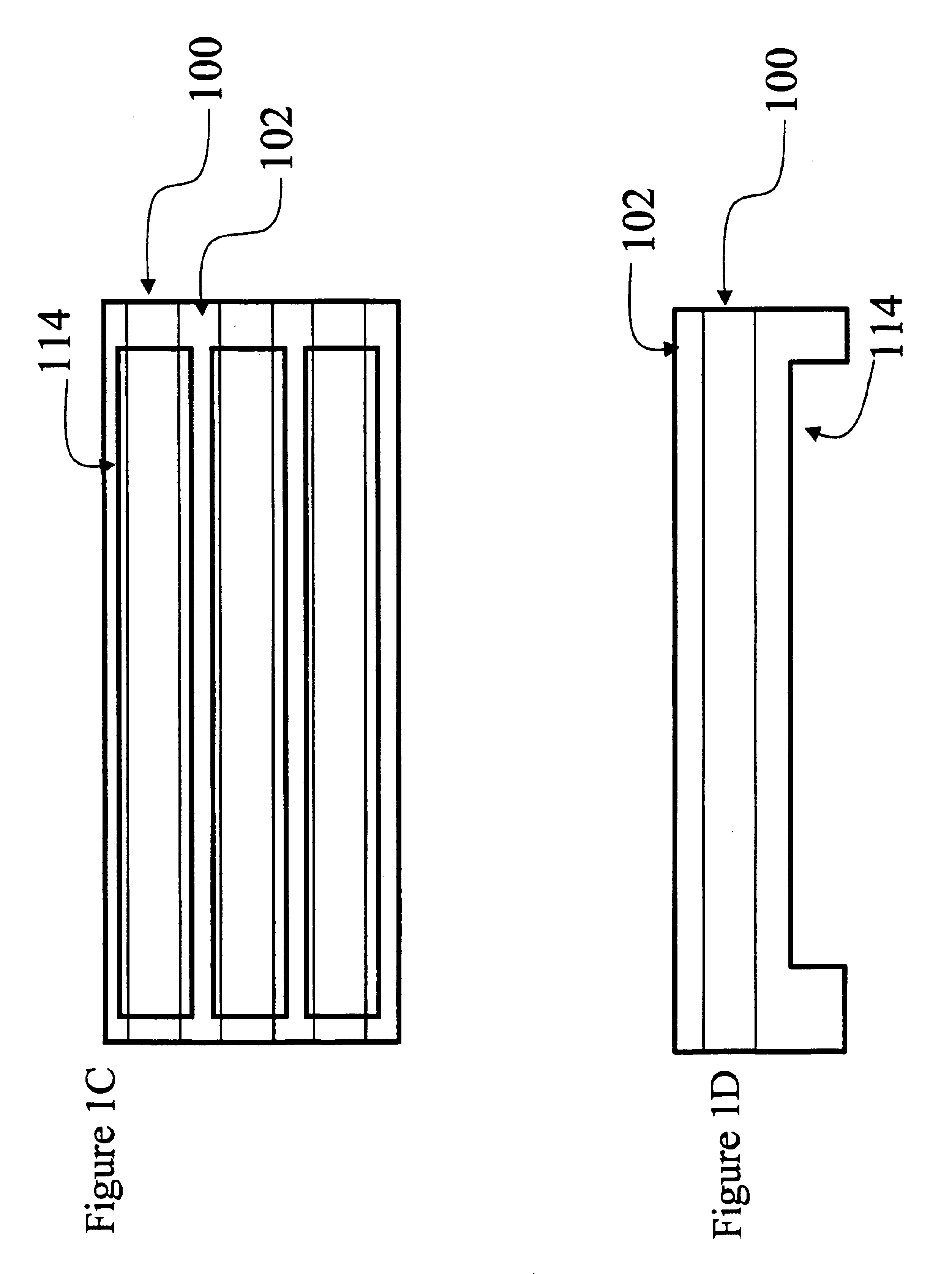

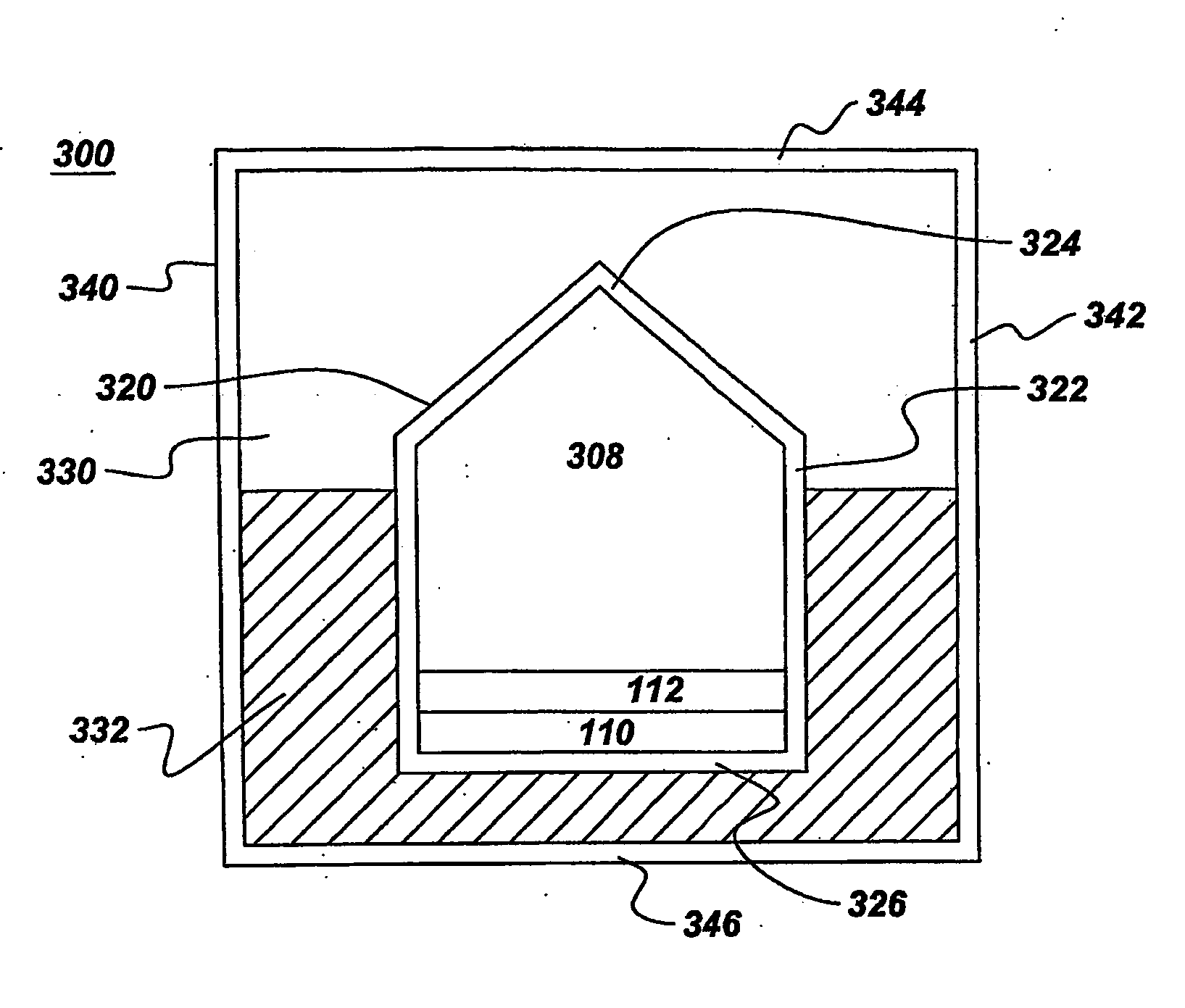

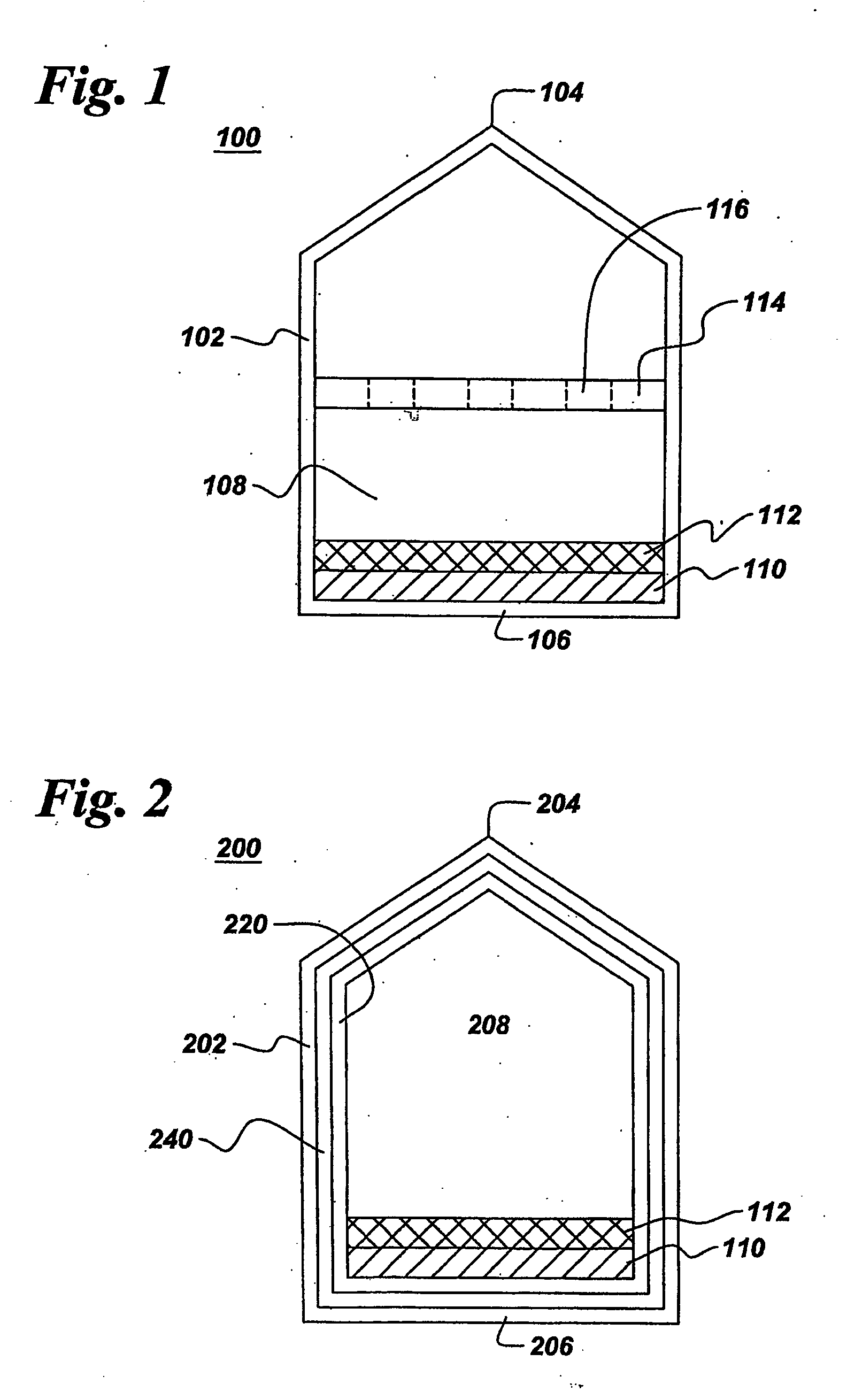

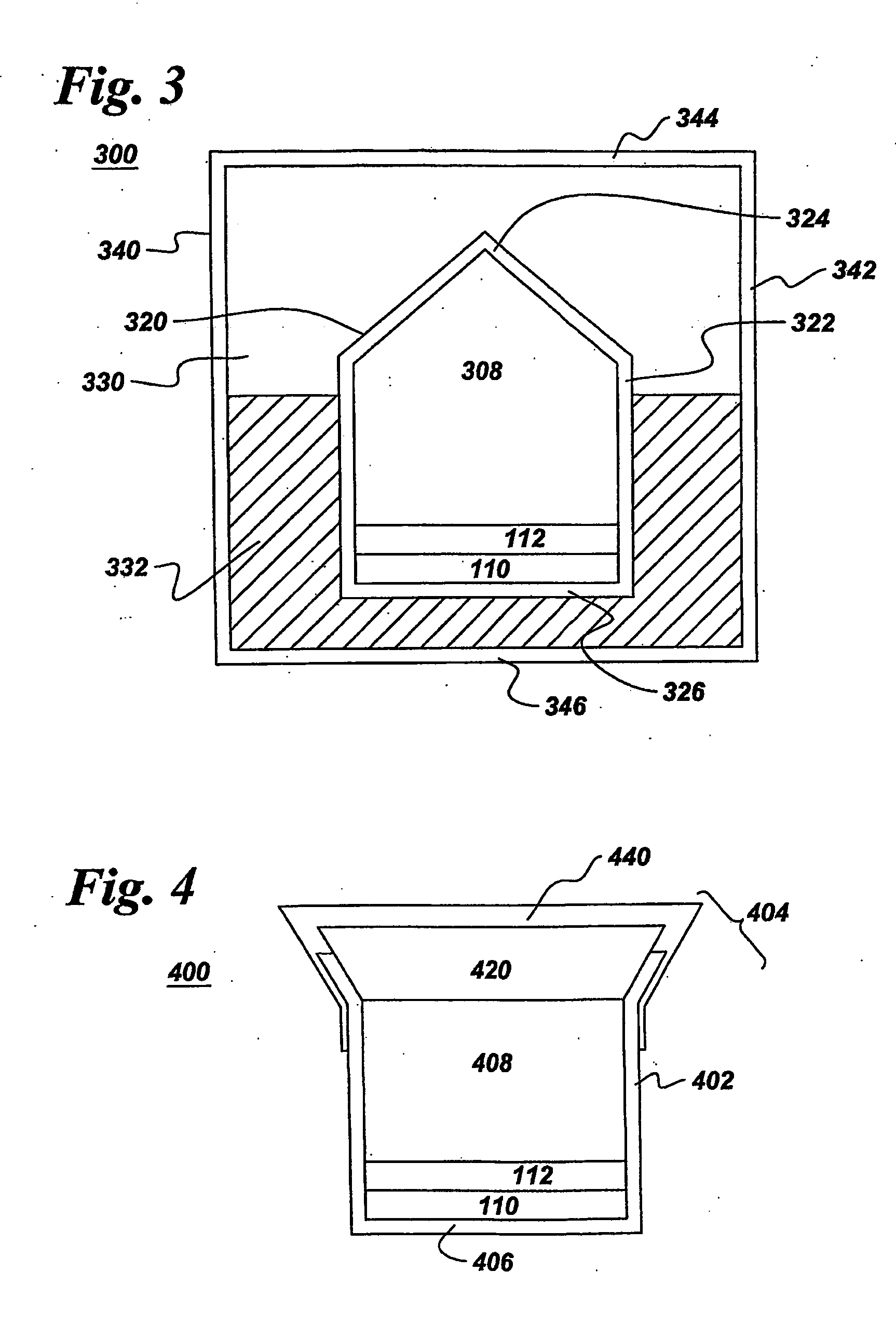

High temperature high pressure capsule for processing materials in supercritical fluids

InactiveUS20050152820A1From normal temperature solutionsUltra-high pressure processesHigh pressureSolvent

A capsule for containing at least one reactant and a supercritical fluid in a substantially air-free environment under high pressure, high temperature processing conditions. The capsule includes a closed end, at least one wall adjoining the closed end and extending from the closed end; and a sealed end adjoining the at least one wall opposite the closed end. The at least one wall, closed end, and sealed end define a chamber therein for containing the reactant and a solvent that becomes a supercritical fluid at high temperatures and high pressures. The capsule is formed from a deformable material and is fluid impermeable and chemically inert with respect to the reactant and the supercritical fluid under processing conditions, which are generally above 5 kbar and 550° C. and, preferably, at pressures between 5 kbar and 80 kbar and temperatures