Systems and methods for implementing an interaction between a laser shaped as a line beam and a film deposited on a substrate

a technology of laser shaped as a line beam and film deposited on a substrate, which is applied in the direction of active medium materials, manufacturing tools, crystal growth processes, etc., can solve the problems of poor grain quality, non-flat surface profile, and unsuitability of crystallized film for certain applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

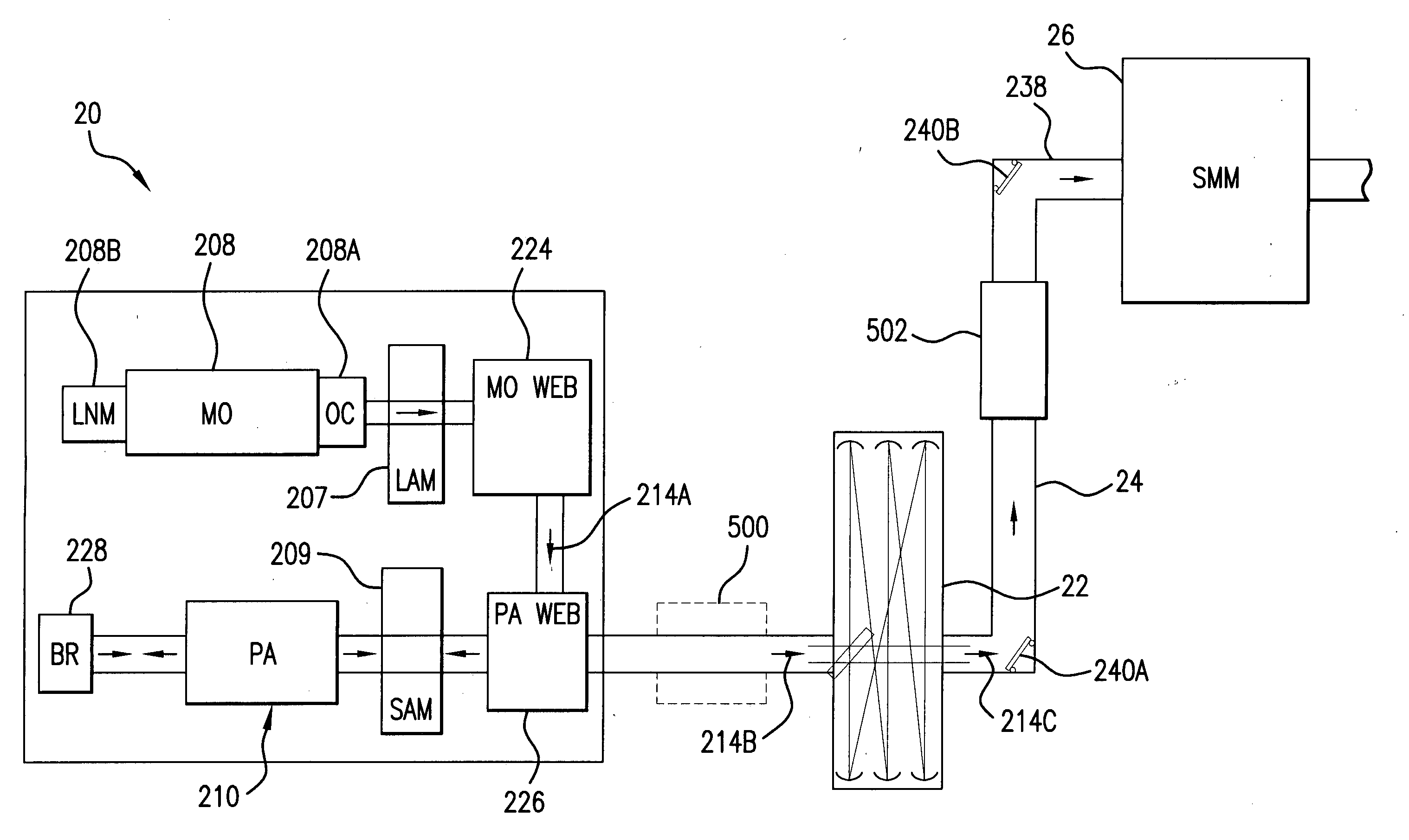

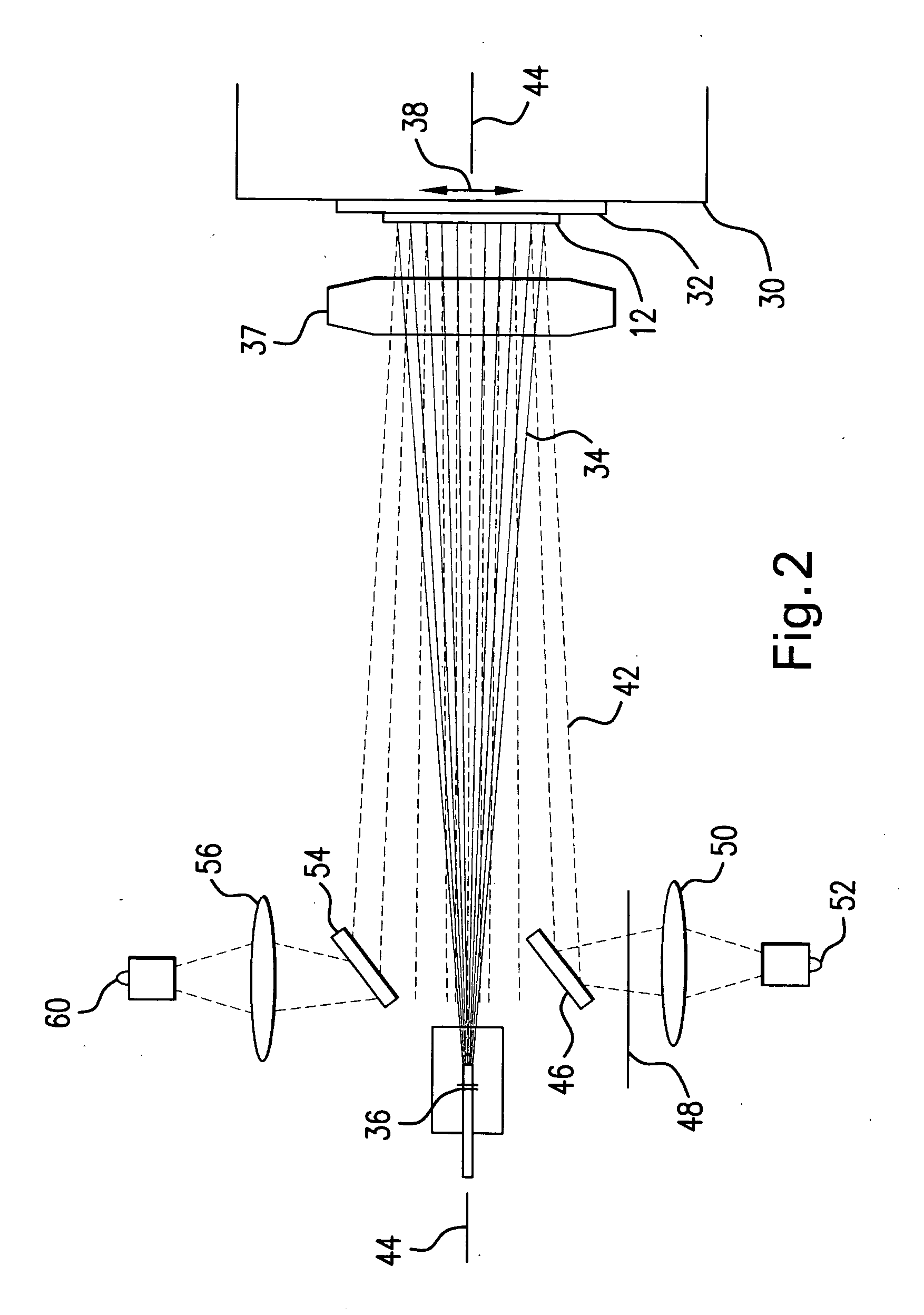

[0027] Referring initially to FIG. 1, there is shown a schematic, not to scale, view of the primary components of an exemplary production system, designated generally system 10, for crystallizing an amorphous silicon film 12. As shown, the system 10 may include a laser source 20 for generating a pulsed laser beam, a pulse stretcher 22 for increasing pulse duration and a beam delivery unit 24 which may have a mechanism to actively steer the beam and / or an active beam expander. The system 10 may further include a stabilization metrology module 26 for measuring one or more beam characteristics, e.g., wavefront and / or beam pointing, and generating control signals for use by the active steering unit and / or the active beam expander. System 10 may also include an optics module 28 for beam homogenization, beam shaping and / or beam focusing, and a moveable stage system 30 for holding and positioning a silicon film 12 that has been deposited on a substrate 32, which can be for example, glass. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com