between 550° C. and about 1500° C. The invention also includes methods of filling the capsule with the solvent and sealing the capsule, as well as an apparatus for sealing the capsule.

Owner:SLT TECH

Crystal substrates and methods of fabricating the same

InactiveUS20070187668A1Thickness is easy to controlSpadesPolycrystalline material growthSingle crystal substrateOptoelectronics

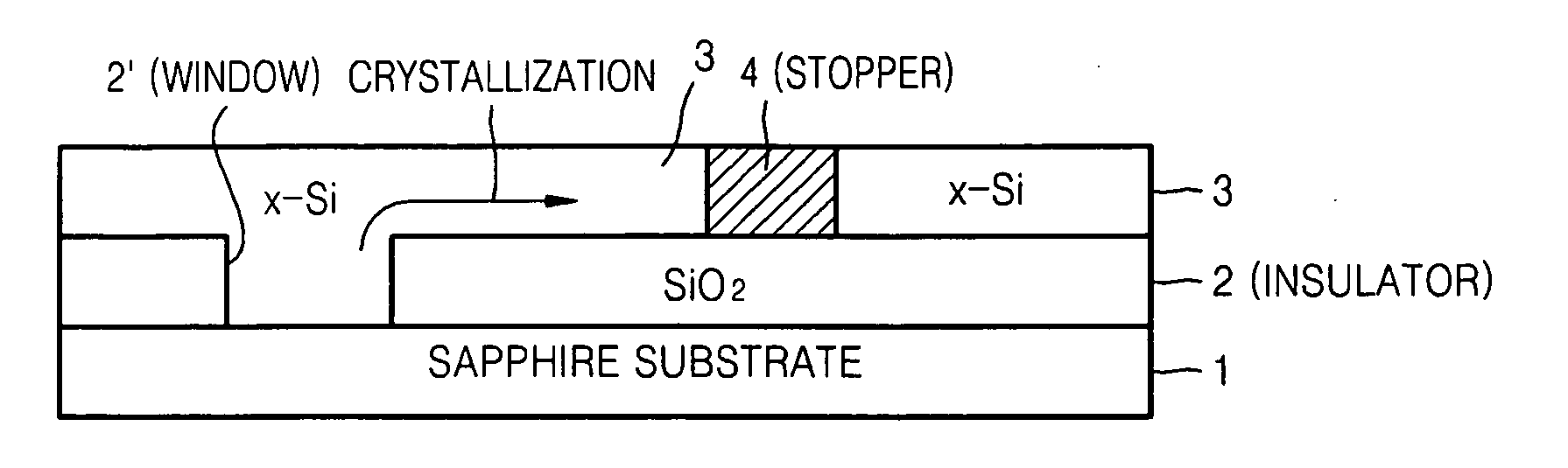

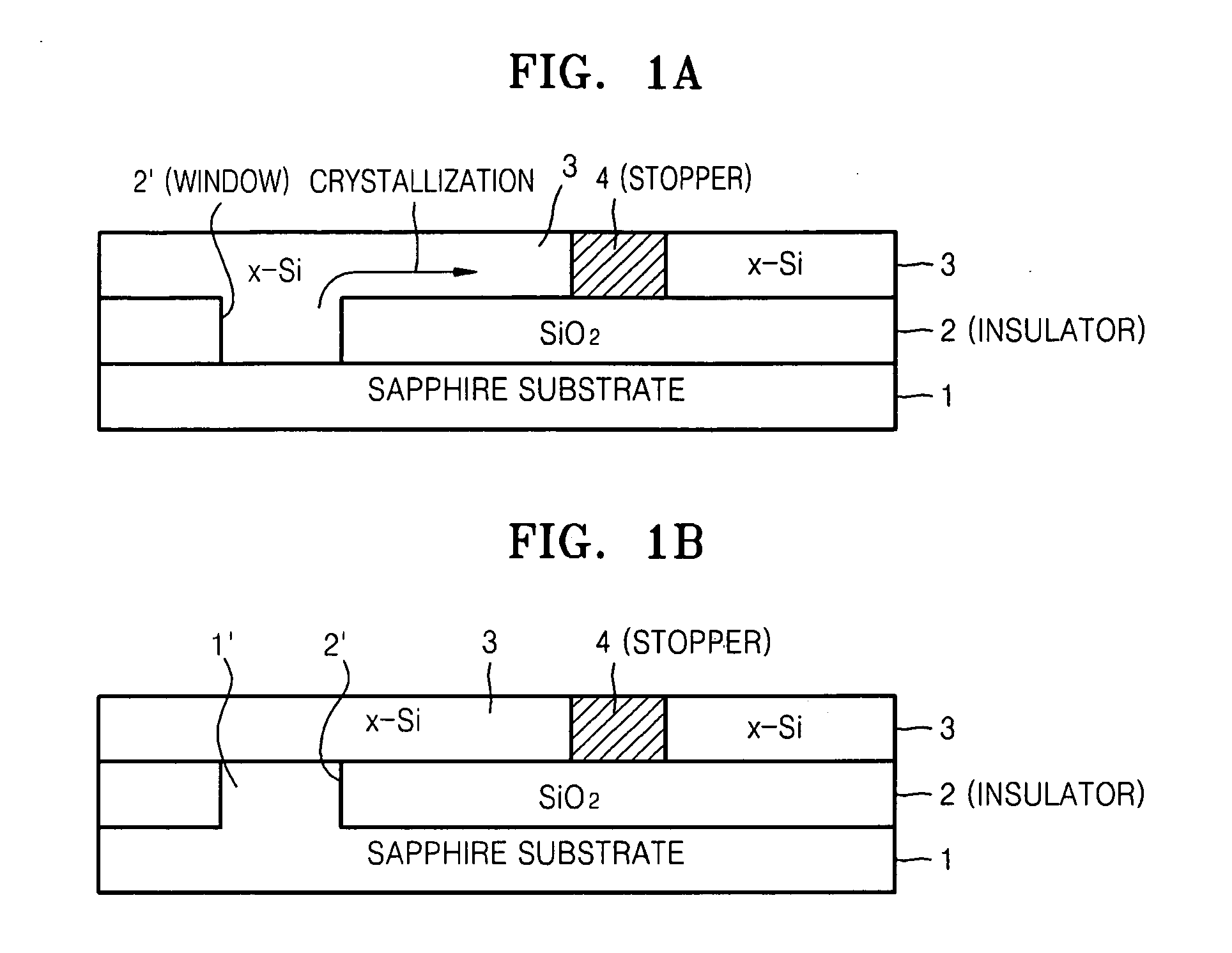

A single crystal substrate and method of fabricating the same are provided. The single crystal substrate includes an insulator having a window exposing a portion of a substrate, a selective epitaxial growth layer formed on the portion of the substrate exposed through the window and a single crystalline layer formed on the insulator and the selective epitaxial growth layer using the selective epitaxial growth layer as an epitaxial seed layer.

Owner:SAMSUNG ELECTRONICS CO LTD

ß-Ga2o3 single crystal growing method, thin-film single crystal growing method, Ga2o3 light-emitting device, and its manufacturing method

InactiveUS20060150891A1Trend downHigh crystallinityPolycrystalline material growthBy zone-melting liquidsDopantInfrared

Owner:WASEDA UNIV

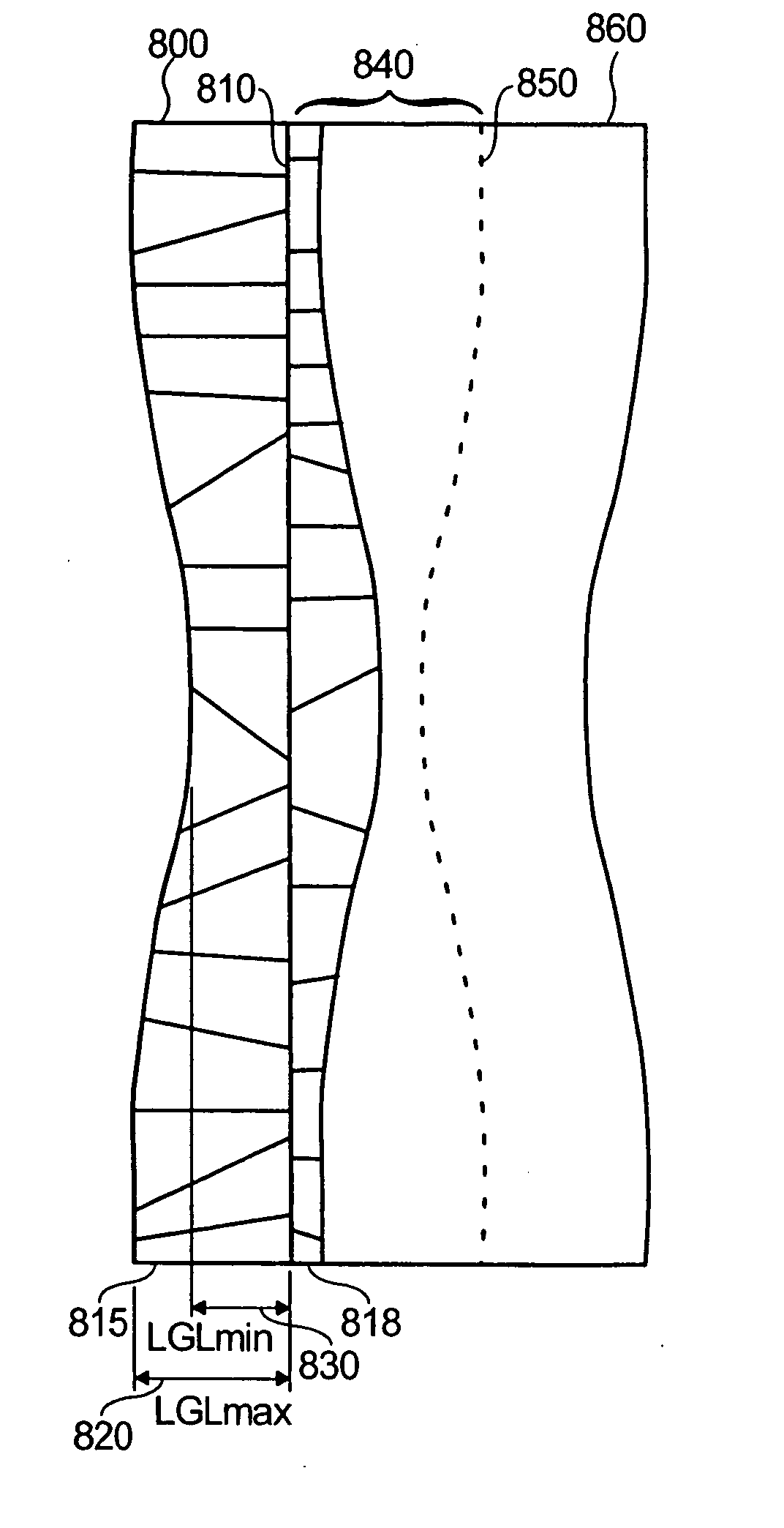

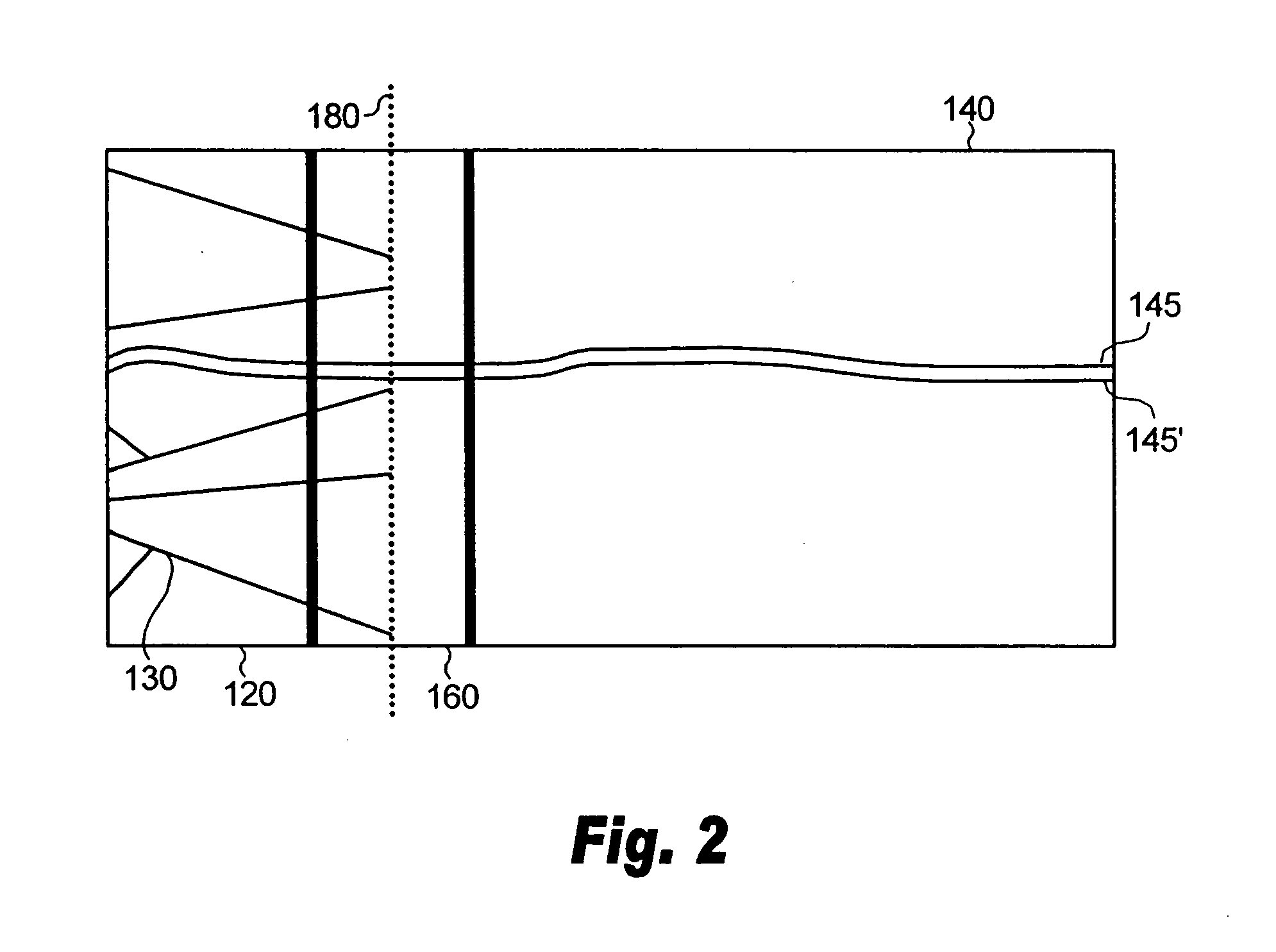

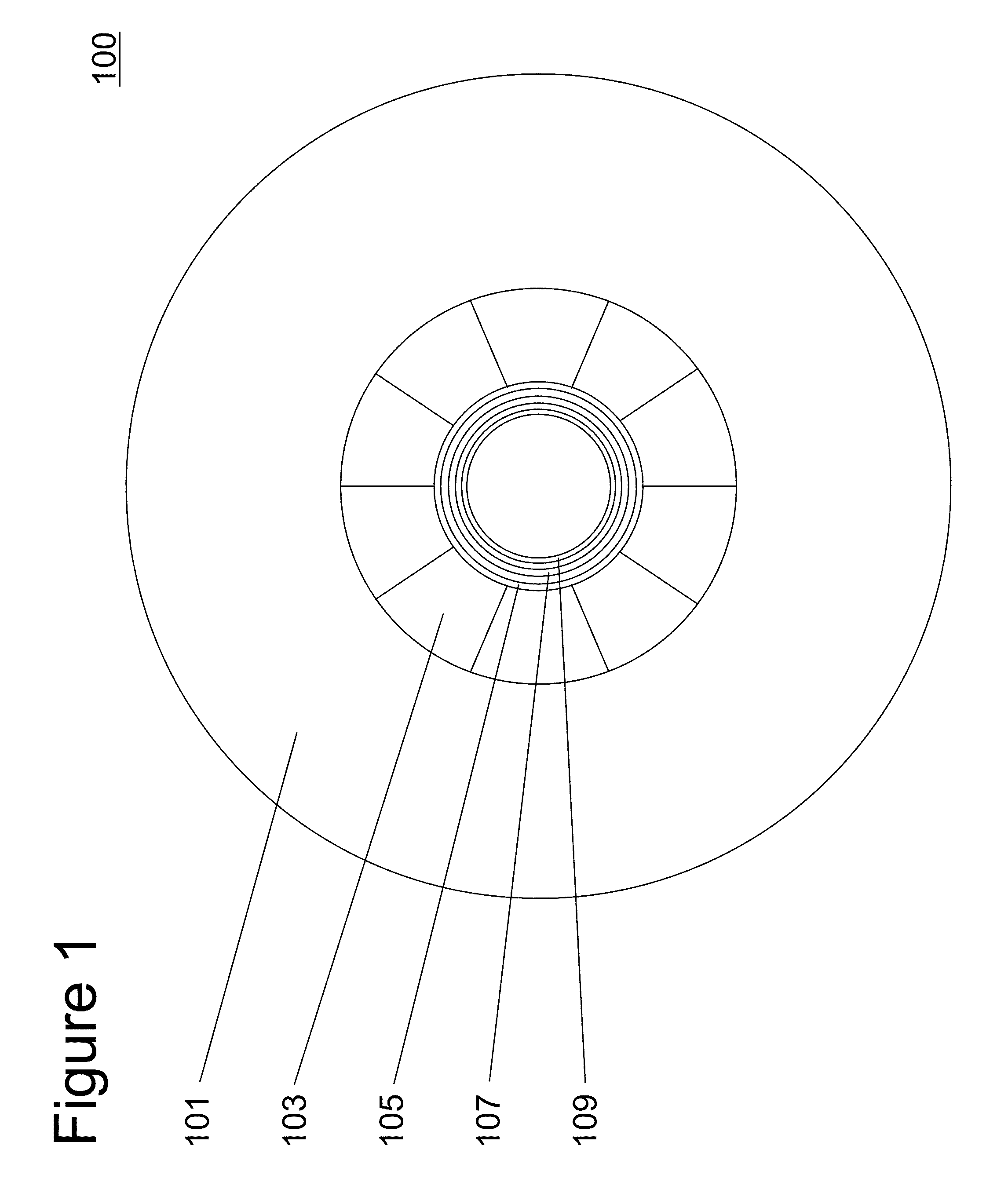

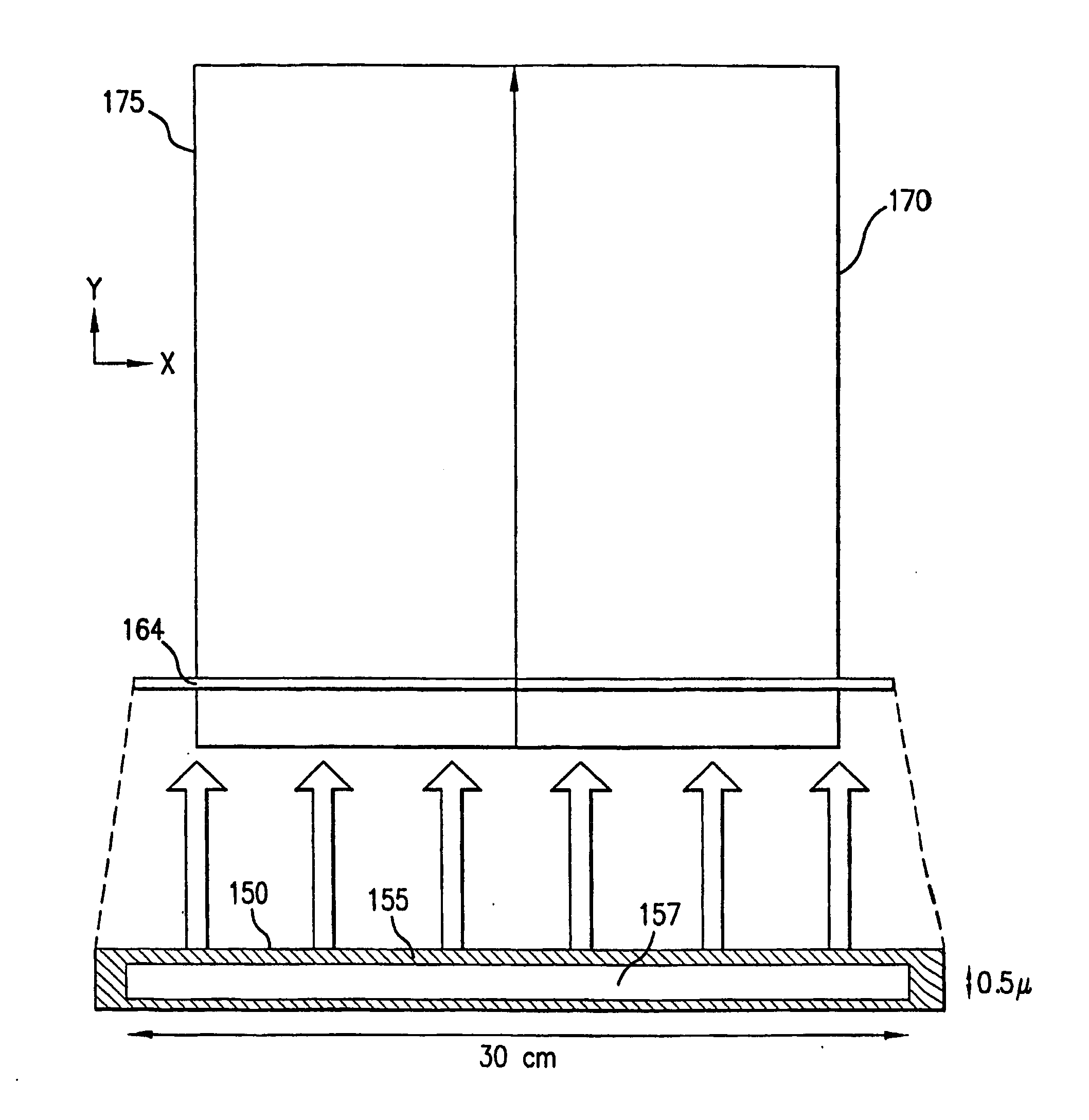

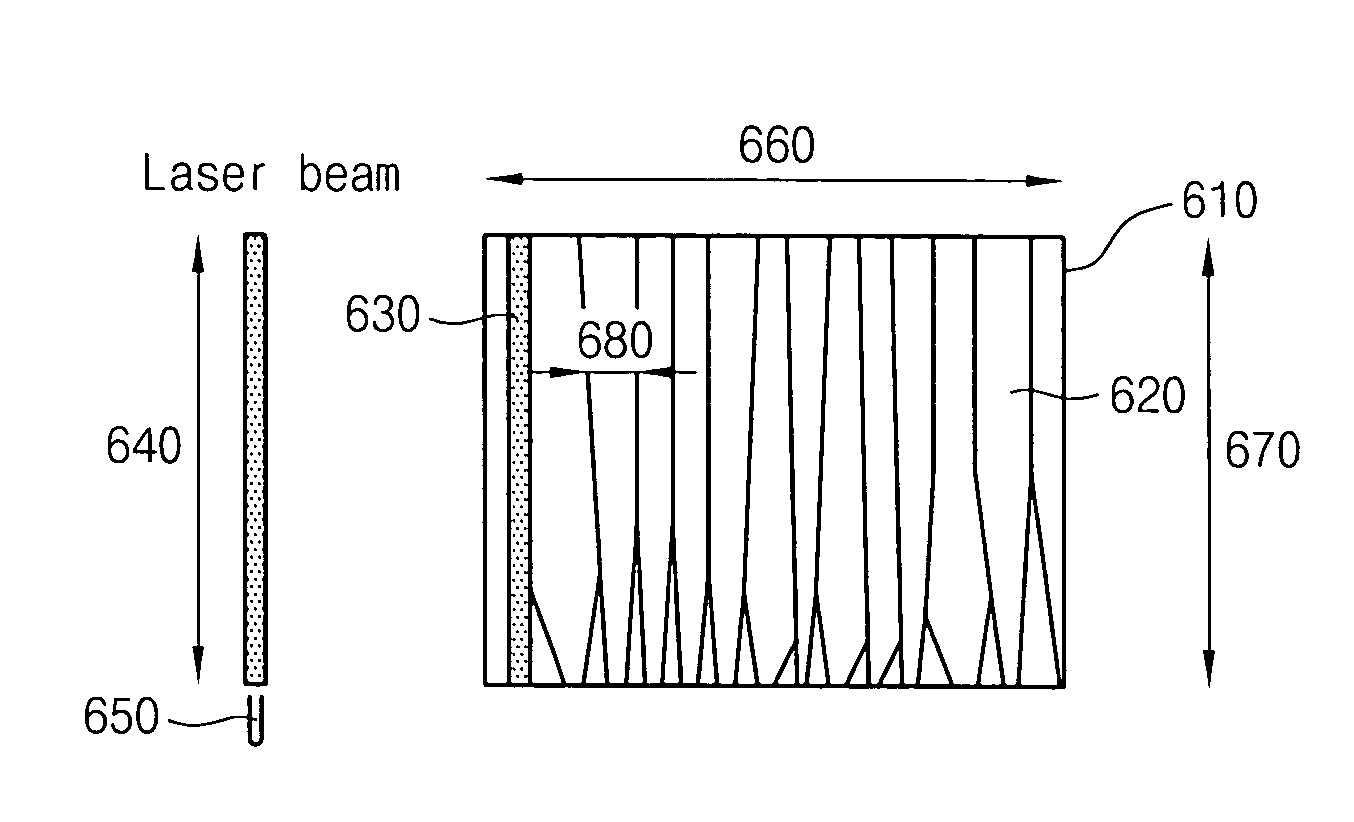

Line scan sequential lateral solidification of thin films

ActiveUS20060254500A1Improve uniformityReduce sharpnessFrom gel statePolycrystalline material growthOptoelectronicsNucleation

A polycrystalline film is prepared by (a) providing a substrate having a thin film disposed thereon, said film capable of laser-induced melting, (b) generating a sequence of laser pulses having a fluence that is sufficient to melt the film throughout its thickness in an irradiated region, each pulse forming a line beam having a predetermined length and width, said width sufficient to prevent nucleation of solids in a portion of the thin film that is irradiated by the laser pulse, (c) irradiating a first region of the film with a first laser pulse to form a first molten zone, said first molten zone demonstrating a variation in width along its length to thereby define a maximum width (Wmax) and a minimum width (Wmin), wherein the first molten zone crystallizes upon cooling to form one or more laterally grown crystals, (d) laterally moving the film in the direction of lateral growth a distance that is greater than about one-half Wmax and less than Wmin; and (e) irradiating a second region of the film with a second laser pulse to form a second molten zone having a shape that is substantially the same as the shape of the first molten zone, wherein the second molten zone crystallizes upon cooling to form one or more laterally grown crystals that are elongations of the one or more crystals in the first region.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

High throughput screening of crystallization of materials

InactiveUS7052545B2Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:RGT UNIV OF CALIFORNIA +1

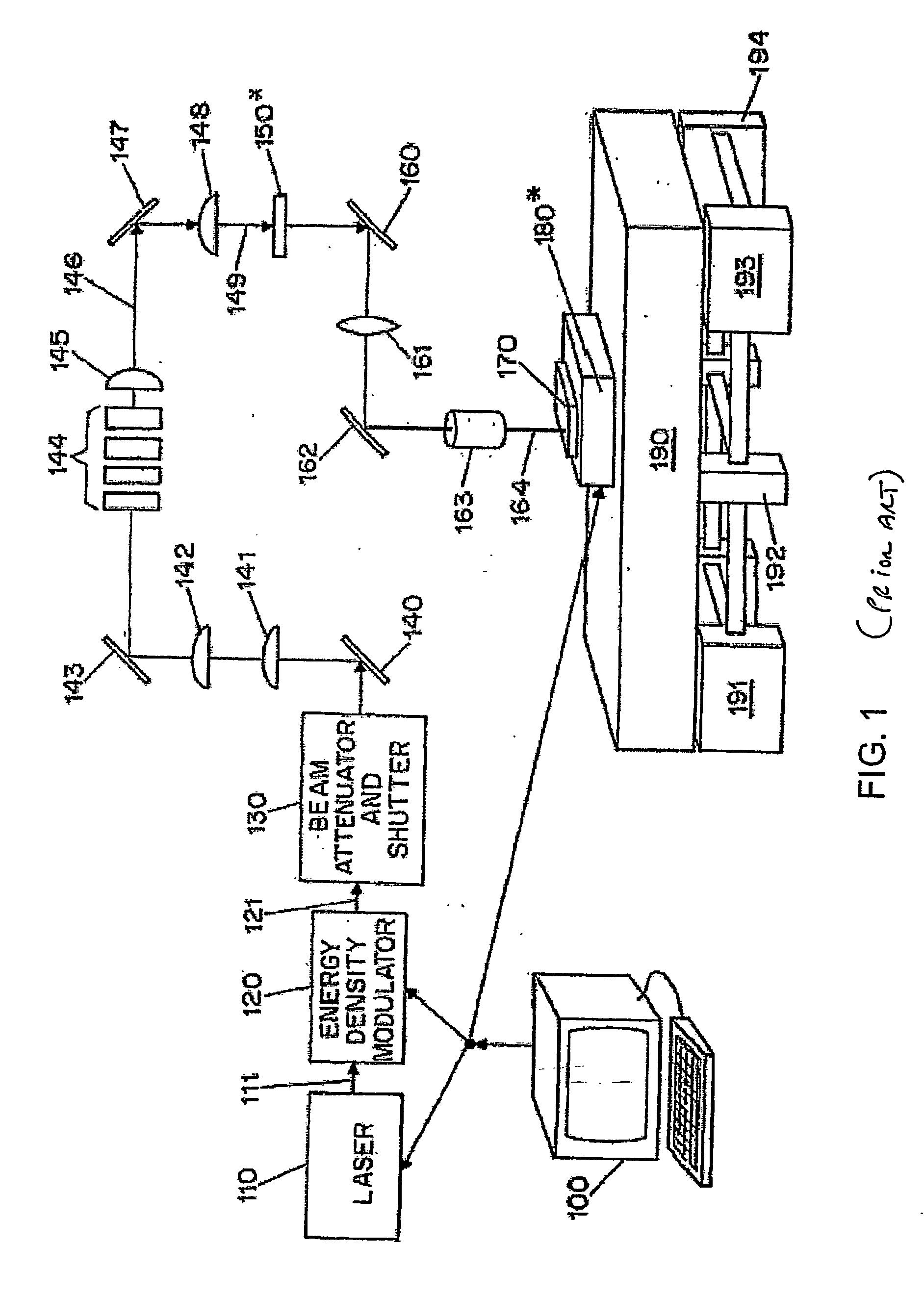

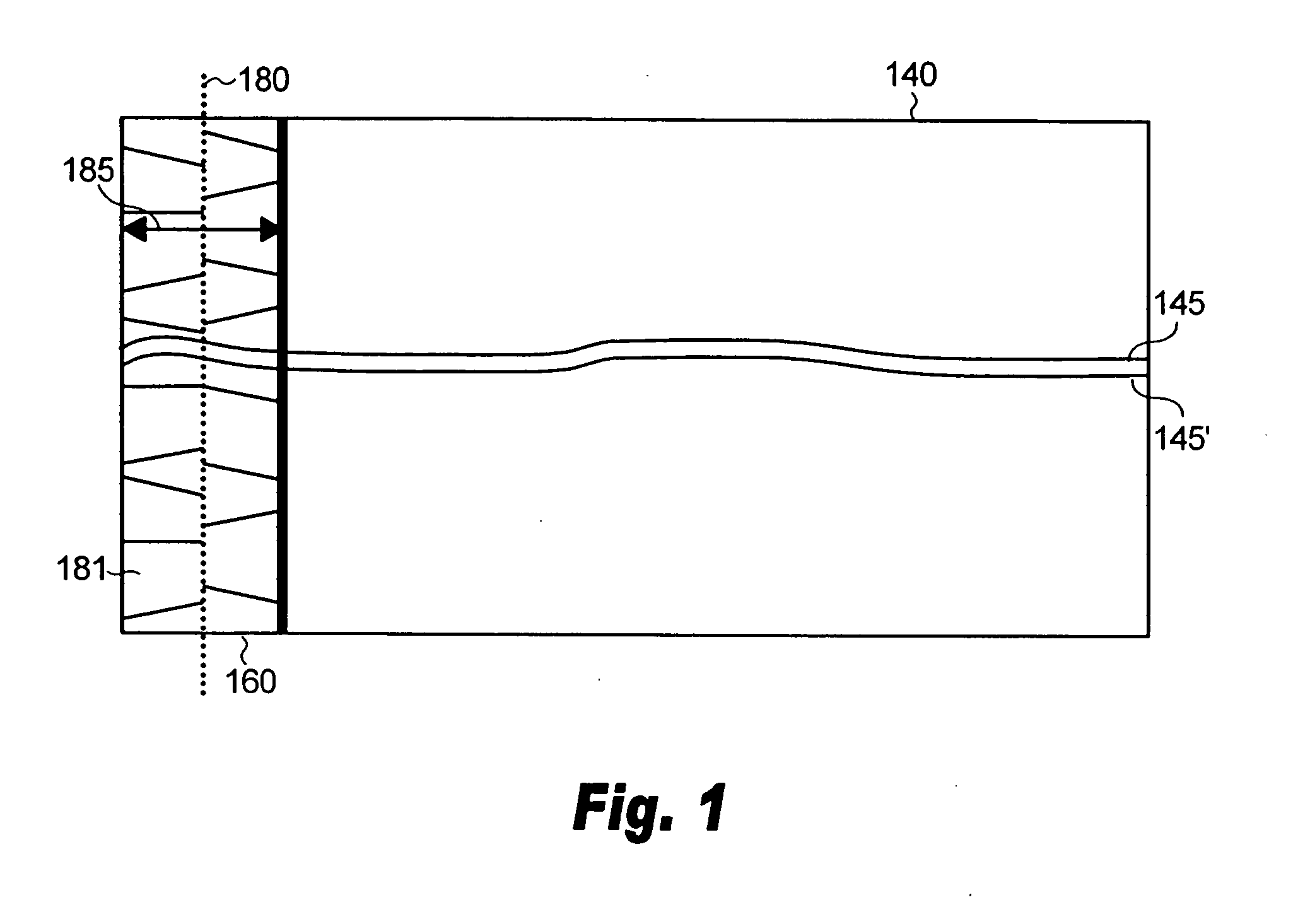

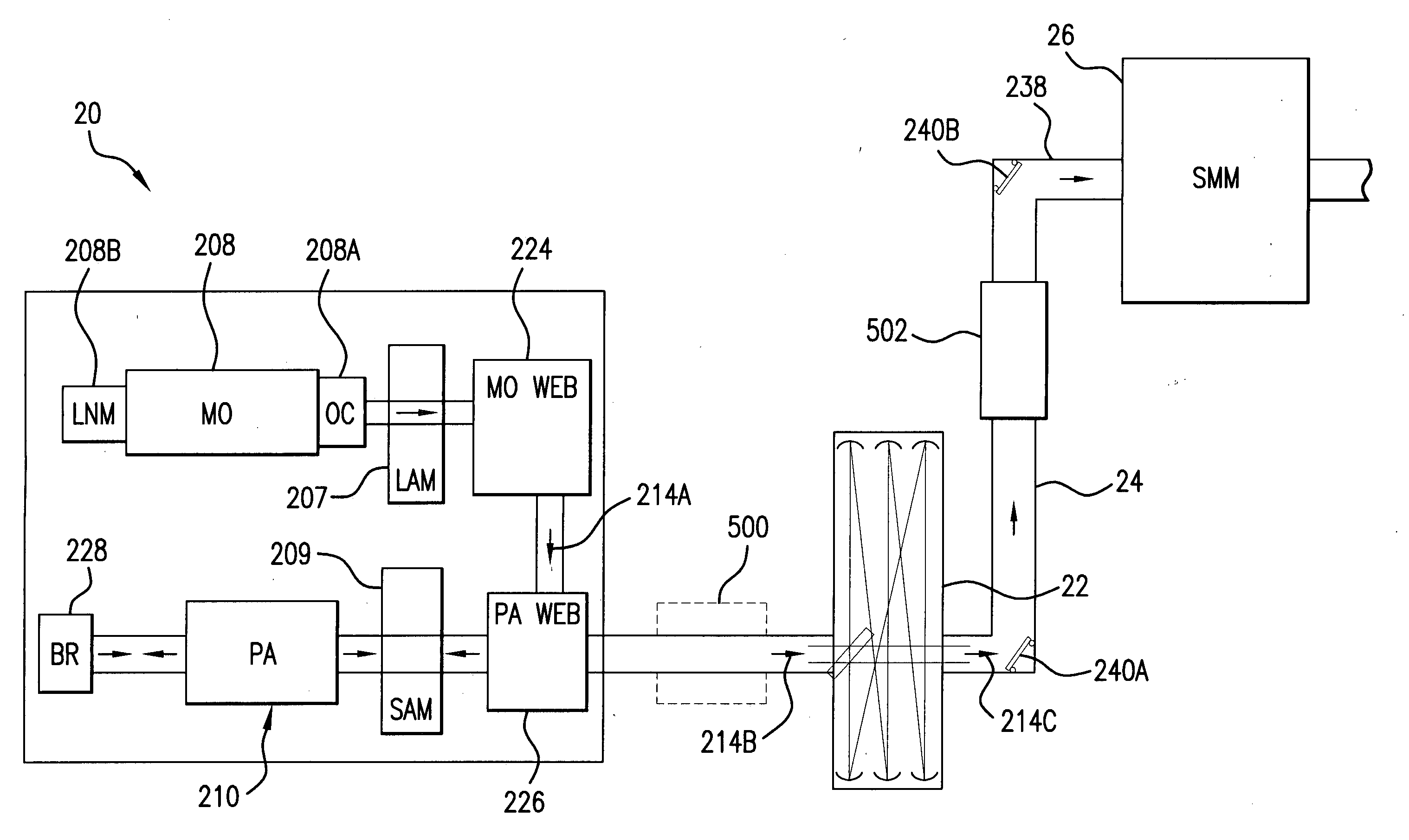

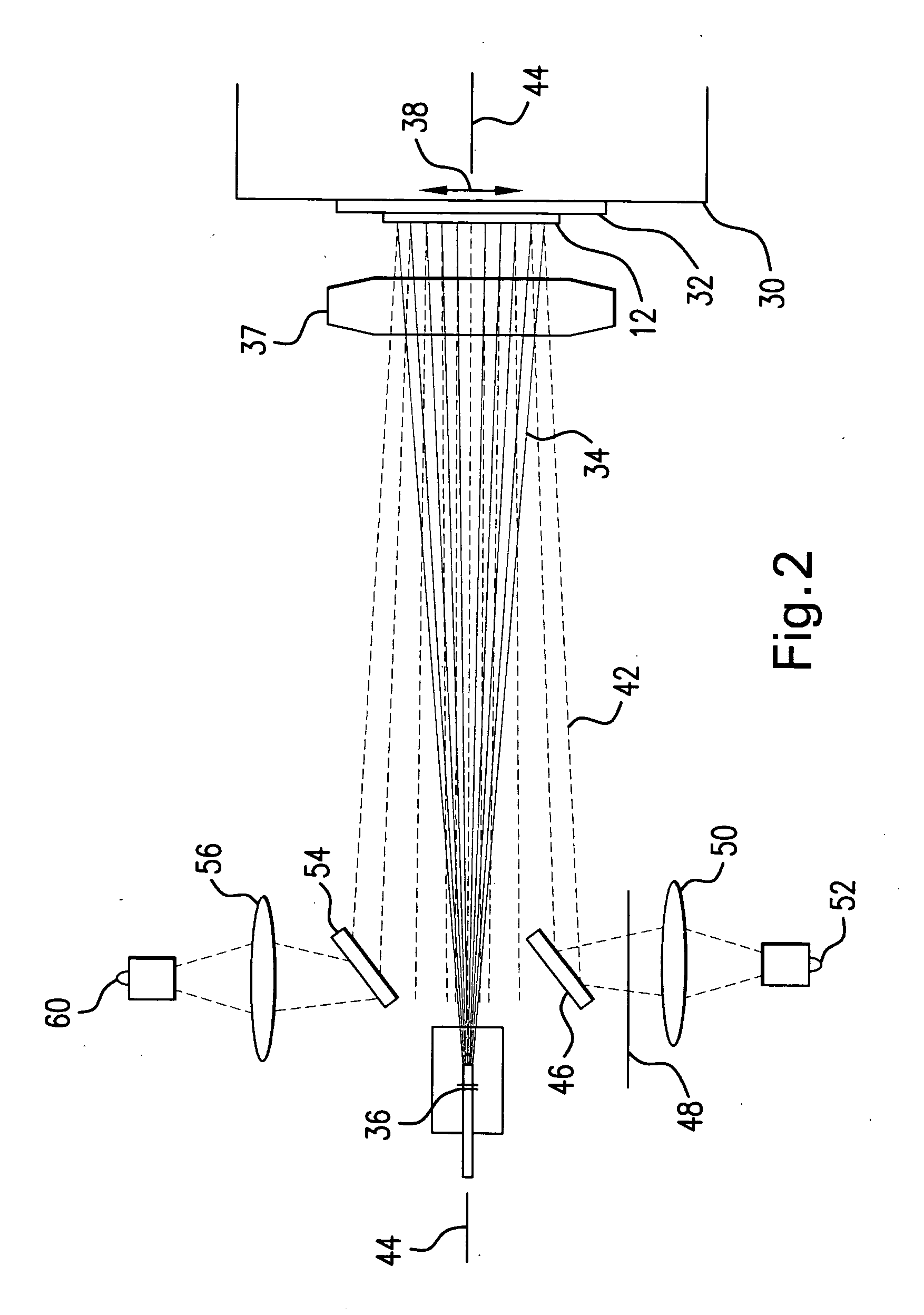

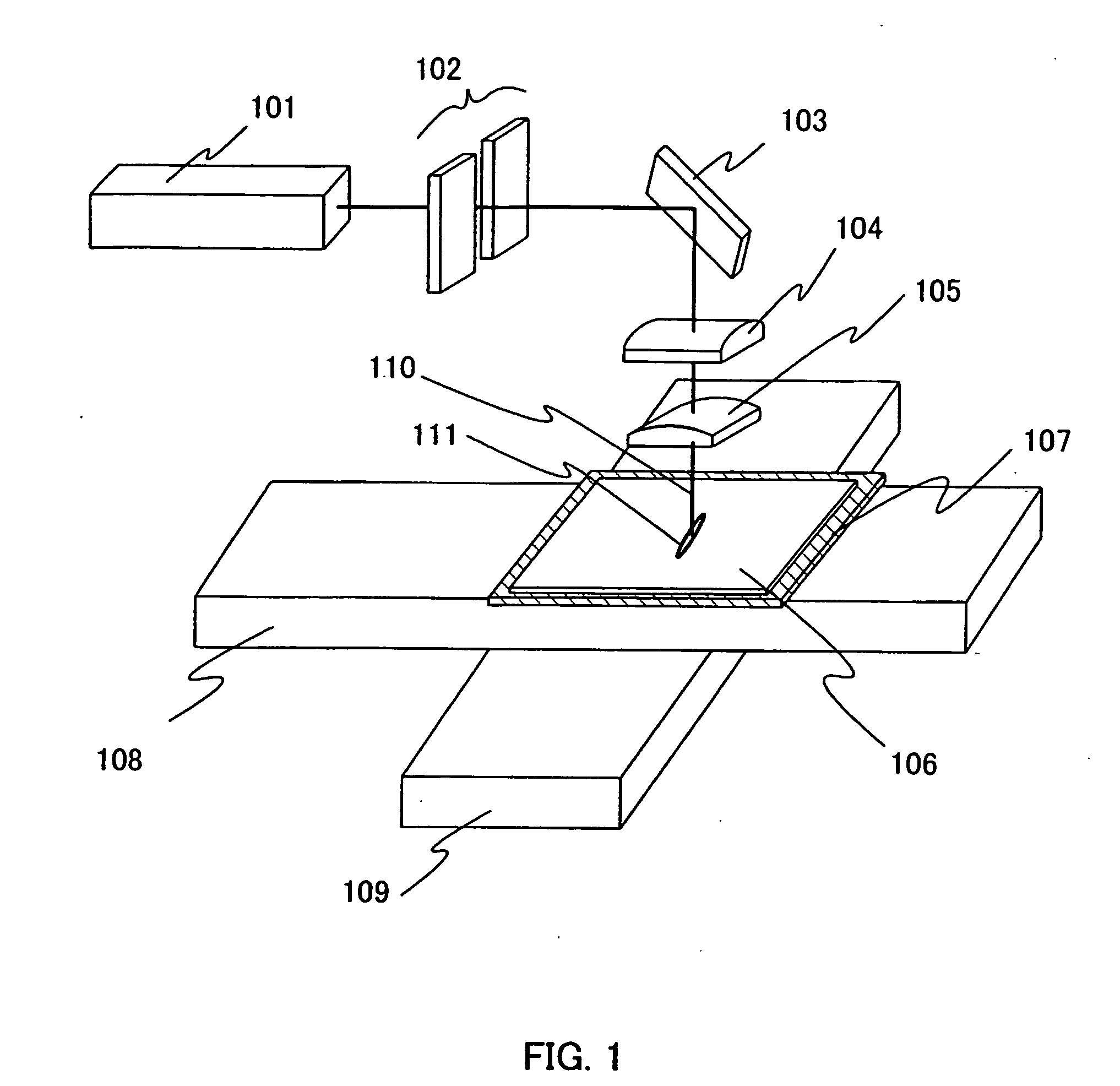

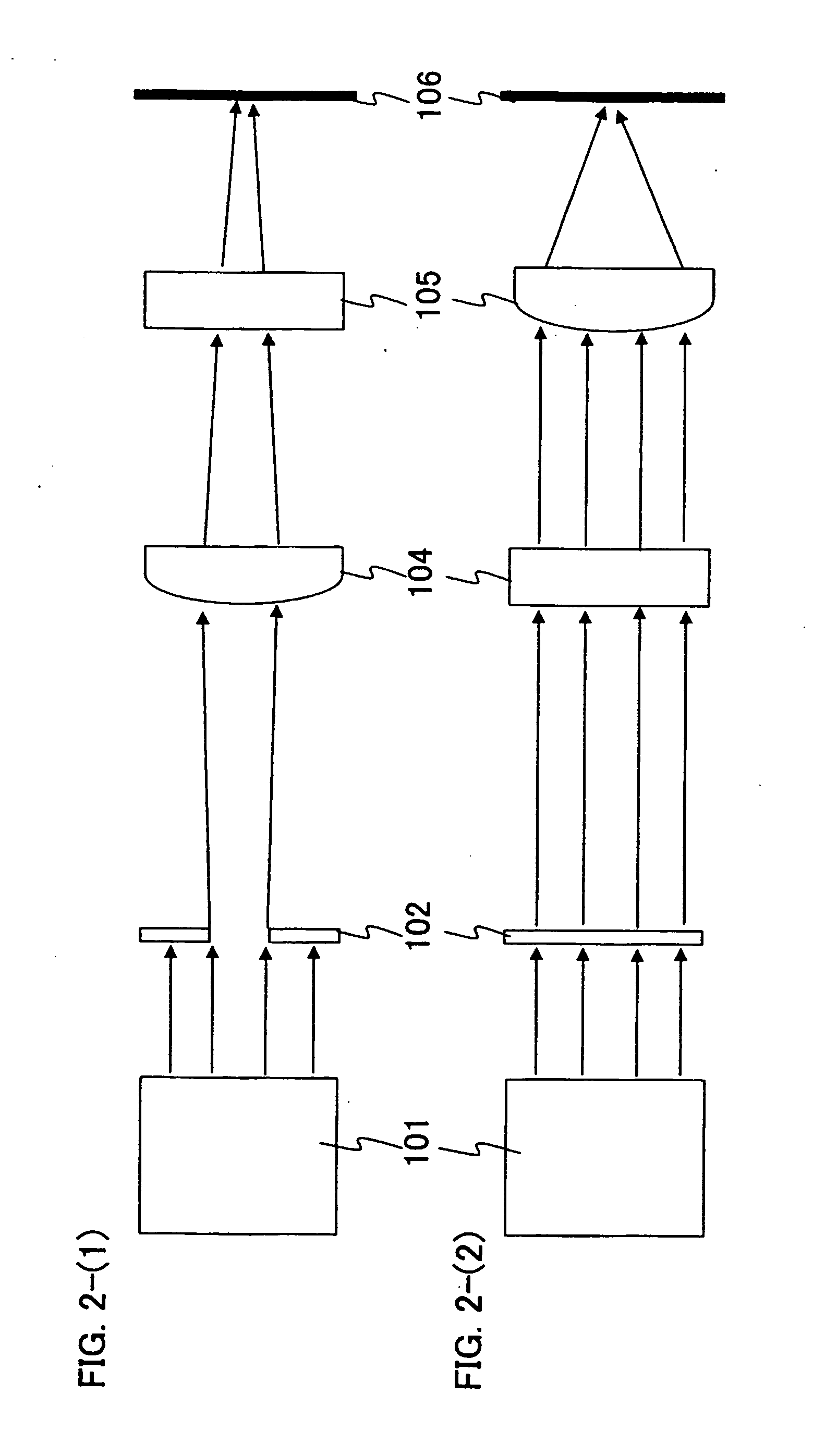

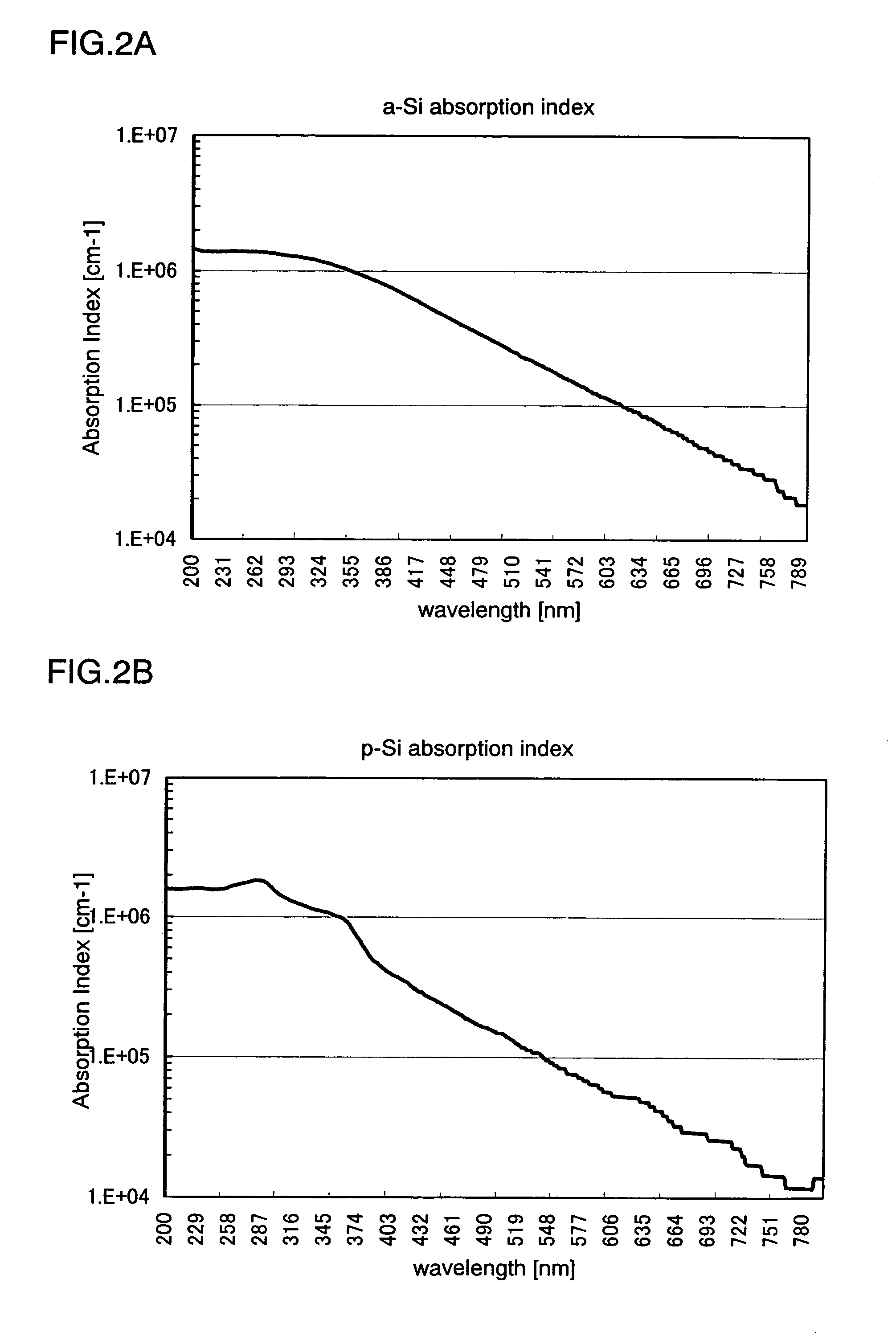

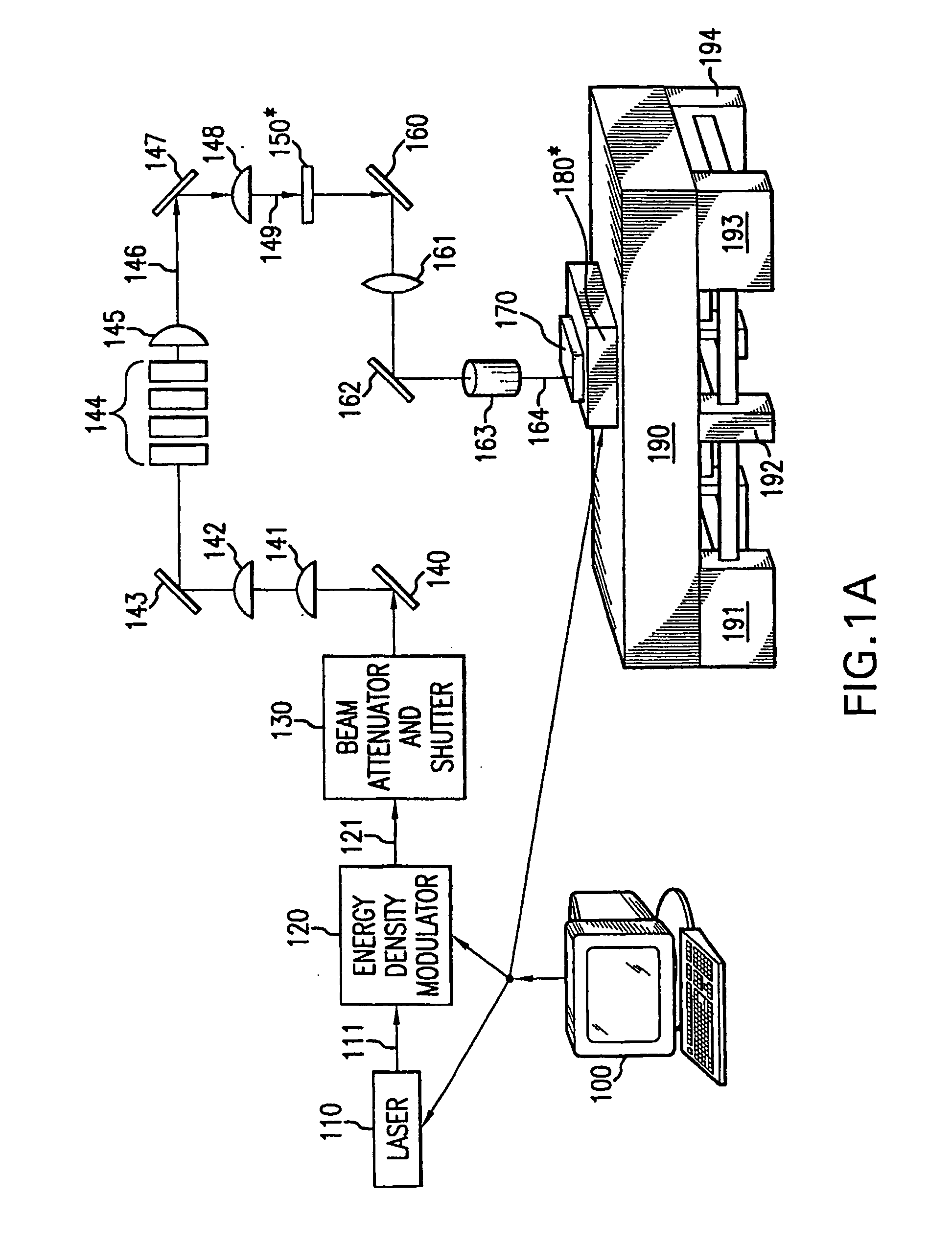

Systems and methods for implementing an interaction between a laser shaped as a line beam and a film deposited on a substrate

InactiveUS20050259709A1Maintain energy densityFrom solid stateBy zone-melting liquidsLaser crystallizationLight beam

A laser crystallization apparatus and method are disclosed for selectively melting a film such as amorphous silicon that is deposited on a substrate. The apparatus may comprise an optical system for producing stretched laser pulses for use in melting the film. In still another aspect of an embodiment of the present invention, a system and method are provided for stretching a laser pulse. In another aspect, a system is provided for maintaining a divergence of a pulsed laser beam (stretched or non-stretched) at a location along a beam path within a predetermined range. In another aspect, a system may be provided for maintaining the energy density at a film within a predetermined range during an interaction of the film with a shaped line beam.

Owner:CYMER INC

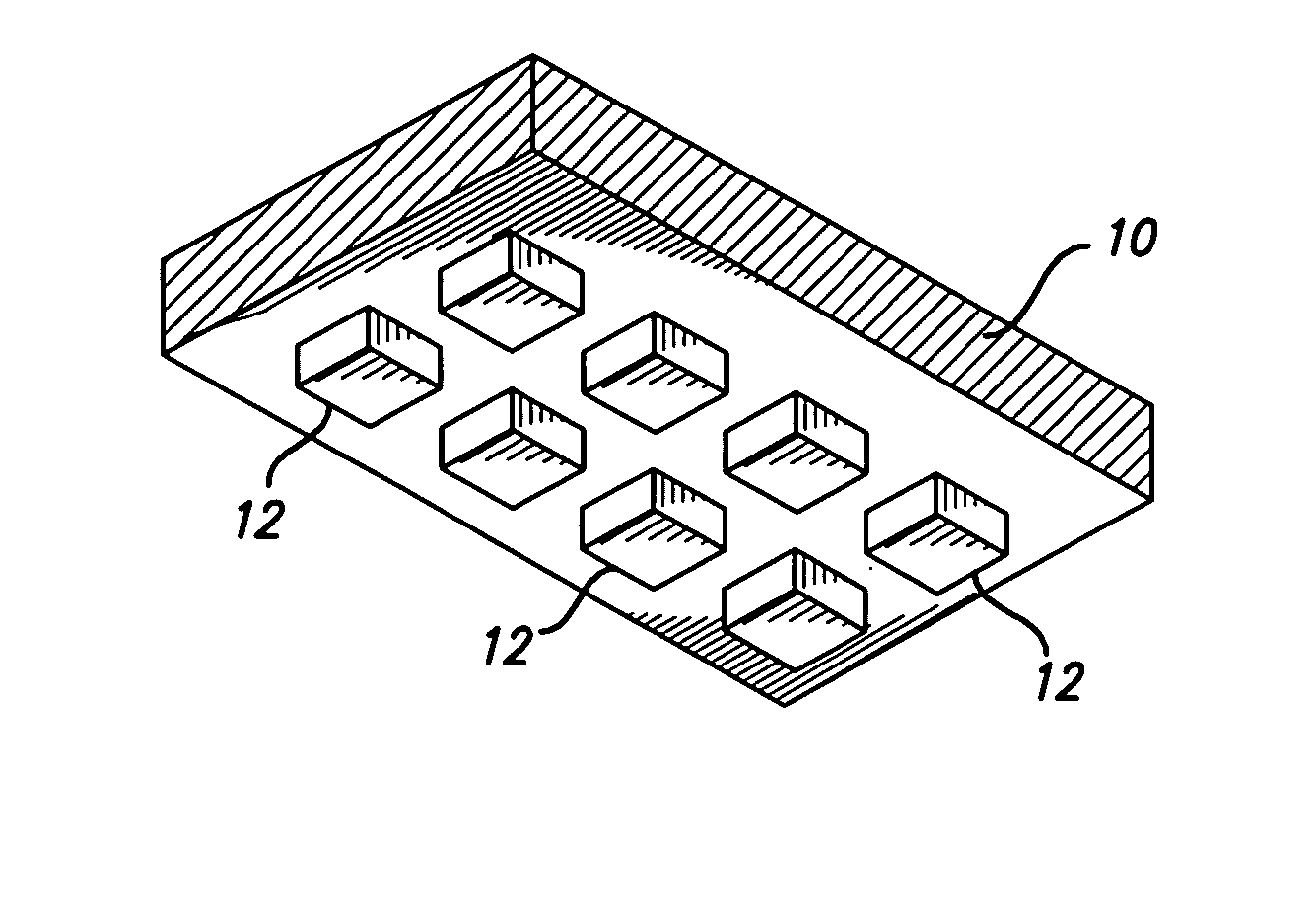

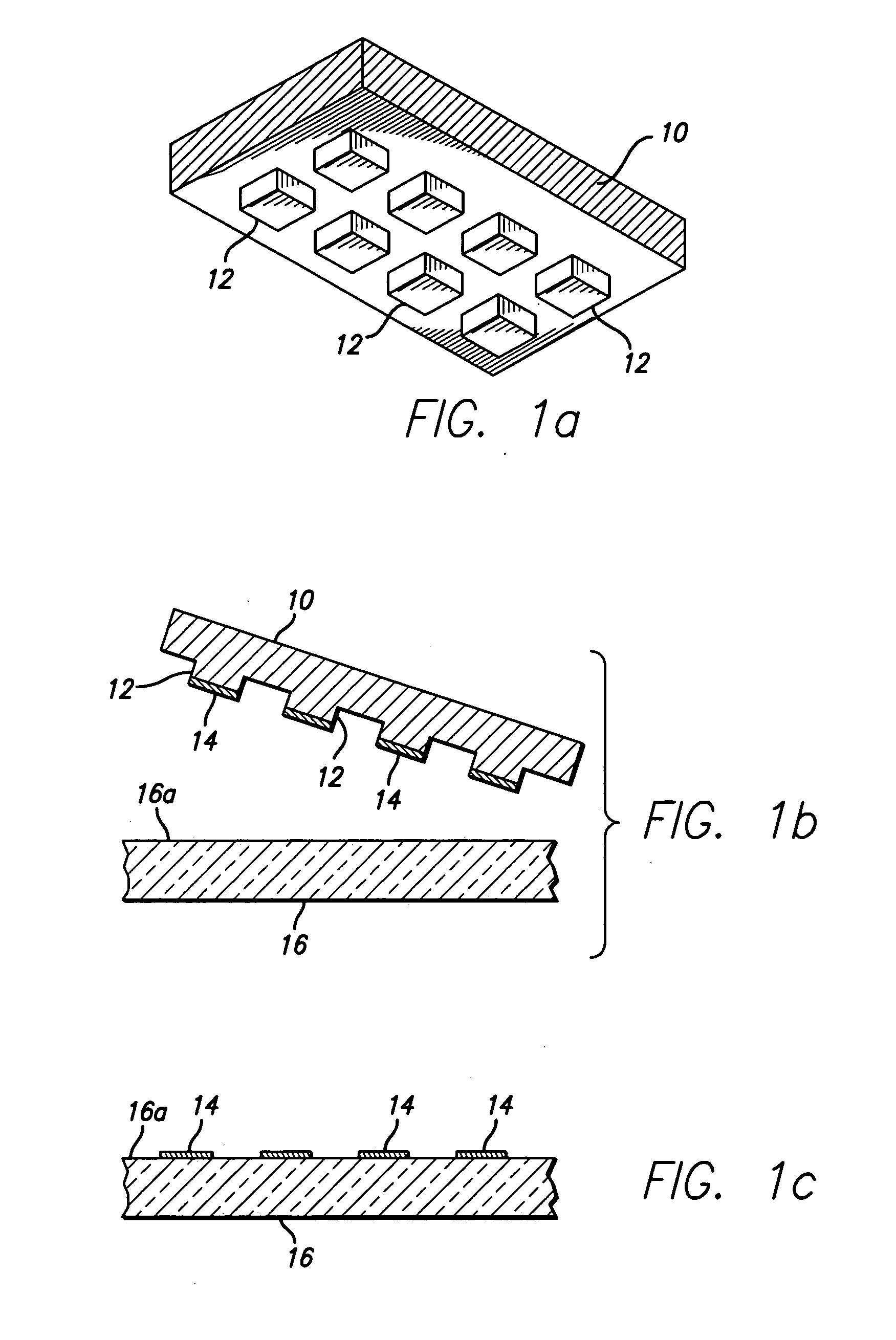

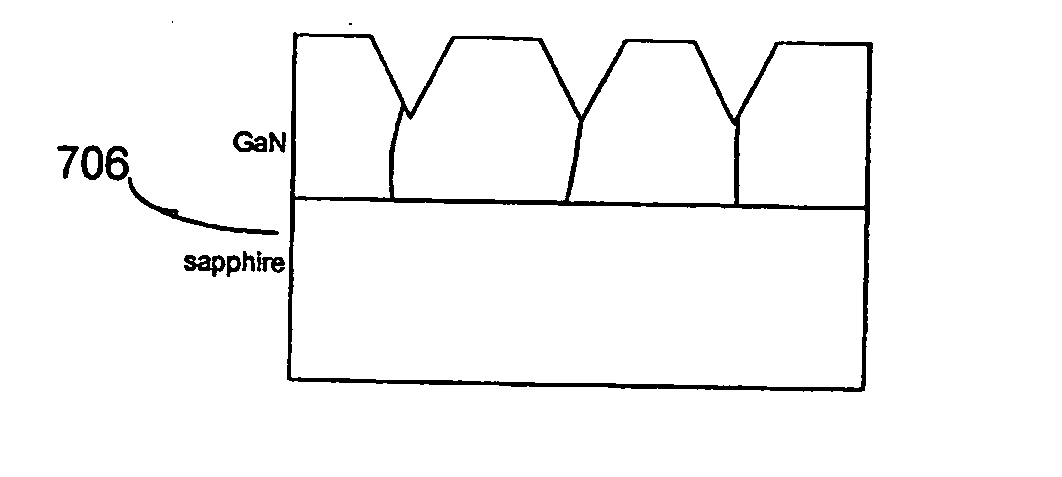

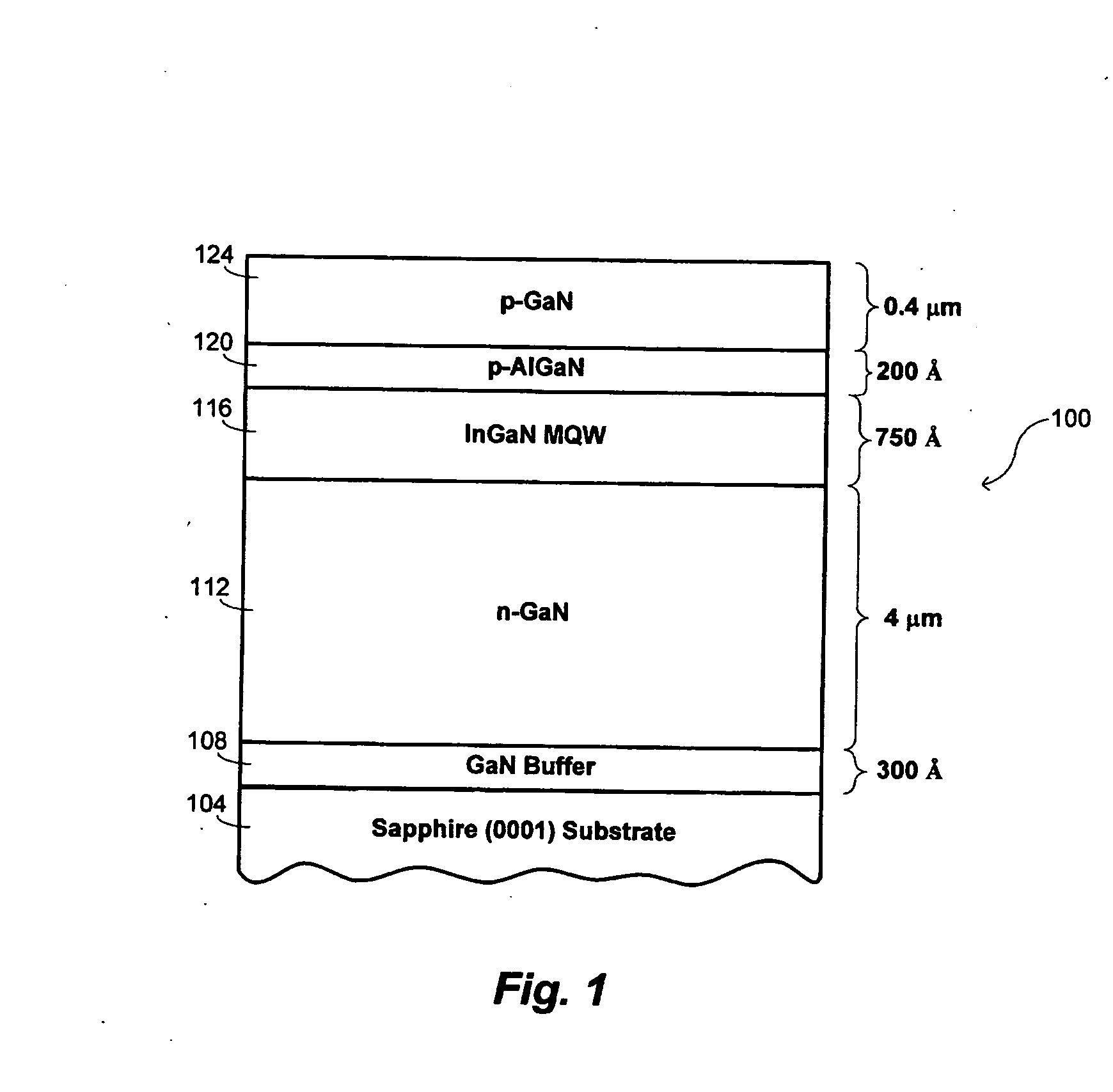

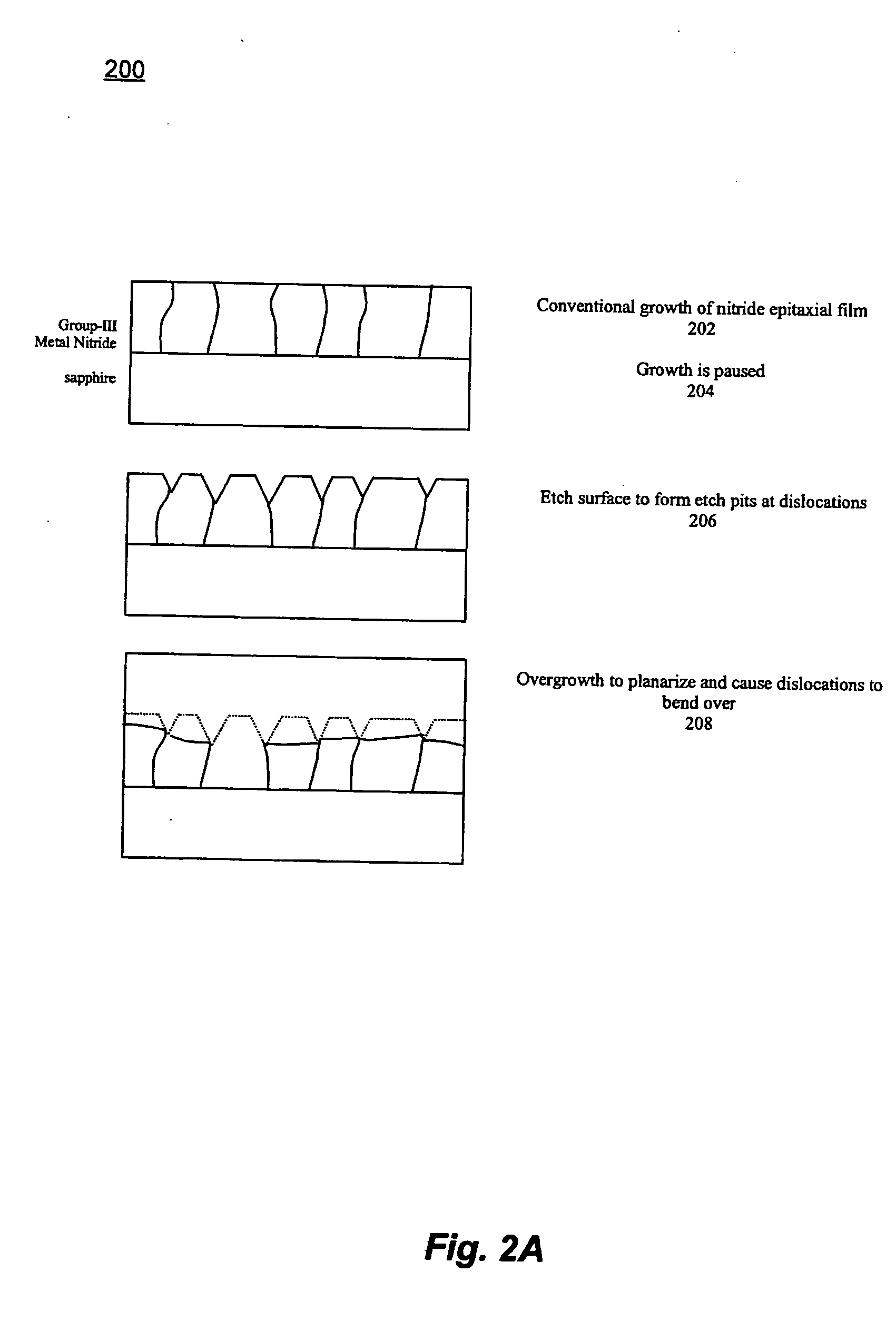

Dislocation-specific lateral epitaxial overgrowth to reduce dislocation density of nitride films

InactiveUS20070259504A1Reduce dislocation densityInhibit threading of the lattice mismatchPolycrystalline material growthBy zone-melting liquidsEtchingDislocation

In accordance with the present invention, improved methods for reducing the dislocation density of nitride epitaxial films are provided. Specifically, an in-situ etch treatment is provided to preferentially etch the dislocations of the nitride epitaxial layer to prevent threading of the dislocations through the nitride epitaxial layer. Subsequent to etching of the dislocations, an epitaxial layer overgrowth is performed. In certain embodiments, the etching of the dislocations occurs simultaneously with growth of the epitaxial layer. In other embodiments, a dielectric mask is deposited within the etch pits formed at the dislocations prior to the epitaxial layer overgrowth.

Owner:APPLIED MATERIALS INC

Laser irradiation method, laser irradiation apparatus and method for manufacturing semiconductor device

InactiveUS20070178672A1High output powerImprove mobilityPolycrystalline material growthBy zone-melting liquidsNonlinear opticsDevice material

In conducting laser annealing using a CW laser or a quasi-CW laser, productivity is not high as compared with an excimer laser and thus, it is necessary to further enhance productivity. According to the present invention, a fundamental wave is used without putting laser light into a non linear optical element, and laser annealing is conducted by irradiating a semiconductor thin film with pulsed laser light having a high repetition rate. A laser oscillator having a high output power can be used for laser annealing, since a non linear optical element is not used and thus light is not converted to a harmonic. Therefore, the width of a region having large grain crystals that is formed by scanning once can be increased, and thus the productivity can be enhanced dramatically.

Owner:SEMICON ENERGY LAB CO LTD

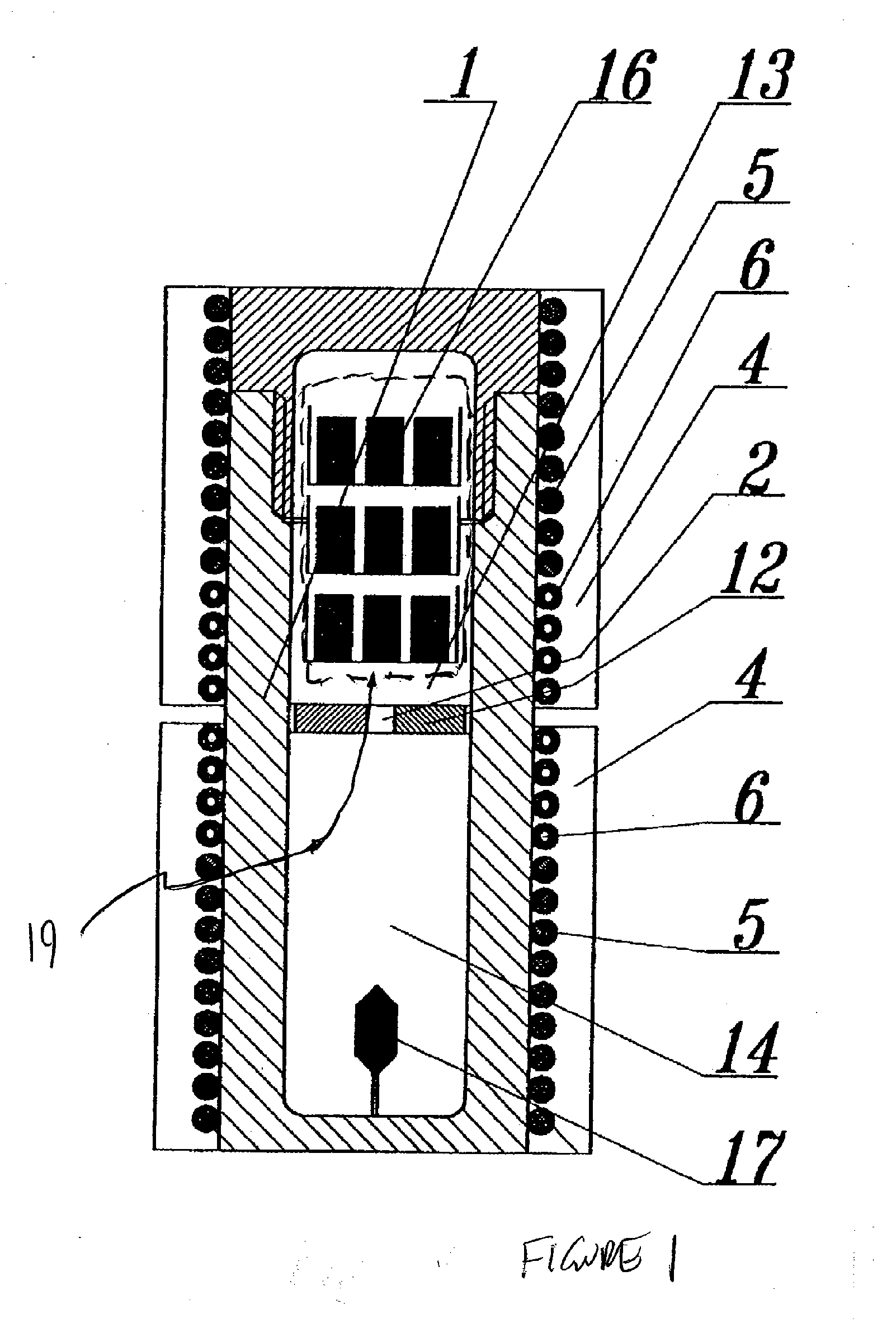

High Pressure Apparatus and Method for Nitride Crystal Growth

ActiveUS20110183498A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsHigh pressureNitride

An improved high pressure apparatus and methods for processing supercritical fluids is described. The apparatus includes a capsule, a heater, and at least one ceramic ring contained by a metal sleeve. The apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C.

Owner:SLT TECH

Method for manufacturing semiconductor apparatus, and semiconductor apparatus and electric appliance

ActiveUS7056810B2Low costImprove throughputPolycrystalline material growthSemiconductor/solid-state device detailsEngineeringCw laser

According to the package and the method for manufacturing the package of the present invention, a chip can be formed extremely to be thin, and manufactured at lower cost and higher throughput, and the variations of a chip thickness can be reduced without back grind that causes cracks or polishing marks. In the present invention, a semiconductor film with a thickness of at most 500 μm deposited over a substrate serving as a support medium is crystallized with a CW laser light, and a chip having a semiconductor device is formed to have a total thickness of 5 μm, preferably at most 2 μm by using the crystallized semiconductor film. Consequently, the chip is mounted on an interposer after separating a substrate.

Owner:SEMICON ENERGY LAB CO LTD

Crystal production process using supercritical solvent, crystal growth apparatus, crystal and device

InactiveUS20090092536A1Efficient productionEasy to controlPolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

To control the precipitation position of a crystal and increase the yield of the crystal by performing the crystal growth according to the solvothermal method while allowing a predetermined amount of a substance differing in the critical density from the solvent to be present in the reaction vessel; and to prevent mixing of an impurity into the crystal and improve the crystal purity.

Owner:MITSUBISHI CHEM CORP +1

Processes and systems for laser crystallization processing of film regions on a substrate utilizing a line-type beam, and structures of such film regions

ActiveUS20070010104A1Similar performanceAvoid radiationAfter-treatment apparatusFrom solid stateLaser crystallizationIrradiation

Process and system for processing a thin film sample, as well as at least one portion of the thin film structure are provided. Irradiation beam pulses can be shaped to define at least one line-type beam pulse, which includes a leading portion, a top portion and a trailing portion, in which at least one part has an intensity sufficient to at least partially melt a film sample. Irradiating a first portion of the film sample to at least partially melt the first portion, and allowing the first portion to resolidify and crystallize to form an approximately uniform area therein. After the irradiation of the first portion of the film sample, irradiating a second portion using a second one of the line-type beam pulses to at least partially melt the second portion, and allowing the second portion to resolidify and crystallize to form an approximately uniform area therein. A section of the first portion impacted by the top portion of the first one of the line-type beam pulses is prevented from being irradiated by trailing portion of the second one of the line-type beam pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Method for fabricating single crystal silicon film

The present invention relates to a method for fabricating a single crystal silicon thin film at the desired location to the desired size from an amorphous or polycrystalline thin film on a substrate using laser irradiation and laser beam movement along the substrate having the semiconductor thin films being irradiated. This method comprises the steps of: forming a semiconductor layer or a metal thin film on a transparent or semi-transparent substrate; forming a single crystal seed region on the substrate of the desired size by a crystallization method using laser irradiation; and converting the desired region of the semiconductor layer or metal thin film into a single crystal region, using the single crystal seed region.

Owner:BOE HYDIS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com